Lithium tantalate thin film infrared detector and manufacturing method

A technology of infrared detectors and infrared detection heads, applied in the field of infrared detectors, can solve problems such as large interference signals of detectors, detector interference, weak infrared radiation energy, etc., and achieve the effect of solving excessive volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

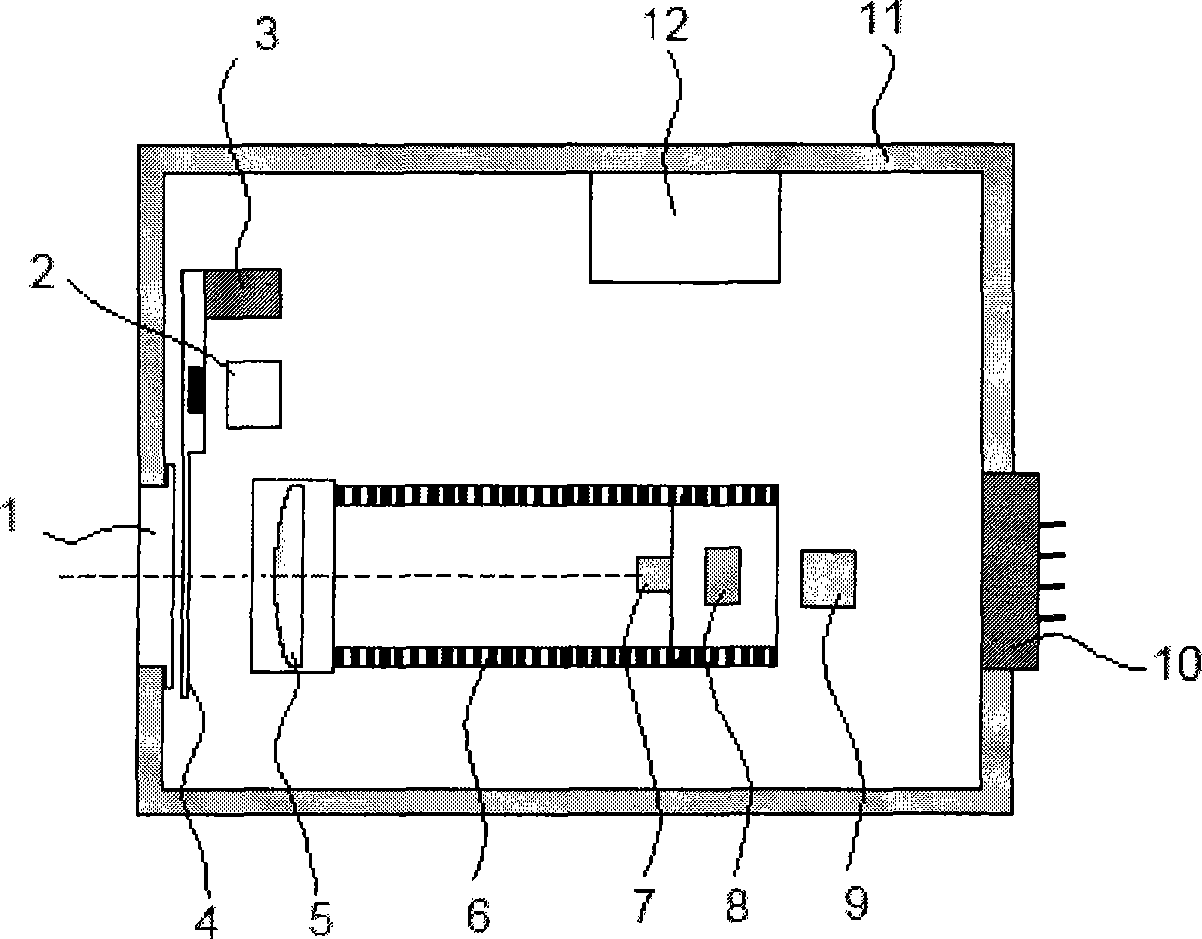

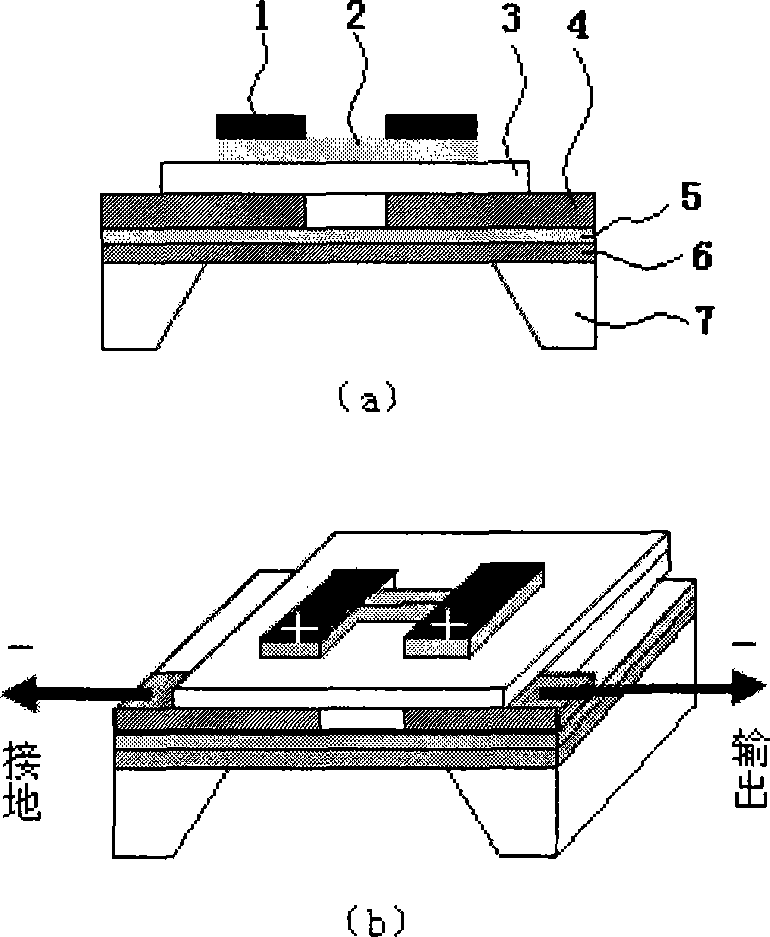

[0048] refer to figure 1 , The invention is an unrefrigerated pyroelectric lithium tantalate film infrared detector modulated by resonance chopping. The detector structure includes: an infrared filter window 1, a chopper modulator (chopper base 2, an excitation device 3 (electromagnetic coupling or piezoelectric drive device), a resonant plate and an excitation head 4 (the excitation head is a permanent magnet block or Lithium tantalate crystal piezoelectric sheet)), focusing lens coated with anti-reflection film 5, heat sink 6, pyroelectric lithium tantalate thin film infrared detection head 7, preamplifier 8, low-pass filter 9, detector power supply and Signal output interface 10 , detector housing 11 and ambient temperature detection compensator 12 . The infrared filter window 1 is the first main device that the infrared detector contacts with the outside world. The infrared light of the incident radiation passes through the infrared filter window 1 to filter out backgroun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com