Patents

Literature

51results about How to "Excels in resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum alloy sheet for lithographic printing plate

InactiveUS20050013724A1Improve uniformityGood coarsening effectPlate printingFoil printingAlloySoftening

The present invention provides an aluminum alloy sheet for a lithographic printing plate which allows pits to be uniformly formed by electrochemical roughening, and excels in strength and heat softening resistance. The aluminum alloy sheet for a lithographic printing plate includes 0.1-0.3% of Mg, more than 0.05%, but 0.5% or less of Zn, 0.2-0.6% of Fe, 0.03-0.15% of Si, 0.02% or less of Cu, and 0.003-0.05% of Ti, the remainder being Al and impurities. The aluminum alloy sheet may include more than 0.05%, but 0.3% or less of Mn.

Owner:SUMITOMO LIGHT METAL INDS LTD +1

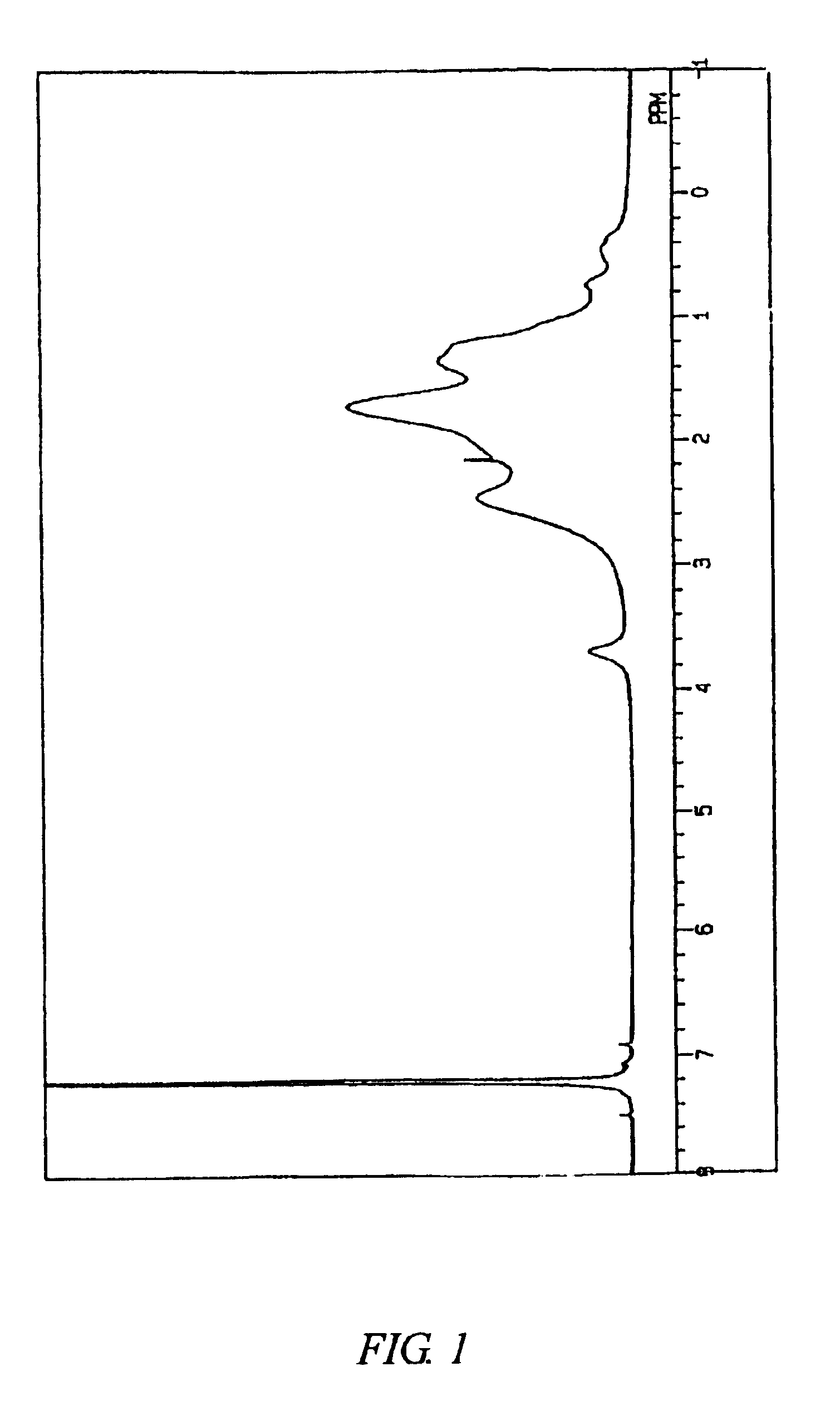

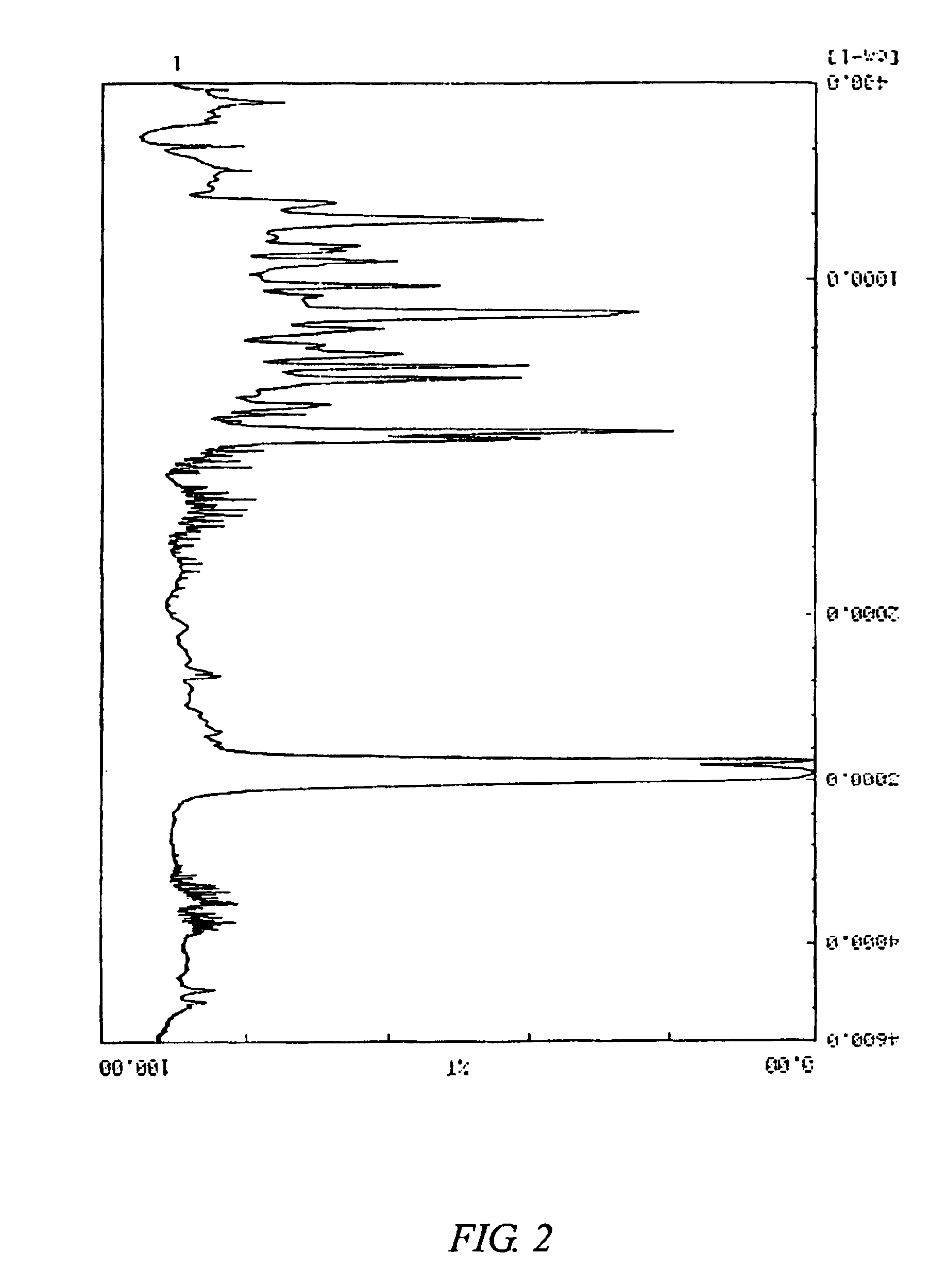

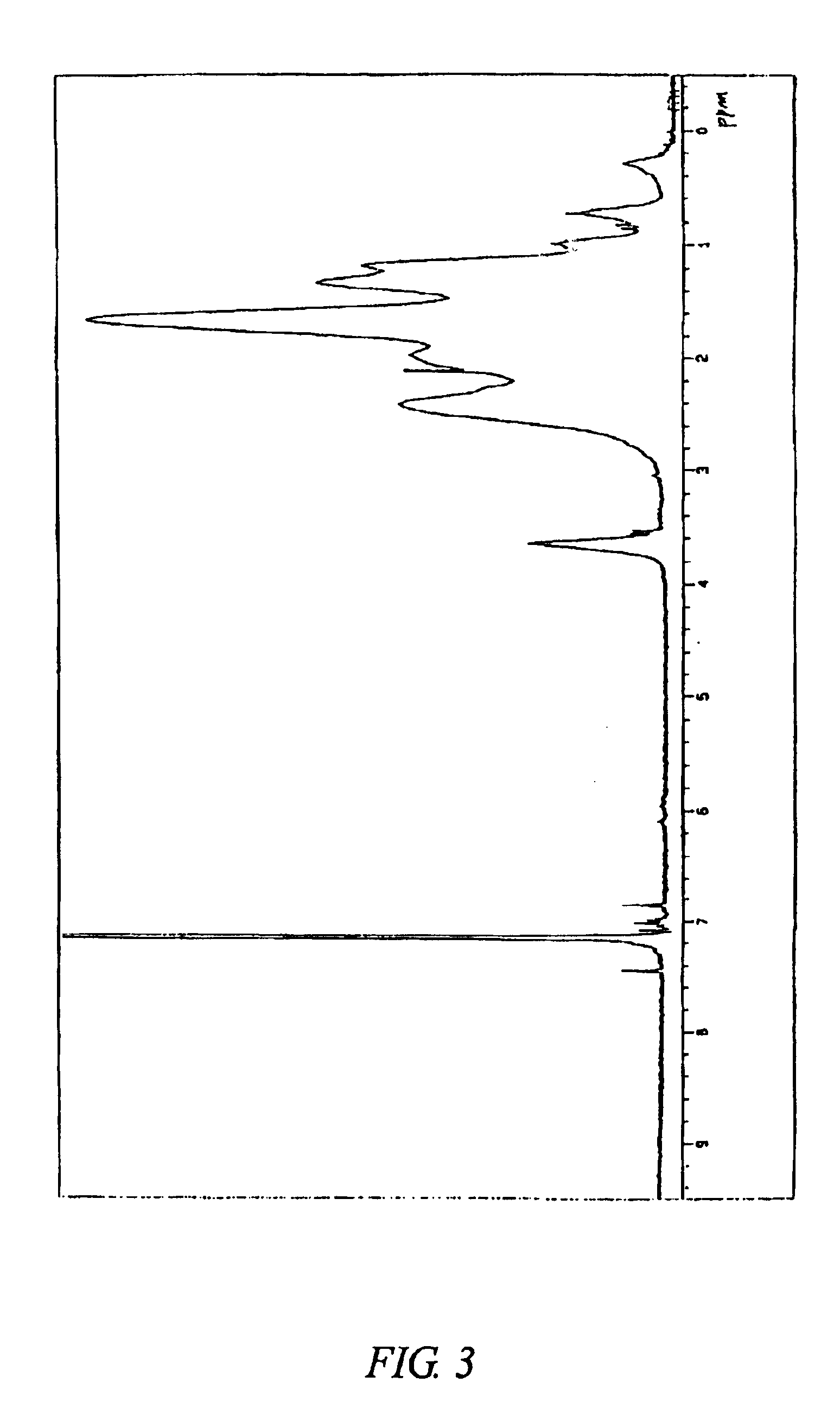

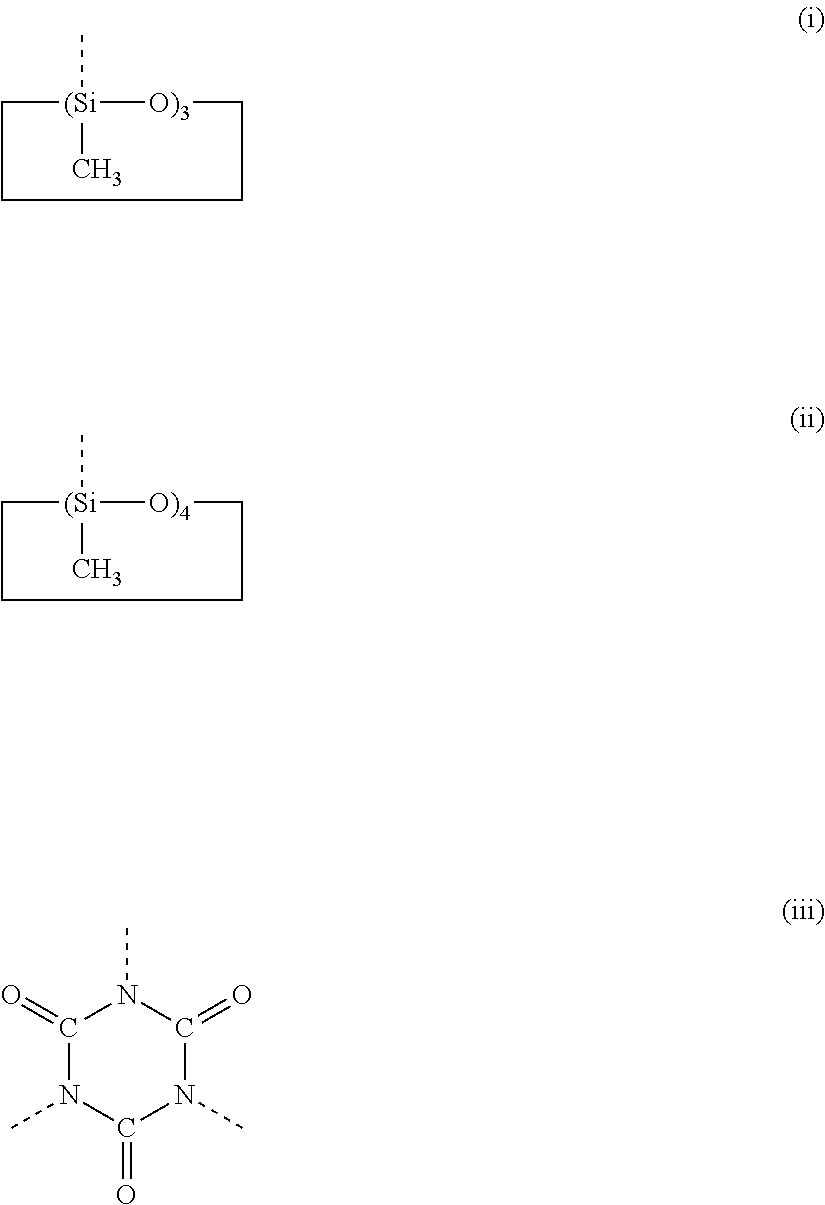

Cyclic olefin addition copolymer and process for producing same, crosslinking composition, crosslinked product and process for producing same, and optically transparent material and application thereof

InactiveUS6844403B2Good dimensional stabilityGood solvent resistanceLiquid crystal compositionsSpecial tyresSilyleneOptical transparency

The present invention provides a cyclic olefin addition copolymer which has a reactive silyl group having a specific structure, excels in optical transparency, heat resistance, and adhesion, and is capable of producing a crosslinked product having improved dimensional stability, solvent resistance, and chemical resistance. The present invention also provides a process for producing the cyclic olefin addition copolymer, a crosslinking composition, a crosslinked product and a process for producing the same, and an optically transparent material (transparent resin film) comprising the cyclic olefin addition copolymer. The optically transparent material excels in optical transparency and heat resistance, exhibits improved dimensional stability, adhesion, solvent resistance, and chemical resistance, and is capable of improving fragility and preventing occurrence of cracks in the film.

Owner:JSR CORPORATIOON

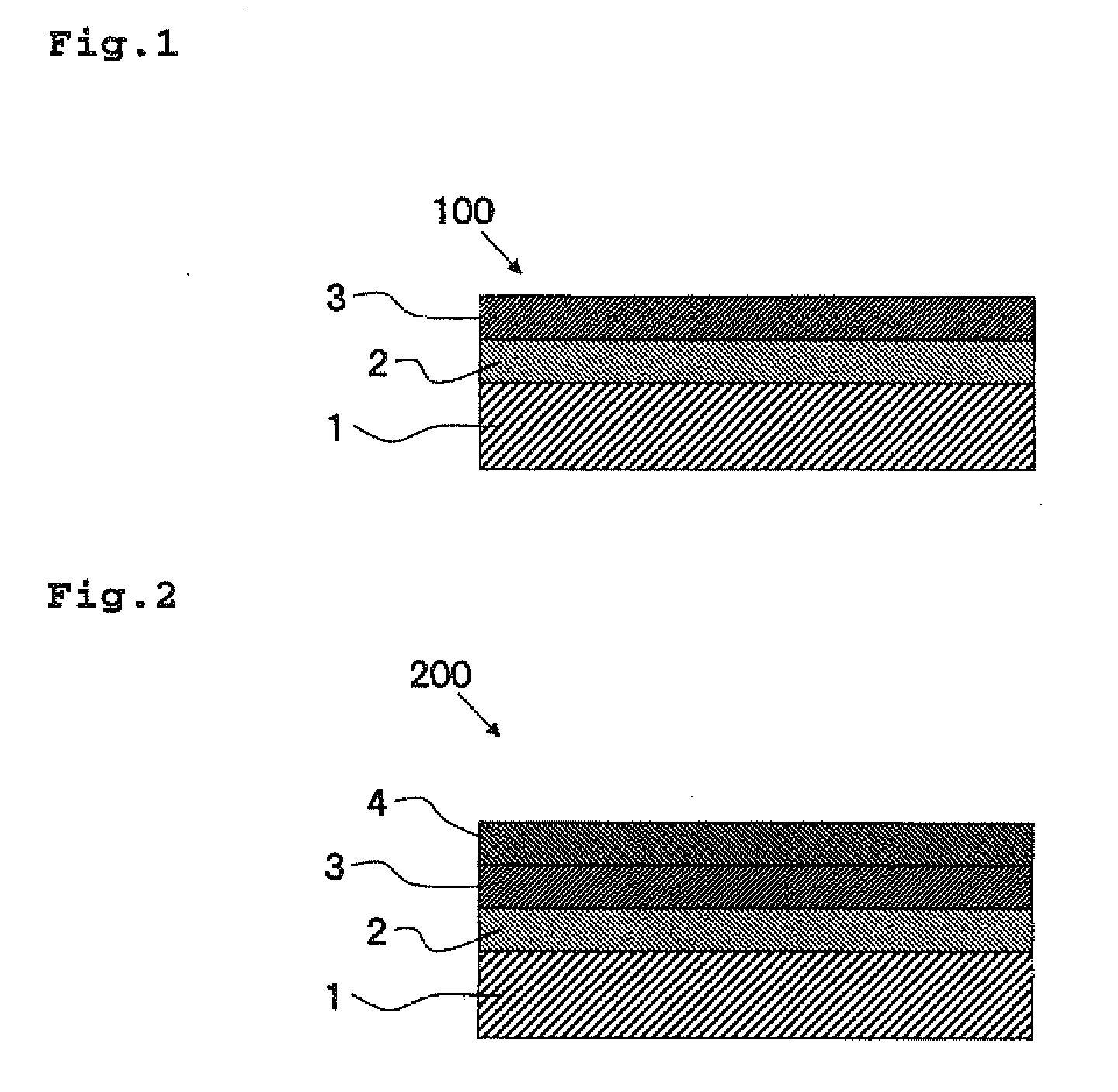

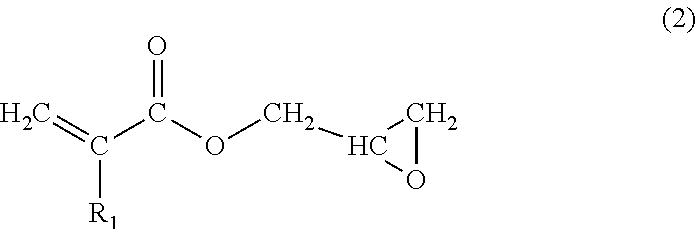

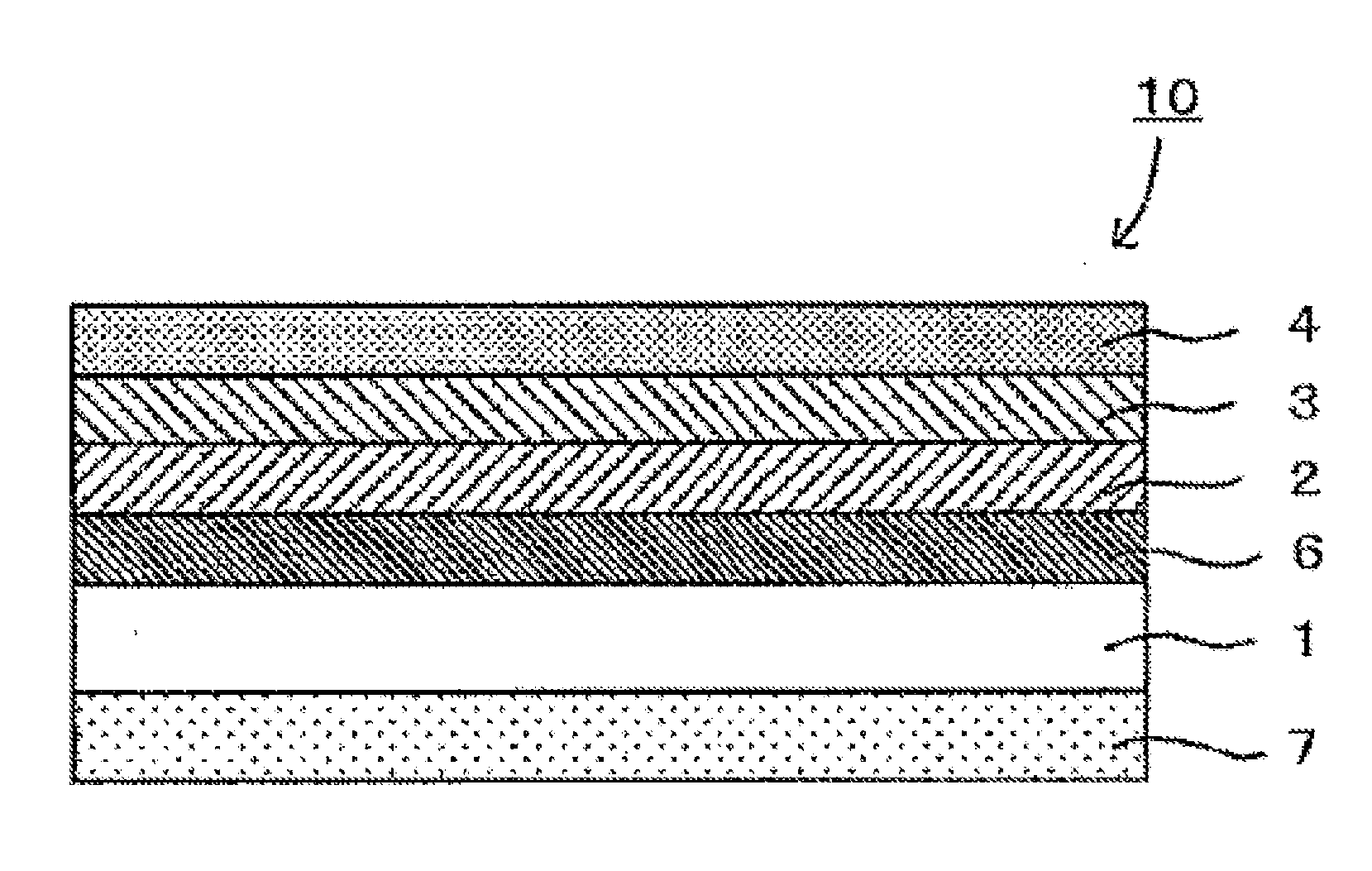

Pressure sensitive adhesive composition, product using the same, and display using the product

InactiveUS20090068459A1Excels in adhesivenessExcels in coatabilityLayered productsEster polymer adhesivesPolymer scienceAlkoxy group

Disclosed is a pressure-sensitive adhesive composition which contains an acrylic polymer and a crosslinking agent. The acrylic polymer has a weight-average molecular weight of 40×104 to 160×104 and contains at least an alkoxyalkyl acrylate (Component A) and an acrylic monomer having a crosslinkable functional group (Component B). The monomer components constituting the acrylic polymer contain 45 to 99.5 parts by weight of Component A and 0.5 to 4.5 parts by weight of Component B to 100 parts by weight of total monomer components constituting the acrylic polymer, and the monomer components constituting the acrylic polymer contain substantially no carboxyl-containing monomers. This relates to improvements to provide pressure-sensitive adhesive compositions that show excellent coatability, transparency, adhesion (typically low-temperature adhesion), and resistance to blistering / separation and concurrently have anticorrosive properties.

Owner:NITTO DENKO CORP

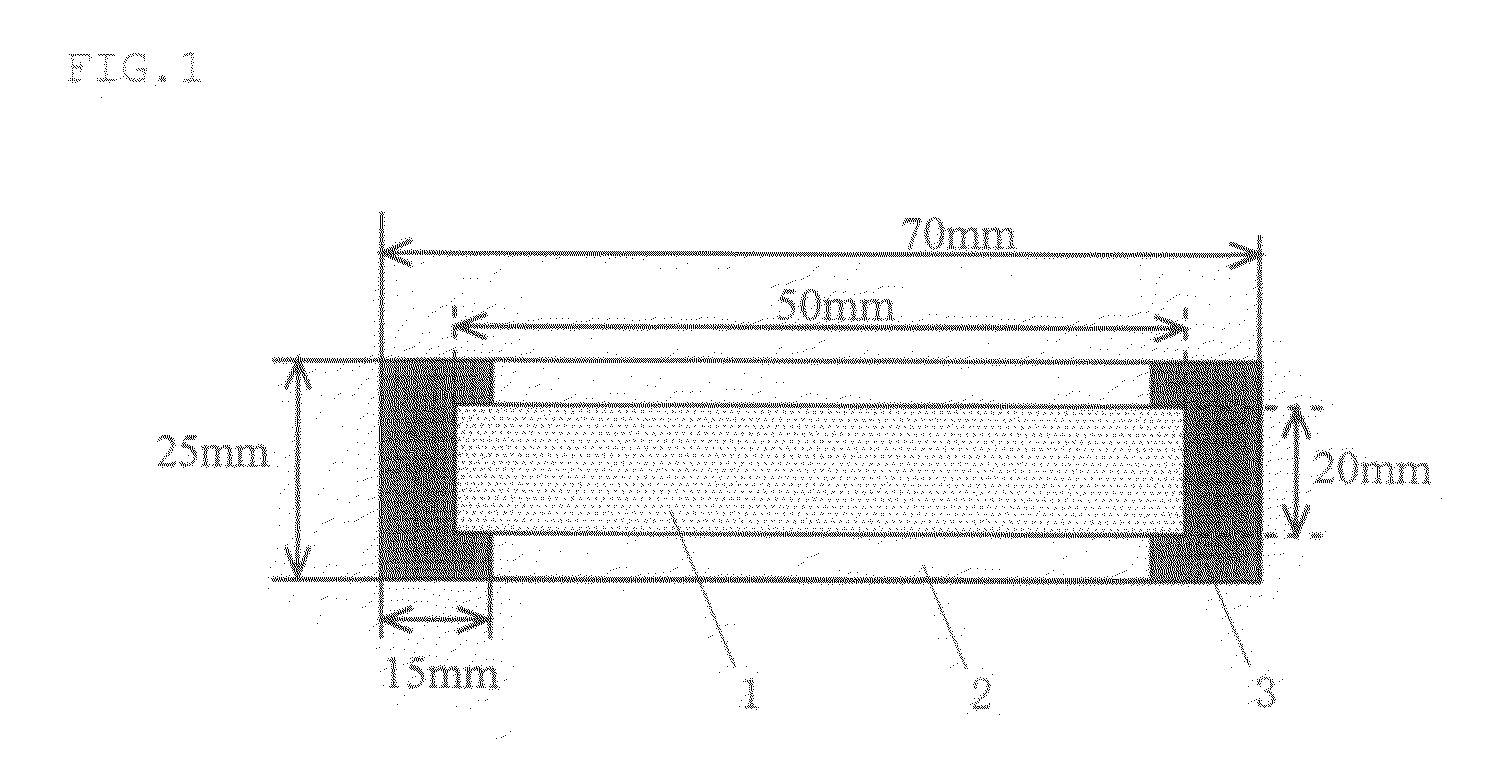

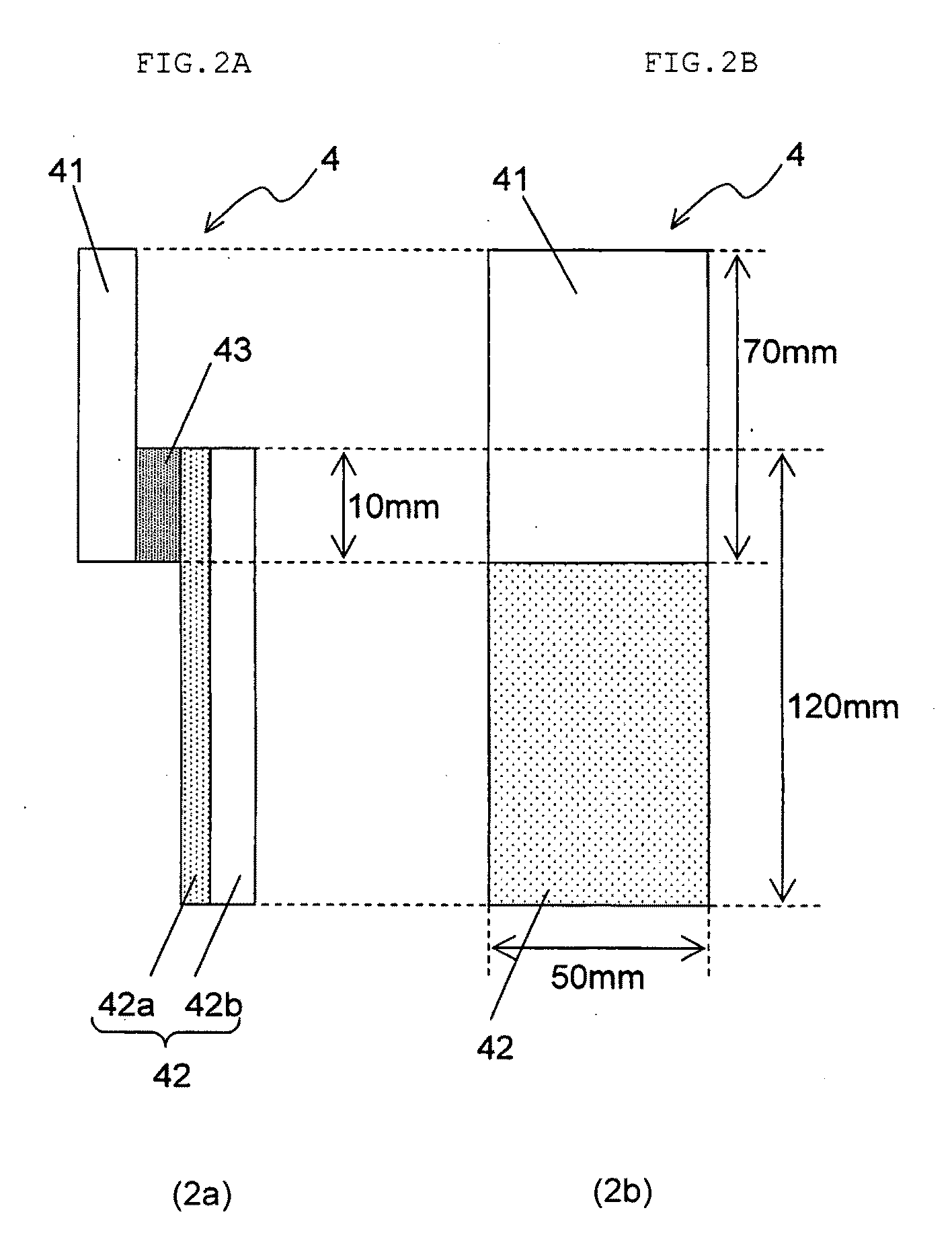

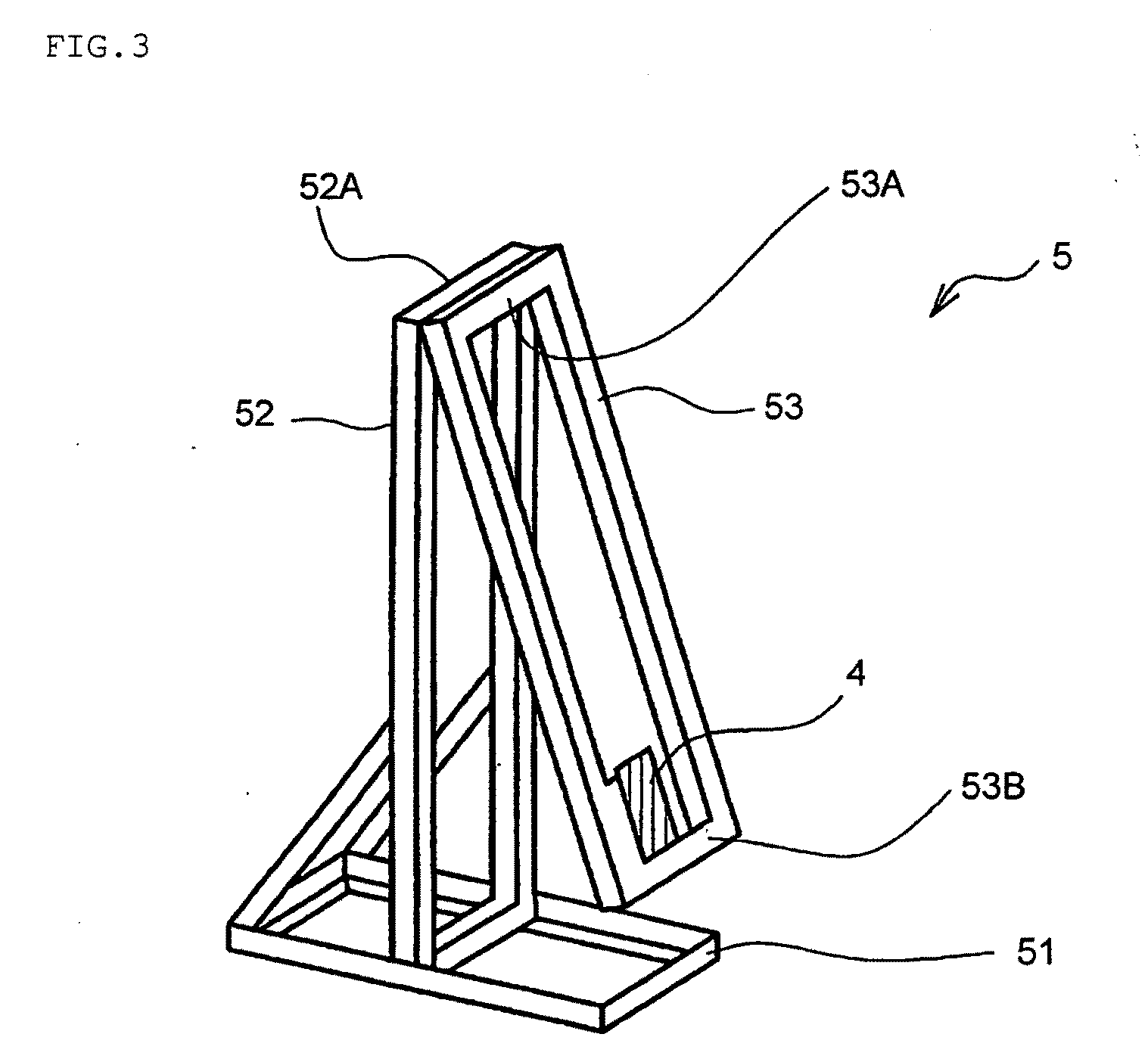

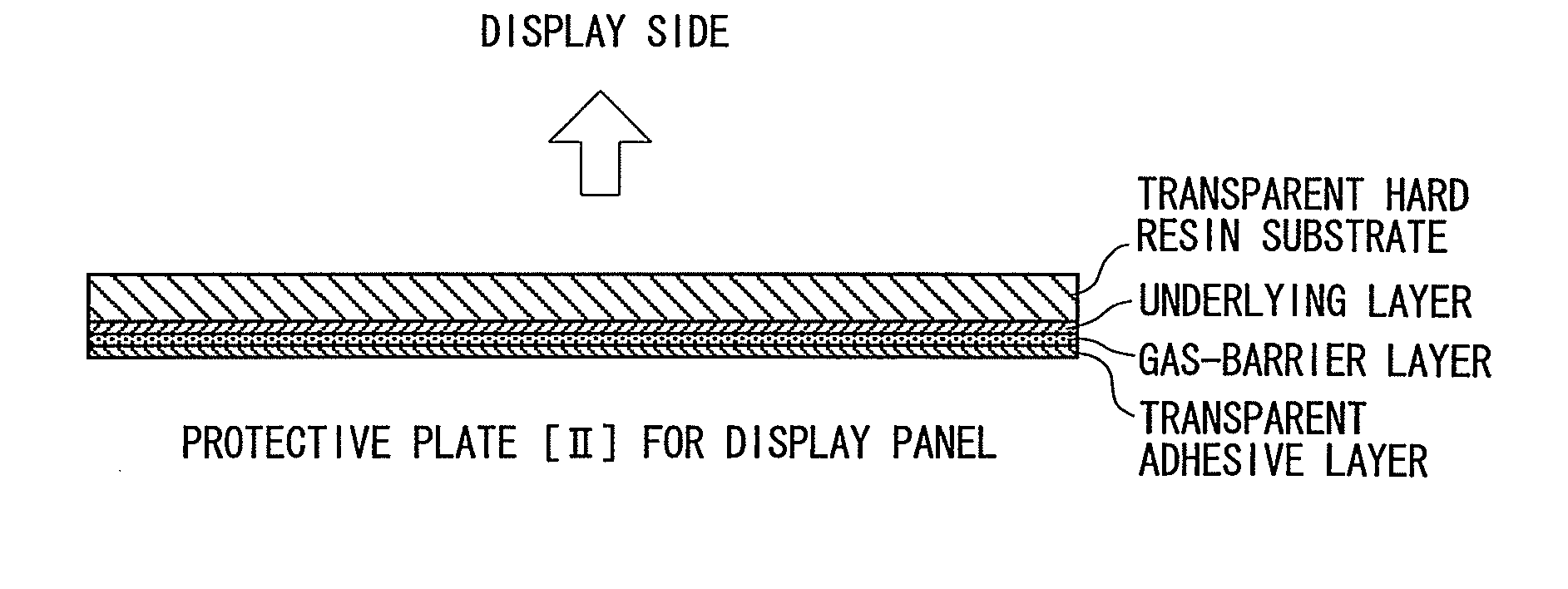

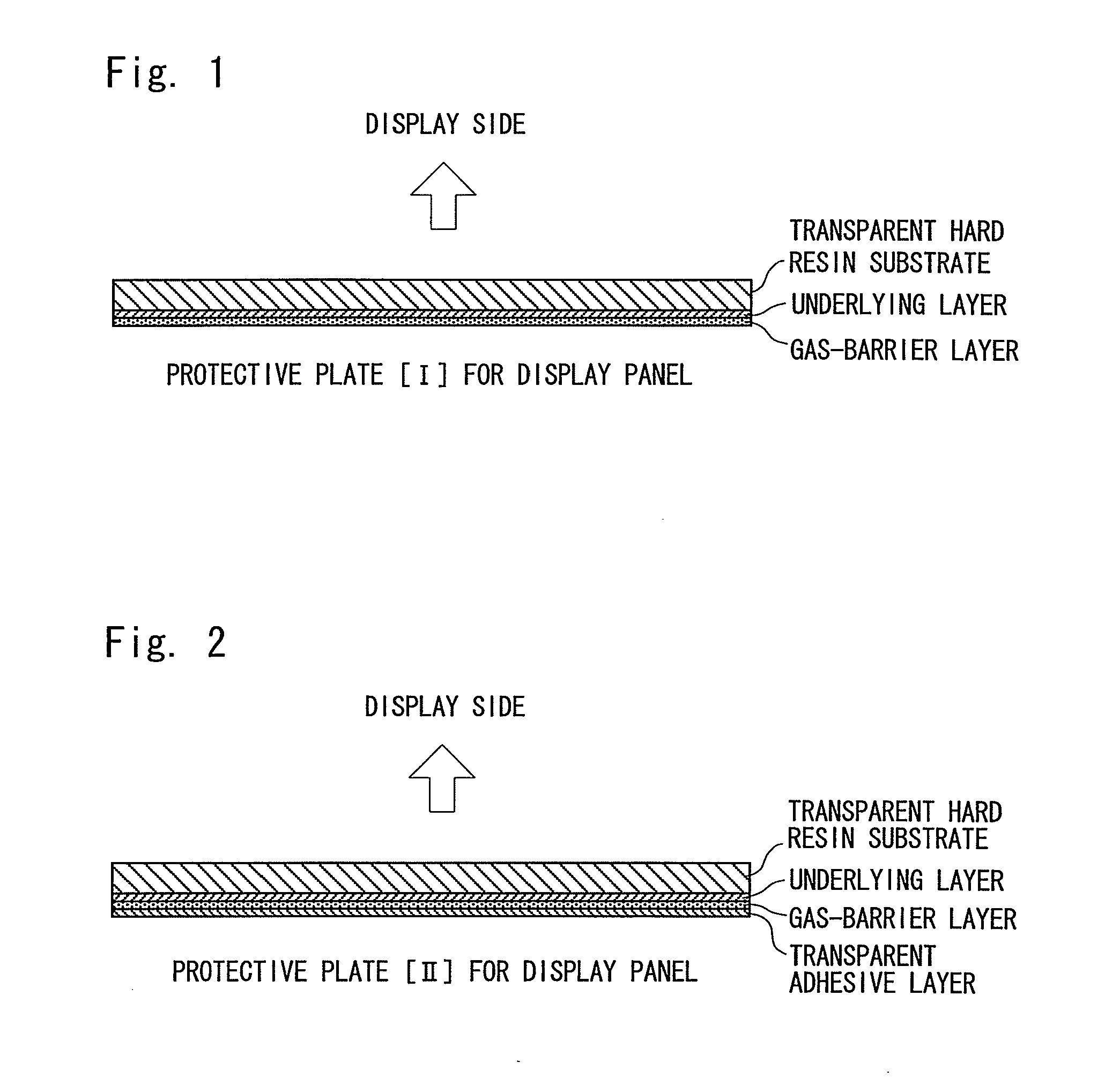

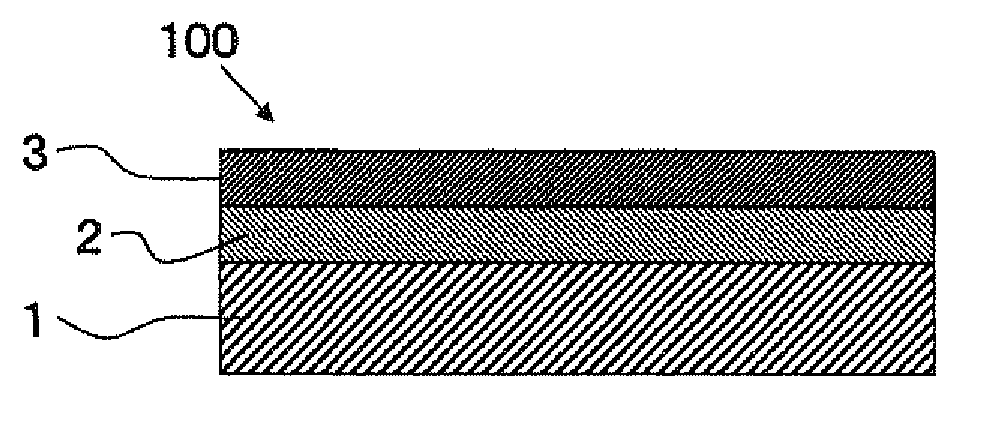

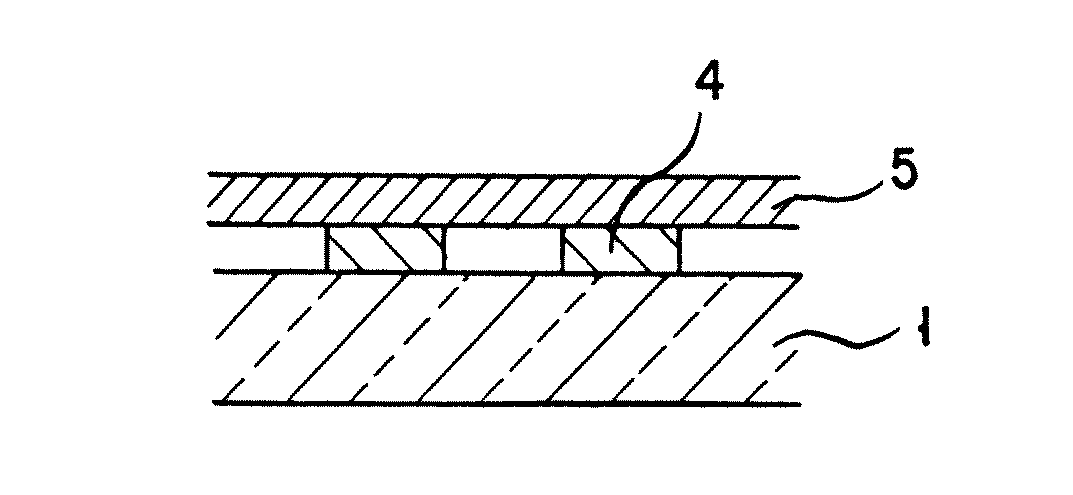

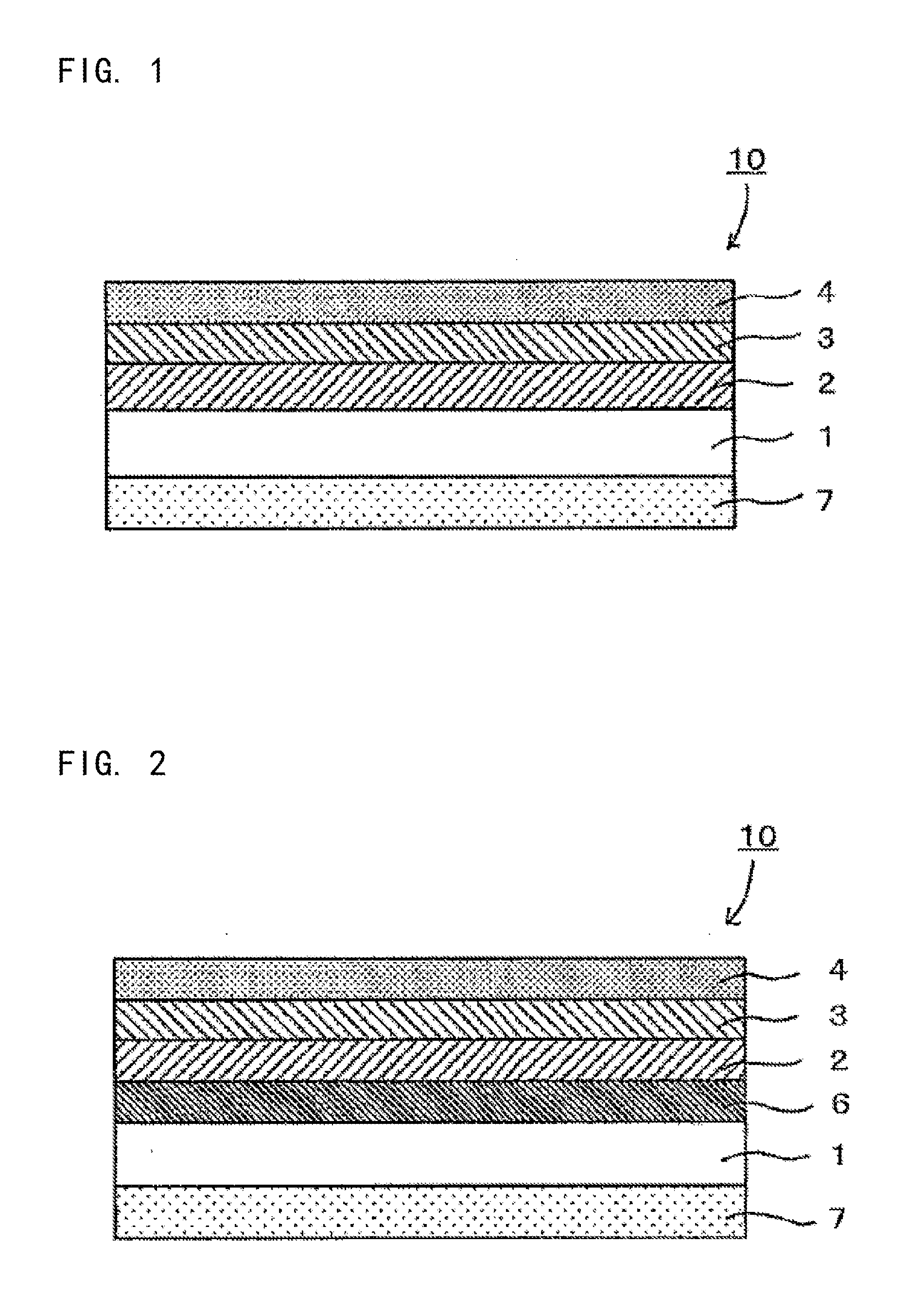

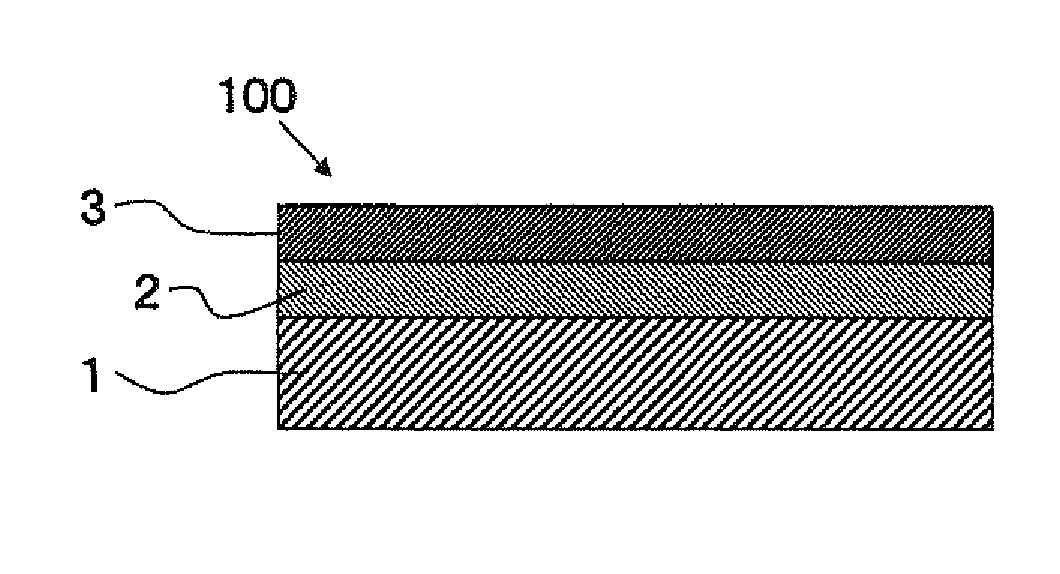

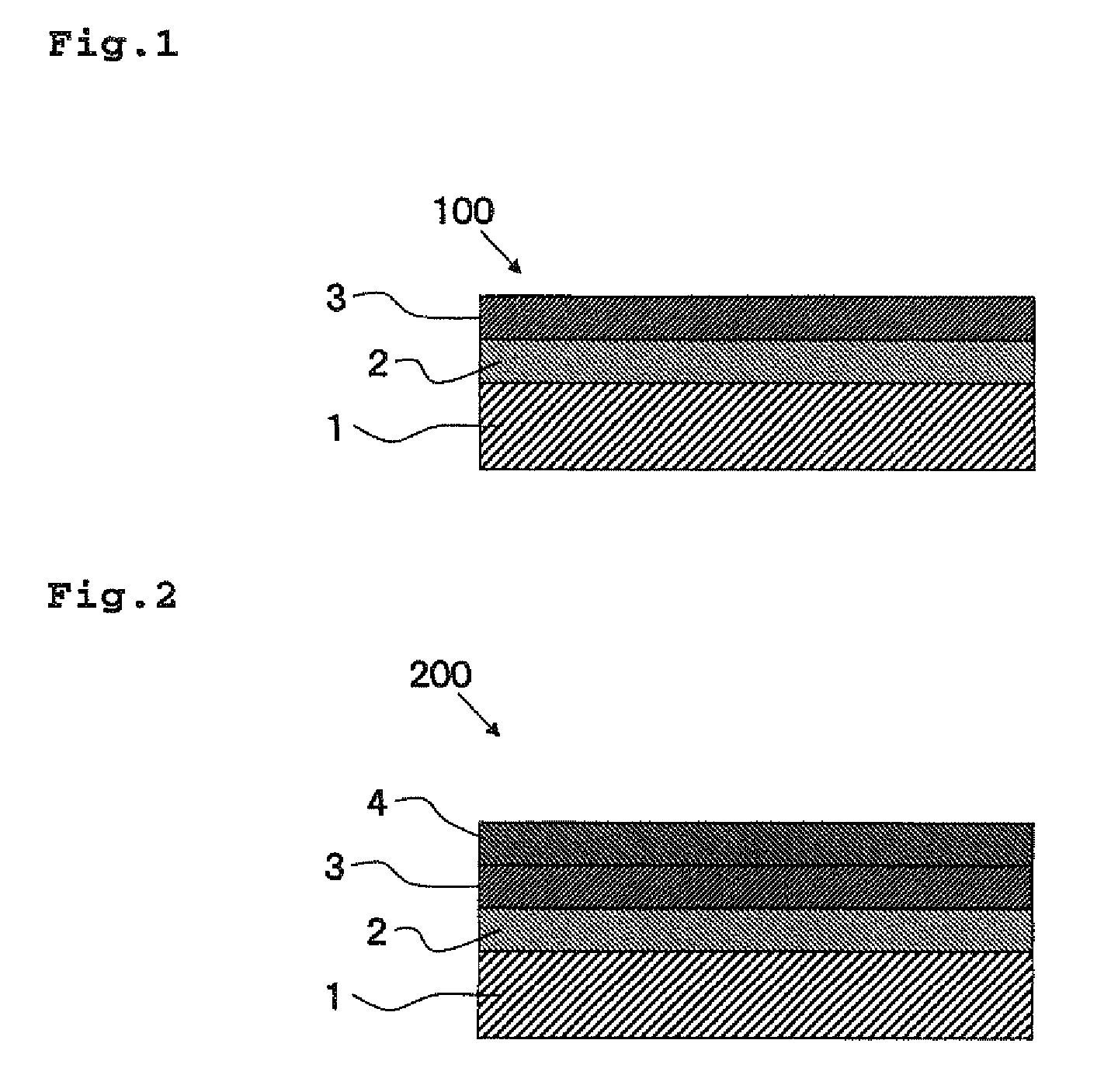

Transparent protective plate for display panels and display device

InactiveUS20120301635A1Excels in resistanceExcels in visibilityLiquid crystal compositionsSynthetic resin layered productsDisplay devicePolymethyl methacrylate

To provide a highly transparent and highly strong protective plate for display panel which, when mounted on a display panel, does not permit bubbles to evolve in the inner layer or does not permit the layer to peel off even in high temperature and high humidity conditions that could temporarily occur, for example, in an automobile, and a display device equipped with the protective plate.[Means for Solution] A transparent protective plate for display panel having an underlying layer, a gas-barrier layer and, as required, a transparent adhesive layer of an acrylic adhesive successively laminated on a transparent hard resin substrate such as of a polymethyl methacrylate resin or an aromatic polycarbonate resin, wherein the underlying layer comprises a cured body obtained by polymerizing an underlying material solution that contains 90 to 20 parts by mass of an urethane acrylate adhesive resin (A), and 10 to 80 parts by mass of a silicon compound (B) selected from the group consisting of an alkoxysilane compound and a hydrolyzed product thereof, a silane coupling agent and a hydrolyzed product thereof, and a fine particulate silica; and the gas-barrier layer comprises a cured body of a dense silicon oxide obtained by curing a polysilazane compound (C) in the presence of an amine catalyst (D).

Owner:FUKUBI KAGAKU IND

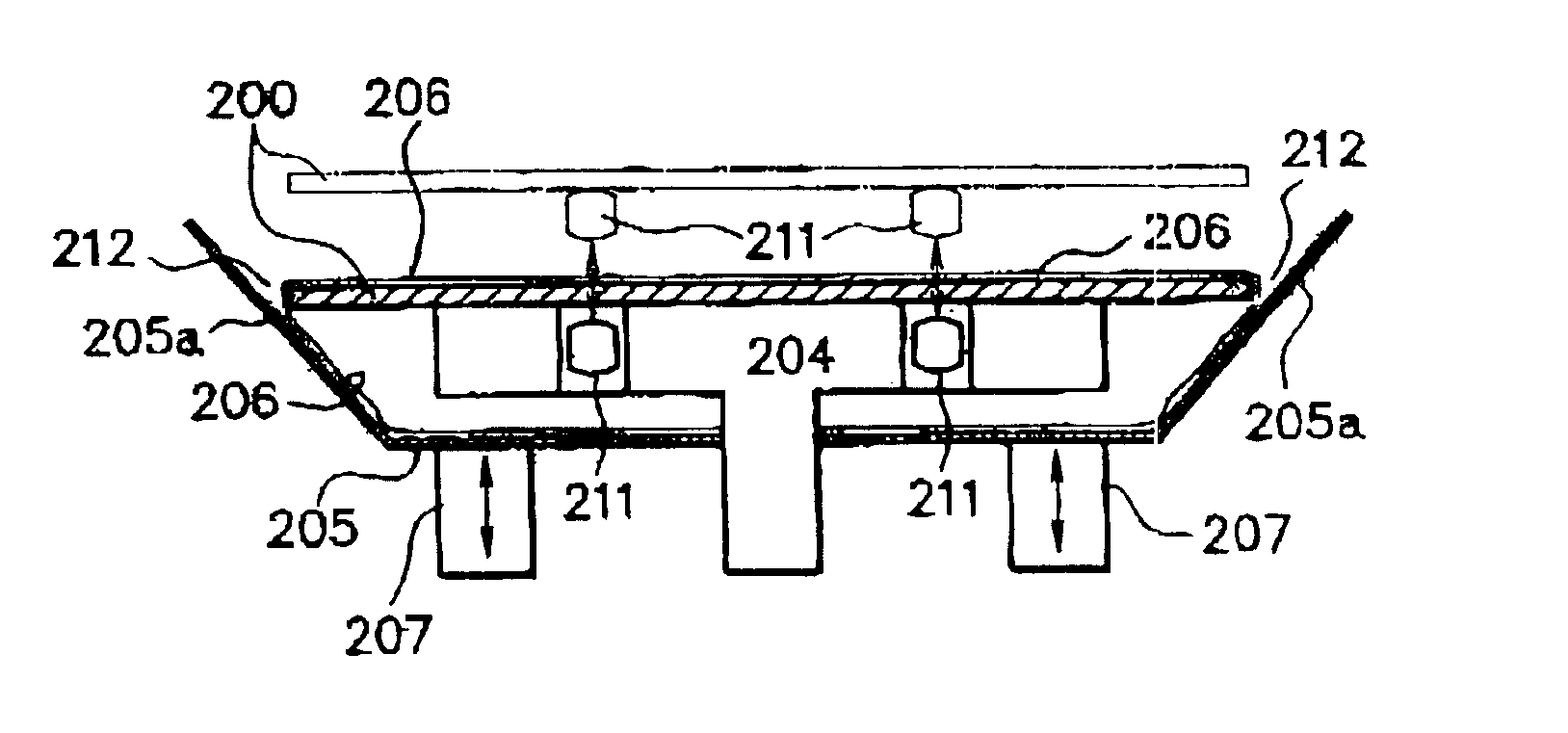

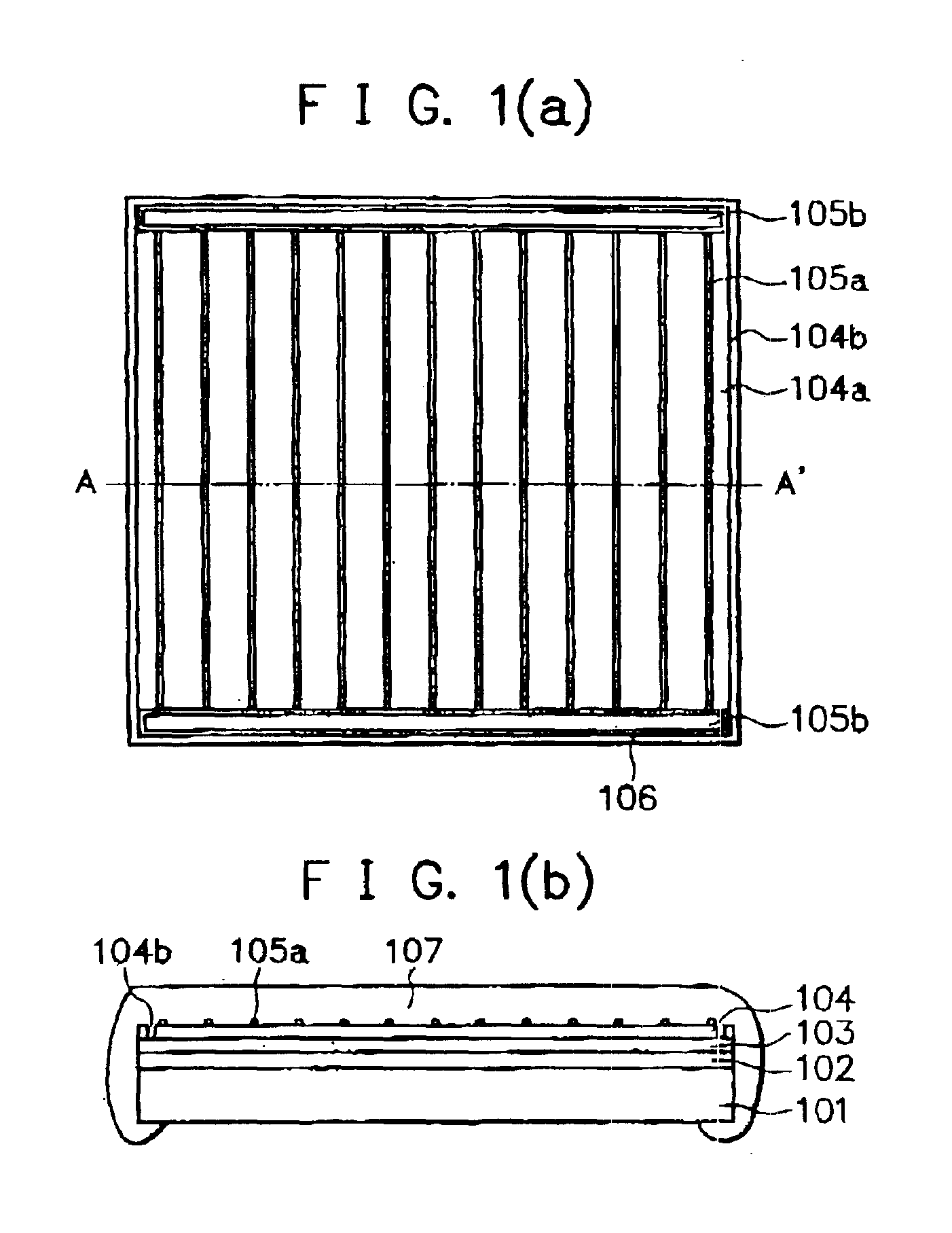

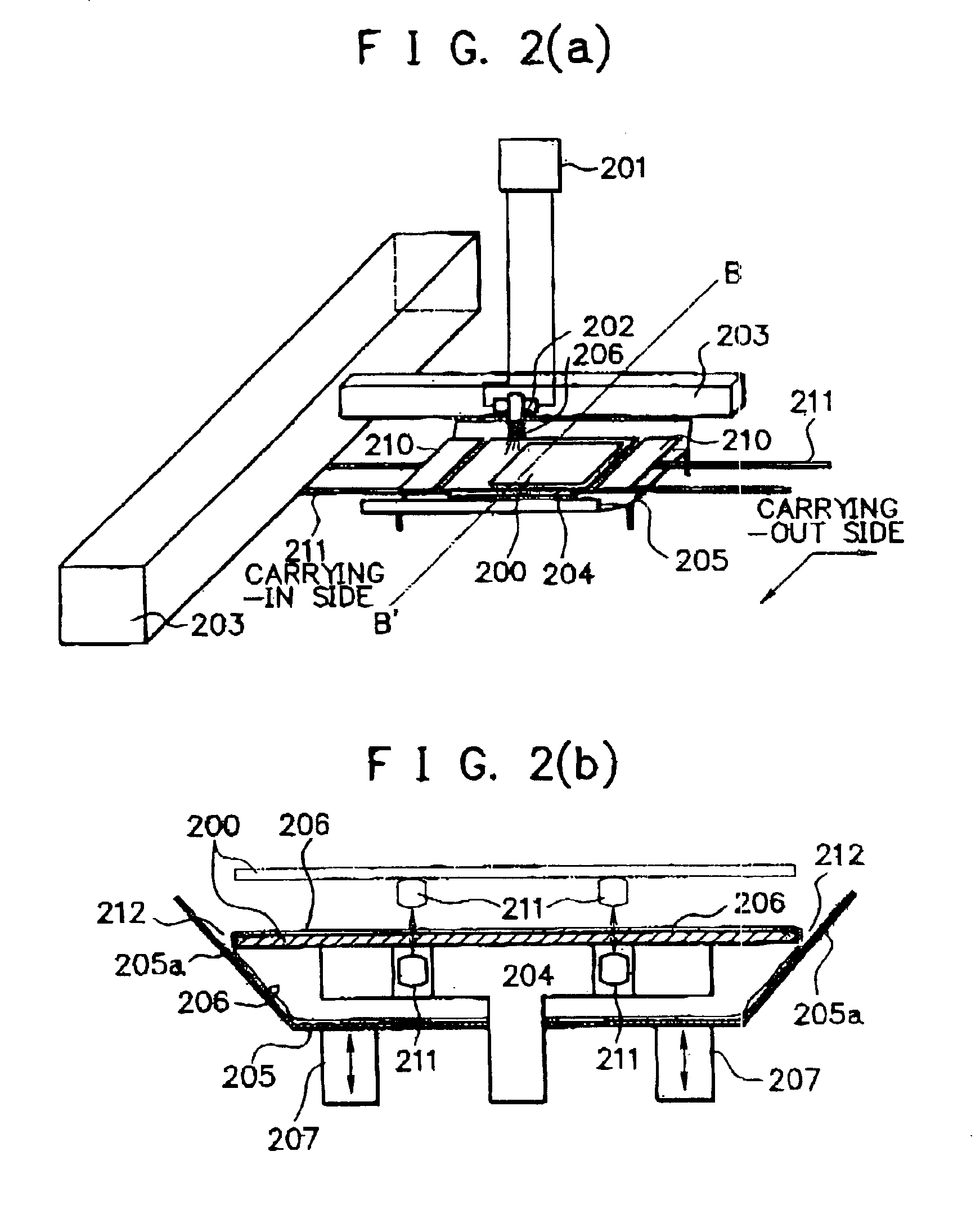

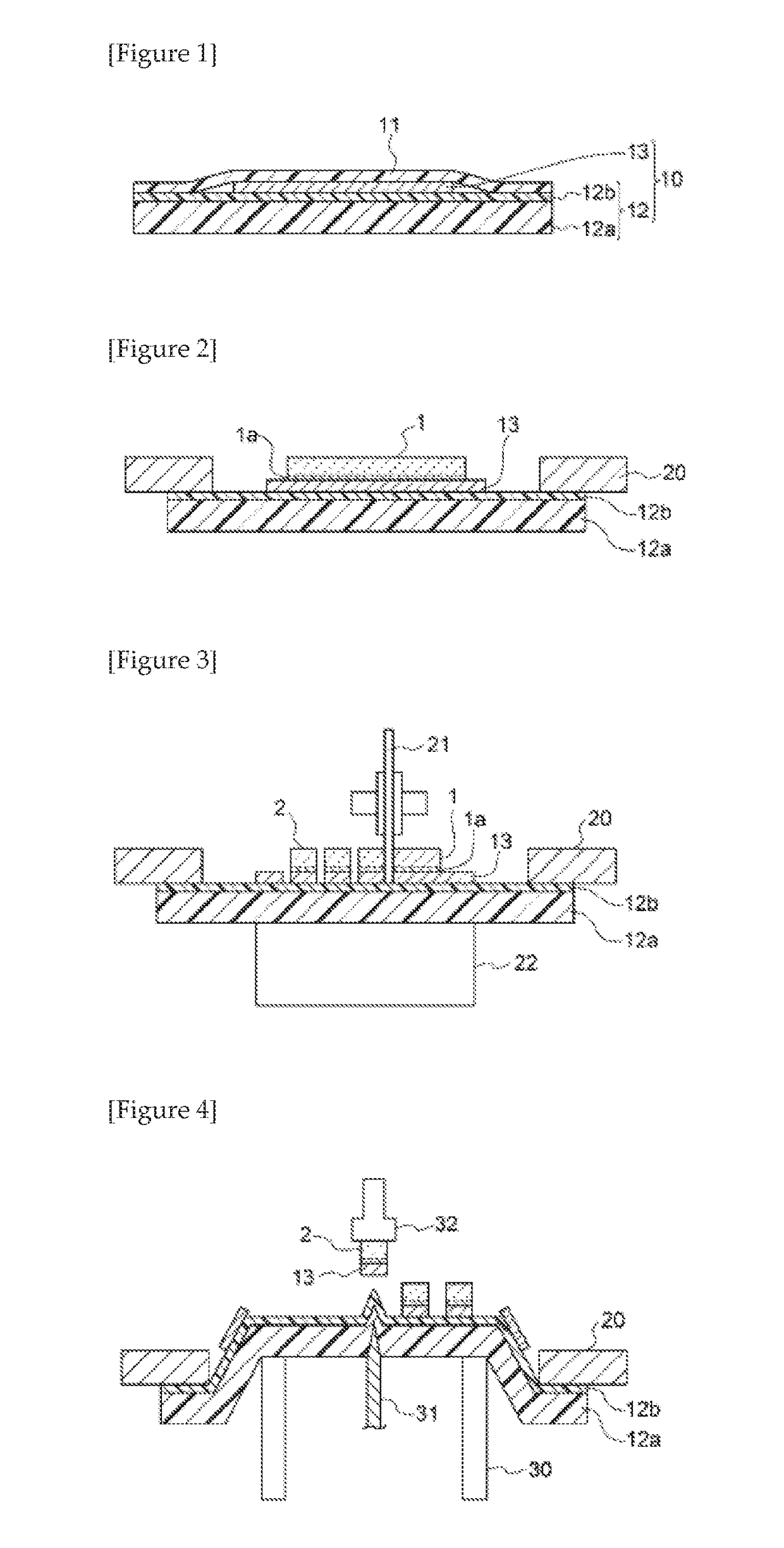

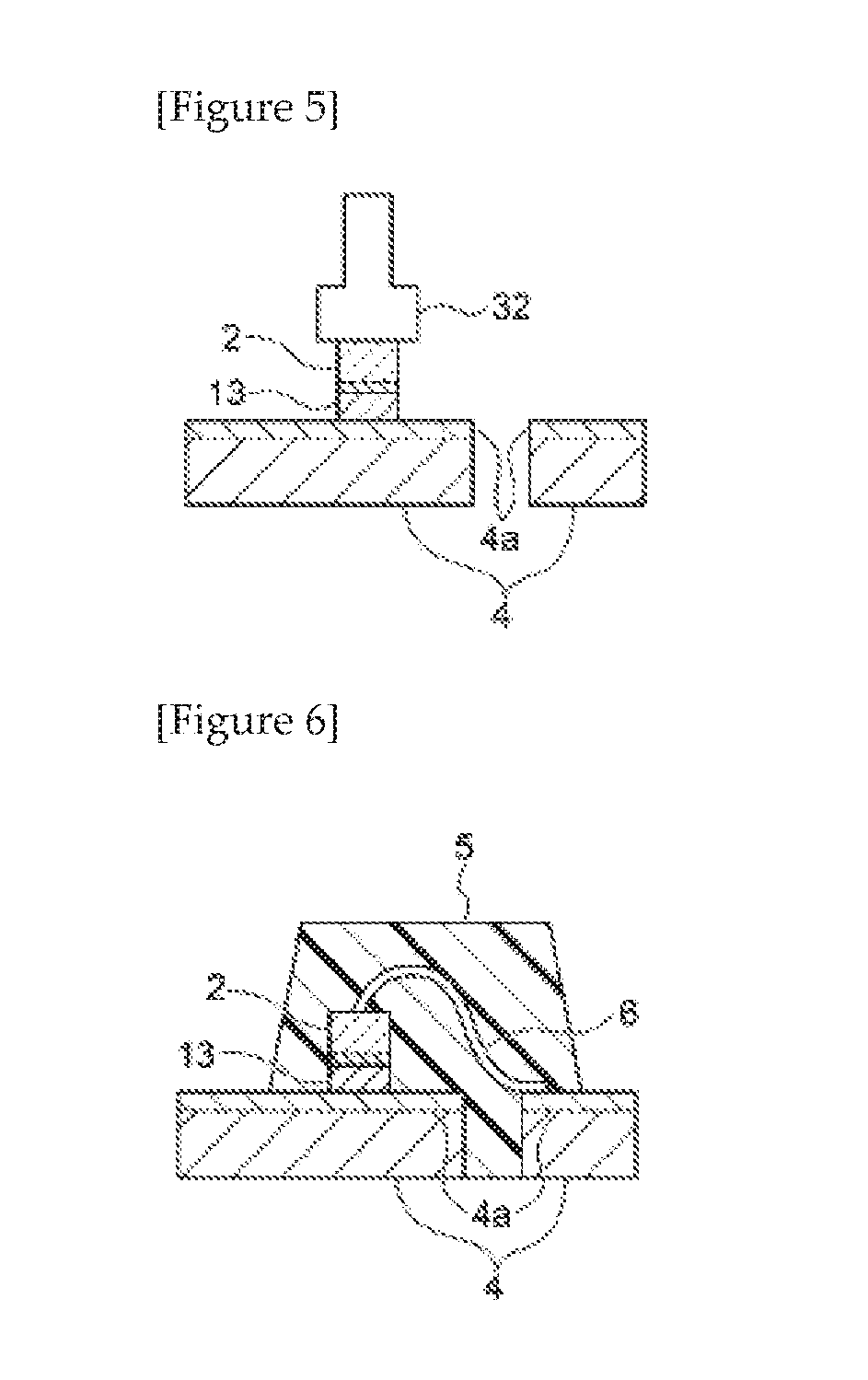

Process and apparatus for producing a substrate having a coating resin layer

InactiveUS6953599B2Maintenance frequency be diminishOperation efficiency be improvePretreated surfacesSpray nozzlesComposite materialCoating

A process for producing a substrate having a coating resin layer includes the steps of carrying in a substrate on a fastening table and fastening the substrate to the table and, while moving a spout for spouting a resin layer precursor or the fastening table in a horizontal direction, spouting the resin layer precursor to apply the resin layer precursor onto the substrate to form a resin layer precursor layer on the substrate. Additional steps include carrying out the substrate having the resin layer precursor layer from the fastening table, and drying and curing the resin layer precursor layer on the substrate to form a coating resin layer on the substrate.

Owner:CANON KK

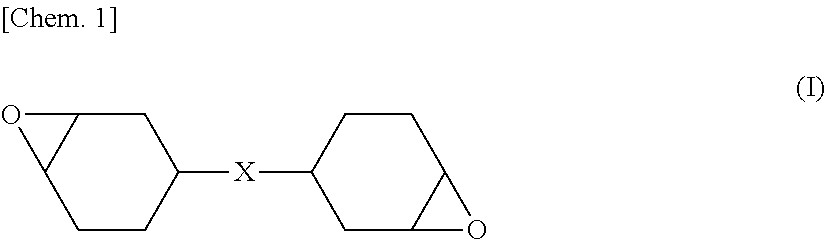

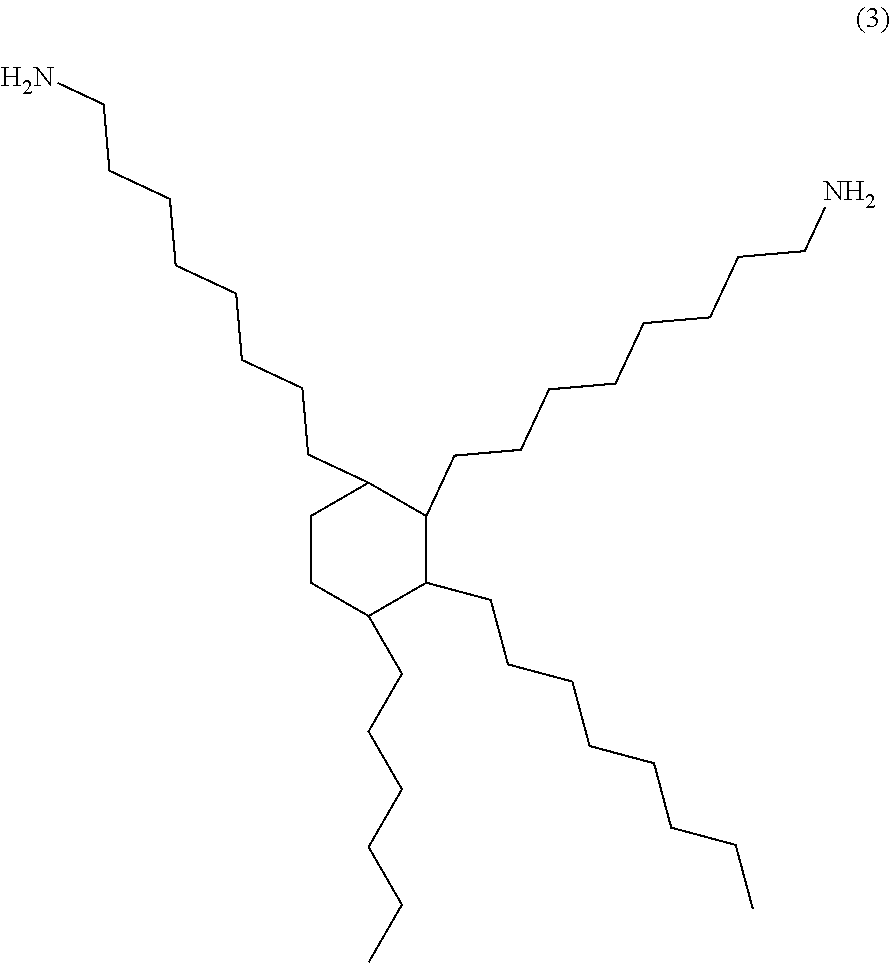

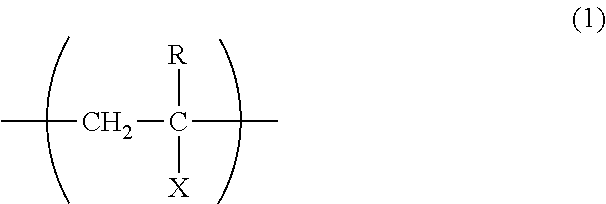

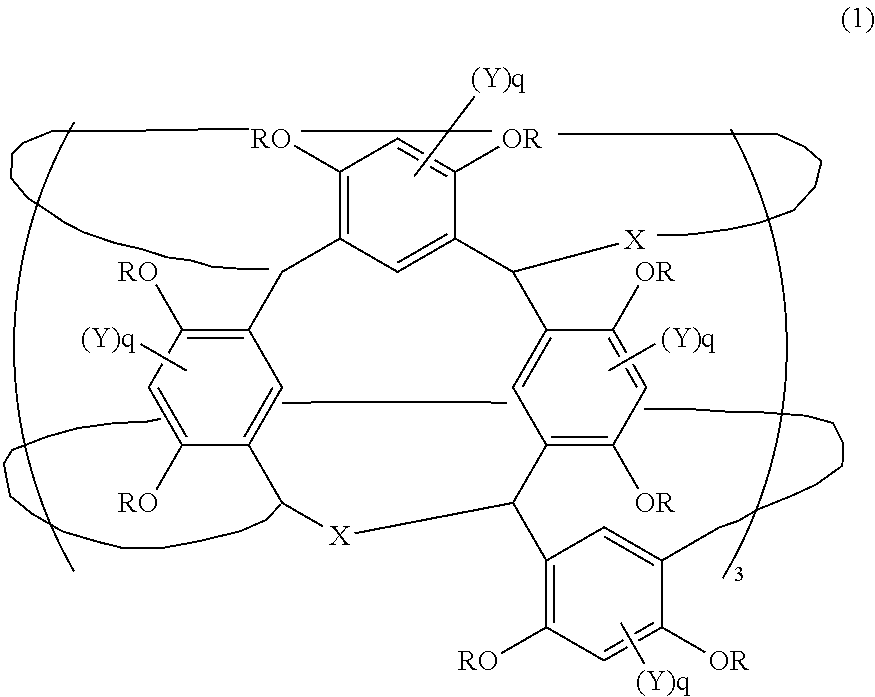

Curable composition, cured product thereof, optical member and optical device

ActiveUS20150212300A1High mechanical strengthExcels in heat resistanceOptical articlesOptical elementsVitrificationSingle bond

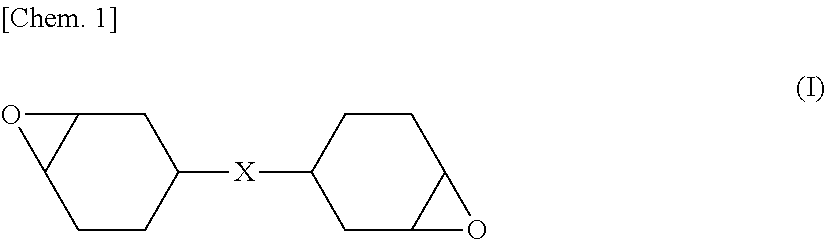

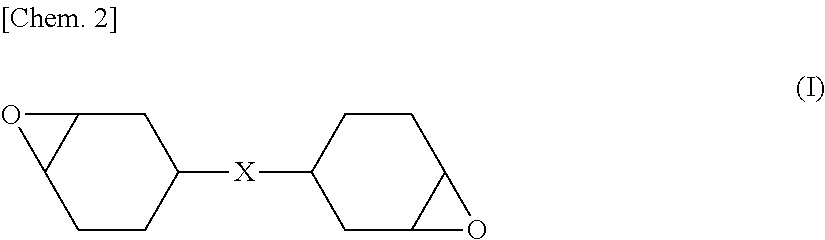

An object of the present invention is to provide a curable composition that can be cured satisfactorily and can form a cured product having a high glass transition temperature as maintained and having high mechanical strength. A curable composition includes a siloxane (A), a cycloaliphatic epoxide (B), and a curing agent (C). The siloxane (A) contains at least two epoxy groups per molecule. The cycloaliphatic epoxide (B) in the curable composition is preferably a compound represented by Formula (I):wherein X is selected from a single bond and a linkage group.

Owner:DAICEL CHEM IND LTD

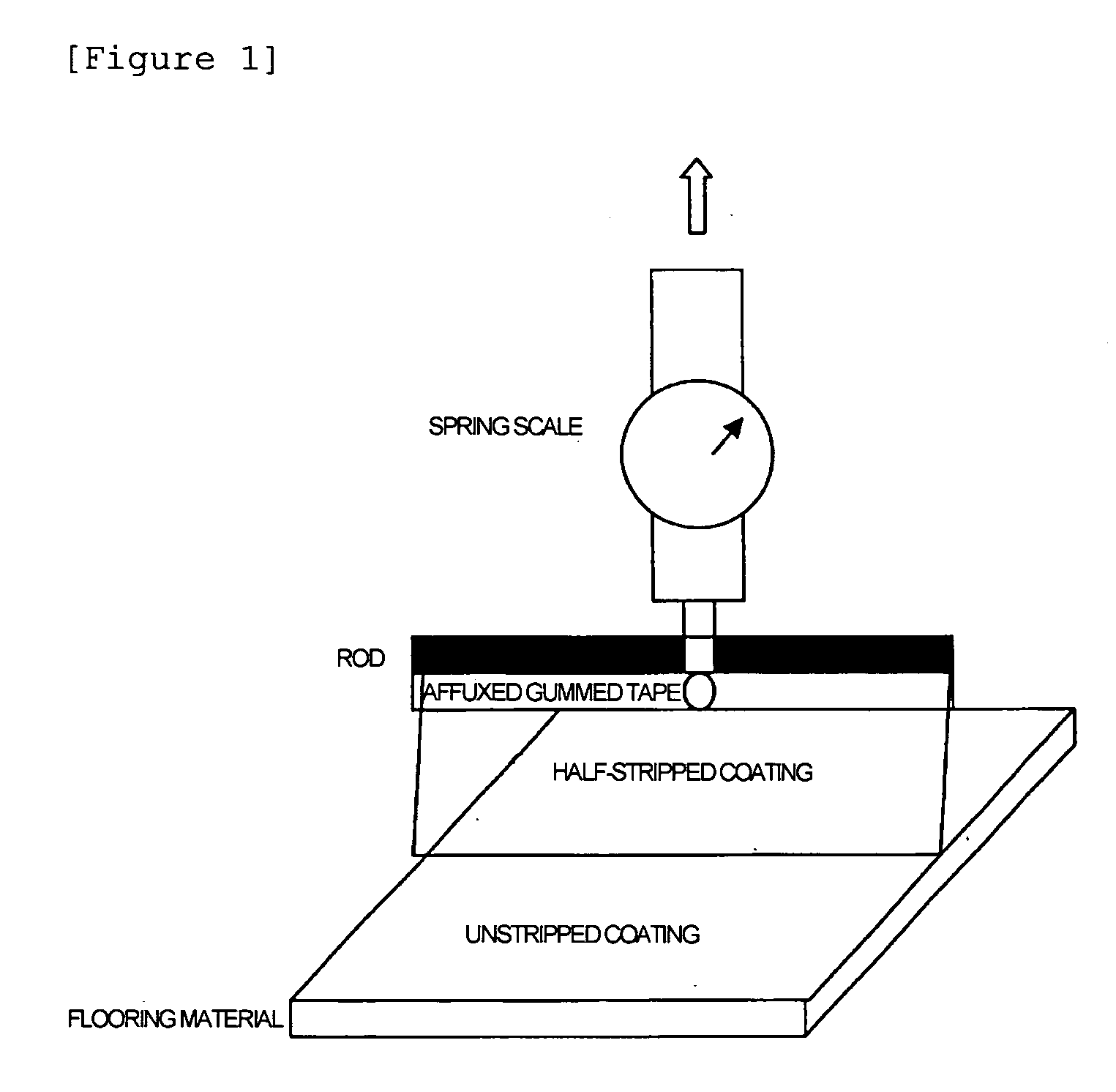

Strippable Floor Coating and Method of Forming the Coating

InactiveUS20090130454A1Excels in soiling resistanceBeautiful appearanceSynthetic resin layered productsPaper coatingWaxEmulsion

Disclosed is a strippable floor coating which includes an undercoat layer (A) to be applied to a floor surface, and a strippable overcoat layer (B) over the undercoat layer (A). The undercoat layer (A) is formed from an undercoating agent mainly containing a wax or analogue thereto and having film-formability. The overcoat layer (B) is formed from a floor polish composition mainly containing an aqueous emulsion. The undercoat layer (A) has greater adhesion to the floor surface than to the overcoat layer (B). Even when applied to various flooring materials, this strippable floor coating does not peel off practically and is excellent in soiling resistance and wear resistance to retain a beautiful appearance over long time. If necessary, the coating can be easily stripped off.

Owner:DUSKIN CO LTD +1

Fluororesin composite material, coating film made from the composite material and coated body with the coating film

InactiveUS20110039093A1Improve corrosion resistanceIncreased durabilityConductive materialSynthetic resin layered productsPolyether ether ketoneInorganic sulfide

(Problems) To provide a coating film which excels in corrosion resistance and processability as well as high durability and little suffers from electrification.(Means for Solving Problems) A fluororesin composite material including: a fluororesin microencapsulating silicon carbide, an amount of the silicon carbide being 5 to 9% by weight with respect to a total of the fluororesin composite material; and at least one of polyphenylene sulfide (PPS), polyether sulphone (PES) and polyether ether ketone (PEEK).

Owner:NIPPON FUTSUSO INDS

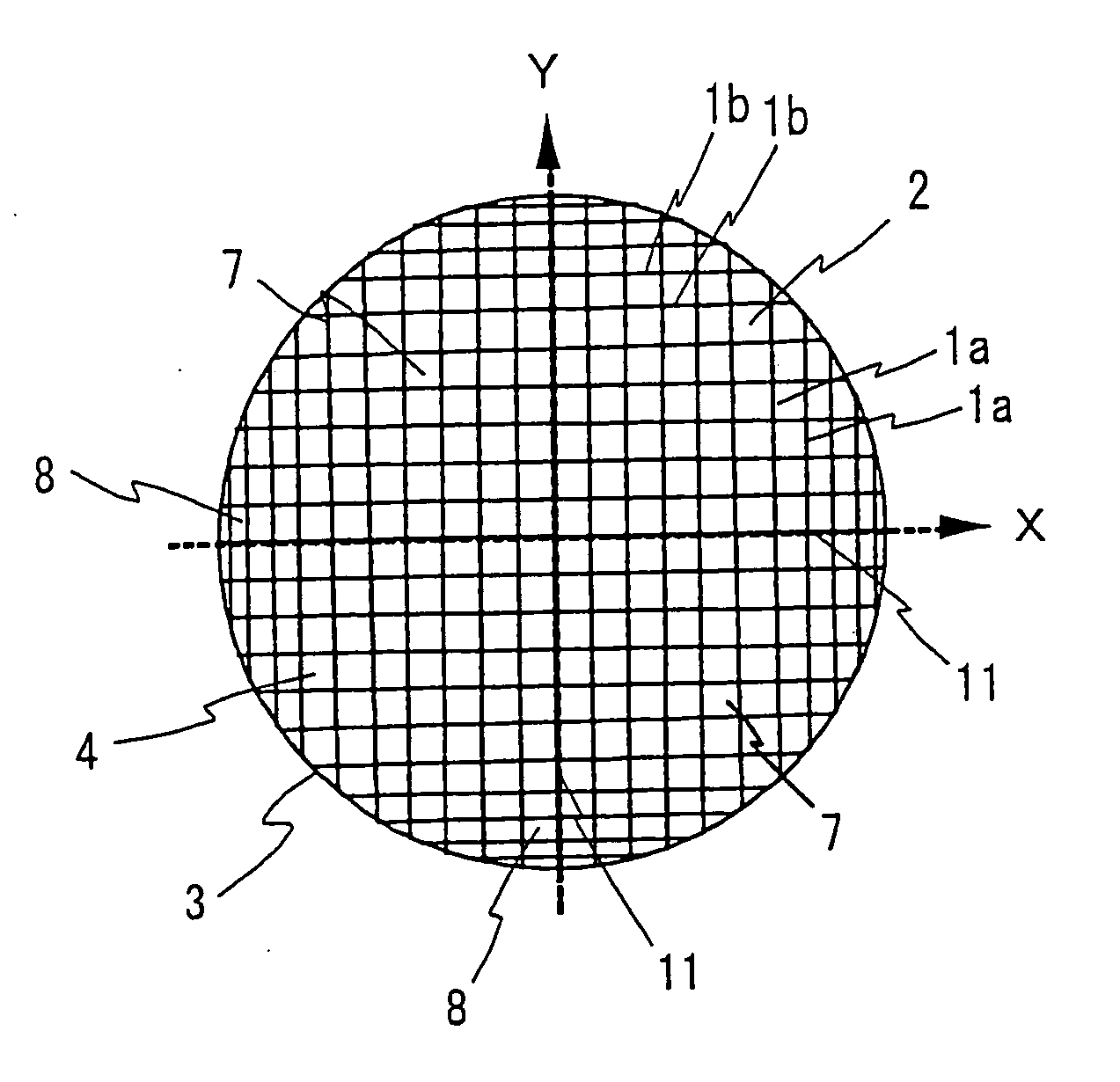

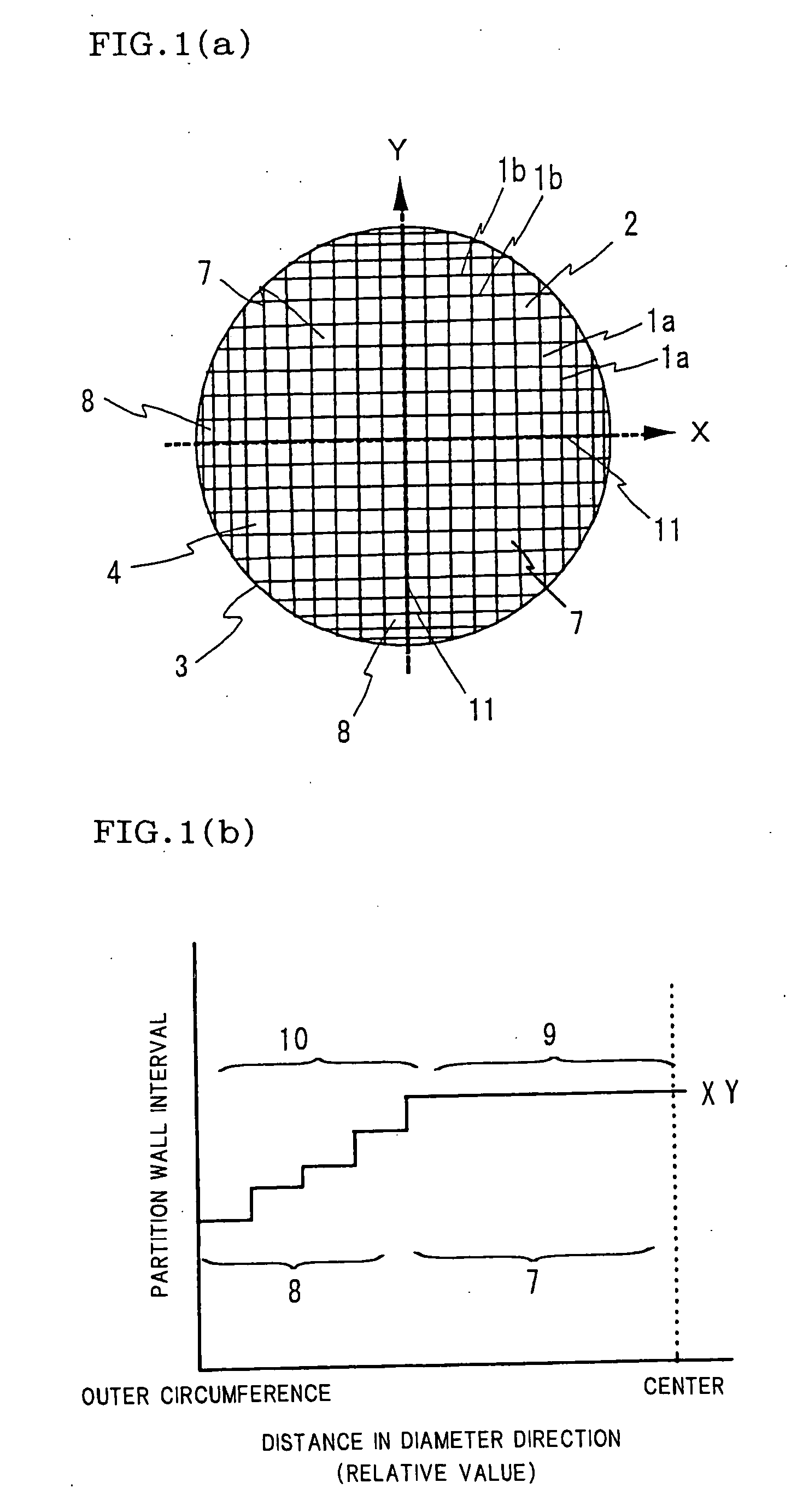

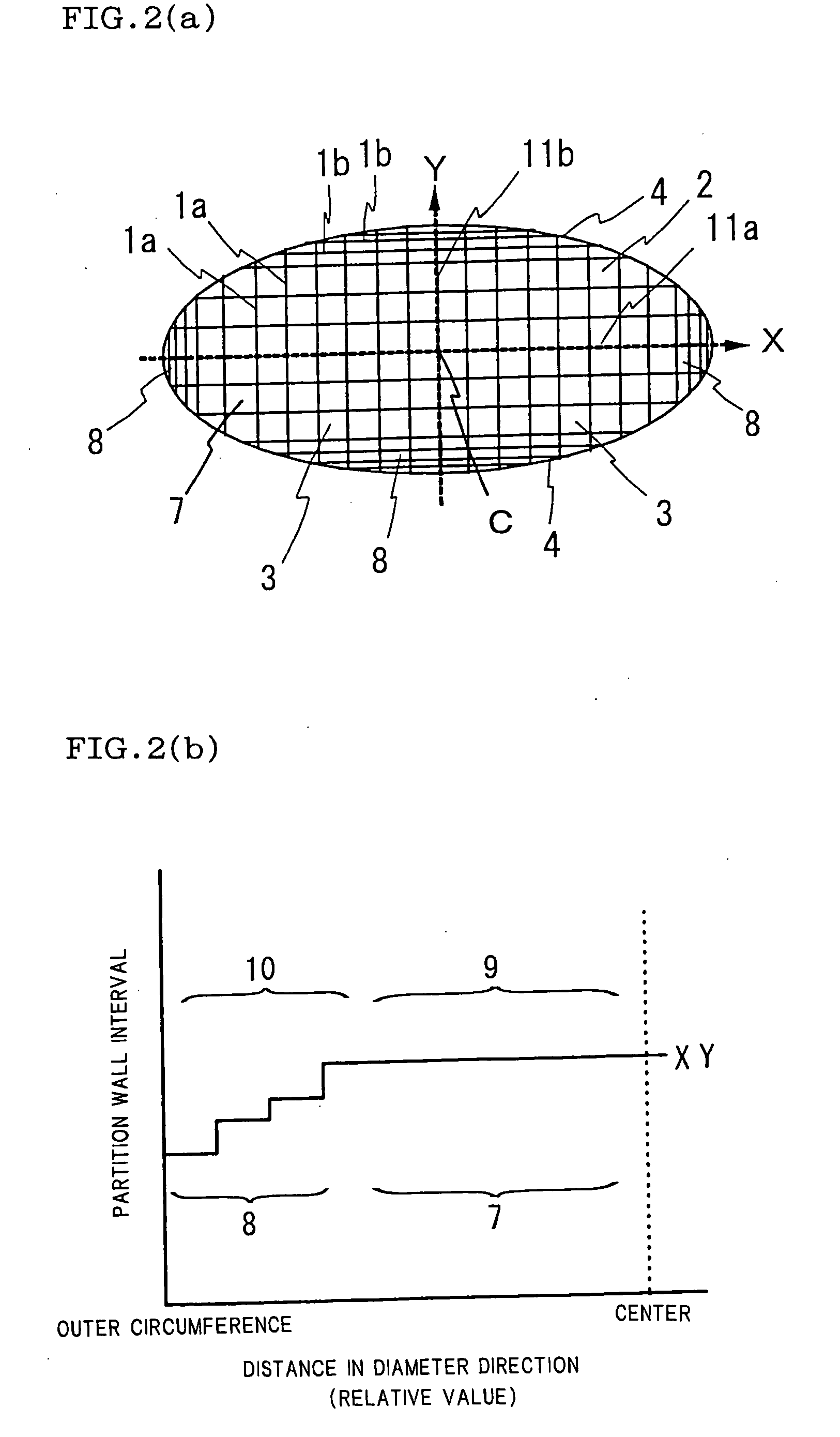

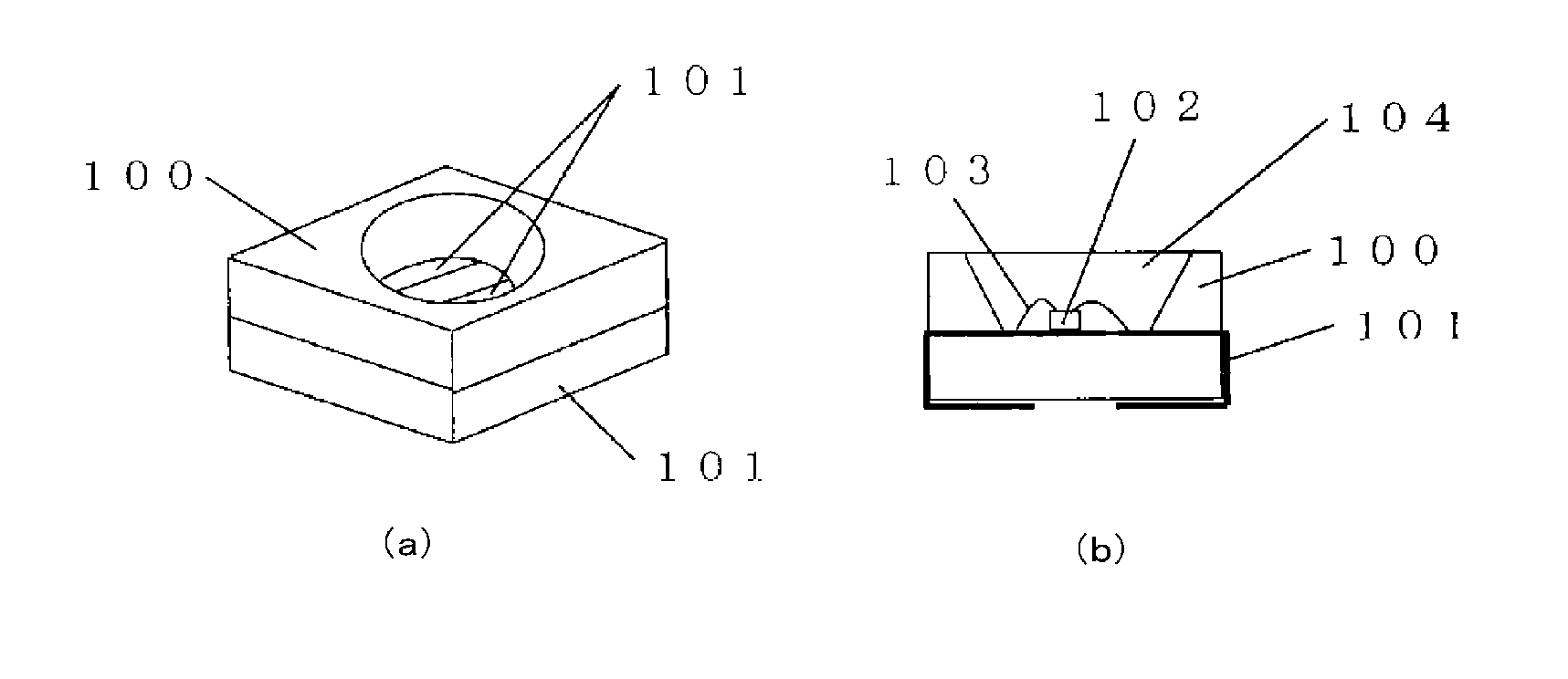

Honeycomb structure, and honeycomb structure forming honeycomb

ActiveUS20050241266A1Excels in resistanceExcels in strengthInternal combustion piston enginesDispersed particle filtrationStructural engineeringUnit structure

The present invention provides a honeycomb structure which includes a cell structure section 3 including a plurality of cells 2 partitioned by a plurality of partition walls 1a and 1b, and an outer circumferential wall section 4 surrounding the cell structure section 3. The cell structure section 3 includes a first partition wall group having the partition walls 1a positioned in parallel and a second partition wall group having the partition walls 1b which intersect the partition walls of the first partition wall group at right angles and are positioned in parallel, each of the partition walls 1a and 1b connecting two different locations of the outer circumferential wall section 4 through one continuous plane. In this honeycomb structure, the partition wall intervals of the partition walls 1a and 1b of each partition wall group positioned in parallel are varied stepwise in at least a part of the cell structure section 3, at least some of the cells have a rectangular cross-sectional shape, and all the partition walls 1a and 1b have such a ratio of the cell side length to the partition wall thickness that the partition wall can withstand pressure during canning. According to the present invention, a honeycomb structure which excels in isostatic strength and thermal shock resistance and has such a high industrial applicability that the honeycomb structure can be manufactured at low cost can be provided.

Owner:NGK INSULATORS LTD

Electrically conductive adhesive film and dicing-die bonding film using the same

ActiveUS20180346767A1Improve heat resistanceExcels in in reliabilityConductive layers on insulating-supportsNon-macromolecular adhesive additivesNitrogen atmosphereMetal particle

The electrically conductive adhesive film comprises a metal particle (Q), a resin (M), and at least one of a prescribed organic phosphine (A) and a prescribed sulfide-based compound (B), the resin (M) comprises a thermosetting resin (M1), and has a storage elastic modulus at 1 Hz measured in a state after sintering of 20 GPa or less and a thermal weight loss ratio when heated for 2 hours at 250° C. under a nitrogen atmosphere of less than 1%.

Owner:FURUKAWA ELECTRIC CO LTD

Hard coating film, material coated with hard coating film and die for cold plastic working and method for forming hard coating film

InactiveUS20100189835A1Increased durabilityReduce coefficient of frictionConfectioneryVacuum evaporation coatingFrictional coefficientWear resistance

The present invention provides hard coating film which excels conventional surface coating layer in wear resistance, has lower frictional coefficient and better slidability, a material coated with the hard coating film, a die for cold plastic working, and a method for forming the hard coating film. The hard coating film according to the present invention is a hard coating film comprising (NbxM1-x)y(BaCbN1-a-b)1-y, where0.2≦x≦1.0 Equation (1)0≦a≦0.3 Equation (2)0≦1-a-b≦0.5 Equation (3)0.5≦b≦1 Equation (4)0.4≦1-y≦0.9 Equation (5)[however, M denotes at least one species of elements belonging to Groups 4a, 5a, and 6a and Si and Al; x, 1-x, a, b, and 1-a-b represent respectively the atomic ratio of Nb, M, B, C and N; and y and 1-y represent respectively the ratio of (NbxM1-x) and (BaCbN1-a-b).]

Owner:KOBE STEEL LTD

Polybutylene terephthalate resin composition

ActiveUS20120232200A1Excels in resistanceExcels in retardancyPolytetramethylene terephthalatePolybutylene terephthalate

To provide a polybutylene terephthalate resin composition that excels in the anti-heat shock property, flame retardation and hydrolysis resistance. A polybutylene terephthalate resin composition is prepared by combining a halogenated benzylacrylate compound, an antimony oxide compound and a carbodiimide compound with the polybutylene terephthalate resin. The content of the carbodiimide compound may be an amount that makes the amount of the carbodiimide functional group to be at least 0.3 equivalents and no more than 5.0 equivalents, when the terminal carboxyl equivalent of the polybutylene terephthalate is set as 1.

Owner:POLYPLASTICS CO LTD

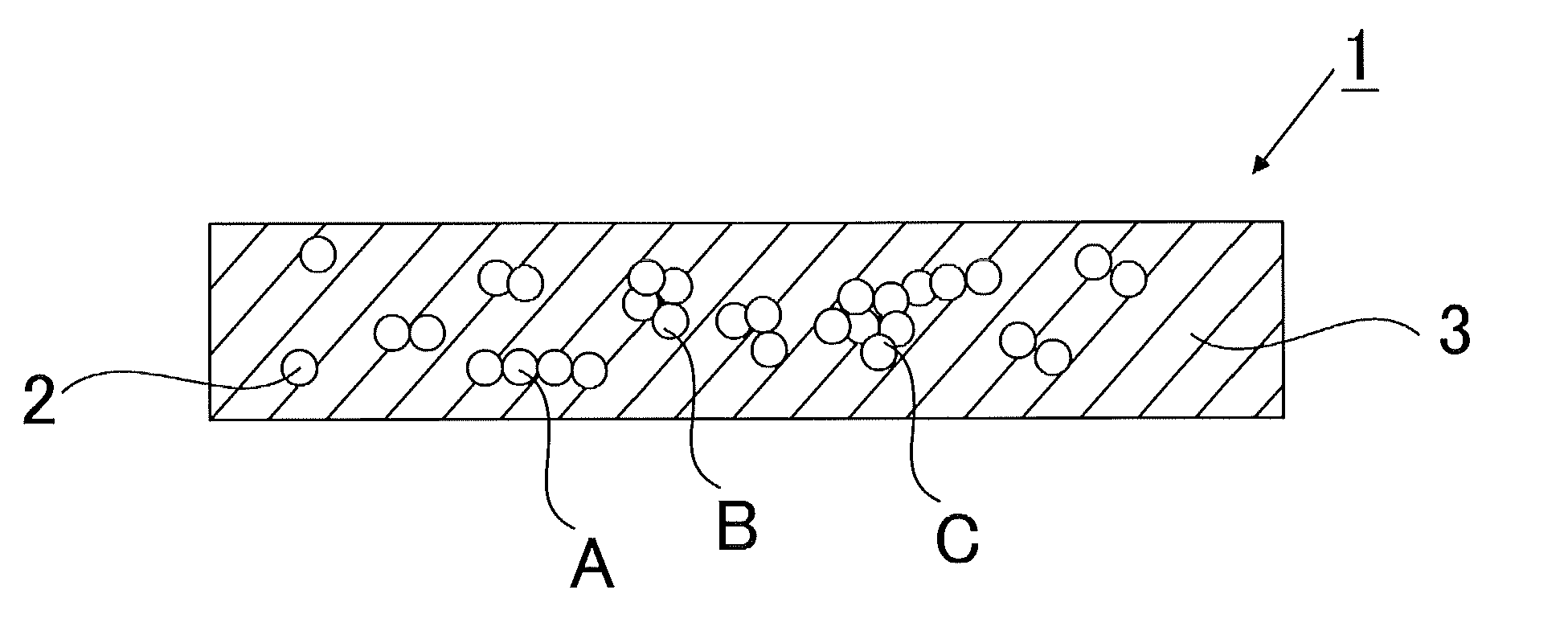

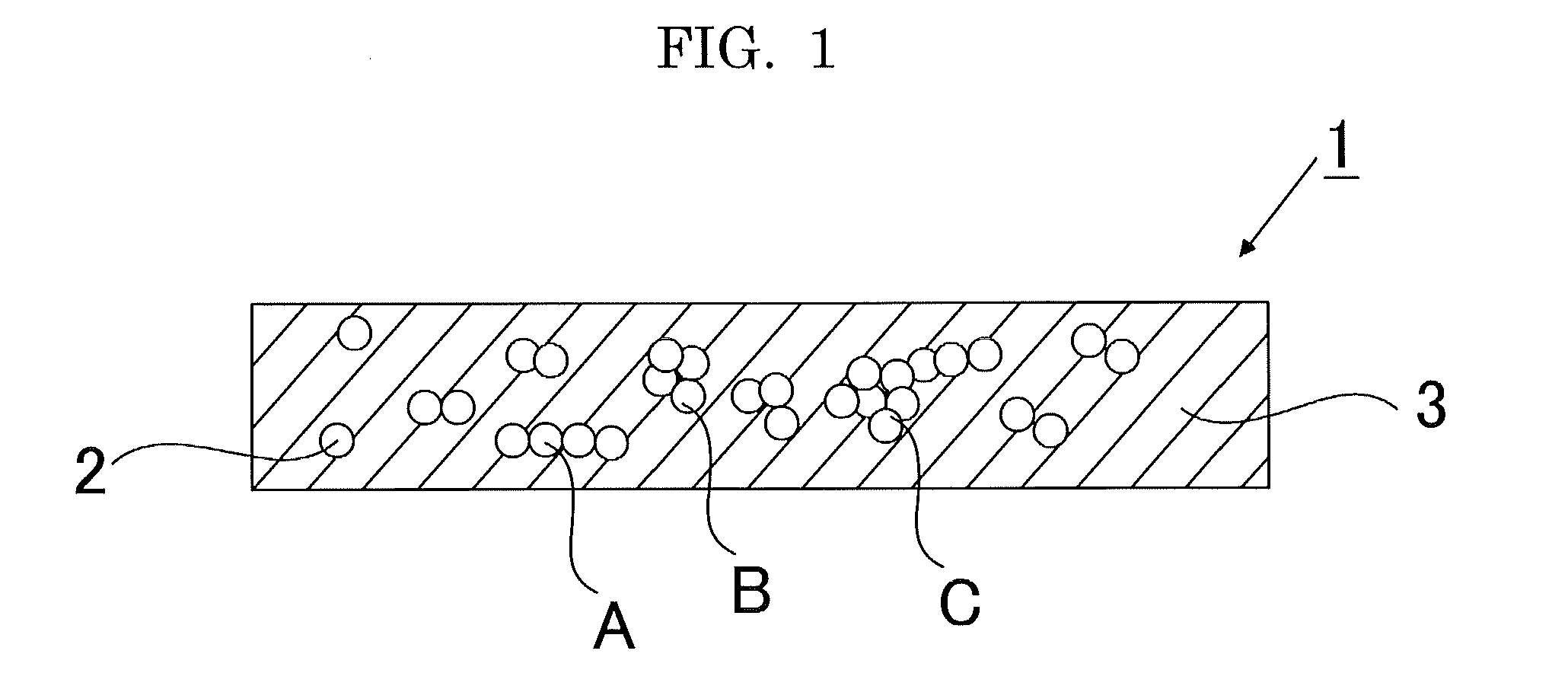

Anisotropic conductive film, anisotropic conductive film production method, connecting method, and bonded structure

ActiveUS20140168919A1Excels in conduction resistanceExcels in rateMagnetic materialsPrinted circuit manufactureAnisotropic conductive filmOptoelectronics

To provide an anisotropic conductive film, which contains conductive particles, wherein the anisotropic conductive film is an anisotropic conductive film configured to anisotropic conductively connect a terminal of a substrate with a terminal of an electronic component, wherein the conductive particles are conductive particles, in each of which a metal plated layer and an insulating layer are sequentially provided on a surface of a resin particle, or conductive particles, in each of which an insulating layer is provided on a metal particle, or both thereof, and wherein 3.0 to 10.0 conductive particles are linked together on average.

Owner:DEXERIALS CORP

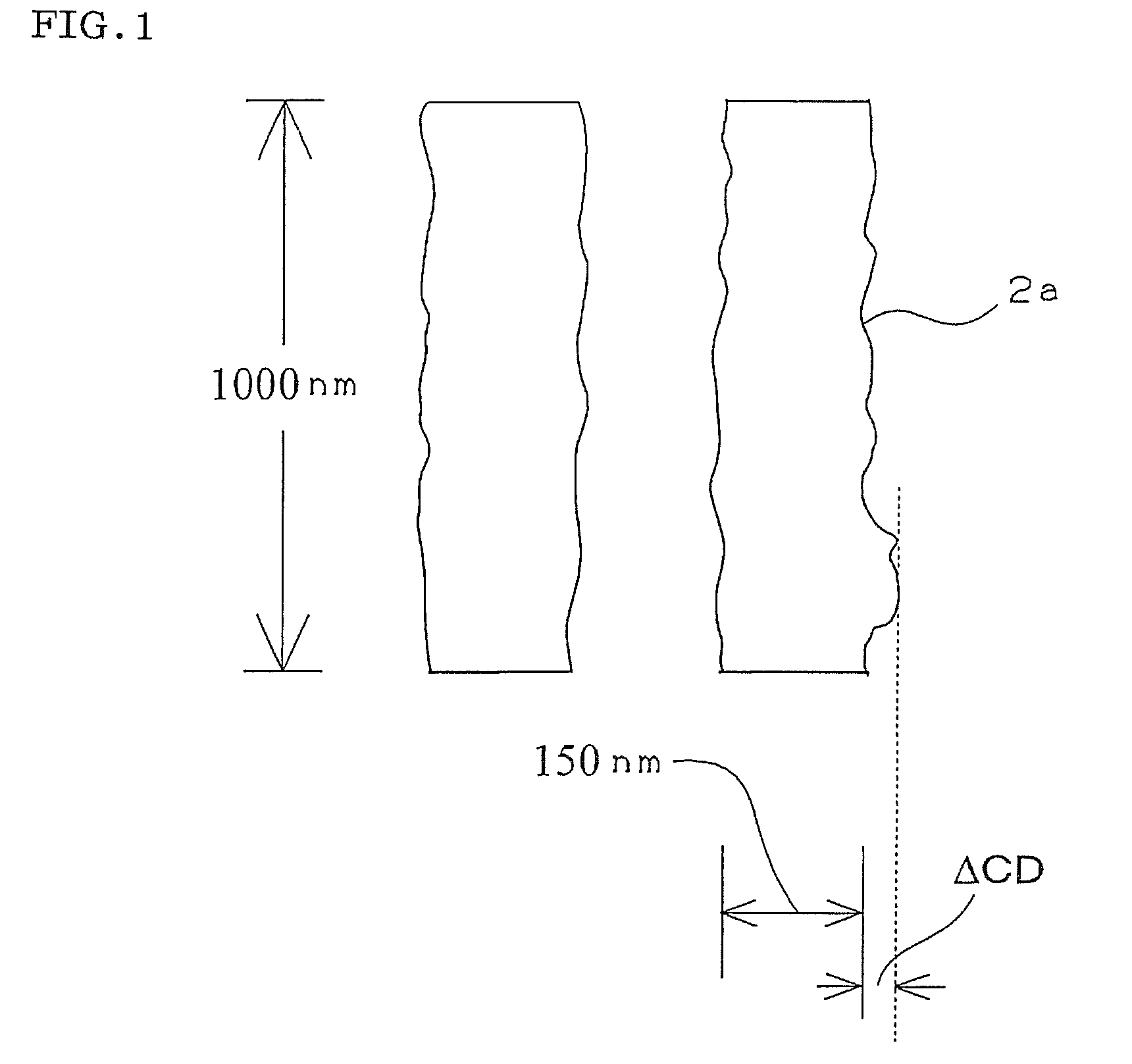

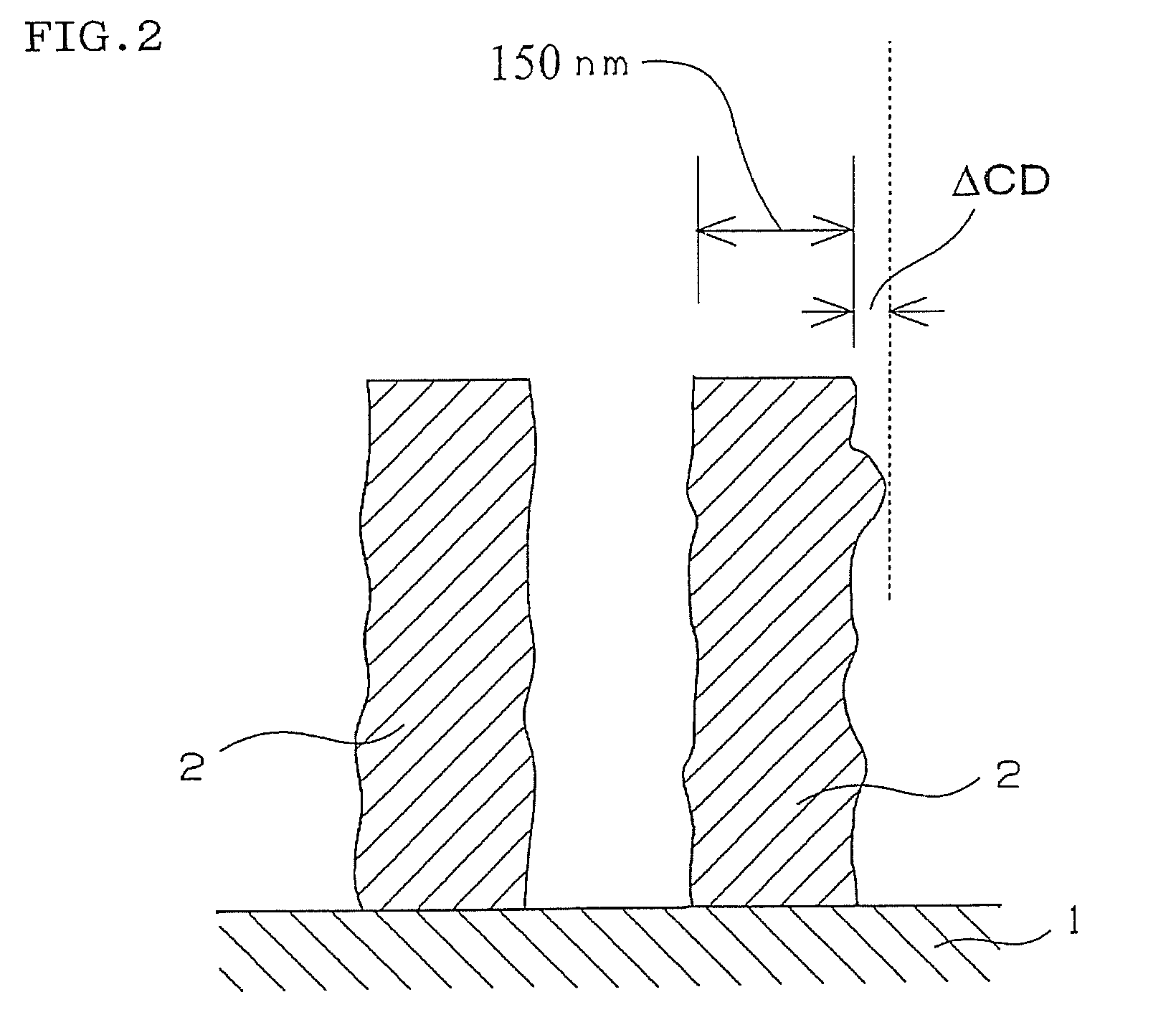

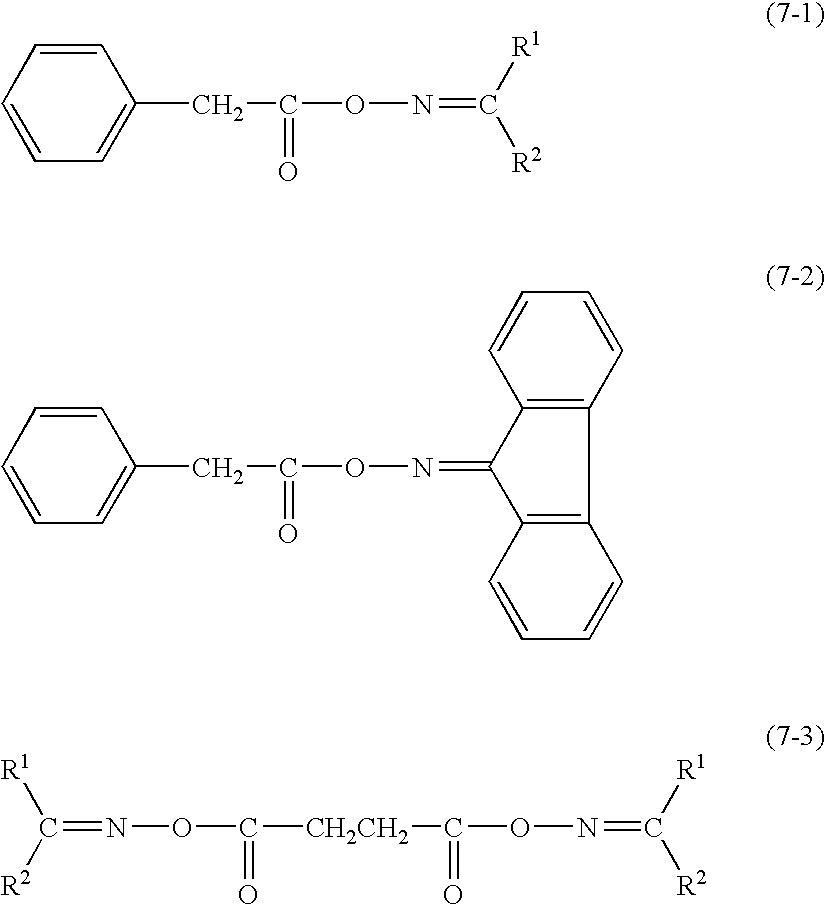

Compound and radiation-sensitive composition

ActiveUS8173351B2Reduce roughnessExcels in resistanceOrganic chemistryOrganic compound preparationResistRadiation sensitivity

Owner:JSR CORPORATIOON

Composition for forming adhesive pattern, laminated structure obtained by using same, and method of producing such laminated structure

ActiveUS7829180B2Improve adhesionHigh hardnessPhototackifying patterningAdhesive processesEpoxyAqueous solution

Owner:TAIYO INK MFG CO LTD

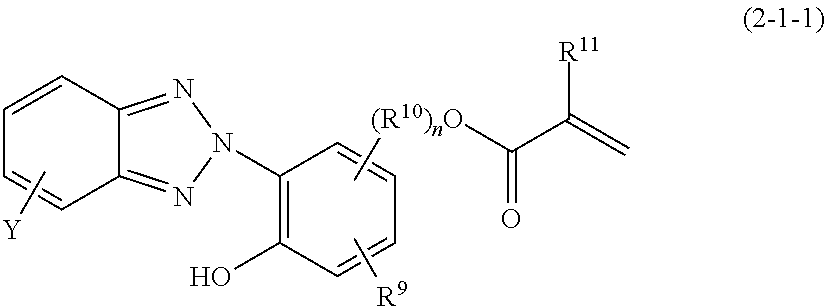

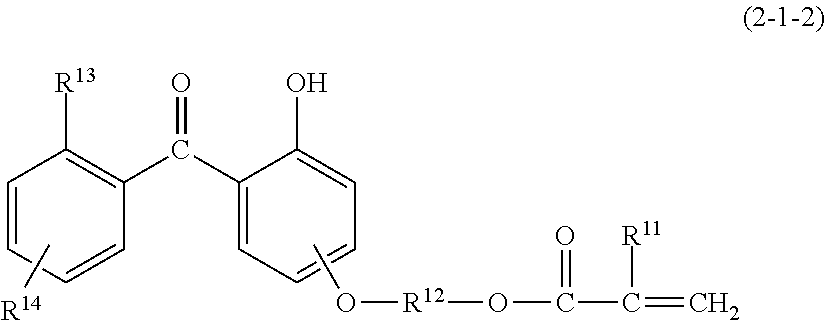

Weather-resistant hard coating composition and coated article

InactiveUS20120258312A1Excels in lightExcels in resistance solventSynthetic resin layered productsDyeing processEpoxySide chain

A weather-resistant hard coating composition to be used for direct coating on at least one surface of an organic resin substrate, the composition containing the following components.(1) A silicone resin resulting from (co)hydrolysis and condensation of at least one selected from those alkoxysilanes represented by the following formulas (1-1), (1-2), and (1-3) or condensates of their partial hydrolyzates,(R1)m(R2)nSi(OR3)4-m-n (1-1)(R4O)3-p(R6)pSi—R8—Si(R7)q(OR5)3-q (1-2)X—[(R15)Si(R16)y(OR17)3-y]z (1-3)(2) A vinyl copolymer having in its side chain an organic ultraviolet-absorbing group and a reactive group selected from an alkoxysilyl group, hydroxyl group, epoxy group, carboxylic acid group, and amino group,(3) A curing catalyst, and(4) A solvent.The silicone resin as component (1) and the vinyl copolymer as component (2) exist in such amounts in terms of solids that the ratio of (1) / (2) is from 10 / 90 to 50 / 50 by weight.

Owner:SHIN ETSU CHEM IND CO LTD

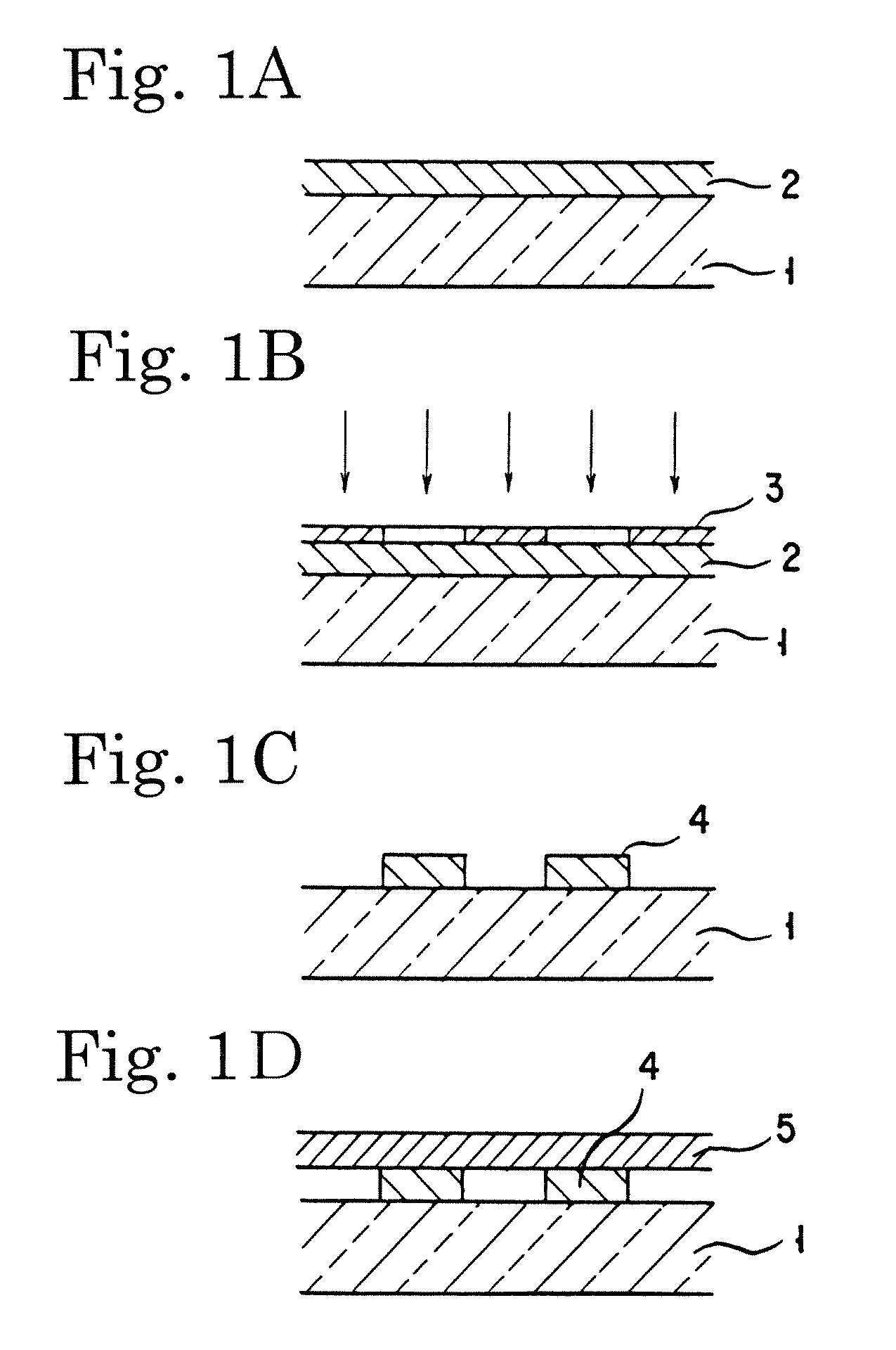

Method of forming pattern and composition for forming of organic thin-film for use therein

ActiveUS20100233635A1Excels in etching resistanceExcels in resolutionOrganic chemistryOther chemical processesRadiation sensitivityRadiation rays

A method for forming a pattern contains (1) a step of forming an underlayer film containing (A) a radiation-sensitive acid generator capable of generating an acid upon exposure to radiation rays or (B) a radiation-sensitive base generator capable of generating a base upon exposure to radiation rays on a substrate; (2) a step of irradiating the underlayer film with radiation rays through a mask with a predetermined pattern to obtain an exposed underlayer film portion having been selectively exposed through the predetermined pattern; (3) a step of forming (C) an organic thin film on the underlayer film so as to attain chemical bonding of the exposed underlayer film portion with the organic thin-film formed on the exposed underlayer film portion; and (4) a step of removing the organic thin film formed on areas of the underlayer film other than the exposed underlayer film portion.

Owner:JSR CORPORATIOON

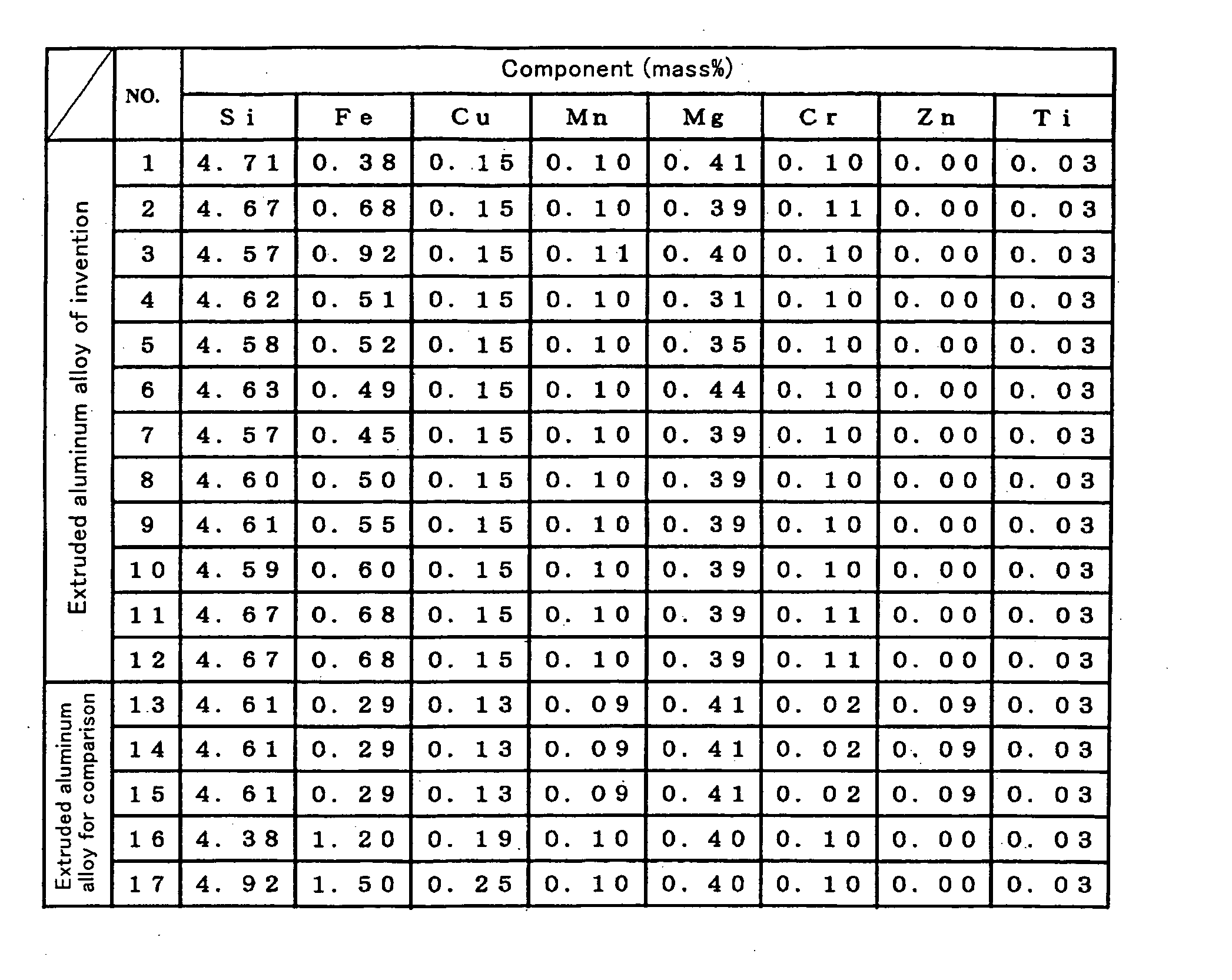

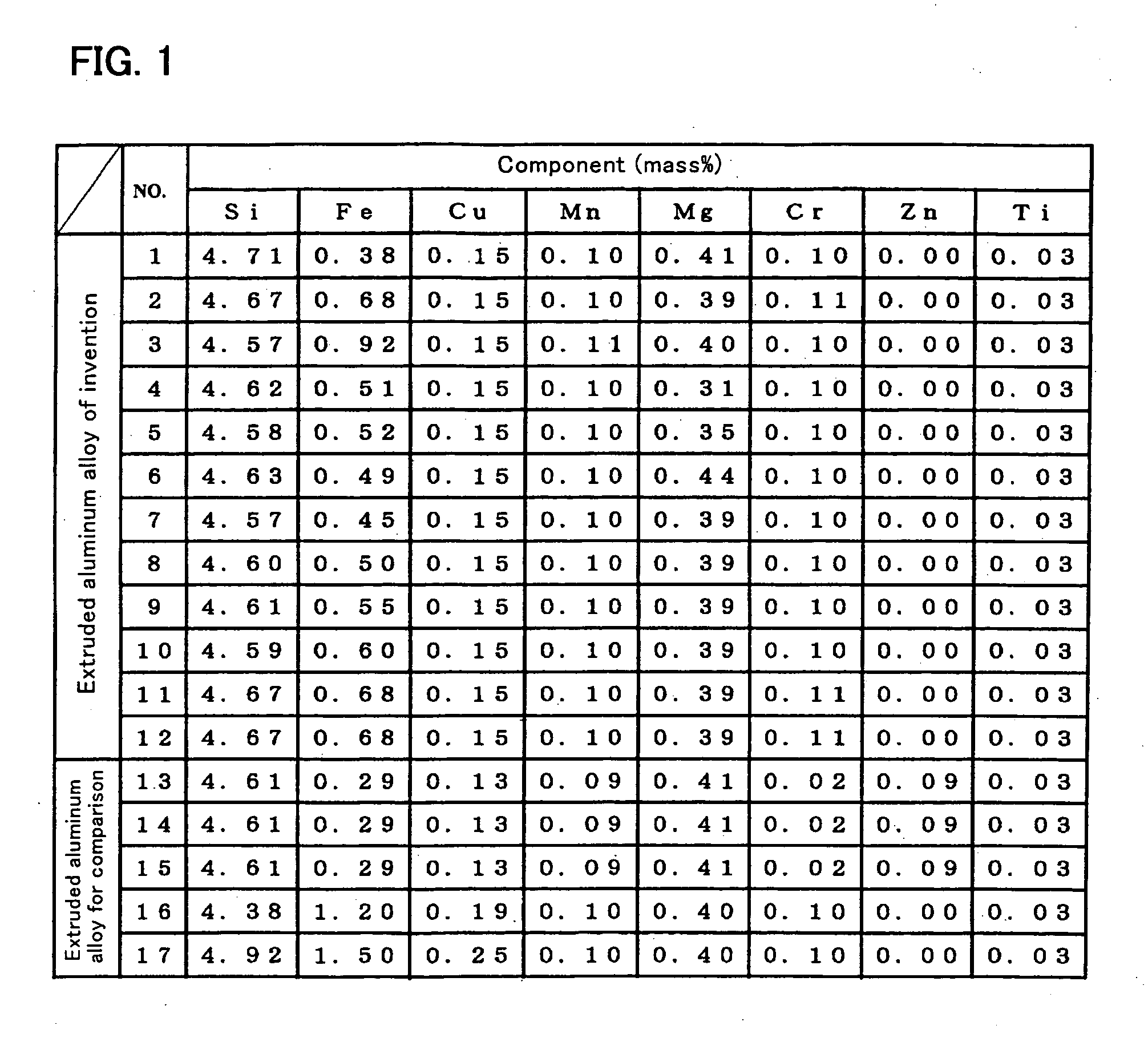

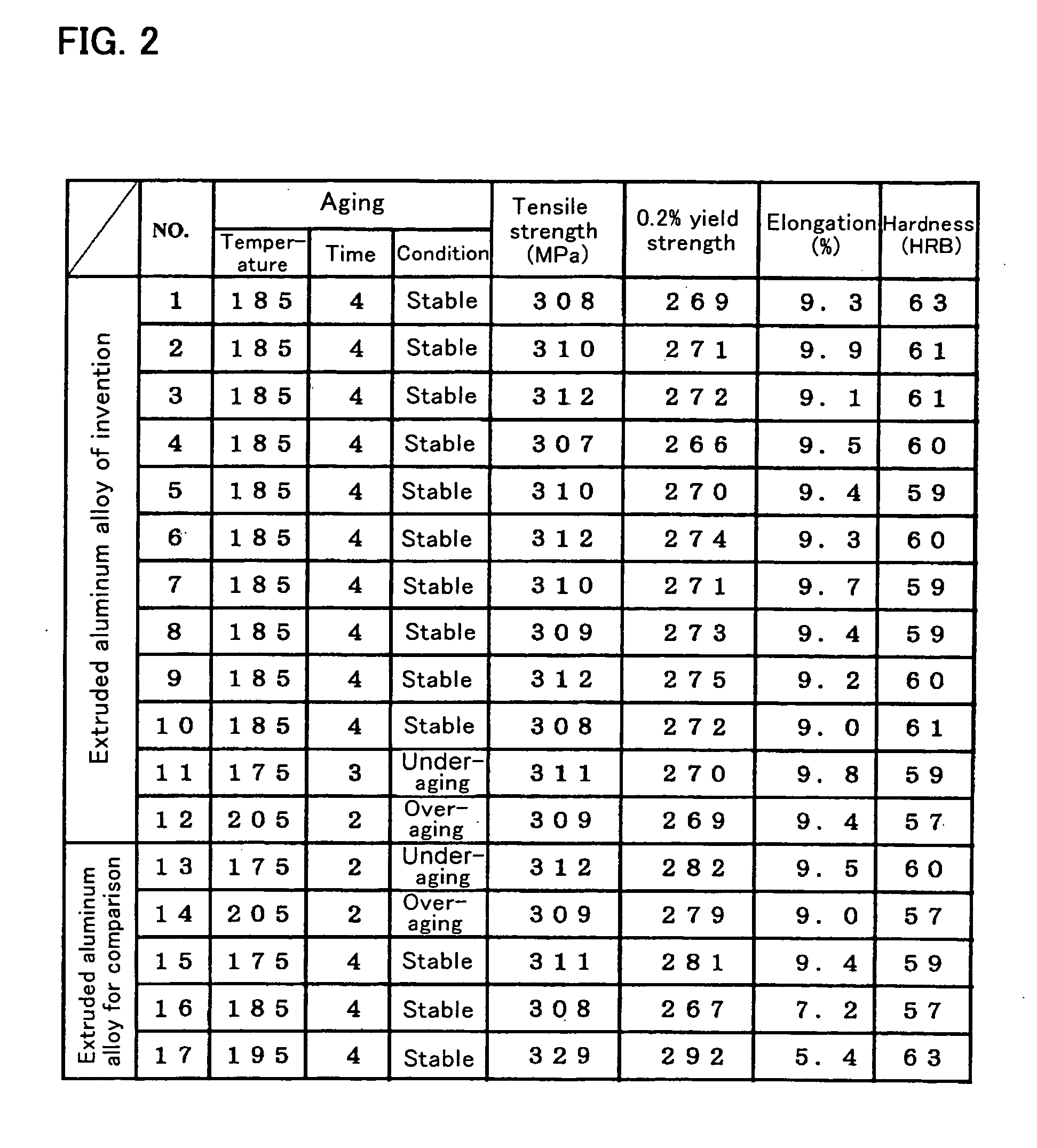

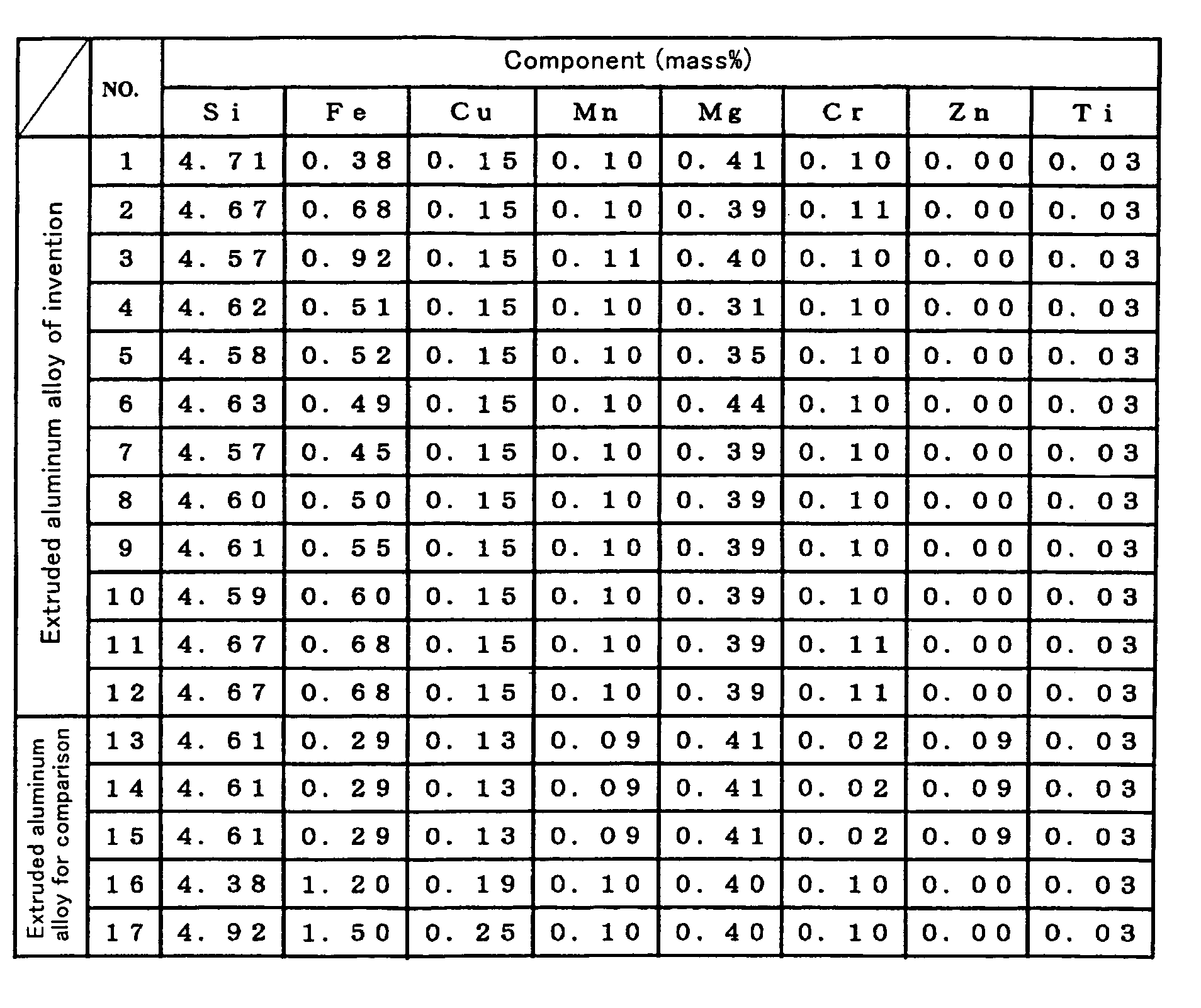

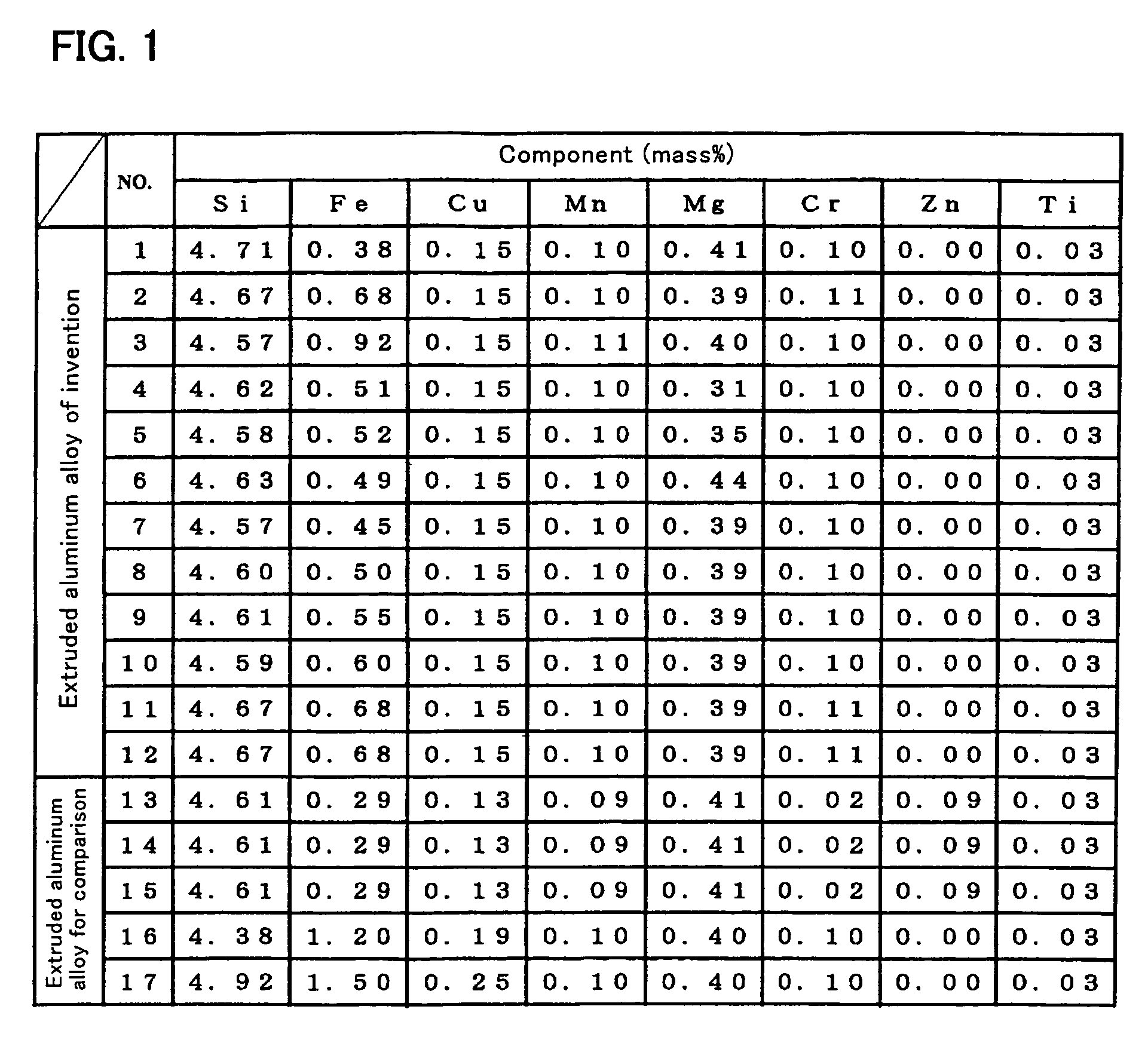

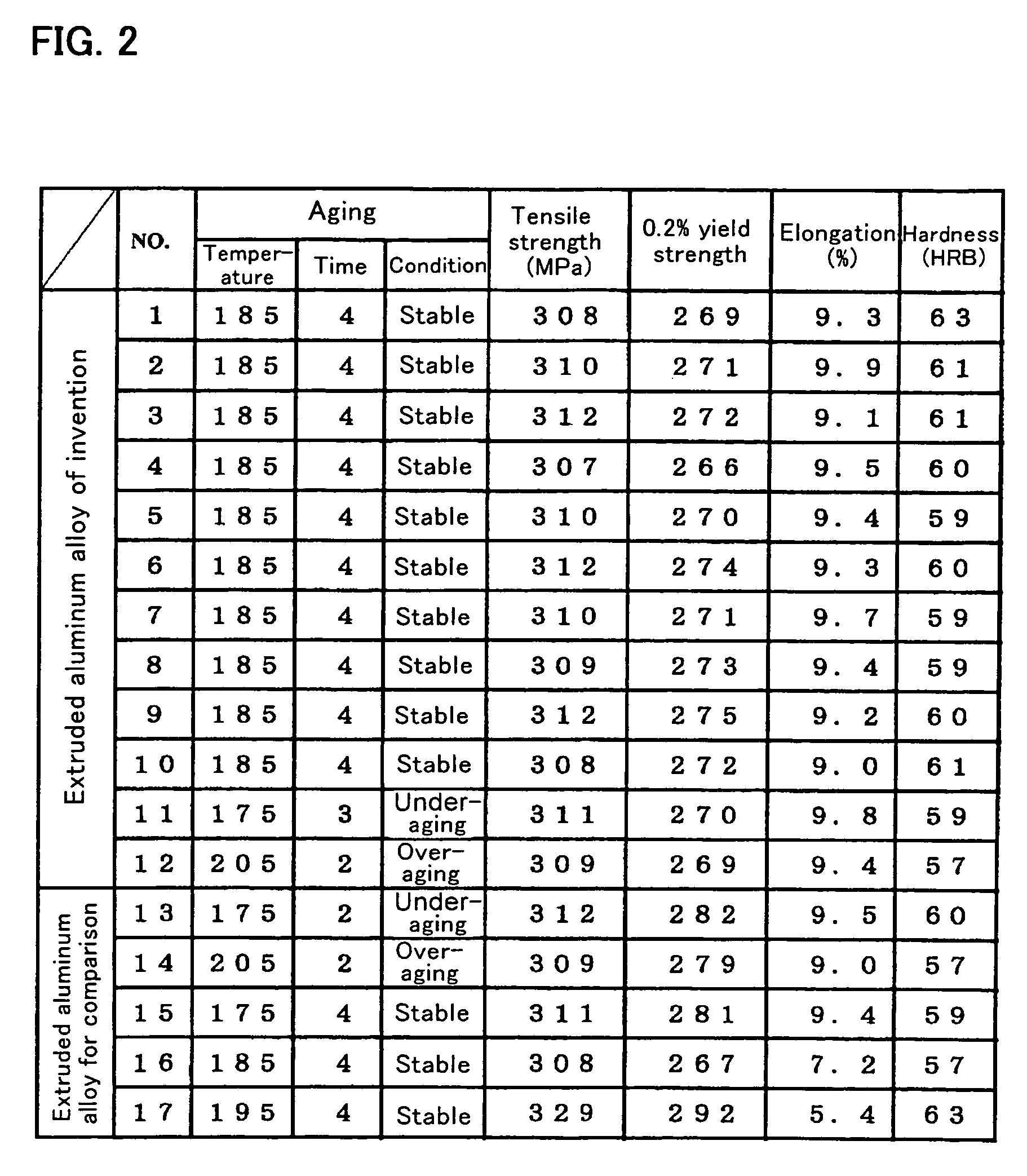

Extruded aluminum alloy which excels in machinability, caulking properties, and wear resistance

Extruded aluminum alloy which excels in machinability, caulking properties, and wear resistance, the extruded aluminum alloy including 3.0 to 6.0 mass % of Si, 0.1 to 0.45 mass % of Mg, 0.01 to 0.5 mass % of Cu, 0.01 to 0.5 mass % of Mn, and 0.40 to 0.90 mass % of Fe, with the balance being Al and unavoidable impurities.

Owner:AISIN KEIKINZOKU CO LTD

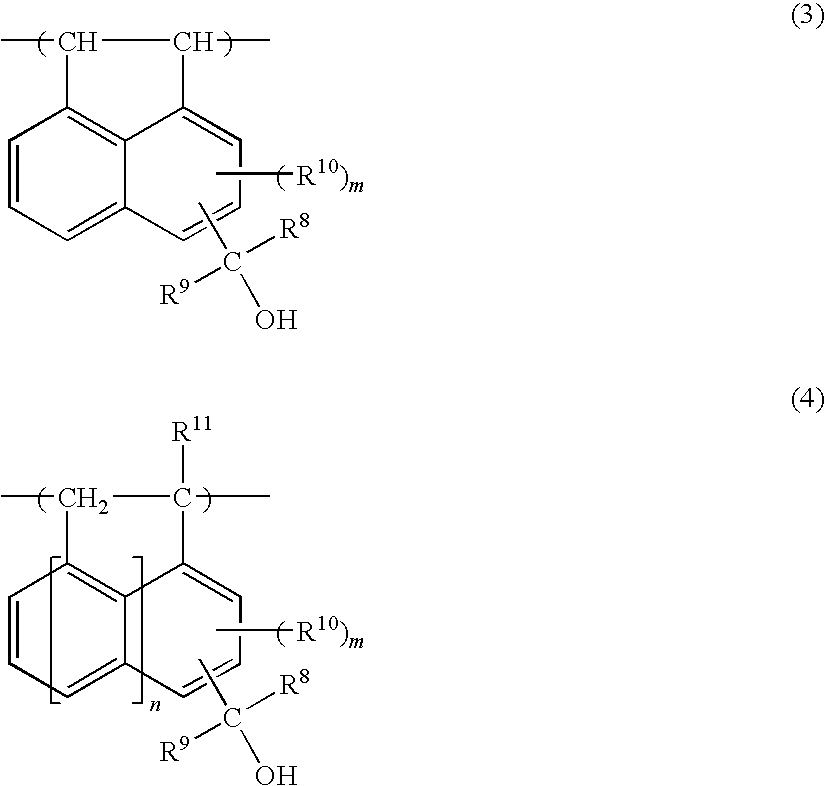

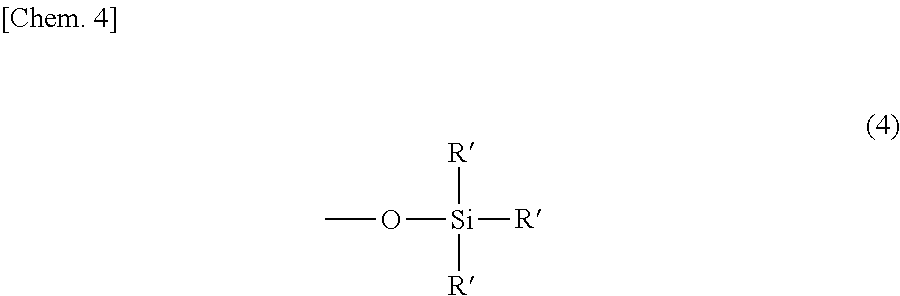

Curable resin composition and cured product thereof, encapsulant, and semiconductor device

InactiveUS20150368514A1Improve barrier propertiesQuality improvementSemiconductor/solid-state device detailsSolid-state devicesArylHeat resistance

Provided is a curable resin composition capable of forming a cured product that has excellent heat resistance and transparency and, in particular, offers excellent barrier properties to a corrosive gas.The curable resin composition according to the present invention includes a polyorganosiloxane (A), an isocyanurate compound (B), and a silane coupling agent (C). The polyorganosiloxane (A) is an aryl-containing polyorganosiloxane. The polyorganosiloxane (A) preferably includes a polyorganosiloxane having a number-average molecular weight (Mn) of 500 to 4000 as determined by gel permeation chromatography and calibrated with a polystyrene standard.

Owner:DAICEL CHEM IND LTD

Extruded aluminum alloy which excels in machinability, caulking properties, and wear resistance

Extruded aluminum alloy which excels in machinability, caulking properties, and wear resistance, the extruded aluminum alloy including 3.0 to 6.0 mass % of Si, 0.1 to 0.45 mass % of Mg, 0.01 to 0.5 mass % of Cu, 0.01 to 0.5 mass % of Mn, and 0.40 to 0.90 mass % of Fe, with the balance being Al and unavoidable impurities.

Owner:AISIN KEIKINZOKU CO LTD

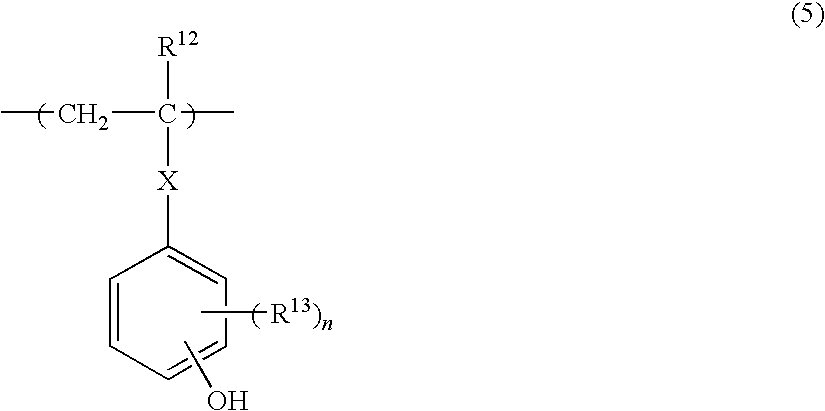

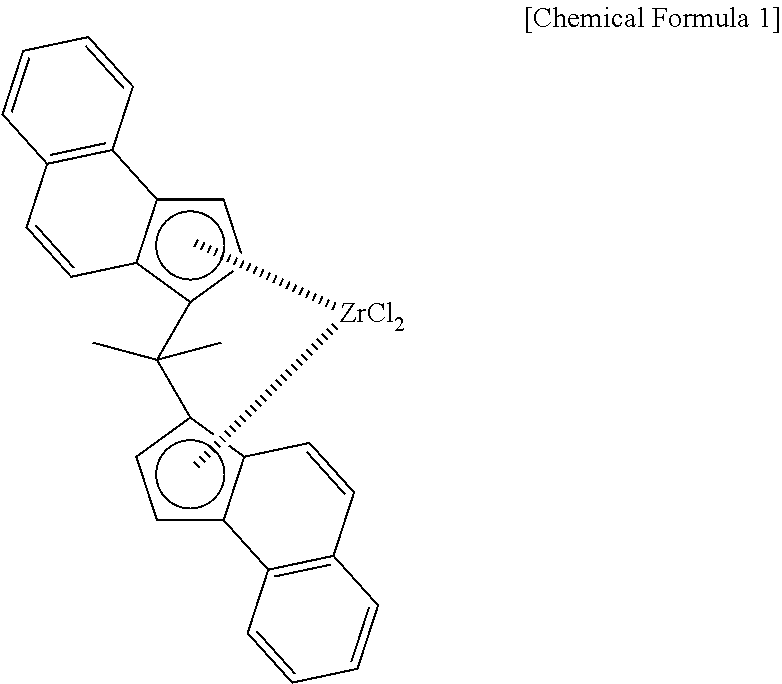

Cyclic olefin addition copolymer and process for producing same, crosslinking composition, crosslinked product and process for producing same, and optically transparent material and application thereof

InactiveUS6992154B2Improve heat resistanceImprove featuresLiquid crystal compositionsPolymer scienceOptical transparency

The present invention provides a cyclic olefin addition copolymer which has a reactive silyl group having a specific structure, excels in optical transparency, heat resistance, and adhesion, and is capable of producing a crosslinked product having improved dimensional stability, solvent resistance, and chemical resistance. The present invention also provides a process for producing the cyclic olefin addition copolymer, a crosslinking composition, a crosslinked product and a process for producing the same, and an optically transparent material (transparent resin film) comprising the cyclic olefin addition copolymer. The optically transparent material excels in optical transparency and heat resistance, exhibits improved dimensional stability, adhesion, solvent resistance, and chemical resistance, and is capable of improving fragility and preventing occurrence of cracks in the film.

Owner:JSR CORPORATIOON

Cyclic olefin addition copolymer and process for producing same, crosslinking composition, crosslinked product and process for producing same, and optically transparent material and application thereof

InactiveUS20050107552A1Improve heat resistanceImprove featuresLiquid crystal compositionsOptical transparencyHeat resistance

The present invention provides a cyclic olefin addition copolymer which has a reactive silyl group having a specific structure, excels in optical transparency, heat resistance, and adhesion, and is capable of producing a crosslinked product having improved dimensional stability, solvent resistance, and chemical resistance. The present invention also provides a process for producing the cyclic olefin addition copolymer, a crosslinking composition, a crosslinked product and a process for producing the same, and an optically transparent material (transparent resin film) comprising the cyclic olefin addition copolymer. The optically transparent material excels in optical transparency and heat resistance, exhibits improved dimensional stability, adhesion, solvent resistance, and chemical resistance, and is capable of improving fragility and preventing occurrence of cracks in the film.

Owner:JSR CORPORATIOON

Hard coating film, material coated with hard coating film, and die for cold plastic working

InactiveUS20120115760A1Excels in resistanceExcels in slidabilityVacuum evaporation coatingSemiconductor/solid-state device manufacturingChemical compositionFrictional coefficient

Disclosed herein are a hard coating film, a material coated with the hard coating film, and a die for cold plastic working, the coating film excelling conventional surface coating layers in wear resistance as well as slidability with a low frictional coefficient.The hard coating film is characterized by a chemical composition of (VxM1-x)(BaCbN1-a-b), where0.4≦x≦0.95 (1A)0≦a≦0.2 (2A)0≦1-a-b≦0.35 (3A)0.6≦b≦1 (4A)M denotes at least one species of elements belonging to Groups 4a, 5a, and 6a and Si and Al; and x, 1-x, a, b, and 1-a-b represent respectively the atomic ratio of V, M, B, C, and N.

Owner:KOBE STEEL LTD

Hard coating film, material coated with hard coating film, and die for cold plastic working

ActiveUS20090068478A1Excels in wear resistance and slidabilityGood durabilityNitrogen-metal/silicon/boron binary compoundsVacuum evaporation coatingChemical compositionFrictional coefficient

Disclosed herein are a hard coating film, a material coated with the hard coating film, and a die for cold plastic working, the coating film excelling conventional surface coating layers in wear resistance as well as slidability with a low frictional coefficient.The hard coating film is characterized by a chemical composition of (VxM1-x) (BaCbN1-a-b), where0.4≦x≦0.95 (1A)0≦a≦0.2 (2A)0≦1-a-b≦0.35 (3A)0.6≦b≦1 (4A)M denotes at least one species of elements belonging to Groups 4a, 5a, and 6a and Si and Al; and x, 1-x, a, b, and 1-a-b represent respectively the atomic ratio of V, M, B, C, and N.

Owner:KOBE STEEL LTD

Pressure sensitive adhesive composition, product using the same, and display using the product

InactiveUS8551615B2Excels in adhesivenessExcels in coatabilityLayered productsEster polymer adhesivesPolymer scienceAlkoxy group

Disclosed is a pressure-sensitive adhesive composition which contains an acrylic polymer and a crosslinking agent. The acrylic polymer has a weight-average molecular weight of 40×104 to 160×104 and contains at least an alkoxyalkyl acrylate (Component A) and an acrylic monomer having a crosslinkable functional group (Component B). The monomer components constituting the acrylic polymer contain 45 to 99.5 parts by weight of Component A and 0.5 to 4.5 parts by weight of Component B to 100 parts by weight of total monomer components constituting the acrylic polymer, and the monomer components constituting the acrylic polymer contain substantially no carboxyl-containing monomers. This relates to improvements to provide pressure-sensitive adhesive compositions that show excellent coatability, transparency, adhesion (typically low-temperature adhesion), and resistance to blistering / separation and concurrently have anticorrosive properties.

Owner:NITTO DENKO CORP

Thermal transfer image-receiving sheet and manufacturing method for thermal transfer image-receiving sheet

InactiveUS20130344261A1Excels in adhesivenessExcels in resistanceSynthetic resin layered productsPretreated surfacesAcrylic resinPorous layer

Disclosed is a thermal transfer image-receiving sheet which excels in adhesiveness to a receiving layer and solvent resistance, and a manufacturing method thereof. In the thermal transfer image-receiving sheet, which includes a porous layer, a barrier layer, a receiving layer which are stacked in this order on a substrate, the porous layer includes a binder resin and hollow particles, and the barrier layer includes (i) (A) a first acrylic resin and (B) one or more kinds of resins selected from the group consisting of polyester resins, polyvinyl pyrrolidone type resins, polyester type urethane resin, and a second acrylic resin which differs from the first acrylic resin; or (ii) a polyvinyl pyrrolidone type resin.

Owner:DAI NIPPON PRINTING CO LTD

Hard coating film, material coated with hard coating film, and die for cold plastic working

ActiveUS8216700B2Excels in resistanceExcels in slidabilityNitrogen-metal/silicon/boron binary compoundsVacuum evaporation coatingChemical compositionFrictional coefficient

Disclosed herein are a hard coating film, a material coated with the hard coating film, and a die for cold plastic working, the coating film excelling conventional surface coating layers in wear resistance as well as slidability with a low frictional coefficient.The hard coating film is characterized by a chemical composition of (VxM1-x) (BaCbN1-a-b), where0.4≦x≦0.95 (1A)0≦a≦0.2 (2A)0≦1-a-b≦0.35 (3A)0.6≦b≦1 (4A)M denotes at least one species of elements belonging to Groups 4a, 5a, and 6a and Si and Al; and x, 1-x, a, b, and 1-a-b represent respectively the atomic ratio of V, M, B, C, and N.

Owner:KOBE STEEL LTD

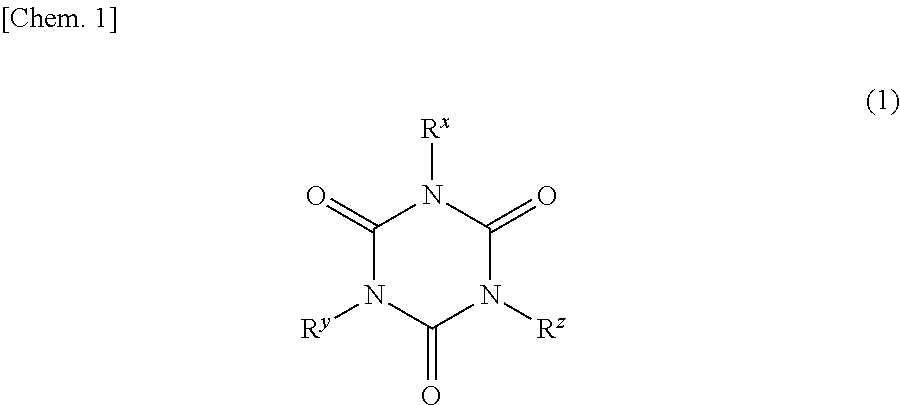

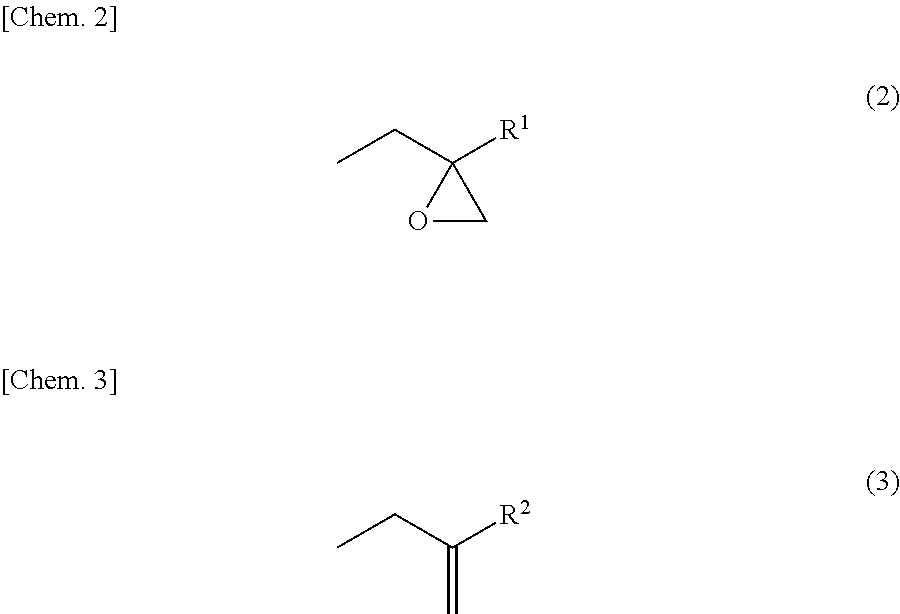

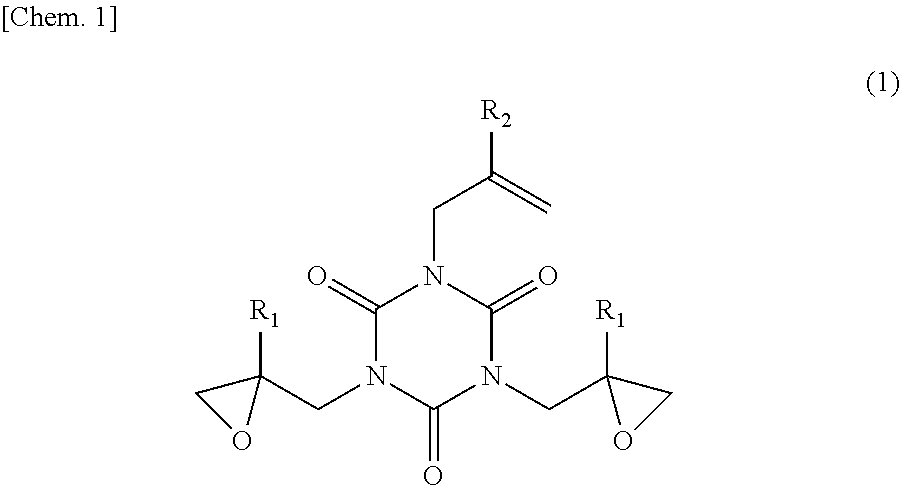

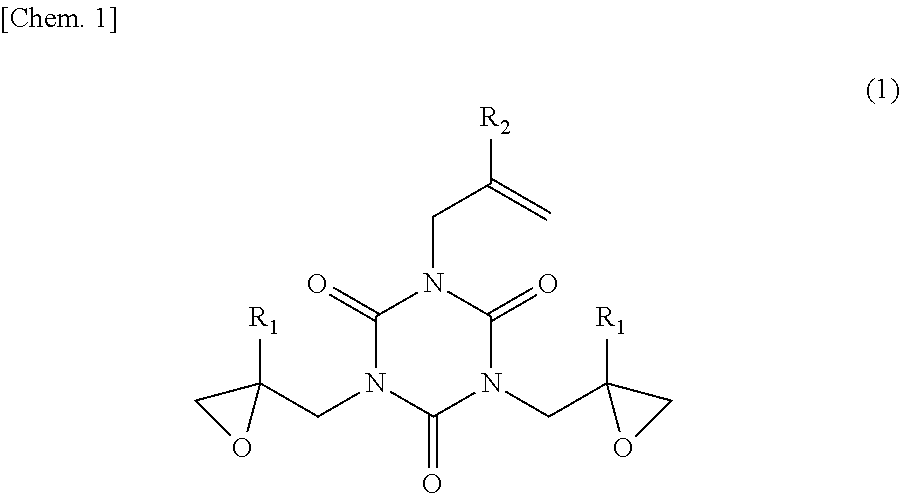

Curable epoxy resin composition

InactiveUS8853734B2High fastnessImprove stabilitySemiconductor/solid-state device detailsSolid-state devicesEpoxyPolymer science

Provided are: a curable epoxy resin composition including an alicyclic epoxy compound (A), a monoallyl diglycidyl isocyanurate compound (B) represented by following Formula (1) where each of R1s and R2 represents a hydrogen atom or an alkyl group having 1 to 8 carbon atoms, and a curing agent (C) or curing catalyst (D); and a cured article obtained through curing of the curable epoxy resin composition. The alicyclic epoxy compound (A) preferably has cyclohexene oxide group as the alicyclic epoxy group.

Owner:DAICEL CHEM IND LTD

Fluororesin composite material, coating film made from the composite material and coated body with the coating film

InactiveUS8241529B2Excels in processabilityExcels in resistanceConductive materialSynthetic resin layered productsPolyether ether ketoneMaterials science

(Problems)To provide a coating film which excels in corrosion resistance and processability as well as high durability and little suffers from electrification.(Means for Solving Problems)A fluororesin composite material including: a fluororesin microencapsulating silicon carbide, an amount of the silicon carbide being 5 to 9% by weight with respect to a total of the fluororesin composite material; and at least one of polyphenylene sulfide (PPS), polyether sulphone (PES) and polyether ether ketone (PEEK).

Owner:NIPPON FUTSUSO INDS

Thermoplastic elastomer resin composition

InactiveUS20160289437A1Excels in resistanceImprove abilitiesSynthetic resin layered productsMedical devicesBreaking strengthPolyolefin

[Problem] To provide a thermoplastic elastomer resin composition that excels in tensile breaking strength, softness, oil resistance and scratch resistance, and that has good heat fusion ability with respect to polyolefin resins. [Solution] A thermoplastic elastomer resin composition consisting of: 15 to 89 mass % of a cross-copolymer having a polymer consisting of aromatic vinyl monomer units as a cross-chain structure on an aromatic vinyl-olefin-aromatic polyene copolymer main chain consisting of 9.99 to 29.99 mol % of aromatic vinyl monomer units, 70 to 90 mol % of olefin monomer units and 0.01 to 0.5 mol % of aromatic polyene monomer units; 1 to 55 mass % of a hydrogenated block copolymer; and 10 to 60 mass % of a polypropylene resin.

Owner:DENKA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com