Gas distributor in chloroethylene synthesis fluidized bed and chloroethylene synthetic method

A technology of gas distributor and synthesis method, which is applied in the fields of chemical instruments and methods, organic chemistry, hydrogen halide addition preparation, etc., can solve problems such as inflexibility, difficulty in effective evacuation, difficulty in dealing with sudden accidents, etc., and achieve Flexible control, extended continuous operation cycle, and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

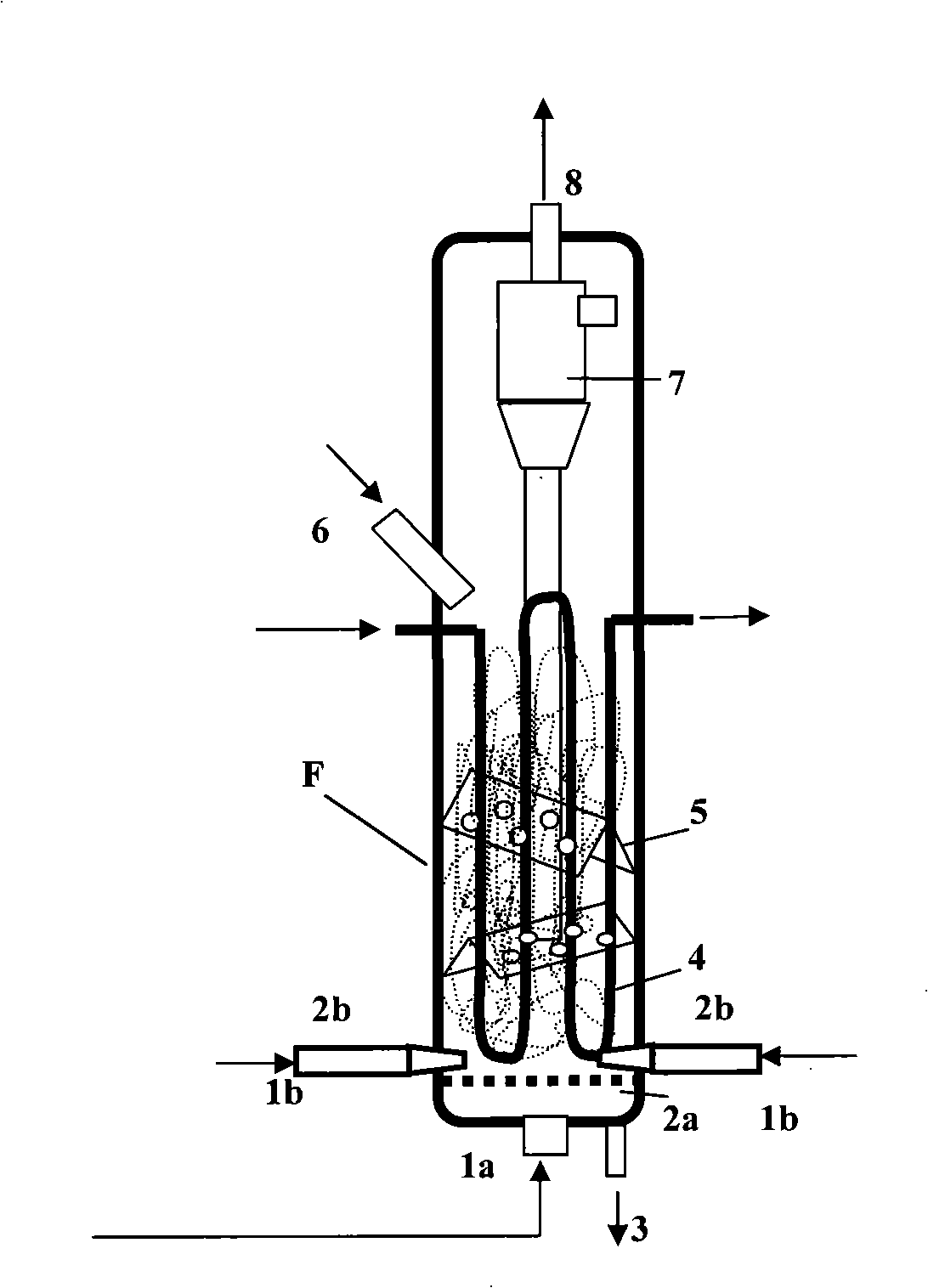

[0040] figure 1 It is a schematic diagram of a fluidized bed in the form of a plate distributor and a set of gas (liquid) nozzles. A plate gas distributor 2a is arranged at the bottom of the fluidized bed F, and eight gas (liquid) nozzles 2b are arranged above it to connect with the tube wall of the fluidized bed F; a gas inlet 1a and a catalyst are arranged on the tube wall at the bottom of the fluidized bed F Outlet 3, a catalyst inlet 6 is set on the upper tube wall of the fluidized bed; a heat exchange tube 4, a component 5 and a cyclone separator 7 are set in the fluidized bed F; a gas outlet 8 is set on the tube wall at the top of the fluidized bed F and Connected with cyclone separator 7.

[0041] The active components of the catalyst are 10wt% mercuric chloride, 2wt% tin chloride and 0.1wt% lanthanum chloride, and the rest is carrier activated carbon. The catalyst is made by ball milling method, with a particle size of 0.1mm and a specific surface area of 600m 2 / g...

Embodiment 2

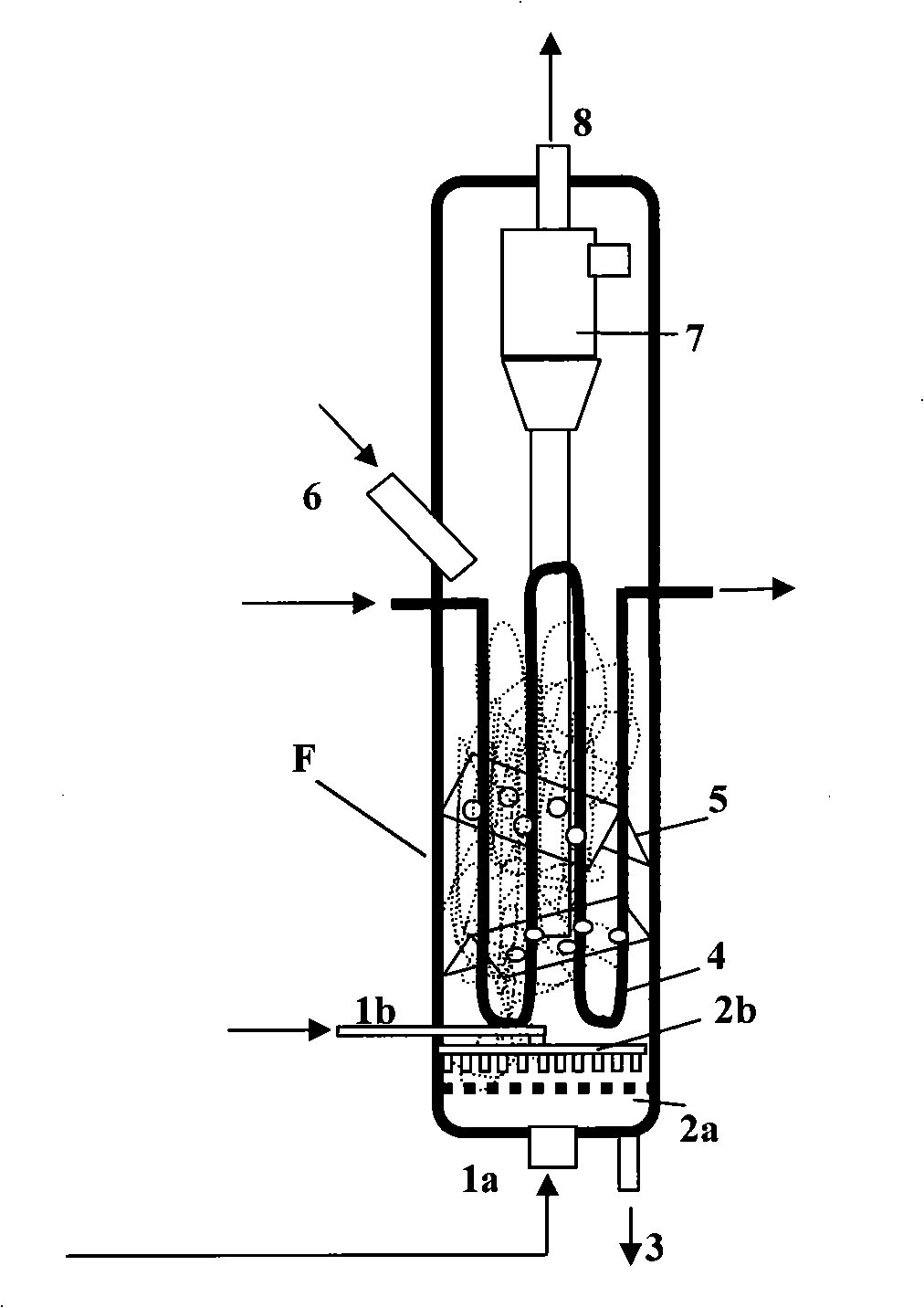

[0047] figure 2 A schematic diagram of a fluidized bed in the form of a plate distributor and a tube distributor. A plate gas distributor 2a is arranged at the bottom of the fluidized bed F, and a tube distributor 2b is arranged above it to be connected with the tube wall of the fluidized bed F; a gas inlet 1a and a catalyst outlet 3 are arranged on the tube wall at the bottom of the fluidized bed F, and A catalyst inlet 6 is set on the upper tube wall of the fluidized bed; a heat exchange tube 4, a member 5 and a cyclone separator 7 are set in the fluidized bed F; a gas outlet 8 is set on the tube wall at the top of the fluidized bed F and connected with the cyclone separator 7 connected.

[0048] The active components of the catalyst are 8wt% mercuric chloride, 5wt% zinc chloride and 0.1wt% barium chloride, and the rest is carrier activated carbon. The catalyst is made by ball milling method, with a particle size of 0.05mm and a specific surface area of 1000m 2 / g, the ...

Embodiment 3

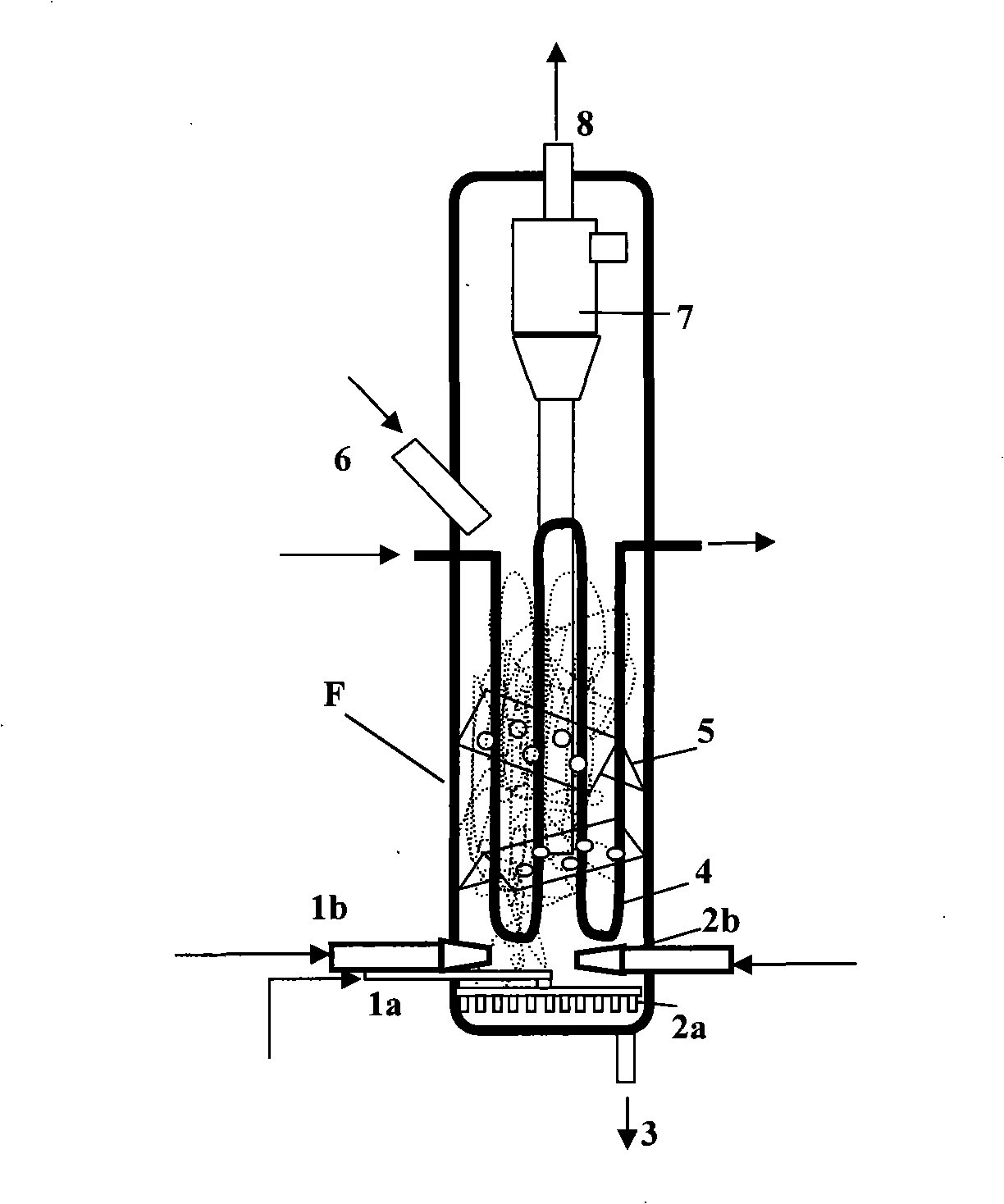

[0054] image 3 It is a schematic diagram of a fluidized bed in the form of a tube distributor and a set of gas (liquid) nozzles. A tubular gas distributor 2a is arranged at the bottom of the fluidized bed F, and 20 gas (liquid) nozzles 2b are arranged above it to be connected with the tube wall of the fluidized bed F; a gas inlet 1a and a gas inlet 1a are arranged on the tube wall at the bottom of the fluidized bed F Catalyst outlet 3, catalyst inlet 6 is set on the upper tube wall of the fluidized bed; heat exchange tube 4, component 5 and cyclone separator 7 are set in the fluidized bed F; gas outlet 8 is set on the tube wall at the top of the fluidized bed F And be connected with cyclone separator 7.

[0055] The active components of the catalyst are 14wt% mercuric chloride and 0.1wt% manganese chloride, and the rest is the carrier silica-alumina molecular sieve. The catalyst is made by ball milling method, the particle size is 0.3mm, and the specific surface area is 200m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com