Patents

Literature

34results about How to "Reduce the burden of separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

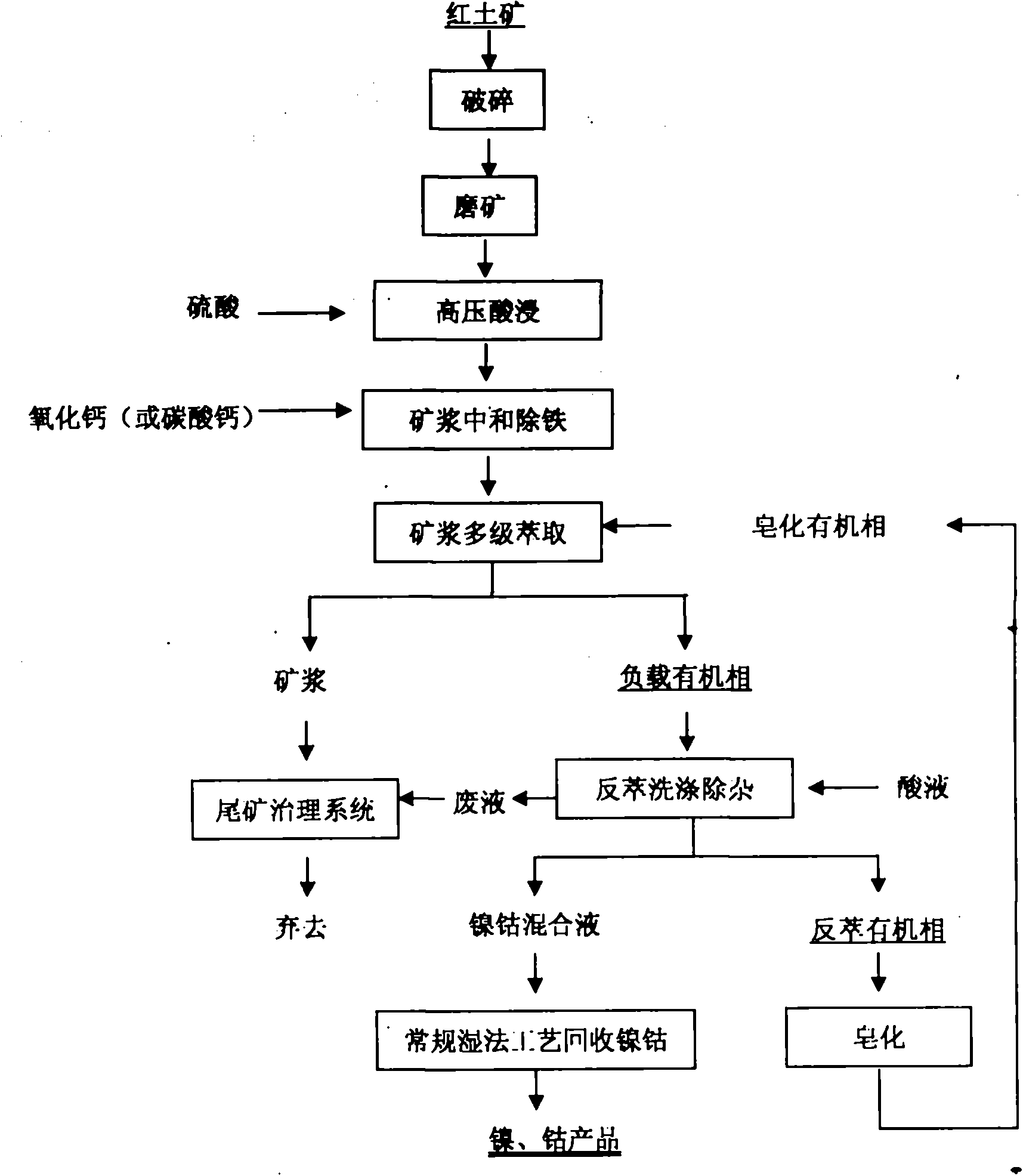

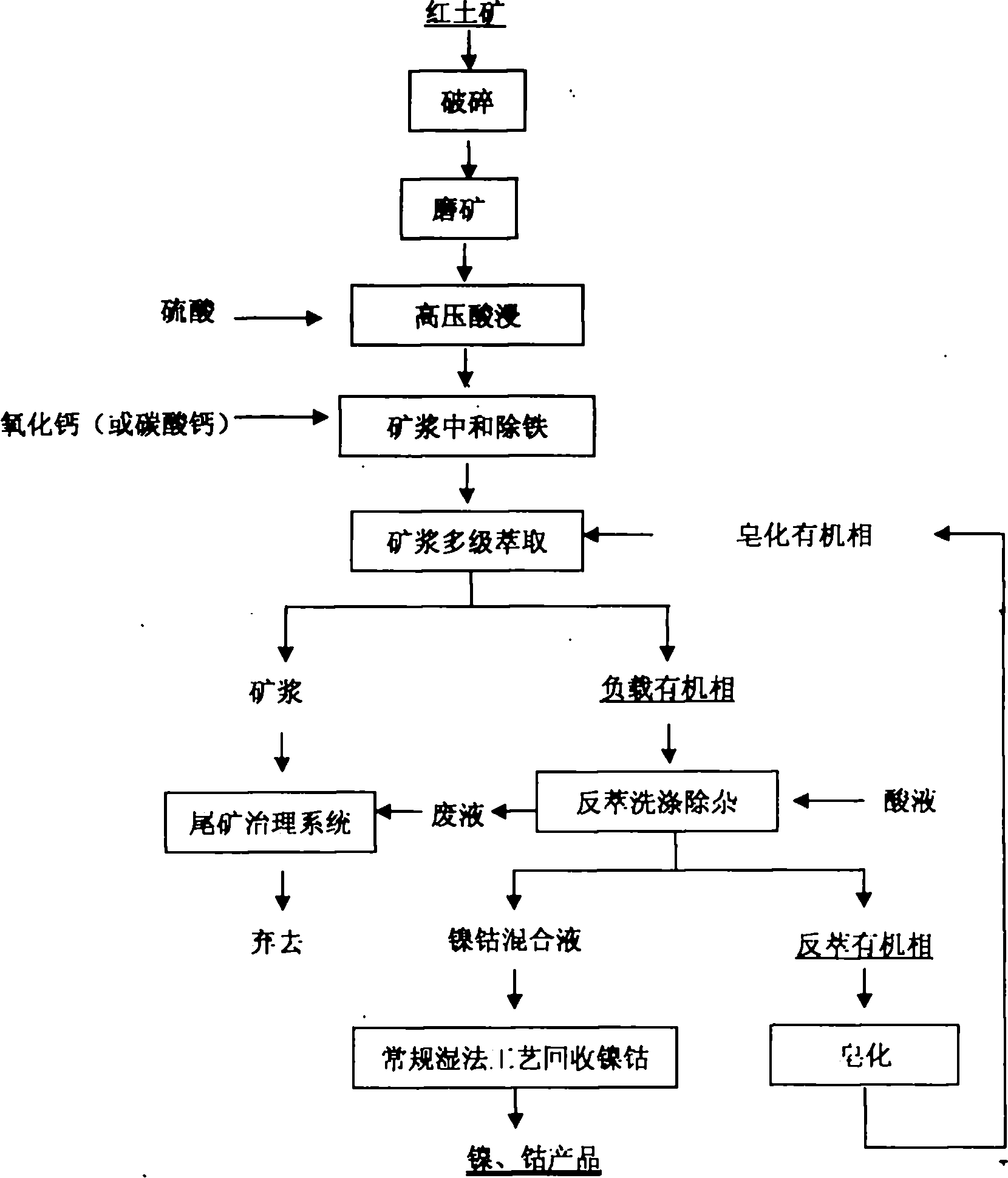

Process for extracting nickel and cobalt from laterite by ore pulp extraction technology

ActiveCN102010993AReduce consumptionReduce the burden of separationProcess efficiency improvementHigh concentrationHigh pressure

The invention relates to a process for extracting nickel and cobalt from laterite by ore pulp extraction technology, which comprises the following steps of: crushing and grinding the laterite; putting into a high-pressure kettle, and carrying out high-pressure acid leaching to remove iron; pouring into a mixing settling extraction tank with a stirring and settling tank and a baffle plate, carrying out 5-12 grade of extraction, back extraction and phase splitting and washing to respectively obtain mixed solution of nickel and cobalt, waste liquid containing impurities and the ore pulp; extracting and separating nickel from cobalt to respectively obtain pure nickel solution and pure cobalt solution; and precipitating and calcining to obtain nickel oxide and cobalt oxide products. The solution with high concentration is obtained by extraction, the process is shortened, the liquid-solid separation load and a number of washing and filtering processes are reduced, so that energy consumption of production and production cost are reduced and the economic benefit is improved. An extracting agent can be used repeatedly after being saponified and has relatively low comprehensive consumption. The speed of the extraction process is high and is commonly less than 10 minutes. The extraction efficiency is high. The extracted ore pulp can be neutralized uniformly so as to reduce the treatment cost of tailings. The process is simple; the recovery rate is higher; and the nickel and cobalt recovery rates are both more than or equal to 90 percent and the process is easy to popularize.

Owner:JILIN JIEN NICKEL IND +1

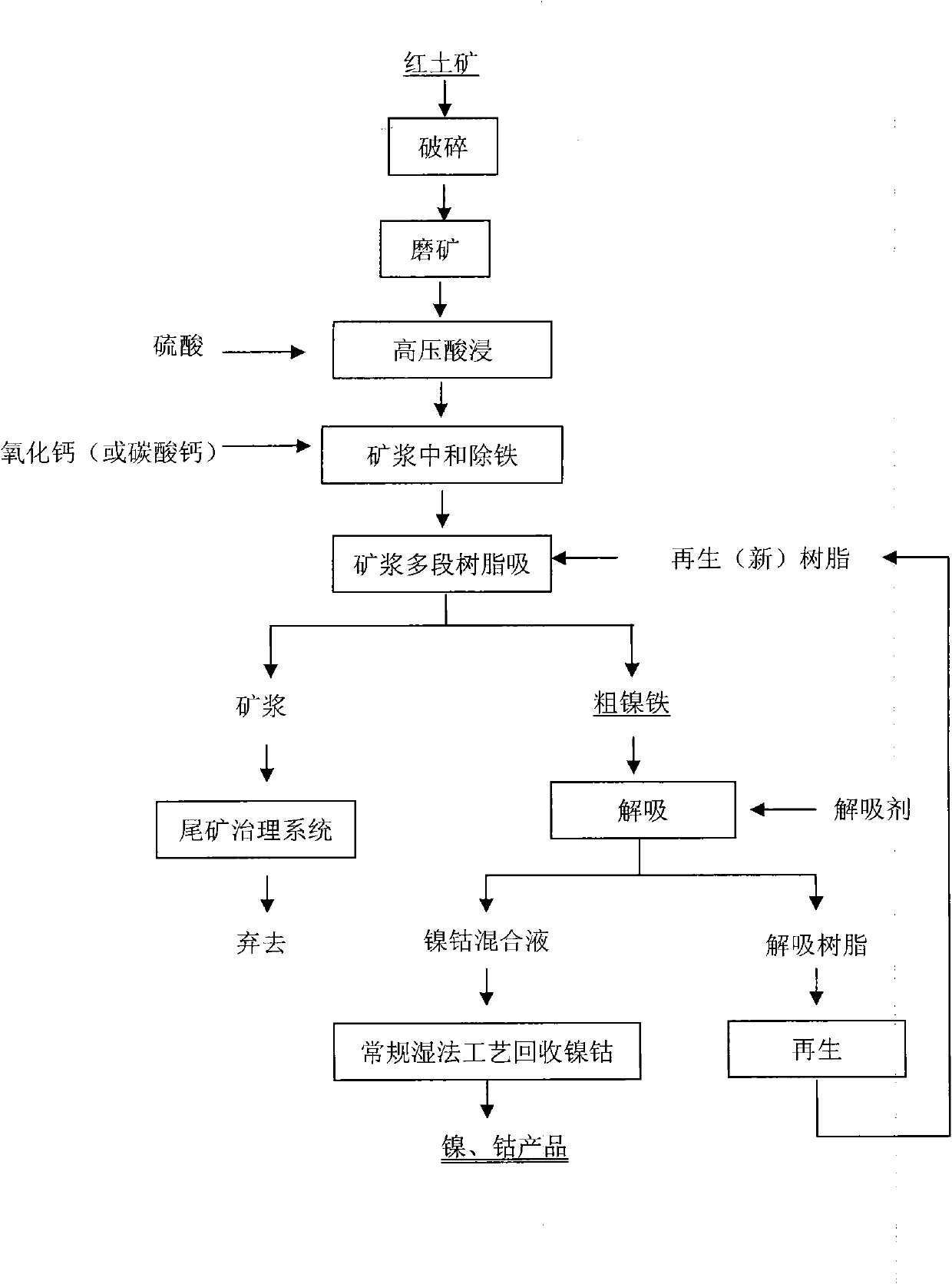

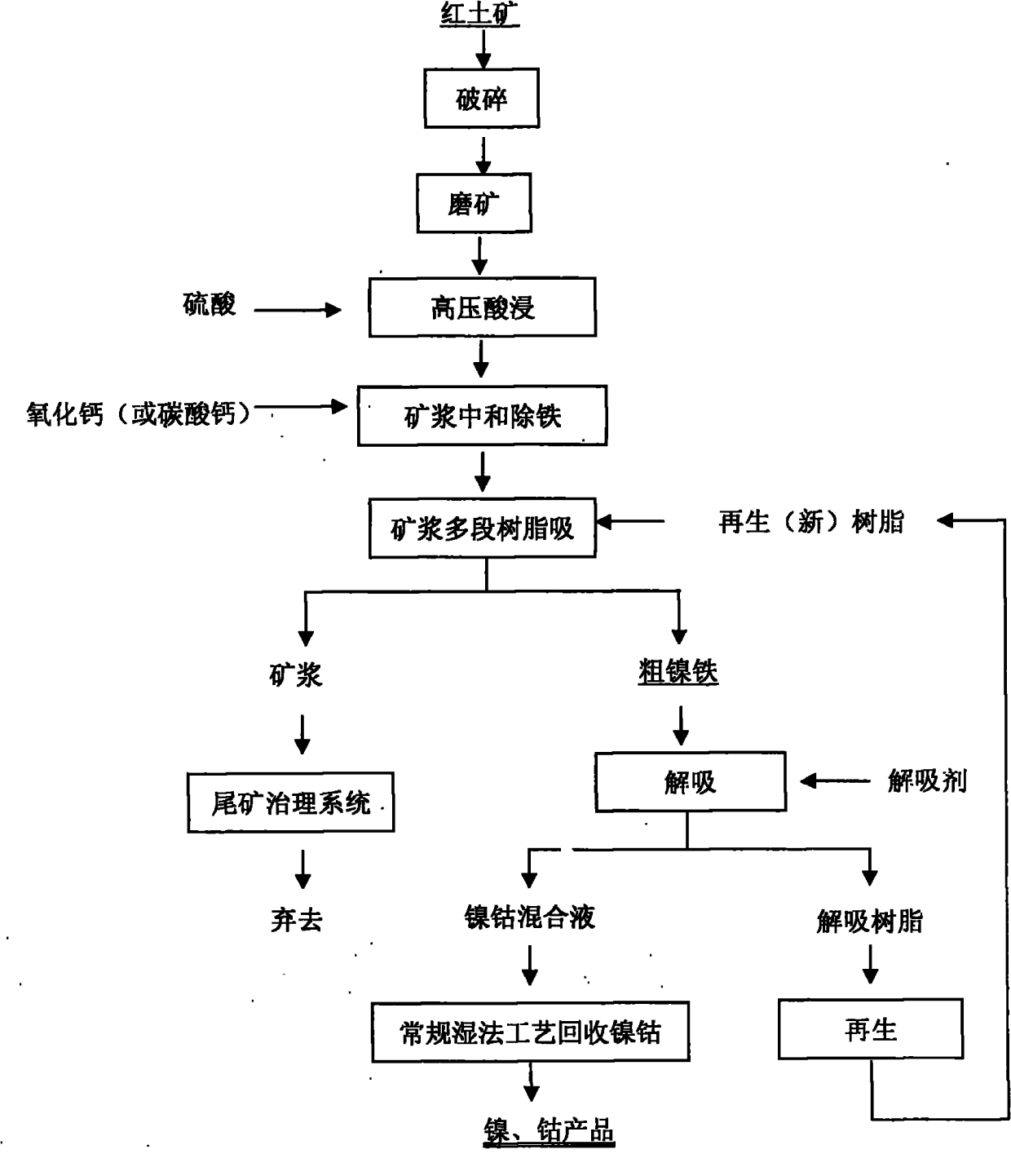

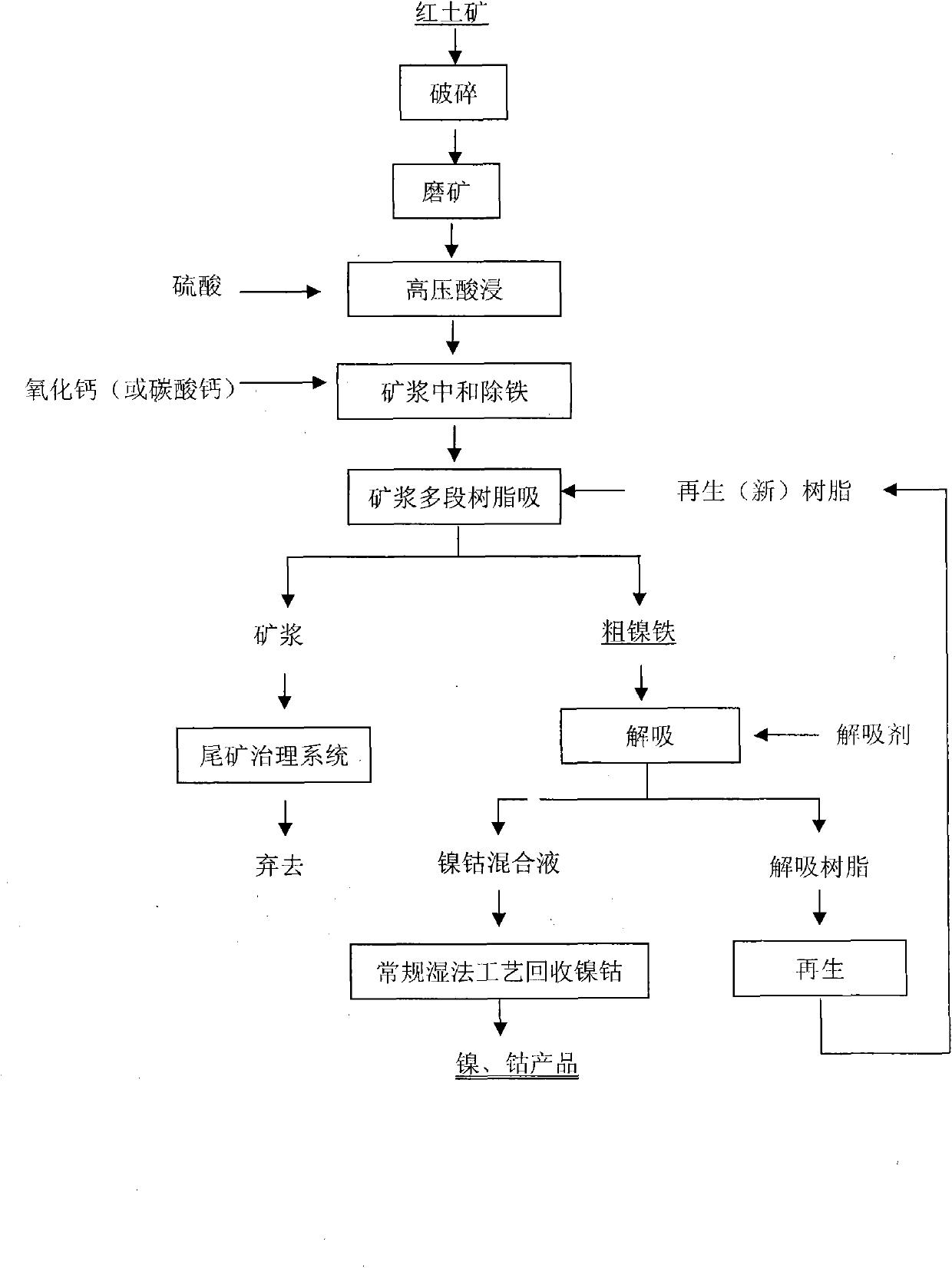

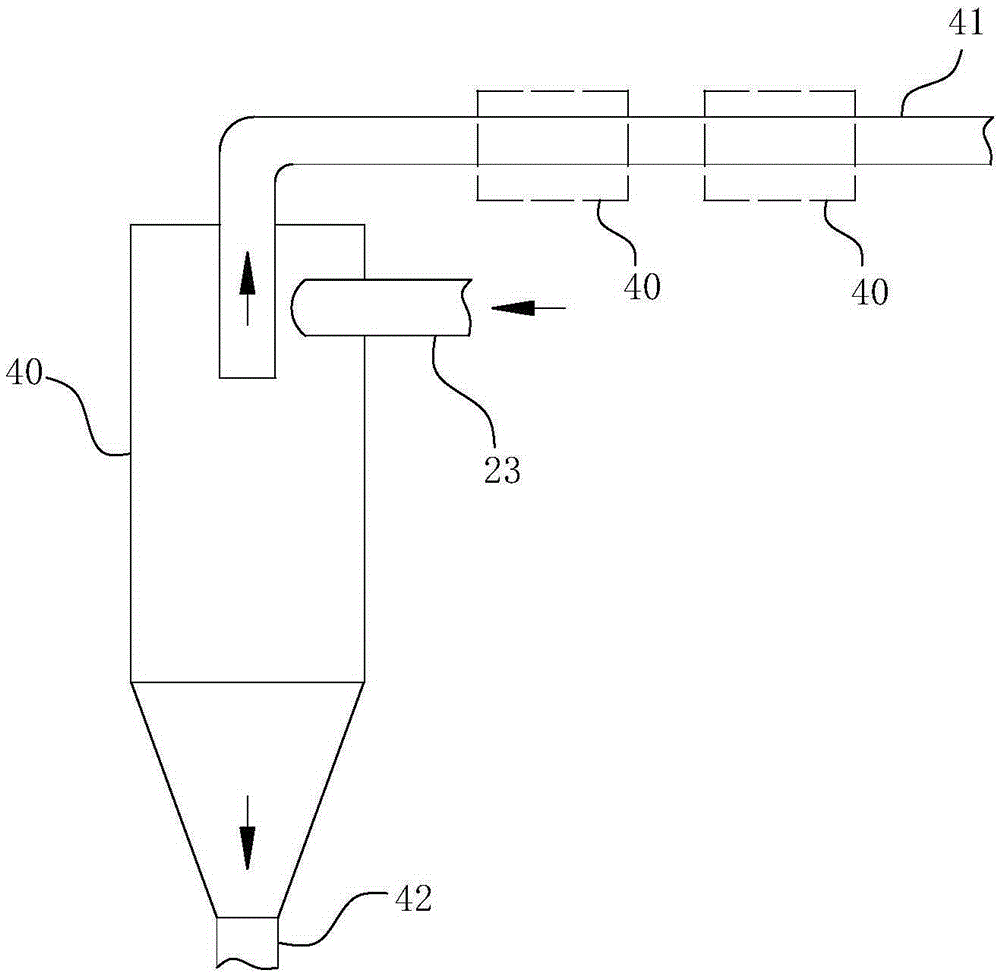

Process for extracting nickel-cobalt from laterite by using resin-in-pulp adsorption technology

ActiveCN101974685AReduce governance costsReduce the burden of separationProcess efficiency improvementDesorptionLaterite

The invention relates to a process for extracting nickel-cobalt from laterite by using resin-in-pulp adsorption technology. The process comprises the following steps of: milling the laterite, and adding sulfuric acid into the milled laterite to perform high-pressure leaching; pouring the ore pulp after the leaching into a reaction kettle for neutral impurity removal; directly pouring the ore pulpafter the impurity removal into an adsorption tank to perform resin adsorption; adopting multilevel counter current absorption to perform desorption on the loaded resin so as to obtain pure nickel and cobalt mixed solution; and performing extraction separation to obtain a nickel-cobalt product. The resin can be used repeatedly after regeneration, the damaged resin is less, the service life of theresin is long, the desorption of the loaded resin and the regeneration of a poor resin are performed at normal temperature and normal pressure and are simple and easy to operate without a pressure vessel and heat regeneration device, thereby saving energy resources and reducing equipment investment. The ore pulp after adsorption is uniformly neutralized to reduce the tailings treating cost. The process shortens the technological process, reduces the liquid-solid separation burden, and reduces a great number of washing and filtering process steps, thereby reducing the production energy consumption and reducing the production cost. The process is simple, and the recovery rate of nickel and cobalt is over 90 percent.

Owner:JILIN JIEN NICKEL IND +1

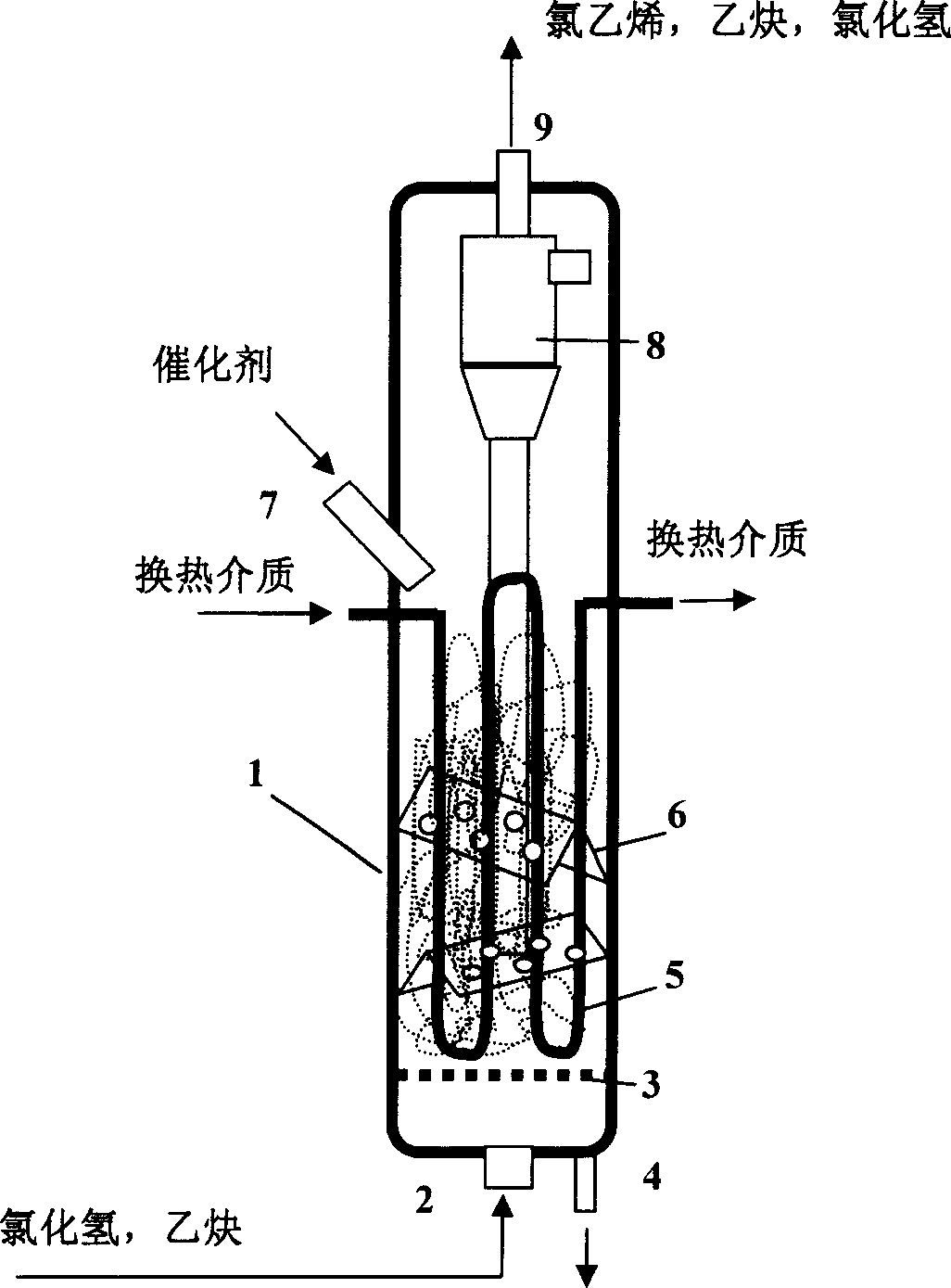

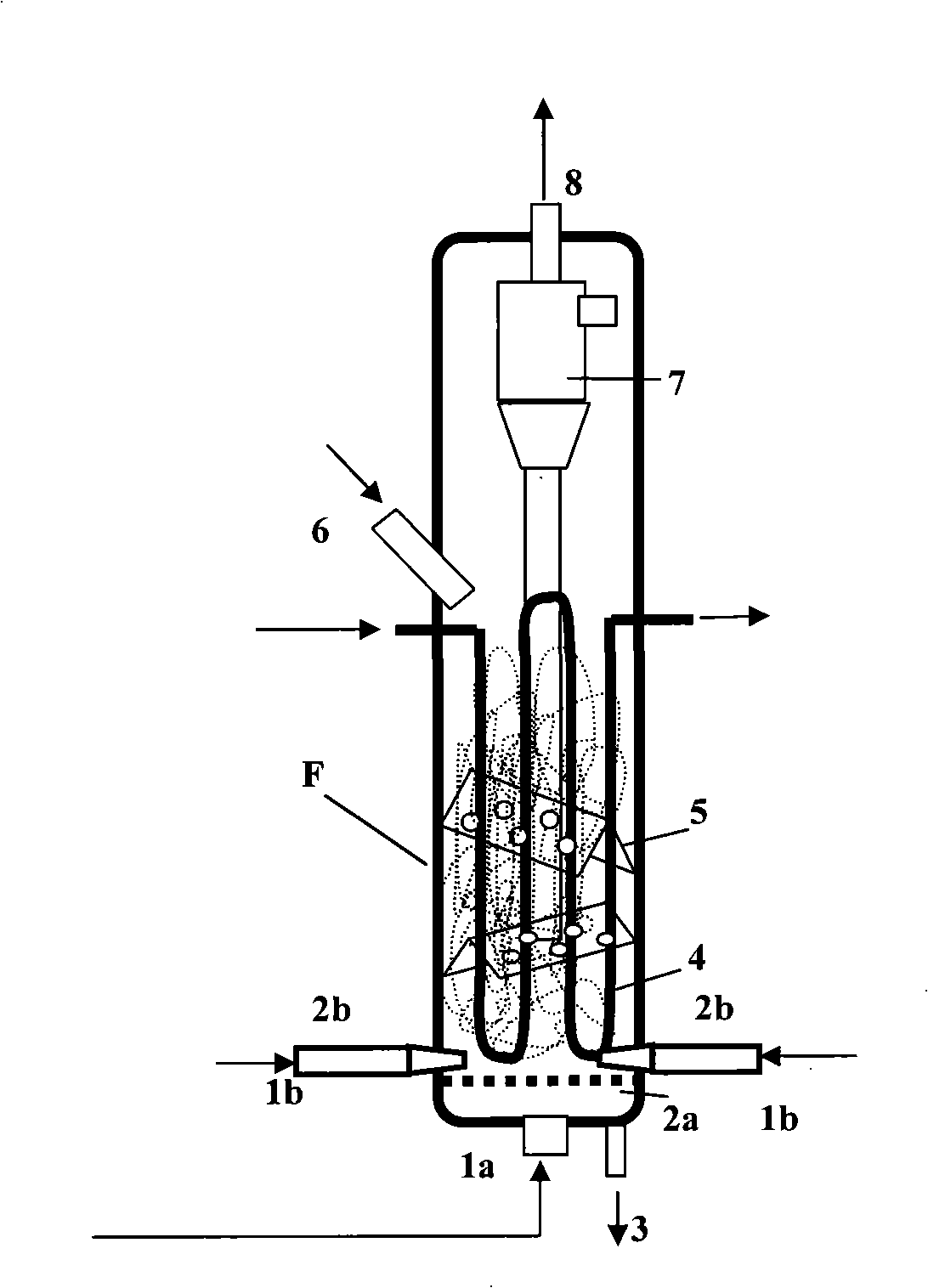

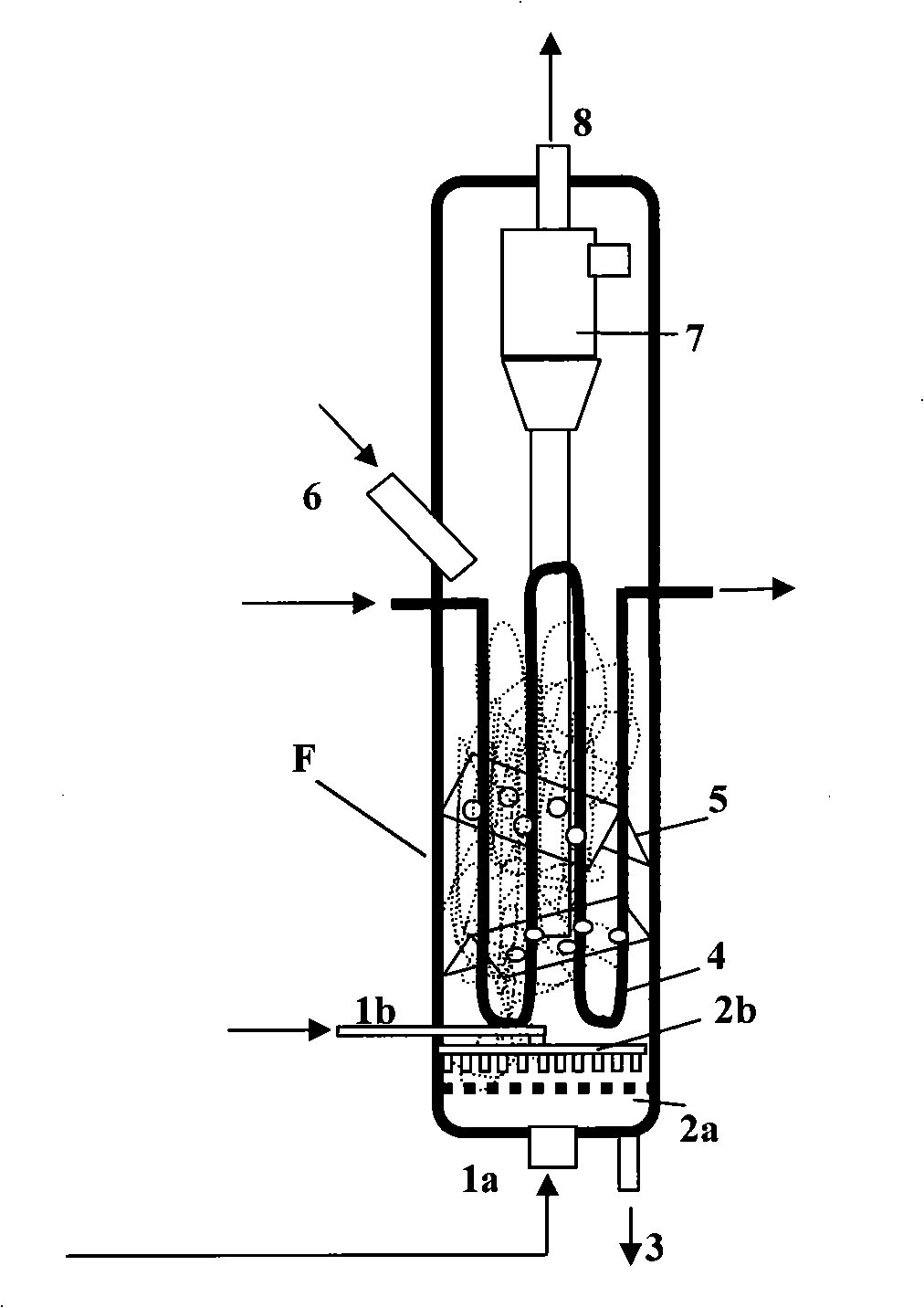

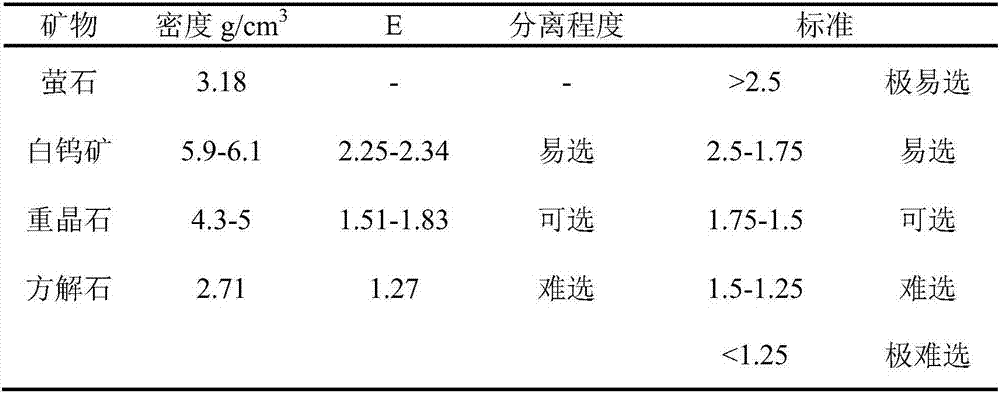

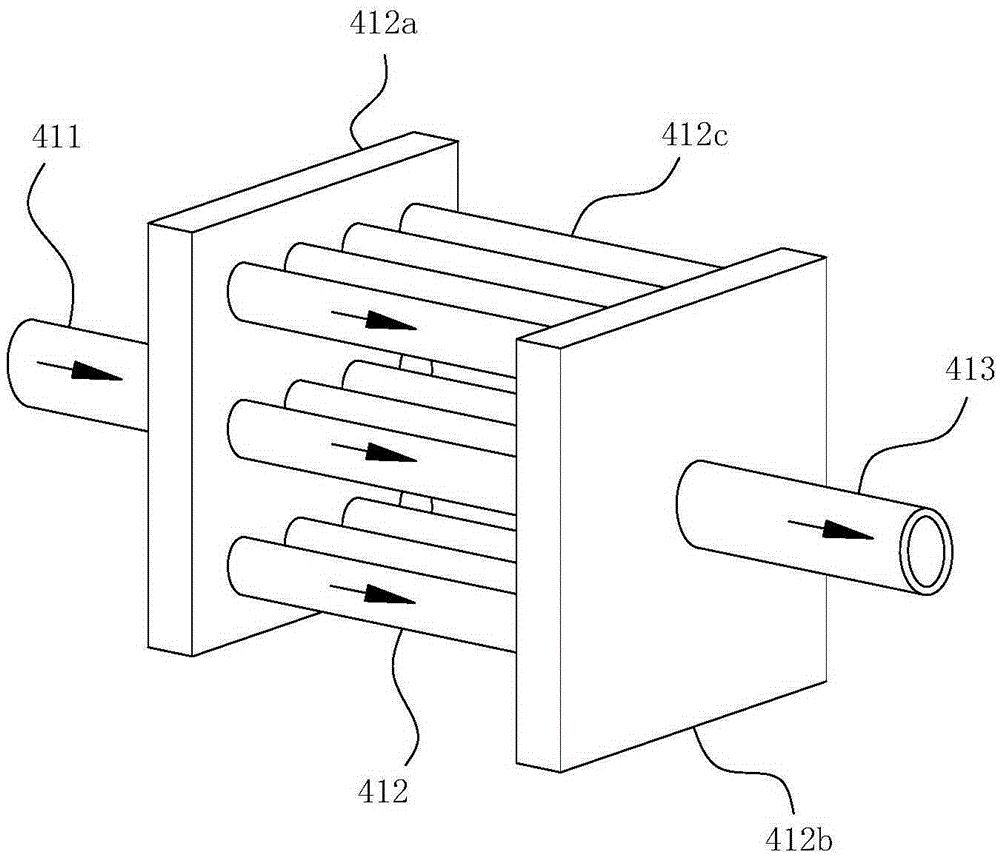

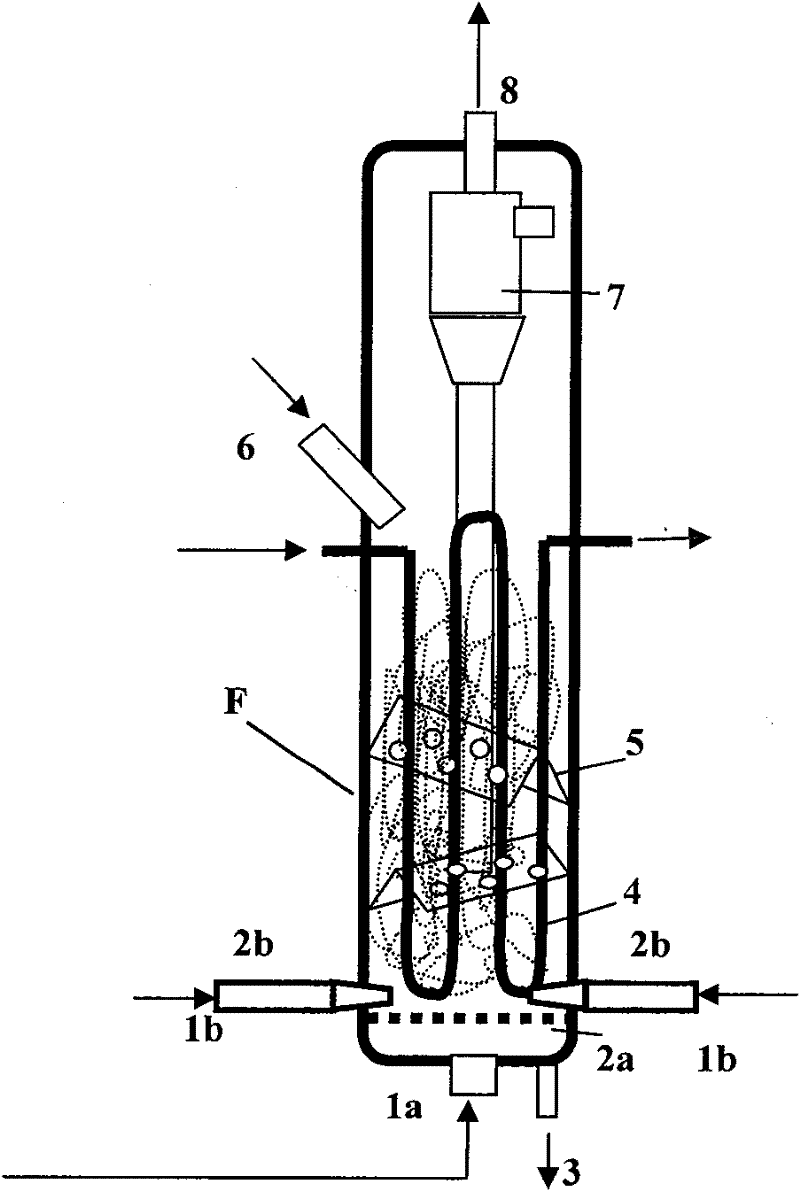

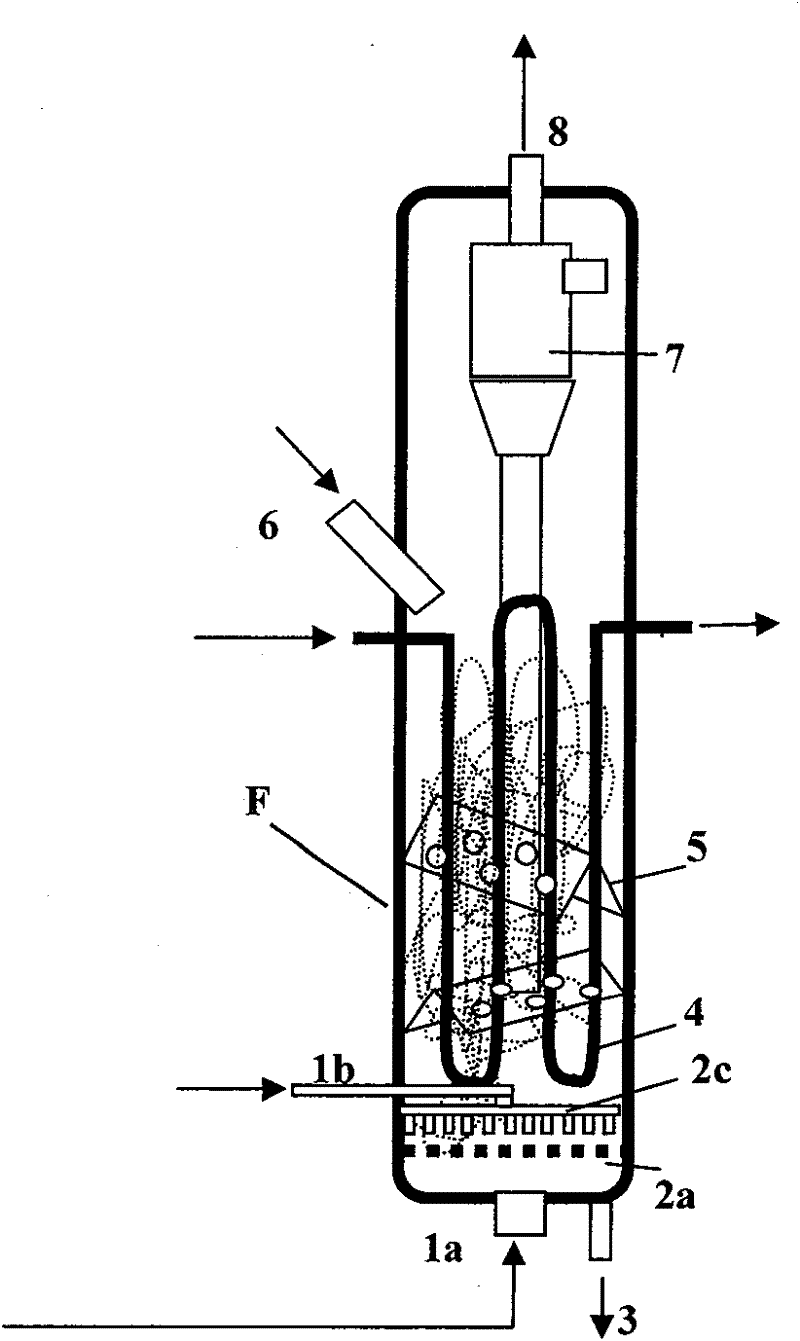

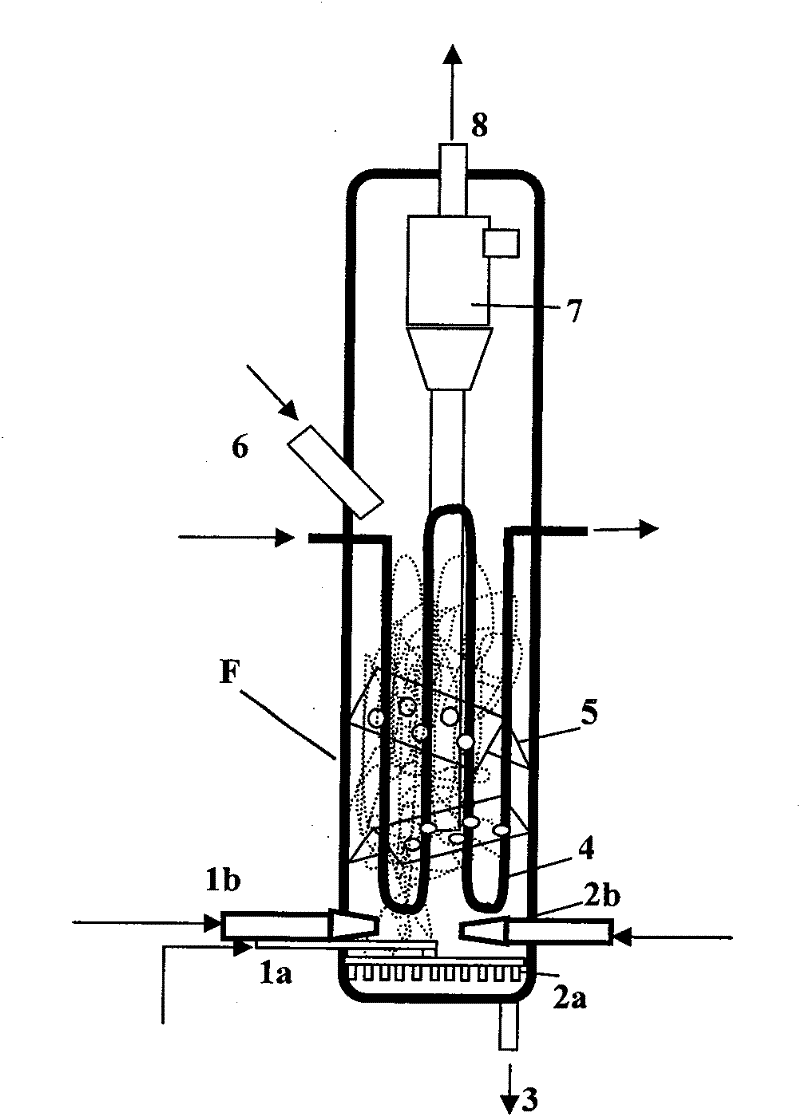

Fluidized bed reactor for preparing vinyl chloride by hydrogen chloride and acetylene reaction and method

InactiveCN1900036APromote conversionInhibit transformationPreparation by halogen halide additionChemical/physical processesPtru catalystFluidized bed

The fluidized bed reactor for preparing vinyl chloride through reaction between hydrogen chloride and acetylene and preparation process belongs to the field of chemical technology. The fluidized bed reactor includes fluidized bed, reactant material gas inlet, heat exchange pipes, member, cyclonic separator, reacted gas outlet, catalyst feeding port and catalyst removing port connected successively to the wall of the fluidized bed. After the catalyst in the molar ratio to the reactant material of 1.01-1.1 to 1 is fed, hydrogen chloride and acetylene are introduced are converted through reaction into vinyl chloride completely, and the reacted product is made to enter the post equipment through the gas outlet. The present invention has simple reaction member, high bubble crushing effect, low catalyst loss, greatly strengthened gas-solid contact, high vinyl chloride product purity and other advantages.

Owner:TSINGHUA UNIV

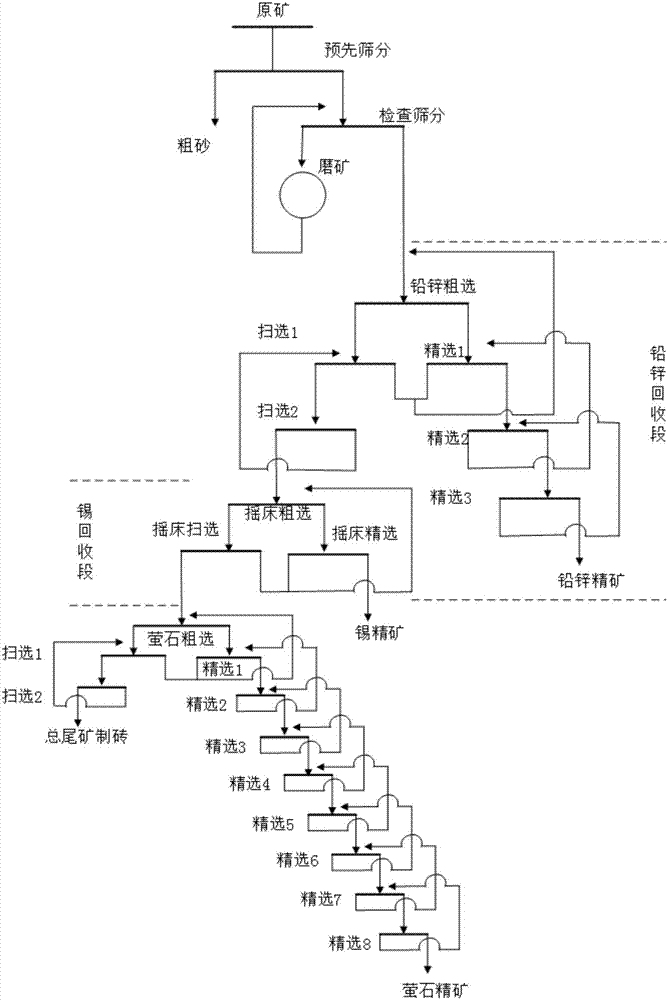

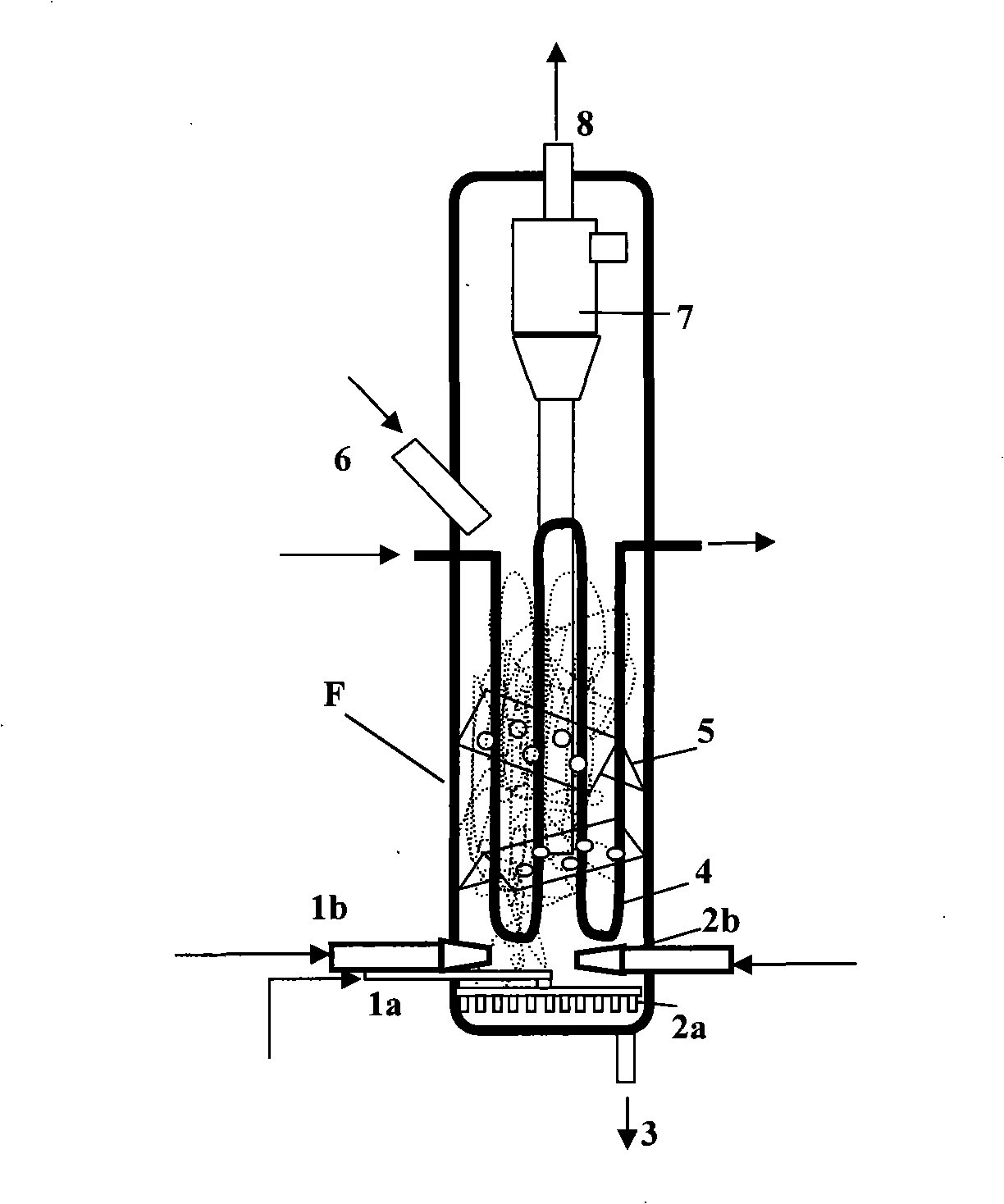

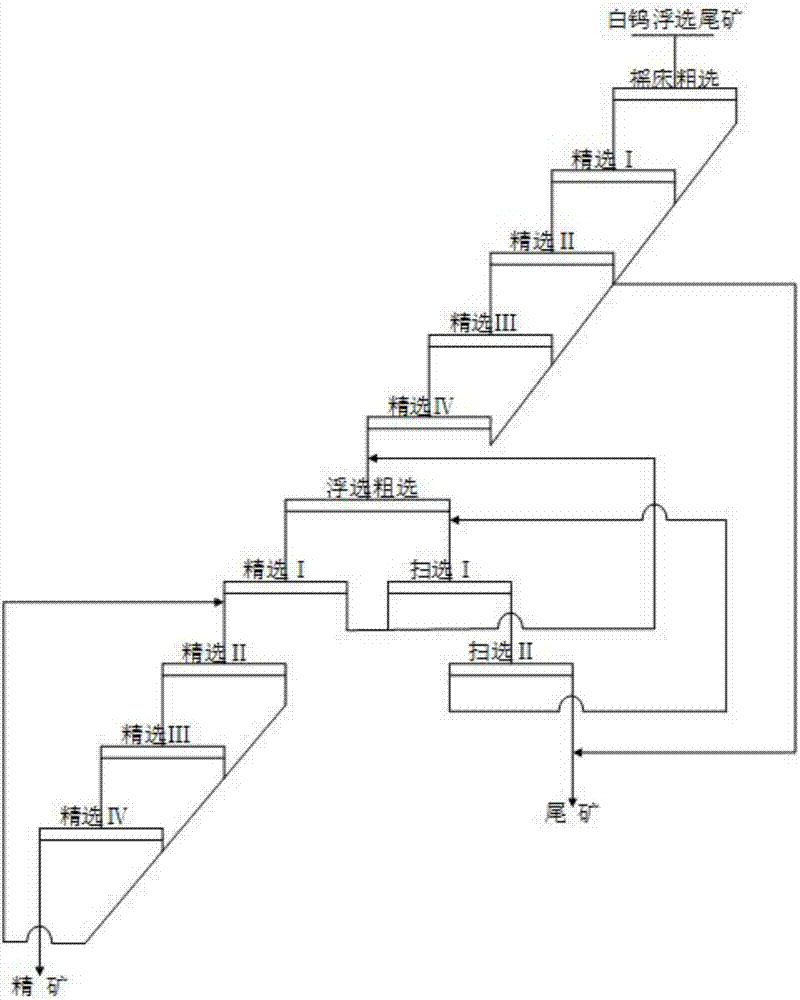

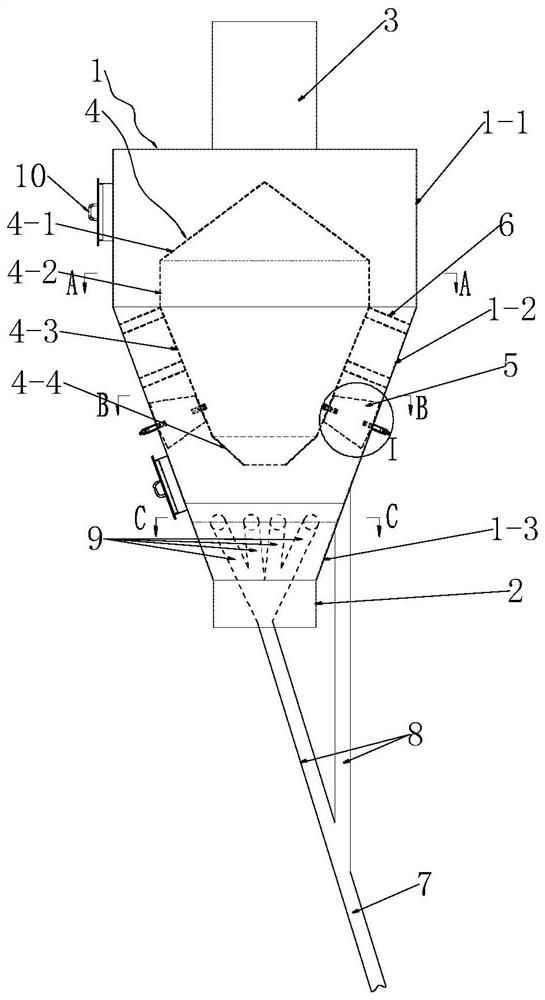

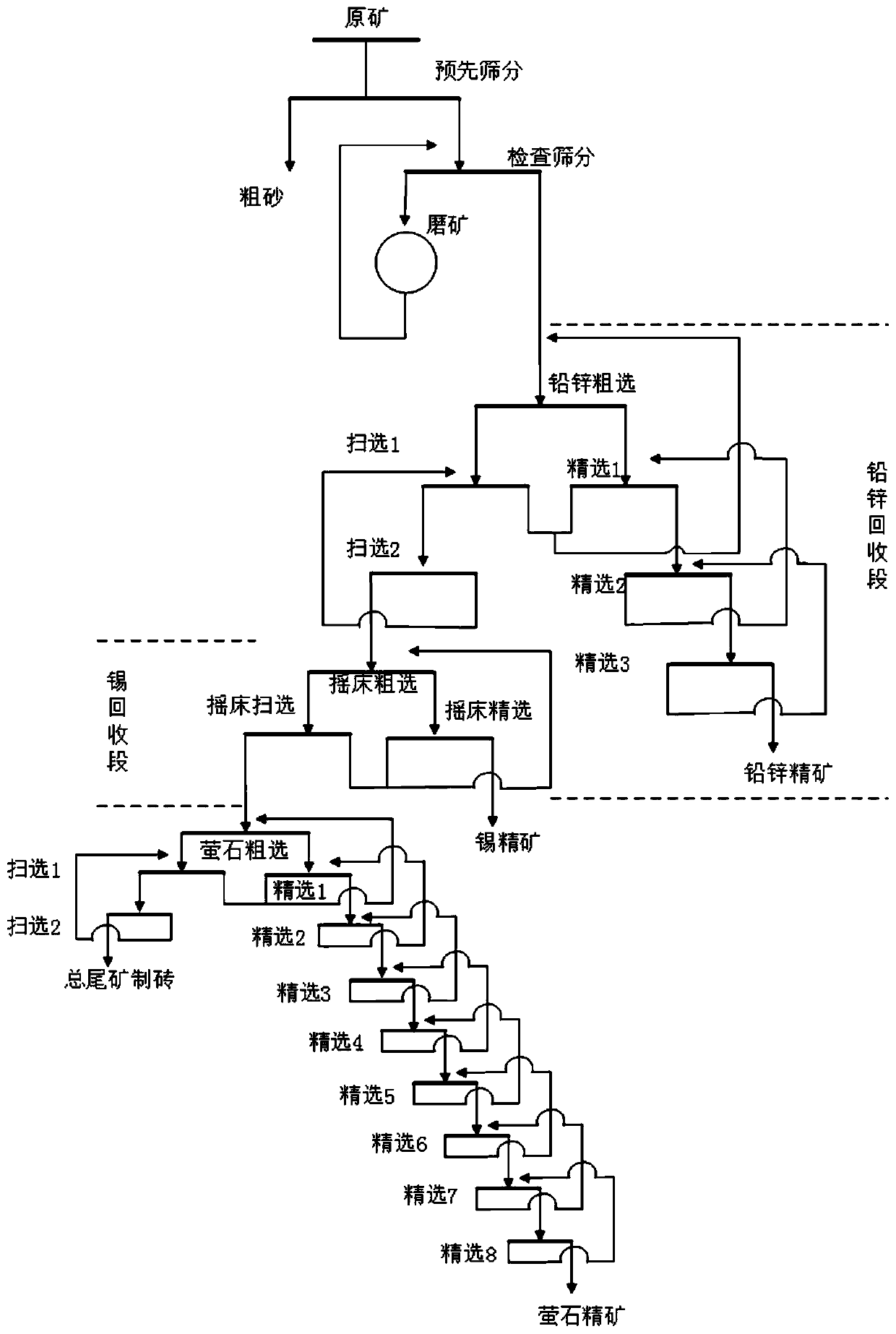

Method for comprehensively recycling lead, zinc, tin and fluorite from tailings

ActiveCN107029870AReduce the burden of separationLow costFlotationMechanical material recoveryFroth flotationPre screening

The invention discloses a method for comprehensively recycling lead, zinc, tin and fluorite from tailings. The method includes the following steps that firstly, the tailings are pre-screened; then the tailings of -20 meshes are subjected to ore grinding, and an ore grinding product with the preset fineness is obtained; then the ore grinding product is subjected to floatation which includes one time of rough floatation, three times of finish floatation and two times of scavenging, and lead and zinc in the tailings are recycled; then the floated tailings enter a shaking table to be subjected to re-floatation which includes one time of rough floatation, one time of finish flotation and one time of scavenging, and tinstone is recycled through re-floatation; and finally, the re-floated tailings are subjected to fluorite re-floatation which includes one time of rough floatation, eight times of finish floatation and two times of scavenging. By means of the technical means of floatation, re-floatation and re-floatation, the problems that at present, the recycling rate of poor, varied and thin tailings is low, the cost is high, and pollution is large are solved, and the process is simple and practical.

Owner:湖南临武嘉宇矿业有限责任公司

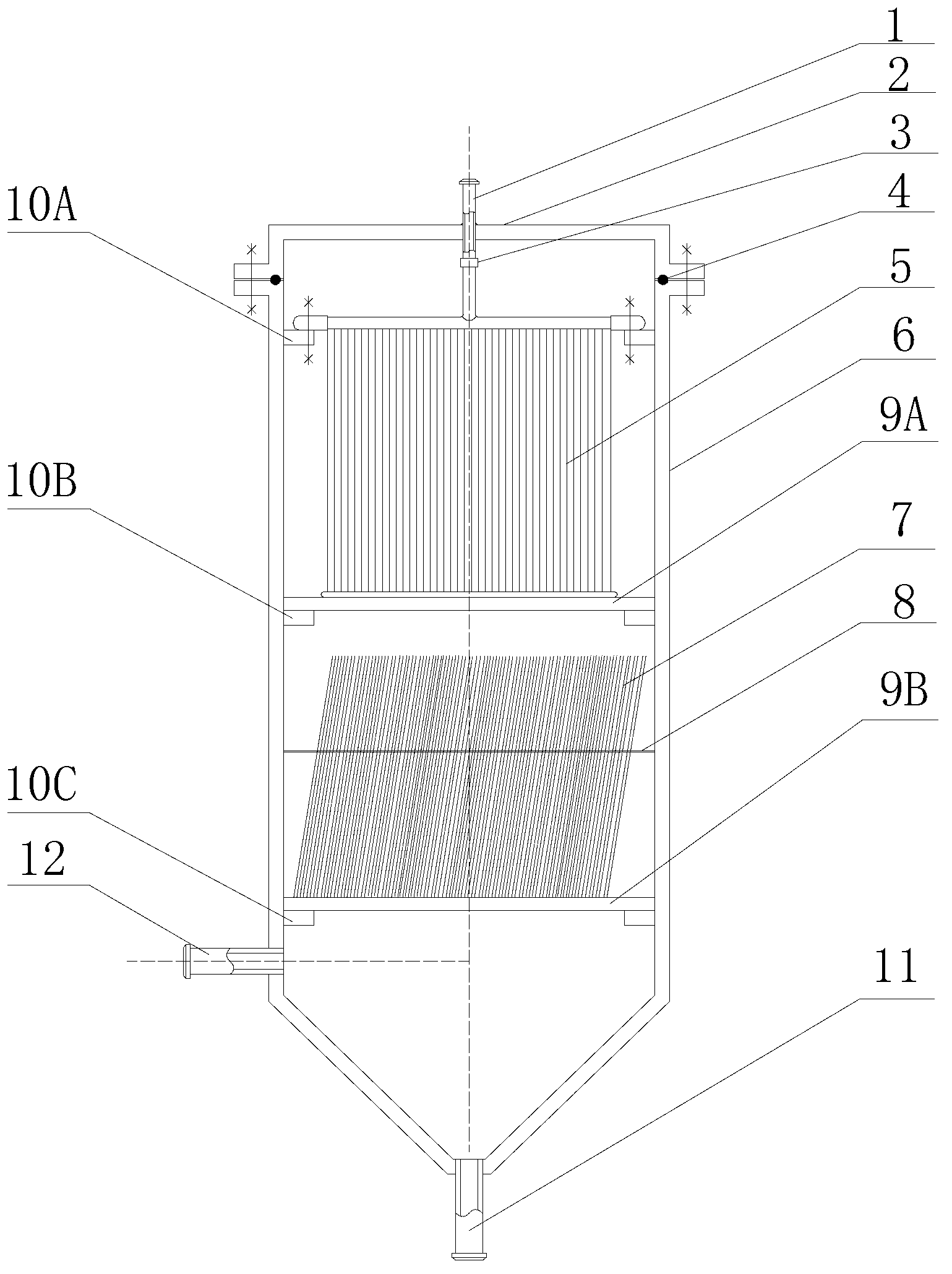

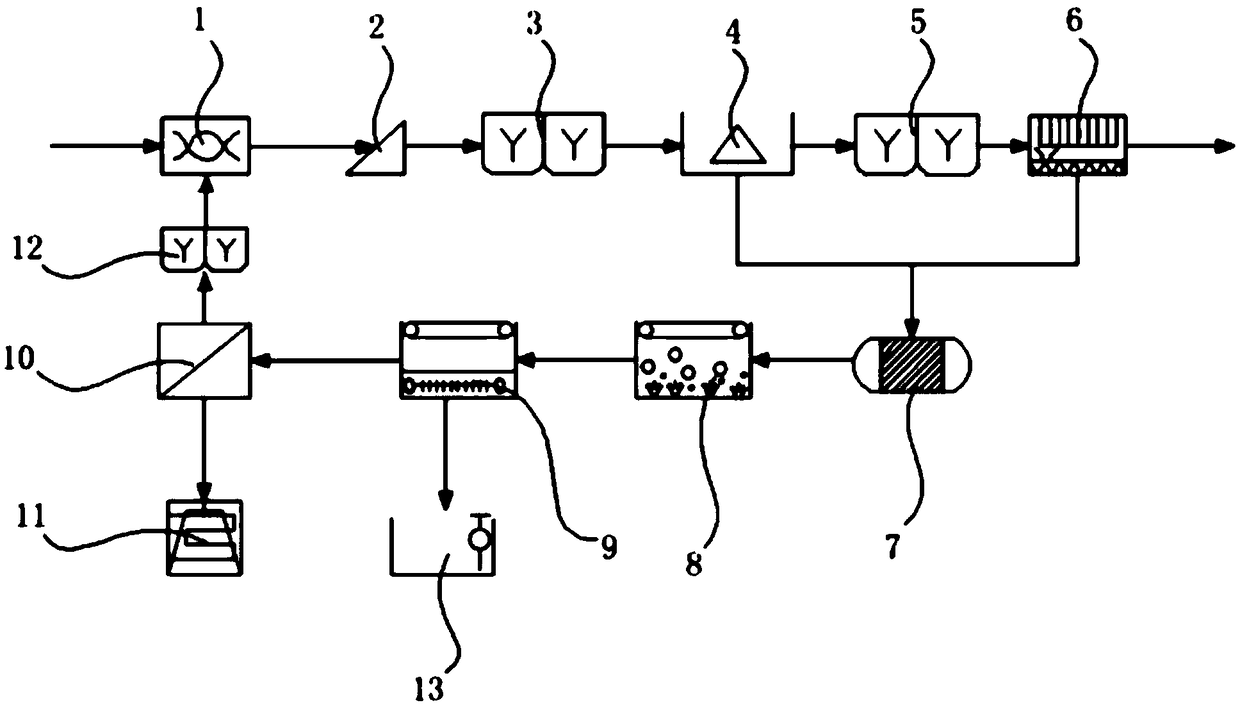

Device and technique for purifying and processing titanium white waste acid

InactiveCN102838091AReduce the burden of separationGuaranteed uptimeSulfur-trioxide/sulfuric-acidTitaniumRotational flow

The invention relates to a device and technique for purifying and processing titanium white waste acid. The device comprises a separating pot, a sealing cover, a filter core, a connector, a porous plate, supporting rings, an inclined plate and an inclined plate partition plate, wherein the separating pot and the sealing cover are fixed by a sealing ring; the sealing cover is provided with a clear solution outlet; the separating pot is of a structure with shaped cylindrical upper part and a conical lower part; the bottom of the cone is provided with a solution outlet; a material solution inlet is arranged below the cylinder; the three supporting rings are arranged from top to bottom in the separating pot; the porous plate provided with the inclined plate is arranged on the lower supporting ring; the middle supporting ring is arranged on the inclined plate and provided with the porous plate which is provided with the filter core; the upper part of the filter core is arranged on the upper supporting ring; and the water outlet of the filter core is connected with the clear solution outlet by the connector. A material solution is configured to form a rotational flow after entering the separating pot, a part of particles sink directly, the liquid flows upwards by the porous plate, a large amount of particles are settled by the inclined plate firstly, the particle impurities are removed by the filter core, the clear waste acid solution is obtained by the collection at the clear solution outlet, and the accumulated particles and powder are discharged by a solution discharge opening.

Owner:江苏江盛南节能科技有限公司

Chlorination method for industrial production of sucralose-6-acetate

InactiveCN102964397AReduce the difficulty of recyclingFacilitated releaseEsterified saccharide compoundsSugar derivativesOrganic solventSucrose

A chlorination method for industrial production of sucralose-6-acetate. The method comprises steps of: (a) adding thionyl chloride into an organic solvent below 30 DEG C to form a mixed solution, with a molar ratio of the organic solvent to thionyl chloride of 3.5-4.6:1; (b) adding sucrose-6-acetate with water content of 0.2%-0.8% into the mixed solution, and stirring, wherein a molar ratio of added sucrose-6-acetate to thionyl chloride is 1:7-9; and (c) slowly heating to 110-113 DEG C in 6-7 h; and after the reaction, subjecting the reaction product to neutralization, solvent removal, decolorization by adding water and crystallization to obtain the sucralose-6-acetate crude product. According to the invention, sucrose-6-acetate containing water is adopted for chlorination, and thionyl chloride is added once without cooling, so as to speed up the process, and reduce energy consumption. The employed solvent is more conducive to release of gas products such as sulfur dioxide generated in the chlorination process and promotion of yield increase, and reduces the generation of the other salts and separation burden.

Owner:LIYANG WEIXIN CHEM

Process for extracting nickel-cobalt from laterite by using resin-in-pulp adsorption technology

ActiveCN101974685BReduce governance costsReduce the burden of separationProcess efficiency improvementDesorptionHigh pressure

Owner:JILIN JIEN NICKEL IND +1

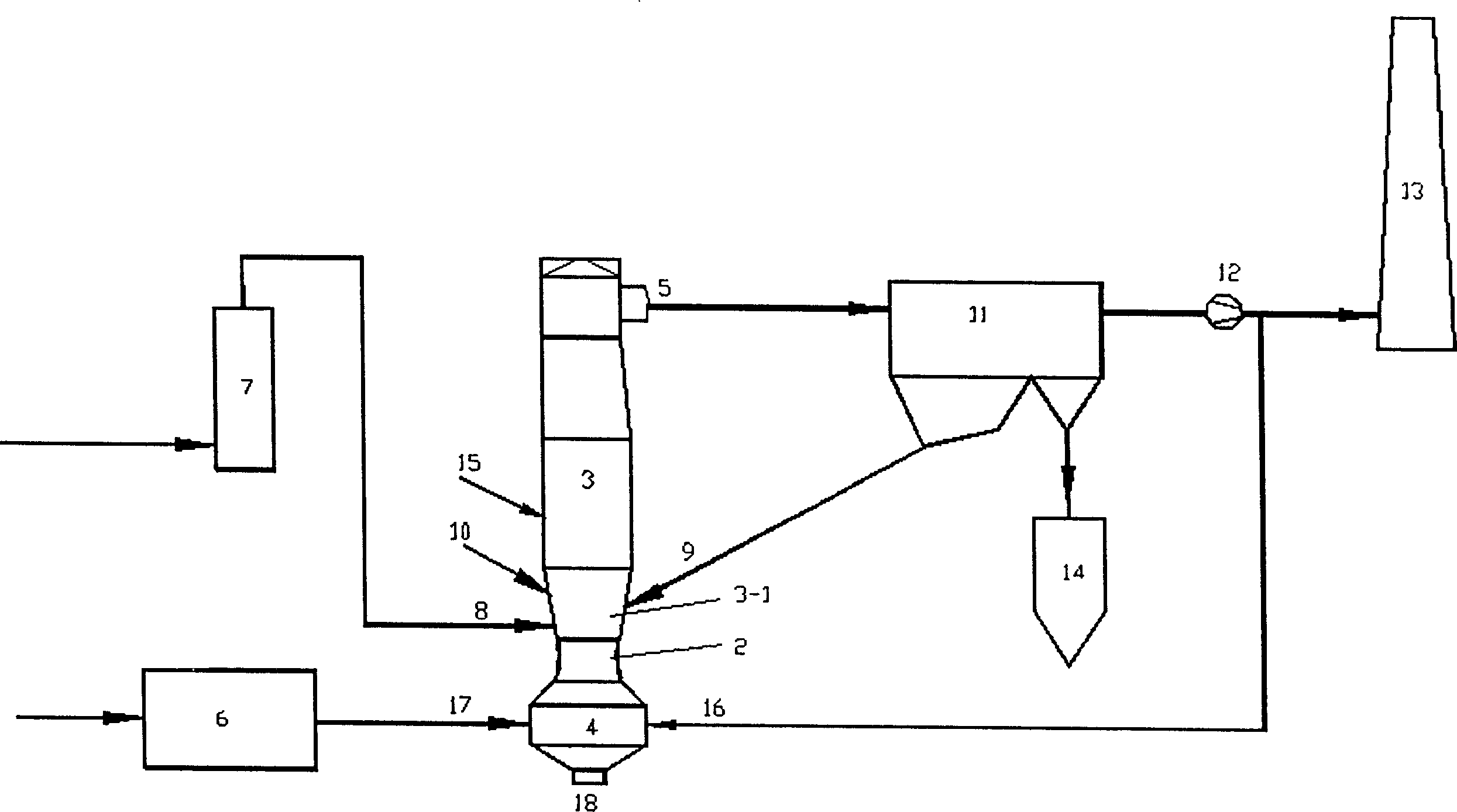

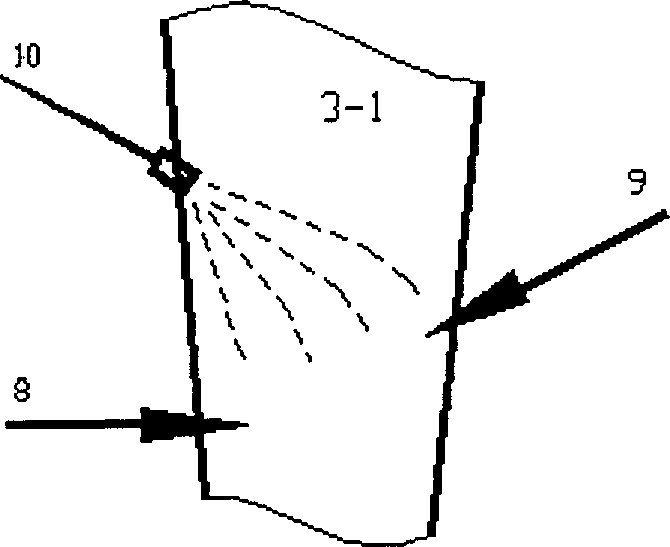

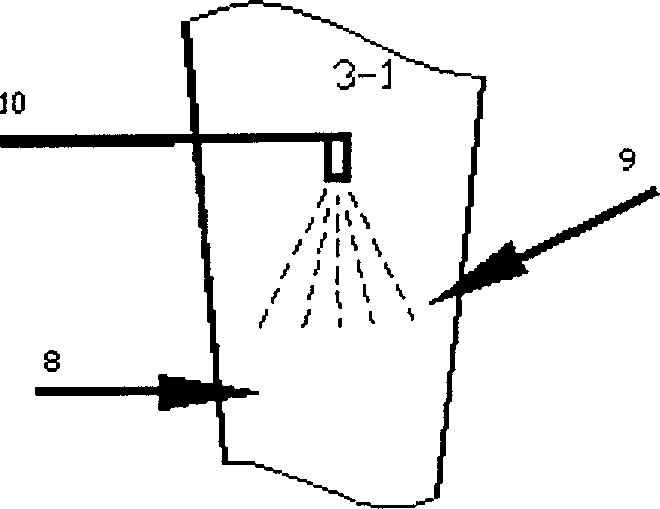

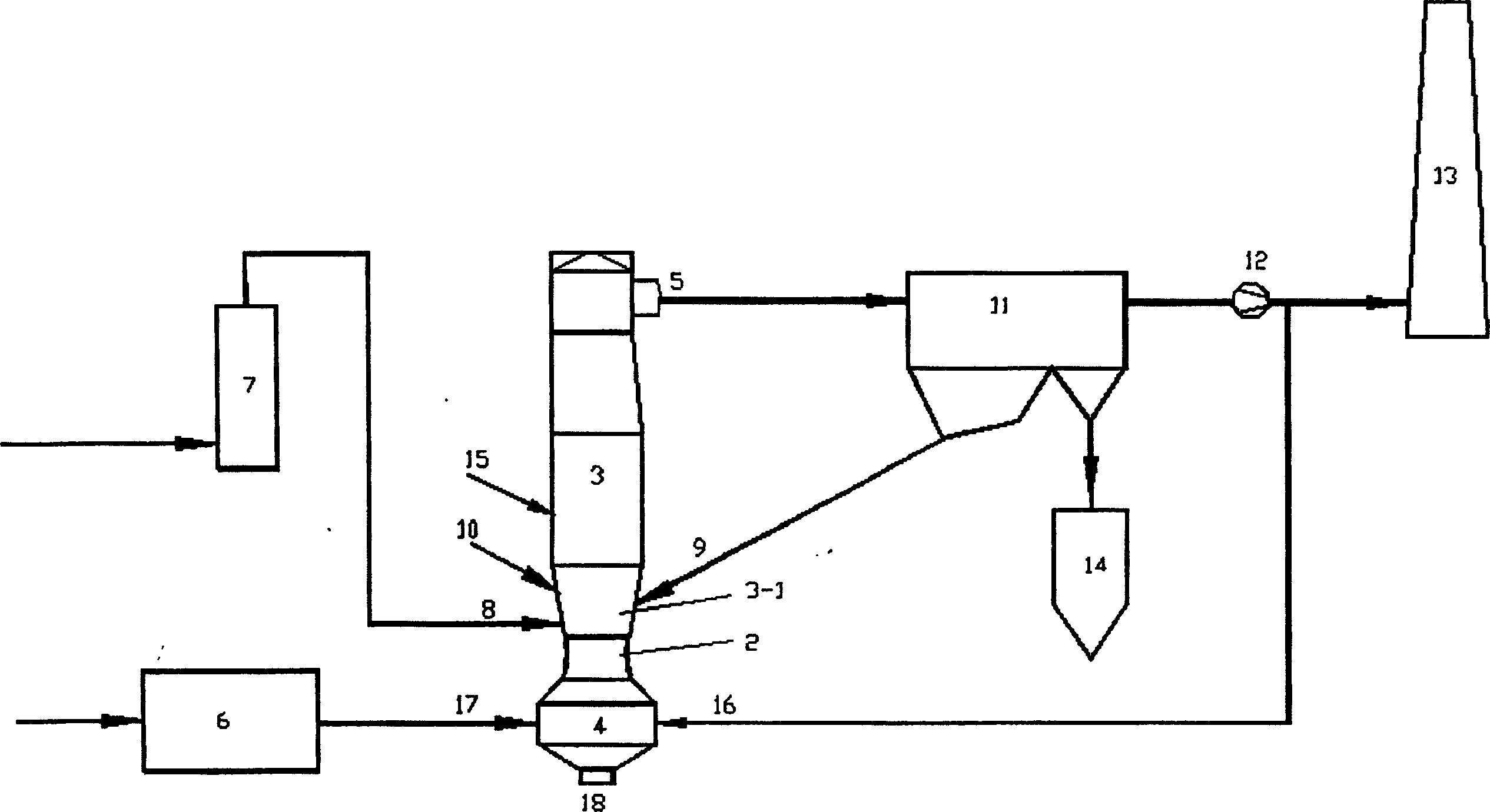

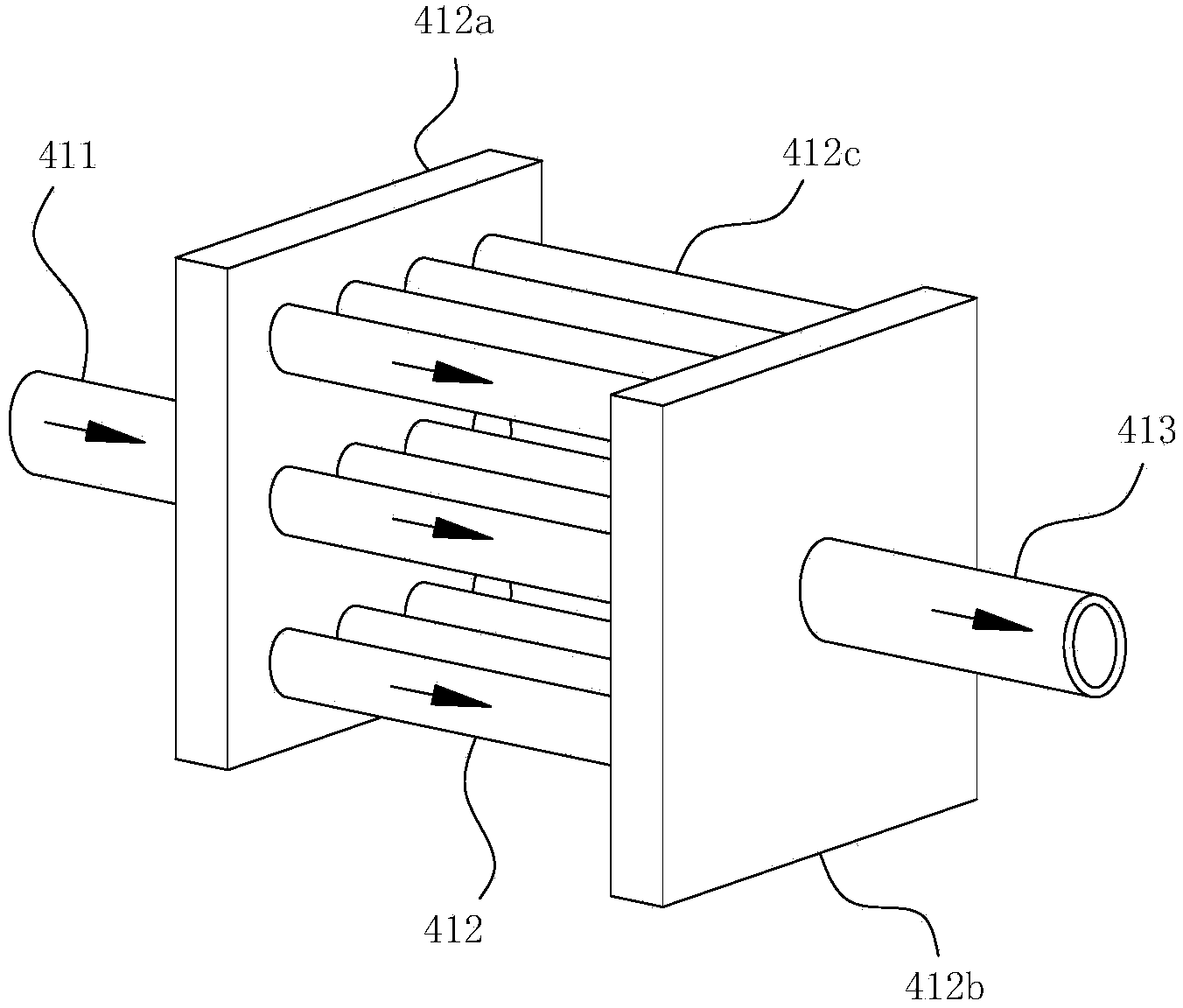

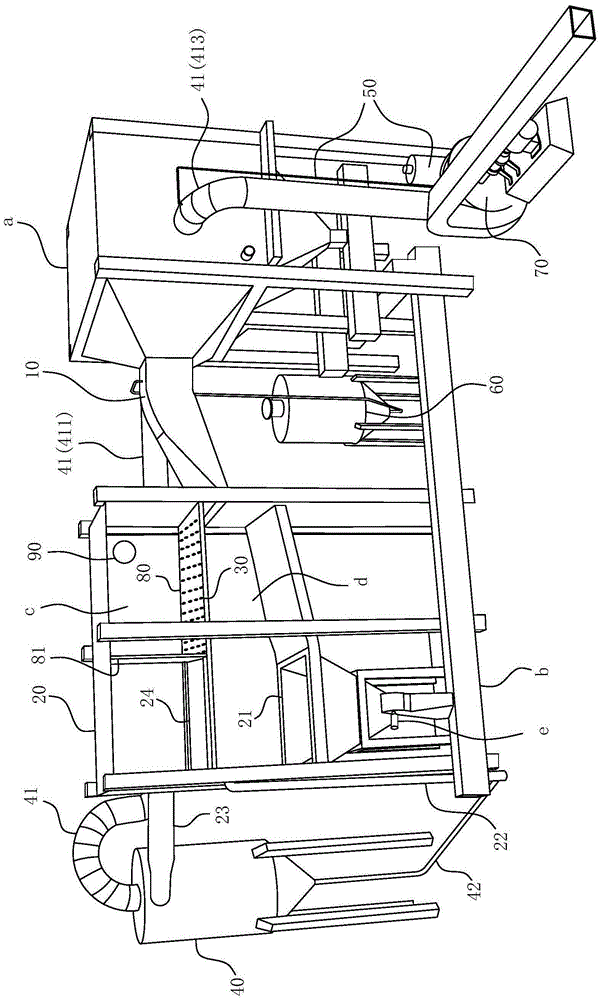

Dry flue gas desulfurizing process with independent feeding, back-returning and water-spraying devices

InactiveCN1515349AImprove desulfurization reaction efficiencyReduce back flowDispersed particle separationProcess engineeringDigestion

The present invention provides a dry flue gas desulfurizing process with independent feeding, feeding back and water-spraying device. It includes desulfurizing agent preparation digestion system, desulfurizing reaction tower and desulfurizing reaction system and exterior desulfurizing granules separation and recirculating system. The water-spraying atomization device of desulfurizing reaction tower, desulfurizing agent feeding device and granules recirculating feed back device are independently placed, and the different heights of the desulfurizing reaction tower are equipped with respective nozzles, so that the structure can raise the utilization rate of the desulfurizing agent and can raise the desulfurizing effect.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

Gas distributor in chloroethylene synthesis fluidized bed and chloroethylene synthetic method

InactiveCN101328107AExtend your lifeReduce manufacturing costPreparation by halogen halide additionChemical/physical processesSynthesis methodsDistributor

The invention particularly relates to a gas distributor of the vinyl chloride synthesis fluidized bed and a synthesis method of vinyl chloride belonging to the field of chemical equipment and technology. Double distributors or one distributor and one group of gas(liquid) nozzles are arranged on the bottom of the fluidized bed. The invention also discloses a method for preparing vinyl chloride by reacting hydrogen chloride with acetylene in a fluidized bed reactor containing the distributor, which comprises controlling the feed temperature, the ratio of composition and flow of the double distributors or one distributor and a group of gas(liquid) nozzles, adjusting the temperature of the gas distributor area by of the cold shock principle of the low temperature gas(liquid). The method of the invention has advantages that the temperature control is sensitive and convenient, the highest and average temperature of the gas distributor area are reduced, the active component loss on the catalyst is inhibited and the coke on the catalyst is reduced, thereby prolonging the catalyst service life, improving the purity of the vinyl chloride product and simplifying the product exhaust post treatment with a low cost.

Owner:TSINGHUA UNIV

Method for low temperature preparation of isopropanol

InactiveCN104478660AImprove performanceControl particle size distributionOrganic compound preparationHydroxy compound preparationHydrogenMetal

The invention discloses a method for low temperature preparation of isopropanol; acetone is added with hydrogen and subjected to a reaction under the action of a catalyst to generate isopropanol, and the specific steps include that a carbon-based material is used as a carrier to prepare the double-metal supported catalyst represented by M1-M2 / C, wherein M1 is selected from one of Mo, Au and Ru, and M2 is selected from one of Re, Ag and Mn; liquid acetone is placed in a batch autoclave, the prepared catalyst is added, hydrogen is introduced, the reaction is carried out for a period of time, and thus isopropanol is obtained. The operation temperature for preparing isopropanol is low, the reaction is quick, the conversion rate is high, and the product has high selectivity.

Owner:XIAMEN UNIV

Method of reclaiming fluorite from scheelite tailings

The invention discloses a method for recovering fluorite from scheelite tailings. The method mainly adopts a gravity separation-flotation combined process. Firstly, the scheelite tailings are removed through a shaker gravity separation process of one coarse and four fines The scheelite and barite minerals in the process are enriched with fluorite minerals; and then the fluorite is recovered through a flotation process of one rough, four fine and two sweeps. Under the condition of fully recovering fluorite, the present invention greatly reduces the cost, improves the recovery rate of fluorite, reduces the amount of chemicals used in the flotation process, reduces the separation burden of the flotation process, and reduces the impact on the environment. pollution and promote the comprehensive utilization of resources.

Owner:湖南临武嘉宇矿业有限责任公司

Catalyst for preparing 3-pentanol through 3-pentanone hydrogenation and preparation method of catalyst for preparing 3-pentanol through 3-pentanone hydrogenation

InactiveCN104368359AMild operating temperatureMild operating pressureOrganic compound preparationHydroxy compound preparationHydrogenation process3-Pentanol

The invention discloses a catalyst for preparing 3-pentanol through 3-pentanone hydrogenation. The catalyst comprises a carbon-based carrier and a multi-metal component recorded as M1-M2-M3 / C, wherein M1 is selected from one of Ru, Mn and Ag; M2 is selected from one of Ir, Au and Cu; and M3 is selected from one of La, Ce and Y. The catalyst is applied to the liquid phase 3-pentanone hydrogenation process. The conversion rate of 3-pentanone can be 100 percent within a short time, and the selectivity of the 3-pentanol is 100 percent. The invention also provides a method for preparing the catalyst, and the industrial preparation is easily realized.

Owner:XIAMEN UNIV

Method of modifying phenol substances through CO2 biological conversion method and application of the method

InactiveCN106916855ABiotransformation method acceptedEmission reductionBacteriaTransferasesAlcoholPhenol

The invention discloses a method of modifying phenol substances through a CO2 biological conversion method. The method comprises the steps of: by means of gene-engineering bacteria, combining CO2 onto an aromatic ring of a phenol substance to obtain hydroxybenzoic acid and a derivative; and reducing the carboxyl group, which is generated after carboxylation of the phenol substance, thereby generating corresponding aldehydes or alcohols. The method not only completely reduces carbon emission, but also technically avoid introduction of solid or liquid impurities due to addition of other carbon sources, so that the method reduces synthesis steps, reduces work load of separation and is more economical.

Owner:TIANJIN UNIV OF SCI & TECH

Sulfonation waste mud treatment process

PendingCN108689563AGood effectReduce the burden of separationSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesSolid phasesElectrochemical response

The invention discloses a sulfonation waste mud treatment process. The process includes steps: after fluidization reaction of sulfonation mud, removing fine sand from sulfonation mud; performing homogenization reaction in a first homogenization tank; performing solid-liquid separation; subjecting a solid phase obtained in separation to secondary homogenization reaction in a second homogenization tank, and allowing a liquid phase obtained by filter pressing to enter a temporary storage device; subjecting the liquid phase in the temporary storage device to air flotation treatment in a micro-nanoair flotation treatment; after electrochemical reaction of the liquid phase in a high-voltage pulse electrocoagulation treatment unit, subjecting the liquid phase to double-layer filtration in a double-film filter device, enabling part of clean water obtained after filtration to enter a preparation tank to realize agent preparation, and enabling a small quantity of concentrated water to enter anMVR evaporation device to realize evaporative crystallization. The novel process is provided for sulfonation mud treatment, technical simplicity, energy saving and high treatment efficiency are realized, and treated sulfonation mud reaches discharge standards.

Owner:库车畅源生态环保科技有限责任公司

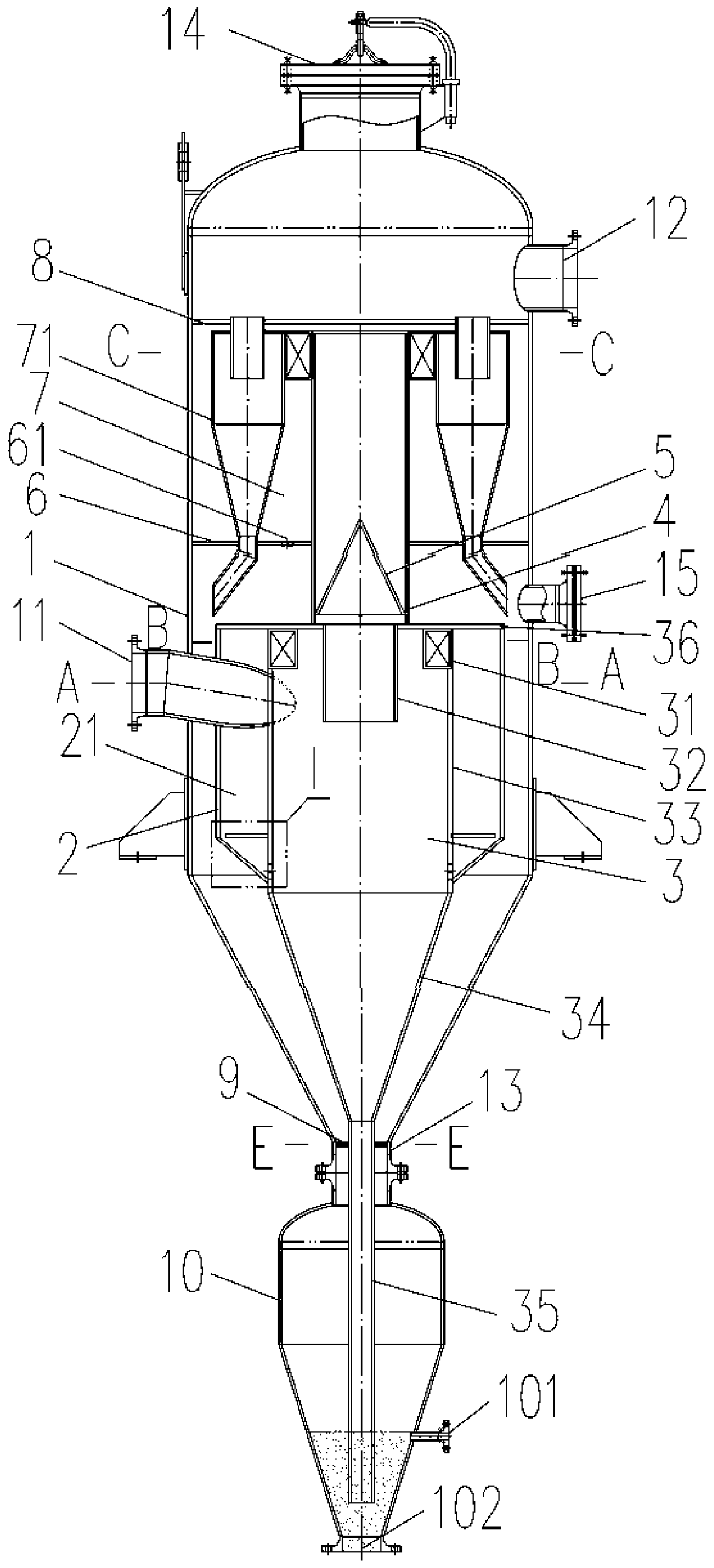

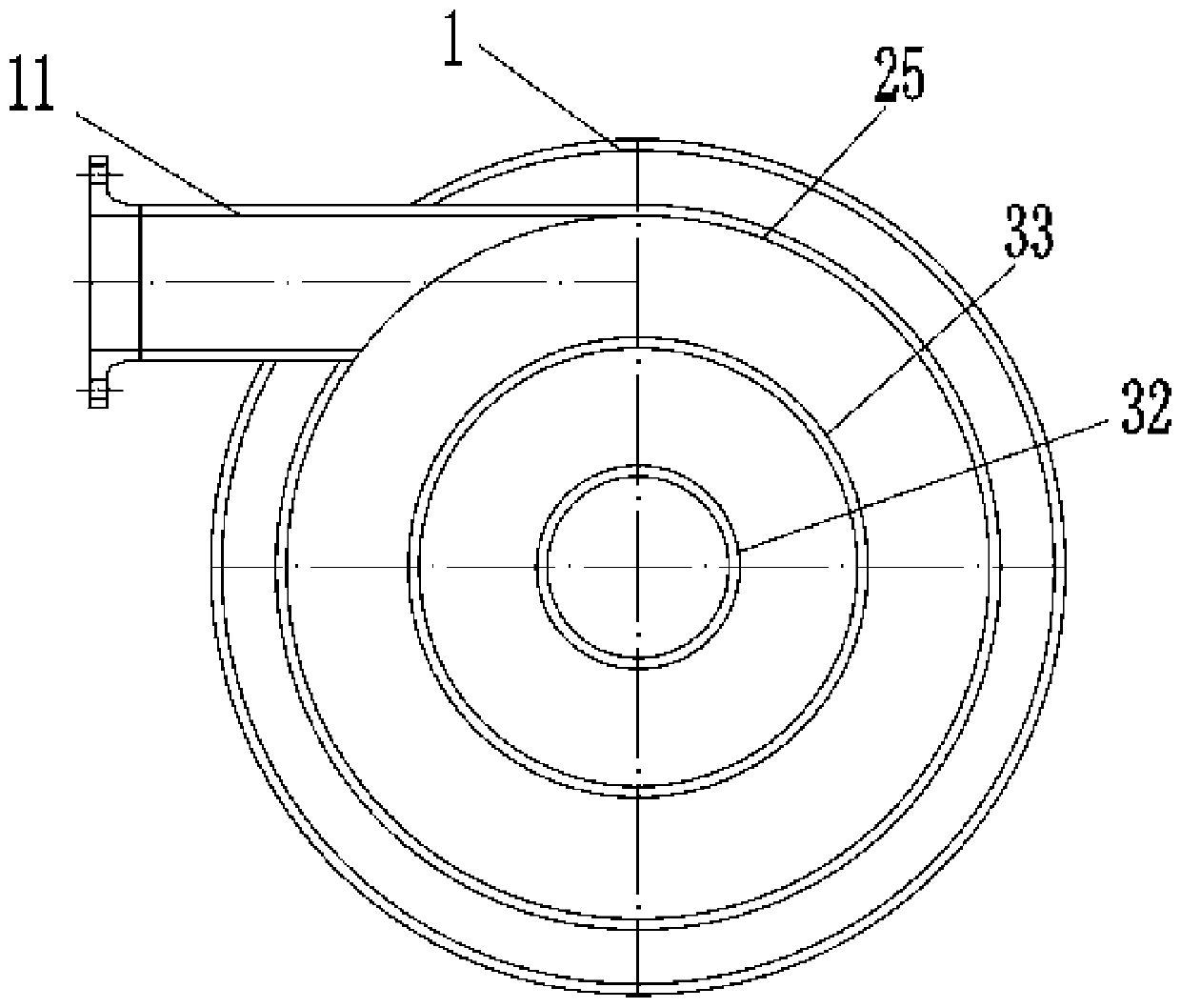

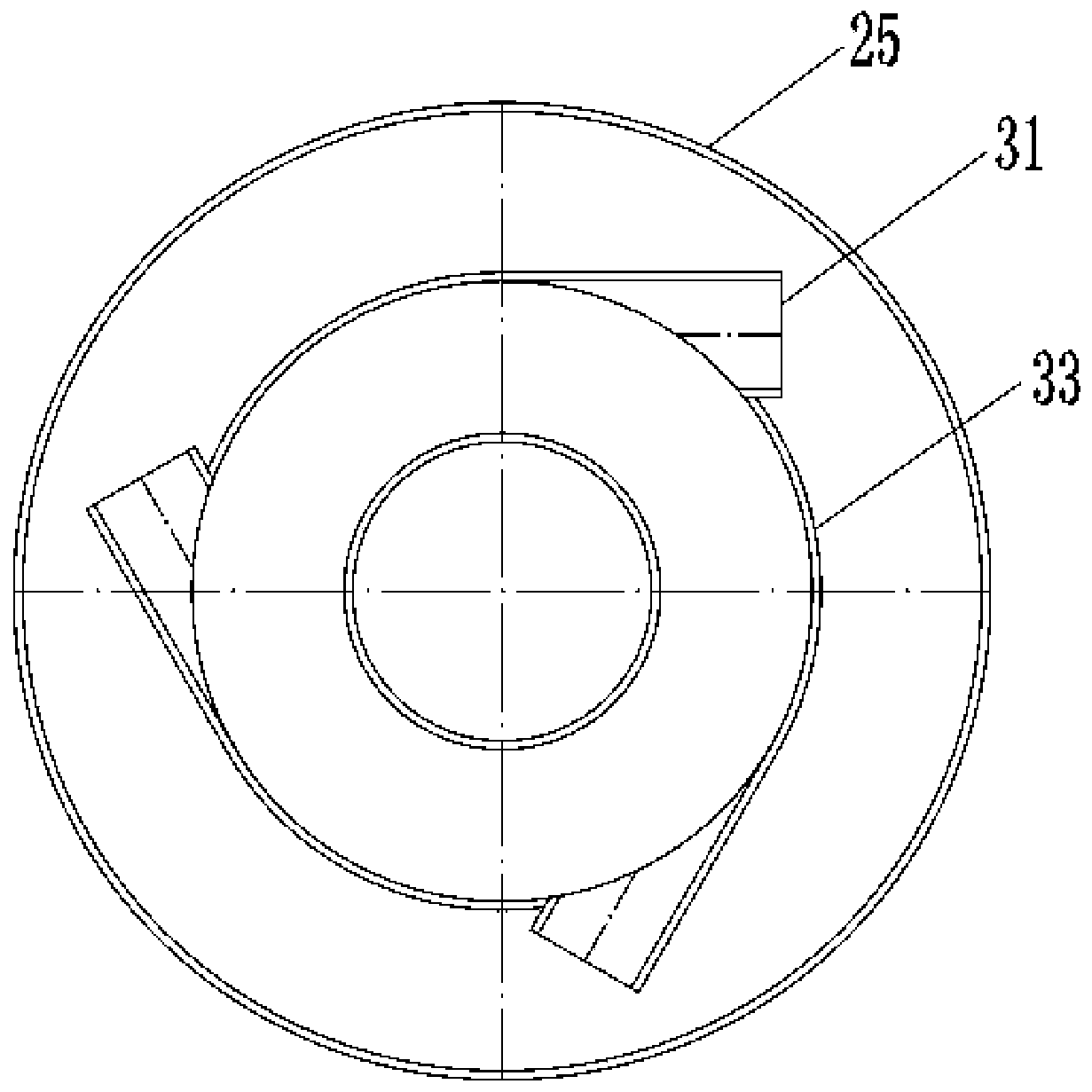

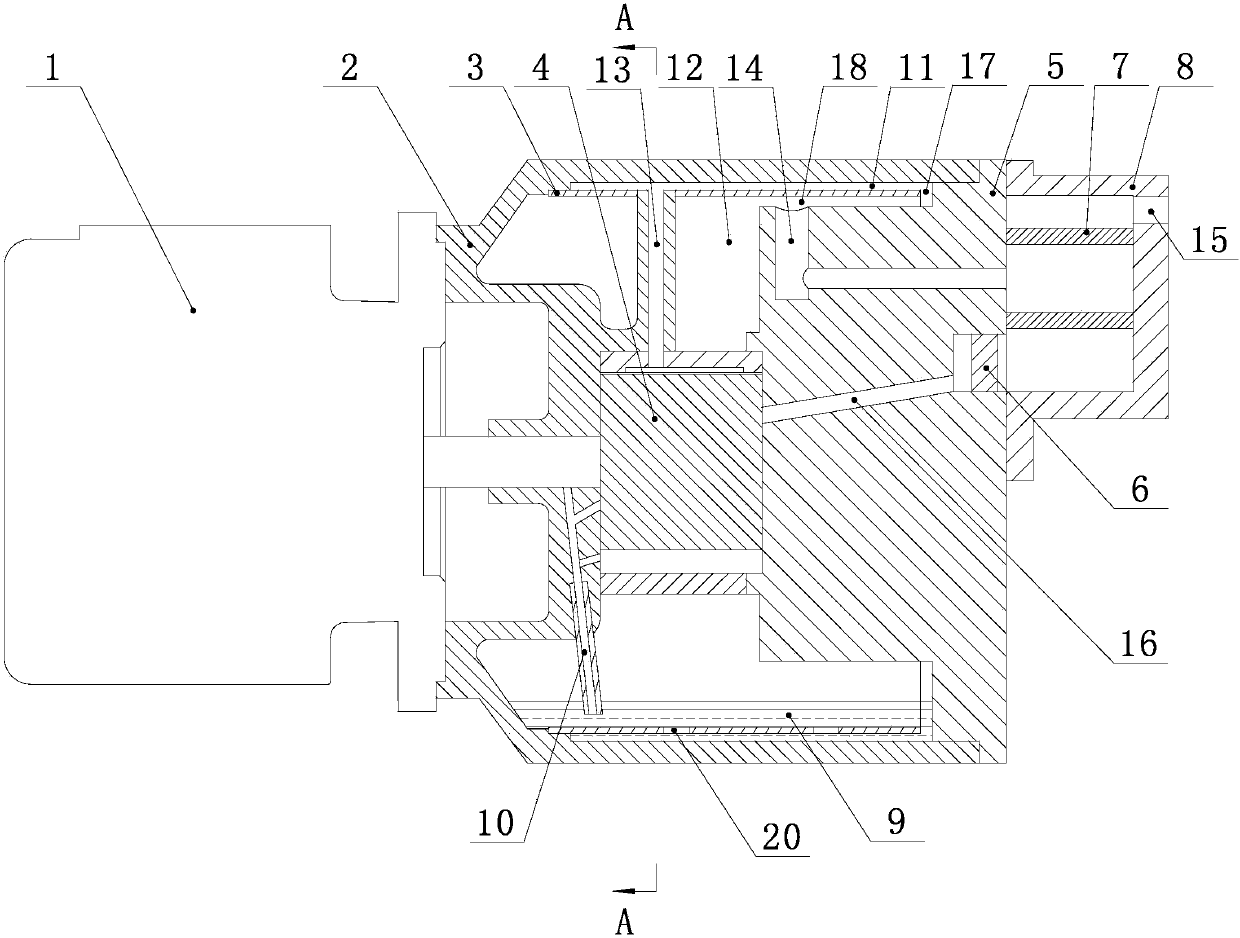

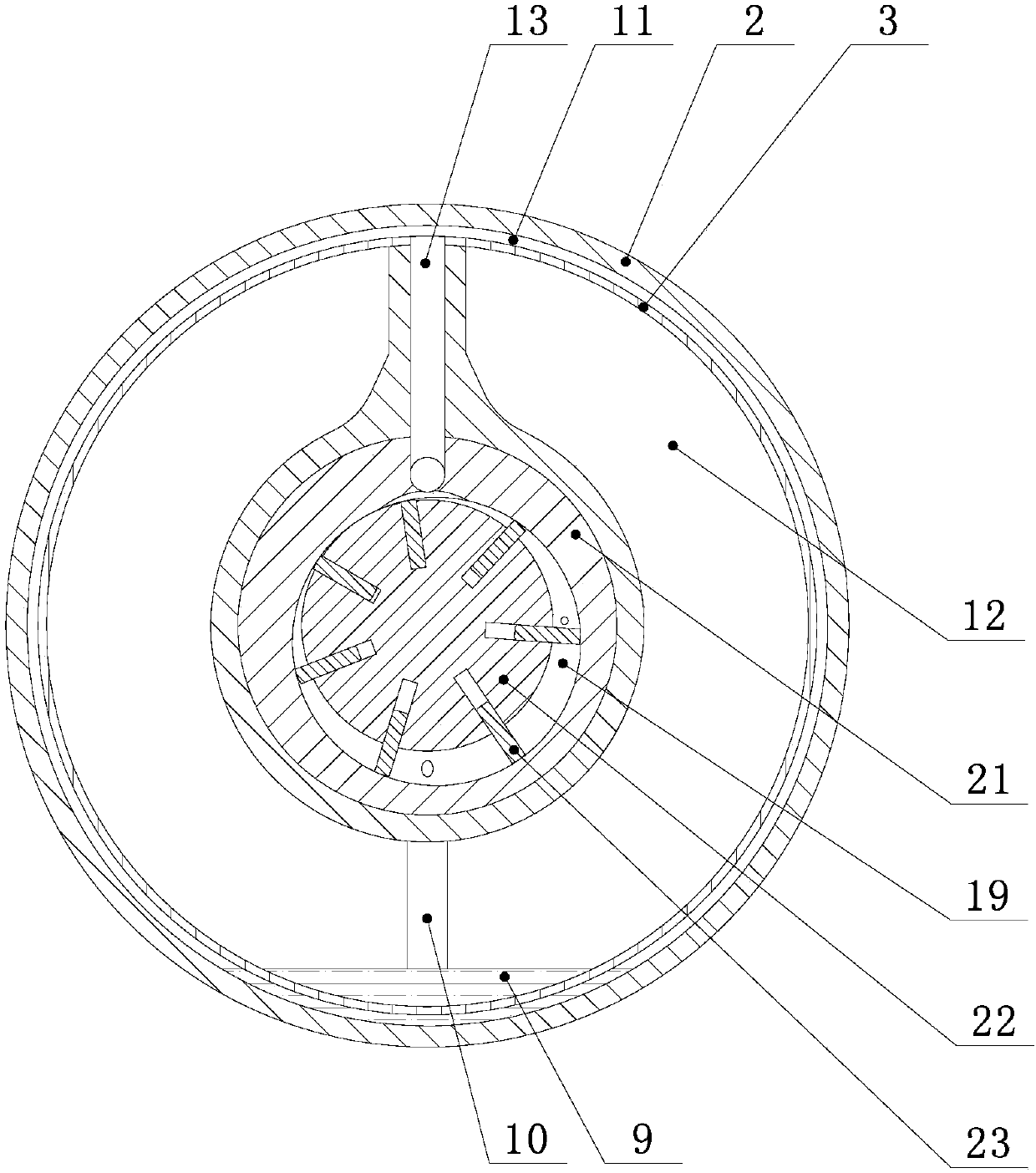

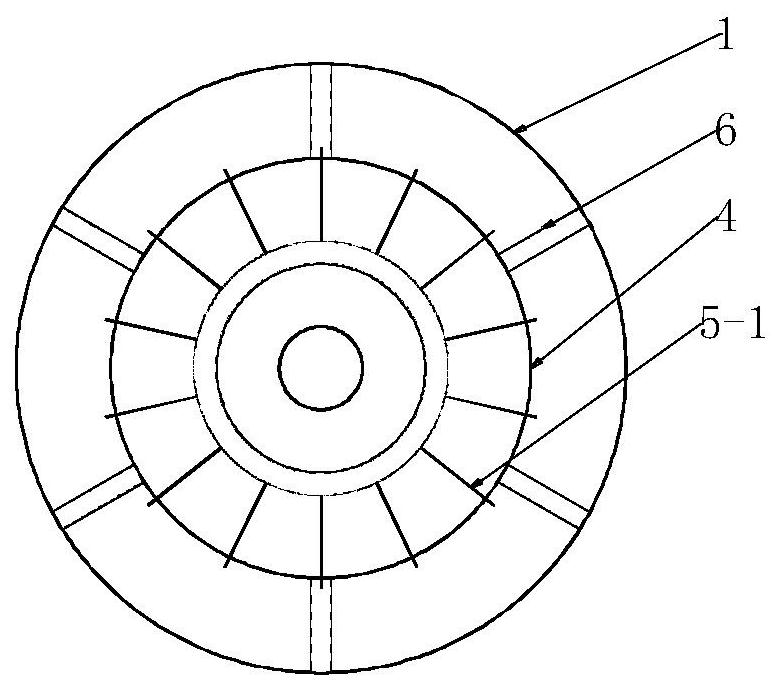

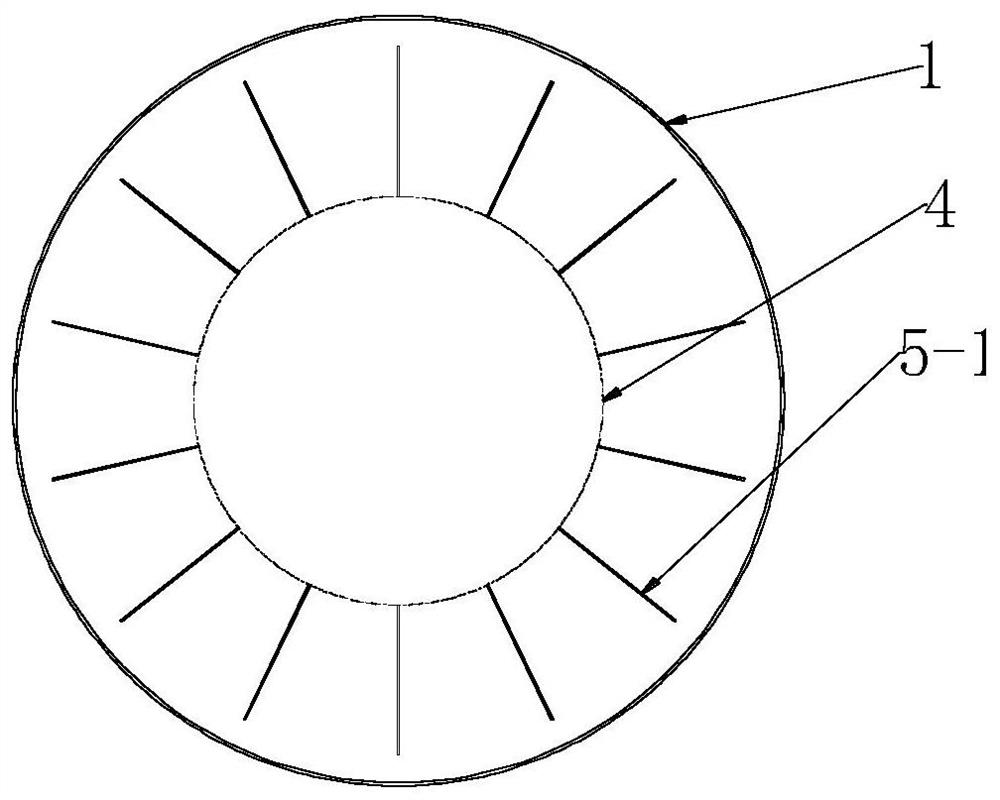

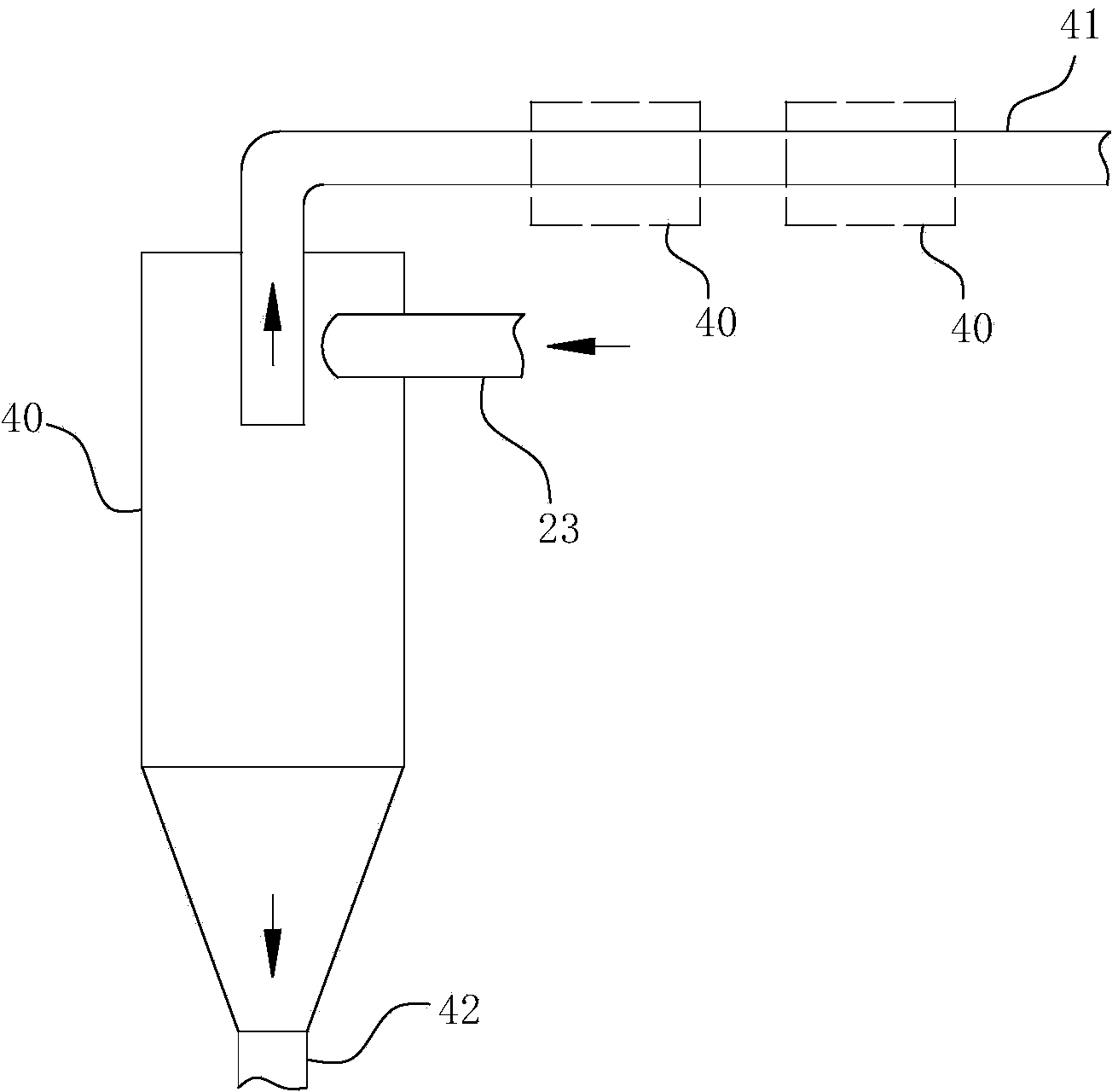

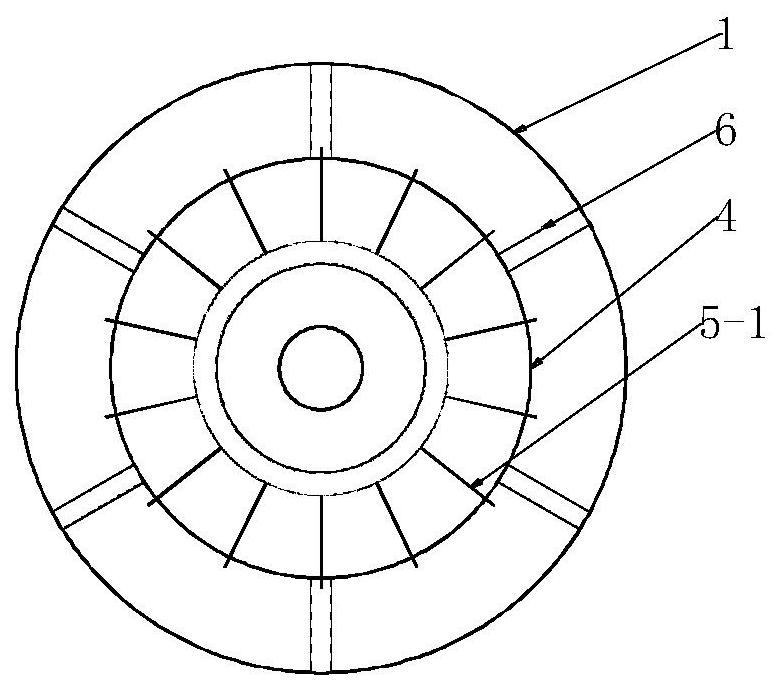

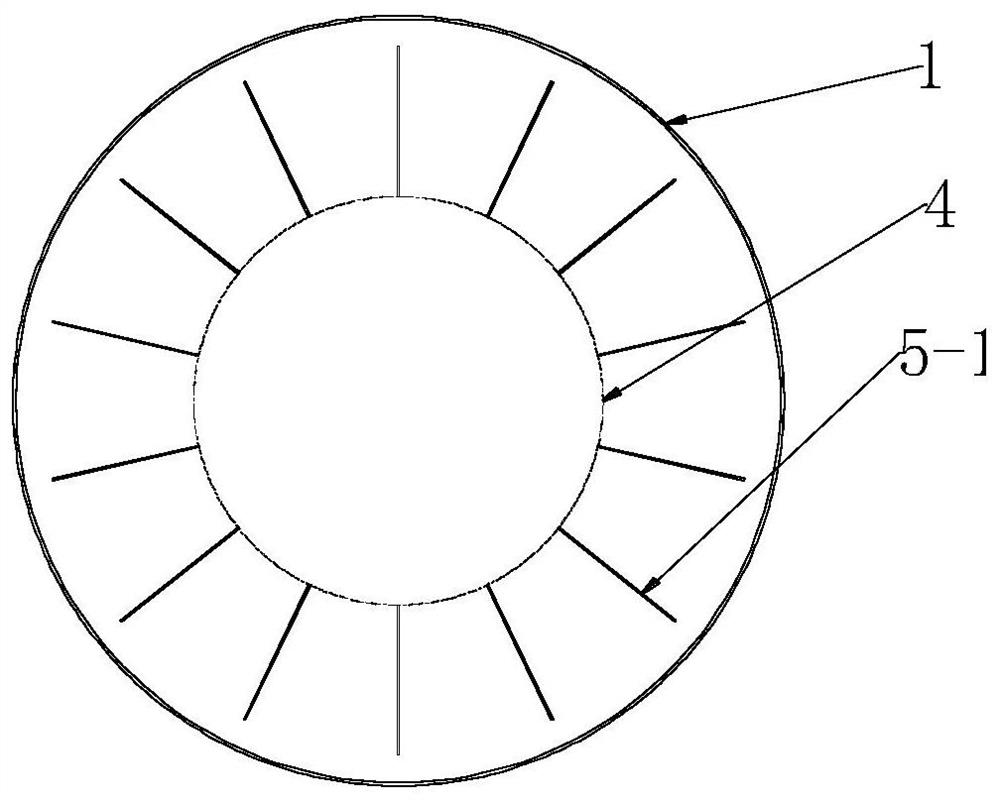

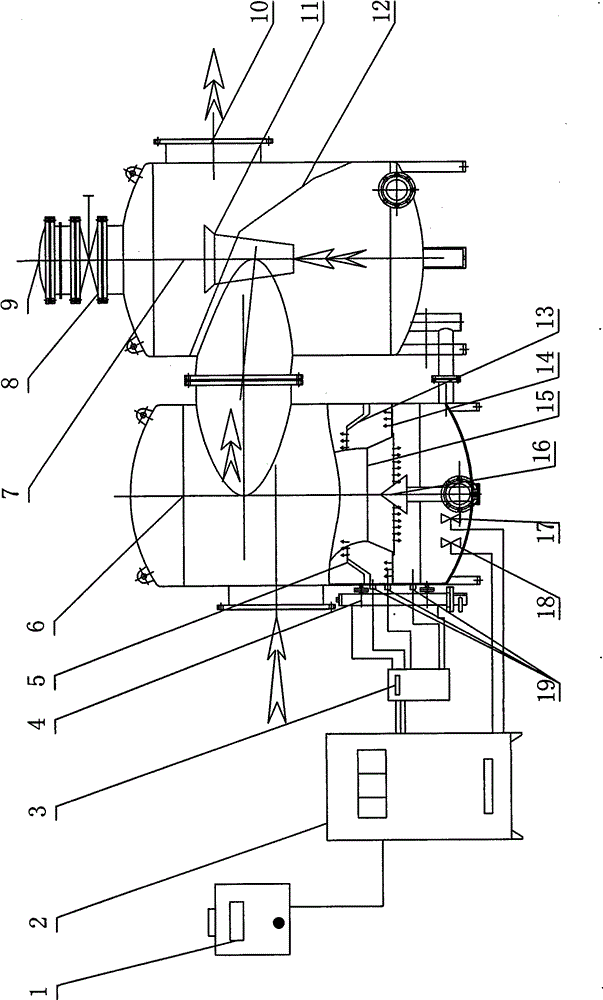

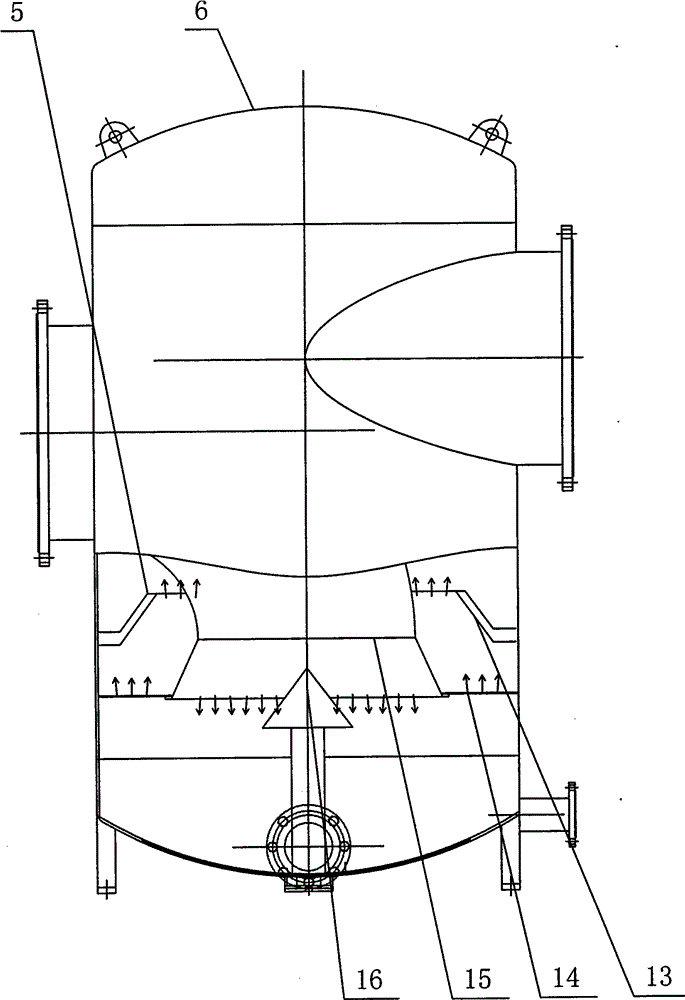

Integrated two-stage high-efficiency cyclone separator

PendingCN111330750AReduce the burden of separationImprove separation efficiencyReversed direction vortexSewage outfallEnvironmental engineering

The invention discloses an integrated two-stage high-efficiency cyclone separator. The integrated two-stage high-efficiency cyclone separator comprises a casing (1), a gas inlet (11) formed in the middle of the casing, a gas outlet (12) formed in the upper portion of the casing, a sewage outlet (13) formed in the bottom of the casing, and a dust hopper (10) connected with the sewage outlet; a pre-separator (2), a first-stage cyclone separator (3), a gas rising pipe (4) and a second-stage cyclone separator (7) are arranged in the casing (1), the first-stage cyclone separator is arranged in thepre-separator, and a pre-separation cavity (21) is formed between the pre-separator and the first-stage cyclone separator; and the first-stage cyclone separator penetrates through the sewage outlet and communicates with the dust hopper, the first-stage cyclone separator communicates with the second-stage cyclone separator through the gas rising pipe, and the gas inlet runs through the casing and communicates with the pre-separator. Multi-stage separation is achieved in one separator, and the separator has high separation efficiency and low operation resistance and can operate stably for a longperiod; and impurities collected in each stage of separation are collected together and centralizedly discharged through the same sewage outlet.

Owner:上海卓旋化工科技有限公司

Dry flue gas desulfurizing process with independent feeding, back-returning and water-spraying devices

InactiveCN1226073CImprove reaction efficiencyImprove desulfurization reaction efficiencyDispersed particle separationFlue gasProcess engineering

The present invention provides a dry flue gas desulfurizing process with independent feeding, feeding back and water-spraying device. It includes desulfurizing agent preparation digestion system, desulfurizing reaction tower and desulfurizing reaction system and exterior desulfurizing granules separation and recirculating system. The water-spraying atomization device of desulfurizing reaction tower, desulfurizing agent feeding device and granules recirculating feed back device are independently placed, and the different heights of the desulfurizing reaction tower are equipped with respective nozzles, so that the structure can raise the utilization rate of the desulfurizing agent and can raise the desulfurizing effect.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

Air compressor oil-gas separation device and oil-gas separation method thereof

InactiveCN106050671BAchieving primary separationImprove separation efficiencyRotary/oscillating piston pump componentsLiquid fuel engine componentsGas compressorCompression device

The invention discloses an oil-gas separation device of an air compressor. The device comprises an oil-gas separation shell; a spacing sleeve is arranged in the oil-gas separation shell; a gap is formed between the end part of the spacing sleeve and an end cover; an interval is formed between the inner wall of the spacing sleeve and the end cover; an oil-gas separation cavity is formed between the spacing sleeve and the oil-gas separation shell; a compression device is arranged in the oil-gas separation shell; a pressure keeping cavity is formed between the compression device and the spacing sleeve; the oil-gas separation cavity is communicated with the pressure keeping cavity through the gap and the interval in sequence; the compression device is communicated with the oil-gas separation cavity through an oil-gas separation exhaust pipe; an end cover exhaust pipe is arranged in the end cover; an inlet of the end cover exhaust pipe is communicated with the interval; an oil-gas separator shell is arranged on the outer side of the end cover; and an oil-gas separator is arranged in the oil-gas separator shell. The device improves the oil-gas separation efficiency and separation effect through layer-by-layer oil-gas separation, reduces the separation burden of the oil-gas separator, and prolongs the service life of the oil-gas separator.

Owner:烟台正祺科技有限公司

A kind of method for preparing isopropanol at low temperature

InactiveCN104478660BLower operating temperatureReduce energy consumptionOrganic compound preparationHydroxy compound preparationHydrogenMetal

The invention discloses a method for low temperature preparation of isopropanol; acetone is added with hydrogen and subjected to a reaction under the action of a catalyst to generate isopropanol, and the specific steps include that a carbon-based material is used as a carrier to prepare the double-metal supported catalyst represented by M1-M2 / C, wherein M1 is selected from one of Mo, Au and Ru, and M2 is selected from one of Re, Ag and Mn; liquid acetone is placed in a batch autoclave, the prepared catalyst is added, hydrogen is introduced, the reaction is carried out for a period of time, and thus isopropanol is obtained. The operation temperature for preparing isopropanol is low, the reaction is quick, the conversion rate is high, and the product has high selectivity.

Owner:XIAMEN UNIV

Chlorination method for industrial production of sucralose-6-acetic ester

ActiveCN101619083BImprove conversion rateQuick releaseEsterified saccharide compoundsSugar derivativesSucroseN dimethylformamide

The invention discloses a chlorination method for industrial production of sucralose-6-acetic ester and relates to the chlorination method for industrial production of the sucralose-6-acetic ester which is a key intermediate of sucralose. The method specifically comprises the steps of adding 7-11 times of molar ratio of N, N-dimethylformamide into pre-synthesized sucrose-6-acetic ester solid or dry syrup, carrying out homogenization, dissolving in 2-6 times of volume ratio of organic solvent, dripping thionyl chloride with molar weight which is equal to that of N, N-dimethylformamide below 0 DEG C, generating a vilsmeier reagent, stirring, naturally increasing the temperature to room temperature, further using 2-14 hours for slowly increasing the temperature to 110-115 DEG C, keeping the temperature for 1-3 hours at 110-115 DEG C, and carrying out neutralization, solvent removal, dissolution by adding water, decolorization and crystallization after the completion of reaction, so as toobtain a sucralose-6-acetic ester coarse product. The method has the advantages of high yield, simple operation, convenient post-treatment and ability of being applicable to industrial production.

Owner:JK SUCRALOSE

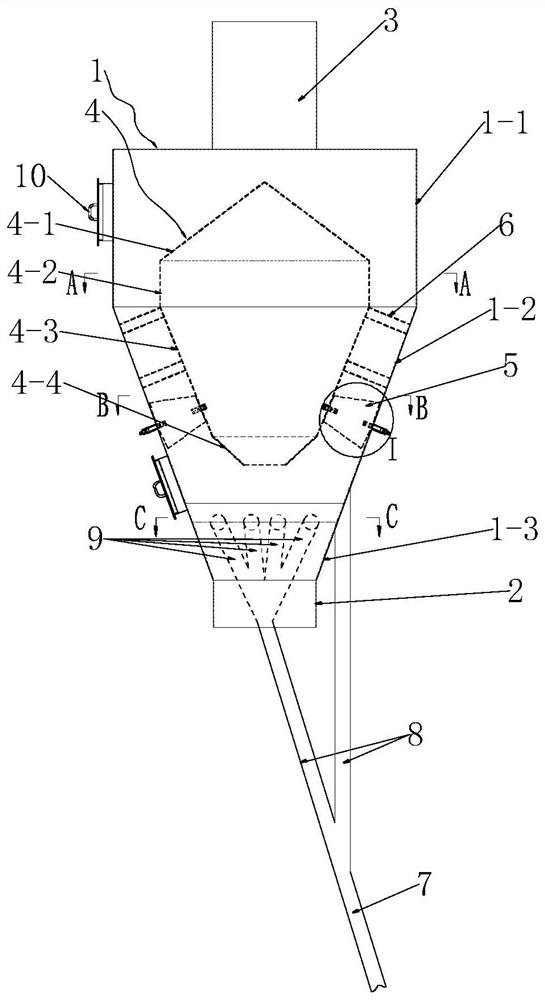

Air flow separator for gypsum powder

ActiveCN111617963AReduce the burden of separationEasy to separateGas current separationCalcium/strontium/barium sulfatesThermodynamicsEngineering

The invention discloses an air flow separator for gypsum powder, and belongs to the gypsum powder production equipment. The technical aim of the air flow separator for the gypsum powder is how to avoid accumulation of large particles at the furnace bottom of a boiling furnace, guarantee the boiling effect, improve the quality of the gypsum powder, meanwhile decrease the number of times of furnacecleaning, lower the labor intensity of workers and improve the working efficiency. According to the adopted scheme, the air flow separator structurally comprises an air flow separating cylinder, a feeding cylinder is arranged at the lower end of the air flow separating cylinder, and a discharging cylinder is arranged at the upper end of the air flow separating cylinder; a material blocking cylinder is arranged on the upper position of the inner middle of the air flow separating cylinder, and an air blocking structure is arranged between the outer side wall of the material blocking cylinder andthe inner side wall of the air flow separating cylinder; and a large particle flowing-out structure is arranged on the lower position of the middle of the air flow separating cylinder, the inlet endof the large particle flowing-out structure is located on the lower position of the inner middle of the air flow separating cylinder, and the outlet end of the large particle flowing-out structure islocated at the oblique lower part outside the air flow separating cylinder.

Owner:山东腾飞机电科技有限公司

A method for comprehensive recovery of lead, zinc, tin and fluorite from tailings

ActiveCN107029870BReduce the burden of separationLow costFlotationMechanical material recoveryMining engineeringMineralogy

The invention discloses a method for comprehensively recycling lead, zinc, tin and fluorite from tailings. The method includes the following steps that firstly, the tailings are pre-screened; then the tailings of -20 meshes are subjected to ore grinding, and an ore grinding product with the preset fineness is obtained; then the ore grinding product is subjected to floatation which includes one time of rough floatation, three times of finish floatation and two times of scavenging, and lead and zinc in the tailings are recycled; then the floated tailings enter a shaking table to be subjected to re-floatation which includes one time of rough floatation, one time of finish flotation and one time of scavenging, and tinstone is recycled through re-floatation; and finally, the re-floated tailings are subjected to fluorite re-floatation which includes one time of rough floatation, eight times of finish floatation and two times of scavenging. By means of the technical means of floatation, re-floatation and re-floatation, the problems that at present, the recycling rate of poor, varied and thin tailings is low, the cost is high, and pollution is large are solved, and the process is simple and practical.

Owner:湖南临武嘉宇矿业有限责任公司

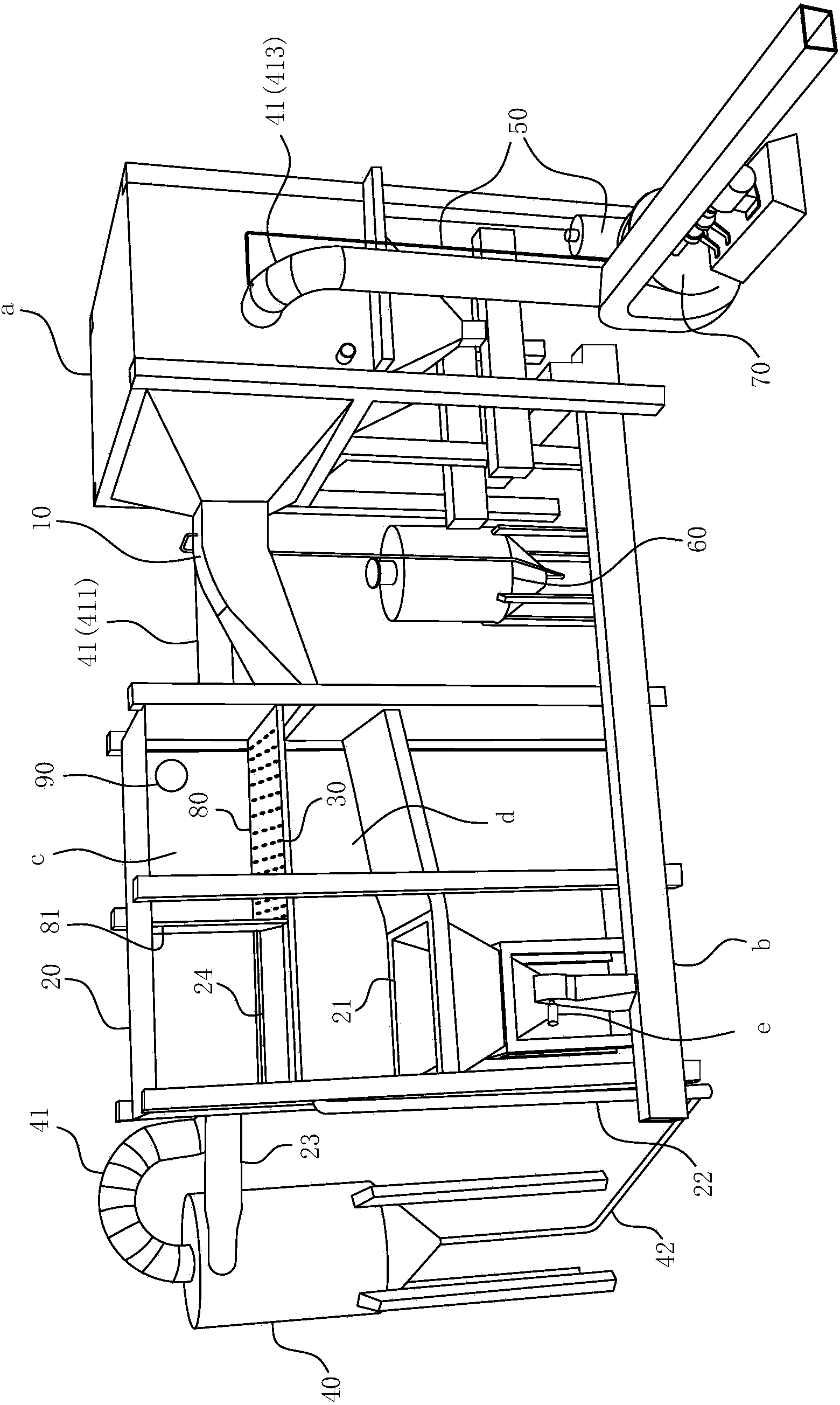

Flue-gas purifying system of incineration furnace

InactiveCN104368226AEasy to separateTo achieve the purpose of water vapor separationCombination devicesWater dischargeFlue gas

The invention belongs to the field of waste incineration equipment and particularly relates to a flue-gas purifying system of an incineration furnace applicable to treating flue gas from incineration of the incineration furnace. The flue-gas purifying system at least comprises a flue-gas leading-out pipe and a treating chamber, wherein a water curtain part is arranged at the treating chamber, and the water discharging direction of the water curtain part is vertical to or intersected with the moving direction of the flue gas at the outlet of the flue-gas leading-out pipe; a precipitate deslagging port is arranged at the bottom part of the treating chamber; the treating chamber is internally provided with a communicating pipe for communicating with an external inner-circulation reservoir and a steam discharging pipeline; a gas discharging pipe of a water-steam separating component extends towards the tail end of a flue and penetrates into an inner cavity of the flue; and a water discharging pipe of the water-steam separating component is communicated with the external inner-circulation reservoir. The flue-gas purifying system also comprises a carbon-powder distributor and a lime distributor. The flue-gas purifying system can provide a basic hardware platform for treating the flue gas of the current high-efficiency incineration furnace, is high in flue-gas treating efficiency and good in working reliability, and can be well qualified for the need of high-efficiency, harmless and rapid treatment of the flue gas from incineration of various current incineration furnaces.

Owner:HEFEI HUANKUN SLUDGE DRYING EQUIP

A gypsum powder air separator

ActiveCN111617963BReduce the burden of separationEasy to separateGas current separationCalcium/strontium/barium sulfatesThermodynamicsEngineering

The invention discloses a gypsum powder airflow separator, which belongs to the gypsum powder production equipment. The technical problem to be solved by the invention is how to avoid the accumulation of large particles at the bottom of the boiling furnace, ensure the boiling effect, improve the quality of the gypsum powder, and at the same time reduce the times of cleaning the furnace, To reduce the labor intensity of workers and improve the work efficiency, the technical scheme adopted is as follows: the structure includes an airflow separation cylinder, a feed cylinder is arranged at the lower end of the airflow separation cylinder, a discharge cylinder is arranged at the upper end of the airflow separation cylinder, and an upper middle part of the airflow separation cylinder is arranged. The position is provided with a material blocking cylinder, a wind blocking structure is set between the outer side wall of the material blocking cylinder and the inner side wall of the airflow separation cylinder, and a large particle outflow structure is set at the lower position of the middle part of the airflow separation cylinder, and the inlet end of the large particle outflow structure is located in the airflow. At the lower position in the middle of the separation cylinder, the outlet end of the large particle outflow structure is located at the obliquely lower position outside the air separation cylinder.

Owner:山东腾飞机电科技有限公司

Self-balancing water-seal-type anti-explosion device

InactiveCN102900459BAvoid enteringKeep constantDust removalFire preventionWater dischargeWater level

The invention discloses a self-balancing water-seal-type anti-explosion device which consists of a water seal device, a steam-water separation explosion venting device and an intelligent water level monitoring device, wherein a water seal device cylinder body is internally provided with a primary divergent speed reduction device connected with an air inlet pipeline and a secondary divergent speed reduction device connected with an air outlet pipeline; the air outlet pipeline of the water seal device cylinder body is connected with the steam-water separation explosion venting device; the steam-water separation explosion venting device comprises a tank body, an air inlet, an air outlet, a water discharge adapter tube, a pressure relieving device and a separation device arranged in the tank body; an air outlet pipeline of the water seal device is connected with the air inlet; and the water discharge adapter tube is arranged at the bottom of the tank body, and is communicated with the water seal device cylinder body. According to the invention, the automatic monitoring and automatic supplying of a water seal surface are achieved through combining the cycling of steam and water and the time-to-time monitoring of the water level, thus the water seal surface is kept to be constant, and water is prevented from entering a pumping and extracting system, and pipelines are prevented from being blocked so as to guarantee the safe running of the whole system.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

Chlorination method for industrial production of sucralose-6-acetate

InactiveCN102964397BReduce the difficulty of recyclingFacilitated releaseEsterified saccharide compoundsSugar derivativesOrganic solventSucrose

A chlorination method for industrial production of sucralose-6-acetate. The method comprises steps of: (a) adding thionyl chloride into an organic solvent below 30 DEG C to form a mixed solution, with a molar ratio of the organic solvent to thionyl chloride of 3.5-4.6:1; (b) adding sucrose-6-acetate with water content of 0.2%-0.8% into the mixed solution, and stirring, wherein a molar ratio of added sucrose-6-acetate to thionyl chloride is 1:7-9; and (c) slowly heating to 110-113 DEG C in 6-7 h; and after the reaction, subjecting the reaction product to neutralization, solvent removal, decolorization by adding water and crystallization to obtain the sucralose-6-acetate crude product. According to the invention, sucrose-6-acetate containing water is adopted for chlorination, and thionyl chloride is added once without cooling, so as to speed up the process, and reduce energy consumption. The employed solvent is more conducive to release of gas products such as sulfur dioxide generated in the chlorination process and promotion of yield increase, and reduces the generation of the other salts and separation burden.

Owner:LIYANG WEIXIN CHEM

Incinerator flue gas purification system

InactiveCN104368226BTo achieve the finishing touchImprove cleanlinessCombination devicesFlue gasEnvironmental engineering

The invention belongs to the field of waste incineration equipment and particularly relates to a flue-gas purifying system of an incineration furnace applicable to treating flue gas from incineration of the incineration furnace. The flue-gas purifying system at least comprises a flue-gas leading-out pipe and a treating chamber, wherein a water curtain part is arranged at the treating chamber, and the water discharging direction of the water curtain part is vertical to or intersected with the moving direction of the flue gas at the outlet of the flue-gas leading-out pipe; a precipitate deslagging port is arranged at the bottom part of the treating chamber; the treating chamber is internally provided with a communicating pipe for communicating with an external inner-circulation reservoir and a steam discharging pipeline; a gas discharging pipe of a water-steam separating component extends towards the tail end of a flue and penetrates into an inner cavity of the flue; and a water discharging pipe of the water-steam separating component is communicated with the external inner-circulation reservoir. The flue-gas purifying system also comprises a carbon-powder distributor and a lime distributor. The flue-gas purifying system can provide a basic hardware platform for treating the flue gas of the current high-efficiency incineration furnace, is high in flue-gas treating efficiency and good in working reliability, and can be well qualified for the need of high-efficiency, harmless and rapid treatment of the flue gas from incineration of various current incineration furnaces.

Owner:HEFEI HUANKUN SLUDGE DRYING EQUIP

Catalyst for preparing 3-pentanol by hydrogenation of 3-pentanone and preparation method thereof

InactiveCN104368359BMild operating temperatureReduce energy consumptionOrganic compound preparationHydroxy compound preparationHydrogenation process3-Pentanol

The invention discloses a catalyst for preparing 3-pentanol through 3-pentanone hydrogenation. The catalyst comprises a carbon-based carrier and a multi-metal component recorded as M1-M2-M3 / C, wherein M1 is selected from one of Ru, Mn and Ag; M2 is selected from one of Ir, Au and Cu; and M3 is selected from one of La, Ce and Y. The catalyst is applied to the liquid phase 3-pentanone hydrogenation process. The conversion rate of 3-pentanone can be 100 percent within a short time, and the selectivity of the 3-pentanol is 100 percent. The invention also provides a method for preparing the catalyst, and the industrial preparation is easily realized.

Owner:XIAMEN UNIV

Gas distributor in chloroethylene synthesis fluidized bed and chloroethylene synthetic method

InactiveCN101328107BExtend your lifeReduce manufacturing costPreparation by halogen halide additionChemical/physical processesSynthesis methodsDistributor

The invention particularly relates to a gas distributor of the vinyl chloride synthesis fluidized bed and a synthesis method of vinyl chloride belonging to the field of chemical equipment and technology. Double distributors or one distributor and one group of gas or liquid nozzles are arranged on the bottom of the fluidized bed. The invention also discloses a method for preparing vinyl chloride by reacting hydrogen chloride with acetylene in a fluidized bed reactor containing the distributor, which comprises controlling the feed temperature, the ratio of composition and flow of the double distributors or one distributor and a group of gas or liquid nozzles, adjusting the temperature of the gas distributor area by of the cold shock principle of the low temperature gas or liquid. The method of the invention has advantages that the temperature control is sensitive and convenient, the highest and average temperature of the gas distributor area are reduced, the active component loss on the catalyst is inhibited and the coke on the catalyst is reduced, thereby prolonging the catalyst service life, improving the purity of the vinyl chloride product and simplifying the product exhaust post treatment with a low cost.

Owner:TSINGHUA UNIV

Method for preparing sorbitol from cellulose

ActiveCN106146256AIncrease the rate of hydrolysisReduce the burden of separationOrganic compound preparationHydroxy compound preparationCelluloseLiquid product

The invention relates to a method for preparing sorbitol through cellulose hydrolysis and hydrogenation. The method comprises that under carbon dioxide pressure of 0.1-3MPa, in the presence of a hydrogen mesoporous ZSM-5 zeolite-loaded Pt-Ni catalyst, under conditions of a temperature of 230-250 DEG C and H2 pressure of 0.5-6 MPa, sorbitol is prepared through cellulose hydrolysis and hydrogenation, wherein a sorbitol yield is 53.2% and a ratio of sorbitol to sorbitol isomer mannitol is greater than 12, and after the reaction, carbon dioxide spontaneously separates from the liquid product. The method is free of a liquid inorganic acid so that acid pollution and equipment corrosion are avoided. The method solves the problem that a sorbitol yield is low at a high reaction temperature of 230-250 DEG C, realizes rapid cellulose conversion and improves a sorbitol yield.

Owner:CHANGCHUN UNIV OF TECH

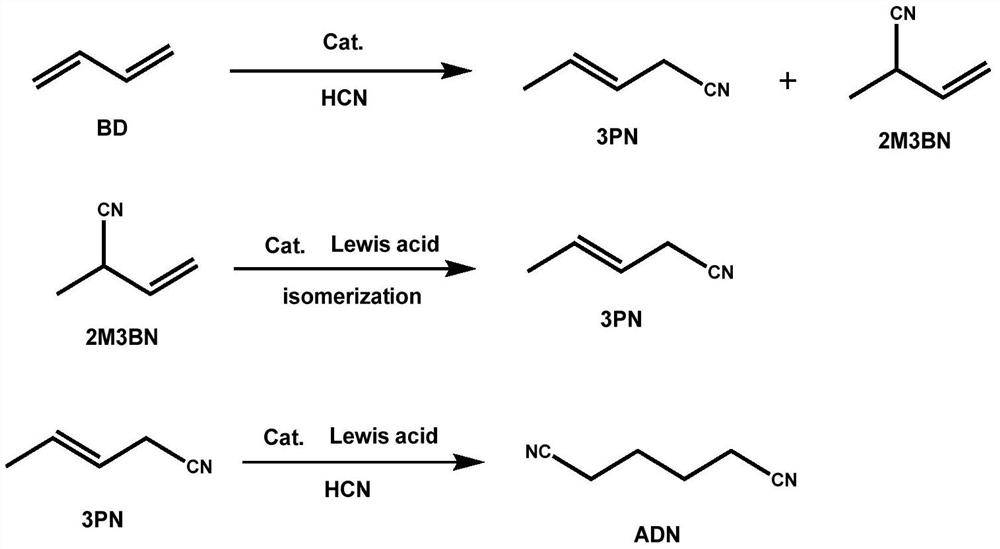

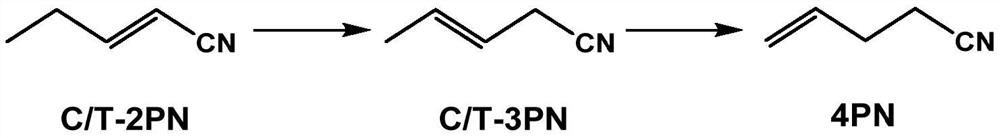

2-pentenenitrile isomerization reaction generates the method for 3-pentenenitrile

ActiveCN109651195BReduce adverse effectsReduce inactivationCarboxylic acid nitrile preparationOrganic compound preparationIsomerizationPtru catalyst

The invention discloses a method for generating 3-pentenenitrile by isomerization reaction of 2-pentenenitrile, which is characterized in that it comprises the following steps: 2-pentenenitrile, catalyst, bidentate phosphorus ligand, Lewis acid, solvent Mix to obtain a reaction system; under the condition of nitrogen protection, the reaction system in step 1 is reacted at a reaction pressure of 0.1 to 0.5Mpa and a reaction temperature of 80 to 150°C; after the reaction is completed, the unreacted 2-pentenenitrile and the product 3-pentenenitrile are separated. The invention has the advantages of increasing the yield of the target product, shortening the reaction process and reducing the difficulty of product separation.

Owner:ANHUI ANQING SHUGUANG CHEM GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com