Patents

Literature

245 results about "Pt electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enabling nanostructured materials via multilayer thin film precursor and applications to biosensors

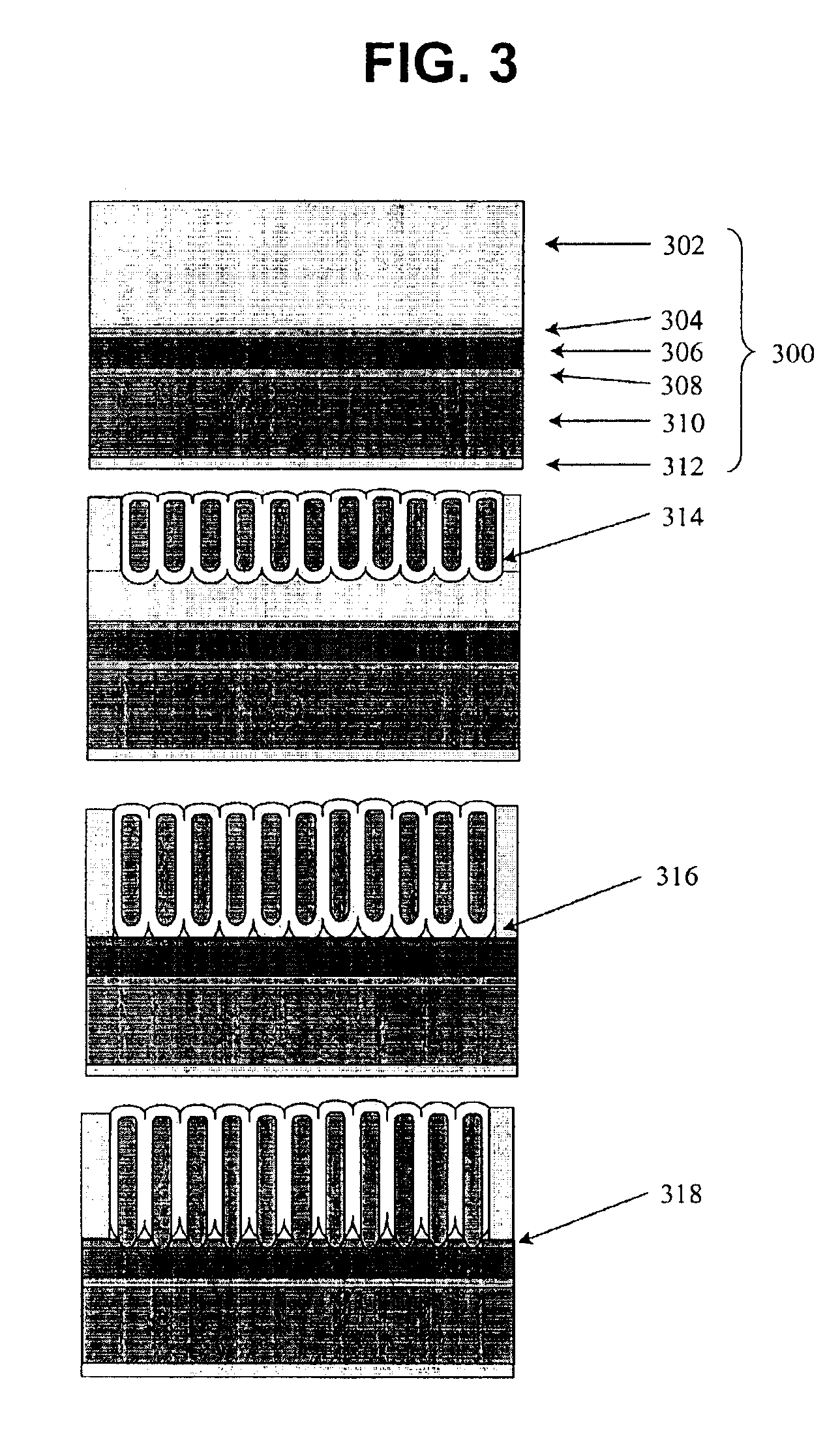

A thin film based nanoporous alumina template has been developed which allows the in situ removal of an electrically insulating alumina barrier layer at the pore bases. This barrier free nanoporous system has great utility for electrodeposition of a wide variety of nanowire materials. An exemplary multilayer thin film precursor is provided comprising Al (anodization layer), Ti (diffusion barrier) and Pt (active electrode) on a Si substrate. Aluminum anodization in sulfuric acid with a subsequent applied voltage ramping program produces a Pt electrode at the base of the nanopores without the additional steps of alumina removal, barrier layer dissolution, and metal deposition onto the pore bottoms.

Owner:UNIV OF NOTRE DAME DU LAC

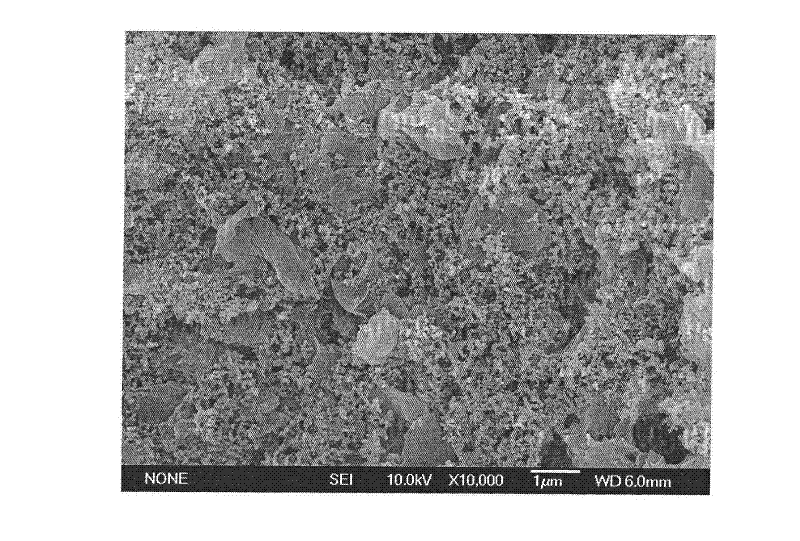

Graphene composite porous counter electrode, preparation method and application thereof

ActiveCN102347143AGuaranteed normal transmissionLarge active surface areaLight-sensitive devicesFinal product manufacturePorosityFluid electrolytes

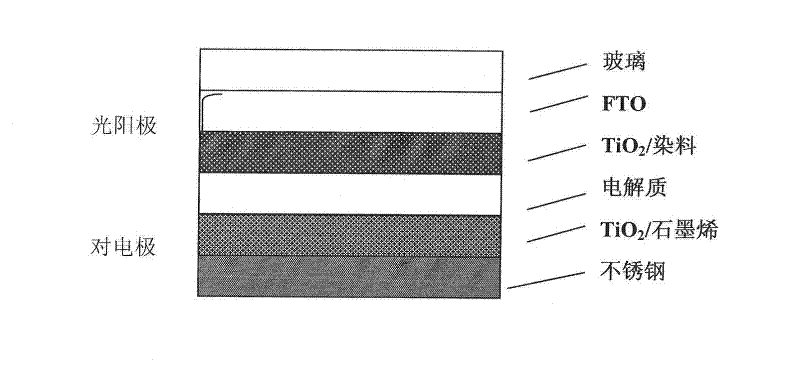

The invention discloses a graphene composite porous counter electrode, a preparation method and application thereof. The composite porous counter electrode is a mixture of grapheme and inorganic nanometer particles coated on a conductive substrate. The preparation method concretely comprises the following steps of: mixing the grapheme prepared through chemical reduction with the inorganic nanometer particles; adding a small amount of organic binder; coating the organic binder on a substrate material, such as metal, conductive glass or conductive plastic and the like; and obtaining the graphene composite porous counter electrode through thermal treatment. The porosity of the composite counter electrode ensures that the composite counter electrode and a liquid electrolyte have larger effective contact area; and the composite counter electrode has the photoelectric conversion efficiency equivalent to a magnetron sputtering Pt electrode when being applied to a dye sensitized solar cell. The composite electrode has the advantages of low cost, favorable stability and mechanical property and the like and has important significant on the wide application of the dye sensitized solar cell.

Owner:中国科学院上海硅酸盐研究所苏州研究院

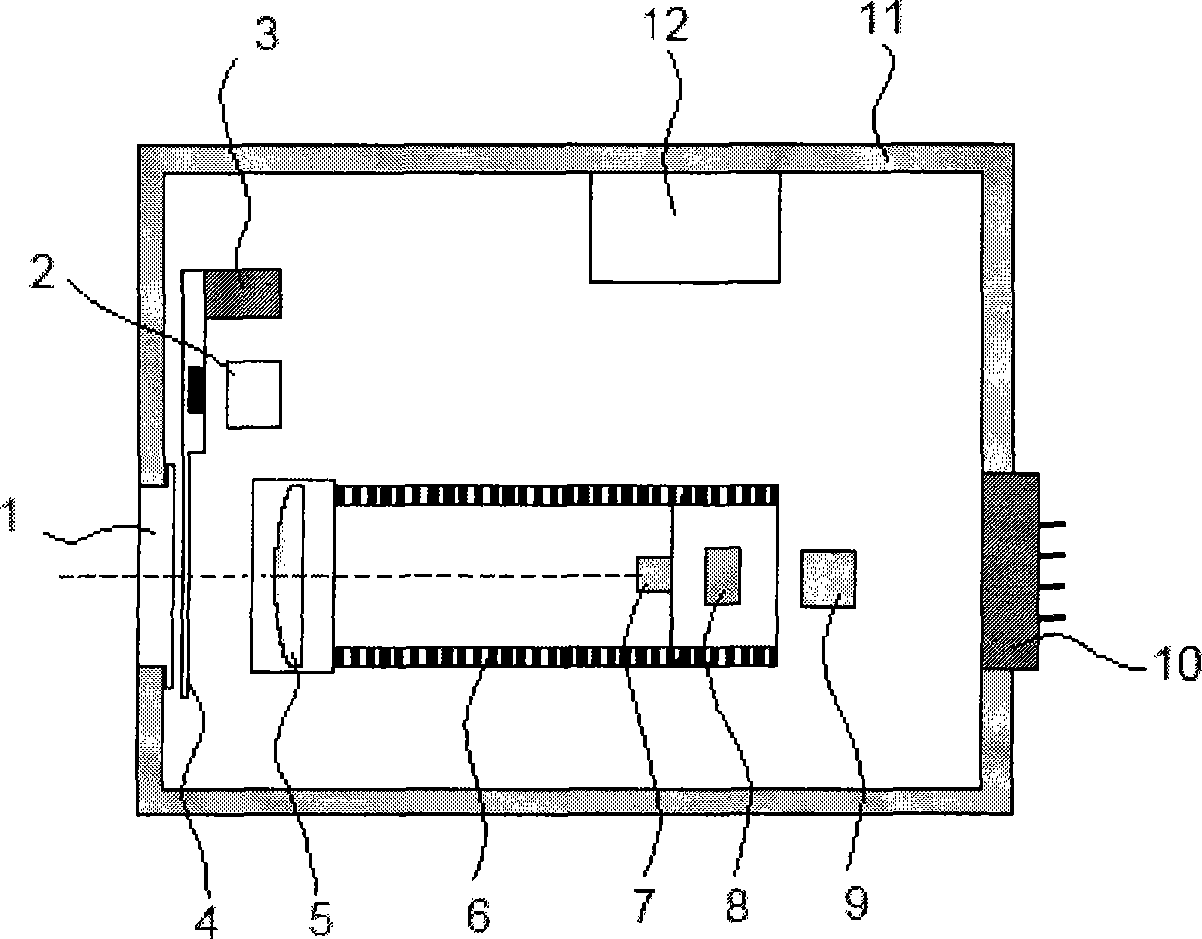

Lithium tantalate thin film infrared detector and manufacturing method

InactiveCN101246055AAchieve Impedance MatchingAchieve modulationRadiation pyrometryLow-pass filterOptoelectronics

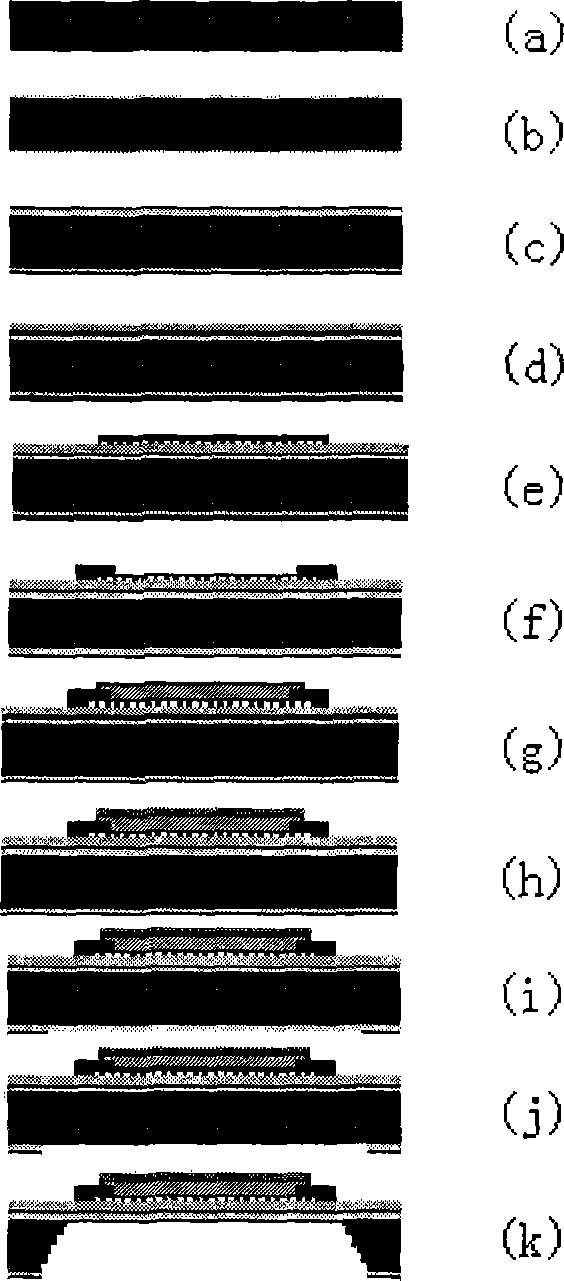

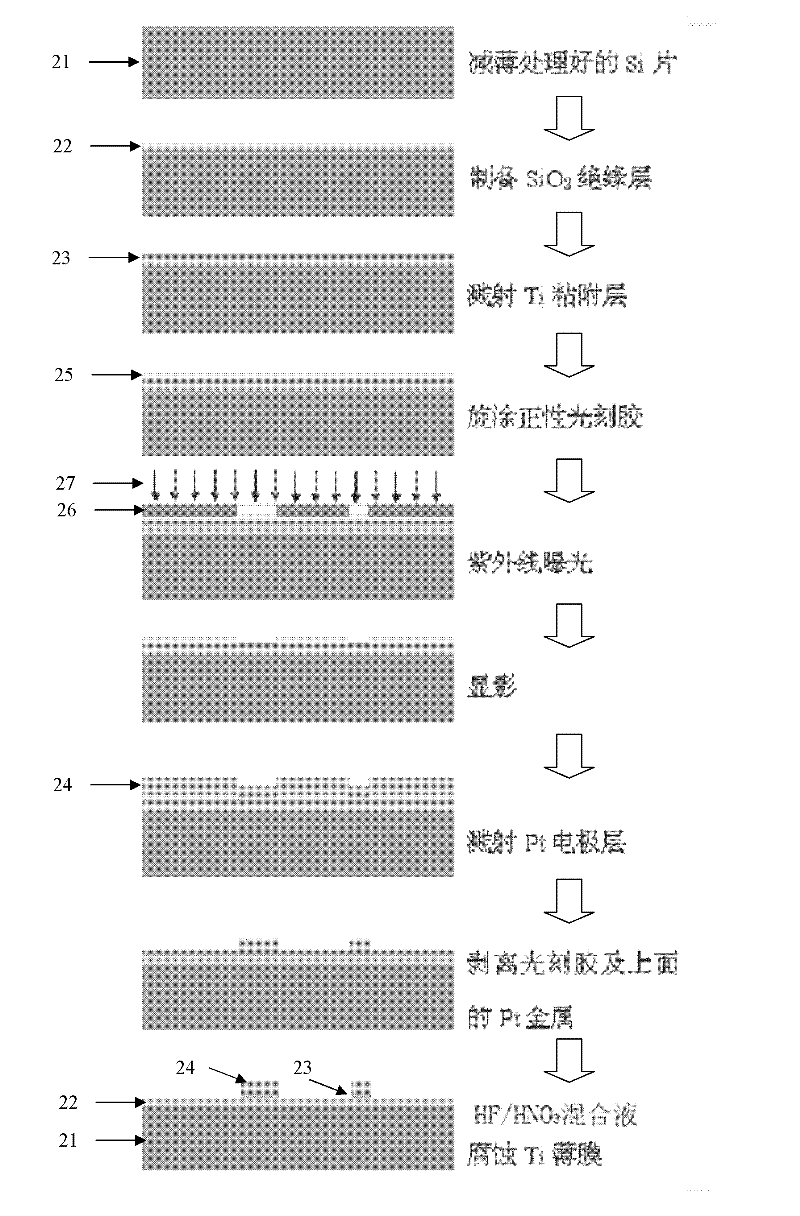

The present invention relates to a lithium tantalate film infrared detector and the preparing method thereof. The invention comprises the following components: an infrared filtering window, a resonance chopped wave modulator, a focusing lens, a pyroelectric lithium tantalate film infrared measuring probe, a heat sink cavity, a preamplifier, a low-pass filter, an electric power and signal output interface, a casing and an environment temperature detecting filter. The method for preparing the detector comprises the following steps: selecting a substrate, growing a SiO2 layer on the front and back surface, depositing Si3N4 layer on the front surface in sequence, sputtering a Ti layer, sputtering a photoetching Pt electrode layer, producing a lithium tantalate film layer, depositing a phototeching Al electrode layer, growing a photoetching SiNX antireflection layer and sputtering a black layer to complete the double unit structure infrared probe. The focusing lens is coated with an anti-reflection film. The infrared window is pasted with a narrowband filtering film. The preamplifier is built with a JFET tube or operational amplifier. The low-pass filter is built with an operational amplifier. The resonance chopped wave modulator is driven by piezoelectricity or electromagnet, and the resonance frequency is 1Hz-1000Hz.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Solvothermal preparation method of in-situ molybdenum disulfide electrode

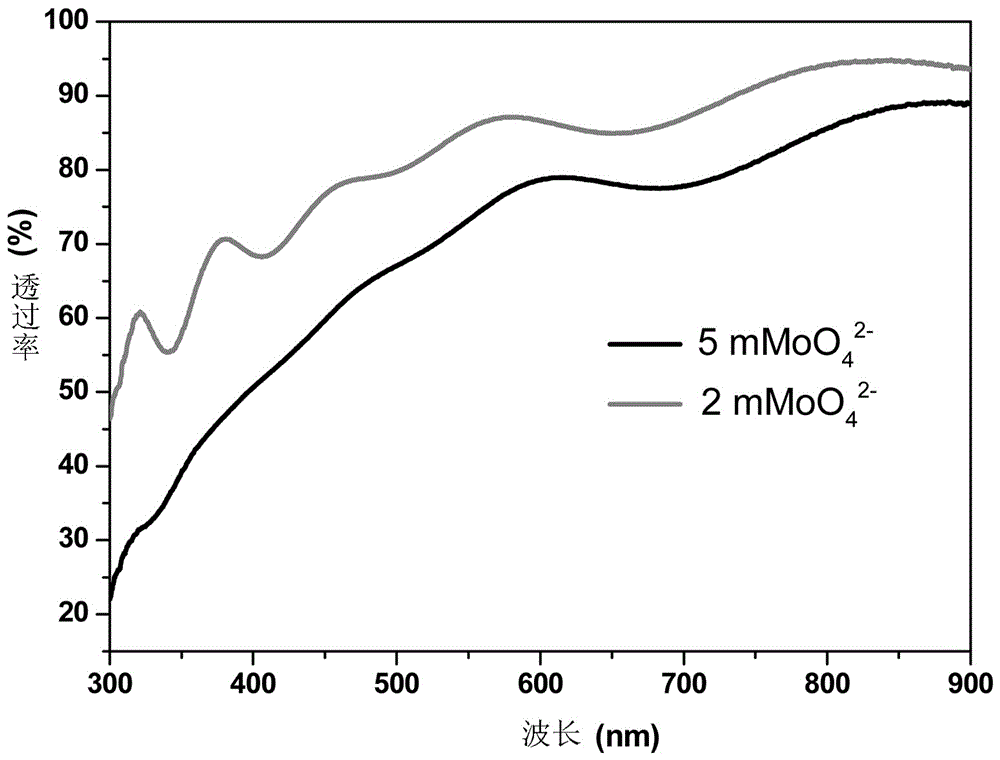

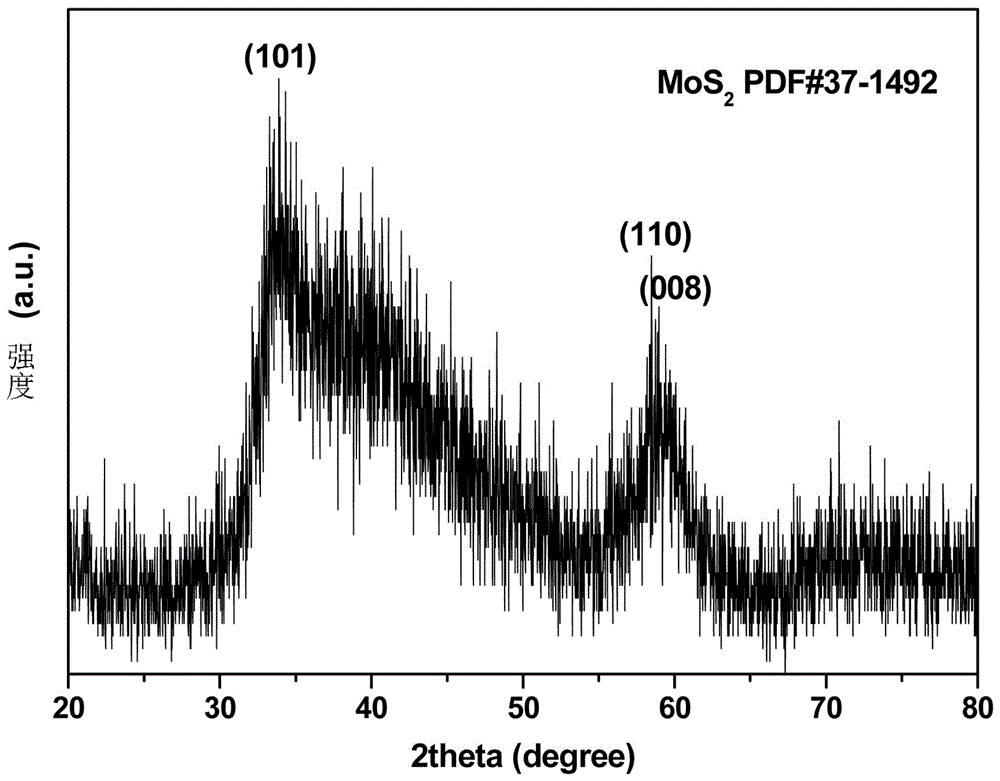

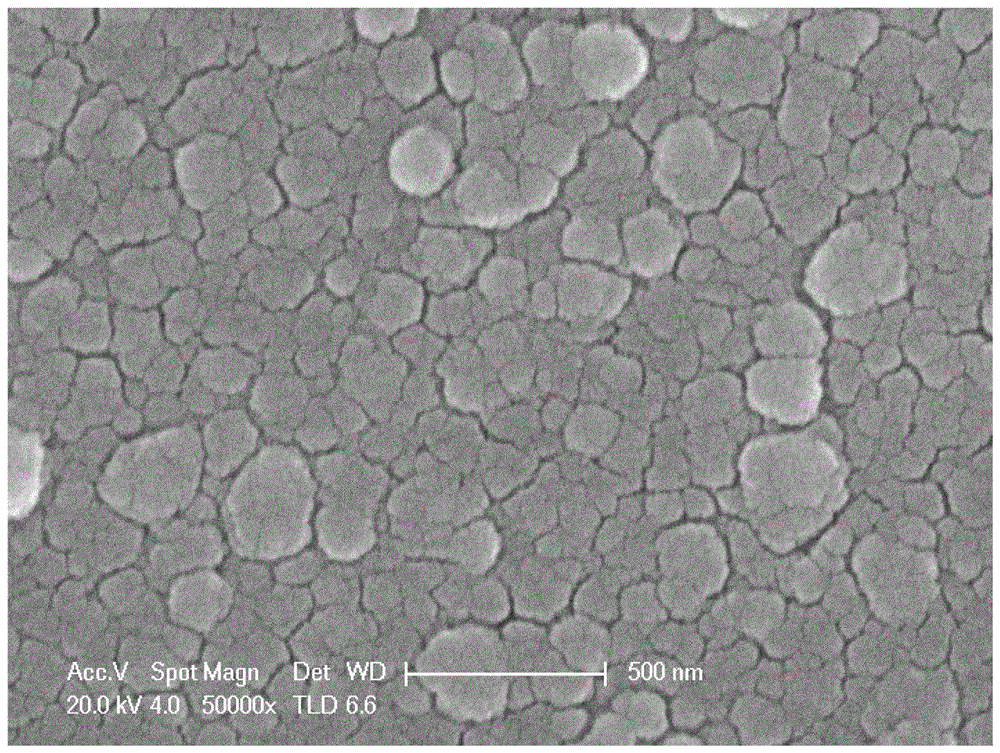

The invention discloses a solvothermal preparation method of an in-situ molybdenum disulfide electrode. The preparation method comprises the following steps: dissolving molybdenum-containing salts (sodium molybdate, etc.) into an alcohol solution containing a sulfur source (thiourea, etc.), adding a substrate material, then filling the mixture into a hydrothermal kettle, carrying out solvothermal reactions for 6 to 24 hours at a temperature of 180 to 230 DEG C; taking out the substrate, and cleaning and drying the substrate. If people want to improve the crystallization property of molybdenum disulfide, the substrate can be annealed in an atmosphere of N2 for one hour at a temperature of 500 DEG C. The prepared in-situ molybdenum disulfide electrode has the advantages of high transparency and uniformity, and strong adhesion force on substrate. The dye-sensitized solar cell prepared from the provided in-situ molybdenum disulfide electrode has a higher photoelectric conversion efficiency, compared with the cells prepared from a conventional pyrolytic Pt electrode, and the result shows that the prepared molybdenum disulfide electrode has an extremely good electro-catalytic activity.

Owner:CHINA THREE GORGES UNIV

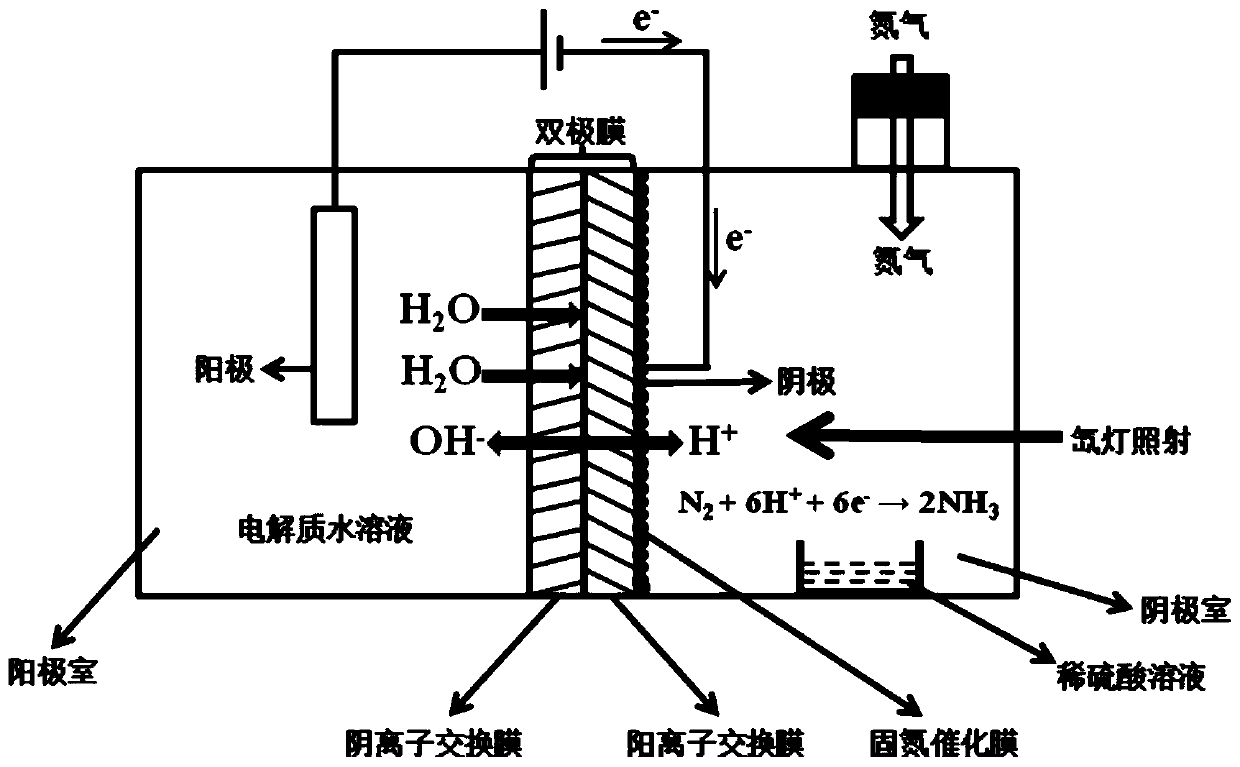

Device and method for synthesizing ammonia through photoelectrocatalysis nitrogen fixation

ActiveCN110079816AInhibition of hydrogen evolution side reactionAvoid hydrogen evolution reactionCellsMetal/metal-oxides/metal-hydroxide catalystsElectrolysisNitrogen gas

The invention provides a device and a method for synthesizing ammonia through photoelectrocatalysis nitrogen fixation and relates to the technical field of electro-catalysis electrolysis. The device for synthesizing ammonia through photoelectrocatalysis nitrogen fixation comprises a photoelectric composite membrane, wherein the photoelectric composite membrane consists of a bipolar membrane and anano nitrogen fixation catalysis membrane and is used for dividing an anode chamber and a cathode chamber into a double-chamber electrolytic bath; the bipolar membrane comprises an anion exchange membrane and a cation exchange membrane; the nano nitrogen fixation catalysis membrane is carried on the surface of the cation exchange membrane; an electrolyte solution is put into the anode chamber; thecathode chamber is filled with nitrogen; a BiVO4 or Pt electrode is adopted as an anode; a nitrogen fixation catalyst membrane is used as a cathode; a container filled with dilute sulfuric acid is arranged in the cathode chamber and is used for absorbing generated ammonia gas; a xenon lamp is adopted as a light source; an external direct-current power supply is adopted to provide electric field force; a positive pole and a negative pole of the external direct-current power supply are respectively connected with the anode and the cathode. The device is adopted for photoelectrocatalysis nitrogen fixation in a non-water solution, and has benefits that hydrogen evolution side reactions can be effectively inhibited, and the photoelectrocatalysis nitrogen fixation efficiency can be improved.

Owner:TAIYUAN NORMAL UNIV

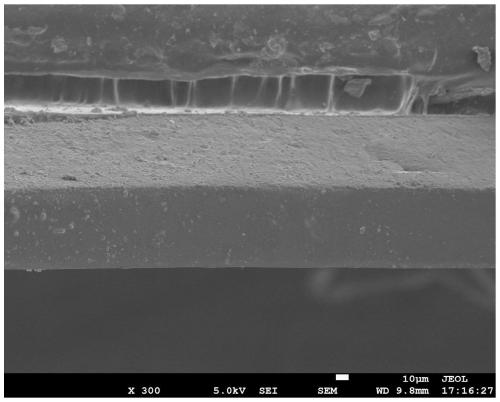

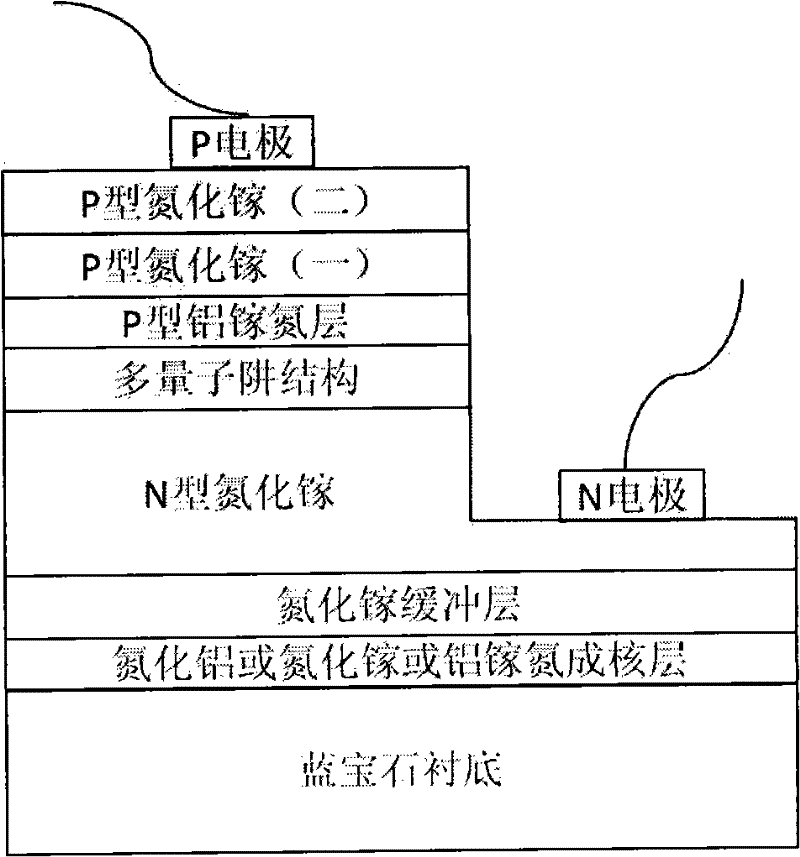

Method for coarsening surface of GaN-based LED epitaxial wafer

ActiveCN102130223AAvoid damageSimple processPolycrystalline material growthAfter-treatment detailsGallium nitrideLight-emitting diode

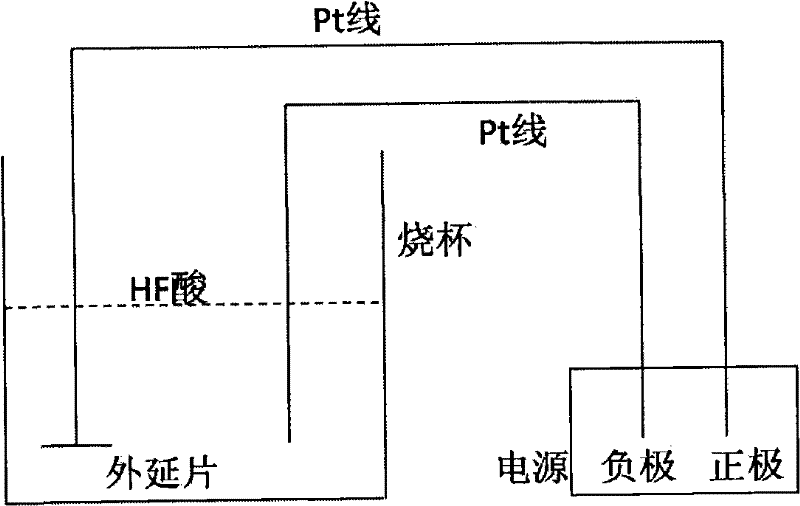

The invention provides a method for coarsening the surface of a gallium nitride (GaN)-based light-emitting diode (LED) epitaxial wafer, which comprises the following steps of: (1) preparing an epitaxial wafer, growing a nucleating layer on a substrate epitaxially, growing a GaN buffer layer, an N-type GaN layer, a luminescent layer multi-quantum well structure, a P-type AlGaN layer and a P-type GaN layer on the nucleating layer sequentially, wherein the growth of the P-type GaN layer is divided into two parts; (2) preparing solution of hydrofluoric acid (HF); (3) welding a Pt lead serving as a positive electrode on the surface of the P-type GaN layer by using metal, and connecting a Pt electrode serving as a negative electrode with the HF solution prepared in the step (2); (4) connecting a power supply of 10 to 50 V between the positive electrode and the negative electrode; and (5) corroding, so that an obvious coarsening graph is formed on the surface of the P-type GaN layer. In the method, the coarsened surface of the GaN-based LED epitaxial wafer is prepared by changing the epitaxial growth condition and combining photo-electrochemical (PEC) etching, a process is simple, and the cost is reduced, the coarsening effect is obvious, the light extraction efficiency is high, and the damage of dry etching or high-temperature corrosion to quantum wells is prevented simultaneously.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

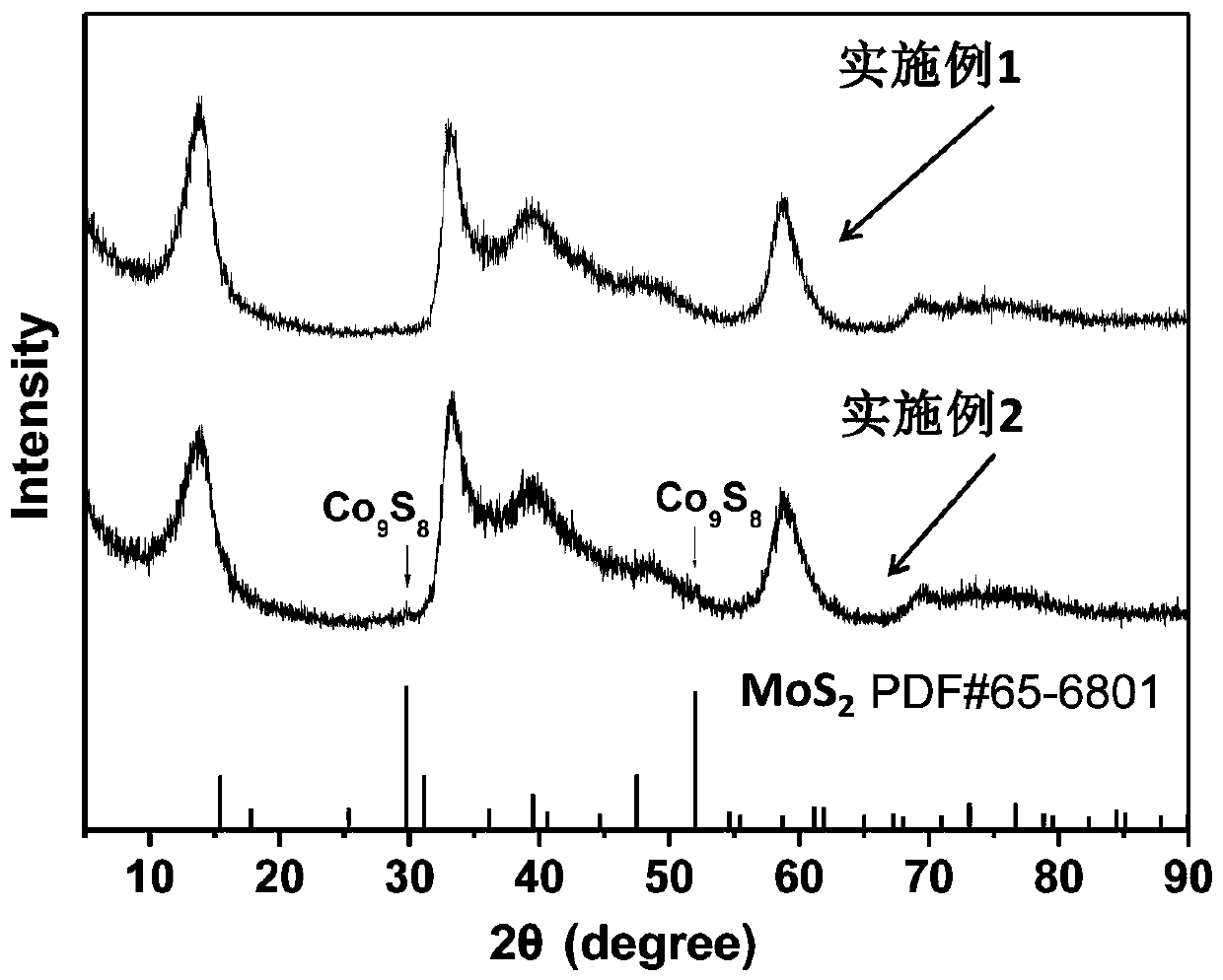

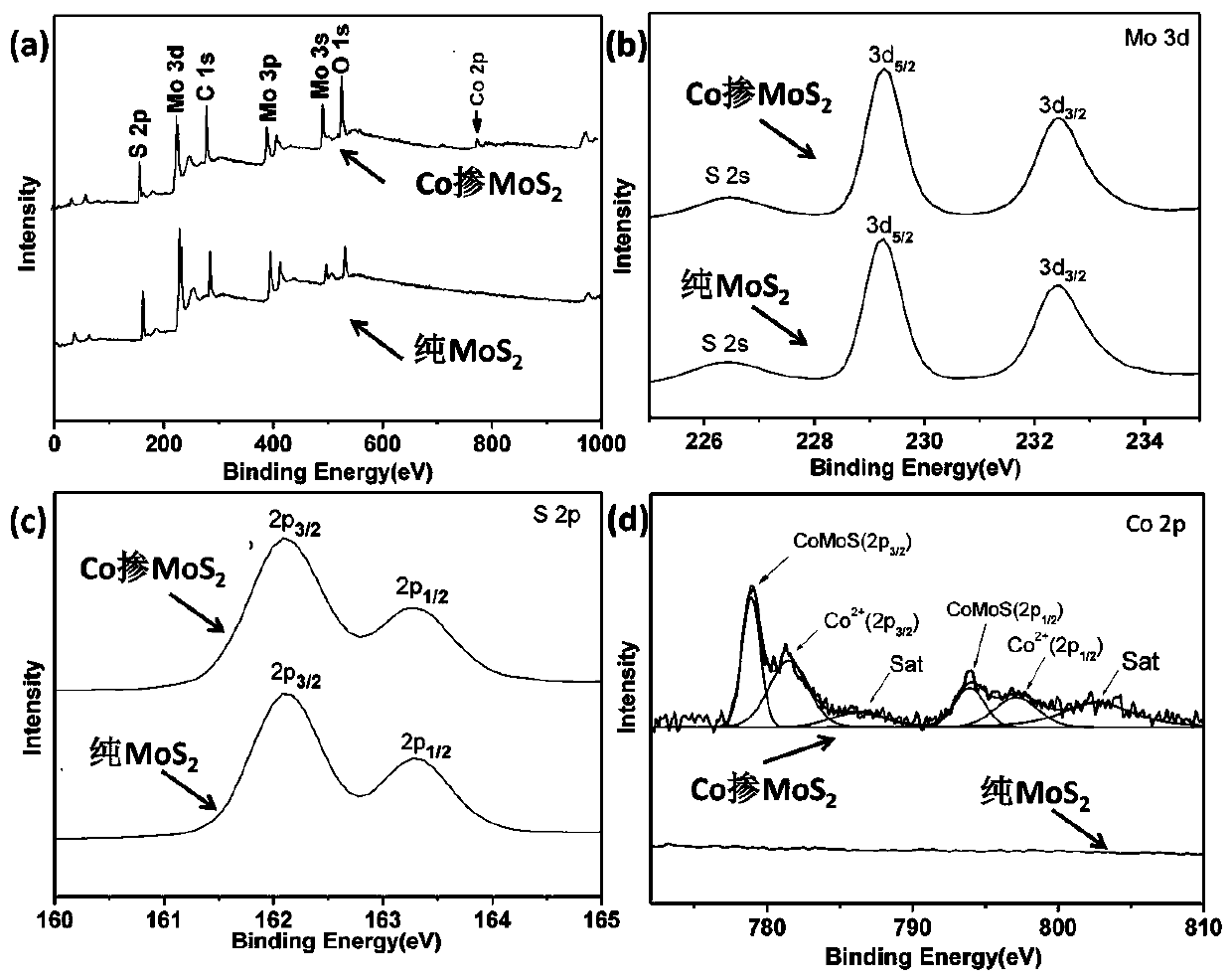

Co-doped in-situ MoS2 electrode and a preparation method thereof

The invention provides a Co-doped in-situ MoS2electrode. Co-doped MoS2 is formed by uniformly replacing Mo with Co, and the physical phase of Co-doped MoS2 is 2H MoS2. A specific preparation method comprises steps as follows: MoCl5 is dissolved in an ethanol solution at room temperature, Co salt is added, then thiourea is added, the materials are stirred and dissolved, and a Co-Mo-S precursor solution is obtained; the precursor solution is dropwise or rotationally applied to a substrate and rapidly dried at 70-100 DEG C, and a precursor film is obtained; the precursor film obtained in the steptwo is sintered for 0.5-2 h at 500-800 DEG C under argon or nitrogen protection, cooled with the furnace and then taken out, and the Co-doped in-situ MoS2 electrode is obtained. On the basis of mixing uniformity of Co, Mo and S atoms in the Co-Mo-S precursor solution and the easy uniform film-forming property of the Co-Mo-S precursor solution, Co-doped MoS2 is prepared through high-temperature solid phase reaction at the temperature of 500-800 DEG C; compared with pyrolytic Pt electrodes, the Co-doped in-situ electrode grows with higher stability.

Owner:CHINA THREE GORGES UNIV

Electrolyte of dye-sensitized solar cells and preparation method and application thereof

InactiveCN101635200APrevent leakageSimplify the packaging processLight-sensitive devicesFinal product manufactureSolid state electrolyteCross-link

The invention relates to an electrolyte of dye-sensitized solar cells, disclosing a quasi solid electrolyte and a preparation method thereof; the method in the invention comprises the following steps: (1) blending polymeric ionic liquid, nonpolymeric ionic liquid, ionic liquid cross linking agent and initiating agent according to the mass ratio of 15-60:20-80:2-10:1-5, and obtaining the polymer gel through random copolymerization at the temperature of 20-80 DEG C; and (2) immersing the polymer gel into iodic solution or iodic vapor for adsorption of iodic simple substance to obtain the electrolyte. In the invention, the well-prepared ionic liquid monomer / ionic liquid mixture is dipped between a light anode and a Pt electrode and quasi solid polymer gel is formed through in situ polymerization; the polymer gel is dipped into iodic solution or iodic vapor for the adsorption of iodic simple substance to prepare the quasi solid full-ionic liquid electrolyte which is used in solar cells, and the dye-sensitized solar cells are prepared simultaneously. The electrolyte prepared by the method has strong electrolytic adhesive ability and easy encapsulation, thus simplifying battery assembly program.

Owner:SUZHOU UNIV

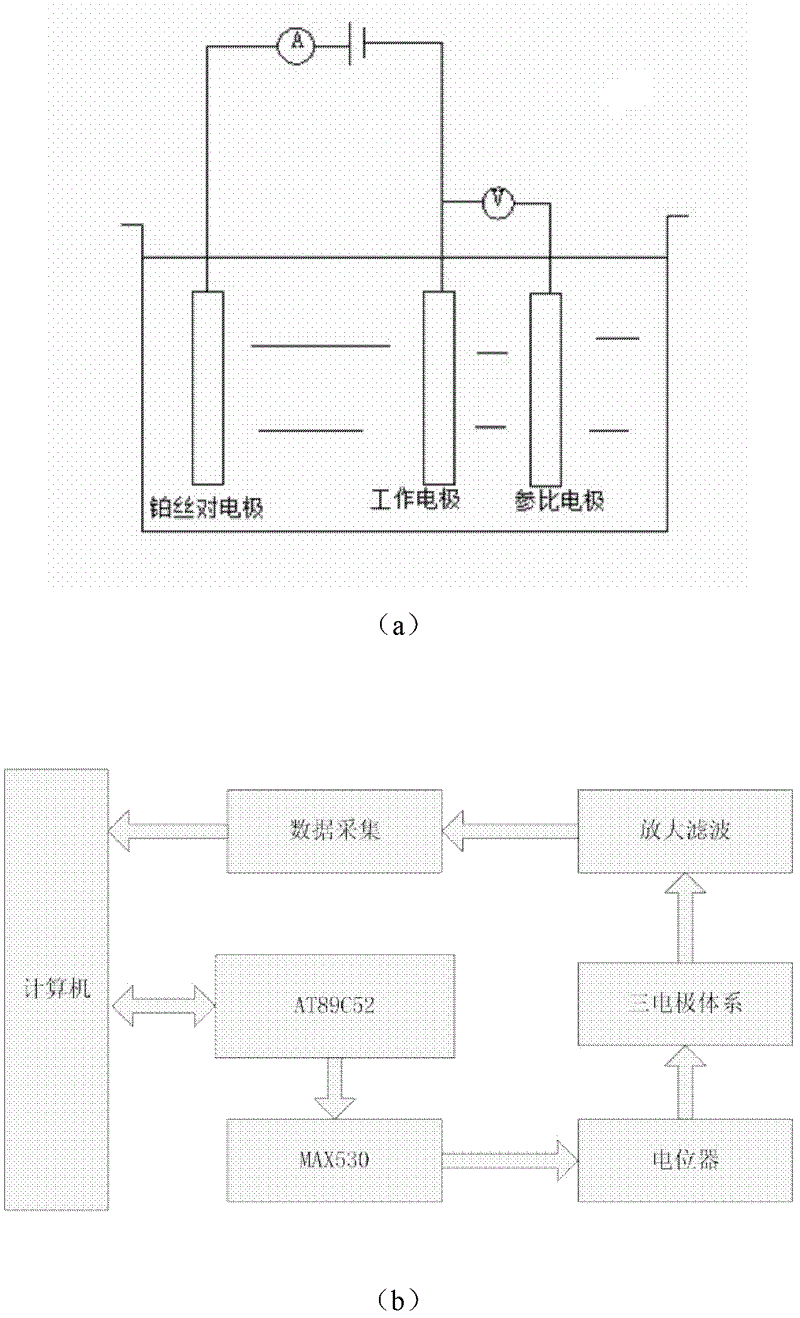

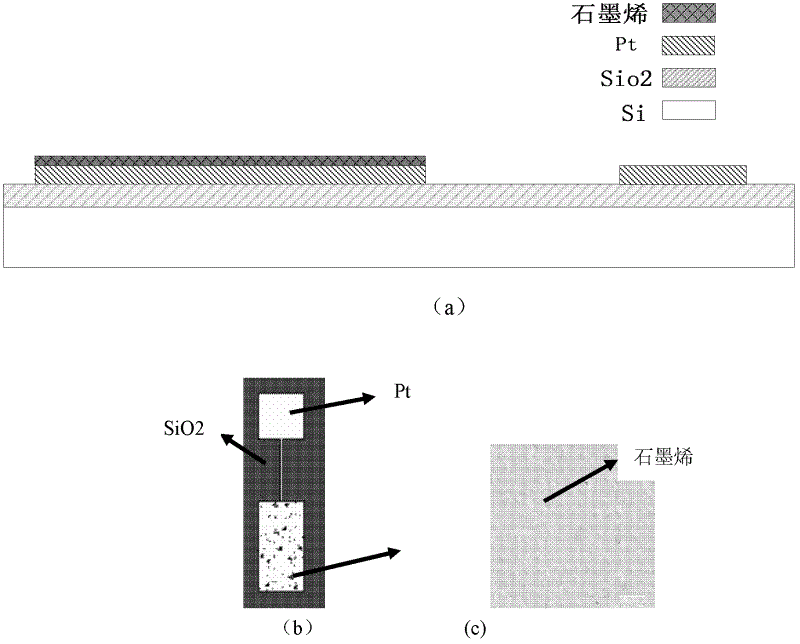

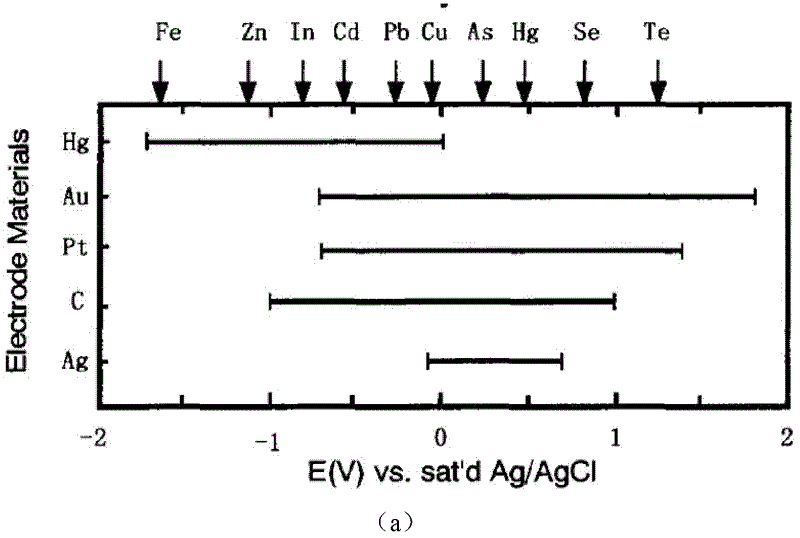

Grapheme-modified Pt electrode and method for detecting trace amount heavy metal

ActiveCN102621199ADetection speedImprove resolutionMaterial electrochemical variablesSilicon dioxidePt element

The invention relates to a grapheme-modified platinum electrode. The grapheme-modified platinum electrode is formed by oxidizing a platinum electrode on a silicon chip to generate a carbon dioxide layer for serving as a substrate, evaporating a metal platinum electrode on the carbon dioxide substrate and growing grapheme on the platinum electrode. A stripping voltammetry method is adopted, the grapheme-modified platinum electrode manufactured with an MEMS (Micro-electromechanical System) is taken as a working electrode, an Ag / AgCl electrode is taken as a reference ratio electrode, a platinum wire electrode is taken as a counter electrode, parameter selection of post-treatment, enriching time, potential setting, stripping voltammetry are performed, the heavy metal extreme value is 0.05 mg / L according to detection, and a provided G / Pt electrode has remarkably higher detection sensitivity than a naked Pt electrode.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

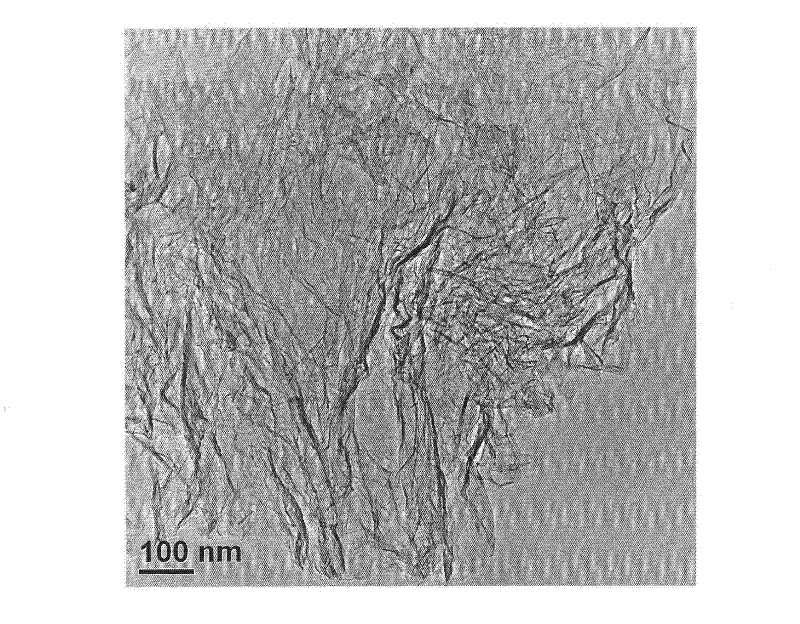

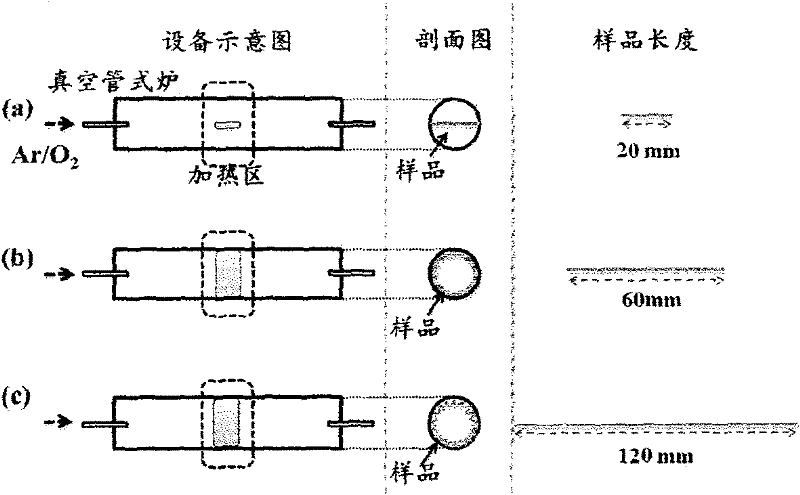

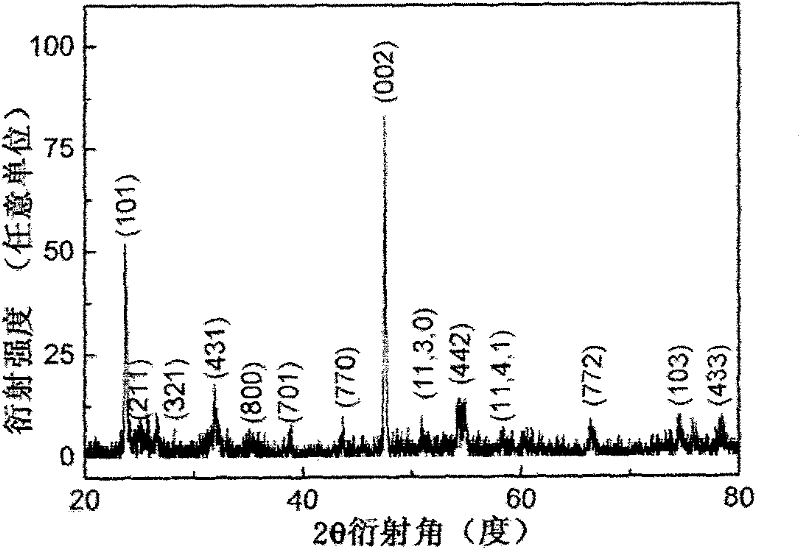

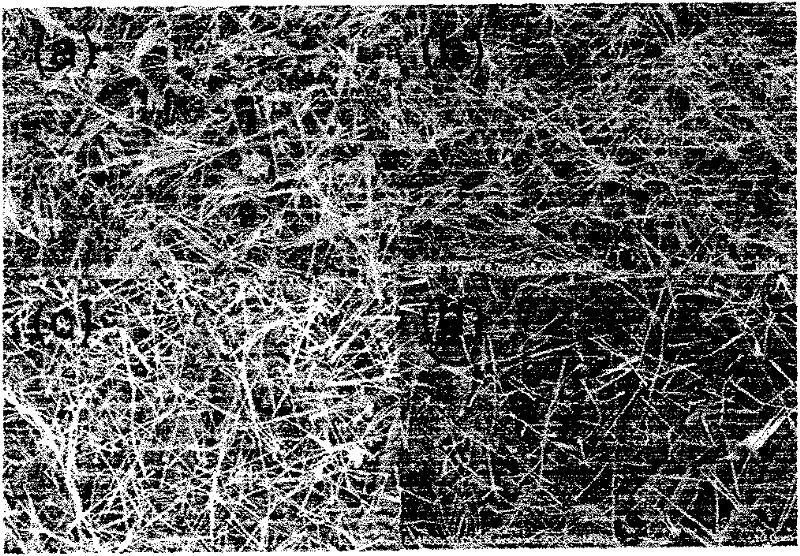

Large-scale preparation method of niobium pentoxide nanowires and hydrogen-sensitive element thereof

InactiveCN102180518AIncrease surface areaRealize large-area synthesisSolid-state devicesNanotechnologyNanowireEngineering

The invention discloses a large-scale preparation method of niobium pentoxide nanowires and a hydrogen-sensitive element thereof. The preparation method particularly comprises the following steps of: strictly cleaning Nb foils cut into suitable sizes, arranging the foils in a vacuum tube type furnace after a bending or folding treatment, and strictly controlling processing conditions (such as Ar flow rate, O2 flow rate, holding temperature, time and the like) of a thermal oxidation process to synthesize large-scale Nb2O5 nanowires with higher length diameter ratios. By adopting the large-scale preparation method disclosed by the invention, the large-scale synthesis of the Nb2O5 nanowires with the higher length diameter ratios can be realized in a limited-volume furnace tube, thus the production cost can be effectively reduced. Hydrogen-sensitive elements manufactured from Pt electrodes, prepared by sputtering Nb2O5 nanowires as sensitive materials, have the characteristics of small size, low energy consumption and the like, and represent higher response speed and higher sensitivity at the room temperature towards a hydrogen-containing atmosphere; and the size, the energy consumption and the production cost of hydrogen sensors can be hopefully reduced.

Owner:武汉正光恒远科技有限公司

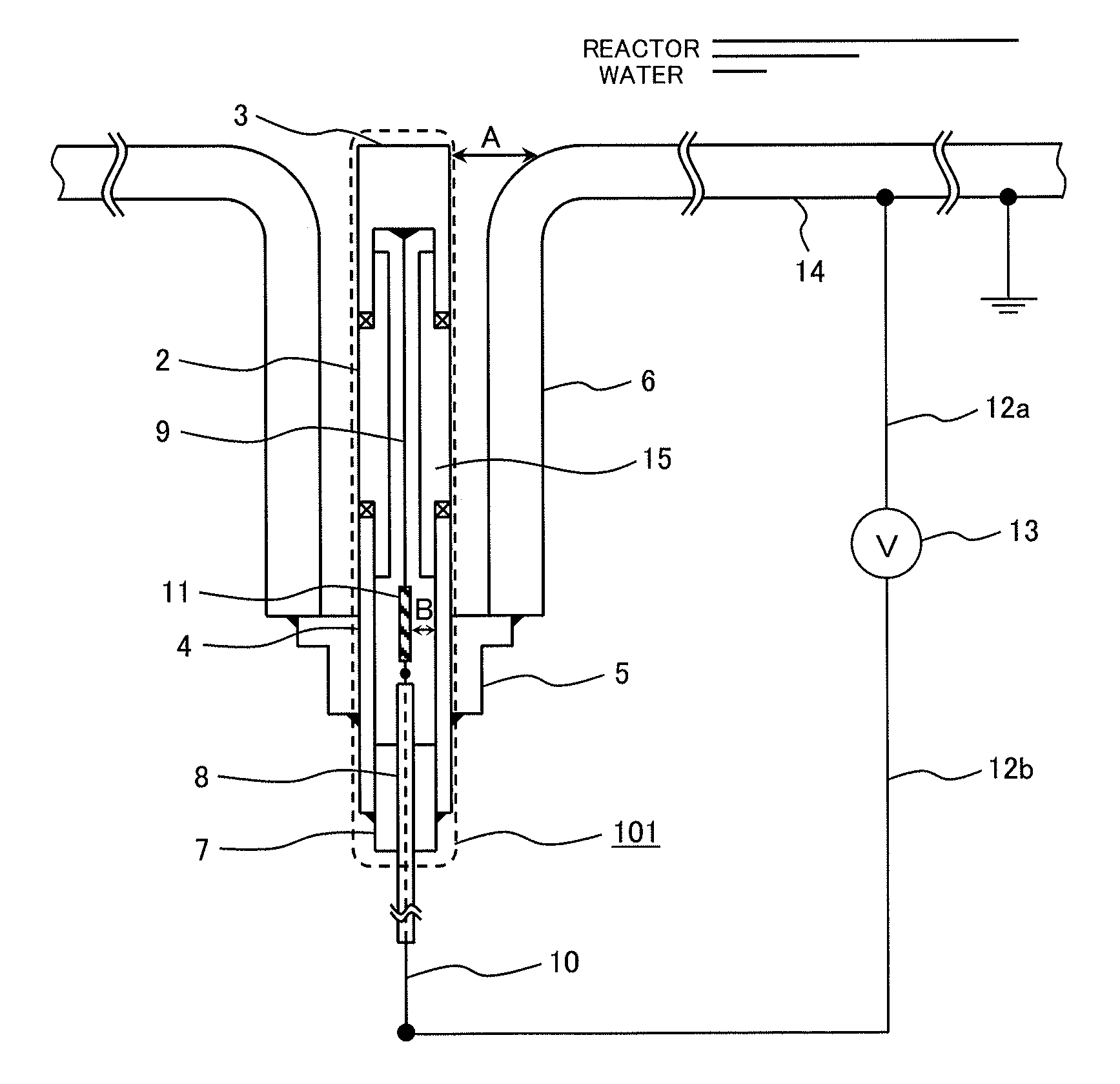

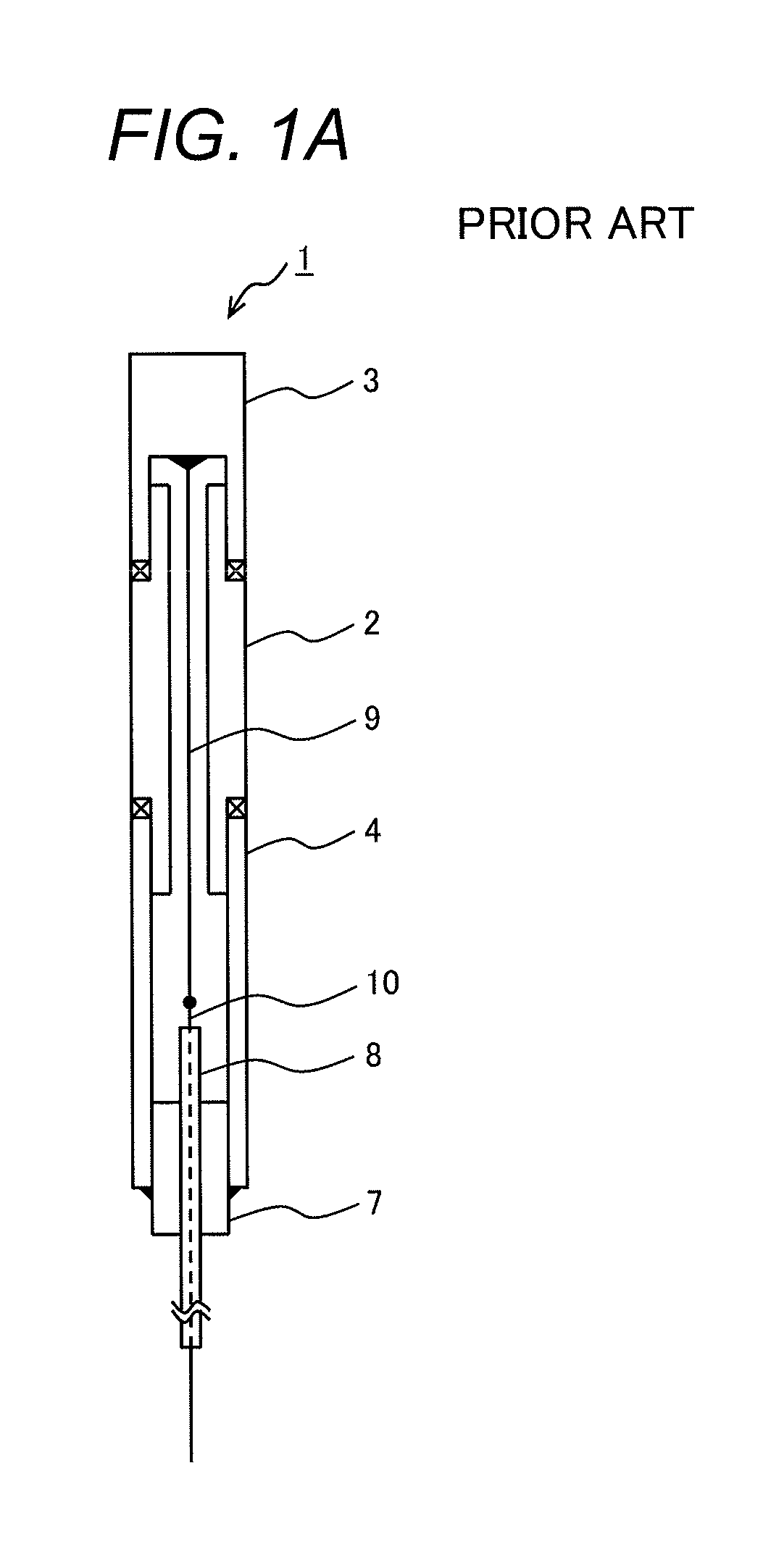

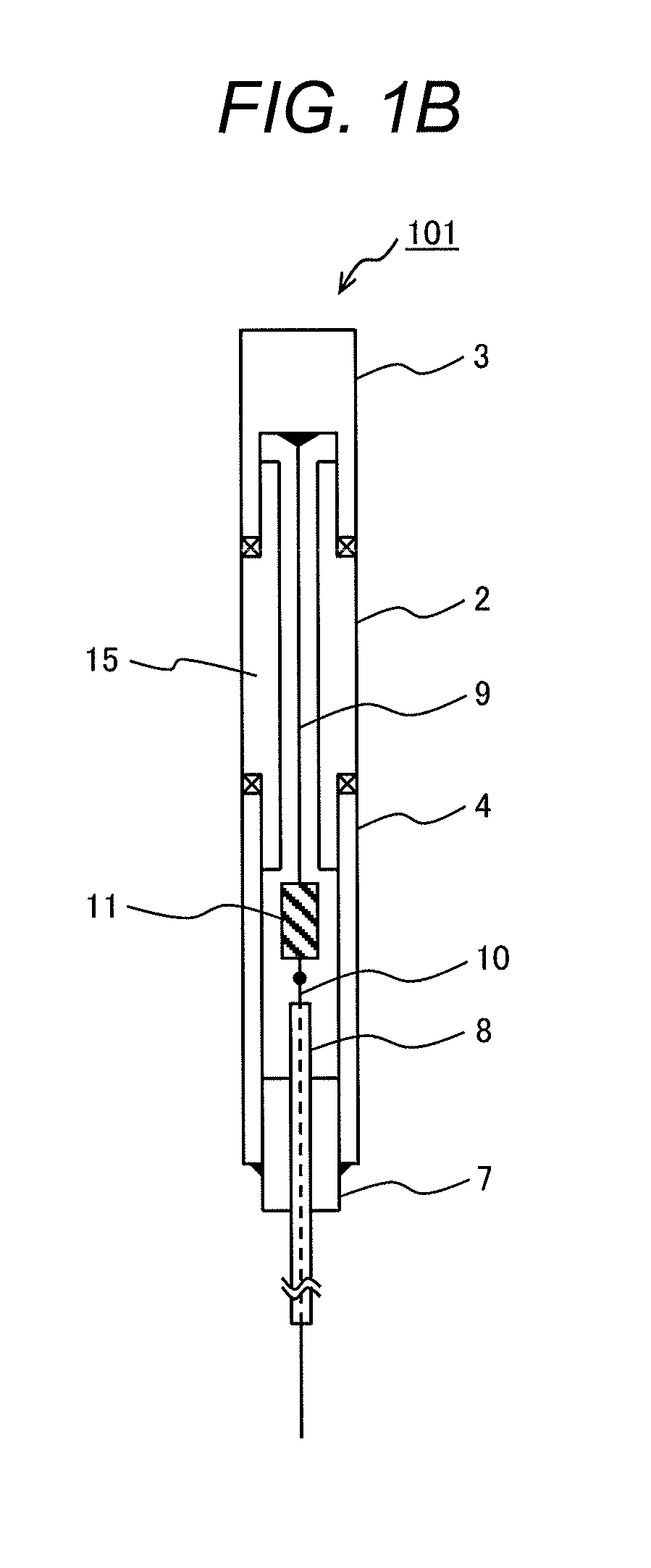

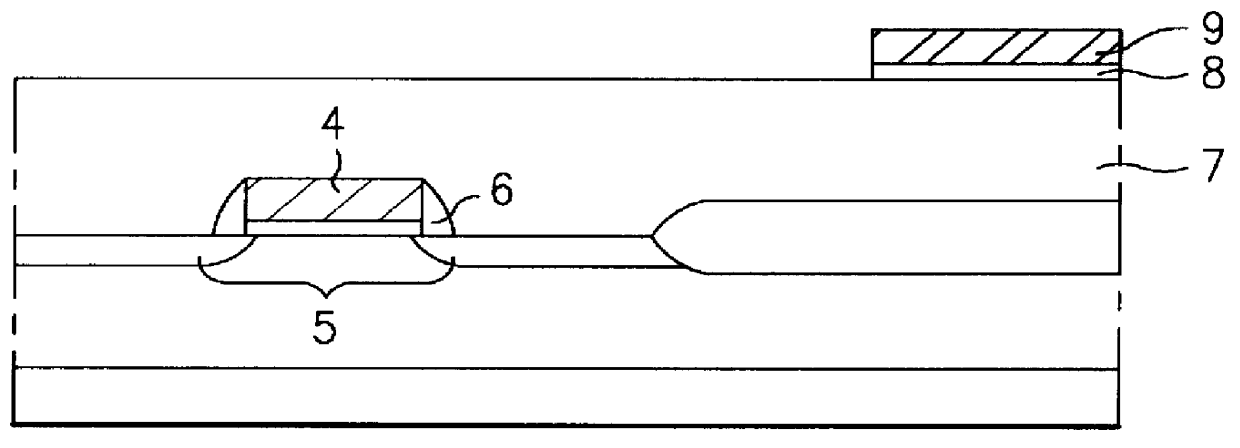

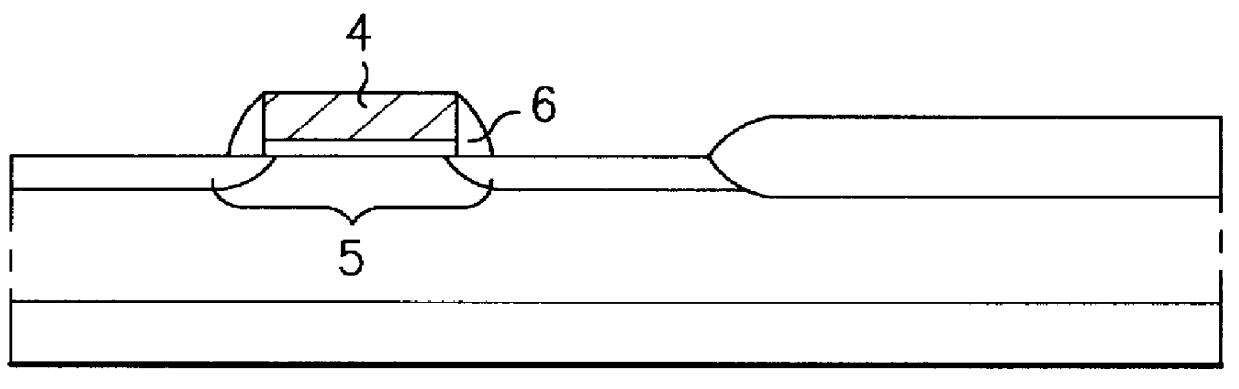

Electrochemical Corrosion Potential Sensor

InactiveUS20140069810A1Accurate measurementContinuous monitoringWeather/light/corrosion resistanceElectricityElectrochemical corrosion

An electrochemical corrosion potential sensor has a sensor unit, a lead wire and a quasi-reference electrode. A sensor unit includes a tube-shaped insulator, a tube-shaped metal casing joined to an end portion of the insulator, and a Pt electrode joined to another end portion of the insulator. A lead wire connected to the Pt electrode passes through the insulator and the metal casing. The quasi-reference electrode disposed in the metal casing is made of a less noble metal and electrically connected with the lead wire.Since an electrochemical corrosion potential sensor has the quasi-reference electrode, the measurement of the corrosion potential of a structural member of a nuclear power plant and an abnormality occurrence (water intrusion) can be accurately detected during the operation of a nuclear power plant.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

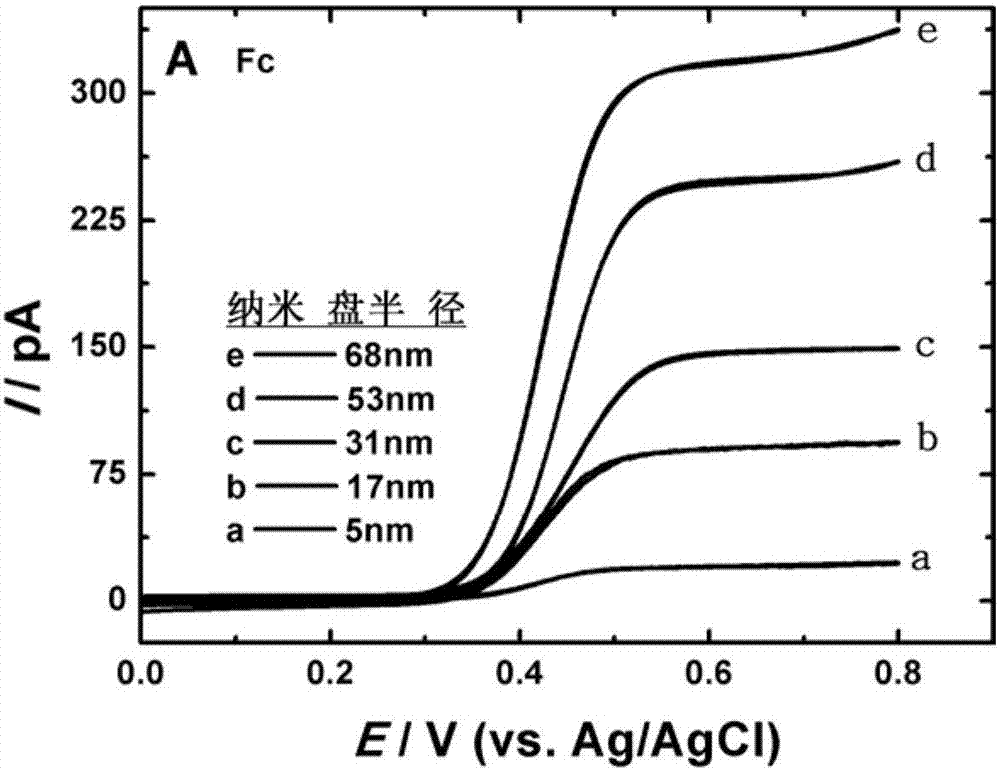

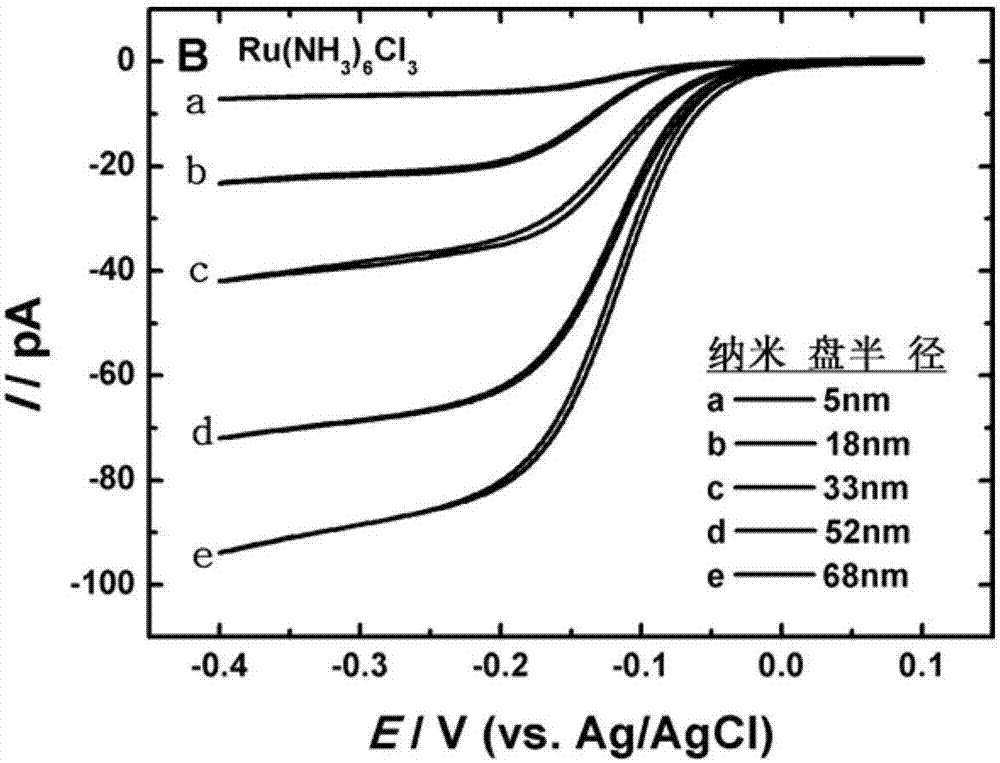

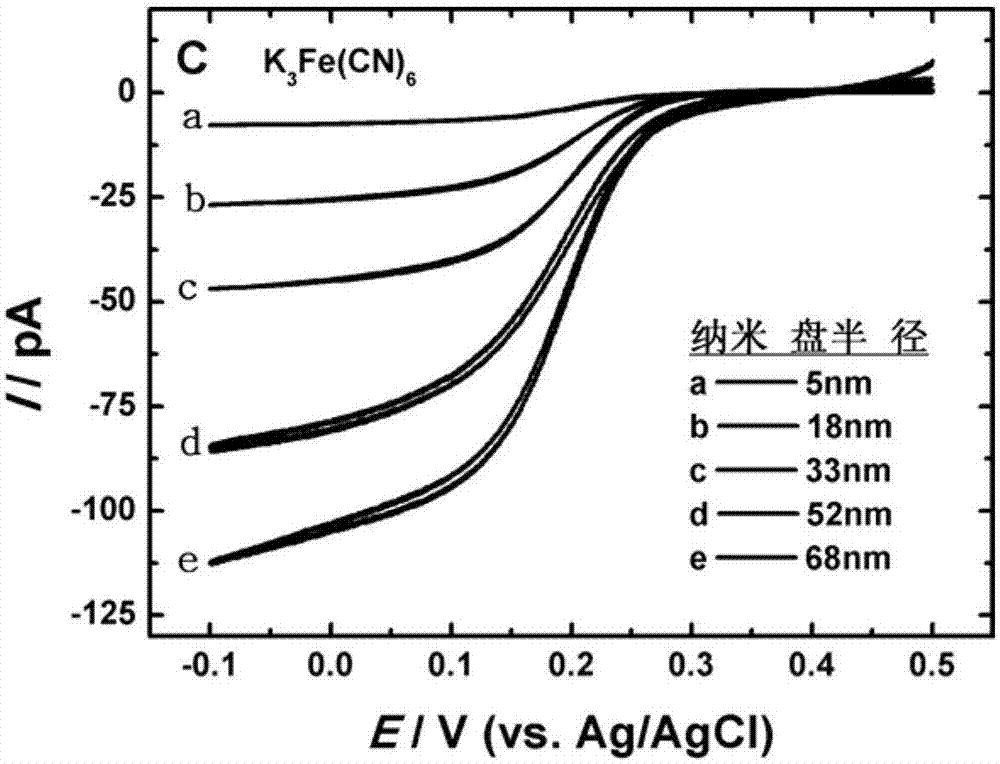

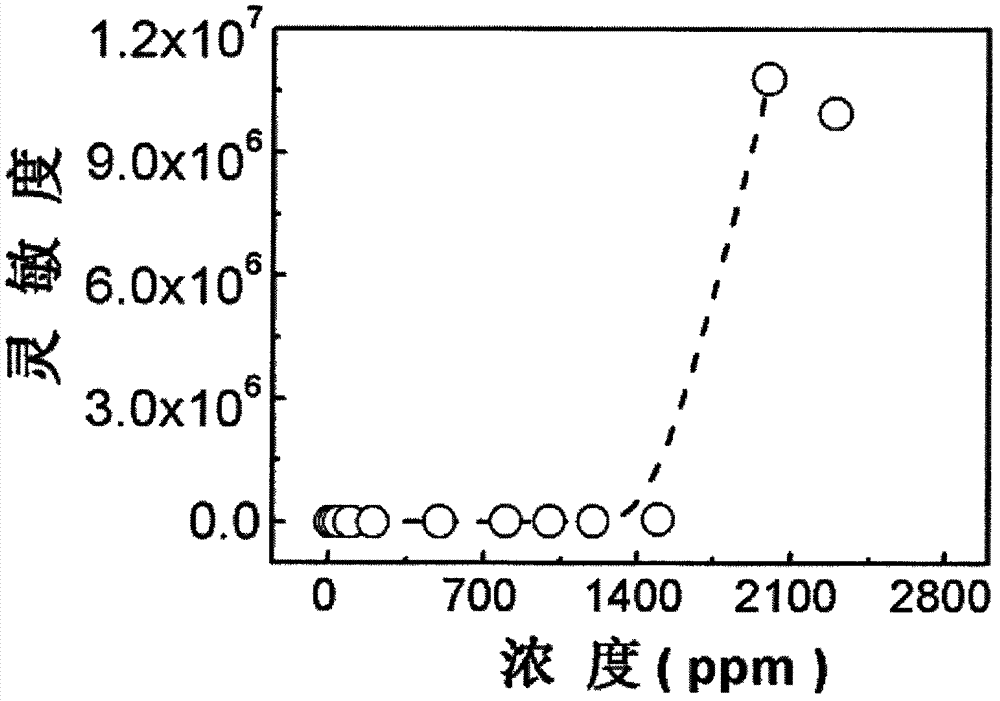

Au@Pt core-shell structure nano electrode, preparing method and application of Au@Pt core-shell structure nano electrode

InactiveCN107287596AUniform thinningExcellent electrode propertiesMaterial nanotechnologyTransportation and packagingPower flowEtching

The invention provides an Au@Pt core-shell structure nano electrode, a preparing method and application of the Au@Pt core-shell structure nano electrode. Compared with the prior art, the method for preparing a gold nano disk electrode is simple, the size can be controlled within the nano scale range, and the method can be used for preparing the gold nano disk electrode and is similarly applicable to nano disk electrodes of other metals. Meanwhile, about the technology for preparing the gold nano disk electrode, the Au@Pt core-shell structure nano electrode is obtained through etching and under potential deposition, very good electro-catalysis activity is achieved for hydrogen peroxide, the prepared Au@Pt core-shell structure nano electrode has very good response to the redox reaction for hydrogen peroxide catalysis, the current is obviously increased along with increasing of the concentration of hydrogen peroxide, and a linear relation between hydrogen peroxide concentration and current signals is constructed; and accordingly the concentration of the hydrogen peroxide solution is detected.

Owner:ANHUI NORMAL UNIV

Preparation method of dye-sensitized solar battery cobalt-nickel sulfide counter electrode

InactiveCN105719836AHigh mechanical strengthNo sheddingLight-sensitive devicesPhotovoltaic energy generationNickel saltSlurry

The invention discloses a method for preparing a cobalt-nickel sulfide counter electrode. The steps include: first step, hydrothermally reacting cobalt salt, nickel salt and excess sodium hydroxide or sodium carbonate at 120-200°C to generate hydrogen Oxycobalt nickel or basic cobalt nickel carbonate; the second step, mix the hydroxide cobalt nickel or basic cobalt nickel carbonate with a certain concentration of sulfur source aqueous solution, and heat it at 140-230 ° C; the third step is to generate the sulfur Cobalt nickel is made into a slurry and coated on a conductive substrate, and dried at room temperature. The electrode prepared by the invention does not need to be sintered under vacuum or protective atmosphere, and the preparation process is simple; the prepared cobalt-nickel sulfide counter electrode has high mechanical strength and no shedding phenomenon; Better electrocatalytic activity; Dye-sensitized solar cells assembled with cobalt-nickel sulfide electrodes obtained higher photoelectric conversion efficiency than dye-sensitized solar cells assembled with pyrolyzed Pt electrodes.

Owner:CHINA THREE GORGES UNIV

Solar cell gel electrolyte and preparation method and application thereof

InactiveCN101901692APromote migrationImprove conductivityLight-sensitive devicesSolid-state devicesSolventQuasi-solid

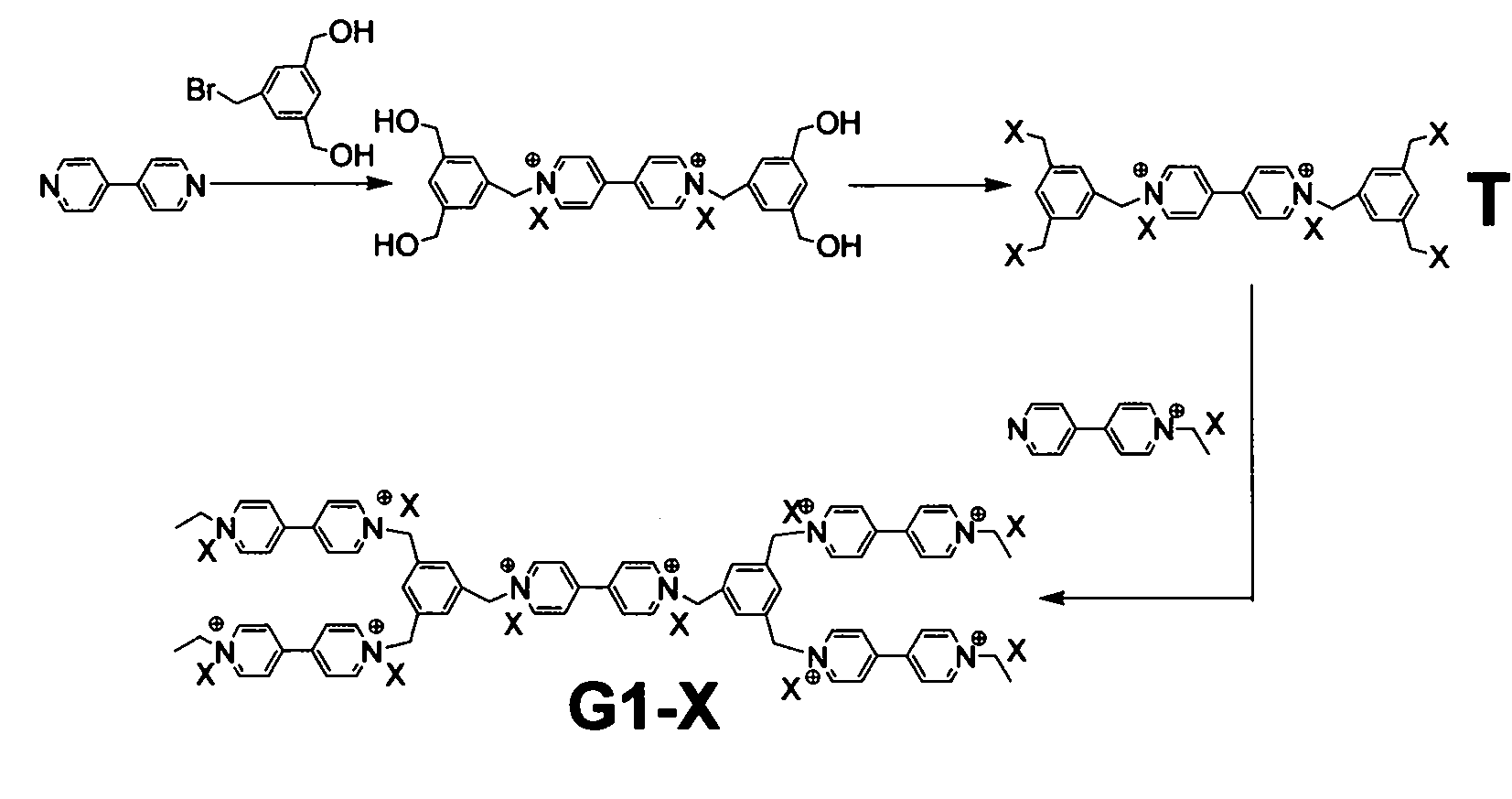

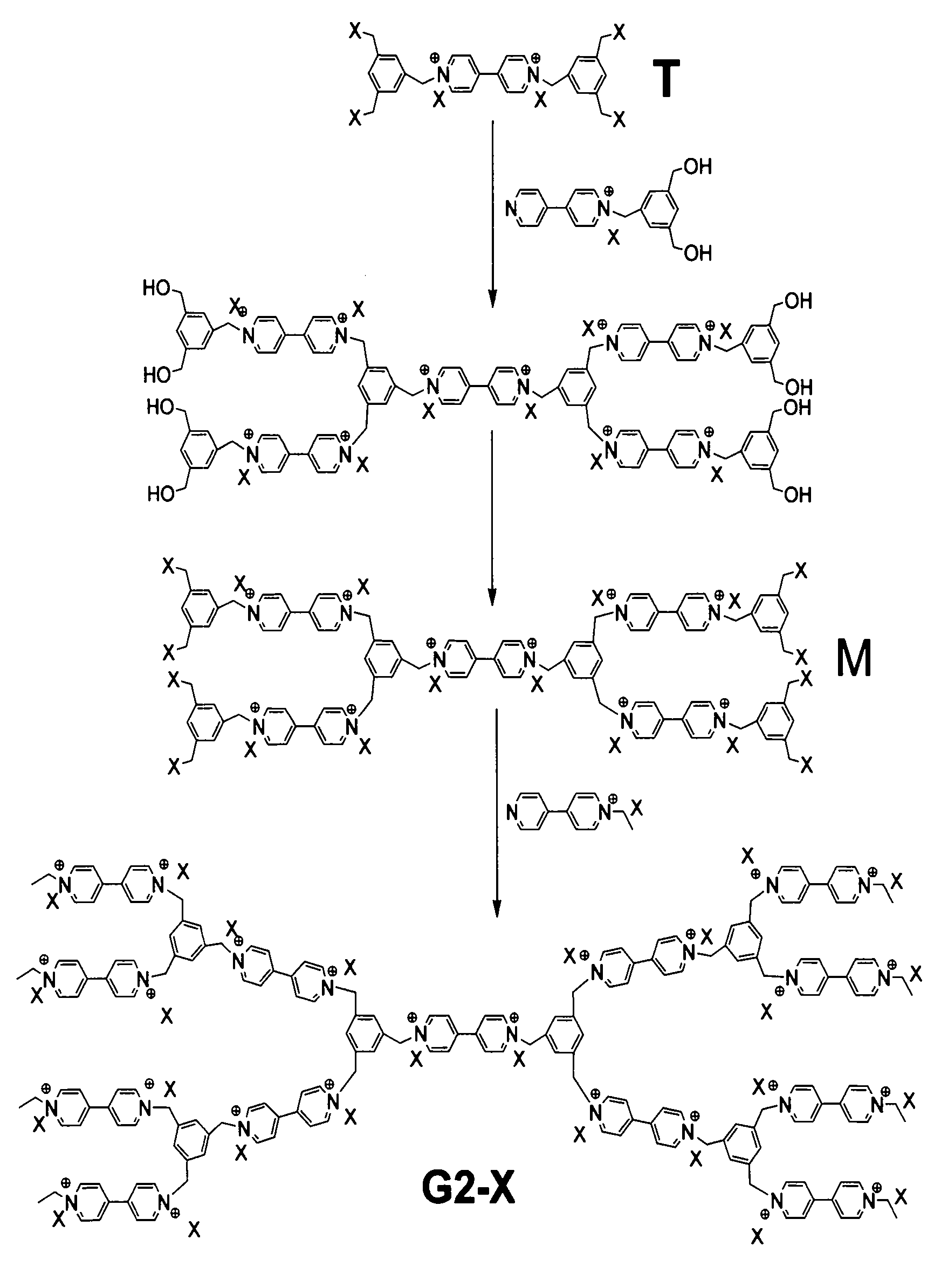

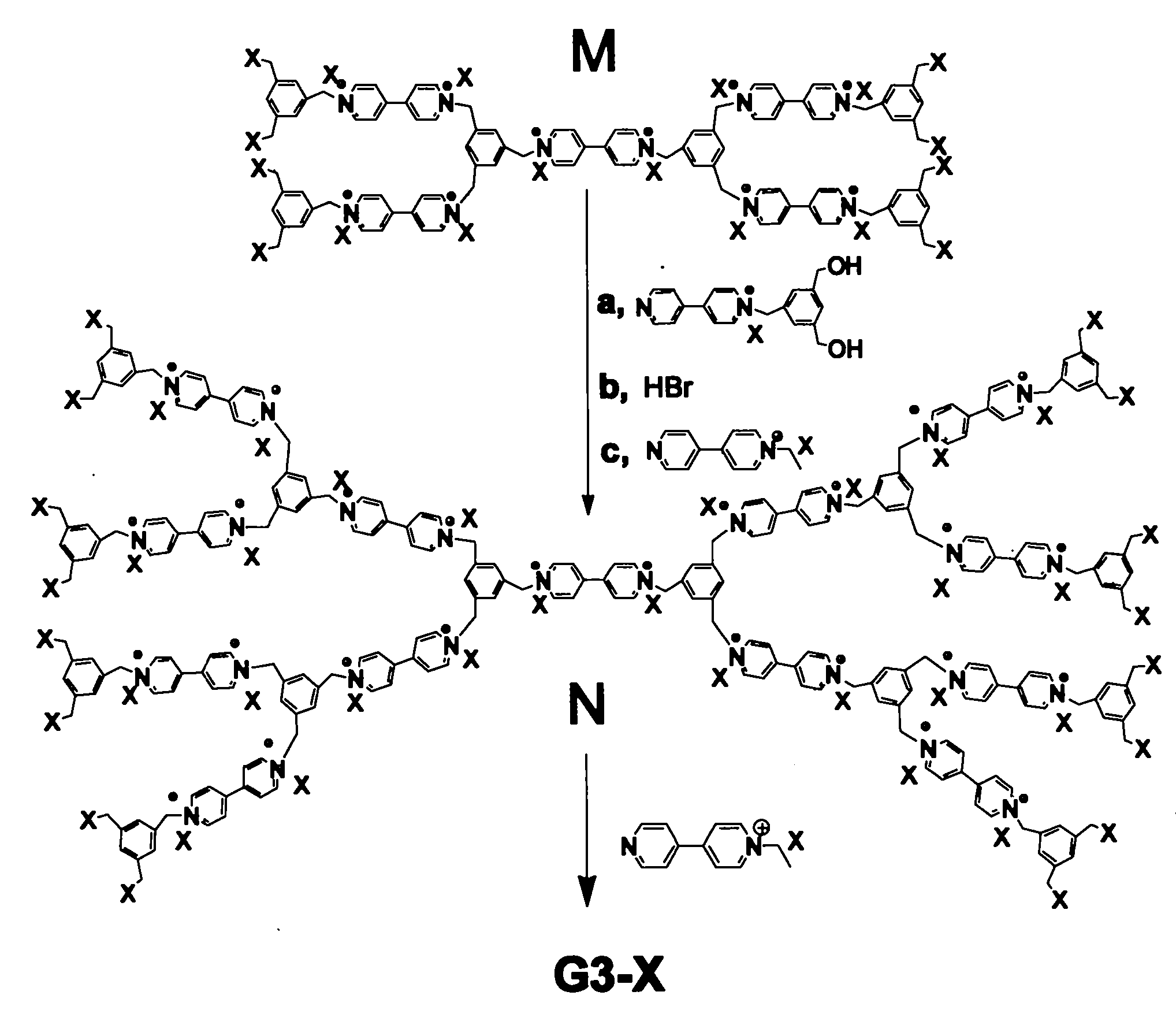

The invention discloses a solar cell gel electrolyte and a preparation method and application thereof. In the invention, the gel electrolyte is prepared by adding novel dendritic ionic liquid into liquid electrolyte of non-polymeric ionic liquid, additive and iodine monomer, hermetically stirring the mixture for 1 to 20 hours at the temperature of between 50 and 140 DEG C and uniformly dissolving the novel dendritic ionic liquid. The gel electrolyte is dropwise added or injected into the space between a photoanode dye titanium dioxide membrane and a Pt electrode while the gel electrolyte is hot; the gel electrolyte is further heated and subjected to evacuation, so that the gel electrolyte is completely impregnated into the titanium dioxide membrane serving as a porous membrane; and the components are packaged to prepare a quasi-solid fully ionic liquid gel solar cell. The gel electrolyte prepared in the invention does not comprise conventional toxic solvents and thus has the advantages of ready availability, easy package and high stability and high efficiency of the cell. The cell has a few assembly processes and low cost. When a xenon lamp is utilized to simulate the sunshine at the room temperature environment, the measured maximum photoelectric conversion efficiency of the cell is 6.0 percent under the condition that the light intensity is 100mW / cm<2>.

Owner:SUZHOU UNIV

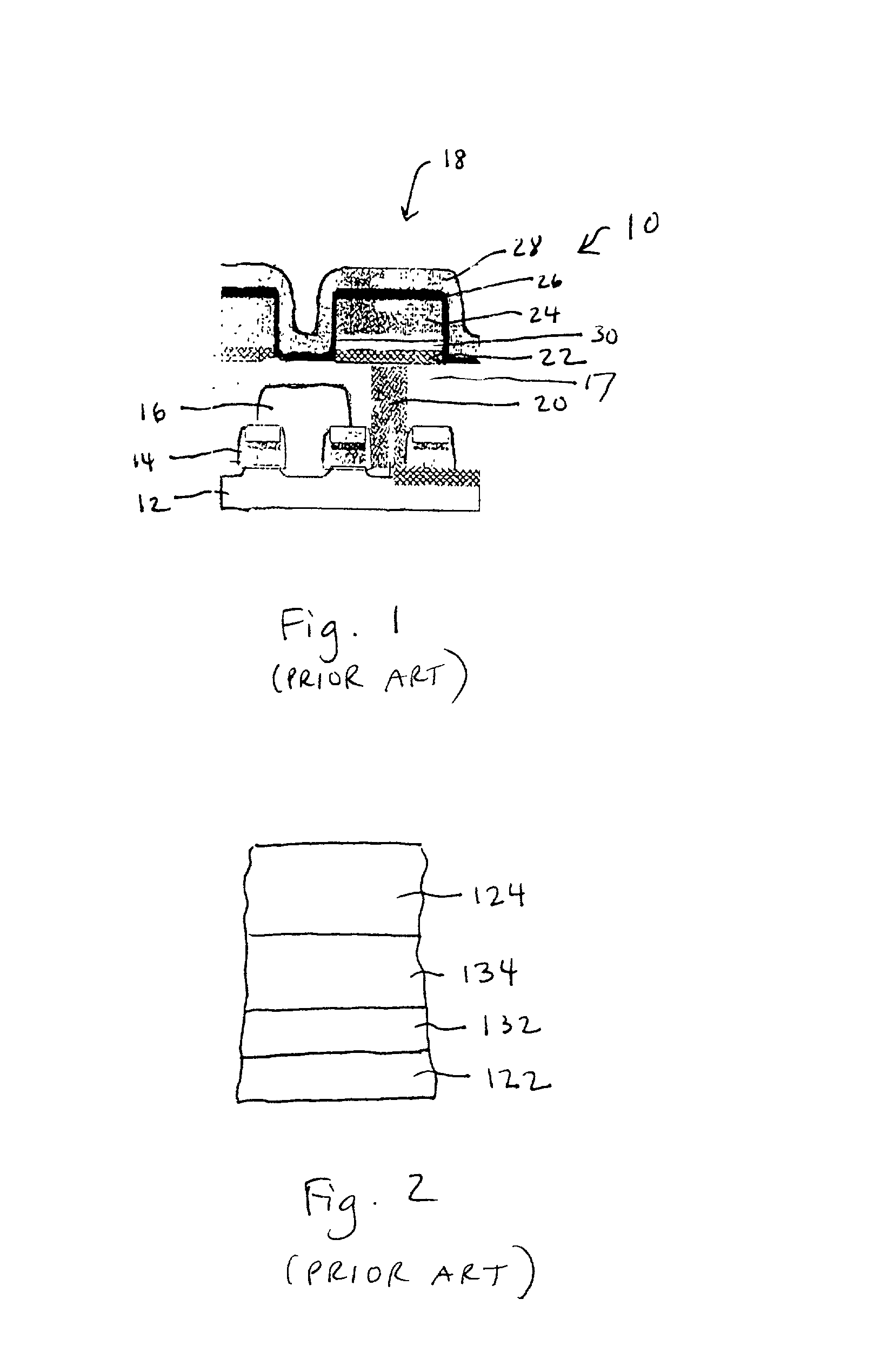

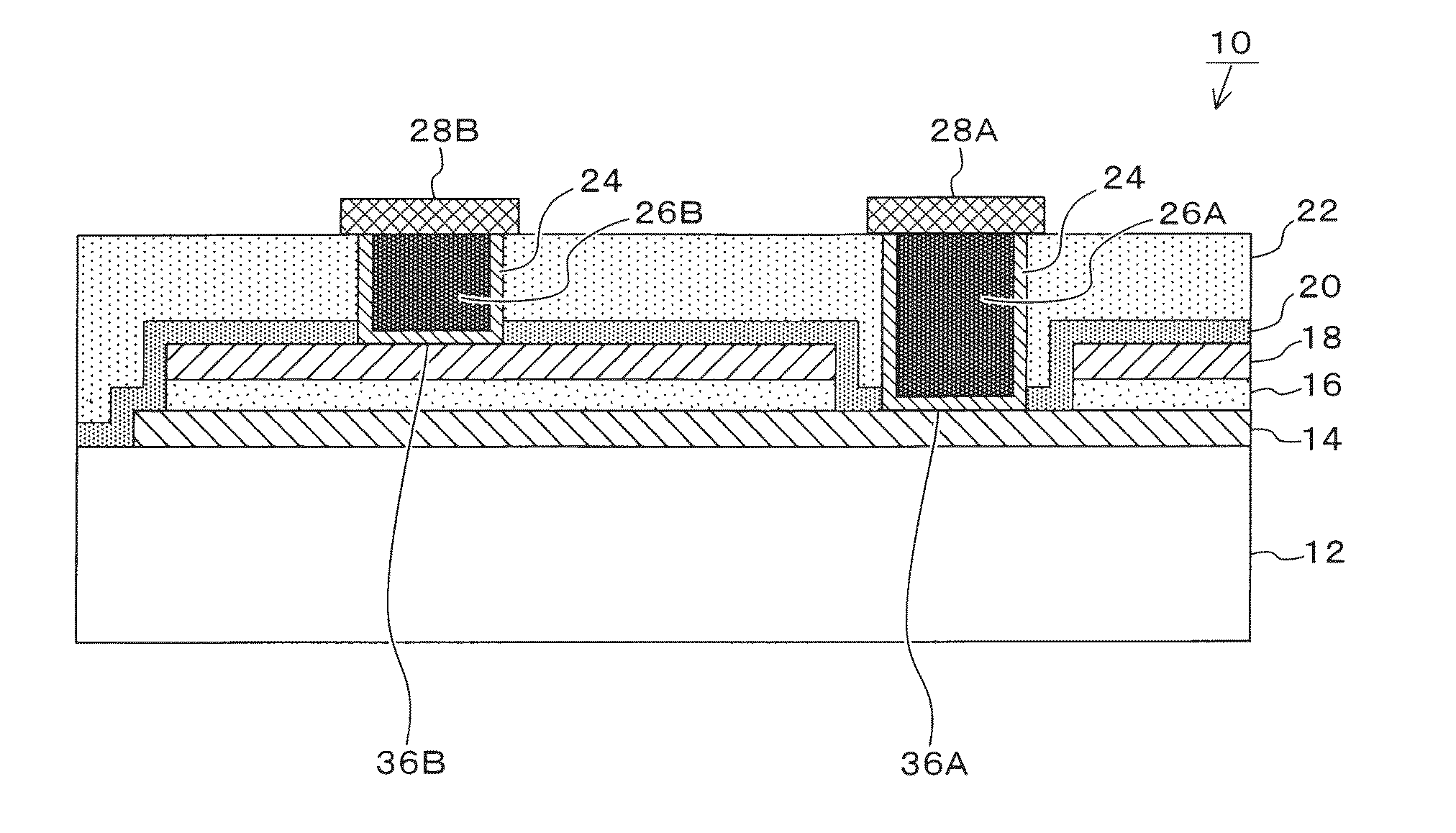

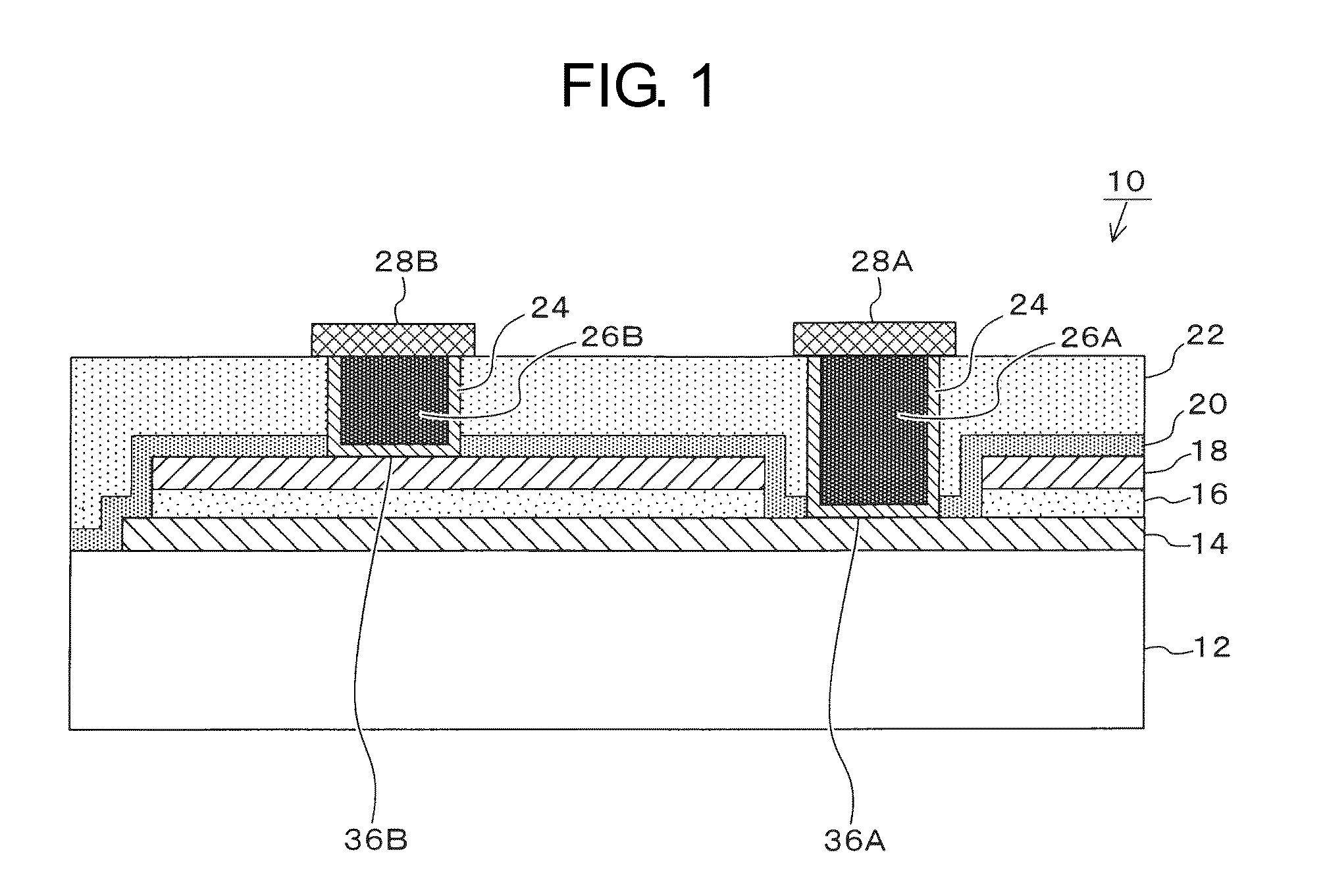

Semiconductor memory device and method for fabricating the same

A semiconductor memory device and method of fabricating the same, which improves adhesion of the lower electrode of a ferroelectric planar capacitor, and prevents inter-diffusion between the Pt electrode of the capacitor and adhesion layer placed under the Pt electrode. The semiconductor memory device includes an insulating layer formed on a substrate, a paraelectric layer formed on the insulating layer, and a conductive layer formed on the paraelectric layer.

Owner:LG SEMICON CO LTD

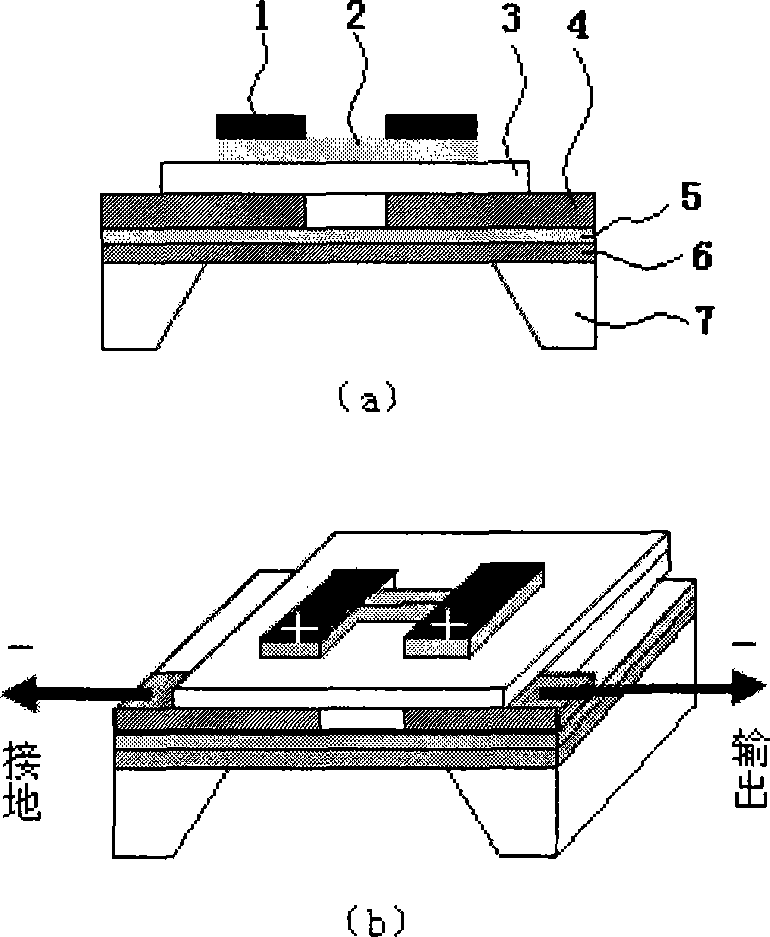

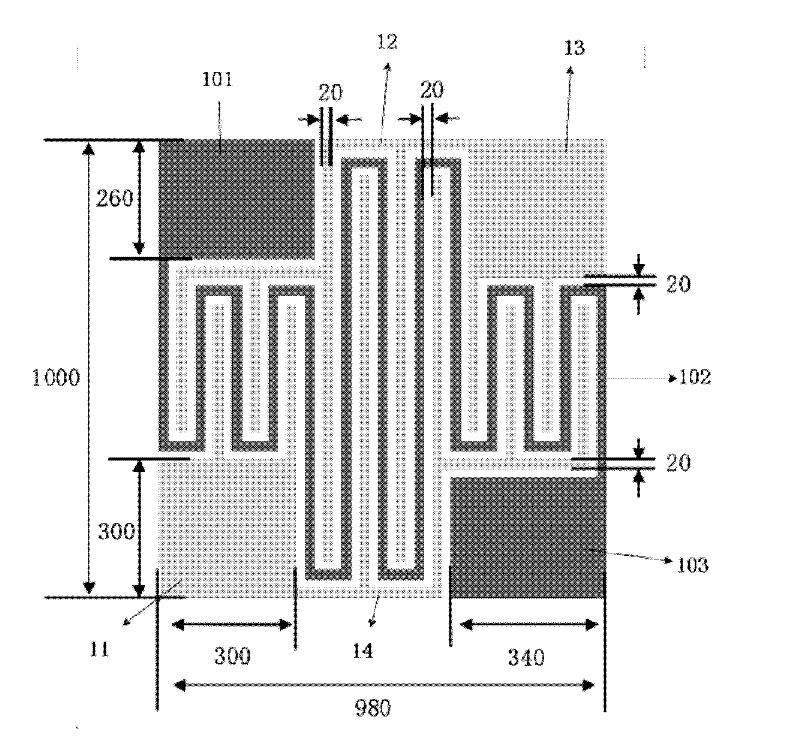

Silicon-based coplanar micro-gas sensor chip and its application in micro-gas sensor preparation

InactiveCN102358612ASimple preparation stepsReduce manufacturing costDecorative surface effectsMaterial analysis by electric/magnetic meansMicro nanoCrystal orientation

Owner:JILIN UNIV

Measurements of Redox Potential and Concentration of Redox Active Substances

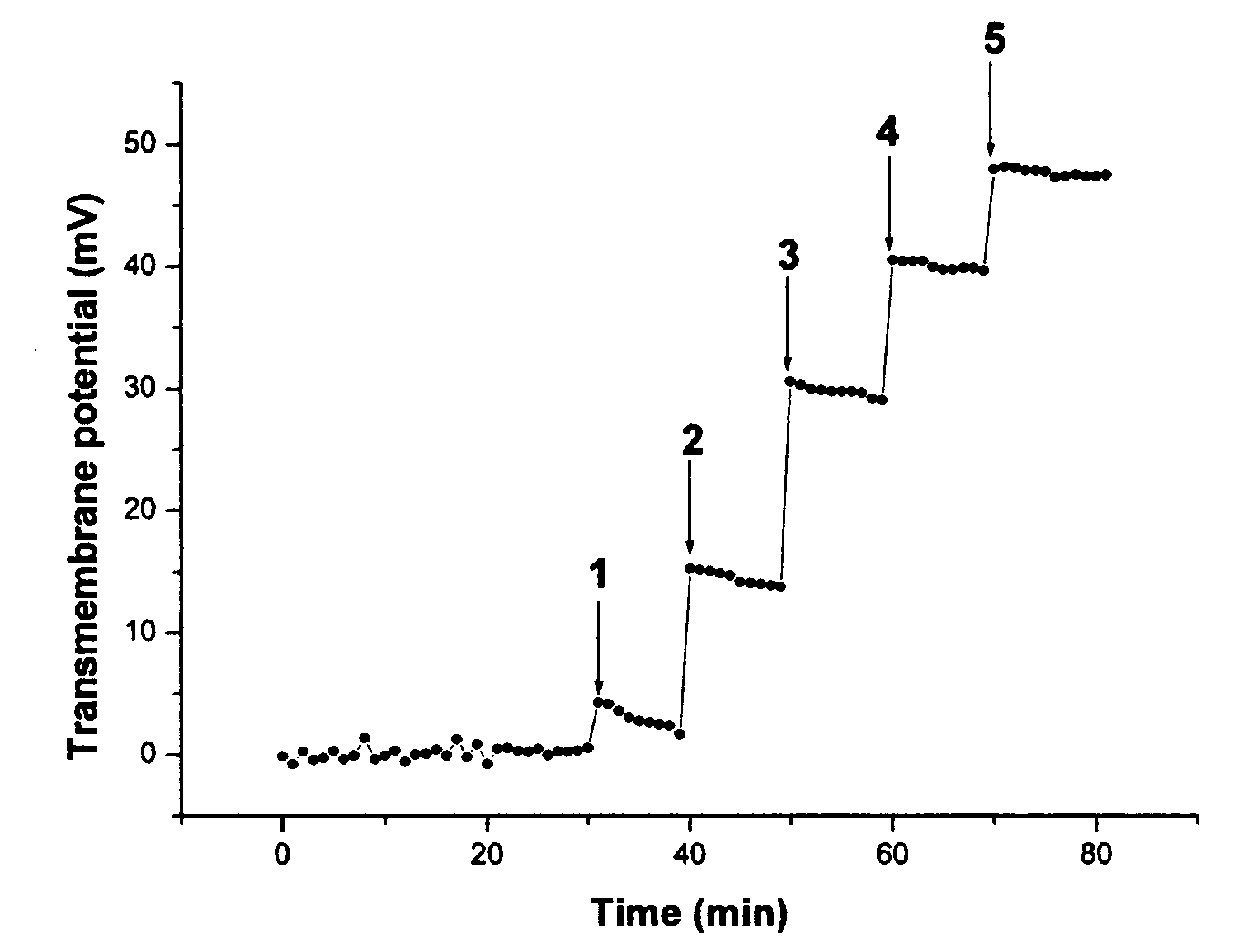

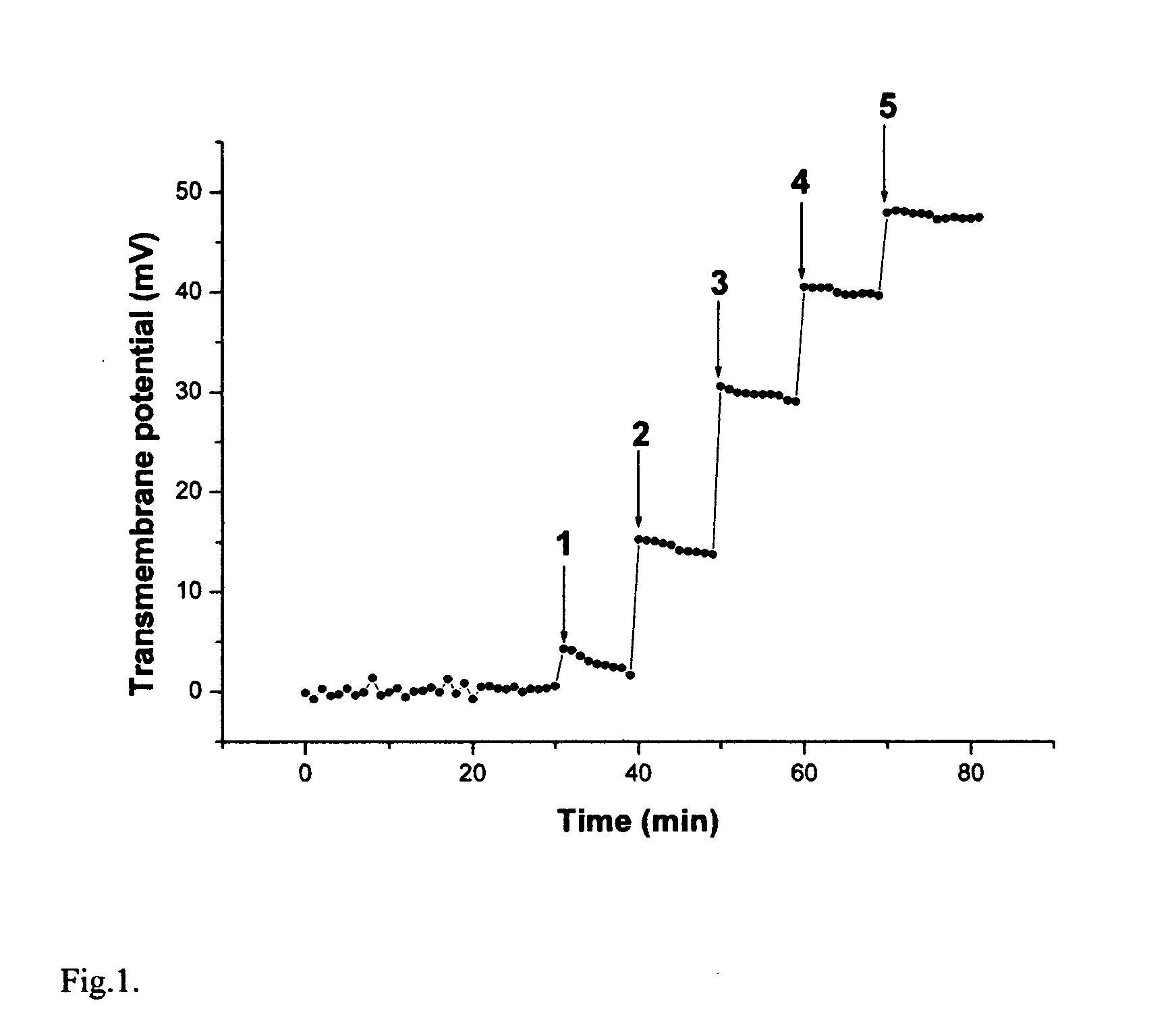

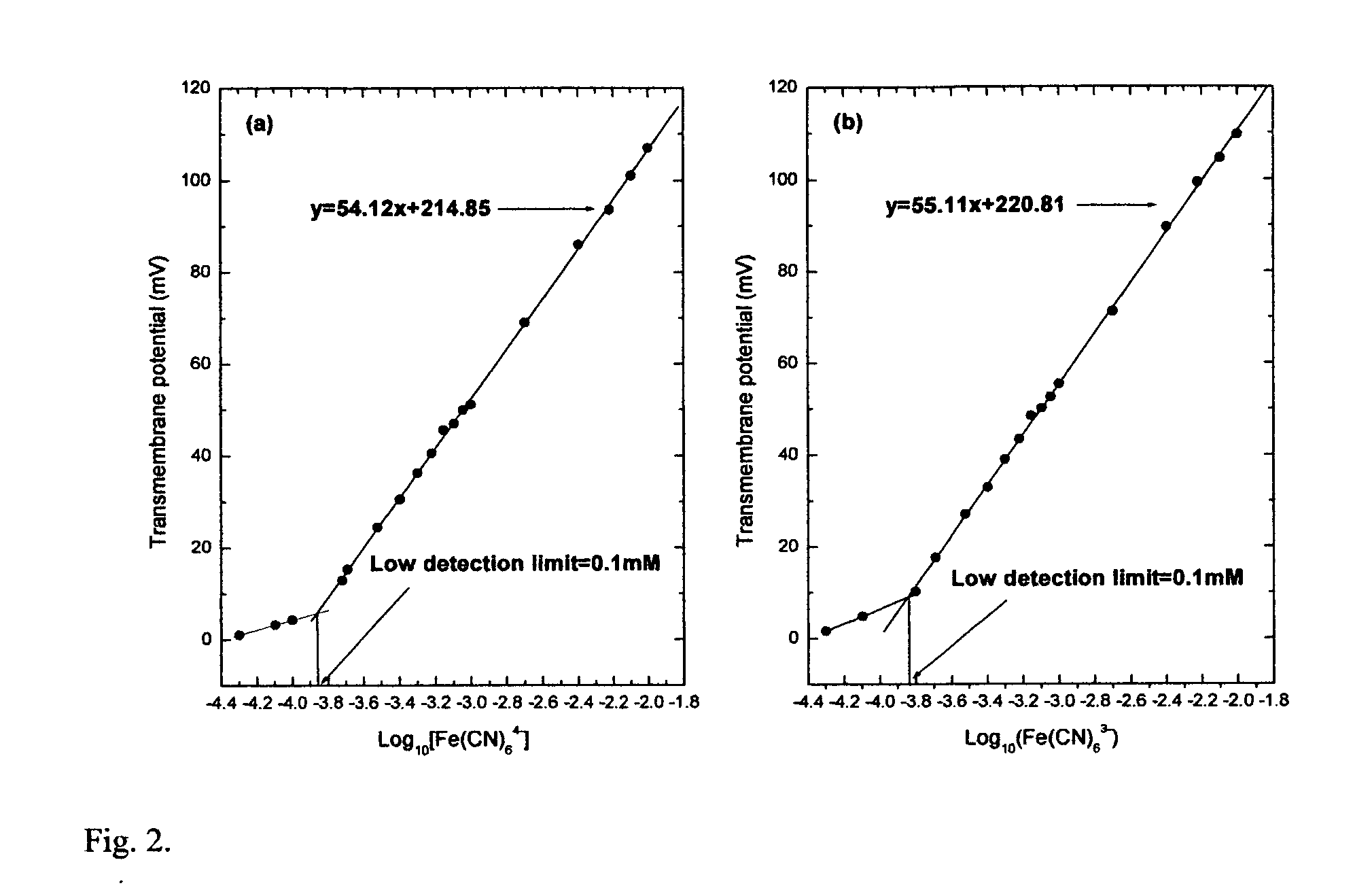

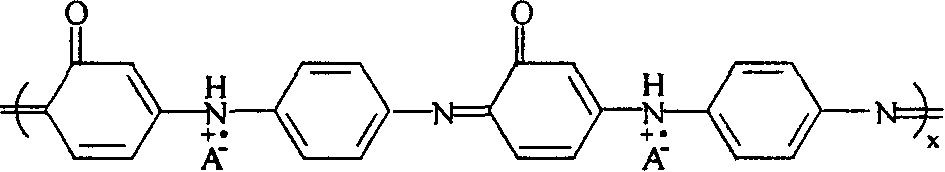

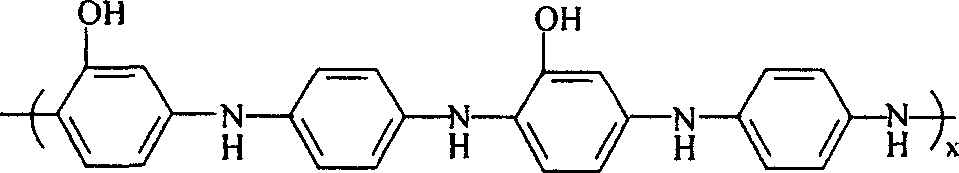

InactiveUS20100033160A1Limit of sensitivityGood Nernstian responseCurrent/voltage measurementMaterial analysis by electric/magnetic meansN-phenylanthranilic acidConductive polymer

A method to measure redox potentials and concentrations of redox active substances in an aqueous solution is described. The method is based on measurements of transmembrane electric potential through an electroconductive polymer membrane, for example, through a d,l-camphor sulfonic acid (CSA) doped polyaniline (PANI) membrane. Transmembrane electric potential demonstrates good Nernstian response as a function of redox potential in solutions,of the redox couples of Fe2+ / Fe3+ and Fe(CN)64− / Fe(CN)63−. The membrane gives good response to redox active substances such as L-Ascorbic acid and redox active dyes Neutral red, Nile blue and N-phenylanthranilic acid that do not induce satisfactory response on Pt electrode. The lower detection limits can be as low as 0.2 mM. In the absence of redox processes it is also possible to measure Cl− concentration at least from 0.05 mM to 100 mM.

Owner:KOCHERGINSKY NIKOLAI

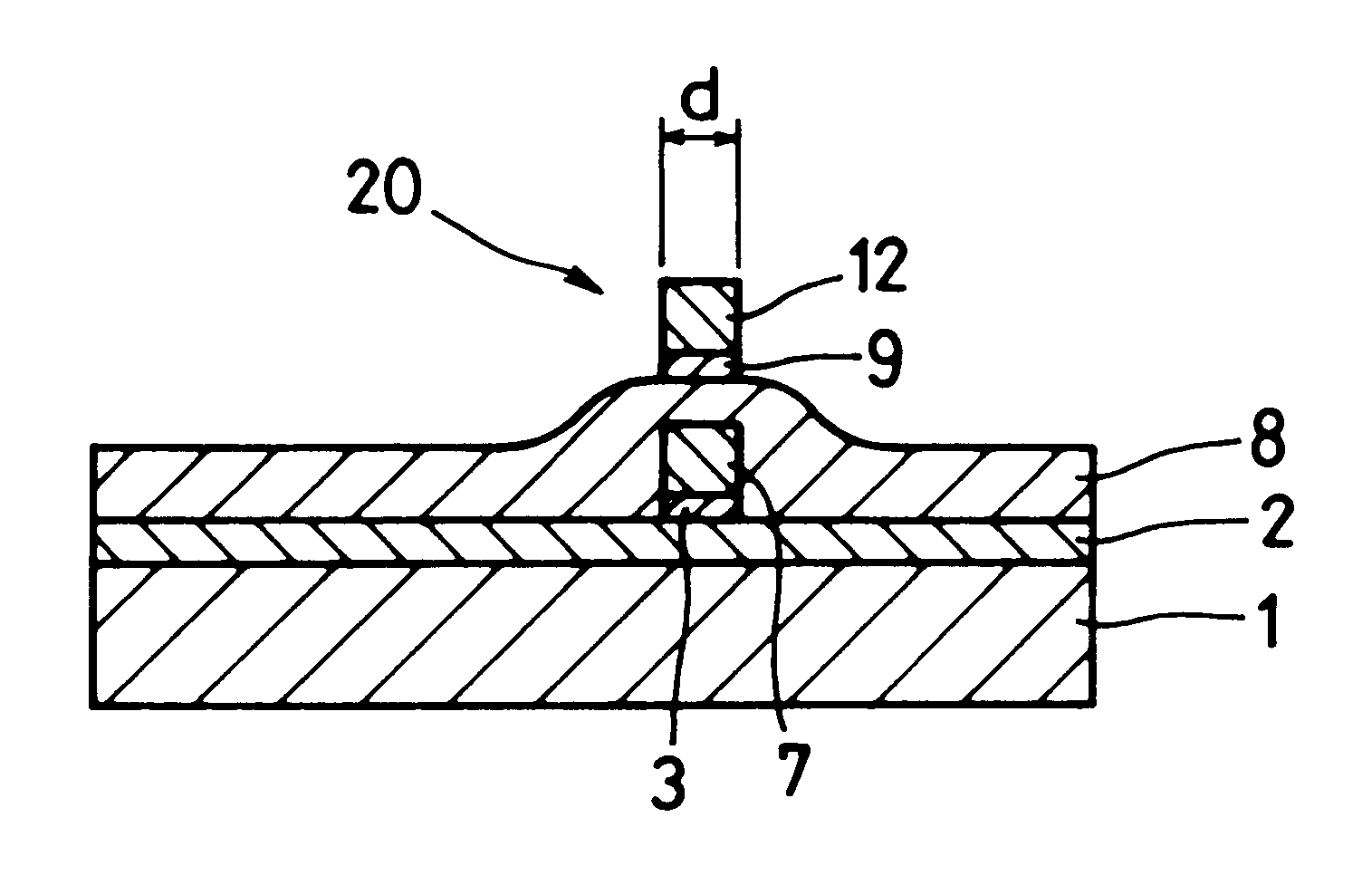

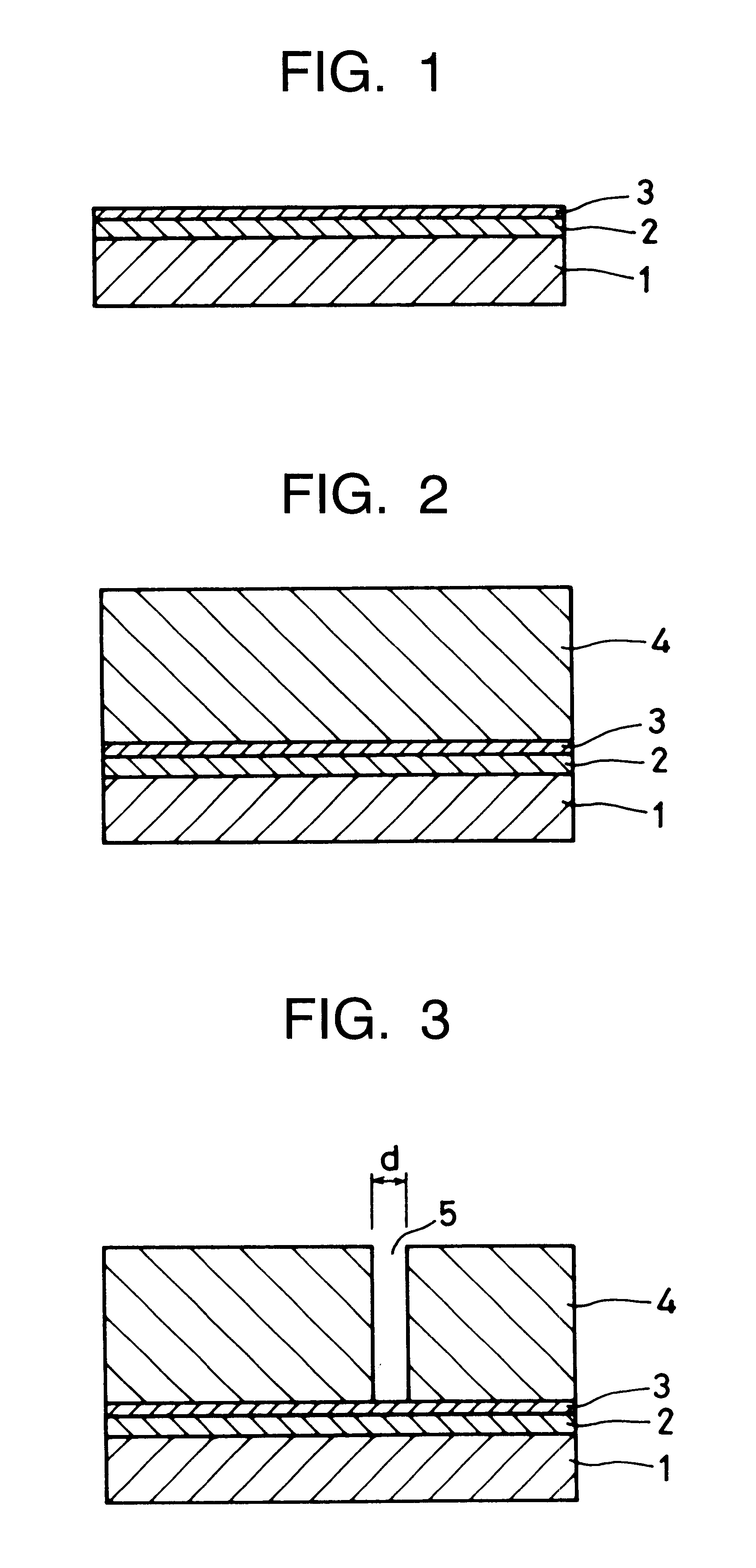

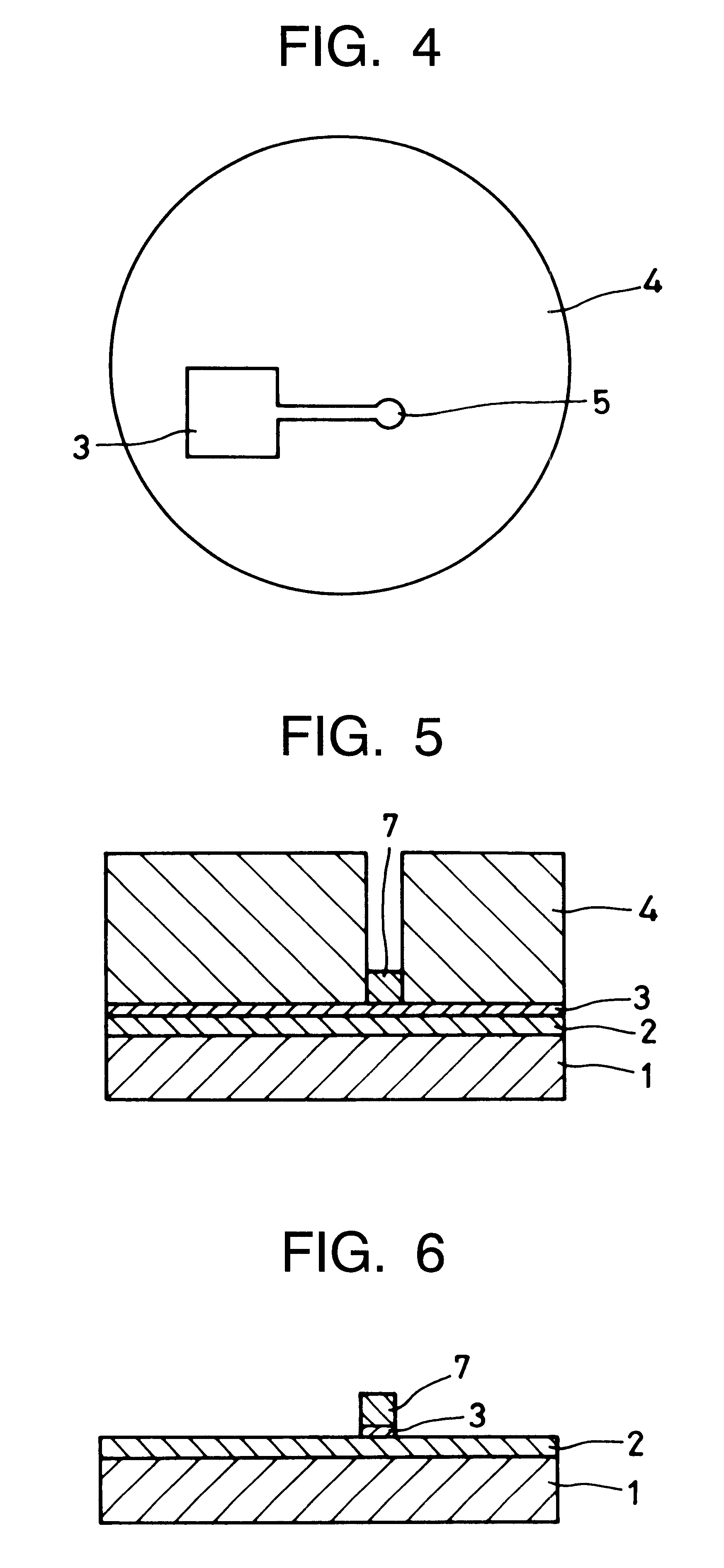

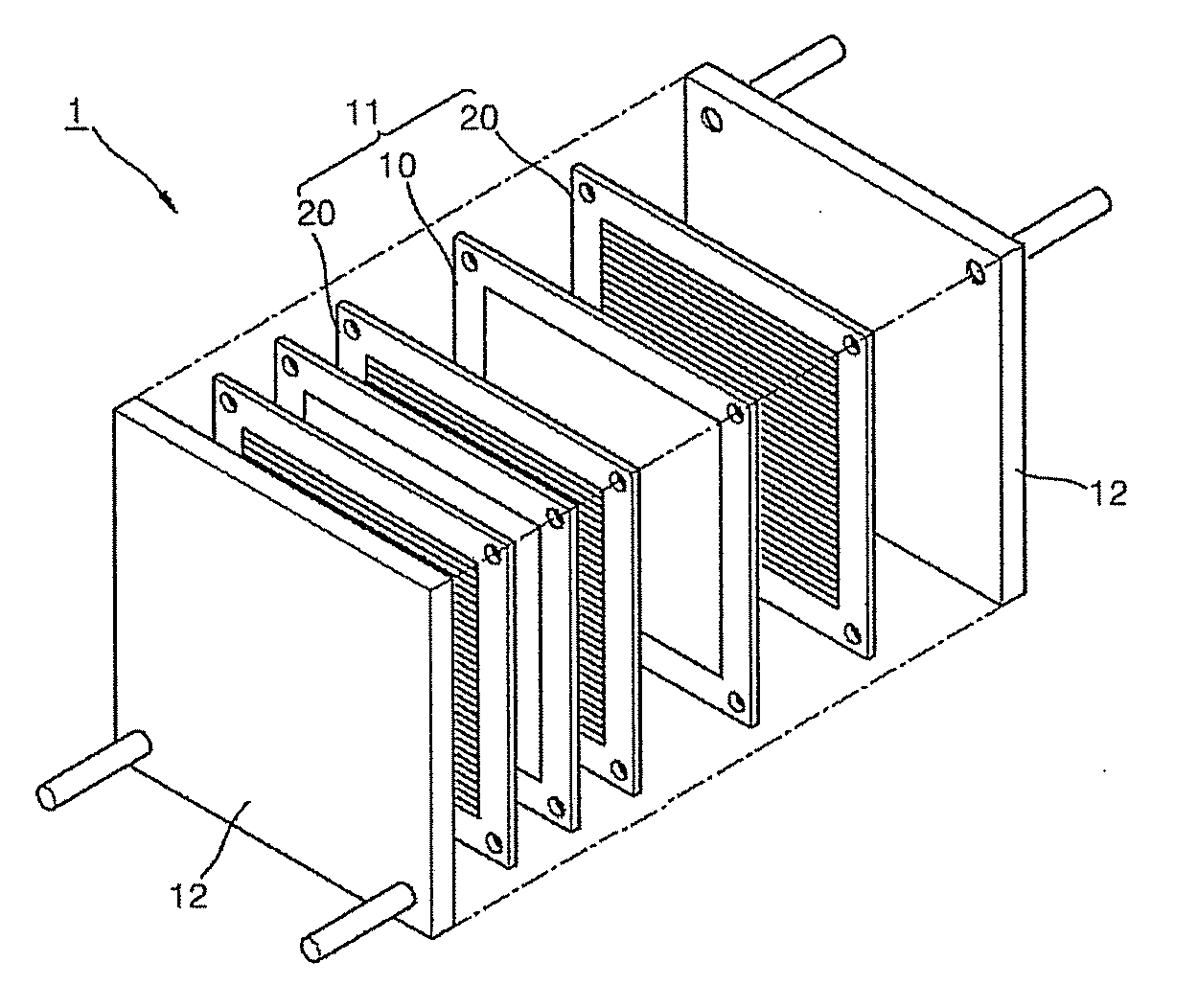

Dielectric element and method for fabricating the same

It is disclosed a dielectric element comprising a lower electrode, a dielectric layer, and an upper electrode which are provided on a substrate, in which at least one of the electrodes is a Pt layer, a Ru layer is used as a base layer for the Pt layer. In the fabrication of the dielectric element, the Pt layer is formed by electroplating, a photoresist pattern is used as a plating mask, and an Ru layer is formed as a seed layer. The present invention makes it possible to provide a dielectric element using Pt as an electrode material, that is capable of easily forming a Pt electrode having excellent electrical characteristics without generating voids or seams, that is capable of forming a fine pattern, and that does not occur contamination in a processing chamber, and a method for fabricating a dielectric element of having the characteristics mentioned above.

Owner:TOKYO OHKA KOGYO CO LTD

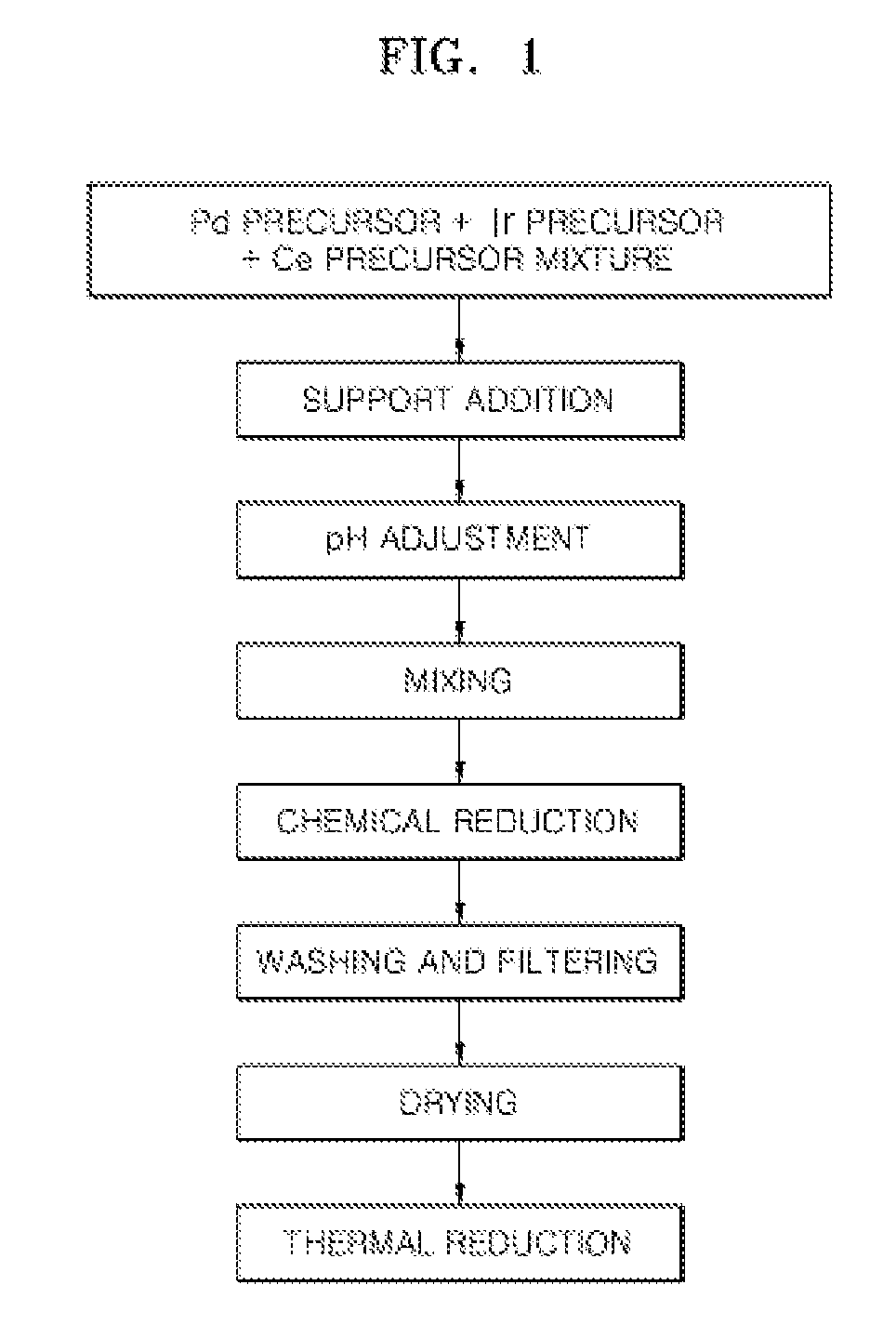

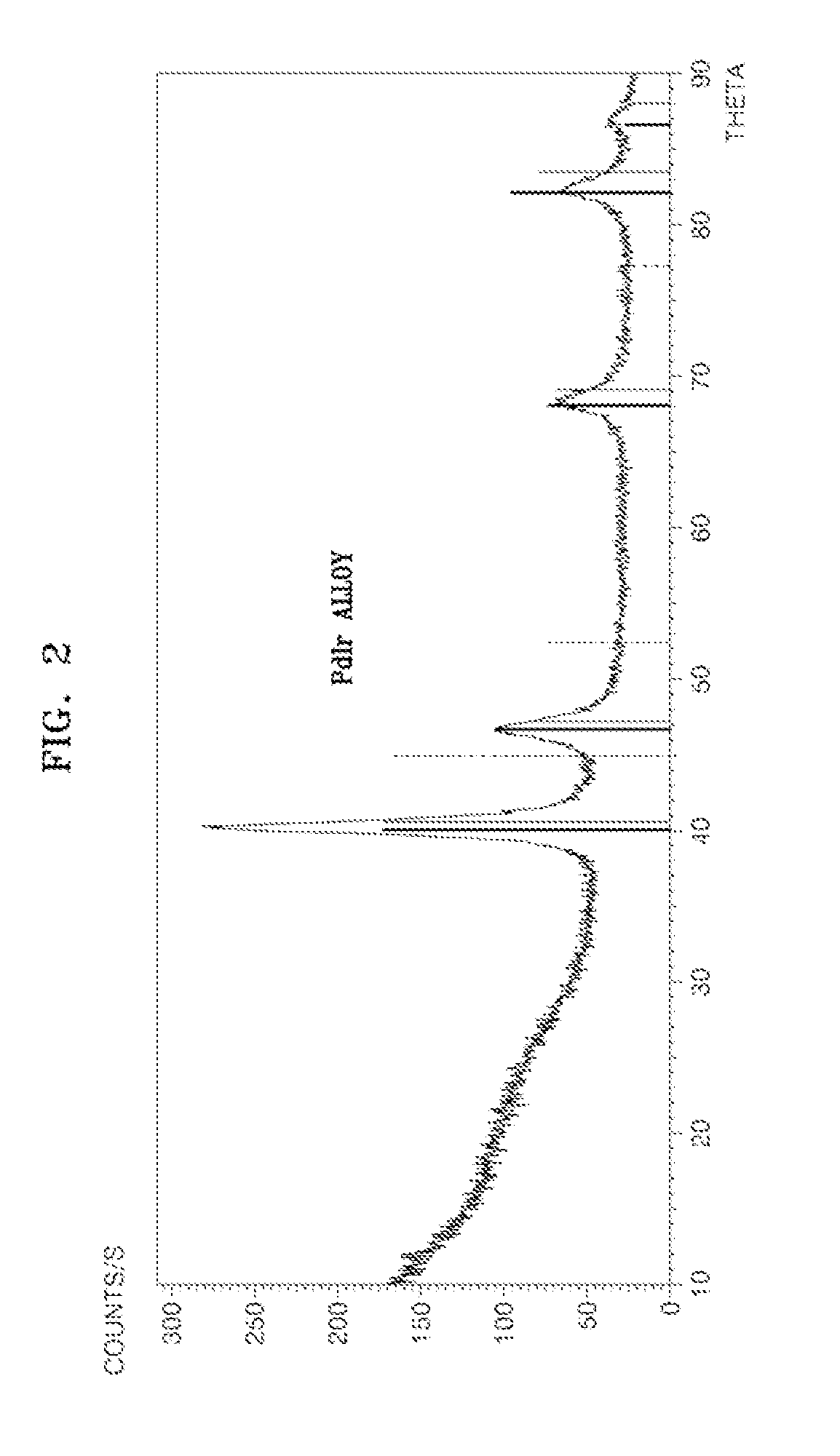

Electrode catalyst for fuel cell, method of preparing electrode catalyst, and fuel cell using electrode catalyst

ActiveUS20110081599A1Reducing pH-adjusted mixtureFinal product manufactureActive material electrodesIridiumFuel cells

Non-platinum (Pt) electrode catalysts for fuel cells, methods of manufacturing the same, and fuel cells including the non-Pt electrode catalysts. Each of the non-Pt electrode catalysts for fuel cells includes at least palladium (Pd) and iridium (Ir), and further includes a metal, oxide of the metal, or mixture thereof for compensating for the activity of Pd and Ir.

Owner:SAMSUNG ELECTRONICS CO LTD

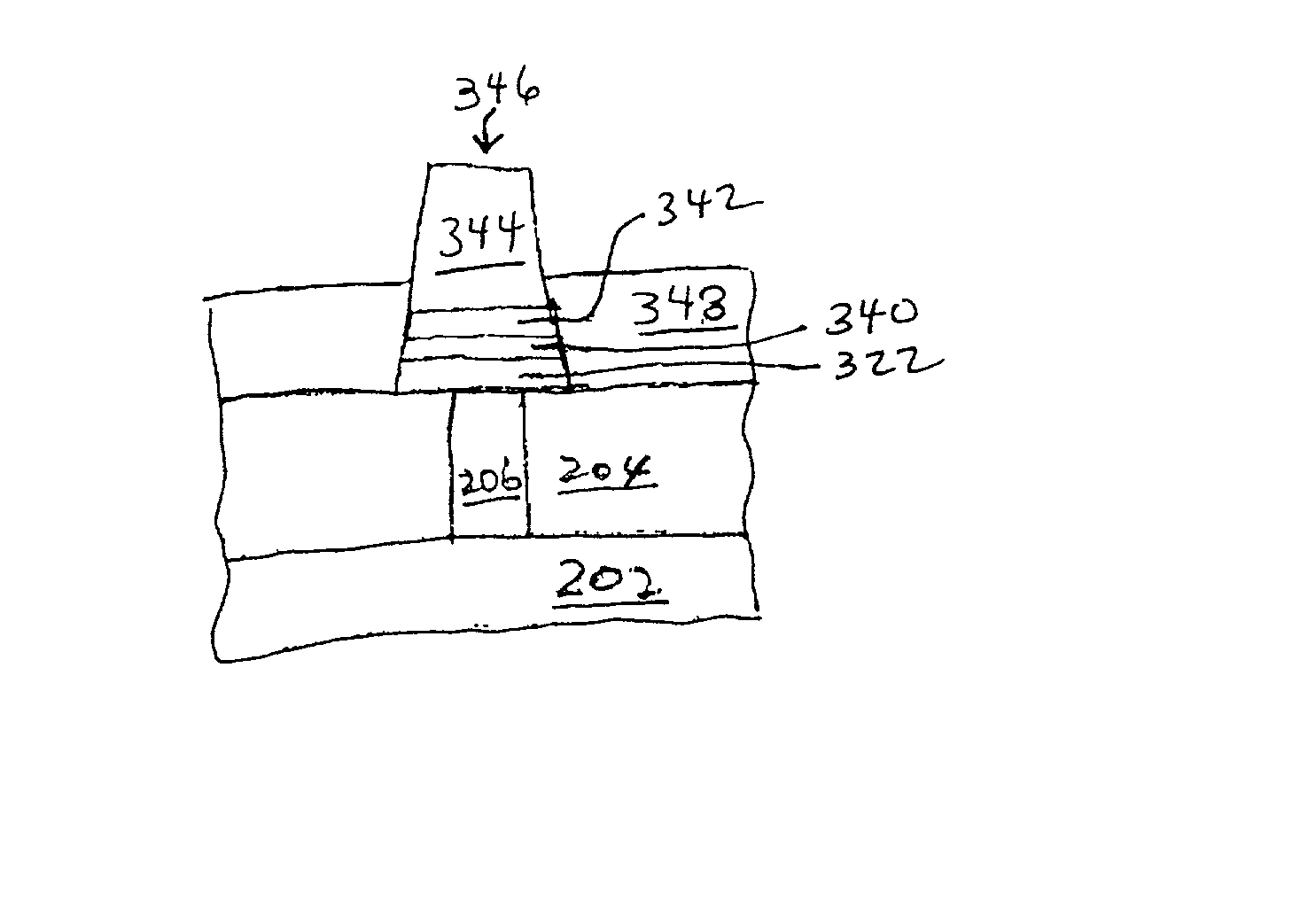

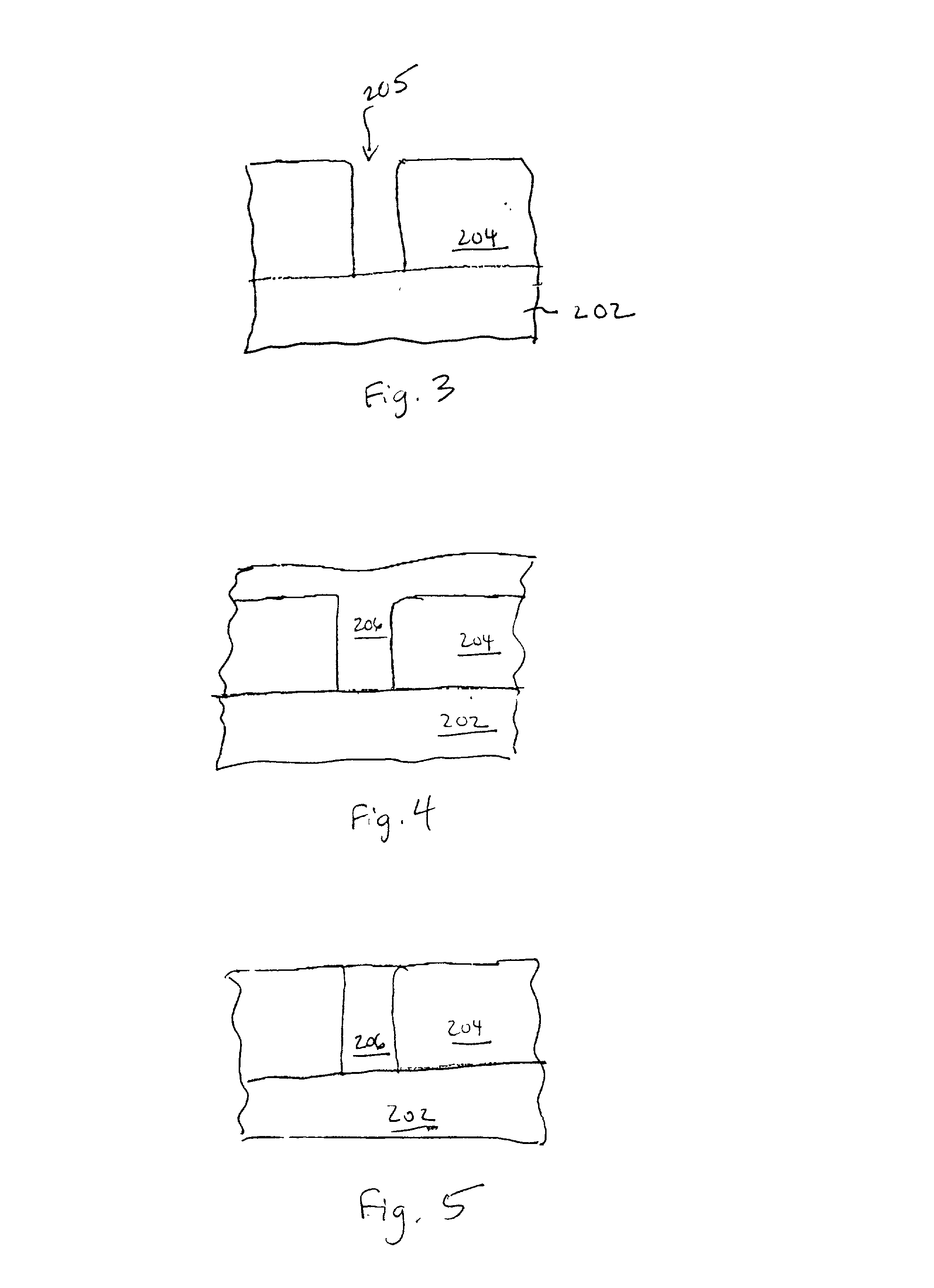

Multi-layer Pt electrode for DRAM and FRAM with high K dielectric materials

InactiveUS20020084481A1Increase in electrode resistanceReduce variationTransistorSolid-state devicesThin layerOptoelectronics

A multi-layer electrode (246) and method of fabrication thereof in which a conductive region (244) is separated from a barrier layer (222) by a first conductive liner (240) and a second conductive liner (242). First conductive layer (240) comprises Pt, and second conductive liner (242) comprises a thin layer of conductive oxide. The multi-layer electrode (246) prevents oxygen diffusion through the top conductive region (244) and reduces material variation during electrode patterning.

Owner:POLARIS INNOVATIONS

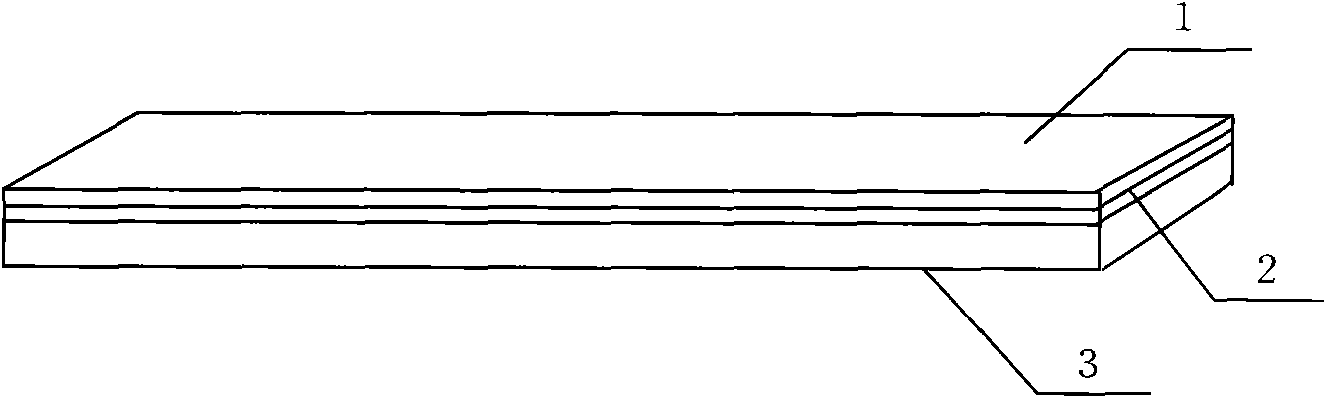

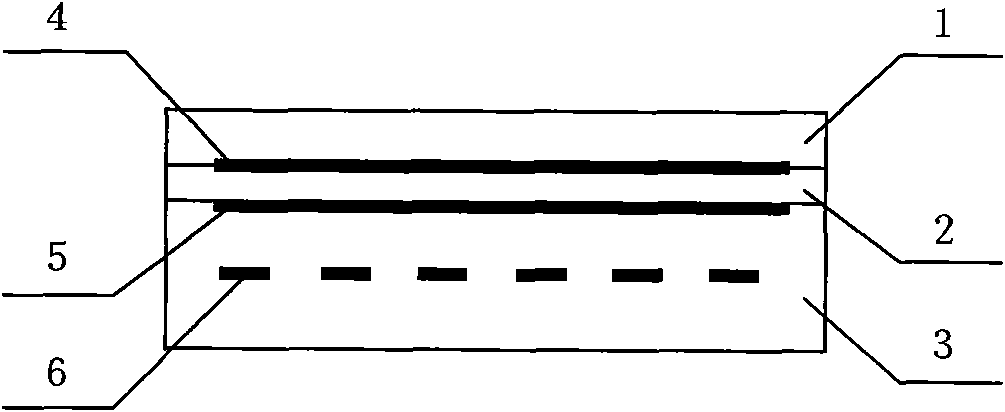

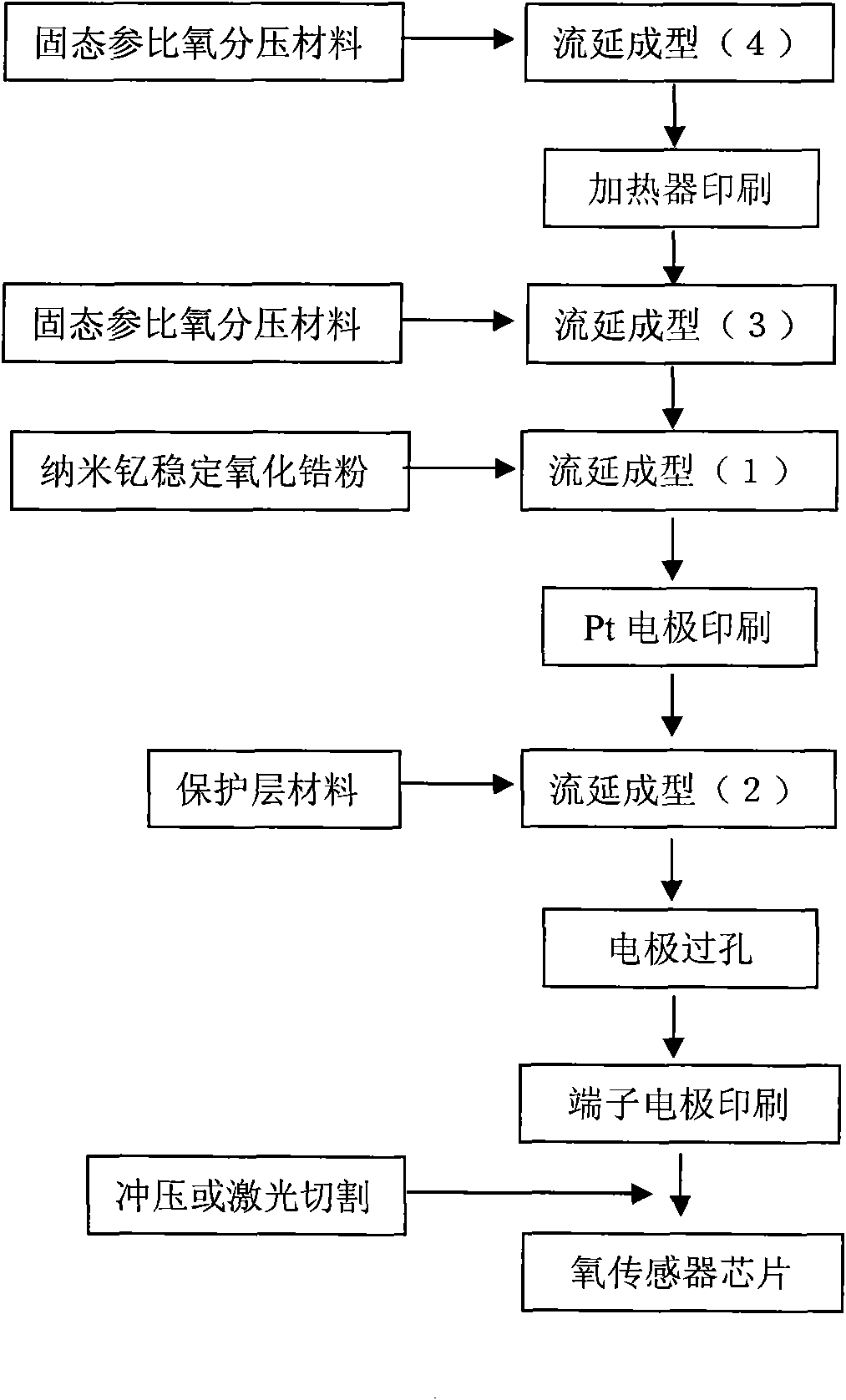

ZrO2 oxygen sensor for solid state reference partial pressure of oxygen and manufacture method thereof

The invention relates to a slice type oxygen sensor used for air-fuel delivery ratio control of a vehicle engine and a manufacture method thereof. The manufacture method comprises the following steps: slurry made of yttrium stabilization zirconia powder forms a slice blank through a casting technology; Pt electrodes which have certain gaps are respectively manufactured in silk screens at both sides of the slice blank; a solid state oxygen partial pressure reference slice is prepared on the yttrium stabilization zirconia slice blank through a secondary casting technology; an RuO material heater is printed in a silk screen in the middle of a secondary casting layer, and the thickness of the layer is of 6 to 7 times of a yttrium stabilization zirconia layer; a porous protective layer is formed at the side of an outer electrode on the yttrium stabilization zirconia slice blank in a curtain coating mode; finally, a prefabricated substrate blank is punched into a strip shape according to a required size, an electrode connecting hole is manufactured, and vacuum sintering is carried out in the program temperature rising process with the temperature of as high as 1600 DEG C to manufacture a sensor chip. The method fully utilizes the curtain coating technology of ceramic slice type materials and the silk screen printing technology of slurry electrodes, and has the advantages of less production technology links, high product consistency, high yield and low cost.

Owner:JILIN UNIV +1

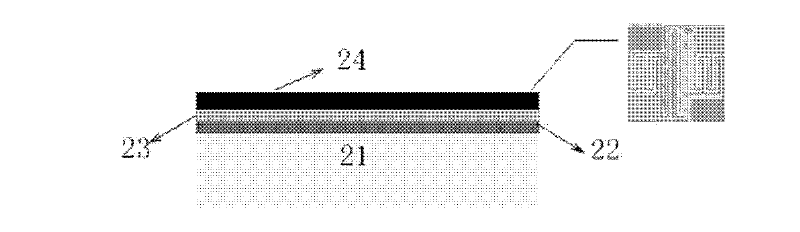

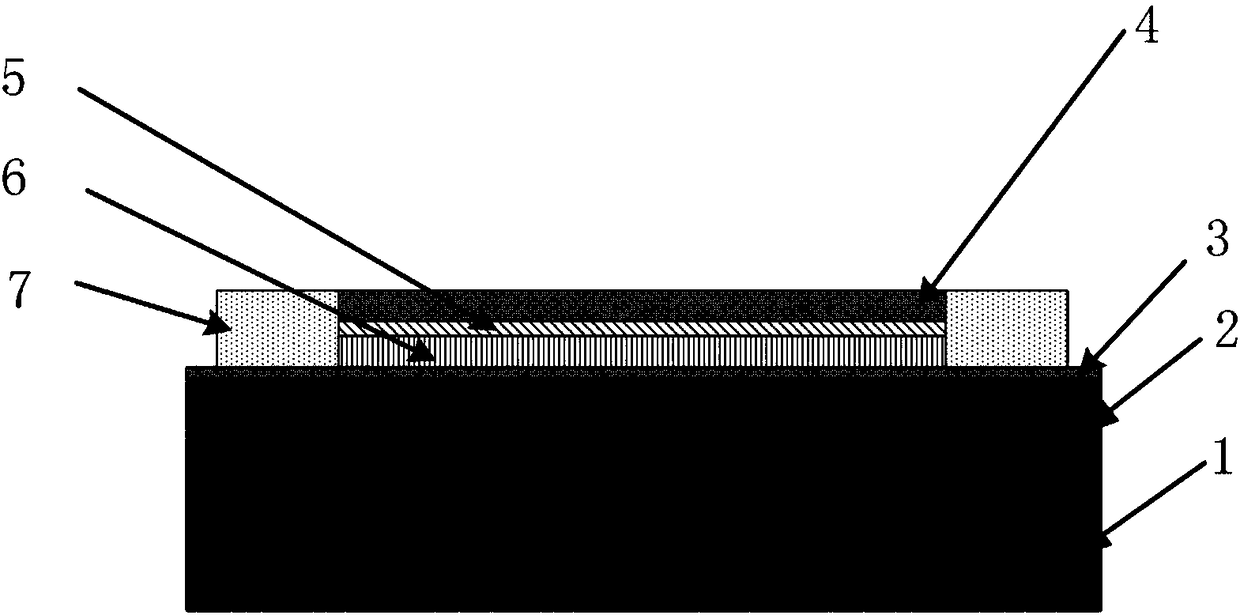

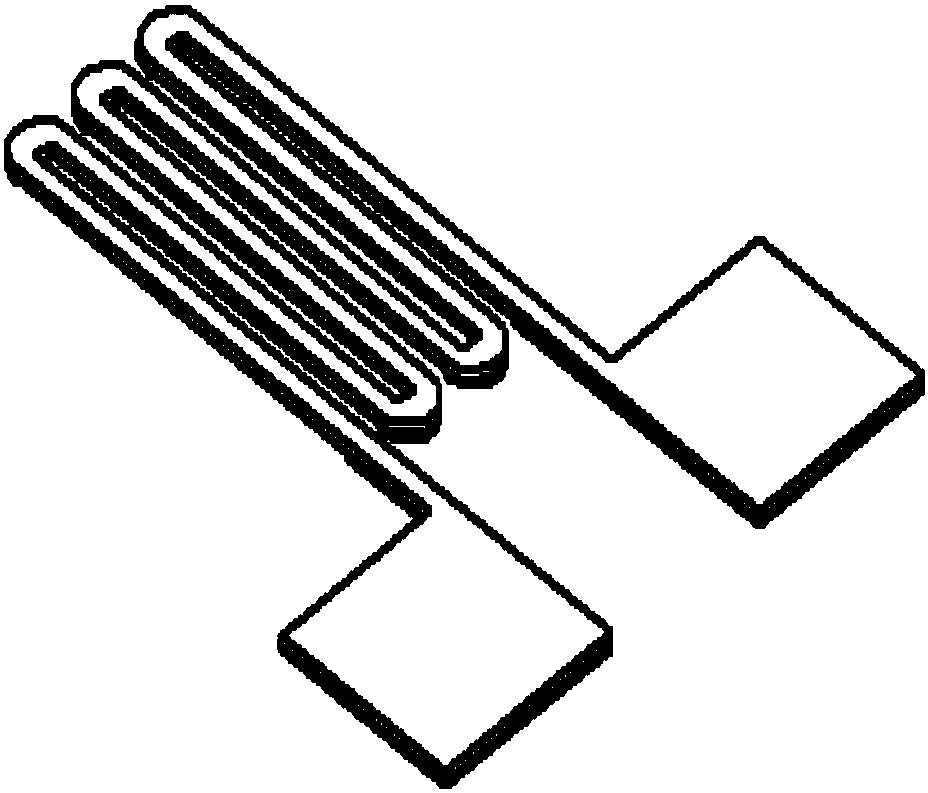

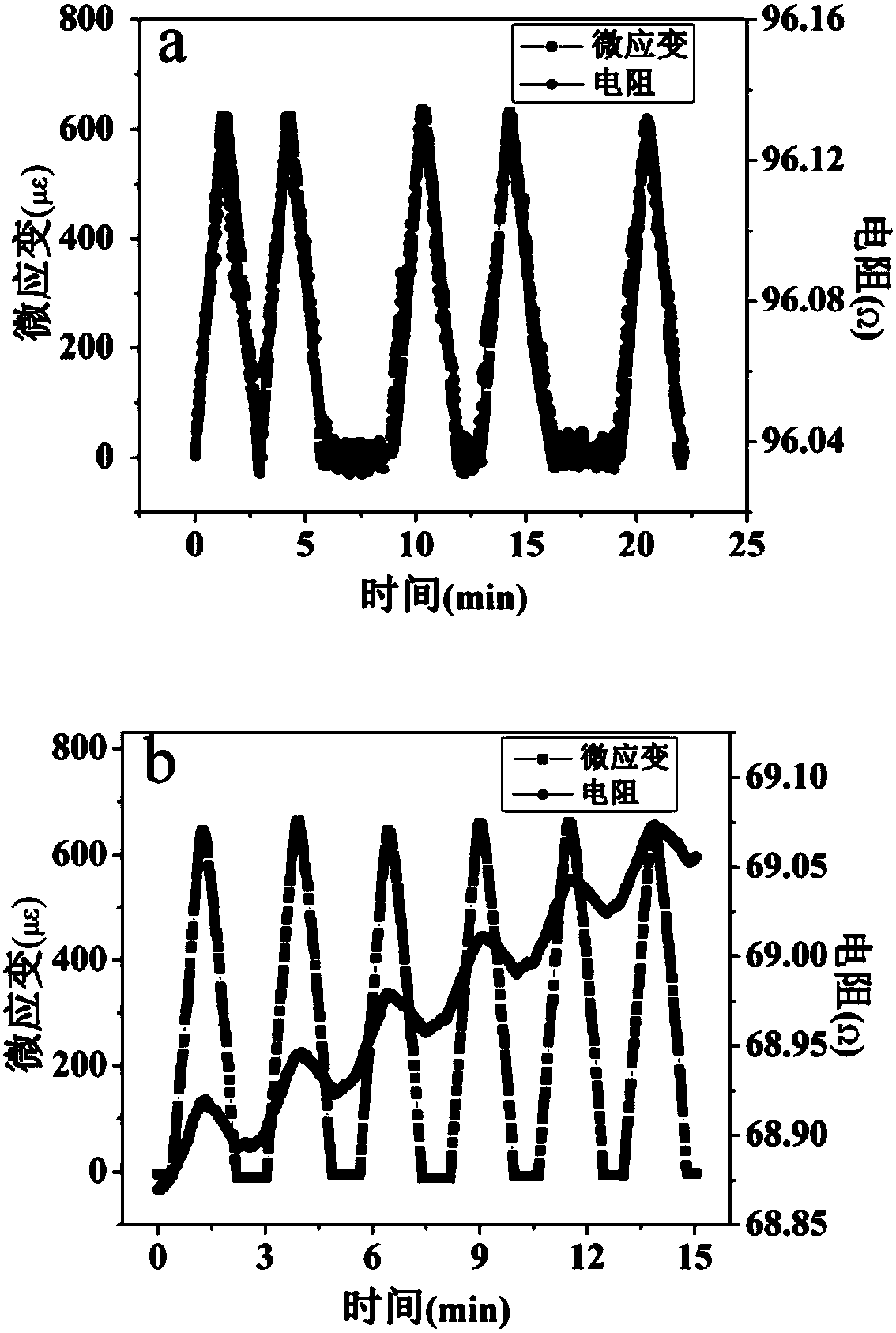

High-temperature thin film strain meter of composite protection layer and preparation method thereof

ActiveCN108088610AImprove protectionImprove high temperature stabilityDecorative surface effectsFluid pressure measurement using ohmic-resistance variationRadio frequency magnetron sputteringOxidation resistant

The invention relates to a high-temperature thin film strain meter of a composite protection layer and a preparation method thereof. The strain meter comprises a high-temperature alloy component substrate, an alloy transition layer, an aluminum oxide insulating layer, an aluminum oxide protection layer, an aluminum intermediate layer, a PdCr strain layer and a Pt electrode. the strain meter takesa high-temperature alloy component as a substrate, a transition layer alloy is firstly subjected to magnetron sputtering on the substrate and is subjected to high-temperature oxidation to generate a thin-layer aluminum oxide film, the aluminum oxide insulating film is deposited by double ion beam sputtering, and a PdCr strain layer is subjected to radio frequency magnetron sputtering on the insulating film, and the ion beams sputter AL intermediate layer and an AL2O3 protective layer. The strain meter is suitable for the real-time measurement of the strain of a component in the high-temperature working process, a universal MEMS patterning process is adopted, and the PDCR is sputtered to serve as a strain layer, the ion beams sputter to prepare Al and Al2O3 to obtain a composite protectionlayer by heat treatment, so that the oxidation of the PdCr thin film is prevented, and the oxidation resistance and the stability of the strain meter are improved.

Owner:SHANGHAI JIAO TONG UNIV

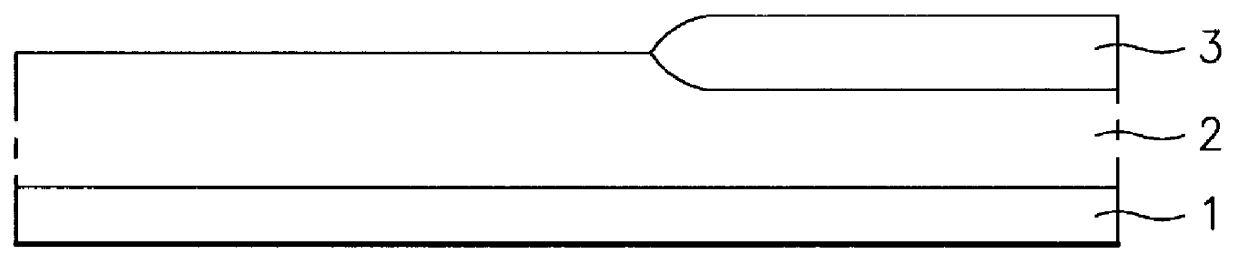

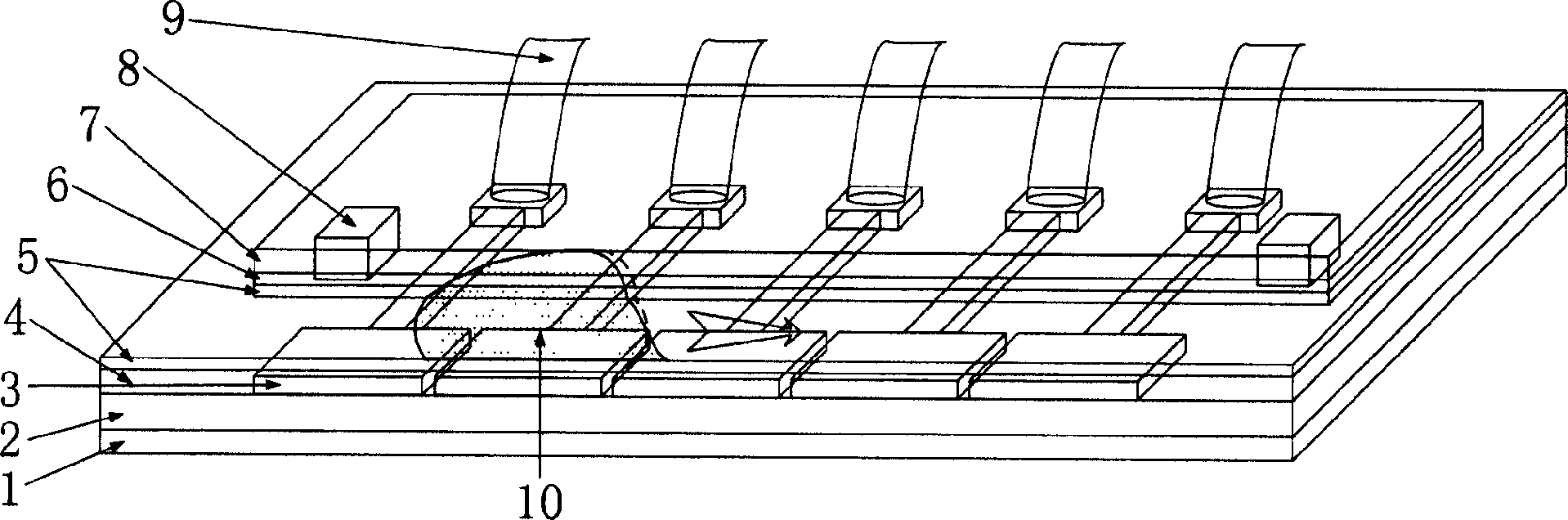

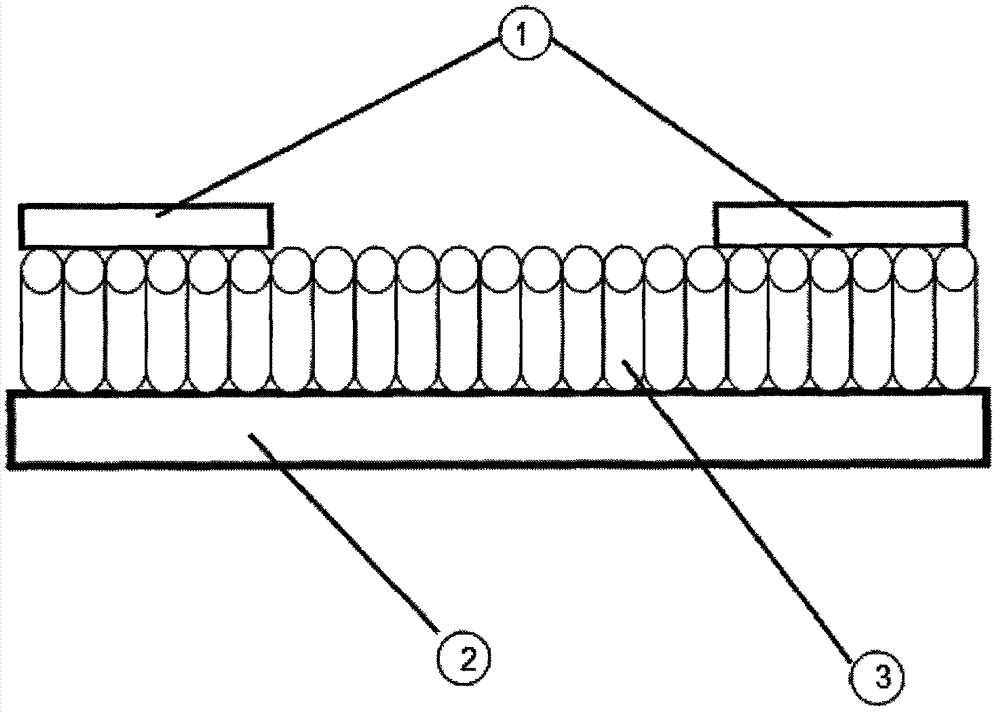

Micro liquid drop driver based on power-on wetting of medium layer

InactiveCN1587023AReduce the driving voltageLow costSolid-state devicesFluid speed measurementGlass sheetWater layer

The present invention discloses one kind of micro liquid drop driver based on electric wetting on medium layer and belongs to the field of micro complete analysis system and micro electromechanical system. On monocrystal silicon, there are one lower plate substrate layer of hot oxide SiO2, one Ti / Pt electrode array, one thin film medium layer, one hydrophobic layer of fluorocarbon polymer, and upper plate glass sheet with hydrophobic layer and ITO and supported with some support, successively. The micro liquid drop driver has low micro liquid drop driving voltage, simple making process and low cost, and other liquid drop operation may be further integrated on the same chip.

Owner:TSINGHUA UNIV

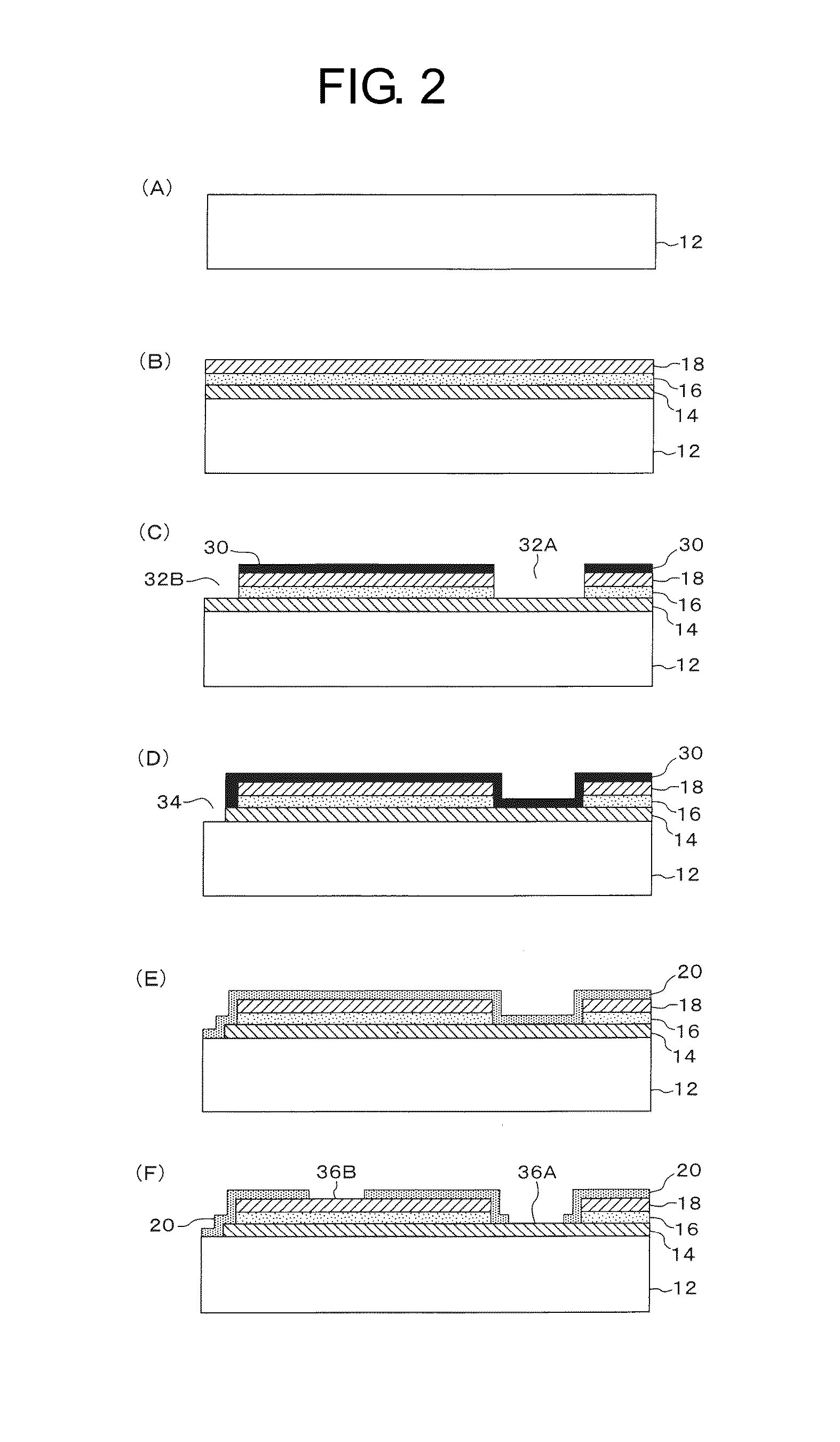

Thin-film capacitor

InactiveUS20130094120A1Excellent I-V characteristicImprove reliabilityFixed capacitor electrodesSolid-state devicesDielectric layerNitride

A thin-film capacitor 10 has an MIM structure in which a lower electrode 14, a dielectric layer 16, and an upper electrode 18 are formed in order on a substrate 12. Of the upper and lower electrodes 18 and 14, at least the upper electrode 18 is formed of a laminated electrode in which a nitride and a metal are laminated. The nitride preferably contains a high-melting point metal, such as Ta or Ti. In addition, the metal laminated along with the nitride is preferably the same as the metal contained in the nitride. Yet additionally, the nitride may contain Si. Thus, by using the laminated electrode containing the nitride in at least the upper electrode 18, identical I-V characteristics can be obtained and reliability is improved without the need for an annealing treatment for characteristic recovery necessary when a Pt electrode is used. Still additionally, adhesion between the dielectric layer 16 and the upper electrode 18 is improved, and therefore, delamination does not occur.

Owner:TAIYO YUDEN KK

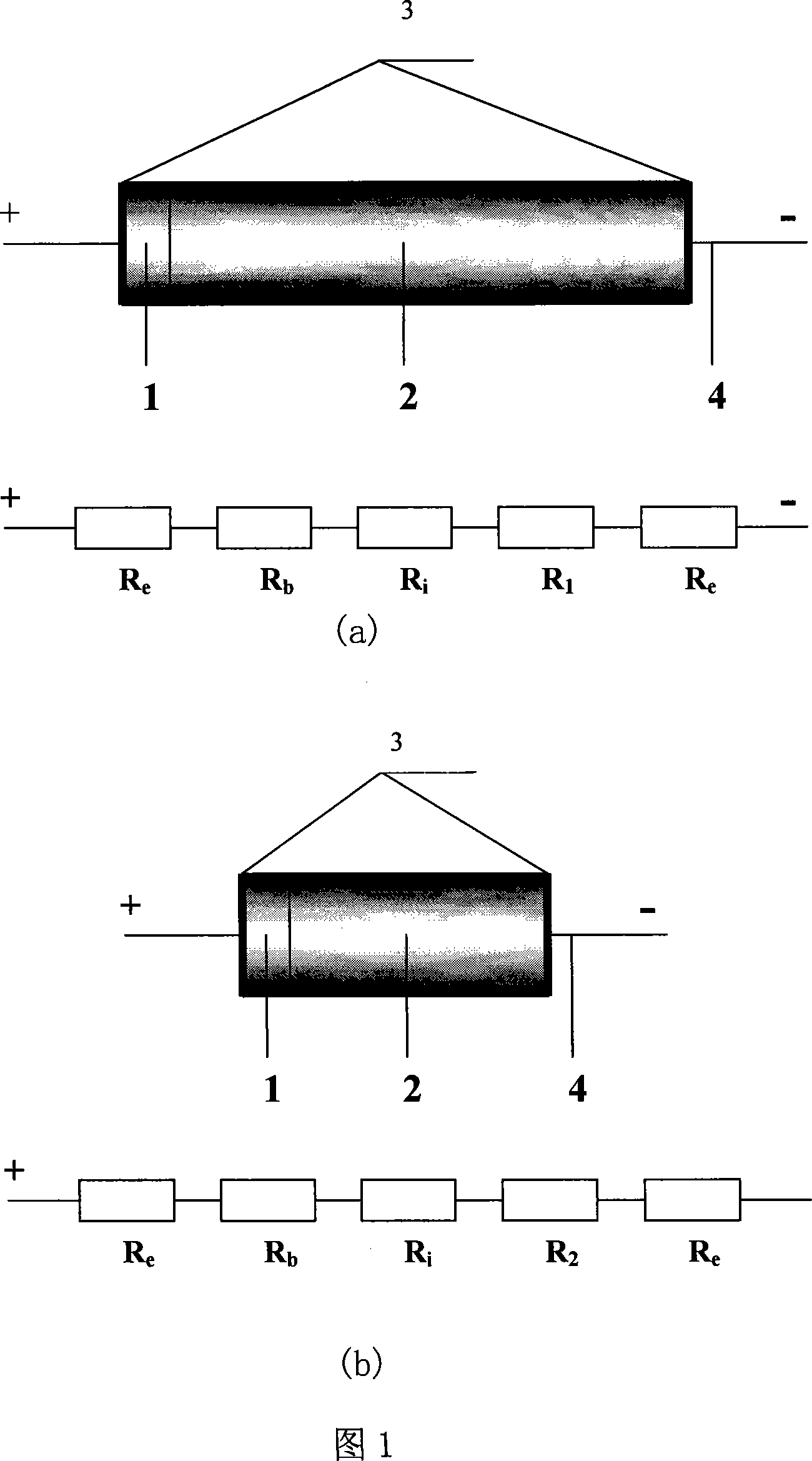

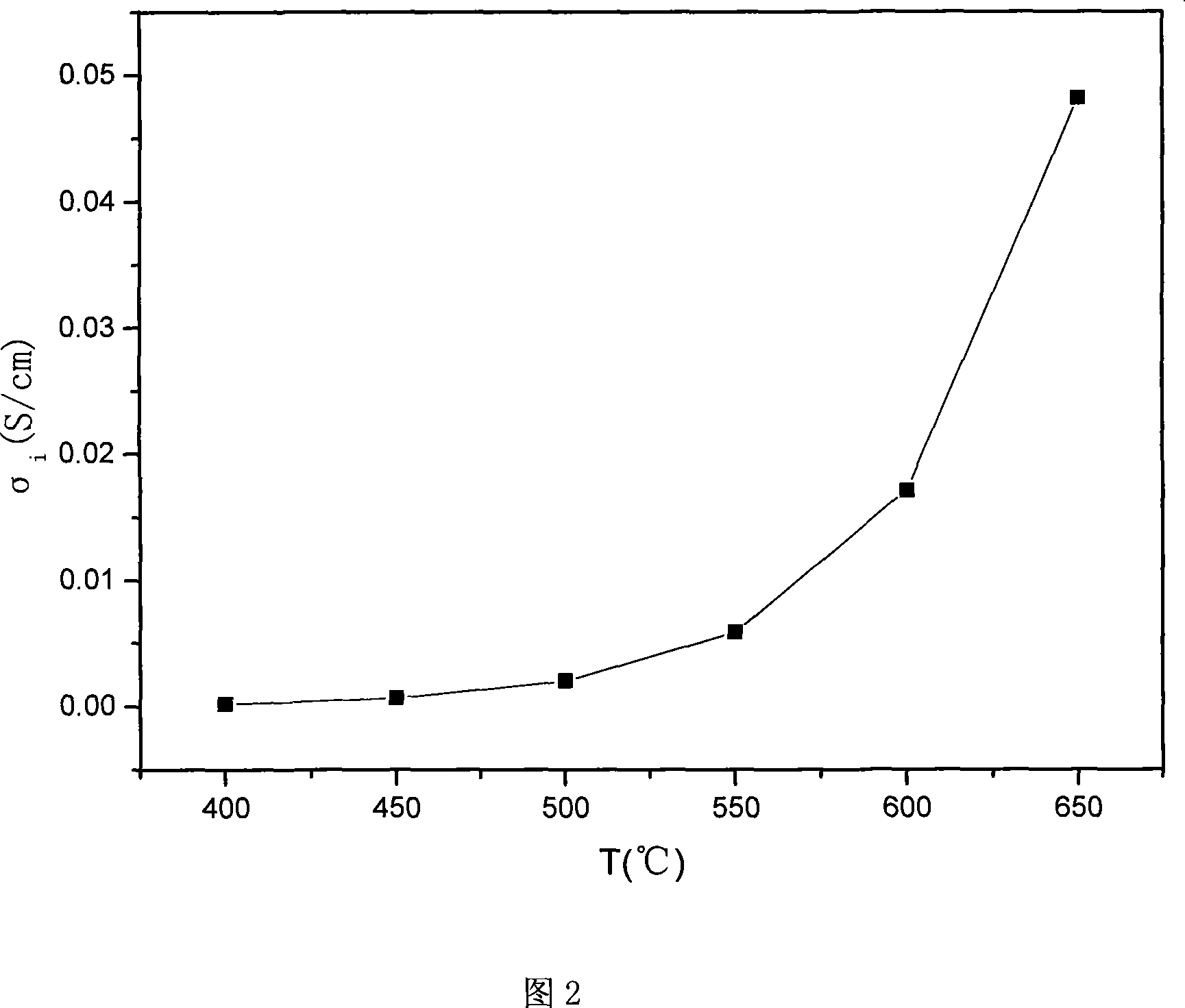

Oxygen ion-electron mixed conductor ion electric conductivity measuring method

InactiveCN101101271ASimple structureAvoid errorsMaterial impedanceSpecial data processing applicationsElectrical resistance and conductanceElectrical conductor

The invention relates to measuring method of the oxyanion hyphen electron mixed conductor material ionic conductivity. The mixed conductor is a ceramic material which has oxyanion and electron conduction power. The characteristics of measuring method is that it calculates and gets the ionic conductivity resulting the changes of resistance with the change of needed detection mixed conductor sample geometry after the electron block; because the tangent condition has not any changed before and after of mixed conductor block electrode, not considering the interfacial resistance, block electrode resistance and Pt electrode resistance, avoiding the error from this. The calculating formula of mixed conductor ionic conductivity is sigma i= (L1-L2) / [S*(R-R')].The measuring method of this invention is simply and convenience, the structure of measuring battery is simplify, reducing the factors of importing error.

Owner:SHANGHAI UNIV

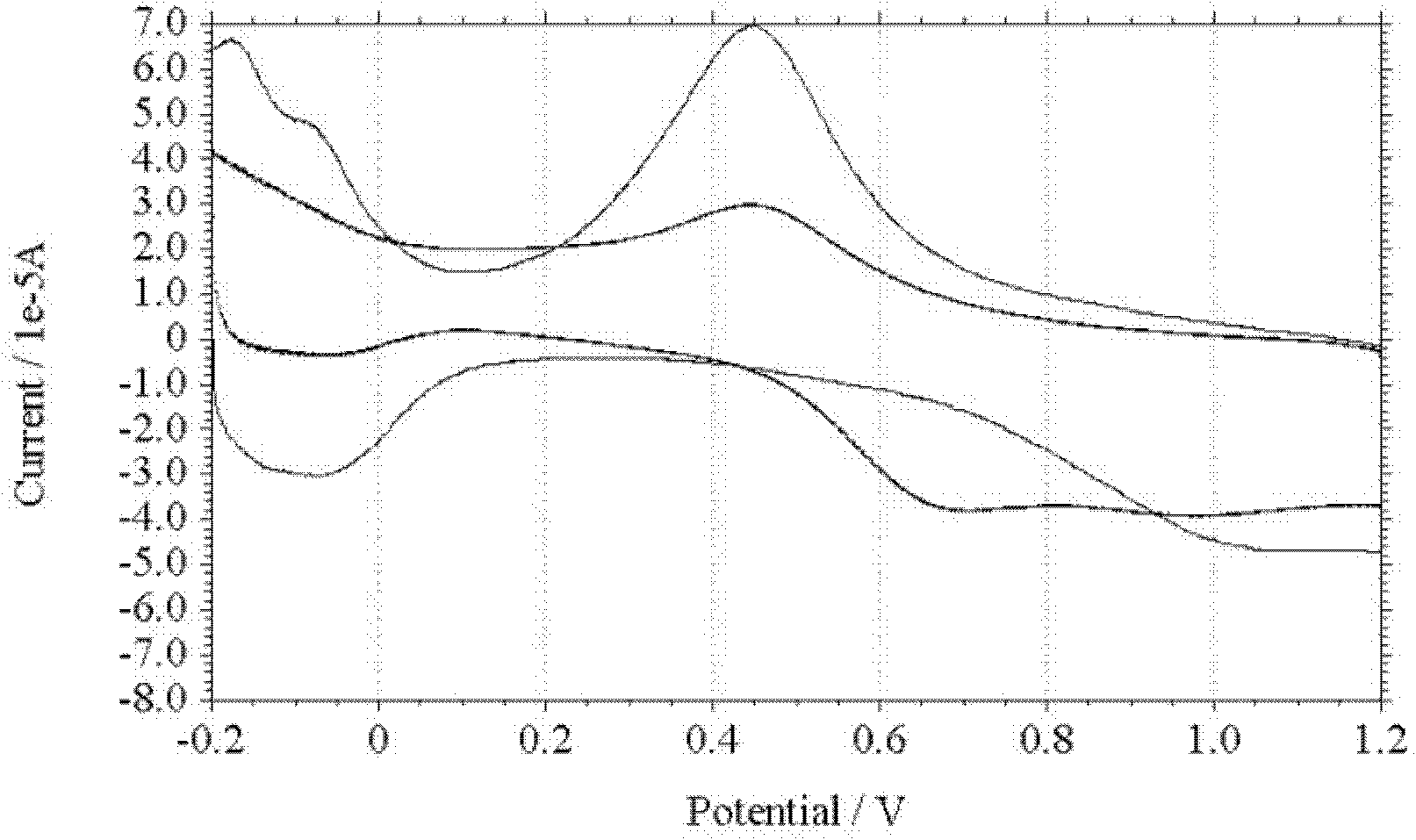

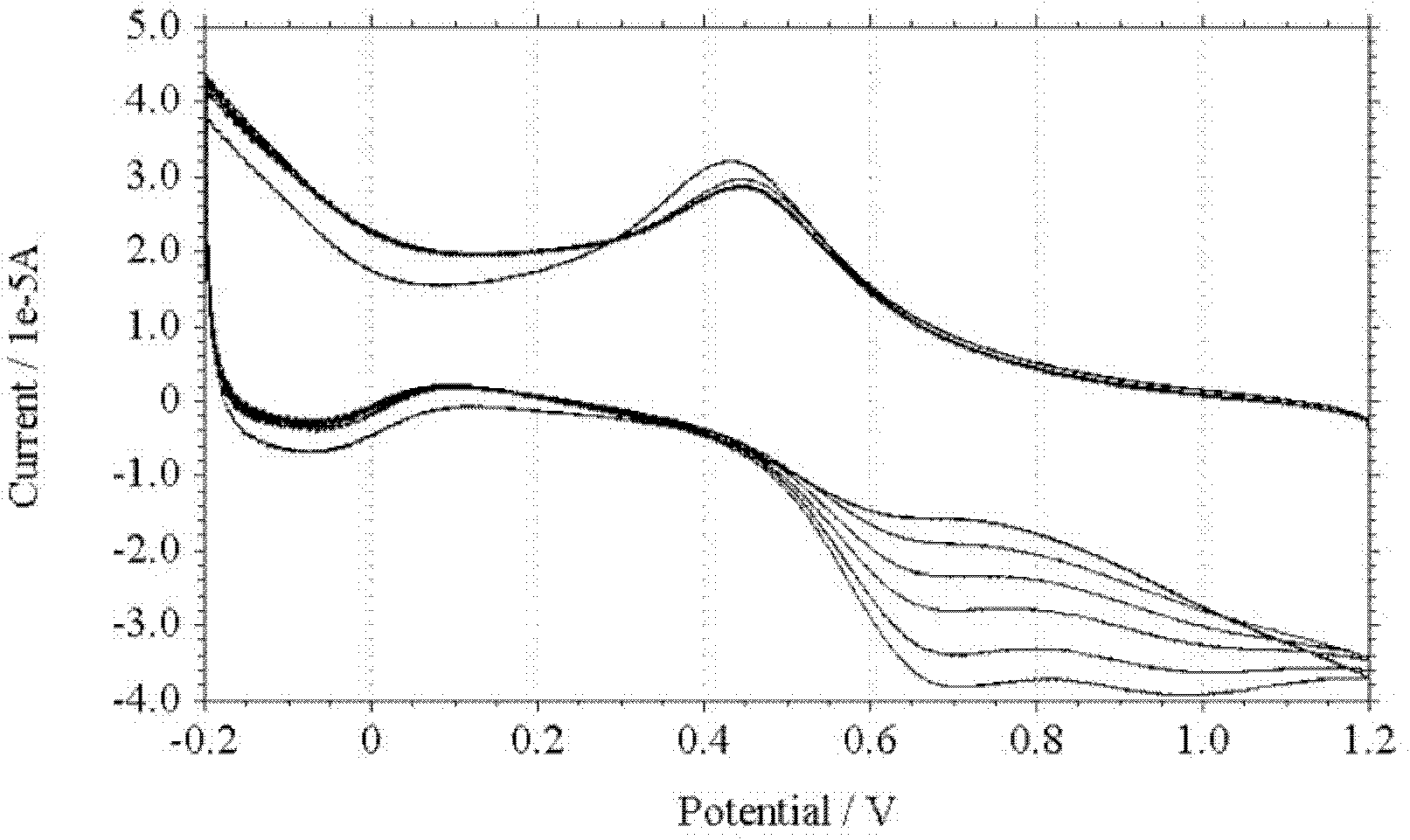

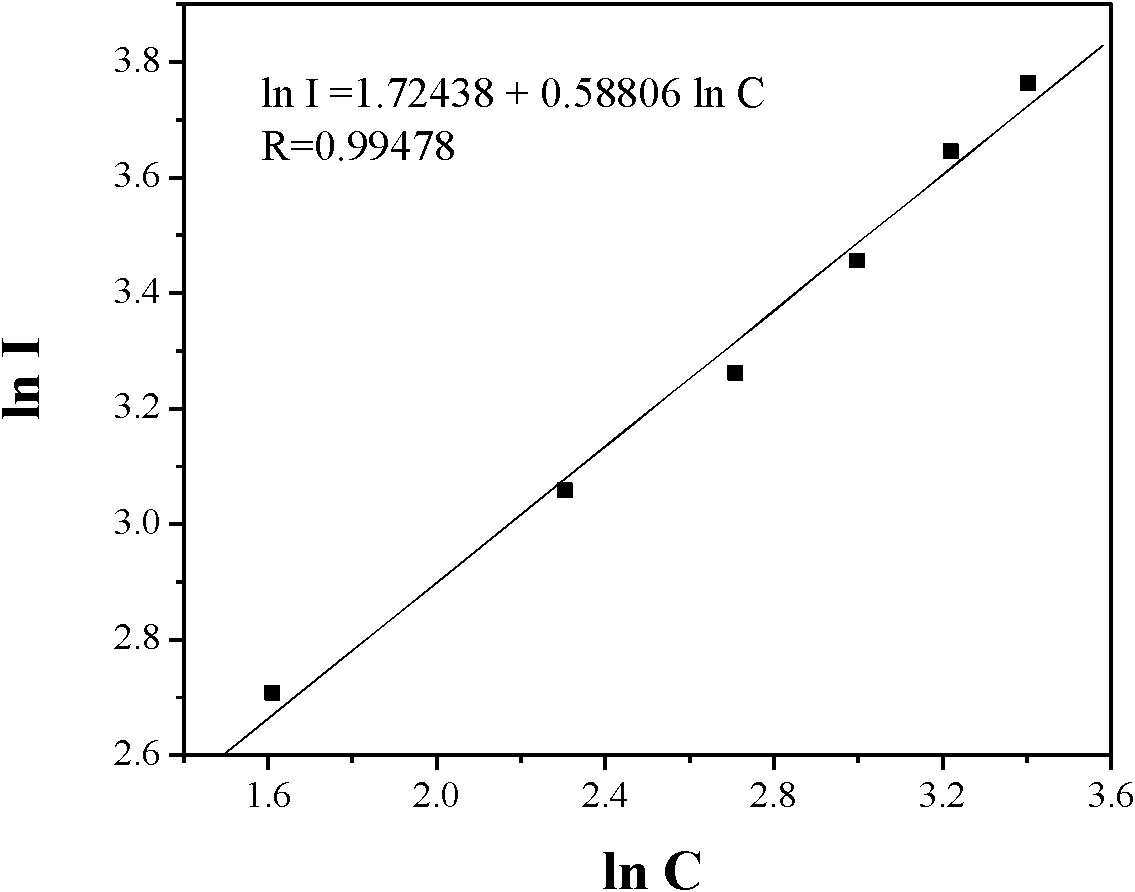

Method for determining concentration of phosphite by cyclic voltammetry

InactiveCN102141538AExperimental conditions are simpleFast experimental conditionsMaterial electrochemical variablesIon exchangePeak value

The invention discloses a method for determining the concentration of phosphite by cyclic voltammetry, which comprises the steps of: establishing a working curve by determining the quantitative proportional relation between the oxide peak current intensity of phosphite on a bare Pt electrode and the concentration of phosphite and fitting the working curve as a linear formula, and substituting theoxide peak value of a sample to be detected in the formula to obtain the concentration of phosphite. The method of the invention is accurate in detection results, has the advantages of being simple in experimental conditions, simple and convenient in operation and saving time compared with the traditional methods for determining the concentration of phosphite, such as an oxidation reduction titration method, a paper chromatography, a thin-layer chromatography and an ion exchange chromatography, and has tremendous popularization and application prospect in paint, electroplating and other fields.

Owner:SHANDONG UNIV

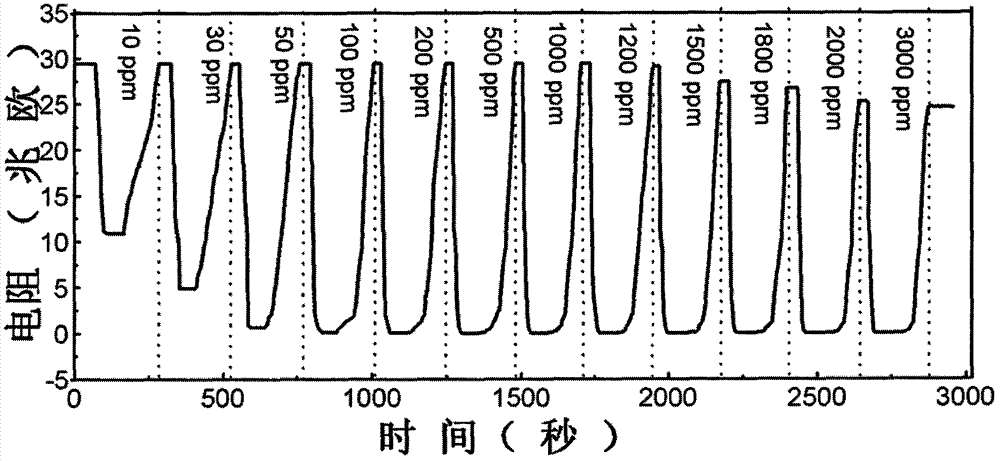

TiO2 nano tube array room temperature hydrogen sensor covered by Pt electrode on surface

The invention discloses a room temperature hydrogen sensor, and particularly relates to preparation and performance detection of a TiO2 nano tube array hydrogen sensitive element covered by a Pt electrode on the surface. A preparation method of the hydrogen sensitive element, provided by the invention, comprises the steps of strictly cleaning an appropriately cut high-purity industrial Ti foil and then placing in an ammonium fluoride and ethylene glycol water solution for carrying out anodic oxidation treatment for 3h to prepare a TiO2 nano tube array with the uniform surface and ordered height. The TiO2 nano tube array covered by the Pt electrode on the surface is used as the hydrogen sensitive element, and thus the sensitivity of the sensor is improved, the response speed of the sensor is increased, and the work temperature is lowered.

Owner:山东飞龙农业科技有限公司

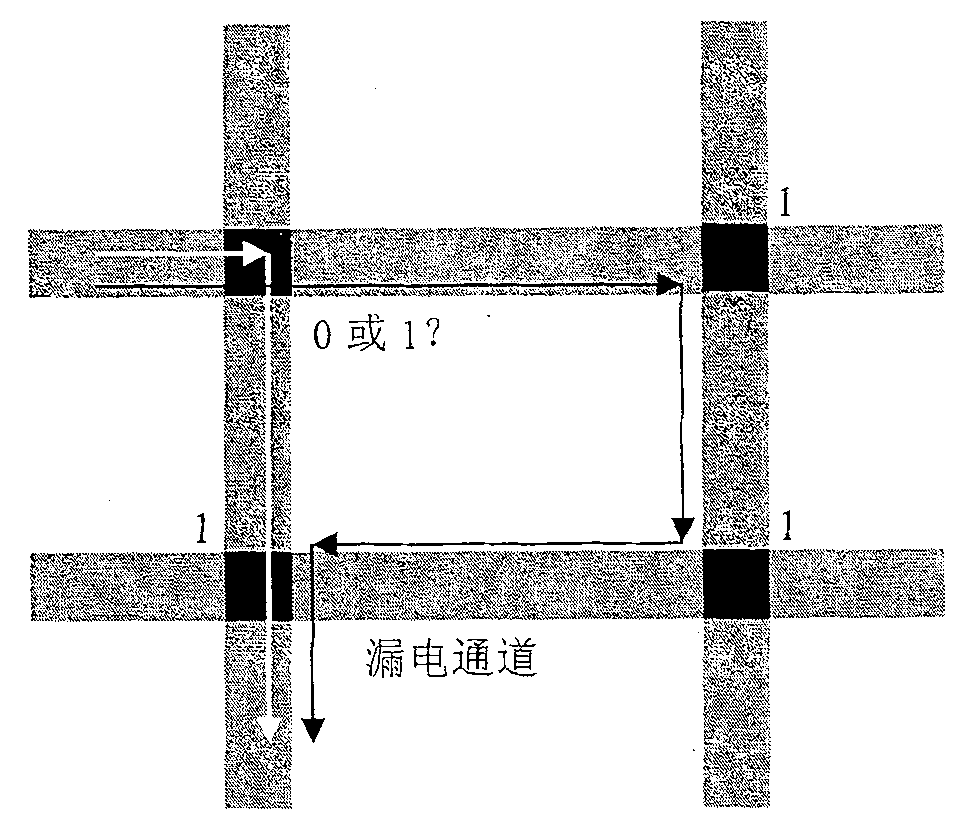

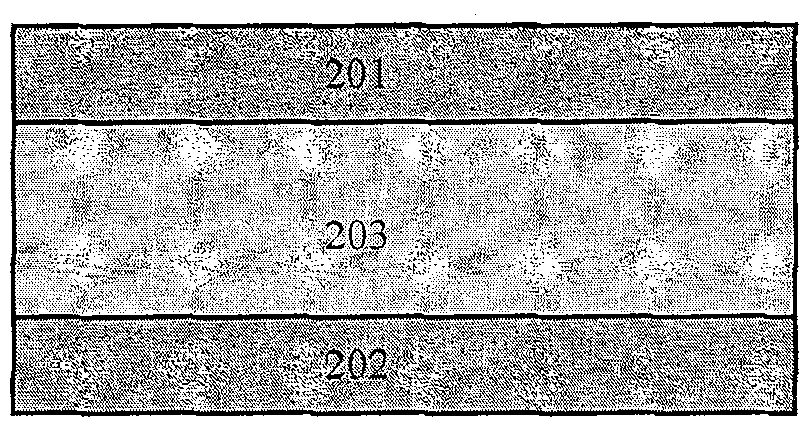

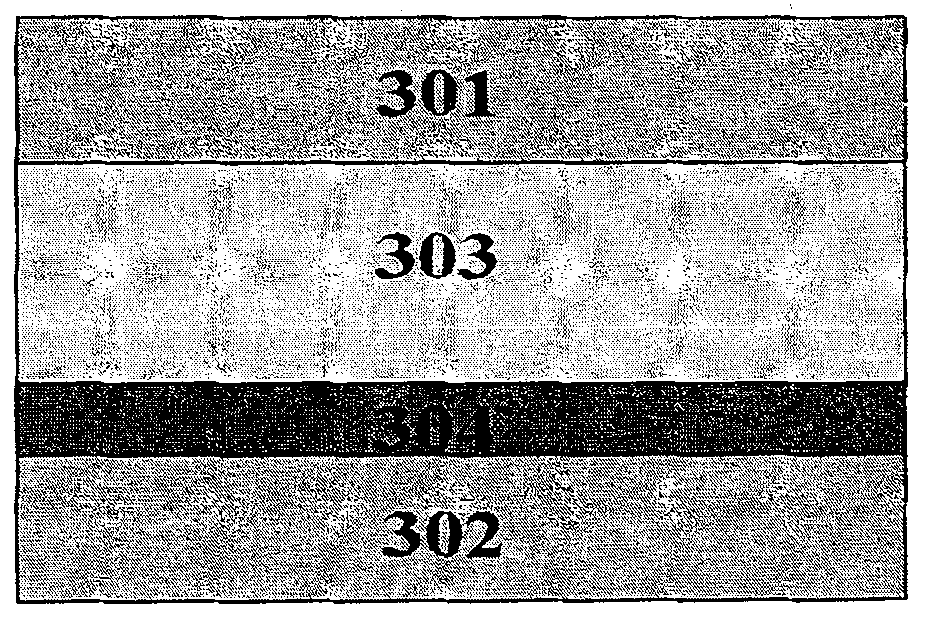

Non-volatile resistor change type memory with self-rectification effect

InactiveCN101783388AProcessing technology compatibleImprove storage densityDigital storageSemiconductor devicesCMOSChange Type

The invention discloses a non-volatile resistor change type memory with the self-rectification effect. The non-volatile resistor change type memory comprises an upper Pt electrode, a lower Pt electrode, a binary transition metal oxide thin film and a PtOx boundary layer, wherein the binary transition metal oxide thin film is positioned between the upper Pt electrode and the lower Pt electrode, and the PtOx boundary layer is positioned between the binary transition metal oxide thin film and the lower Pt electrode. The non-volatile resistor change type memory with the self-rectification effect has the advantages of simple structure, easy integration, low cost, compatible process with the traditional silicon planer CMOS, and the like, and is beneficial to the wide popularization and the application of the invention.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

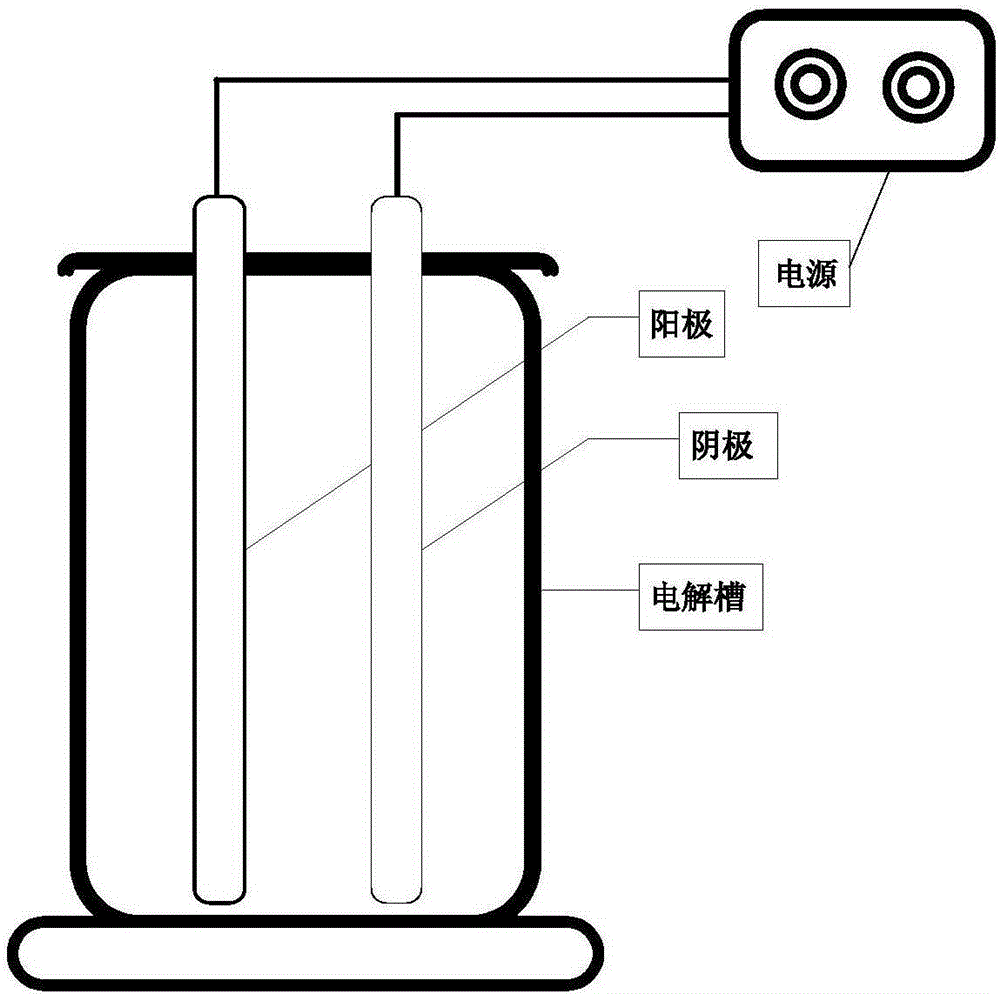

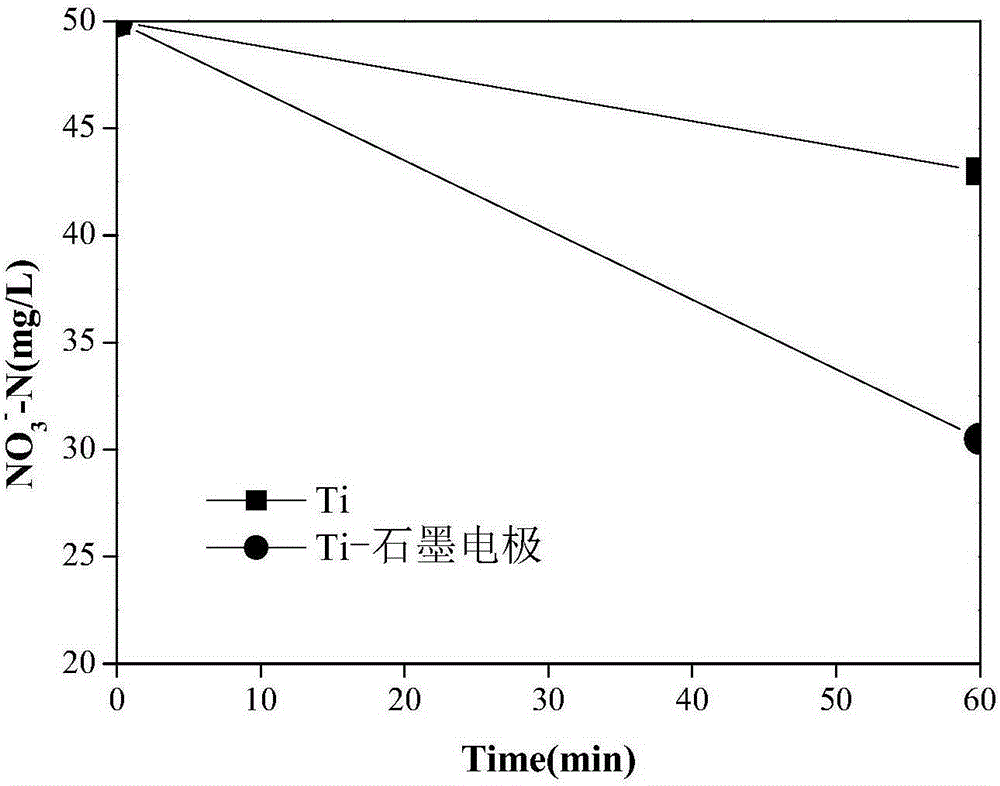

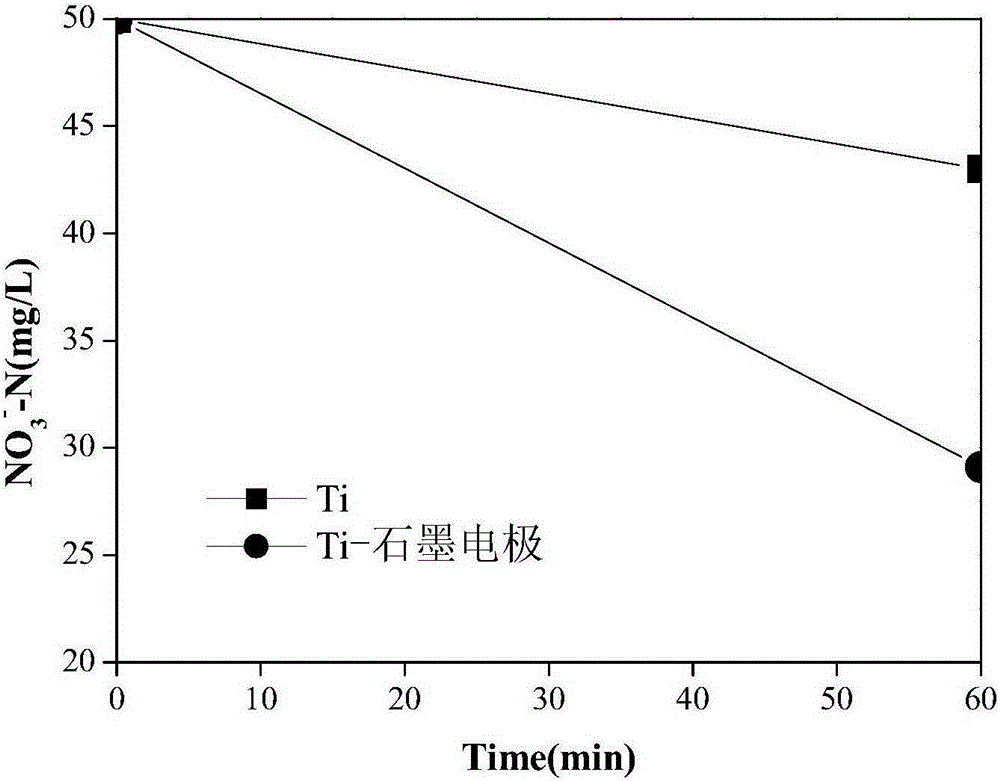

Method for efficiently removing nitrate from underground water through Ti-graphene electrode

ActiveCN105198046AEasy to controlImprove electronic conductivityWater contaminantsWater/sewage treatmentElectrochemical responseElectrolysis

A method for efficiently removing nitrate from underground water through a Ti-graphene electrode includes the following steps of adding crystalline graphite powder into a beaker, adding NaNO3, H2SO4, KMnO4, deionized water and H2O2 at the temperature of 60 DEG C into the beaker in sequence, going through the low-temperature stage, the intermediate-temperature stage and the high-temperature stage, conducting centrifuging, cooling and drying to obtain graphene oxide powder, preparing a graphene oxide solution, adding sodium dodecyl benzene sulfonate, soaking a preprocessed Ti electrode plate in the solution and then pulling the preprocessed Ti electrode plate out of the electrode plate, naturally drying the electrode plate to obtain the finished product Ti-graphene electrode, adding sodium sulfate to nitrate polluted water, setting current electrolysis with the Ti-graphene electrode as the cathode and a Ti / Pt electrode as the anode, conducting reduction to remove nitrate, and reducing nitrate to generate nitrogen, nitrite or ammonia after nitrate obtains electrons on the cathode so that the nitrate removing aim can be achieved. By means of the Ti-graphene electrode prepared with the aid of graphene oxide, nitrate is effectively removed in an electrochemical reaction tank without other auxiliary processing devices.

Owner:TSINGHUA UNIV

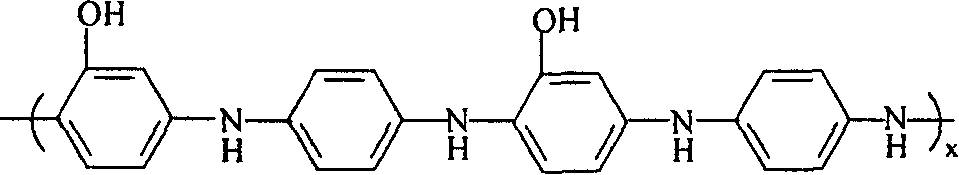

Copolymer of conductive polyaniline and m-aminophenol and its synthesis process

The present invention is aniline-m-aminophenol copolymer as one kind of conductive polymer and its synthesis. Inside an electrolytic bath with Pt electrode or C electrode, aniline, m-aminophenol and sulfuric acid or hydrochloric acid are electrolyzed to obtain the conductive polymer, aniline-m-aminophenol copolymer, which is washed with dilute hydrochloric acid solution and dried. The conductive polymer has excellent characteristic similar to that of polyaniline, and capacity of maintaining high chemical activity in strong acid solution and pH 1.0-11.0 sodium sulfate solution. When the pH value of the copolymer raises from 5.0 to 11.0, it has chemical activity lowered to 58.3 %. The copolymer has wide application potential range,(-0.2 to 0.80 Vú¼vs.SCE), conductivity of 0.8-1.4S / cm, and lower dependence on pH value.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com