Release-controlled coated urea and its preparation method

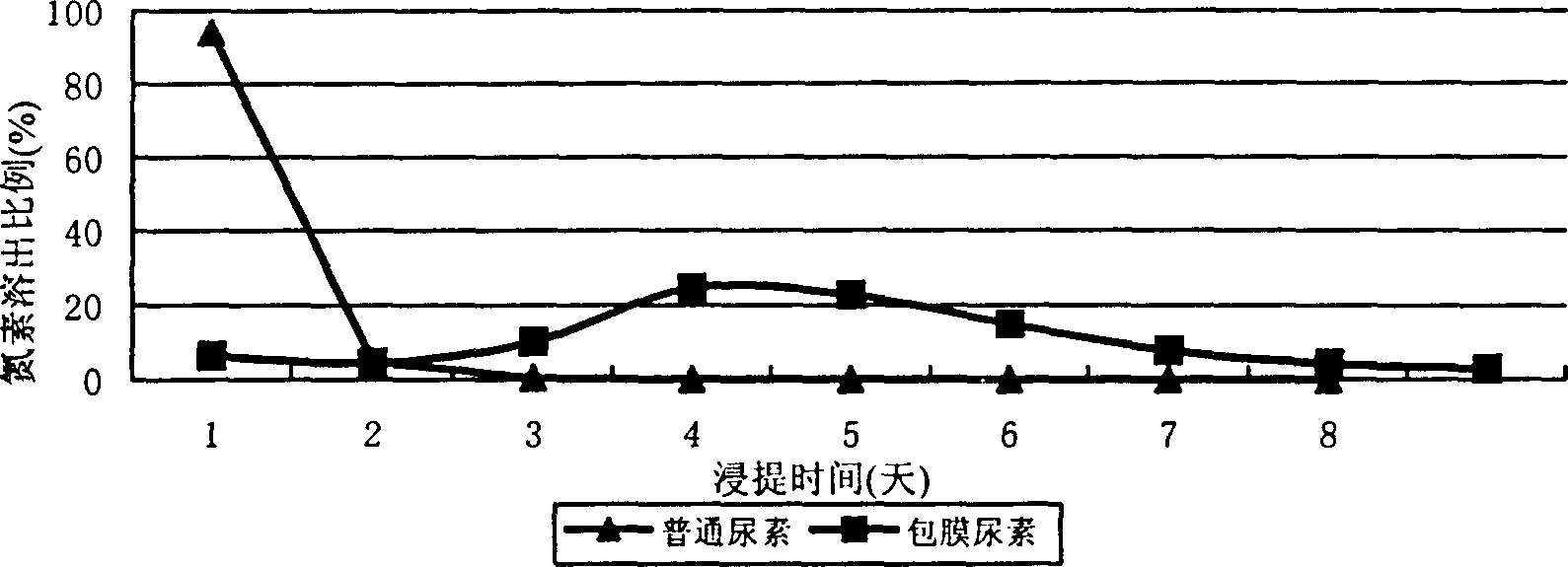

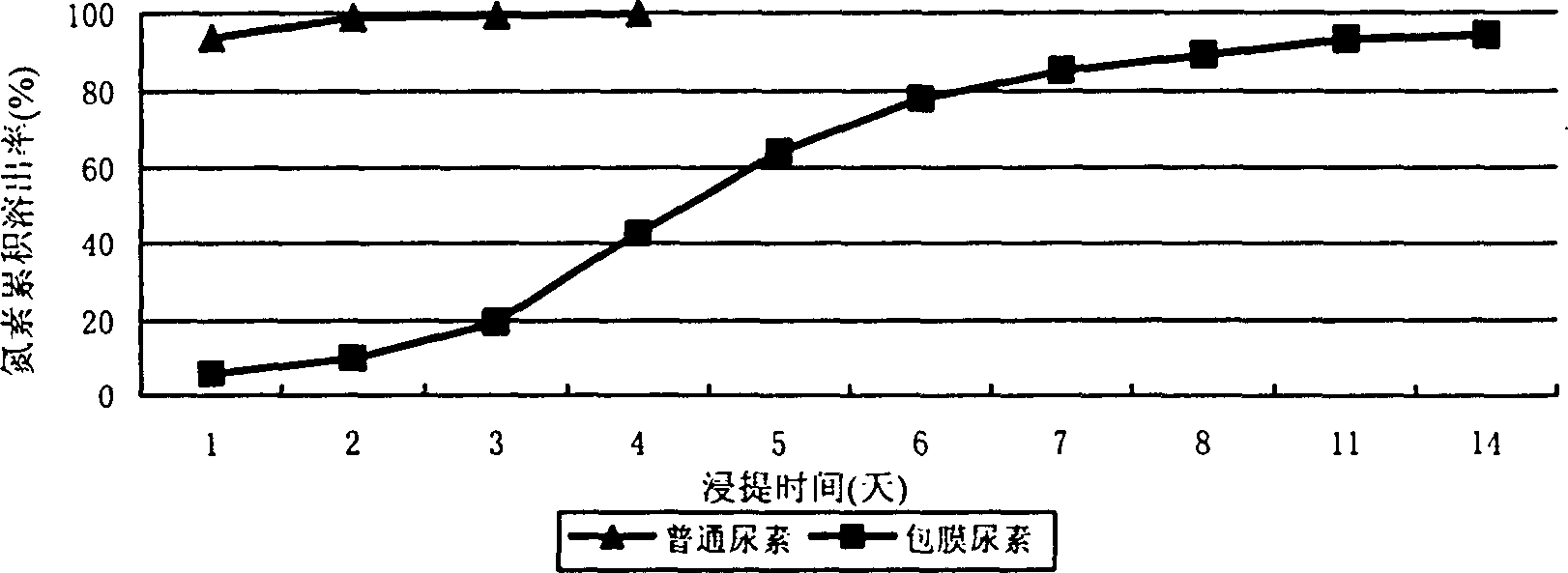

A slow-release bag and urea technology, which is applied in the direction of urea compound fertilizer, nitrogen fertilizer, fertilizer mixture, etc., can solve the problems of affecting the price and popularizing the use, complex production process, and rising production cost, and achieves low cost, wide and easy availability, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

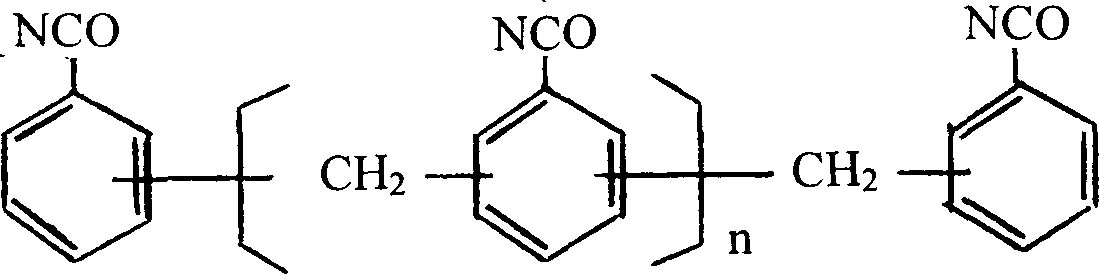

[0040] Take by weighing 75% urea granules, 23% 120 mesh dolomite powder and 2% polymethylene polyphenyl polyisocyanate according to the rated volume of the sugar coating machine, and the urea granules have a diameter of 2 to 3 mm.

[0041] Put all the urea granules and about 1 / 5 (ie 0.4% of the total weight) of polymethylene polyphenyl polyisocyanate into the sugar coating machine, rotate and stir for 1 to 2 minutes to make the liquid polymethylene polyphenyl polyisocyanate After the isocyanate is uniformly adhered to the urea granules, add about 1 / 5 (ie 4.6% of the total weight) of dolomite powder, and under the rotation of the turntable of the sugar coating machine, the dolomite powder will gradually bond with the polymethylene powder adhering to the surface of the urea granules. Polyphenyl polyisocyanate ester produces a "solid-liquid" film-forming reaction to form a thin film that is tightly wrapped on the surface of urea. After more than 95% of the dolomite powder is wrapp...

Embodiment 2

[0043] According to the rated installed capacity of the sugar-coating machine, take by weighing 70% of the total weight of urea with a particle diameter of 3 to 4 mm, 26% of the uniform powder of a mixture of phosphate rock powder and zeolite (both are equal in weight) with a particle size of 100 mesh, and 4% of urea. Polymethylene polyphenyl polyisocyanate. All the urea granules and about 1 / 4 (that is, 1% of the total weight) of polymethylene polyphenyl polyisocyanate are evenly adhered to the urea granules, and about 1 / 4 (that is, 6.5% of the total weight) of the mineral mixture powder is added, In the process of machine rotation, the mineral powder and polymethylene polyphenyl polyisocyanate produce a "solid-liquid" film-forming reaction, and a thin layer is tightly wrapped on the surface of urea particles, and 95% or more of the urea to be added After the mineral powder is bonded into the coating, add about 1 / 4 of polymethylene polyphenyl polyisocyanate to coat the above c...

Embodiment 3

[0045]According to the rated installed capacity of the sugar coating machine, take 72% of the total weight of urea particles with a particle diameter of 2.5 to 4mm, 25% of the mineral powder whose particle size is a mixture of phosphate rock and medical stone equal to 100 meshes, and 3% of polysulfide Methyl polyphenyl polyisocyanate. Put all the urea granules and about 1 / 4 (that is, 0.75% of the total weight) of polymethylene polyphenyl polyisocyanate into the sugar coating machine and rotate it for about 1 to 2 minutes, until the liquid polymethylene polyphenyl polyisocyanate After evenly adhering to the surface of urea granules, add about 1 / 4 (that is, 6.25% of the total weight) of mineral powder. During the rotation of the machine, the mineral powder and polymethylene polyphenyl polyisocyanate gradually form a film to cover the surface of urea granules. , after 95% or more of the mineral powder forms a coating, add about 1 / 4 of polymethylene polyphenyl polyisocyanate for t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com