Patents

Literature

41results about How to "Increase production energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified composite material of woods and plastics as well as its usage and manufacturing method

A modified wood-plastics composition is prepared from wood flour, plastic, assistant, and grafting agent through graft modifying of wood flour and plastics, and continuous extruding out. Its advantage is high tension strength, bending strength and impact strength.

Owner:BEI JING NEW BUILDING MATERIALGRP

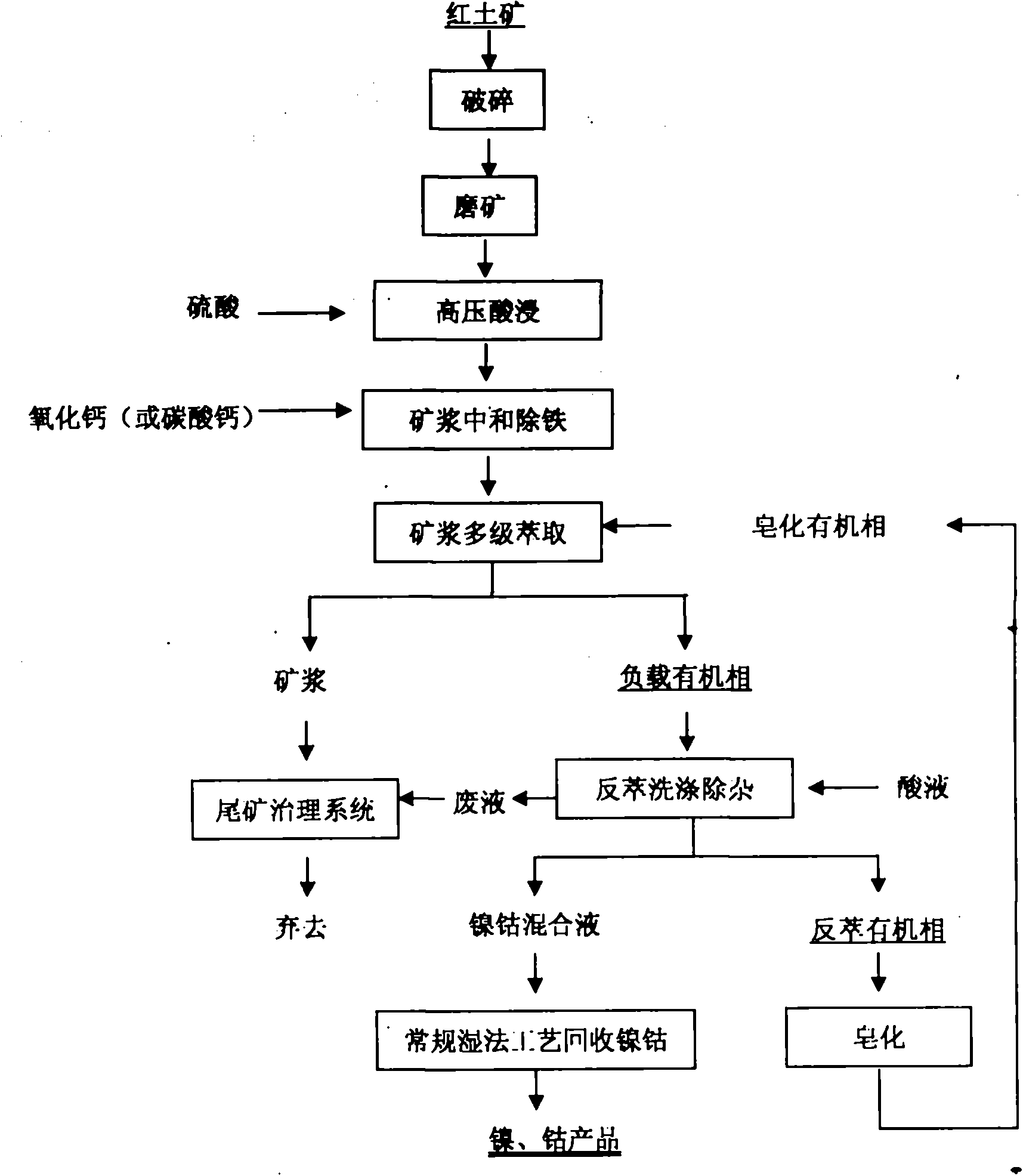

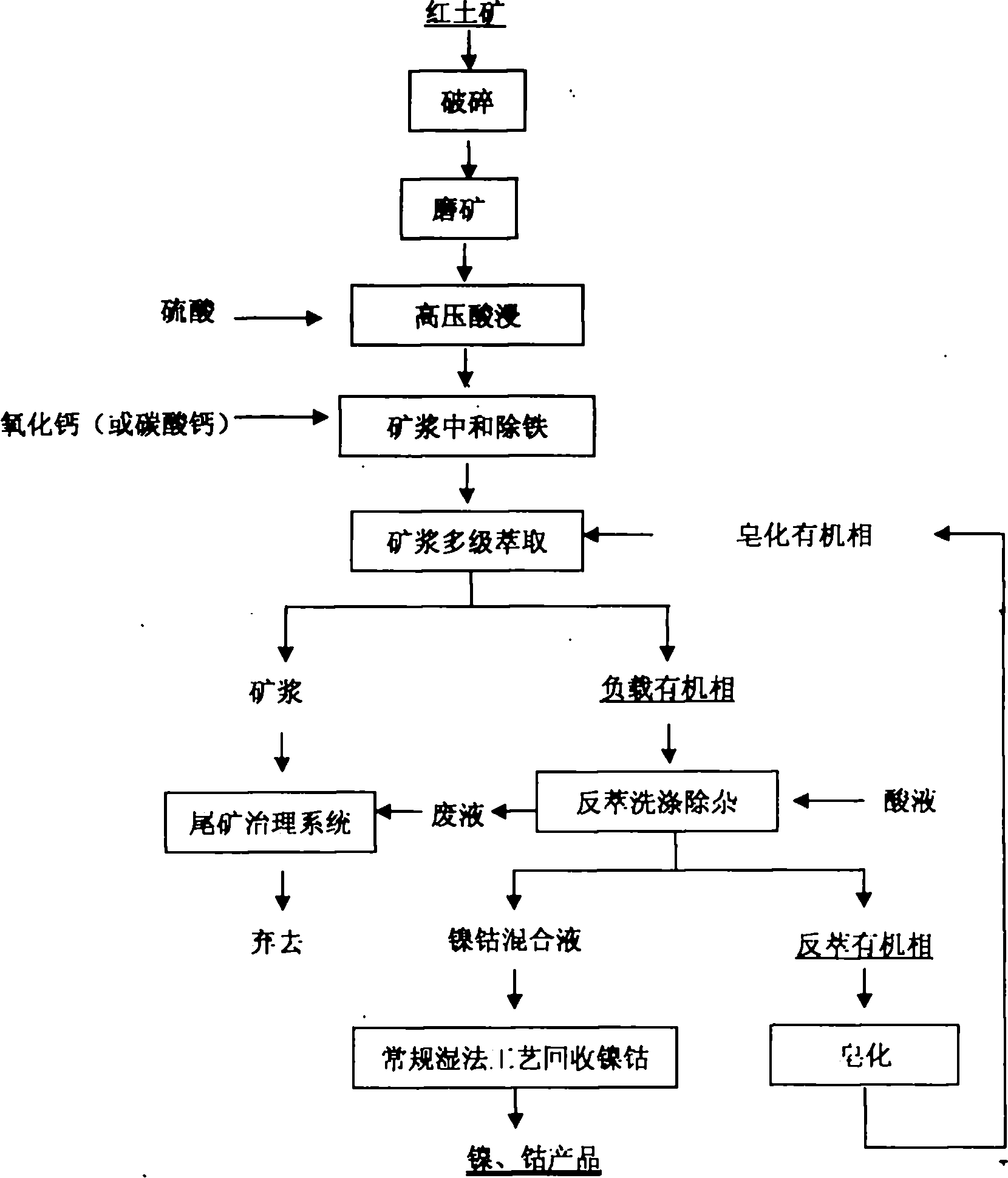

Process for extracting nickel and cobalt from laterite by ore pulp extraction technology

ActiveCN102010993AReduce consumptionReduce the burden of separationProcess efficiency improvementHigh concentrationHigh pressure

The invention relates to a process for extracting nickel and cobalt from laterite by ore pulp extraction technology, which comprises the following steps of: crushing and grinding the laterite; putting into a high-pressure kettle, and carrying out high-pressure acid leaching to remove iron; pouring into a mixing settling extraction tank with a stirring and settling tank and a baffle plate, carrying out 5-12 grade of extraction, back extraction and phase splitting and washing to respectively obtain mixed solution of nickel and cobalt, waste liquid containing impurities and the ore pulp; extracting and separating nickel from cobalt to respectively obtain pure nickel solution and pure cobalt solution; and precipitating and calcining to obtain nickel oxide and cobalt oxide products. The solution with high concentration is obtained by extraction, the process is shortened, the liquid-solid separation load and a number of washing and filtering processes are reduced, so that energy consumption of production and production cost are reduced and the economic benefit is improved. An extracting agent can be used repeatedly after being saponified and has relatively low comprehensive consumption. The speed of the extraction process is high and is commonly less than 10 minutes. The extraction efficiency is high. The extracted ore pulp can be neutralized uniformly so as to reduce the treatment cost of tailings. The process is simple; the recovery rate is higher; and the nickel and cobalt recovery rates are both more than or equal to 90 percent and the process is easy to popularize.

Owner:JILIN JIEN NICKEL IND +1

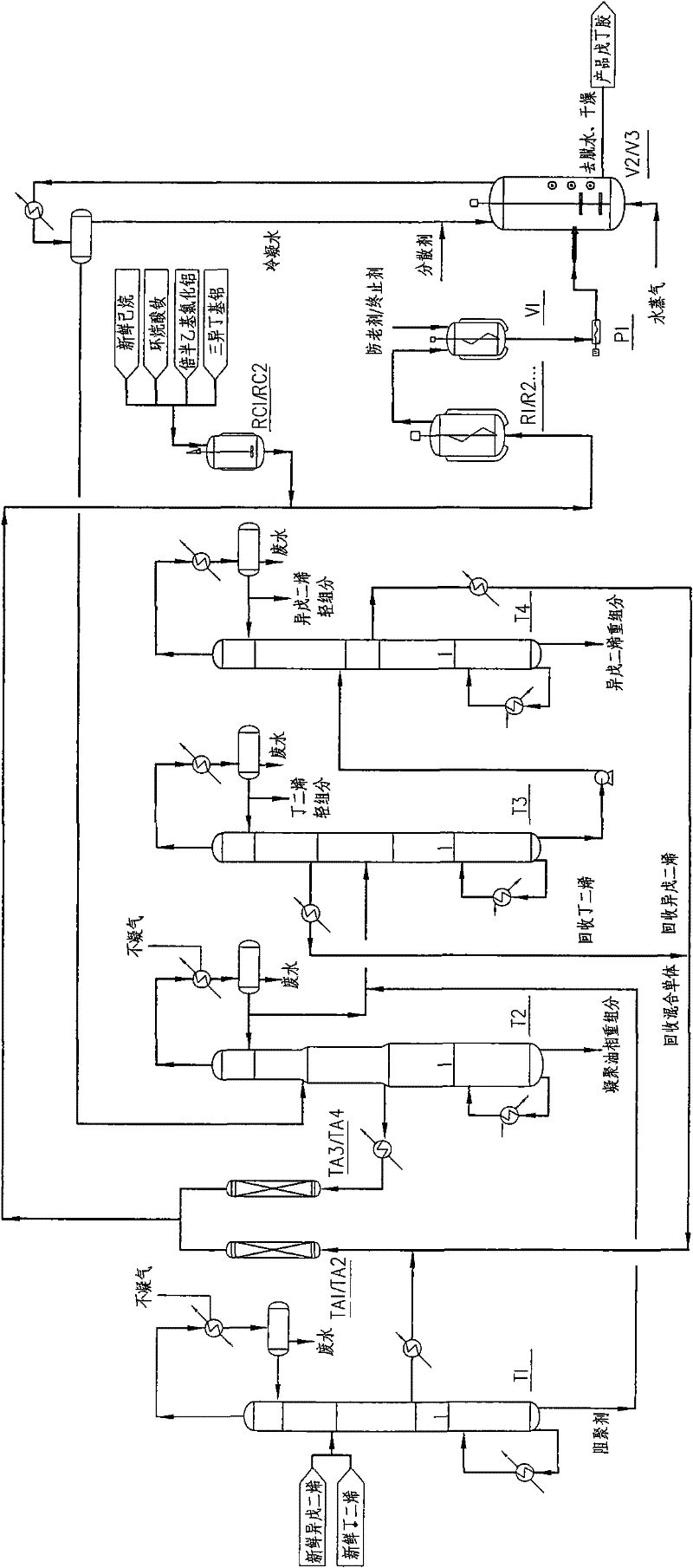

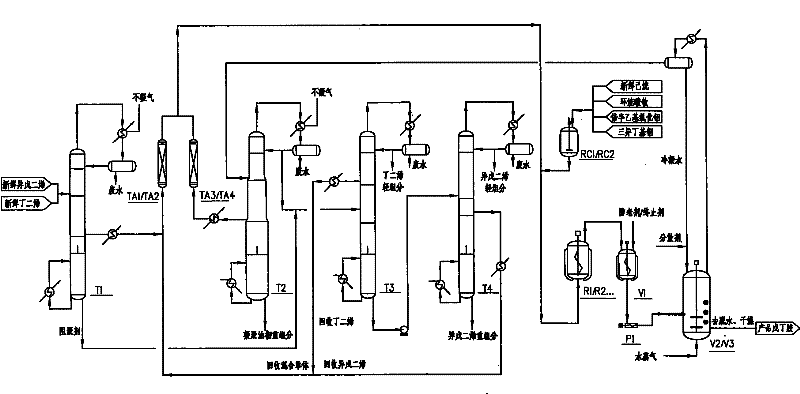

Method for producing rare-earth isoprene butadiene rubber

ActiveCN102234356AIncrease production energy consumptionReduce production energy consumptionSpecial tyresPolymer scienceRare earth

The invention discloses a method for producing rare-earth isoprene butadiene rubber. Two refined monomers, namely isoprene and 1, 3-butadiene are proportioned and mixed, and subjected to polymerization reaction in the presence of a rare earth catalyst to form random copolymer rubber. A multi-tower circular preparation process flow is adopted, and the problem of low purity of recovered monomers and solvents caused by crossed boiling points of various monomers and impurities thereof is solved, so that the production efficiency and molecular weight of the rare-earth isoprene butadiene rubber areimproved and the whole production cost is reduced. In the rare-earth isoprene butadiene rubber, the molar content of polyisoprene units is 40 to 90 percent, the cis-content in the polyisoprene units is more than 95 percent, the cis-content in polybutadiene units is more than 99 percent, the weight-average molecular weight is 2,000,000 to 3,000,000, the molecular weight distribution is 3 to 7, andthe anti-ageing agent content is 1 to 2 percent. The rare-earth isoprene butadiene rubber copolymer can replace a binary blend of natural rubber (or high cis-isoprene rubber) and butadiene rubber, and has the characteristics of capacity of being easily mixed, low themogenesis, wear resistance, crack growth resistance and the like.

Owner:FUSHUN YIKESI NEW MATERIAL

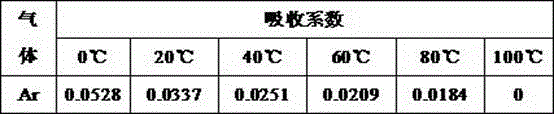

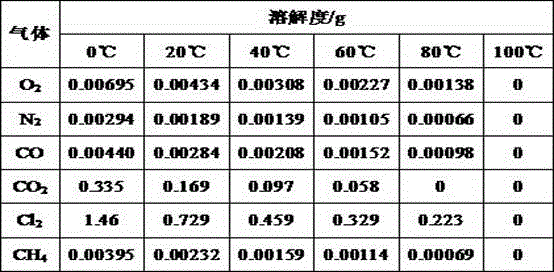

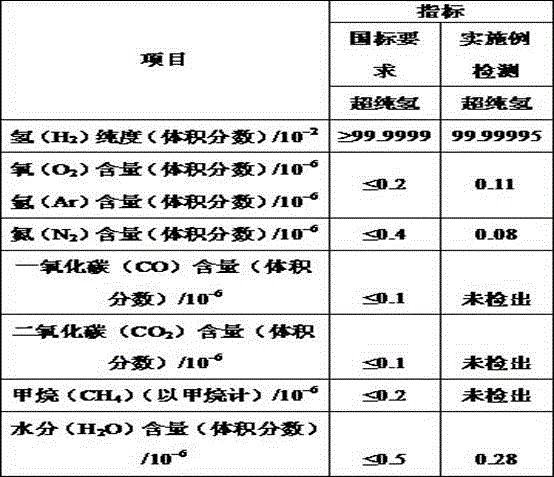

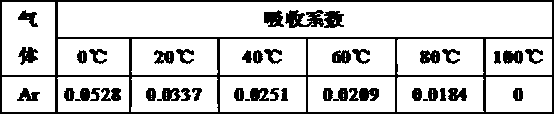

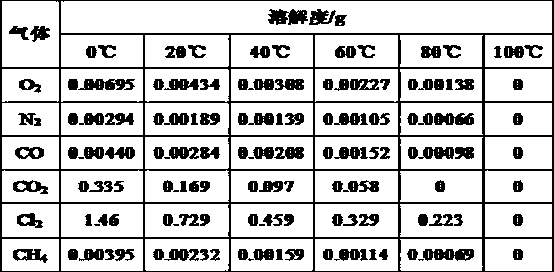

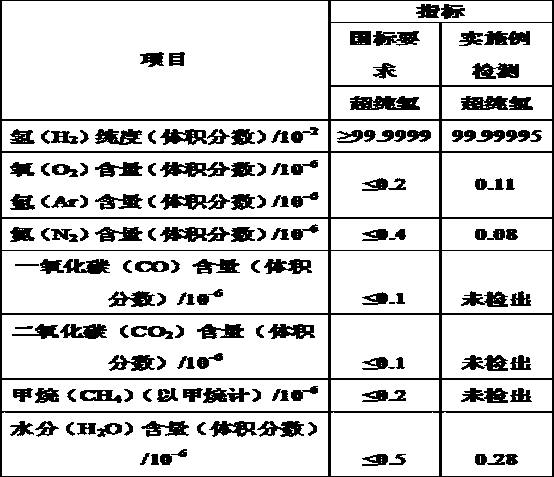

Method for preparing ultra-pure hydrogen

ActiveCN106283101ALow costEasy to operateElectrolysis componentsHydrogen separationElectrolysisSoftened water

The invention discloses a method for preparing ultra-pure hydrogen. The electrolytic hydrogen production process is adopted in the method. Softened water before electrolysis is pretreated, the softened water is heated, and various sorts of gases like N2 and Ar dissolved in the softened water are removed completely; high-purity oxygen is supplied for pressure maintaining; and then the ultra-pure hydrogen meeting 'GBT 3634.2-2011 pure hydrogen, high-purity hydrogen and ultra-pure hydrogen' requirements can be produced by the adoption of the catalyst catalytic deoxidation and molecular sieve dehydration process, filtering dust removal process and steel cylinder drying treatment process. The method for preparing the ultra-pure hydrogen has the beneficial effects that the defects that a palladium alloy diffusion film (pipe) separation method is high in cost and small in production amount, a hydrogen storage alloy absorbing and desorbing method is short in hydride service life and instable in production, a low-temperature adsorption method needs to use liquid nitrogen and thus the requirements for equipment are high are overcome successfully; and the characteristics of being low in production energy consumption, high in flow-path efficiency, simple in process, stable in production and the like are achieved.

Owner:山东泓达生物科技有限公司

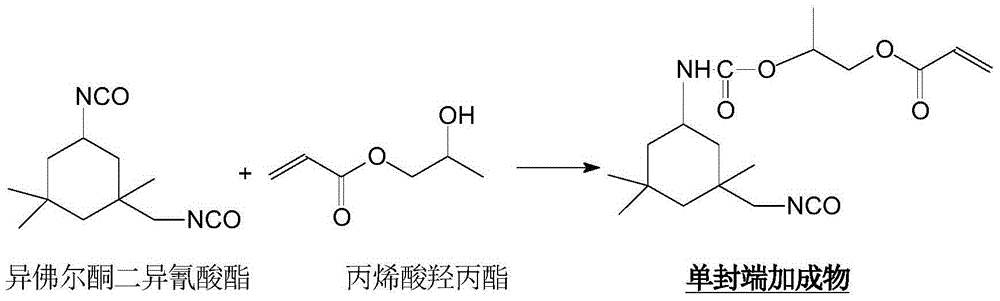

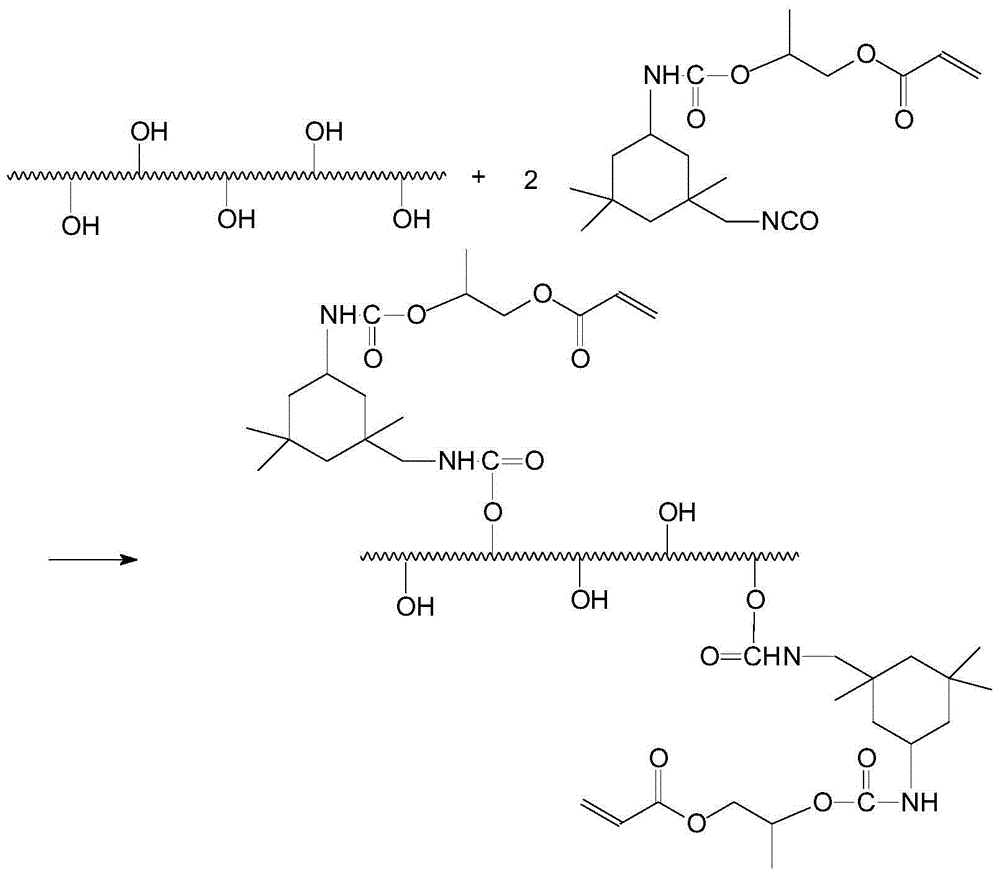

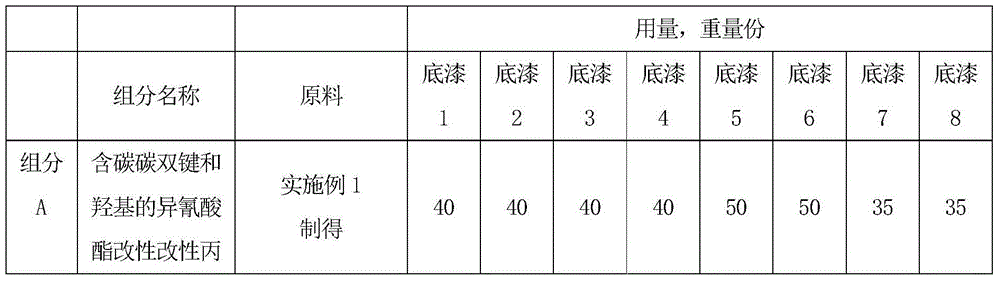

Ultraviolet light-heat dual-curing primer for vacuum coating of vehicle headlight and application method

ActiveCN104312420AReduce internal stressImprove adhesionPretreated surfacesPolyurea/polyurethane coatingsAcrylic resinUltraviolet lights

The invention relates to an ultraviolet light-heat dual-curing primer for vacuum coating of a vehicle headlight and an application method. The primer comprises a component A and a component B, wherein the component A is prepared from 35-70 parts of isocyanate modified acrylic resin containing carbon-carbon double bonds and hydroxyl, 5-20 parts of a low polymer containing carbon-carbon double bonds, 10-50 parts of a compound containing at least two (meth)acryloyl groups, 2-5 parts of a photo-initiator, 10-40 parts of a solvent, and 0.1-3 parts of organic silicon or fluorocarbon flatting agent, and the sum of the components is 100 parts by weight; the component B is a polyfunctional isocyanate curing agent; and before construction, the components A and B are mixed evenly according to the molar ratio of -OH groups contained in the component A to -NCO groups contained in the component B being (0.8-1.3) to 1. Due to adoption of the primer and the application method thereof disclosed by the invention, a primer film has good adhesive force and heat resistance on a plastic substrate which is difficult to attach.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

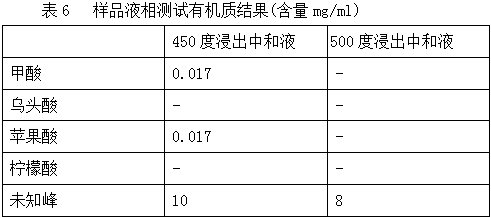

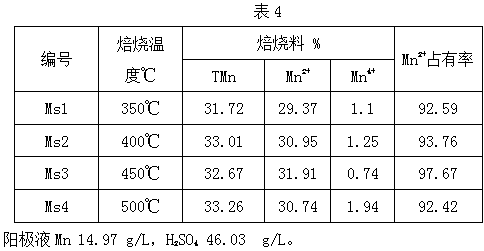

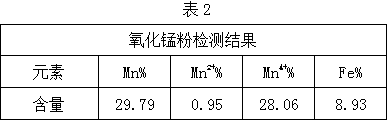

Method for producing MnO through reducing roasting of MnO ore by utilizing wood chips

InactiveCN108165730AImprove conversion efficiencyReduce the cost of reduction roastingManganeseMaterials science

The invention belongs to the fields of metallurgy and chemical engineering, and particularly relates to a method for producing MnO through the reducing roasting of MnO ore by utilizing wood chips. According to the method, the wood chips are adopted as a reductant, so that the MnO ore can be reduced into MnO under the condition of low temperature (300-500 DEG C); consequently, the production energyconsumption can be greatly reduced and the service life of equipment can be prolonged; the method is simple in process, convenient to operate, low in roasting temperature, and high in efficiency of the conversion from high-valent Mn to bivalent Mn; the cost of the reducing roasting of the MnO ore can be remarkably reduced; and furthermore, qualified MnO can be produced by adopting the method.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

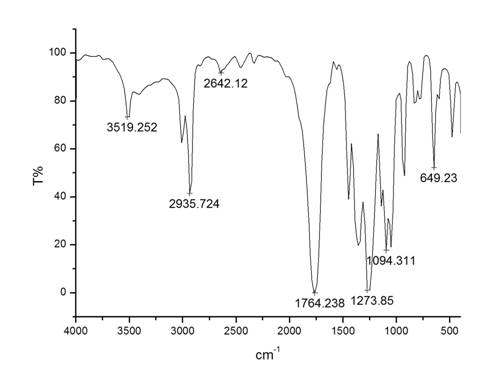

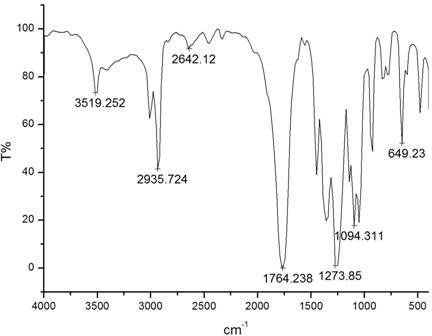

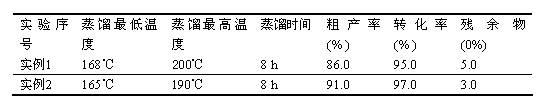

Method for preparing lactide by catalytic method under reduced pressure

InactiveCN102675277ALower distillation temperatureProduct yield is highOrganic chemistryDodecylsulfonic acidDistillation

The invention discloses a method for preparing lactide by a catalytic method under reduced pressure, which is characterized by comprising the following steps: firstly, removing free water in lactic acid at a temperature is 75-90 DEG C and at a vacuum degree of 0.080-0.090 MPa for 1-2 hours; secondly, adding a catalyst and a surfactant, wherein the catalyst consists of zinc oxide with a reactant mass percentage of 0.5-1 percent and stannous octoate with a reactant volume ratio of 0.5-1 percent, the surfactant is Tween 80 with a reactant volume ratio of 0.5-1 percent or sodium dodecyl sulfate with a reactant mass percentage of 0.5-1 percent ; thirdly, at a vacuum degree of 0.080-0.090 MPa and a temperature of 125-135 DEG C, removing combined water and reacting for 5 hours; and fourthly, agitating and raising the temperature to 165-200 DEG C, distilling and collecting the lactide with a crude production rate of 83-91 percent. The method has the beneficial effects that the distillation temperature of the lactide in the lactide preparation process can be reduced, the energy consumption is reduced, the by-product quantity generated at high temperature is reduced, the preparation production rate of the lactide is further improved, and the production cost is reduced.

Owner:NANYANG INST OF TECH

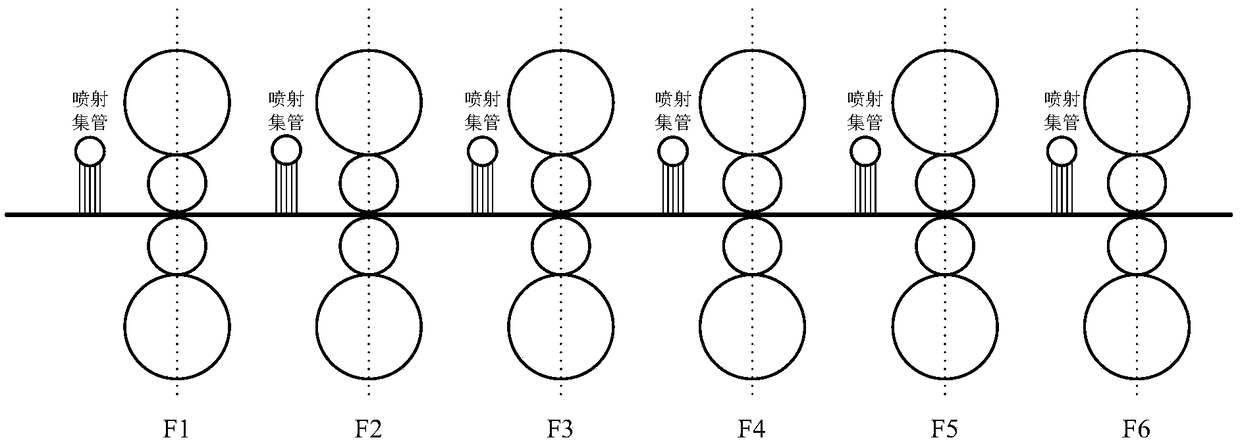

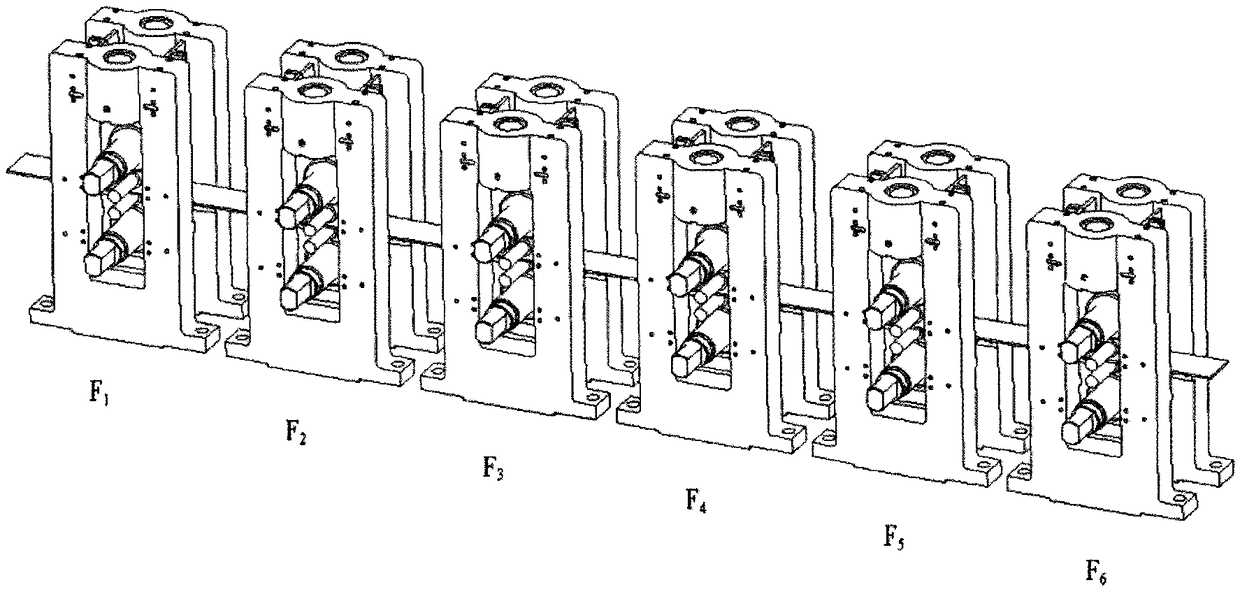

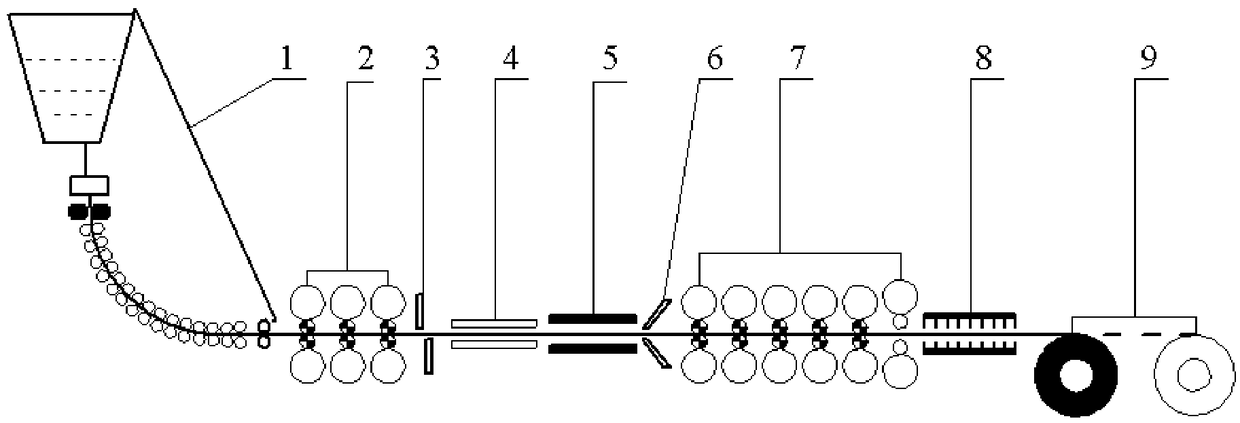

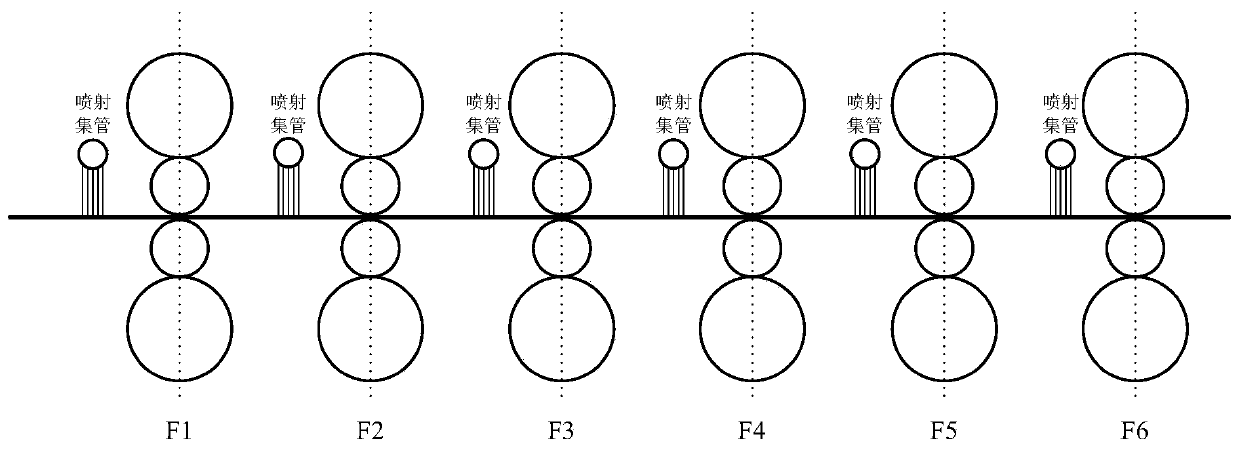

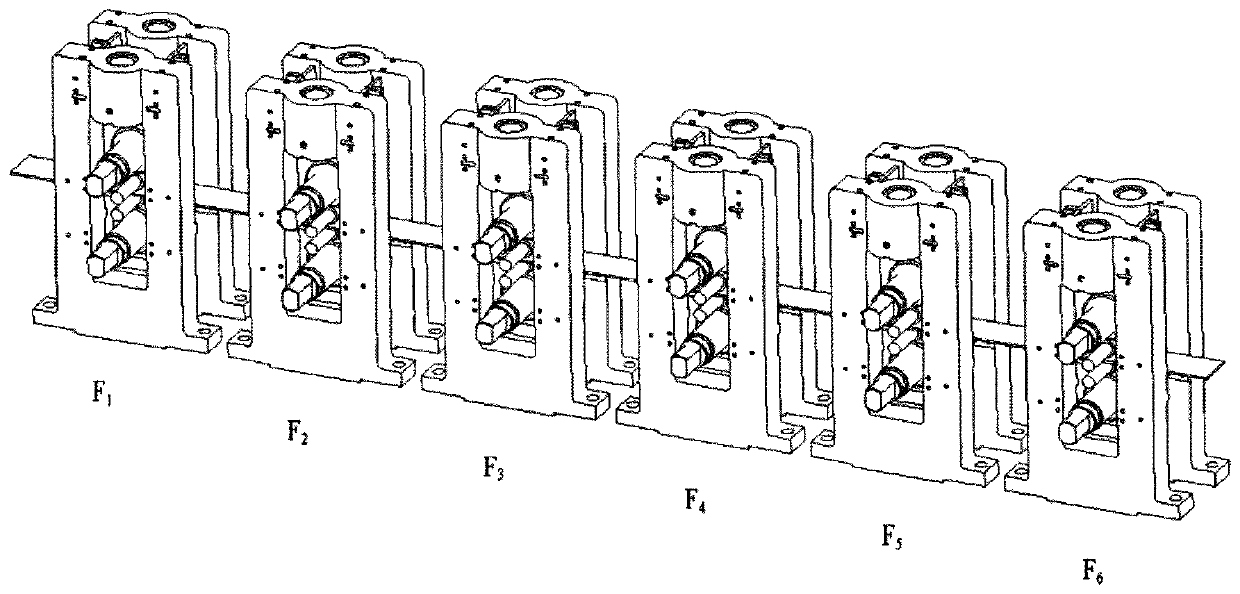

Finishing rolling unit in ESP endless rolling and rolling method

ActiveCN109201758AReduce wearReduce temperature riseTemperature control deviceWork cooling devicesProduction lineEngineering

The invention discloses a finishing rolling unit in ESP endless rolling and a rolling method, and belongs to the field of steel and iron material engineering. The finishing rolling unit in the ESP endless rolling of the invention comprises a plurality of finishing mills arranged in the order of a finishing rolling process, and is characterized in that one of the finishing mills is a standby finishing mill for replacing the worn finishing mill; a spray header is arranged in front of the preceding finishing mill in the standby finishing mill and the worn finishing mill by the order; and the spray header spray cold water to cool a strip plate to complete the transformation process of austenite to ferrite. According to the invention, the full-continuous non-stop flexible rolling technology canbe realized, the productivity drop caused by the forced stop of the production line due to the downtime and roll change of the finishing rolling unit is avoided, and the output is also improved; andthe roll temperature rise can be reduced, so that the fatigue cracking and fracturing of the roll due to the thermal stress are reduced, the wear of the roll is reduced, the surface quality of endlessrolled products is improved, and the production cost is significantly lowered.

Owner:YANSHAN UNIV

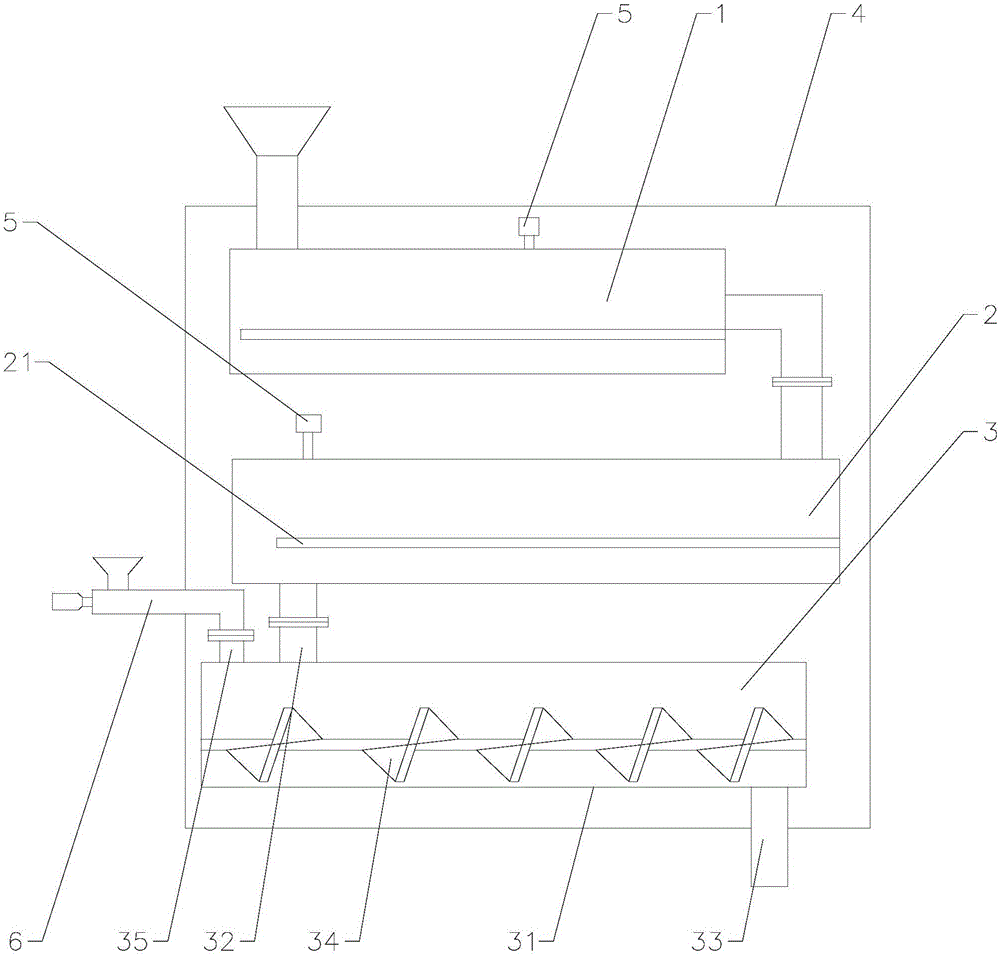

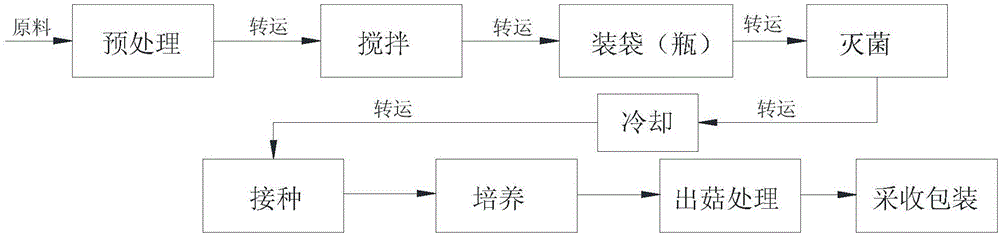

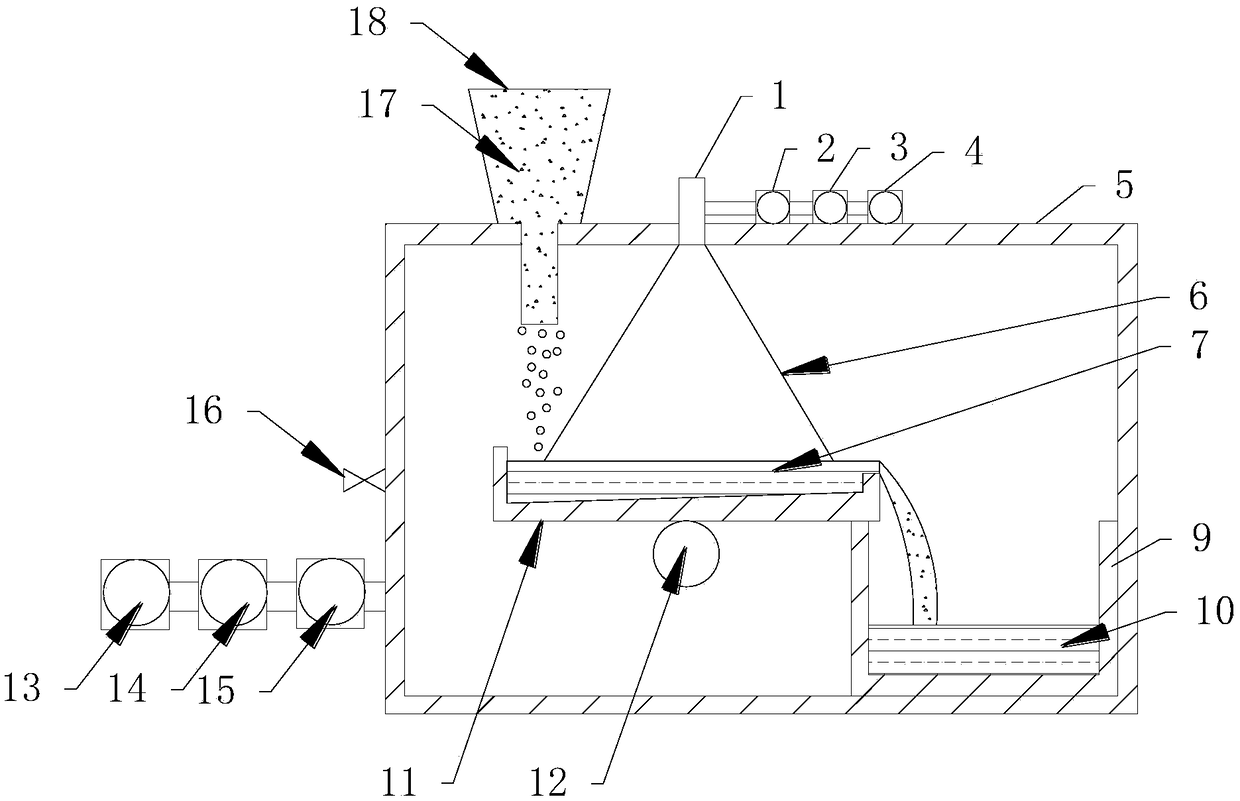

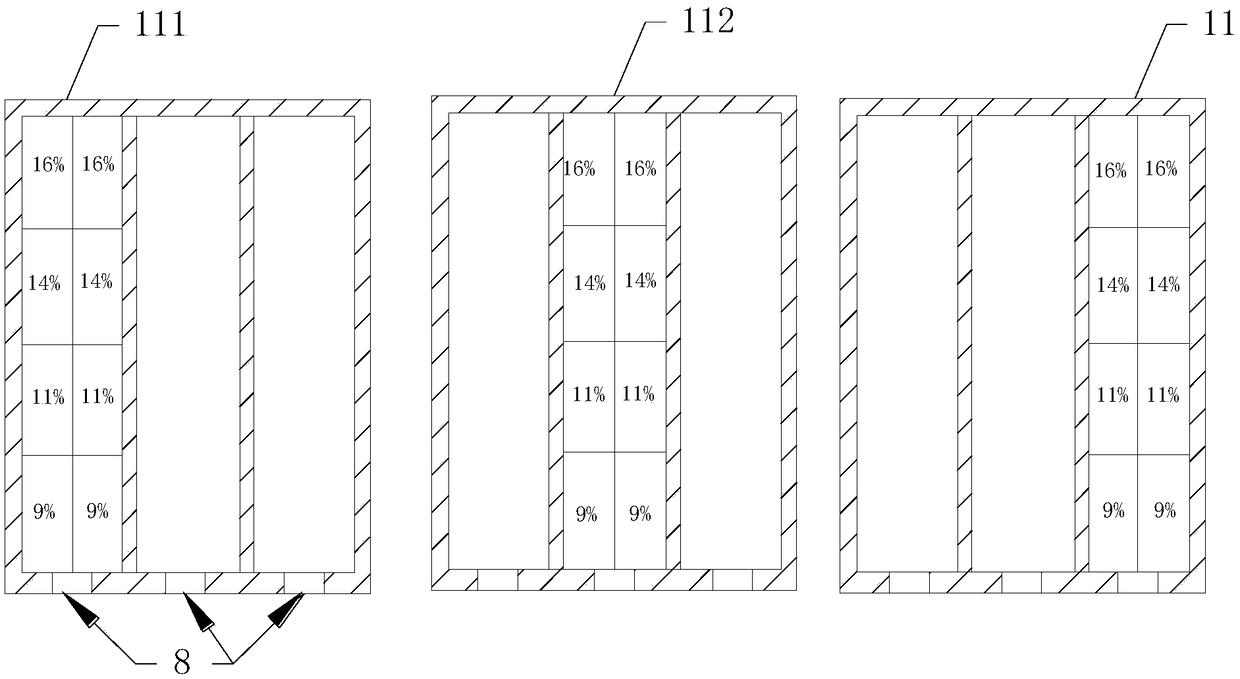

Production equipment for edible mushroom inoculation

InactiveCN105075661AMeet the requirements of industrial mass productionReduce occupancyCultivating equipmentsMushroom cultivationBiotechnologyAnimal science

The invention relates to the technical field of edible mushroom inoculation and especially relates to a kind of integrated production equipment for the edible mushroom inoculation. The production equipment for the edible mushroom inoculation comprises a sterilization device, a cooling device, an inoculation device, a control device and a box body, wherein the inoculation device comprises a shell body, a feeding connecting hole, a discharge connecting hole and a first transmission mechanism used to stir and convey a solid culture medium, the shell body is equipped with a feeding hole used to add edible mushroom bacteria into the solid culture medium, and the feeding connecting hole and the discharge connecting hole are disposed in the shell body and firmly connected to the shell body; and the sterilization device, the cooling device and the inoculation device are disposed inside the box body, an outlet of the sterilization device is firmly connected to an inlet of the cooling device, an outlet of the cooling device is firmly connected to the feeding connecting hole, and the control device is connected to the first transmission mechanism by signals. In this way, problems such as that an existing edible mushroom inoculation device cannot realize automatic and continuous production can be effectively solved.

Owner:JIANGSU TIAN DE POWER EQUIP

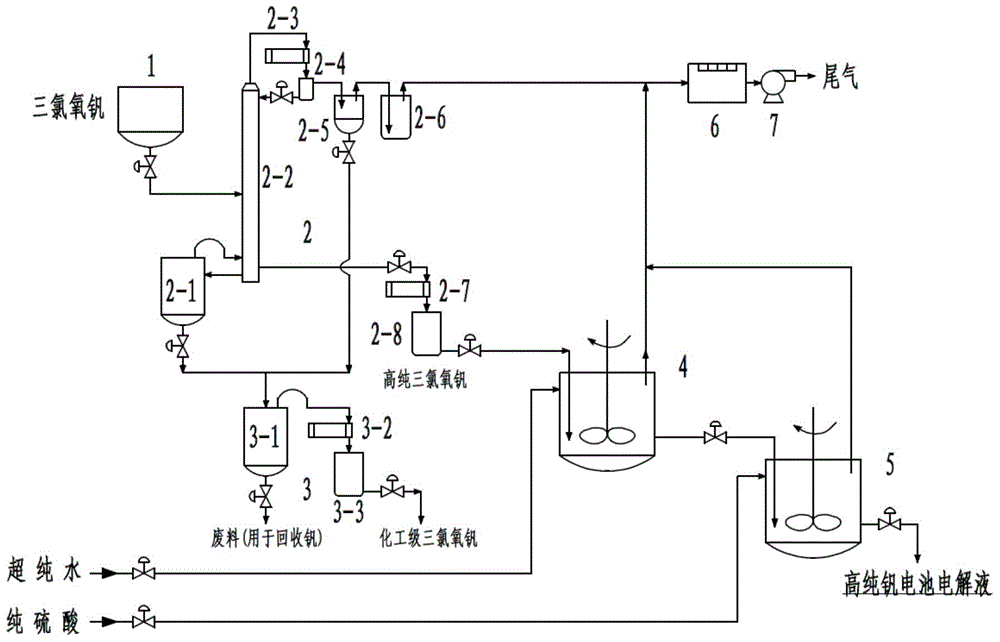

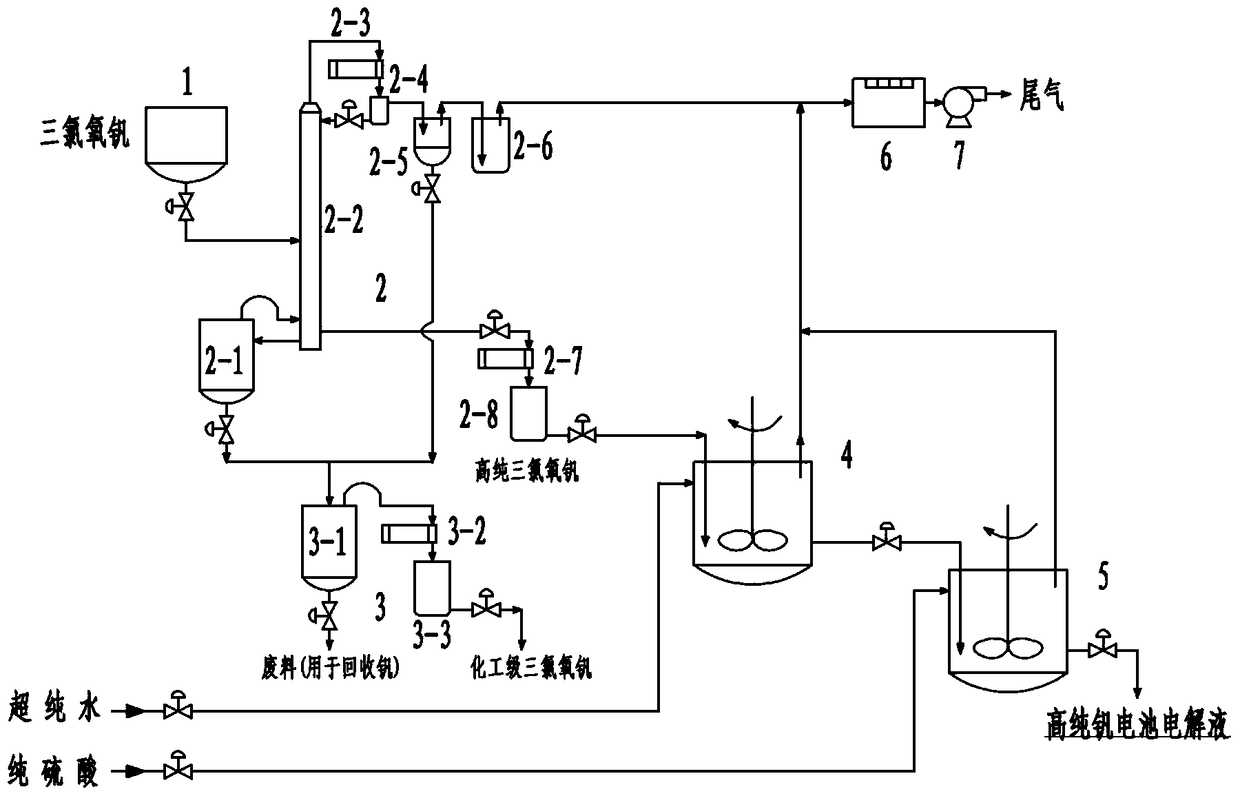

Preparation system and method thereof of high-purity vanadium battery electrolyte

ActiveCN105990593AIncrease production energy consumptionIncrease production costRegenerative fuel cellsChemical industryDistillation

The invention belongs to the fields of chemical industry and material, and concretely discloses a preparation system and a method thereof of a high-purity vanadium battery electrolyte. The preparation system takes industrial-grade vanadium oxytrichloride as a raw material, the industrial-grade vanadium oxytrichloride is subjected to distillation purification to obtain the high-purity vanadylic chloride with purity of more than 4N, the high-purity vanadium oxytrichloride is subjected to hydrolysis as well as chlorinity regulation and control, further, sulfuric acid is added for preparing the high-purity vanadium battery sulfuric acid-hydrochloric acid mixed acid electrolyte. The preparation system and the method have the advantages of strong raw material adaptability, simple flow, cleaning and no pollution, low production energy consumption and low operation cost, and controllable electrolyte quality, are suitable for large-scale continuous production of the high-purity vanadium battery electrolyte, and have good economic benefit and social benefit.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

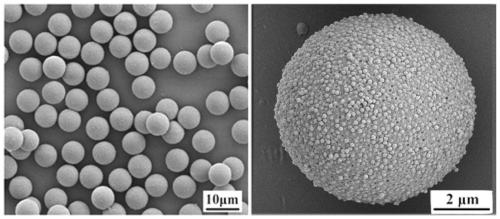

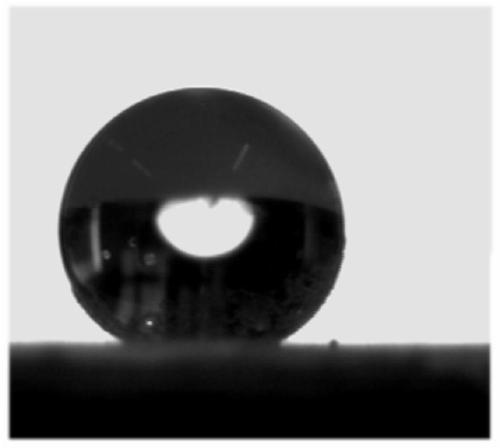

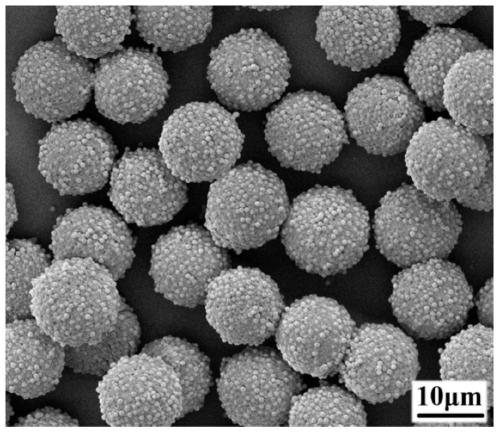

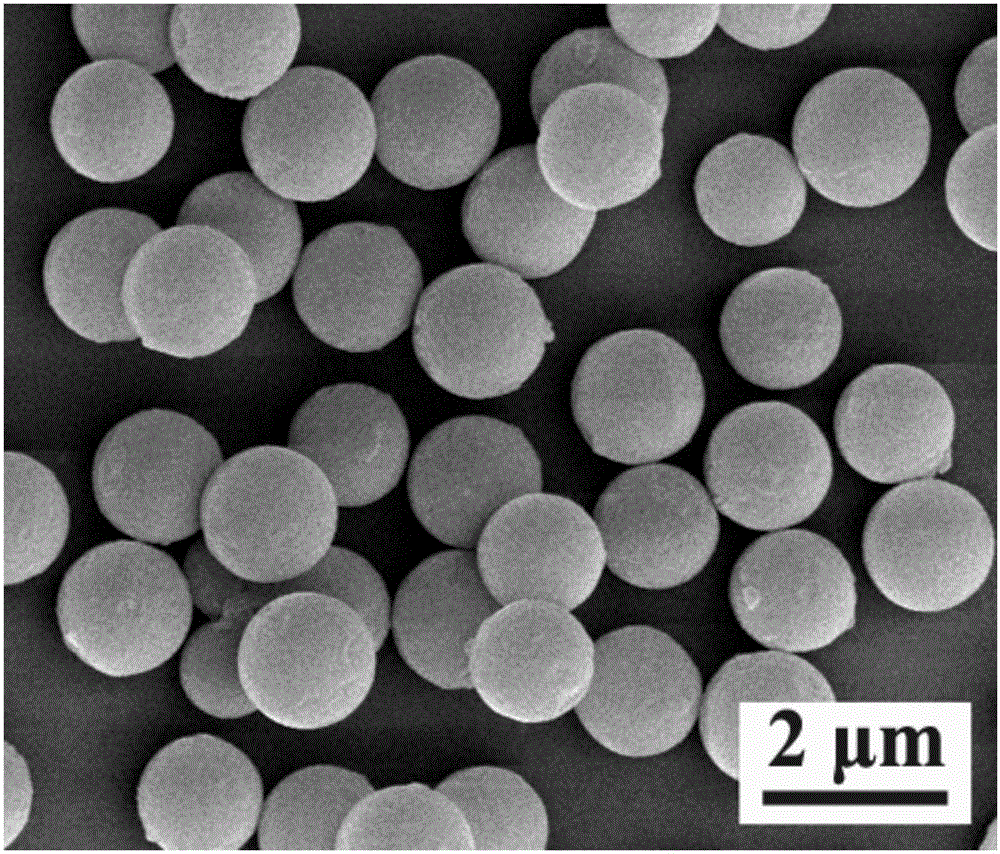

Method for preparing strawberry type inorganic particle-polyurea composite microspheres and super-hydrophobic coating thereof

ActiveCN109880498AHydrophobic adjustmentSimple system componentsPolyurea/polyurethane coatingsMicroballoon preparationMicrosphereReaction temperature

The invention relates to a method for preparing strawberry type inorganic particle-polyurea composite microspheres and a super-hydrophobic coating of the strawberry type inorganic particle-polyurea composite microsphere, which comprises the following steps: adding inorganic nanoparticles and a diisocyanate monomer into a reaction medium, and conducting precipitation polymerization to prepare the strawberry type composite microspheres, and uniformly coating the surface of a base material with the obtained microspheres to prepare the super-hydrophobic coating. The size and the surface roughnessof the obtained microspheres can be adjusted by simply changing the dosage of the inorganic particles and diisocyanate monomer, the reaction temperature and other conditions, so that the hydrophobic property of the strawberry type microsphere coating is adjusted. The method does not need any emulsifier, stabilizer or catalyst and the like; the strawberry-type composite microspheres can be preparedin one step without surface modification; the method has the characteristics of single system component, simple operation process, short time consumption and high microsphere yield, and the polymerization reaction can be carried out under the condition of standing without stirring, so that the production cost and the energy consumption are lower, and the large-scale production of the microspheresis facilitated.

Owner:山东金昌树新材料科技有限公司

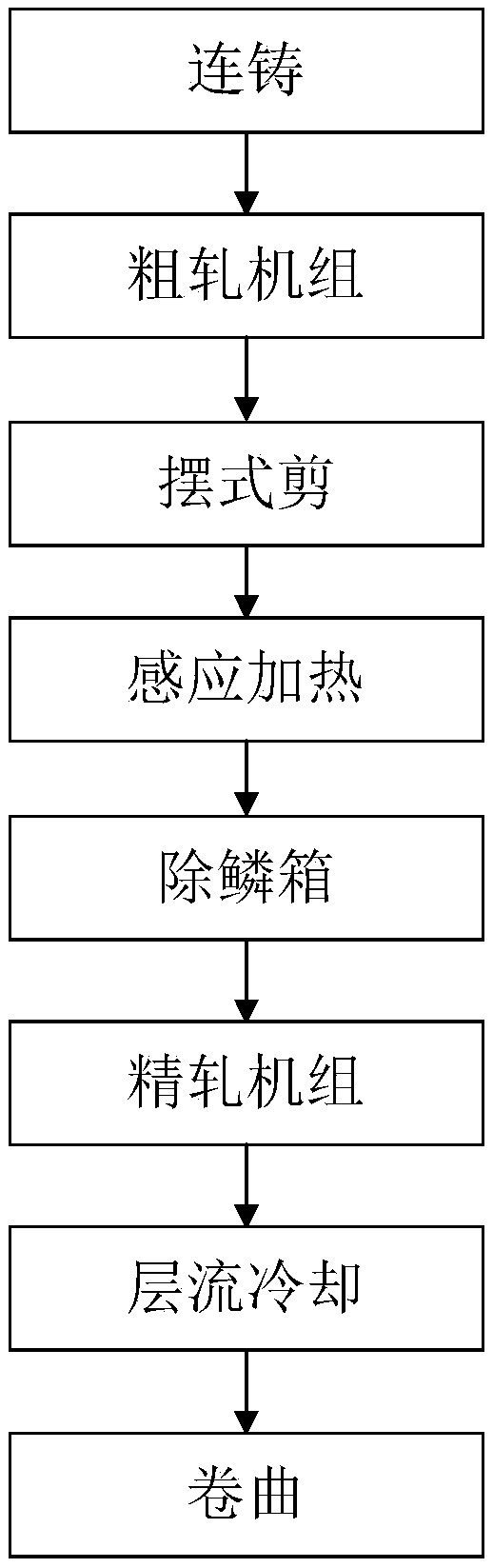

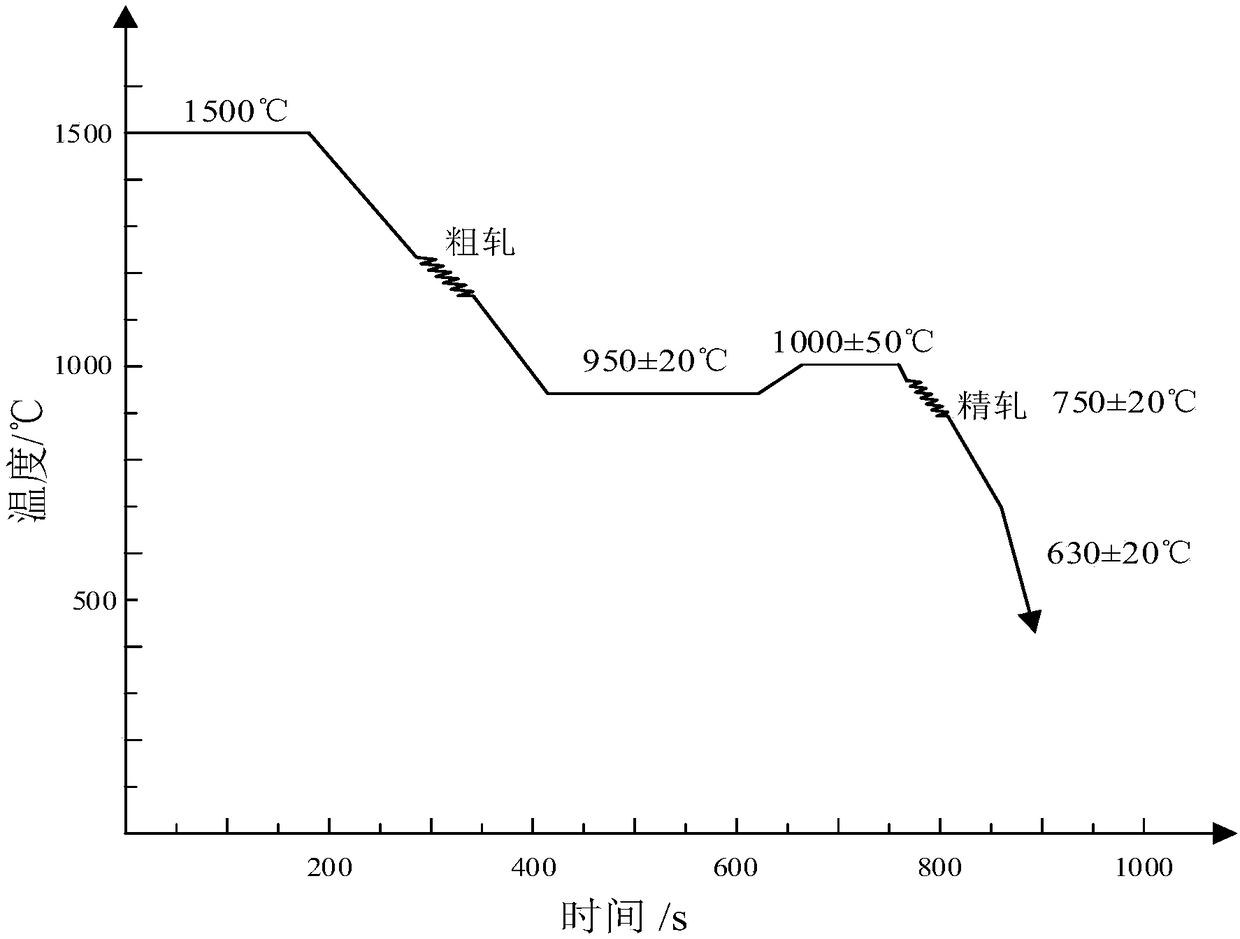

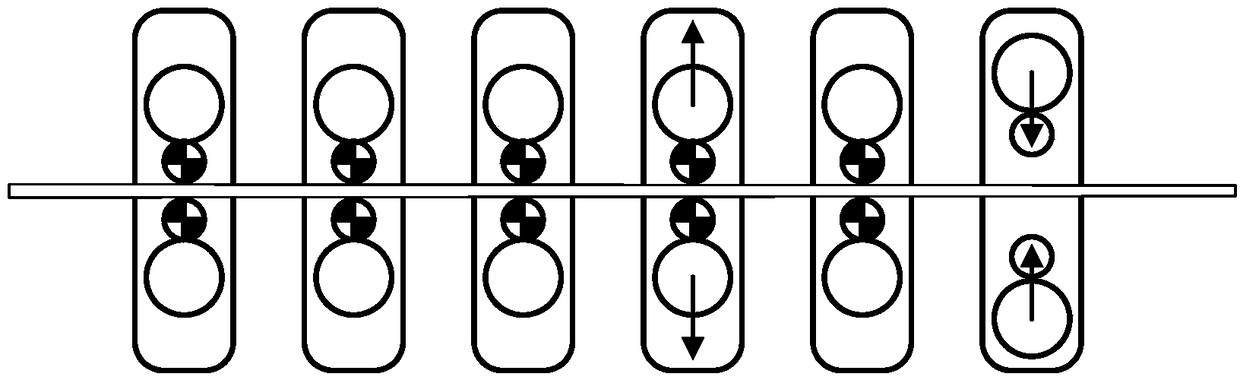

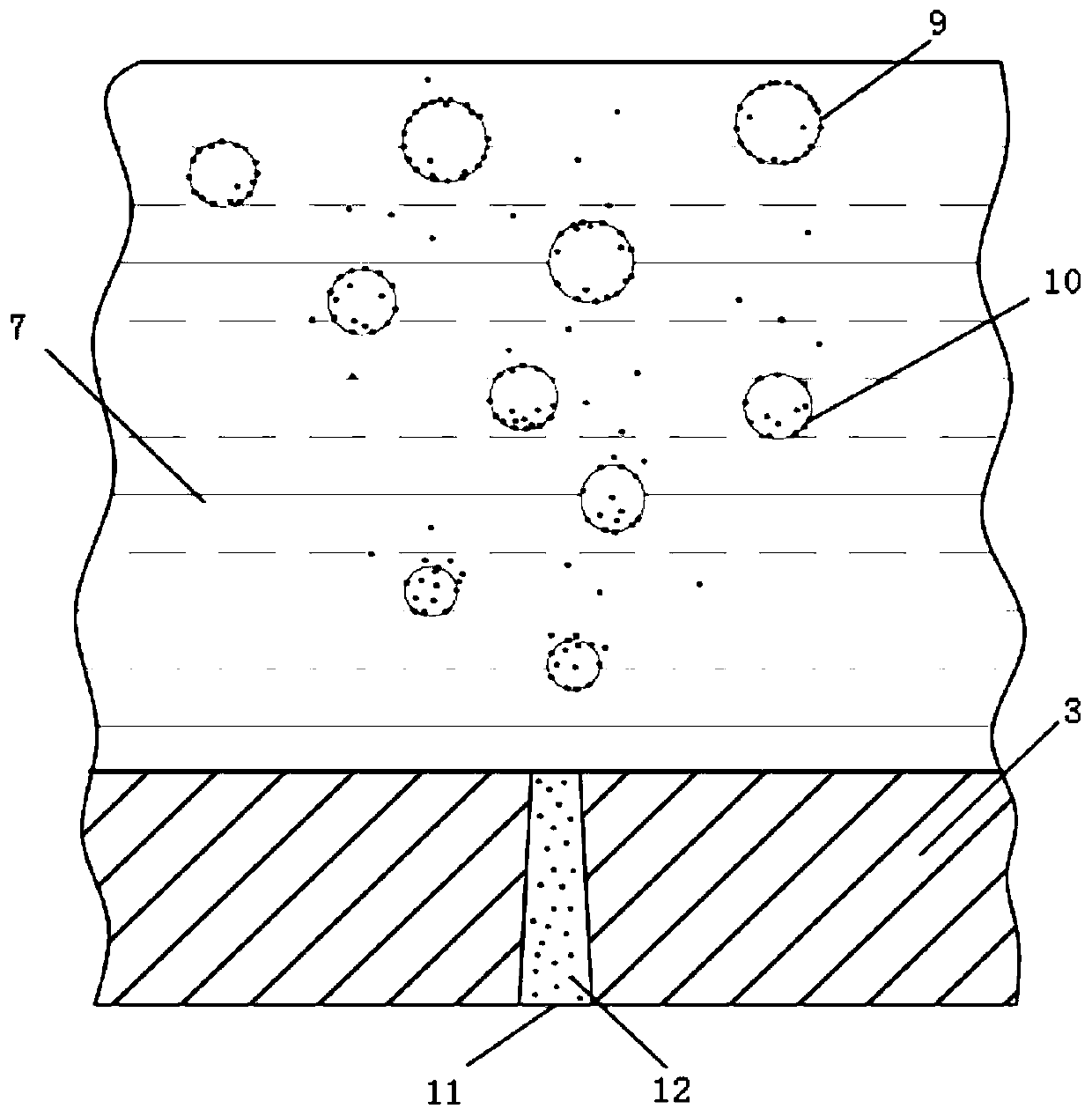

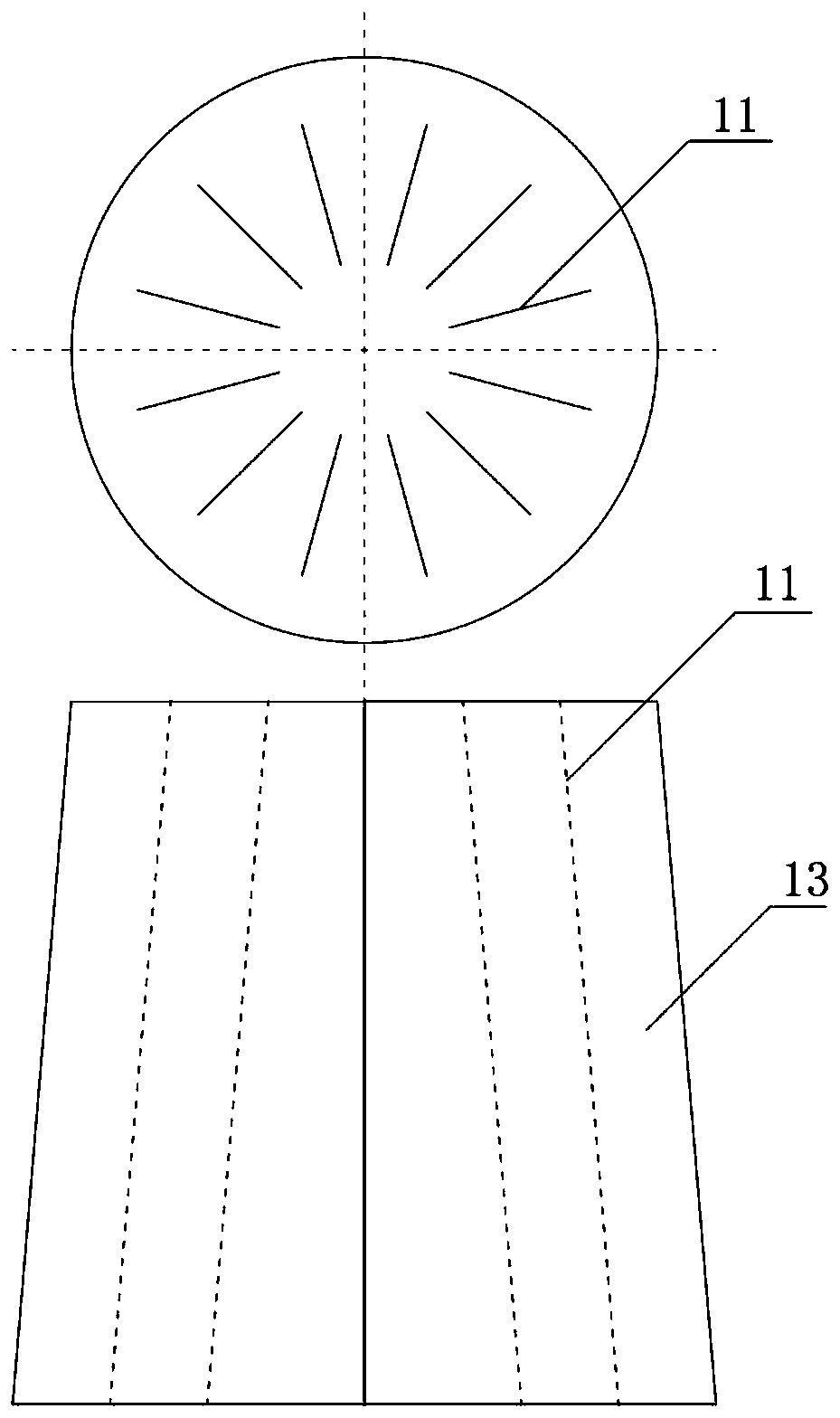

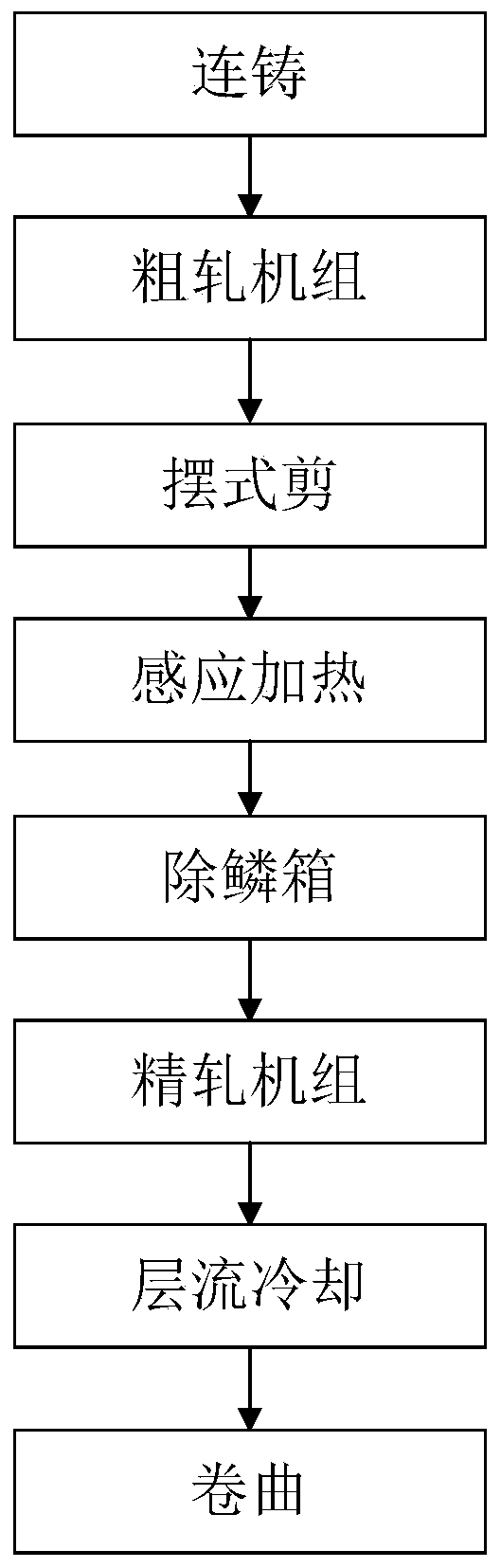

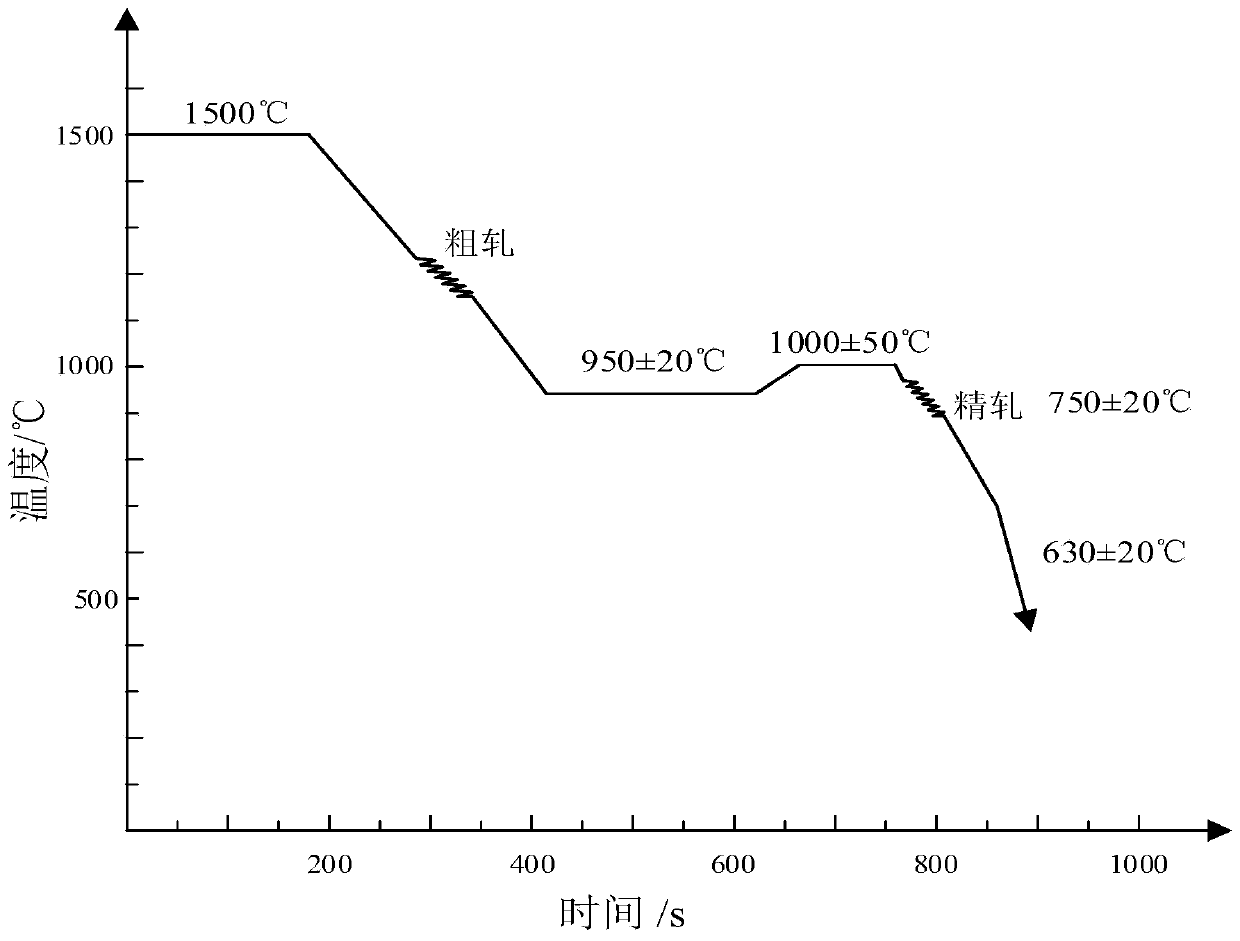

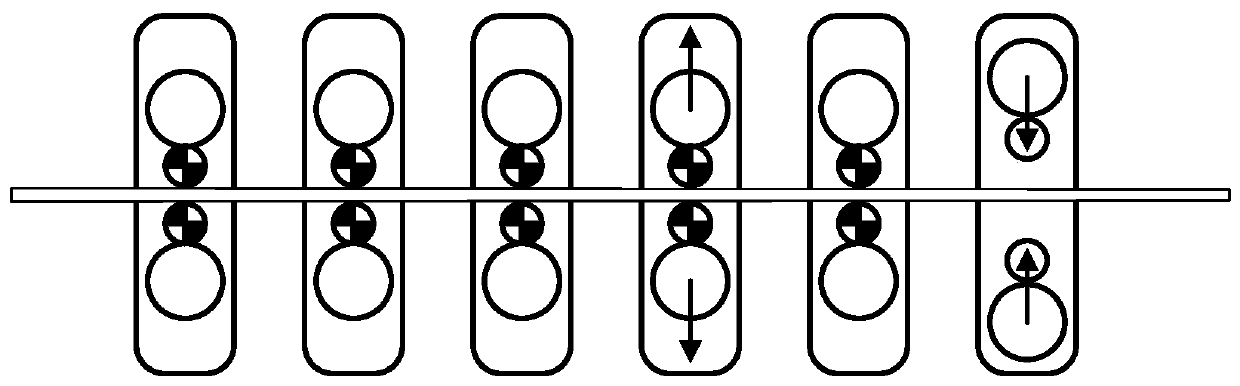

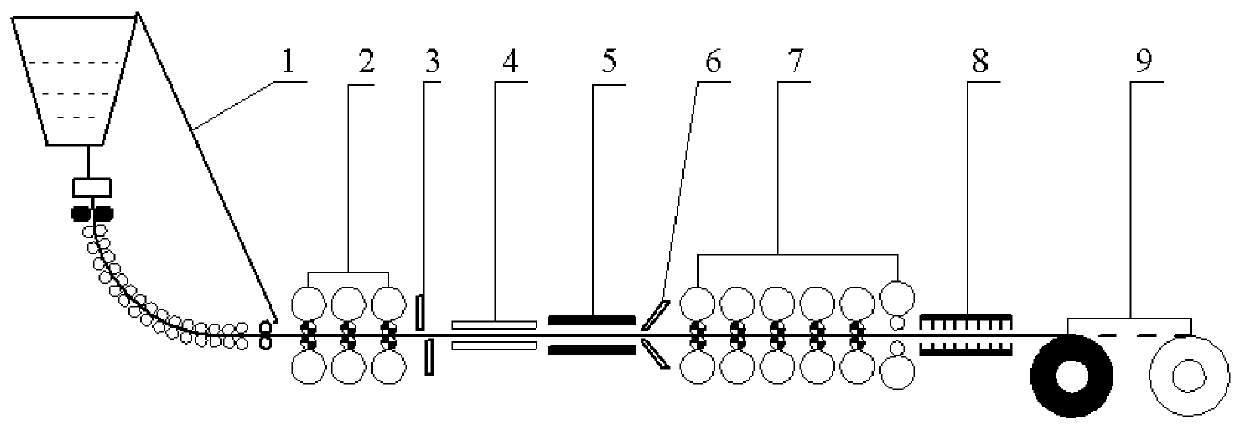

Dynamic variable procedure ferrite rolling method based on endless rolling

ActiveCN109482646AReduce wearImprove surface qualityTemperature control deviceWork cooling devicesProduction lineEconomic benefits

The invention discloses a dynamic variable procedure ferrite rolling method based on endless rolling. A cooling channel is arranged between induction heating and a finishing rolling mill group, and the temperature matching is adjusted and controlled between the induction heating and the cooling channel, so that the finishing rolling mill group realizes austenite zone rolling and ferrite zone rolling in the dynamic variable procedure correspondingly. The ferrite rolling method realizes continuous non-stop production under the condition that an existing production line is basically unchanged. Meanwhile, through the cooperative use of the induction heating and the cooling channel, full continuous non-stop flexible rolling can be realized, the yield is further improved. In addition, during andafter the process of dynamic variable procedure of the endless rolling, lower heating temperature is adopted by the induction heating, the temperature rise of a roll can further be reduced, thus thefatigue cracking and fracture of the roll caused by thermal stress are reduced, the roll abrasion is reduced and the surface quality of endless rolling products is improved, the heating energy consumption of enterprises can be greatly reduced, and an important role in energy conservation, environmental protection and improving economic benefits of the enterprises is played.

Owner:YANSHAN UNIV

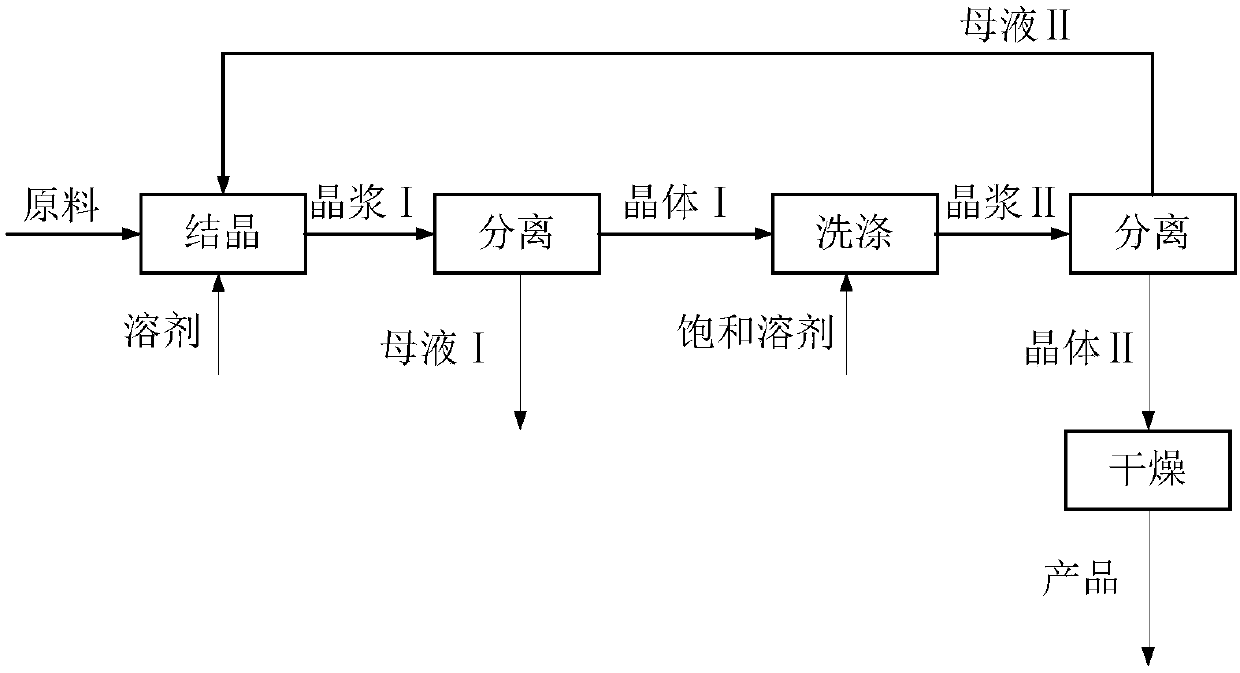

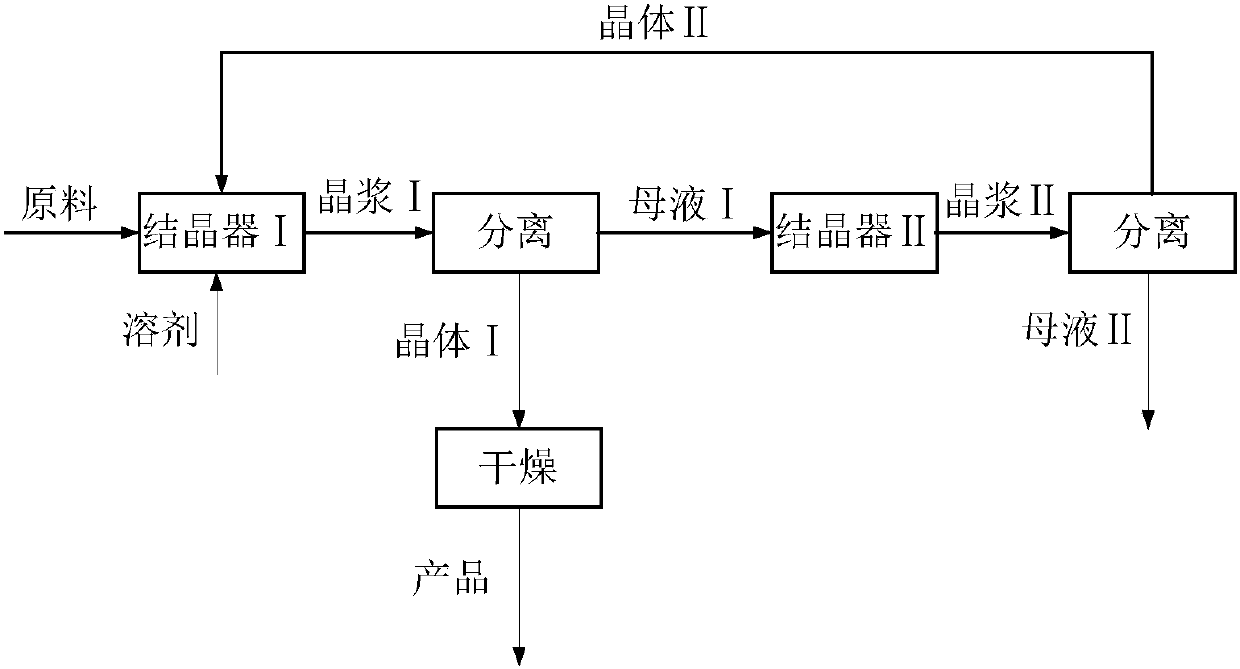

Dicumyl peroxide production method

ActiveCN109694342AImprove product qualityReduce production energy consumptionOrganic compound preparationPeroxy compound preparationSolventHigh energy

The invention relates to a dicumyl peroxide production method, which comprises: co-feeding a dicumyl peroxide raw material and a crystallization solvent into a crystallizer, carrying out cooling crystallization, and carrying out solid-liquid separation on the obtained crystal slurry to obtain a dicumyl peroxide crystal I and a crystallization mother liquor I; discharging the crystallization motherliquor I out of the crystallization device, and carrying out solvent recovery; feeding the dicumyl peroxide crystal I into a beating washing tank, and carrying out beating washing on the dicumyl peroxide crystal I by using a washing liquid; carrying out solid-liquid separation on the obtained crystal slurry to obtain a dicumyl peroxide crystal II and a crystallization mother liquor II; drying thedicumyl peroxide crystal II, and discharging as the product; and returning the crystallization mother liquor II to the crystallizer, and continuously crystallizing. According to the present invention, the dicumyl peroxide production method can solve the problems of poor product quality, irregular crystal shape, poor transparency, serious crystal occlusion and coalescence, non-uniform size and non-uniform distribution of crystal particles, low yield of large particle crystals and high energy consumption in the prior art, and can be used in the production of dicumyl peroxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

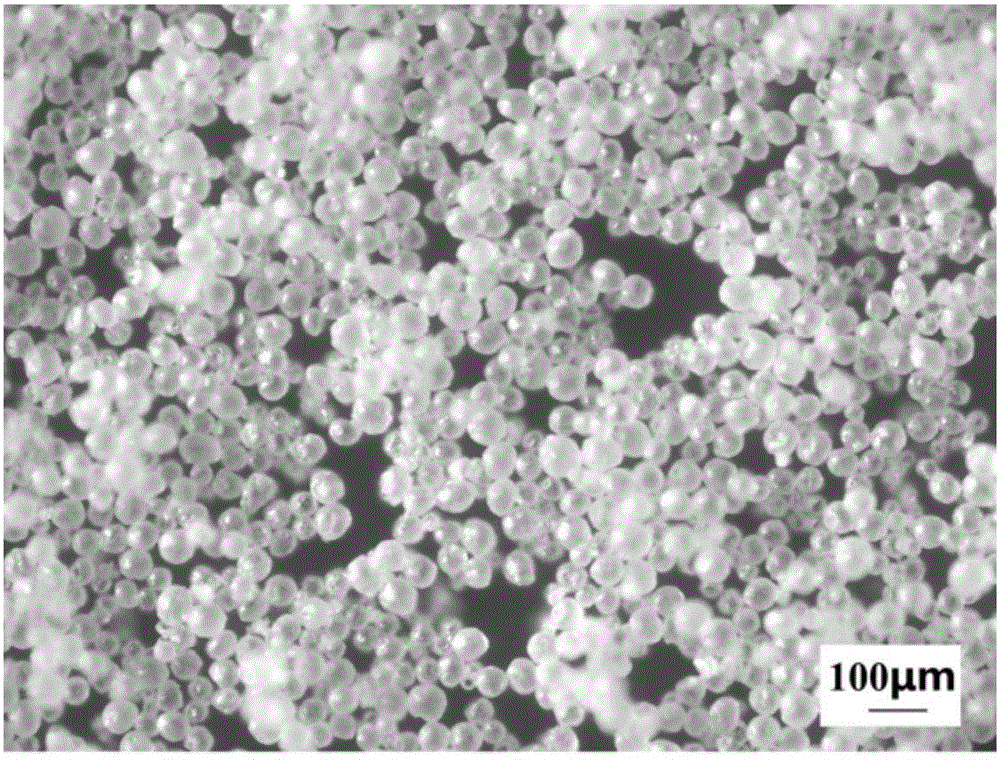

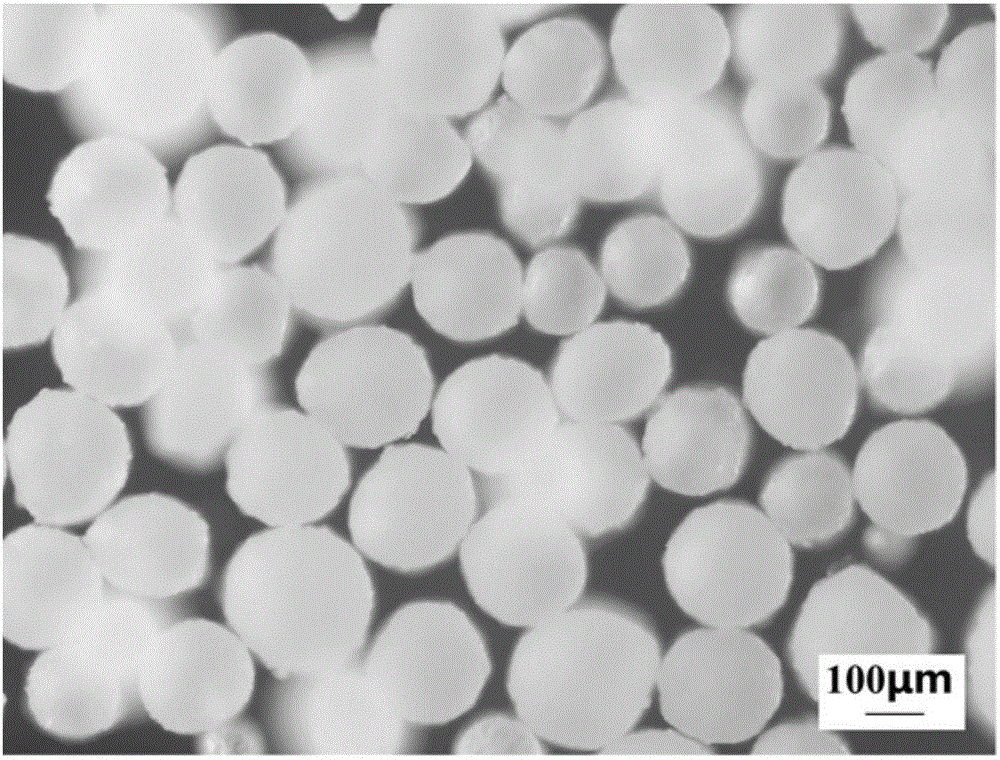

Method for preparing paraffin dispersion liquid and paraffin microspheres using polymer microspheres as stabilizer

The invention relates to a method for preparing paraffin dispersion liquid and paraffin microspheres using polymer microspheres as a stabilizer. Water and ethanol are used as dispersing medium agent. The preparation method comprises the steps of adding paraffin and polymer microspheres into the water-ethanol component solvent for one time, heating until the melting of the paraffin, then shaking with a reciprocating oscillator to acquire the the paraffin dispersion liquid with a surface overlaid with polymer microspheres. The preparation method requires little amount of stabilizer, and no other assistants. The prepared paraffin microspheres have a clean surface. The present invention can achieve a one-step process of the preparation of paraffin dispersion liquid of paraffin microspheres with uniform size. The test process is simple, costs short time, and has high production efficiency. At the same time in the preparation process, the high speed agitation and high speed homogenizing equipment are not necessary. Ordinary water bath shake is enough for the preparation of stable paraffin dispersion liquid. The production cost and energy consumption are all starkly reduced, thus being beneficial to achieve the industrial production and application of the paraffin dispersion liquid.

Owner:UNIV OF JINAN

Method and apparatus for efficiently purifying silicon material after medium smelting

ActiveCN109110766AEfficient smeltingIncrease production energy consumptionChemical industrySilicon compoundsCrucibleImpurity

The invention relates to the field of production of solar-grade polycrystalline silicon, in particular to a method and an apparatus for efficiently purifying a silicon material after the medium smelting. A structure of a smelting crucible of the apparatus is arranged in a manner that the rear end inclines towards a liquid guiding opening; a plurality of compartments are provided in the smelting crucible, an inner groove of each compartment corresponds to one smelting groove, and each smelting groove corresponds to the liquid guide opening; and when in use, the electron beam smelting energy distribution mode corresponding to the structure of the smelting crucible is gradually reduced from the rear end to the liquid guide opening. By selecting the electron beam smelting energy distribution mode and selecting a multi-mode smelting crucible structure, the silicon carbide and volatile impurity element in the silicon material after the medium smelting can be eliminated, the cost is low, andthe effect is good.

Owner:QINGDAO BLUE LIGHT NEW MATERIAL CO LTD

Method for extracting red pigment in Viburnum sargentii fruit

The invention provides a method for extracting red pigment from a fruit of Viburnum sargentii, and relates to the method for extracting pigments from the fruit of Viburnum sargentii. The invention solves the problem that no prior method is specially for extracting the red pigment from the fruit of Viburnum sargentii. The red pigment of the fruit of Viburnum sargentii is extracted according to the following steps: acetic acid-sodium acetate solution, pectinase, and the fruit of Viburnum sargentii are put in a mixer and broken to homogenate, infused to a 15 ml plug pipe, and then put in a thermostat water bath; enzymolysis is conducted; the enzymolysis liquid is filtered; the filtrate is rotationally evaporated to remove the solvent, and cooled and dried; and red pigment powder of Viburnum sargentii is acquired. The method uses the pectinase to extract the red pigment of Viburnum sargentii, thereby avoiding the problems of low production rate, low purity, residual solvent, difficult solvent recycling, and long production cycle produced when a solvent method is used to extract the red pigment. The method has the advantages of high production rate and short production cycle; and the acquired red pigment belongs to flavonoid naturalpigment, has no harm to a human body, and can be used for coloring food.

Owner:NORTHEAST FORESTRY UNIVERSITY

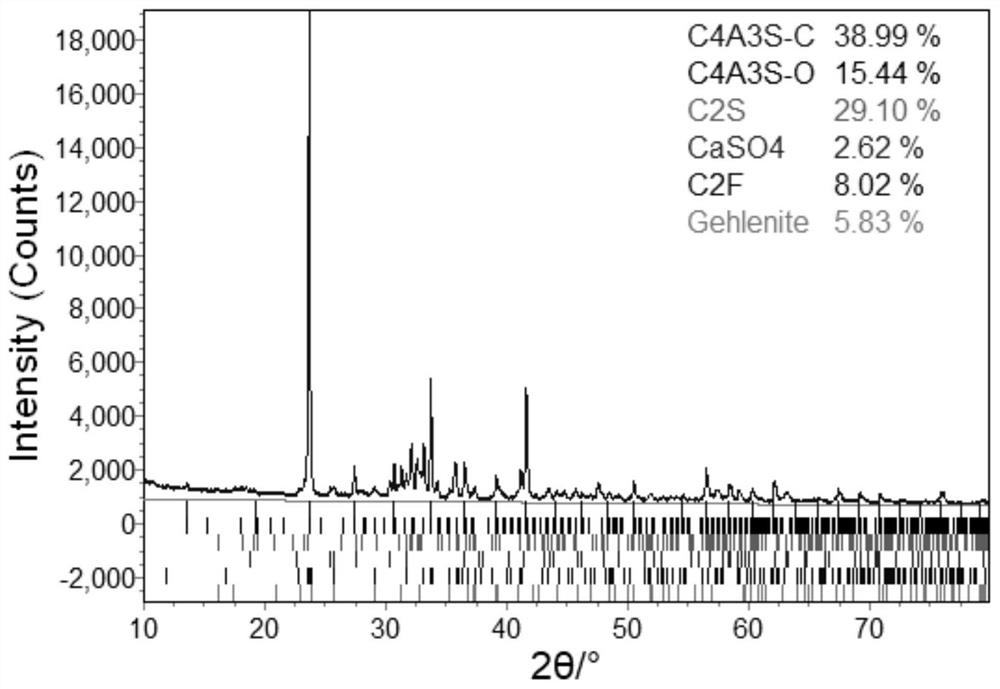

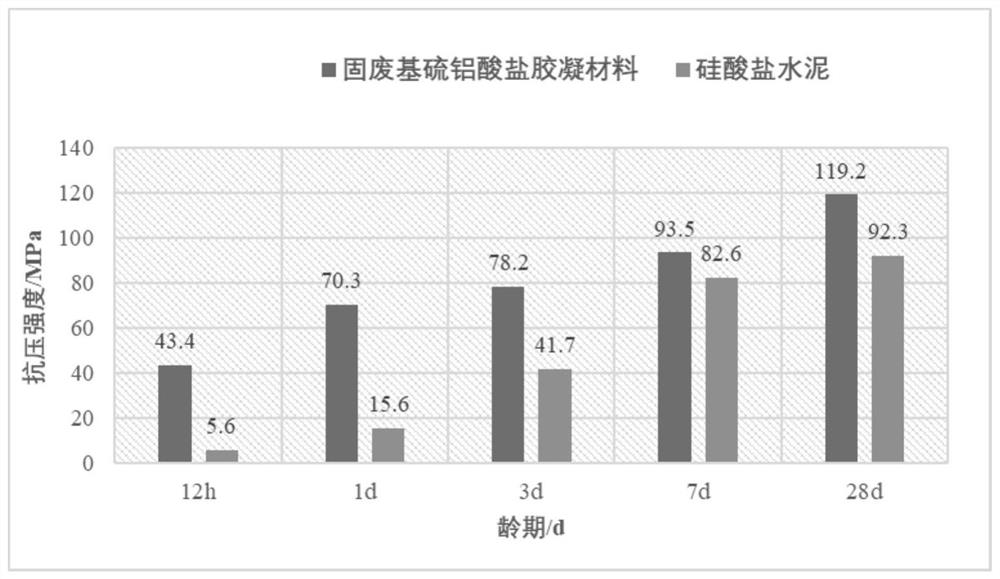

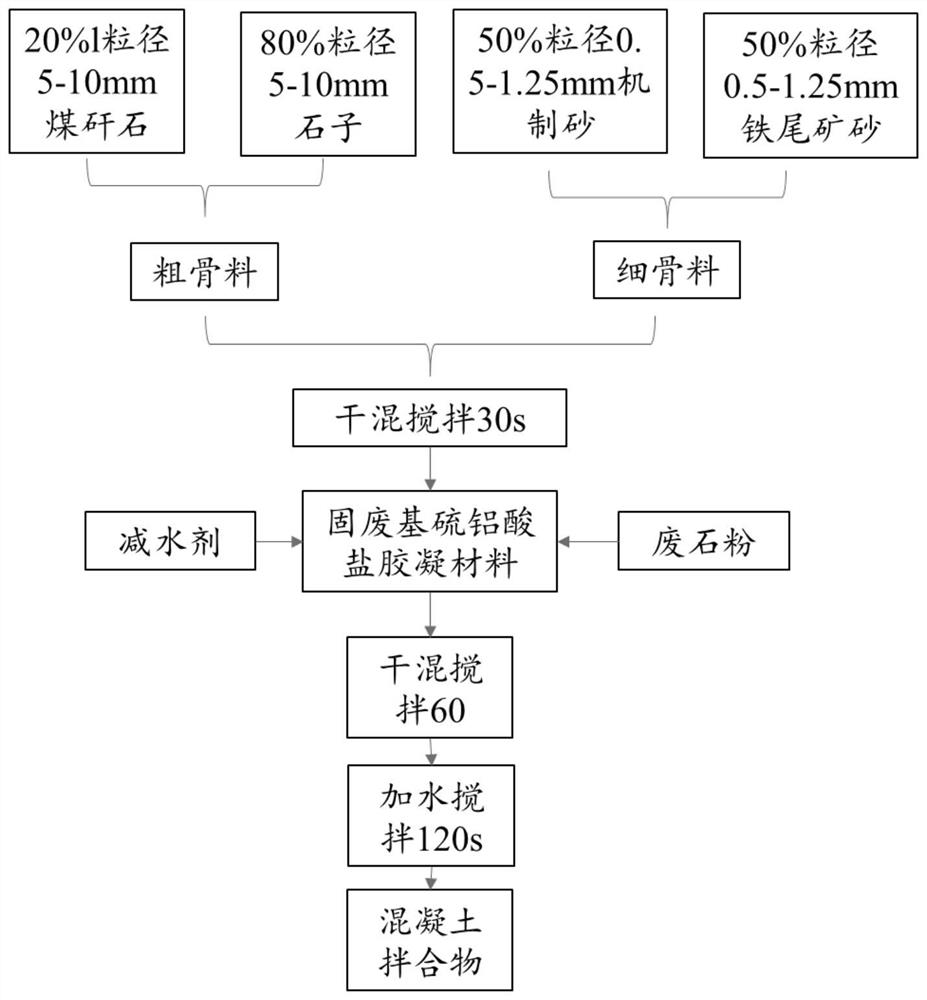

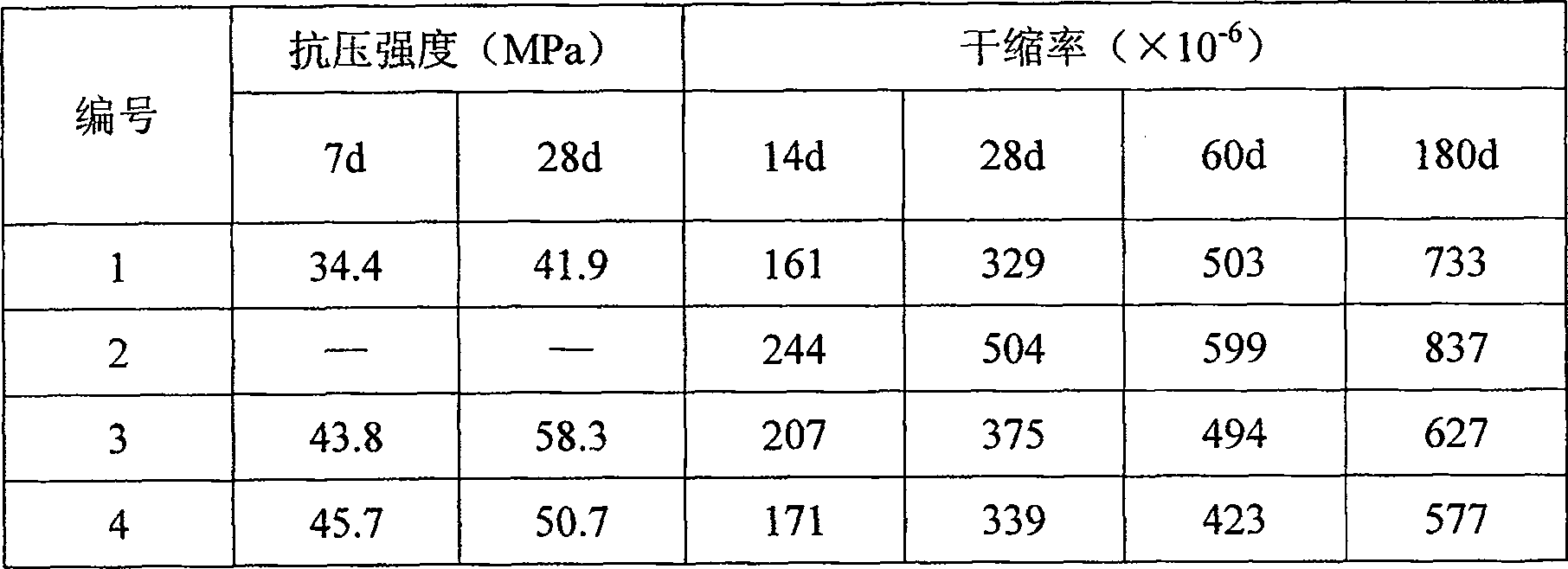

Environment-friendly pervious concrete for roads as well as preparation method and application thereof

The invention provides environment-friendly pervious concrete for roads as well as a preparation method and application thereof. The environment-friendly pervious concrete for roads is prepared from the following raw materials or consists of the following components in parts by weight: 150-250 parts of a solid waste-based sulphoaluminate cementing material, 600-750 parts of coarse aggregate, 40-80 parts of fine aggregate, 10-15 parts of waste stone powder, 0.2-0.25 parts of a water reducing agent and 1 part of a thickening agent, wherein the water-binder ratio is 0.20-0.25. The shape-maintaining pervious concrete for roads has the characteristics of air permeability, water permeability and light weight, has better mechanical properties, is simple in process, low in cost, low-carbon and environment-friendly, and is high in added value by adopting solid waste resource products.

Owner:SHANDONG UNIV

Dicumyl peroxide production method

ActiveCN109694341AImprove uniformityHigh yieldOrganic compound preparationPeroxy compound preparationHigh energySlurry

The invention relates to a dicumyl peroxide production method, which comprises: carrying out cooling crystallization on a dicumyl peroxide raw material and a crystallization solvent in a crystallizerI, and carrying out solid-liquid separation on the obtained crystal slurry I to obtain a dicumyl peroxide crystal I and a crystallization mother liquor I; washing the dicumyl peroxide crystal I, drying, and discharging as the product; making the crystallization mother liquor I enters a crystallizer II, continuously crystallizing, and carrying out solid-liquid separation on the obtained crystal slurry II to obtain a dicumyl peroxide crystal II and a crystallization mother liquor II; and making the dicumyl peroxide crystal II return to the crystallizer I, and discharging the crystallization mother liquor II out of the crystallization device to carry out solvent recovery. According to the present invention, with the technical scheme, the problems of poor product quality, irregular crystal shape, poor transparency, serious crystal occlusion and coalescence, non-uniform size and non-uniform distribution of crystal particles, low yield of large particle crystals and high energy consumption in the prior art are well solved; and the dicumyl peroxide production method can be used in the production of dicumyl peroxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Activator of large doped quantities of levigated slag concrete

This invention discloses an activator used in large-doping-amount finely ground slag concrete. The activator is composed of: gypsum 60-81 wt.%, naphthalin high-performance water reducer 7-10 wt.%, hydroxyl compound 0-0.02 wt.%, surfactant 0-0.002 wt.%, and finely ground slag 9-30 wt.%. The activator can replace 4-6% of cement in large-doping-amount finely ground slag. The concrete added with the activator has such advantages as high mixability, high pumpability, and high volume stability. With the activator, the doping amount of finely ground slag in the concrete can be increased to 70%.

Owner:NANJING RUIDI HIGH TECH

A kind of preparation method of ultrapure hydrogen

ActiveCN106283101BLow costEasy to operateElectrolysis componentsHydrogen separationElectrolysisSoftened water

The invention discloses a method for preparing ultra-pure hydrogen. The electrolytic hydrogen production process is adopted in the method. Softened water before electrolysis is pretreated, the softened water is heated, and various sorts of gases like N2 and Ar dissolved in the softened water are removed completely; high-purity oxygen is supplied for pressure maintaining; and then the ultra-pure hydrogen meeting 'GBT 3634.2-2011 pure hydrogen, high-purity hydrogen and ultra-pure hydrogen' requirements can be produced by the adoption of the catalyst catalytic deoxidation and molecular sieve dehydration process, filtering dust removal process and steel cylinder drying treatment process. The method for preparing the ultra-pure hydrogen has the beneficial effects that the defects that a palladium alloy diffusion film (pipe) separation method is high in cost and small in production amount, a hydrogen storage alloy absorbing and desorbing method is short in hydride service life and instable in production, a low-temperature adsorption method needs to use liquid nitrogen and thus the requirements for equipment are high are overcome successfully; and the characteristics of being low in production energy consumption, high in flow-path efficiency, simple in process, stable in production and the like are achieved.

Owner:山东泓达生物科技有限公司

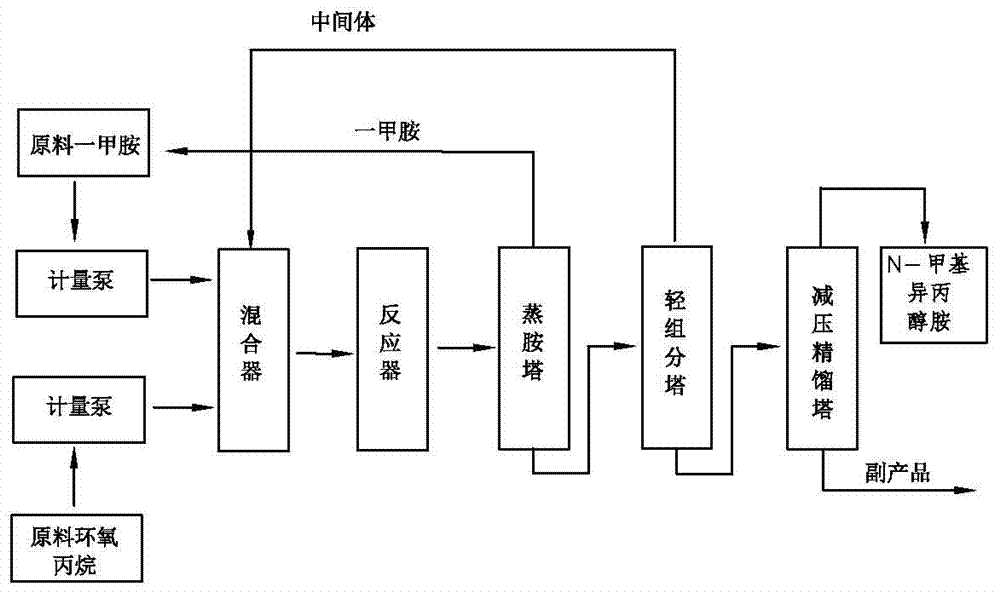

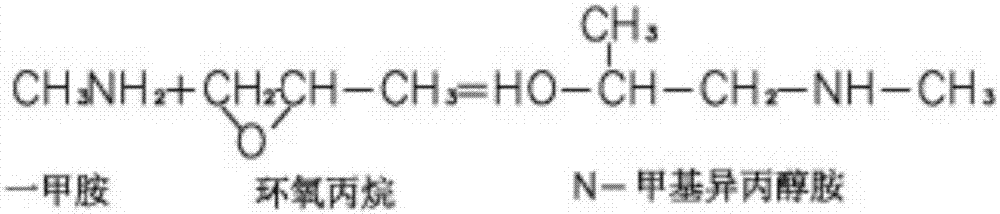

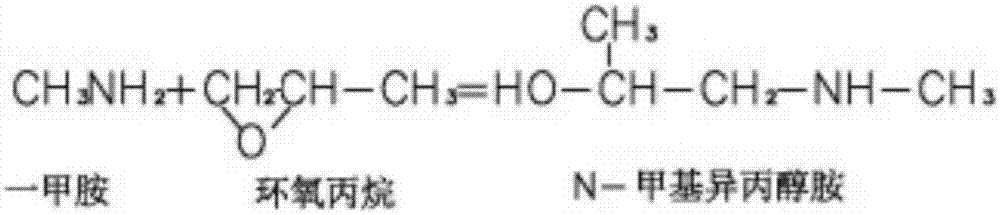

Method for continuous production of N-methylisopropanolamine

ActiveCN107226781AIncrease manpowerSave human effortOrganic compound preparationAmino-hyroxy compound preparationPetrochemicalChemistry

The invention relates to the technical field of petrochemical products and particularly relates to a method for continuous production of N-methylisopropanolamine. The method comprises respectively metering monomethylamine and propylene epoxide, feeding the monomethylamine and propylene epoxide into a mixer, carrying out uniform mixing, feeding the mixture into a reactor, carrying out a reaction process, and carrying out separation purification on the crude product containing N-methylisopropanolamine orderly through an amine distillation column, a light component column and a reduced-pressure rectification column to obtain a refined product of N-methylisopropanolamine. The method fills the gap of high efficiency production of N-methylisopropanolamine in the industry and realizes continuous and stable mass production of N-methylisopropanolamine. The product has stable quality. The method is an eco-friendly process.

Owner:MAOMING YUNLONG IND DEV

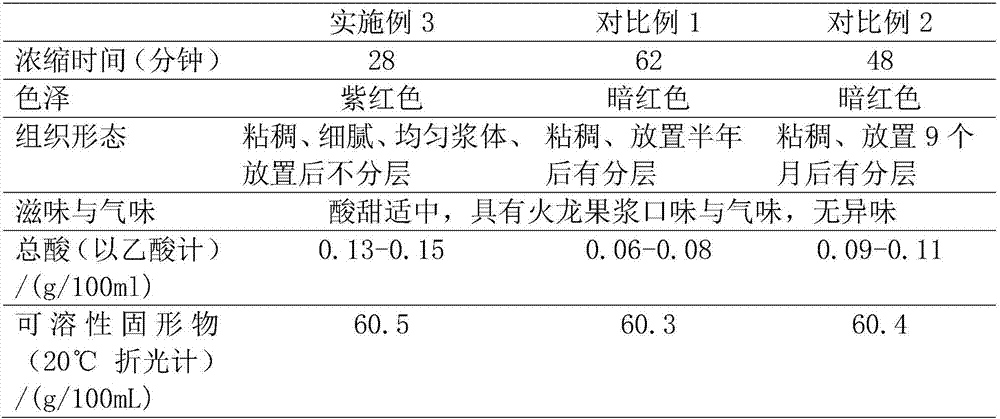

Hylocereus undulatus pulp and preparation method thereof

InactiveCN107136447AIncrease viscosityReduce resistanceFood thermal treatmentInorganic compound food ingredientsFiltrationFilter material

The invention discloses hylocereus undulatus pulp and a preparation method thereof. The preparation method comprises the following steps of (1) performing pretreatment: choosing fresh hylocereus undulatus, and cleaning the chosen hylocereus undulatus; (2) performing pulping: conveying the cleaned hylocereus undulatus into a pulping machine, and performing pulping; (3) performing heating and degumming: heating pulp obtained through pulping in the step (2), removing foam floating upwards, and filtering off dregs; (4) performing blending and concentration: uniformly mixing white granulated sugar with xanthan gum to obtain a mixture, adding the mixture to materials obtained in the step (3) and having equal weight as the mixture, continuing stirring while adding the mixture to obtain a new mixture, then putting the new mixture into a steam explosion pot, wherein the pressure is 3.5MPa, maintaining the pressure of 3.5MPa for 3min, performing instantaneous release, heating the obtained materials, concentrating the heated materials until the concentrated materials have a certain content of solid matters, and performing filtration, and taking filtered materials out of the pot; and (5) performing filling, performing sterilization and performing packaging.

Owner:GUANGXI QINZHOU MASHI FOOD

Activator of large doped quantities of levigated slag concrete

This invention discloses an activator used in large-doping-amount finely ground slag concrete. The activator is composed of: gypsum 60-81 wt.%, naphthalin high-performance water reducer 7-10 wt.%, hydroxyl compound 0-0.02 wt.%, surfactant 0-0.002 wt.%, and finely ground slag 9-30 wt.%. The activator can replace 4-6% of cement in large-doping-amount finely ground slag. The concrete added with the activator has such advantages as high mixability, high pumpability, and high volume stability. With the activator, the doping amount of finely ground slag in the concrete can be increased to 70%.

Owner:NANJING RUIDI HIGH TECH

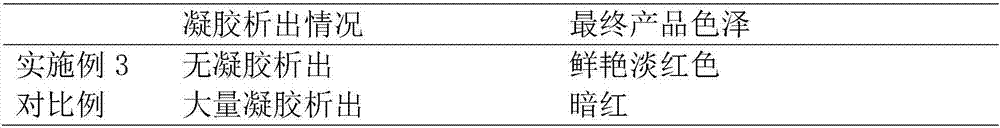

Dragon fruit juice and processing method for reducing gel precipitation

InactiveCN107048102AIncrease stickinessIncrease production energy consumptionFood scienceFruit juicePurified water

The invention discloses a dragon fruit juice and a processing method for reducing gel precipitation. The dragon fruit juice is prepared by 1), pretreatment: picking and cleaning fresh dragon fruits; 2), pulping: feeding the cleaned fruits to a pulping machine to pulp; 3), dilution and filtering: mixing the fruit pulp obtained in step 2) with purified water evenly, statically placing and removing floats, and filtering to obtain clean juice; 4), clarifying: adding color fixative in the clean juice obtained in step 3), and then putting into a steam blasting tank; keeping for 3 min under the pressure of 3.5 MPa; instantly releasing; 5) concentration and settlement: concentrating the materials obtained in step 4) to the weight of step 2) and filtering the materials; 6), mixing: adding sugar and acid; after dissolving evenly, heating the juice and adding potassium sorbate; filtering the juice; 7), filling, sterilizing and packaging the dragon fruit juice.

Owner:GUANGXI QINZHOU MASHI FOOD

Method for extracting red pigment in Viburnum sargentii fruit

InactiveCN101438813BPromote dissolutionHigh recycling costsFood preparationSodium acetateWater baths

The invention provides a method for extracting red pigment from a fruit of Viburnum sargentii, and relates to the method for extracting pigments from the fruit of Viburnum sargentii. The invention solves the problem that no prior method is specially for extracting the red pigment from the fruit of Viburnum sargentii. The red pigment of the fruit of Viburnum sargentii is extracted according to thefollowing steps: acetic acid-sodium acetate solution, pectinase, and the fruit of Viburnum sargentii are put in a mixer and broken to homogenate, infused to a 15 mL plug pipe, and then put in a thermostat water bath; enzymolysis is conducted; the enzymolysis liquid is filtered; the filtrate is rotationally evaporated to remove the solvent, and cooled and dried; and red pigment powder of Viburnum sargentii is acquired. The method uses the pectinase to extract the red pigment of Viburnum sargentii, thereby avoiding the problems of low production rate, low purity, residual solvent, difficult solvent recycling, and long production cycle produced when a solvent method is used to extract the red pigment. The method has the advantages of high production rate and short production cycle; and the acquired red pigment belongs to flavonoid naturalpigment, has no harm to a human body, and can be used for coloring food.

Owner:NORTHEAST FORESTRY UNIVERSITY

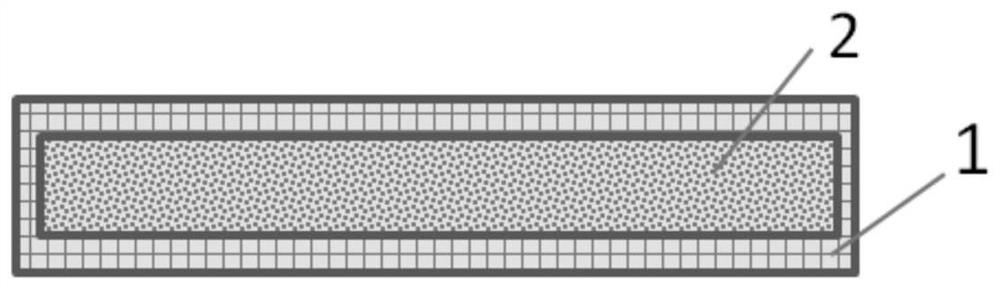

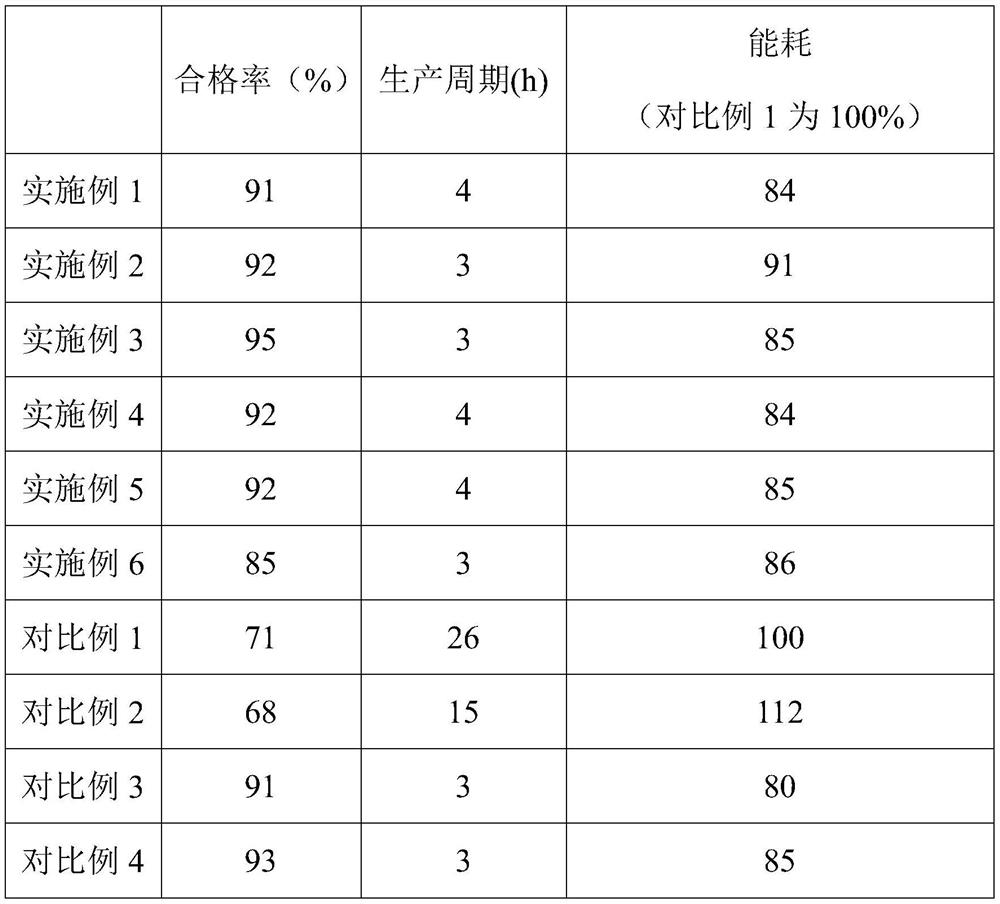

Vacuum insulation panel and preparation method and application thereof

PendingCN113586842AReduce loss rateImprove pass rateThermal insulationPipe protection by thermal insulationCompression moldingHot melt

The invention provides a vacuum insulation panel and a preparation method and application thereof. The preparation method comprises the following steps: (1) mixing a thermal insulation material and a hot melt adhesive, and carrying out compression molding to obtain a core material; and (2) putting the core material obtained in the step (1) into a barrier packaging bag, vacuumizing, sealing and carrying out heat treatment to obtain the vacuum insulation panel. The hot melt adhesive and the thermal insulation material are firstly pressed and formed to obtain the core material, in the heat treatment process, the core material and the core material and the barrier packaging bag can be bonded and fixed together through the hot melt adhesive in the core material, the step of pressing and forming the core material with the barrier packaging bag in a traditional manufacturing method is avoided, the breakage rate of the barrier packaging bag is effectively reduced, and the product qualification rate and the production efficiency are improved, and the method is suitable for large-scale industrial production.

Owner:FIRST NEW MATERIAL TECH DEV +1

A kind of preparation system and method of high-purity vanadium battery electrolyte

ActiveCN105990593BIncrease production energy consumptionIncrease production costRegenerative fuel cellsSocial benefitsPhysical chemistry

The present invention belongs to the fields of chemical engineering and materials. Specifically disclosed are a system and method for preparing a high-purity vanadium battery electrolyte-solution; vanadium oxytrichloride is taken as a starting material, and distilled and purified to obtain high-purity vanadium oxytrichloride having a purity of 4N or higher; the obtained vanadium oxytrichloride is hydrolyzed and the chlorine content thereof is controlled; further, sulfuric acid is added to prepare and obtain a high-purity vanadium-battery mixed sulfuric-acid / hydrochloric-acid electrolyte solution. The present invention has the advantages of being very adaptable, having a simple process, being clean and non-polluting, having low energy consumption in production and low costs in operation, and the quality of the electrolyte solution being controllable; the invention is suitable for use in the large-scale continuous production of high-purity vanadium batteries, and has good economic and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

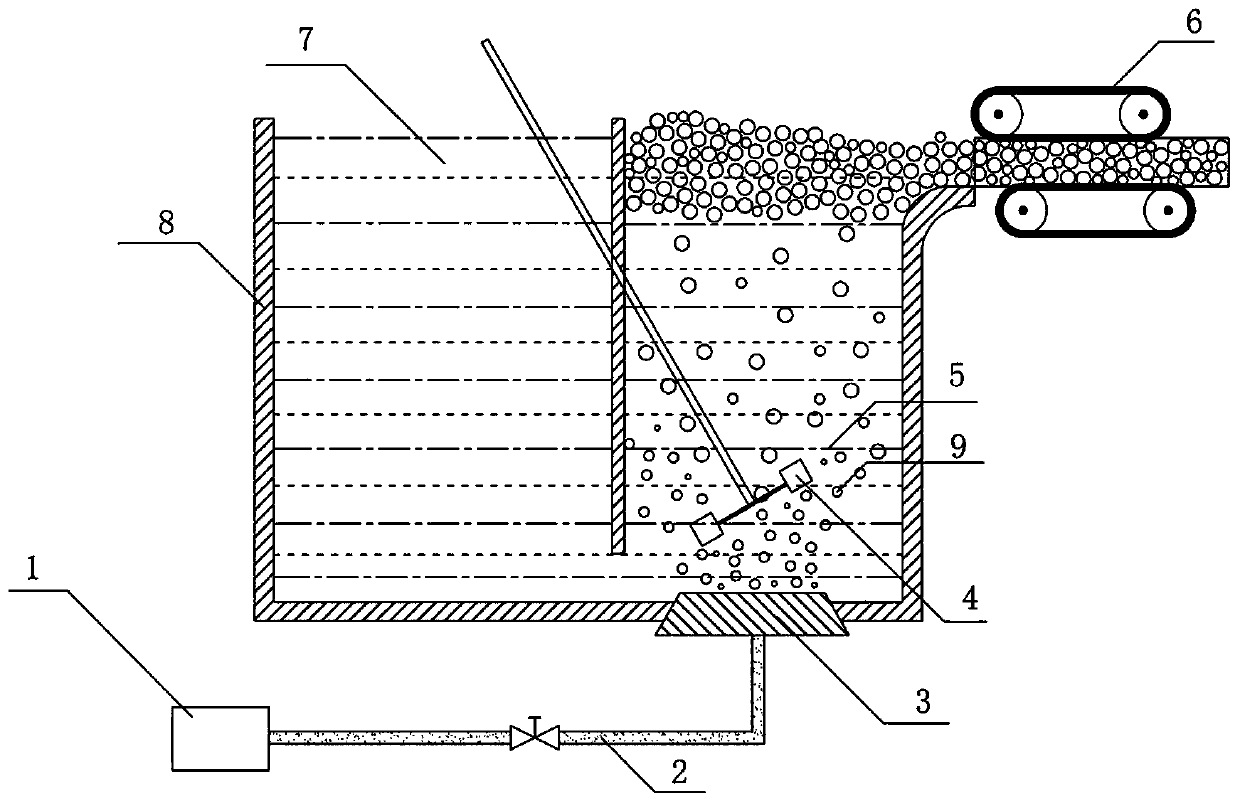

A device and method for preparing foamed aluminum by bottom blowing powder spraying method

The invention belongs to the field of material preparation, and discloses a device and method for preparing aluminum foam by using a bottom blowing powder spraying method. The powder spraying system transports foaming gas and fluidized additive particles to slit-type breathable bricks through a blowing pipeline. The foaming gas and particles are blown into the molten aluminum from the bottom of the foaming chamber by the slit-type breathable brick, and the two processes of adding particle stirring and blowing foam in the traditional aluminum foam preparation process are simplified to blowing gas and particles together Aluminum liquid, the bubbles float up to form foam, which is collected, cooled, annealed and rolled by the rolling system to realize the continuous production of foamed aluminum; the device for preparing foamed aluminum by the bottom blowing powder spraying method includes powder spraying system, blowing pipeline, Slit-type air-permeable bricks, crucibles, agitators and rolling systems; the invention uses the method of bottom blowing and powder spraying to blow gas and particles into the aluminum liquid at the same time, so that the particles are evenly dispersed and not easy to agglomerate, and the particle dispersibility is improved. The performance of the aluminum foam material is improved, and the production power consumption is reduced at the same time.

Owner:NORTHEASTERN UNIV LIAONING

A kind of finish rolling unit and rolling method in ESP endless rolling

ActiveCN109201758BReduce wearAchieve coolingTemperature control deviceWork cooling devicesThermodynamicsAustenite

The invention discloses a finishing rolling unit in ESP endless rolling and a rolling method, and belongs to the field of steel and iron material engineering. The finishing rolling unit in the ESP endless rolling of the invention comprises a plurality of finishing mills arranged in the order of a finishing rolling process, and is characterized in that one of the finishing mills is a standby finishing mill for replacing the worn finishing mill; a spray header is arranged in front of the preceding finishing mill in the standby finishing mill and the worn finishing mill by the order; and the spray header spray cold water to cool a strip plate to complete the transformation process of austenite to ferrite. According to the invention, the full-continuous non-stop flexible rolling technology canbe realized, the productivity drop caused by the forced stop of the production line due to the downtime and roll change of the finishing rolling unit is avoided, and the output is also improved; andthe roll temperature rise can be reduced, so that the fatigue cracking and fracturing of the roll due to the thermal stress are reduced, the wear of the roll is reduced, the surface quality of endlessrolled products is improved, and the production cost is significantly lowered.

Owner:YANSHAN UNIV

Ferritic rolling method based on dynamic change schedule of endless rolling

ActiveCN109482646BReduce wearImprove surface qualityTemperature control deviceWork cooling devicesThermodynamicsEconomic benefits

The invention discloses a dynamic variable procedure ferrite rolling method based on endless rolling. A cooling channel is arranged between induction heating and a finishing rolling mill group, and the temperature matching is adjusted and controlled between the induction heating and the cooling channel, so that the finishing rolling mill group realizes austenite zone rolling and ferrite zone rolling in the dynamic variable procedure correspondingly. The ferrite rolling method realizes continuous non-stop production under the condition that an existing production line is basically unchanged. Meanwhile, through the cooperative use of the induction heating and the cooling channel, full continuous non-stop flexible rolling can be realized, the yield is further improved. In addition, during andafter the process of dynamic variable procedure of the endless rolling, lower heating temperature is adopted by the induction heating, the temperature rise of a roll can further be reduced, thus thefatigue cracking and fracture of the roll caused by thermal stress are reduced, the roll abrasion is reduced and the surface quality of endless rolling products is improved, the heating energy consumption of enterprises can be greatly reduced, and an important role in energy conservation, environmental protection and improving economic benefits of the enterprises is played.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com