Patents

Literature

4021 results about "Gas protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gas protection is a technical solution to prevent or to control gas penetration into properties. The control of gas migration is normally achieved by blocking the pathway or removing the source of the gas generation. There are several methods available to achieve the protection of existing/new build properties and also another factor is the use of the property and size (economic factors).

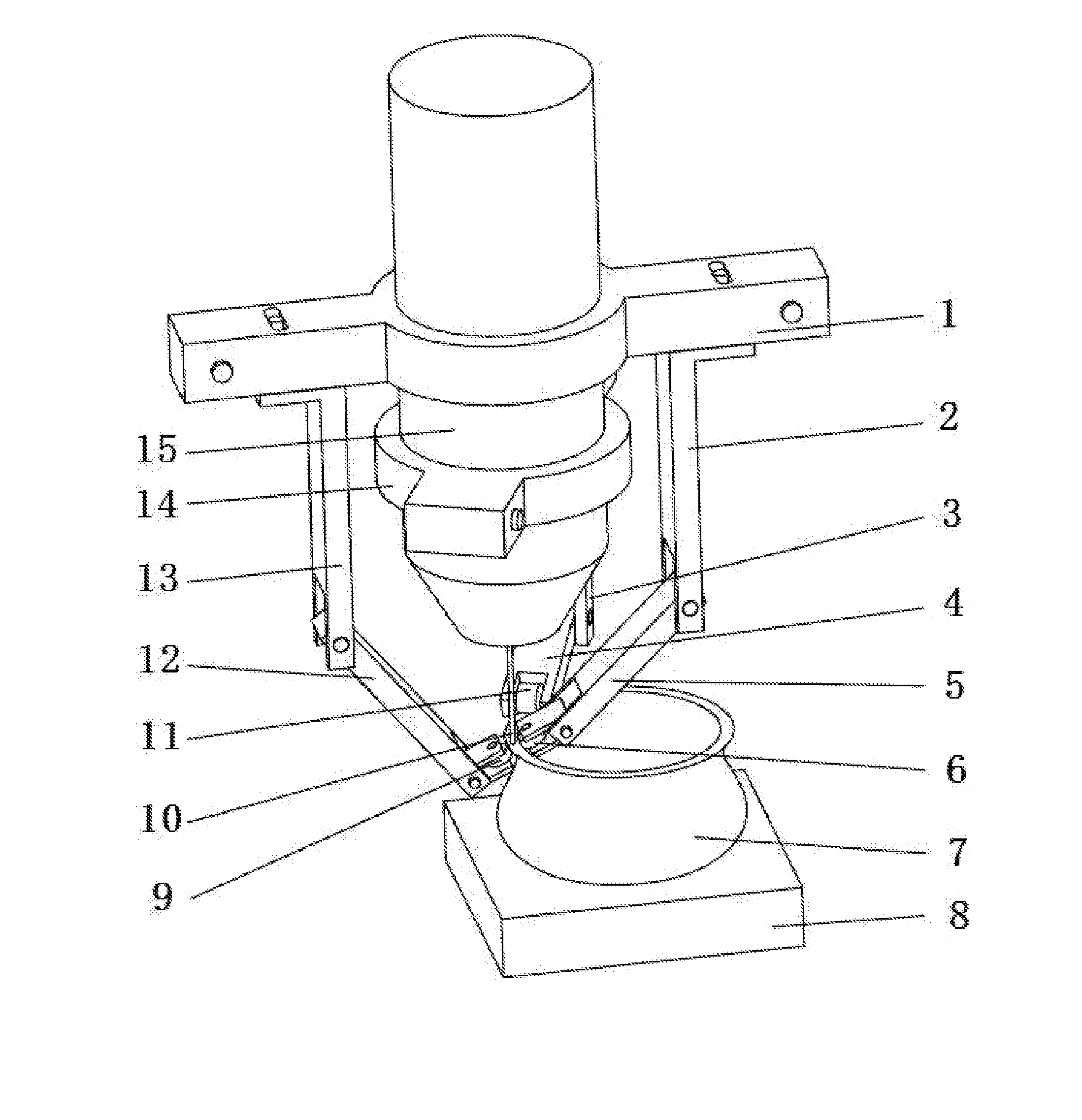

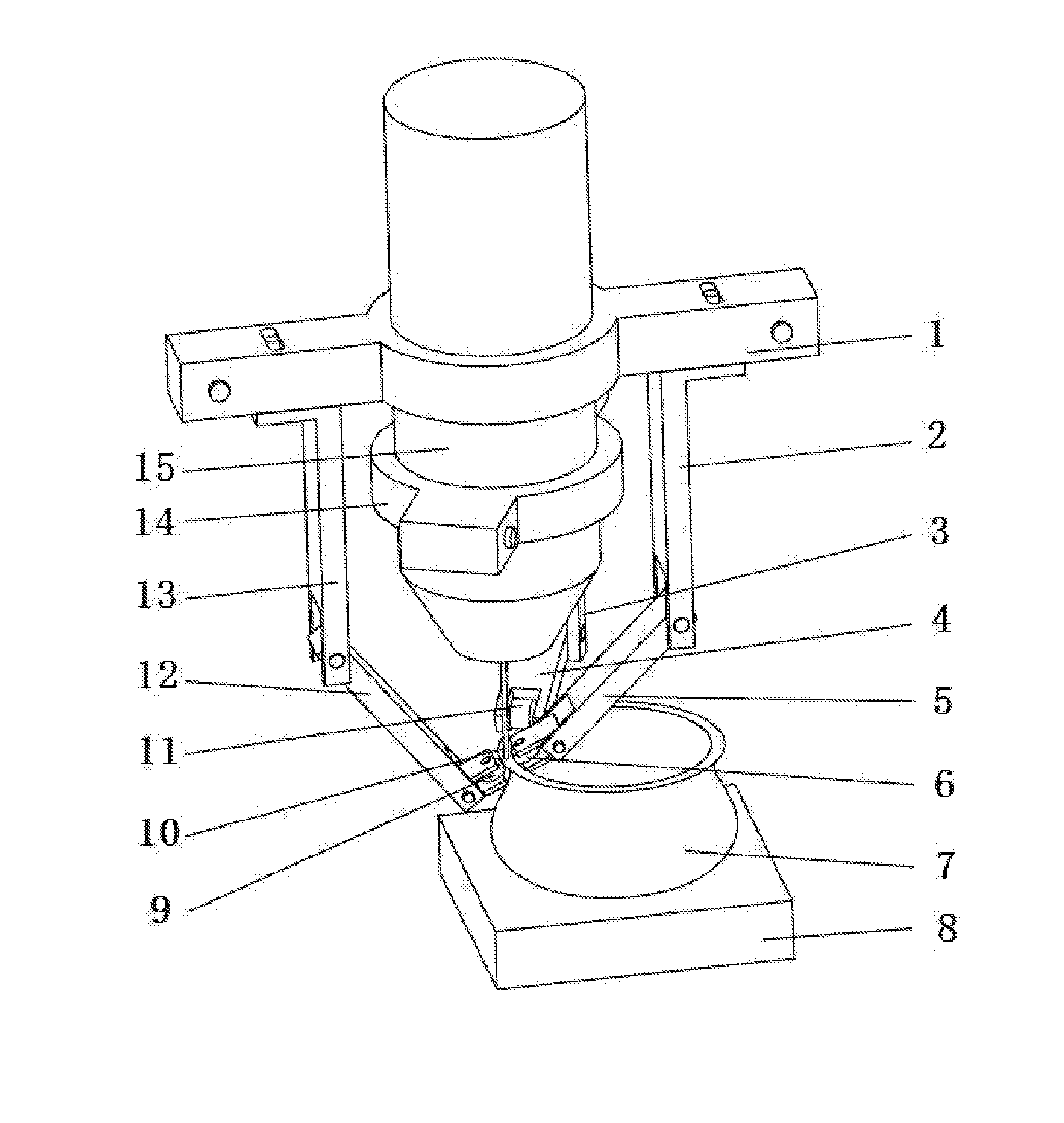

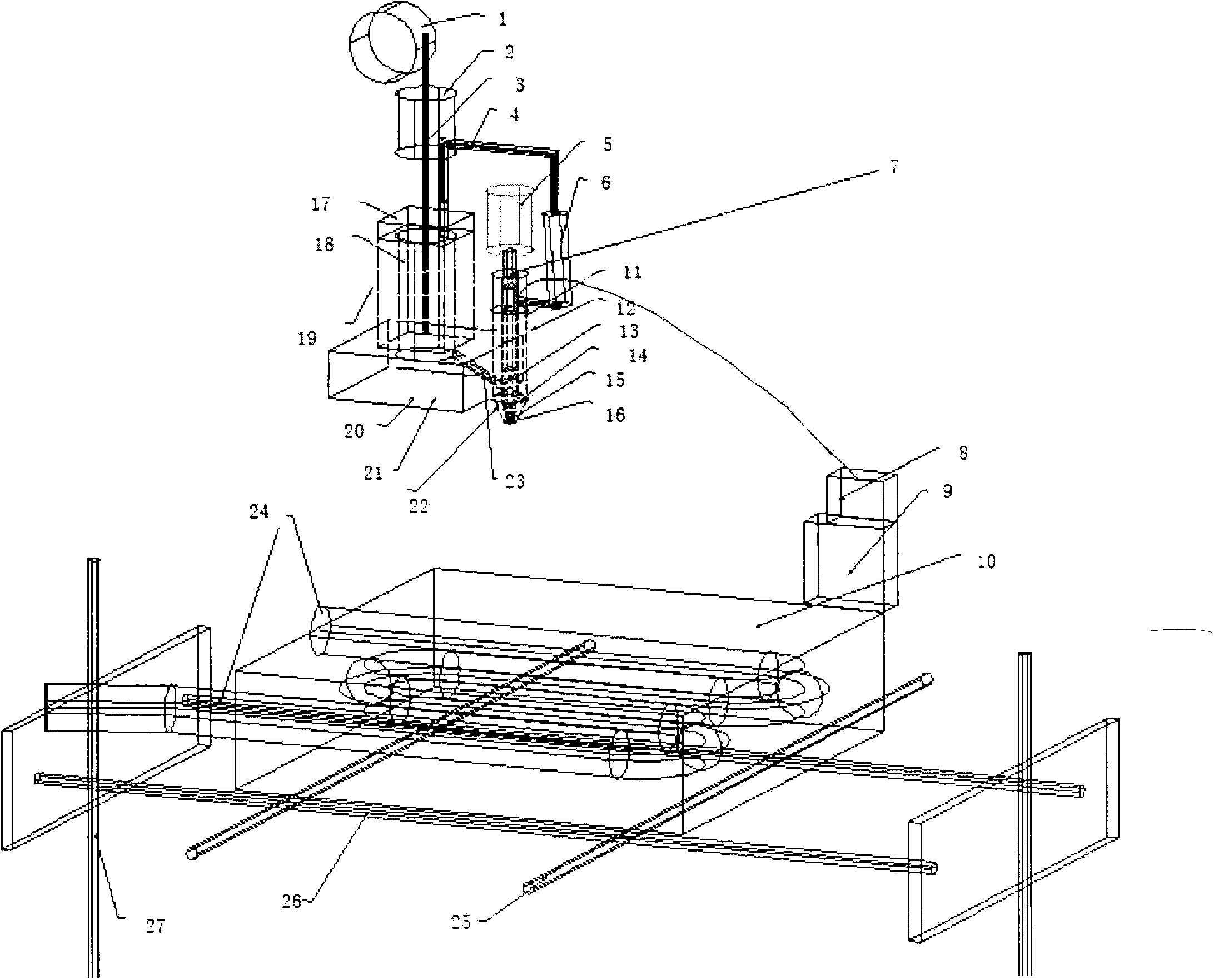

Method for manufacturing metal parts and molds and micro-roller used therefor

ActiveUS20130197683A1Formability of complexImprove accuracyArc welding apparatusAdditive manufacturing with liquidsNumerical controlWire rod

A method for manufacturing parts and molds by: 1) slicing a three-dimensional CAD model of a part or mold; 2) planning a modeling path according to slicing data of the three-dimensional CAD model, whereby generating numerical control codes for modeling processing; and 3) performing fused deposition modeling of powders or wire material of metal, intermetallic compounds, ceramic and composite functional gradient materials by layer using a welding gun on a substrate layer via a numerical control gas shielded welding beam or laser beam according to a track specified by the numerical control code for each layer. A micro-roller or a micro-extrusion unit is installed at a contact area between melted and softened areas. The micro-roller or the micro-extrusion unit synchronously moves along with fused deposition area, which results in compressing and processing of the fused deposition area during the fused deposition modeling.

Owner:HUAZHONG UNIV OF SCI & TECH

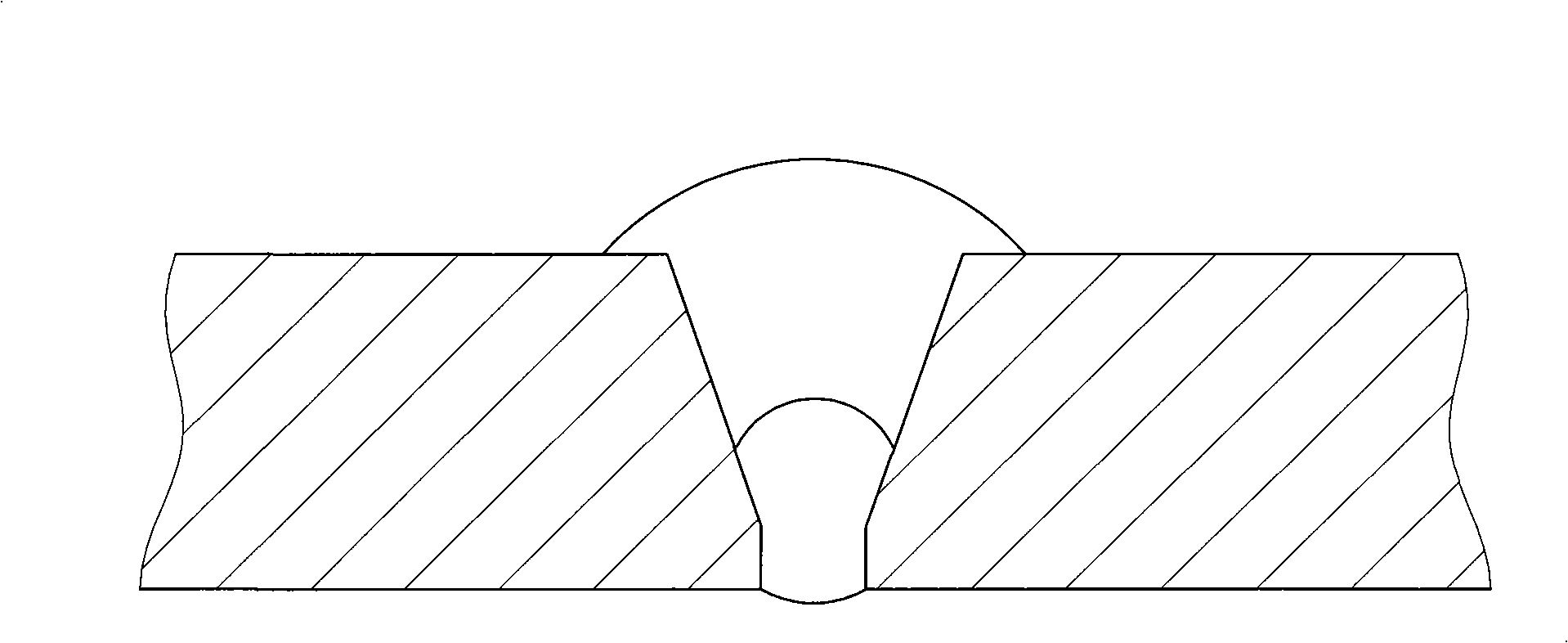

Marine engineering large thick steel plate submerged arc welding process method in low-temperature environment

InactiveCN101879645AIncrease productivityReduce labor intensityArc welding apparatusWelding/cutting media/materialsEngineeringWeld seam

The invention belongs to the field of welding, in particular to a process method applicable to marine engineering large thick steel plate submerged arc welding in low-temperature environment, which comprises a welding method, welding material selection, a welding order, a welding process and the selection and control of various welding process parameters. The method renders with carbon dioxide gas protection welding, and fills and faces through an automatic submerged arc welding; stops welding when the welding reaches more than two thirds of the thickness of a large groove during the welding process, clears chips on the back side and completes the welding of the other side; finally completes the welding of the first side; strictly controls all relevant process parameters of the welding during the welding process, and solves the problems of poorer anti-crack toughness of welding seams and heat affected zones caused by too high cooling speed of the welding seams and too high temperature; can ensure good anti-crack toughness of a welding seam connector without heat treatment after welding; and can meet the requirements of welding of an E36 plate with the thickness of 35 to 77mm under the working environment at the temperature of above -30DEG C, simplifies the production process, shortens the production cycle and reduces the cost.

Owner:PENGLAI JUTAL OFFSHORE ENG HEAVY IND CO LTD

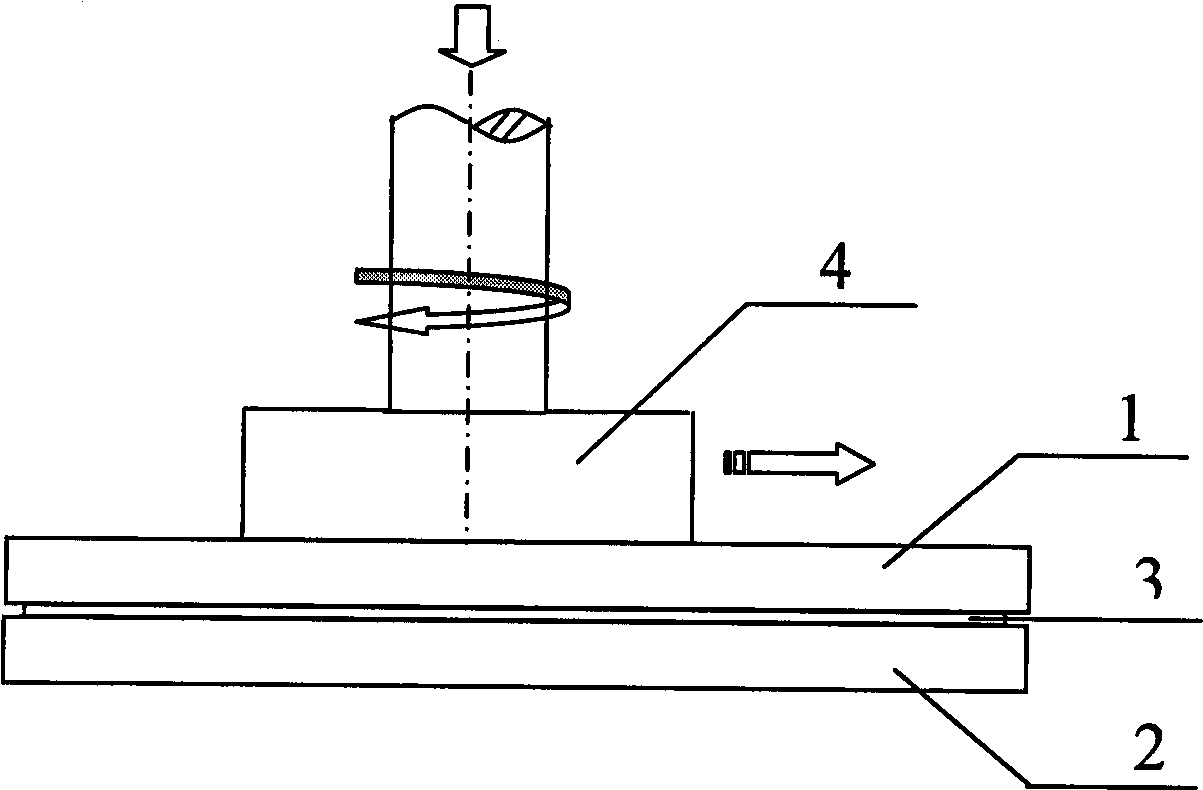

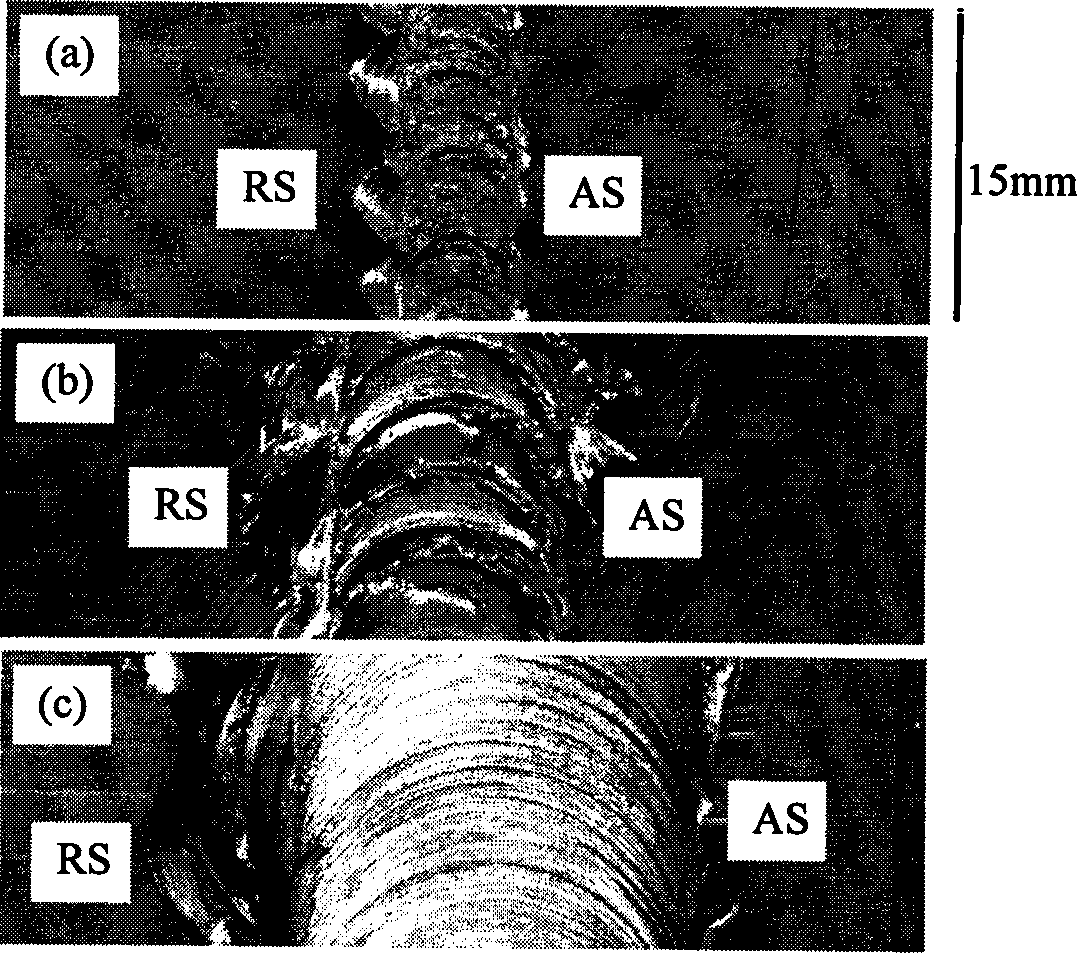

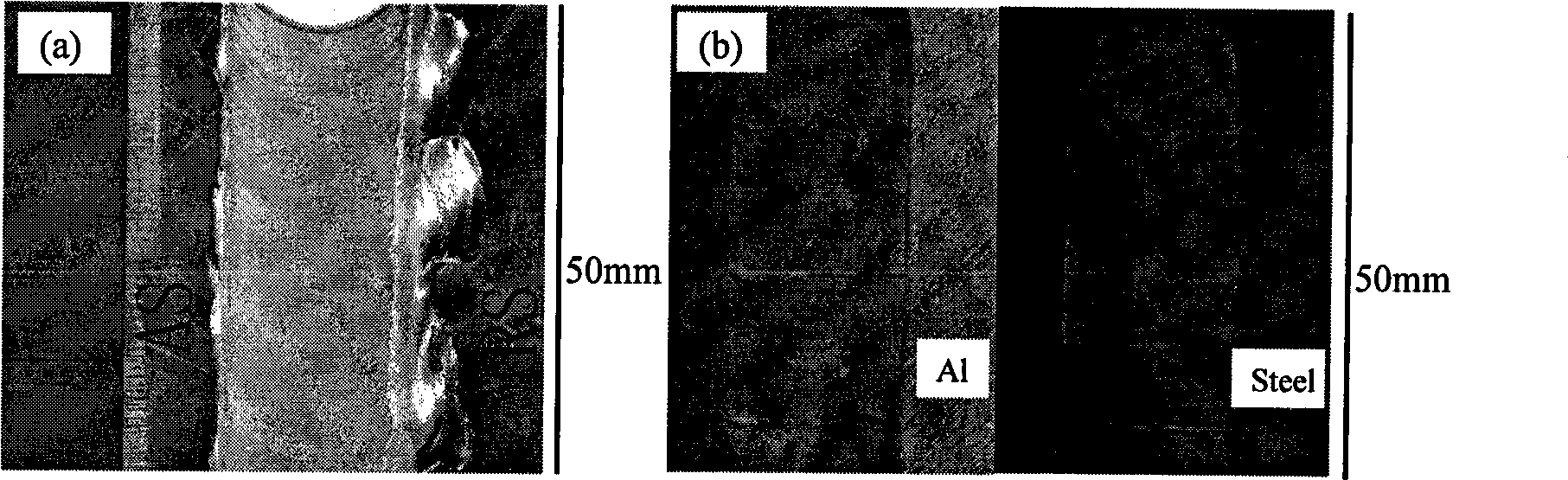

Method for preparing bimetal composite plate by stirring friction braze welding

InactiveCN101530947APrevent thinningAvoid direct contactNon-electric welding apparatusSurface layerShielding gas

The invention discloses a method for preparing a bimetal composite plate by stirring friction braze welding. The method comprises that: a plate with small hardness is used as a covering layer metal plate; a plate with high hardness is used as a base layer metal plate; the covering layer metal plate and the base layer metal plate are horizontally fixed on a working platform surface in a lap joint mode; solders which can generate eutectic reaction with one of the upper / base layer metal plates are preset between the upper / base layer metal plates; a non-needle type cylinder friction device is arranged over the covering layer metal plate; the non-needle type cylindrical friction device is made to rotate and be pressed to be closely contacted with the surface layer of the covering layer metal plate, but not penetrate the covering layer metal plate, and the non-needle type cylindrical friction device rotates in the original position or moves forward along the surface of the covering layer metal plate while rotating; by utilizing frictional heat to melt the solders, the upper / base layer metal plates are both quickly melted in the solders, thereby achieving excellent interface combination; and the excessive solders are squeezed out, and a thin and dense soldering seam is formed, so that the bimetal composite plate is prepared. Compared with the braze welding in a furnace, the method has the advantages of high efficiency, energy conservation, pressure lead-in, unnecessary soldering flux and gas protection and short holding time at a high temperature.

Owner:XI AN JIAOTONG UNIV

Low alloy steel flux-cored welding wire for carbon dioxide gas protection welding

InactiveCN101104232AImprove impact toughnessAccelerated corrosionArc welding apparatusWelding/cutting media/materialsArc stabilityCrack resistance

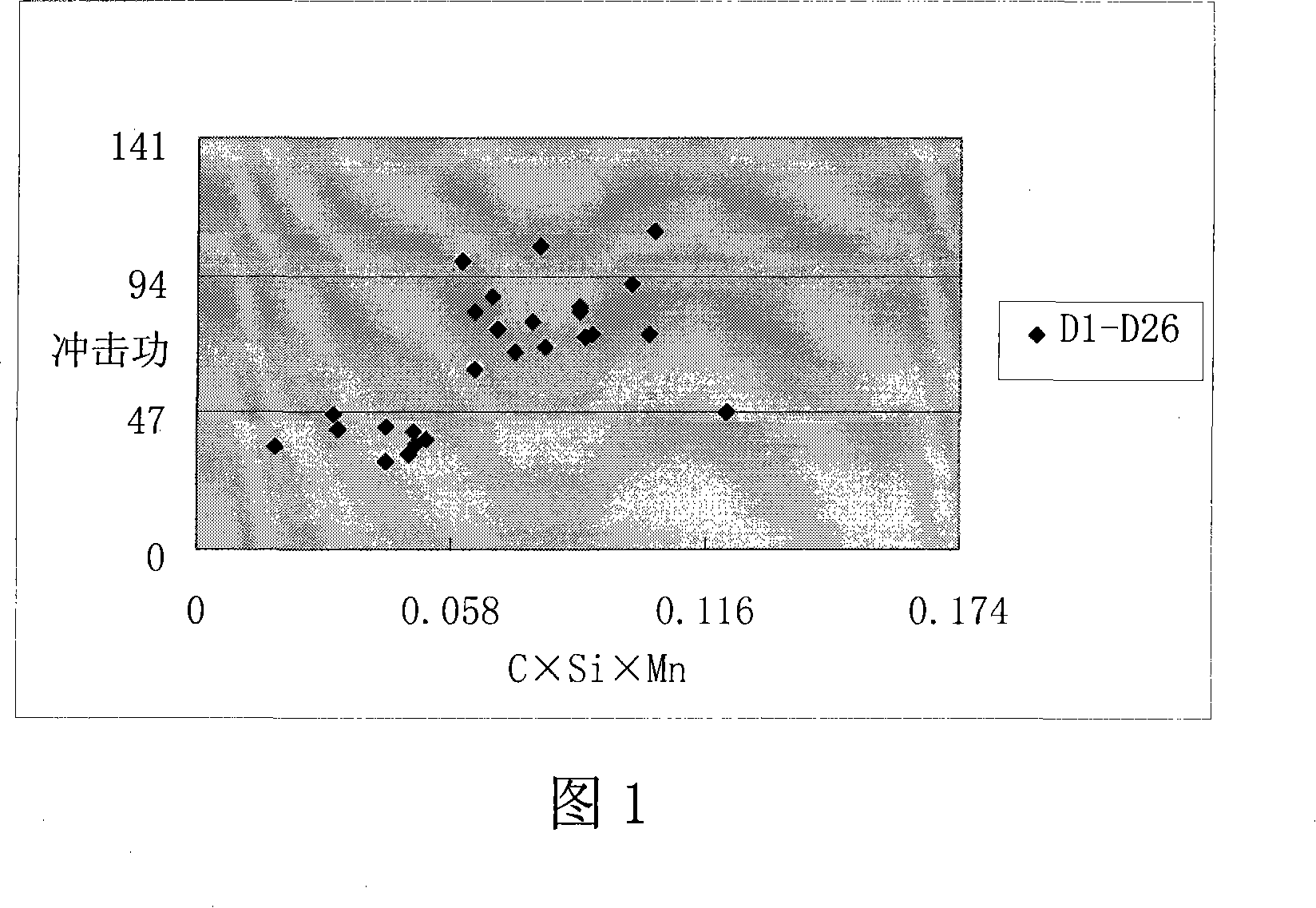

Disclosed is a low alloy steel drug core welding wire used in the carbon dioxide arc welding. The components of the drug core and the content occupying the total weight of the welding wire(percent ratio) are as following: Ti01 3-6, Si 0.3-0.5, Mn 1.5-3.2, Si02 0.1-0.8,Zr02 0.1-0.5, Fe 2-7, Al plus Mg 0.5-1.2, Ni 0.5 -5, B 0.002-0.015, Ti 0.1-0.3; oxide or fluoride of alkali metal K, Na and Li is converted into the content of K, Na and Li, that is, 0.1-0.35; the content of fluoride F is 0.05-0.2; fluoride or oxide of rare earth metal is converted into the content of the rare earth metal, that is, 0.005-0.2; the product of the contents of C, Si and Mn in the welding wire is 0.058-0.11. The invention has good process property for the whole position welding of high strength low alloy steel, and can keep good stability of electric arc and welding operating property in the conditions of large current and fast-speed welding with smooth welding seam, high connecting intensity, good impact toughness minus 40 DEG C low temperature and good crack resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Large posted sides pipeline narrow gap tungsten electrode noble gas protecting all-position automatic soldering method

ActiveCN101077547AReduce fillingReduce welding costsArc welding apparatusWelding/cutting media/materialsNoble gasEngineering

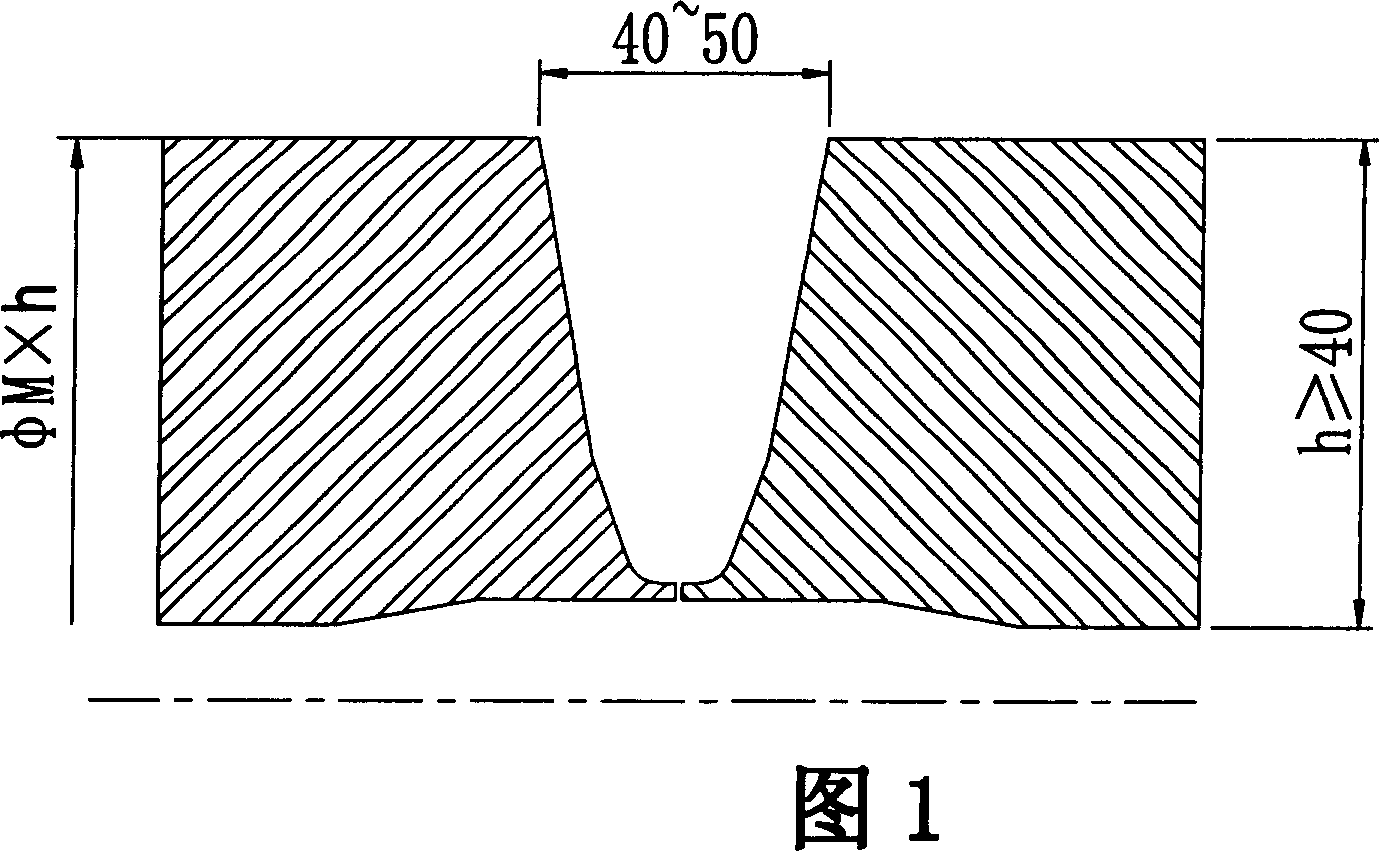

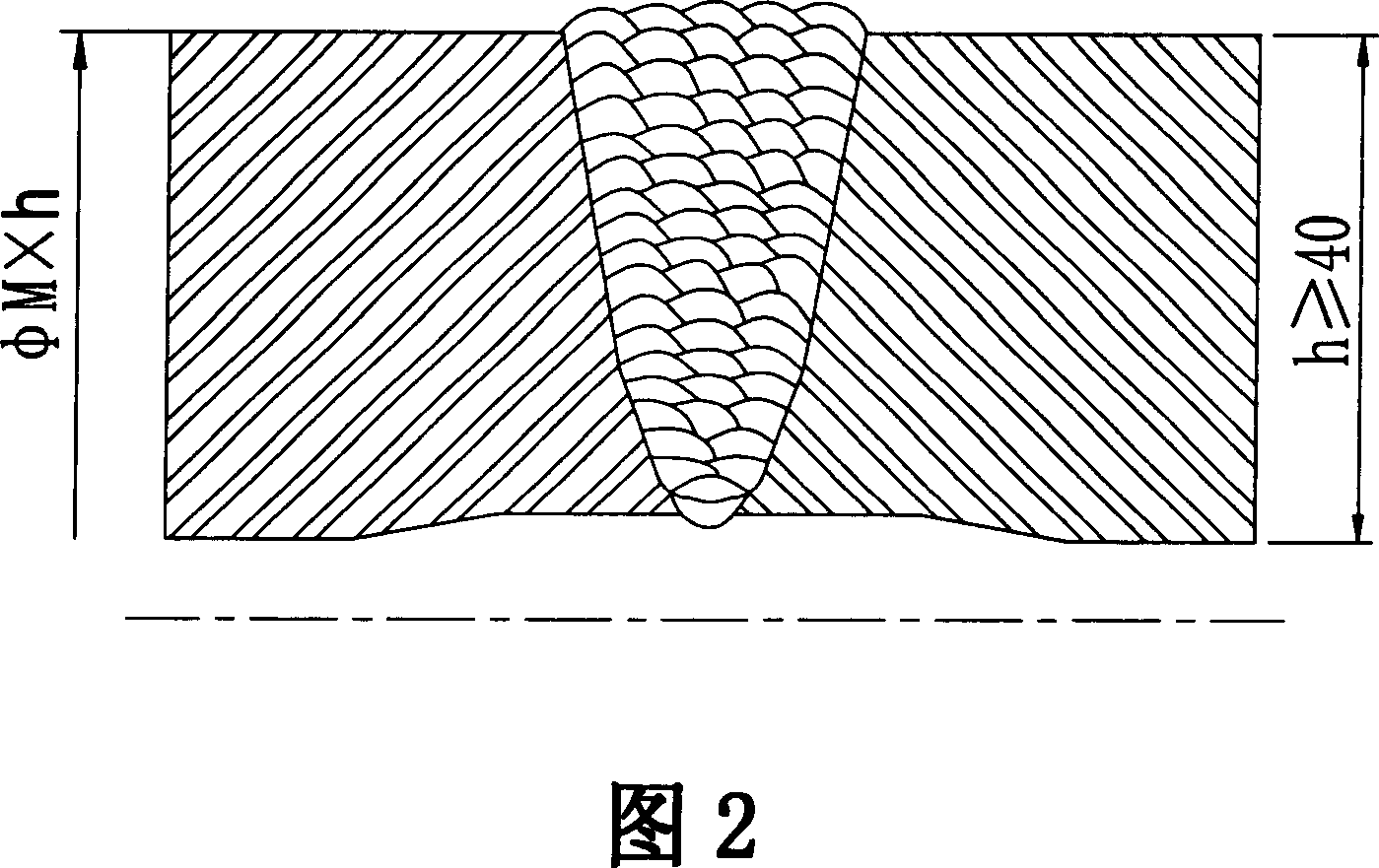

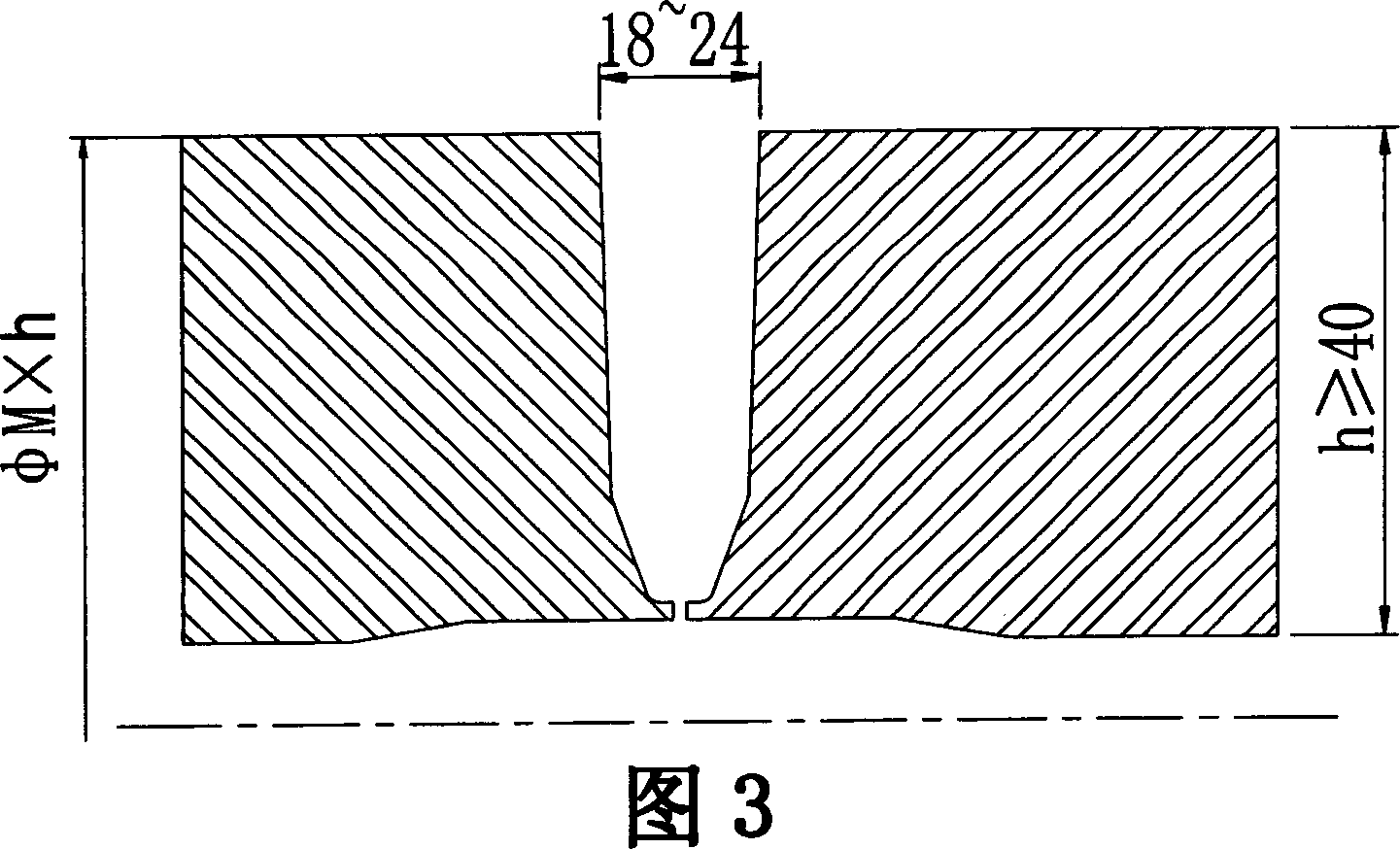

The present invention relates to inert gas protected automatic narrow gap tungsten electrode welding process for large thick pipe with diameter over 325 mm and thickness over 40 mm. The automatic welding process includes forming combining chamfer in the opposite ends to be welded before welding, bottoming welding, single layer filling welding, and covering welding in linear or swinging weld pass. The process has less filled deposited metal, low welding cost, high welding efficiency and other advantages.

Owner:CHINA NUCLEAR IND 23 CONSTR

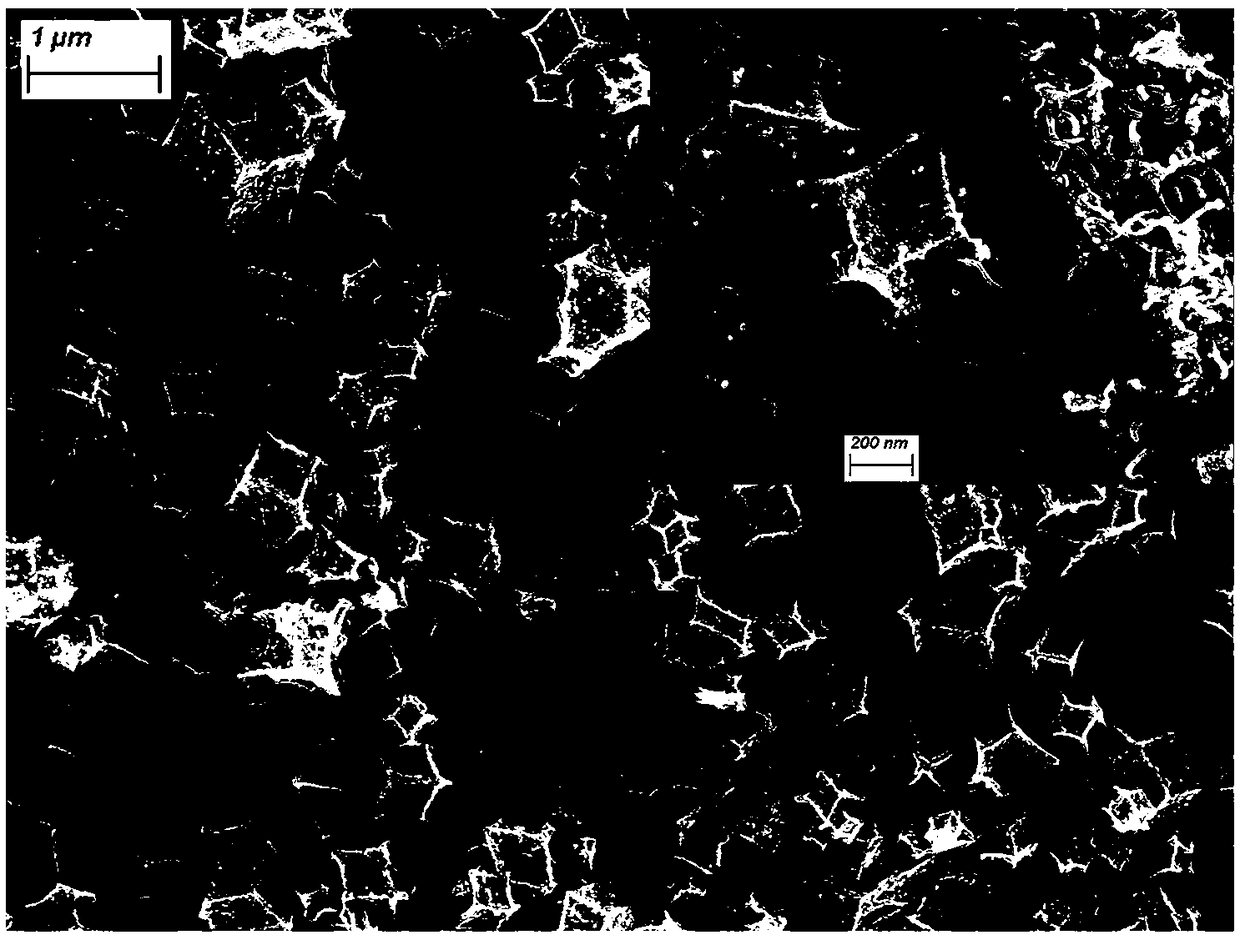

Method for preparing graphene powder

InactiveCN101966988AGood dispersionIncrease the amount of dissolutionBulk chemical productionCentrifugationReaction temperature

The invention discloses a method for preparing graphene powder, which belongs to the field of graphene preparation and aims to solve the technical problems of low efficiency, low yield and environmental protection in the conventional graphene preparation methods. The method of the invention comprises the following steps of: 1, preparing graphite oxide; 2, stripping the graphite oxide; 3, performing purification, namely, performing centrifugation treatment and collecting upper-layer solution; and 4, controlling the reaction temperature to be above the supercritical temperature of a solvent in the step 2 to perform reaction for 1 to 24 hours under the conditions of the protection of an inert gas and the pressure of 20 to 100 MPa, naturally cooling or quenching with water a reaction kettle, and slowly exhausting the gas from the kettle to obtain the graphene powder. The graphene powder prepared by the method is goose feather-like black fluffy powder. The method of the invention has the advantages of the high efficiency of 100 percent, high yield and less environmental pollution.

Owner:HARBIN INST OF TECH

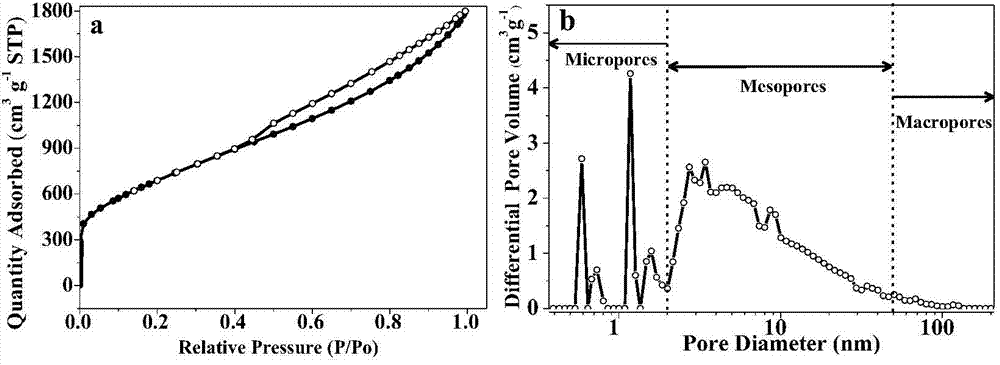

Mesoporous-macroporous carbon production method

The invention belongs to the field of chemical engineering and industry, and particularly relates to a mesoporous-macroporous carbon production method. The production method comprises: completely mixing a phenol formaldehyde resin, an epoxy resin and the like or a mixture thereof, and a curing agent according to a certain weight ratio, carrying out heating curing, adding polyvinyl alcohol and the like as pore forming agents and adding graphite powder and the like as support agents after the cured material is crushed, completely mixing, pressing to form a preform, and carrying out high temperature carbonization under the protection of gas to obtain the mesoporous-macroporous carbon. The mesoporous-macroporous carbon prepared by using the production method has advantages of simple preparation method, easy pore size control and the like, wherein the pore size of the mesoporous-macroporous carbon can be adjusted within 50 nm-10 mum, has a specific surface area of 100-1000 m<2> / g, and can be used in electrode materials of supercapacitors, electrode materials of lithium ion batteries, electrode materials of capacitance method desalination devices, blood purification, catalyst carriers, water treatments, gas purification, solvent recovery and the like.

Owner:NO 63971 TROOPS PLA

Method and device for recycling residual powder on metal material increase manufacturing substrate

ActiveCN105170988APrevent oxidationPrevent moistureAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringHigh pressure

The invention discloses a method and device for recycling residual powder on a metal material increase manufacturing substrate. The device comprises a sealing bin, a pneumatic vibrator arranged outside the sealing bin, and a vibration clamping part arranged on the inner side wall of the sealing bin and used for transmitting vibration. The vibration clamping part is connected with the pneumatic vibrator and used for clamping a substrate of a forming part and providing mechanical vibration for the substrate. The sealing bin is provided with a high-pressure gas gun and an inert gas inlet. By means of the method and device, residual powder on the substrate can be thoroughly removed, the powder where impurities are removed can be recycled, and materials are saved; and due to the fact that the whole recycling process is performed under the protection of inert gas, the powder is prevented from being oxidized and affected with damp, and it is guaranteed that the original quality of the powder does not change.

Owner:SOUTH CHINA UNIV OF TECH

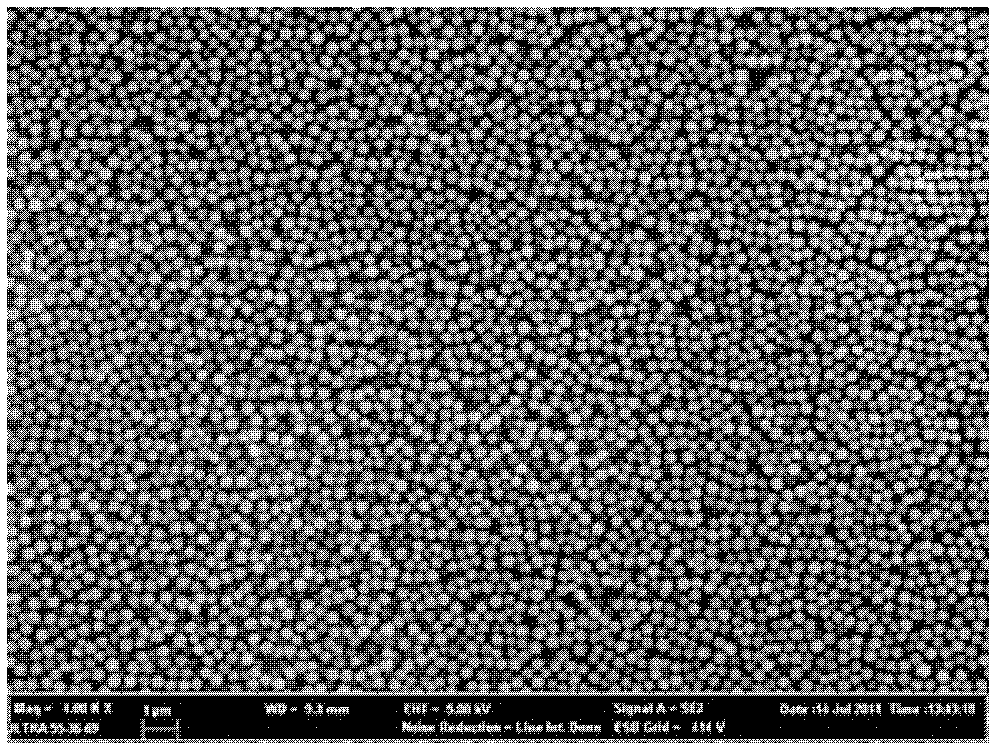

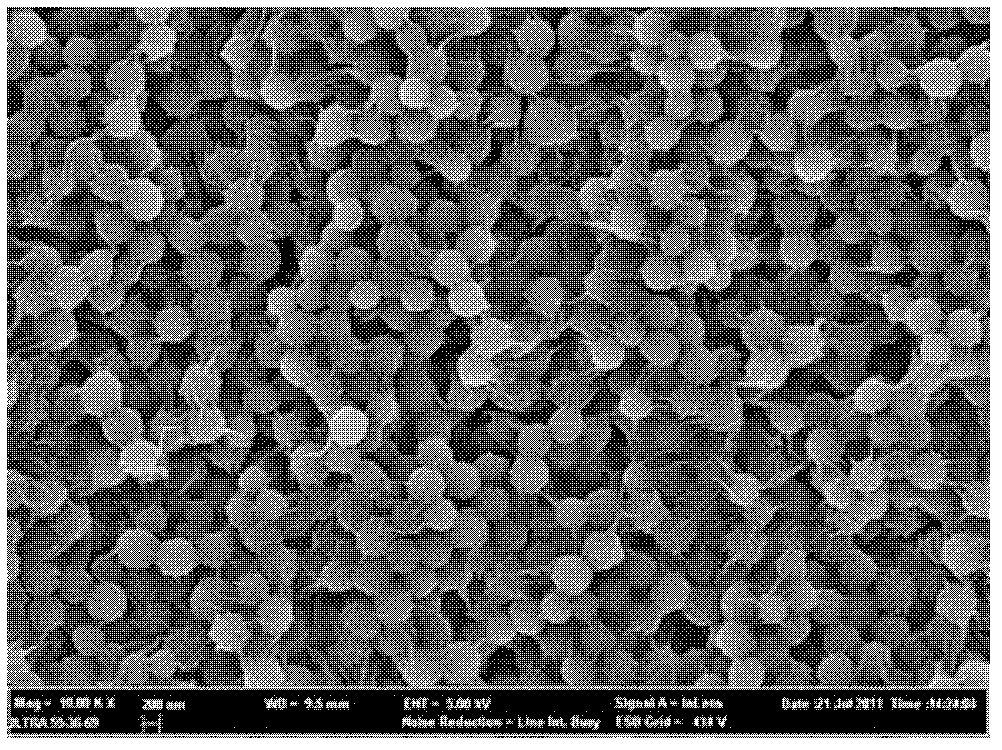

Method for preparing graphene-coated carbon microsphere material by coating graphene oxide on carbon microsphere

InactiveCN102544459AWide range of optional preparation equipmentCell electrodesSucroseHazardous substance

The invention relates to a method for preparing a graphene-coated carbon microsphere material by coating graphene oxide on a carbon microsphere. The method comprises the following steps of: preparing a graphene oxide dispersion solution; preparing the carbon microsphere through taking glucose, sucrose and starch as a carbon source by using a hydrothermal method under acidic conditions; adding the dried carbon microsphere into the graphene oxide dispersion solution; filtering and drying to obtain a graphene-oxide-coating carbon microsphere product; and carrying out thermal reduction on the graphene-oxide-coating carbon microsphere product under a gas protective atmosphere, and naturally cooling to room temperature to obtain a graphene-coaed carbon microsphere product. Compared with the prior art, the method provided by the invention has the advantages that no harmful substances are used in a preparation process, the range of selectable preparation equipment is wide, the raw materials, i.e. graphene and the carbon microsphere, are not required for being subjected to further modification and processing, the water resources used in the preparation process can be recycled and utilized, and products with different proportions and different degrees of reduction can be prepared according to different needs, so that a precondition is provided for the diversity of materials.

Owner:上海碳源汇谷新材料科技有限公司

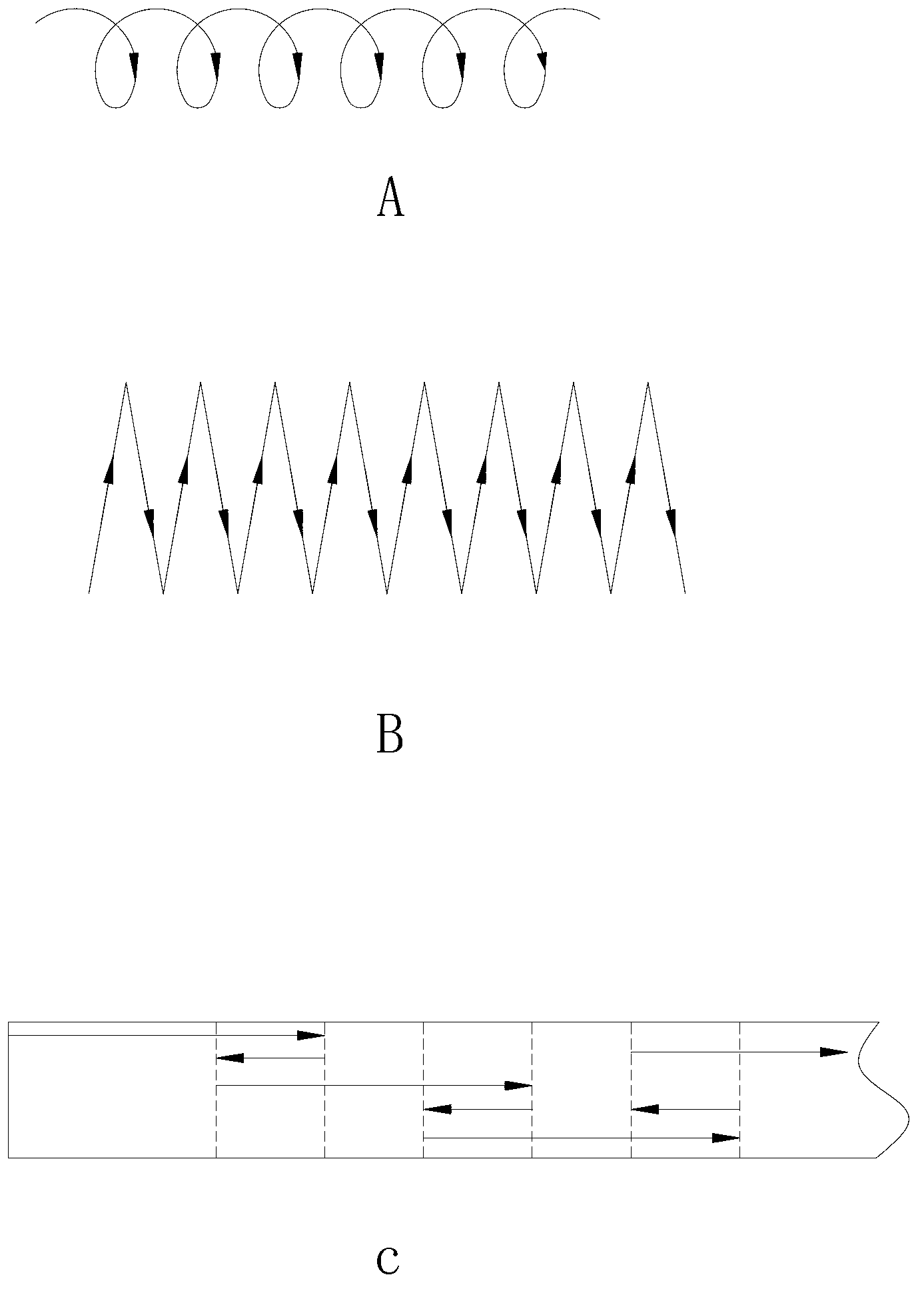

Method for improving compactness of 3D (three dimensional) printing metal part by adopting second laser beam

InactiveCN103173760AImprove densification performanceEvenly distributedMetallic material coating processesAlloyPre treatment

The invention discloses a method for improving the compactness of a 3D (three dimensional) printing metal part by adopting a second laser beam. The method comprises the following steps of: (a) pretreating a printing base and a printing baseplate; (b) carrying out 3D printing on the printing baseplate by using a first laser beam and alloy powder according to a preset moving trajectory by the way of lap joint step by step and superimposing layer by layer, protecting the surface of a workpiece and the flow field of the alloy powder by an inert gas in the process of printing, and melting the alloy powder by using the first laser beam to form a printing layer; (c) remelting the printing layer which is obtained by carrying out 3D printing by using the following second laser beam, wherein the second laser beam advances spirally or zigzag or telescopes back and forth according to the moving trajectory of the first laser beam; and (d) post-processing the metal part. Because the printing layer is remolten synchronously by adopting the second laser beam, the defects of holes, air pockets, thermal cracks and interface cracks generated in the process of carrying out 3D printing can be reduced, and the compactness of a metal tool can be improved.

Owner:张翀昊

Microbeam tungsten argon arc welding method for magnesium alloy thin-walled tube

InactiveCN102554418AIncrease the difficultyLow yieldArc welding apparatusWelding/cutting media/materialsArc stabilityManganese

The invention relates to a microbeam tungsten argon arc welding method for a magnesium alloy thin-walled tube. A low-magnesium aluminum alloy welding wire is used as a filling material, and the thin-walled tube is welded by a microbeam tungsten argon arc welding process under inert gas shielding. The low-magnesium aluminum alloy welding wire comprise 9.5%-11.6% of Al (aluminum), 0.6%-1.75% of Zn (zinc), 0.15%-0.35% of Mn (manganese), 0.01%-0.05% of Cu (copper), 0.02%-0.05% of Si (silicon) and the balance Mg (magnesium) in mass percent. The microbeam tungsten argon arc welding method for the magnesium alloy thin-walled tube is high in welding efficiency and convenient and flexible in application, and can be used for obtaining a crack-free welding joint without magnesium-aluminum brittle compounds. Compared with a conventional tungsten argon arc welding method, the microbeam tungsten argon arc welding method has the advantages that arc stability of microbeam argon arc welding for the magnesium alloy thin-walled tube is obviously improved, the tensile strength of the welding joint is 30% higher than that of a conventional tungsten argon arc welding joint, the elongation of the welding joint is increased by 10%, and the use requirements of industrial production on magnesium alloy thin-walled tube welding component can be met.

Owner:SHANDONG UNIV

Manufacture method of X80 pipeline JCOE direct sew submerged arc welding tube

The invention discloses a method for producing a JCOE longitudinal submerged arc welded pipe of an X80 pipeline steel. The invention is used for producing an oil and gas conveying tube with high intensity and high tenacity. The method includes using an HTP X80 controlled rolling steel pipe with a chemical composition of 0.03 to 0.05 percent of C, 0.20 to 0.30 percent of Si, 1.65 to 1.75 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.005 percent of S, 0.10 to 0.15 percent of Nb plus Ti and 0.5 to 0.7 percent of Ni plus Cr plus Cu. A steel plate is made into the oil and gas conveying tube with high intensity and high tenacity through the working procedures like edge milling, edge bending, a 'JCO' forming technique under multi-pass pressing, gas protection prewelding, inside welding, outside welding, diameter enlarging, ultrasonic checking, x-ray checking, hydraulic pressure testing, tube end to arris, ultrasonic checking and X-ray checking, etc. The inside welding and the outside welding of a steel tube adopt four-wire serial union melt welding and control the technical parameters of welding through selecting a suitable welding wire and a welding fluid; thereby controlling the components and organizations of a weld joint to lead the performance of the weld joint to reach the performance requirements of X80.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

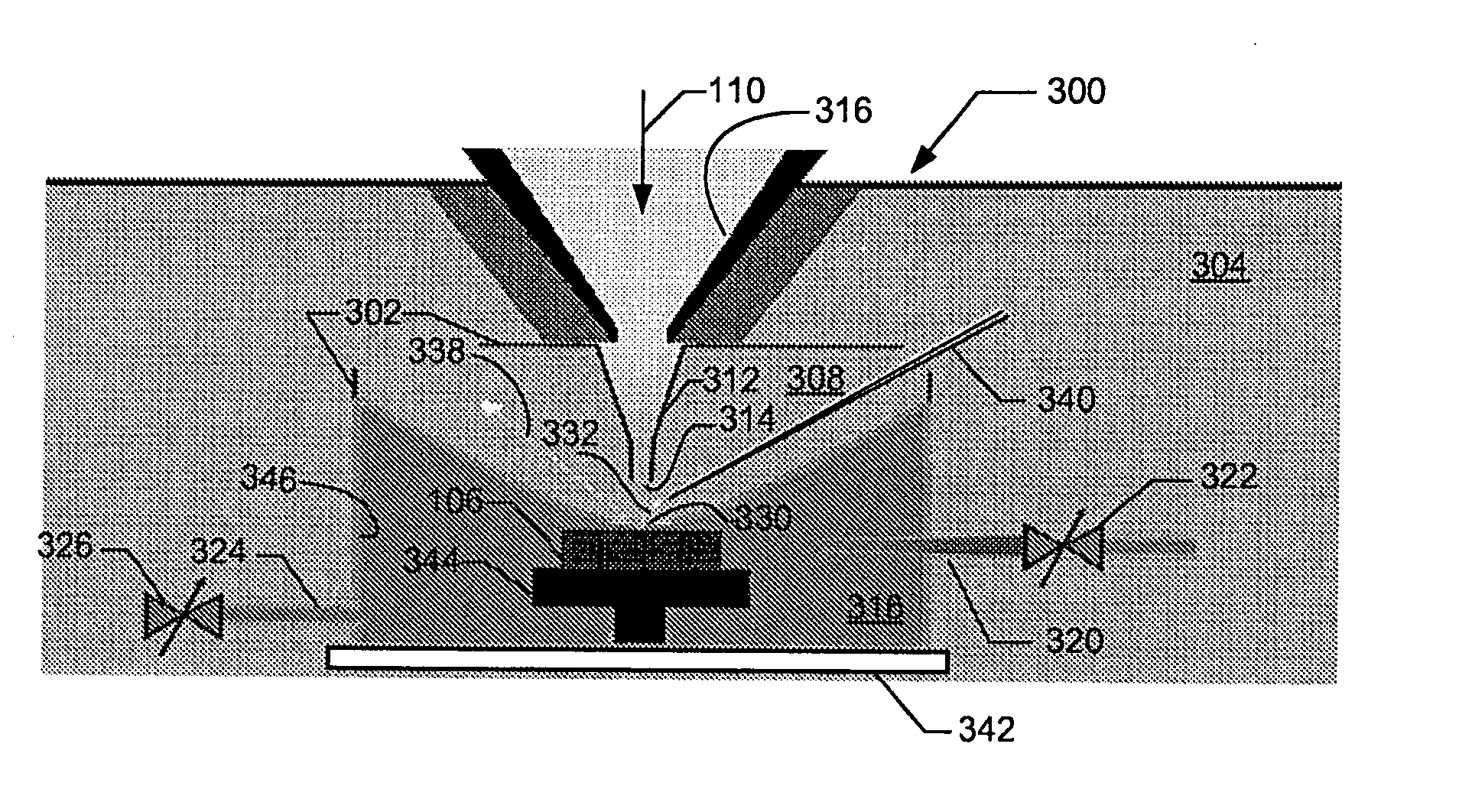

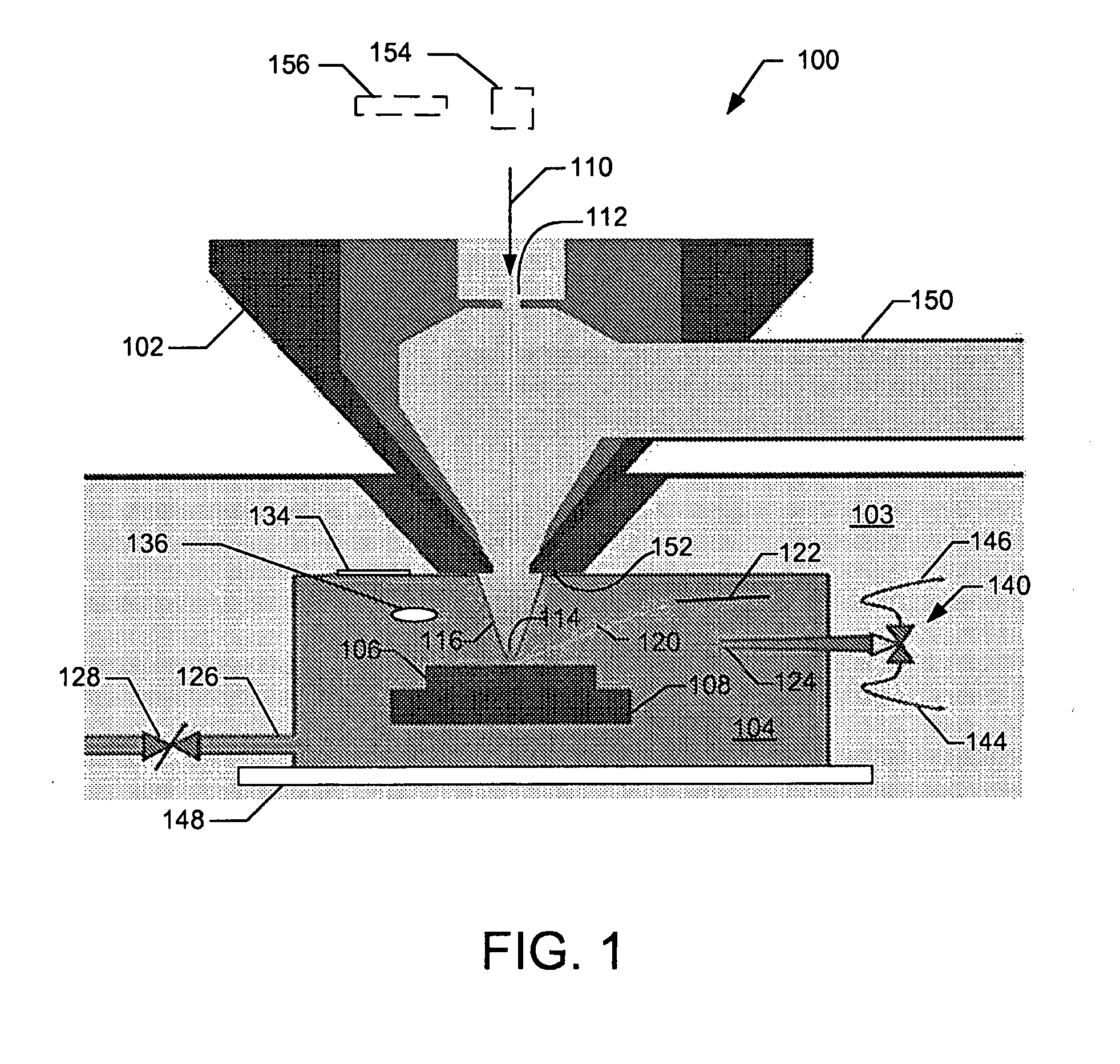

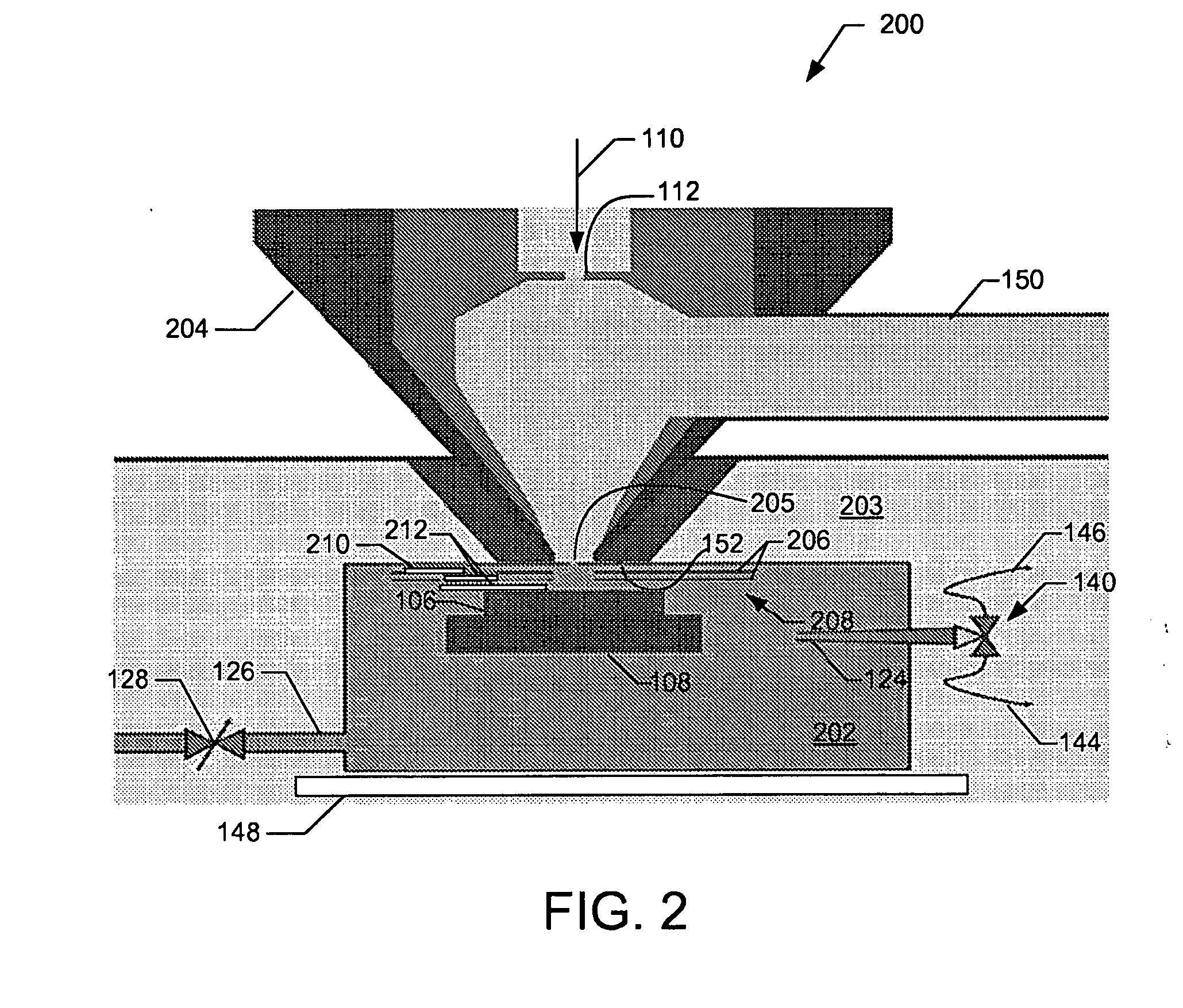

High pressure charged particle beam system

ActiveUS20110031394A1Reduce gas volumeFast exhaustMaterial analysis using wave/particle radiationElectric discharge tubesHigh pressureMolecular physics

The current invention includes methods and apparatuses for processing, that is, altering and imaging, a sample in a high pressure charged particle beam system. Embodiments of the invention include a cell in which the sample is positioned during high pressure charged particle beam processing. The cell reduces the amount of gas required for processing, thereby allowing rapid introduction, exhaustion, and switching between gases and between processing and imaging modes. Maintaining the processes gases within the cell protects the sample chamber and column from contact with the gases. In some embodiments, the temperature of the cell walls and the sample can be controlled.

Owner:FEI CO

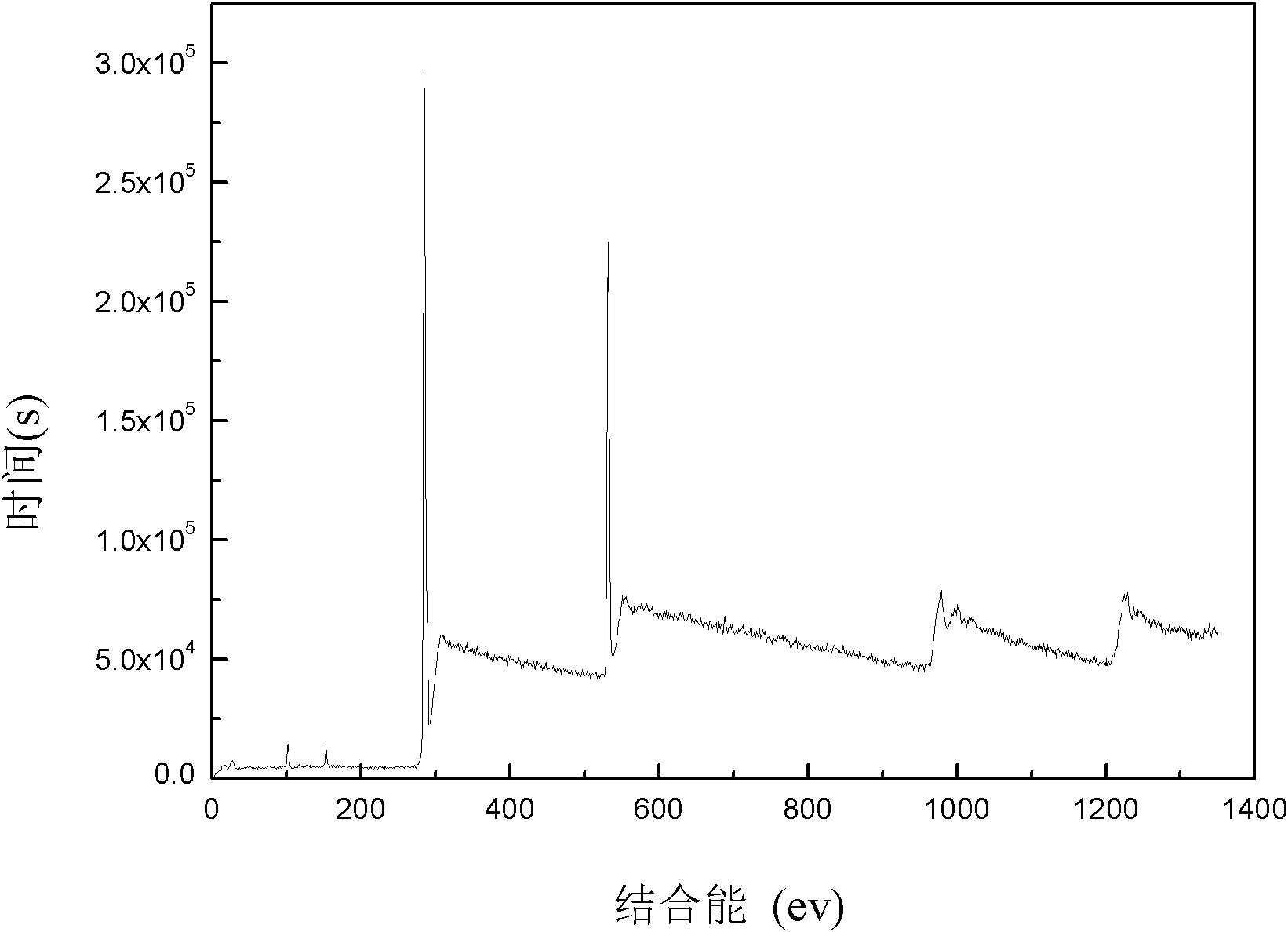

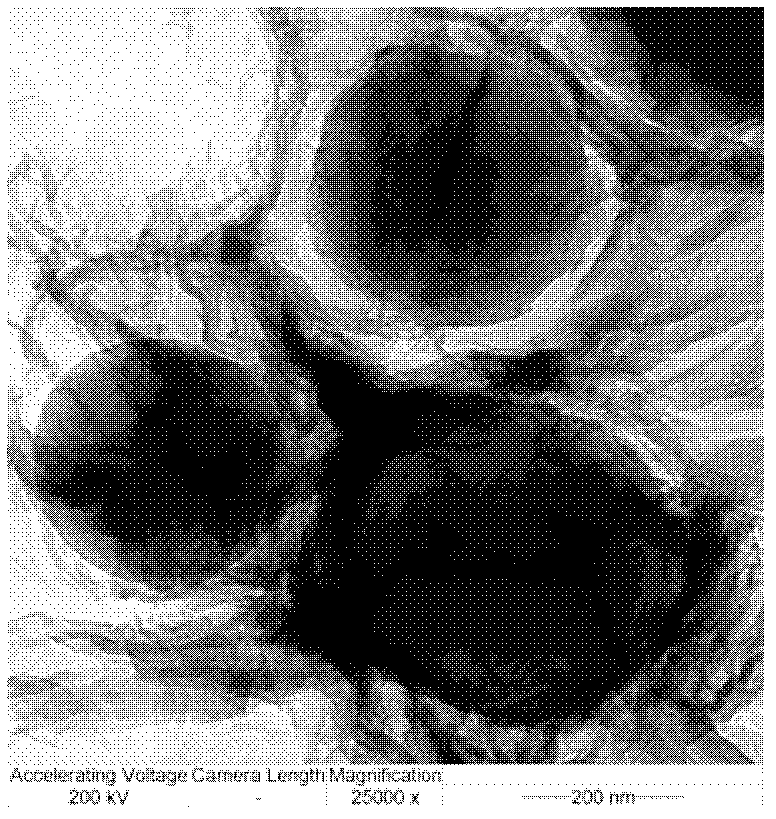

MOFs (Metal Organic Frameworks)-based NiCo@N-C dual-function oxygen electrode catalyst and preparation method thereof

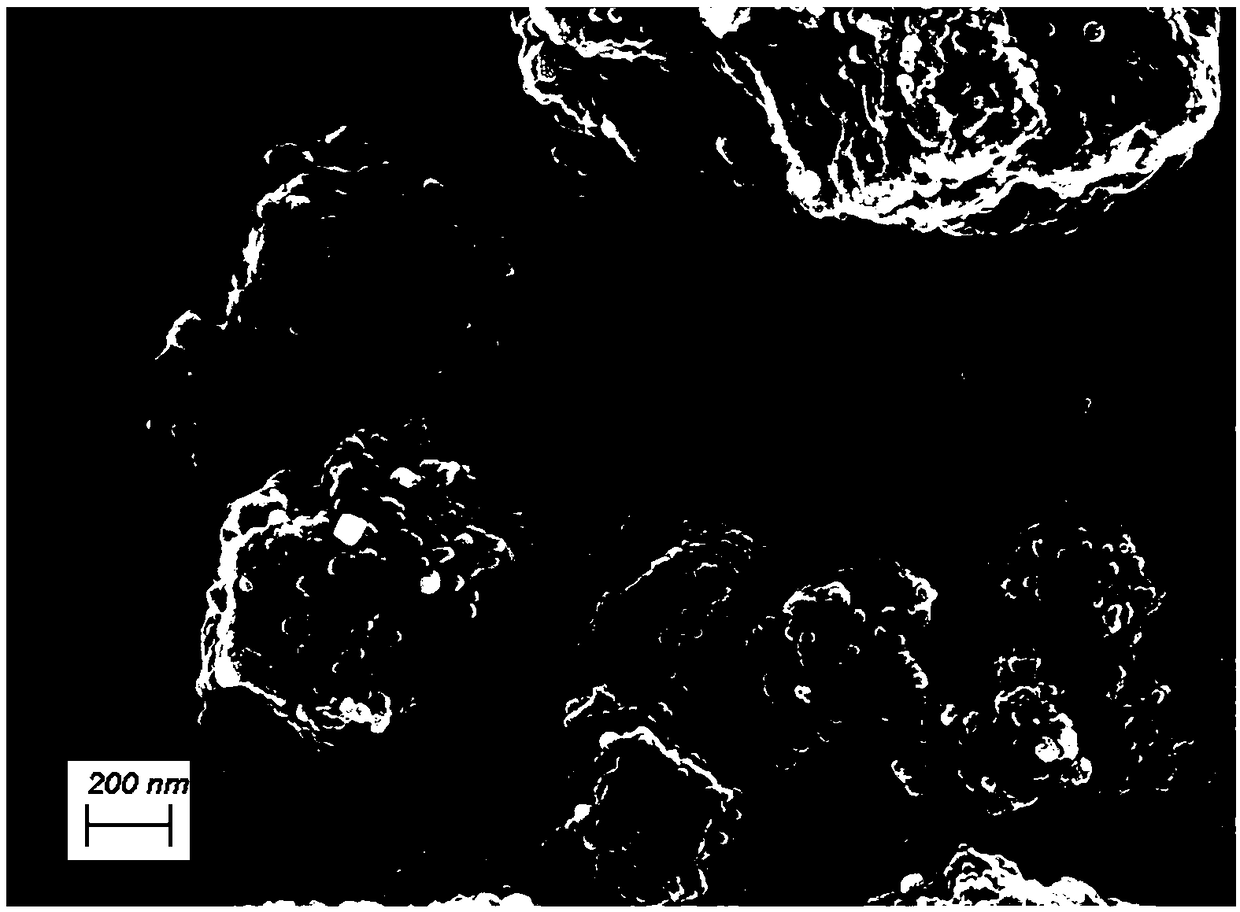

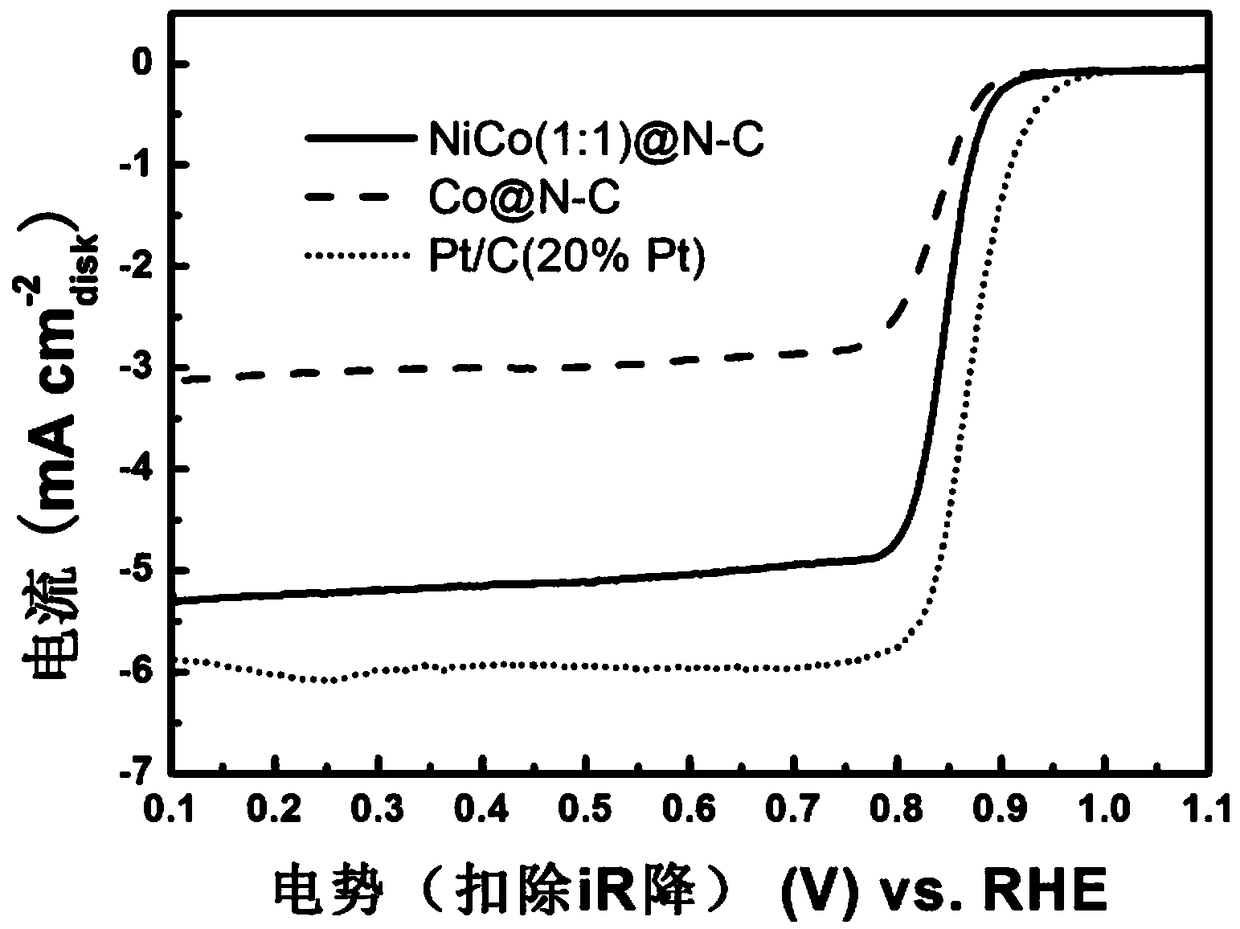

InactiveCN108722460AImprove conductivityImprove stabilityCatalyst activation/preparationNickel saltCarbonization

The invention discloses an MOFs (Metal Organic Frameworks)-based NiCo@N-C dual-function oxygen electrode catalyst and a preparation method thereof. The NiCo@N-C dual-function oxygen electrode catalystis a rhombic polyhedral having a carbon nano tube structure on the surface. The NiCo@N-C dual-function oxygen electrode catalyst has the BET superficial area of 169.9-268.7m<2> / g and the total pore volume of 0.26-0.20cm<3> / g, and is of an N-doped C cage coated NiCo alloy structure. The preparation method disclosed by the invention comprises the following steps: performing coordination on a cobaltsalt and a nickel salt with dimethylimidazole in an organic reagent so as to obtain NiCo bimetallic MOFs of different atomic ratios, performing high-temperature pyrolysis under inert gas shielding bytaking the bimetallic MOFs as a template, performing one-step carbonization on N-containing organic ligands to produce an N-doped coating structure coated with the NiCo alloy. Therefore, electronic structure control of metal catalytic activity is realized, highly regular porous structure and high specific surface area are remained, and the high N doping amount and conductivity of the obtained N-Cmaterial are improved.

Owner:HUBEI UNIV

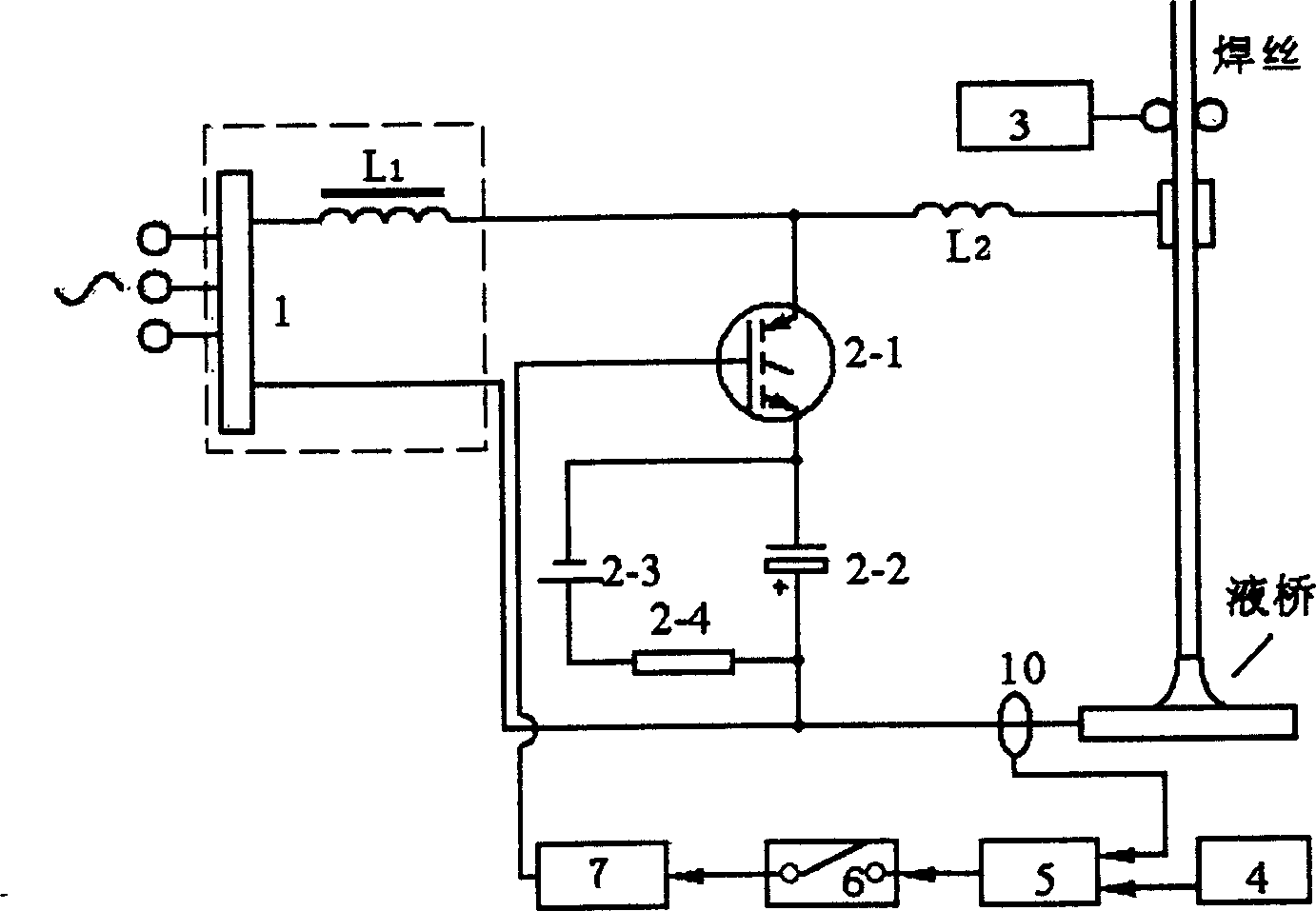

Method and system for reducing splash in gas shielded welding of short-circuiting transfer

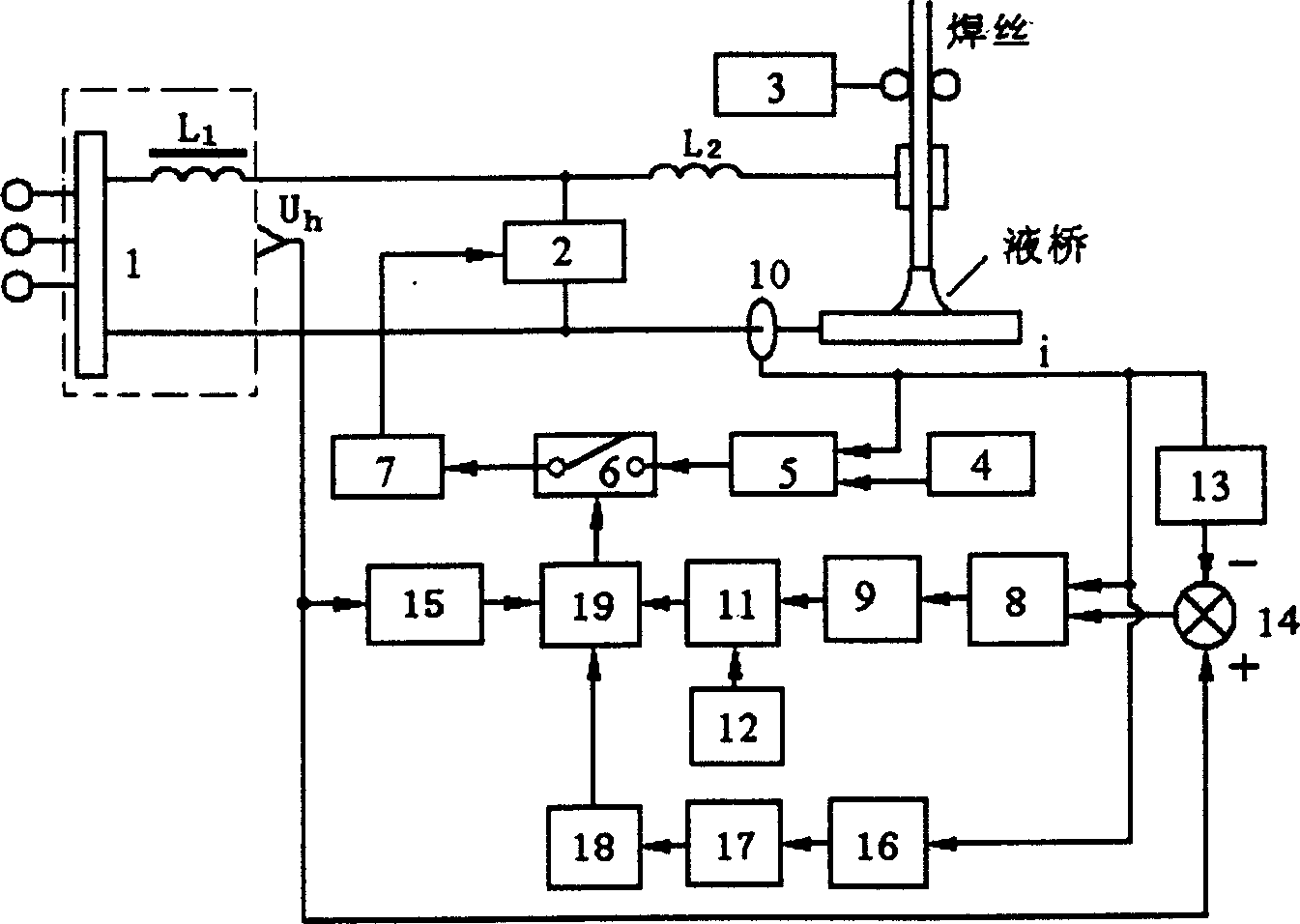

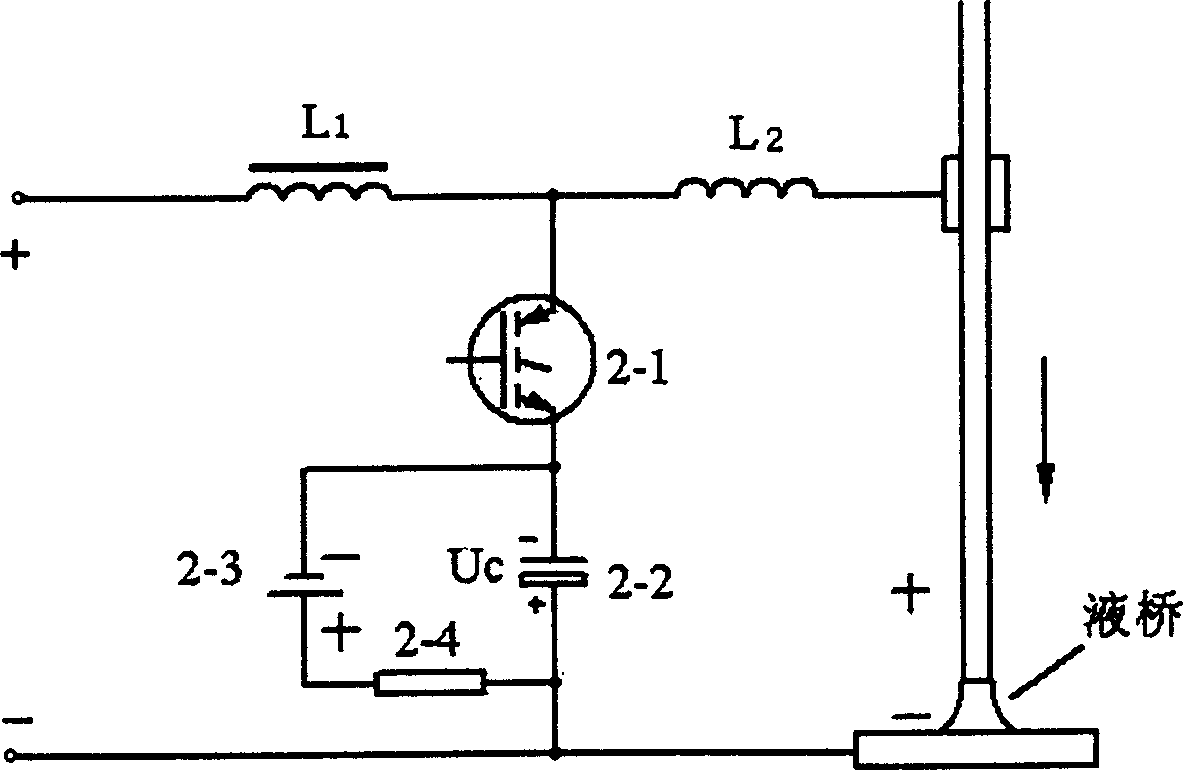

InactiveCN1600486ALiquid bridge current reductionLess welding spatterArc welding apparatusElectrical resistance and conductancePower flow

A method for reducing splash in gas shielded welding of short-circuiting transfer is disclosed. The invention judges a short-circuiting liquid bridge diameter by detecting a resistance change rate of a welding circuit or an impedance change rate of the welding circuit during a welding process, when the short-circuiting liquid bridge diameter is reduced to a predetermined value, a liquid bridge current is rapidly falled by performing flow division control on the short-circuiting liquid bridge current, and the liquid bridge is held in a break state, thereby the short-circuiting liquid bridge is transferred flexibly under a condition of small current, welding splash is reduced. In addition, also disclosed is a system for realizing the method.

Owner:TSINGHUA UNIV

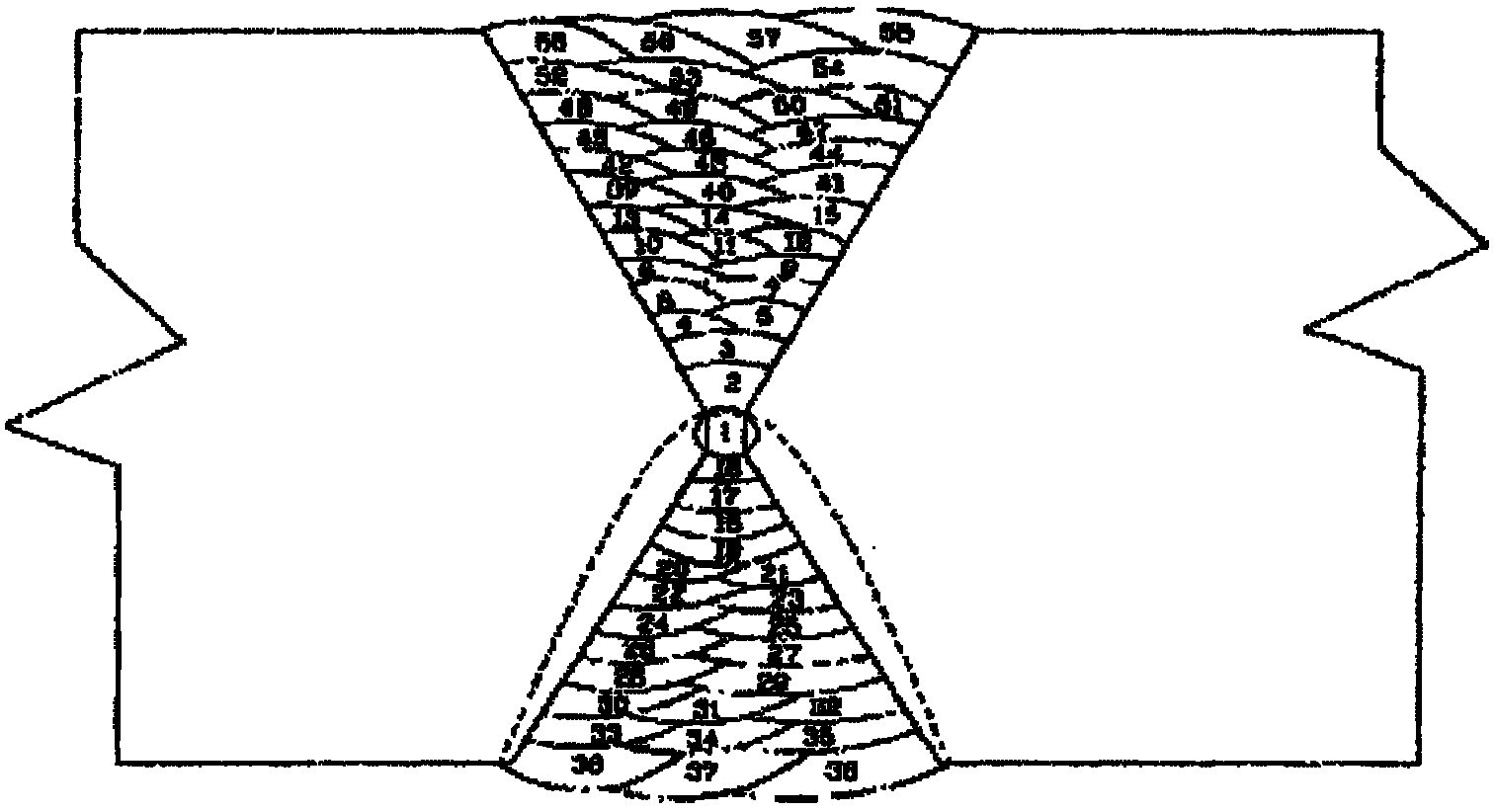

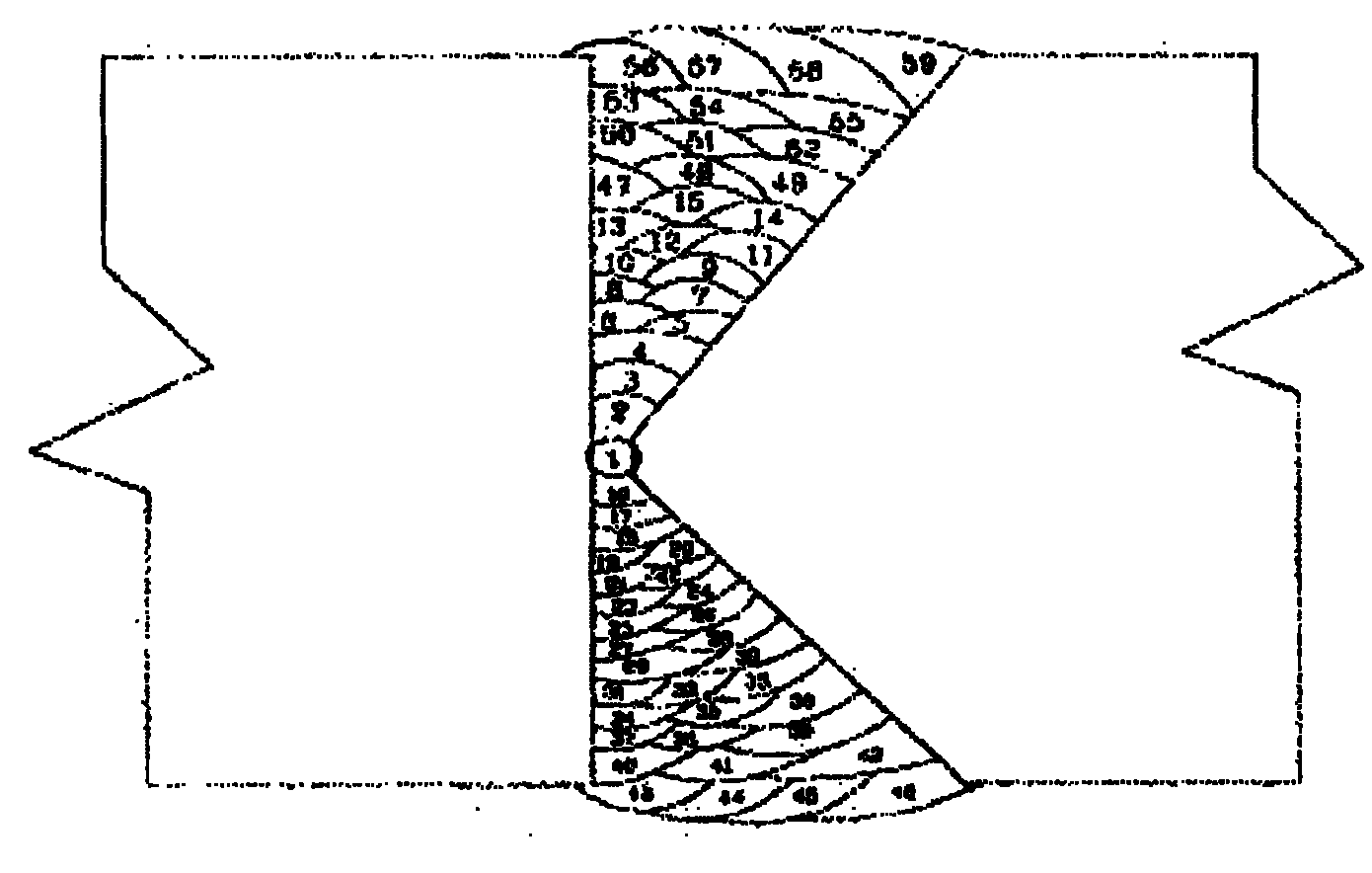

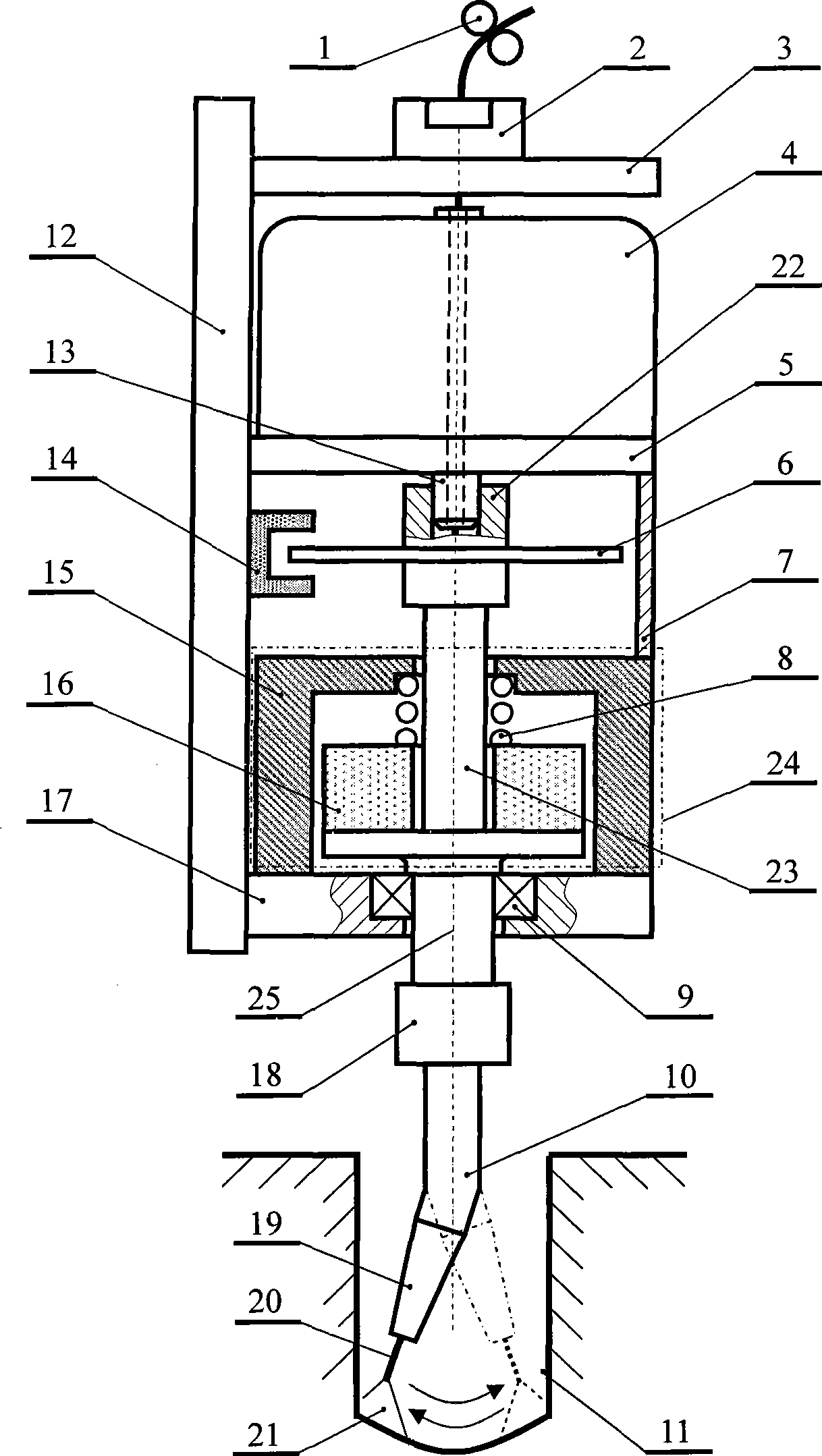

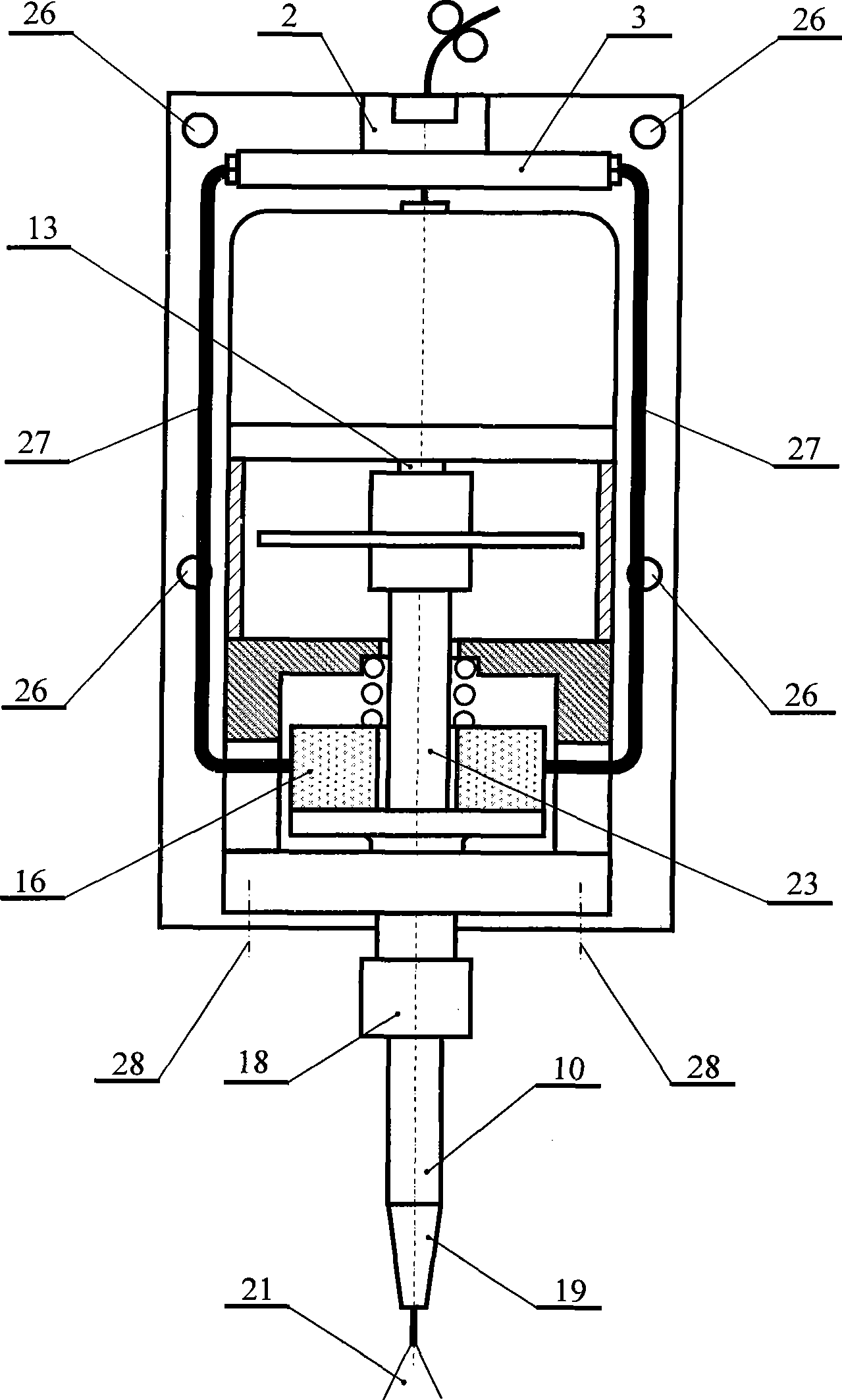

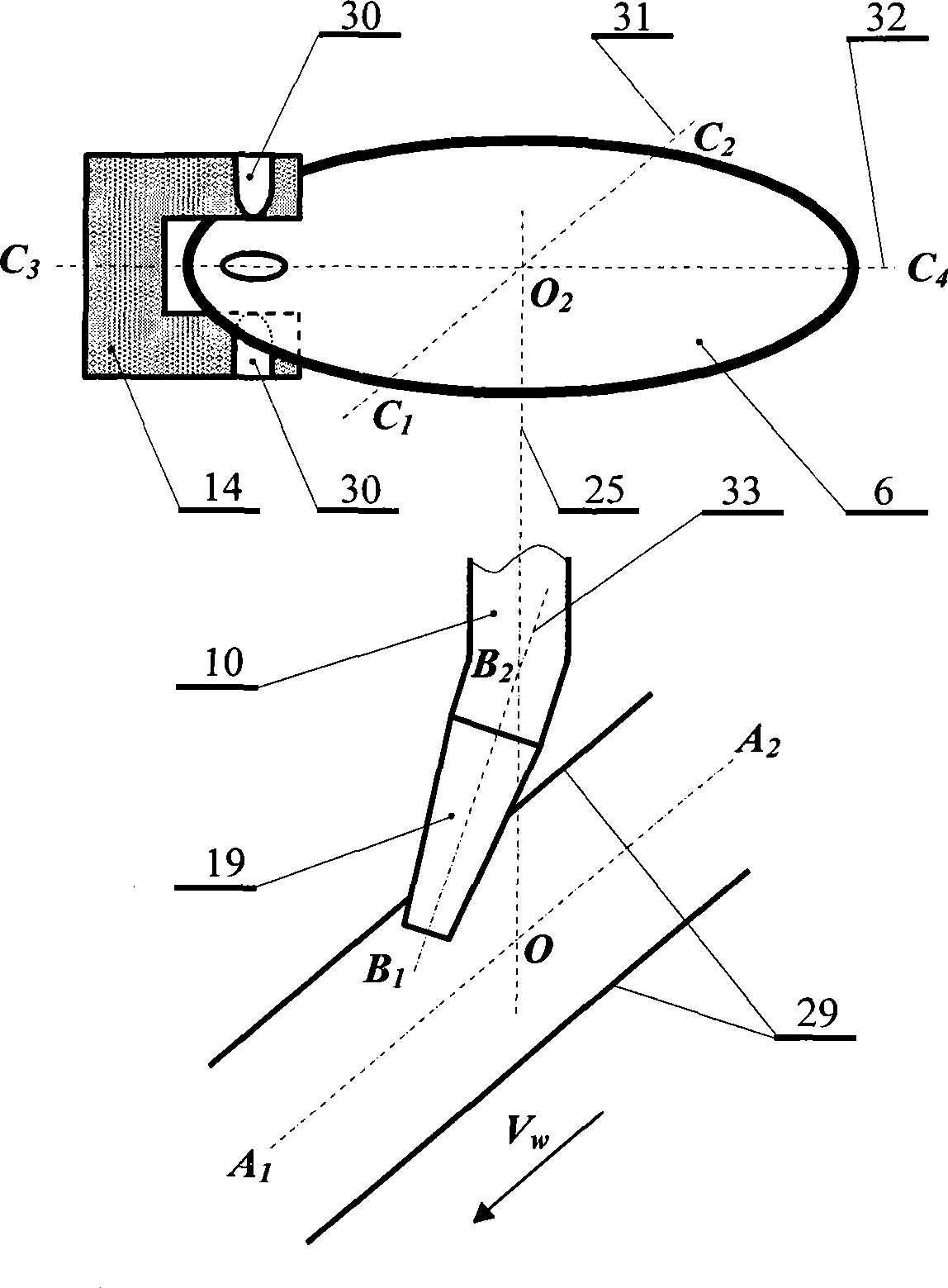

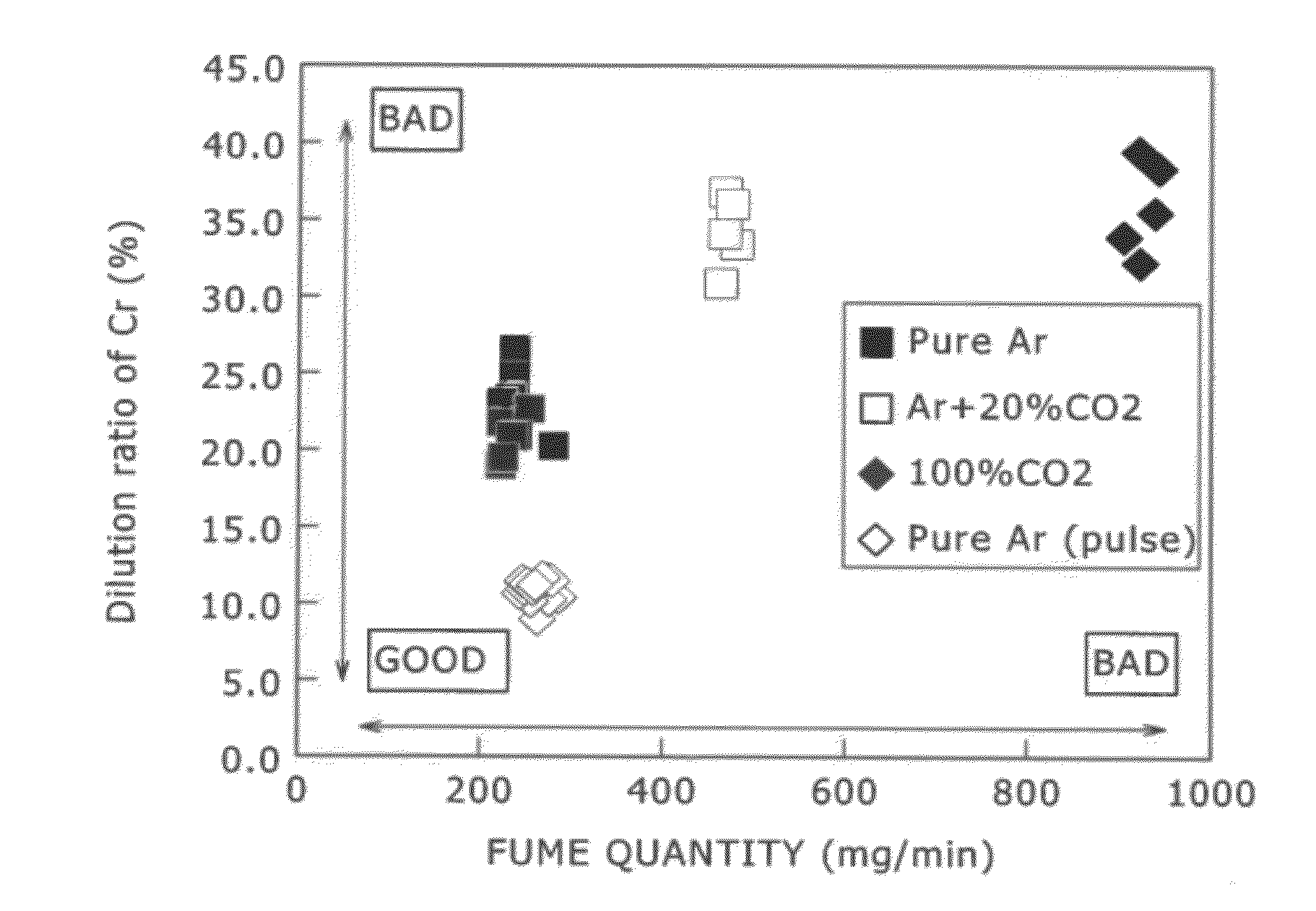

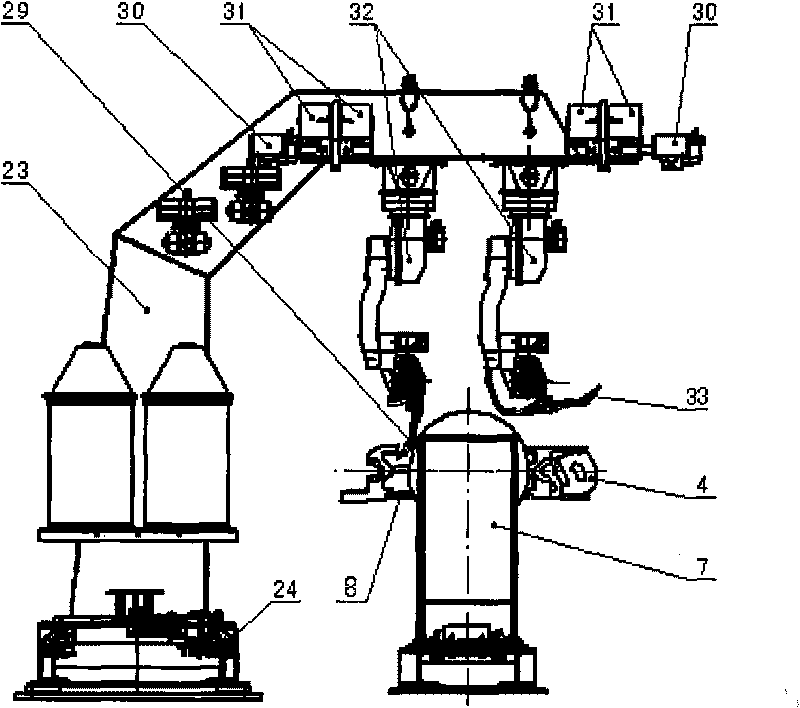

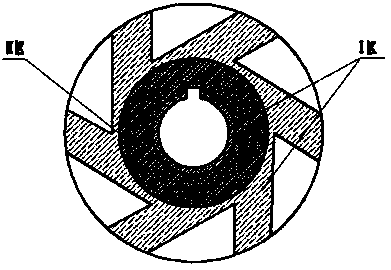

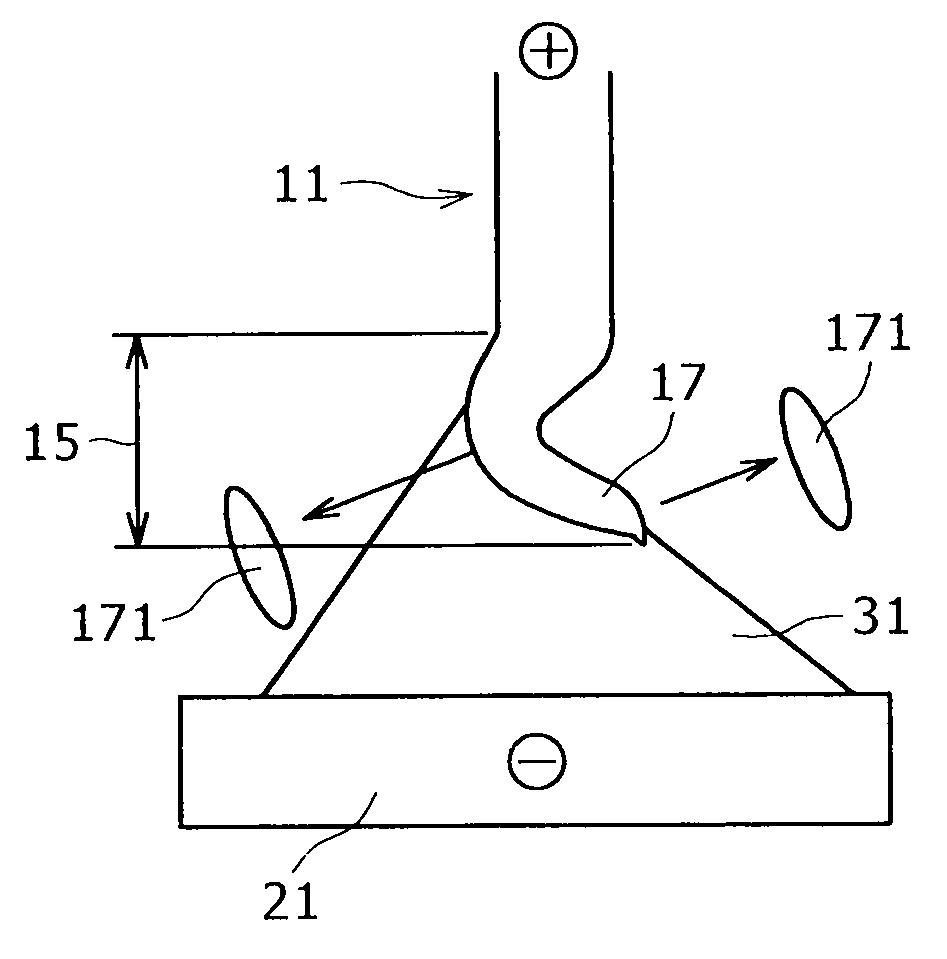

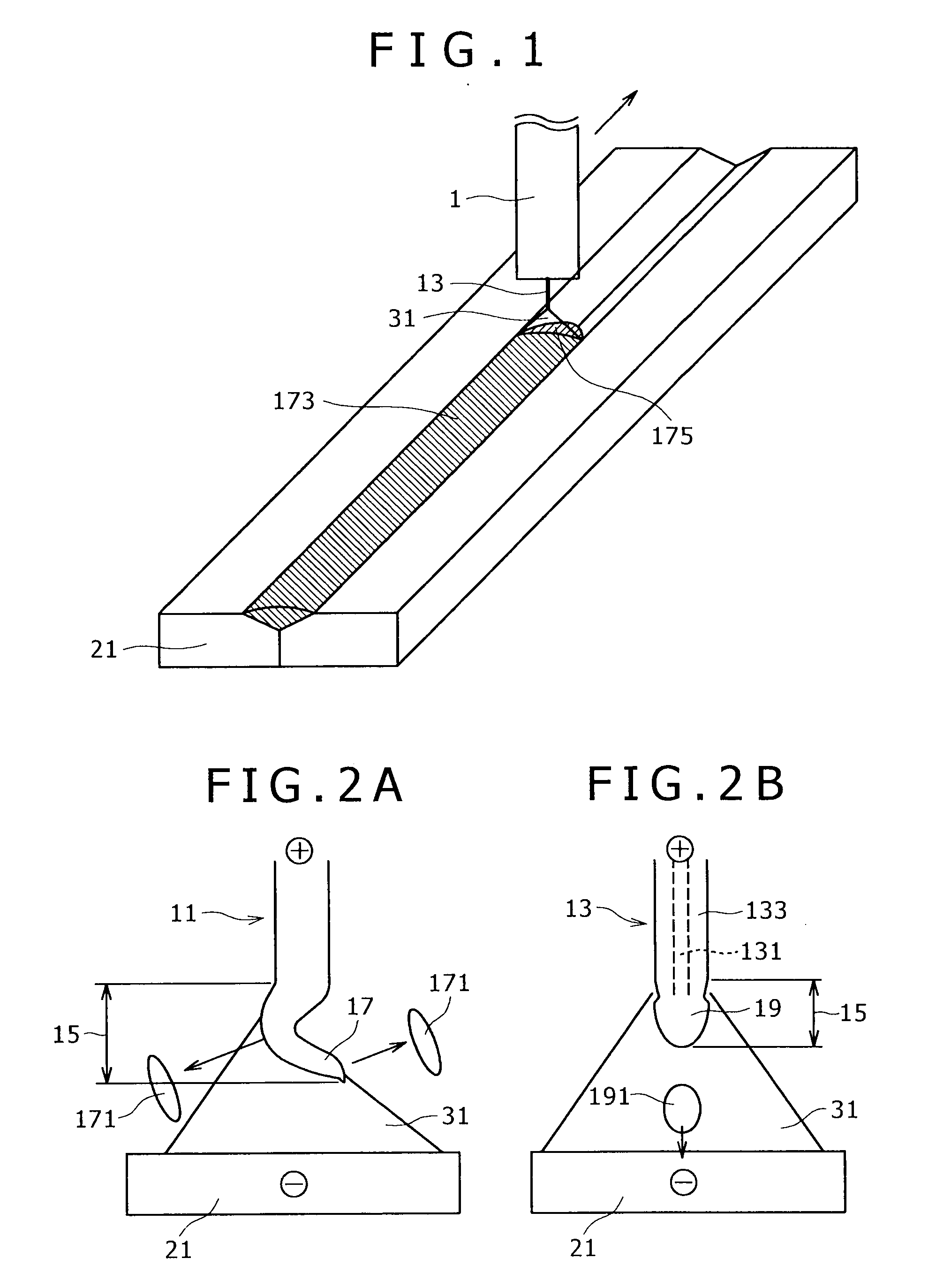

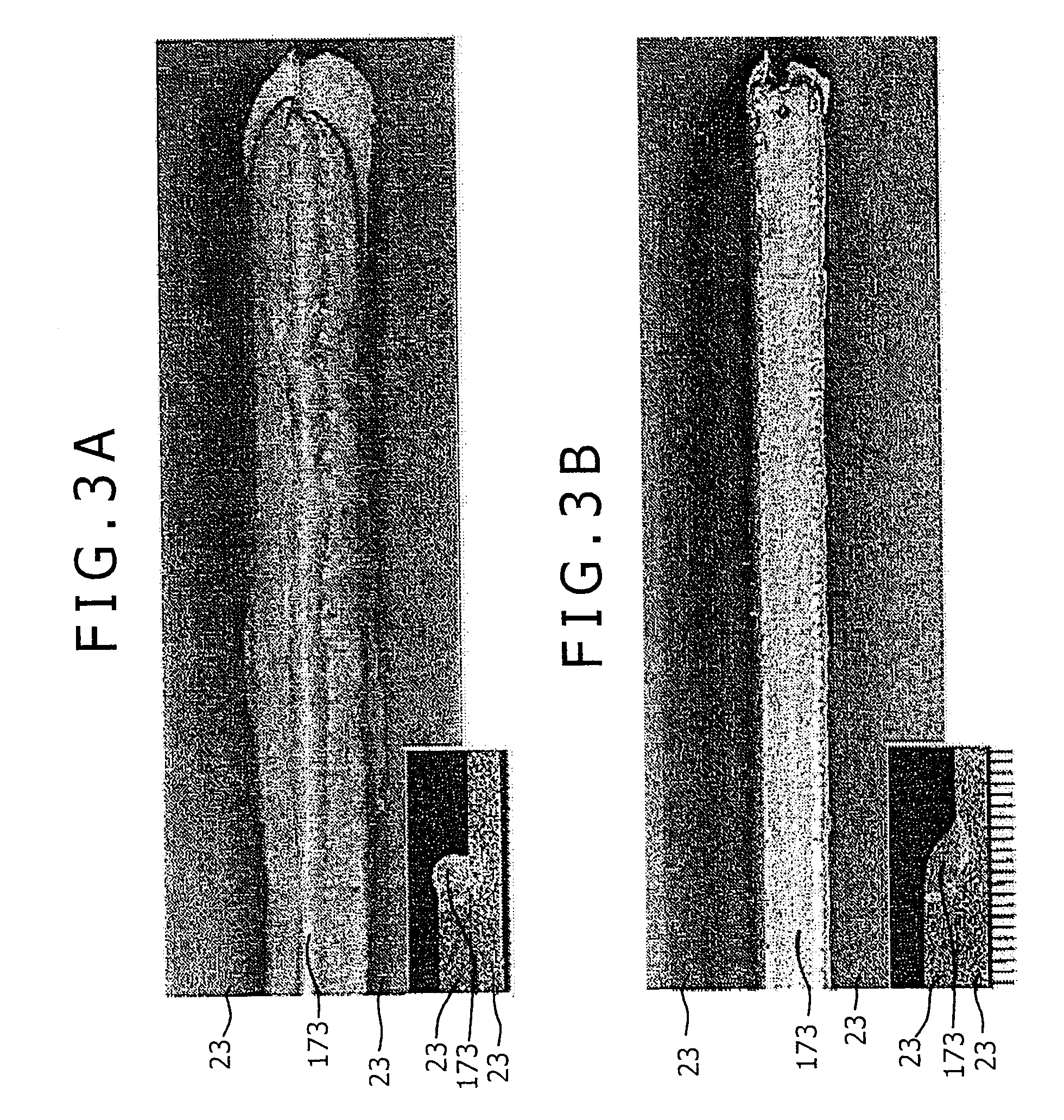

Method for welding rocking arc narrow clearance melting electrode with gas protection and welding torch

InactiveCN101412143AMeet the needs of different welding processes for weldsReduce drive powerElectrode supporting devicesCouplingEngineering

The invention discloses a rocking arc narrow gap consumable electrode gas shielded welding method and a welding torch. The method comprises the following steps: a connecting cable is fixed on an electric brush mechanism and a coupling head; a hollow shaft motor is connected with a straight conducting rod through a shaft joint; a welding wire passes through a center hole of a cable coupling head, and penetrates out a center hole of a current contact nozzle; the lower end of the straight conducting rod is fixed with a connecting piece; and one end of a minor bend conducting rod is connected with the straight conducting rod through the connecting piece, while the other end of the minor bend conducting rod is connected with the current contact nozzle. The hollow shaft motor directly drives the straight conducting rod and the minor bend conducting rod capable of extending into a divided edge of a workpiece to make reciprocating rotation around the central axial line of the welding torch, thereby driving electric arc of the end of the welding wire send from the center hole of the current contact nozzle to make arc rocking in the divided edge of the workpiece so as to realize rocking arc narrow gap welding. The welding torch has the advantages of simple and compact structure, low implementation cost, high reliability of operation, strong practicality, and can adapt requirement of welding process for mean position and spatial position with different welding seams. The welding wire has strong rocking regulation, good directivity of the electric arc, and high welding quality.

Owner:JIANGSU UNIV OF SCI & TECH

Welding technique for rolled steel

The invention relates to a welding process of ASTM A572 GR65 steel, which adopts mixed gas protection welding of argon and carbon dioxide for carrying out the backing welding and adopts the mixed gas protection welding of argon and carbon dioxide for filling and cover surface welding under the operating environment with temperature above 5 DEG C, and the operation is carried out according to the following steps: (1) the determination of parameters of the welding process; (2) the preparation before the welding: groove preparation and contra-aperture assembly; (3) the requirements of the assembly of the tack welding; (4) the backing welding by the mixed gas protection welding of argon and carbon dioxide; (5) the filling and the cover surface welding by the mixed gas protection welding of argon and carbon dioxide. The invention provides the welding process of the ASTM A572 GR65 steel which can prevent the welded steel pipes generating low-plastic quenched structure, prevent the overheating during the austenitic transformation, strengthen the austenitic stability and lower the welding deformation which is reduced by the welding stress.

Owner:ZHEJIANG SHENGDA STEEL TOWER +2

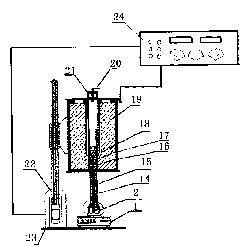

Detection method and device of coke reactivity and post-reaction heat-treatability

ActiveCN101825548AAppear thermal characterizationWeighing by removing componentThermometers using electric/magnetic elementsHearthEngineering

The invention discloses a detection method and device of the reactivity and post-reaction heat-treatability of coke and the method and device are used to detect the gasifying starting temperature, reactivity and post-reaction heat-treatability of coke. The detection method adopts an electric furnace as a heating furnace and uses an electronic balance for to weight. The reactivity detection method is performed on the condition of first heating and second keeping temperature constant, the electronic balance is used to measure the mass loss of a coke sample; and when the coke weight-loss ratio equals a specified value, the measurement weight-loss ratio (time) minus one is used as the reactivity index; the detection method of the post-reaction heat-treatability of coke is that when the coke weight-loss ratio equals the specified value, coke is continuously heated under the protection of inert gas, and the coke weight-loss ratio is used as the post-reaction heat-treatability index during the detection period of heat treatment. The detection device comprises the electronic balance, a reaction tube support, a reaction tube, the heating furnace and a heating furnace elevating mechanism. The method and device of the invention can provide 1500-1600 DEG C of detection temperature and the coke thermal characterization in the bosh (before an air port) and the hearth can be displayed.

Owner:山西今日太工煤焦技术研究有限公司

Waste water treatment catalyst and preparation method thereof

ActiveCN102049256AIncrease contentEvenly distributedCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsManganeseBULK ACTIVE INGREDIENT

The invention relates to a waste water treatment catalyst and a preparation method thereof. The catalyst of the invention takes active carbon as a carrier and one or several of oxides of metals such as copper, iron, manganese, vanadium, zinc and titanium as an active ingredient. The preparation method comprises: firstly, preparing high-temperature active carbon carrier at 350 to 700 DEG C; secondly, immersing the high-temperature active carbon carrier in the immersion liquor containing active metal components or spraying immersion liquor containing active metal components to immerse the high-temperature active carbon carrier so as to load a catalytic active component onto the active carbon carrier quickly; and finally, cooling, washing and drying to obtain the catalyst. The catalyst prepared by the method has the advantages that the content of the active metal components is high, and the active metal components are insusceptible to loss in waste water. The catalyst is mainly used in the catalytic oxidization treatment process of waste water.

Owner:CHINA PETROLEUM & CHEM CORP +1

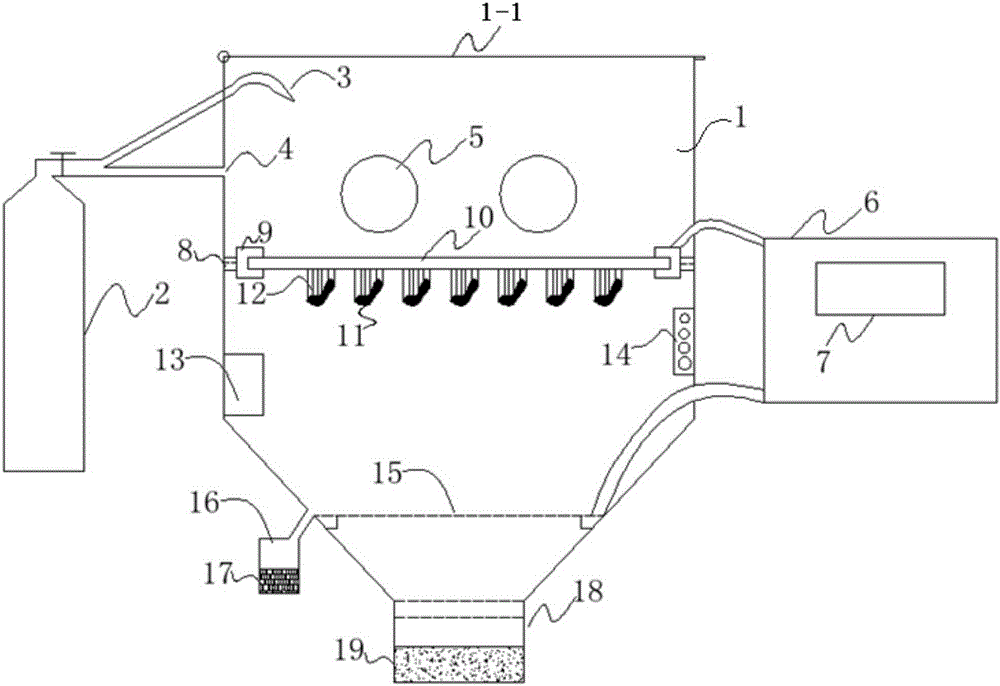

Three-dimensional (3D) metal printer

InactiveCN103551572AAdditive manufacturing apparatusIncreasing energy efficiencyMetallic materialsLiquid metal

The invention discloses a three-dimensional (3D) metal printer. A printing head integrating a ceramic melting furnace and a liquid metal ejector is a key technology for the 3D metal printer. The printing head is made of high temperature resistant ceramic or graphite material, a water cooling eddy current coil is installed on an outer layer, the melting furnace is filled with inert gas to protect liquid metal, and the ejector is a reciprocating type plunger pump. The water cooling eddy current coil is electrified with high-frequency current, and heating power can be adjusted through a high-frequency controller according to factors such as material types, model requirements and processing speeds. The inert gas keeps a certain pressure while protecting the molten metal, flow of the liquid metal is facilitated, and metal residue in the plunger pump and the melting furnace is removed by means of gas simultaneously during shutdown. Besides application to the 3D metal printer, the printing head can also be used for devices for die-cast molding and injection molding of metal material and the like.

Owner:王璐瑶

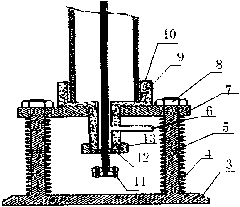

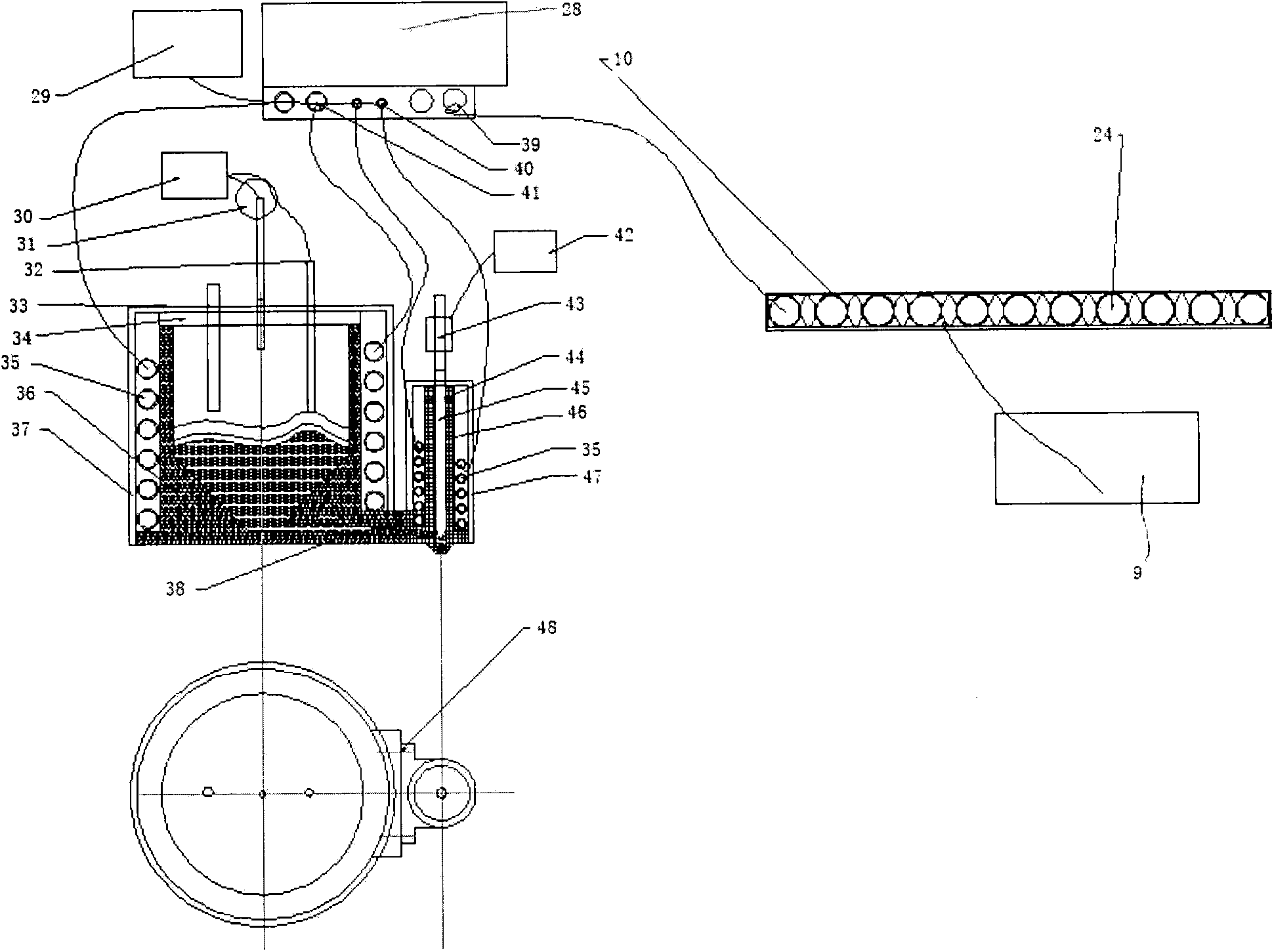

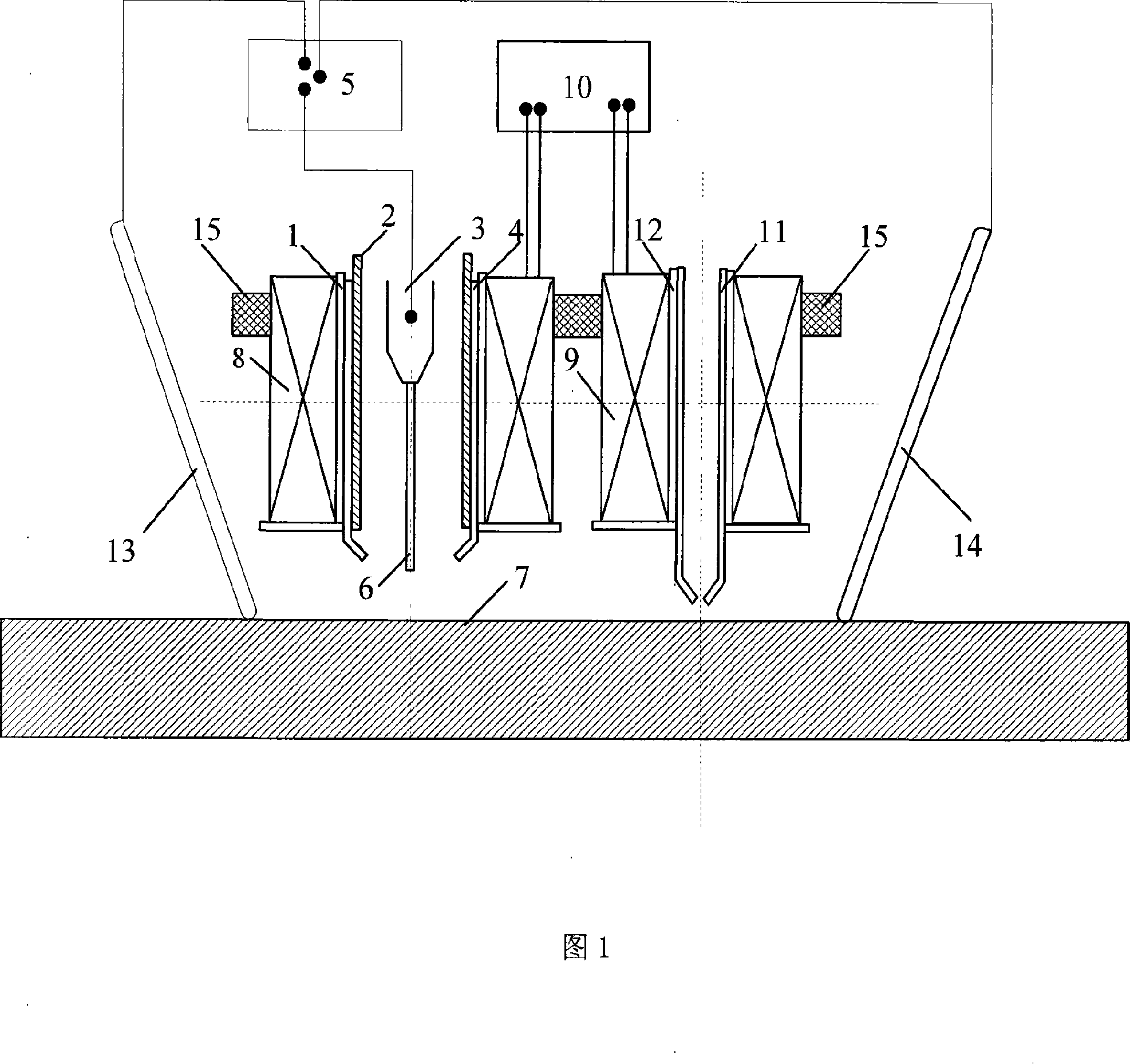

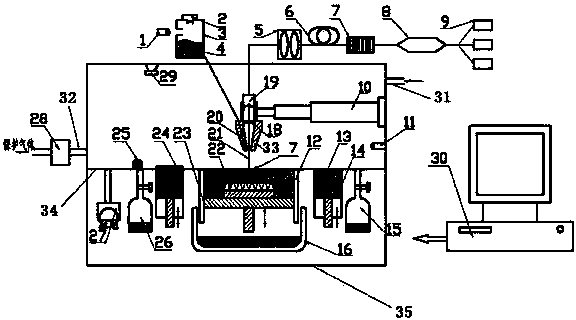

Ultrasound wave and melt pole electrical arc compound welding method

The invention provides a weld method compounding an ultrasonic and a gas metal arc welding so as to make use of the cavitation effect and the vibration effect of the ultrasonic to lead welding drops generated by the gas metal arc welding to be smoothly transmitted to a welding pool when the drops are still small. And when in welding, an electric arc shrinks under the effect of the ultrasonic and then the stiffness of the electric arc can be enhanced, which has a significant application value for welding of special positions such as a full-position welding, an overhead position welding, a flat position welding and a horizontal position welding, etc.. The invention includes the following steps: an ultrasonic generator is connected with an ultrasonic transducer 2 to convert ultrasonic energy into mechanical vibration; an ultrasonic transformer 3 enlarges amplitude; a conductive tip 5 is combined with the ultrasonic transformer; a protective gas nozzle 4 is fixed on the vibration node of the transformer; a welding wire 1 is connected with the conductive tip 5 to start a welding power supply 9 and then start an ultrasonic power supply after the electric arc becomes stable, then the transducer converts electrical energy into vibration and the ultrasonic transformer enlarges the ultrasonic amplitude which is transmitted to a melting electrode.

Owner:HARBIN INST OF TECH

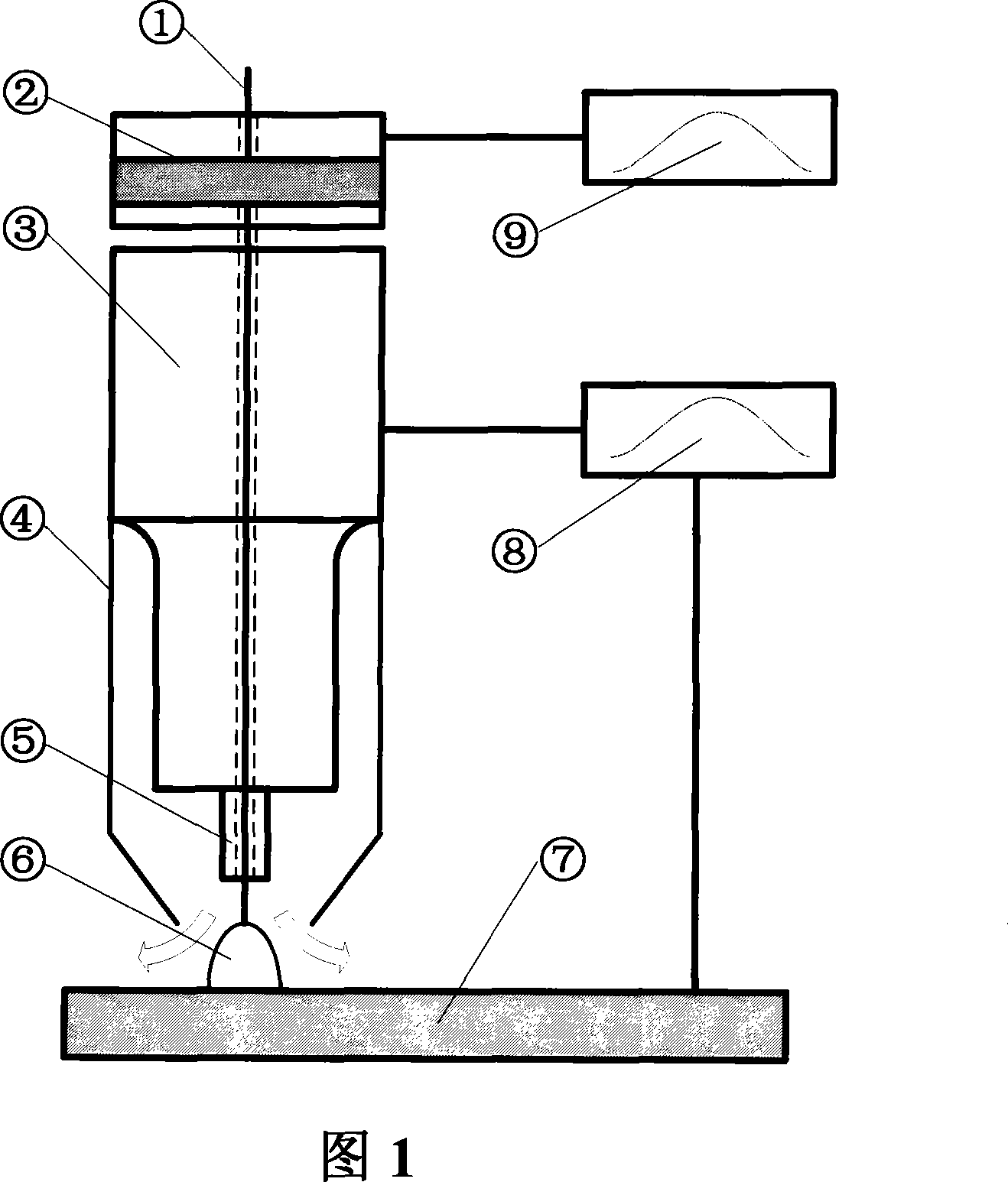

Flux-cored welding wire and method for arc overlay welding using the same

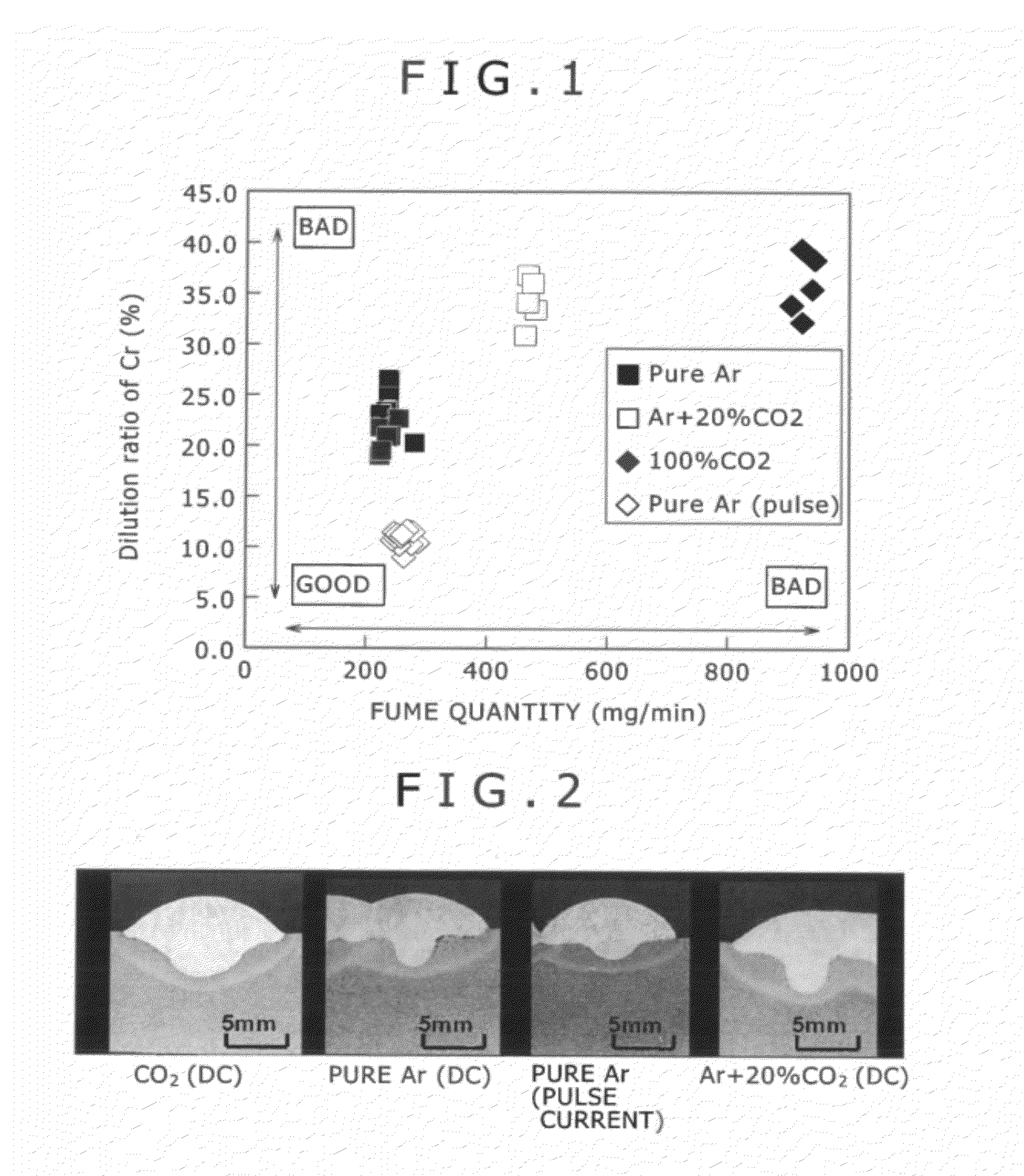

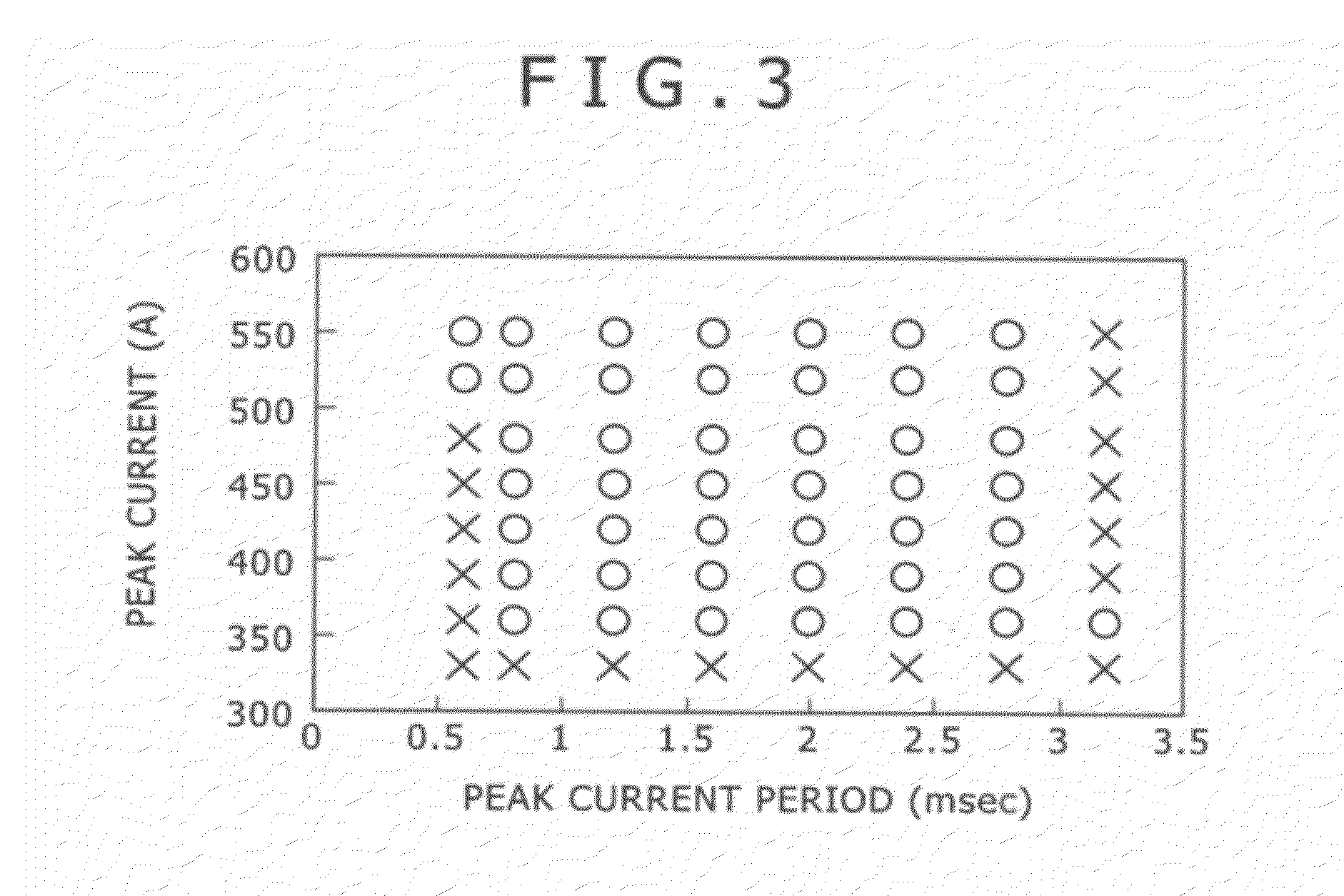

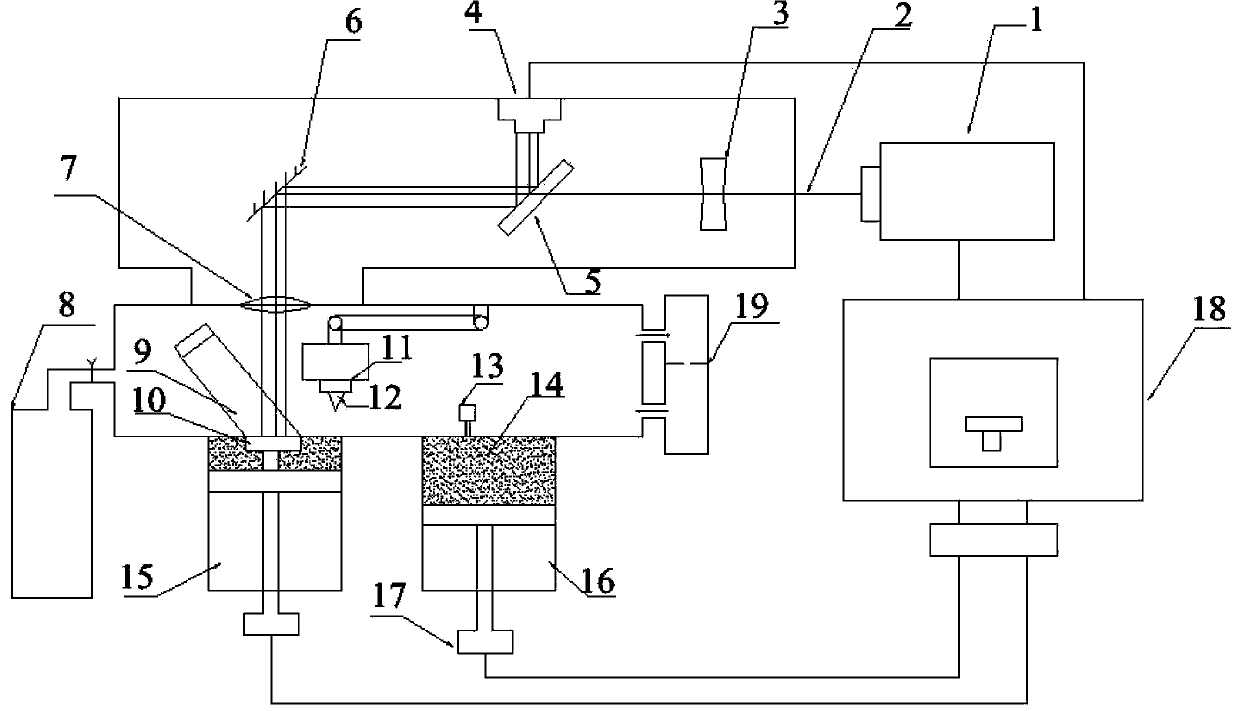

InactiveUS20120055903A1Improve solderabilityLow dilution ratioArc welding apparatusWelding/cutting media/materialsShielding gasCorrosion resistant

To provide a flux-cored welding wire and a method for arc overlay welding attaining excellent weldability and low dilution ratio and obtaining a weld bead excellent in corrosion resistance in overlay welding using the flux-cored welding wire having an advantage of high deposition rate and deposition efficiency. The flux-cored welding wire for gas shielded arc welding including flux filled up in an outer sheath and using pure Ar as a shielding gas contains, as percentage to the total mass of the flux-cored welding wire, C: 0.20 mass % or below, Si: 15.00 mass % or below, Mn: 20.00 mass % or below, P: 0.0500 mass % or below, S: 0.0500 mass % or below, and Cr: 15.0-50.0 mass %, with the remainder being Fe and inevitable impurities.

Owner:KOBE STEEL LTD

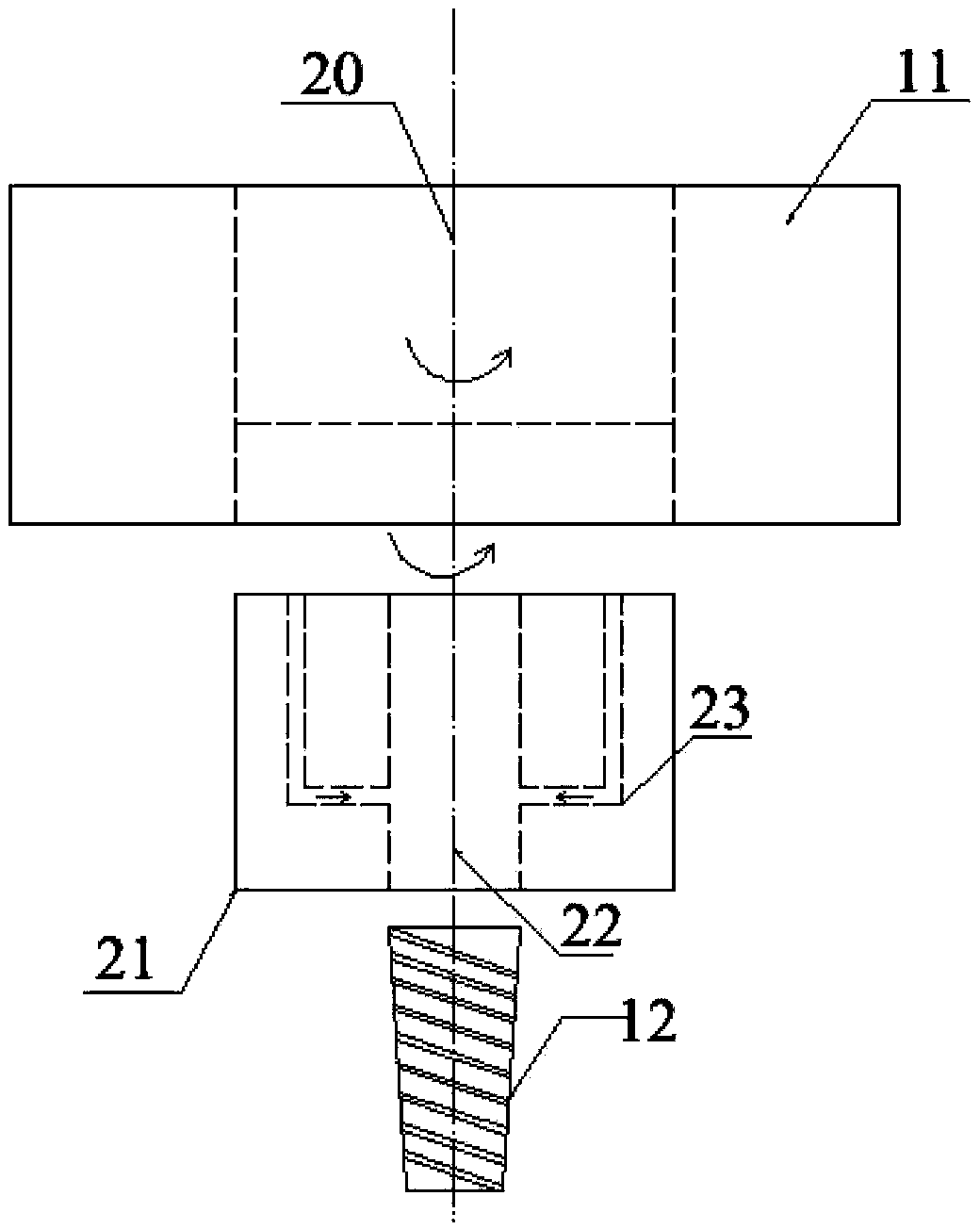

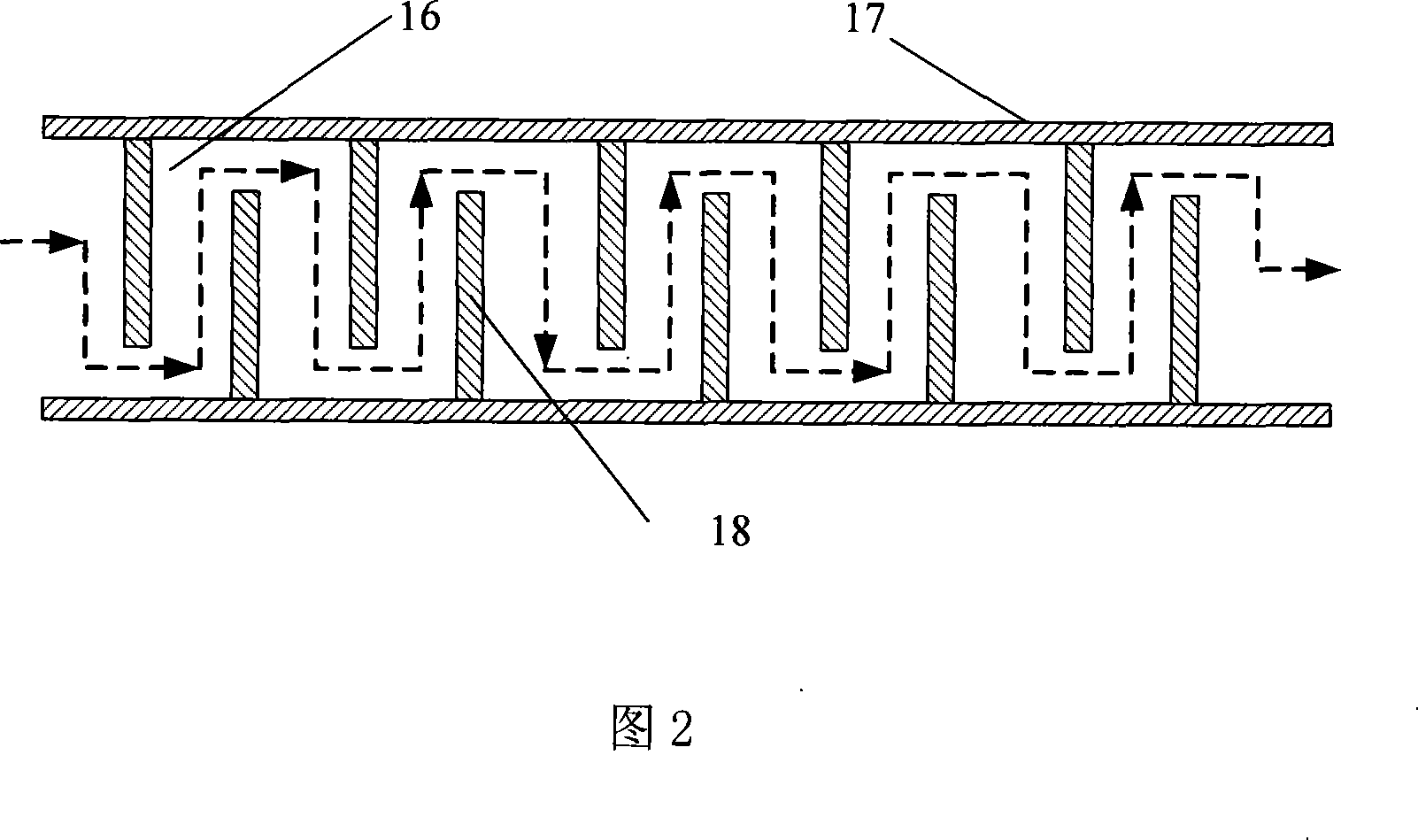

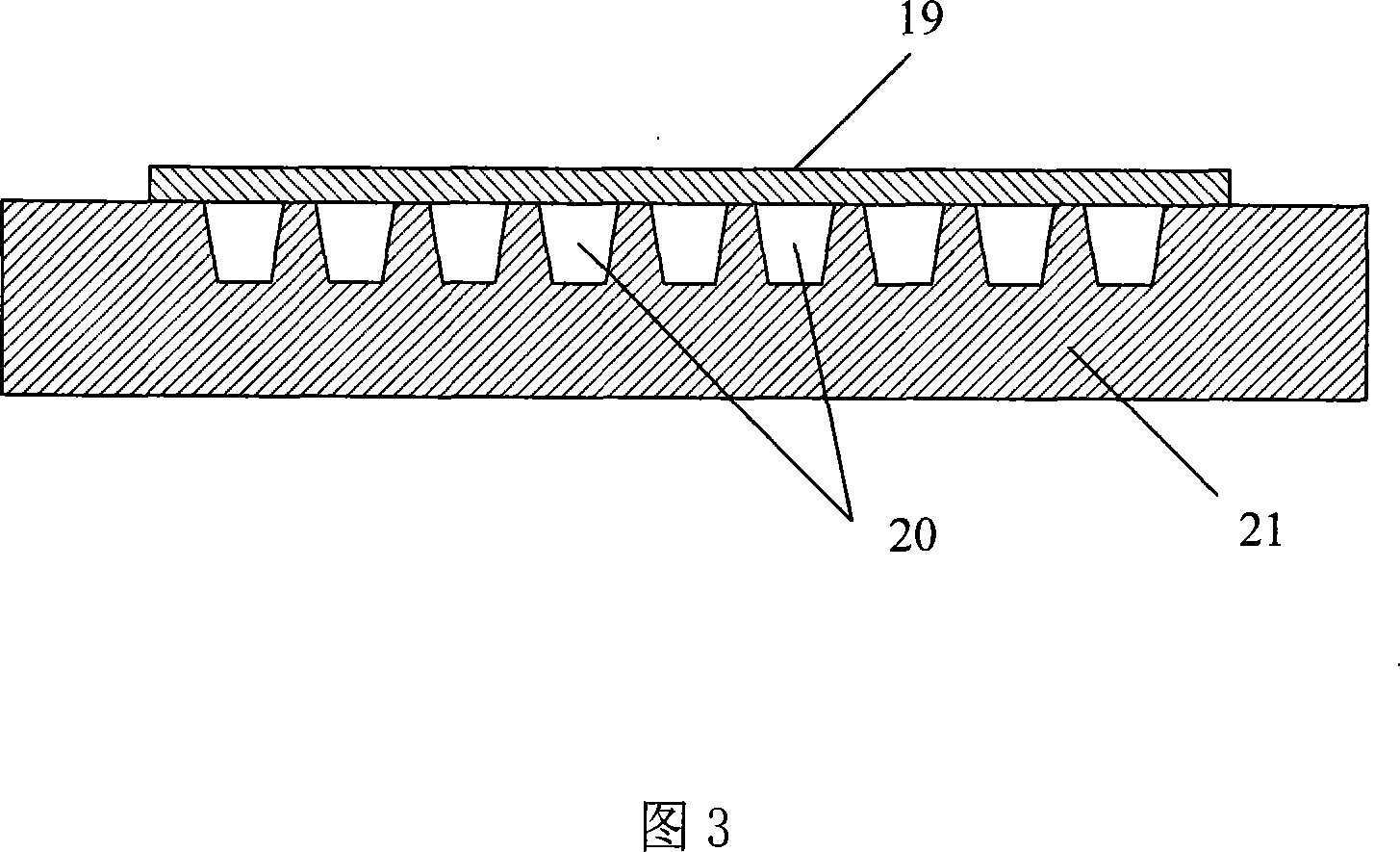

Combination manufacturing method and device for injection mold with conformal cooling water path

ActiveCN103418985AEasy to manufactureAvoid defectsIncreasing energy efficiencyManufacturing technologyLight beam

The invention discloses a combination manufacturing method and device for an injection mold with a conformal cooling water path. The device comprises a light beam focusing system, a close wave length coaxial vision positioning system, a powder pavement system and a gas protection system. The gas protection system comprises a sealed forming chamber, a shielding gas device and a powder purification device, wherein the shielding gas device is connected to one side of the sealed forming chamber, and the powder purification device is connected to the other side of the sealed forming chamber. The method is a combination processing method combined with the laser region selection fusion technology and the precision cutting processing technology, the advantages of the laser region selection fusion flexible processing are retained, and the feature that the precision of the high-speed cutting processing is good is given to play. In the process of region selection laser fusion processing, laser surface refusion processing is carried out on each layer, and the compactness and the surface quality of the mold are improved. The technique of density changing rapid manufacturing is adopted, and manufacturing efficiency is improved. Precision mold components with the interior special-shape cooling water path and the complex inner cavity structure can be integrally processed at a time.

Owner:SOUTH CHINA UNIV OF TECH

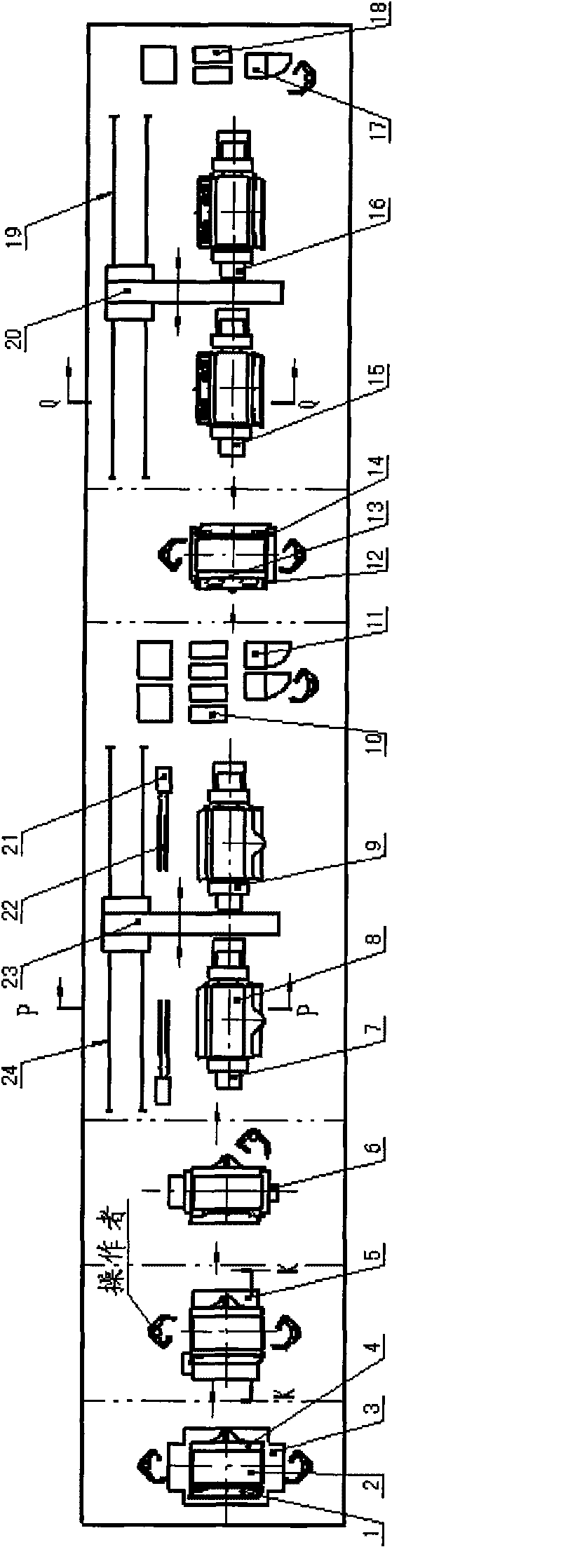

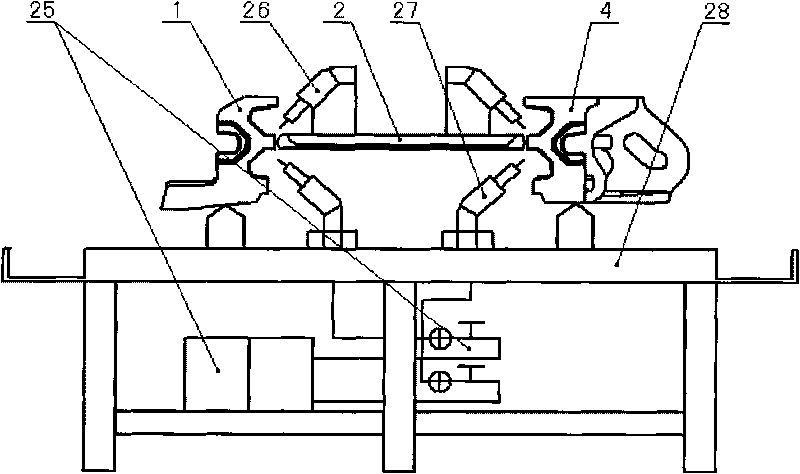

Robot automatic welding production line of middle groove and technological method thereof

ActiveCN101722373AImprove welding qualityEfficient automatic weldingWelding/cutting auxillary devicesArc welding apparatusProduction lineManufacturing technology

The invention relates to the technical field of production manufacturing of a cast middle groove by a heavy-duty scraper conveyor used on coal mines, and provides a robot automatic welding production line of a middle groove and a technological method thereof. The production line designs 8 stations according to the manufacturing process flow of the middle groove, comprises 6 parts of a primary assembly station, a middle plate preheating station, a backing welding station, a middle plate and bottom plate robot welding work station, a secondary assembly station and a bending rail rest robot welding work station, and forms an integrated production line layout of the middle groove. The invention integrates and uses multiple technologies of a welding robot, double-wire welding, digital double-pulse welding power source, computer control, high-efficiency flame preheating and the like, and establishes technical measures of preheating temperature, bevel form, welding sequence, welding parameters and the like; and the welding process is controlled by a computer, thereby realizing high-efficiency automatic robot welding of the middle groove in the overall process. Compared with the traditional manual gas shielded welding, the invention obviously improves the welding quality of the middle groove and increases the welding efficiency by 3-4 times.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

Consumable electrode surfacing method of electromagnetic complex field, and the device and extension application thereof

InactiveCN101032788AStir wellChange the crystallization stateWelding/cutting auxillary devicesArc welding apparatusComposite fieldEngineering

The present invention relates to one kind of composite electromagnetic field build-up welding method, apparatus and expanded application, and is composite electromagnetic field controlled gas protected build-up welding method. The welding apparatus is provided with exciting power source, exciting device, auxiliary electric field device and water cooling system. The exciting device has electromagnetic stirring exciting coil and electromagnetic heat treatment exciting coil; and the auxiliary electric field device includes one pair of movable electrodes. Through electromagnetic stirring, electromagnetic heat treatment and the compound effect of auxiliary electric field and the welding torch, the present invention realizes the build-up welding of alloy material in high efficiency, high quality and low cost.

Owner:CHONGQING UNIV

High chromium cast iron self protective build-up welding cored welding wire and its usage

InactiveCN1714986ARealize direct surfacingOverlay welding wear-resistant and corrosion-resistantArc welding apparatusWelding/cutting media/materialsHigh carbonManganese

The self-protective high chromium cast iron cored build-up welding wire has metal powder core comprising nickel powder 6-8 wt%, middle carbon manganese iron 8-10 wt%, No. 45 ferrosilicon 9-12 wt%, high carbon ferrochromium 65-75 wt%, metal Cr powder 18-21 wt%, ferromolybdenum 5-7 wt% and Al-Mg powder 1.5-2.5 wt%, and with one welding wire filling amount of 0.49-0.53. The present invention makes it possible to use the welding wire in submerged arc welding without needing added flux and protecting gas, results in raised comprehensive welding performance and raised welding quality, and may be applied widely in build-up welding field requiring high antiwear, anticorrosive and anticracking performance.

Owner:XIANGTAN UNIV

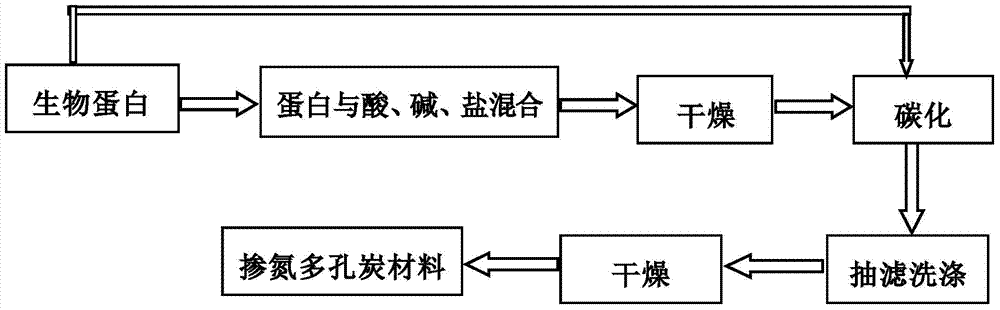

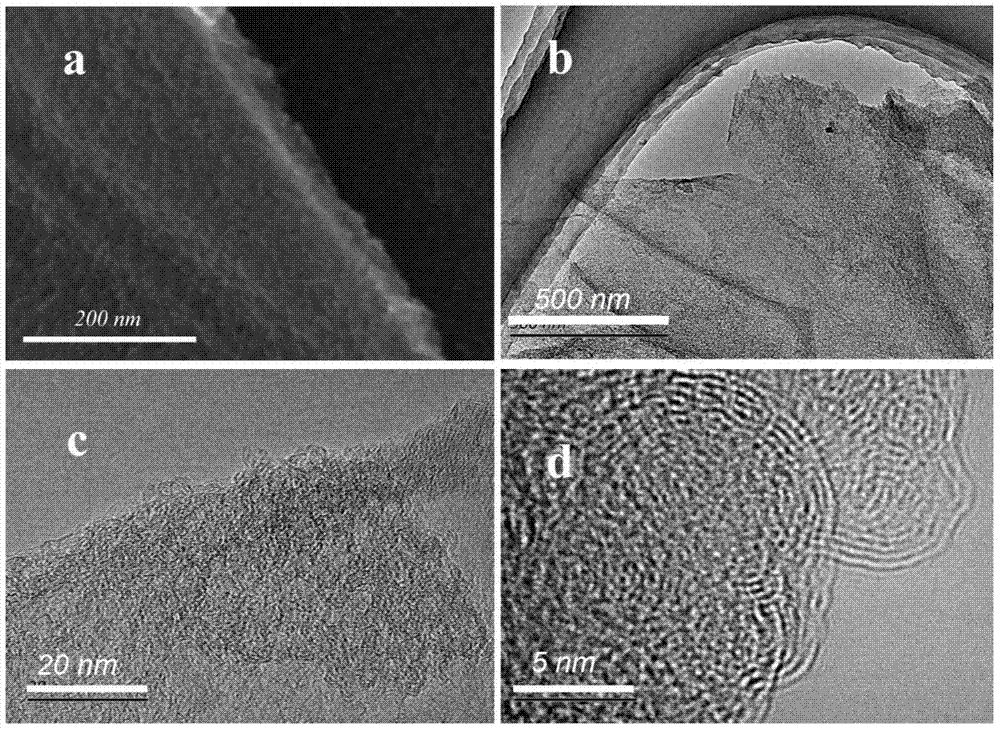

Method for preparing nitrogen doped porous carbon material by using biologic proteins

The invention provides a method for preparing a nitrogen doped porous carbon material by using biologic proteins. The method mainly comprises the following steps: 1, mixing the biologic proteins with an acid or alkali or salt solution; 2, carbonizing the above obtained dried mixture under the protection of inert gas; and 3, carrying out distilled water addition, pumping filtration and washing until the pH value is 6.4-7, and drying to obtain solid powder which is the nitrogen doped porous carbon material. The widely and easily available biologic proteins are adopted as raw materials, and the raw materials comprise silk fibroin, albumen and soybean proteins, so the method has the advantages of simple operating technology, convenient control, cleanness, environmental protection, and easy industrial realization. The prepared nitrogen doped porous carbon material has the advantages of large specific surface area, low ash content and good conductivity. The nitrogen doped porous carbon material can be used in lithium ion batteries, lithium sulfur batteries, super capacitors and other electrode materials, and fields of carbon dioxide capture, hydrogen storage, catalyst carriers, active carbon adsorbents and biologic applications.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method of high-reaction-activity hydroxyl acrylic resin

InactiveCN103130944AImprove molecular structureHigh glass transition temperaturePolyurea/polyurethane coatingsAcrylic resinSolvent

The invention relates to a preparation method of high-reaction-activity hydroxyl acrylic resin. According to the invention, a solvent in a reactor is heated to a preset temperature under the protection of an inert gas; a mixture of a monomer component A with hard monomer as a main component (and comprising a small amount of soft monomer, hydroxyl monomer and carboxyl monomer) and an initiation agent is slowly added; a reaction is carried out for a certain period of time with maintained temperature; a mixture of a monomer component B with soft monomer as a main component (and comprising a small amount of hard monomer, hydroxyl monomer and carboxyl monomer) and an initiation agent is slowly added; and reaction is carried out for a certain period of time with maintained temperature, such that acrylic resin comprising hydroxyl is obtained. The invention has the characteristic that common monomers are adopted, and only the synthesis process is changed wherein monomer dropping sequence is changed, such that resin molecular structure is substantially changed, and the synthesized hydroxyl acrylic resin shows high reaction activity during a curing reaction. The method provided by the invention also has the advantages of low cost, simple process, and suitability for industrialized productions.

Owner:XI AN JIAOTONG UNIV +1

Device and method for use of impeller of laser 3D (three dimensional) -printing pump

ActiveCN104226996AImprove mechanical propertiesGeneral mechanical propertiesTurbinesOther manufacturing equipments/toolsManufacturing cost reductionLow speed

The invention discloses a device and a method for the use of an impeller of a laser 3D (three dimensional) -printing pump, and belongs to the field of 3D printing technology. The device comprises a laser system, a gas protection system, a preheating system, a powder feeding system, a powder paving system, a powder recycle system and a computer system. The manufacturing method mainly comprises the following steps that 1, a CAD solid model of the pump impeller is drawn, and the model is subjected to hierarchical slicing along the Z direction; 2, the slice in each layer is zoned into a zone I and a zone II according to the performance requirements of the pump impeller; 3, the zone I of each slice layer is subjected to low-speed sintering by using powder A, and the zone II is subjected to low-speed sintering by using powder B. The surface of a workpiece and the powder flow filed are subjected to the inert gas shielding in the process of printing. According to the device and the method for the use of the impeller of the laser 3D-printing pump, different requirements of different positions of the pump impeller on mechanical performance can be met, the printing quality and speed are also improved, and the manufacturing cost is reduced.

Owner:江苏大学扬州(江都)新能源汽车产业研究所

Pure ar gas shielded welding mig flux-cored wire and mig arc welding method

InactiveUS20090261085A1High static tensile strengthLow-cost and stable pure Ar-MIG weldingArc welding apparatusWelding/cutting media/materialsSlagGreenhouse effect

A pure Ar-MIG welding wire for welding steel according to the present invention is formed of a flux-cored wire. The flux-cored wire is formed in the manner that a formation formed by welding a carbon steel hoop into a pipe shape or a seamless pipe is used as an outer sheath, the outer sheath is filled with a flux, and a wire drawing process is performed. The flux accounts for 7 to 27 mass % of the total wire mass. The wire contains graphite in the amount of 0.16 to 2.00 mass % on the basis of the total wire mass and iron powder in the amount of 20 mass % on the basis of the total flux mass. According to the construction, neither expensive metal resource nor a greenhouse effect gas is used, slag and fume generation is inhibited, and a weld joint having a high static tensile strength and fatigue strength can be obtained.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com