Method for coarsening surface of GaN-based LED epitaxial wafer

A LED epitaxial wafer, surface roughening technology, applied in the field of optoelectronics, can solve problems such as complex process, lower product yield, quantum well damage, etc., achieve high light extraction efficiency, reduce cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

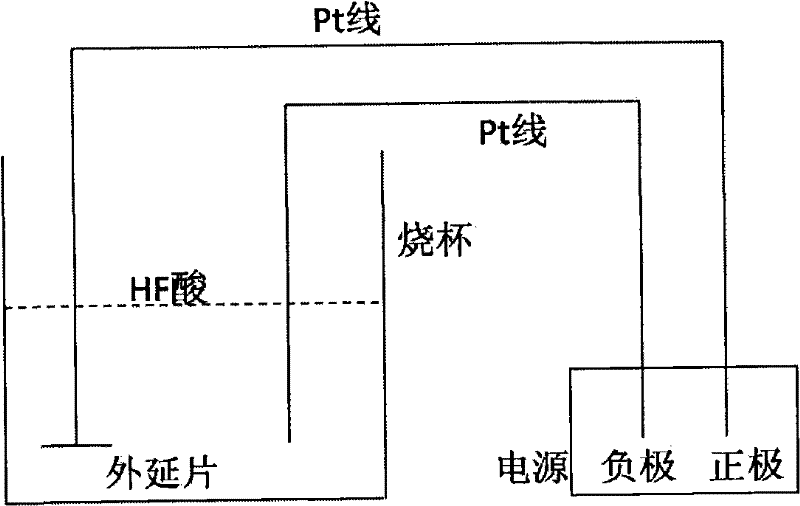

[0018] The surface roughening method of the GaN-based LED epitaxial wafer of the present invention specifically includes the following steps:

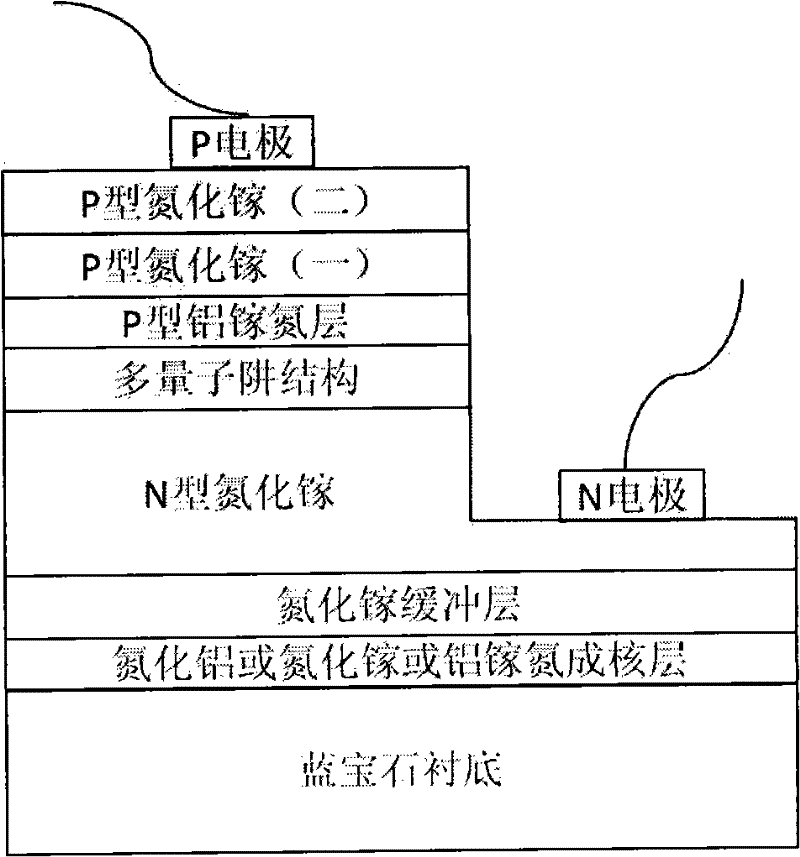

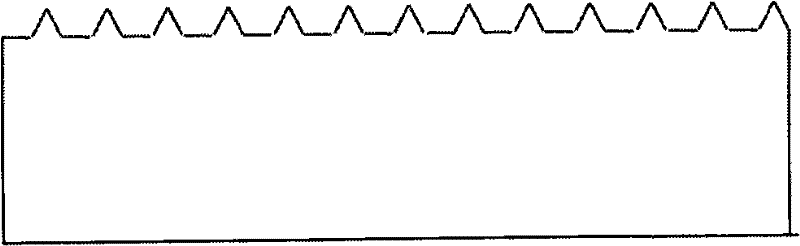

[0019] (1) According to the conventional MOCVD (metal organic chemical vapor deposition) method, grow the LED epitaxial layer structure on the sapphire, PSS or SiC substrate, firstly grow the GaN, AlN or AlGaN nucleation layer on the sapphire, PSS or SiC substrate. Then, a GaN buffer layer, an N-type GaN layer, a light-emitting layer multiple quantum well structure, a P-type AlGaN layer, and a P-type GaN layer are sequentially grown on the nucleation layer. The structure of the prepared epitaxial wafer is as figure 1 Shown. The growth of the P-type GaN layer is divided into two parts. The first part is grown under the conditions of a growth pressure of 100-200torr, a P-type GaN growth rate of 0.5μm / hour--2μm / hour, and a growth temperature of 900℃-1050℃ P-type GaN, the thickness of the P-type GaN in this part is 100nm-300nm, and the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com