Patents

Literature

49 results about "Inverse magnetostrictive effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The inverse magnetostrictive effect, magnetoelastic effect or Villari effect is the change of the magnetic susceptibility of a material when subjected to a mechanical stress.

AUV pipeline inspection using magnetic tomography

ActiveUS8949042B1Avoid and shadowingAccurate readingSpecial data processing applicationsElectric/magnetic detectionMagnetic field gradientMagnetic susceptibility

The present invention discloses an autonomous magnetic tomography method (MTM) and device for magnetographic identification and magnetographic analysis of mechanical flaws and defects along structures located deep in the sea or otherwise located underwater and further underground. The invention optimizes the inspection and maintenance processes of extended metallic constructions, e.g., pipelines. The device is based on the inverse magnetostrictive effect (i.e., the Villari effect)—the variation of a material's magnetic susceptibility under applied mechanical stress. The changes in magnetic susceptibility result in distribution of a magnetic field gradient along a structure's surface area, thus providing information about the presence and the value of the magnetic field anomaly at a given and precise location on the structure. The device and method is capable of autonomous and offline operation underwater at depths up to 1,500 meters below sea level.

Owner:GOROSHEVSKIY VALERIAN +2

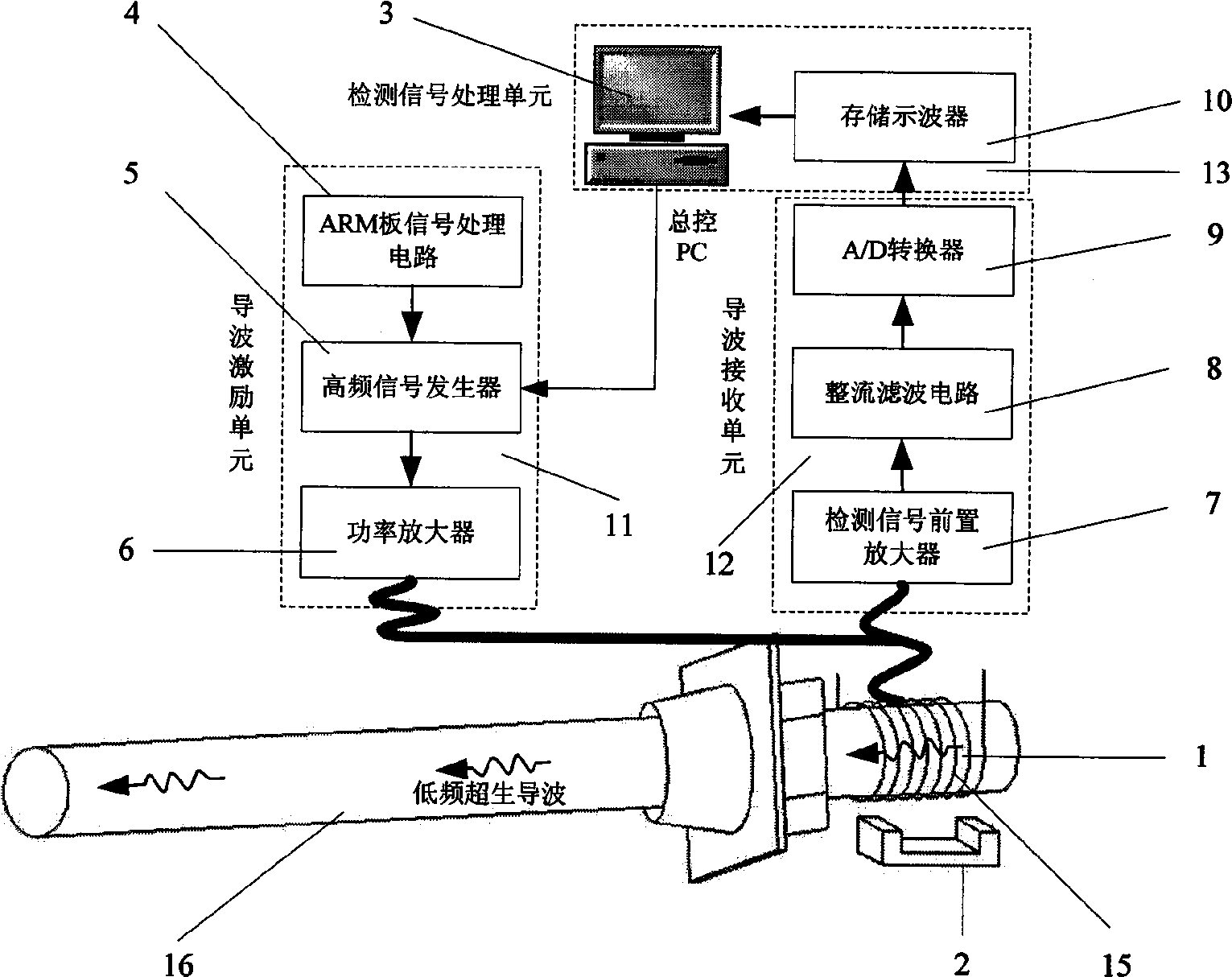

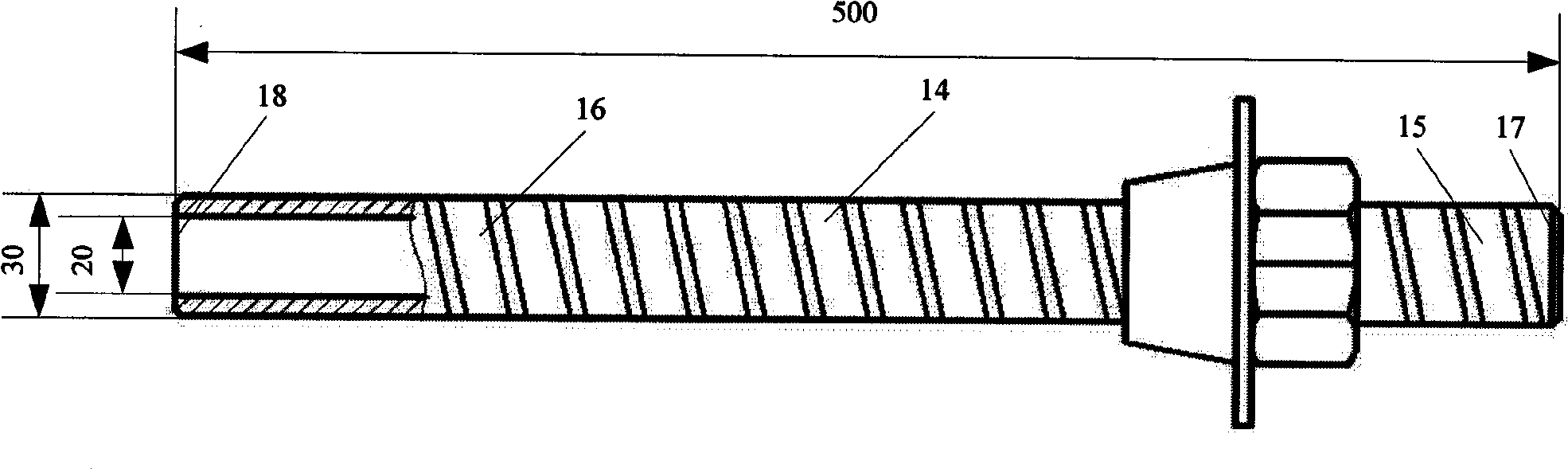

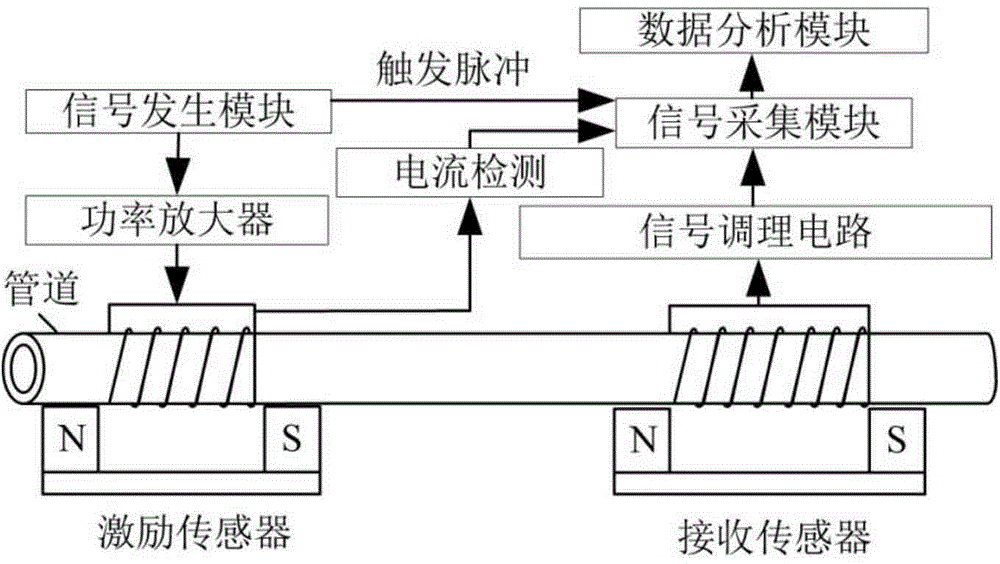

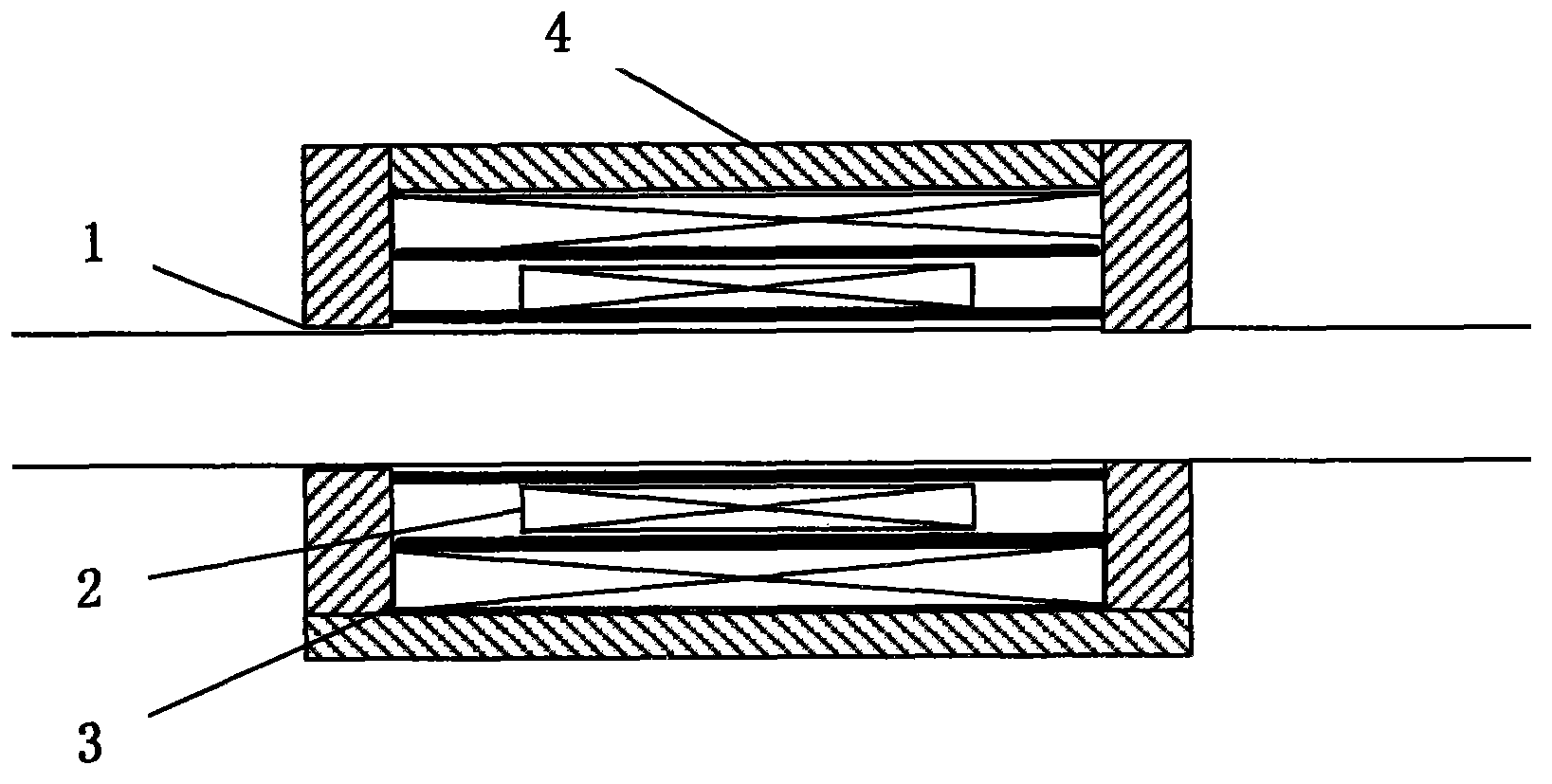

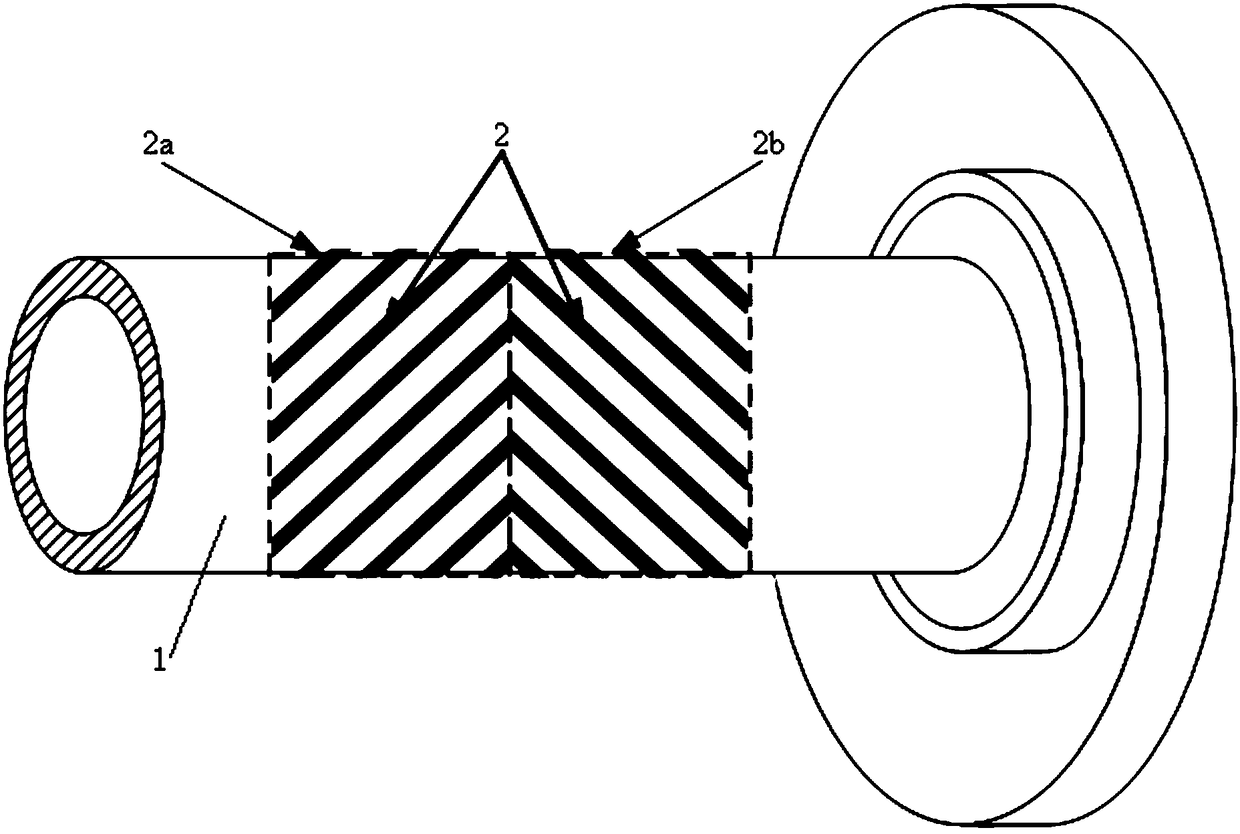

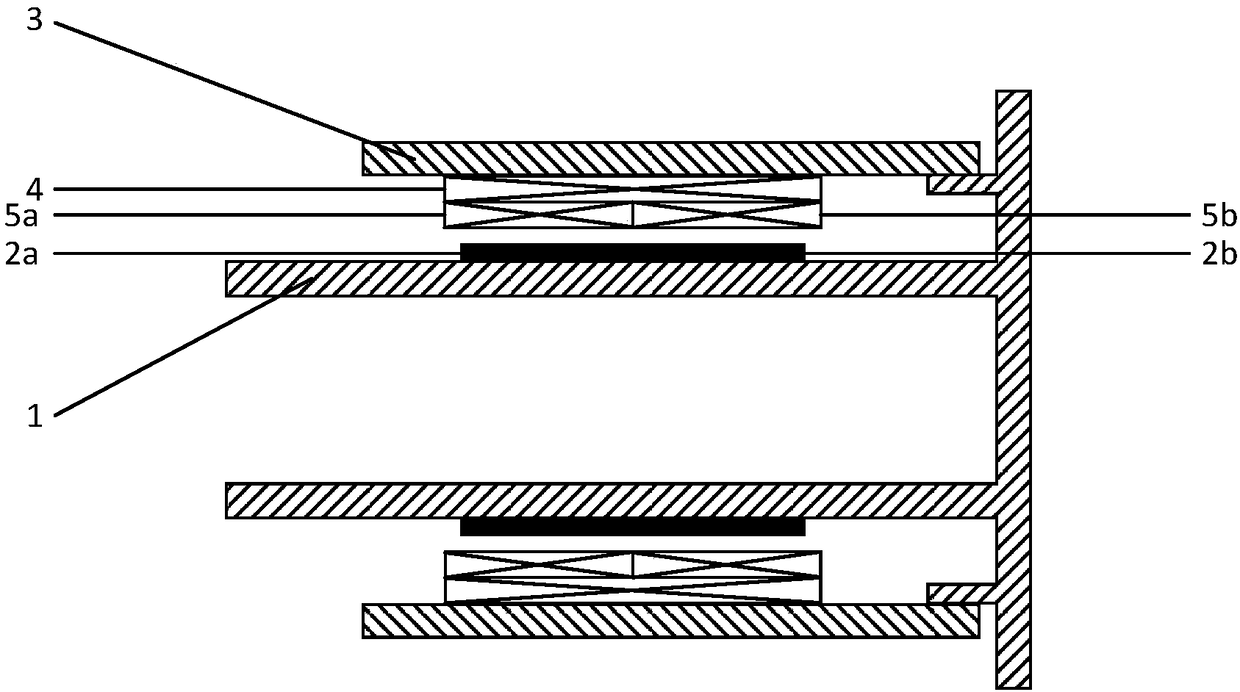

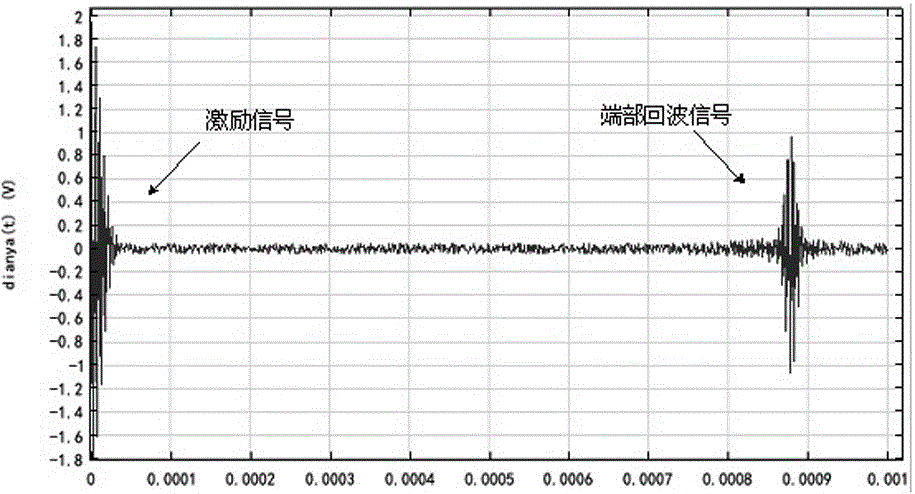

Ferromagnet magnetostrictive effect-based method for testing length of anchor rod

InactiveCN101545755ANo close contactNo need for tight media couplingUsing electrical meansInverse magnetostrictive effectFiltration

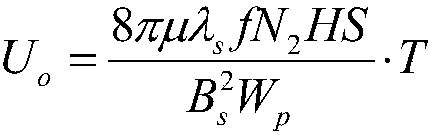

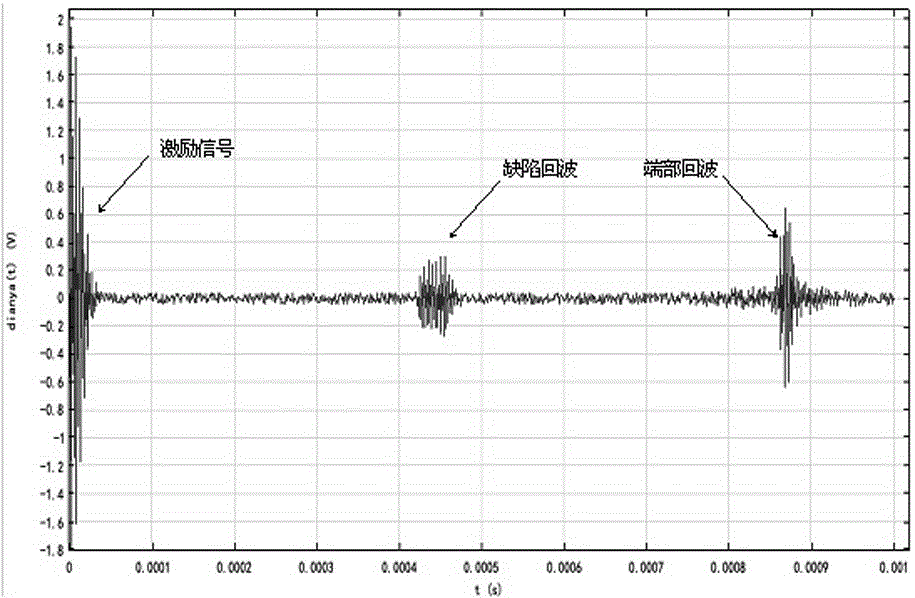

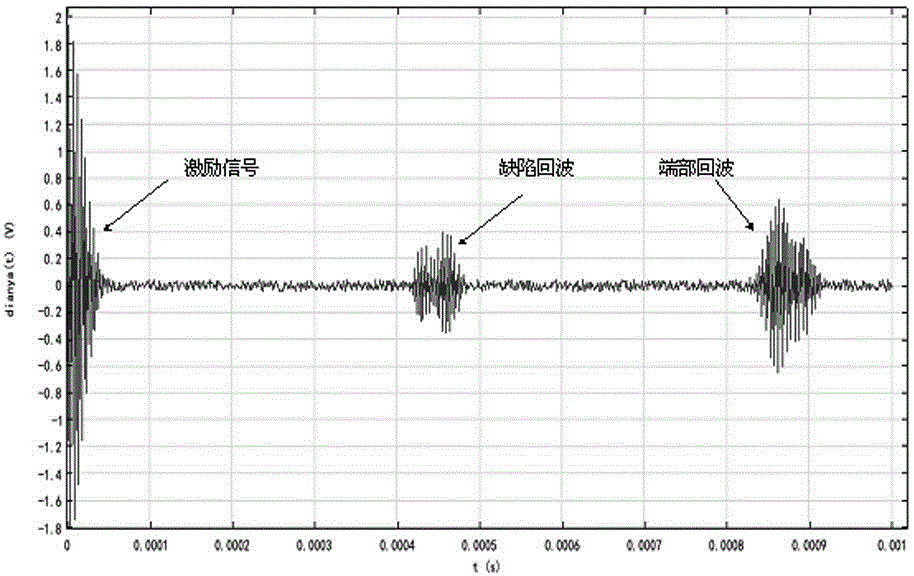

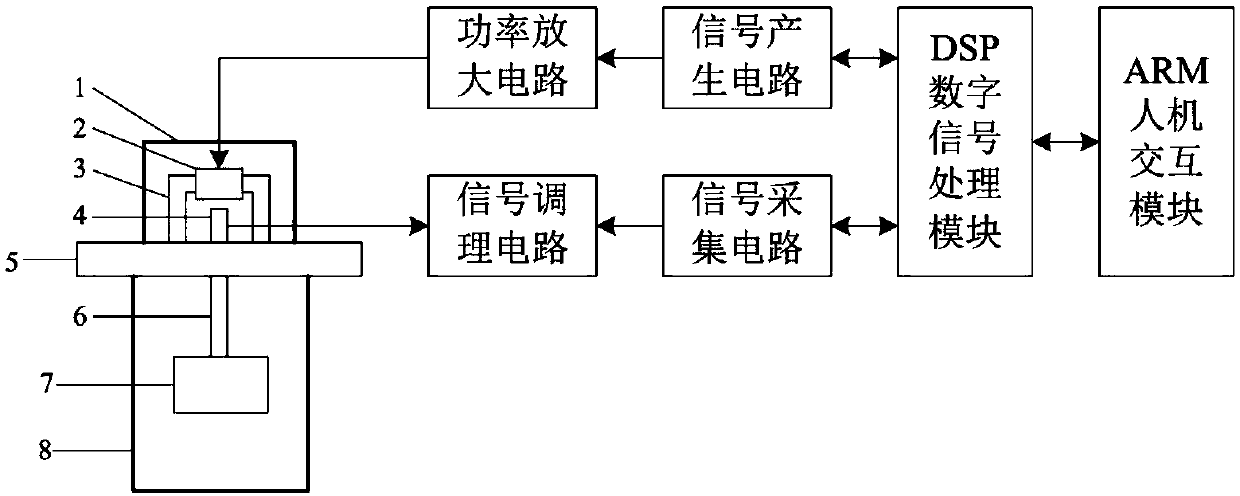

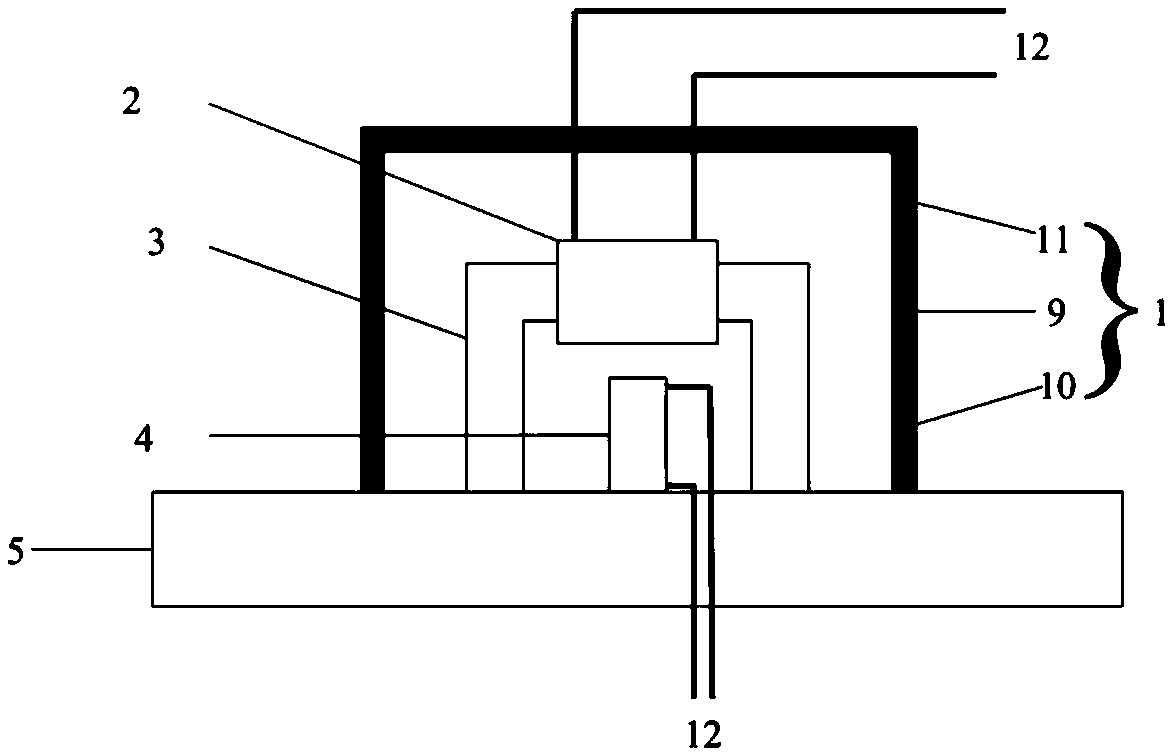

The invention discloses a ferromagnet magnetostrictive effect-based method for testing the length of an anchor rod, which comprises the following steps that: a magnetostrictive waveguide sensor is arranged on the free end of an anchor rod to be tested; a static bias magnetic field is applied at the mounting position of the magnetostrictive waveguide sensor; an exciting pulse signal is applied to the magnetostrictive waveguide sensor to excite mechanical vibration on the free end of the anchor rod; the sizes of the exciting pulse signal, exciting frequency and the static bias magnetic field are set to excite waveguides mainly in a longitudinal mode in the anchor rod; a receiving unit converts an elastic wave signal in a member to be tested into an electrical signal by using an inverse magnetostrictive effect, and after signal amplification, filtration and rectification, signal averaging and A / D conversion treatment, the electrical signal enters a test signal processing unit to test the actual length of the anchor rod to be tested. The method can realize the excitation and detection of ultrasonic waves in the anchor rod. The test signal contains information on the length and defects of the anchor rod and the actual length of a measured anchor rod can be measured accurately through the processing and analysis of a waveguide reflected wave signal.

Owner:ZHEJIANG UNIV

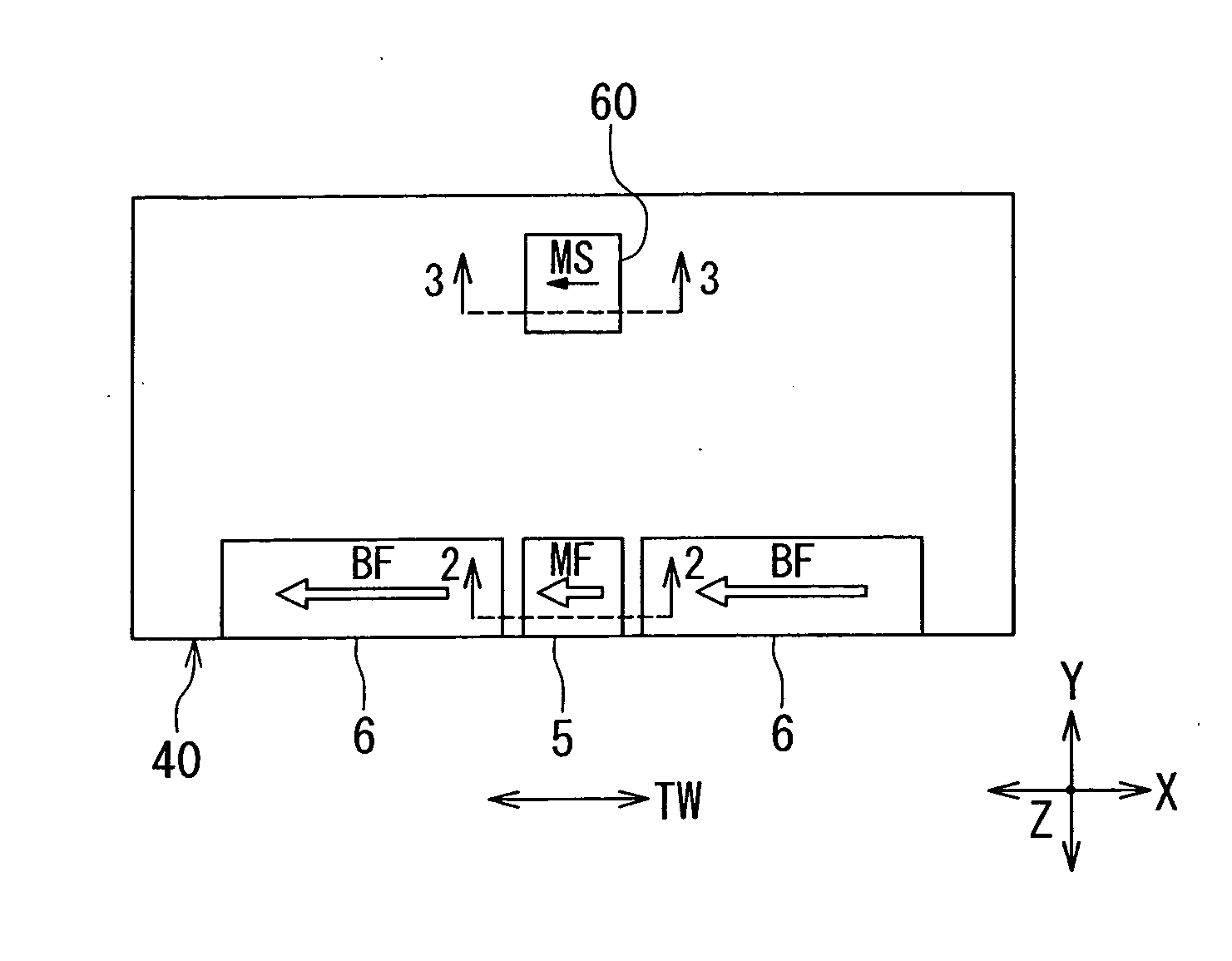

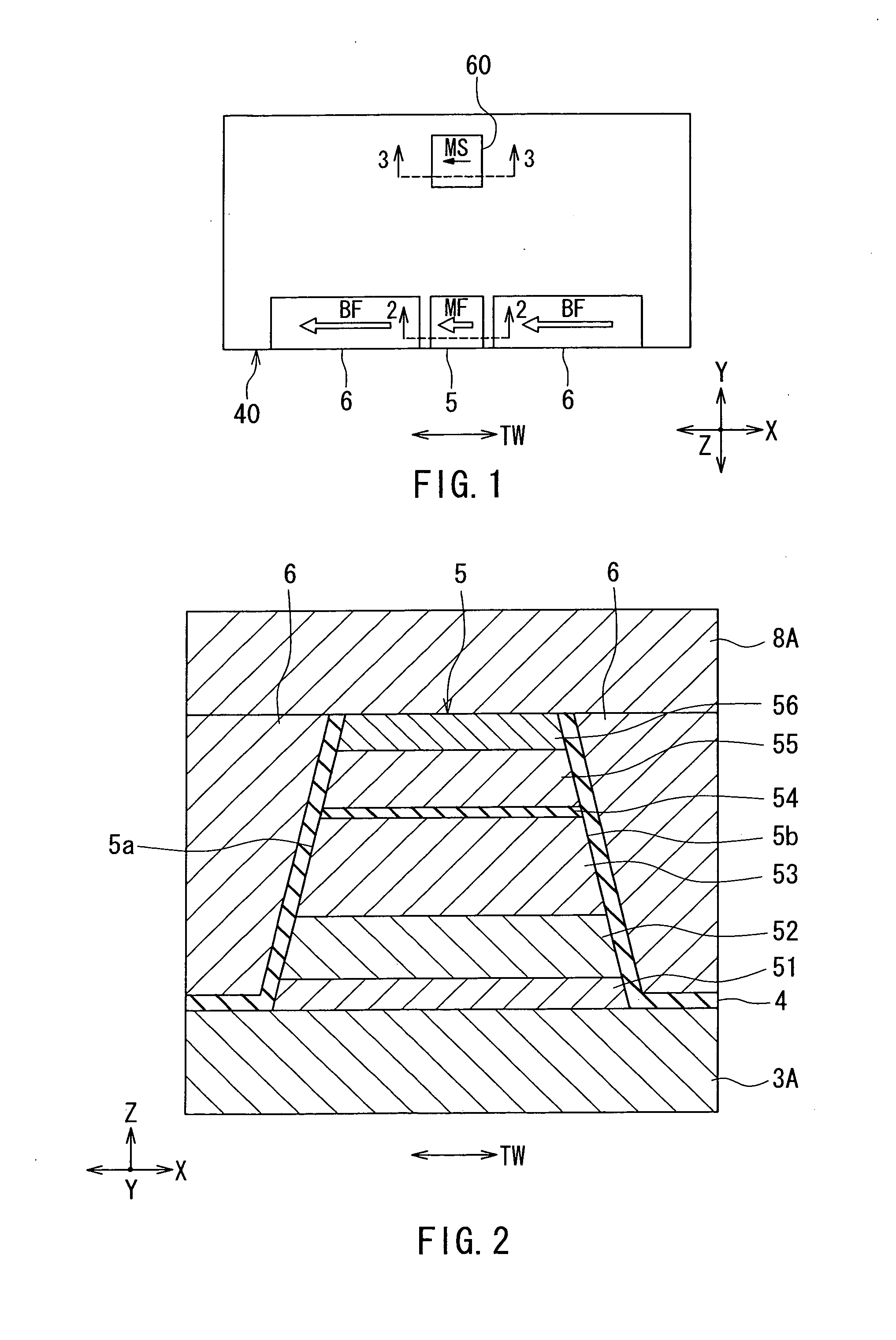

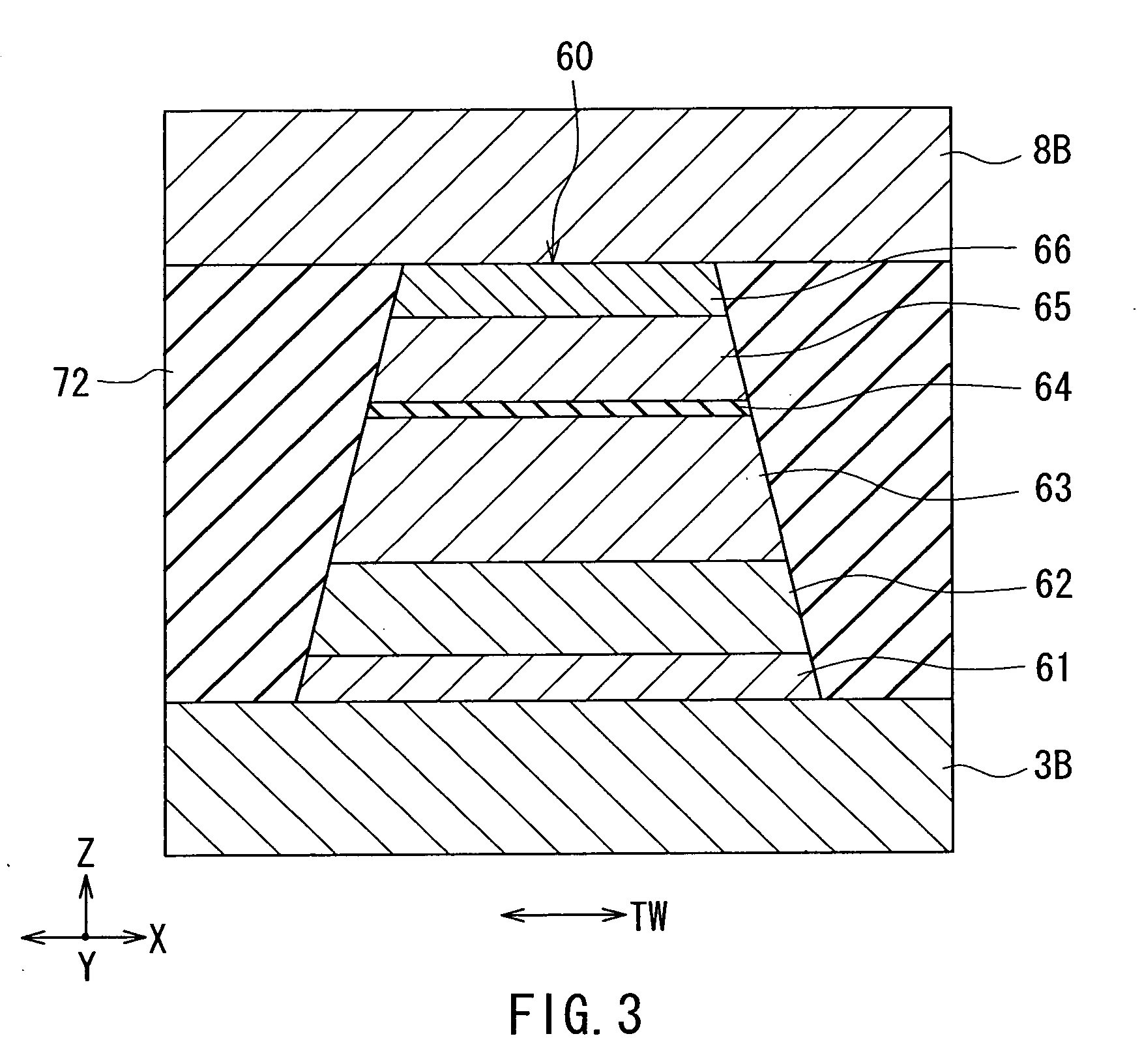

Magnetic detector including magnetoresistive element and impact sensor

ActiveUS20100182723A1Convenient amountNanomagnetismRecord information storageInverse magnetostrictive effectMagnetic reluctance

A magnetic detector includes a magnetoresistive element and an impact sensor. The magnetoresistive element has a plurality of element-constituent layers that are stacked and include a free layer having a magnetization direction that changes in response to a magnetic field to be detected by the magnetic detector. The impact sensor has a plurality of sensor-constituent layers that are made of materials the same as those of the element-constituent layers and stacked in the same order as the element-constituent layers. The plurality of sensor-constituent layers include an impact detecting layer corresponding to the free layer and having a magnetization direction that changes by an inverse magnetostrictive effect in response to distortion created in the impact detecting layer by an impact received by the magnetic detector. The impact detecting layer exhibits a greater amount of change in magnetization direction when the magnetic detector receives an impact, compared with the free layer.

Owner:TDK CORPARATION

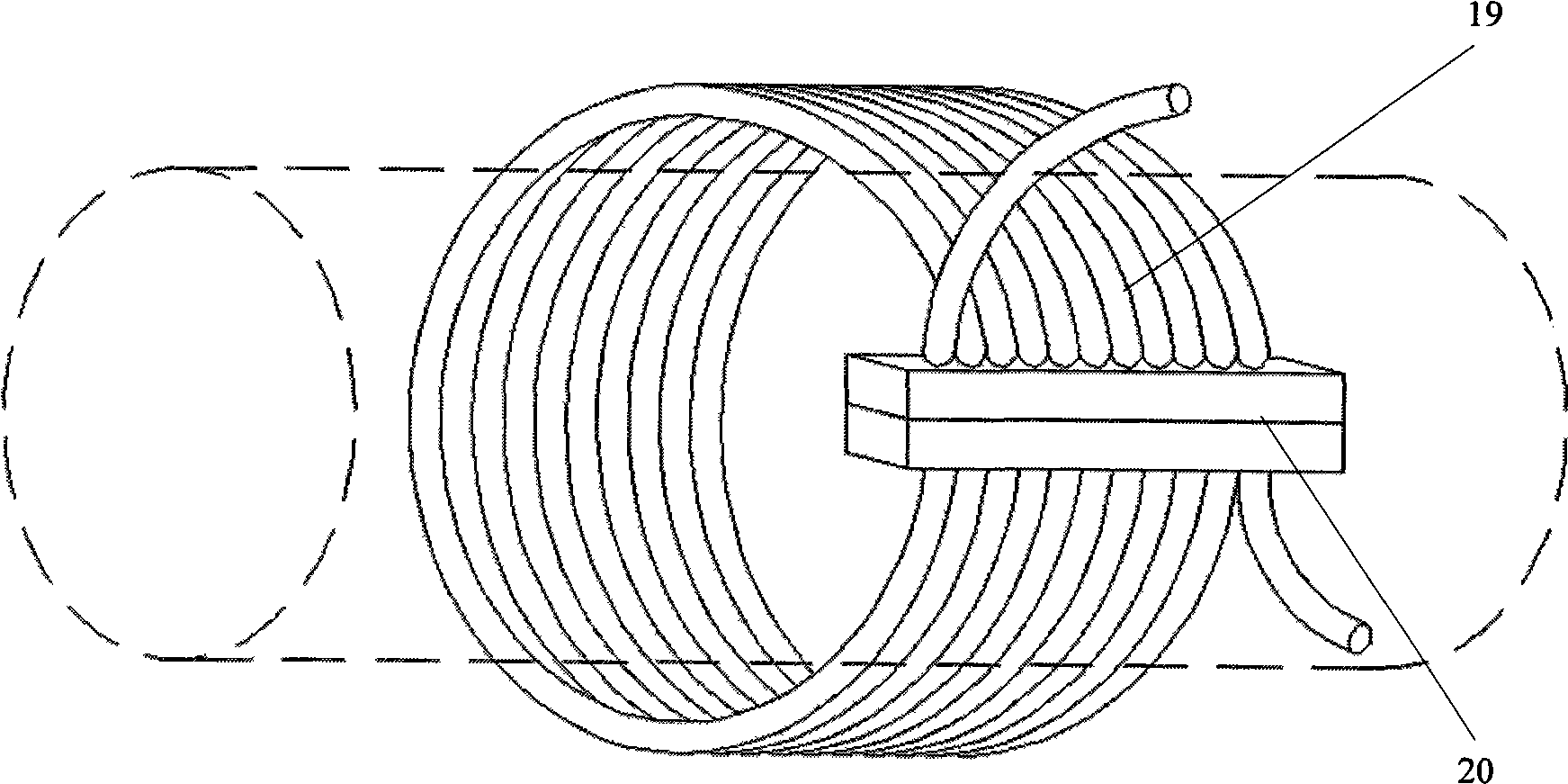

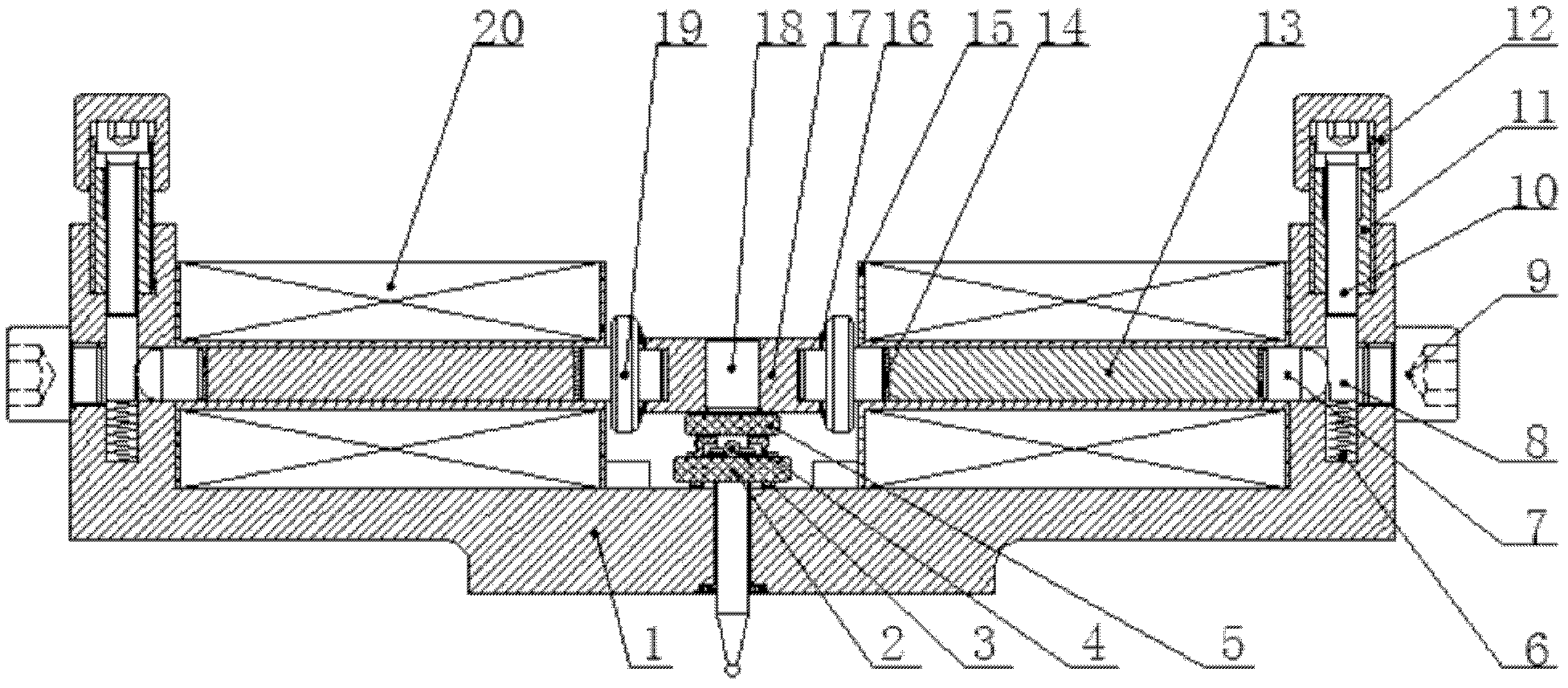

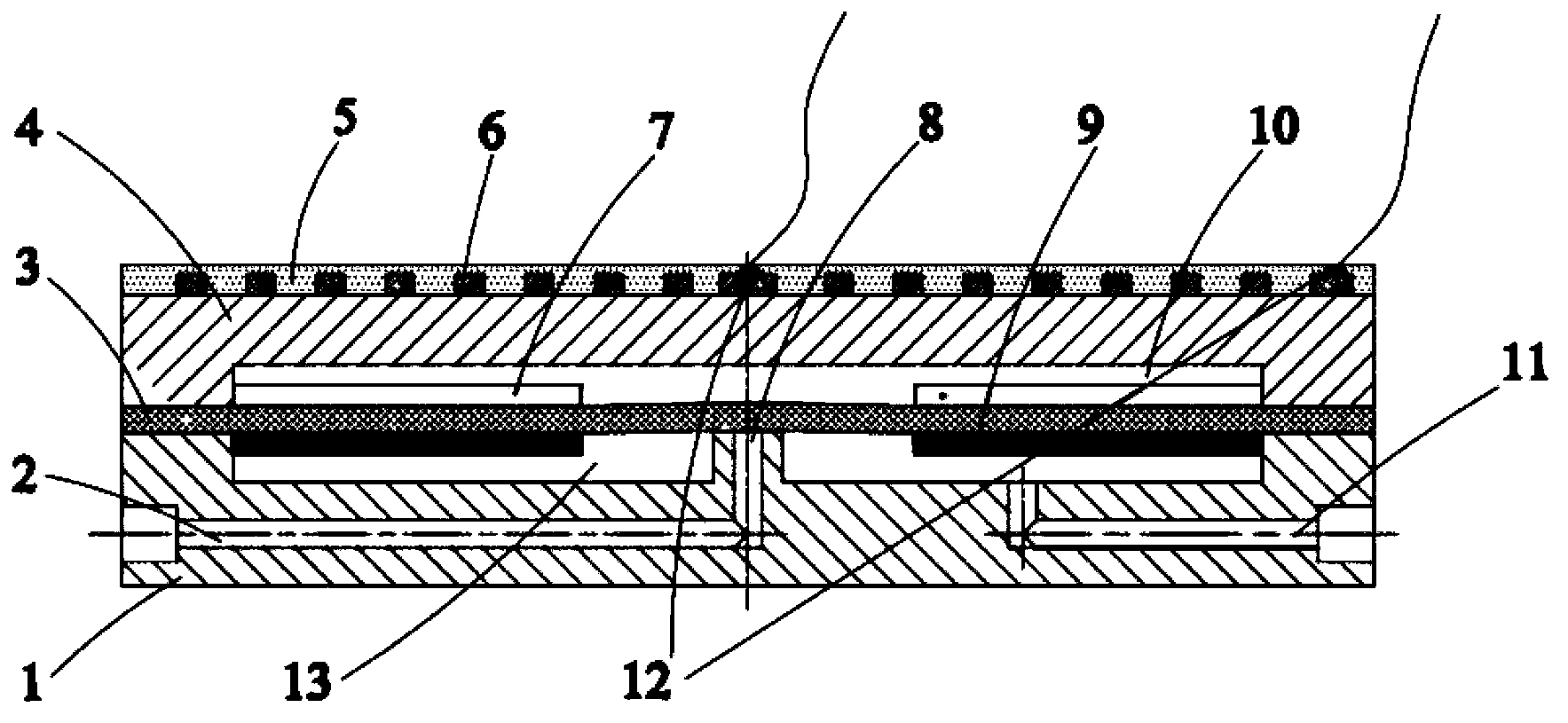

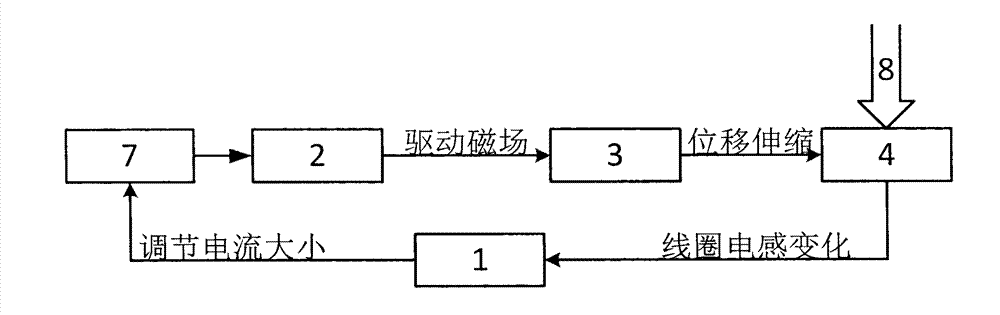

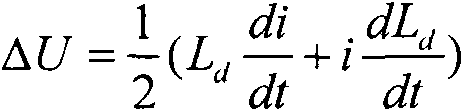

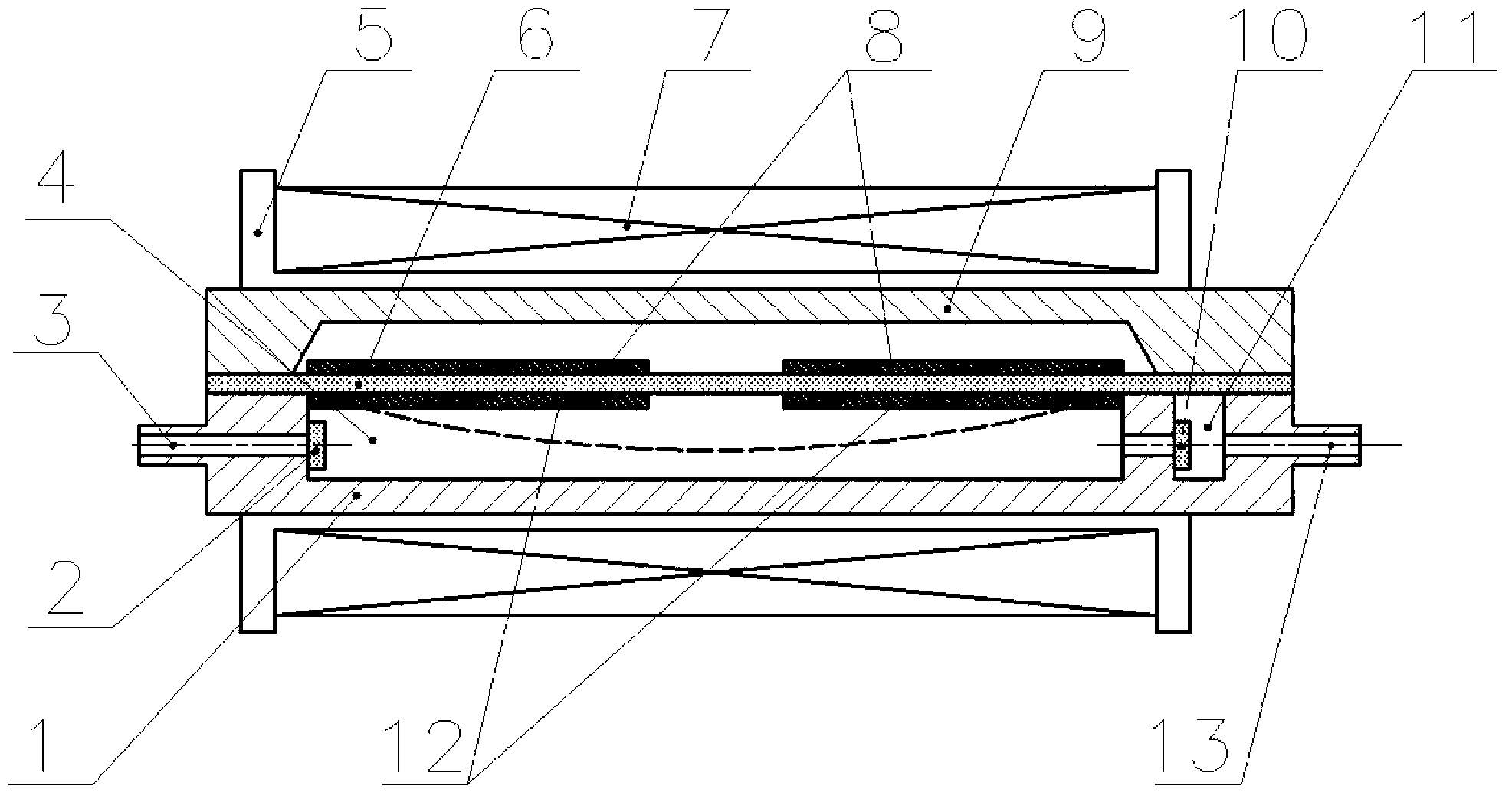

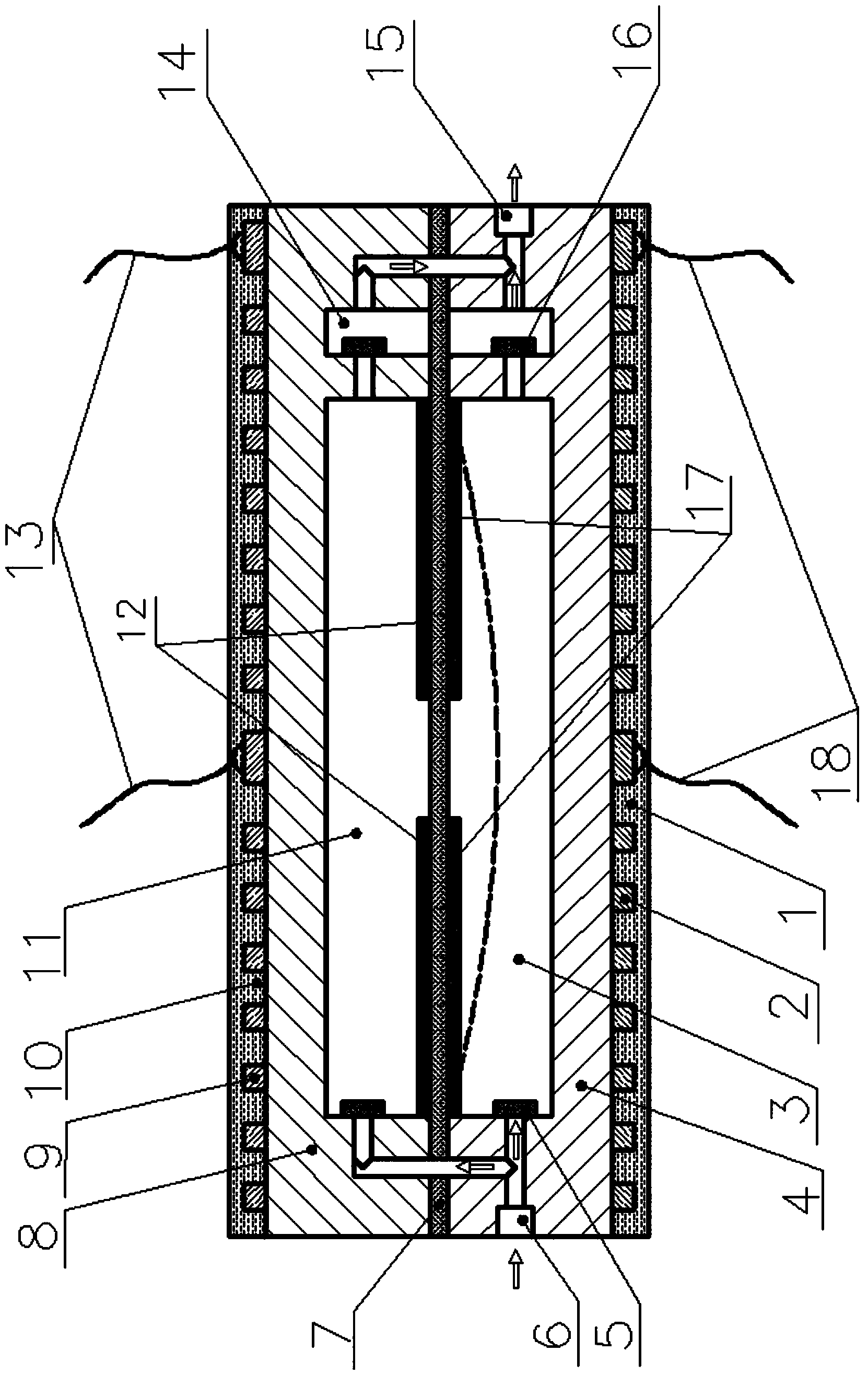

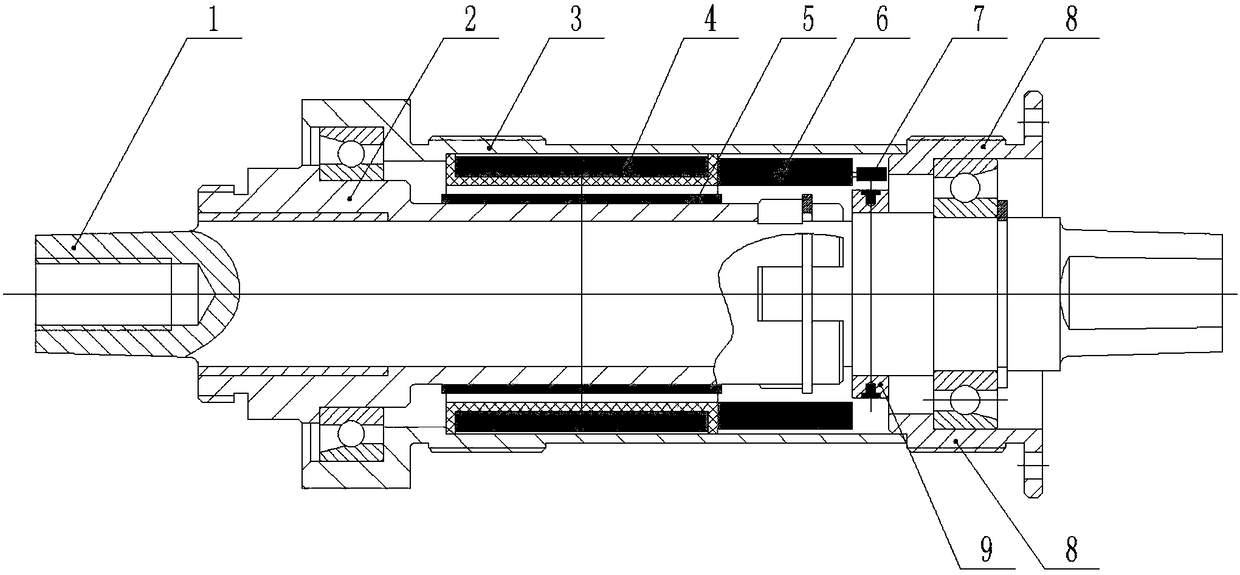

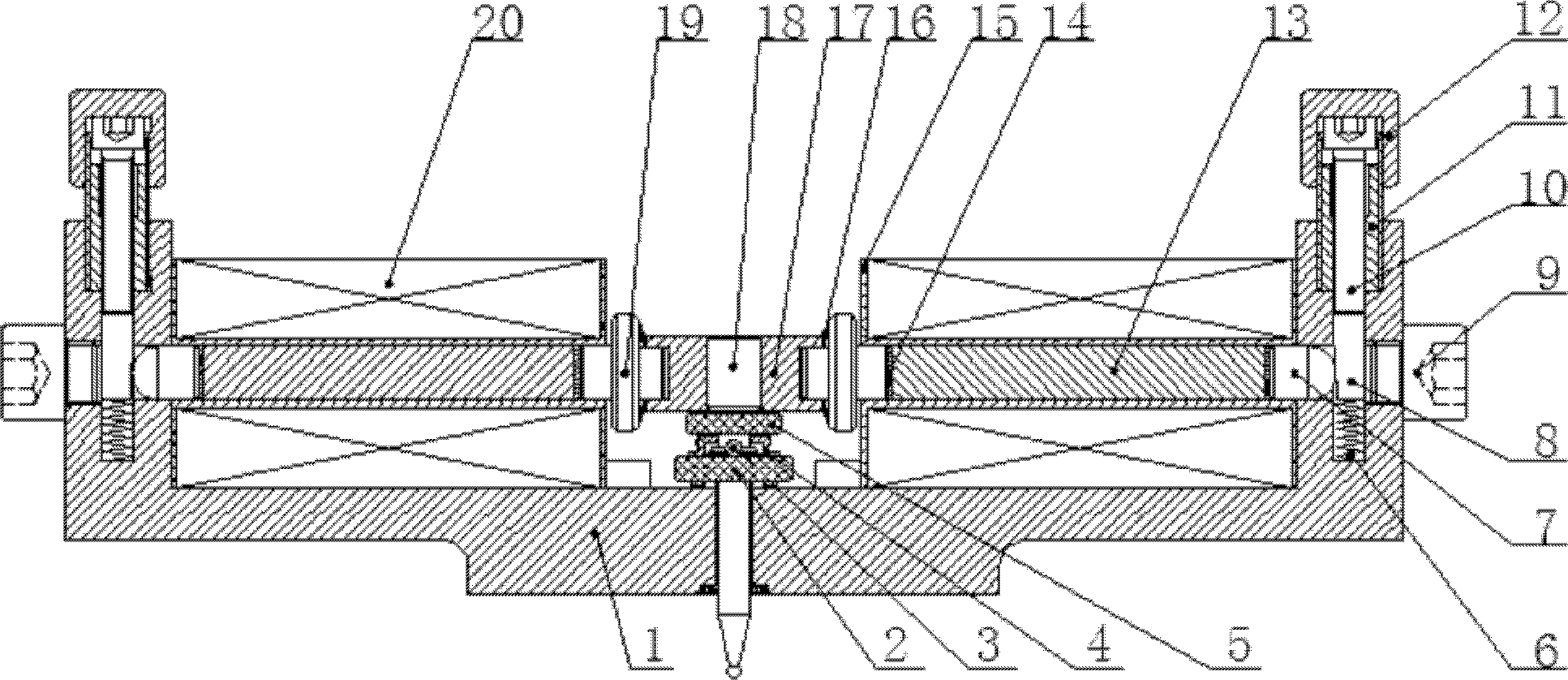

Two-phase opposed super magnetostrictive self-sensing driver

InactiveCN102620031AImprove response speedHigh control precisionOperating means/releasing devices for valvesPiezoelectric/electrostriction/magnetostriction machinesInverse magnetostrictive effectMicrocontroller

The invention discloses a two-phase opposed super magnetostrictive self-sensing driver, relates to a super magnetostrictive material self-sensing technology and a micro drive technology and belongs to the technical fields of micro drive and electrical control. According to the two-phase opposed super magnetostrictive self-sensing driver disclosed by the invention, the driving and self-sensing function of the driver is achieved by using magnetostriction and converse magnetostriction effects of a super magnetostrictive rod; two self-sensing driving assemblies are symmetrically arranged on two sides of a connecting piece (17) by disc springs (16) for mutually coupling to output a certain displacement and driving force; the pre-compression of the super magnetostrictive rod is accurately controlled and finely adjusted, so that the super magnetostrictive rod works in a linear interval; stable differential voltage is applied to two driving coils by a dual-output digital control power supply with a self-sensing detection and feedback function and a self-sensing signal is monitored in real time by using a real-time dynamic balance signal based on a DSP (Digital Signal Processor) high-speedsinglechip microcomputer, so that the real-time control and accurate positioning for the displacement of the connecting piece (17) are realized; and the two-phase opposed super magnetostrictive self-sensing driver is especially suitable for the field of hydraulic servo control.

Owner:BEIJING UNIV OF TECH

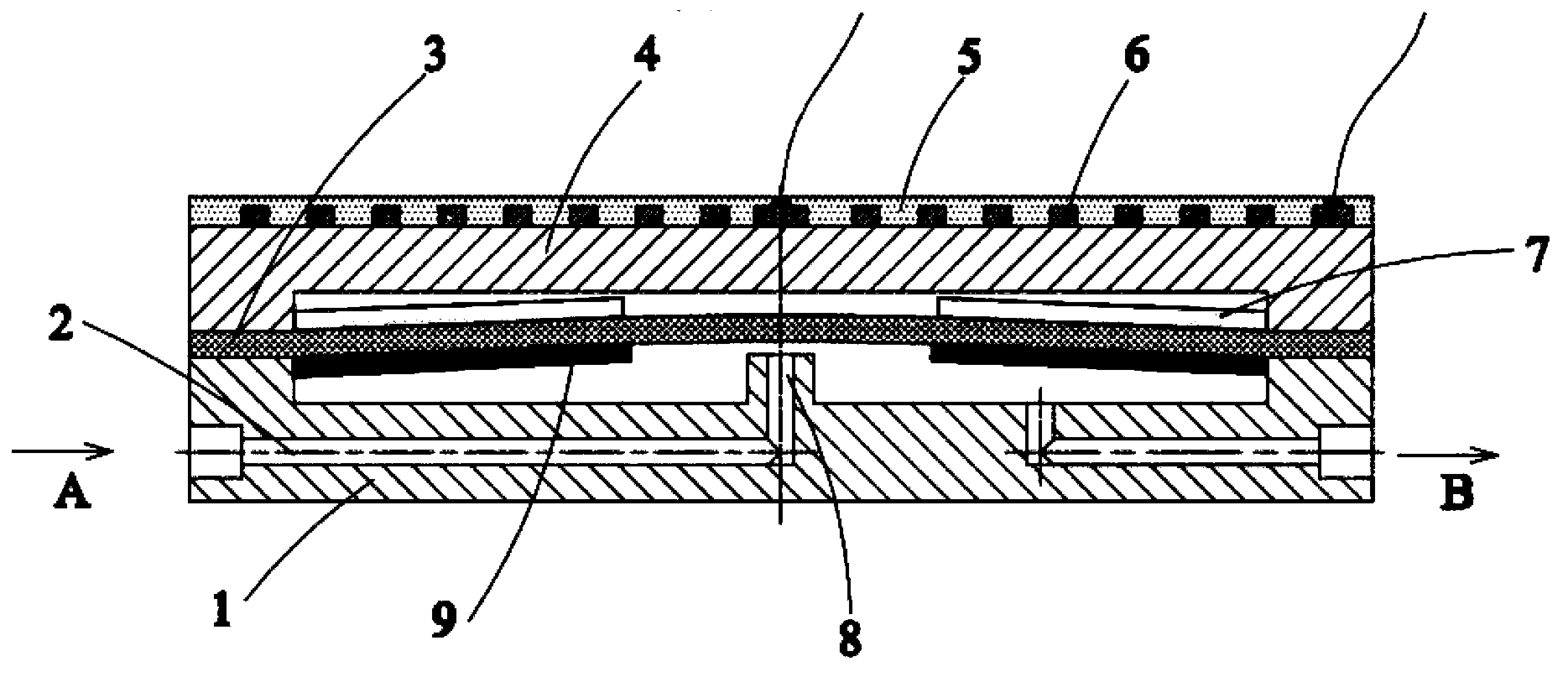

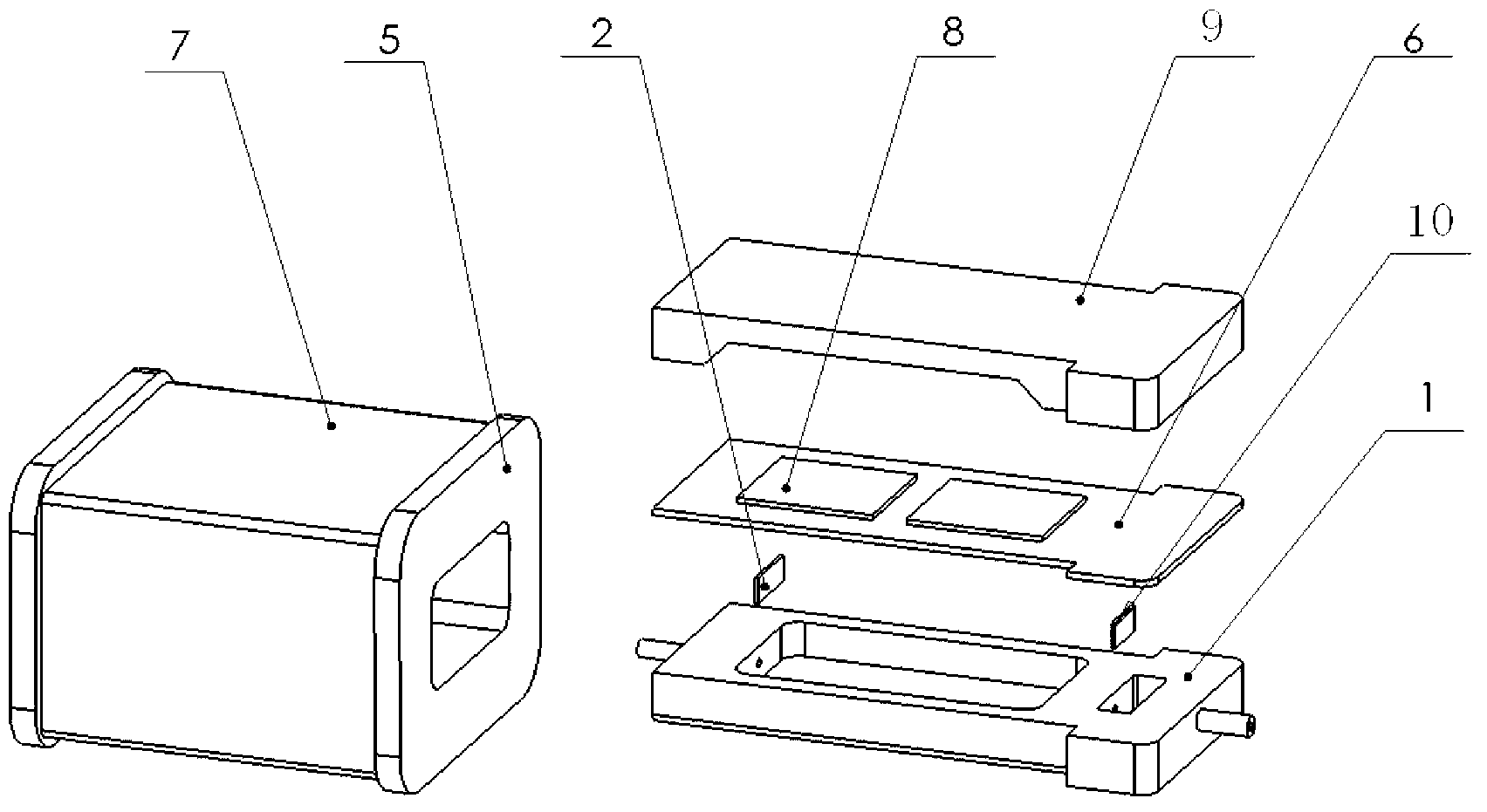

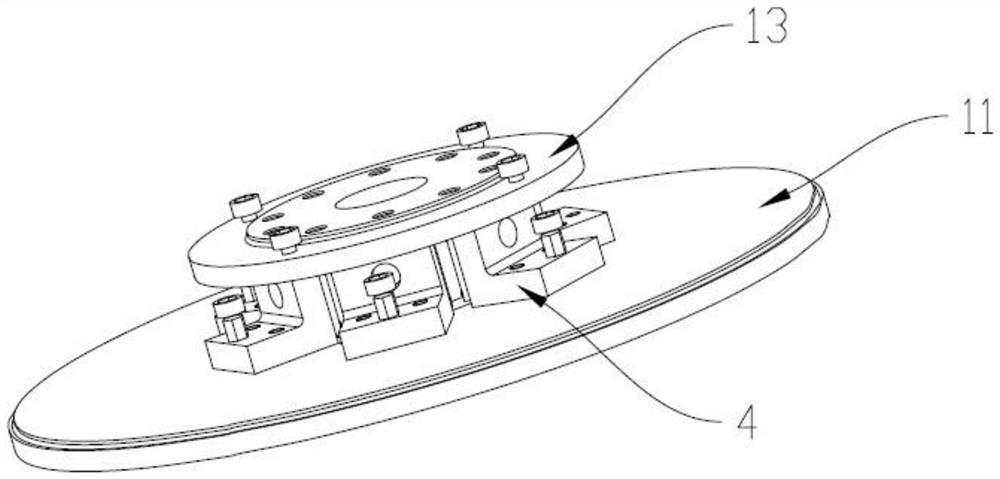

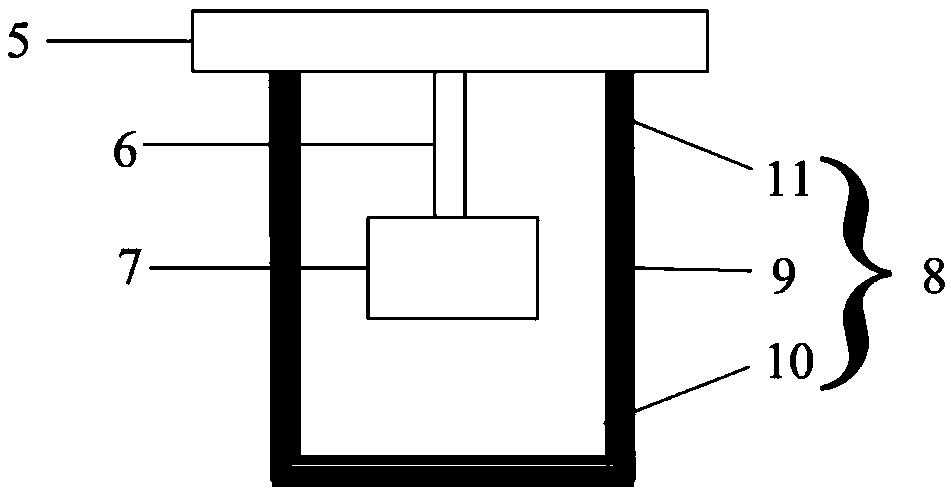

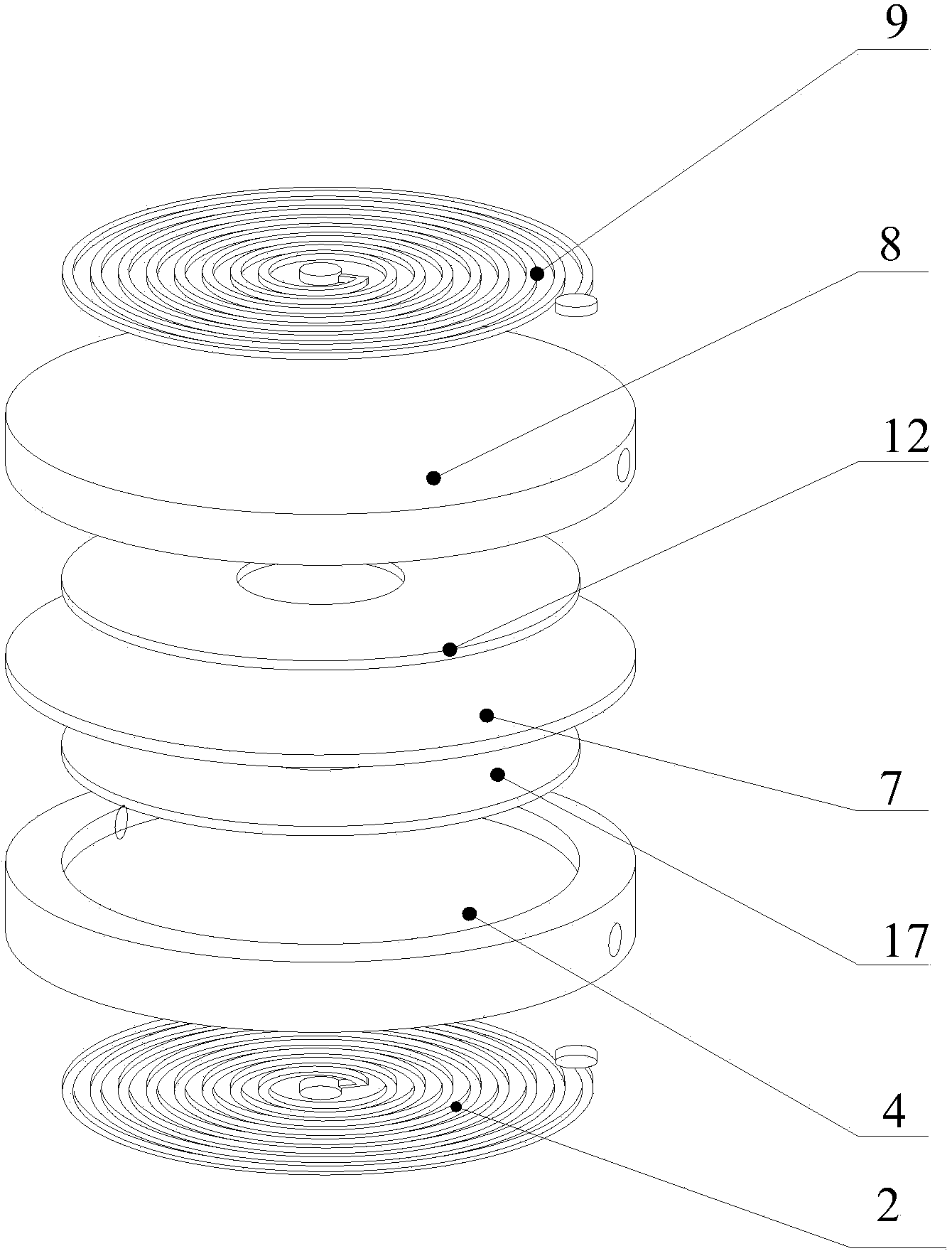

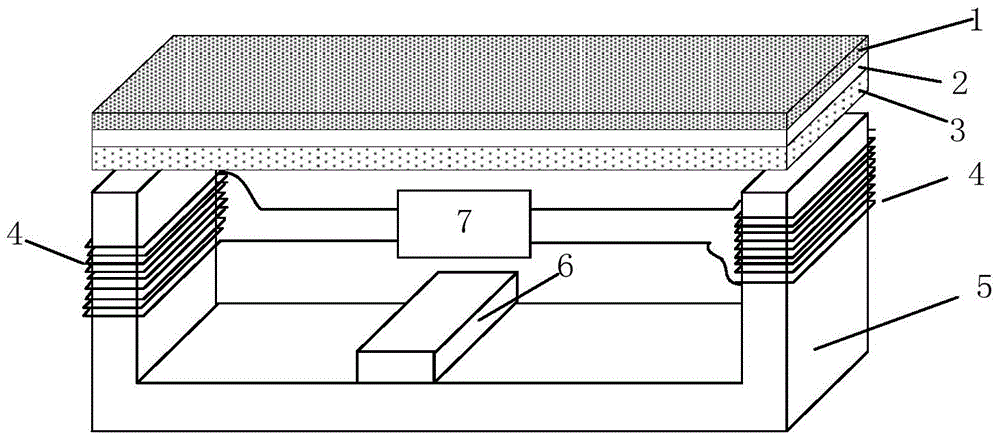

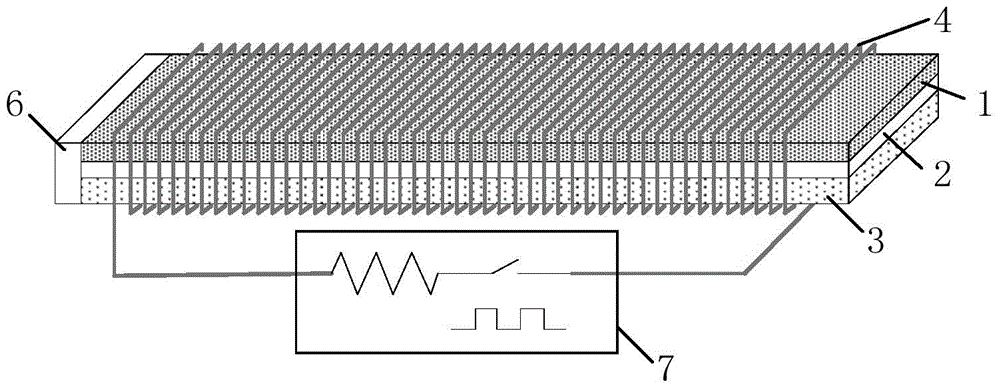

Planar coil driving-type microvalve based on super-magnetostriction film driver

InactiveCN102797872AImprove work performanceQuick responseDiaphragm valvesOperating means/releasing devices for valvesInverse magnetostrictive effectWorking fluid

The invention discloses a planar coil driving-type microvalve based on a super-magnetostriction film driver, which comprises a lower valve body (1), basal pieces (3), an upper valve body (4) and planar spiral coils (6), wherein the basal pieces (3) are sequentially laminated on the lower valve body (1); the bottom part of the lower valve body is respectively provided with a liquid inlet flow channel (2) and a liquid outlet flow channel (11) in the radial direction; a liquid chamber (13) is formed at the upper part of the lower valve body; the liquid inlet flow channel (2) is provided with a vertical upward flow channel mouth communicated with the liquid chamber; the liquid outlet flow channel (11) is communicated with the liquid chamber; inverse magnetostriction-effect films (7) are plated on the upper surfaces of the basal pieces (3); joule magnetostriction-effect films (9) are plated on the lower surfaces of the basal pieces (3); and after the planar spiral coils (6) are electrified, under the action of the excitation magnetic field, the magnetostriction film driver deforms and upward bends to open the working liquid flow channel so as to turn on / off the loop of a hydraulic system. The planar coil driving-type microvalve based on a super-magnetostriction film driver has the characteristics of small size, easiness in miniaturation, high response speed, strong controllability and the like.

Owner:ANHUI UNIV OF SCI & TECH

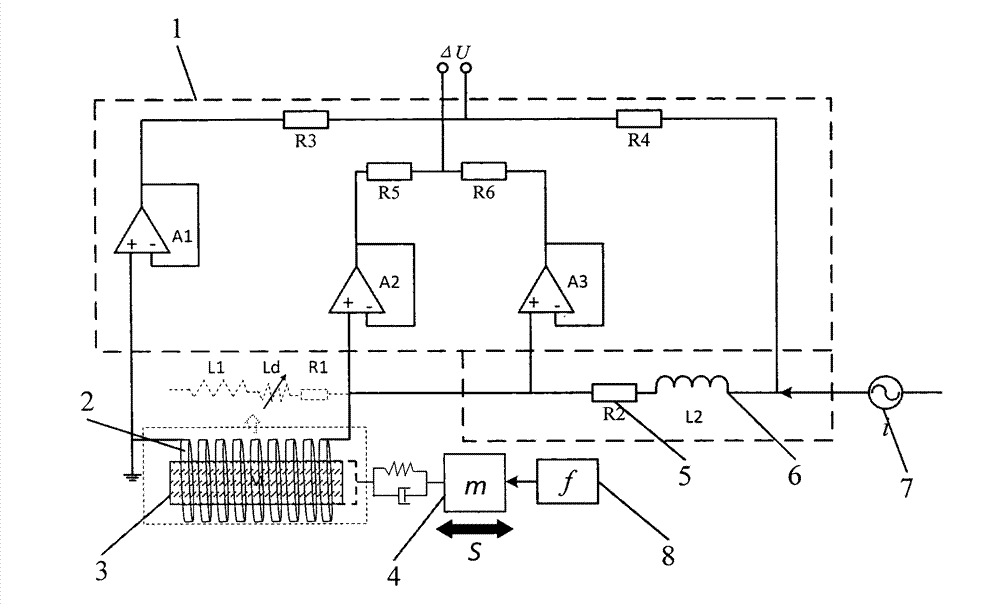

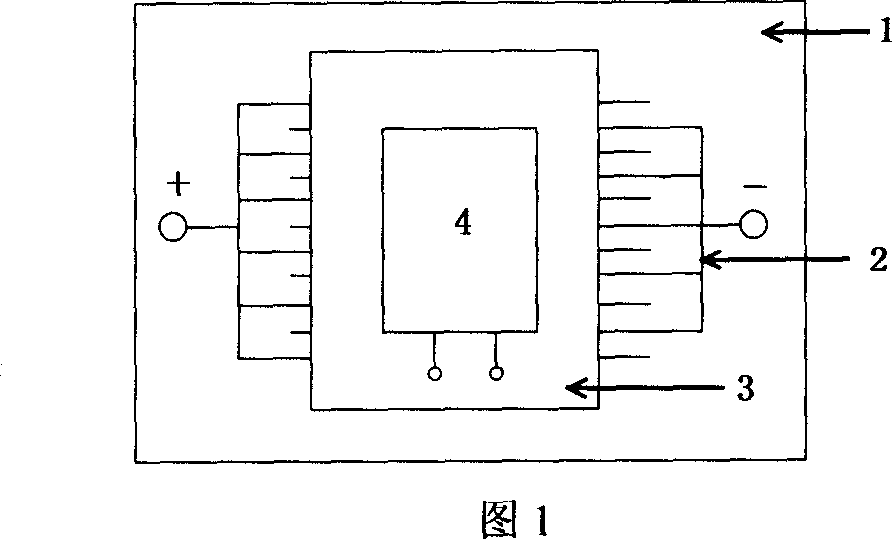

Giant magnetostrictive micro-displacement self-sensing driving method and actuator

InactiveCN103049005AHigh measurement accuracyHigh positioning accuracyControl using feedbackInverse magnetostrictive effectCoil inductance

The invention provides a giant magnetostrictive micro-displacement self-sensing driving method and an actuator, belongs to the field of ultra-precise machining and measurement, and particularly relates to a rapid ultra-precise positioning motion control method and device. The giant magnetostrictive micro-displacement self-sensing driving method can realize self-sensing of force by measuring inductance of a coil through magnetic conductivity variation of a giant magnetostrictive material, namely inductance of an exciting coil, caused by an external force, based on an inverse magnetostrictive effect. According to the giant magnetostrictive micro-displacement self-sensing driving method provided by the invention, the inductance of the exciting coil can be measured by an inductance bridge, so that matched inductive reactance and impedance can be adjusted, and the bridge is balanced. The bridge is not balanced when being stressed by disturbance of the external force, and an inductance value variation of the exciting coil can be obtained by measuring unbalanced voltage through differential motion and operational amplification, so that a disturbing force can be obtained. The actuator mainly consists of a cylindrical magnetostrictive rod, the exiting coil, an elastic membrane and a water cooling sleeve. According to the giant magnetostrictive micro-displacement self-sensing driving method provided by the invention, the cylindrical coil not only provides a driving magnetic field but also is used as a sensor for measuring the disturbing force. In a high-speed ultra-precise positioning motion process, the error interference generated by the external disturbing force is reduced.

Owner:HARBIN INST OF TECH

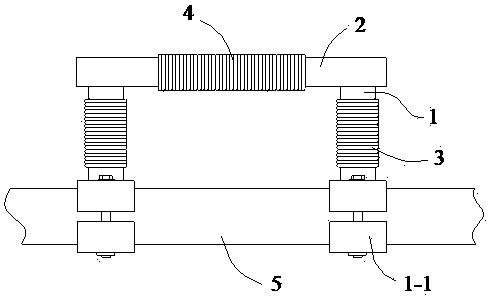

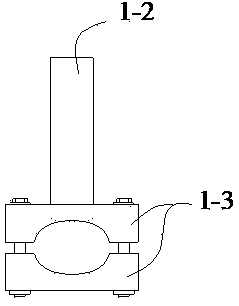

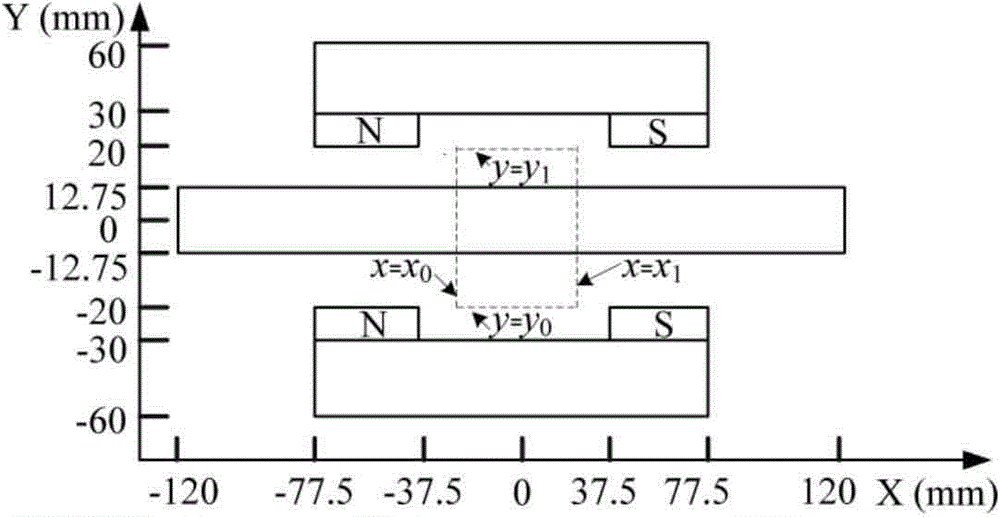

Inverse magnetostrictive effect-based suspender tension sensor and tension measuring method thereof

InactiveCN103868630ASimple structureEasy to assemble and disassembleForce measurement by measuring magnetic property varationInverse magnetostrictive effectMagnetic poles

An inverse magnetostrictive effect-based suspender tension sensor consists of two clamps, a connecting rod, two excitation coils and a detecting coil; a clamping part is formed at one end of each clamp, a connecting part is formed at the other end of each clamp, and the clamps are fixedly connected with a suspender to be measured by the clamping parts and are connected with the connecting rod by the connecting parts; the excitation coils are wound between the connecting parts and the clamping parts of the clamps; the detecting coil is wound between the two connecting parts on the connecting rod; the connecting rod forms a yoke, the clamps form magnetic poles, and the yoke, the two magnetic poles and the suspender to be measured between the two magnetic poles form a closed magnet loop. The inverse magnetostrictive effect-based suspender tension sensor has the beneficial technical effects of greatly simplifying the mounting process of the tension sensor, widening the application environment of a tensile stress sensor and providing a new means for the stress monitoring of the suspender.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

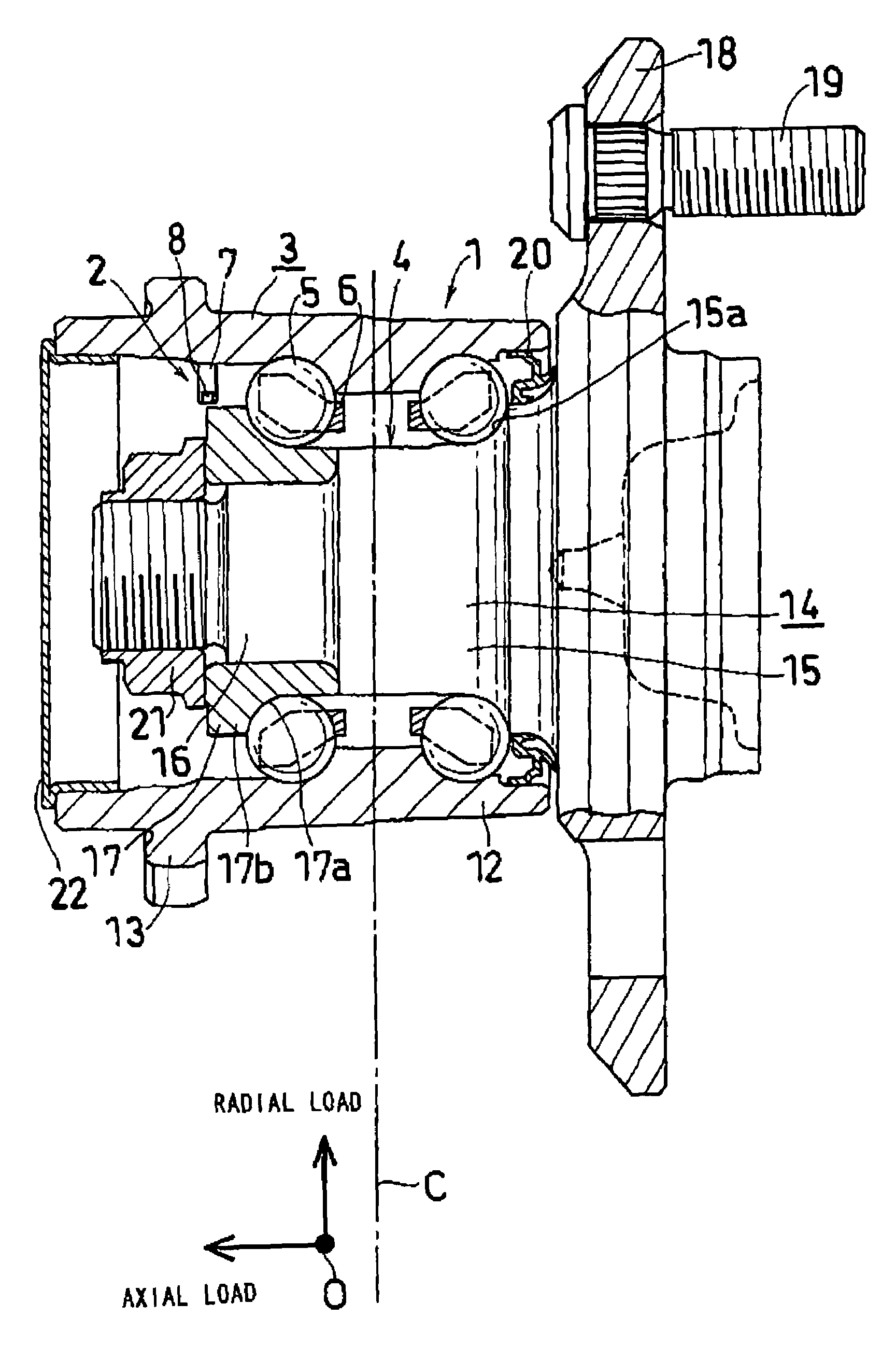

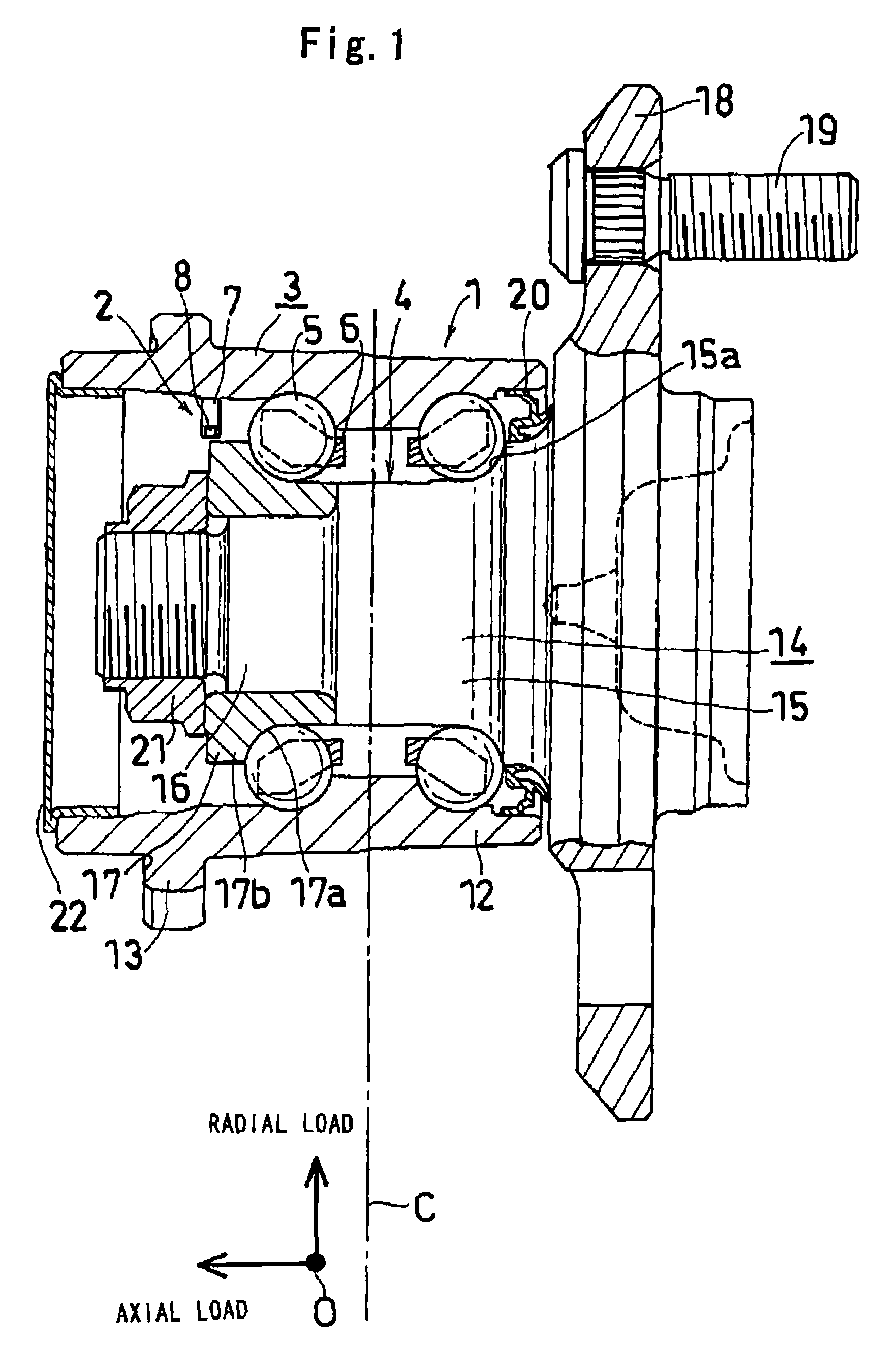

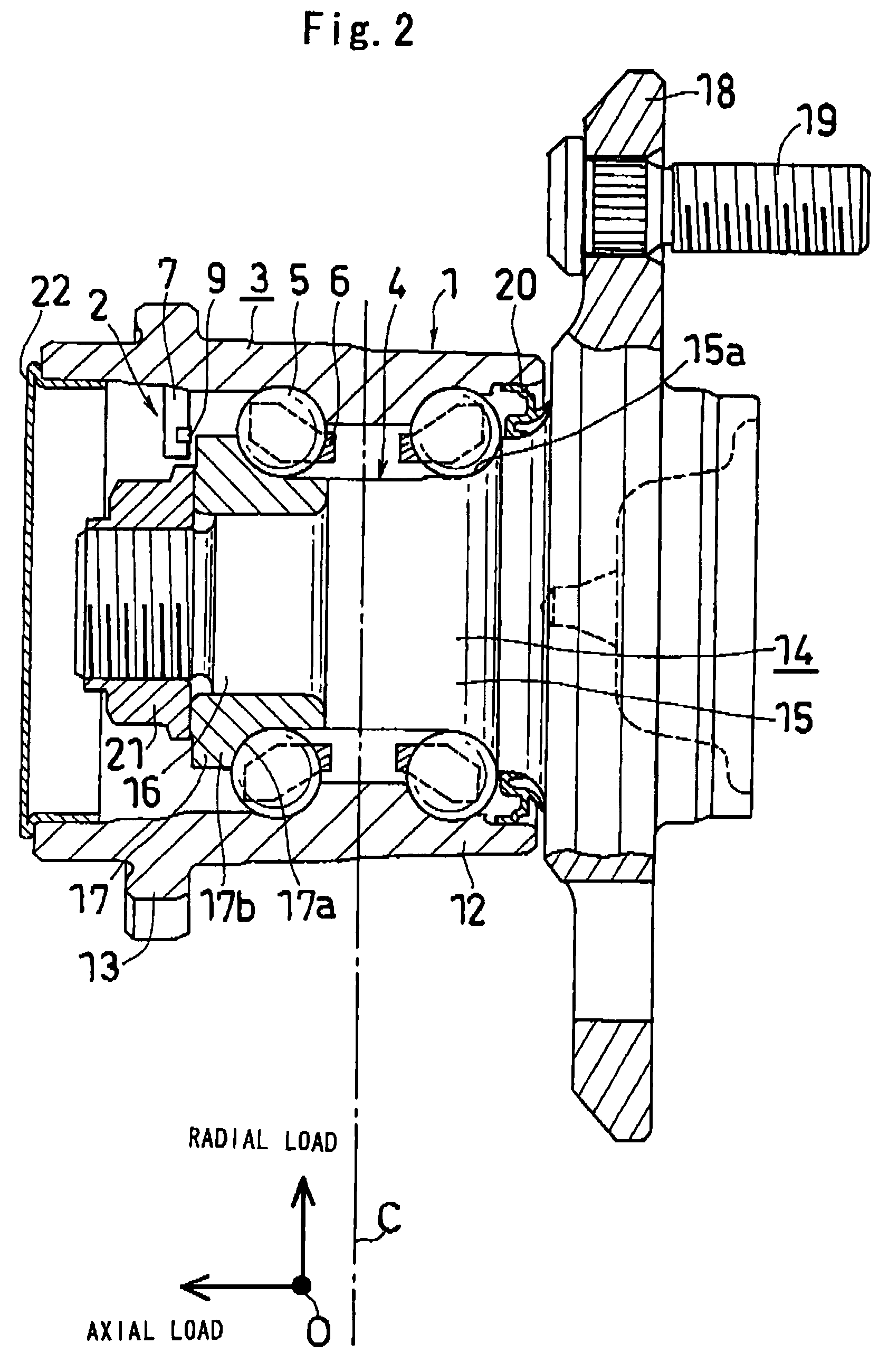

Hub unit with sensor

InactiveUS7520183B2High correlationLarge strainRolling contact bearingsBearing assemblyTensile strainInverse magnetostrictive effect

A hub unit with a sensor comprises a hub unit 1 including a body-side raceway member 3, a wheel-side raceway member 4 and two rows of rolling elements 5, and a sensor device 2. The sensor device 2 includes a magnetostrictive sensor 8 for detecting the inverse magnetostrictive effect, and the magnetostrictive sensor 8 is mounted to the body-side raceway member 3 so as to be capable of measuring the tensile strain in the uppermost part of an inner wheel 17 of the wheel-side raceway member 4. From the output of the magnetostrictive sensor 8, the tire grounding load and the rotational velocity are detected.

Owner:JTEKT CORP

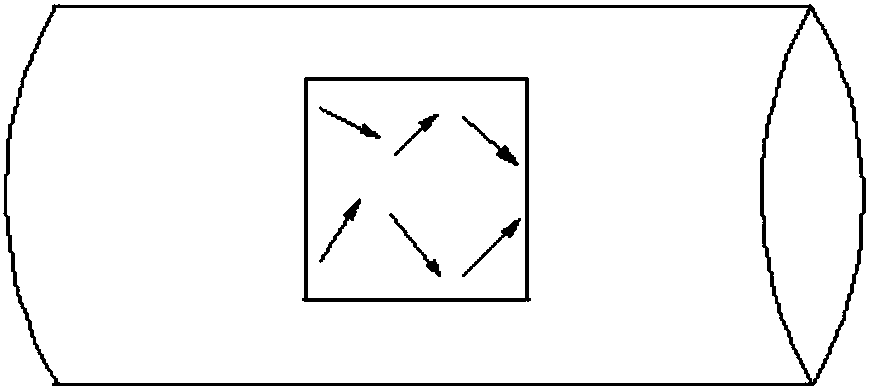

Intrinsic frequency measuring method for long and thin object

ActiveCN104374468AExcellent measurement methodAccurate measurementSubsonic/sonic/ultrasonic wave measurementUsing electrical meansInverse magnetostrictive effectFrequency spectrum

The invention provides an intrinsic frequency measuring method which can be widely used for measuring the intrinsic frequency of structures which are formed by permeability magnetic materials such as pipelines, anchor rods, steel wire ropes, stay cables, plates and tanks or non-permeability magnetic materials. According to the intrinsic frequency measuring method, contact type or non-contact type excitation and detection of a vibration signal are achieved by means of a sensor according to the magnetostrictive effect and the inverse magnetostrictive effect, so that the Fourier spectrum distribution curve corresponding to a system frequency response function H[a],[b] (f) is obtained, and the peak point of the Fourier spectrum distribution curve corresponding to the system frequency response function H[a],[b] (f) is determined, so that the intrinsic frequency of a system is obtained, wherein a is a measure point, and b is an excitation point. According to the intrinsic frequency measuring method, contact measurement is available, measurement of the lift-off distance between a large sensor and an object to be measured is also available, weak vibration signals can be detected, and the intrinsic frequency measuring method has a broad application prospect in intrinsic frequency measurement.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

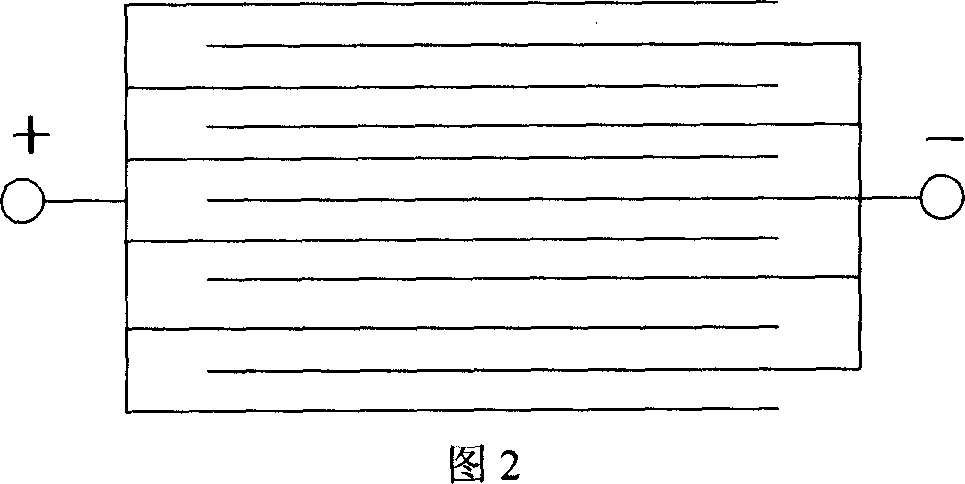

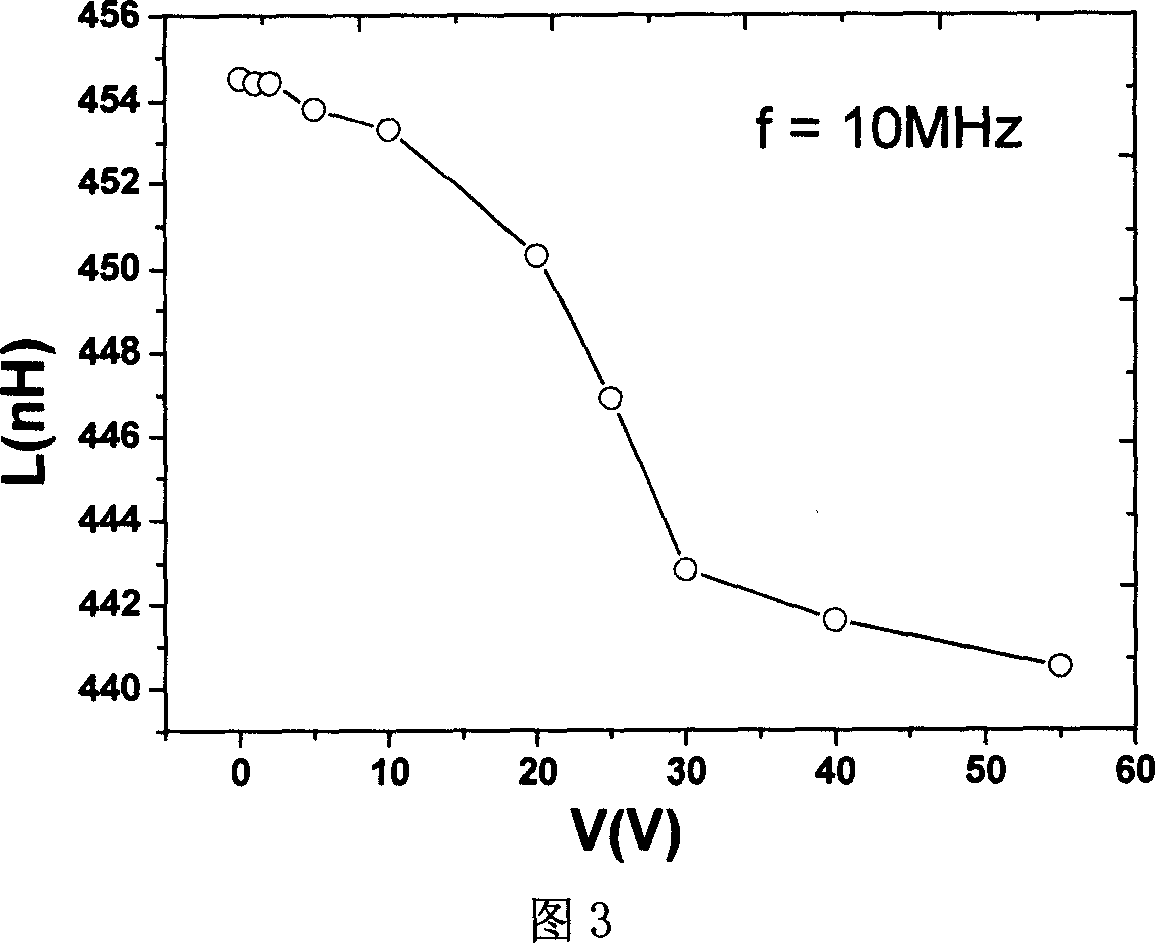

Voltage-control adjustable film inductor

InactiveCN1921164AEasily adjust the oscillation frequencyAchieve Impedance MatchingInductances/transformers/magnets manufacturePiezoelectric/electrostrictive/magnetostrictive devicesInverse magnetostrictive effectImpedance matching

The invention relates to a voltage-control adjustable film inductance. Wherein, on the piezoelectric ceramic substrate, it prepares film inductance with magnetic layer; uses the inverse piezoelectric effect of piezoelectric ceramic and the inverse magnetic flexible effect of magnetic film, via external voltage, to adjust the deformation of substrate and change the magnetic conductivity of magnetic film, to adjust the inductance. The invention can be used in movable communicator, T / R element, GPS, etc.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

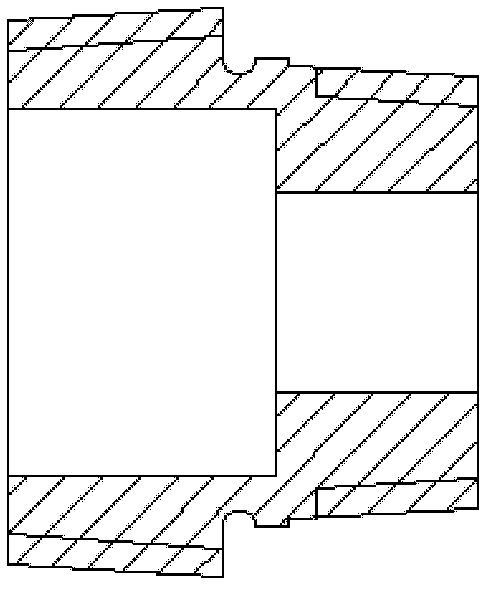

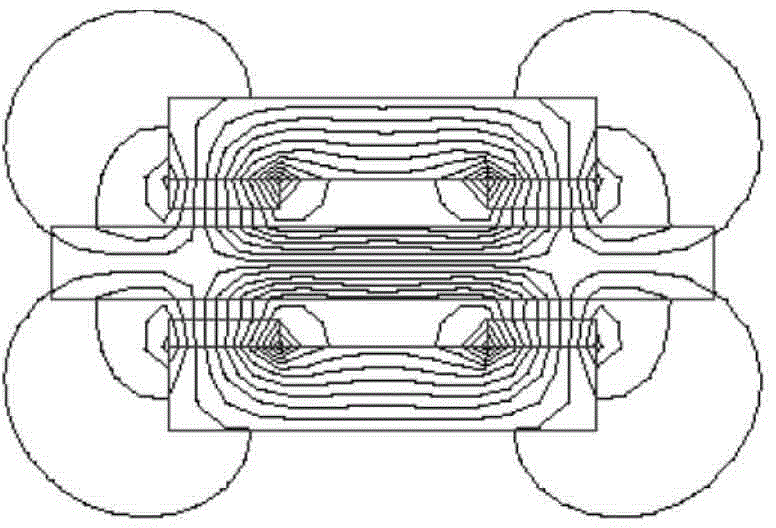

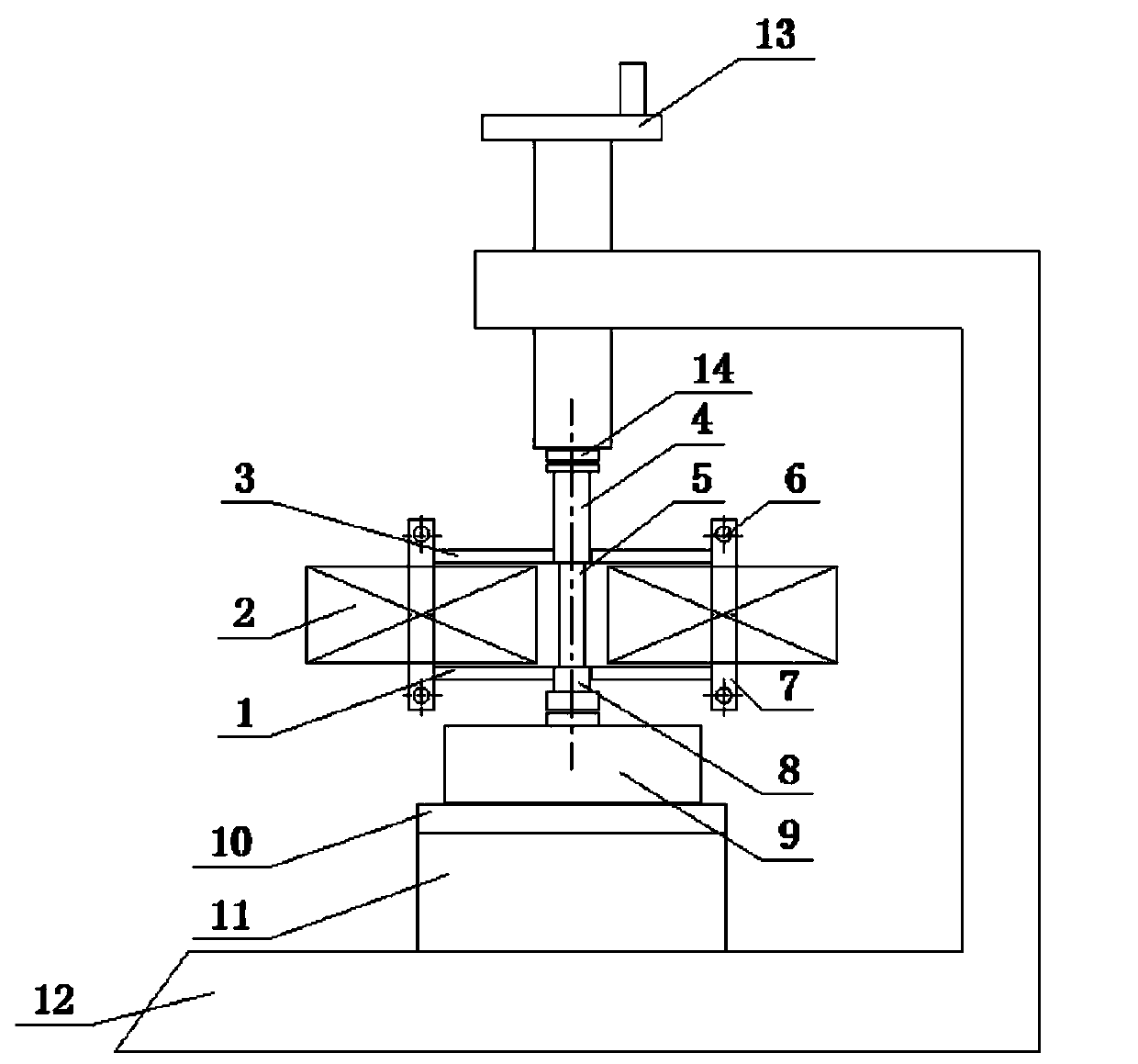

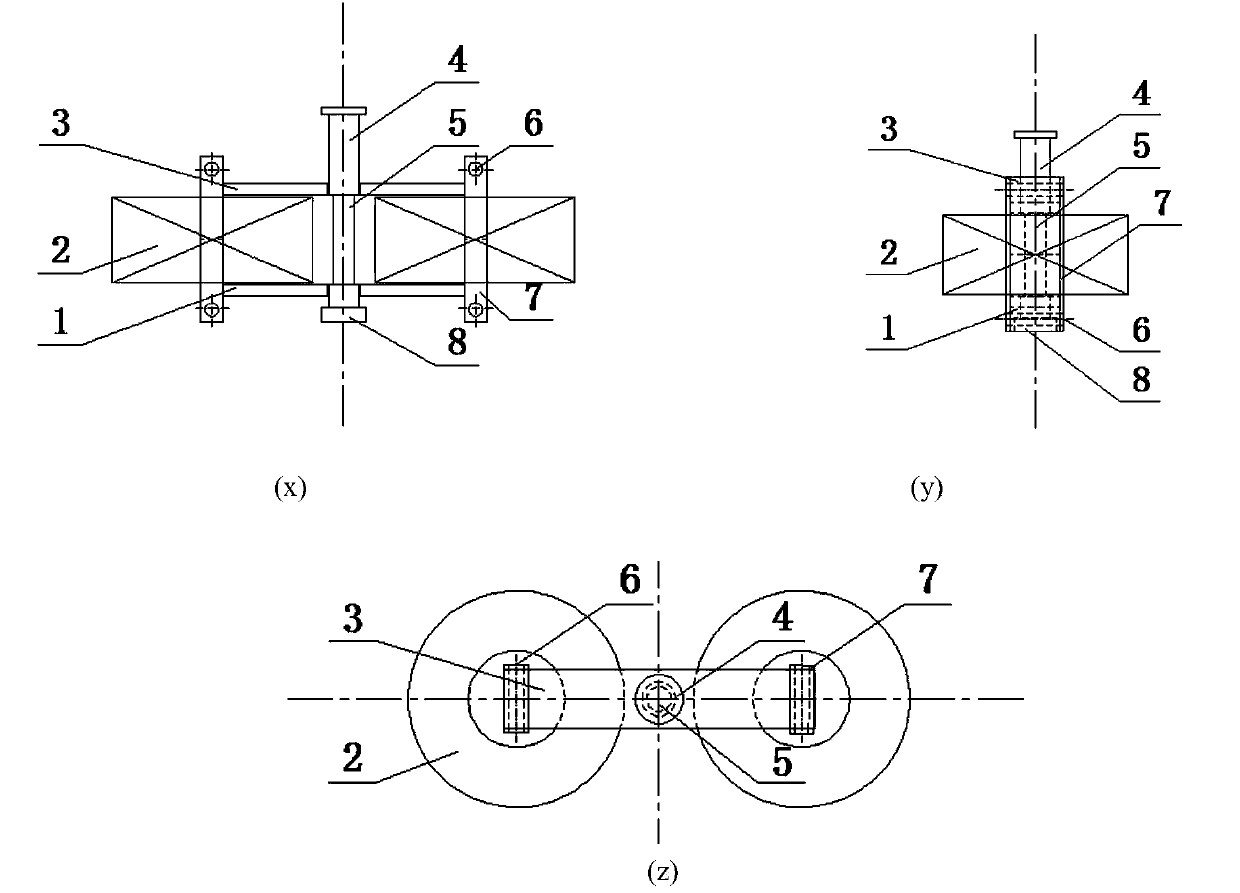

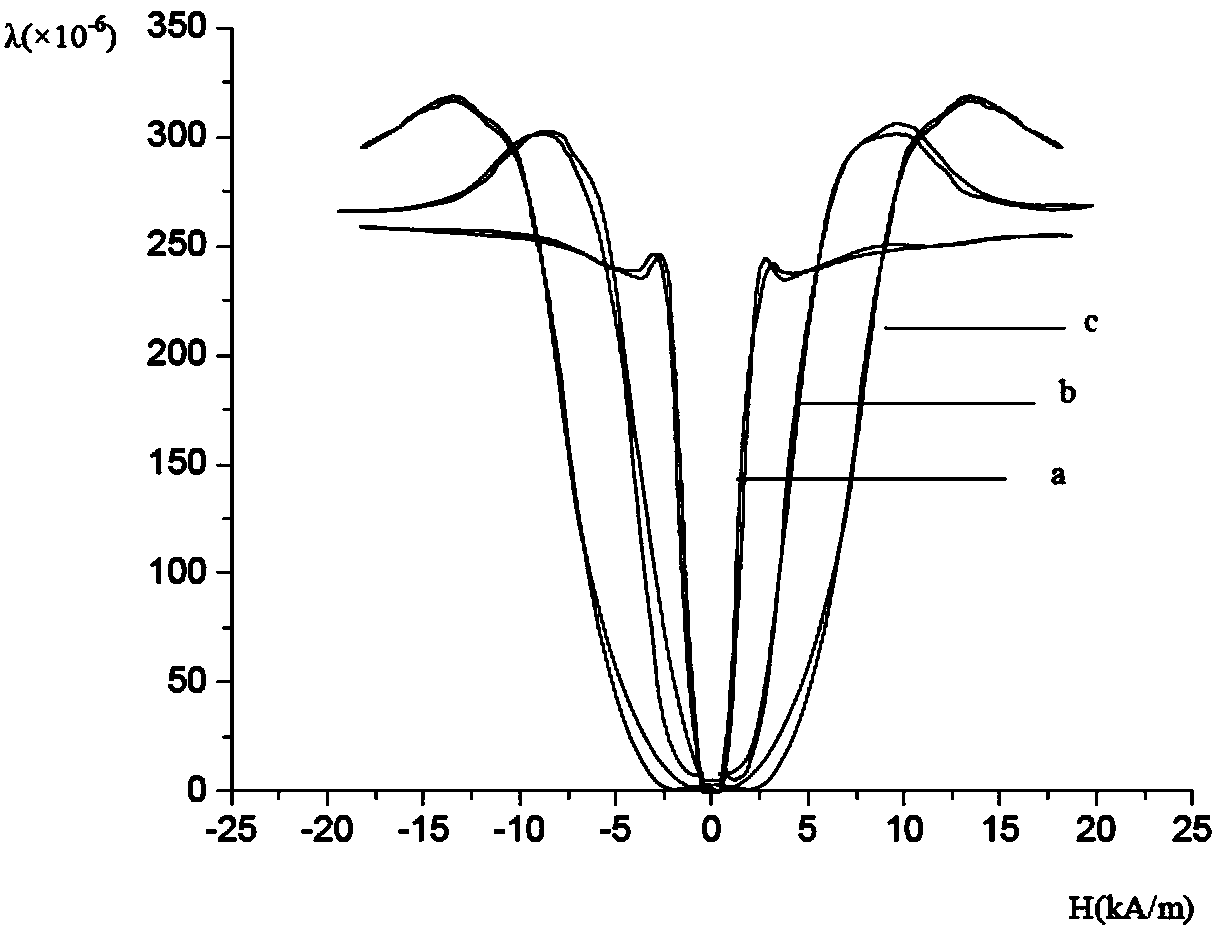

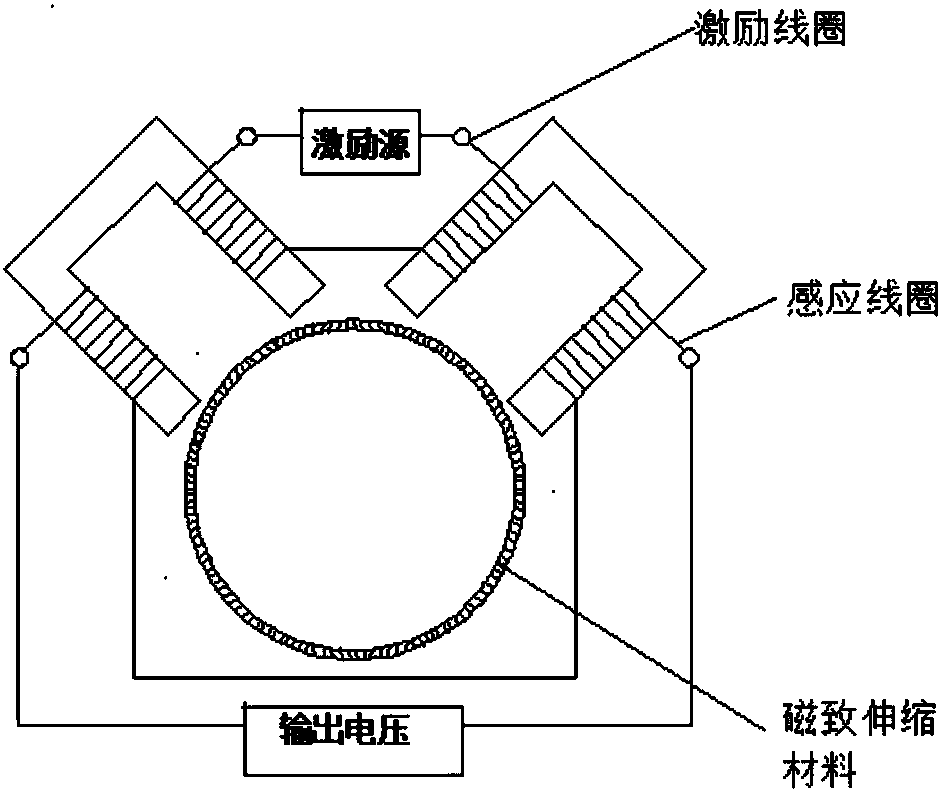

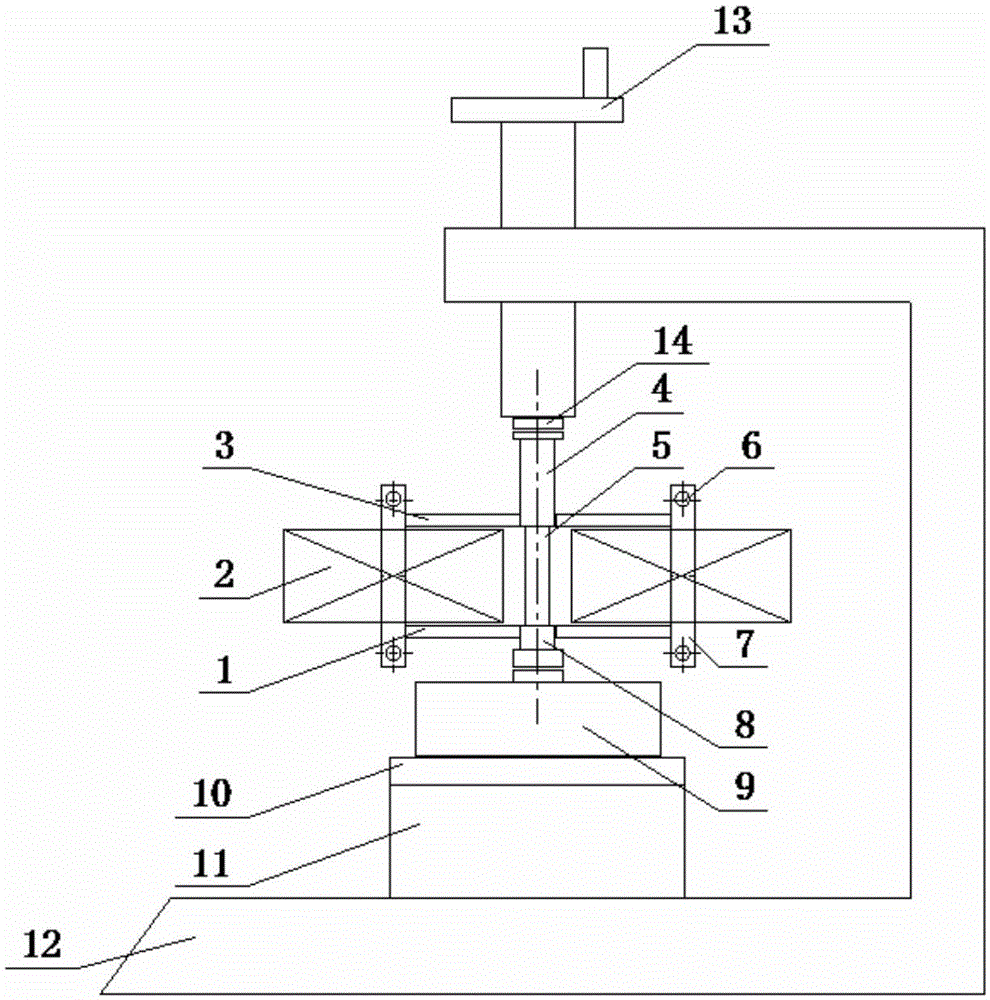

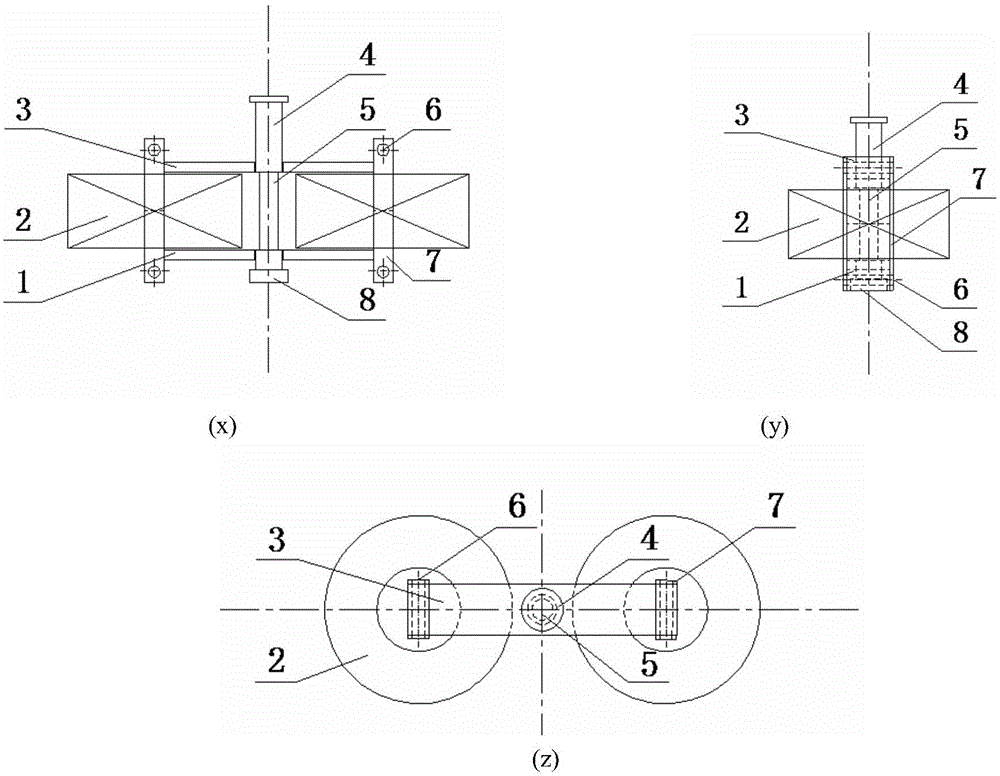

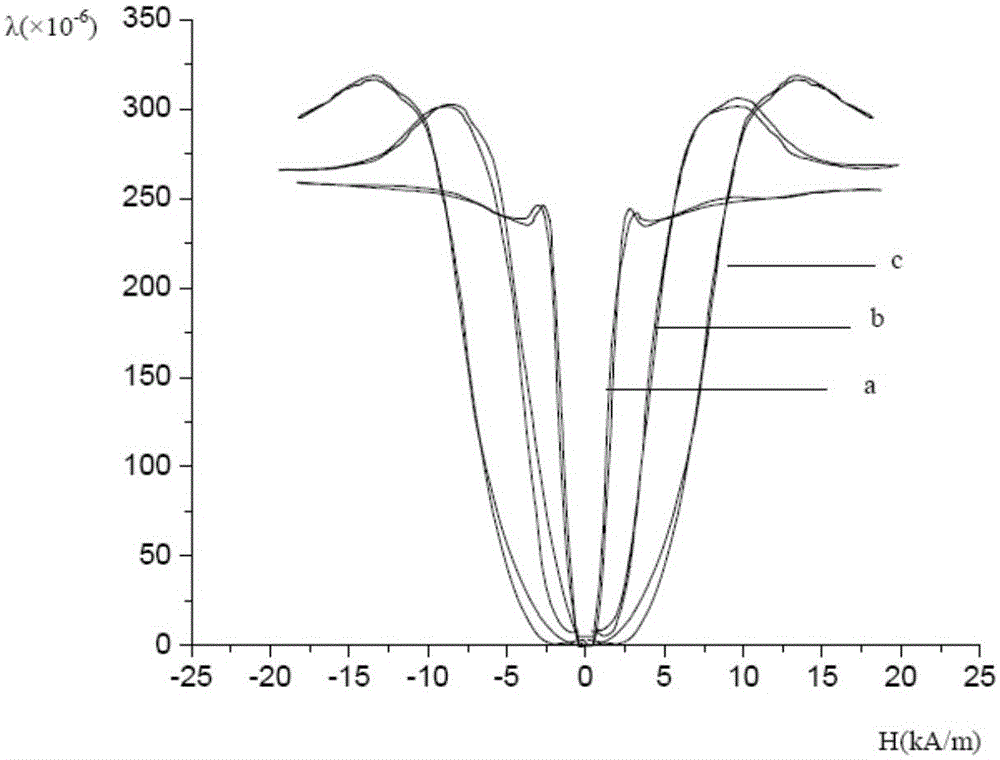

Tester for magnetic property of magnetostriction material

ActiveCN103558569AUniform magnetic field strengthSolve the problem that the inverse effect characteristic test of materials cannot be measuredMagnetostrictive property measurementsInverse magnetostrictive effectTester device

The invention relates to a tester for the magnetic property of a magnetostriction material. The tester comprises a main measurement component, a standard force sensor, a stress applying device and a permanent magnet. The main measurement component is composed of an upper loop module, a lower loop module, an upper pole head, a lower pole head, a left exciting coil, a right exciting coil and the magnetostriction material to be tested. The overall structure of the main measurement component is in bilateral symmetry. Through the application of the main measurement component and the stress applying device, the device can test the property of the positive magnetostriction effect and the property of the converse magnetostriction effect, can carry out a magnetic property test under the condition of dynamic excitation, and is simple in structure and high in flexibility.

Owner:HEBEI UNIV OF TECH

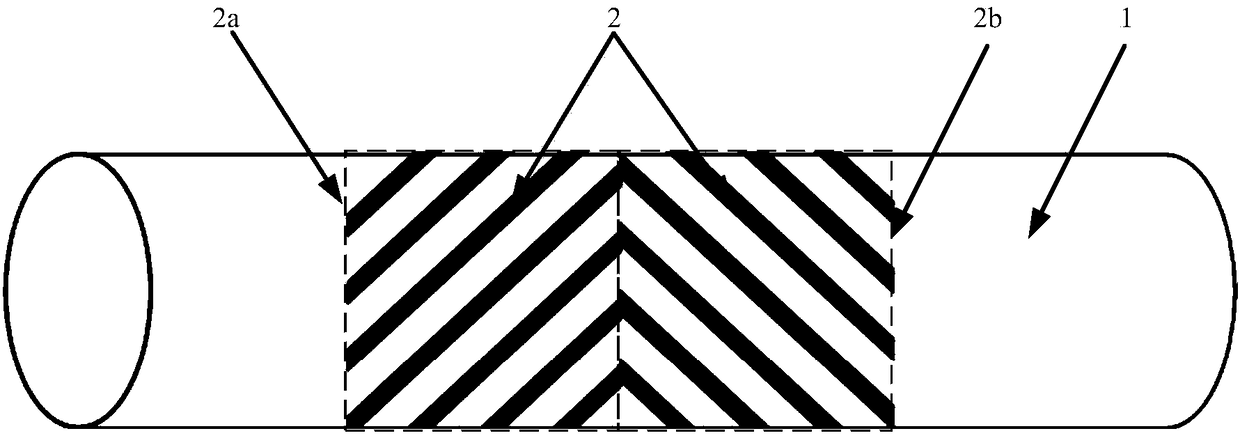

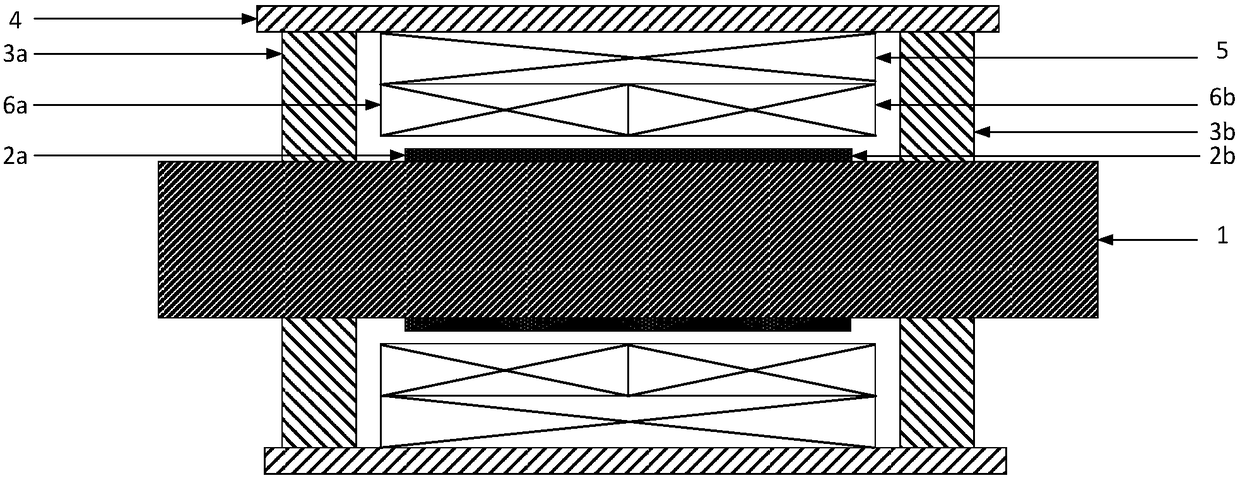

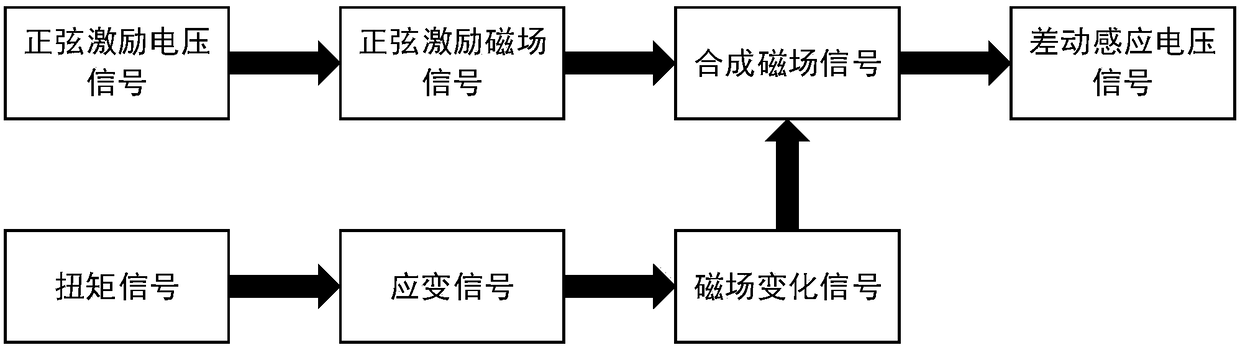

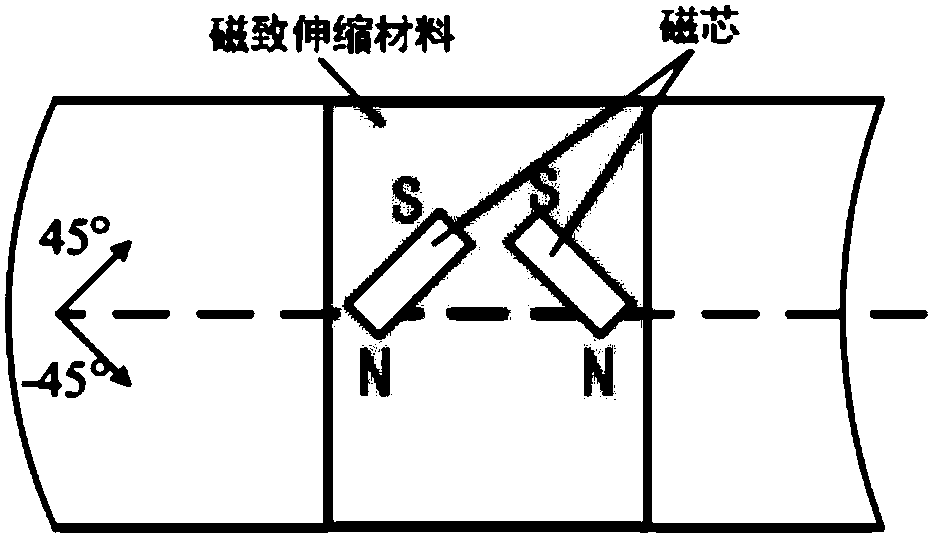

Non-contact torque measurement device based on counter-magnetostrictive effect

InactiveCN108562388ASimple measuring principleImprove accuracyWork measurementTorque measurementInverse magnetostrictive effectMeasurement device

The invention discloses a non-contact torque measurement device based on a counter-magnetostrictive effect and belongs to sensor measurement technologies. According to technical key points, a measuredrotating shaft is coated with giant magnetostrictive material coating strips, the giant magnetostrictive material coating strips are divided into positive giant magnetostrictive material coating strips and negative giant magnetostrictive material coating strips; the positive giant magnetostrictive material coating strips and negative giant magnetostrictive material coating strips obliquely coat the measured rotating shaft in an axial direction at equal intervals in a bilateral symmetry manner; left and right ends of the measured rotating shaft are respectively nested into inner holes of a left bearing and a right bearing; the left bearing and the right bearing are respectively nested into the left and right ends of a shaft sleeve; an exciting coil is assembled onto the inner wall of the shaft sleeve; a left measuring coil and a right measuring coil of the same specification are assembled in parallel on the inner walls of the exciting coil in the axial direction. According to the measurement device disclosed by the invention, the torque is dynamically measured in real time at high accuracy and high precision without being in contact with a transmission shaft or changing a stress state of the transmission shaft and under rotary and dynamic operating conditions.

Owner:HARBIN INST OF TECH

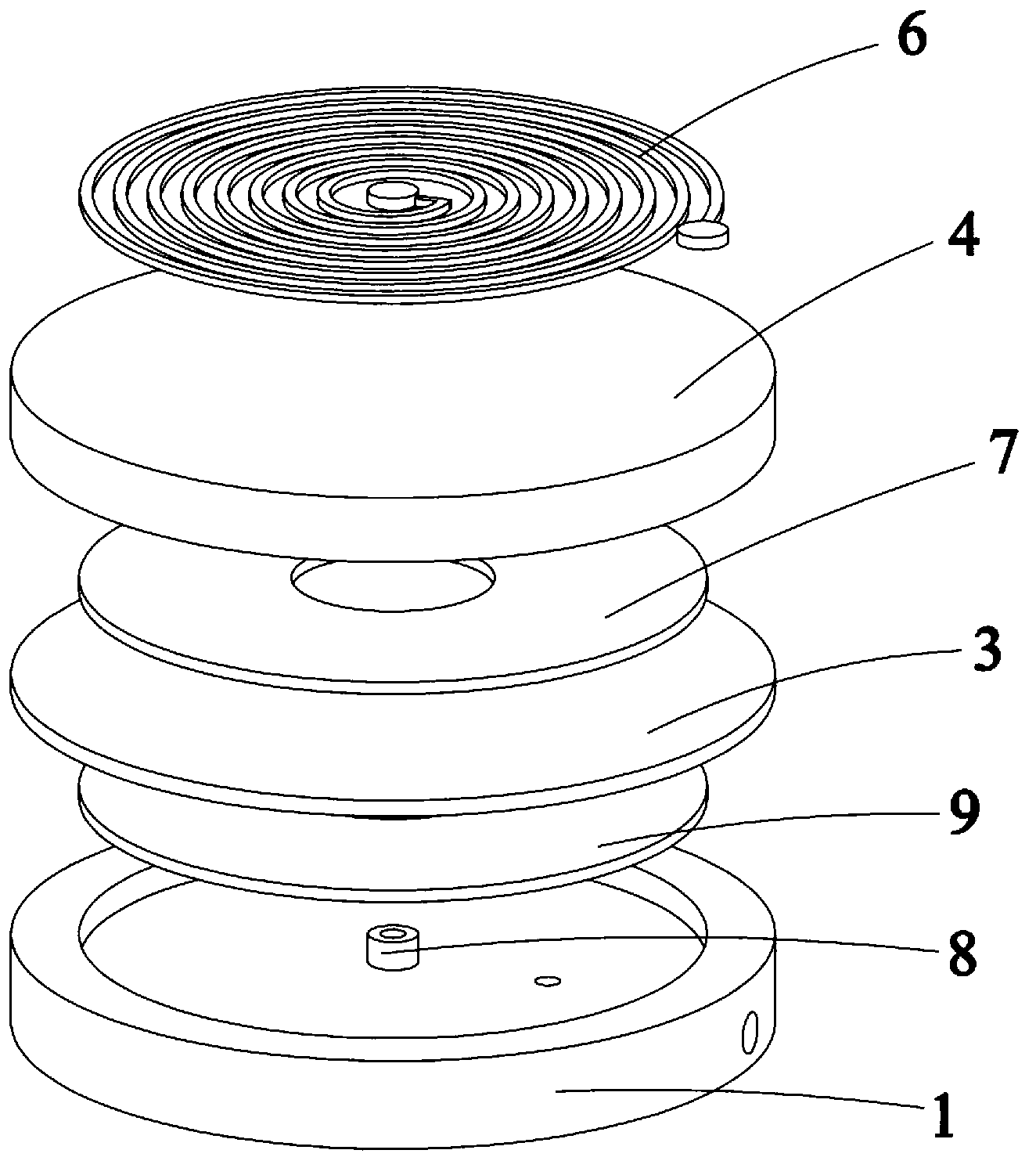

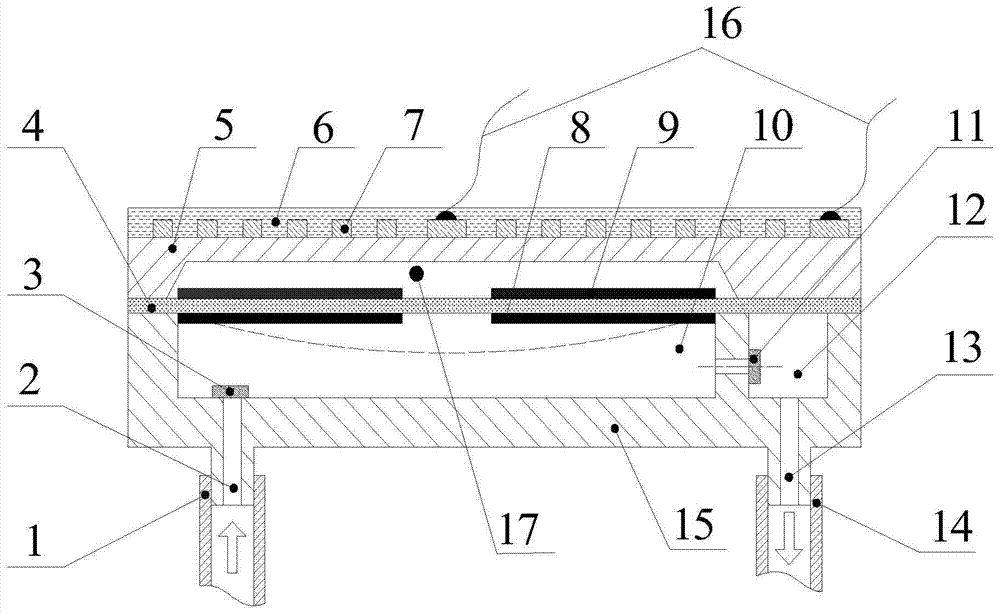

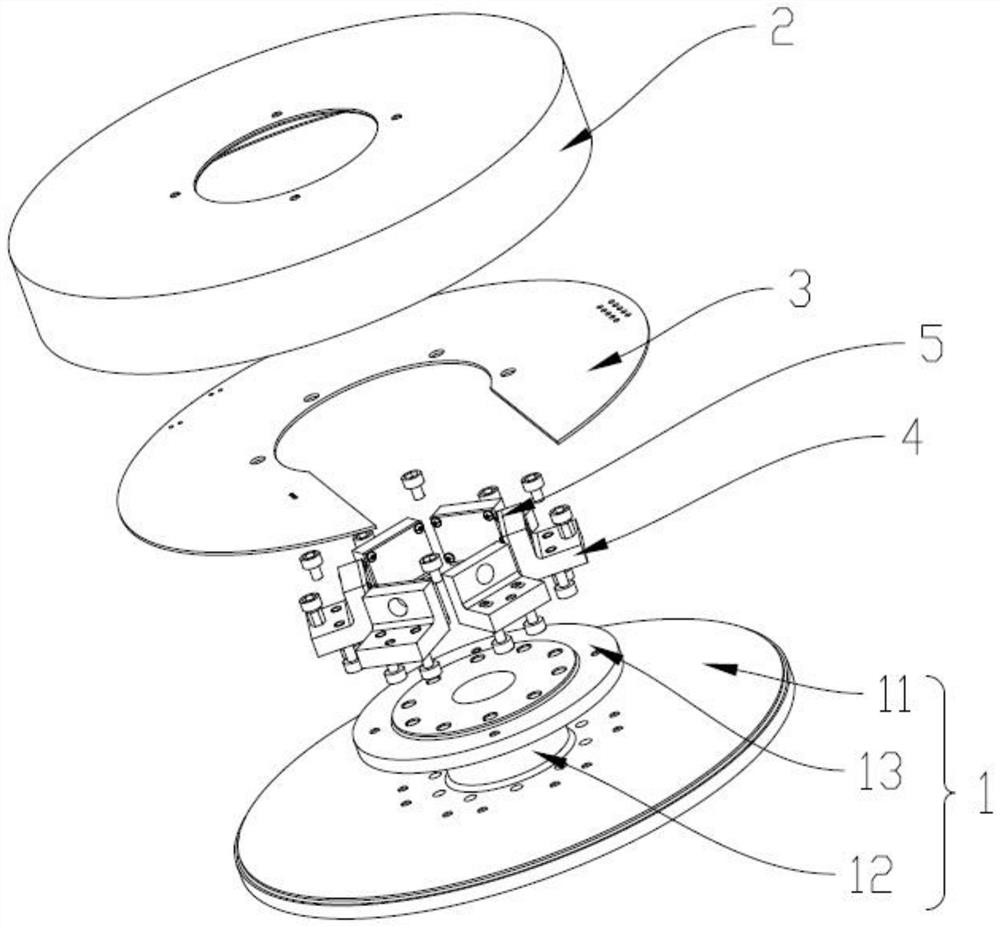

Micro-pump based on super-magnetostrictive film driver

InactiveCN102797667AEasy to implement security controlSmall driving currentPositive displacement pump componentsFlexible member pumpsInverse magnetostrictive effectEngineering

The invention discloses a micro-pump based on a super-magnetostrictive film driver. The micro-pump comprises a lower pump body (1), a substrate (6) and an upper pump body (9), wherein the substrate (6) and the upper pump body (9) are laminated on the lower pump body (1) in sequence; a film (8) with a positive magnetostrictive effect is plated on the upper side of the substrate (6) and a film (12) with a converse magnetostrictive effect is plated on the lower side of the substrate (6); a pump cavity (4) and a valve cavity (11) are formed by the bottom surface of the substrate (6) and the lower pump body; the pump cavity (4) is communicated with the valve cavity (11) through a through hole; the pump cavity is connected with a liquid inlet pipeline (3), and the valve cavity is connected with a liquid outlet pipeline (13); the pump cavity and the valve cavity are respectively provided with a valve diaphragm of a cantilever valve structure; a coil rack (5) is arranged outside the pump body and is wound with a drive coil (7); and the films with magnetostrictive effect drive the substrate (6) to sway vertically under the action of a magnetic field, so that liquid inside the pump cavity (4) is pressed to circularly flow in a unidirectional direction. The micro-pump provided by the invention has the characteristics of large output pressure, high driving frequency, strong controllability and the like.

Owner:ANHUI UNIV OF SCI & TECH

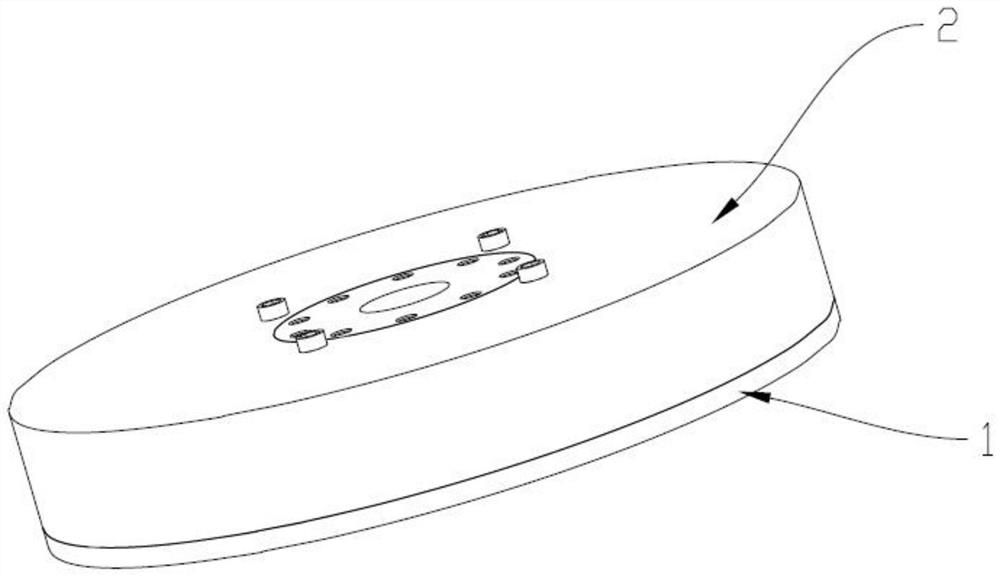

Micropump based on ultra-magnetostriction thin film actuator

InactiveCN103939317AQuick responseHigh frequency responseFlexible member pumpsPositive-displacement liquid enginesInverse magnetostrictive effectElectricity

The invention discloses a micropump based on an ultra-magnetostriction thin film actuator. The micropump comprises a pump body and a base sheet dividing the pump body into an upper pump body and a lower pump body, the lower pump body is provided with a liquid inlet and a liquid outlet, a valve cavity is formed in the lower pump body, and a planar spiral coil is arranged on the upper surface of the upper pump body and electrically connected with an external power source; a liquid cavity is formed by the base sheet and the lower pump body and communicated with the liquid inlet and the valve cavity, the valve cavity is communicated with the liquid outlet, the connecting position of the liquid cavity and the liquid inlet is provided with a one-way liquid inlet film, and the connecting position of the liquid cavity and the valve cavity is provided with a one-way liquid outlet film; the base sheet is provided with a joule magnetostrictive effect thin film on the upper surface and provided with a reverse magnetostrictive effect thin film on the lower surface. The micropump is made of ultra-magnetostriction materials and therefore has the advantages of being high in response speed, high in frequency response and the like; the micropump is driven by a magnetic field provided by the planar coil, small in size and simple in structure, working performance of the micropump is improved substantially, the micropump is driven by the planar spiral coil, so that the structure of the micropump is simplified, and the size of the micropump is reduced.

Owner:ANHUI UNIV OF SCI & TECH

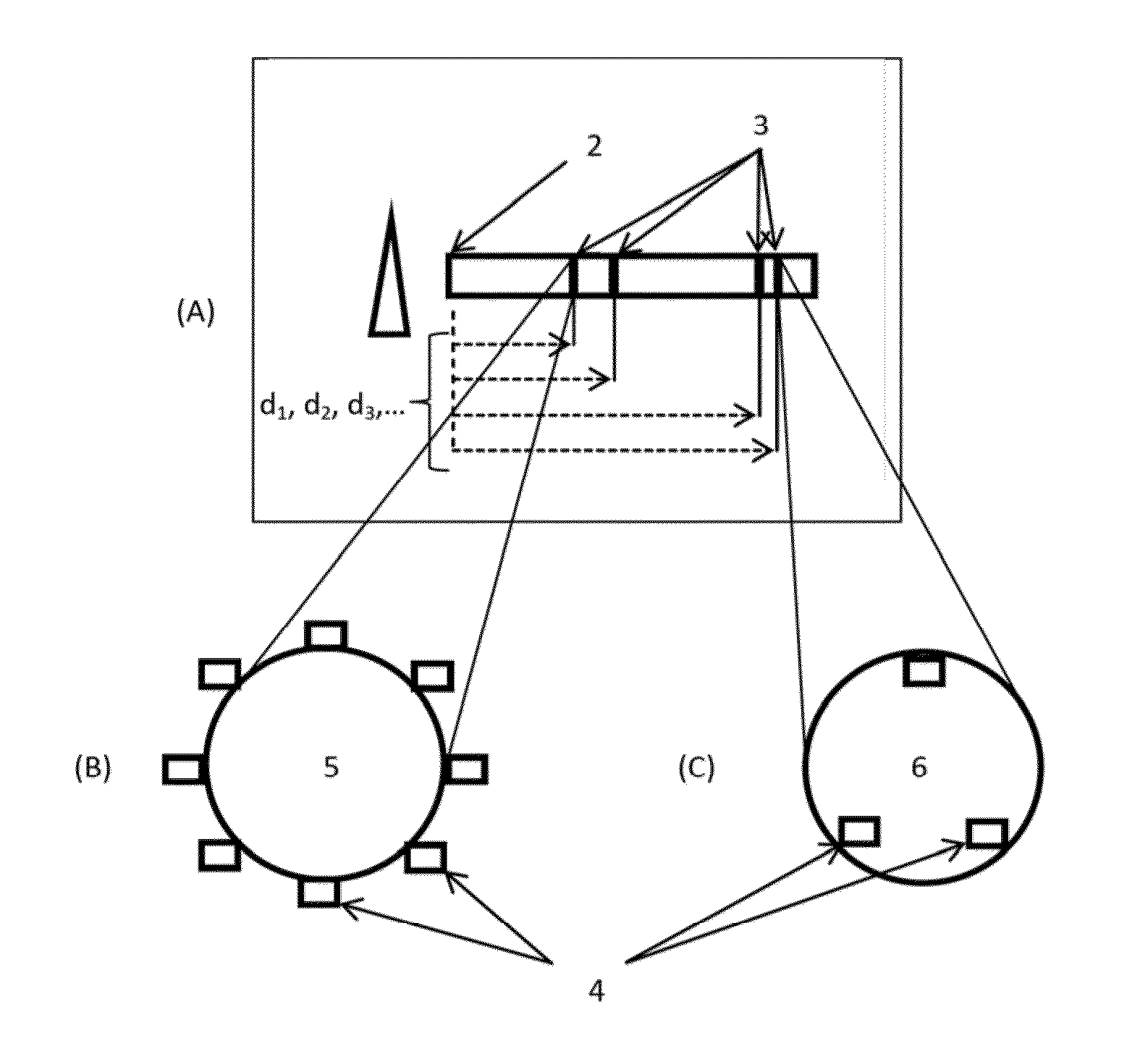

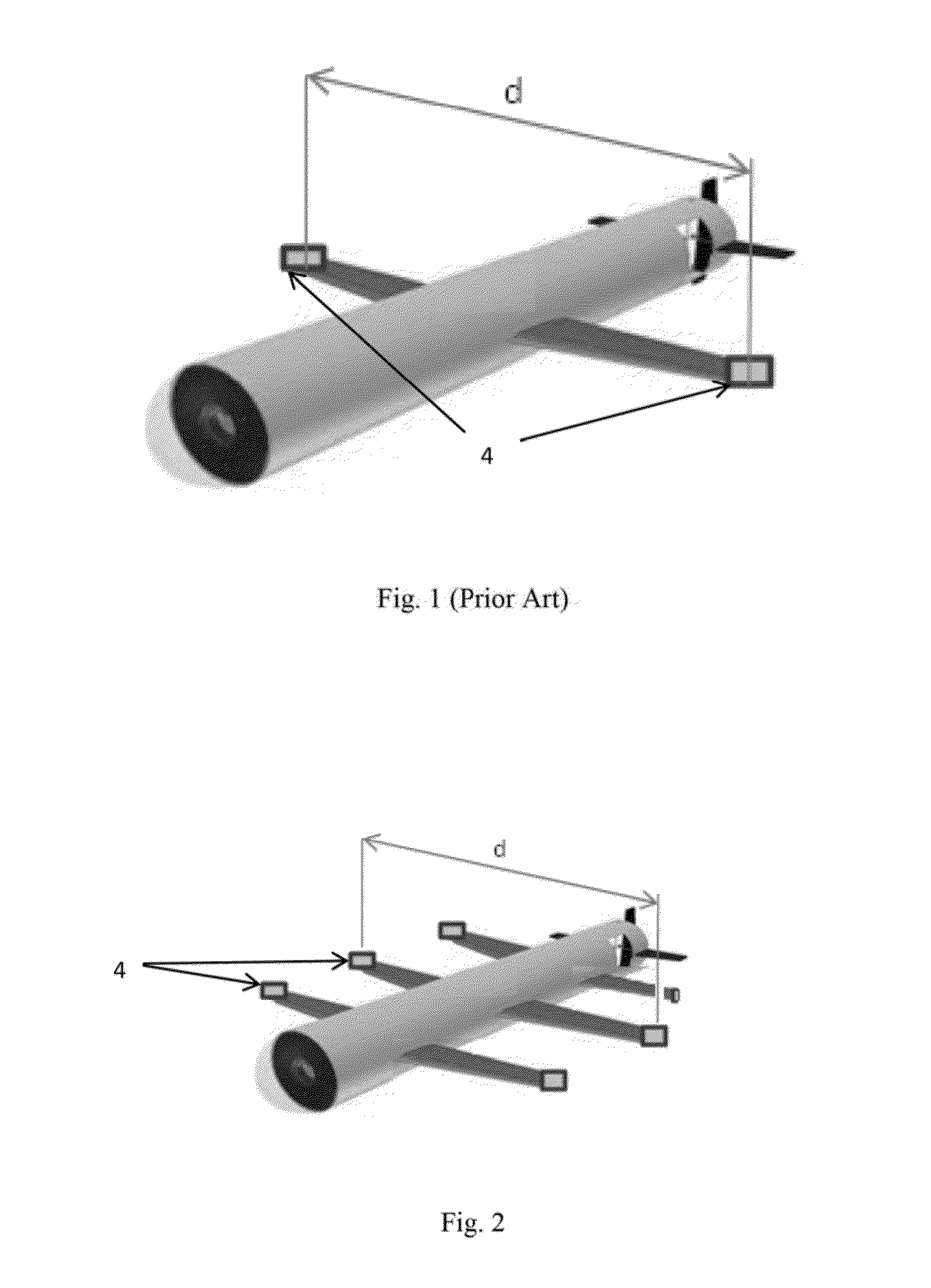

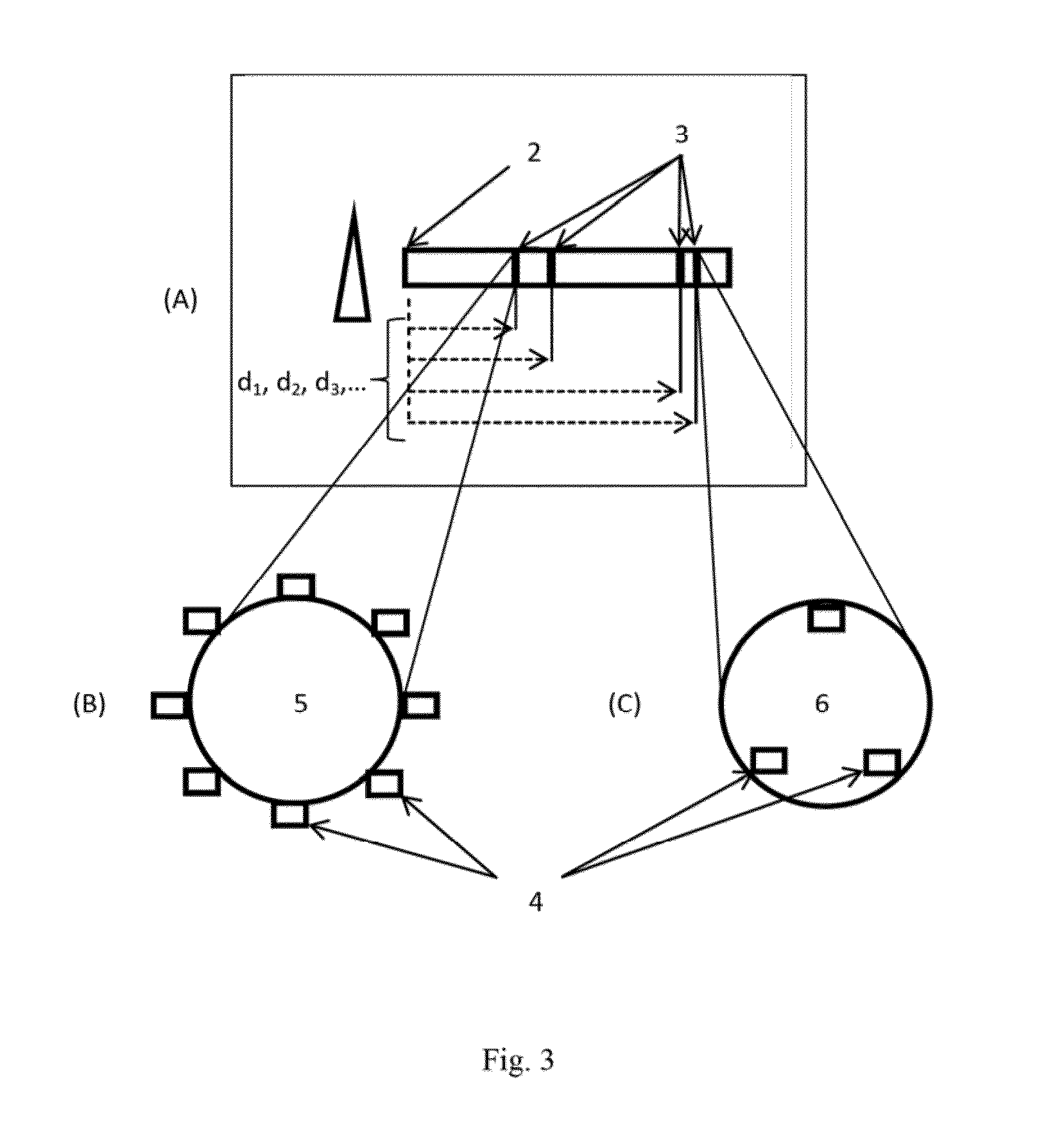

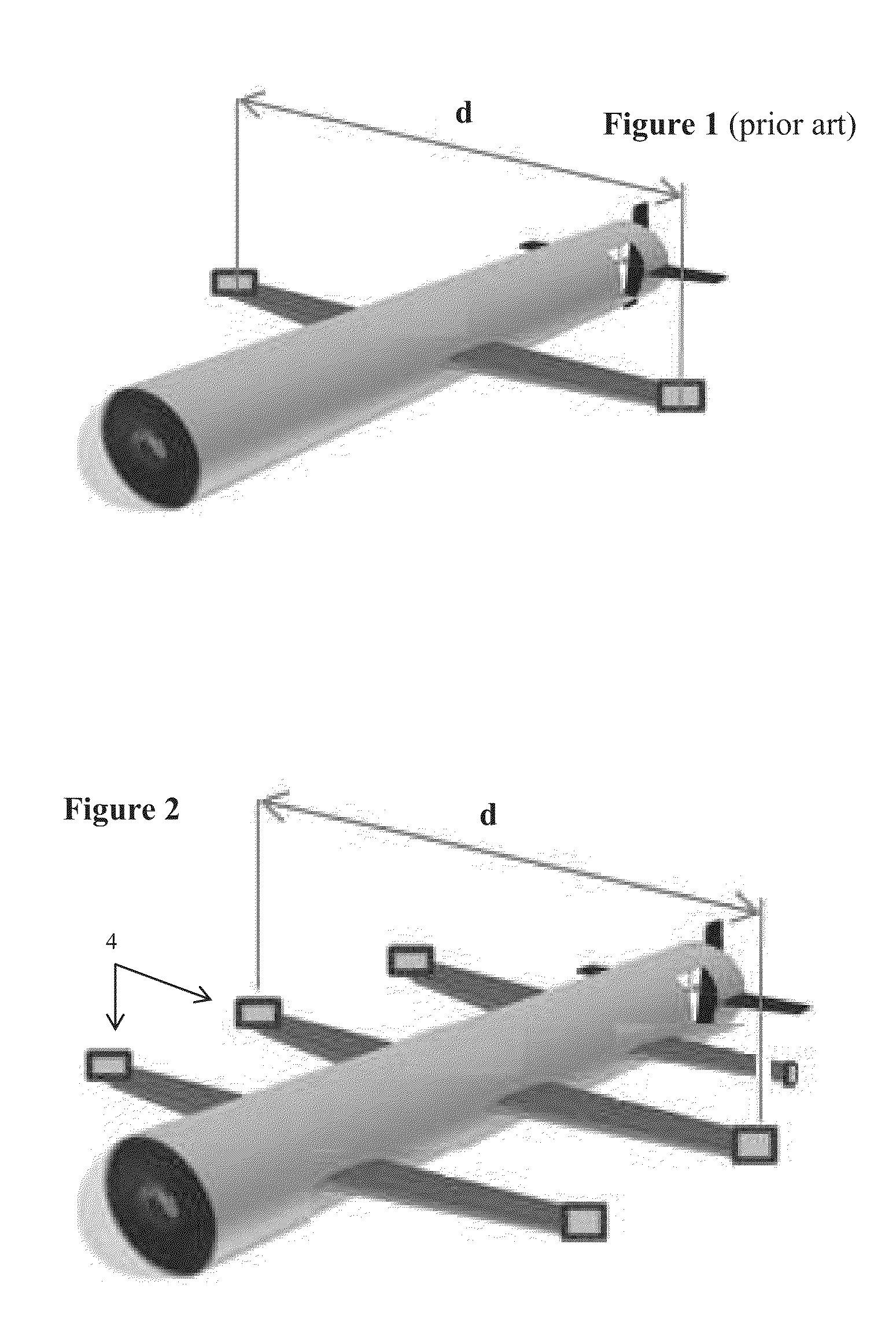

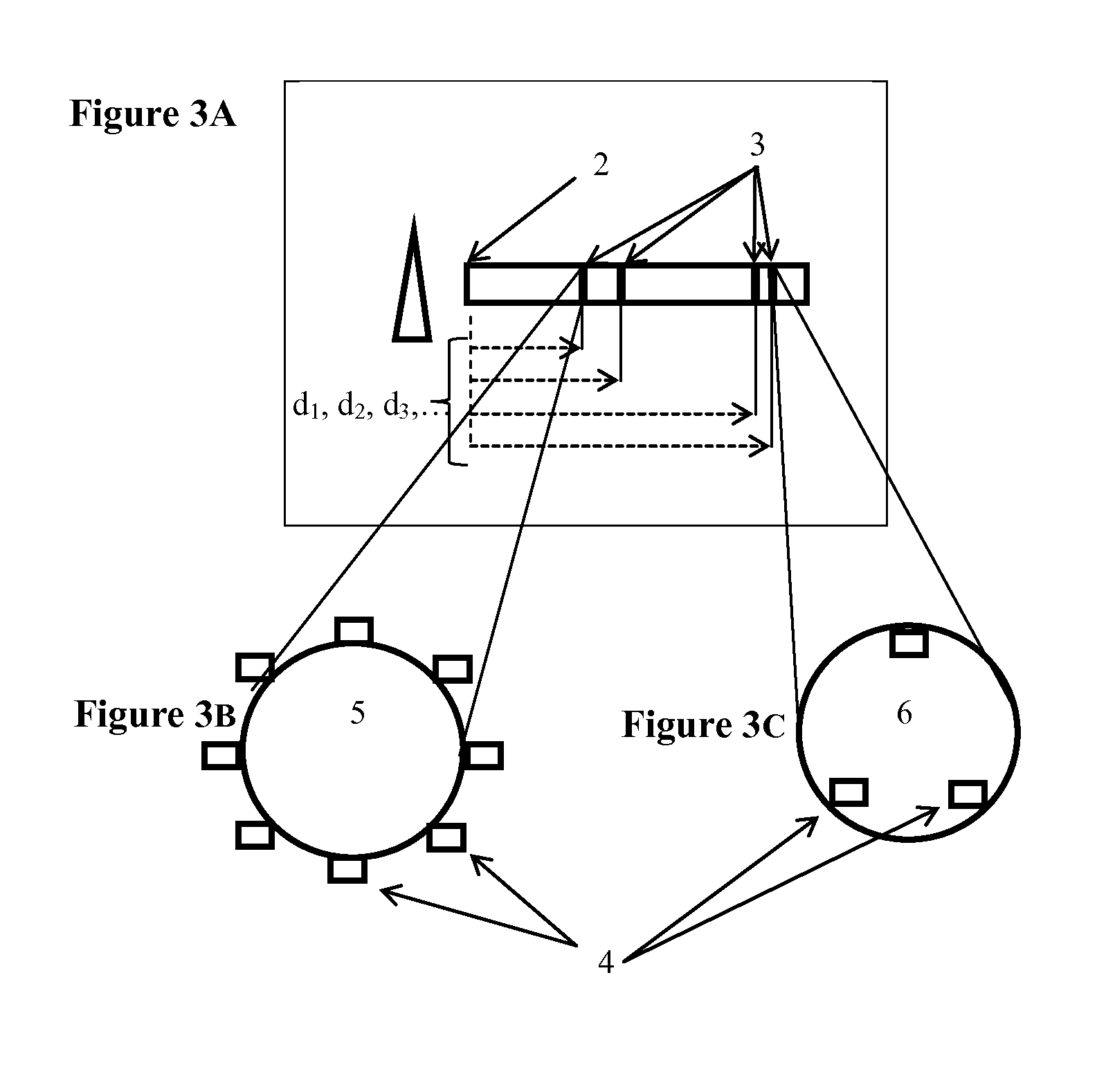

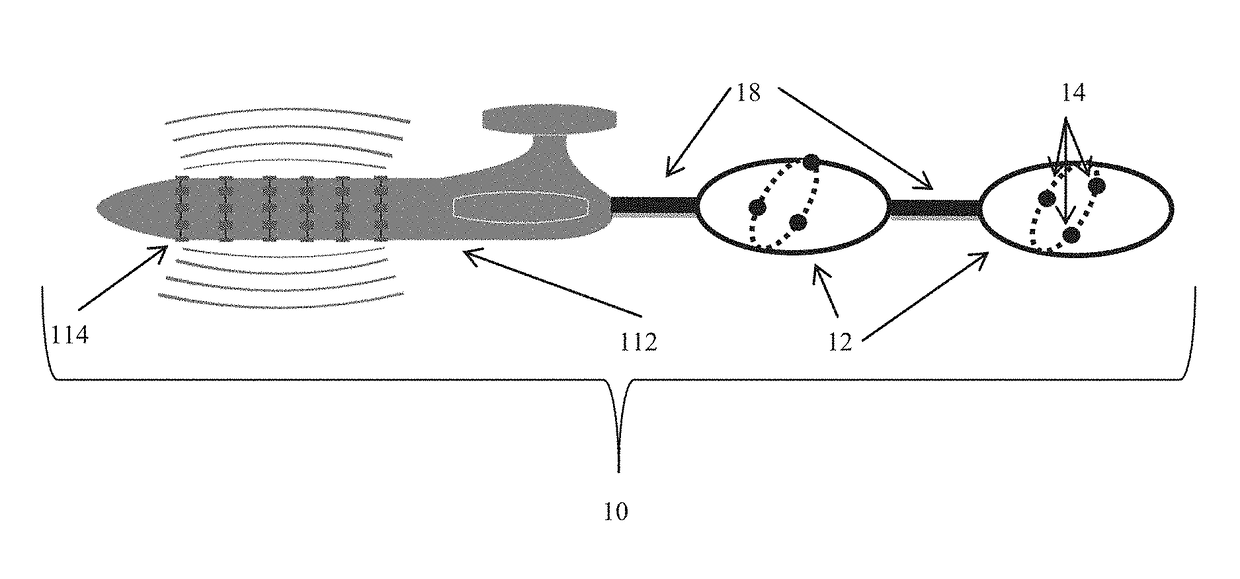

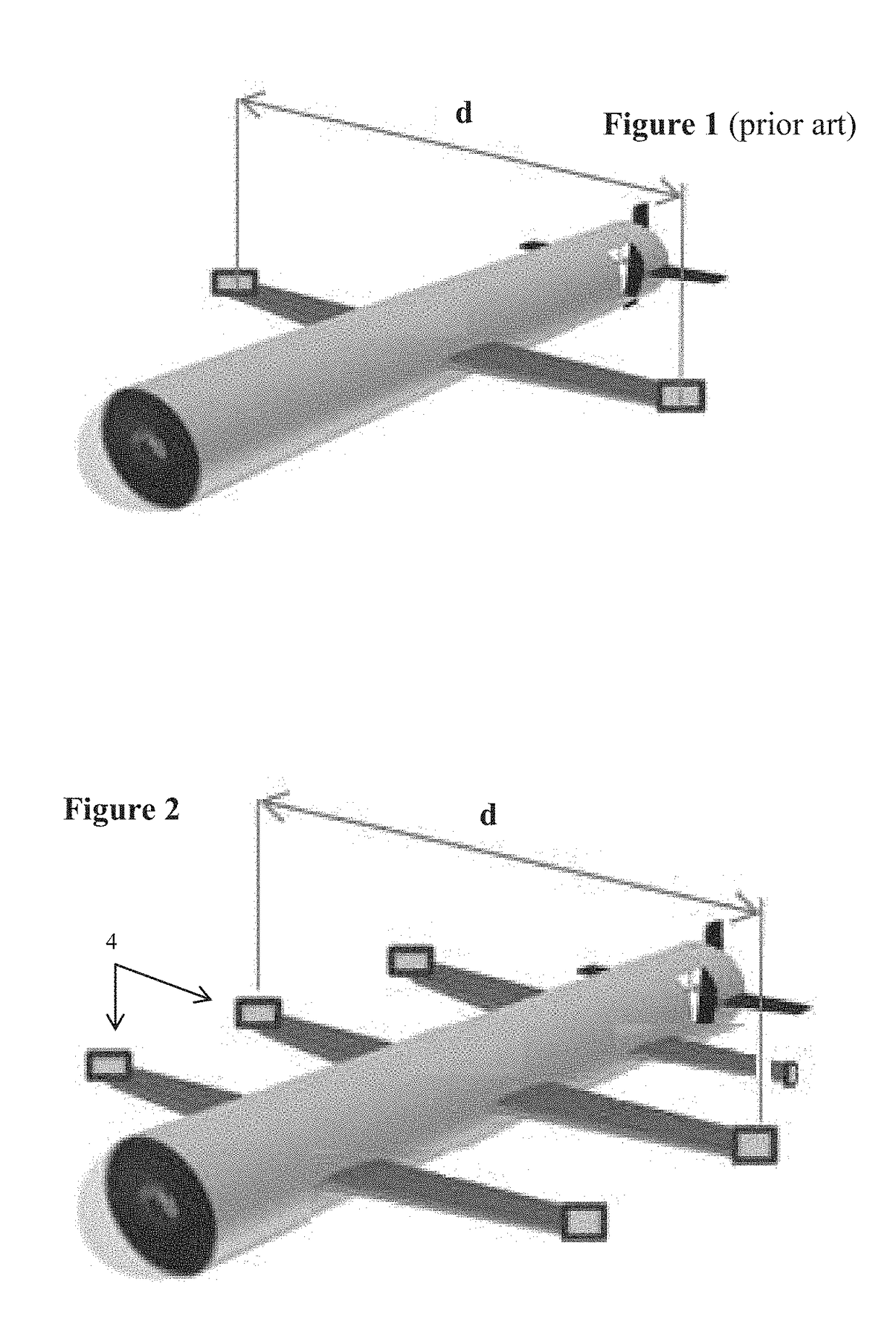

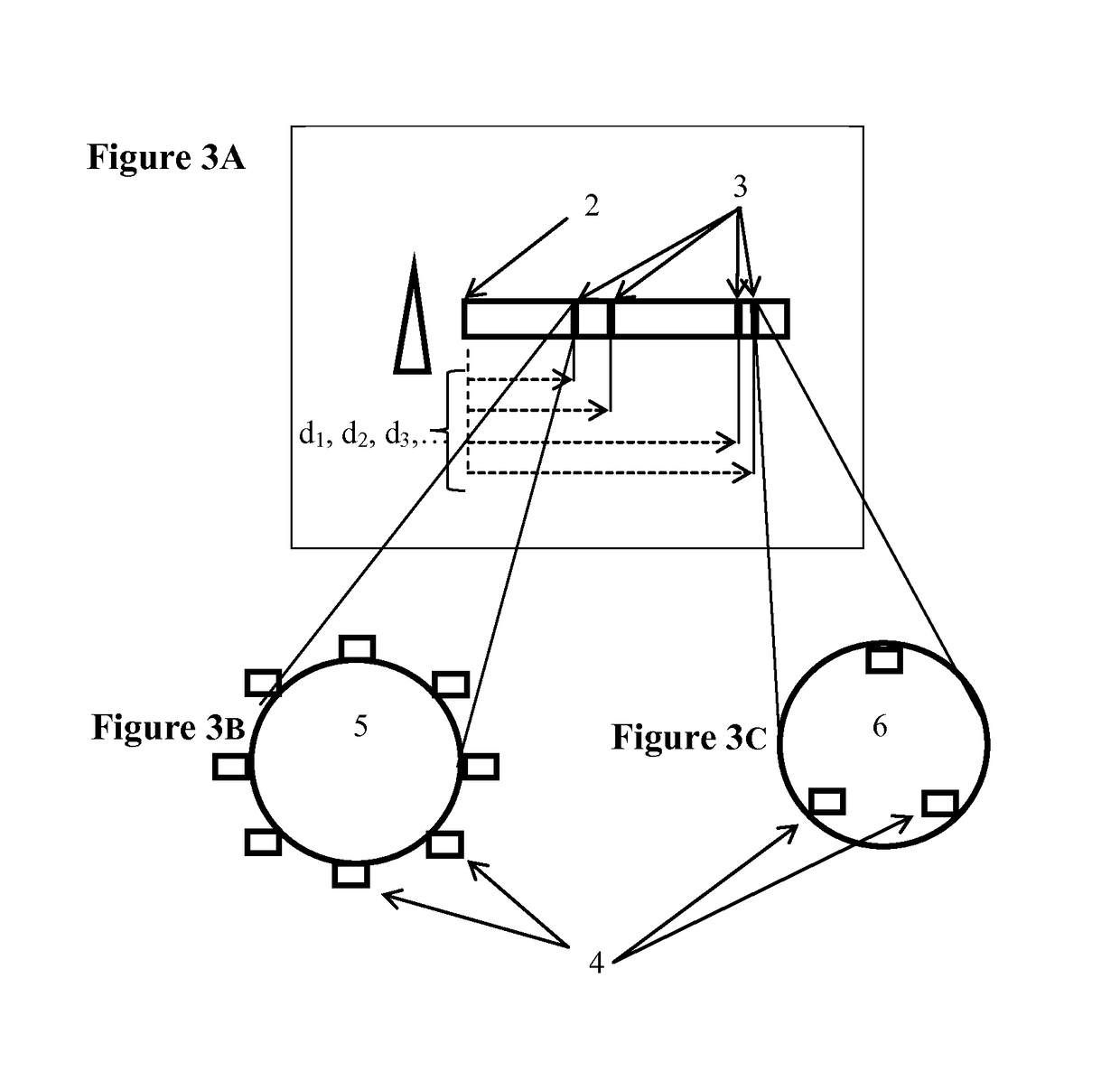

Autonomous pipeline inspection using magnetic tomography

ActiveUS20160146758A1Surface cleaningAvoid collisionWeather/light/corrosion resistanceUnderwater vesselsInverse magnetostrictive effectOdometry

The present invention discloses a device and system for magnetographic analysis of mechanical flaws and defects along structures located underwater for example, metallic pipelines, utilizing an autonomous magnetic tomography method (MTM) apparatus based on the inverse magnetostrictive effect for magnetographic identification, in the form of an array of flexible autonomous undersea vehicle (AUV) torpedo constructions of interconnected elements or pods. The array of AUV torpedo constructions are flexibly linked together so that the device can readily navigate within the contours of pipeline to be inspected using the flow media as propulsion means or alternatively by means of independent motive means without interfering with the system flow. The torpedo construction elements or pods each contain three MTM sensors situated 120 degrees apart on a non-perpendicular cross section arrangement, and perform a variety of independent functions. e.g., data storage data, sensor data memory unit, odometer distance measurements, GPS location, geomagnetic navigation capability.

Owner:GOROSHEVSKIY VALERIAN +2

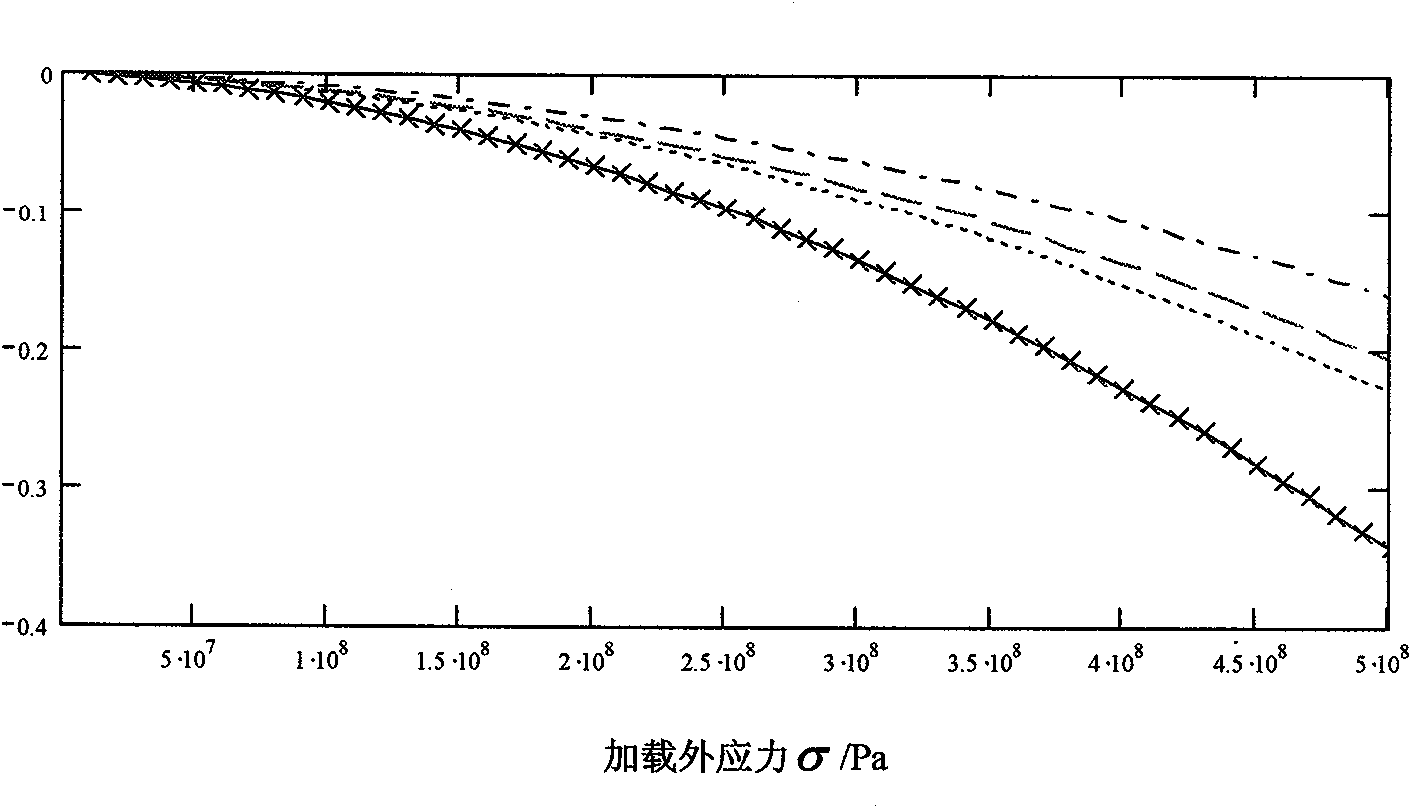

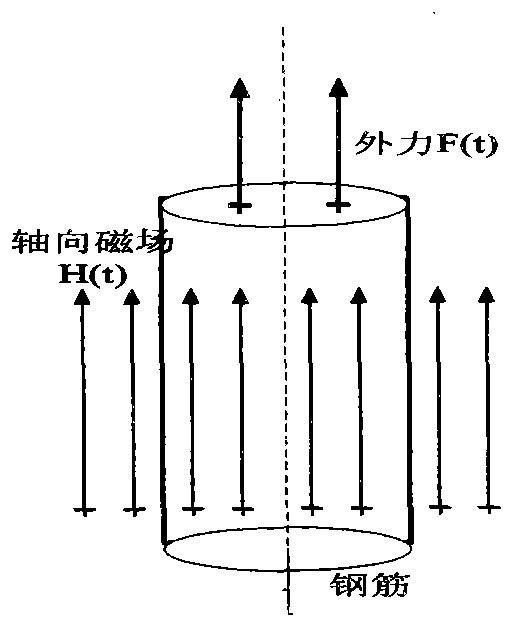

Concrete bridge steel bar tension measuring method based on converse magnetostriction

ActiveCN103454024AGet the right measurementsIncreased sensitivityApparatus for force/torque/work measurementInverse magnetostrictive effectEngineering

The invention discloses a concrete bridge steel bar tension measuring method based on converse magnetostriction. The method includes the following steps: (1) an induction coil and an excitation coil are respectively arranged on a detected bridge steel bar from the inside to the outside, and the induction coil and the excitation coil are coaxially wound and separated in an insulating mode; (2) excitation voltage parameters are preset, excitation voltage is applied to the excitation coil according to the preset excitation voltage parameters, and parameters of induction voltage generated on the induction coil due to the excitation voltage are detected; (3) tension of the steel rib is divided into a slow change and an alternating change according to any group of the parameters measured in the step (2), and the tension of the steel rib can be calculated in different steps. The method has the advantages of being easy to achieve, good in sensitivity and high in reliability.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

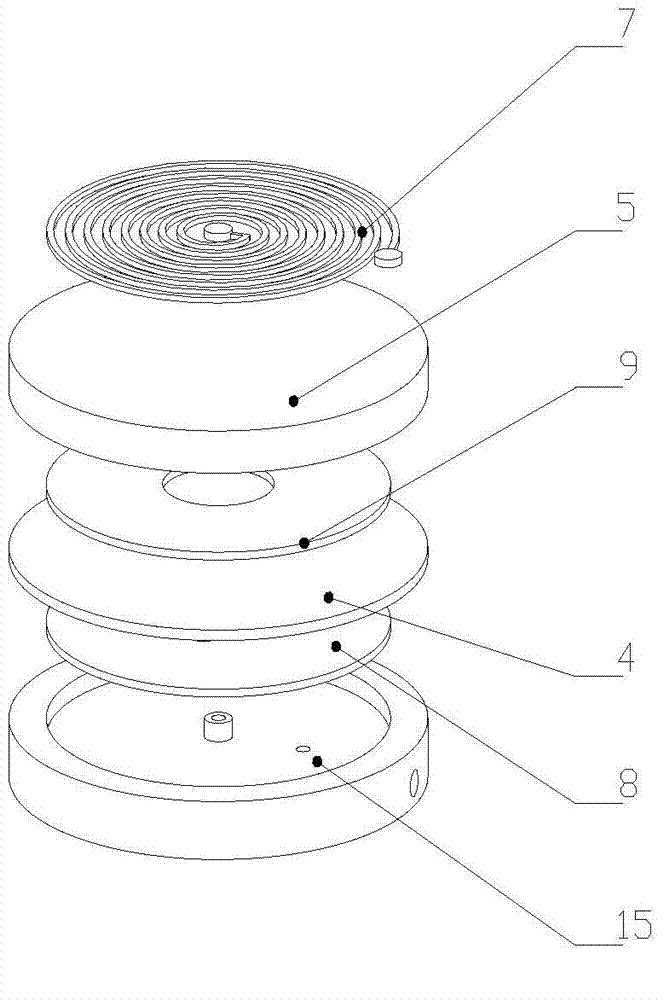

Vibration power generation device

ActiveCN107492999ASimple designImprove power generation efficiencyPiezoelectric/electrostriction/magnetostriction machinesDynamo-electric machinesInverse magnetostrictive effectGeneration process

The invention discloses a vibration power generation device comprises a power generation part and a support part, wherein the power generation part comprises a top cover, an upper permanent magnet, a magnetostrictor and a lower permanent magnet which are sequentially laminated and fixed, a coil is wound around the magnetostrictor, and the support part comprises an elastic part and a base. During usage, pressure is applied to the top cover, so that the upper permanent magnet, the magnetostrictor, the coil and the lower permanent magnet downwards move together to cause change of the length of a magnetic path, the coil generates a changing magnetic field, and an induced electromotive force is generated in the coil according to a Faraday law of electromagnetic induction, namely electromagnetic power generation; and when the top cover is pressed, the base is extruded by the lower permanent magnet and is knocked, so that the magnetic path is closed, meanwhile, a generated counter-reacting force acts on the magnetostrictor, the changing magnetic field is generated in the coil according to an inverse magnetostriction effect, and the induced electromotive force is further generated, namely piezomagnetic power generation. The device is simple to design and comprises two power generation processes of electromagnetic power generation and piezomagnetic power generation, and the power generation efficiency is improved.

Owner:GUANGDONG UNIV OF TECH

Torque sensor based on magnetoelastic effect

PendingCN114705328ASuitable for online monitoringEasy to install and maintainForce measurement by measuring magnetic property varationWork measurementInverse magnetostrictive effectCircular disc

A torque sensor based on a magnetoelastic effect disclosed by the present invention comprises a stepped shaft, the stepped shaft comprises an elastic shaft and a fixed disc, the side surface of the elastic shaft is provided with an amorphous alloy detection sheet, the periphery of the elastic shaft is uniformly distributed with a plurality of coil supports, the coil supports are fixed on the fixed disc, and the coil supports are fixed on the fixed disc. A magnet exciting coil is arranged on the coil bracket; a circuit board is arranged above the coil bracket; according to the invention, the magnitude of the torsional force is detected based on the inverse magnetostrictive effect, and the device has incomparable advantages compared with other measurement methods, is simple in installation and maintenance, strong in anti-interference capability, good in durability, capable of realizing non-contact measurement, easy to develop towards miniaturization, and especially suitable for online monitoring of torque, and in addition, the magnetoelastic non-contact torque measurement is adopted, so that the measurement accuracy is improved. The control error caused by the reduction of the system rigidity can be effectively reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

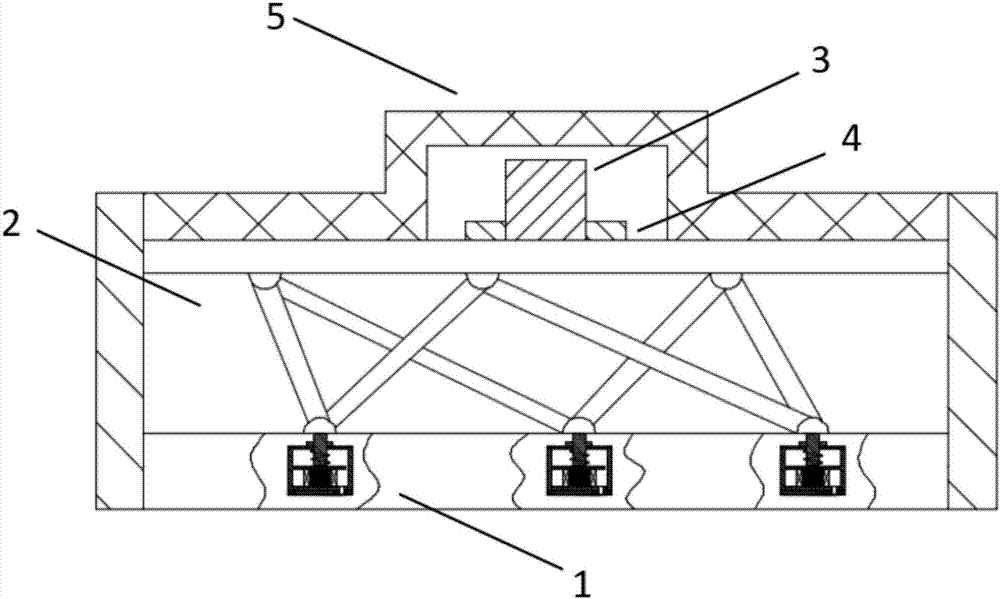

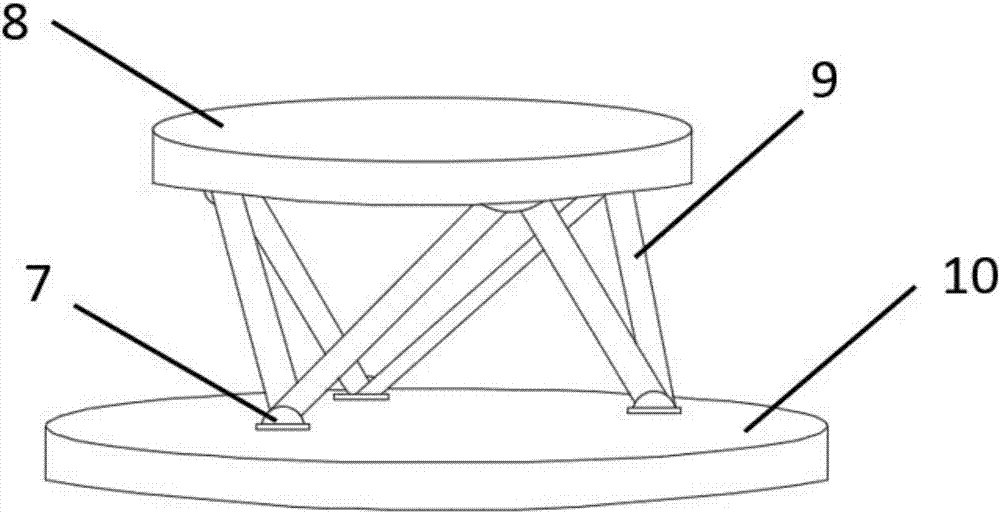

Vibration reduction and power generation device based on inverse magnetostriction principle

ActiveCN107222129AReduce manufacturing costFixedBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesInverse magnetostrictive effectEngineering

The invention discloses a vibration reduction and power generation device based on an inverse magnetostriction principle, and belongs to the field of vibration reduction and vibration power generation products. The vibration reduction and power generation device comprises a vibration reduction module, a vibration conversion module, an inverse magnetic power generation module and a battery module, wherein a main body comprises a base, a six-degree-of-freedom platform, a first top rod, a first fastening screw and a piezoelectric rubber vibration isolator, the six-degree-of-freedom platform is embedded into a part above the base, the first top rod and the first fastening screw are fixed on an upper surface of the six-degree-of-freedom platform, the piezoelectric rubber vibration isolator is encircled at an outer side, is in contact with the base and the upper surface of the six-degree-of-freedom platform and is fixed, and a stepped cavity is formed between the first top rod and the first fastening screw. The vibration reduction and power generation device is low in production cost, small in size and light in weight, is easy to fix and expand and can stand a severe vibration environment, and high-efficiency power generation is achieved. The device is relatively simple in structure and high in stability, and can be installed in an array way.

Owner:HARBIN ENG UNIV

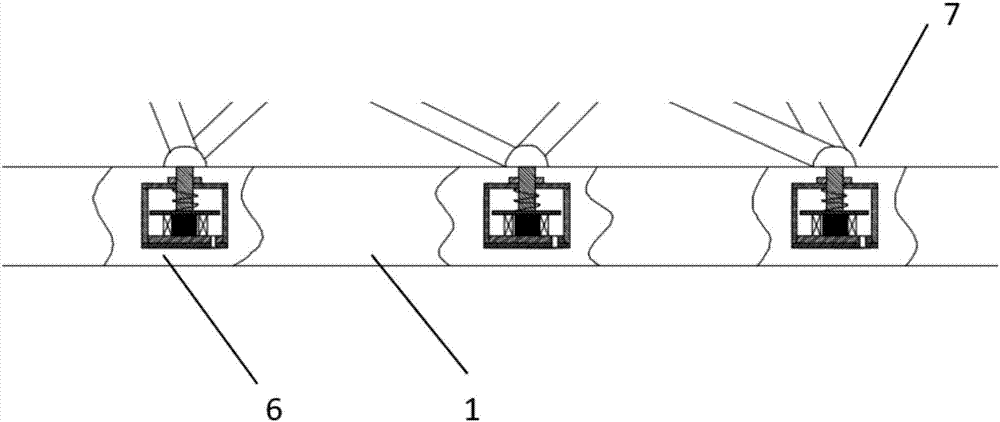

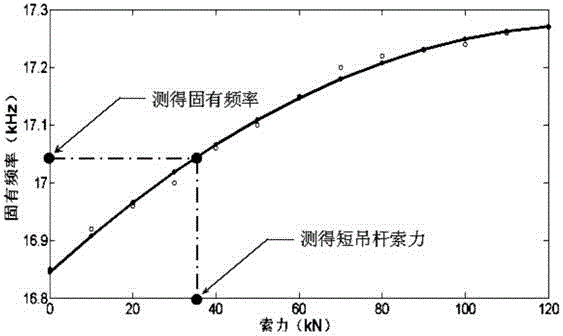

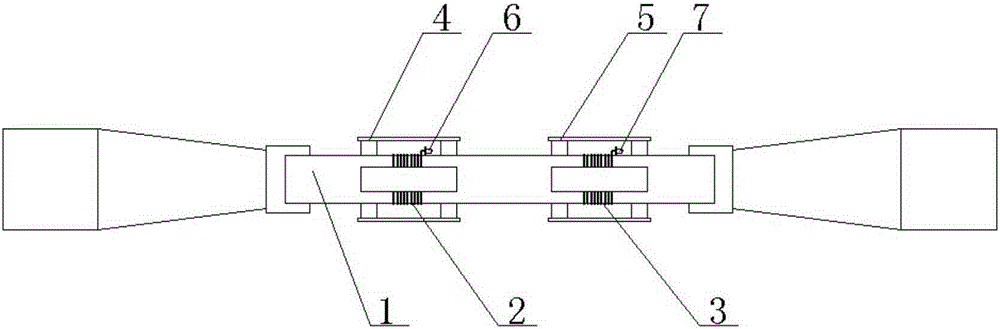

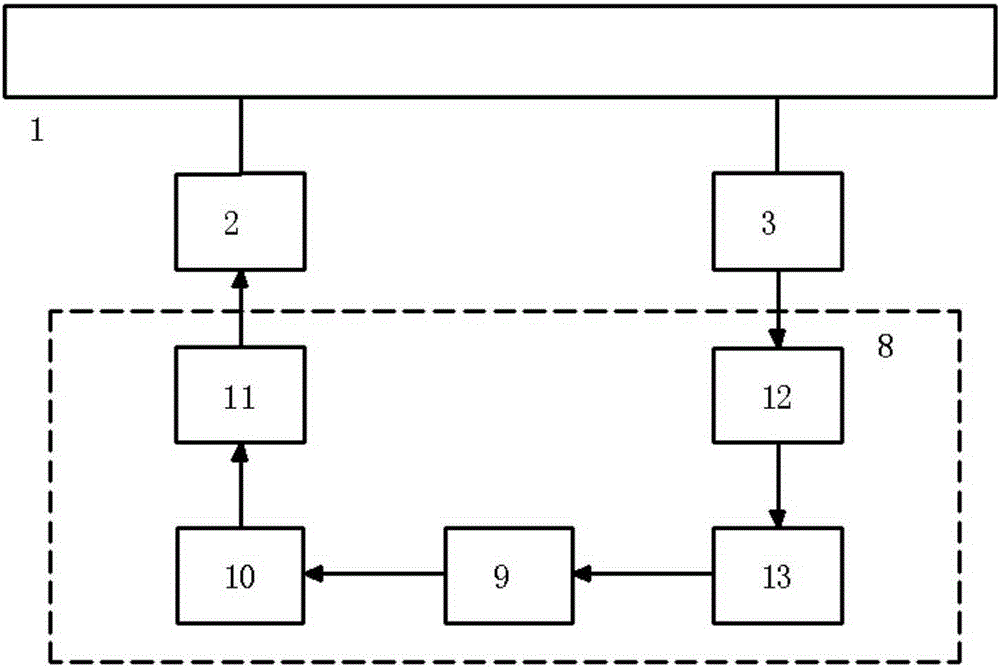

Magnetostriction-guide-wave-based measurement apparatus and method of short suspender cable force

InactiveCN105181184ASpeed up the efficiency of cable force measurementReduce volumeForce measurement by measuring magnetic property varationTension measurementInverse magnetostrictive effectFrequency spectrum

The invention relates to a magnetostriction-guide-wave-based measurement apparatus and method of a short suspender cable force. The apparatus is composed of an excitation bias magnetizer, a receiving bias magnetizer, an excitation coil, a receiving coil, and a guide wave measuring instrument. According to the magnetostrictive effect principle, excitation is carried out inside the short suspender by the excitation coil for long timer to form steady-state vibration; and an induction signal is obtained at the receiving coil based on a counter-magnetostrictive effect and the induction signal is analyzed and calculated to obtain a short suspender cable force. According to the method, with long-time frequency excitation by a magnetostrictive guide wave, the steady-stage vibration is generated in the short suspender; after excitation, vibration signals of the short suspender during the period from the excitation suspending to attenuation to zero are extracted and spectral analyses are carried out to obtain a longitudinal inherent frequency of the short suspender; and on the basis of the correspondence relation of the longitudinal inherent frequency and the cable force, the cable force value of the short suspender is obtained. With the apparatus and method, the cable force measurement is free from limitation of the short suspender boundary condition and the flexural rigidity, so that the measurement becomes convenient; and the measurement repeatability is high.

Owner:HUAZHONG UNIV OF SCI & TECH

Non-contact robot joint torque measuring device based on inverse magnetostrictive effect

InactiveCN108548622ASimple measuring principleImprove accuracyWork measurementTorque measurementInverse magnetostrictive effectMeasurement device

The invention relates to a non-contact robot joint torque measuring device based on the inverse magnetostrictive effect and belongs to the sensing measurement technology of robot robotic arm precisioncontrol. The measuring device is characterized in that an output shaft of the robot joint torque is coated with giant magnetostrictive material coating strips, the giant magnetostrictive material coating strips comprise positive giant magnetostrictive material coating strips and negative giant magnetostrictive material coating strips, the positive giant magnetostrictive material coating strips and the negative giant magnetostrictive material coating strips are obliquely coated on the output shaft at equal intervals along the axial direction symmetrically left and right, a sleeve is sleeved onthe output shaft on the outer side of the giant magnetostrictive material coating strips, an excitation coil is mounted on an inner wall of the sleeve, and left and right measuring coils in the samespecification are mounted side by side on the inner wall of the excitation coil in the axial direction. The measuring device is advantaged in that high-accuracy high-precision real-time dynamic measurement of the torque is carried out without touching a driving shaft and without changing the force condition of the driving shaft and rotary and dynamic working conditions, and thereby precise controlon robot arms is realized.

Owner:HARBIN INST OF TECH

A self-closed rock bolt nondestructive testing method based on a magnetostrictive effect

InactiveCN106053602AEasy to installAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalInverse magnetostrictive effectExternal bias

A self-closed rock bolt nondestructive testing method based on a magnetostrictive effect is disclosed and belongs to the field of nondestructive testing. Electromagnets are adopted to form an external bias magnetic field. A high-frequency alternating-current coil is prepared into a self-exciting and self-receiving self-closed sensor. In the bias magnetic field environment, an excitation signal is provided for the high-frequency coil, the magnetostrictive effect occurs in a rock bolt, excited ultrasonic guided waves propagate in the rock bolt, and echo information is received by utilizing an inverse magnetostrictive effect and transferred to a computer. By utilizing correlative fusion, deconvolution and other signal processing methods, reflection time recognition is achieved, and rock bolt related geometrical parameters and a primary defect status are acquired, thus achieving rock bolt quality evaluation. The method has advantages of a high detection efficiency, good detection precision, no need of a coupling agent, and the like and is suitable for nondestructive testing of rock bolts in complex engineering environments.

Owner:SHIJIAZHUANG TIEDAO UNIV

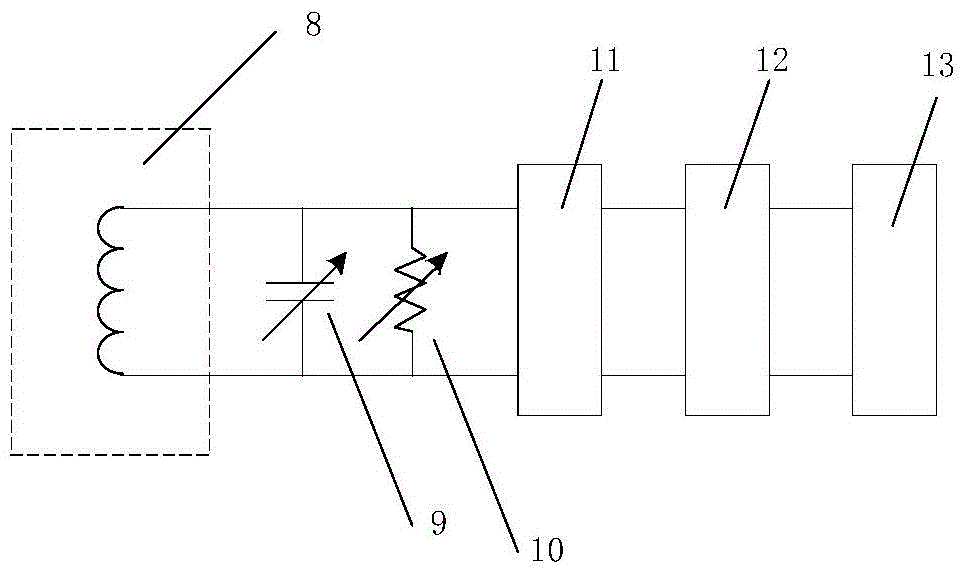

Micro-thrust measurement system based on Barkhausen effect

InactiveCN109632156ASimple structureEasy to operateForce measurement by measuring magnetic property varationElectricityInverse magnetostrictive effect

The invention provides a micro-thrust measurement system based on the Barkhausen effect. According to characteristics of the electric propulsion thrust as well as the inverse magnetostrictive effect (magnetism principle) and the Barkhausen effect, a thruster applies the thrust to a magnetoelastic element and then the change of Barkhausen noises is measured to obtain the change of the internal stress of the magnetoelastic element, so that the magnitude and variation of the thrust are obtained. The a micro-thrust measurement system has advantages of simple structure, great convenience in operation, high reliability, and high detection sensitivity and accuracy; the change of stress is measured in real time; and the small transient thrust of the electric thruster is measured precisely.

Owner:NAT UNIV OF DEFENSE TECH

Ship shaft horsepower measuring method based on counter-magnetostriction effect

InactiveCN108375437ADoes not affect measurement accuracyNo maintenanceWork measurementTorque measurementInverse magnetostrictive effectLinearity

The invention discloses a ship shaft horsepower measuring method based on a counter-magnetostriction effect; the method comprises the following steps: 1, mounting a counter-magnetostriction torque testing device on a shafting; 2, gathering torque signals: using magnetic circuit calculation or test to obtain characteristic parameters in the testing device, and further obtaining a corresponding relation between an output voltage signal and the torque, wherein the characteristic parameters include an amplification factor, sensitivity, linearity and a measuring range; 3, using the counter-magnetostriction torque testing device to measure the voltage signal U and the sensitivity K, using a rotating speed sensor to measure a rotating speed signal n, and calculating the shafting power in real working. The method is simple in process, and can ensure the measuring precision.

Owner:WUHAN UNIV OF TECH

Biplane oil driven micropump based on giant magnetostrictive film driver

InactiveCN104358674ALarge pump chamberHigh trafficFlexible member pumpsPositive-displacement liquid enginesInverse magnetostrictive effectMicropump

The invention discloses a biplane oil driven micropump based on a giant magnetostrictive film driver. The biplane oil driven micropump comprises a pump body, and a substrate dividing the pump body into an upper pump body and a lower pump body, wherein an upper plane spiral coil is arranged on the upper surface of the upper pump body; the upper plane spiral coil is electrically connected with an external power supply; a positive magnetostrictive effect film is arranged on the upper surface of the substrate; an inverse magnetostrictive effect film is arranged on the lower surface of the substrate; a liquid inlet and a liquid outlet are formed in the pump body; a valve cavity is arranged in the pump body; the substrate forms an upper liquid cavity with the upper pump body and forms a lower liquid cavity with the lower pump body; both the liquid inlet and the valve cavity are communicated with the upper and lower liquid cavities; the valve cavity is communicated with the liquid outlet; one-way liquid inlet films are arranged in positions where the upper and lower liquid cavities are connected with the liquid inlet; one-way liquid outlet films are arranged in positions where the upper and lower liquid cavities are connected with the valve cavity. The biplane oil driven micropump adopts double liquid cavities, and has a larger pump cavity in the condition of the same volumes, with the flow being larger than that of the conventional film micropump.

Owner:ANHUI UNIV OF SCI & TECH

Controllable composite damping structure adopting magnetostrictive material

InactiveCN106269450ALower impedanceReduce volumeMechanical vibrations separationDynamo-electric machinesInverse magnetostrictive effectElastic substrate

The invention provides a controllable composite damping structure adopting a magnetostrictive material. The controllable composite damping structure comprises a magnetostrictive material layer and a viscoelastic material layer which are attached to an elastic substrate, an electromagnetic induction coil and a matching control circuit; the elastic substrate can be a controlled object and can also be a structural part which is additionally arranged and used for being connected with the controlled object; the magnetostrictive material layer is used for coupling mechanical deformation of the elastic substrate and converting mechanical energy generated during mechanical deformation of the elastic substrate into magnetic energy based on the counter-magnetostrictive effect, and consequently dynamic magnetization is generated; the viscoelastic material layer provides initial damping for the composite damping structure; the electromagnetic induction coil converts the magnetic energy generated by the magnetostrictive material layer into electric energy and then outputs the electric energy to the matching control circuit; the matching control circuit is used for controlling the magnitude of the damping of the composite damping structure. Damping parameters of the controllable composite damping structure can be controlled, the control range is wide, and the control circuit for controlling damping is small in size.

Owner:NANJING UNIV OF SCI & TECH

Autonomous pipeline inspection using magnetic tomography

ActiveUS9746444B2Easy to passSufficient flexibilityWeather/light/corrosion resistanceUnderwater vesselsInverse magnetostrictive effectOdometry

The present invention discloses a device and system for magnetographic analysis of mechanical flaws and defects along structures located underwater for example, metallic pipelines, utilizing an autonomous magnetic tomography method (MTM) apparatus based on the inverse magnetostrictive effect for magnetographic identification, in the form of an array of flexible autonomous undersea vehicle (AUV) torpedo constructions of interconnected elements or pods. The array of AUV torpedo constructions are flexibly linked together so that the device can readily navigate within the contours of pipeline to be inspected using the flow media as propulsion means or alternatively by means of independent motive means without interfering with the system flow. The torpedo construction elements or pods each contain three MTM sensors situated 120 degrees apart on a non-perpendicular cross section arrangement, and perform a variety of independent functions. e.g., data storage data, sensor data memory unit, odometer distance measurements, GPS location, geomagnetic navigation capability.

Owner:GOROSHEVSKIY VALERIAN +2

A magnetostrictive material magnetic characteristic tester

ActiveCN103558569BUniform magnetic field strengthEasy to operateMagnetostrictive property measurementsInverse magnetostrictive effectTester device

The invention relates to a tester for the magnetic property of a magnetostriction material. The tester comprises a main measurement component, a standard force sensor, a stress applying device and a permanent magnet. The main measurement component is composed of an upper loop module, a lower loop module, an upper pole head, a lower pole head, a left exciting coil, a right exciting coil and the magnetostriction material to be tested. The overall structure of the main measurement component is in bilateral symmetry. Through the application of the main measurement component and the stress applying device, the device can test the property of the positive magnetostriction effect and the property of the converse magnetostriction effect, can carry out a magnetic property test under the condition of dynamic excitation, and is simple in structure and high in flexibility.

Owner:HEBEI UNIV OF TECH

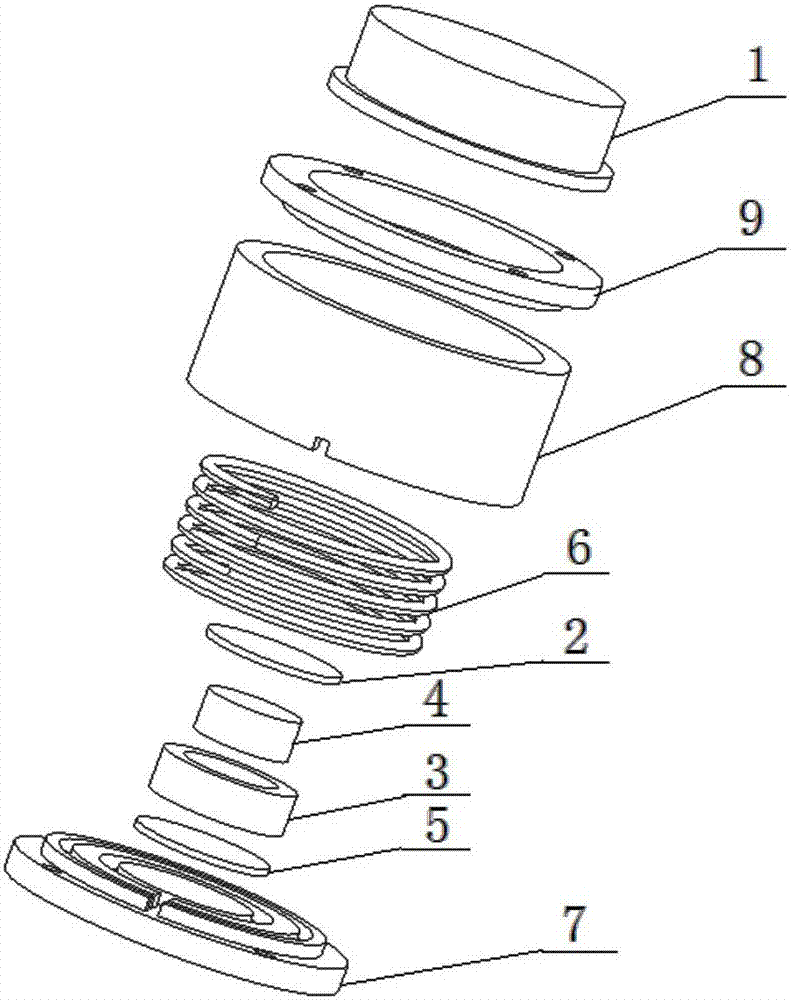

Bilateral mid-axle torque sensor of booster bicycle based on converse magnetostriction effect

PendingCN108163128ARealize non-contact measurementGood repeatabilityWork measurementTorque measurementInverse magnetostrictive effectEngineering

The invention relates to the technical field of bicycle mid-axle torque detection, in particular to a bilateral mid-axle torque sensor of a booster bicycle based on the converse magnetostriction effect. The sensor includes a through axle, an elastic sleeve, a mid-axle-outer sleeve, a coil assembly, a magnetostriction coating, a circuit board, a Hall sensor, a mid-axle end cover and a multi-stage magnet ring; the through axle is connected with the elastic sleeve through a key, the elastic sleeve is rotatably connected onto the interior of the mid-axle-outer sleeve, the right end of the throughaxle is rotatably connected onto the interior of the mid-axle end cover, the outer surface of the elastic sleeve is coated with the magnetostriction coating, a cavity between the mid-axle-outer sleeveand the elastic sleeve is internally provided with the coil assembly and the circuit board, the through axle is fixedly connected with the multi-stage magnet ring, the Hall sensor is arranged betweenthe multi-stage magnet ring and the mid-axle-outer sleeve, and the output ends of the coil assembly and the Hall sensor are each connected with the input end of the circuit board through a wire. Thesensor solves the problem that in an existing torque sensor, the mechanical structure is complex, the reliability is low, the cost is high, and the technical difficulty is high.

Owner:苏州哈工拓普智行科技有限公司

Two-phase opposed super magnetostrictive self-sensing driver

InactiveCN102620031BImprove response speedHigh control precisionOperating means/releasing devices for valvesPiezoelectric/electrostriction/magnetostriction machinesInverse magnetostrictive effectMicrocontroller

The invention discloses a two-phase opposed super magnetostrictive self-sensing driver, relates to a super magnetostrictive material self-sensing technology and a micro drive technology and belongs to the technical fields of micro drive and electrical control. According to the two-phase opposed super magnetostrictive self-sensing driver disclosed by the invention, the driving and self-sensing function of the driver is achieved by using magnetostriction and converse magnetostriction effects of a super magnetostrictive rod; two self-sensing driving assemblies are symmetrically arranged on two sides of a connecting piece (17) by disc springs (16) for mutually coupling to output a certain displacement and driving force; the pre-compression of the super magnetostrictive rod is accurately controlled and finely adjusted, so that the super magnetostrictive rod works in a linear interval; stable differential voltage is applied to two driving coils by a dual-output digital control power supply with a self-sensing detection and feedback function and a self-sensing signal is monitored in real time by using a real-time dynamic balance signal based on a DSP (Digital Signal Processor) high-speedsinglechip microcomputer, so that the real-time control and accurate positioning for the displacement of the connecting piece (17) are realized; and the two-phase opposed super magnetostrictive self-sensing driver is especially suitable for the field of hydraulic servo control.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com