Cooling method of battery pack and battery pack with cooling device

A technology of a cooling device and a cooling method, which is applied to secondary batteries, circuits, electrical components, etc., can solve the problems of thermal runaway, poor cooling effect, and low effective weight, and achieve the effect of preventing thermal runaway.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

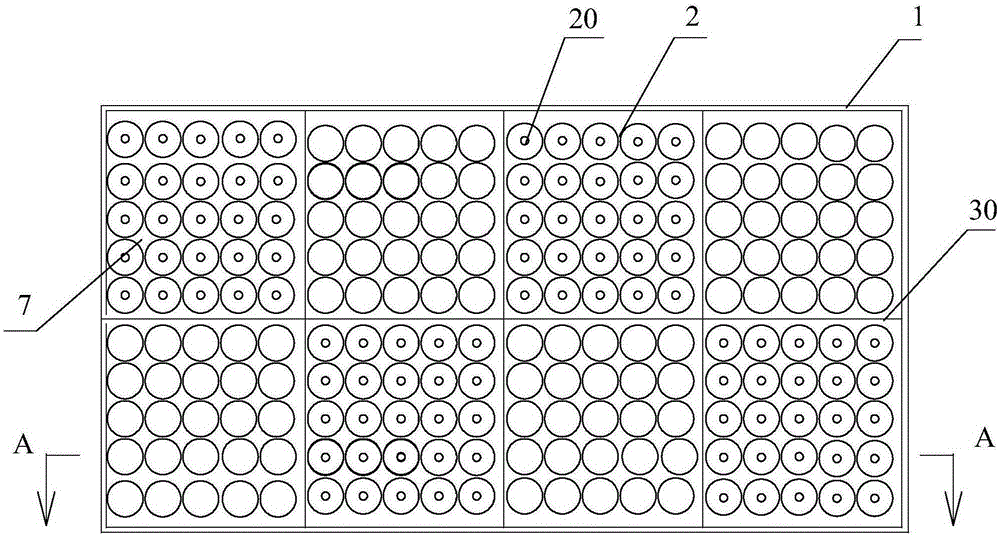

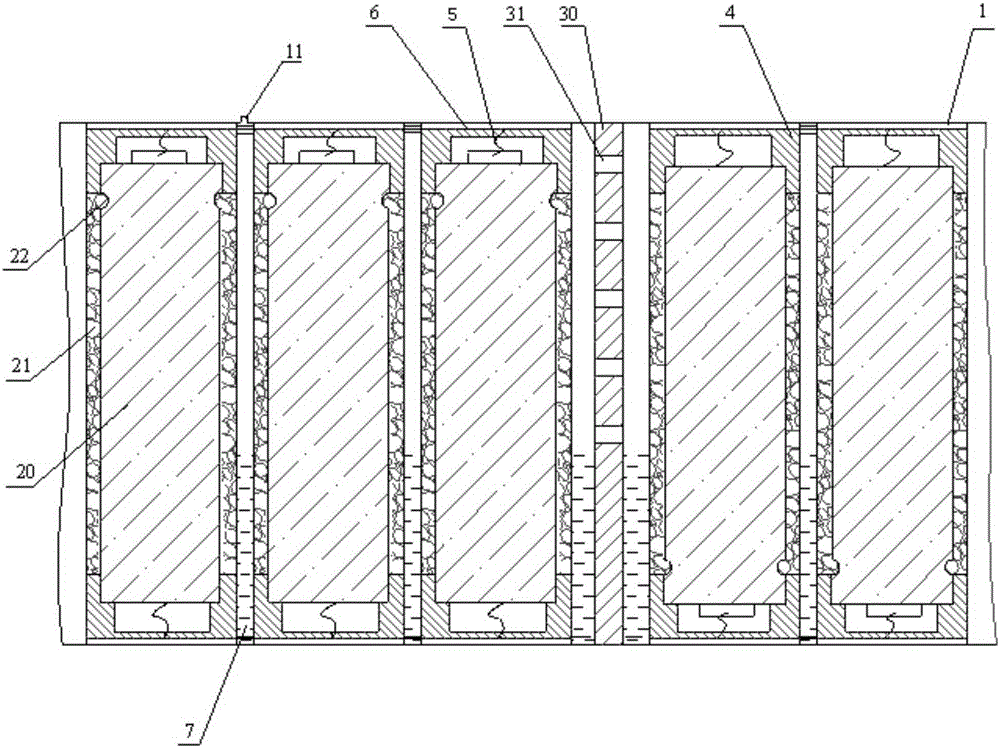

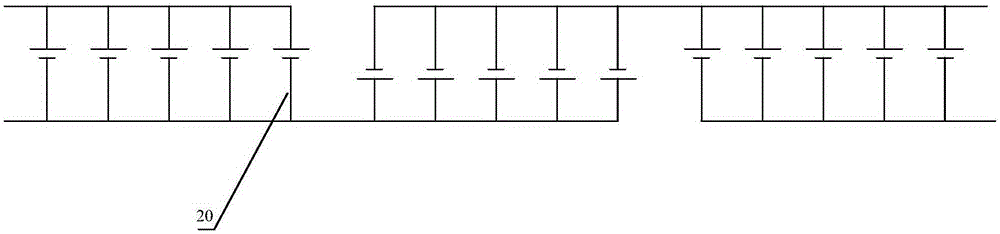

[0082] Embodiment 1. A battery pack with a cooling device, which includes a sealed casing 1, and in the inner cavity of the casing 1, a grid-shaped partition formed by criss-crossing partitions 30 (for example, Such as figure 1 The eight divisions mentioned above), one battery group 2 is set in each division, the battery group 2 with the positive pole upward and the battery group 2 with the negative pole upward are arranged alternately in the above division, and the battery group 2 passes through The main circuit conductors are connected in parallel and in series (such as image 3 said, note: the way of parallel series belongs to the conventional technology). The main circuit wire can be designed in an integrated form with the housing 1, which can simplify the structure more.

[0083] Remarks: In order to make the drawing clearer; the above main circuit wires are omitted in the drawing.

[0084] The specific structure of each battery group 2 is as follows:

[0085] Each b...

Embodiment 2

[0120] Embodiment 2. Combining several battery packs with cooling devices described in Embodiment 1:

[0121] When due to the needs of the installation layout, these several battery packs with cooling devices must be installed separately, when several battery packs are used together, a gas conduit 12 can be arranged on the upper part of the casing 1 of each battery pack, The lower part of the body 1 is provided with a liquid conduit 13 ; the cooling liquid vapor generated by the evaporation of the cooling liquid 7 flows through the gas conduit 12 , and the cooling liquid 7 flows through the liquid conduit 13 . In this way, the mutual flow of coolant vapor and coolant between the battery packs is realized. That is, the gas layer on the upper layer and the liquid layer on the lower layer in the casing 1 are connected through independent pipes, so as to ensure unimpeded communication between the gas and the cooling liquid.

[0122] The rest of the working methods are the same as...

Embodiment 3

[0123] Embodiment 3, when the battery pack is placed upright:

[0124] When the external layout requires that the battery pack must be placed vertically, the cooling medium (coolant 7) needs to submerge all the battery cells 20. Therefore, compared with Embodiment 1, the use of "wrapping the outer surface of the battery cells 20" can be cancelled. The absorbent layer 21".

[0125] The heat exchange of the cooling liquid 7 needs to be heated by natural convection, and it is difficult to obtain heating conditions for the deep battery cells 20. At this time, a gas circulation pump 8 can be added outside the battery pack, and the two ends of the gas circulation pump 8 are respectively connected to the casing The top and bottom of the inner cavity of 1 are connected; thus, the gaseous medium in the upper layer is pumped to the lowermost layer for circulation, and the overall uniform gas-liquid coexistence state in the shell 1 can be maintained to provide uniform temperature perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com