Comprehensive treatment technology and system for ammonia containing organic waste gas and ammonia containing organic waste water

A technology for organic waste water and organic waste gas, which is applied in gas treatment, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of exhaust gas temperature higher than 200℃, high equipment investment cost and low treatment efficiency. , to achieve the effect of preventing condensation, no denitration agent consumption, and no fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

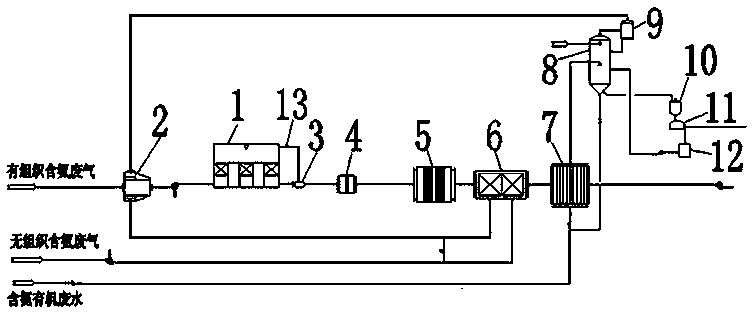

[0042] A kind of comprehensive treatment process of ammonia-containing organic waste gas and ammonia-containing organic waste water of the present invention, it comprises the following steps,

[0043] (1) Separately collect organized ammonia-containing waste gas, unorganized ammonia-containing waste gas and ammonia-containing organic wastewater;

[0044] (2) The ammonia-containing organic wastewater is sent to the forced heater through the forced circulation pump, and the waste heat in the flue gas is recovered. The temperature of the ammonia-containing organic wastewater is raised into high-temperature ammonia-containing organic wastewater, and the high-temperature ammonia-containing organic wastewater is sent to the spray evaporator Spray evaporation is carried out to evaporate most of the water and ammonia in the wastewater into ammonia-containing water vapor. The temperature of the ammonia-containing water vapor is 90°C. The evaporation of water increases the concentration ...

Embodiment 2

[0053] A kind of comprehensive treatment process of ammonia-containing organic waste gas and ammonia-containing organic waste water of the present invention, it comprises the following steps,

[0054] (1) Separately collect organized ammonia-containing waste gas, unorganized ammonia-containing waste gas and ammonia-containing organic wastewater;

[0055] (2) The ammonia-containing organic wastewater is sent to the forced heater through the forced circulation pump, and the waste heat in the flue gas is recovered. The temperature of the ammonia-containing organic wastewater is raised into high-temperature ammonia-containing organic wastewater, and the high-temperature ammonia-containing organic wastewater is sent to the spray evaporator Spray evaporation is carried out to evaporate most of the water and ammonia in the wastewater into ammonia-containing water vapor. The temperature of the ammonia-containing water vapor is 90°C. The evaporation of water increases the concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com