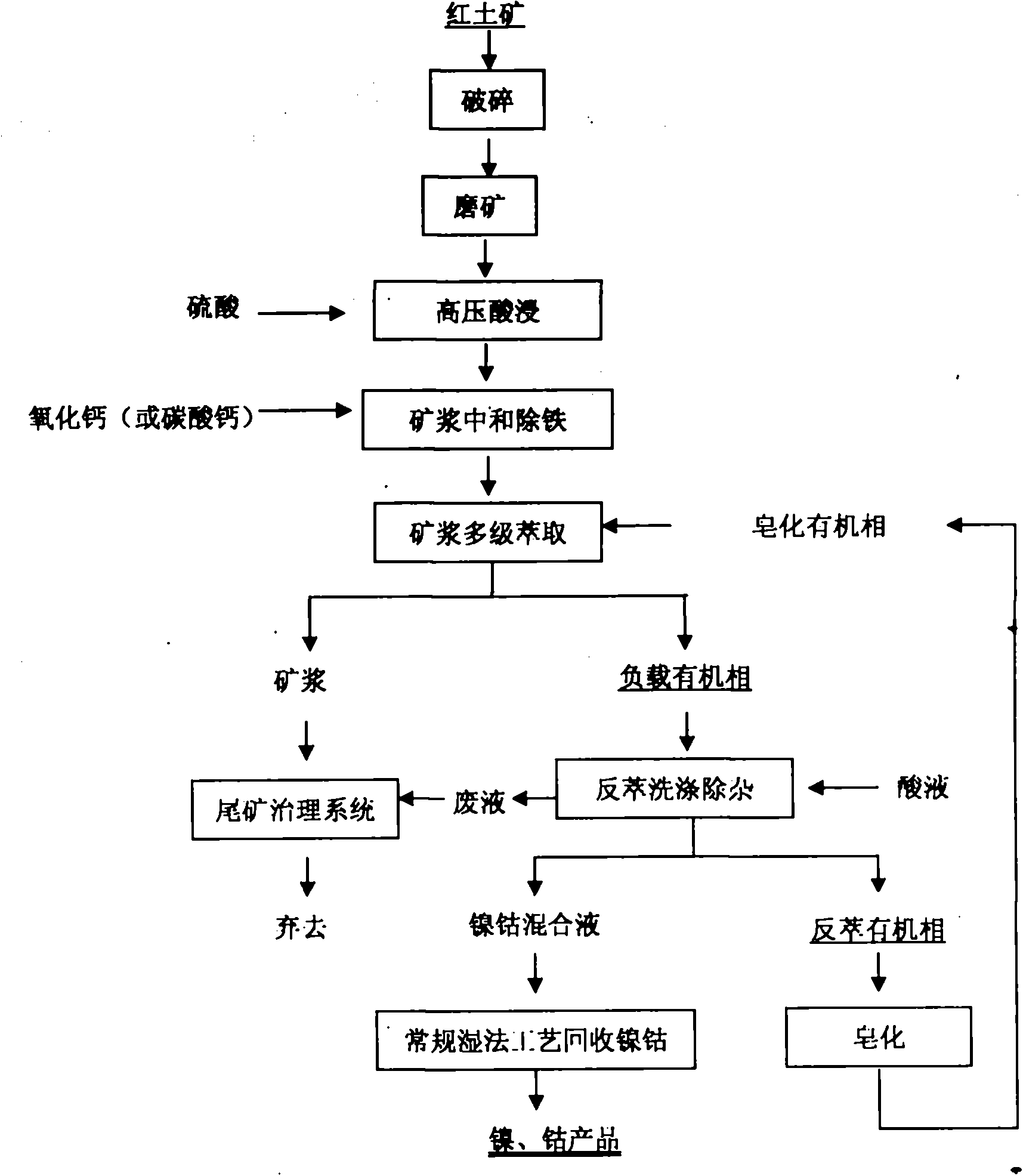

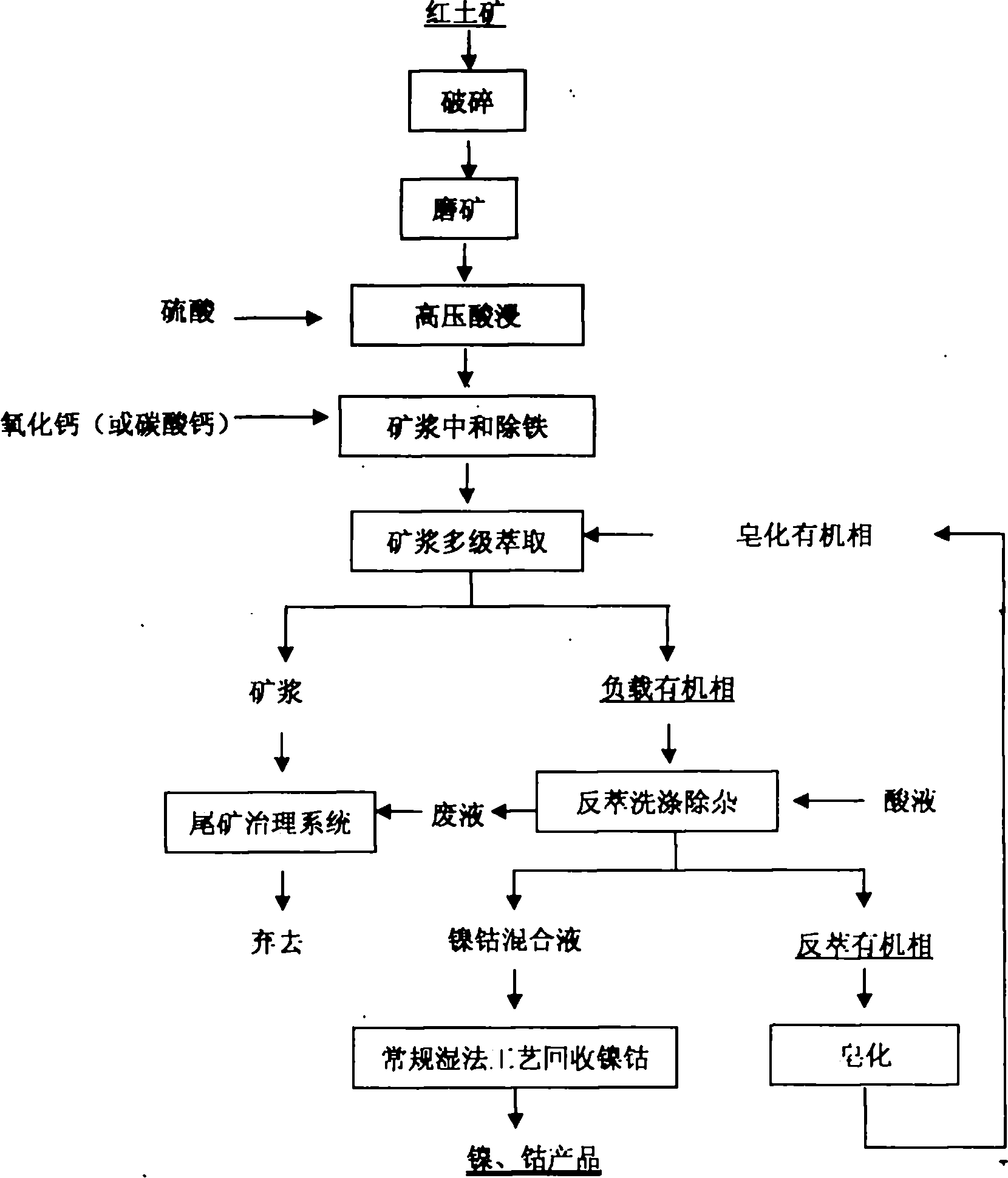

Process for extracting nickel and cobalt from laterite by ore pulp extraction technology

An extraction technology and a technology of laterite ore, applied in the field of non-ferrous metal hydrometallurgy, can solve the problems of heavy filtration burden, unrecoverable nickel and cobalt, high viscosity of precipitate and difficult to wash, etc., achieve low comprehensive consumption, reduce the burden of liquid-solid separation, and recover high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] a. Take 1000g of laterite ore and crush it, add 2000ml of water to the laterite ore, and grind until the particle size is less than 0.074mm;

[0027] b. Put the ground pulp into the autoclave, add 1500ml of 5% sulfuric acid at a ratio of 2 / 1 to the pulp for high-pressure acid leaching;

[0028] c Inject the leached pulp into the normal pressure reactor, add CaCO 3 Adjust the pH value of the solution to 1.55; at the same time, pass hot air into the blast to oxidize, stir and react for 2 hours, and the temperature is 90°C, so that iron is oxidized to ferric ion hydrolysis and precipitation, and the iron content in the solution after iron removal is less than 5mg / l;

[0029]d. The ore pulp after iron removal is poured into the mixed sedimentation extraction tank with stirring, settling tank and baffle, and is extracted by P204 extraction agent in 5 stages, the extraction temperature is 20°C, washed with 1% sulfuric acid solution, and then washed with 3N hydrochloric acid s...

Embodiment 2

[0033] a. Take 1000g of laterite ore and crush it, add 3000ml of water to the laterite ore, and grind until the particle size is less than 0.074mm;

[0034] b. Put the ground pulp into the autoclave, and add 1000ml of sulfuric acid with a concentration of 10% in the ratio of 3 / 1 of the pulp to carry out high-pressure acid leaching;

[0035] c. Inject the leached ore pulp into the normal pressure reaction kettle, add CaO to adjust the pH of the solution to 2.0; at the same time, pass hot air into it for oxidation, stir for 3 hours, and the temperature is 90°C to oxidize iron into ferric ions, hydrolyze and precipitate, and remove iron The iron content in the final solution is less than 5mg / l;

[0036] d. The ore pulp after iron removal is poured into the mixed sedimentation extraction tank with stirring, settling tank and baffle, and is extracted by P204 extractant at 8 stages, the extraction temperature is 30°C, washed with 2% sulfuric acid solution, and then washed with 4N hy...

Embodiment 3

[0040] a. Take 1000g of laterite ore and crush it, add 4000ml of laterite ore water, and grind until the particle size is less than 0.074mm;

[0041] b. Put the ground pulp into the autoclave, add 1000ml of 13% sulfuric acid at a ratio of 4 / 1 to the pulp for high-pressure acid leaching;

[0042] c Inject the leached ore slurry into the normal pressure reactor, add Na 2 CO 3 Adjust the pH of the solution to 4; at the same time, pass hot air into it to oxidize, stir and react for 2-5 hours, and the temperature is 90°C, so that iron is oxidized to trivalent iron ion hydrolysis and precipitation, and the iron content in the solution after iron removal is less than 5mg / l;

[0043] d. The ore pulp after iron removal is injected into the mixed sedimentation extraction tank with stirring, settling tank and baffle, and is extracted with P204 extractant at 10 levels, the extraction temperature is 40 ° C, washed with 4% sulfuric acid solution, and then washed with 5N hydrochloric acid s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com