Patents

Literature

77 results about "Vanadium oxytrichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vanadium oxytrichloride is the inorganic compound with the formula VOCl₃. This yellow distillable liquid hydrolyzes readily in air. It is an oxidizing agent. It is used as a reagent in organic synthesis. Samples often appear red or orange owing to an impurity of vanadium tetrachloride.

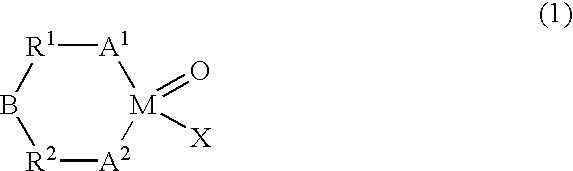

Olefin polymerization catalysts and olefin polymer production methods using said olefin polymerization catalysts

InactiveUS6525150B1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparation1-OcteneOctene

Olefins are homopolymerized or copolymerized in the presence of a catalyst containing a reaction product obtained from vanadium oxytrichloride and 2,2'-thiobis(6-t-butyl-4-methylphenyl), an organic aluminum compound, such as trimethylaluminum, and an ionized ionic compound, such as N,N-dimethylanilinium tetrakis(pentafluorophenyl)borate, and the like. By using this catalyst to polymerize ethylene with an alpha-olefin, such as propylene, 1-heptene, 1-octene, and the like, or a non-conjugated diene, such as 5-ethylidene-2-norbomene, and the like, a polymer having a high degree of copolymerization is obtained.

Owner:JSR CORPORATIOON

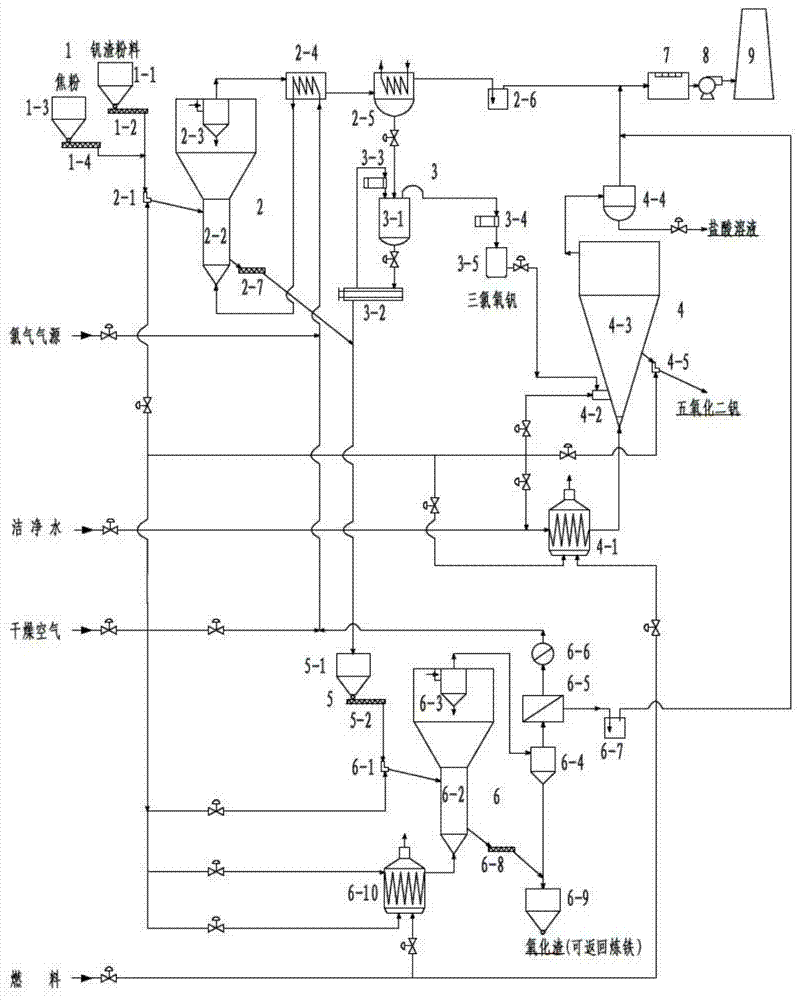

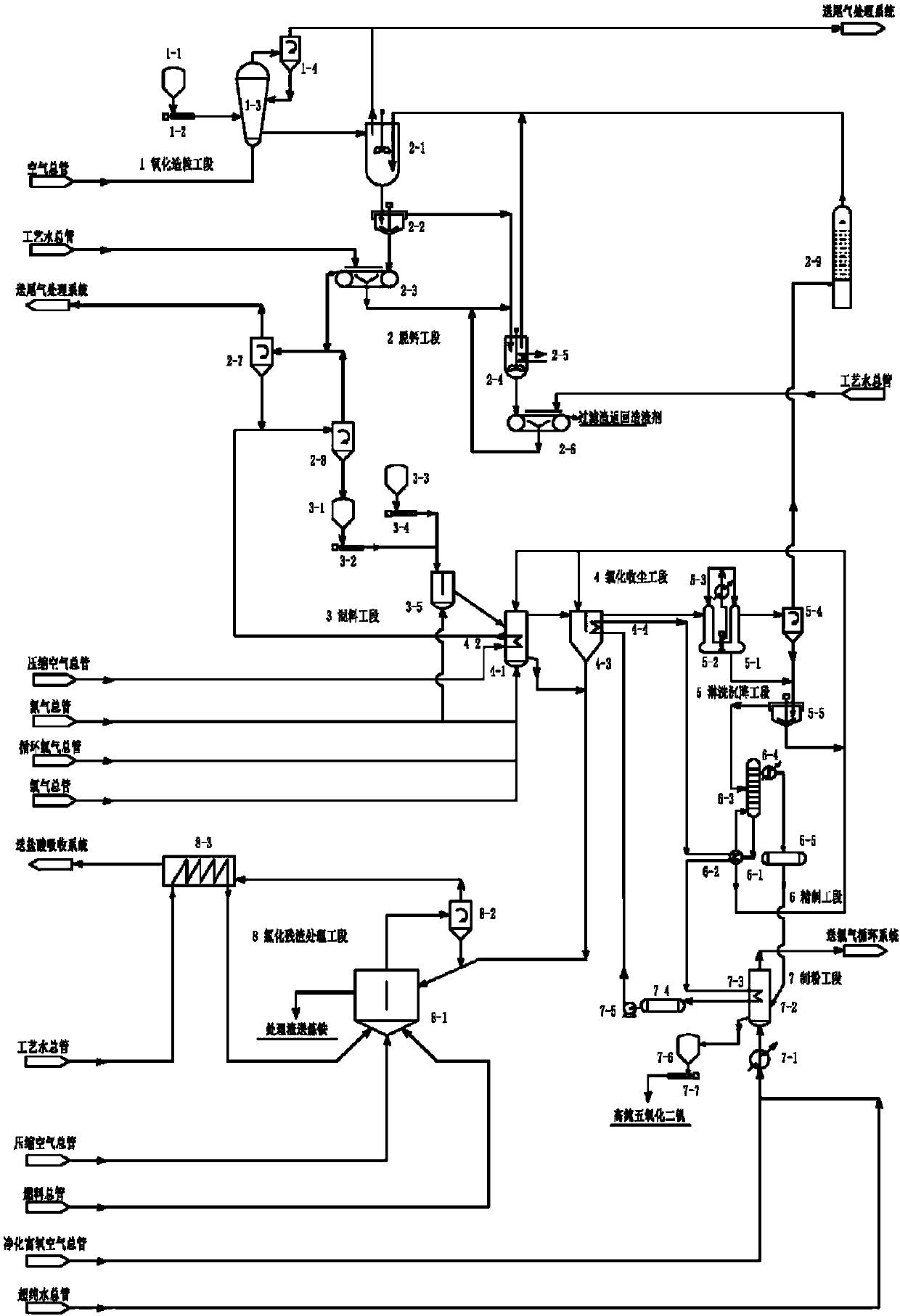

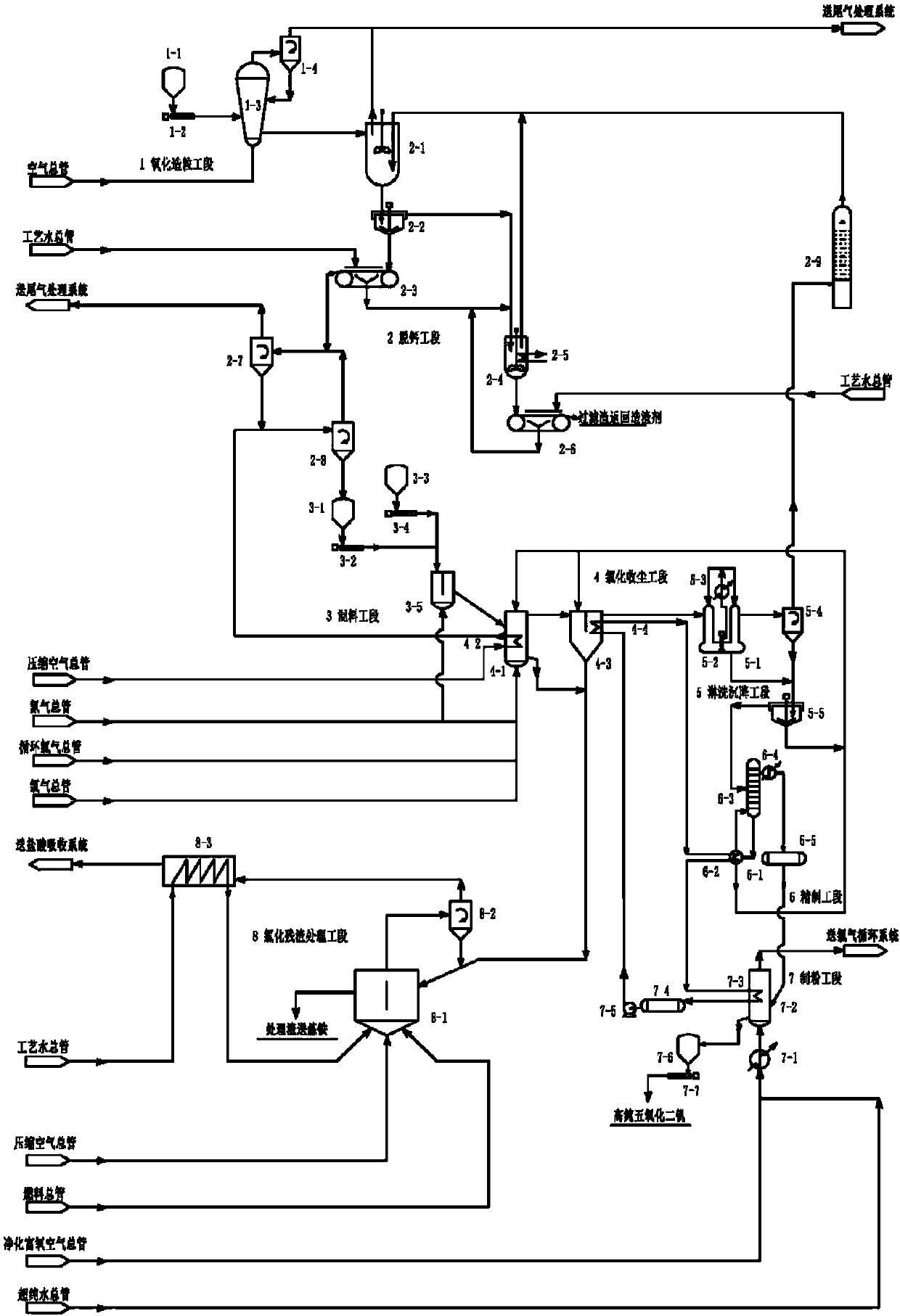

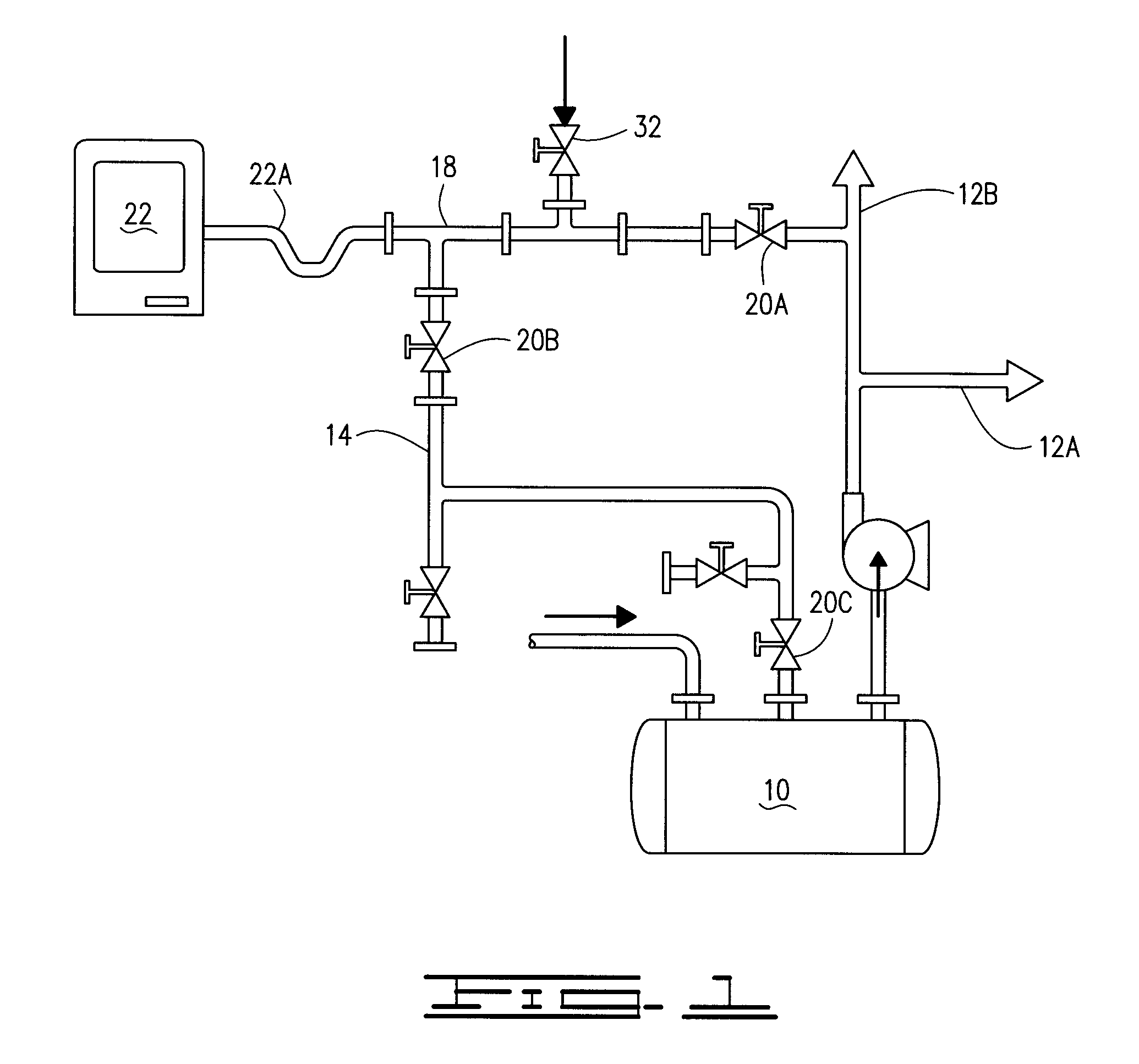

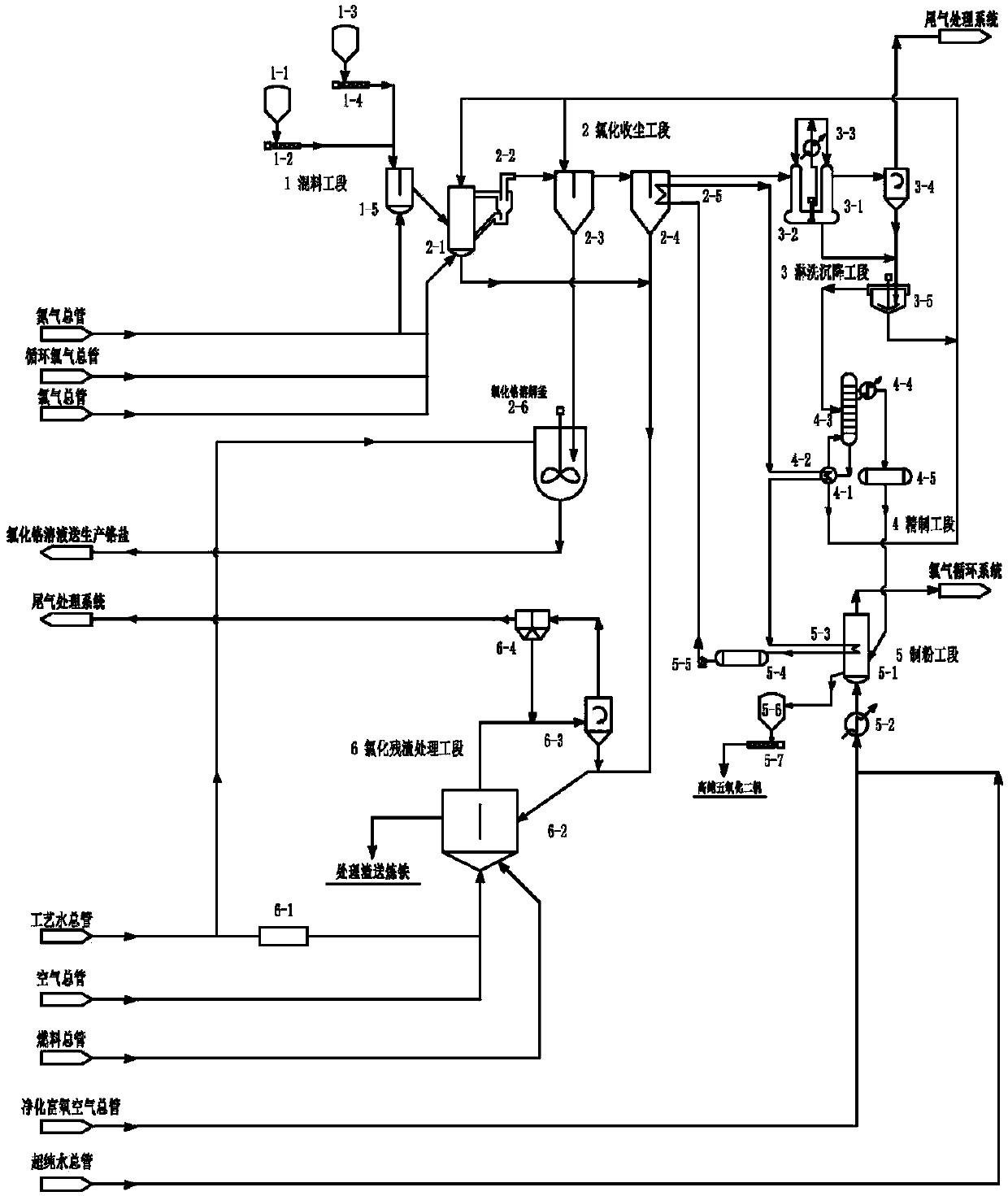

A system and method for efficiently chlorinating vanadium from vanadium slag

ActiveCN105986126BAchieve warm-upUniform temperature distributionVanadium oxidesProcess efficiency improvementSlagGas phase

Provided are a system and method for highly effective chlorination and vanadium extraction from vanadium slag. By means of heat exchange between a chlorination gas and a chlorination flue gas, a chlorination gas is preheated and an appropriate amount of air is added, which causes coke powder to partially combust, thus providing a balanced supply of heat during the process of chlorination; also, by means of high-temperature fluidization oxidation of the chlorinated slag, the chlorinated slag is used in a comprehensive manner, and the chlorine gas is recycled; further, by means of vapor-phase hydrolysis of the vanadium oxytrichloride product of chlorination, a powdered divanadium pentoxide product is obtained; the reaction efficiency of chlorination is improved, the consumption of chlorine gas is reduced, the harm of chlorinated slag is eliminated, and the pollution problem caused by conventional ammonium salt precipitation is prevented.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

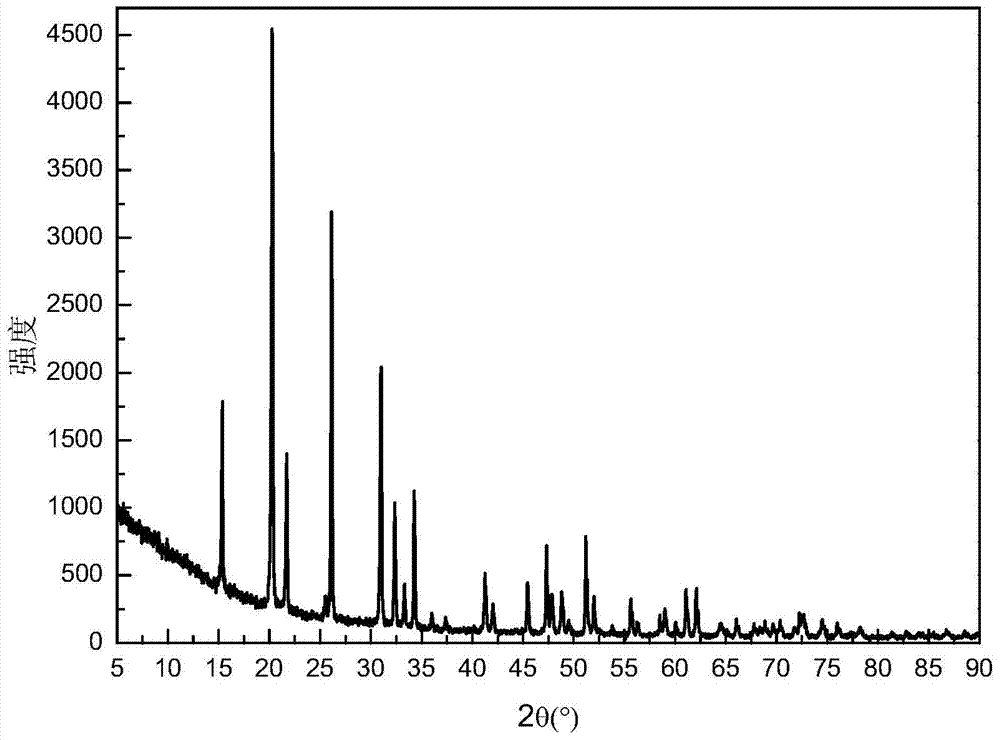

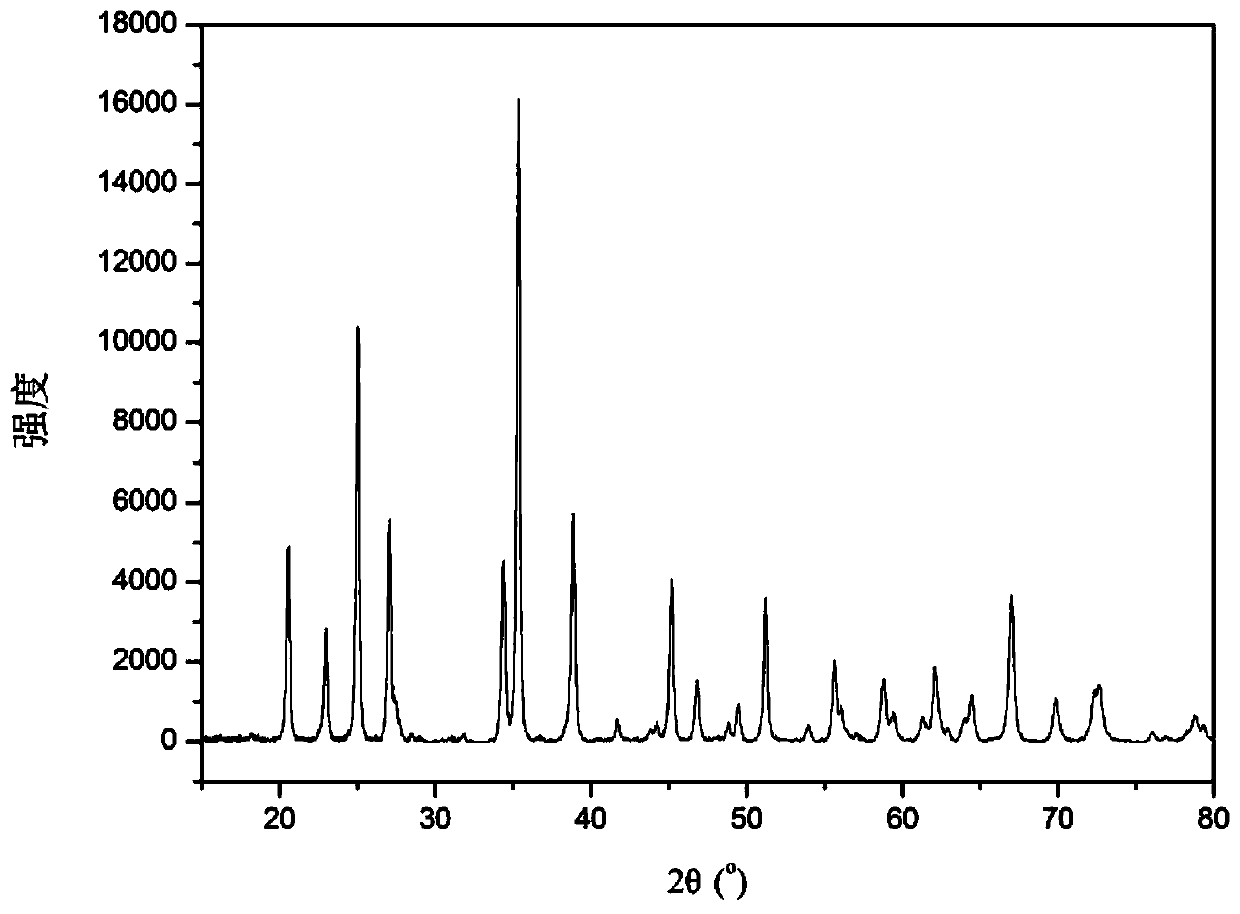

Method for preparing high-purity vanadium pentoxide by using vanadium-contained material

ActiveCN106676289AHigh purityMild process conditionsVanadium oxidesProcess efficiency improvementReaction temperatureImpurity

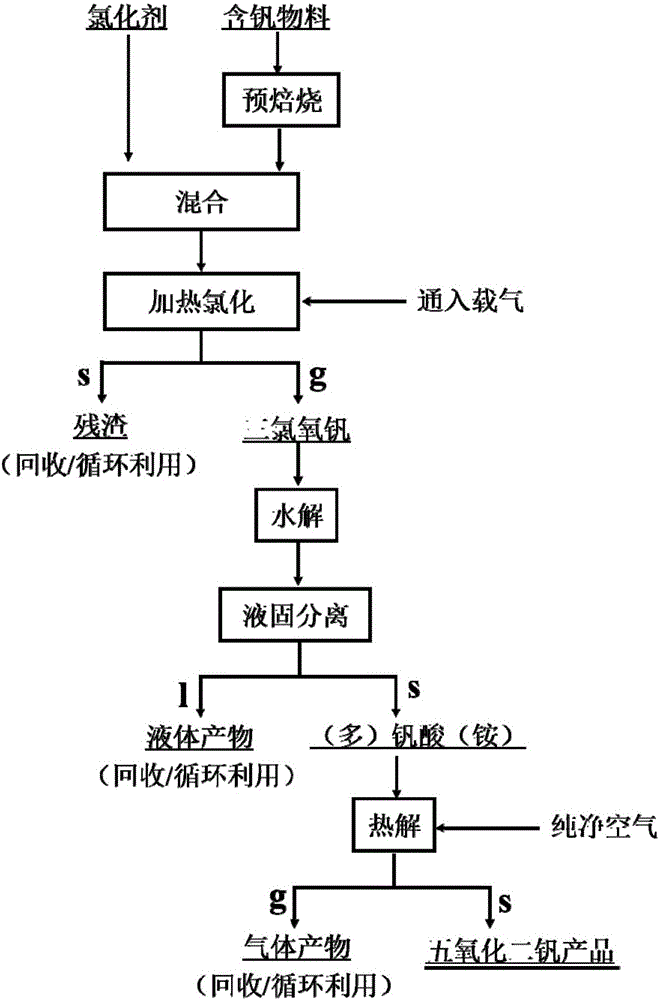

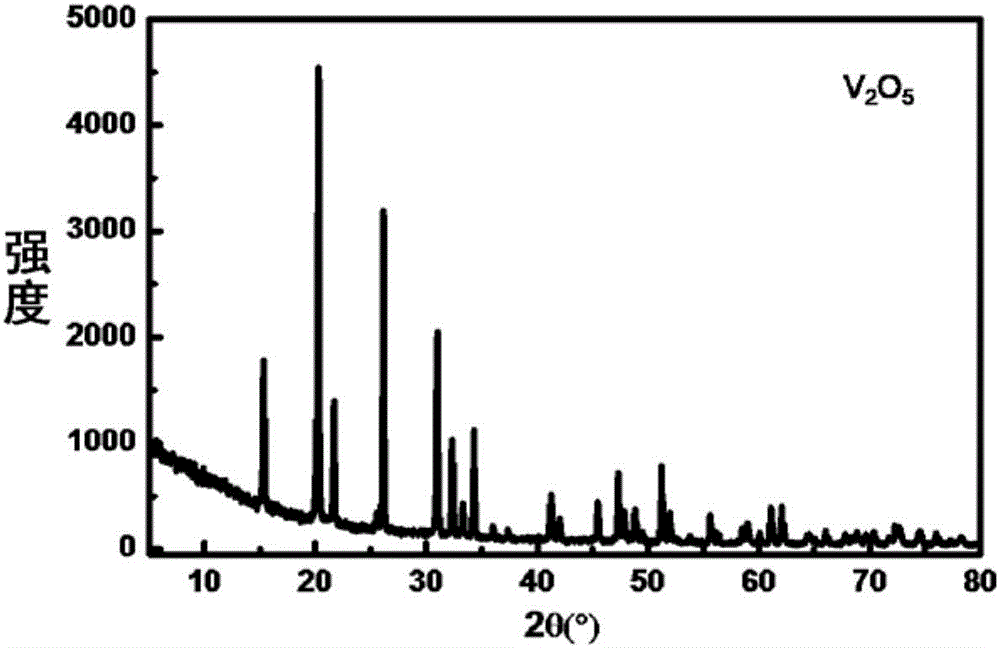

The invention provides a method for preparing high-purity vanadium pentoxide by using a vanadium-contained material. The method comprises the following steps: the vanadium-contained material is roasted to obtain a roasted product with the content of vanadium pentoxide below 49 wt%; then, the roasted product and a chlorinating agent are reacted in an inert atmosphere at a reaction temperature of 150-200 DEG C to obtain vanadium oxytrichloride gas and residues; the aftertreatment is performed for the vanadium oxytrichloride gas to obtain the high-purity vanadium pentoxide; and the chlorinating agent is selected from anhydrous aluminum trichloride or a mixture of anhydrous aluminum trichloride and sodium chloride. The method is mild in conditions, escapes vanadium in a gas form, is easy to separate vanadium from other substances, is higher in product purity, saves subsequent separation and impurity removal steps, and can obtain vanadium pentoxide products with the purity of not lower than 99%. The method is simple in technological process, short in needed reaction time, wide in raw material sources and easy to obtain raw materials, effectively reduces the production cost, reduces generation of three wastes, and is low in environmental pollution.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

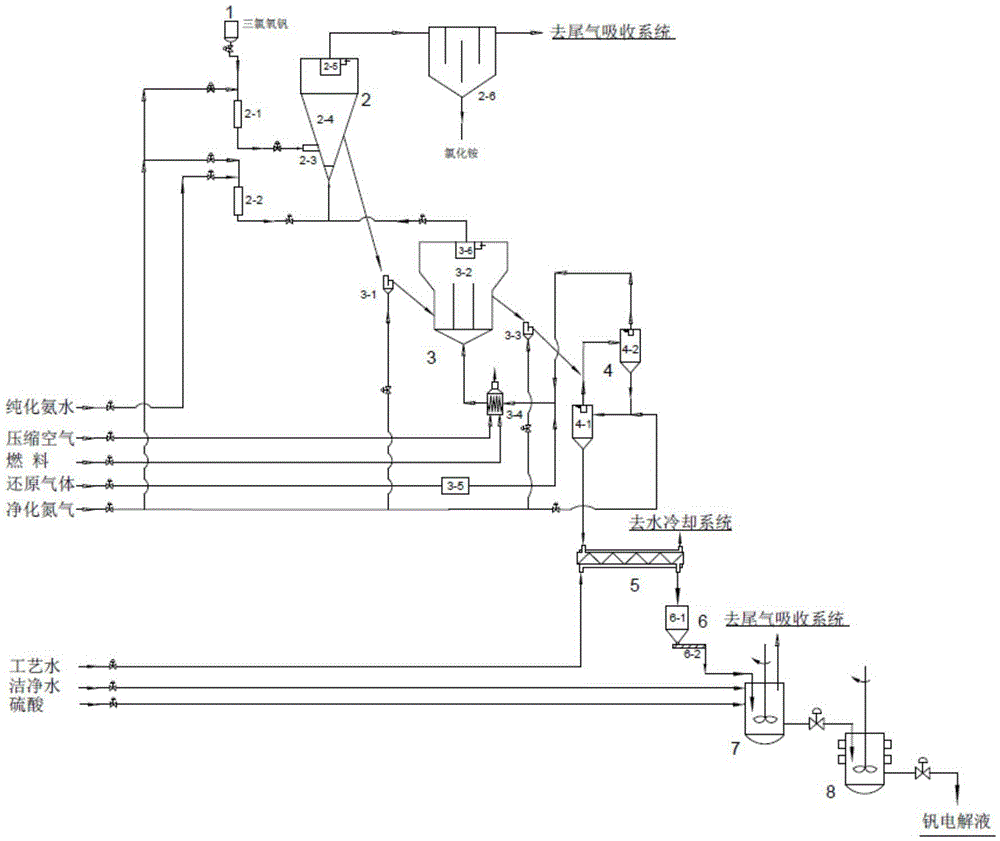

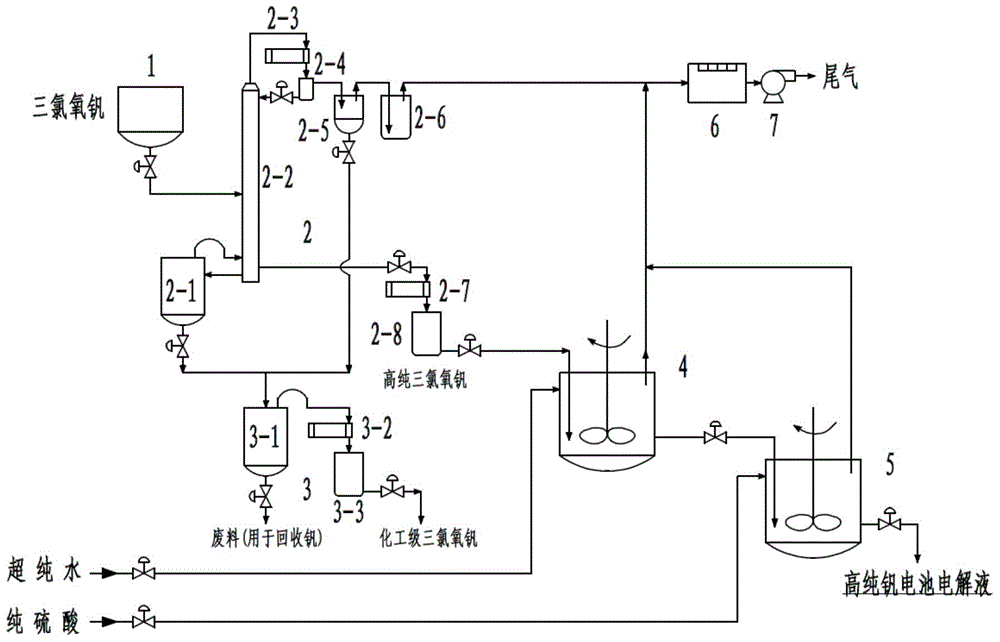

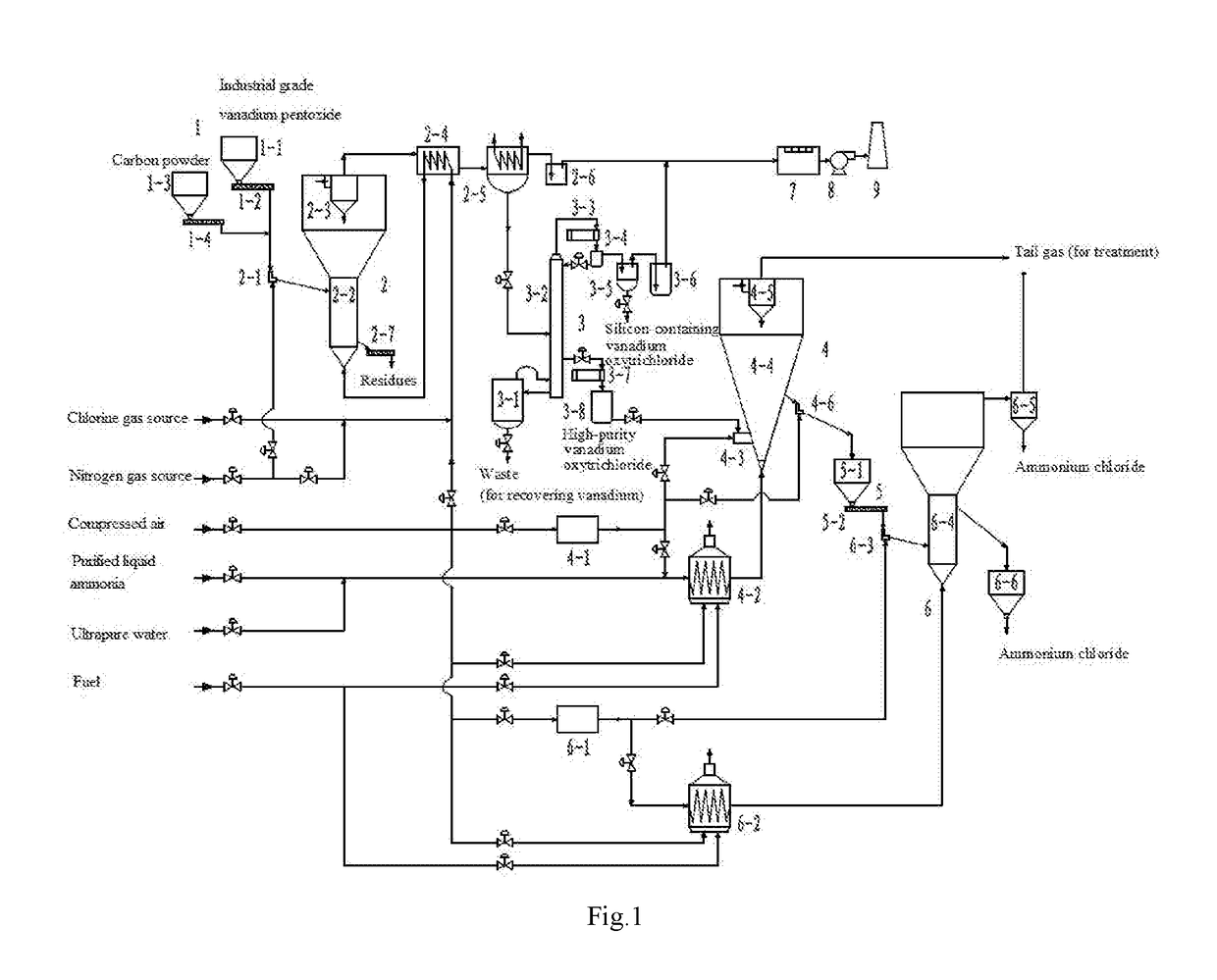

System for producing 3.5-valent high-purity vanadium electrolyte and method thereof

ActiveCN106257728AHigh purityHigh activityRegenerative fuel cellsVanadium oxidesGas phaseVanadium oxide

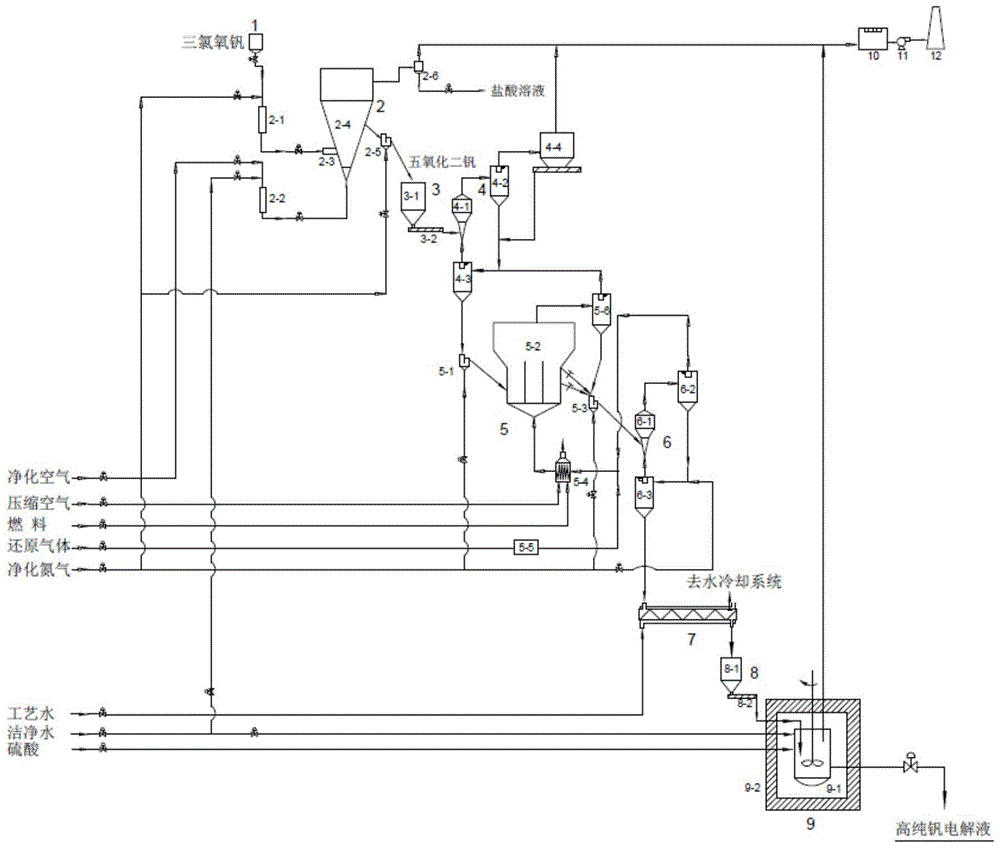

The invention discloses a system for producing a 3.5-valent high-purity vanadium electrolyte and a method thereof. According to the invention, fluidized bed gas phase hydrolysis is employed for hydrolyzing high-purity vanadium oxytrichloride to vanadic anhydride, vanadic anhydride in a reduction fluidized bed is accurately controlled and reduced to the low-valent vanadium oxide with vanadium average valence of 3.5, under applied microwave field, the 3.5-valent high-purity vanadium electrolyte is dissolved at low temperature by adding water and a sulfuric acid solution, and the electrolyte is directly used in all-vanadium redox flow battery new electric pile. The method for preparing vanadic anhydride through fluidized bed gas phase hydrolysis has the advantages of short flow and high efficiency, arrangement of an inner member in the reduction fluidized bed realizes accurate regulation and control of valence of the reduction products, dissolving of vanadium oxide is promoted and the vanadium ions are activated through special chemical effect of the microwave field, the electrolyte is prepared through dissolving in a low temperature zone, and the electrolyte activity is greatly increased. The system has the advantages of short flow, high efficiency cleaning, and stable product quality, is suitable for large-scale industrial production, and has good economic benefit and social benefit.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Water-borne rust-based anticorrosion coating and preparation method thereof

InactiveCN103183989AGood compatibilityImprove stabilityAnti-corrosive paintsMetallic material coating processesVanadium oxytrichlorideMaterials science

The invention discloses a water-borne rust-based anticorrosion coating which comprises the following raw materials by weight portion: 60-70 portions of styrene-acrylic emulsion, 30-40 portions of water-borne acrylic emulsion, 2-4 portions of alcohol ester-12 forming additive, 2-3 portions of vanadium oxytrichloride, 0.5-0.8 portions of benzotriazole, 3-4 portions of glycerine, 2-4 portions of 2- methyl-1,3- propylene glycol, 2-3 portions of hydroquinone, 1-2 portions of pyrocatechol, 2-3 portions of Ethylene Diamine Tetra Methylene Phosphonic Acid Sodium, 3-4 porptions of citric acid, 1-2 portions of modified adhesive, 0.1-0.2 portions of carboxymethyl cellulose and an appropriate amount of deionized water. The coating has good comprehensive performances including base body adhesive power, rot resistance, adhesive power, can completely avoid coating preprocessing processes, including sand blasting and shot-blasting, and can provide lasting and efficient protection for iron steels, the surfaces of which are rusty and not subjected to pre-processing; and accordingly, not only is the service life of an anti-corrosion finishing coat prolonged, but also the anti-corrosion coating process is simpler, and more efficient, economical and environment-friendly.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

Recovery method and equipment of vanadium-containing slurry produced from titanic chloride refining process

InactiveCN101417813AEfficient separationReach recoverySludge treatmentNature of treatment waterRecovery methodChloride

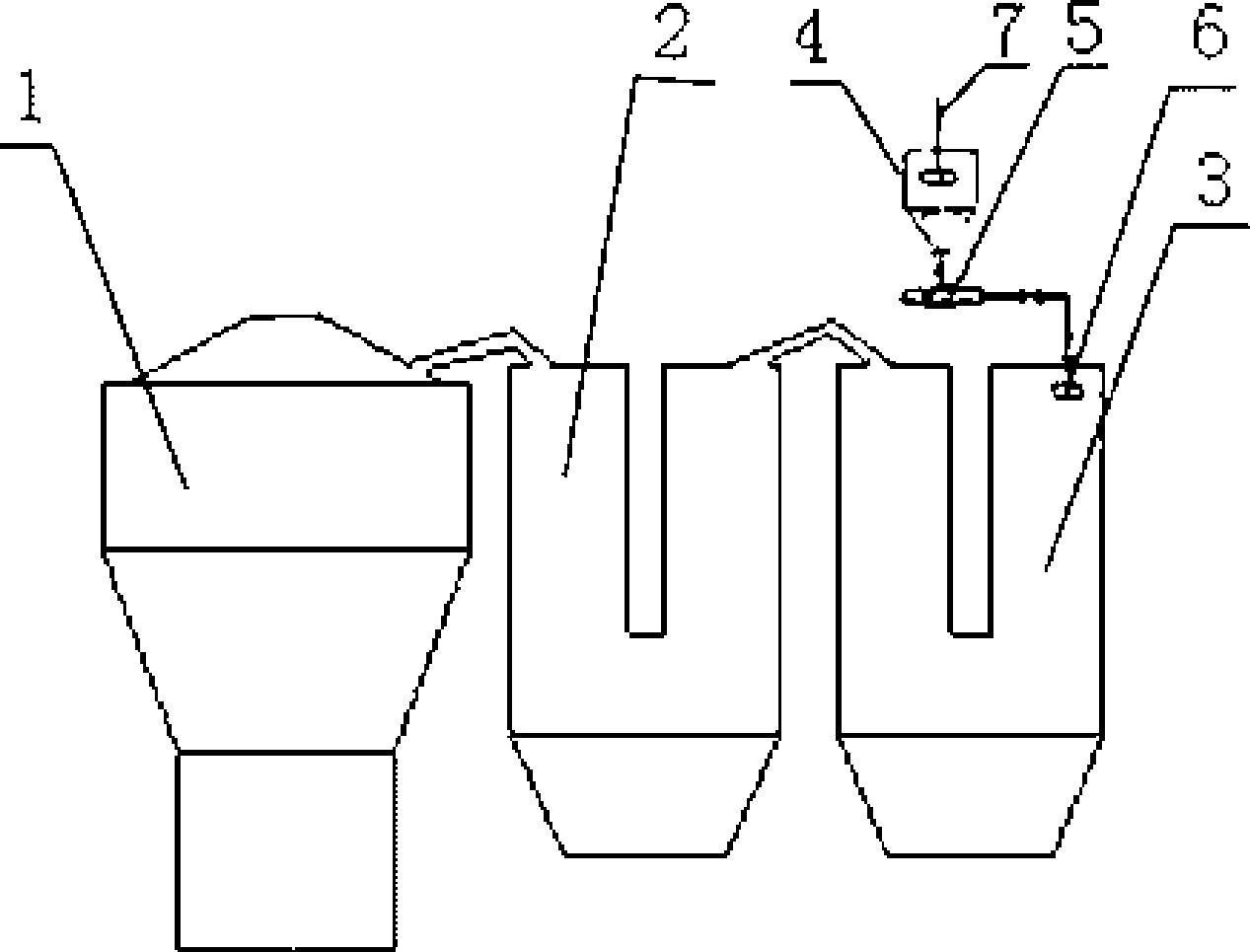

The invention provides a method for recovering vanadium contained slurry produced in the refining process of titanium tetrachloride and equipment thereof, wherein the method comprises: treating the vanadium contained slurry, converting the vanadium oxytrichloride in the vanadium contained slurry into vanadyl dichloride, and spraying the vanadium contained slurry to a chlorination system under the condition of controlling the temperature of the spraying point between 150 and 190 DEG C. The applied equipment comprises a chlorination furnace (1), a primary gravity dust precipitator (2) and a secondary gravity dust precipitator (3); the top of the secondary gravity dust precipitator (3) is provided with a vanadium contained slurry storage groove (4) which is connected with a single-screw pump (5), the single-screw pump (5) is connected with an atomizing device (6) and the atomizing device (6) is positioned inside the secondary gravity dust precipitator (3). Compared with the prior art, the method can effectively separate and recover the titanium tetrachloride in the vanadium contained slurry, thus reducing pollution, simplifying production process and saving production cost.

Owner:GUIYANG AL-MG DESIGN & RES INST

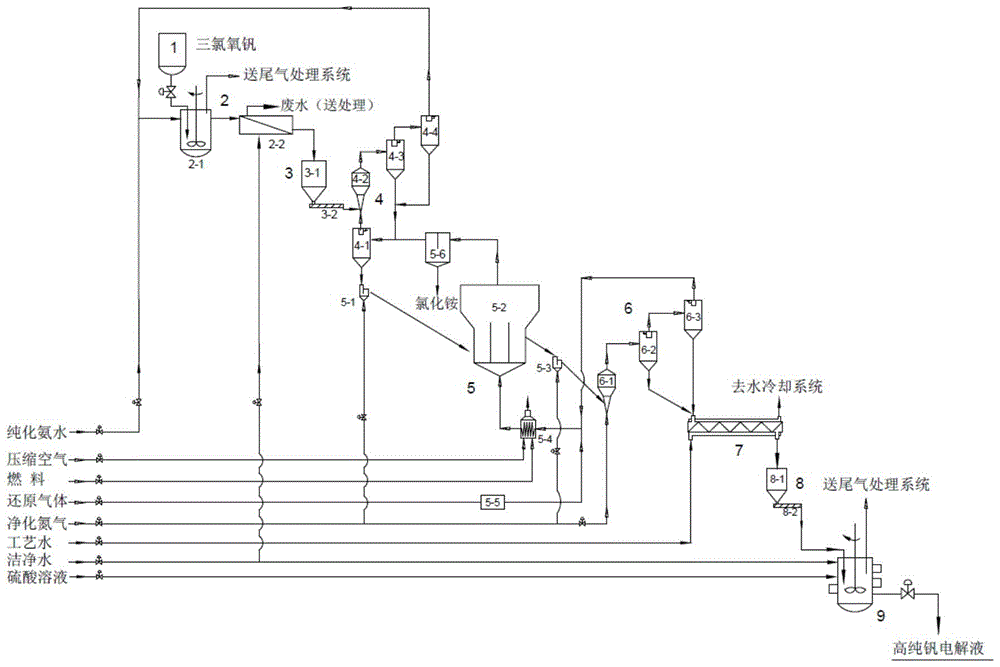

System for producing high-purity high-activity vanadium electrolyte and method thereof

ActiveCN106257726AHigh purityEasy to getRegenerative fuel cellsVanadium oxidesGas phaseBiological activation

The invention discloses a system for producing a high-purity high-activity vanadium electrolyte and a method thereof. According to the invention, fluidized bed gas phase ammoniation is employed for conversing high-purity vanadium oxytrichloride to ammonium salt, ammonium salt in the other fluidized bed is reduced to the low-valent vanadium oxide with vanadium average valence of 3.5, by adding clean water and sulfuric acid for dissolving, the 3.5-valent high pure vanadium electrolyte is obtained by employing supersonic wave activation, and the electrolyte is directly used in all-vanadium redox flow battery new electric pile. The method for preparing vanadium-containing ammonium salt through fluidized bed gas phase ammoniation has the advantages of short flow and high efficiency, arrangement of an inner member in the reduction fluidized bed realizes accurate regulation and control of valence of the reduction products, the vanadium ions are activated through ultrasonic treatment, and the electrolyte activity is greatly increased. The system has the advantages of short flow, high efficiency cleaning, and stable product quality, is suitable for large-scale industrial production, and has good economic benefit and social benefit.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

System and method of high purity vanadium electrolyte preparation

ActiveCN106257724AHigh purityHigh activityFinal product manufactureRegenerative fuel cellsDissolutionNitrogen gas

The invention discloses a system and method of high purity vanadium electrolyte preparation. Vanadium oxytrichloride as a raw material is precipitated by an ammonium salt, the precipitates are subjected to liquid reduction so that a low valent vanadium oxide is produced, a sulfuric acid solution and clean water are added into the low valent vanadium oxide and the mixture is treated under conditions of supersonic wave-assisted dissolution and activation at a low temperature so that a high purity vanadium electrolyte is formed. Through heat exchange between an ammonium salt and reduction tail gas and between a reduction product and fluidized nitrogen, heat is efficiently used. The ammonia gas in the reduction tail gas is recovered and used for vanadium precipitation so that ammonia gas recycling is realized. An inner member is arranged in a reduction fluidized bed so that accurate control of a reduction product valence is realized. Through use of supersonic wave-assisted dissolution and activation, the vanadium electrolyte is prepared at a low temperature and electrolyte activity is greatly improved. The method has the advantages of short process, high efficiency, cleaness and stable product quality, is suitable for large scale industrial production and has good economic benefits and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

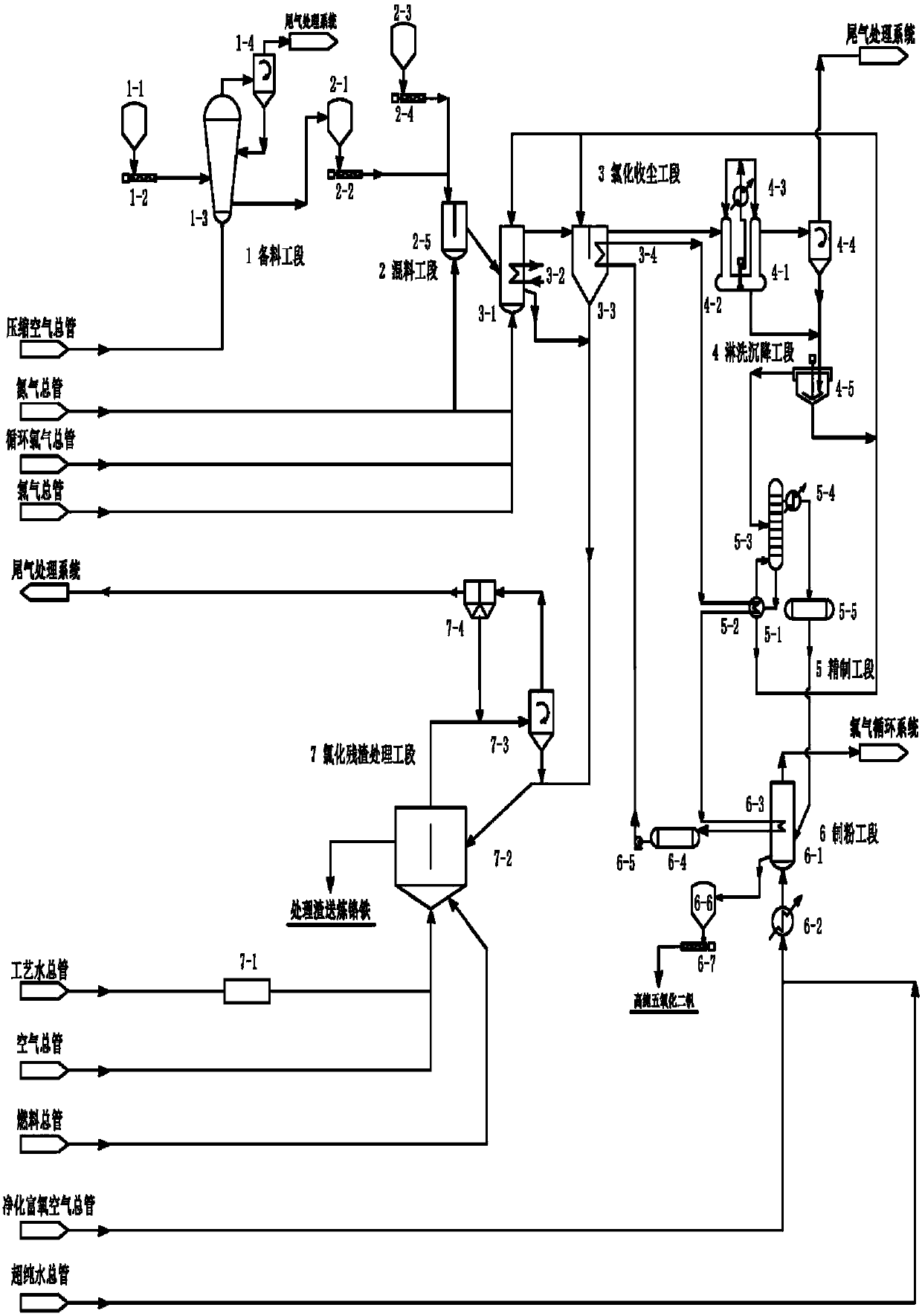

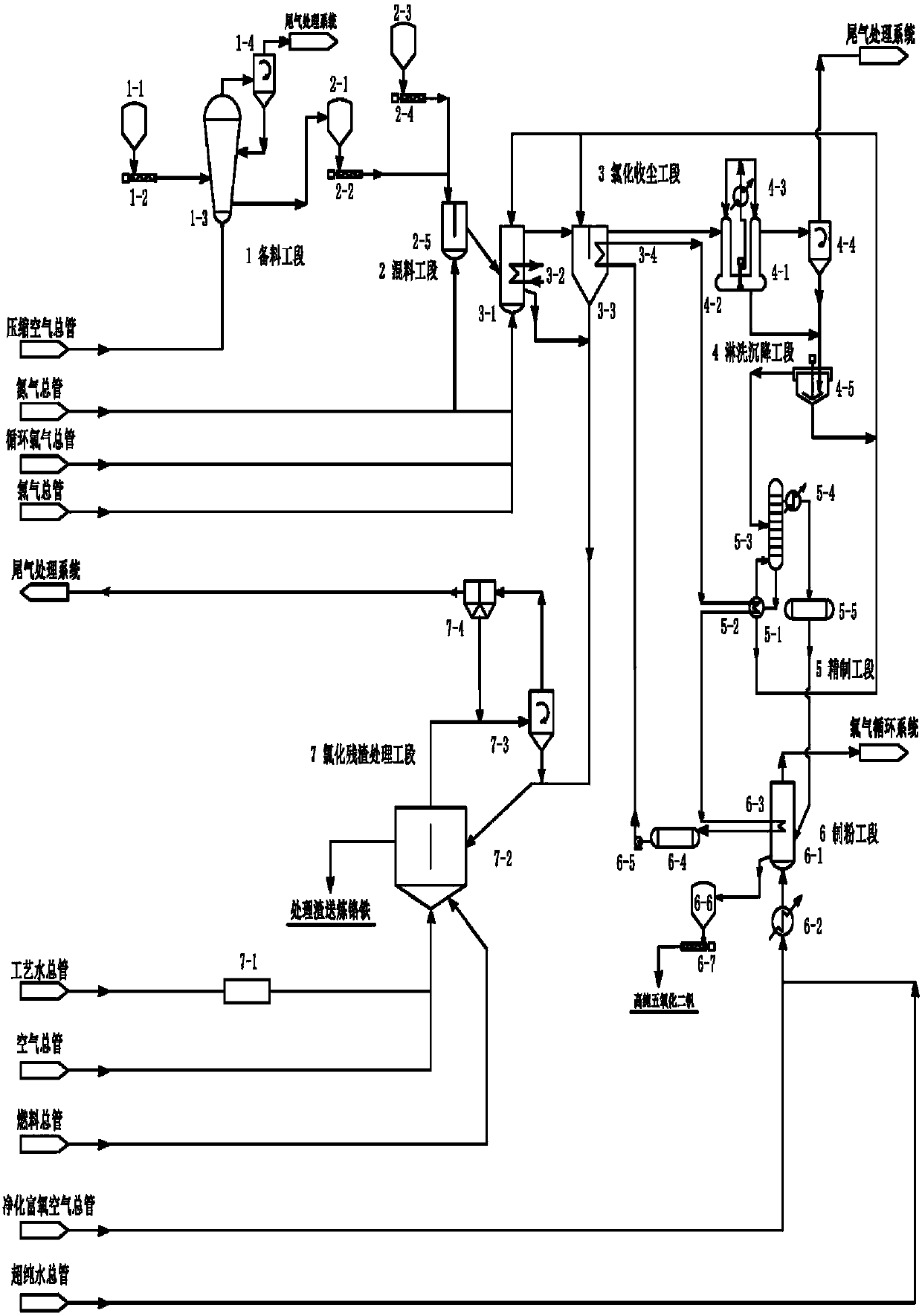

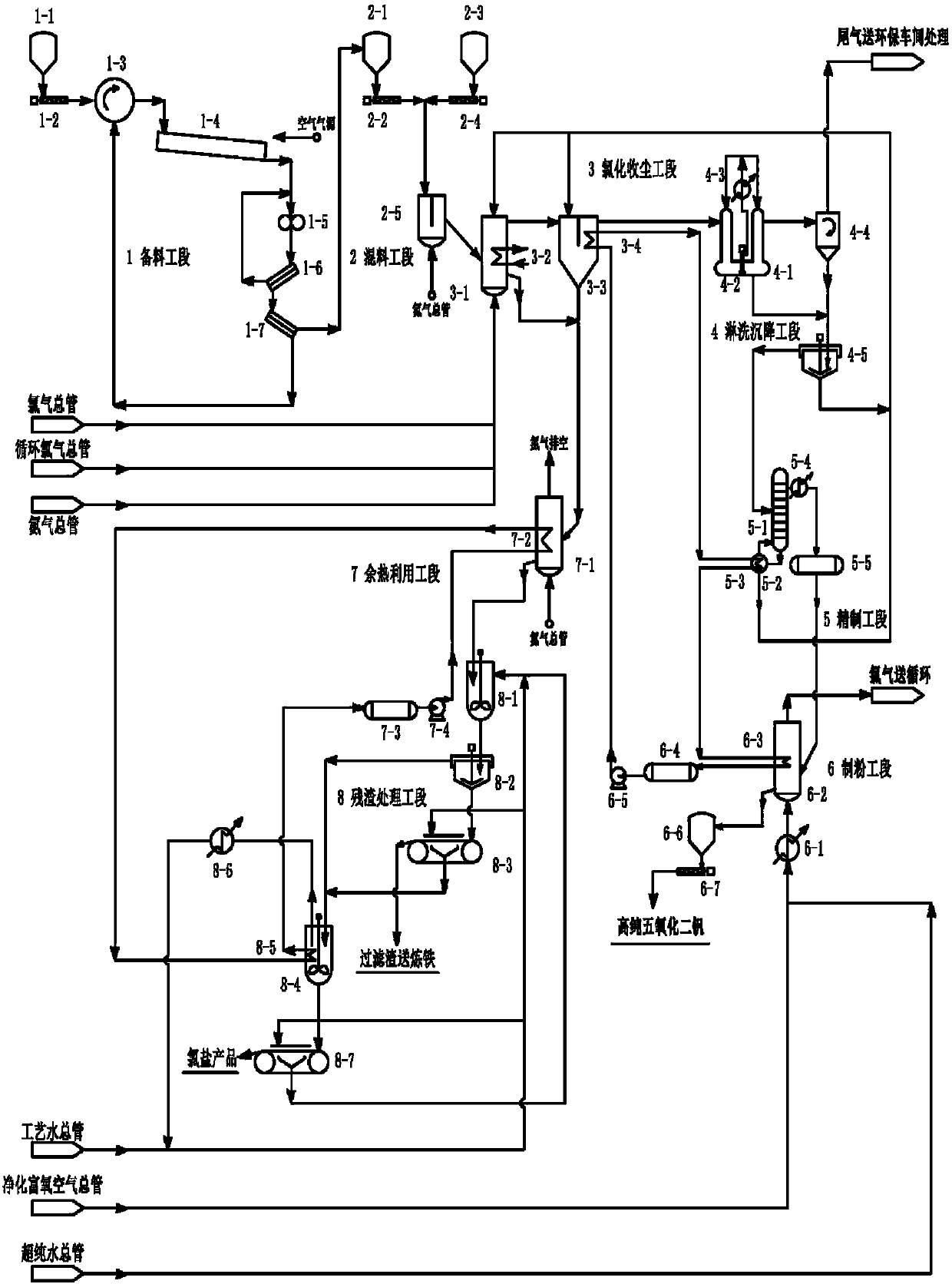

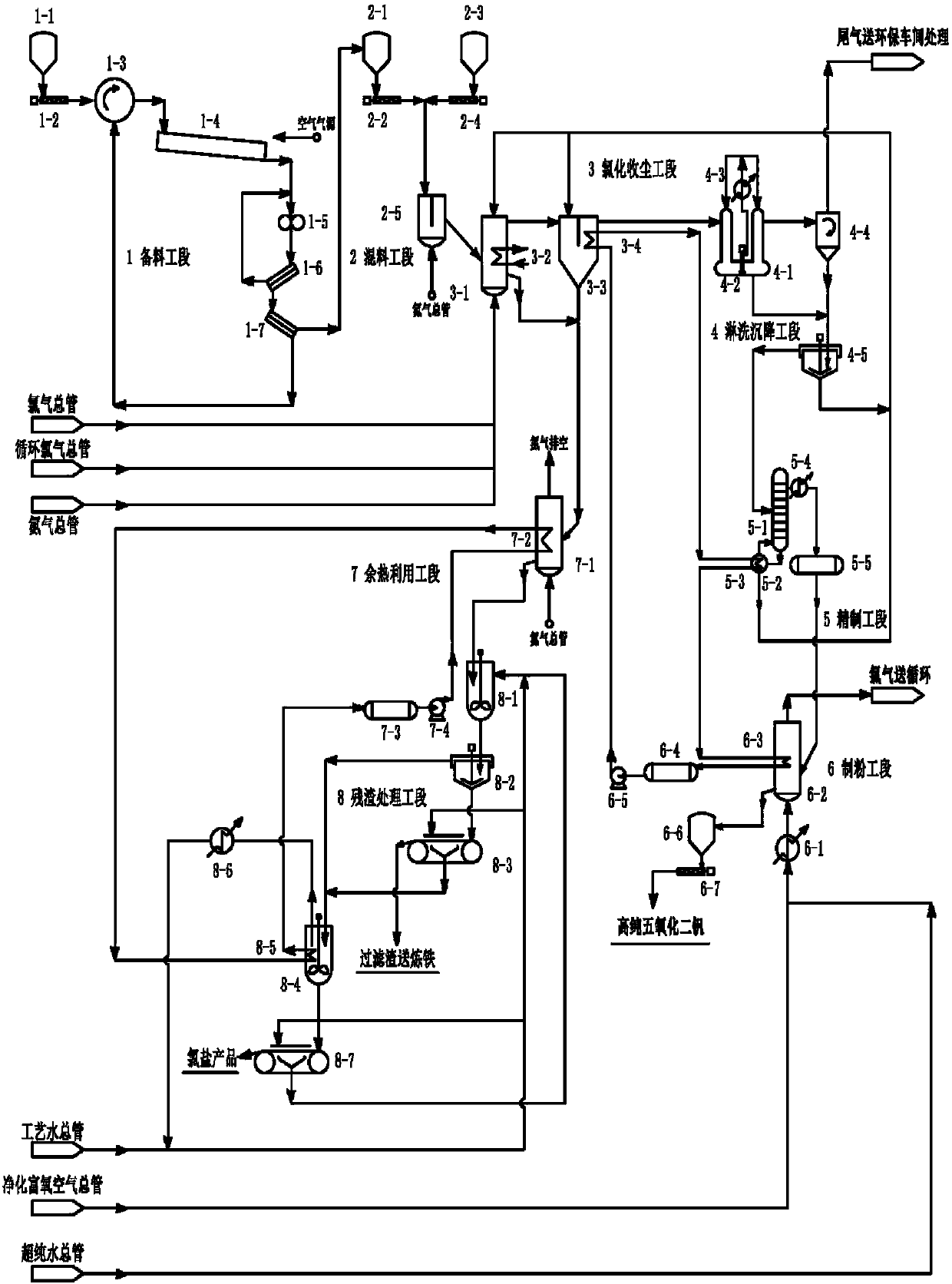

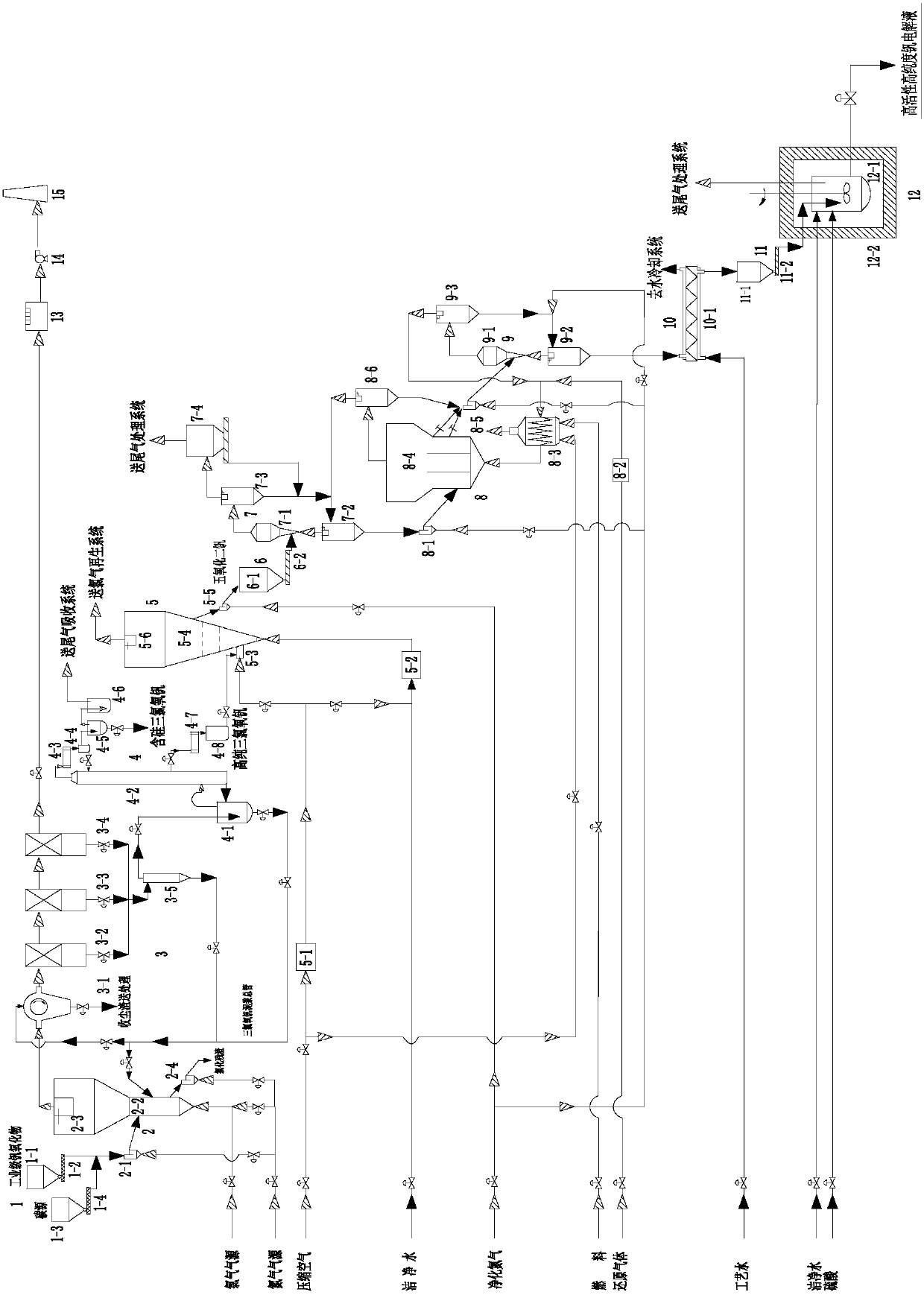

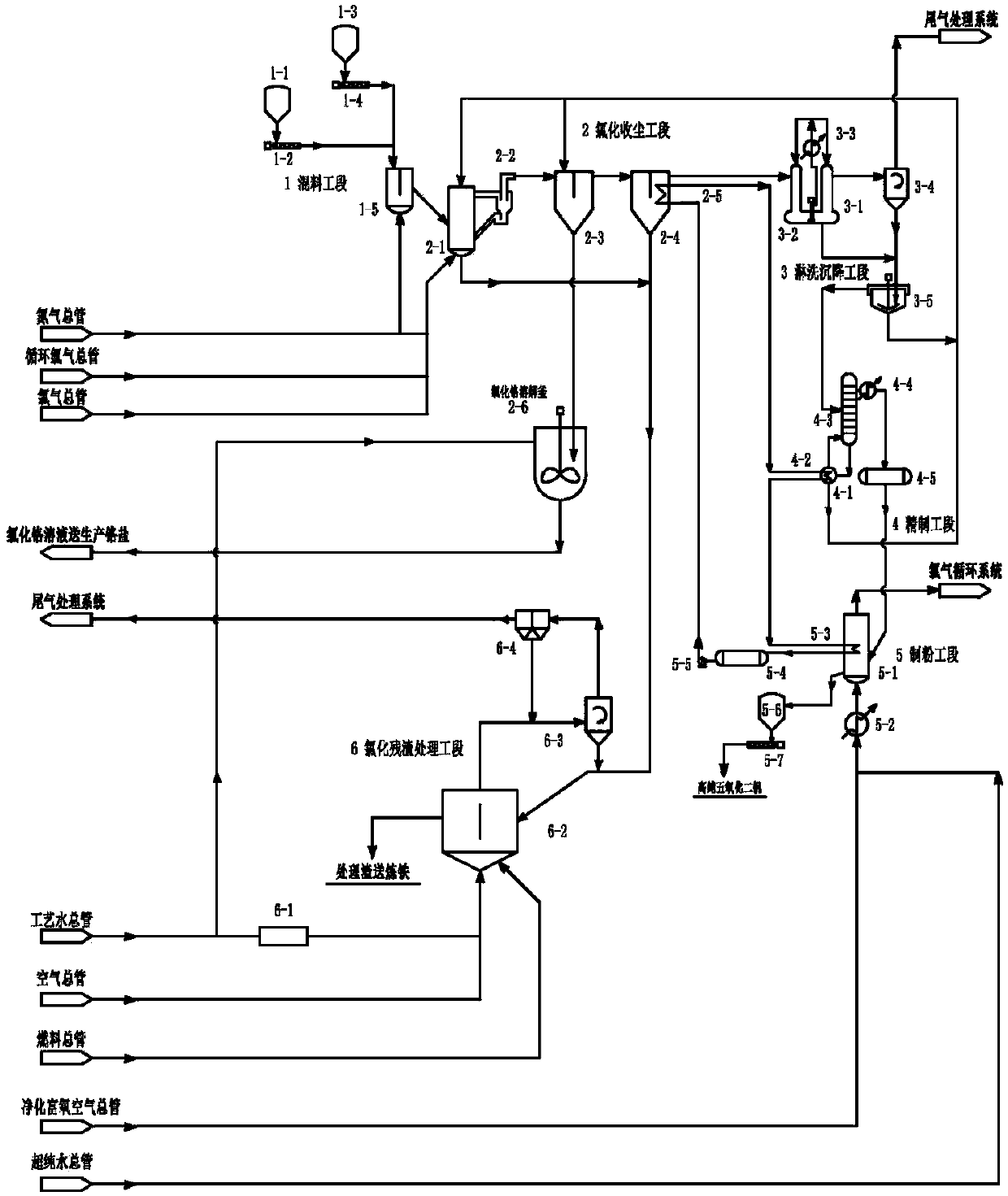

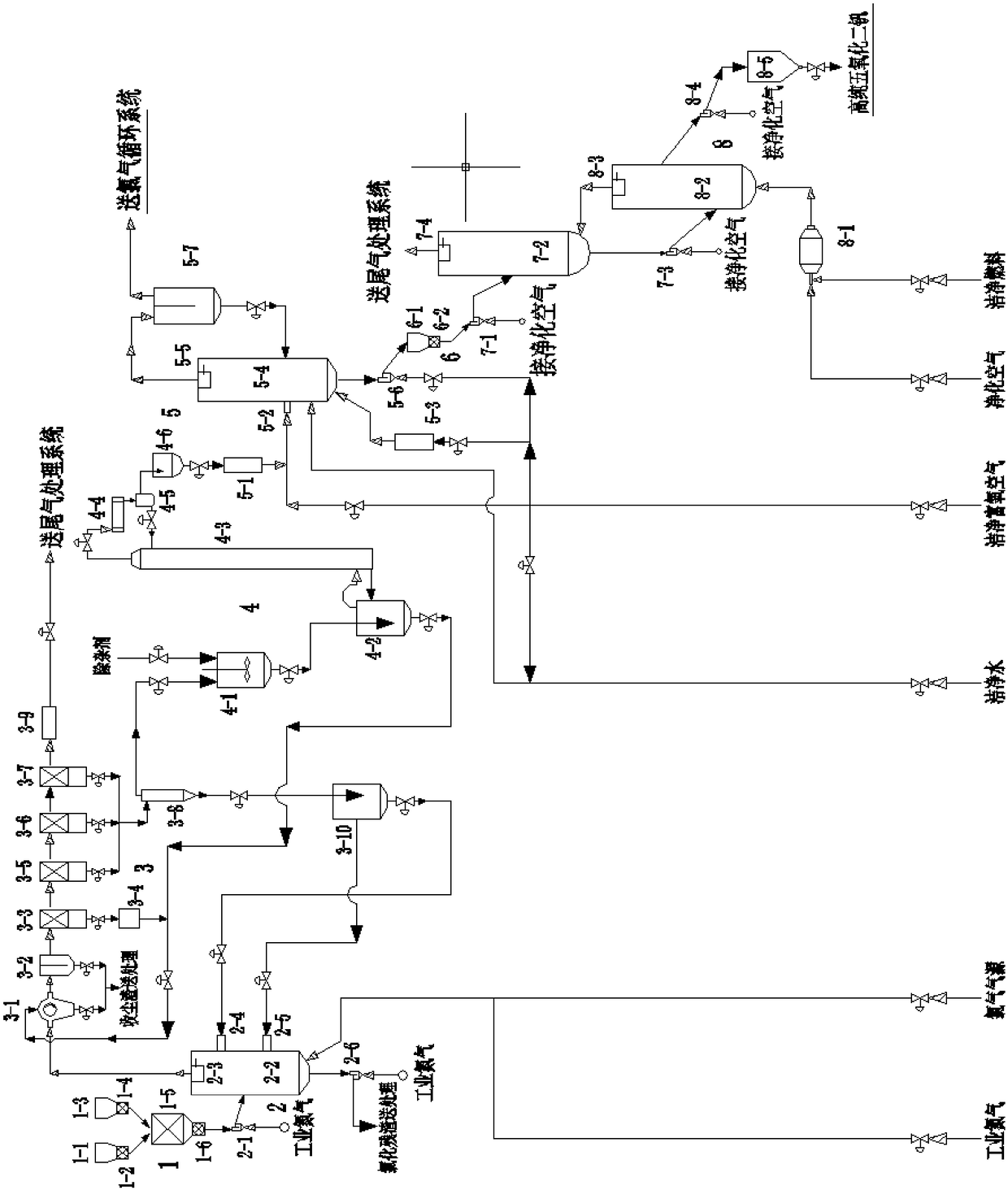

System and method for producing high-purity vanadium pentoxide through clean chlorination of vanadium residue

ActiveCN109835949AImprove chlorination selectivityAchieve separationChemical industryVanadium oxidesFlue gasFluidized bed

The invention discloses a system and a method for producing high-purity vanadium pentoxide through clean chlorination of vanadium residue. According to the present invention, through fluidized bed oxidative granulation treatment, the mineral phase reforming and the mineral particle growth of the vanadium residue are achieved; the vanadium in the vanadium residue is converted into gaseous vanadiumoxytrichloride through selective chlorination, and most of impurities such as chromium, iron, calcium, phosphorus, manganese, titanium, silicon and the like are remained in the chlorinated residue soas to achieve effective separation of other impurities such as vanadium, chromium and the like; the gaseous vanadium oxytrichloride is sequentially subjected to dust removal, leaching, settlement, rectification purification, catalytic oxidation and other processes to prepare the high-purity vanadium pentoxide; the chlorinated residue is subjected to gas phase hydrolysis dechlorination treatment, and the treated residue returns to ferrochromium smelting; and with the system and the method, the clean comprehensive utilization of vanadium residue is achieved, and the sensible heat of the high temperature flue gas of the chlorination furnace is effectively utilized so as to achieve the purposes of energy saving and consumption reduction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

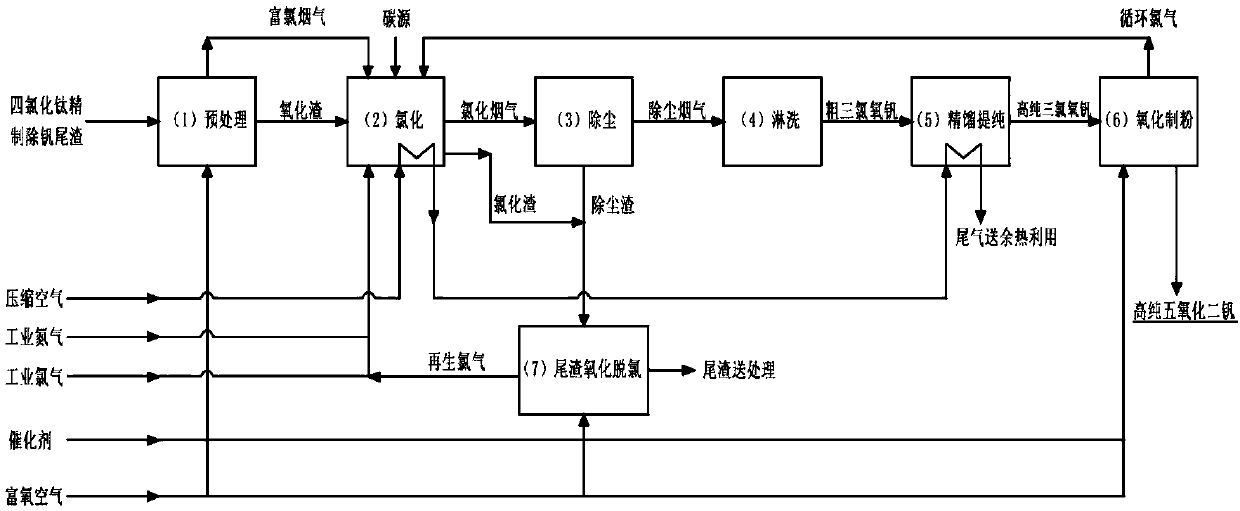

Method for producing high-purity vanadium pentoxide through titanium tetrachloride refined vanadium-removed tailings

The invention discloses a method for producing high-purity vanadium pentoxide through titanium tetrachloride refined vanadium-removed tailings. The method includes the seven processes: pre-treatment (1), chlorination (2), dust removal (3), drip washing (4), distillation purification (5), oxidation powdering (6) and tailing oxidation dechlorination (7). According to the method, in the pre-treatmentprocess, the titanium tetrachloride refined vanadium-removed tailings are subjected to oxidation dechlorination to obtain corresponding oxidized slag and circulating chlorine gas; in the process of feeding the oxidized slag into chlorination, selective chlorination of vanadium oxide is achieved, and chlorinated flue gas and chlorinated slag are obtained; the chlorinated flue gas is subjected to the processes of dust removal, drip washing and distillation purification, and high-purity vanadium oxytrichloride is obtained; and high-purity vanadium pentoxide powder is obtained from the high-purity vanadium oxytrichloride under action of oxygen-rich air and a catalyst. The method is suitable for treatment of the vanadium-removed tailings, and has the advantages of high raw material adaptability, good selectivity, low reaction temperature, chlorine gas recycling, energy saving and consumption reduction, environmental friendliness, high product additional value and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

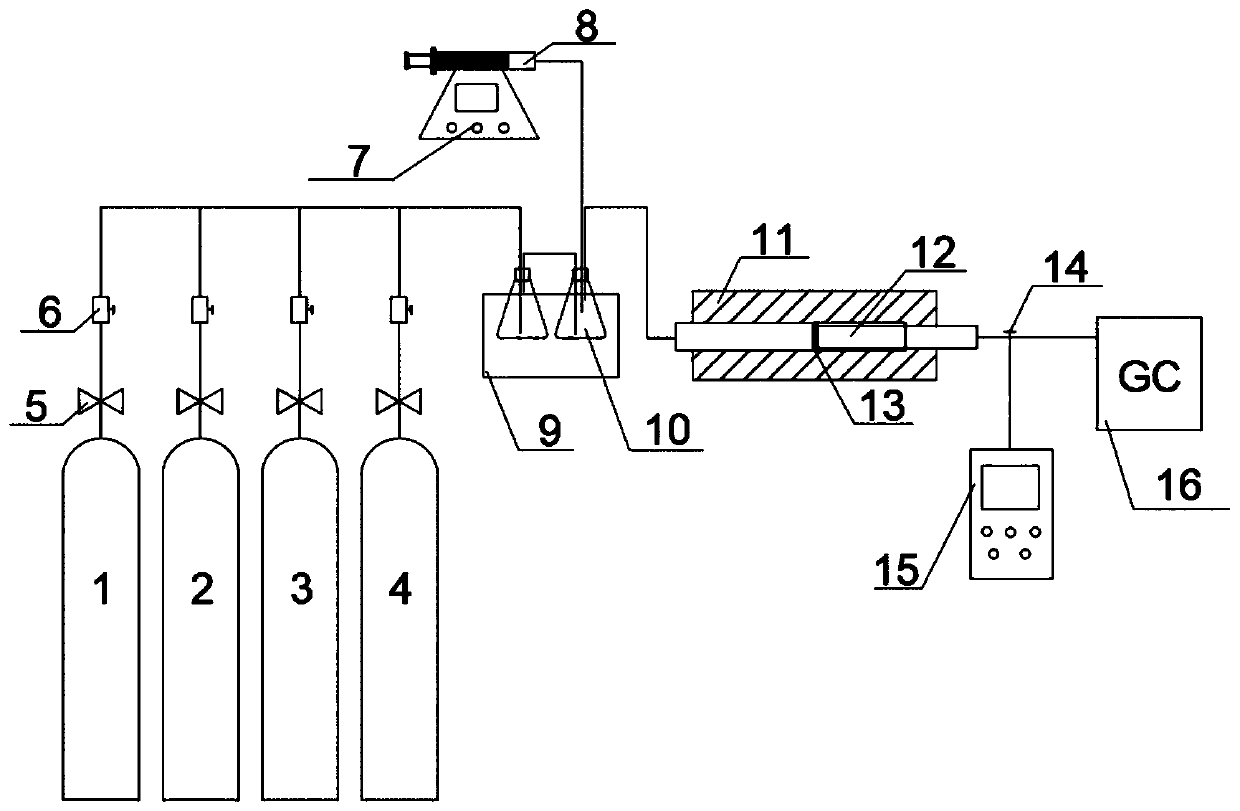

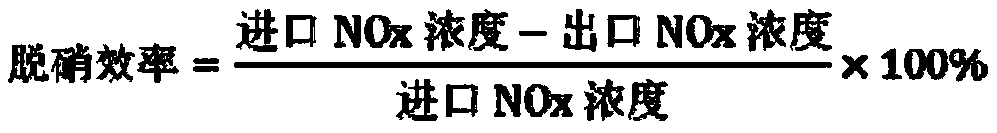

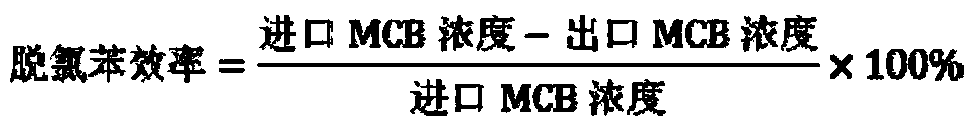

Integrated filtering material, preparation method and applications thereof

ActiveCN110975415ALarge specific surface areaProtect the physical structureGas treatmentDispersed particle filtrationPtru catalystChemical reaction

The invention provides an integrated filtering material, a preparation method and applications thereof, wherein the filtering material comprises a commercial dust removal filtering material and a catalyst growing on the filtering material and capable of simultaneously decomposing nitric oxide and dioxin. The preparation method comprises the following steps: impregnating a filtering material with aprecursor solution of manganese oxide and cerium oxide, and growing the manganese oxide and the cerium oxide on the filtering material through a chemical reaction; and impregnating the filtering material by using vanadium oxytrichloride as a precursor of vanadium oxide, carrying out a reaction in water, and carrying out drying, hydrothermal treatment and other processes to obtain the product. Theprepared composite filtering material can remove three pollutants in flue gas at the same time, and the catalyst is firm in loading and not prone to falling off.

Owner:NANJING UNIV OF TECH +1

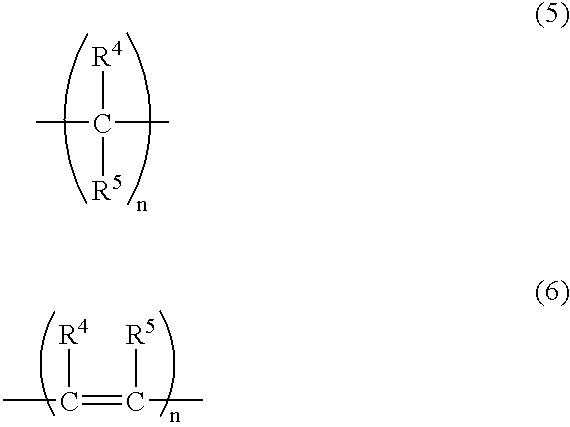

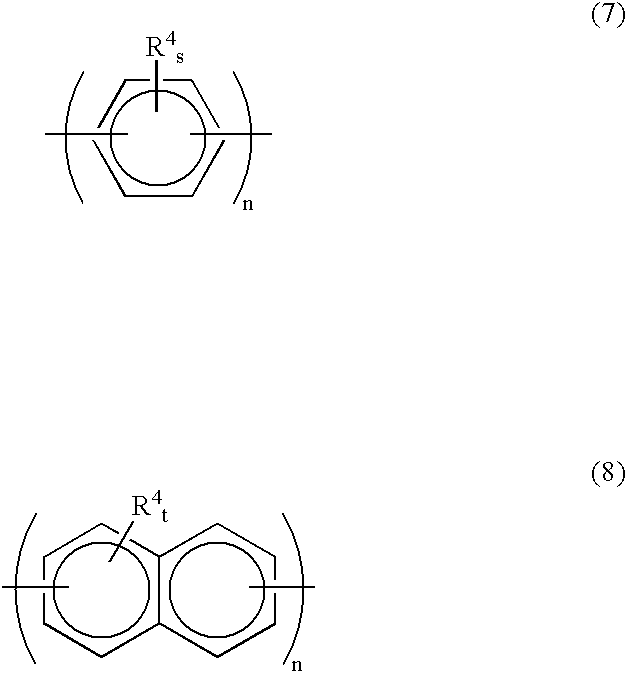

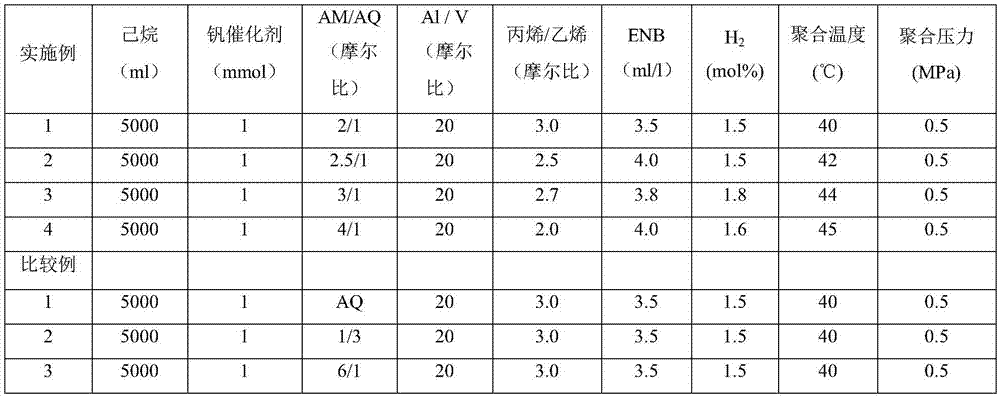

Preparation method for ethylene-series random copolymer

The invention provides a preparation method for an ethylene-series random copolymer. The preparation method comprises the following steps: subjecting a reaction vessel to waterless oxygen-free treatment with nitrogen in a vacuum state, then adding a solvent, ethylene, alpha-olefin, unconjugated diene and a molecular weight regulator, and carrying out uniform mixing under stirring; adding a main catalyst, a cocatalyst and an activator for polymerization; adding ethanol to terminate polymerization and then adding an antioxidant; subjecting a glue solution obtained in the previous step to desolventization, and separating glue so as to obtain the product ethylene-series random copolymer; and drying the product so as to obtain dry glue, wherein the dry glue contains 0.8 to 1 wt% of the antioxidant; the main catalyst is alcohol-modified vanadium oxytrichloride; the cocatalyst is a mixture of aluminum diethyl monochloride and triethyldialuminum trichloride; the molecular weight regulator is diethyl zinc or hydrogen; the solvent is aliphatic alkane, cycloalkane or an aromatic compound; the activator is ethyl trichloroacetate; and the antioxidant is 2,6-di-t-butyl-p-cresol.

Owner:PETROCHINA CO LTD

System and method for producing powdery vanadium by using chlorination process

ActiveCN109835951AImprove chlorination selectivityAchieve separationDispersed particle separationEnergy inputGas phaseCatalytic oxidation

The present invention discloses a system and a method for producing powdery vanadium by using a chlorination process. According to the present invention, through fluidized bed oxidative granulation treatment, the mineral phase reforming and the mineral particle growth of the vanadium residue are achieved; through calcium fixing treatment with carbon dioxide, the decalcification of the vanadium residue is achieved; the vanadium in the vanadium residue is converted into gaseous vanadium oxytrichloride through selective chlorination, and most of impurities such as iron, manganese, phosphorus, titanium, silicon and the like are remained in the chlorinated residue so as to effectively separate vanadium and other impurities; the gaseous vanadium oxytrichloride is sequentially subjected to dust removal, leaching, settlement, rectification purification, catalytic oxidation and other processes to prepare the high-purity vanadium pentoxide powder (powdery vanadium); the chlorinated residue is subjected to gas phase hydrolysis dechlorination treatment, and the dechlorination residue returns to iron making; and with the system and the method, the clean comprehensive utilization of vanadium residue is achieved while the sensible heat of the high temperature flue gas of the chlorination furnace is effectively utilized so as to achieve the purposes of energy saving and consumption reduction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

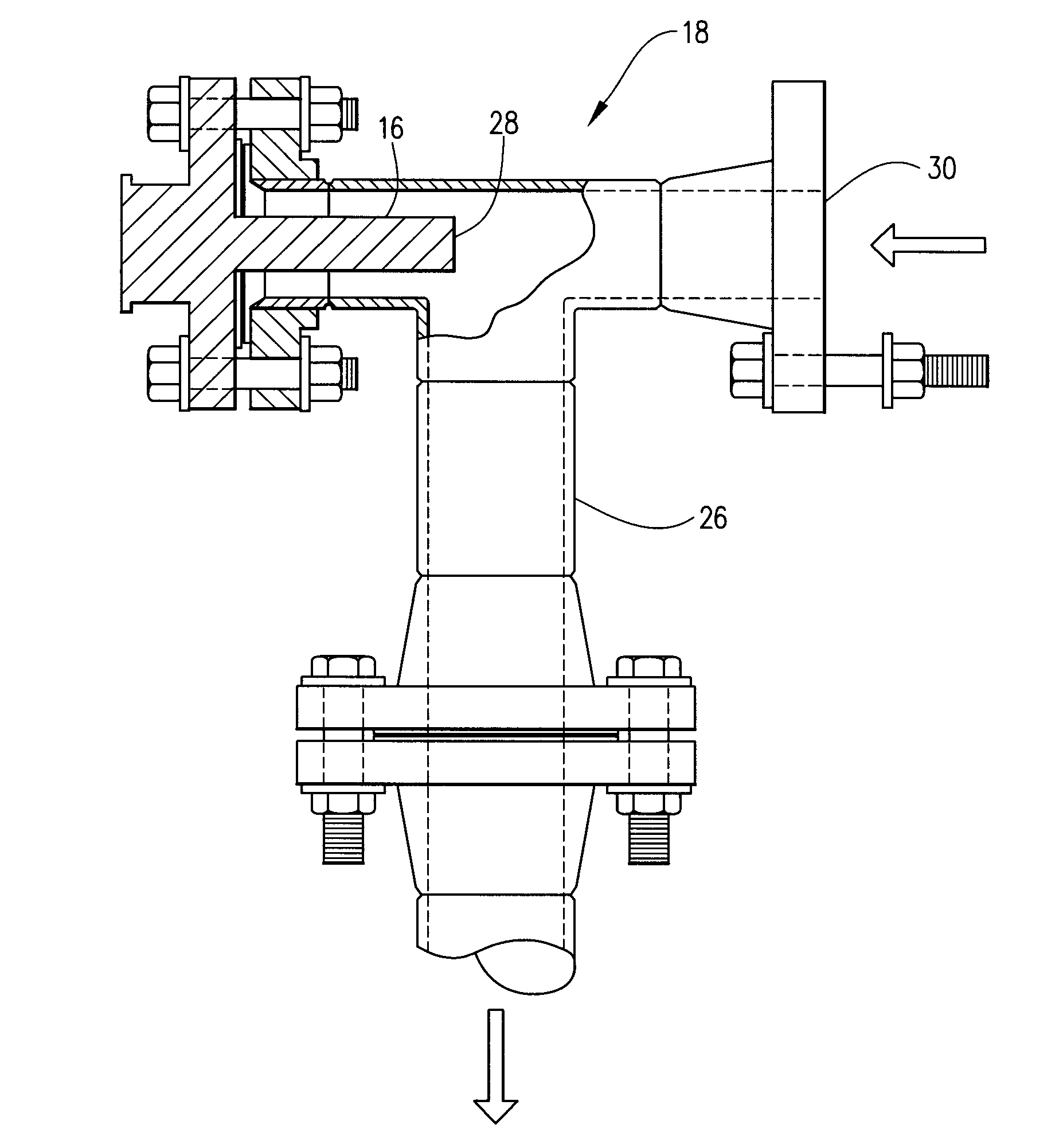

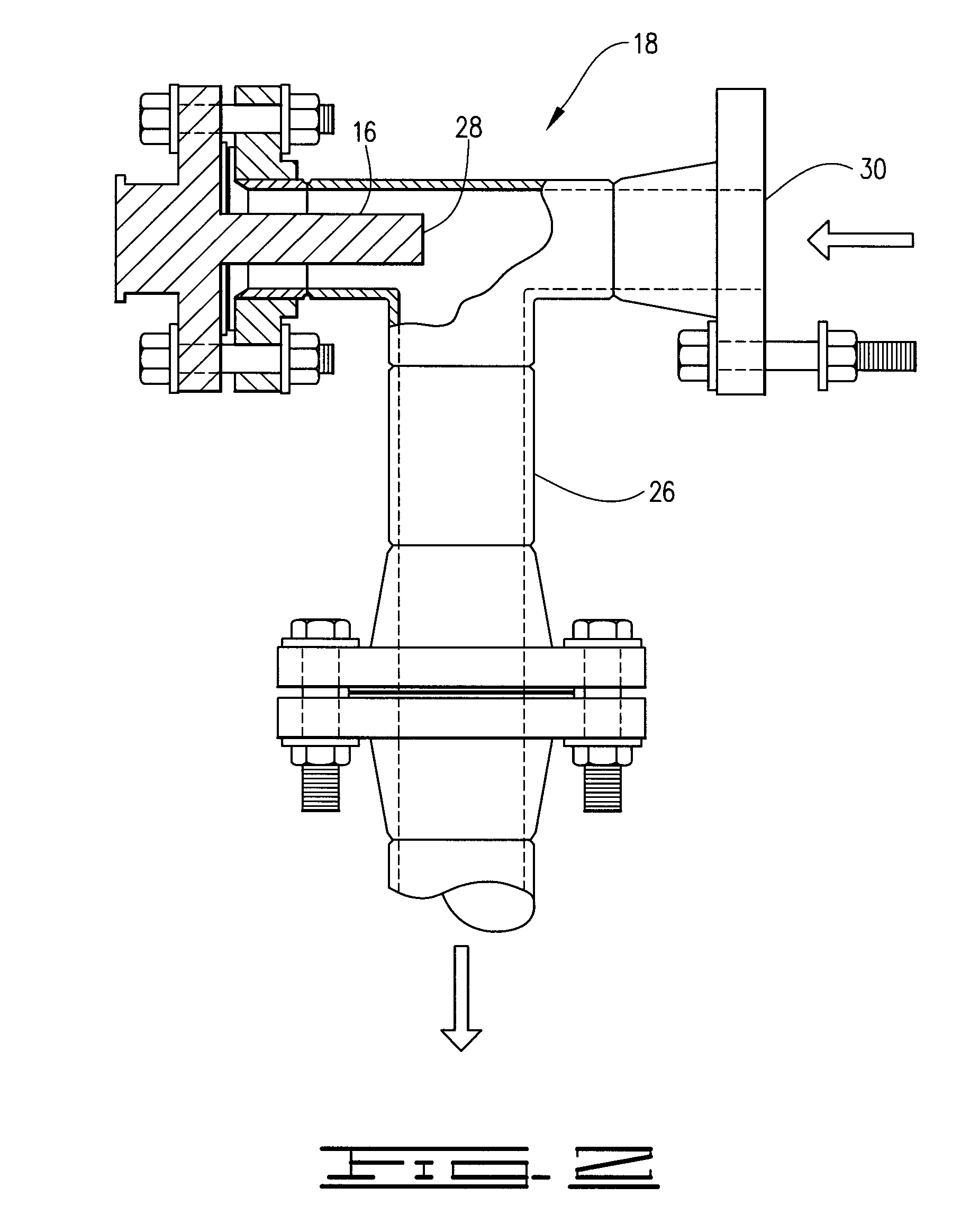

Continuous Process for Producing Titanium Tetrachloride Using On-Line Monitoring of Vanadium Oxytrichloride (VolcL3) With Anti-Fouling Management

InactiveUS20100129278A1More accurate and consistent on-line process controlQuantity minimizationZirconium compoundsTitanium tetrachlorideNiobiumTitanium tetrachloride

An improved continuous process for producing titanium tetrachloride having a vanadium content of less than 5 ppm using on-line monitoring of vanadium oxytrichloride in crude titanium tetrachloride with effective anti-fouling management of precipitated niobium oxytrichloride.

Owner:MILLENNIUM INORGANIC CHEM

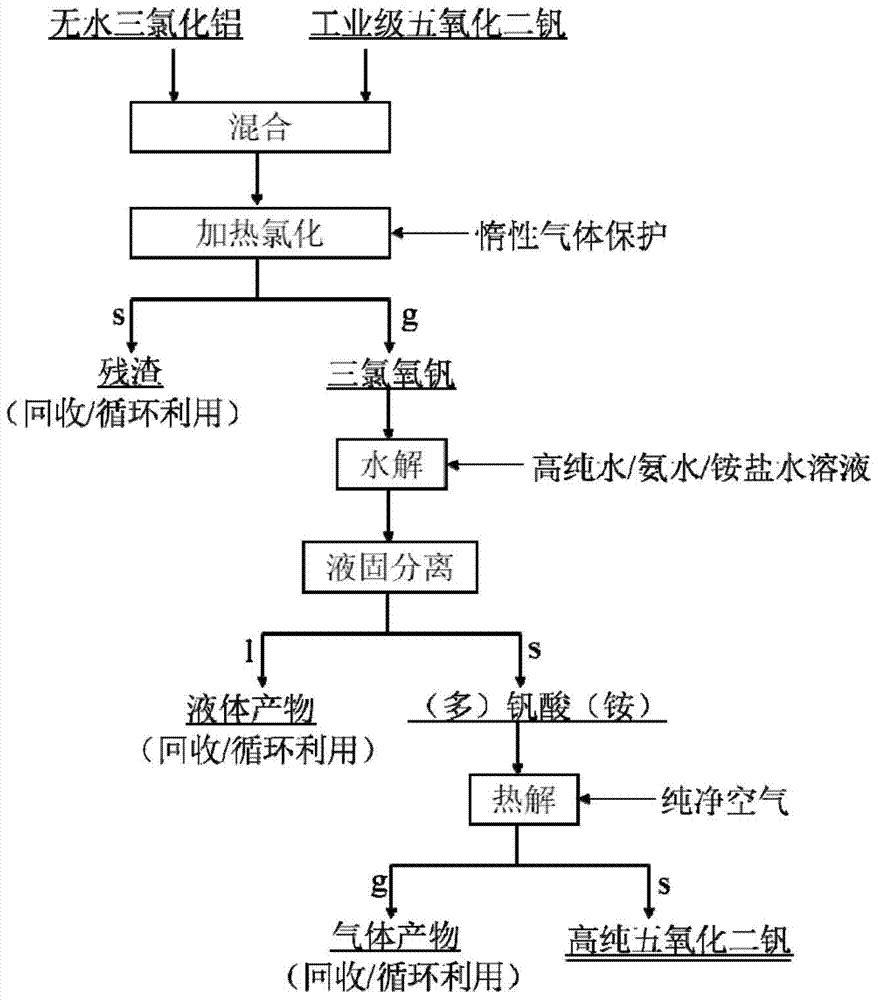

Vanadium pentoxide purification method

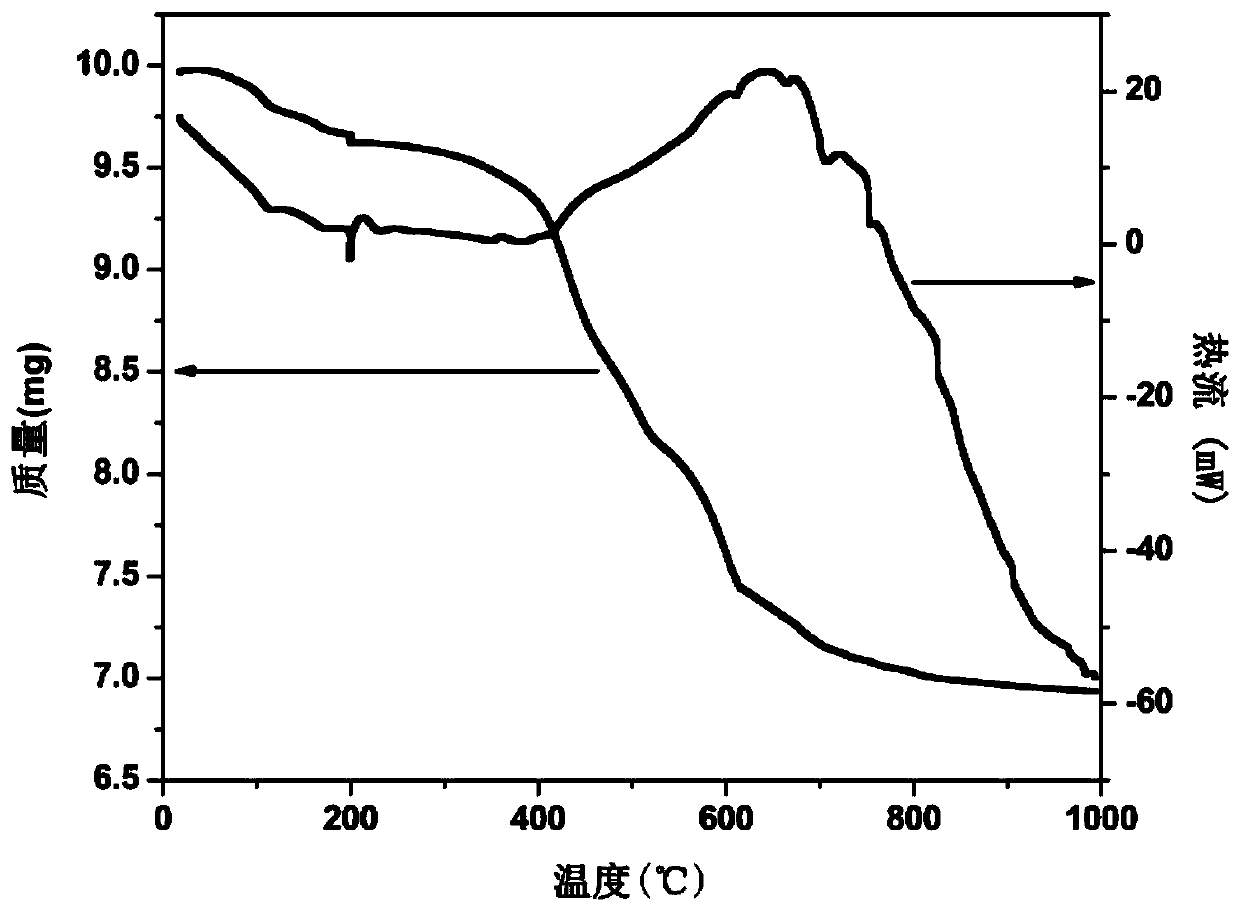

The present invention provides a vanadium pentoxide purification method, which comprises: carrying out a reaction on vanadium pentoxide to be purified and anhydrous aluminum trichloride at a temperature of 150-200 DEG C in an inert atmosphere to obtain vanadium oxytrichloride gas and residue, and carrying out post-treatment on the vanadium oxytrichloride gas to obtain the high purity vanadium pentoxide, wherein the post-treatment comprises: condensing the vanadium oxytrichloride gas, carrying out hydrolysis, carrying out liquid-solid separation on the hydrolysis product to obtain a solid product and a liquid product, and carrying out pyrolysis on the slid product, wherein the residue and the liquid product can be recovered. According to the present invention, the method has characteristics of short process, effective production cost reducing, three-waste generation reducing, and low environmental pollution; the prepared vanadium pentoxide has the high purity (the purity of more than or equal to 99.99%) and can meet the requirements of vanadium aluminum alloys and all-vanadium batteries for aerospace and other fields; and the method provides the basis for the small batch or large-scale production of the high purity vanadium pentoxide.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation system and method thereof of high-purity vanadium battery electrolyte

ActiveCN105990593AIncrease production energy consumptionIncrease production costRegenerative fuel cellsChemical industryDistillation

The invention belongs to the fields of chemical industry and material, and concretely discloses a preparation system and a method thereof of a high-purity vanadium battery electrolyte. The preparation system takes industrial-grade vanadium oxytrichloride as a raw material, the industrial-grade vanadium oxytrichloride is subjected to distillation purification to obtain the high-purity vanadylic chloride with purity of more than 4N, the high-purity vanadium oxytrichloride is subjected to hydrolysis as well as chlorinity regulation and control, further, sulfuric acid is added for preparing the high-purity vanadium battery sulfuric acid-hydrochloric acid mixed acid electrolyte. The preparation system and the method have the advantages of strong raw material adaptability, simple flow, cleaning and no pollution, low production energy consumption and low operation cost, and controllable electrolyte quality, are suitable for large-scale continuous production of the high-purity vanadium battery electrolyte, and have good economic benefit and social benefit.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

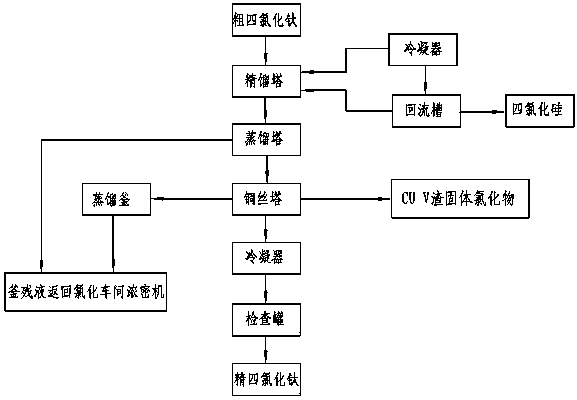

Titanium tetrachloride refining processing technology

The invention relates to a titanium tetrachloride refining processing technology. The technology includes: bringing the coarse titanium tetrachloride coming from a chlorination workshop into an elevated tank, passing the coarse titanium tetrachloride through a flowmeter and adding it into a tower from the middle part of a float valve tower, performing air flow exchange when the coarse titanium tetrachloride and a backflow fluid encounter the rising steam in a distillation kettle, condensing low fluorine silicon tetrachloride and other chlorides and bringing them into a backflow tank, returning part of the chlorides to the tower top to undergo backflow, and letting the redundant overflow to a silicon tetrachloride storage pot, vaporizing low boiling point impurity removed titanium tetrachloride, and bringing it into a copper wire distillation kettle from the bottom of the float valve tower to contact the copper wire so as to remove vanadium oxytrichloride and copper, then bringing the titanium tetrachloride into a condenser and carrying out condensing, thus obtaining a refined titanium tetrachloride fluid, checking it whether it is up to the standards, then sending it to a storage pot if it is qualified, and supplying it to a reduction process, returning the high boiling point titanium tetrachloride gathered in the distillation kettle and elevated tank to a chlorination workshop thickener regularly, and discharging the tail gas of all towers and equipment into the atmosphere by an acid sealing pot. The technology provided in the invention not only is simple, but also guarantees the quality of refined titanium tetrachloride.

Owner:ZUNYI SHENGTAI MACHINERY EQUIP MFG

System and method for producing high-purity vanadium pentoxide through clean chlorination of vanadium resources

ActiveCN109835950AImprove chlorination selectivityEfficient separationEnergy inputVanadium oxidesCatalytic oxidationManganese

The present invention discloses a system and a method for producing high-purity vanadium pentoxide through clean chlorination of vanadium resources. According to the present invention, vanadium resources are subjected to granulation, oxidation, crushing, screening and other pretreatment processes, the pre-treated vanadium resources enter a chlorination furnace and are selectively chlorinated, thevanadium in the vanadium resources is converted into gaseous vanadium oxytrichloride, and most of impurities such as iron, chromium, calcium, phosphorus, manganese, titanium, silicon and the like in the vanadium resources are retained in the chlorinated residue so as to achieve the effective separation of vanadium and other impurities; the gaseous vanadium oxytrichloride is sequentially subjectedto dust removal, leaching, settlement, rectification purification, catalytic oxidation and other processes to prepare the high-purity vanadium pentoxide; the chlorinated residue is sequentially subjected to waste heat recovery, water washing dechlorination, settlement separation, filtering washing and other processes to obtain filter residue and a washing liquid, the filter residue returns to ironsmelting, and the washing liquid is subjected to evaporation crystallization to obtain a chlorine salt; and with the system and the method, the clean comprehensive utilization of vanadium resources is achieved while the sensible heat of the high temperature flue gas of the chlorination furnace and the high temperature chlorination residue is effectively utilized so as to achieve purposes of energy saving and consumption reduction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

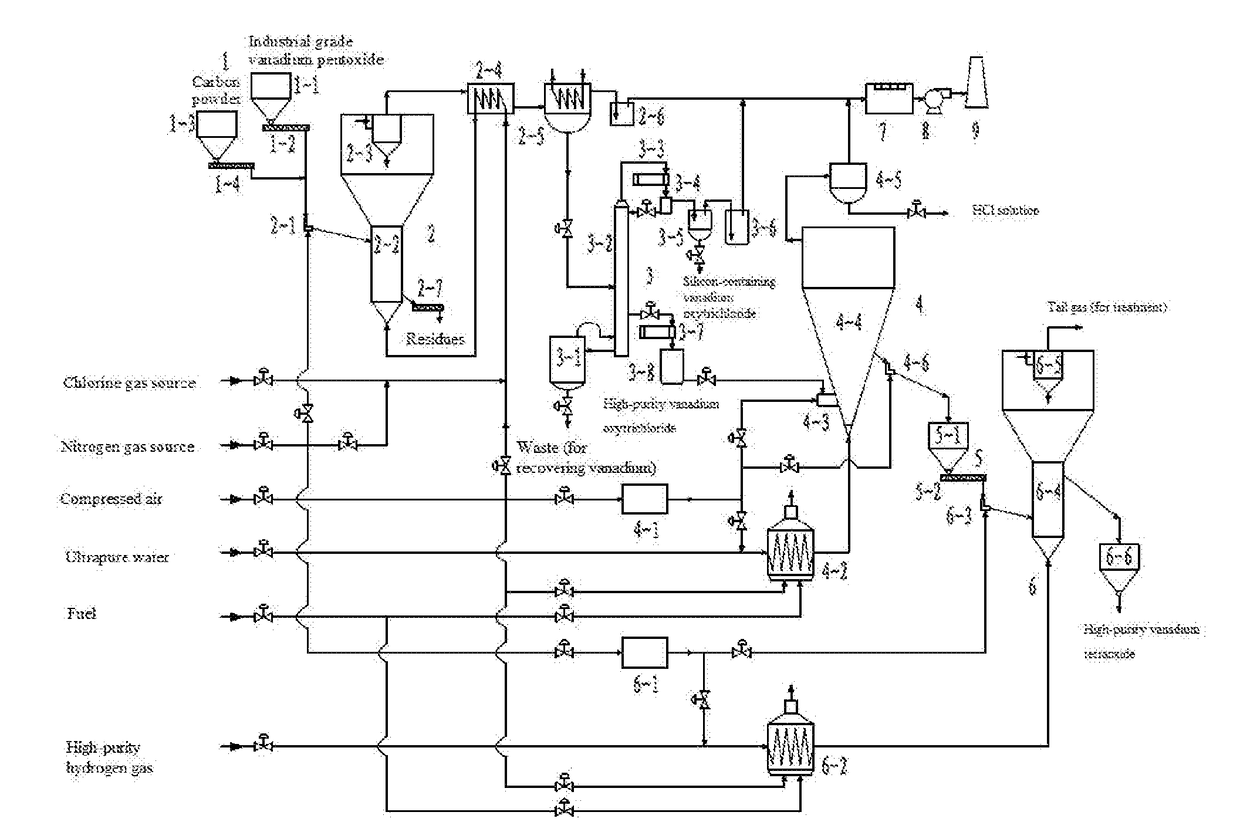

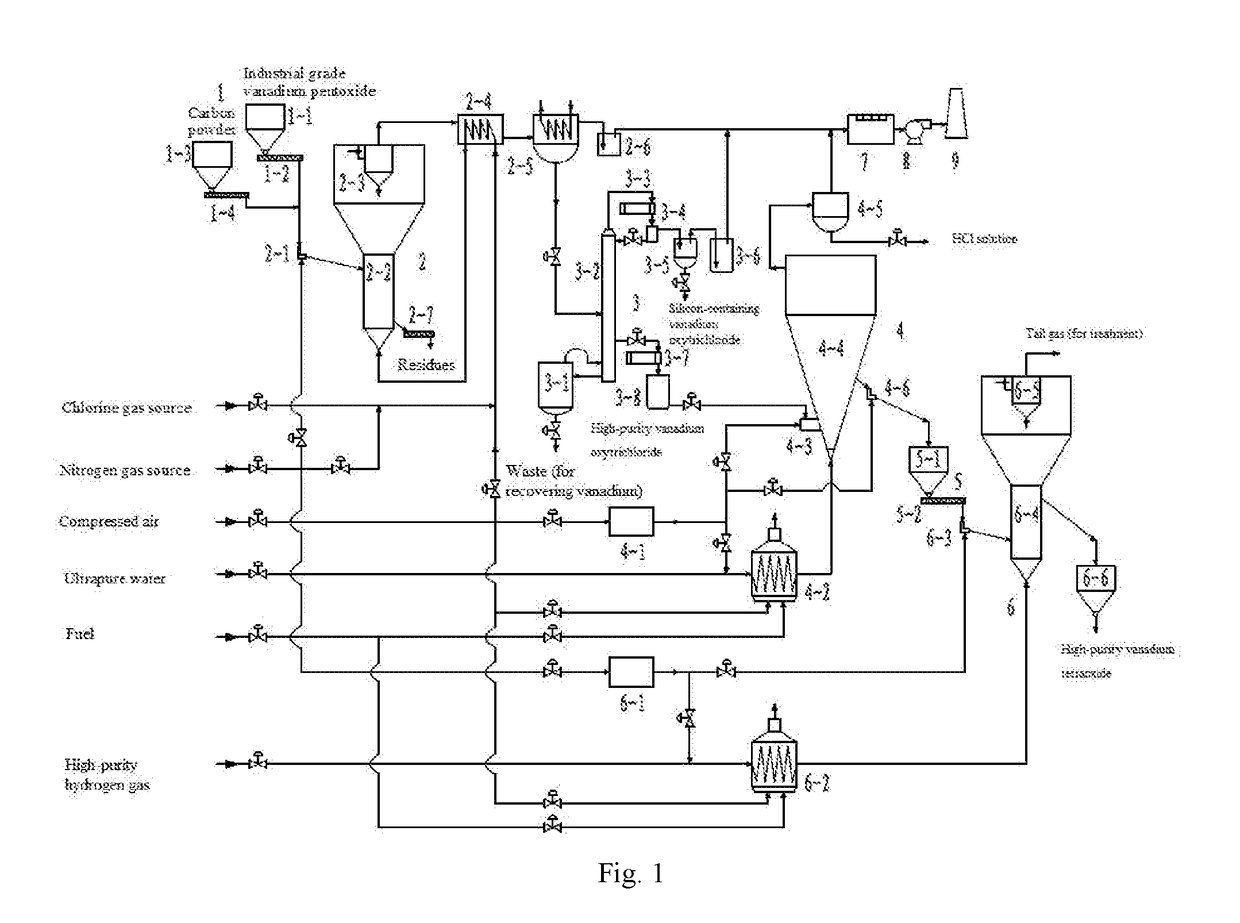

System and method for producing high-purity vanadium tetraoxide powder

ActiveUS20180009674A1Inhibit productionGood choiceChloride preparationEnergy inputGas phaseTechnical grade

The present invention provides a system and method for producing high-purity vanadium tetraoxide powder. Industrial grade vanadium pentoxide is converted to vanadium oxytrichloride by low temperature fluidizing chlorination, wherein chlorinating gas is preheated via heat exchange between fluidizing gas and chlorination flue gas, and an appropriate amount of air is added to enable a part of carbon powder to combust so as to achieve a balanced heat supply during the chlorination, thereby increasing the efficiency of chlorination and ensuring good selectivity in low temperature chlorination. The vanadium oxytrichloride is purified by rectification, and then subjected to fluidized gas phase hydrolyzation, thereby producing a high-purity vanadium pentoxide product and a by-product solution of hydrochloric acid, and further obtaining a high-purity vanadium tetraoxide powder product through fluidized hydrogen reduction. The system and method have advantages of favorable adaptability to raw material, no discharge of contaminated wastewater, low energy consumption, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

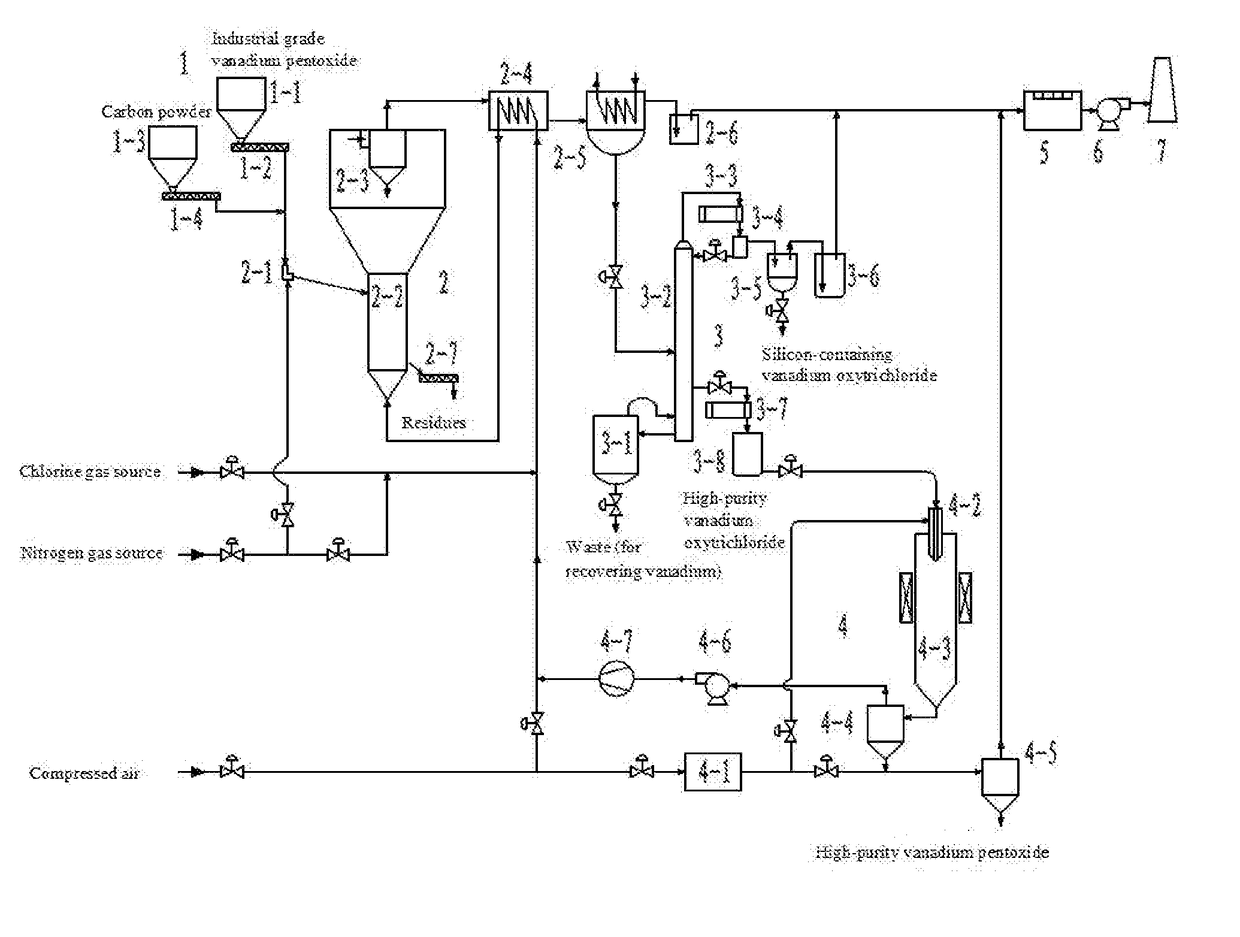

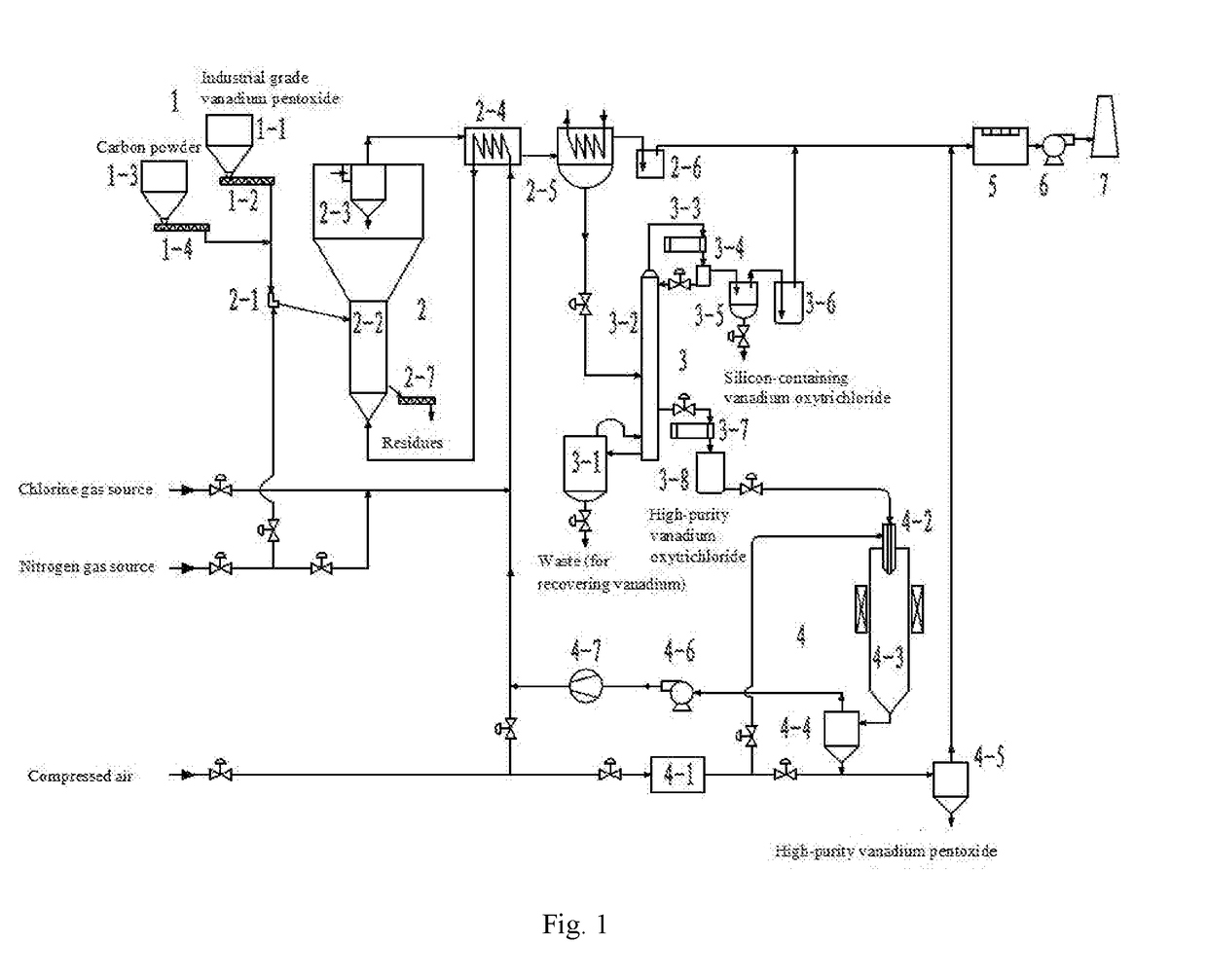

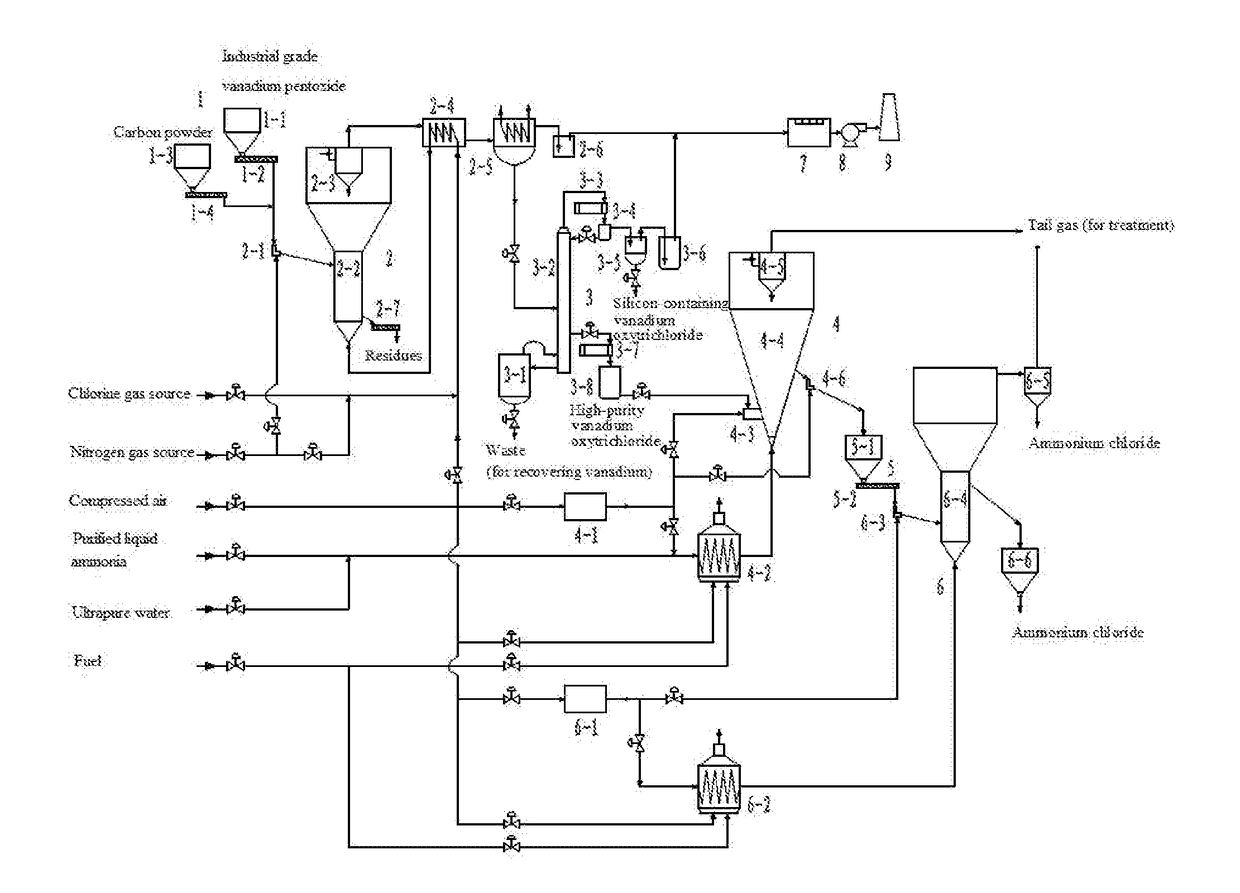

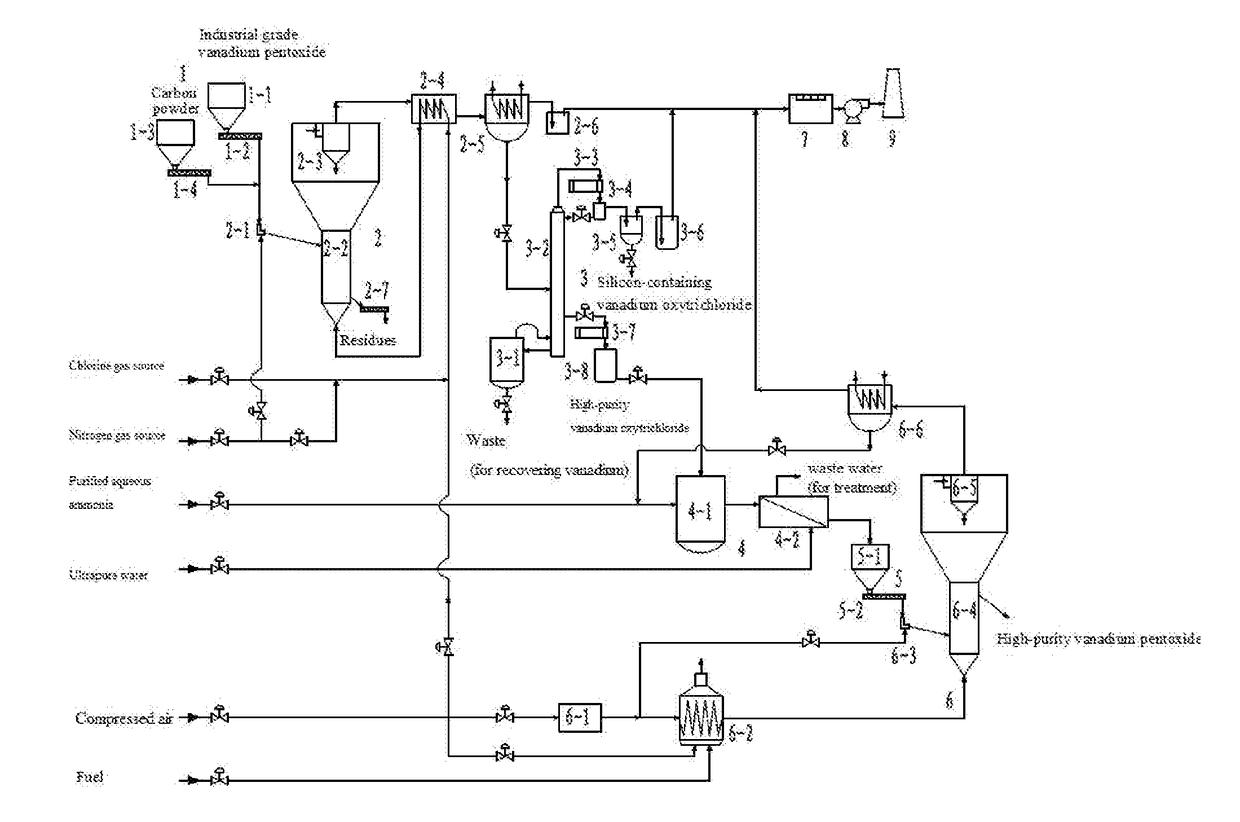

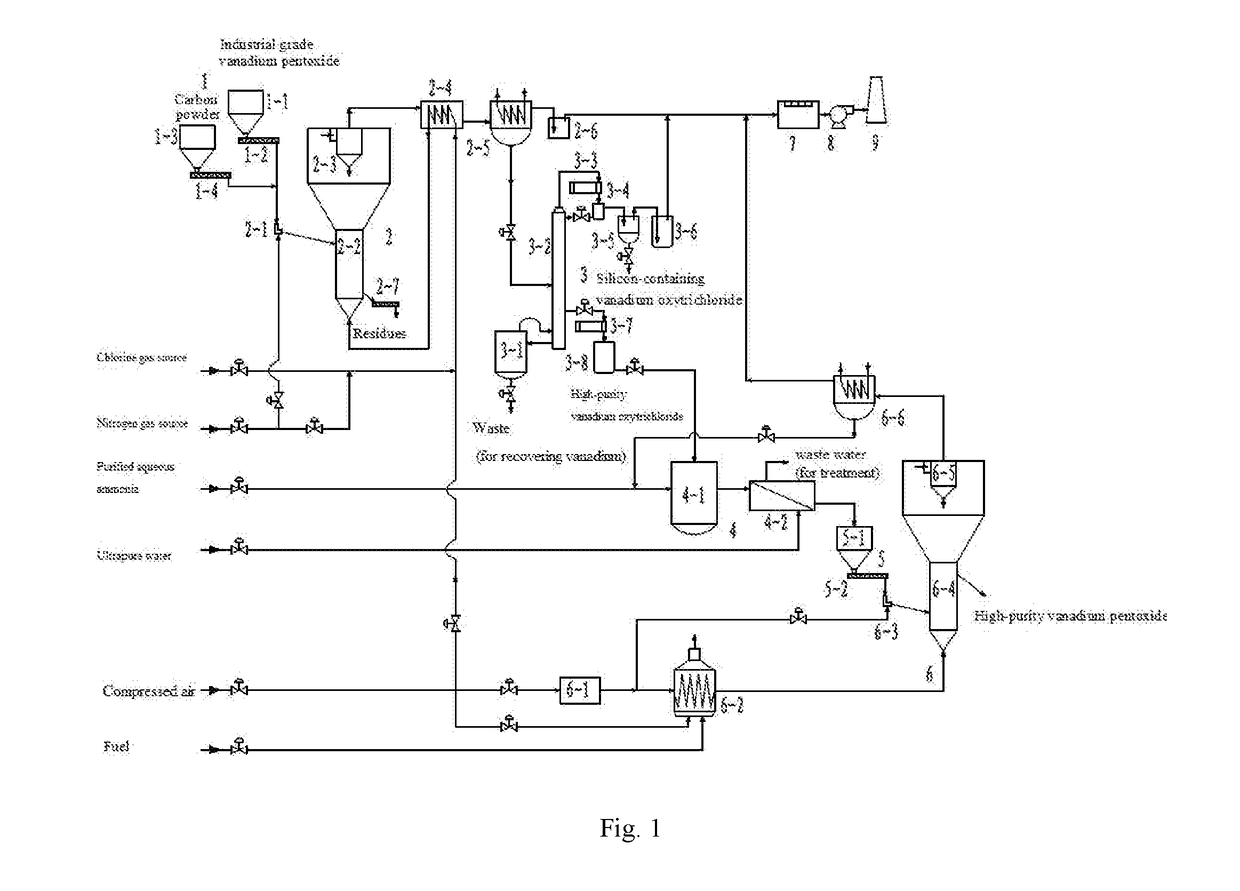

System and Method for Purifying Vanadium Pentoxide

InactiveUS20180002190A1Improve inefficiencyUniform temperature distributionLiquid degasificationVanadium oxidesFlue gasWastewater

The present invention provides a system and method for purifying vanadium pentoxide. Industrial grade vanadium pentoxide is converted to vanadium oxytrichloride by low temperature fluidizing chlorination, wherein chlorinating gas is preheated via heat exchange between fluidizing gas and chlorination flue gas, and an appropriate amount of air is added to enable a part of carbon powder to combust so as to achieve a balanced heat supply during the chlorination, thereby increasing the efficiency of chlorination and ensuring good selectivity in low temperature chlorination. The vanadium oxytrichloride is purified by rectification, and then subjected to plasma oxidation, thereby obtaining a high-purity vanadium pentoxide product and chlorine gas. The chlorine gas is returned for low temperature chlorination. The system and method have advantages of favorable adaptability to raw material, no discharge of contaminated wastewater, low energy consumption and chlorine consumption in production, stable product quality, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

System and method for purifying and preparing high-purity vanadium pentoxide powder

ActiveUS20180009673A1Improve inefficiencyUniform temperature distributionTransportation and packagingNitrogen-metal/silicon/boron binary compoundsGas phaseAmmonium metavanadate

The present invention provides a system and method for purifying and preparing vanadium pentoxide powder. Industrial grade vanadium pentoxide is converted to vanadium oxytrichloride by low temperature fluidizing chlorination, wherein chlorinating gas is preheated via heat exchange between fluidizing gas and chlorination flue gas, and an appropriate amount of air is added to enable a part of carbon powder to combust so as to achieve a balanced heat supply during the chlorination, thereby increasing the efficiency of chlorination and ensuring good selectivity in low temperature chlorination. The vanadium oxytrichloride is purified by rectification, and then subjected to fluidized gas phase ammonification, thereby obtaining ammonium metavanadate, and further obtaining a high-purity vanadium pentoxide powder product through fluidized calcination. The system and method have advantages of favorable adaptability to a raw material, no discharge of contaminated wastewater, low energy consumption and chlorine consumption in production, stable product quality and so on.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

System and method for preparing high-activity and high-purity vanadium electrolyte with specific valence state

ActiveCN107565153ASolve temperature balance problemsUniform temperature distributionRegenerative fuel cellsChemical industryCatalytic oxidation

The invention belongs to the field of chemical industry and energy and provides a system and method for preparing a high-activity and high-purity vanadium electrolyte with a specific valence state. The method comprises the steps of transforming industrial vanadium oxide into vanadium trichloride oxide by using fluidzed chlorination and obtaining crude vanadium trichloride oxide through dedusting and leaching; obtaining high-purity and low-valence vanadium oxide through rectification, catalytic oxidation and precise control reduction, wherein the average valence state of vanadium can be any value from 3.0 to 4.0; and adding pure water and a pure sulfuric acid solution for low-temperature dissolution under the action of an activation device to obtain the high-activity and high-purity vanadium electrolyte with the specific valence state, wherein the high-activity and high-purity vanadium electrolyte can be directly applied to an all-vanadium redox flow battery. According to the system andthe method, the reaction efficiency is improved through arranging an internal component in a catalytic oxidation fluidized bed; the reductive degree is regulated through arranging a vertical baffle plate and discharge openings of different heights in a reduced fluidized bed; and the activity of the vanadium electrolyte is improved through activating treatment. The system and the method have the advantages of being high in raw material adaptability, free of pollution, low in production energy consumption and operation cost, stable in product quality and suitable for large-scale industrial production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of vanadium oxytrichloride

InactiveCN110937630AAvoid poisoningAccelerated corrosionVanadium compoundsPhysical chemistryAmmonium metavanadate

The invention provides a preparation method of vanadium oxytrichloride, which comprises the following steps: mixing and grinding a vanadium source and a chlorine source in a molar ratio of 3: 2, placing the mixture in a roasting furnace, roasting the mixture in a non-oxidizing atmosphere at a roasting temperature of 400-900 DEG C for 10-120 minutes, and collecting distillate, namely vanadium oxytrichloride, wherein the vanadium source is one or more of ammonium metavanadate, ammonium polyvanadate, vanadium pentoxide, VONH4HPO4, VPO4, VOPO4, (VO2)3PO4, (VO)4P2O7, (VO)2P2O7, VOSiO3, (VO2)2SiO3 and (VO2)4SiO4. According to the preparation method of the vanadium oxychloride, no toxic and harmful substances are generated, and harm of high-corrosivity and high-toxicity chlorine to human bodies and the environment is avoided.

Owner:DALIAN RONGKE ENERGY STORAGE GRP CO LTD

System and Method for Preparing High-Purity Vanadium Pentoxide Powder

ActiveUS20180022616A1Improve calcination decomposition efficiencyGood choiceDistillation in boilers/stillsChemical liquid solidificationTechnical gradeVanadium oxytrichloride

The present invention provides a system and method for preparing high-purity vanadium pentoxide powder. Industrial grade vanadium pentoxide is converted to vanadium oxytrichloride by low temperature fluidizing chlorination, wherein chlorinating gas is preheated via heat exchange between fluidizing gas and chlorination flue gas, and an appropriate amount of air is added to enable a part of carbon powder to combust so as to achieve a balanced heat supply during the chlorination, thereby increasing the efficiency of chlorination and ensuring good selectivity in low temperature chlorination. The vanadium oxytrichloride is subjected to purification by rectification, ammonium salt precipitation and fluidized calcination, thereby obtaining high-purity vanadium pentoxide, wherein the ammonia gas produced during calcination is condensed and then recycled for ammonium salt precipitation. The system and method have advantages of favorable adaptability to raw material, less pollution, low energy consumption in production, low operation cost, stable product quality, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

System and method for high-value comprehensive utilization of high-chromium vanadium slag

ActiveCN109837395AReduce overflowImprove chlorination efficiencyProcess efficiency improvementSlagManganese

The invention discloses a system and method for high-value comprehensive utilization of a high-chromium vanadium slag. Vanadium, chromium and iron in the high-chromium vanadium slag are converted through selective chlorination by a circulating fluidized bed to corresponding gaseous chlorides, and most impurities such as manganese, titanium, and silicon are remained in the chlorinated residue, so that valuable elements are separated from other impurities. The gaseous chlorides separates crude chromium trichloride by high temperature dust collection, separates crude ferric chloride by medium temperature dust collection, and separates crude vanadium oxychloride from low temperature elution. The crude chromium trichloride is dissolved and stirred to obtain an aqueous solution to recover the chromium salt; the crude ferric chloride and chlorinated residue are hydrolyzed and dechlorinated by high temperature to obtain an oxidized slag for iron production; and the crude vanadium oxychloride vanadium is subjected to sedimented purification, rectification and refinement, and catalytic oxidation to obtain high-purity vanadium pentoxide powder. By means of the system and the method, the high-value comprehensive utilization of the high-chromium vanadium slag is achieved, and the chromium chloride solution and high purity vanadium pentoxide powder are produced by the method of one-step of chlorination with multi-step recovery.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

System and method for preparing high-purity vanadium pentoxide powder through efficient clean chlorination method

ActiveCN108622936AUniform temperature distributionStrong chlorination selectivityVanadium oxidesFurnace temperatureChemical industry

The invention belongs to the fields of metallurgy and chemical industry, and specifically discloses a system and a method for preparing high-purity vanadium pentoxide powder through an efficient cleanchlorination method, wherein industrial-grade vanadium oxide is converted into vanadium oxytrichloride by combing fluidization and carbon chlorination, two-stage dust removal and four-stage leachingare performed to obtain crude vanadium oxytrichloride, and the crude vanadium oxytrichloride is subjected to purification, catalytic oxidation and calcination to obtain the high-purity vanadium pentoxide powder. According to the present invention, the too high furnace temperature is prevented by spraying the vanadium oxytrichloride slurry into the boiling chlorination furnace; the chlorine gas isregenerated by blowing clean oxygen-rich air into the catalytic oxidation fluidized bed; the hydrogen chloride is recycled by returning the hydrochloric acid to the catalytic oxidation fluidized bed;and the system and the method have advantages of strong raw material adaptability, self-circulation of chlorine gas, no vanadium-containing hydrochloric acid emission, low production energy consumption, low operation cost, stable product quality and the like, are suitable for the large-scale industrial production of high-purity vanadium pentoxide powder with the purity of more than 4N, and have good economic and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Corrosion-resistant metal surface silicane treating agent and preparation method

ActiveCN103059728AImprove corrosion resistanceExtended service lifeAnti-corrosive paintsEthylenediamineWater based

The invention discloses a corrosion-resistant metal surface silicane treating agent. The corrosion-resistant metal surface silicane treating agent is characterized in that: each liter of a mixed solution which is prepared from the following components comprises the components in parts by weight (gram) of: 23-30 g of N-phenyl-3-aminopropyl trimethoxysilane, 21-26 g of carbamido propyl triethoxysilane, 180-210 g of a water-based nanometer zinc oxide material, 3-5 parts of sodium ethylenediamine teramethylene phosphonate, 3-4 g of 2-methyl-1,3-propylene glycol, 2-3 g of ethylene glycol monobutyl ether, 2-3 g of oxalic acid, 2-3 g of sodium monofluorophosphate, 1-2 g of tetrahydrofuran, 1-2 g of vanadium oxytrichloride, 0.8-1 g of plant ash, 0.6-0.8 g of tert-butyl hydroperoxide, and the balance of water. The water-based nanometer zinc oxide material prepared by the technology of the invention has high dispersion stability and efficient adhesiveness, and is uniformly coated on the metal surface to enable the metal to have high compactness and anti-ion permeability; and due to the addition of the auxiliary agents such as the sodium ethylenediamine teramethylene phosphonate, the corrosion-resistant metal surface silicane treating agent adds the compactness of a silciane absorption film, improves film forming quality, and is environment-friendly and free from pollution.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

Method for preparing vanadium oxychloride by low-temperature chlorination of blast furnace slag

InactiveCN110642294AEfficient recyclingShort processVanadium compoundsProcess efficiency improvementSlagWater chlorination

The invention belongs to the technical field of chemical engineering and metallurgy, and particularly relates to a method for preparing vanadium oxychloride through low-temperature chlorination of blast furnace slag. The technical problem to be solved by the invention is to provide the method for preparing the vanadium oxytrichloride by low-temperature chlorination of the blast furnace slag, whichcomprises the following steps: mixing the blast furnace slag and a carbonaceous reducing agent, preheating, and introducing chlorine to react to obtain a vanadium oxytrichloride-containing mixed product. According to the method, vanadium in the blast furnace slag can be well recycled.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

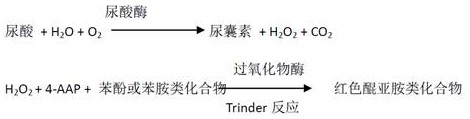

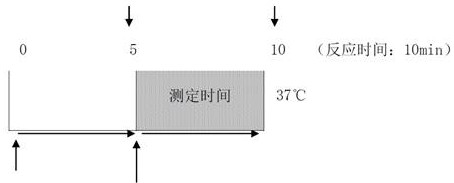

Uric acid test kit capable of eliminating drug interference of calcium dobesilate and etamsylate in serum and preparation method thereof

ActiveCN111733211AEliminate negative interferenceImprove stabilityMicrobiological testing/measurementBiological material analysisPeroxidaseActive agent

The invention discloses a uric acid test kit capable of eliminating drug interference of calcium dobesilate and etamsylate in serum and a preparation method thereof. According to the technical point,the test kit comprises a reagent R1 and a reagent R2, wherein the reagent R1 comprises a buffer solution, peroxidase, ascorbic acid oxidase, a preservative, a Trinder's reactant A, metallate or a nonionic surfactant; and the reagent R2 comprises a buffer solution, serum albumin, uricase, a preservative and a Trinder's reactant B or a nonionic surfactant. According to the uric acid test kit disclosed by the invention, one or more than one of high-redox-potential oxidized metallate, vanadium pentoxide and vanadium oxychloride is / are added into R1 to be mixed, and calcium dobesilate and etamsylate are oxidized by utilizing the metallate, H2O2 generated by uricase in decomposing uric acid after R2 is added is prevented from being consumed, and an accurate uric acid measured value is rapidly obtained.

Owner:ZHONGSHAN BGH BIOTECH CO LTD

High-alkali-resistance internal wall paint and preparation method thereof

The invention discloses a high-alkali-resistance internal wall paint which is prepared from the following raw materials in parts by weight: 42-50 parts of styrene-acrylic emulsion, 13-20 parts of modified bonding agent, 10-20 parts of calcite powder, 15-20 parts of feldspar powder, 3-4 parts of methyl hydroxyethyl cellulose, 1-2 parts of vanadium oxytrichloride, 1-3 parts of 2-methyl-1,3-propanediol, 2-3 parts of ethylene glycol, 2-4 parts of sodium monofluorophosphate, 1-2 parts of diethylene glycol butyl ether, 2-3 parts of 2,2,4-trimethyl-1,3-pentanediol mono(2-methylpropanoate), 1-2 parts of diethanolamine, 1-3 parts of sodium ethylenediamine tetramethylene phosphonate, 1-2 parts of 2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane, 0.2-0.4 part of polyoxypropylene glycerol ether and 20-40 parts of deionized water. The formula components have favorable compatibility, dispersity and temperature property; the produced paint product has the advantages of firm coating, smooth surface, high adhesive force, high scrub resistance, high acid / alkali resistance, high fouling resistance, high safety and environmental protection; and the added modified bonding agent further enhances the bonding property of the coating, so that the coating can not easily fall off, and the properties of the paint are enhanced.

Owner:ANHUI ZHENXIN PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com