Patents

Literature

105results about How to "Raise the exhaust gas temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

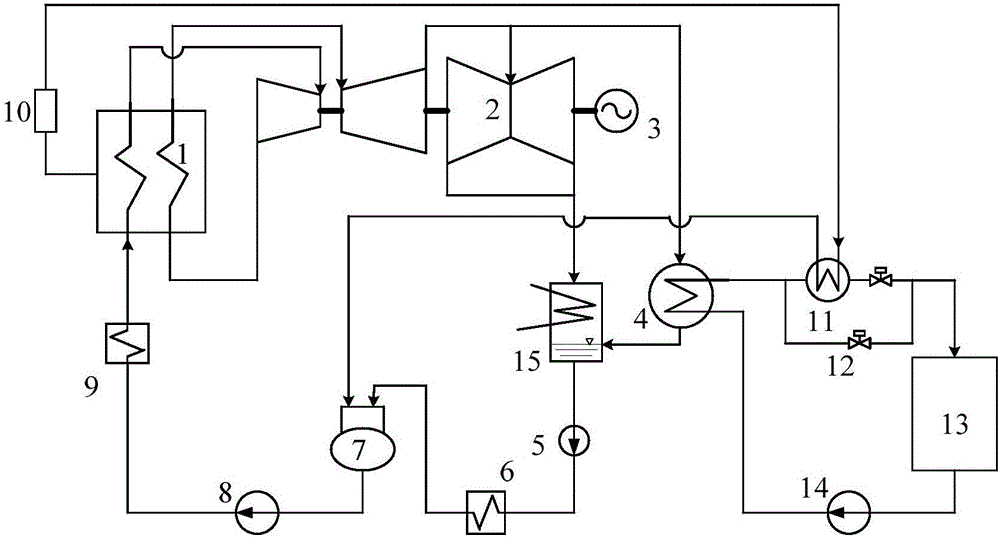

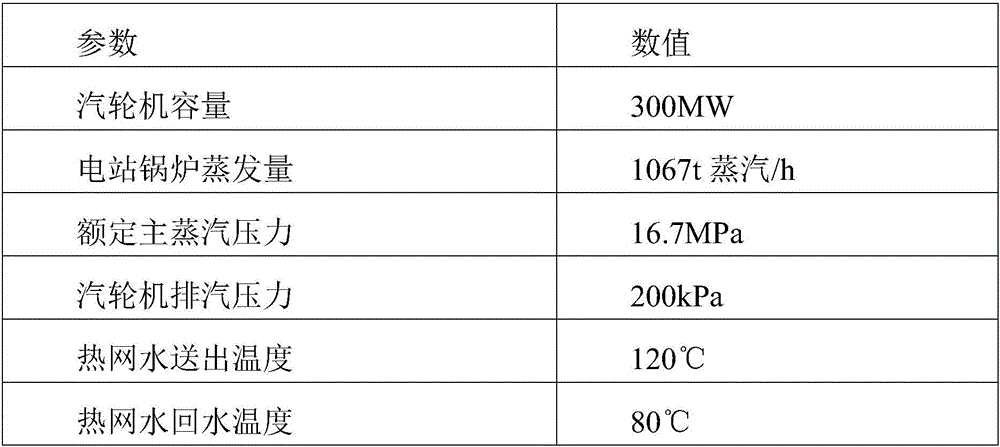

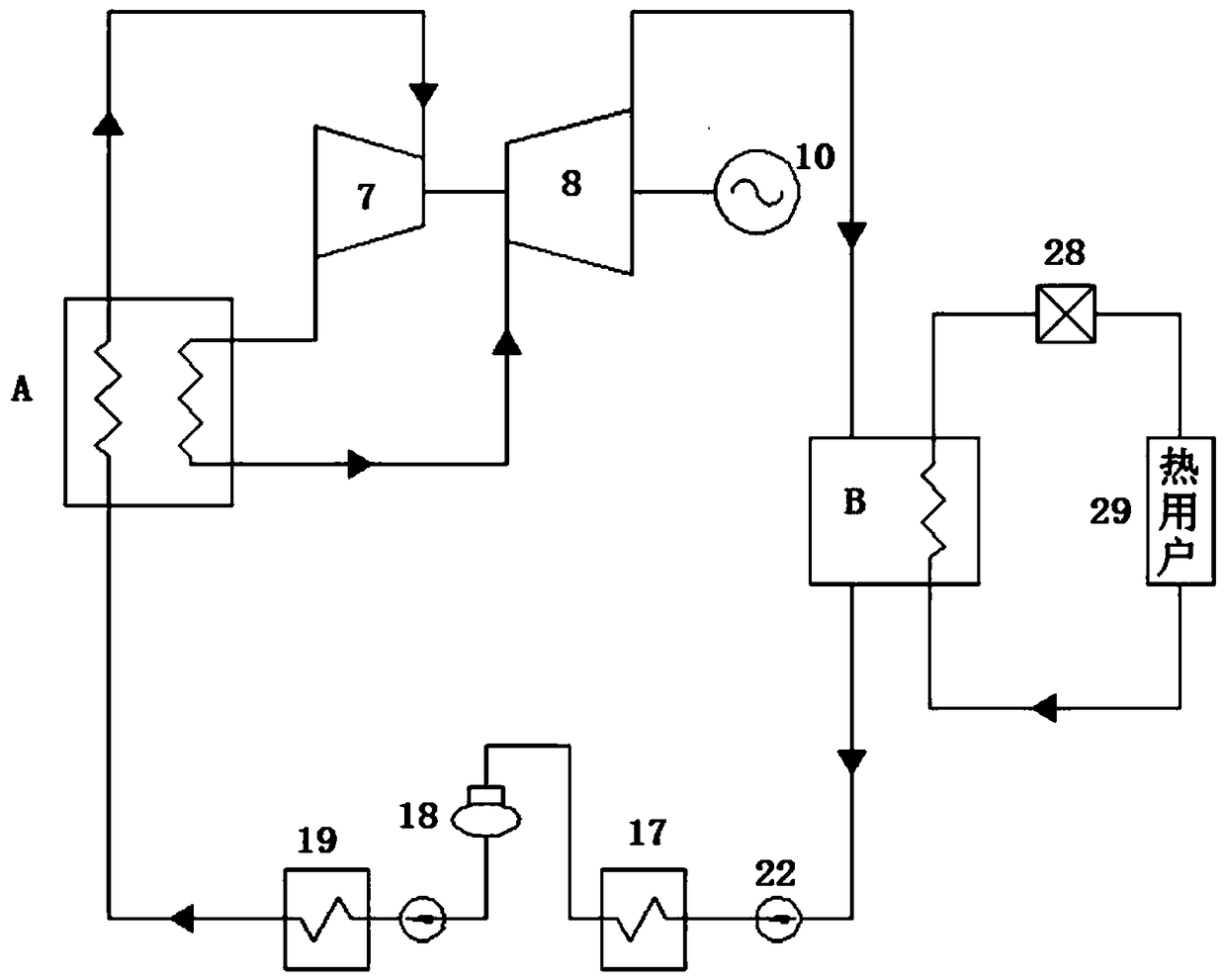

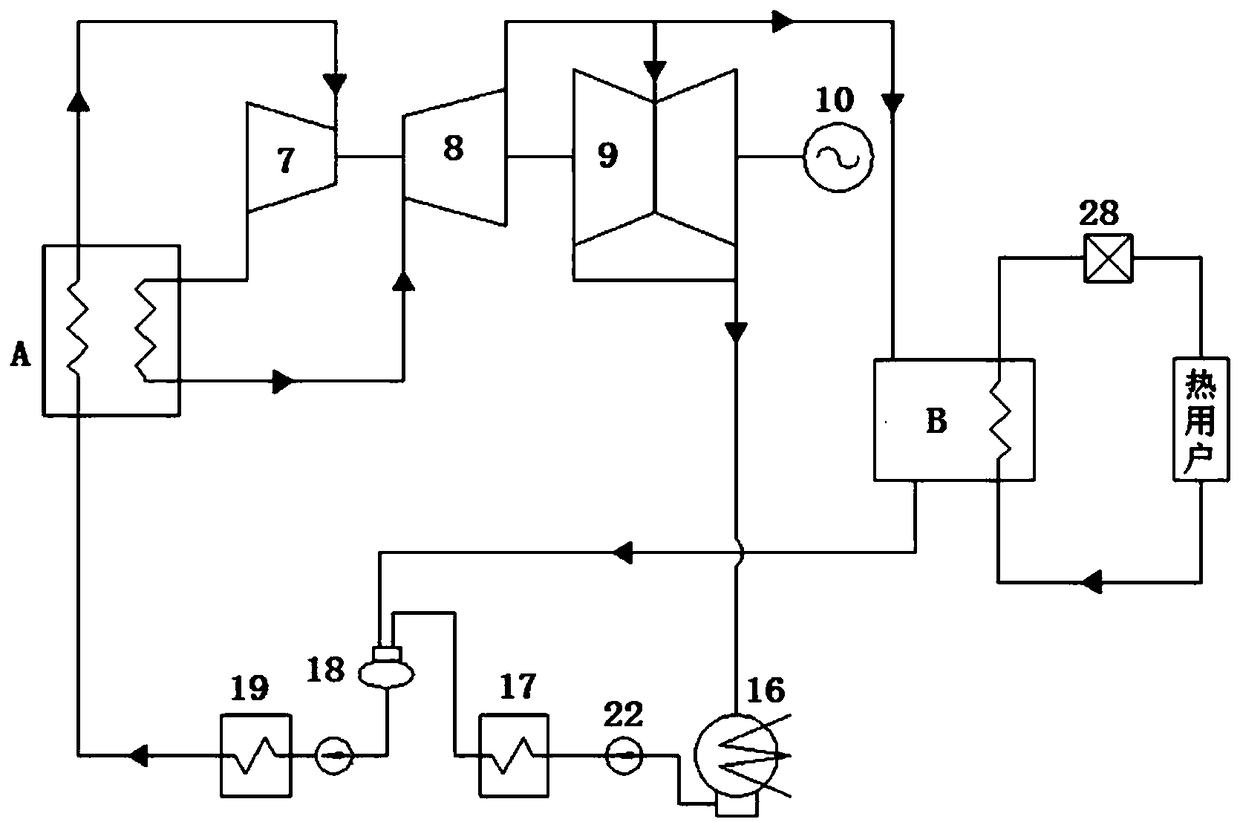

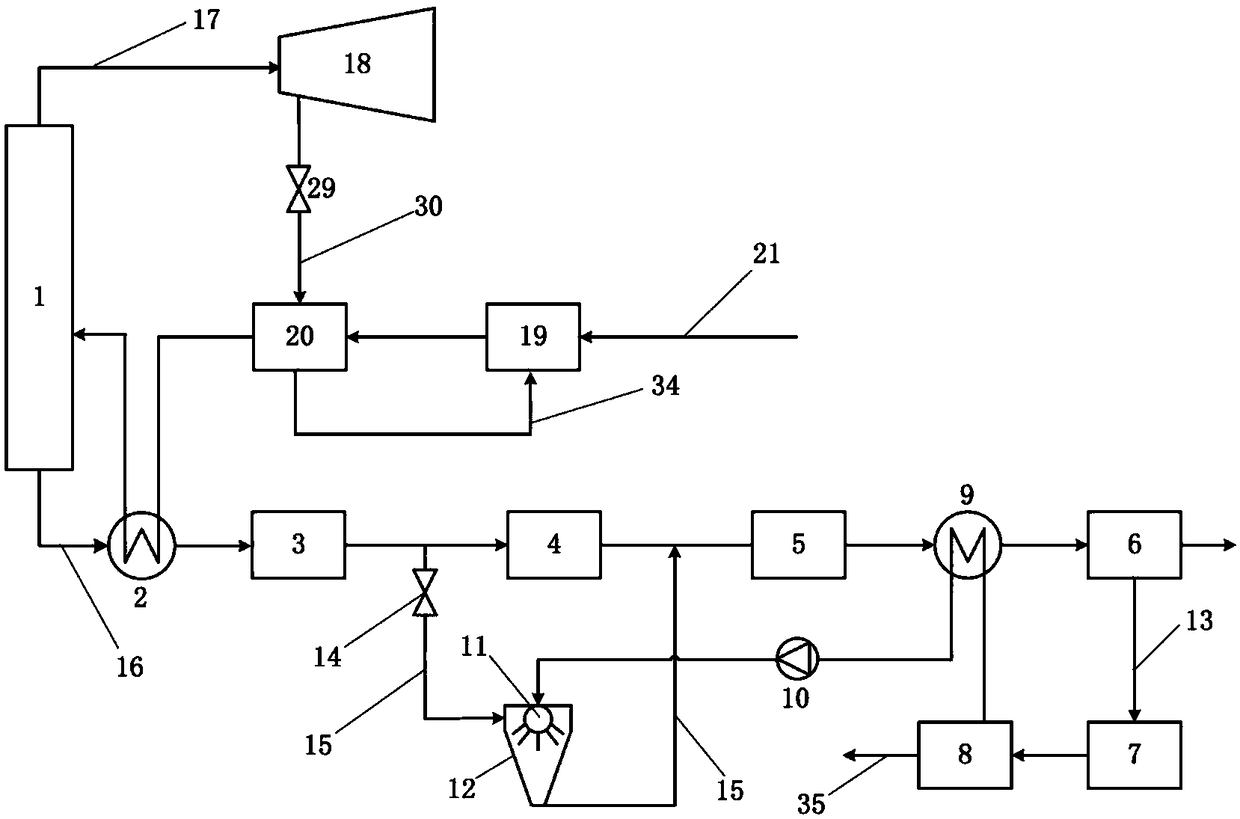

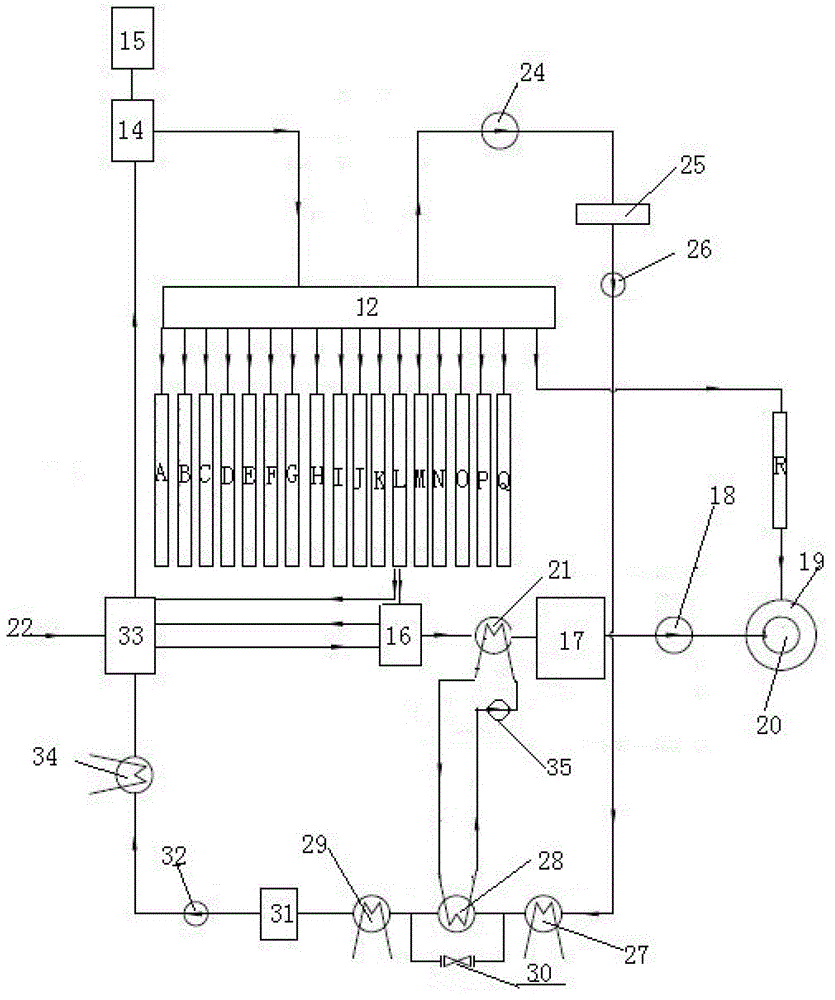

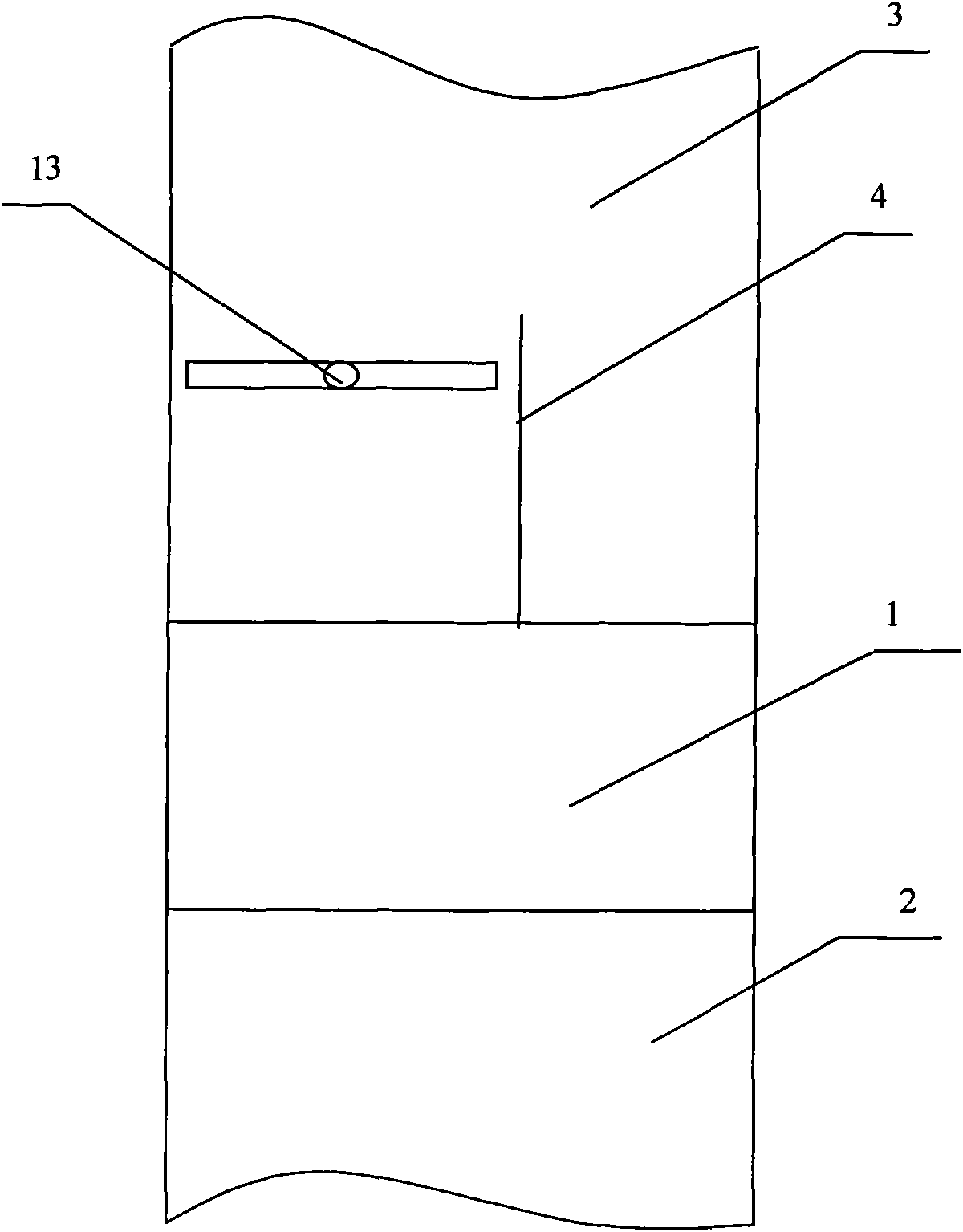

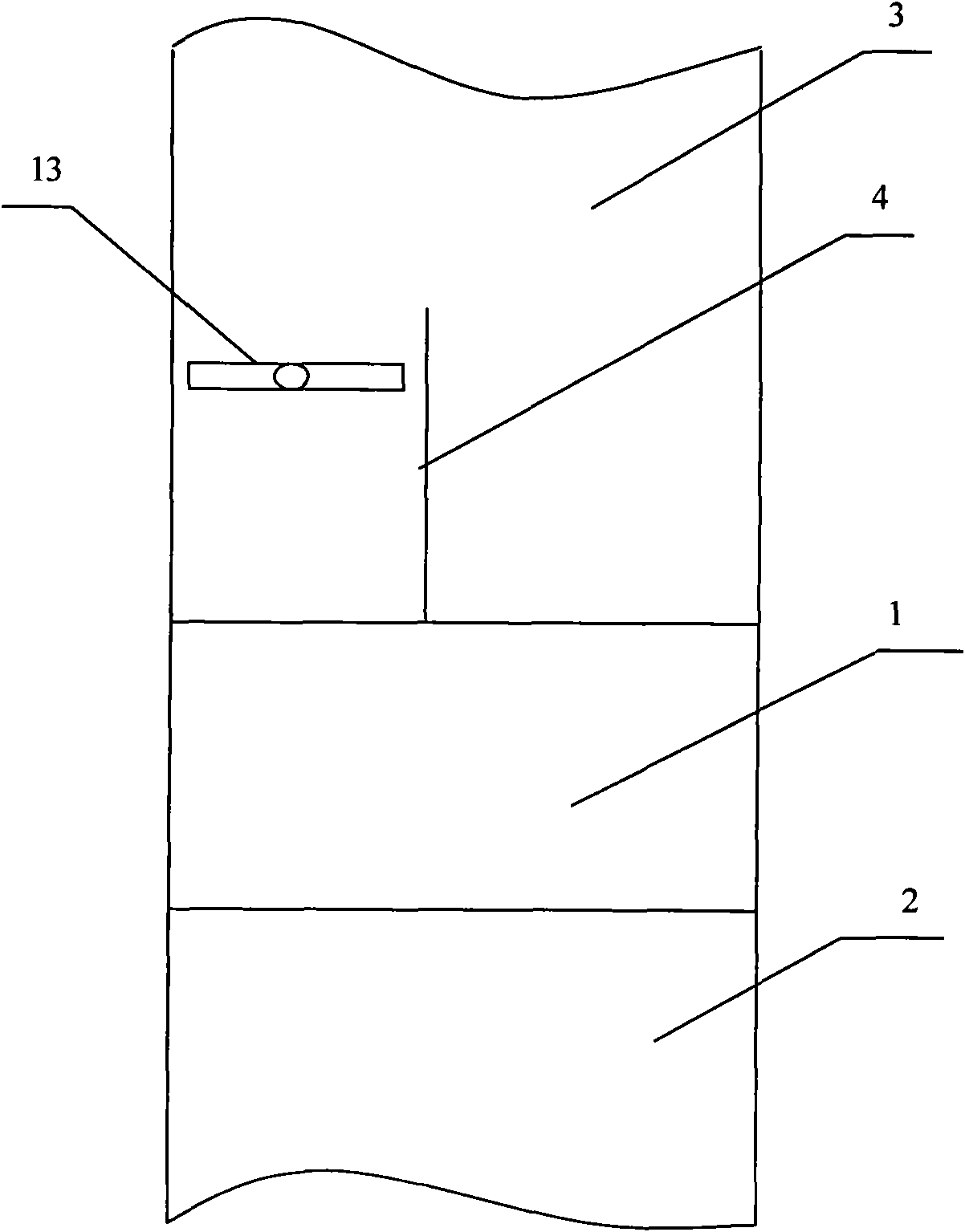

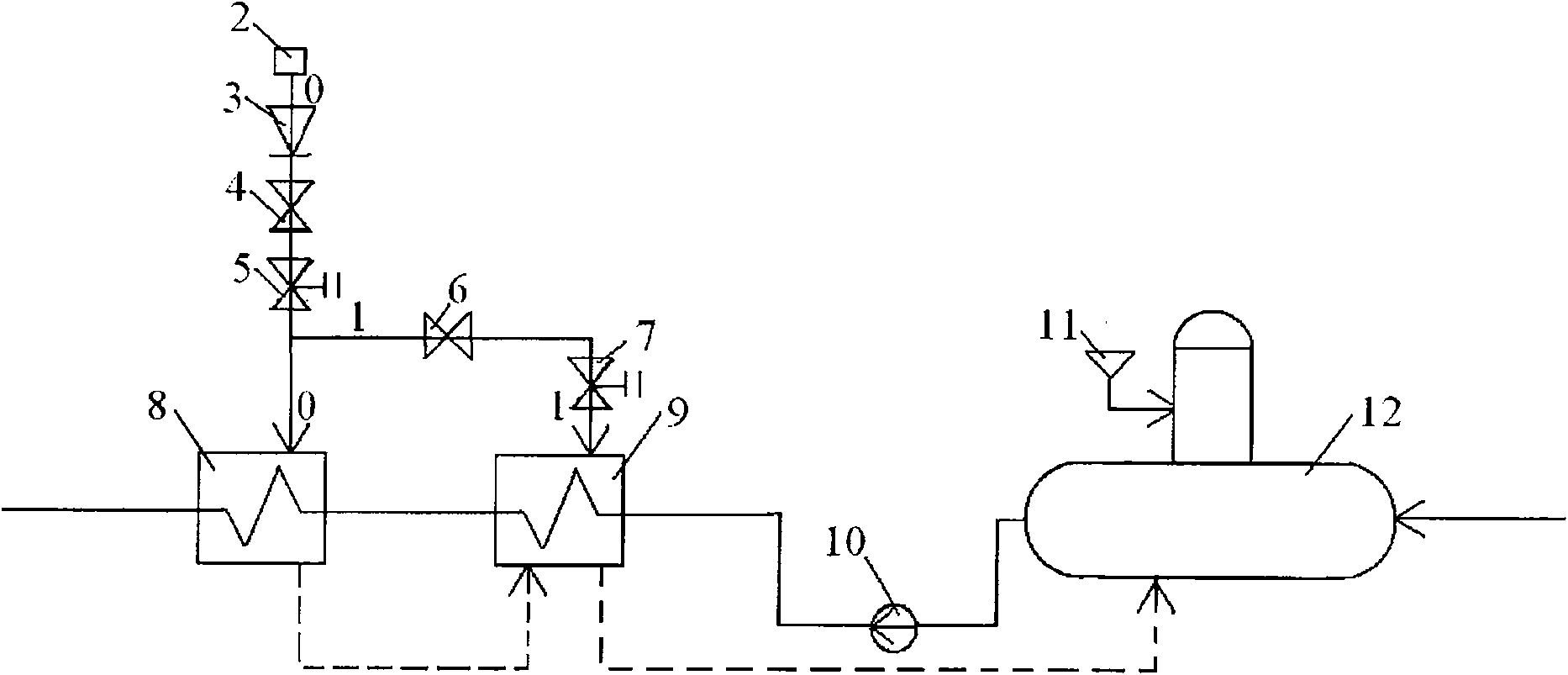

Thermoelectric decoupling heating system extracting steam from utility boiler

InactiveCN106194296AAchieve thermoelectric decouplingCapable of peak regulationSteam engine plantsEngineeringHigh pressure

The invention discloses a thermoelectric decoupling heating system extracting steam from a utility boiler. A steam condensing heat exchanger is mainly adopted for heating return water of a heating network, a steam extraction heater is then additionally arranged behind the steam condensing heat exchanger, and heat source steam of the steam extraction heater is extracted from an overheating section or a reheating section of the utility boiler. When a turbine power generation system is under the high load, exhaust steam of a turbine or steam extracted from a medium-pressure cylinder and low-pressure cylinder communicating pipe of the turbine is completely adopted to be condensed in the steam condensing heat exchanger to release heat to heat the water of the heating network, when the load of the turbine power generation system is reduced and the heating capability of the steam condensing heat exchanger is insufficient, high-pressure steam is extracted from the utility boiler, subjected to pressure reduction and sent to the steam extraction heater, the water of the heating network is further heated, and therefore it is ensured that the heating capability is not reduced under the low power generation load. According to the thermoelectric decoupling heating system extracting the steam from the utility boiler, thermoelectric decoupling of a heating power plant can be achieved, it is ensured that the heating capability under the low power generation load is not reduced, in addition, decreasing of the temperature of tail smoke of the utility boiler under the low load can be relieved, and it is ensured that a boiler denitration system works normally.

Owner:HUANENG POWER INT INC +1

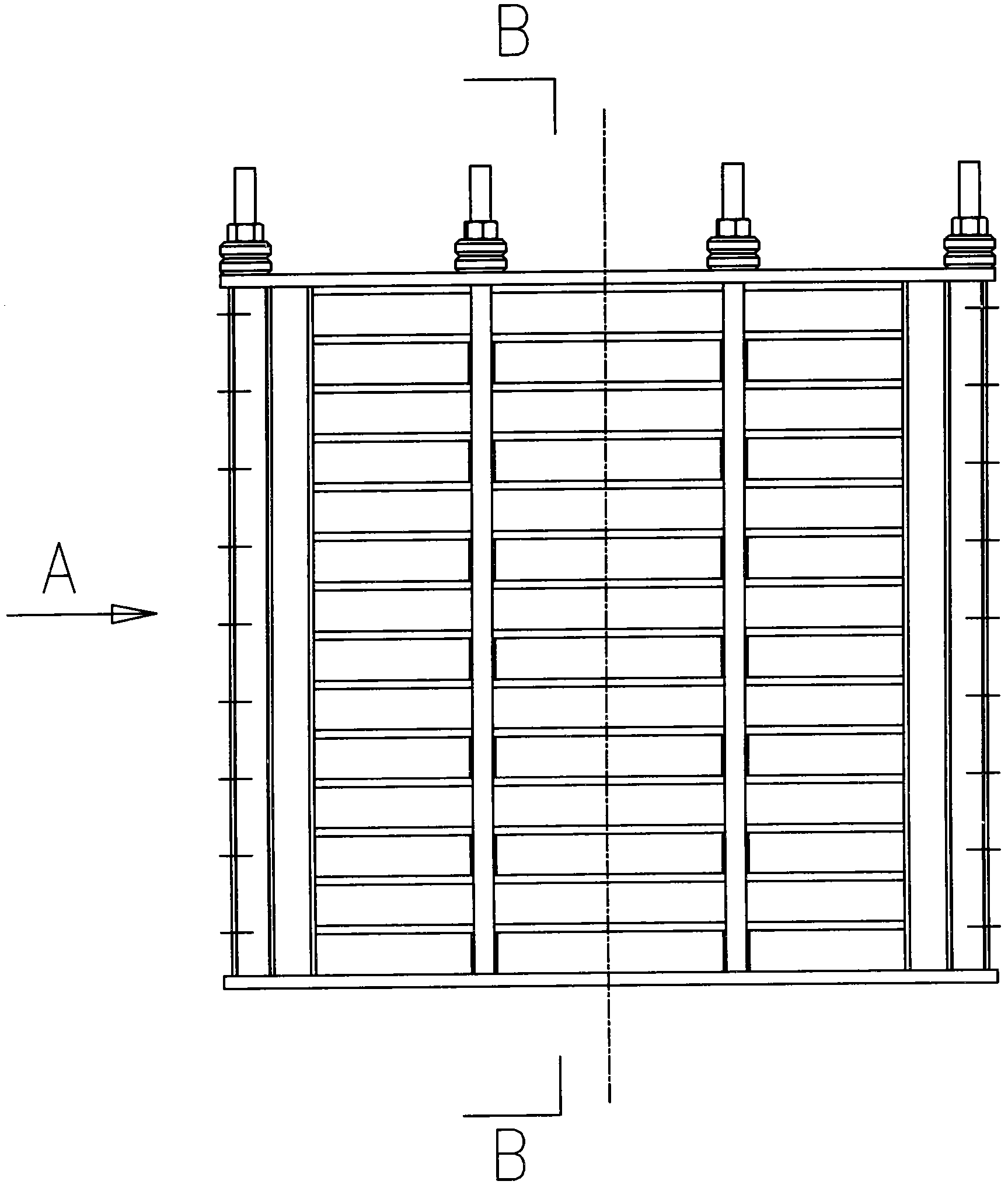

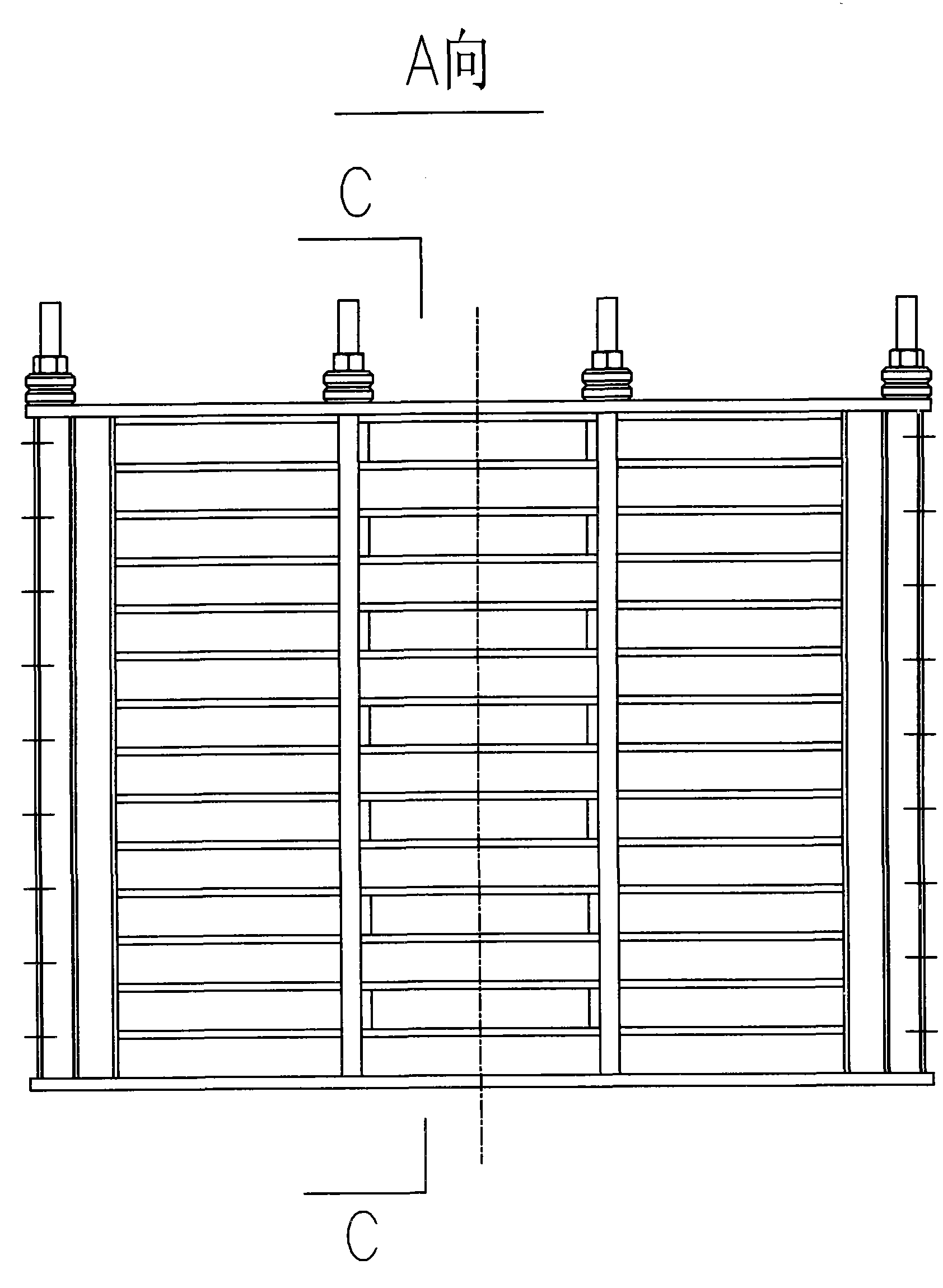

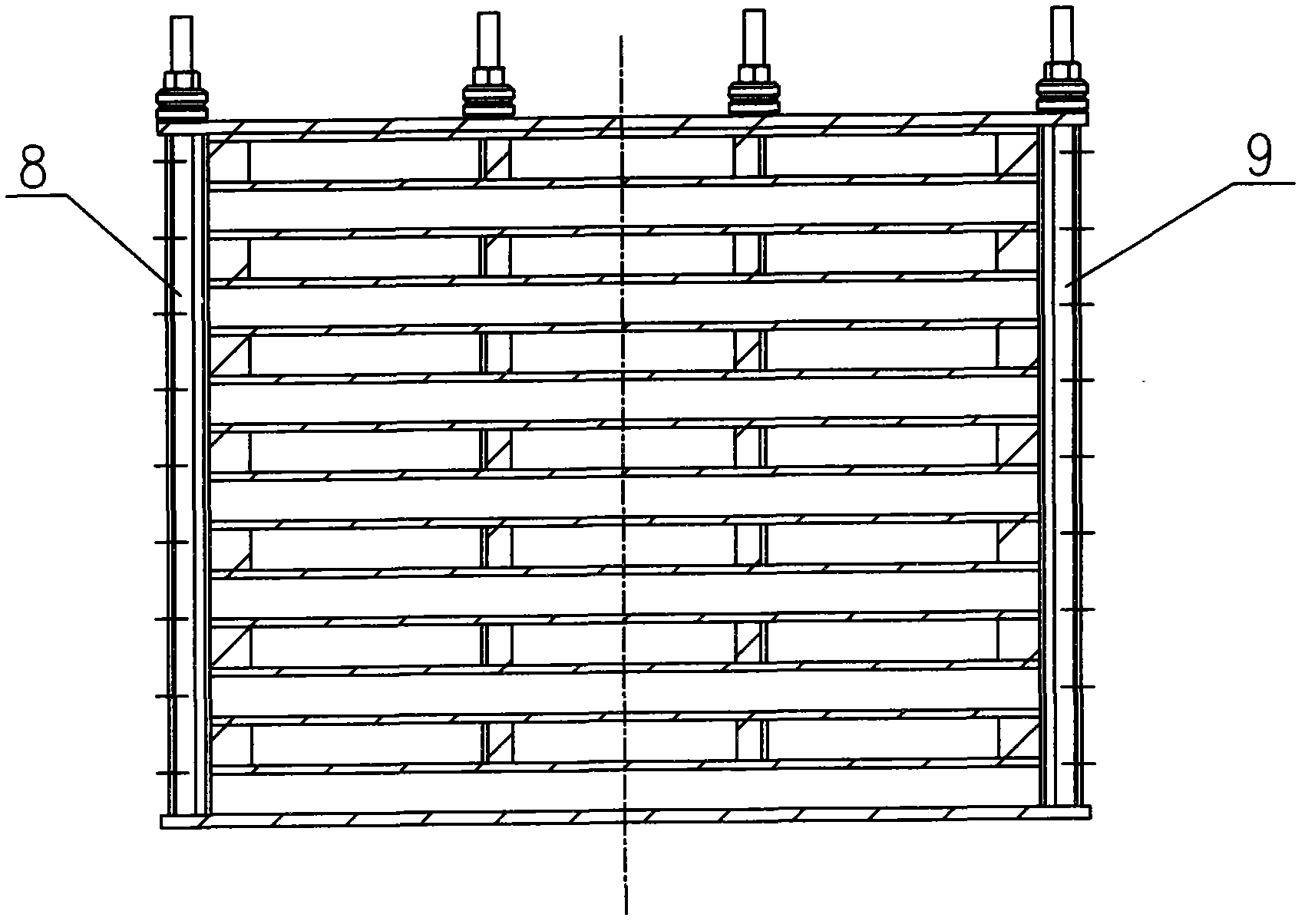

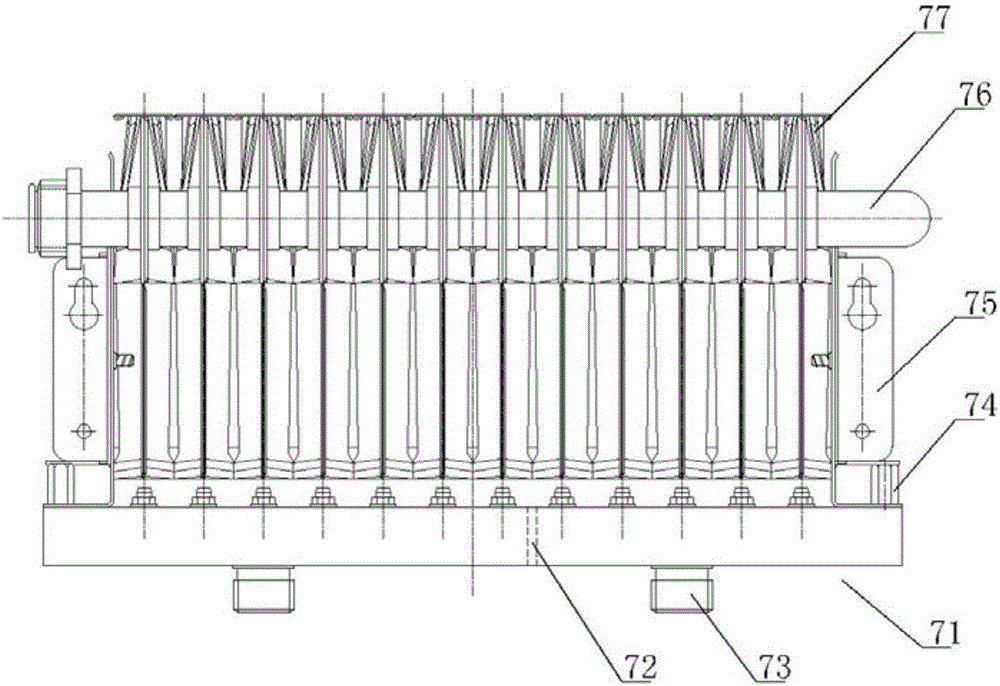

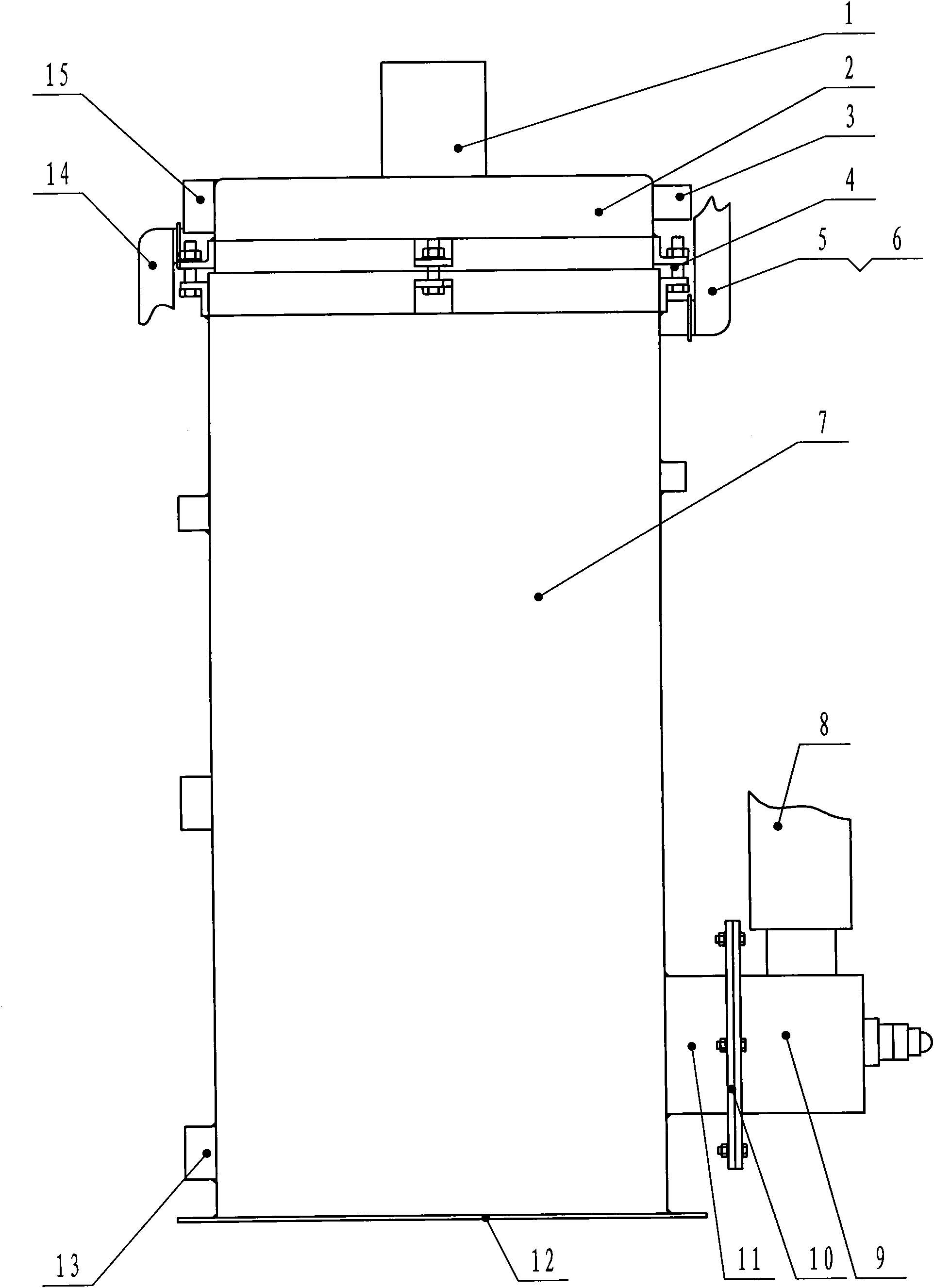

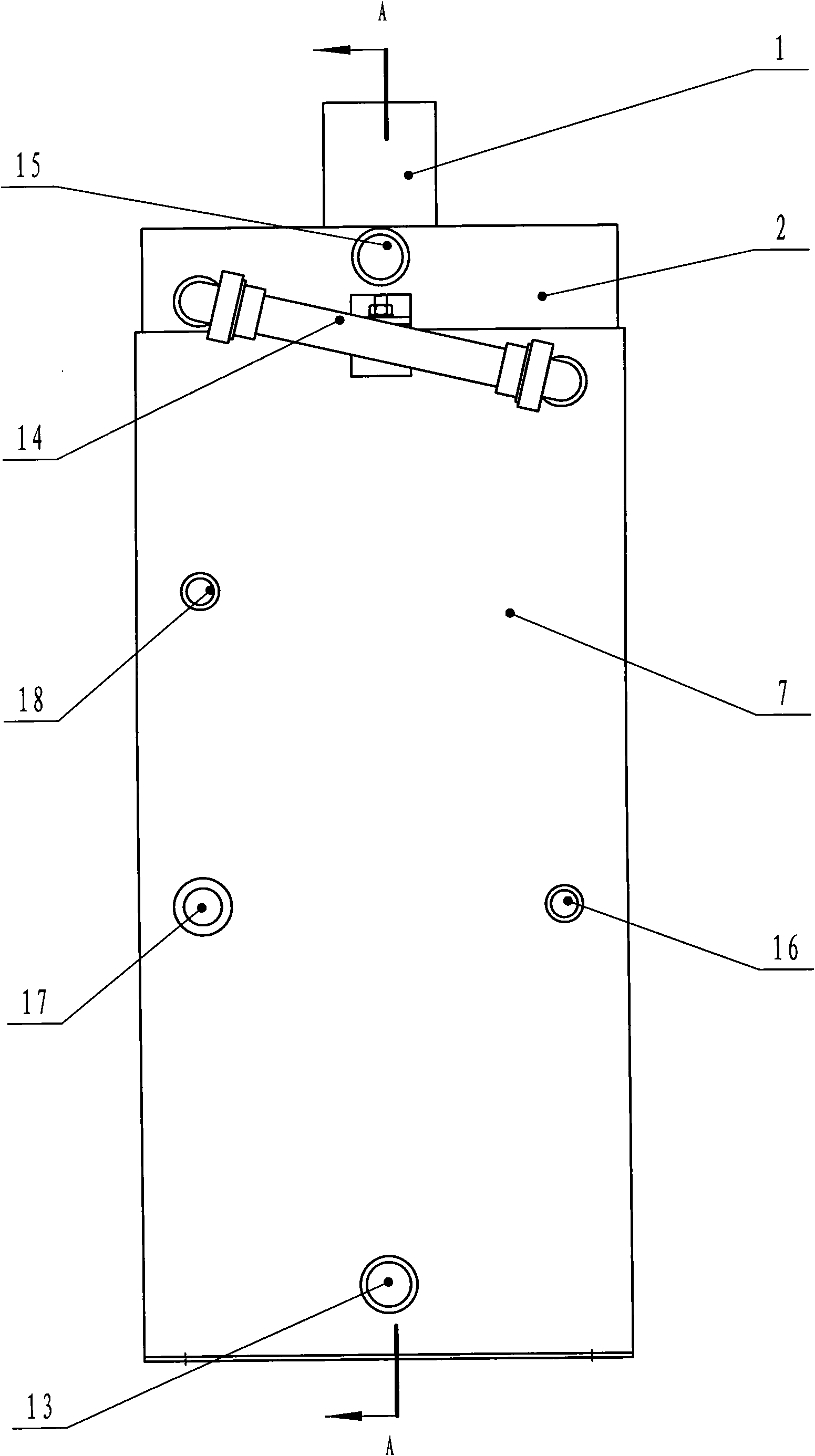

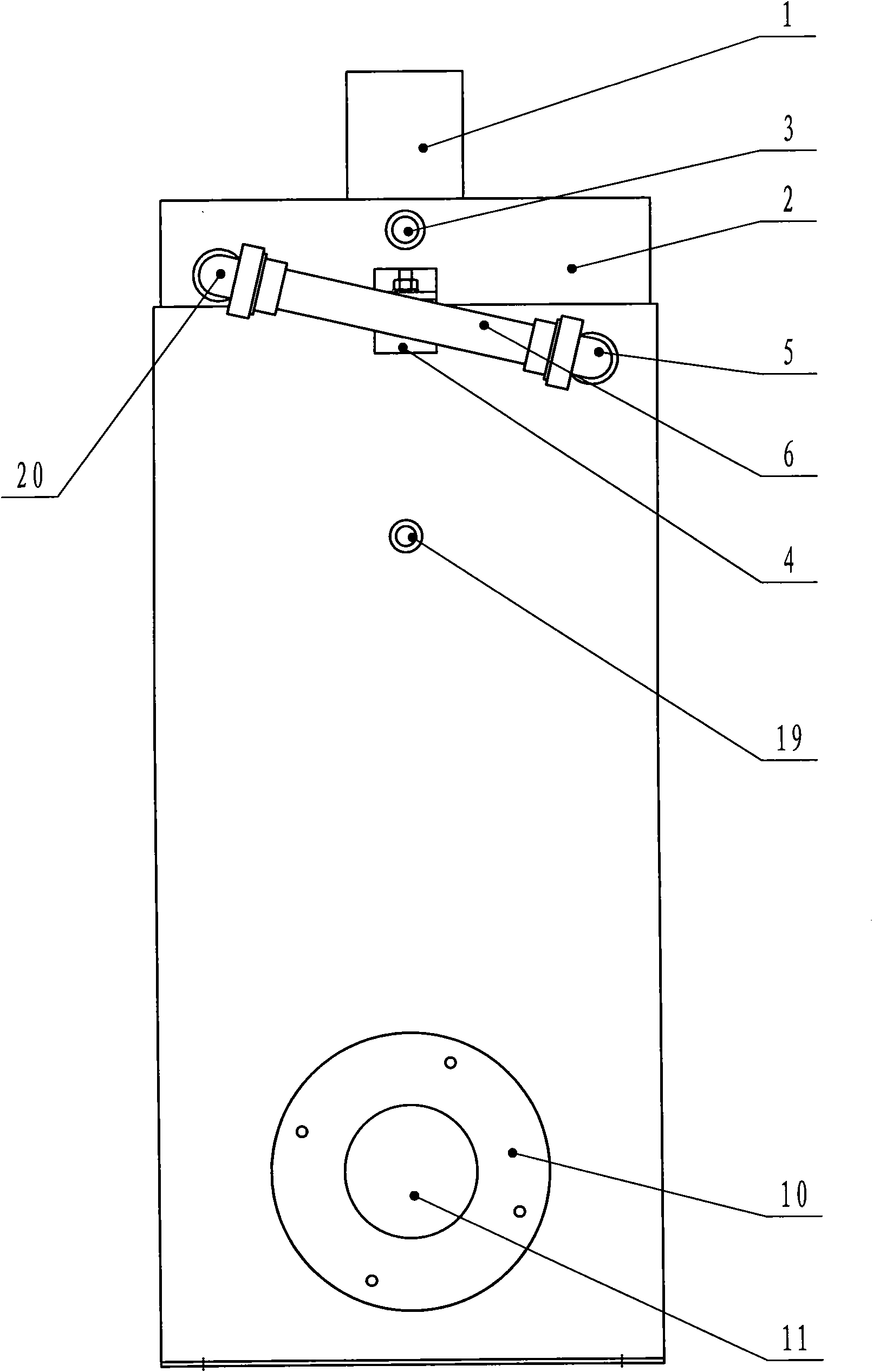

Plate type air preheater with glass as heat exchange plate

ActiveCN102032587AStrong corrosion resistanceGood energy saving effectIndirect carbon-dioxide mitigationHeat exchanger casingsDew pointCorrosion

The invention provides a plate type air preheater with glasses as heat exchange plates, belonging to the technical field of heat exchangers. The plate type air preheater comprises an air preheater frame, the air preheater frame comprises an upper cover plate (10), a lower bottom plate (11) and a stand column (5) and is internally provided with a plurality of heat exchange plates (1) which are correspondingly placed in vertical direction; a sealing strip (4) is arranged between every two heat exchange plates (1) which are adjacent in vertical direction; the sealing strips (4) are mutually staggered at 90 degrees and form a plurality of sealing fluid channels which are adjacent and mutually staggered at 90 degrees by being placed in a staggered way so as to respectively form hot fluid channels and cold fluid channels; rectangular glass plates are adopted as the heat exchange plates (1), and the glass can be silicon-boron glass and boron-free low-alkali glass or quartz glass; and supporting strips (2) which are rectangular or S-shaped nonmetal plate bars are arranged among the fluid channels formed by the upper and lower heat exchange plates (1). The invention has dew point corrosion resistance, efficiently recovers the low-temperature exhaust heat of smoke and can reduce the temperature of discharged smoke and enhance the efficiency of a heating furnace.

Owner:LUOYANG RUICHANG PETROCHEM EQUIP

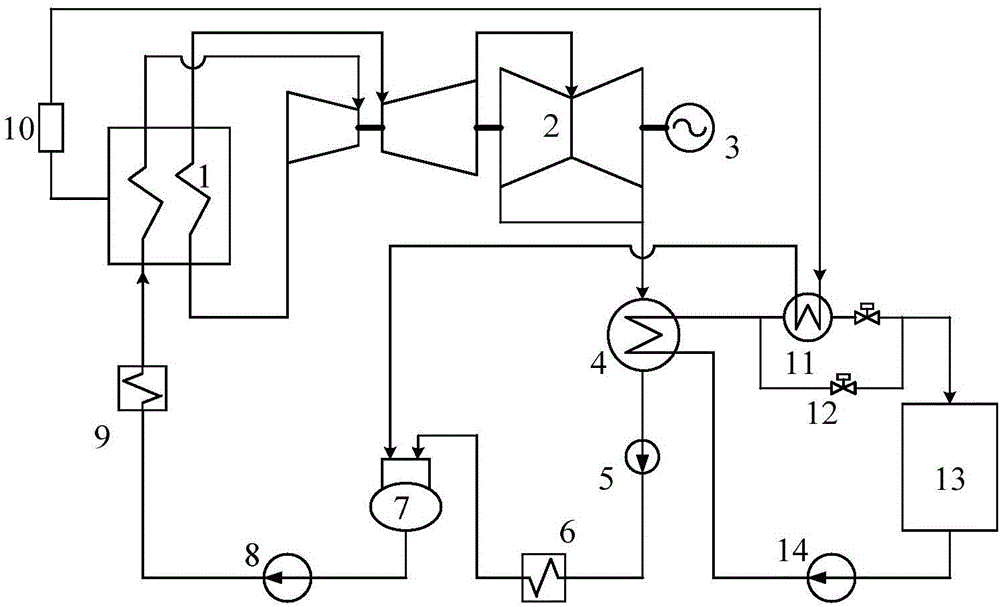

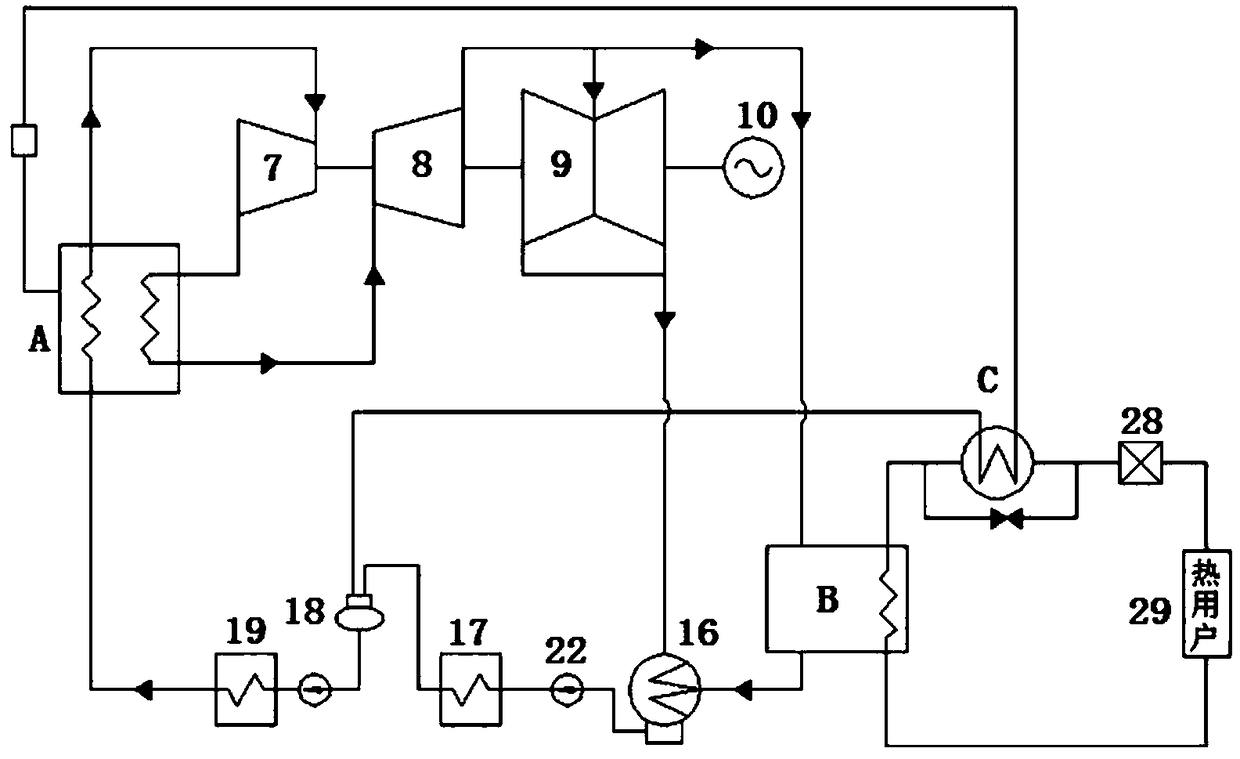

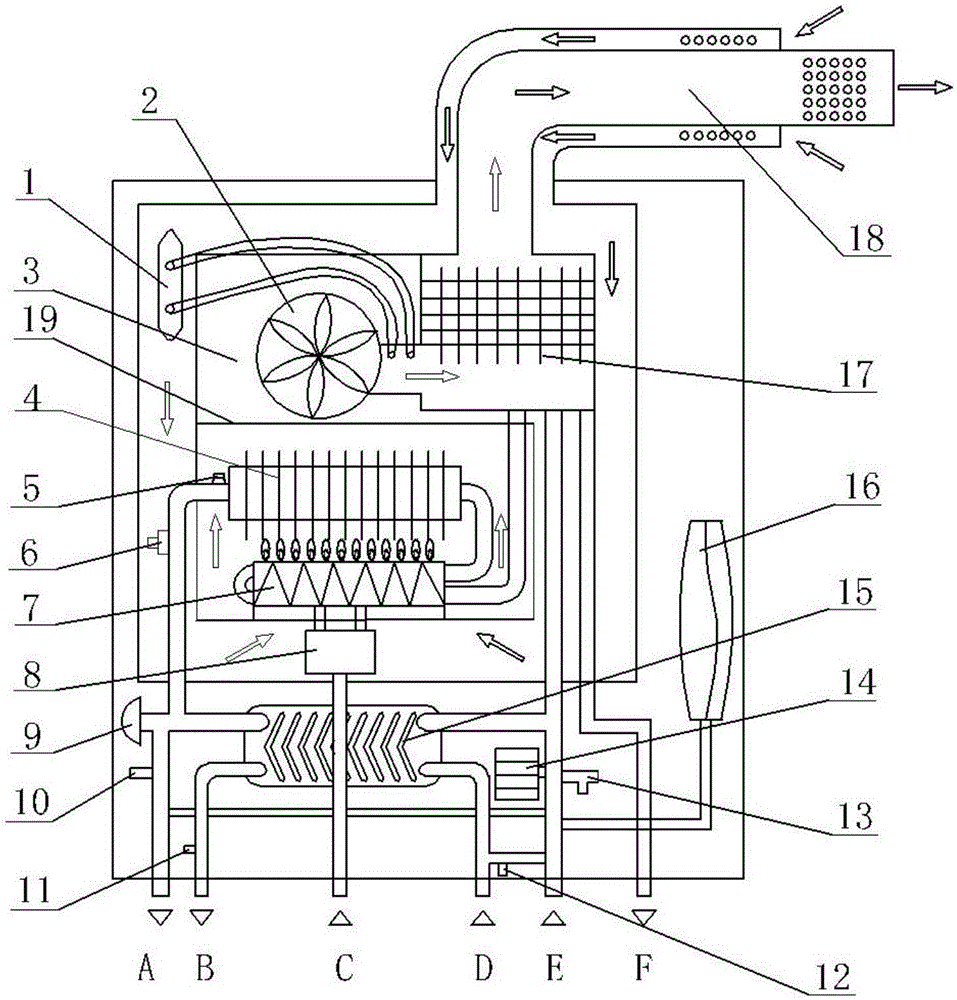

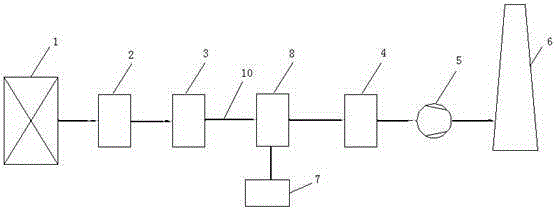

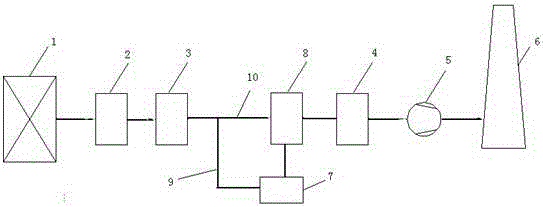

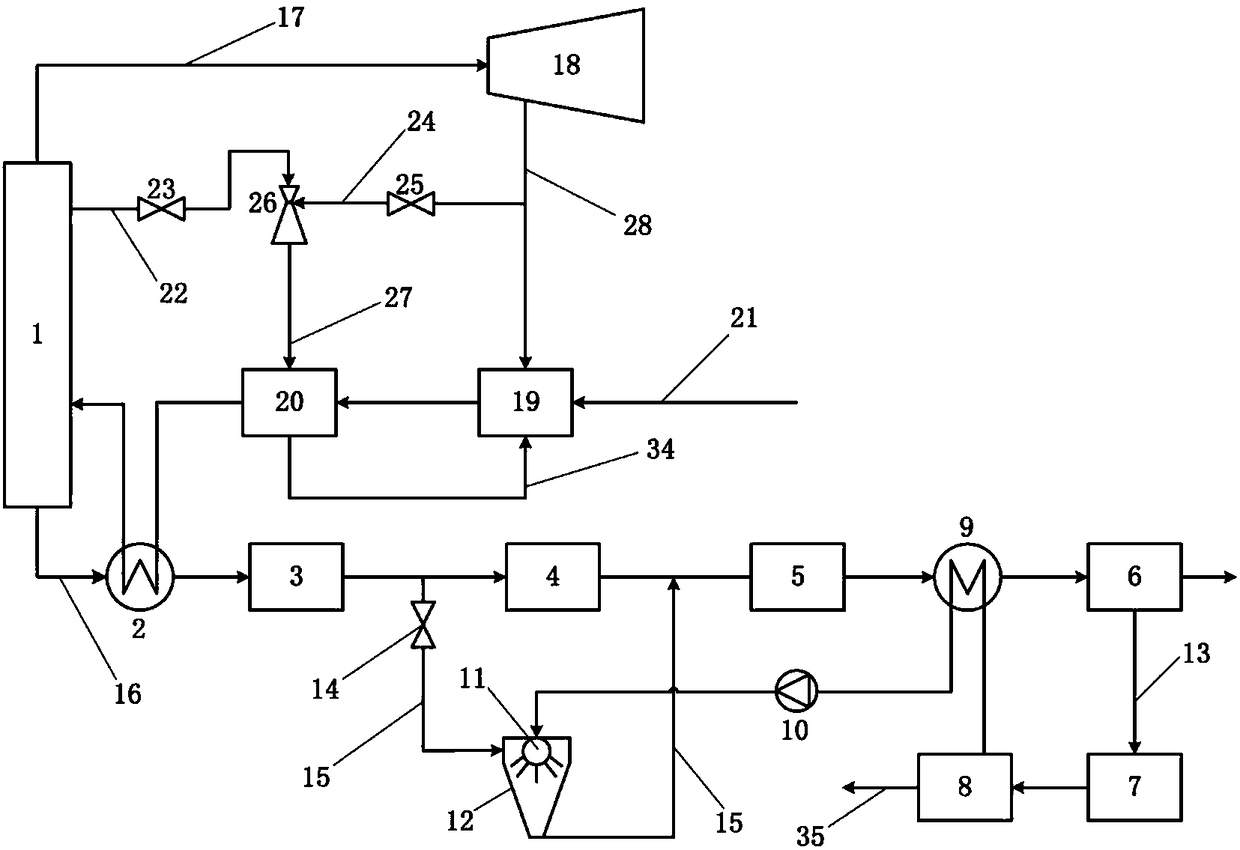

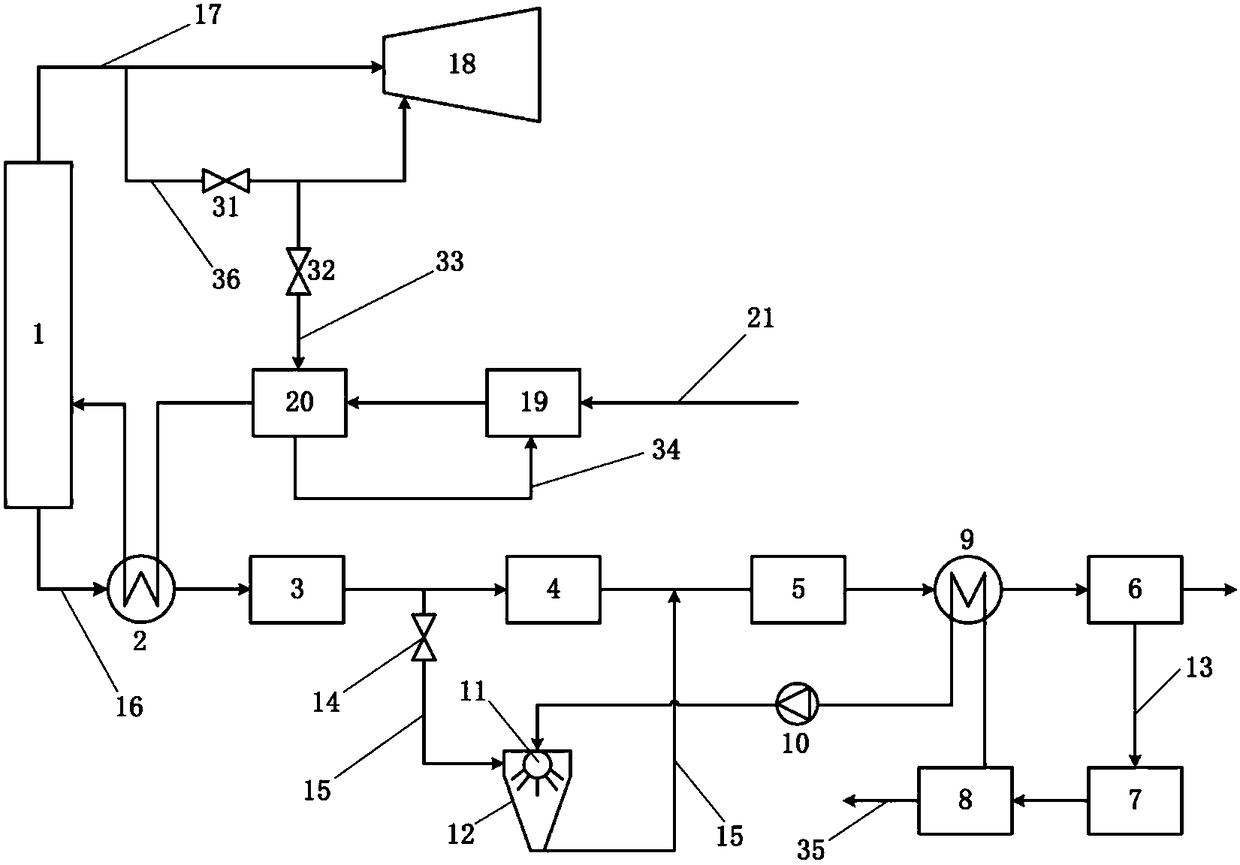

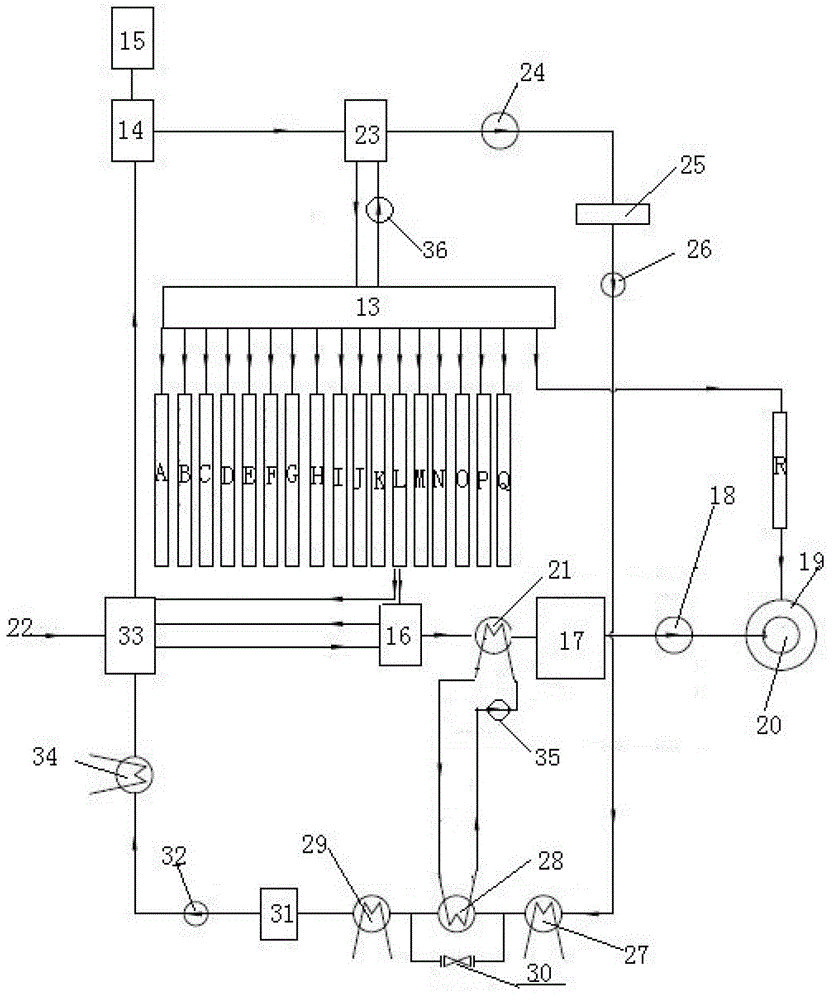

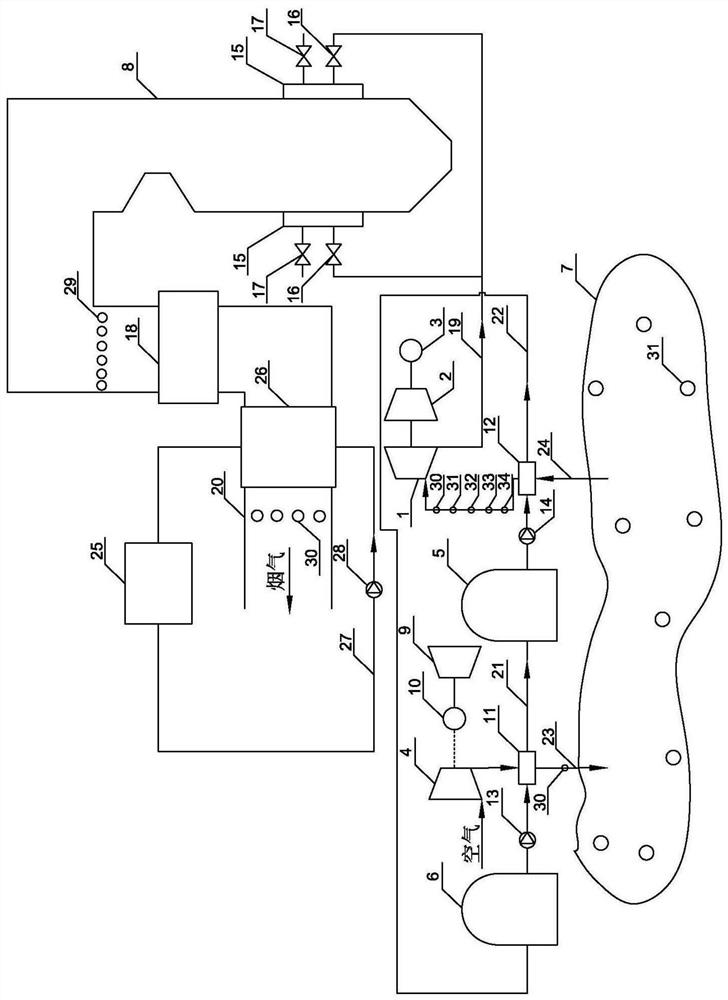

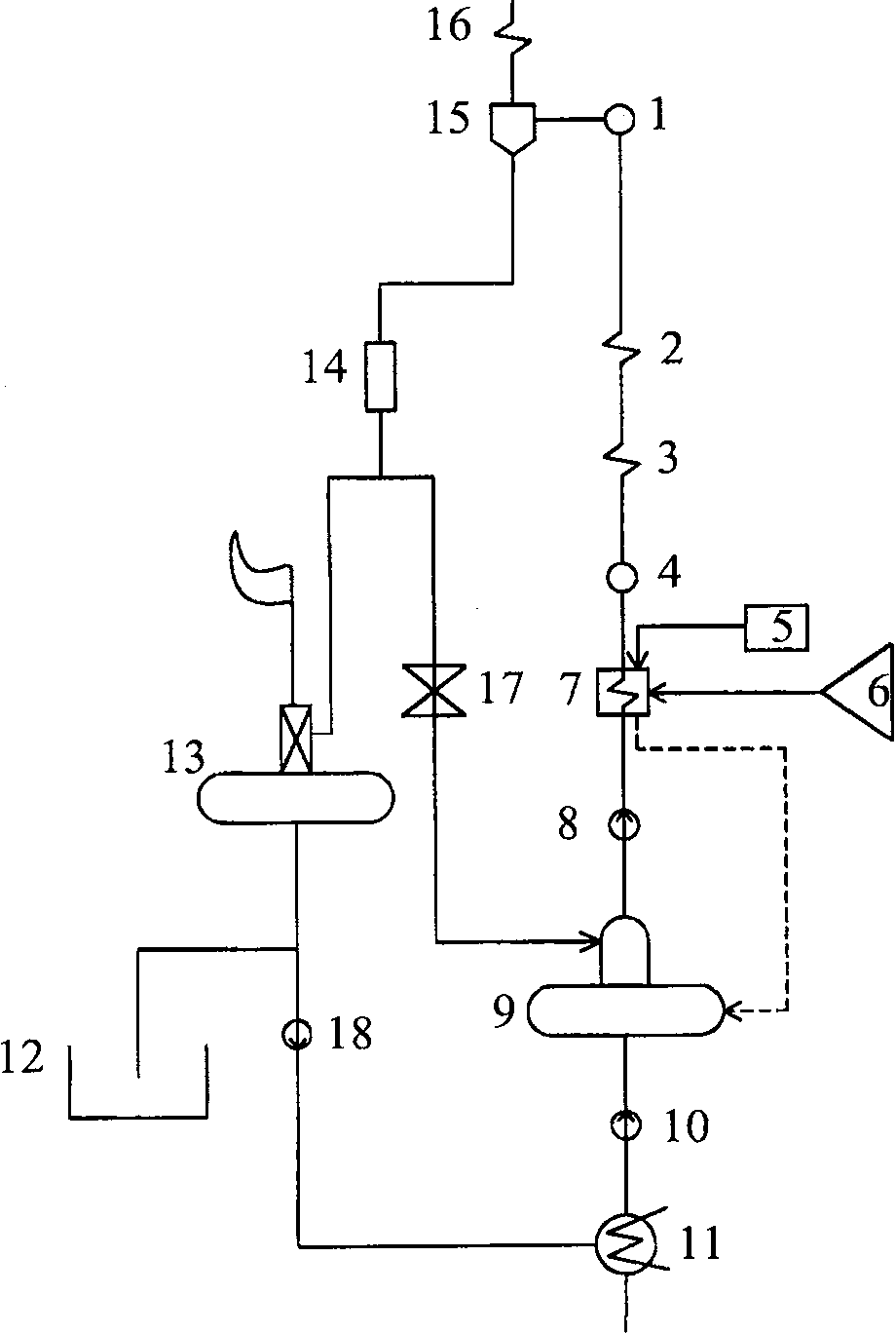

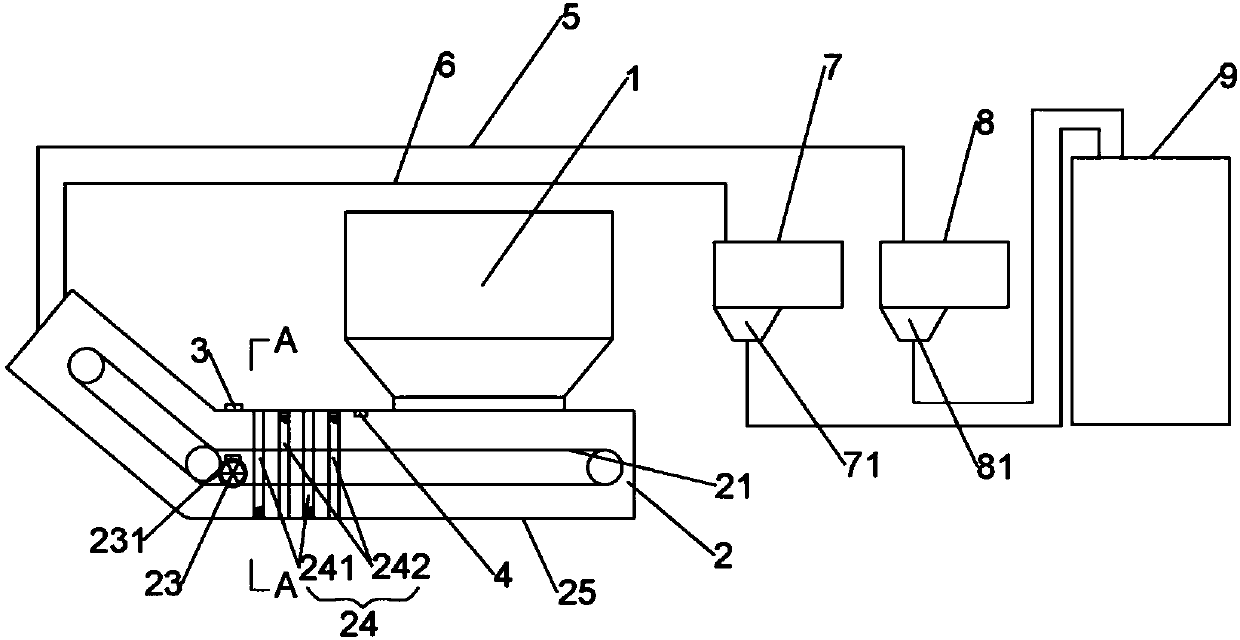

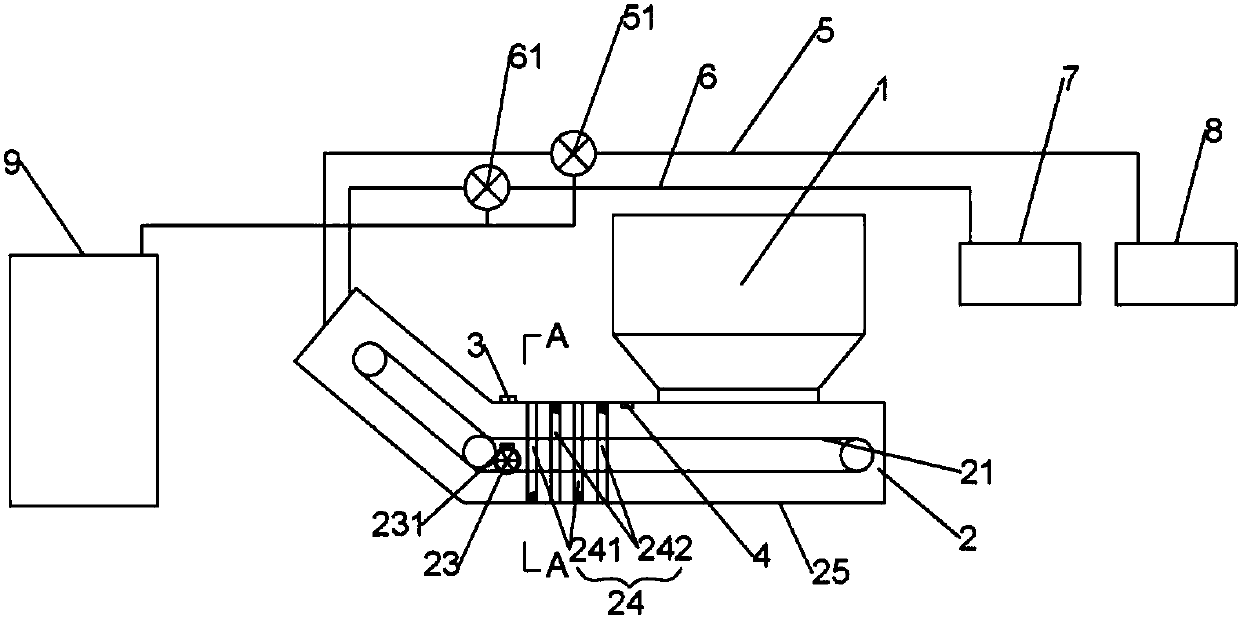

Thermodynamic system for improving heat supply unit electric output adjusting capacity

The invention relates to a thermodynamic system for improving heat supply unit electric output adjusting capacity. The thermodynamic system is characterized in that main steam or reheating section steam is subject to temperature and pressure reduction to directly serve as heat source steam for industrial heat users; an absorption heat pump 23 of a first-stage heat exchange device serves as a heatsource of a first-stage heat exchange station 25 in the heating period to supply heat to heat users 29 and supplies cold to the users in the non-heat supply period; a high-pressure electric boiler 24of a second-stage heat exchange device improves the boiler water feeding temperature, reduces heat absorbed by boiler fed water in an economizer 4, accordingly improves the boiler tail smoke discharging temperature, and guarantees normal running of an SCR denitration device 5; and according to a three-stage heat exchange device, exhaust steam of a turbine intermediate pressure cylinder 8 serves asheat source steam of a third-stage heat exchange station 27, the unit heat load is guaranteed, and the heat using requirement of the heat users 29 is met. The electric output adjusting capacity of the heat supply unit can be improved, it is guaranteed that the unit heat supply capacity is not decreased under the low load running working conditions, pyroelectric decoupling is achieved, and the electric output adjusting capacity of the heat supply unit is improved.

Owner:NORTHEAST DIANLI UNIVERSITY +2

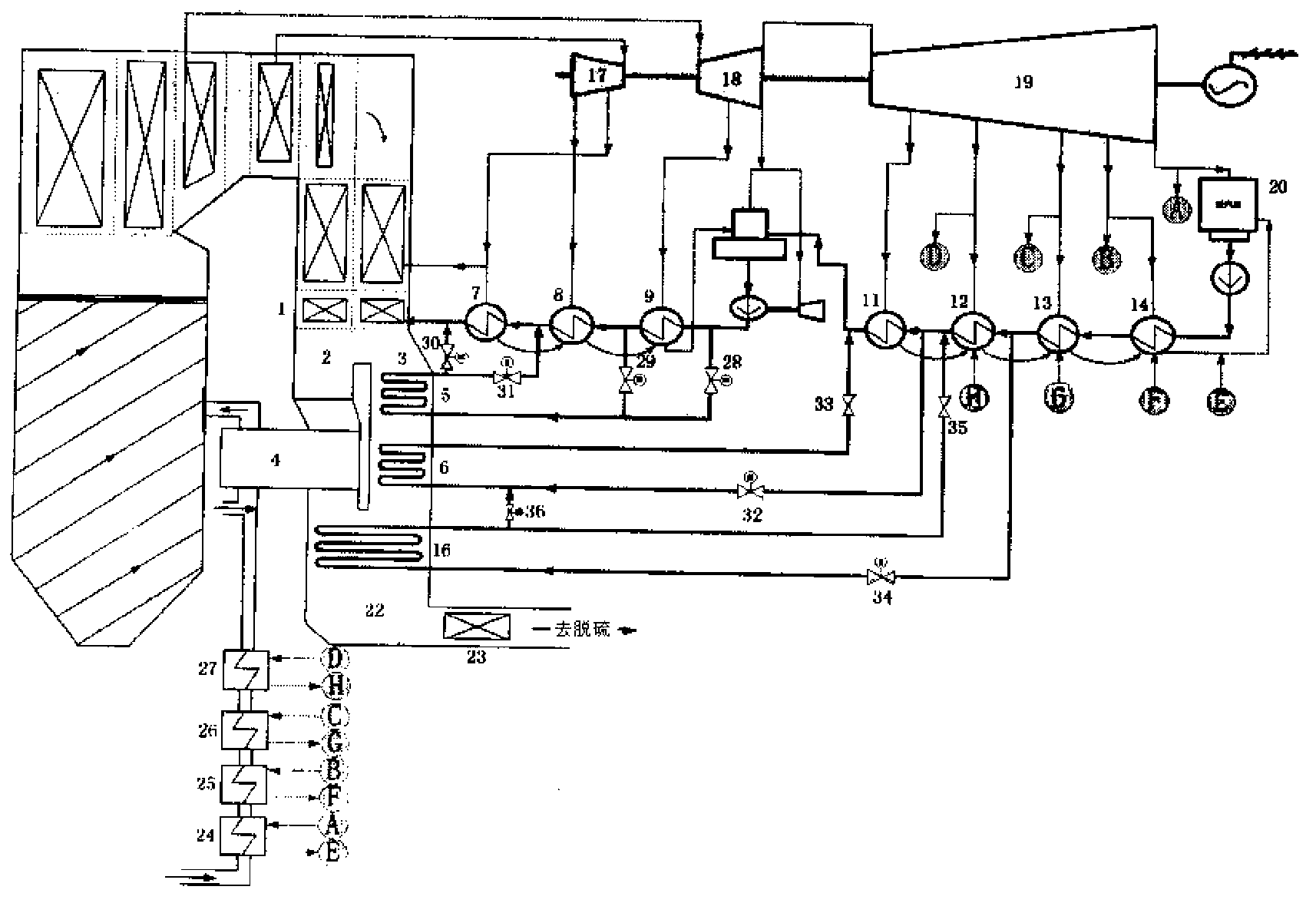

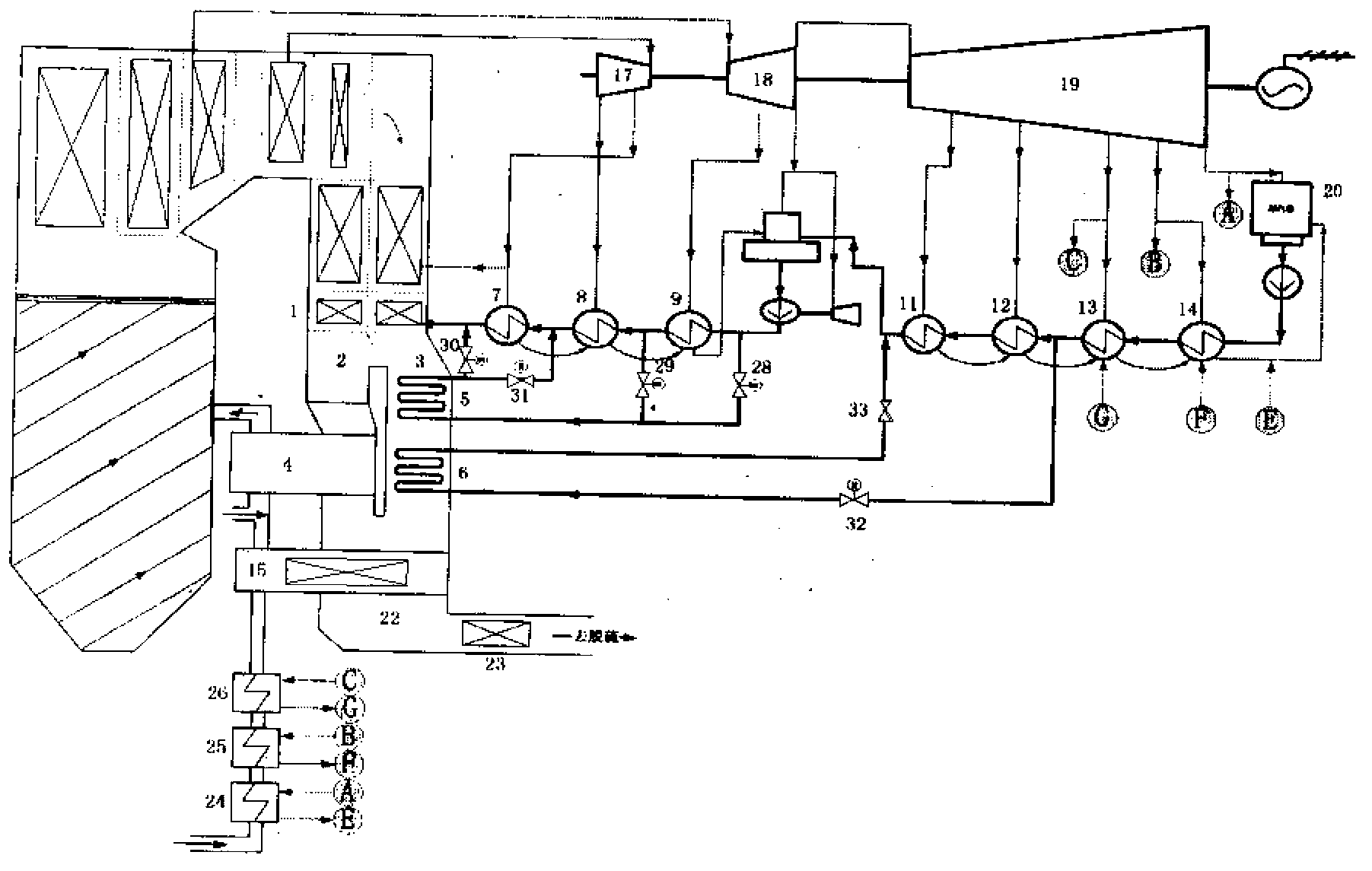

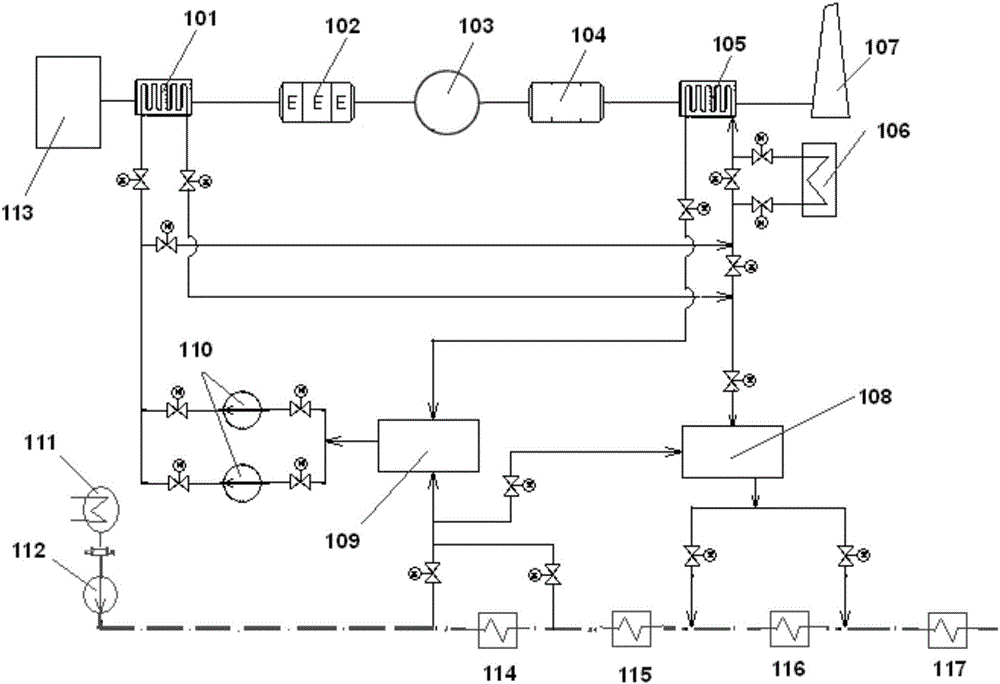

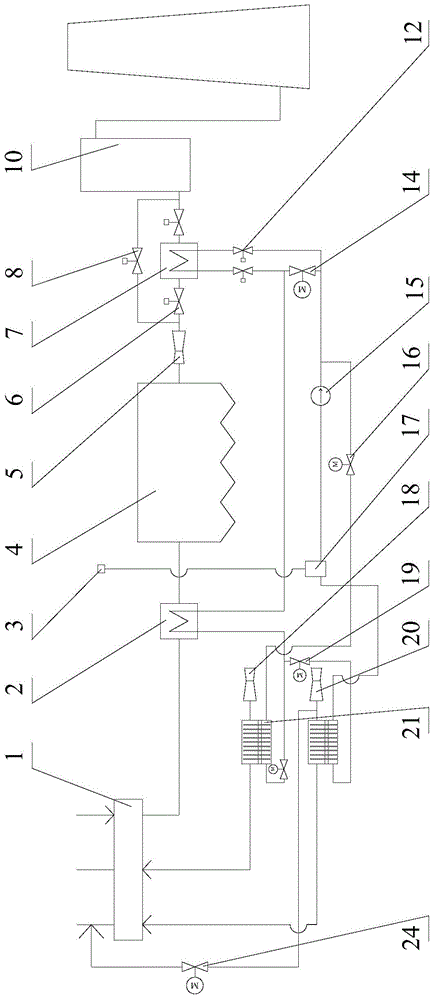

Power station machine furnace integrated cold end comprehensive optimization system

The invention discloses a power station machine furnace integrated cold end comprehensive optimization system which belongs to the field of power station energy saving. The system mainly comprises a steam turbine, a main economizer, a main flue, a bypass flue, a convergence flue, a main air pre-heater, smoke-water heat exchangers, a high pressure heater, a low pressure heater, a deaerator, a smoke-air heater and steam extraction condensed air pre-heaters. Multi-stages of the steam extraction condensed air pre-heaters are serially arranged, sequentially extract a part of exhaust steam of the steam turbine and corresponding low-pressure-stage extraction steam and preheat cold air stage by stage; and the first, second and third stage smoke-water heat exchangers are used for heating feeding water and condensed water, and high-pressure extraction steam of the steam turbine is replaced. According to the machine furnace integrated cold end comprehensive optimization system, by means of efficient waste-heat utilization, low-pressure extraction steam is used for heating air, and the high-pressure extraction steam for backheating is saved so that unit output power is obviously increased, deep energy saving and consumption reduction of the coal-fired power generation unit are achieved, the problem of low-temperature corrosion on a heated surface during waste-heat utilization is solved, and economical benefits are remarkable.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

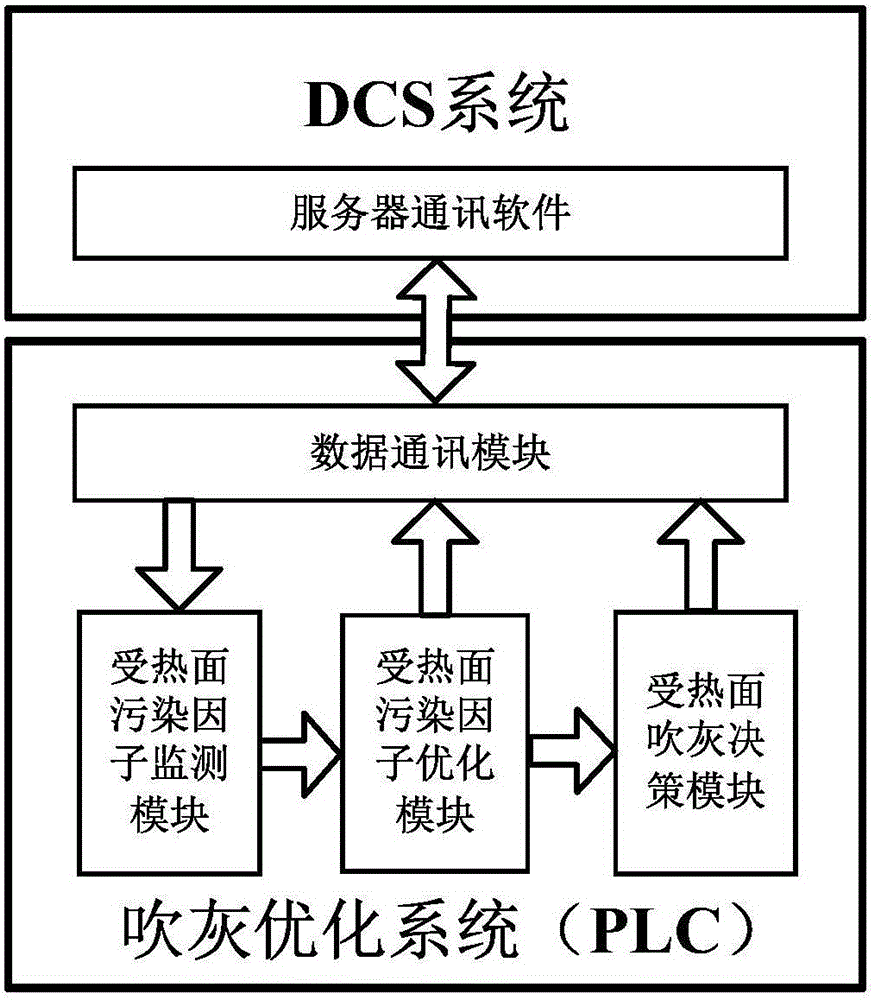

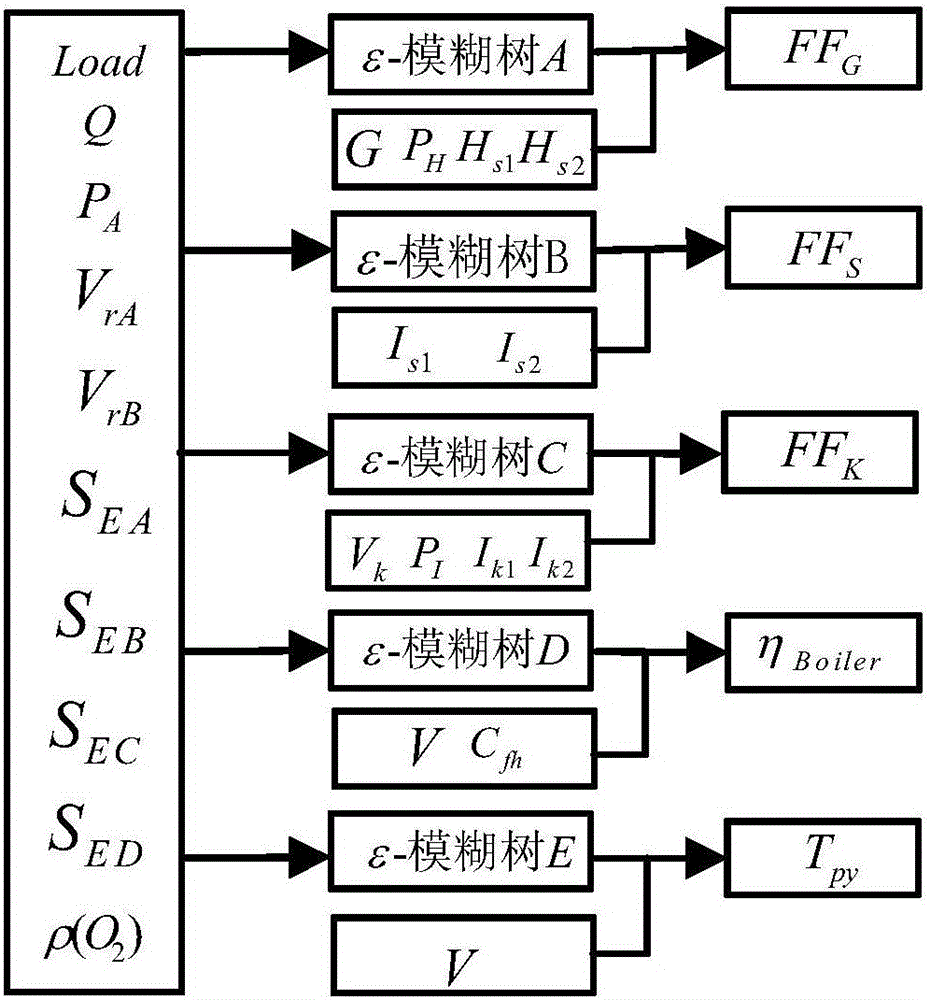

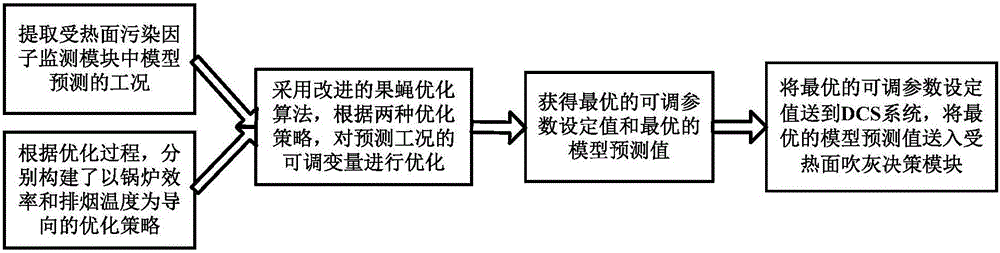

Optimization system and method for sootblowing of circulating fluidized bed boiler

InactiveCN105972585AOptimizing ForecastsReduce energy savingFluidized bed combustionSolid removalAir preheaterSuperheater

The invention relates to an optimization system and method for sootblowing of a circulating fluidized bed boiler. A heat-delivery surface pollution factor monitoring module is used for establishing a predictive model of pollution factors of an overheater or a reheater, pollution factors of an economizer, pollution factors of an air preheater, exhaust gas temperature and boiler efficiency by an epsilon-fuzzy tree method through process data which is read by a data communication module from a DCS; then a heat-delivery surface pollution factor optimizing module uses the exhaust gas temperature and the boiler efficiency as guiding and adopts an improved drosophila optimization algorithm for optimizing a predictive value in the heat-delivery surface pollution factor monitoring module so that an optimal set value with adjustable variables is obtained, and the optimal adjustable variable value is transmitted to the DCS through the data communication module so that the operation of site equipment is guided; a heat-delivery surface sootblowing decision-making module is used for setting a critical pollution factor value through real-time monitored situations, and when the monitored heat-delivery surface pollution factors exceed critical pollution factors, sootblowing of a heat-delivery surface is guided. According to the optimization system and method disclosed by the invention, the purposes of energy-saving sootblowing and sootblowing as required are fundamentally achieved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

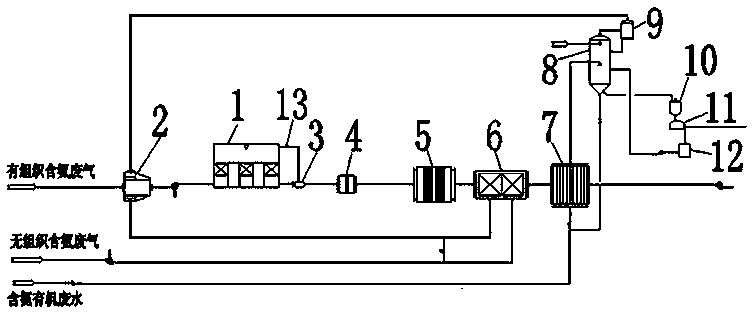

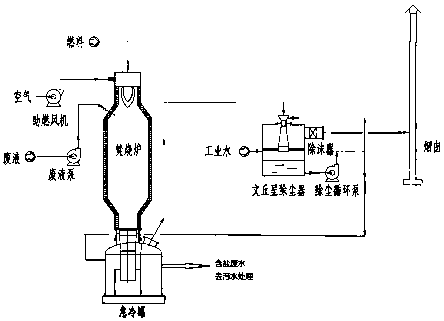

Comprehensive treatment technology and system for ammonia containing organic waste gas and ammonia containing organic waste water

ActiveCN109442438AHigh removal rateRaise the exhaust gas temperatureGas treatmentSpecific water treatment objectivesTreatment systemChemistry

The invention relates to a comprehensive treatment technology and system for ammonia containing organic waste gas and ammonia containing organic waste water. The comprehensive treatment technology comprises the steps that high-temperature furnace inflow waste gas is conveyed into an RTO heat accumulation type incinerator through a waste gas draught fan to be incinerated, and clean smoke is subjected to nitrogen oxide catalytic reduction through an SCR reactor. The comprehensive treatment system comprises the RTO heat accumulation type incinerator, a waste gas mixer is arranged at the front endof the RTO heat accumulation type incinerator, a mixer is arranged at the rear end of the RTO heat accumulation type incinerator and connected with a metal filter, the metal filter is connected withthe SCR reactor, the SCR reactor is connected with a plate heat exchanger, and the plate heat exchanger is connected with a forcing heat exchanger. Low-temperature smoke waste heat is circularly utilized, the furnace feeding temperature is increased, the exhaust temperature of an incinerator system is increased and meets the smoke catalysis denitration technology requirement, no fuel consumption and no denitration agent consumption are achieved, waste water can be treated while waste gas is treated, and secondary pollutants are avoided.

Owner:JIANGSU DAXIN ENVIRONMENTAL SCI & TECH

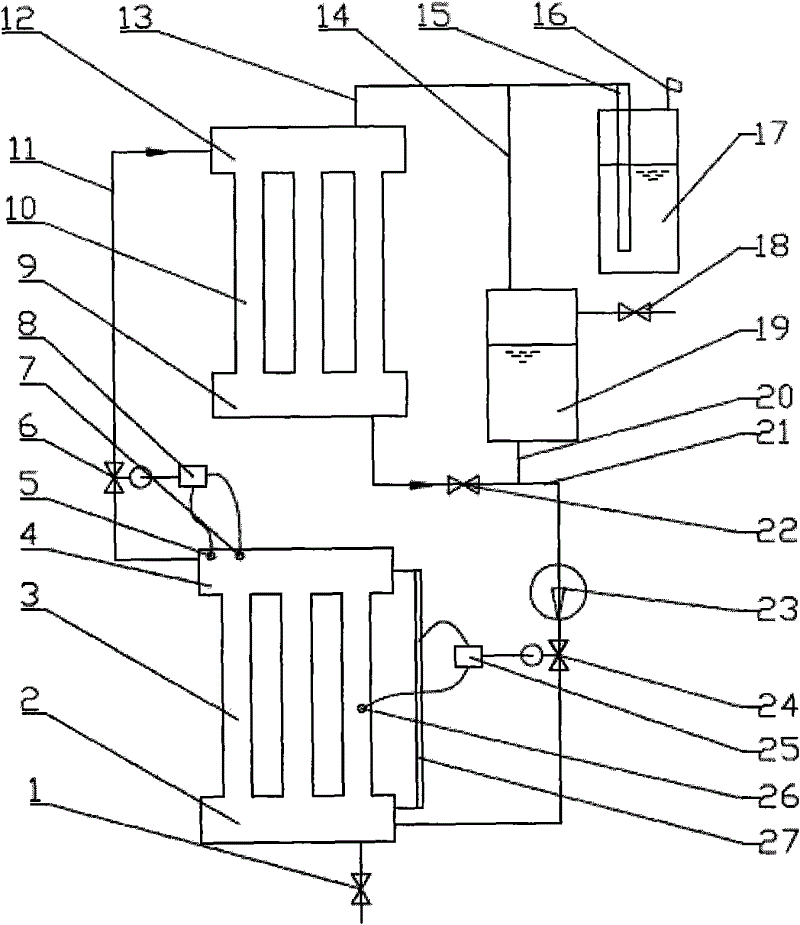

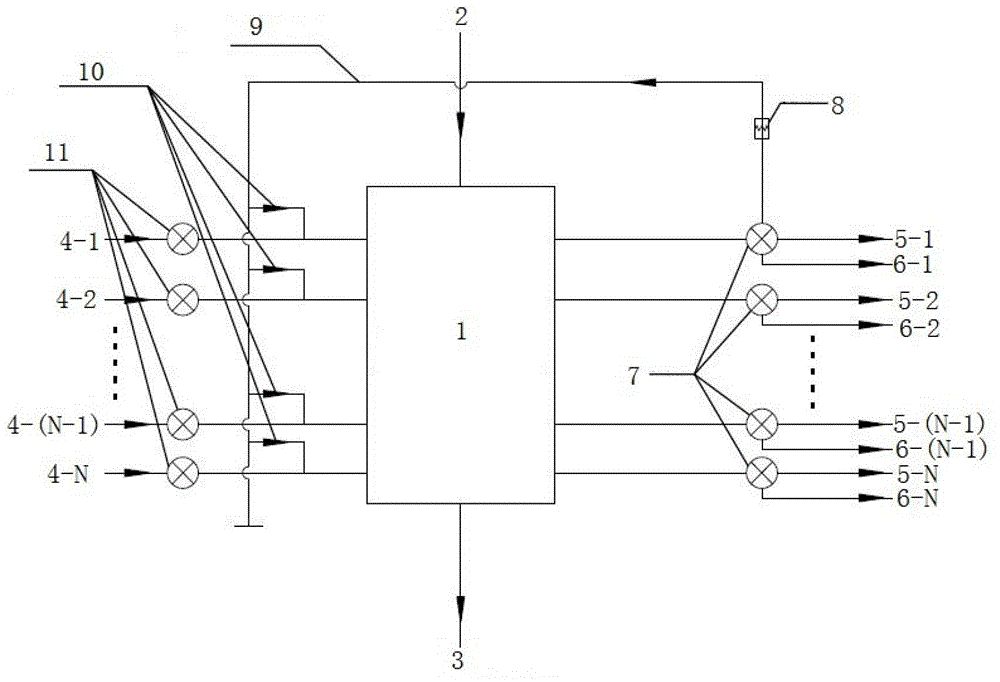

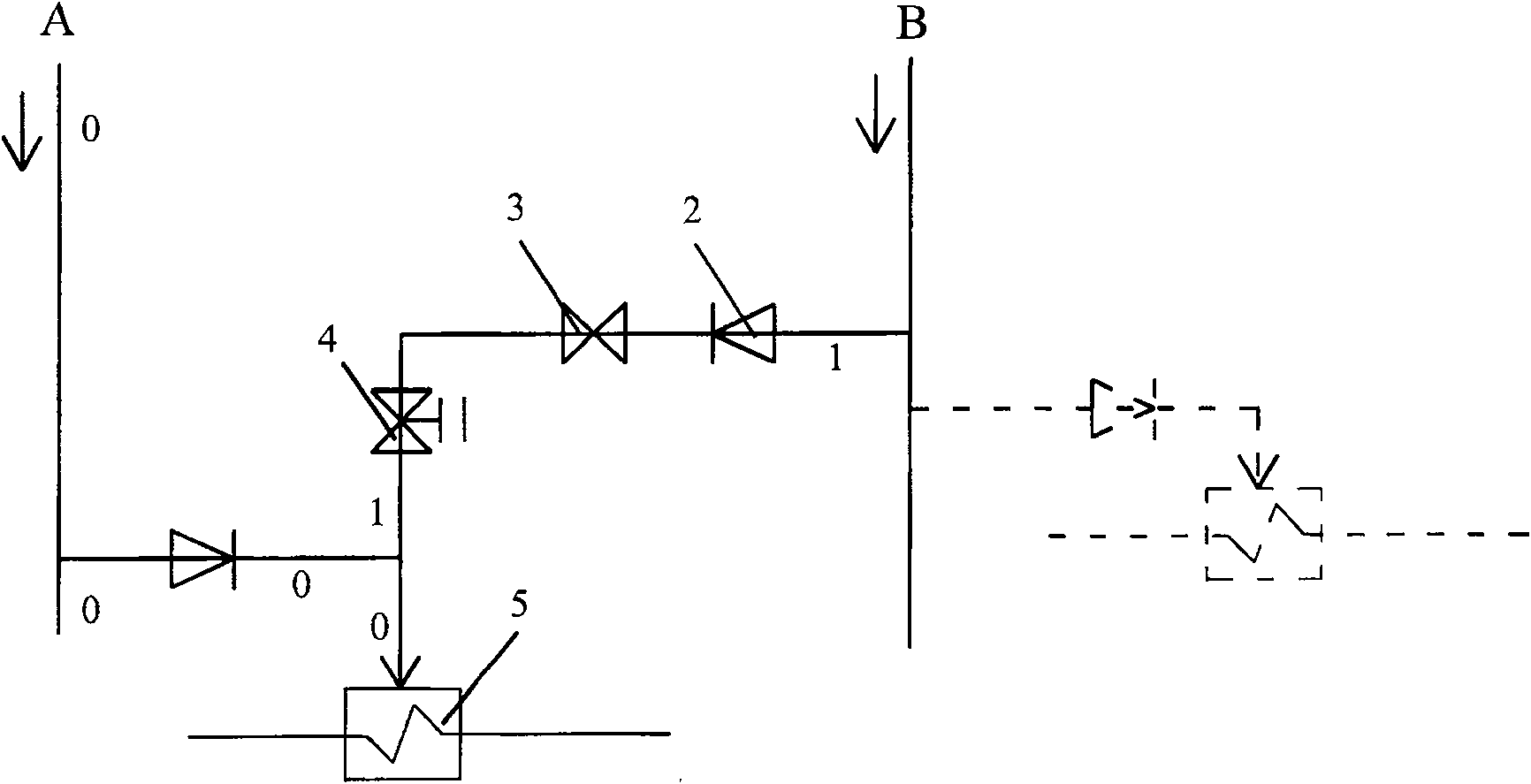

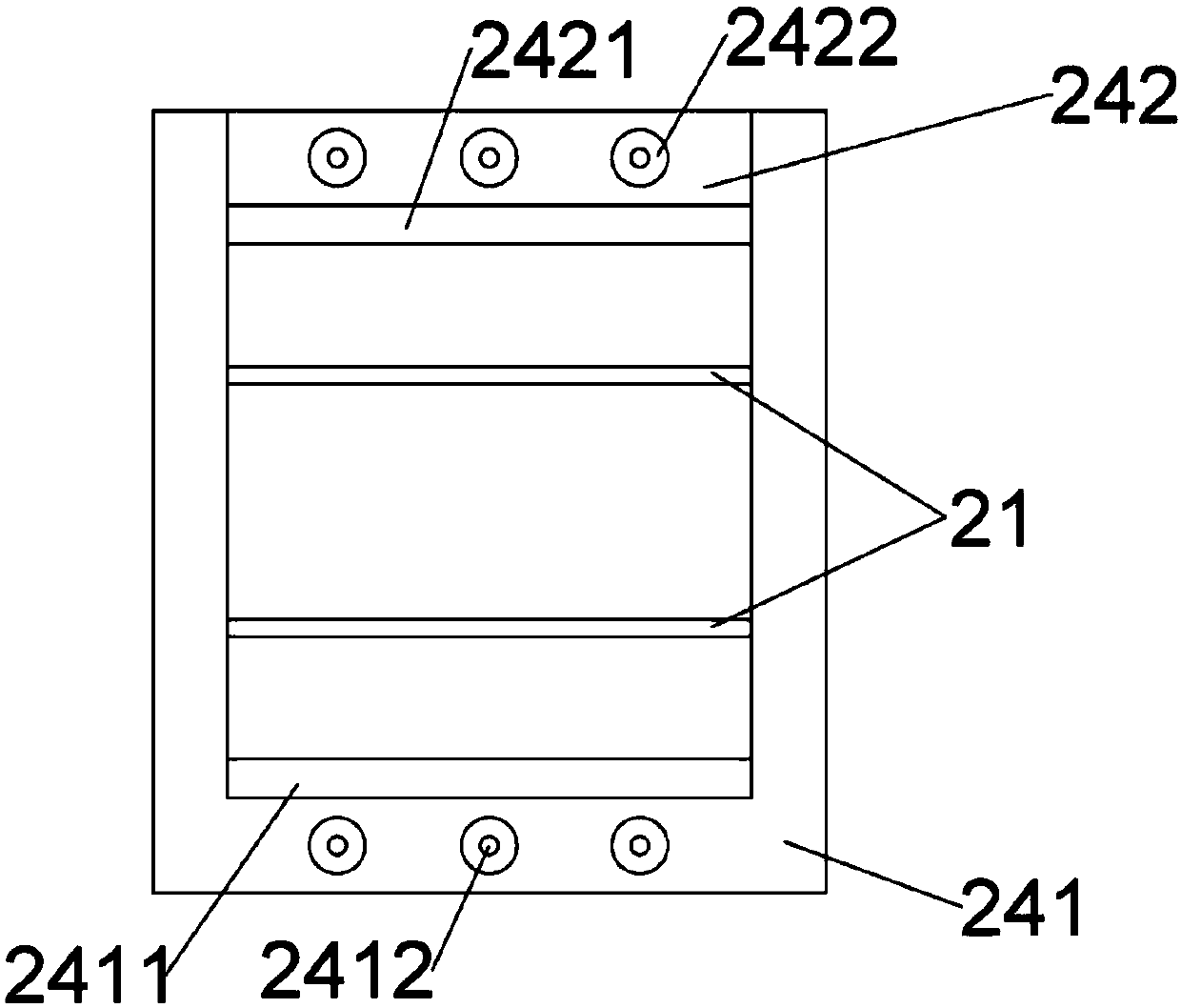

Sub-control phase change heat transfer system and sub-control phase change heat transfer method

InactiveCN102620583AImprove reliabilityHigh precisionIndirect heat exchangersHeat exchange apparatusEngineeringPhase change heat transfer

The invention relates to a sub-control phase change heat transfer system. The sub-control phase change heat transfer system comprises a heat absorption device and a heat release device which are mutually communicated through a vapor pipe (11) and a condensed fluid pipe (21) so as to form a sub-control phase change heat transfer loop. The sub-control phase change heat transfer system is characterized by comprising an airflow regulating valve (6), an airflow regulating valve controller (8), a liquid flow regulating valve (24) and liquid flow regulating valve controller (25), wherein the airflow regulating valve (6) is arranged in the pipeline of the vapor pipe (11) and the opening of the airflow regulating valve (6) is controllable; and the liquid flow regulating valve (24) is arranged in the pipeline of the condensed fluid pipe (21) and the opening of the liquid flow regulating valve (24) is controllable. The invention also provides a sub-control heat transfer method. In the method, the phase change heat transfer parameters of the heat absorption device and the heat release device are respectively independently controlled.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

Low-nitrogen condensation wall-mounted furnace and application method thereof

The invention discloses a low-nitrogen condensation wall-mounted furnace and an application method thereof. The low-nitrogen condensation wall-mounted furnace comprises a draught fan, a fume collecting hood, a gas valve and a water-cooling combustor. An inner cavity of a gas distributing pipe of the water-cooling combustor is divided into two independent sections through a block plate, and each section is connected with a gas inlet joint. The gas valve is composed of a main on-off valve, a proportion regulating valve and two on-off valves, the main on-off valve is connected with a main gas inlet pipe, and outlets of the two on-off valves communicate with the two sections of the gas distributing pipe separately. The gas distributing pipe is sectioned, all fire rows or a part of fire rows on the gas distributing pipe are controlled to combust, small duty ratio is reduced, and the problems of flameout and too hot water temperature in summer can be solved. In addition, the constant-speed draught fan is adopted for the wall-mounted furnace, so the problem of corrosion of condensate water to a main heat exchanger can be solved. A ventilation baffle is further arranged at the bottom of the fume collecting hood to solve the problem of excessive CO emission under limit gas test conditions. Through experimental verification, when the small load regulation ratio of the wall-mounted furnace is between 0.35-0.5, the problems of flameout and too hot water temperature in summer can be solved.

Owner:MACRO THERMAL ENERGY TECH

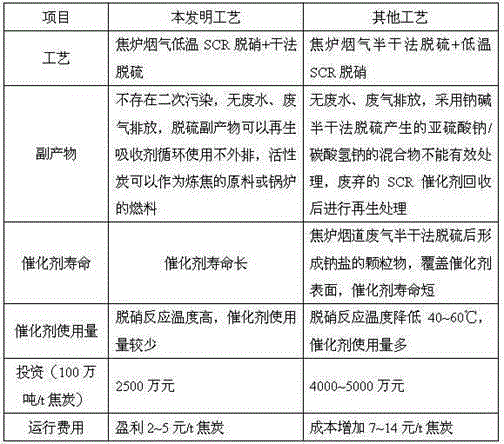

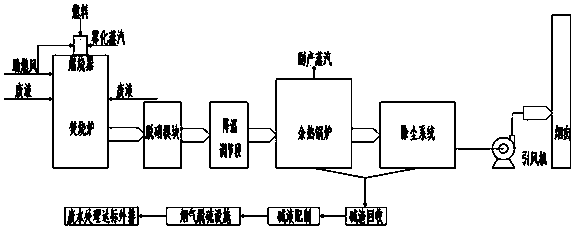

Coke oven flue waste gas desulfurization and denitrification and waste heat recovery integrated process

InactiveCN105214478AMuch waste heat recoveryIncrease evaporationDispersed particle filtrationAir quality improvementFlueFlue-gas desulfurization

The invention provides a coke oven flue waste gas desulfurization and denitrification and waste heat recovery integrated process. Coke oven flue waste gas is subjected to an SCR reaction under the effect of a low-temperature SCR denitrification catalyst to remove nitric oxides in flue waste gas, a sodium-based dry powder absorbent is sprayed to flue waste gas for desulfurization after waste heat is recovered through a waste heat boiler, and desulfurized flue waste gas is discharged up to standard after dust removal is conducted through a filter. The process is free of waste water, waste gas emission and heating, denitrification can be directly conducted, the absorbent can be recycled, investment is reduced, and energy is saved.

Owner:CHENGDU HUAXITANG INVESTMENT

System and method for evaporating desulfurization wastewater by using exhaust gas waste heat under underload working condition

PendingCN107935292ARaise the exhaust gas temperatureIncrease profitWater treatment parameter controlAuxillary pretreatmentWastewaterEvaporation

The invention relates to a system and a method for evaporating desulfurization wastewater by using exhaust gas waste heat under an underload working condition. The system comprises an economizer fumebypass subsystem, a desulfurization wastewater high-temperature flue bypass evaporation subsystem as well as an air pre-heater bypass flue, wherein the economizer fume bypass subsystem comprises an economizer bypass flue; the desulfurization wastewater high-temperature flue bypass evaporation subsystem comprises a softening tank, a concentration device, a wastewater pump, a wastewater preheater and a double-fluid atomization ejector which are connected in sequence through a wastewater pipeline; the softening tank is connected with a desulfurizer; an evaporator is arranged on the air pre-heaterbypass flue; the double-fluid atomization ejector is arranged at the top end inside the evaporator. The invention further relates to a method for achieving zero desulfurization wastewater emission under the underload working condition on the basis of the system for evaporating the desulfurization wastewater by utilizing the exhaust gas waste heat. By adopting the system and the method, the energyutilization rate of a machine set is increased, and zero wastewater emission is achieved.

Owner:DATANG ENVIRONMENT IND GRP

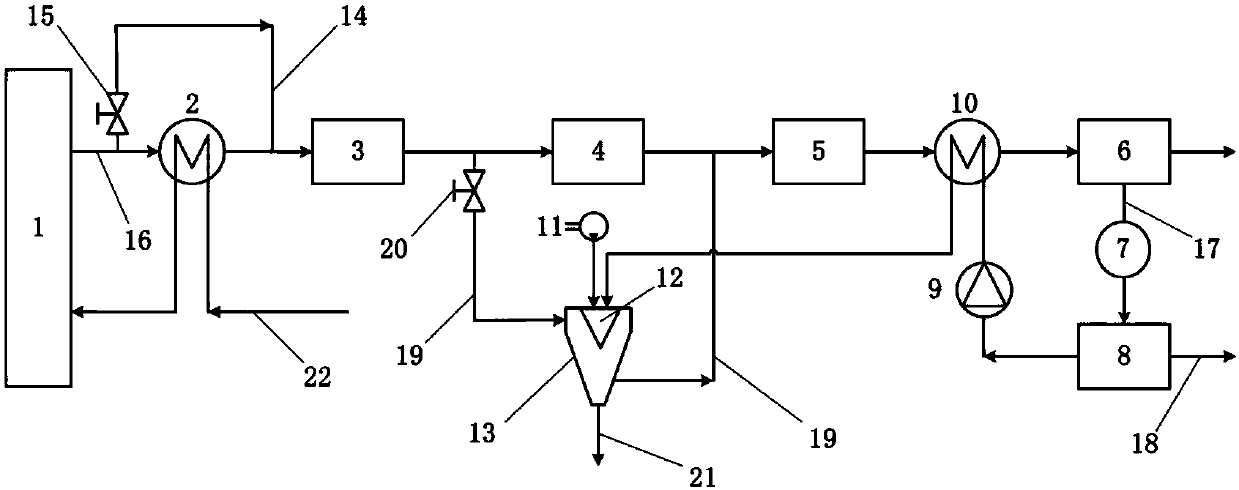

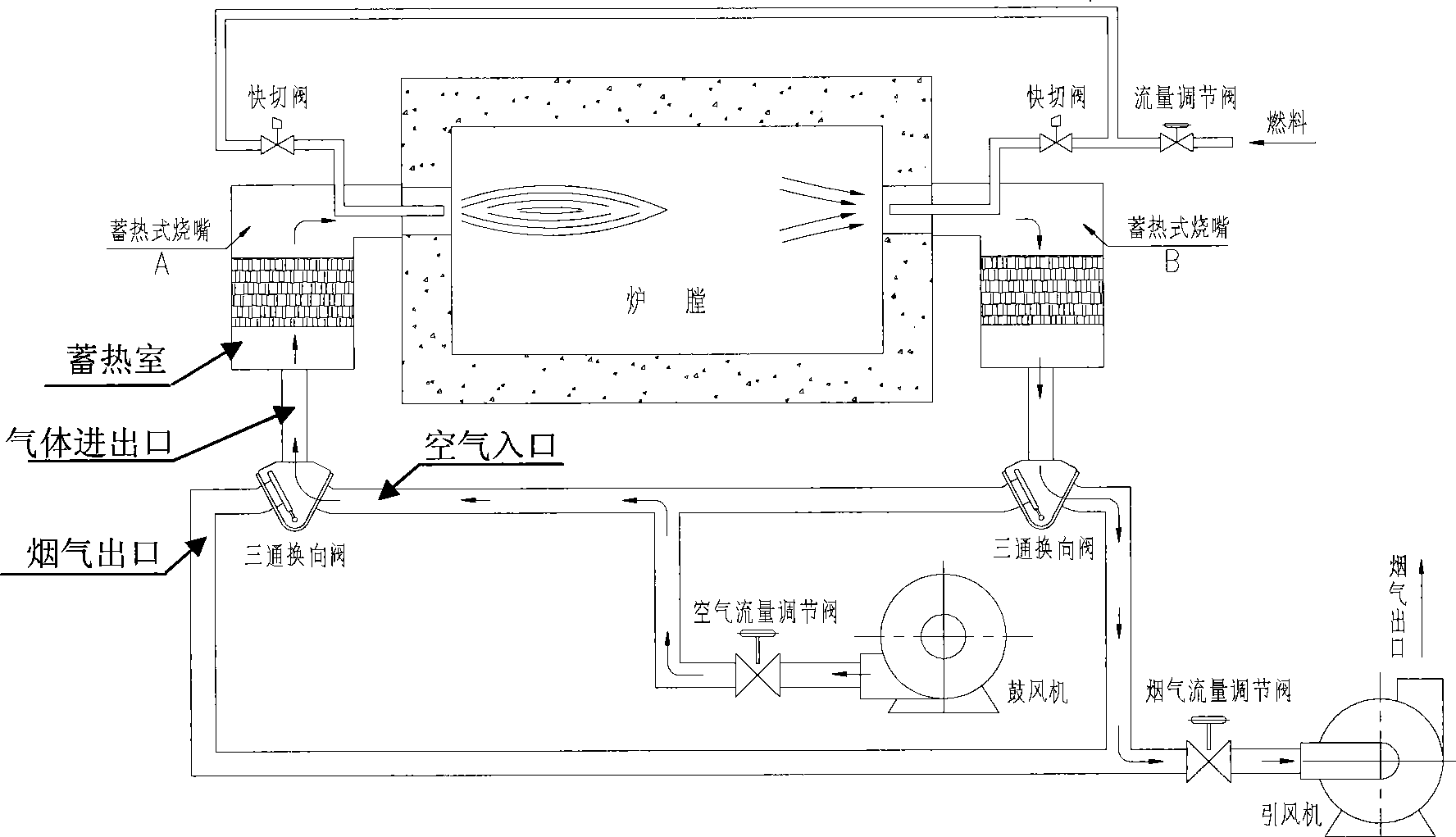

Coal-based direct reduction iron rotary hearth furnace and combustion method thereof

ActiveCN101413041ALower exhaust gas temperatureRaise the exhaust gas temperatureRotary drum furnacesFurnace temperatureCombustion

The invention discloses a coal-based direct reduction iron rotary hearth furnace and a combustion method thereof. The furnace comprises a ring-shaped inner wall and a ring-shaped outer wall, a rotary hearth is arranged between the inner wall and the outer wall, and the inner wall and the outer wall are provided with a plurality of regenerative burners. When the furnace is fired, part of the regenerative burners are fired, and of the left burners are used to discharge smoke; when the preset combustion time is up, the firing burners stop firing and start to discharge smoke, the unfired burners start firing, and the rotation is performed periodically. When the burners discharge smoke, a regenerator absorbs heat so as to lower the temperature of discharged smoke; when the burners are fired, the regenerator releases heat so as to preheat oxidizing air or fuel and increase the combustion temperature. All fuels, of which the thermal values are between 750 and 9000kcal / Nm<3>, can be used, the furnace temperature and furnace inside atmospheres can meet the process requirements for direct reduction iron.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Liquid coke inhibitor

InactiveCN102329676AReduce dust accumulationHas cleaning effectFuel additivesBULK ACTIVE INGREDIENTOxygen

The invention discloses a liquid coke inhibitor, and belongs to the technical field of clean coal combustion. Main active ingredients of the liquid coke inhibitor are an organic surfactant and nitrate. When the organic surfactant is at high temperature, an organic polymer compound has a dirt cleaning effect, and the organic polymer compound is reacted at high temperature to generate a large number of air bubbles so as to make coke blocks loose. The nitrate can generate microexplosion and release oxygen at high temperature, can continuously release oxygen in a range from low temperature to high temperature to make soot formation and carbon deposition layers on different parts loose and contribute to more fully combusting pulverized coal; metal ions in the nitrate can promote low melting point compounds in a coke layer to be converted into loose high melting point compounds, which can contribute to removing a coking layer and prevent high temperature corrosion.

Owner:SNTO TECH GRP

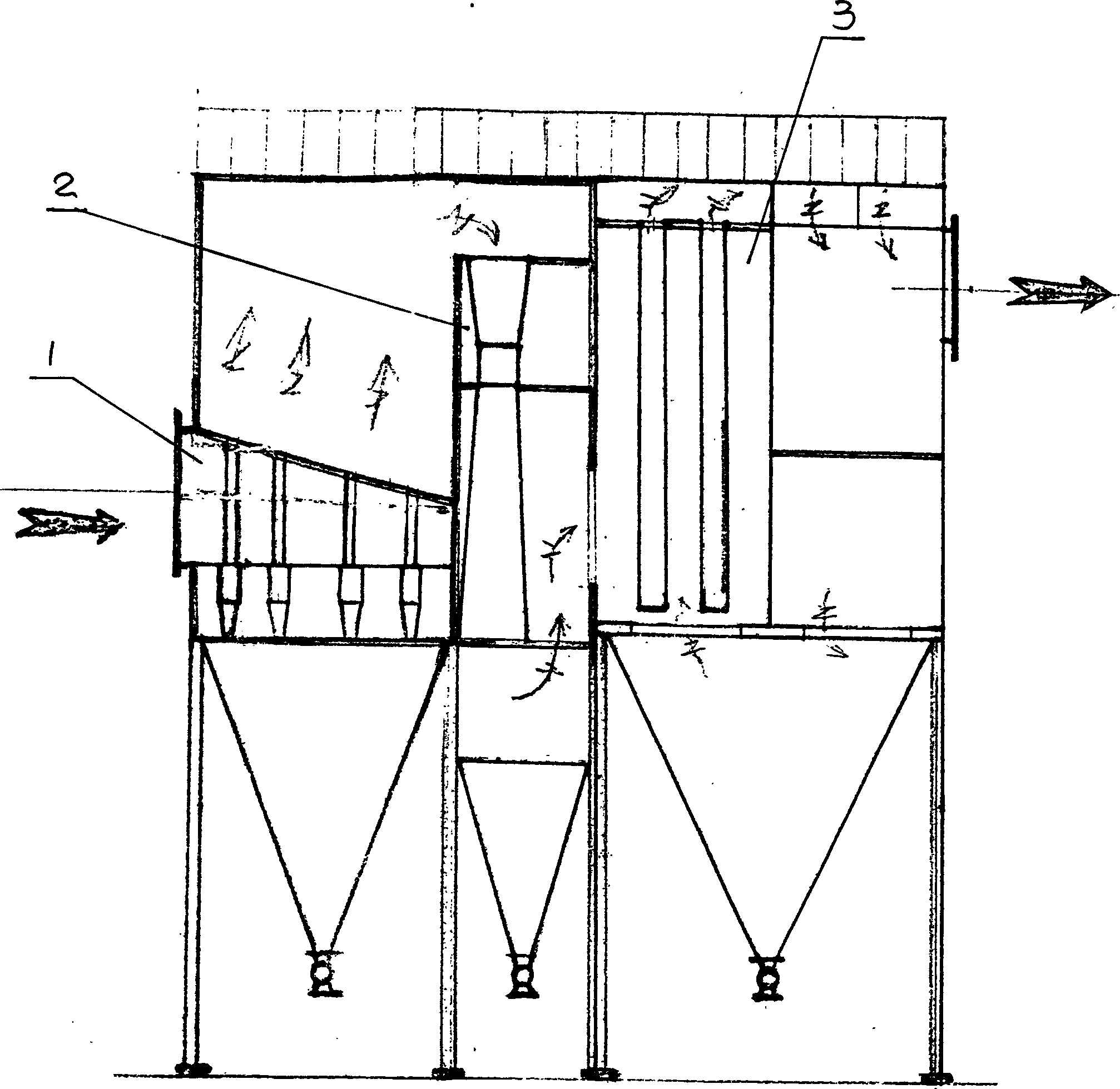

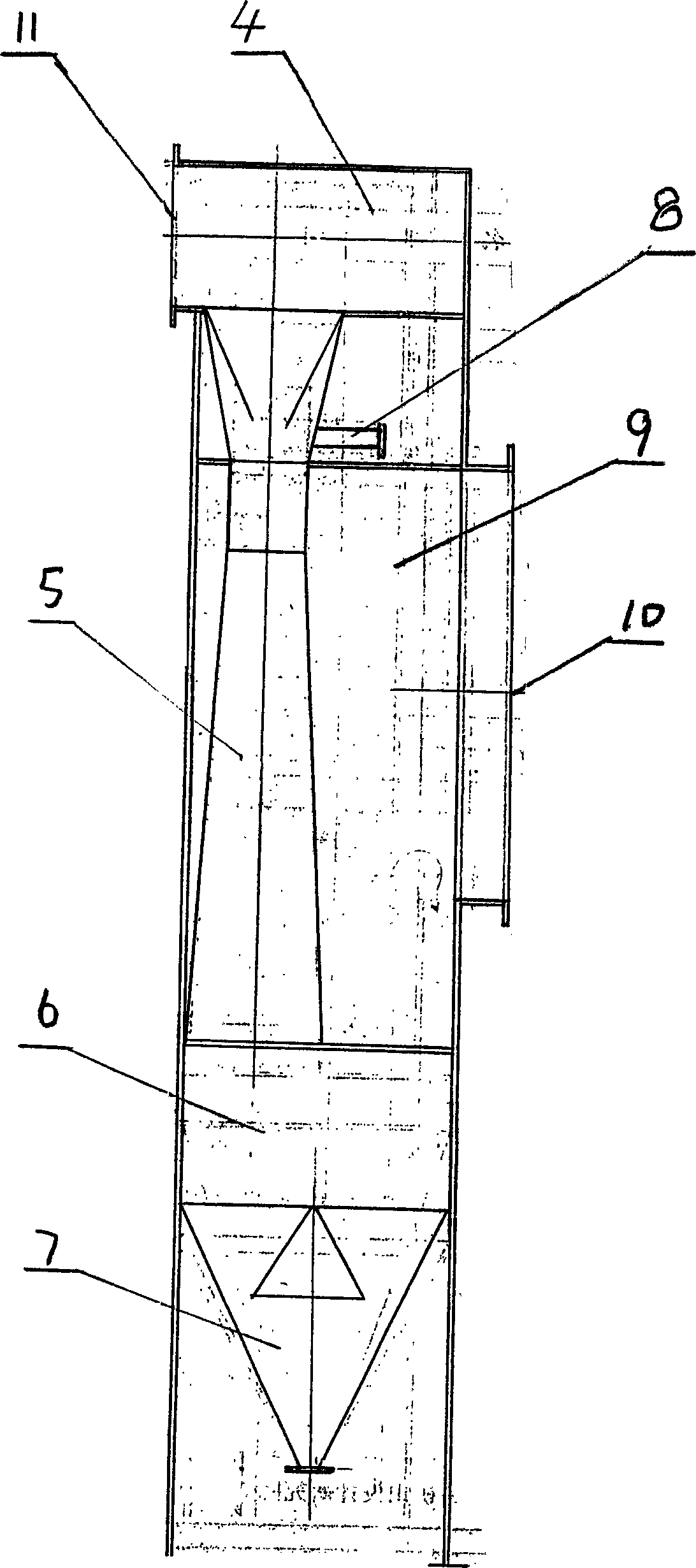

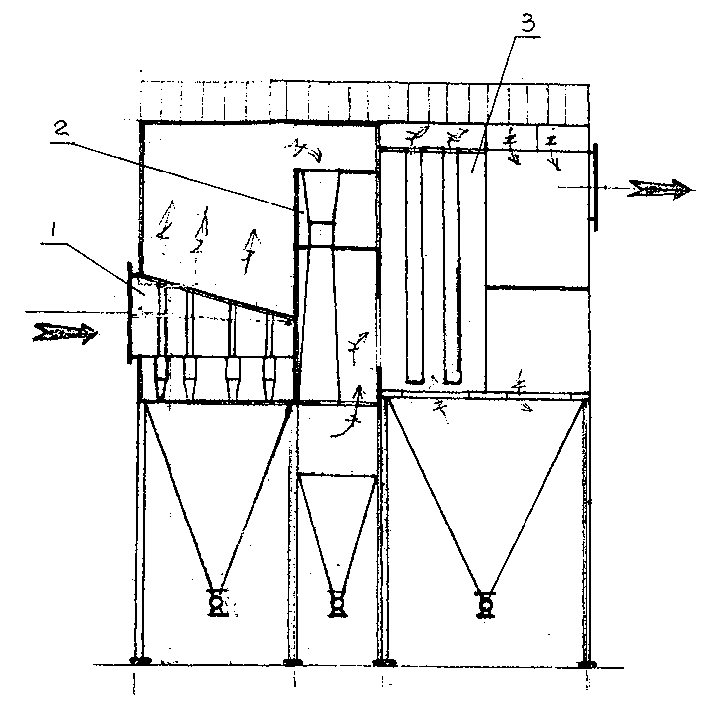

Combined two-stage flue gas desulfurization and dust-eliminating process

InactiveCN1454699ASimple processBest matchCombination devicesUsing liquid separation agentSulfurEngineering

The invention refers to a compound double-grade smoke desulfurizing and dust eliminating process which can desulfurize sulfur and eliminate dust effectively. It is made up of the first, the second and the third parts: the first part is ceramics multi-pipe dust catcher or electrostatic dust catcher, it carries on the first grade dust eliminating, it eliminates 90-99% dust in the smoke; the second part is venturi drying and absorbing tower, the sulfur in smoke reacts with desulfurizing liquid and is absorbed, realizes the first grade desulfurizing; the third part is bag desulfurizing and dust catcher, it eliminates the resultant in desulfurizing reaction and carries on secondary dust eliminating to the tiny particles in smoke.

Owner:樊金鑫

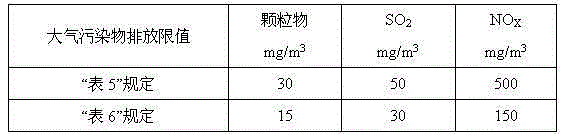

Integrated system for coke oven flue gas desulfurization and denitrification and waste heat recovery

InactiveCN105169943AMuch waste heat recoveryIncrease evaporationDispersed particle filtrationSteam generation using hot heat carriersPulverizerFlue-gas desulfurization

The invention provides an integrated system for coke oven flue gas desulfurization and denitrification and waste heat recovery. The integrated system comprises a coke oven, a low-temperature SCR denitrification system, a waste heat boiler, a flue, a pulverizer, a filtering system and a chimney. The coke oven, the low-temperature SCR denitrification system, the waste heat boiler, the filtering system and the chimney are sequentially connected through the flue, a dry powder absorbent inlet is formed in the portion, between the waste heat boiler and the filtering system, of the flue and is connected with an outlet of the pulverizer through a pipeline, and an absorbent inlet is formed in the pulverizer. The system is free from waste water and gas emission and capable of directly carrying out denitrification without heating, absorbent can be used circularly, investment can be reduced, and energy can be saved.

Owner:CHENGDU HUAXITANG INVESTMENT

Vertical gas fired boiler

InactiveCN102022821ALow gas consumptionIncrease heat conduction areaWater heatersBoiler furnaceHearth

The invention relates to a vertical gas fired boiler, comprising a chimney, a smoke venting cover, an outer boiler furnace, water jackets, a fire tube, hearths and a boiler door tube, wherein the chimney is welded on the smoke venting cover; the smoke venting cover is installed at the top of the outer boiler furnace; an upper hearth is formed between the lower part of the smoke venting cover and each of an upper side plate and an upper embossed plate; the outer boiler furnace is internally provided with the fire tube; a lower hearth is positioned in an inner boiler furnace; the boiler door tube is communicated with the lower hearth; the gap between the periphery of the inner boiler furnace and the outer boiler furnace forms a lower interlayer water jacket; an upper interlayer water jacketis communicated with the upper part of a water containing cavity; and the lower part of the water containing cavity is communicated with the lower interlayer water jacket. The vertical gas fired boiler is characterized in that the fire tube is internally provided with a water tube, the upper hearth is internally provided with an upper horizontal water tube, the lower hearth is internally providedwith a lower horizontal water tube, the upper end of the water tube is welded on the through hole of the upper horizontal water tube, and the lower end of the water tube is welded on the through holeof the lower horizontal water tube. A water interlayer and a horizontal water tank can also be arranged on the smoke venting cover. The vertical gas fired boiler has large heat exchange area and highthermal efficiency.

Owner:曲沃县秀水炉业有限公司

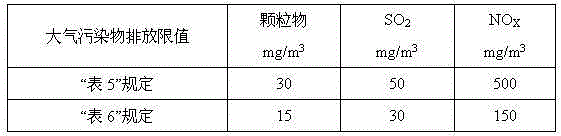

Open lower temperature waste heat utilization system of ultra-clean emission coal-fired unit

PendingCN106765265AAvoid condensationAvoid Low Temperature CorrosionFeed water supplyCombustion technology mitigationGas heaterGas cooler

The invention discloses an open lower temperature waste heat utilization system of ultra-clean emission coal-fired unit, and relates to a steady controllable open MGGH system. A water outlet of a gas cooler is communicated with a gas-gas heater and a water inlet of waste heat recovery hot water mixer through pipeline systems with valves respectively, and the water inlet pipeline of the gas-gas heater is also provided with an auxiliary steam heater; the water outlet of the gas-gas heater is communicated with the water inlet of the gas cooler through a circulating water and make-up water mixer, a variable frequency booster pump and the pipeline systems with the valves; the water inlet of the circulating water and make-up water mixer is also communicated with a condensation water pipeline, and the water outlet of the waste heat recovery hot water mixer is communicated with a low-temperature heating system pipeline through at least two pipelines with the valves. In the invention, the problems that the inlet gas temperature of an electrostatic precipitator and chimney inlet gas temperature are difficult to control, the low-temperature heating adjustment of the unit is difficult to control and the disturbance is severe due to poor heat exchange effect of a plate heat exchanger in the existing MGGH technology are solved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

System and method for realizing zero emission of desulfurization waste water by denitrifying wide negative charges and utilizing waste heat

PendingCN108128956ARaise the exhaust gas temperatureAchieving zero emissionsDispersed particle separationScale removal and water softeningAir preheaterLow load

The invention relates to a system and a method for realizing zero emission of desulfurization waste water by denitrifying wide charges and utilizing waste heat, and belongs to the fields of energy conservation and emission reduction of thermal power generation. The system comprises a boiler, a coal economizer, an SCR denitrification device, an air preheater, an electric dust remover and a desulfurization tower which are connected sequentially through a main flue; a steam turbine is connected with the boiler through a main steam pipeline; a No.1 high-pressure heater and a No.0 high-pressure heater are arranged on a water supply pipeline sequentially; and the system also comprises a water supply backheating subsystem and an air preheater bypass flue evaporation subsystem. The invention alsorelates to a method for realizing zero emission of the desulfurization waste water by denitrifying the wide negative charges and utilizing the waste heat based on the system for realizing zero emission of the desulfurization waste water. Denitrification effect improvement, zero emission of desulfurization waste water and utilization of flue gas waste heat can be realized simultaneously by increasing the smoke discharge temperature of the boiler under various low-load working conditions of a machine unit.

Owner:DATANG ENVIRONMENT IND GRP

Smoke waste heat utilization system

ActiveCN105135468AMeet the working temperatureWorking temperature is suitableCombustion processIndirect carbon-dioxide mitigationAir preheaterPlate heat exchanger

The invention discloses a smoke waste heat utilization system. The system comprises an air preheater, wherein the air preheater is connected with a high-temperature smoke cooler, the high-temperature smoke cooler is connected with a dust removal device, the dust removal device is connected with a desulfurizing device, a low-temperature smoke cooler is further connected between the dust removal device and the desulfurizing device, a heating medium channel of the high-temperature smoke cooler and a heating medium channel of the low-temperature smoke cooler are both connected with a heat exchange device used for heating air supplied to the air preheater, and the heat exchange device is a heat-pipe type heat exchanger. The system can recover smoke waste heat between the air preheater and the dust removal device, can also recover smoke waste heat between the dust removal device and the desulfurizing device and can transfer recovered heat to the air supplied to the air preheater through the heat exchange device, then the heat is recovered to a thermal system of a boiler, and the utilization efficiency of the smoke waste heat of the boiler is greatly improved.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +3

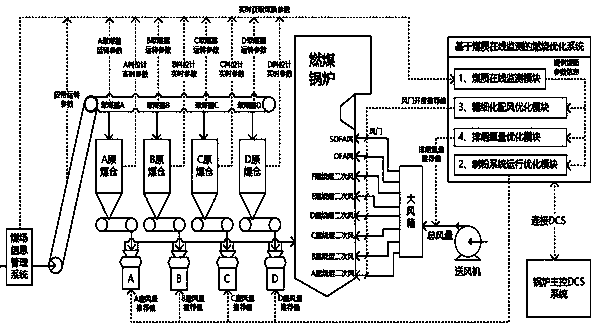

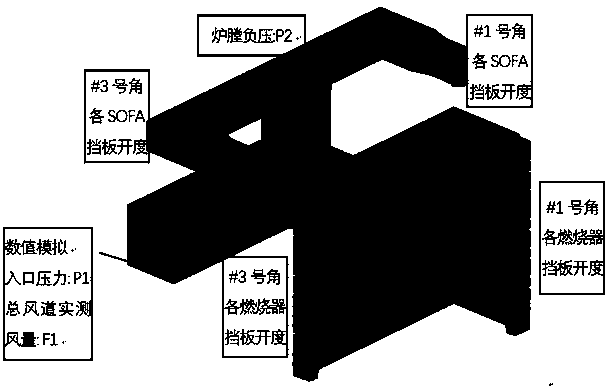

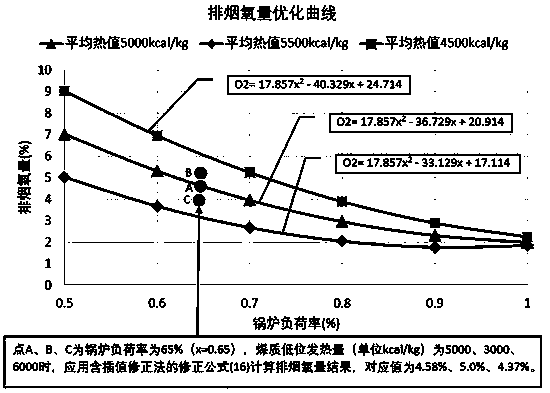

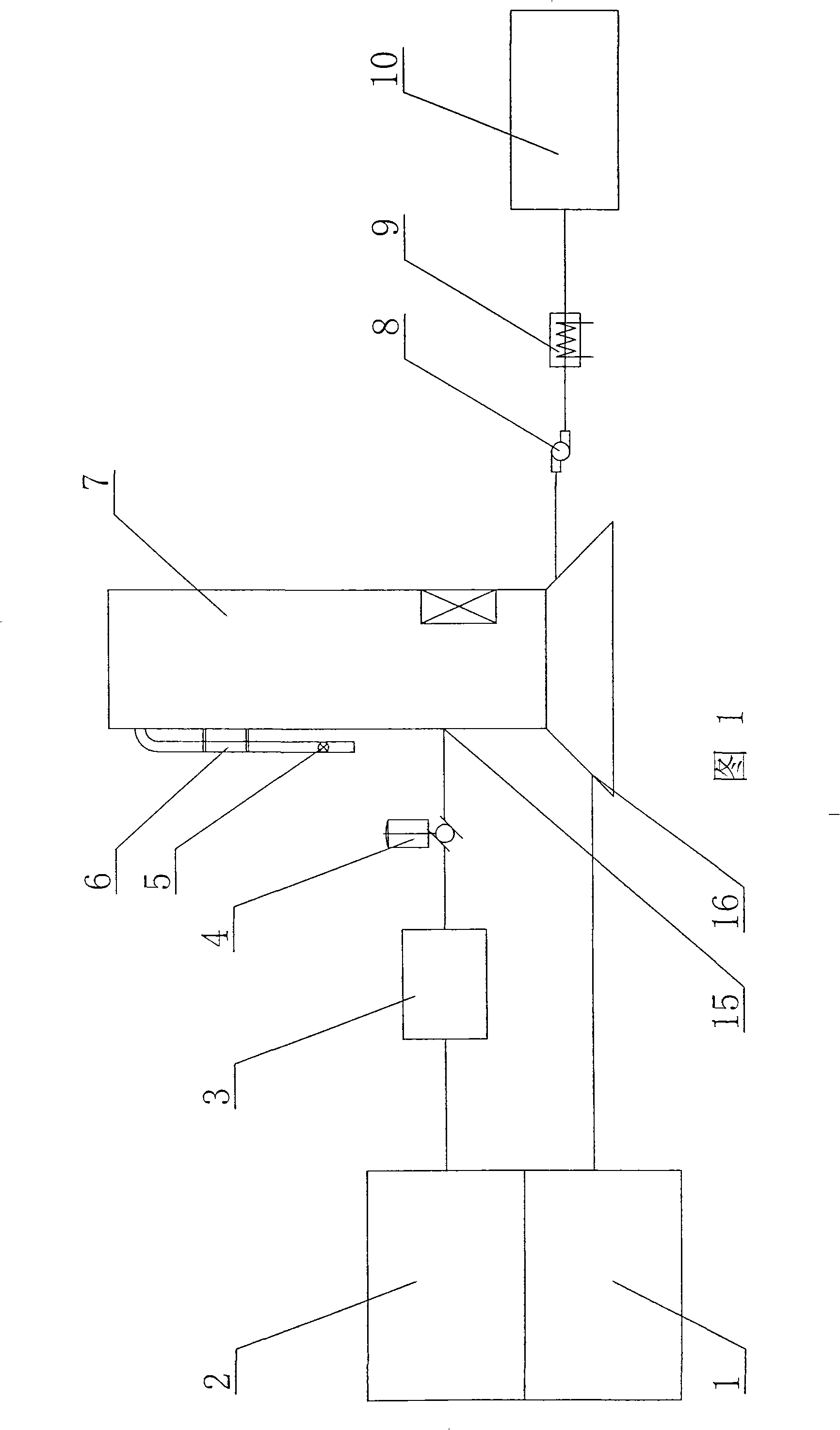

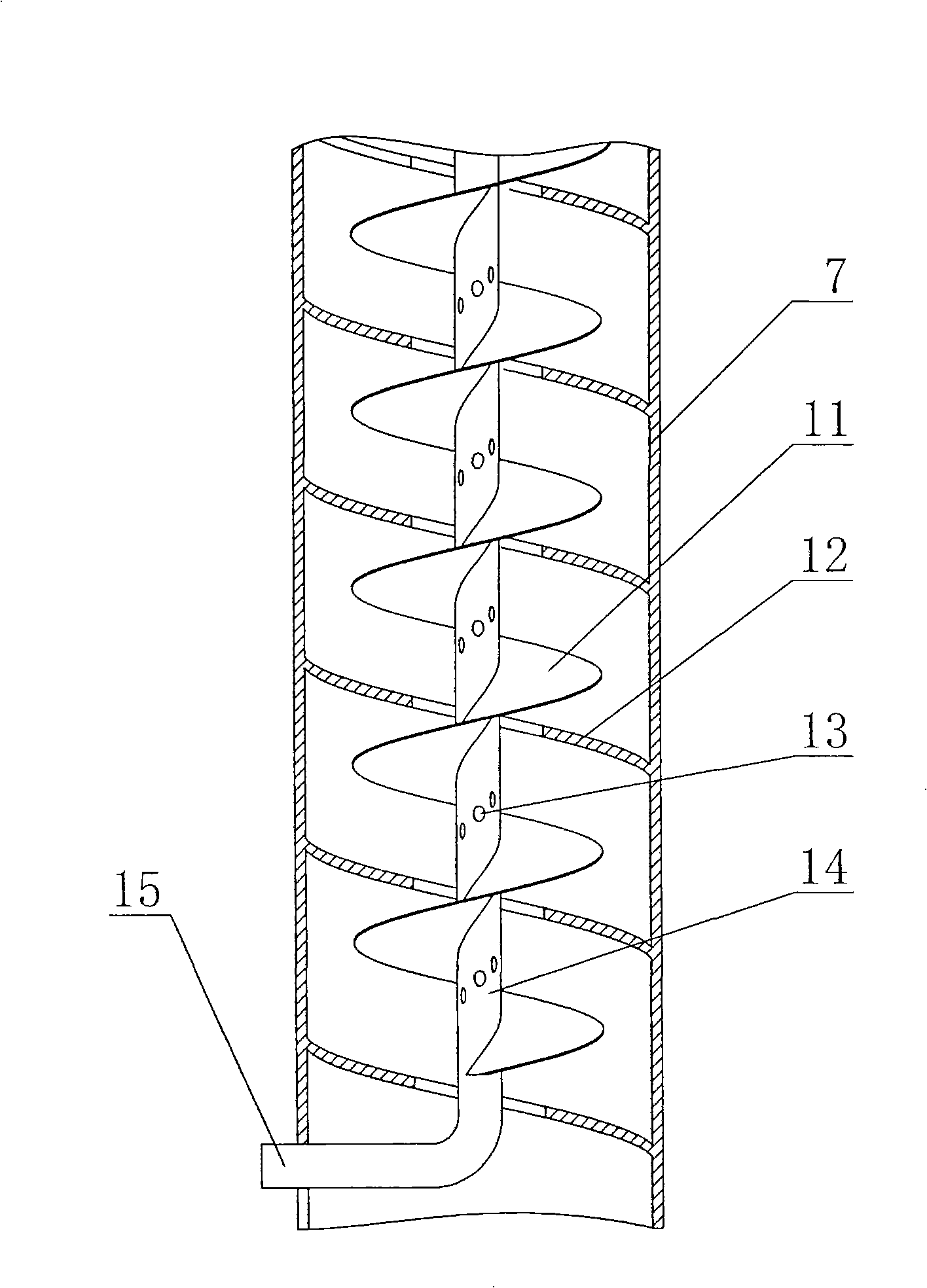

Combustion optimization method based on coal quality on-line monitoring

ActiveCN110848733ASolve the problem of difficult real-time measurement of coal qualitySolve the problem of difficult real-time measurementForecastingCombustion regulationAir volumeCombustor

Owner:NANJING SCIYON AUTOMATION GRP

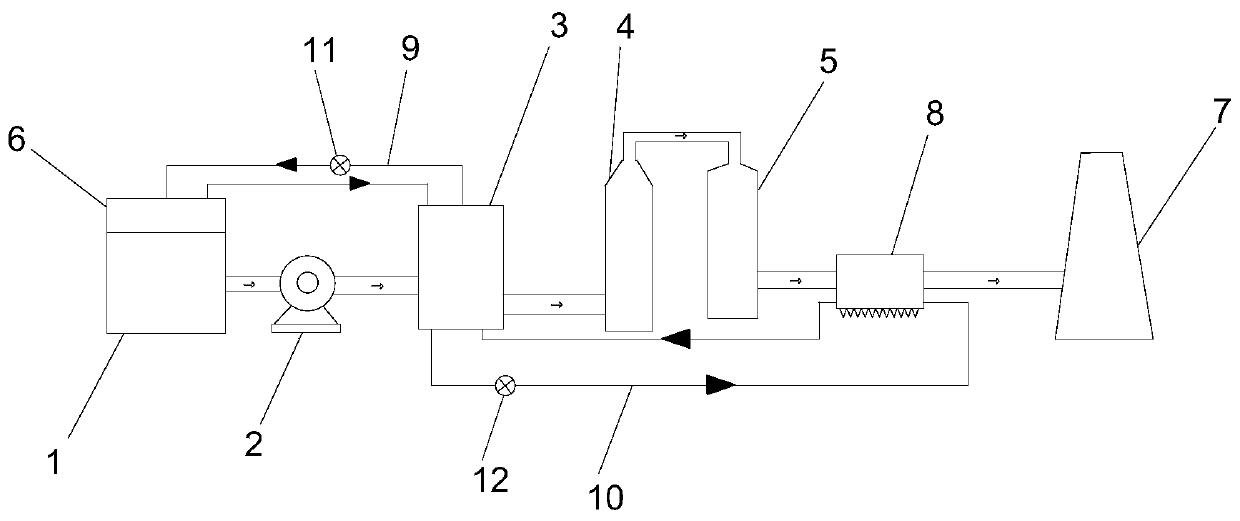

Double reduction method energy-saving emission-reducing environment-friendly complete equipment

ActiveCN101338977AReduce energy consumptionImprove purification effectHuman health protectionUsing liquid separation agentSulfur dioxideSewage

The invention discloses an energy-saving emission reduction complete plant which is friendly to the environment and which adopts the double reduction method. The complete plant comprises a high temperature radiator connected with the smoke pipes of industrial kilns and boilers; the high temperature radiator is connected with a purification tower by an exhaust blower; the bottom of the purification tower is provided with a waterway which is connected with a sewage tank; the sewage tank is connected with a clean water basin; the clean water basin is connected with an intake arranged on the purification tower through a chemical neutralizer and a rot-proof pump; the horizontal section of the purification tower is round; the intake is connected with an upright pipe arranged in the center of the purification tower; spiralling internal guide vanes are arranged around the upright pipe; the internal wall of the purification tower is provided with spiralling external guide vanes. The turning directions of the internal guide vanes and the external guide vanes are the same, and the internal guide vanes and the external guide vanes are arranged alternately; a plurality of nozzles are arranged around the upright pipe. The complete plant effectively purifies emission by consuming little energy; the cost of manufacture is low; the pollution of ash and sulfur dioxide is reduced; the complete plant is applicable for purifying the emission of various industrial kilns and boilers.

Owner:江苏绿塔环境工程有限公司

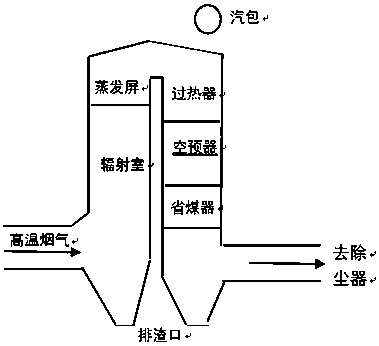

High-salinity wastewater treatment method of epoxypropane/styrene co-production device

InactiveCN109974014AReduce processing costsReduce consumptionGas treatmentDispersed particle separationLiquid wasteSlag

The invention discloses a high-salinity wastewater treatment method of epoxypropane / styrene co-production device. The method adopts a novel process scheme featuring incineration, waste heat boiler andsoda slag comprehensive utilization. The method mainly comprises the steps including liquid waste incineration; denitration treatment; cooling regulating; waste heat recovering; dedusting treatment;and soda slag recycling. According to the method, high-temperature flue gas entering a waste heat boiler is cooled firstly, molten inorganic salt can be precipitated in the solid form and is preventedfrom entering the waste heat boiler, then high-temperature flue gas enters the waste heat boiler to produce steam of the required grade as a by-product, soda slag produced by a system can be collected from the bottom of a vertical incinerator, the lower portion of the waste heat boiler and the interior of a dust remover, is pretreated and is then used for wet method alkali washing desulfurizationfacility comprehensive utilization, and accordingly, the purposes of treatment of wastes with processes of wastes against one another, energy-saving, cost-reducing and turning waste into valuable areachieved.

Owner:SINOCHEM QUANZHOU PETROCHEM CO LTD

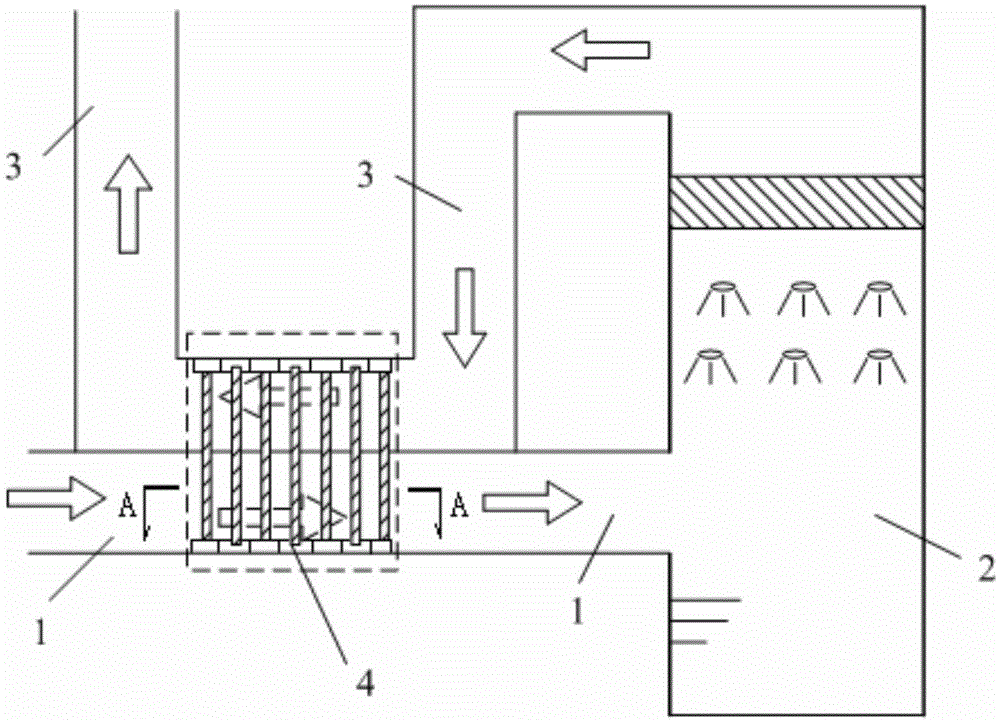

Integrated heat exchange device for wet desulphurization system

ActiveCN105889959AReduce the temperatureIncrease lift heightIndirect heat exchangersWork performanceFlue gas

The invention provides an integrated heat exchange device for a wet desulphurization system. The wet desulphurization system is provided with an inlet flue, an outlet flue and a desulphurization tower. The inlet flue and the outlet flue are provided with a horizontal intersection segment which comprises multiple columns of hot tube bundles. Each column of hot tube bundles comprises a plurality of hot tubes distributed linearly and evenly. The heat absorbing ends of the hot tubes extend into the inlet flue, and the heat release ends of the hot tubes extend into the outlet flue. Each column of hot tube bundles and the adjacent hot tube bundles are distributed in parallel in a staggered mode. Heat of flue gas in a high-temperature segment is used for heating flue gas in a low-temperature segment, an external heat source is not needed, work performance of the system is improved, diffusion of flue gas emission is promoted, and engineering construction investment and occupied area are reduced. Compared with a traditional GGH system and various heat exchange devices replacing the GGH system, the integrated heat exchange device is simple and light in structure, the number of corresponding flue supporting structures can be reduced, overall operation of a heat exchange system is not affected when single hot tubes break down, and stability is high.

Owner:DATANG ENVIRONMENT IND GRP

Thermoelectric-coupling type comprehensive energy-utilizing system based on air-cooling device and working method

ActiveCN103334802AIncrease profitTotal engineering cost reductionBiofuelsSteam useCold airInlet channel

The invention discloses a thermoelectric-coupling type comprehensive energy-utilizing system based on an air-cooling device and a working method of the thermoelectric-coupling type comprehensive energy-utilizing system. The system comprises the air-cooling device, wherein the air-cooling device is connected with a condensed-water pump, the condensed-water pump is connected to a steam engine through a condensed-water booster pump, a plurality of stages of low-pressure heating systems, a deoxidizing device, a water-feeding pump, a high-pressure heating system and a boiler in sequence, and the steam engine is respectively connected with a generator and the air-cooling device; the air-cooling device comprises an air-cooling central island, wherein the inlet of the air-cooling central island is communicated with a plurality of cold-air inlet channels, the outlet of the air-cooling central island is communicated with a plurality of hot-air outlet channels, a switching valve is arranged on each hot-air outlet channel, the switching valve comprises two valve positions, one valve position is communicated to a residual-heat utilizing user, and the other valve position is communicated to a hot-air temporarily-diffusing channel; and at least one switching valve also comprises a third valve position, the third valve position is communicated to a hot-air recycling-pipeline mother pipe through an air heater, and a plurality of hot-air recycling-pipeline branch pipes are arranged on the hot-air recycling-pipeline mother pipe, are correspondingly converged into the cold-air inlet channels one by one and are communicated to the air-cooling central island.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

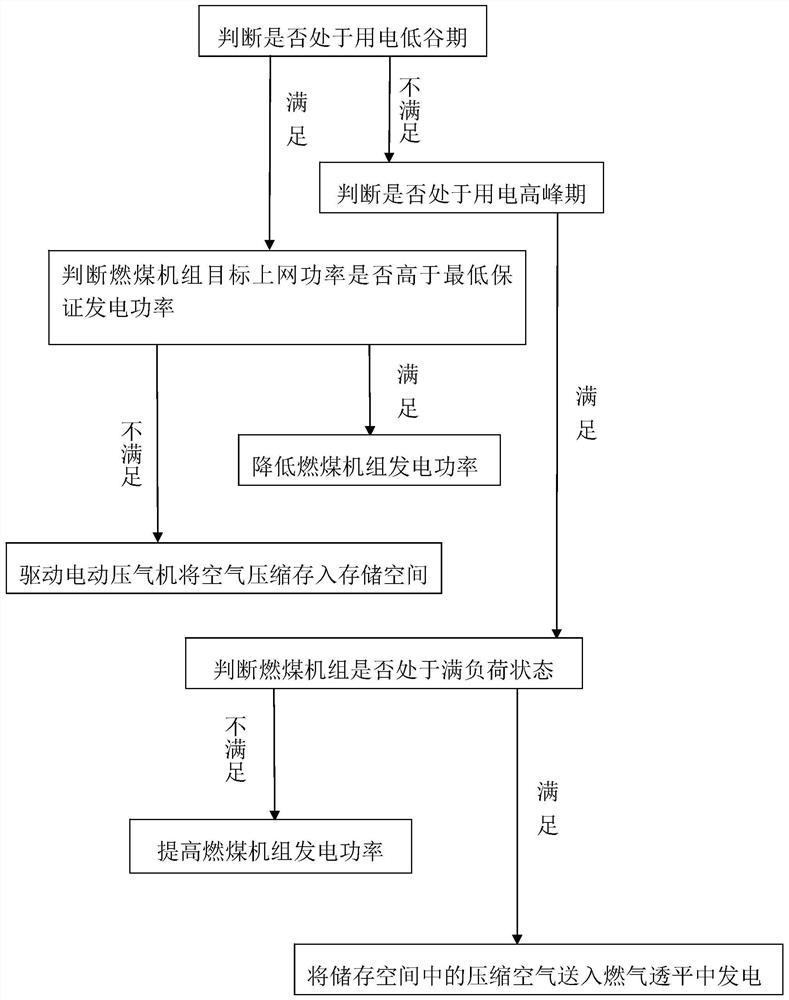

Peak regulation power generation system and method coupled with compressed air energy storage

ActiveCN113202574AIncrease power generationReduce internet powerPumpsSteam engine plantsNatural gas consumptionAir compression

The invention discloses a peak regulation power generation system and method coupled with compressed air energy storage. With the development and utilization of large-scale renewable energy sources, the peak-valley difference of a power grid is increasingly increased, and the bearing capacity is also limited. According to the technical scheme, when the power grid is in a power consumption valley period, air is compressed through power generated by a coal-fired unit and then stored in a storage space, and on the premise that it is guaranteed that the actual generation power of the coal-fired unit is higher than the minimum guaranteed generation power, the on-grid power of the coal-fired unit is effectively reduced; and when the power grid is in a power consumption peak period, the compressed air in the storage space is fed into a gas turbine for power generation, so that the power consumption of a main compressor is reduced, the on-grid power of the gas turbine is improved, and the natural gas consumption is reduced. According to the peak regulation power generation system and method coupled with compressed air energy storage, support can be provided for peak load shifting of the power grid, so that the renewable energy consumption capability is improved, and the usage amount of high-grade energy such as natural gas can be reduced on the premise that the on-grid power of the system meets the power grid adjustment requirement.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

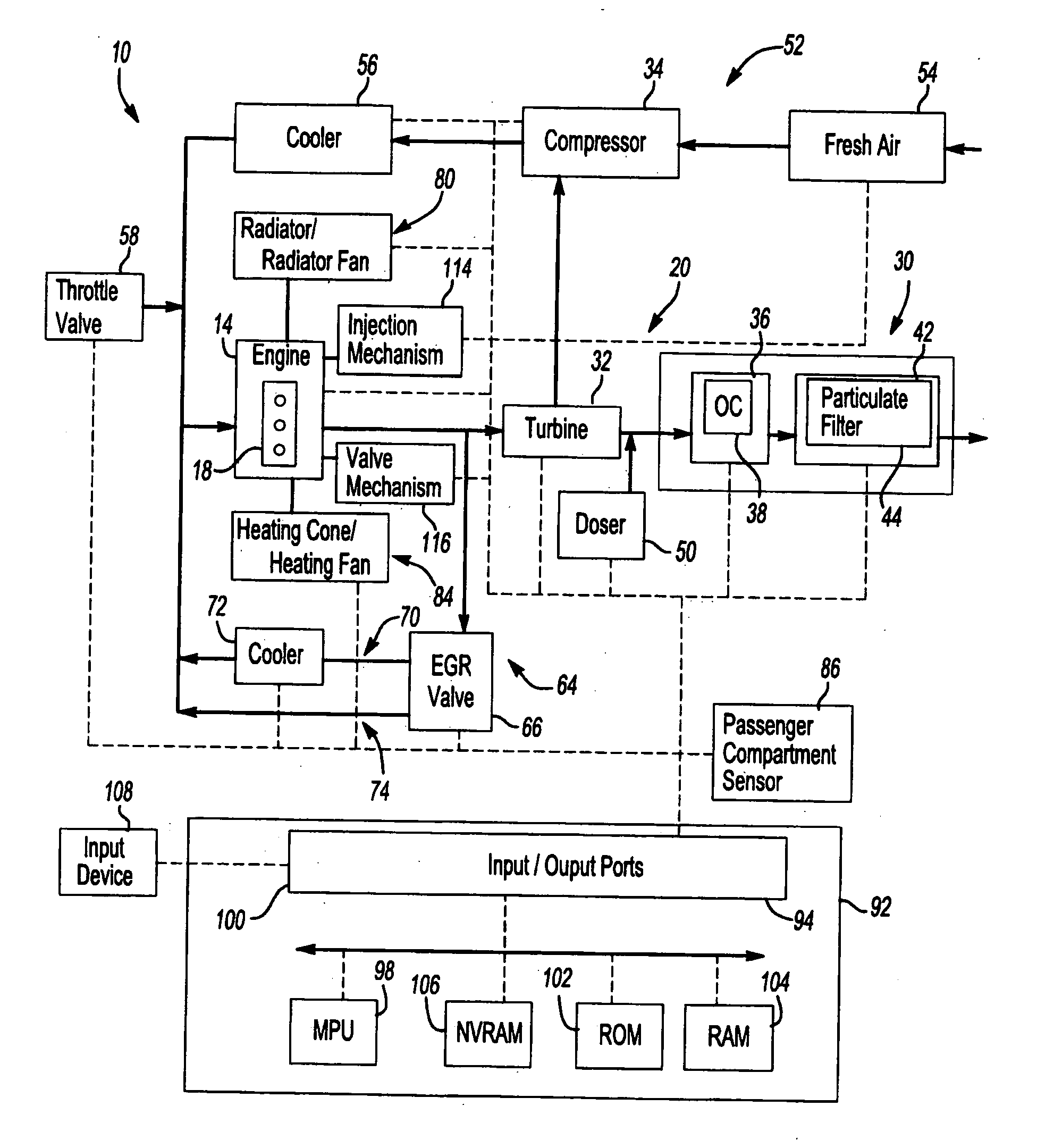

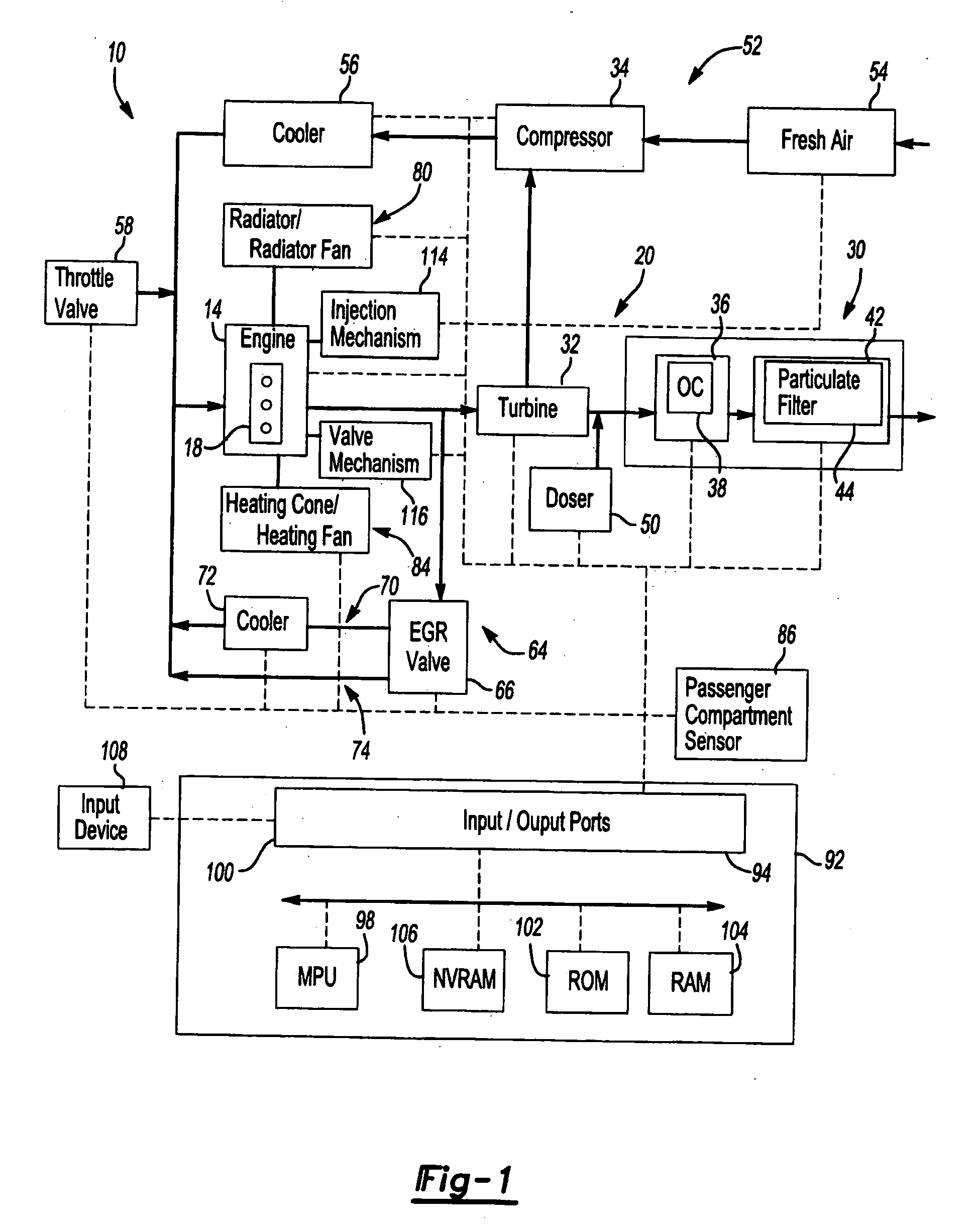

Method and system for controlling temperatures of exhaust gases emitted from an internal combustion engine to facilitate regeneration of a particulate filter

InactiveUS20060130466A1Increase engine temperatureRaise the exhaust gas temperatureElectrical controlNon-fuel substance addition to fuelParticulatesExhaust fumes

Method, system, and controller for increasing exhaust gas temperatures through controlled operation of a radiator fan in order to facilitate regeneration of a particulate filter. The method, system, and controller being applicable in systems having an engine which emits exhaust gases having particulates which are captured by the particulate filter.

Owner:DETROIT DIESEL CORP

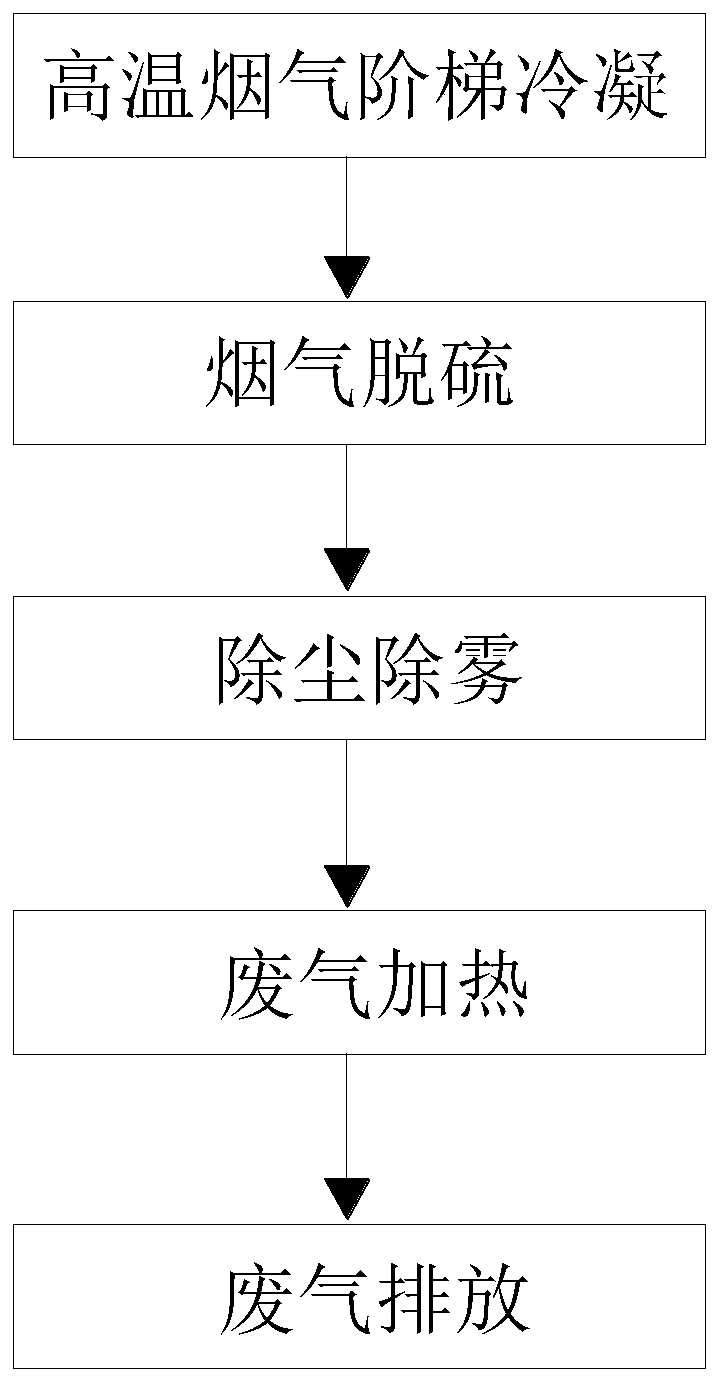

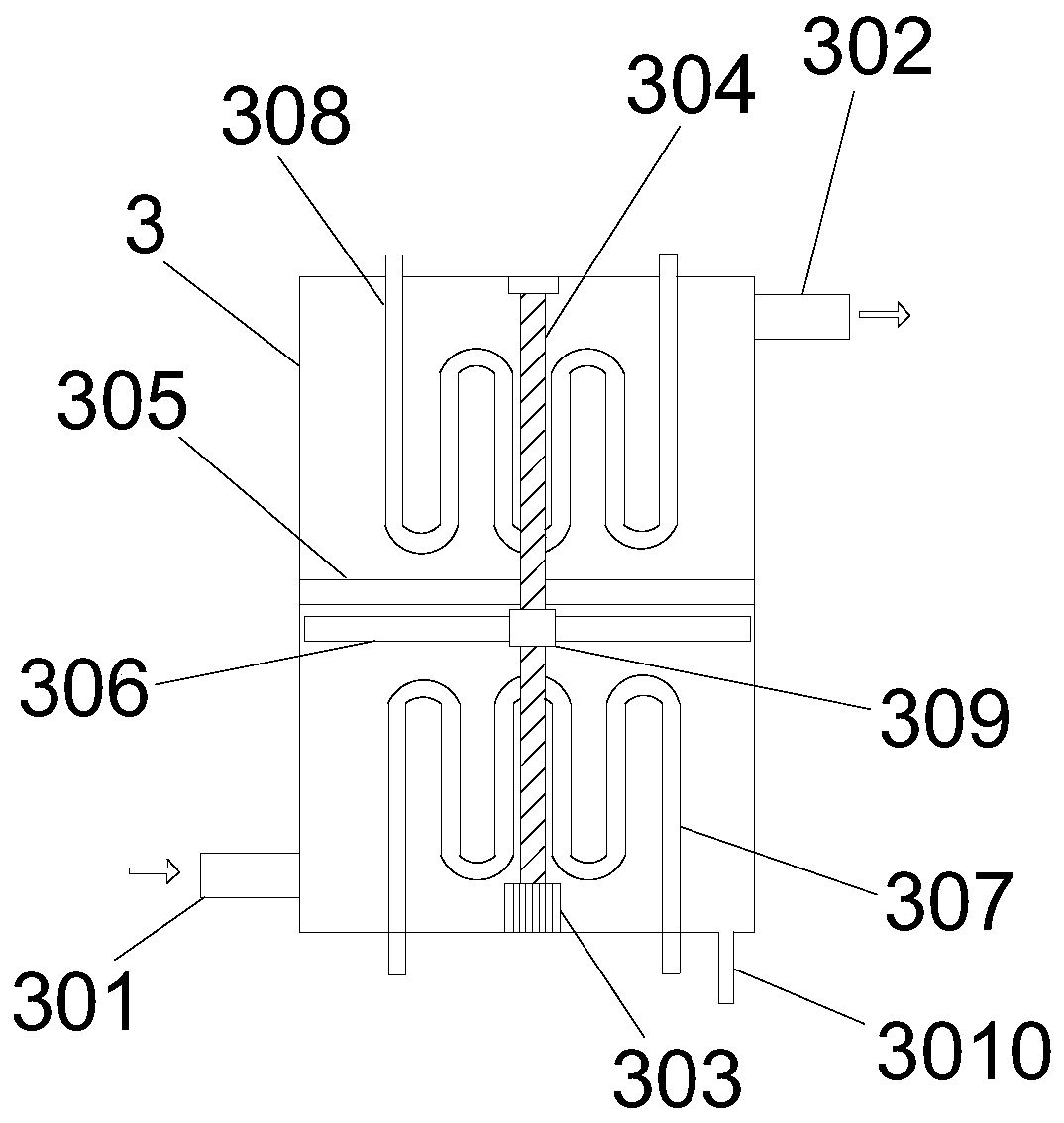

Flue gas white smoke plume removing method for increasing heat energy utilization rate

InactiveCN110385007AExtended stayImprove heat utilizationGas treatmentDispersed particle separationThermal energyChemical reaction

The invention relates to a flue gas white smoke plume removing method for increasing the heat energy utilization rate. The flue gas white smoke plume removing method comprises the following steps: S1,high-temperature flue gas is subjected to stepped condensation, specifically, a condenser is divided into a high-temperature chamber and a low-temperature chamber, flue gas sequentially enters the high-temperature chamber and the low-temperature chamber to be condensed, steam is condensed, and thus stepped cooling is achieved; S2, the flue gas is subjected to desulfuration, specifically, the fluegas condensed in the step S1 enters a desulfurizing tower, acid flue gas flows upwards from the bottom and is in reverse contact with sprayed alkaline desulfuration slurry to be subjected to chemicalreaction, thus sulphurous acid is generated and falls into the bottom of the desulfurizing tower to be recovered; S3, dust removing and demisting are conducted, specifically, the flue gas subjected to desulfuration in the step S2 passes through an efficient micro-cyclone dust removing and demisting device, while liquid water with the grain size being 5 [mu]m or below is effective captured, vaporous water in the saturated flue gas is partially converted into liquid water, and the flue gas is transformed from the saturated state to the undersaturation state; S4, waste gas is heated, specifically, the flue gas subjected to dust removing and demisting in the step S3 is heated and warmed up through a water gas heat exchanger; and S5, the waste gas is discharged, specifically, after the flue gas is warmed up in the step S4, the saturability of the flue gas is reduced, and the flue gas is discharged into the atmosphere through a chimney.

Owner:河南迪诺环保科技股份有限公司

Flue gas system for unbalance control of flue gas flow

InactiveCN101566351ASolve corrosiveSolve the cloggingCombustion processIndirect carbon-dioxide mitigationAir preheaterFlue gas

The invention relates to a flue gas system for unbalance control of flue gas flow, which comprises an air preheater, an air preheater outlet flue and an air preheater inlet flue which are communicated with the air preheater. N partition boards are arranged in the air preheater inlet flue to partition the air preheater inlet flue into N+1 small flue gas passages in which N adjusting doors are arranged. By adjusting the flue gas flow through the adjusting doors, the flue gas flow flowing through the air preheater forms certain deviation according to the metal temperature variation of a heat storage plate, namely when the metal temperature of the heat storage plate is lower, the heat transfer temperature pressure with the flue gas is larger, and the flue gas flow flowing through the surface of the air preheater is relatively large; and when the metal temperature of the heat storage plate is raised in the flue gas passage along with the rotation of the air preheater, the flue gas flow flowing through the surface of the air preheater is relatively reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

Start-up method of dewatering capacity-enlarging start-up monotube boiler near steam heating boilers

ActiveCN100557304CRaise the exhaust gas temperatureImprove operating conditionsSteam generation using hot heat carriersFeed-water heatersWater flowEngineering

The invention discloses a method for starting a steam-heated boiler adjacent to a once-through boiler with drainage and capacity expansion. The high-pressure heater on the unit to be started is connected with a pipeline that can receive heating steam from other sources; Boiler feed water temperature rise; when starting in cold state or warm state or hot state, indirectly heat the heating surface of the boiler, increase the flow of feed water to above the minimum ignition flow after its temperature is close to the saturation temperature of steam heated by other sources, start the air and smoke system, and the boiler Ignition, use the bypass system to increase the thermal load as soon as possible after starting the pulverizing system, cut off the fuel and enter the normal starting mode after the thermal load of coal burning is higher than the minimum oil cut-off thermal load; When the temperature difference between the feed water and the boiler water wall is less than the specified value, increase the feed water flow rate to above the minimum ignition flow rate, and the boiler will be ignited. After the thermal load of coal combustion is higher than the minimum oil cut-off heat load, the fuel oil will be cut off and enter the normal start-up mode. The method of the invention has the effect of saving energy.

Owner:冯伟忠

Slag sensible heat recycling system for air-cooling dry slag machine

ActiveCN107741021AAvoid influenceImprove efficiencyIndirect carbon-dioxide mitigationAir/fuel supply for combustionAir preheaterAir volume

The invention relates to a slag sensible heat recycling system for an air-cooling dry slag machine. A horizontal segment, close to one side of a lifting segment, of the dry slag machine is provided with a shutter rotation opening-closing mechanism air inlet; the side, away from the lifting segment, of the air inlet is provided with an isolating device; the position, on the inner side of the top ofan outer shell, close to a joint of the dry slag machine and a boiler is provided with a temperature sensor; and the outer wall of the outer shell is provided with a controller, and the top of the dry-slag-machine lifting segment in the air-cooling dry slag machine is connected with a second air preheater and a first air preheater correspondingly through air pipes. The slag sensible heat recycling system for the air-cooling dry slag machine is reasonable in design, the influence of cold air on the operation of the boiler can be effectively avoided, the slag cooling efficiency is improved, meanwhile the slag sensible heat is used sufficiently, the low temperature corrosion environment of the air preheaters is improved, the tail gas temperature of the boiler is raised, at the same time theheat can be recycled by a low temperature economizer to raise the feed-water temperature, the total air volume entering the boiler is controlled, the low nitrogen combustion and low oxygen combustionare achieved, the discharging of NOX from boiler combustion is lowered, the amount of ammonia spraying in SCR area is reduced, and the efficiency of the boiler is improved.

Owner:史震伟

System and method for low-load denitration of boiler

PendingCN112050247AReduce minimum steady fire loadIncrease effective hoursEmission preventionDamper arrangementPhysicsFlue

The invention discloses a system and method for a low-load denitration of a boiler. The system comprises a hearth outlet flue, a low-temperature superheater flue, a low-temperature reheater flue, a bypass flue, an economizer flue and a denitration flue. The bypass flue is a bypass of a low-temperature reheater, a low-temperature superheater and an economizer. According to the method, mainly, whenthe smoke temperature of a denitration inlet is too low, some smoke enters the denitration inlet through the bypass flue, thus the smoke temperature of the denitration inlet rises, and thus the denitration system can achieve normal investment under the low-load circumstance of the boiler. The system and the method have environment-friendly and energy-saving effects, adjusting flexibility of a unitcan be improved, the utilization rate of the unit is increased, and economic benefits of the unit are increased.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com