Tester for magnetic property of magnetostriction material

A magnetostrictive material and tester technology, applied in magnetostrictive performance measurement, magnetic performance measurement, etc., can solve the problems that multi-parameter magnetic measurement systems cannot achieve measurement, etc., and achieve the effect of strong practicability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

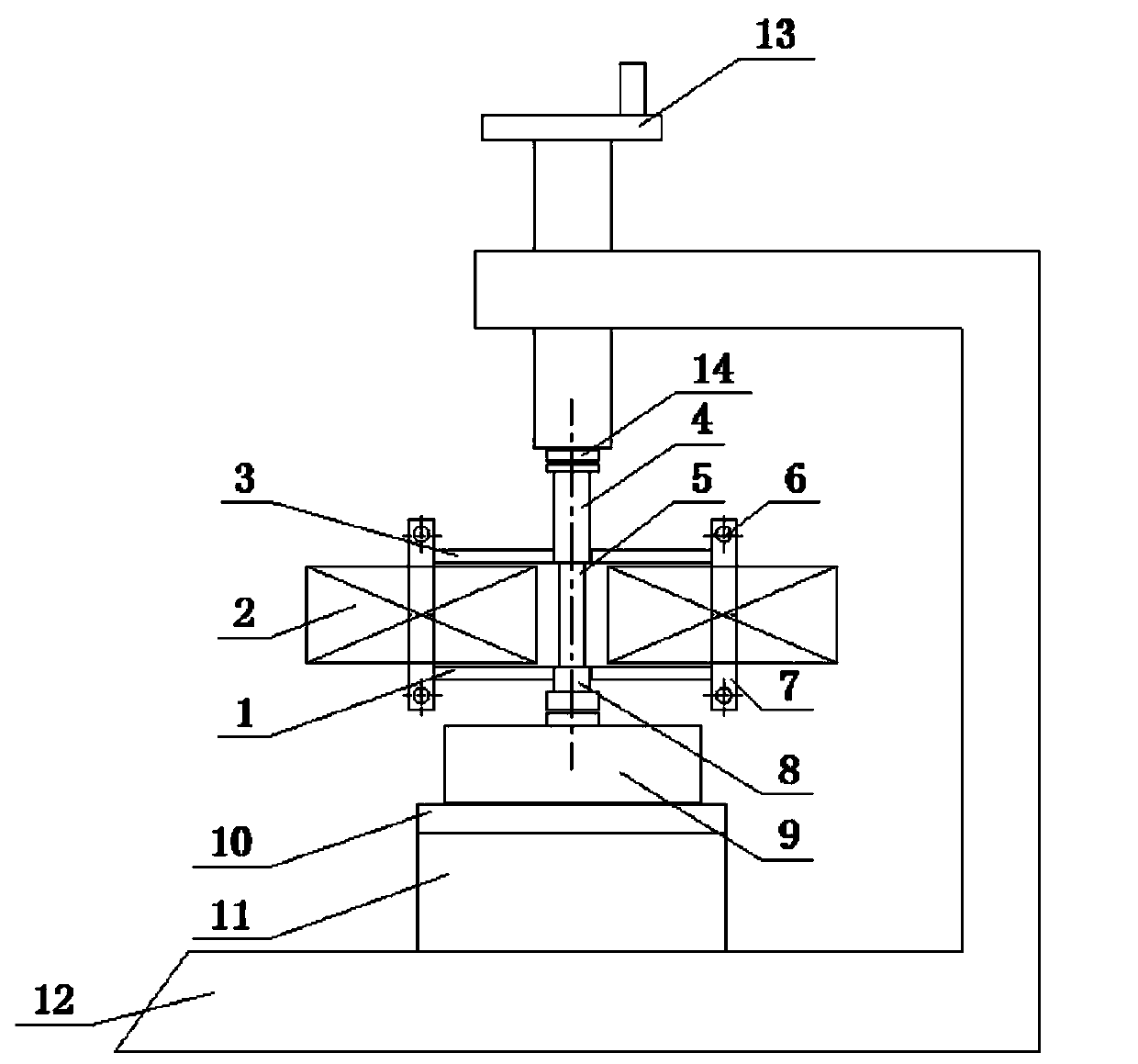

[0036] Embodiment 1 Magnetostrictive material positive magnetostrictive effect measurement: the measured magnetostrictive material of low saturation magnetic field in the present embodiment adopts Fe-Ga alloy rod, and this material diameter is 10mm, and length is 40mm, and Fe-Ga alloy composition It is polycrystalline Fe83Ga17. The stress applying device is 769YP-24B powder hydraulic tablet press, whose maximum output force can reach 2400N. Standard force sensor 9 selects JLBU-5T type standard force sensor for use. figure 1 A schematic diagram of the tester.

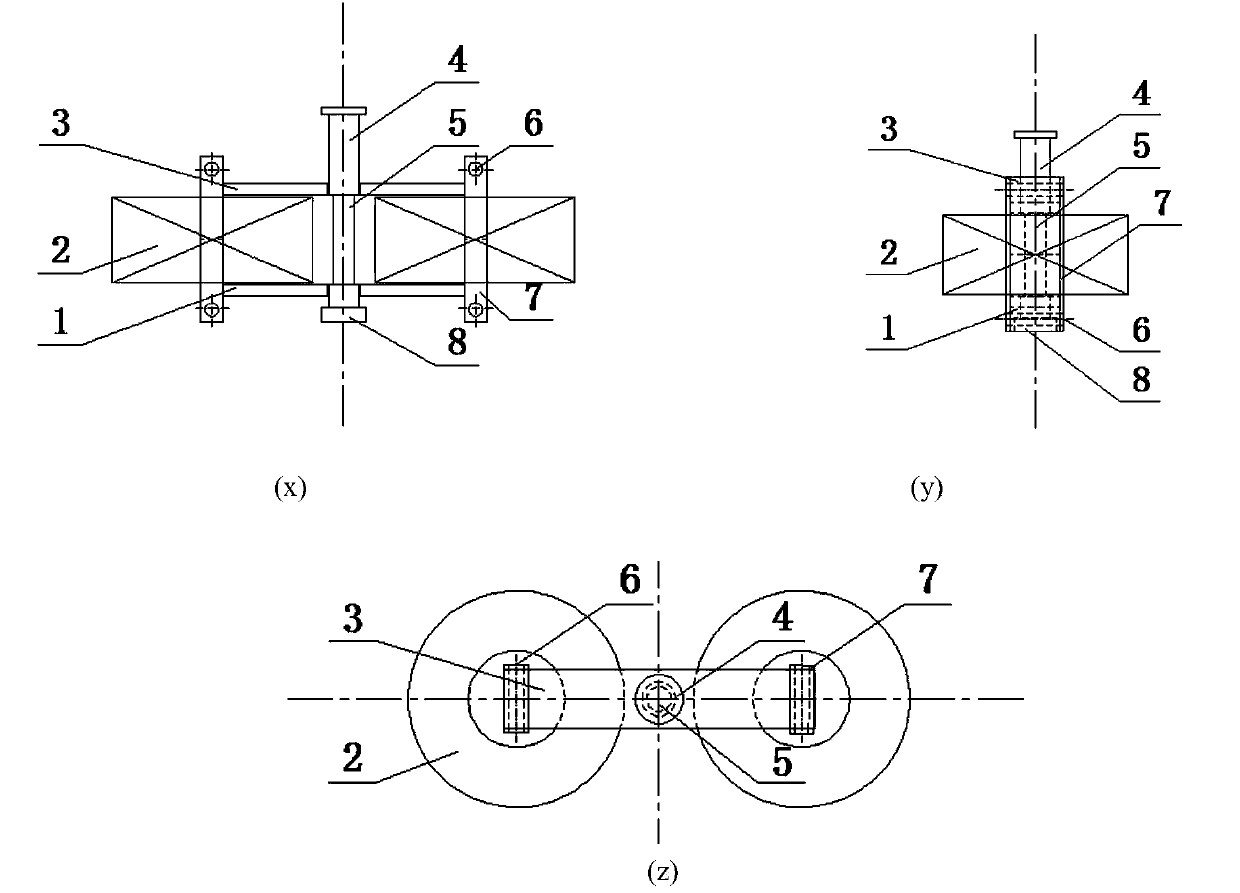

[0037] The installation process of the experimental platform is as follows: figure 2 The method shown pre-installs the main measurement part of the tester. Take out the tester figure 1 The permanent magnet 14 in. Place the standard force sensor 9 on the top cover 10, place the main measuring part on the force sensor 9, and turn the hand wheel 13 to fix the hand wheel, the main measuring part and the force sensor co...

Embodiment 2

[0039] Embodiment 2 Magnetostrictive material inverse magnetostrictive effect measurement: the measured magnetostrictive material of low saturation magnetic field in the present embodiment adopts Fe-Ga alloy rod, and this material diameter 10mm, length 40mm, Fe-Ga alloy composition polycrystalline Fe 83 Ga 17 . The 769YP-24B powder hydraulic tablet press is selected, and its maximum output force can reach 2400N. Choose JLBU-5T standard force sensor. figure 1 A schematic diagram of the tester.

[0040] The installation process of the experimental platform is the same as in Example 1.

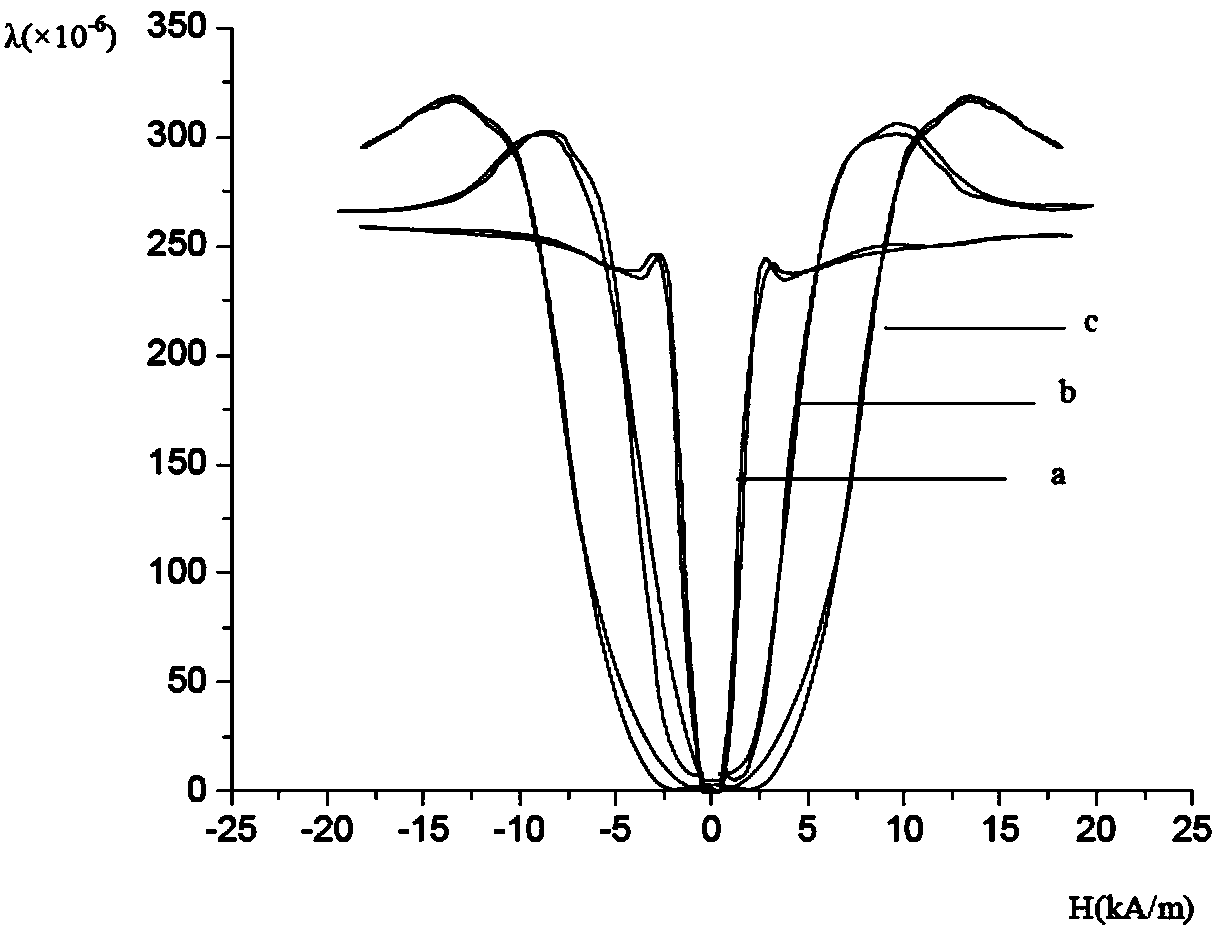

[0041] Experimental process and results: At room temperature, connect DF1731SL10A DC regulated power supply, Hall element A1321LUA power supply, SDY2103 dynamic strain gauge power supply, HT701 digital fluxmeter power supply, and force sensor JLBU-5T sensor power supply. Applying a DC current to the coil 2 in the device generates the required bias magnetic field. The tablet press output pre...

Embodiment 3

[0042] Embodiment 3 Measurement of dynamic characteristics of magnetostrictive material: the measured magnetostrictive material of low saturation magnetic field in this embodiment adopts Fe-Ga alloy rod, the diameter of this material is 10mm, the length is 40mm, and the composition of Fe-Ga alloy is polycrystalline Fe 83 Ga 17 . The 769YP-24B powder hydraulic tablet press is selected, and its maximum output force can reach 2400N. Choose JLBU-5T standard force sensor. figure 1 A schematic diagram of the tester.

[0043] The installation process of the experimental platform: place the standard force sensor 9 on the top cover 10 of the tablet press, place the main measuring part on the force sensor 9, and place the permanent magnet 14 on the handwheel 13 and the upper pole head 4 of the main measuring part Between, turn handwheel 13 and make handwheel, permanent magnet, main measuring part, force sensor coaxially fix. The permanent magnet is used to generate the bias magneti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com