Patents

Literature

484 results about "Coated urea" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

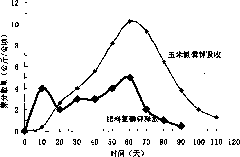

Coated urea fertilizers are a group of controlled release fertilizers consisting of prills of urea coated in less-soluble chemicals such as sulfur, polymers, other products or a combination. These fertilizers mitigate some of the negative aspects of urea fertilization, such as fertilizer burn. The coatings release the urea either when penetrated by water, as with sulfur, or when broken down, as with polymers.

Heavy polymer coated slow-release fertilizer with sulfide as bottom coat

InactiveCN1569774AStrong impact resistanceImprove wear resistanceFertiliser formsUrea compound fertilisersControl releaseCoated urea

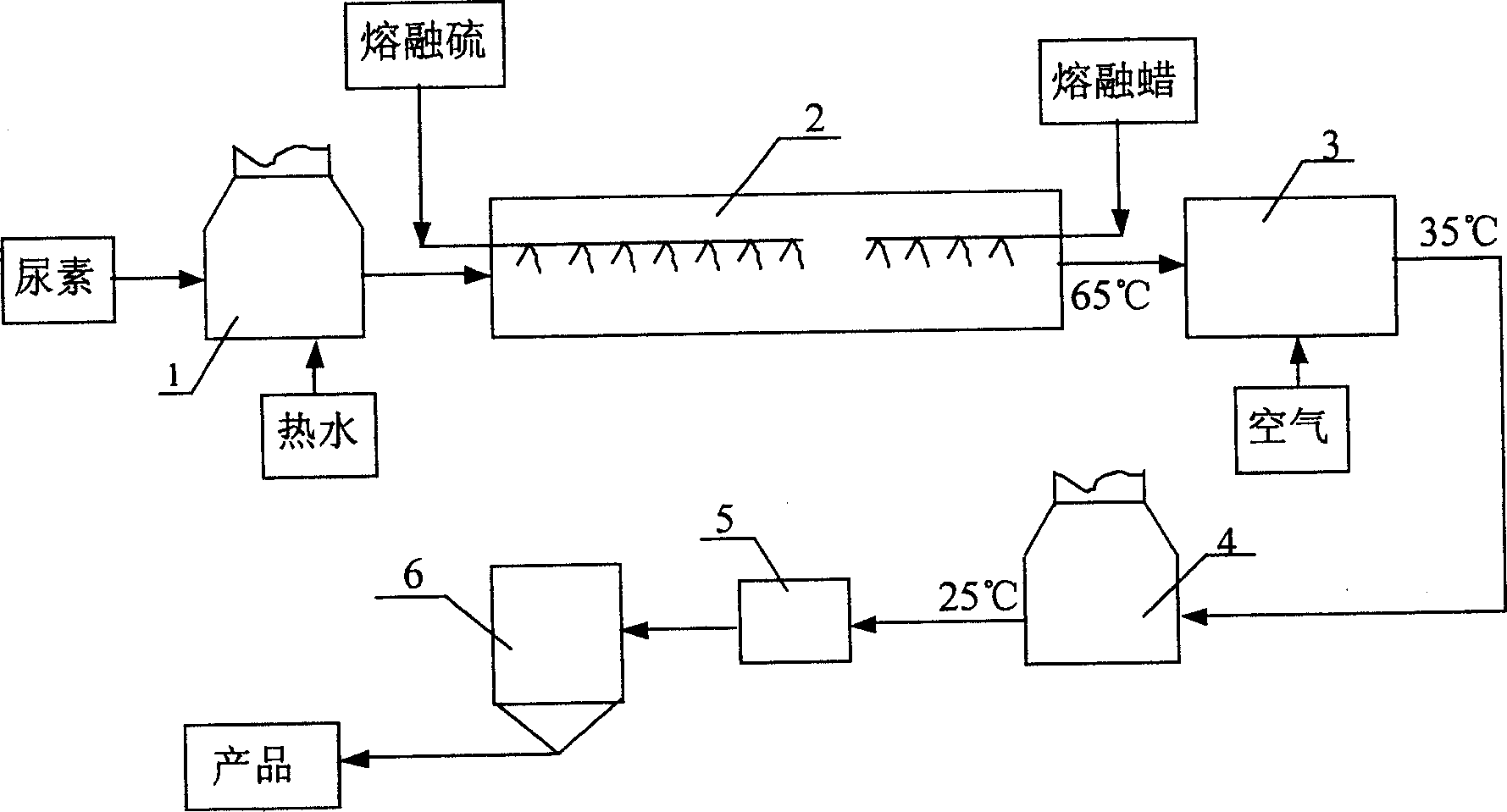

The invention relates to an enveloped controlled release fertilizer and method for preparation which consists of, preheating the urea particles to a predetermined temperature, spraying the molten liquid state sulfur to the urea particles, forming a layer of smooth and compact sulfur-coated urea, charging hot-curing resin component on the sulfur-coated urea for even distribution onto the urea particle surface and fast formation.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Heavy polymer coated slow-release fertilizer with sulfide as bottom coat

InactiveCN1246265CStrong impact resistanceImprove wear resistanceFertiliser formsUrea compound fertilisersControl releaseCoated urea

The invention relates to an enveloped controlled release fertilizer and method for preparation which consists of, preheating the urea particles to a predetermined temperature, spraying the molten liquid state sulfur to the urea particles, forming a layer of smooth and compact sulfur-coated urea, charging hot-curing resin component on the sulfur-coated urea for even distribution onto the urea particle surface and fast formation.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Acetic ester coated controlled-release urea fertilizer and preparation technique

InactiveCN101200400ALow priceReduce manufacturing costAgriculture gas emission reductionUrea compound fertilisersGreen environmentControl release

The invention relates to a coated urea fertilizer, substantially an acetate starch-coated controlled-release urea fertilizer which is prepared by utilizing high-substitute degree acetate starch and a preparation process. The urea is implemented on coating by the coating material which is made by utilizing high-substitute degree acetate starch and other ingredients, so that the acetate starch-coated controlled-release urea fertilizer is generated; the coated urea can be ordinary bulky grain urea or the bulky grain urea with biochemical inhibitor on the surface; the biochemical inhibitor is urease inhibitor or / and nitrification inhibitor, thereby the acetate starch-coated controlled-release urea fertilizer is made. The most notable characteristic of the acetate starch-coated controlled-release urea fertilizer is that: the coating is implemented by utilizing the coating material high-substitute degree acetate starch which can be biodegraded fully, the soil environmental will not be polluted after being fertilized on by the coated urea fertilizer, thereby the coated urea fertilizer is a real green environment-friendly coated fertilizer. And the source of coated material is board and is easy to be obtained, and the price is lower, so the production cost of the coated urea fertilizer can be reduced greatly.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

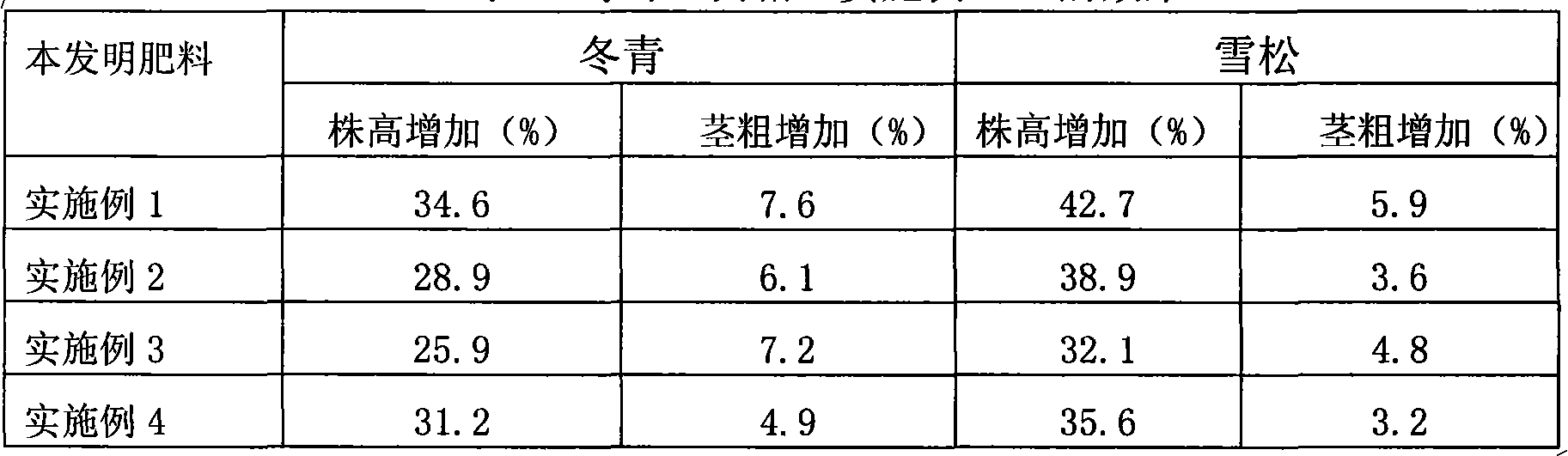

Sustained-release fertilizer for nursery stocks in landscaping and preparation and application

The invention relates to a sustained-release fertilizer for nursery stocks in landscaping and preparation and application. Raw materials are selected from different types of controlled release fertilizers: sulfur macromolecular polymer coated urea, 8 percent thermoplastic and thermosetting double-layer coated urea, 10 percent recycled thermoplastic resin coated urea, urea priming coat 5 percent modified epoxy resin coated diammonium phosphate, urea priming coat 5 percent modified epoxy resin coated potassium nitrate and diammonium phosphate. The sustained-release fertilizer for the afforesting nursery stocks is prepared through the formulation of various coated fertilizer raw materials according to nutrient release regularities of the raw materials in soil. The sustained-release fertilizer can be applied to a planting hole at one time in the transplanting process, and the sustained-release fertilizer has the advantages of no harm to a root system, 2 to 3-year useful life, high utilization rate and labor saving.

Owner:菏泽金正大生态工程有限公司

Resin film coated controlled-release fertilizer and preparation method

InactiveCN101200399AFacilitated releaseTight and dense envelopeAgriculture gas emission reductionFertiliser formsControl releaseOrganic solvent

The invention relates to a controlled-release fertilizer, substantially a resin-coated controlled-release fertilizer which is prepared by coating with biochemical inhibitor on the surface of urea granules and a preparation method. The urease inhibitor or / and nitrification inhibitor is mixed with the copolymer of acrylic resin and ethyl cellulose as well as organic solvent to form the suspension; and the suspension is equably coated on the surface of the urea granules so as to make the coated urea core fertilizer; and then the surface of the coated urea core fertilizer is wrapped with crylic acid resin film. Based on making the coated inhibitor urea core fertilizer with the biochemical inhibitor in the first layer, the coating is implemented, which are processed in two steps. The most notable characteristic of the controlled-release fertilizer is that the coating is implemented on the basis of making the coated inhibitor urea core fertilizer with the biochemical inhibitor in the first layer, thereby the coating is tight, and the result on controlling biochemical inhibitor and urea release is obvious.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

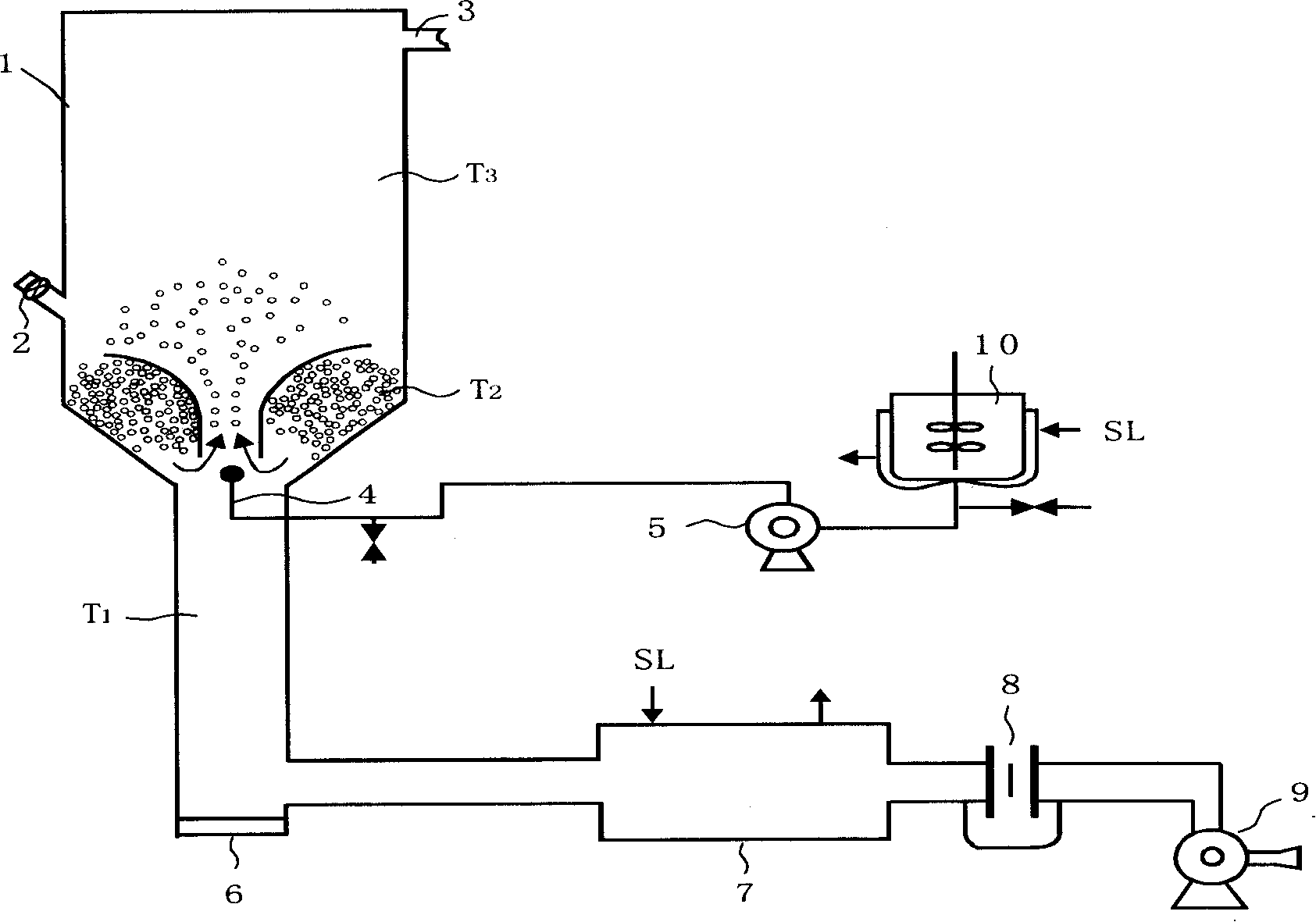

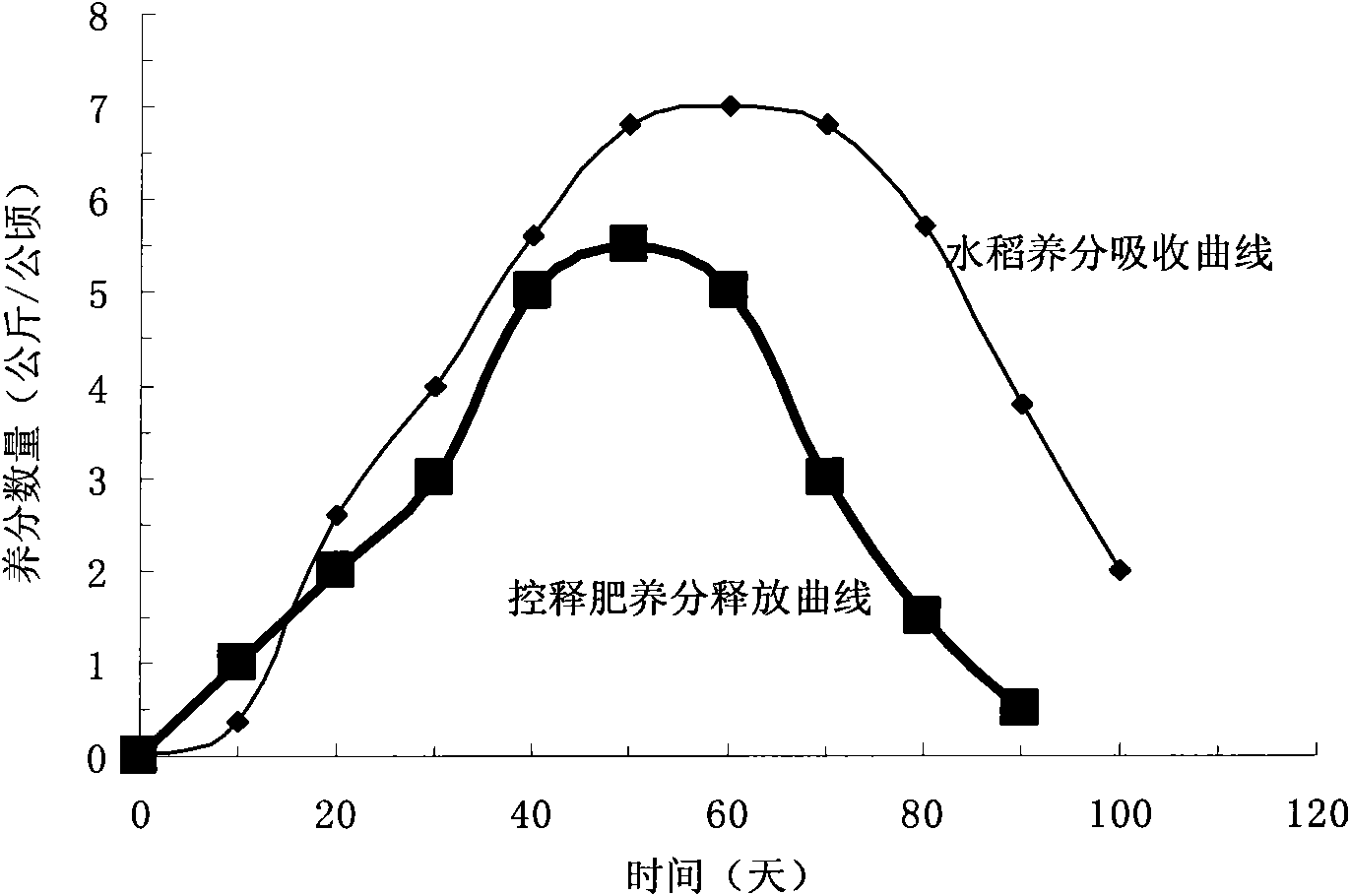

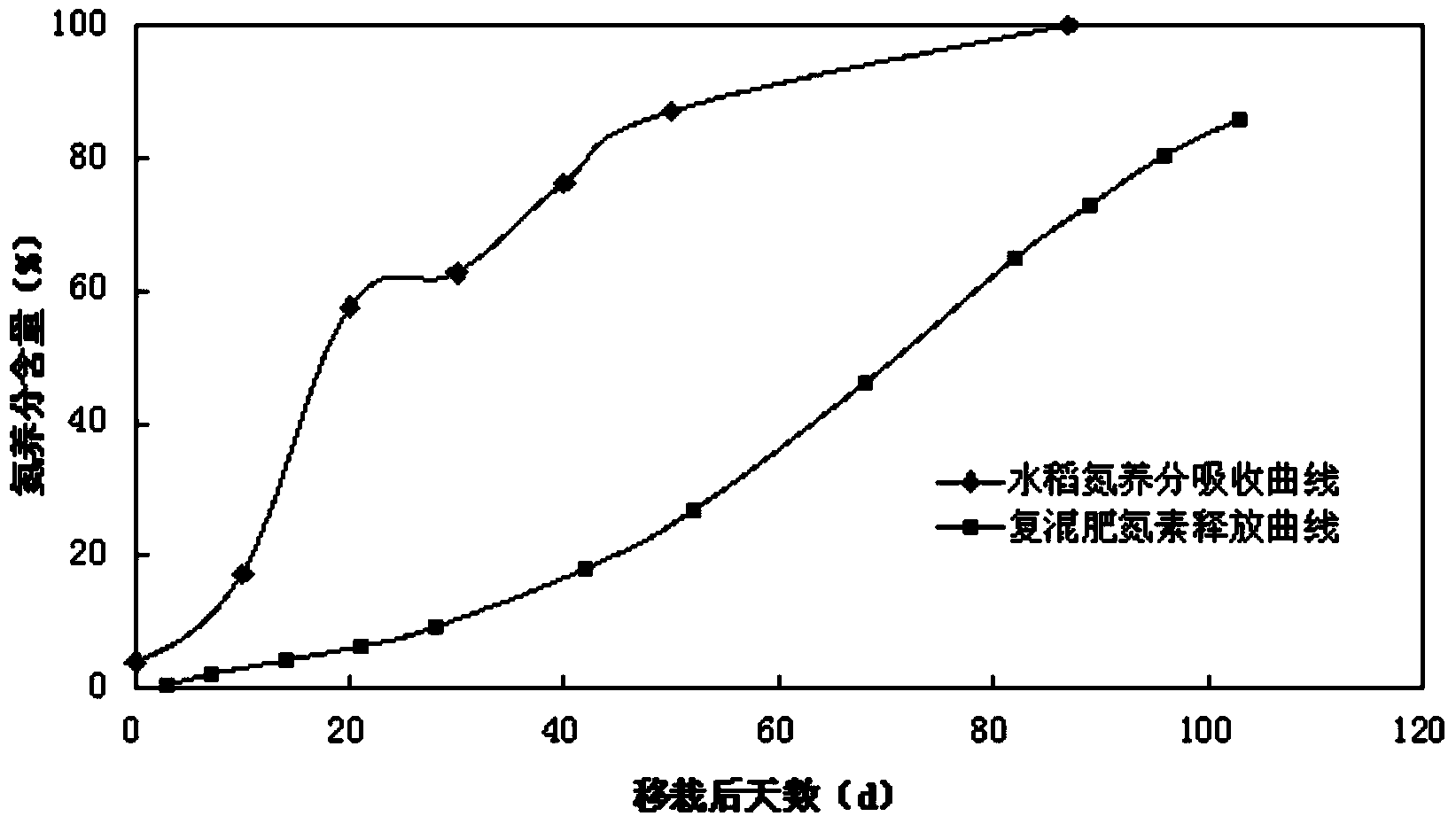

Rice special controlled-release fertilizer applied once in processes of rice transplantation and seedling culture and preparation method thereof

The invention relates to a rice special controlled-release fertilizer applied once in processes of rice transplantation and seedling culture and a preparation method thereof. The controlled-release fertilizer comprises the following raw materials: urea coated with sulfur and high molecular polymer, compound fertilizer coated with sulfur and high molecular polymer, 6% of thermoplastic and thermosetting double-layer coated urea, compound fertilizer coated with humic acid and zinc sulfate. The preparation method comprises the following steps of: weighing all the raw materials according to the formula, putting the raw materials into a stirrer for stirring and mixing uniformly, metering, and packing. The nutrient release of the controlled-release fertilizer of the invention is matched with the nutrient absorption of rice; the controlled-release fertilizer can not harm seeds when the controlled-release fertilizer is in direct contact with the seeds; the controlled-release fertilizer can be applied to the places near seeds in the processes of the rice transplantation and the seedling culture, can not harm the seeds, and is beneficial to absorption of root systems; and on the basis of ensuring the rice yield, the consumption of the fertilizer can be greatly reduced, and the utilization rate of the fertilizer can be improved.

Owner:KINGENTA ECOLOGICAL ENG GRP

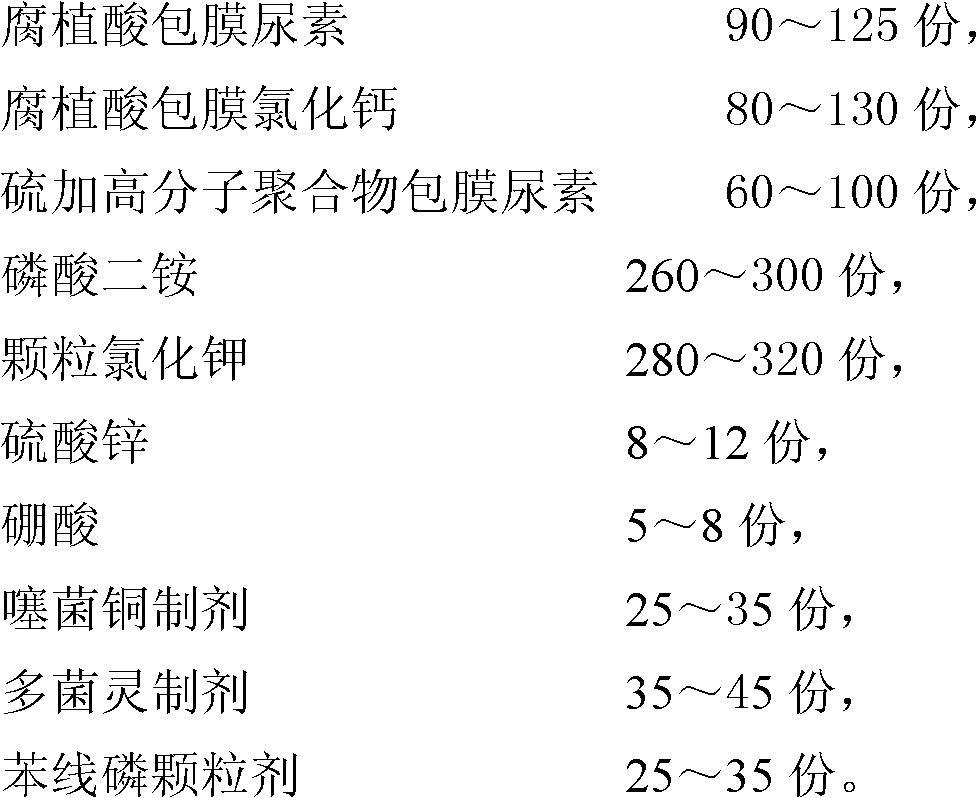

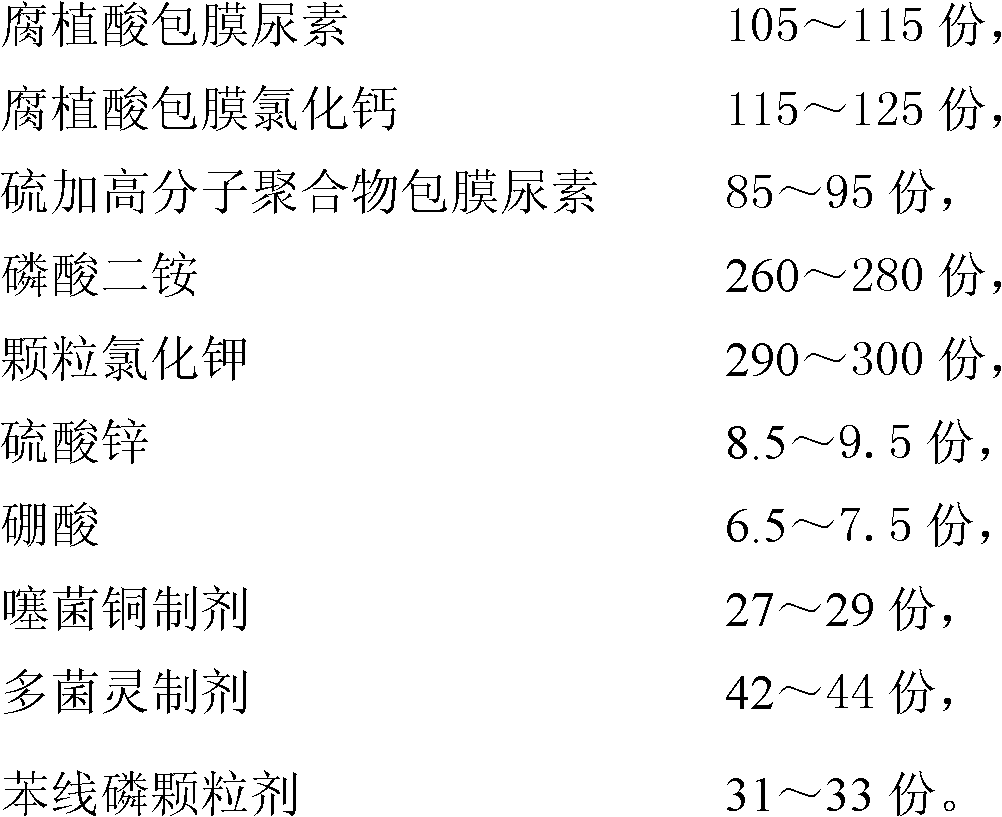

Disease-preventing type special controlled-release fertilizer for Shandong peanuts as well as preparation method and application thereof

ActiveCN102211968AEnhance disease preventionImprove the effect of increasing productionFertilizer mixturesDiseaseCoated urea

The invention relates to a disease-preventing type special controlled-release fertilizer for Shandong peanuts as well as a preparation method and application thereof. The disease-preventing type controlled-release fertilizer is prepared from the following raw materials: humic acid coated urea, humic acid coated calcium chloride, sulfur-polymer coated urea, diammonium phosphate, granular potassium chloride, zinc sulfate, boric acid, thiodiazole-copper preparation, carbendazim preparation and fenamiphos granular formulation. The release and proportioning of nutrients in the controlled-release special fertilizer for Shandong peanuts are suitable for nutrient conditions and peanut absorption requirements of soil in main peanut production areas in Shandong, and simultaneously, medicaments for preventing and controlling main diseases such as peanut stem rot, root rot, bacterial wilt, root-knot nematode and the like are added. When peanuts are seeded, the disease-preventing type special controlled-release fertilizer for Shandong peanuts is applied for one time, so that labor and time are saved, and disease-preventing and yield-increasing effects are good.

Owner:菏泽金正大生态工程有限公司

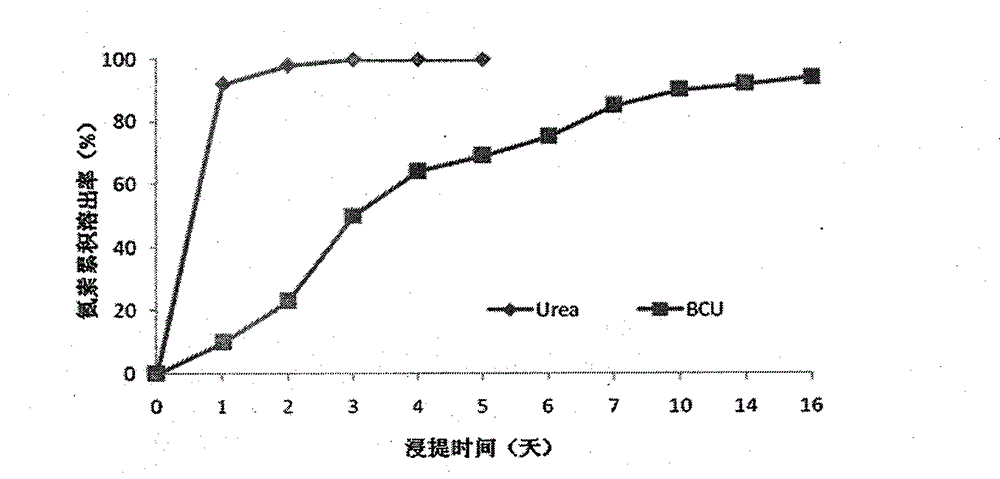

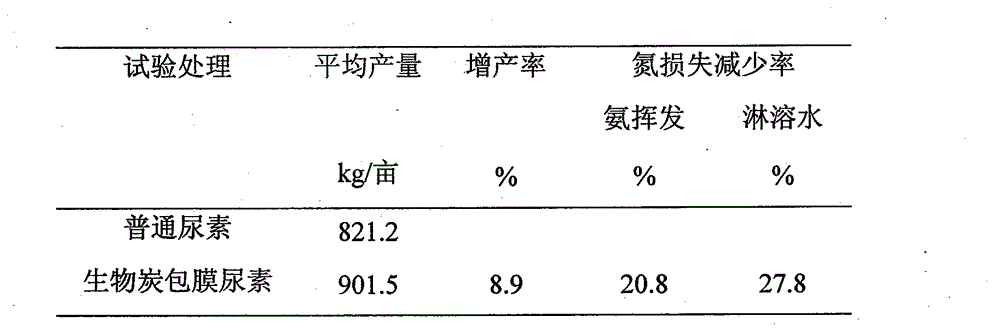

Formula and film-coating preparation method for biological carbon coated urea

InactiveCN105294363ALow costRich varietyClimate change adaptationEnergy inputCoated ureaLow nitrogen

The invention relates to a formula and a film-coating preparation method for biological carbon coated urea. The biological carbon coated urea is characterized in that the outside of a fertilizer core is coated with solid-powder-shaped biological carbon, sulfur, dicyandiamide and bentonite by using granular urea with a size of 3 to 4 mm as the fertilizer core and oxidized corn starch as bonding liquid, wherein the above-mentioned components have weight proportions as follows: 50 to 80 parts of the urea, 10 to 30 parts of the biological carbon, 2 to 10 parts of the sulfur, 2 to 3 parts of the dicyandiamide, 2 to 3 parts of the bentonite and 3 to 5 parts of the corn starch. The film-coating preparation method for the biological carbon coated urea comprises the following steps: placing the urea into a disc granulator, carrying out preheating with hot air for 5 min, spraying the bonding liquid on the surface of the urea with a high-pressure spray gun, blowing the hot air for 3 to 5 min, adding a mixed film-coating material into the disc granulator in batches and carrying out rotating for 10 min, then spraying the bonding liquid again, and carrying out drying in the air so as to obtain the biological carbon coated urea. According to the invention, the biological carbon can improve physical and chemical properties of soil and adsorb ammonium-nitrogen and nitrate-nitrogen ions; the dicyandiamide reduces nitrification; and S4O62- generated by decomposition of the sulfur can delay decomposition of the dicyandiamide, and H+ and S2O32- generated by decomposition of the sulfur can inhibit nitrification. The biological carbon coated urea provided by the invention has the advantages of low ammonia volatilization, slow generation of nitrate nitrogen, low nitrogen loss and high nitrogen effectiveness.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

Seed-friendly corn-specific controlled-release fertilizer

ActiveCN101823923ASuitable for mechanical fertilizationGood lookingFertilizer mixturesSulfate zincSoil science

The invention relates to a seed-friendly corn-specific controlled-release fertilizer which comprises the components of raw materials: high polymer sulfur-coated urea, high polymer sulfur-coated potassium chloride, 4.5% of thermoplastic heating solid double-layer coated urea, 5.0% of thermoplastic heating solid double-layer coated urea, diammonium phosphate, potassium chloride particles and zinc sulfate. The nutrient release of the corn-specific controlled-release fertilizer coincides with corn nutrient absorption, and the seed-friendly corn-specific controlled-release fertilizer is suitable for mechanical fertilizer application, is convenient for construction and labor-saving, leads the fertilizer to be close to the root system, and has high utilization rate.

Owner:KINGENTA ECOLOGICAL ENG GRP

Biodegradable coated carbamide and preparation method thereof

InactiveCN101723751AReduce releaseReduce rateUrea compound fertilisersFertilizer mixturesCoated ureaNitrification inhibitors

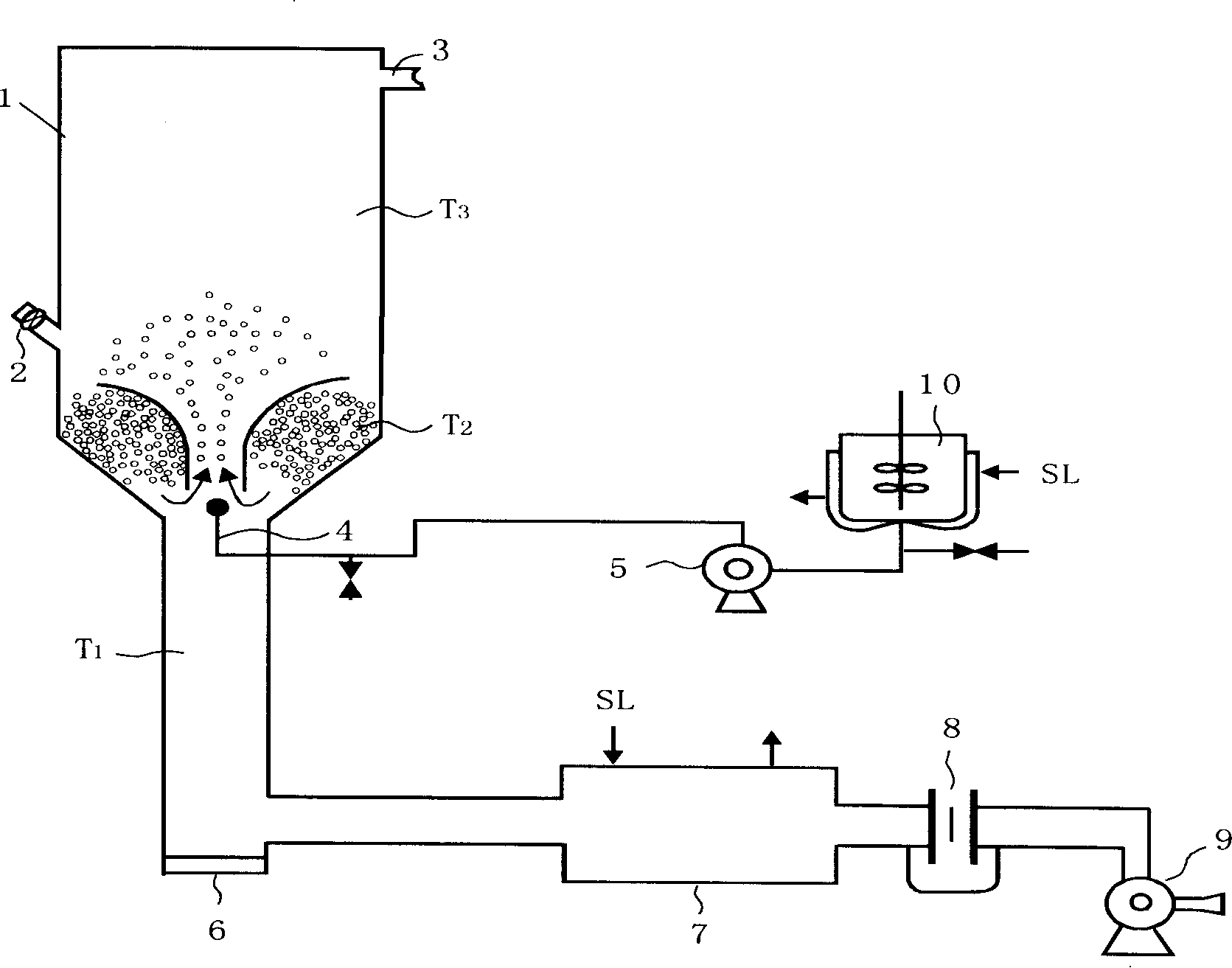

The invention relates to coated carbamide, in particular to a totally biodegradable coated carbamide and a preparation method thereof. The coated carbamide consists of a coated layer and a carbamide core. The main body of the coated layer is polylactic acid and / or polybutylene succinate. The coating process adopts fluidized bed spraying-coated technology, and comprises the following steps: dissolving polylactic acid and / or polybutylene succinate in trichloromethane, adding carboxymethylcellulose, organic and / or inorganic conditioner, urease and / or nitrification inhibitor in the solution, spraying and coating the surfaces of the fluidized carbamide after uniformly mixing the mixture under the stirring of a stirrer to form the uniform and complete organic polymeric membrane layer. The process has the advantages of easy implementation, and capacity of effectively slowing down the release of the nutrient to the outside and the conversion rate of nitrogen in soils, effectively controlling the release of the nitrogen nutrient in soils, and reducing the pressure on environment caused by the rapid release of nutrient. The coated material can be totally biodegradable, and the degradation products have no secondary pollution to the environment.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Organic-inorganic long-acting corn special-purpose compound fertilizer

InactiveCN101255082AMeet nutrient needsMaintain and improve structureAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersGrowth phasePhosphate

The invention relates to a fertilizer. A organic-inorganic slow-release compound fertilizer special for maize, contains grained inorganic nitrogen, phosphorus and potasium fertilizers, which is characterized in that: the grained inorganic nitrogen, phosphorus and potasium fertilizers are macroaggregate urea, slow-release coated urea, monoammonium phosphate and kalium sulphuricum; and the fertilizer is mixed with an organic grained fertilizer used animal manure, bean cake And straw as raw materials; where the fertilizer contains 18-20by weight of macroaggregate urea, 34-36by weight of slow-release coated urea, 15-17by weight of monoammonium phosphate, 14-16by weight of kalium sulphuricum and 14-15by weight of organic grained fertilizer. The invention can provides a long time nutrient based on the nutritional needs of each growth phase of the maize by once fertilization, can hold and improve soil structure and fertility, and solves the technical problems of convenient preparation, storage, transport and fertilization.

Owner:SHANGHAI ACAD OF AGRI SCI

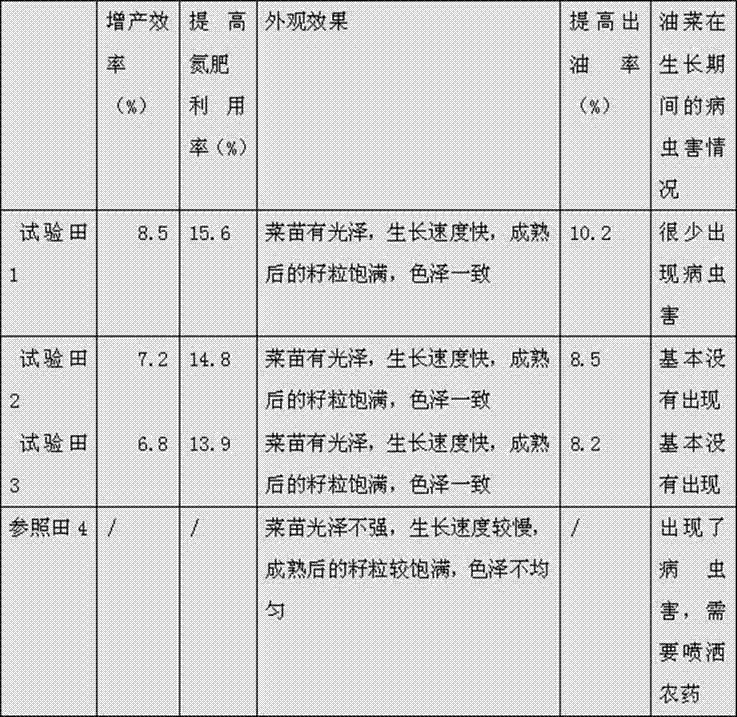

Special rapeseed fertilizer and preparation method of special rapeseed fertilizer

ActiveCN102826898AReduce invalid releaseIncrease the chelating structureFertilizer mixturesCellulosePhosphate

The invention provides a special rapeseed fertilizer consisting of the following raw materials in parts by weight: 40-50 parts of agricultural straws, 20-30 parts of enveloped sulfur urea, 10-12 parts of monoammonium phosphate, 10-12 parts of enveloped ammonium sulfate, 16-18 parts of enveloped potassium chloride, 20-30 parts of plant ashes, 1-2 parts of manganese sulfate, 1-2 parts of ferrous sulfate, 1-2 parts of magnesium sulfate, 0.1-0.5 part of zinc sulfate, 0.1-0.3 part of boric acid, 10-12 parts of cinerite, 5-7 parts of wood charcoals, 3-4 parts of neem fruit powders, 3-4 parts of radix stemonae powders, 10-15 parts of bagasse, 10-15 parts of quartz sands, 18-22 parts of decomposed coals, 3-4 parts of carboxymethylcellulose, 15-20 parts of 30% of sulfuric acid, 5-10 parts of limes, 10-15 parts of animal hairs and 4-6 parts of wintergreen oil. The special rapeseed fertilizer is prepared by a method comprising the following steps: conducting acidolysis on hairs to generate amino acid, then generating a micro element fertilizer liquid and an intermediate element fertilizer liquid chelated with amino acid, then sintering the quartz sands to prepare a fertilizer carrier, fermenting an organic fertilizer, mixing a nitrogen-phosphorus-potassium fertilizer, the carrier, the organic fertilizer and a vegetable insecticide, then granulating, and finally adopting the wintergreen oil for enveloping. According to the special rapeseed fertilizer provided by the invention, the fertilizer utilization ratio is improved obviously, the slow release effect is achieved, the fertilizer application amount is lowered, the pesticide residual is lowered, the output and the quality of winter wheat are improved, and the effects of turning waste into wealth and recycling economy are realized.

Owner:江苏科邦生态肥有限公司

Efficient slow-release urea and preparation method thereof

ActiveCN102584496AIncrease profitEasy to separateAgriculture gas emission reductionFertilizer mixturesCoated ureaAdhesive

The invention discloses an efficient slow-release urea. The efficient slow-release urea is prepared by coating urea by utilizing a coating slow-release solution and drying and solidifying the coated urea, wherein the coating slow-release solution consists of the following components in percentage by mass: 1 to 5 percent of gamma-polyglutamic acid, 1 to 5 percent of nitration inhibitor, 0.5 to 5 percent of adhesive, 0.05 to 2 percent of surfactant and the balance of water; and the pH of the efficient slow-release urea is 5.5 to 6.5. The invention also discloses the preparation method of the efficient slow-release urea. The gamma-polyglutamic acid in the efficient slow-release urea has the effects of coating and chelating the urea and the nitration inhibitor, so that separation of the nitration inhibitor and a nitrogen fertilizer is reduced, leaching and runoff losses of nitrate nitrogen are reduced, one-time fertilization can be realized, top dressing is not required, the utilization rate of the fertilizer can be improved by over 15 percent, and the yield of the crops is increased by 10 to 30 percent.

Owner:NANJING UNIV OF TECH

Slow-release compound fertilizer for mechanical transplanting of rice seedlings

ActiveCN103922853AAbsorption synchronizationExtend the fertilization timeFertilising methodsFertilizer mixturesCoated ureaPotassium

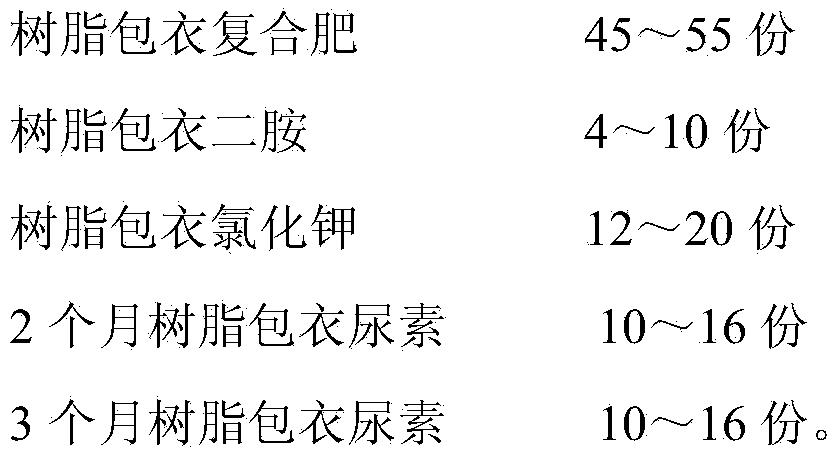

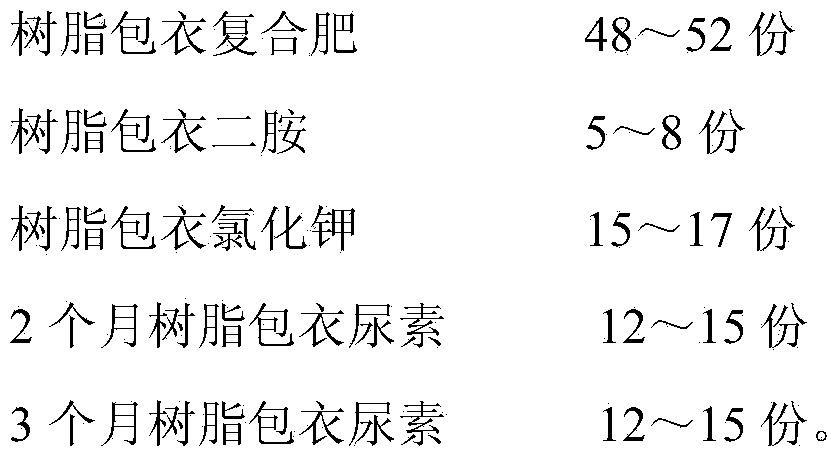

The invention belongs to the technical field of the production of fertilizers, and discloses a slow-release compound fertilizer for mechanical transplanting of rice seedlings. An envelop slow-release component of the slow-release compound fertilizer comprises the following components in parts by mass: 45-55 parts of resin coated compound fertilizer, 4-10 parts of resin coated diamine, 12-20 parts of resin coated potassium chloride, 10-16 parts of 2-month resin coated urea and 10-16 parts of 3-month resin coated urea. The slow-release compound fertilizer only needs to be applied for one time, the fertilizer supply time is prolonged, and the synchronism of nutrient release and crop nutrient absorption can be realized, so that the release of the fertilizer nutrients can be basically matched with the later-stage nutritional demand of the rice growth. By adopting the slow-release compound fertilizer, the mechanical operation is facilitated, and the labor can be greatly reduced. Compared with a conventional way for applying the fertilizer in multiple times, the compound fertilizer has the advantages that the yield can be increased by about 7.36 percent, and the utilization rate of the nitrogen fertilizer is increased by 33.6 percent.

Owner:NANJING AGRICULTURAL UNIVERSITY

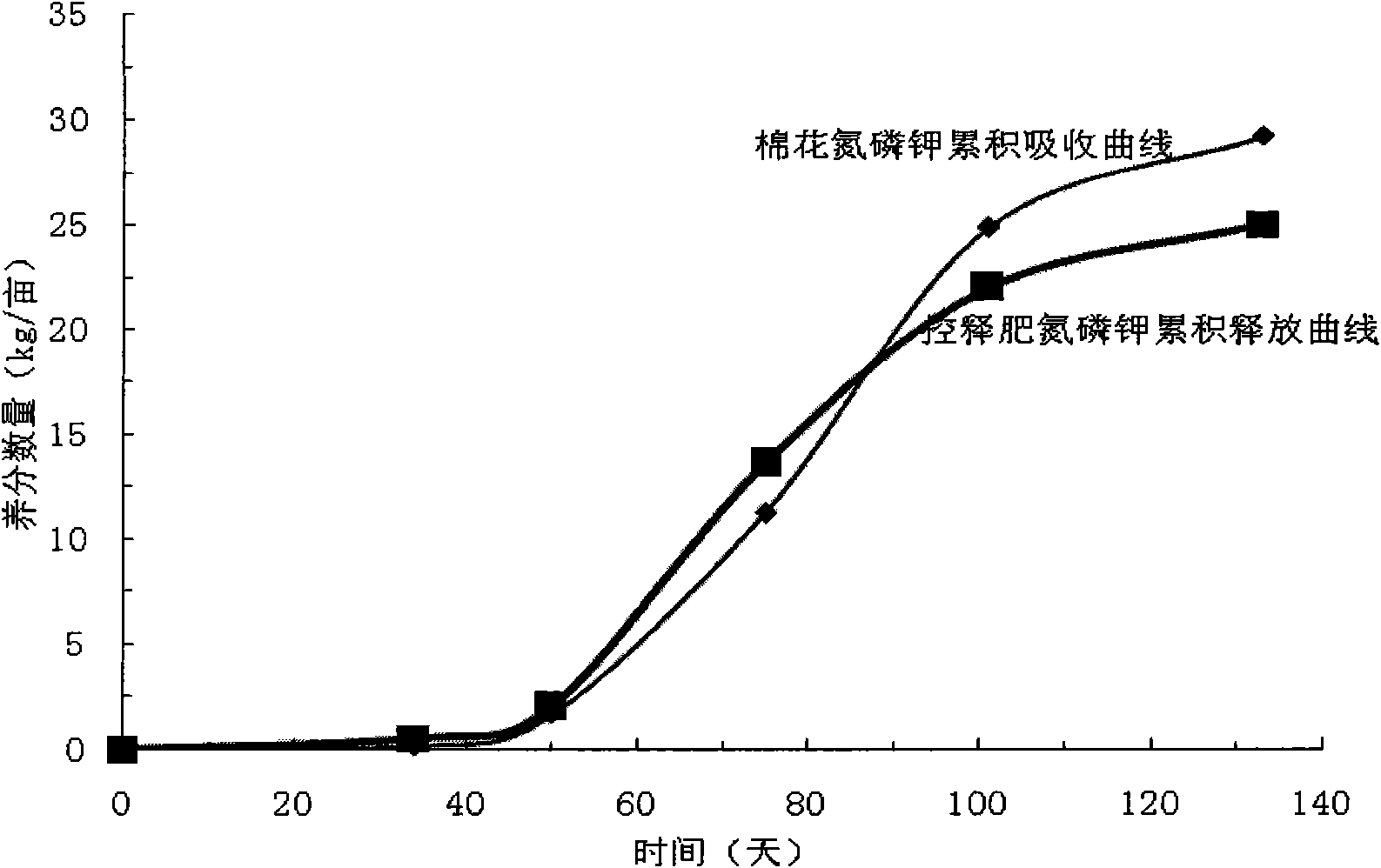

Synchronous nutrient controlled release fertilizer special for cotton and application thereof

ActiveCN101891550AIncrease profitReduce dosageFertilising methodsHorticultureThermoplasticCoated urea

The invention relates to a synchronous nutrient controlled release fertilizer special for cotton and application thereof. The controlled release fertilizer special for cotton is prepared by compounding a humic acid coated controlled release fertilizer, a sulfurated high polymer coated controlled release fertilizer, thermoplastic and thermosetting double-layer coated urea, zinc sulfate and boric acid. The nutrient release rule of the controlled release fertilizer special for the cotton and the nutrient absorption rule of the cotton are synchronous, the controlled release fertilizer special for the cotton is applied to a planting ditch in a concentration way at one time when the cotton is seeded or transplanted, the top application is not needed any more, the controlled release fertilizer special for the cotton has no harm to root systems, and the fertilizer utilization rate is high.

Owner:菏泽金正大生态工程有限公司

Special fertilizer for watermelon base fertilizer as well as preparation method of special fertilizer

ActiveCN102816020AIncrease the chelating structureReduce invalid releaseFertilizer mixturesCelluloseCamellia oleifera

The invention provides a special fertilizer for a watermelon base fertilizer. The special fertilizer is prepared by the following raw materials by weight: 10-20 parts of oil tea cakes, 5-6 parts of coated urea, 20-25 parts of ammonium dihydrogen phosphate, 18-22 parts of coated potassium chloride, 20-30 parts of bentonite, 0.2-0.5 parts of ferrous sulfate, 1-2 parts of zinc sulfate, 0.1-0.3 part of manganese sulfate, 10-12 parts of attapulgite, 5-7 parts of plant ashes, 3-4 parts of neem bark powders, 3-4 parts of bone powders, 10-15 parts of bagasse, 10-15 parts of potassium feldspar, 18-22 parts of municipal sludge, 3-4 parts of carboxymethylcellulose, 15-20 parts of 30% of sulfuric acid, 5-10 parts of limes, 10-15 parts of animal hairs and 4-6 parts of liquid paraffin. A preparation method for the special fertilizer comprises the steps as follows: carrying out acidolysis on the hairs to obtain amino acid; generating an amino acid chelated micro or medium fertilizer solution; sintering the potassium feldspar to prepare a fertilizer carrier; fermenting by an organic fertilizer; mixing a nitrogen-phosphorus-potassium mixed fertilizer and the carrier with the organic fertilizer and a plant insecticide; spraying the amino acid chelated micro or medium fertilizer solution; granulating; and coating with the liquid paraffin at last. According to the special fertilizer, the utilization rate of fertilizer efficiency can be remarkably increased, the slow release effect is achieved, the fertilizing amount is reduced, and the pesticide residues are reduced, so that the yield of watermelon is increased and the quality of watermelon is increased.

Owner:江苏科邦生态肥有限公司

Lignin-bound biochar coated urea and preparation method thereof

InactiveCN104628482ASimple structureHigh porosityUrea compound fertilisersLayered/coated fertilisersCoated ureaAgricultural biomass

The invention relates to lignin-bound biochar coated urea and a preparation method thereof and belongs to the technical field of utilization of agricultural biomass. A binder used in the lignin-bound biochar coated urea comprises acid-precipitated lignin, a pyroligneous liquid and water in different weight ratios. The preparation method comprises the following steps of dissolving acid-precipitated lignin in a pyroligneous liquid or a pyroligneous liquid and water to obtain the binder; and granulating, spraying and drying to obtain the lignin-bound biochar coated urea finished product. The binder is novel in components and environment-friendly; the preparation method is reasonable and simple, the preparation process is simple and feasible, low in production cost; and the urea has the advantages of high fertilizer utilization rate, long fertilizer effect time, light environmental pollution and good antibacterial effect, and the soil structure is improved.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Special fertilizer for early rice as well as preparation method thereof

ActiveCN102816018AReduce invalid releaseIncrease the chelating structureFertilizer mixturesCelluloseNerium oleander

The invention provides a special fertilizer for early rice. The special fertilizer is prepared by the following raw materials by weight: 10-20 parts of vinasse, 8-10 parts of coated urea, 35-45 parts of calcium superphosphate, 8-10 parts of coated potassium chloride, 20-30 parts of decomposed coal, 1-2 parts of ferrous sulfate, 1-3 parts of zinc sulfate, 0.1-0.3 part of borax, 10-12 parts of medical stone, 5-7 parts of fulvic acid, 3-4 parts of radix euphorbiae lantu powders, 3-4 parts of oleander powders, 10-15 parts of bagasse, 10-15 parts of dolomites, 18-22 parts of chicken manure, 3-4 parts of carboxymethylcellulose, 15-20 parts of 30% of sulfuric acid, 5-10 parts of limes, 10-15 parts of tea seed meals and 4-6 parts of cottonseed oil. A preparation method for the special fertilizer comprises the steps as follows: carrying out acidolysis on hair to obtain amino acid; generating an amino acid chelated micro or medium fertilizer solution; sintering the dolomites to prepare a fertilizer carrier; fermenting by an organic fertilizer; mixing a nitrogen-phosphorus-potassium mixed fertilizer and the carrier with the organic fertilizer and a plant insecticide; spraying the amino acid chelated micro or medium fertilizer solution; granulating; and finally coating with the cottonseed oil at last. According to the special fertilizer, the utilization rate of fertilizer efficiency can be remarkably increased, the slow release effect is achieved, the fertilizing amount is reduced, and the pesticide residues are reduced, so that the yield of the rice is increased and quality of the rice is improved.

Owner:MAANSHAN KEBANG ECO FERTILIZER

Nutritional composition fertilizer for paddy rice

ActiveCN101941859AFully absorbedOvercome the shortcomings of shortness and weak absorption capacityFertilising methodsFertilizer mixturesNutritionCoated urea

The invention relates to a nutritional composition fertilizer for paddy rice. The fertilizer consists of a seedling culturing fertilizer, a base fertilizer and a foliar fertilizer, wherein the seedling culturing fertilizer is the combination of humic acid coated urea, diammonium phosphate, zinc sulfate and boric acid; the base fertilizer is the combination of sulfur plus macromoleclar polymer coated urea, the diammonium phosphate or monoammonium phosphate and potassium chloride; and the foliar fertilizer is the combination of urea and monopotassium phosphate. The seedling culturing fertilizer is uniformly mixed into nutrient soil during the seedling culturing of the paddy rice, the base fertilizer is uniformly applied to a field in the whole layer before the transplanting of the paddy rice and the foliar fertilizer is applied separately or applied by combing the spraying of a pesticide during the growth and at the later stage of the paddy rice. The fertilizer of the invention has the advantages of meeting the nutrient requirement of the paddy rice in the whole growth period, increasing the utilization ratio of the fertilizer and increasing yield, along with convenient application and correct nutrition combination.

Owner:菏泽金正大生态工程有限公司

Special winter wheat base fertilizer and preparation method of special winter wheat base fertilizer

ActiveCN102826896AIncrease the chelating structureReduce invalid releaseFertilizer mixturesCelluloseCoated urea

The invention provides a special winter wheat base fertilizer consisting of the following raw materials in parts by weight: 10-20 parts of tea-seed pancakes, 4-5 parts of sulfur coated urea, 18-20 parts of enveloped diammonium phosphate, 5-8 parts of potassium chloride, 20-30 parts of coal ashes, 1-2 parts of ferrous sulfate, 0.1-0.5 part of zinc sulfate, 0.1-0.3 part of boric acid, 10-12 parts of sepiolite, 5-7 parts of bamboo charcoals, 3-4 parts of celastrus orbiculatus powders, 3-4 parts of oleander powders, 10-15 parts of bagasse, 10-15 parts of iron ores, 18-22 parts of cow dung, 3-4 parts of carboxymethylcellulose, 15-20 parts of 30% of sulfuric acid, 5-10 parts of limes, 10-15 parts of bean pulps and 4-6 parts of epoxidized soybean oil. The special winter wheat base fertilizer is prepared by a preparation method comprising the following steps: conducting acidolysis on hairs to generate amino acid, then generating a micro element fertilizer liquid and an intermediate element fertilizer liquid chelated with amino acid, then sintering the iron ores to prepare a fertilizer carrier, fermenting an organic fertilizer, mixing nitrogen-phosphorus-potassium fertilizer, the carrier, the organic fertilizer and a vegetable insecticide, then spraying the micro element fertilizer liquid and the intermediate element fertilizer chelated with amino acid, granulating, and finally adopting the epoxidized soybean oil for enveloping. According to the special winter wheat base fertilizer provided by the invention, the fertilizer utilization ratio is improved obviously, the slow release effect is achieved, the fertilizer application amount is lowered, the pesticide residual is lowered, and the output and the quality of winter wheat are improved.

Owner:江苏科邦生态肥有限公司

Special controlled-release fertilizer for sulfur, resin film coated banana and manufacturing method therefor

ActiveCN101182258APromote growthFast absorption rateAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersControl releaseCoated urea

The invention relates to a special controlled release fertilizer for banana and a preparation method thereof and belongs to the technical field of sustained release fertilizer and controlled release fertilizer. According to the rule of the fertilizer requirement of the banana, the invention remixes 6 percent and 7 percent thermoplastic resin coated urea, sulfur coated urea, potassium sulfate complex fertilizer, the potassium sulfate, diammonium phosphate, zinc sulfate and borax exactly to form the special controlled release fertilizer for banana. The nutrient release rule of the controlled release fertilizer is in accordance with the nutrition absorption rule of the banana, which improves the fertilizer absorption and utilization rate and reduces the cost of the controlled release fertilizer, and the effect of production increase is good.

Owner:广东金正大生态工程有限公司

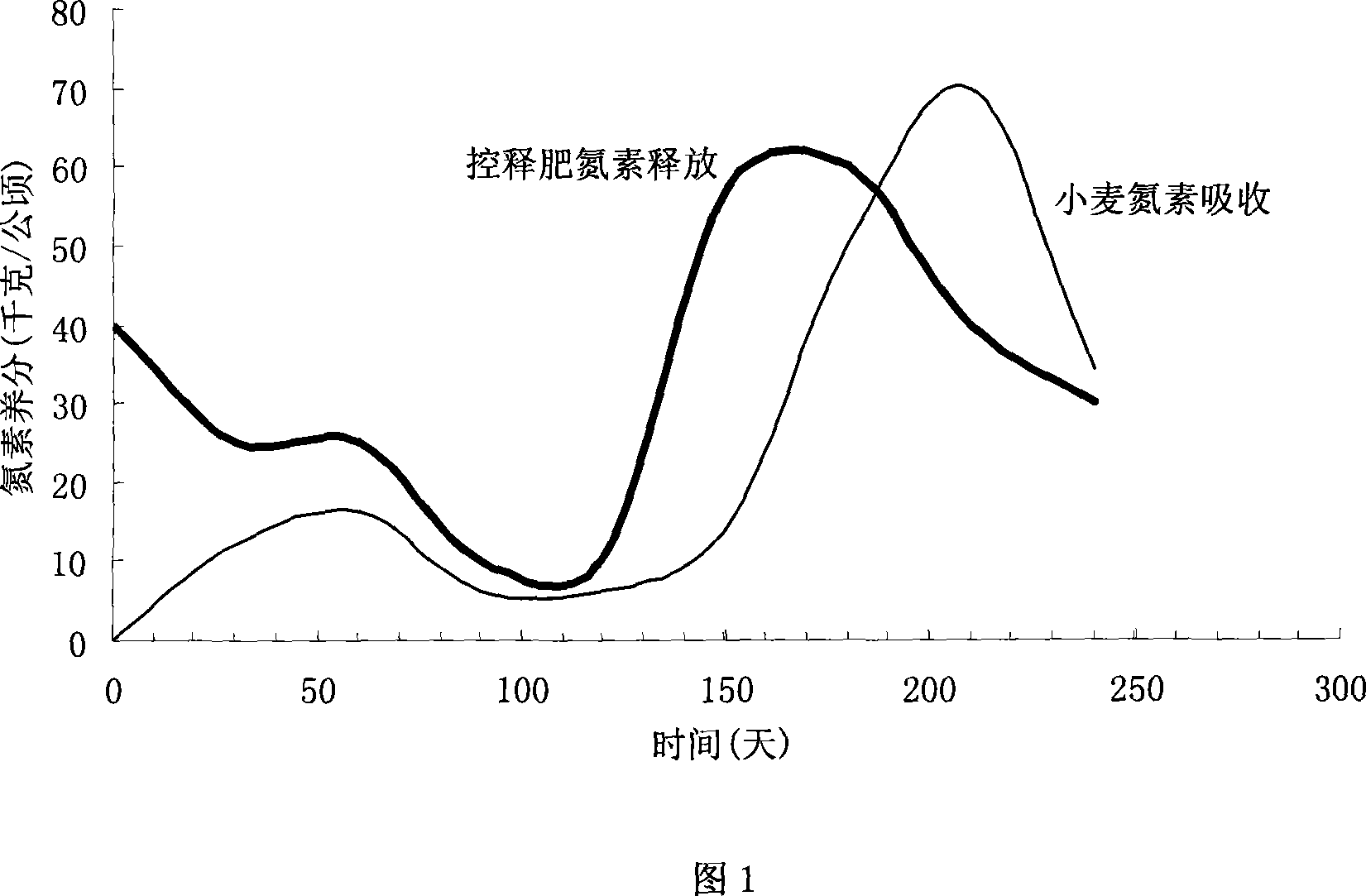

Special controlled-release fertilizer for sulfur, resin film coated wheat and manufacturing method therefor

ActiveCN101182260ALow costReduce lossesAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersControl releaseSulfur

The invention relates to a special controlled release fertilizer for wheat and a preparation method thereof and belongs to the technical field of sustained release fertilizer and controlled release fertilizer. According to the rule of the fertilizer requirement of the wheat, the invention remixes 5 percent, 6 percent and 7 percent thermoplastic resin coated urea, sulfur coated urea, potassium chloride complex fertilizer, the potassium chloride, diammonium phosphate and zinc sulfate exactly to form the special controlled release fertilizer for wheat. The nutrient release rule of the controlled release fertilizer is in accordance with the nutrition absorption rule of the wheat, and the cost of the controlled release fertilizer is reduced; no more fertilization is required after one time of the fertilization of the controlled release fertilizer before the wheat is seeded, which reduces the labor intensity of the farmer and the labor cost.

Owner:KINGENTA ECOLOGICAL ENG GRP

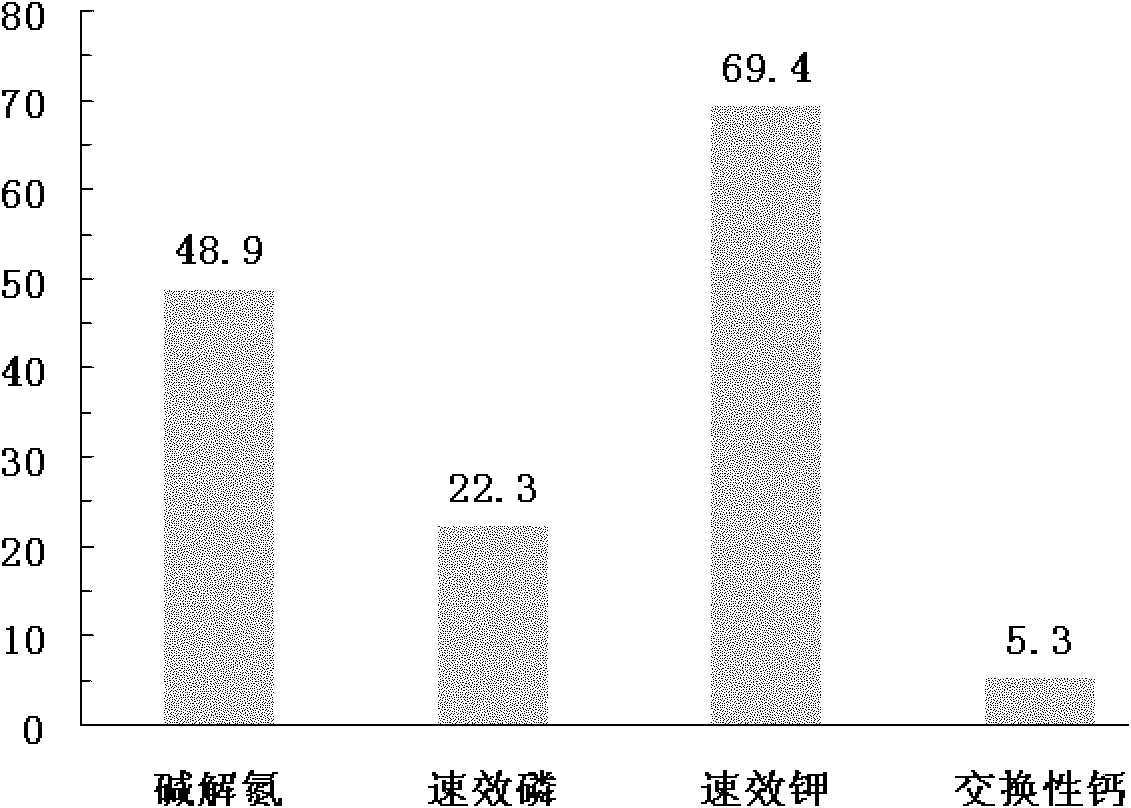

Slow-release fertilizer special for saline alkali soil improvement and preparation method thereof

InactiveCN104045492ACombination slow effectReduce alkalinityFertilizer mixturesEcological environmentAlkali soil

The invention provides a slow-release fertilizer special for saline alkali soil improvement, and the fertilizer comprises the following components by weight: 18%-20% of large granular urea, 35%-40% of slow-release coated urea, 12%-15% of an organic granulated fertilizer, 15%-18% of monoammonium phosphate and 12%-15% of potassium sulfate. The low-release fertilizer special for saline alkali soil improvement combines nutrient slow release and salt and alkali resistance, effectively reduces alkalescence of soil, effectively increases the aggregate structure of the soil, increases fertilizer retention properties of the soil, increases soil porosity, reduces soil bulk density, changes the saline alkali soil compaction structure, creates the good soil environment for crops, is comprehensive in nutrient and lasting in fertilizer efficiency, and reduces environmental pollution caused by fertilization, the nitrogen utilization rate can reach more than 45%, the input total amount of the fertilizer can be reduced, low carbon production can be maintained, and the slow-release fertilizer is conducive to the improvement of the worsening ecological environment. The slow-release fertilizer has the advantages of simple preparation method, is suitable for industrial production, and has great application value.

Owner:SHANGHAI ACAD OF AGRI SCI

Release-controlled coated urea and its preparation method

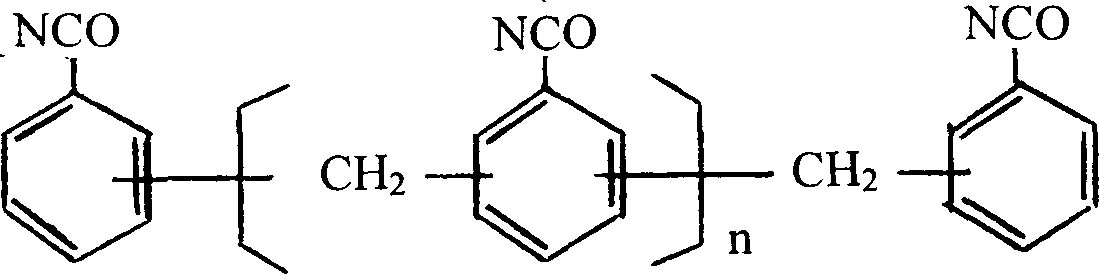

InactiveCN1699293ALow costRich varietyUrea compound fertilisersFertilizer mixturesCoated ureaPolyphenyl isocyanate

The invention discloses a release-controlled coated urea which comprises a core layer of urea and a coated layer enclosing the surface of the urea, wherein the coated layer is formed from solid inorganic mineral powder and polymethylene polyphenyl isocyanate, the coated layer amounts to 15-30% of the total weight, its thickness is 100-120 microns.

Owner:上海市农业科学院环境科学研究所

Drought-resistant controlled-release fertilizer special for corn in northwest regions as well as preparation method and applications thereof

ActiveCN102086137ASuitable for high production needsMeet the needs of high productionHorticultureFertilizer mixturesControl releaseCoated urea

The invention relates to a drought-resistant controlled-release fertilizer special for corn in northwest regions as well as a preparation method and the applications thereof. The fertilizer is prepared by compounding water swelling and conservation composition, sulfur high-molecular polymer coated urea, sulfur coated urea, potassium chloride composite fertilizer and zinc sulfate, wherein the water swelling and conservation composition is prepared by mixing and pelleting weathered coal, water-absorbent resin, soybean meal and corn cob powder; and the fertilizer is mainly suitable for drought and semiarid soil in Gansu, Ningxia, northern Shaanxi, southern Xinjiang and west Inner Mongolia in China and used as a base fertilizer to be applied once before rowing corn. With the nutrient proportion, the special fertilizer is suitable for the high-yield need of corn in northwest regions, the effect of the controlled-release fertilizer and is improved, and the fertilizer application problem of coated corn in northwest regions is solved.

Owner:菏泽金正大生态工程有限公司

Method for planting selenium-enriched rice at high yield

InactiveCN105815165AIncrease selenium contentAvoid breedingAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAdditive ingredientCoated urea

The invention provides a method for planting selenium-enriched rice at a high yield. The method comprises the following steps: 1), preprocessing seeds; 2) plowing the soil and fertilizing; 3) culturing seedlings; 4) transplanting the seedlings; 5) additionally fertilizing; 6) harvesting. According to the method provided by the invention, a seed processing step is additionally adopted to sterilize and disinfect the seeds, and meanwhile, the seeds are soaked with sodium selenite to increase the selenium content in rice seeds. A long-acting selenium-enriched coated controlled release compound fertilizer applied for rice planting comprises a core fertilizer and a coated layer coating the surface of the core fertilizer. The core fertilizer adopts sulphur coated urea to form a three-layer structure, such that the controlled release efficiency is remarkable, and the fertilizer efficiency is long. Only a little amount of fertilizer needs to be applied additionally after planting to save time and labor. Both the core fertilizer and the coated layer are prepared from organic degradable materials, such that the fertilizer efficiency can be kept in the degradation process. The core fertilizer is rich in microelements, thus promotes the nutrimental value of rice, and the soil quality can also be improved on the premise of degradability. The ingredients of the fertilizer are friendly to soil, low in production cost, beneficial for market promotion and good in economic benefits.

Owner:TAICANG XINLIAN GRAIN PRODN SPECIALIZED COOP

Improved sulfur coated thiourea slow release fertilizer and its manufacturing method

ActiveCN1948227AGood control releaseImprove toughnessUrea compound fertilisersFertilizer mixturesMicrocrystalline waxCoated urea

The present invention discloses a kind of sulfur-coated urea slowly-released fertilizer and its preparation method. It is characterized by that the urea granule surface has first coating sulfur, and on the urea granule sulfur coating layer a composite coating layer containing hydrocarbon wax and polymer also is set. The above-mentioned two coating layers can be implemented by adopting one-step process and utilizing two coolers.

Owner:汉枫缓释肥料(江苏)有限公司

Humic acid coated urea and production method thereof

InactiveCN104058898ARealize green environmental protectionIncrease profitAgriculture gas emission reductionFertilizer mixturesWater basedEmulsion

The invention provides multifunctional humic acid type coated urea and a production method thereof. The production method comprises the following step: by taking urea as an inner core, humic acid and derivatives thereof as a main coating material and carrier, and a water-based emulsion as viscose, adding corresponding functional components and various auxiliary materials, thus obtaining the multifunctional humic acid type coated urea. The multifunctional humic acid type coated urea has the functions of moisture retention, fertilizer maintenance, slow dissolution, slow release and the like, and the utilization ratio of the urea is improved more effectively; and since the coated urea is produced under the condition of normal temperature and pressure, the process is easy to operate and control and easy to realize continuous large-scale production.

Owner:YANSHAN UNIV

Slow-release and high-yield fertilizer special for cucumbers

InactiveCN105254411AIncrease productionReduce churn rateFertilizer mixturesBacillus licheniformisCoated urea

The invention discloses slow-release and high-yield fertilizer special for cucumbers. The slow-release and high-yield fertilizer is prepared from, by weight, 20-40 parts of composite film-coated urea, 5-15 parts of ammonium nitrate, 20-40 parts of monoammonium phosphate, 40-80 parts of potassium sulphate, 5-15 parts of potassium chloride, 1-2 parts of calcium hydrophosphate, 0.1-0.5 part of sodium silicate, 0.1-0.5 part of EDTA chelated zinc, 0.2-0.6 part of diaminoferric xanthohumate, 0.1-0.4 part of EDTA chelated zinc, 40-80 parts of composted chicken manure, 20-40 parts of molasses powder, 20-40 parts of grass carbon, 5-15 parts of decomposed coal, 5-15 parts of kaolin, 0.001-0.007 part of bacillus subtilis, 0.02-0.05 part of bacillus licheniformis and 0.005-0.009 part of paenibacillus polymyxa. By means of the slow-release and high-yield fertilizer, no topdressing needs to be conducted after one-time fertilization, the fertilizer efficiency is remarkable and durable, the slow release effect is good, the soil structure can be improved, nutrient elements required for growth of cucumbers are provided, and yield of cucumbers is high.

Owner:天长市翔净蔬菜种植发展有限公司

Soil conditioning type controlled release fertilizer special for fruit vegetable in facility, and preparation and application thereof

ActiveCN102351595AIncrease productionImprove utilization efficiencyFertilising methodsFertilizer mixturesEpoxyPotassium nitrate

The invention relates to a soil conditioning type controlled release fertilizer special for fruit vegetable in a facility, and preparation and application thereof. Raw materials for the fertilizer comprise a soil conditioning composition, sulfur and high-molecular polymer coated urea, 5% humic acid coated urea, 6% of recyclable thermoplastic resin coated urea, a urea ground coat of 4% of modified epoxy resin coated potassium nitrate, a urea ground coat of 4% of modified epoxy resin coated diammonium phosphate, 5% humic acid coated diammonium phosphate, 5% humic acid coated potassium nitrate and a potassium sulfate composite fertilizer; and the soil conditioning type controlled release fertilizer is prepared by mixing all above-mentioned raw materials. When fruit vegetable is transplanted in a facility, the fertilizer is used as a base fertilizer and applied into planting holes once for all, and no topdressing of the fertilizer is needed. The fertilizer provided in the invention has a conditioning effect on soil; release of nutrients in the fertilizer is suitable for growth and absorption of fruit vegetable in the facility.

Owner:KINGENTA ECOLOGICAL ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com