Polycarbonate resin composition, polycarbonate resin molded article, and manufacturing method therefor

A polycarbonate resin, polycarbonate technology, used in manufacturing tools, glass manufacturing equipment, etc., to achieve excellent heat resistance and mechanical properties, enhanced presentation effect, and reduced visual recognition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11 and comparative example 1~11

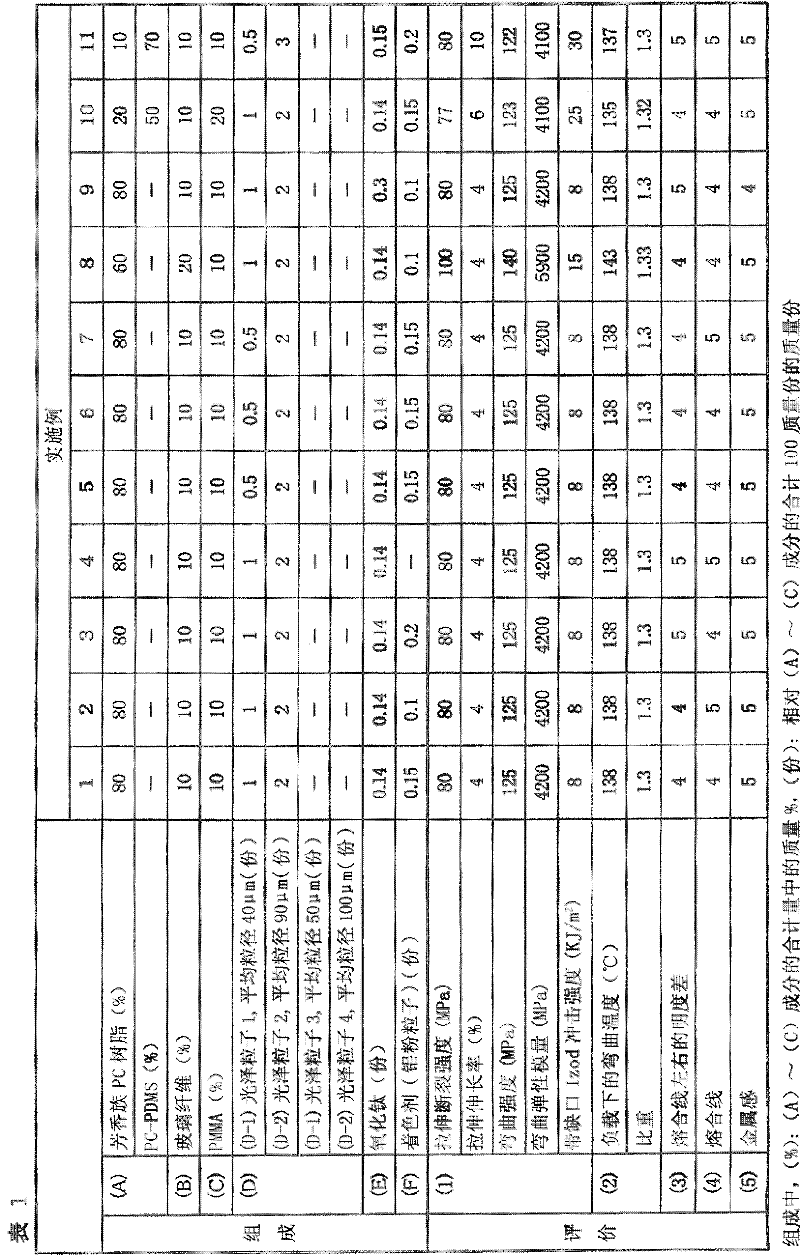

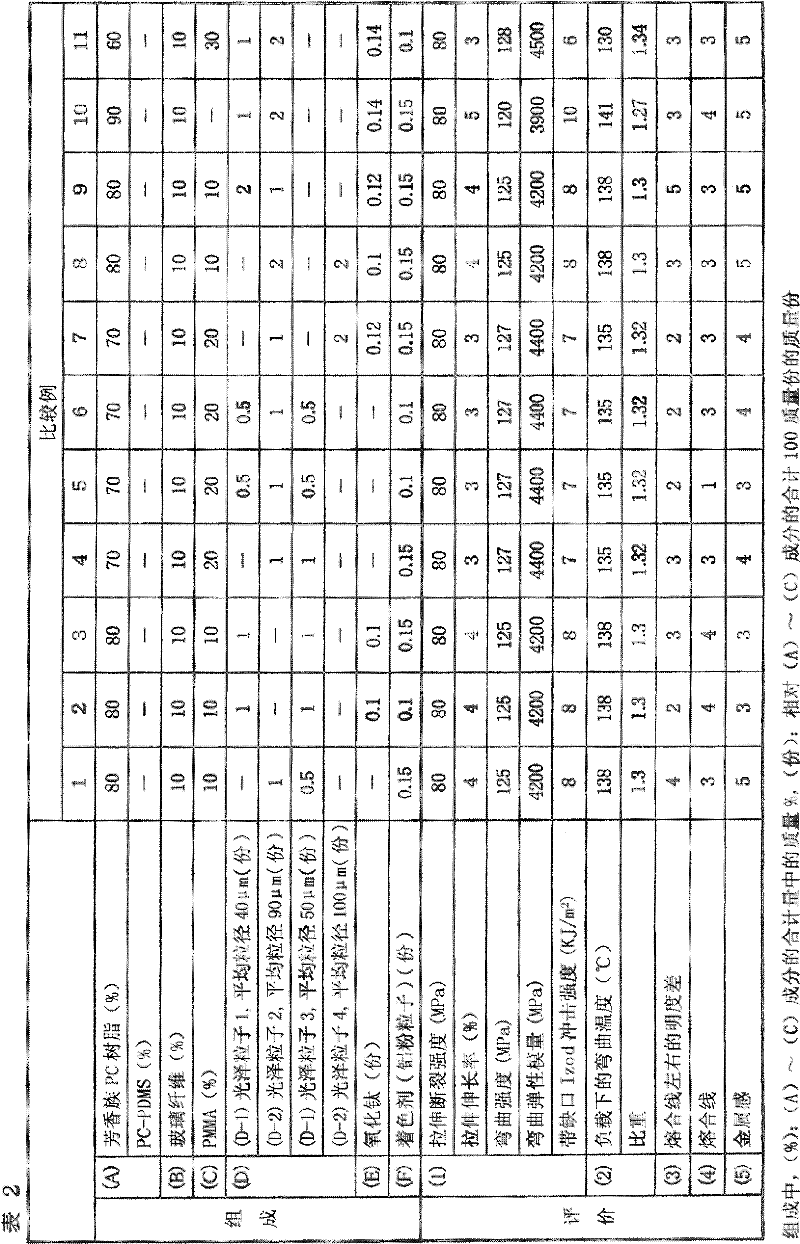

[0183] Mix the various components according to the compounding ratios shown in Tables 1 and 2, melt and knead at 280°C using a twin-screw extruder [manufactured by Toshiba Machine Co., Ltd., equipment type name "TEM-35B"], and produce Each polycarbonate resin composition pellet. Using these various pellets, the aforementioned evaluation tests were performed. The results are listed in Tables 1 and 2 together.

[0184] [Table 1]

[0185]

[0186] [Table 2]

[0187]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com