Patents

Literature

63results about How to "Reduce oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

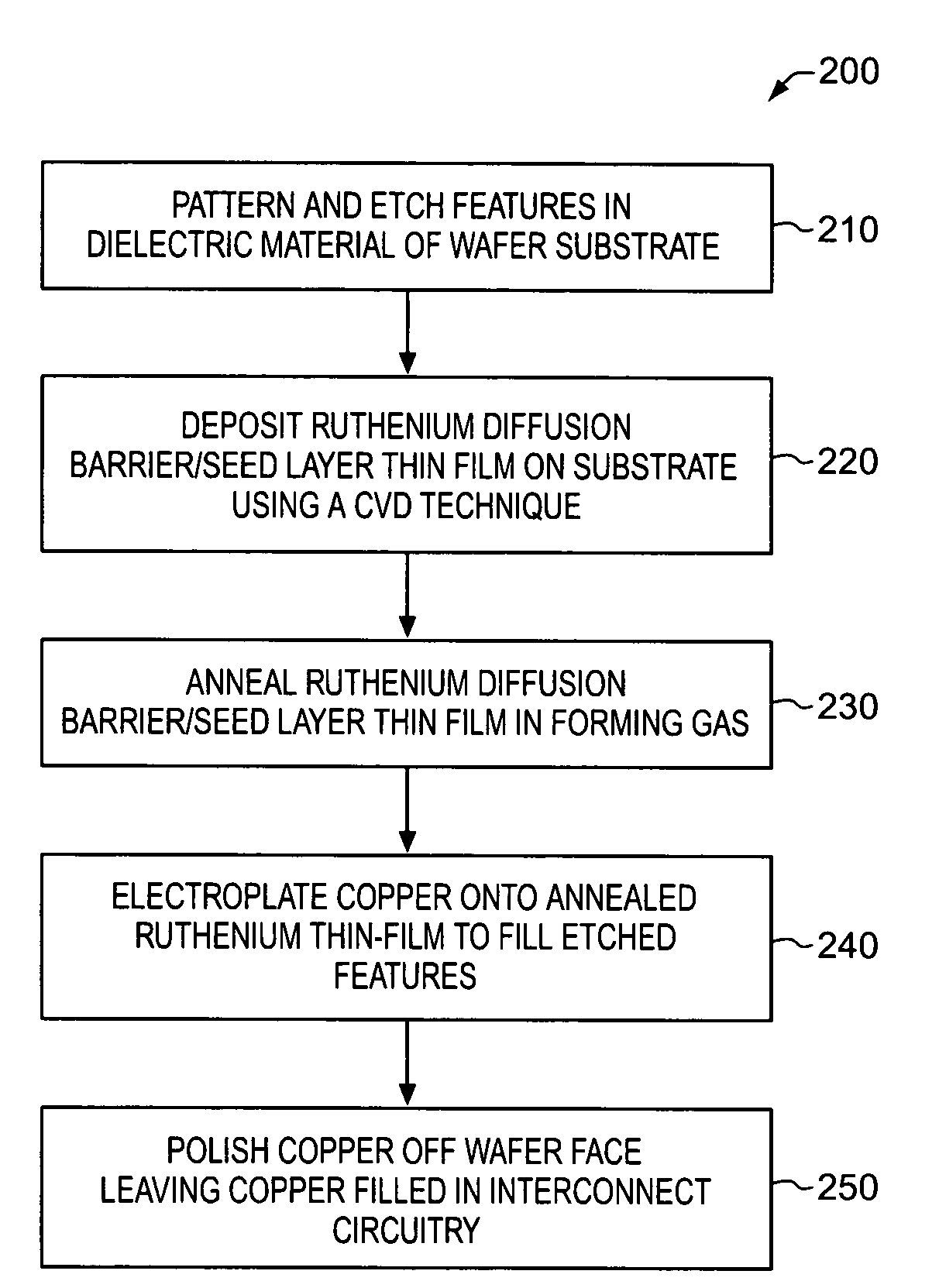

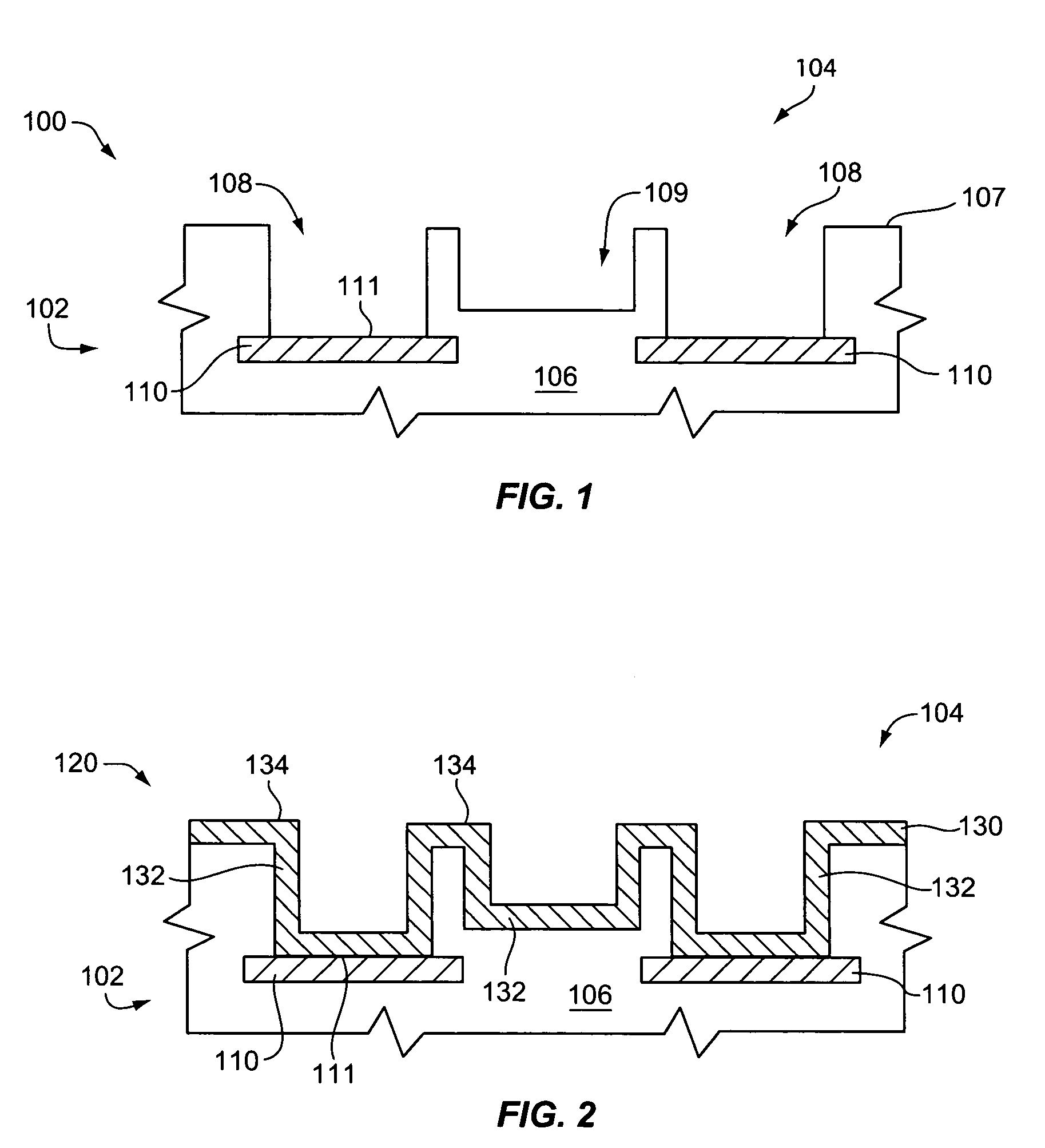

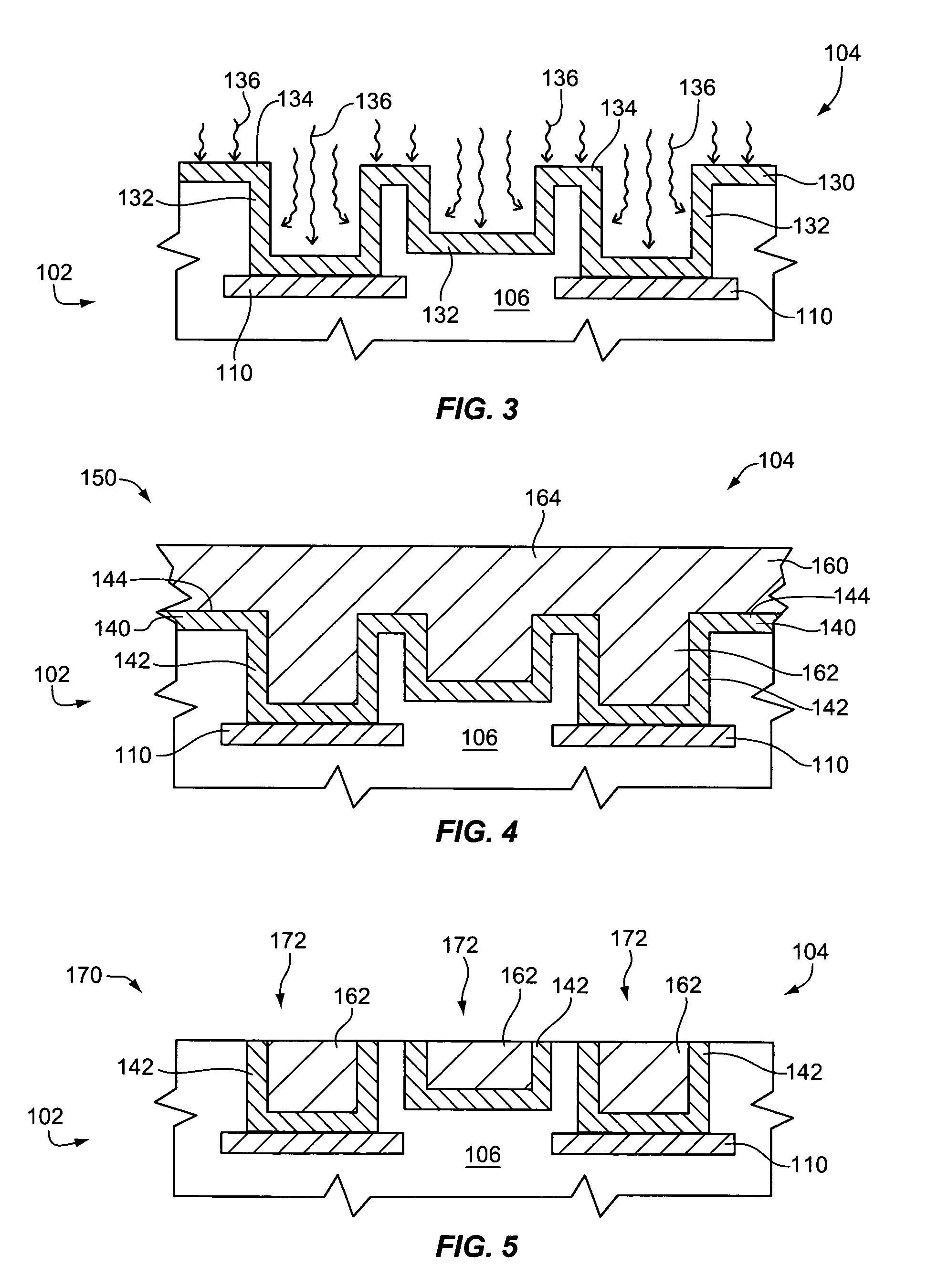

Anneal of ruthenium seed layer to improve copper plating

InactiveUS7442267B1Reduce oxideReduce the impactVacuum evaporation coatingSurface reaction electrolytic coatingCopper platingRuthenium

A ruthenium-containing thin film is formed. Typically, the ruthenium-containing thin film has a thickness in a range of about from 1 nm to 20 nm. The ruthenium-containing thin film is annealed in an oxygen-free atmosphere, for example, in N2 forming gas, at a temperature in a range of about from 100° C. to 500° C. for a total time duration of about from 10 seconds to 1000 seconds. Thereafter, copper or other metal is deposited by electroplating or electroless plating onto the annealed ruthenium-containing thin film. In some embodiments, the ruthenium-containing thin film is also treated by UV radiation.

Owner:NOVELLUS SYSTEMS

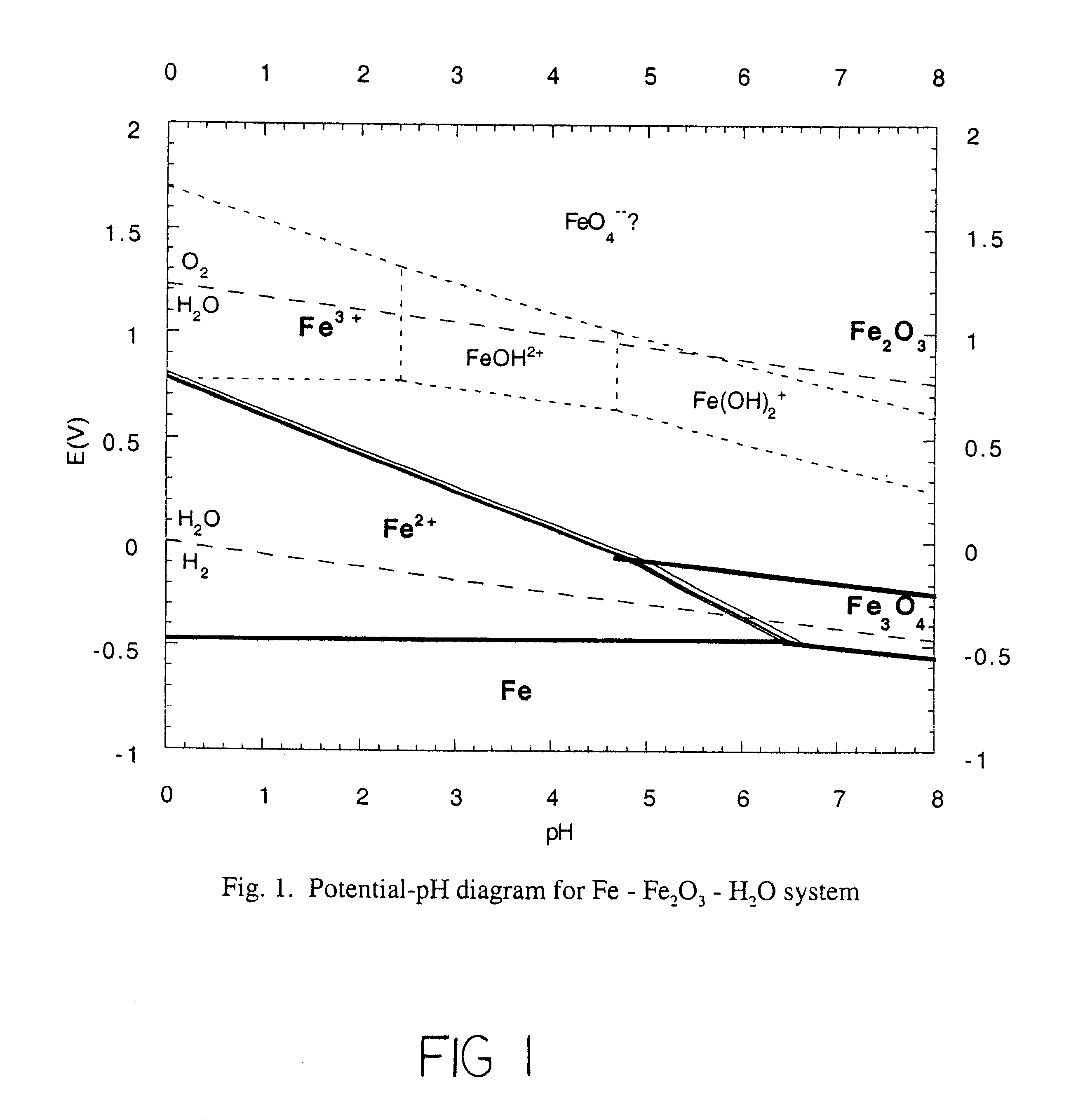

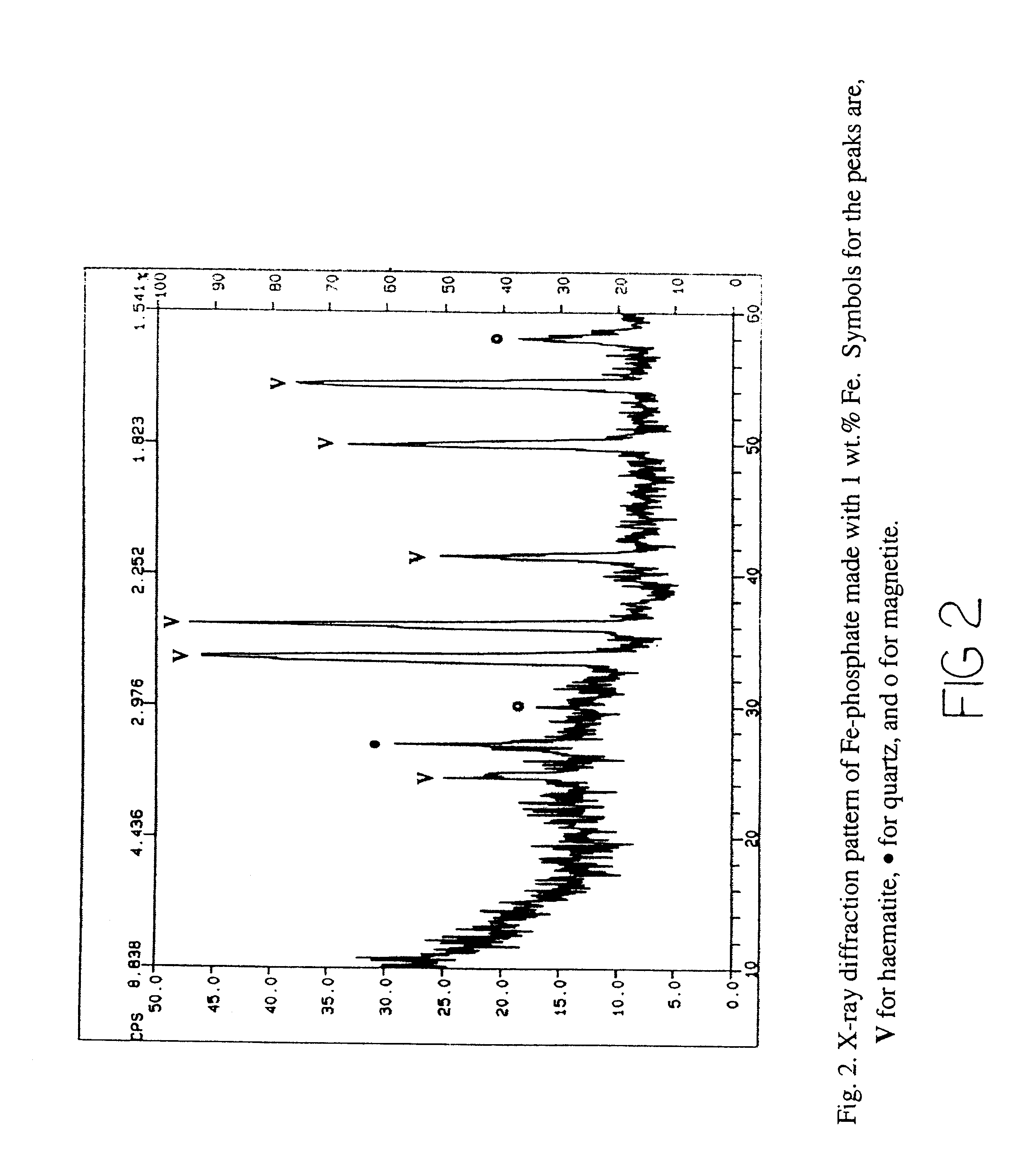

Chemically bonded phosphate ceramics of trivalent oxides of iron and manganese

A new method for combining elemental iron and other metals to form an inexpensive ceramic to stabilize arsenic, alkaline red mud wastes, swarfs, and other iron or metal-based additives, to create products and waste forms which can be poured or dye cast.

Owner:CHICAGO UNIV OF +1

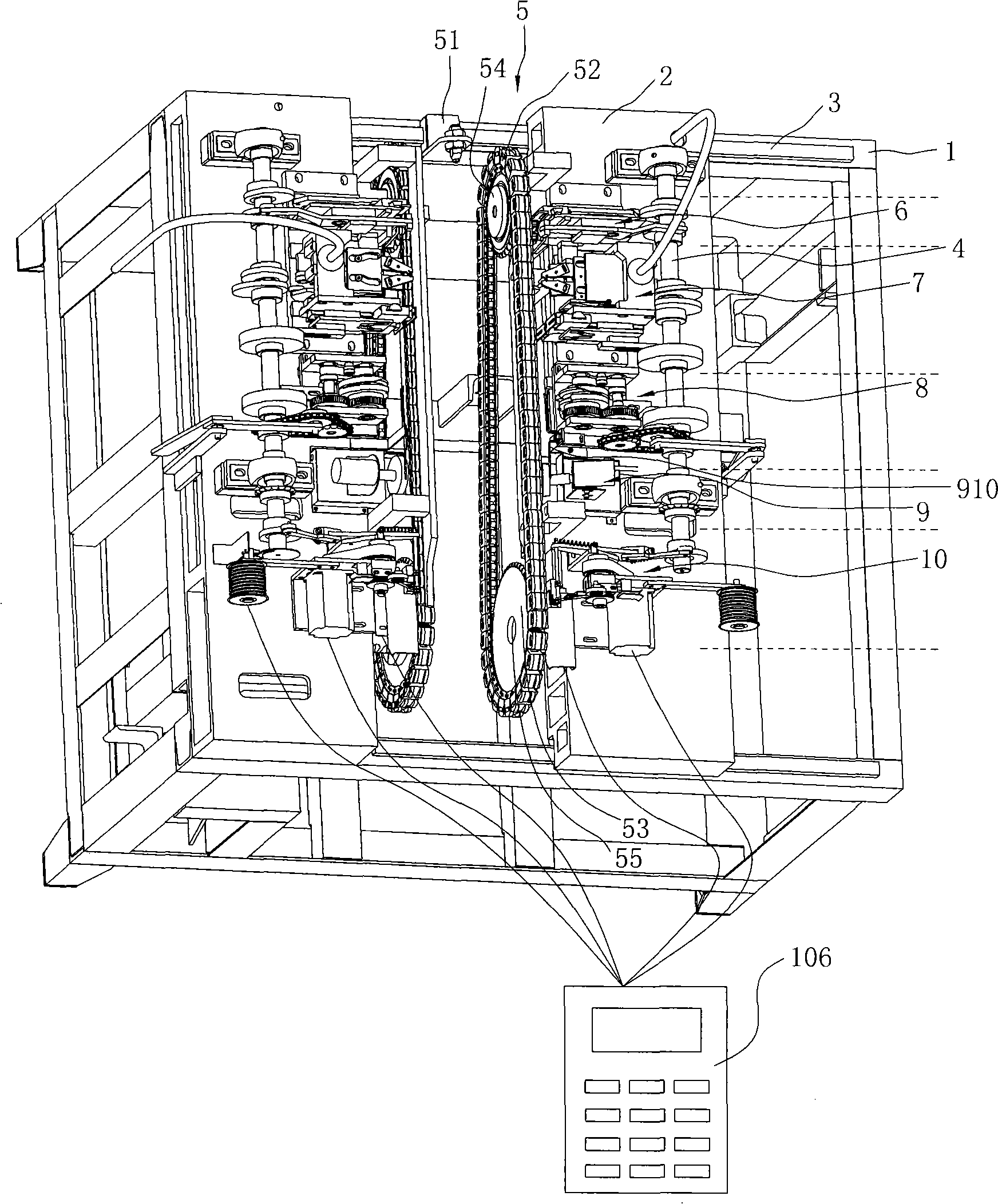

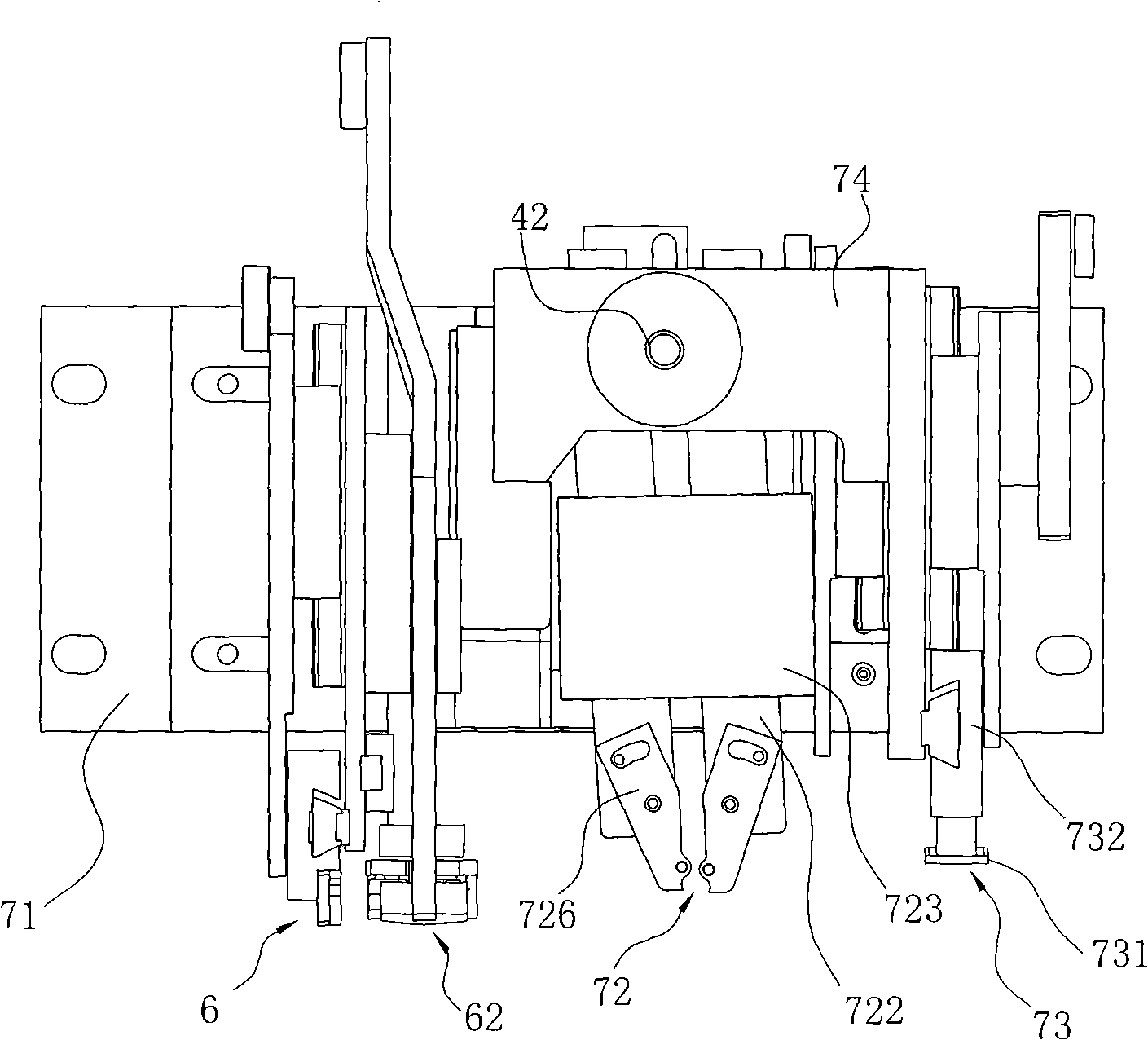

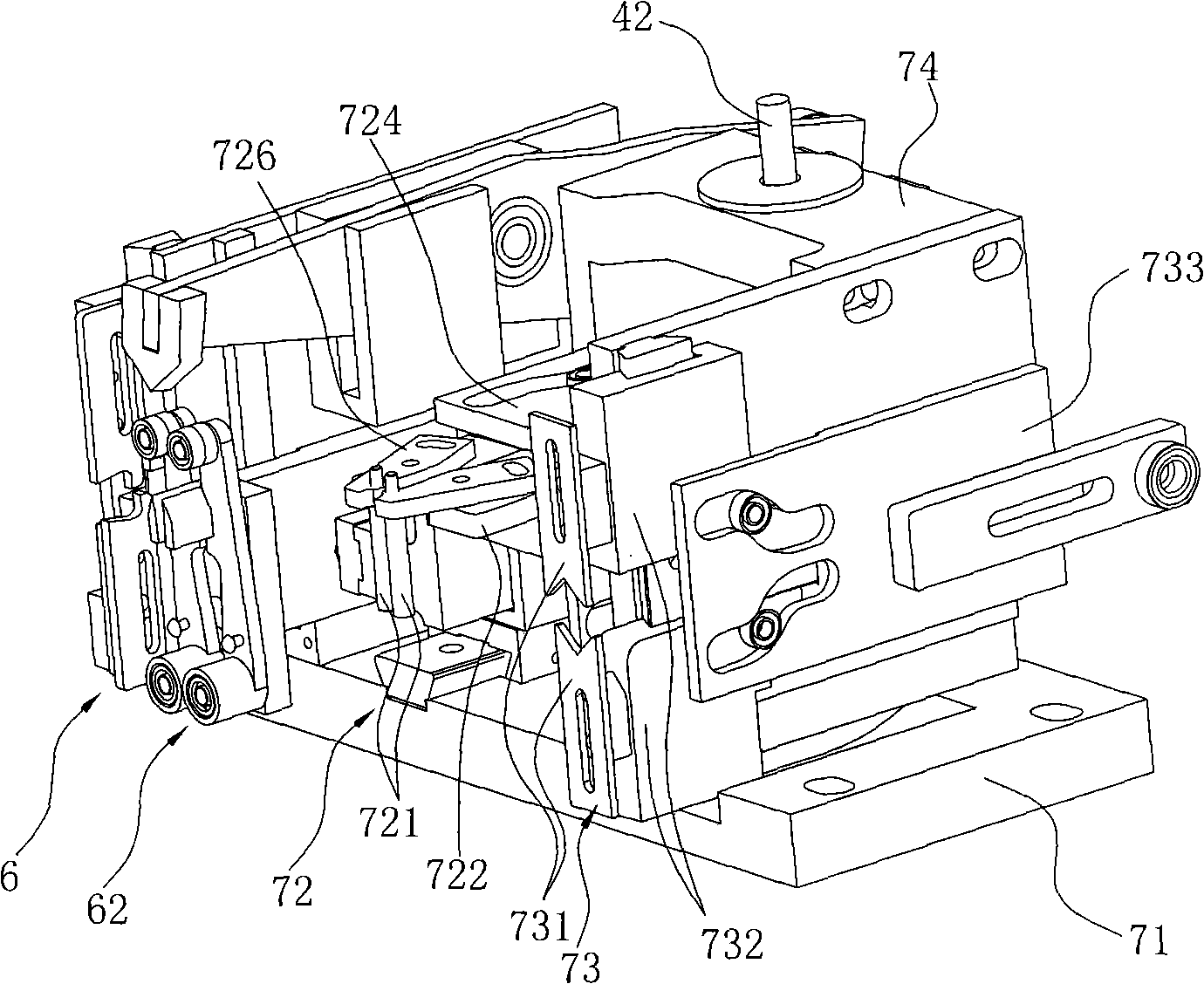

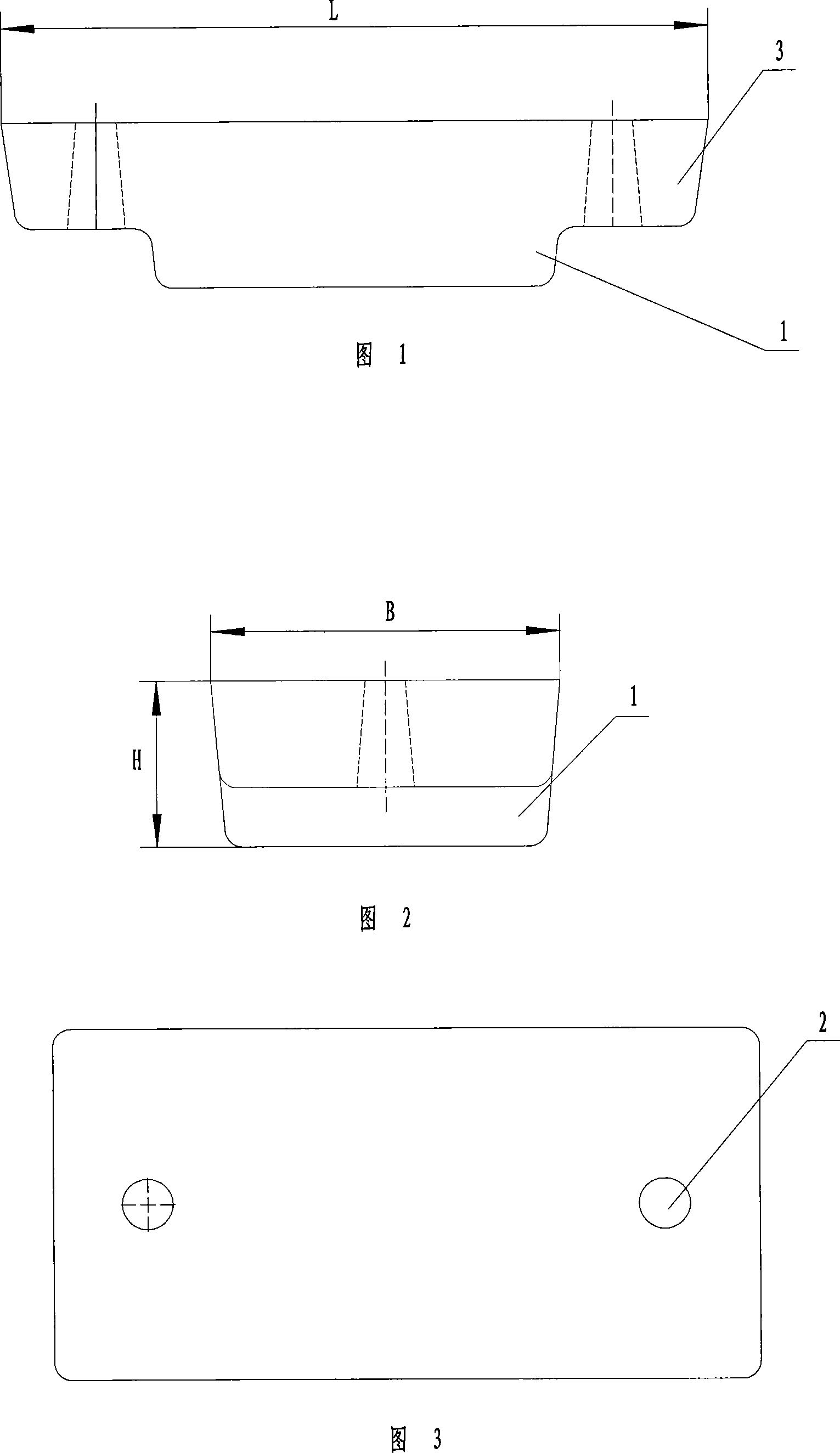

Automatic wire-stripping tin plating machine

An automatic wire stripping soldering machine belongs to the lead processing mechanical field. The prior art has unitary function and does not realize the mechanical lead soldering. The invention comprises a frame, a power transmission device mounted on the frame, a working table and a wire transmission device; the working table is parallely provided with a lead cutting device driven by the power transmission device and a wire separating device; the wire transmission device comprises a wire transmission machine and a lead transmission chain; the wire transmission machine is arranged on the frame on one side of the wire transmission gear and is connected with the power transmission device; the invention is characterize in the that: the working table on the other side of the wire separating device is orderly provided with a wire stripping device and a lead soldering device along the moving direction of the lead transmission chain; it has the advantages of realizing the lead mechanical soldering.

Owner:吴志浩

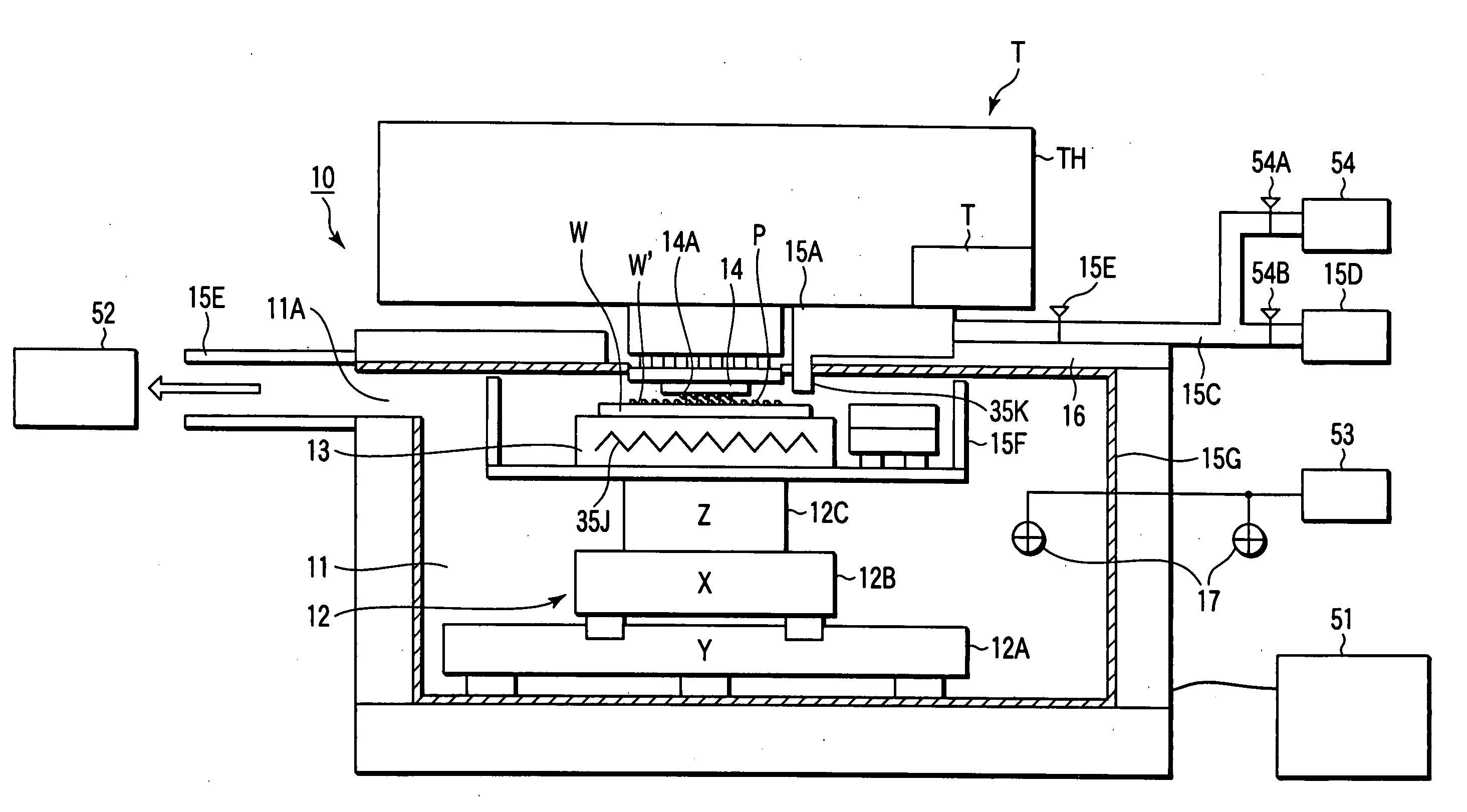

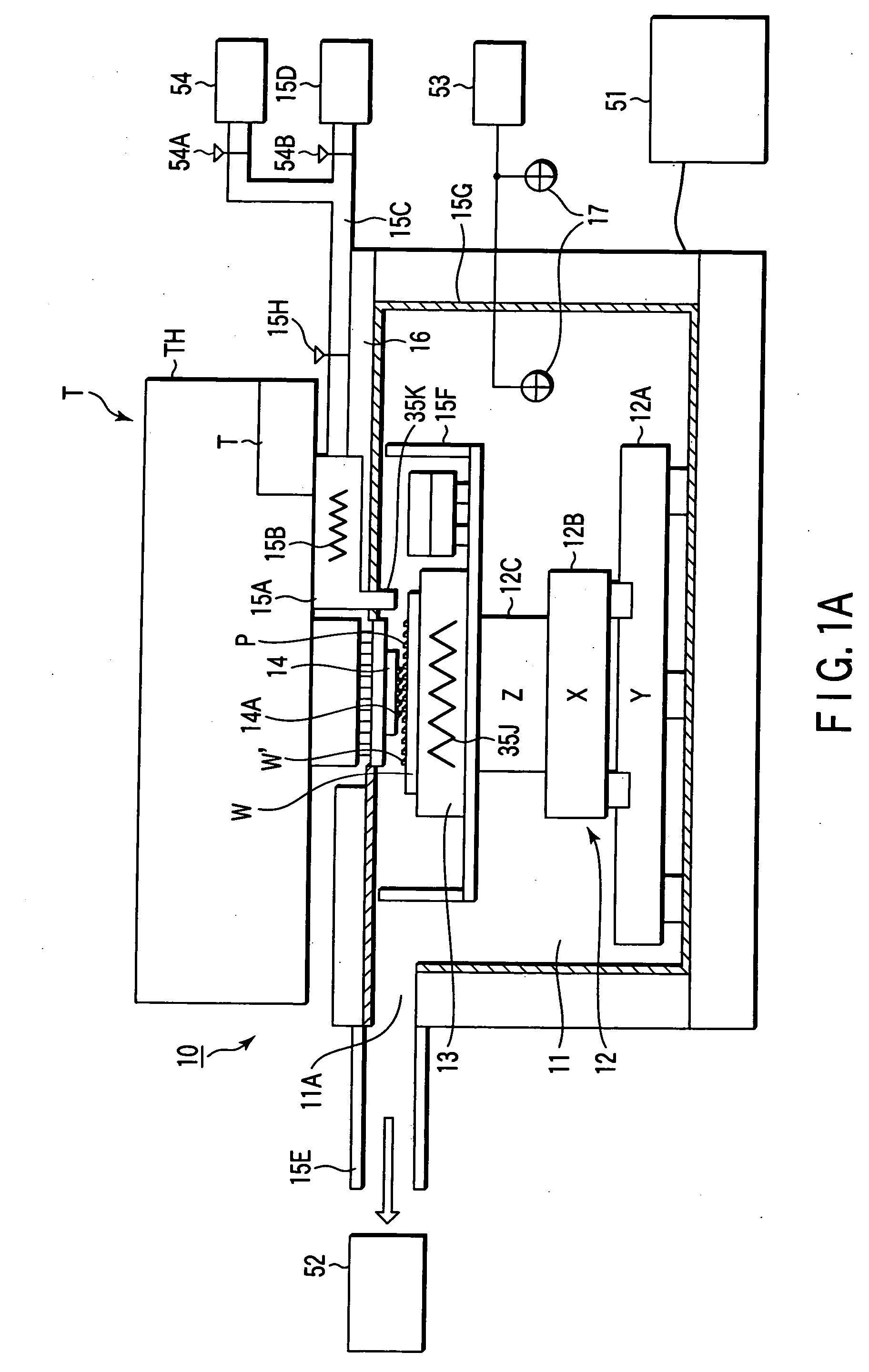

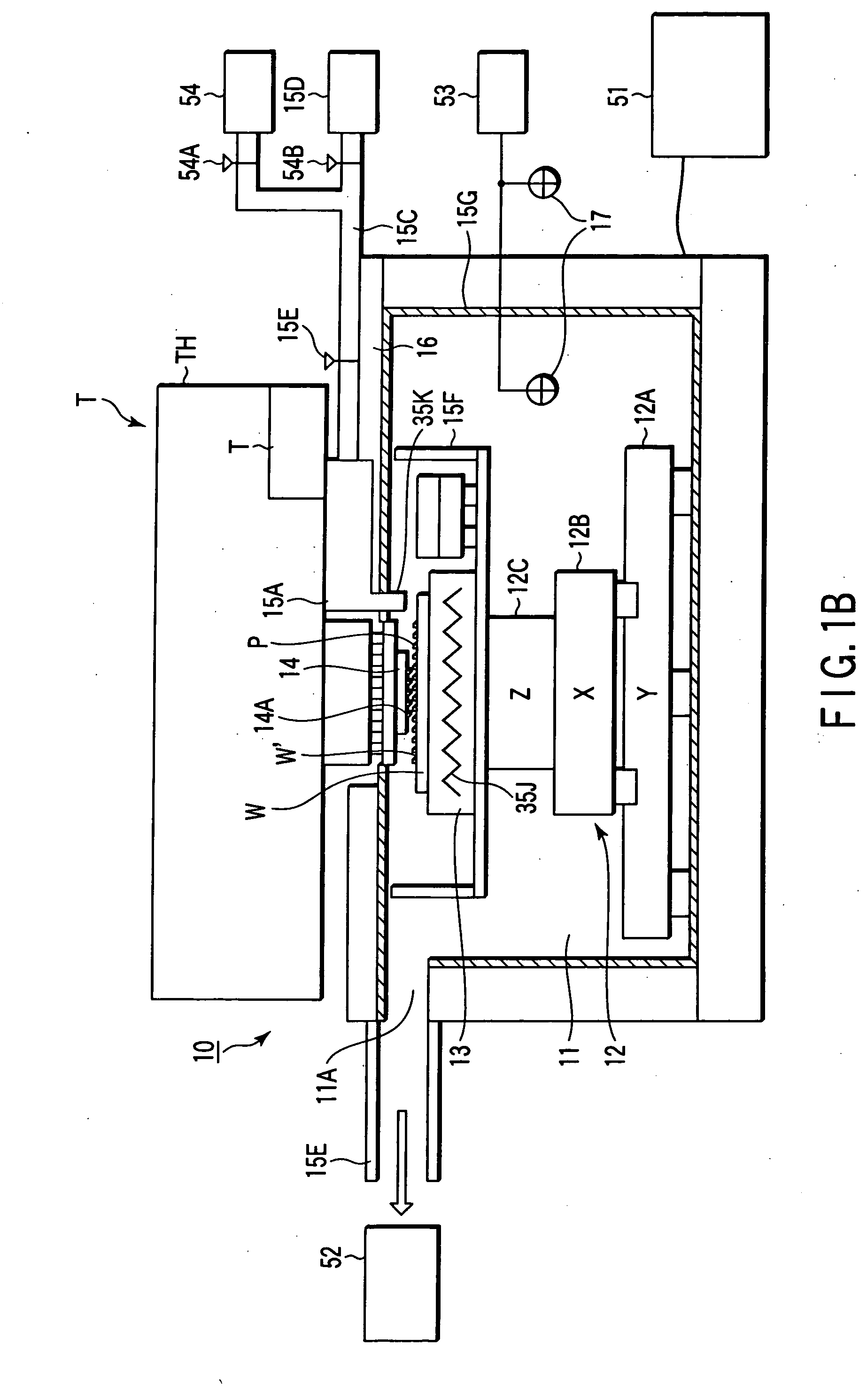

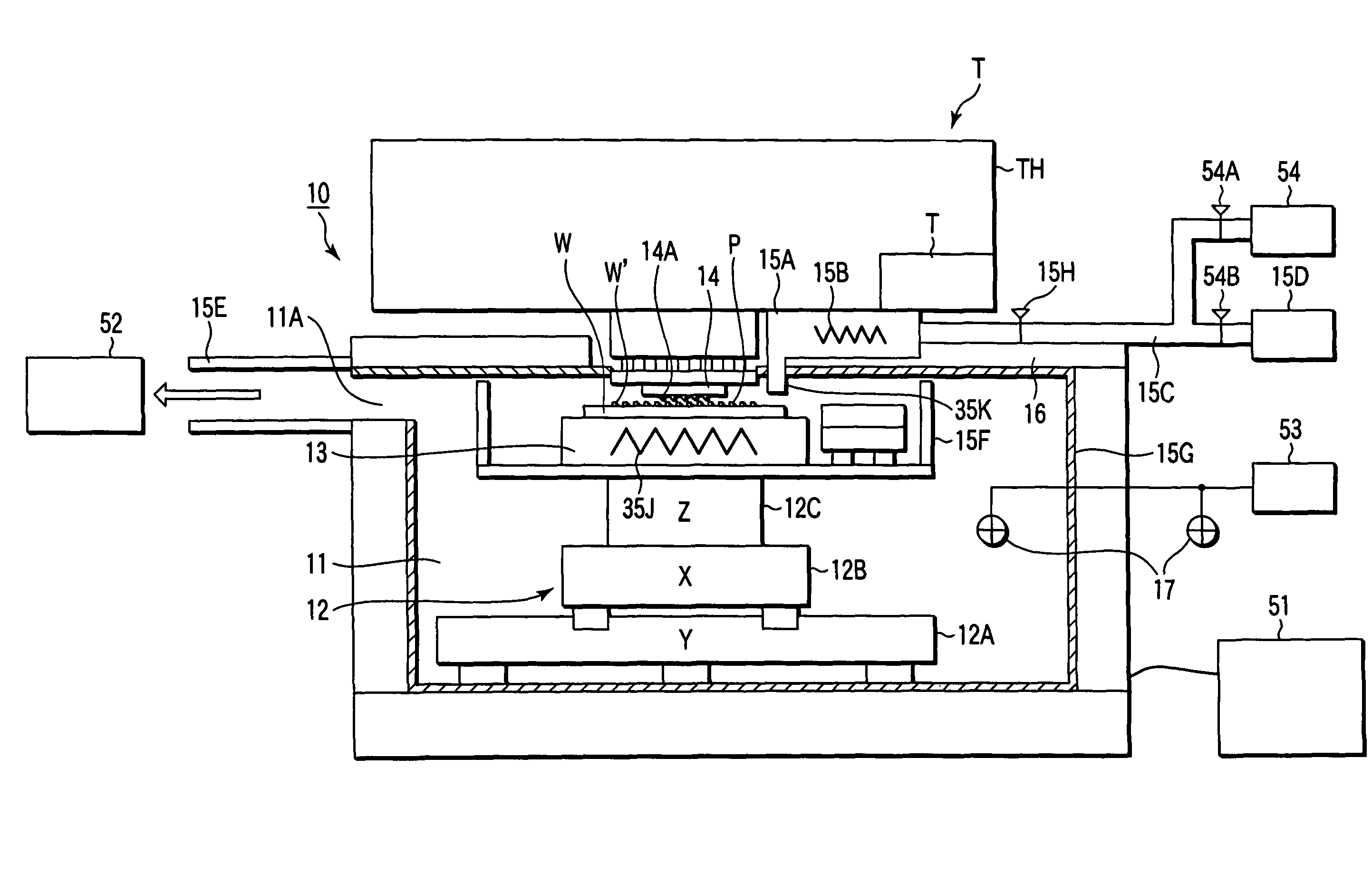

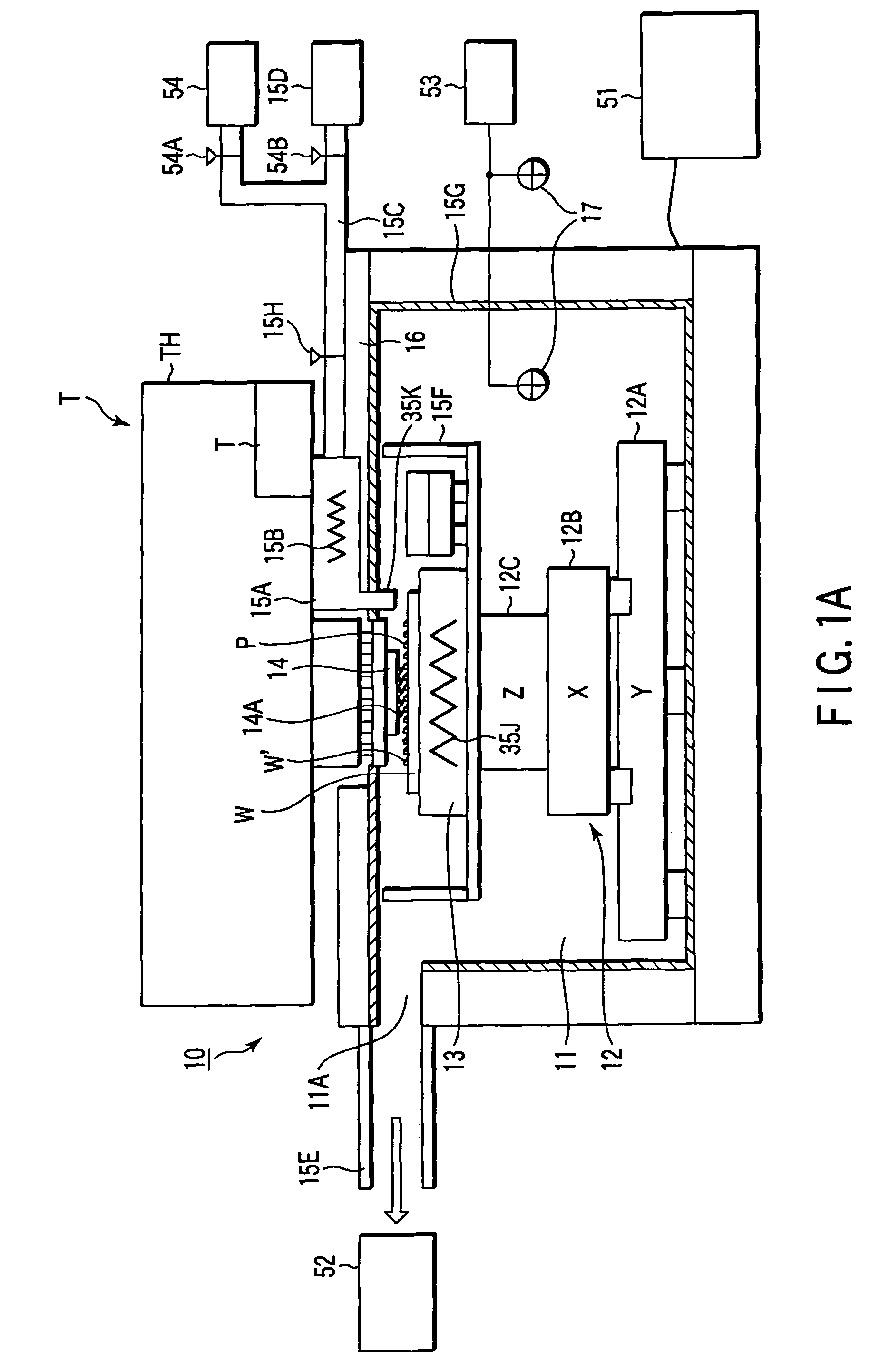

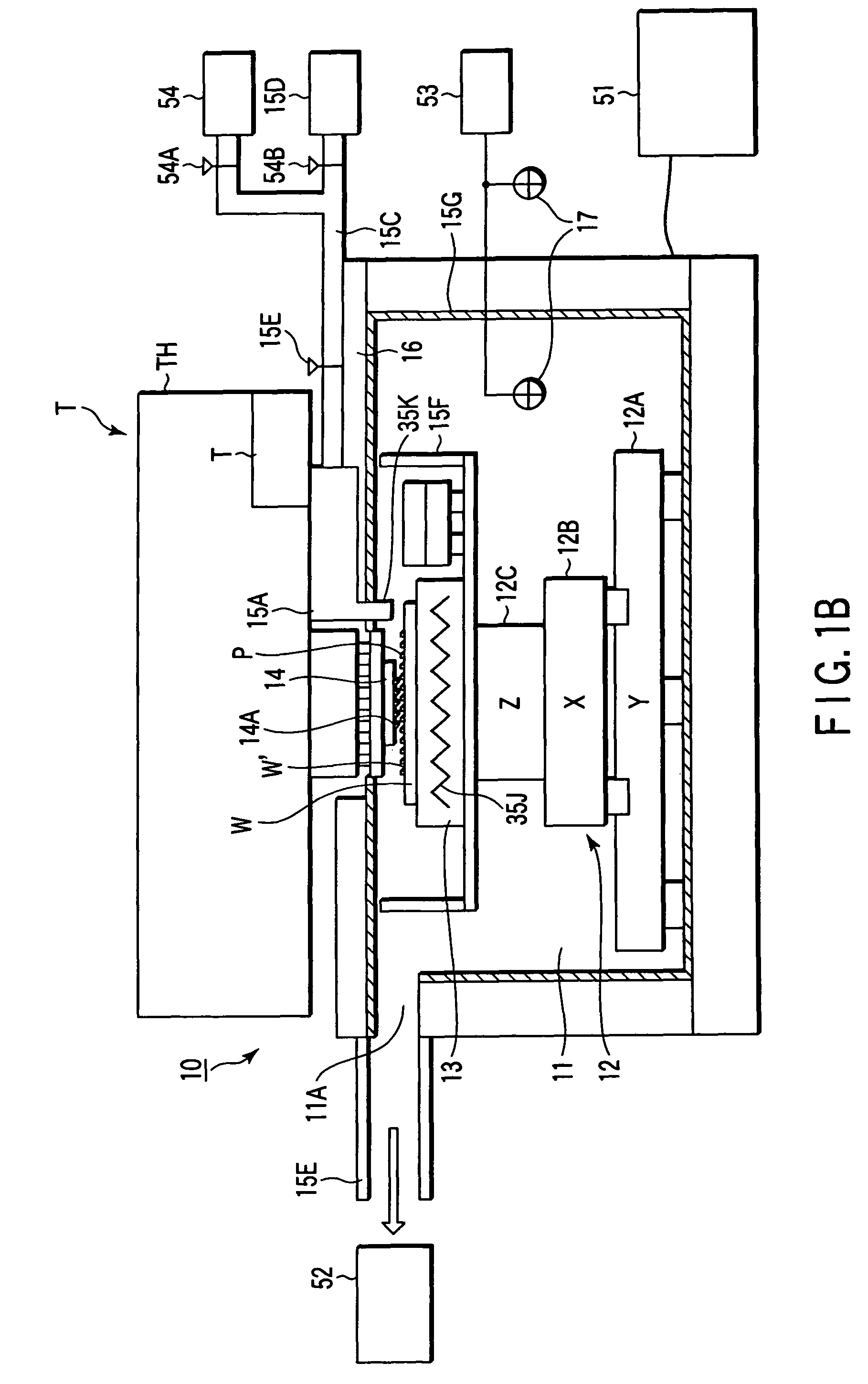

Probe method, prober, and electrode reducing/plasma-etching processing mechanism

InactiveUS20050151549A1Reduce oxideReduce harmElectronic circuit testingProcess mechanismForming gas

A probe method of this invention includes a step of reducing an electrode of a wafer by using a forming gas, and a step of bringing the electrode and a probe pin into contact with each other in a dry atmosphere. The probe method further includes, prior to a reducing process of an electrode of the object to be tested, placing the object to be tested in an inert gas atmosphere and heating the object to be tested. The reducing process is performed by bringing a reducing gas into contact with the electrode of the object to be tested under atmospheric pressure.

Owner:OCTEC INC +1

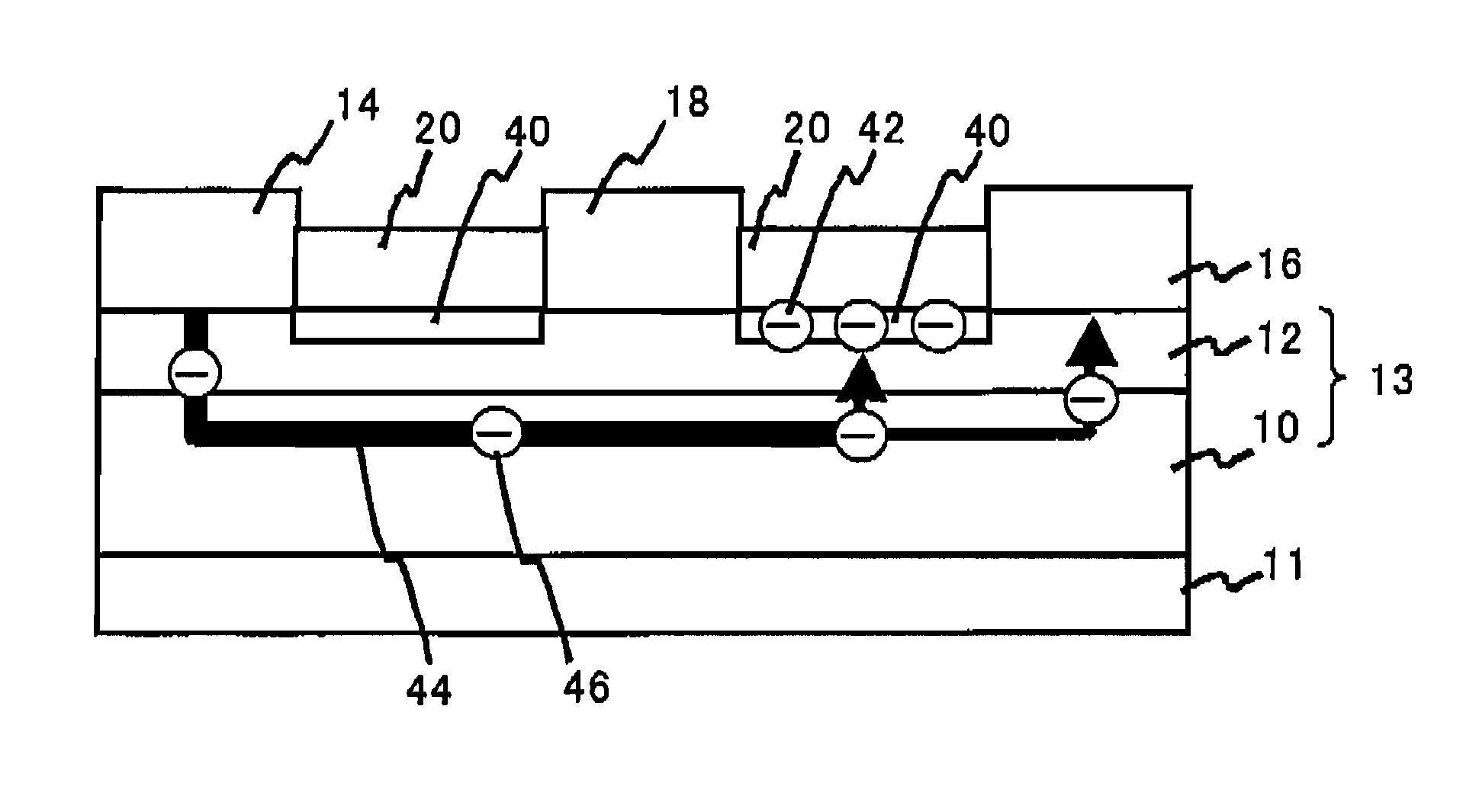

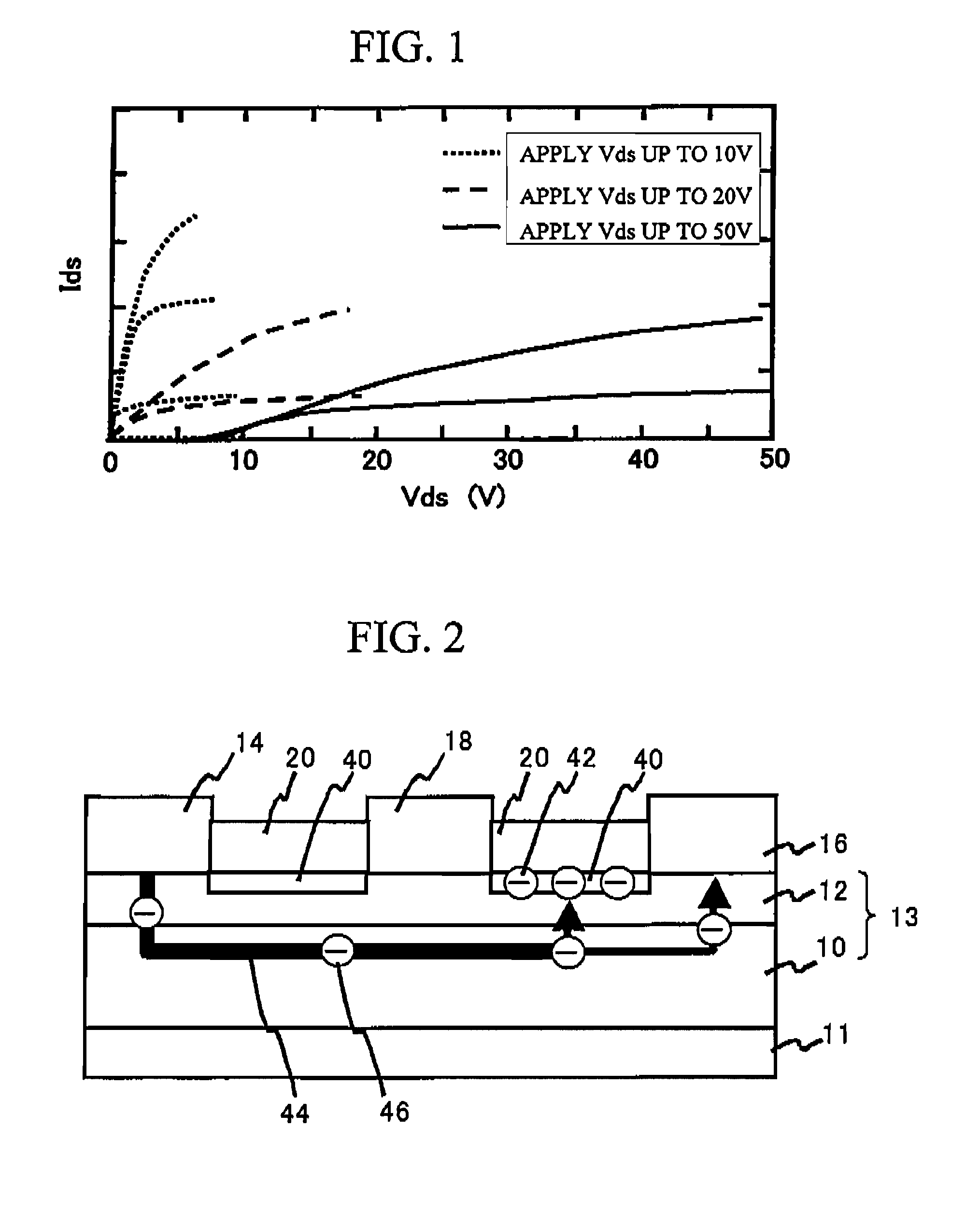

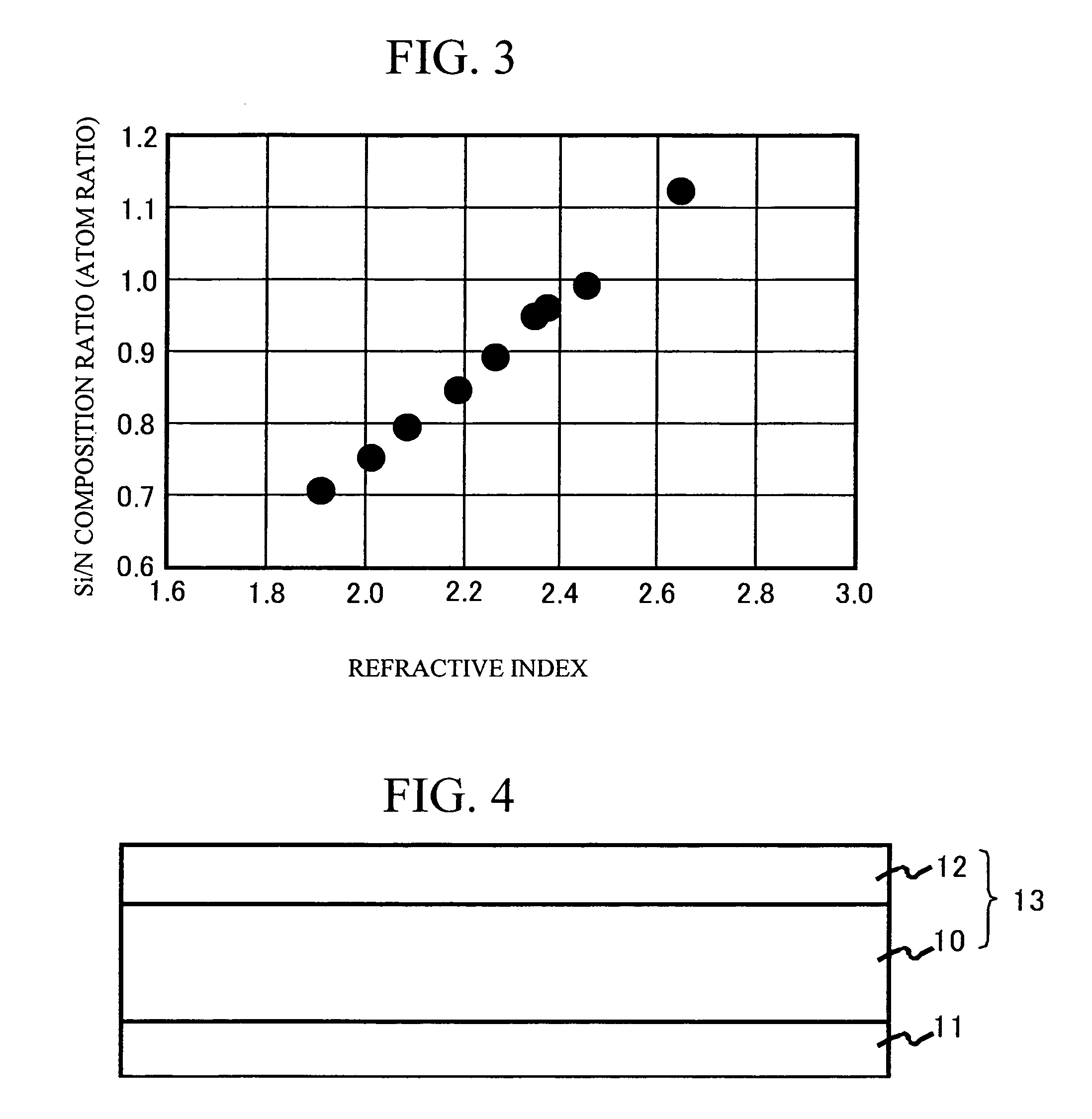

Semiconductor device having GaN-based semiconductor layer and select composition ratio insulating film

A semiconductor device includes a GaN-based semiconductor layer formed on a substrate, and an insulating film composed of any one of silicon nitride in which the composition ratio of silicon to nitrogen is 0.85 to 3.0, silicon oxide in which the composition ratio of silicon to oxygen is 0.6 to 3.0, or silicon oxide nitride in which the composition ratio of silicon to nitrogen and oxygen is 0.6 to 3.0 that is formed on a surface of the GaN-based semiconductor layer, a gate electrode formed on the GaN-based semiconductor layer, and a source electrode and a drain electrode formed with the gate electrode therebetween.

Owner:EUDYNA DEVICES INC

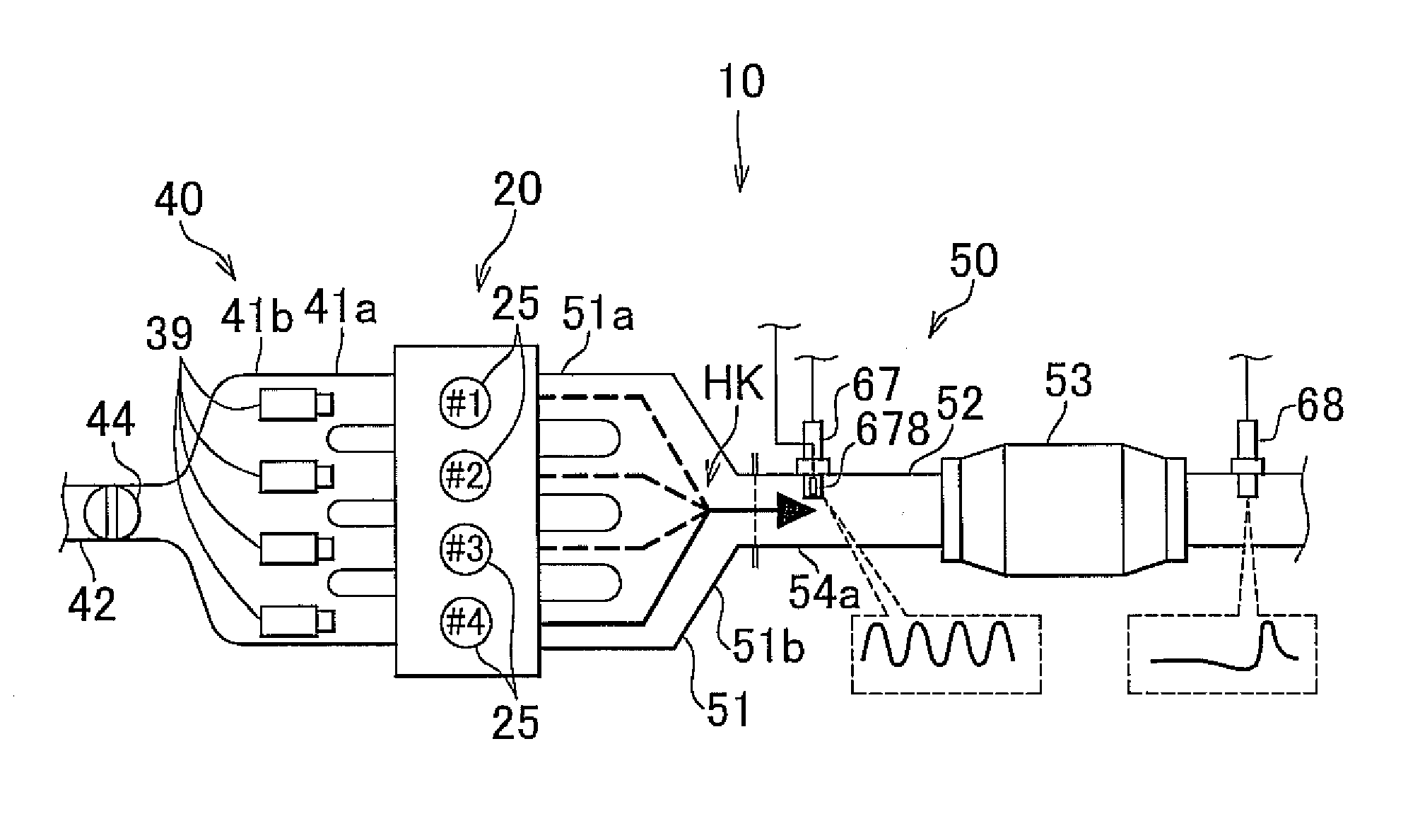

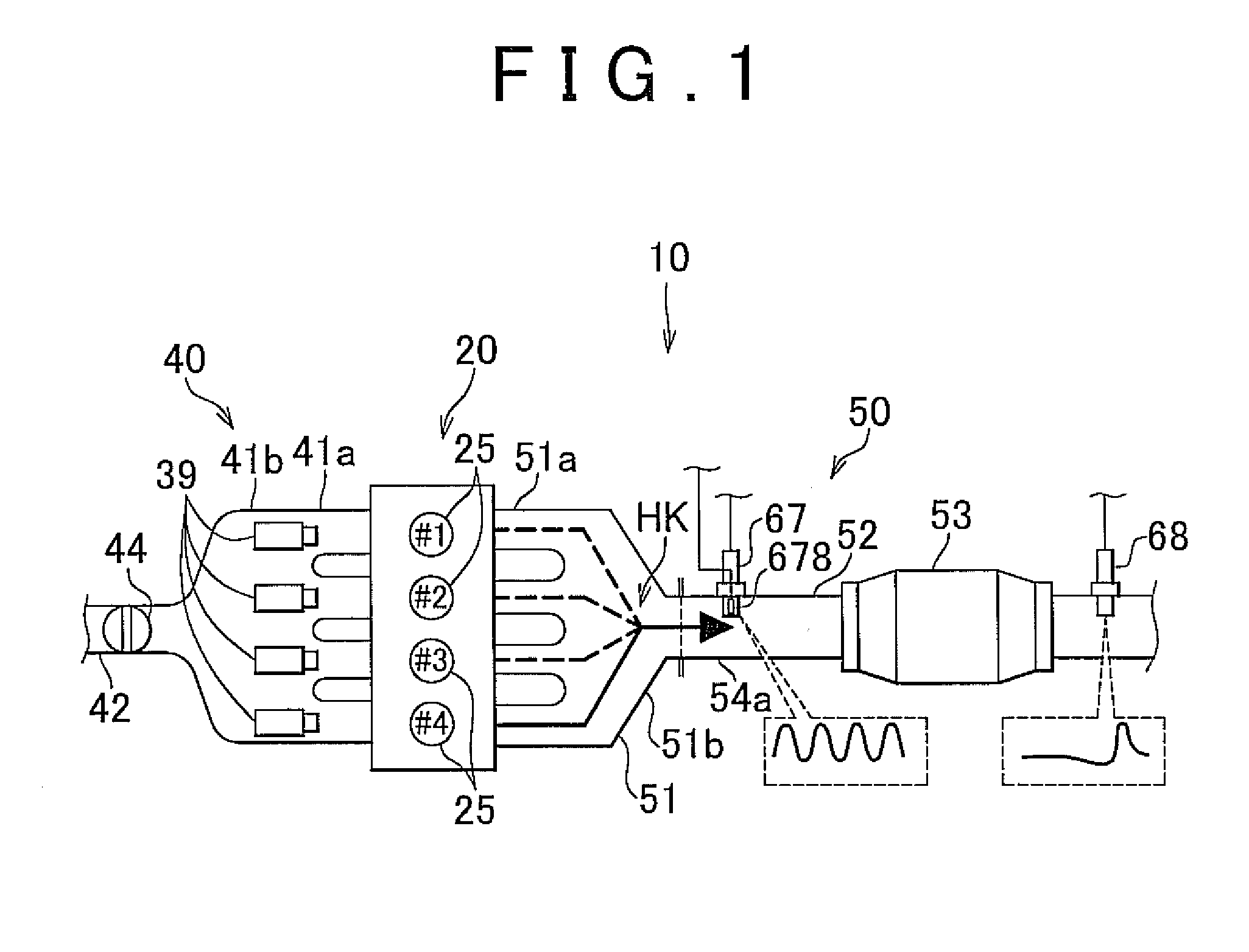

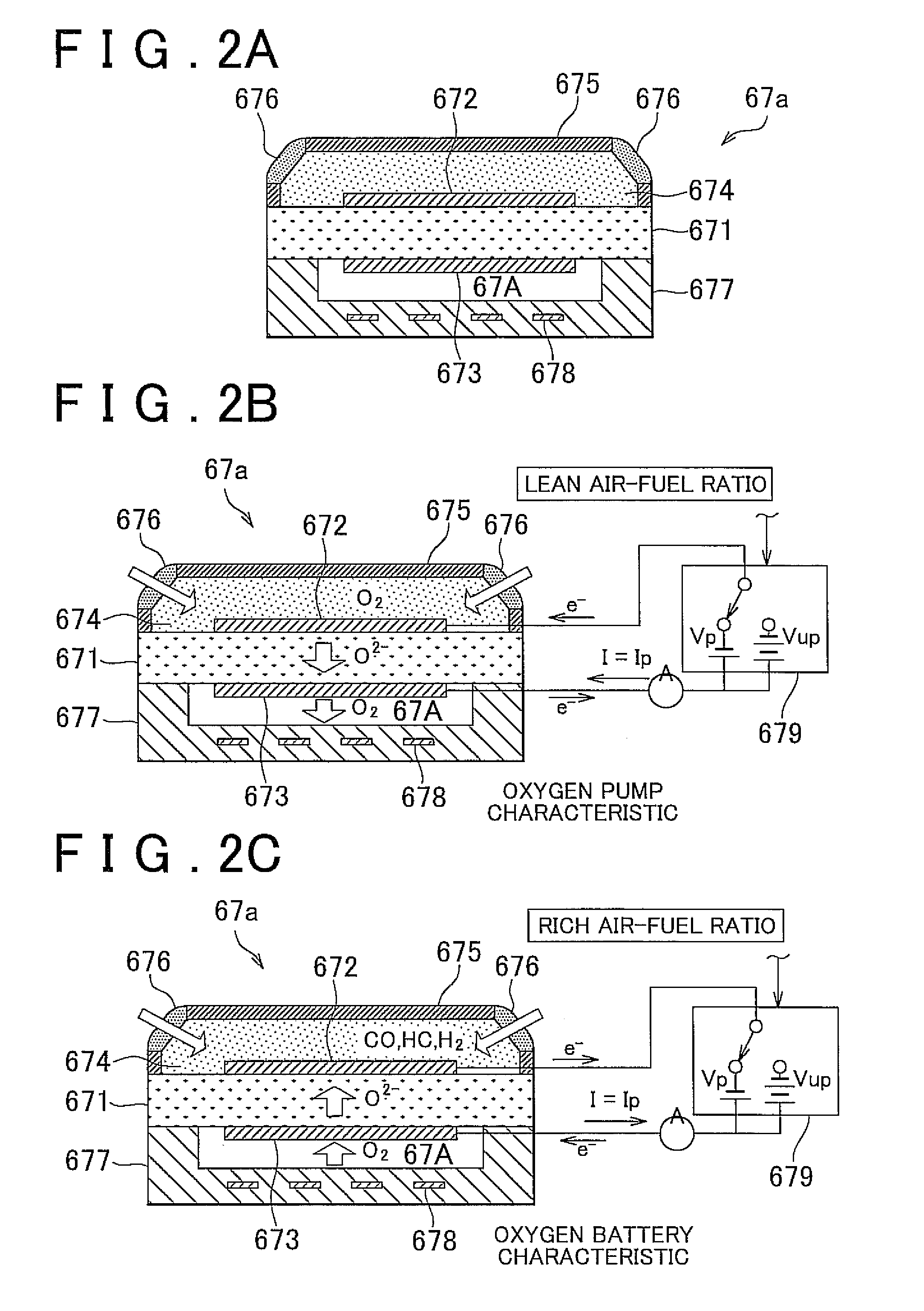

Internal combustion engine control device and control method thereof

InactiveUS20110308506A1Improves output responsivenessAvoids power consumptionElectrical controlMachines/enginesExhaust gasAir–fuel ratio

An internal combustion engine control device and a control method therefore in which feedback control is performed such that a detected air-fuel ratio of exhaust gas detected on the basis of a critical electric current flowing in a solid electrolyte layer of an air-fuel ratio sensor when an air-fuel ratio detection voltage is applied between an exhaust-side electrode layer and an atmosphere-side electrode layer of the sensor matches a stoichiometric air-fuel ratio. When a parameter acquired as an imbalance determination parameter is larger than an imbalance determination threshold, an air-fuel ratio inter-cylinder imbalance state is determined to have occurred. The output responsiveness of the air-fuel ratio sensor when the air-fuel ratio changes from a lean to a rich (or changes in the opposite direction) is acquired, and when this output responsiveness is low, “a sensor responsiveness increasing voltage that is higher than the air-fuel ratio detection voltage” is applied between the exhaust-side electrode layer and the atmosphere-side electrode layer.

Owner:TOYOTA JIDOSHA KK

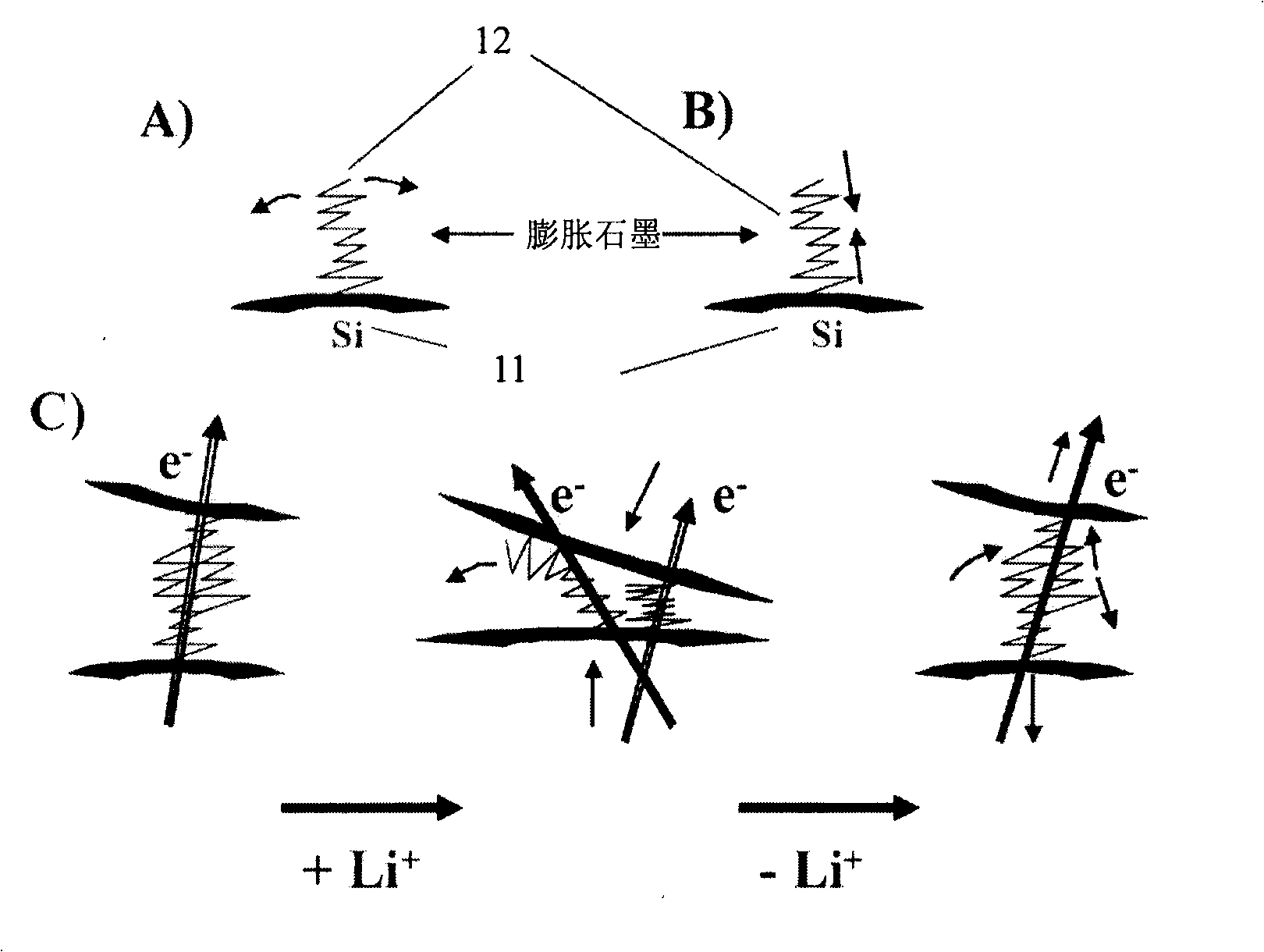

Secondary battery material

InactiveCN101494286AIncrease capacitySolution to short lifeElectrode manufacturing processesLi-accumulatorsCarbon coatingState of art

Embodiments of the invention relate to materials used in secondary batteries and the method for manufacturing the same. To address the problems of the prior art, an object of the present invention is to provide a negative electrode material for a non-aqueous Li-ion cell comprising active component particles capable of reversibly intercalating or alloying with lithium ions with a carbon coating layer containing an electronically conductive, elastic, carbon material capable of reversibly expanding and contracting to maintain electrical contact between the particles within an electrode matrix as the material is cycled electrochemically. Accordingly, several objects and advantages of embodiments of the invention include improved cycle life of high capacity active materials suitable for use in secondary batteries and the high capacity, long life cells.

Owner:FARASIS ENERGY

Heat treatment process of high-carbon chromium bearing steel

The invention provides a heat treatment process of high-carbon chromium bearing steel and belongs to the technical field of steel materials and heat treatment. The heat treatment process comprises the steps of smelting, forging, incomplete annealing, normalizing, quenching and tempering, double-refining processing, carbonitriding and surface chromizing. According to the invention, repeated quenching, tempering and other heat treatment, surface carbonitriding and surface chromizing processes are mainly adopted to reinforce the hardness and strength and prolong the service life of a bearing, so that the finally produced bearing is higher in strength, stronger in hardness and longer in service life.

Owner:ANQING YINTAI BEARING

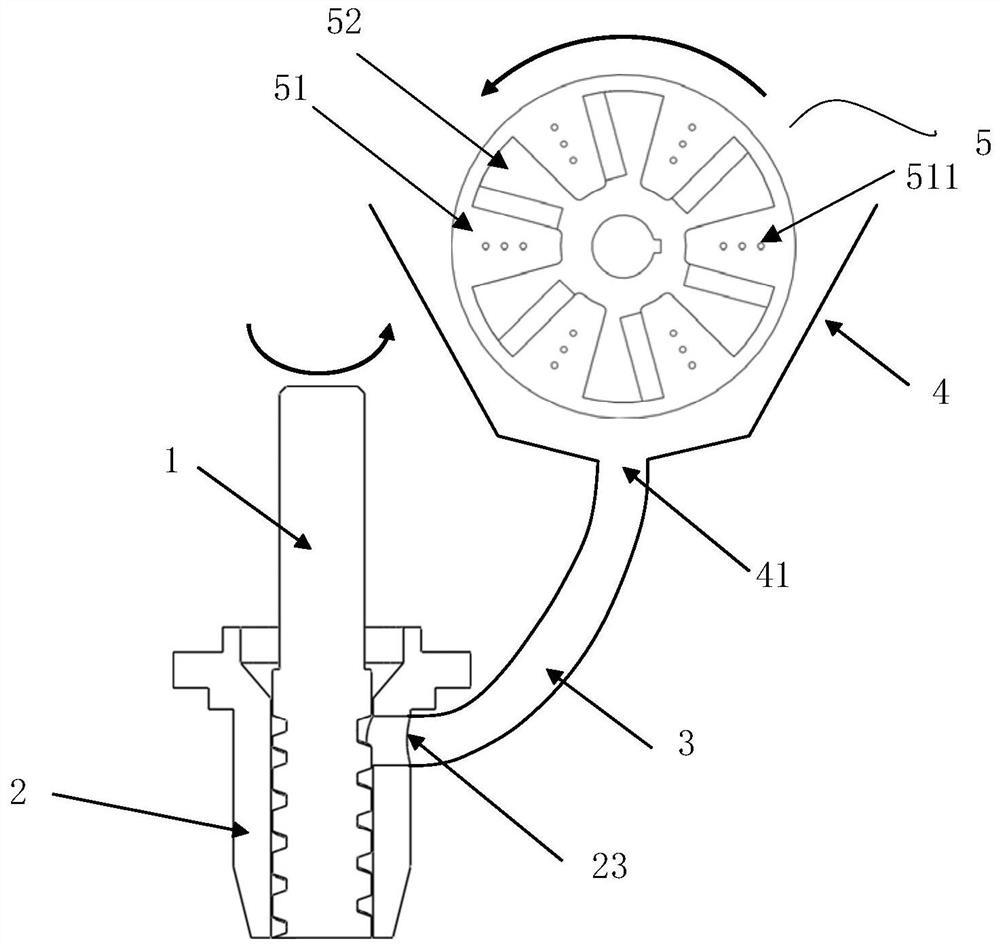

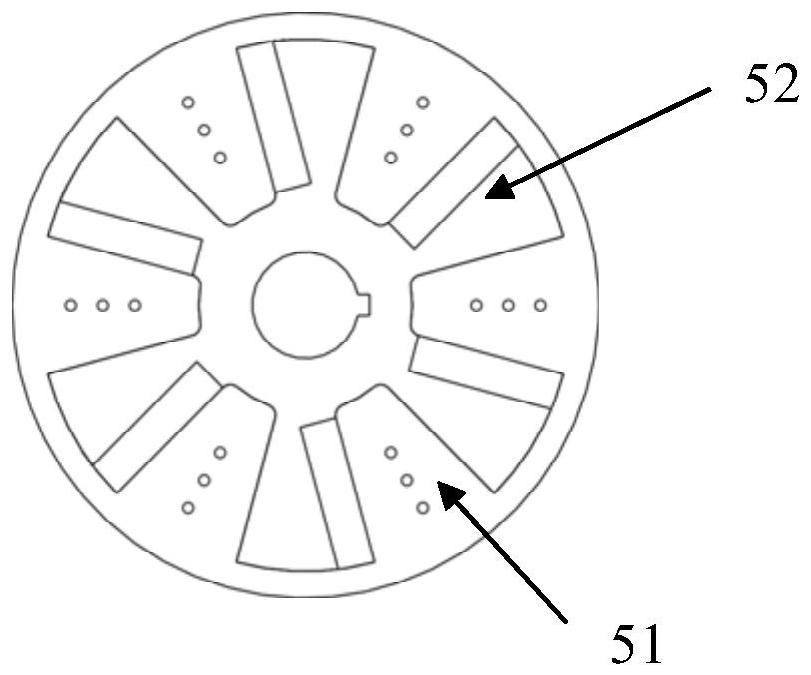

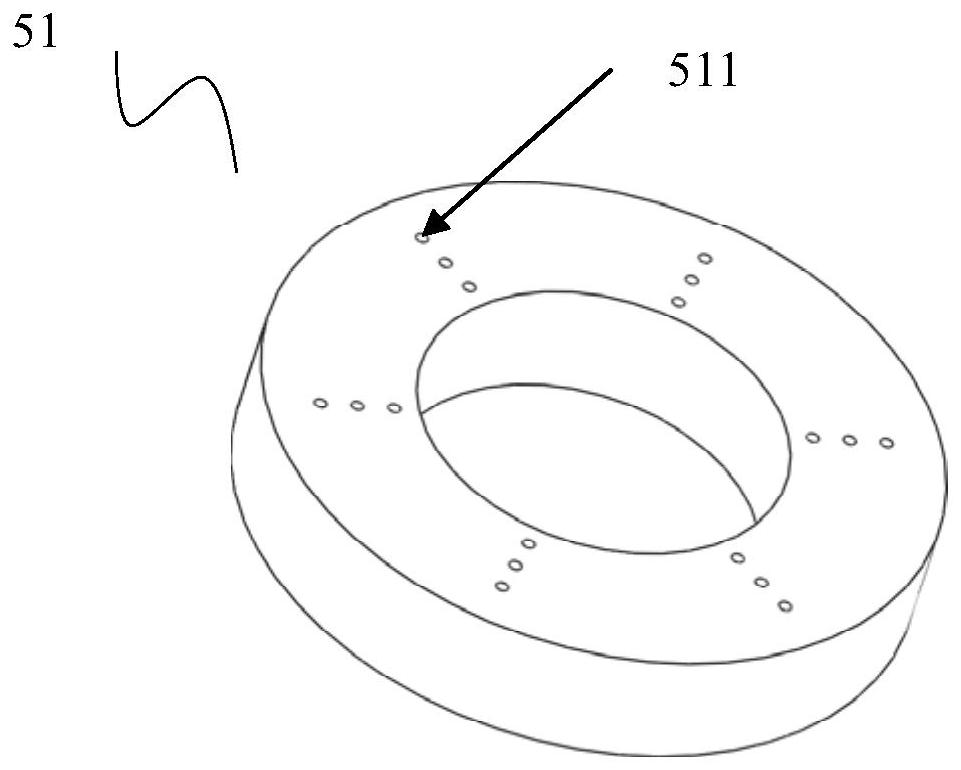

Particle type friction stir additive manufacturing device and method

ActiveCN113118612ANot easy to throw outLess impuritiesAdditive manufacturing apparatusIncreasing energy efficiencyMechanical engineeringAdditive layer manufacturing

The invention provides a particle type friction stir additive manufacturing device and method. The particle type friction stir additive manufacturing device comprises a wire shearing mechanism, the wire shearing mechanism comprises a base and a shearing part with a cutting edge, a wire guide hole is formed in the base, and a wire can pass through the wire guide hole. The particle type friction stir additive manufacturing device is characterized in that the shearing part is in close contact with the base, the shearing part rotates with the geometric center of the base as the axis, so that the cutting edge intermittently cuts the wire sent out from the wire guide hole. According to the particle type friction stir additive manufacturing device, additive particles of different diameters, different lengths and different materials can be obtained at the same time, friction stir additive manufacturing of gradient composite materials is achieved, and it can be guaranteed that the additive particles are continuously and stably provided; and meanwhile, operation is easy, and multi-layer additive manufacturing can be achieved under the condition that an additive device does not need to be adjusted.

Owner:安徽万宇机械设备科技有限公司

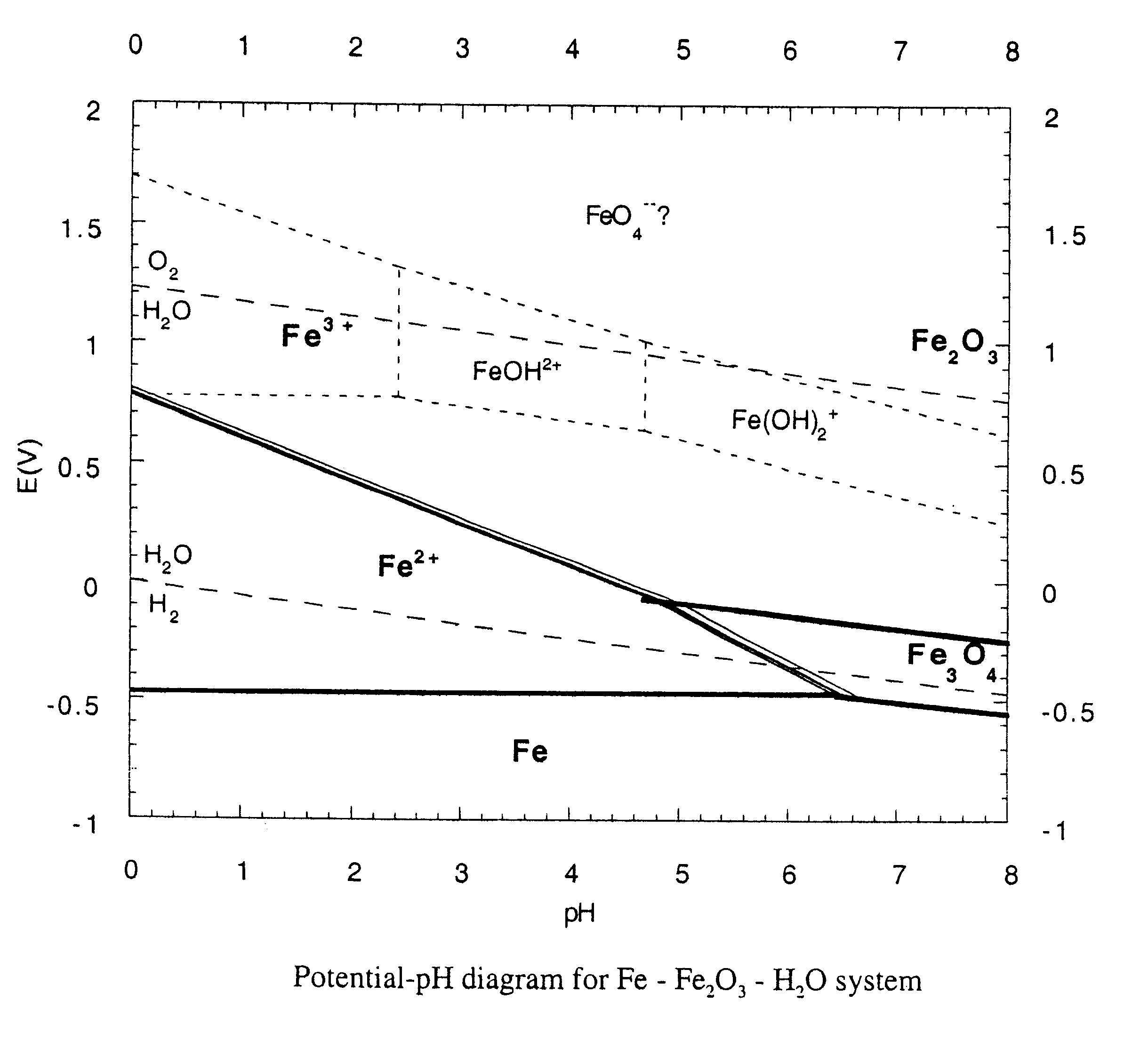

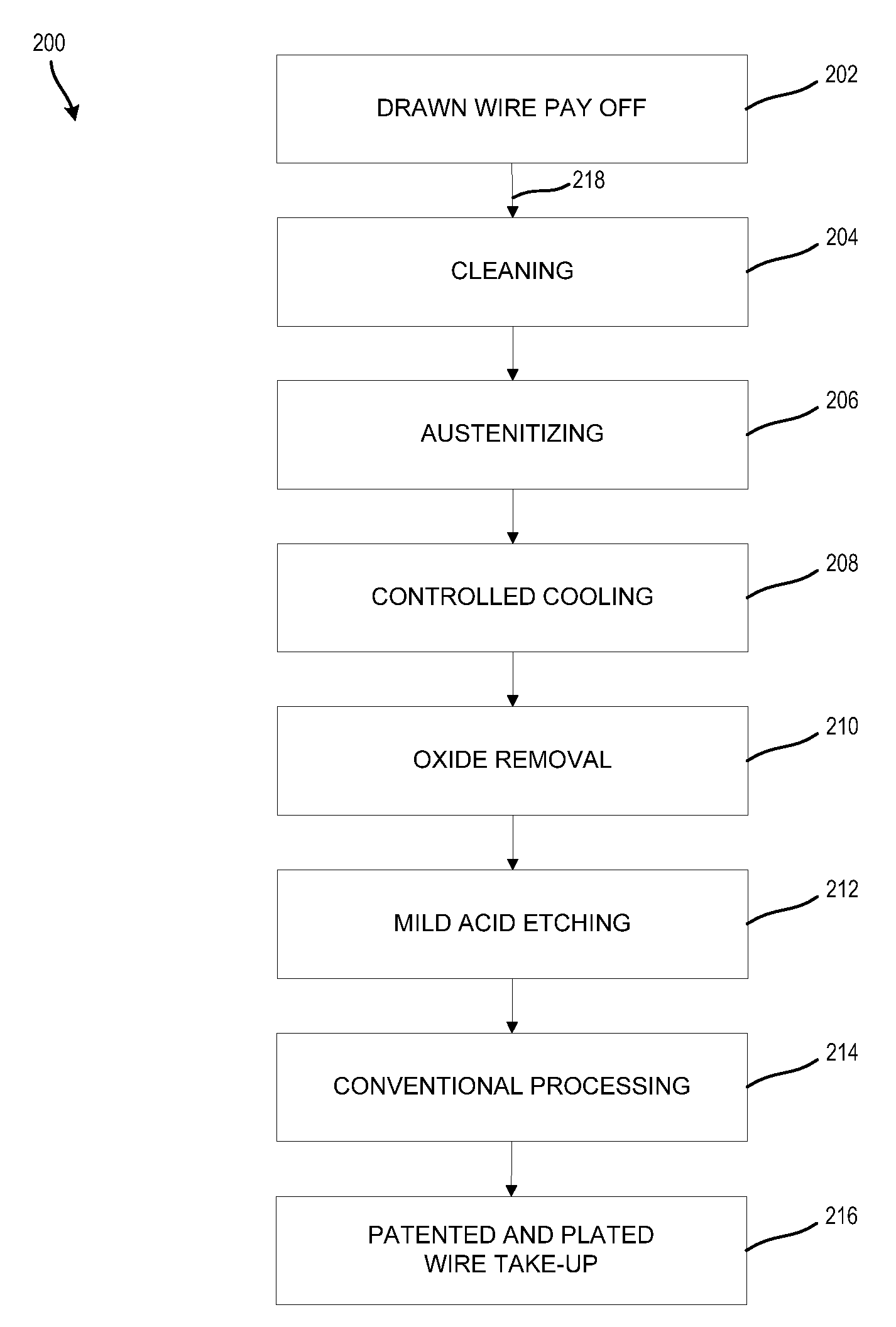

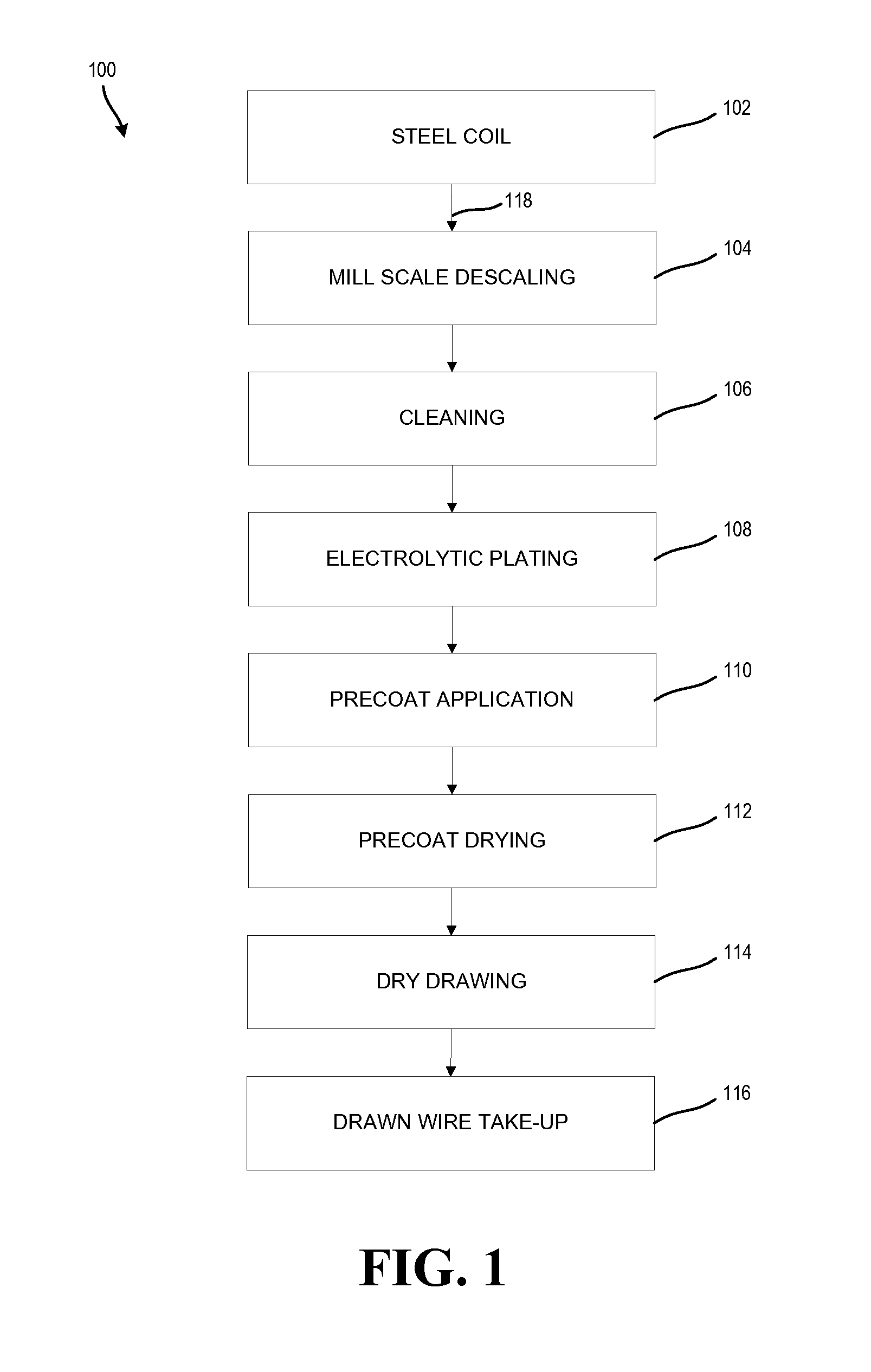

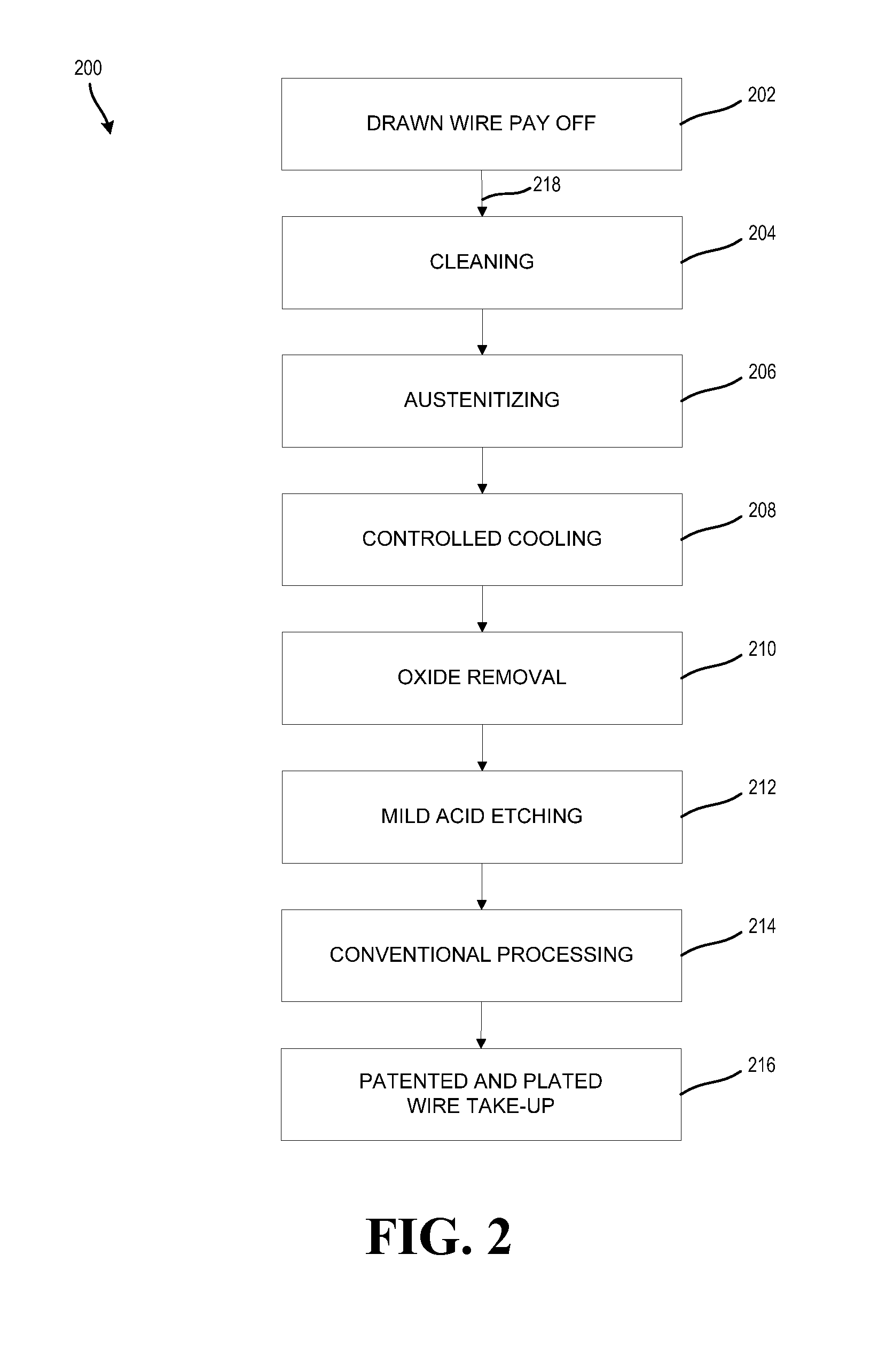

Methods and Systems for Preventing Iron Oxide Formulation and Decarburization During Steel Tempering

InactiveUS20090007997A1Prevent iron oxide formationInhibition of decarburizationFurnace typesHeat treatment furnacesCopper platingElectrolysis

The technology described herein provides a method and system to prevent iron oxide formation and decarburization during strand heat treating of a steel product without the subsequent required use of acid pickling, which has associated health and environmental risks. Additionally, this technology provides placing a coating, such as copper plating, to the surface of a steel wire prior to strand heat treating to avoid both iron oxide formation and decarburization through the surface of the steel wire by preventing interactions between the steel wire and the furnace atmosphere. To remove oxides formed by the plating metal, the oxides are chemically reduced by passing the steel wire through a reducing gas, electrolytically reduced by plating with the wire anodic, mechanically reduced through the use of brushes, or the like, or chemically reduced by acid pickling.

Owner:TYL THOMAS WILSON

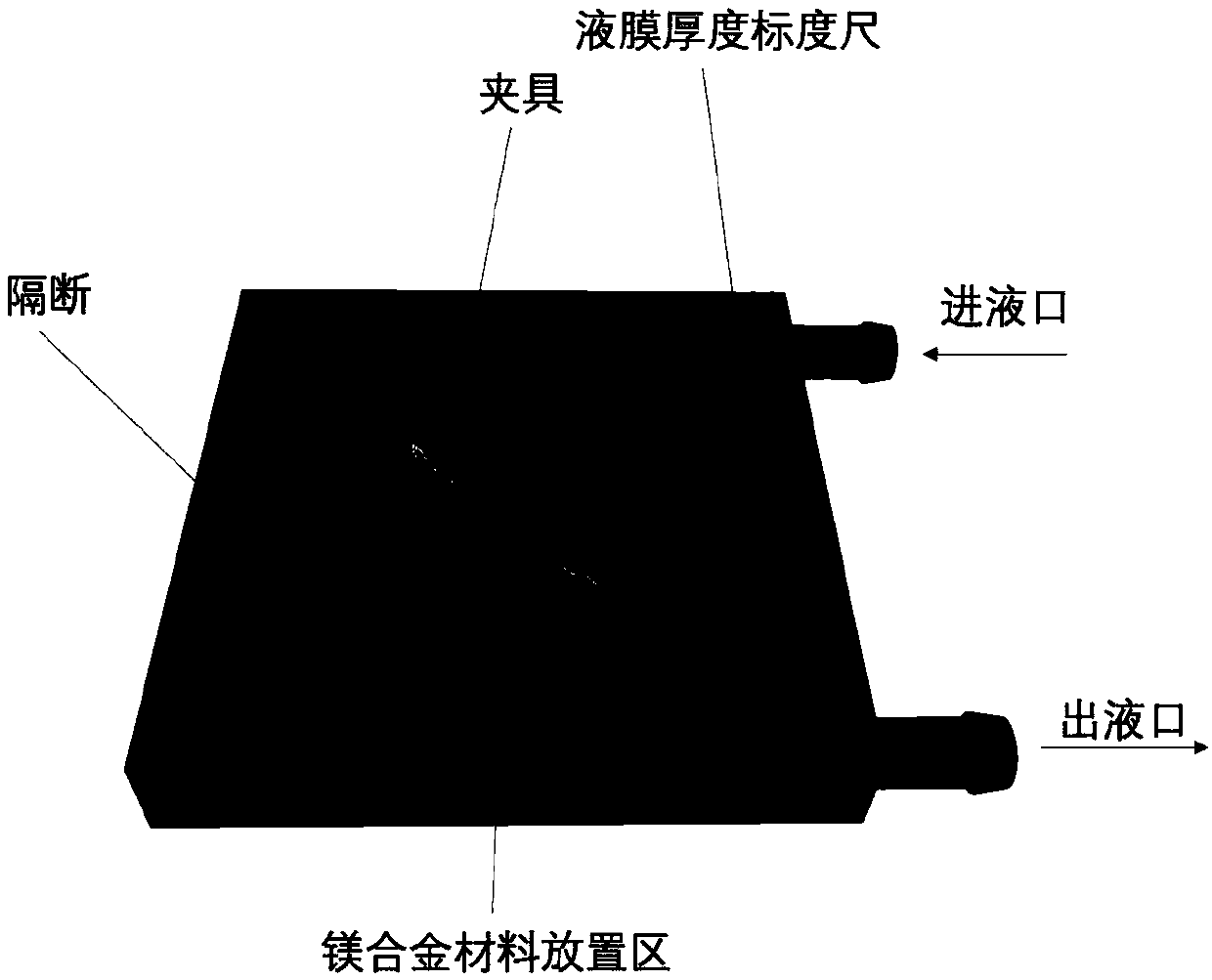

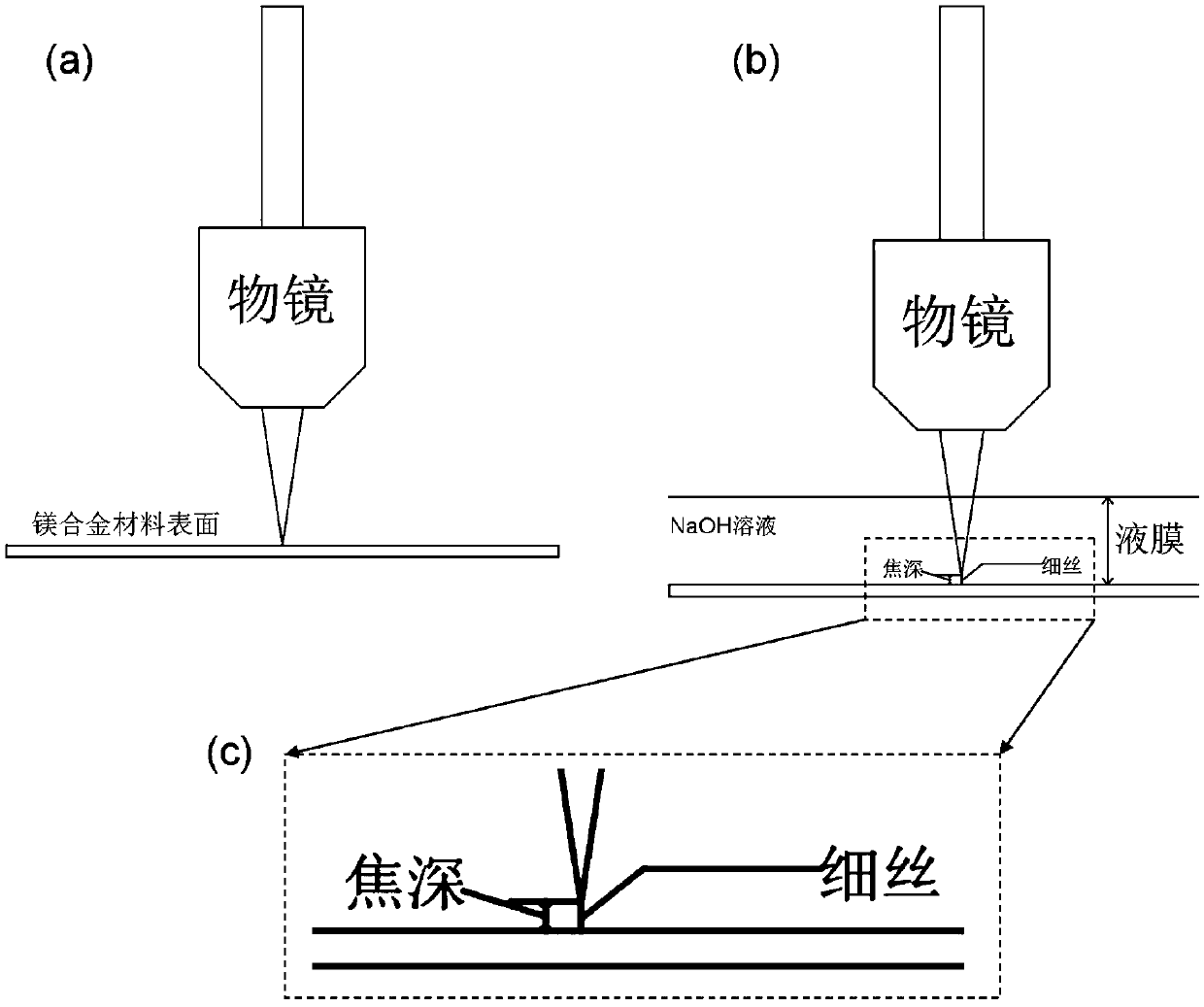

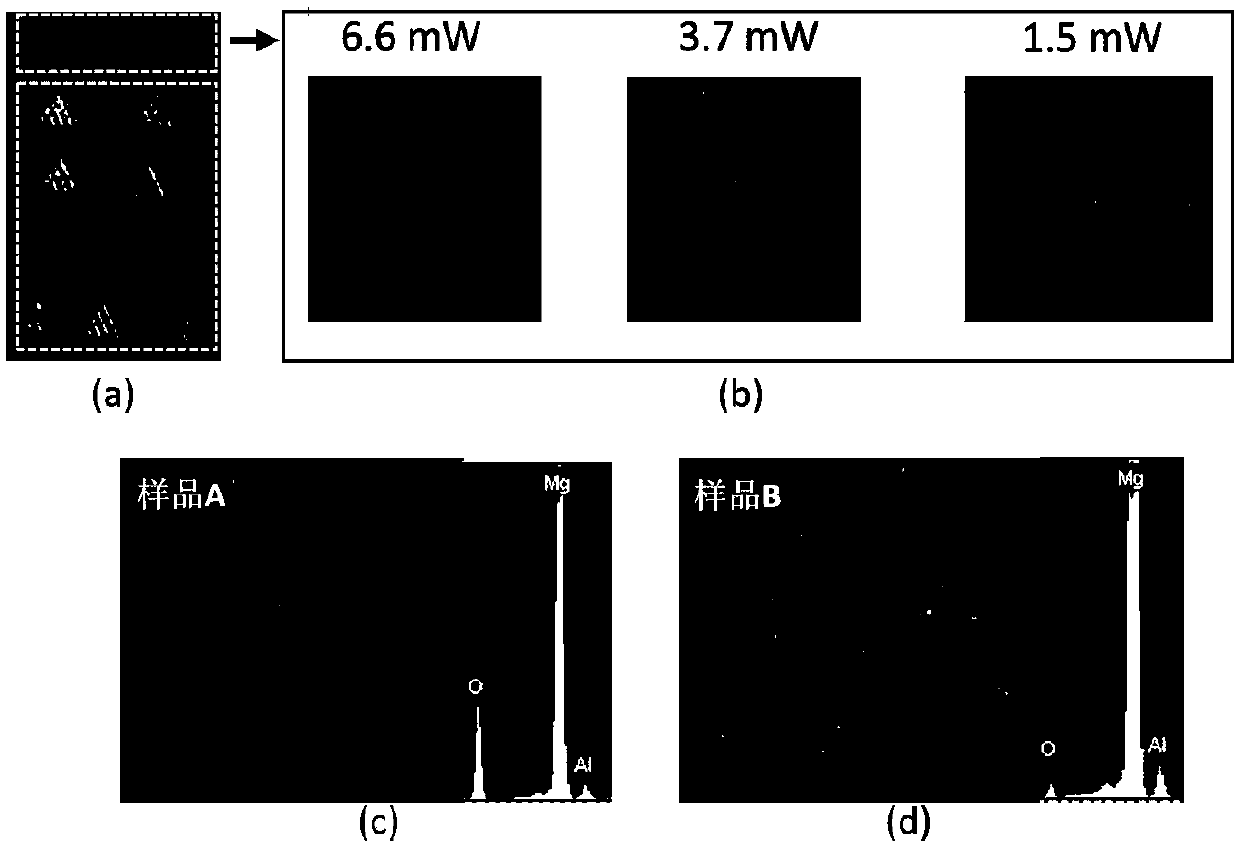

Degradable metal guided tissue regeneration barrier membrane and preparation method thereof

ActiveCN109620429ASignificant progressAvoid rapid degradationTeeth fillingTeeth cappingMicro nanoLiquid medium

The invention discloses a degradable metal guided tissue regeneration barrier membrane and a preparation method thereof. A transparent liquid medium which does not react with metal is used as a protective solution, and especially when a sodium hydroxide solution is adopted, it is achieved that pure magnesium and magnesium alloy materials are processed in water. By using a flowing liquid membrane,the heat diffusion situation on the periphery of a processing site can be obviously improved, and self cleaning in the processing process is achieved. On the basis that the processing quality of the micro-nano structure of the metal surface is ensured, the processing precision is obviously improved, the processing precision reaches about 10 micrometers, and it is of great significance for loadingof a specific drug, such as a drug of a specified size. The content of oxides in the processing product can be remarkably reduced, the adverse effects of excessive oxides on drug loading are avoided,and the degradability and the mechanical property of the metal guided tissue regeneration membrane are ensured. Through the multi-level mesh hole structure of micro-nano patterns, level-by-level release of the drug is achieved; compared with the prior art that deep holes are directly dug in the surface of magnesium alloy to load the drug, the medical treatment effects of treating inflammation andguiding tissue regeneration are greatly improved.

Owner:浙江沣沅生物科技有限公司

Method for thermally spraying Babbitt-metal coating on surface of crosshead

InactiveCN103014589AHigh bonding strengthReduce oxideMolten spray coatingMetal coatingPhysical chemistry

The invention relates to a method for thermally spraying Babbitt metal coating on the surface of a crosshead, comprising the following steps: (1) decontaminating the surface of the crosshead; (2) sandblasting and roughing the decontaminated surface of the crosshead; (3) thermally spraying nickel and aluminum on the roughed surface of the crosshead to form a priming coating; and (4) thermally spraying Babbitt metal work coating to cover the nickel-aluminum priming coating. Due to the characteristics of the Babbitt metal, the Babbitt-metal coating formed on the surface of the crosshead by thermally spraying the Babbitt metal can be well used as an anti-friction coating. The crosshead coated with the Babbitt metal on the surface can be used for an air cylinder to store oil and reduce the coefficient of friction. The hardness of the crosshead is lower than that of the cylinder material, and the crosshead can be used as a friction pair.

Owner:上海大豪纳米材料喷涂有限公司

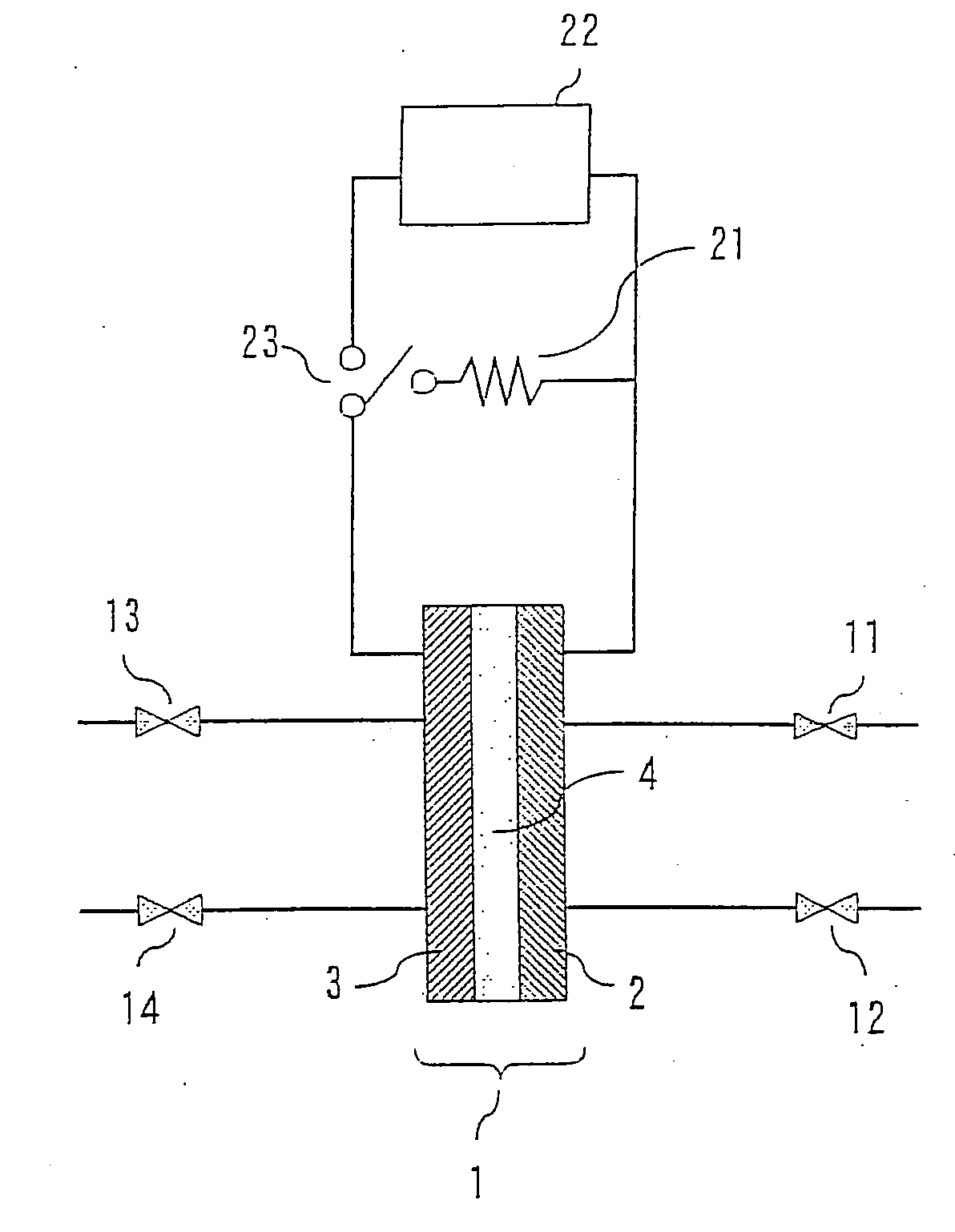

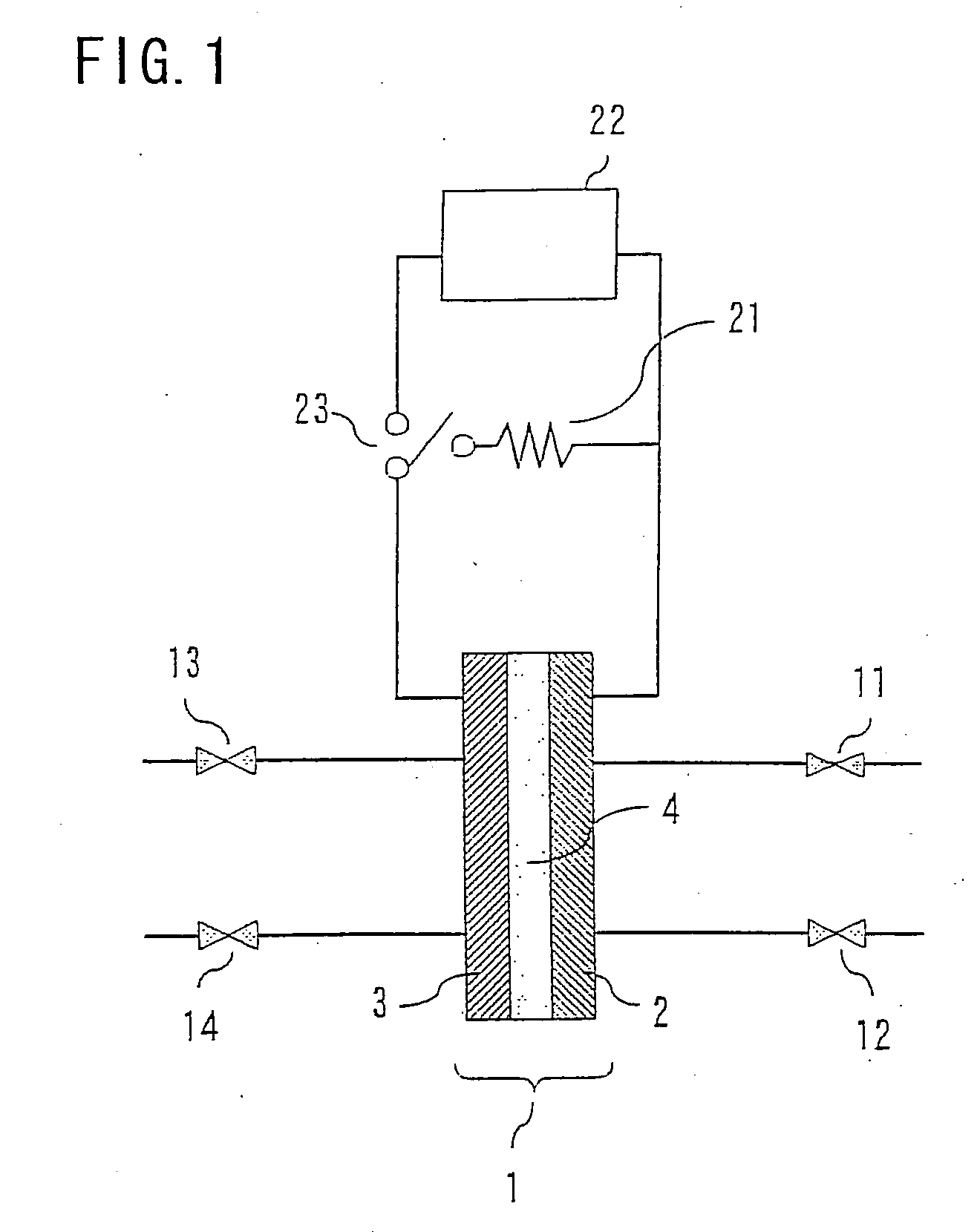

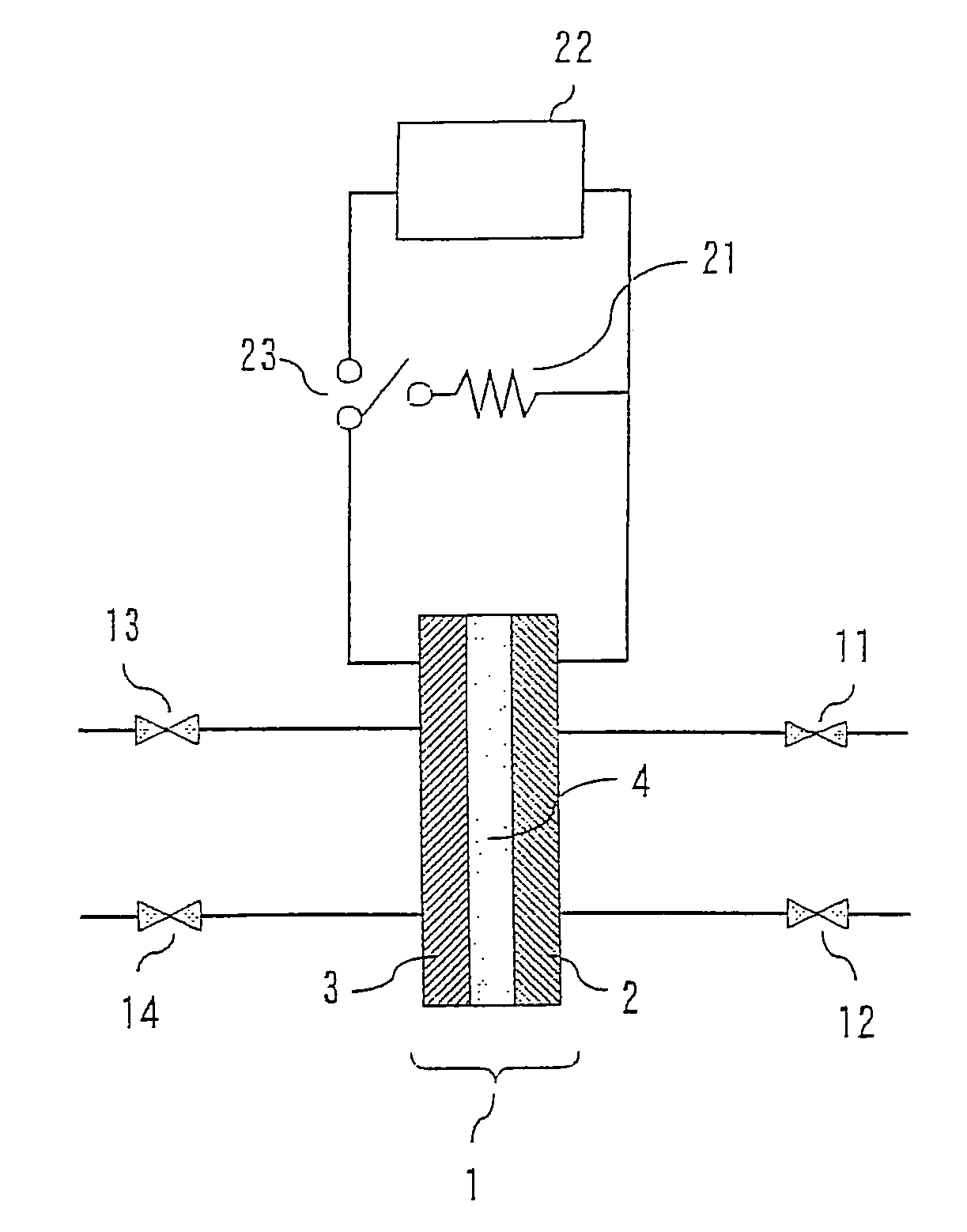

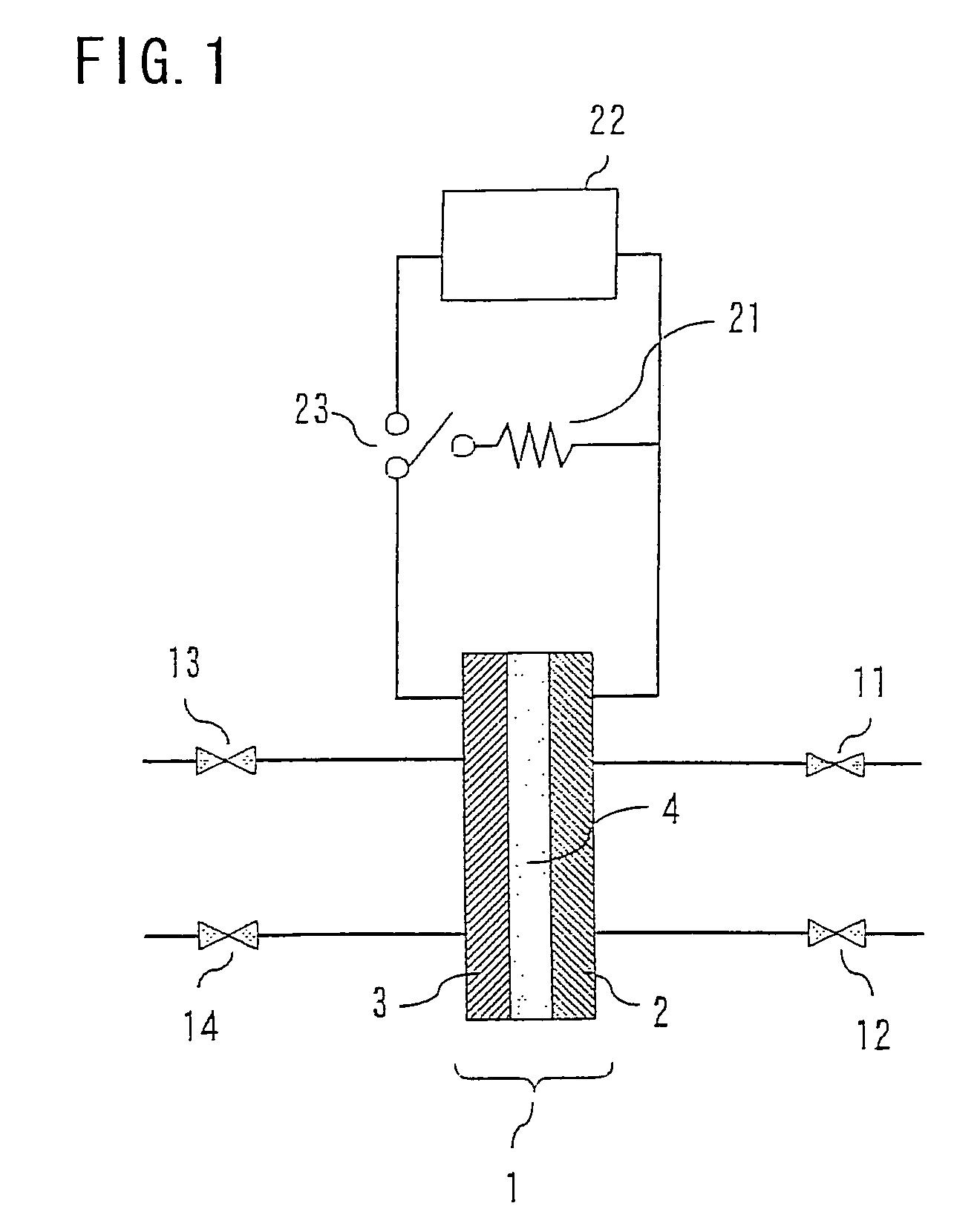

Method of operating fuel cell

InactiveUS20060183007A1Restore performanceSimple and inexpensiveFuel cell auxillariesElectrochemical responseHydrogen

A method of operating a fuel cell including a fuel electrode, an oxidant electrode, and an electrolyte layer having hydrogen ion conductivity sandwiched between the fuel electrode and the oxidant electrode, so that the fuel cell generates electricity as a result of an electrochemical reaction between a fuel and an oxidant. Each time the fuel cell is started from a non-operating condition, the fuel is supplied to the fuel electrode with the fuel electrode and the oxidant electrode electrically interconnected to produce hydrogen at the oxidant electrode by provoking electrochemical reactions expressed by the chemical equations H2→2H++2e− and 2H++2e−→H2 at the fuel electrode and the oxidant electrode, respectively, reducing oxides on the oxidant electrodes using the hydrogen produced at the oxidant electrode. Then the oxidant is supplied to the oxidant electrode to begin normal continuing operation of the fuel cell.

Owner:MITSUBISHI ELECTRIC CORP

Process for producing conductive coating film, and conductive coating film

InactiveUS20140141238A1Efficient removalReduce oxideConductive layers on insulating-supportsSurface layering apparatusConductive coatingMetal powder

An object of the present invention is to provide a conductive coating film formed on a polyimide-based insulating substrate by using a metal powder paste which can exhibit a good conductivity and good adhesion to the insulating substrate. By forming a resin cured layer having a solvent-soluble content of not more than 20% by weight and a thickness of not more than 5 μm on a polyimide-based insulating substrate; forming a metal powder-containing coating layer on the resin cured layer by using a metal powder paste; and then subjecting the resulting coating layer to heat treatment with superheated steam, it is possible to obtain a conductive coating film which can exhibit a good conductivity and good adhesion to the insulating substrate.

Owner:TODA IND +1

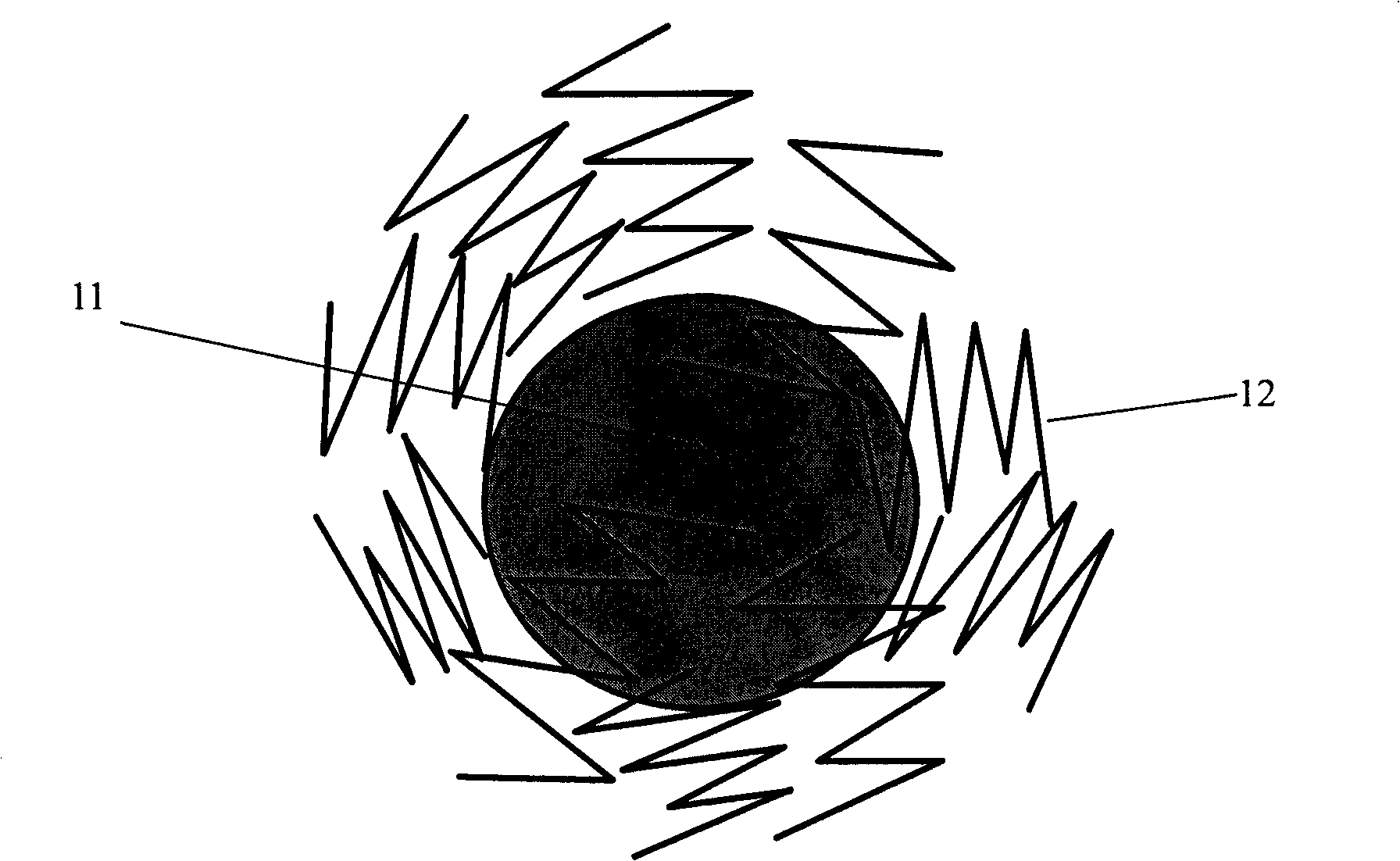

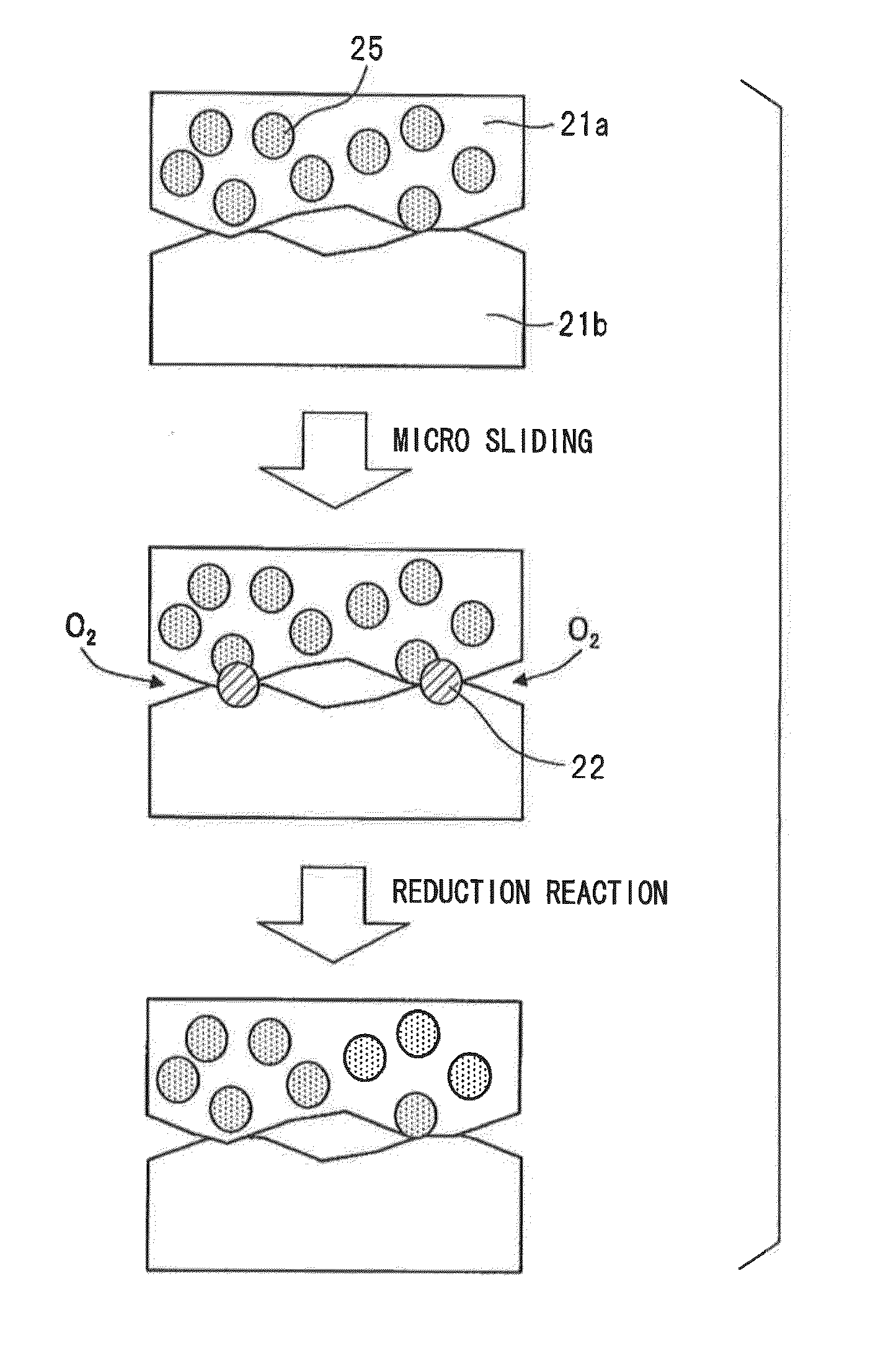

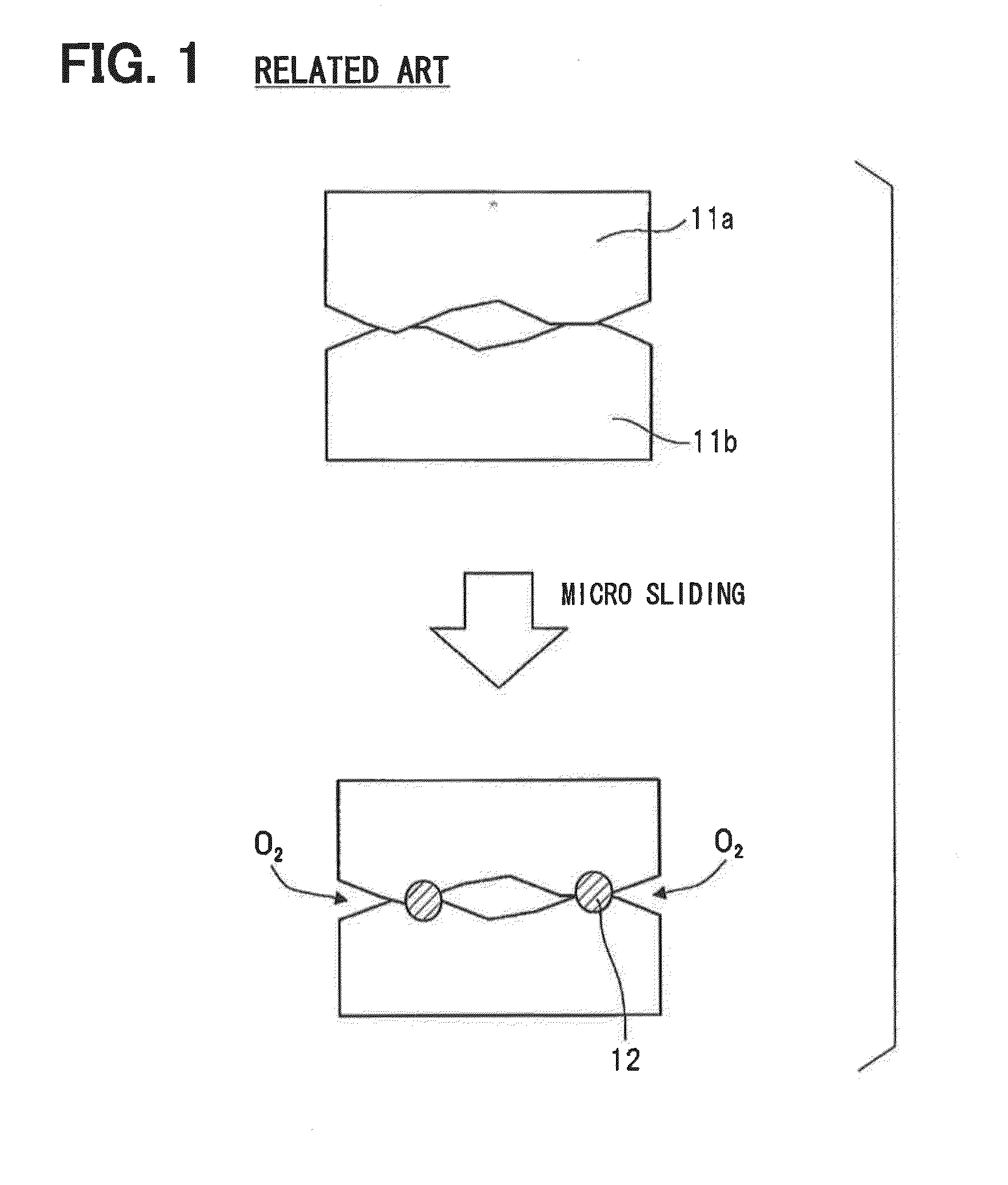

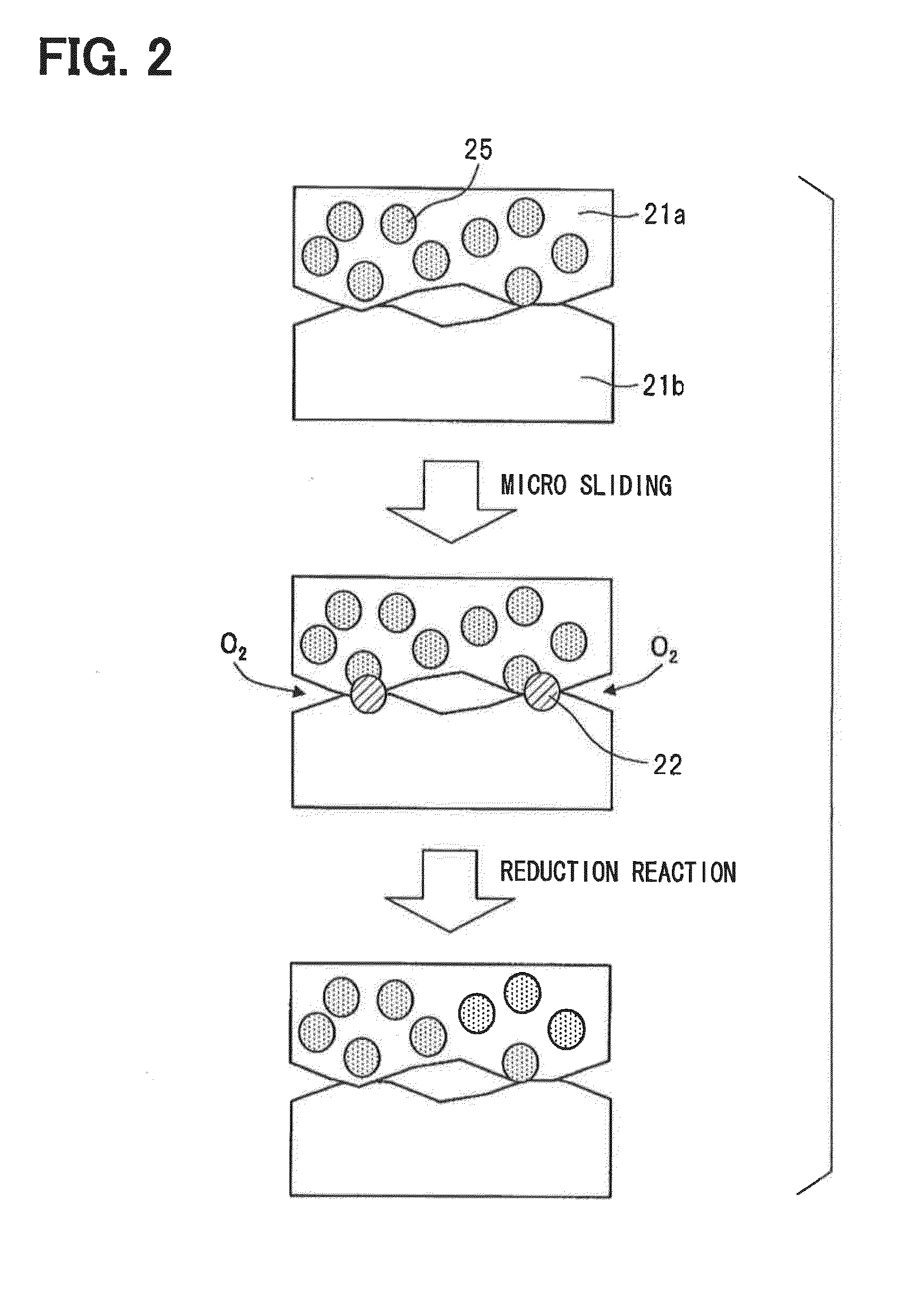

Composite material, electric contact electrode, electric contact film, conductive filler, electric contact structure using composite material, and manufacturing method of composite material

ActiveUS20130081855A1Prolong lifeReduce oxideNon-insulated conductorsElectrolytic coatingsThin membraneReducing agent

A composite material includes a metal matrix of a metal and a reducing agent. The reducing agent is dispersed in the metal matrix and is capable of reducing an oxide of the metal at room temperature. Even when the oxide of the metal is generated on a surface of the composite material, the reducing agent reduces the oxide of the metal to the metal

Owner:DENSO CORP

Probe method, prober, and electrode reducing/plasma-etching processing mechanism

InactiveUS7750654B2Reduce oxideReduce harmElectronic circuit testingFault location by increasing destruction at faultProcess mechanismForming gas

A probe method of this invention includes a step of reducing an electrode of a wafer by using a forming gas, and a step of bringing the electrode and a probe pin into contact with each other in a dry atmosphere. The probe method further includes, prior to a reducing process of an electrode of the object to be tested, placing the object to be tested in an inert gas atmosphere and heating the object to be tested. The reducing process is performed by bringing a reducing gas into contact with the electrode of the object to be tested under atmospheric pressure.

Owner:OCTEC INC +1

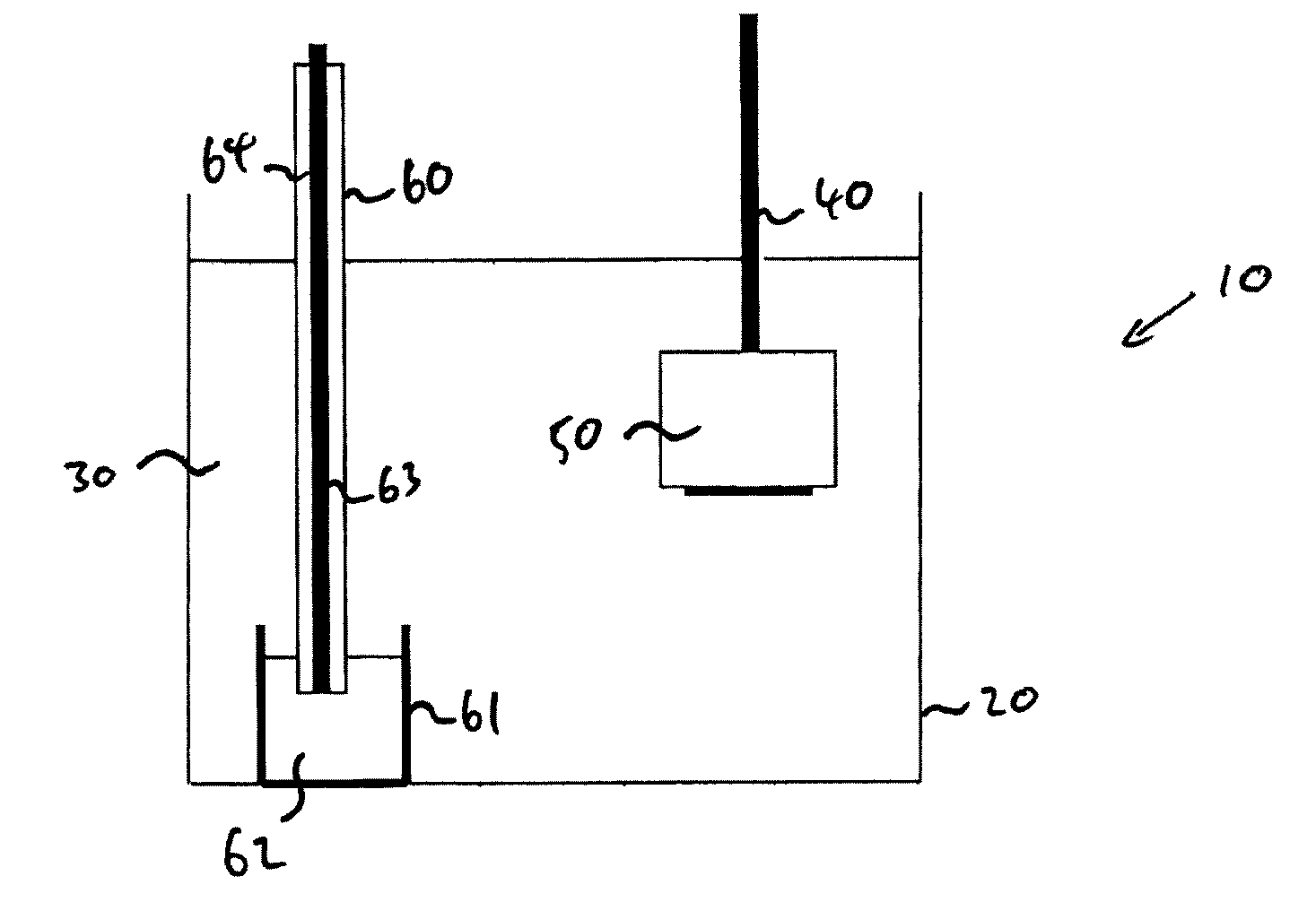

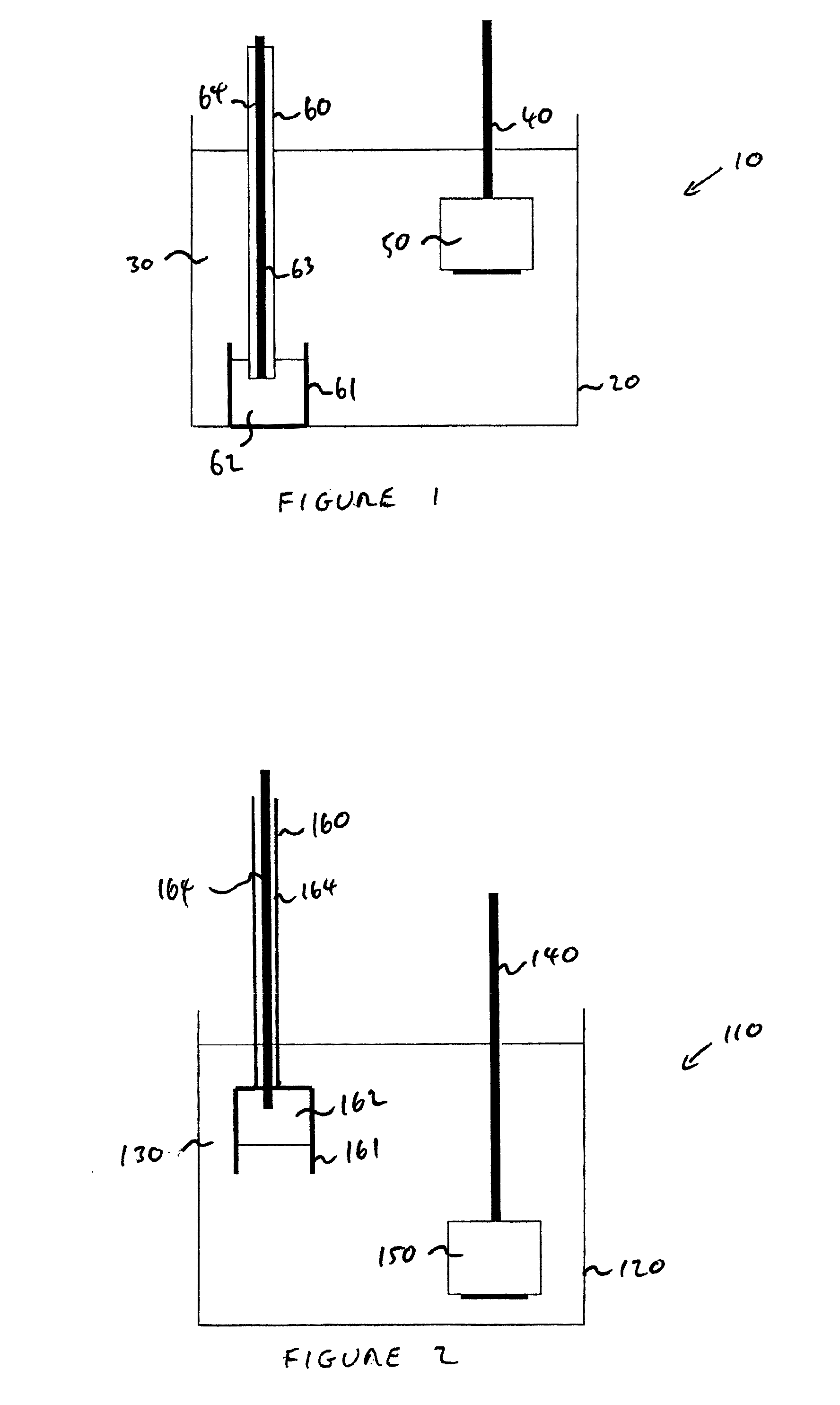

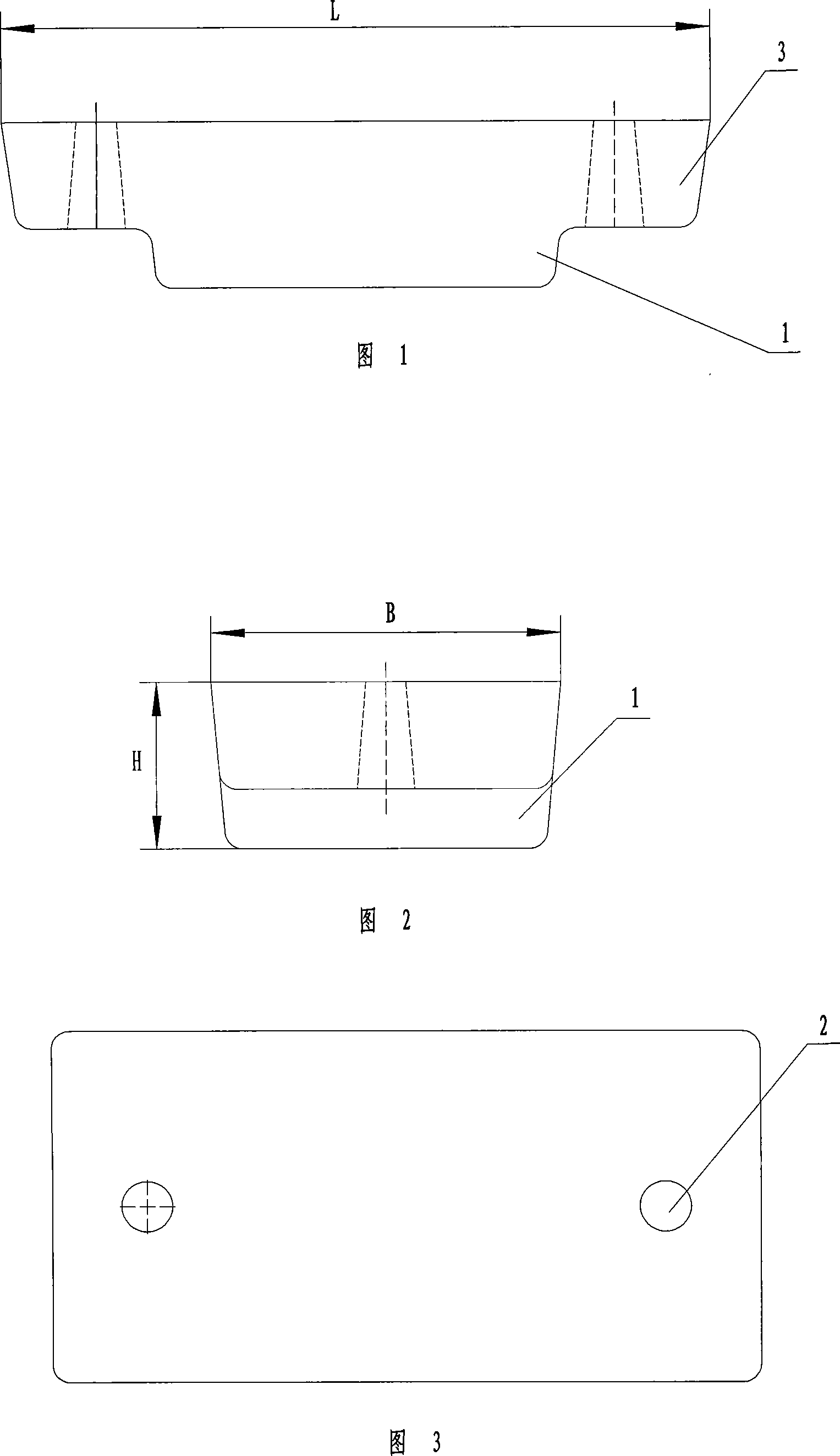

Method and apparatus for producing metal by electrolytic reduction

A method is provided for producing metal by electrolytic reduction of a feedstock comprising an oxide of a first metal. The method comprises the steps of arranging the feedstock in contact with a cathode and a molten salt within an electrolysis cell, arranging an anode in contact with the molten salt within the electrolysis cell, and applying a potential between the anode and the cathode such that oxygen is removed from the feedstock. The anode comprises a second metal, which at the temperature of electrolysis within the cell is a molten metal. The second metal is a different metal to the first metal. Oxygen removed from the feedstock during electrolysis reacts with the molten second metal to form an oxide comprising the second metal. Thus, oxygen is not evolved as a gas at the molten anode.

Owner:METALYSIS

Method of operating fuel cell

InactiveUS7276305B2Simple and inexpensiveRestore performanceFuel cell auxillariesElectrochemical responseFuel cells

Owner:MITSUBISHI ELECTRIC CORP

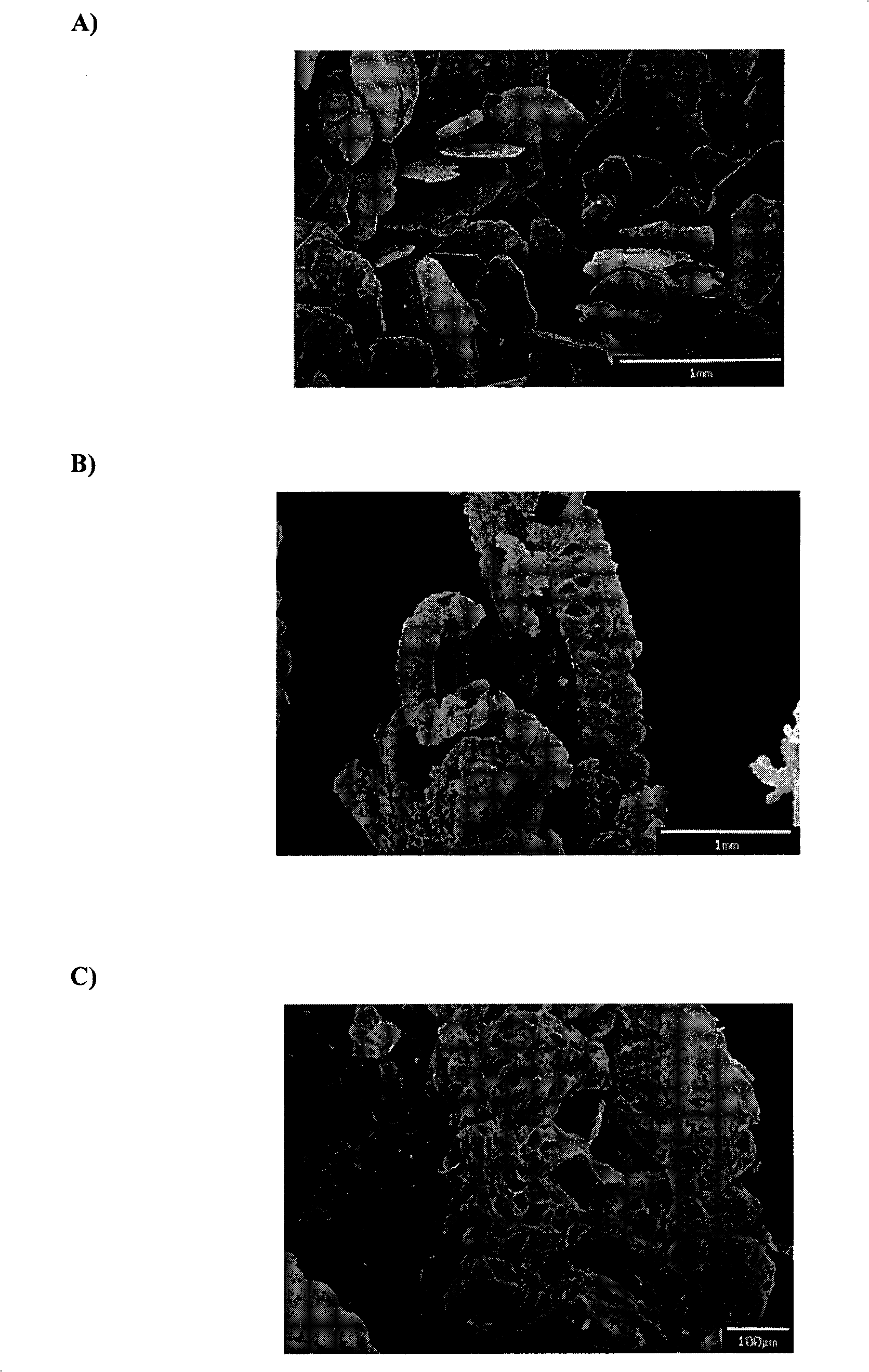

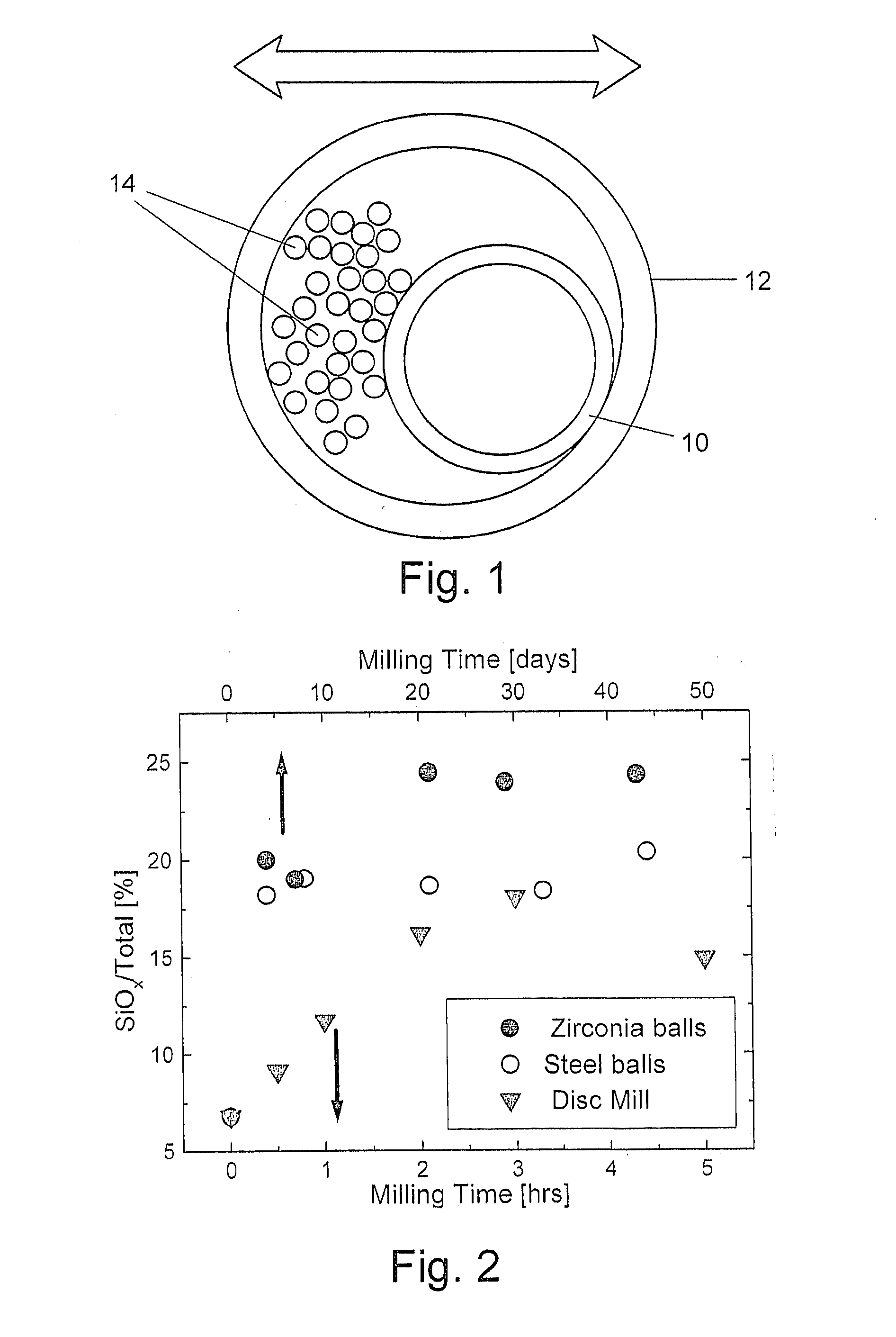

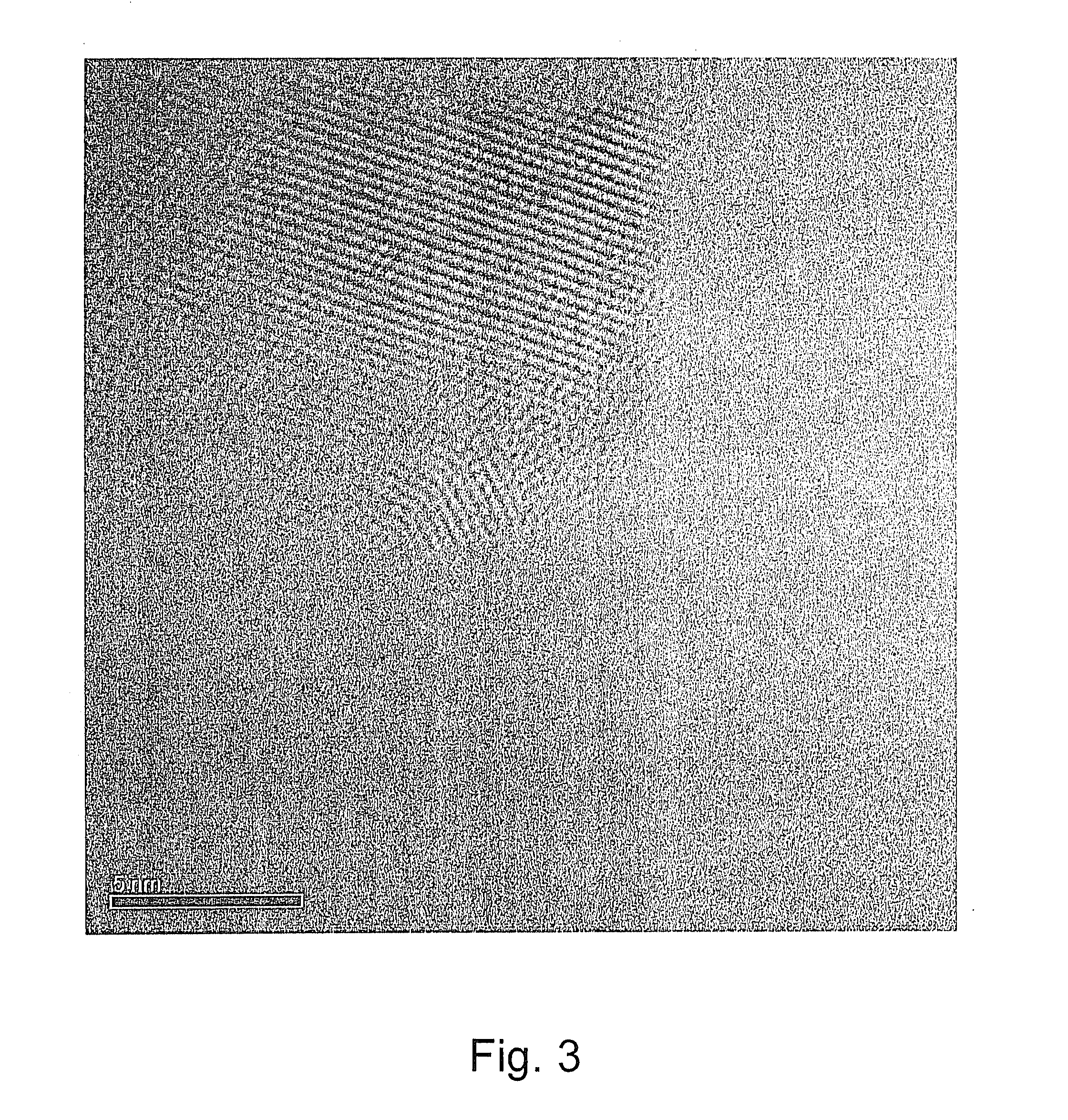

Method of Producing Stable Oxygen Terminated Semiconducting Nanoparticles

InactiveUS20120018551A1Avoid formingInhibition formationMaterial nanotechnologyCell electrodesSemiconductor materialsHigh energy

A method is provided of producing inorganic semiconducting nanoparticles having a stable surface. The method comprises providing an inorganic bulk semiconductor material, such as silicon or germanium, and milling the bulk semiconductor material in the presence of a selected reducing agent. The reducing agent acts to chemically reduce oxides of one or more component elements of the semiconductor material, or prevent the formation of such oxides by being preferentially oxidised, thereby to provide semiconducting nanoparticles having a stable surface which allows electrical contact between the nanoparticles. The milling may take place in a mill in which the milling media and / or one or more components of the mill comprise the selected reducing agent. For example, the milling can be carried out in a high energy mill with a hammer action in which a pestle of the mill, a mortar of the mill, or both are composed of the selected reducing agent, or a low energy, stirred media mill, such as a ball mill, a rod mill or similar, in which the milling media, a lining of the mill, or both are composed of the reducing agent. The milling media or mill are typically composed of a metal selected from the group comprising iron, chromium, cobalt, nickel, tin, titanium, tungsten, vanadium, and aluminium, or an alloy containing one or more of said metals. In another embodiment of the method, the selected reducing agent comprises a liquid contained in the mill during milling of the bulk semiconductor material. The liquid is typically an acidic solution containing any of hydrochloric, sulphuric, nitric, acetic, formic, or carbonic acid, or a mixture thereof. The invention extends to a mill for carrying out the method.

Owner:PST SENSORS

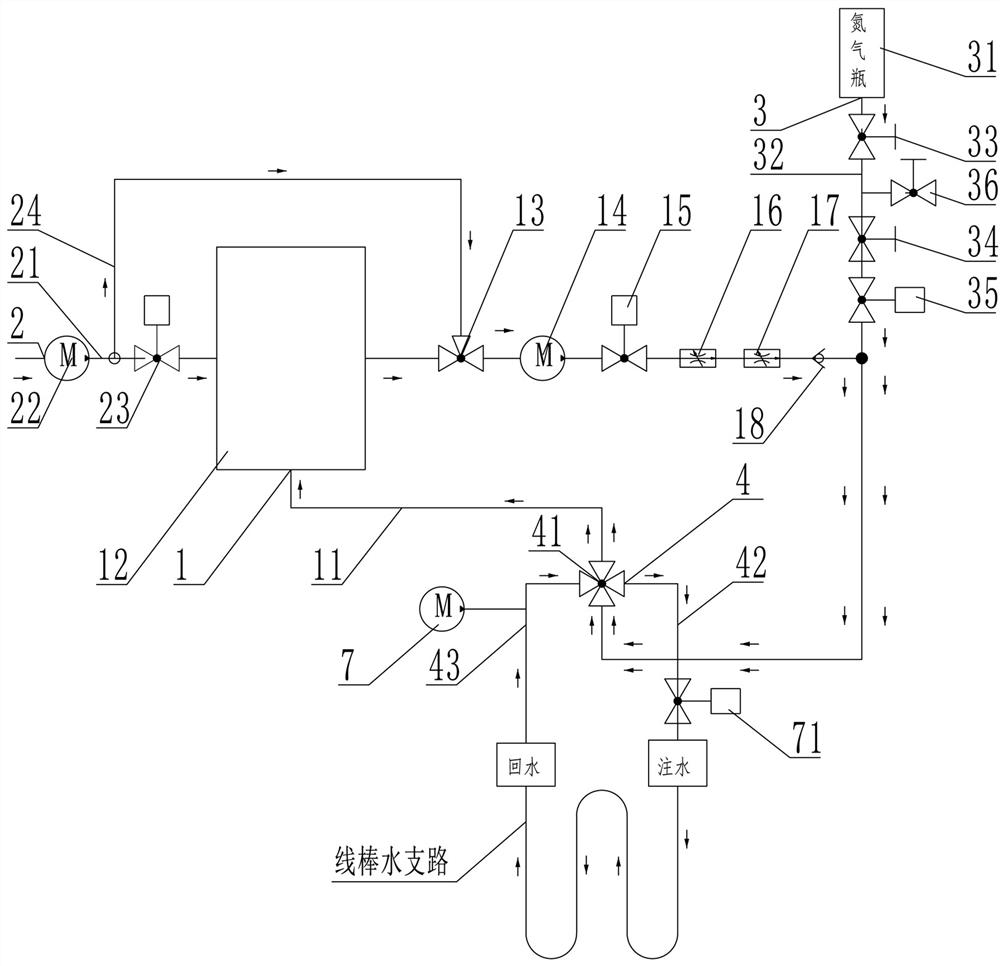

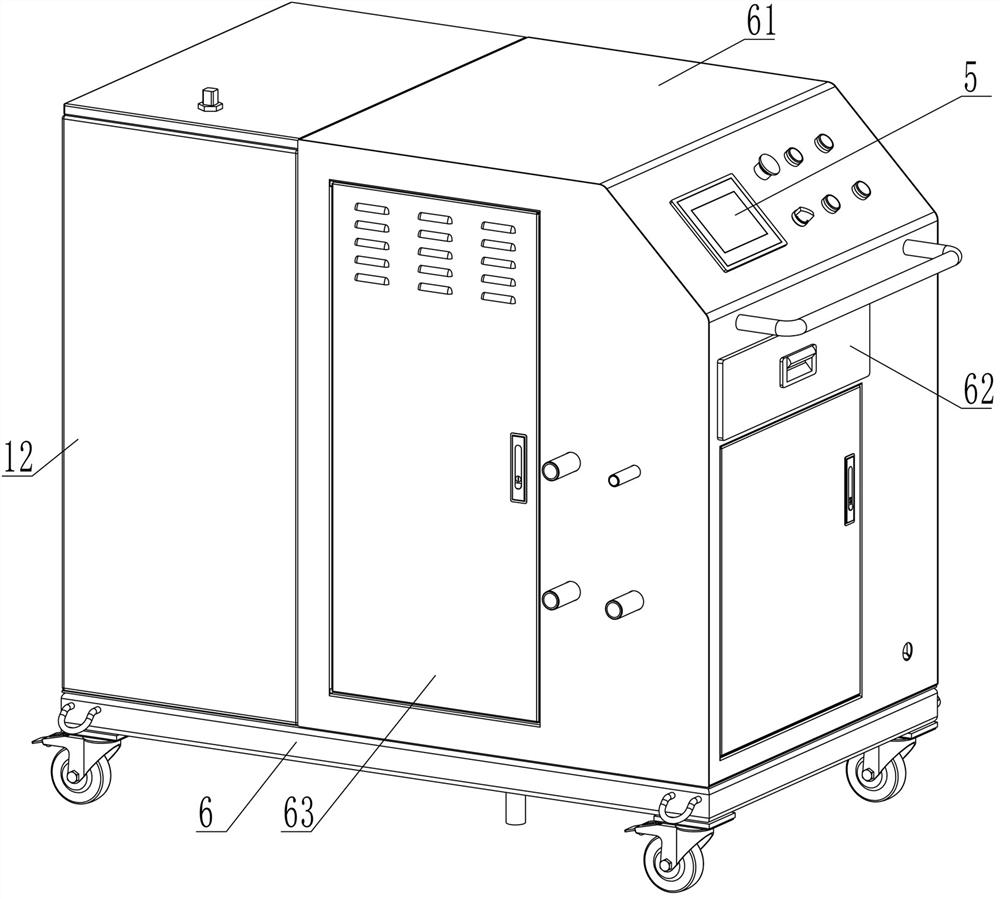

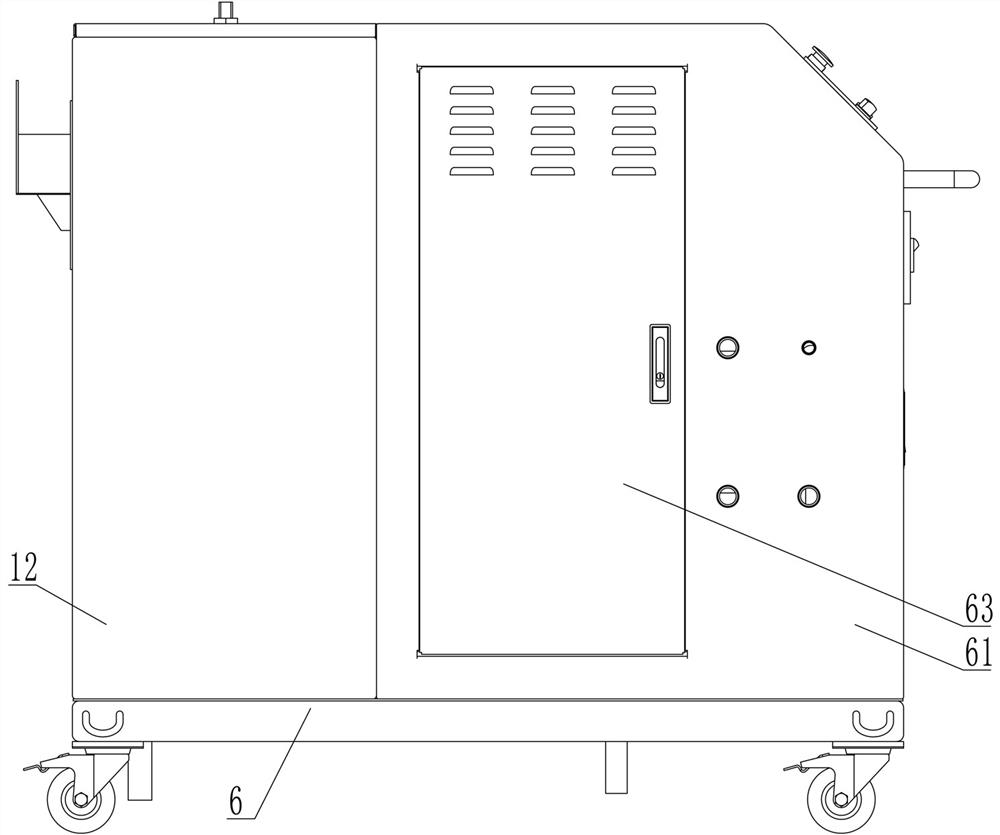

Cold and hot water positive and negative water vapor interaction pulse washing and drying device and method

InactiveCN113000495AWash thoroughlySimple structureFluid heatersHollow article cleaningThermodynamicsControl system

The invention provides a cold and hot water positive and negative water vapor interaction pulse washing and drying device and method. A water supplementing device is connected with a water tank of a water circulation system, a gas supplementing device is connected with a water circulation pipeline of the water circulation system, a three-position four-way reversing electric valve of a coil bar washing loop is located in the water circulation system and connected with the water circulation system, and a vacuum device is connected with the coil bar washing loop. A PLC control system controls the water supplementing device to supplement water to the water circulation system, the gas supplementing device supplements gas to the water circulation system or dries a coil bar water branch after washing, a formed water-gas mixture enters the coil bar washing loop to wash and descale the coil bar water branch, and the vacuum device extracts water, gas and impurities. The problems that the coil bar water branch of an internal water cooling generator is not thoroughly washed, the blockage removal capacity is insufficient, and the inner wall of a coil bar is likely to be oxidized are solved, and the cold and hot water positive and negative water vapor interaction pulse washing and drying device and method have the characteristics of being simple in structure, adjustable in water-gas pulse ratio, capable of achieving self-circulation and direction-changing washing, capable of saving energy, thorough in washing, beneficial to reduction of oxide in the washing process and easy and convenient to operate.

Owner:CHINA YANGTZE POWER +1

Hot dip galvanizing Al rare earth alloy for steel and iron member hot dip galvanizing and its ingot type and method

ActiveCN101086047AAvoid uneven compositionAvoid burnsHot-dipping/immersion processesSymmetrical earsRare earth

The invention relates to a zinc alloy for steel component galvanizing, the ingot shape and the method. The comprised component and weight proportion are as follows: 0.008%-0.012%(wt)Al,0.006%-0.01%(wt)RE, the rest is zinc and unavoidable impurities. The ingot shape is'T'cuboid with two symmetrical ear-warps, the bottom of cuboid is plane, ear-warps are equipped with hoisting holes, and the four sides are inclined plane which is narrow-end-up shape. It is characterized by direct fusion of said alloy to zinc bath, simple utilization, stable and homogeneous Al and rare earth content in zinc alloy, improved coating brightness and zinc flowability, decreased coating thickness, and saved zinc plating cost. The proper zinc alloy ingot shape and weight meets the demand of zinc addition for large-capacity galvanizing equipment, and it is convenient for hoisting and cross transportation, specific surface area is small, which is suitable for multi-layer stacking storage.

Owner:湖南株冶环保科技有限公司

Hot dipping zinc aluminum nickel bismuth rare earth alloy used for steel component hot dipping zinc and ingot case and method thereof

ActiveCN101109053AAvoid uneven compositionImprove corrosion resistanceHot-dipping/immersion processesRare earthZinc alloys

The invention relates to a zinc alloy used by steel structural component in zinc hot dip plating and the ingot shape and the method thereof. The alloy component and the weight per cent are of 0.008 per cent (wt) to 0.012 per cent (wt) Al, 0.04 per cent (wt) to 0.06 per cent (wt) Ni, 0.02 per cent (wt) to 0.08 per cent (wt) Bi, 0.006 per cent (wt) to 0.01 per cent (wt) RE, and zinc and impurity as the rest composition. The ingot shape is of T-shaped cuboid with two symmetrical ear curls; wherein, the bottom of the cuboid is a plane; the ear curls are provided with hoisting holes; the cuboid is of four included side planes, taking in a big top and small bottom shape. The zinc hot dip plating method is to melt the alloy directly into zinc bath; the application is simple; the zinc bath alloy elements Al, Bi, Ni and RE with stable and uniform content can alleviate or eliminate the Sandelin Effect generated by an active steel galvanization, perfect the wetting behavior and flow property of the iron matrix and the zinc bath, improve corrosion resistance performance and mechanical performance of the coating, reduce the thickness of the coating and lower the cost. With the appropriate shape as well as ingot weight, the zinc alloy ingot shape has the advantages of able to meet zinc adding requirement of the large capacity galvanization equipment, convenient hoisting and fork transport, small specific surface area, suitable for storage and multiple layers stacking tier, saving storing room, and stability as well as safety.

Owner:ZHUZHOU SMELTER GRP

Electrochemical Method and Apparatus For Removing Oxygen From a Compound or Metal

InactiveUS20080302655A1Improve conductivityEfficiently transferring oxygenPolycrystalline material growthFrom normal temperature solutionsOxygenElectrochemistry

A cathode comprising an oxygen-containing compound, or a metal containing dissolved oxygen, is arranged in contact with a melt comprising a hydroxide of an alkali metal. An inert anode, advantageously comprising nickel, is also arranged in contact with the melt and a potential is applied between the anode and the cathode such that oxygen is removed from the compound or the metal.

Owner:CAMBRIDGE ENTERPRISE LTD

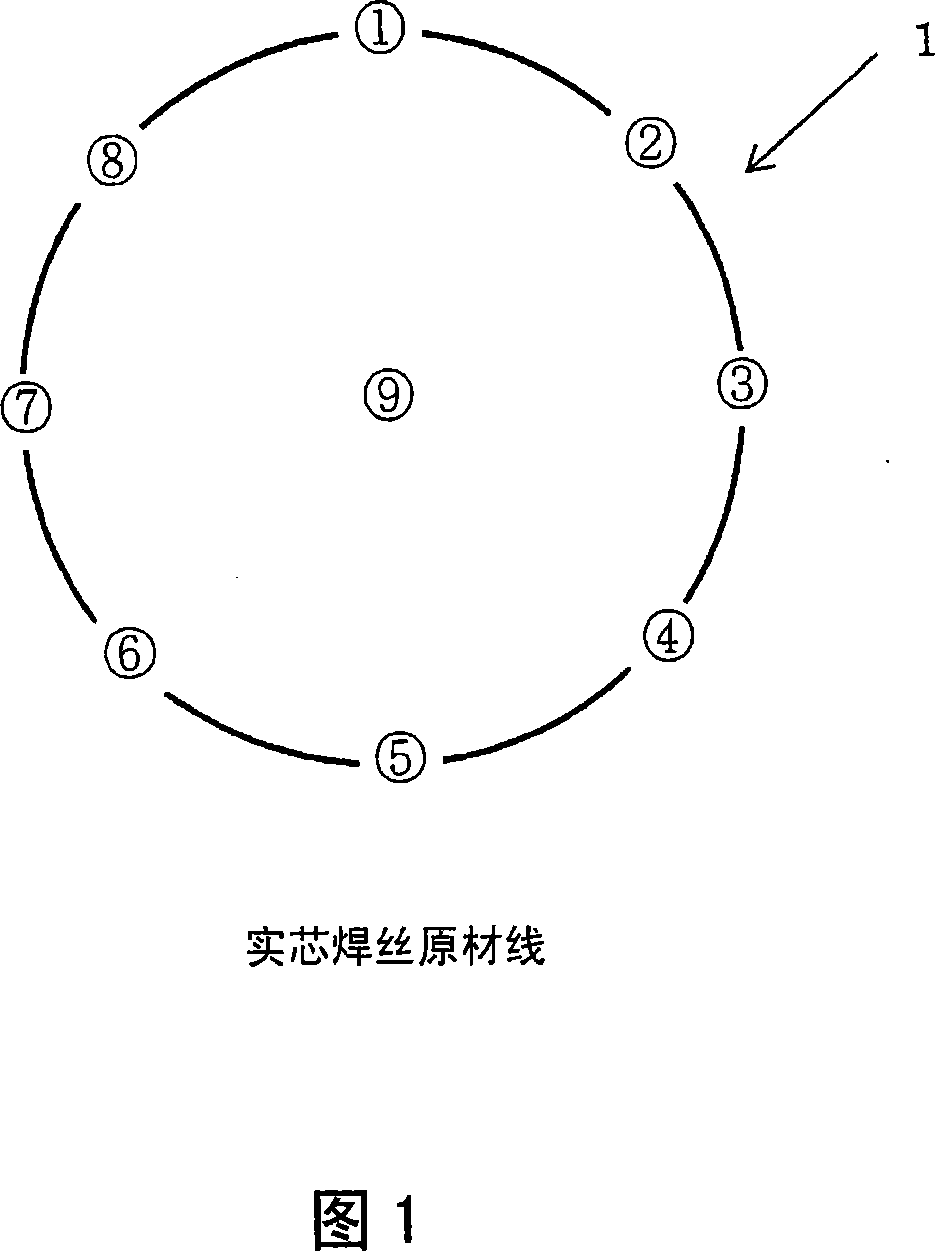

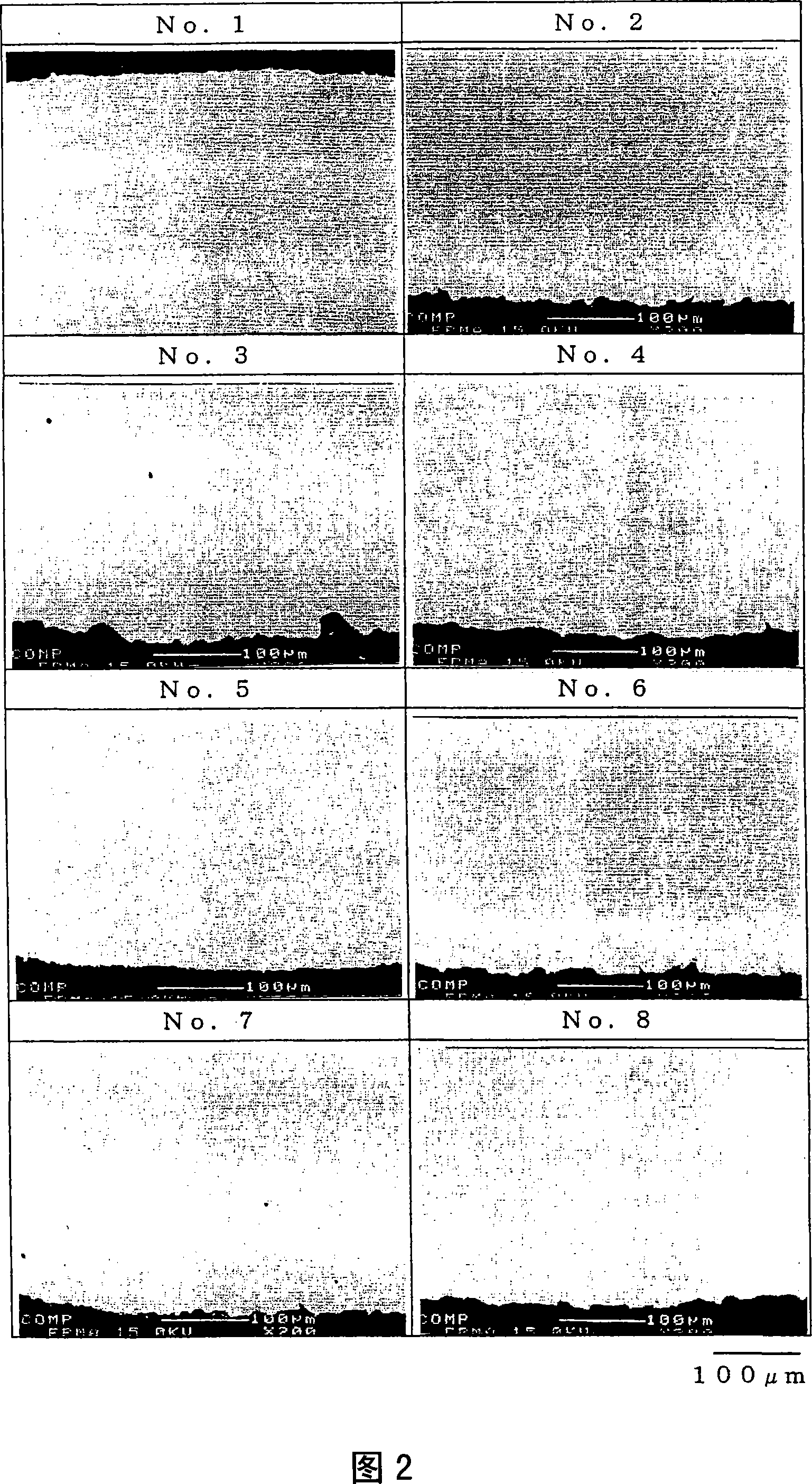

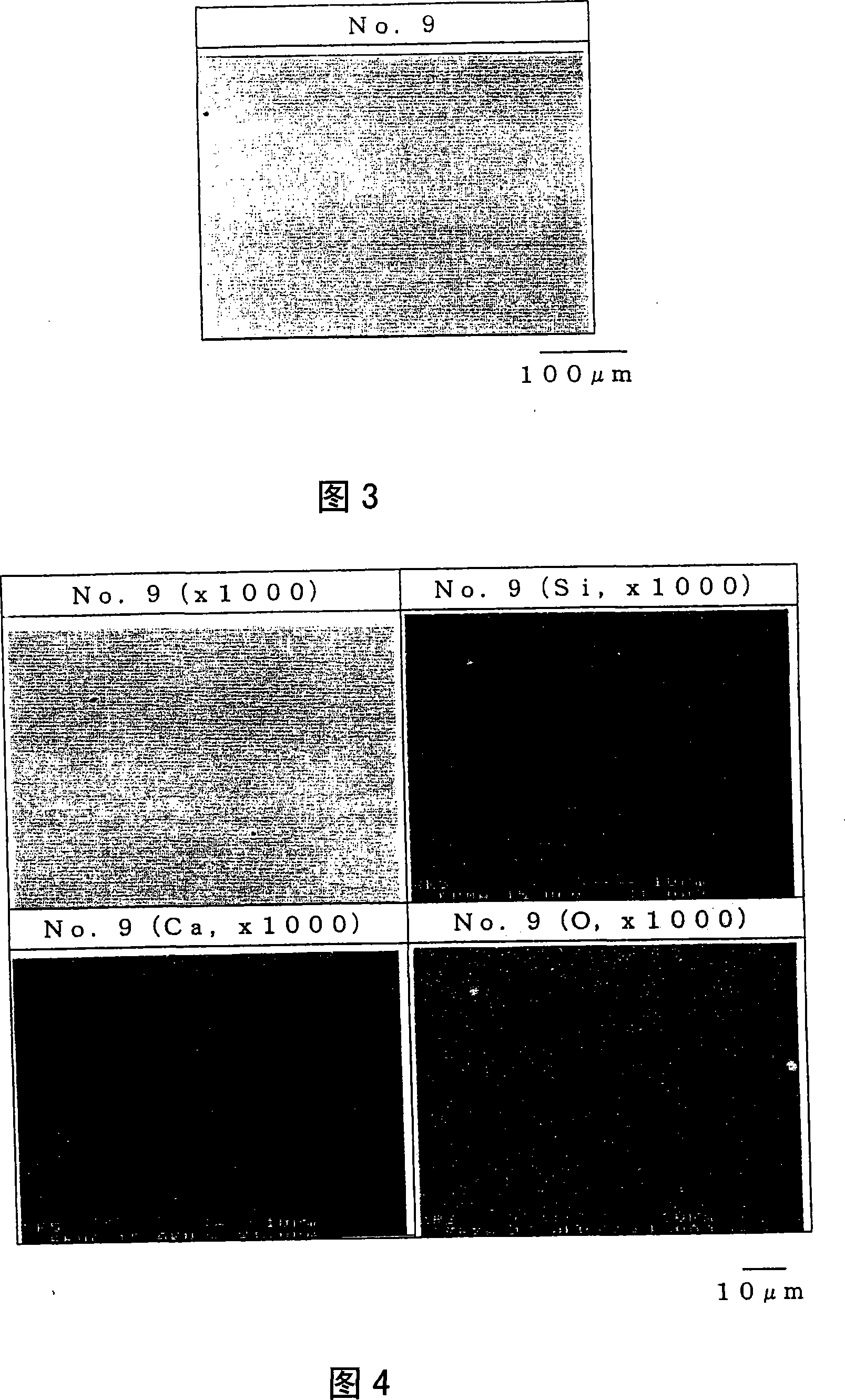

Solid core welding stick original material wire

InactiveCN101088699AReduce oxideImproved arc stabilityWelding/cutting media/materialsSoldering mediaArc stabilityImpurity

To provide a solid wire raw material wire for manufacturing a solid wire for gas-shielded arc welding, the solid wire reduces the slight deviation of the arc voltage caused by the solid wire itself during welding, and can obtain excellent arc stability . The solid wire raw material contains: C: 0.02-0.15% by mass, Si: 0.1-1.0% by mass, Mn: 0.5-2.0% by mass, and the balance is Fe and unavoidable impurities. There are a total of 9 points in total at 8 points at equal intervals around the periphery, and when the viewing area of each point is set to 3.4 μm × 4.6 μm for observation, Ca oxides and Al oxides with a maximum length of 0.5 μm or more are in total at the 9 points There are no more than 10.

Owner:KOBE STEEL LTD

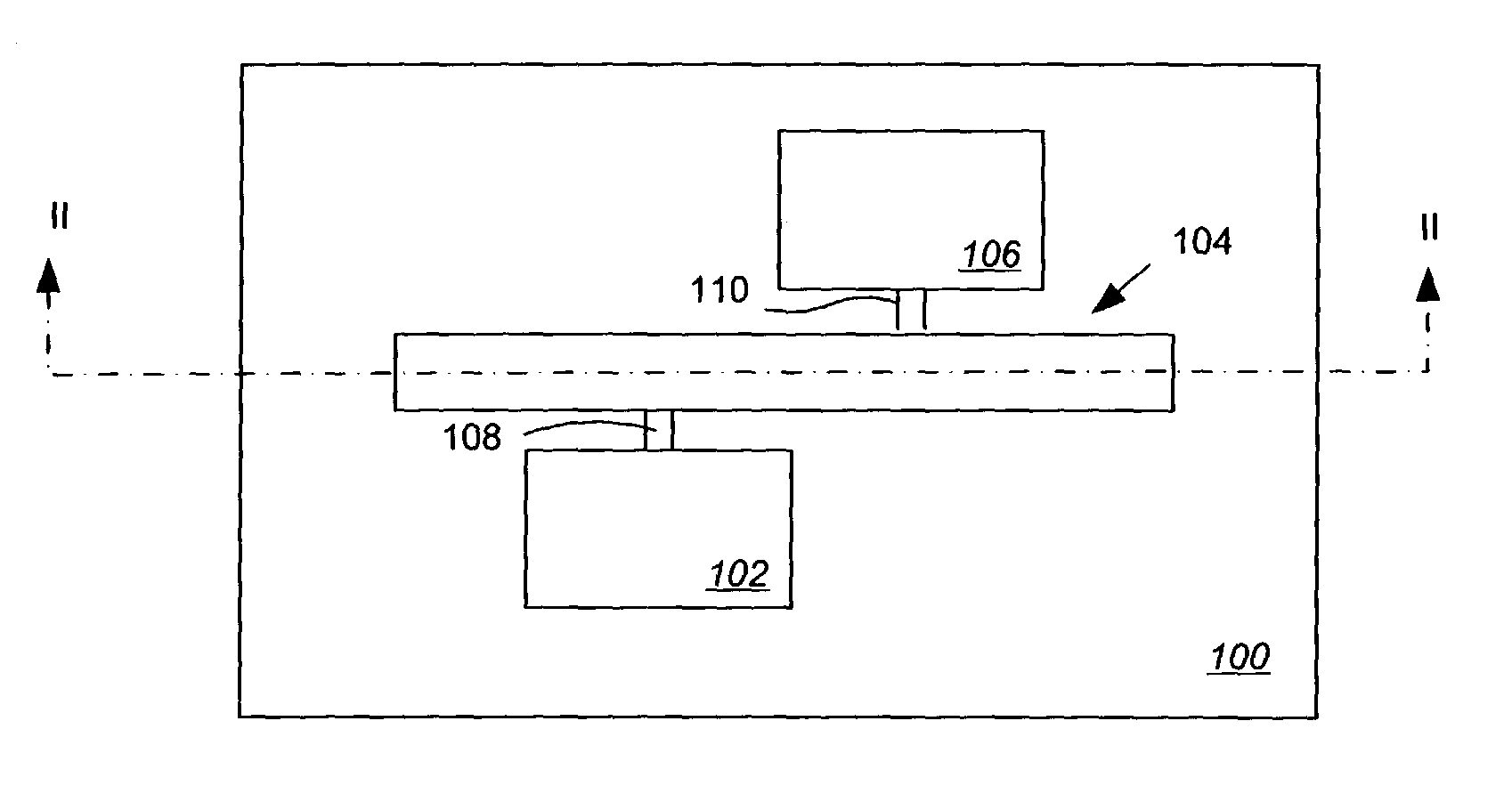

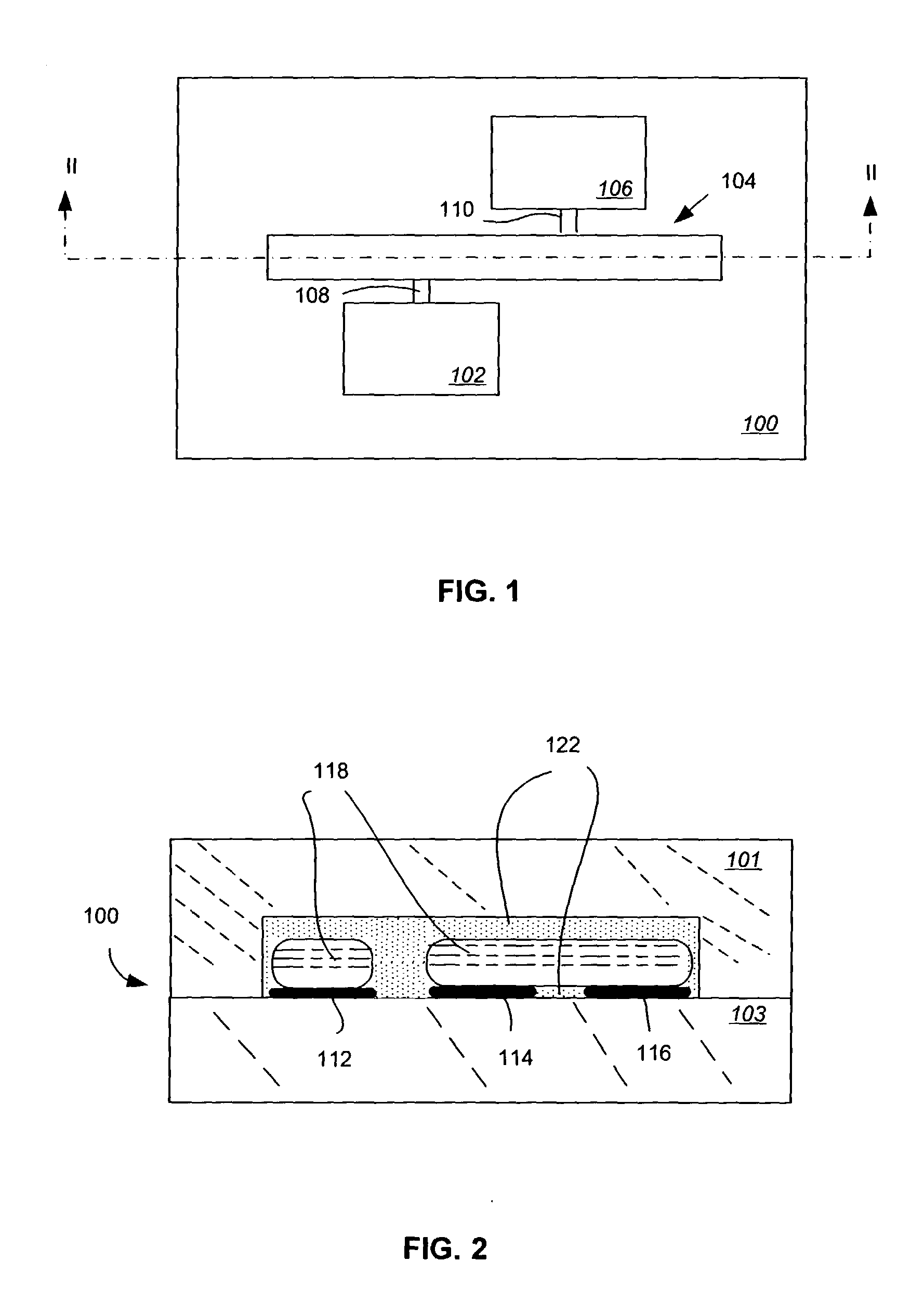

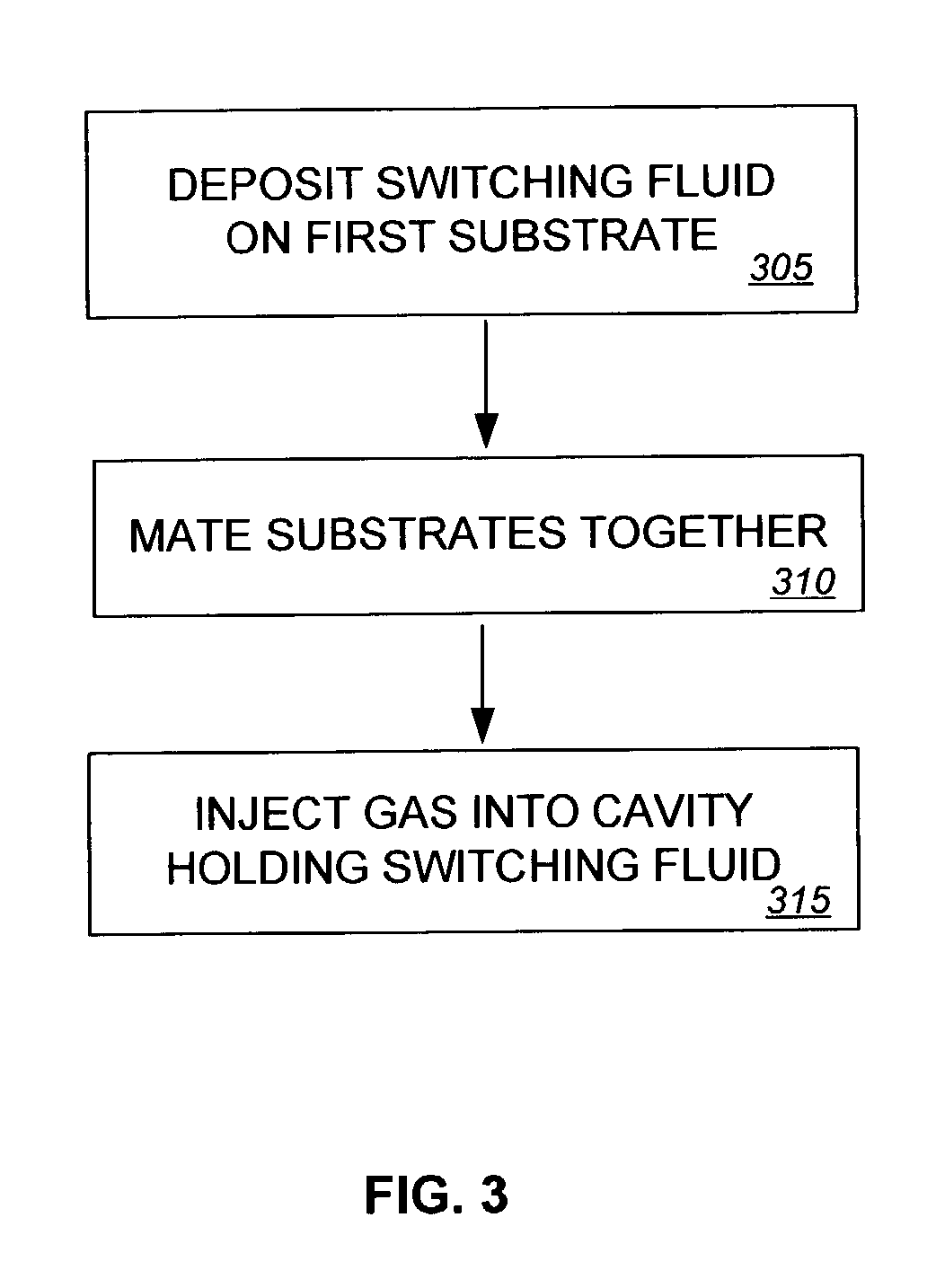

Reducing oxides on a switching fluid in a fluid-based switch

InactiveUS20050034962A1Reduce oxideElectrothermal relaysCoupling light guidesOxygenElectrical and Electronics engineering

Fluid-based switch and methods for reducing oxides on switching fluid are disclosed. In one method, oxides are reduced by depositing a switching fluid on a first substrate, mating the first substrate to a second substrate, the first substrate and the second substrate defining therebetween a cavity holding the switching fluid, the cavity being sized to allow movement of the switching fluid between first and second states, and creating a gas in the cavity holding the switching fluid, the gas to react with at least one of oxygen in the cavity and oxides on the switching fluid.

Owner:AGILENT TECH INC

Process for purification of oligoanilines and oligoanilines

ActiveCN1984941AReduce oxideInhibitionAmino compound purification/separationElectroluminescent light sourcesActivated carbonHydrogen

Oligoanilines of the general formula (1) exhibiting absorption coefficients (e) of 30 or below at 560 nm are obtained by dissolving a crude oligoanilne which contains an oligoaniline of the general formula (1) and oxides thereof and exhibits an absorption coefficient (e) of 80 to 1000 at 560 nm in a solvent to form an oligoaniline solution, treating the solution with 4 to 20 % by mass of activated carbon based on the crude oligoanilne, and subjecting the resulting solution to recrystallization. According to the process, oligoanilines which little contain impurities and can exert electroluminescent characteristics with high reproducibility can be obtained. (1) [wherein R<1> to R<3> are each independently hydrogen, hydroxyl, or the like; A and B are each independently a divalent group represented by the general formula (2) or (3), R<4> to R<11> are each independently hydrogen, hydroxyl, or the like; and m and n are each independently an integer of 1 or above and satisfy the relationship: m + n < 20.

Owner:NISSAN CHEM IND LTD

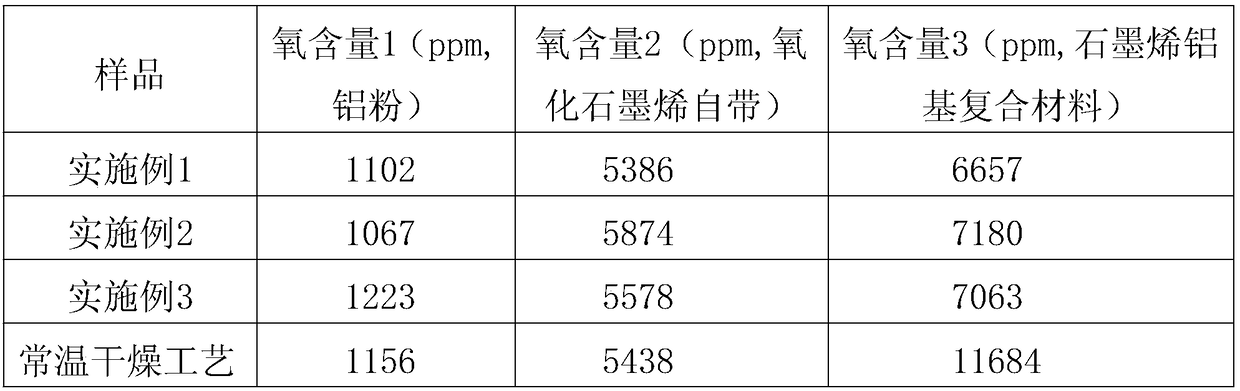

Preparation method of graphene aluminum matrix composite

InactiveCN109128148AReduce oxidationReduce oxideTransportation and packagingMetal-working apparatusMetal particleGraphene

The invention provides a preparation method of a graphene aluminum matrix composite and belongs to the field of nanometer materials. The preparation method of the graphene aluminum matrix composite comprises the following steps of stirring and mixing an oxidized graphene water solution and metal particles under 0-30 DEG C, and conducting rapid spray drying through a centrifugal spray drying towerto obtain the graphene aluminum matrix composite, wherein aluminum powder or aluminum alloy powder serves as the metal particles. According to the preparation method of the graphene aluminum matrix composite, an environment-friendly and continuous mass production scheme is provided; the oxidation degree of the metal powder can be controlled by controlling the mixing temperature, the drying speed and the drying temperature, so that the prepared composite has the low oxygen content, the preparation cost is minimized, and the electrical conductivity of a metal matrix can be further enhanced. Meanwhile, the preparation process can be used for industrial mass production.

Owner:新疆烯金石墨烯科技有限公司

Process for producing conductive coating film, and conductive coating film

InactiveUS10154585B2Efficient removalReduce oxideConductive layers on insulating-supportsPrinted circuit dryingConductive coatingMetal powder

Owner:TODA IND +1

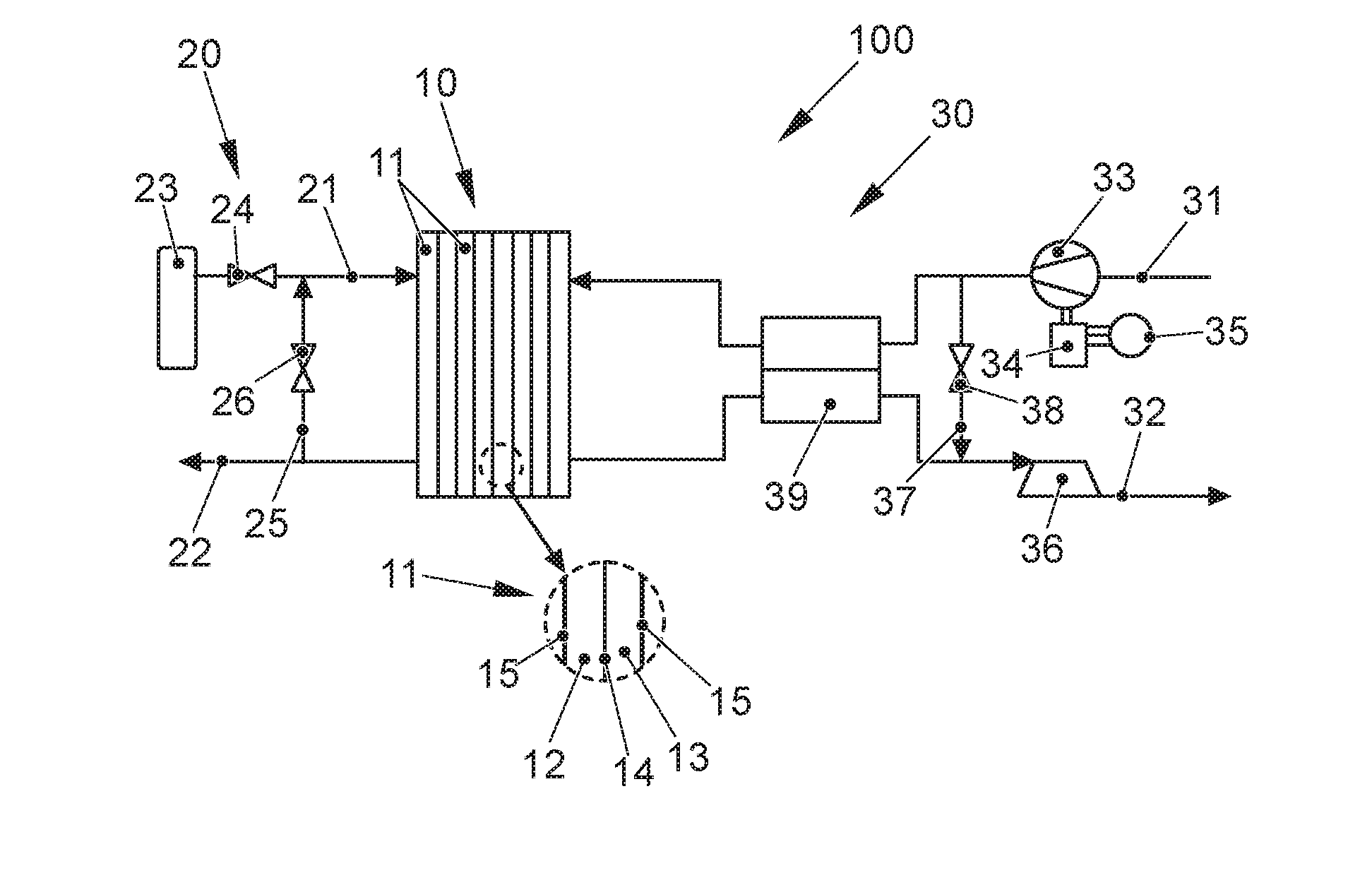

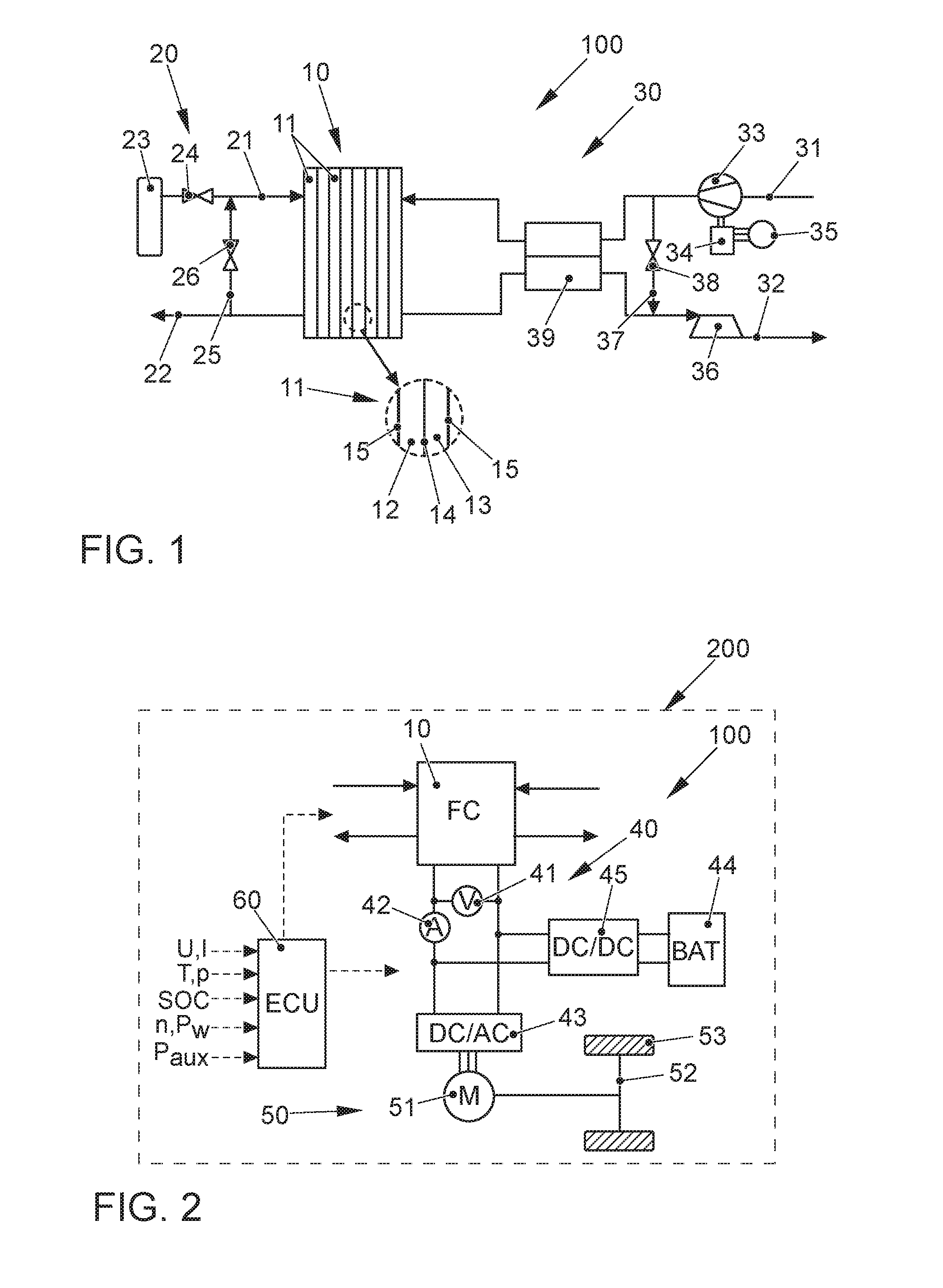

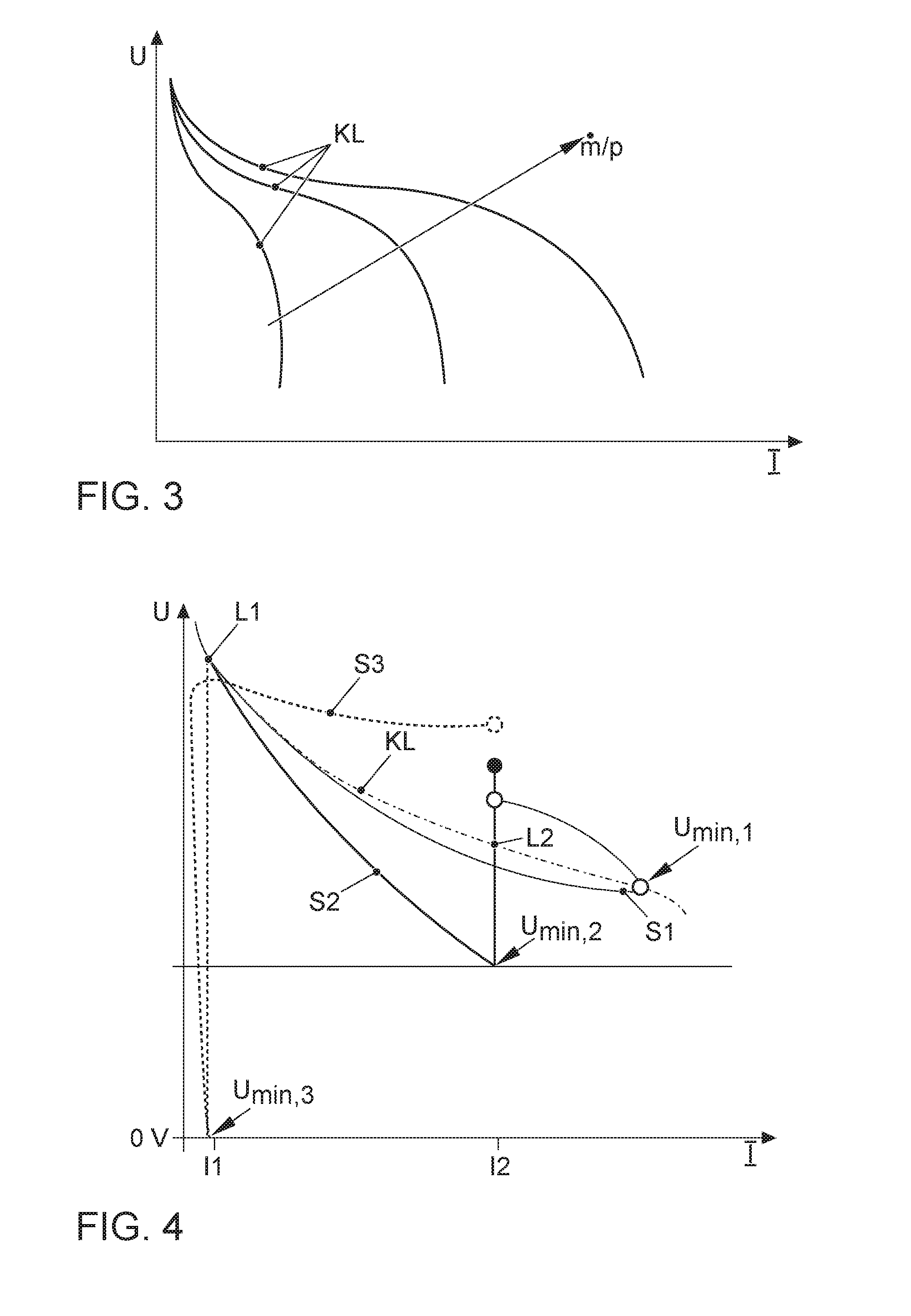

Method for controlling an operating point change of a fuel cell stack and a fuel cell system

ActiveUS20160315334A1Reduce materialEliminate the problemMotive system fuel cellsTransportation hydrogen technologyPower flowOperating point

A method for controlling an operating point change of a fuel cell stack (10) operated with an anode operating medium and with a cathode operating medium, in which the fuel cell stack (10) is controlled in such a way that, starting from an initial electric power (L1), the fuel cell stack generates a target power (L2) requested by an electrical consumer (51), which is greater than the initial power (L1) is provided. It is provided that the electric power generated by the fuel cell stack (10) is controlled in accordance with a predetermined current-voltage profile (S1, S2, S3), so that a voltage present at the fuel cell stack (10), starting from an initial voltage (U1) corresponding to the initial power (L1), passes through a local voltage minimum (Umin) and then increases to an end voltage corresponding to the target power (L2).

Owner:VOLKSWAGEN AG +1

Preparation method for powder metallurgy high-strength copper aluminum materials

The invention discloses a preparation method for powder metallurgy high-strength copper aluminum materials, and belongs to the field of powder metallurgy. Copper aluminum alloys comprise components of11-13% of Al and 87-89% of Cu; materials are mixed by a mixer by 1-2 h at a speed of 30-80 r / min; pressing blanks are prepared in a split steel mold; and formed blanks are sintered, are protected byadopting H2, are heated to 380 DEG C at a heating speed of 5 DEG C / min for insulation by 0.5-1.5 h, are heated to 660 DEG C at a heating speed of 5 DEG C / min for insulation by 0.5-1.5 h, are finally heated to 980-1010 DEG C at a heating speed of 5 DEG C / min for insulation by 1.5-2.5 h, and are cooled to a normal temperature after sintering to obtain copper aluminum alloys. The copper aluminum alloys prepared by the method are uniform in structure; pearlites in the alloys are uniformly laminar without segregating; holes in the alloy structures are uniform, fine and round; oxides in the alloys are reduced, so that the expansion in the sintering process is prevented, and the sintering density can be preferably controlled; and the tensile strength of the prepared sintering samples exceeds 400MPa.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com