Patents

Literature

627results about How to "Wide range of sources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition containing aloe, probiotics and prebiotics and application of composition

InactiveCN104740138AIncrease the number ofThe effect of significantly modulating the intestinal flora of animalsOrganic active ingredientsMetabolism disorderBifidobacteriumIntestinal structure

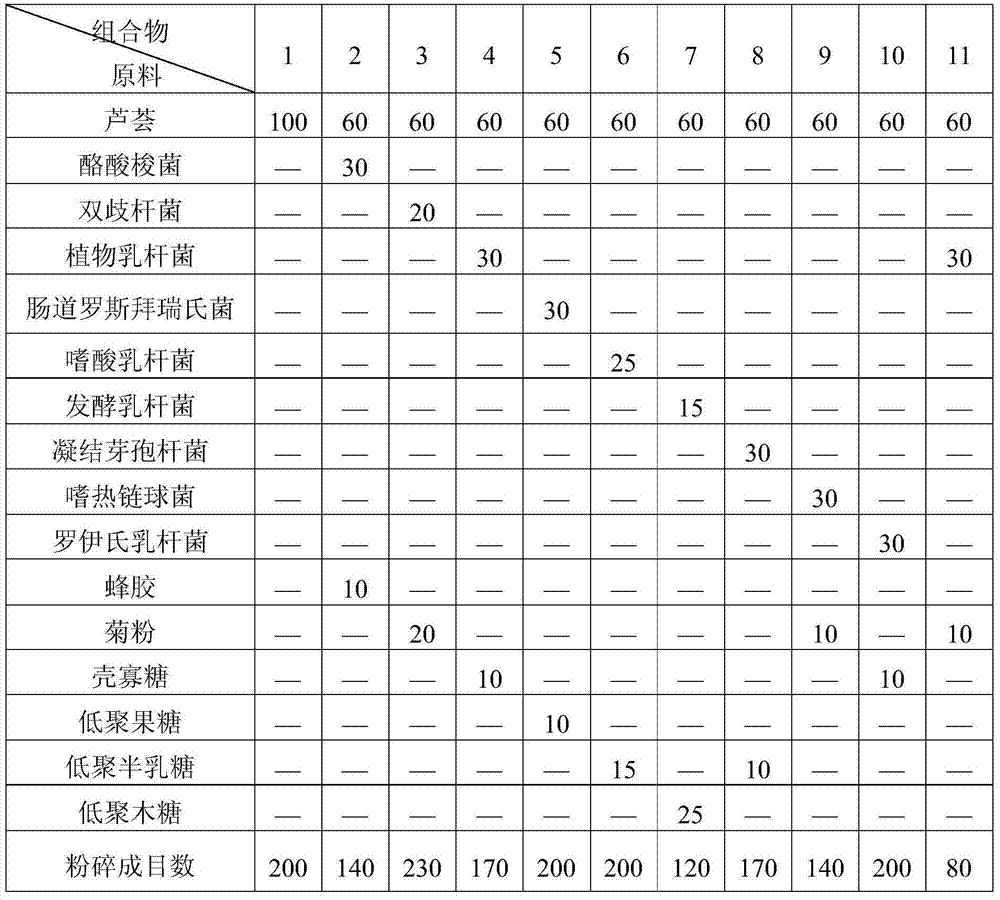

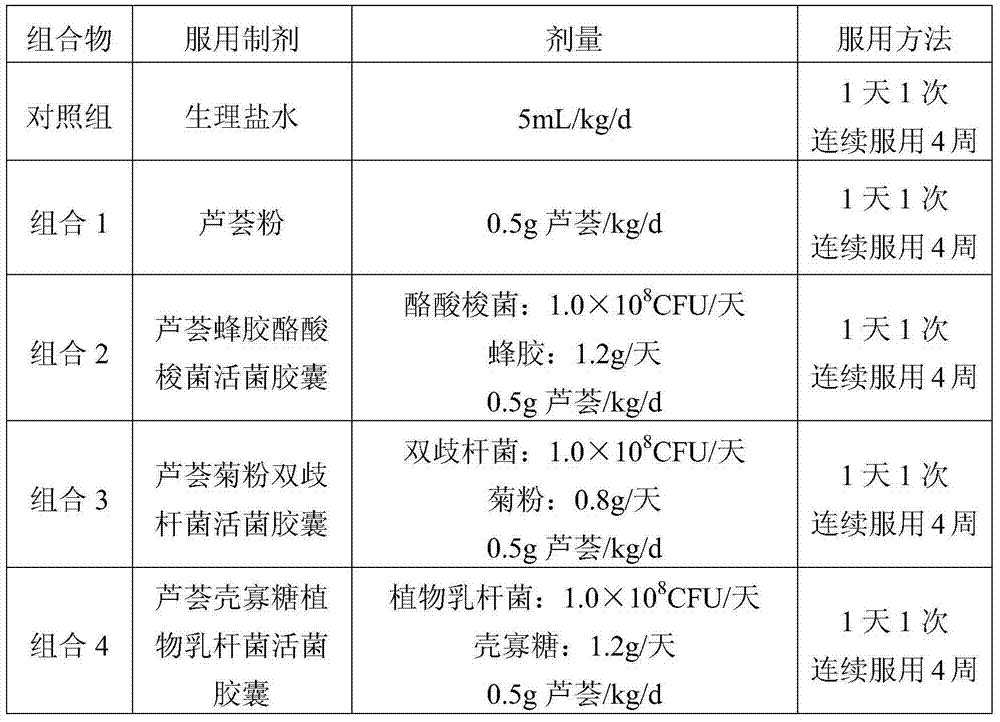

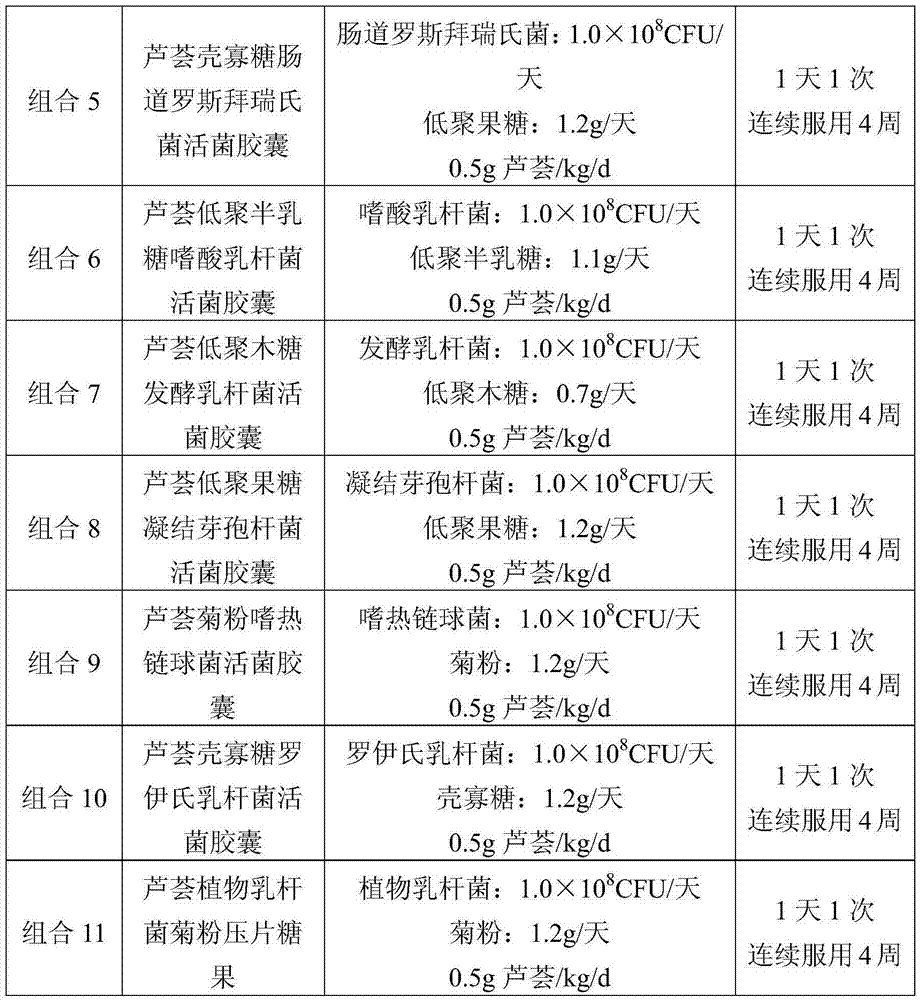

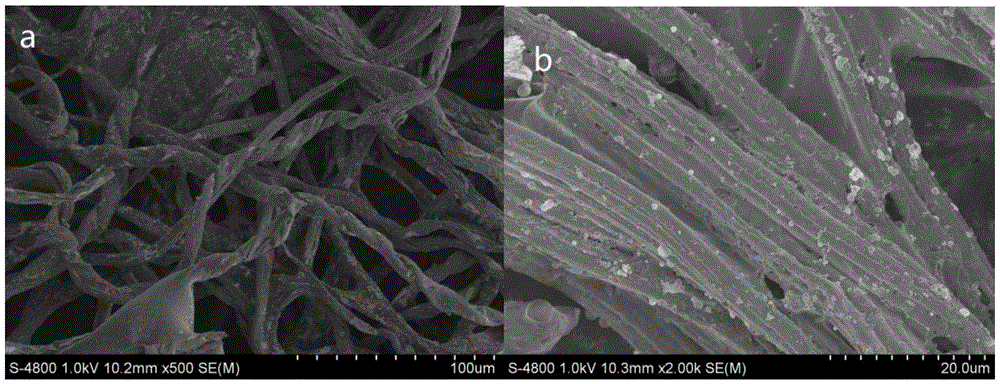

The invention discloses a composition and an application thereof in regulating intestinal flora of animals. The composition contains aloe, probiotics and prebiotics, wherein the mass ratio of the aloe to the probiotics to the prebiotics is (6 to 3 to 1)-(6 to 1 to 3). The inventor discovers that the composition disclosed by the invention can effectively promote the proliferation of useful bacteria such as bifidobacterium and lactobacilli in animal intestines, so as to effectively regulate the intestinal flora of animals; therefore, the composition can be used for preventing or treating diabetes on the basis of the effect of the intestinal flora.

Owner:深圳华大基因农业控股有限公司 +1

Method for efficiently preparing cotton based mesoporous activated carbon fiber

InactiveCN105480973AWide range of sourcesLow priceFibre chemical featuresChemistryHydrothermal carbonization

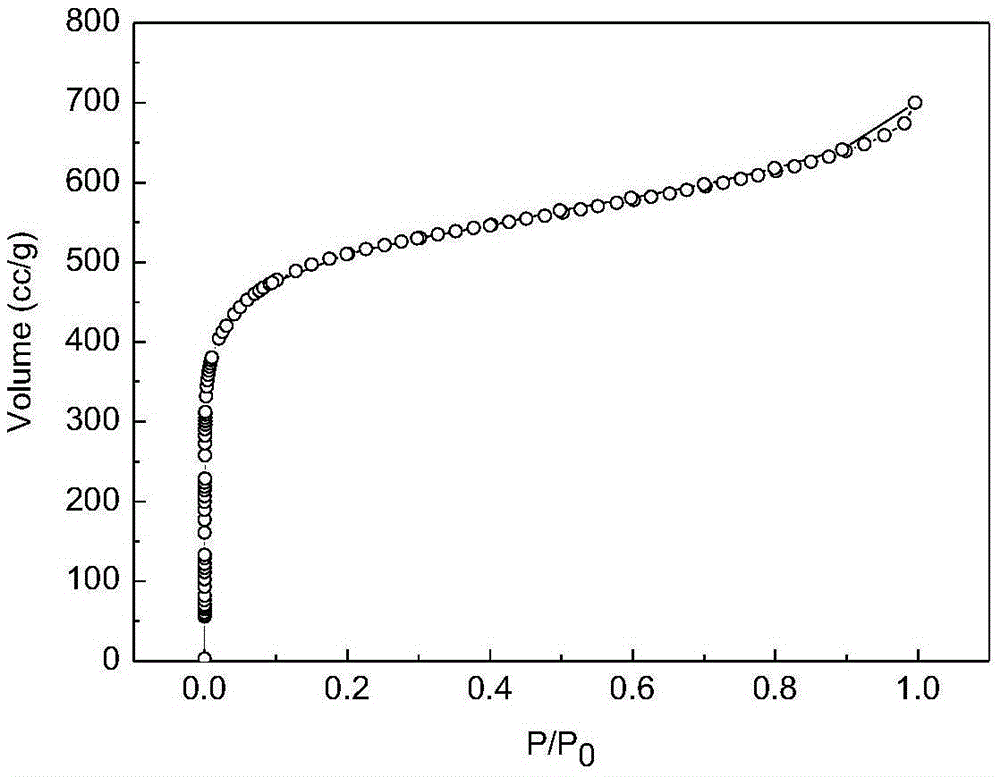

The invention relates to a method for efficiently preparing cotton based mesoporous activated carbon fiber. The method comprises a step (1) of washing cotton, placing the cotton in a hydrothermal reaction kettle, performing heating to 150-200 DEG C at the heating rate of 5-30 DEG C / min, performing hydrothermal carbonization, performing heat preservation for 1-3 hours and then performing cooling to room temperature; a step (2) of dipping carbonization materials obtained from the step (1) into activator solution, performing microwave-ultrasonic joint dipping for 5-30 minutes and then performing filtration, sending filtration materials to a microwave heating device, performing activation for 5-15 minutes at 250-350 DEG C and then stopping microwave output, and a step (3) of washing the activated materials to be neutral and performing drying to obtain the activated carbon fiber. According to the method, the characteristics of microwave inner heating and selective heating are fully utilized, the technological process is simple, the activation temperature is only 250-350 DEG C, the activation time is only 5-15 minutes, the mesoporous proportion of the activated carbon fiber of the product reaches 50-90%, and the adsorptive property is good.

Owner:HEBEI UNIV OF TECH

Ink-jet recording material and preparation method thereof as well as method for preparing ink absorption layer coating liquid

ActiveCN102092209ALow priceIncrease polarityStarch dervative coatingsConjugated diene hydrocarbon coatingsPolymer scienceAdhesive

The invention provides an ink-jet recording material and a preparation method thereof as well as a method for preparing an ink absorption layer coating liquid, and relates to an ink-jet material and a preparation method thereof as well as a method for preparing an ink absorption layer coating liquid, so that the problems of poor ink absorption effect, nonuniform color distribution of printed images, unclear printed images and higher preparation cost of the existing ink-jet recording material can be solved. The ink-jet recording material is prepared from the ink-jet layer coating liquid which is prepared from PVC (polyvinyl chloride) serving as a base material, a 20-30% polyacrylic acid emulsion serving as a primer, an inorganic nano-pigment with the thickness of 10-100nm, a dispersing agent, acetic acid, deionized water and an adhesive aqueous solution. The prepared ink-jet recording material prepared through PVC material corona treatment, PVC substrate glue coating, drying, ink absorption layer coating and drying has the advantages that that the printed image is clear, the ink droplet does not diffuse, and the color is distributed uniformly; and the ink-jet recording material has excellent performances of color definition, color saturation, glossiness and the like. The raw material cost and the manufacture cost are low, so the ink-jet recording material is advantageous to industrial production, popularization and application.

Owner:HARBIN INST OF TECH

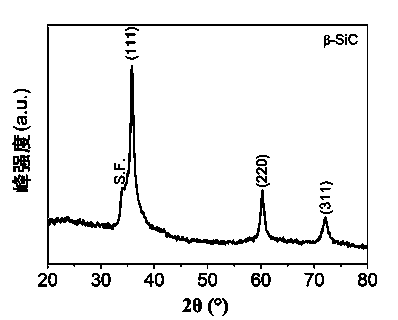

Preparation method of porous silicon carbide nanofiber

ActiveCN103966701AUniform diameterLarge specific surface areaArtificial filament chemical after-treatmentFiltrationElectrospinning

The invention discloses a preparation method of a porous silicon carbide nanofiber. The preparation method comprises the following steps of: (1) preparing a carbon nanofiber precursor polymer spinning solution; (2) performing electrostatic spinning to prepare a polymer nanofiber; (3) carrying out pre-oxidization crosslinking on the polymer nanofiber; (4) carrying out high-temperature firing on the pre-oxidized polymer nanofiber to prepare a carbon nanofiber; and (5) carrying out carbon thermal reduction on the carbon nanofiber and silicon powder to obtain the porous silicon carbide nanofiber. According to the preparation method, the morphology, the diameter and the ordering of the obtained silicon carbide nanofiber can be effectively regulated and controlled through simple means; the production cycle is relatively short so that expanded production can be conveniently realized and the preparation process is simple so that the industrial production can be conveniently realized; the porous silicon carbide nanofiber has wide application prospect in the fields of high-temperature filtration, high-temperature catalysis, catalyst carriers, heat insulation and sound insulation, gas separation, chemical sensors and the like.

Owner:NAT UNIV OF DEFENSE TECH

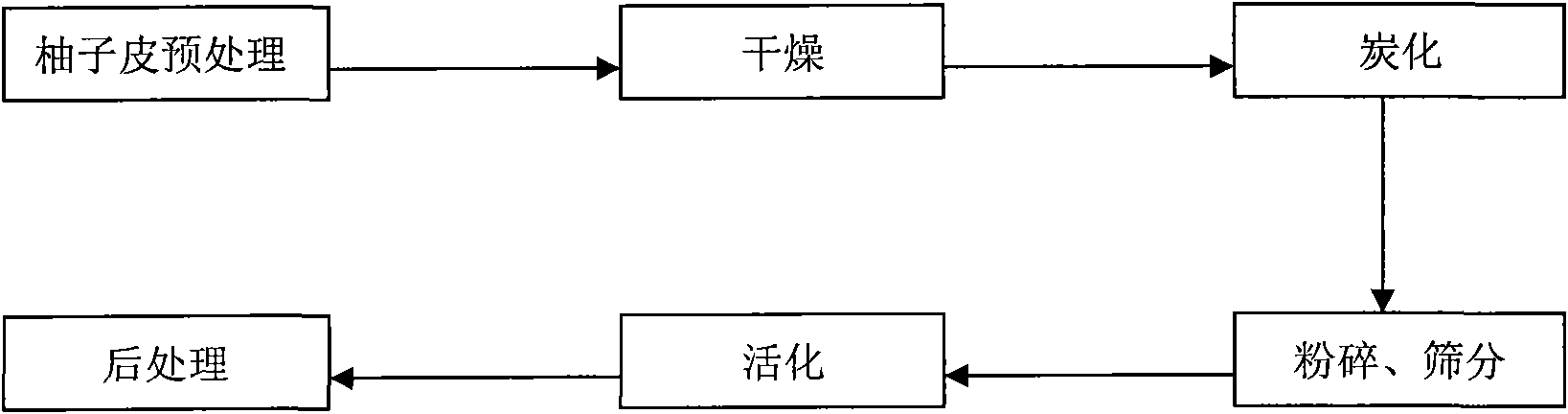

Shaddock peel activated carbon preparation method

InactiveCN101654247ARich in channelsImprove adsorption capacityCarbon compoundsActivated carbonCarbonization

The invention relates to a shaddock peel activated carbon preparation method, comprising (1) washing the shaddock peels and removing the surface foreign materials and drying at 110-120 DEG C; (2) moving into a carbonization furnace for carbonizing 120-180 minutes at the carbonization temperature of 500-600 DEG C and in the oxygen isolation condition; (3) grinding, mixing with KOH powder and activating in the air flow at 700-800 DEG C and under 0.10-0.15 MPa; (4) activating the product and adding water to wash, dewatering, crushing and grading the solid material. The inventive method has simpleoperation, low cost, and environmental protection. Compared with the activated carbon prepared from other materials, the obtained activated carbon has more ducts, good adsorption, larger specific surface area and bigger pore volume.

Owner:DONGHUA UNIV

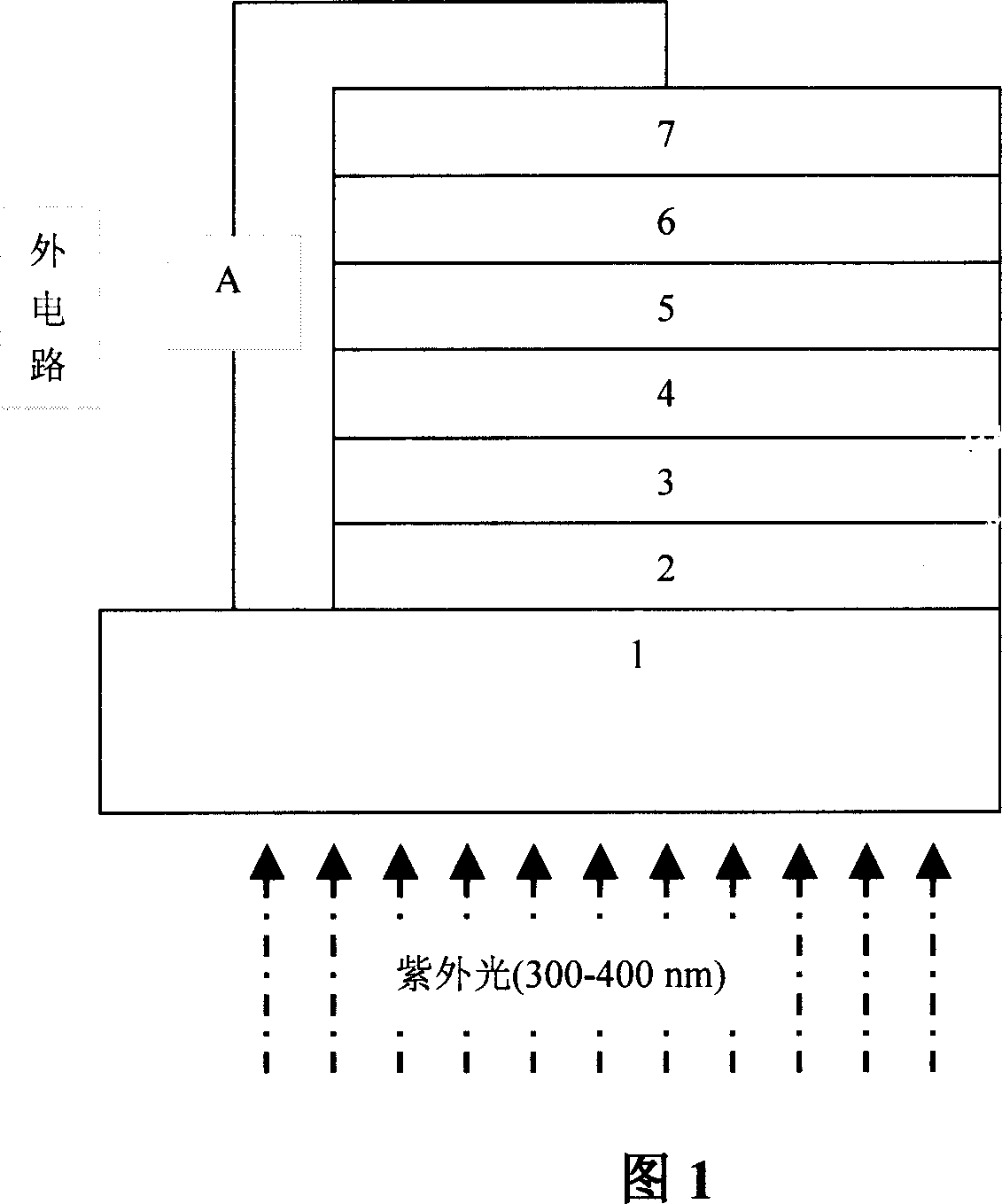

Organic ultraviolet detector

InactiveCN101055205AReduce volumeReduce weightPhotometry using electric radiation detectorsUltraviolet detectorsUltraviolet lights

The invention belongs to the material and component field of organic ultraviolet detector comprising a substrate, a transparent conductive film, an electronic donor layer, a mixing layer, an electronic receptor layer, and an electronic collection electrode layer, characterized in that: the thin mixing layer of electronic donor and electronic receptor is disposed between the electronic donor layer and the electronic receptor layer, and the absorption band of the used functional material is located in the ultraviolet region of 300-400nm, the UV light with center wavelength of 365nm are used as UV light source. The organic light detector is organic photovoltaic diode which is sensitive to ultraviolet light and not sensitive to the visual light, can be applicable in the science, industry and business field with simple fabricating process, cheap material and component, small volume, and convenience for carrying, therefore tending to be used widely.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Health staple food flour special for diabetes patients and preparation method thereof

InactiveCN101564162AStrong targetingNutritional balanceDough treatmentFood preparationDiabetes mellitusDisease

The invention discloses a health staple food flour special for diabetes patients, which is prepared from full wheat flour taken as a raw material, and tartary buckwheat swelling powder, oat swelling powder, soybean protein powder, young oat powder, wheat gluten and stevia rebaudiana taken as accessories in certain proportion. The preparation method for the health staple food flour special for the diabetes patients comprises that: high-quality full wheat flour, the tartary buckwheat swelling powder, the oat swelling powder, the soybean protein powder, the young oat powder, the wheat gluten are firstly selected and baked respectively, weighted in proportion, mixed evenly, screened and packaged into a finished product. The health staple food flour special for the diabetes patients and the preparation method thereof have scientific formula and strong pertinency, change the current situation that more diseases are generated due to nutrition deficiency and physical condition deterioration caused by depending on the control of the staple food in the prior diabetic treatment, and provide a novel food therapy concept of sufficient staple food, balanced nutrition and systematic interference.

Owner:田向东

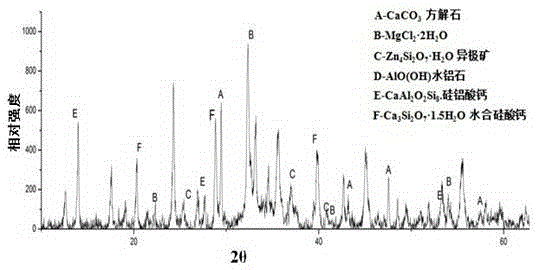

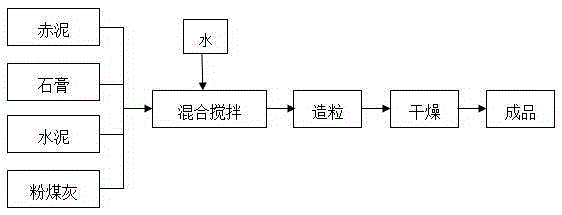

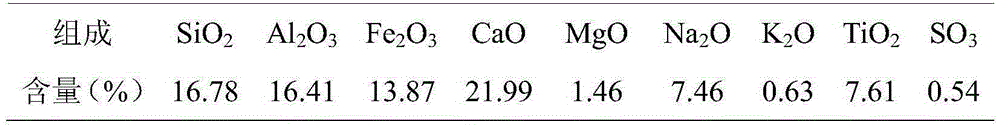

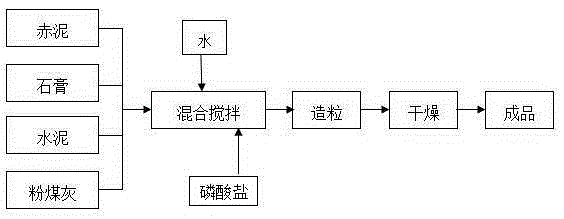

Red mud particle soil repairing adhesives and preparation method thereof

The invention discloses red mud particle soil repairing adhesives and a preparation method and application thereof. The red mud particle soil repairing adhesives are prepared through a series of steps of water adding, mixing, ball forming, room-temperature drying and solidifying by using red mud as the raw material, mixing gypsum into the red mud and using binding material Portland cement and powdered coal in a compound mode to achieve the synergistic interaction result and remarkably improve the red mud gelling property. Red mud powder is granulated and prepared at a room temperature, the obtained red mud particle soil repairing adhesives have certain mechanical strength and quite good heavy metal stabile solidifying performance, soil or mud polluted by heavy metal can be effectively treated, and meanwhile OH radical ions can be slowly released; the pH of soil is kept between 6.7 and 8.1 after soil is repaired through the repairing adhesives, the problems that when soil is repaired through red mud powder, the pH of soil rises too fast and plant growth is not facilitated can be effectively solved, and high application value and environment benefits are achieved.

Owner:国家电投集团山西铝业有限公司 +1

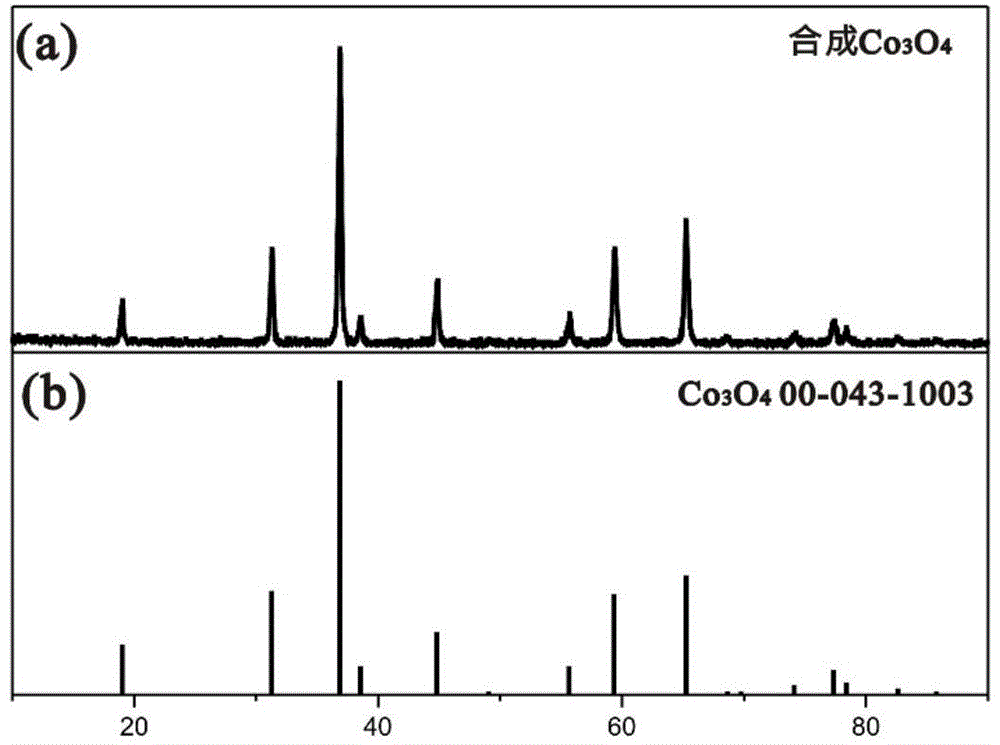

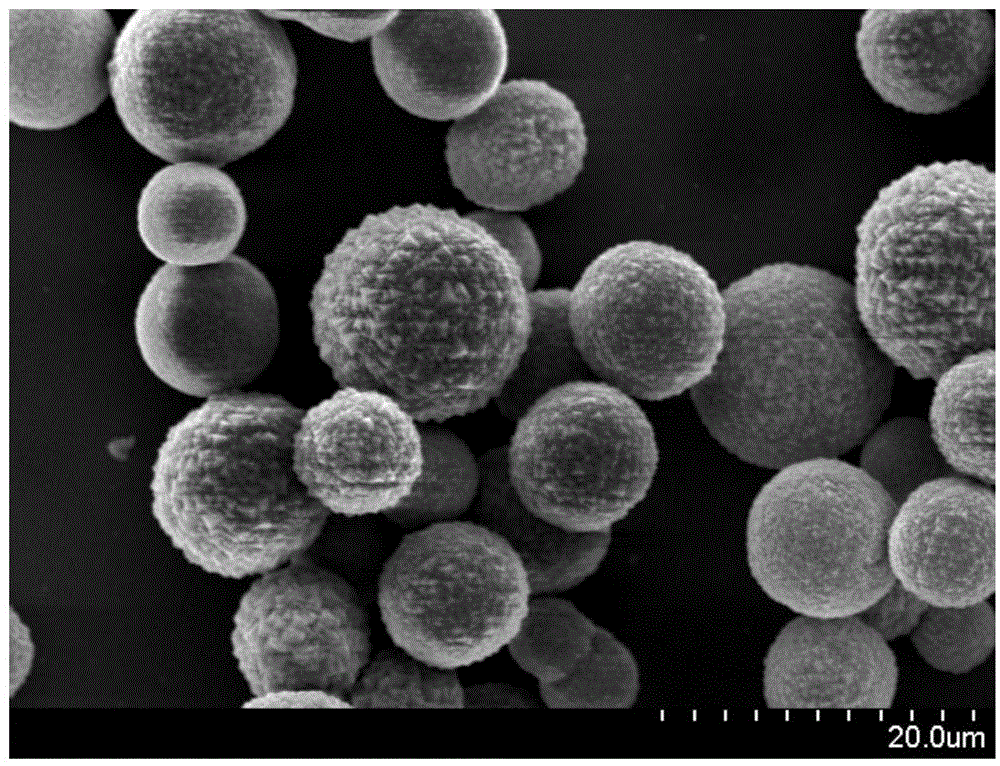

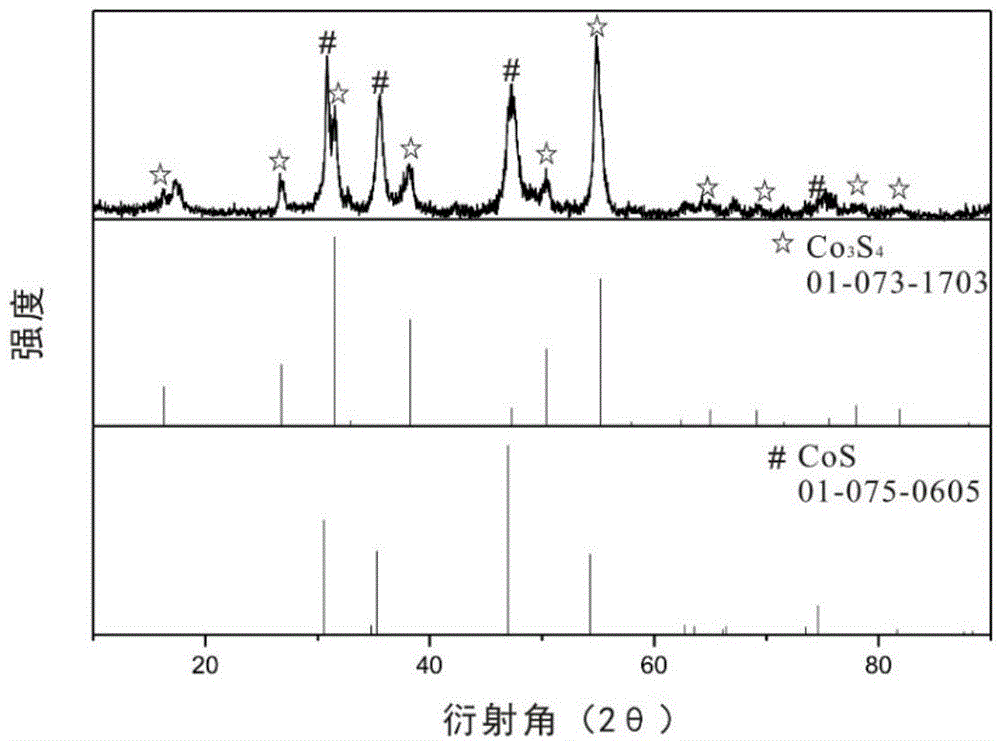

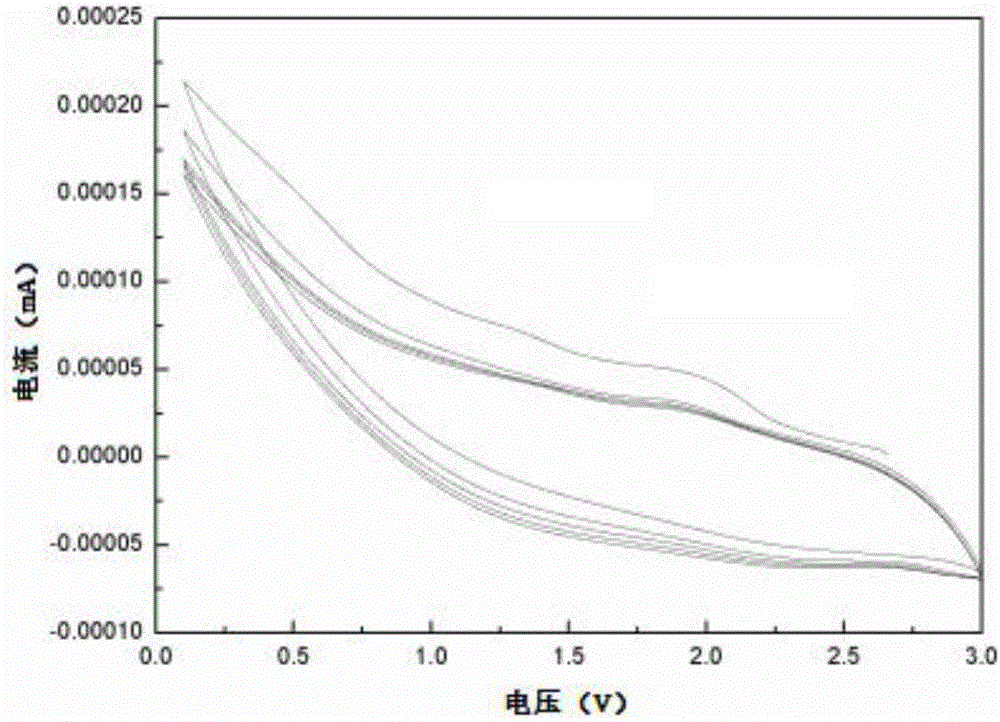

Preparation method and application of cobalt sulfur compound

ActiveCN104993132AWide range of sourcesHigh specific capacityCobalt sulfidesCell electrodesSemiconductor materialsSolar cell

Relating to cobalt sulfur compounds, the invention provides a preparation method and application of a cobalt sulfur compound. The method includes: dissolving a water soluble cobalt source and urea in a mixed solvent to form a solution, carrying out reaction to obtain cobalt carbonate, performing calcinations to obtain a cobalt oxide, and reacting the cobalt oxide with a sulfur source in a reducing atmosphere to obtain a micrometer-scale cobalt sulfur compound. The micrometer-scale cobalt sulfur compound can be spherical cobalt sulfur compound or lamellar square-like cobalt sulfur compound, and the obtained cobalt sulfur compound can be Co9S8, CoS, Co3S4 and CoS2, etc. The cobalt sulfur compound prepared by the preparation method provided by the invention can be applied as an electrode active material in preparation of secondary battery electrodes. According to the invention, specific shape cobalt sulfide can be prepared, is low in synthesis cost and has high tap density, and can be applied to secondary battery electrode materials, optical parametric oscillators, semiconductor materials, solar cells and other aspects.

Owner:XIAMEN UNIV

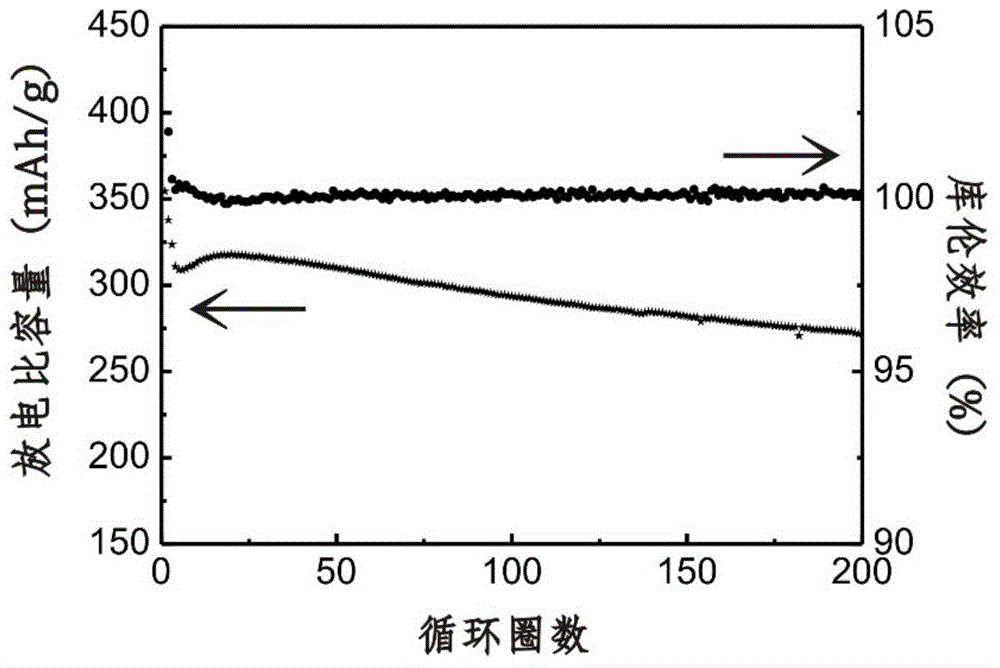

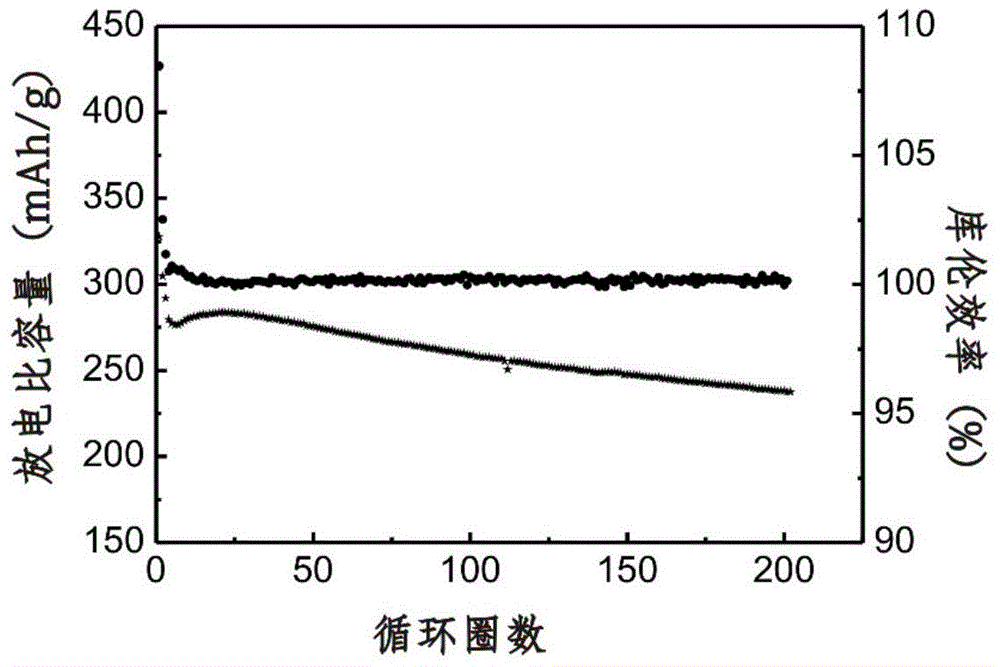

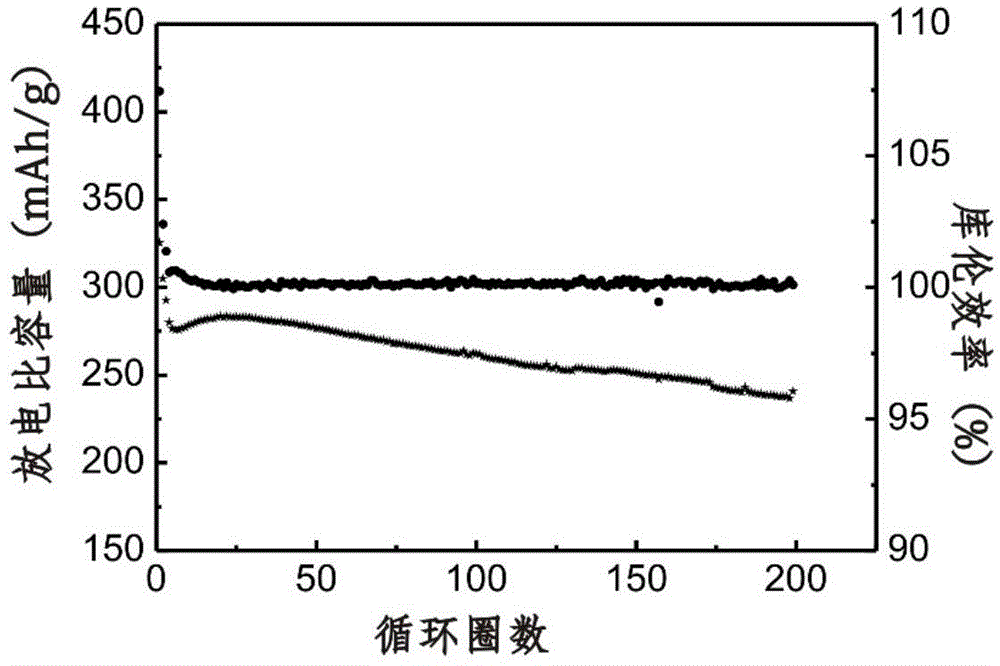

Transition metal sulfide coated with carbon, preparation method and application

InactiveCN104835961AGood electrical conductivityGood cycle stabilityCell electrodesSecondary cellsCarbon coatingCarbon source

A transition metal sulfide coated with carbon, a preparation method and an application relate to transition metal sulfide. The transition metal sulfide coated with the carbon comprises a nucleus and a coating layer on the surface of the nucleus, wherein the nucleus is a transition metal sulfide nucleus, and the coating layer is a carbon coating layer. The preparation method comprises the steps as follows: dissolving the transition metal sulfide in water, adding a carbon source, and coating the surface of the transition metal sulfide with carbon. The transition metal sulfide coated with the carbon is applied to preparation of an electrode material, and the electrode material could be a battery electrode material or the like, and is specifically used as an electrode active material to be applied in a secondary battery. The transition metal sulfide coated with the carbon is greatly improved in conductive performance, further improved in charge and discharge capacity and rate capability, greatly improved in coulombic efficiency and cycle performance, and low in material cost and simple in preparation process. The composite material used as an electrode material of a secondary lithium battery has high energy density, excellent cyclicity, and especially excellent rate capability, and is safe and reliable.

Owner:XIAMEN UNIV

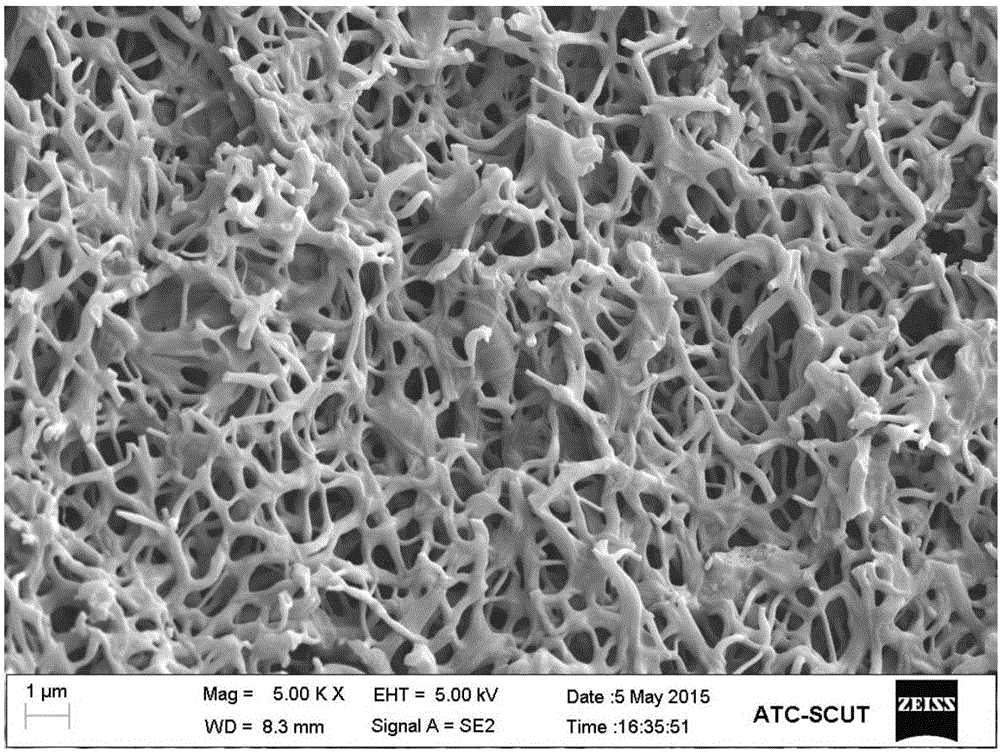

Alkali lignin-based electrostatic spinning carbon fiber and preparation method and application thereof

InactiveCN105862173AWide range of sourcesGreenCell electrodesFibre chemical featuresAir atmosphereN dimethylformamide

The invention belongs to the technical field of the biomass material processing and discloses an alkali lignin-based electrostatic spinning carbon fiber and a preparation method and application thereof. The preparation method comprises the steps of dissolving alkali lignin and polyacrylonitrile in N, N-dimethylformamide to obtain a uniform lignin / polyacrylonitrile solution; then performing electrostatic spinning to obtain a lignin-based nanofiber membrane; heating the membrane in carbonization equipment to 200-280 DEG C; pre-oxidizing for 2-8h in an air atmosphere, heating to 600-900 DEG C, carbonizing in nitrogen gas or argon gas atmosphere and grinding to obtain the alkali lignin-based electrostatic spinning carbon fiber. According to the method, alkali lignin and polyacrylonitrile are used as carbon sources of carbon materials, and the method has the advantages of environment friendliness and low preparation cost; and the carbon fiber can replace graphite to be used as the positive electrode material of a lithium battery.

Owner:SOUTH CHINA UNIV OF TECH

Production process of high-elasticity non-woven three-dimensional cotton

The invention discloses a production process of high-elasticity non-woven three-dimensional cotton, comprising the following steps: mixing a low melting point hot melting viscose fiber and at least two fibers of other fibers in proportion; opening and scotching, and feeding cotton and carding and delivering to a vertical lapping forming machine to carry out vertical forming process. A fiber net is continuously folded and descends in a forming curtain at the action that a pendulum-type swinging folding mechanism swings left and right reciprocately, becomes continuous fiber net layers which are arranged in a vertical direction in a steerable channel, and finally forming the three-dimensional cotton which is arranged in a vertical direction through heat setting and cooling setting. The production process in the invention realizes production through a conventional non-woven heat setting machine at the condition of not adding any chemical adhesive, and sets the product thickness and density according to the process requirements; the process is simple, practical and efficient; any fiber can be used as the basic fiber of the material; the regenerated fiber also can be used for forming; and the material source is wide, is easy to obtain, and is relatively environment-friendly.

Owner:杭州缔星纤维科技有限公司

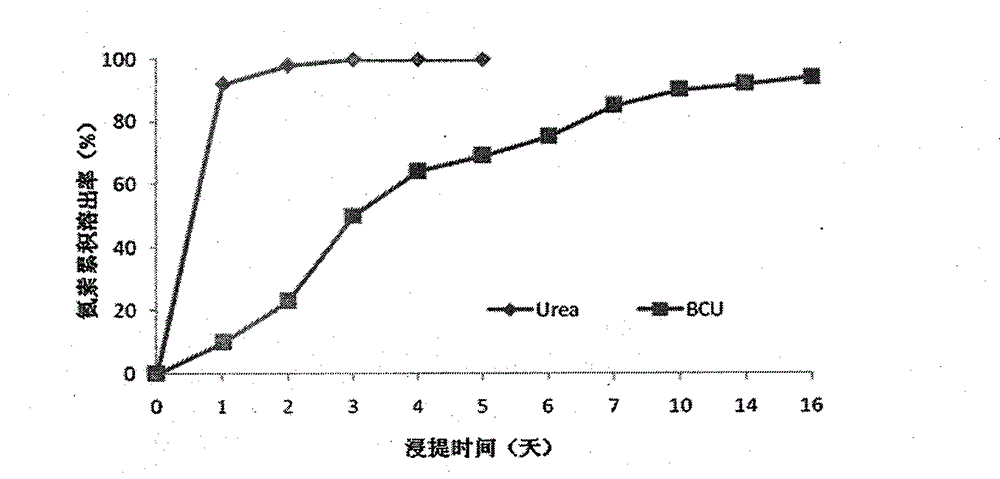

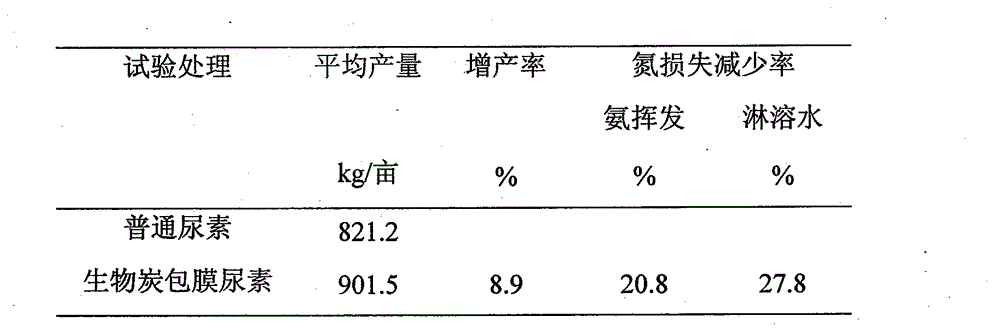

Formula and film-coating preparation method for biological carbon coated urea

InactiveCN105294363ALow costRich varietyClimate change adaptationEnergy inputCoated ureaLow nitrogen

The invention relates to a formula and a film-coating preparation method for biological carbon coated urea. The biological carbon coated urea is characterized in that the outside of a fertilizer core is coated with solid-powder-shaped biological carbon, sulfur, dicyandiamide and bentonite by using granular urea with a size of 3 to 4 mm as the fertilizer core and oxidized corn starch as bonding liquid, wherein the above-mentioned components have weight proportions as follows: 50 to 80 parts of the urea, 10 to 30 parts of the biological carbon, 2 to 10 parts of the sulfur, 2 to 3 parts of the dicyandiamide, 2 to 3 parts of the bentonite and 3 to 5 parts of the corn starch. The film-coating preparation method for the biological carbon coated urea comprises the following steps: placing the urea into a disc granulator, carrying out preheating with hot air for 5 min, spraying the bonding liquid on the surface of the urea with a high-pressure spray gun, blowing the hot air for 3 to 5 min, adding a mixed film-coating material into the disc granulator in batches and carrying out rotating for 10 min, then spraying the bonding liquid again, and carrying out drying in the air so as to obtain the biological carbon coated urea. According to the invention, the biological carbon can improve physical and chemical properties of soil and adsorb ammonium-nitrogen and nitrate-nitrogen ions; the dicyandiamide reduces nitrification; and S4O62- generated by decomposition of the sulfur can delay decomposition of the dicyandiamide, and H+ and S2O32- generated by decomposition of the sulfur can inhibit nitrification. The biological carbon coated urea provided by the invention has the advantages of low ammonia volatilization, slow generation of nitrate nitrogen, low nitrogen loss and high nitrogen effectiveness.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

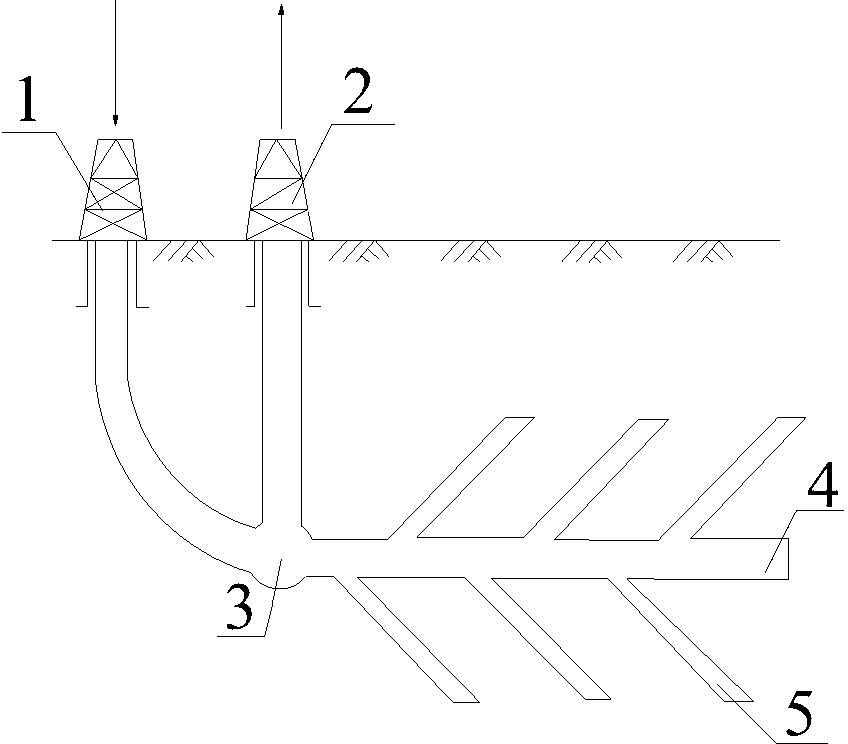

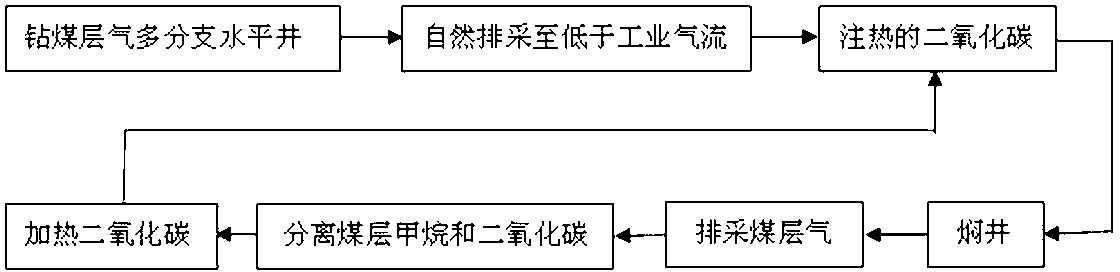

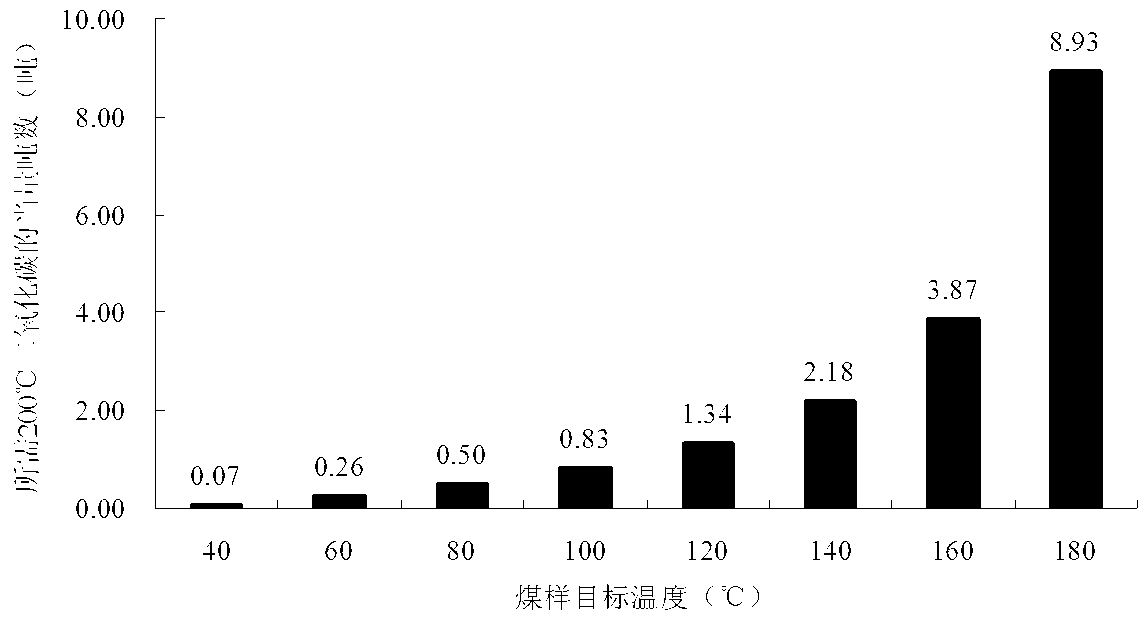

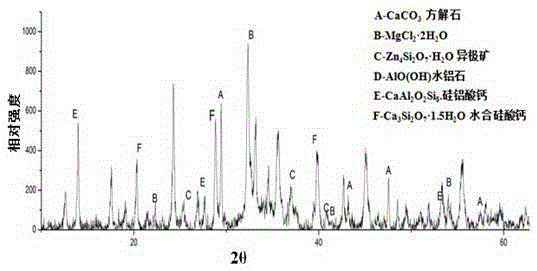

Method for enhancing recovery ratio of coal-bed gas by injecting hot carbon dioxide into coal bed

The invention provides a method for enhancing recovery ratio of coal-bed gas by injecting hot carbon dioxide into a coal bed, which comprises the following steps: 1) after implementing a coal-bed gas multi-branch horizontal well on the ground, draining water of a single well to reduce the pressure, and naturally generating gas until the yield is lower than the industrial gas flow standard; 2) draining water to reduce the pressure, and injecting hot carbon dioxide into the well, wherein the temperature of the injected hot carbon dioxide is 180-220 DEG C, and the injection pressure does not exceed 5 MPa; 3) shutting in the gas well for soaking; 4) draining water to reduce the pressure, and generating gas; 5) separating carbon dioxide and coal-bed gas from the generated gas; and 6) repeating the steps 2)-5) until the yield is lower than the industrial gas flow standard, and shutting in the well. The method provided by invention can effectively lower the coal-bed methane content and greatly enhance the coal-bed gas yield, thereby achieving the goal of industrialized development of coal-bed gas.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

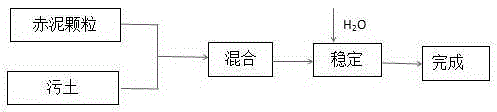

Method for repairing heavy metal-polluted soil by using red mud granular material

The invention discloses a red mud granular material and an application thereof. A red mud particle soil repairing agent takes red mud powder, gypsum, cement and fly ash as main materials, phosphate is doped as an activation material, thereby, gelling capability of red the mud powder and capability for fixing heavy metal ions in a stable mode can be increased, a series of processes of mixing by adding water, balling, and drying solidification at normal temperature can be carried out, so that the spherical particle soil repairing agent can be obtained by composite moulding of the red mud raw ore powder material. The method realizes preparation of the red mud powder with granulation at normal temperature, the obtained red mud particle soil repairing agent has certain mechanical strength and good heavy metal stable solidification performance, the heavy metal-polluted soil or sludge can be effectively processed, OH radical ions can be slowly released simultaneously, a pH value of the soil after restoration by the repairing agent is basically stabilized below 7.5, problems of fast increase of the pH value of the soil and poor growth condition for plants during a soil restoration process by the red mud powder can be effectively overcome, and the method has high application value and environment benefit.

Owner:SUN YAT SEN UNIV

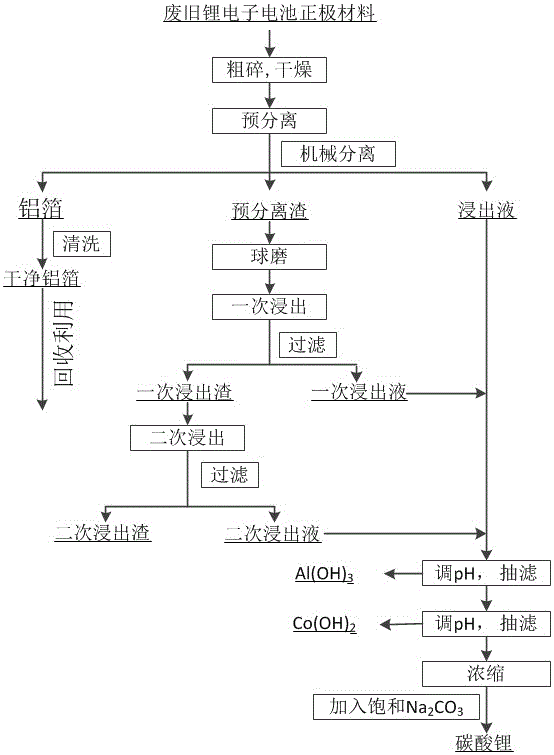

Method for mixed acid leaching and recovery of positive pole materials of waste and old lithium ion batteries

ActiveCN106848471AWide range of sourcesImprove leaching efficiencyWaste accumulators reclaimingBattery recyclingAluminium hydroxideFiltration

The invention provides a method for mixed acid leaching and recovery of metal components of positive pole materials of waste and old lithium ion batteries. The method comprises carrying out coarse crushing on wastes, drying the crushed wastes, pre-leaching the wastes through a mixed acid containing a reduction agent to obtain pre-separated residues, carrying out ball milling, carrying out primary and secondary leaching, mixing the primary and secondary leachates and the pre-leachate, adjusting pH of the mixture, carrying out suction filtration to obtain aluminum hydroxide and raffinate containing cobalt and lithium, adjusting pH of the raffinate containing cobalt and lithium at a high temperature, carrying out suction filtration to obtain cobalt hydroxide and raffinate containing lithium, carrying out concentration on the raffinate containing lithium at a high temperature, adding a saturated sodium carbonate solution into the concentrate to obtain high purity lithium carbonate, and recovering aluminum foil. The method utilizes a mixed acid leaching agent, has high leaching efficiency, can gradually acquire high purity aluminum, aluminum hydroxide, cobalt hydroxide and high purity lithium carbonate (having purity of 99.9%), realizes efficient recovery, overall recovery and collaborative recovery of high-value metals in the waste and old lithium-ion batteries and has a good application prospect.

Owner:BOTREE CYCLING SCI &TECH CO LTD

Cementing material for preparing road base material through using brick and concrete building wastes, and application thereof

The invention discloses a cementing material for preparing a road base material through using brick and concrete building wastes. The cementing material is obtained through uniformly mixing 50-70 parts by mass of slag, 10-30 parts by mass of gypsum, 5-20 parts by mass of lime, 5-25 parts by mass of fly ash and 0-5 parts by mass of sodium sulfate. When the cementing material is applied, regenerated brick and concrete aggregates and the cementing material, or industrial slag, a mine tailing material and the cementing material are used as basic raw materials, and are mixed to prepare the road base material. The advantages comprising environmental protection, waste utilization, cheapness, economy and the like are possessed in the invention.

Owner:HUNAN YUNZHONG REGENERATION TECH CO LTD

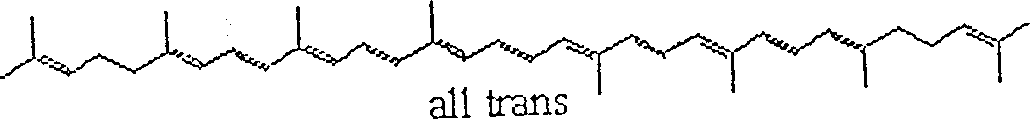

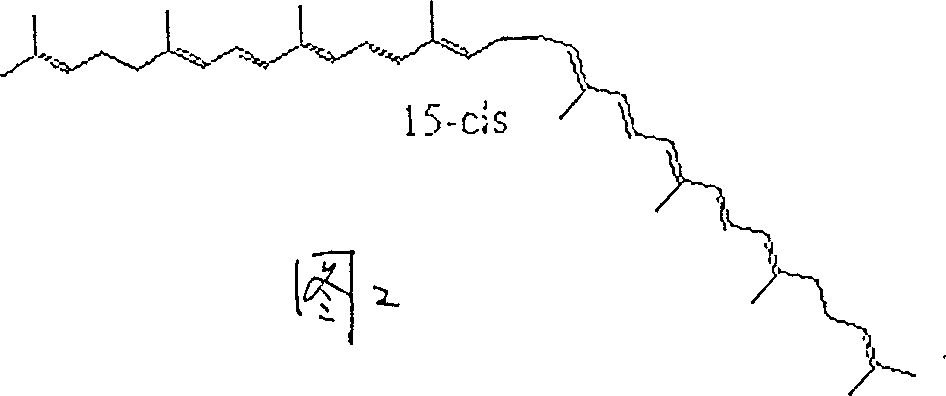

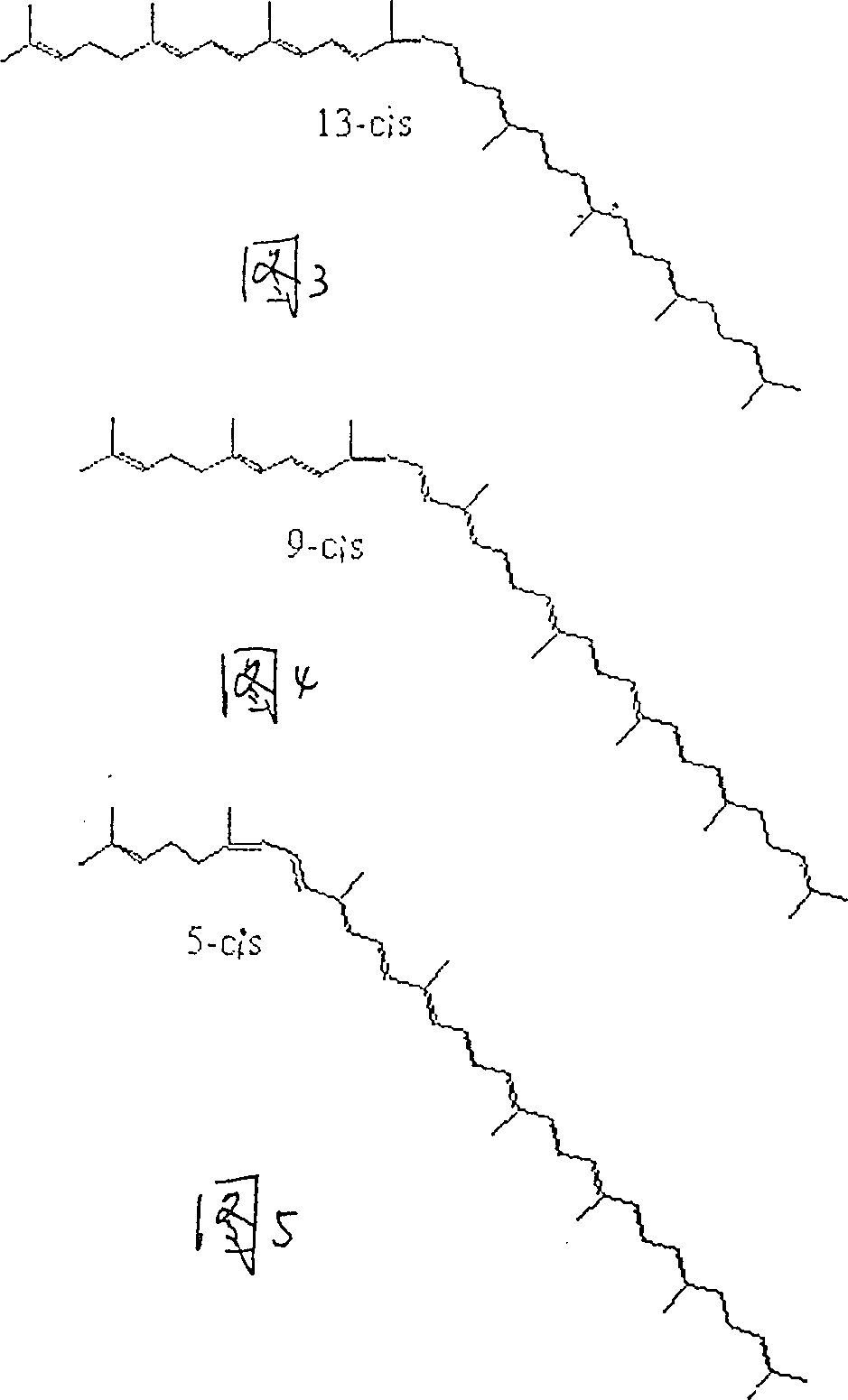

Preparation method of lycopene richly containing cis-isomer

InactiveCN1380009ANo pollution in the processEasy to prepareNatural dyesFood preparationLycopeneEdible oil

The preparation method of lycopene richly containing cis-isomer is characterized by that the tomato paste and edible oil are heated in a reactor and stirred, then filtered to obtain edible oil clear liquor and tomato paste residuum, and the tomato paste residuum and edible oil are undergone the process of 1-6 above-mentioned circulating operations to obtain edible oil clear liquor, heated and evaporated, condensed at -0.05 to -0.1 MPa and refluxed so as to obtain the invented product. It has the advantages of simple technological process, no pollution, easily available raw material and low cost, etc.

Owner:北京丰德天元科技有限公司

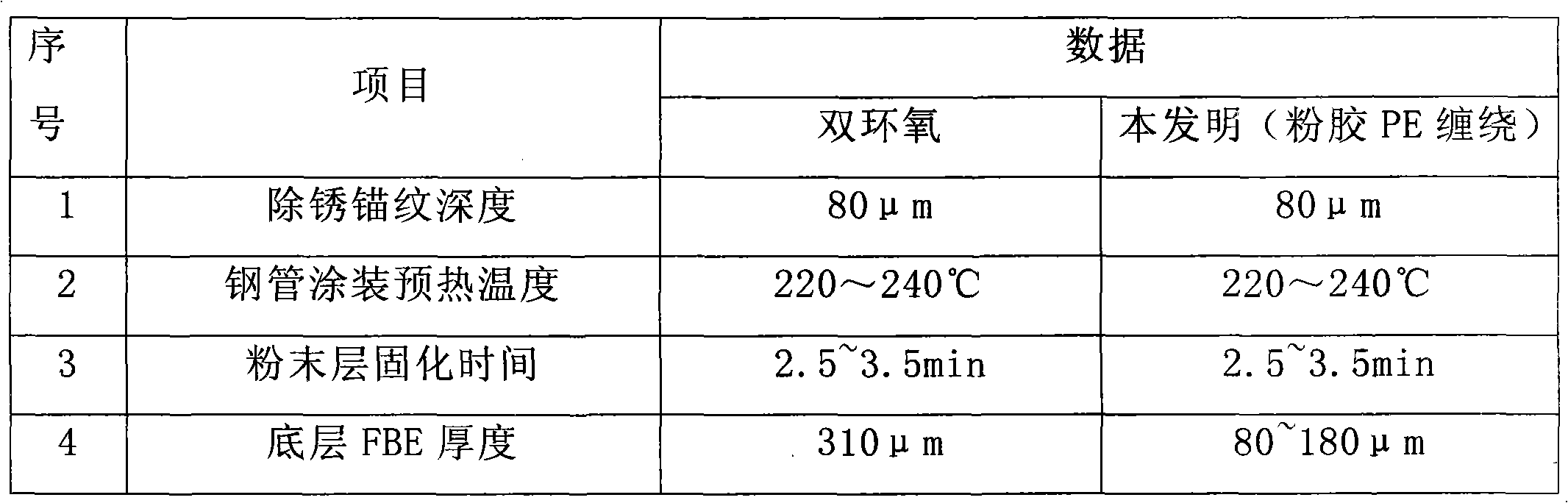

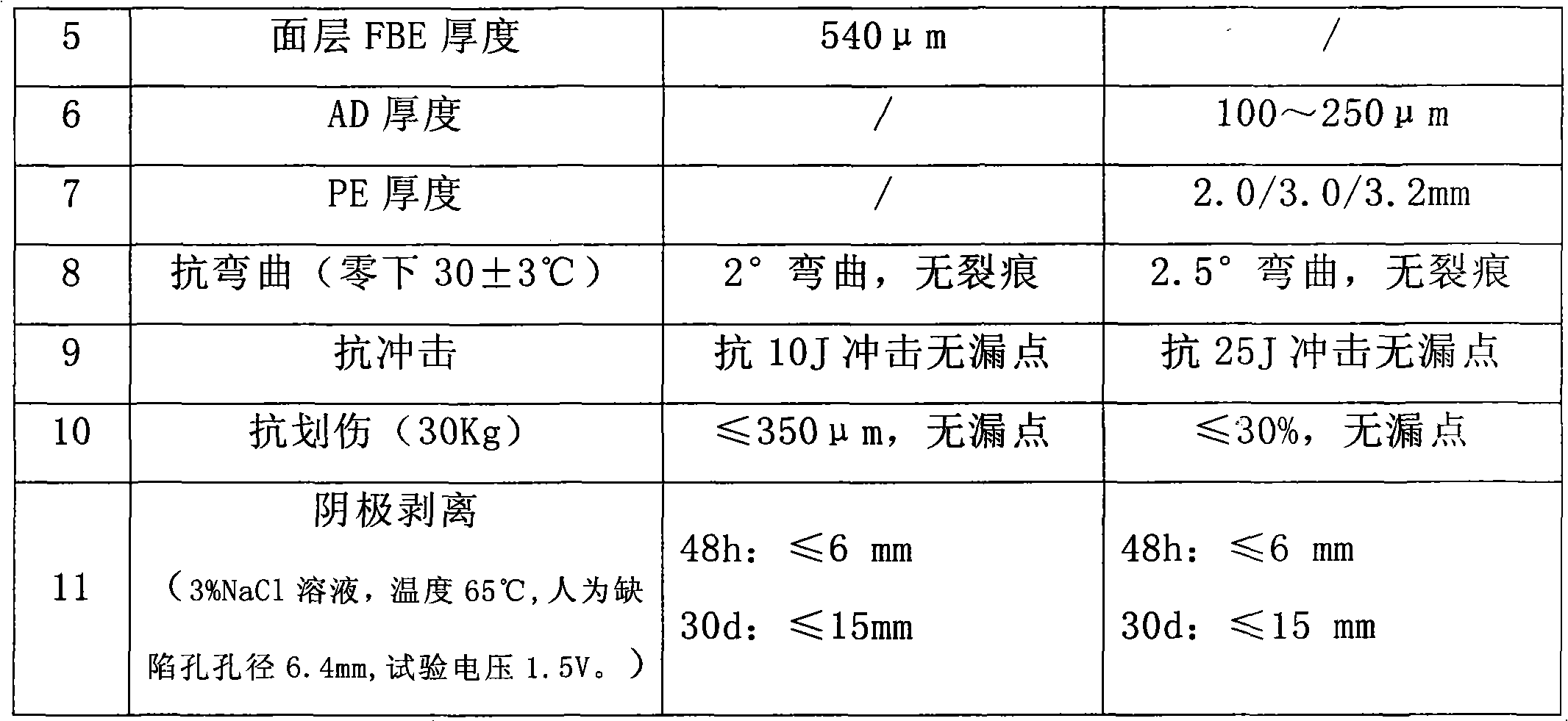

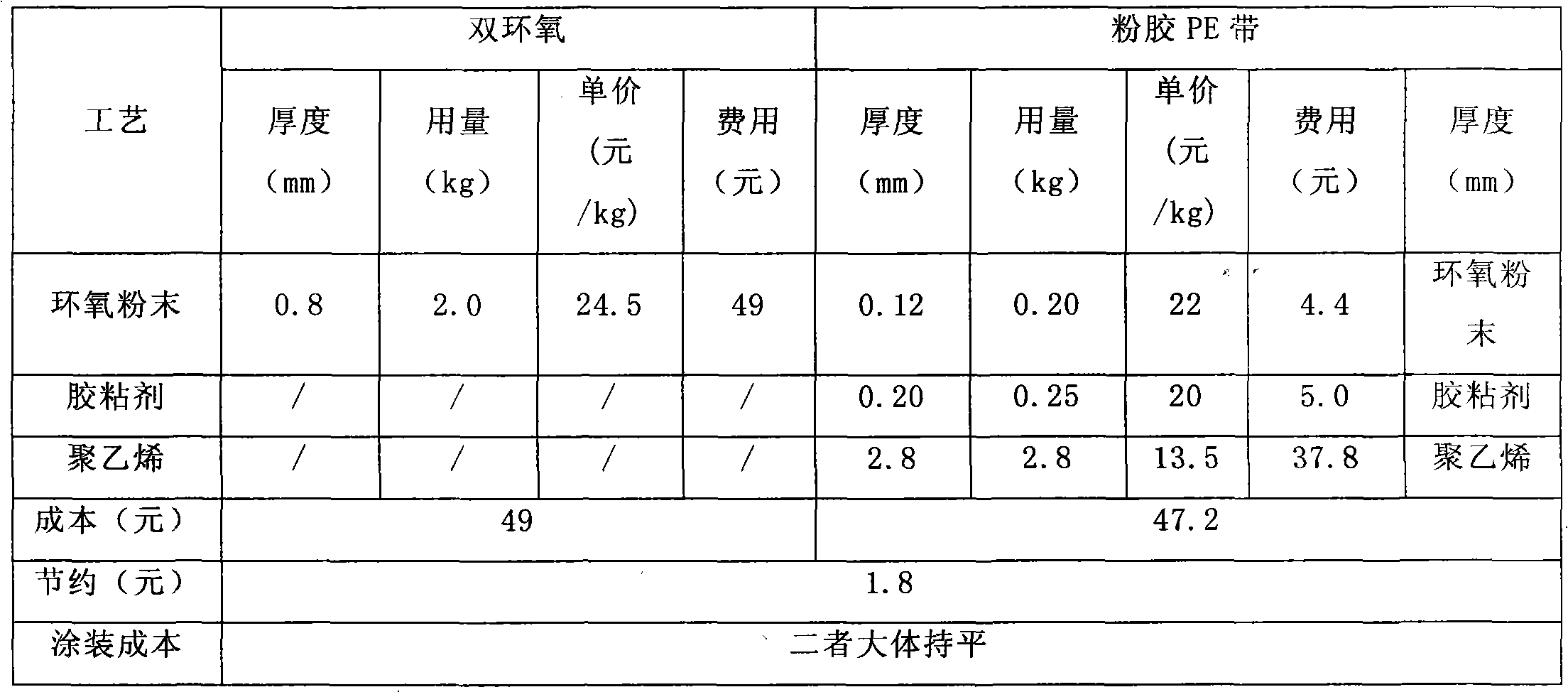

Coating process for pipeline three-layer structural anticorrosive coating

InactiveCN102107176ASolve the problem of not easy bondingImproves adhesion propertiesLiquid surface applicatorsCorrosion preventionEpoxyDielectric

The invention discloses a coating process for a pipeline three-layer structural anticorrosive coating. The coating process comprises the following steps of: 1) performing fusion bonded epoxy (FBE) coating, namely heating a coated substrate, and spraying epoxy powder to the surface of the coated substrate by an electrostatic spraying process to melt an epoxy powder coating and cure the epoxy powder coating into a bottom coating; 2) performing air dielectric (AD) coating, namely coating adhesive powder to the surface of the coated substrate during gelling of the epoxy powder, wherein the surface temperature of the coated substrate is between 170 and 225 DEG C, and the coating thickness is between 80 and 350 mu m; and 3) performing polyolefin coating, namely winding a fabricated polyolefin coil strip on the coated substrate before an adhesive is cooled, wherein the coating thickness is between 0.5 and 4.0mm. By the AD powder coating process, the wound coating is tightly adhered to the substrate, and the anticorrosive coating has high integrity, cathodic disbonding resistance and compactness.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

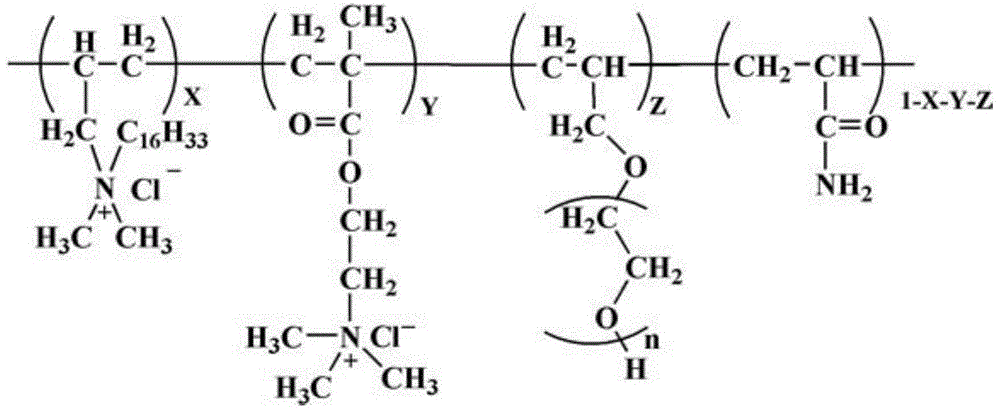

Hydrophobically associated type cation acid solution retardant and preparation method thereof

InactiveCN105001849AWide range of sourcesImprove thermal stabilityDrilling compositionEtherThermal stability

The invention relates to a hydrophobically associated type cation acid solution retardant for oil gas well acidification in petroleum industry and a preparation method thereof. According to the invention, a retarded acid is utilized for acidifying deep parts of the stratum, in order to improve the acid treatment effect. The technical scheme is as follows: the acid solution retardant is polymerized from four monomers, including acrylamide AM, allylpolyoxyethylene ether APEG-1000, methacryloxyethyltrimethyl ammonium chloride DMC, and cetyl dimethyl diallyl ammonium chloride DMAAC-16. The method of preparation is as follows: adding APEG-1000 whose mole percent is 2.00-8.00% into a flask, adding water 50.00-150.00g, carrying out stirring and dissolving, adding materials in percentage by mole including 63.40-79.60% of AM, 15.80-28.25% of DMC and 0.30-0.70% of DMAAC-16, and obtaining a solution whose concentration is 15%; finally adding an initiator, allowing reaction for 6 hours at 50 DEG C, carrying out washing by ethanol and drying, and obtaining the acid solution retardant. The retardant has a good retardance performance, so that deposition is not easy to be produced, and the retardant has good heat stability, good temperature tolerance and compatibleness.

Owner:SOUTHWEST PETROLEUM UNIV

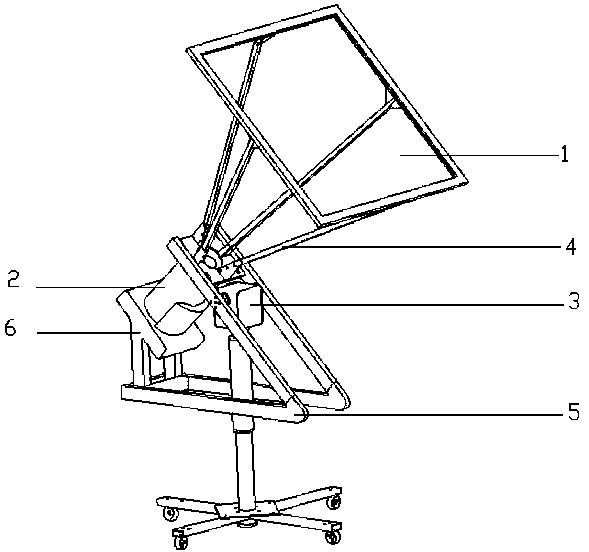

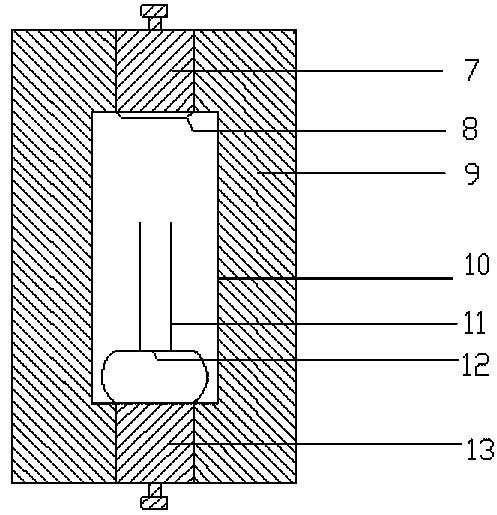

Nanometer molten salt phase-change energy storage solar furnace

InactiveCN103471256AWith heat storage functionNo outdoor operation requiredSolar heating energySolar heat devicesInsulation layerMolten salt

The invention discloses a nanometer molten salt phase-change energy storage solar furnace which comprises a Fresnel condenser, a phase-change energy storage heat exchanger, a longitude and latitude double-shaft tracker, stay rods, a V-shaped balance support and a bottom bracket. The phase-change energy storage heat exchanger with heat absorption, heat release and heat storage functions is mounted at a condensation focus of the Fresnel condenser, nanometer molten salt composite phase-change energy storage materials are arranged in the phase-change energy storage heat exchanger, a heat absorption cavity and a heat release furnace end are arranged on the phase-change energy storage heat exchanger, and a heat-insulation layer wraps the outside of the phase-change energy storage heat exchanger. Heat utilization requirements such as water heating, cooking and barbecue for general family life can be met by the solar furnace. Compared with the traditional direct condensation type solar furnace, the nanometer molten salt phase-change energy storage solar furnace has the advantages that the heat collecting temperature is high, outdoor operation is omitted, the nanometer molten salt phase-change energy storage solar furnace can continue being used at night without the sun, and the like.

Owner:GUANGDONG UNIV OF TECH

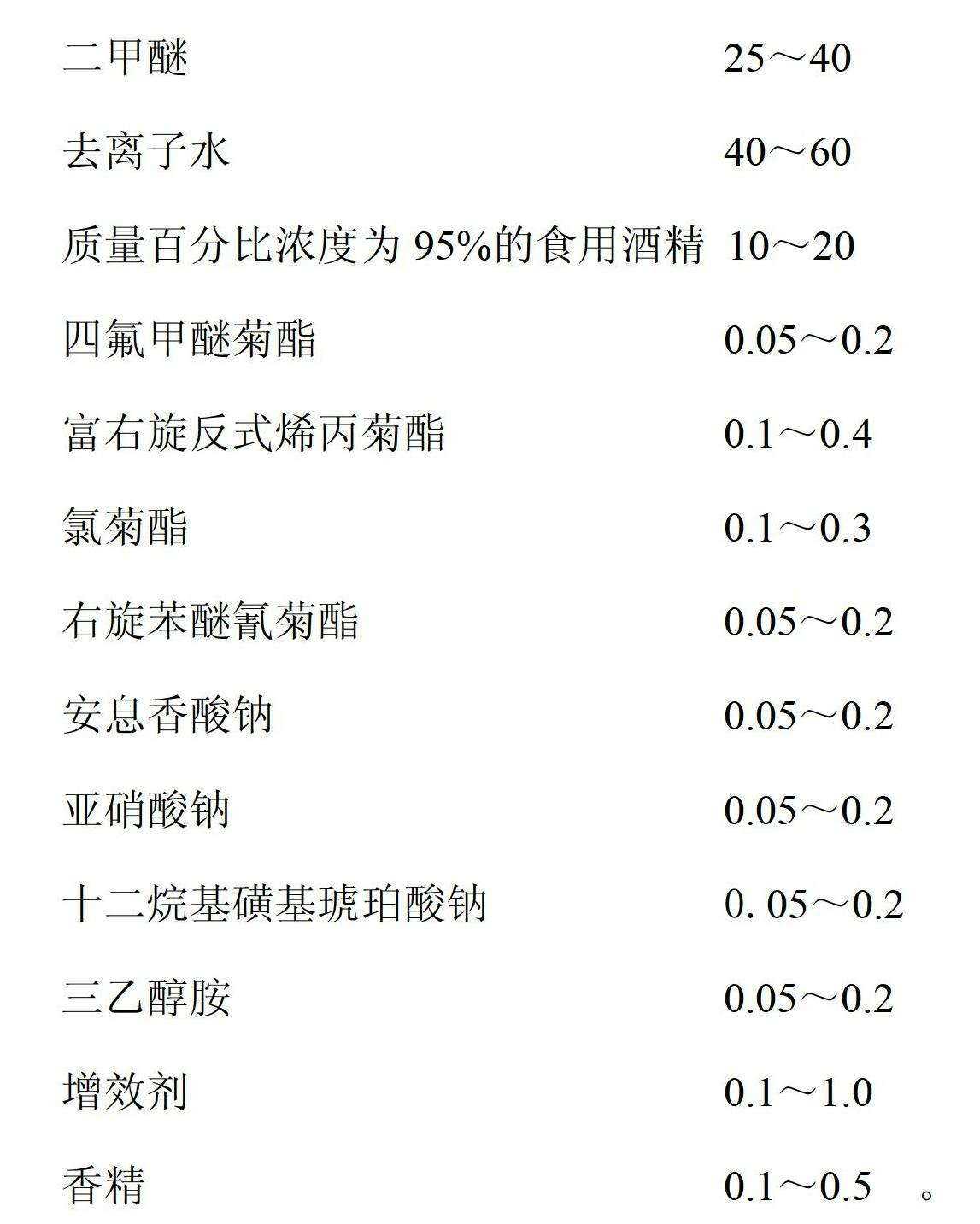

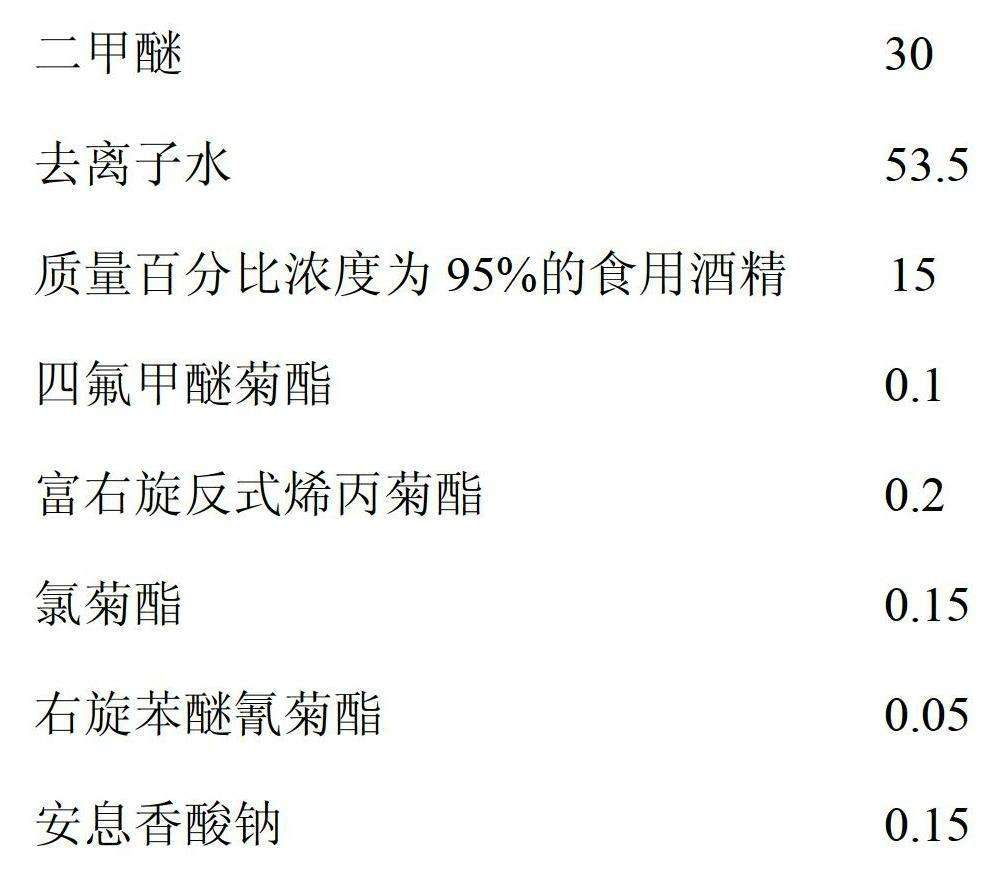

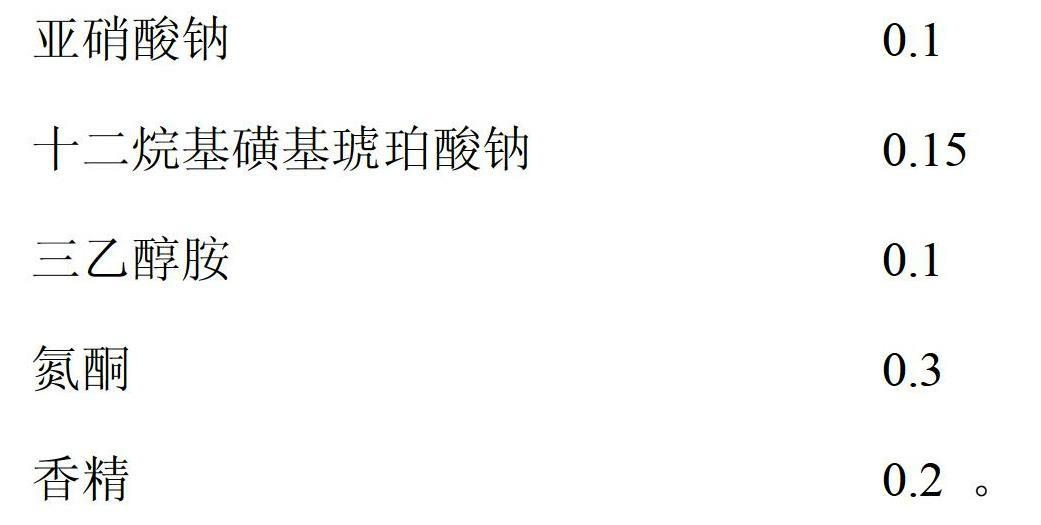

Homogeneous and high-efficient water-based pesticide aerosol with low VOC (Volatile Organic Compounds) content

The invention provides homogeneous and high-efficient water-based pesticide aerosol with low VOC (Volatile Organic Compounds) content. The homogeneous and high-efficient water-based pesticide aerosol comprises the following components in parts by weight: 25-40 parts of dimethyl ether, 40-60 parts of de-ionized water, 10-20 parts of edible alcohol with mass-percentage concentration of 95 percent, 0.05-2 parts of dimefluthrin, 0.1-0.4 part of rich-d-transallethrin, 0.1-0.3 part of permethrin, 0.05-0.2 part of d-trans-cyphenothrin, 0.05-0.2 part of sodium benzoate, 0.05-0.2 part of sodium nitrite, 0.05-0.2 part of sodium dodecyl sulfate succinate, 0.05-0.2 part of triethanolamine, 0.1-1.0 part of synergist and 0.1-0.5 part of essence. According to the homogeneous and high-efficient water-based pesticide aerosol with low VOC content, disclosed by the invention, the advantages of good atomizing effect and insert-killing effect can be achieved without vibration and shaking before use.

Owner:山东美多包装有限公司

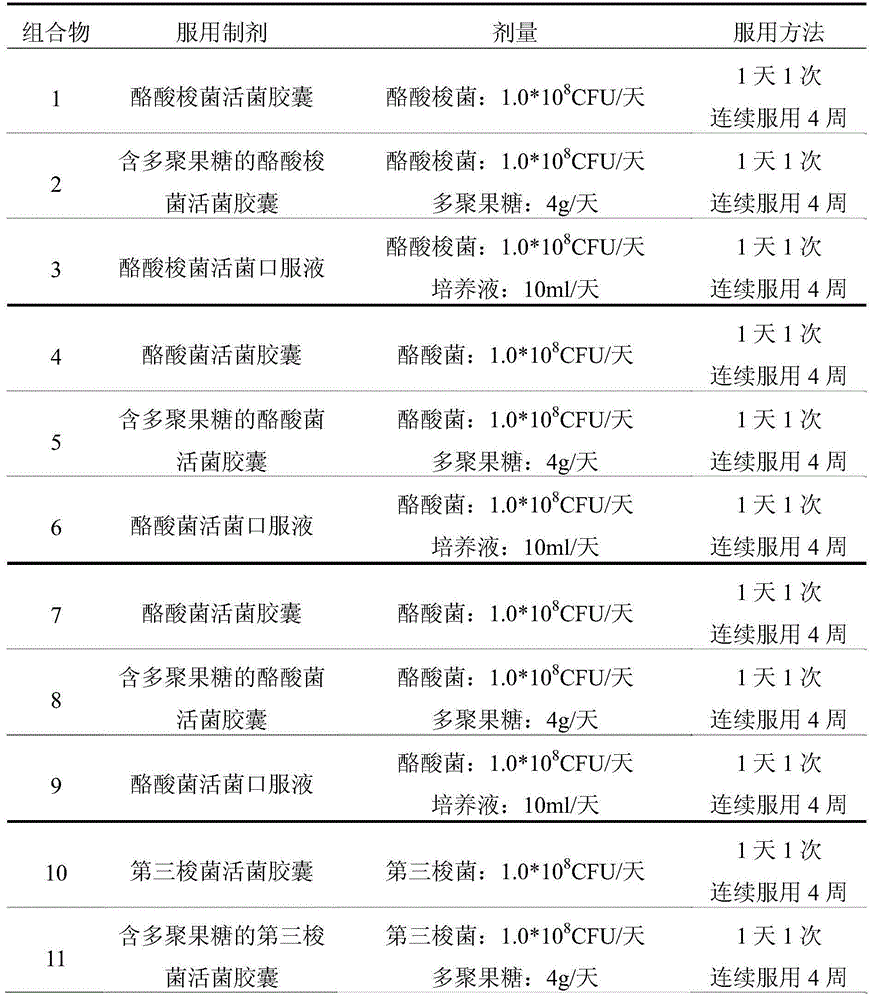

Edible composition and use thereof

ActiveCN104432001ANo side effectsRaw materials are widely availableLactobacillusStrepto/lacto-coccusCulture mediumsProbiotic

The invention discloses an edible composition, comprising a probiotic culture. The probiotic culture is obtained by cultivating probiotics by using a culture medium. The edible composition disclosed by the invention has the functions of adjusting intestinal flora, regulating blood sugar level, reducing blood fat and improving the immunity.

Owner:BGI SHENZHEN CO LTD

Soil conditioner for reducing cadmium and lead pollution to crop

InactiveCN101724405AChange pHImprove adsorption capacitySolid waste managementOrganic fertilisersLeafy vegetablesPb contaminated soil

The invention relates to a soil conditioner for reducing the cadmium and lead pollution to crops, comprising inorganic components and organic components, wherein the effective components of the inorganic components are Ca(OH)2 and Na2SiO7 or mixtures of the Ca(OH)2 and the Na2SiO7; and the organic components include rice straws and tephrosia caudida casts or mixtures of the rice straws and the tephrosia caudida casts. The soil conditioner is used before the crops are cultivated; the inorganic components are prepared into agricultural-grade powder and 0.5-4 g of the inorganic components is used for one kilogram of wind drying soil; and the grain diameter of the crushed organic components is less than 1 cm and 5-40 g of the organic components is used for one kilogram of wind drying soil. The soil conditioner effectively reduces the biological effectiveness of heavy metal, the absorption of cadmium and lead by the crops and the heavy metal pollution to the crops and especially leafy vegetables without reducing the production property of the corps.

Owner:SUN YAT SEN UNIV

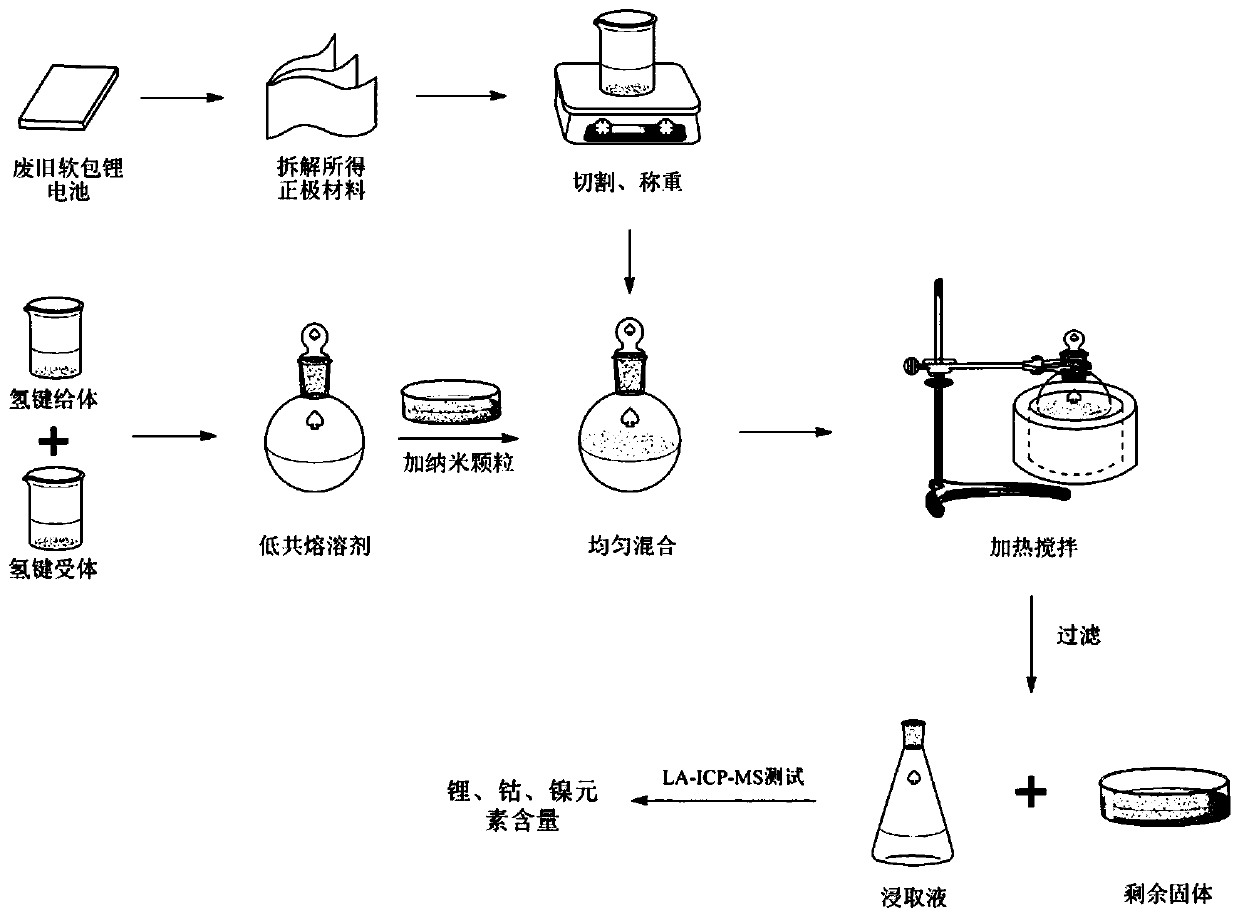

Method for recycling waste lithium ion battery anode materials based on deep-eutectic solvent nanofluid

ActiveCN111074074AWide range of sourcesShorten the timeWaste accumulators reclaimingProcess efficiency improvementPhysical chemistryNanofluid

The invention discloses a method for recycling waste lithium ion battery anode materials based on deep-eutectic solvent nanofluid. The method mainly comprises the following several steps that (1) a dispersing agent and nano particles are sequentially added into a deep-eutectic solvent, and nanofluid with the deep-eutectic solvent as base fluid is prepared through stirring and ultrasonic treatment;(2) waste lithium ion batteries are disassembled after being completely discharged, and anode plates are obtained through separation; and (3) the anode plates are added into a prepared deep-eutecticsolvent nanofluid solution, stirring is carried out for 24-72 h under the temperature ranging from 25 DEG C to 220 DEG C, filtering is carried out, and the contents of valuable metal elements nickel,cobalt and lithium in the reacting solution are detected. The deep-eutectic solvent nanofluid is used for recycling the lithium ion battery anode materials, the process is simple, the recovery rate ofvaluable metal is high, and application and popularization are easy.

Owner:CHINA UNIV OF MINING & TECH

Preparation and use of sludge-stalk fibrous composite

ActiveCN101475332AImprove adhesionGuaranteed longevitySolid waste managementClimate change adaptationPlant rootsSludge

The invention relates to a method for preparing a sludge-straw fibre composite material and application. Municipal sludge, straw fibre and industrial waste slag (desulfurized clinker and steel slag) are used as raw materials to prepare a sludge-fibre micelle copolymer by sludge modification technology and copolymer even stirring technology; the sludge-fibre micelle copolymer is used for ecological protection and restoration of a rock slope, a clay slope and a landfill field slope. The sludge-fibre micelle copolymer prepared by the technology recycles and utilizes sludge and straw fibre which are difficult to process; and compared with various green substrates, the sludge-fibre micelle copolymer does not need to add nitrogen, phosphorus, potassium and organic fertilizer to soil, reutilizes waste and greatly reduces cost. The straw fibre improves the tensile and flexural mechanical performance of the sludge-fibre micelle copolymer and further achieves the mechanical strength index of the slope protection. Grass seeds are mixed to the copolymer; and the hydrological effect of plant and mechanical reinforcement effect of a plant root system are utilized to effectively circulate moisture and achieve the functions of reinforcing the slope and greening environment.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Method utilizing waste and bacterium dreg generated during process of producing edible fungi from straw raw materials to produce microorganism organic bacterium fertilizer

The invention relates to a method utilizing waste and bacterium dreg generated during the process of producing edible fungi from straw raw materials to produce a microorganism organic bacterium fertilizer. The method takes the waste and bacterium dreg generated in the process of producing edible fungi from straw as the raw material, and then subjects the raw materials to technology processes of bacterium dreg pretreatment, preparation of an activating and fermenting liquid, and microorganism secondary fermentation so as to produce the microorganism organic bacterium fertilizer. The product can be used as a normal microorganism bacterium fertilizer, can improve the agricultural crop output by 3% or more, and achieves the goals of soil structure modification, soil pH value adjustment, fertilizer cost reduction, output and quality improvement, and pesticide residue degradation, and the like. The method provided by the invention has the advantages of mature and practicable technology route, abundant and wide source of raw material for production, low cost, and convenient preparation; has production technology innovation and an application promotion value, solves the problems of resource waste and secondary pollution existing in the straw cyclic utilization, increases the economic income for farmers, and achieves the goal of agricultural development.

Owner:孙悦迎

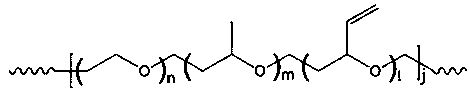

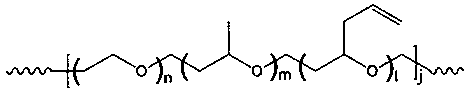

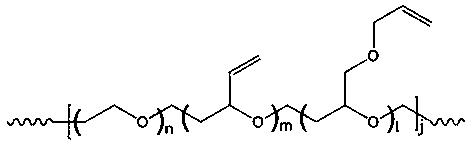

All-solid-state polymer electrolyte with semi-interpenetrating network structure, and preparation method of electrolyte

ActiveCN110233288AImprove mechanical propertiesHigh room temperature ionic conductivitySolid electrolytesSecondary cellsCross-linkPolymer science

The invention discloses an all-solid-state polymer electrolyte with a semi-interpenetrating network structure, and a preparation method of the electrolyte. The all-solid-state polymer electrolyte is mainly prepared from the following raw materials in parts by weight: 50-95 parts of a modified block copolymer, 5-50 parts of a polyether acrylate oligomer monomer, a proper amount of a solvent, 0.1-1part of an initiator, 10-60 parts of lithium salt and 0-50 parts of an assistant. The all-solid-state polymer electrolyte is a polyether electrolyte with the semi-interpenetrating network structure; the modified block copolymer is used as a matrix; and the acrylate oligomer monomer containing multi-alkenyl functional groups is introduced to generate a cross-linking polymerization reaction so as toform two polyether semi-interpenetrating network structures. Compared with an existing polymer electrolyte, other inorganic fillers or toughening agents do not need to be doped; the obtained polymerelectrolyte has good mechanical properties; the ionic conductivity at the room temperature is greatly improved; and an electrochemical window is wider, so that the matching of high-voltage electrode materials is facilitated, and a lithium battery with higher energy density is obtained.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

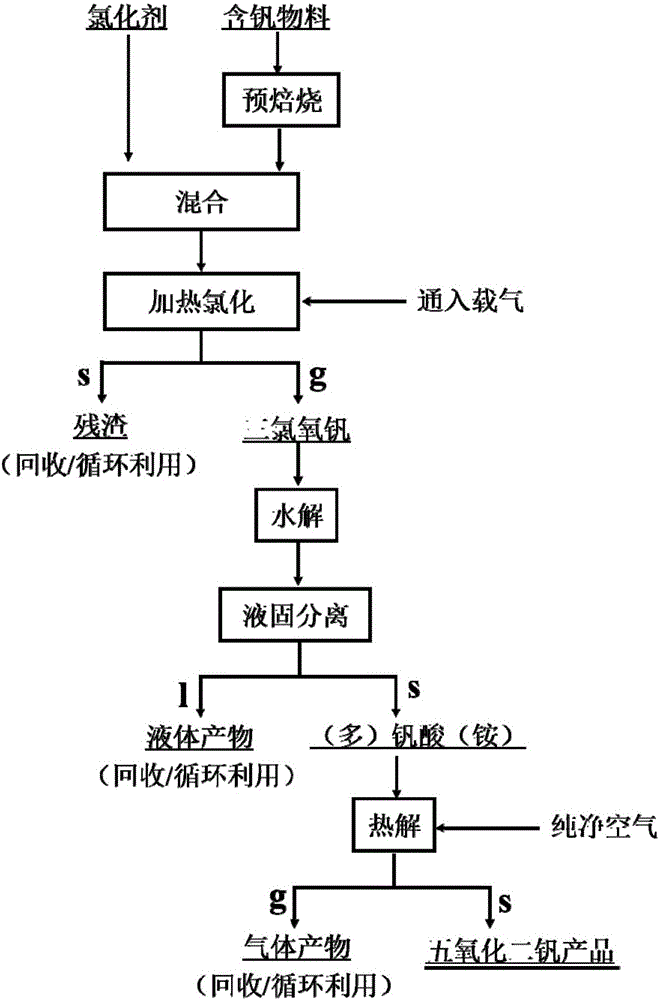

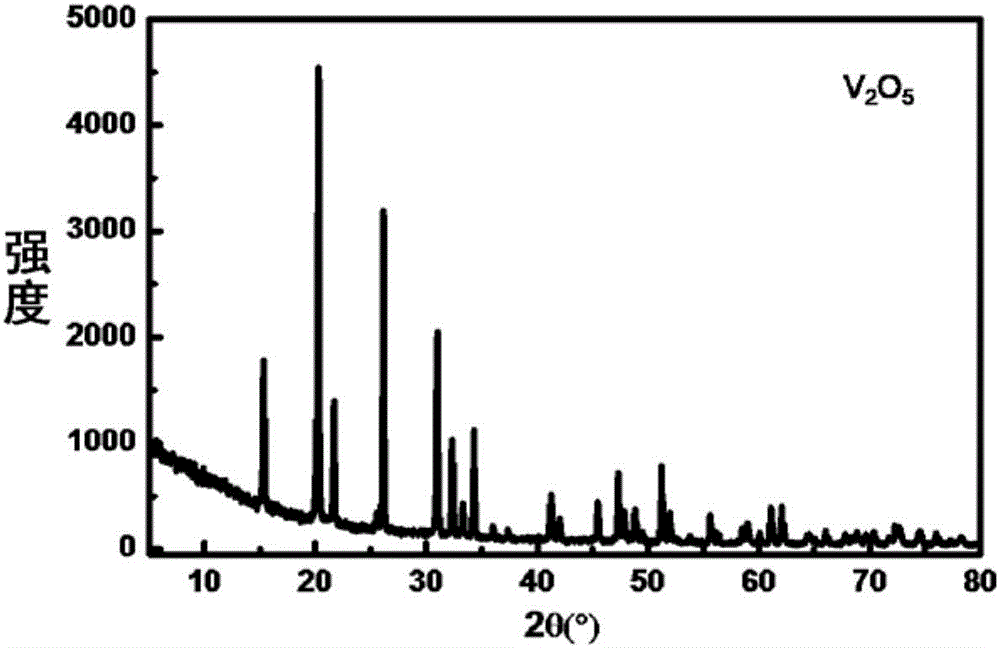

Method for preparing high-purity vanadium pentoxide by using vanadium-contained material

ActiveCN106676289AHigh purityMild process conditionsVanadium oxidesProcess efficiency improvementReaction temperatureImpurity

The invention provides a method for preparing high-purity vanadium pentoxide by using a vanadium-contained material. The method comprises the following steps: the vanadium-contained material is roasted to obtain a roasted product with the content of vanadium pentoxide below 49 wt%; then, the roasted product and a chlorinating agent are reacted in an inert atmosphere at a reaction temperature of 150-200 DEG C to obtain vanadium oxytrichloride gas and residues; the aftertreatment is performed for the vanadium oxytrichloride gas to obtain the high-purity vanadium pentoxide; and the chlorinating agent is selected from anhydrous aluminum trichloride or a mixture of anhydrous aluminum trichloride and sodium chloride. The method is mild in conditions, escapes vanadium in a gas form, is easy to separate vanadium from other substances, is higher in product purity, saves subsequent separation and impurity removal steps, and can obtain vanadium pentoxide products with the purity of not lower than 99%. The method is simple in technological process, short in needed reaction time, wide in raw material sources and easy to obtain raw materials, effectively reduces the production cost, reduces generation of three wastes, and is low in environmental pollution.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

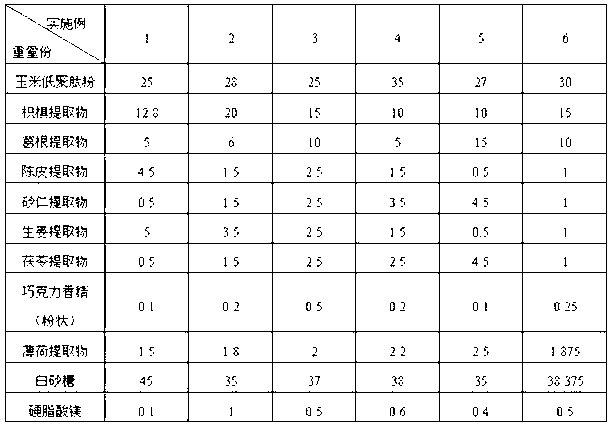

Corn oligopeptide powder buccal tablet and preparation method thereof

ActiveCN103005440ASlows the rate at which ethanol is absorbedAvoid damageFood preparationFood additiveAlcoholisms

The invention discloses a corn oligopeptide powder buccal tablet and a preparation method thereof. The corn oligopeptide powder buccal tablet comprises the following components in part by weight: 25-3-5 parts of corn oligopeptide powder, 10-20 parts of hovenia acerba extract, 5-1-5 parts of kudzu root extract, 0.5-5 parts of dried tangerine peel extract, 0.5-5 parts of amomum extract, 0.5-5 parts of ginger extract, 0.5-5 parts of poria extract, 0.1-0.-5 parts of food additive, 1.5-2.-5 parts of mint extract, 35-4-5 parts of white granulated sugar and 0.1-1 part of anti-caking agent. The preparation method comprises the following steps: crushing raw materials, softening the raw materials, granulating by a wet method, drying, sieving, finishing granules, adding the anti-caking agent, tabletting and packaging. The corn oligopeptide powder buccal tablet is scientific and reasonable in formulation, all-around in nutritional and health-care functions of protecting the liver, relieving alcoholism, strengthening the spleen and the stomach and reducing the blood pressure and the blood lipid, good in palatability, safe and non-toxic; and the preparation method is simple and feasible and low in cost.

Owner:江苏青贝健康科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com