Patents

Literature

1698 results about "Radiant heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radiant heat is heat which radiates out from an element, warming objects rather than the air. An example of this heat that many people may be familiar with is the heat which comes off an electric element on a stove.

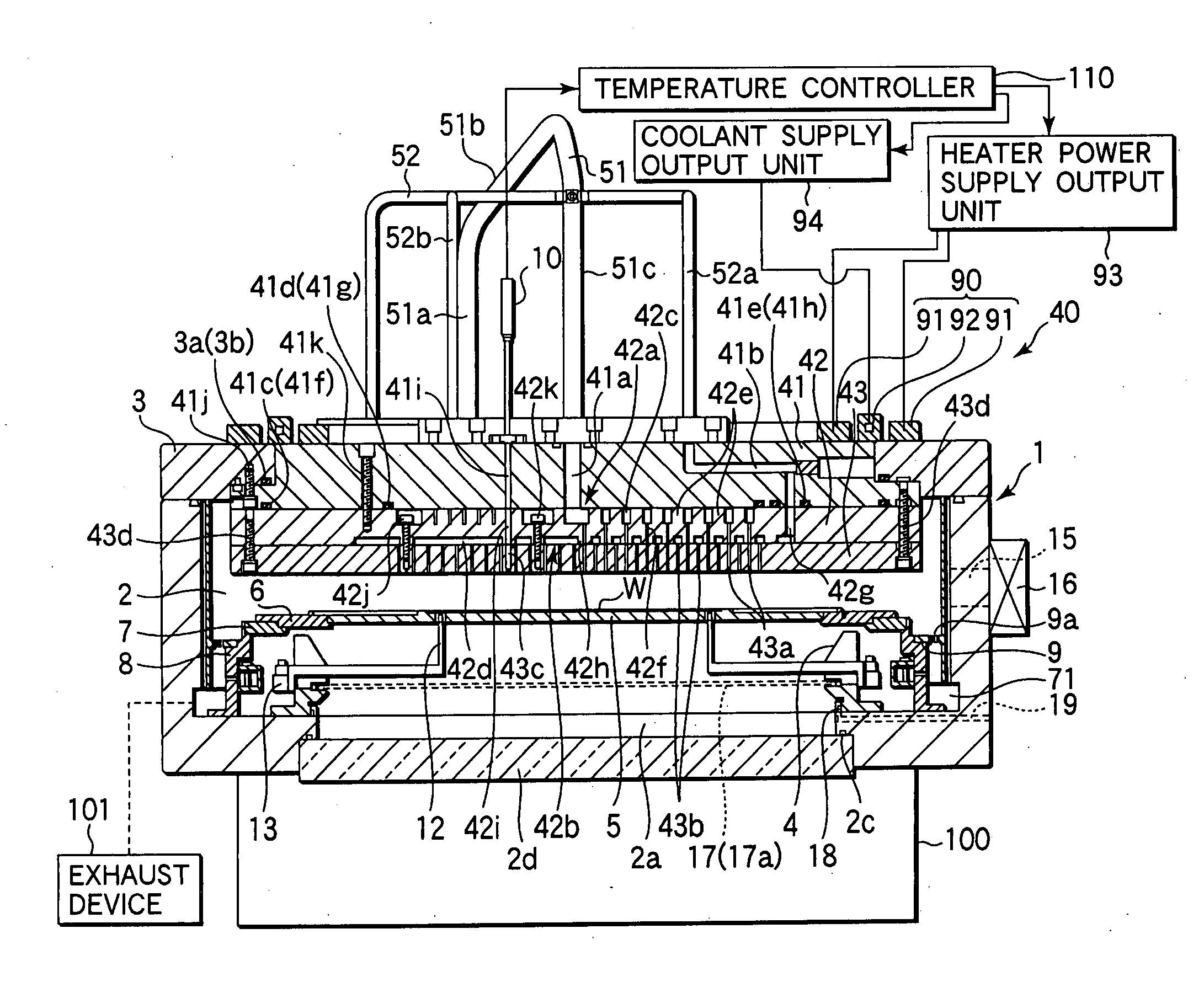

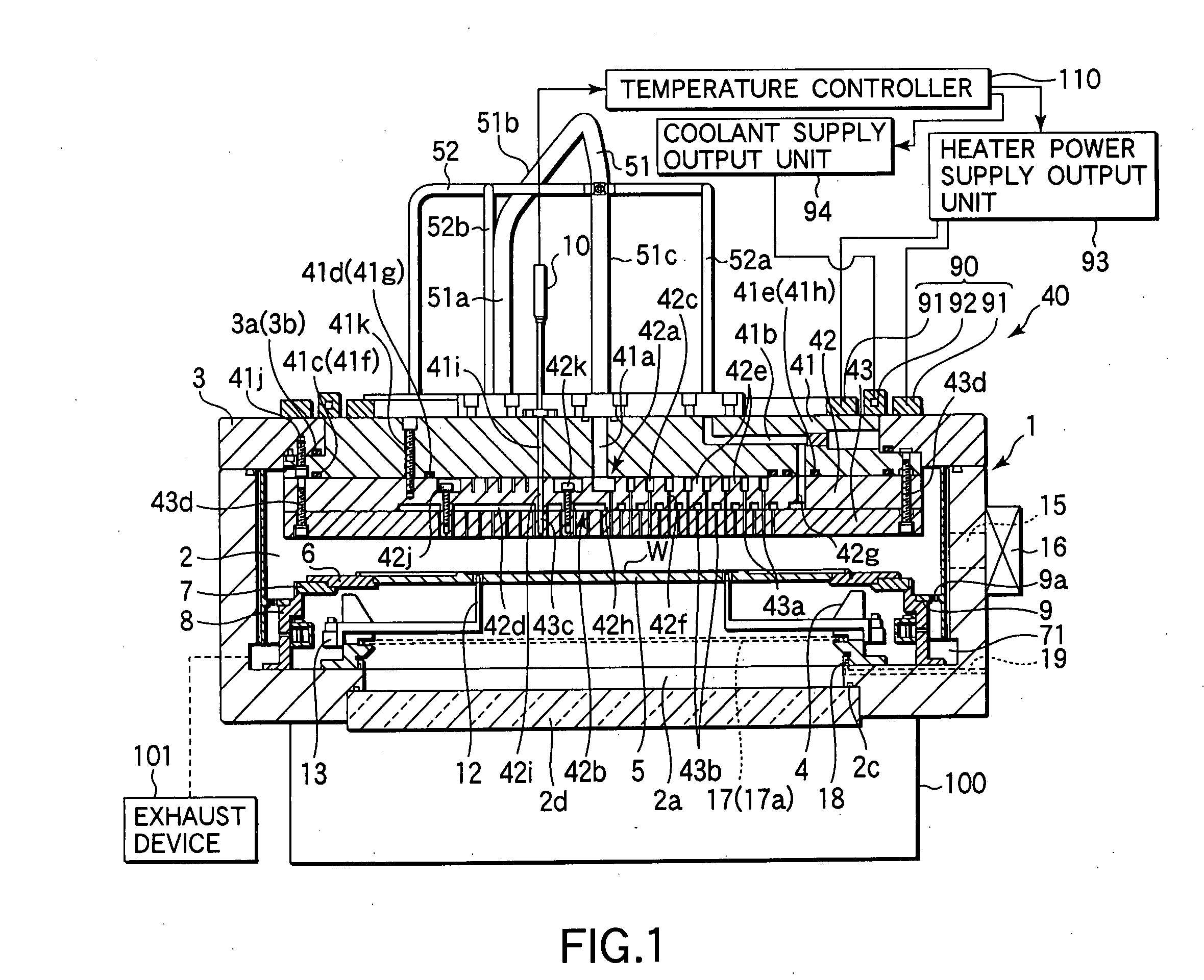

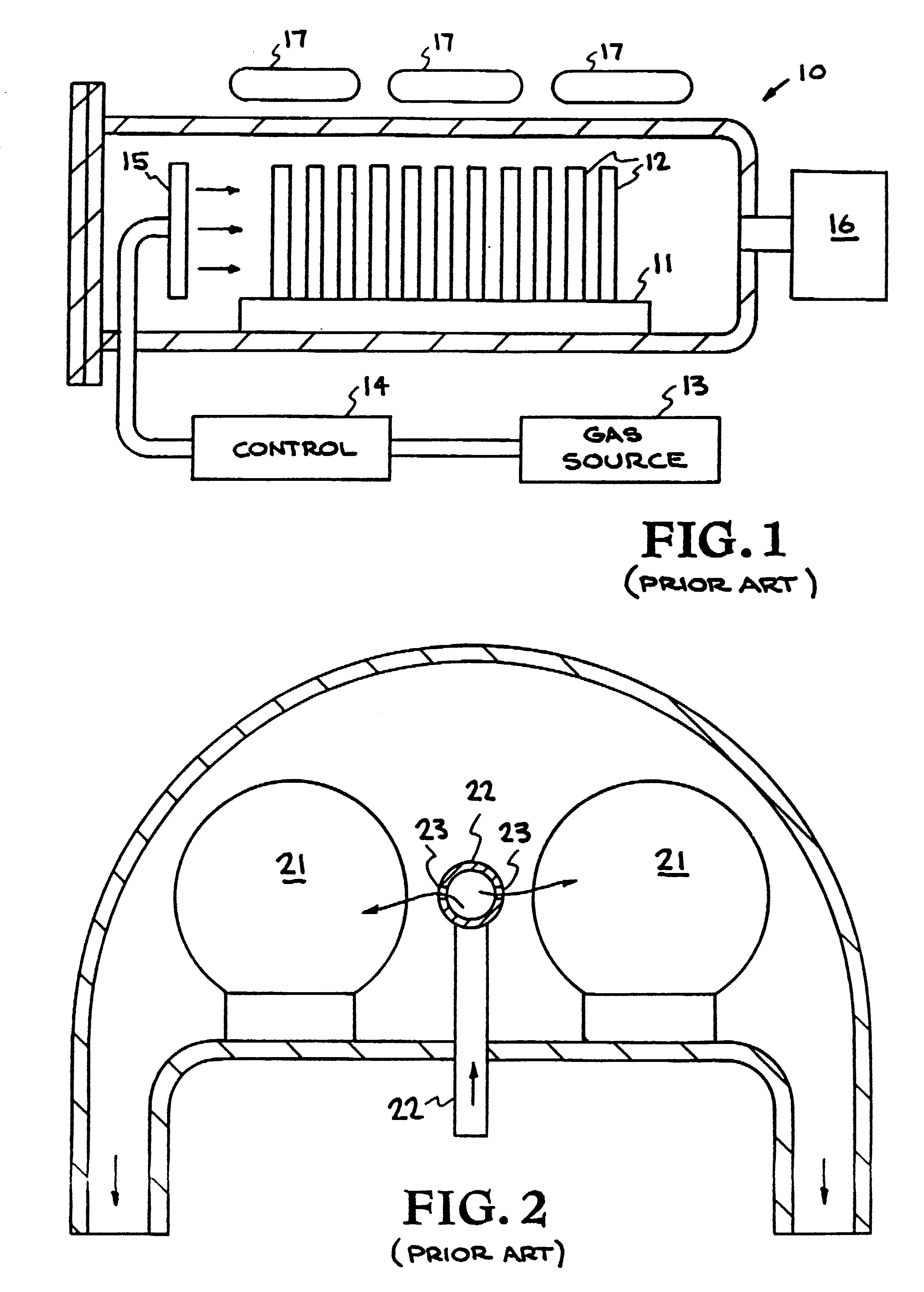

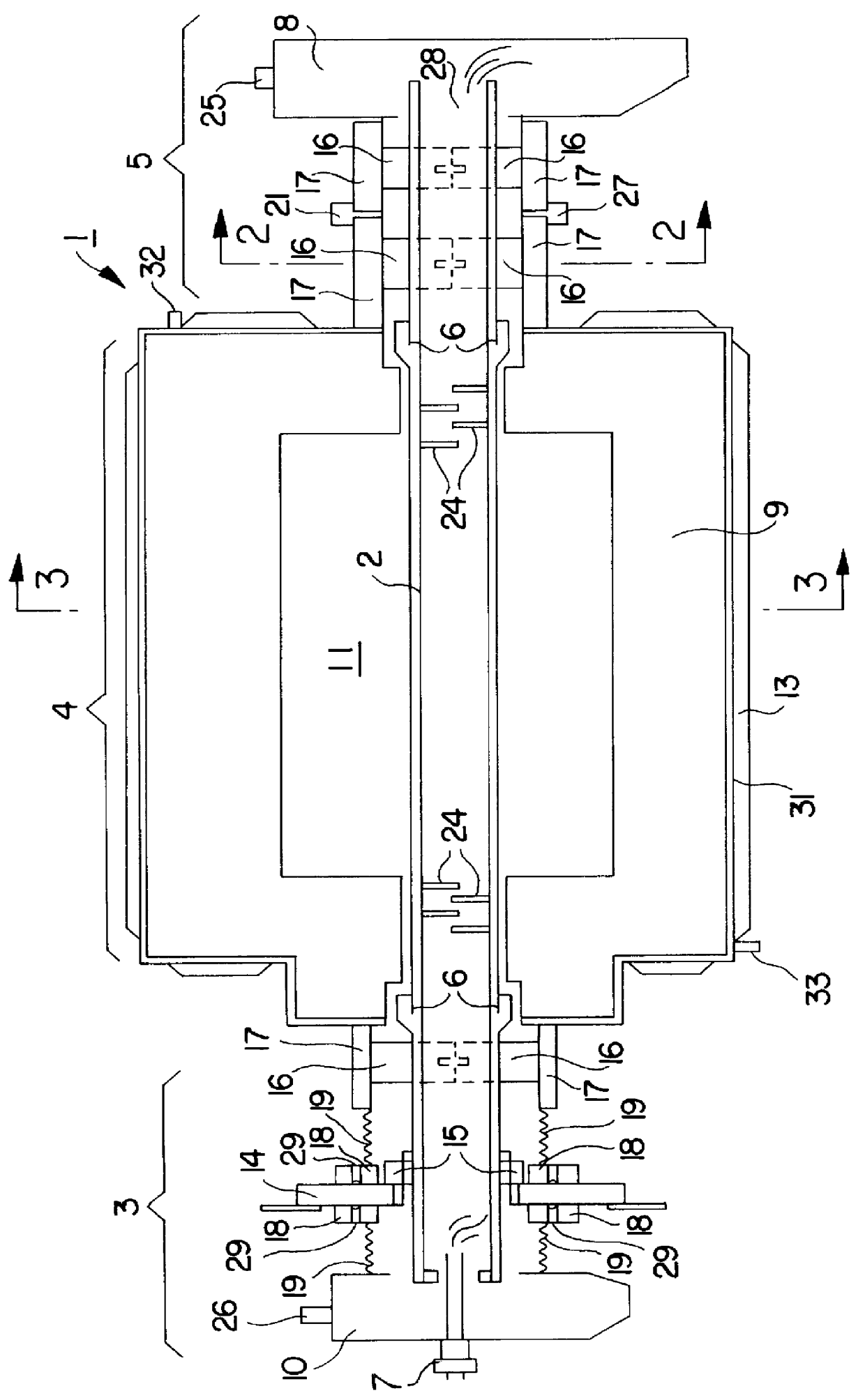

Gas treatment device and heat readiting method

InactiveUS20070022954A1Improve cooling efficiencyInhibit temperature riseSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringRadiant heat

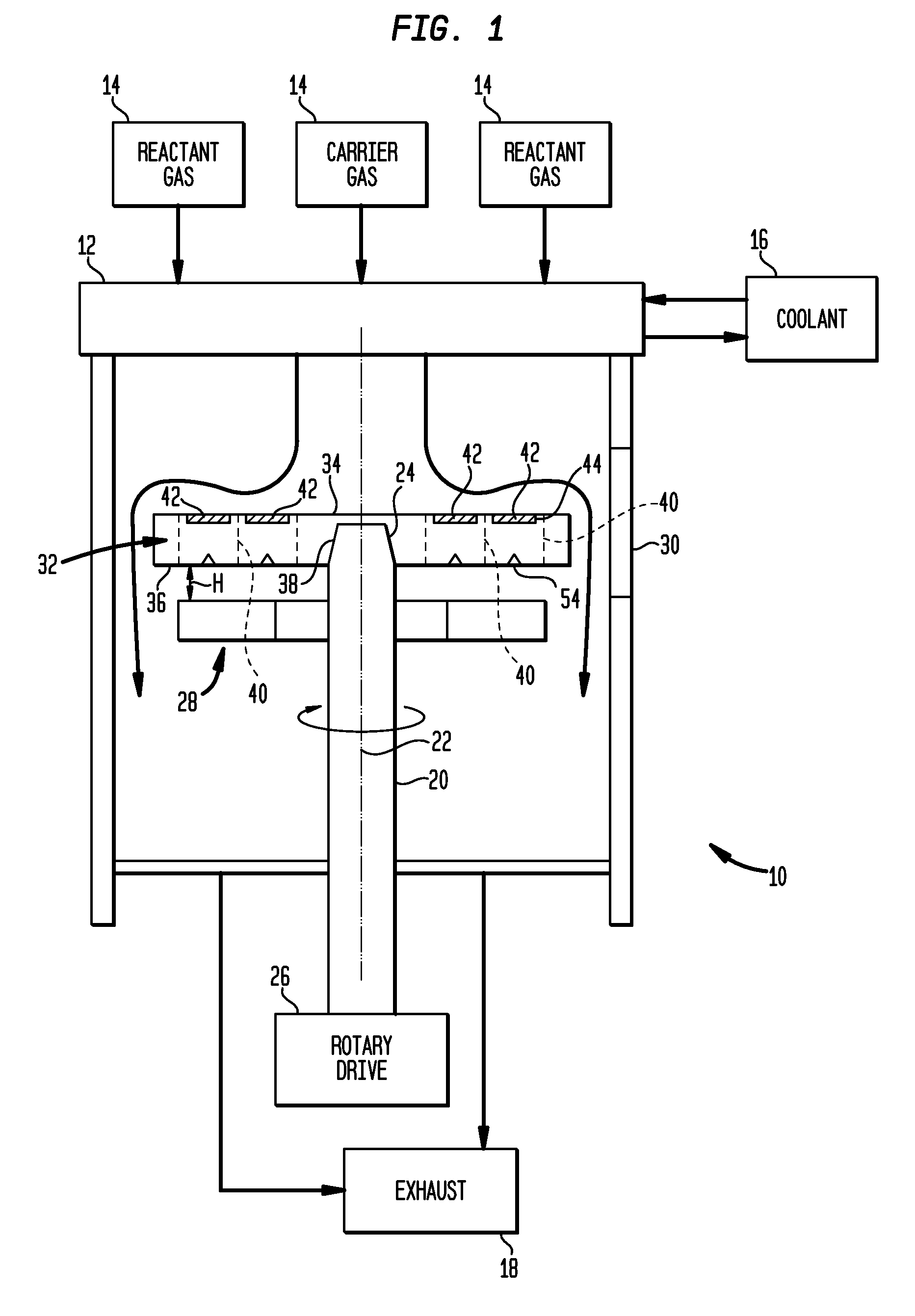

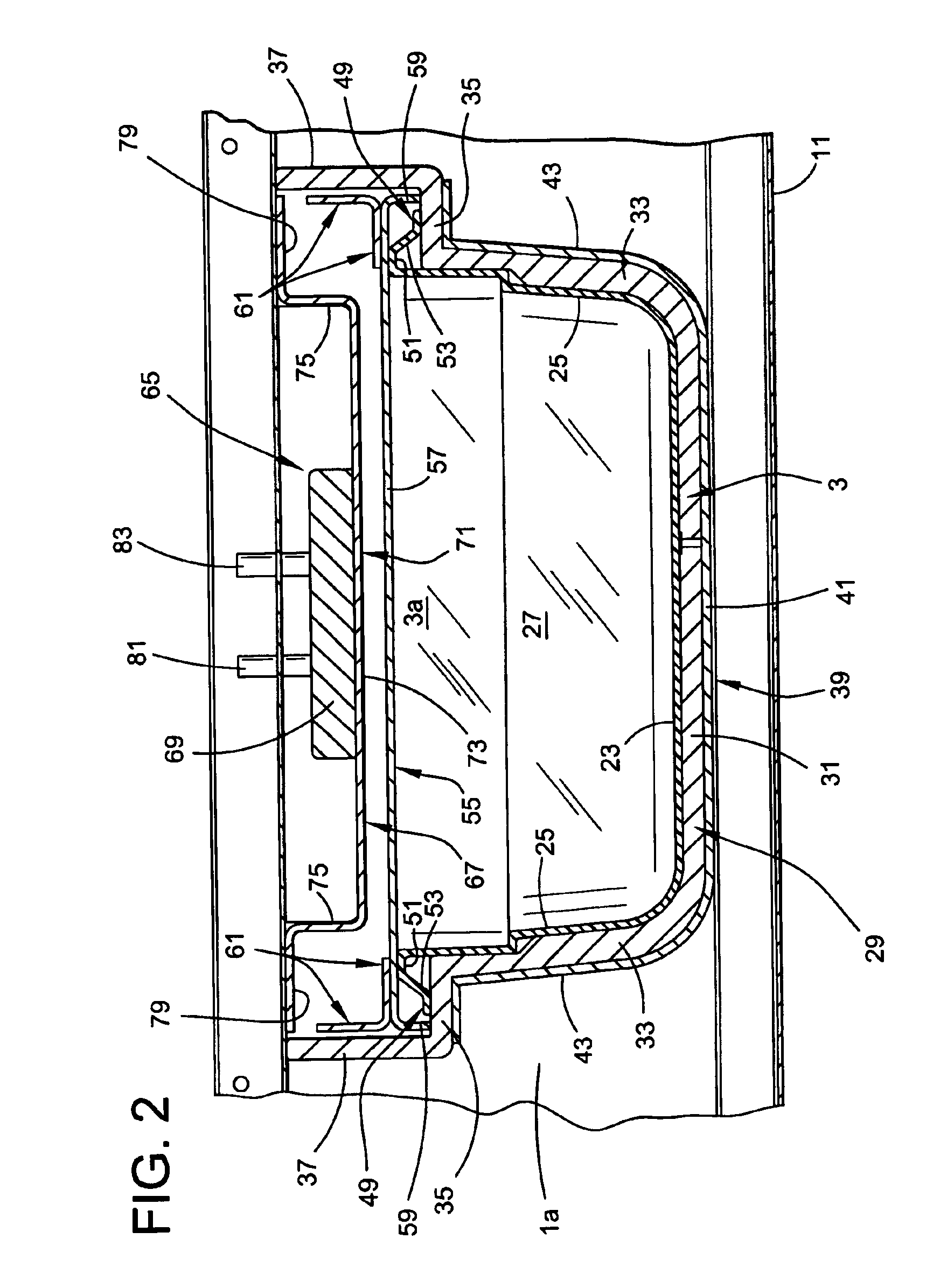

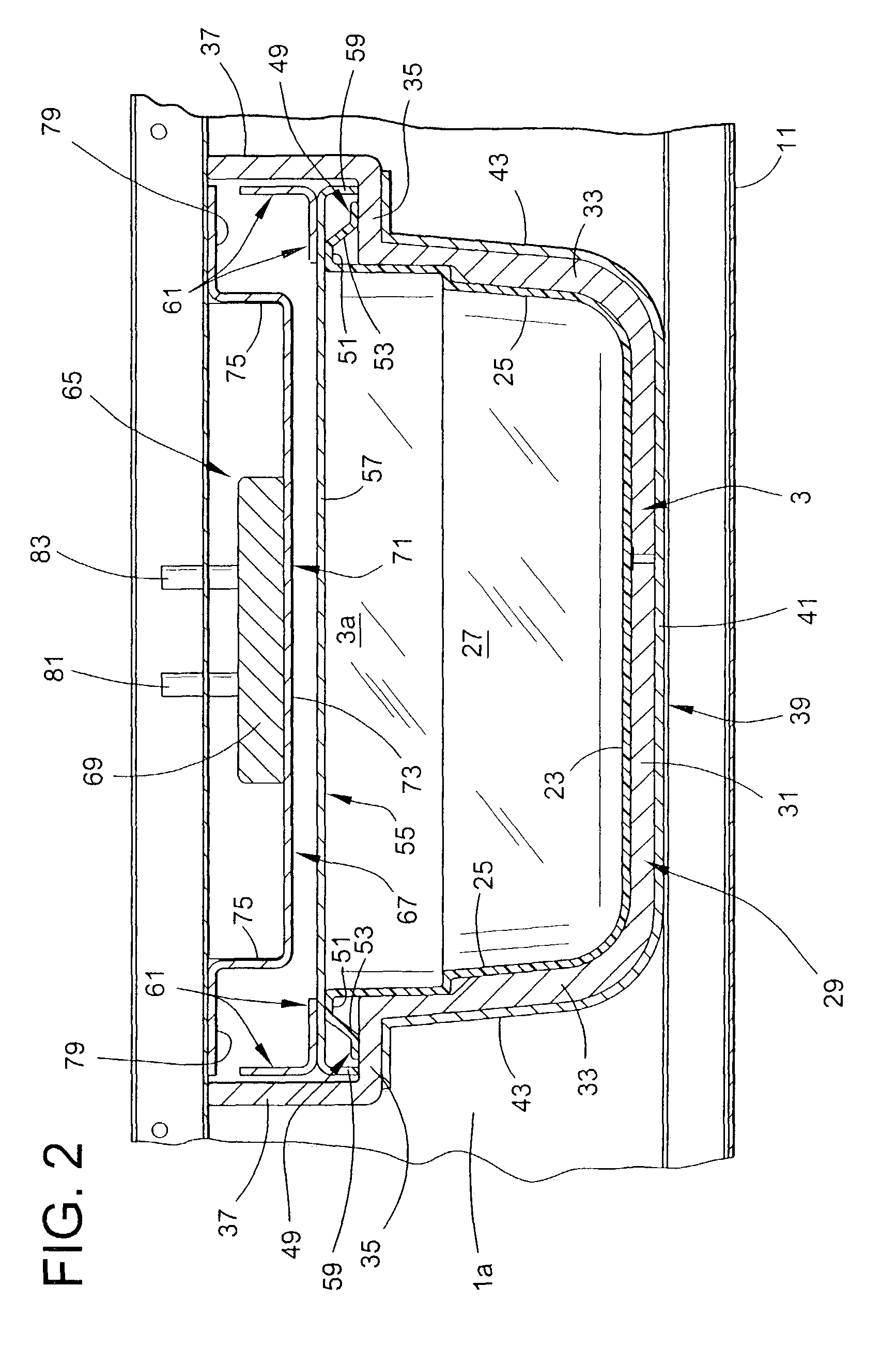

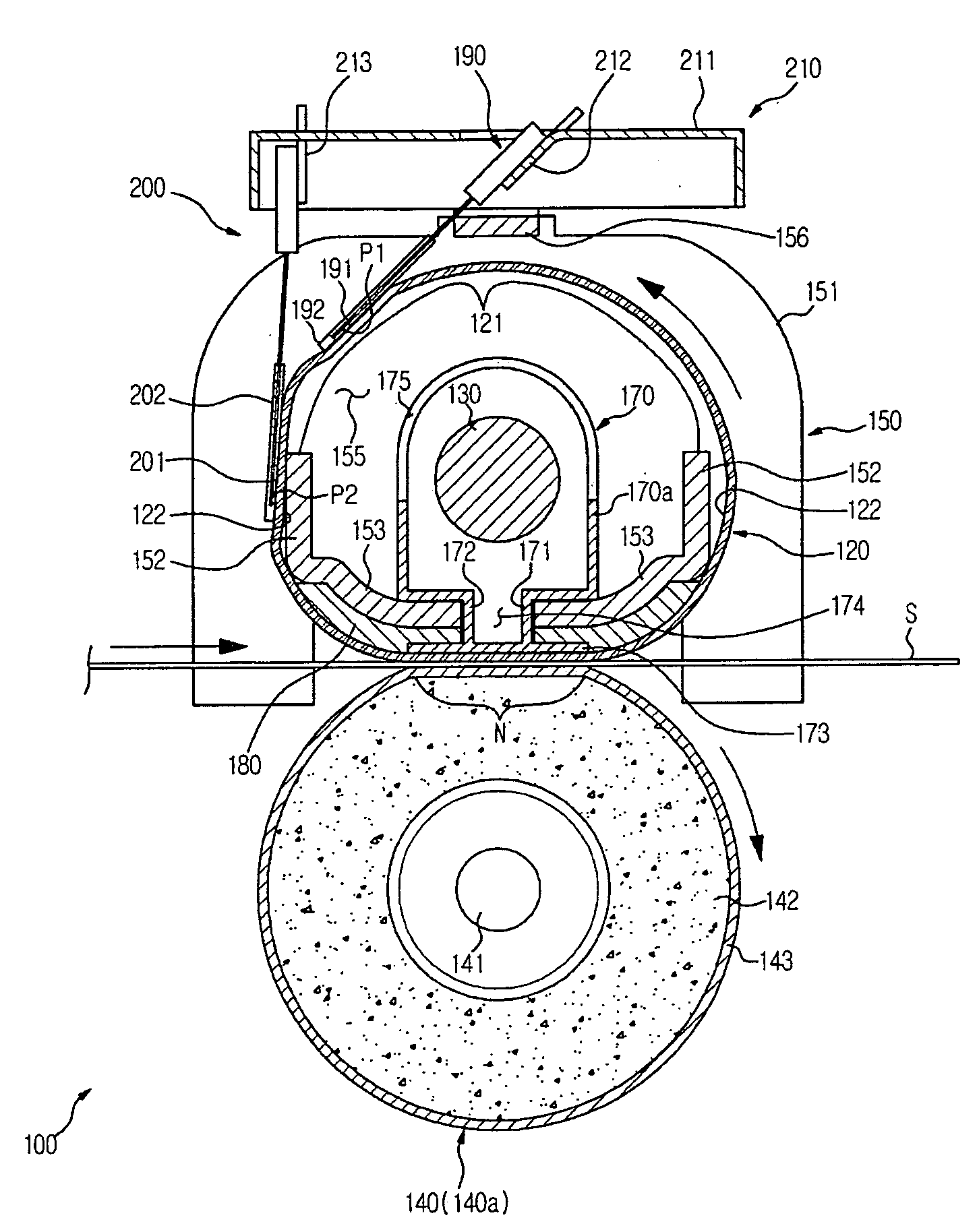

A shower head formed by stacking a shower base, a gas diffusion plate, and a shower plate and supplying material gas and oxidizer gas to a wafer on a loading table through a first gas diffusion part and a second gas diffusion part formed in both faces of the gas diffusion plate, first gas outlets formed in the shower plate and communicating with a first gas diffusion space, and second gas outlets formed in the shower plate and communicating with a second gas diffusion space. A plurality of heat transfer columns fitted closely to the lower surface of the shower base are installed in the first gas diffusion part so that portions therebetween can form the first gas diffusion space, and radiant heat from the loading table is transmitted by the heat transfer columns in the thickness direction of the shower head.

Owner:TOKYO ELECTRON LTD

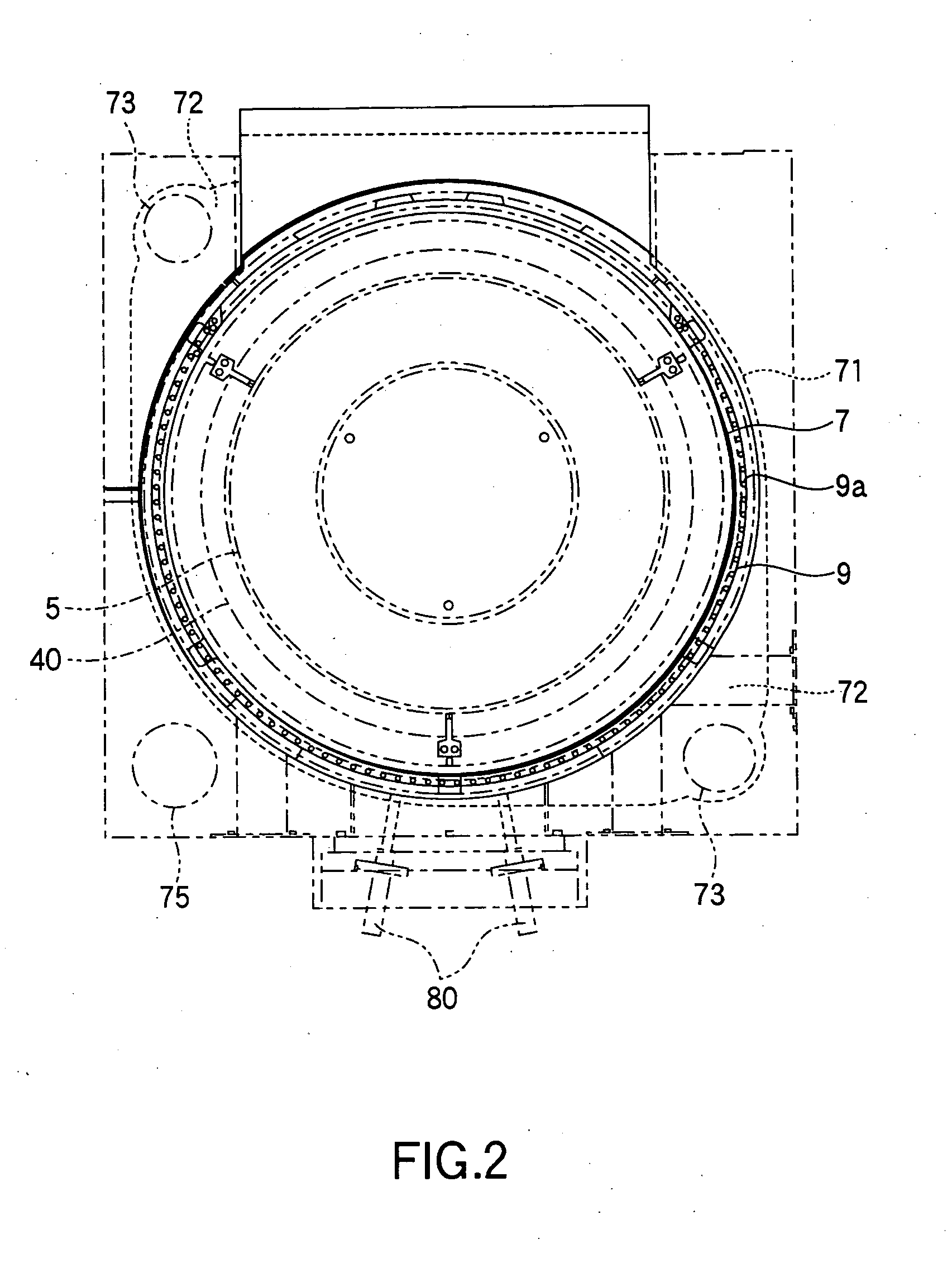

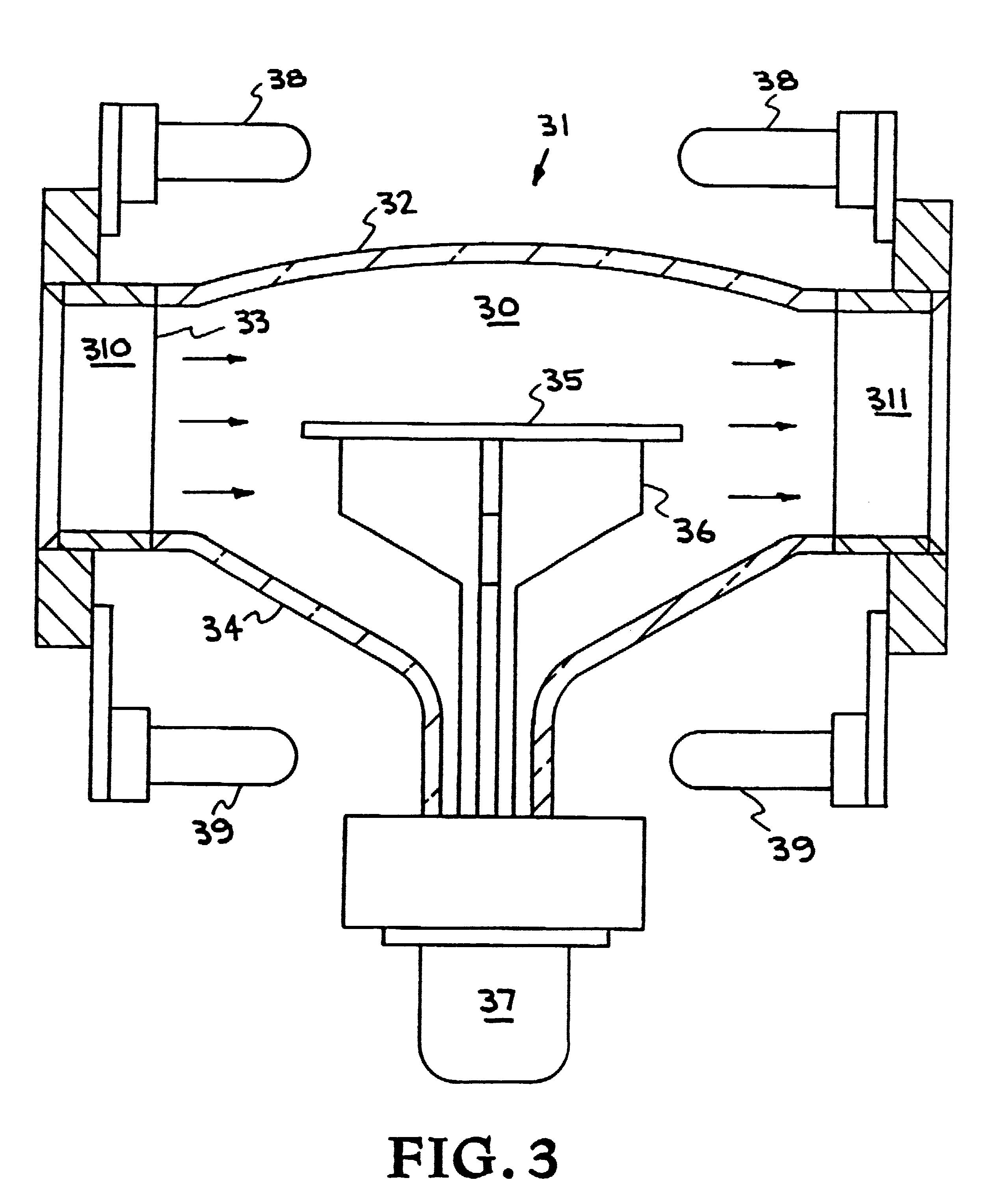

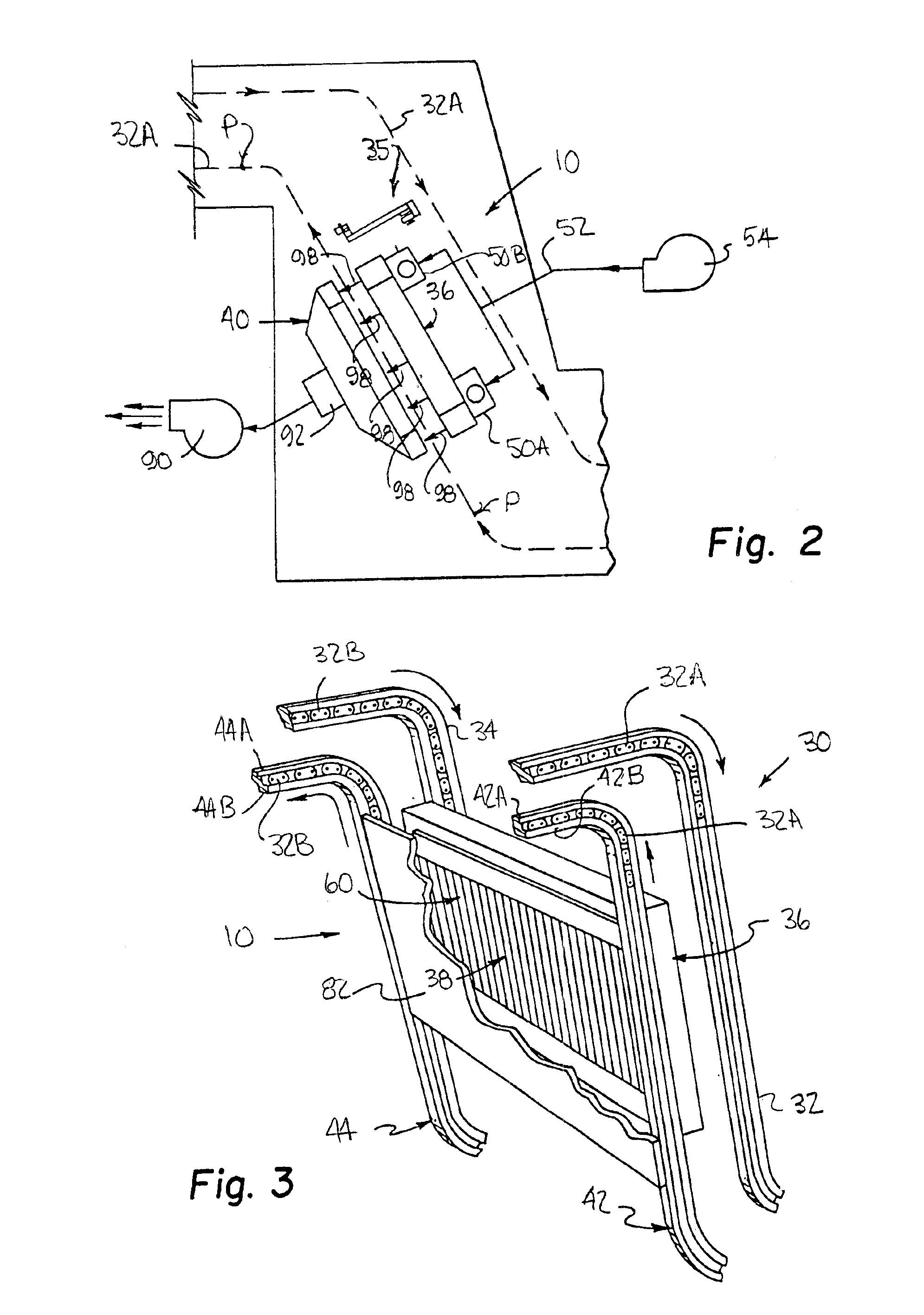

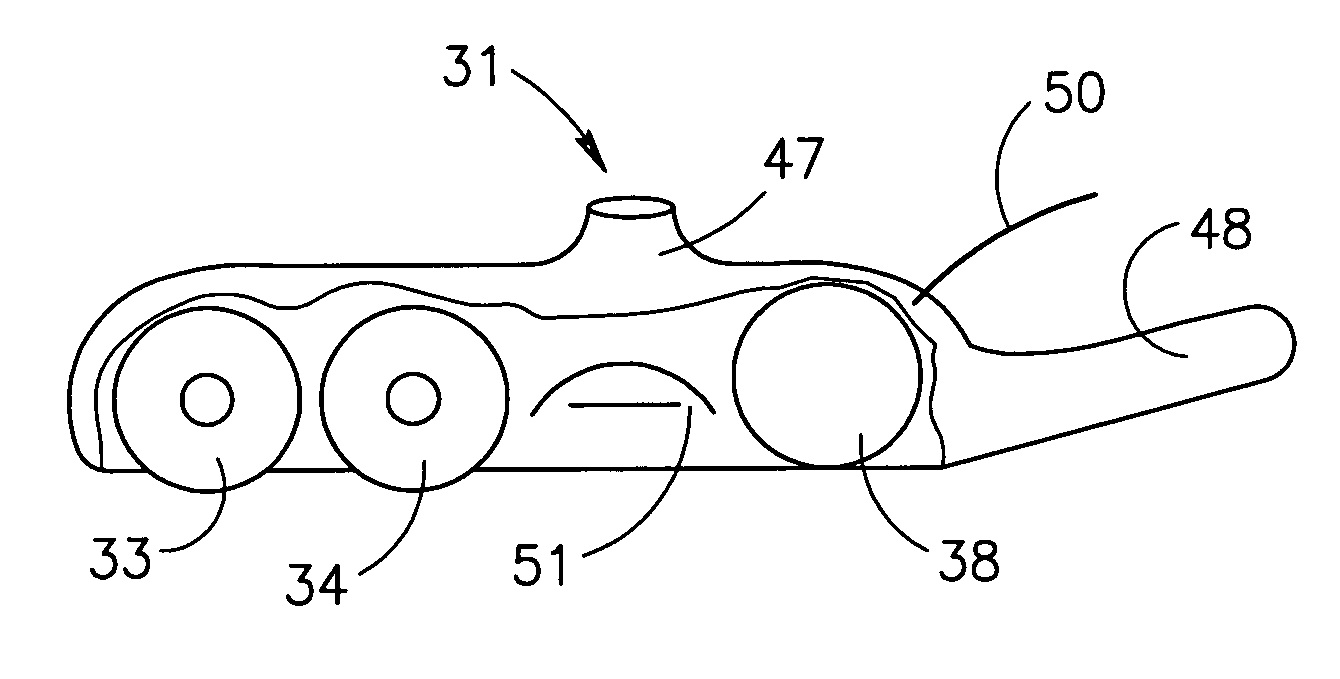

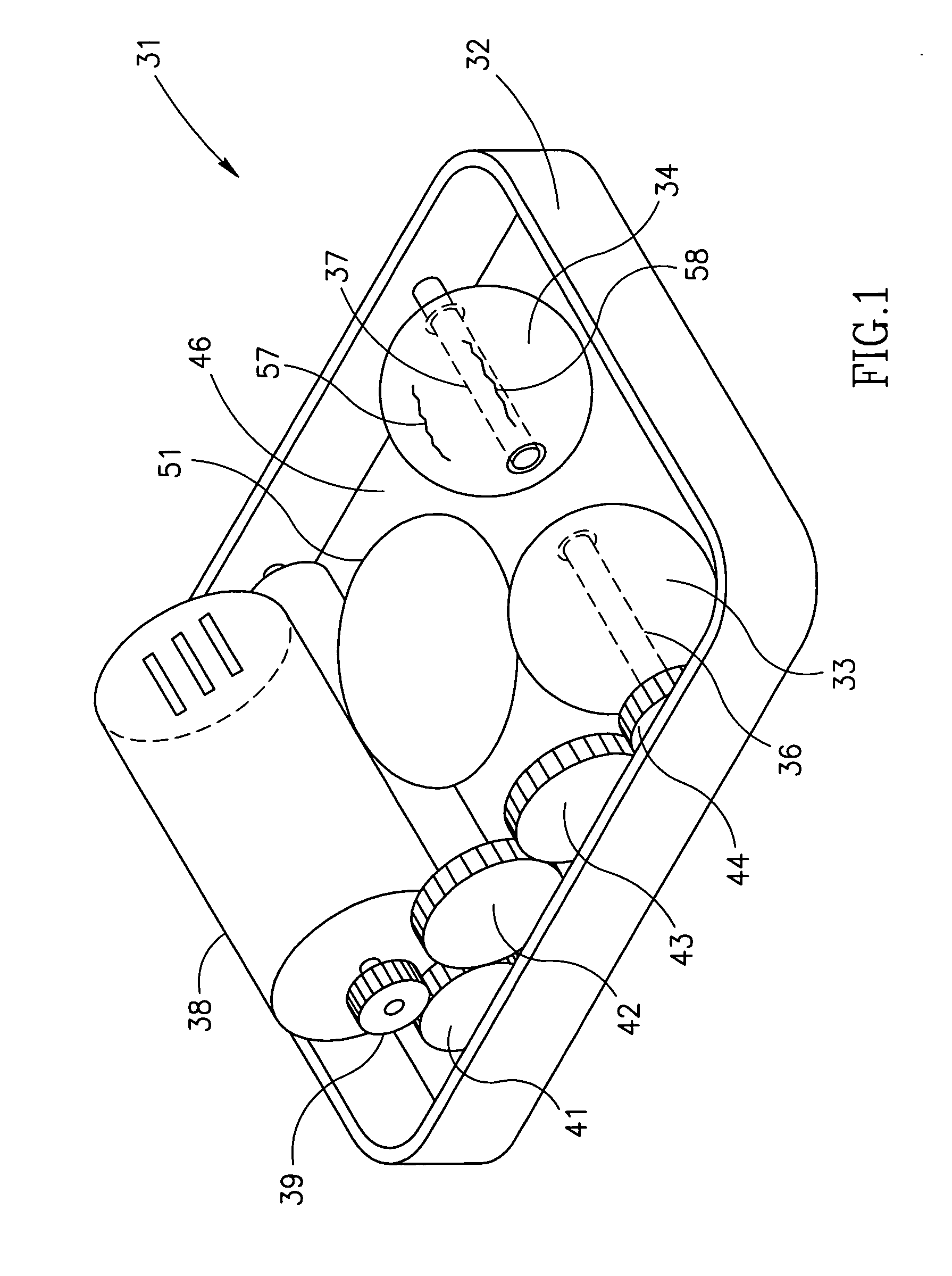

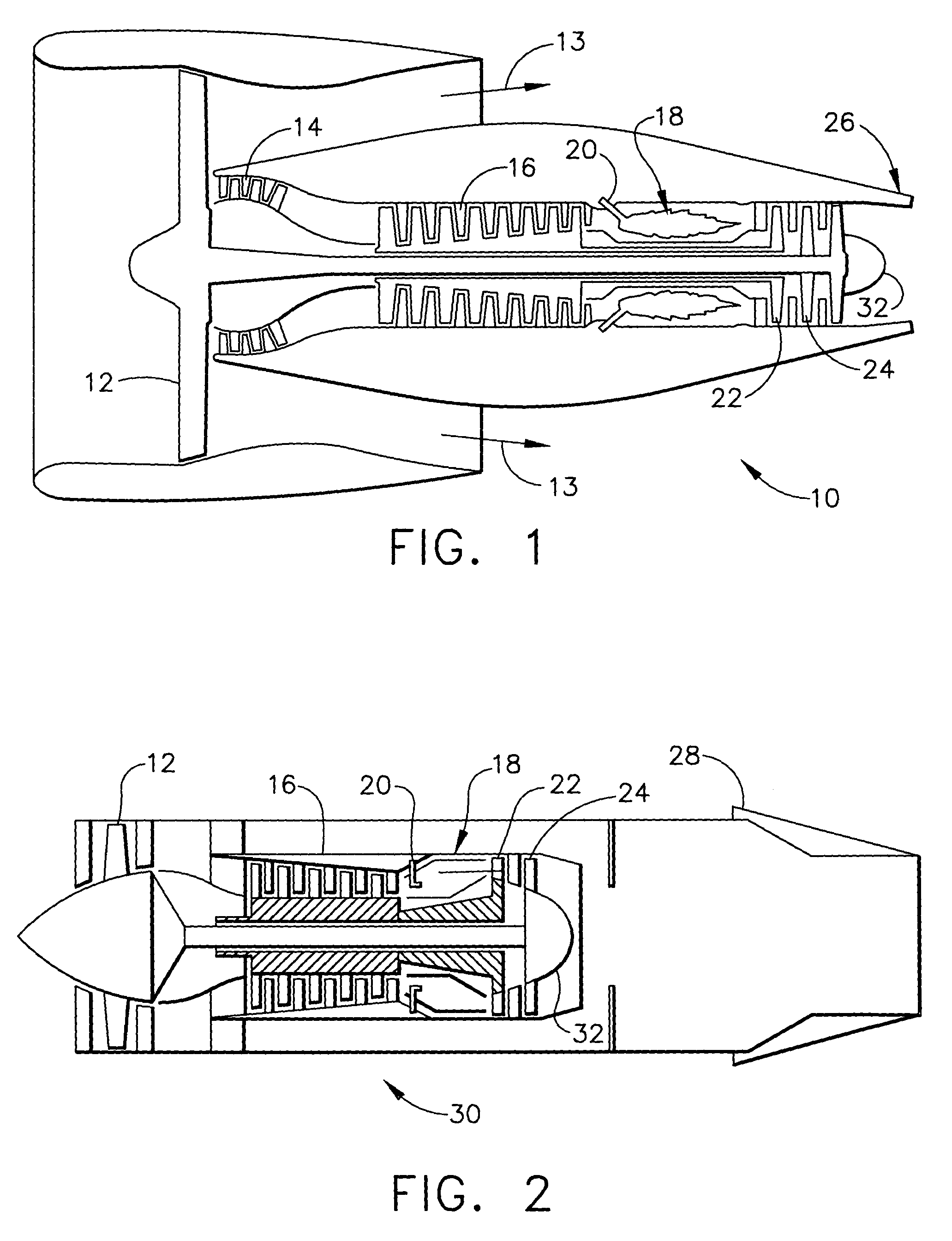

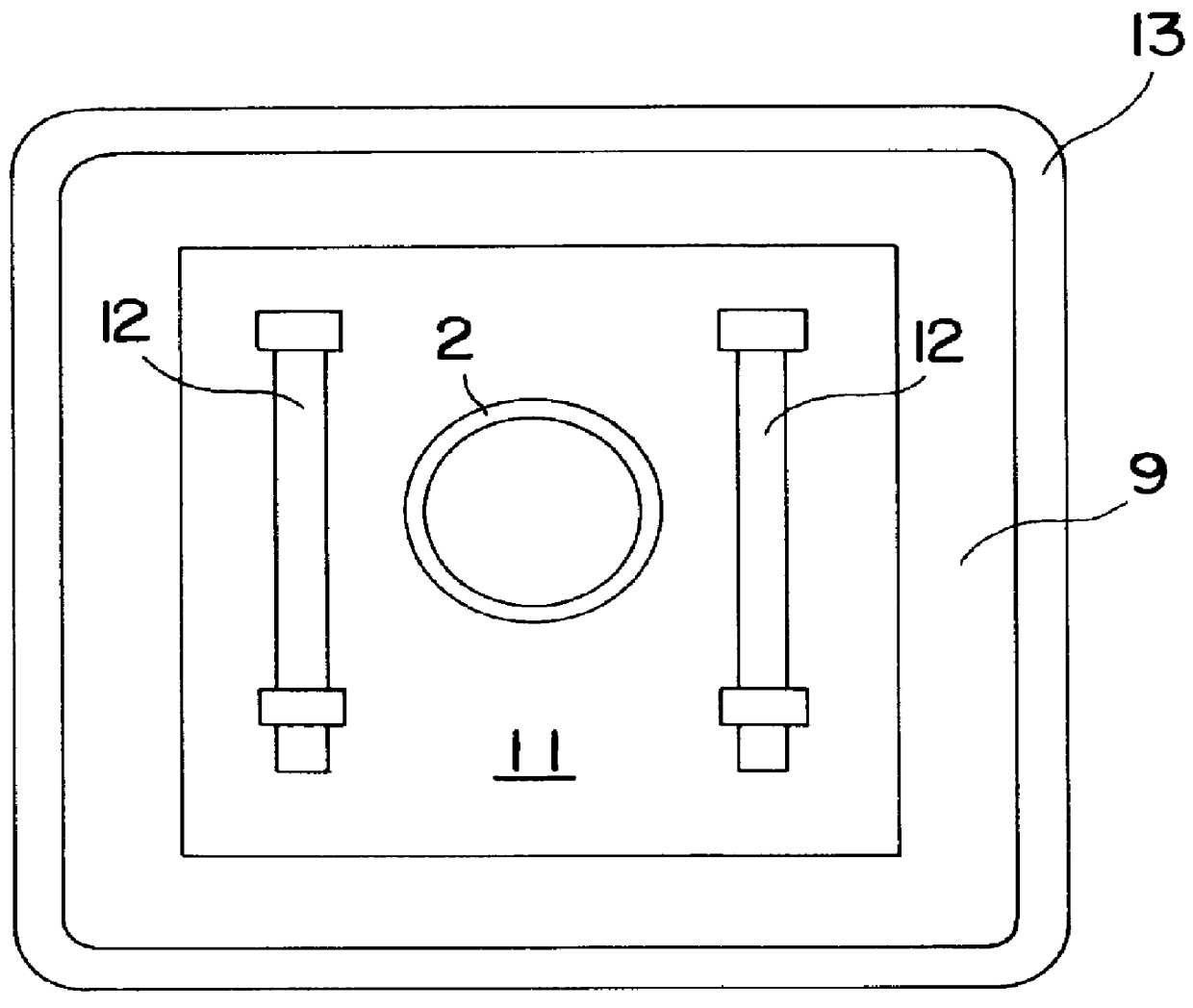

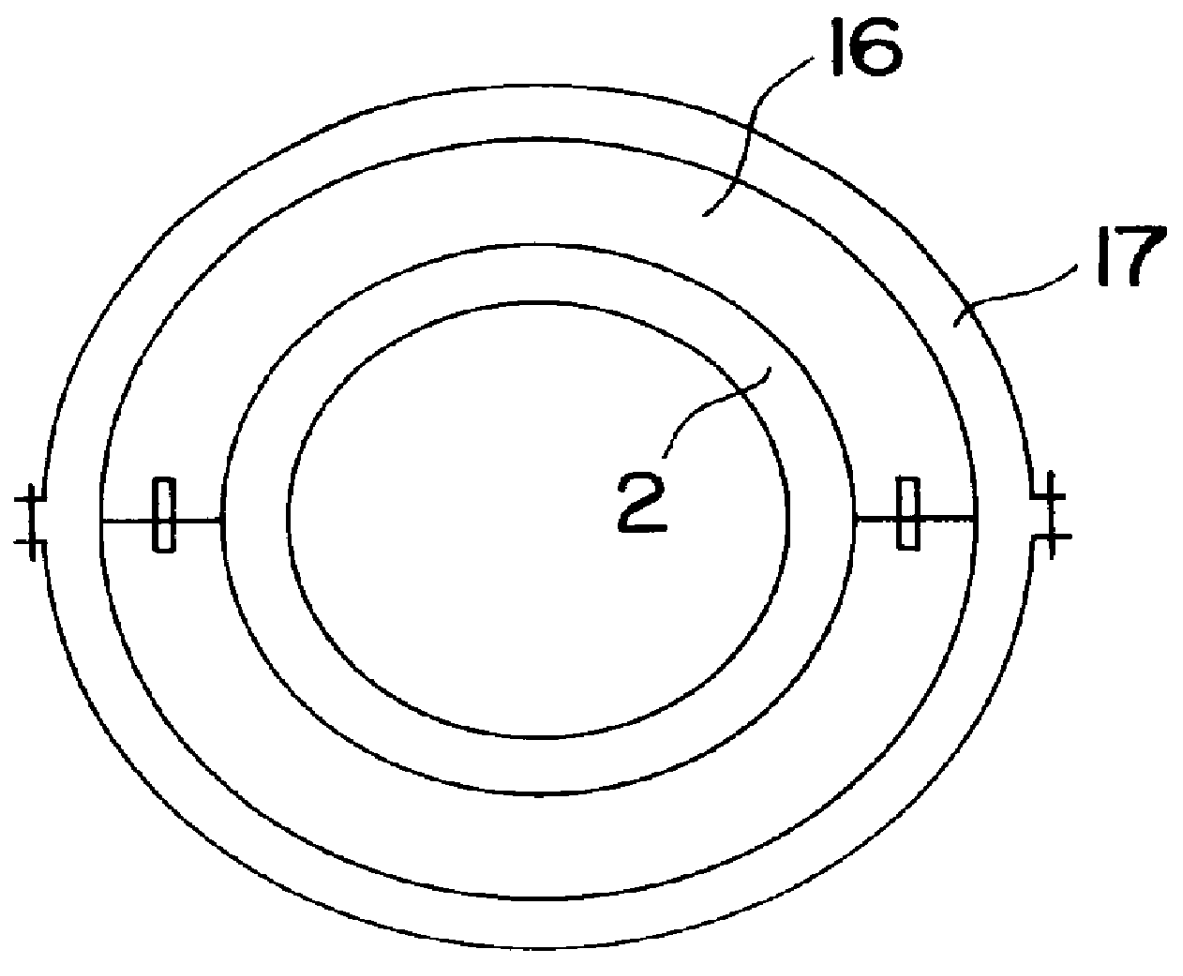

Wafer carrier with varying thermal resistance

InactiveUS20100055318A1Minimize contactImprove temperature uniformityLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringRadiant heat transfer

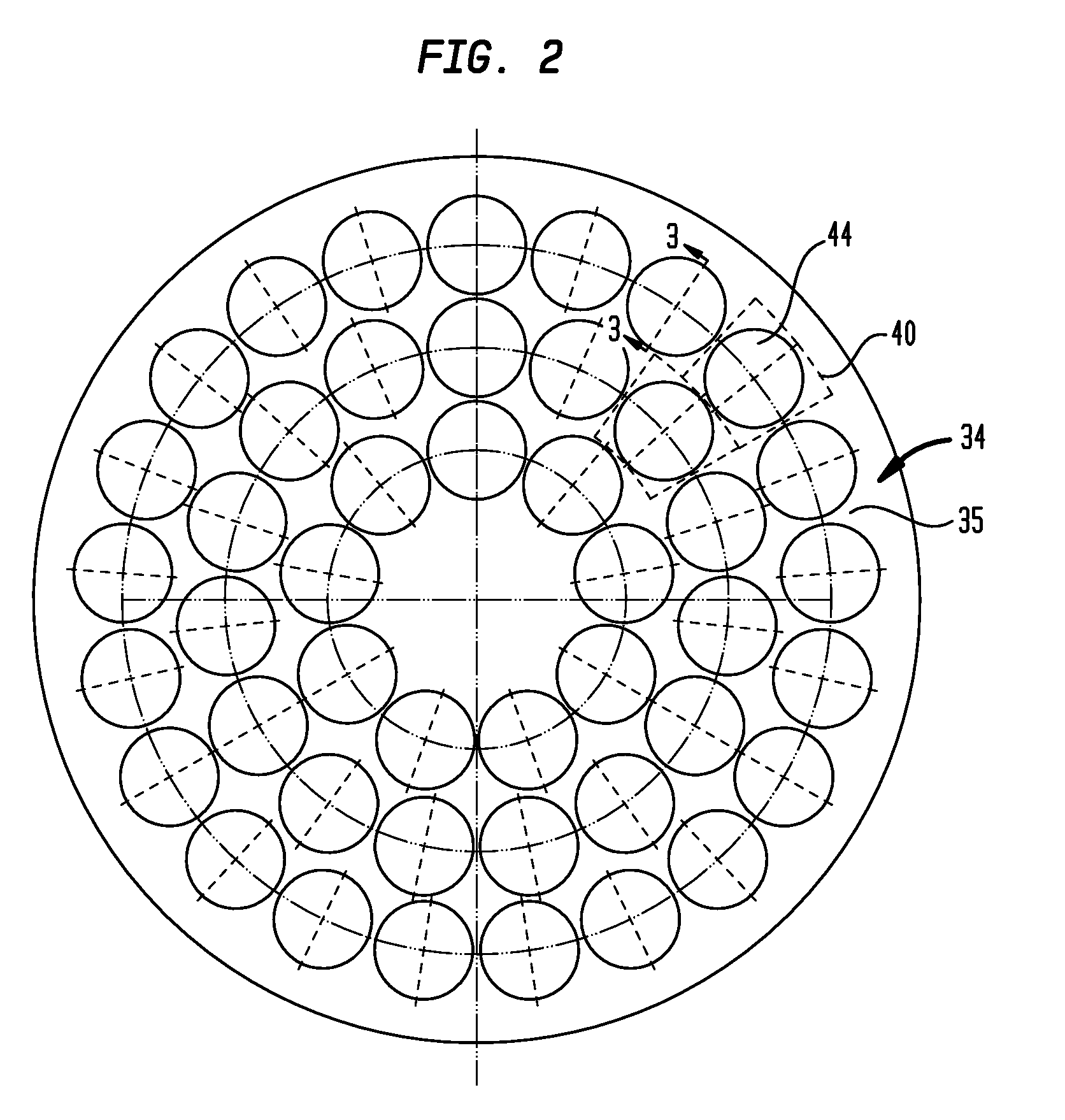

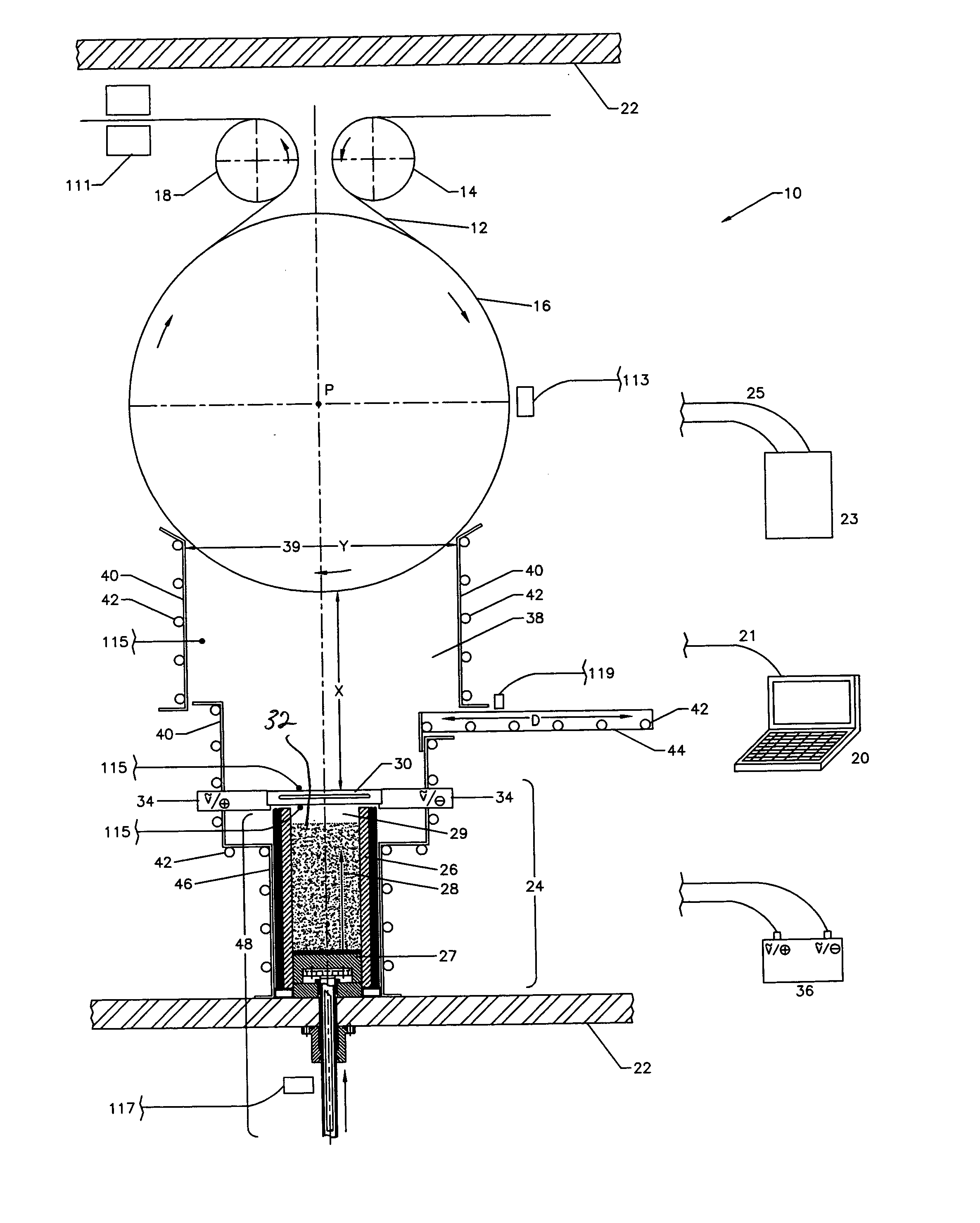

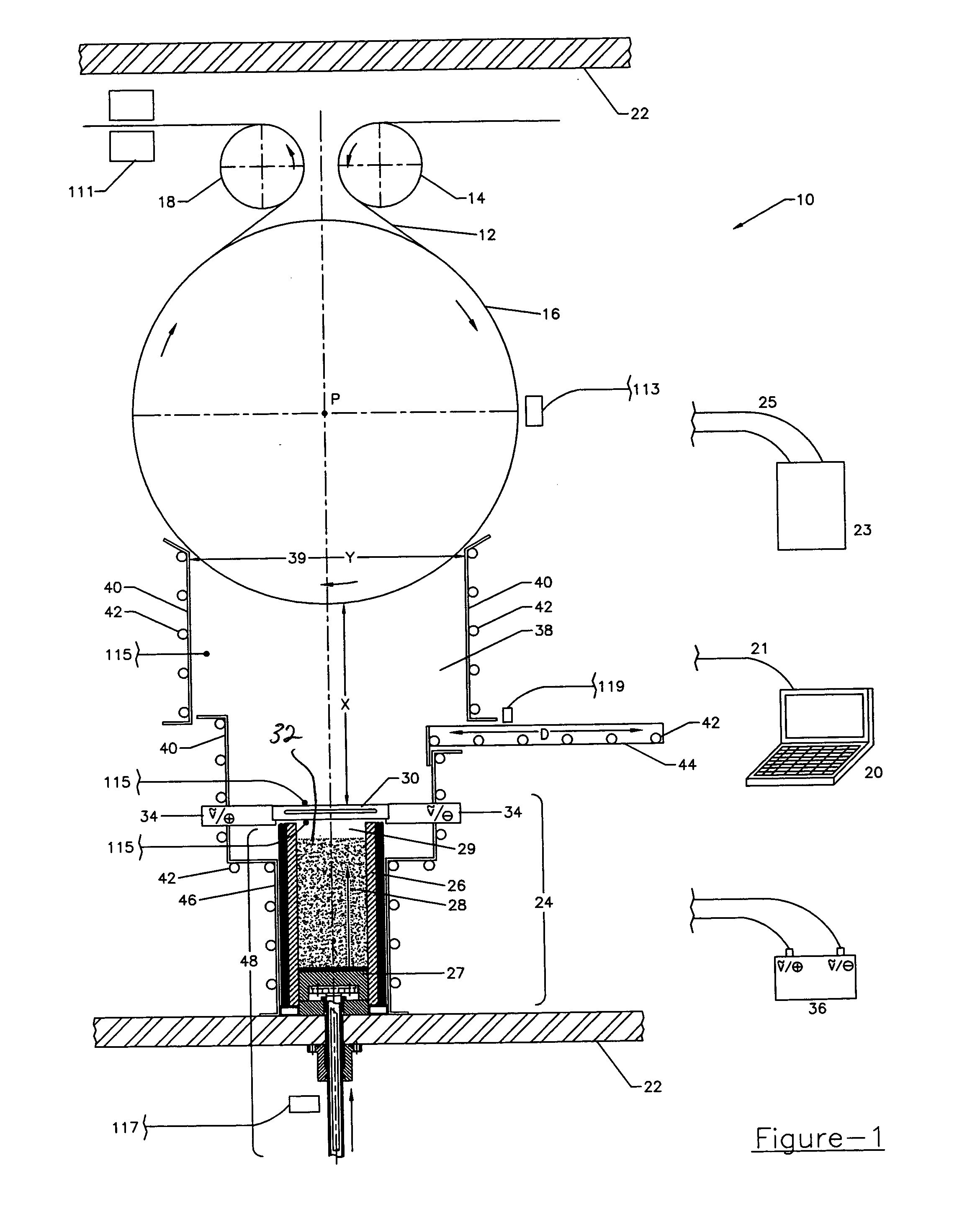

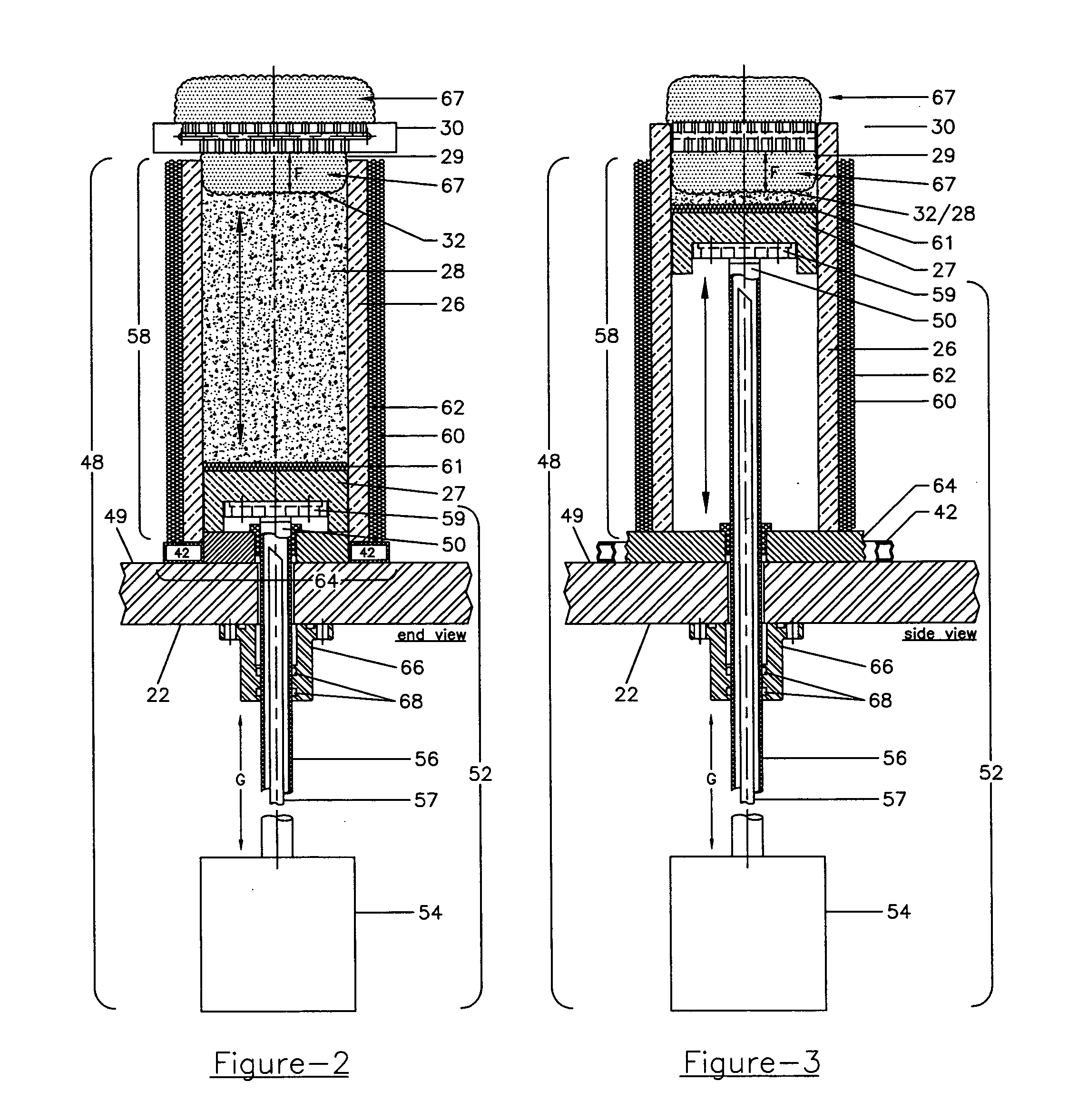

In chemical vapor deposition apparatus, a water carrier (32) has a top surface (34) holding the wafers and a bottom surface (36) heated by radiant heat transfer from a heating element (28). The bottom surface (36) of the wafer carrier is non-planar due to features such as depressions (54) so that the wafer carrier has different thickness at different locations. The thicker portions of the wafer carrier have higher thermal resistance. Differences in thermal resistance at different locations counteract undesired non-uniformities in heat transfer to the wafer. The wafer carrier may have pockets with projections (553, 853) for engaging spaced-apart locations on the edges of the wafer.

Owner:VEECO INSTR

Movable radiant heat sources

ActiveUS7725012B2Semiconductor/solid-state device manufacturingHigh-frequency/infra-red heating bakingEngineeringRadiant heat

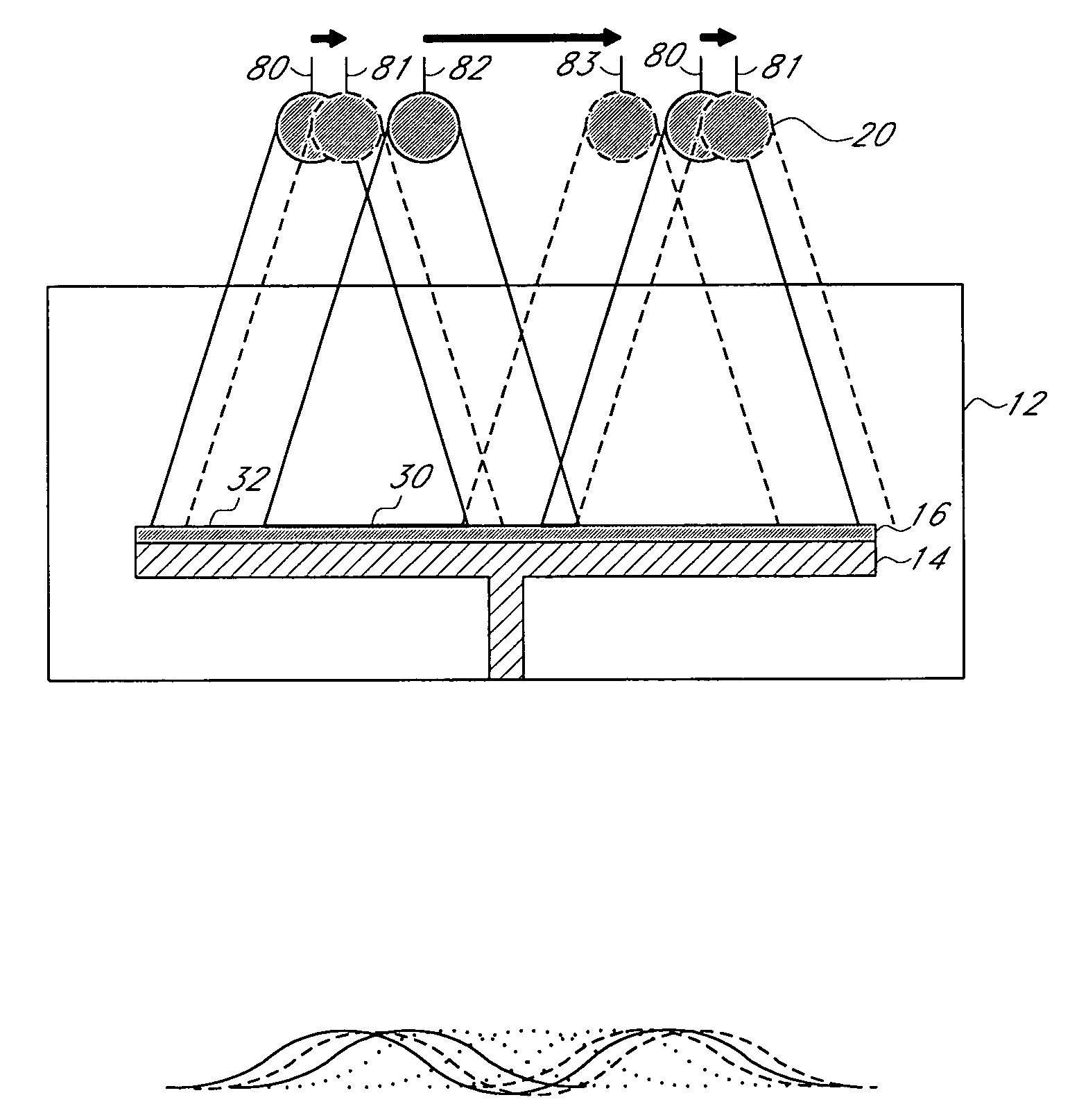

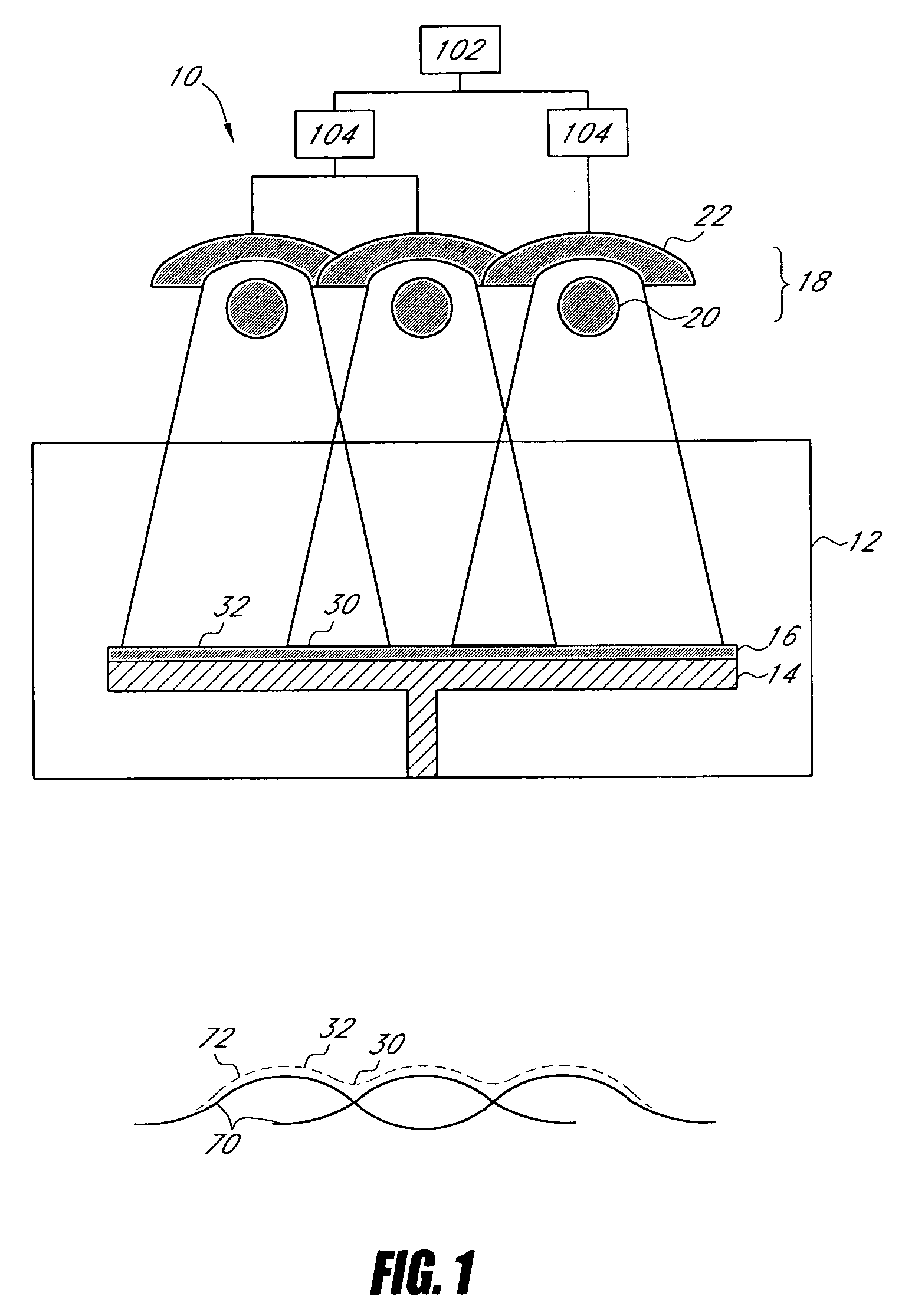

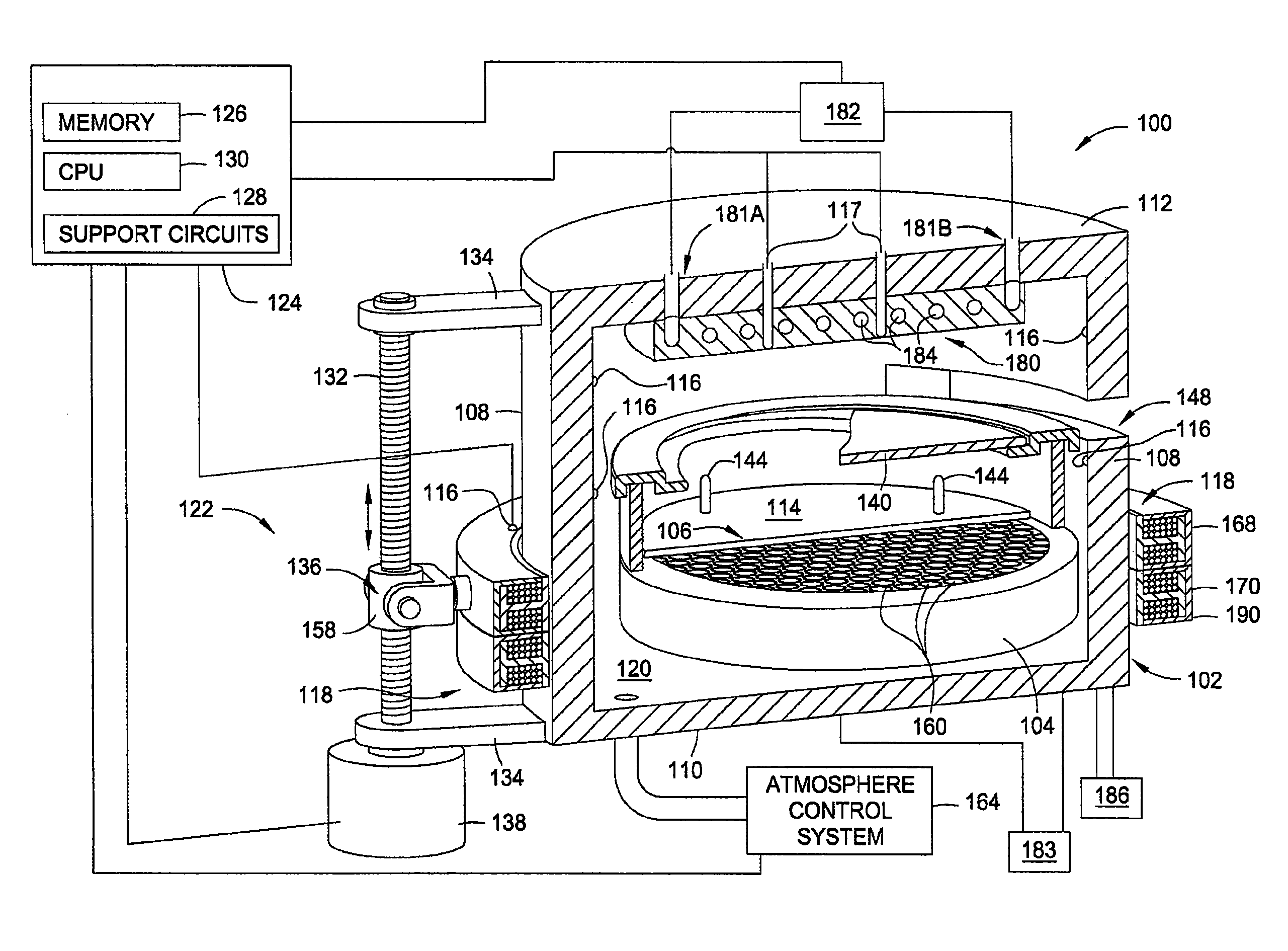

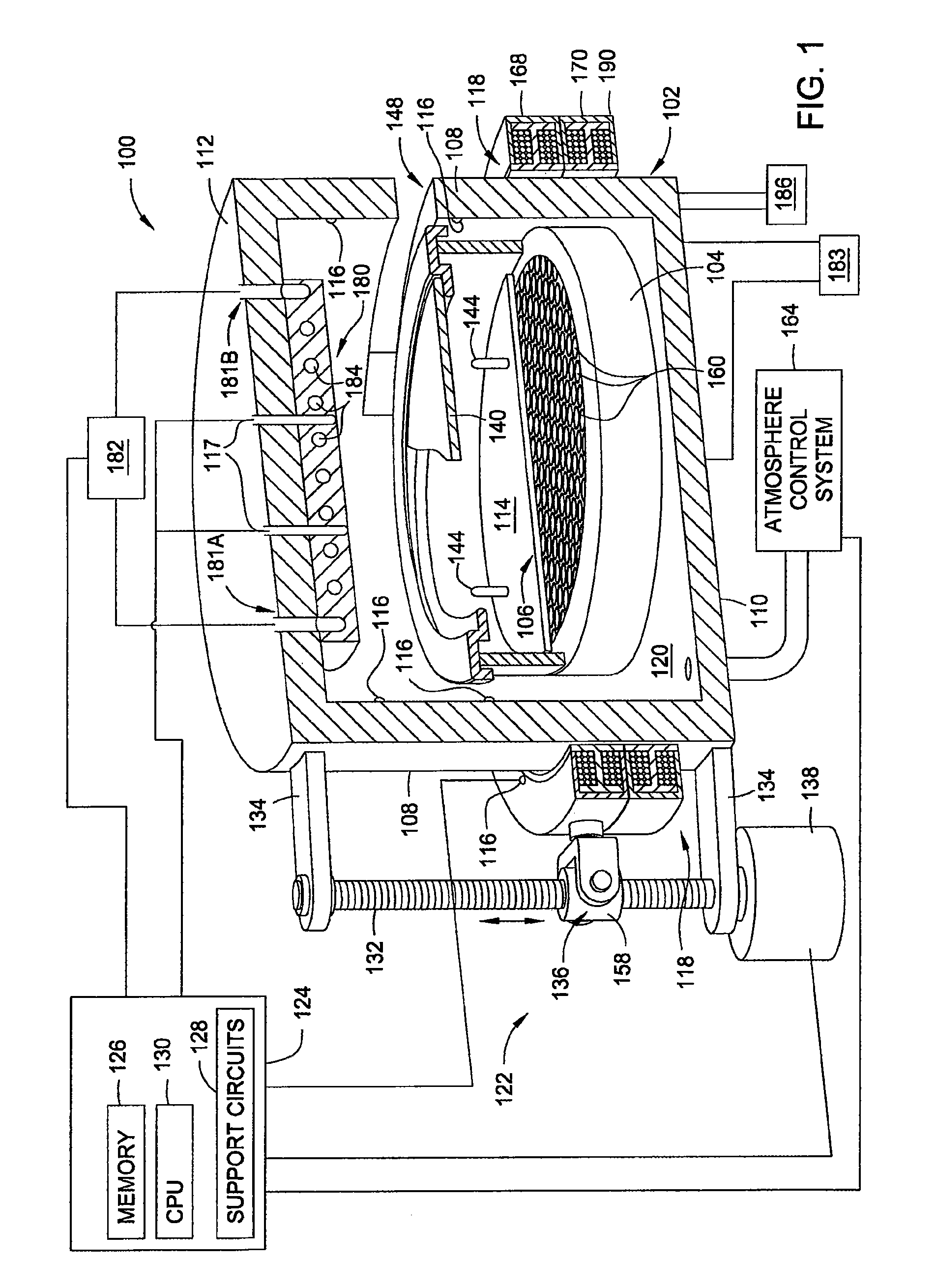

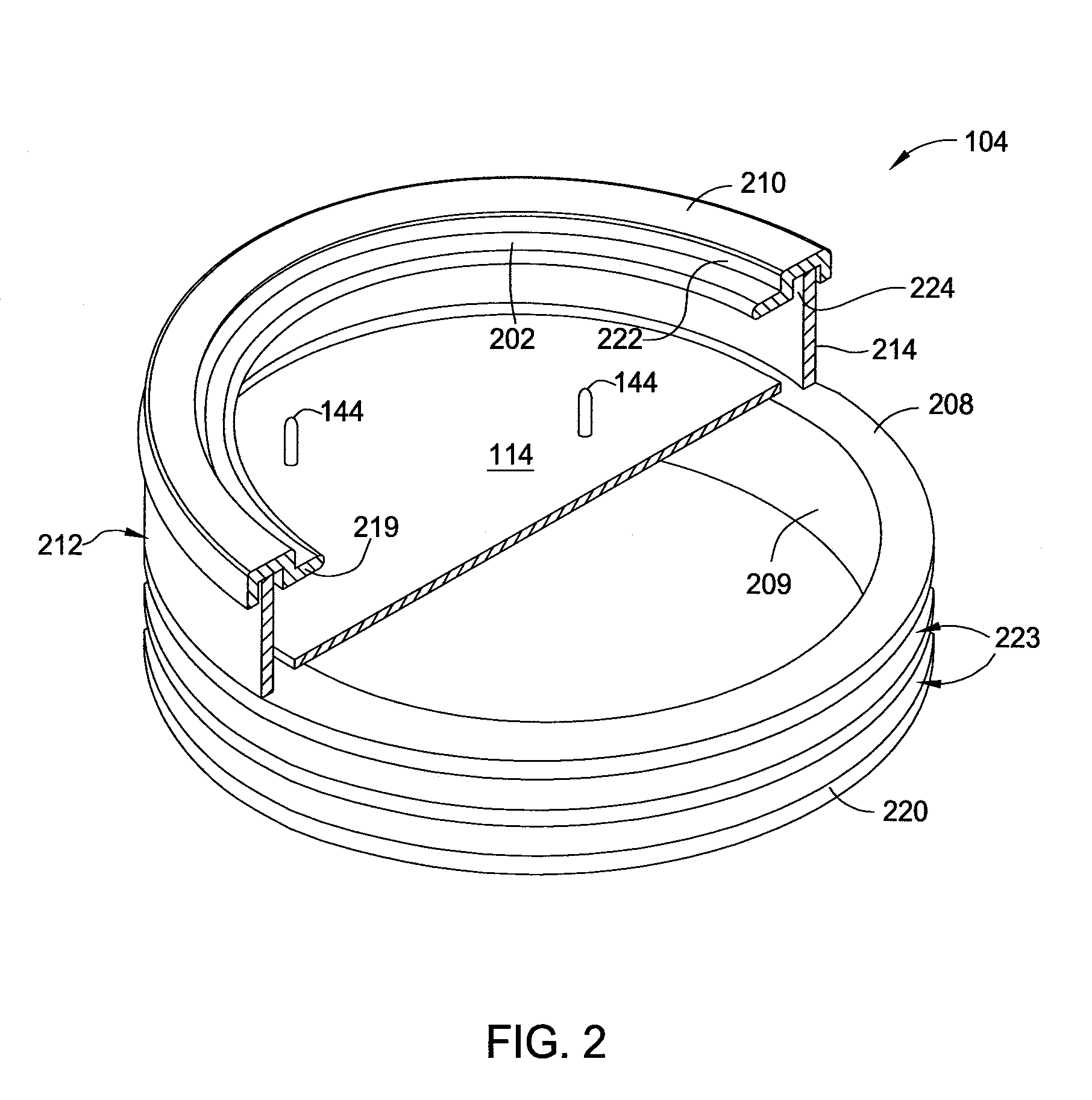

A semiconductor processing apparatus including a processing chamber and a plurality of radiant heat sources. The radiant heat sources heat a workpiece within the chamber. At least one of the radiant heat sources is movable during processing in an oscillatory motion along a path less than about 10 mm from a geometric center of the oscillatory motion.

Owner:ASM IP HLDG BV

Rapid conductive cooling using a secondary process plane

A method and apparatus for thermally processing a substrate is described. The apparatus includes a substrate support configured to move linearly and / or rotationally by a magnetic drive. The substrate support is also configured to receive a radiant heat source to provide heating region in a portion of the chamber. An active cooling region comprising a cooling plate is disposed opposite the heating region. The substrate may move between the two regions to facilitate rapidly controlled heating and cooling of the substrate.

Owner:APPLIED MATERIALS INC

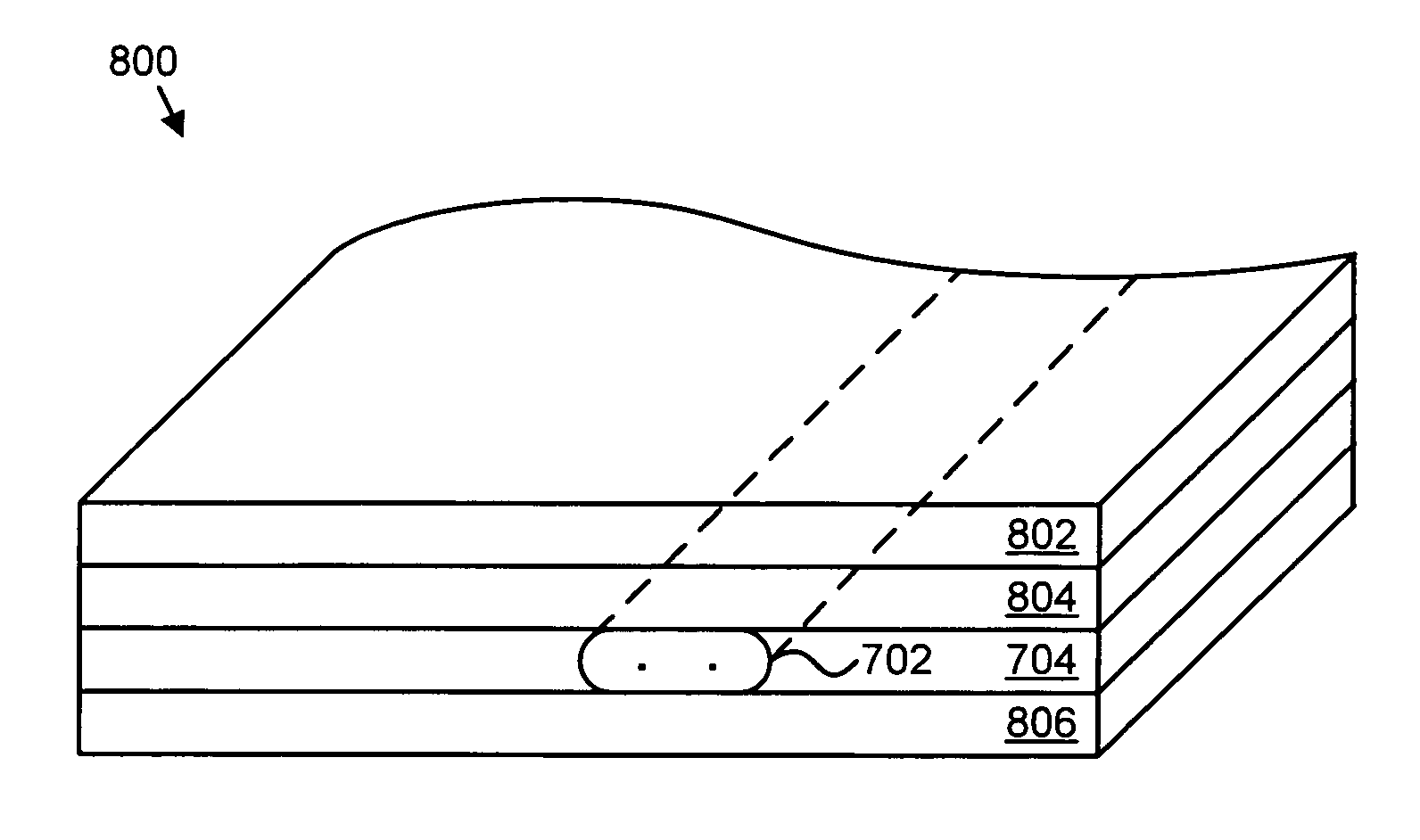

Multi-layered radiant thermal evaporator and method of use

InactiveUS20050072361A1Stable and reliableHigh quality usefulnessVacuum evaporation coatingSputtering coatingCrucibleVacuum chamber

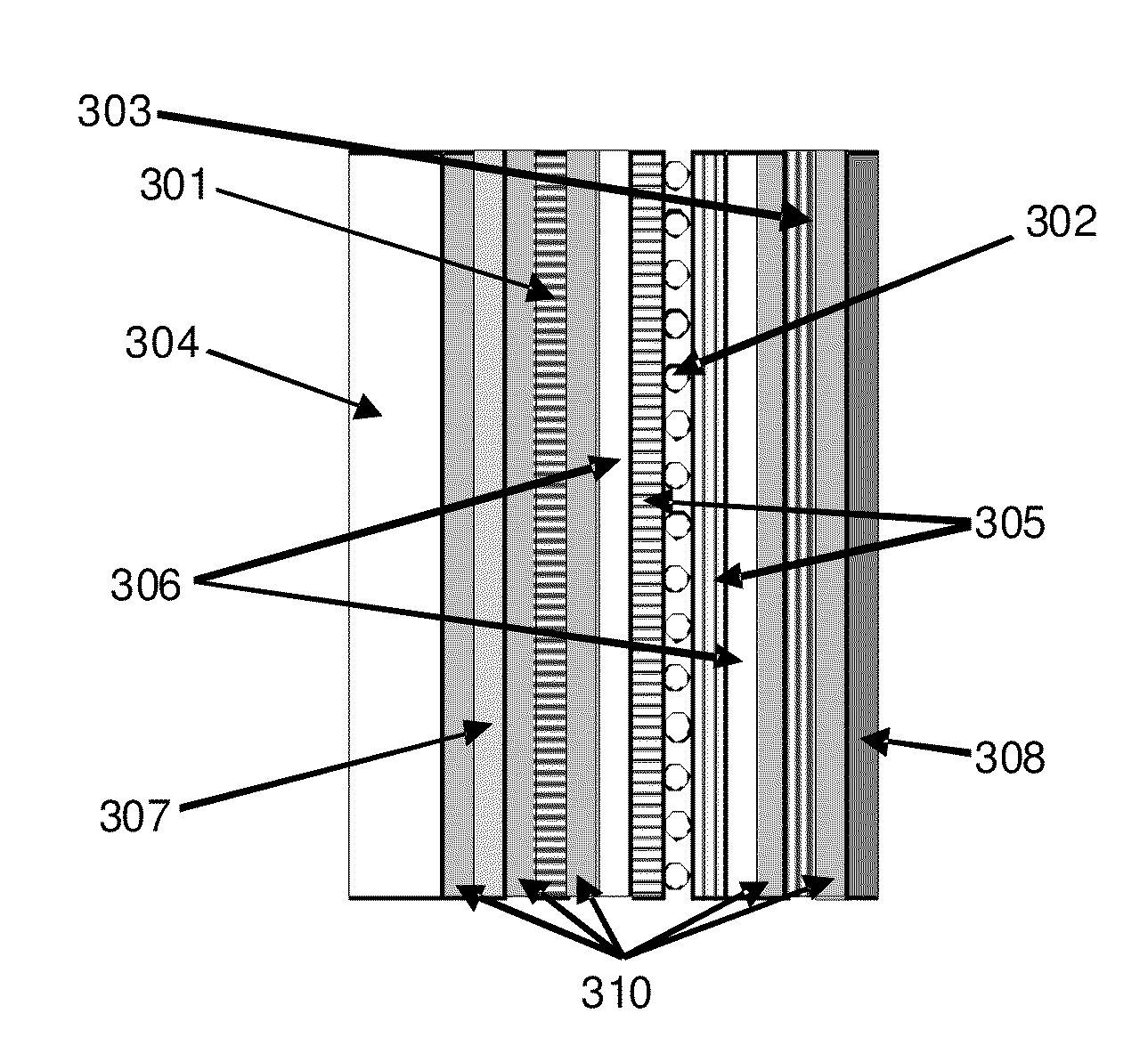

The present invention provides a system and method for uniform coating of a substrate at high deposition rates by evaporating a coating material in a vacuum chamber. The system includes an evaporator having a heating crucible for containing a coating material to be evaporated and a generally planar heat source disposed so as to heat a surface of a coating material contained in the heating crucible. Preferably, the heat source is manufactured from a ceramic or intermetallic material and includes a first layer defining a first set of openings and a second layer defining a second set of openings wherein the second layer overlies the first layer and is spaced apart therefrom. The first and second sets of openings allow the evaporated coating material to pass therethrough for dispersion of the coating material in a deposition zone defined by a containment shield disposed above the heat source.

Owner:DARLY CUSTOM TECH

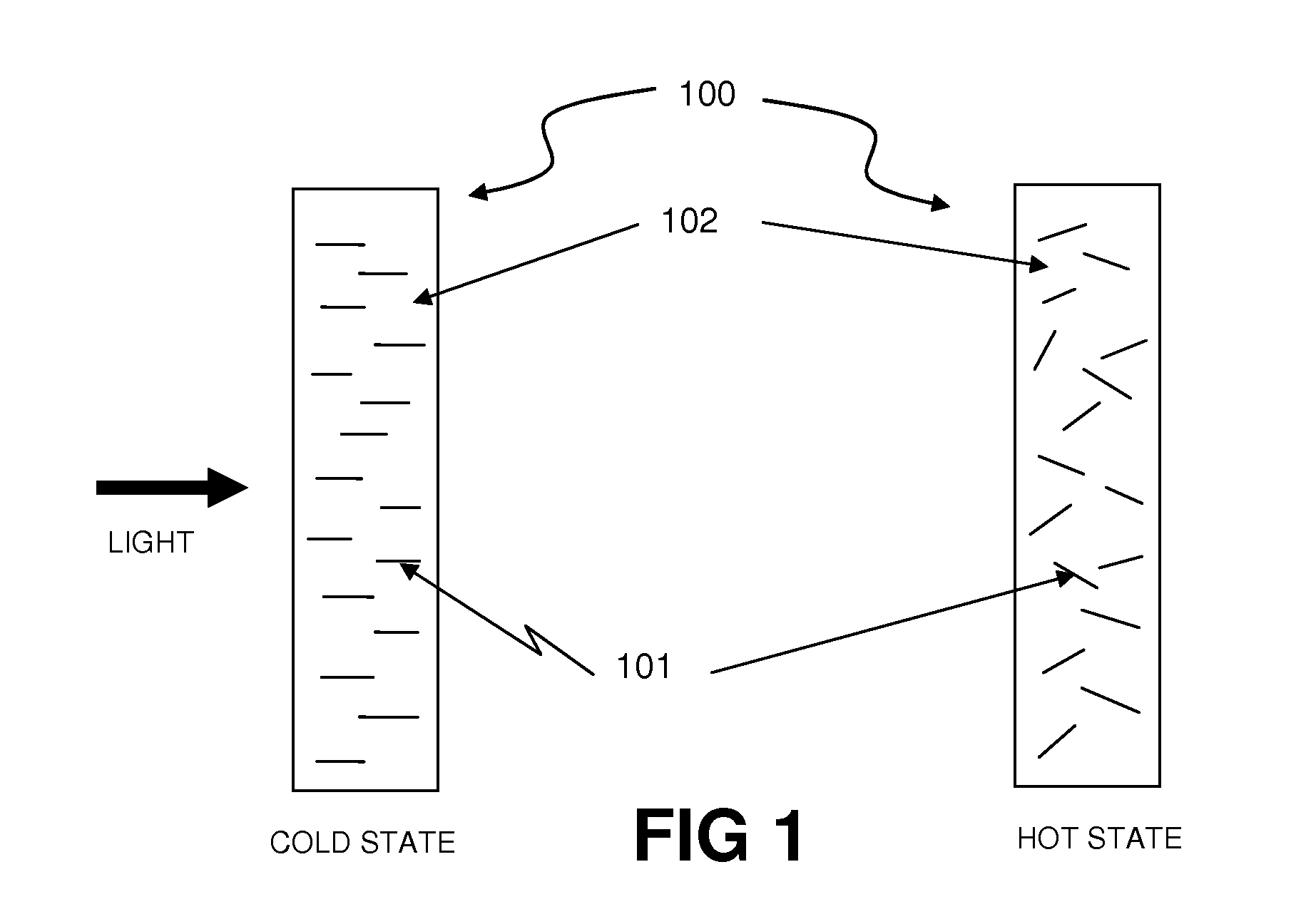

Methods for Fabricating Thermochromic Filters

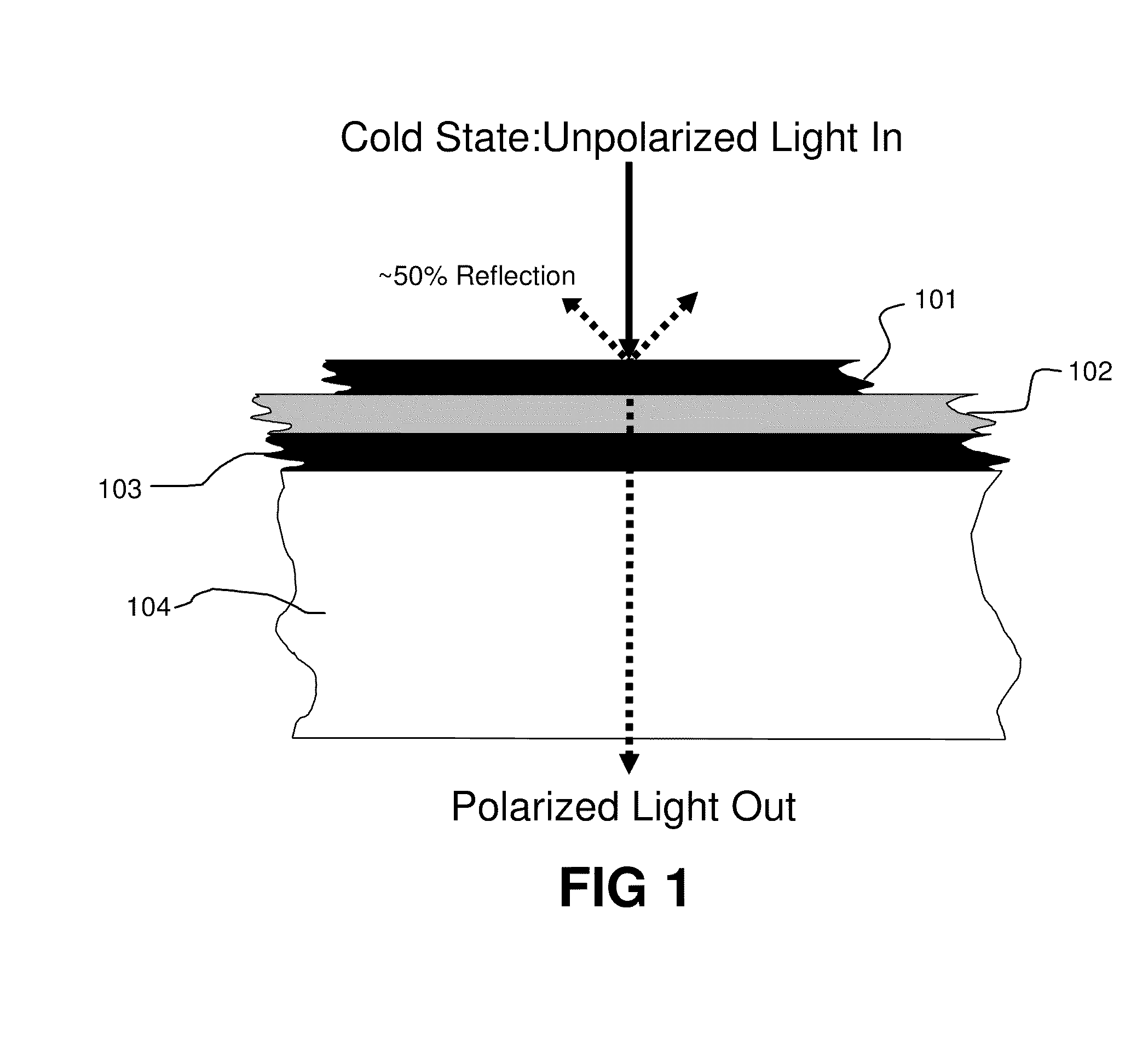

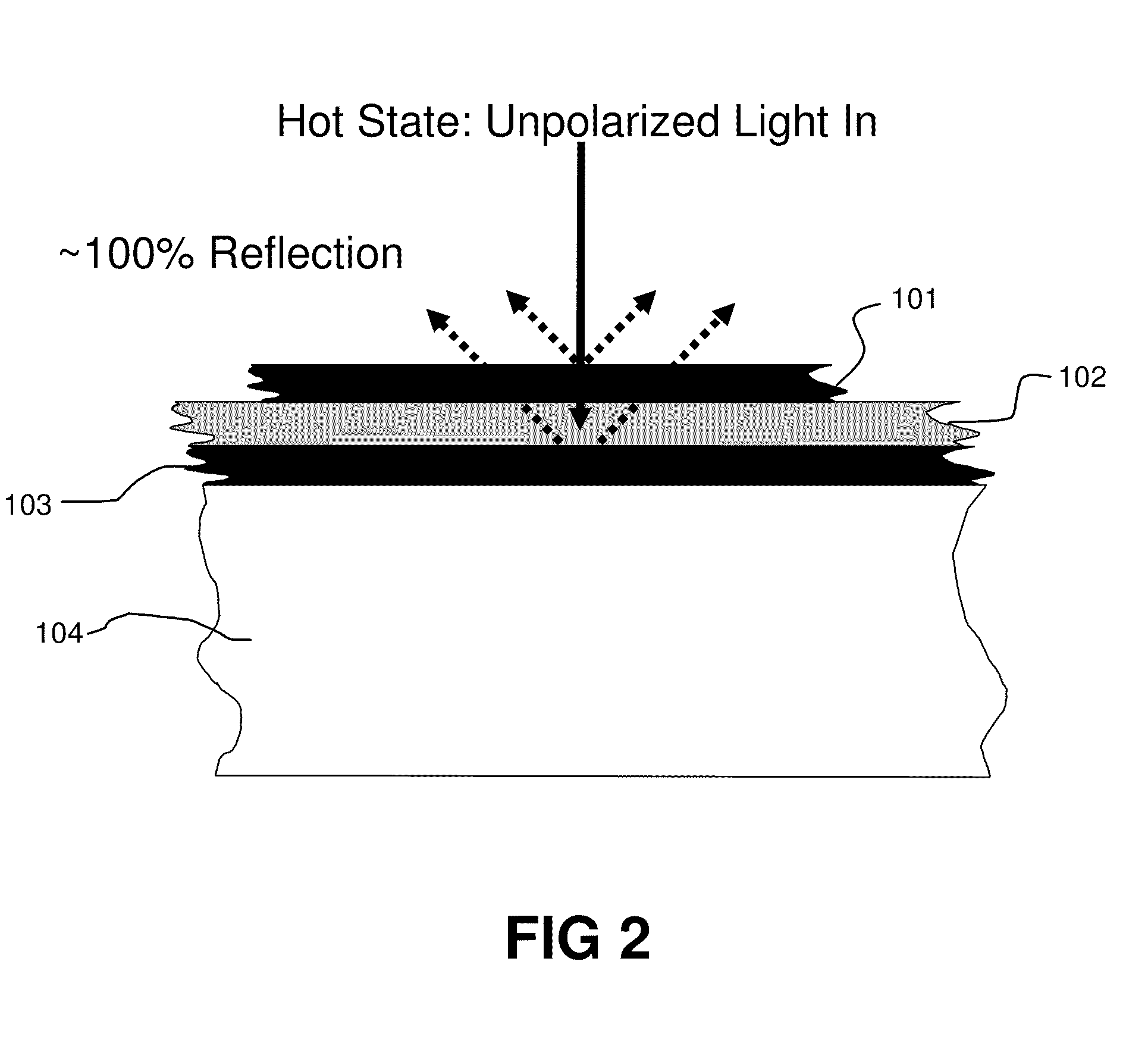

InactiveUS20100045924A1Easy and less-expensive to manufactureEasy to installSolar heating energySolar heat collector controllersSelective reflectionElectrical polarity

Thermochromic liquid crystal filters are fabricated by providing two polarizers oriented at offset polarity with respect to each other; providing alignment structures adjacent the inner surfaces of the polarizers; placing a plurality of spacers between the polarizers; and filling a space created by the spacers with a thermotropic liquid crystal that acts as a wave block in an isotropic state and acts as a depolarizer in a nematic state. Alternatively, the filters can be created by encapsulating a thermochromic liquid crystal with a polymer material to form a flexible film and orienting the thermochromic liquid crystal in the polymer material to create a structure that functions as a thermochromic optical filter. Such filters can control the flow of light and radiant heat through selective reflection, transmission, absorption, and / or re-emission. The filters have particular application in passive or active light-regulating and temperature-regulating films, materials, and devices, and particularly as construction materials.

Owner:RAVENBRICK

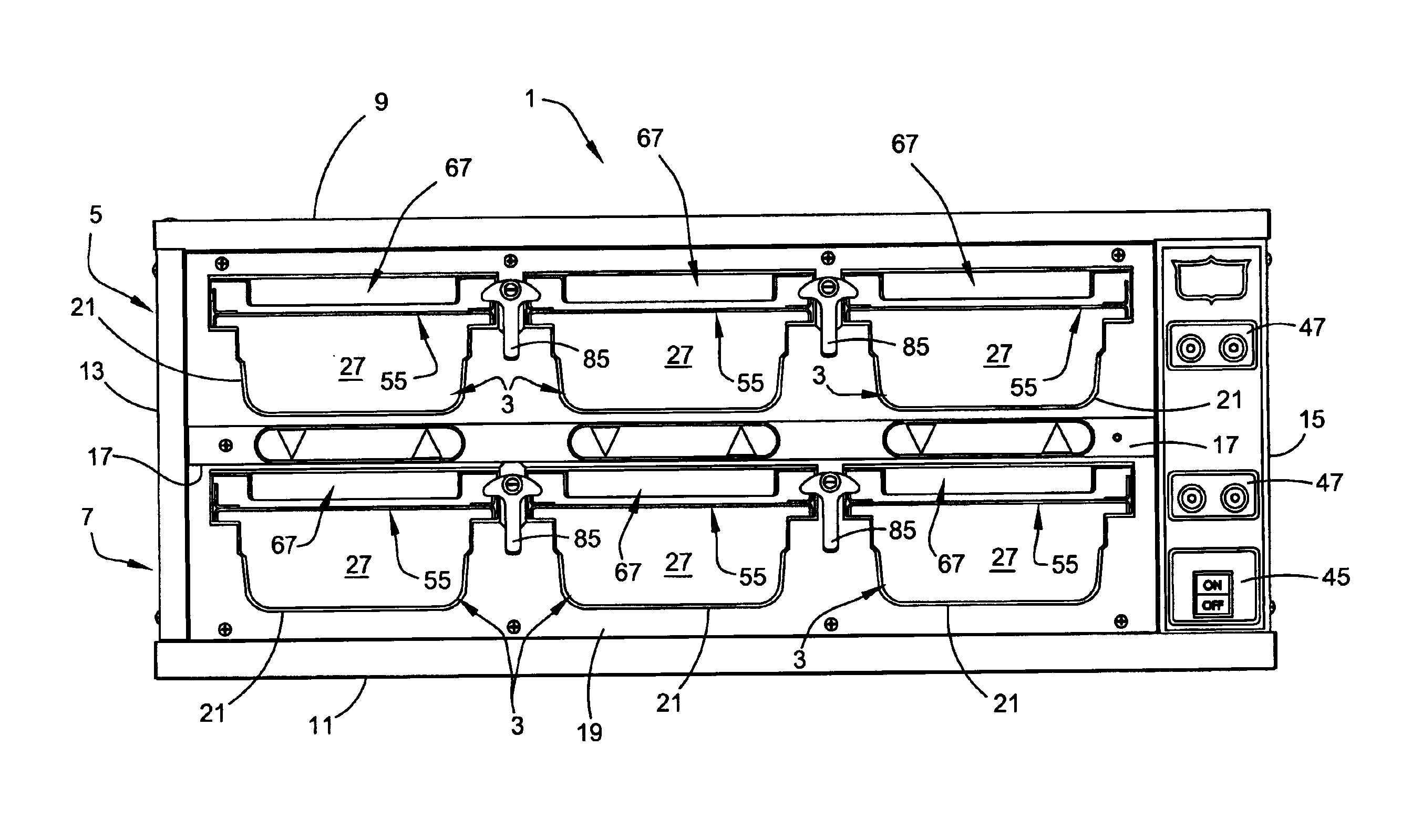

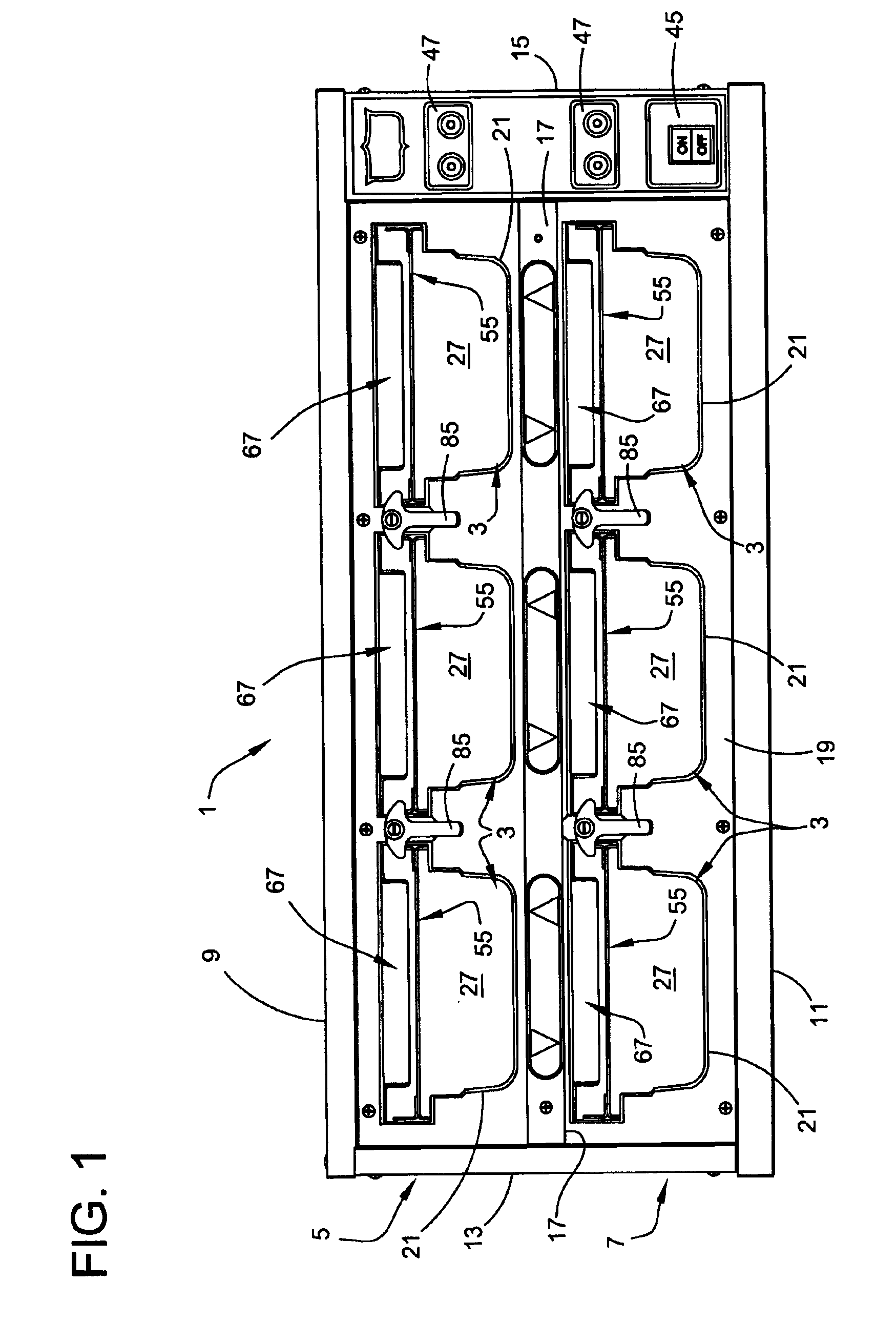

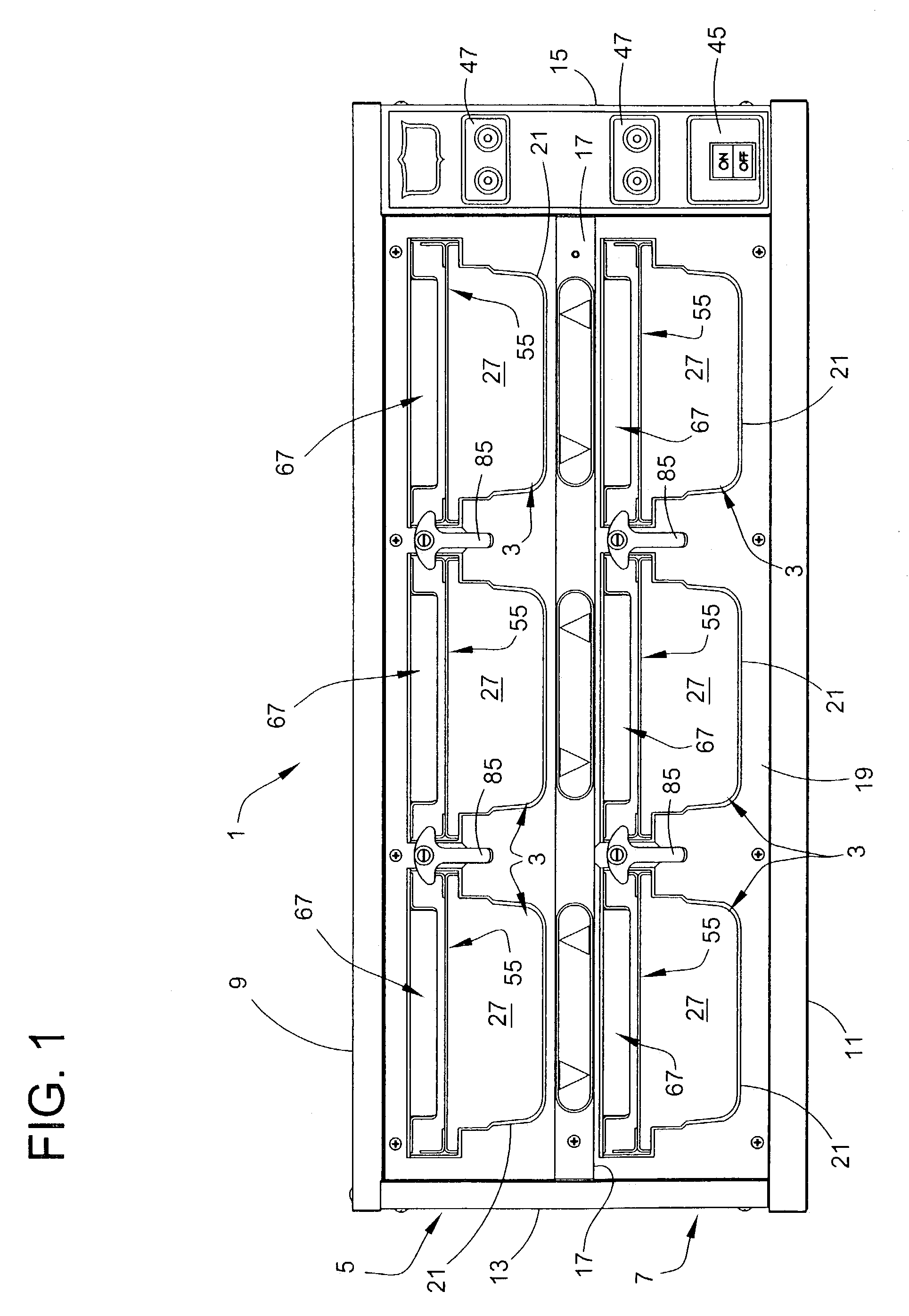

Food warming apparatus and method

InactiveUS7105779B2Less spaceImprove food qualityDomestic stoves or rangesStoves/ranges shelves or racksEngineeringRadiant heat

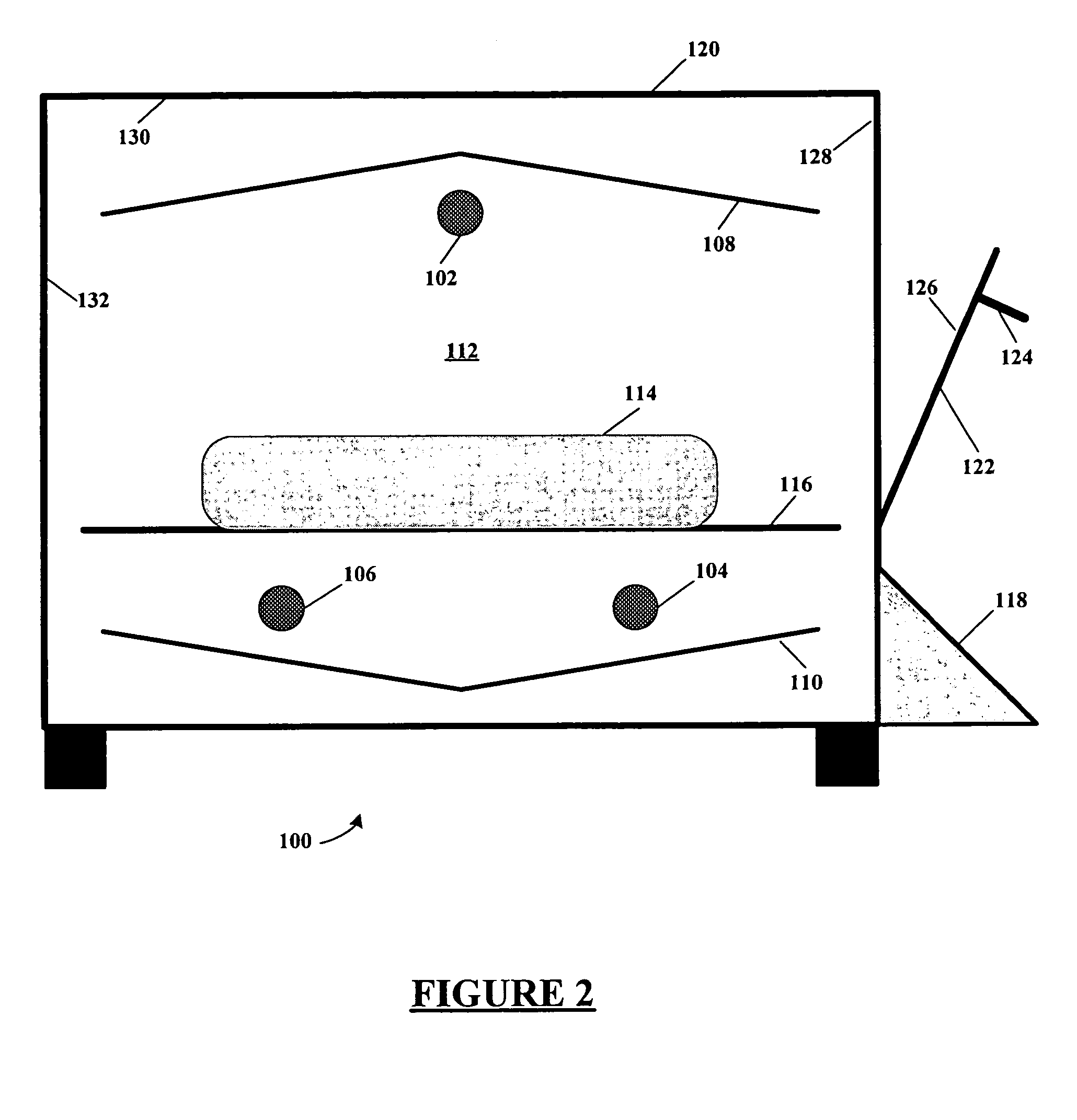

In general, one embodiment of the invention is directed to food holding apparatus for holding pre-cooked food at a selected holding temperature. The apparatus comprises a cabinet having at least one holding compartment therein, and pre-cooked food in the holding compartment, the food having been previously cooked in a cooking appliance. At least one radiant heat source is spaced above the food a distance less than 12 inches for delivering radiant heat to the food. A control mechanism varies the amount of radiant heat delivered by the heat source to the food to maintain the food at the selected holding temperature. A related method is also disclosed.

Owner:DUKE MANUFACTURING COMPANY

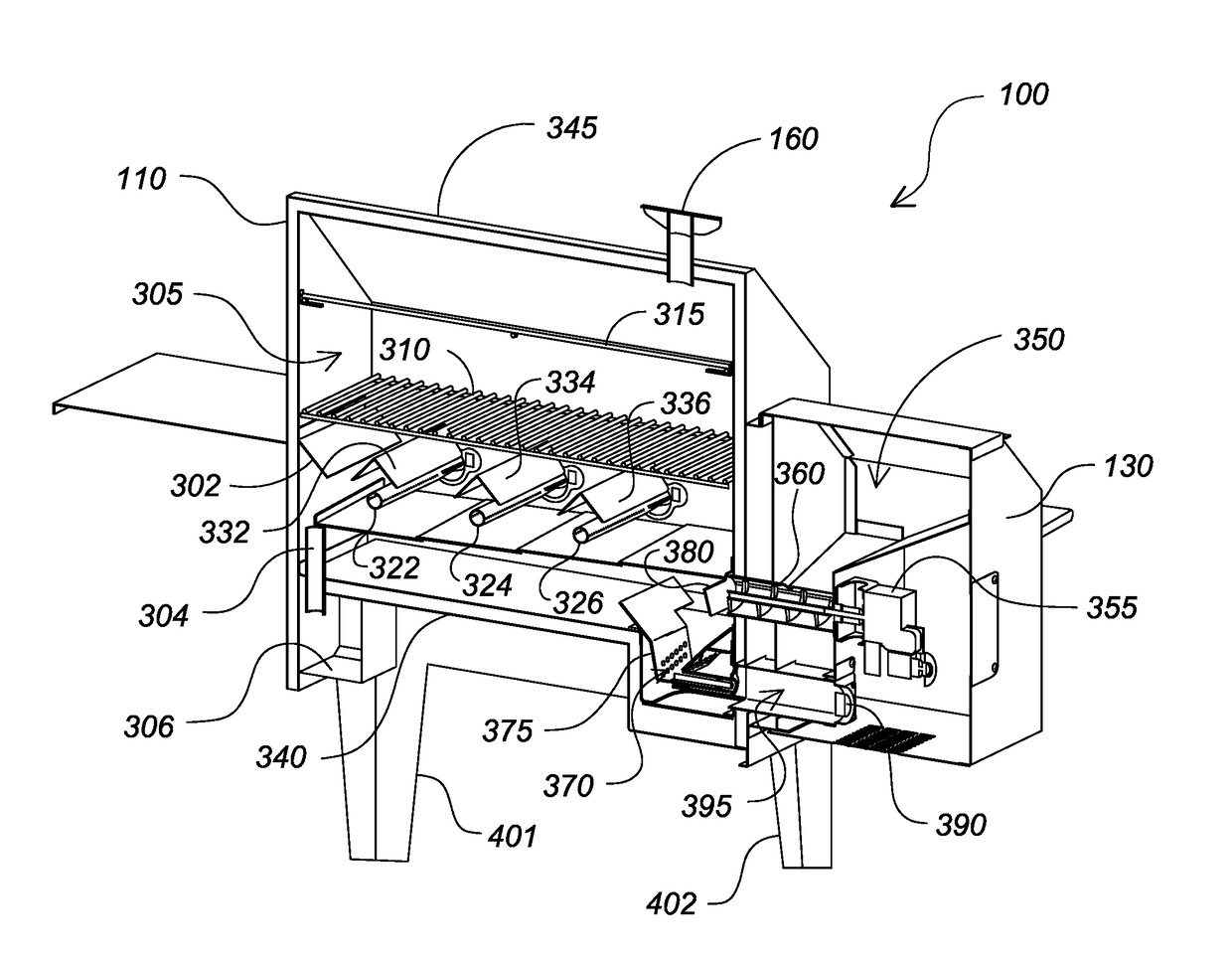

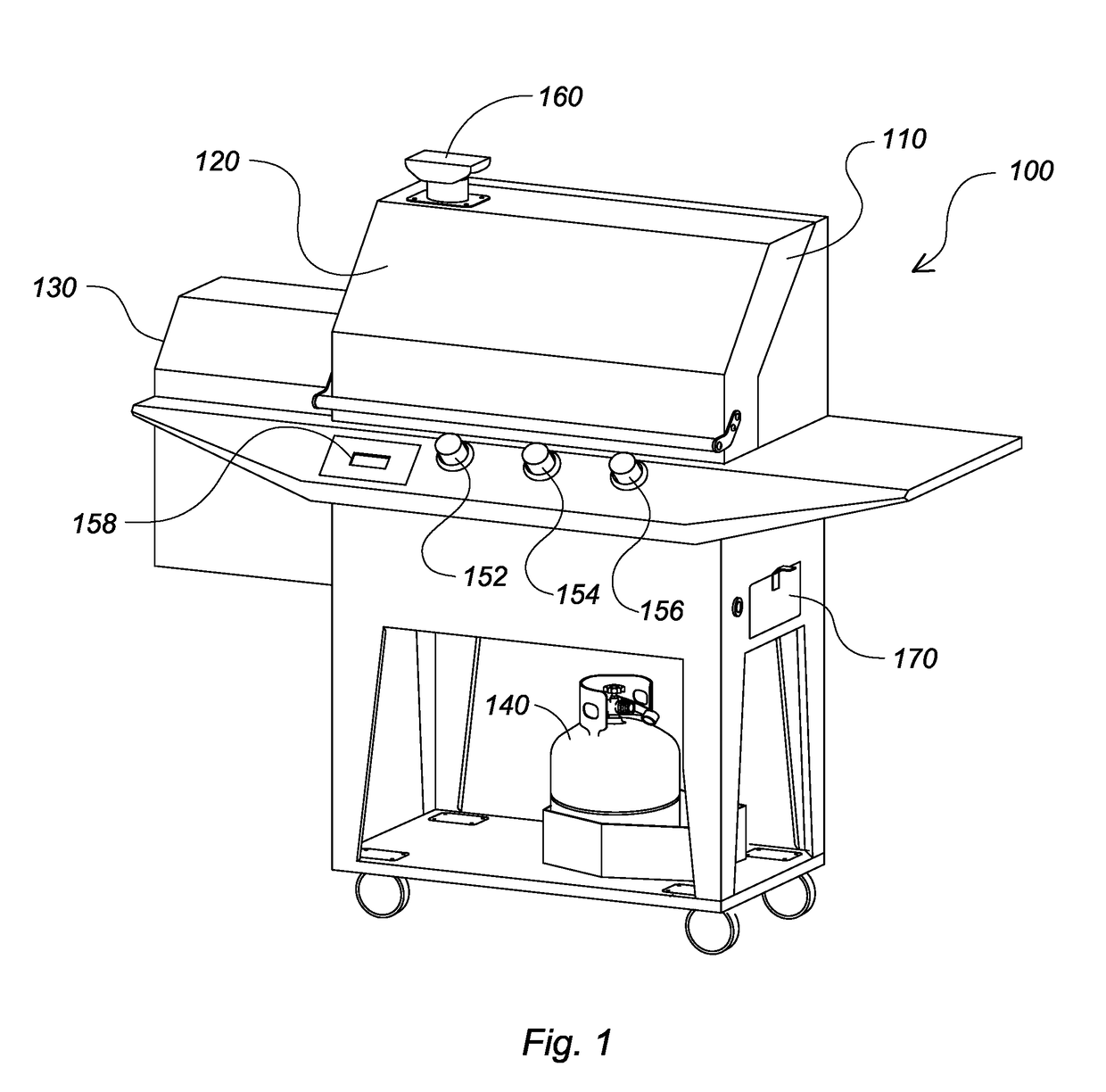

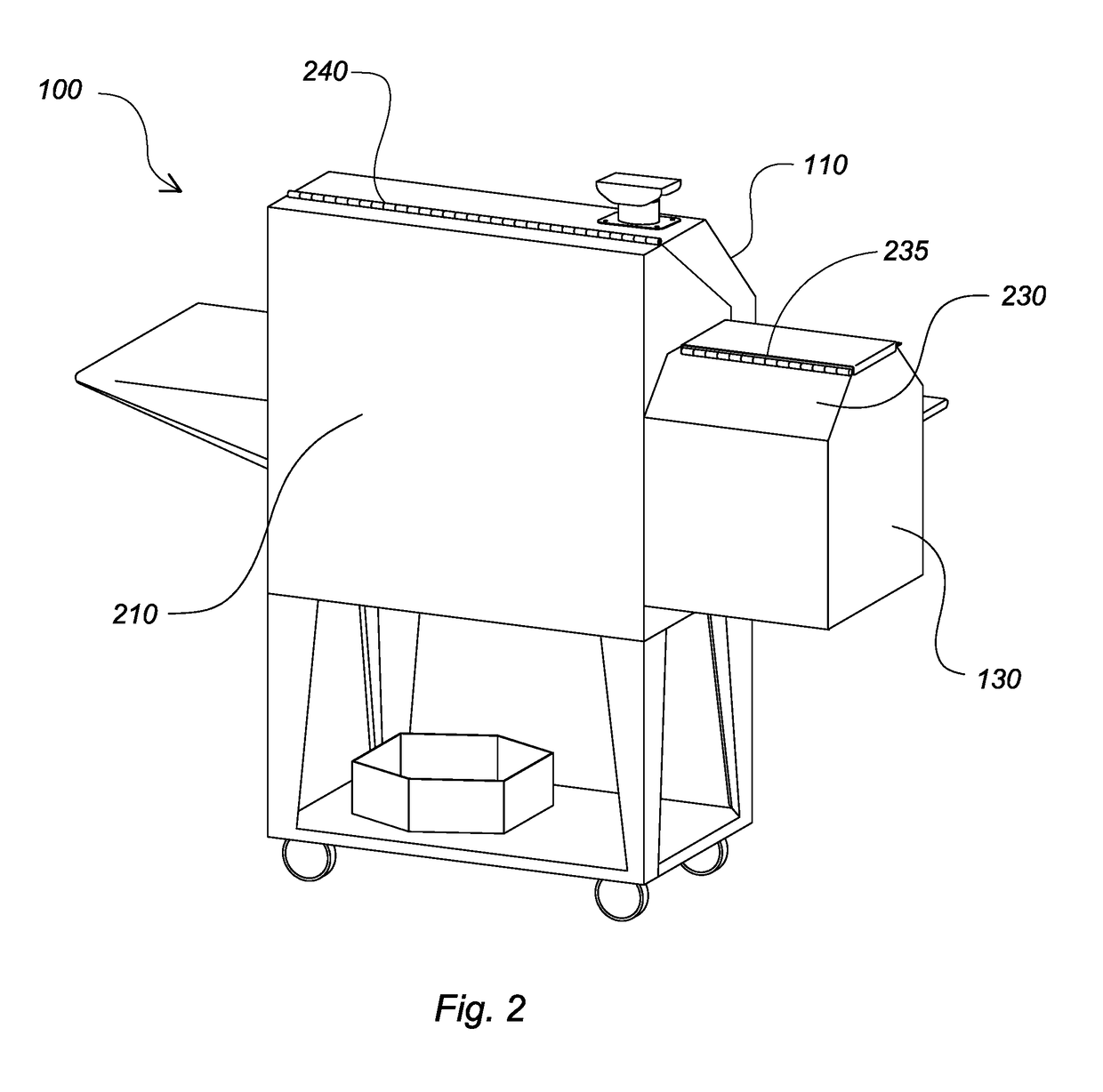

Multiple fuel cooking unit

InactiveUS20170164783A1Maintain sufficiencyWide rangeDomestic stoves or rangesLiquid heating fuelElectrical resistance and conductanceAutomatic control

A cooking unit may operate using multiple types of fuel to cook food. One or more first heat source, such as gas burners, electrical resistive heaters, and / or other heating technology, may provide radiant heat to a cooking chamber. One or more second heat source, such as a firebox, may provide indirect heat to the cooking chamber, for example by producing smoke. User operable controls and / or an automated control unit may alter the rate at which a fuel and / or air is supplied to one or more heat source.

Owner:SMOKESTEAK LLC

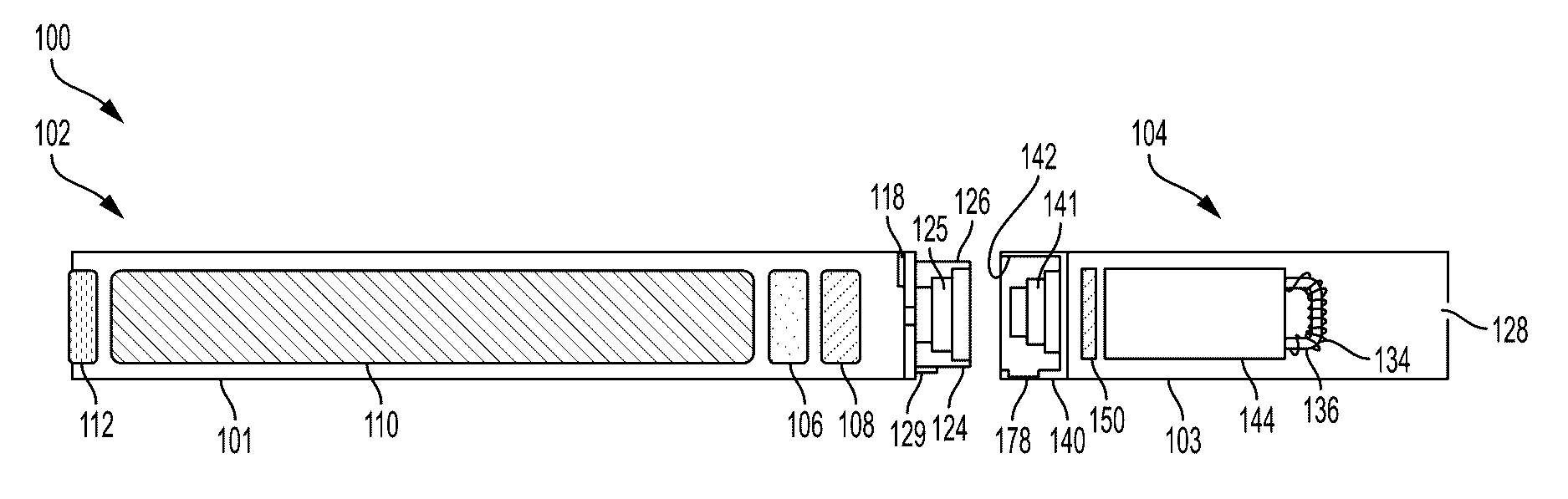

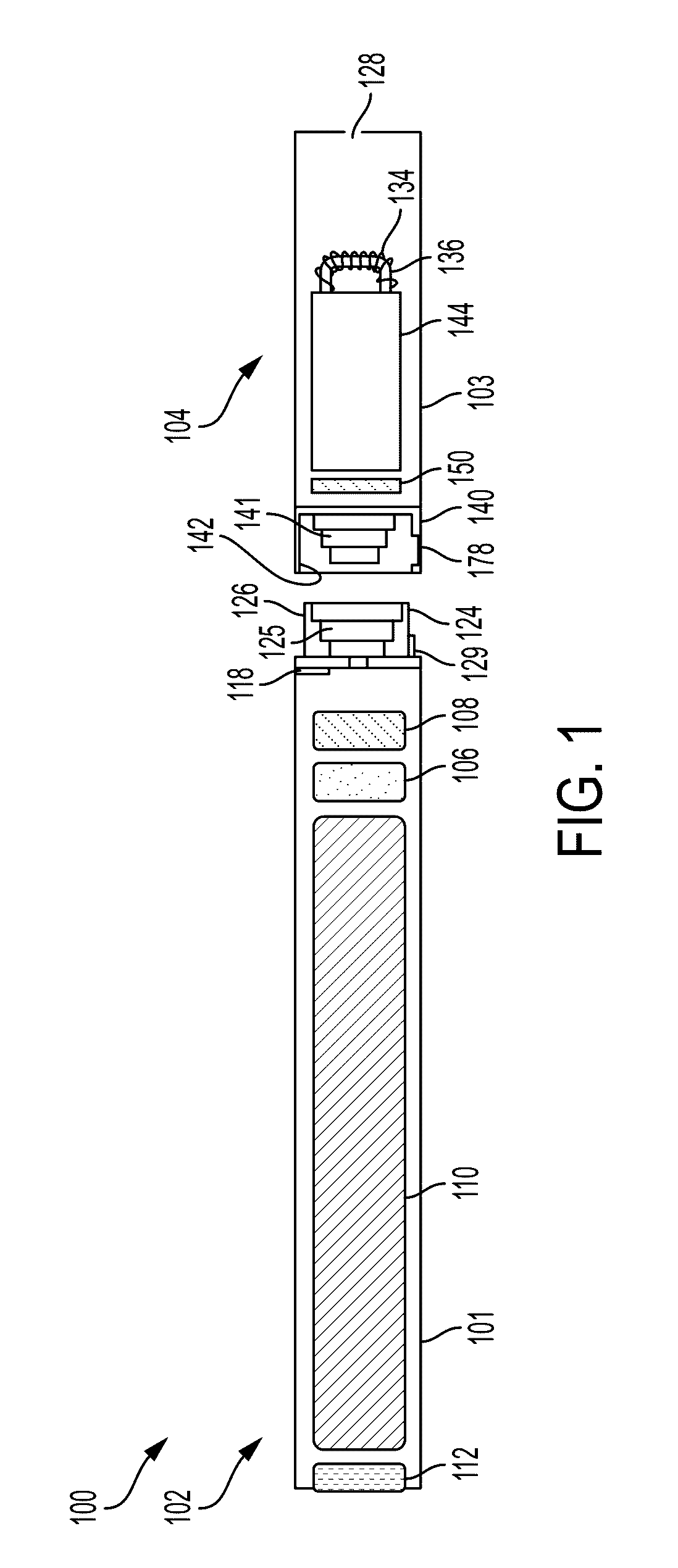

Aerosol delivery device with radiant heating

ActiveUS20170020193A1Increase heatExtended service lifeRespiratorsOhmic-resistance waterproof/air-tight sealsBlack bodyVaporization

The present disclosure relates to aerosol delivery devices, methods of forming such devices, and elements of such devices. In some embodiments, the present disclosure provides devices configured for vaporization of an aerosol precursor composition through radiant heating. The radiant heat source may be a laser diode or further element suitable for providing electromagnetic radiation, and heating may be carried out within an optional chamber, which can be a radiation-trapping chamber. In some embodiments, an interior of such chamber may be configured as a black body or as a white body.

Owner:RAI STRATEGIC HLDG INC

In situ method for cleaning silicon surface and forming layer thereon in same chamber

InactiveUS6197694B1Semiconductor/solid-state device manufacturingElectrostatic cleaningHydrogenEngineering

A method is described for cleaning a silicon surface of a semiconductor wafer in a vacuum chamber while radiantly heating said silicon surface to maintain it within a first temperature range in the presence of hydrogen gas; then quickly cooling the wafer down to a second temperature range by reducing the radiant heat; and then forming a layer of either polysilicon or oxide over the cleaned surface within this second temperature range without removing the cleaned wafer from the chamber. By cleaning the wafer and then depositing polysilicon or growing oxide over the cleaned silicon surface in the same vacuum chamber, formation of oxides and other contaminants on the cleaned silicon surface between the cleaning step and the deposition or growth step is inhibited, resulting in a higher quality polysilicon or oxide layer formed over the cleaned silicon surface.

Owner:APPLIED MATERIALS INC

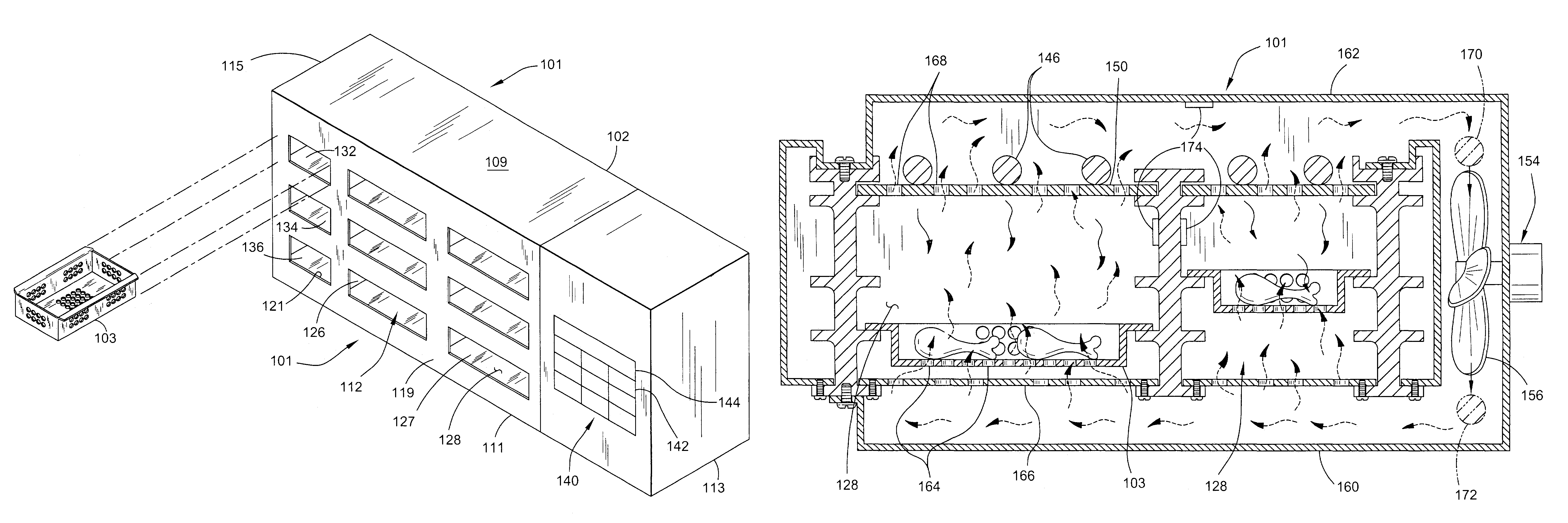

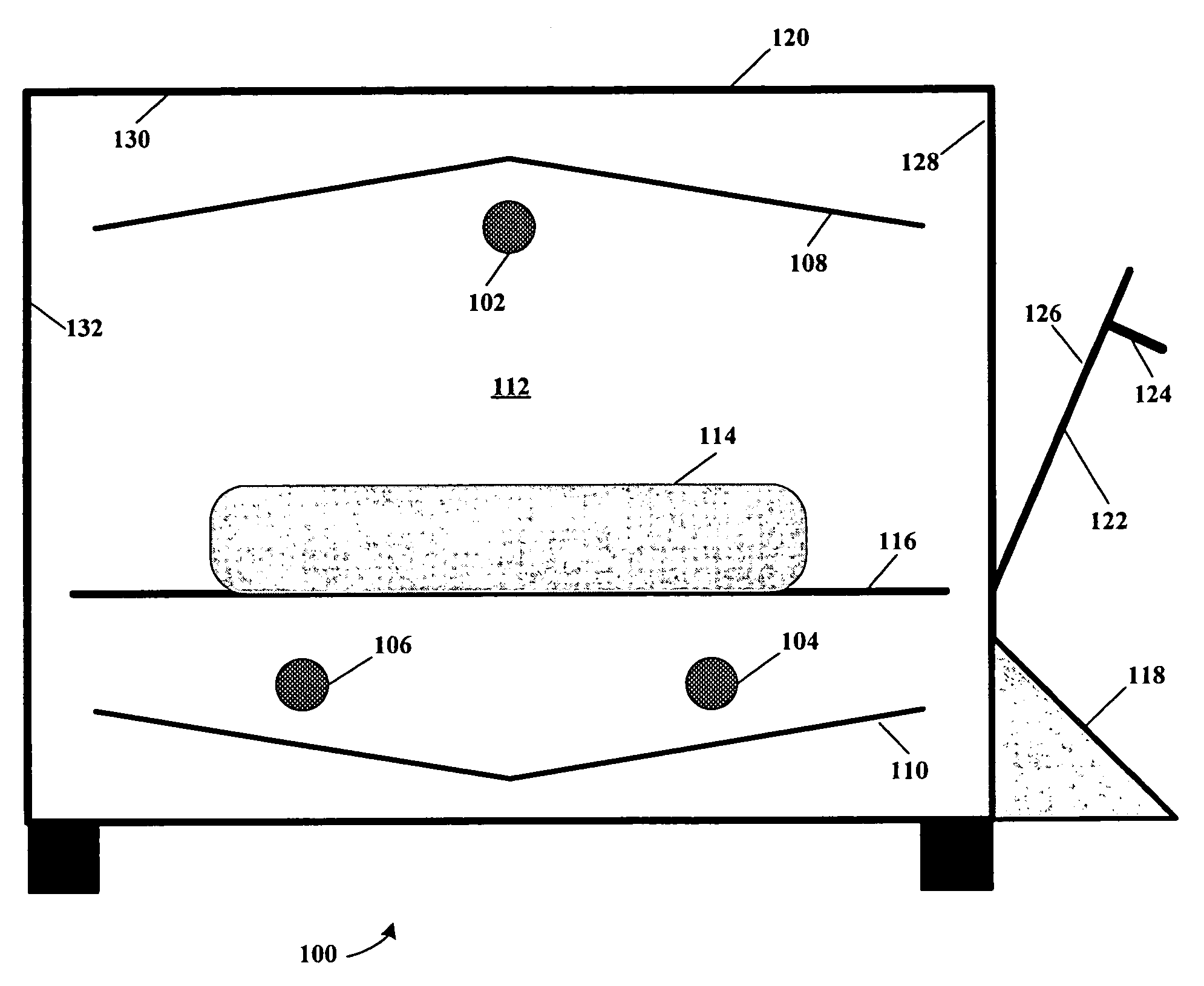

Food warming apparatus and method

InactiveUS7227102B2Improve food qualityLonger heldDomestic stoves or rangesMuffle furnacesForced-airEngineering

An oven for transferring heat to food in trays and a method for using the oven. The oven includes a cabinet with partitions dividing the interior into a plurality of separate, thermally isolated holding compartments each adapted for removably receiving a tray of food. Heat sources above the tray emit radiant heat to warm the food in the trays. A control mechanism controls the duration of the total hold time for the food having a duration of heated holding time during which a respective heat source is activated. The oven also includes a forced air mechanism under the control of the control mechanism for delivering forced air into the compartments. The heat sources are activated and deactivated during successive duty cycles to thereby to maintain the food in a respective compartment at a selected holding temperature for a duration of heated holding time.

Owner:DUKE MANUFACTURING COMPANY

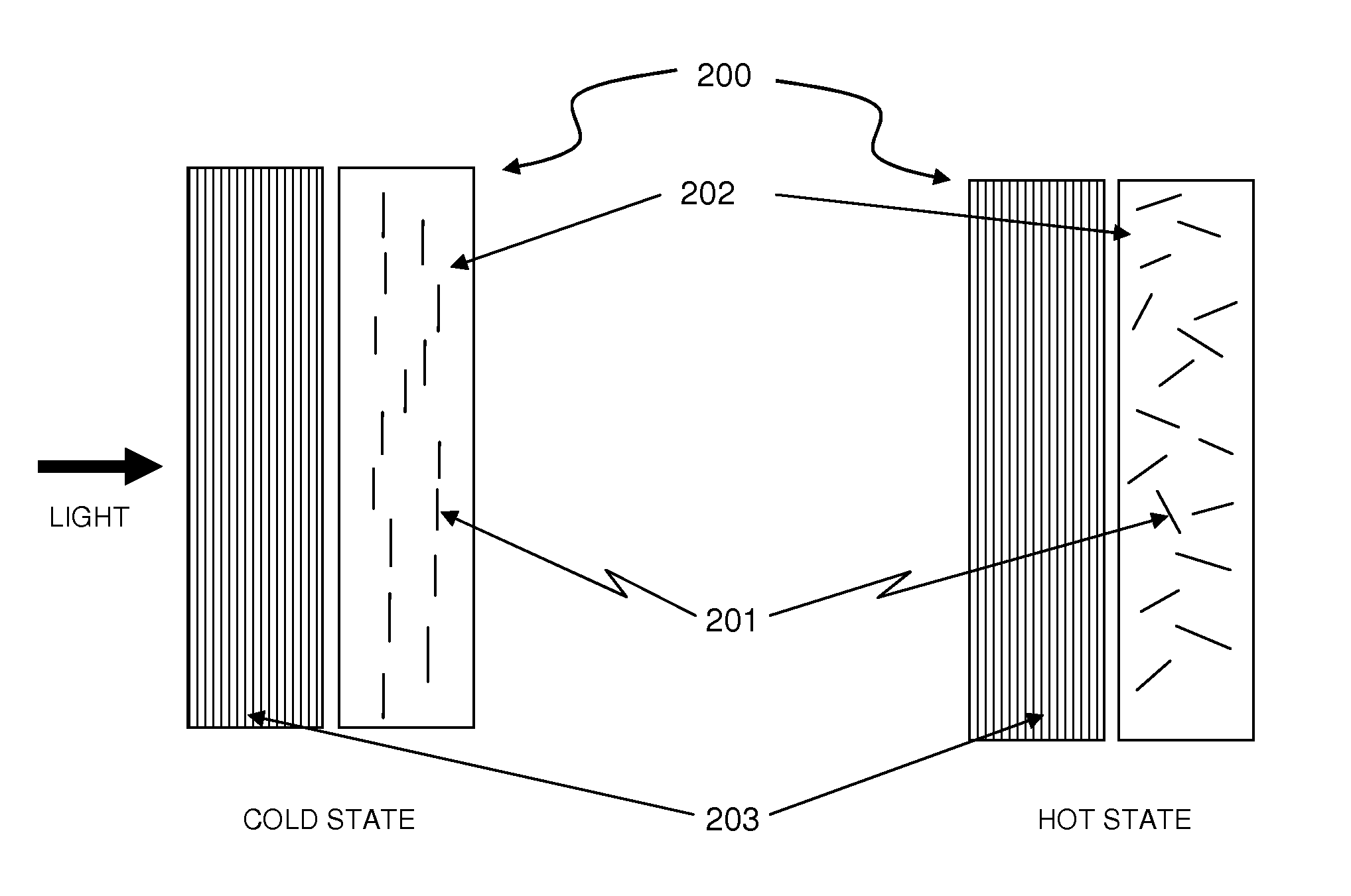

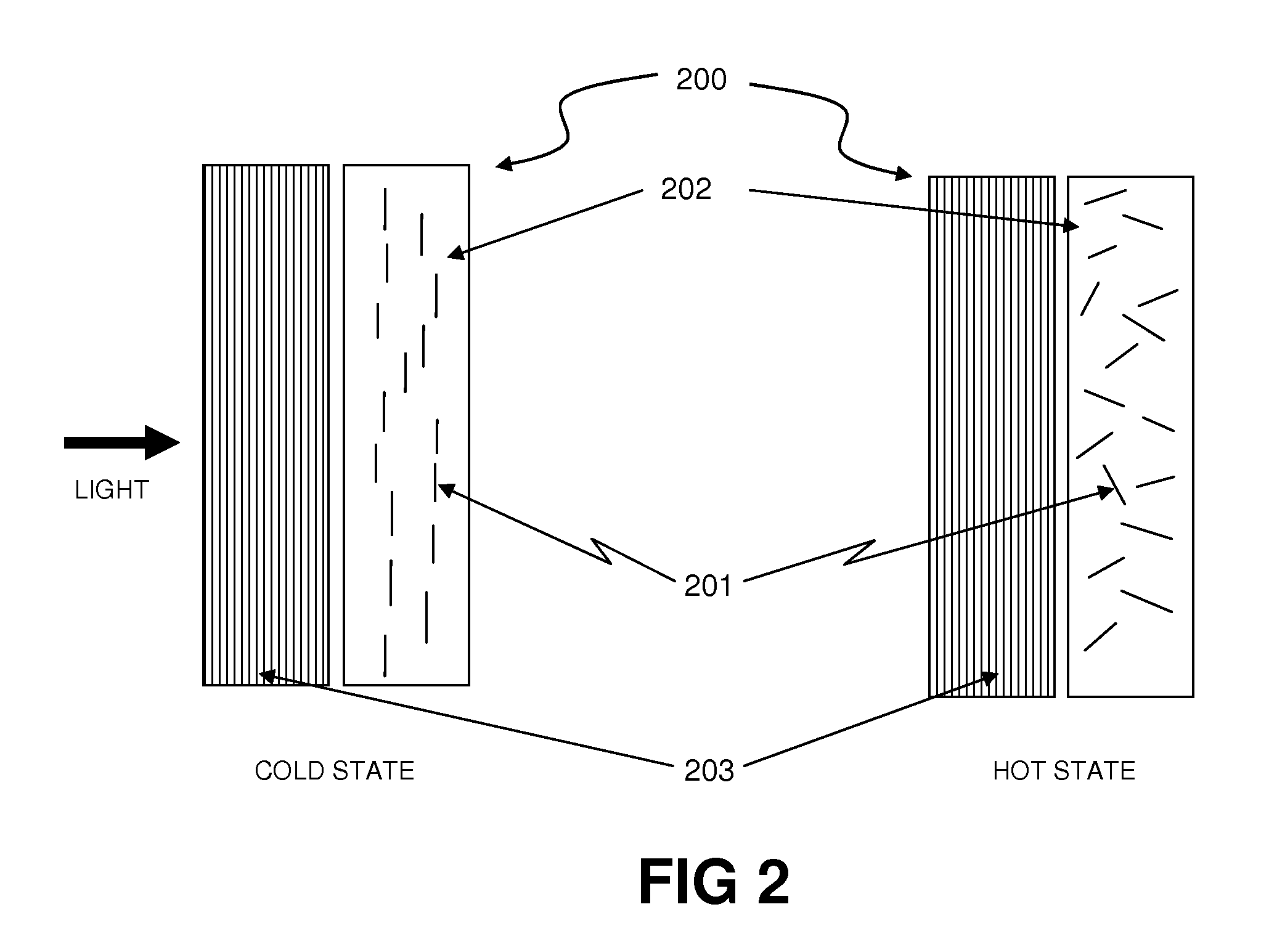

Thermally Switched Optical Filter Incorporating a Guest-Host Architecture

InactiveUS20100259698A1Avoid concentrationLess transmissiveLiquid crystal compositionsStatic indicating devicesLiquid crystallineSelective reflection

Thermochromic filters are constructed using absorptive, reflective, or fluorescent dyes, molecules, polymers, particles, rods, or other orientation-dependent colorants that have their orientation, order, or director influenced by carrier materials, which are themselves influenced by temperature. These order-influencing carrier materials include thermotropic liquid crystals, which provide orientation to dyes and polymers in a Guest-Host system in the liquid-crystalline state at lower temperatures, but do not provide such order in the isotropic state at higher temperatures. The varying degree to which the absorptive, reflective, or fluorescent particles interact with light in the two states can be exploited to make many varieties of thermochromic filters. Thermochromic filters can control the flow of light and radiant heat through selective reflection, transmission, absorption, and / or re-emission. The filters have particular application in passive or active light-regulating and temperature-regulating films, materials, and devices, and particularly as construction materials and building and vehicle surfaces.

Owner:RAVENBRICK

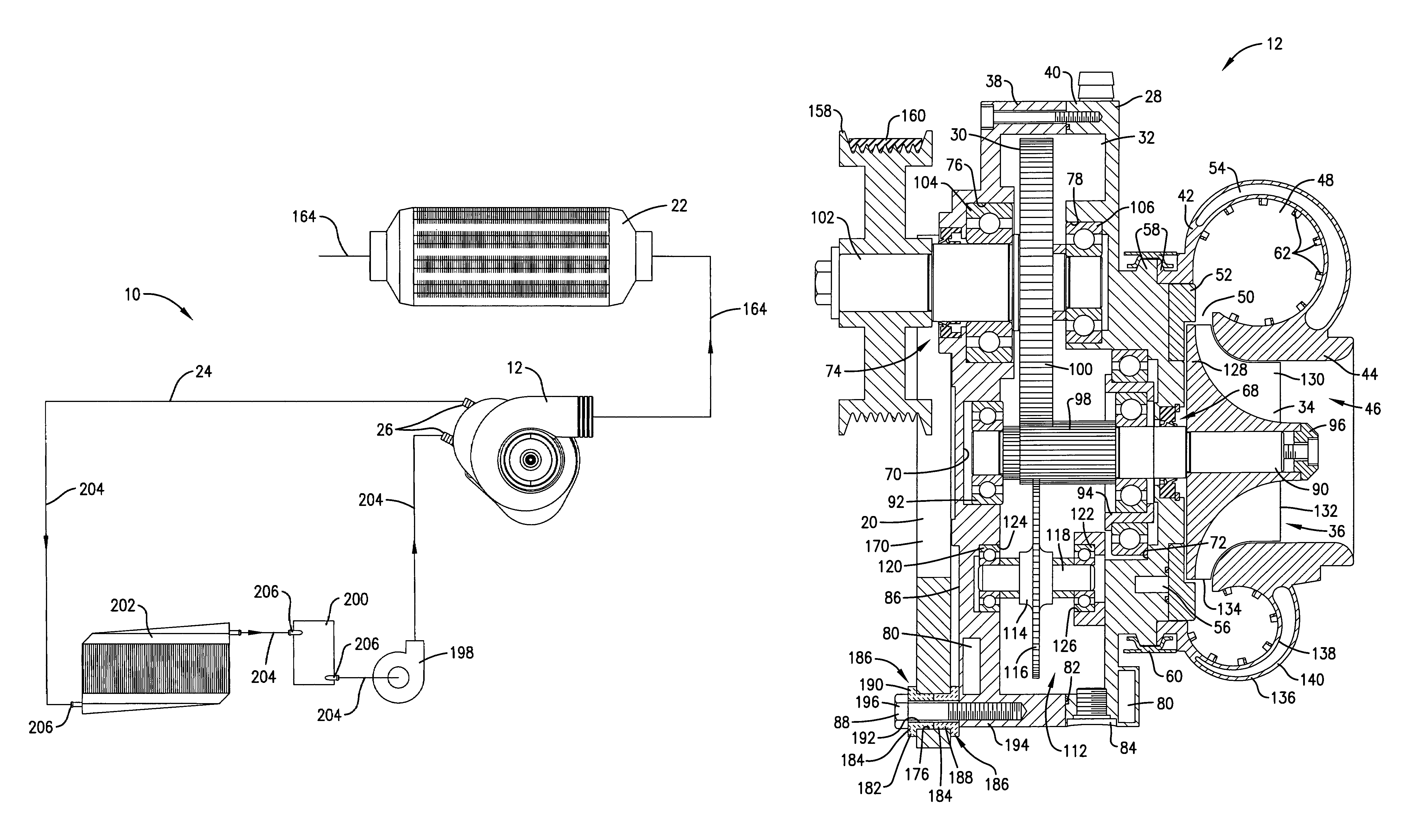

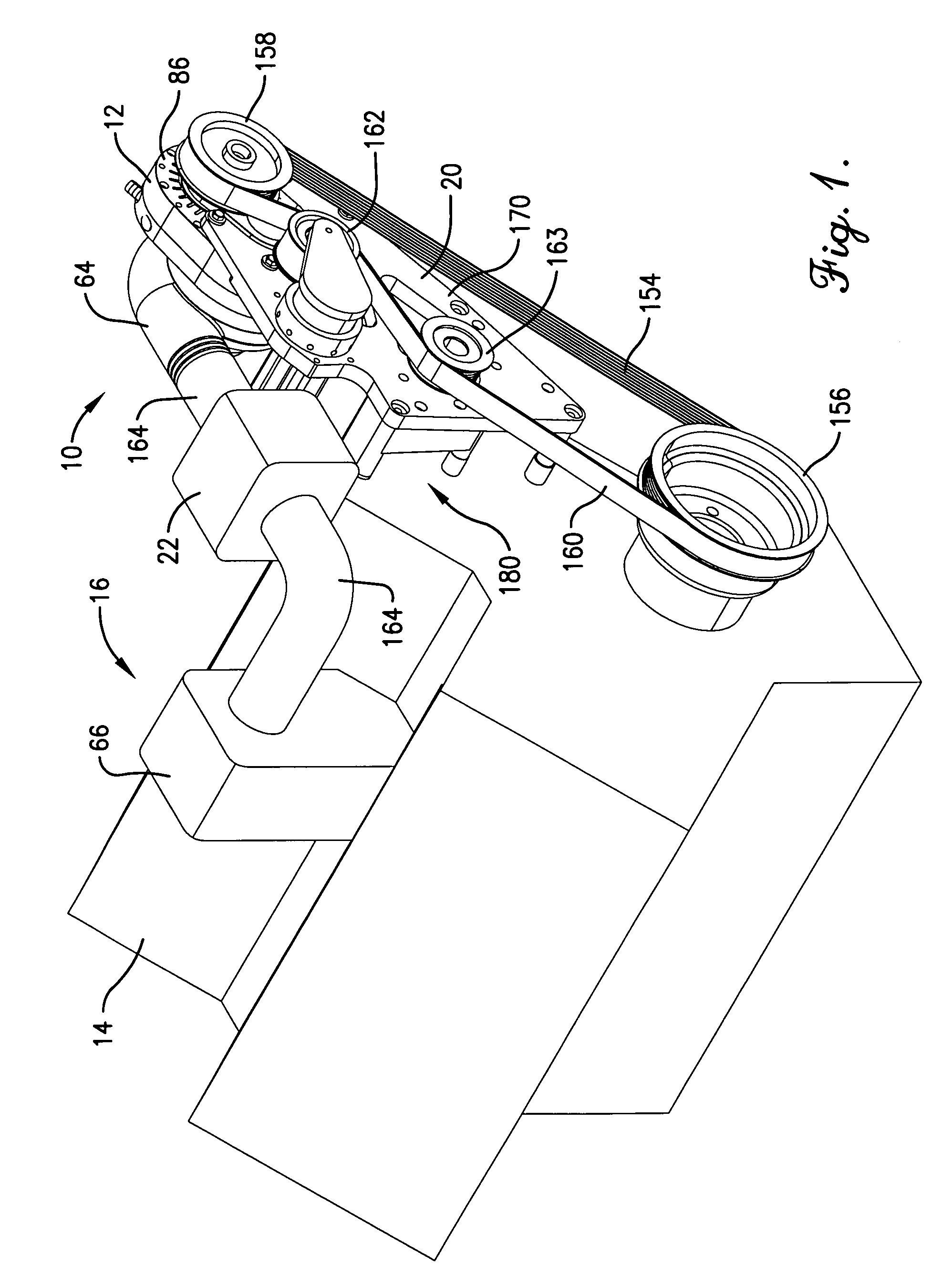

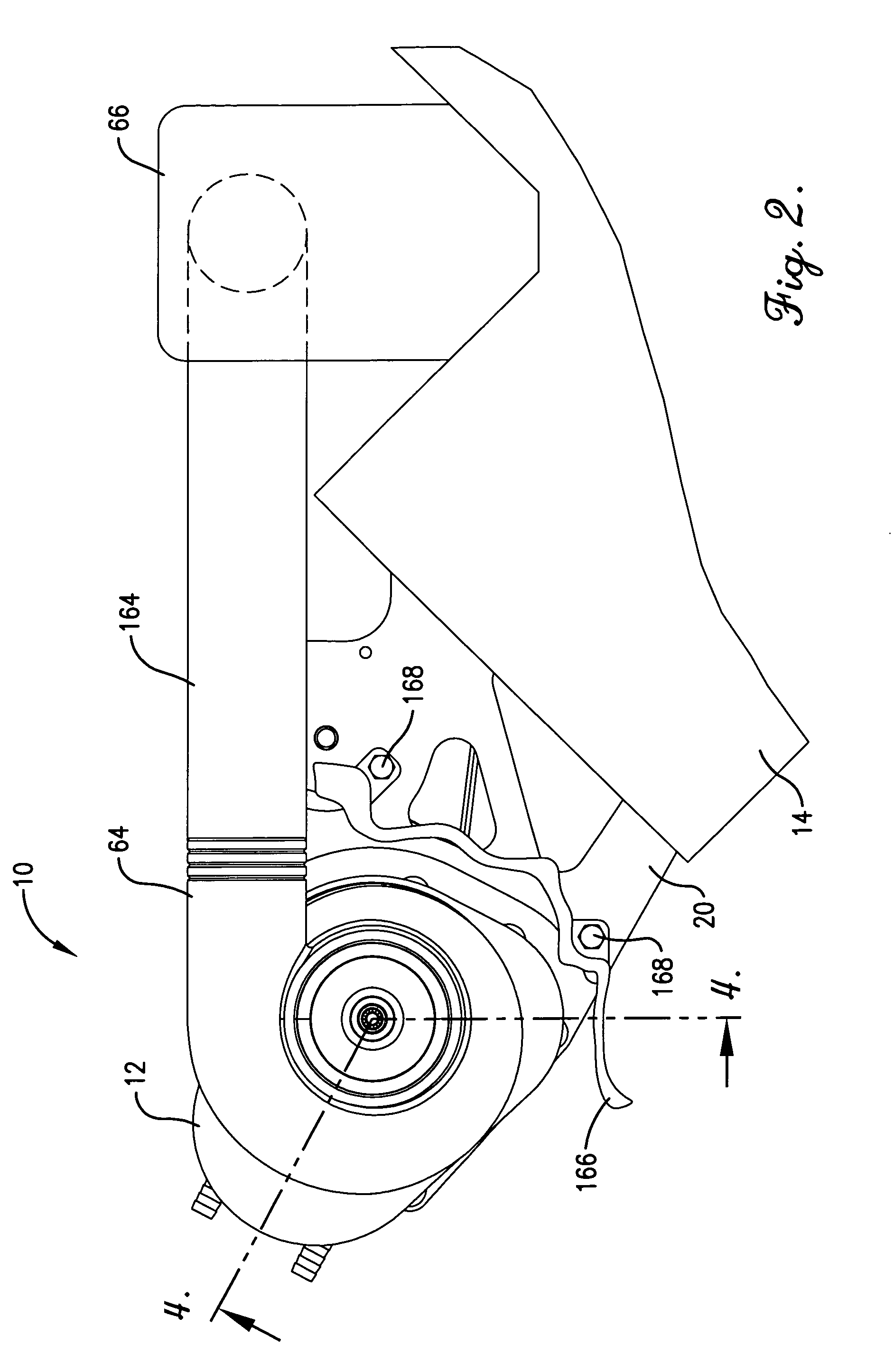

Fluid cooled supercharger

InactiveUS7469689B1Promotes an increase in inductionRaise transfer toPump componentsCombustion enginesForced-airIntercooler

A forced air induction system for use with a powered vehicle is disclosed as including a centrifugal supercharger supported by the vehicle's engine and a recirculating induction coolant system that cools the supercharger and the compressed induction fluid provided by the supercharger. The induction coolant system operates by providing coolant to the supercharger and to an intercooler of the forced air induction system. The supercharger case includes internal passageways for cooling the transmission and compressor. The forced air induction system further includes spacers and radiant heat shields for rejecting heat transferred conductively and radiantly from the engine.

Owner:ACCESSIBLE TECHONOLOGIES

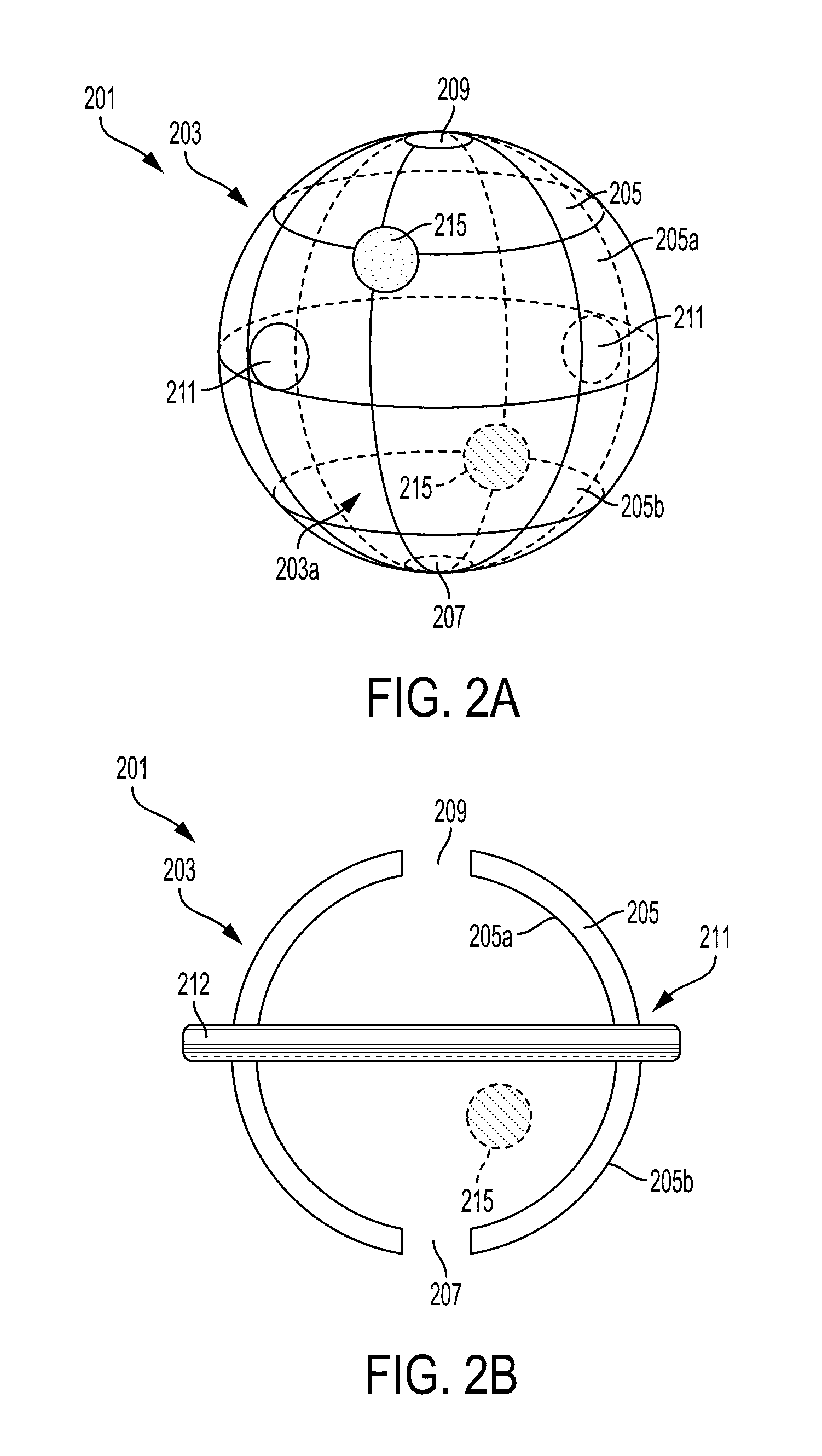

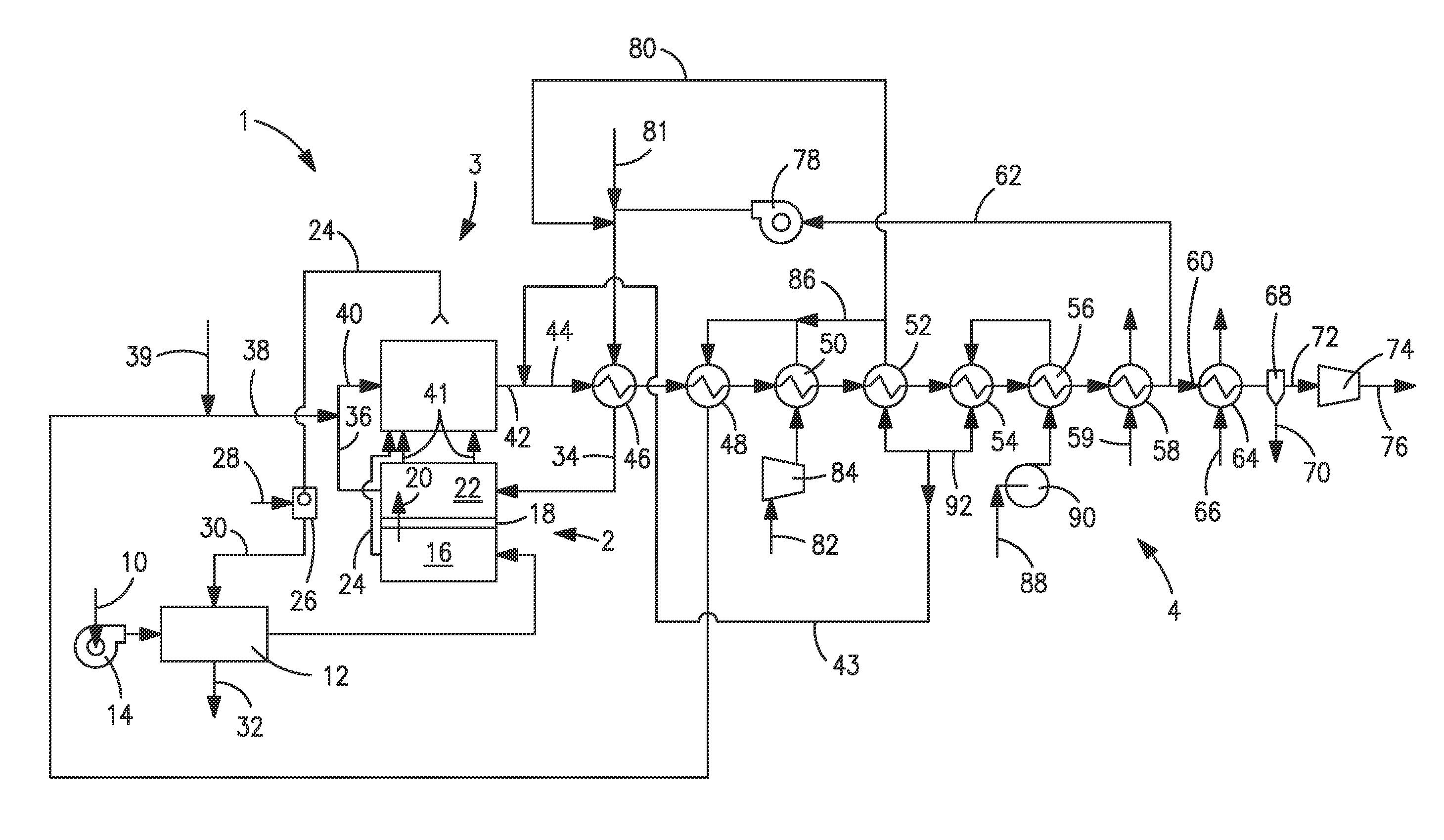

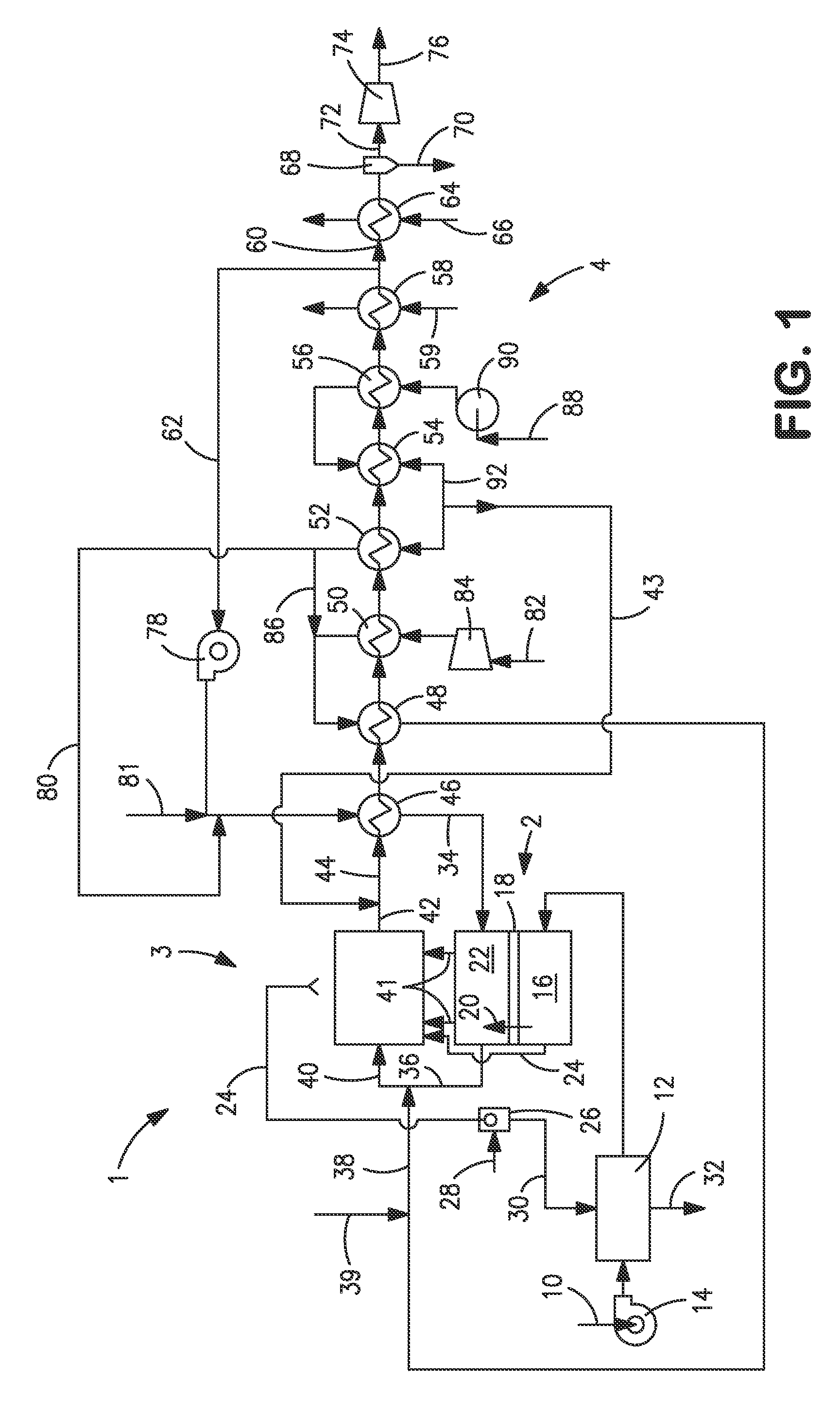

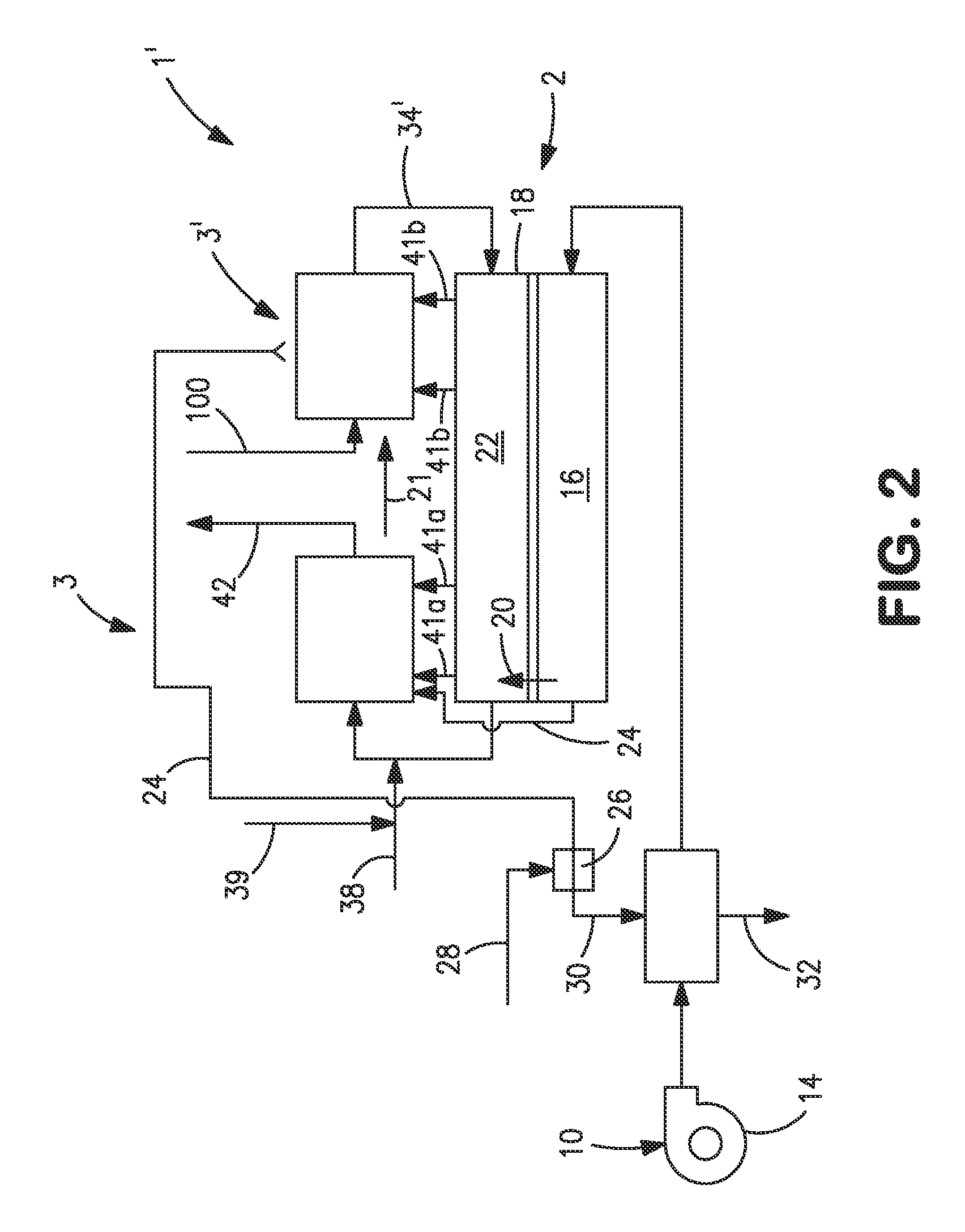

Oxygen transport membrane system and method for transferring heat to catalytic/process reactors

A method and apparatus for producing heat used in a synthesis gas production process is provided. The disclosed method and apparatus include a plurality of tubular oxygen transport membrane elements adapted to separate oxygen from an oxygen containing stream contacting the retentate side of the membrane elements. The permeated oxygen is combusted with a hydrogen containing synthesis gas stream contacting the permeate side of the tubular oxygen transport membrane elements thereby generating a reaction product stream and radiant heat. The present method and apparatus also includes at least one catalytic reactor containing a catalyst to promote the steam reforming reaction wherein the catalytic reactor is surrounded by the plurality of tubular oxygen transport membrane elements. The view factor between the catalytic reactor and the plurality of tubular oxygen transport membrane elements radiating heat to the catalytic reactor is greater than or equal to 0.5.

Owner:PRAXAIR TECH INC

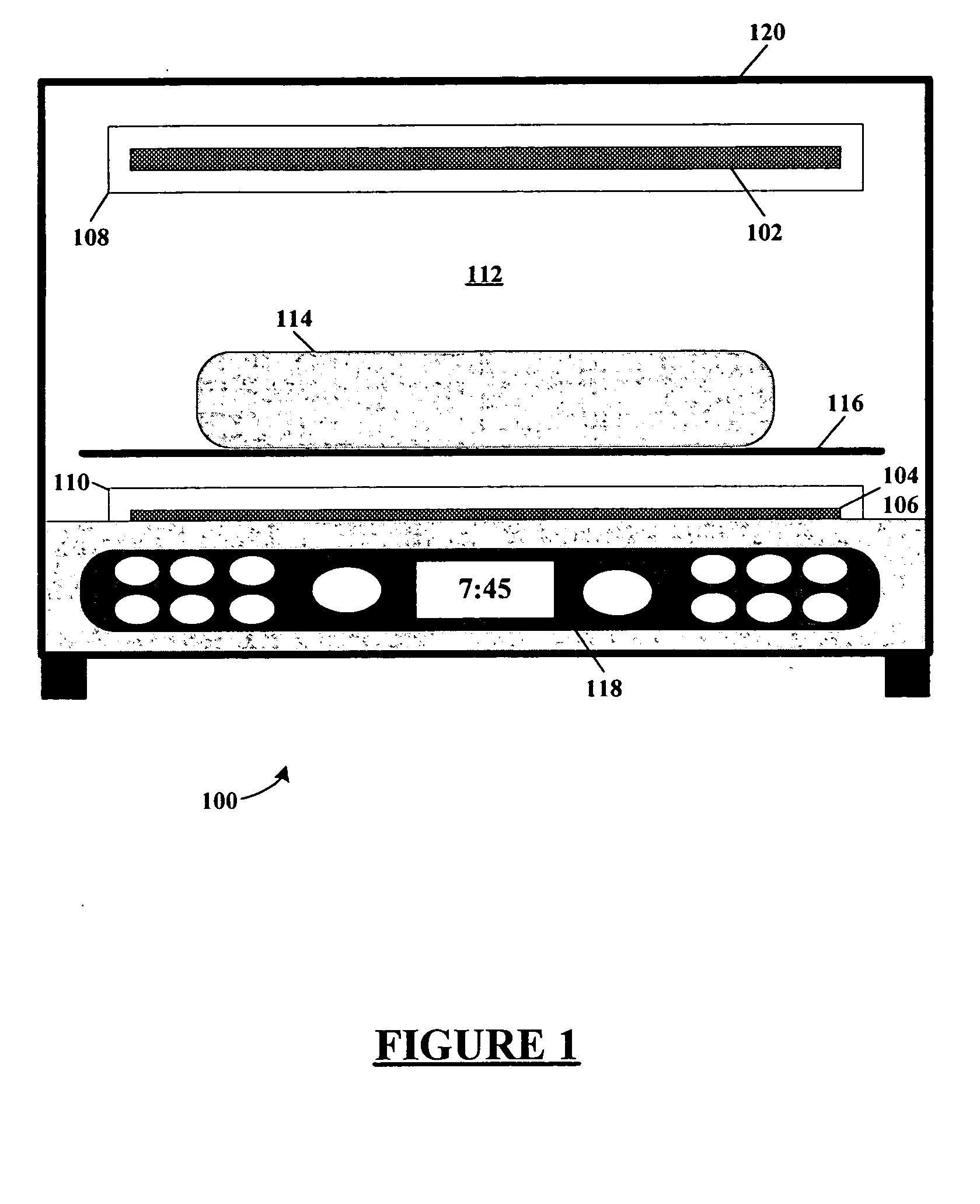

Multi-purpose oven using infrared heating for reduced cooking time

ActiveUS20050173400A1Quality improvementHigh speedDomestic stoves or rangesElectrical heating fuelThermal energyCooked food

An oven using radiant heat at infrared wavelengths optimized for producing rapid and uniform cooking of a wide variety of foods. The infrared oven toasts, bakes, broils, and re-heats food at a much faster speed while maintaining high quality in taste and appearance of the cooked food. Optimal infrared wavelengths of the radiant heat sources are used for the best balance of cooking performance, while also reducing the time required to cook the food. Typically short to medium wavelength infrared radiant energy will result in good performance for toasting and browning of food. Medium to long wavelength infrared radiant energy is well suited for delivering more deeply penetrating radiant energy into the food. This deep penetration of radiant infrared heat energy results in a more thorough internal cooking of the food than with conventional methods of conduction and convection cooking.

Owner:APPLICA CONSUMER PRODS

Low temperature horticultural light apparatus

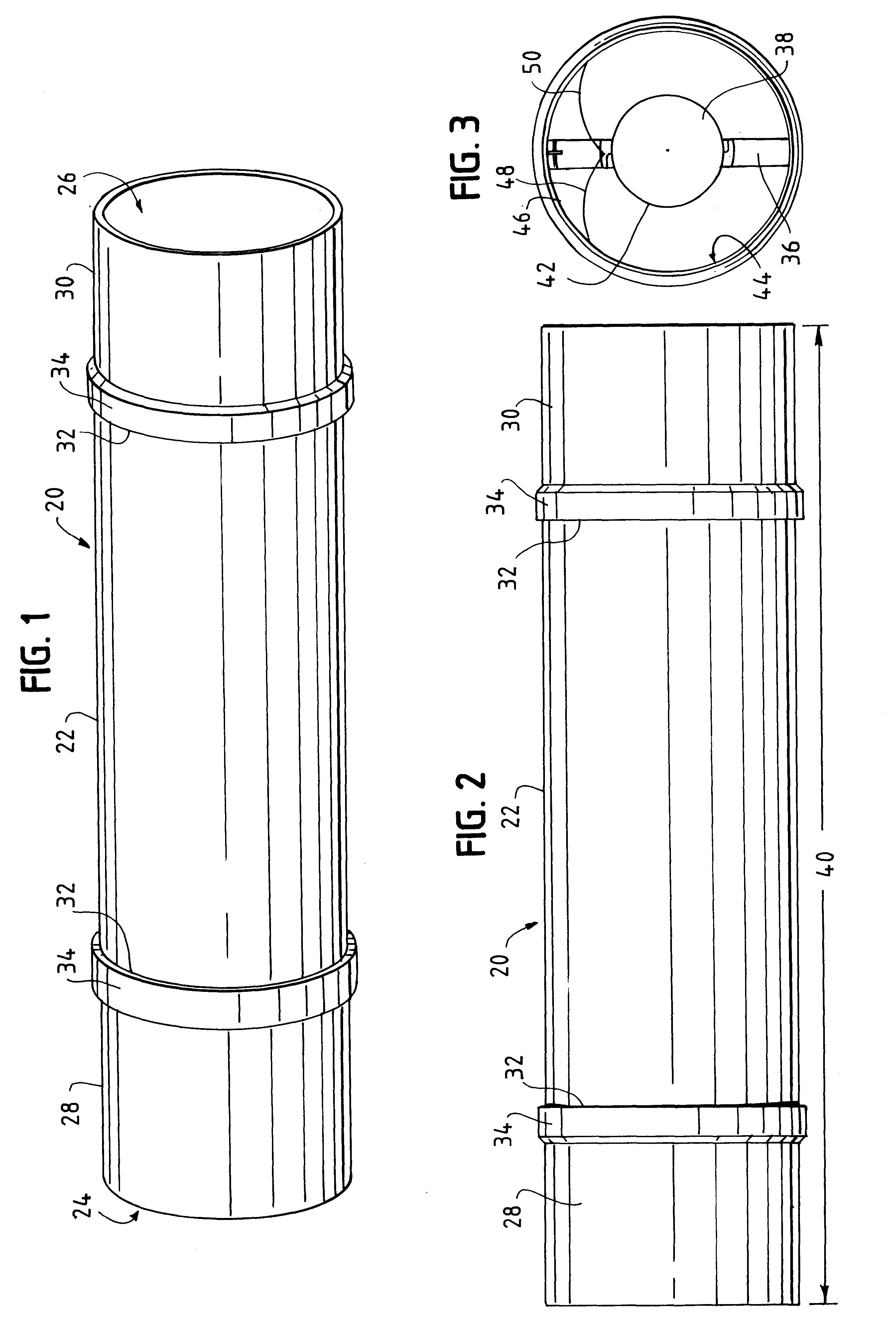

InactiveUS6267483B1Heat generation is minimizedMinimizing heat generationElongate light sourcesElectric lighting sourcesEngineeringRadiant heat

A horticultural light apparatus that reduces heat transmitted to plants that are being illuminated is provided. The Inventive Device includes a hollow, transparent, cylindrical tube, preferably made of glass. The tube is open at both ends and adapted to receive spigot members, the spigot members also being open ended. A support bracket to mount a lightbulb is affixed to at least one of the spigots. A reflector is also installed on the interior of the tube. In use, a lightbulb is inserted into the tube and secured by the spigots. Because of the open ends, air can flow through the tube, thus eliminating over-heating of the lightbulb. The glass absorbs much of the radiant heat generated by the lightbulb while emitting substantially all of the light generated by the lightbulb. The reflector directs the light in a generally downward direction. Means for suspending the Device are also included.

Owner:HEMBERY DANIEL

Heat-insulating energy-saving paint for vehicle and method for producing the same

InactiveCN101195725AIncrease reflectionInsulate heat radiationFireproof paintsPolyester coatingsRadiant heatAbsorption rate

The invention relates to heat insulating and energy saving coating used for the vehicle, and the preparation method thereof. The invention takes organic resin film forming material as the main material, the coating at least includes infrared reflection pigment, hollow ceramic micro-spheres and silicon dioxide aerogel, an organic resin film having low sunlight absorption rate is formed in the coating through the organic resin film forming material with high transparency, the visible light and the near infrared ray in the sunlight are reflected through the infrared reflection pigment, the rutile type titanium dioxide and the hollow ceramic micro-spheres, and simultaneously a compact vacuum layer and an inert gas layer are formed on the surface of a coated object through the hollow ceramic micro-spheres and the silicon dioxide aerogel, so as to effectively isolate the radiant heat of the sun, and to reduce the heat conduction of air, and finally the heat insulating and energy saving coating used for the vehicle is formed, which not only can effectively reflect the energy in the sunlight, but also can effectively isolate the radiant heat of the sun and reduce the heat conduction of air, and simultaneously has good weather resistant performance, chemicals resistant performance, mechanical property and decorative property.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

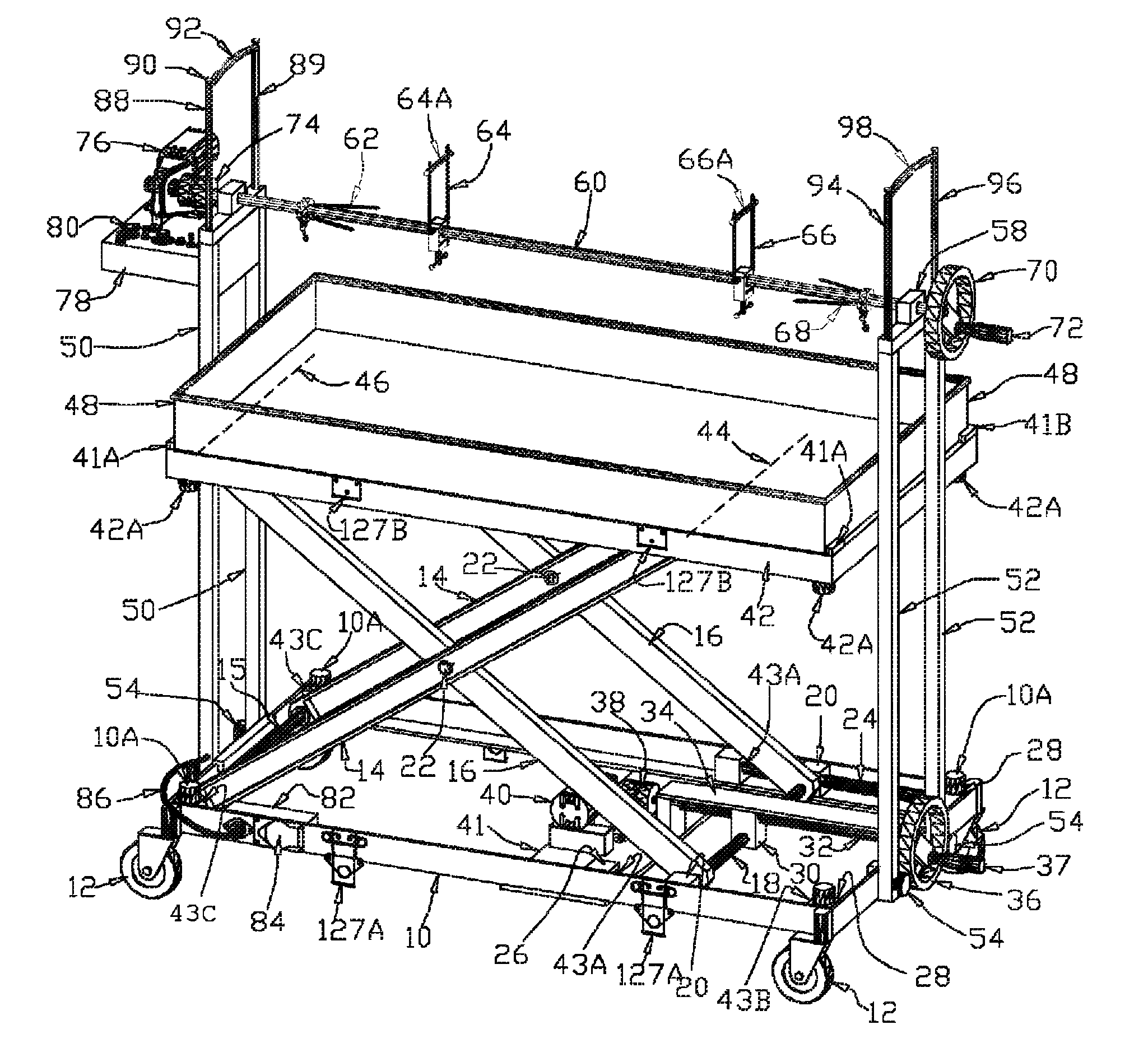

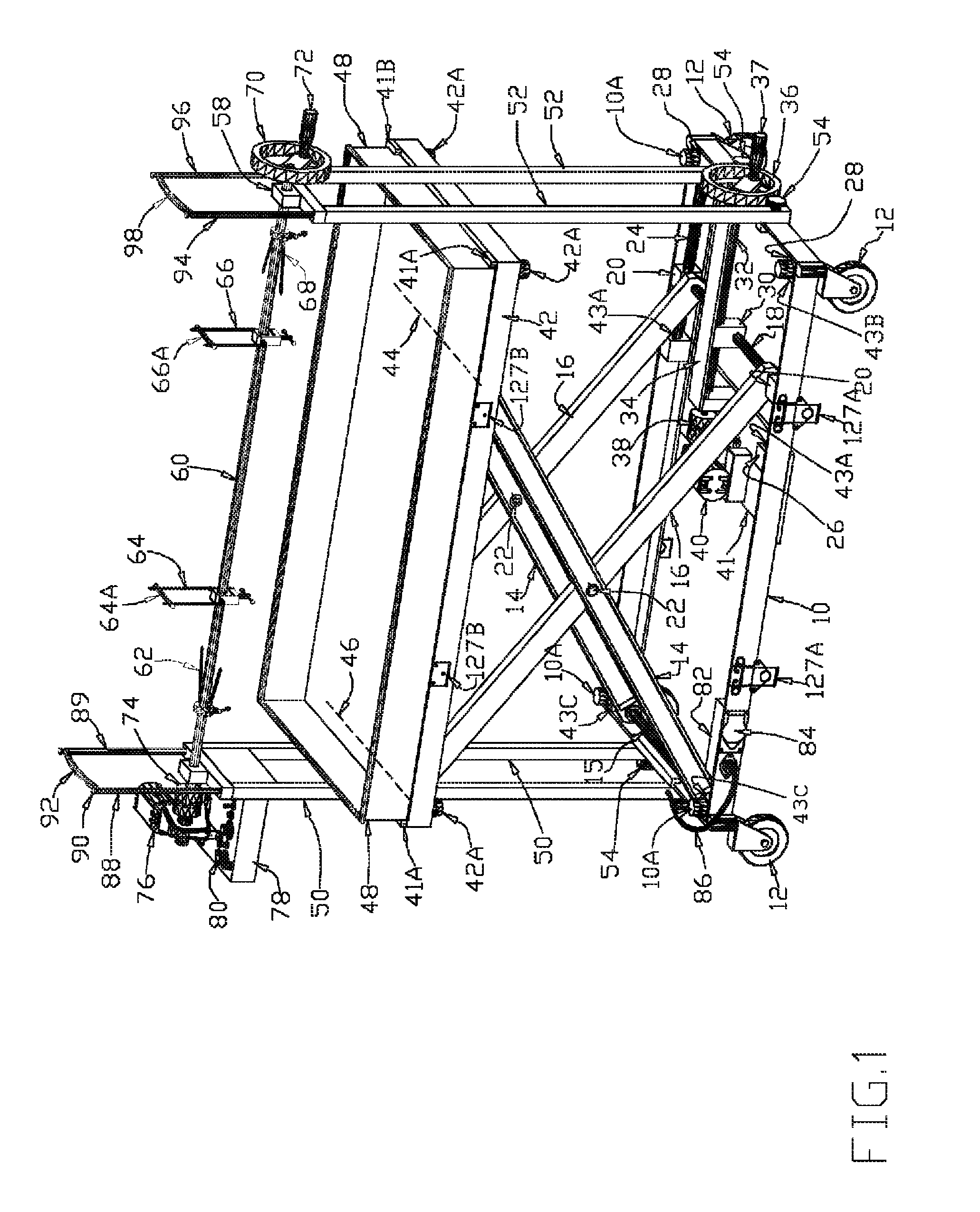

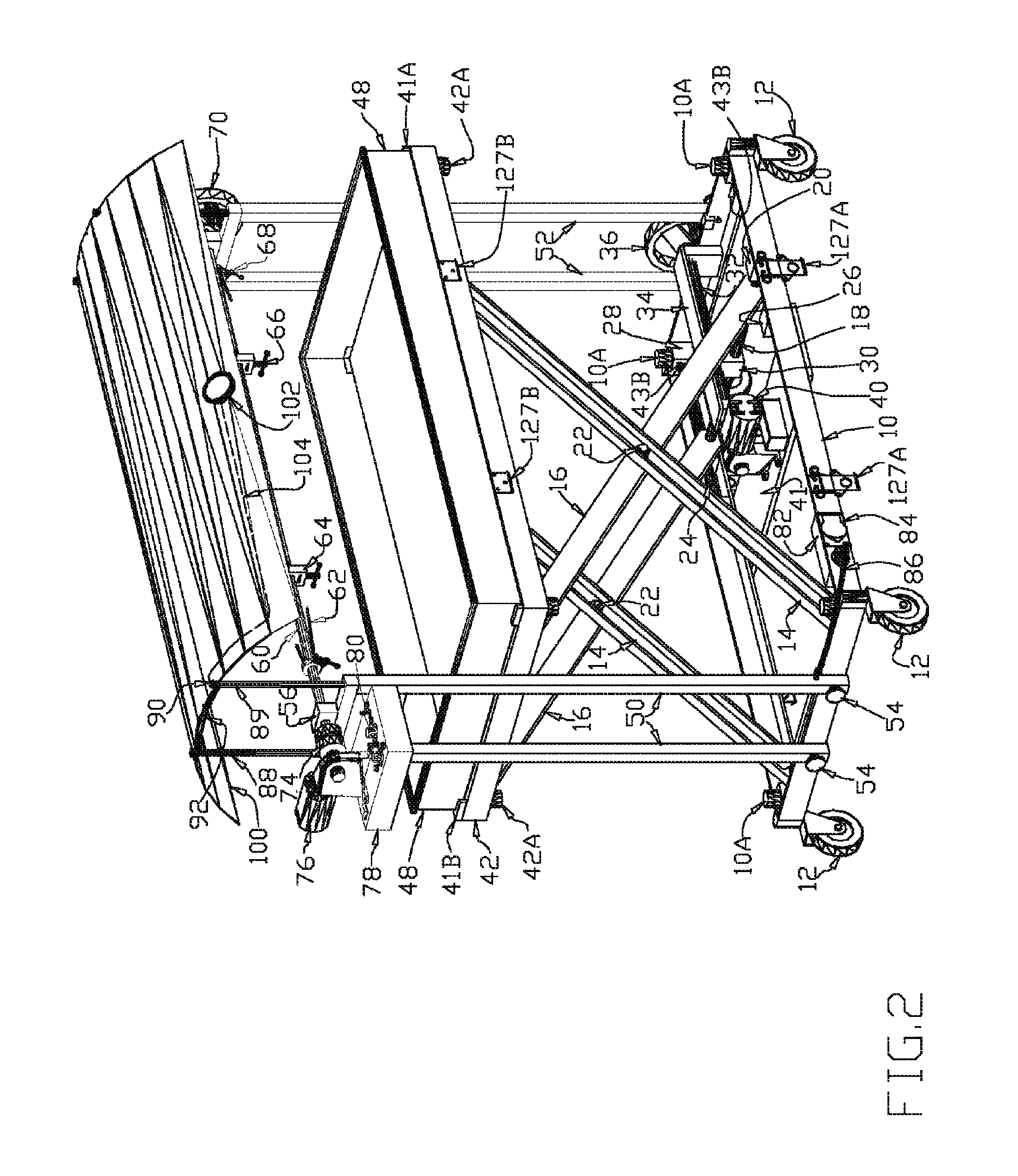

Collapsible barbeque with variable firebed position and method of use

InactiveUS7856924B1Easy to adjustLow profileDomestic stoves or rangesLighting and heating apparatusHeat flowThermostat

A cooking apparatus has a food support with food engaging structure, such as a rotisserie spit. A firebed is mounted under the food support to heat food at the food support. A heat reflective vault is mounted over the food support for reflecting radiant heat back down toward the food support. The vault extends over the food support while still providing access from the side. A drive mechanism can vertically adjust the firebed to adjust heat flowing toward the food support. An elevator motor may be coupled to the drive mechanism for vertically positioning the firebed. A thermostat responsive to heat from the firebed and coupled to the elevator motor can control elevation of the firebed.

Owner:STIHI DORU

Power saving automatic zoned dryer apparatus and method

InactiveUS6877247B1Eliminates and greatly reduces needImprove paper qualityDrying solid materials with heatDrying gas arrangementsAuto regulationEngineering

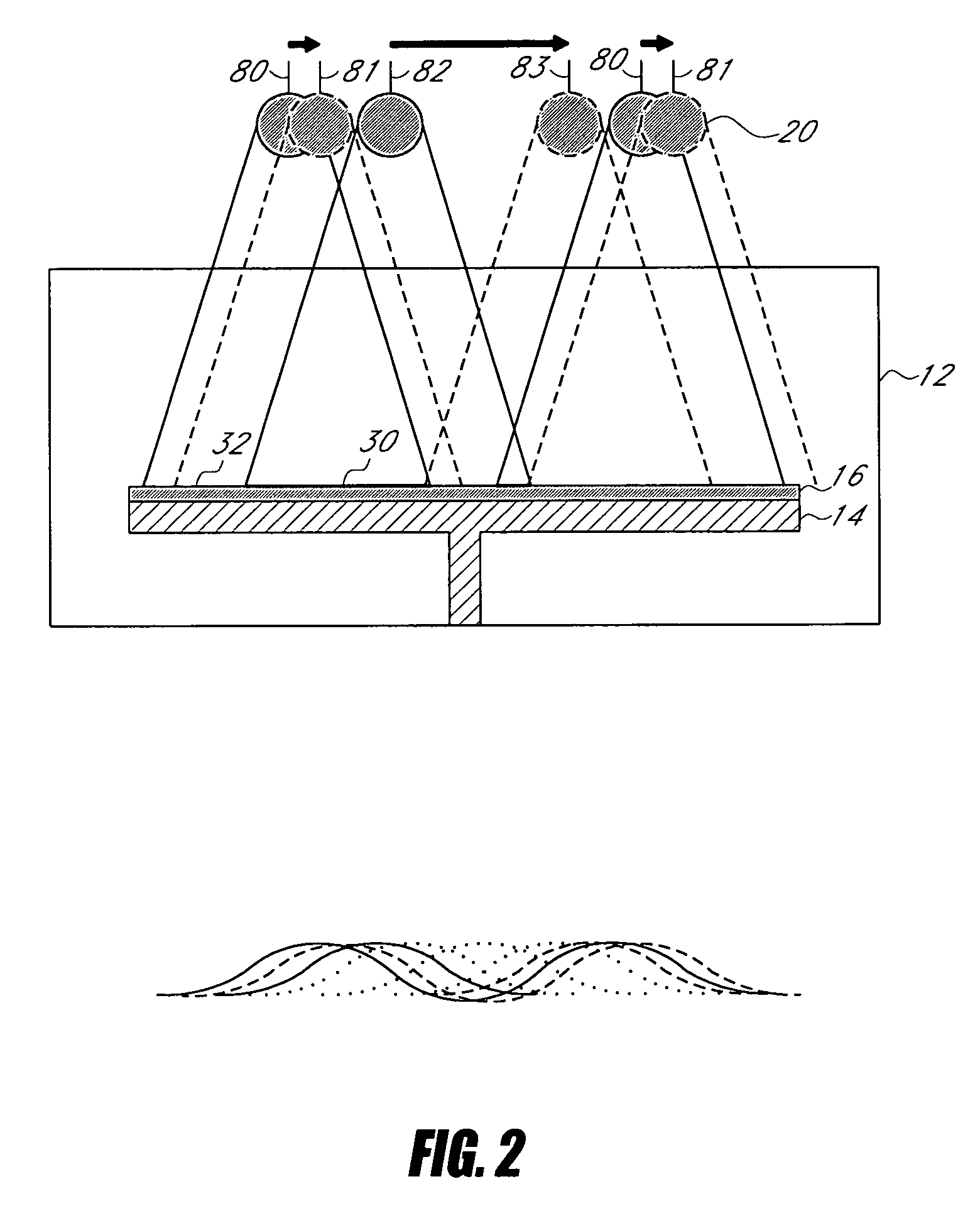

A computer controlled power saving automatic zoned dryer for a printing press has a dryer head facing the substrate travel path, having a multiplicity of IR lamps connected individually or in groups to form a plurality of heating zones running longitudinally and each extending laterally side by side across the substrate travel path. The radiant heat output of each heating zone is controlled separately by means of a control unit connected to a power supply. The control unit individually regulates output of the heating zones. Unneeded zones are turned off to reduce cost of power and conserve energy. A plurality of heat sensors spaced laterally across the substrate path measure the surface temperature of substrate heated areas corresponding to the heating zones being operated and maintain an automatic set point temperature. The temperature of each individual heated area can be regulated automatically by adjusting the output of its heating zone whereby printed substrates having a more even temperature profile are delivered. In an alternate manual mode any zone can be set independently to operate at any percentage of full available power from zero to 100%. Separate high velocity air scrubbers and additional air extraction are used to enhance the total drying effect of the zoned dryer assembly.

Owner:PRINTING RES

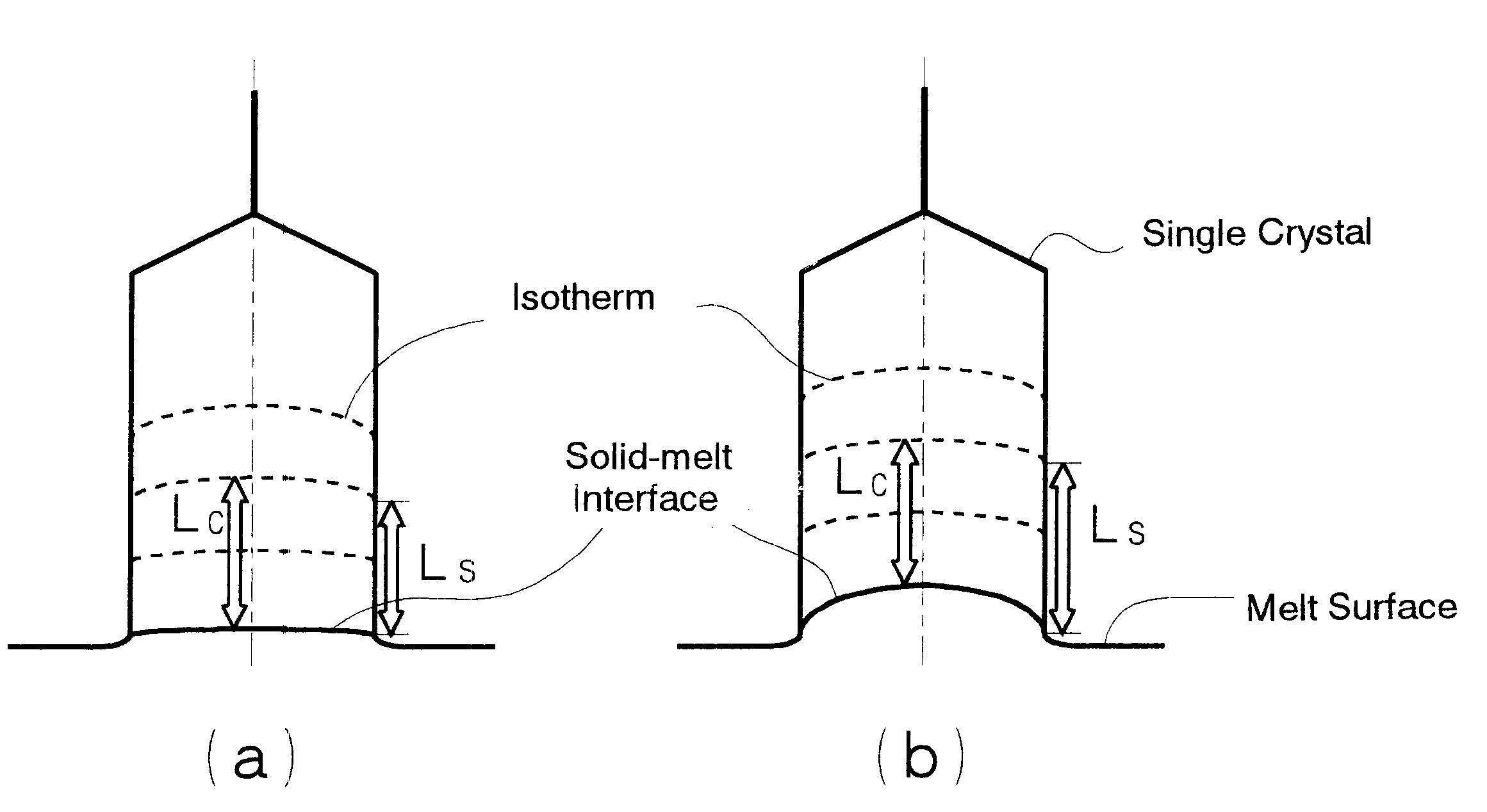

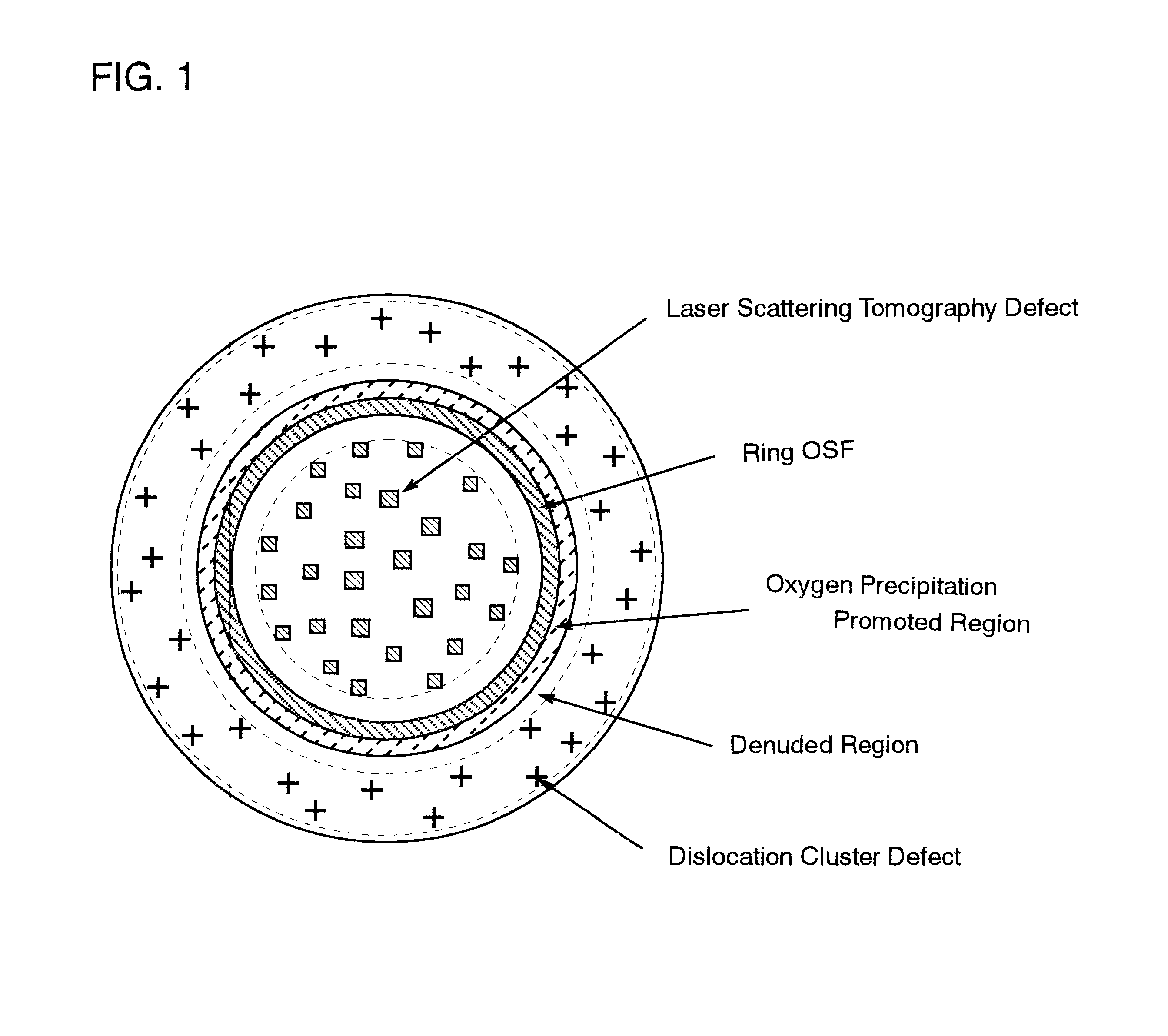

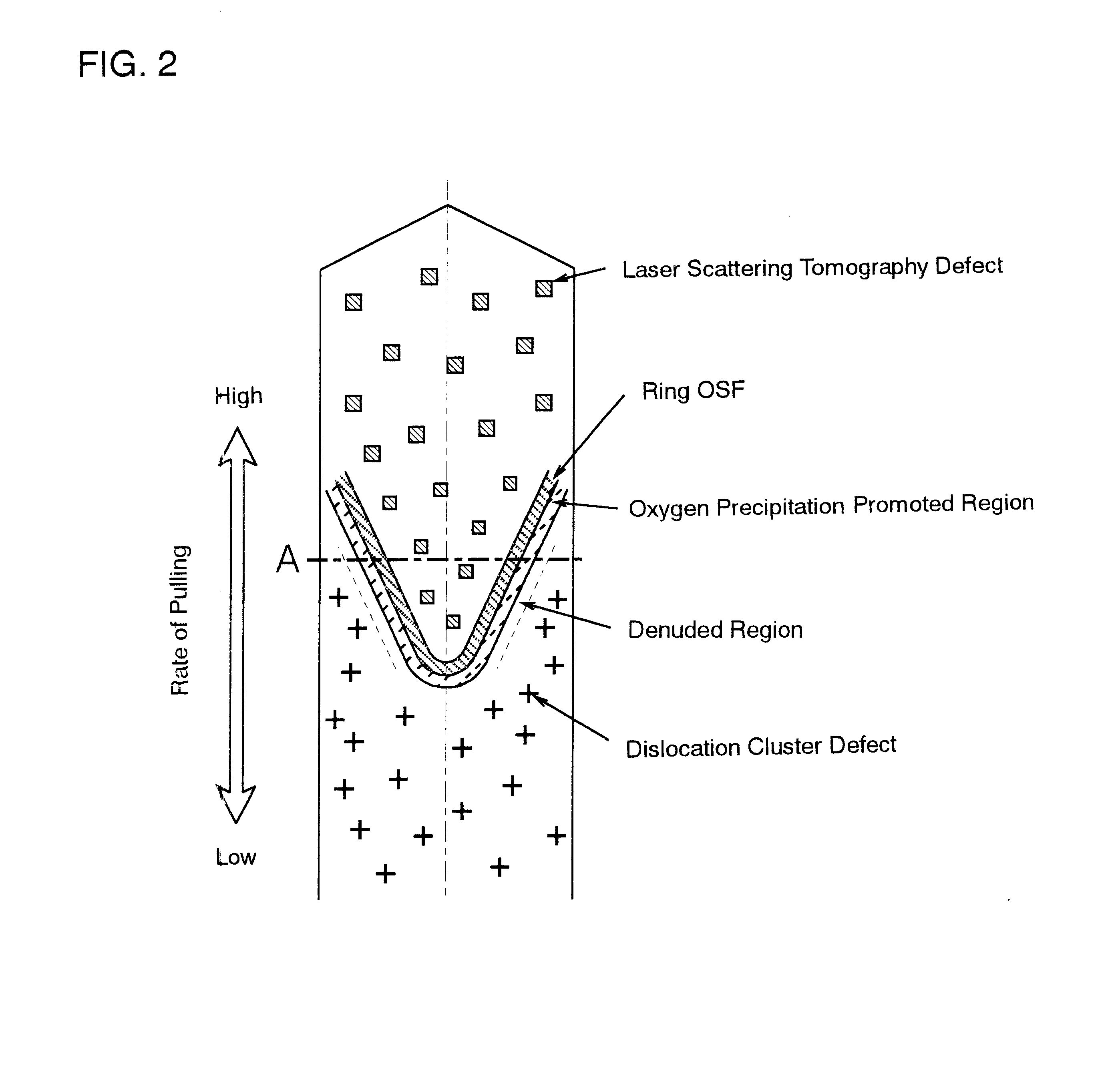

Method of producing high-quality silicon single crystals

InactiveUS6458204B1Polycrystalline material growthSemiconductor/solid-state device manufacturingLaser scatteringSingle crystal

A method of producing high-quality and large-diameter single crystals by the Czochralski method is disclosed which can provide wafers with a minimized number of such grown-in defects as dislocation clusters and laser scattering tomography defects. Specifically, it is a method of producing silicon single crystals which comprises carrying out the crystal pulling while maintaining the solid-melt interface during pulling in the shape of an upward convex with the central portion of the interface being higher by at least 5 mm than the peripheral region thereof and while applying a magnetic field, and optionally in addition to the above, while maintaining the temperature gradient in the direction of axis of pulling in the peripheral region at a level lower than that in the central portion in the range of from the melting point to 1,200° C. In this case, it is desirable that the portion of the single crystal surface lying at least 50 mm above the melt surface be shielded from direct radiant heat from the heater and / or crucible wall, that a horizontal magnetic field of 0.08 to 0.3 T be applied in parallel with the melt surface or a cusped magnetic field showing an intensity of 0.02 to 0.07 T at a crucible wall site on the melt surface be applied and that the crucible be rotated at a speed of not more than 5 min-1 and the single crystal at a speed of not less than 13 min-1.

Owner:SUMITOMO MITSUBISHI SILICON CORP

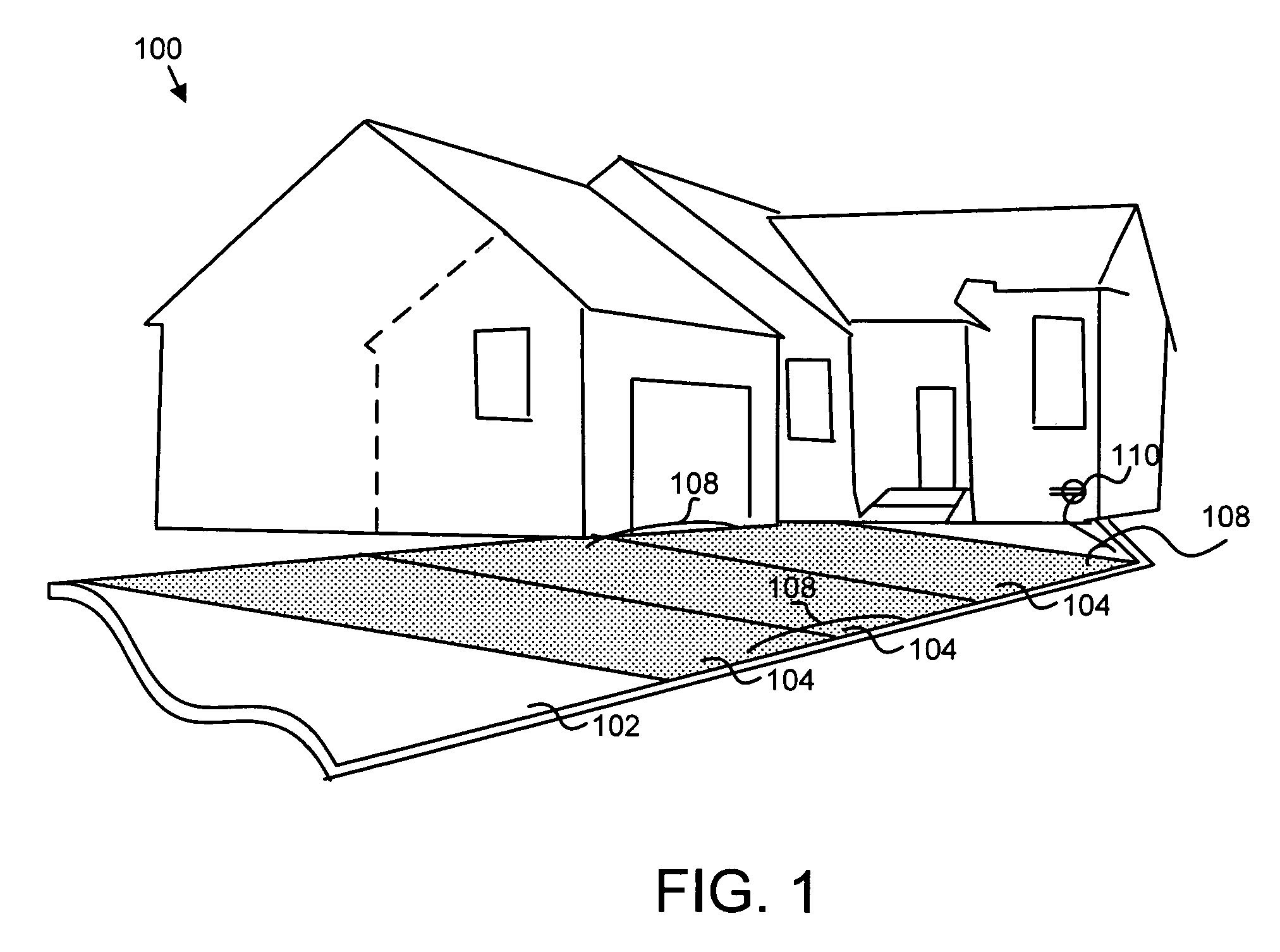

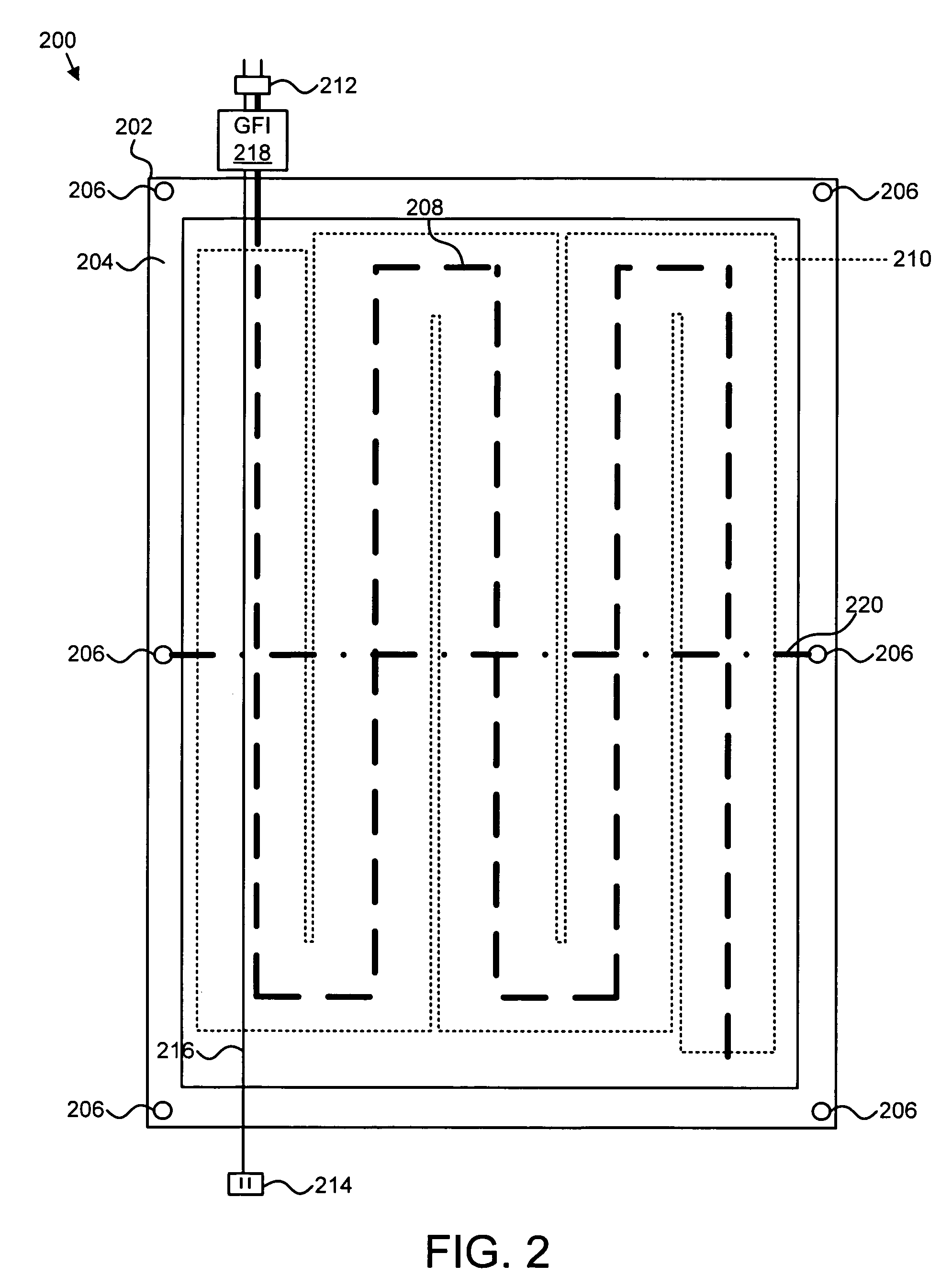

Modular heated cover

The modular heated cover is disclosed with a first pliable outer layer and a second pliable outer layer, wherein the outer layers provide durable protection in an outdoor environment, an electrical heating element between the first and the second outer layers, the electrical heating element configured to convert electrical energy to heat energy, and a thermal insulation layer positioned above the active electrical heating element. Beneficially, such a device provides radiant heat, weather isolation, temperature insulation, and solar heat absorption efficiently and cost effectively. The modular heated cover quickly and efficiently removes ice, snow, and frost from surfaces, and penetrates soil and other material to thaw the material to a suitable depth. A plurality of modular heated covers can be connected on a single 120 Volt circuit or on a single 240 Volt circuit protected by a 20 Amp breaker.

Owner:GREENHEAT IP HLDG LLC

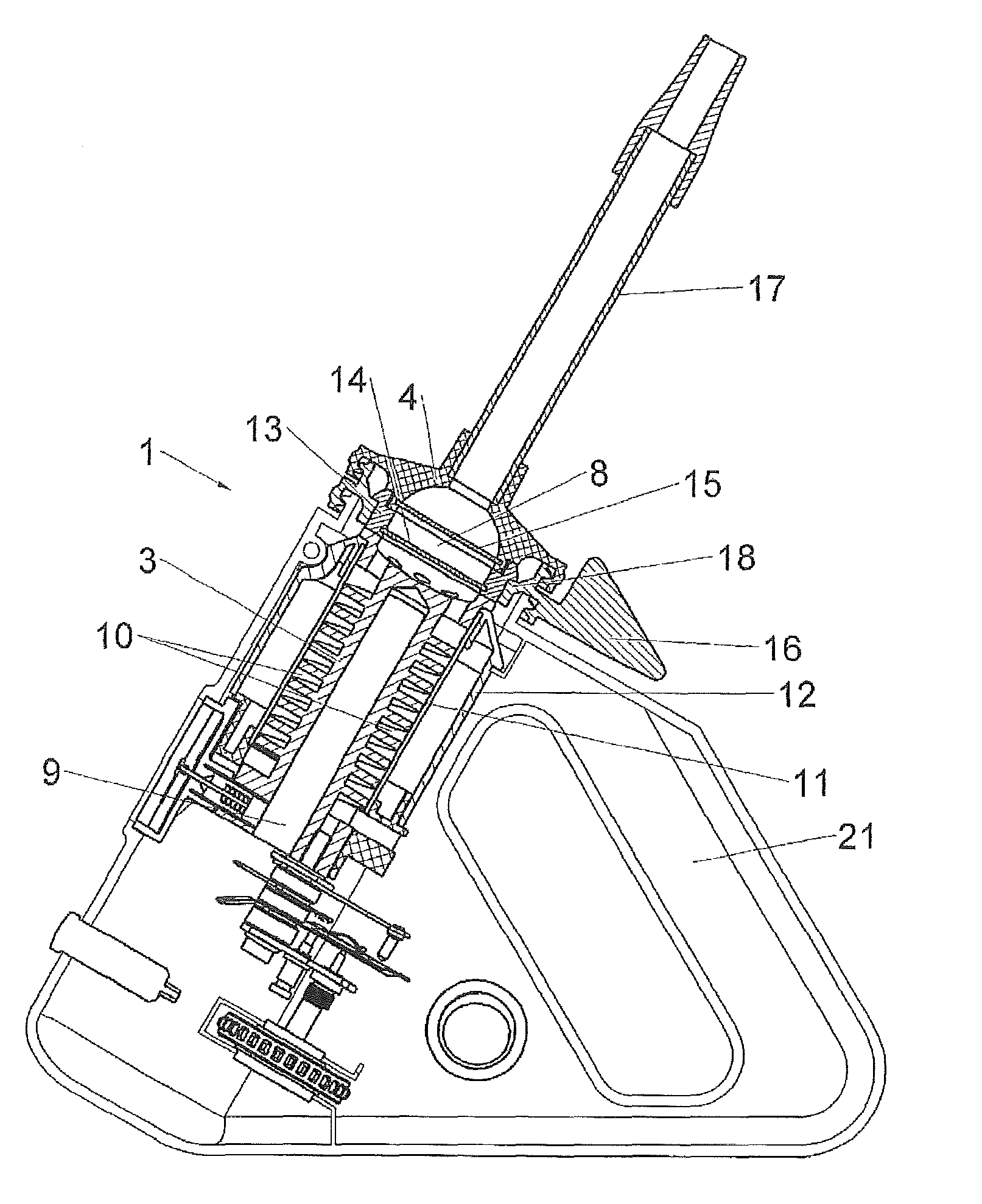

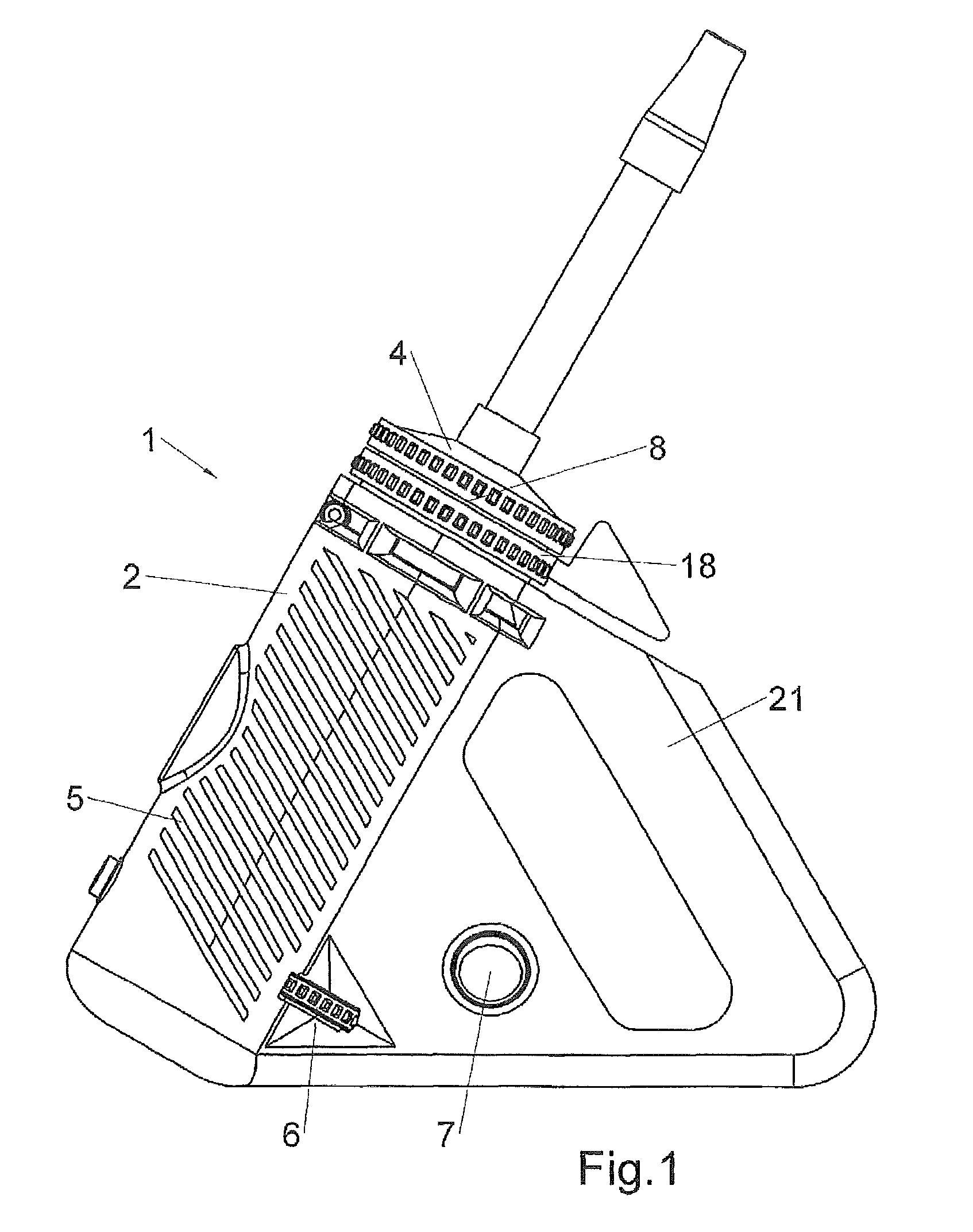

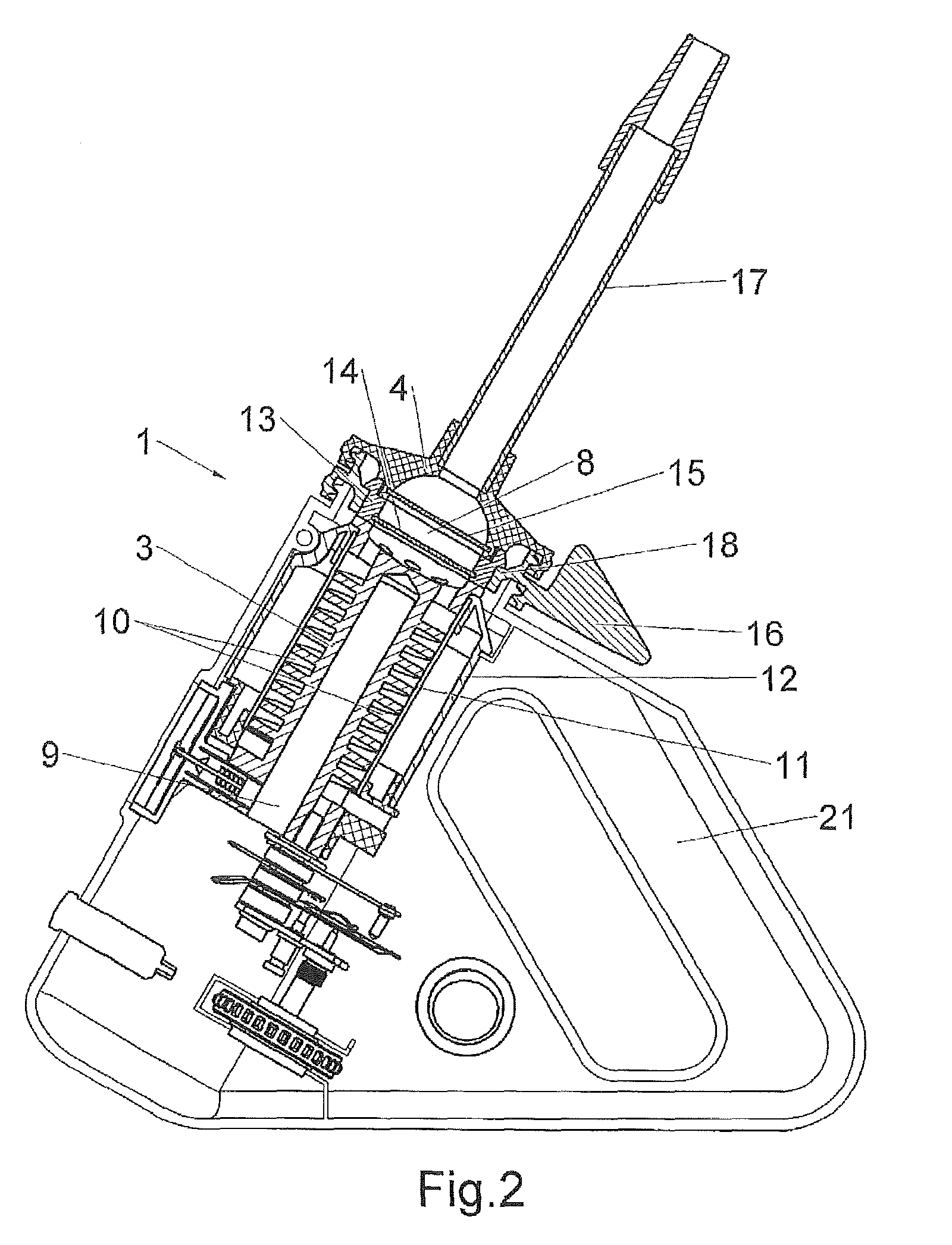

Vaporizer with combined air and radiation heating

A hot air extraction vaporizer that is provided with a heat exchanger, a filling chamber for accommodating a substance generating an aerosol when subjected to heat, and a vaporizer outlet for inhaling the aerosol / air mixture. The heat exchanger is in a thermally conductive connection with the filling chamber that when heated up subjects the substance to radiant heat. The heat exchanger is provided with at least one airflow channel generating a hot airflow. The filling chamber comprises at least one of airflow passages and a mesh allowing the hot airflow to pass through the filling chamber and the substance provided therein.

Owner:STORZ & BICKEL GMBH

Method for reducing the appearance of skin cellulites using vacuum radiant heat and mechanical manipulation

InactiveUS6926683B1Effectively combat effectReducing and combating celluliteAnti-cellulite devicesPneumatic massageMedicineRadiant heat

A massaging apparatus that includes at least one massaging element in a housing and extending therefrom for use in manipulating a subject's tissue and further including a radiant heat source.

Owner:TENSOR TECH

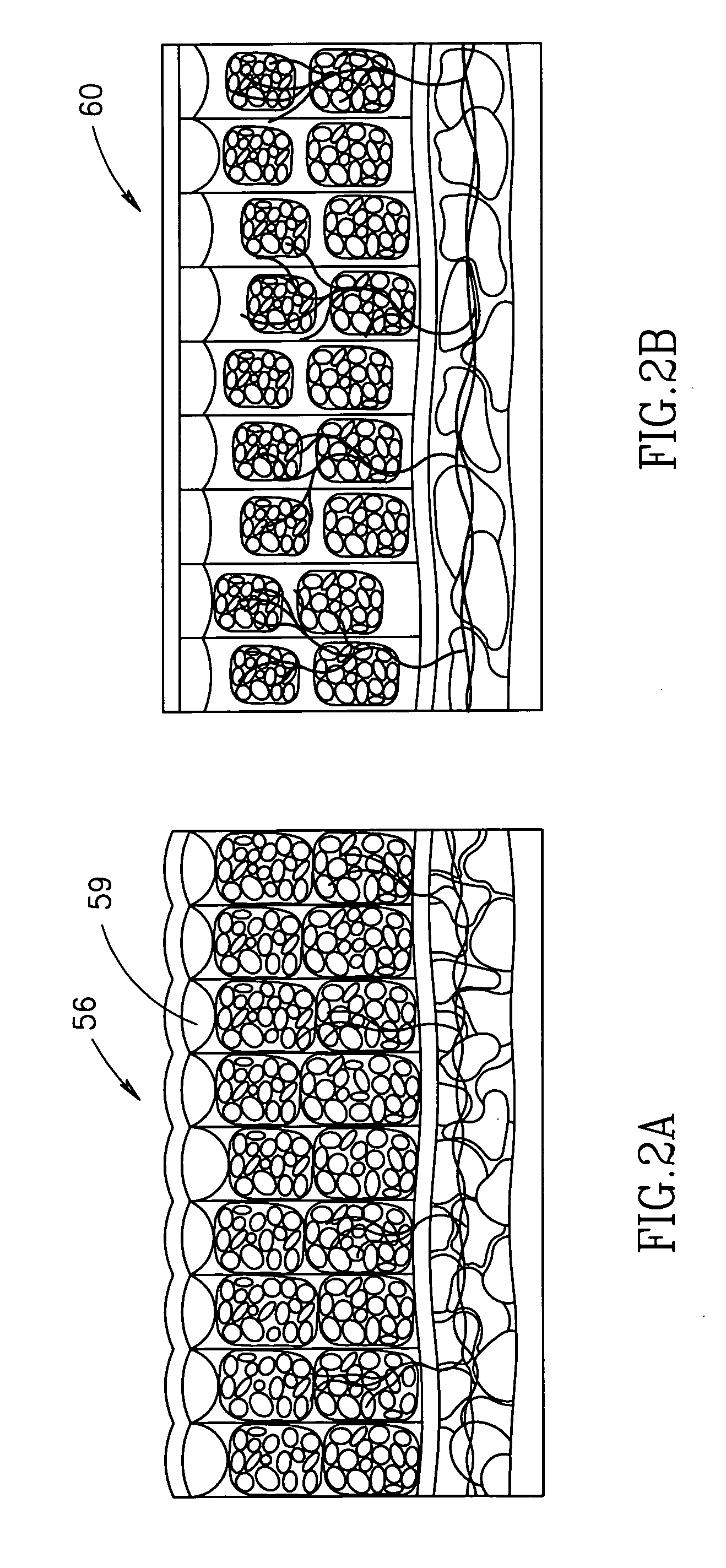

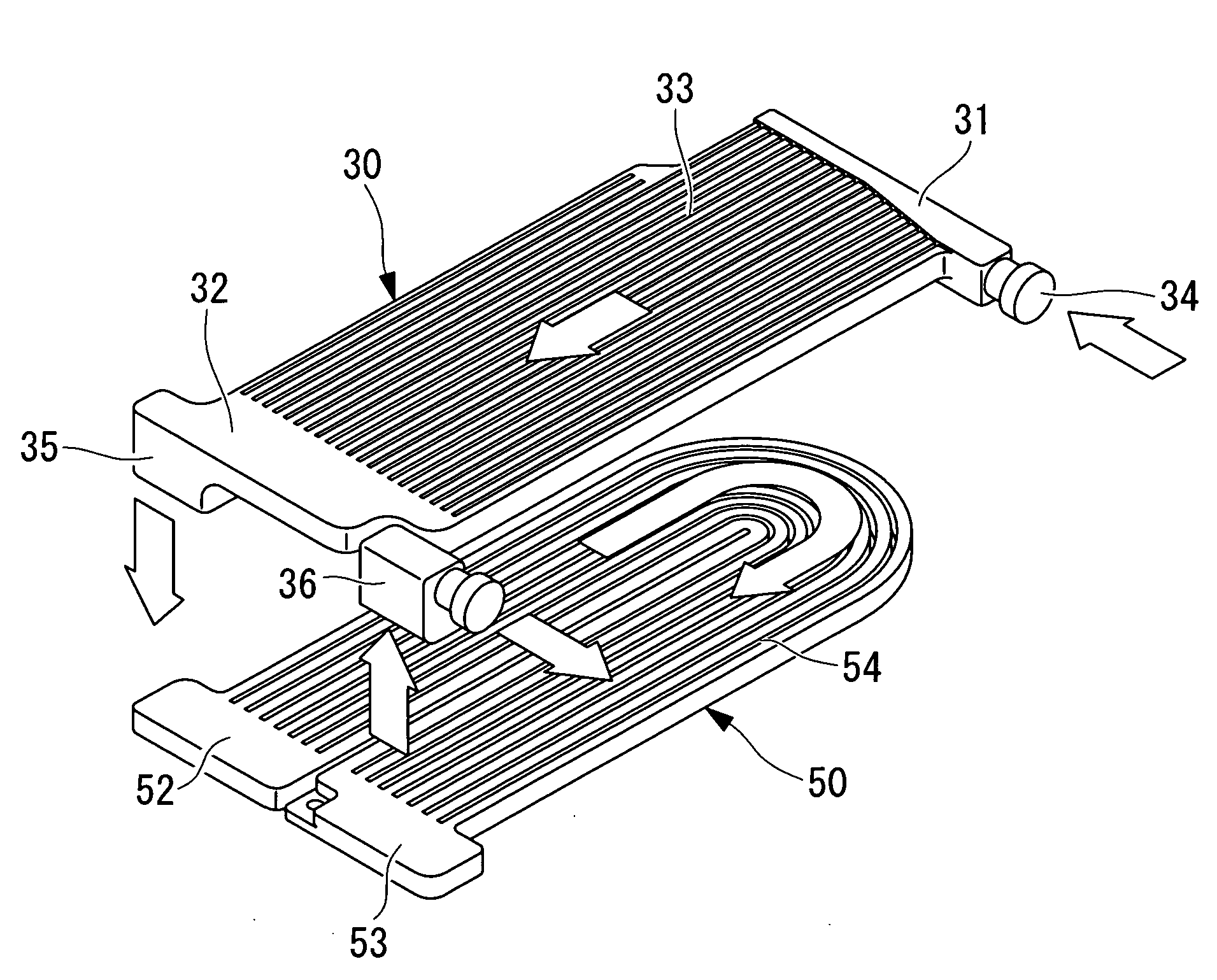

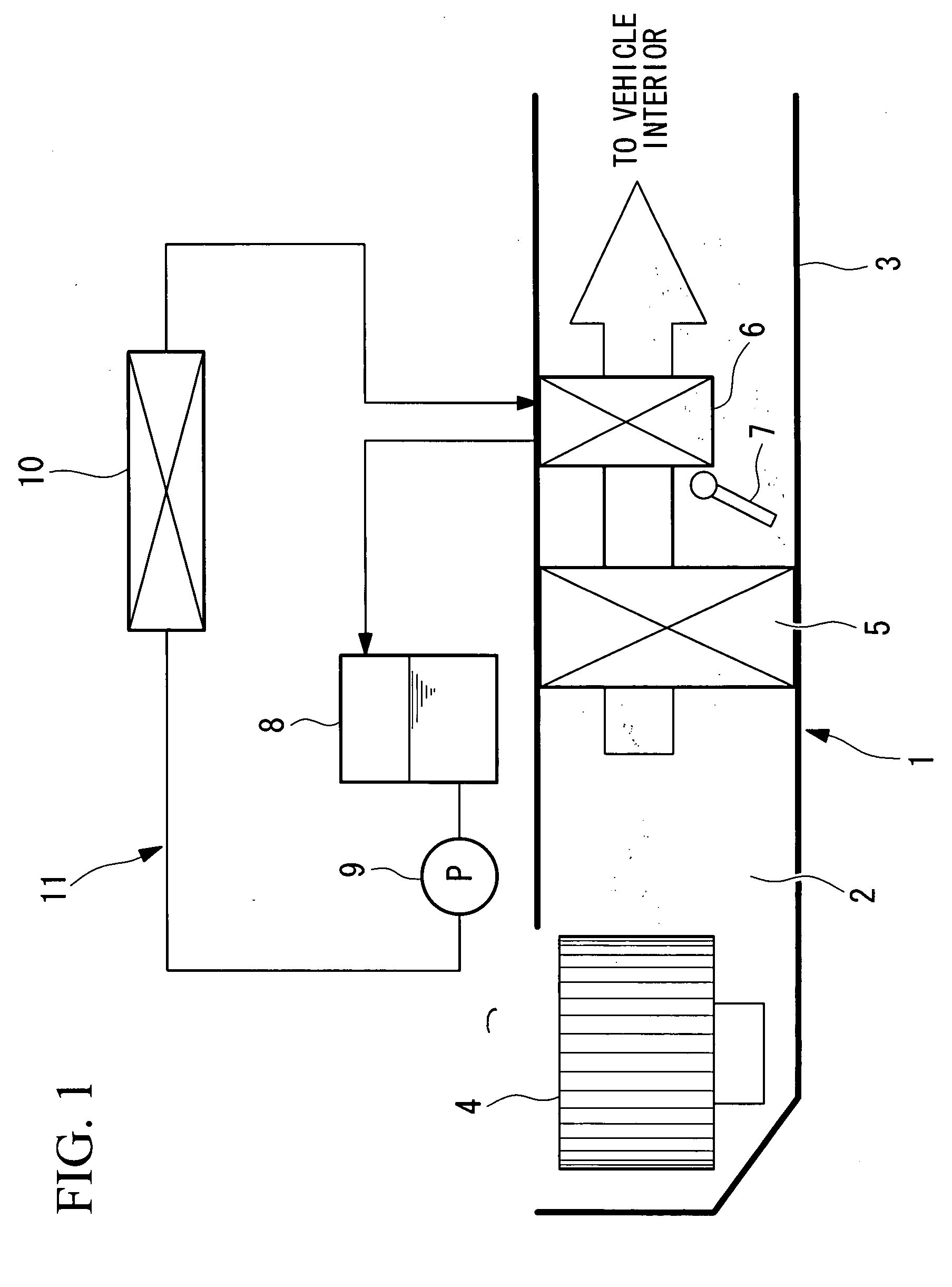

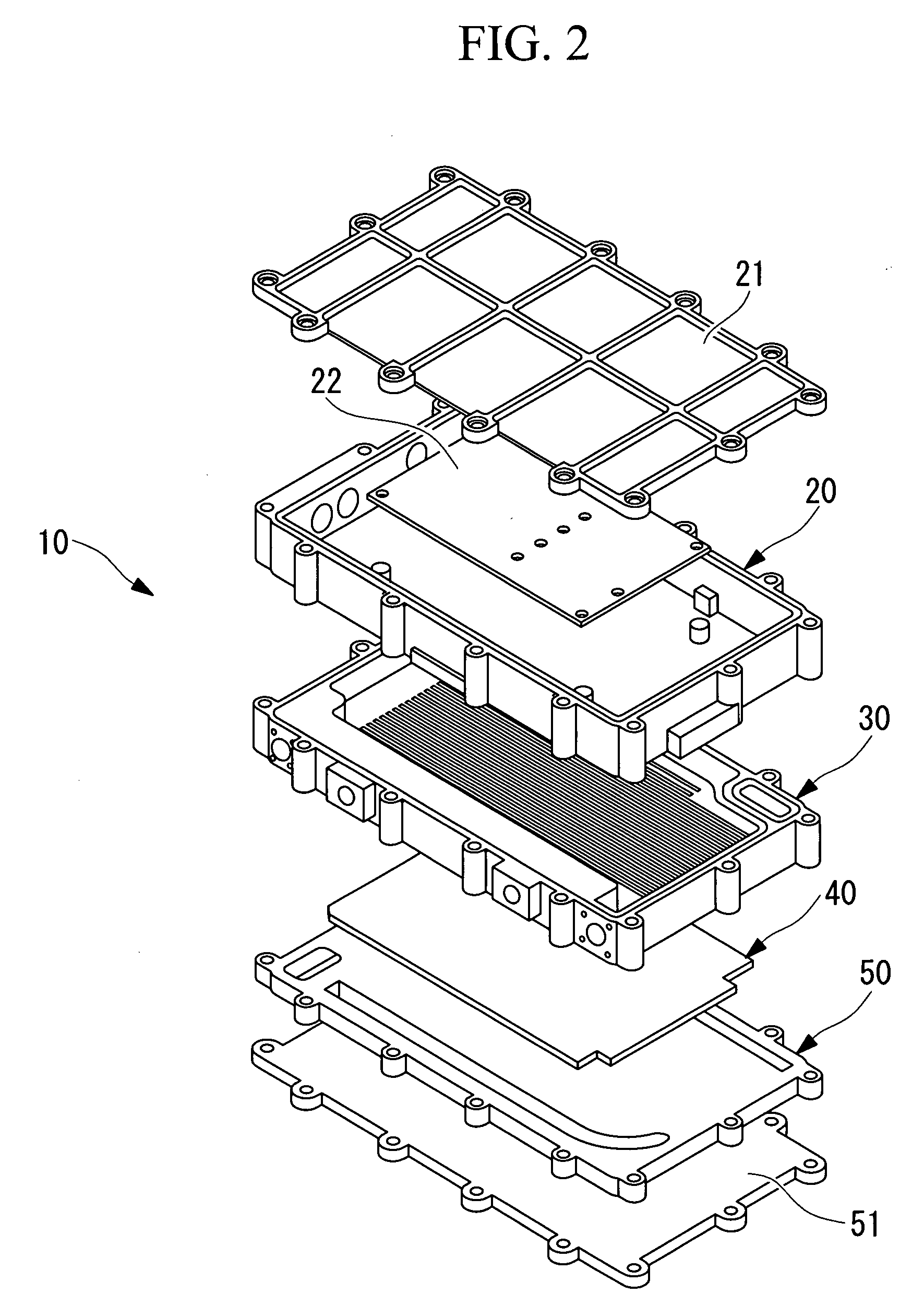

Heat-transer-medium heating apparatus and vehicular air-conditioning

ActiveUS20080053981A1Superior ease of assemblyMaintain good propertiesOhmic-resistance heating detailsImmersion heating arrangementsEngineeringRadiant heat

The invention provides a heat-transfer-medium heating apparatus using a PTC heater and a vehicular air-conditioning apparatus using such a heating apparatus, which have superior heat-conducting properties and ease of assembly, which can improve the heating capacity, and which can ensure sufficient electrical insulation. Included are a PTC heater having a stacked construction in which an electrode plate, an incompressible insulating layer, and a compressible heat-conducting layer are sequentially provided on each side of a PTC element so as to sandwich the PTC element; and heat-transfer-medium circulating boxes, respectively disposed in close contact with the two surfaces of the PTC heater and having circulating channels for the heat-transfer-medium formed therein. The heat transfer medium circulating inside the heat-transfer-medium circulating boxes is heated by radiant heat from the two surfaces of the PTC heater.

Owner:MITSUBISHI HEAVY IND LTD

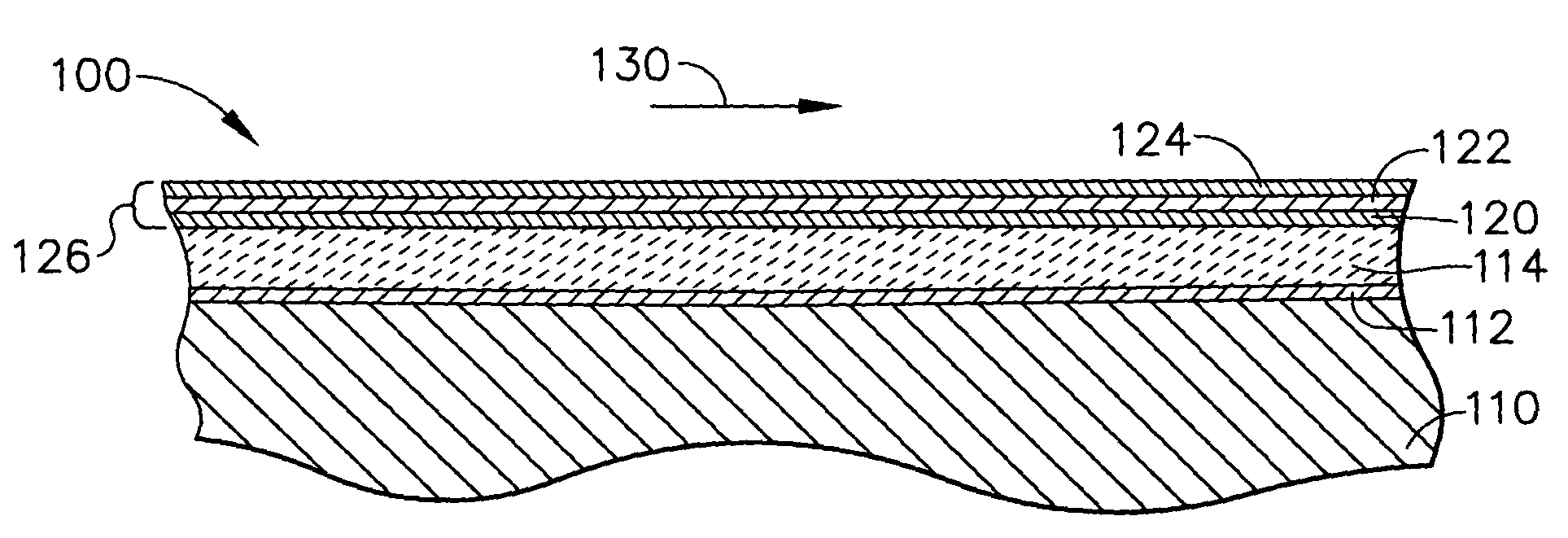

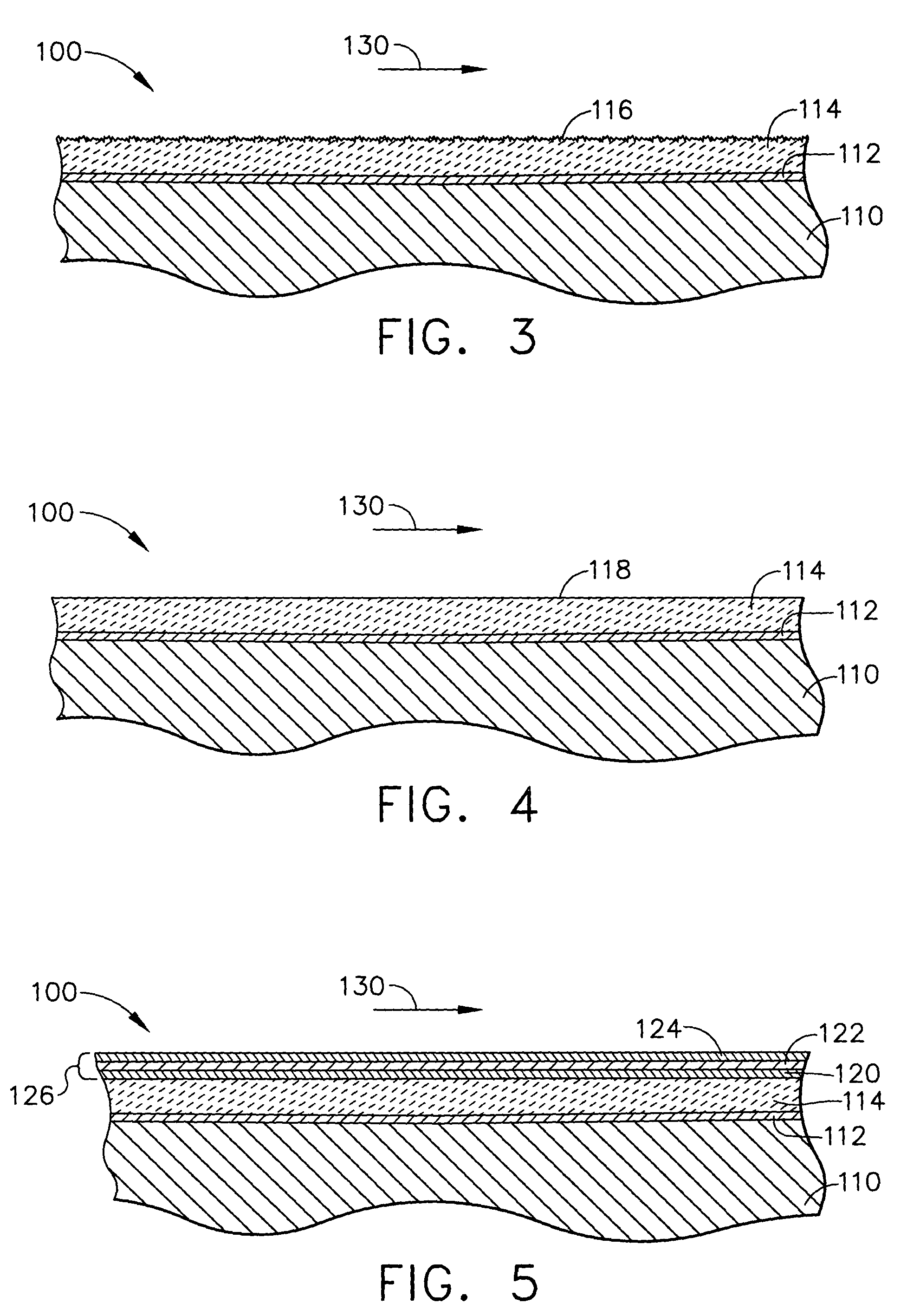

Optical reflector for reducing radiation heat transfer to hot engine parts

InactiveUS7208230B2Prolong lifeLess mean timePropellersMagnetic materialsOptical reflectionCoating system

A high temperature gas turbine component for use in the gas flow path that comprises a specular optical reflector coating system. A thin specular optical reflector coating system is applied to the gas flow path of the component, that is, the surface of the component that forms a boundary for hot combustion gases. The component typically includes a thermal barrier coating overlying the high temperature metallic component that permits the component to operate at elevated temperatures. The thermal barrier coating must be polished in order to provide a surface that can suitably reflect the radiation into the gas flow path. The thin reflector coating system comprises a thin high temperature and corrosion resistant refractory stabilizing layer, which is applied over a thin reflective metal layer, which is applied over a thin high temperature and corrosion resistant refractory sealing layer. The coating system is applied over the polished thermal barrier coating by a process that can adequately adhere the reflector to the polished surface without increasing the roughness of the surface. The coating system reflects radiation back into the hot gas flow path or into the atmosphere. The reflected radiation is not focused onto any other hardware component. The design of the component is such that the radiation is returned to the gas flow path or sent to the atmosphere rather than absorbed into a component that only serves to increase the temperature of such a component.

Owner:GENERAL ELECTRIC CO

Graphite rotary tube furnace

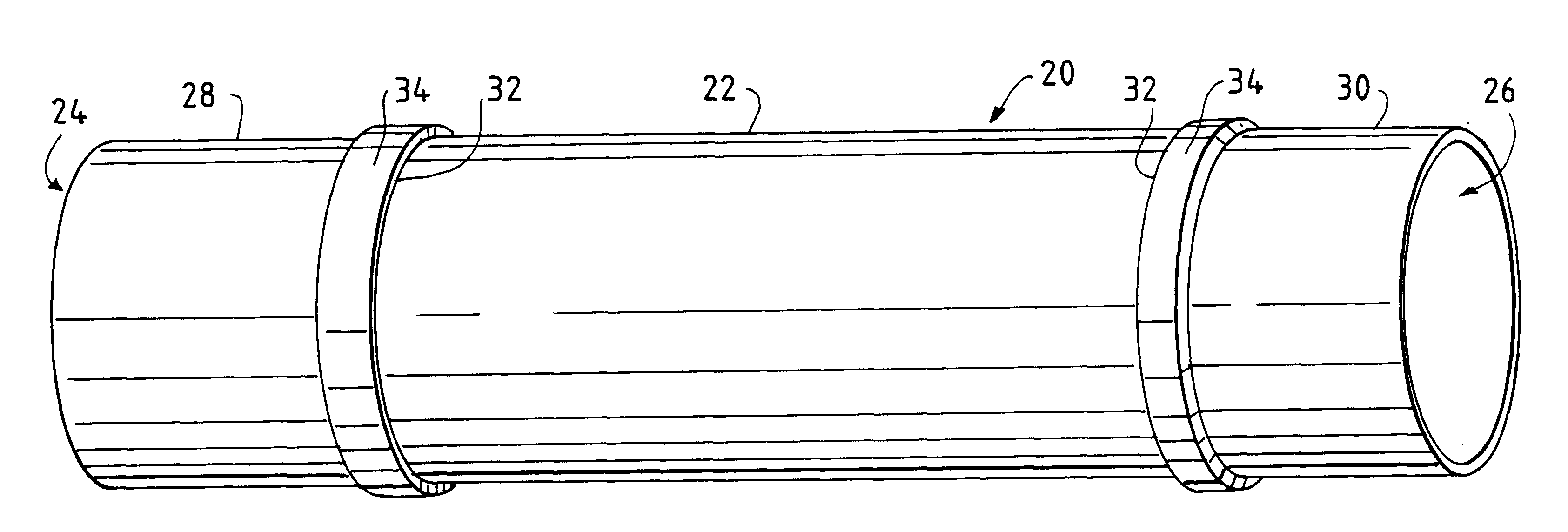

InactiveUS6042370AMinimizing radiation heat lossStable temperatureRotary drum furnacesCharge supportsRadiative heat lossRadiant heat

A rotary tube furnace suitable for operation in controlled atmospheres at temperatures in the range of 1500 DEG to 2800 DEG comprises a generally horizontal rotatable graphite tube slidably supported on water-cooled split ring graphite bearings. The graphite tube is rotated by means of a stainless steel drive plate and is contained within a flexible atmospheric sealing assembly and enclosure for the containment of a selected atmosphere around and within the tube and allows for the co-current or counter-current flow of gas during operation. Radiation baffles in the interior of the graphite tube inhibit radiant heat loss at the ends of the tube. The graphite tube may be constructed in two or more sections having threaded ends for ease of installation as well as removal or replacement for maintenance purposes. A heating section of the tube is heated by a plurality of graphite electrical heating elements contained within an insulated heating chamber.

Owner:HARPER INT CORP

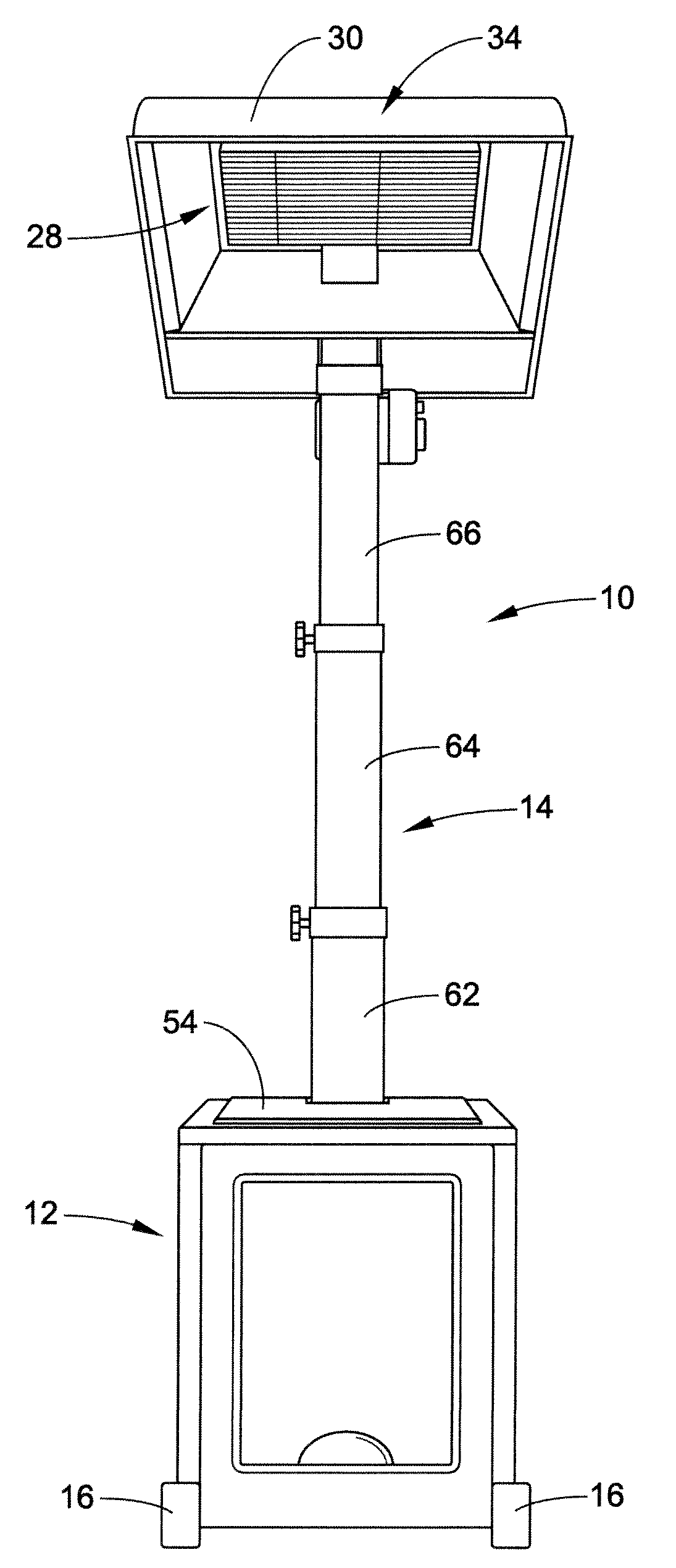

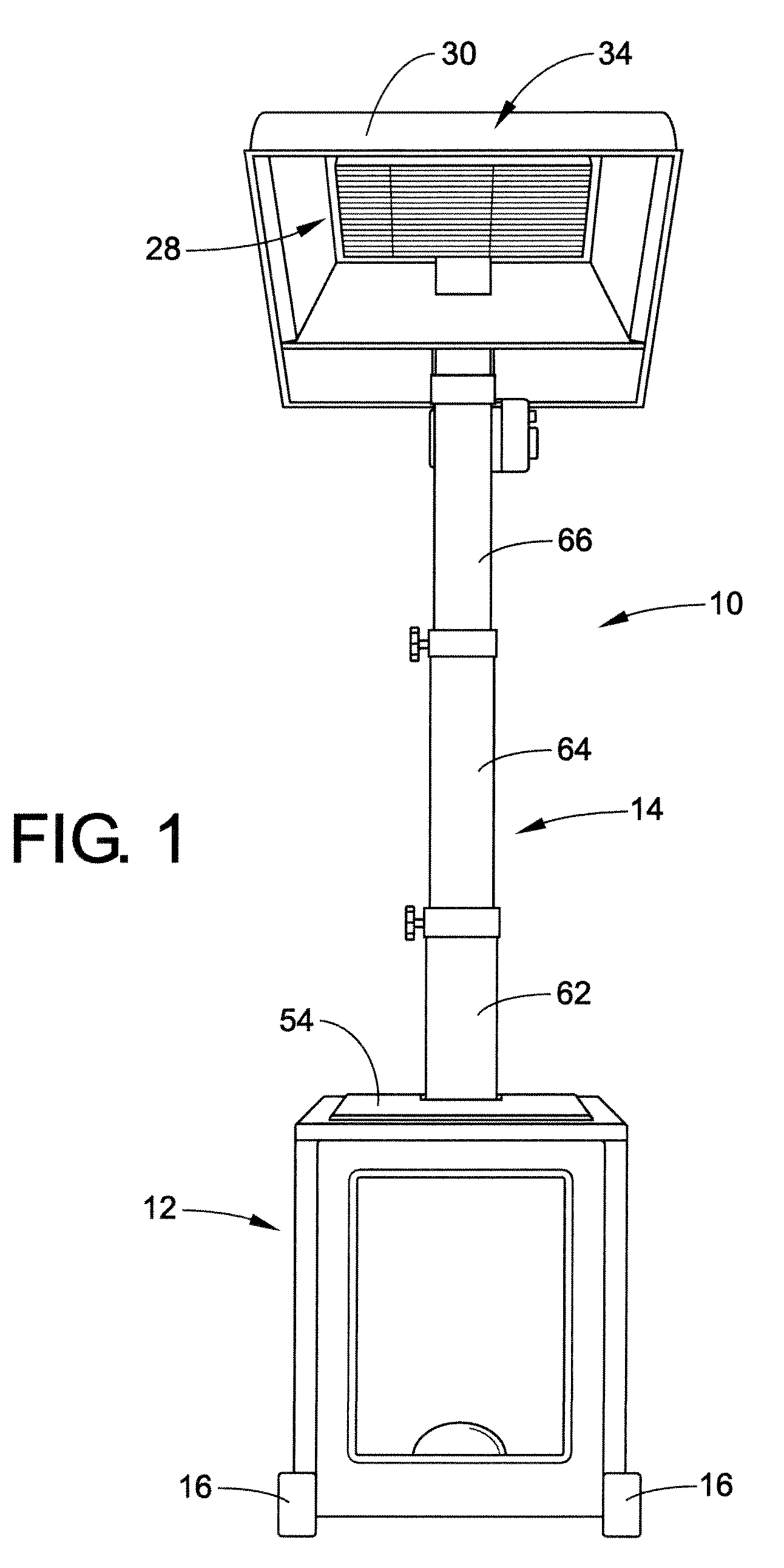

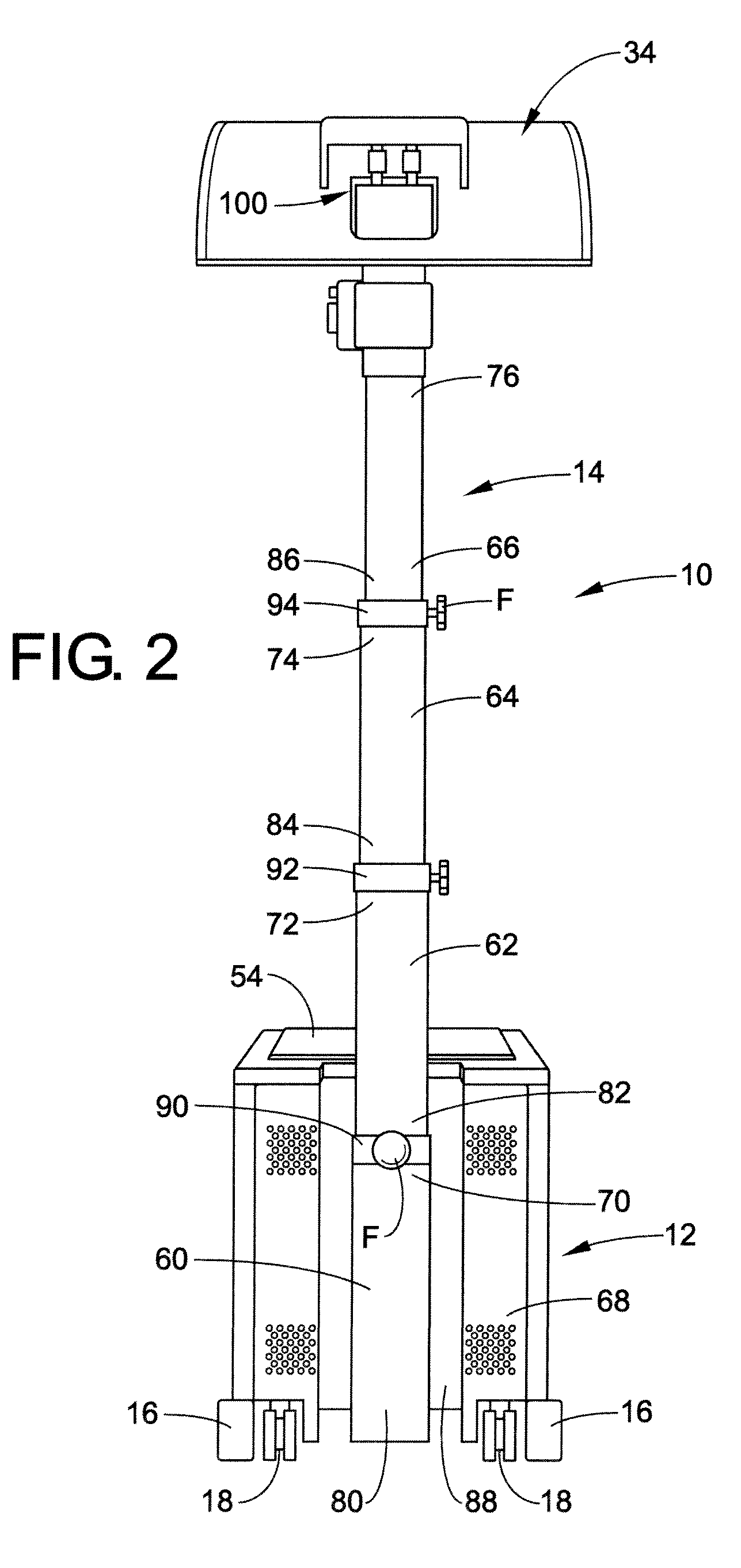

Portable collapsible radiant heater

InactiveUS20080152329A1Easy to storeVehicle headlampsDomestic stoves or rangesRadiant heaterEngineering

A portable, collapsible radiant heater includes a base and a support mounted to the base. The support has a collapsed position wherein the base is configured to at least partially receive the support, and an extended position wherein the support extends upwardly from the base. A heater-head for generating radiant heat is connected to the support. A reflector is mounted to one of the heater-head and the support. The reflector at least partially surrounds the heater-head for downwardly reflecting radiant heat generated by the heater-head. The reflector and heater-head are reciprocally movable between the collapsed position wherein the reflector and heater-head are in close proximity to the base and the extended position wherein the reflector and heater-head are distant from the base.

Owner:J F MESKILL ENTERPRISES

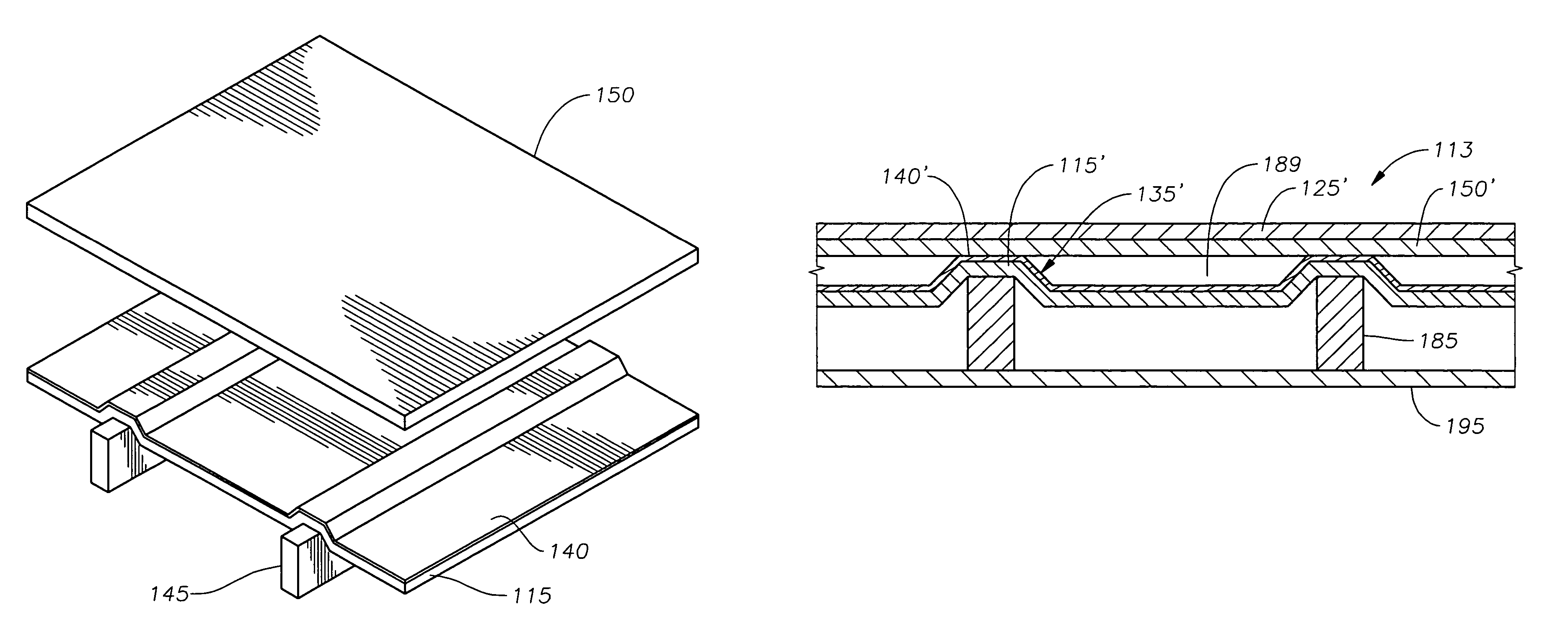

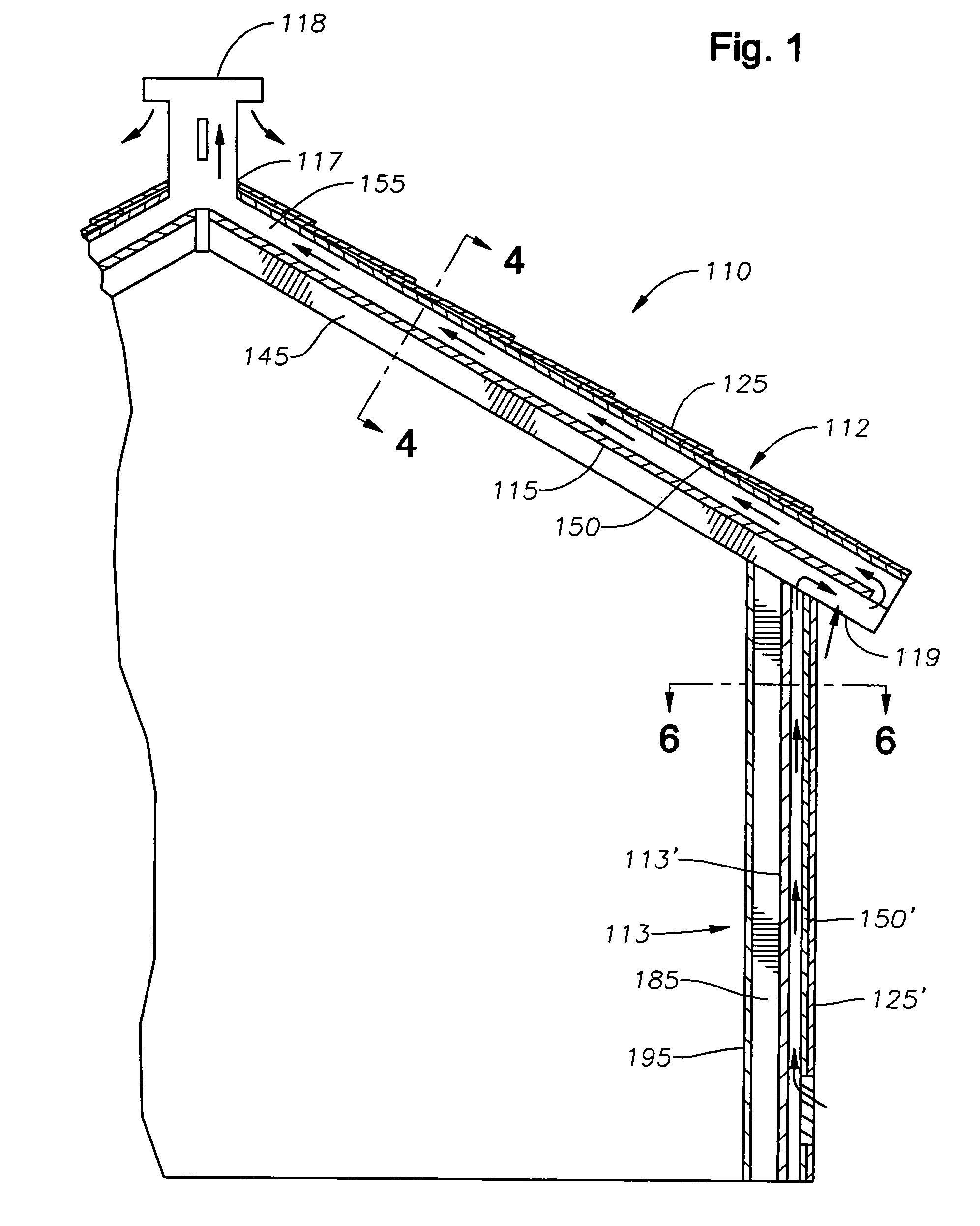

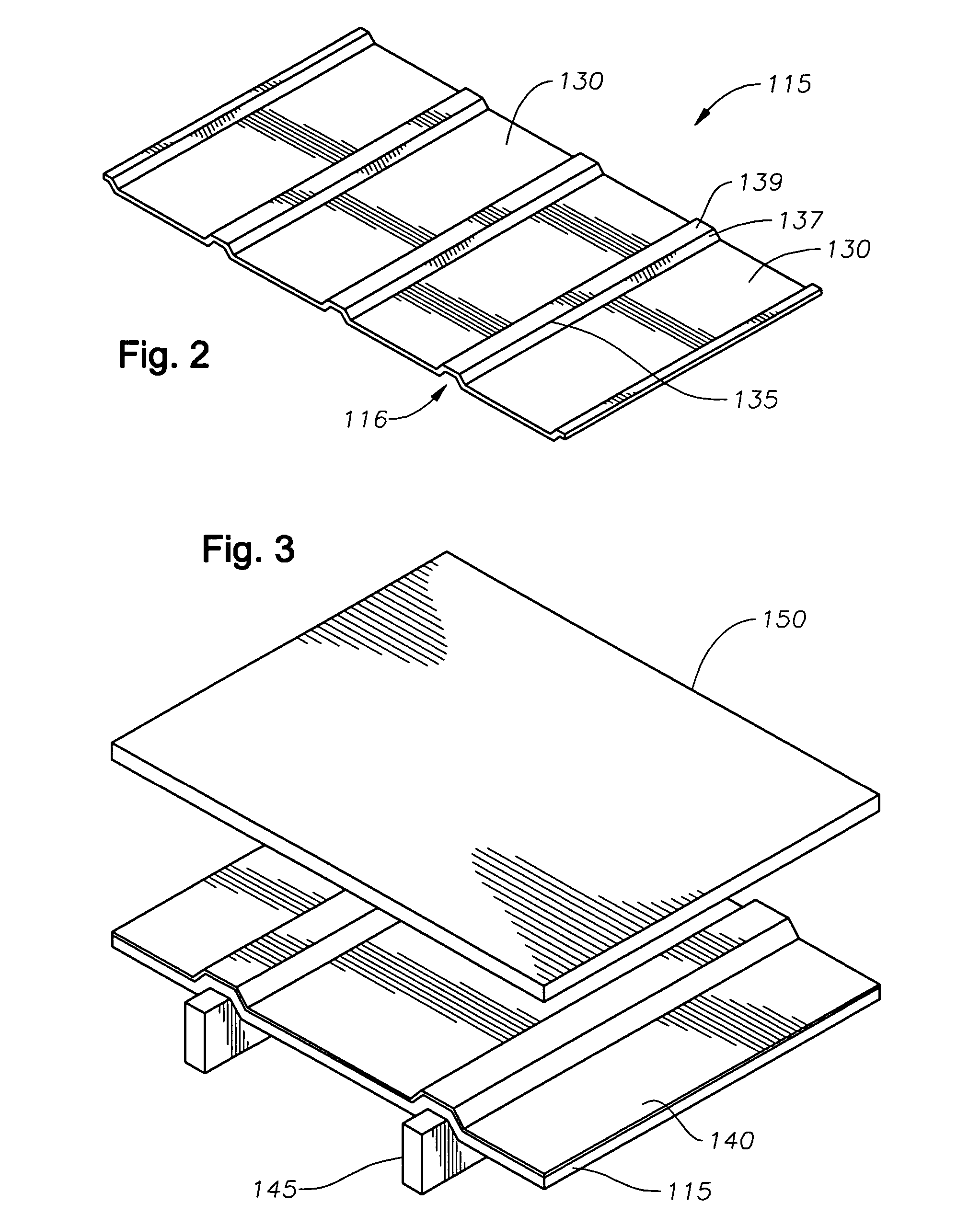

Thermal insulation for a building

An insulation system of a building having a plurality of spaced-apart support members has an insulator with a plurality of ribs are formed thereon. A concave portion of each rib receives one of the support members. A panel covers, and is secured to the support members. An exterior covering element is secured to an exterior side of the panel. A radiant heat barrier is bonded between the insulator and the panel. The insulator defines air ventilation channels between the foam insulator and the panel for venting air from building. An insulator assembly for a building has a sheet of foam insulation with a plurality of channels intermittently formed in the sheet of insulation. Each channel has a concave side and a convex side. The concave side is adapted to receive a support member of the building. A radiant heat barrier is bonded to a surface of the foam insulation.

Owner:ELLIS BILLY

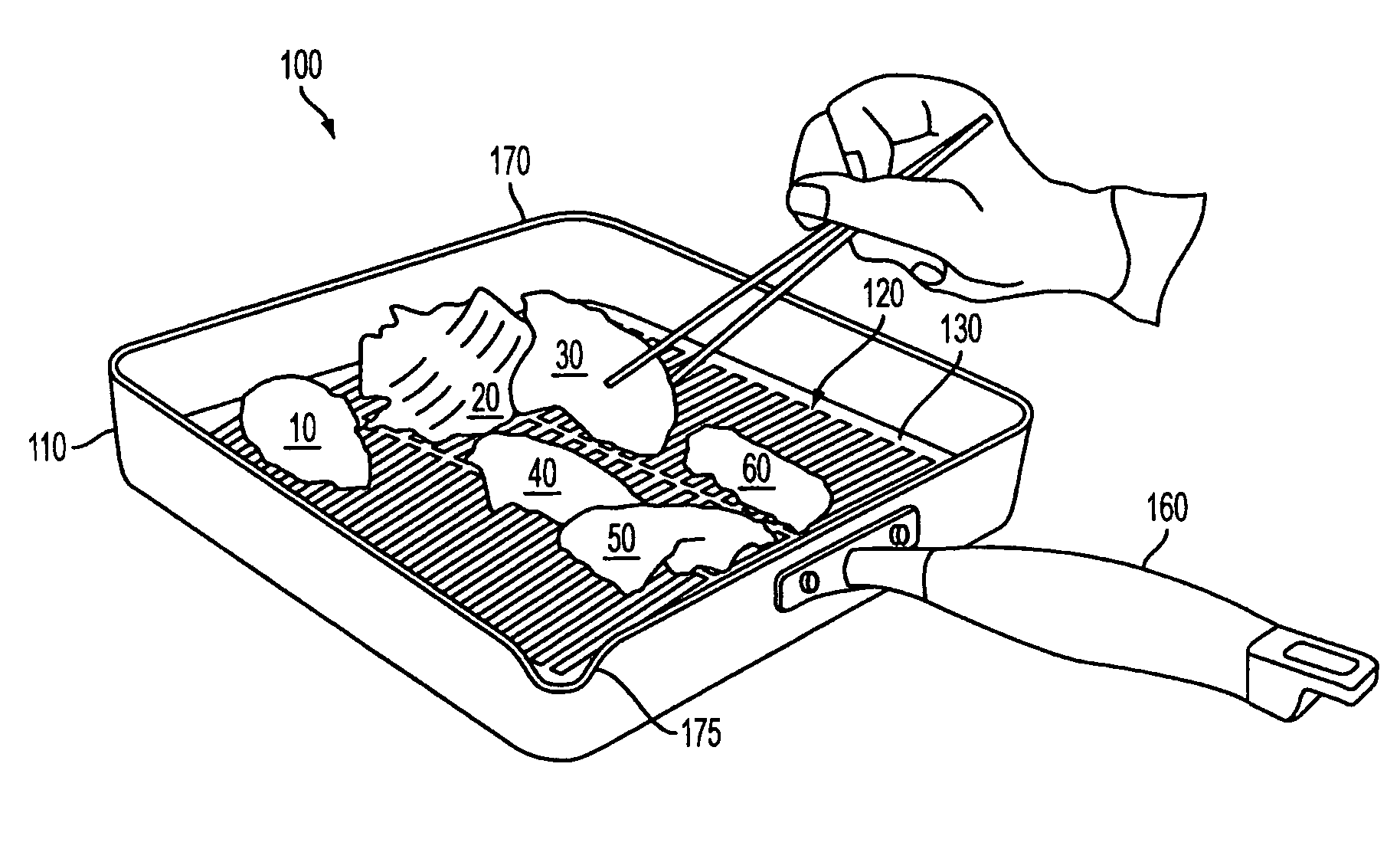

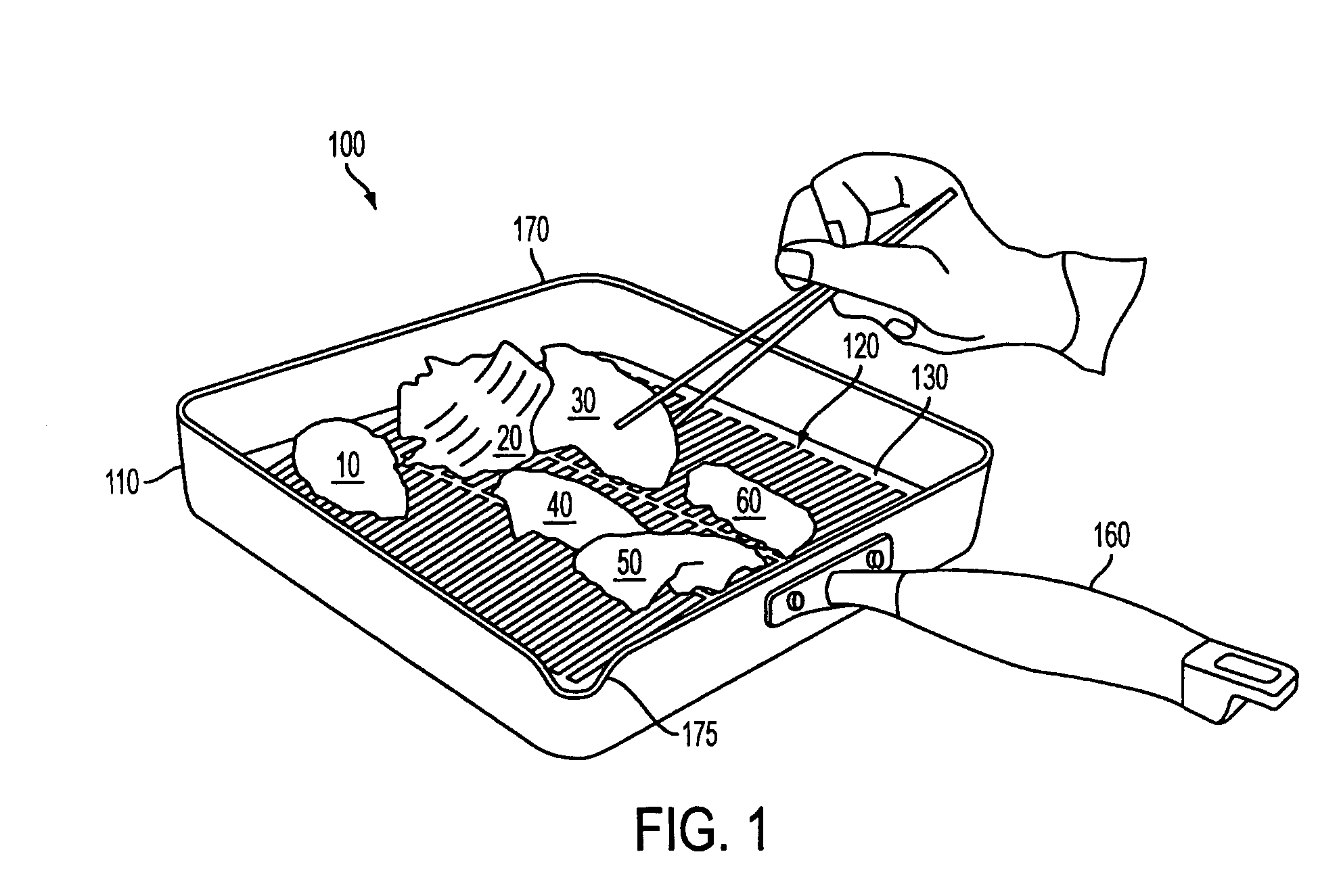

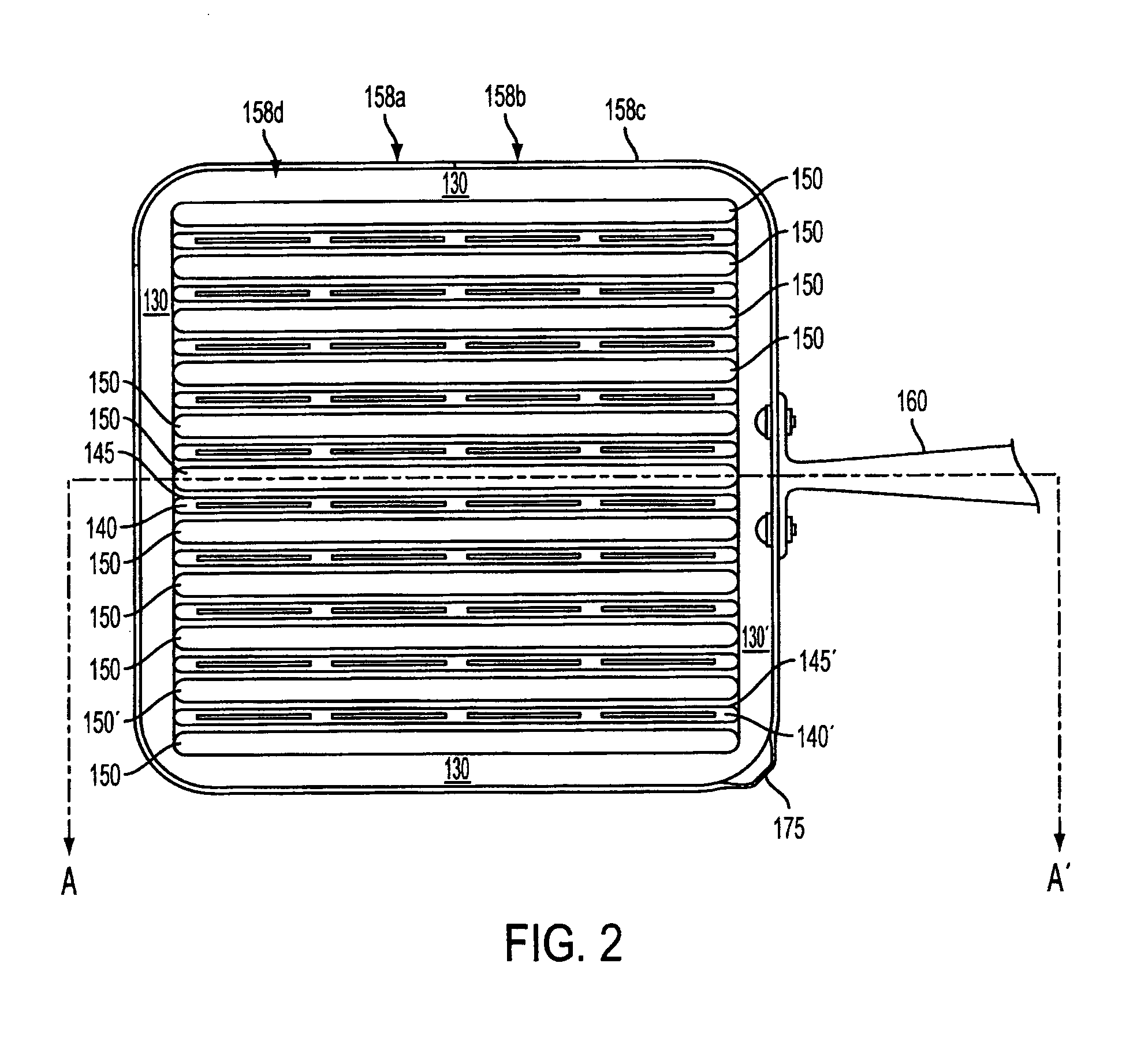

Grill pan

A grill surface or pan provide for the removal of fats and oils by supporting the foodstuffs on ribs that slope downward such that the intervening regions form channels for transporting fluids to the edge of the pan, and away from the cooking food stuffs. The draining channels are interrupted by intervening ribs of a lower height than the first set of foodstuff supporting ribs. The intervening ribs have a series of slits or holes formed in there apex to enable the direct cooking of the foodstuff by radiant heat from a flame or heating source disposed underneath the grill surface. The grill surface may be combined in a pan that provides a peripheral fluid collecting channels at the termination or junction of the draining channels disposed between the sets of rib food supporting and slotted or perforated ribs.

Owner:MEYER INTPROP

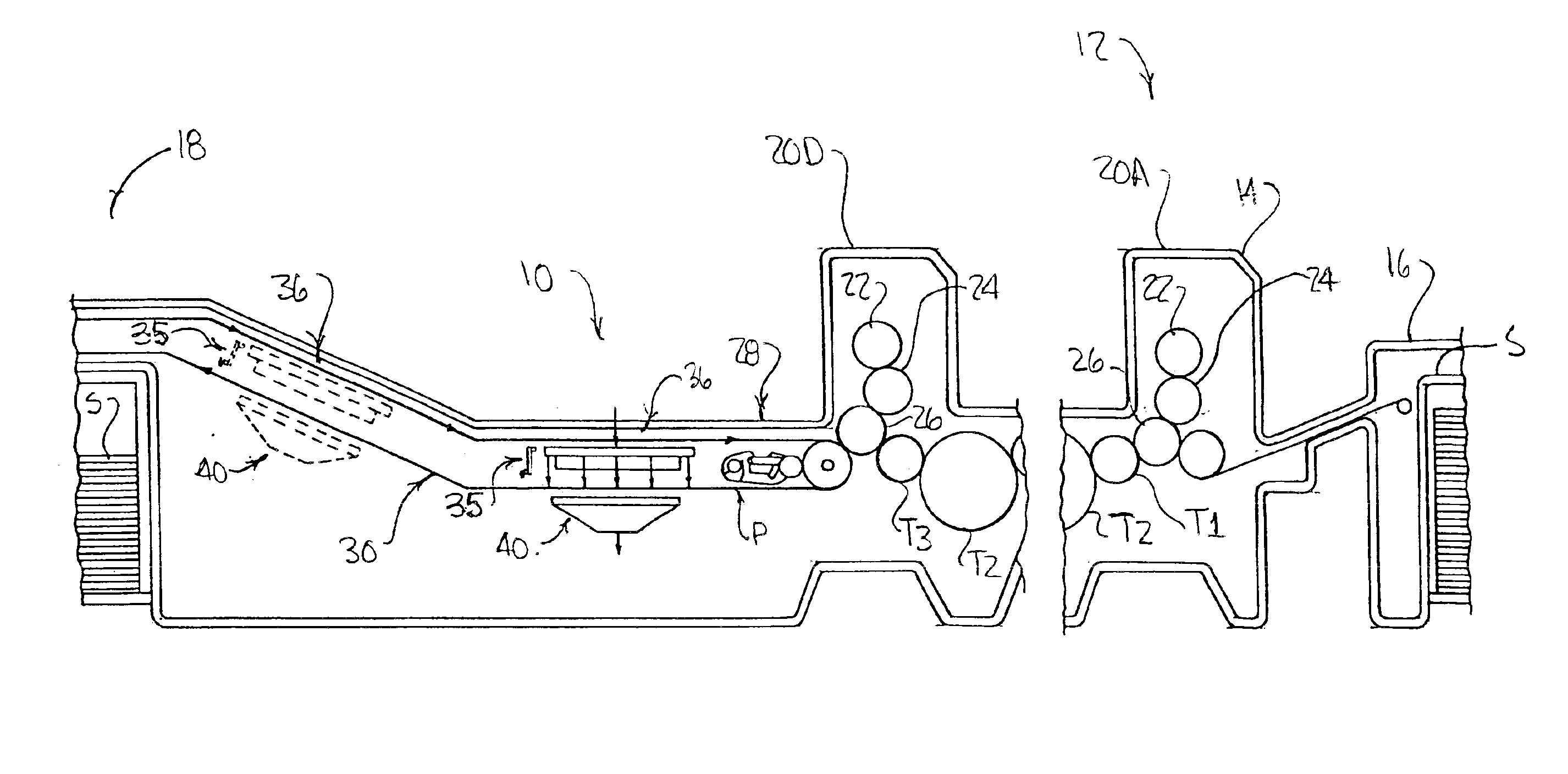

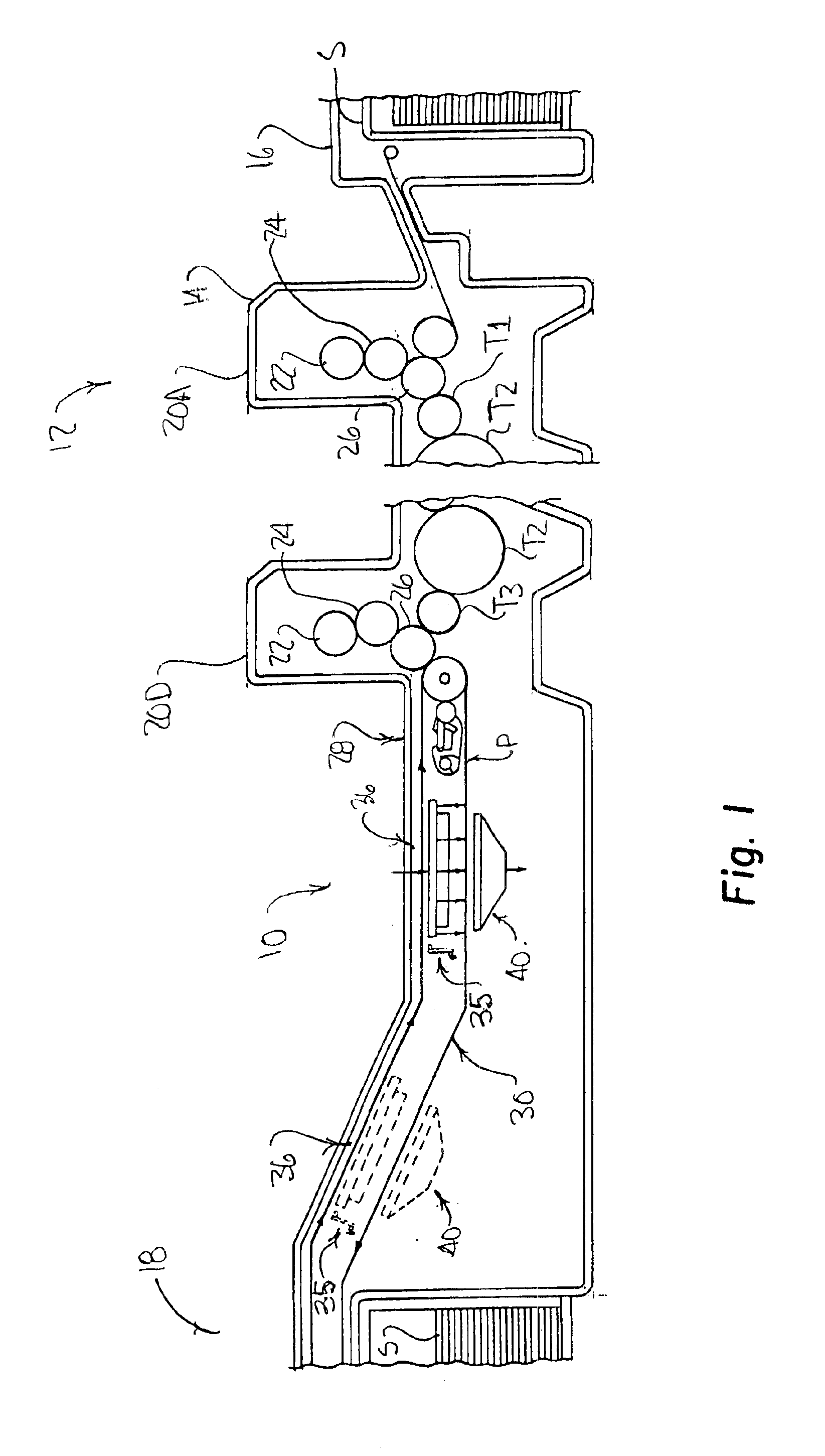

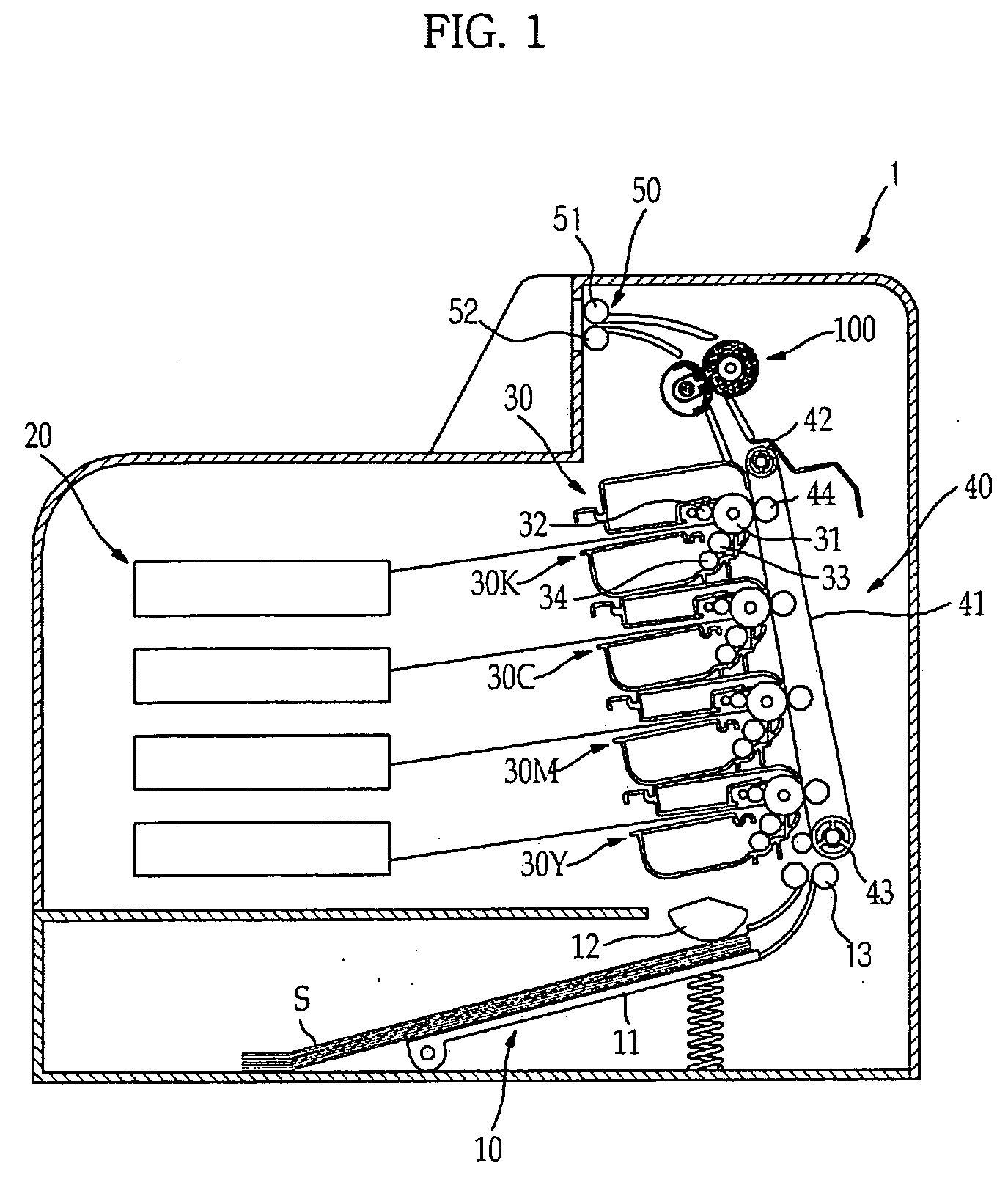

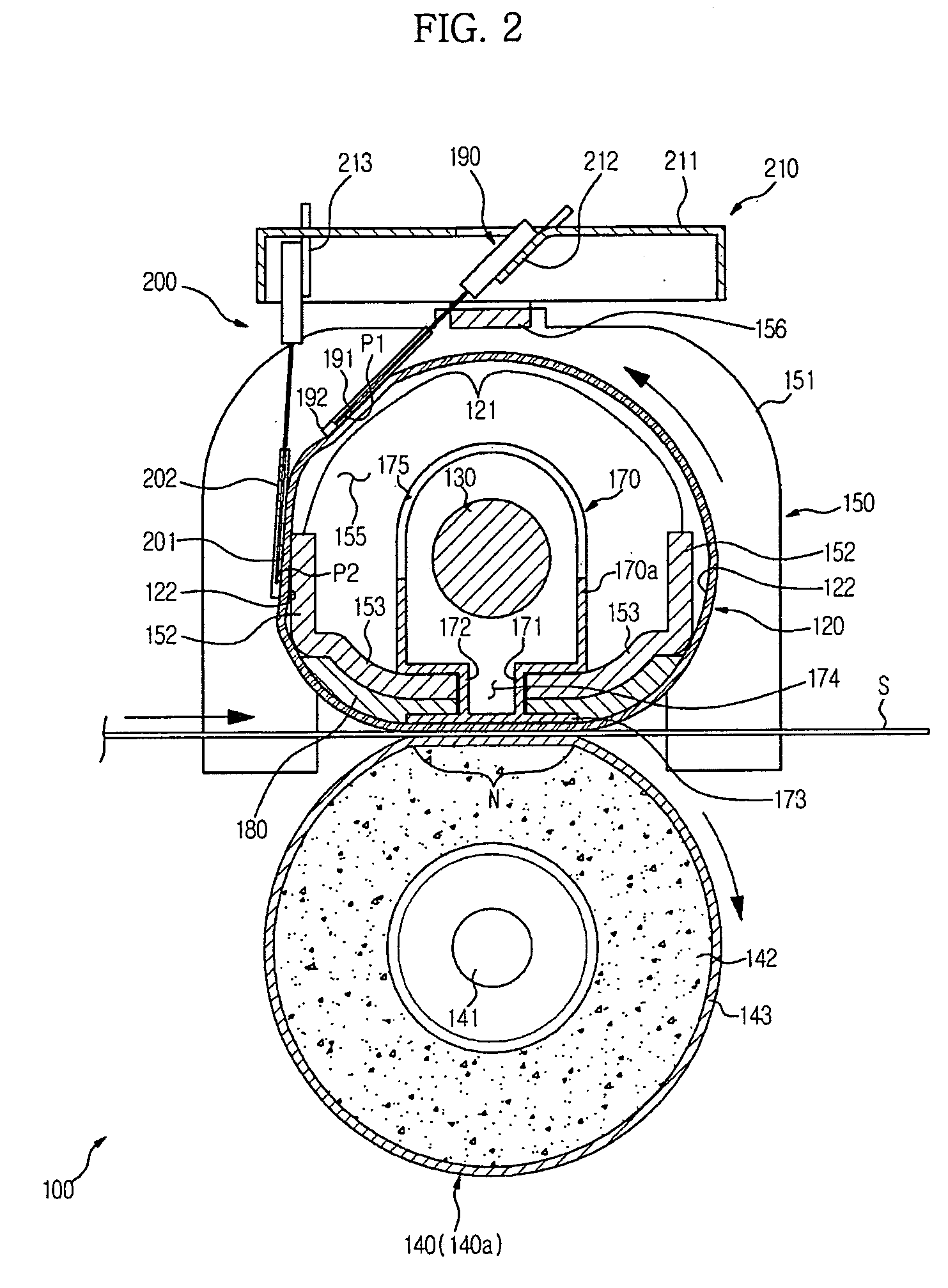

Image forming apparatus, fusing device thereof and method of controlling fusing device

An image forming apparatus that is capable of preventing a damage to a fusing belt or hazardous conditions due to the overheating of the fusing belt and a fusing device thereof are disclosed. The image forming apparatus has a fusing device including a fusing belt, a heat source disposed in the fusing belt, a support member to support the fusing belt, the support member having an opening through which heat emitted from the heat source passes to at least a portion of the fusing belt, and a first temperature sensor positioned to measure temperature of the fusing belt at the portion directly heated by radiant heat transmitted through the opening. A control unit of the image forming apparatus controls the heat source based on the temperature measured by the first temperature sensor.

Owner:HEWLETT PACKARD DEV CO LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com