Patents

Literature

285 results about "Feed temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feed temperature. Feed temperature is one of the major factors in influencing the overall heat balance of a distillation column system. Increased feed enthalpy can help reduce the required energy input from the reboiler at the same degree of separation.

Methods for deoxygenating biomass-derived pyrolysis oil

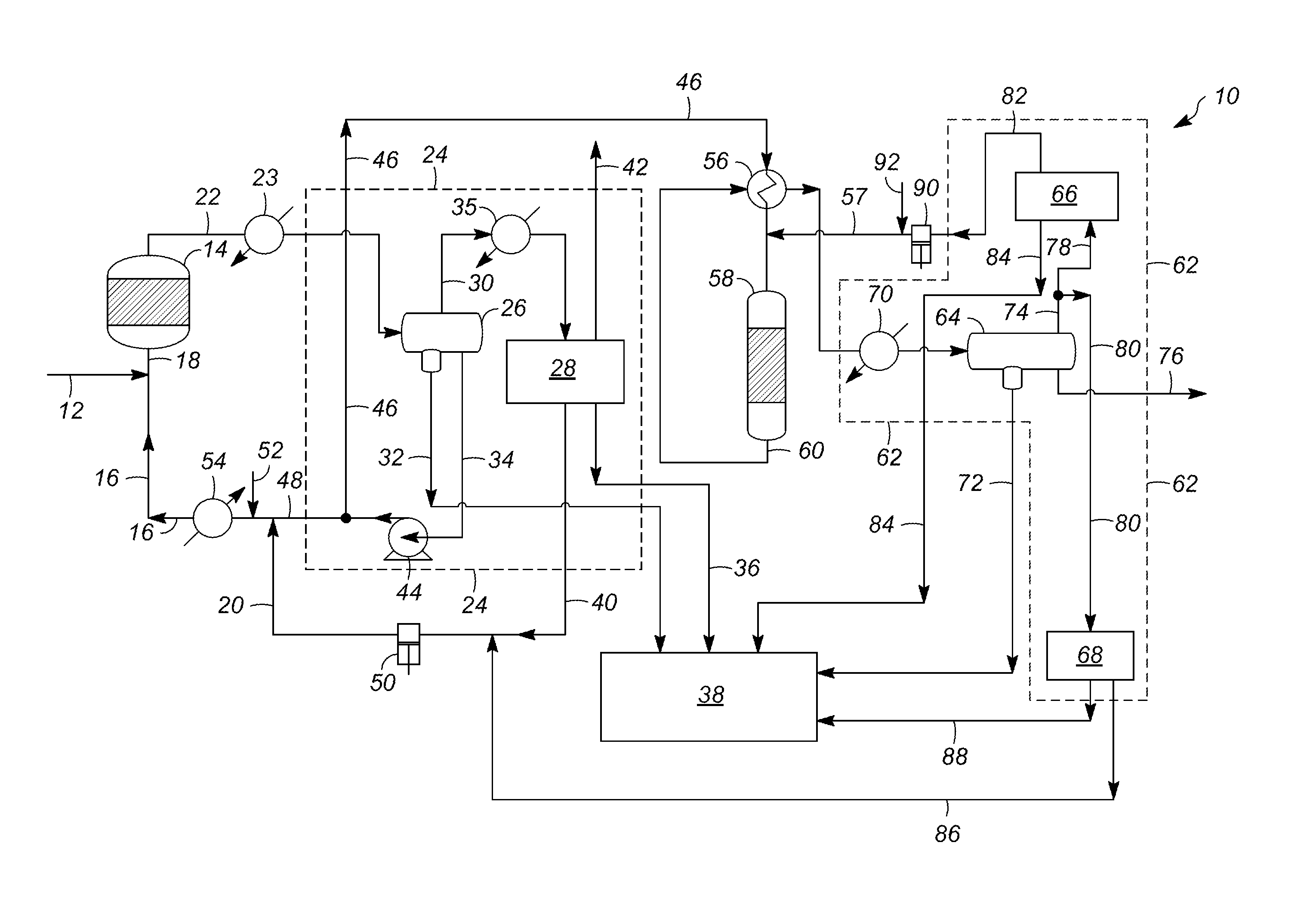

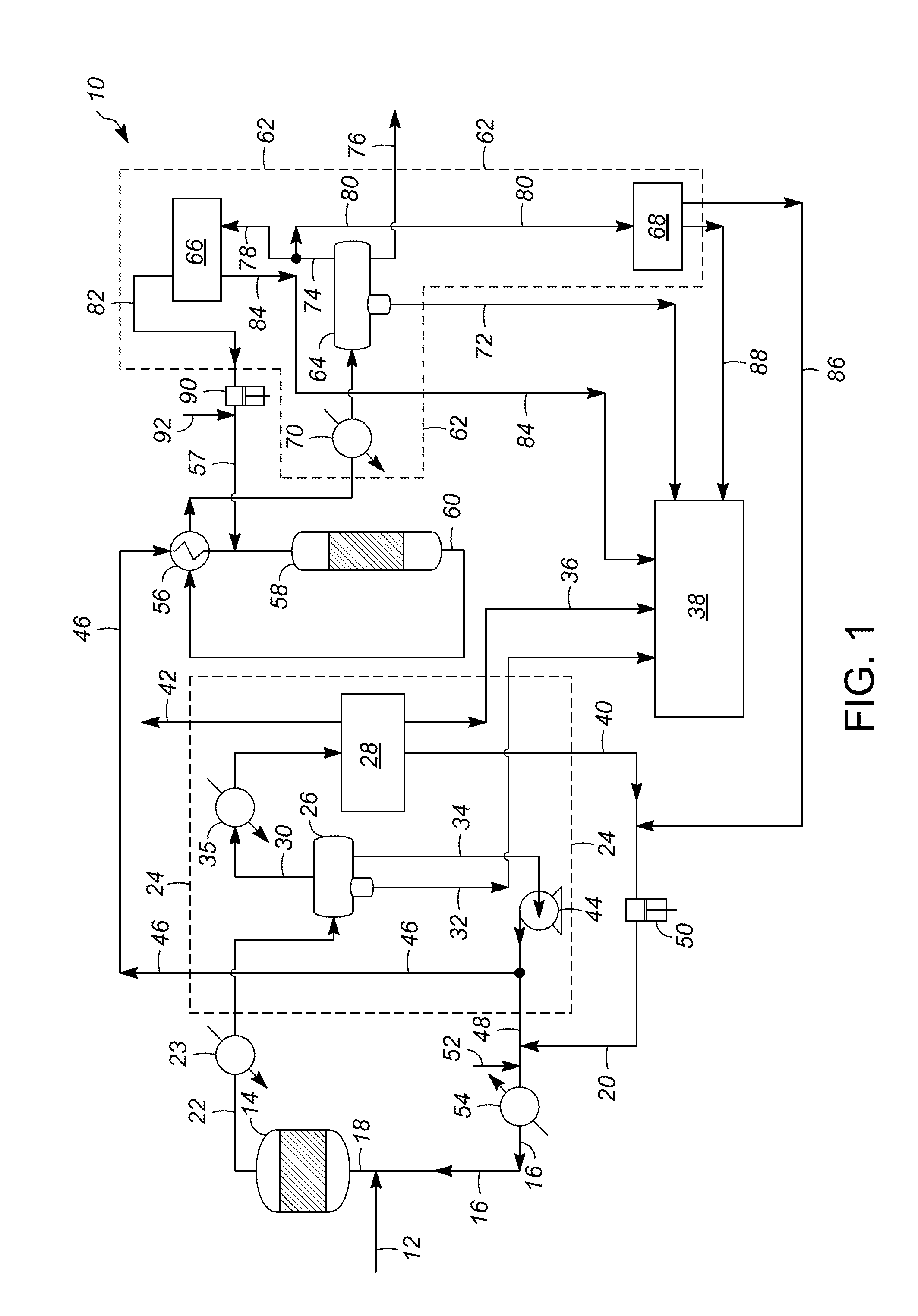

Methods for deoxygenating a biomass-derived pyrolysis oil are provided. In an embodiment, a method for deoxygenating a biomass-derived pyrolysis oil comprises the steps of combining a biomass-derived pyrolysis oil stream with a heated low-oxygen-pyoil diluent recycle stream to form a heated diluted pyoil feed stream. The heated diluted pyoil feed stream has a feed temperature of about 150° C. or greater. The heated diluted pyoil feed stream is contacted with a first deoxygenating catalyst in the presence of hydrogen at first hydroprocessing conditions effective to form a low-oxygen biomass-derived pyrolysis oil effluent.

Owner:UOP LLC

Hydrogen enrichment scheme for autothermal reforming

Recycling a portion of autothermal reformer effluent into the steam-hydrocarbon feed stream with a thermo-compressor ejector is disclosed, using the preheated feed mixture as motive fluid. Syngas recycle-motive fluid molar ratios are 0.2-1.0, selected to optimize the overall configuration. The recycle introduces hydrogen and steam into the feed, and elevates the feed temperature, for operating the reformer in a soot-free regime. There is some pressure drop between the raw feed steam-natural gas mixture and the reformer feed, which requires the raw feed mixture to be supplied at a higher pressure, but this is offset by the lower pressure drop in the process heater and other upstream and downstream equipment due to lower quantities of steam. The feed pre-heater can have a lower duty, and the upstream and downstream equipment can be reduced in size, while the size of the autothermal reformer is about the same compared to the size needed for operation without effluent recycle.

Owner:KELLOGG BROWN & ROOT INC

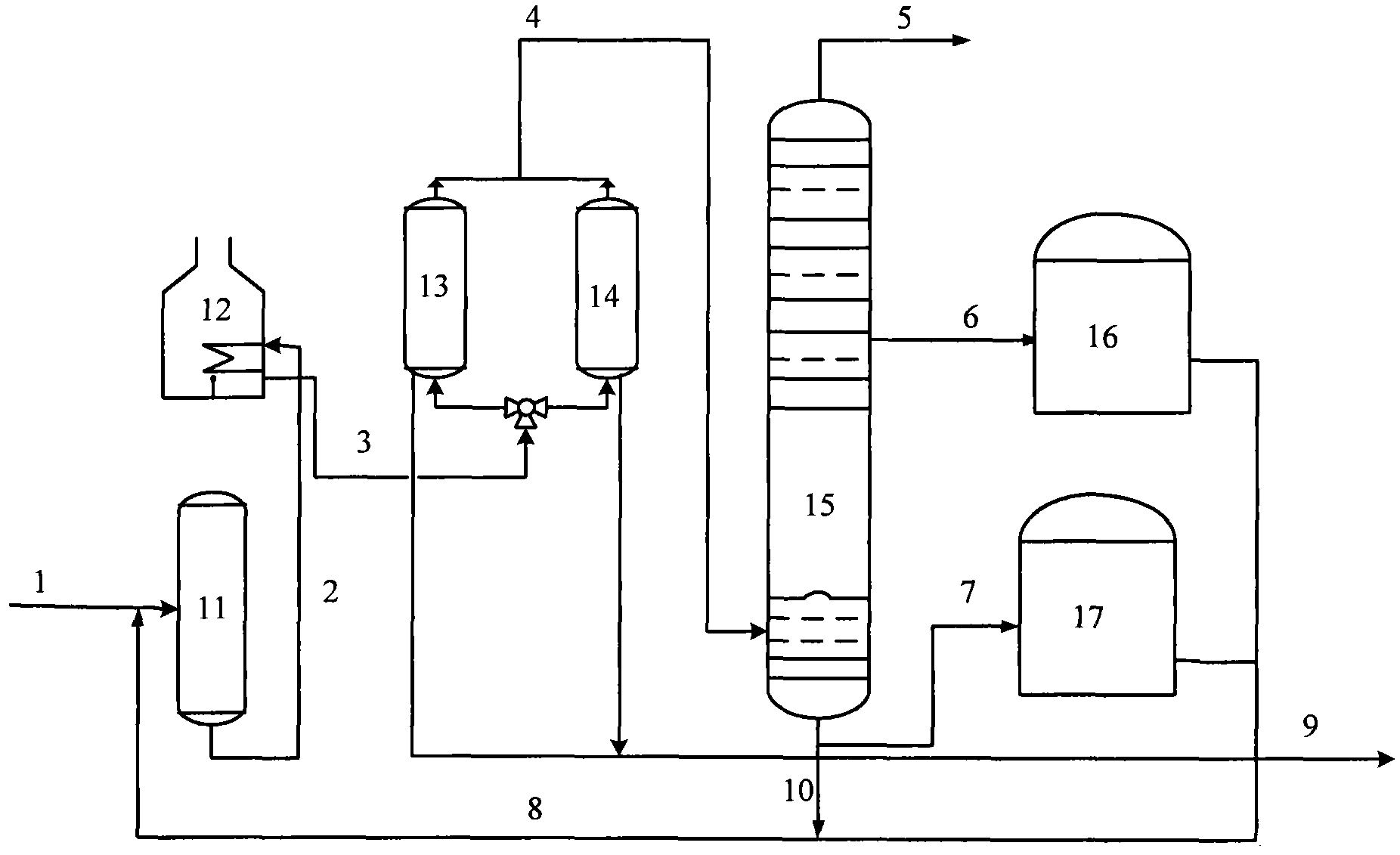

Production method of homogeneous petroleum needle coke

ActiveCN103184057AImproved Anti-wear IndexSolve for uniformityTreatment with plural serial stages onlyCoking carbonaceous materialsHeating furnaceTower

The invention relates to a production method of a homogeneous petroleum needle coke. The method comprises the steps of: (1) heating the raw material for needle coke production to a relatively low temperature of 400-480DEG C by a heating furnace, then leading the raw material into a coking tower to make the coking raw material form flowable intermediate phase liquid crystals; (2) when the low temperature fresh raw material charging stage is completed, gradually raising the temperature of a heating furnace outlet, and at the same time, charging the coking heating furnace with a fresh raw material and heavy distillate oil from a fractionating tower; and (3) when the materials in the coking tower reach a curing coking temperature, charging the coking heating furnace with the coking intermediate distillate oil generated in step (1), and simultaneously raising the coking heating furnace feed temperature to make the internal temperature of the coking tower reach 460-510DEG C, thus finishing high temperature curing of petroleum coke. The method provided in the invention can make the properties of needle coke at different parts inside the coking tower more uniform.

Owner:CHINA PETROLEUM & CHEM CORP +1

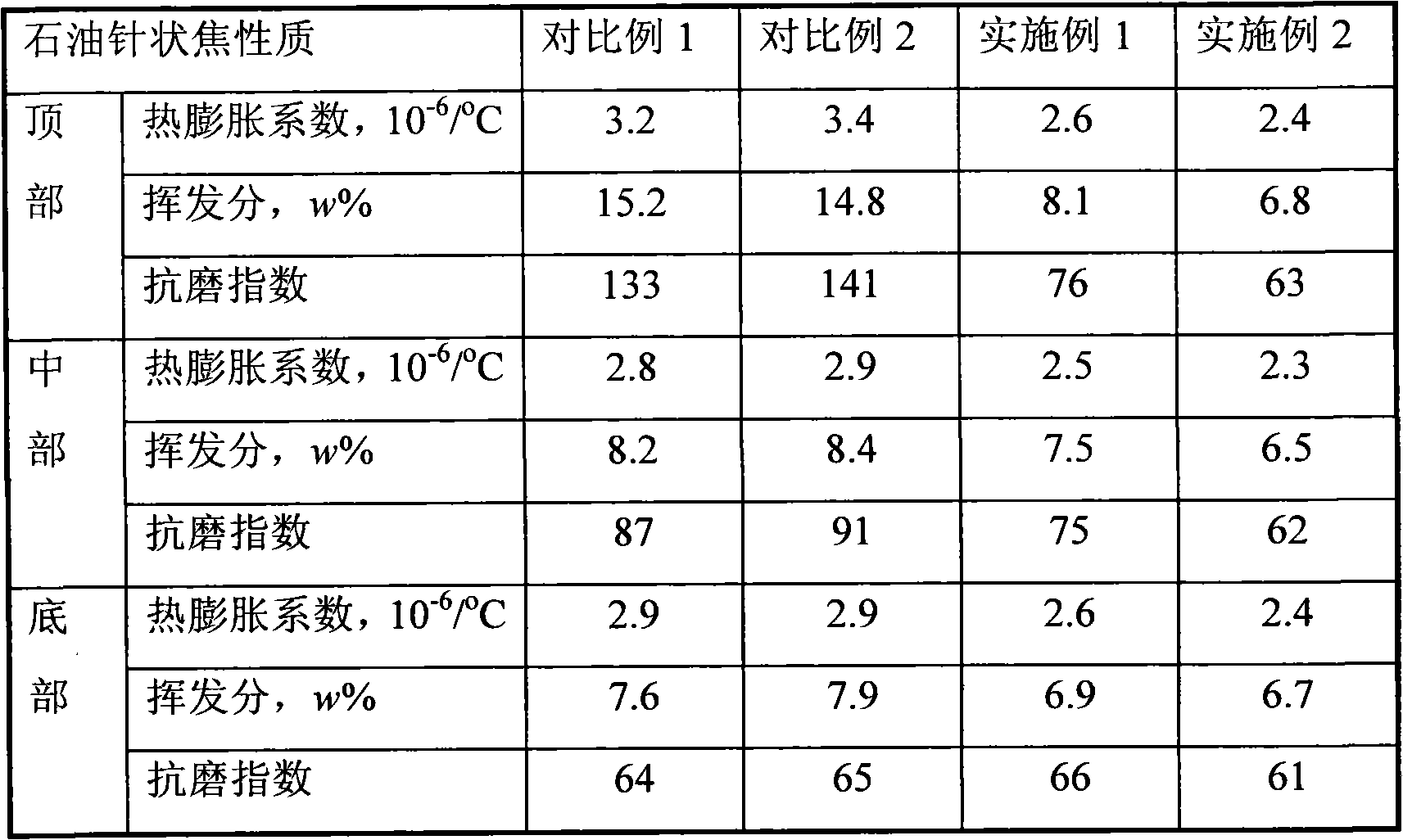

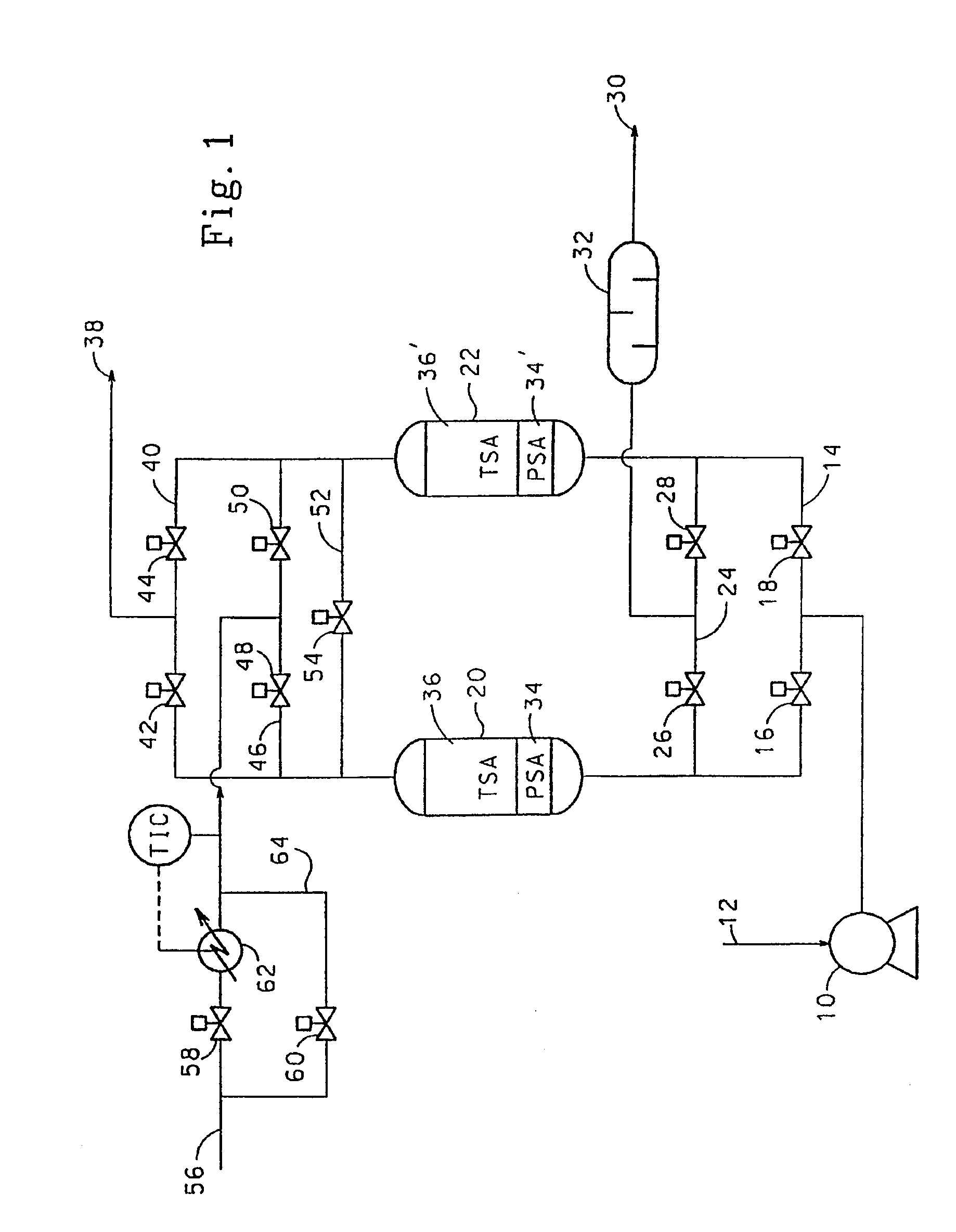

Purification of air

ActiveUS8734571B2Large capacitySmall sizeNitrous oxide captureGas treatmentFeed temperatureChemistry

Reduction of water, CO2 and N2O in an air stream comprising: passing said air stream at a feed temperature through a first adsorbent, whose Henry's Law selectivity for CO2 / N2O is at least 12.5, and a second adsorbent, whose Henry's Law constant for CO2 is less than 1020 mmol / g / atom and whose Henry's Law selectivity for CO2 / N2O is at most 5; and passing a heated regenerating gas at a temperature which is between 20° C. and 80° C. to at least the second adsorbent, and passing a second regenerating gas at a temperature less than the temperature of the heated regenerating gas to the first and second adsorbents in a direction opposite to the feed direction; the second adsorbent occupying from 25% to 40% of the total volume of the adsorbents, and the temperature of the heated regenerating gas being 10° C. to 60° C. higher than the feed temperature.

Owner:AIR PROD & CHEM INC

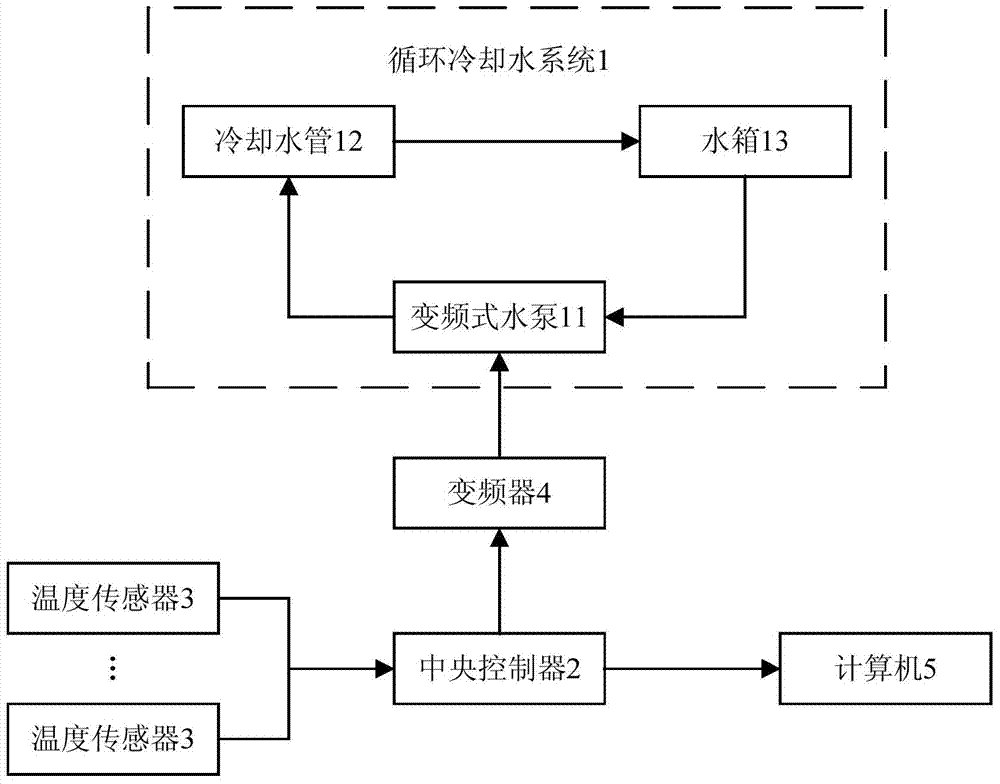

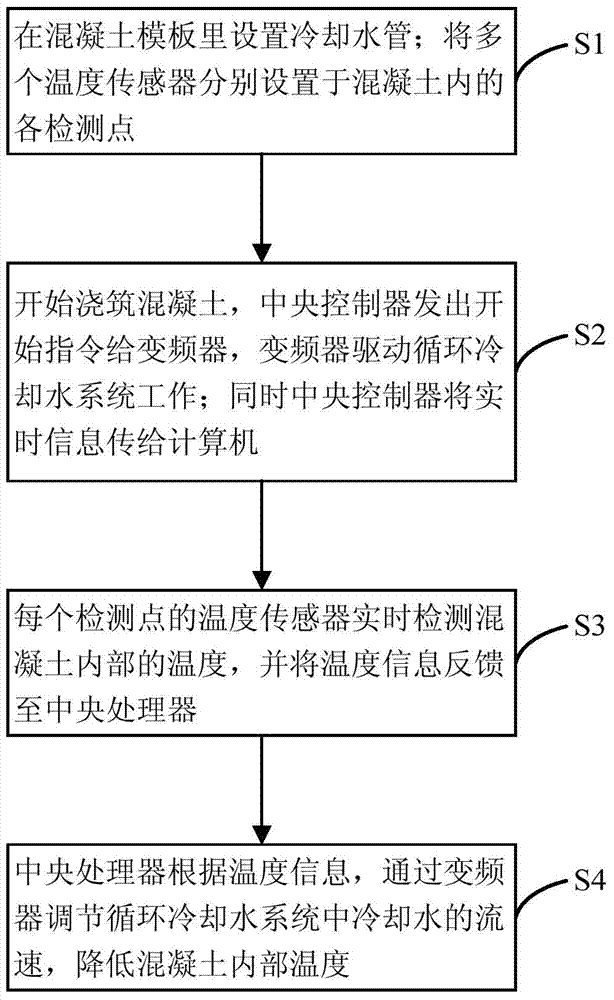

System and method for measuring and controlling hydration heat in mass concrete

InactiveCN103485542AImprove certaintyReduce labor intensityBuilding material handlingFrequency changerTime information

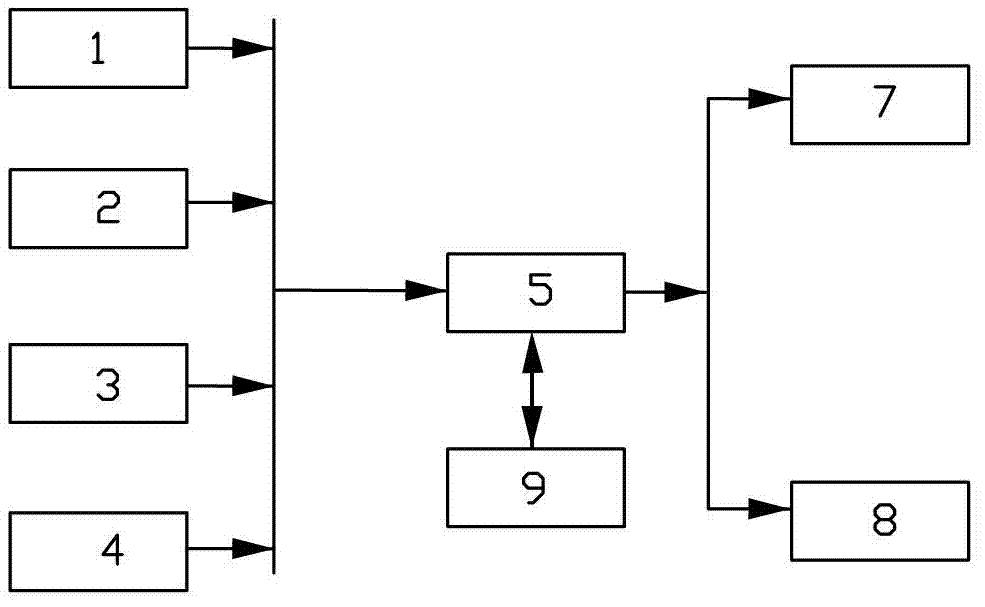

The invention relates to a system and a method for measuring and controlling hydration heat in mass concrete and relates to the field of automatic control systems for civil engineering construction. The system comprises a circulating cooling water system, a central control unit, a frequency converter, a plurality of temperature sensors and a computer. The central control unit is connected with the frequency converter, the computer and the temperature sensors. The frequency converter is further connected with the circulating cooling water system. The temperature sensors are disposed inside concrete and feed temperature information back to the central control unit. The central control unit sends a control command to the frequency converter according to the temperature information. The frequency converter drives the circulating cooling water system to change flow of circulating cooling water, and meanwhile, the central control unit transmits real-time information to the computer. The system and the method have the advantages that manual work is omitted, temperature changes inside concrete can be measured in real time, and work efficiency is improved; flow quantity of cooling water is automatically adjusted, so that implementation controllability is ensured; storage and subsequent analysis of data can be facilitated.

Owner:CHINA MAJOR BRIDGE ENG

Method for controlling amine solvent regeneration system

InactiveCN101642629ARealize automatic controlReduce investmentAmino compound purification/separationDispersed particle separationControl systemReboiler

The invention provides a method for controlling an amine solvent regeneration system, belongs to the technical field of amine solvent recovery, and comprises an amine recovery tower. The method is characterized in that a heat supply regulating valve of a tower bottom reboiler is related to system pressure; and a distilled line regulating valve of a tower top product is related to the gas-phase temperature of the tower top. The method can meet the requirement on purification degree of an amine solvent product on the tower bottom only by presetting a system pressure value and a tower top gas-phase temperature vale; and the control system can trace variations of feeding flow rate, feeding quality and feeding temperature to realize automatic regulation and obtain perfect tower bottom products.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

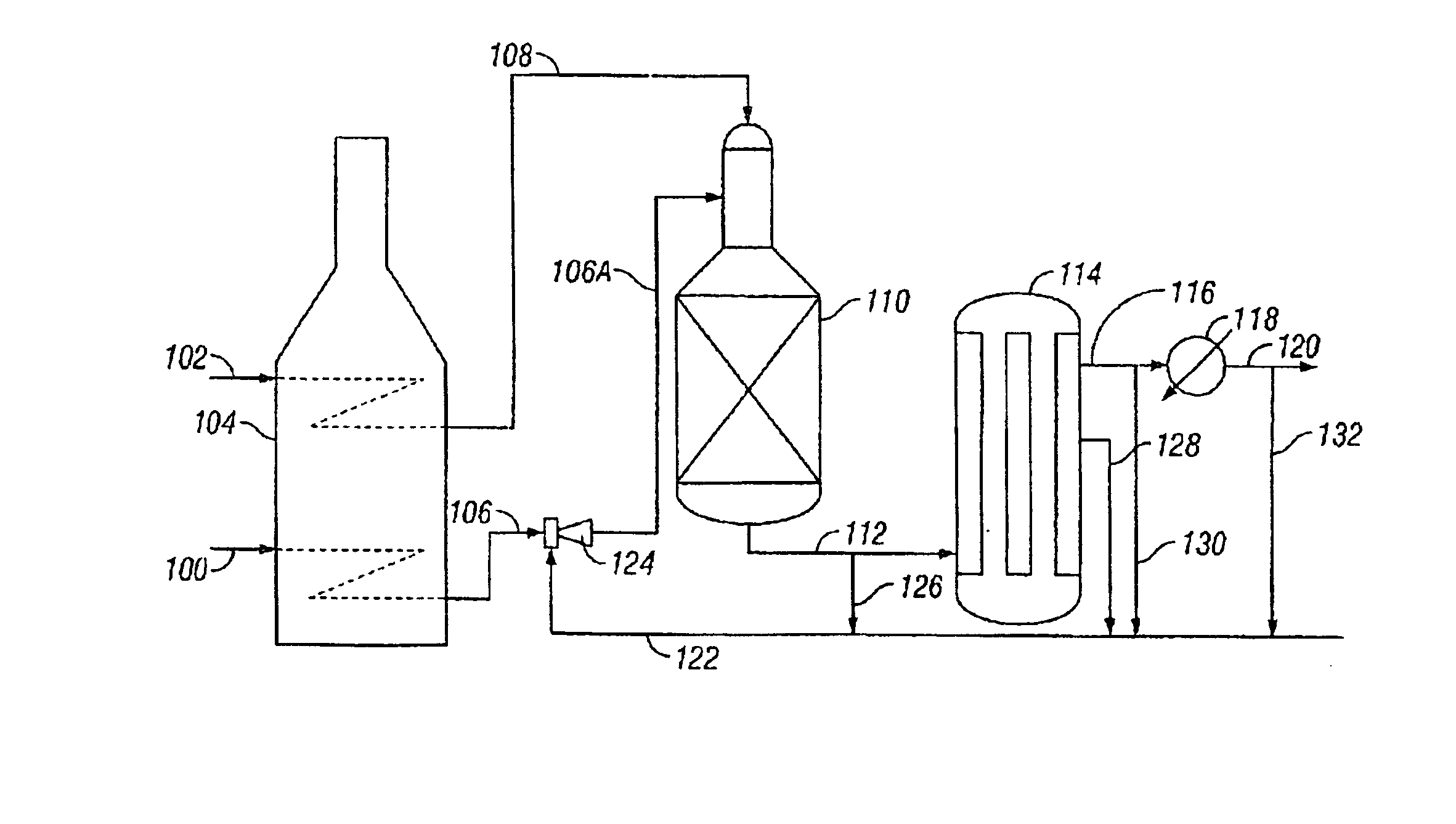

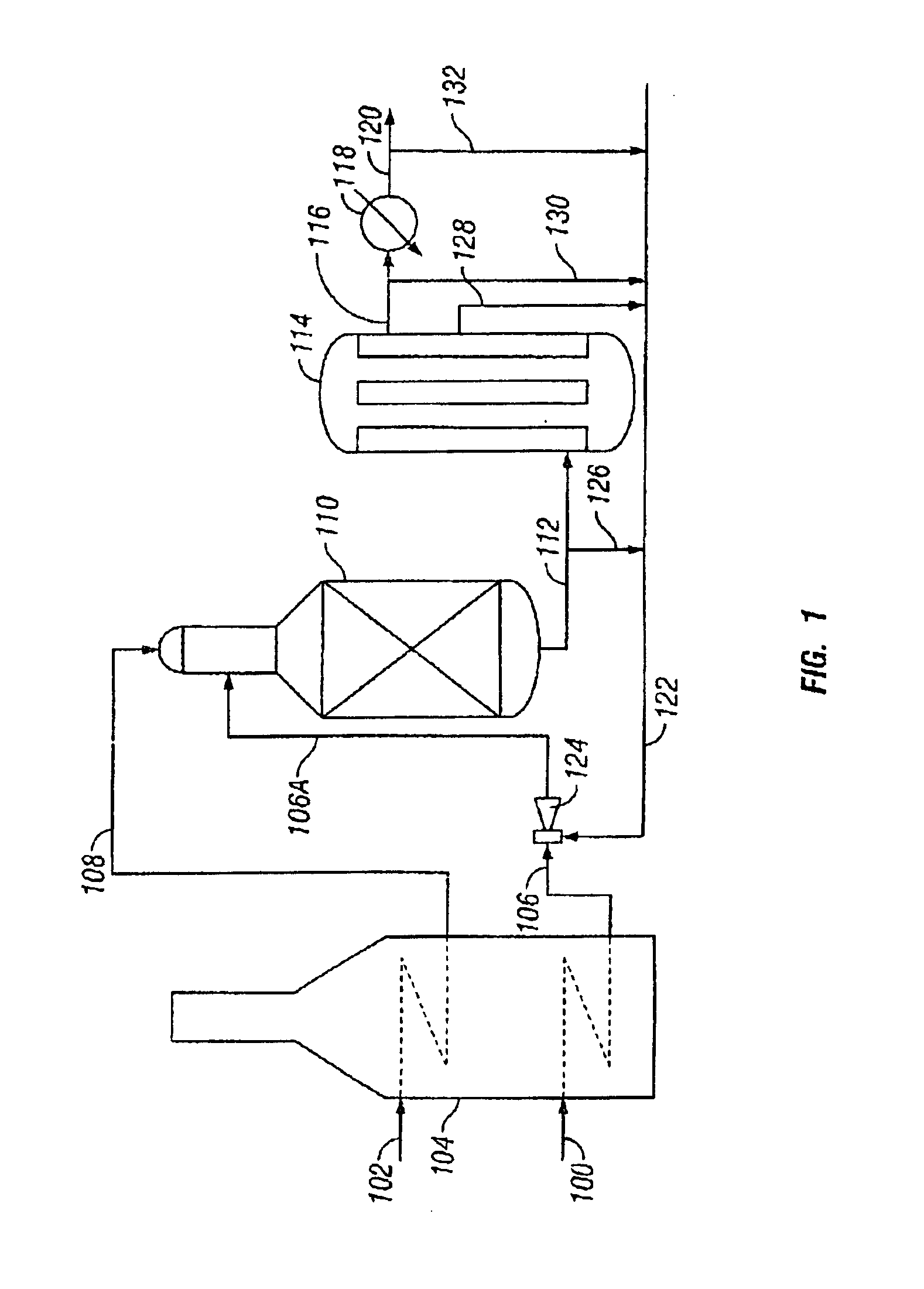

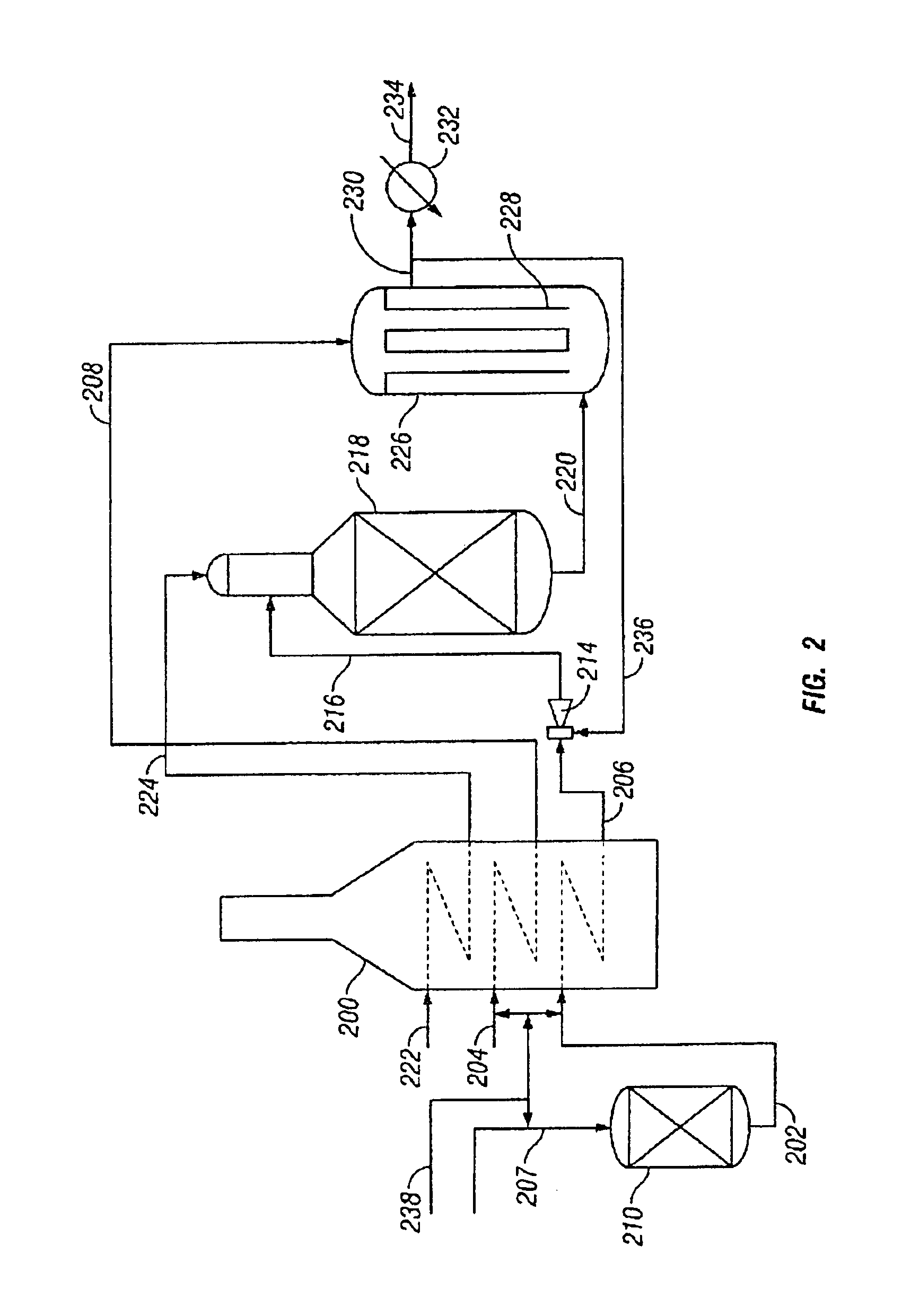

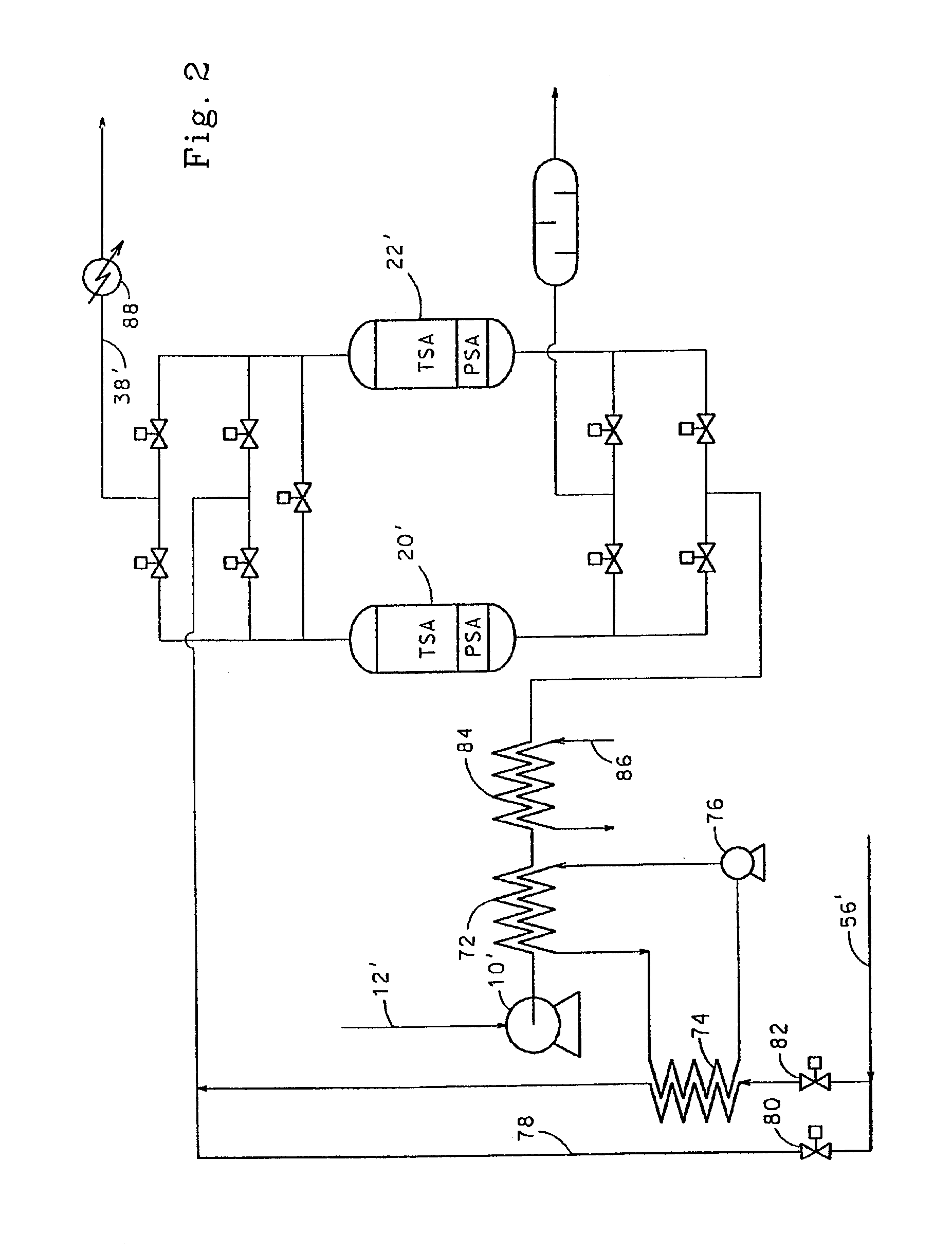

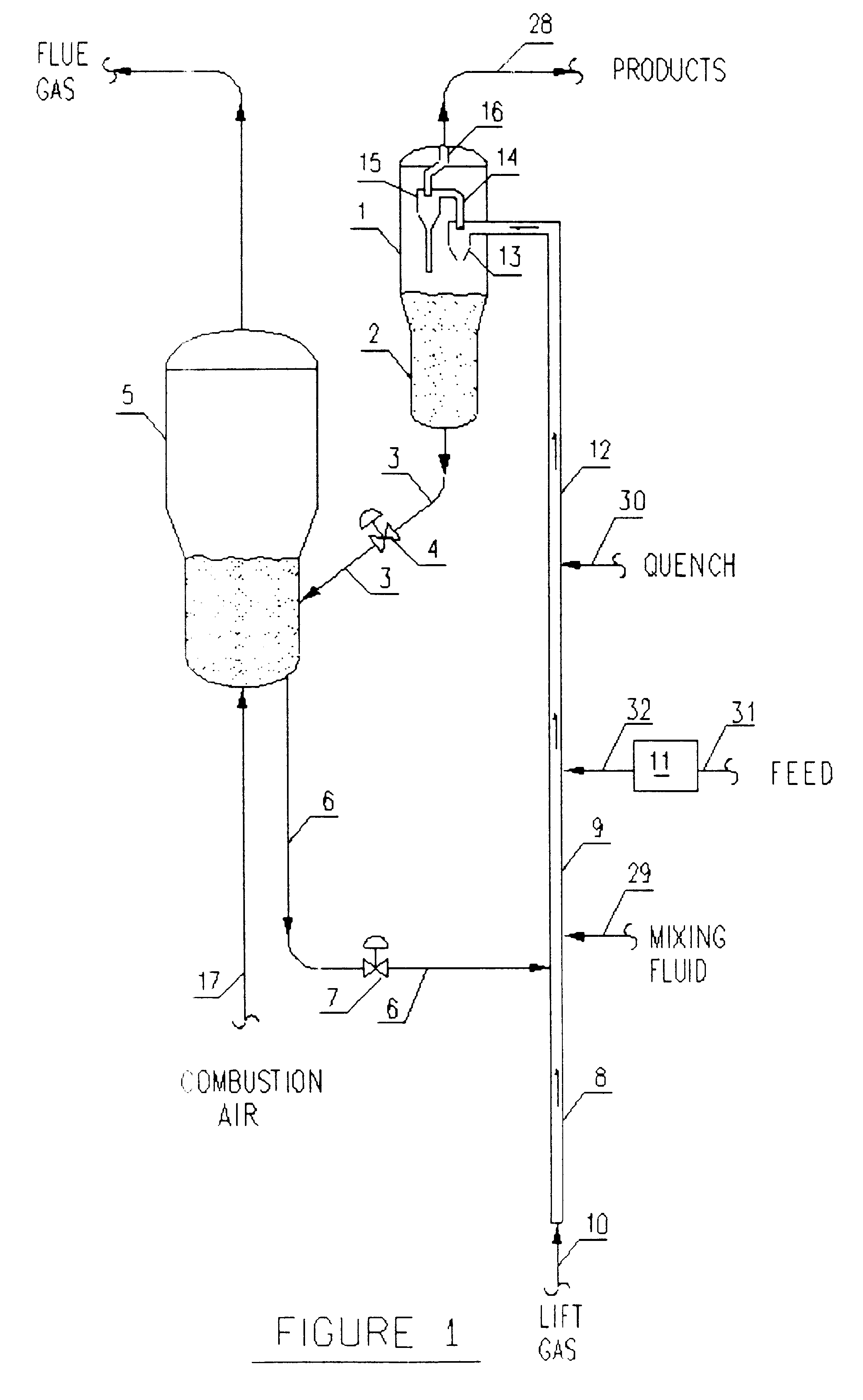

Hydrogen enrichment scheme for autothermal reforming

InactiveUS20040057898A1Convenient introductionMolar ratio can not be raisedHydrogenCatalytic crackingSyngasProcess engineering

Recycling a portion of autothermal reformer effluent into the steam-hydrocarbon feed stream with a thermo-compressor ejector is disclosed, using the preheated feed mixture as motive fluid. Syngas recycle-motive fluid molar ratios are 0.2-1.0, selected to optimize the overall configuration. The recycle introduces hydrogen and steam into the feed, and elevates the feed temperature, for operating the reformer in a soot-free regime. There is some pressure drop between the raw feed steam-natural gas mixture and the reformer feed, which requires the raw feed mixture to be supplied at a higher pressure, but this is offset by the lower pressure drop in the process heater and other upstream and downstream equipment due to lower quantities of steam. The feed pre-heater can have a lower duty, and the upstream and downstream equipment can be reduced in size, while the size of the autothermal reformer is about the same compared to the size needed for operation without effluent recycle.

Owner:KELLOGG BROWN & ROOT INC

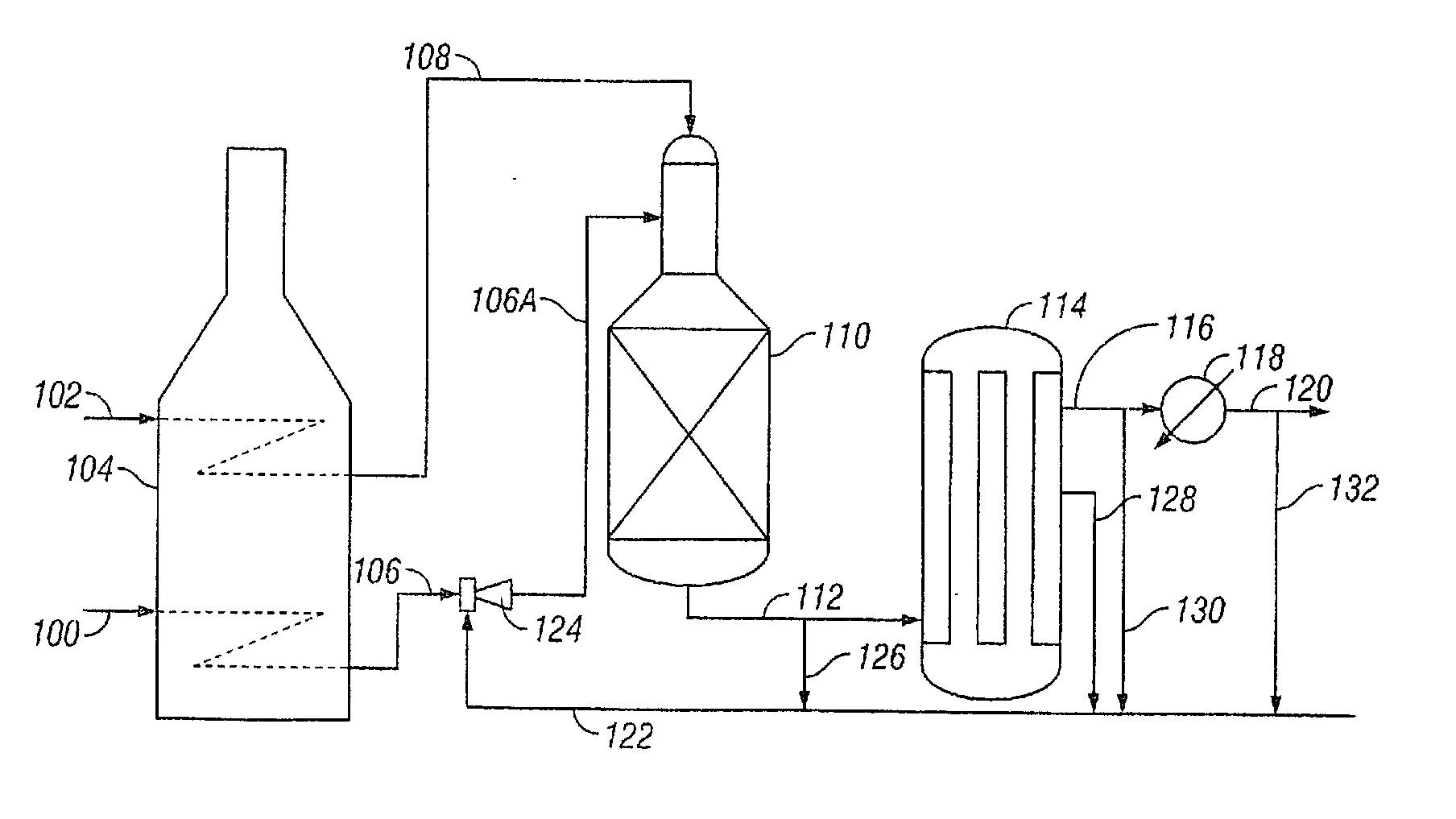

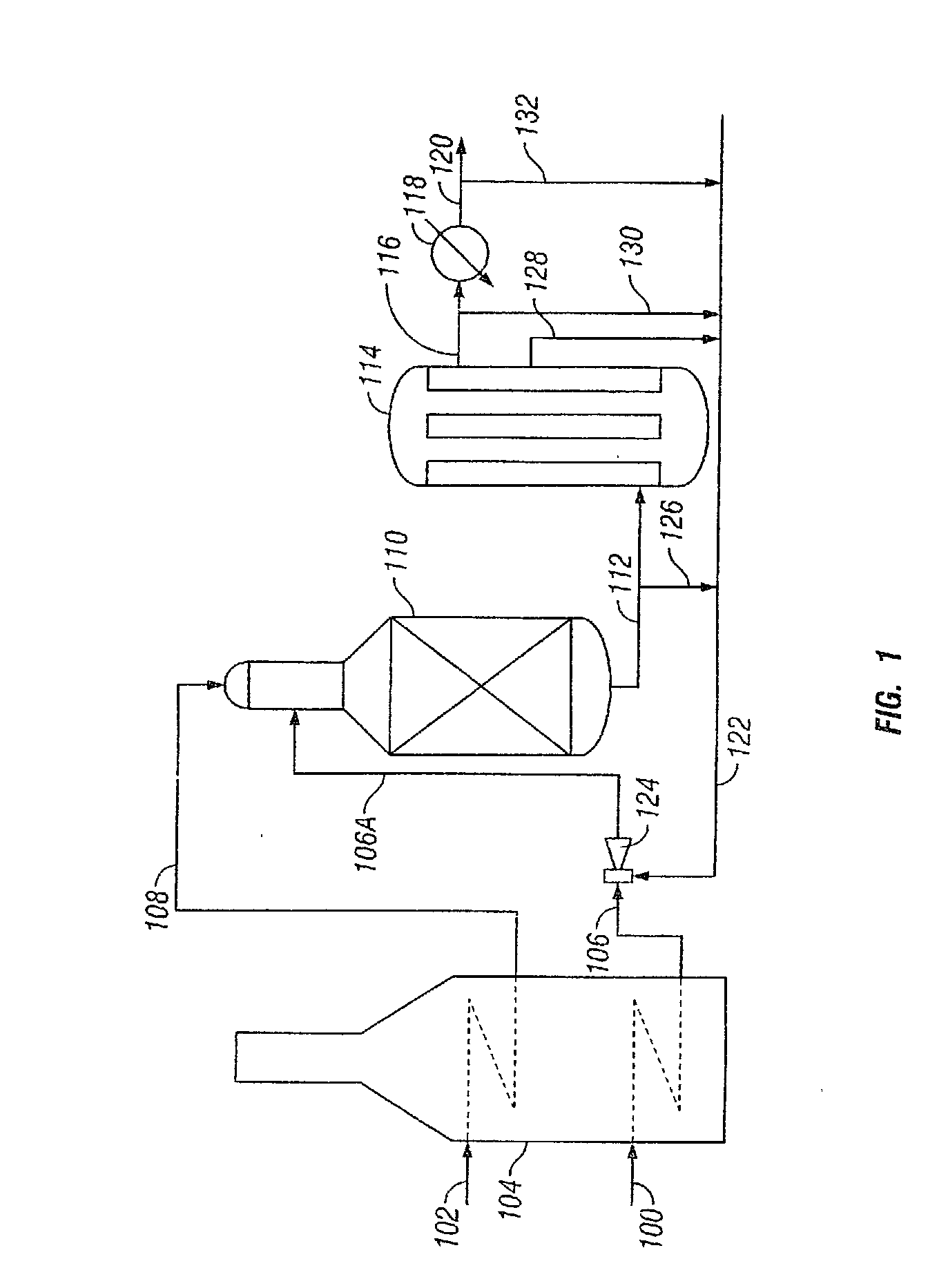

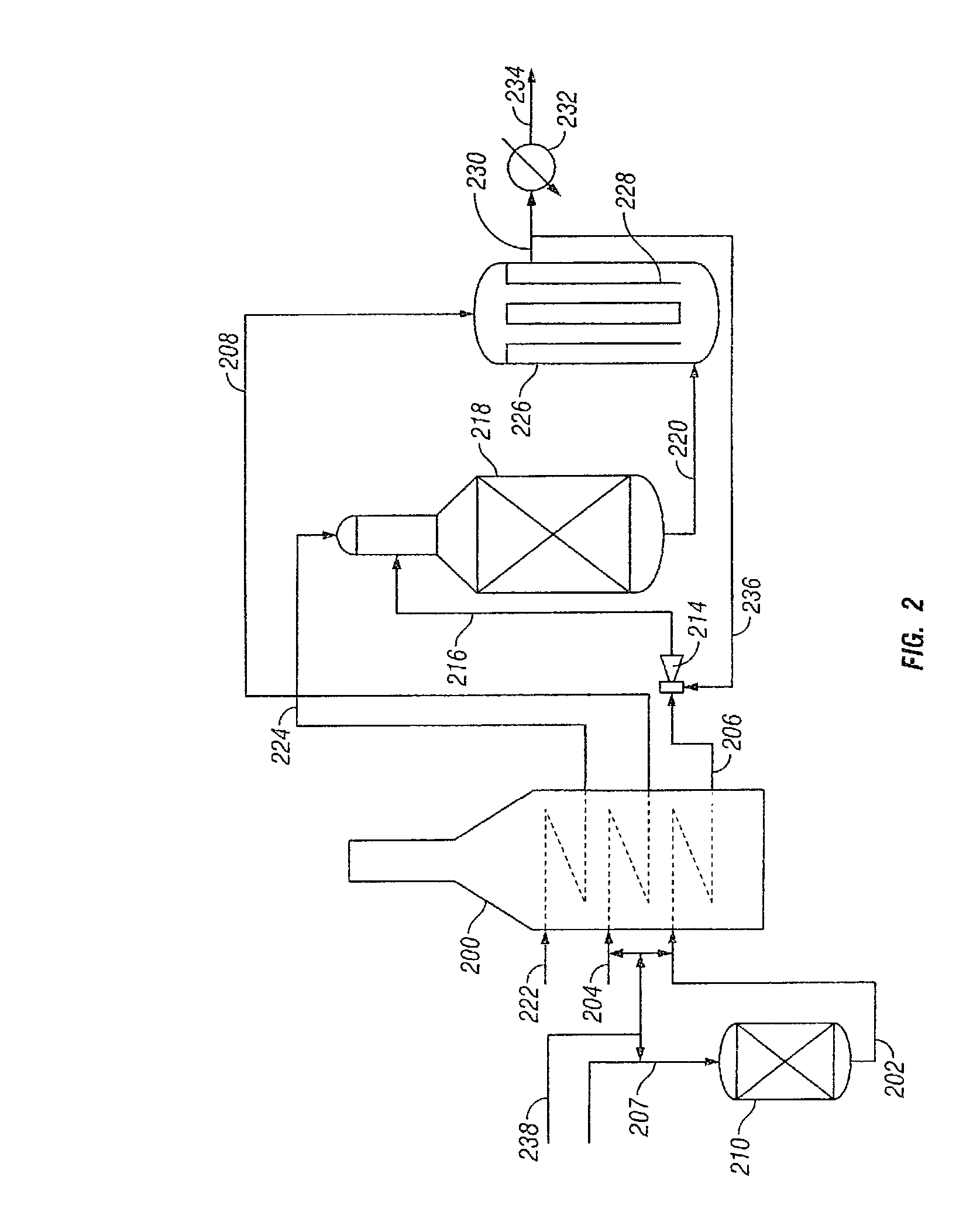

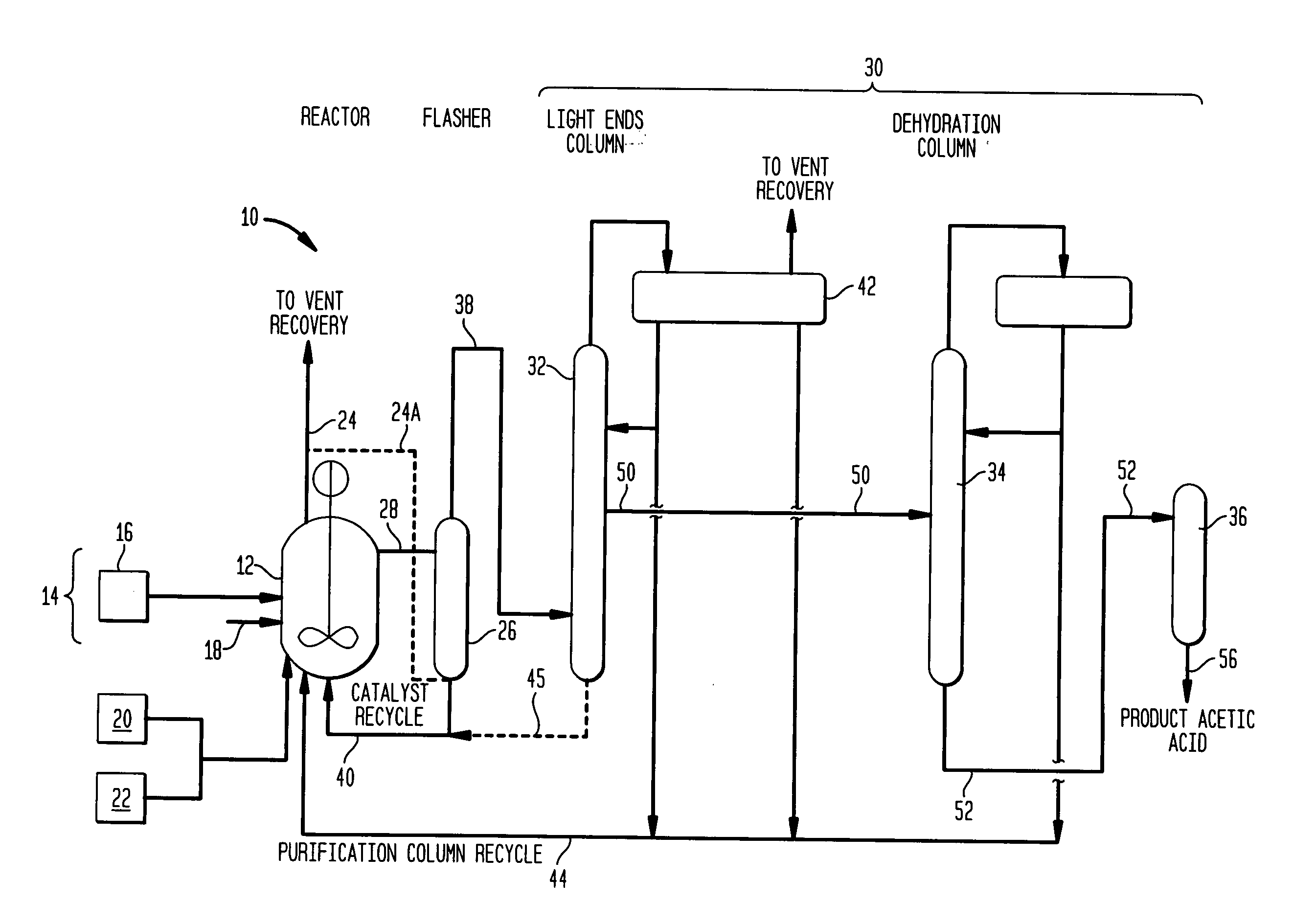

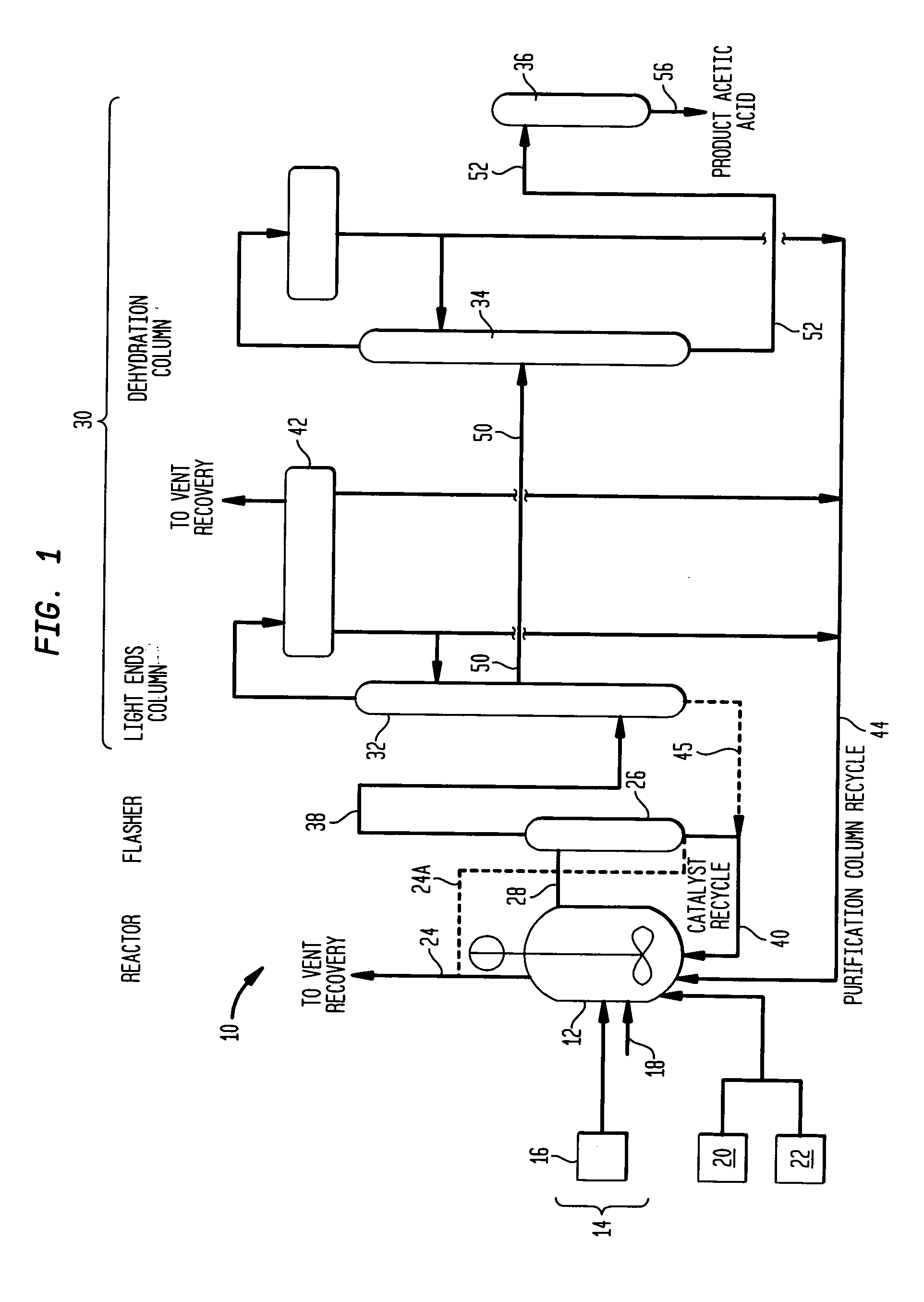

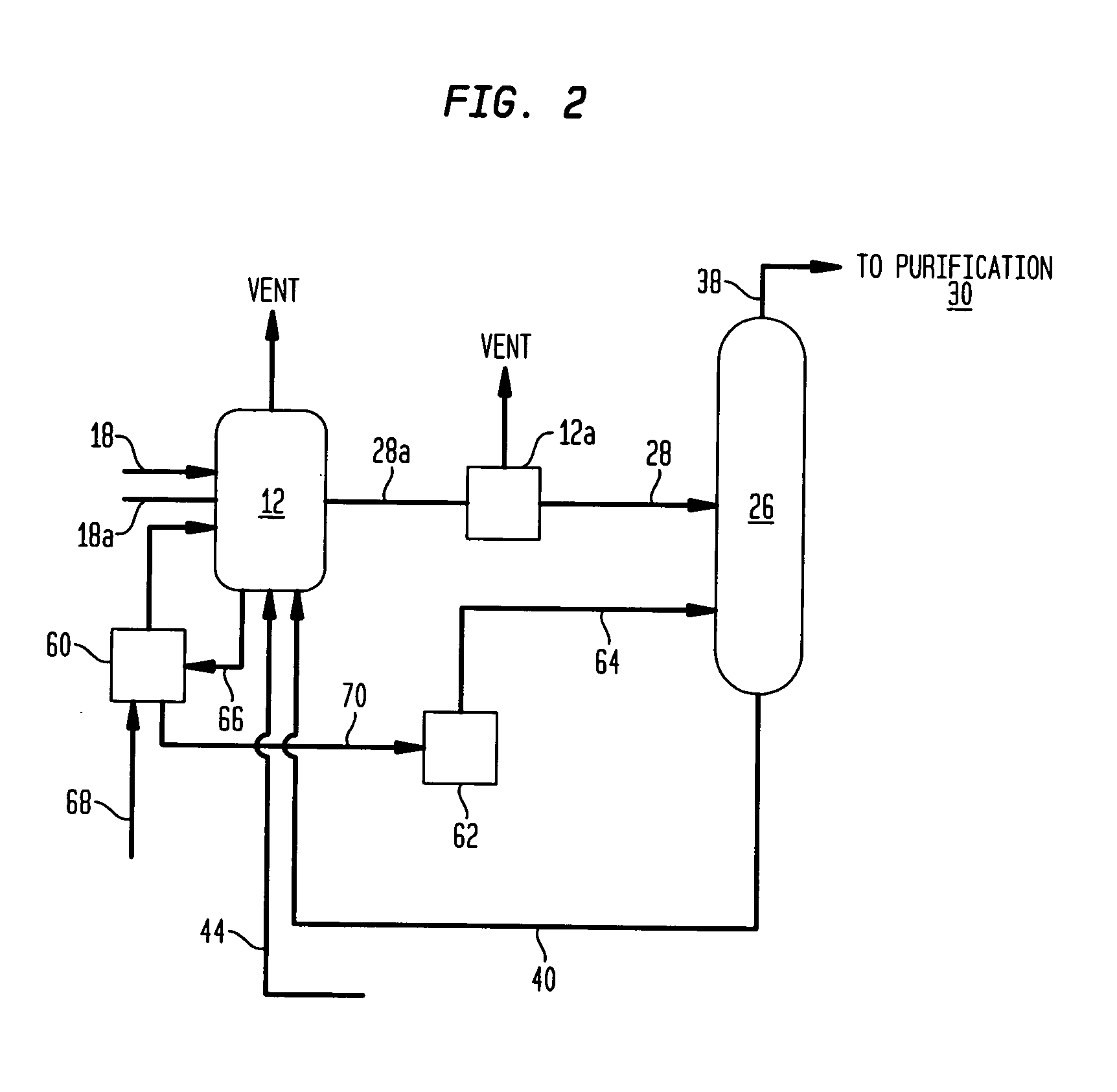

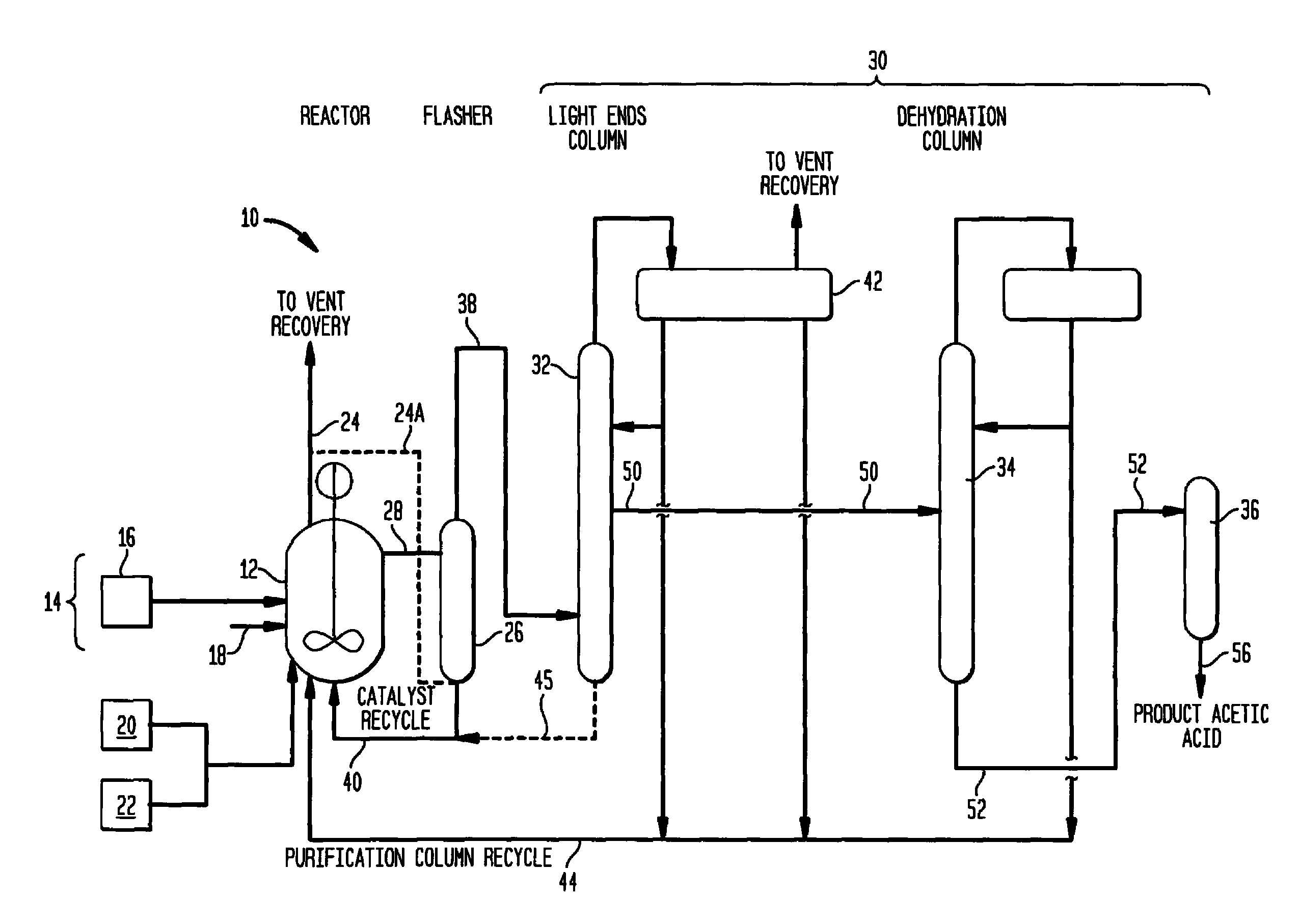

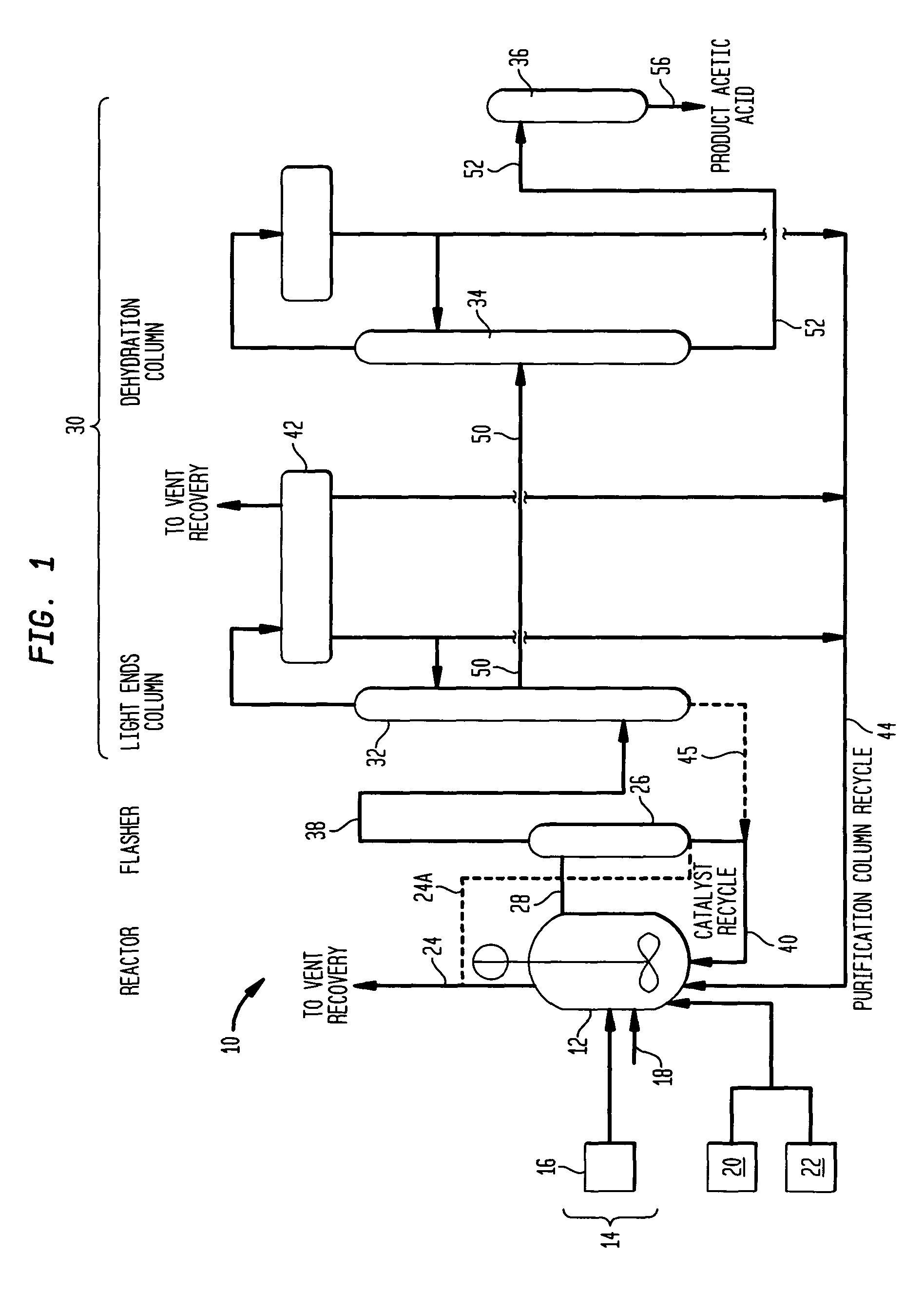

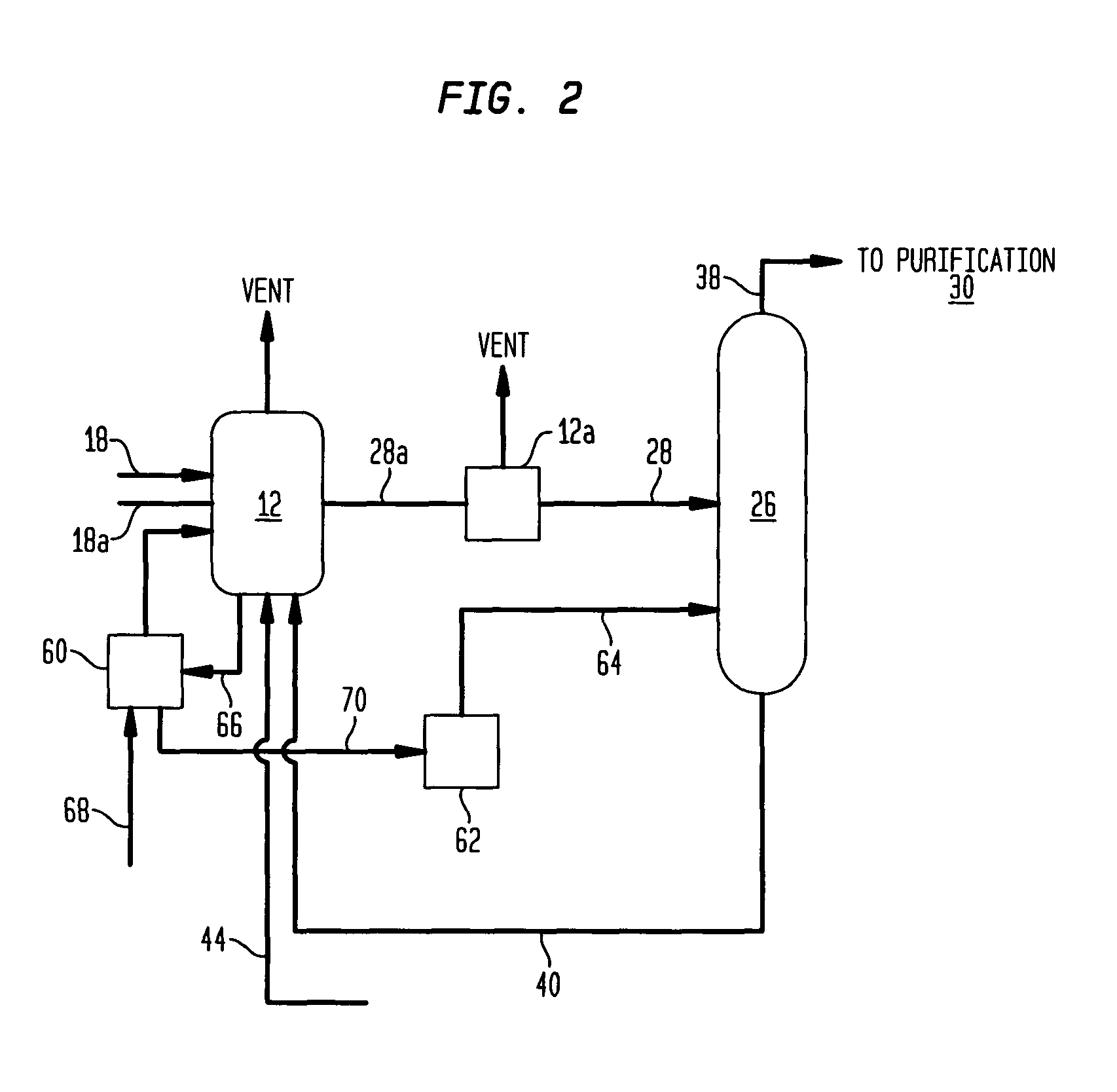

Method and apparatus for carbonylating methanol with acetic acid enriched flash stream

ActiveUS20090270650A1Improve concentrationShorten the purification processOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMetal catalystMethyl acetate

A carbonylation process for producing acetic acid including: (a) carbonylating methanol or its reactive derivatives in the presence of a Group VIII metal catalyst and methyl iodide promoter to produce a liquid reaction mixture including acetic acid, water, methyl acetate and methyl iodide; (b) feeding the liquid reaction mixture at a feed temperature to a flash vessel which is maintained at a reduced pressure; (c) heating the flash vessel while concurrently flashing the reaction mixture to produce a crude product vapor stream, wherein the reaction mixture is selected and the flow rate of the reaction mixture fed to the flash vessel as well as the amount of heat supplied to the flash vessel is controlled such that the temperature of the crude product vapor stream is maintained at a temperature less than 90° F. cooler than the feed temperature of the liquid reaction mixture to the flasher and the concentration of acetic acid in the crude product vapor stream is greater than 70% by weight of the crude product vapor stream.

Owner:CELANESE INT CORP

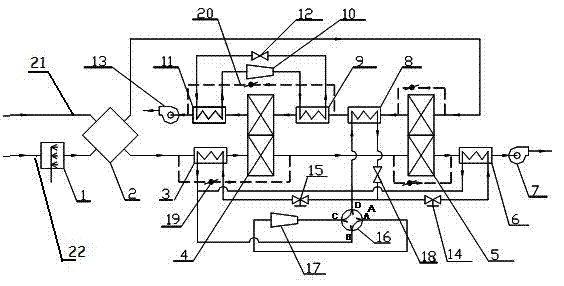

Multi-stage heat recovery compound dehumidification fresh air air handler

InactiveCN102261701ALow regeneration temperatureReduce heating energy consumptionEnergy recovery in ventilation and heatingLighting and heating apparatusEvaporative coolerMoisture

The invention discloses a multilevel heat recovery composite dehumidifying fresh air treatment machine, which comprises an air treatment path consisting of a plate heat exchanger, a precooling dehumidifier, a drying rotary wheel, a moisture heat recovery rotary wheel, an air feed temperature regulator and an air feed fan which are connected in series in turn through an air pipe, and an air regeneration path consisting of an evaporative cooler, a plate heat exchanger, a moisture heat recovery rotary wheel, a low-temperature heat pump heat recovery device, a high-temperature heat pump condenser, a drying rotary wheel, a high-temperature heat pump evaporator and a regenerating fan which are connected in series in turn. Due to multilevel heat recovery, heating energy consumption of regenerating air and cooling energy consumption of treating air are reduced, and the aim of saving energy is fulfilled. Meanwhile, due to two-stage combined dehumidification, the dehumidifying capacity of the set can be effectively improved, and the air treatment machine is applicable to air conditioning in summer and heating in winter for various public buildings, commercial buildings and industrial buildings, and is suitable for fresh air treatment for a large central air-conditioning system and particularly suitable for fresh air treatment for an independent temperature and humidity control air-conditioning system in a warm and humid area.

Owner:HUNAN UNIV OF SCI & TECH

Method and apparatus for carbonylating methanol with acetic acid enriched flash stream

ActiveUS7820855B2Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMetal catalystMethyl acetate

Owner:CELANESE INT CORP

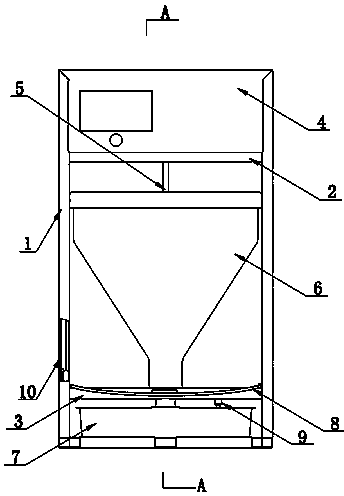

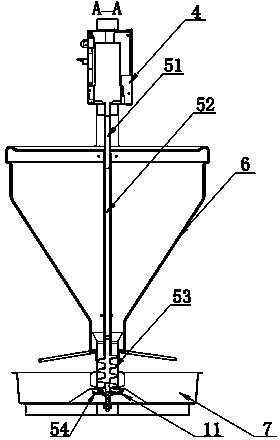

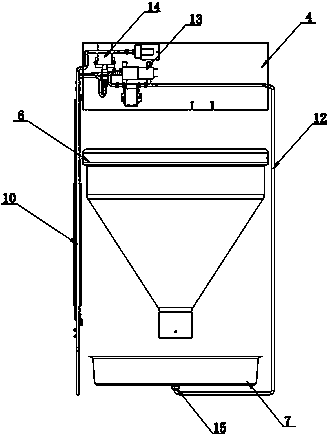

Piglet feeding device

ActiveCN103704156AGuaranteed freshGuaranteed freshnessAnimal watering devicesAnimal feeding devicesEngineeringMaterial resources

The invention discloses a piglet feeding device. The piglet feeding device comprises a support, a control box, a hopper and a feeding trough. The control box, the hopper and the feeding trough are sequentially fixed to the support from top to bottom. A packing auger is connected to the bottom of the control box. The packing auger penetrates through the hopper and the bottom of the packing auger extends into a stirring chest of the feeding trough. A water supply system is fixed inside the control box. The water supply system is connected with a water delivery pipe fixed to one side of the support. The bottom end of the water delivery pipe is connected with a water nozzle fixed to the bottom of the feeding trough. The top end of the water nozzle extends into the stirring chest. The piglet feeding device has the advantages that the piglet feeding device is simple in structure and convenient to operate; water is supplied automatically when feed is discharged automatically; meanwhile, the water and the crushed feed are fully mixed through the packing auger, so that the shortcoming that feed temperature, freshness, feeding time and the like can not be controlled in an existing device is overcome, manual control is not needed for the whole operation process, manpower and material resources are saved, the feed is made the best of, waste of the feed is reduced, the freshness of the feed is maintained, and the taste of the feed is improved.

Owner:SHENZHEN JINXINNONG FEED +3

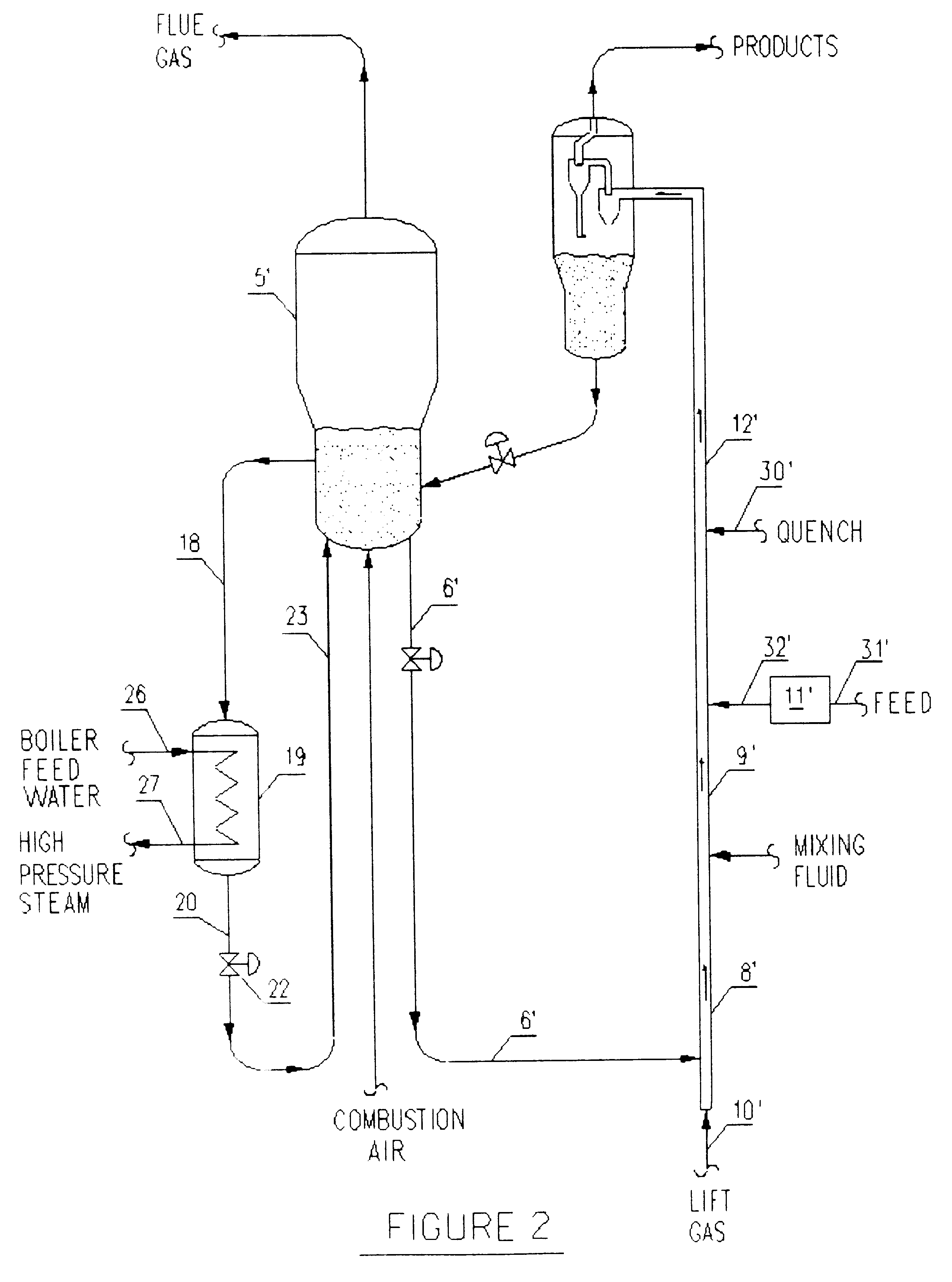

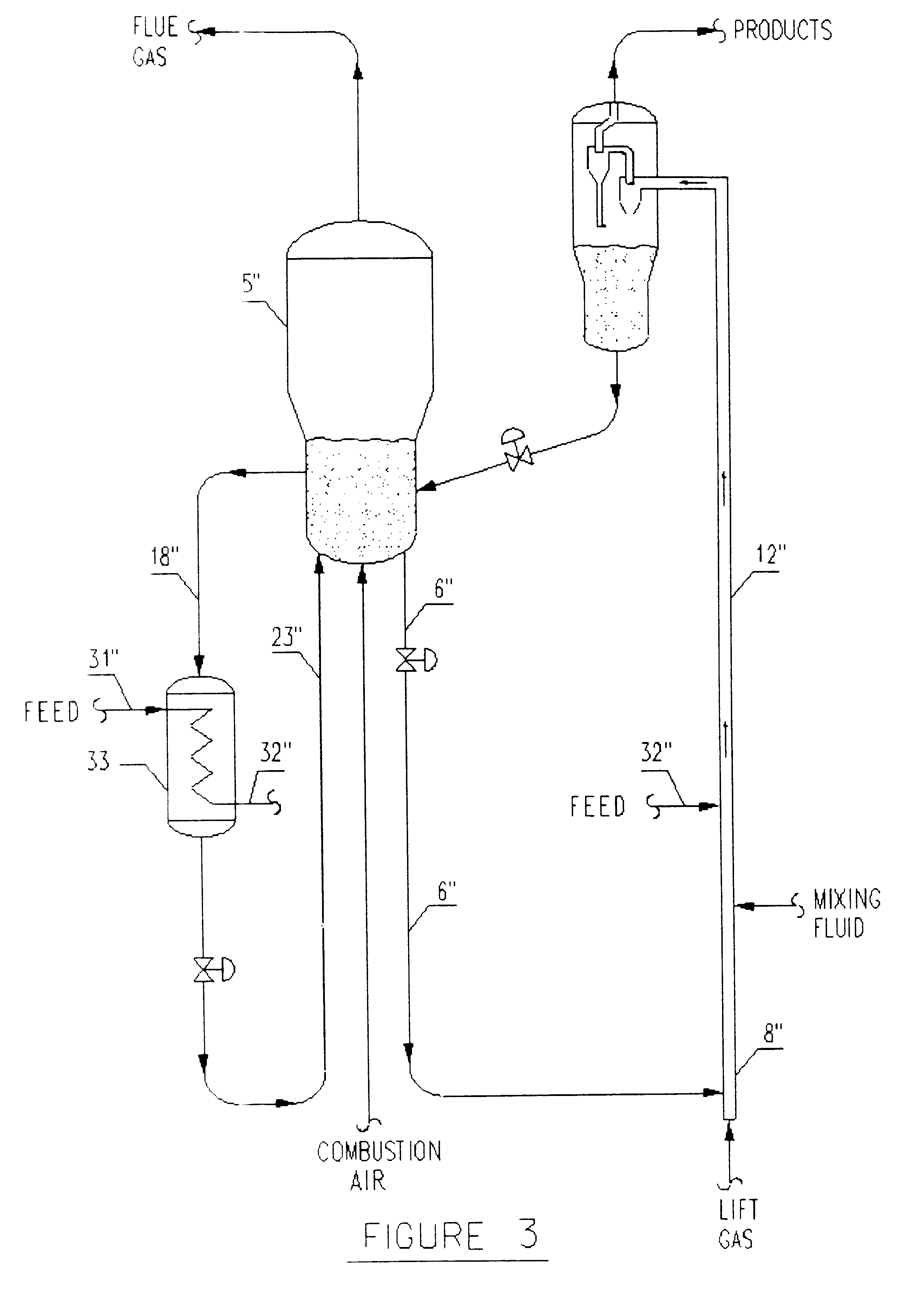

Process for the fluid catalytic cracking with pre-vaporized feed

InactiveUS6558530B2Reduce contact timeIncrease temperatureCatalytic crackingCatalytic naphtha reformingFluidized bedGasoline

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

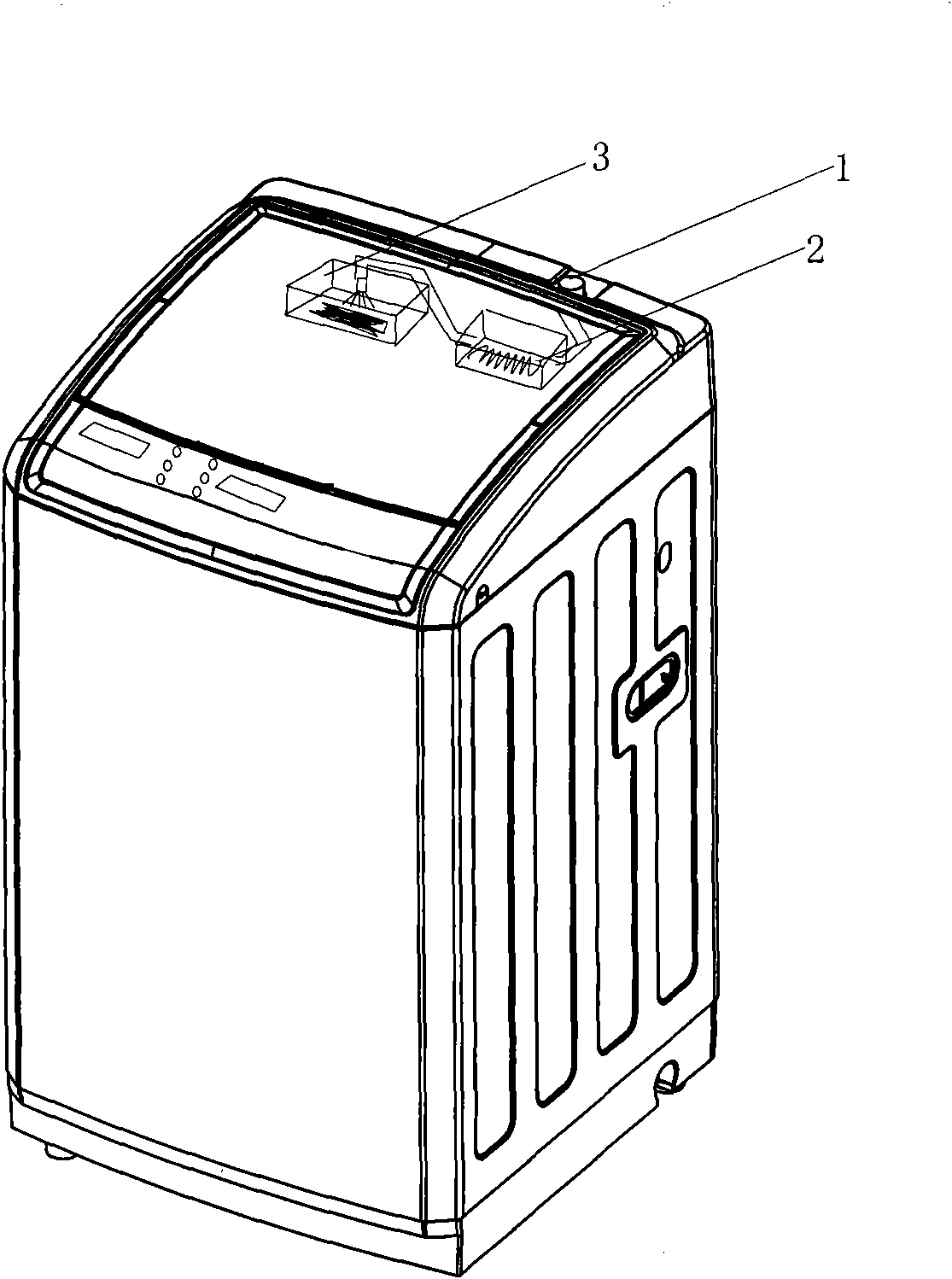

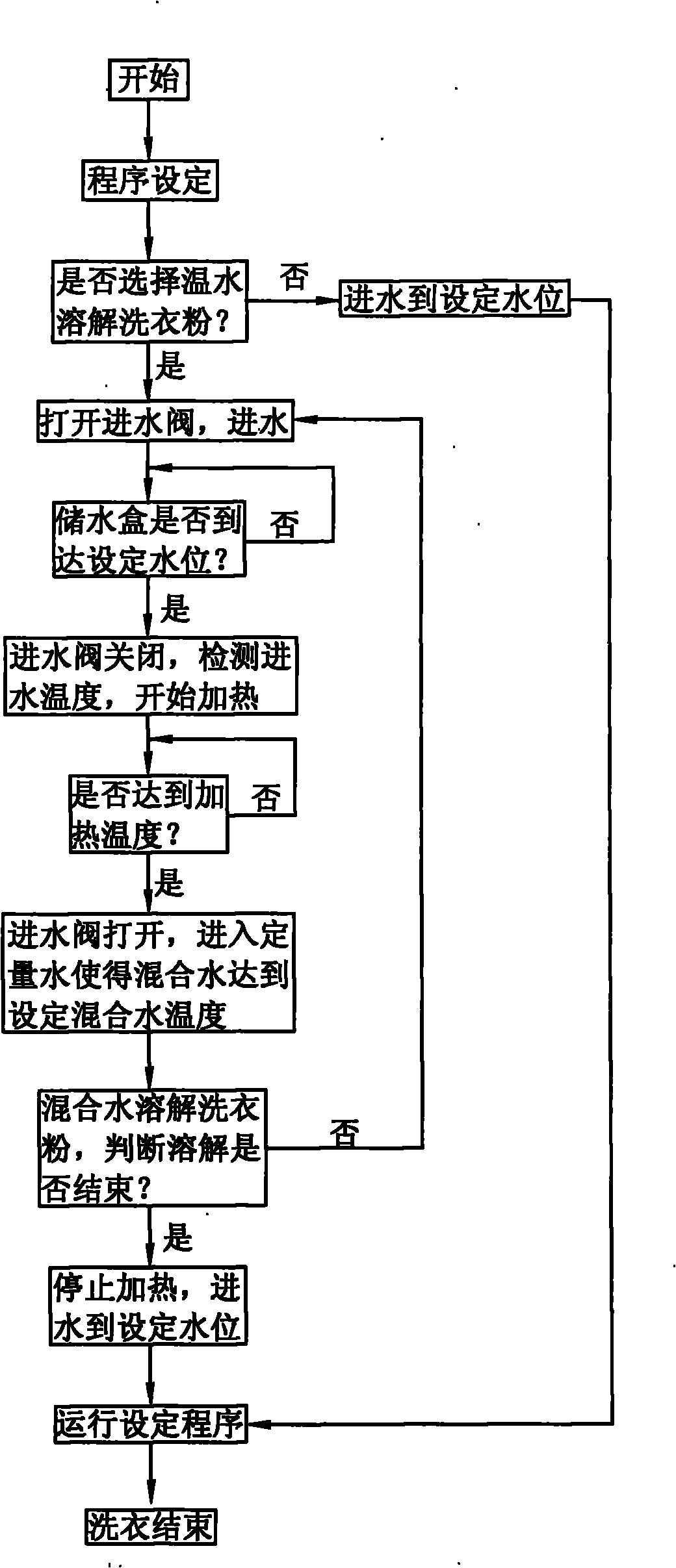

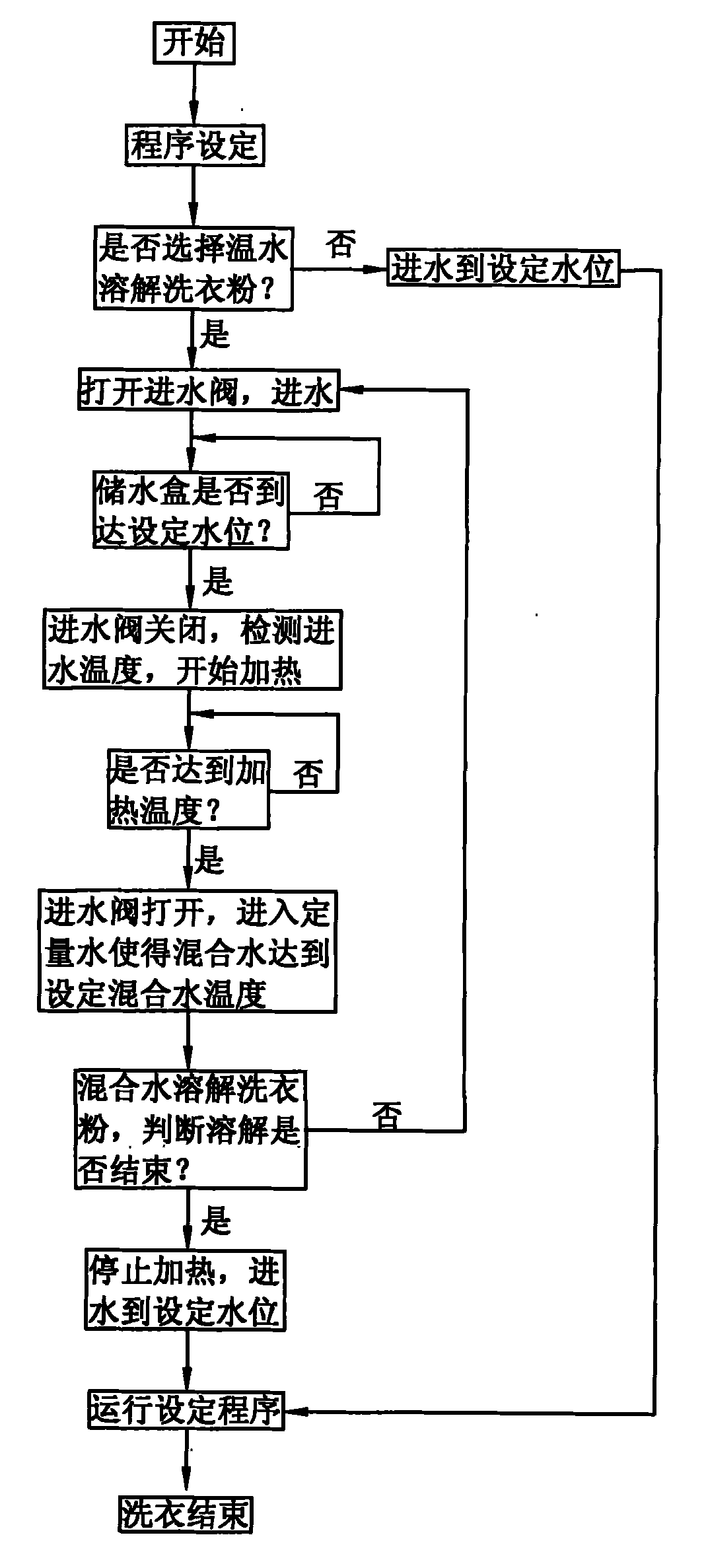

Method for controlling water feeding dissolution of washing powder in washing machine and washing machine thereof

ActiveCN102080323AImprove cleaning rateImprove uniformityOther washing machinesControl devices for washing apparatusWater storageDissolution

The invention discloses a method for controlling water feeding dissolution of washing powder in a washing machine and a washing machine thereof. The washing machine comprises a water feeding valve, a water storage box and a washing powder box, wherein the water storage box is arranged between the water feeding valve and the washing powder box and is communicated with the washing powder box; when the washing powder is dissolved, water is firstly fed into the water storage box to reach a set water level, the water is heated to a set heating temperature after the water feeding temperature is detected, a fixed amount of water is continuously fed according to the relationship of the amount of the heated water in the water storage box, the set heating temperature and the water feeding temperature so that the heated water and the fed water in the water storage box are mixed to generate mixed water with the temperature, suitable for the dissolution of the washing powder; the mixed water simultaneously flows into the washing powder box to dissolve the washing powder sufficiently, washing articles are then uniformly soaked in the washing powder-dissolved water in the manner of internally circulated sprinkling and stirring; and finally, the water is fed to reach the set water level for the purpose of washing, therefore, the cleaning rate and the uniformity of the washing articles are improved.

Owner:HAIER GRP CORP +2

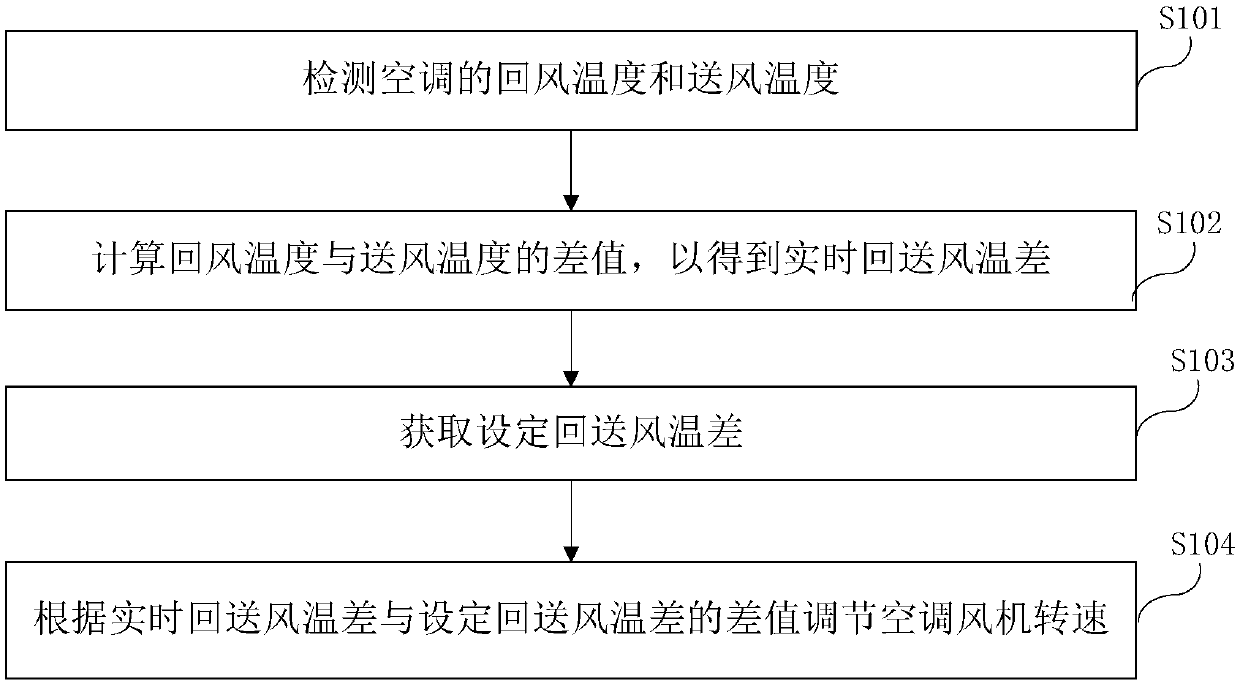

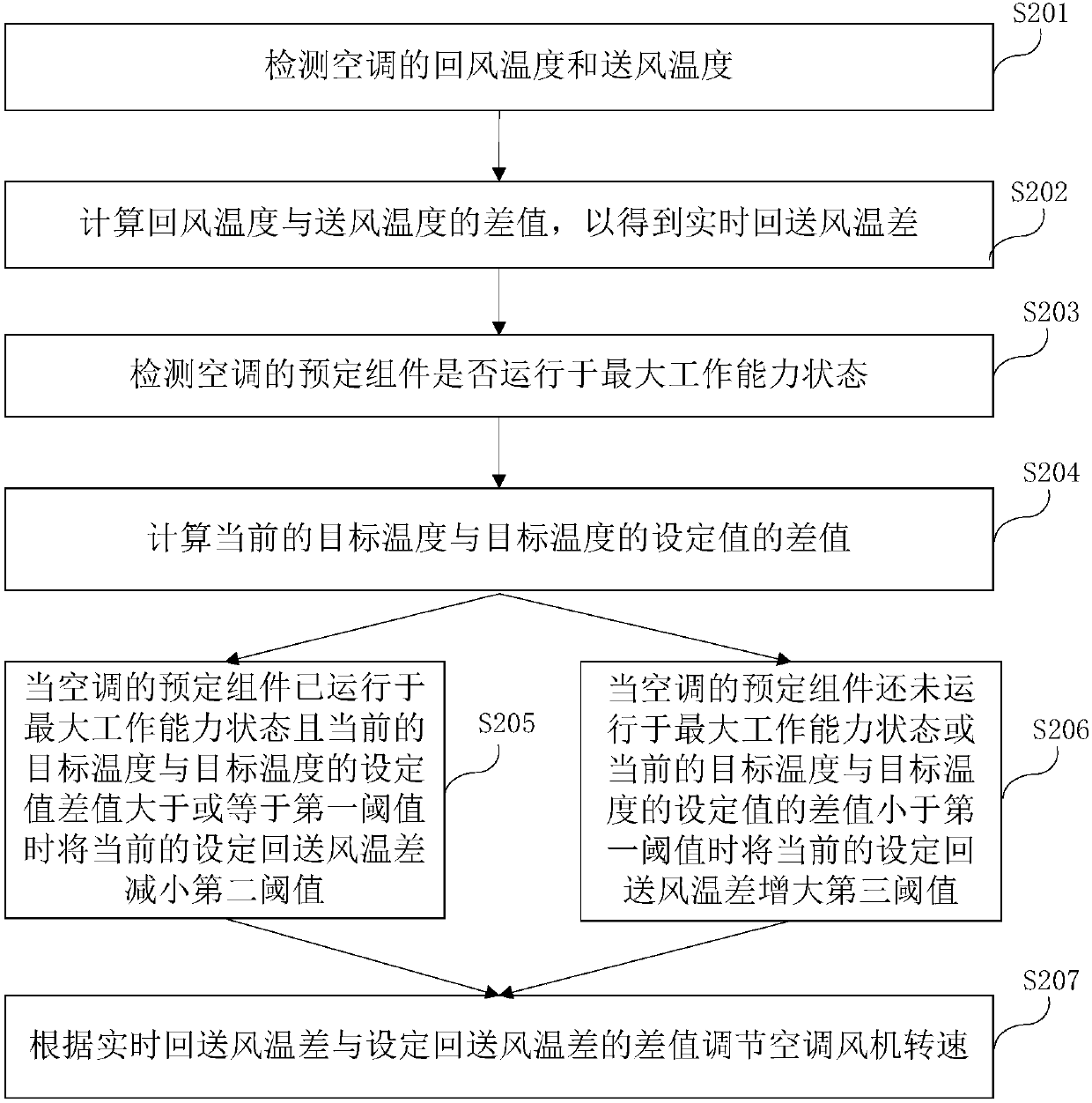

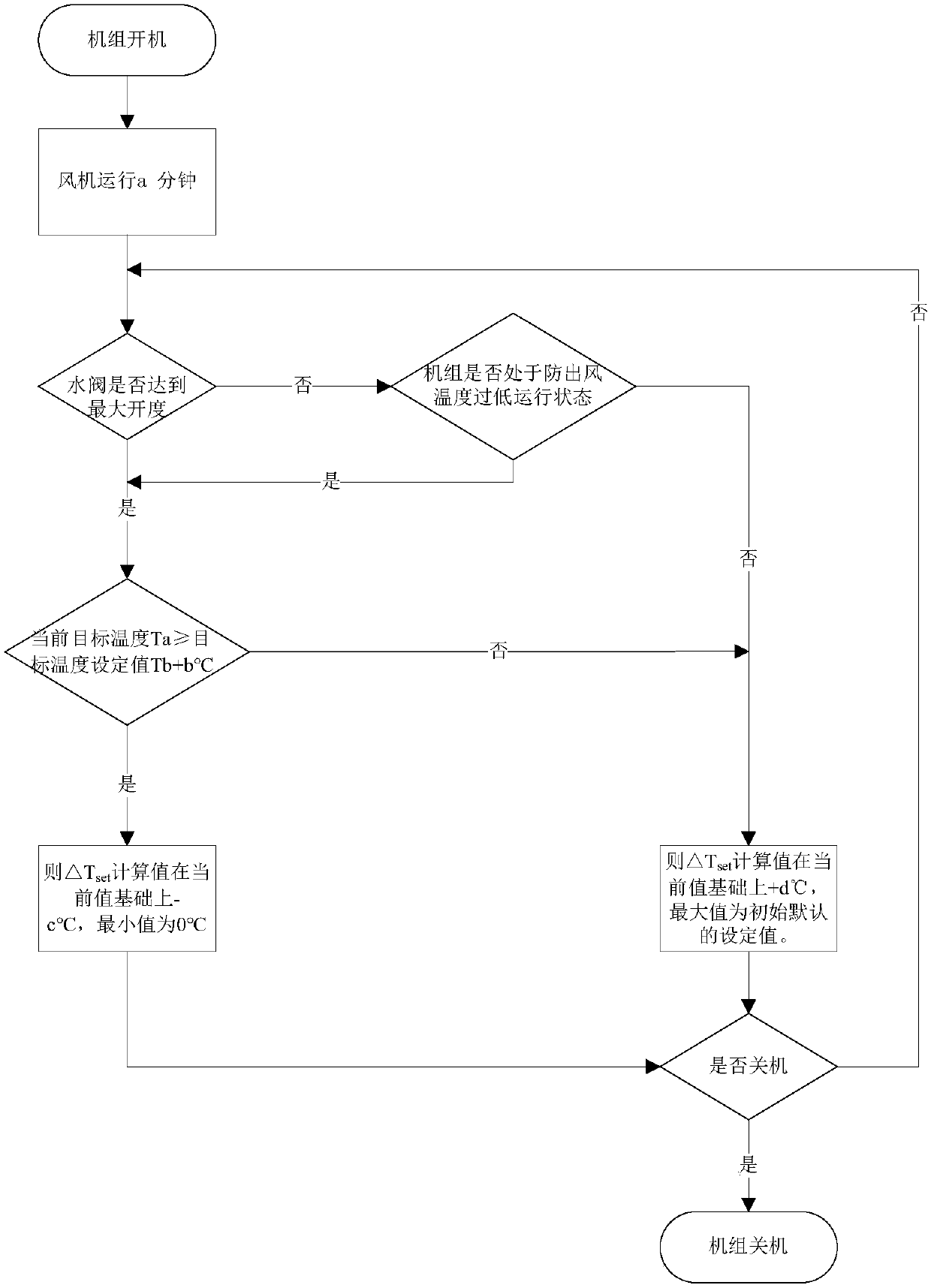

Air conditioner draught fan rotating speed control method and air conditioner system

ActiveCN107906686AImprove cooling effectIncrease heating capacityMechanical apparatusSpace heating and ventilation safety systemsFeed temperatureComputer engineering

The invention discloses an air conditioner draught fan rotating speed control method and an air conditioner system. The air conditioner draught fan rotating speed control method comprises the steps that the air return temperature and the air feed temperature of an air conditioner are detected; the difference value of the air return temperature and the air feed temperature is calculated so as to obtain the real-time air return and feed temperature difference; the set air return and feed temperature difference is obtained, wherein the set air return and feed temperature difference is the set difference value of the air return temperature and the air feed temperature; and according to the difference value of the real-time air return and feed temperature difference and the set air return and feed temperature difference, the rotating speed of an air conditioner draught fan is adjusted. Through the air conditioner draught fan rotating speed control method and the air conditioner system, therotating speed of the draught fan can be adjusted according to the difference value of the real-time air return and feed temperature difference and the set air return and feed temperature difference,change of the room load is rapidly responded, and the proper refrigerating quantity and heating quantity are output in time.

Owner:GREE ELECTRIC APPLIANCES INC

Batch extractive distillation separation method of methylal-methanol azeotropic mixture

InactiveCN102627536AReduce energy consumptionFlexible operationOrganic compound preparationHydroxy compound preparationSeparation technologyExtractive distillation

Belonging to separation technologies of methylal-methanol azeotropic mixtures, the invention discloses a batch extractive distillation separation method of a methylal-methanol azeotropic mixture. The method takes propanol, isopropanol, butanol, tert-butyl alcohol, 1, 3-propylene glycol or dimethyl sulfoxide as the extracting agent. An extractive distillation tower are operated according to the operation conditions that, under normal pressure or reduced pressure, the extracting agent and an overhead product are in a mass ratio of 0.5:1-10:1, the feed temperature of the extracting agent is 20-40DEG C, and the extractive distillation tower top is controlled at different temperatures and reflux ratios, so that a methylal product, a methylal-methanol transition section I, a methanol product and a methanol-extracting agent transition section II can be obtained from the extractive distillation tower top respectively. When composition of the extracting agent of a heating kettle meets requirements, the extracting agent is pumped into a high storage tank, and feeding is conducted for next batch of extractive distillation separation. The method of the invention has the advantages of low cost of single-tower equipment, flexible operation, adoption of an extracting agent to destroy a methylal-methanol azeotropic system, and can obtain high purity methanol and methylal products.

Owner:UNIV OF JINAN

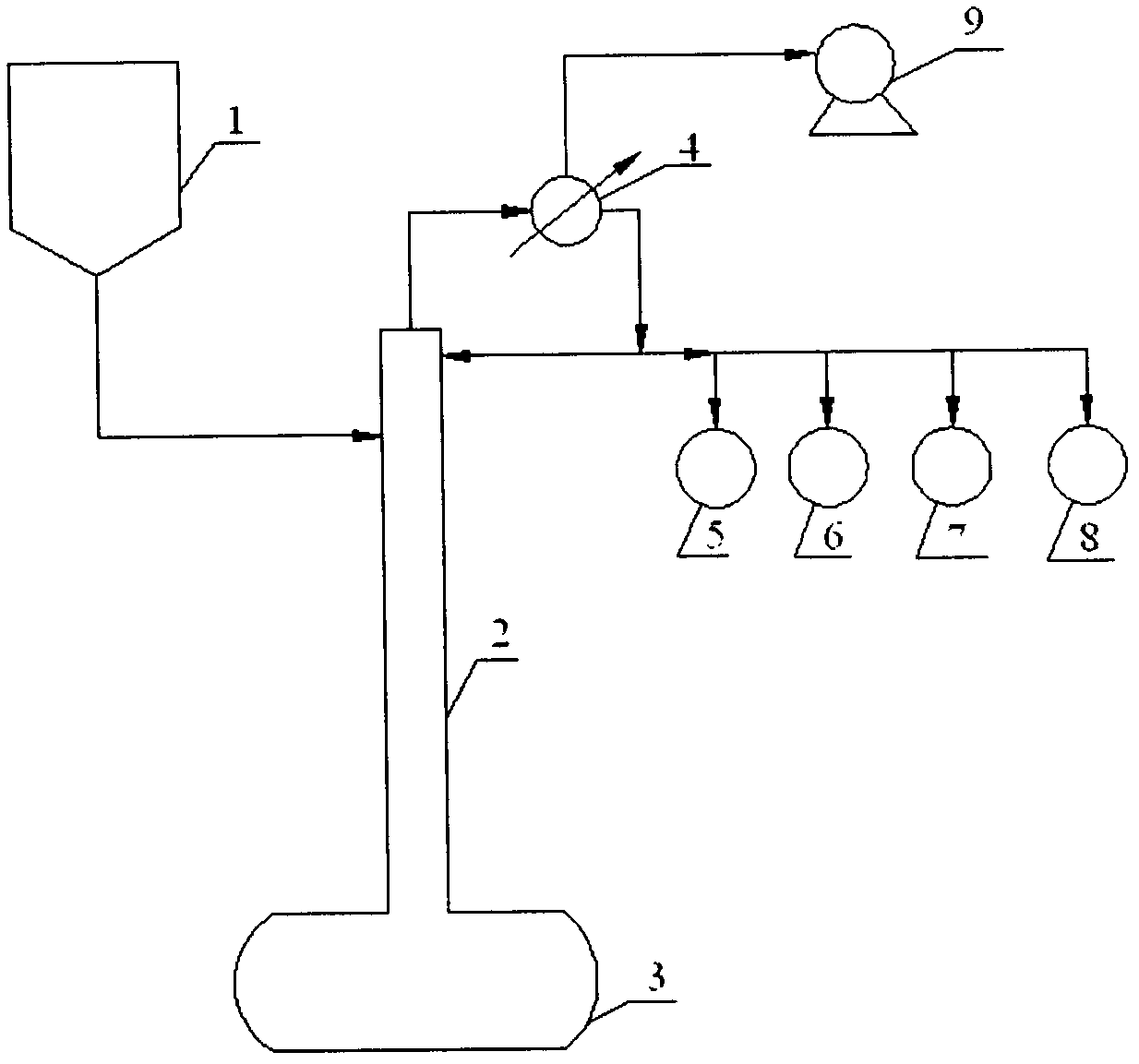

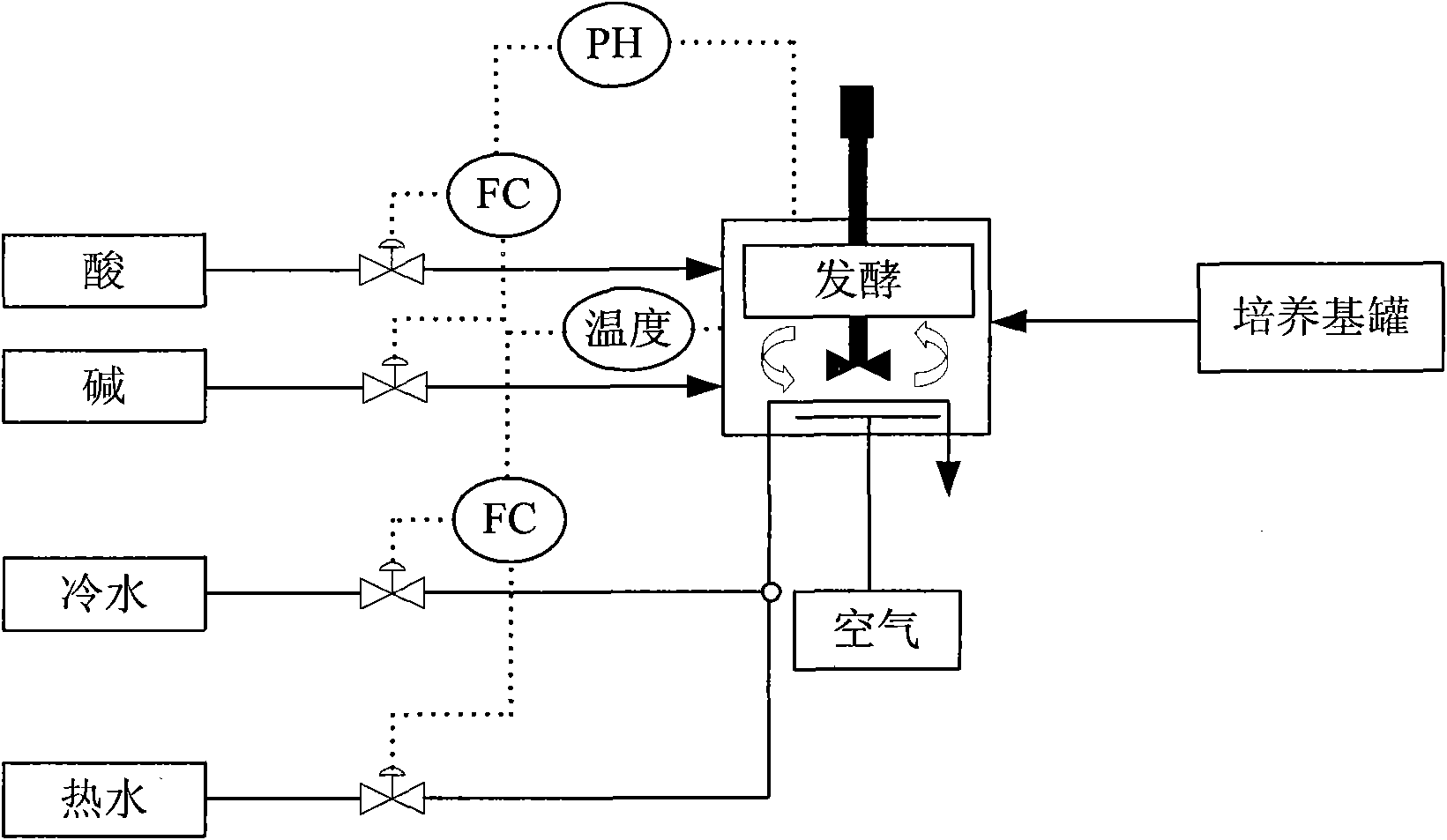

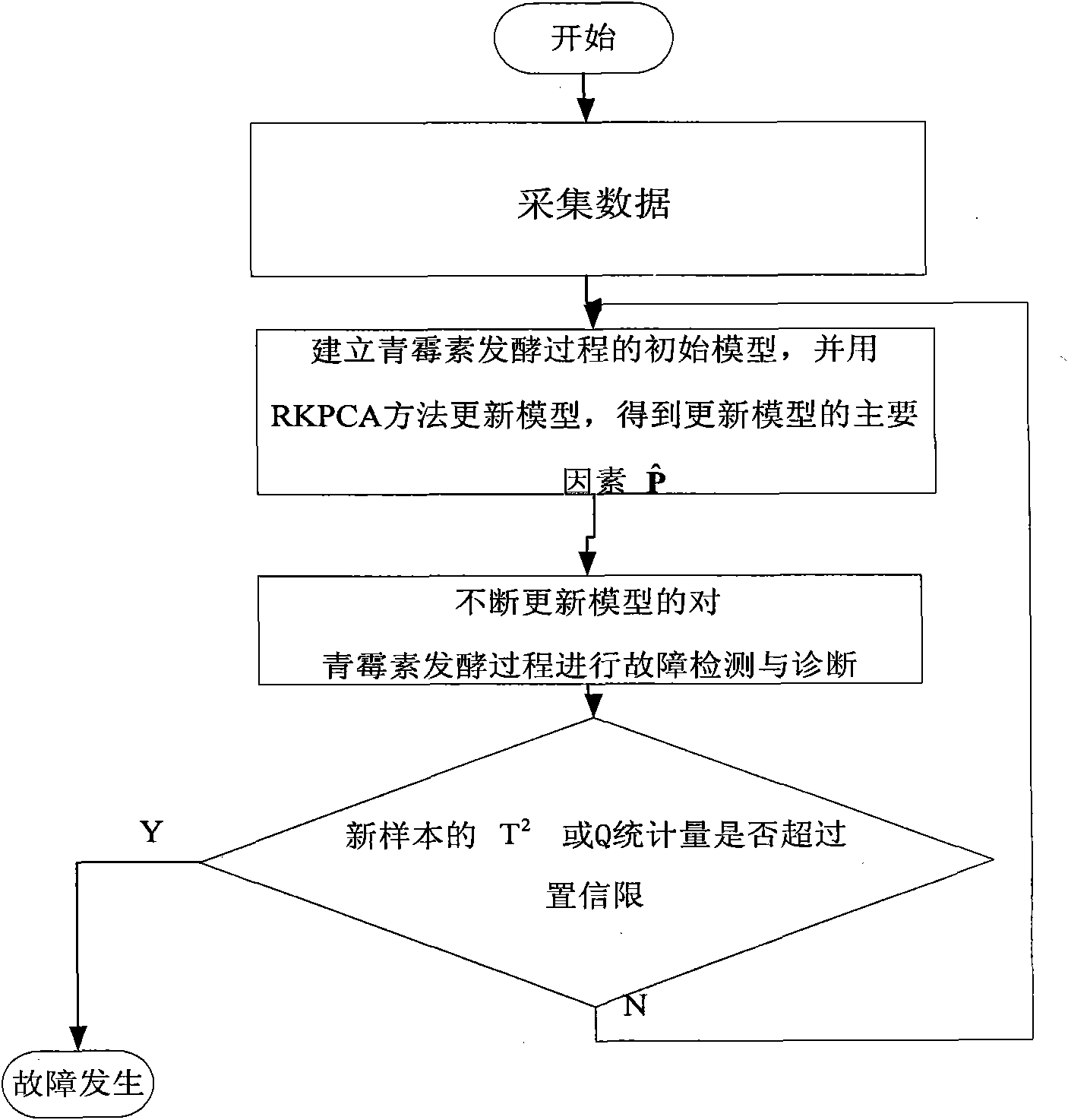

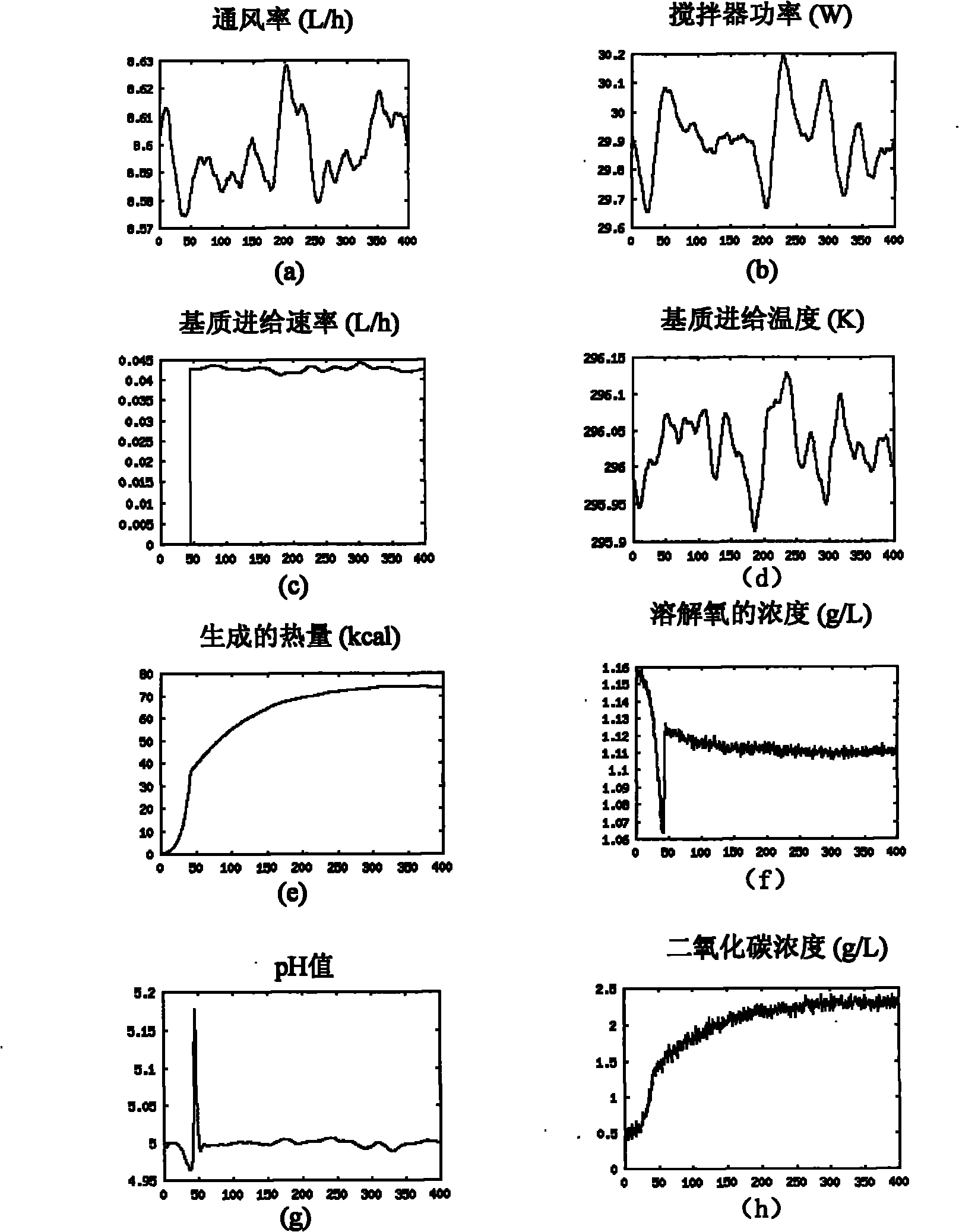

Penicillin fermentation process failure monitoring method based on recursive kernel principal component analysis

InactiveCN101964021ASolve nonlinear problemsReduce false alarmsSpecial data processing applicationsCovarianceRecursive computation

The invention relates to a penicillin fermentation process failure monitoring method based on recursive kernel principal component analysis (RKPCA), which belongs to the technical field of failure monitoring and diagnosis. The method comprises the following steps: acquiring the ventilation rate, stirrer power, substrate feed rate, substrate feed temperature, generated heat quantity, concentrationof dissolved oxygen, pH value and concentration of carbon dioxide; and establishing an initial monitoring model by using the first N numbered standardized samples, updating the model by a RKPCA method, and computing the characteristic vectors to detect and diagnose the failure in the process of continuous annealing, wherein when the T2 statistics and SPE statistics exceed the respective control limit, judging that a failure exists, and otherwise, judging that the whole process is normal. The method mainly solves the problems of data nonlinearity and time variability; and the RKPCA method is used for updating the model by carrying out recursive computation on the characteristic values and characteristic vectors of the training data covariance. The result indicates that the method can greatly reduce the false alarm rate and enhance the failure detection accuracy.

Owner:NORTHEASTERN UNIV

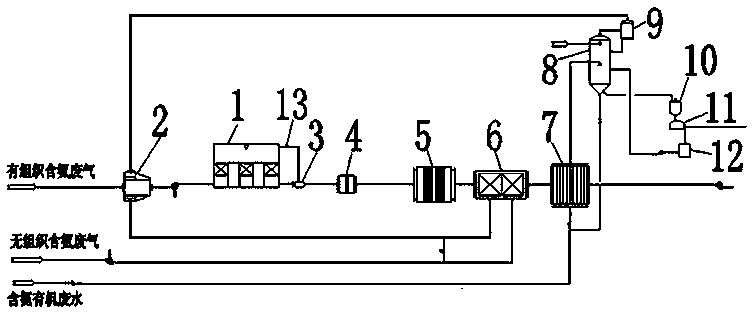

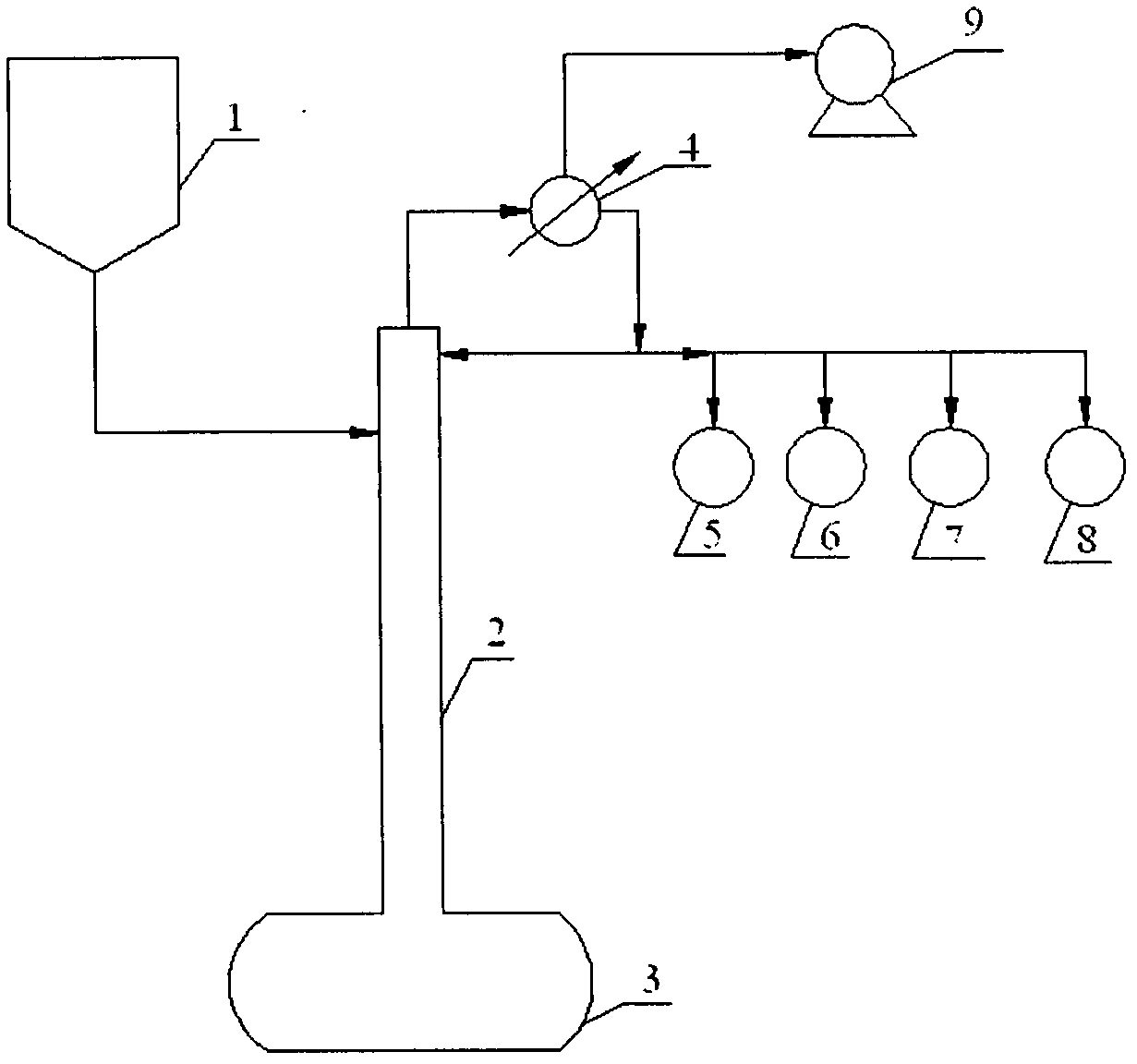

Comprehensive treatment technology and system for ammonia containing organic waste gas and ammonia containing organic waste water

ActiveCN109442438AHigh removal rateRaise the exhaust gas temperatureGas treatmentSpecific water treatment objectivesTreatment systemChemistry

The invention relates to a comprehensive treatment technology and system for ammonia containing organic waste gas and ammonia containing organic waste water. The comprehensive treatment technology comprises the steps that high-temperature furnace inflow waste gas is conveyed into an RTO heat accumulation type incinerator through a waste gas draught fan to be incinerated, and clean smoke is subjected to nitrogen oxide catalytic reduction through an SCR reactor. The comprehensive treatment system comprises the RTO heat accumulation type incinerator, a waste gas mixer is arranged at the front endof the RTO heat accumulation type incinerator, a mixer is arranged at the rear end of the RTO heat accumulation type incinerator and connected with a metal filter, the metal filter is connected withthe SCR reactor, the SCR reactor is connected with a plate heat exchanger, and the plate heat exchanger is connected with a forcing heat exchanger. Low-temperature smoke waste heat is circularly utilized, the furnace feeding temperature is increased, the exhaust temperature of an incinerator system is increased and meets the smoke catalysis denitration technology requirement, no fuel consumption and no denitration agent consumption are achieved, waste water can be treated while waste gas is treated, and secondary pollutants are avoided.

Owner:JIANGSU DAXIN ENVIRONMENTAL SCI & TECH

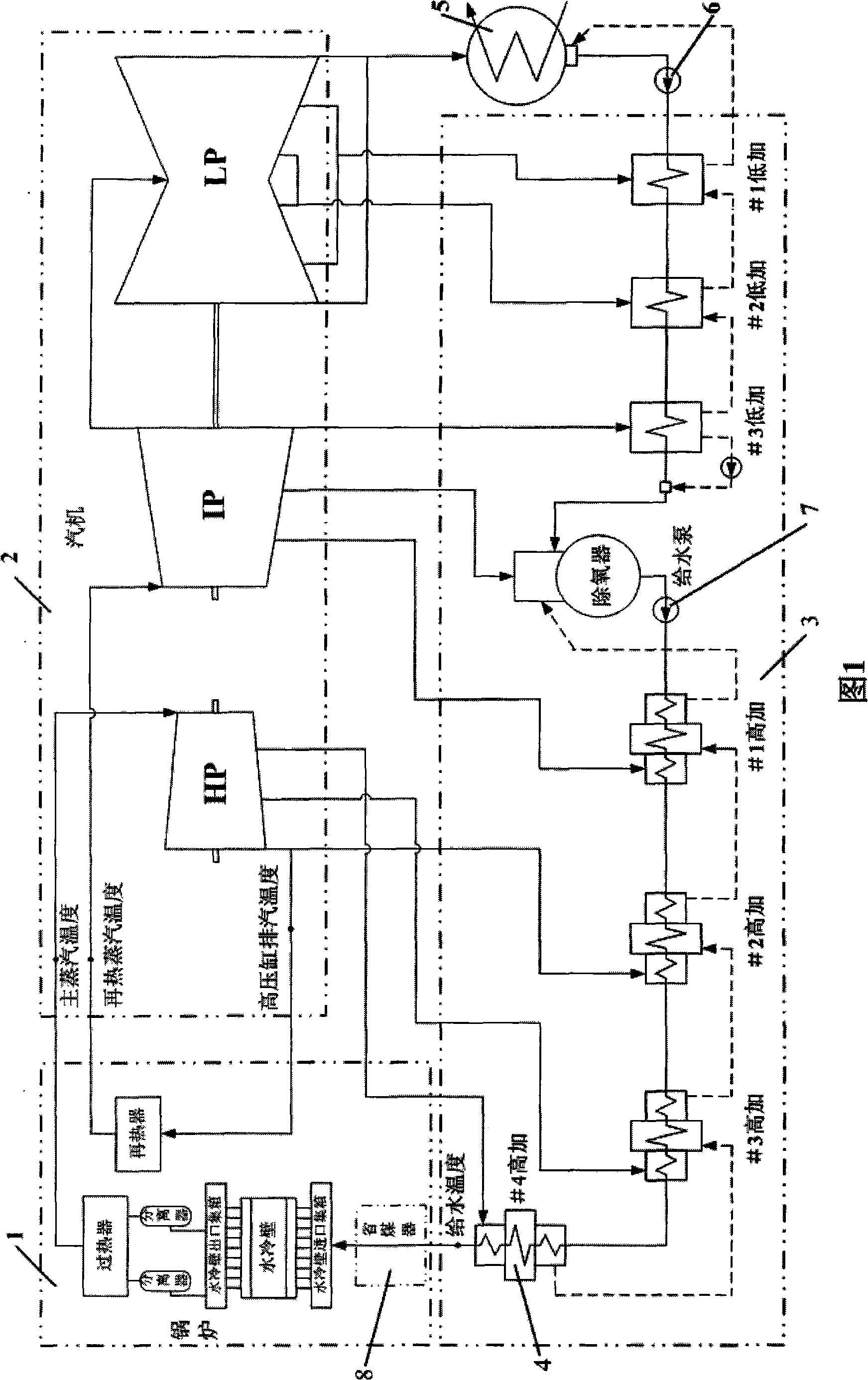

Super or super supercritical coal fired power generation heat system improvement method

InactiveCN101261002AIncrease feed water temperatureRaise the average endothermic temperatureSteam generation heating methodsIndirect carbon-dioxide mitigationAir preheaterSteam pressure

The invention discloses a measure for improving a supercritical or ultra supercritical coal-burning power generation thermal system belonging to the thermal power generation technical field, relating to the supercritical or ultra supercritical coal-burning power generation thermal system without an economizer and a parameter configuration. The invention concretely comprises following steps of removing the economizer which is requisite for a conventional boiler to simplify the flow of a boiler and reduce the flow resistance of a system and the station service power consumption rate; increasing a primary high-voltage bleeder heater to increase the feed temperature; possibly reducing the exhaust steam pressure and the temperature of a high pressure cylinder to enable the exhaust steam temperature of the high pressure cylinder to be equal or similar to the feed temperature; possibly increasing the temperature of reheat steam on the premise of guarantee of safety; and increasing or providing an air preheater and increasing the temperature of secondary wind to improve the average temperature of heat release of flue gas of the boiler to the cycle fluid of power generation and improve the second-law efficiency of the boiler and the combustion stability of unit coal species changing.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

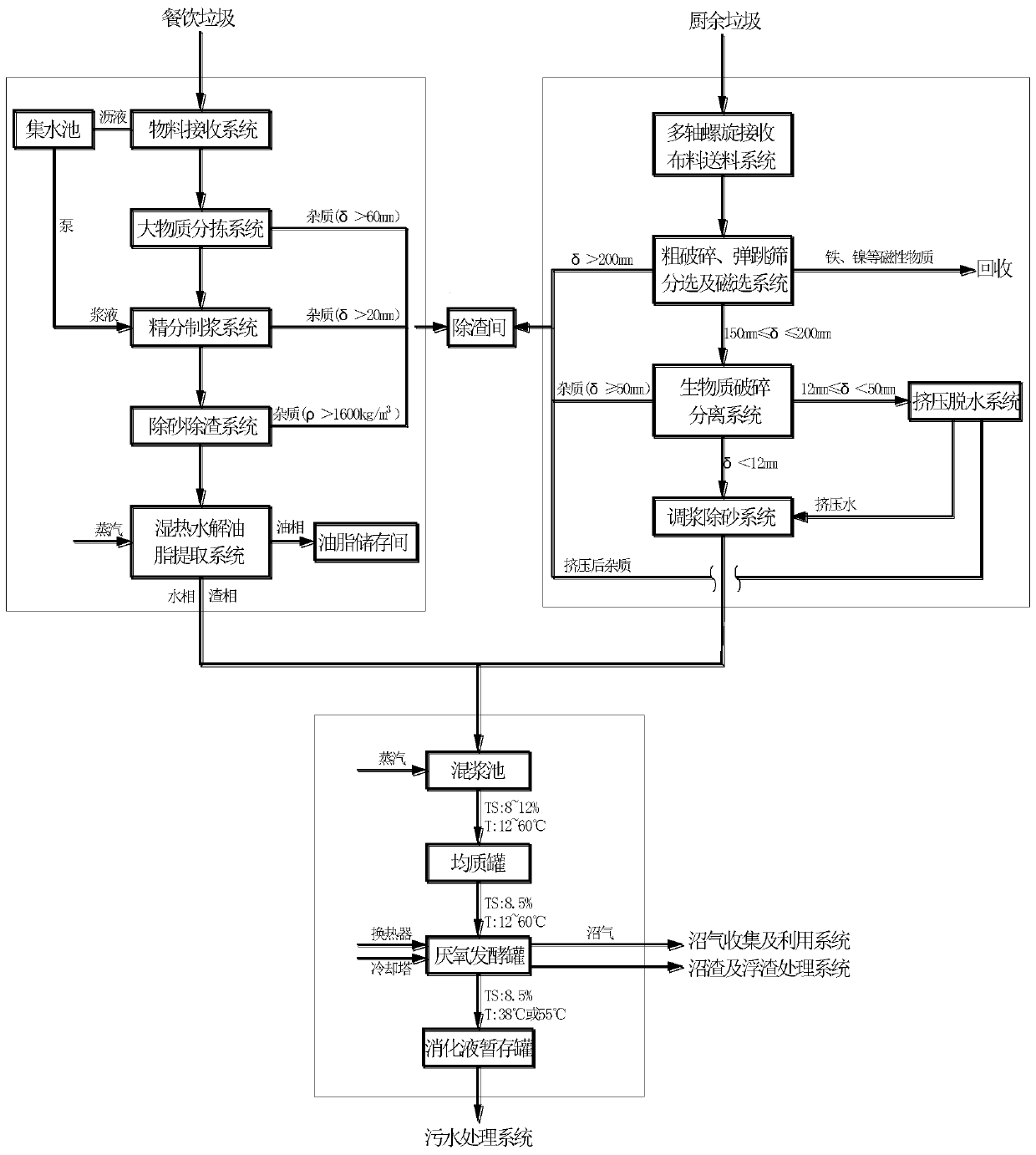

Coprocessing method of catering garbage and kitchen garbage

The invention provides a coprocessing method of catering garbage and kitchen garbage. The coprocessing method comprises the steps of (1) pretreating catering garbage, and performing large substance sorting, fine separation pulping, desanding and deslagging, and performing damp and hot hydrolyzing fat extraction, so as to prepare organic pulp; (2) pretreating kitchen garbage, and performing crude shredding, bouncing and sieving, magnetic separation, biomass separation breaking and conditioning and desanding to obtain organic pulp; and (3) when the catering garbage is not subjected to damp and hot hydrolyzing fat extraction, performing medium-temperature anaerobic treatment in a system, and when the catering garbage is subjected to damp and hot hydrolyzing fat extraction, performing high temperature anaerobic treatment. Compared with the prior art, the catering garbage and the kitchen garbage are pretreated and then subjected to coordination anaerobic treatment; and the catering garbageenters an oil extraction system or surpasses the oil extraction system according to the feeding nature, so that the feeding temperature of the anaerobic system is decided, and medium-temperature anaerobic treatment or high-temperature anaerobic treatment is further selected, and the purpose of resource utilization to the maximum extent and being energy-saving and cost-reducing is achieved.

Owner:WUXI MUNICIPAL DESIGN INST

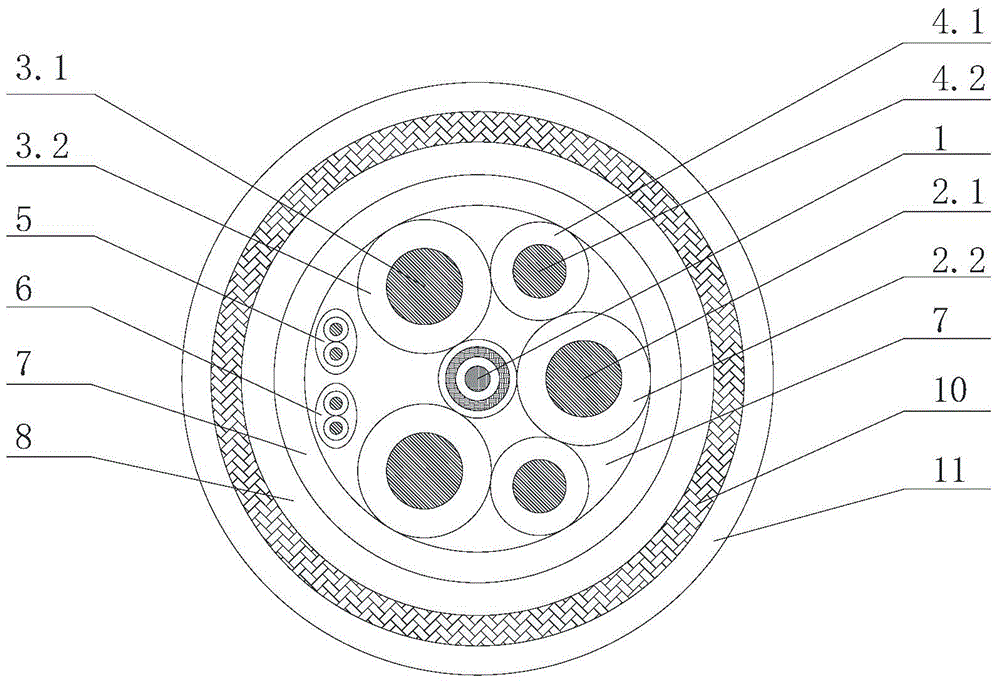

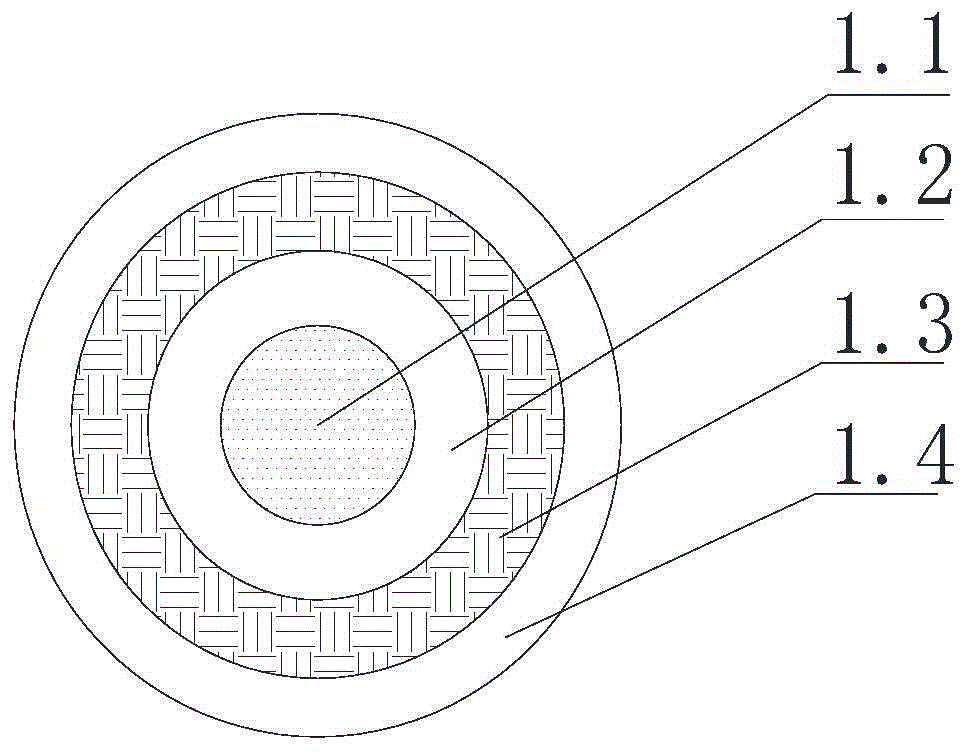

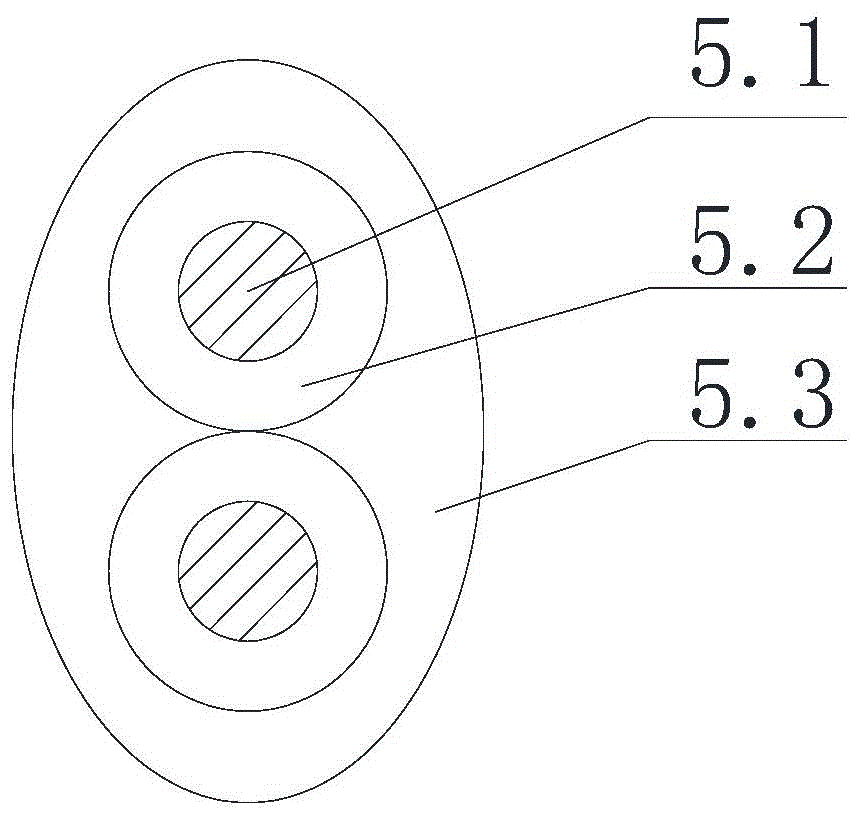

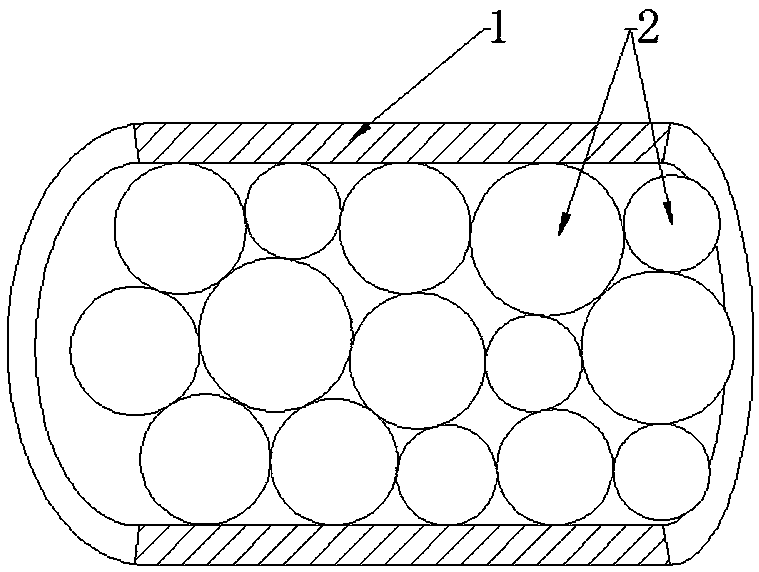

Electric vehicle charging pile cable

InactiveCN104882221AAvoid fireImprove water resistancePlastic/resin/waxes insulatorsClimate change adaptationTemperature controlPower cable

The invention discloses an electric vehicle charging pile cable, and belongs to the power cable technical field; the electric vehicle charging pile cable comprises a feed temperature optical fiber, two main power lines, a ground line, two auxiliary power lines, a pair of charging connection confirm lines, and a pair of charging communication lines; the wire cores are twisted to form a cable, and gaps are filled with filling material; the cable is wrapped in sequence from inside-out by a wrapping tape, an inner sheath, a shield layer and an outer sheath. The electric vehicle charging pile cable is excellent in flexibility, highly flame retardant, wear resistant, high in weatherability and anti-UV property, can feed back temperature control of the cable and contact points, thus preventing fire hazard caused by overheating; a waterstop rope is water resistant, so cable water tree and creep deformation can be prevented, thus prolonging life of the charging pile cable.

Owner:BEIJING HENGTONG SIBO COMM TECH CO LTD

Environment-friendly alloying method of metal bismuth for free-cutting steel

The invention relates to an environment-friendly alloying method of metal bismuth for free-cutting steel, belongs to the technical field of metallurgy and aims to prevent violent reaction produced bydirection addition of metal bismuth, reduce smoke pollution, increase yield of bismuth and further normalize a bismuth alloying method. According to the method, metal bismuth is fed into molten steelin an alloy cored wire manner by a wire feeder, diameter of a bismuth cored wire is 8-14 mm, thickness of steel skin is 0.5-1.5 mm, and diameter of bismuth particles is 0-3 mm; bottom blowing stirringis performed on a steel ladle, feeding temperature is in a range of 1600-1780 DEG C, feeding rate is 80-110 m / min, and stirring is continued for 3-8 min after feeding. With adoption of the method, the problems of high volatilization, sedimentation and oxidation loss caused by low melting and boiling points and active nature of metal bismuth are solved, yield reaches 50% or higher, and splashing danger and a large amount of smoke pollution due to the violent reaction produced by direction addition of metal bismuth are effectively reduced.

Owner:TAIYUAN IRON & STEEL GROUP

Intermittent extractive distillation separation method of methanol-methyl propionate azeotropic mixtures

InactiveCN102584525AFlexible operationReduce cost inputOrganic compound preparationCarboxylic acid esters preparationChlorobenzeneExtractive distillation

The invention discloses an intermittent extractive distillation separation method of methanol-methyl propionate azeotropic mixtures, which belongs to the separation technology of the methanol-methyl propionate azeotropic mixtures and includes: ethylene glycol, 1,2-propylene glycol, glycerol, anisole and toluene or chlorobenzene are used as extracting agents, under operation conditions of an extracting rectifying tower, mass ratio of the extracting agents and overhead distillate is 0.5:1-10:1at ordinary pressure or reduced pressure, feeding temperature of the extracting agents is 20-60 DEG C, different temperatures and different reflux ratios at the top of the extracting rectifying tower are controlled, methanol products, a methanol-methyl propionate transition section I, methyl propionate products and a methyl propionate-extracting agent transition section II are respectively picked out through the extracting rectifying tower, and when extracting agent components of a heating kettle meet requirements, the extracting agents are pumped into a high-level storage groove and materials are fed for the next intermittent extractive distillation separation. The intermittent extractive distillation separation method has the advantages that the single tower is low in device cost and flexible in operation, and the extracting agents are adopted to damage a methanol-methyl propionate azeotropic system to separate out high-purity methanol products and high-purity methyl propionate products.

Owner:UNIV OF JINAN

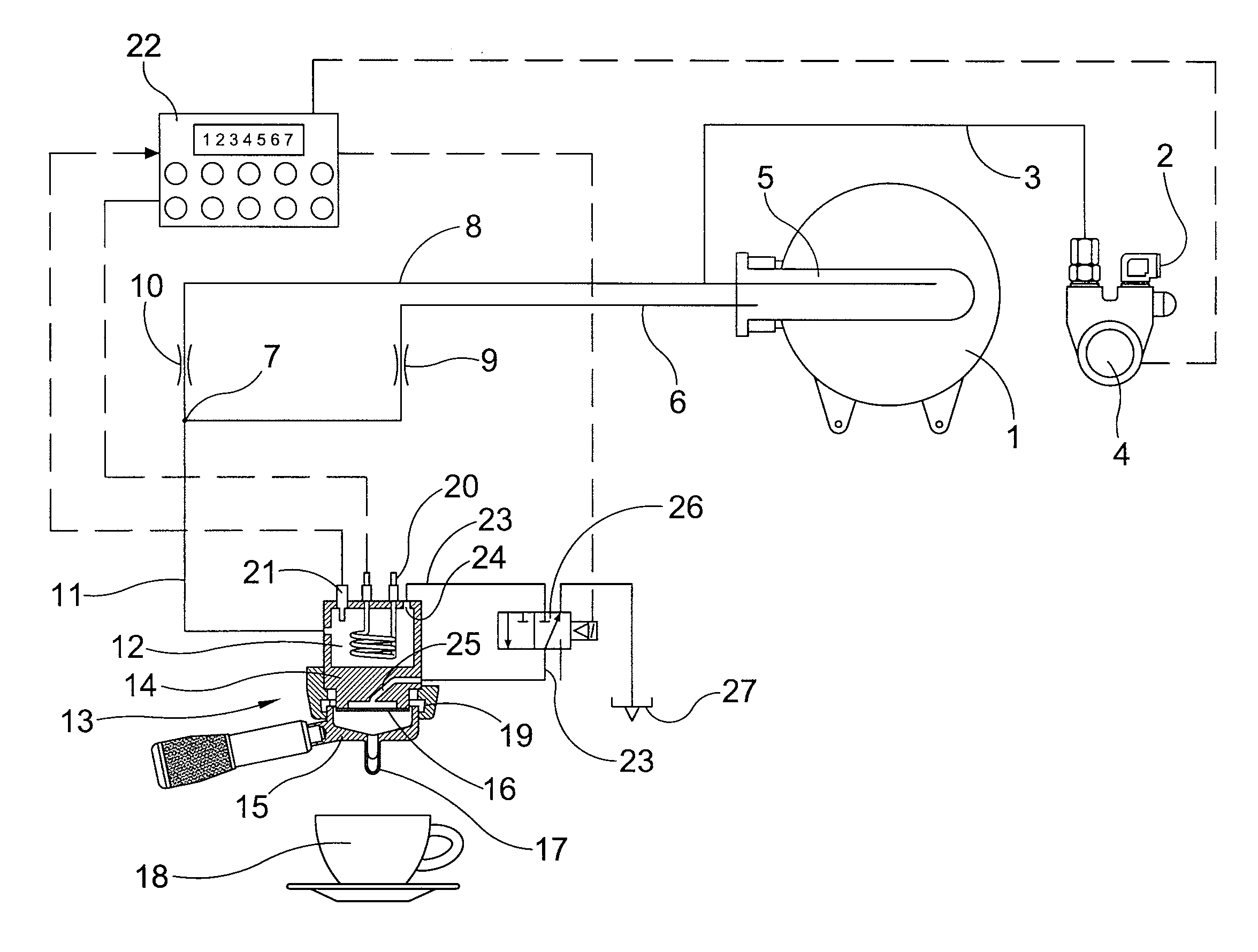

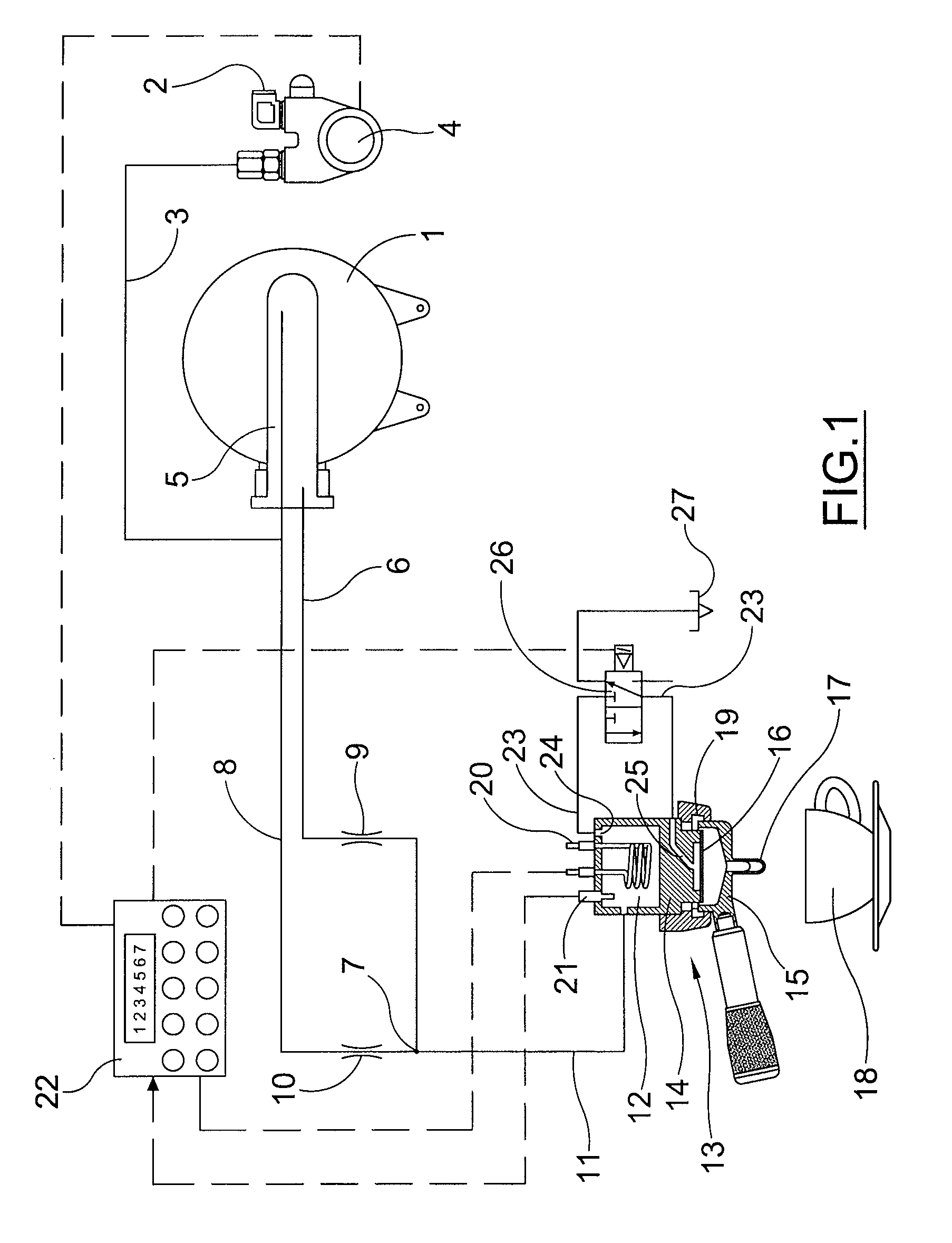

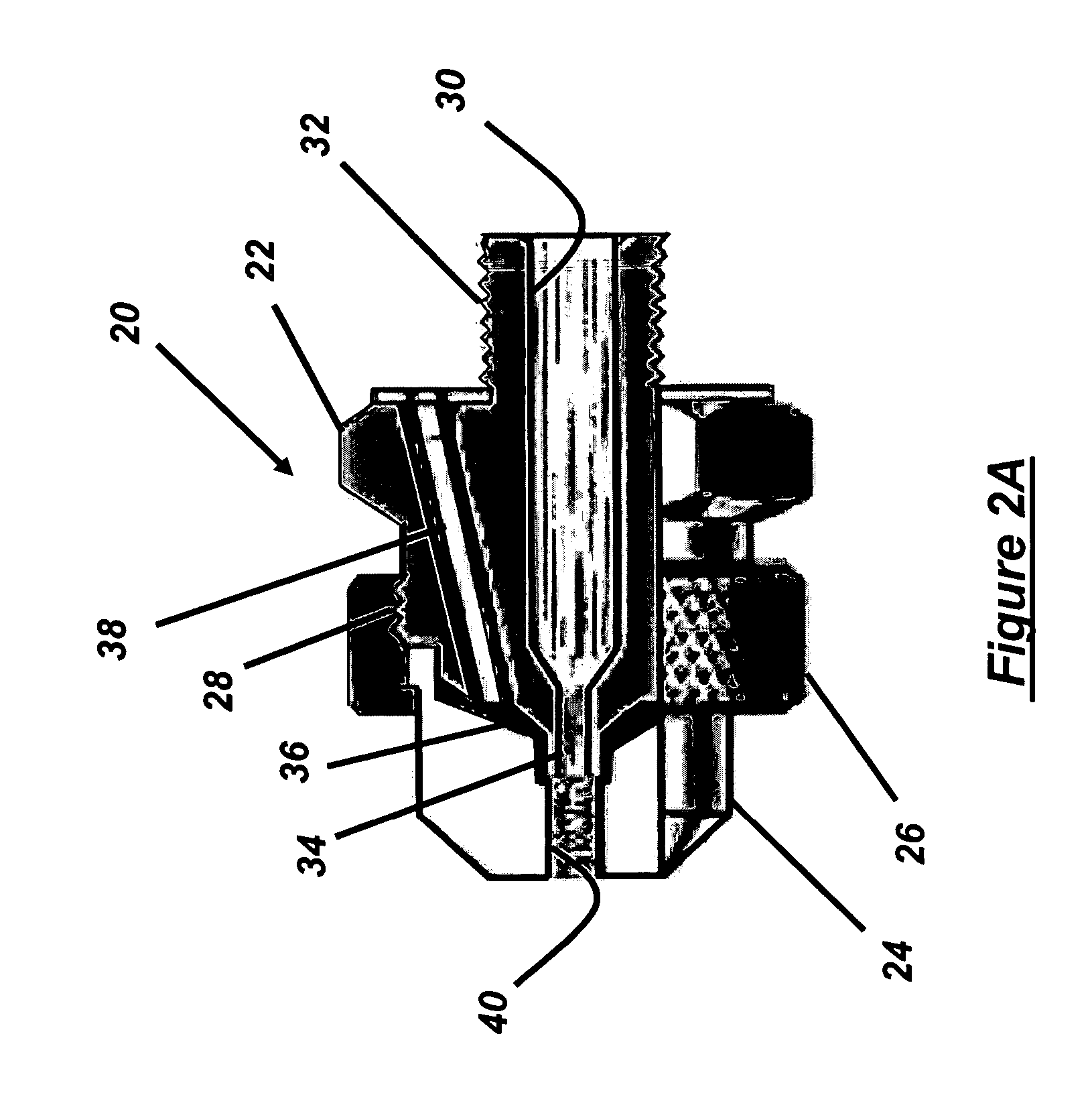

Coffee Machine with Thermally Regulated Dispenser

ActiveUS20090308255A1Low costReduce power consumptionBeverage vesselsProcess engineeringFeed temperature

A coffee machine for producing and dispensing coffee-based beverages, comprising: a water supply pipe (11); at least one dispensing device (13) comprising an infusion unit (15) apt to contain coffee powder, wherein said dispensing device (13) includes an infusion body (14) apt to admit water into said infusion unit (15) when said infusion unit is engaged with said dispensing device (13), a heating chamber (12) in fluid communication with the supply pipe (11), the heating chamber (12) comprising heating means (20) and being provided with an outlet (24) for permitting the admission of water at a dispensing temperature (T2) into a connecting pipe (23) in fluid communication with the infusion body (14) via a shut-off valve (26). The water supply pipe (11) is in fluid communication with a source of water (7) at a feed temperature (T1) and thermally coupled to a heat source (5), the feed temperature (T1) being less than said dispensing temperature (T2).

Owner:GRUPPO CIMBALI SPA

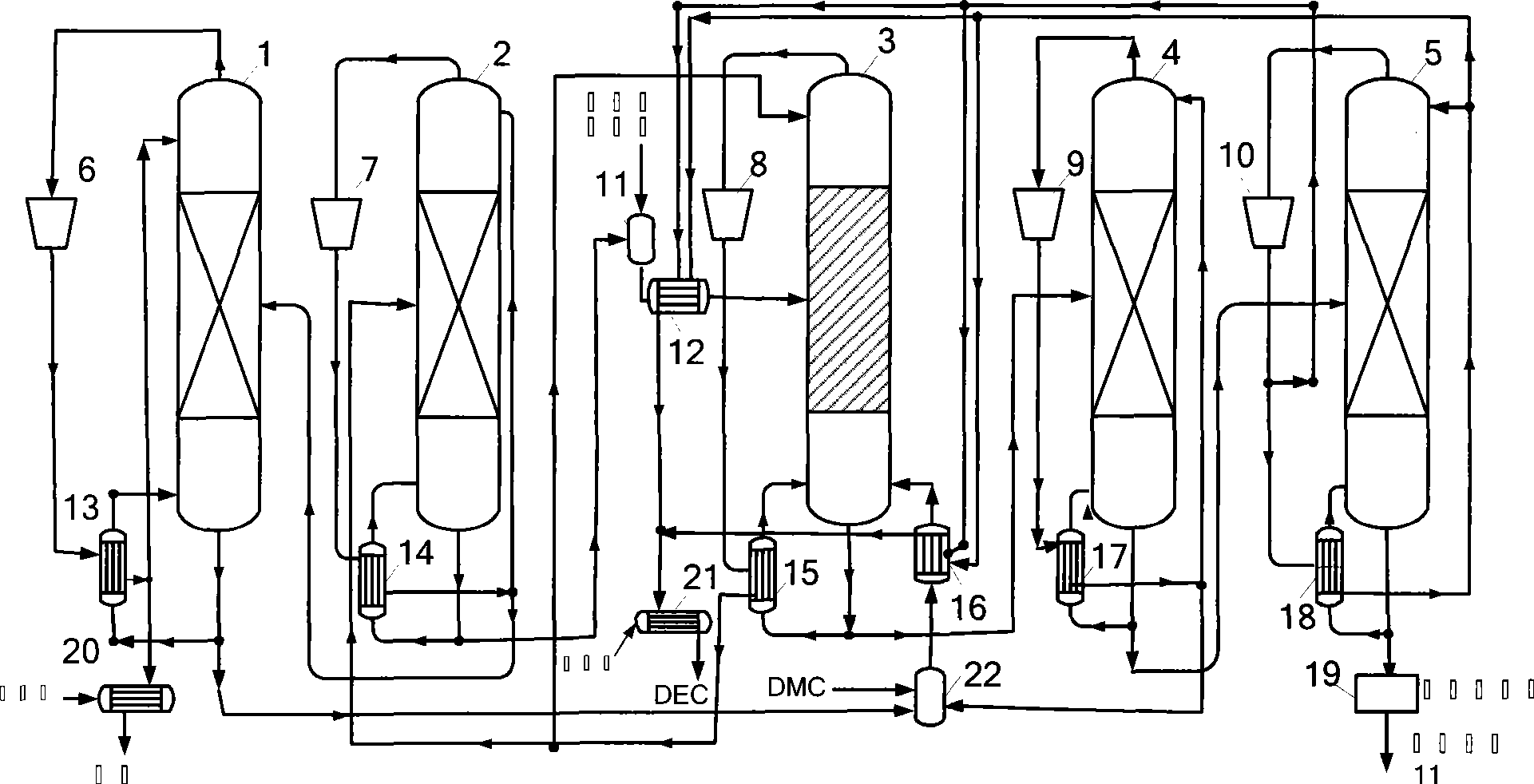

Heat pump distillation apparatus and process for diethyl carbonate

InactiveCN101367733AReduce consumptionReduce energy consumptionPreparation from organic carbonatesReboilerChemistry

The present invention relates to a heat pump distillation device for diethyl carbonate and a technology thereof. The device comprises a reaction distillation column, a heavy component distillation column, a light component distillation column, a dimethyl carbonate separation column and a diethyl carbonate rectification column; after steam materials at the tops of the five columns are led into a compressor and pressurized, and the condensing temperature is raised, the steam materials are then added into a reboiler on the column bottom to heat liquid materials coming from the column bottom; wherein, heat is exchanged among products at the top of the diethyl carbonate rectification column, dimethyl carbonate fed from the bottom of the reaction distillation column and ethyl alcohol fed from the middle part of the reaction distillation column, so as to meet the requirements for the temperature of materials fed into the reaction distillation column; the diethyl carbonate after the heat exchange and methanol steam at the top of the dimethyl carbonate separation column are both cooled by cooling water, or cooled by material solution in other technological methods; the whole material handling system is operated under the completely sealed condition; except a small amount of energy required for maintaining the operation of the compressor, the self-balance of heat can be realized in the present invention, the energy consumption required for producing unit diethyl carbonate is greatly reduced, no boiler is required for heat supply, simultaneously the consumption of cooling water is reduced, and the present invention achieves multiple benefits of energy conservation, water saving and environmental protection.

Owner:XI AN JIAOTONG UNIV

Intelligent combustion system and control method thereof

ActiveCN103162309AThe discharge temperature is stable and reliableQuality improvementHeating arrangementCombustion regulationCombustion systemOil pressure

The invention discloses an intelligent combustion system and a control method of the intelligent combustion system. The method includes collecting aggregate feeding temperature information, tail gas temperature and carbon monoxide (CO) content information, aggregate discharging temperature information and combustion flame image information, returning the collected information to a central processing unit (CPU), comparing the fed back information with set parameters of a combustor and calculating, controlling oil feeding amount, air feeding amount and atomization oil pressure according to calculated results, and inputting alarming information through an alarming device if abnormal information or mechanical failure information occurs in a process. Compared with the prior art, the intelligent combustion system and the control method of the intelligent combustion system can guarantee that flame is completely combusted and aggregate discharging temperature is controlled to be stable and reliable, and therefore the intelligent combustion system and the control method of the intelligent combustion system can guarantee that combustion heat is not wasted and quality of final end products is stable and reliable.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

Fixed fluidized bed reactor for test

InactiveCN102553496AAvoid stockpilingFully contactedChemical/physical processesCatalytic pyrolysisFluidized bed

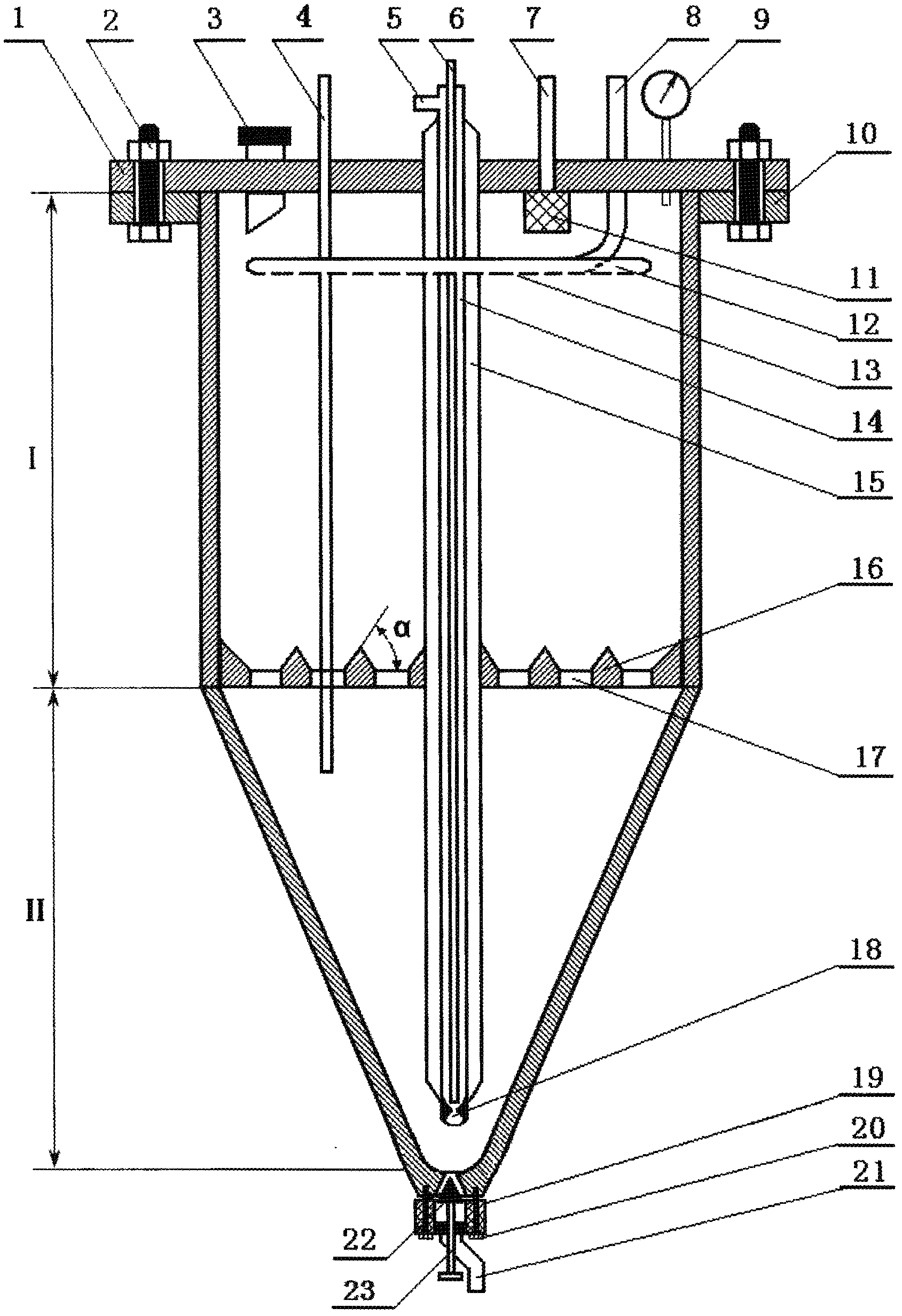

A fixed fluidized bed reactor for tests comprises a cylindrical settling section [I] and an inverted conical reaction section [II]; the cylindrical settling section [I] and the inverted conical reaction section [II] are of a same diameter and are fixedly connected; an upper end of the cylindrical settling section [I] is sealed by a top cover flange [1]; the fixed fluidized bed reactor for tests also comprises a cooling medium inlet tube [8] and a cooling medium distributor [12] used for cooling materials in the reactor, a concentric combined casing pipe composed of a raw material oil inlet pipe [6], an atomized steam inlet pipe [14], and a heat insulation pipe [15], a grid plate [16] with a conical projection, and a conical plug valve [19] for discharging catalysts from the bottom. The reaction is applicable to both catalytic cracking and catalytic pyrolysis reactions, has the characteristics of a constant charging temperature and state, good raw material oil atomization, full agent-oil contact, complete agent discharging, a stable reaction pressure, and wide raw material application scope, can increase the security of the test process, and the accuracy and repeatability of test results.

Owner:洛阳康润石油化工科技开发有限公司

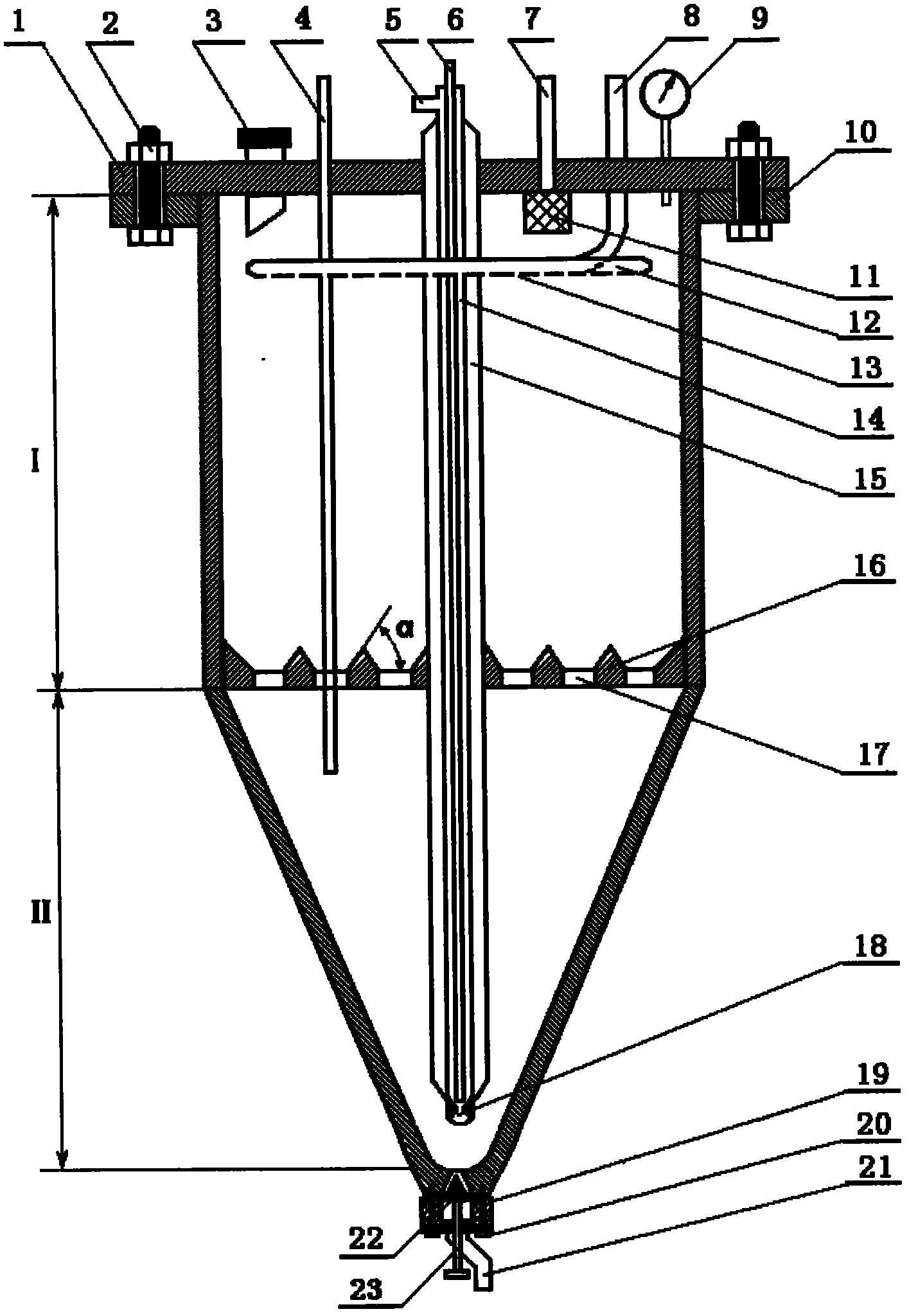

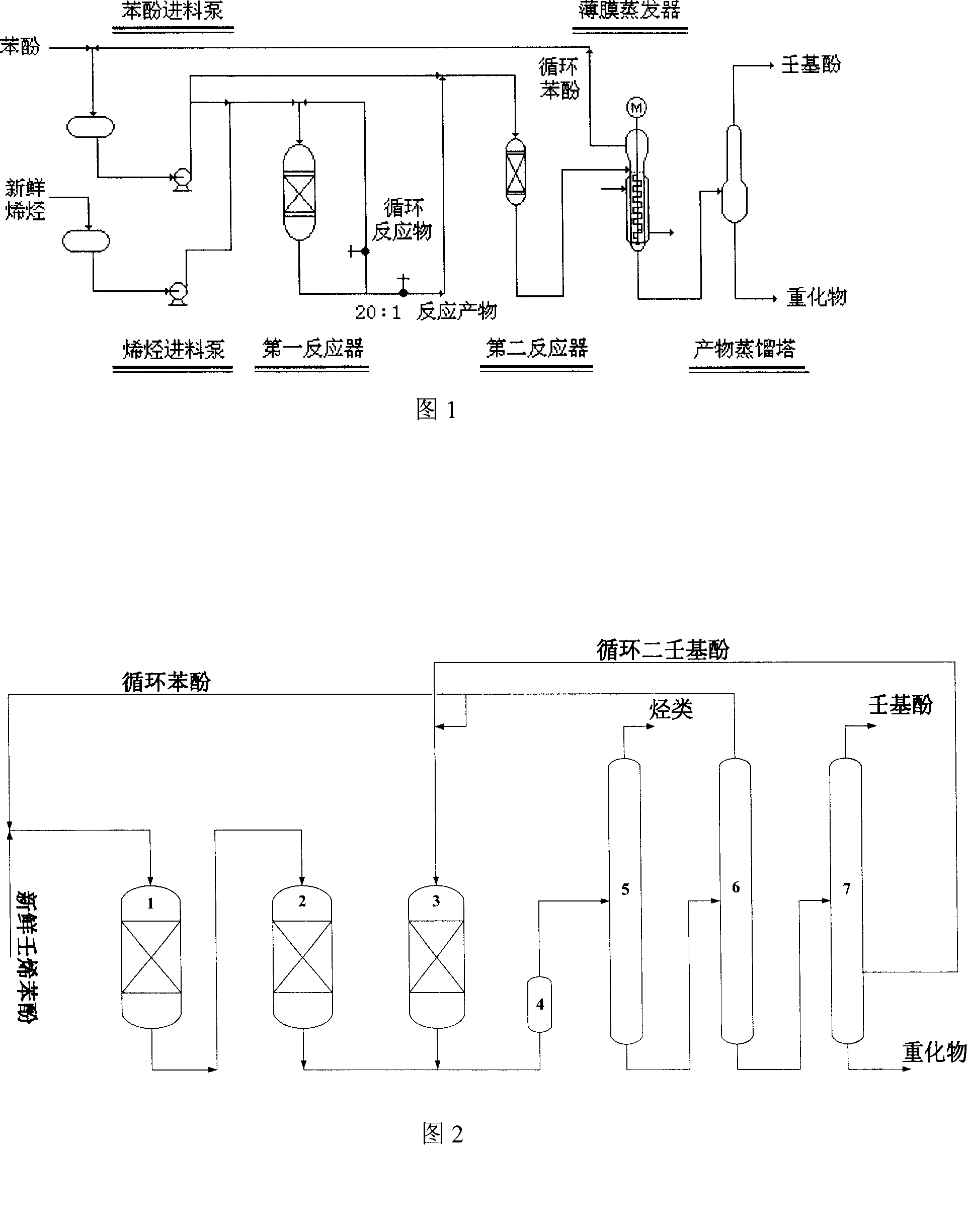

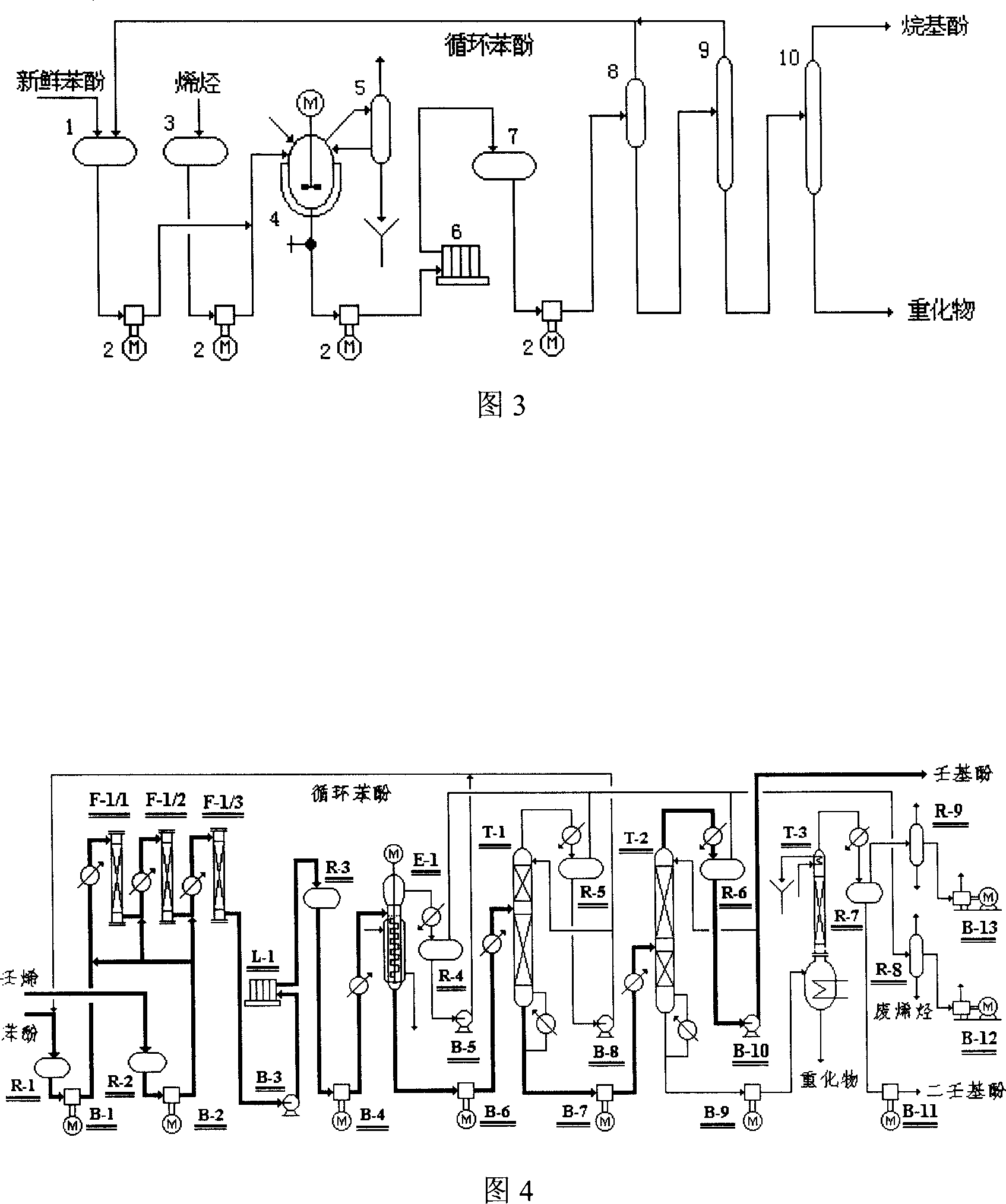

Nonyl phenol refining process

ActiveCN1970519AImproved color stabilityHigh yieldOrganic chemistryOrganic compound preparationTheoretical plateProcess engineering

The invention discloses a refining technique to synthesize industrial nonyl phenol, which comprises the following steps: a) evaporating to remove most of phenol in the industrial nonyl phenol; obtaining evaporator bottom material; b) distilling to remove phenol; obtaining rough nonyl phenol; setting the temperature of feed material into distill tower at 70-120 deg.c and tower top temperature at 40-85 deg.c and tower autoclave temperature at 170-215 deg.c; setting the total fill pressure at 0.4-1.0Kpa; controlling the reflux rate R between 0.5 and 2; obtaining the theoretical tower boards at 6-30 blocks; c) rectifying the rough nonyl phenol to obtain refined nonyl phenol and rough dinonyl phenol; setting the feed temperature of rectifying tower at 90-130 deg.c and tower top temperature at 80-170 deg.c and tower autoclave temperature at 180-260 deg.c; setting the total fill pressure at 0.4-1.0Kpa; controlling the reflux rate R between 0.4 and 2.5; obtaining the theoretical tower boards at 4-28 blocks.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for formation of micro-prilled polymers

ActiveUS20060115535A1Low viscosityPowder deliveryGranulation by liquid drop formationCost effectivenessPrill

A method for formation of micro-prilled poloxamer particles is disclosed. The particles find special use in pharmaceutical formulations. The process involves use of atomizing nozzles at higher than normal pressure atomizing gas, high atomizing gas temperature, use of high feed temperatures to reduce the viscosity of the poloxamer and optionally sieving after prill formation in prilling towers. The poloxamer particles are spherical and preferably have an average nominal diameter of less than or equal to 106 microns. The process is very cost effective and rapid.

Owner:BASF CORP

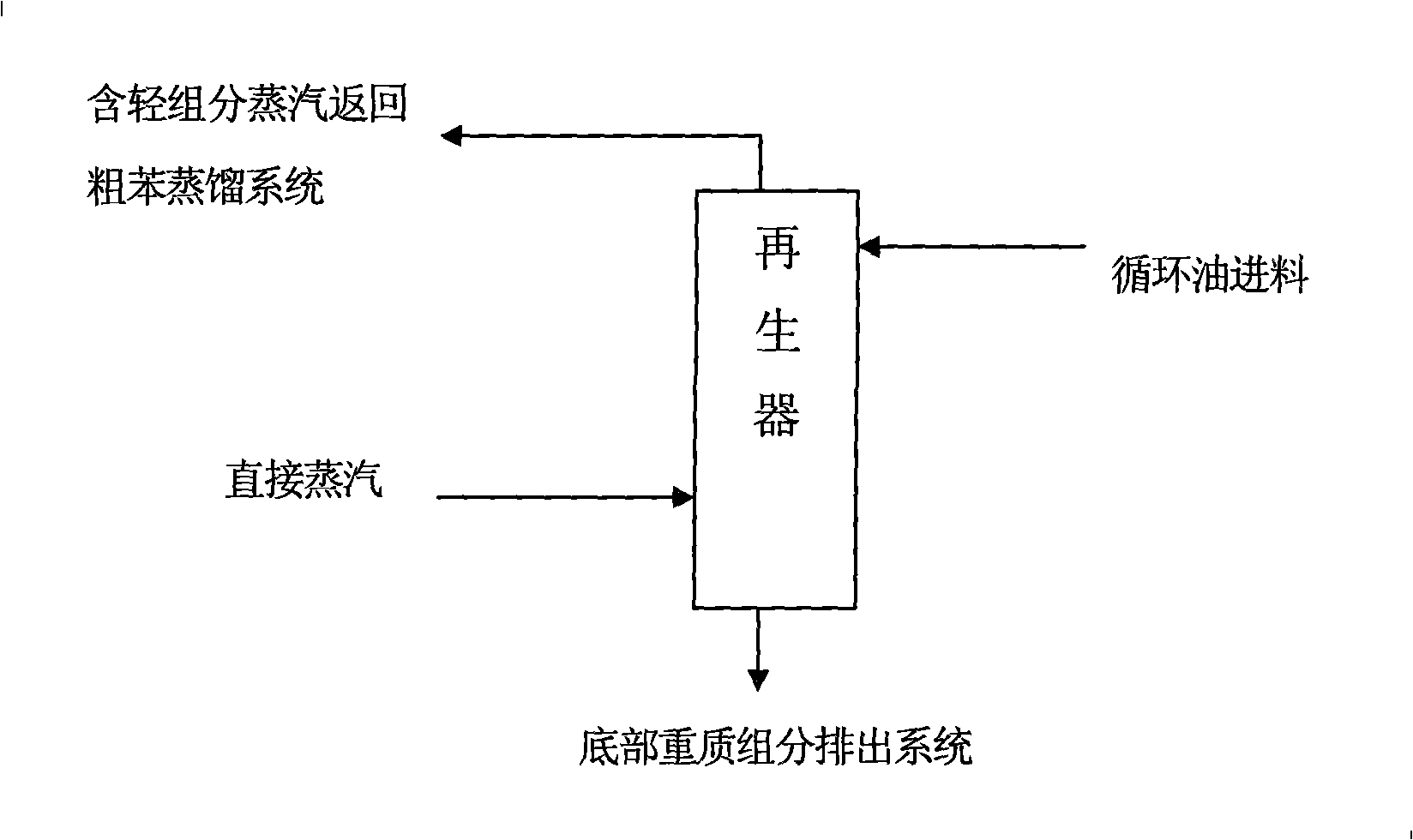

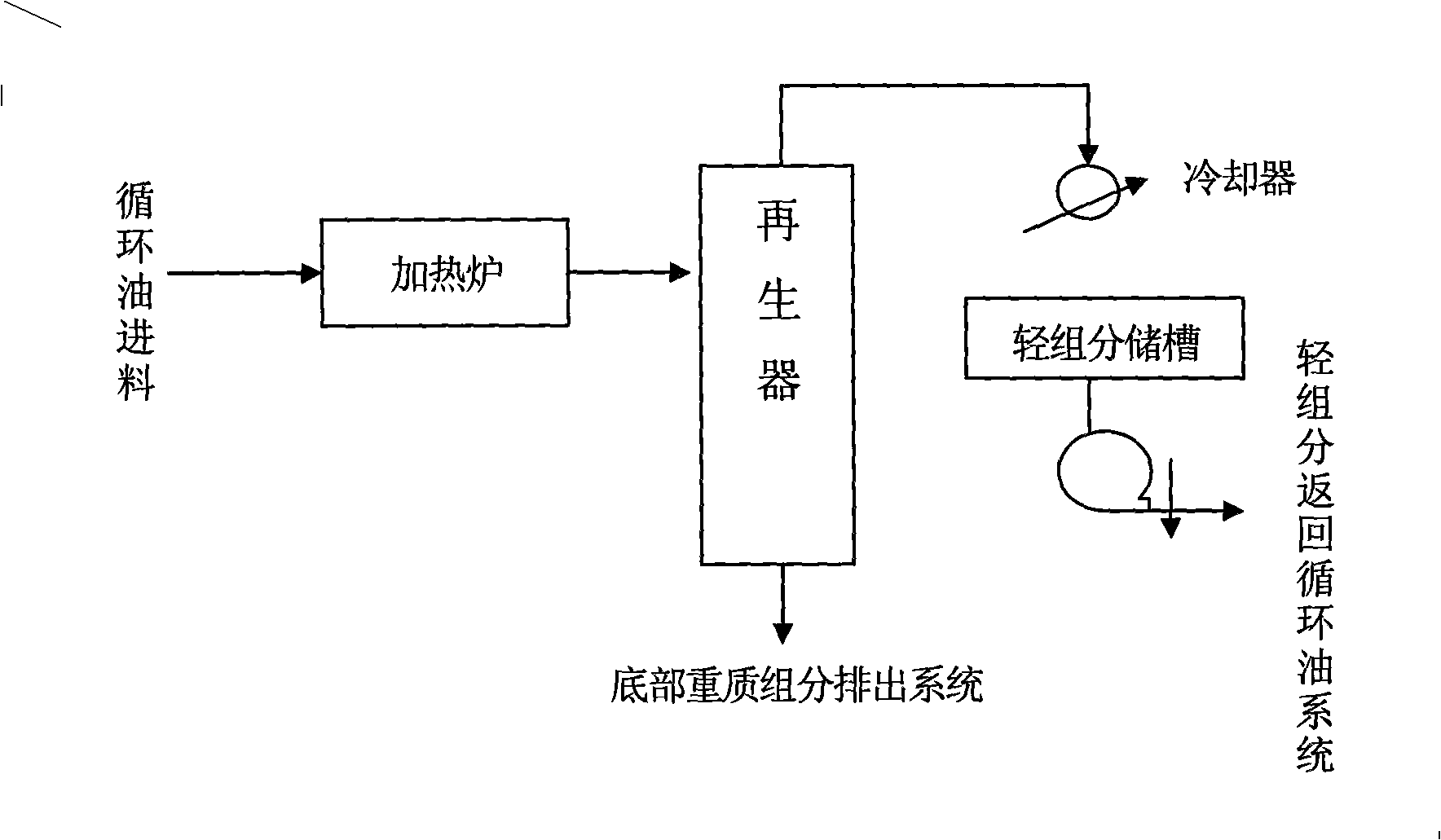

Novel regeneration process for circulation oil of crude benzol device

InactiveCN101289633AIncrease discharge viscosityImprove regeneration efficiencyCombustible gas purificationGas phaseDistillation

The invention discloses a novel method for regenerating crude benzole device cycle oil. The method adopts a flash distillation mode to carry out regeneration of cycle oil; a heating furnace is arranged in front of a regenerator, i.e. a flash tower; an indirect heating mode is adopted to raise the temperature of cycle regeneration feed oil which is fed in the regenerator from the upper part of the flash tower; after flash distillation and regeneration, light compositions in the tower top are cooled down by a top gas phase cooler and then are fed back to a cycle oil system by a pump, while heavy compositions in the bottom of the tower are discharged outside the system; the feeding capacity of regeneration oil is controlled to 1 to 2 percent of the circulating load of the cycle oil of the system; the feed temperature of the cycle regeneration oil at the outlet of the heating furnace is controlled to between 250 and 270 DEG C; the release viscosity of the heavy oil at the bottom of the regenerator is controlled to less than 7 (Engler viscosity); and the viscosity of the light oil at the top of the regenerator is controlled to between 1.0 and 1.2 (Engler viscosity). The method can effectively increase the regeneration efficiency of cycle oil and improves the quality of cycle oil.

Owner:BAOSHAN IRON & STEEL CO LTD

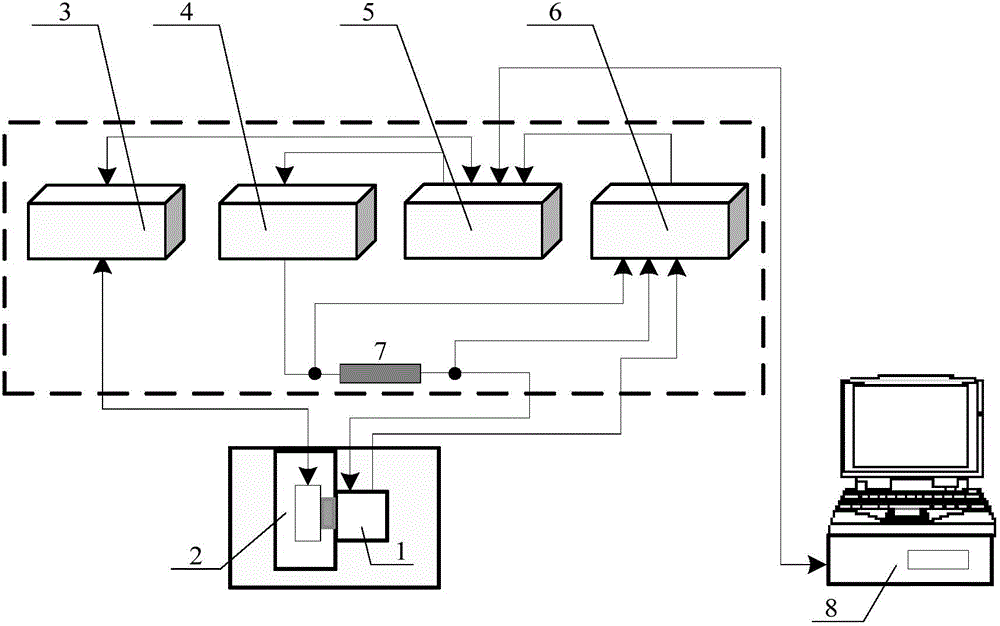

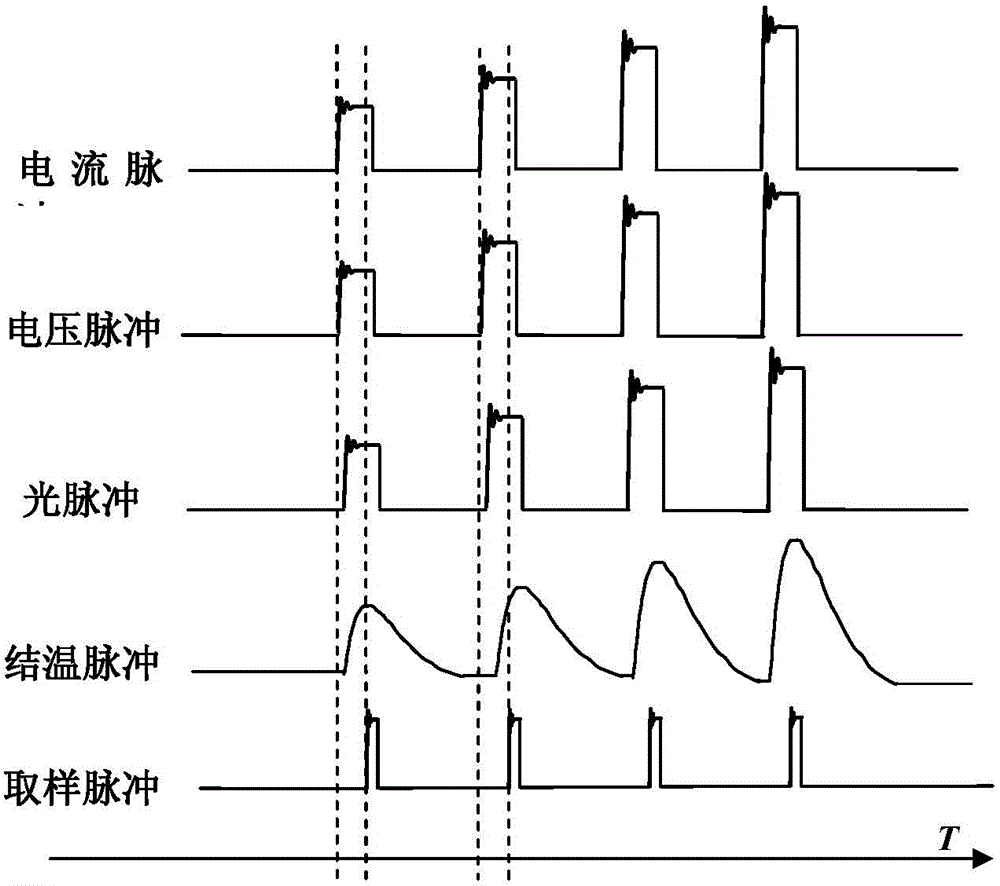

Pulse type power mode LED voltage-current-junction temperature characteristic testing device

InactiveCN104020405ANo heat build-upWill not cause temperature riseIndividual semiconductor device testingPulse parameterJunction temperature

The invention discloses a pulse type power mode LED voltage-current-junction temperature characteristic testing device and relates to a light emitting diode characteristic testing device. The device is provided with a clamp, a temperature control module, a pulse current source, a digital control module, a data collecting module, a precise sampling resistance and a computer, wherein a to-be-tested LED is installed on the clamp, the temperature control module is connected with the digital control module for setting and feeding temperature back, the temperature control module is connected with the clamp for heating or refrigerating and monitoring temperature, the pulse current source is connected with the digital control module for setting pulse parameters, the pulse current source is connected with one end of the precise sampling module and the other end of the precise sampling module is connected with the to-be-tested LED; both ends of the precise sampling module and the to-be-tested LED are connected with the data collecting module for collecting current and end voltage passing through the to-be-tested LED; the data collecting module is connected with the digital control module for data feedback, and the digital control module is connected with a computer through a USB.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com