Slag sensible heat recycling system for air-cooling dry slag machine

A slag drying machine and air-cooling technology, applied in lighting and heating equipment, combustion air/fuel supply, non-flammable liquid/gas transportation, etc. The problem of low slag cooling efficiency, etc., can improve the low-temperature corrosion environment, rational design, and improve slag cooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

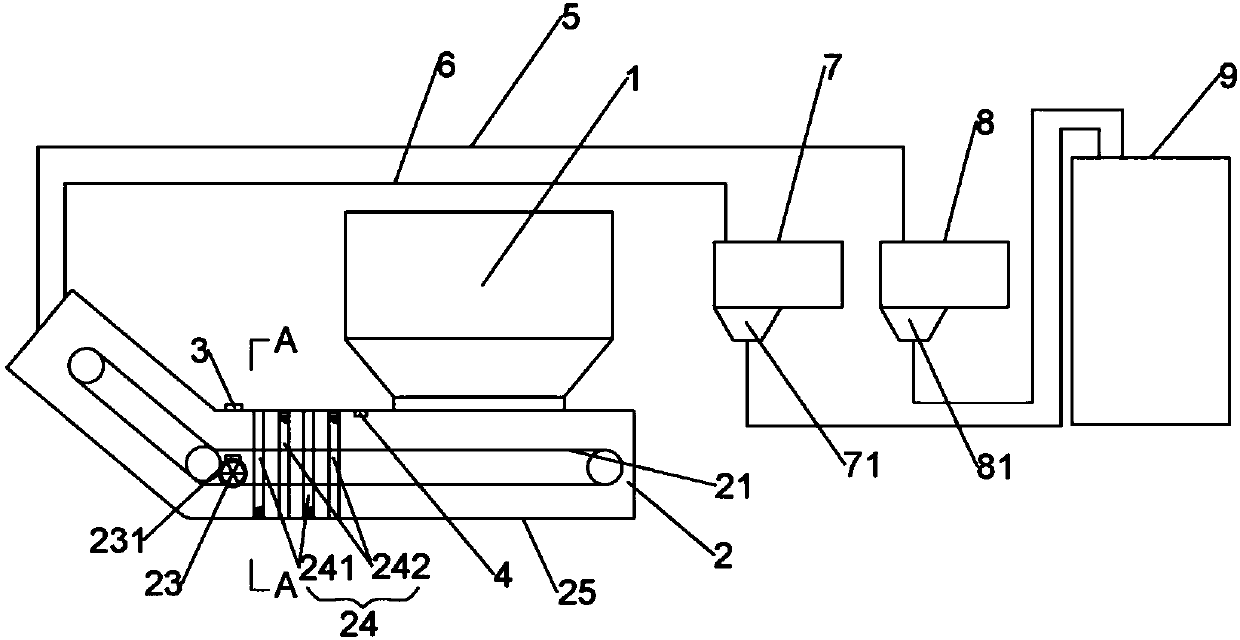

[0025] Such as figure 1 with figure 2 An air-cooled slag drying machine slag sensible heat recovery system is shown, including an air-cooled slag drying machine and a slag sensible heat recovery system;

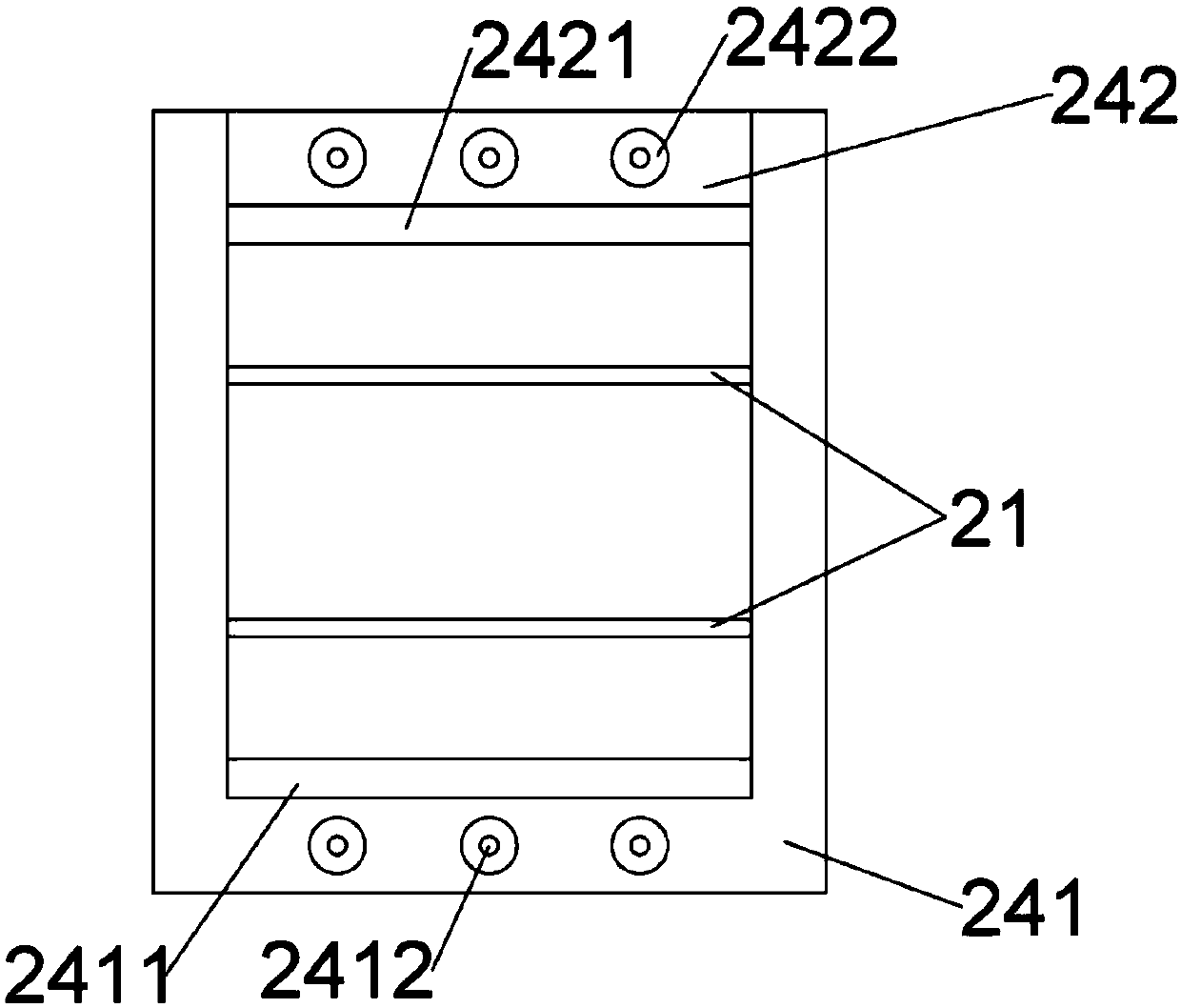

[0026] The air-cooled slag drying machine includes a boiler 1 and a slag drying machine 2. The slag drying machine 2 is divided into a horizontal section and a lifting section, and includes a casing 25 and a conveyor belt 21 arranged in the casing 25. In the slag drying machine 2 An air inlet 23 is arranged on the horizontal section near the lifting section, and the air inlet 23 is arranged in the middle position of the two crawlers of the conveyor belt 21, and is opened and closed by a driving device 231; the air inlet 23 is opened and closed by a shutter rotation mechanism, the drive device 231 realizes opening and closing by turning the rotary seat at the bottom of the air inlet 23 . A temperature sensor 4 is set on the inner side of the top of the shell 25 near the con...

Embodiment 2

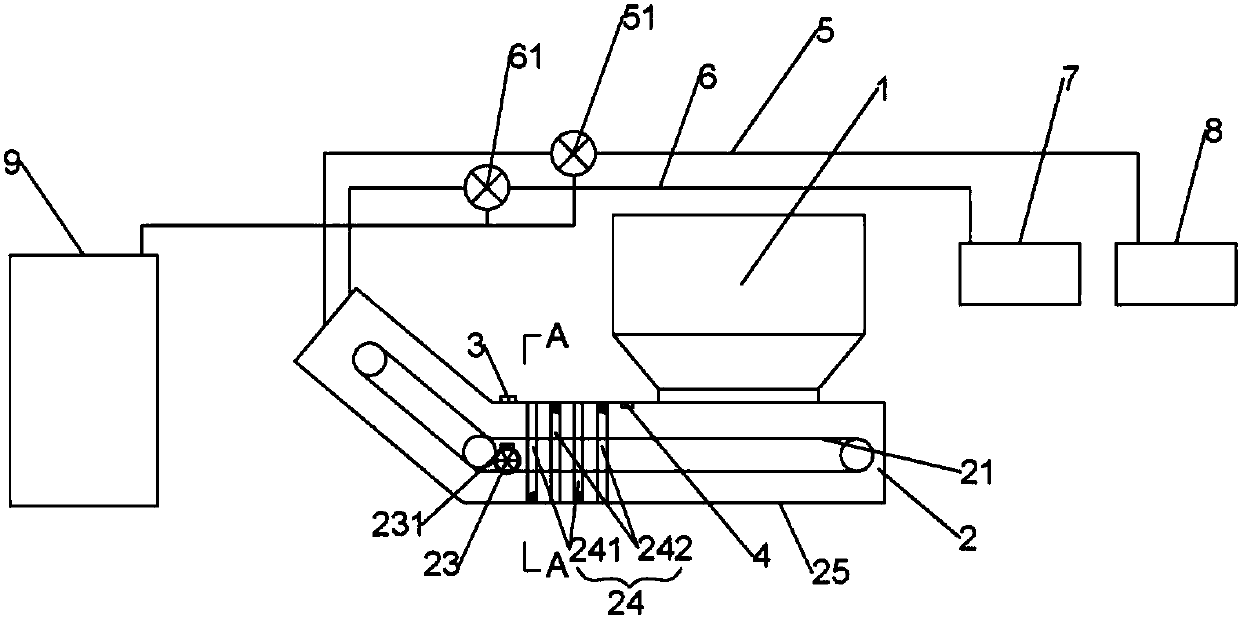

[0030] Such as figure 1 with image 3 An air-cooled slag drying machine and a slag sensible heat recovery system are shown, including an air-cooled slag drying machine and a slag sensible heat recovery system;

[0031] The air-cooled slag drying machine includes a boiler 1 and a slag drying machine 2. The slag drying machine 2 is divided into a horizontal section and a lifting section, and includes a casing 25 and a conveyor belt 21 arranged in the casing 25. In the slag drying machine 2 An air inlet 23 is arranged on the horizontal section near the lifting section, and the air inlet 23 is arranged in the middle position of the two crawlers of the conveyor belt 21, and is opened and closed by a driving device 231; the air inlet 23 is opened and closed by a shutter rotation mechanism, the drive device 231 realizes opening and closing by turning the rotary seat at the bottom of the air inlet 23 . A temperature sensor 4 is set on the inner side of the top of the shell 25 near t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com