Patents

Literature

137 results about "Polymethylmethacrylate resin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

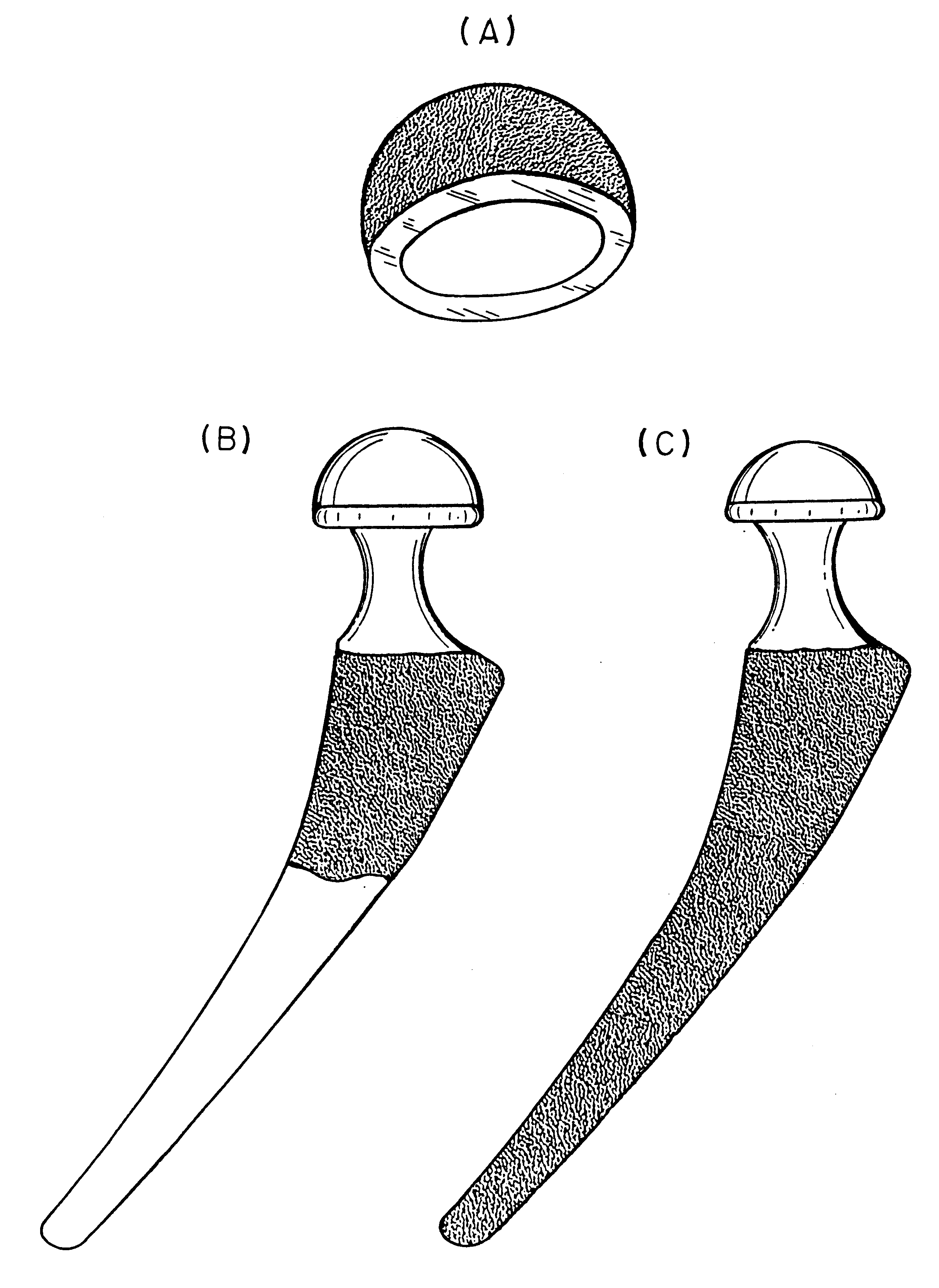

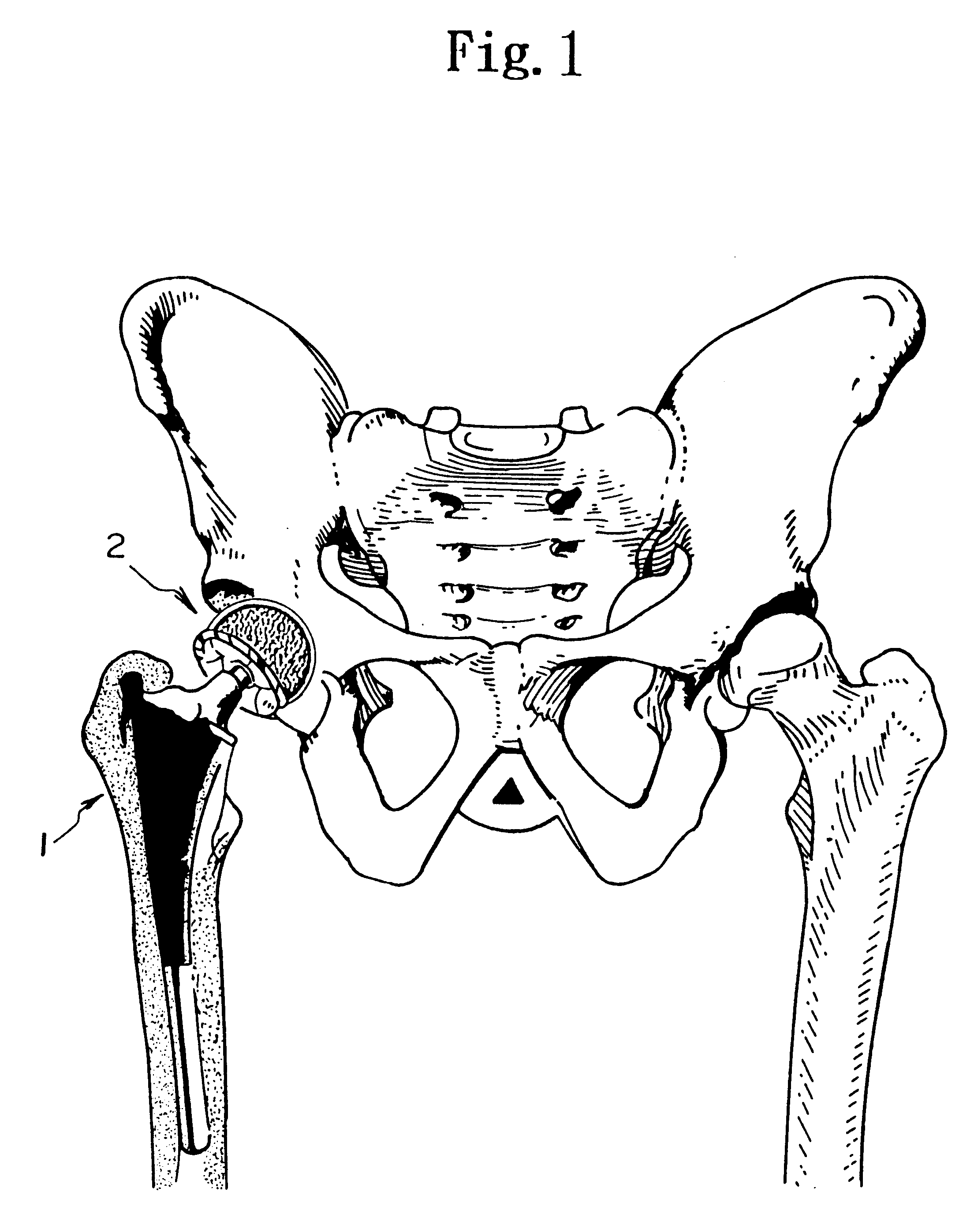

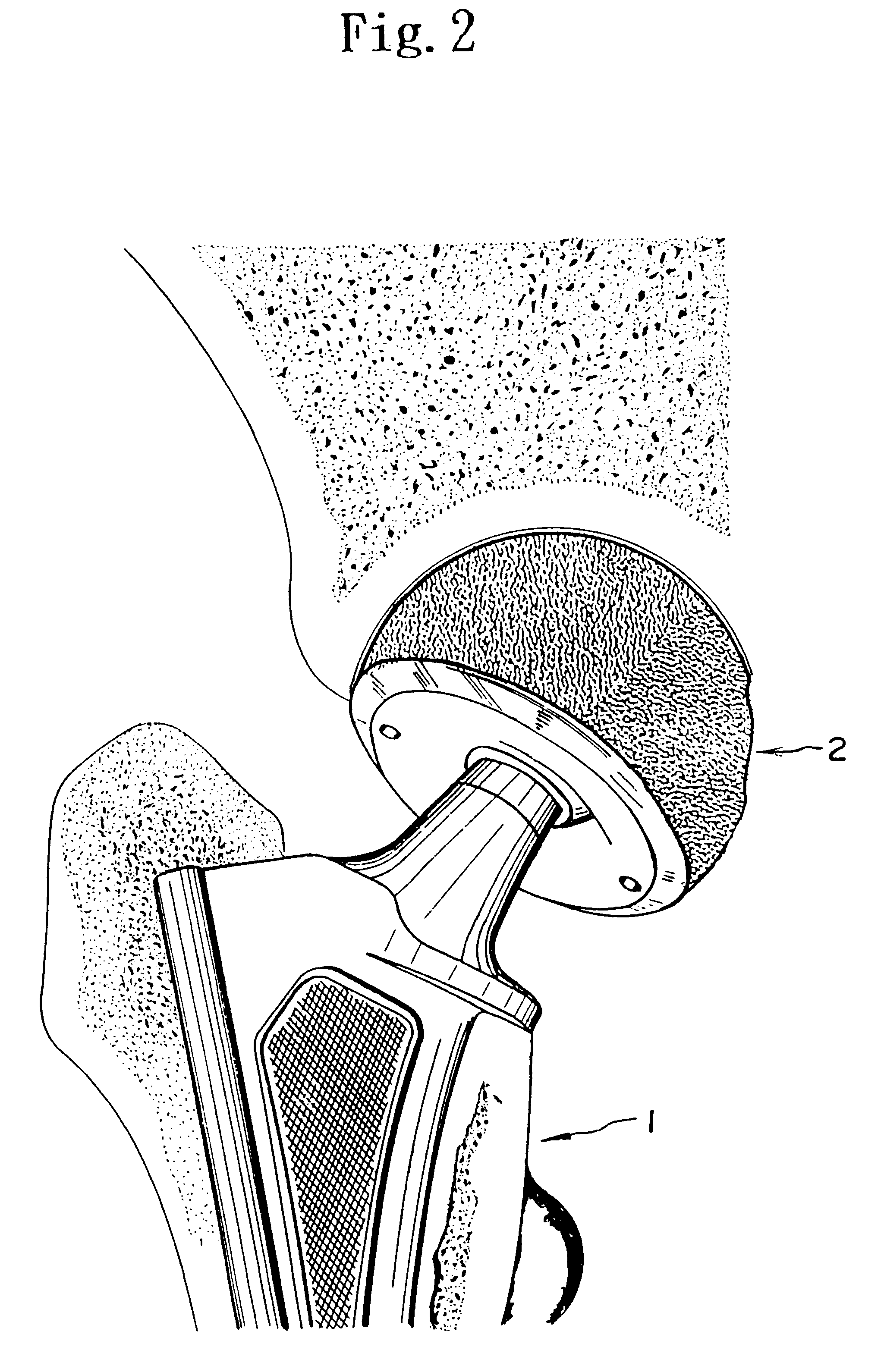

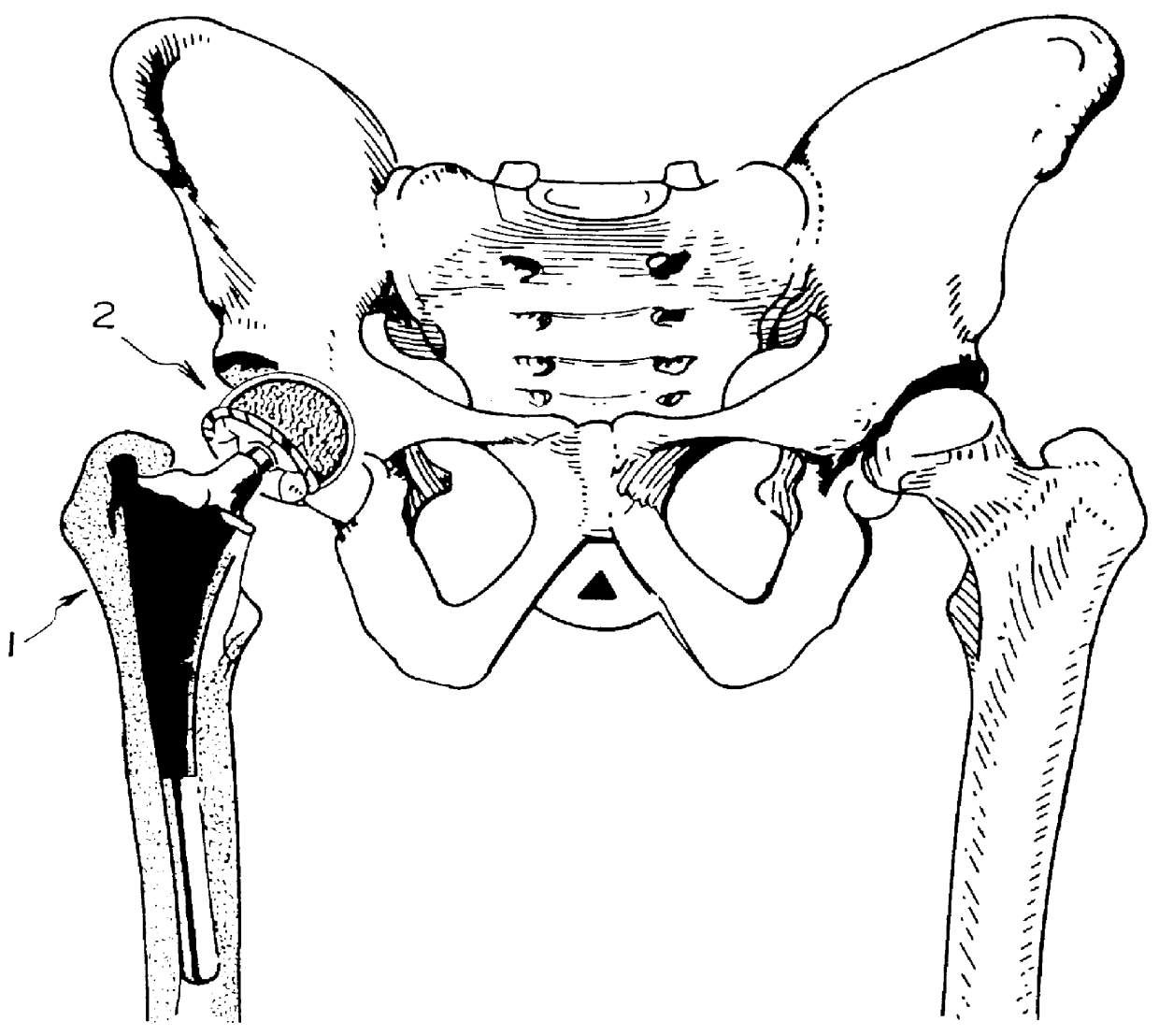

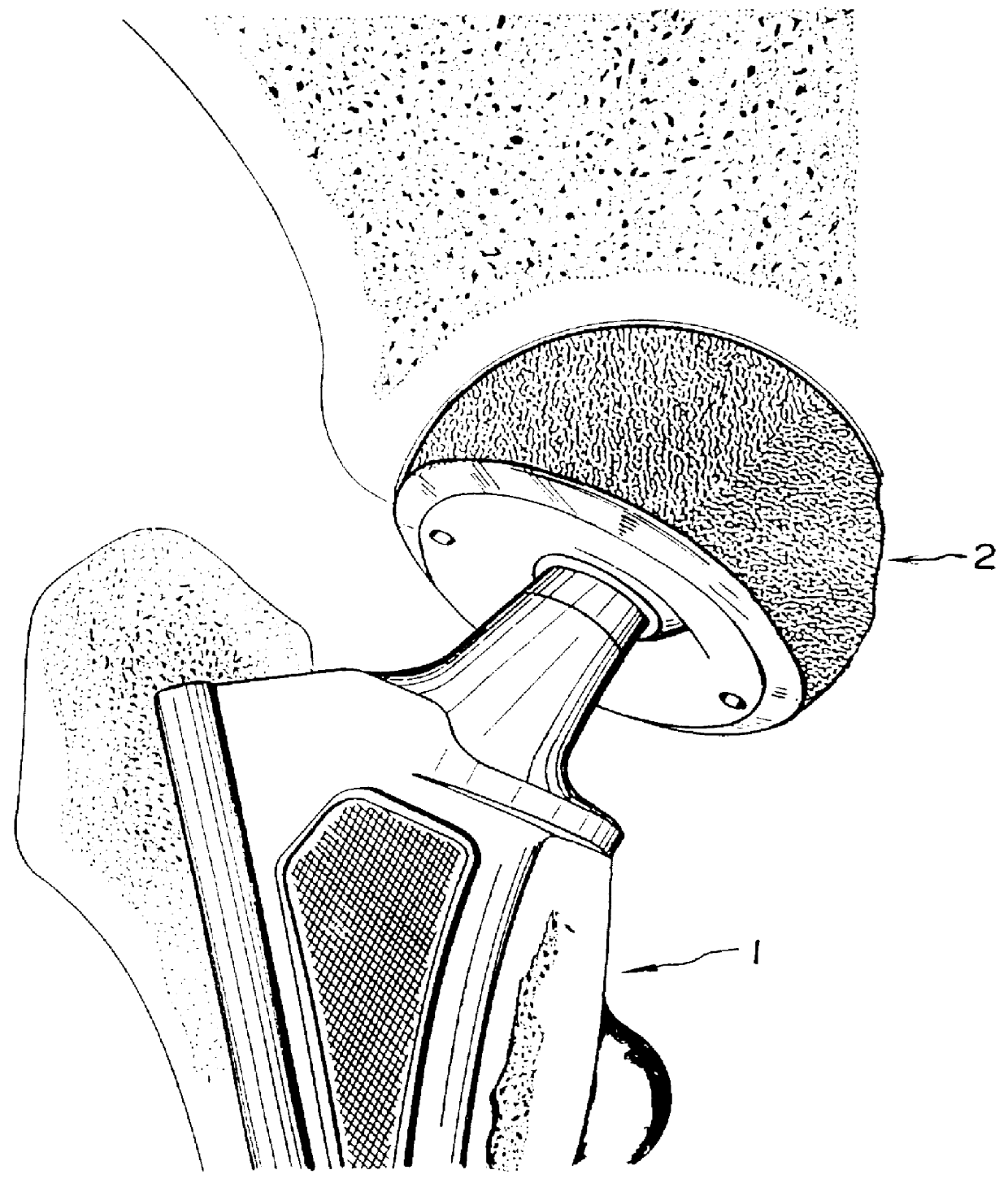

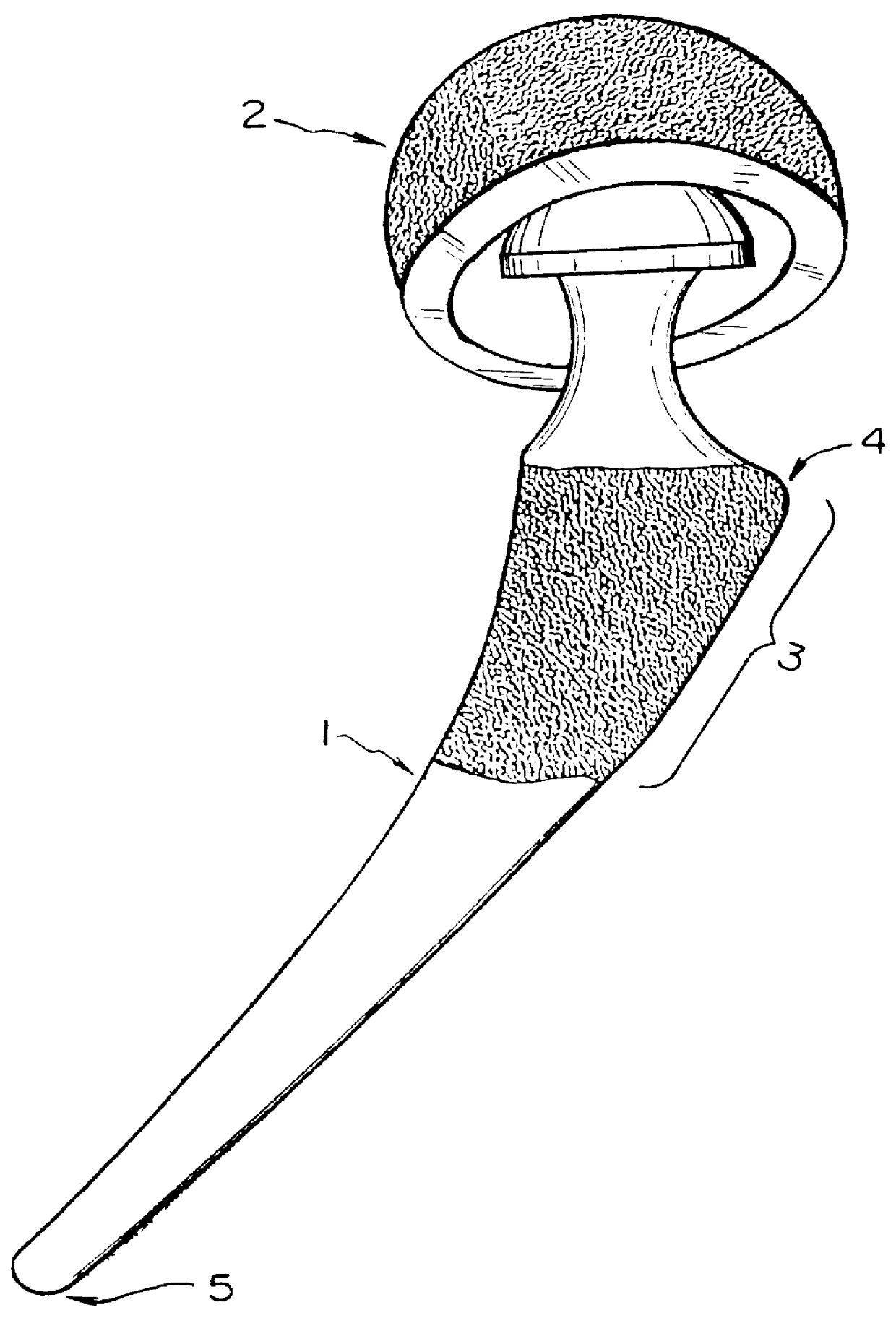

Orthopedic implant system

InactiveUS6312473B1Easy to fixAvoid excessive temperatureSurgical adhesivesBone implantFemoral stemPolymethyl methacrylate

It is an object of the present invention to provide an improved orthopedic implant system with satisfied biological, mechanical and morphological compatibilities.Solid metal femoral stem and solid metal acetabular head are covered with diffusion-bonded foamed-shaped sheet made of commercially pure titanium or titanium alloy(s). The open-cells in said foamed metal sheet are impregnated with biocompatible polymethyl methacrylate resin cement, which is reinforced with selected oxides including alumina, magnesia, zirconia, or a combination of these oxides along with an application of a small amount of a metal primer agent.

Owner:OSHIDA YOSHIKI

Orthopedic implant system

InactiveUS6066176AStrong interlocking fixationEasy to fixSurgical adhesivesBone implantPolymethyl methacrylateFemoral stem

It is an object of the present invention to provide an improved orthopedic implant system with satisfied biological, mechanical and morphological compatibilities. Solid metal femoral stem (entirely or partially) and solid metal acetabular head (entirely or partially) are covered with diffusion-bonded foamed-shaped sheet made of commercially pure titanium or titanium alloy(s). The open-cells in said foamed metal sheet are impregnated with biocompatible polymethyl methacrylate resin cement, which is reinforced with selected oxides (e.g., alumina, magnesia, zirconia, or a combination of these oxides) along with an application of a small amount of a metal primer agent.

Owner:OSHIDA YOSHIKI

Scratch-Resistant Flameproof Thermoplastic Resin Composition

ActiveUS20090118402A1Improve scratch resistanceImprove mechanical propertiesPlastic/resin/waxes insulatorsDyeing processPolyethylene terephthalate glycolPolyethylene terephthalate

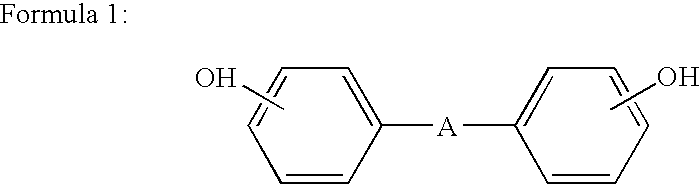

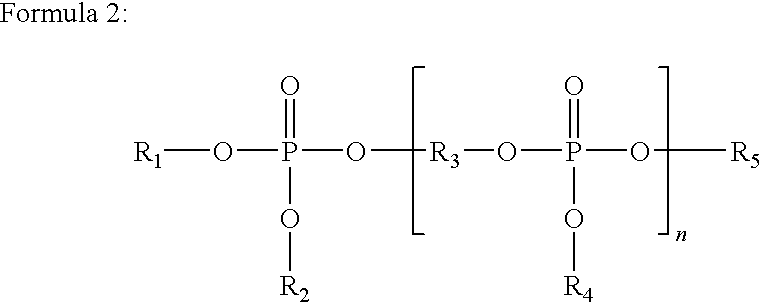

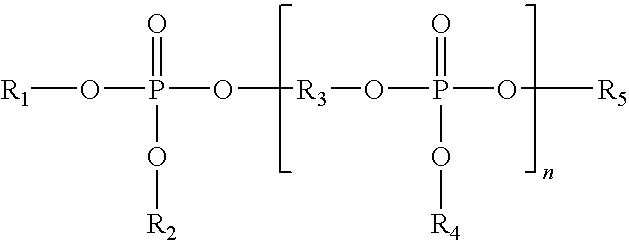

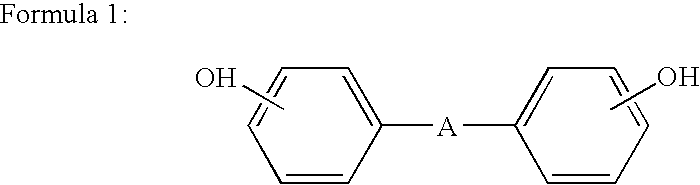

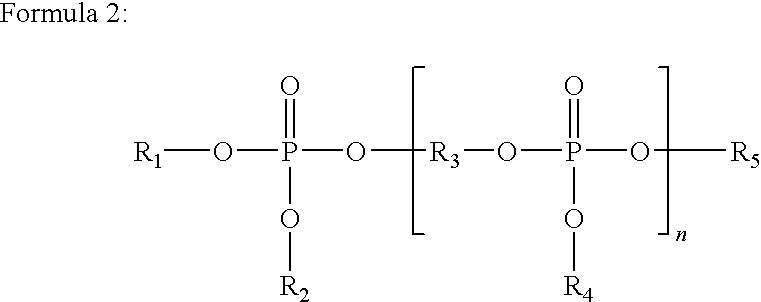

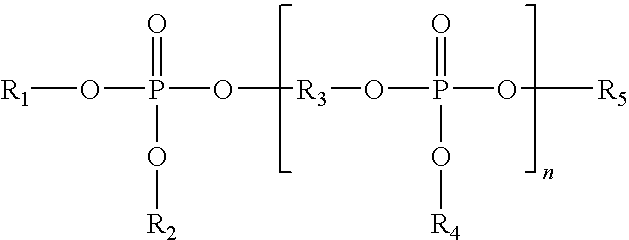

Disclosed herein is a flame retardant thermoplastic resin composition that has superior scratch resistance and mechanical properties, satisfying requirements for the appearance of housing materials resulting from a recent increase in volume of electrical and electronic products, and that contains a phosphorus-based flame-retarding agent, satisfying requirements for fire safety and prevention of environmental problems. The resin composition with scratch resistance comprises a base resin comprising (A) about 30 to about 90 parts by weight of a polycarbonate resin, (B) about 15 to about 50 parts by weight of a polymethylmethacrylate resin and (C) about 5 to about 50 parts by weight of a polyethylene terephthalate-based resin, and (D) about 5 to about 30 parts by weight of a phosphorus-based flame-retarding agent based on 100 parts by weight of the base resin. The composition may further comprise about 1 to about 30 parts by weight of an impact modifier based on 100 parts by weight of the base resin.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Method for preparing organic photochromic nanofibers

InactiveCN102071490AOvercome the disadvantage of low color fastness to washingOvercome the disadvantage of delaying photochromic discoloration reactionFilament/thread formingMonocomponent synthetic polymer artificial filamentFiberBattle fatigue

The invention relates to a method for preparing organic photochromic nanofibers, and the method comprises the following steps: dissolving organic photochromic compounds into a polymer solution so as to obtain a spinning solution; and preparing the spinning solution into nanofibers by using an electrostatic spinning technology, wherein the organic photochromic materials are spirooxazine type, spiropyrane type, diarylethene type, fulgide type and azo dye type photochromic materials, and the like; and the polymer materials refer to polyvinylpyrrolidone resins, polystyrene resins, polymethylmethacrylate resins, polyvinyl alcohol, polyethylene terephthalate (PET) resins and the like. The organic photochromic nanofibers prepared by the method provided by the invention have high sensitivity and excellent endurance performance, and can be applied to clothing materials for garments, shoes and hats, daily fabrics for fabrics and carpets, polymer fibers for cosmetics, discoloration windows, displays, chemical sensors and optical storage devices; and in the military field, the prepared organic photochromic nanofibers can be used for battle fatigues, tents, military machinery, and the like.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Scratch-resistant flameproof thermoplastic resin composition

ActiveUS7732515B2Maintain good propertiesIncrease resistancePlastic/resin/waxes insulatorsDyeing processThermoplasticPolymer science

Owner:LOTTE ADVANCED MATERIALS CO LTD

High-stability microcapsule used for asphalt self-repair

InactiveCN103965644AExtended service lifeWith regenerative functionBuilding insulationsEpoxyPolymethyl methacrylate

The invention provides a high-stability microcapsule used for asphalt self-repair. The microcapsule is characterized in that the microcapsule adopts polymers as wall materials and commercially available asphalt regenerant liquid as a core material; the mass ratio of the wall materials to the core material is (3:1)-(1:3); the polymers used as wall materials are melamine resin, methyl modified melamine resin, phenolic resin, epoxy resin, unsaturated polyester resin and polymethyl methacrylate resin; the core material is an asphalt regenerant, is oily liquid capable of dissolving aged asphalt and has the function of regenerating aged asphalt; after the microcapsule is mixed with molten asphalt at 200 DEG C for one hour, 95% of microcapsule is in a complete state and does not crack; the microcapsule is mixed with asphalt to generate microcracks in the asphalt aging process to crack the microcapsule and the asphalt regenerant is released to self-repair aged asphalt, thus greatly prolonging the service life of asphalt.

Owner:苏峻峰

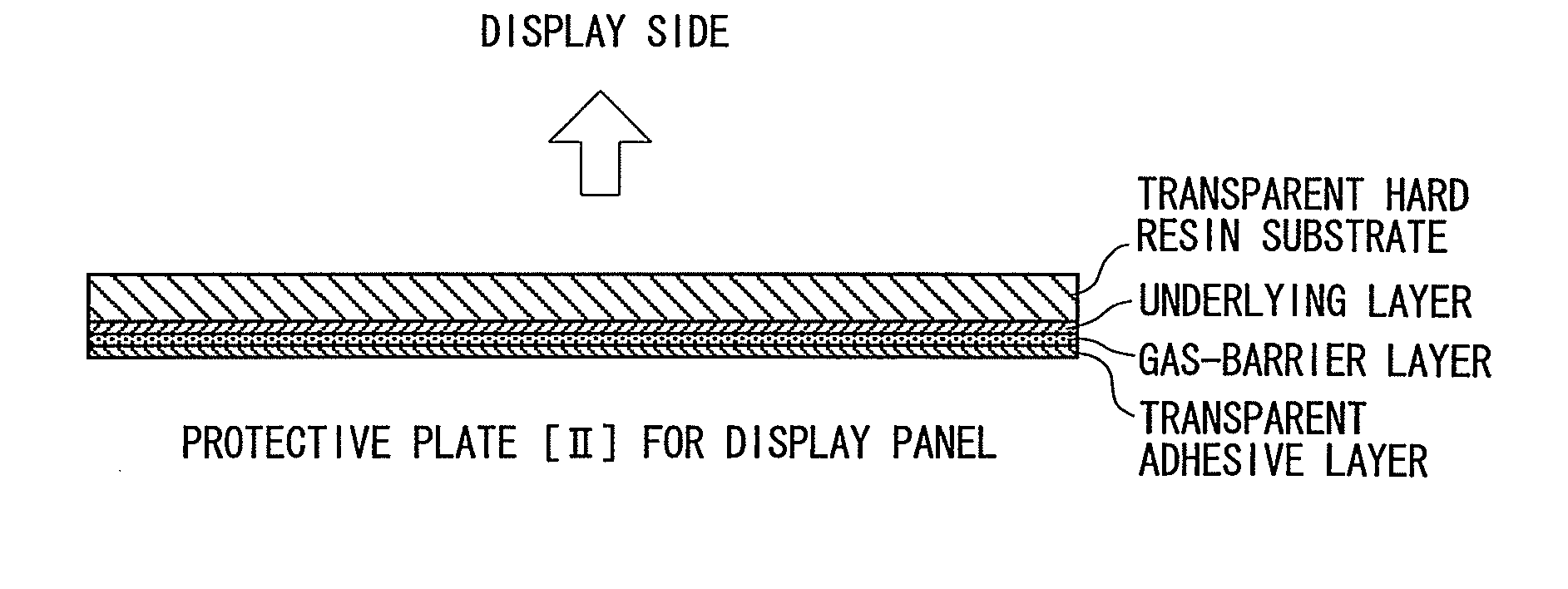

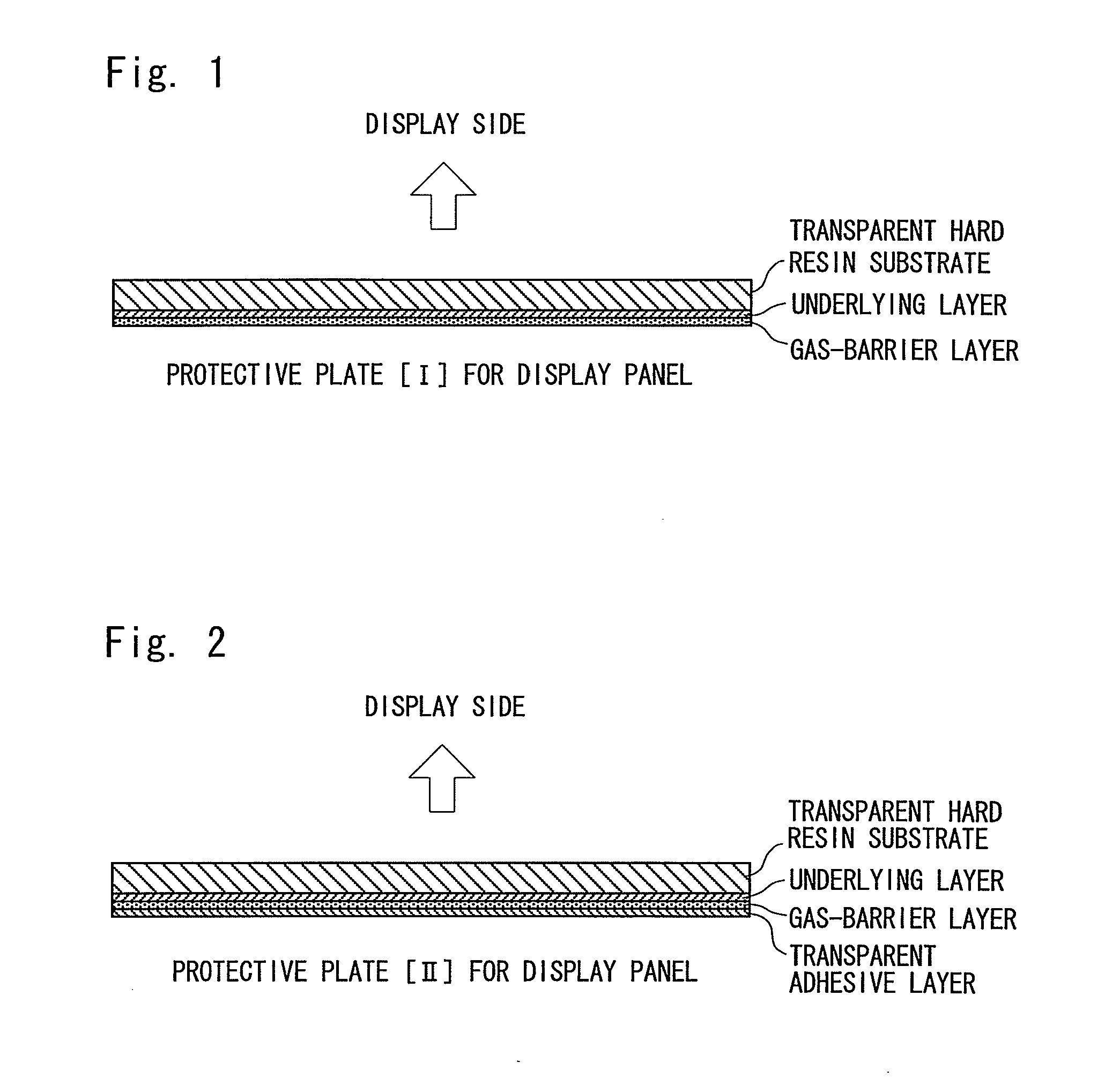

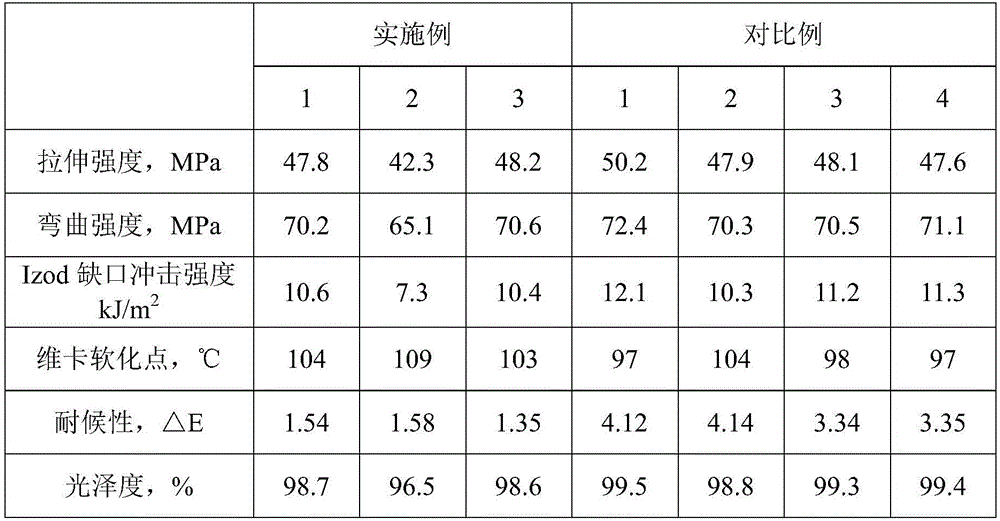

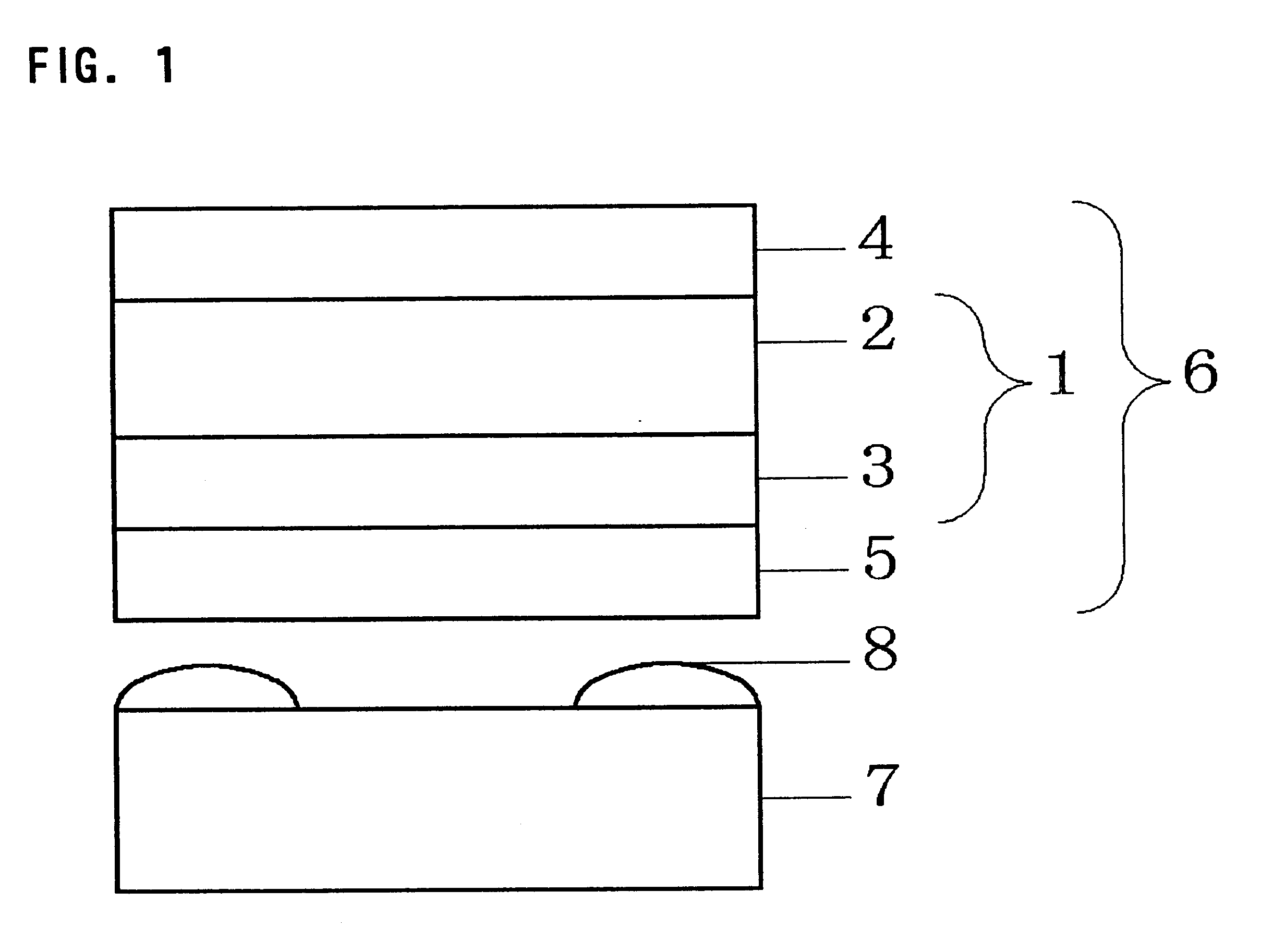

Transparent protective plate for display panels and display device

InactiveUS20120301635A1Excels in resistanceExcels in visibilityLiquid crystal compositionsSynthetic resin layered productsDisplay devicePolymethyl methacrylate

To provide a highly transparent and highly strong protective plate for display panel which, when mounted on a display panel, does not permit bubbles to evolve in the inner layer or does not permit the layer to peel off even in high temperature and high humidity conditions that could temporarily occur, for example, in an automobile, and a display device equipped with the protective plate.[Means for Solution] A transparent protective plate for display panel having an underlying layer, a gas-barrier layer and, as required, a transparent adhesive layer of an acrylic adhesive successively laminated on a transparent hard resin substrate such as of a polymethyl methacrylate resin or an aromatic polycarbonate resin, wherein the underlying layer comprises a cured body obtained by polymerizing an underlying material solution that contains 90 to 20 parts by mass of an urethane acrylate adhesive resin (A), and 10 to 80 parts by mass of a silicon compound (B) selected from the group consisting of an alkoxysilane compound and a hydrolyzed product thereof, a silane coupling agent and a hydrolyzed product thereof, and a fine particulate silica; and the gas-barrier layer comprises a cured body of a dense silicon oxide obtained by curing a polysilazane compound (C) in the presence of an amine catalyst (D).

Owner:FUKUBI KAGAKU IND

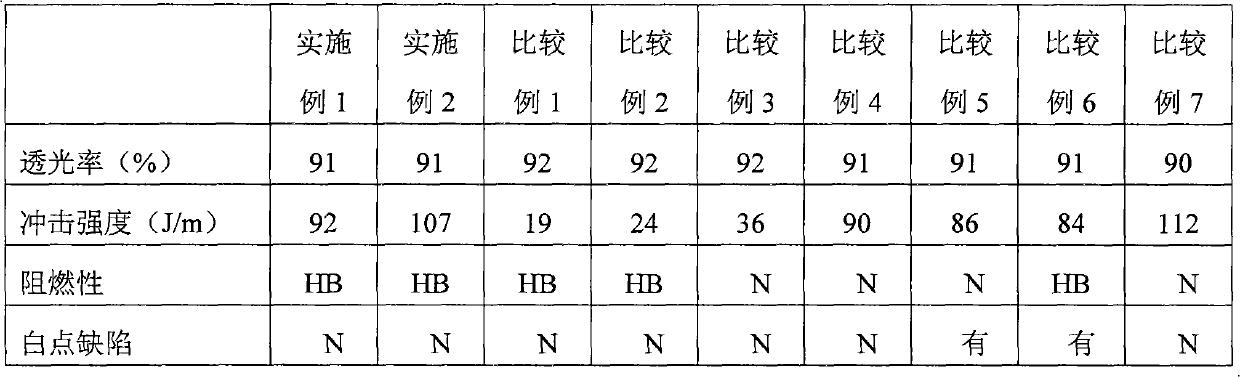

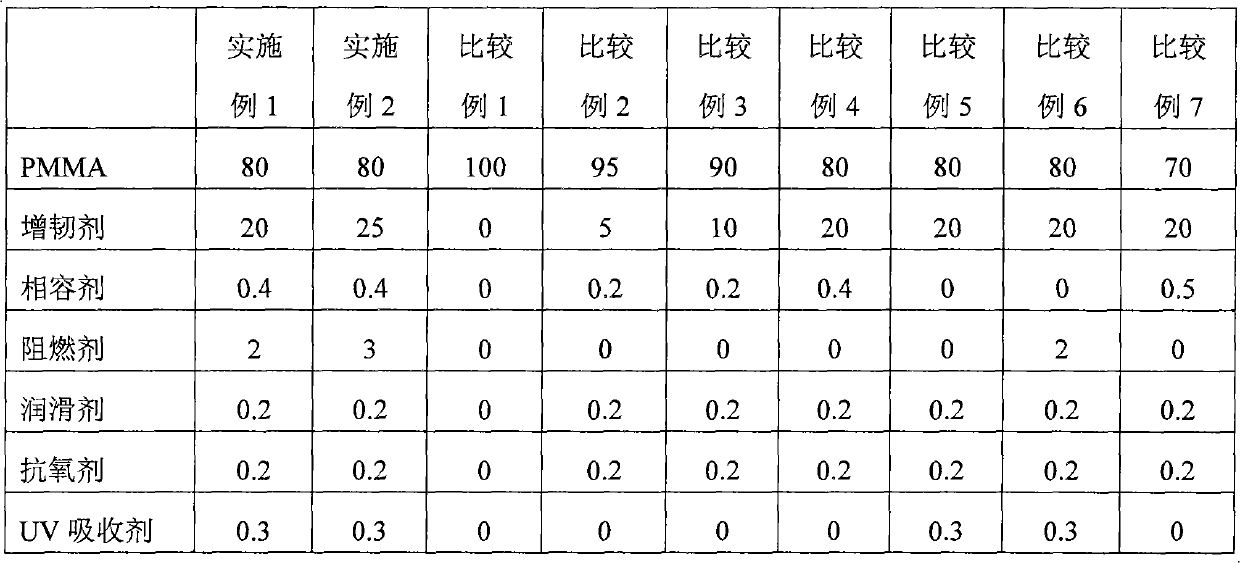

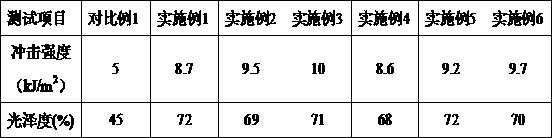

Polymethylmethacrylate composition and preparation method thereof

The invention provides a polymethylmethacrylate composition and a preparation method thereof. The polymethylmethacrylate composition comprises the following components in percentage by weight: 20-70% of polymethylmethacrylate resin, 5-25% of flexibilizer, 0.2-2% of compatilizer, 0.05-5% of flame retardant, 0.1-1% of lubricant, 0.1-1% of UV absorbent and 0.15-2% of antioxygen. The preparation method of the polymethylmethacrylate composition comprises the following steps: weighing the components of the polymethylmethacrylate composition according to the weight proportion; mixing the polymethylmethacrylate, the compatilizer and the flame retardant for 10-30 minutes, then adding the flexibilizer and mixing for 10-30 minutes, and finally adding the lubricant, the UV absorbent and the antioxygen and mixing for 10-30 minutes; and melting, mixing, extruding and granulating the well mixed raw materials in the eight regions of a twin-screw extruder. The polymethylmethacrylate composition of the invention has high processing yield, high light transmittance, high surface hardness, favorable toughness, chemical stability, weather resistance and fire resistance.

Owner:SINOPLAST NEW MATERIAL

Polymethylmethacrylate resin with an impact modifier capsulated therein and a process of preparing for the same

Owner:KOLON IND INC

High-heat-resistant high-weatherability ASA/PMMA (acrylonitrile-styrene-acrylonitrile and polymethyl methacrylate) composite and preparation method thereof

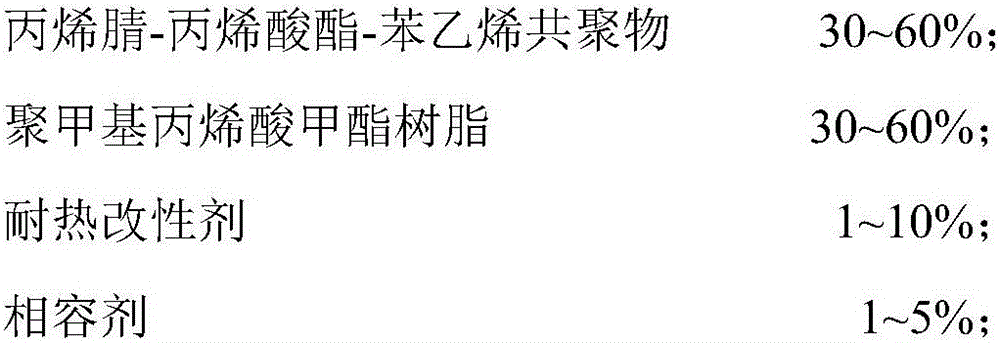

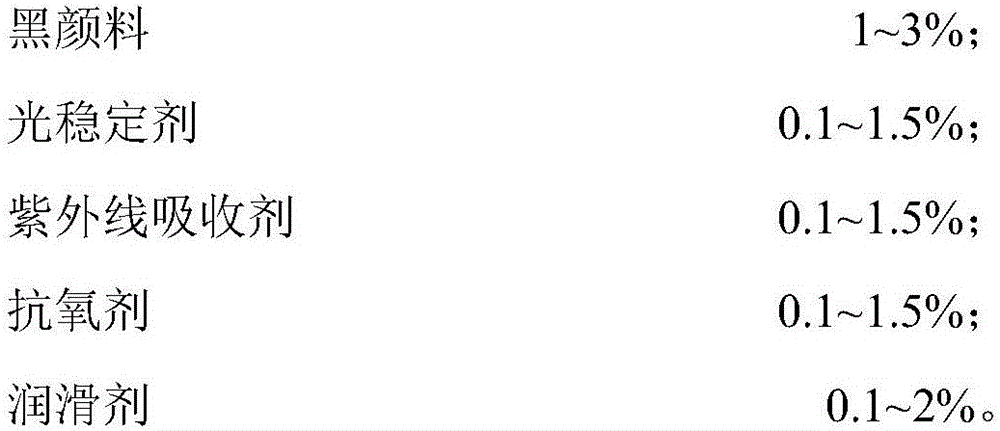

The invention discloses high-heat-resistant high-weatherability ASA / PMMA (acrylonitrile-styrene-acrylonitrile and polymethyl methacrylate) composite and a preparation method thereof, belongs to the field of material modification, and is intended to solve the problem that existing PMMA / ASA alloy resin has Vicat softening point of <100 DEG C and is unable to meet the demand for heat resistance in products and unable to be applied to an environment having high requirement on heat resistance. The composite comprises, by weight, 30-60% of ASA, 30-60% of PMMA, 1-10% of a heat-resistant modifier, 1-5% of a compatibilizer, 1-3% of a black pigment, 0.1-1.5% of a photostabilizer, 0.1-1.5% of an ultraviolet absorbent, 0.1-1.5% of an antioxidant, and 0.1-2% of a lubricant. Actual application shows that the ASA / PMMA composite has excellent heat resistance and weatherability, high surface gloss and good comprehensive properties, has Vicat softening point of 100 DEG C and above, man have effectively extended applicable range, and has a promising application prospect.

Owner:SICHUAN COREMER CO LTD

Easy adhesion film for transparent conductive thin film

An easy adhesion film for a transparent conductive thin film comprises a transparent polymer film and an easy adhesion layer formed on the transparent polymer film, wherein the easy adhesion layer comprises at least an ionizing radiation curable resin binder, a (meth)acrylate copolymer binder and polymethyl methacrylate resin particles. The easy adhesion film has high durability, transparency and anti-Newton ring property when provided with a transparent conductive thin film.

Owner:KIMOTO CO LTD

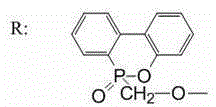

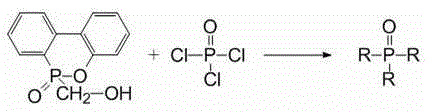

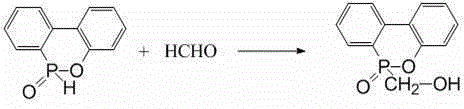

Preparation method of phosphorus-containing flame-retardant polymethyl methacrylate resin

The invention relates to a preparation method of phosphorus-containing flame-retardant polymethyl methacrylate resin. A formula for preparing the phosphorus-containing flame-retardant polymethyl methacrylate resin comprises the following components by weight percent: 17.92 to 22.65 percent of tri((6-oxo-6H-dibenz [c,e][1,2] oxaphosphorin-6-yl)methyl) phosphate, 78.16 to 82.39 percent of methyl methacrylate and 0.16 to 0.76 percent of benzoperoxide. The preparation method comprises the following steps: adding a formula amount of methyl methacrylate, tri((6-oxo-6H-dibenz [c,e][1,2] oxaphosphorin-6-yl)methyl) phosphate and initiator benzoperoxide into a reaction container, stirring about 52 min at 85.2 DEG C, allowing the system to be viscous, then pouring a prepolymer into a mold, cooling to about 40 DEG C, performing the heat insulation for 6h, then heating to 80 DEG C, and performing the heat insulation for 12h to obtain the flame-retardant polymethyl methacrylate resin.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Preparation method and self-repair method of self-repairable polymethylmethacrylate resin film

InactiveCN103159969AAccurate partial repairBroaden your optionsLiquid surface applicatorsCoatingsRepair methodSelf repair

The invention relates to a preparation method and a self-repair method of a self-repairable polymethylmethacrylate resin film. The preparation method solves the problem that polymethylmethacrylate produces cracks and is damaged easily in use. The preparation method comprises the following steps of 1, preparing a polymethylmethacrylate resin solution, 2, preparing a nano-particle / polymethylmethacrylate mixed solution, and 3, preparing the self-repairable polymethylmethacrylate resin film. The self-repair method has a wide repairable-resin selection scope and has stronger popularization. The preparation method can be used for preparation of a self-repairable polymethylmethacrylate resin film and the self-repair method is suitable for self-repair of a damaged polymethylmethacrylate resin film.

Owner:HARBIN INST OF TECH

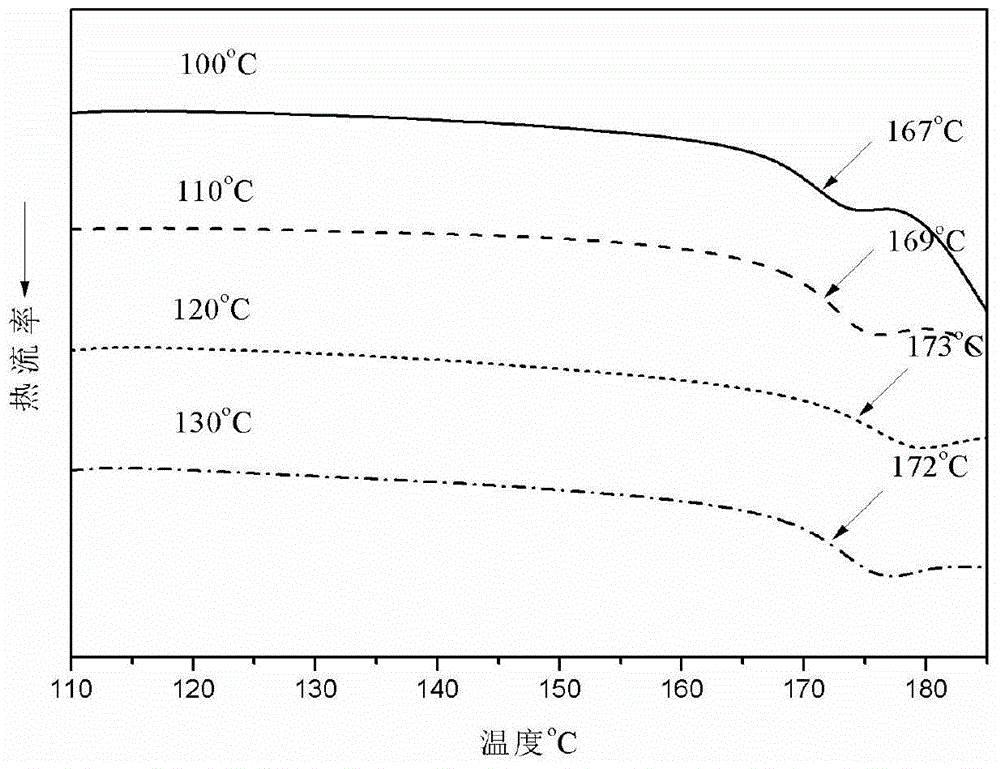

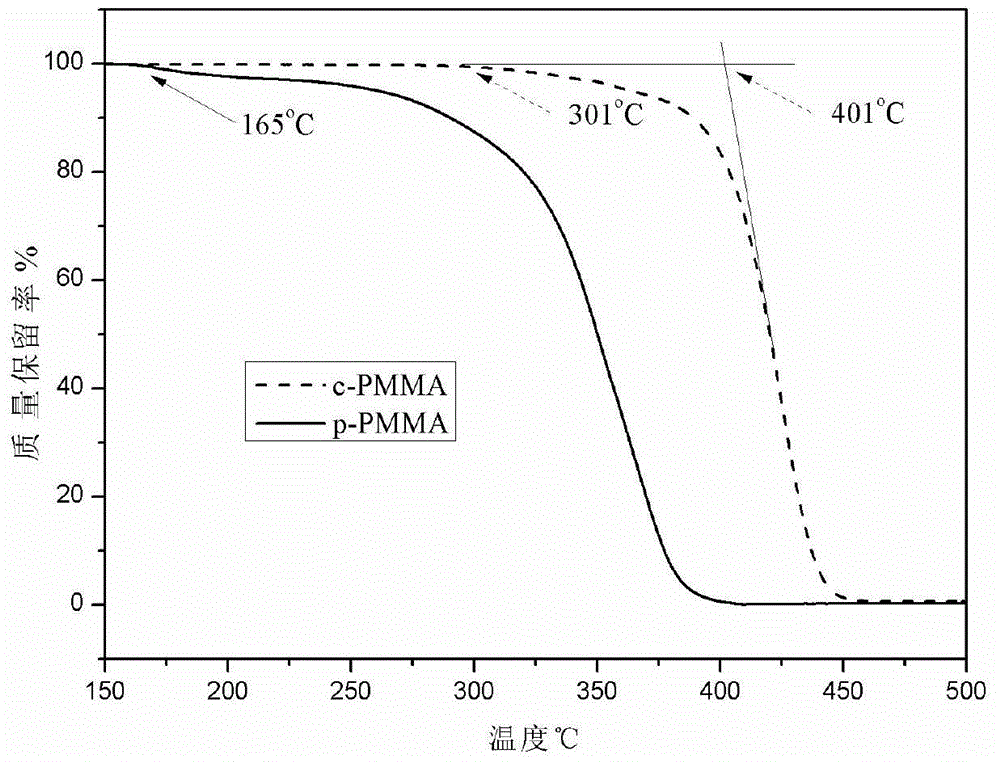

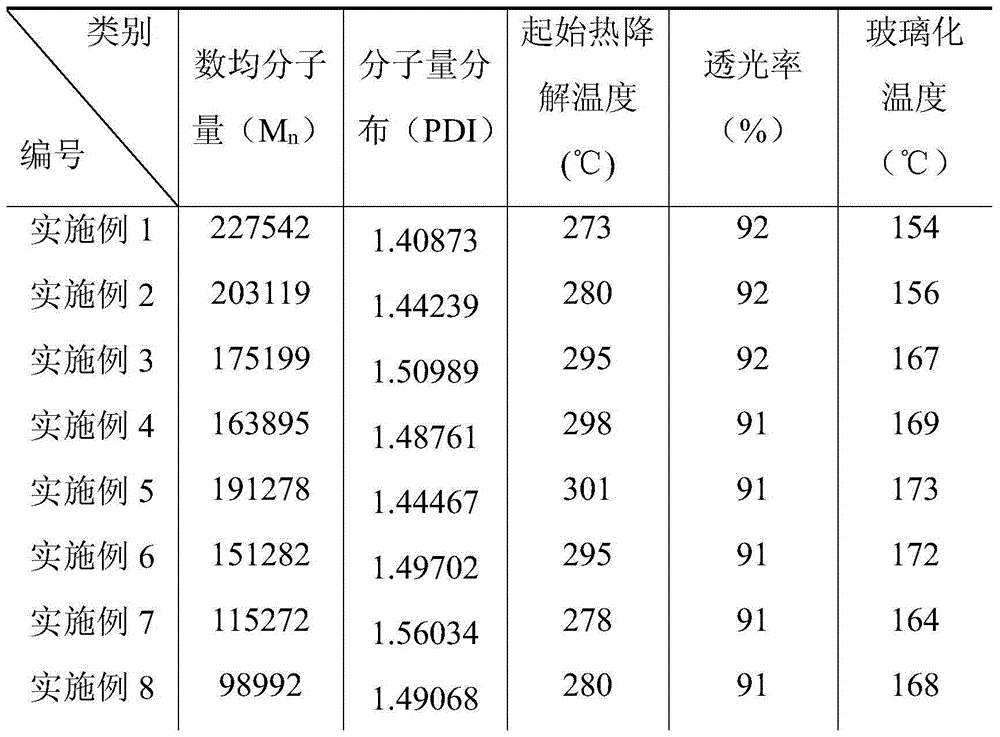

Preparation method for polymethyl methacrylate resin with high heat resistance

ActiveCN104650286AImprove heat resistanceImprove thermal stabilityPolymer sciencePolymethyl methacrylate

The invention provides a preparation method for polymethyl methacrylate resin with high heat resistance, and belongs to the field of high polymer material preparation methods. The preparation method is used for solving the problems that an existing preparation method for the polymethyl methacrylate resin is complex in post-treatment process, the solvent is toxic and the product performances are poor. According to the preparation method disclosed by the invention, continuous solution polymerization is adopted, alcohol is taken as a solvent, monomer with reactive hydrogen and methyl methacrylate are polymerized into binary copolymer at a high temperature, and a purpose of improving the heat resistance of the polymethyl methacrylate resin is improved by controlling a ratio of charge and a polymerization temperature of the polymethyl methacrylate monomer and the acrylamide monomer. According to the experimental results, the glass transition temperature Tg of the polymethyl methacrylate resin prepared by the preparation method can reach 173 DEG C, the thermal degradation initial temperature is over 301 DEG C, the obvious thermal degradation temperature is up to 401 DEG C and the molecular weight distribution is about 1.5.

Owner:CHANGCHUN UNIV OF TECH

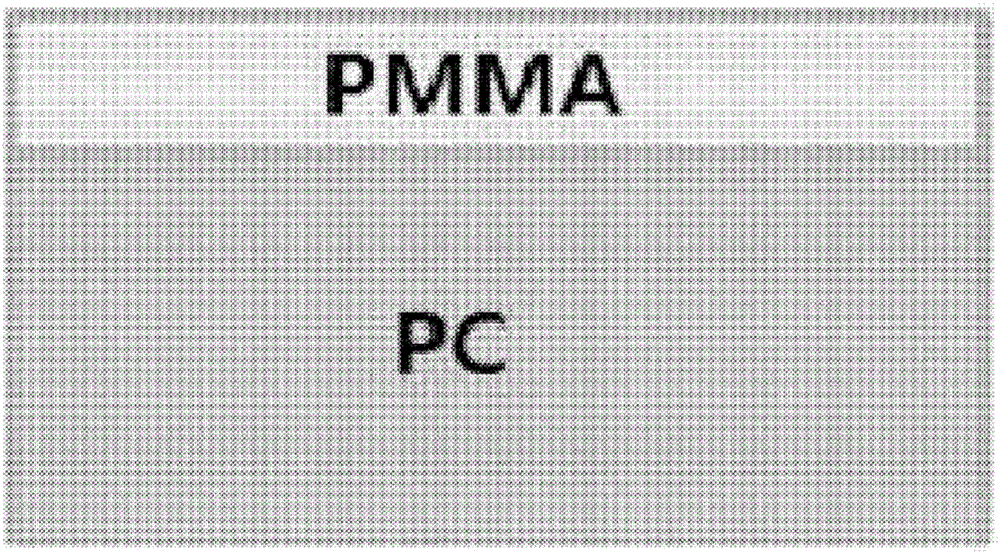

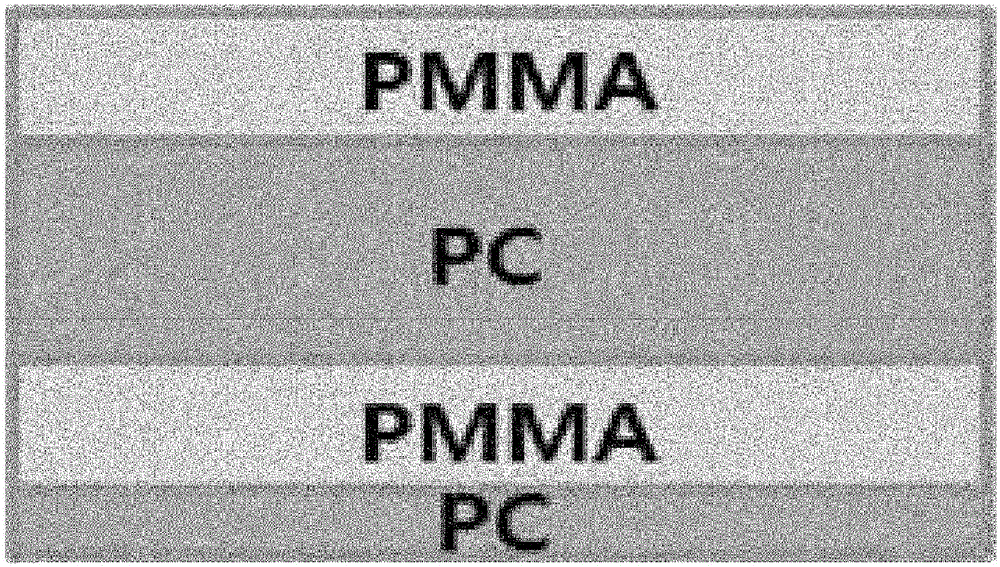

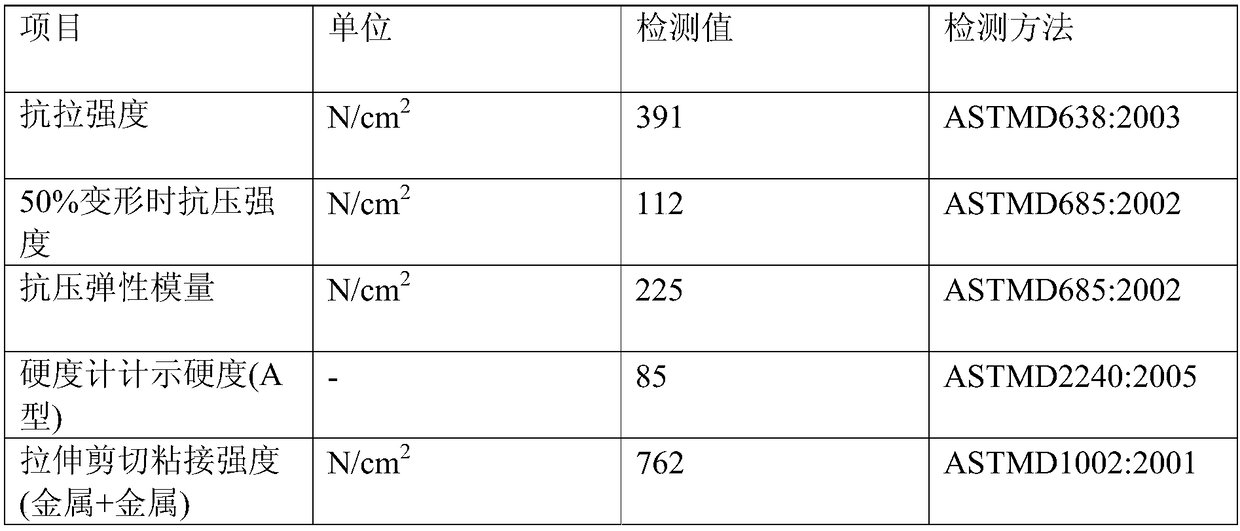

Transparent plastic sheet

The present invention provides a transparent plastic sheet comprising: a support layer including a polycarbonate resin layer; and a polymethylmethacrylate resin layer, which is formed as a surface layer on the support layer and has a glass transition temperature of 120-135degrees centigrade, wherein the thickness of the polymethylmethacrylate resin layer is 5-20% of the total thickness of the sheet, and the overall transmittance of the sheet is 89-94% based on ASTM D1003. Therefore, the deformation of the transparent plastic sheet can be minimized under high-temperature and high-humidity conditions, and thus the transparent plastic sheet can be favorably applied, as a window cover for glass replacement, to various display products.

Owner:KOLON IND INC

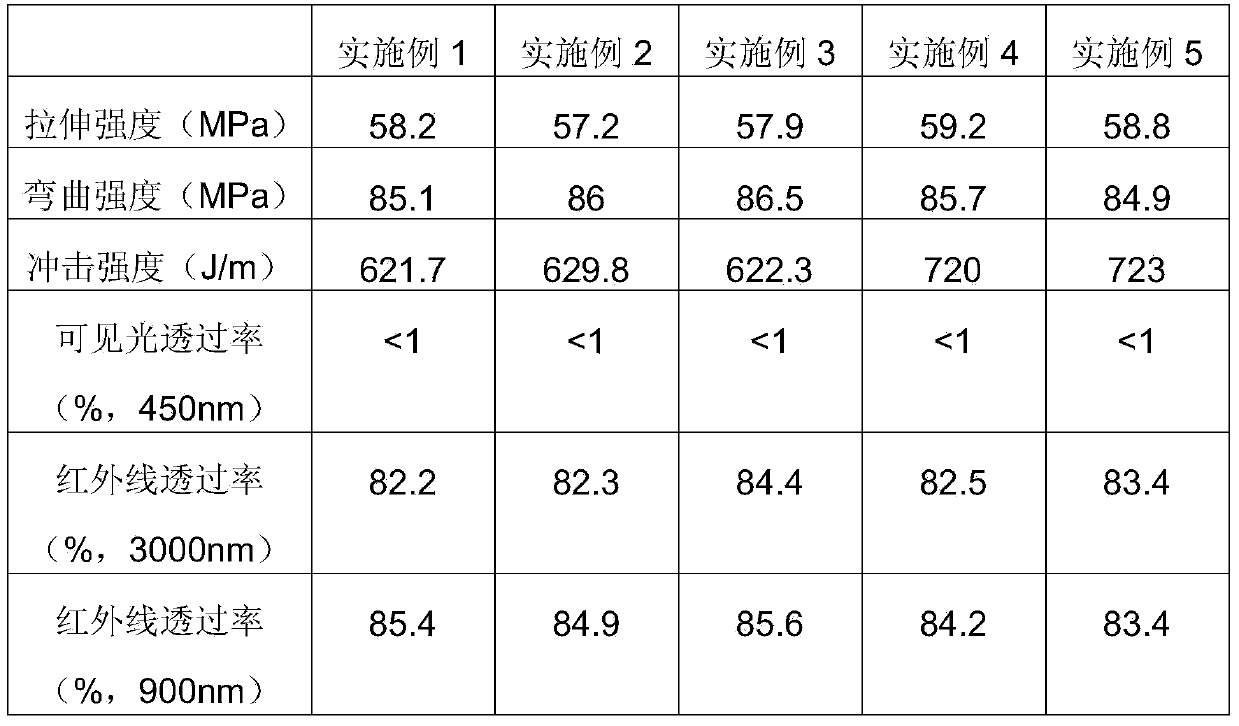

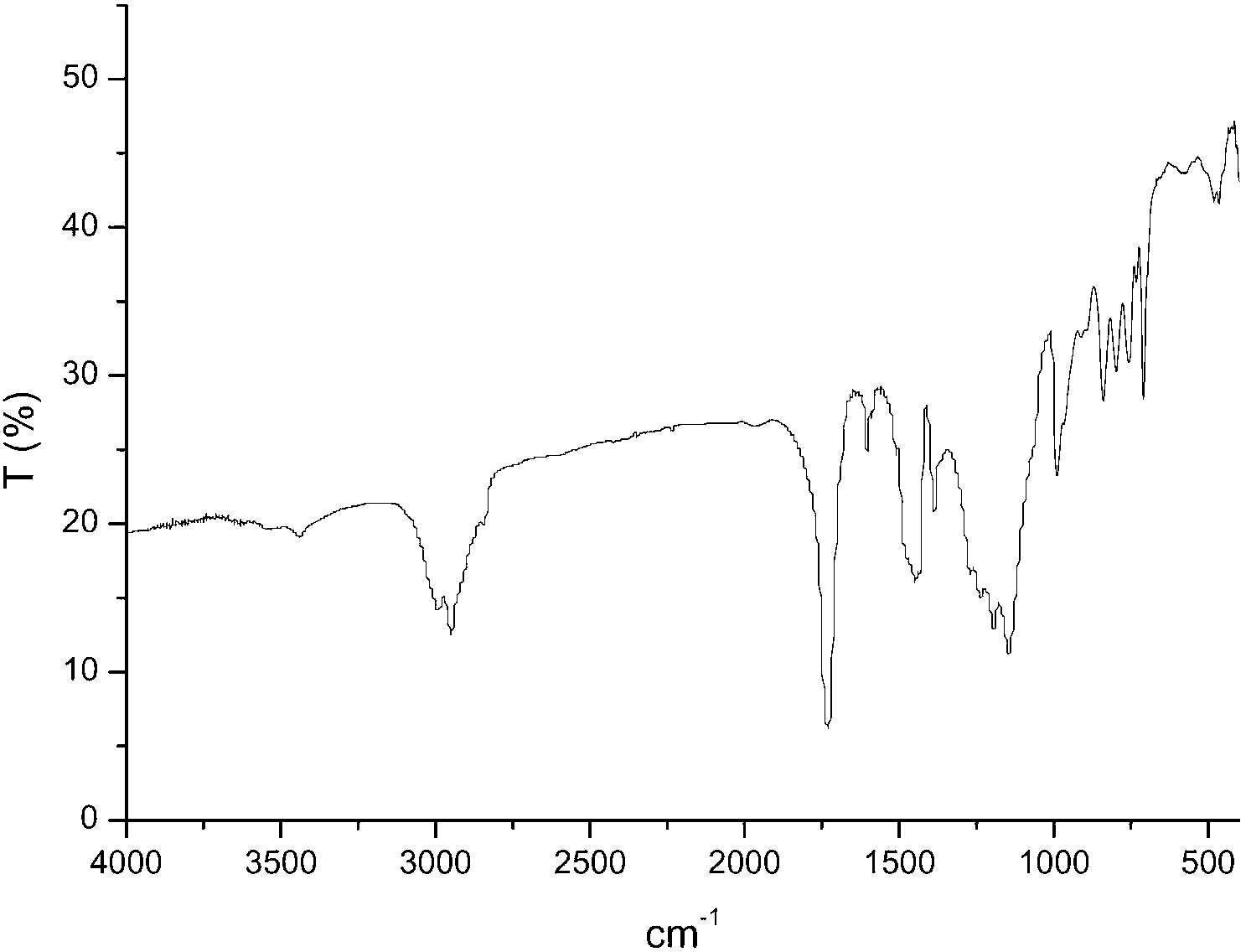

Infrared ray-penetrable polymethyl methacrylate composition

The invention provides an infrared ray-penetrable polymethyl methacrylate composition. The infrared ray-penetrable polymethyl methacrylate composition comprises polymethyl methacrylate, an infrared ray penetration promoter and a surface hardness modifier. The infrared ray-penetrable polymethyl methacrylate composition has high penetration rates of infrared rays having different wavelengths, has the infrared ray penetration rates more than 80% and a visible light penetration rate less than 1%, retains excellent mechanical properties, thermal properties and environmental suitability of polymethyl methacrylate, and has a low manufacturing cost.

Owner:宁波力达得为高分子科技有限公司

PMMA/ASA alloy material with high heat resistance and high black brightness and preparation method and application of PMMA/ASA alloy material

ActiveCN111690222AImprove scratch resistanceNo decrease in surface glossRadiatorsAcrylonitrilePolymethyl methacrylate

The invention discloses a PMMA / ASA alloy material with high heat resistance and high black brightness and a preparation method and application thereof. The PMMA / ASA alloy material is prepared from thefollowing components in parts by weight: polymethyl methacrylate (PMMA) resin, acrylonitrile-styrene-acrylate copolymer (ASA rubber powder), a heat-resisting agent, an antioxidant, a light stabilizer, an anti-scraping agent and a coloring agent. According to the PMMA / ASA alloy material prepared through the method, HDT can reach 95 DEG C or above and is improved by 20 DEG C or above compared withmature materials on the market, the surface gloss is basically not reduced, the blackness L value is 22.5, and the effect of piano black can be achieved. Meanwhile, the scratch resistance is also obviously improved, and a five-finger scratch test and a surface wear resistance test can be passed.

Owner:DONGGUAN HONOUR E P

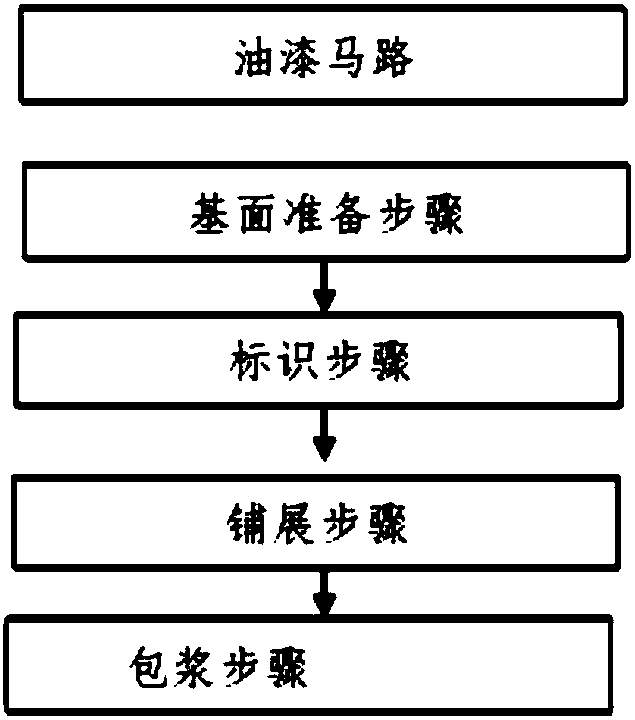

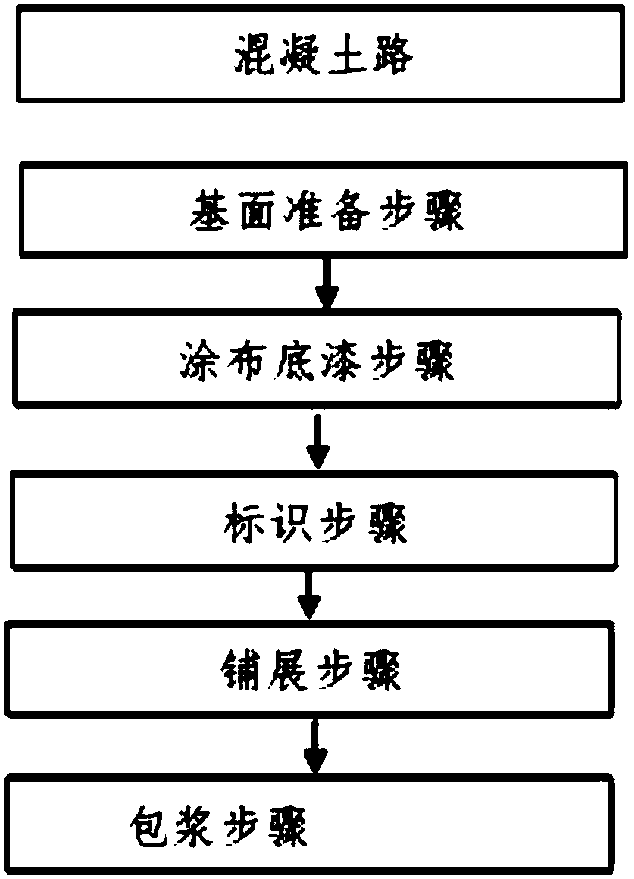

Anti-skid colored paving material for roads, and preparation method and construction process of paving material

InactiveCN108546383ALong construction periodAdvantage manufacturing methodSidewalk pavingsPaving detailsPolymethyl methacrylateDrying time

The invention provides an anti-skid colored paving material for roads, and a preparation method and a construction process of the paving materials. The anti-skid colored paving material for roads comprises the following components in parts by weight: 40-50 parts of polymethyl methacrylate resin, 10-20 parts of calcium carbonate, 1-5 parts of nano silicon dioxide, 2-5 parts of inorganic pigment, 5-15 parts of bauxite and 5-8 parts of quartz sand. The anti-skid colored paving material for roads provided by the invention has a shortened hardening time, and the bauxite with excellent acid resistance, alkali resistance and chemical resistance is used as the main material, so that an original working procedure of additional removal of anti-skid aggregates can be omitted, and the problems that the aggregate easily peels off from the paving material and uniform spreading is difficult due to uneven aggregate shape existed in the additional removal of the aggregates can be solved. Pre-mixing iscarried out for coating the aggregate with the quartz sand, the aggregate does not fall off easily, the drying time is faster, the traffic condition can be reached only in one hour, and the traffic pressure is greatly reduced.

Owner:TIANJIN BAISITE NEW MATERIAL TECH

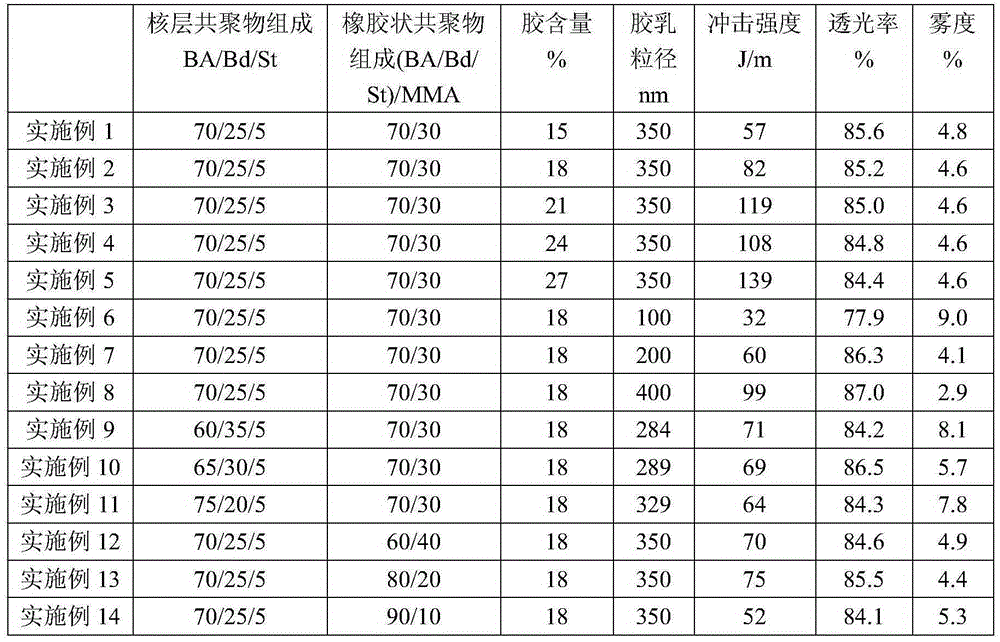

Transparent rubber modified polymethyl methacrylate resin composition and preparation method thereof

The invention provides a transparent rubber modified polymethyl methacrylate resin composition, and belongs to the technical field of high polymer materials. The composition comprises 12-23.14 parts of rubber copolymer and 48-36.86 parts of PMMA matrix resin according to weight parts, wherein the rubber copolymer comprises 20-80 parts of nuclear copolymer and 80-20 parts of shell polymer according to weight parts; the nuclear copolymer comprises 60-75 parts of a butyl acrylate monomer, 20-40 parts of a butadiene monomer and 0-10 parts of a styrene monomer according to weight parts; the shell polymer is polymethyl methacrylate. The invention further provides a preparation method for the transparent rubber modified polymethyl methacrylate resin. The transparent resin is obtained through adjustment of biphase refraction index, so that the resin has better transparency and toughness.

Owner:CHANGCHUN UNIV OF TECH

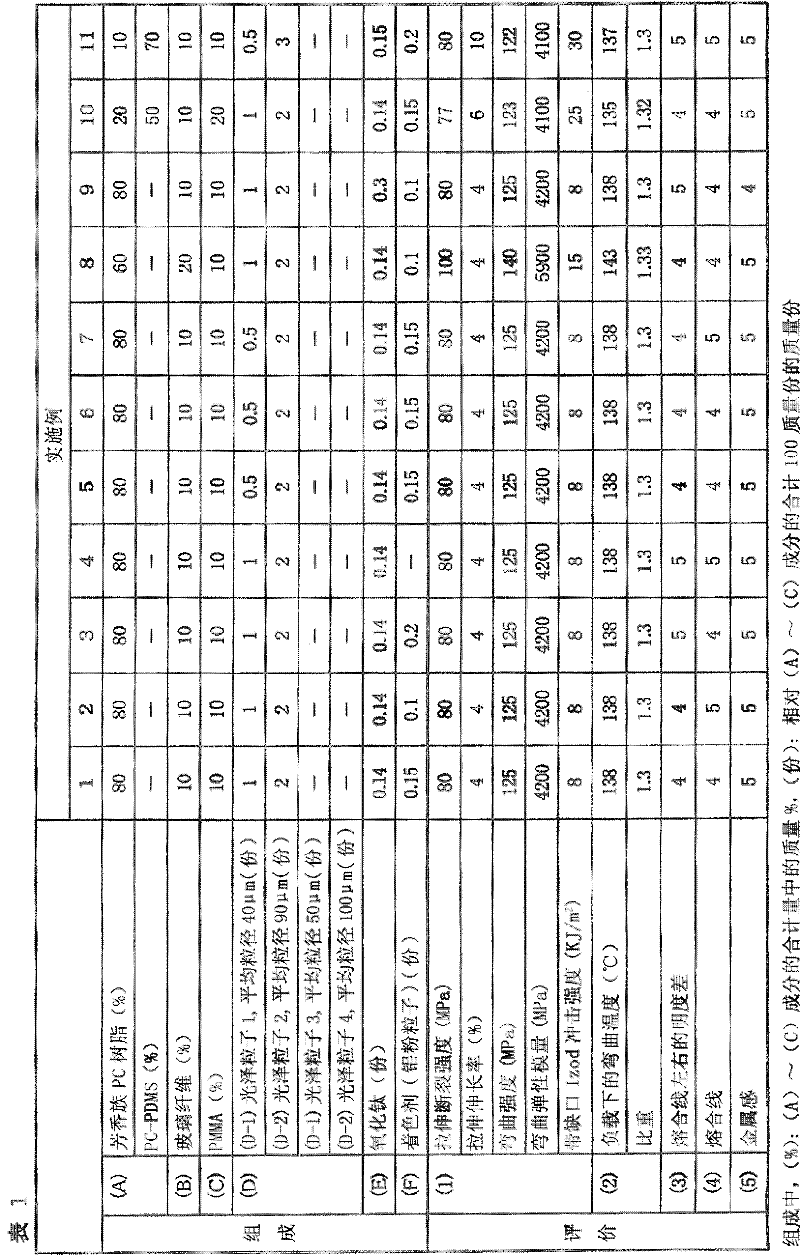

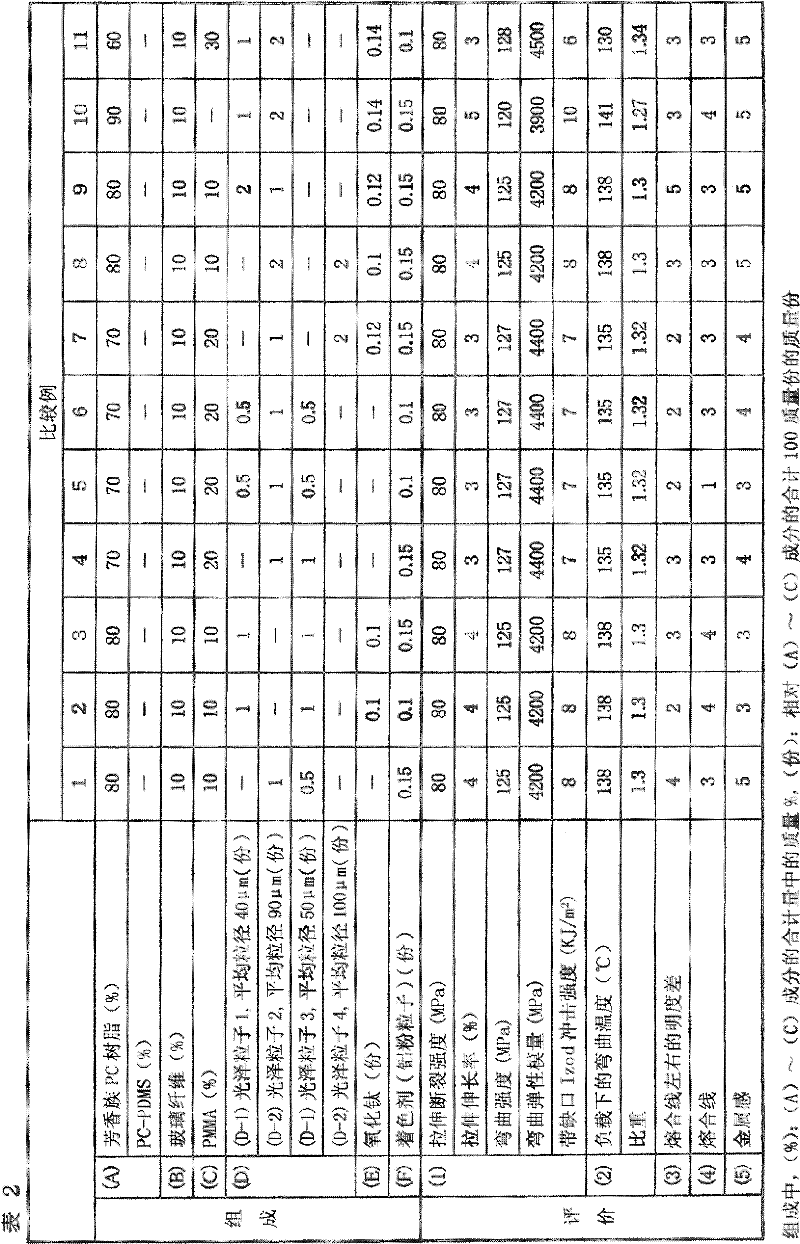

Polycarbonate resin composition, polycarbonate resin molded article, and manufacturing method therefor

InactiveUS20120220709A1Improve mechanical propertiesPromote metallic feeling-expressing effectGlass making apparatusSpecial tyresFiberPolymer science

Provided are: a polycarbonate resin composition, including, with respect to 100 parts by mass of a glass fiber-containing resin component formed of 60 to 90 mass % of (A) an aromatic polycarbonate resin, 5 to 20 mass % of (B) such glass fibers that a difference in refractive index between the aromatic polycarbonate resin and each of the fibers is 0.02 or less, and 5 to 25 mass % of (C) a polymethyl methacrylate resin, (D) 0.005 to 1.5 parts by mass of (D-1) glossy particles having an average particle diameter of 10 μm or more and less than 60 μm, and 0.005 to 5 parts by mass of (D-2) glossy particles having an average particle diameter of 60 to 300 μm, and 0.05 to 0.4 part by mass of (E) titanium oxide having an average particle diameter of 0.05 to 3 μm; a resin molded article obtained by molding the resin composition; and a method of producing the resin molded article. The polycarbonate resin composition is capable of providing a molded article having reduced visibility of a weld line fusion portion, no visible difference in luminosity between the left and right sides of a weld line, and a good metallic or galactic appearance, the composition being excellent in heat resistance and mechanical properties.

Owner:IDEMITSU KOSAN CO LTD

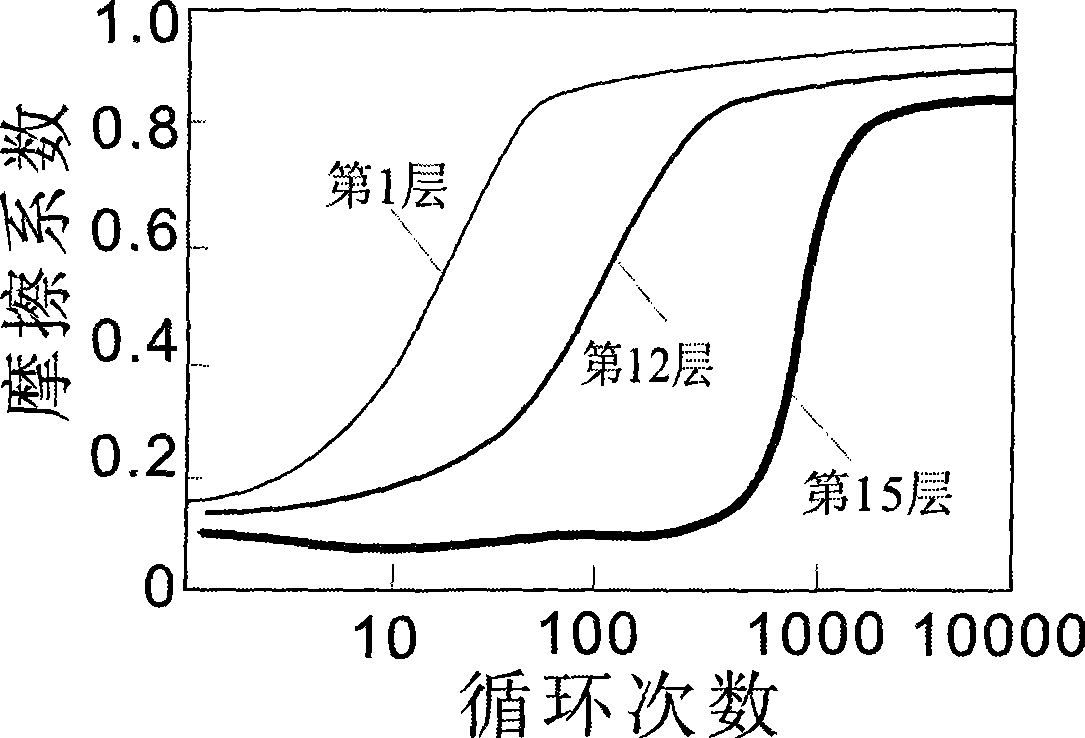

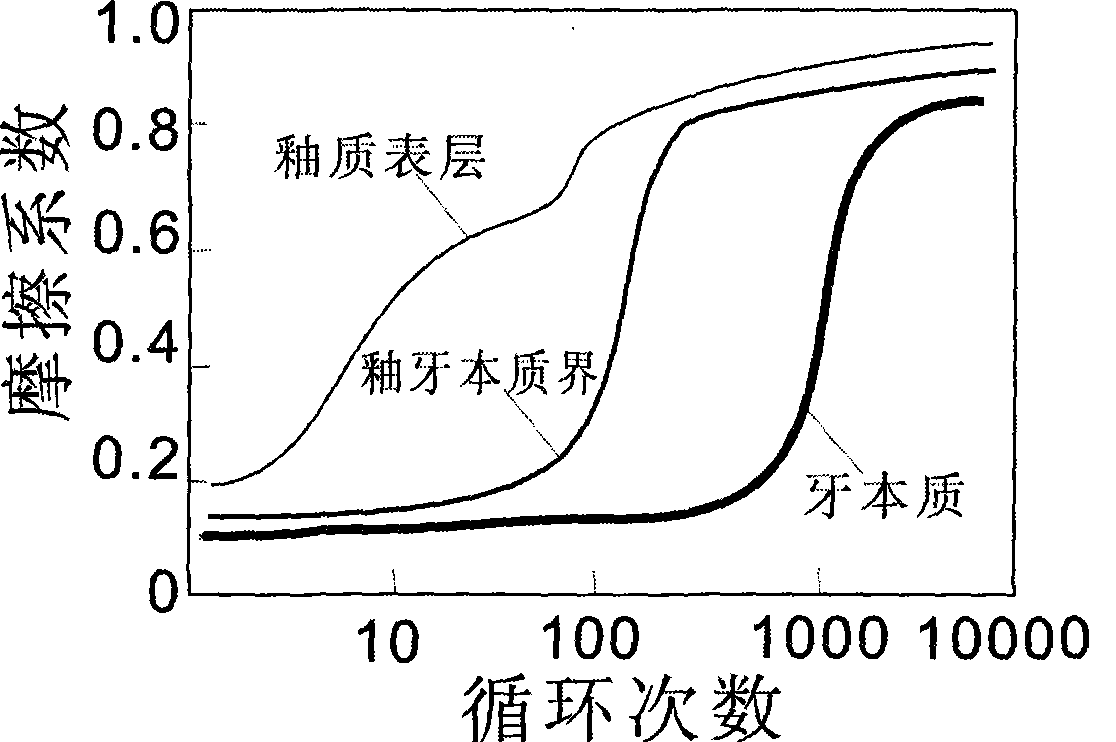

Wear-bionic nano-ceramic composite artificial tooth and method for preparing same

ActiveCN101518469AImprove bindingNot easy to fall offImpression capsArtificial teethNatural toothCeramic composite

The invention discloses a wear-bionic nano-ceramic composite artificial tooth, which comprises 12 to 15 layers of nano-ceramic / resin composite material layers covering on lap ridge parts of the artificial tooth made from polymethyl methacrylate resin, wherein the content of the nano-ceramic material in the innermost first composite material layer is 10 percent, the content of the nano-ceramic material in the composite material layers from the inside to the outside increases gradually, and the content of the nano-ceramic material in the outermost layer is 30 percent; and the thickness of each layer of the composite material layers at an occlusal surface is between 180 and 220 mu m. The artificial tooth is well combined with a base tray, has similar wear resistance to a natural tooth, and not only has the characteristics of beautiful appearance and wear resistance of a ceramic tooth, but also has small wear to the natural tooth like a resin tooth. The clinical service life of the artificial tooth of the invention is long.

Owner:SICHUAN UNIV

PMMA/ASA alloy material for PVC profile coextrusion surface layer and preparation thereof

The invention discloses a PMMA / ASA alloy material for a PVC profile coextrusion surface layer and preparation thereof. The PMMA / ASA alloy material is prepared from the following raw materials in percentage by ,mass: 0.5 to 3 percent of chain extender, 0 to 5 percent of inorganic nano particle, coupling agent accounting for 0 to 3 percent of the mass of the inorganic nano particle, and the balanceof PMMA resin and ASA resin, wherein the mass ratio of the PMMA resin to the ASA resin is 1:0.25-4; the PMMA resin is polymethylmethacrylate resin; the ASA resin is acrylonitrile-styrene-acrylate grafted copolymer; and the chain extender contains groups which can react with the carboxyl. The PMMA / ASA alloy material has excellent performance such as high intensity, high toughness, high glossiness,friction and abrasion resistance, and the like.

Owner:ZHEJIANG UNIV OF TECH

Polycarbonate resin composition, polycarbonate resin molded article, and manufacturing method therefor

InactiveCN102575095AImprove heat resistanceExcellent mechanical propertiesGlass making apparatusParticulatesRefractive index

Owner:IDEMITSU KOSAN CO LTD

Transparent rubber modified thenylethylene resin composition

The invention discloses a rubber particle discontinuous phase and transparent rubber modified styrene resin compound, which is characterized by the following: forming rubber particle discontinuous phase with rubber copolymer; comprising 10-50 rubber particle discontinuous phase and 90-50 wt base blending copolymer; setting the rubber particle discontinuous phase as 20-80 wt core layer copolymer and 80-20 wt shell layer copolymer; setting the core layer copolymer as 5-50 wt styrene monomer and 95-50 wt diene monomer; setting the shell layer copolymer as 10-70 wt styrene monomer and 90-30 wt (metyl group) acrylic ester monomer; setting the base blending copolymer as 20-80 wt polymethyl methacryate resin and 80-20 wt styrene-acrylonitrile copolymer resin; setting the grain diameter of the core layer copolymer at 100-1000nm. This product possesses good transparency, shockproof property and chemical medicine resistance property.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

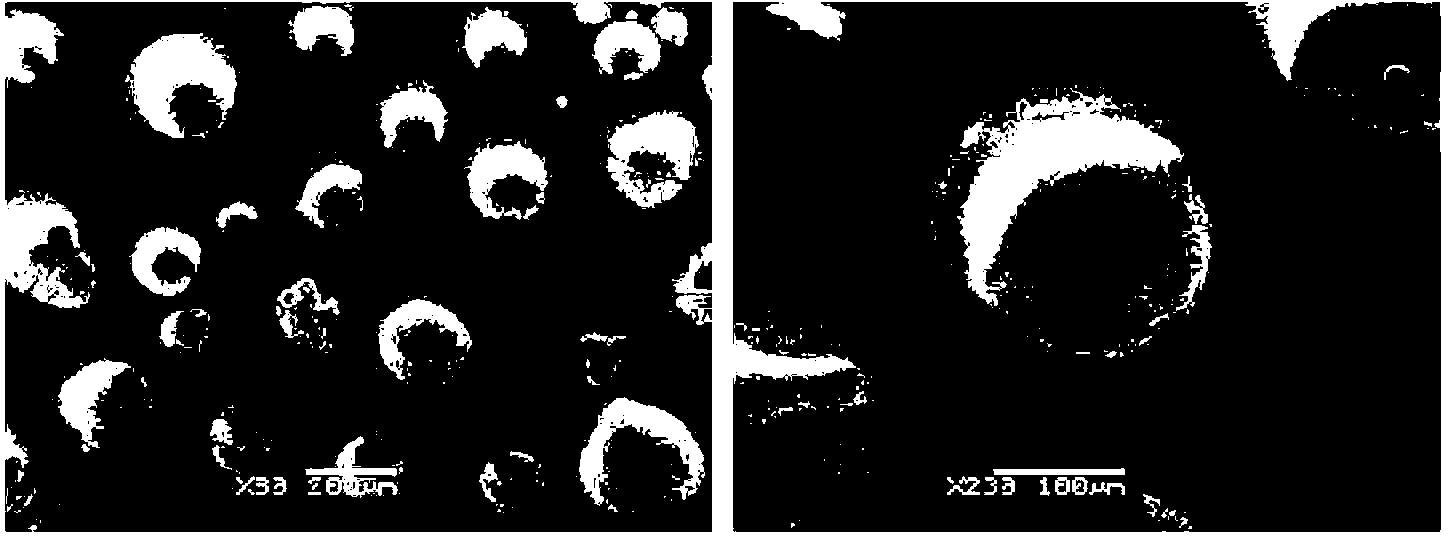

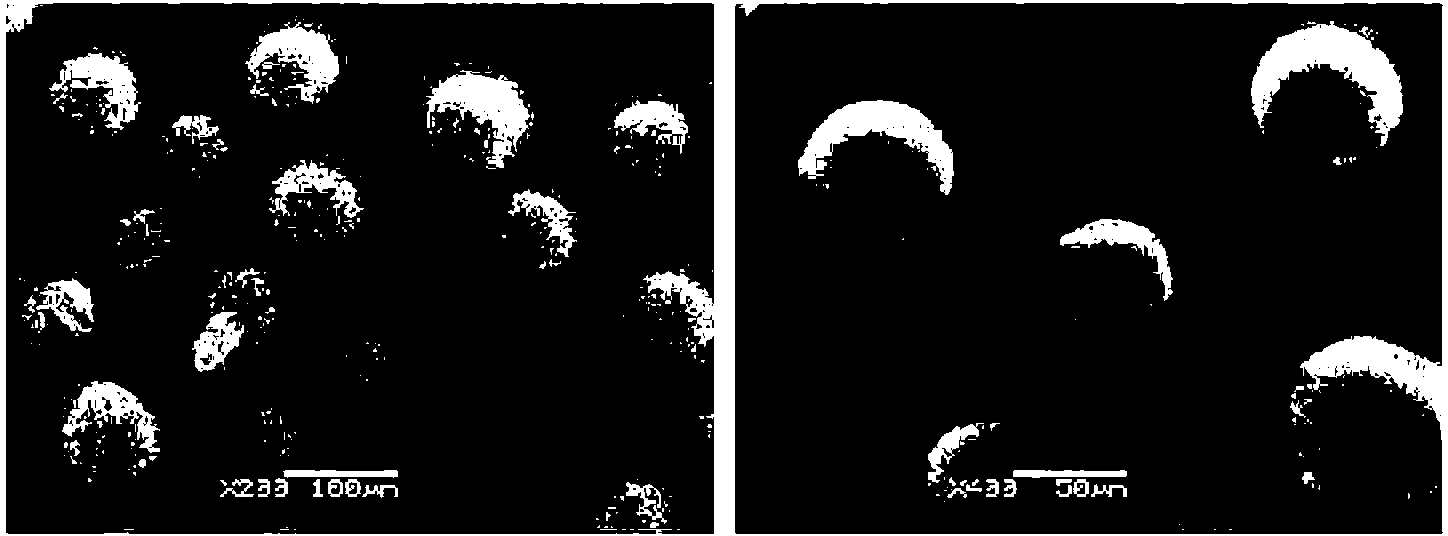

Preparation method of crosslinked polymethyl methacrylate resin microspheres with narrow particle size distribution

The invention relates to a preparation method of crosslinked polymethyl methacrylate resin microspheres with narrow particle size distribution. The technical scheme is as follows: thoroughly mixing methyl methacrylate monomer, crosslinking agent, pore-forming agent and initiator, adding the mixture into a dispersant-surfactant water solution, heating while stirring to react, pouring out the supernatant to obtain a mixed solution containing the polymethyl methacrylate resin microspheres, washing with water, and eluting with ethyl acetate to obtain the polymethyl methacrylate resin microspheres. The particle sizes of the methyl-methacrylate resin microspheres prepared by the method are adjustable within the range of 20-350 micrometers; the sphericity is higher than 95%; and the preparation method can effectively enhance the yield of the methyl-methacrylate resin microspheres by heating once, is simple to operate, uses economical dispersant, surfactant, solvent and the like, and can easily implement industrialized mass production.

Owner:平邑经济开发区投资发展有限公司

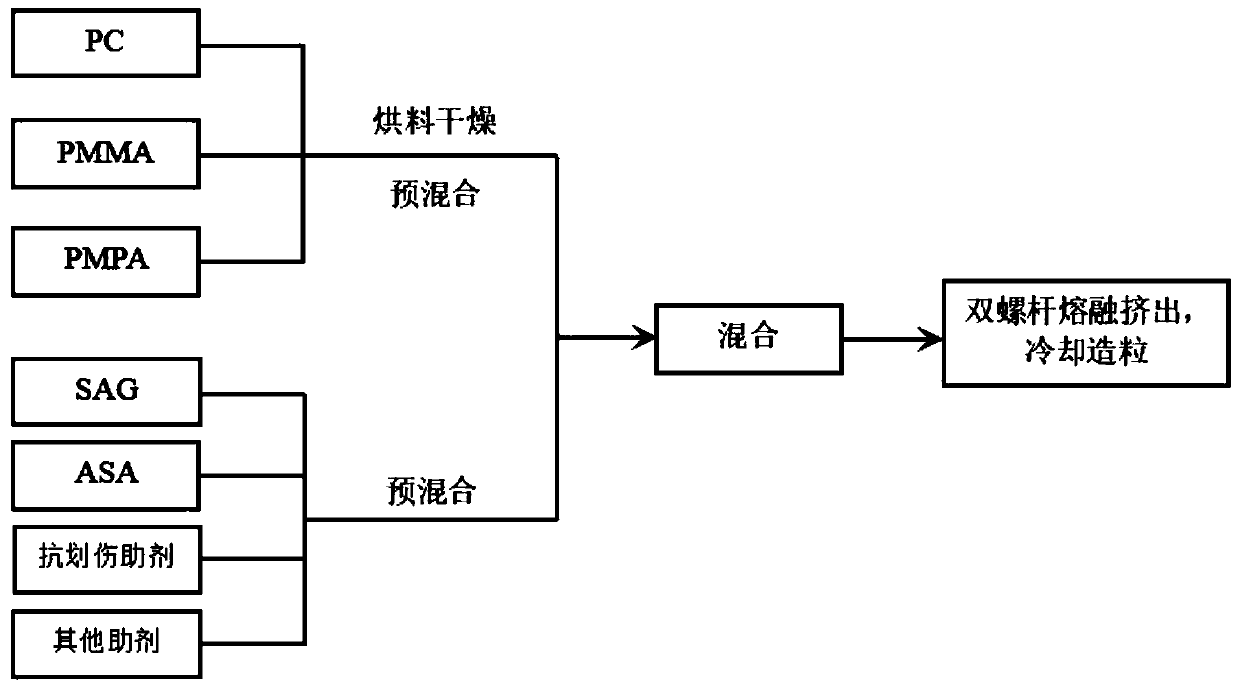

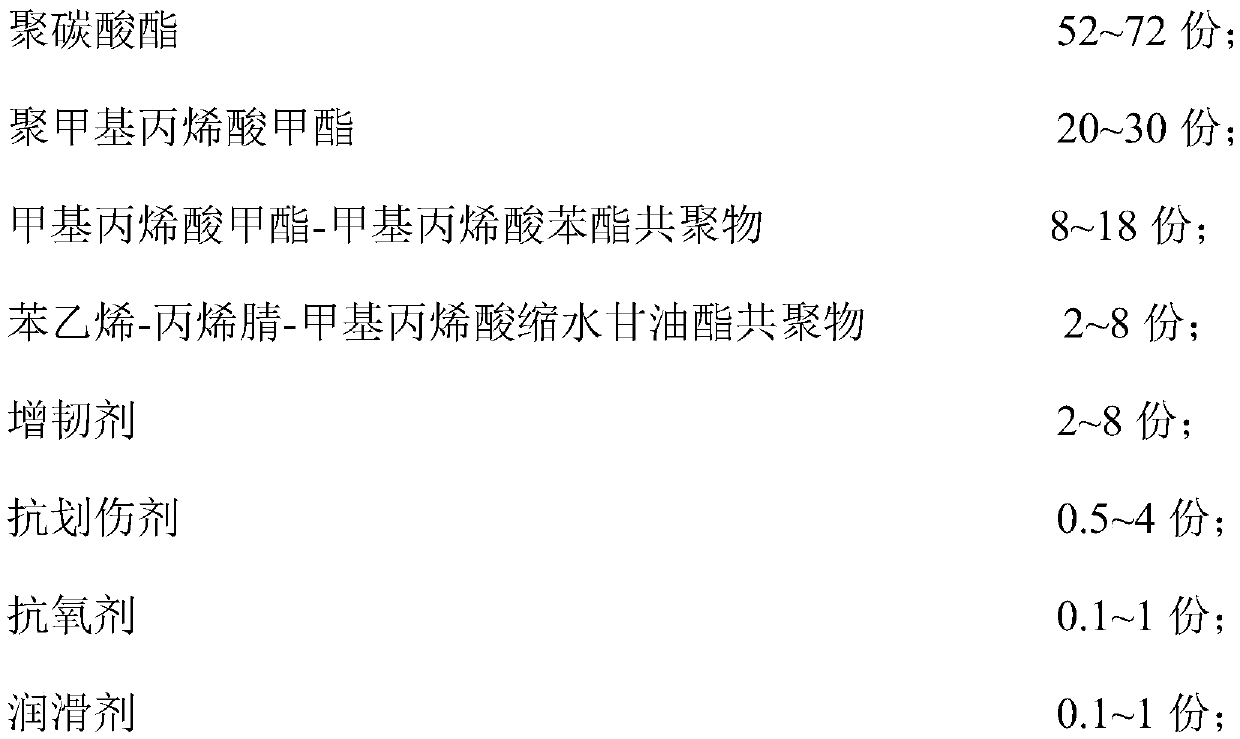

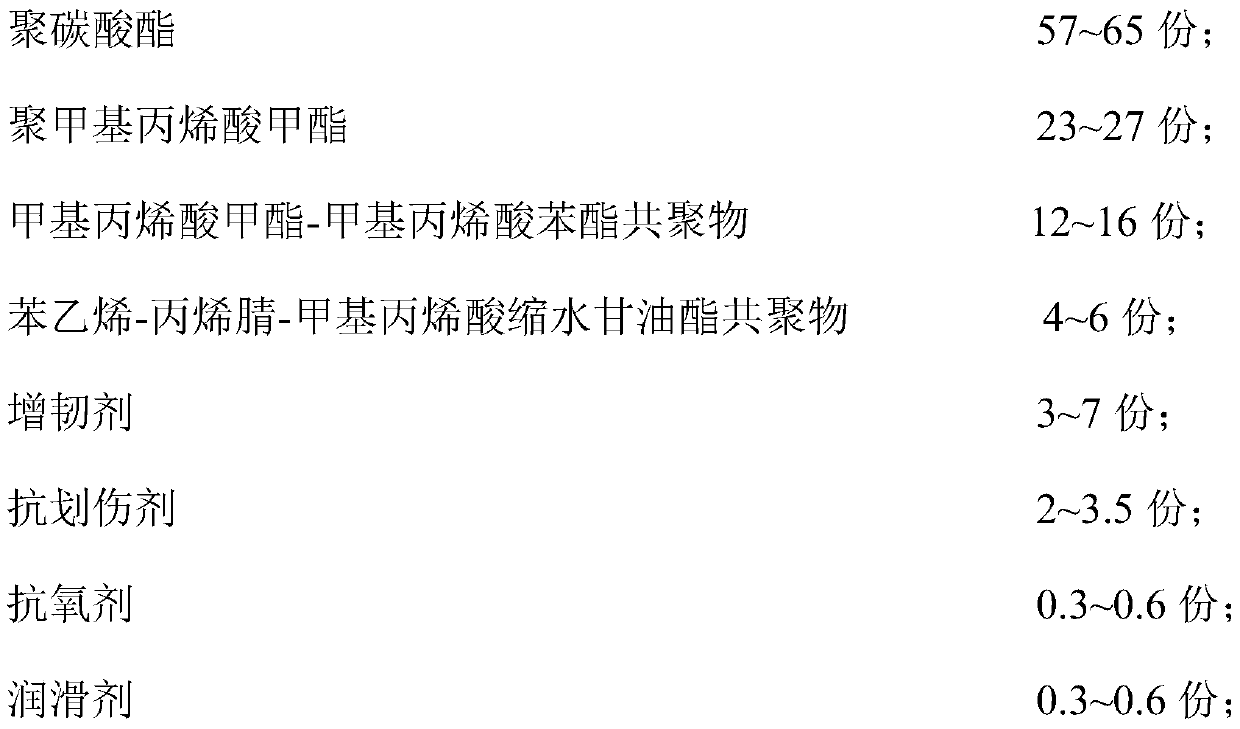

Polycarbonate composition and preparation method thereof

The invention relates to a polycarbonate composition and a preparation method thereof. The polycarbonate composition is prepared from, by weight, 52-72 parts of polycarbonate resin (PC), 20-30 parts of polymethyl methacrylate resin (PMMA), 8-18 parts of a methyl methacrylate-phenyl methacrylate copolymer (PMPA), 2-8 parts of a styrene-acrylonitrile-glycidyl methacrylate copolymer (SAG), 2-8 partsof a toughening agent, 0.5-4 parts of an anti-scratch agent, 0.1-1 part of an antioxidant and 0.1-1 part of a lubricant. The prepared polycarbonate composition has the advantages of high toughness, high gloss and excellent scratch resistance, and achieves a good application effect and prospect in the fields of automobiles, electronic appliances, instruments and meters, packaging and the like.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

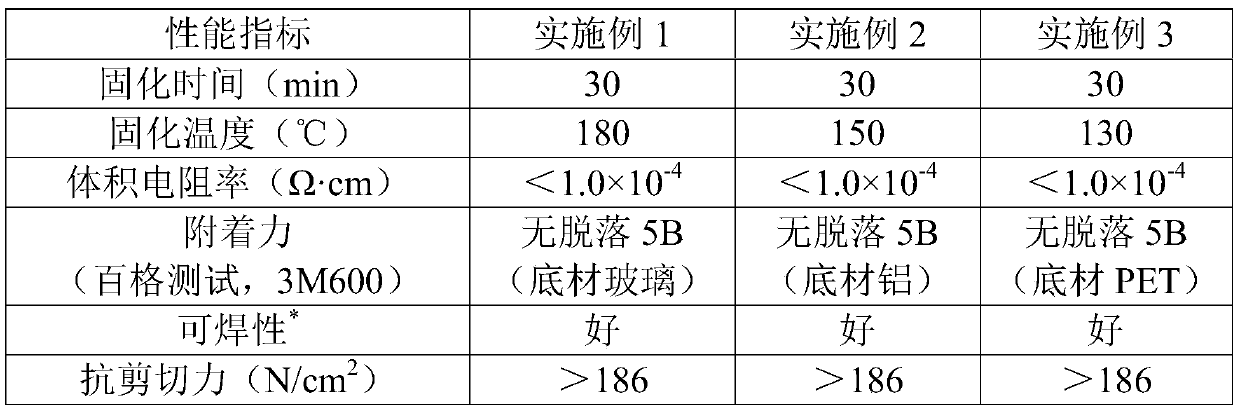

Solderable low-temperature curing type functional silver paste and preparation method thereof

ActiveCN109887639AHigh densityFirmly assembledNon-conductive material with dispersed conductive materialCable/conductor manufactureCross-linkSilver paste

The invention discloses a solderable low-temperature curing type functional silver paste and a preparation method thereof. The composition mass percent of the solderable low-temperature curing type functional silver paste is: 85-95wt% of silver powder and 5-15wt% of organic carrier, wherein the organic carrier comprises 75-90wt% of modified polymethyl methacrylate PMMA resin, 0-15wt% of organic solvent, 5-20wt% of cross-linking agent and 5-15wt% of auxiliary agent. A functional silver paste is prepared from silver powder, modified polymethyl methacrylate PMMA resin, organic solvent, cross-linking agent and auxiliary agent, and the prepared functional silver paste can meet the solderability requirements of wave soldering, reflow soldering, gold soldering and indium soldering after being cured at low temperature. The invention provides a solderable low-temperature curing functional silver paste and a preparation method thereof for assembling high-density and high-reliability electronic products in the field of information electronics, and has wide application prospect and market value.

Owner:KUNMING INST OF PRECIOUS METALS

High-solid low-viscosity laser alumite imaging layer coating and preparation method thereof

The invention discloses a high-solid low-viscosity laser alumite imaging layer coating and a preparation method thereof. The high-solid low-viscosity laser alumite imaging layer coating is prepared from the following raw materials in parts by weight: 10-30 parts of polymethyl methacrylate resin, 5-10 parts of styrene-maleic anhydride resin, 1-5 parts of cellulose acetate butyrate, 5-10 parts of isobornyl methacrylate, 1-5 parts of fluorine-containing polyacrylate, 50-70 parts of butanone, 1-8 parts of n-propyl acetate and 1-5 parts of propylene glycol ether. Polymer monomers contained in the formula of the imaging layer coating are of special structures or functional groups, and meanwhile comprehensive performance of polymer is taken into consideration; under the condition that the performance, such as heat resistance, of the polymer coating is not influenced, the viscosity of polymer solution can be obviously reduced, the using amount of an organic solvent is reduced, the leveling property of a coating film in the coating process is improved, and the coating film also has relatively low surface energy, so that acting force between a laser operating plate and a polymer coating layer in a high-temperature mold pressing process is reduced to achieve an effect of preventing plate adhesion.

Owner:玉溪春和纸业有限公司

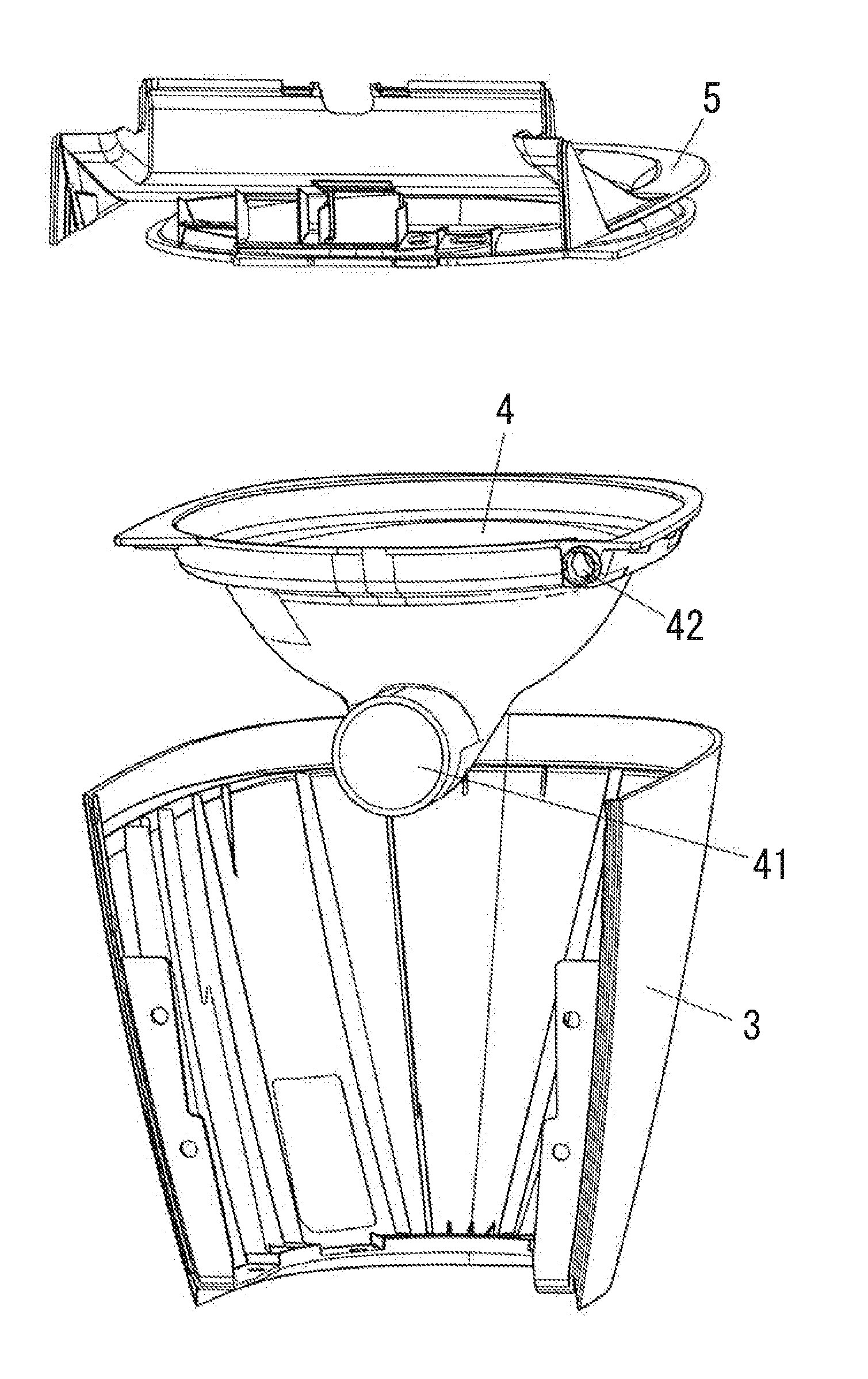

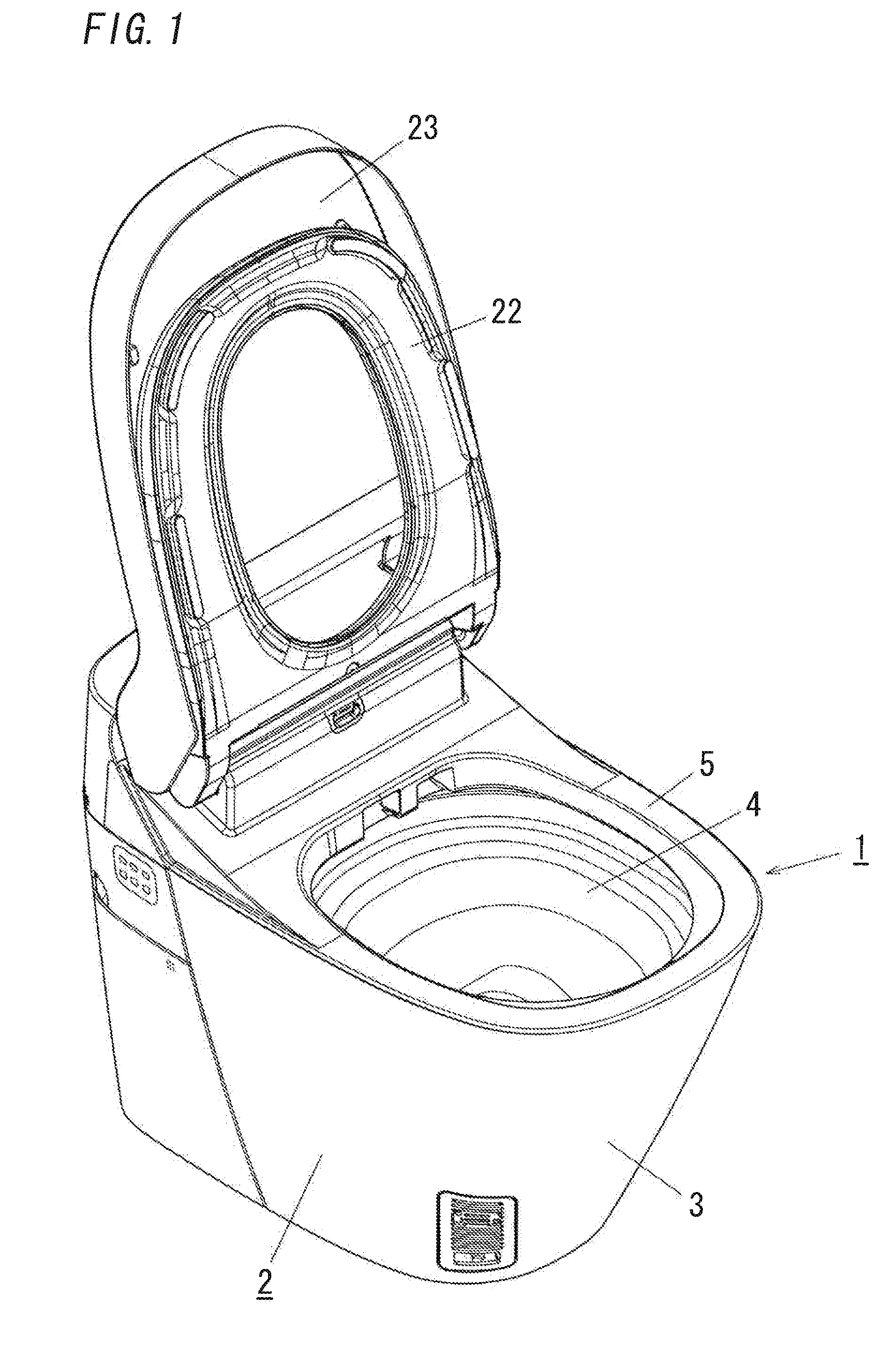

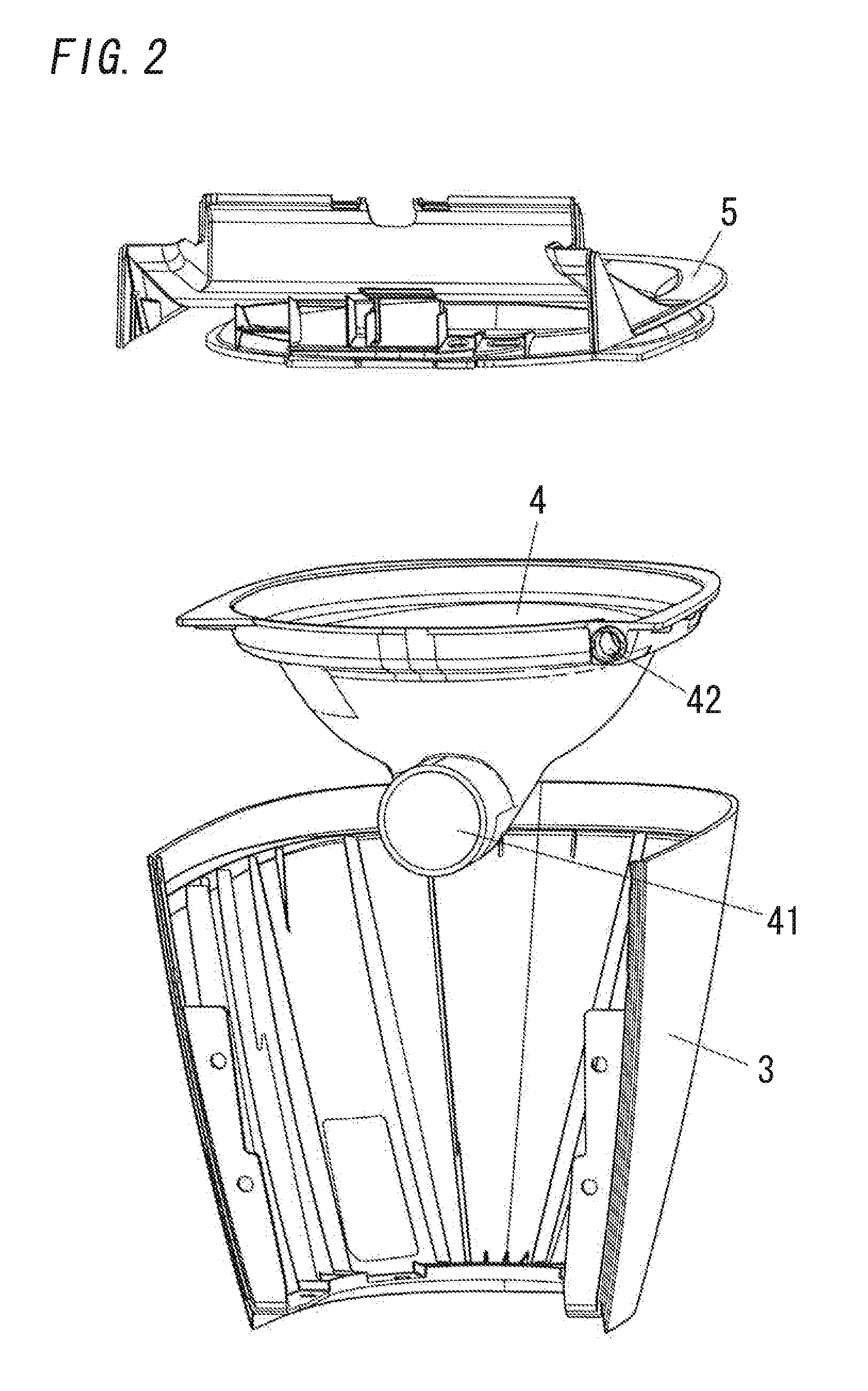

Molding material for a household plumbing equipment and a household plumbing equipment fabricated using the same

InactiveUS20130007953A1Excellent surface hardnessImprove waterproof performanceWater closetsWash-standsPolyethylene terephthalatePolytrimethylene terephthalate

Providing: a molding material for a household plumbing equipment which has superior surface hardness as well as superior water resistance for use in the household plumbing equipment inherent from a polymethyl methacrylate resin, and yet has improved solvent resistance; and a household plumbing equipment fabricated using the molding material. The molding material for a household plumbing equipment is characterized by containing a thermoplastic resin comprising the polymethyl methacrylate resin and a polytrimethylene terephthalate resin in a mass ratio of 90:10-50:50.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Acrylonitrile-butadiene-styrene copolymer composite material and preparation method

The invention discloses an ABS (acrylonitrile-butadiene-styrene) composite material, which is prepared from 50-80 parts by weight of acrylonitrile-butadiene-styrene (ABS) resin, 25-65 parts by weight of polymethyl methacrylate (PMMA) and 0.1-10 parts by weight of an ethylene-methacrylate (EMA) copolymer. The invention also discloses a preparation method of the ABS composite material. The ABS composite material prepared by the invention has good glossiness, interfacial compatibility and toughness. The adding of EMA makes the ABS and PMMA systems uniformly distributed. Meanwhile, the EMA is spherically dispersed in the ABS composite system, plays a stress concentration role, and endows the ABS composite material with good toughness. Thus, the ABS composite material can be widely used in various molding products, especially in products with glossiness and scratch resistance requirements in the instrument and meter industry.

Owner:滁州格美特科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com