Patents

Literature

535 results about "Process mechanism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process | mechanism |. is that process is a series of events to produce a result, especially as contrasted to product while mechanism is within a machine or machinery; any mechanical means for the conversion or control of motion, or the transmission or control of power.

System and method for using timestamps to detect attacks

InactiveUS20070157315A1Overcome problemsEnabling detectionMemory loss protectionError detection/correctionData packProcess mechanism

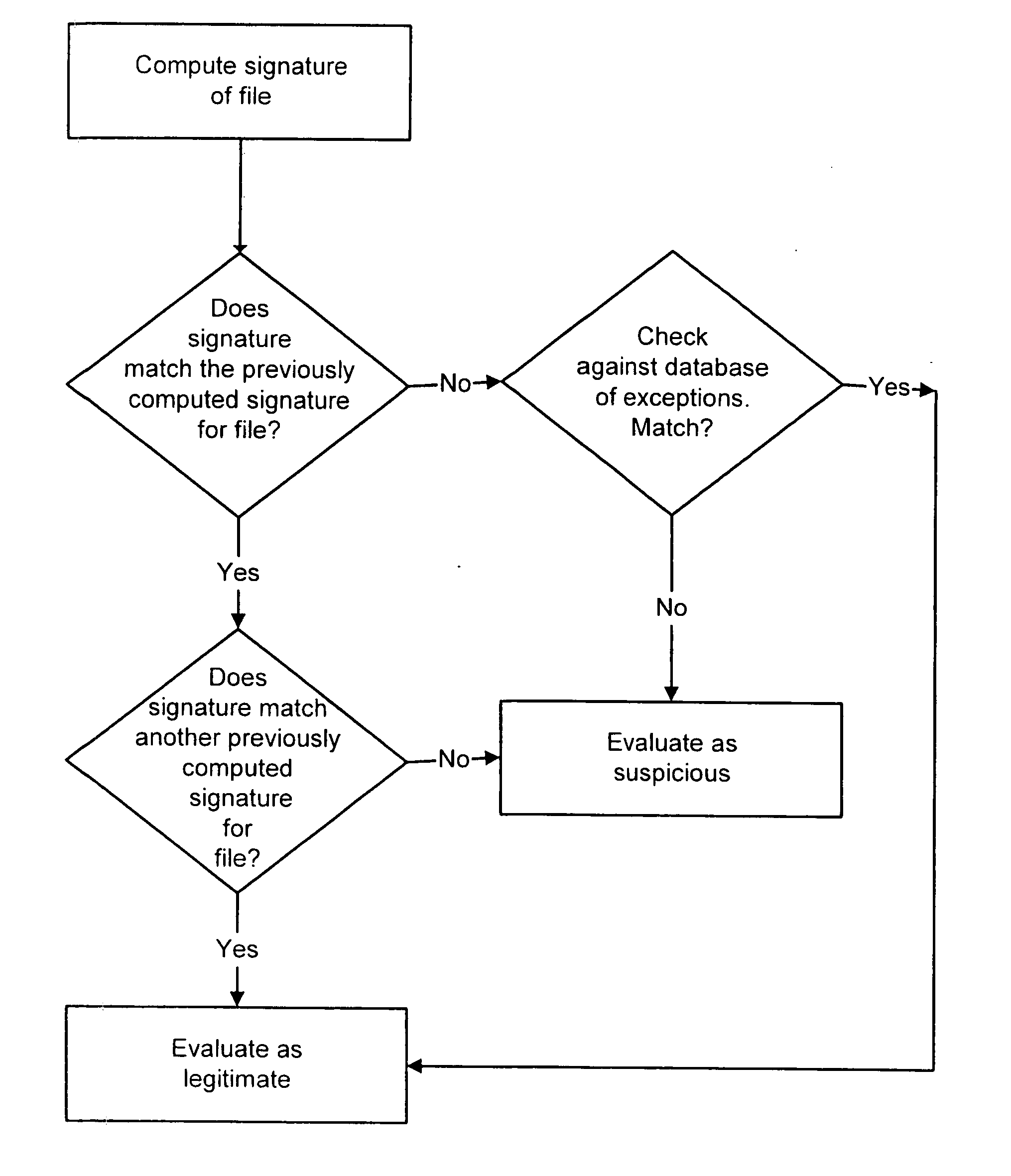

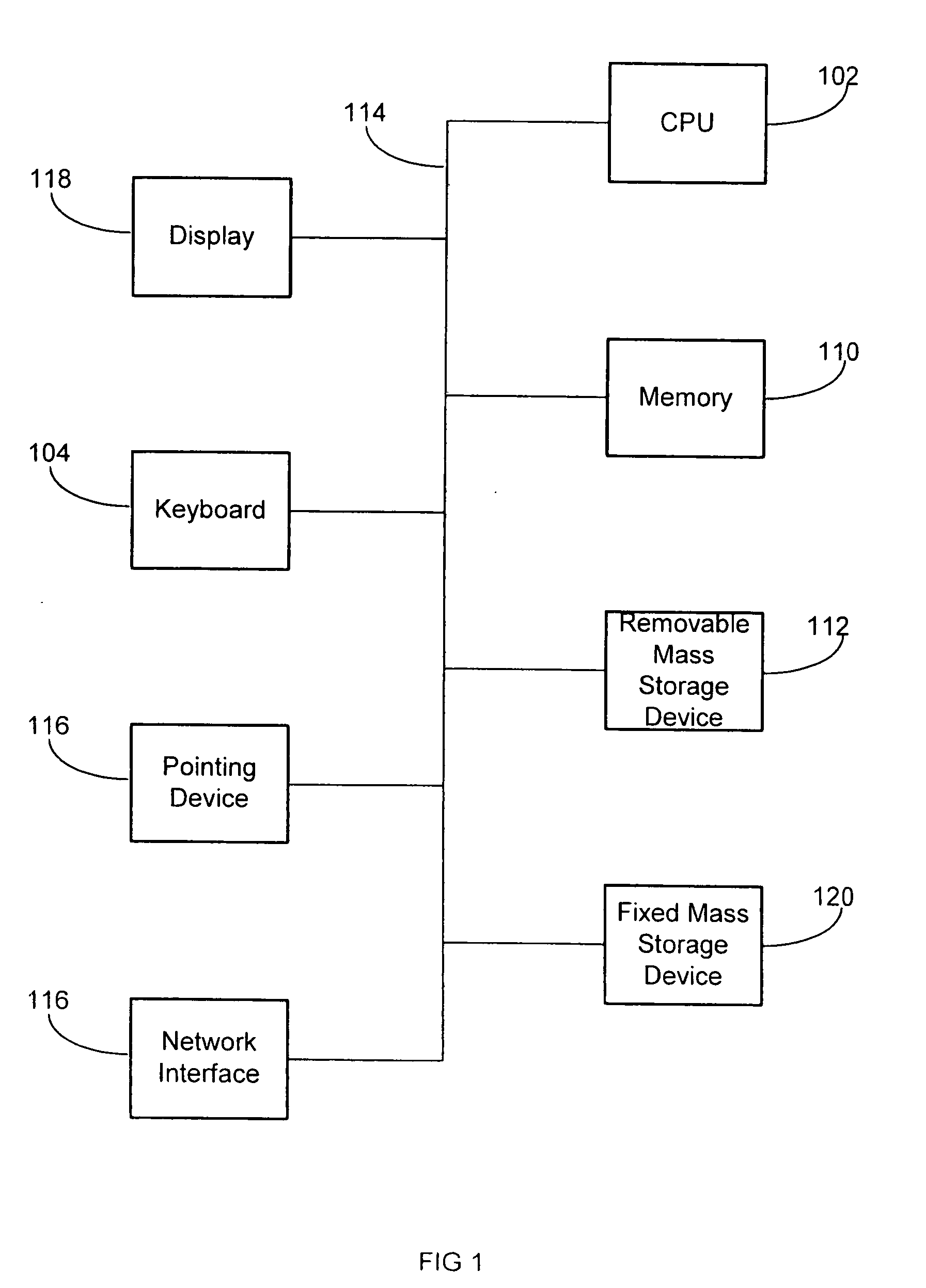

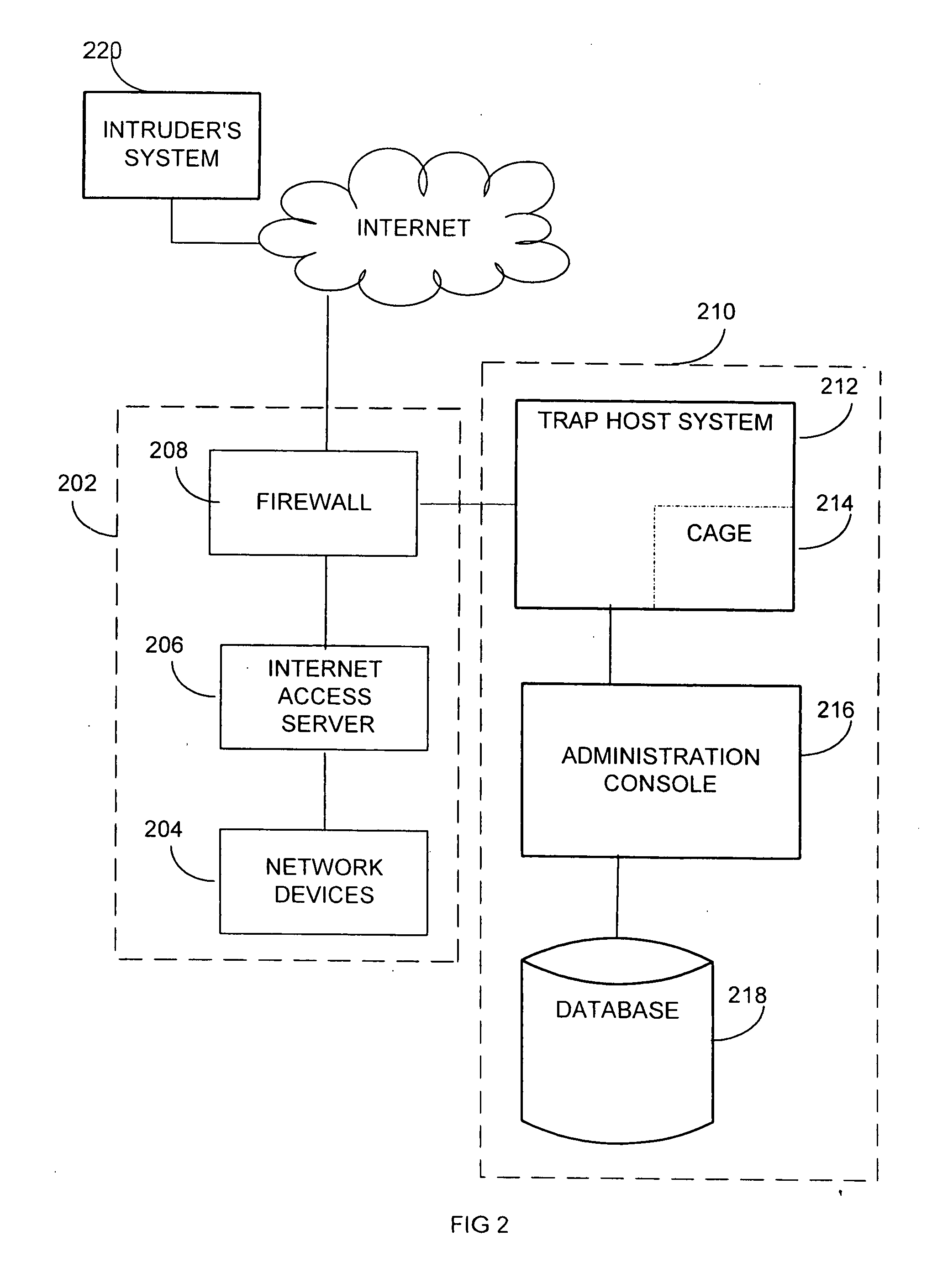

A system and method are disclosed for detecting intrusions in a host system on a network. The intrusion detection system comprises an analysis engine configured to use continuations and apply forward- and backward-chaining using rules. Also provided are sensors, which communicate with the analysis engine using a meta-protocol in which the data packet comprises a 4-tuple. A configuration discovery mechanism locates host system files and communicates the locations to the analysis engine. A file processing mechanism matches contents of a deleted file to a directory or filename, and a directory processing mechanism extracts deallocated directory entries from a directory, creating a partial ordering of the entries. A signature checking mechanism computes the signature of a file and compares it to previously computed signatures. A buffer overflow attack detector compares access times of commands and their associated files. The intrusion detection system further includes a mechanism for checking timestamps to identify and analyze forward and backward time steps in a log file.

Owner:SYMANTEC CORP

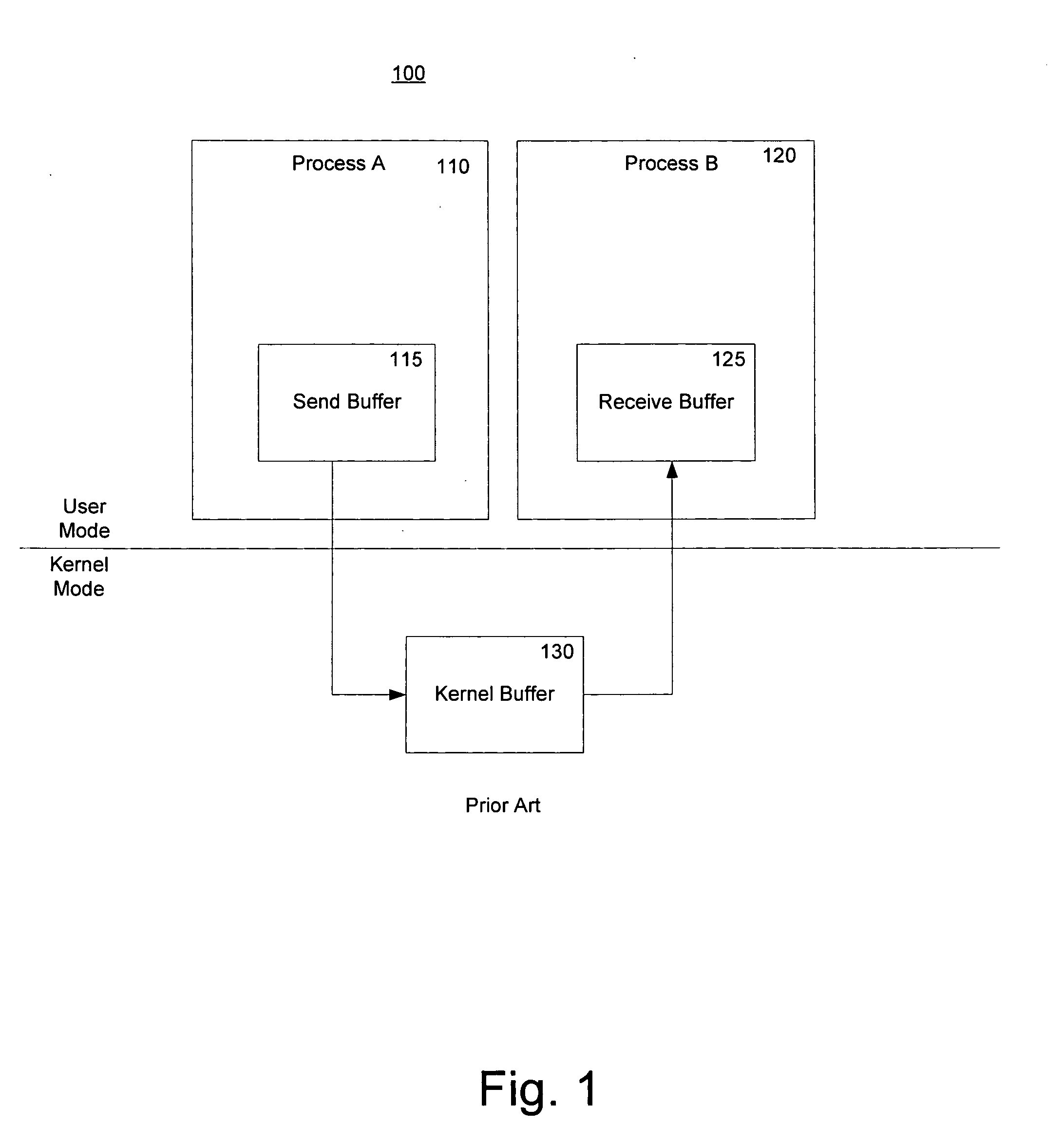

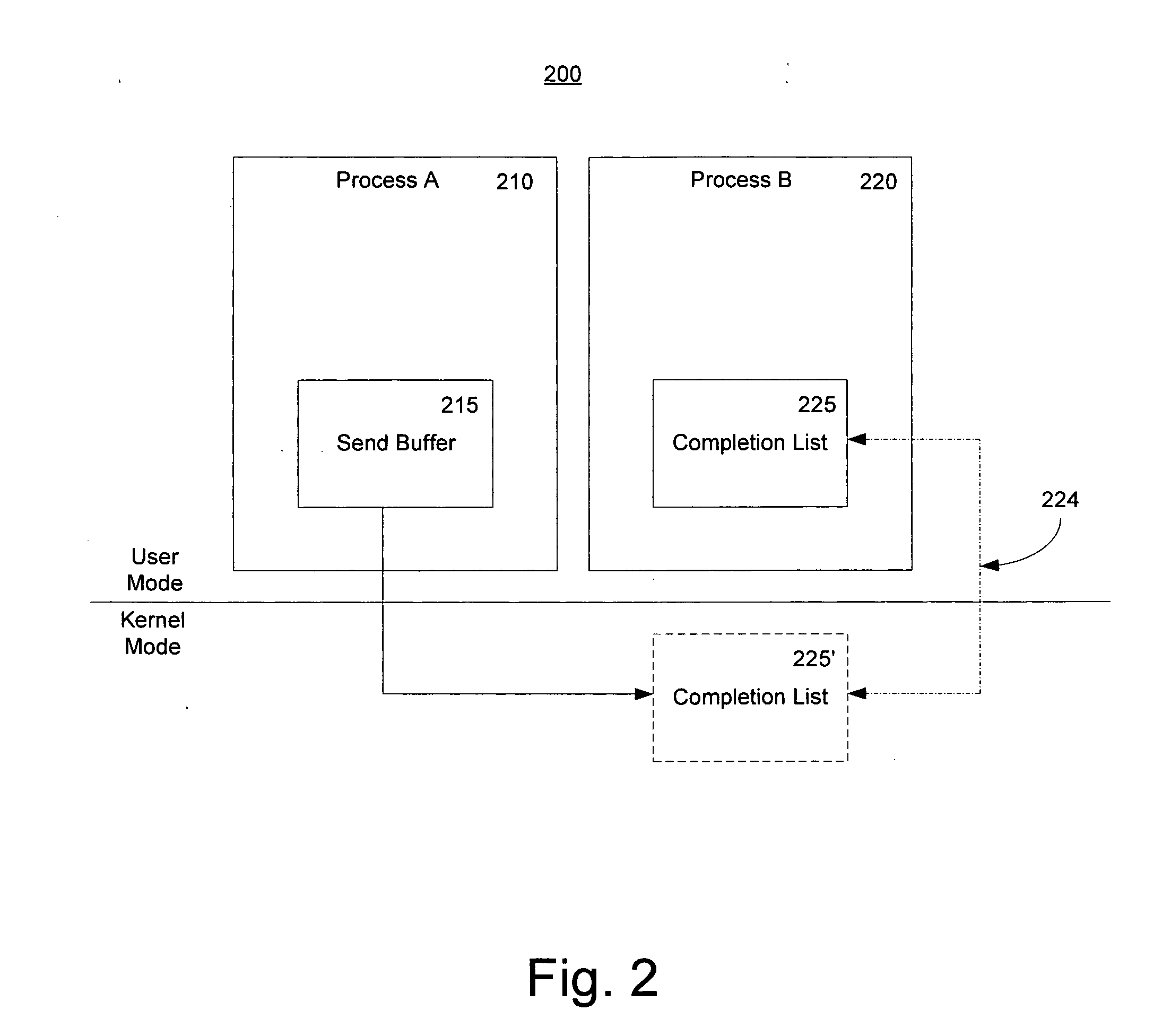

Inter-process message passing

InactiveUS20070011687A1Reduce the number of copiesMultiprogramming arrangementsProcess mechanismOperational system

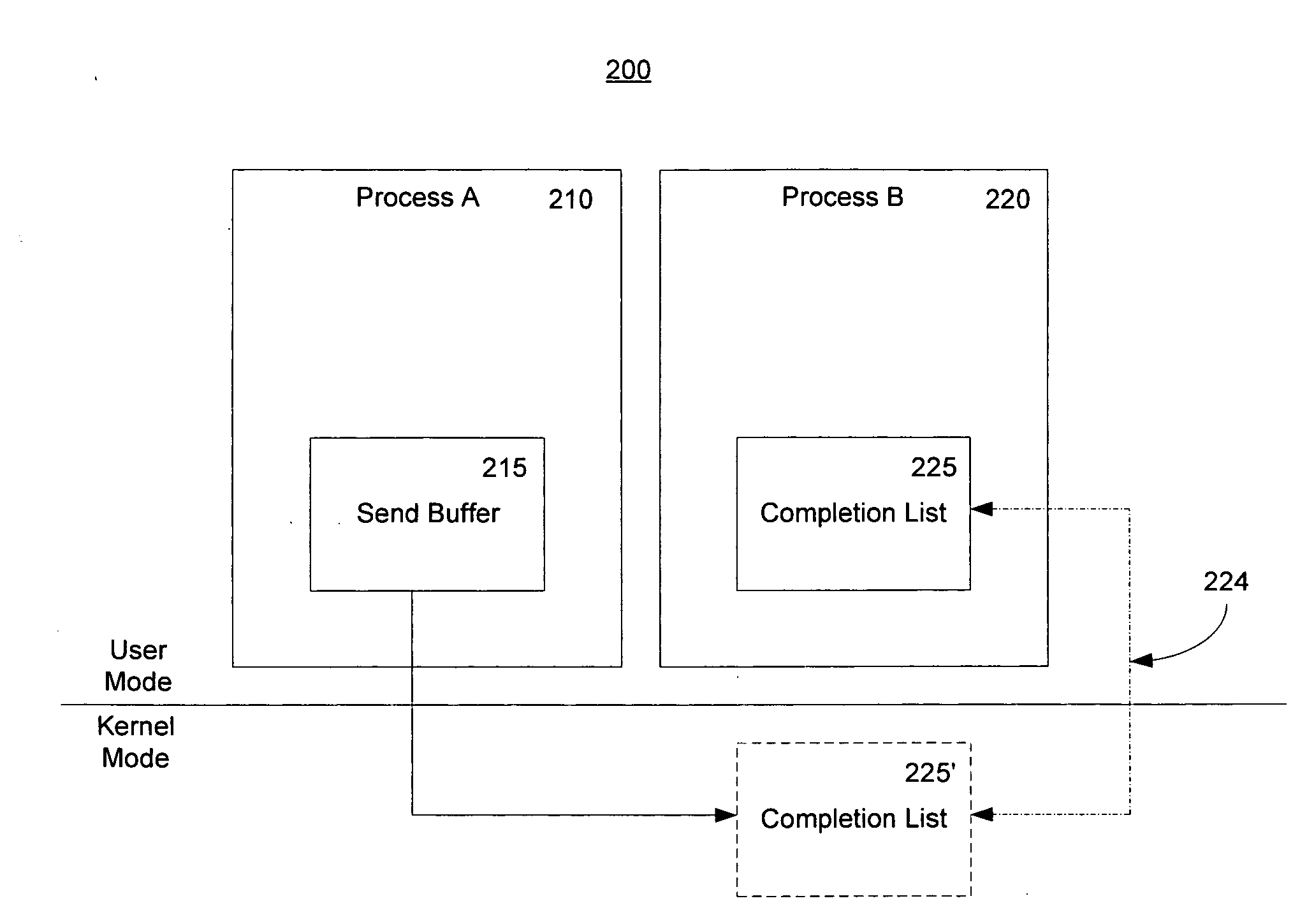

The number of copies of a message to be transferred from one process to another process in a computer where each process has a differing address space may be reduced through the use of a message-passing data structure. The sending process generates an operating system service call to copy the message to be transferred into the message-passing data structure. The receiving process need not generate a system service request to the kernel in order to retrieve the sent message and also does not require an additional copy of the transferred message to be made by the kernel, in order to read the message content. The data structure permits a mapping of the message into the address space of the receiving process as well as the address space of the kernel. The inter-process mechanism for exchanging messages provides proper flow control, synchronization, and security when two processes exchange data.

Owner:MICROSOFT TECH LICENSING LLC

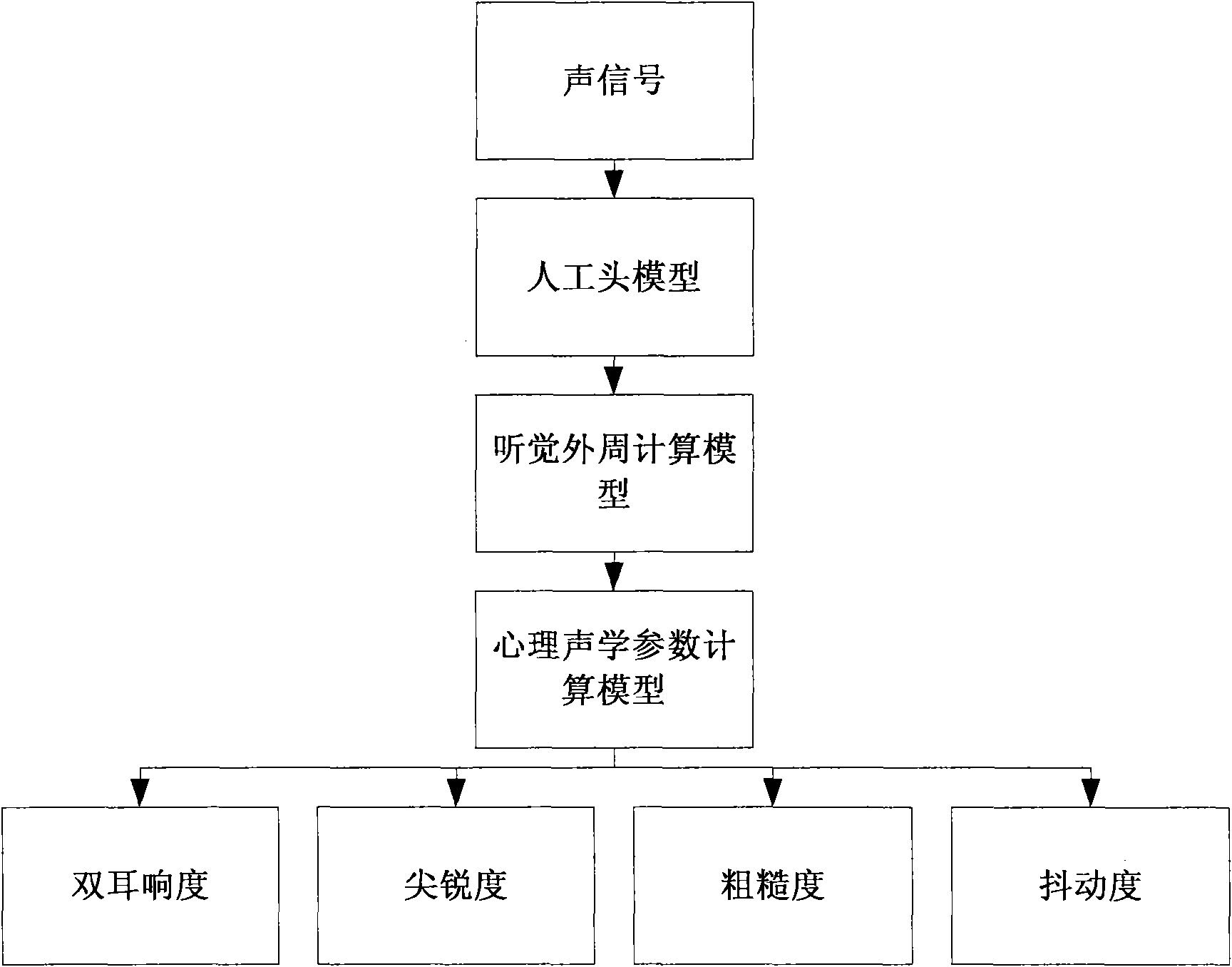

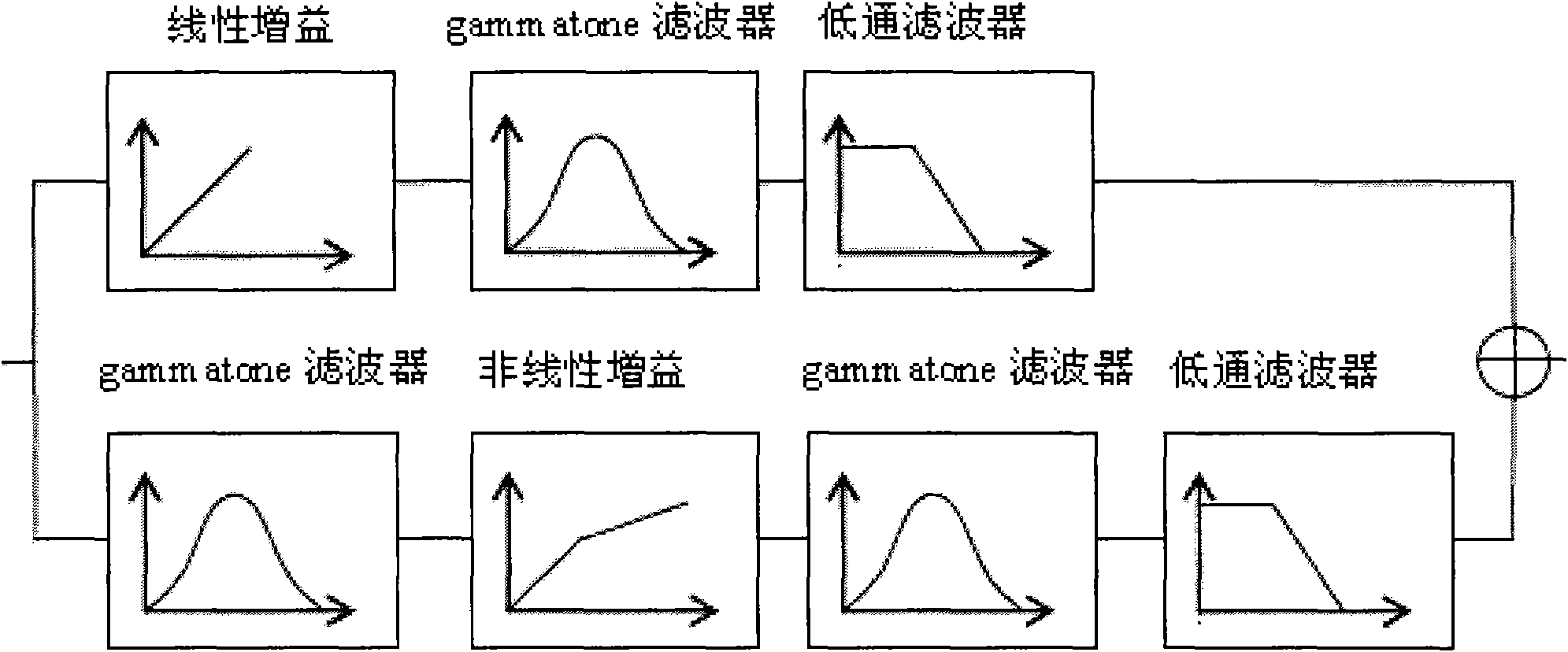

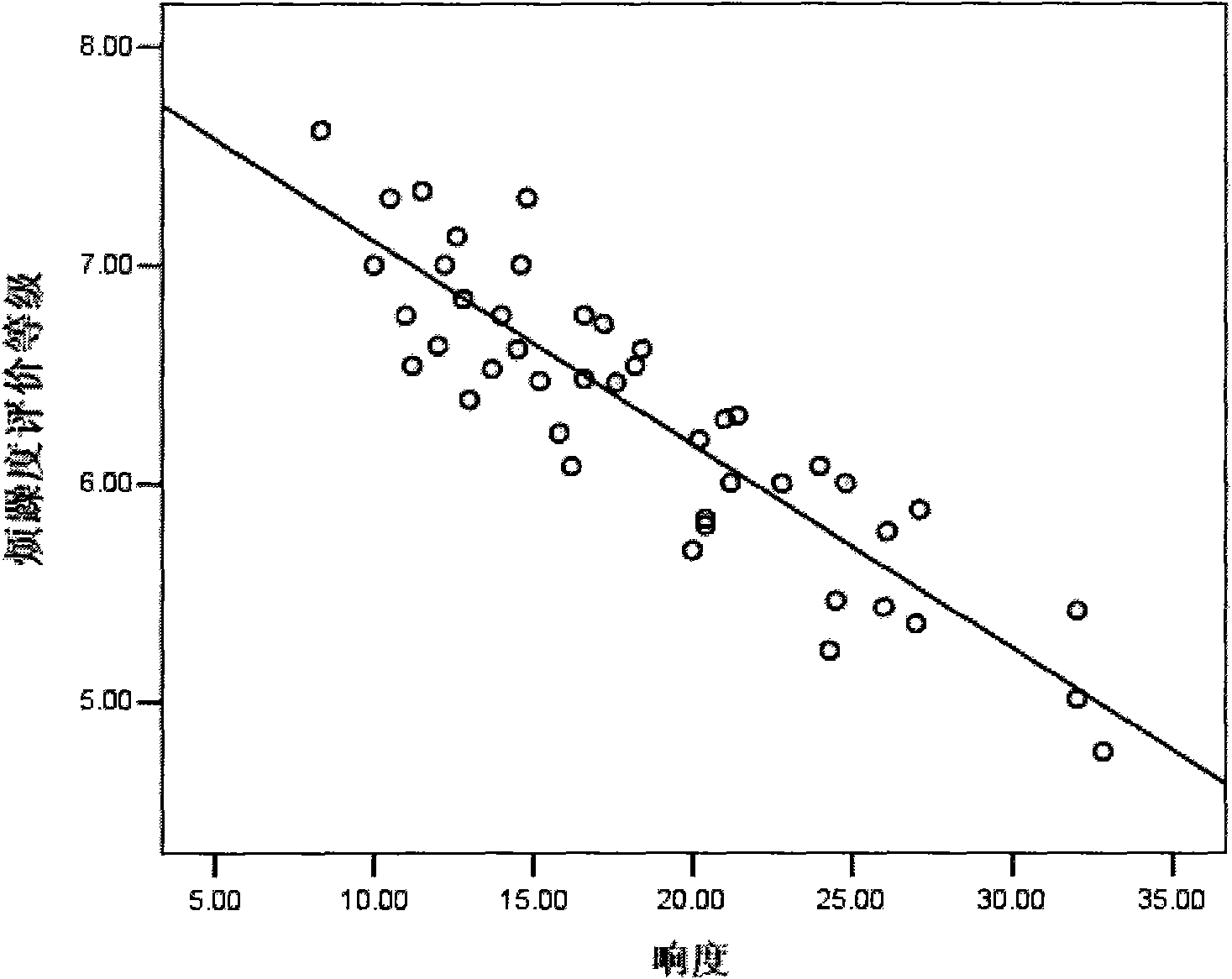

Method for objectively and quantifiably evaluating noise fret degree in vehicle based on auditory model

InactiveCN101672690AImprove performanceOvercoming complexityVibration measurement in fluidPsychotechnic devicesHuman bodyProcess mechanism

The invention relates to a method for objectively and quantifiably evaluating noise fret degree in a vehicle based on an auditory model, in particular to an evaluation method of psychoacoustics and vehicle sound quality. The method comprises the following steps: designing a dummy head model; imitating a processing mechanism of the middle ear and the inner ear of a human body to the sound by usingan auditory peripheral calculation model; collecting vehicle noise signals under the working conditions of uniform, accelerated and idle speed; pre-treating the noise sample and processing the loudness in specification; obtaining a psychoacoustics parameter by using a sound quality calculation model; obtaining subjective evaluation result test data by using a grouped and paired comparison method;calculating and painting a correlated scatter plot chart between each parameter and the ranking value of the subjective evaluation result; and analyzing and calculating to obtain the objectively quantifiable model of the subjective fret degree under each working condition. The invention can realize the psychoacoustic parameter calculation of objectively evaluating the sound quality with differentvehicle types, gears and speeds, wherein the calculated value has good pertinence and consistency with the evaluated result of the subjective evaluation method. The invention has stable evaluated result and high reliability, and can improve the sound quality and competitiveness of vehicles combined with the design of new CAE cars.

Owner:JILIN UNIV

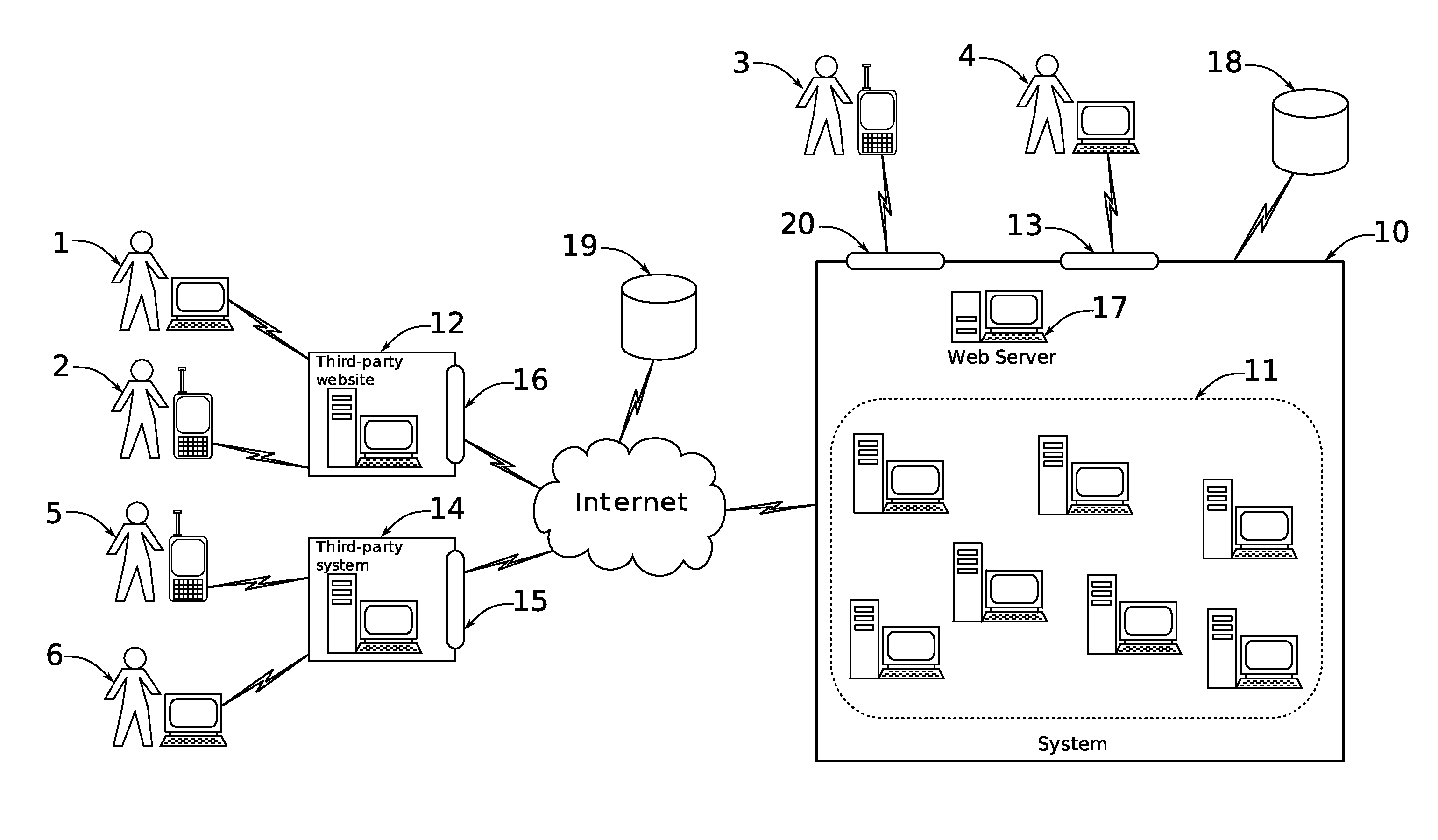

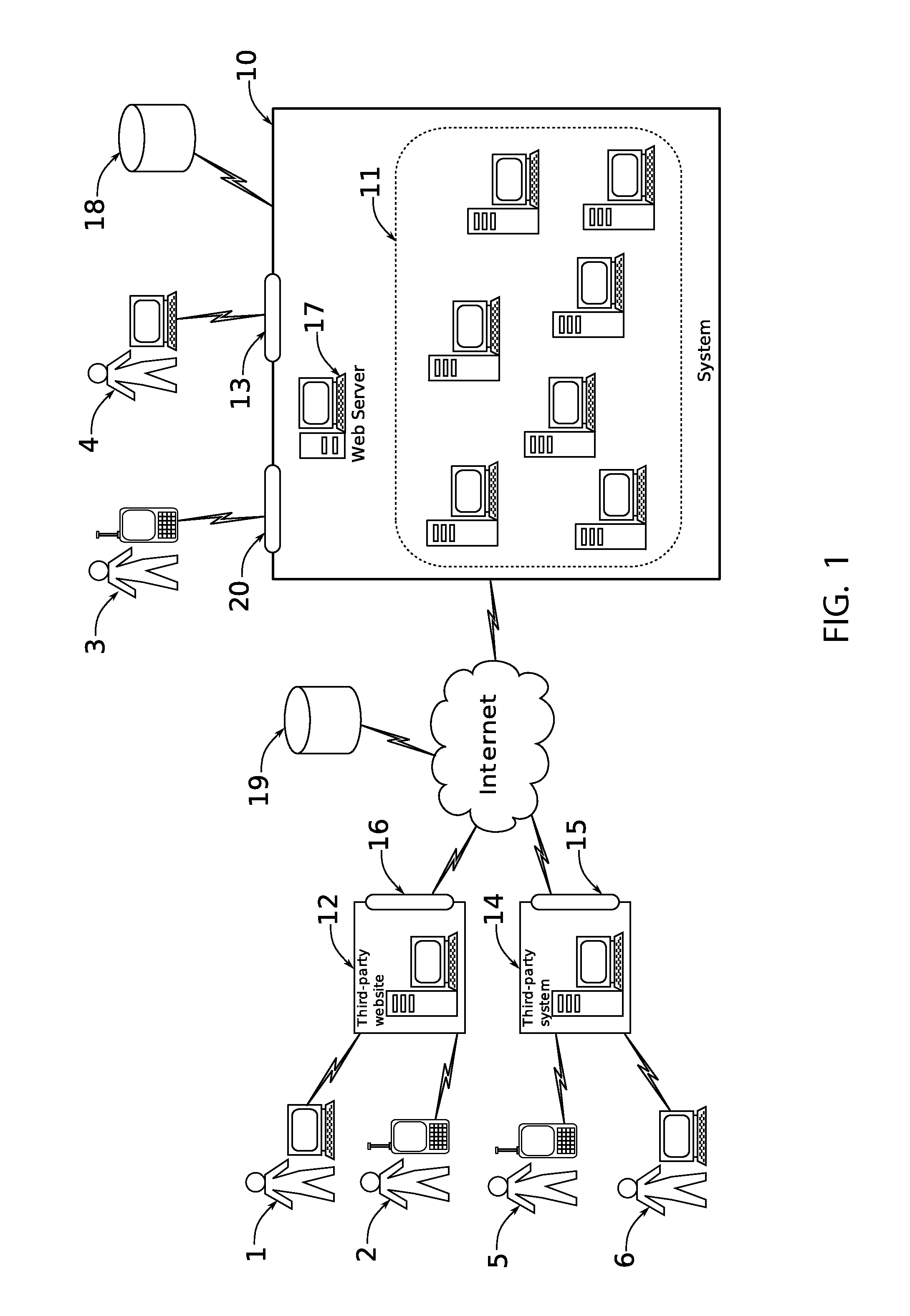

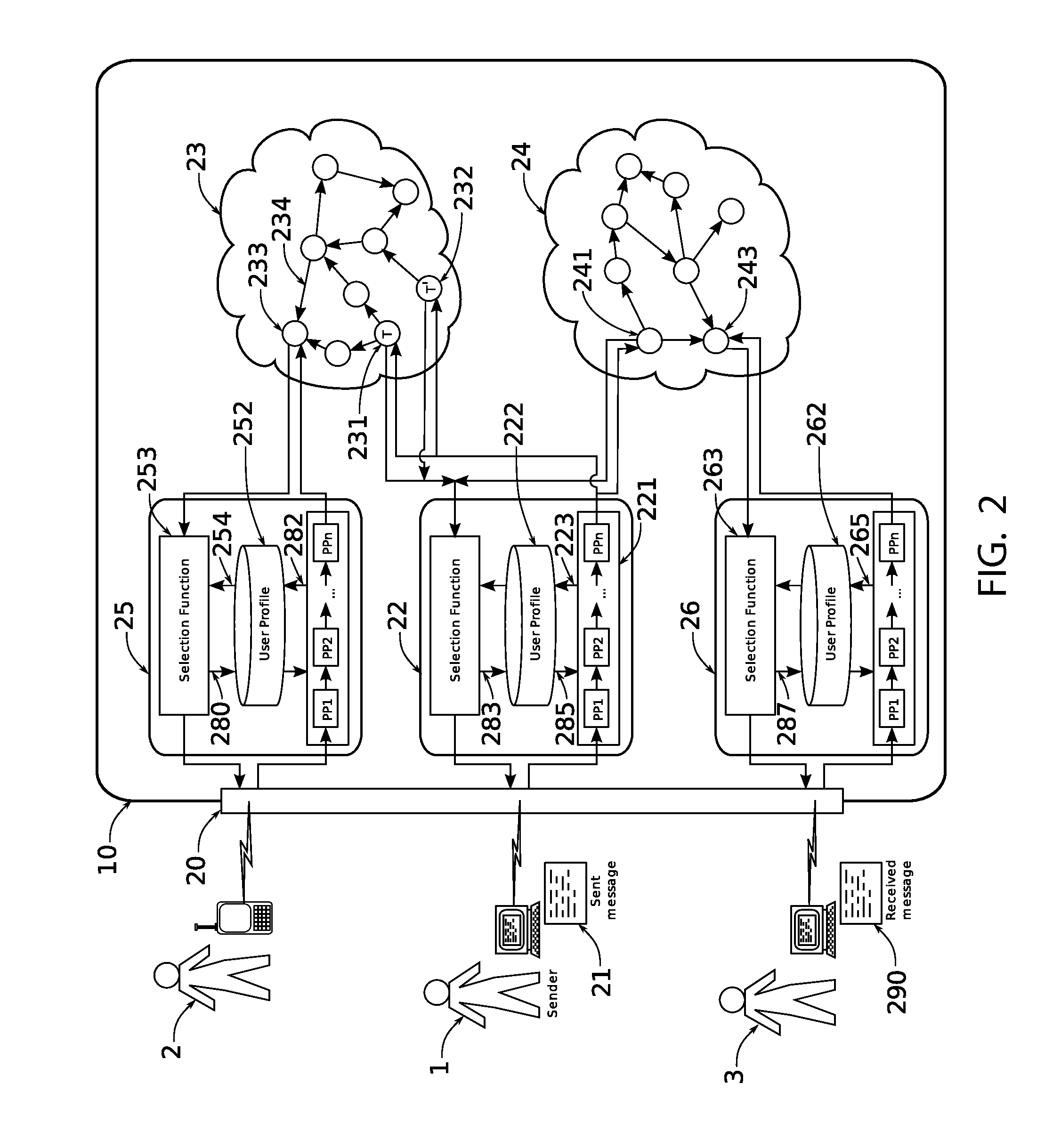

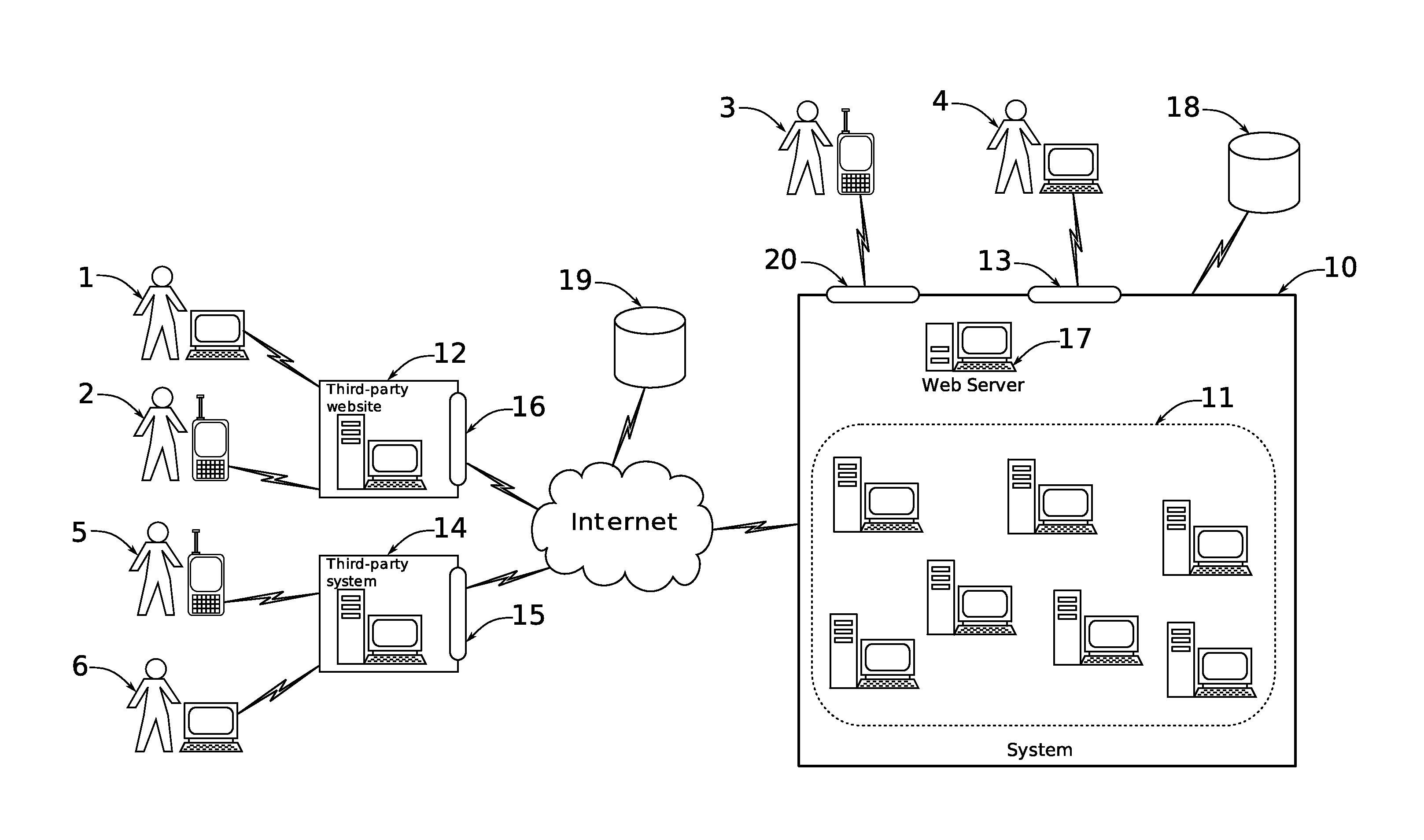

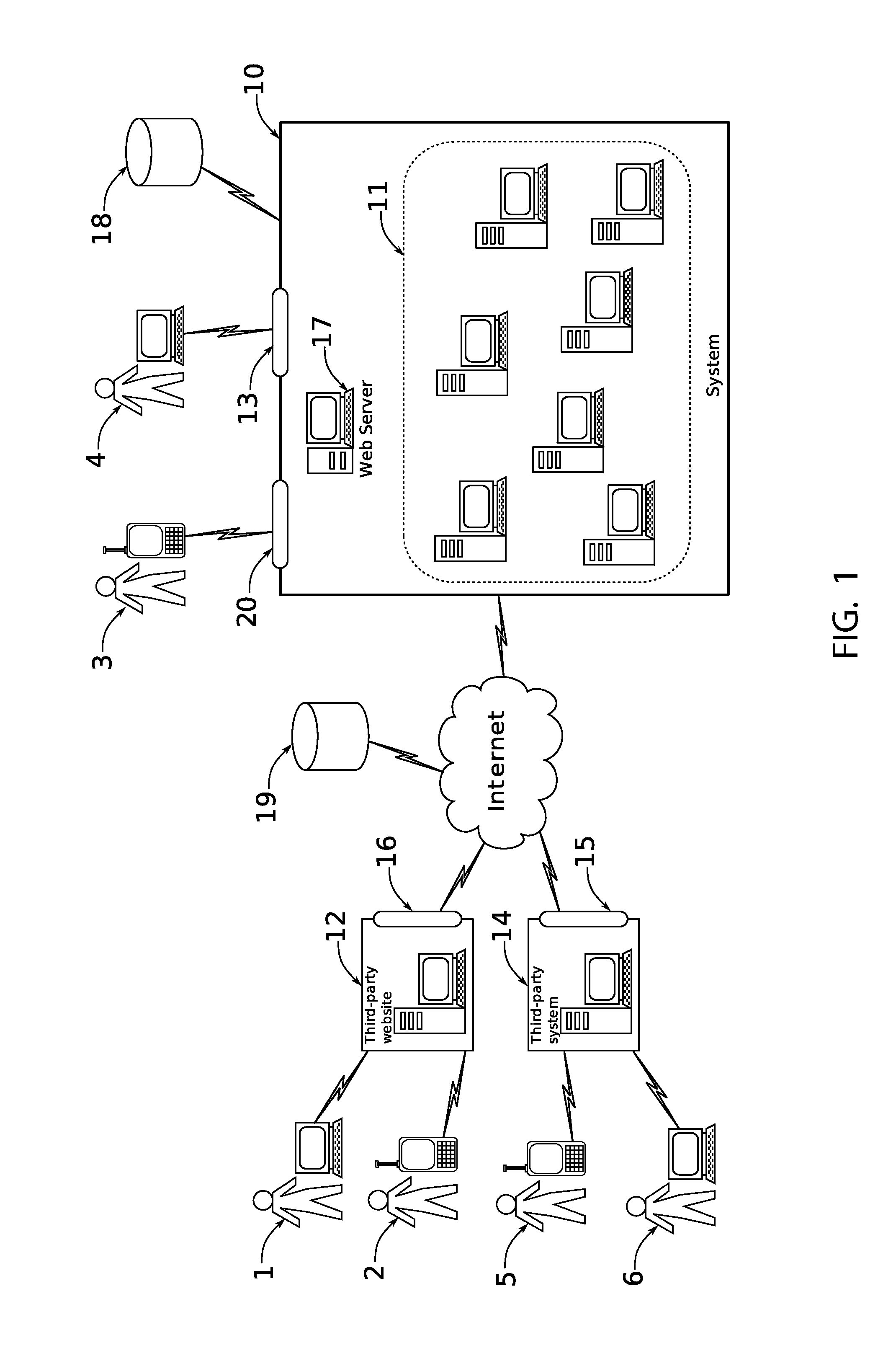

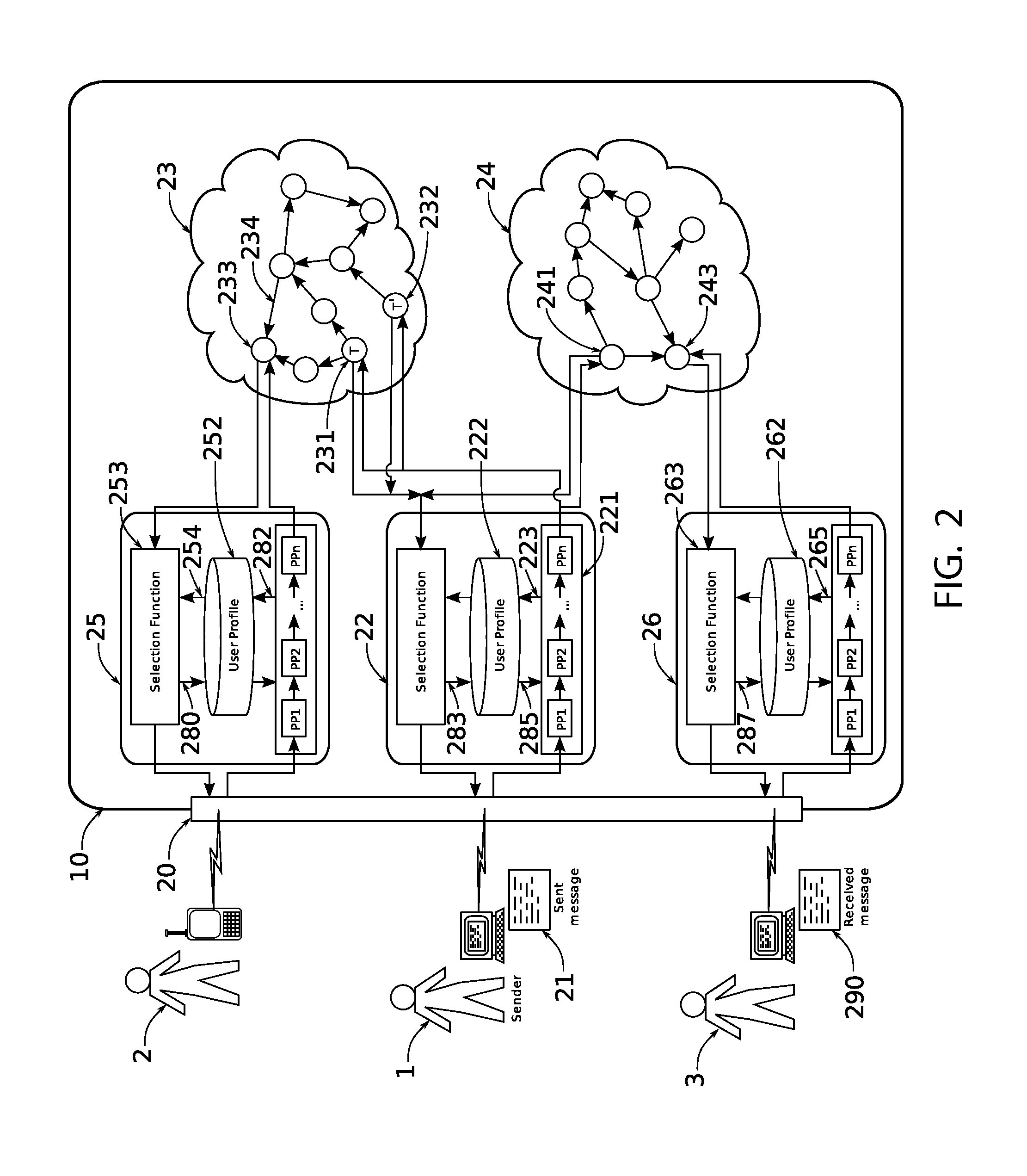

Method, system and architecture for delivering messages in a network to automatically increase a signal-to-noise ratio of user interests

InactiveUS20120102130A1Improve signal-to-noise ratioMultiple digital computer combinationsData switching networksProcess mechanismGraphics

The present invention pertains to a method for delivering messages in a social network to increase a signal-to-noise ratio for the recipients of messages, characterized in that a process mechanism comprises of a diffusion process and a selection process combined through an adaptive process, in which:the diffusion process dispatches each message through dynamic routing graphs defined between the sender user and a set of potentially interested recipient users;the selection process locally filters the messages that are transmitted from sender users and received by potentially interested recipient users, according to the result of the application of a selection function on the metadata values constituting a message profile extracted from each transmitted message and weighted feature values constituting a user profile of the recipient to establish an estimate of interest for the user regarding each message, andthe adaptive process continuously adjusts processing functions to adapt the graphs structure according to the user profiles dynamically updated by message metadata.

Owner:SEMIOCAST

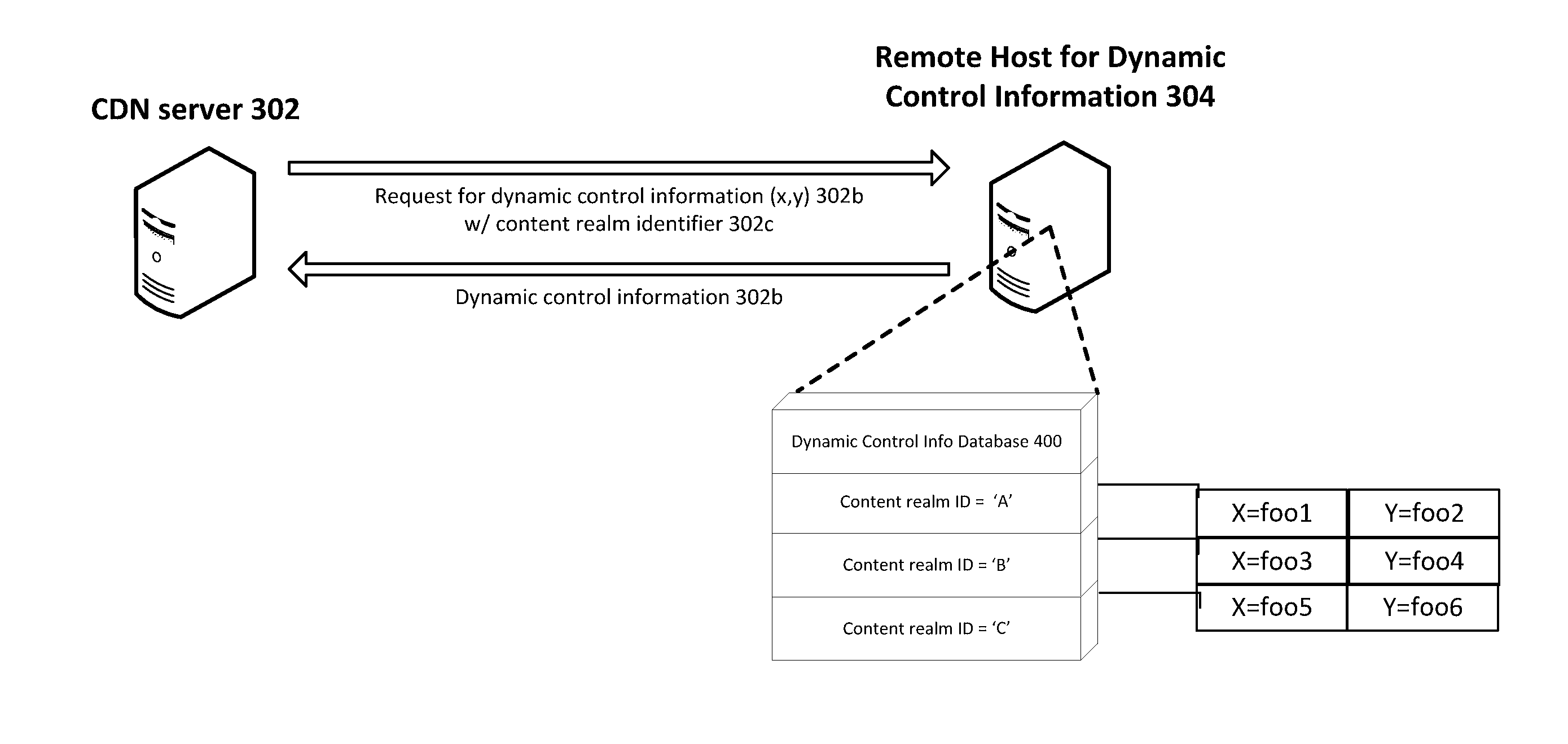

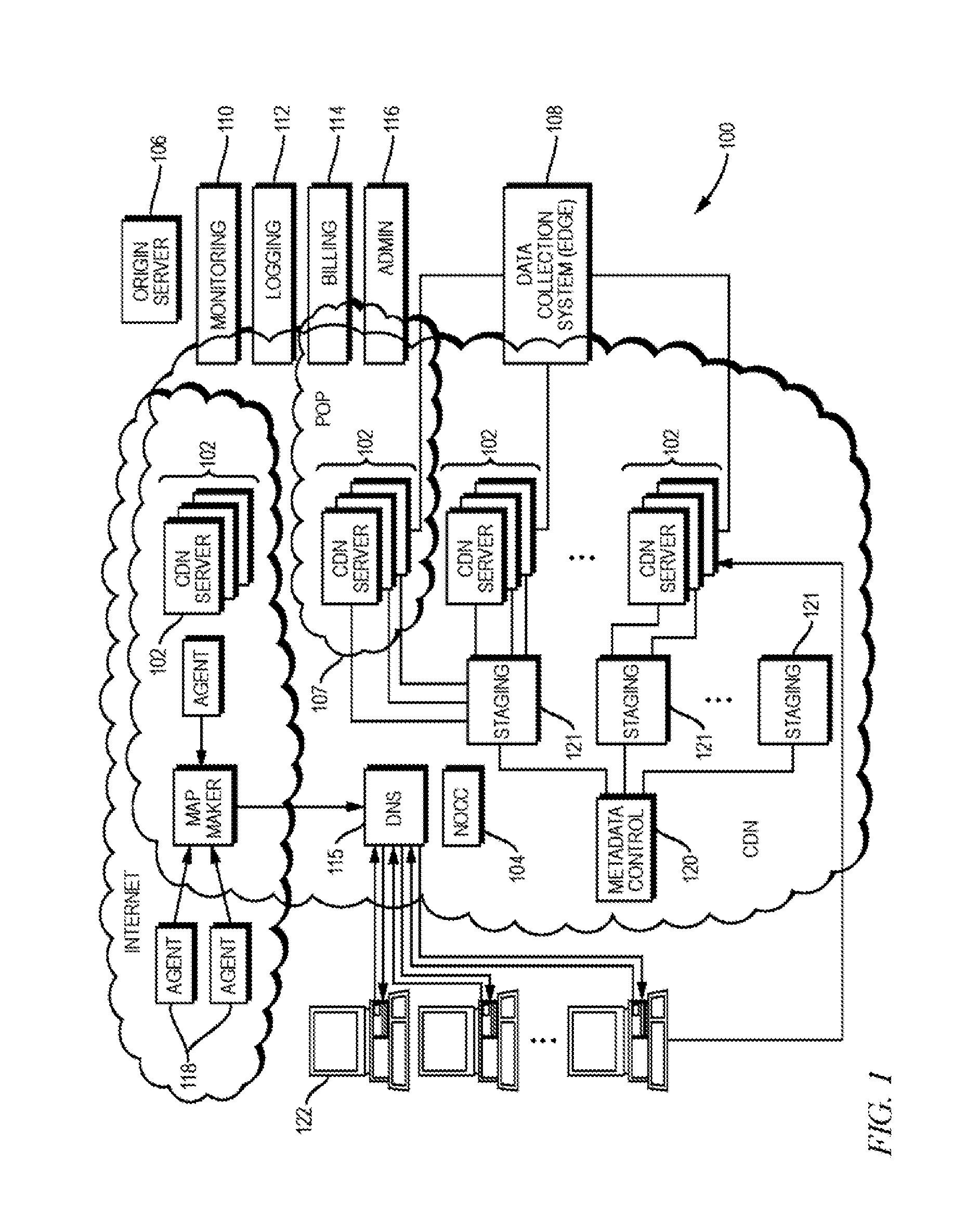

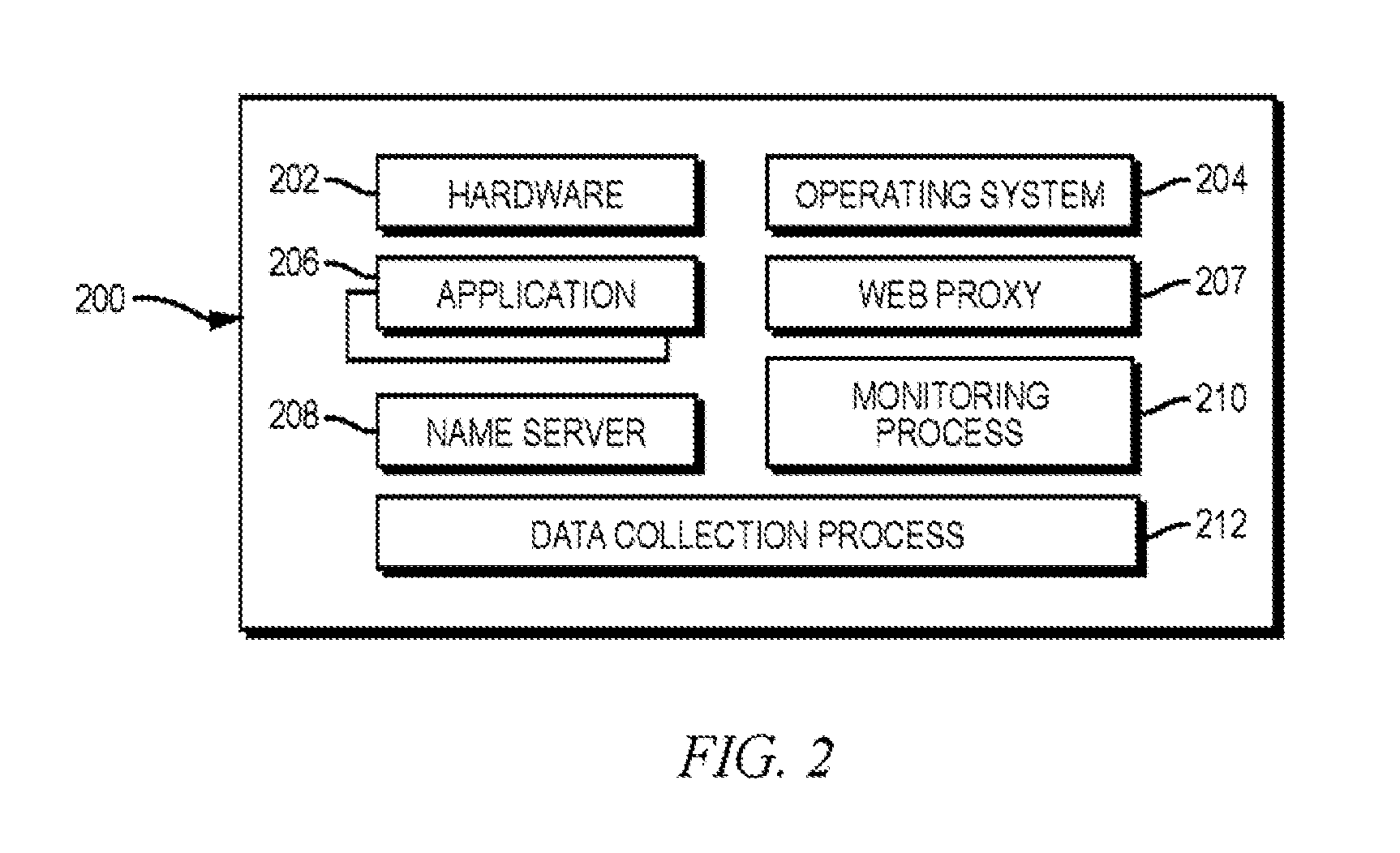

Scalable content delivery network request handling mechanism

Described herein are improved systems, methods, and devices for delivering and managing metadata in a distributed computing platform such as a content delivery network (CDN) so as to configure content servers to handle client requests. The teachings hereof provide, among other things, scalable and configurable solutions for delivering and managing metadata, preferably by leveraging dynamically obtained control information. For example, in one embodiment, a given content server may store metadata, e.g., in a configuration file, that references dynamic, late-bound control information for use in satisfying dependencies. This dynamic control information can be requested by the CDN content server, typically from a remote host, when needed to parse and execute the metadata.

Owner:AKAMAI TECH INC

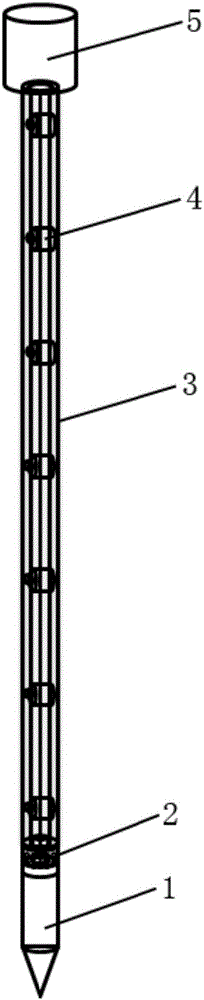

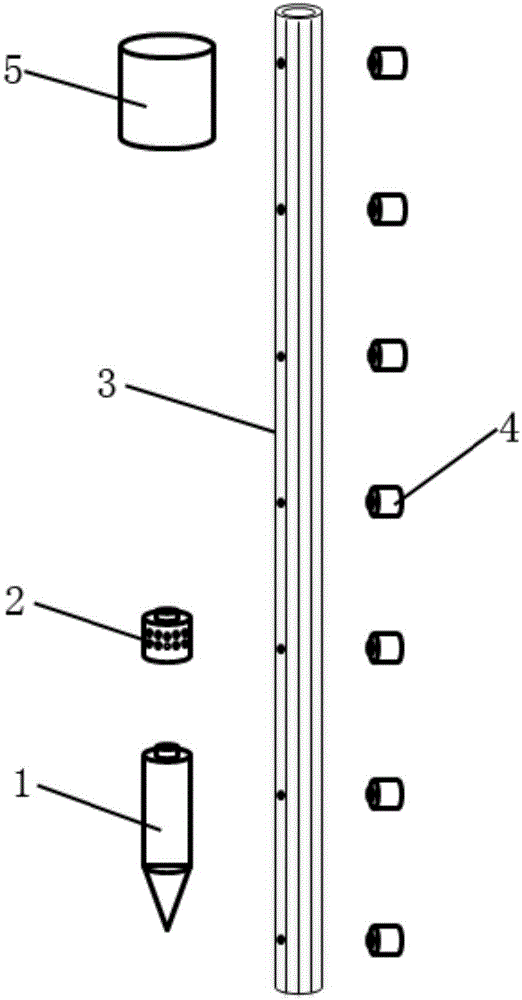

Penetration type multifunctional submarine sediment in-situ observation probe rod

ActiveCN106802132APore water pressure real-time monitoringPorosity real-time monitoringForce measurement by measuring optical property variationUsing optical meansProcess mechanismOcean bottom

The invention relates to a penetration type multifunctional submarine sediment in-situ observation probe rod, including a static sounding probe, a resistivity measuring module, a deformation measuring tube and a control cabin which are connected in sequence from bottom to top. The resistivity measuring module includes a resistivity measuring module main body, and point electrodes are distributed at equal intervals on the outer circumferential surface of the resistivity measuring module main body. The deformation measuring tube is of a tubular structure, includes a deformation rubber tube and embedded pore water pressure sensors inside the deformation rubber tube, eight stress and strain measuring optical fibers are distributed at equal intervals along an axial direction on the outer wall of the deformation rubber tube, a row of water drainage holes are distributed along the axial direction, and each water drainage hole is connected with an embedded pore water pressure sensor. The penetration type multifunctional submarine sediment in-situ observation probe rod provided by the invention can realize CPTU detection and can also perform long-term in-situ observation, and add dynamic change process observation of pore water pressure and sediment deformation of different depths; and deformation observation and pore pressure observation are effectively combined, and taking static sounding data for reference, and a dynamic change process mechanism of seabed sediments are interpreted from different angles.

Owner:QINGDAO INST OF MARINE GEOLOGY

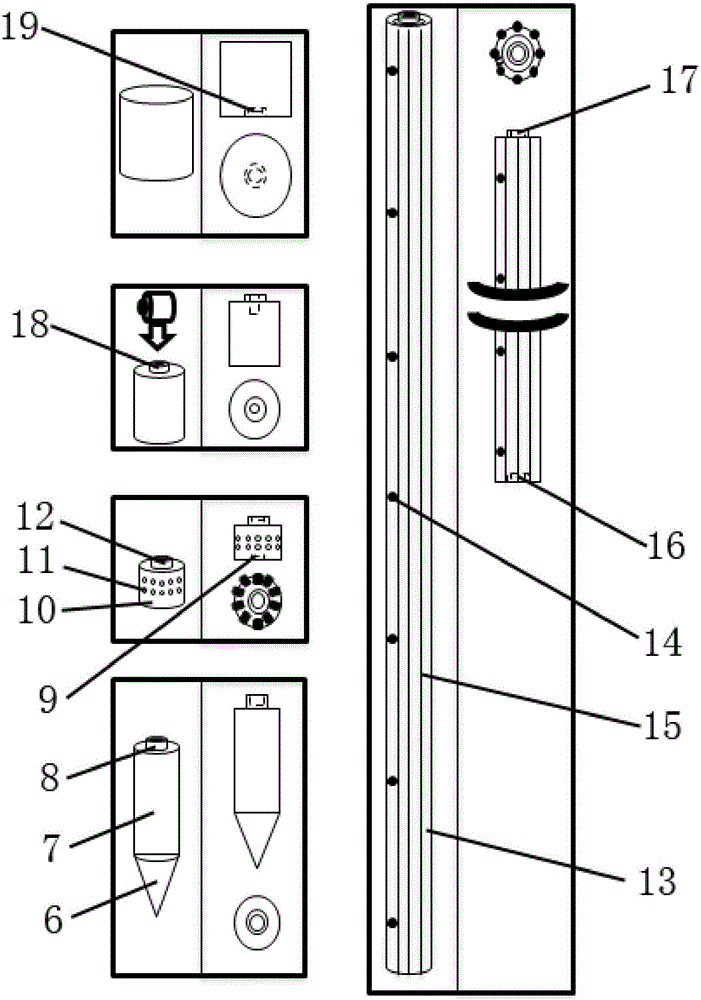

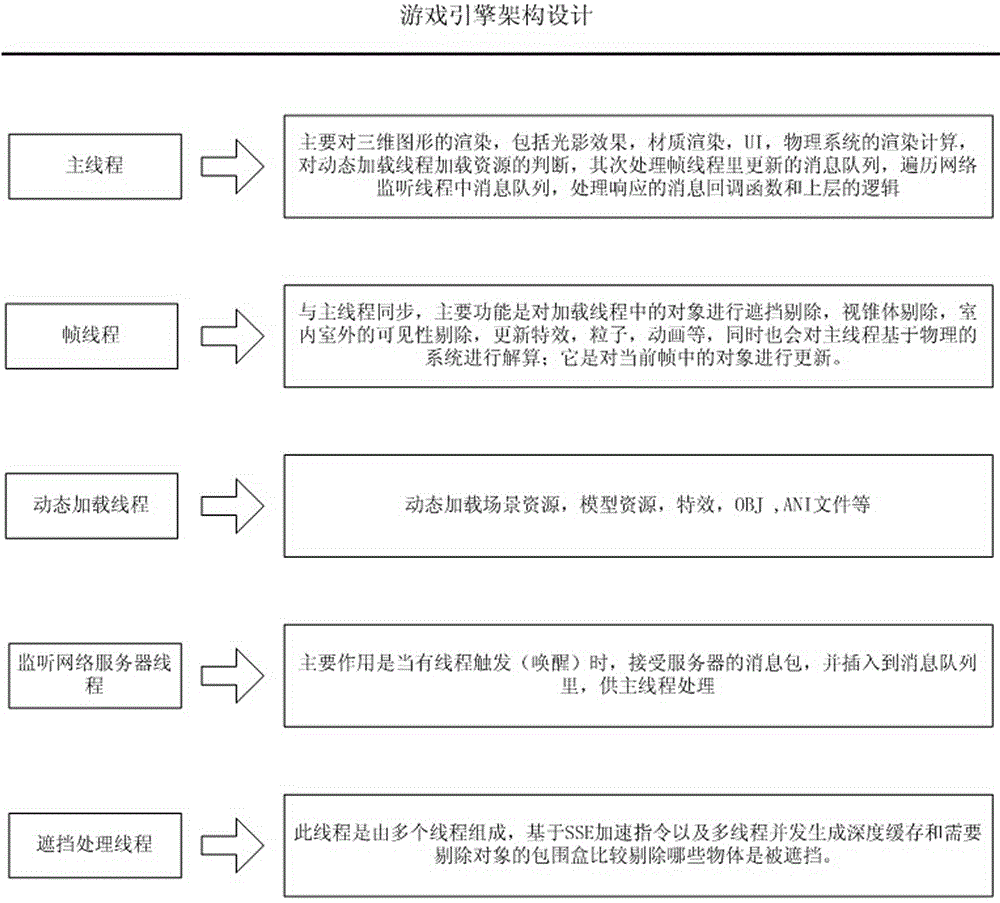

Multithread parallelization based 3D (three dimensional) engine system

ActiveCN104102488ALow costReduce maintenance difficultySpecific program execution arrangements3D-image renderingMessage queueVisibility

The invention discloses a multithread parallelization based 3D (three dimensional) engine system. The multithread parallelization based 3D engine system mainly comprises a main thread, a frame updating thread, a dynamic loading thread and a monitoring network server thread, wherein the main thread is set based on a lockless multithread concurrent processing mechanism and is mainly used for rendering a visibility object list detected by a frame thread in the last frame; the frame updating thread is synchronous with the main thread and mainly used for updating the object in the current frame; the dynamic loading thread is mainly used for dynamically loading scene resources, model resources, special effects, OBJ files and ANI files; the monitoring network server thread is mainly used for receiving message packets transmitted from the server and inserting the packets into a message queue for processing of the main thread. The multithread parallelization based 3D engine system overcomes defects of high cost and maintenance difficulty and poor flexibility and the like in the prior art and has the advantages of low cost and maintenance difficulty and high flexibility.

Owner:WUXI FANTIAN INFORMATION TECH

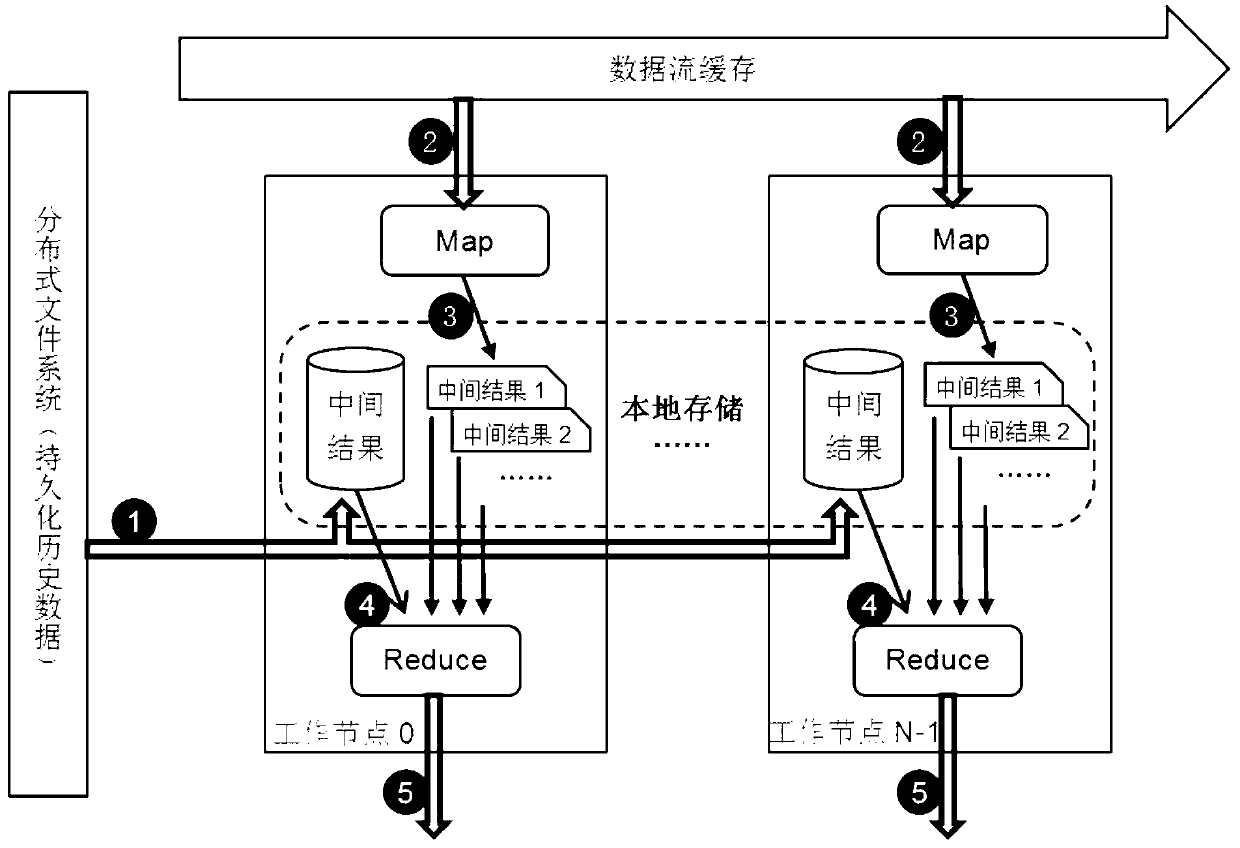

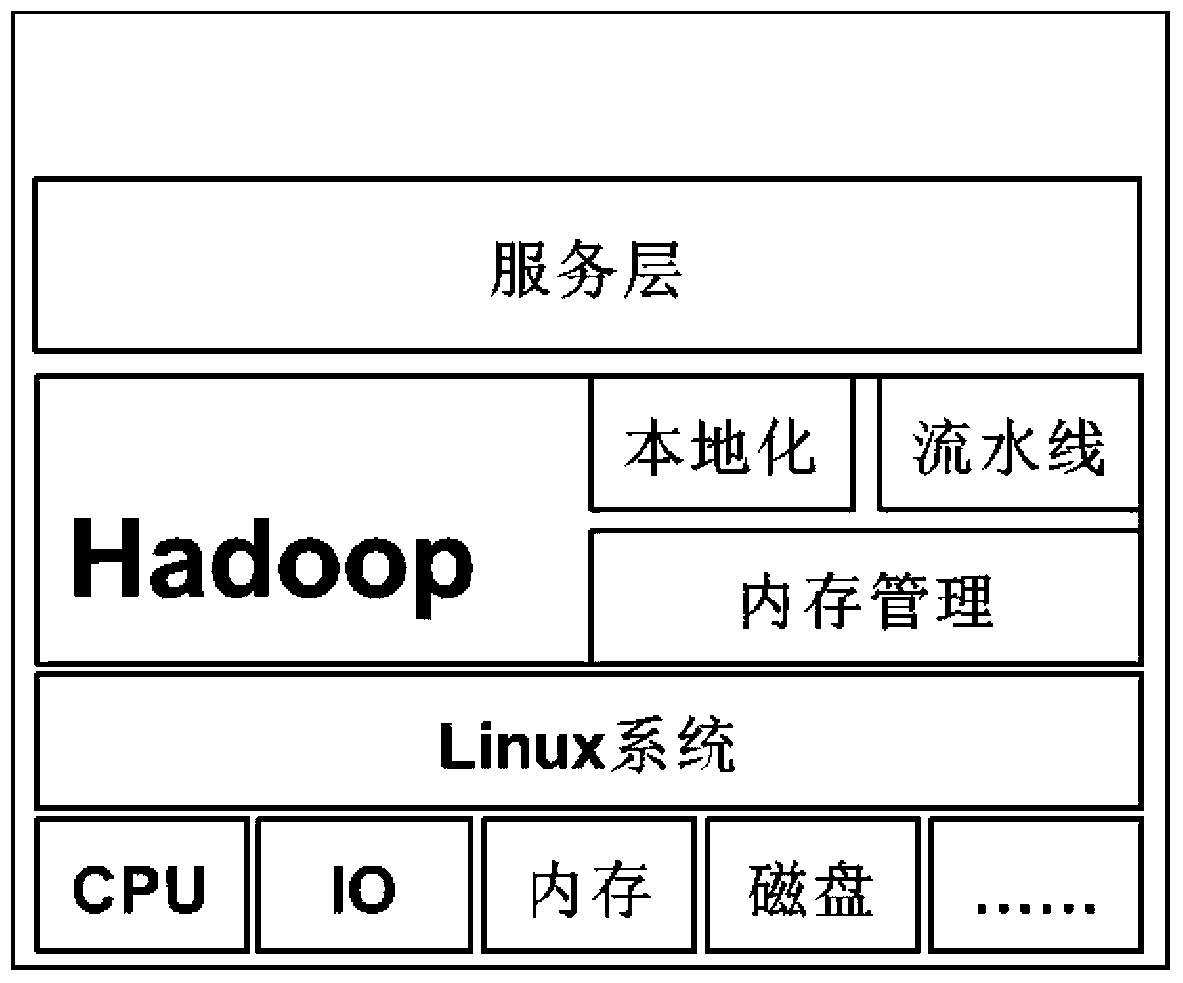

Streamed data processing method in big data environment

InactiveCN103345514AEasy to handleUniform loadSpecial data processing applicationsSpecific program execution arrangementsProcess mechanismStream data

Owner:FOCUS TECH +1

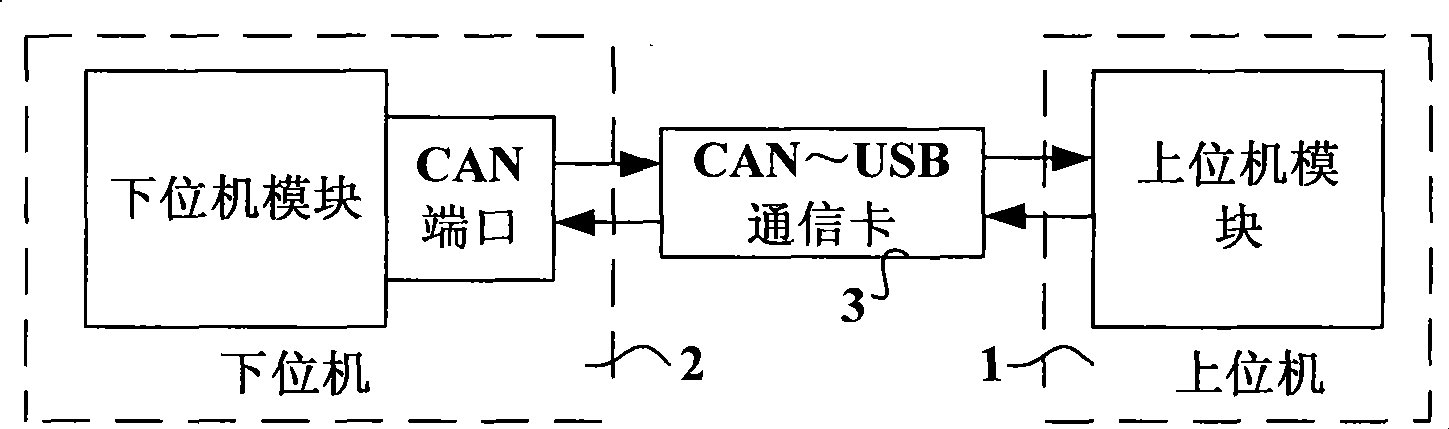

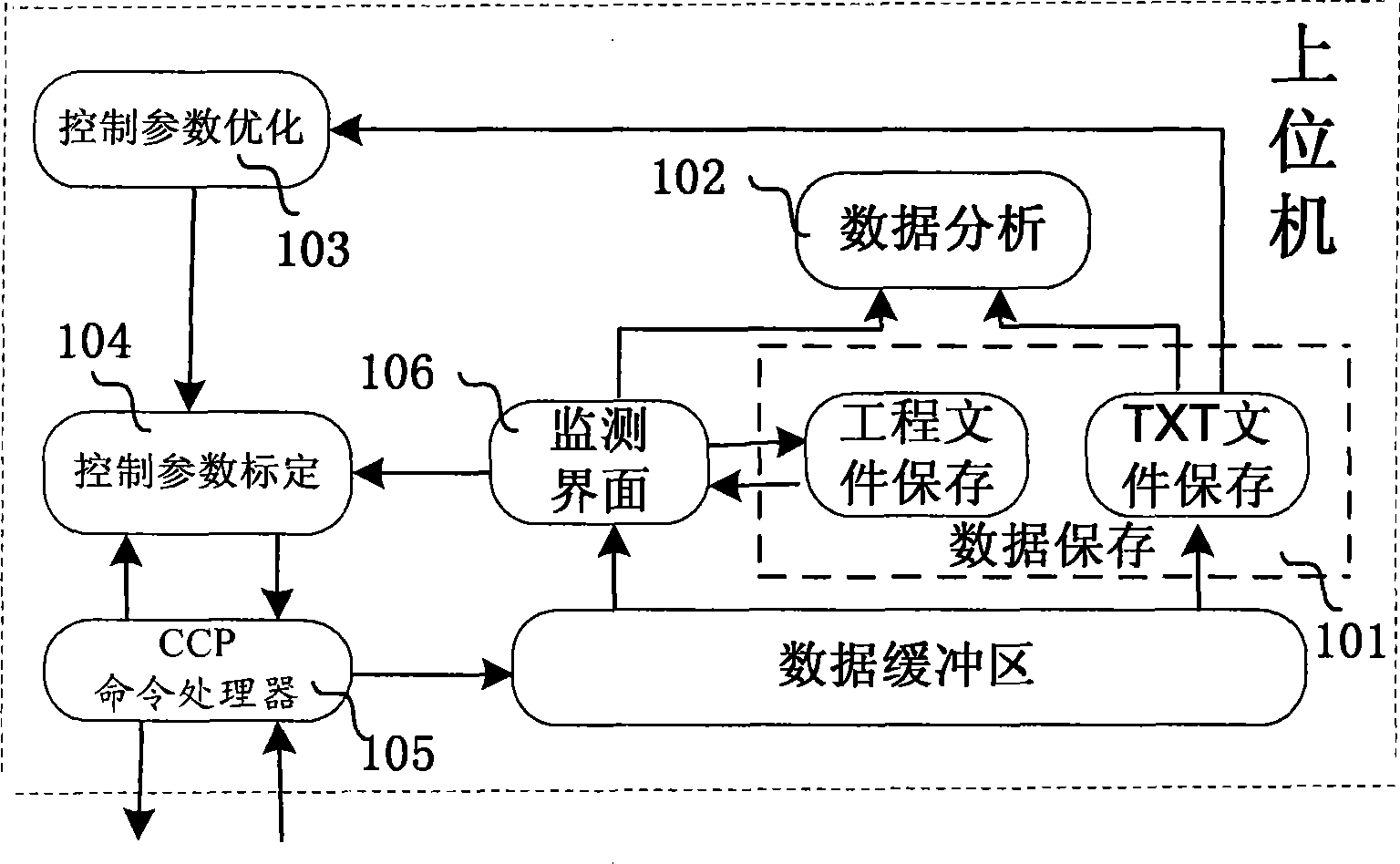

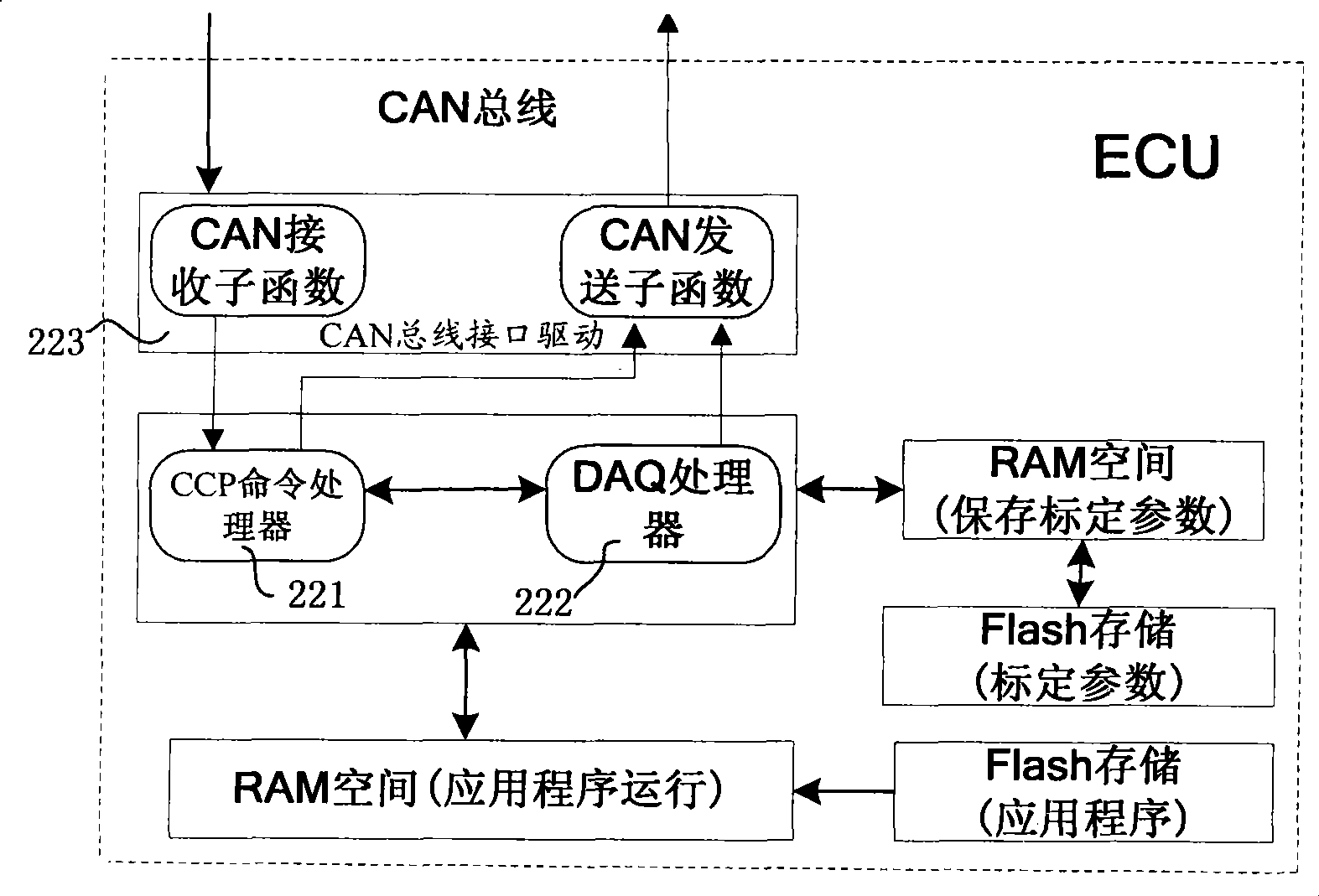

Automobile ABS ECU on-line calibration system and method based on CCP protocol

The invention provides an online calibration system for an automobile ABS ECU based on a CCP protocol. The system comprises an upper computer and a lower computer which are interconnected with each other. The upper computer comprises a data storage module, a data analysis module, a control parameter optimization module, a control parameter calibration module and an upper computer command processor CCP; the lower computer is the automobile ABS ECU and comprises an algorithm module and a data communication module. The invention also provides an online calibration method for the automobile ABS ECU based on the CCP protocol. In the method, the CCP protocol is introduced into design of the calibration system of the automobile ABS ECU, which realizes online optimization and modification of control parameters of an ABS; and the control parameters are monitored in a real-time manner by a real-time message processing mechanism of the CCP protocol, which overcomes the problems of hard parameter modification, long development period and poor operability in the existing development methods.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

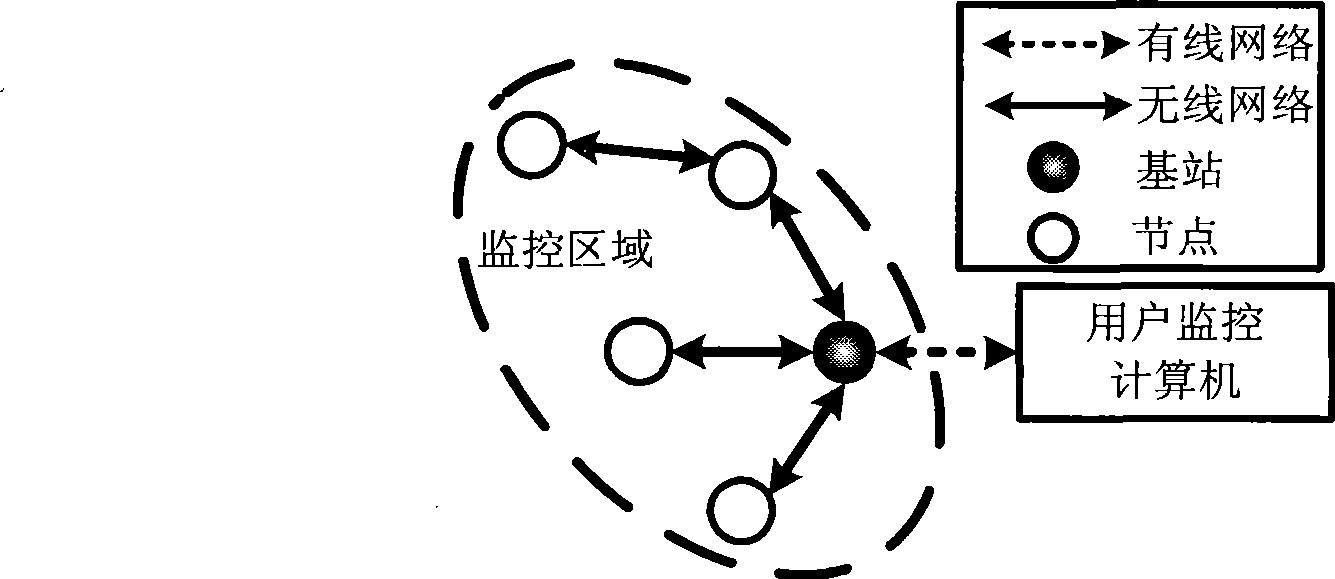

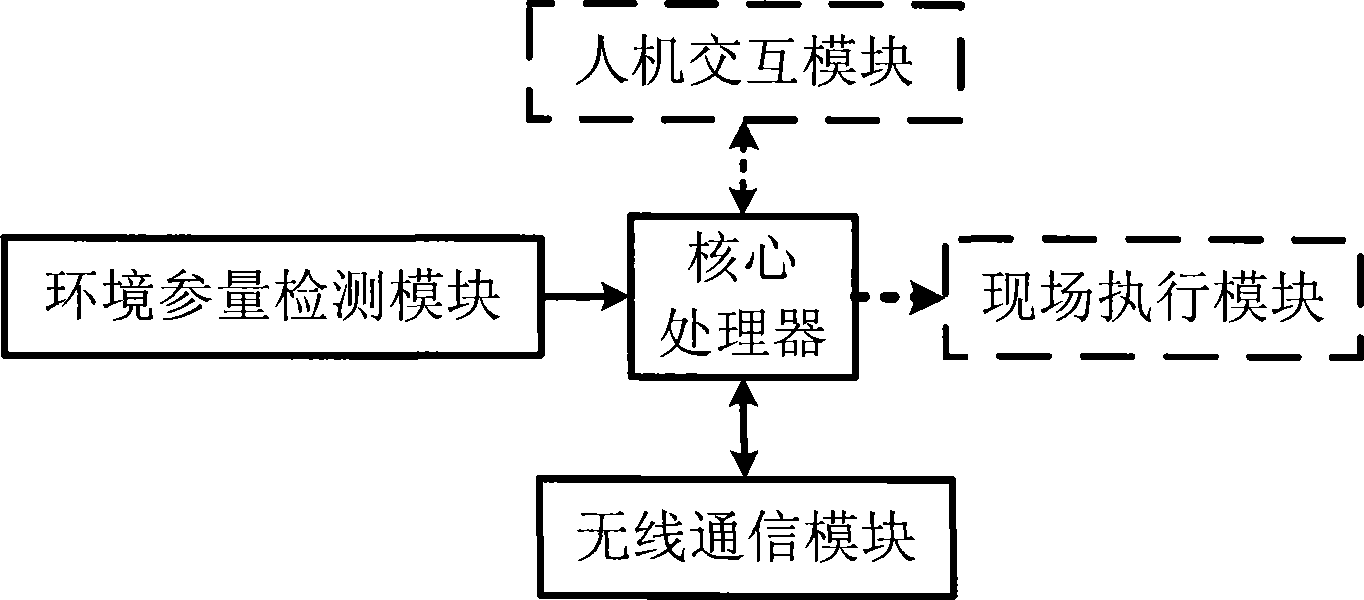

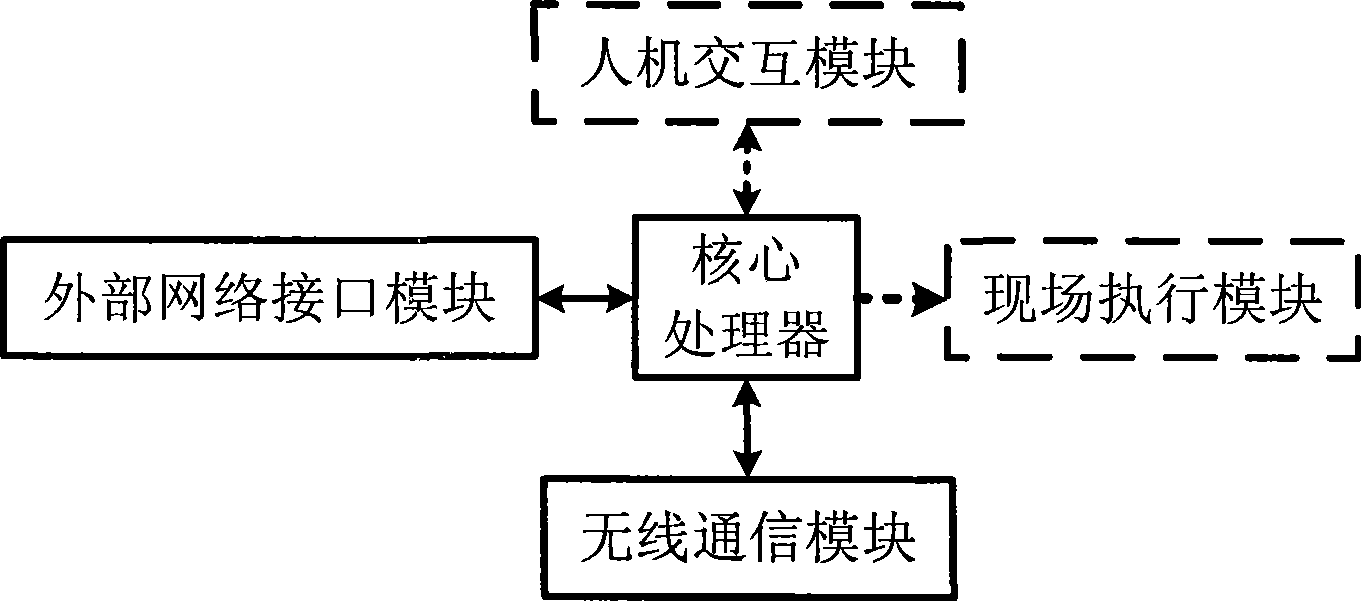

Intelligent environment monitoring system and method based on sensor networks

InactiveCN101448275AImprove stabilityIncrease flexibilityNetwork topologiesIntelligent environmentProcess mechanism

The invention discloses an intelligent environment monitoring system and a method based on sensor networks. The system comprises nodes, a base station and a monitoring computer, wherein the nodes form wireless connections with the nodes and the base station, the base station is connected with the monitoring computer by a bus line, the monitoring nodes are communicated with the central node, and the nodes are communicated with each other as well to realize the routing algorithm of the wireless sensor network. Meanwhile, the monitoring nodes can start an intelligent self-process mechanism under the condition of failure communication to minimize the disaster damage of abnormal situation. Compared with the traditional monitoring systems, the system has better flexibility and stability by the verification of experiment. The invention is applied to places requiring real-time monitoring to environmental parameters and corresponding alarm places such as warehouses, machinery rooms, parking lots, laboratories, banks, and the like, and can also be used for intelligent home, monitoring infants and patients, preventing fire for forests, and the like.

Owner:ZHEJIANG UNIV

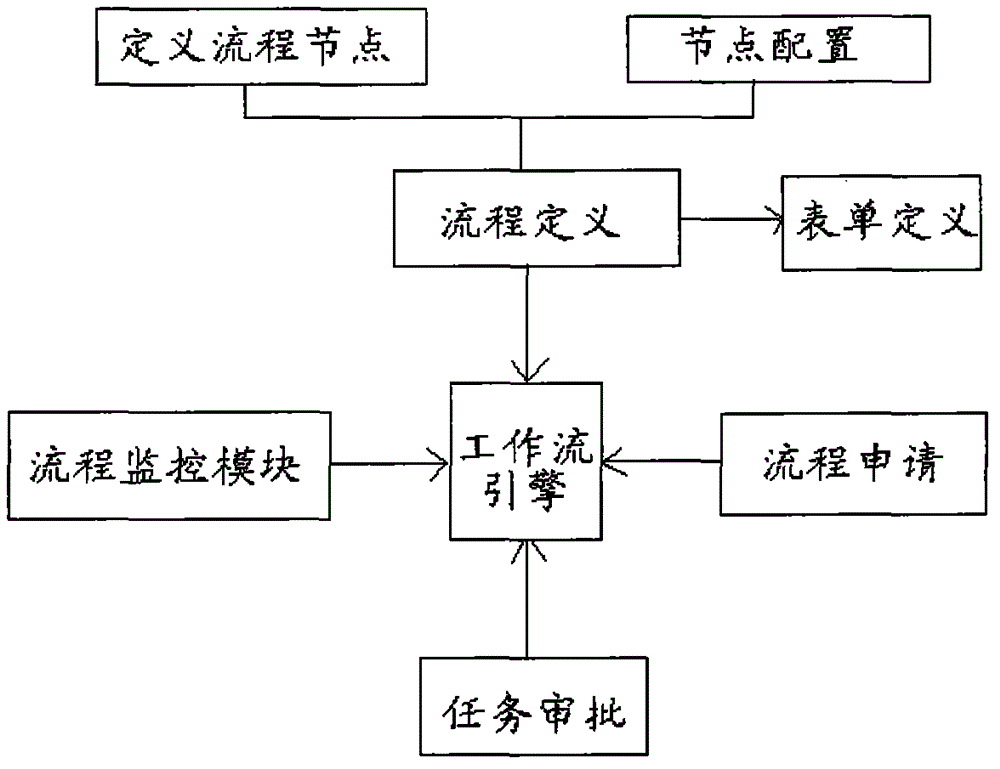

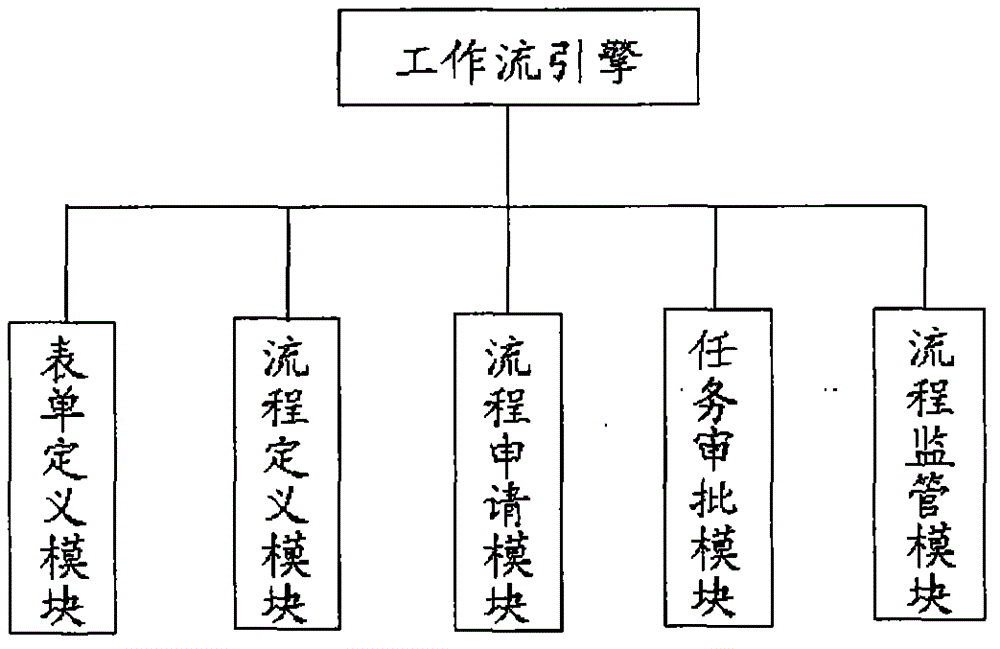

Process customization processing method and workflow engine thereof

InactiveCN105989440AImprove experienceSolve the problem of low scalabilityResourcesProcess mechanismCoupling

The invention discloses a process customization processing method. The method comprises the following steps of (1) form definition; (2) process definition; (3) process application; (4) task approval; and (5) process monitoring. And the invention also provides a workflow engine. The workflow engine comprises a form definition module, a process definition module, a process application module, a task approval module and a process monitoring module. In the invention, through using a workflow node to carry out process customization, a problem that system expansibility is low because a coupling degree of the workflow engine and a process definition link is large is solved so that exploitation personnel can determine a process mechanism of the workflow engine through customization and define a process according to an actual need; an application field of the workflow engine is expanded; a system exploitation period and maintenance cost are reduced; competitiveness of the workflow engine in a market is guaranteed; a user experience is increased and a market application scope is enlarged.

Owner:杨波

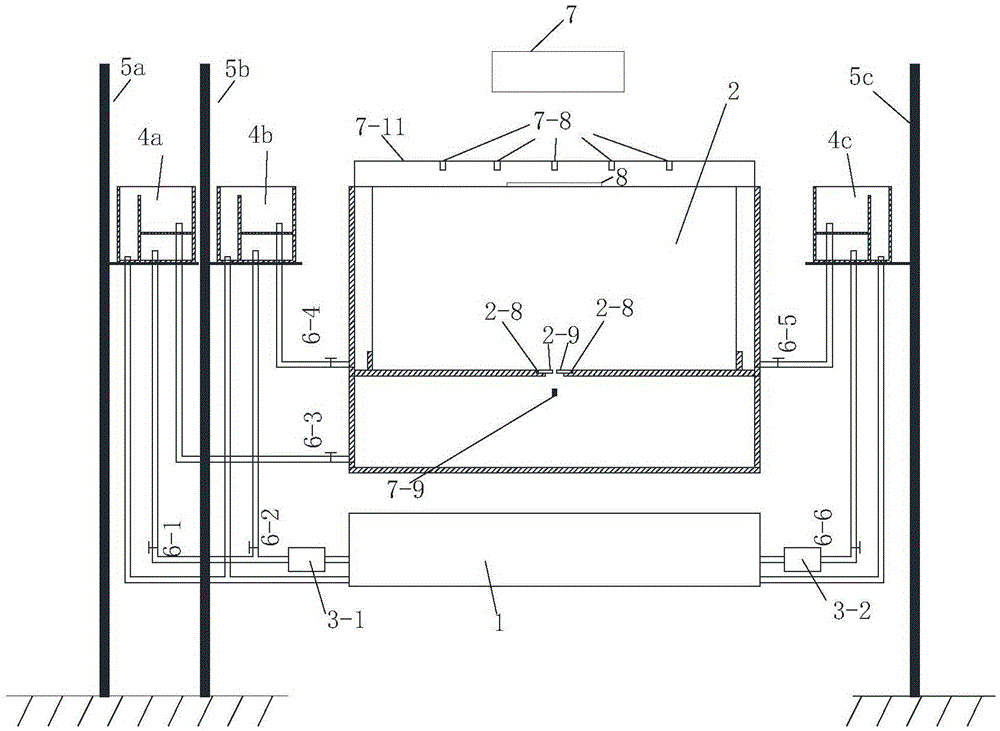

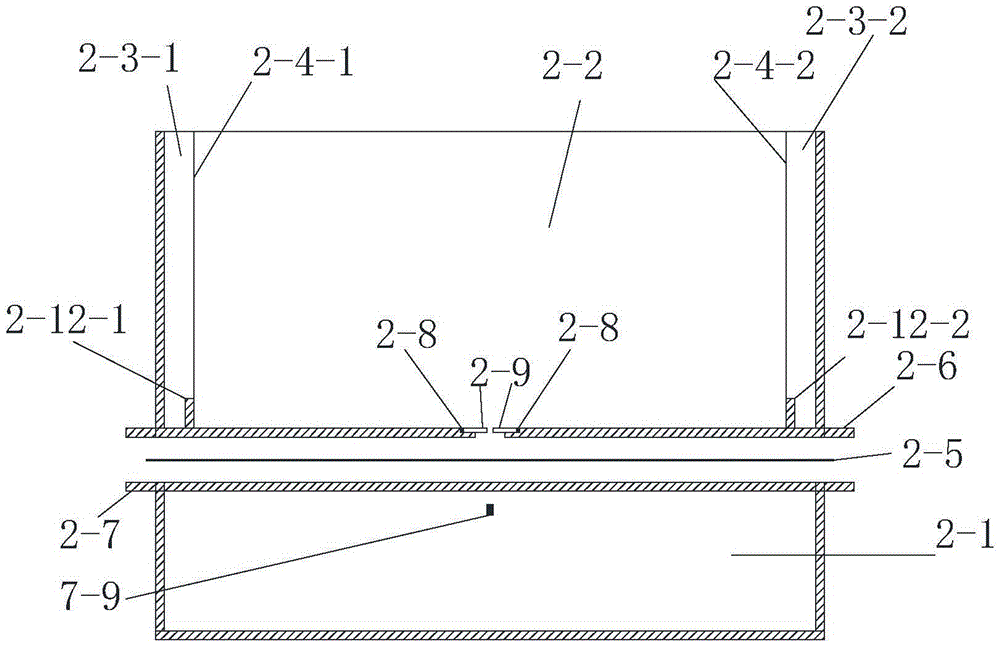

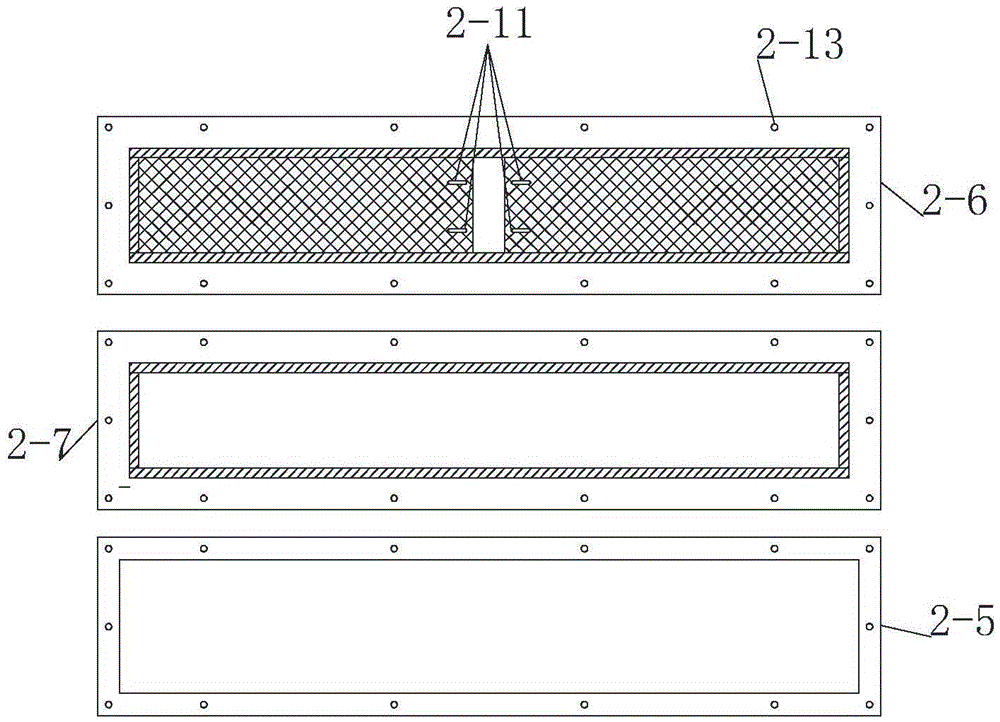

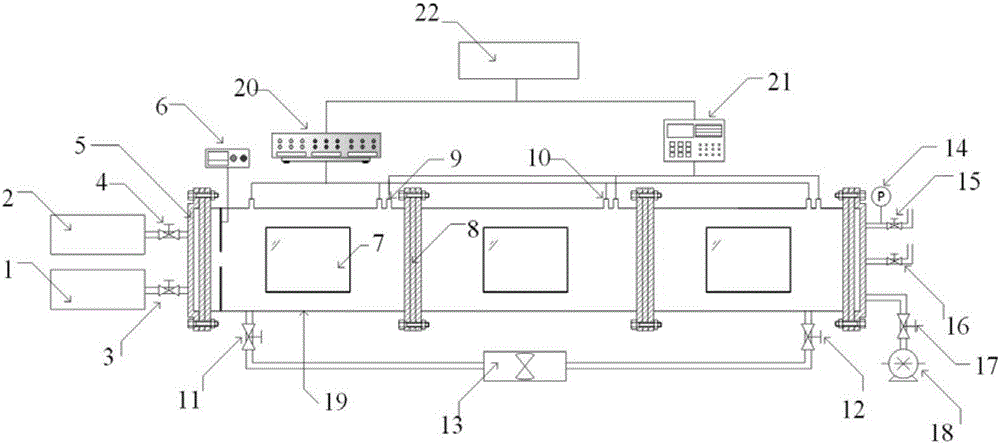

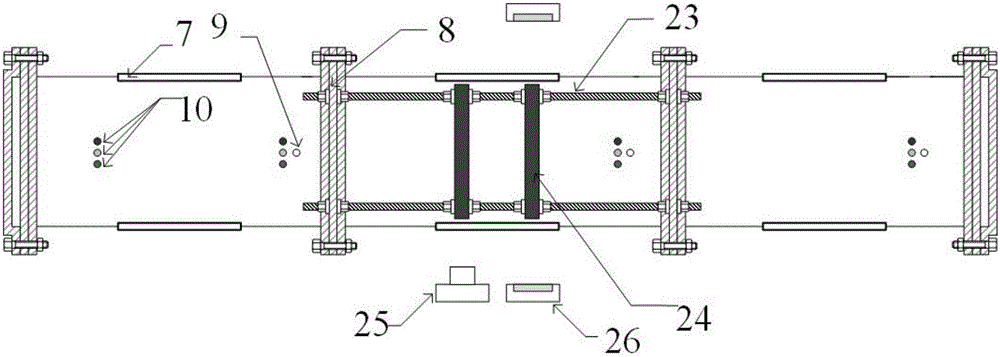

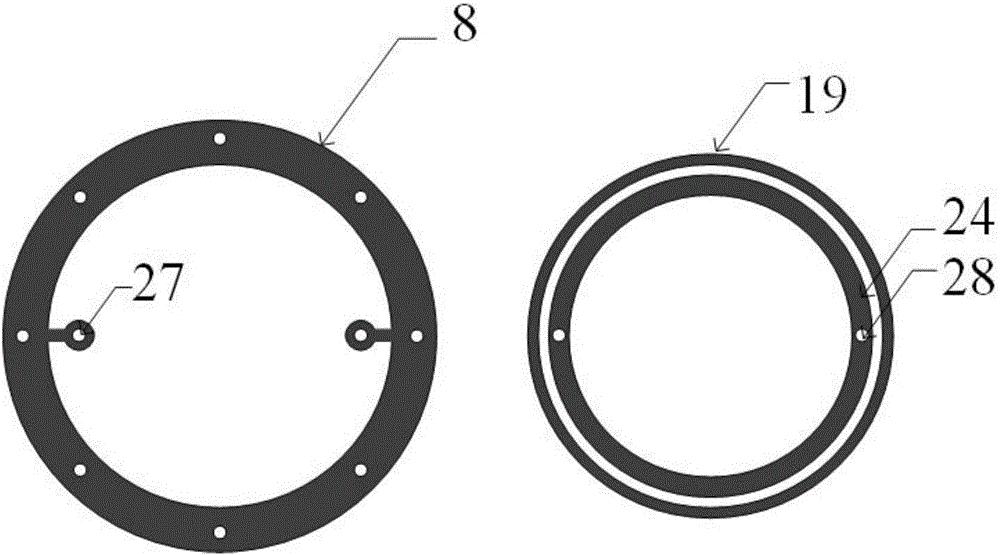

Hydraulic-induced covered karst collapse simulation testing device and using method

InactiveCN105572319AImprove stabilityReduce testing costsEarth material testingProcess mechanismPeristaltic pump

Owner:HOHAI UNIV

Testing apparatus for burning and explosion of combustible gas in narrow, long and restricted space

The invention provides a testing apparatus for burning and explosion of combustible gas in narrow, long and restricted space under the condition of multiple factors. The testing apparatus comprises an ignition device, a pressure-resistant enclosed container, a combustible gas tank, an air compressor and a PLC control assembly unit. The testing apparatus researches on the explosion characteristics and reaction process mechanisms of a variety of combustible gases under different conditions through barrier setting, gas distribution, ignition, measurement, acquisition and integration of an analysis system and provides technical reference for pipeline arrangement, explosion suppression design and safety evaluation.

Owner:CHINA PETROLEUM & CHEM CORP +1

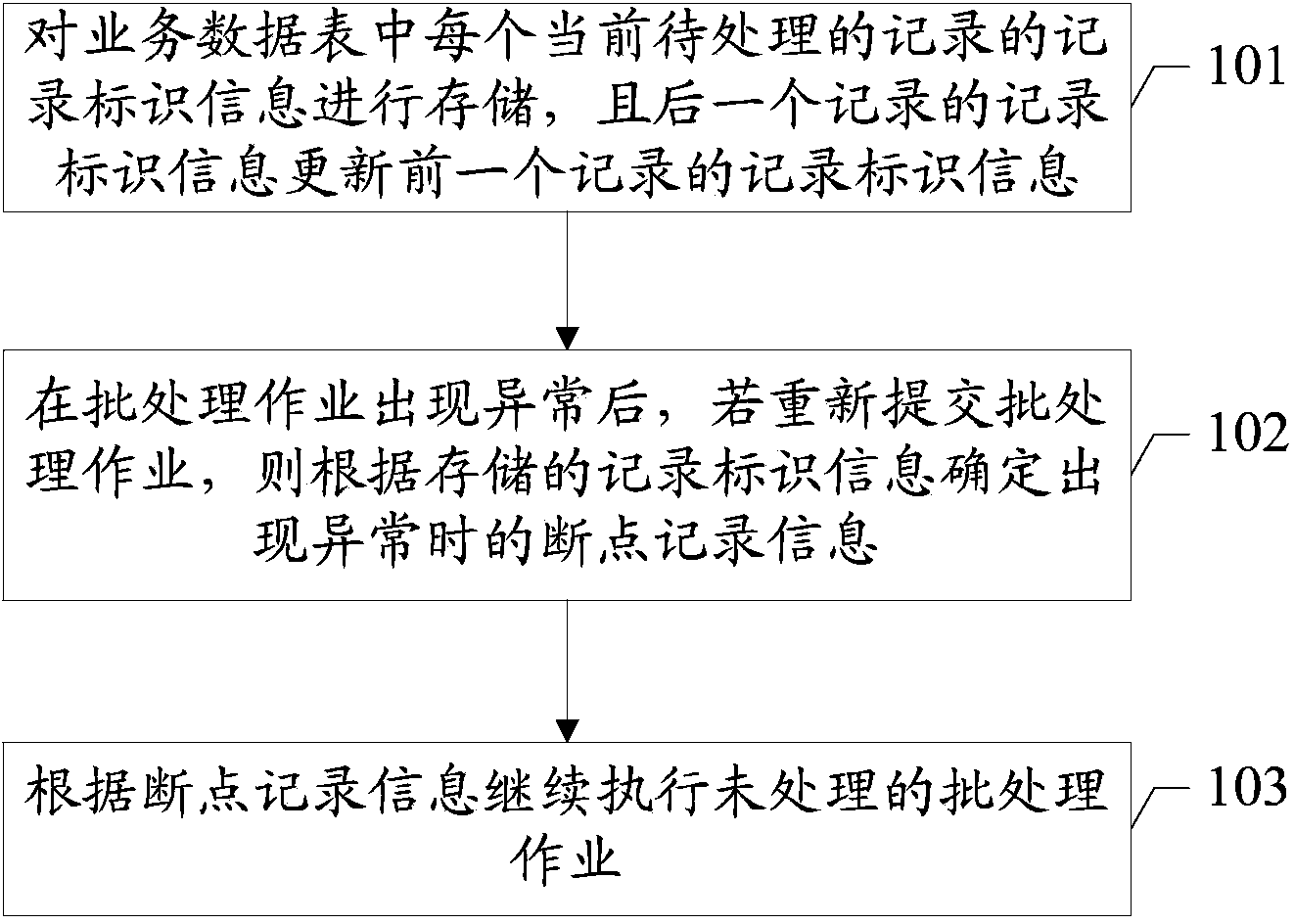

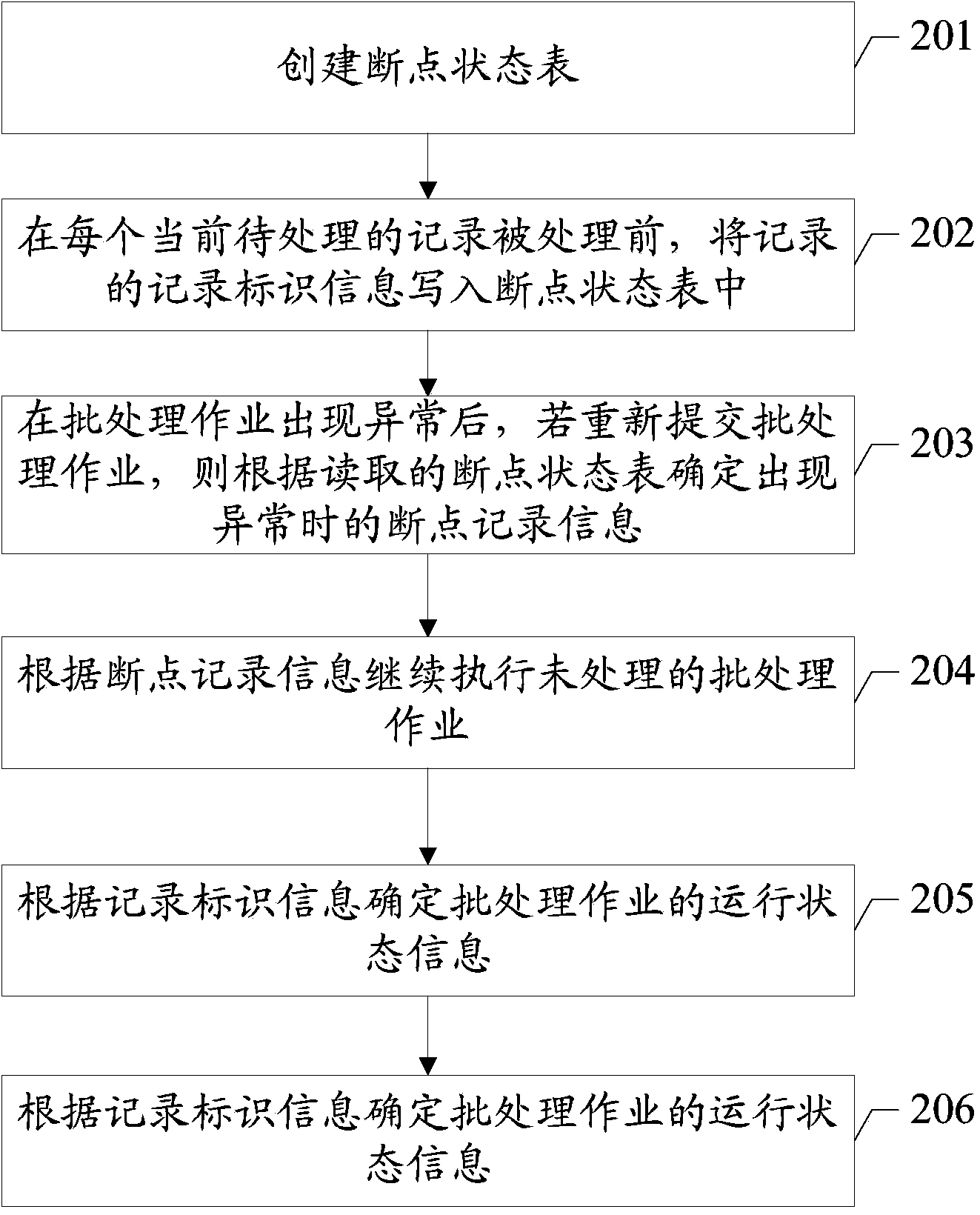

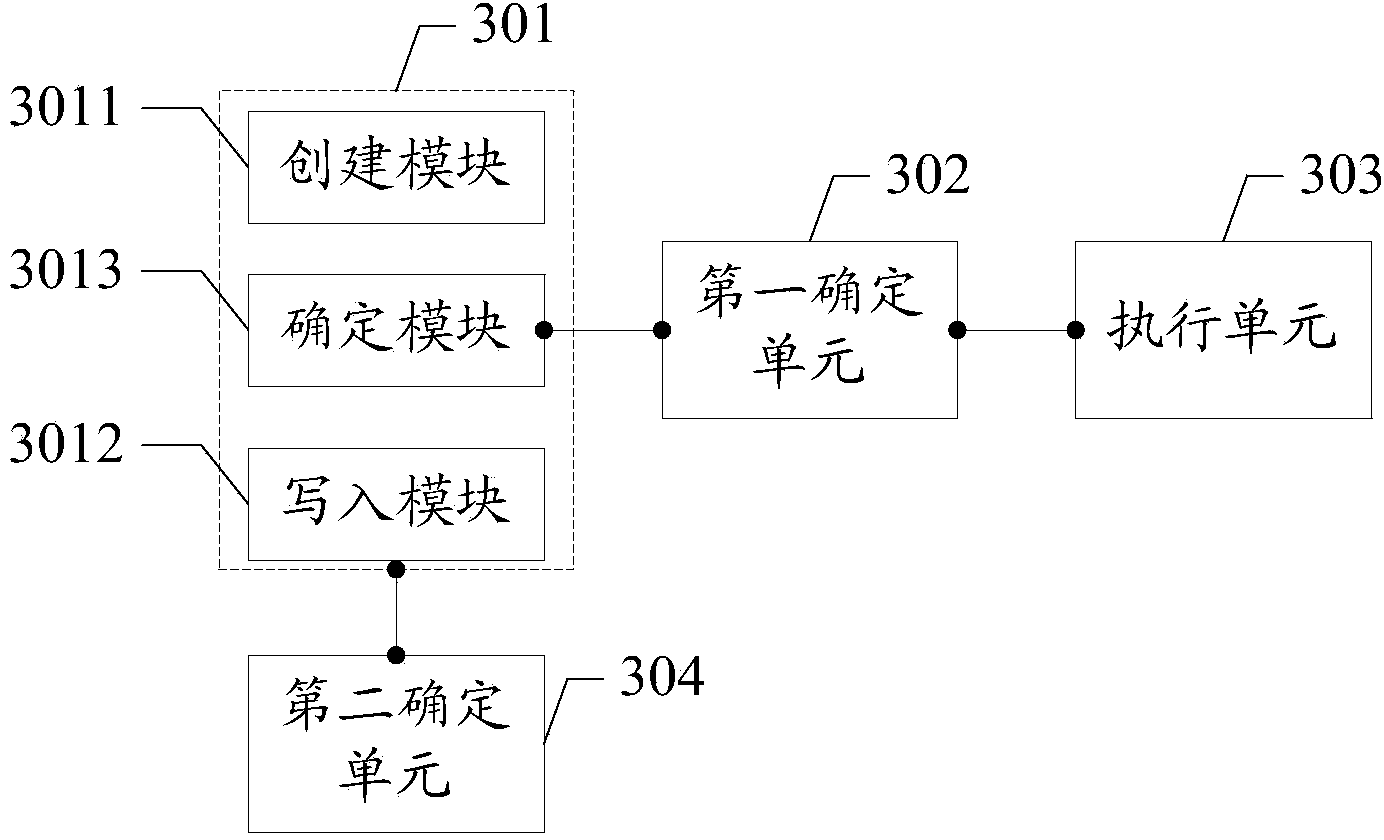

Method and device for processing batch job

The invention discloses a method and a device for processing batch job based on a breakpoint continuous processing mechanism in one embodiment. Before the batch job, the corresponding service data table does not need to be copied; when the batch job needs to be submitted again in case of exception in the batch job, the unprocessed batch job can be executed continuously from the exception part appearing last time, and re-processing of the whole service data table is avoided. The method comprises storing the record identification information of each record to be processed at present in the service data table in the batch job process and updating the record identification information of the previous record by use of the record identification information of the next record, if the batch job is submitted again in case of exception in the batch job, determining the breakpoint record information when the exception appears according to the stored record identification information, and continuously executing the unprocessed batch job according to the breakpoint record information, wherein the record identification information is capable of uniquely identifying the corresponding record.

Owner:CHINA CONSTRUCTION BANK

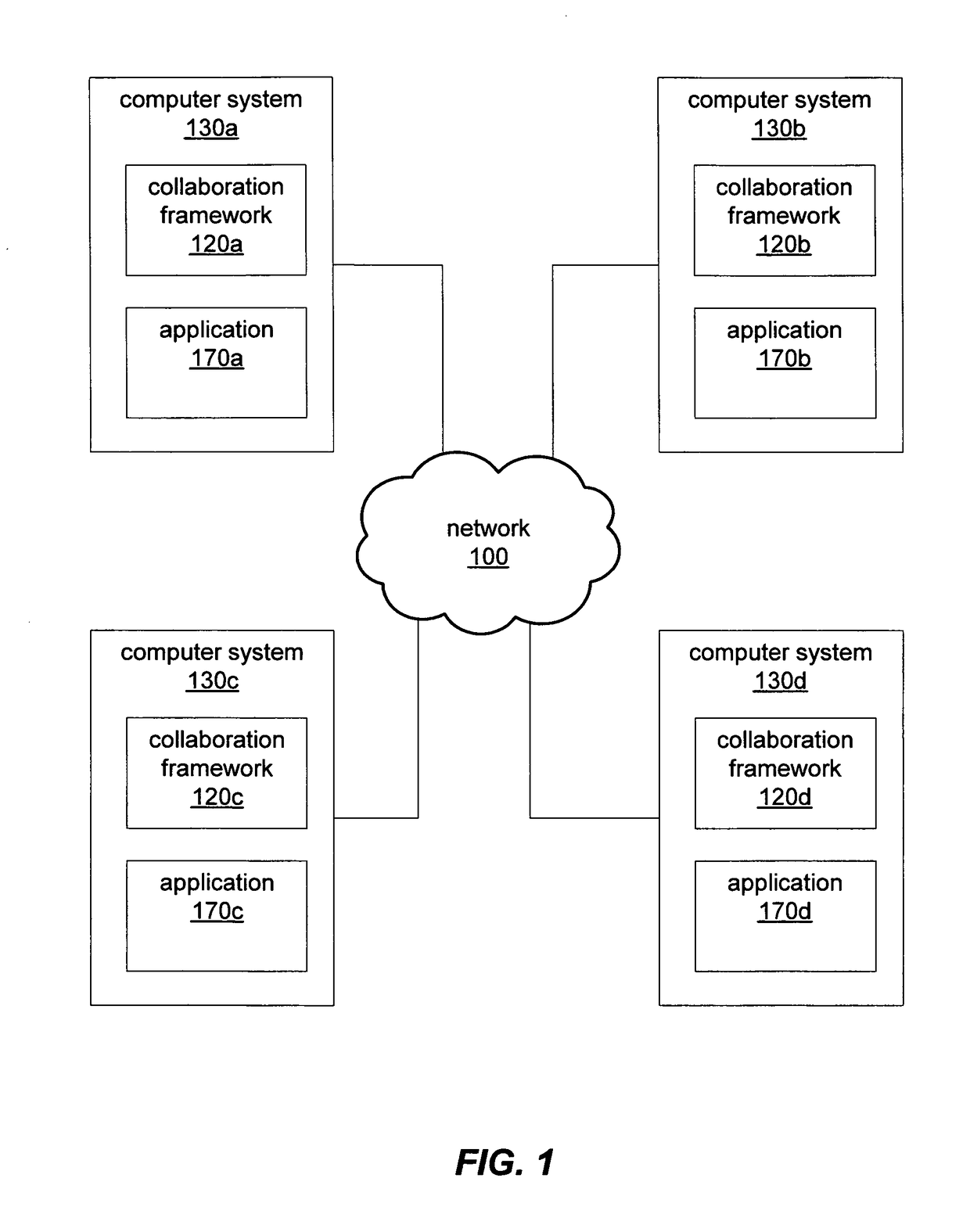

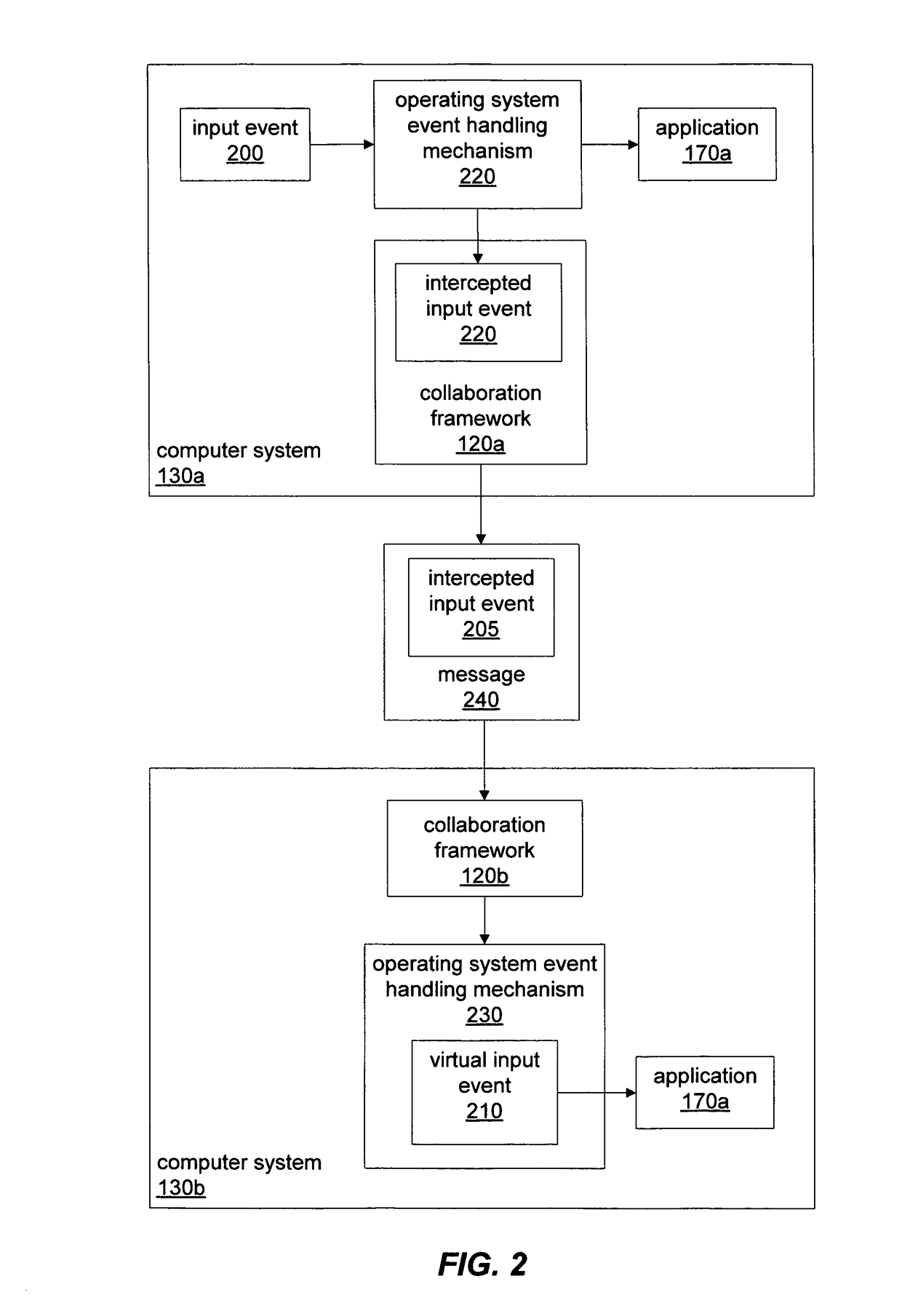

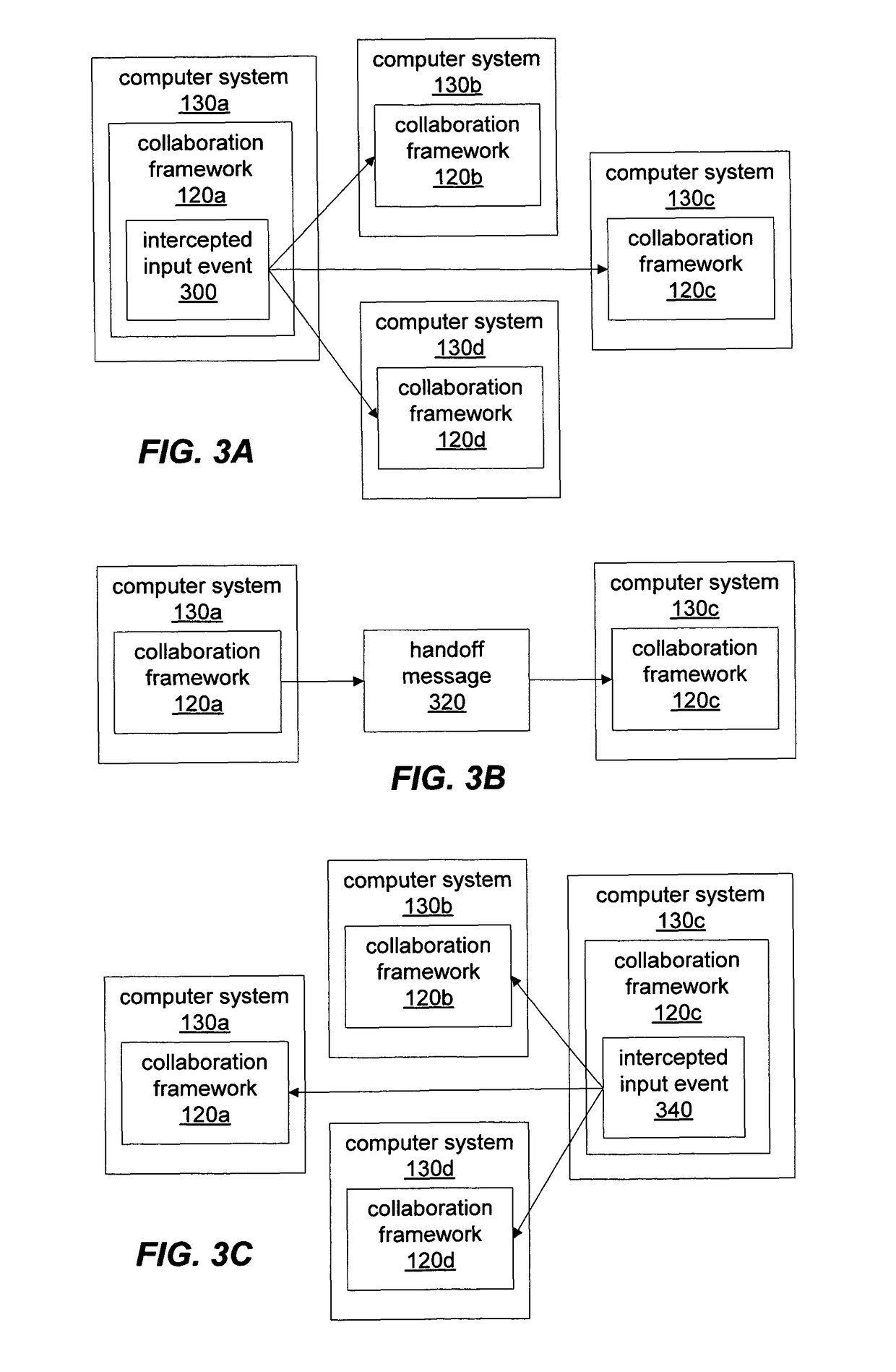

System and method for event-based collaboration

ActiveUS7908325B1Multiple digital computer combinationsProgram controlProcess mechanismOperational system

A first collaboration framework on a first computer system may intercept, via an operating system event handling mechanism on the first computer system, local input events for a first application executing on the first computer system. The first collaboration framework may also send messages including the intercepted input events to other collaboration frameworks executing on other respective computer systems. In response to receiving a message including an intercepted input event, each of the other collaboration frameworks may deliver the input event, via an operating system event handling mechanism to another application. A collaboration framework may deliver an input event intercepted on another computer system to a local application as if the input event were input locally. Delivered input events may cause applications on other computer systems to perform the same one or more actions as performed by the application for which the input event was originally intended.

Owner:ORACLE INT CORP

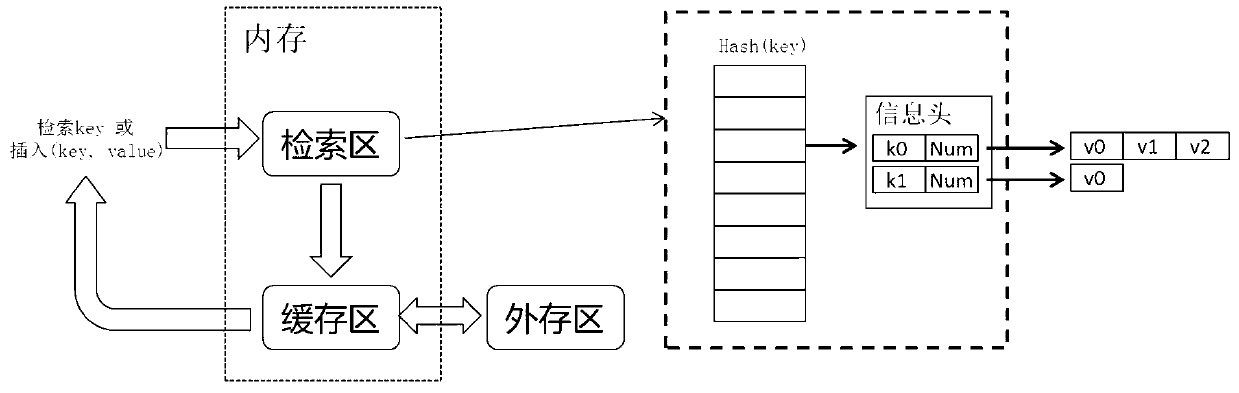

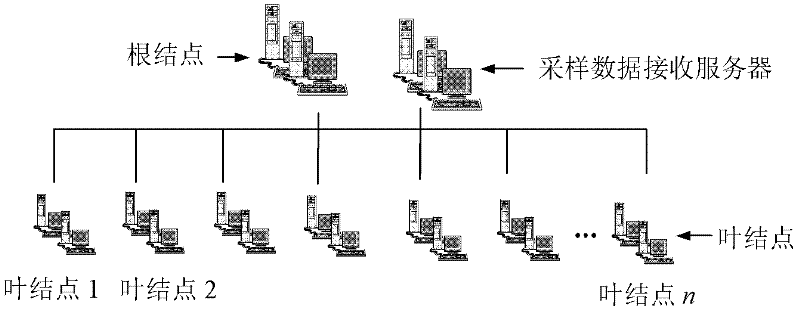

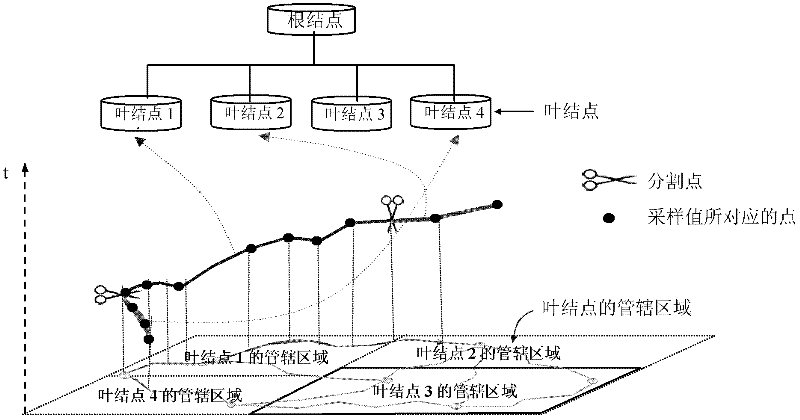

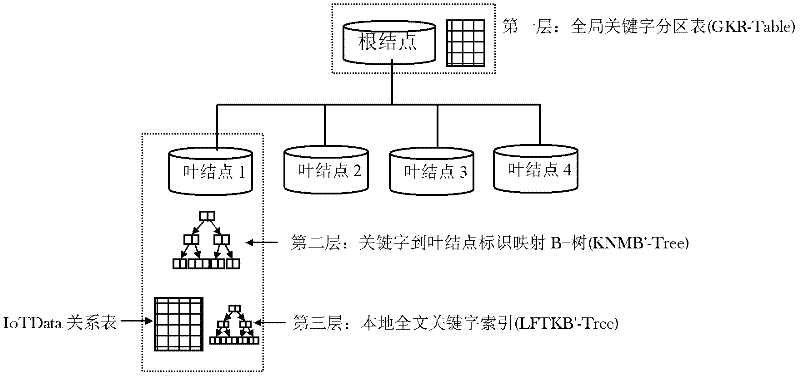

Method for storing and searching mass sensor data

The invention discloses a method for storing and searching mass sensor data and belongs to the field of sensor data. The method comprises the following steps that: two layers of storage frame, which comprise a root node and a plurality of leaf nodes, are established; a receiving server distributes sampling data sent by a sensor to the corresponding leaf nodes; each leaf node stores the historic sampling value of the same monitoring target, which is acquired by the sensor, in an element group of a leaf node database in a uniform form to form a sampling data sequence of the monitoring target; and an overall time and space distributed index and an overall key word distributed index of the two layers of storage frame are established. Quick time and space search and key word search can be supported at the same time through the overall key word index, the overall time and space index and an overall search processing mechanism. Multiple searching types of quick processing are compatible, and the defects that the current time and space database is mainly used for storing relative static space data or relative single time and space data and an efficient heterogeneous data flow representation method is lacked are overcome.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

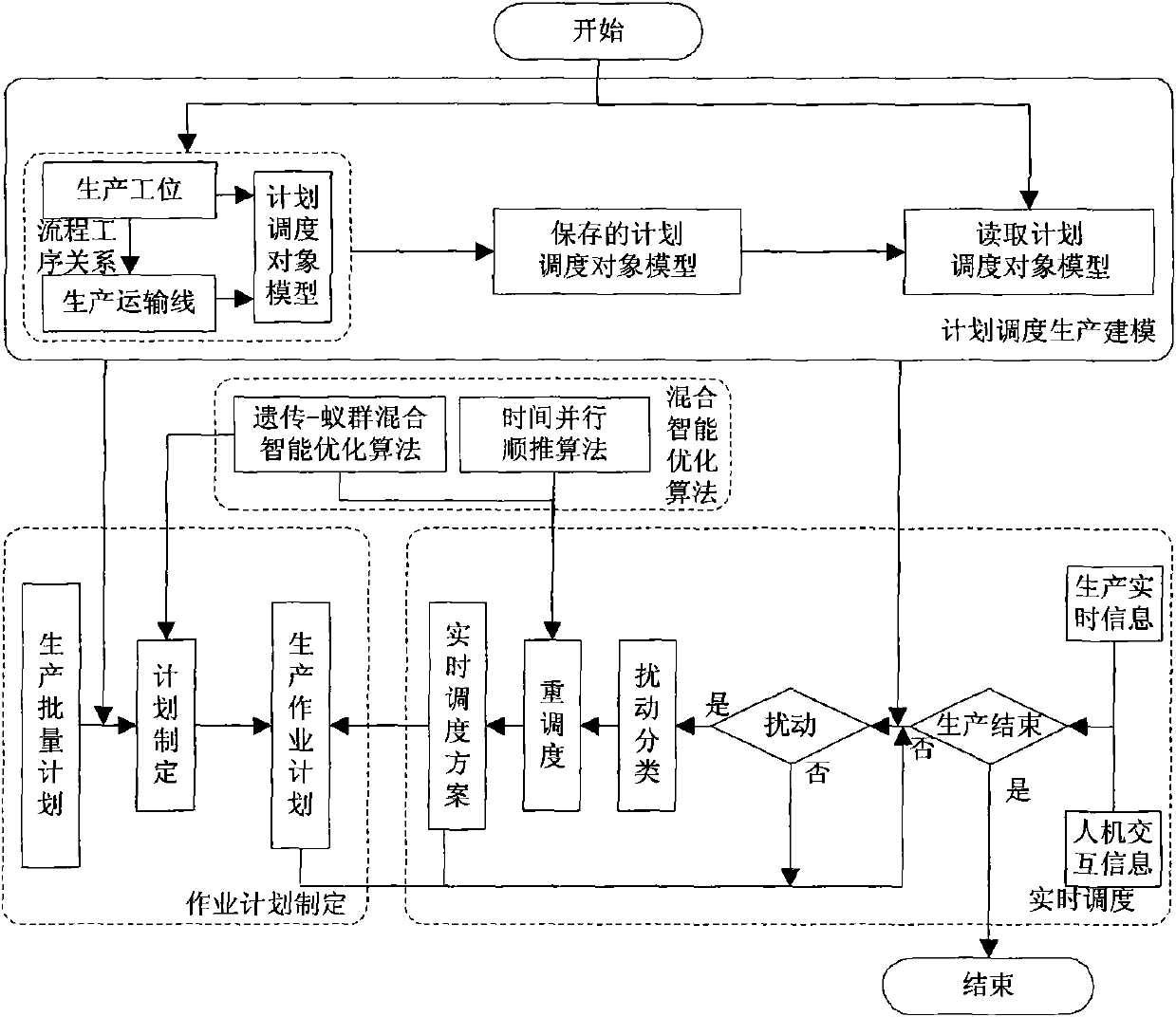

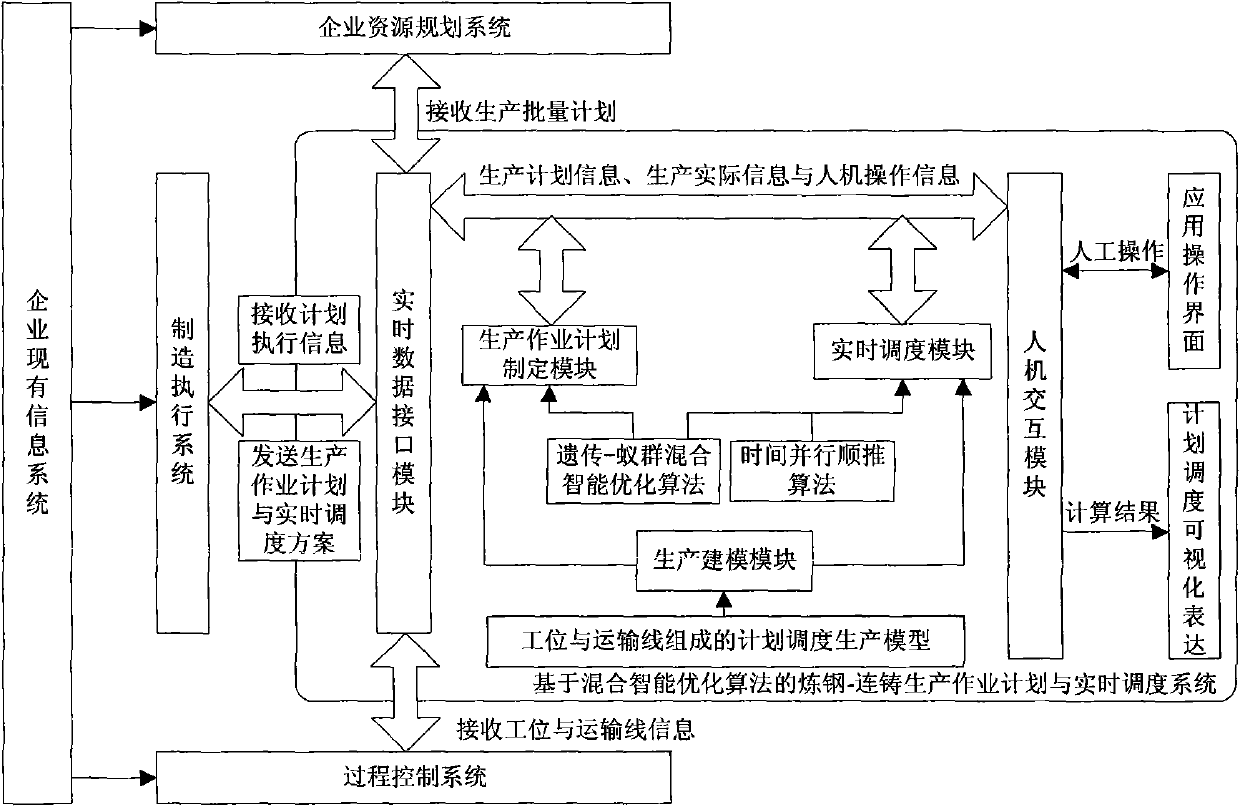

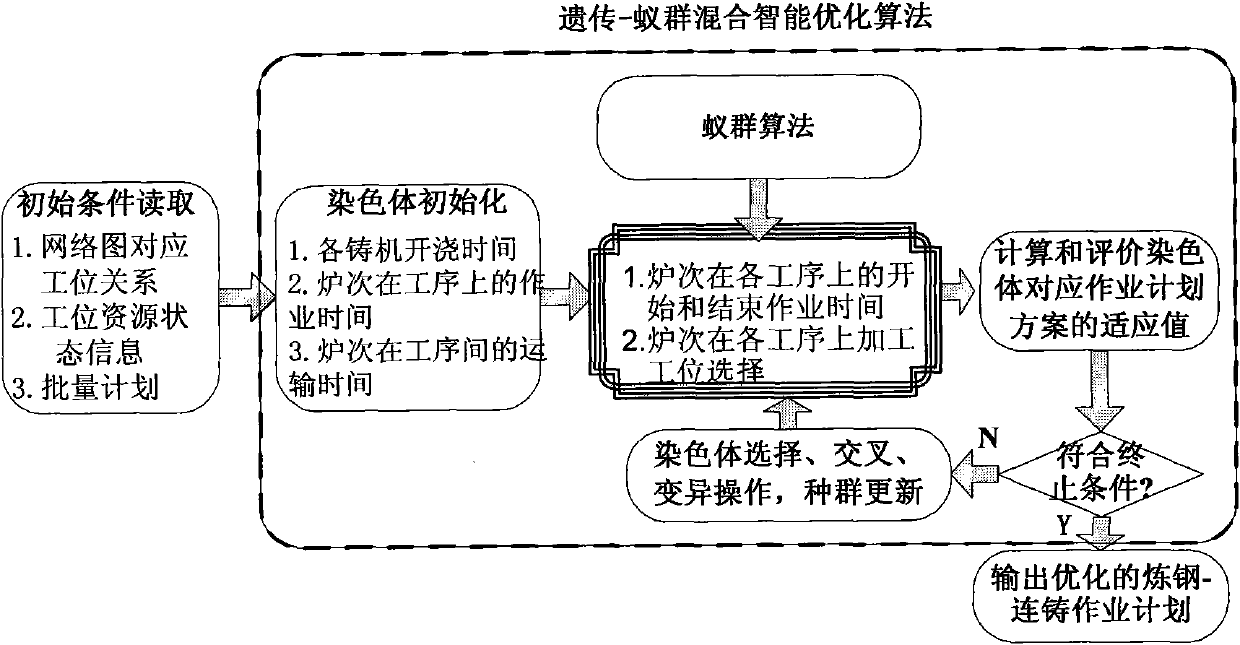

Steelmaking-continuous casting production operation plan and real-time dispatching optimization method and system based on mixed intelligent optimization algorithm

InactiveCN101770615AQuick buildOptimize production scheduleResourcesManufacturing computing systemsProcess mechanismModel method

The invention provides a steelmaking-continuous casting production operation plan and a real-time dispatching optimization method and a system based on a mixed intelligent optimization algorithm. The method comprises the following steps: establishing a production operation plan and an original dispatching proposal by the mixed intelligent optimization algorithm according to a production batch plan; detecting the perturbation in the production process through the established real-time data and a human-computer interaction interface; adopting the mixed intelligent optimization algorithm for remaking the plan on operating plans and unoperated plans; classifying the main perturbation in the production process; and establishing processing mechanisms corresponding to each kind of perturbation. The invention provides the re-planning and re-dispatching functions under the condition of changed production environment, and brings convenience for dispatching personnel to regulate the dispatching proposals according to personnel experience. The method considers the possible conflicts between equipment and the furnace sequence during the generation of the production operation plan and the dispatching proposal, so the calculation results are feasible. Because of the real-time dispatching function, the model method has strong system self organization performance, good adaptability and good universality.

Owner:CHONGQING UNIV

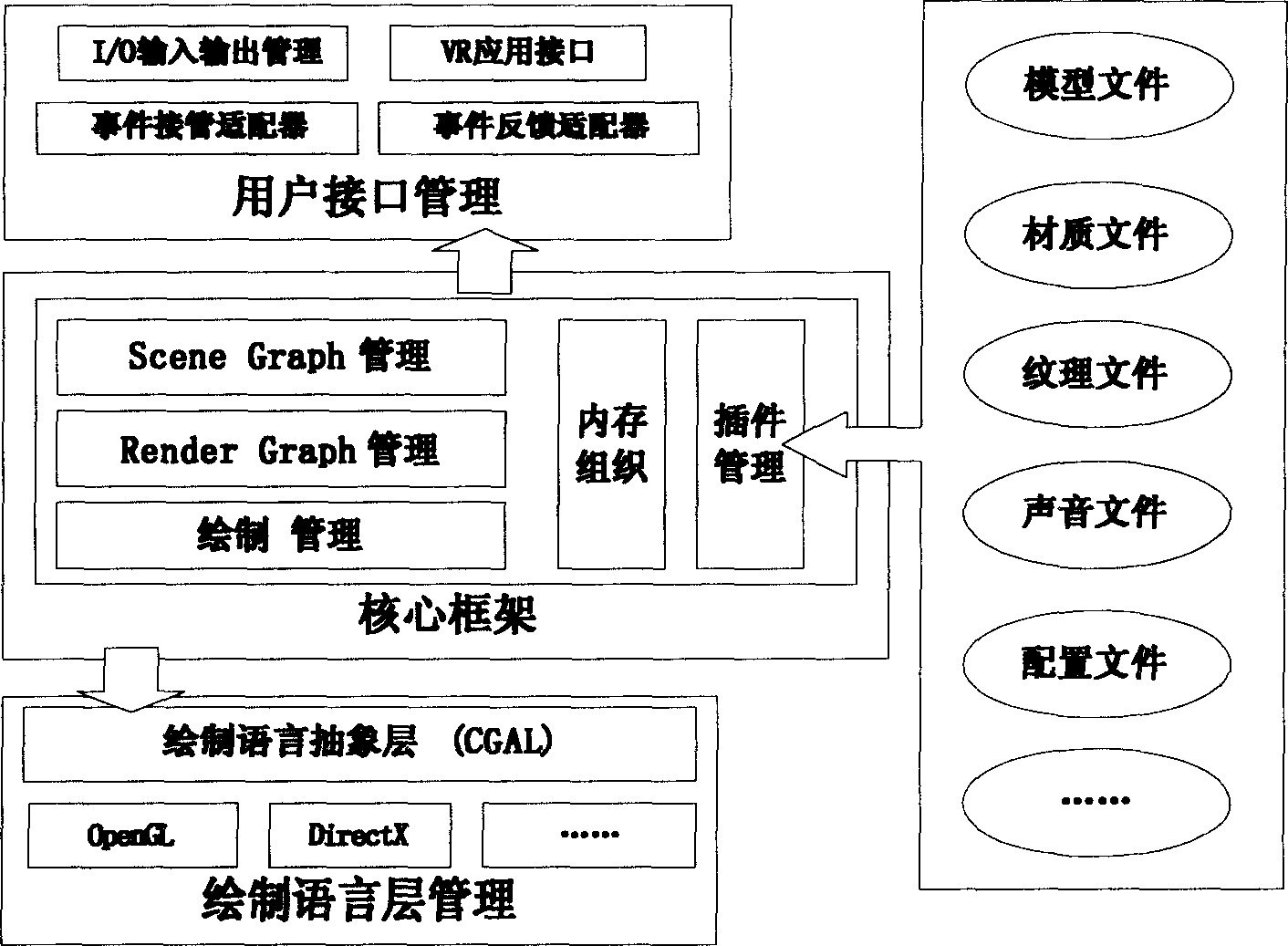

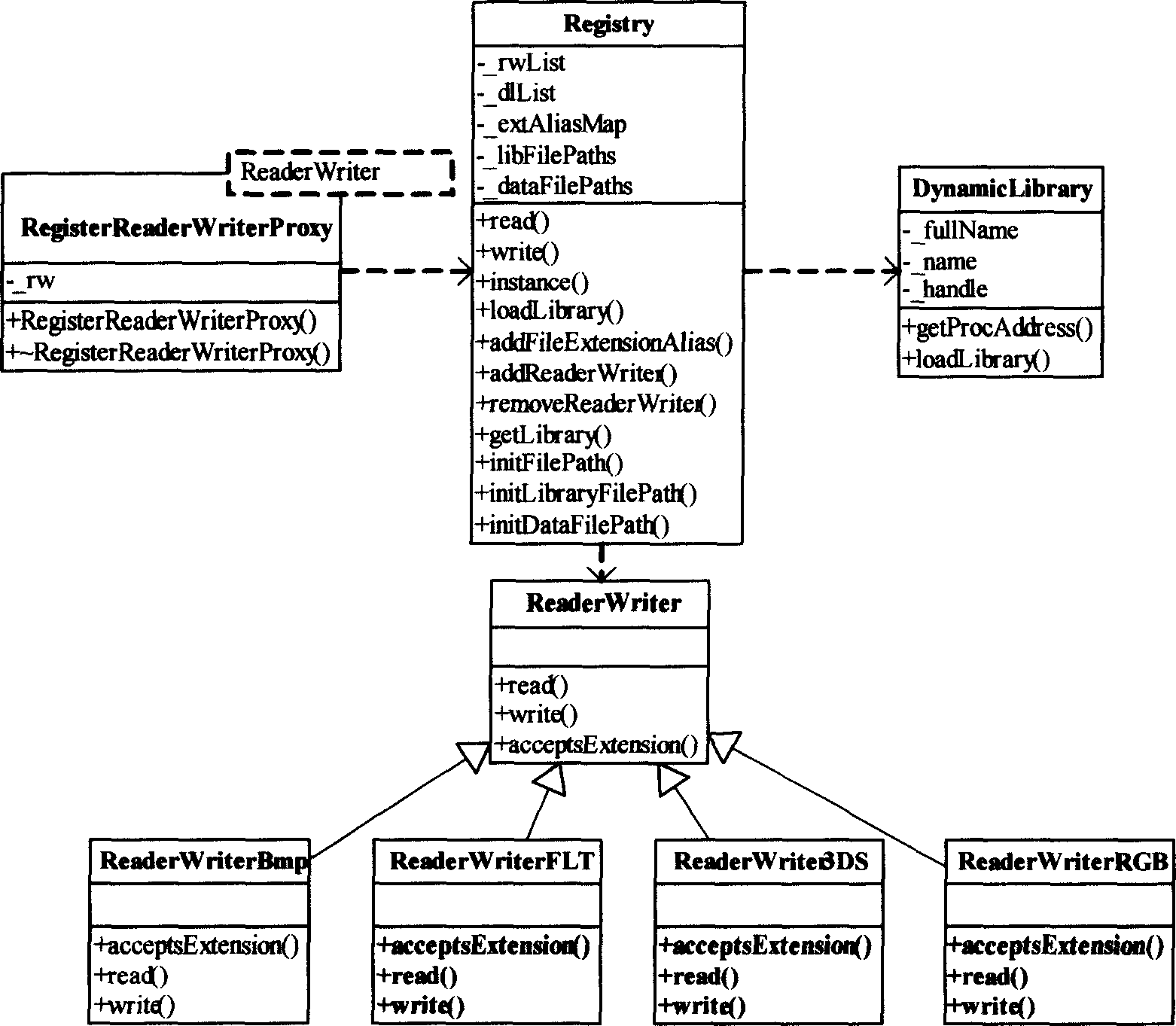

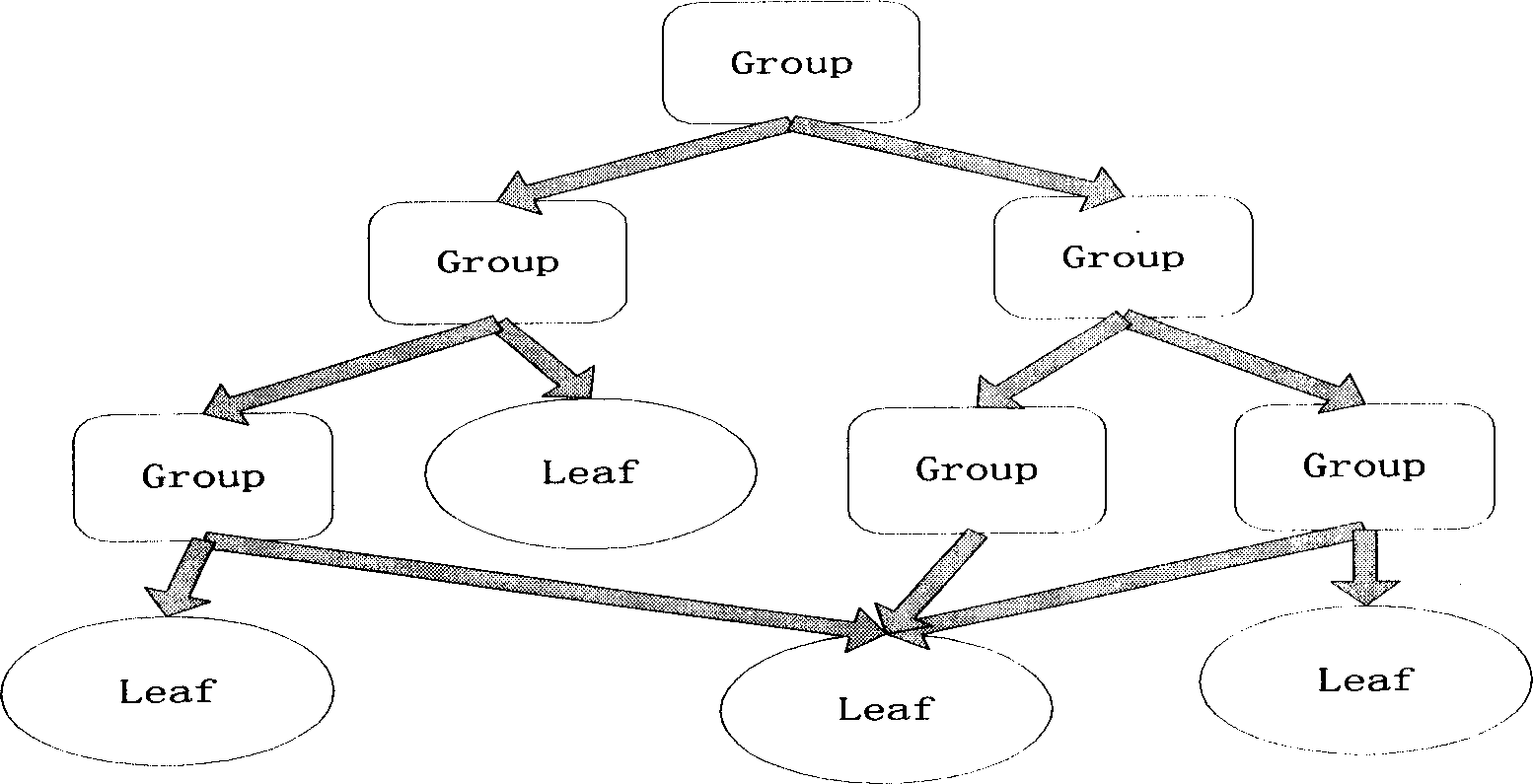

Three-dimensional scene real-time drafting framework and drafting method

InactiveCN1763784AUser-friendly calling mechanismConvenient message processing mechanism3D-image renderingProcess mechanismInterface layer

The invention discloses a three-dimensional scene real-time drafting frame of three-layer system, which is characterized by the following: the bottom layer is drafting language administration layer to call all states and drafting properties of different edition format drafting language; the medium layer contains slot administration, scenegraph administration, drafting graph administration and drafting administration mode; when the top layer displays the call requirement; the slot administration mode reads the model file to form scene image through scenegraph administration mode, which finishes App, Cull and Draw operation of scenegraph through drafting administration mode; the top layer provides interface layer for user, which provides convenient user call mechanism and message disposal mechanism.

Owner:BEIHANG UNIV

Method, system and architecture for increasing social network user interests in messages and delivering precisely targeted advertising messages

The present invention pertains to a method for delivering messages in a social network to increase a signal-to-noise ratio for the recipients of messages, characterized in that a process mechanism comprises of a diffusion process and a selection process combined through an adaptive process, in which:the diffusion process dispatches each message through dynamic routing graphs defined between the sender user and a set of potentially interested recipient users;the selection process locally filters the messages that are transmitted from sender users and received by potentially interested recipient users, according to the result of the application of a selection function on the metadata values constituting a message profile extracted from each transmitted message and weighted feature values constituting a user profile of the recipient to establish an estimate of interest for the user regarding each message, andthe adaptive process continuously adjusts processing functions to adapt the graphs structure according to the user profiles dynamically updated by message metadata.

Owner:SEMIOCAST

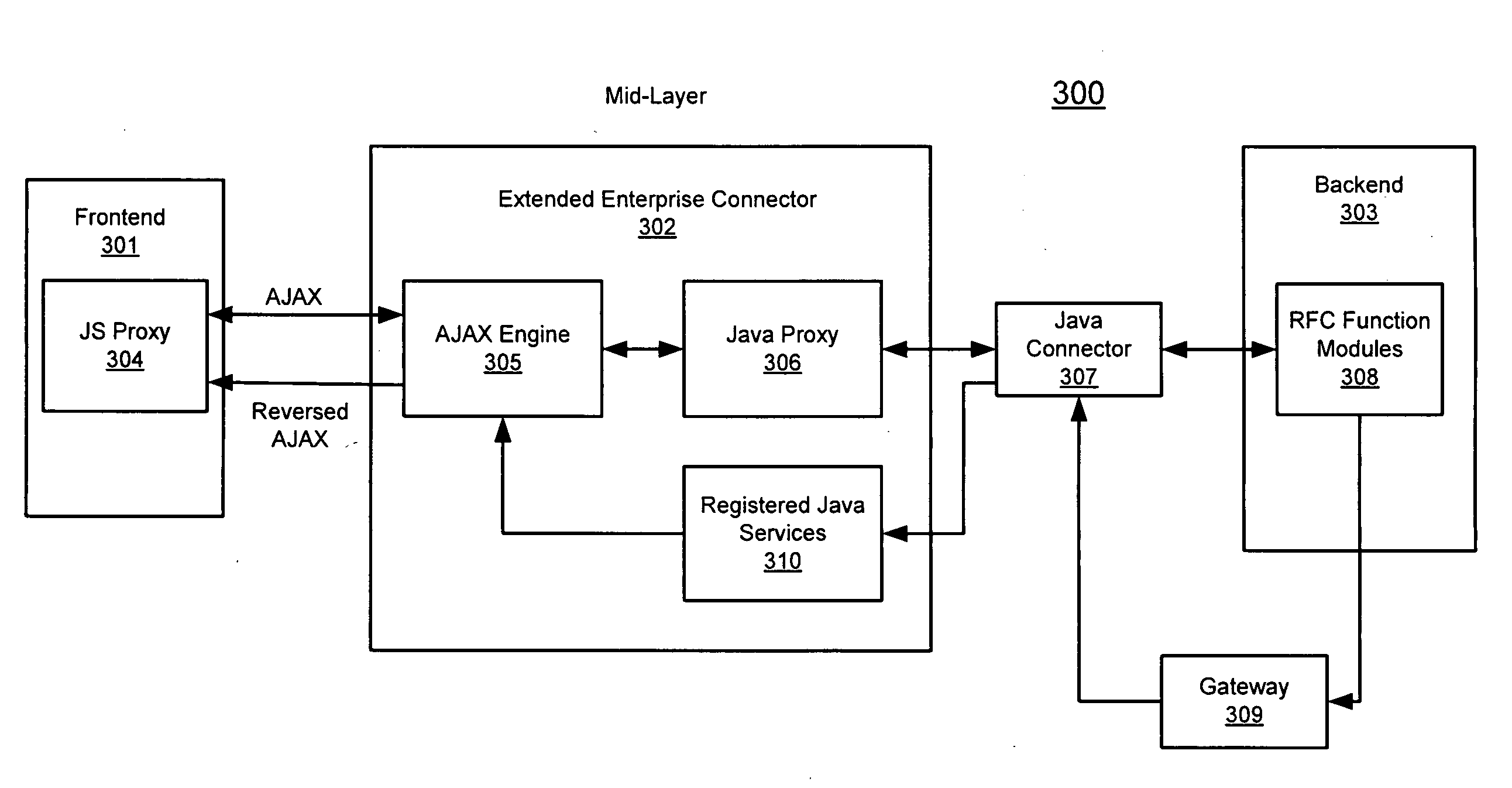

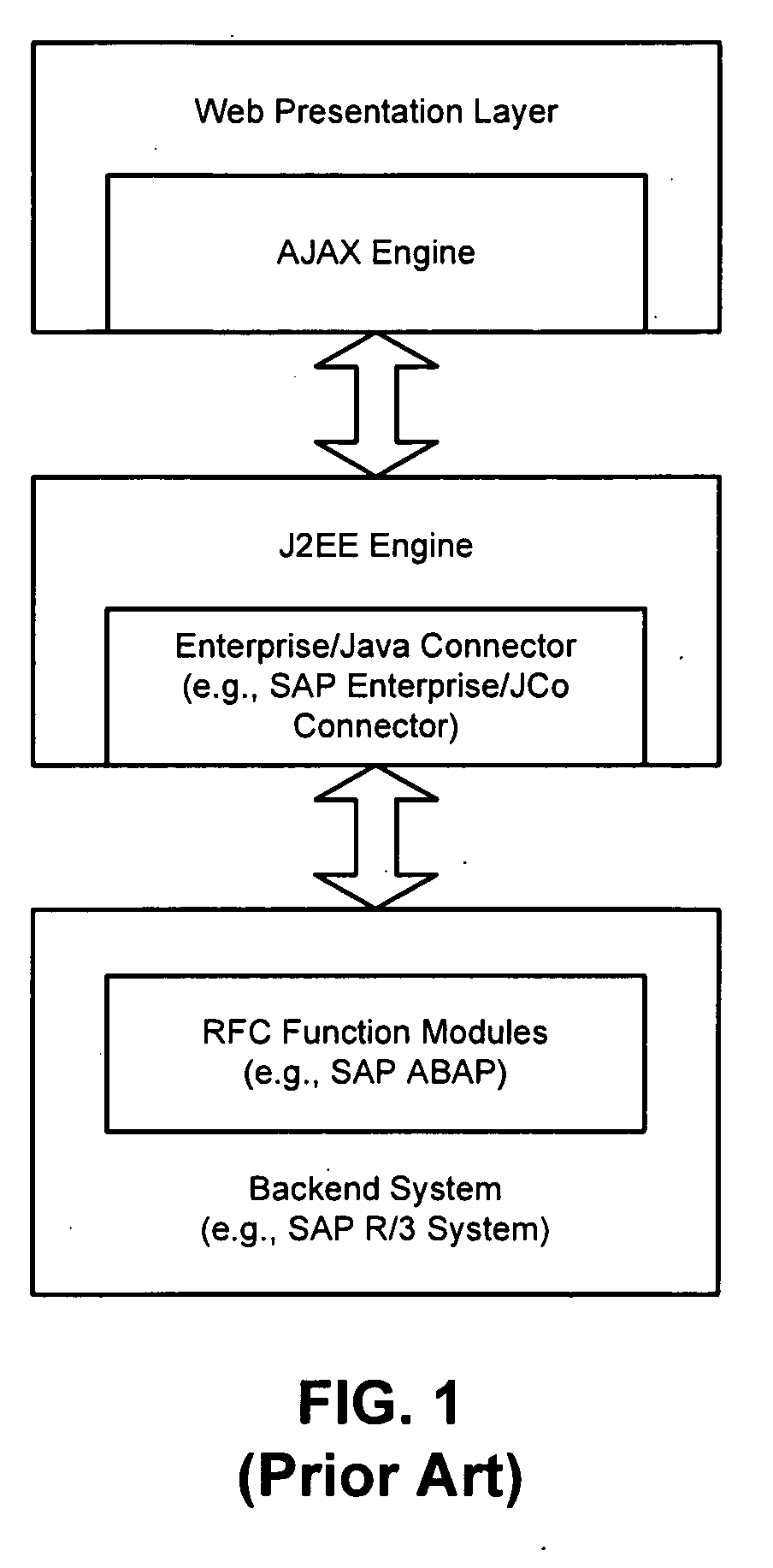

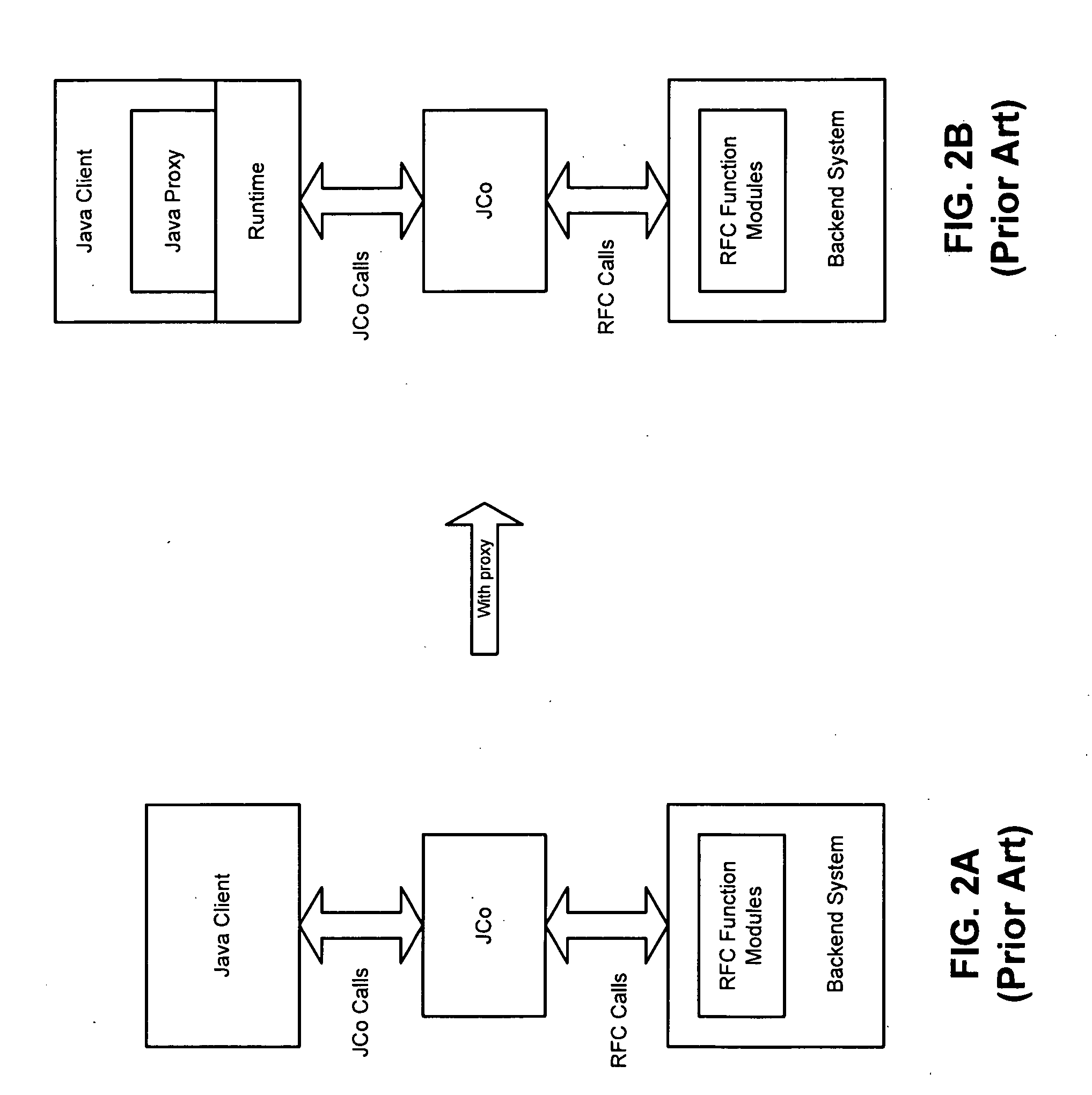

Extended enterprise connector framework using direct web remoting (DWR)

ActiveUS20100031233A1Software reuseSpecific program execution arrangementsProcess mechanismWeb application

Techniques for extended enterprise connector framework are described herein. According to one embodiment, a Java proxy is generated in a form of Java beans at a Web server as a mid-layer, using an enterprise connector. The enterprise connector provides object oriented classes that encapsulate specific function calls of a Java connector which represents a set of proprietary APIs (application programming interfaces) to access RFC modules of a backend enterprise system. A JavaScript proxy is generated for a frontend client that communicates with the Web server over the Web using a DWR (direct Web remoting) mechanism to allow the JavaScript proxy to directly access the Java proxy of the mid-layer via an AJAX (asynchronous Java and extensible markup language or XML) communication mechanism, where the JavaScript is invoked by a Web application of the frontend client at runtime. Other methods and apparatuses are also described.

Owner:SAP AG

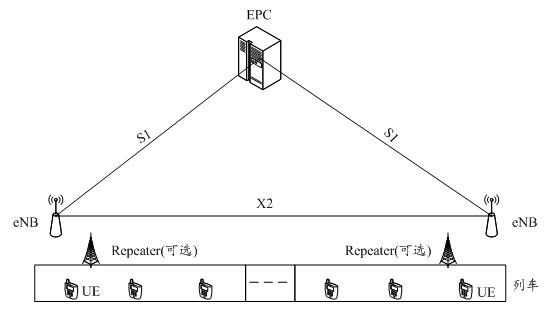

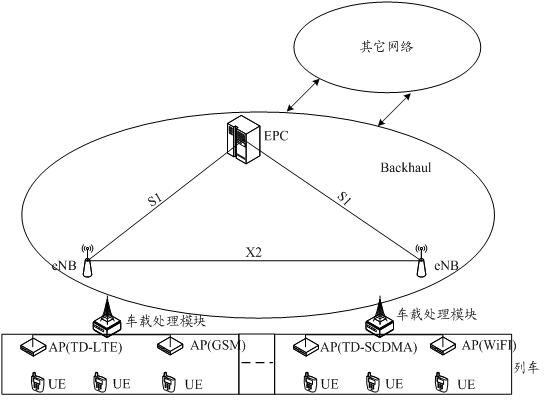

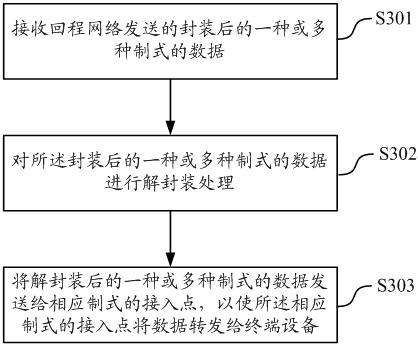

High speed mobile communication realization method and equipment

ActiveCN102130716AImprove stabilityReduce cost inputRadio transmission for post communicationNetwork planningProcess mechanismComputer module

The embodiment of the invention discloses a high speed mobile communication realization method and high speed mobile communication realization equipment. By the technical scheme of the embodiment of the invention, a definite multi-system data communication mechanism and a data processing mechanism in an on-vehicle processing module are established between the on-vehicle processing module and a backhaul network and between access points in a carriage, thereby realizing multi-system data transmission by using the unified on-vehicle processing module in a high speed extraction and utilization communication scene and improving the data transmission stability. The investment and transformation of hardware of corresponding systems are not required to be greatly increased for the multi-system data transmission, so corresponding cost input is saved, the processing mechanism is simplified and designing complexity is reduced.

Owner:DATANG MOBILE COMM EQUIP CO LTD

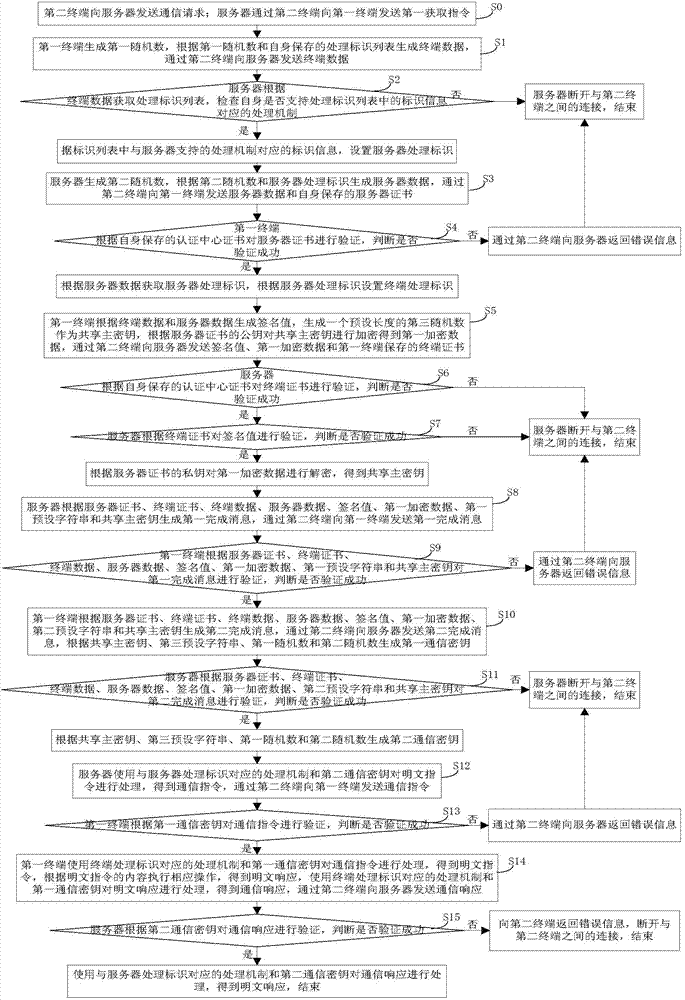

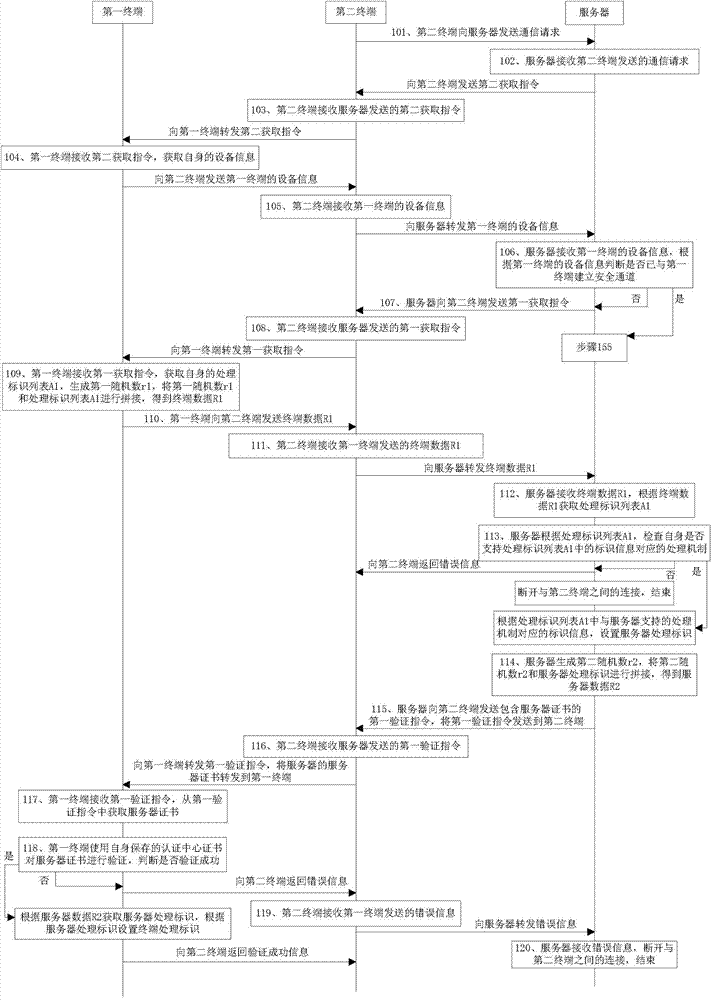

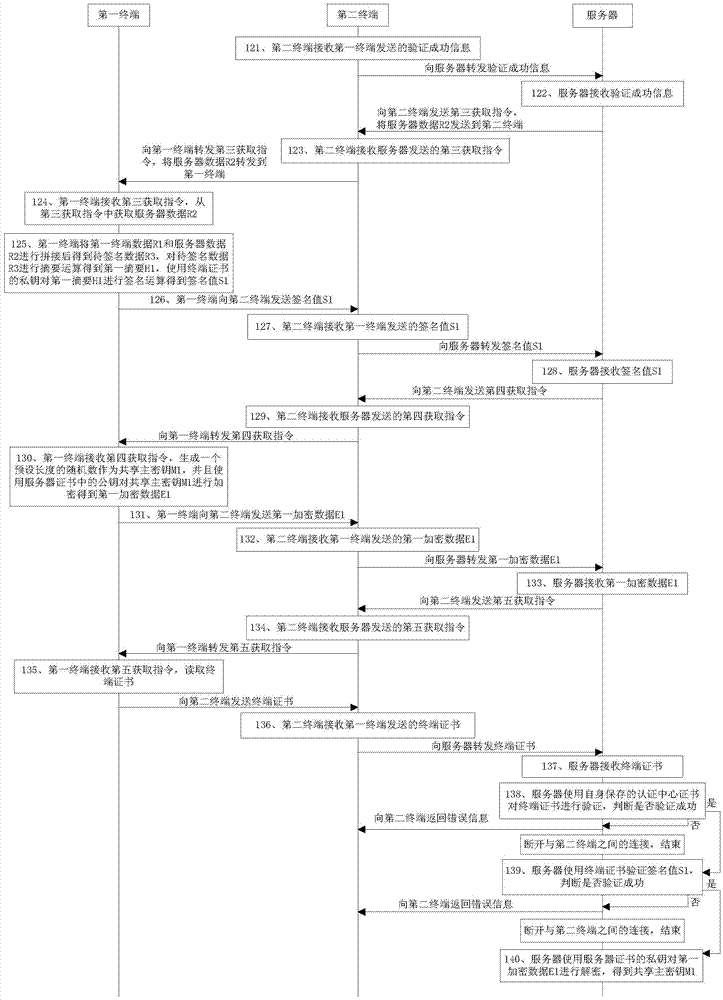

Safety communication method and system

ActiveCN103795545AImprove securityMultiple keys/algorithms usageUser identity/authority verificationPlaintextProcess mechanism

The invention discloses a safety communication method and system. The safety communication method includes the steps that a first terminal generates a first random number and data of the terminal; a server checks whether the server itself supports a processing mechanism or not and generates a second random number and data of the server; the first terminal verifies a certificate of the server and generates a signature value and a sharing master key, and then first encrypted data are acquired through encryption; the server verifies a certificate of the terminal and the signature value and generates a first completion message; the first terminal verifies the first completion message and generates a second completion message and a first communication key; the server verifies the second completion message and processes a plaintext instruction to acquire a communication instruction; the first terminal verifies and processes the communication instruction to acquire a plaintext instruction, executes corresponding operation to acquire a plaintext response, and processes the plaintext response to acquire a communication response; the server verifies the communication response, and therefore safety of the first terminal in the communication process is improved.

Owner:FEITIAN TECHNOLOGIES

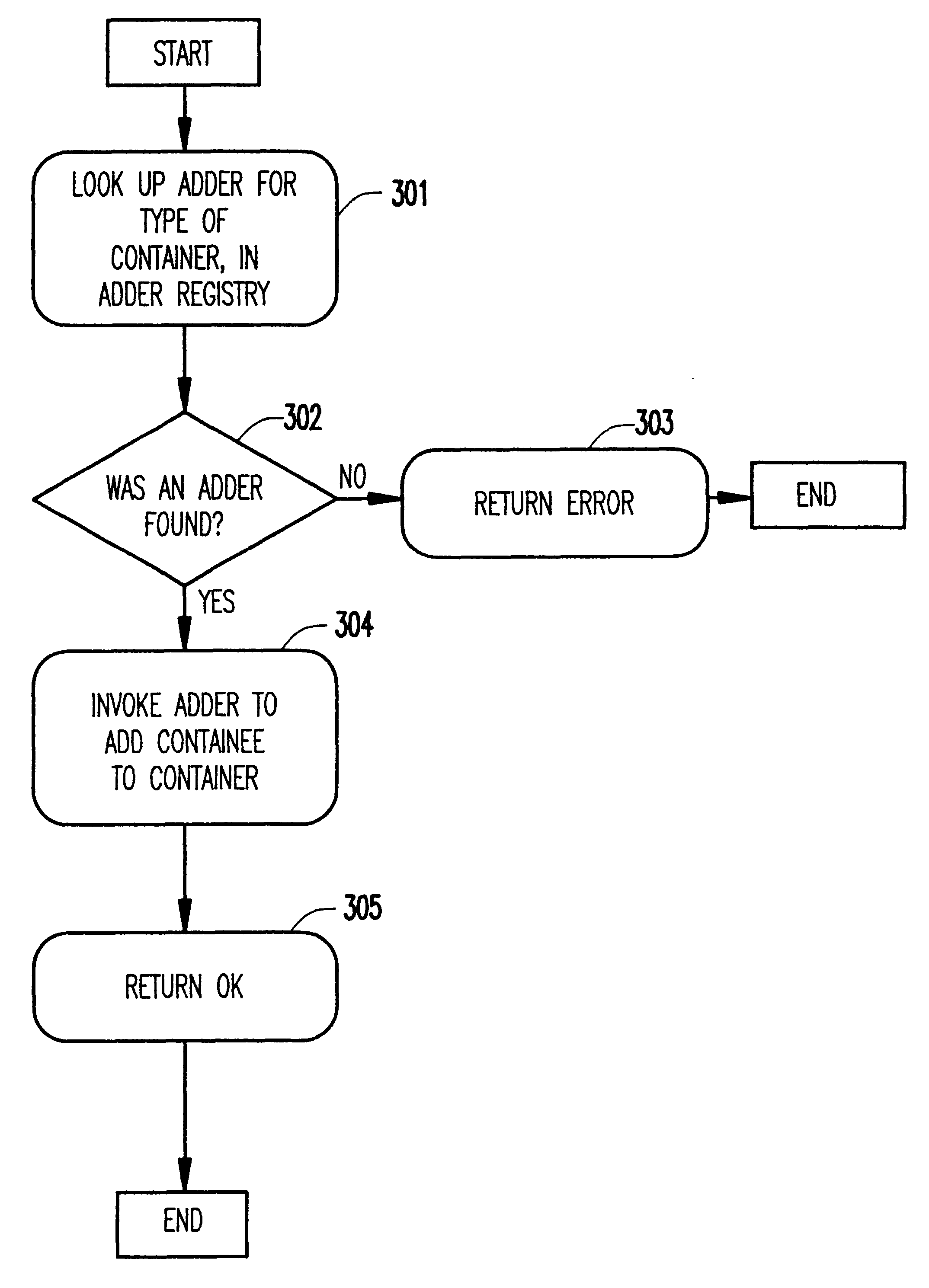

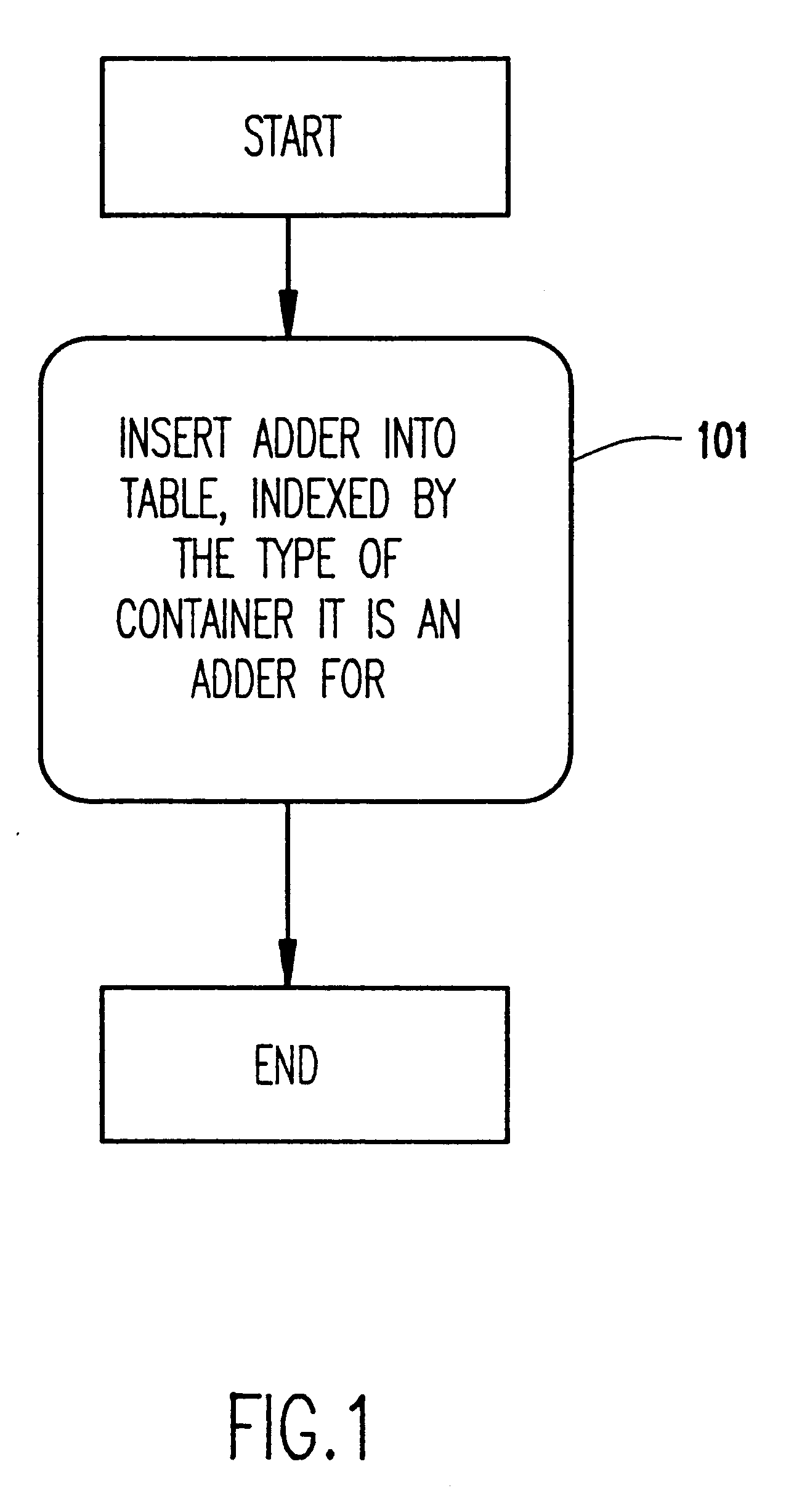

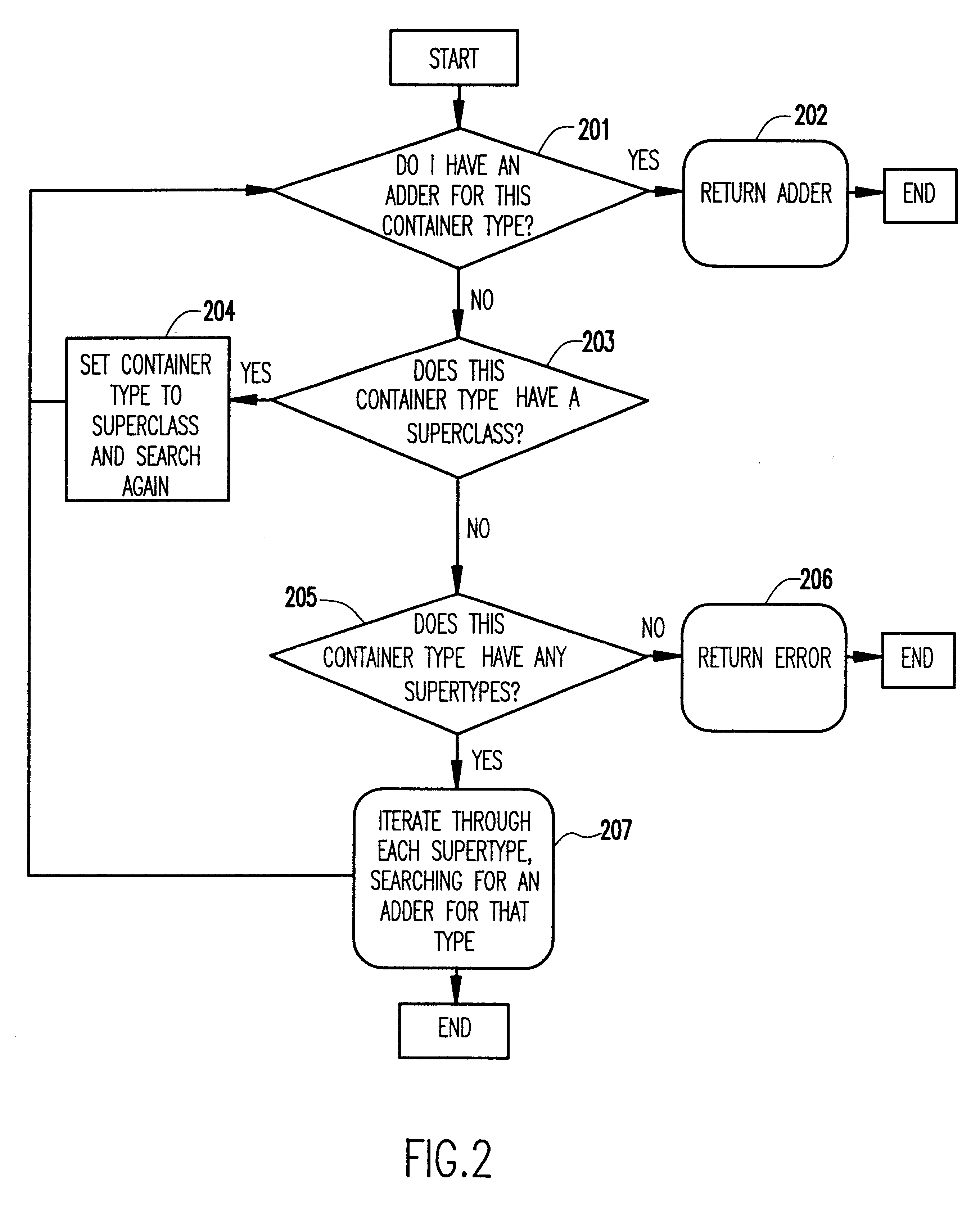

Uniform mechanism for building containment hierarchies

InactiveUS6536033B1Simplified generationSpecific program execution arrangementsMemory systemsProcess mechanismEngineering

A uniform mechanism for building containment hierarchies separates the code / method which actually perform the containment insertion operations on the components from the specification of the containment and then provides an automatic way of obtaining and executing that code when containment hierarchies need to be created. The mechanism consists of an abstract syntax for describing the containment relationships, processing mechanism for creating the containment mechanism, and a registry containing the mechanisms for implementing specific containment policies. Having this abstraction allows an application programmer to be able to construct hierarchies of objects without having to be concerned about the specific details of how that containment is performed. In fact, the details may be deferred until run-time (and even downloaded from elsewhere). Also, having this abstraction significantly simplifies automatic generation of object hierarchy codes, both from the point of view its implementation as well as that of the code that is generated.

Owner:IBM CORP

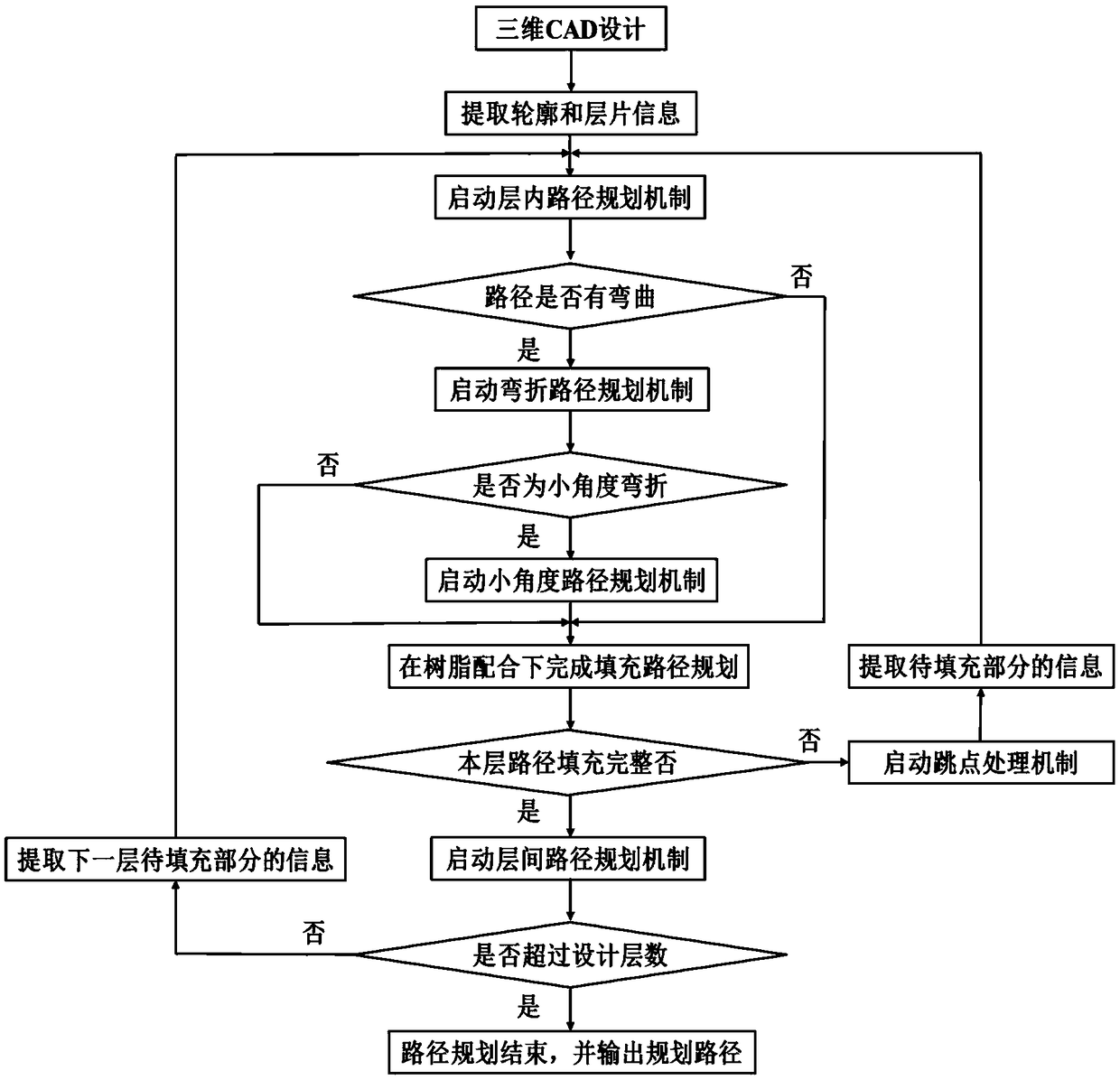

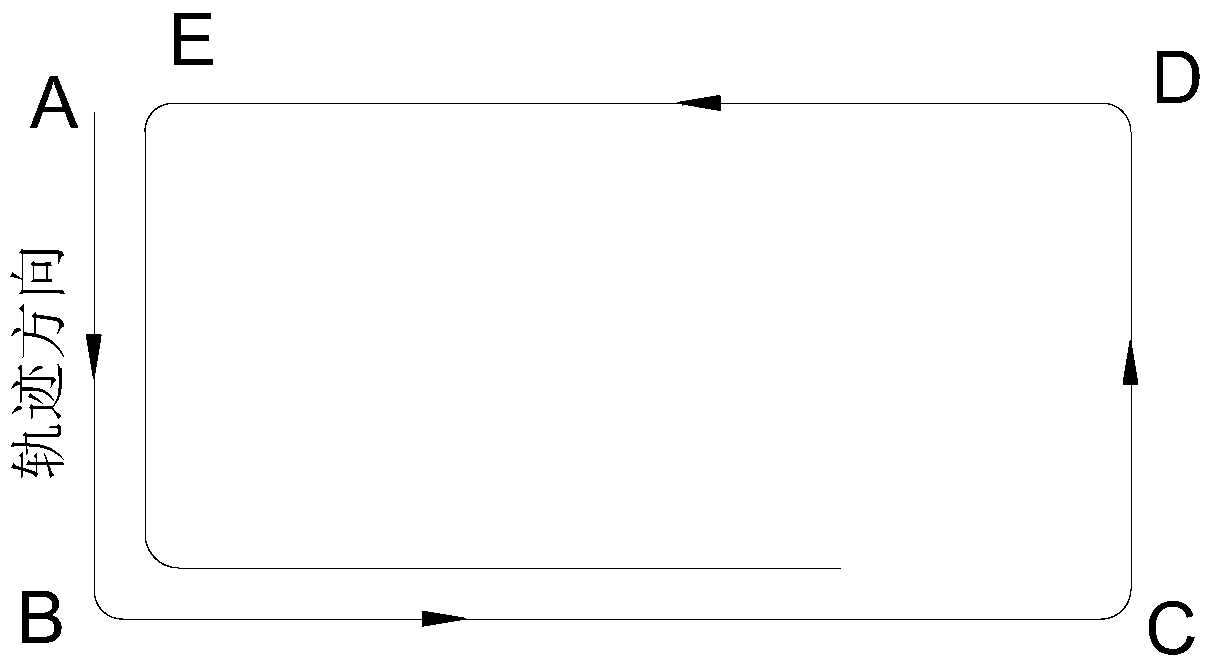

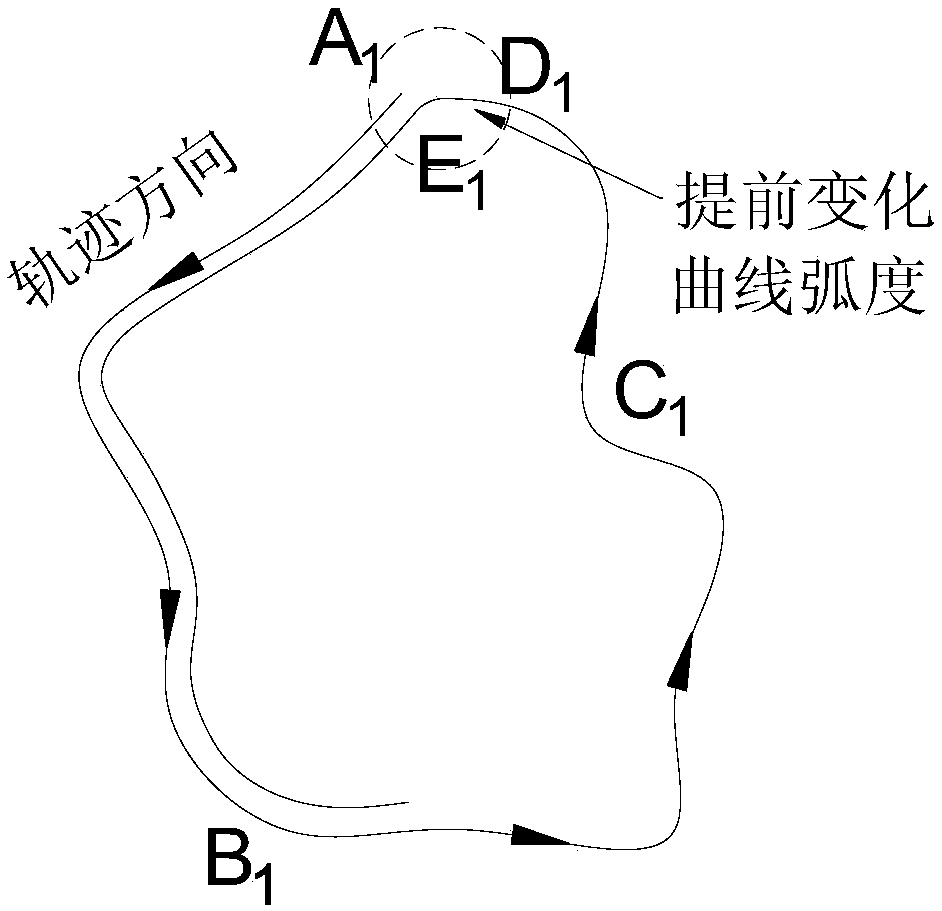

Typical path planning method for 3D (three-dimensional) printing of continuous fiber reinforced composites

ActiveCN108891029AGuaranteed mechanical propertiesReduce molding defectsAdditive manufacturing apparatusManufacturing data aquisition/processingProcess mechanismComputer Aided Design

The invention discloses a typical path planning method for 3D (three-dimensional) printing of continuous fiber reinforced composites and belongs to the field of rapid prototyping of the composites. Inthe method, a three-dimensional model is built by using CAD (computer aided design) modeling software according to actual size requirements of forming components and is subjected to slice stratification by the aid of the three-dimensional software to acquire profile and slice information; the degree of path bending is judged and corresponding path planning mechanisms are started, and with the help of the jump point processing mechanism, jump points can be accurately located and the action of the jump points is completed; fiber interlayer conversion without breakpoint is realized by using an interlayer path planning mechanism, and high quality and high efficiency three-dimensional printing new path of the continuous fiber reinforced composites is realized. In the method, the printing pathwith the least breakpoints is planned out, and mechanical property of the continuous fiber reinforced composites is guaranteed; forming defects in the bending of continuous fiber are effectively reduced, binding force of the continuous fiber in the bending is improved, and integral performance of the forming components is improved.

Owner:DALIAN UNIV OF TECH

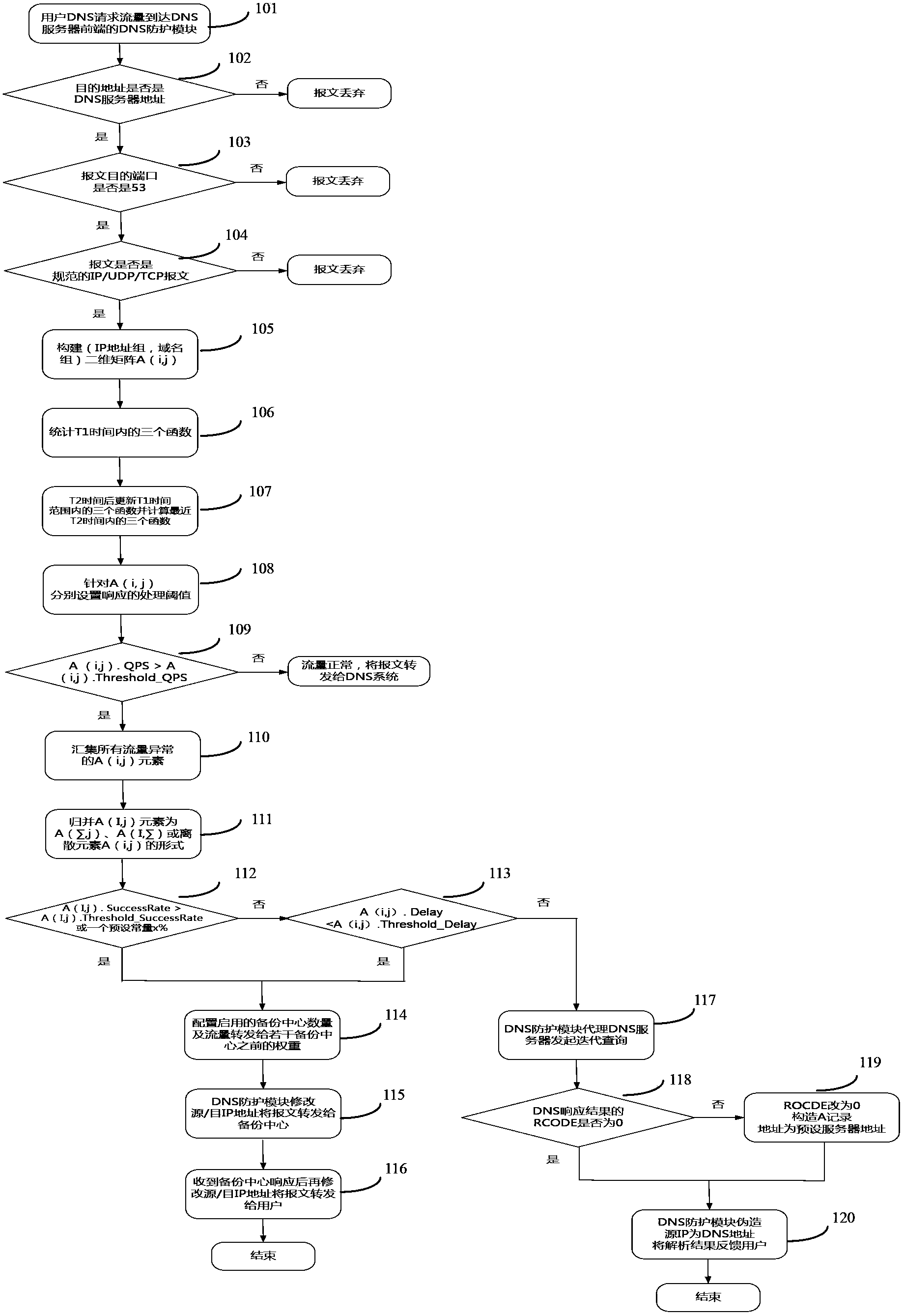

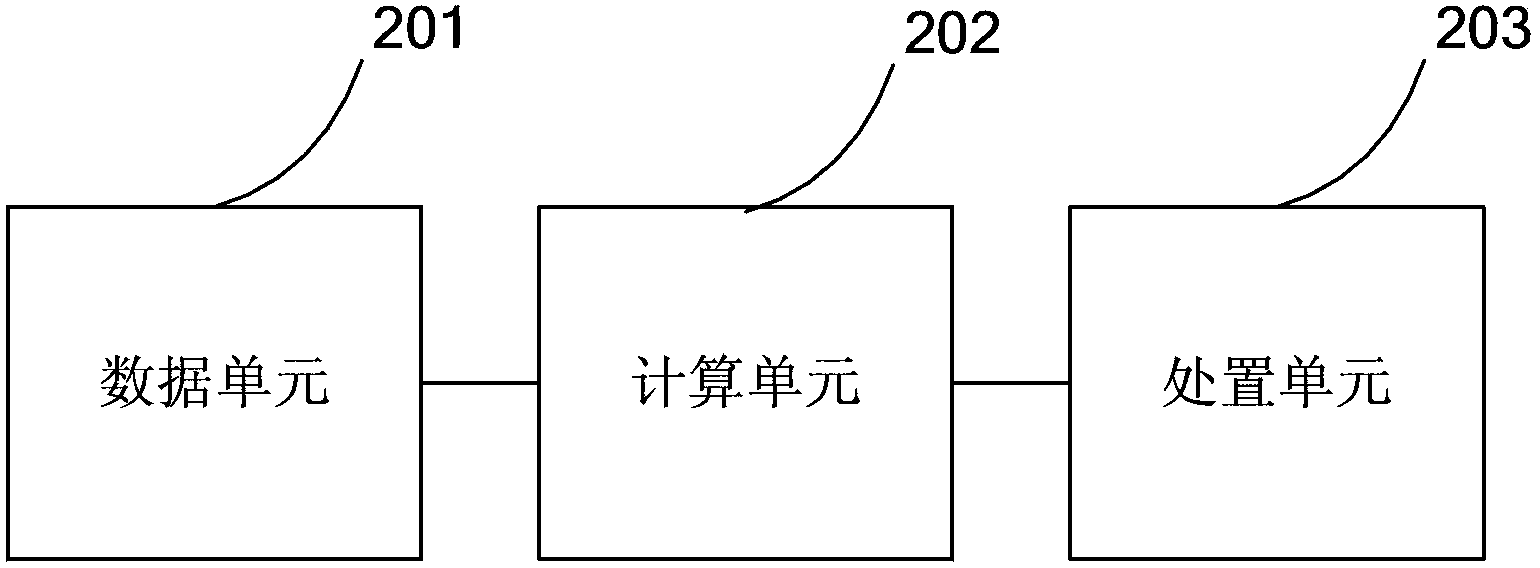

Method and system for protecting domain name system (DNS)

ActiveCN104079421AAvoid out of service problemsData switching networksTraffic characteristicDomain name

The invention discloses a method and a system for protecting a domain name system (DNS). The DNS traffic characteristics of an IP (Internet Protocol) address group and a domain name group are learned, two-dimensional matrix elements with abnormal DNS traffics are identified automatically, abnormal elements are judged through relations among elements in a matrix, and comparative analysis is performed on two functions, namely, a resolving delay threshold and a resolving success rate threshold, so that the abnormal traffics can be classified, and different processing mechanisms are triggered. By adopting two processing mechanisms, the problem of unavailable service of the DNS in a very long time period from the occurrence of a DNS failure to the startup of a backup center DNS server caused by the conventional scheme is solved.

Owner:CHINA MOBILE GRP BEIJING

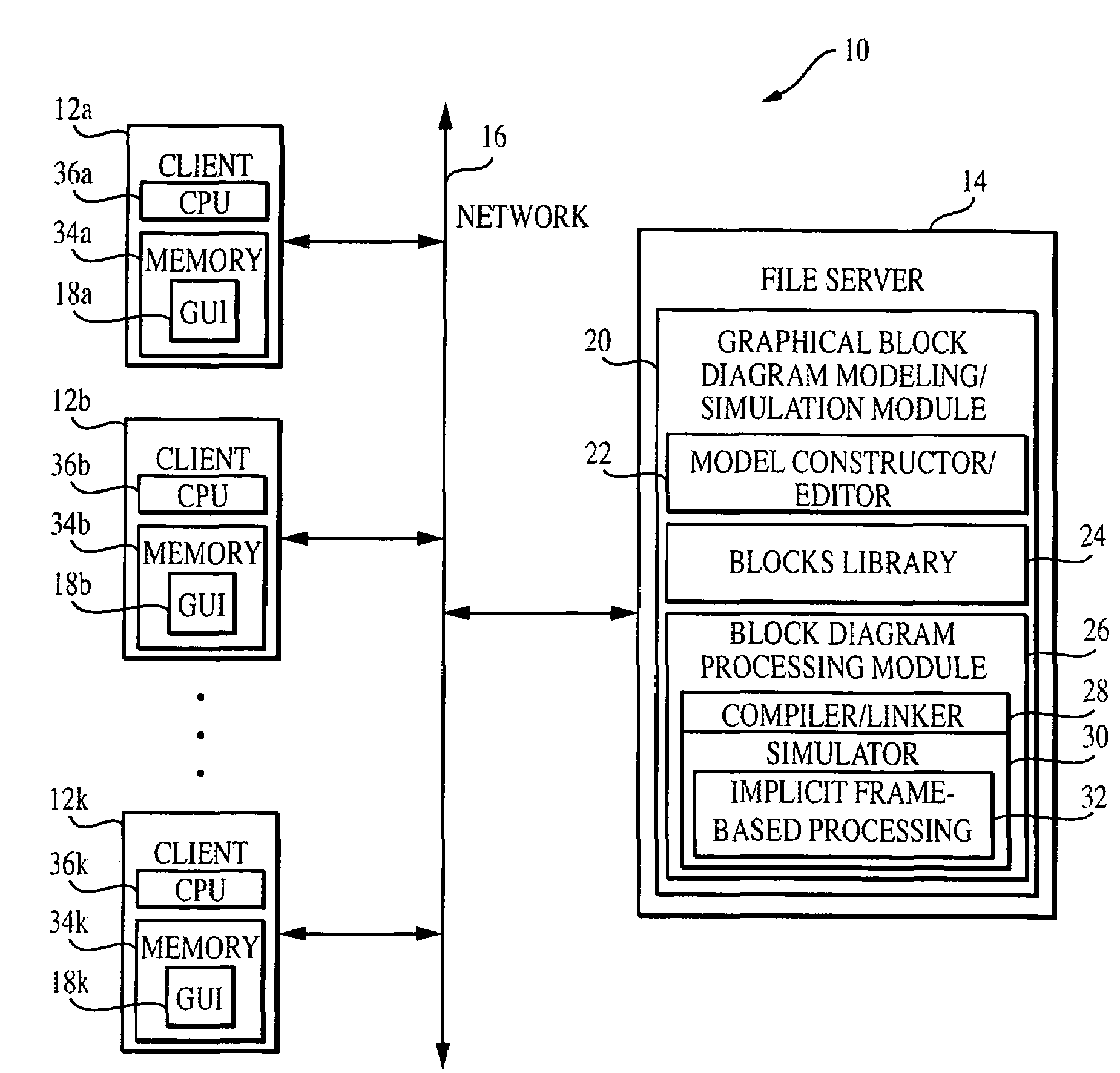

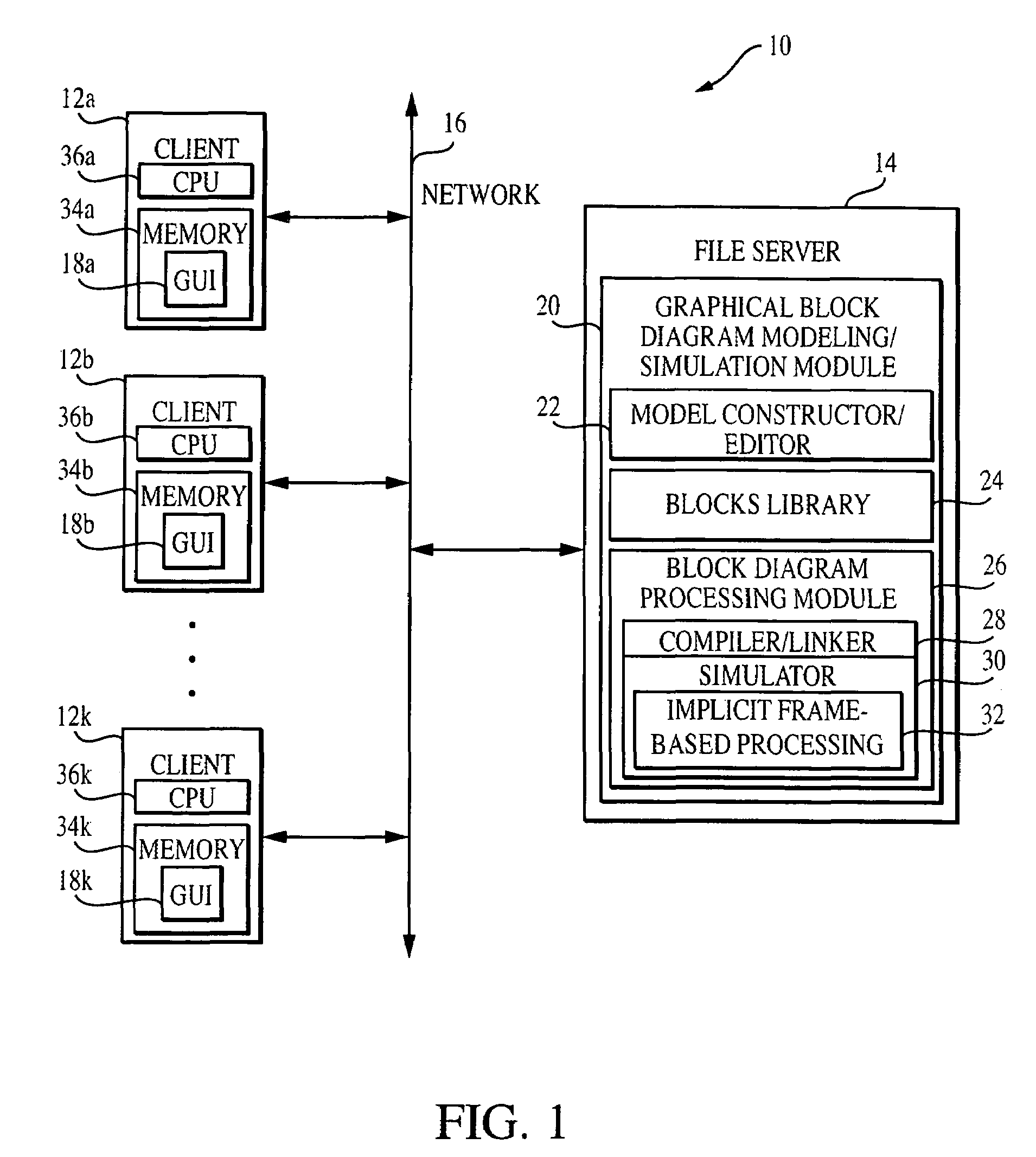

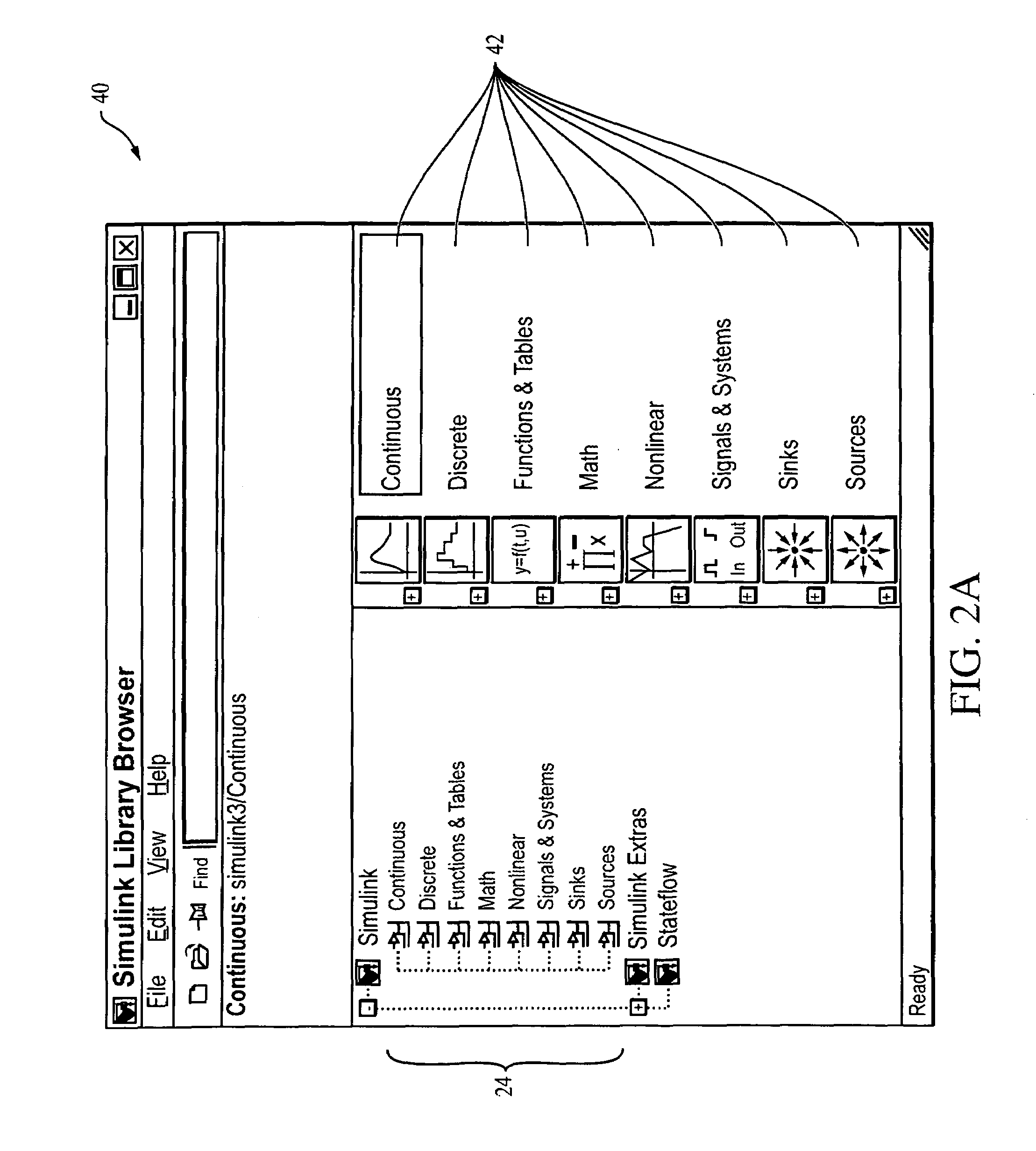

Implicit frame-based processing for block-diagram simulation

InactiveUS7275026B2Analogue computers for electric apparatusCathode-ray tube indicatorsProcess mechanismFrame based

A run-time, frame-based processing mechanism executes a block diagram model by propagating frame attributes information from blocks on which a user specified the frame attributes information to all other blocks in the block diagram model. The frame attributes information includes an indicator that specifies whether or not the data flowing from one block to another is sample-based or frame-based, as well as the size of the frame in terms of number of samples and number of channels.

Owner:THE MATHWORKS INC

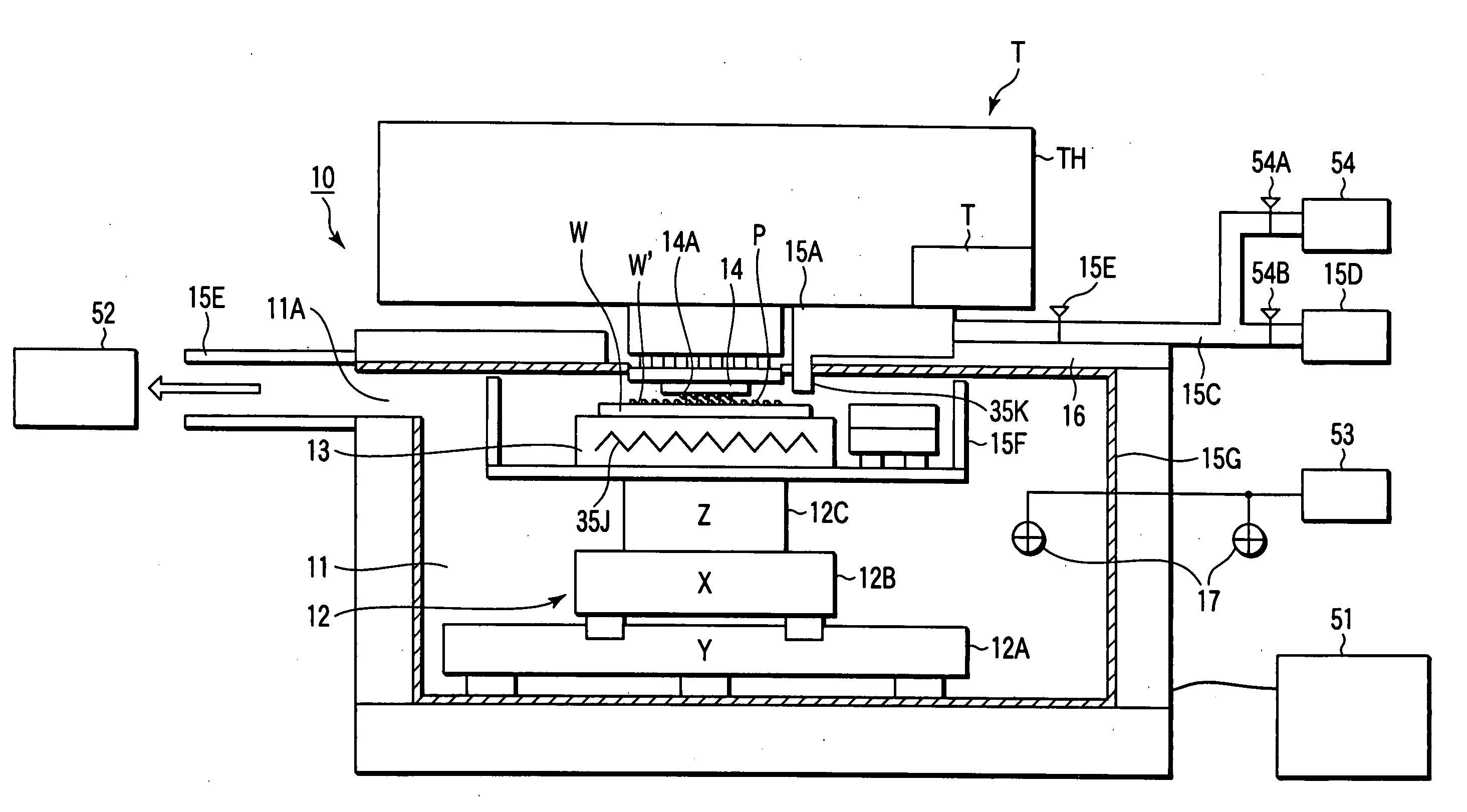

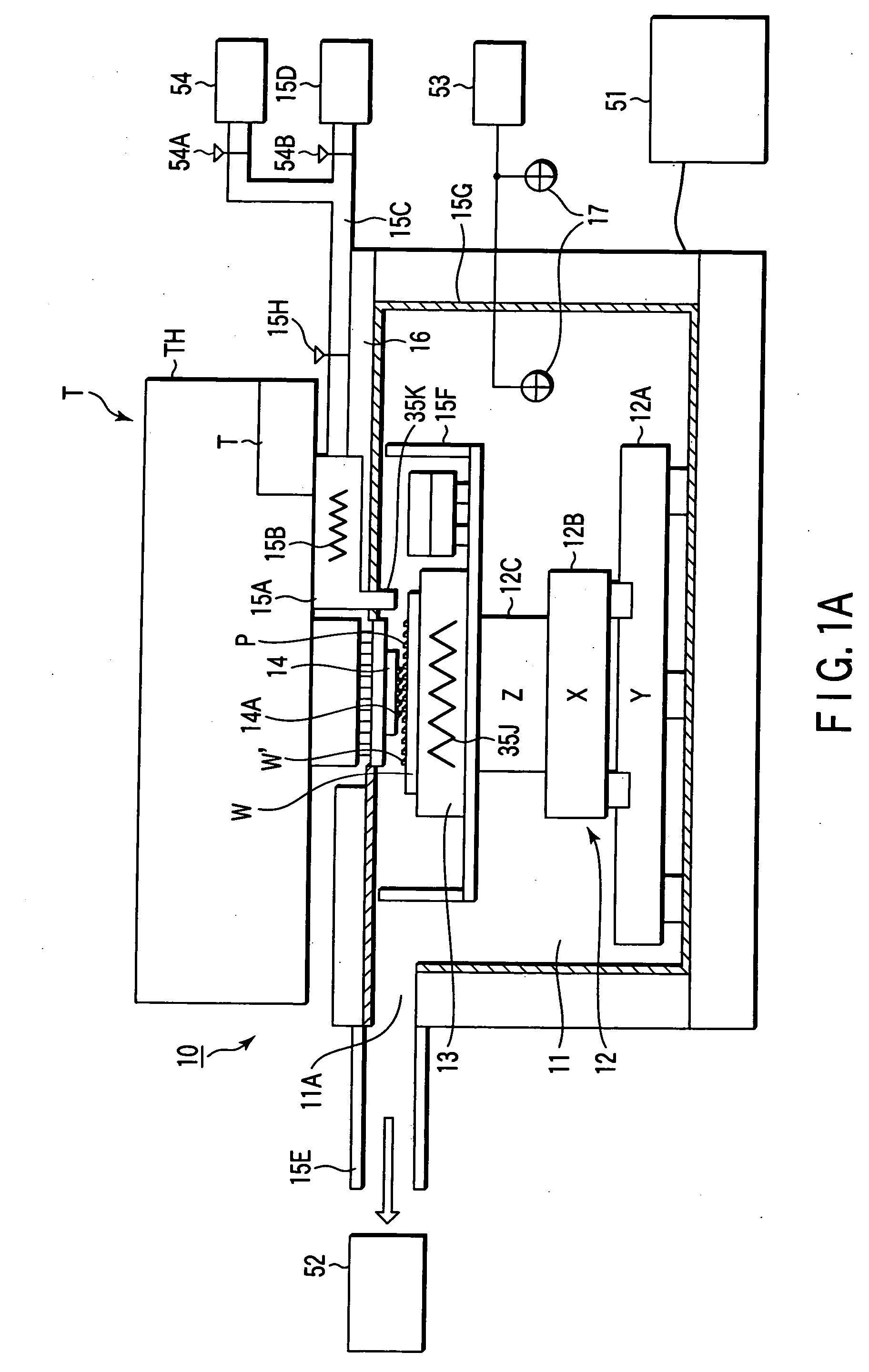

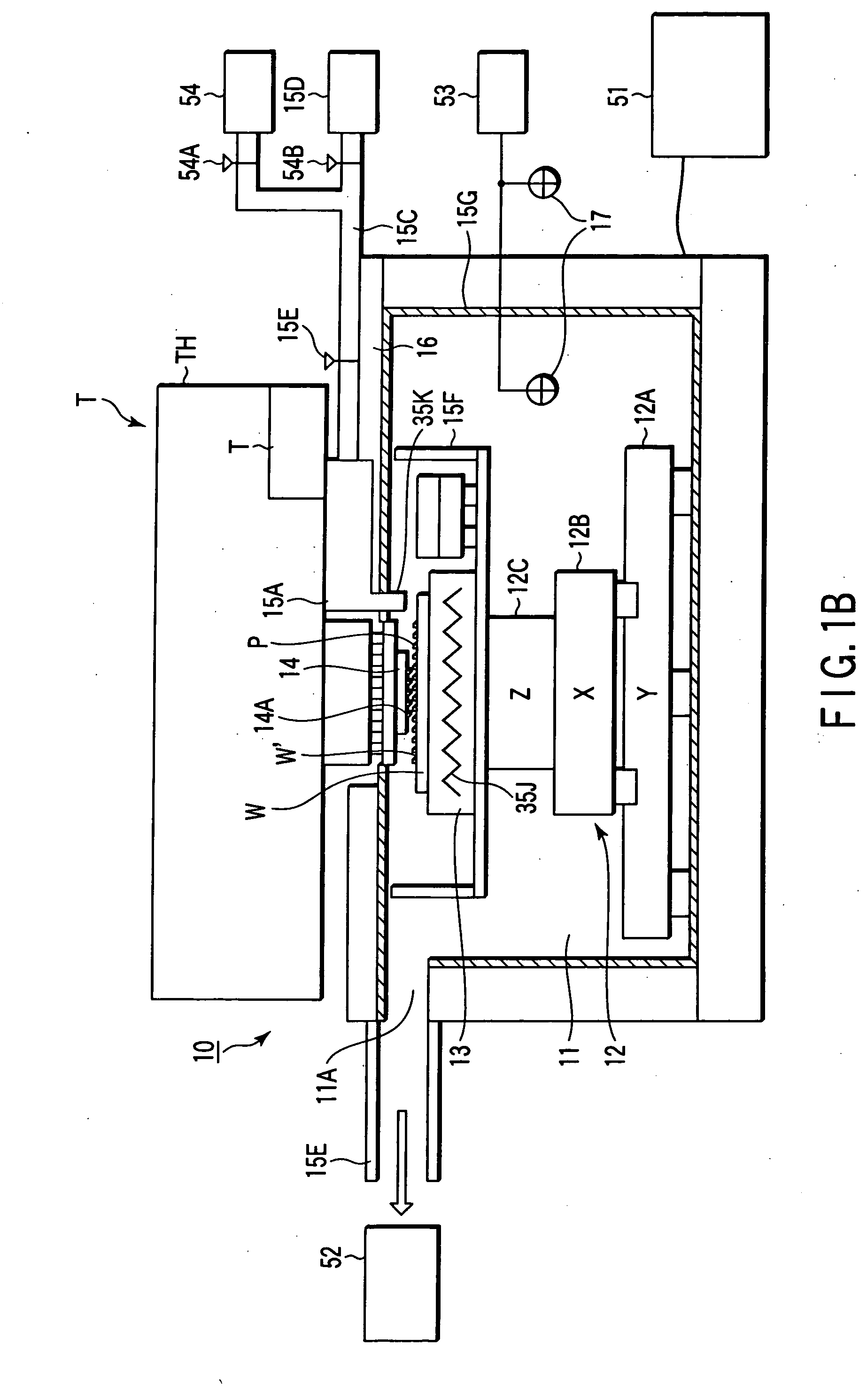

Probe method, prober, and electrode reducing/plasma-etching processing mechanism

InactiveUS20050151549A1Reduce oxideReduce harmElectronic circuit testingProcess mechanismForming gas

A probe method of this invention includes a step of reducing an electrode of a wafer by using a forming gas, and a step of bringing the electrode and a probe pin into contact with each other in a dry atmosphere. The probe method further includes, prior to a reducing process of an electrode of the object to be tested, placing the object to be tested in an inert gas atmosphere and heating the object to be tested. The reducing process is performed by bringing a reducing gas into contact with the electrode of the object to be tested under atmospheric pressure.

Owner:OCTEC INC +1

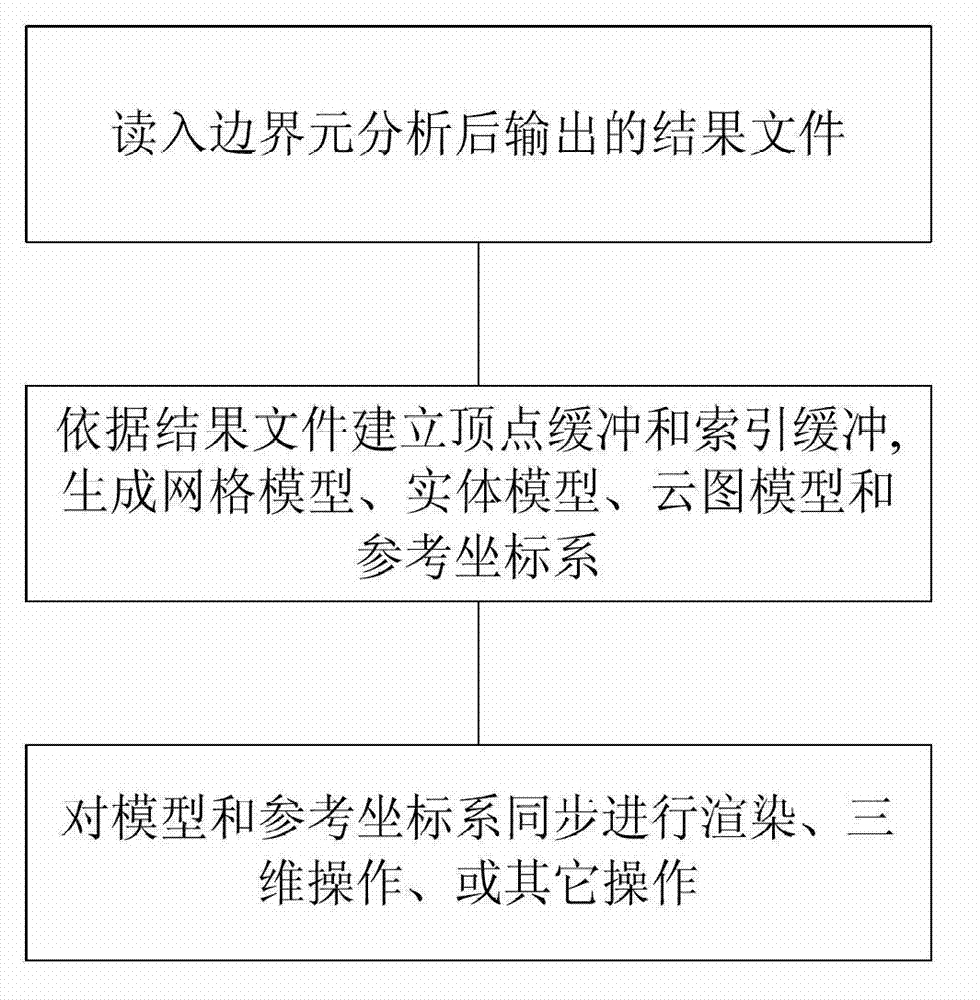

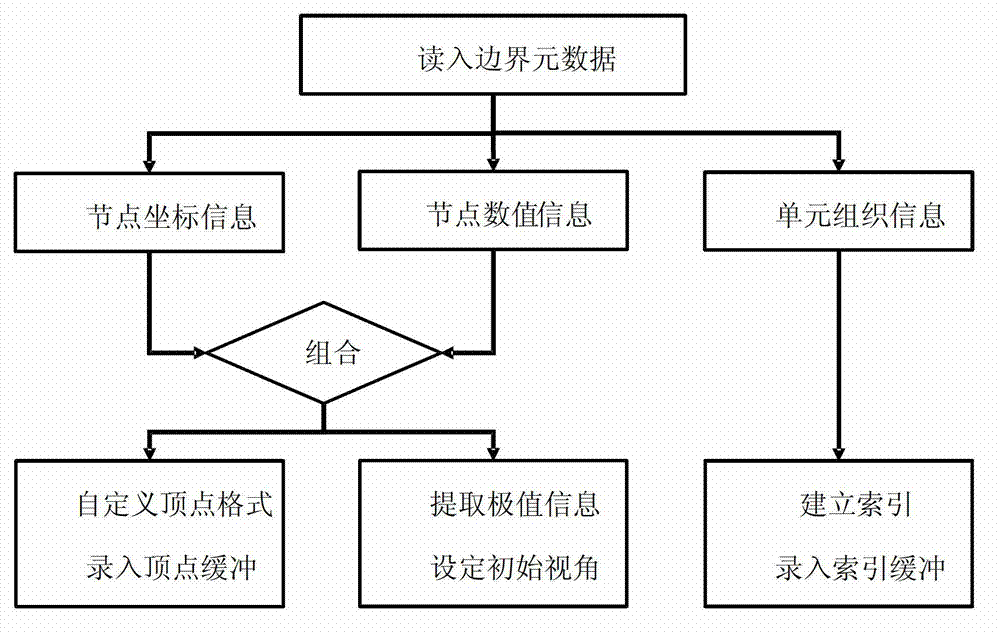

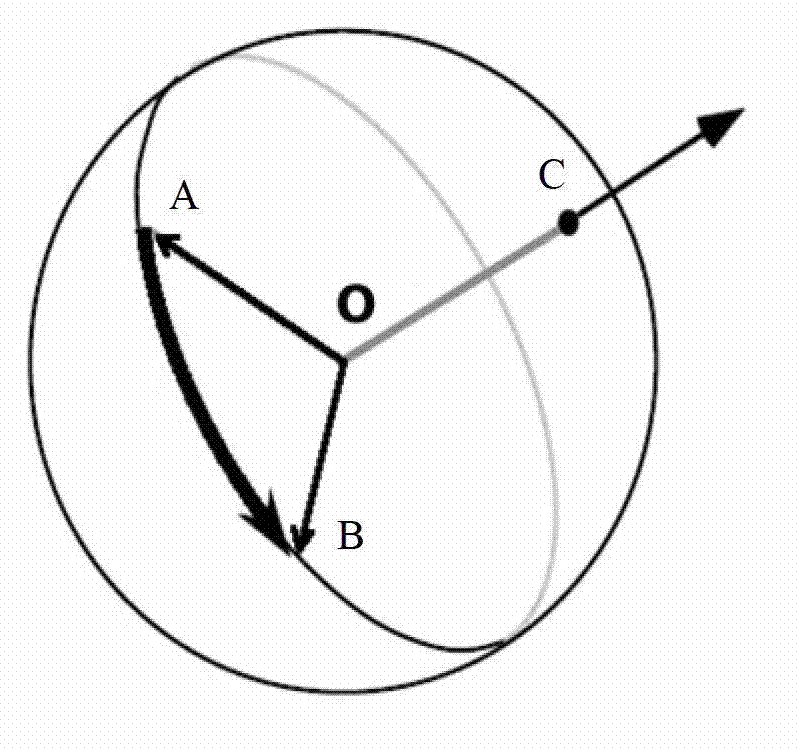

Three-dimensional visualization simulation method directed at boundary element analysis

ActiveCN102902848AMeet the task requirementsFlexible Processing MechanismSpecial data processing applications3D-image renderingProcess mechanismEntity model

The invention discloses a three-dimensional visualization simulation method directed at boundary element analysis. The three-dimensional visualization simulation method comprises reading in result documents output after the boundary element analysis; establishing vertex buffers and index buffers, and recording node coordinate information and node numerical value information into the vertex buffers and unit organization information into the index buffers to generate grid models, entity models, cloud models and reference coordinate systems; and performing rendering, three-dimensional operation or other operation synchronously on the models and the reference coordinate systems. The method processes the result documents after the boundary element analysis, only fundamental information of construction models and clouds is needed to be input, no special requirement exists for formats, and common business engineering software of Ansys, Patran, Sesam and the like can be used for providing input information. The method has a flexible processing mechanism, wide applicability and good practical engineering application values.

Owner:DALIAN UNIV OF TECH

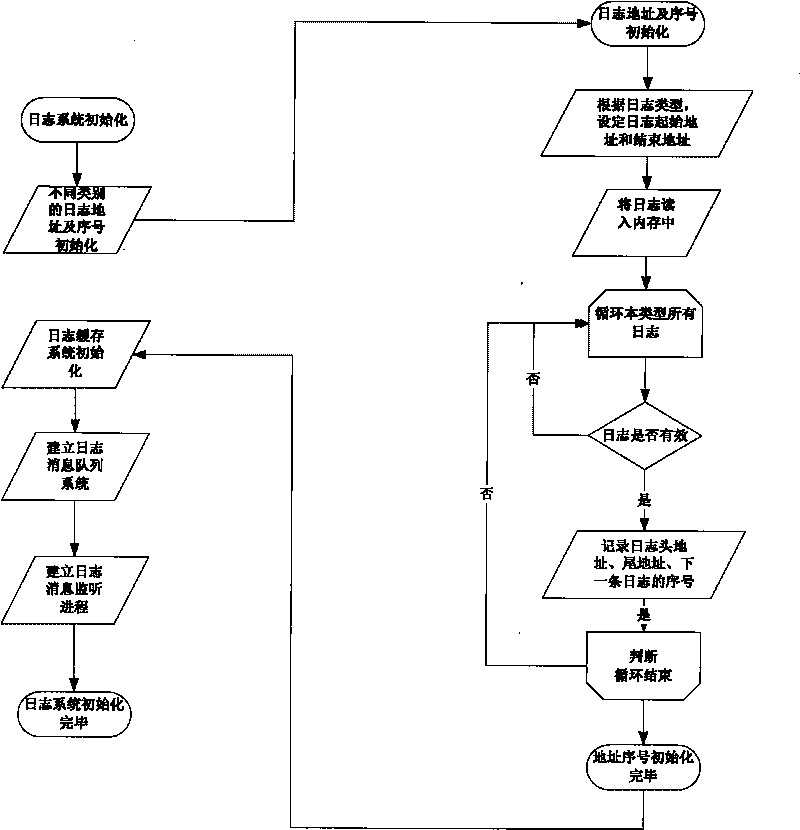

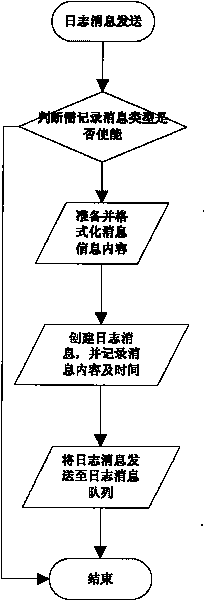

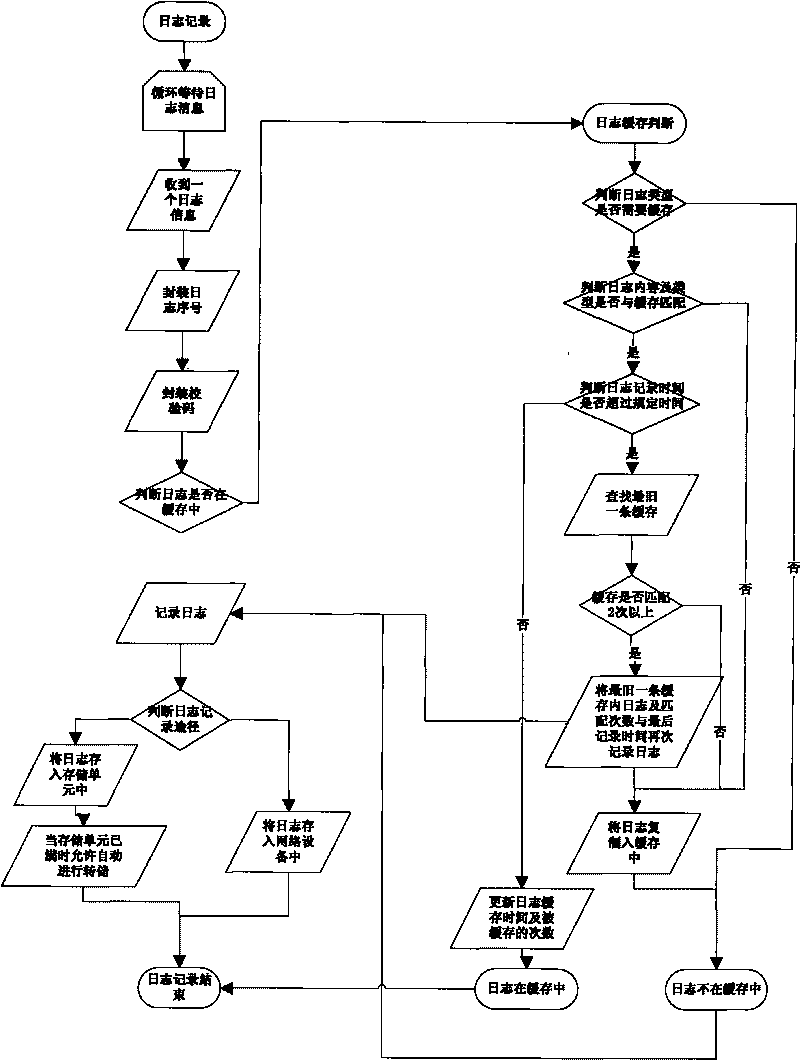

Method for realizing log function

ActiveCN101729295AStrong log analysis and statistics functionAvoid paralysisData switching networksProcess mechanismEmbedded system

The invention discloses a method for realizing a log function, which aims to provide a method for recording and viewing the log function of communication equipment. Key points of the technical scheme thereof are that: the method for realizing the log function utilizes a message mechanism to transmit log information inside the system of the communication equipment, and utilizes a process mechanism to receive and store the log information; a cache system is used for matching logs with same content in short time, and reducing the storage times of repeated logs; and a storage system can write the logs into an internal storage unit or network storage equipment, and the logs in the internal storage unit also allow to be automatically or manually transferred to the network storage equipment. The use of the invention is to provide a safe, conveniently used and flexible method for recording and viewing the log function of the communication equipment. The method can effectively avoid the paralysis of the log function caused by the attack of broadcast and unicast storms.

Owner:KYLAND TECH CO LTD

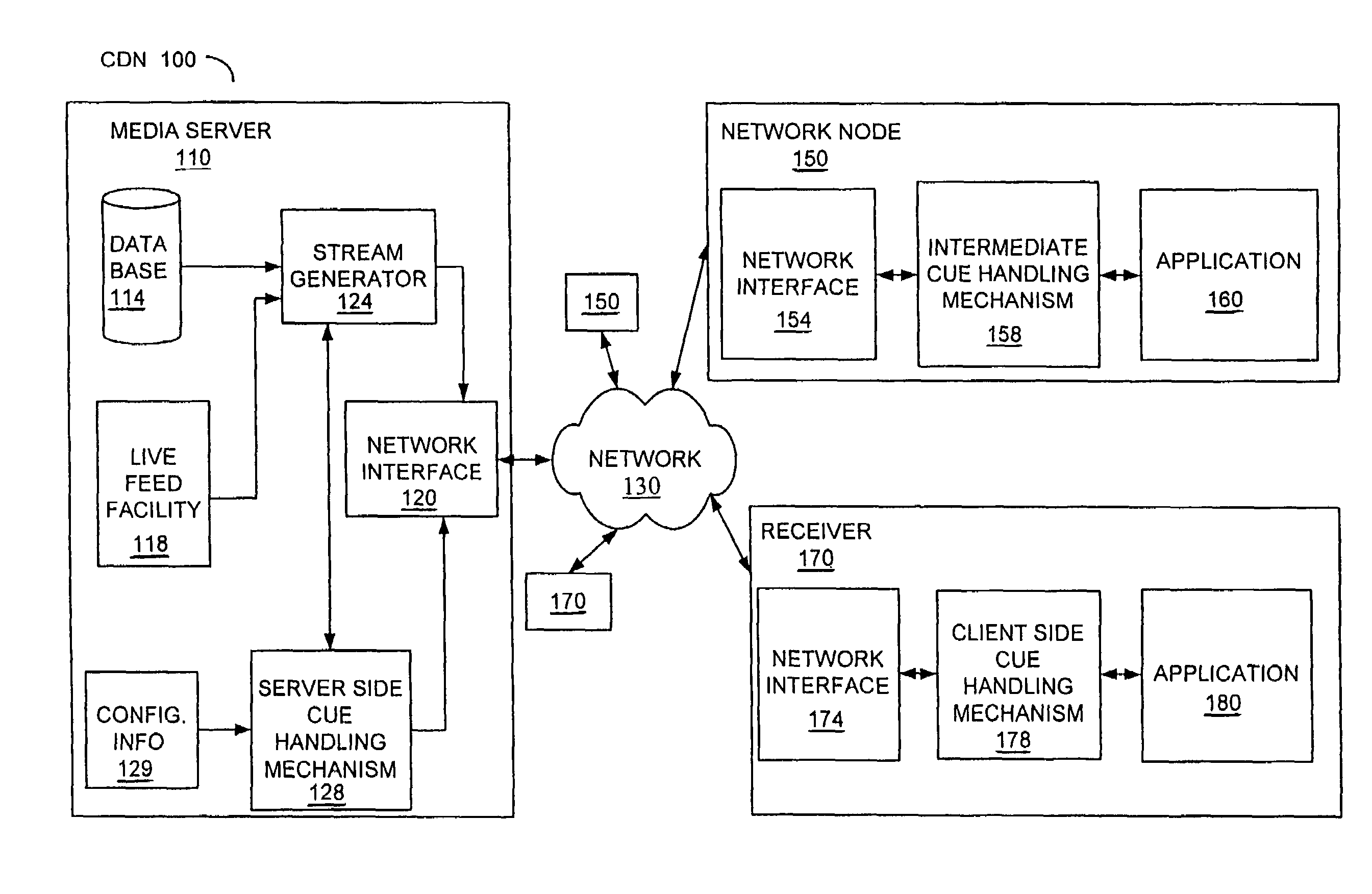

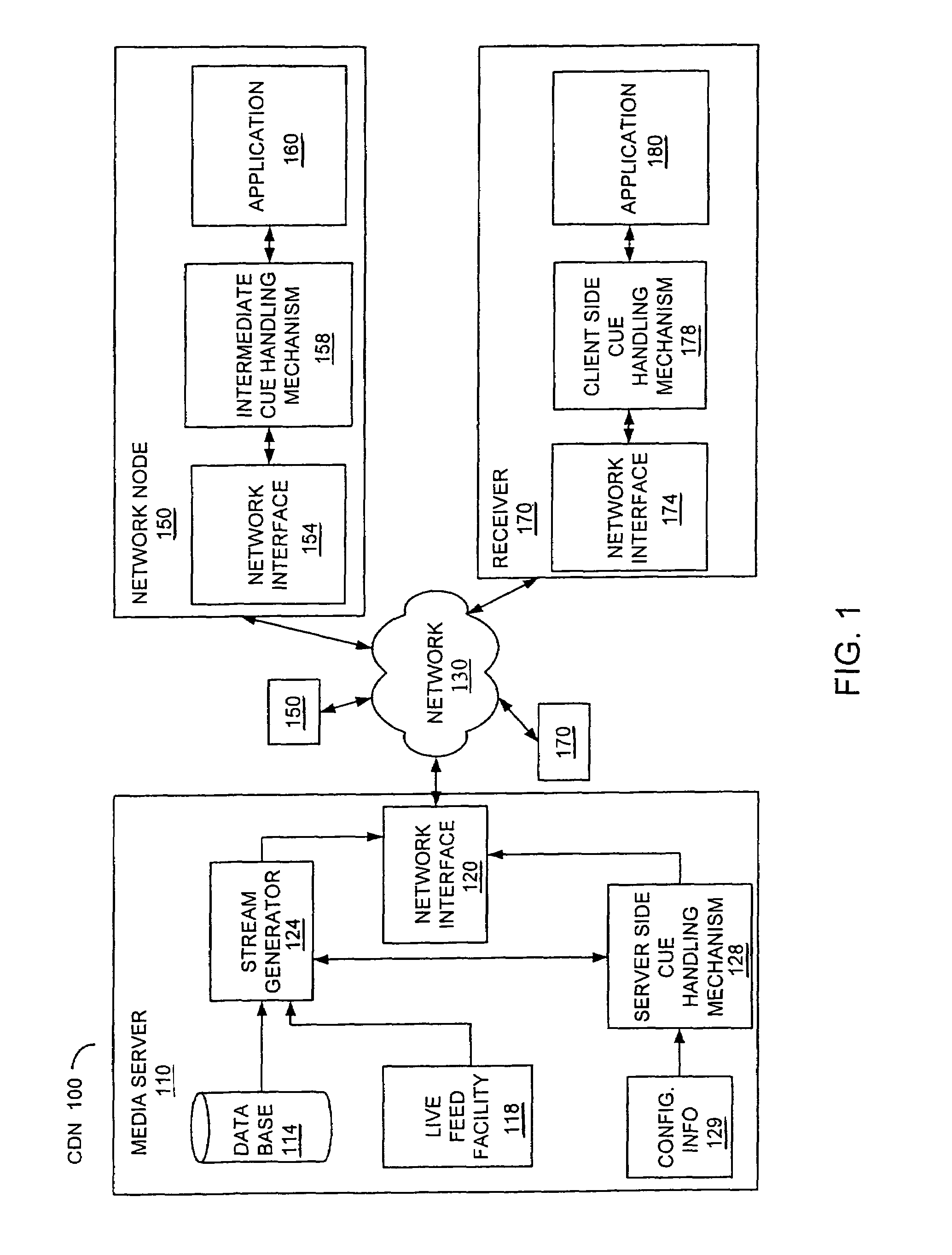

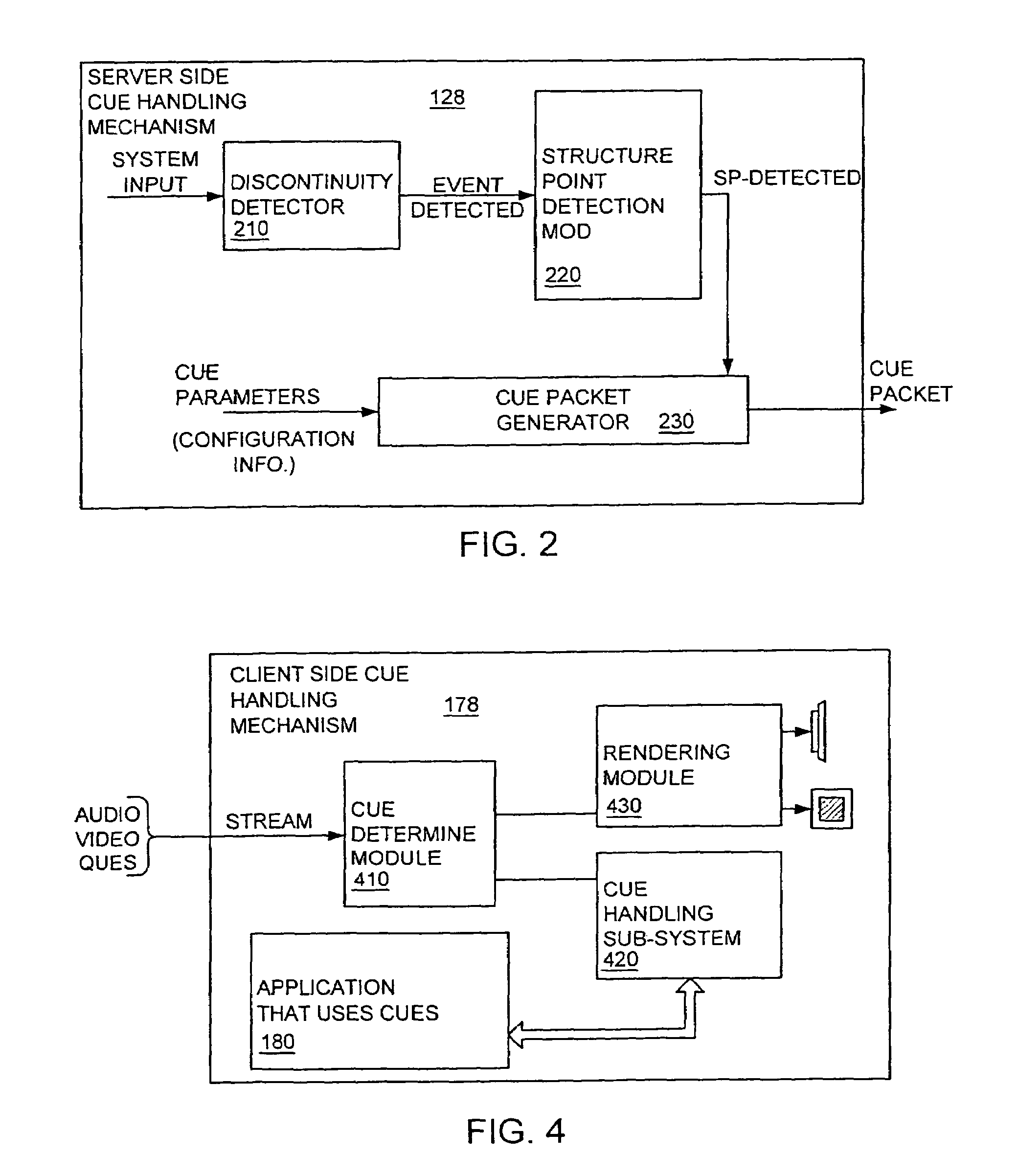

Media program timing and identity delivery method and system

InactiveUS7530086B2Easy to processMultiple digital computer combinationsTwo-way working systemsProgram segmentProcess mechanism

A method and system for delivering program timing, structure, and identity information in media streams. Cues are utilized to indicate an event (e.g., a start or stop time of a program or program segment) whose precise timing is important to receivers. A server-side cue handling mechanism is provided for selectively generating cues based on configuration information and detected events. A client-side cue handling mechanism is provided for detecting cues and providing the cues to applications that can utilize the cues to perform a useful function or task.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com