Method and device for recycling residual powder on metal material increase manufacturing substrate

A metal additive and powder technology, which is applied in the directions of additive manufacturing, additive processing, and process efficiency improvement, can solve the problems of wasting materials, difficult to remove residual powder at the bottom of parts, and injury to operators, and achieves simple and easy technical means. performance, prevent oxidation and moisture, and ensure the same quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

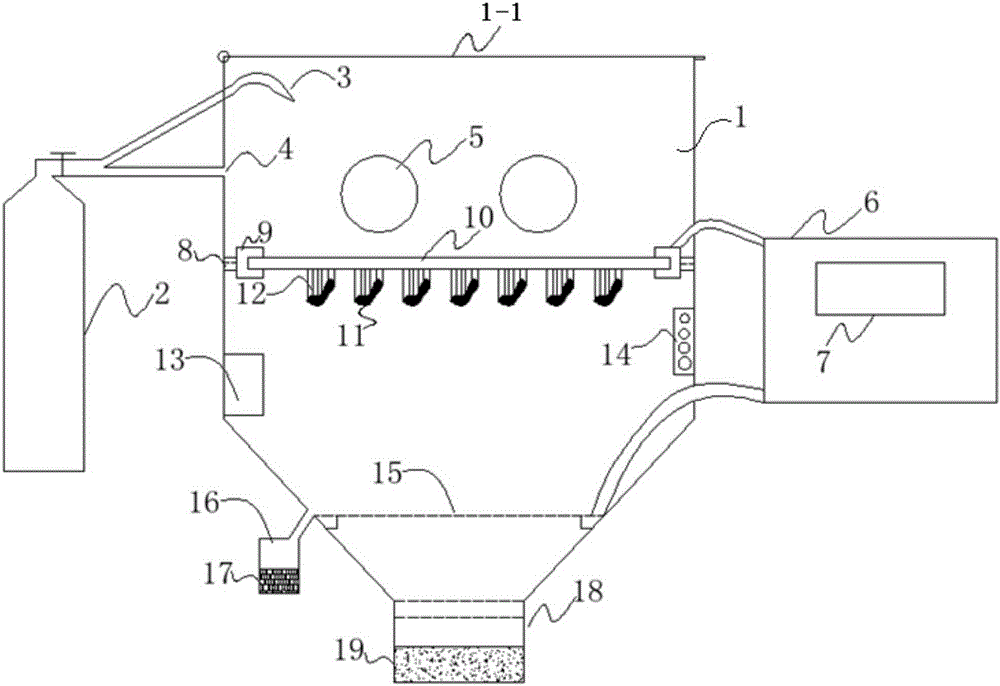

[0029] Such as figure 1 shown. The present invention is a device for recovering residual powder on metal additive manufacturing substrates, comprising a sealed chamber 1, a pneumatic vibrator 6 arranged outside the sealed chamber 1, and a vibration clamp arranged on the inner wall of the sealed chamber 1 for transmitting vibration Components, the vibration clamping component is connected to the pneumatic vibrator 6, and the vibration clamping component is used to clamp the substrate 10 of the molded part 11 and provide mechanical vibration to the substrate 10;

[0030] A high-pressure air gun 3 and an inert gas inlet 4 are provided on the upper side wall of the vibration clamping part in the sealed chamber 1, and the high-pressure air gun 3 and the inert gas inlet 4 are respectively connected to the external inert gas storage tank 2.

[0031] The vibrating clamping part includes a rotating connecting rod 8 and a substrate vibrating fixture 9 for clamping the substrate 10 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com