Patents

Literature

592results about How to "Uniform cooling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

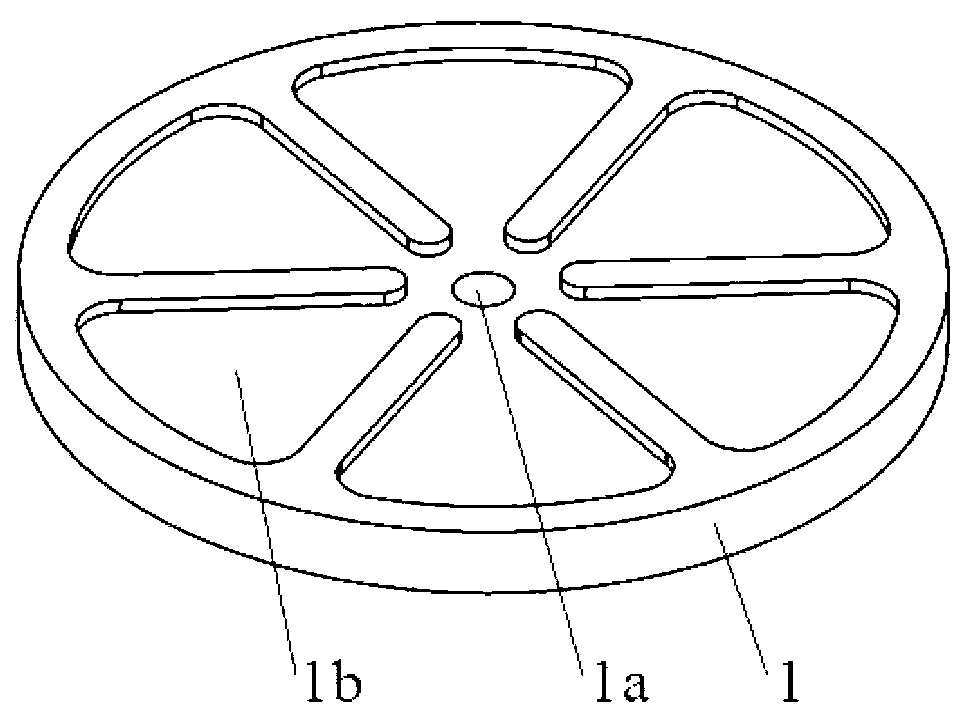

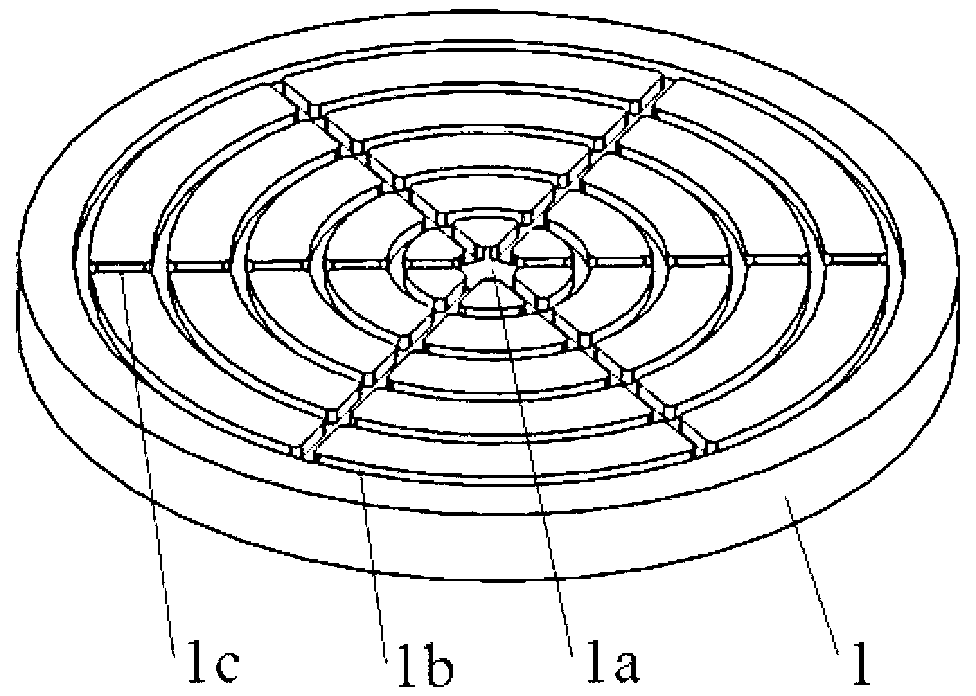

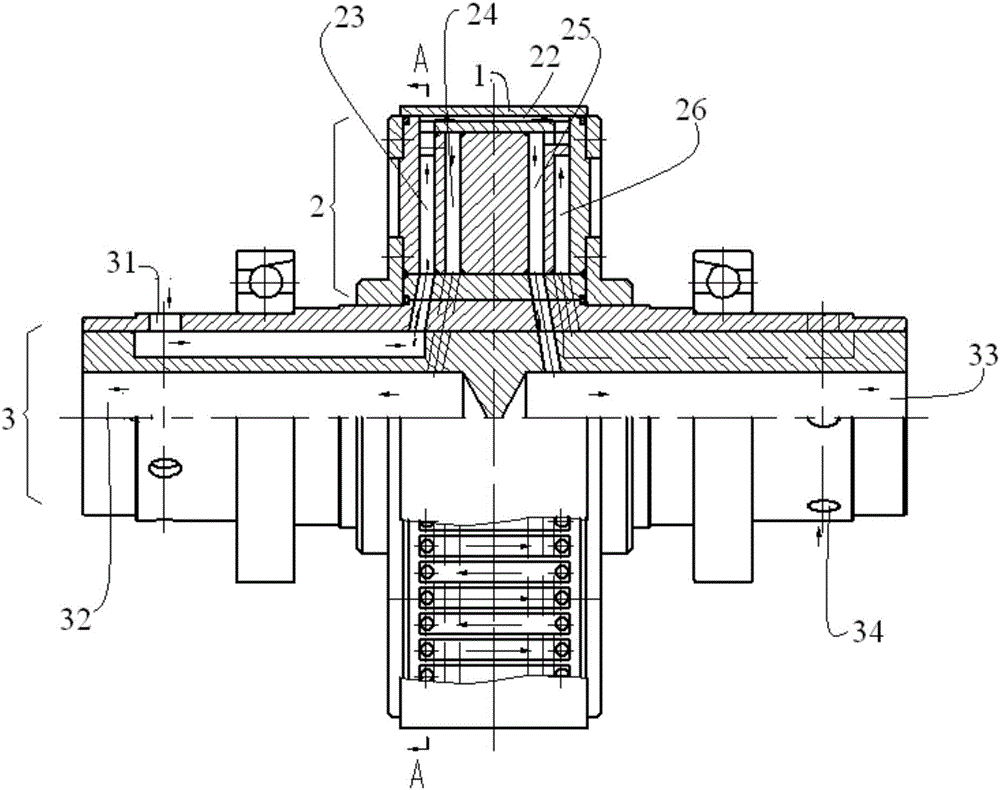

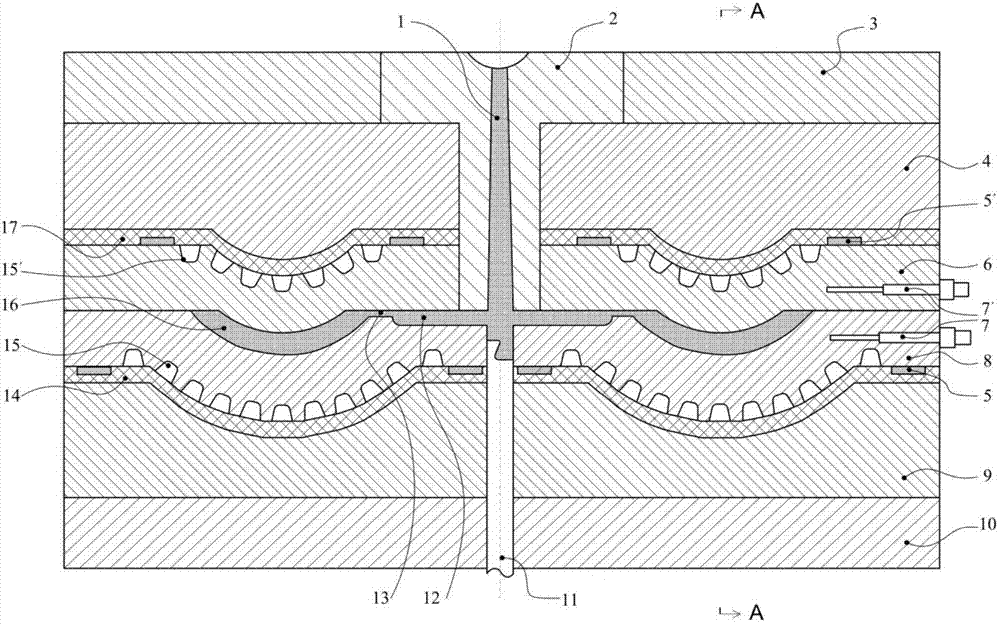

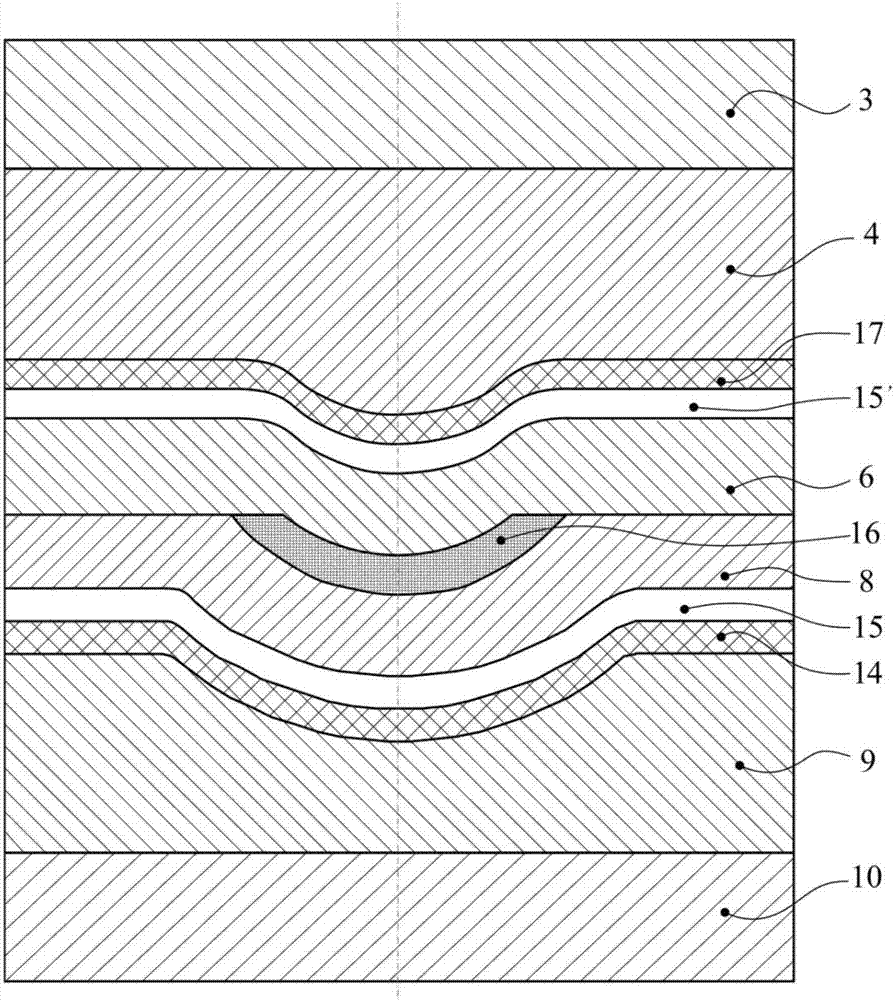

Maze conformal cooling method and structure of mold

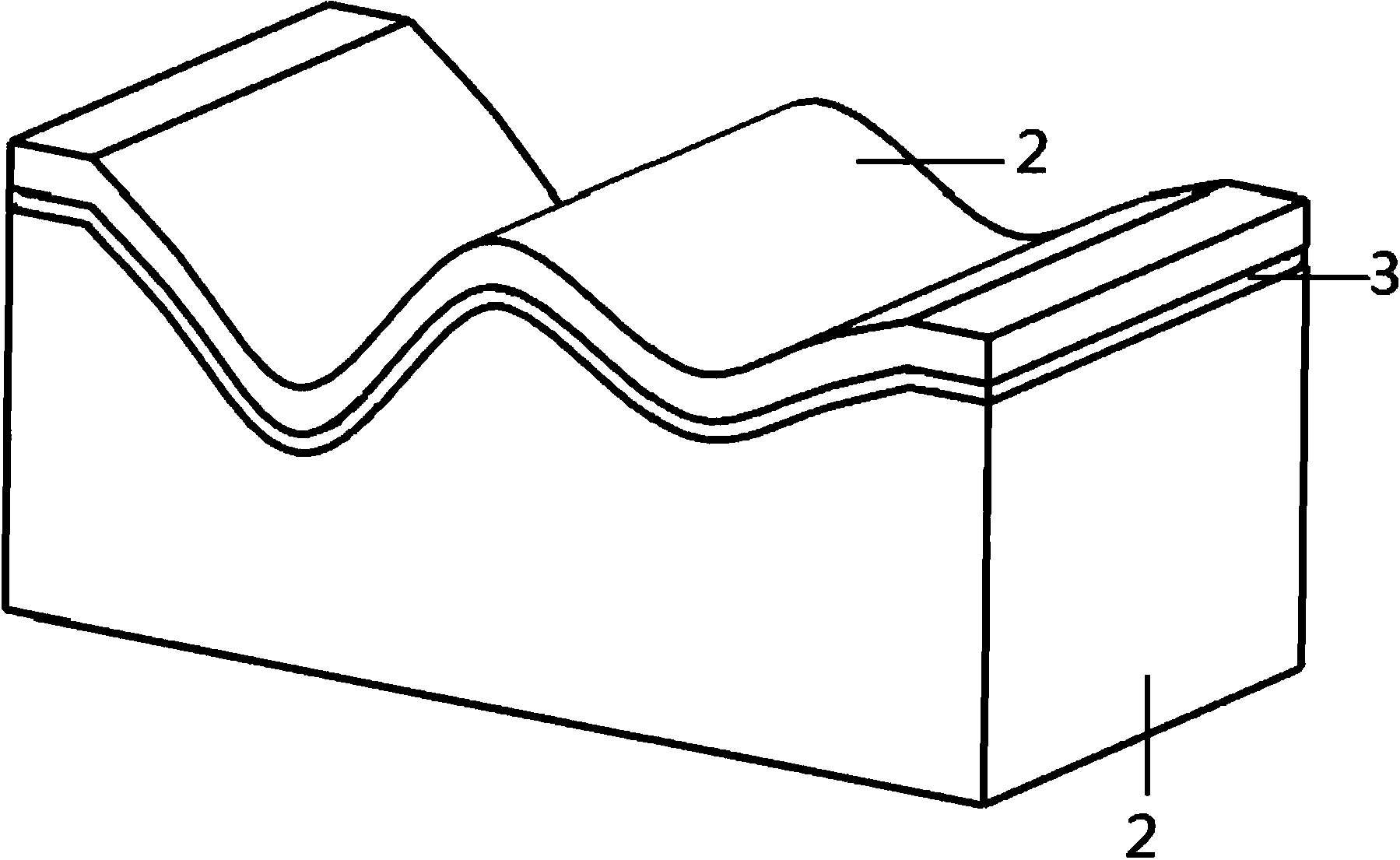

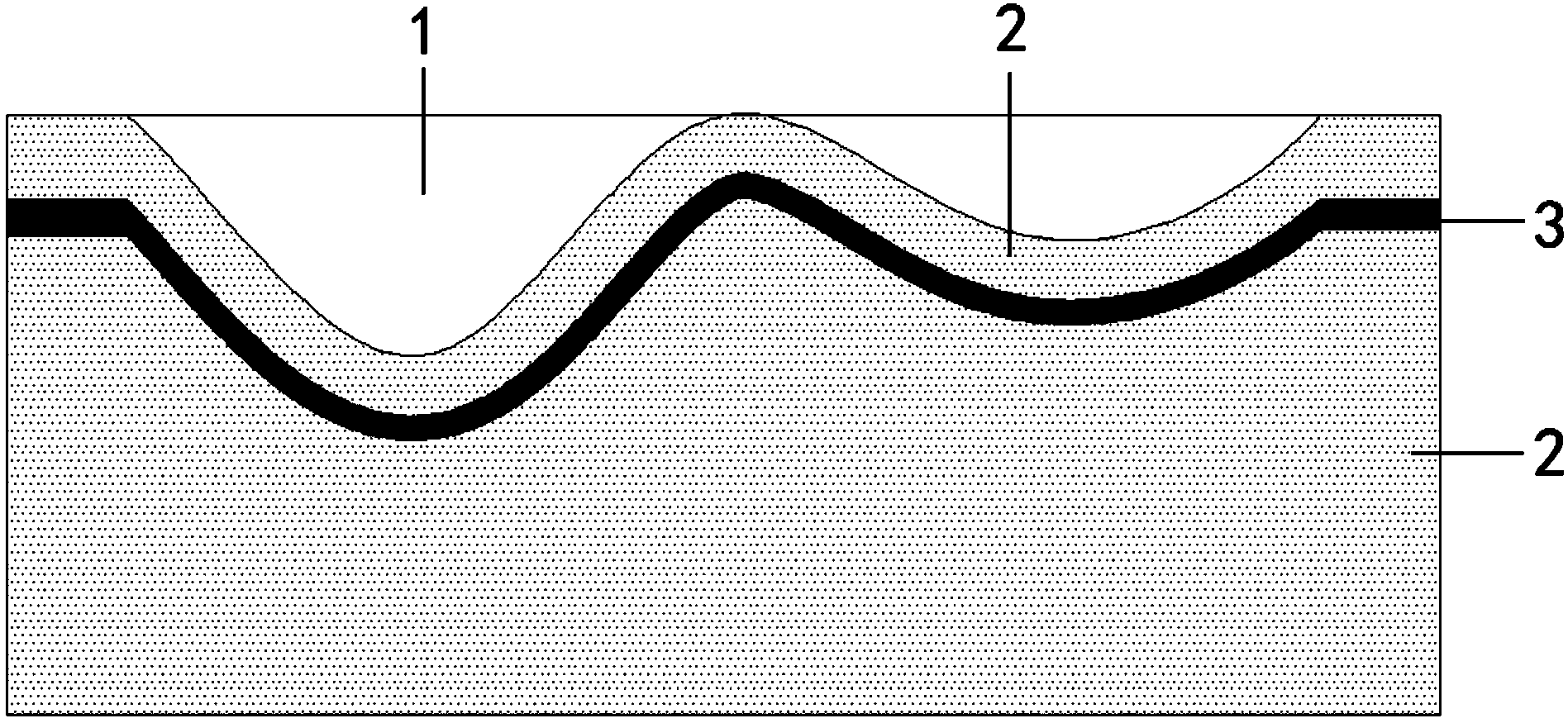

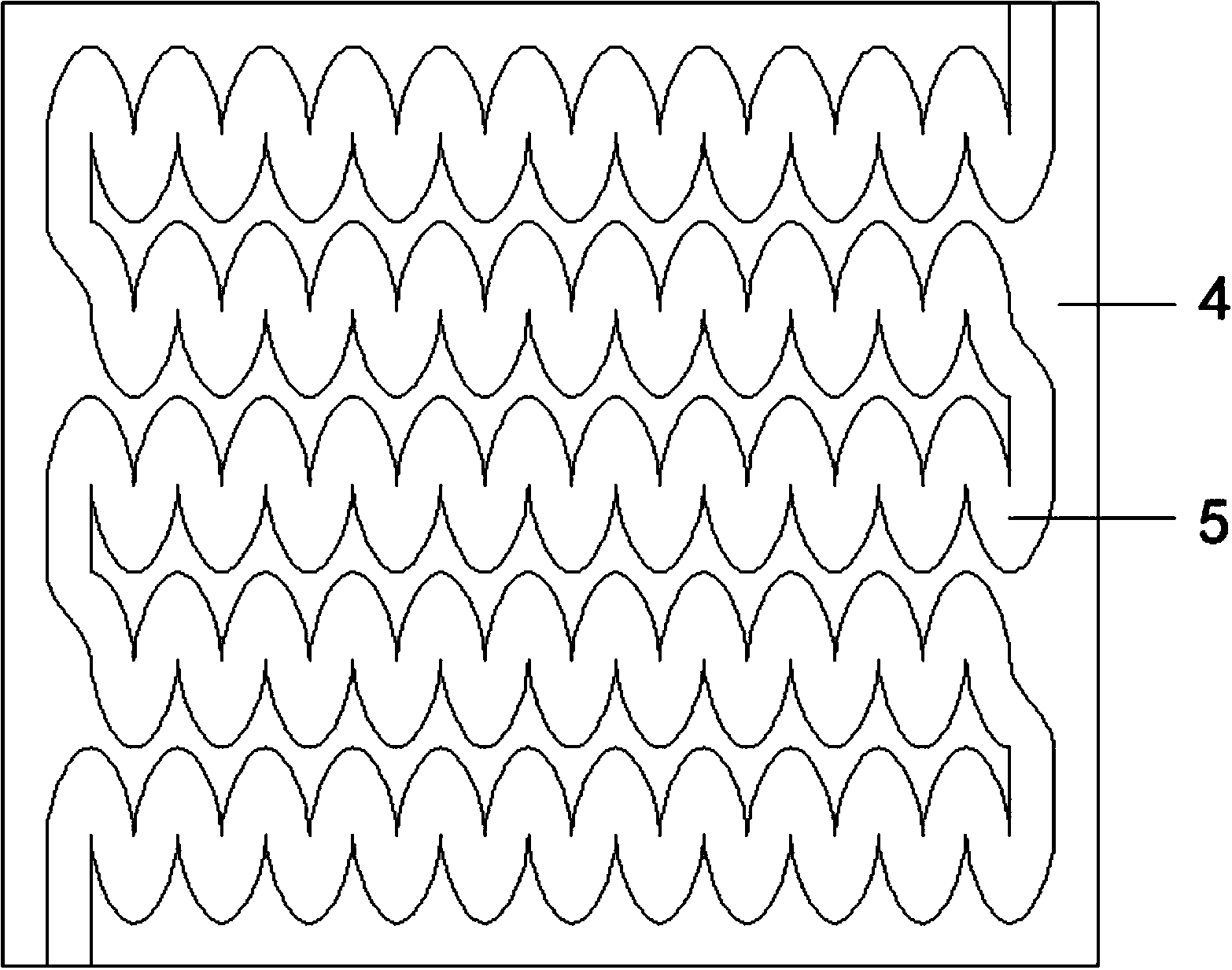

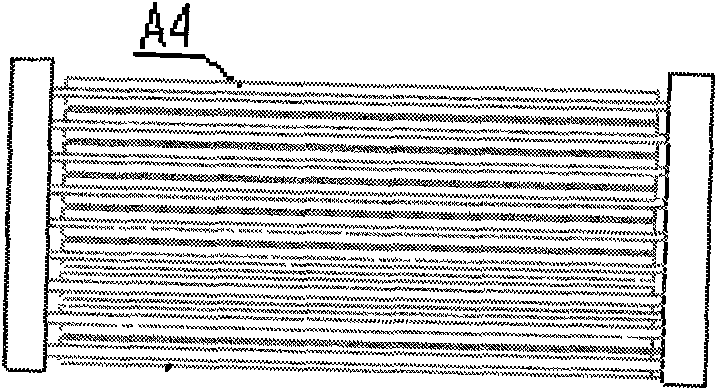

The invention provides a maze conformal cooling method and structure of a mold, and aims to solve the problem that the conventional mold cooling method cannot meet efficient and uniform cooling requirement of a complex mold. Compared with three traditional mold cooling method including a straight hole flow channel, a built-in bent pipe flow channel and a common tubular shape follow-up flow channel, the maze conformal cooling method is high in cooling efficiency and good in cooling effect. According to the structure, a hollow layer nearly parallel to the inner surface of a cavity is arranged in the position, having certain thickness distance from the cavity, in the mold, a maze type partition wall is arranged in the hollow layer, and a cooling medium flows in a channel formed by partition wall gapes in a cooling layer. The maze conformal cooling method and the structure of the mold have the advantages that the cooling state of the cooling medium in the gaps of the maze type partition wall is turbulence, and the contact area between the cooling medium and the mold is increased, so that the cooing efficiency is high, the service life of the mold is long, an injection molding process period is shortened, and the injection molding manufacturing cost is reduced. A 3-dimensional laser printing technology is adopted to directly manufacture the mold with the layered maze flow channel conformal cooling structure, components in the mold are uniform, the molding process is simple, the mold manufacturing period is short, and the mold manufacturing cost is low.

Owner:HUAZHONG UNIV OF SCI & TECH

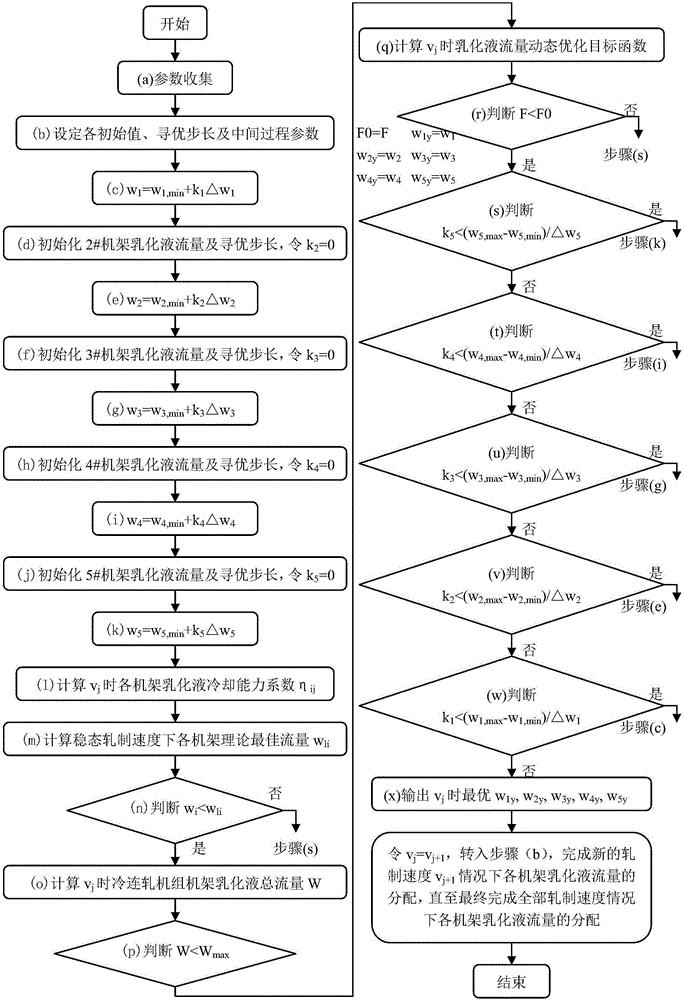

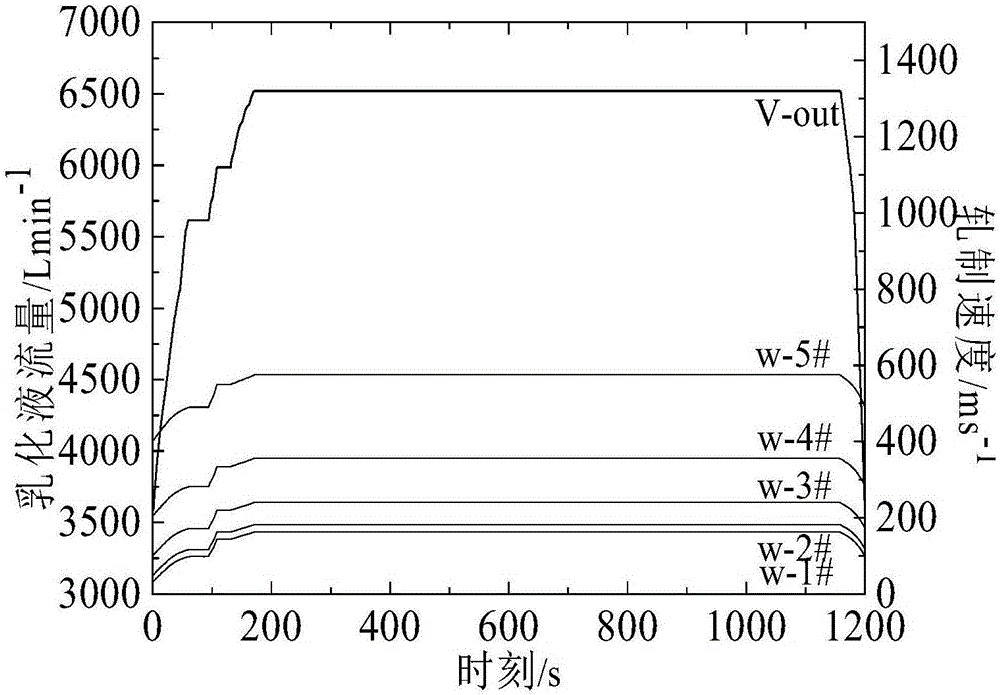

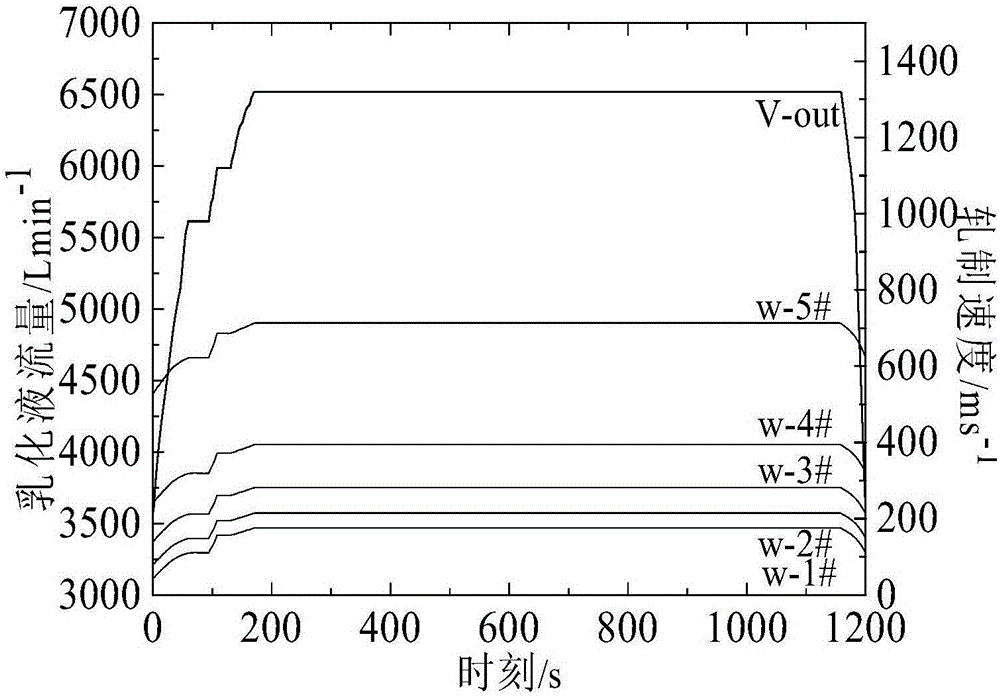

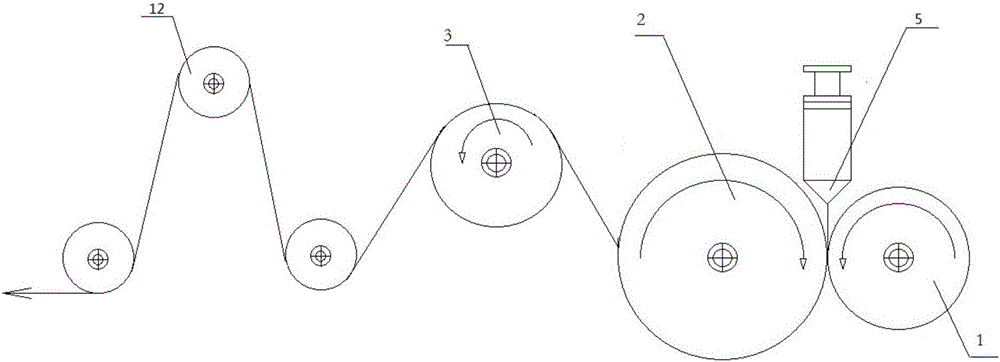

Emulsified liquid flow dynamic and comprehensive optimization setting method suitable for cold continuous rolling unit

ActiveCN106311754AFull cooling effectUniform cooling effectMass flow control deviceMetal rolling arrangementsEngineeringCooling capacity

The invention relates to an emulsified liquid flow dynamic and comprehensive optimization setting method suitable for a cold continuous rolling unit. The method mainly comprises the following steps that (1) parameters are collected; (2) initial values, optimizing step sizes and middle process parameters are set; (3) the flow and the optimizing step sizes of emulsified liquid of a No.2 rack, a No.3 rack, a No.4 rack and a No.5 rack are defined; (4) cooling capacity coefficients of the emulsified liquid of the racks are calculated; (5) the theoretical optimal flow of the racks at the steady rolling speed is calculated; (6) the total flow of the emulsified liquid of the racks is calculated; (7) an emulsified liquid flow dynamic and comprehensive optimization objective function is calculated; (8) the optimal flow of the emulsified liquid of the racks is output; and (9) distribution of the flow of the emulsified liquid of the racks at the new rolling speed is completed till distribution of all the flow is completed. According to the method, the problems that due to fixed distribution of the flow of the emulsified liquid between the racks, the rolling pressure is increased abnormally, and the rolling pressure is inverted are avoided; the cooling capacity of the emulsified liquid is given full play, and the cooling capacity of the emulsified liquid of the racks is more uniform; and the production stability is improved.

Owner:唐山市榕泽钢铁加工有限公司

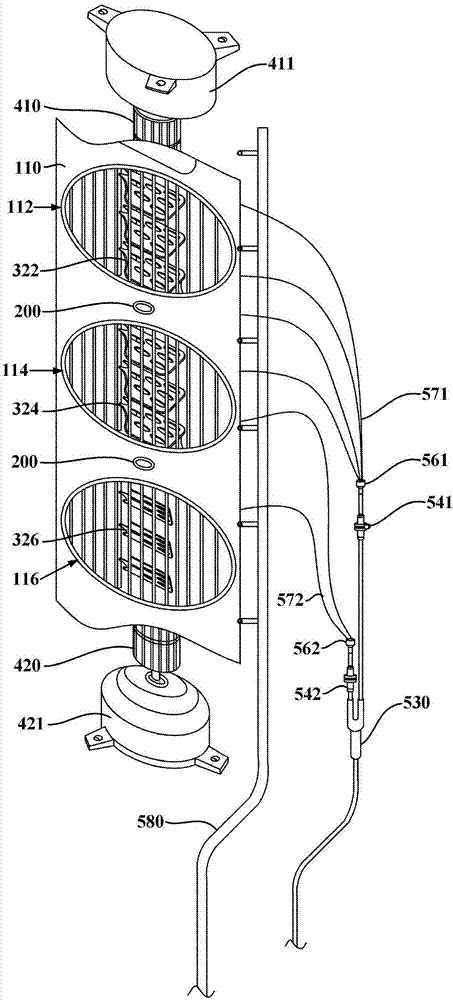

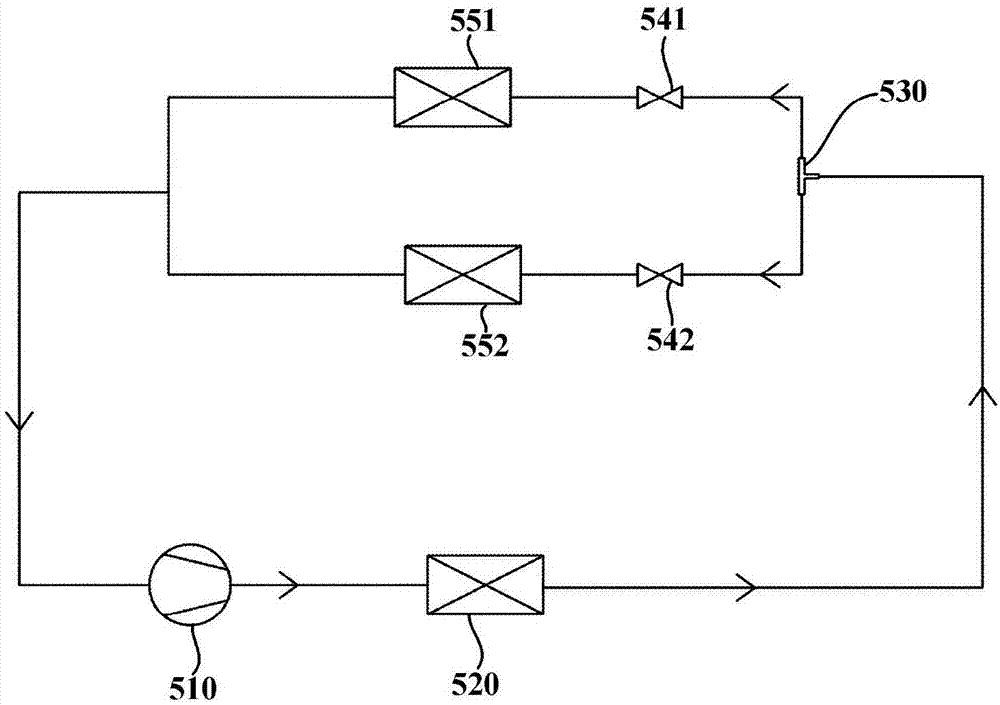

Control method for vertical air conditioner

ActiveCN107367018AReduce energy consumptionRealize intelligent adjustmentSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringRefrigeration

The invention provides a control method for a vertical air conditioner. An indoor unit of the vertical air conditioner comprises an upper evaporator, an upper draught fan and at least one upper air supply port which are matched and further comprises a lower evaporator, a lower draught fan and at least one lower air supply port which are matched. The control method comprises the following steps that the indoor environment temperature Ta is detected; if Ta is higher than the preset refrigeration comfortable temperature zone in the refrigeration mode or is lower than the preset heating comfortable temperature zone in the heating mode, the upper draught fan and the lower draught fan run at the high rotating speed; if Ta is located in the refrigerating comfortable temperature zone in the refrigerating mode or is in the heating comfortable temperature zone in the heating mode, the upper draught fan runs at the high rotating speed, and the lower draught fan runs at the low rotating speed; and if Ta is lower than the refrigerating comfortable temperature zone in the refrigerating mode or is higher than the heating comfortable temperature zone in the heating mode, the upper draught fan runs at the low rotating speed, and the lower draught fan shuts down. According to the control method, air supply is more intelligent, air supply and soft air supply can be achieved according to needs, and the comfort degree of users is improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

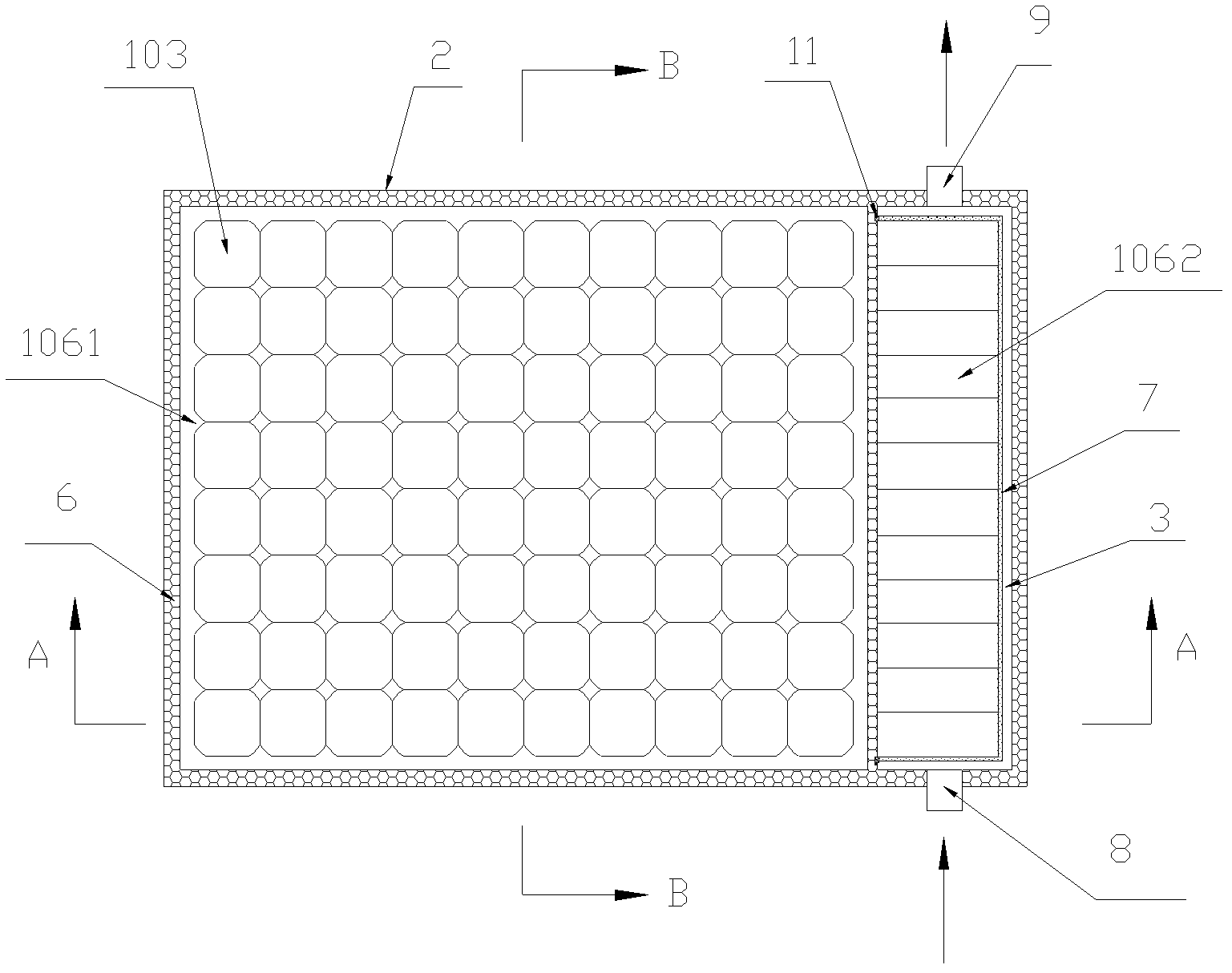

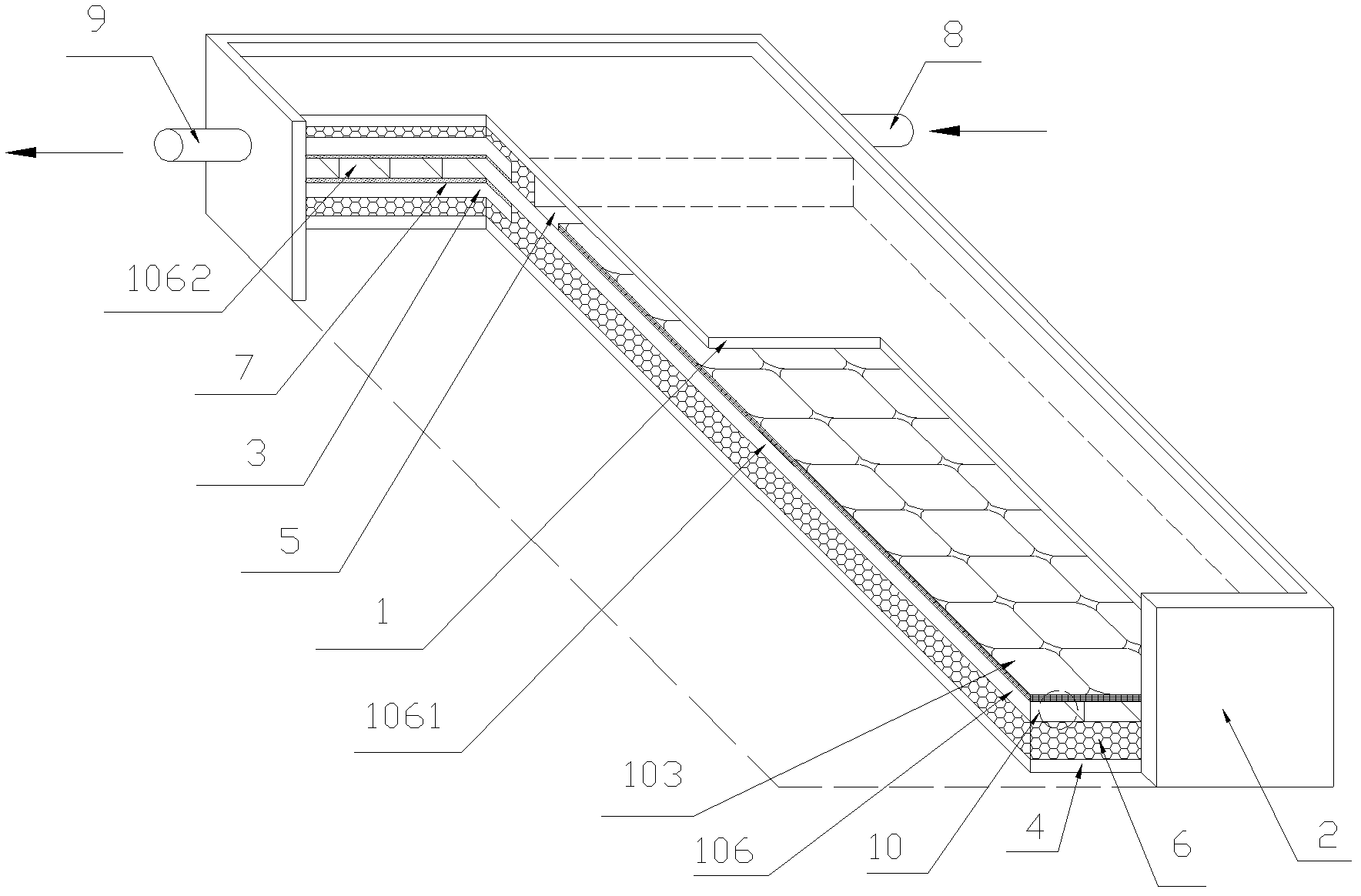

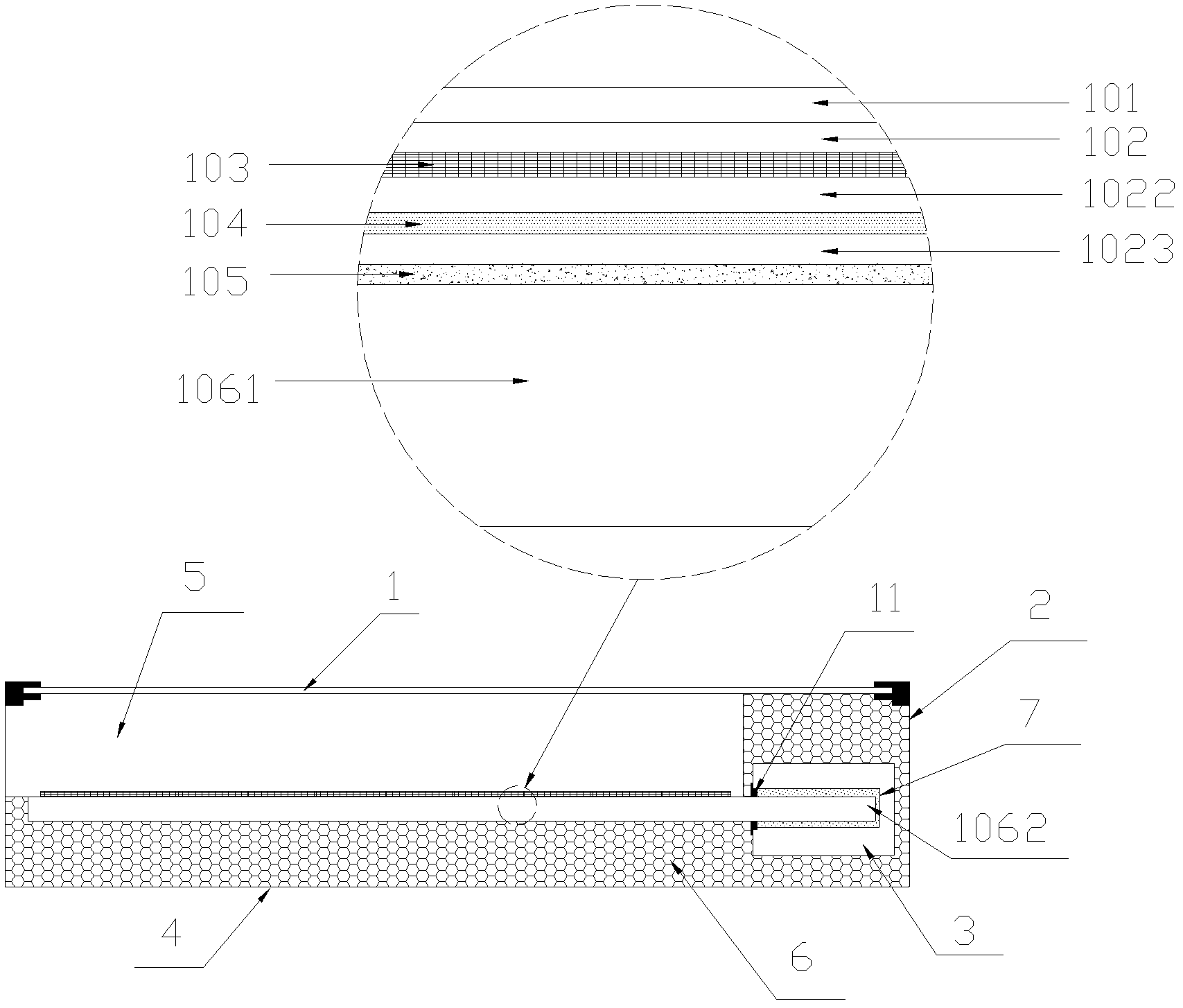

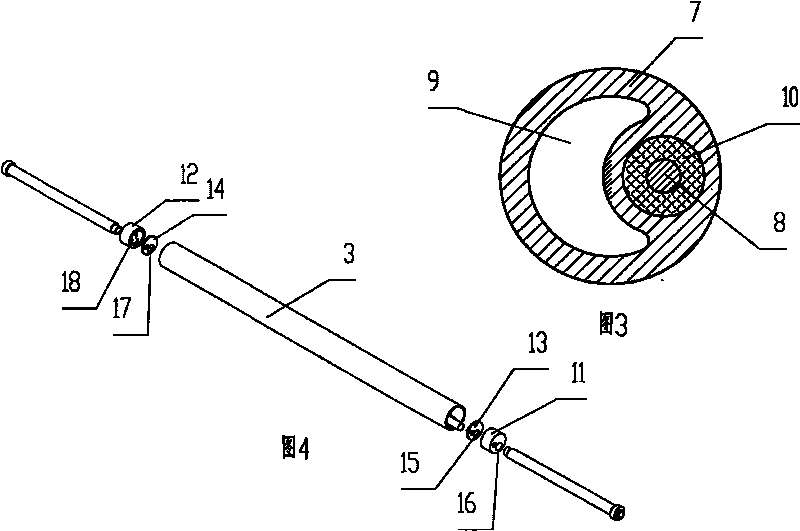

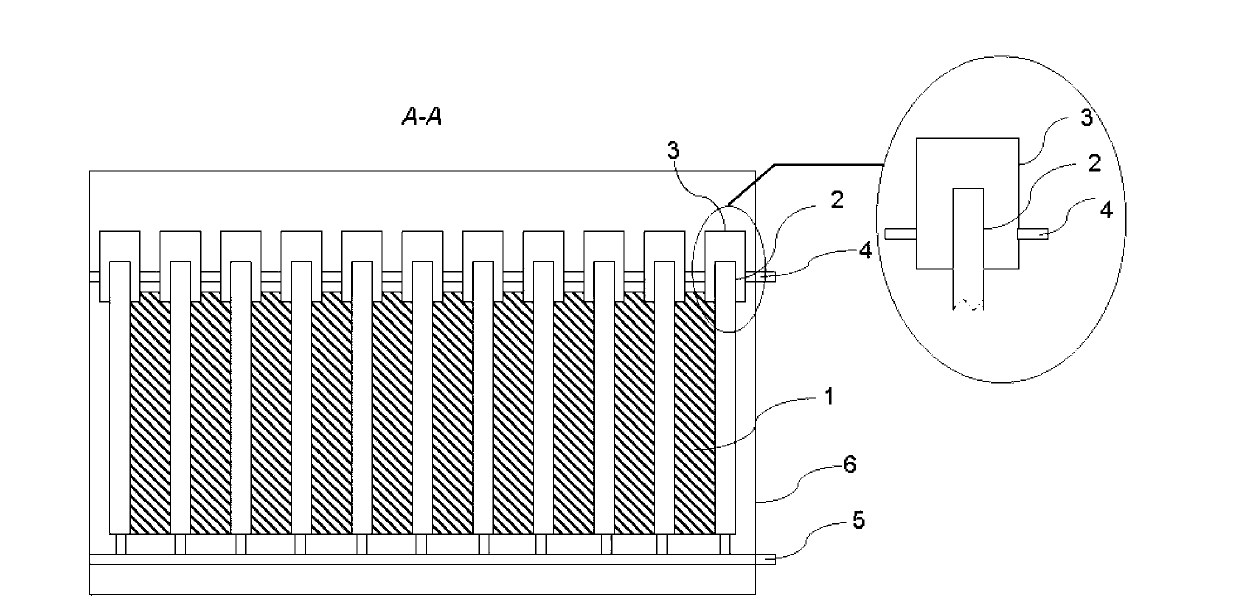

Plate heat tube type solar photovoltaic-photothermal composite heat collector and production process thereof

InactiveCN102646742AImprove power generation efficiencyUniform cooling effectPhotovoltaicsIndirect heat exchangersEvaporationEngineering

The invention discloses a plate heat tube type solar photovoltaic-photothermal composite heat collector and a production process thereof. The plate heat tube type solar photovoltaic-photothermal composite heat collector comprises a glass top cover plate (1), an air interlayer (5), a photovoltaic-photothermal composite component (10), a heat insulating layer (6) and a protective back plate (4), which are sequentially arranged from top to bottom, wherein the heat insulating layer (6) is in adhesive connection with the photovoltaic-photothermal composite component (10). The photovoltaic-photothermal composite component (10) is formed by highly integrating a plate heat tube evaporation section 1061 and a photovoltaic cell 103 by means of lamination process, a condensation section (1062) is connected with a heat collection heat exchanger (3) through a sleeve (7), all parts are fixed into a frame (2), and a circulating water inlet pipe (8) and a circulating water outlet pipe (9) which are respectively connected to the heat collection heat exchanger (3) are arranged on the lateral sides of the frame (2). By means of the plate heat tube type solar photovoltaic-photothermal composite heat collector, the temperature of the photovoltaic cell can be decreased greatly, the photovoltaic cell can be cooled more quickly and evenly, hot water can be outputted while electric energy is outputted, and comprehensive solar utilization efficiency is greatly improved. Further, the plate heat tube type solar photovoltaic-photothermal composite heat collector is simple in manufacturing process, efficient and feasible.

Owner:CENT SOUTH UNIV

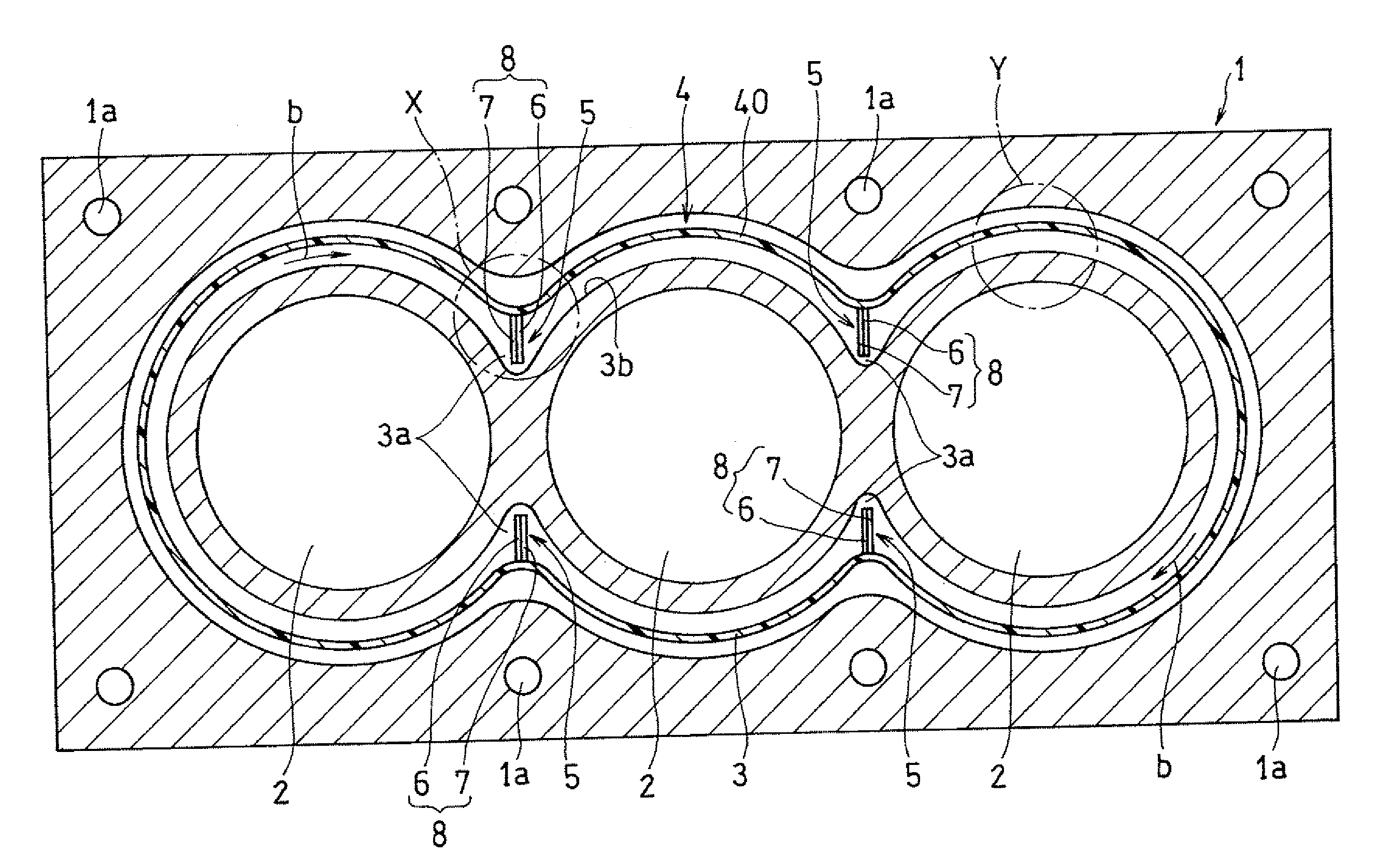

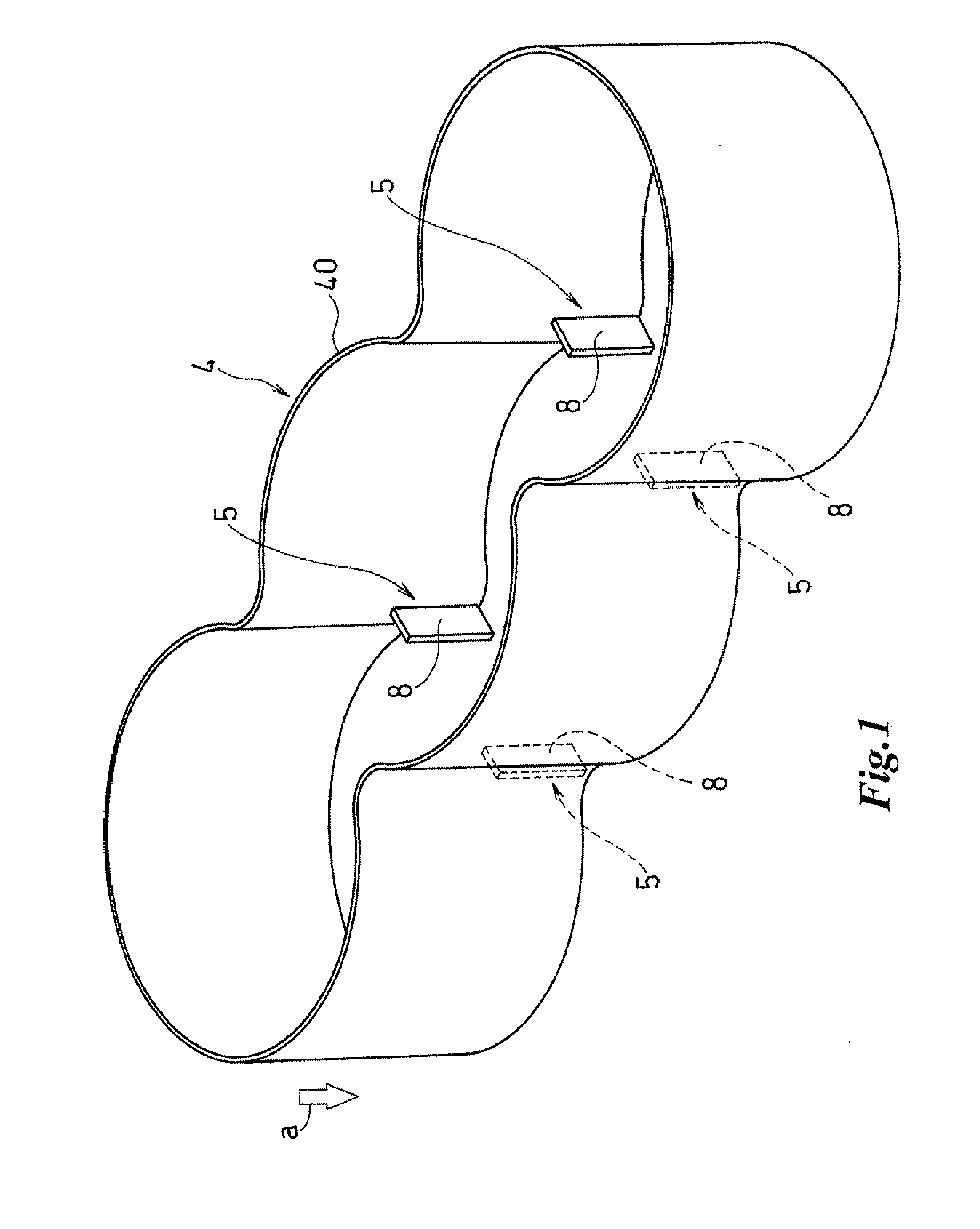

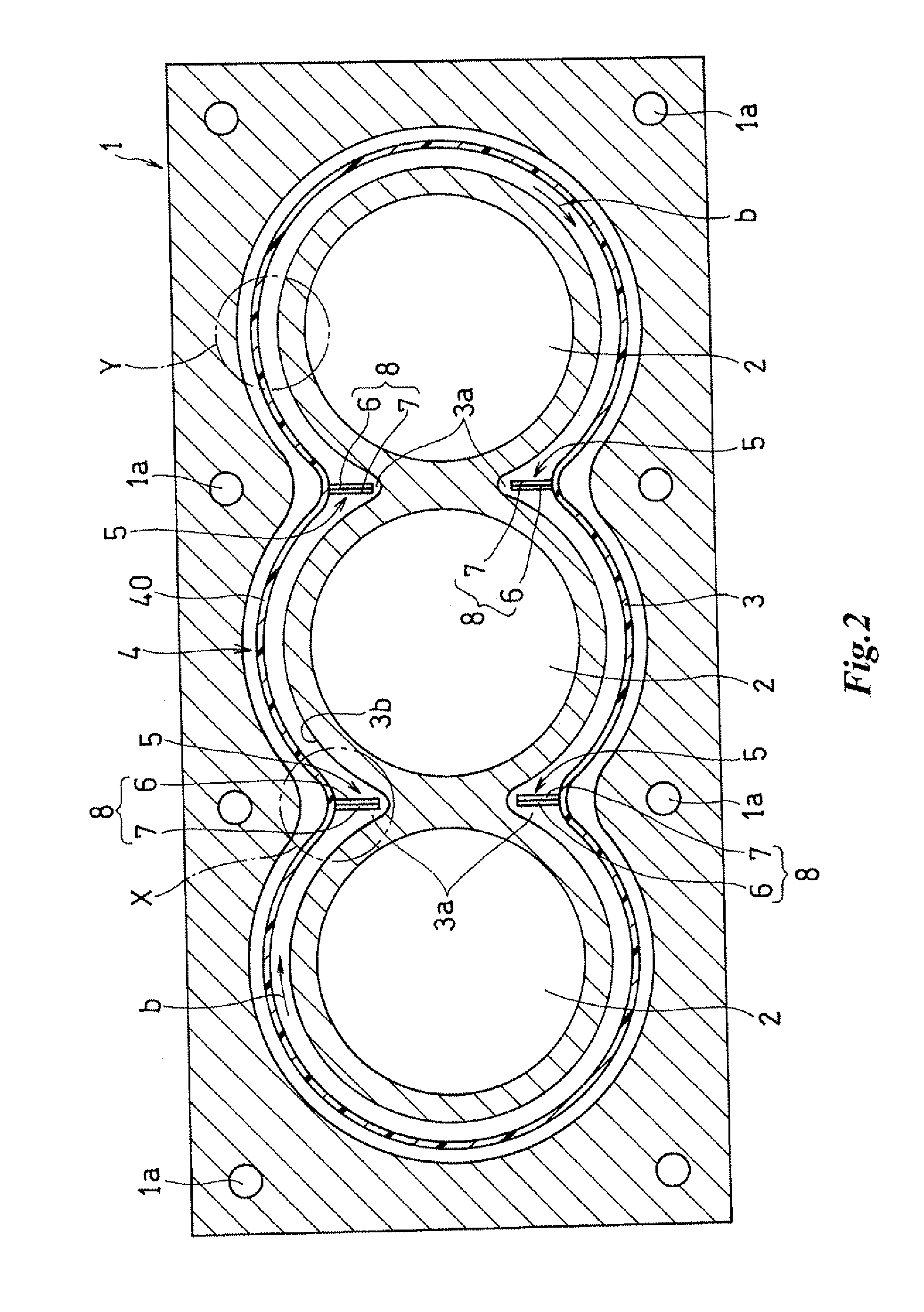

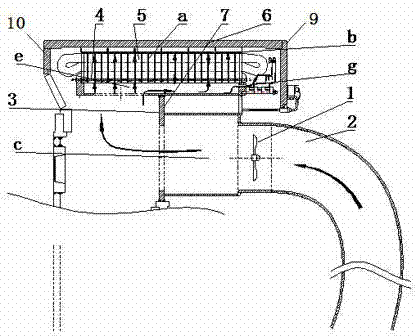

Water Jacket Spacer

InactiveUS20120132157A1Guaranteed smooth assemblySimple processLiquid coolingCylinder headsElastomerWater flow

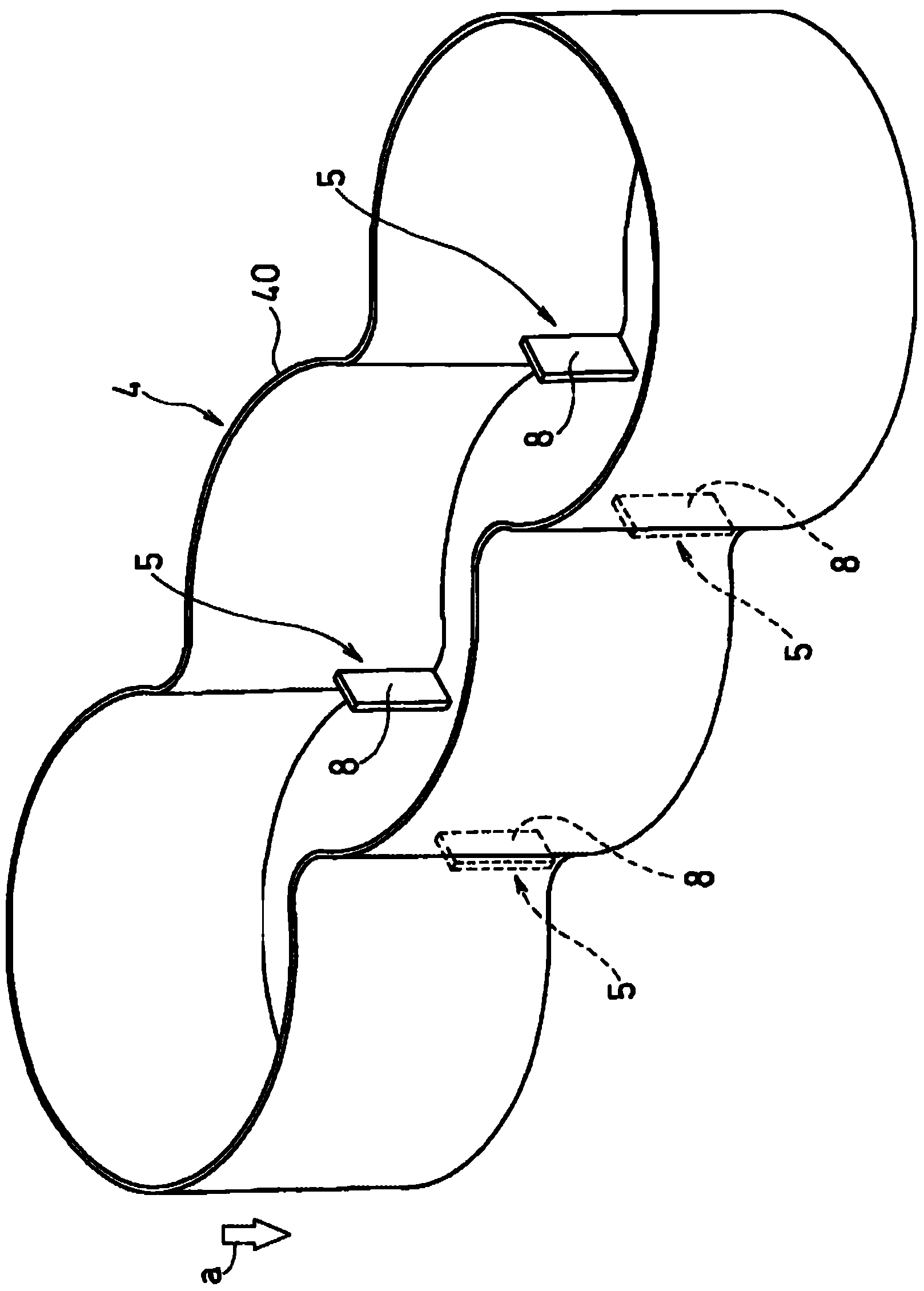

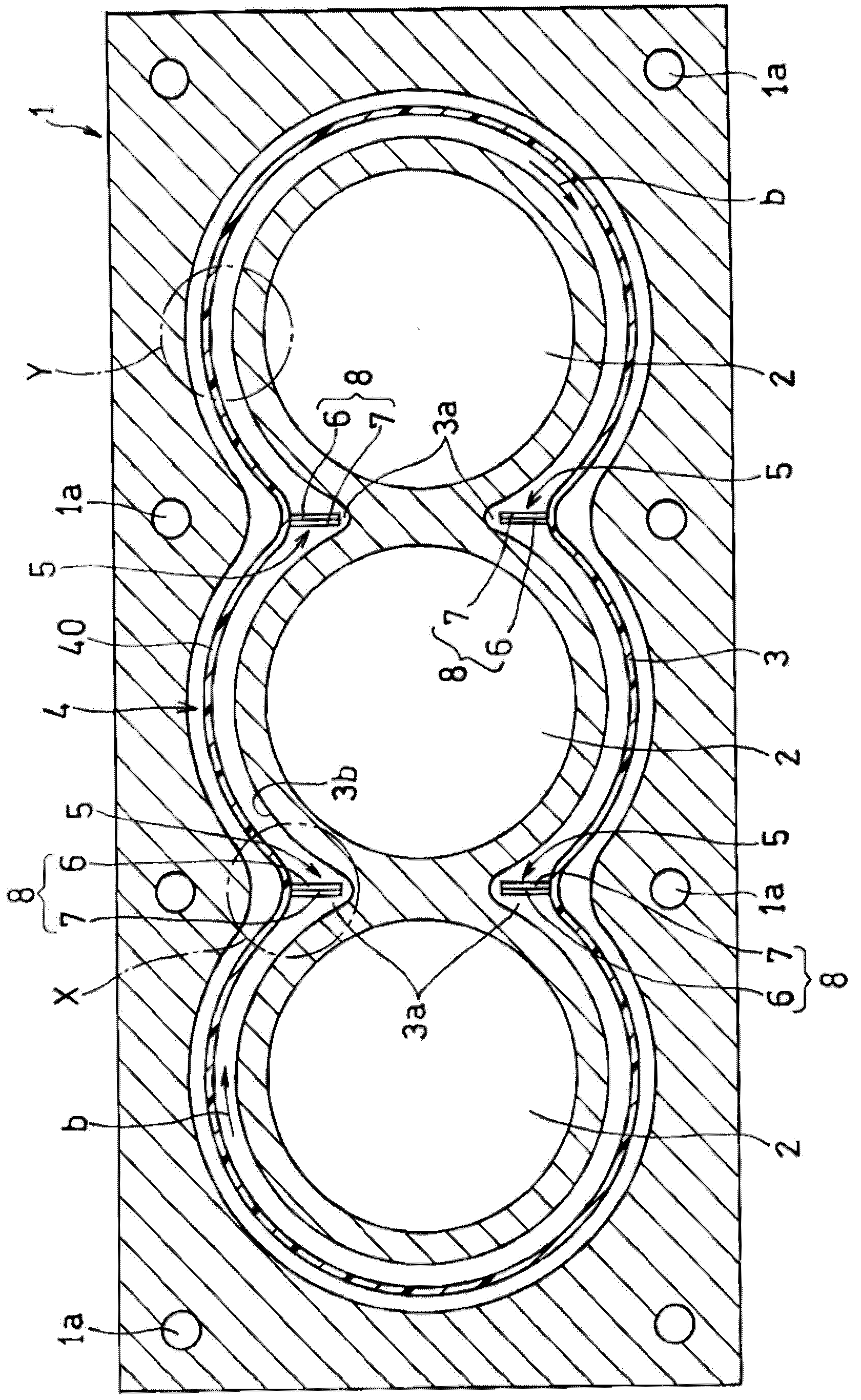

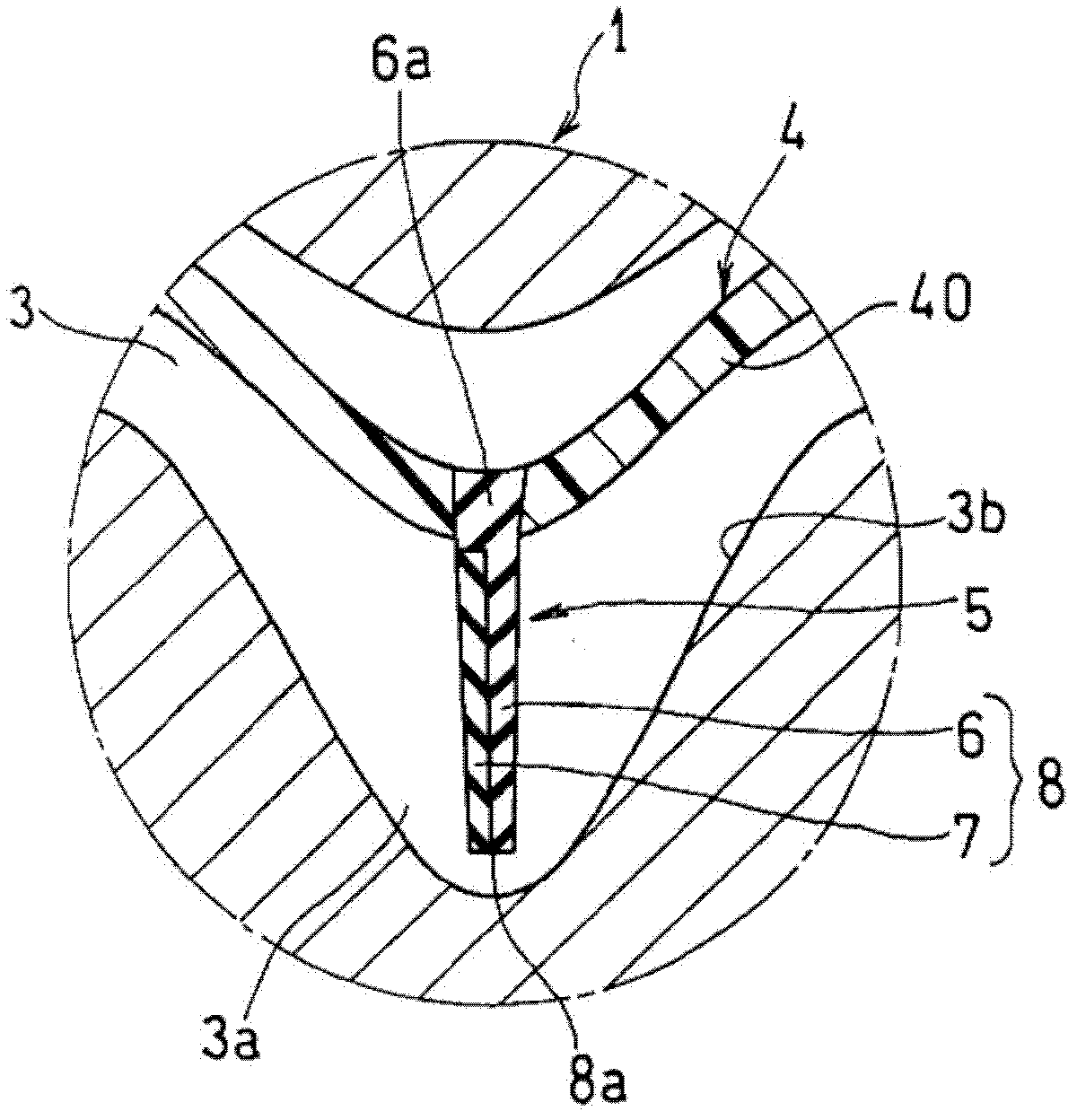

A water jacket spacer has a spacer body molded in conformity to the shape of the water jacket and a regulating member whose one side is fixed to the spacer body. The regulating member is composed of a first member which is not water-swellable and is elastically deformable and a second member made of water-swellable elastomer which is integrally fixed to the first member. The regulating member lies in a state not-contacting an opposed wall of the water jacket when inserted into the water jacket together with the spacer body, whereas it blocks a part of cooling water flowing through the water jacket by deforming such that a side of the regulating member not fixed to the spacer body faces toward the opposed wall of the water jacket when the second member swells by absorbing cooling water flown into the water jacket and thereby the first member is elastically deformed.

Owner:UCHIYAMA MFG

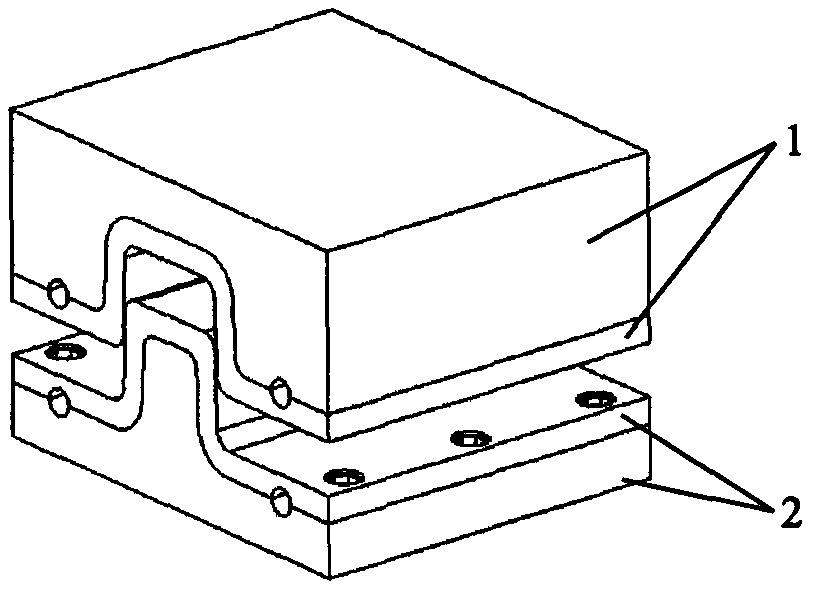

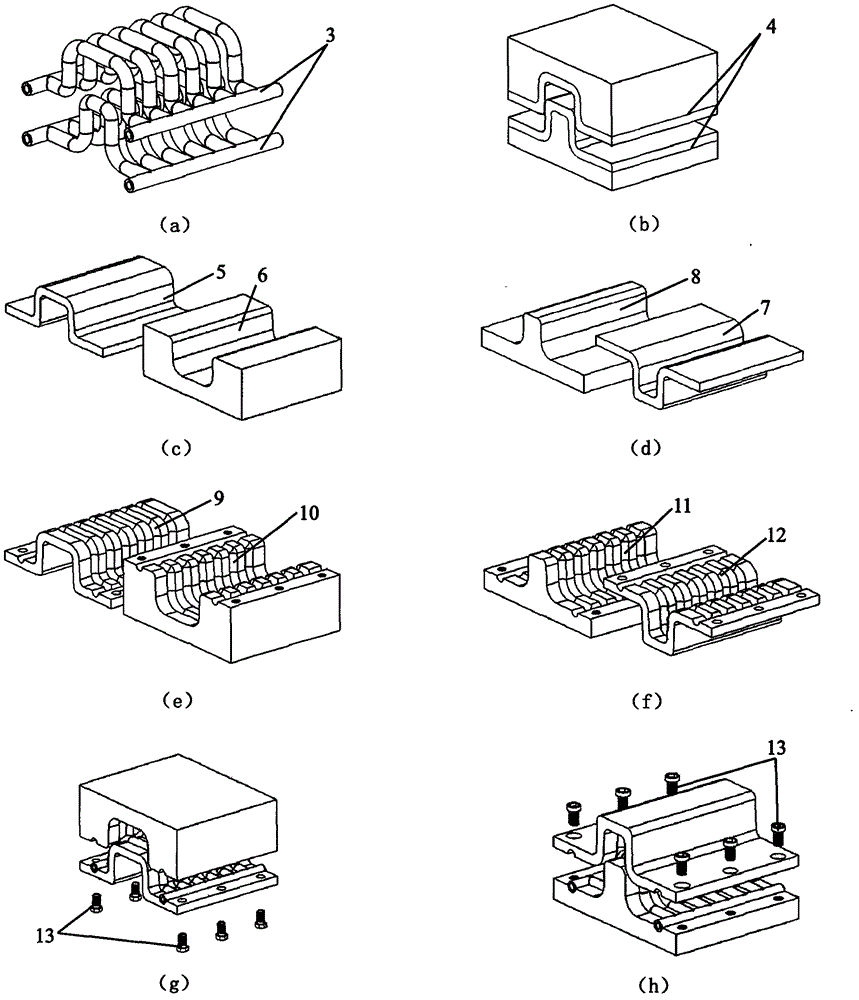

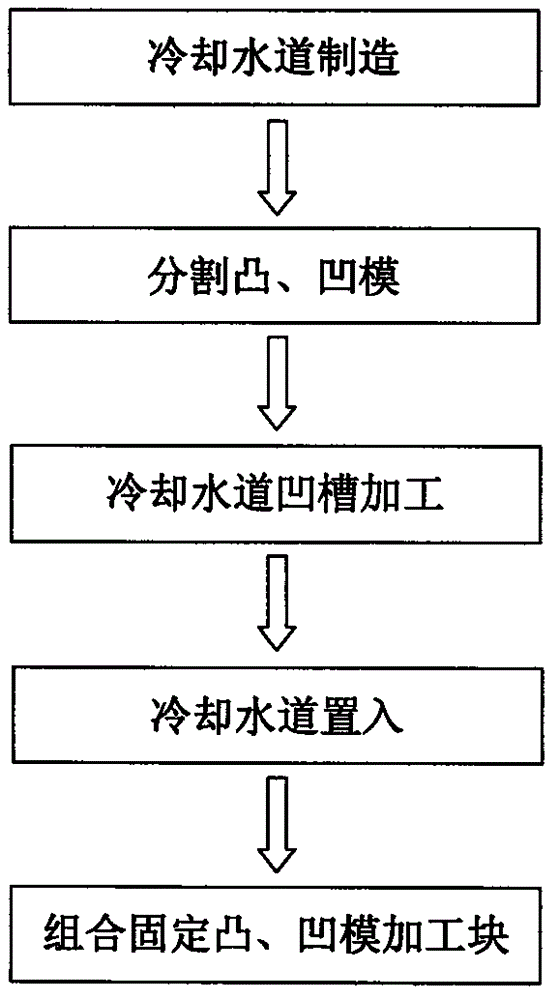

Method for manufacturing high strength steel plate hot stamping die

The invention discloses a method for manufacturing a high strength steel plate hot stamping die and belongs to the technical field of hot stamping forming. Aims at the manufacturing problem that shape follow-up cooling water channels are arranged in bent molded surfaces of male and female dies of the hot stamping die, the method is disclosed. The method comprises the following steps of: firstly, according to the shapes of the molded surfaces of the male and female dies of the die, bending the cooling water channels and connecting the cooling water channels into a pipeline system; then dividing the male and female dies into processing blocks according to the shape follow-up cooling water channels and processing grooves for placing the shape follow-up cooling water channels; and placing the shape follow-up cooling water channels into the grooves; and correspondingly combining and fixing the processing blocks to form a male and female die structure in which the shape follow-up cooling water channels are arranged. The method adopts the process scheme of manufacturing the cooling water channels, cutting the male and female dies, processing the grooves of the cooling water channels, placing the cooling water channels into the grooves and combining and fixing the male and female die processing blocks. According to the process scheme, the hot stamping die of which the cooling water channels follow up the shapes of the molded surfaces of the male and female dies and are at the equal distances with the molded surfaces of the male and female dies of the die can be manufactured; and a high strength steel plate hot stamping part with a uniform cooling effect can be processed by the die.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

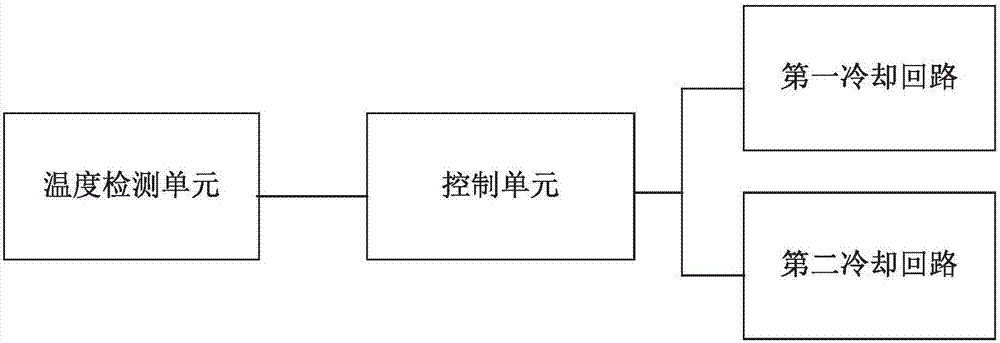

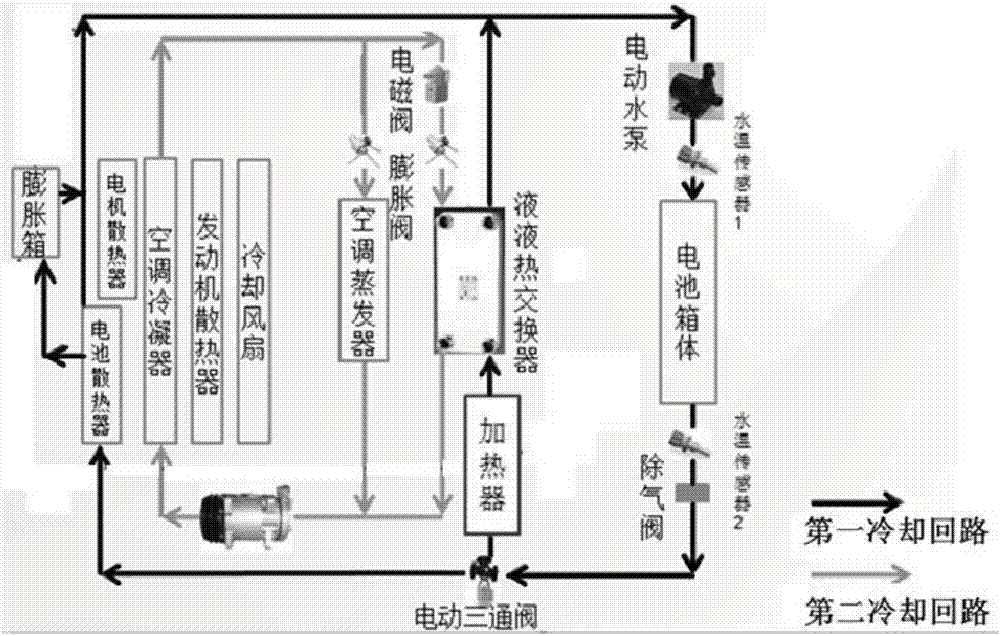

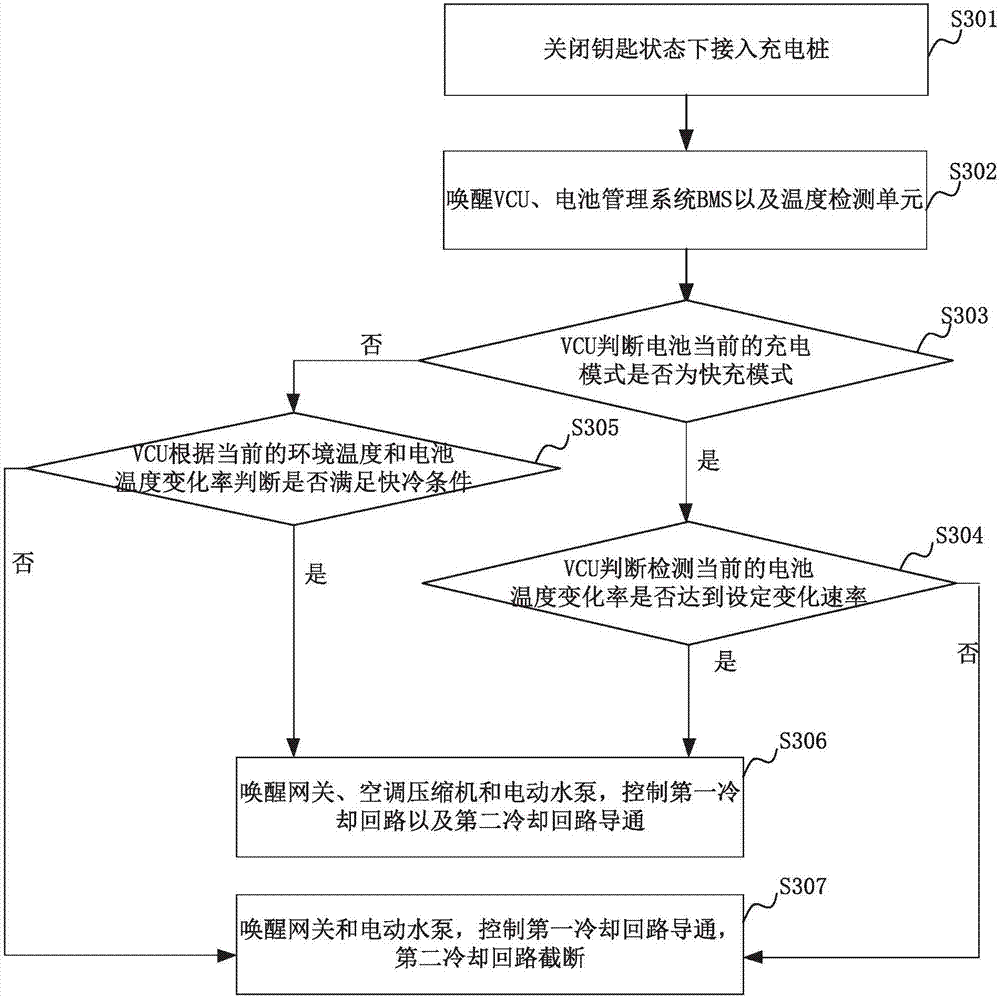

Vehicle battery charging cooling system and method

ActiveCN107394308AUniform cooling effectImprove cooling efficiencySecondary cellsVehicular energy storageBattery chargeAir conditioning

The present invention relates to a vehicle battery charging cooling system and method. The system includes a temperature detection unit which is configured to obtain ambient temperature and battery temperature during a battery charging process and obtain a battery temperature change rate according to the battery temperature; and a control unit for controlling on / off of a first cooling circuit and a second cooling circuit according to current ambient temperature and the battery temperature change rate; when in on state, the first cooling circuit can cool a battery on the basis of flow of a cooling liquid; when in on state, the second cooling circuit is configured to cool the cooling liquid in the first cooling circuit by an air-conditioning refrigerant of a vehicle, wherein the cooling condition is that the ambient temperature is greater than or equal to a set first temperature threshold, and the battery temperature change rate is greater than or equal to a set change rate. The vehicle battery charging cooling system can achieve different heat dissipation requirements during the vehicle battery charging process.

Owner:GAC AION NEW ENERGY AUTOMOBILE CO LTD

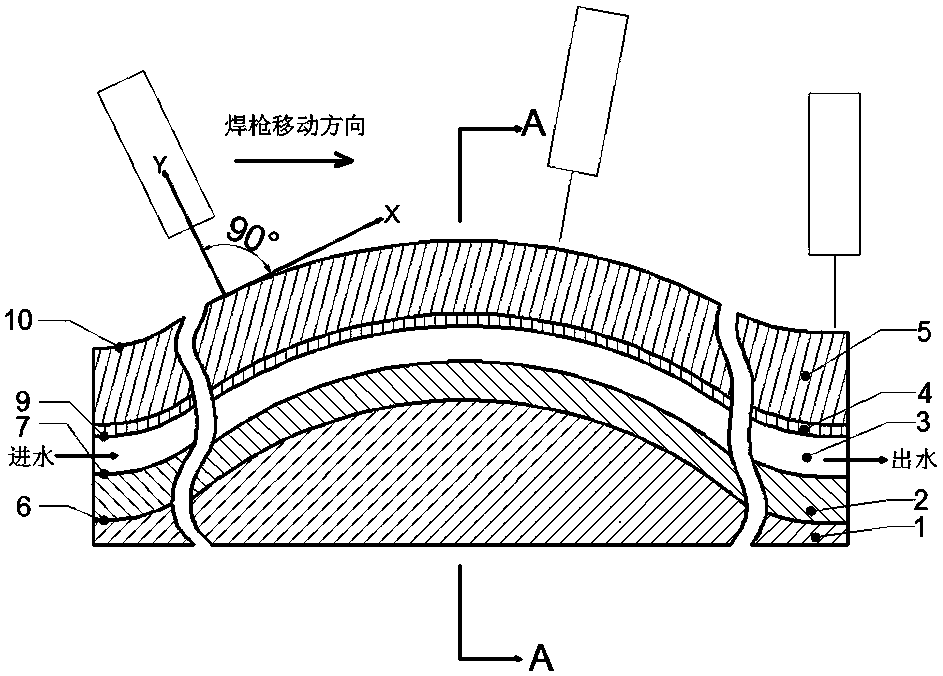

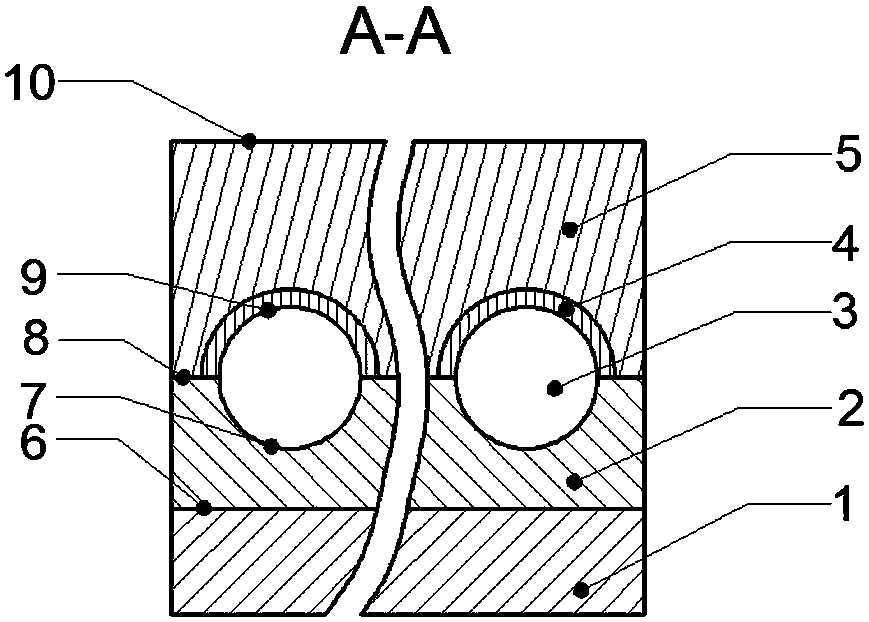

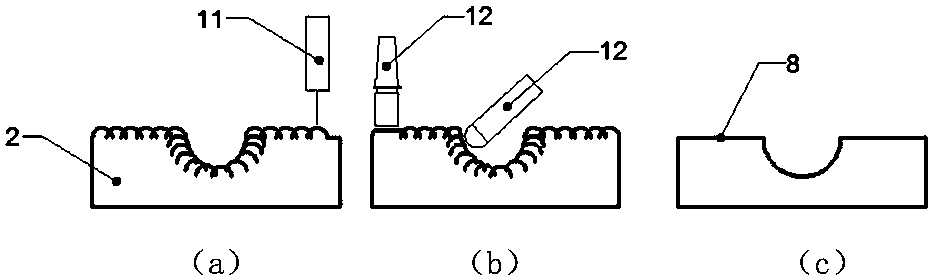

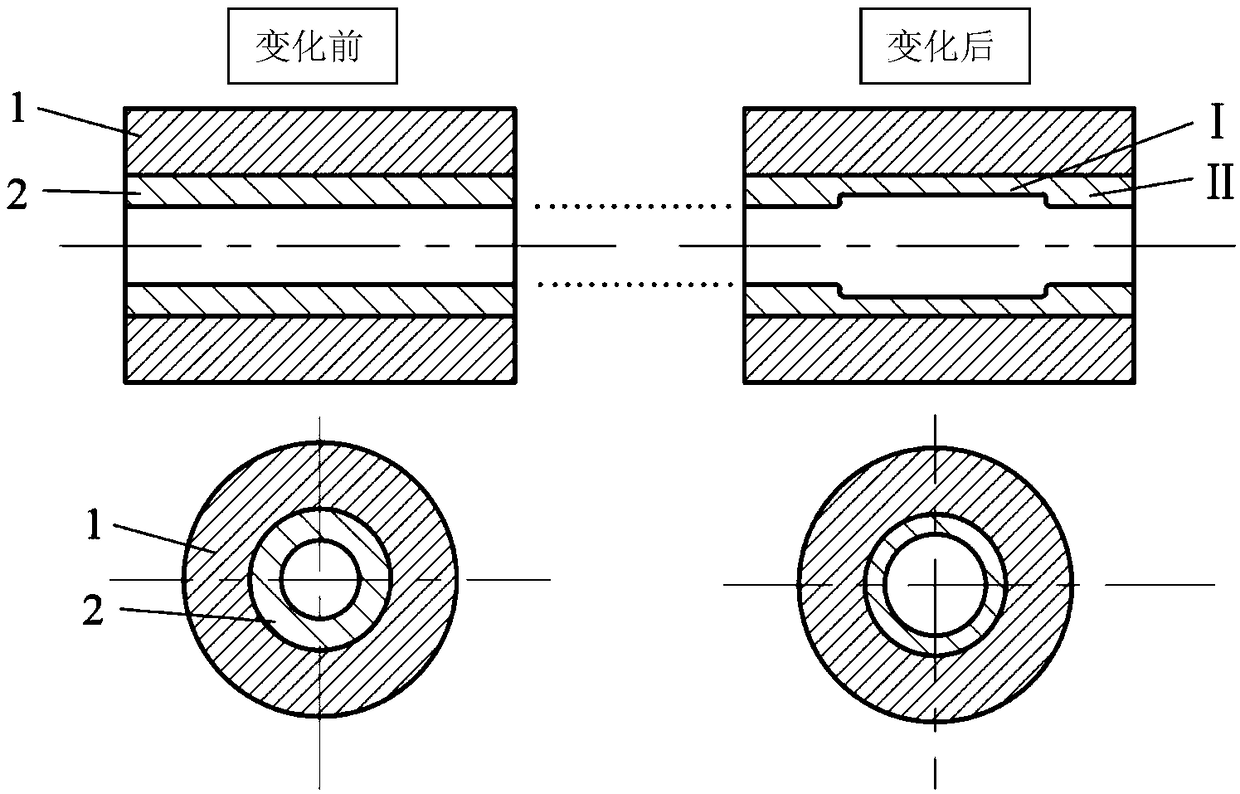

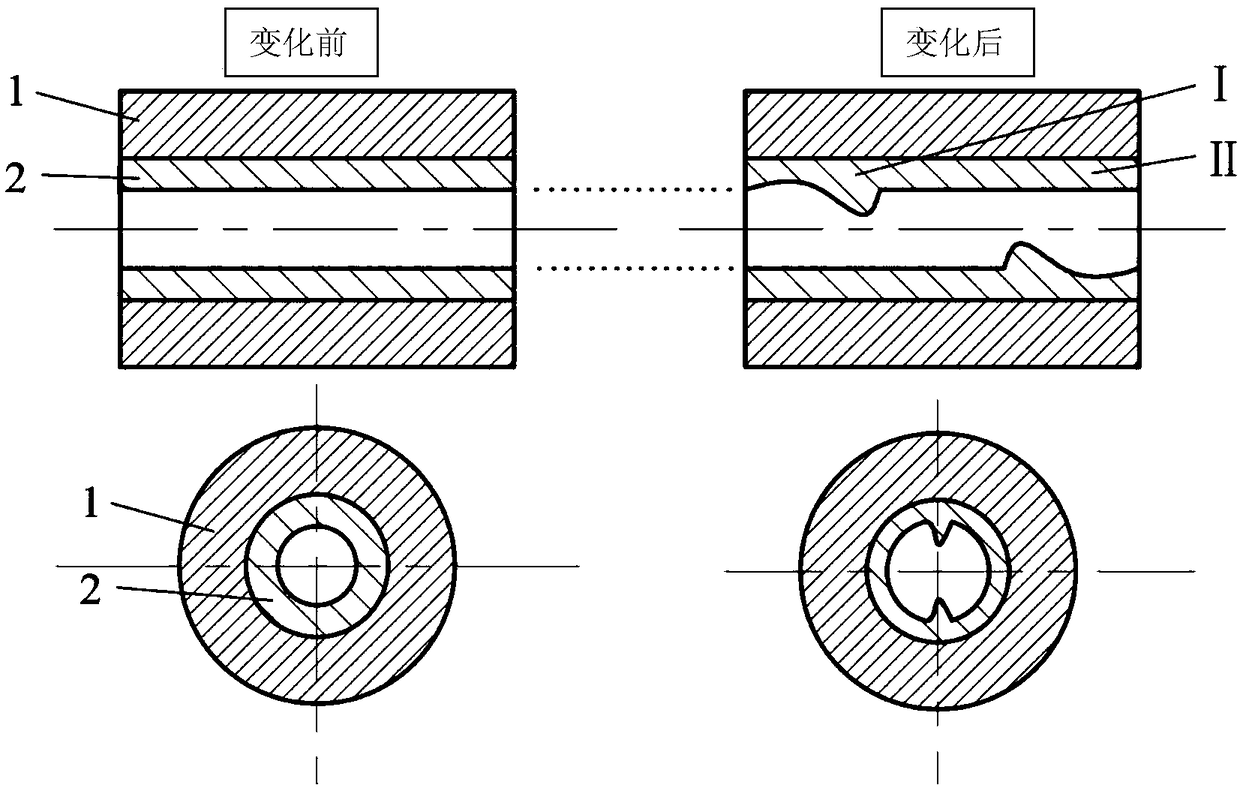

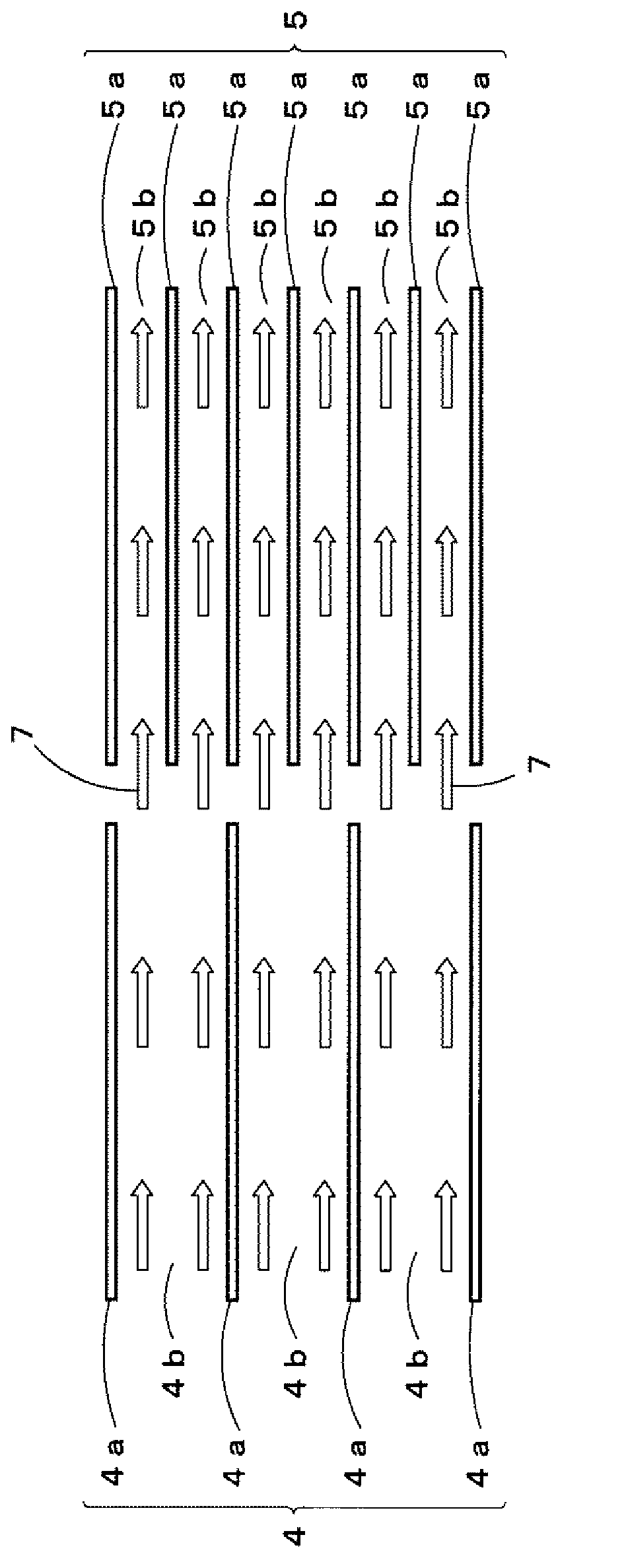

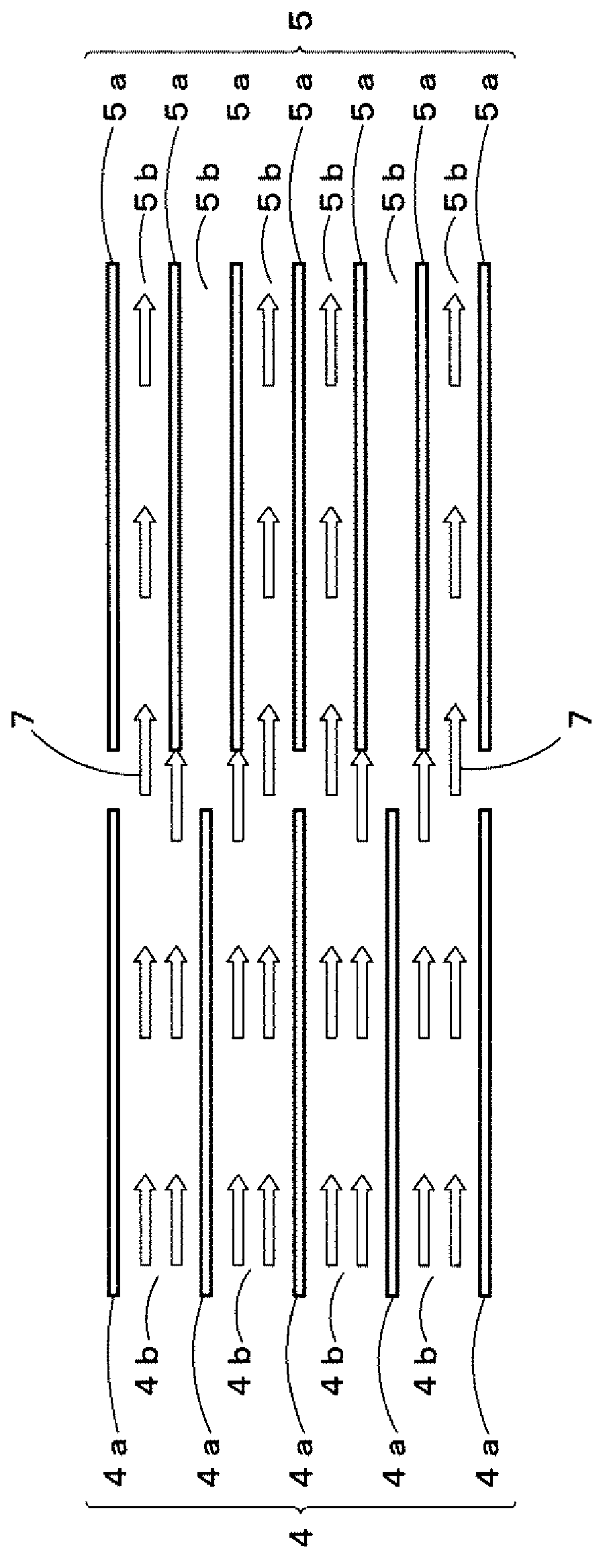

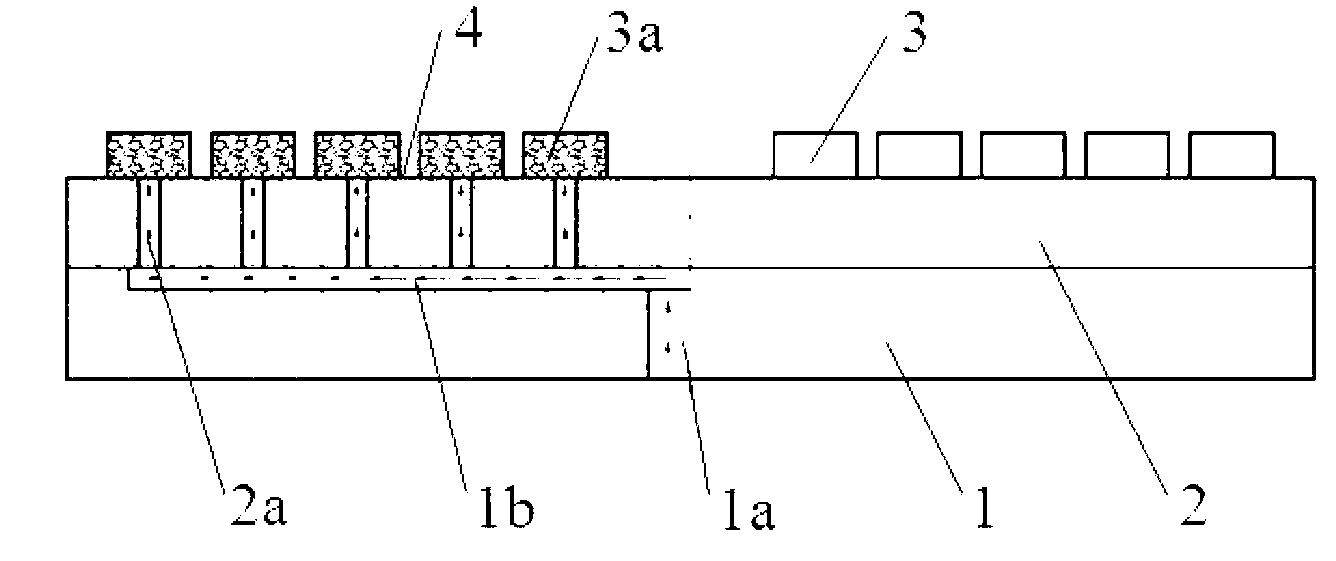

Electric arc additive manufacturing method of conformal cooling passage with circular cross section

ActiveCN108480821AIncrease profitShorten the timeAdditive manufacturing apparatusArc welding apparatusManufacturing cost reductionCircular dichroism

The invention relates to an electric arc additive manufacturing method of a conformal cooling passage with a circular cross section. According to the method, the inner surface of a rough machined moldis used as an additive datum plane, a consumable electrode inert gas protection electric arc additive process is adopted, an internal conformal passage with a circular cross section is manufactured through a specific conformal additive path and a specific angle, a cooling medium flows in the passage, and a flowing direction is parallel to the inner surface of a mold cavity. The method comprises the following steps of S1, designing a structure of a three-dimensional conformal passage with the circular cross section; S2, partitioning the passage structure, and milling the datum plane of a basebody; S3, carrying out additive manufacturing on the lower half part of the passage; S4, carrying out additive manufacturing on an inner wall structure and other structures of the upper half part of the passage; and S5, machining the inner surface of the mold cavity. The electric arc additive manufacturing method of the conformal cooling passage with the circular cross section provided by the invention adopts a low-cost electric arc additive manufacturing process technology for realizing high-efficient manufacturing of the complicated conformal cooling passage of the large-size mold, and has the characteristics that raw materials are saved, the manufacturing cost is reduced, the mold cooling efficiency is high, the cooling uniformity is good, and the like.

Owner:FUZHOU UNIV

Cooling method of battery pack and battery pack with cooling device

ActiveCN105206895AAvoid thermal runawayAchieve uniform temperature controlSecondary cellsVapor pressureInternal pressure

Owner:方乐同

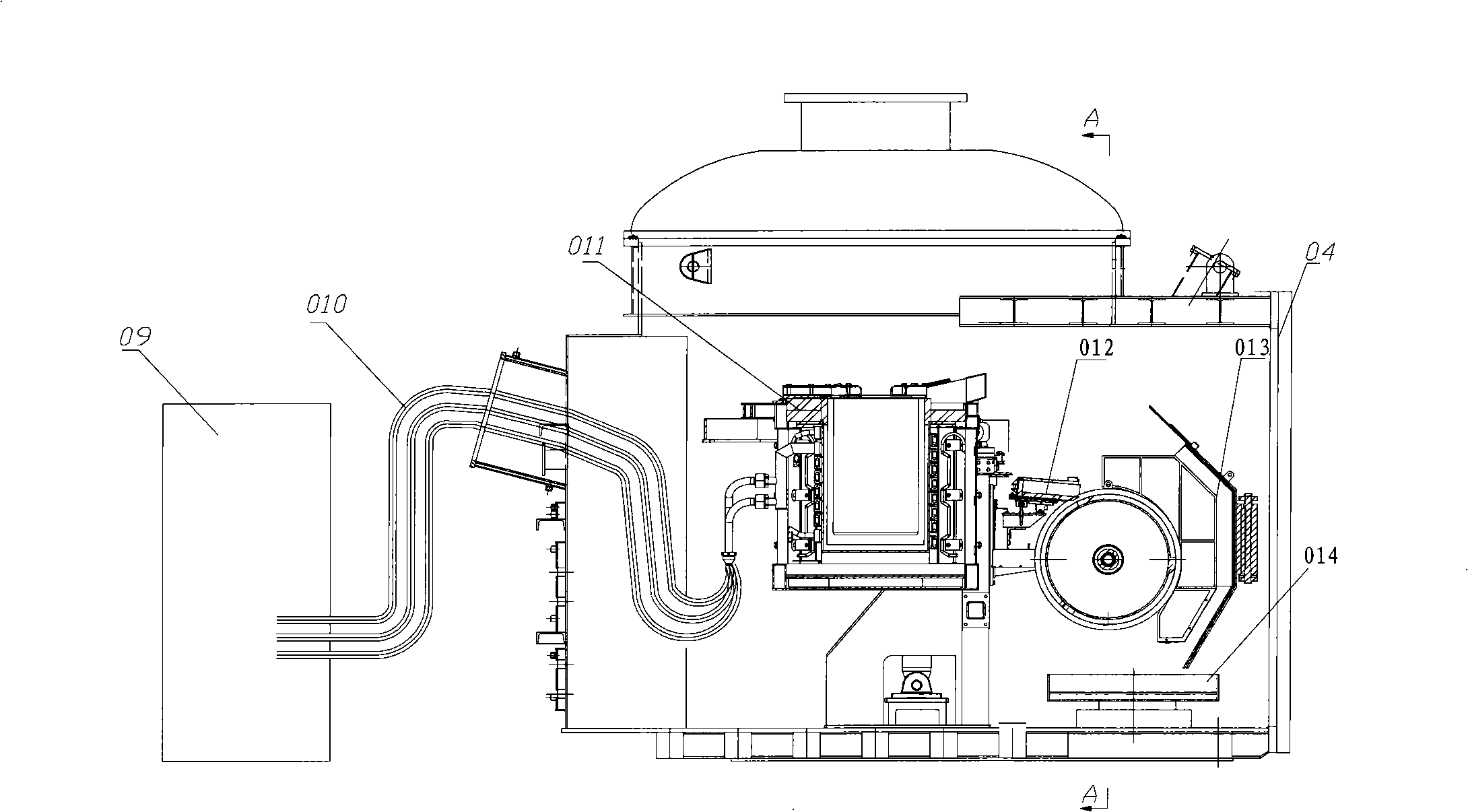

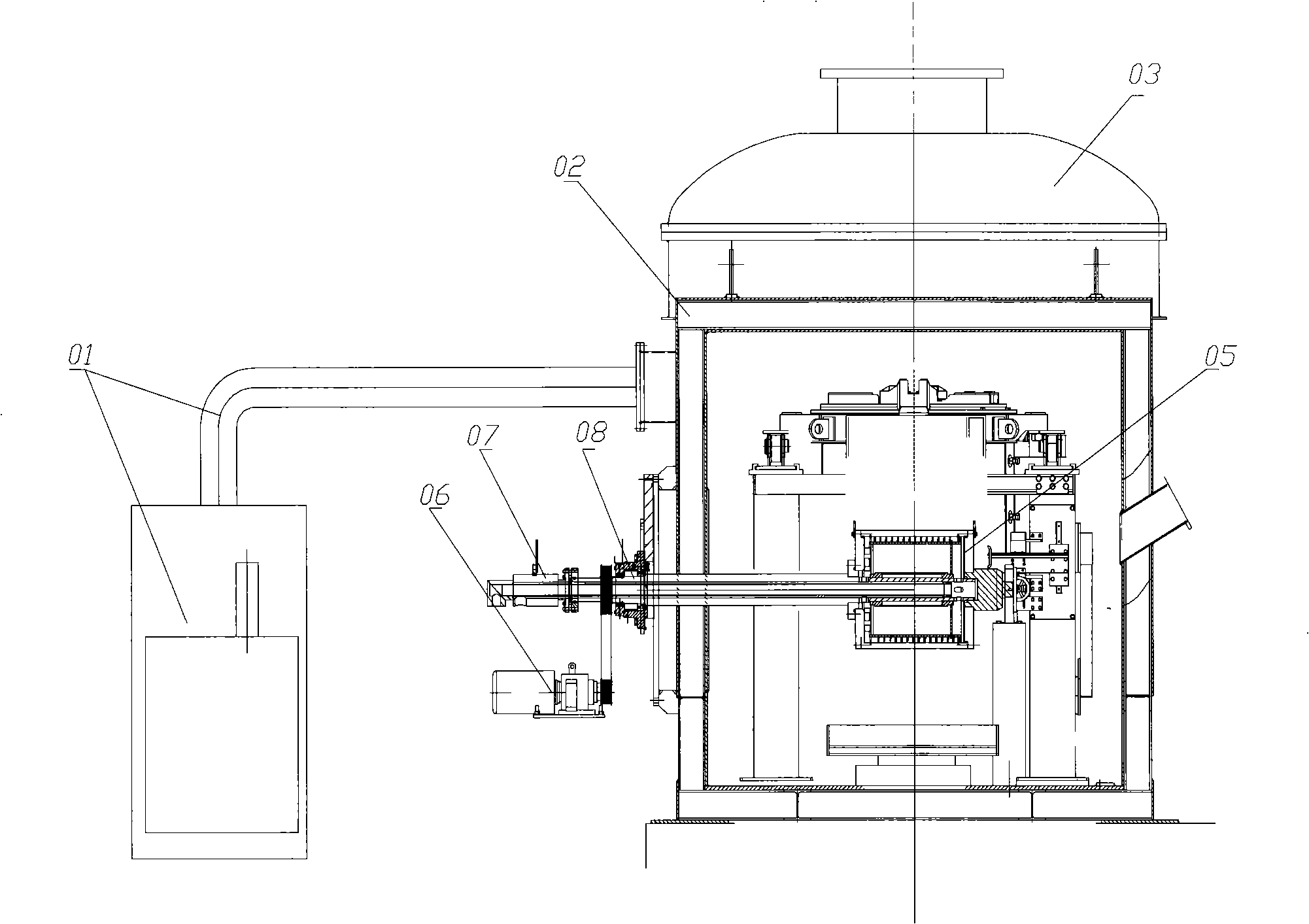

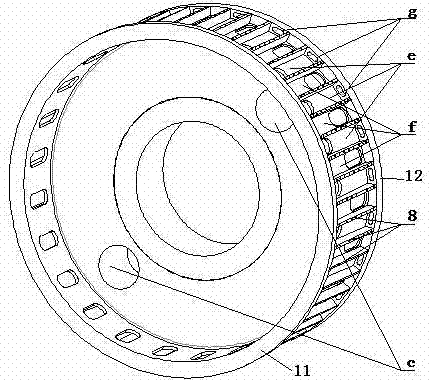

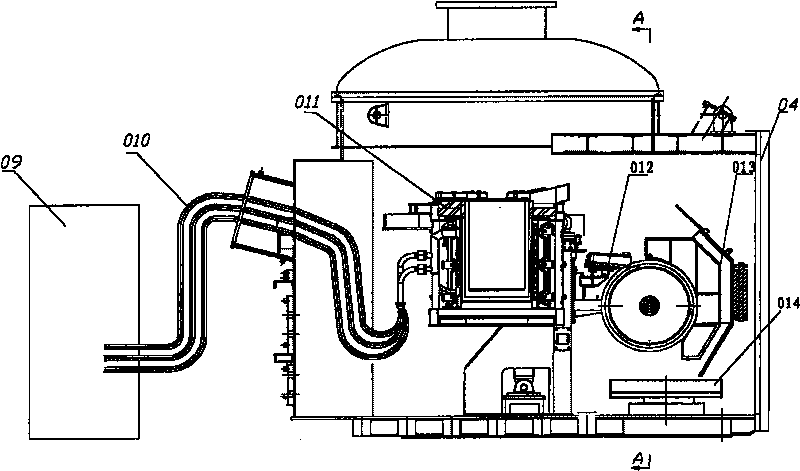

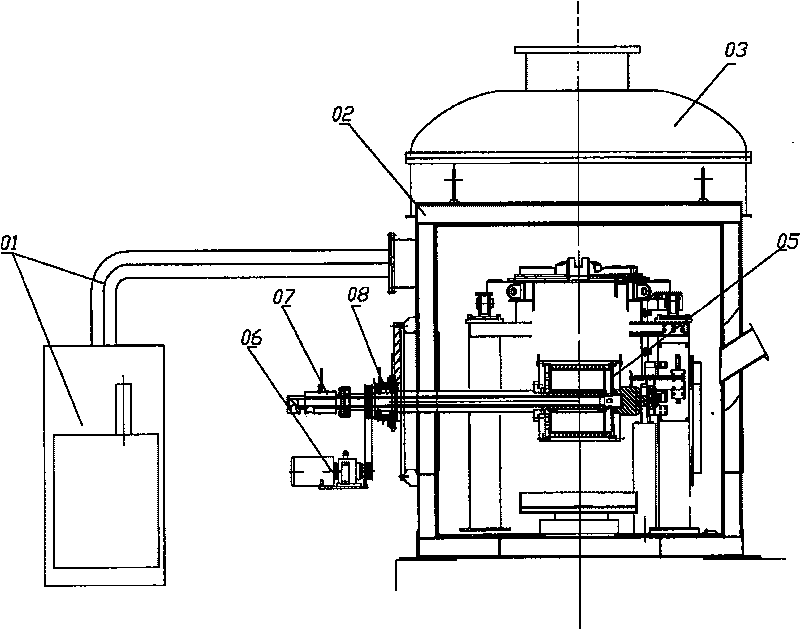

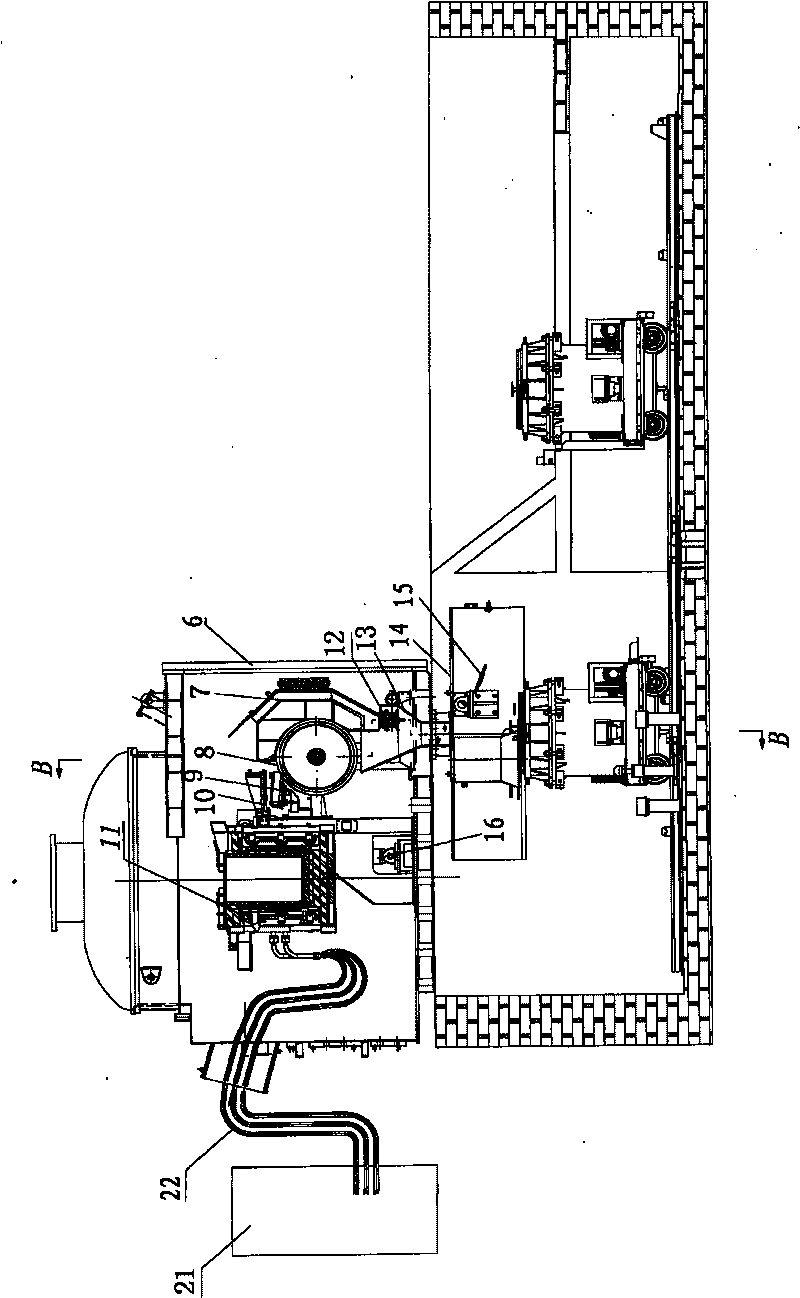

Vacuum induction smelting furnance

ActiveCN101347836AUniform thicknessUniform cooling effectCasting plantsCharge manipulationCooling effectFlap valve

The invention discloses a vacuum induction melting furnace, which relates to a crucible furnace that is suitable for charging treatment in vacuum or special atmosphere. The invention provides an improved vacuum induction melting furnace with better casting cooling effect and good productivity, which comprises a vacuum melting chamber, a medium frequency coil furnace, a set of vacuum pump and a corresponding vacuum pipeline system, a electric control system, a medium frequency power supply system, a hydraulic cylinder control system, a cooling system, and a pit discharging system. The cooling system is provided with a tundish feed divider, a belt wheel cooling mechanism, a baffle cooling mechanism and a turning wheel cooling mechanism. The pit discharging system comprises a medial chamber box, an inner container, an outer container, a walking car, a hydraulic lifting cylinder, a pit track, a flap valve and a guide shell. The guide shell and the flap valve are arranged in the medial chamber box, the outer container is fixedly arranged on the walking car, and the inner container is sheathed at the inner wall of the outer container.

Owner:厦门嘉鹭金属工业有限公司

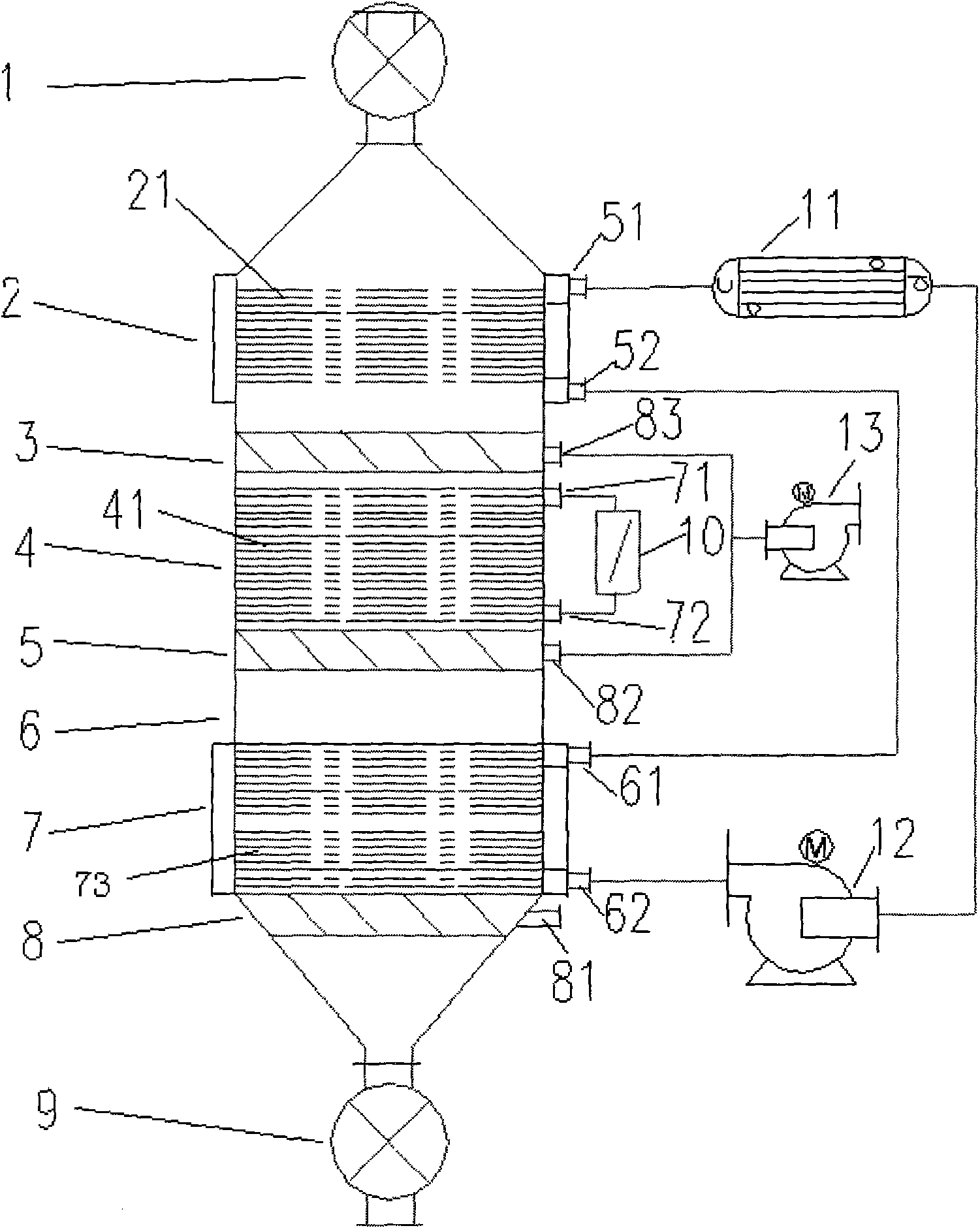

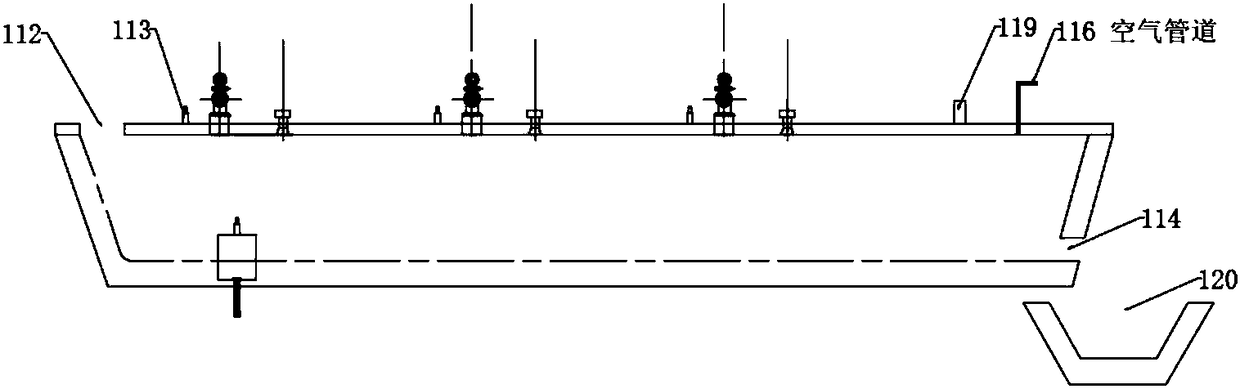

Movable desorption device of activated coke

ActiveCN101584958ASimple structureImprove space utilizationDispersed particle separationCombustible gas purificationProcess engineeringCorrosion

The invention discloses a movable desorption device of activated coke. An inlet blocking valve, a heating chamber, a reaction chamber, a cooling chamber and an outlet blocking valve are sequentially connected from top to bottom in the reactor main body; the heating chamber is provided with a heating heat exchanger therein which is connected with a thermal source device; a cooling heat exchanger is arranged in the cooling chamber; a preheating chamber is arranged between the inlet blocking valve and heating chamber and provided with a preheating heat exchanger, which forms a heat circulating system with a circulating medium heat exchanger, a circulating pump and the cooling heat exchanger; a first cloth gas guide mechanism is arranged between the preheating chamber and heating chamber; a second cloth gas guide mechanism is arranged between the heating chamber and reaction chamber; and the first and second cloth gas guide mechanisms are respectively connected with a gas recovery suction pump for recycling desorption gas. The invention has higher utility ratio of heat energy by redesigning each part in the reactor, and has more complete air suction, higher desorption efficiency and less corrosion to devices by adding the cloth gas guide mechanisms.

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

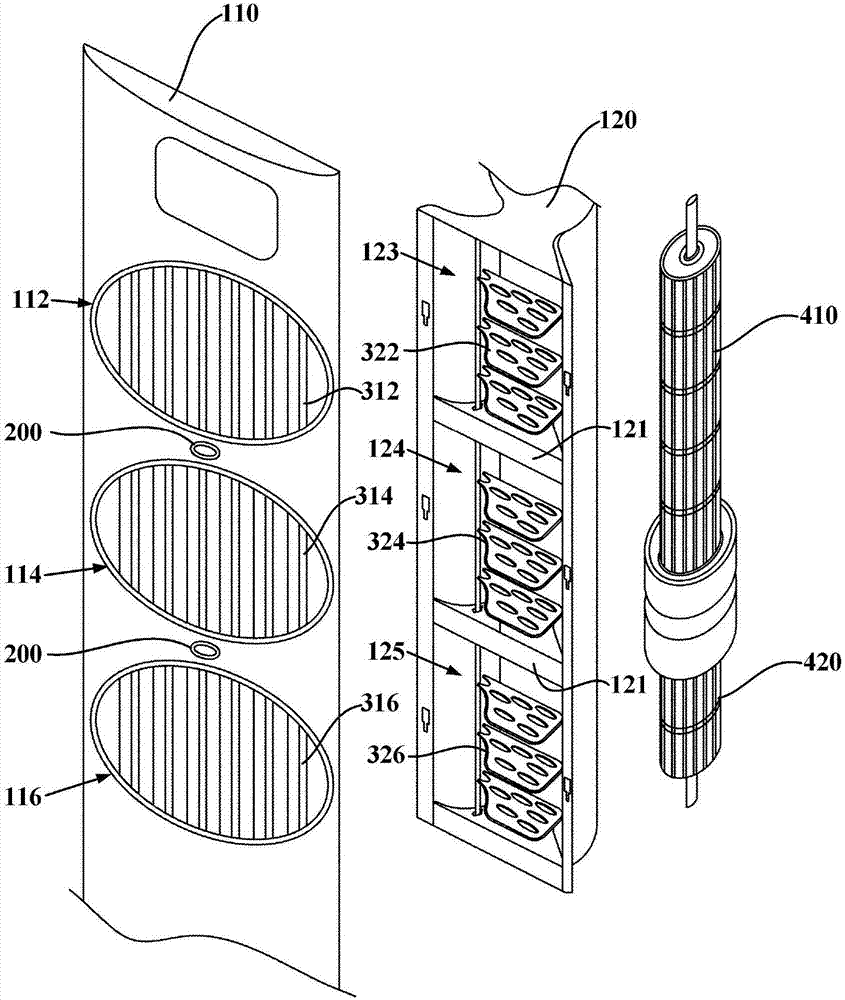

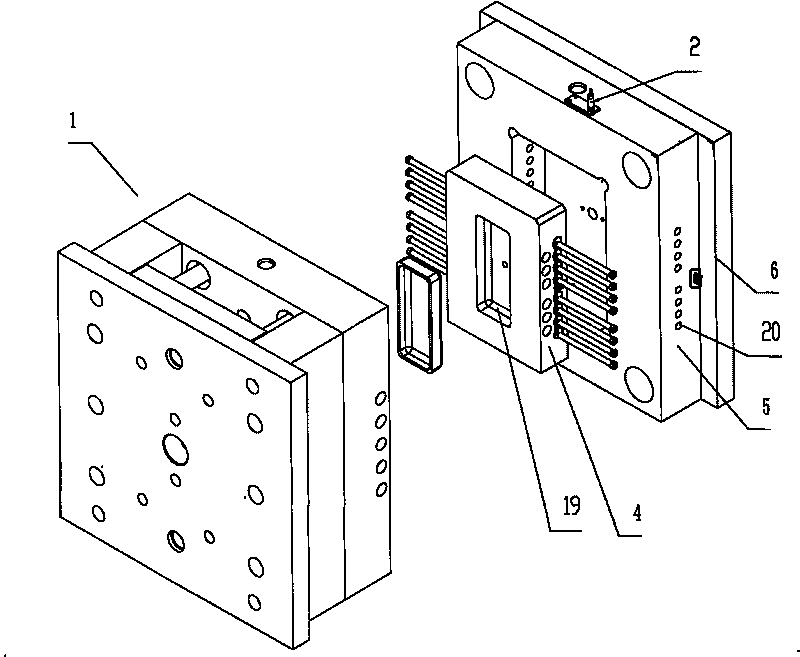

Mold heating and cooling rod and mold capable of realizing rapid cooling and rapid heating

The invention relates to a mold heating and cooling rod which comprises a heating and cooling rod body and a heating element, a cooling thermal insulation hole for introducing a cooling medium when a mold needs to be cooled and discharging the cooling medium when the mold needs to be heated and a heating element accommodating hole are arranged in the heating and cooling rod body along the axial direction, and the heating element is mounted in the heating element accommodating hole; the mold capable of realizing rapid cooling and rapid heating comprises a mold core and the heating and cooling rod, and the heating and cooling rod is in contact with the mold core; and one side of the heating and cooling rod which is provided with the heating element is near to a molding surface of the mold core. The advantages are that, as the molding surface can be rapidly and evenly heated and cooled and rapidly heated to the temperature which is near to or equal to that of melting materials, a molded product has the advantages of good quality, difficult production of weld marks, flow marks, surface bubbles and the like, even color and luster, even density of the product, small shrinkage and ability of reducing the injection pressure and the product deformation caused by residual stress after consolidating and molding the molten materials.

Owner:杨东佐

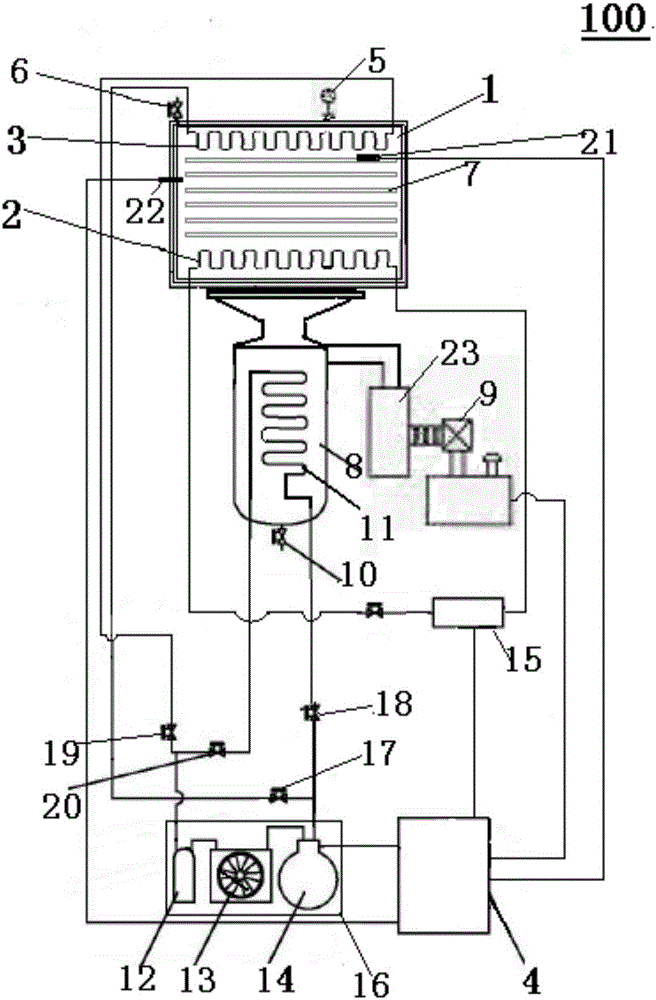

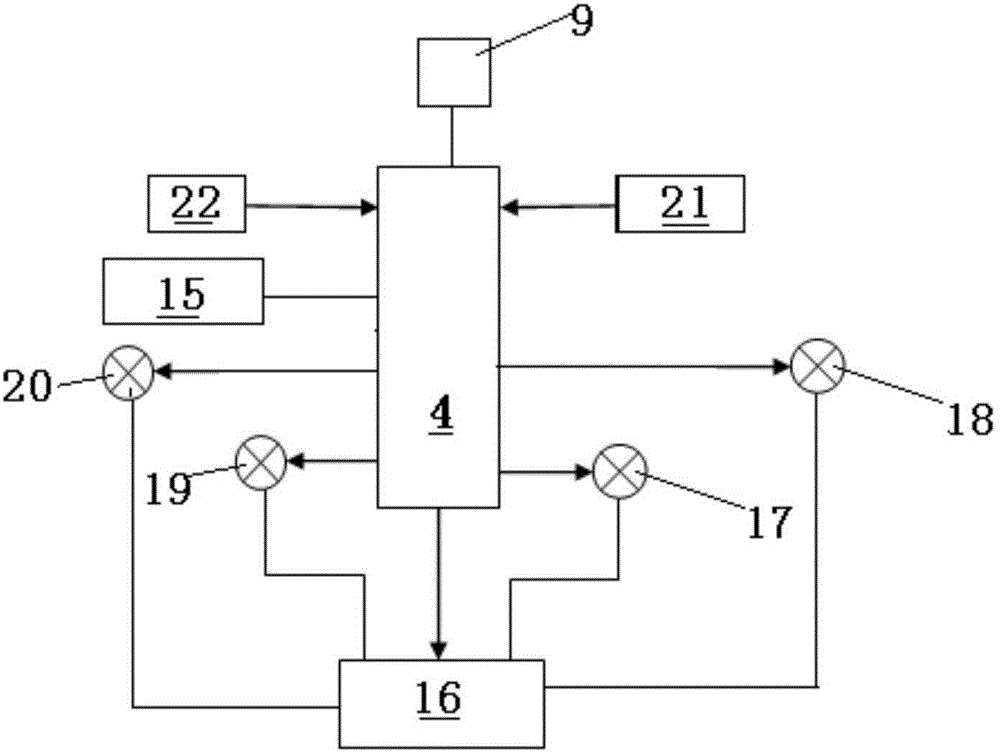

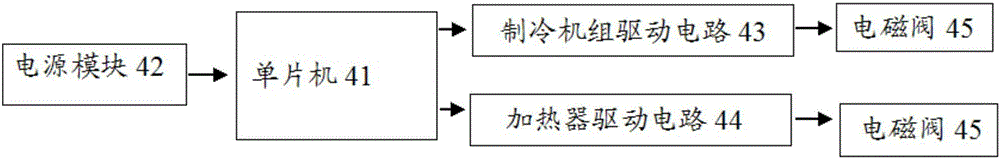

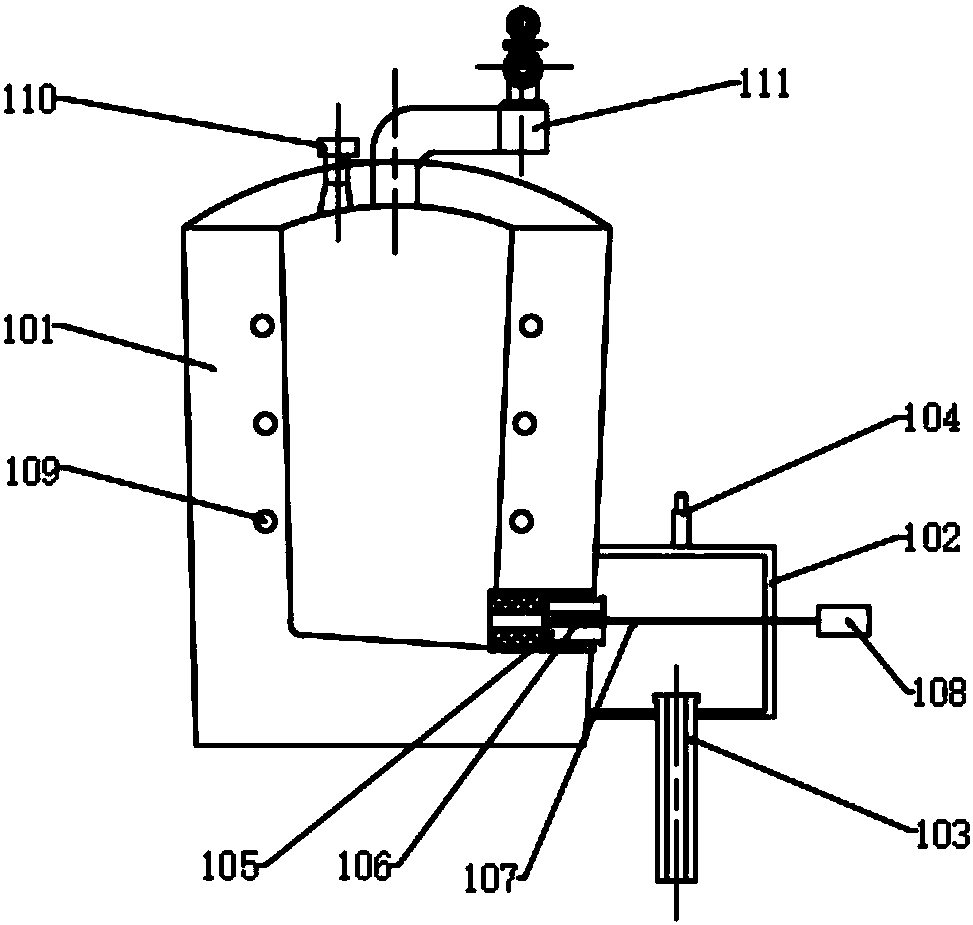

Vacuum freeze drying method and vacuum freeze dryer

ActiveCN104949473AImprove qualityReduce process stepsDrying solid materials without heatSmall footprintFreeze dry

The invention provides a vacuum freeze dryer which comprises a material box, a water catching bin, a refrigerating unit, a heater, a vacuum pump and a control device. The material box is communicated with the water catching bin. The water catching bin is connected with the vacuum pump. The refrigerating unit and the heater are arranged outside the material box. The control device controls the refrigerating unit, the heater and the vacuum pump. The material box is internally provided with a refrigerating pipe and a heating pipe at the same time, and the refrigerating pipe and the heating pipe are used for freezing and drying materials respectively. The inner wall of a material frame and the inner wall of the material box are each provided with a temperature sensor, and the temperature sensors monitor the temperature of the material frame and the temperature of the material box. Materials inside a material bottle are frozen in advance to reach the eutectic point approximately, then the temperature is decreased rapidly, and the materials pass through the eutectic point within the short time as little as possible, so that the grain size of crystals is effectively controlled, the fine freeze-drying powder is obtained, and the freeze-dried powder product quality is improved. The freezing cavity and the drying cavity are integrated, the technological steps are simplified, the occupied space is small, and refrigerating and heating are uniform.

Owner:BEIJING HAIHETIAN TECH DEV

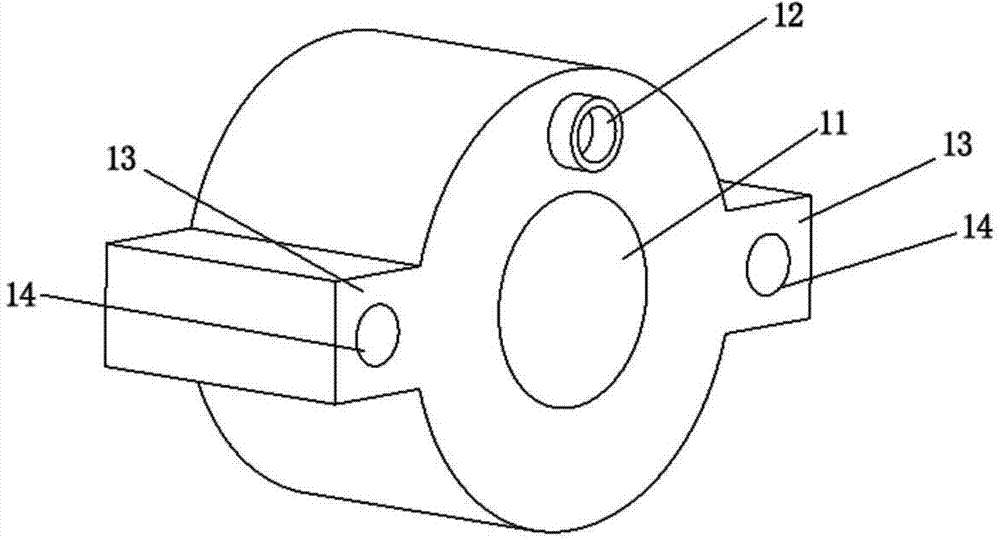

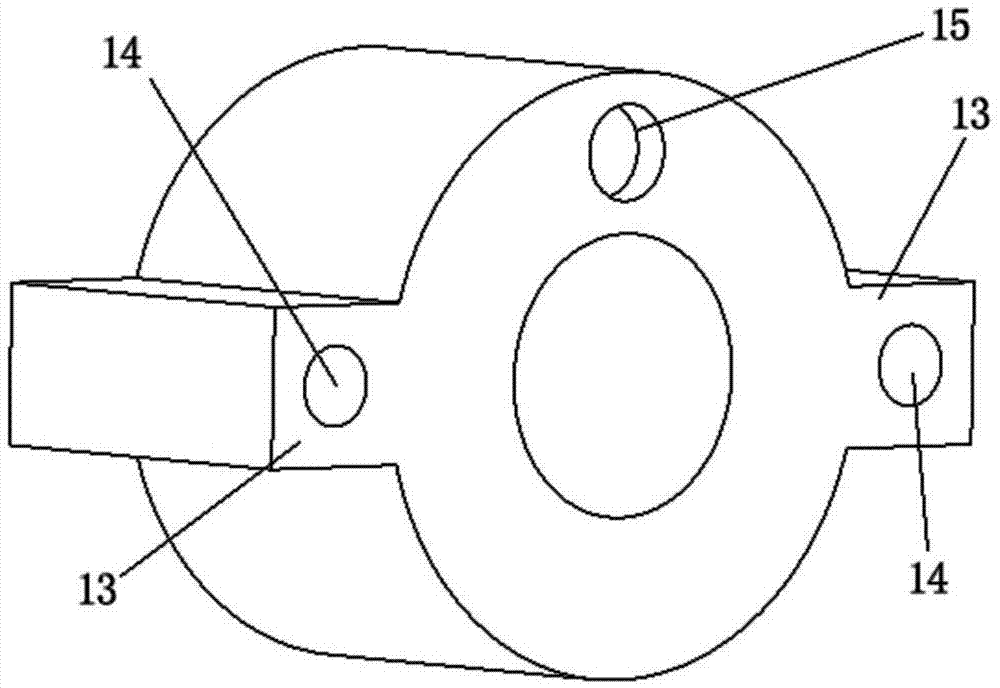

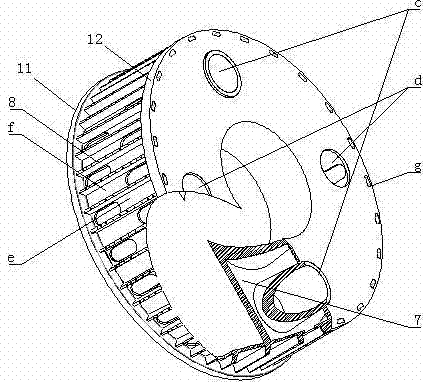

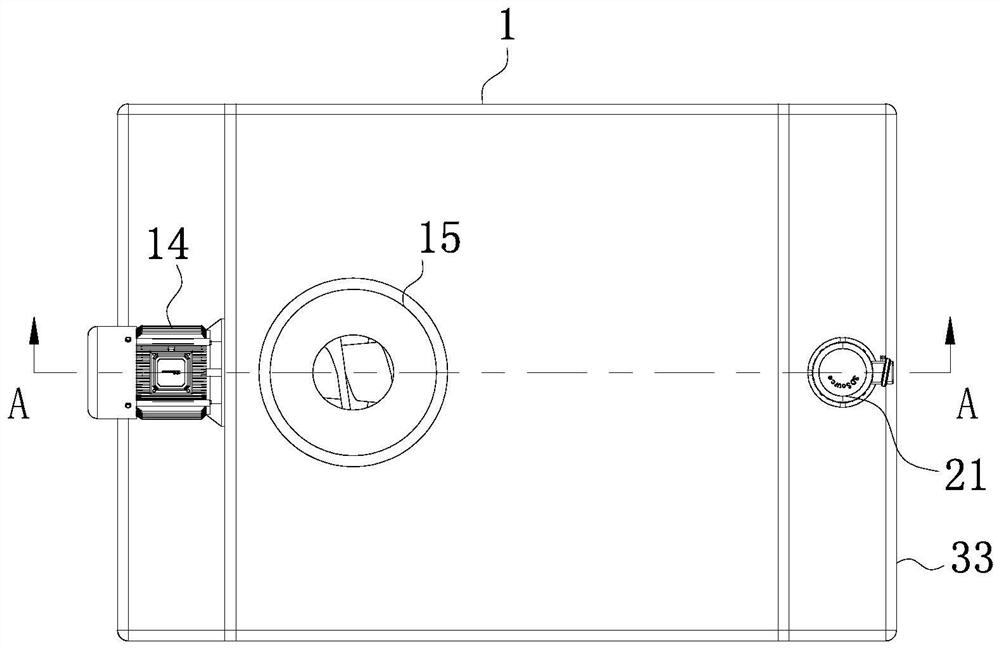

Cooling device provided with annular water channel and based on 3D printing technology

The invention provides a cooling device provided with an annular water channel and based on the 3D printing technology. The cooling device provided with the annular water channel and based on the 3D printing technology comprises two end portion fixing modules and a plurality of conformal cooling modules which are arranged between the two end portion fixing modules. By the adoption of the cooling device provided with the annular water channel and based on the 3D printing technology, one-off forming through metal power can be achieved based on the 3D printing technology, the cooling device is not influenced by the shape of a macroscopic part, and conformal cooling is achieved. By the adoption of the cooling device provided with the annular water channel and based on the 3D printing technology, the cooling efficiency is high, cooling is even, the problems that a cooling device manufactured based on a traditional technology is poor in cooling effect and low in rate of finished products are solved, the advantages of the 3D printing technology can be utilized to the greatest extent, and the economic benefits are increased.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

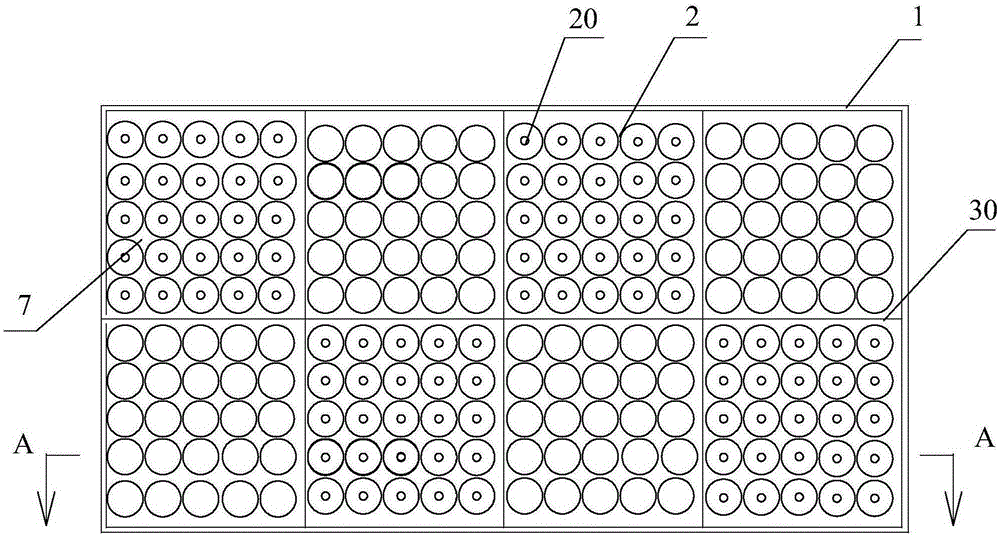

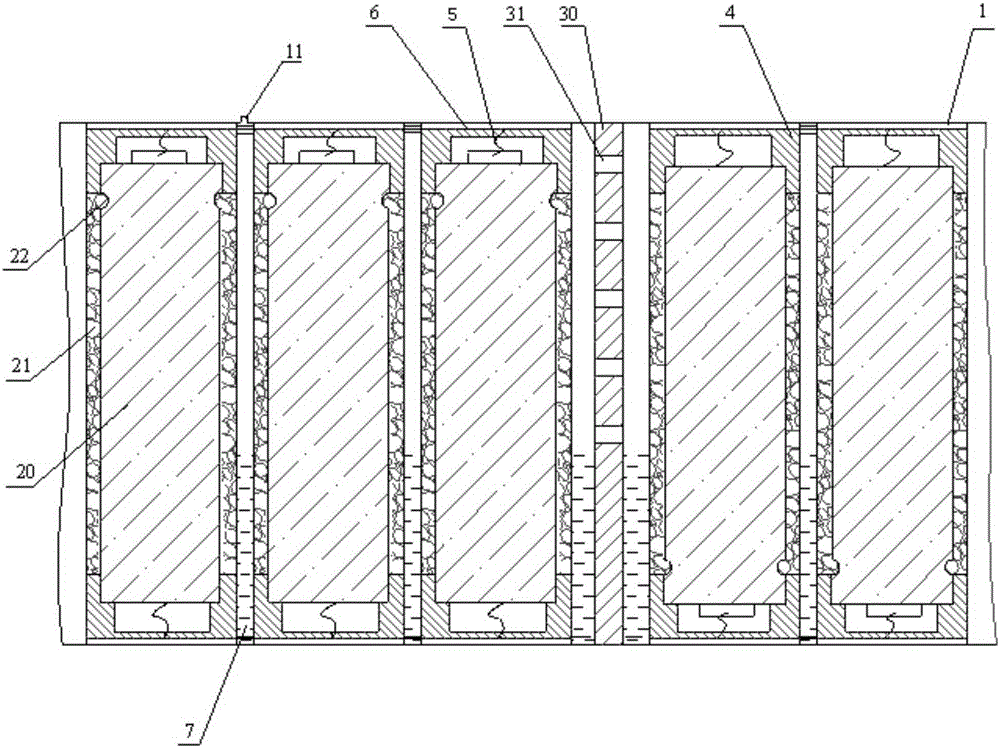

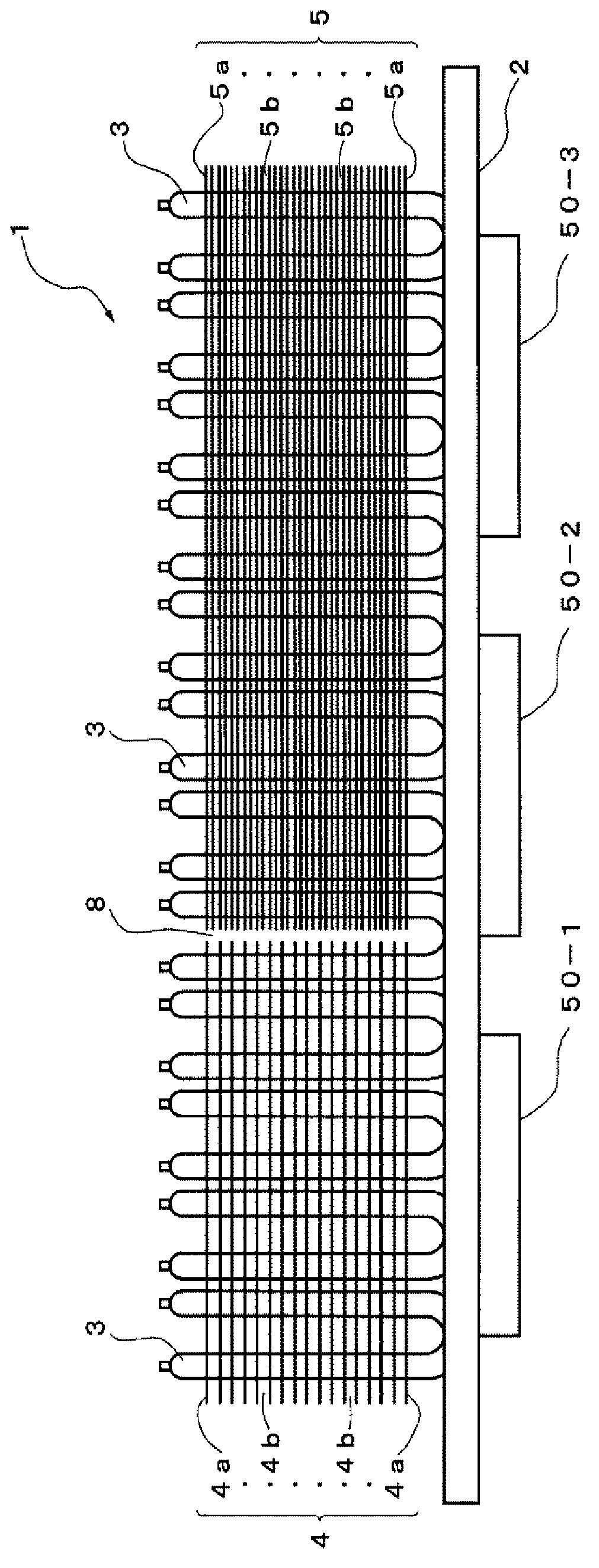

Intelligent conformal cooling channel of mold and manufacturing method thereof

InactiveCN108097953AUniform cooling effectImprove cooling effectAdditive manufacturing apparatusMetallic material coating processesShape changeCooling effect

The invention belongs to the field of mold cooling channels and discloses an intelligent conformal cooling channel of a mold and a manufacturing method thereof. According to the intelligent conformalcooling channel, a memory alloy coating layer is arranged on the inner wall of the conformal cooling channel; the coating layer senses the internal temperature of the conformal cooling channel and conducts shape change according to the temperature so as to make the flow, flow velocity and flow condition of cooling liquid in the cooling channel change. The invention further discloses the manufacturing method of the intelligent conformal cooling channel. Through the intelligent conformal cooling channel of the mold and the manufacturing method thereof, intelligent change of the internal shape ofthe cooling channel is achieved, accurate and high-efficiency cooling is achieved, the cooling efficiency is improved, and the overall cooling effect of the mold is uniform and rapid.

Owner:HUAZHONG UNIV OF SCI & TECH

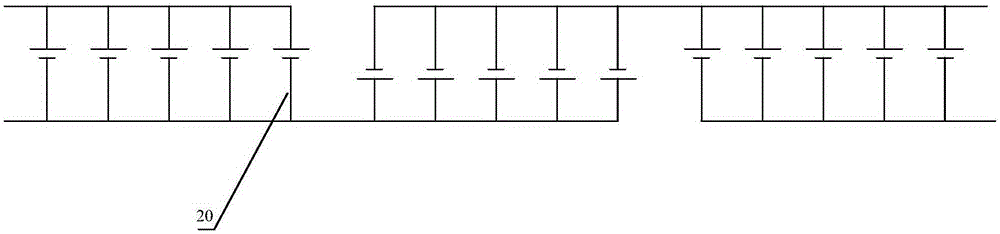

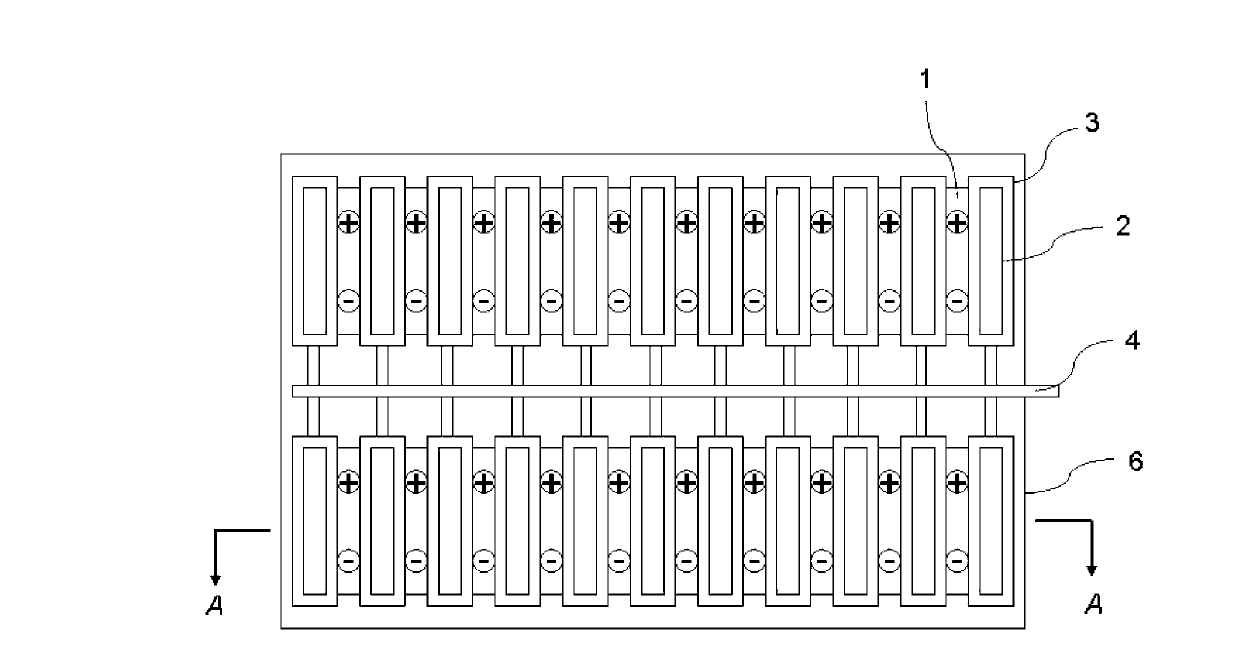

Battery pack

ActiveCN103107385AReduce quality problemsSimple structureSecondary cellsPower stationElectrical battery

The invention discloses a battery pack. The battery pack comprises a plurality of cells and a temperature regulating module, wherein the temperature regulating module comprises a first flow channel, a second flow channel, and a third flow channel communicated with each other; and the third flow channel is vertically arranged between adjacent cells. The battery pack provided by the invention has the advantages of low energy consumption, good internal thermal balance, uniform overall heat dissipation, simple structure, and the like, and can be widely used in the related fields of electric vehicles, energy storage power stations and the like.

Owner:CONTEMPORARY AMPEREX TECH CO

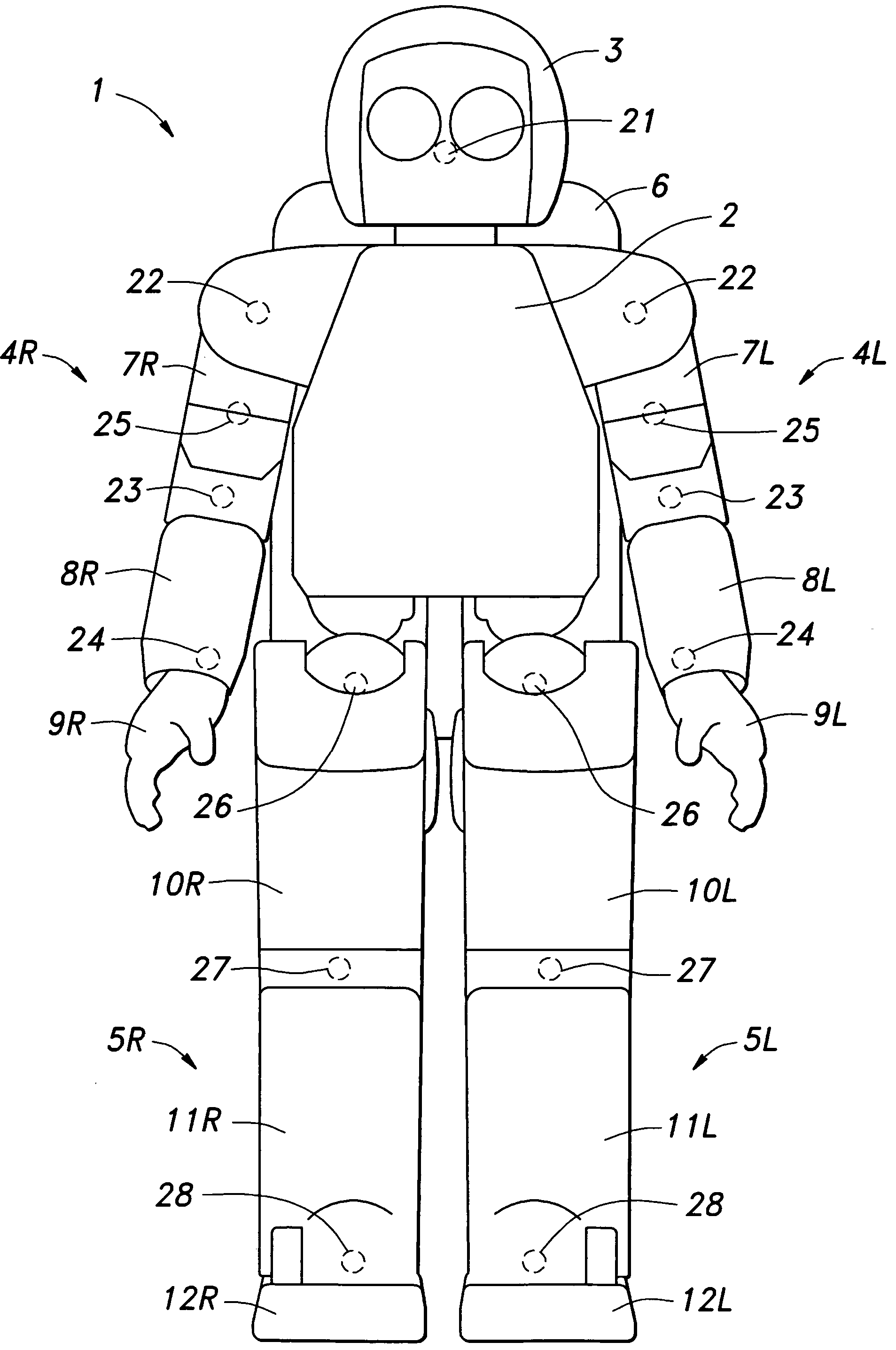

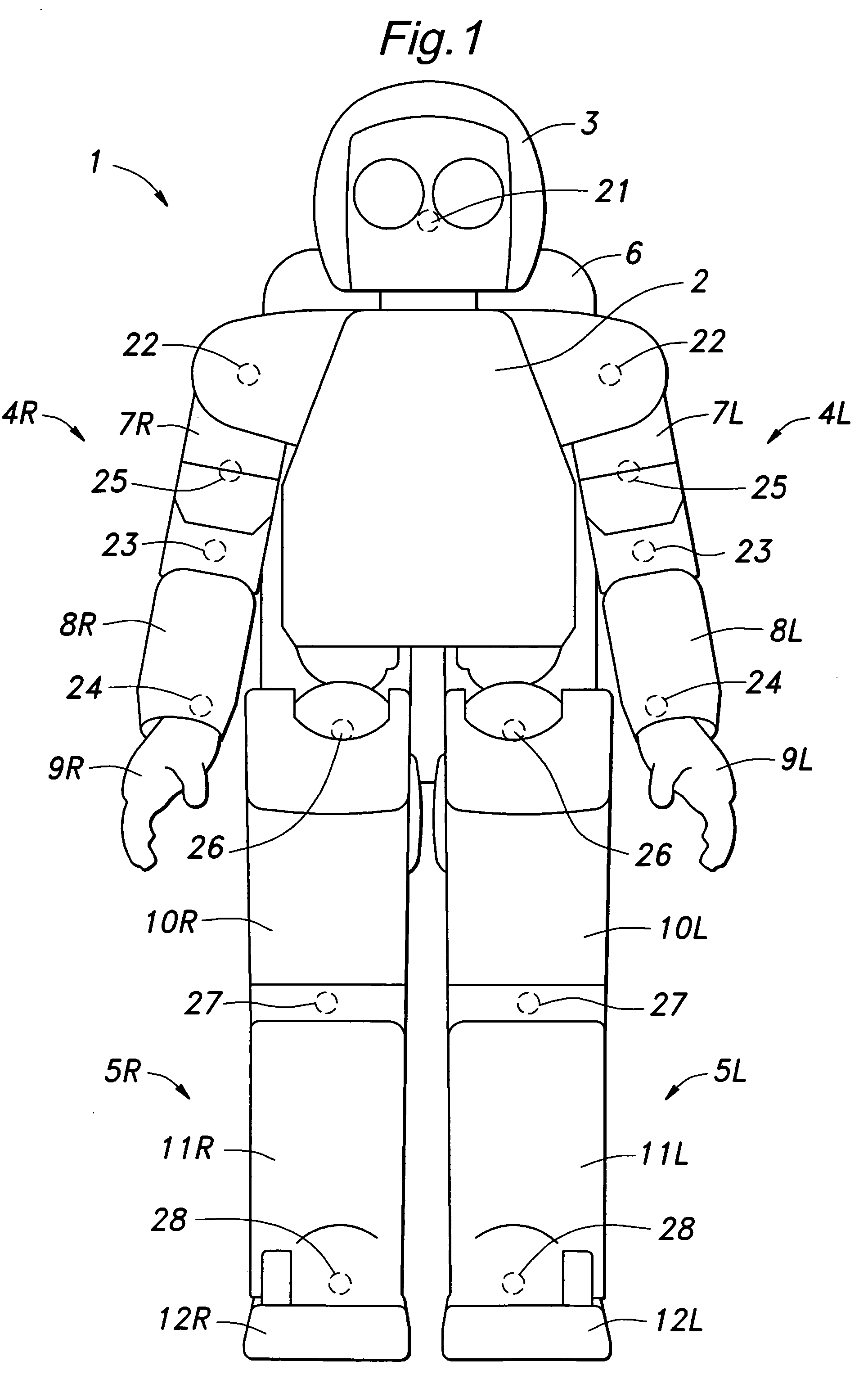

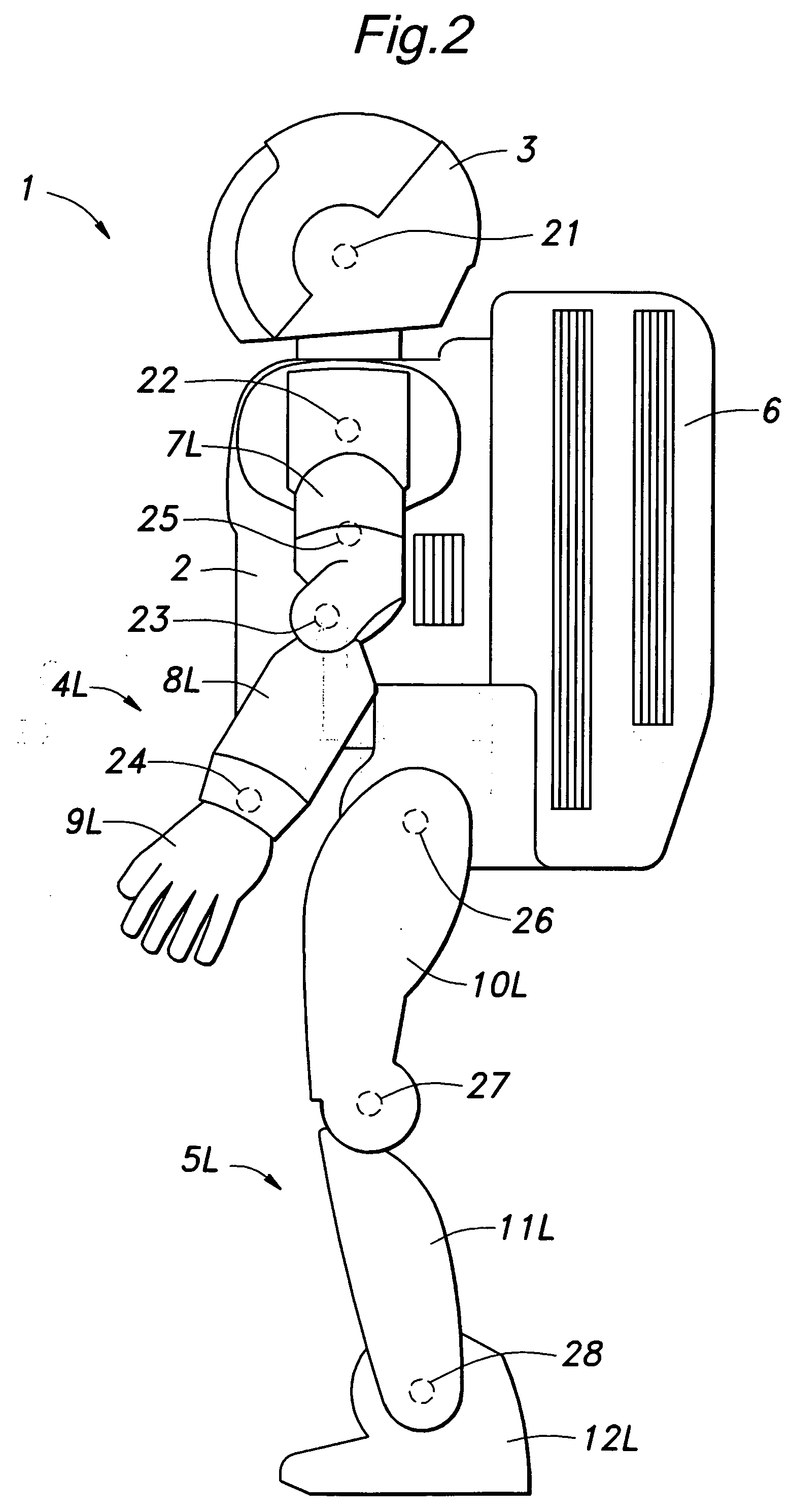

Cooling arrangement for a humanoid robot

InactiveUS20060128261A1Improve cooling effectEffectively and uniformly cooledSampled-variable control systemsDollsNoise generationInterior space

A torso part (2) and a backpack part (6) of a humanoid robot are commonly formed by a shell that defines an inner space that accommodates a heat generating component such as a control computer (31) and a power module (32, 33). The shell comprises an air vent hole (45, 46) provided on one lateral side of the shell, an air inlet hole (47, 48) provided on the other lateral side of the shell and a powered fan (49) provided immediately inside the air vent hole. Because the cooling air can flow laterally across the inner space, the entire part of the heat generating component can contact the air flow, and a uniform cooling effect can be achieved with a minimum power consumption and a minimum noise generation.

Owner:HONDA MOTOR CO LTD

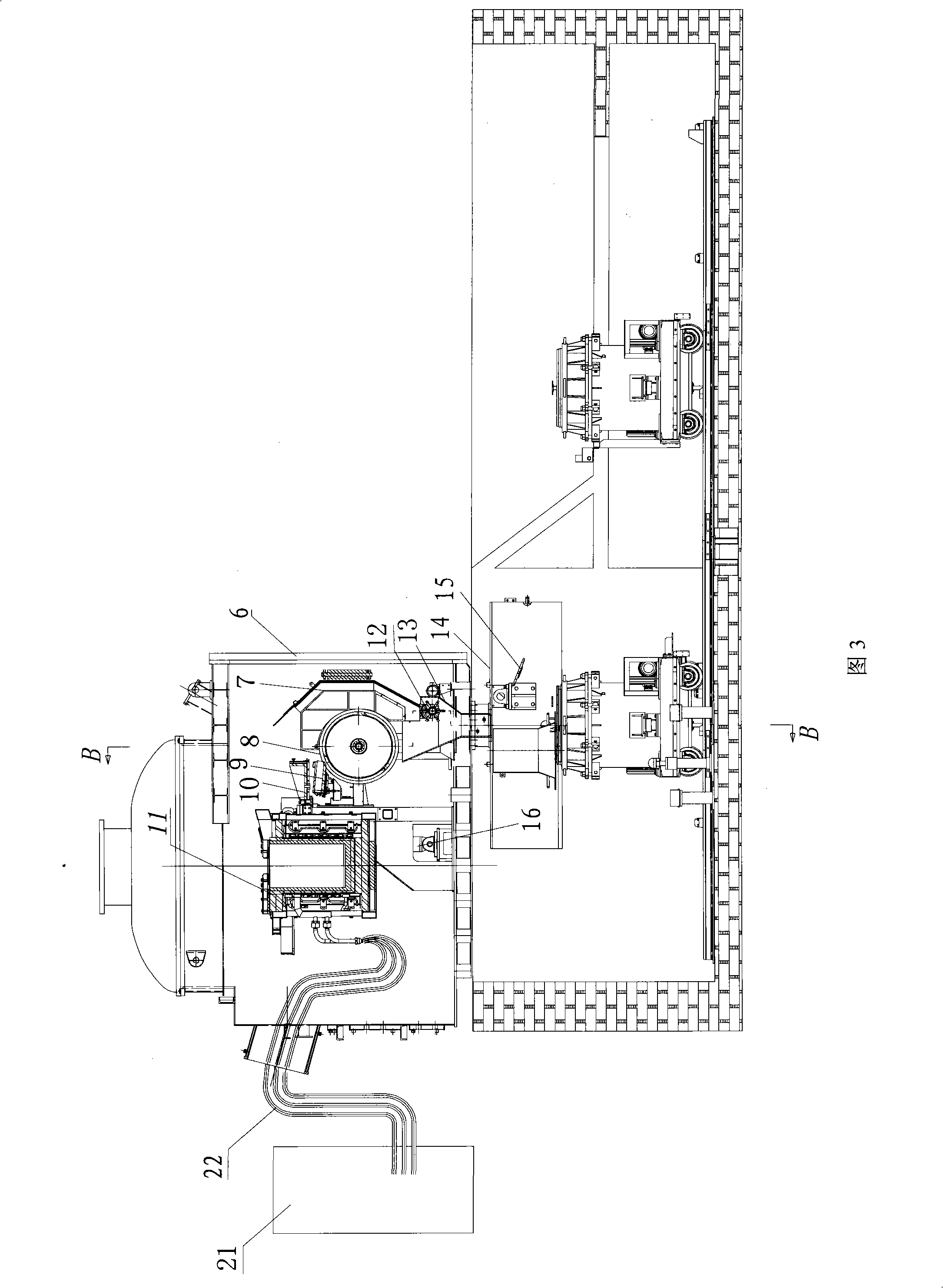

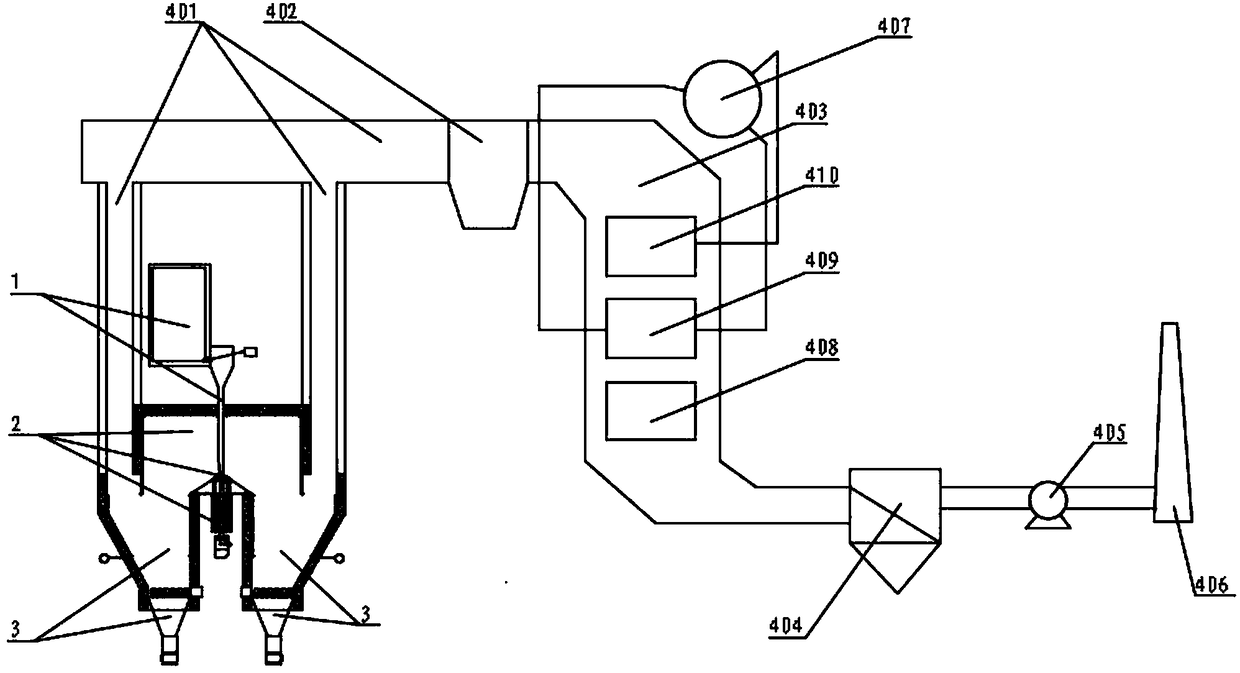

Liquid molten slag dry-type centrifugal granulation and afterheat recycle system having molten slag buffer-storage and flow control functions

ActiveCN108330233AEnsure structural stabilityGuaranteed operational safetyExhaust gas handlingRecycling and recovery technologiesMetallurgyIron industry

The invention discloses a liquid molten slag dry-type centrifugal granulation and afterheat recycle system having molten slag buffer-storage and flow control functions. The system comprises a molten slag buffer-storage and flow control unit, a granulation unit, a mobile bed unit and an afterheat utilization unit; the molten slag buffer-storage and flow control unit is arranged at the upper part ofthe granulation unit and is used for buffer-storage of the liquid molten slag and controlling the flow rate and speed of the liquid molten slag falling to the granulation unit; the granulation unit is used for granulating the falling liquid molten slag; the mobile bed unit is arranged at the lower part of the granulation unit and is used for cooling and temporarily storing the granulated molten slag; hot air inside the granulation unit and the mobile bed unit communicates with the afterheat utilization unit; and the afterheat utilization unit comprises a hot air flue, a primary dust collector, an afterheat boiler, a secondary dust collector, an exhaust fan and a chimney which are arranged in sequence. The system disclosed by the invention does not use water resources, is free of environmental pollution, can effectively recycle high-quality afterheat resources contained in the high-temperature liquid molten slag, and can meet the urgent requirements of energy conservation and emissionreduction of the present steel and iron industry.

Owner:XI AN JIAOTONG UNIV

Cooling device with a plurality of fin pitches

InactiveUS20130112373A1Inhibit temperature riseReduce the temperatureSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

It is an object to provide a cooling device with an increased leeward cooling capacity without increasing the number of heat radiation fins to be installed and the amount of cooling air.The cooling device comprises a heat-receiving block thermally connected to a heat-generating element and heat radiation fin groups having a plurality of fins thermally connected to the heat-receiving block. A flow of cooling air is set in the direction parallel to the heat-receiving block. The plurality of heat radiation fin groups are arranged in tandem along the flow direction of the cooling air. Of the plurality of the heat radiation fin groups, the fin pitch of the heat radiation fin group arranged on the windward side of the cooling air is larger than the fin pitch of the heat radiation fin group arranged on the leeward side of the cooling air.

Owner:FURUKAWA ELECTRIC CO LTD

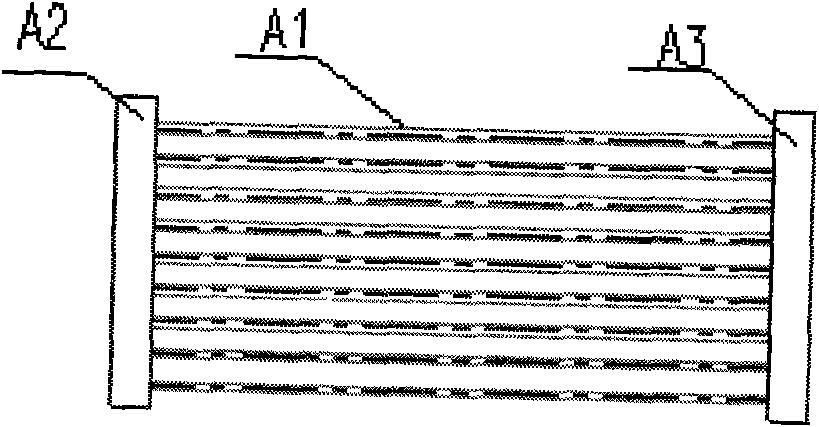

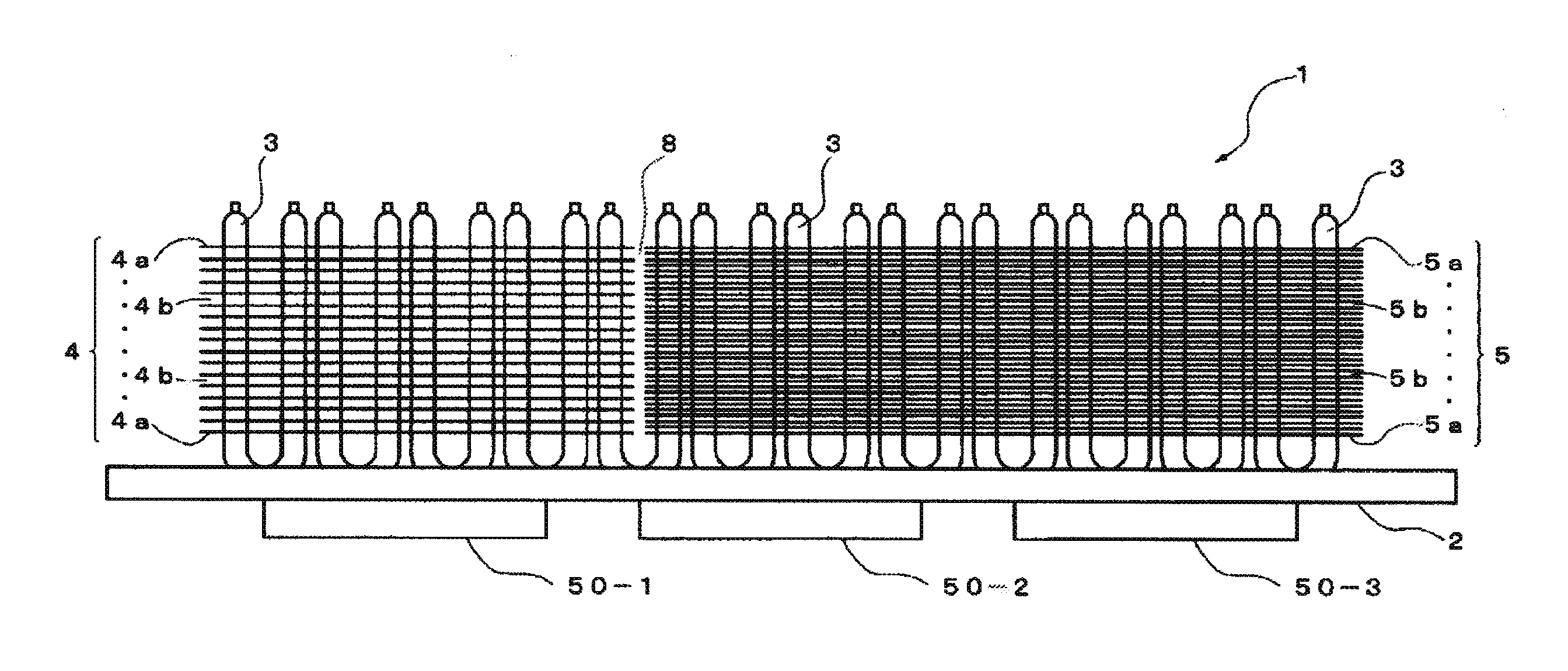

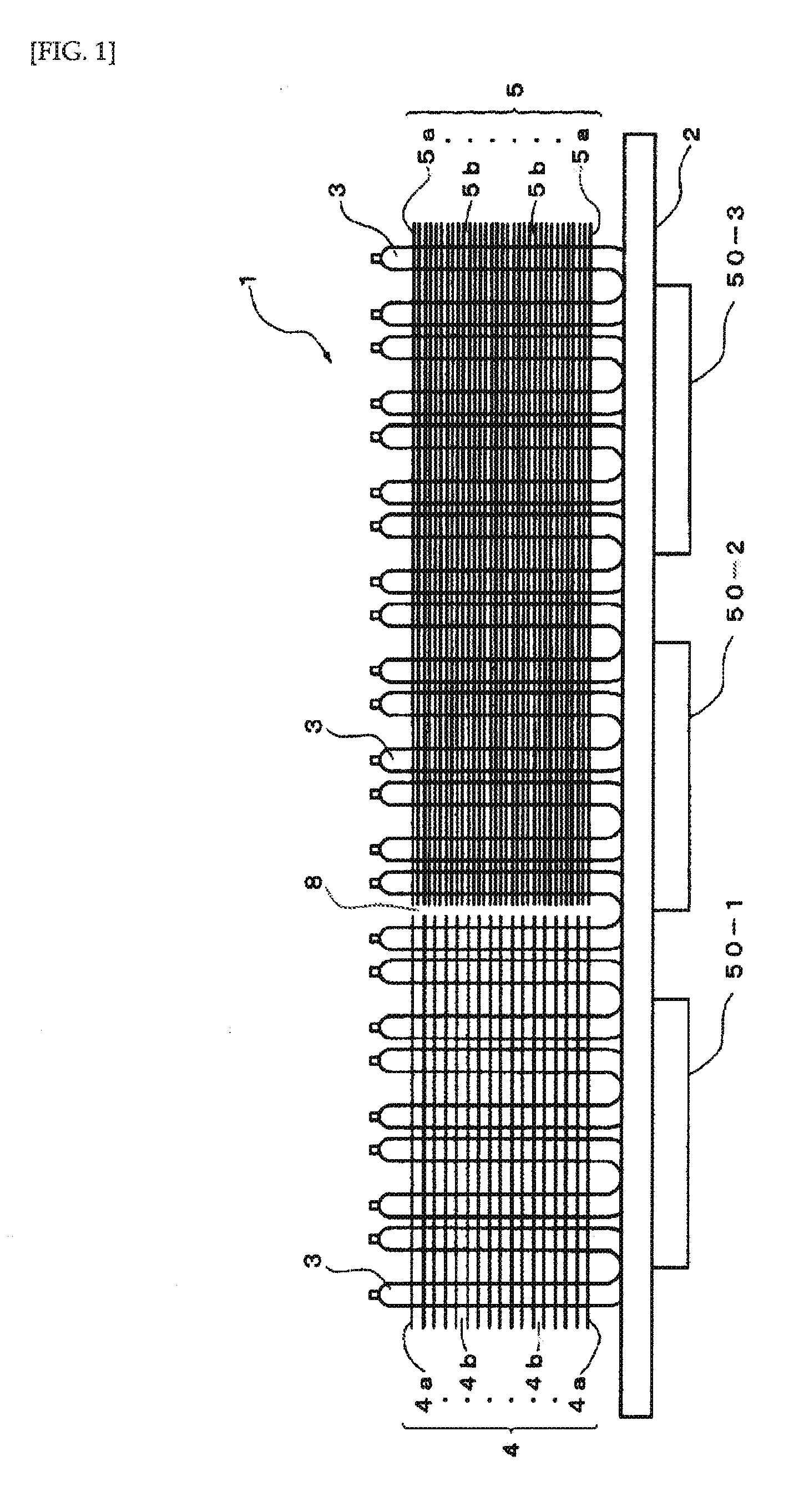

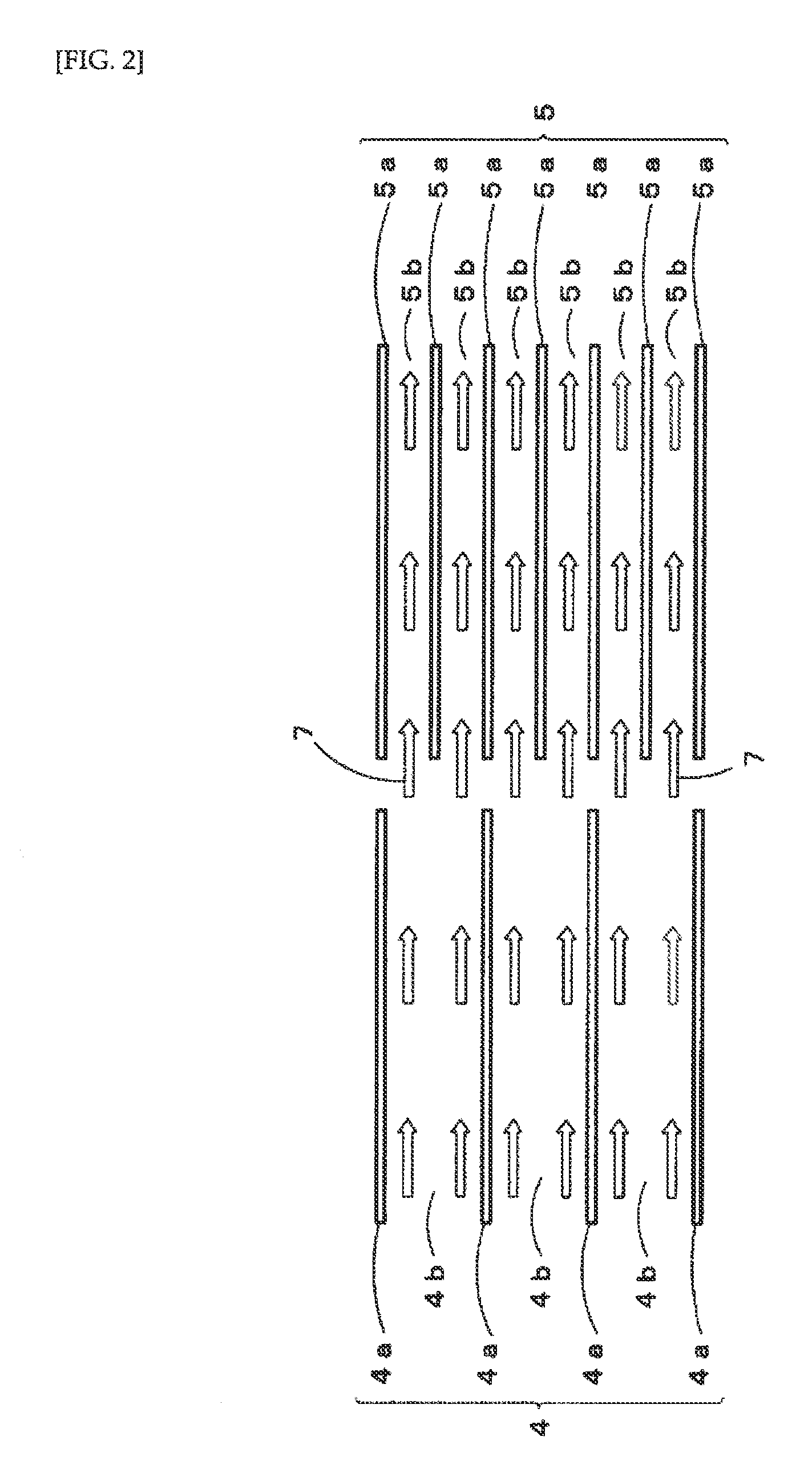

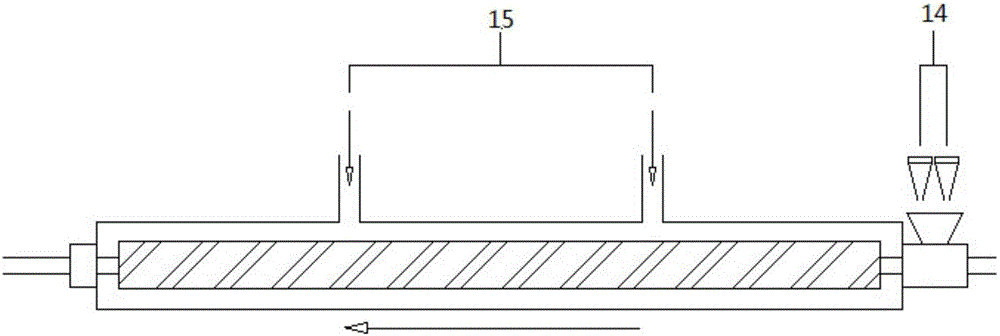

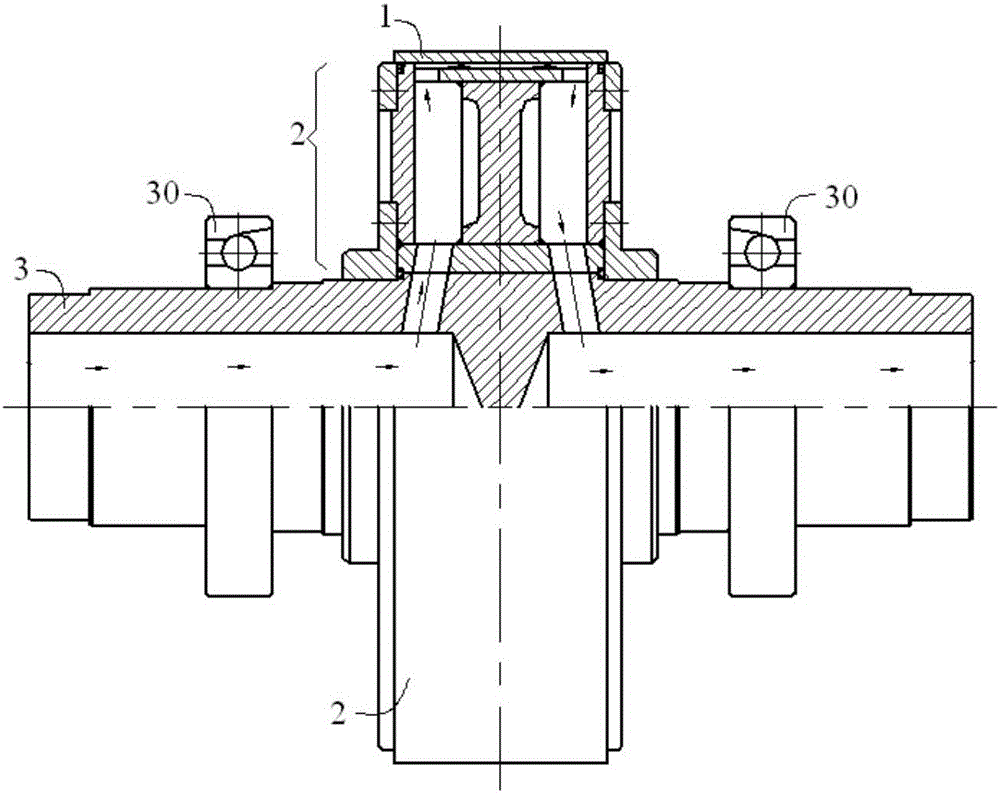

Cooling roller device for preparing lithium-ion battery separator with three cellular structures

ActiveCN106299196AUniform cooling effectUniform thicknessSecondary cellsCell component detailsTemperature controlMetallurgy

The invention provides a cooling roller device for preparing a lithium-ion battery separator with three cellular structures. The cooling roller device comprises a first casting piece roller, a second casting piece roller and a third casting piece roller; a cast film flowed from an extruding die head is fallen on the surface of the second casting piece roller to cool, and forms a storage film between the first casting piece roller and the second casting piece roller; the first casting piece roller and the second casting piece roller are mutually cooperated to cool two surfaces of the storage film at the same time; a space between the first casting piece roller and the second casting piece roller is adjusted through the adjusting device on the first casting piece roller, so as to form a casting piece with uniform thickness; besides, the casting piece is further cooled by the third casting piece roller, so as to carry out the subsequent technique. The cooling device in the production of the lithium-ion battery separator is featured by fast cooling, stable temperature control, and is able to control cellular structures on the prepared lithium-ion battery separator.

Owner:LIAOYUAN HONGTU LI ION BATTERY DIAPHRAGM TECH

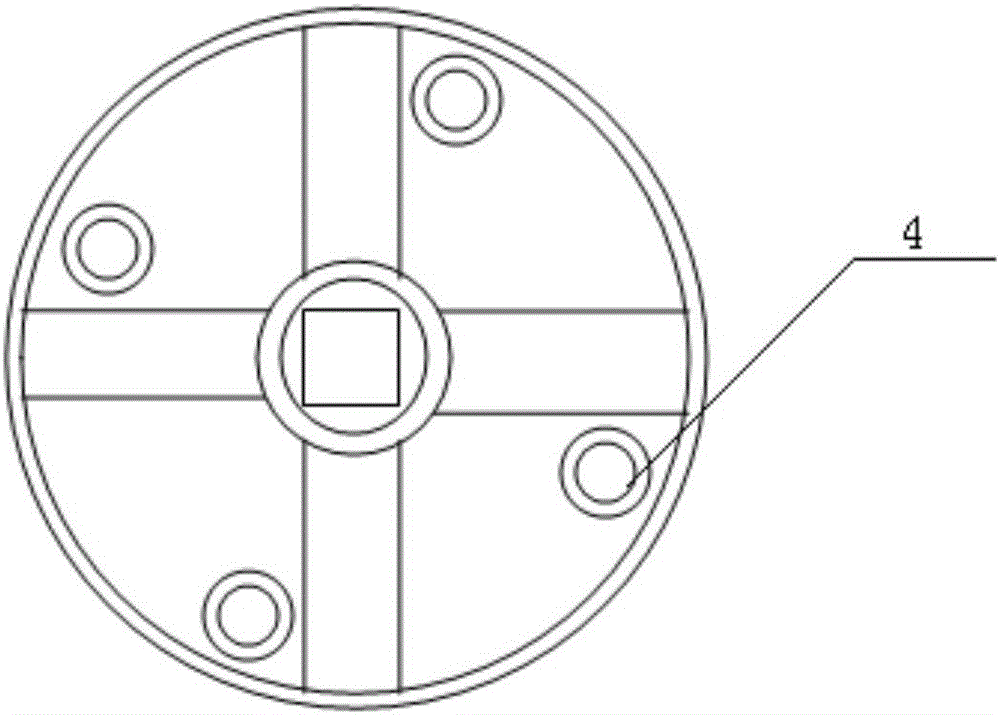

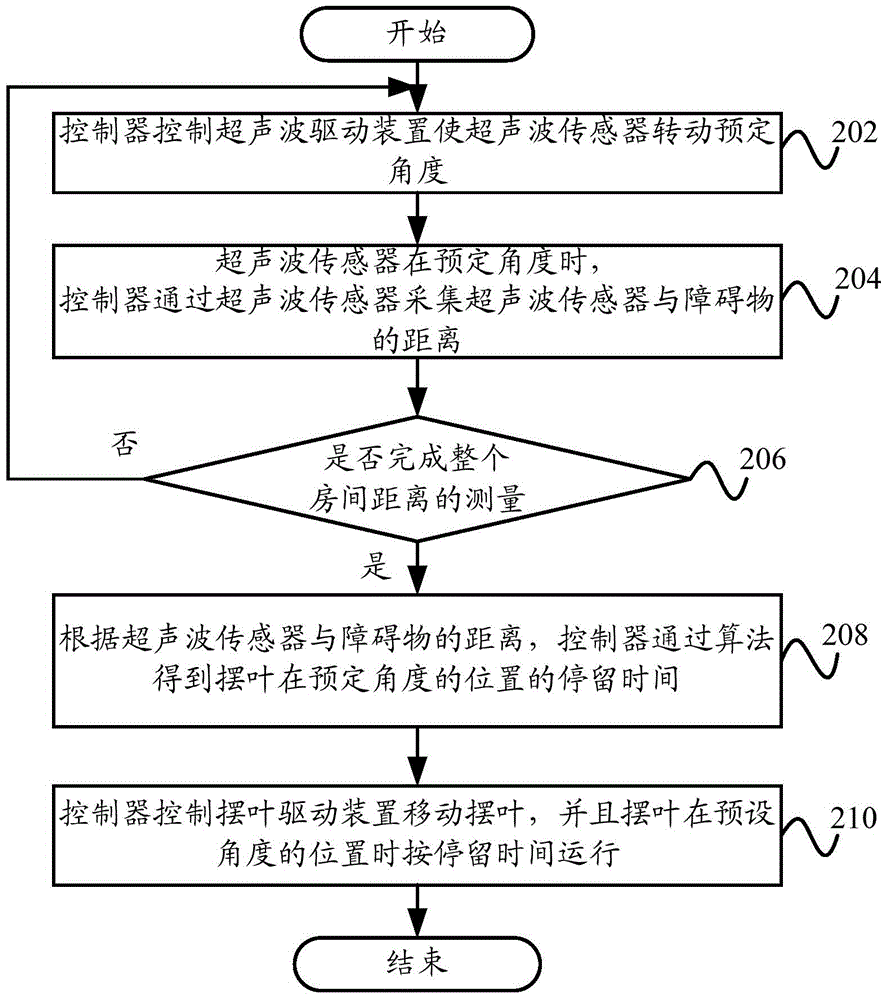

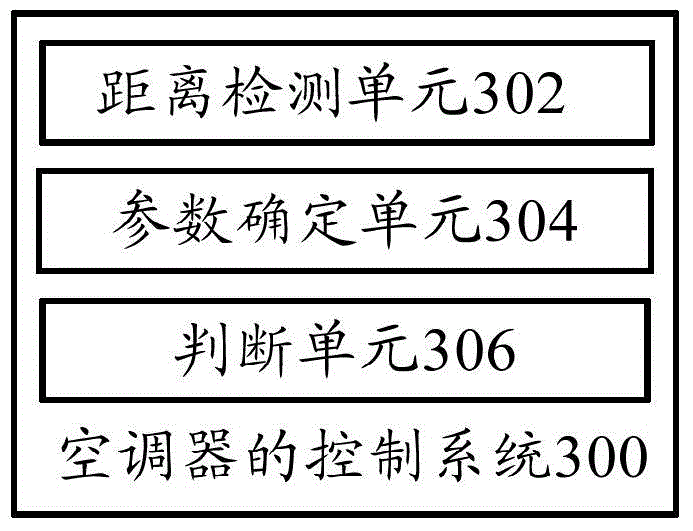

Air conditioner and control method and system thereof

ActiveCN104456853AEvenly distributedImprove comfortMechanical apparatusSpace heating and ventilation safety systemsCold airUltrasonic sensor

The invention provides an air conditioner and a control method and system thereof. The control method includes allowing an ultrasonic sensor to detect a distance from an obstacle to the air conditioner; according to the distance detected, determining operating parameters of the air conditioner to allow the air conditioner to operate according to the operating parameters determined. According to the technical scheme, measures such as longer air supply time and bigger wind force are taken for the obstacle farther away from the air conditioner so that ensured is that hot air or cold air supplied by swing blades of the air conditioner is more evenly distributed to a whole room; the problem that the prior air conditioner has uneven refrigerating and heating action on multiple areas of the room is solved; comfort level is increased for users.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

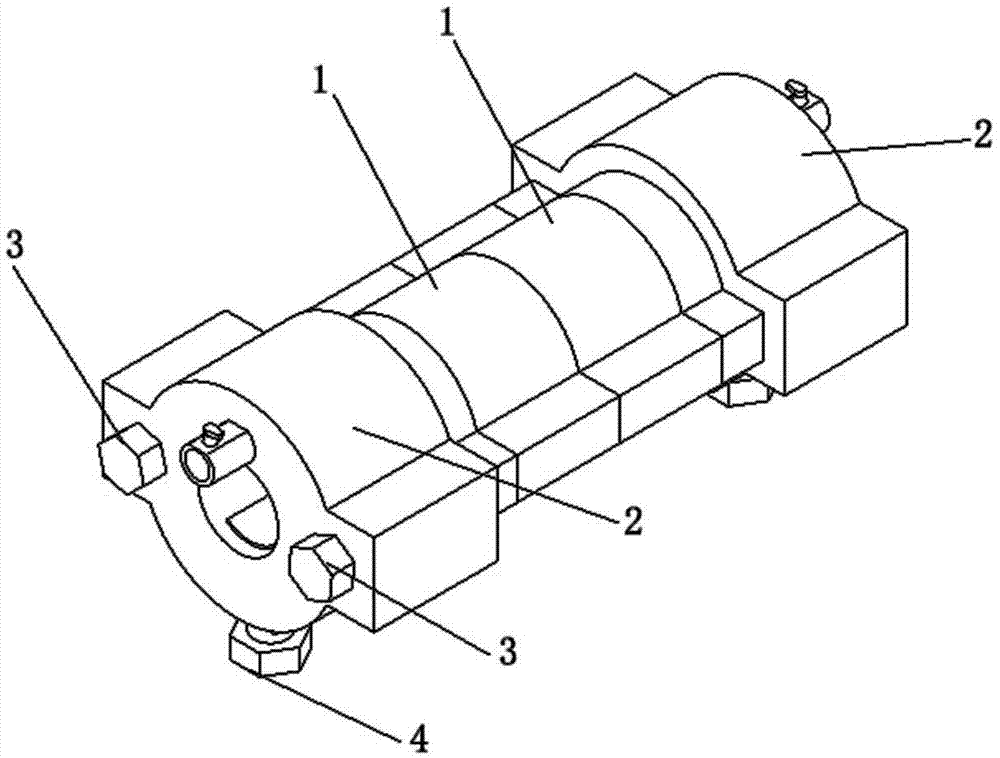

Water jacket spacer

InactiveCN102606334AUniform cooling effectGuaranteed smooth assemblyLiquid coolingCylinder headsElastomerWater flow

A water jacket spacer has a spacer body molded in conformity to the shape of the water jacket and a regulating member whose one side is fixed to the spacer body. The regulating member is composed of a first member which is not water-swellable and is elastically deformable and a second member made of water-swellable elastomer which is integrally fixed to the first member. The regulating member lies in a state not-contacting an opposed wall of the water jacket when inserted into the water jacket together with the spacer body, whereas it blocks a part of cooling water flowing through the water jacket by deforming such that a side of the regulating member not fixed to the spacer body faces toward the opposed wall of the water jacket when the second member swells by absorbing cooling water flown into the water jacket and thereby the first member is elastically deformed.

Owner:UCHIYAMA MFG

Cooling device with a plurality of fin pitches

ActiveCN102884877ASuppress pressure lossAvoid loadSemiconductor/solid-state device detailsSolid-state devicesEngineeringCooling capacity

Provided is a cooling device wherein the cooling capability on the leeward side is improved without increasing the number of installed cooling fins or the airflow of cooling air. A cooling device is provided with a heat-receiving block thermally connected to a heater element; and a group of cooling fins including a plurality of fins thermally connected to the heat-receiving block such that the flow of cooling air is set in parallel with the heat-receiving block, wherein a plurality of the groups of cooling fins is arranged longitudinally along the flow direction of the cooling air, and of the plurality of the groups of cooling fins, the fin pitch of the groups of cooling fins arranged on the windward side of the cooling air is larger than the fin pitch of the groups of cooling fins arranged on the leeward side of the cooling air.

Owner:FURUKAWA ELECTRIC CO LTD

Inner-cooling bonded abrasive grinding disc

ActiveCN103192325AEasy to assemble and disassembleAchieve replacementBonded abrasive wheelsCooling effectSurface roughness

The invention relates to an inner-cooling bonded abrasive grinding disc, belongs to the field of bonded abrasive grinding and processing, and particularly relates to an inner-cooling bonded abrasive grinding disc used for single-side grinding or double-side grinding materials of silicon, sapphire, ceramic, glass and the like. Cooling liquid circulating channels are arranged inside the grinding disc. The grinding disc comprises multi-hole grinding blocks, a base plate and a spreader plate. The multi-hole grinding blocks are provided with abrasives, the base plate is provided with a plurality of hole channels, and a central hole and a groove are reserved on the spreader plate. Each multi-hole grinding block is fixed at one end of the hole channel of the base plate through bonding agents, and the large air holes in the multi-hole grinding blocks are communicated with one another. The cooling liquid circulating channels are formed by the central hole of the spreader plate, the grooves of the spreader plate, the radial grooves of the spreader plate, the hole channels of the base plate and the large air holes of the multi-hole grinding blocks. Since the grinding disc is provided with inner-cooling circulating channels, cooling effect can be improved, the grinding disc and workpieces can be prevented from being burnt off, size accuracy of the processing workpiece is high, and surface roughness is good.

Owner:DALIAN UNIV OF TECH

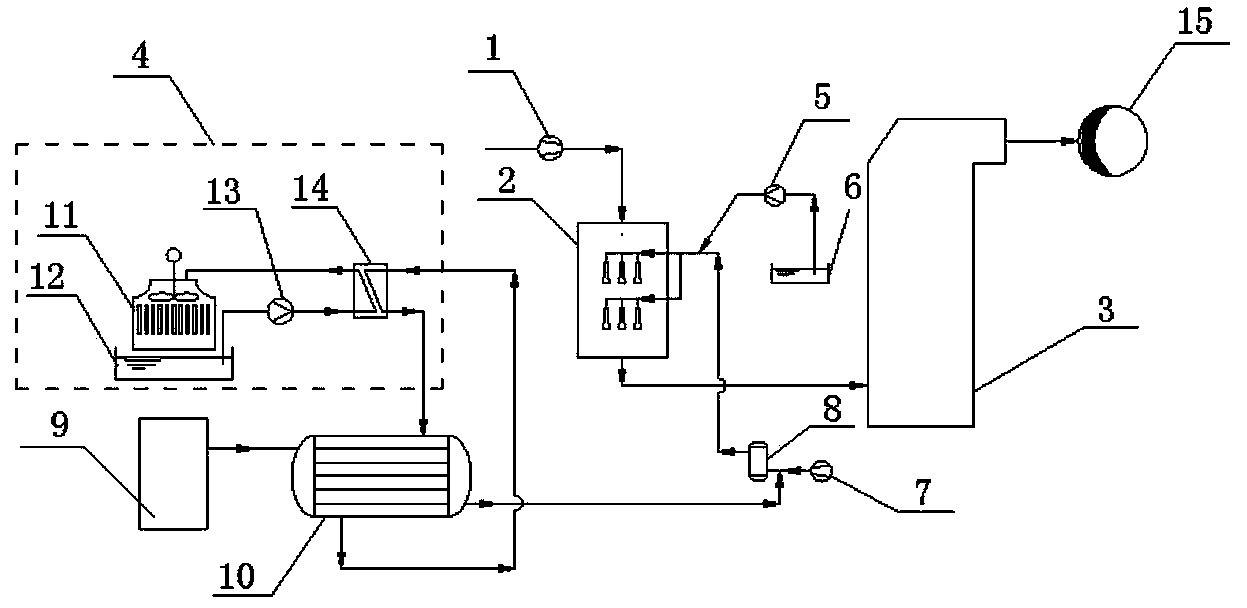

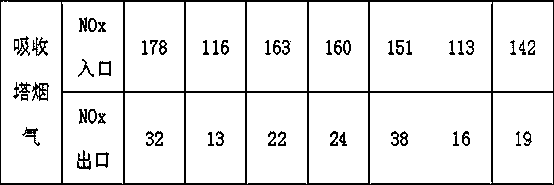

Treatment method for removing nitrogen oxides by virtue of ozone function

InactiveCN104128079AEffective oxidationImprove oxidation efficiencyDispersed particle separationOzone generatorFlue gas

The invention relates to a treatment method for removing nitrogen oxides by virtue of an ozone function. The method comprises the following steps: (1) flue gas containing the nitrogen oxides is introduced into a flue and an ozone adding distributor is additionally arranged; (2) a gas source is introduced into an ozone generator, ozone is generated and diluted and then is mixed in a mixer to obtain ozone diluted uniformly, and the ozone diluted uniformly enters the ozone adding distributor; (3) the ozone diluted uniformly and the flue gas containing the nitrogen oxides are mixed in the ozone adding distributor and are subjected to oxidation reaction, NO in waste gas is converted into high-valent nitrogen oxides and then the high-valent nitrogen oxides enter an absorption tower; and (4) the flue gas is absorbed by the absorption tower and absorption liquid and is purified to obtain tail gas, and the tail gas is exhausted from a chimney. The treatment method for removing the nitrogen oxides has the high efficiency, the low energy consumption and the convenience in use.

Owner:山西易通环保技术有限公司

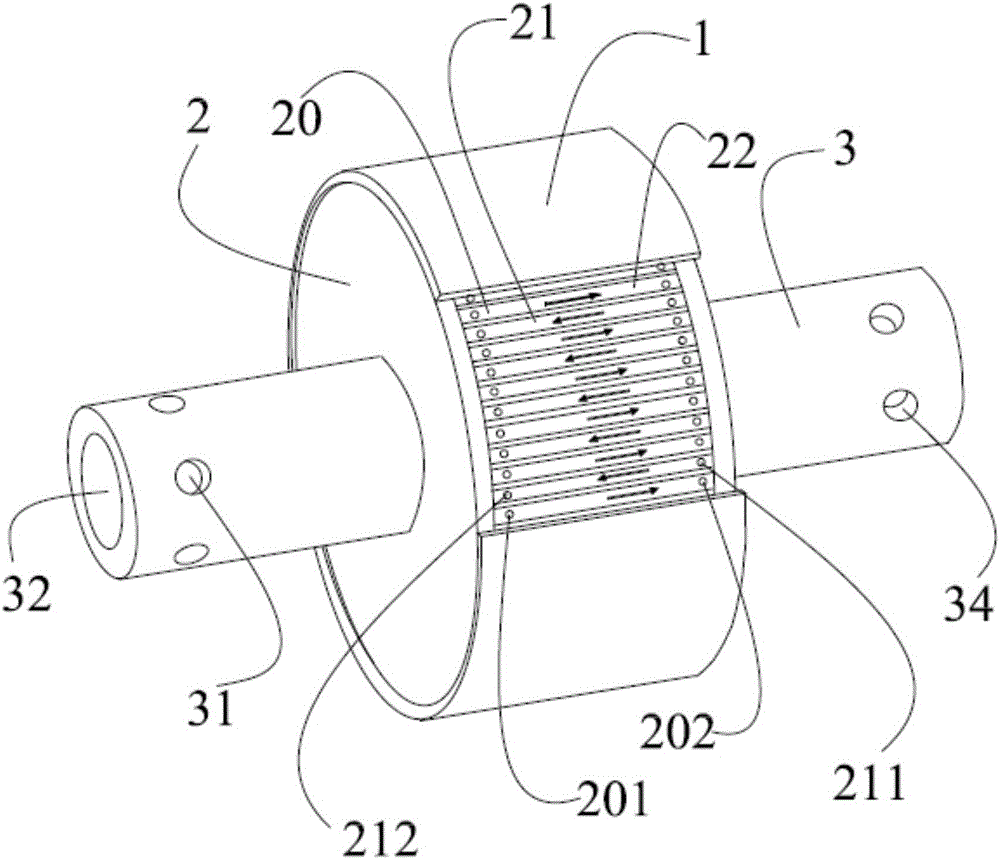

Wind driven generator

ActiveCN102332780AClear functionUniform cooling effectMagnetic circuit stationary partsCooling/ventillation arrangementWind drivenWind force

The invention provides a wind driven generator, comprising a rotor and a stator frame which are mutually matched, wherein a communicated circular air gap is formed between the rotor and the stator frame; the external circumference surface of the stator frame is provided with a circle of annular groove; the two sides of the annular groove are respectively provided with a baffle; the interior of the annular groove is axially provided with vertical rib plates along a stator; the vertical rib plates divide the annular groove into a plurality of ventilating cavities; the ventilating cavities are cold air cavities or hot air cavities; the cold air cavities and the hot air cavities are alternately arranged on the external circumference surface of the stator frame; and the bottoms of each cold air cavity and each hot air cavity are respectively connected with a cold air inputting channel and a hot air outputting channel. According to the wind driven generator provided by the invention, each cold air area channel and each hot air area channel are distributed crosswise, have clear and definite functions and do not interfere with each other; the cooling effect is good, the needed cooling airquantity is greatly reduced, and the work efficiency of the generator is improved; and the wind driven generator has a compact structure, is convenient to structurally design, and has good promotion value.

Owner:DONGFANG ELECTRIC MACHINERY

Uniform-cooling cooling roller device and method for amorphous strip preparing

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

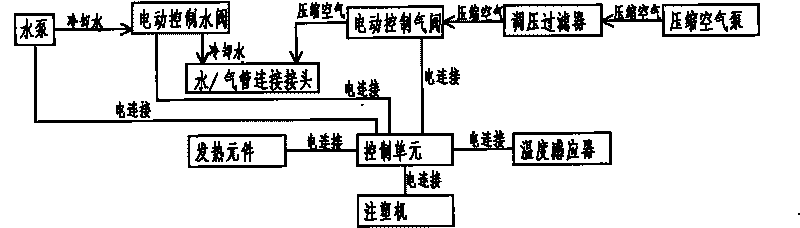

Steam heating type fast heat-circulation injection mould

The invention relates to a steam heating type fast heat-circulation injection mould which comprises a steam heating type sectional cavity plate and an electric heating type sectional core plate, wherein the fast heat-circulation injection mould further comprises a thermal insulation device and a support device which are respectively matched with the steam heating type sectional cavity plate and a steam heating type sectional core plate. The back surfaces of the steam heating type sectional cavity plate and the steam heating type sectional core plate are provided with grooves, the grooves are matched with the surface of the thermal insulation device to form a sealed pipe hole, so as to be used as a heating device and a cooling device. Sealing devices are respectively arranged between the steam heating type sectional cavity plate and the corresponding thermal insulation device and between the steam heating type sectional core plate and the corresponding thermal insulation device. Temperature measurement devices are respectively installed on the steam heating type sectional cavity plate and the steam heating type sectional core plate. The temperature measurement devices, the heating device and the cooling device are connected with a temperature control device. The steam heating type fast heat-circulation injection mould has the outstanding advantages of high heating and cooling efficiency and heating uniformity, so that the surface of a sectional cavity of a three-dimensional complex-shape mould can be uniformly and quickly heated or cooled.

Owner:SHANDONG UNIV

Vacuum induction smelting furnance

ActiveCN101347836BUniform thicknessUniform cooling effectCasting plantsCharge manipulationCooling effectFlap valve

The invention discloses a vacuum induction melting furnace, which relates to a crucible furnace that is suitable for charging treatment in vacuum or special atmosphere. The invention provides an improved vacuum induction melting furnace with better casting cooling effect and good productivity, which comprises a vacuum melting chamber, a medium frequency coil furnace, a set of vacuum pump and a corresponding vacuum pipeline system, a electric control system, a medium frequency power supply system, a hydraulic cylinder control system, a cooling system, and a pit discharging system. The cooling system is provided with a tundish feed divider, a belt wheel cooling mechanism, a baffle cooling mechanism and a turning wheel cooling mechanism. The pit discharging system comprises a medial chamber box, an inner container, an outer container, a walking car, a hydraulic lifting cylinder, a pit track, a flap valve and a guide shell. The guide shell and the flap valve are arranged in the medial chamber box, the outer container is fixedly arranged on the walking car, and the inner container is sheathed at the inner wall of the outer container.

Owner:厦门嘉鹭金属工业有限公司

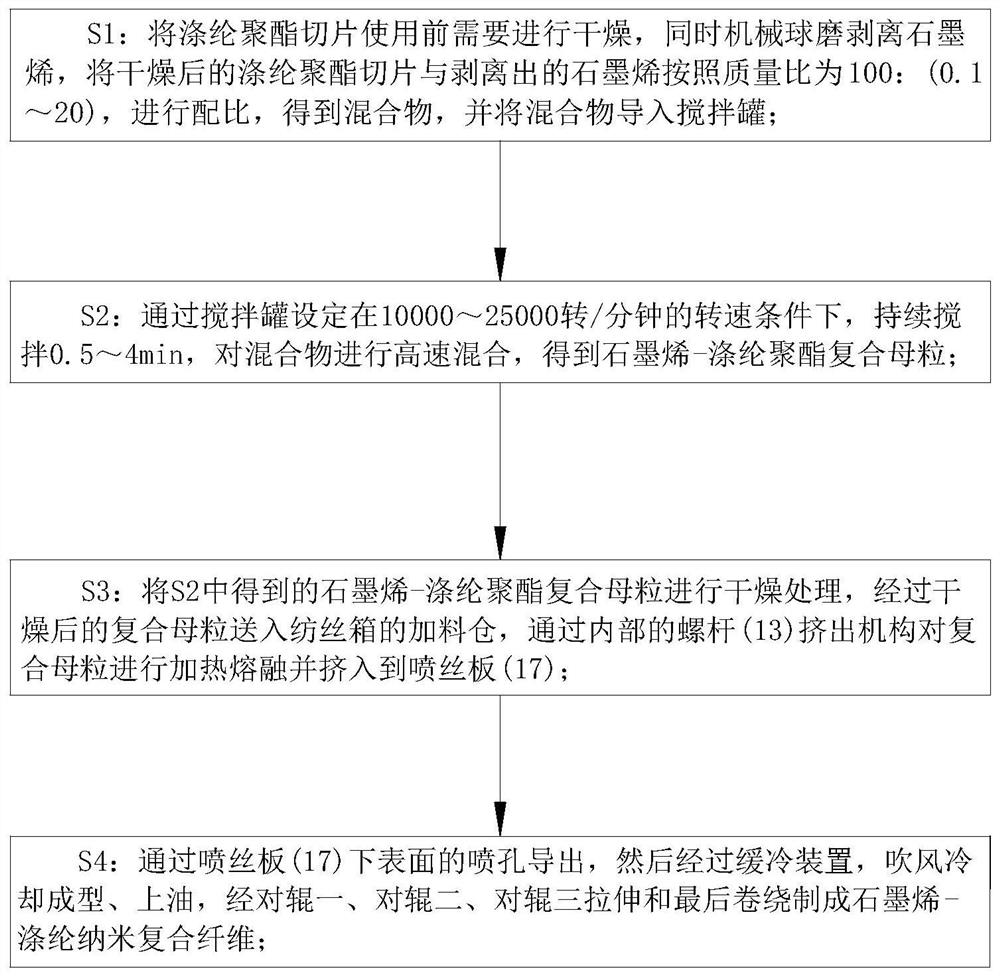

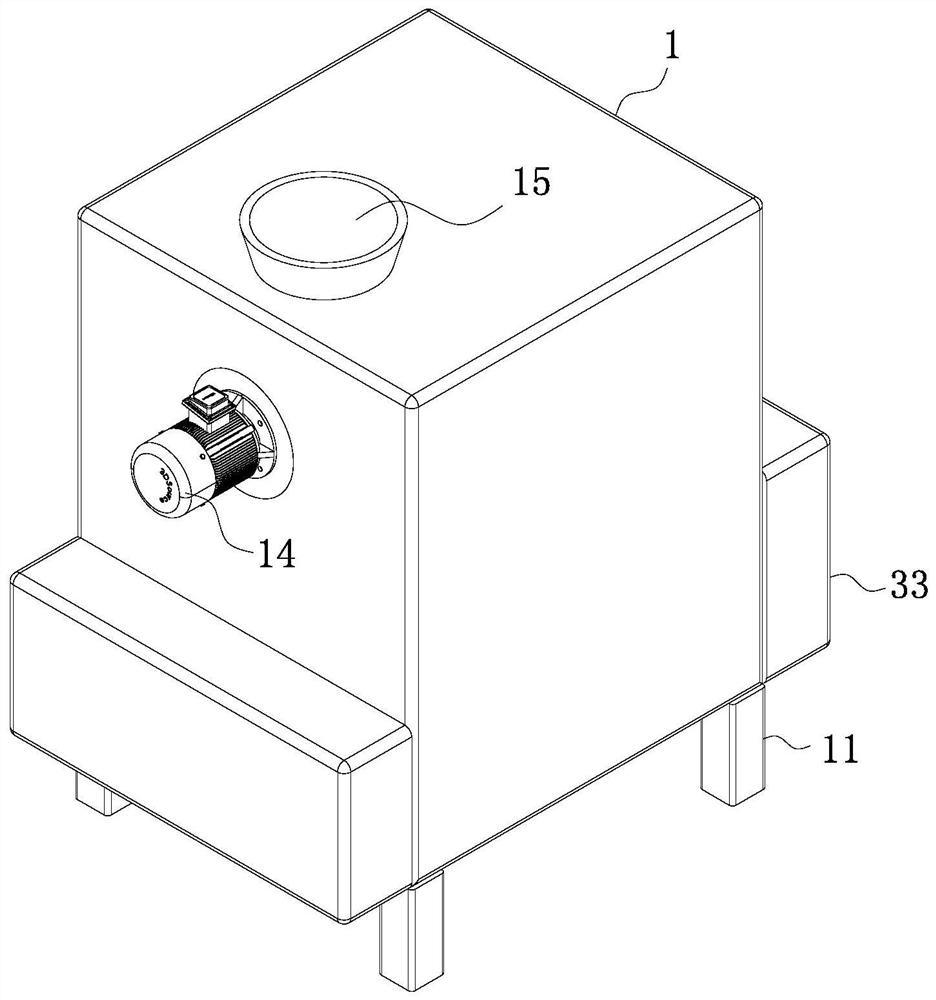

Preparation method of graphene-polyester nanometer composite fiber

InactiveCN111690994AAchieving Parallel Airflow CoolingUniform cooling effectSpinnerette packsMelt spinning methodsPolyesterFiber

The invention belongs to the technical field of composite fibers and specifically relates to a preparation method of a graphene-polyester nanometer composite fiber. A spinning box used in the preparation method of the graphene-polyester nanometer composite fiber is provided with a box body, a rotating disc and an air guide rod; a spinneret plate is arranged in a position, close to the upper surface of the box body, in the box body; a conduit is fixedly connected to the lower surface of the spinneret plate; a cold plate is fixedly connected to the position, close to the lower end surface of theconduit, in the box body; the air guide rod is connected to the interior of the cold plate to slide from left to right; and the rotating disc is rotationally connected to the interior of the conduit.Through adoption of the preparation method of the graphene-polyester nanometer composite fiber, parallel airflow cooling of spun fibers is effectively realized, the wind direction and the fibers areprevented from being in a vertical state, uneven air speed is very easy to cause air turbulence to cause a filament drifting problem, and meanwhile, the cooling effect on the spun fibers is more uniform so that the cooling time of the spun fibers and the drawing ratio are kept consistent with each other; and therefore, the qualities of the prepared spun silks are higher.

Owner:孟伟东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com