Patents

Literature

68results about How to "Good coarsening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum alloy sheet for lithographic printing plate

InactiveUS20050013724A1Improve uniformityGood coarsening effectPlate printingFoil printingAlloySoftening

The present invention provides an aluminum alloy sheet for a lithographic printing plate which allows pits to be uniformly formed by electrochemical roughening, and excels in strength and heat softening resistance. The aluminum alloy sheet for a lithographic printing plate includes 0.1-0.3% of Mg, more than 0.05%, but 0.5% or less of Zn, 0.2-0.6% of Fe, 0.03-0.15% of Si, 0.02% or less of Cu, and 0.003-0.05% of Ti, the remainder being Al and impurities. The aluminum alloy sheet may include more than 0.05%, but 0.3% or less of Mn.

Owner:SUMITOMO LIGHT METAL INDS LTD +1

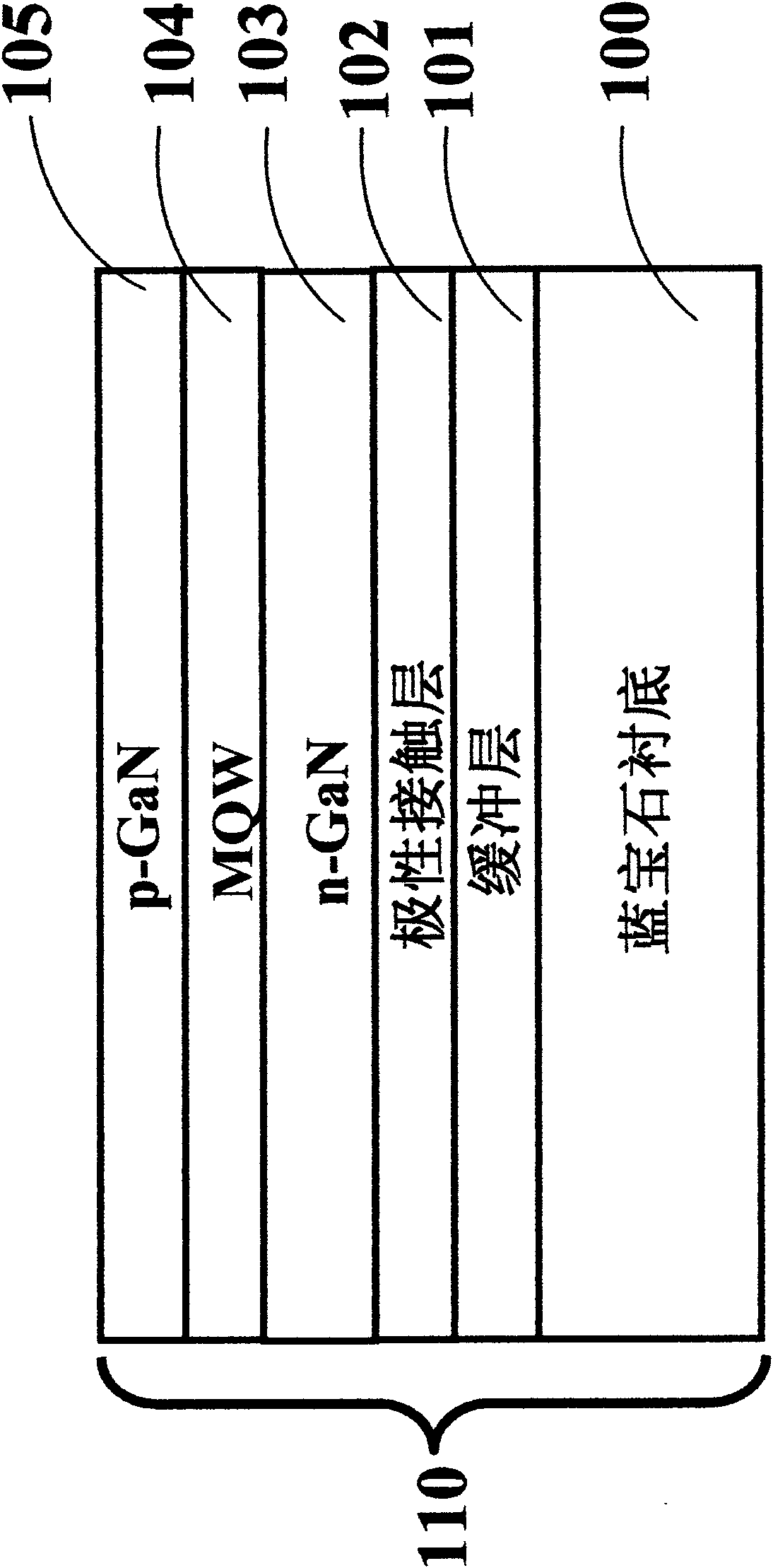

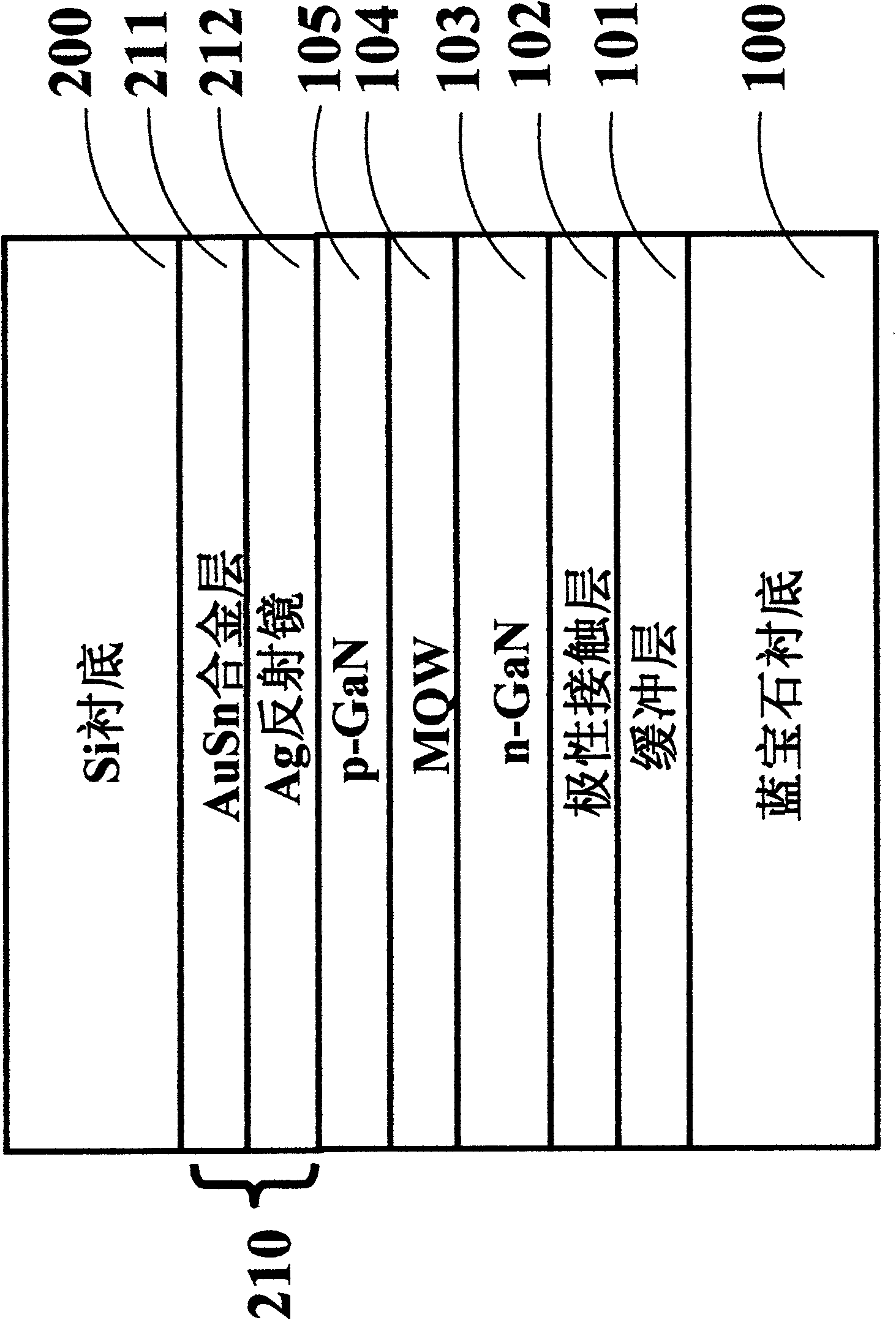

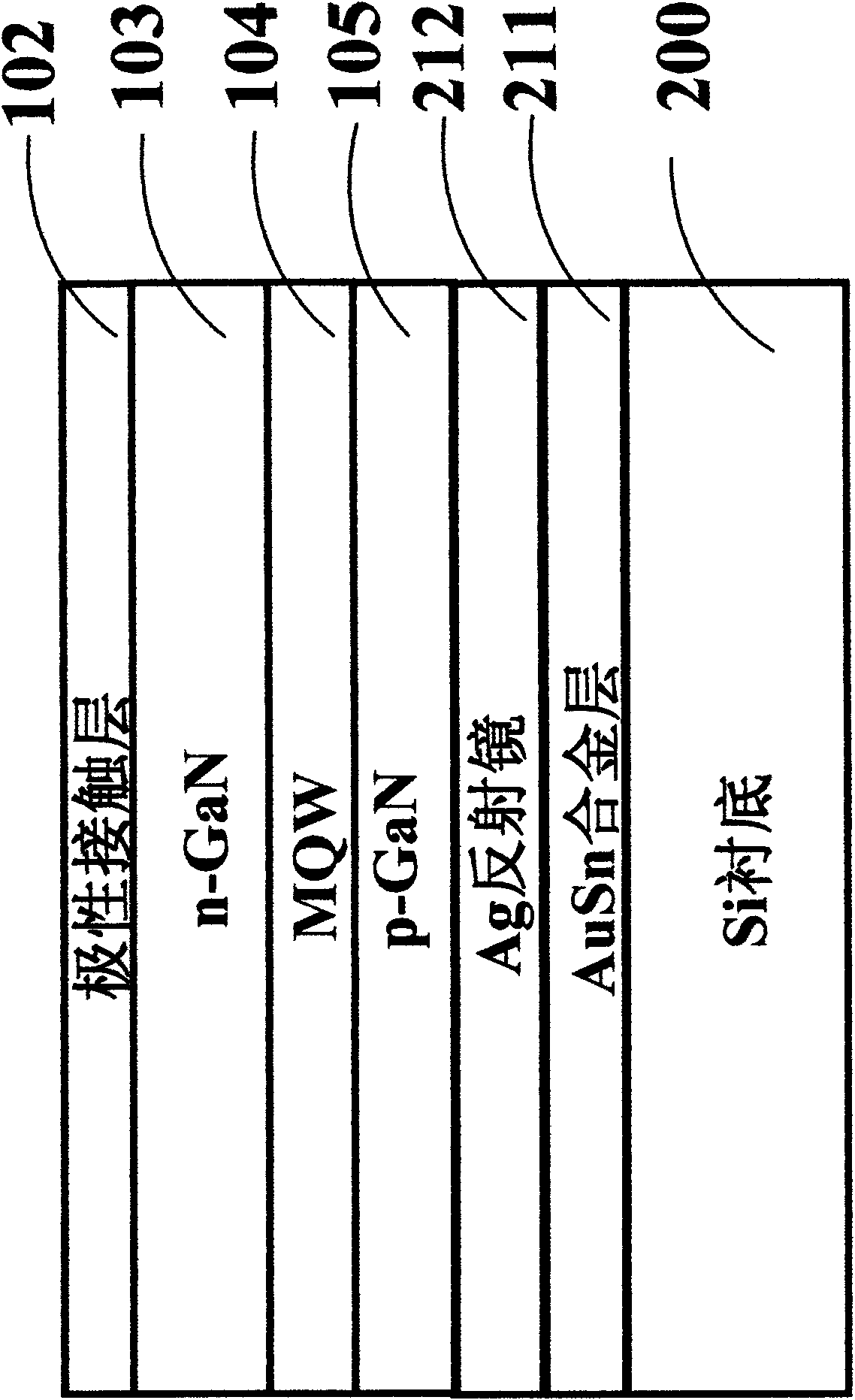

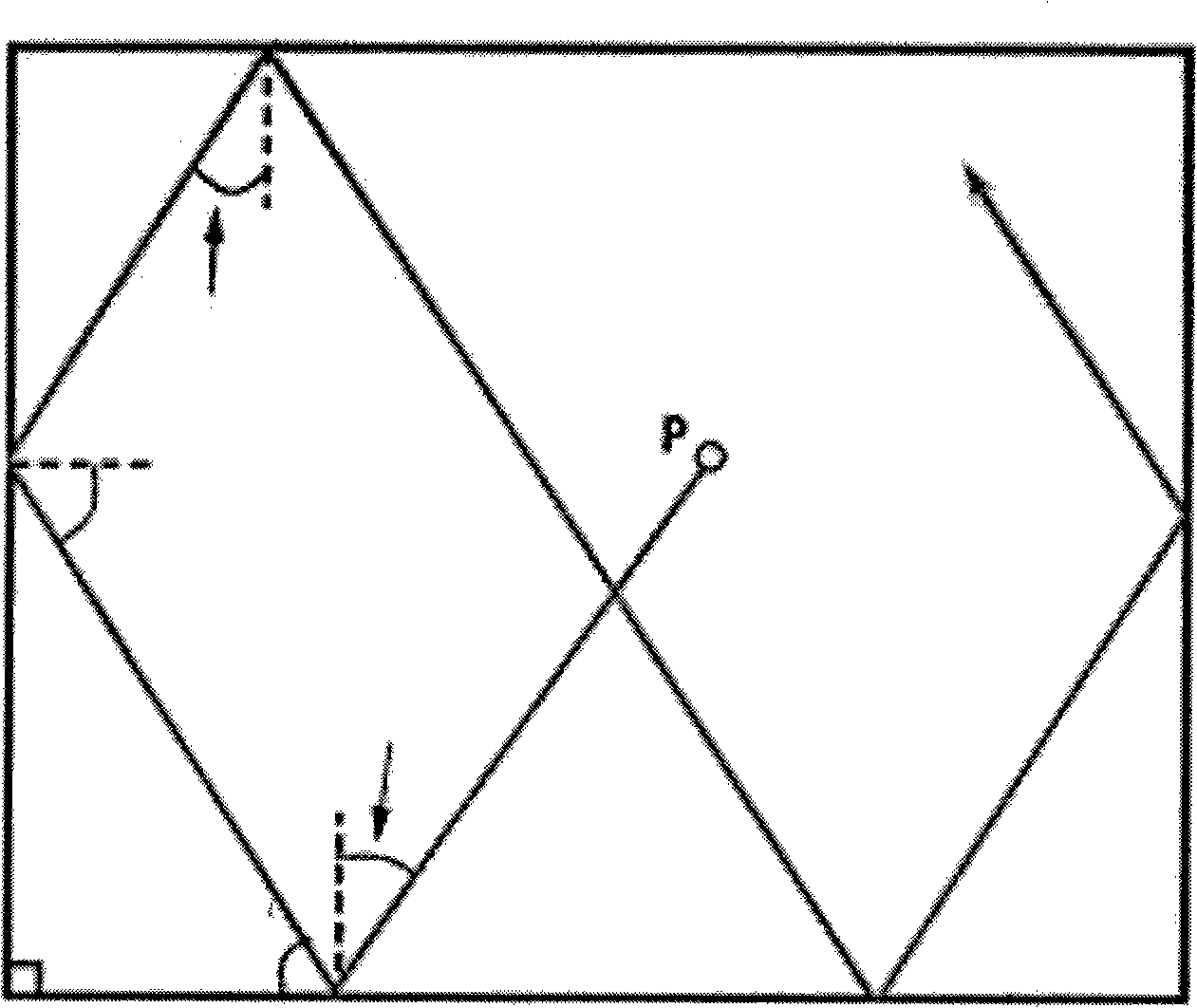

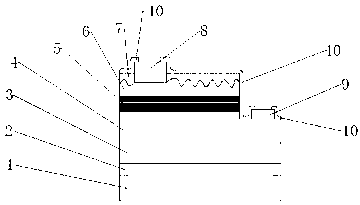

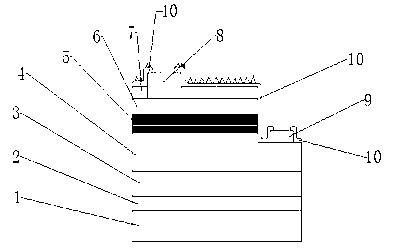

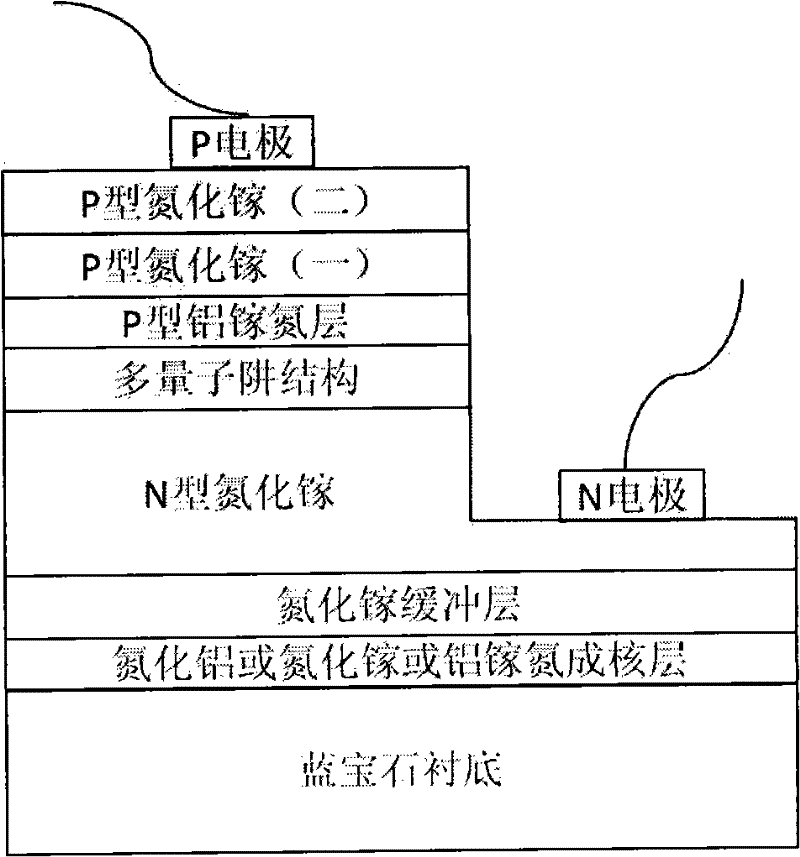

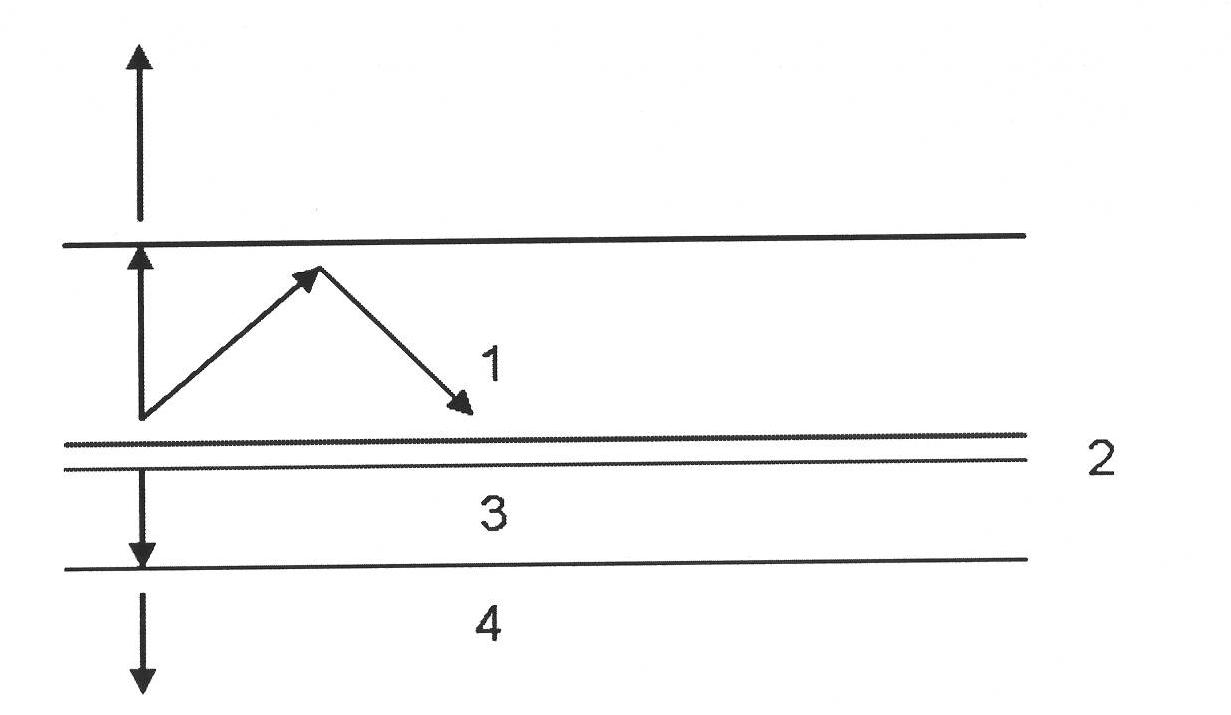

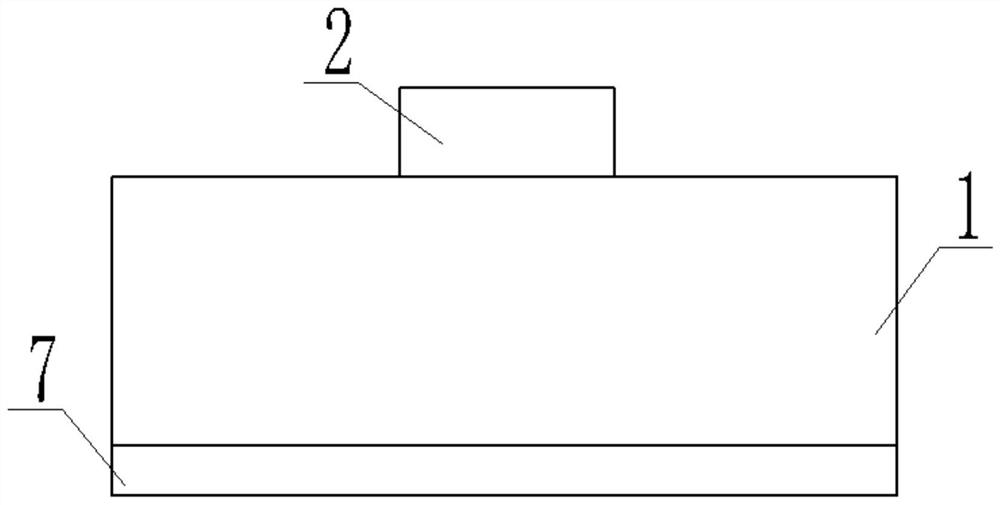

Manufacturing method of gallium nitride based LED with vertical structure

ActiveCN101661985AMaintain luminous efficiencyMaintain reliabilitySemiconductor devicesOhmic contactNitrogen

The invention discloses a manufacturing method for a gallium nitride based LED with a vertical structure. During the manufacture of the gallium nitride based LED with the vertical structure, an n-typeGaN-based material is adopted as a polar contact extension layer which is in nitrogen polarity, and after a temporary growth substrate is removed, the surface of the polar contact extension layer isin gallium polarity; based on the base, an n-type ohm contact electrode, that is n-type ohm contact is formed on the n-type GaN-based material of a gallium polar surface, so the n-type ohm contact with good thermal stability can be obtained and the problem of poor thermal stability of ohm contact on the nitrogen polar surface is avoided; and in the LED with the vertical structure manufactured by the manufacturing process, the n-type ohm contact of which has better thermal stability, the working voltage is not changed along the change of outside temperature, therefore, the illumination efficiency and the reliability of the LED can be maintained.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

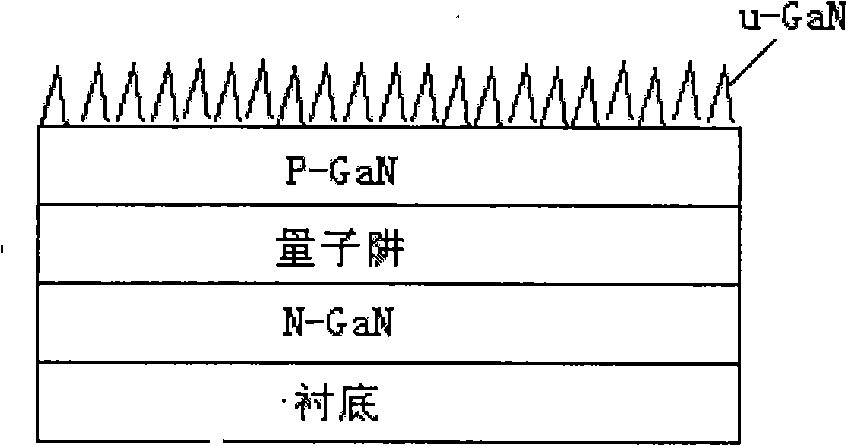

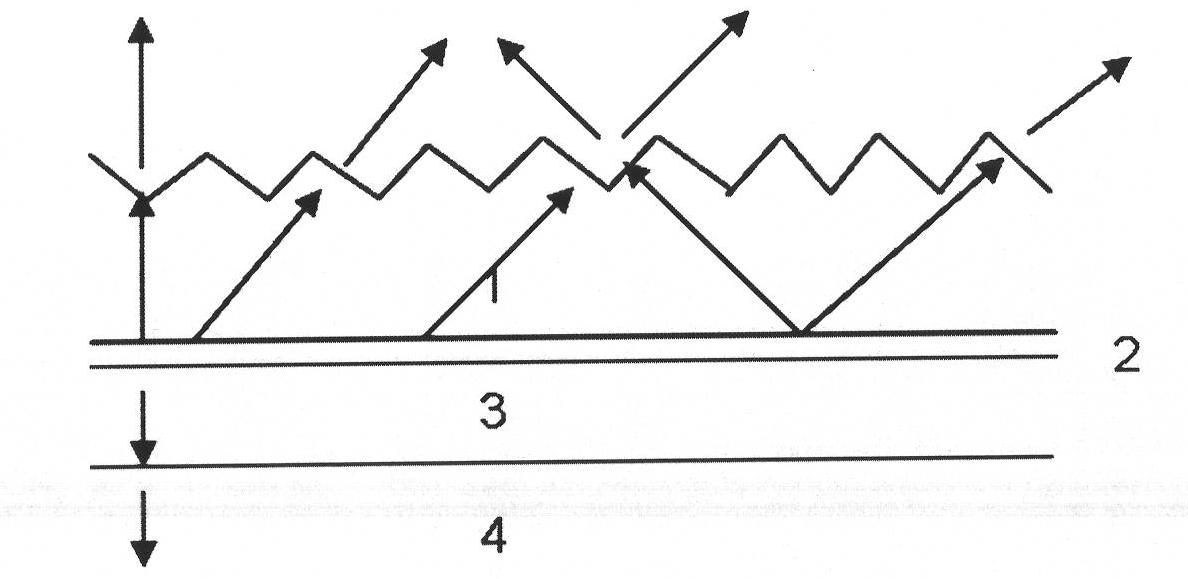

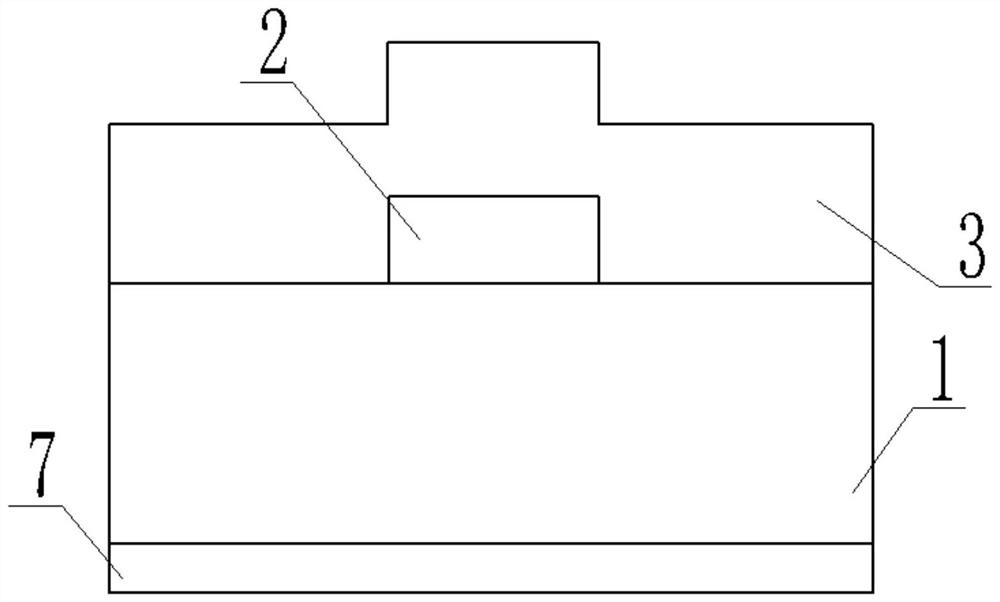

Preparation method for coarsing P-GaN layer surface of LED

The invention discloses a preparation method capable of roughening the surface of a p-GaN layer of an LED. First, an N-GaN layer, a quantum well layer, a P-GaN layer and an undoped roughening GaN layer grow on a semi-conductor substrate in sequence, second, ICP or ion dry etching are adopted to etch the undoped roughening GaN layer so that the shape of the roughening surface of the undoped roughening GaN layer is transmitted to the p-GaN layer, thus causing the surface of the P-GaN layer to be roughened. Compared with the prior art, the preparation method is easy to operate and has better roughening effect.

Owner:EPILIGHT TECH +1

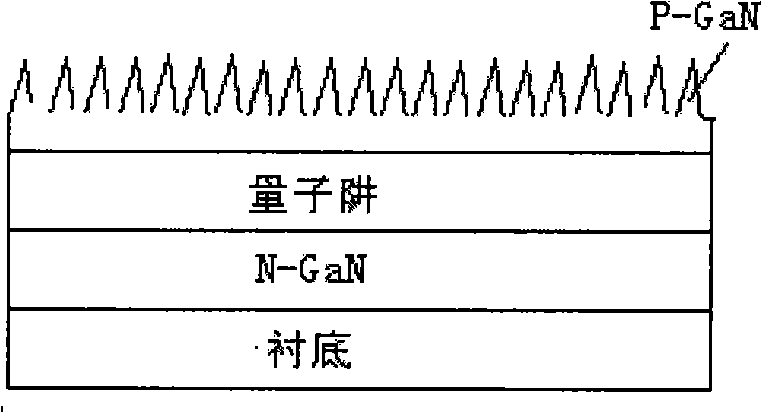

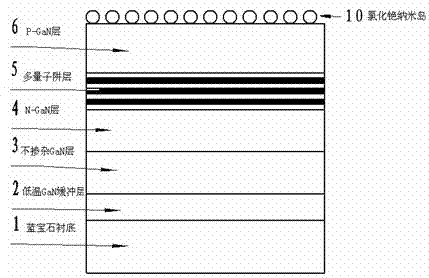

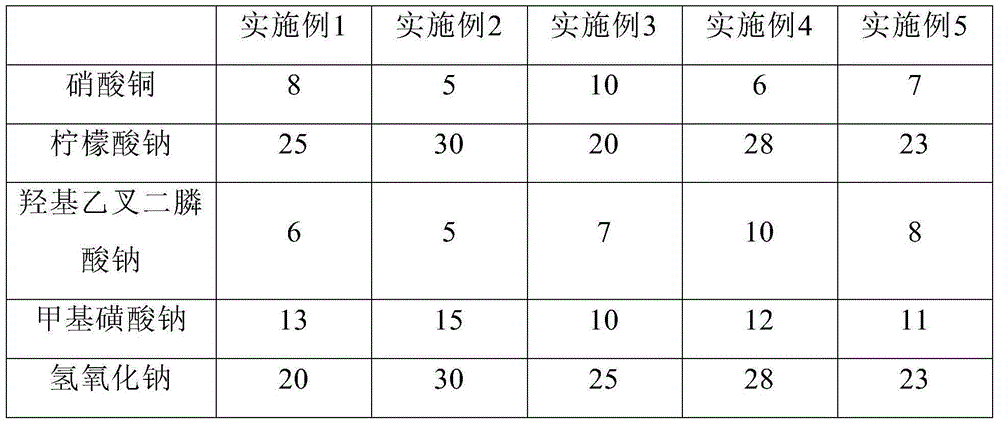

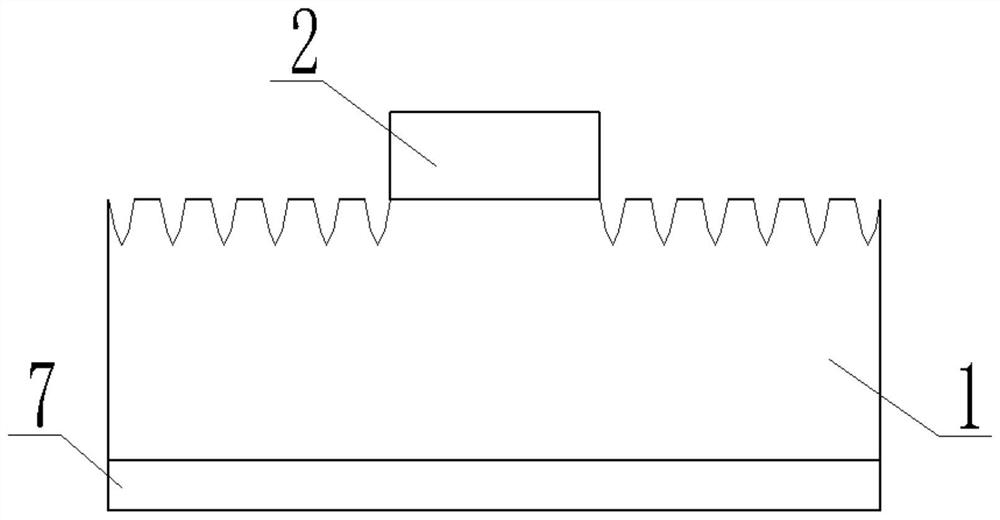

Manufacture method of GaN (gallium nitride)-based LED (light emitting diode) chip with roughened surface

InactiveCN102709426AShort preparation timeProcess stabilitySemiconductor devicesGas phaseQuantum well

The invention discloses a manufacture method of a GaN (gallium nitride)-based LED (light emitting diode) chip with a roughened surface. The manufacture method comprises the steps that a metal organic chemical vapor deposition method is adopted, a low-temperature GaN buffer layer, an undoped GaN layer, a n-GaN layer, a multi-quantum well layer and a P-GaN layer are sequentially grown on a semiconductor substrate, and a GaN epitaxial wafer is formed; the GaN epitaxial wafer enters PECVD (plasma enhanced chemical vapor deposition) equipment so that sediments are in a nanometer island shape; the epitaxial wafer with the roughened surface is formed by using the nanometer island as an etching mask; one side of the GaN epitaxial wafer is subjected to etching, and a table surface is formed; an ITO (indium tin oxide) film is evaporated on the upper surface of the epitaxial wafer; and a P electrode is manufactured on P-GaN of the GaN epitaxial wafer, an N electrode is manufactured on n-GaN, and the device preparation is completed. The manufacture method has the advantages that the photoetching is not needed, the mask is automatically removed in the etching roughening process, the process is simple, the cost is low, the roughening effect is good, and the light extraction efficiency is high.

Owner:HC SEMITEK CORP

Method for surface treating calender copper foil of printing circuit board

InactiveCN101074484AFast degreasingGood degreasing effectInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentCopper foilNickel alloy

A method for treating calendaring copper foil surface of printing circuit board is carried out by pre-treating by weak alkali mixed oil remover with Na2CO3, Na3PO4 and Na2SiO3, primary coarse treating, electroplating copper by electroplating liquid containing copper ion, H2SO4 and arsenic ion, clad treating by barrier, zinc-nickel alloy clad treating, passivating and electroplating chromium clad treating to obtain final product. It has better combination with printing base plate and corrosion resistance.

Owner:SHANGHAI UNIV

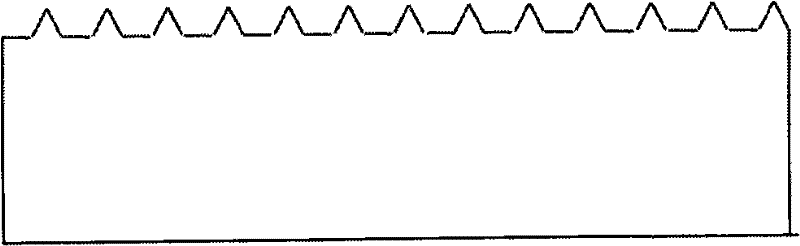

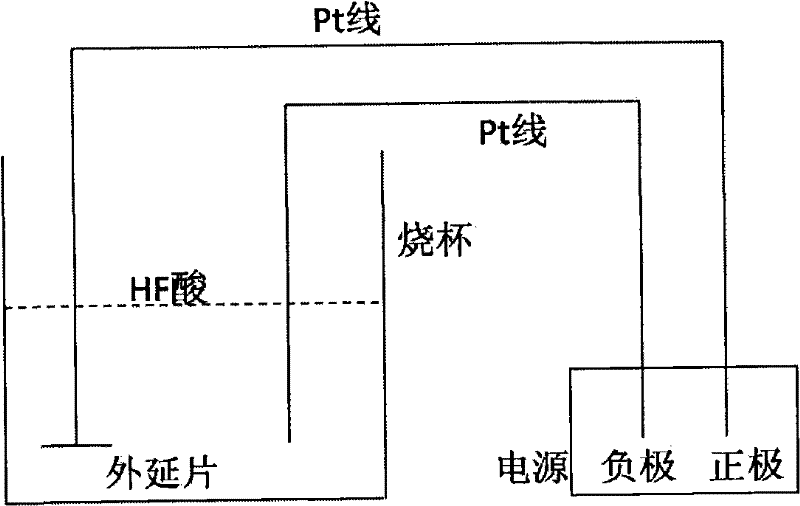

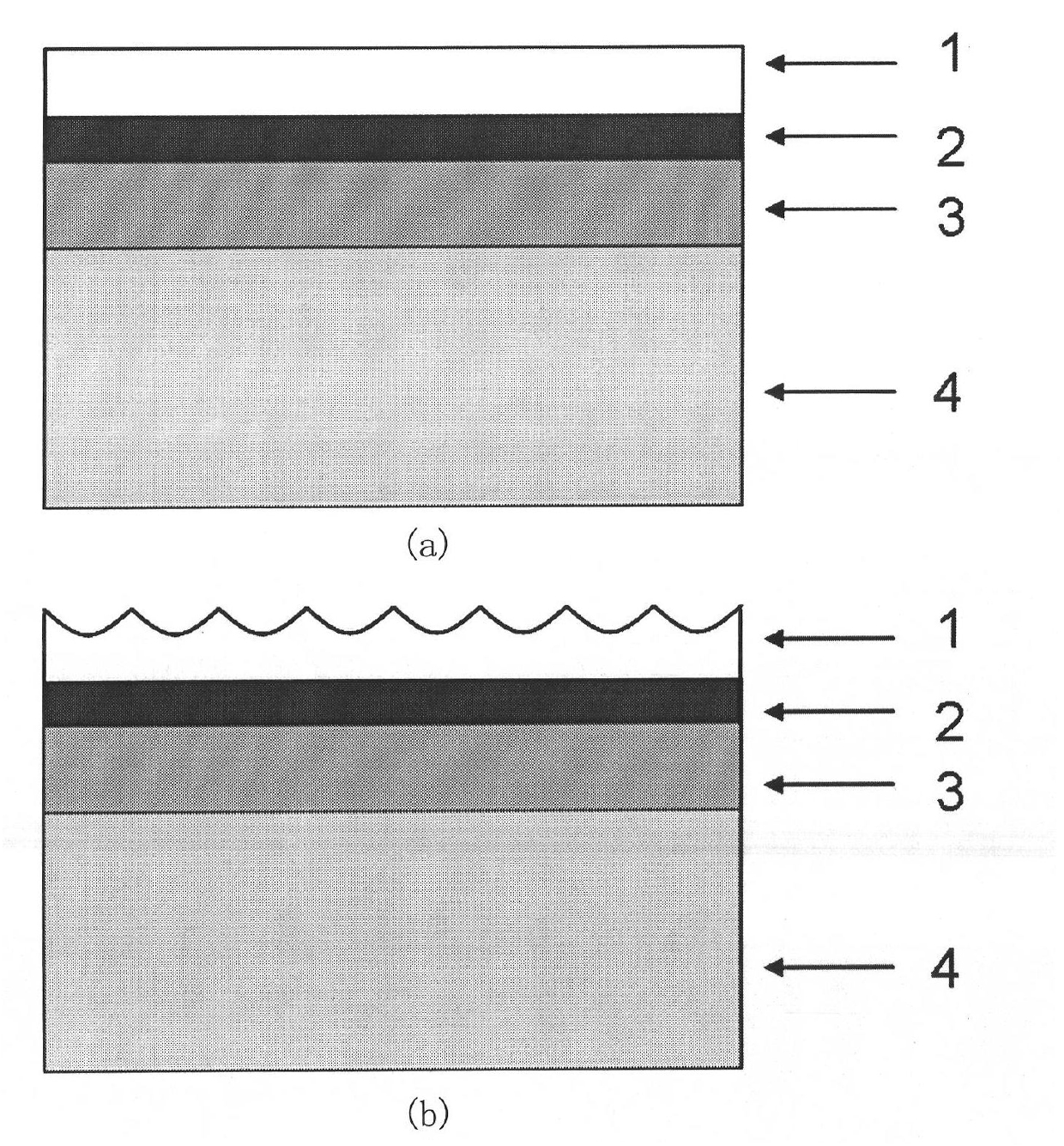

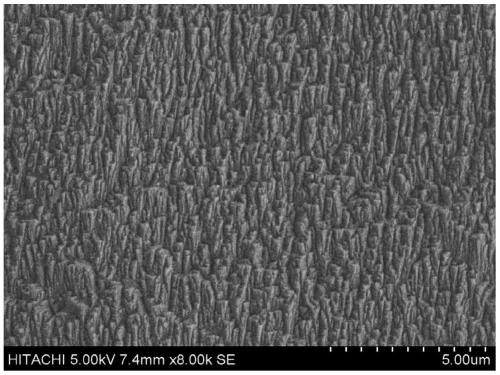

Method for coarsening surface of GaN-based LED epitaxial wafer

ActiveCN102130223AAvoid damageSimple processPolycrystalline material growthAfter-treatment detailsGallium nitrideLight-emitting diode

The invention provides a method for coarsening the surface of a gallium nitride (GaN)-based light-emitting diode (LED) epitaxial wafer, which comprises the following steps of: (1) preparing an epitaxial wafer, growing a nucleating layer on a substrate epitaxially, growing a GaN buffer layer, an N-type GaN layer, a luminescent layer multi-quantum well structure, a P-type AlGaN layer and a P-type GaN layer on the nucleating layer sequentially, wherein the growth of the P-type GaN layer is divided into two parts; (2) preparing solution of hydrofluoric acid (HF); (3) welding a Pt lead serving as a positive electrode on the surface of the P-type GaN layer by using metal, and connecting a Pt electrode serving as a negative electrode with the HF solution prepared in the step (2); (4) connecting a power supply of 10 to 50 V between the positive electrode and the negative electrode; and (5) corroding, so that an obvious coarsening graph is formed on the surface of the P-type GaN layer. In the method, the coarsened surface of the GaN-based LED epitaxial wafer is prepared by changing the epitaxial growth condition and combining photo-electrochemical (PEC) etching, a process is simple, and the cost is reduced, the coarsening effect is obvious, the light extraction efficiency is high, and the damage of dry etching or high-temperature corrosion to quantum wells is prevented simultaneously.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Method for coarsening surface of light-emitting diode (LED) with the aid of metal nanoparticles

InactiveCN102169930AReduce manufacturing costImprove extraction efficiencyLiquid/solution decomposition chemical coatingSemiconductor devicesSemiconductor materialsUltraviolet lights

The invention discloses a method for coarsening a surface of a light-emitting diode (LED) with the aid of metal nanoparticles, belonging to the technical field of manufacture of semiconductor optoelectronic materials and devices. The method comprises the steps: firstly, growing an LED epitaxial wafer on a semiconductor substrate, wherein the LED epitaxial wafer sequentially comprises an N-GaN film, a quantum well layer and a P-GaN layer; then depositing a layer of metal nanoparticles on the surface of the P-GaN layer with the aid of ultraviolet light in the solution of metal salts; placing the LED epitaxial wafer after being deposited with the metal nanoparticles in an etchant solution made from a certain proportion of hydrofluoric acid and oxidant; and performing wet etching with the aid of ultraviolet light. By depositing the metal nanoparticles on the N-GaN film, the electron distribution on the surface of the N-GaN film can be changed, the etching rate is increased, thereby being favorable to forming of a coarsened structure. The method disclosed by the invention is suitable for etching of different semiconductor materials and coarsening of the LED epitaxial wafer; and compared with the prior art, the cost is low, the coarsened area is large, the operation is simple, and an ideal coarsened effect can be obtained.

Owner:SHANDONG UNIV

Method for modifying ABS plastic

The invention provides a modified method of ABS plastic. ABS aggregate and modified powder body which is easy to be eroded are mixed to obtain modified ABS. After the modified ABS plastic obtained by adopting the method is coarsened, the surface area is increased greatly, the hydrophilicity of the surface is strengthened, and the adhesive force of a coating after being plated is increased. The modified ABS plastic only requires shorter acid corrosion and coursing time (the acid corrosion and the coursing in this time cannot erode PC), and the ideal coarsening effect can be achieved. Coupling agent is used, the compatibility between the modified powder body and the ABS can be enhanced, and the fine compound bounding surface can be obtained; solvent can improve the operation effect of the coupling agent; dispersant agent can lead the materials to be mixed to be evener, thus the modified quality is improved.

Owner:BYD CO LTD

Reverse-polarity AlGaInP-based LED side wall coarsening method

InactiveCN104078535AAchieve sidewall rougheningImprove light extraction efficiencySemiconductor devicesQuantum efficiencyEngineering

The invention relates to a reverse-polarity AlGaInP-based LED side wall coarsening method. The method includes the following steps that (1) exposure and development are conducted on a mesa image epitaxial wafer of a reverse-polarity AlGaInP-based LED through an existing photolithographic process, and a constant periodicity edge figure is formed at the periphery of the mesa image epitaxial wafer; (2) the mesa image epitaxial wafer obtained after development in the step (1) is corroded through deionized water containing saturation Br2; (3) cleaning and photoresist removing are conducted on the mesa image epitaxial wafer after being corroded through the step (2) according to the conventional process, and coarsening side wall corresponding to the periodicity edge figure shape is formed. According to the reverse-polarity AlGaInP-based LED side wall coarsening method, the mode that coarsening of the side wall of the LED chip is achieved through the photolithographic technology is first proposed, the light extraction efficiency of the LED, especially the LED chip side face, is improved greatly compared with the prior art, the external quantum efficiency of LED devices is improved, internal heat is reduced, and the service life of the LED is prolonged.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

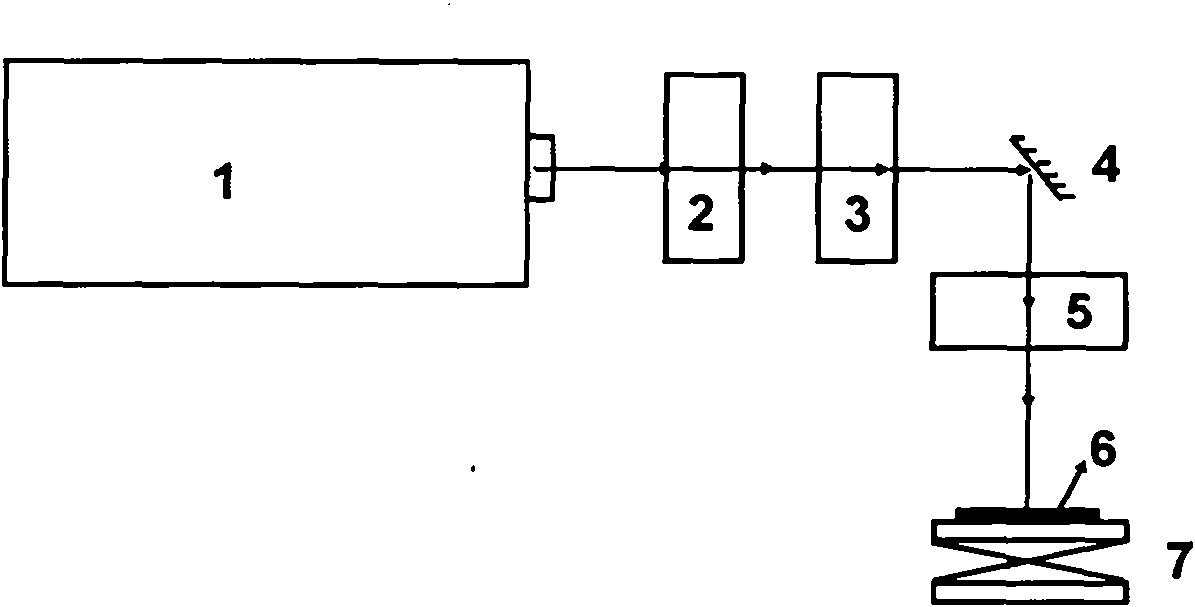

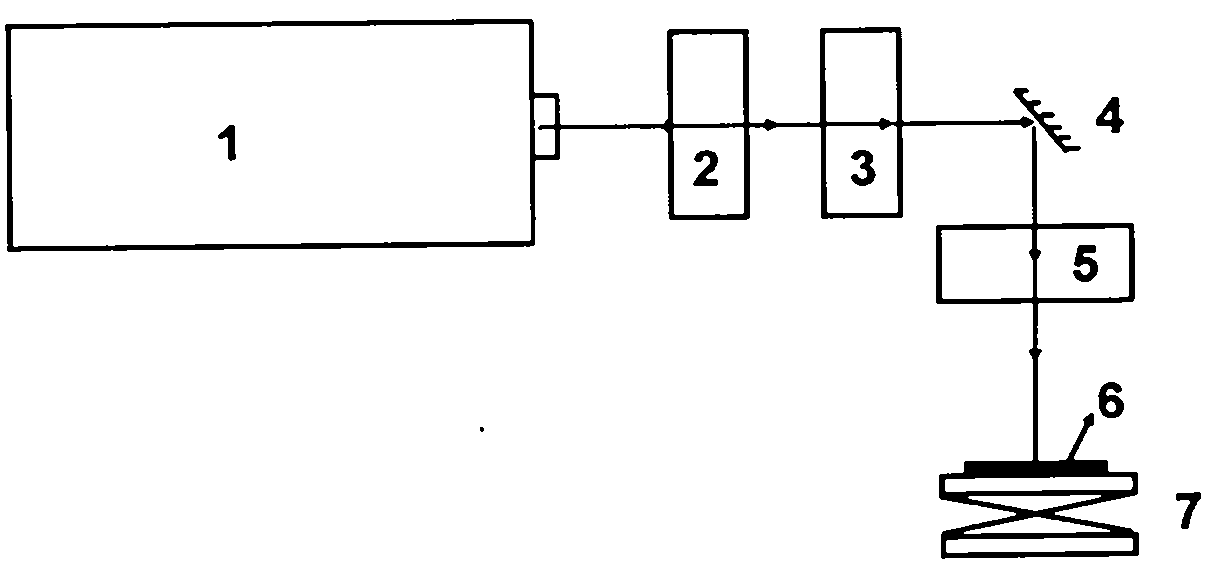

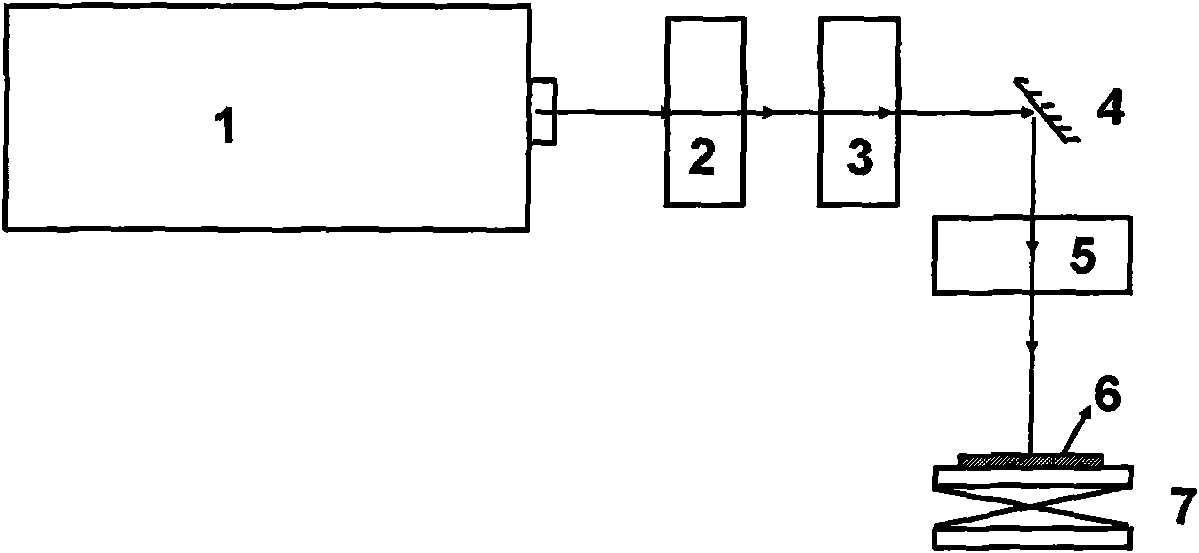

LED large-area controllable surface coarsening and etching method based on laser

InactiveCN101866996AImprove light extraction efficiencySimple production processSemiconductor devicesGalvanometerHigh power lasers

The invention relates to an LED large-area controllable surface coarsening and etching method based on a laser, belonging to the technical field of an LED. The method utilizes semiconductor material for carrying out strong absorption generating gasification on high-power laser with the wavelength less than the band edge absorption wavelength of the semiconductor material, thus realizing surface coarsening for the semiconductor material on the surface of the LED. A high-speed galvanometer or a precise displacement platform is used for controlling the laser processing area or pattern, and can be used for controlling the laser power and the processing line width and depth of focus level adjustment. The LED large-area controllable surface coarsening and etching method can be applied to surface coarsening and etching of the GaAs-based LED and the GaN-based LED of various structures. The laser takes the wavelength less than the band edge absorption wavelength of the processed semiconductor material as reference. The method has the advantages of wide applicable material, rapid processing speed, large area, low cost, good coarsening effect, low damage for the semiconductor material, high controllability of system processing parameters and the like, can effectively solve the problem of p-GaN layer coarsening, and has great application potential in the production of the high-brightness LED.

Owner:SHANDONG UNIV

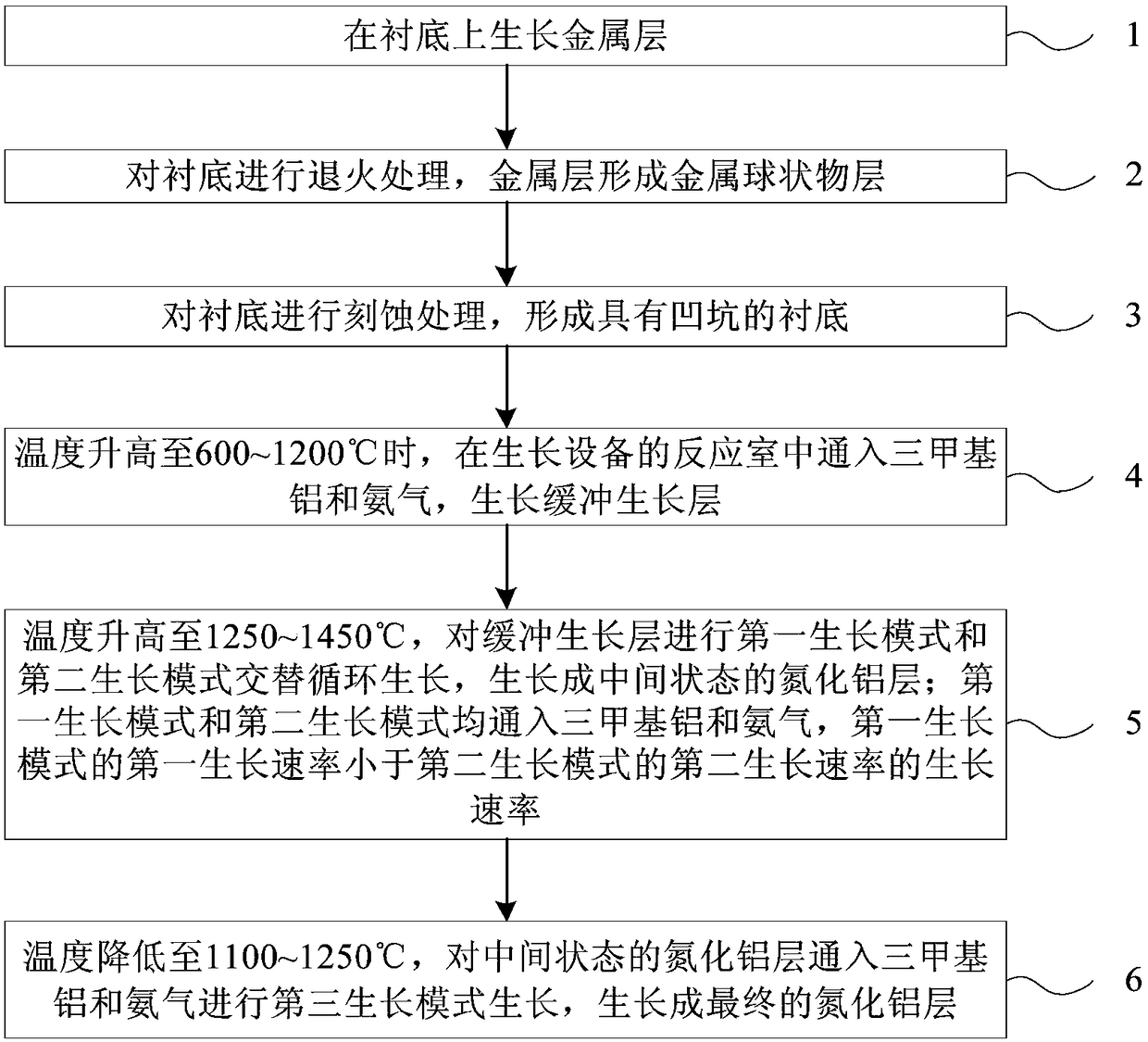

Epitaxial structure of ultraviolet LED with aluminum nitride film and growth method of aluminum nitride film

ActiveCN108257853APromote growthEasy to implementSemiconductor/solid-state device manufacturingChemical vapor deposition coatingUltravioletAmmonia gas

The present invention provides an epitaxial structure of an ultraviolet LED with an aluminum nitride film and a growth method of the aluminum nitride film. The growth method of the aluminum nitride film includes the following steps that: 1) a metal layer is grown on a substrate; 2) annealing treatment is performed on the substrate, so that the metal layer can form a metal ball-shaped object layer;3) etching treatment is performed on the substrate, so that a pitted substrate can be formed; 4) when temperature rises to 600 to 1200 DEG C, trimethylaluminum and ammonia gas are introduced into a reaction chamber, so that a buffer growth layer can be to grown; 5) when temperature rises to 1250 to 1450 DEG C, first growth mode / second growth mode alternate cyclic growth is carried out, so that anintermediate-state aluminum nitride layer can be formed; and 6) when temperature drops to 1100 to 1250 DEG C, the trimethylaluminum and ammonia are introduced into the aluminum nitride layer, so thatthird growth mode growth can be performed. The aluminum nitride film obtained by using the method has good crystal quality; and the surface cracks of the aluminum nitride film can be reduced.

Owner:MAANSHAN JASON SEMICON CO LTD

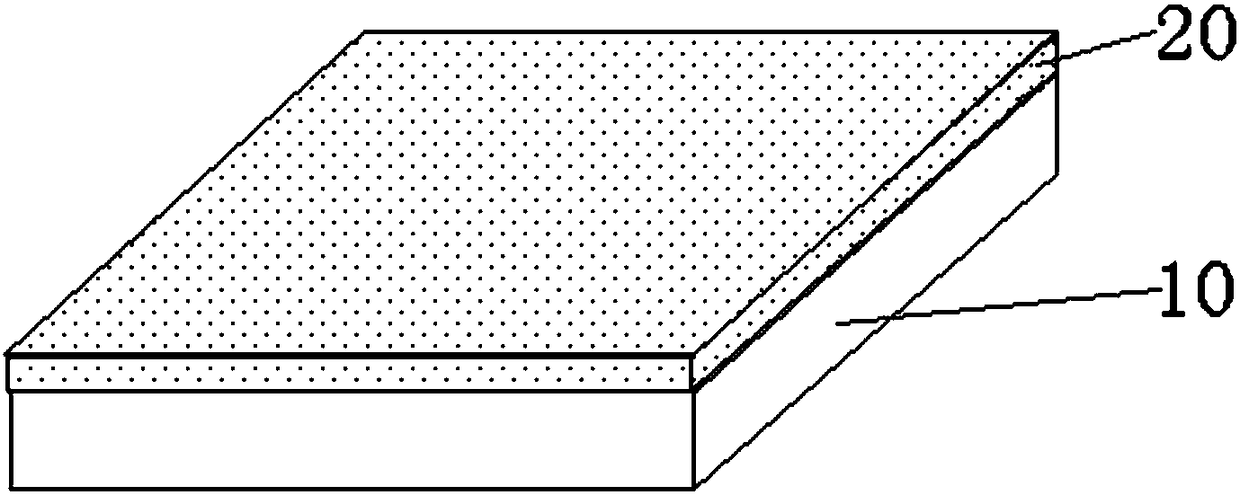

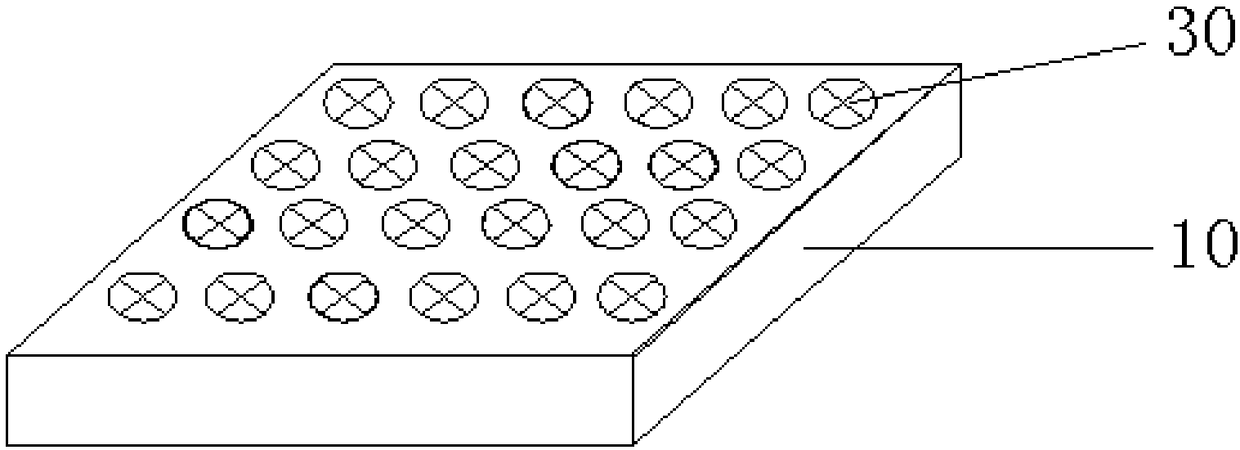

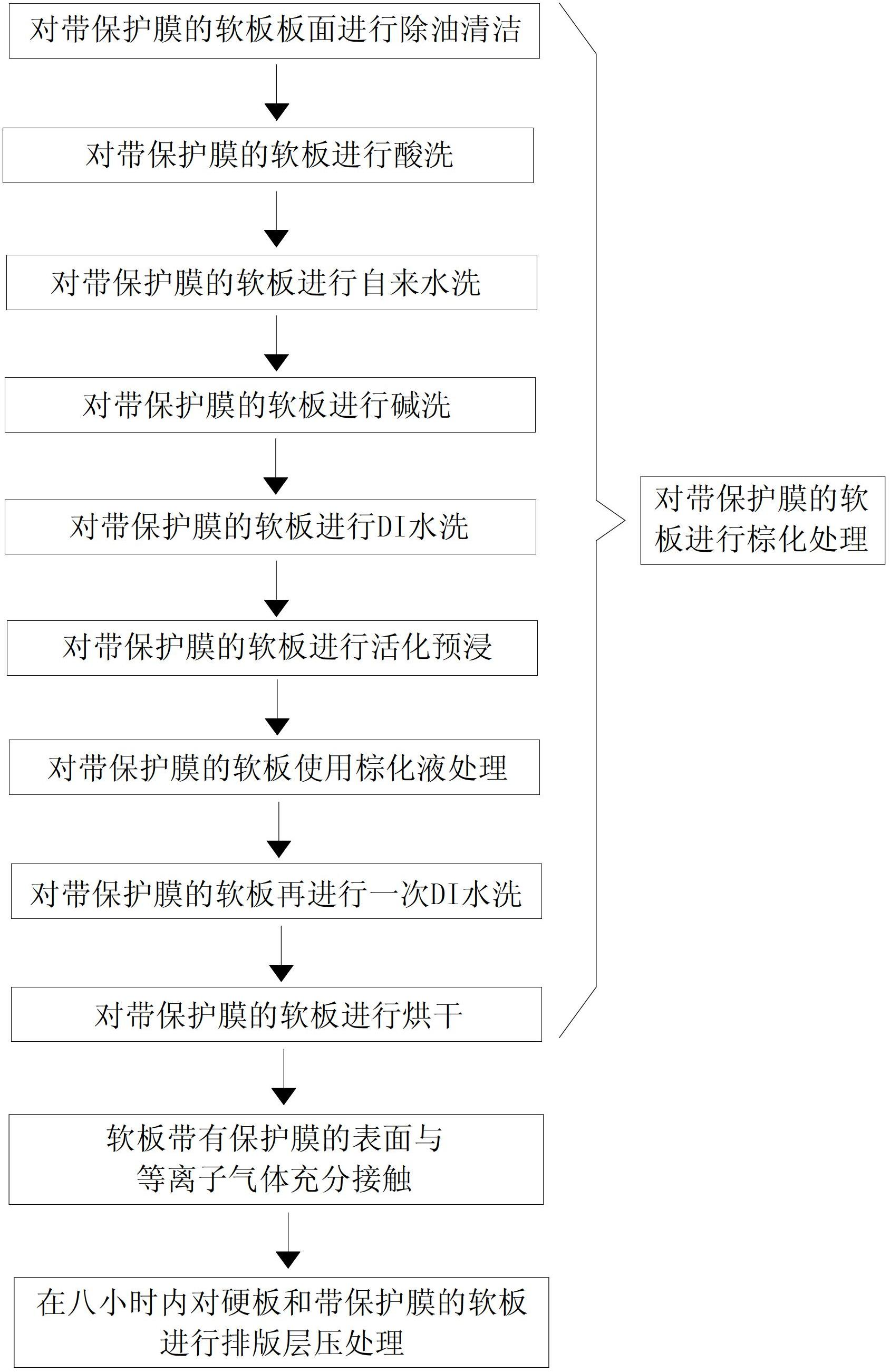

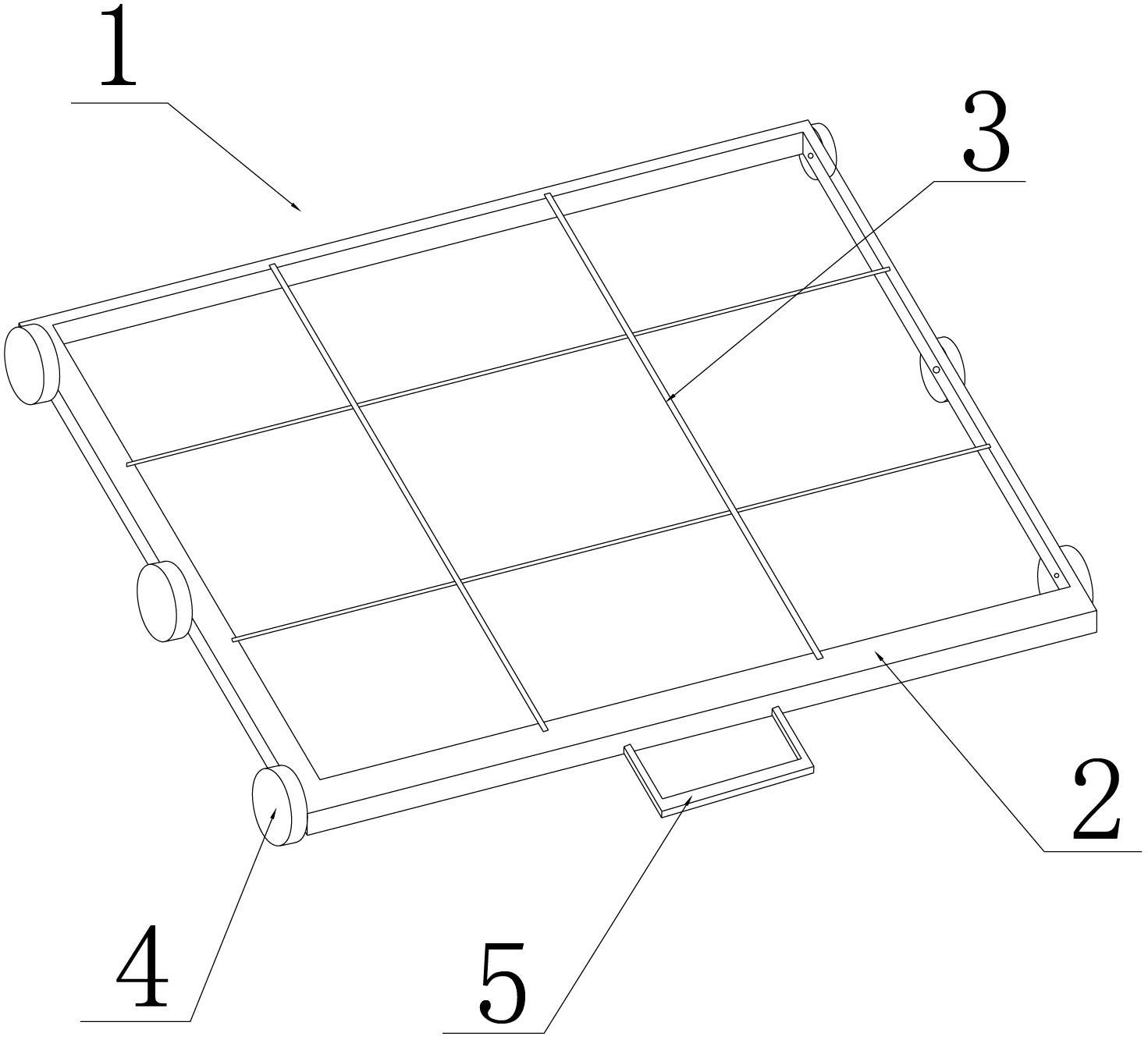

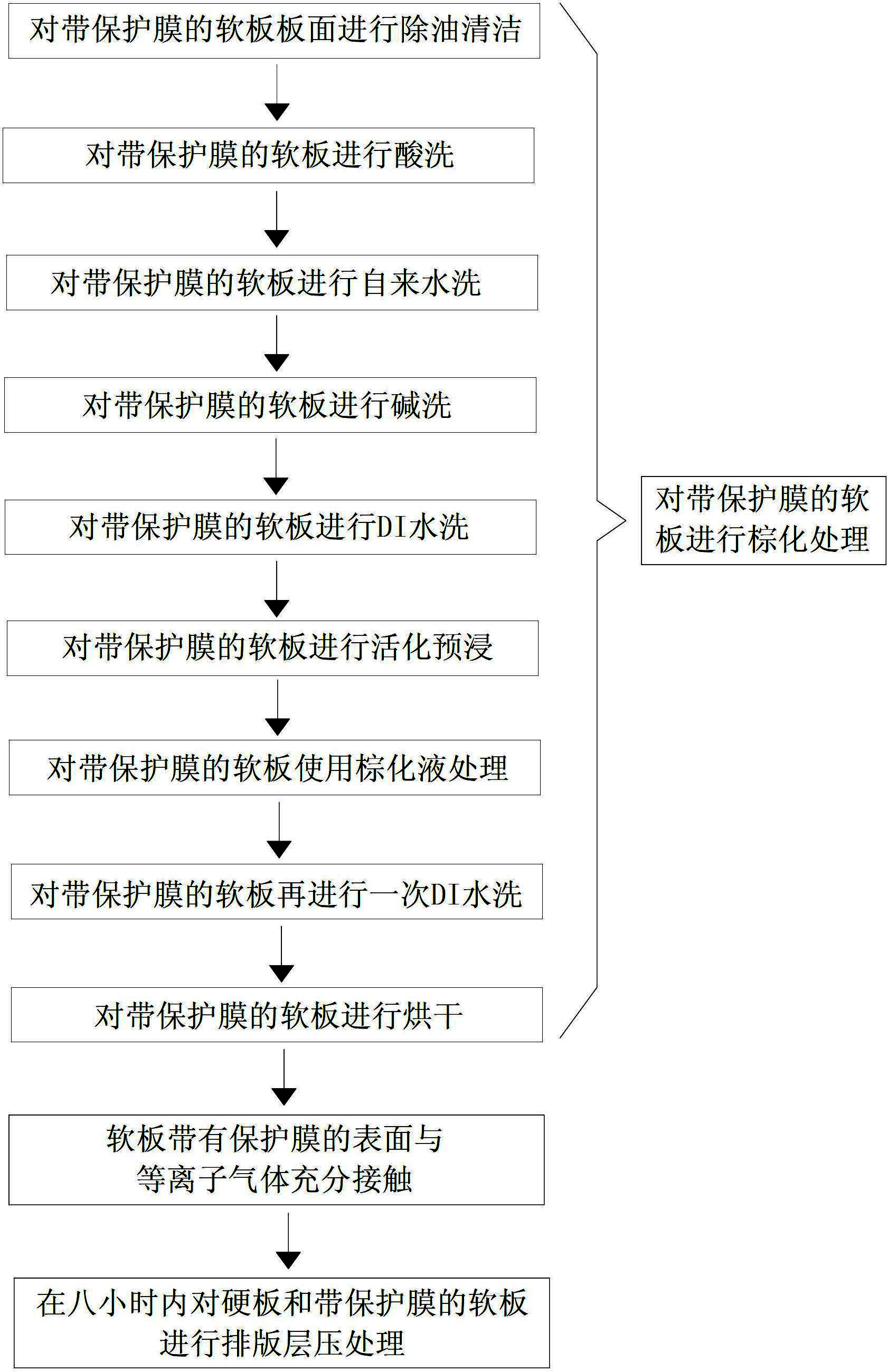

Processing method for enhancing lamination bonding force of rigid and flexible boards

ActiveCN102695374AGood coarsening effectEnhance lamination bondPrinted circuit assemblingTectorial membraneEngineering

The invention discloses a processing method for enhancing lamination bonding force of rigid and flexible boards. The processing method comprises the following steps: A. carrying out brown treatment on a flexible board with a protective film; B. carrying out plasma cleaning treatment on the flexible board with the protective film; and C. carrying out typesetting lamination treatment on a rigid board and the flexible board with the protective film within eight hours. By adopting the processing method, the surface of the flexible board can achieve terrific roughening effect, thus enhancing the lamination bonding force of the flexible board with the rigid board and avoiding stratification of the rigid and flexible boards in the subsequent uncovering process.

Owner:GUANGZHOU MEADVILLE ELECTRONICS

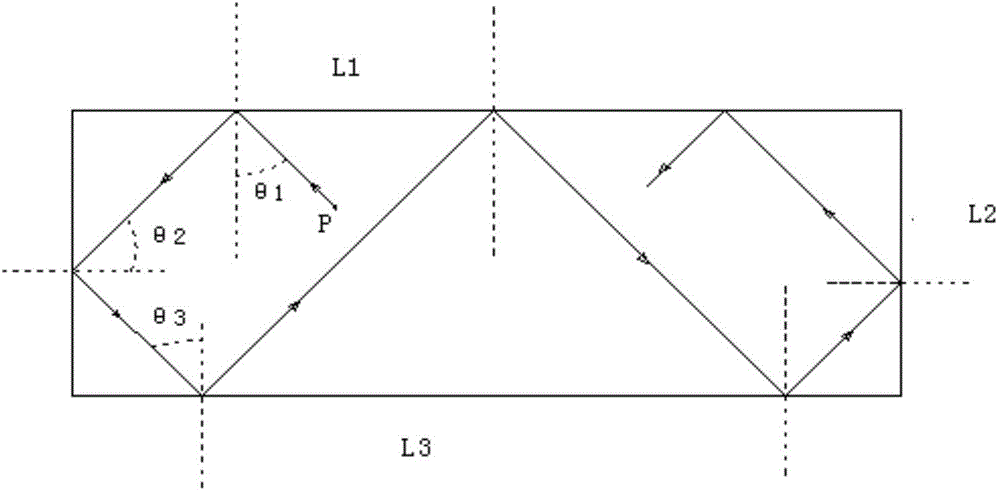

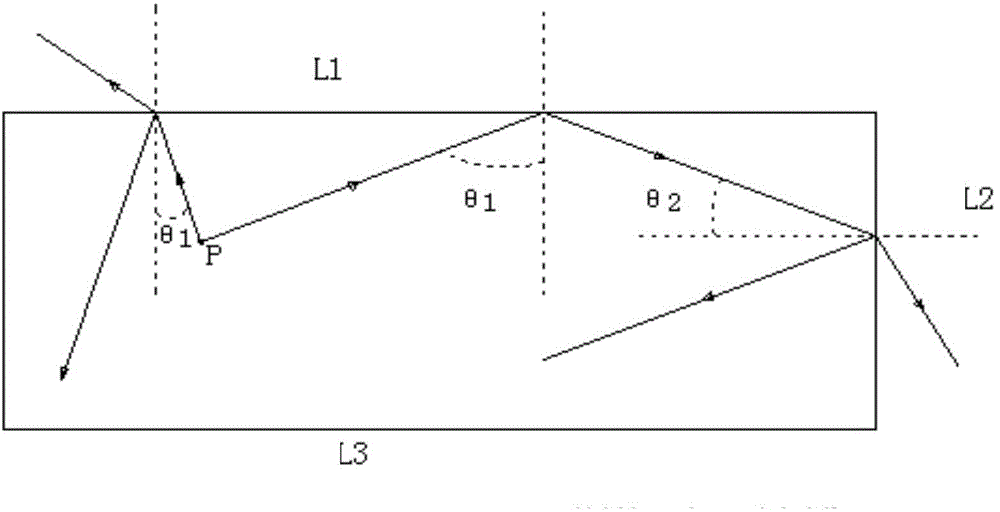

ITO (Indium Tin Oxides) coarsening type evaporation method

InactiveCN103451605AGood coarsening effectImprove external quantum efficiencyVacuum evaporation coatingSputtering coatingQuantum efficiencyIndium

The invention discloses a method for performing ITO (Indium Tin Oxides) coarsening by stepwise ITO evaporation instead of traditional ITO evaporation. The method comprises the following steps of: mixing concentrated sulfuric acid and hydrogen peroxide in proportion of 2: 1; cooling at the same time until reaching 100 DEG C; placing an epitaxial slice into the mixture; fully washing for 5 minutes; taking out the epitaxial slice; cleaning with clean water; fixing the cleaned epitaxial slice into an evaporation pot; and performing the ITO stepwise evaporation mode to change the rate and oxygen flow during the ITO evaporation in each layer, in order to realize the ITO coarsening effect of the outermost layer of the epitaxial slice. The process is simple and feasible in operation; the best ITO surface coarsening effect can be realized after the evaporation based on the process above; and the luminous efficiency is raised, thus the external quantum efficiency of an LED (Light-emitting Diode) chip can be greatly increased.

Owner:KUNSHAN AODELU AUTOMATION TECH

Automobile label plastic electroplating process

InactiveCN105112970AImprove bindingShort processing timeLiquid/solution decomposition chemical coatingProduction rateChemical plating

The invention provides an automobile label plastic electroplating process which comprises the following steps: 1) oil removal; 2) expansion; 3) roughening; 4) reduction; 5) presoaking ; 6) activation; 7) dispergation; 8) copper replacement; 9) copper plating under an acidic condition; 10) copper-tin alloy plating; 11) chrome plating; 12) drying. The set of brand-new plastic electroplating process is provided through complete improvement of a whole set of conventional plastic electroplating process, the whole process is environment-friendly, non-toxic, and free of chemical plating; the operation is easier, the process stability is improved, the wastewater treatment is simple, the production time is greatly shortened, a hanger needs no replacement in the production process, and the production efficiency is greatly improved.

Owner:太仓市金鹿电镀有限公司

Roughing solution and surface plating method for acrylonitrile-butadiene-styrene terpolymer

InactiveCN101876067AGood coarsening effectIncrease Palladium Adsorption CapacityLiquid/solution decomposition chemical coatingSuperimposed coating processPersulfateAcrylonitrile

The invention provides a roughing solution which is a water solution containing potassium permanganate, persulfates and molybdates. The invention also provides a surface plating method for an acrylonitrile-butadiene-styrene terpolymer. The method is realized in a way that: on the surface of the acrylonitrile-butadiene-styrene terpolymer, deoiling, roughing, activating, chemical nickel plating and plating, wherein in the roughing step, the acrylonitrile-butadiene-styrene terpolymer is put in a roughing solution to carry out chemical roughing. In the ABS plastic plating technique, the roughing solution has favorable roughing effect, can enhance the adsorption capacity of colloid palladium after activation and improve the adhesive strength of the a plating layer and a substrate, and does not contain chromium, thereby reducing the environmental pollution, reducing the injuries to operating personnel and lowering the cost for waste liquid disposal.

Owner:安徽新合富力科技有限公司

Nylon material roughing solution and roughing method using same

InactiveCN103388135AHarm reductionGood coarsening effectLiquid/solution decomposition chemical coatingElectroless nickelPolymer science

The invention discloses a nylon material roughing solution and a roughing method using same. The nylon material roughing solution comprises, by weight, 1-16% of sulfuric acid, 1-16% of hydrochloric acid, 5-15% of citric acid, 4-20% of glacial acetic acid, 1-20% of formic acid and 50-70% of water. The roughing method comprises the following steps of 1, cleaning a nylon semifinished product to remove oil and wax and carrying out secondary washing by water, 2, immersing the nylon semifinished product into the nylon material roughing solution and carrying out ultrasonic roughing at a normal temperature for 2-6min, and 3, carrying out water washing, carrying out palladium ion activation, carrying out dispergation, carrying out electroless nickel plating, and carrying out acid copper, nickel and chromium electroplating so that nylon material electroplating is finished. Through the roughing method, a nylon material has good surface roughing effects. The nylon material roughing solution reduces the damage produced by the roughing process on the environment and operators.

Owner:XIAMEN RUNNER IND CORP

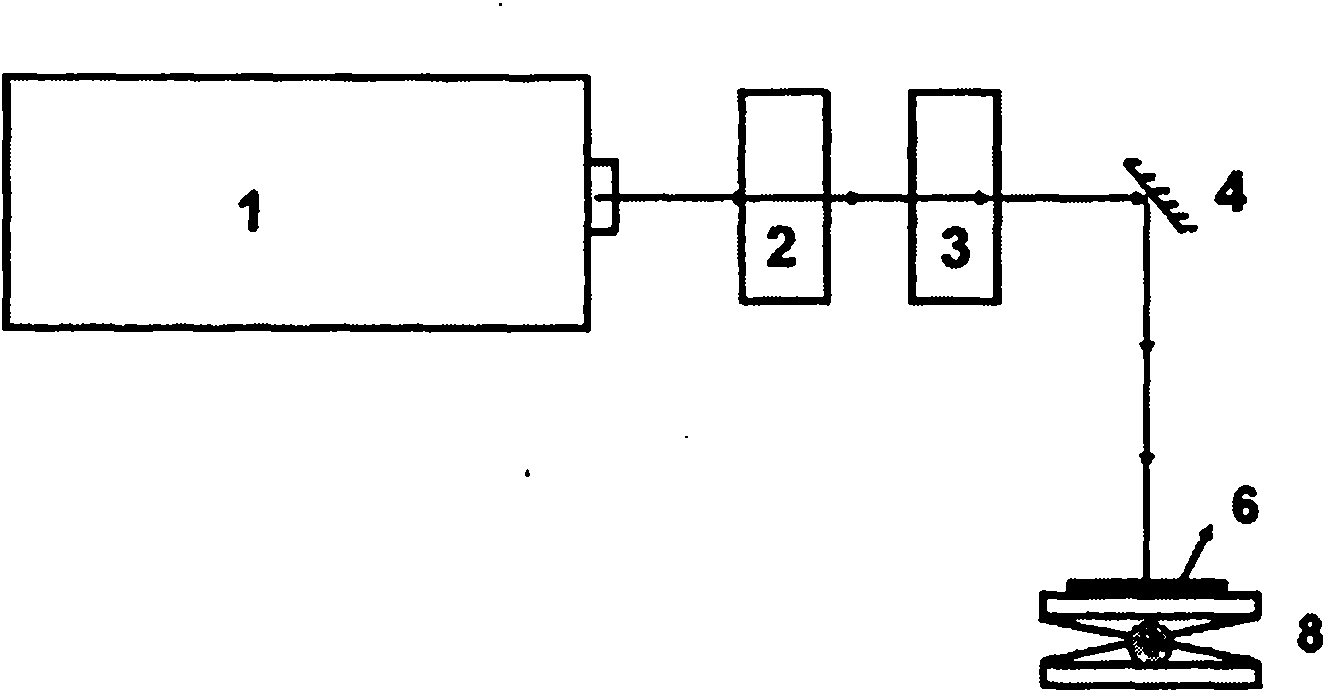

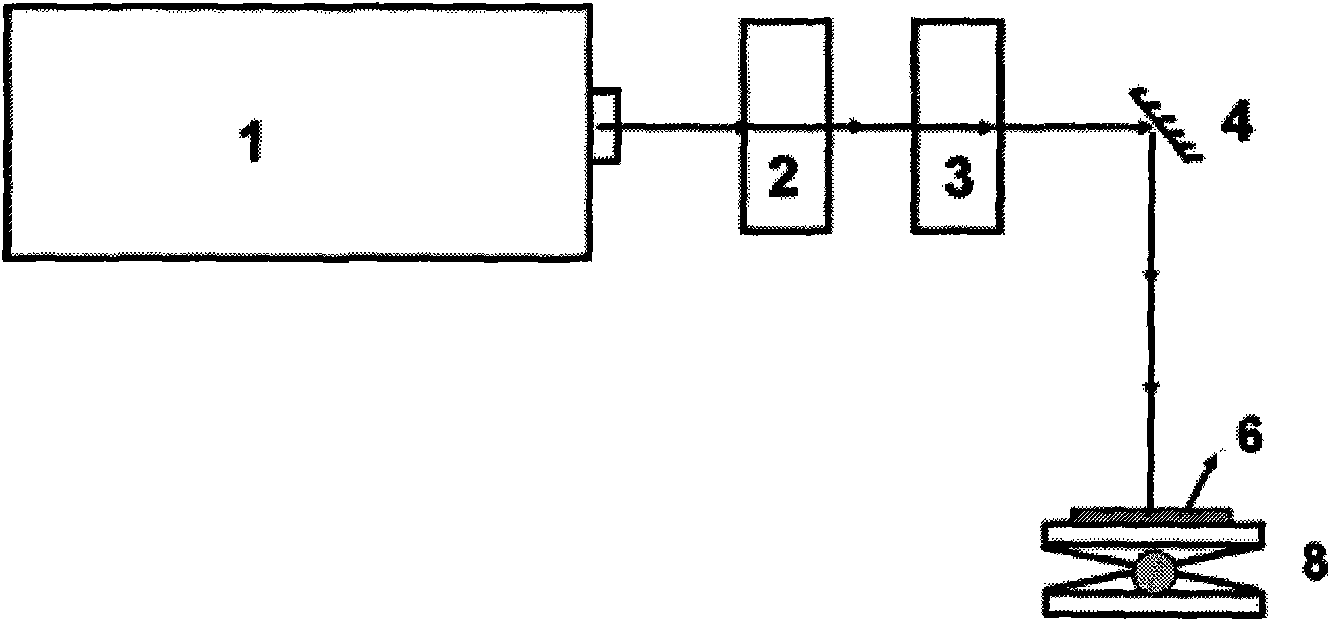

Coarsening and etching method of large-area controllable surface of SiC substrate light emitting diode (LED) based on laser

InactiveCN102110749ANot demandingImprove light extraction efficiencySemiconductor devicesWire widthEtching

The invention provides a coarsening and etching method of a large-area controllable surface of a SiC substrate light emitting diode (LED) based on a laser, belonging to the technical field of LED. The surfaces of the SiC substrate and an LED semiconductor material can be coarsened by utilizing that the semiconductor material highly absorbs high-power laser with a wavelength smaller than the absorption wavelength of the band edge of the semiconductor material to perform gasification. An area and a pattern coarsened and etched by the laser are controlled by a high speed scanner or a precise displacement stage; and the wire width and depth of coarsening and etching are regulated by controlling power and focusing degree of the laser. The method can be applied to coarsening and etching of the surface of the SiC substrate GaN-based LED with various structures. The laser is selected on the basis that the wavelength of the laser is smaller than the absorption wavelength of the band edge of the coarsened and etched semiconductor. The method has the advantages of wide application materials, high coarsening and etching speed, large coarsening and etching area, low cost, good coarsening effect, small damage on the semiconductor material and high controllability of coarsening and etching parameters of the system; and by using the method, the problem of coarsening the p-GaN layer and the SiC substrate can be effectively solved. Thus, the method has a great application potential in high-brightness LED production.

Owner:SHANDONG UNIV

Process for electroplating plastic on automobile mask

InactiveCN105112969AImprove bindingShort processing timeLiquid/solution decomposition chemical coatingProduction rateCopper plating

The invention provides a process for electroplating plastic on an automobile mask. The process comprises the following steps: 1), oil removal; 2), expansion; 3), roughening; 4), reduction; 5), preimpregnation; 6), activation; 7), dispergation ; 8), copper replacement; 9), acid copper plating; 10), copper-tin alloy plating; 11), chrome plating ; 12), drying. The brand-new plastic electroplating process is provided through complete improvement on a whole conventional plastic electroplating process, the whole process is environment-friendly, non-toxic and harmless, chemical plating is not required to be used, the operation is easier, the process stability is improved, the wastewater treatment is simple, the production time is greatly shortened, a hanging tool is not required to be replaced in the production process, and the production efficiency is greatly improved.

Owner:太仓市金鹿电镀有限公司

Electroplating process for high-abrasion-resistant environment-friendly plastic on washing machine door ring surface

The invention provides an electroplating process for a high-abrasion-resistant environment-friendly plastic on a washing machine door ring surface. The electroplating process comprises the following steps: 1) oil removal; 2) expansion; 3) roughening; 4) reduction; 5) presoaking ; 6) activation; 7) dispergation ; 8) copper replacement; 9) copper plating under an acidic condition; 10) copper-tin alloy plating; 11) chrome plating ; 12) drying. The brand-new plastic electroplating process is provided through complete improvement of a conventional plastic electroplating process, the whole process is environment-friendly, non-toxic, and free of use of chemical plating; the operation is easier, the process stability is improved, the wastewater treatment is simple, the production time is greatly shortened, a hanger needs no replacement in the production process, and the production efficiency is greatly improved.

Owner:太仓市金鹿电镀有限公司

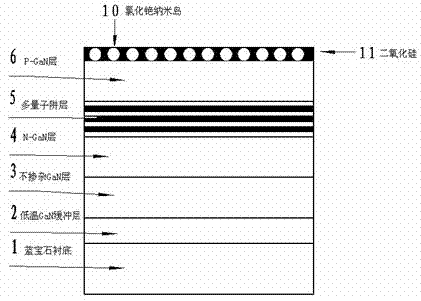

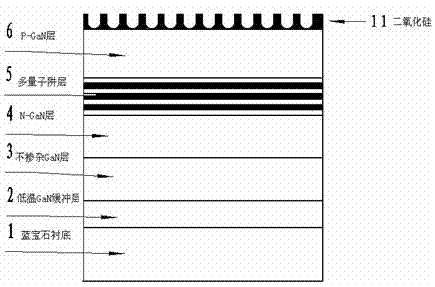

Manufacturing method for GaN-based LED (Light Emitting Diode) chip for coarsening p-GaN layer nanometer bowl-shaped surface

ActiveCN102790153AIncrease chance of shootingIncrease the exit light areaSemiconductor devicesEtchingWater vapor

The invention provides a manufacturing method for a GaN-based LED (Light Emitting Diode) chip for coarsening a p-GaN layer nanometer bowl-shaped surface and relates to the technical field of photoelectric device production. The manufacturing method comprises the following steps: firstly, evaporating a mask cesium chloride film layer for etching on the surface of a P-GaN layer of a GaN epitaxial wafer; filling water vapor into an evaporating platform chamber, thereby forming a plurality of cesium chloride nanometer islands; depositing silicon dioxide layers on the cesium chloride nanometer islands; soaking or ultrasonically treating the epitaxial wafer in deionized water, thereby forming a silicon dioxide nanometer bowl layer; taking the silicon dioxide nanometer bowl layer as an etching mask; after ending the etching, completely removing the silicon dioxide nanometer bowl layer remained on the GaN epitaxial wafer; performing ICP (Inductively Coupled Plasma) etching on one side of the GaN epitaxial wafer, thereby forming a platform; and evaporating an ITO (Indium Tin Oxide) film on the upper surface of the GaN epitaxial wafer. Compared with the conventional GaN-LED, the GaN-LED after being subjected to surface coarsening has the advantage that the luminous power is increased by above 35%.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

Electroplating process for plastic on surface of automobile gear rod

The invention provides an electroplating process for plastic on the surface of an automobile gear rod. The electroplating process comprises the following steps: 1) oil removal; 2) expansion; 3) roughening; 4) reduction; 5) presoaking; 6) activation; 7) dispergation; 8) copper replacement; 9) copper plating under an acidic condition; 10) copper-tin alloy plating; 11) chrome plating; 12) drying. The set of brand-new plastic electroplating process is provided through complete improvement of a whole set of conventional plastic electroplating process, the whole process is environment-friendly, non-toxic, and free of chemical plating; the operation is easier, the process stability is improved, the wastewater treatment is simple, the production time is greatly shortened, a hanger needs no replacement in the production process, and the production efficiency is greatly improved.

Owner:太仓市金鹿电镀有限公司

Polyetherimide chemical roughening and electroplating process

InactiveCN111519226ALower requirementEasy to industrializeLiquid/solution decomposition chemical coatingImidePolyetherimide

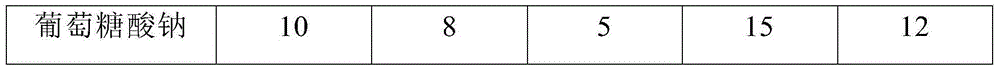

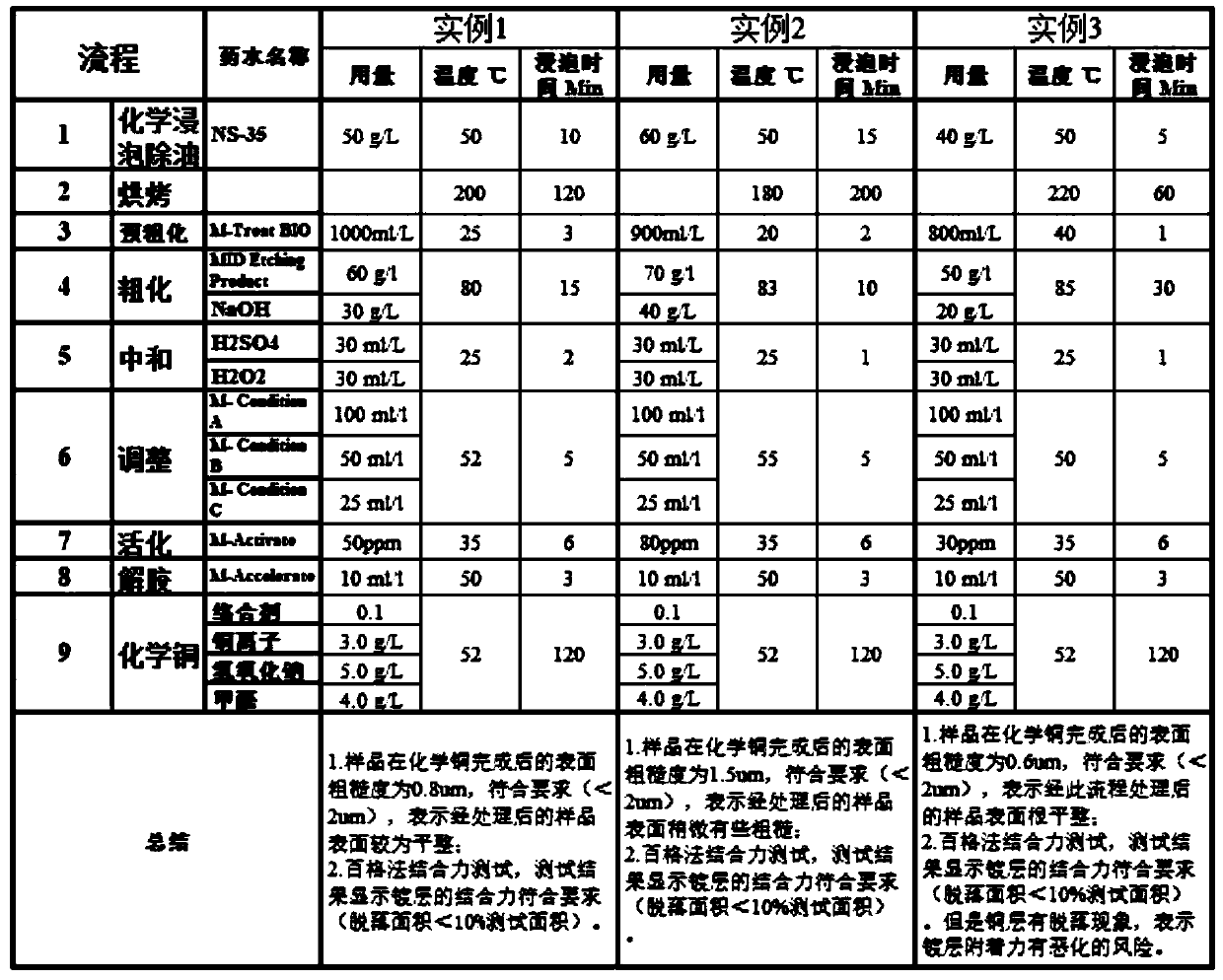

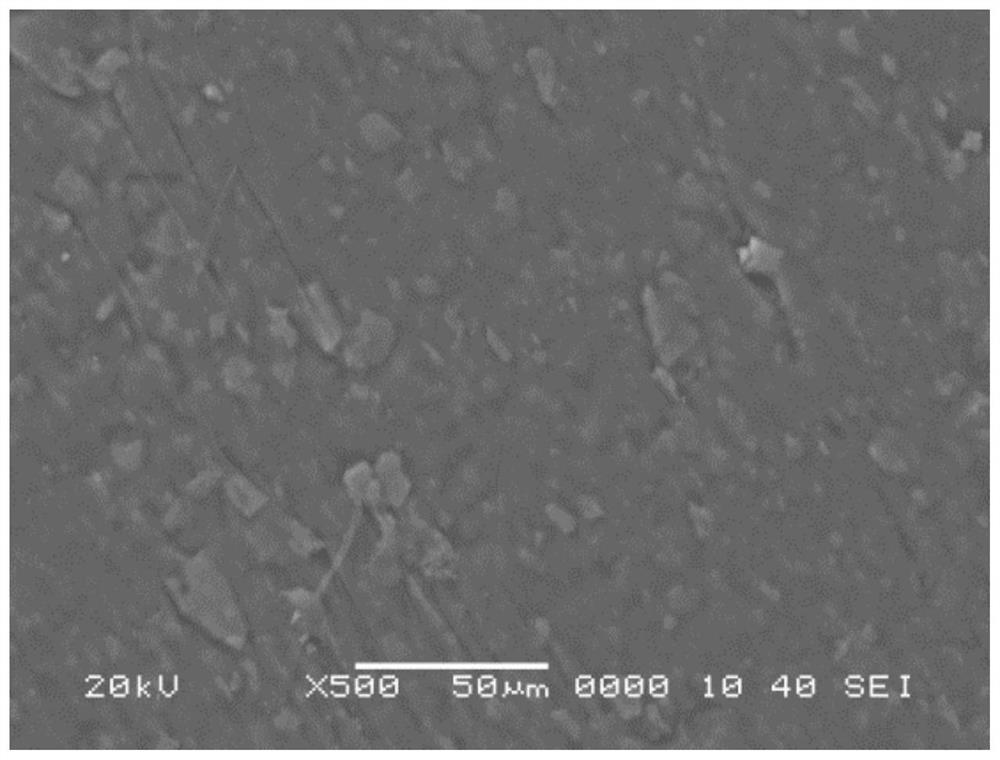

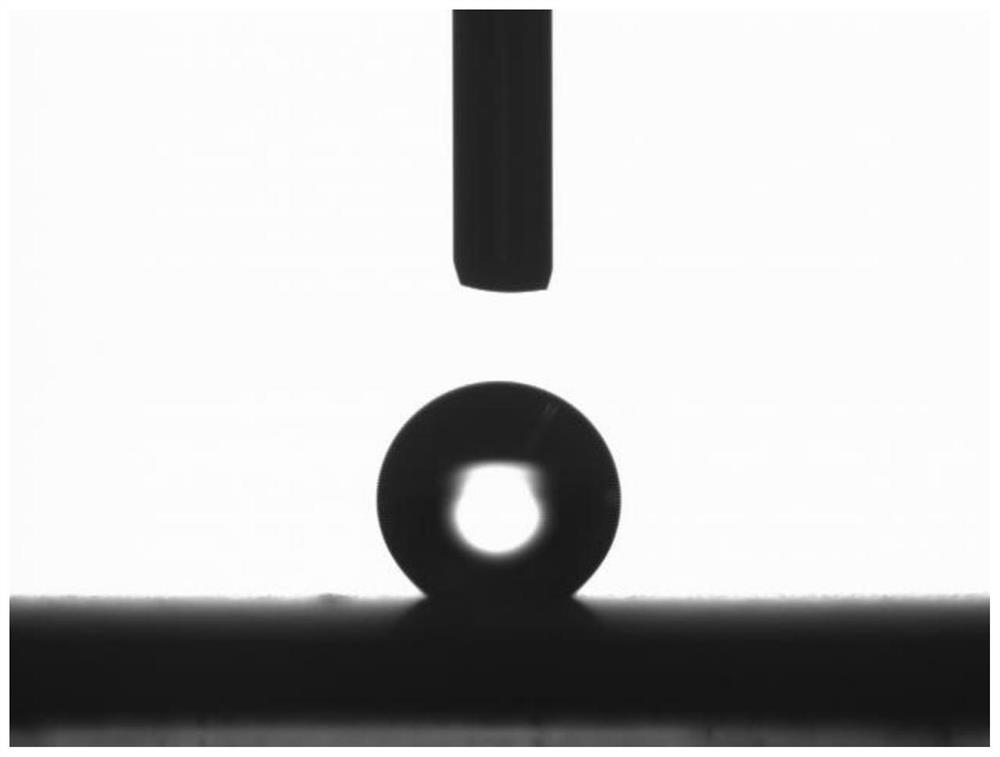

The invention discloses a polyetherimide chemical roughening and electroplating process. The process comprises the following steps of deoiling, wherein deoiling powder is adopted and is matched with ultrasonic equipment to deoil polyetherimide, the operation temperature ranges from 45 DEG C to 55 DEG C, the amount of the deoiling powder ranges from 40 g / L to 60 g / L, and the soaking time ranges from 5 min to 15 min; baking, wherein a high-temperature drying box is used for drying polyetherimide; roughening, wherein a plastic roughening agent is adopted for roughening polyetherimide, and polyetherimide is soaked for 10 min to 30 min under the condition that heating is carried out till the temperature ranges from 80 DEG C to 85 DEG C; neutralization, wherein sulfuric acid and hydrogen peroxide are used for neutralizing the plastic roughening agent, the concentration of each of sulfuric acid and hydrogen peroxide is 30 ml / L, the operation temperature ranges from 20 DEG C to 30 DEG C, and the soaking time ranges from 1 min to 3 min; activation, wherein colloid palladium is used for activating polyetherimide; decollide treatment, wherein decollide liquid is used for soaking polyetherimide; the chemical copper process, wherein the surface of polyetherimide is plated with copper through copper deposition liquor; and electroplating, wherein the surface of polyetherimide is electroplatedwith metal after being plated with copper. According to the polyetherimide chemical roughening and electroplating process, the roughening effect is good, and industrialization can be achieved easily.

Owner:麦德美科技(苏州)有限公司

Environment-friendly method for conducting surface roughening on liquid crystal polymer devices before chemical plating

PendingCN112647065APost-processing is simpleSimplify operation stepsLiquid/solution decomposition chemical coatingChemical platingOxidizing agent

The invention discloses an environment-friendly method for conducting surface roughening on liquid crystal polymer devices before chemical plating. The environment-friendly method for conducting surface roughening on the liquid crystal polymer devices before chemical plating comprises the following steps: placing liquid crystal polymer (LCP) materials in potassium persulfate roughening liquid, introducing ozone, and conducting roughening treatment under the action of ultrasonic waves; and placing liquid crystal polymers subjected to roughening treatment in an oxidant-removing solution, and then taking out the liquid crystal polymers for cleaning to obtain roughened surfaces. According to the environment-friendly method for conducting surface roughening on the liquid crystal polymer devices before chemical plating, by using low-concentration potassium persulfate as the roughening liquid in combination with ring opening and oxidizing by the ozone and the cavitation and crushing action of the ultrasonic waves, the surfaces of the compound materials are subjected to roughening treatment, adopted technology methods and an adopted formula are environmentally friendly, no flammable, combustible or carcinogenic solvents are used, no high-temperature high-pressure operation is conducted, conventional equipment of an electroplate factory is adopted, the operation steps are simple, and the environment-friendly method for conducting surface roughening on the liquid crystal polymer devices before chemical plating has a good effect, and is especially suitable for large-scale surface roughening treatment of LCP devices of the fields of electronics, communication and micro-electronic machines.

Owner:JIANGSU UNIV OF SCI & TECH

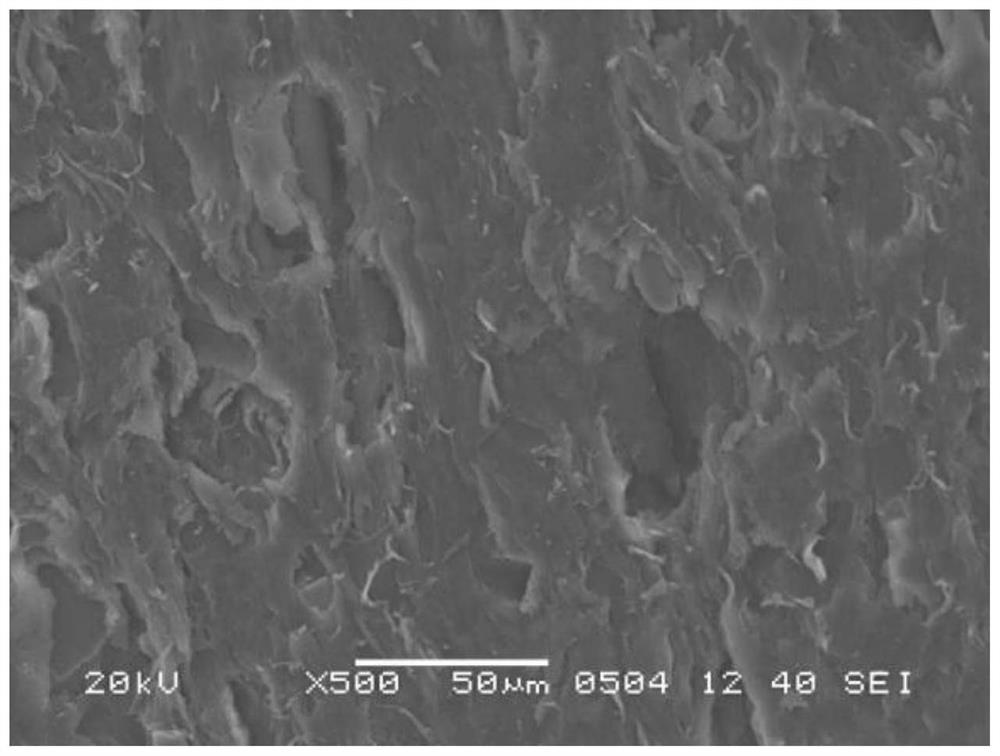

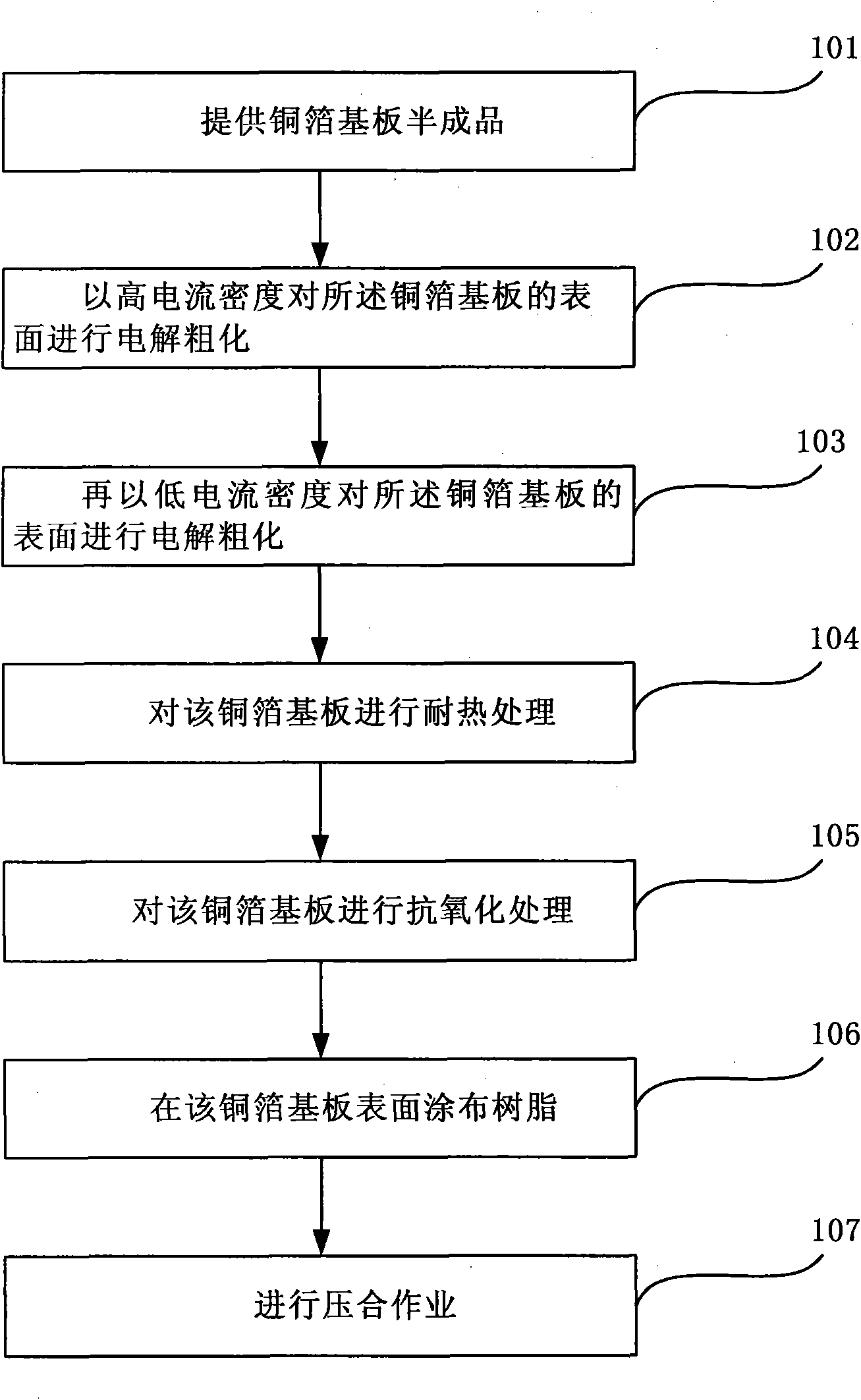

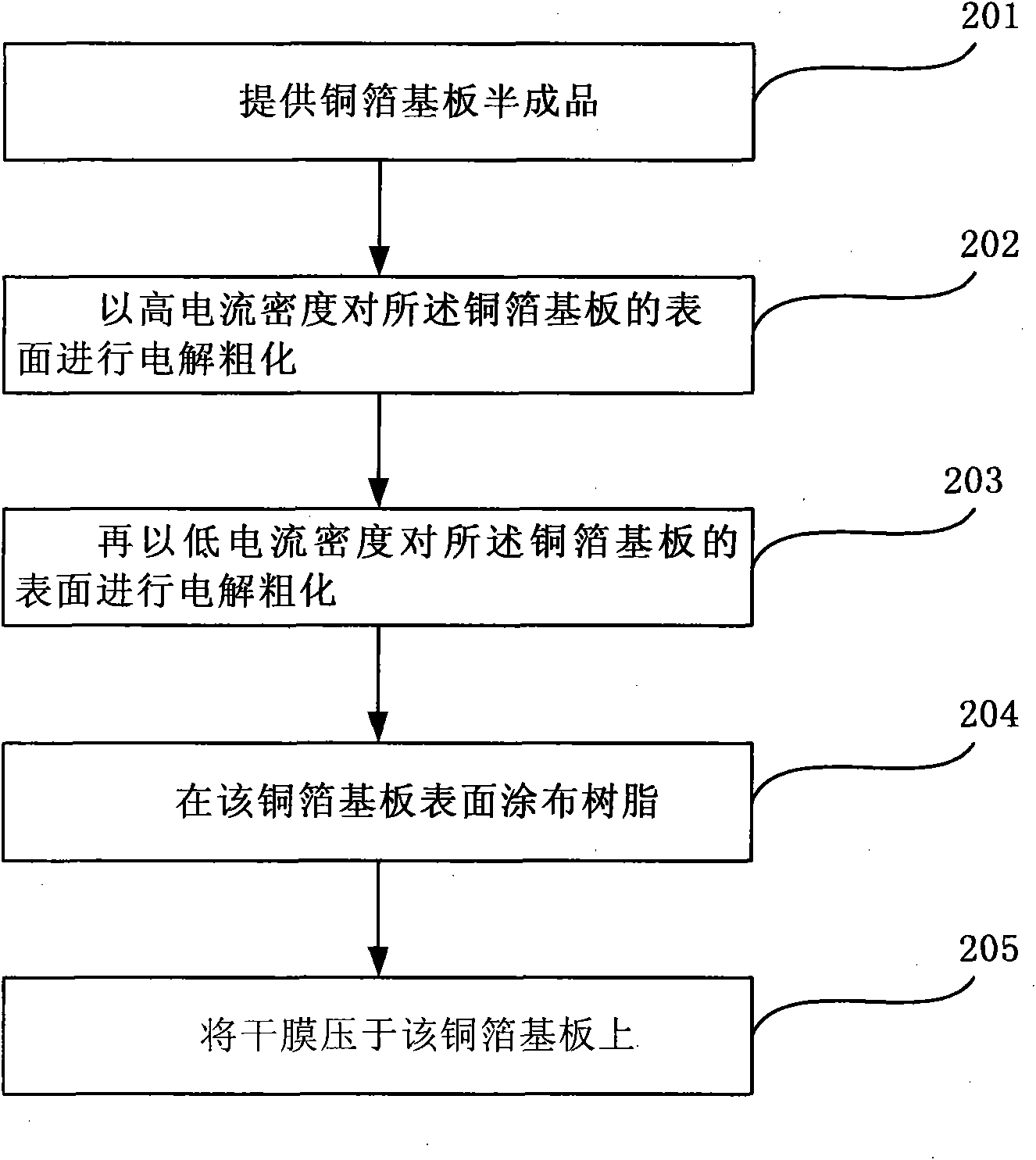

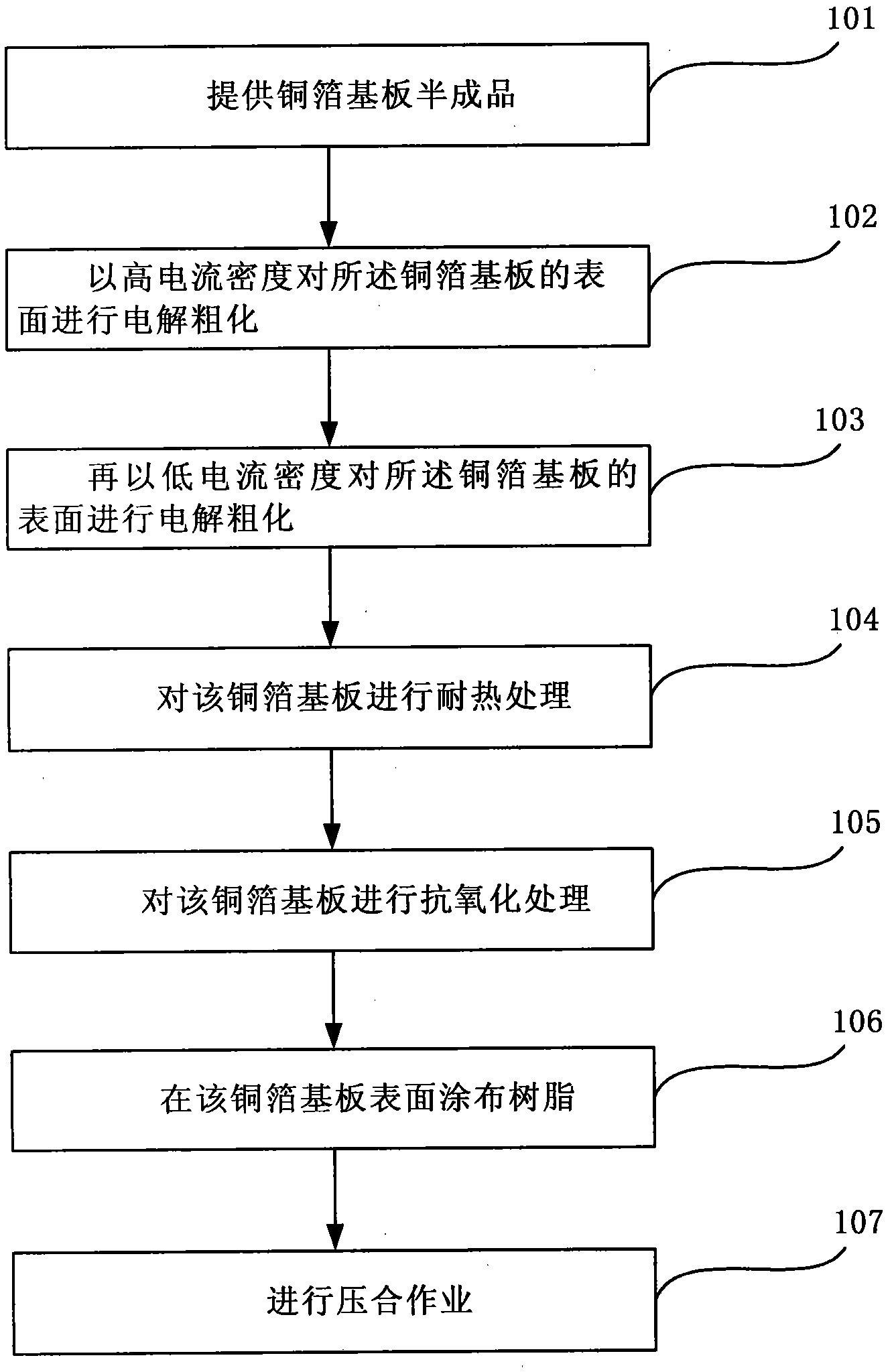

Method for treating surfaces of plates

InactiveCN101778540AGood coarsening effectImprove bindingInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentHigh current densityElectrolysis

The invention discloses a method for treating the surfaces of plates, comprising the following steps of: electrolyzing and coarsening the surfaces of copper foil base plates by sequentially adopting high current density and low current density, and then coating resins on the coarsened surfaces of the copper foil base plates so that a dry film for development and exposure can be pressed on the copper foil base plate. After the electrolyzed and coarsened copper foil base plates are sequentially subjected to heat-resistant treatment and oxidation-resistant treatment, the surfaces of the copper foil base plates can be coated with the resins, thereby two copper foil base plates can be laminated.

Owner:TRIPOD WUXI ELECTRONICS

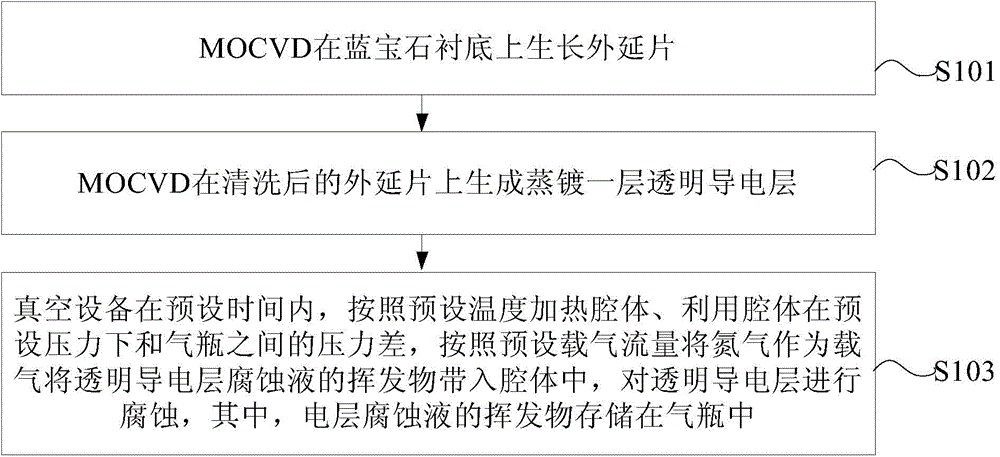

LED transparent conductive layer roughening method and vacuum apparatus

ActiveCN104064638AImprove light extraction efficiencyCoarsening of realityAfter-treatment detailsSemiconductor devicesGas cylinderNitrogen

The invention provides an LED transparent conductive layer roughening method and a vacuum apparatus. The method comprises the following steps: an epitaxial wafer is grown on a substrate; a transparent conductive layer is evaporated onto the cleaned epitaxial wafer; evacuation is performed on a cavity at which the transparent conductive layer is located; and in a preset time, the cavity is heated according to a preset temperature and the volatile matter of the transparent conductive layer corrosive liquid is brought into the cavity by taking nitrogen as the carrier gas according to a preset carrier gas flow through the pressure difference between the cavity in a preset pressure and a gas cylinder, corrosion is performed on the transparent conductive layer, and the volatile matter of the conductive layer corrosive liquid is stored into the gas cylinder. Through the controllable roughening of the transparent conductive layer, the total reflection of the light in the LED can be reduced so as to improve the light outgoing efficiency of the LED.

Owner:JIANGXI EPITOP OPTOELECTRONICS

Circuit board roughening agent

InactiveCN110461104AFast coarseningConstant copper etching rateInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentEtching rateMicrometer

The invention provides a circuit board roughening agent. The circuit board roughening agent comprises, by mass, 15% to 30% of hydrogen peroxide, 5% to 15% of formic acid, 0.1% to 0.8% of methanol andwater balance. The circuit board roughening agent provided by the invention has the advantages of fast roughening speed, constant copper etch rate, good bite rate, good roughening effect and convenient circuit board automation production. By using the circuit board roughening agent provided by the invention, the roughening speed of metal copper on the surface of a circuit board is constantly controlled at 0.5 to 5 micrometers / minute. The biting speed during the roughening process of metal copper on the surface of the circuit board is constant. The need of the existing circuit board automationproduction line for automatic circuit board roughening is met. The production efficiency is improved. The cost is reduced.

Owner:惠州市鸿宇泰科技有限公司

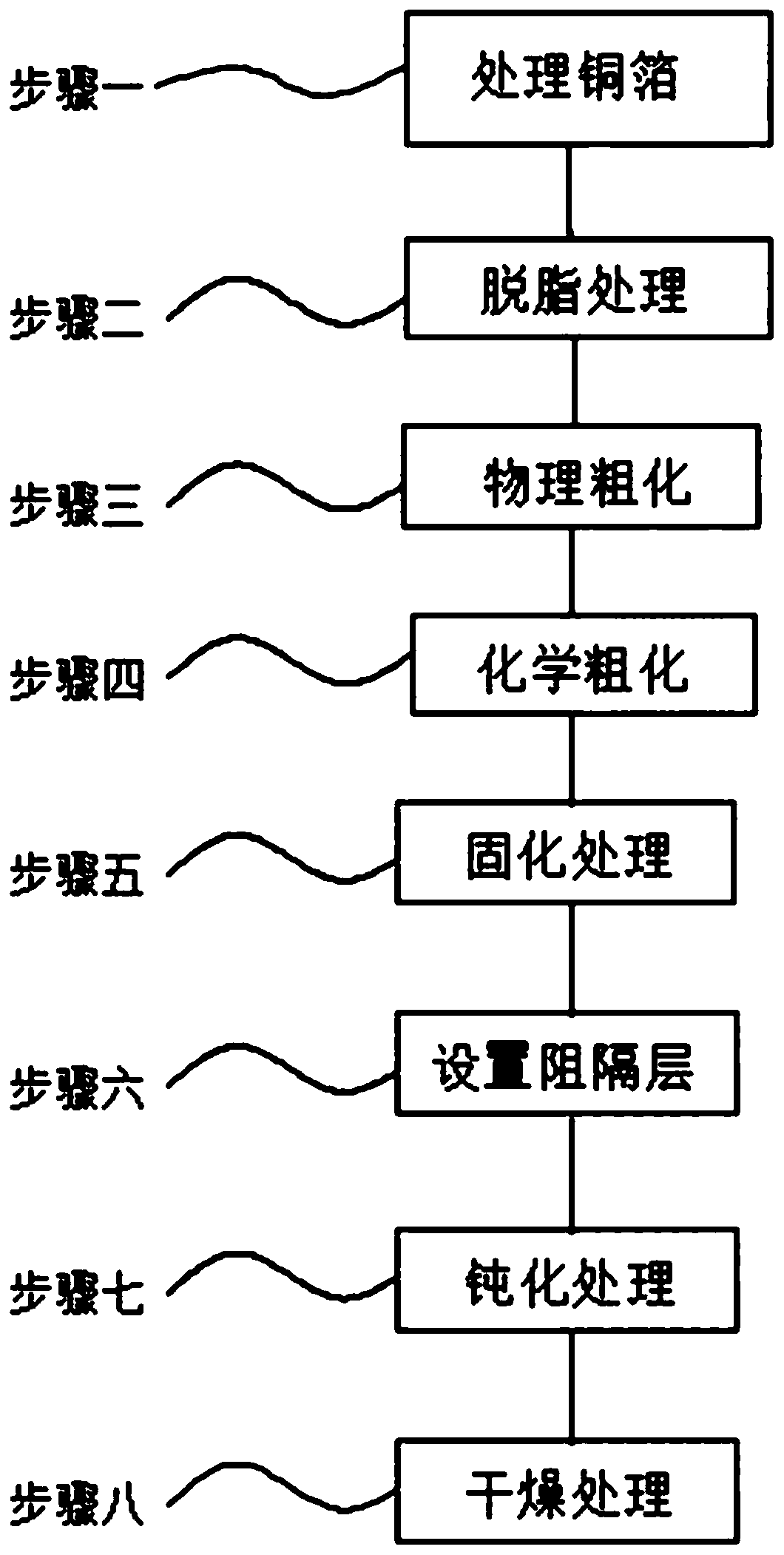

Copper foil surface chromic anhydride passivating treatment process

InactiveCN110219035AGood coarsening effectCoarsening effect improvedChromatisationIsolation effectPhosphoric acid

The invention discloses a copper foil surface chromic anhydride passivating treatment process. The copper foil surface chromic anhydride passivating treatment process comprises the steps of copper foil treatment, degreasing treatment, physical roughening, chemical roughening, curing treatment, obstruction layer arranging, passivation treatment and drying treatment. According to the process, 2000#abrasive paper is used for grinding, ground copper foil is put into a CuSO4 solution contained in a roughening groove to be subjected to chemical roughening, the physical roughening and the chemical roughening are combined, the roughening effect is greatly improved, the better roughening effect is achieved, after curing, alloy liquid is mixed liquid formed through mixing of alloy oxide and phosphoric acid and is adopted for making an obstruction layer, the isolation effect is improved, the oxidation resistance capacity is improved, when passivating treatment is carried out, a passivation powerbinding post is moved backwards from a previous conductive roller, the passivating effect is improved, in the roughening, curing and passivating process, the drug supplementing manner is changed into24-h supplementing of a metering pump from one-time adding, the drug supplementing manner is changed, and the treatment effect is better improved.

Owner:贵州中鼎高精铜箔制造有限公司

Method for manufacturing GaP rough surface of GaAs-based LED wafer

ActiveCN112397624AUniformly roughened surfaceEasy to controlSemiconductor devicesRough surfaceWafering

The invention discloses a method for manufacturing a GaP rough surface of a GaAs-based LED wafer, and the method comprises the steps: preparing a wafer epitaxial layer, carrying out the roughening corrosion of a GaP window layer of the epitaxial layer, dissolving photoresist and roughening corrosion liquid together through a surfactant, forming corrosion sol with a roughening corrosion effect, coating the surface of the GaP window layer with the corrosion sol, baking at a constant temperature of 40-60 DEG C, removing a corrosion film layer and a silicon dioxide layer by using solvents such asacetone and the like, and continuously preparing to obtain an independent tube core; the process method designed by the invention is simple and easy to operate, does not need to introduce special equipment, is lower in cost, is more uniform in coarsening corrosion of the surface of the epitaxial layer, is higher in corrosion controllability, is good in coarsening effect, and solves the problems that the coarsening corrosion is more difficult to control and the coarsening brightness is not improved greatly when a solution is used at present. When the method provided by the invention is used forcoarsening, the light extraction efficiency can be improved by 25-30 percent, and the method has higher practicability.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

Neutral metal surface coarsening treatment solution with super-hydrophilicity and super-oleophilicity, and preparation method and application thereof

The invention provides a neutral metal surface coarsening treatment solution with super-hydrophilicity and super-oleophilicity, and a preparation method and application thereof. The neutral metal surface coarsening treatment solution with super-hydrophilicity and super-oleophilicity comprises the following components according to the total mass of 100%: 2%-10% of chemical components A, 3%-30% of chemical components B and 60%-95% of chemical components C; and the chemical components A comprise mixtures of alkyl siloxane modified nano-silica solutions and catalysts, and the chemical components Acomprise mixtures of fatty acid water alcohol liquid and catalysts. According to the metal surface coarsening treatment solution, through "binary synergy" principles of micro-nano materials, the micro-nano coarsening of the metal surface is achieved, and the super-hydrophilic and super-oleophilic effects of the surface are achieved; and the compatibility of the surface coating materials is higher, and the metal surface adhesion is higher. The coarsening treatment solution provided by the invention is neutral, and is environmentally friendly, safe and recyclable; and zero discharge can be achieved, and the coarsening treatment solution has broad application prospects.

ABS chromium-free coarsening solution, and preparation method and application thereof

PendingCN110172684AImprove stabilityGood coarsening effectLiquid/solution decomposition chemical coatingSuperimposed coating processChromium freeElectrolysis

The invention provides an ABS chromium-free coarsening solution. The coarsening solution is an aqueous solution containing manganese sulfate, sulfuric acid, phosphoric acid and methanesulfonic acid. The invention further provides a coarsening method of the chromium-free coarsening solution for ABS plastic. The prepared chromium-free coarsening solution is electrolyzed by an electrolysis device, the ABS plastic is placed in the coarsening solution for chemical coarsening, and the chromium-free coarsening solution needs to be connected with evaporation equipment so as to maintain the specific gravity of the solution. According to the coarsening solution, the environmental pollution caused by conventional chromium acid coarsening and the use of explosive raw materials such as potassium permanganate are avoided, the coarsening method improves the stability of coarsening liquid and coarsening capability, and the ABS chromium-free coarsening solution has good coarsening effect and industrialapplication value.

Owner:南通柏源汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com