Ultrasound wave and melt pole electrical arc compound welding method

An ultrasonic and melting electrode technology, which is applied in the fields of arc smelting technology, arc processing, and melting electrode arc welding, can solve the problems of complex control system and affecting normal GMA welding speed, etc., and achieve the effect of improving droplet transfer and energy-saving welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

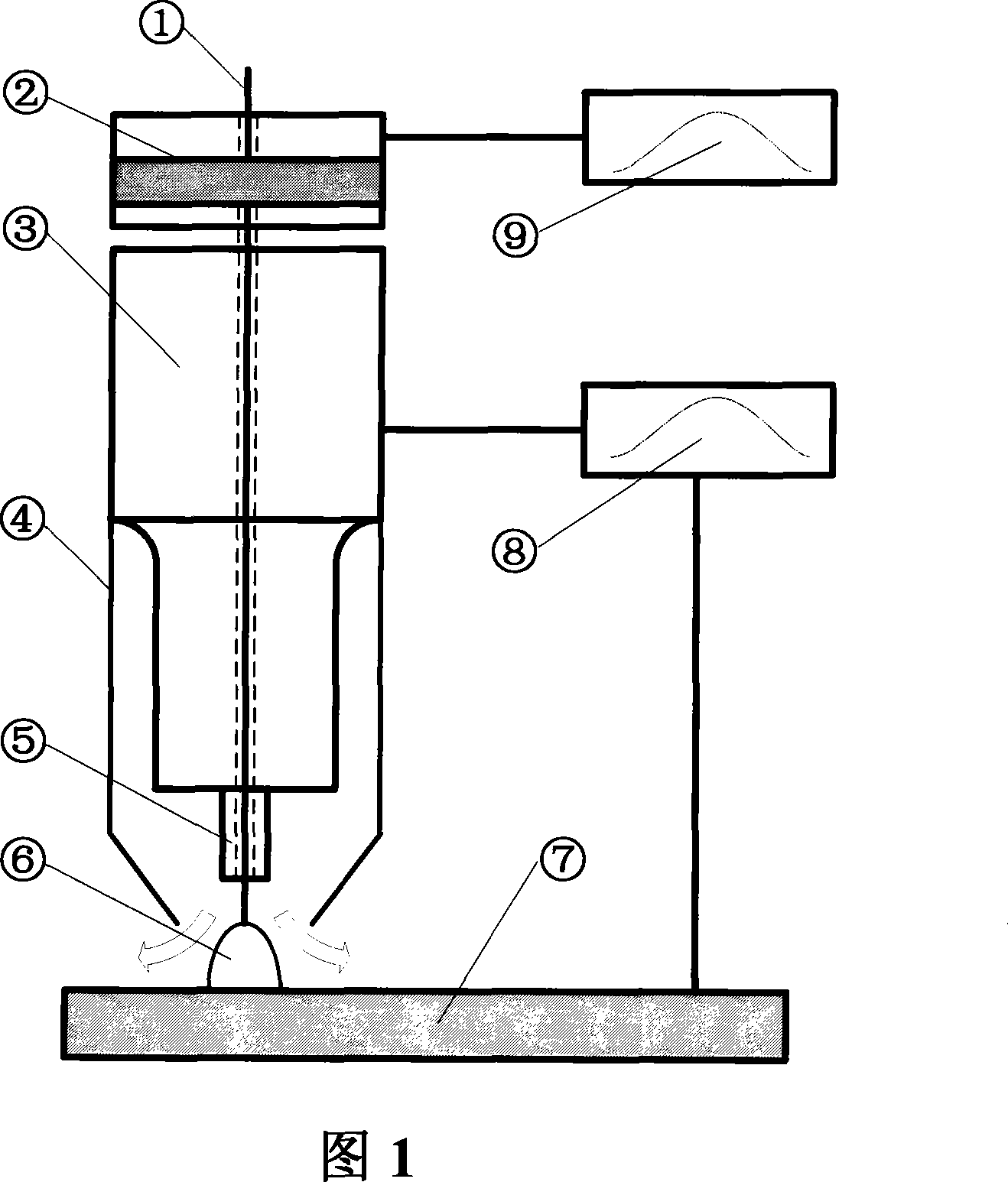

[0021] The combined welding method of ultrasonic wave and gas metal shielded welding proposed by the present invention first needs to redesign the ultrasonic transducer 2 and the horn so as to meet the requirements of gas metal shielded welding. Accurately calculate the designed ultrasonic horn 3 to find the required positions; rationally combine the conductive tip 5 used in welding with the horn to realize the effective transmission of ultrasonic waves and arc power; The nozzle 4 is fixed at the vibration node position of the horn to achieve the minimum loss of ultrasonic energy; when welding, after the arc is started and stabilized, start the ultrasonic power supply 8, convert the electric energy into vibration through the transducer, and convert the electric energy into vibration through the horn. The amplitude of ultrasonic vibration is amplified and finally transmitted to the melting pole.

[0022] In the above method, the ultrasonic power transmitted through the arc is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com