Solid core welding stick original material wire

A technology of solid welding wire and raw material wire, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of not being able to obtain a beautiful weld shape, arc voltage deviation, and arc stability, etc. Achieve excellent arc stability and reduce the effect of small deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

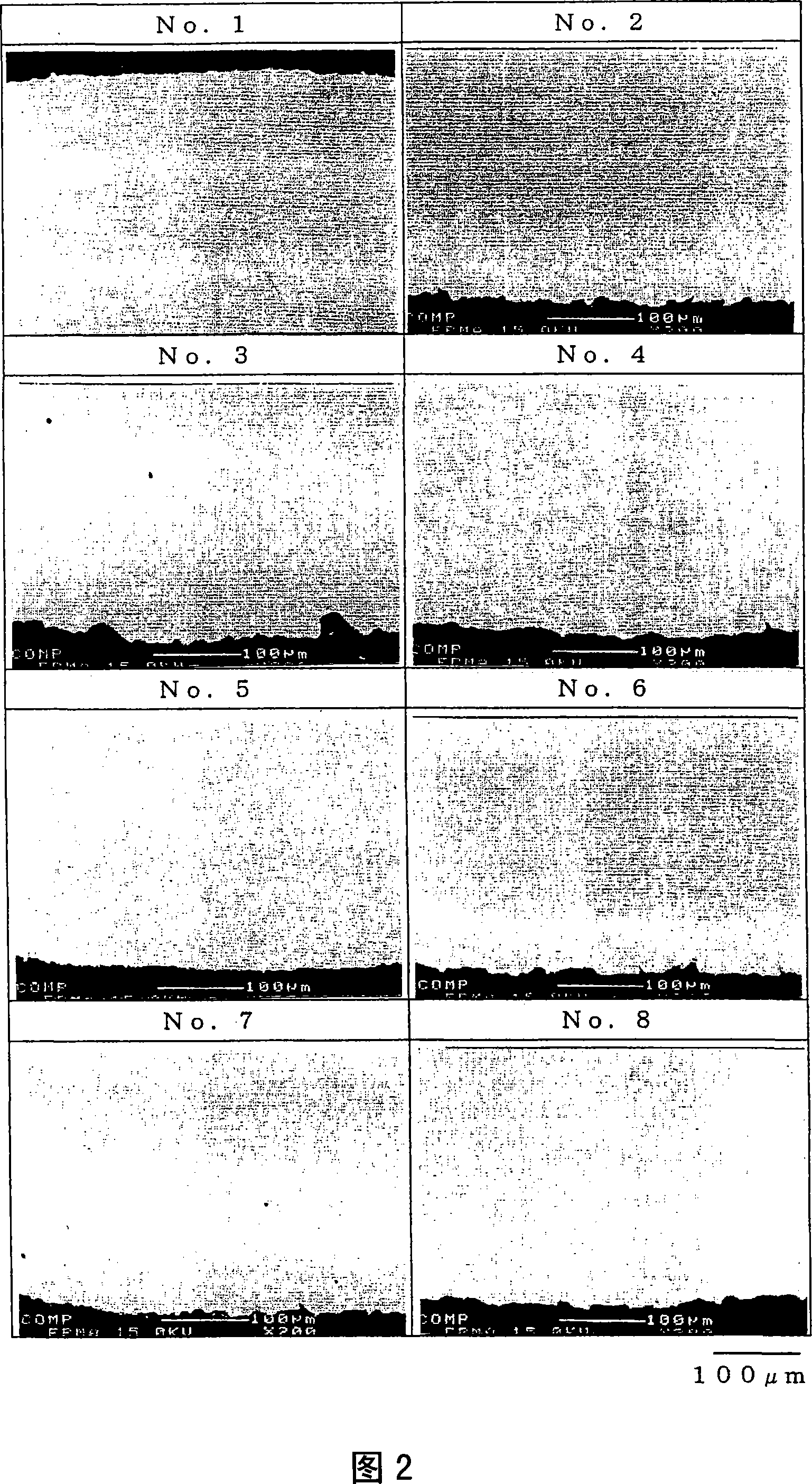

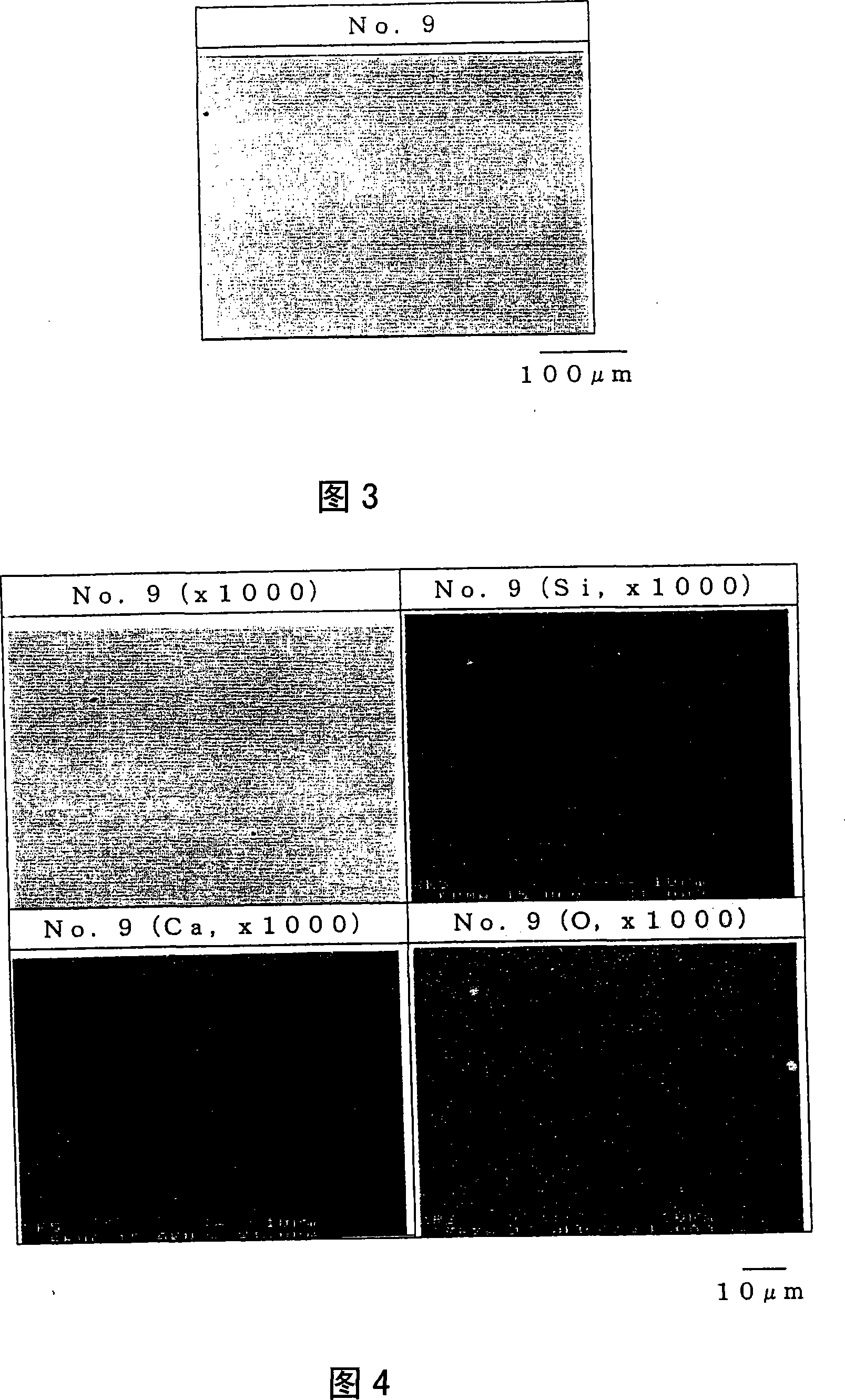

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be specifically described below. First, the solid wire raw material wire which concerns on 1st Embodiment of this invention is demonstrated. The reason for the addition of components and the reason for limiting the composition of the raw material wire of the solid core wire according to the present embodiment will be described.

[0019] "C: 0.02 to 0.15% by mass"

[0020] C is an element necessary to ensure the strength of the weld metal. If the C content of the solid wire raw material wire is less than 0.02% by mass, the solid welding wire manufactured from the solid wire raw material wire is supplied for welding, and the weld metal insufficient strength. On the other hand, if the C content of the raw material wire of the solid core wire exceeds 0.15% by mass, when the solid wire manufactured from the raw material wire of the solid core wire is supplied for welding, the vibration of the droplet and the molten pool will be sev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com