Patents

Literature

139 results about "Radiant heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radiant heat transfer flows from the warmer object to the colder object. Heat from a campfire is felt without touching the flames. The sun shines and heat travels through empty space, arriving with the strength to burn.

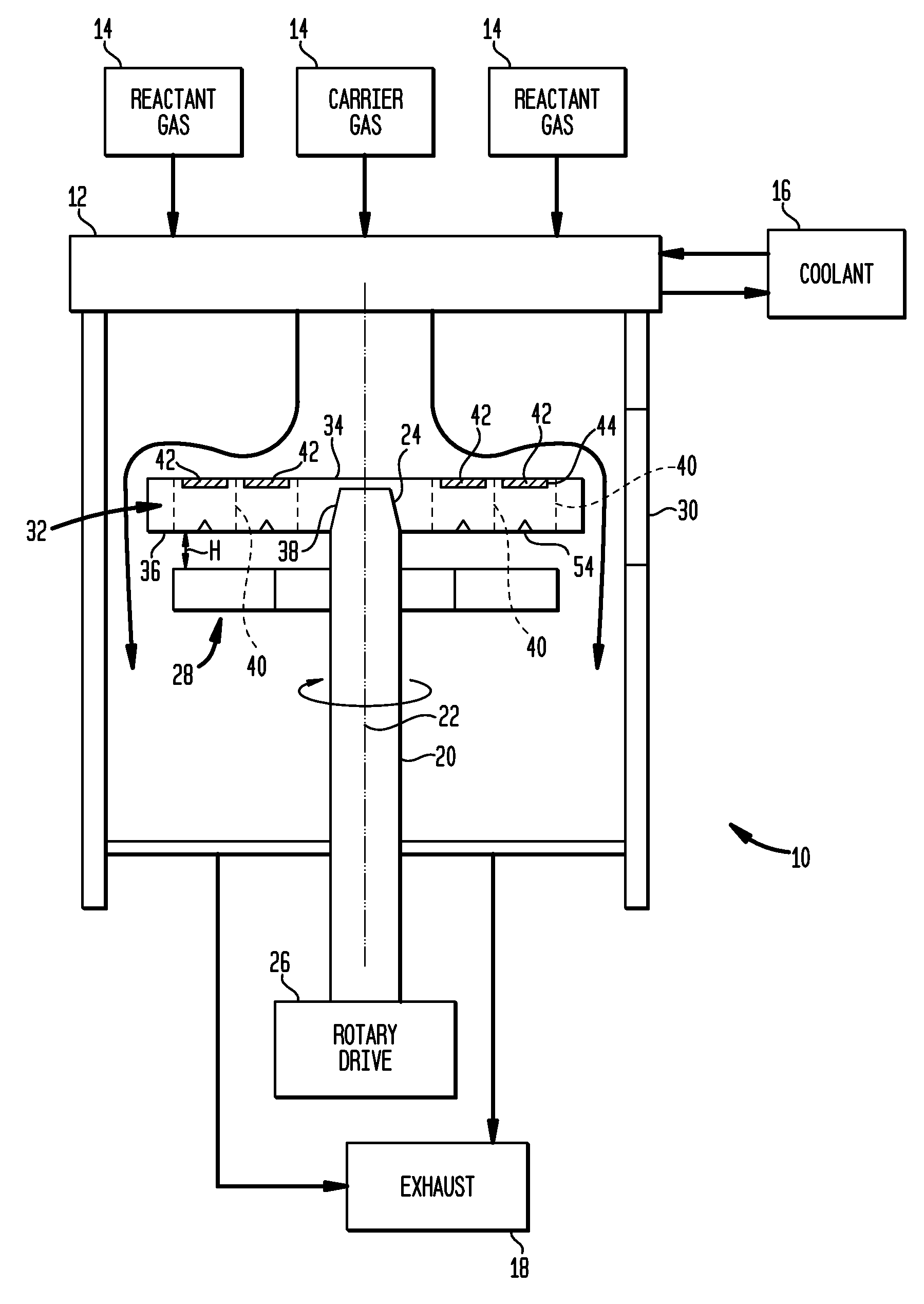

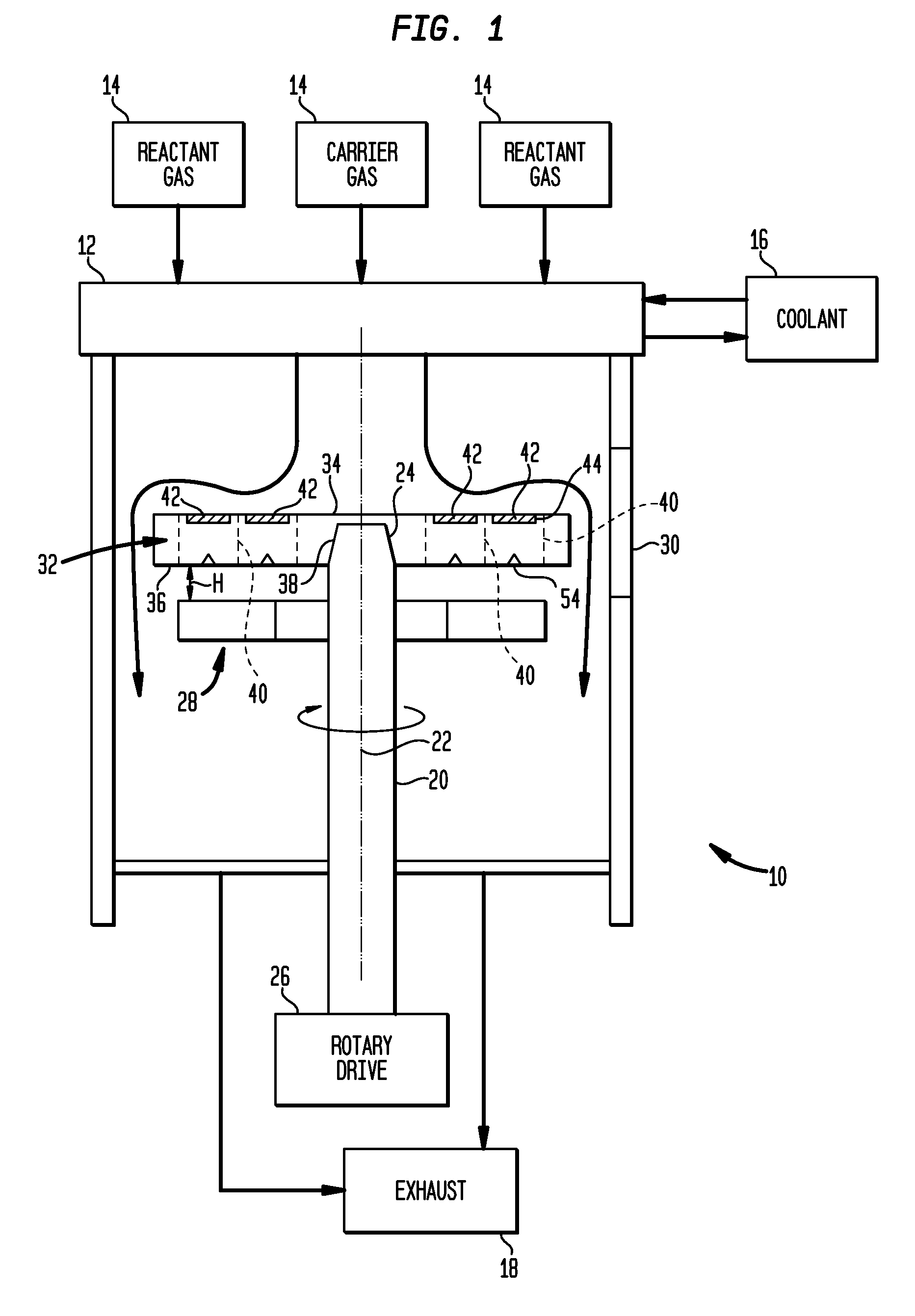

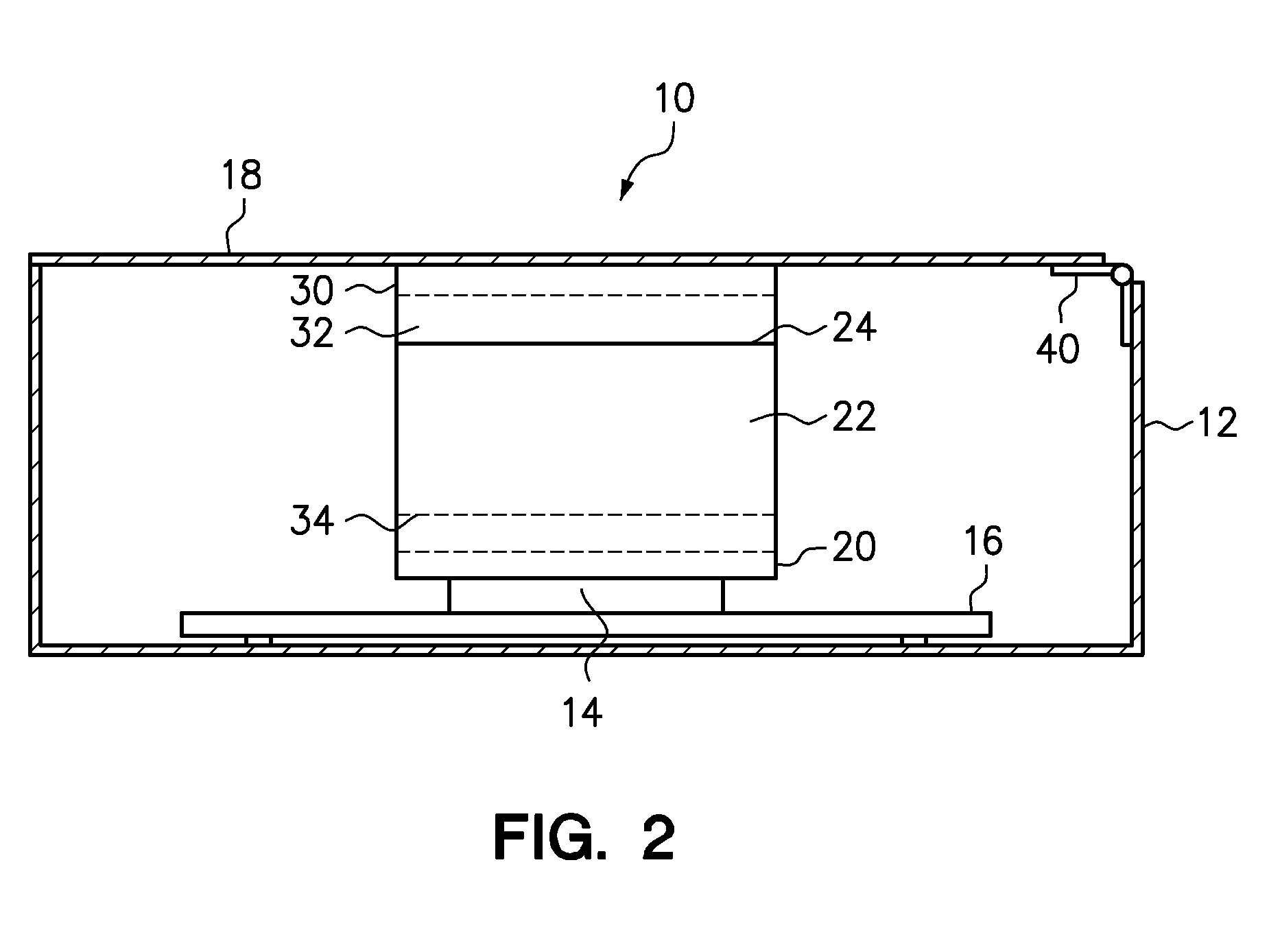

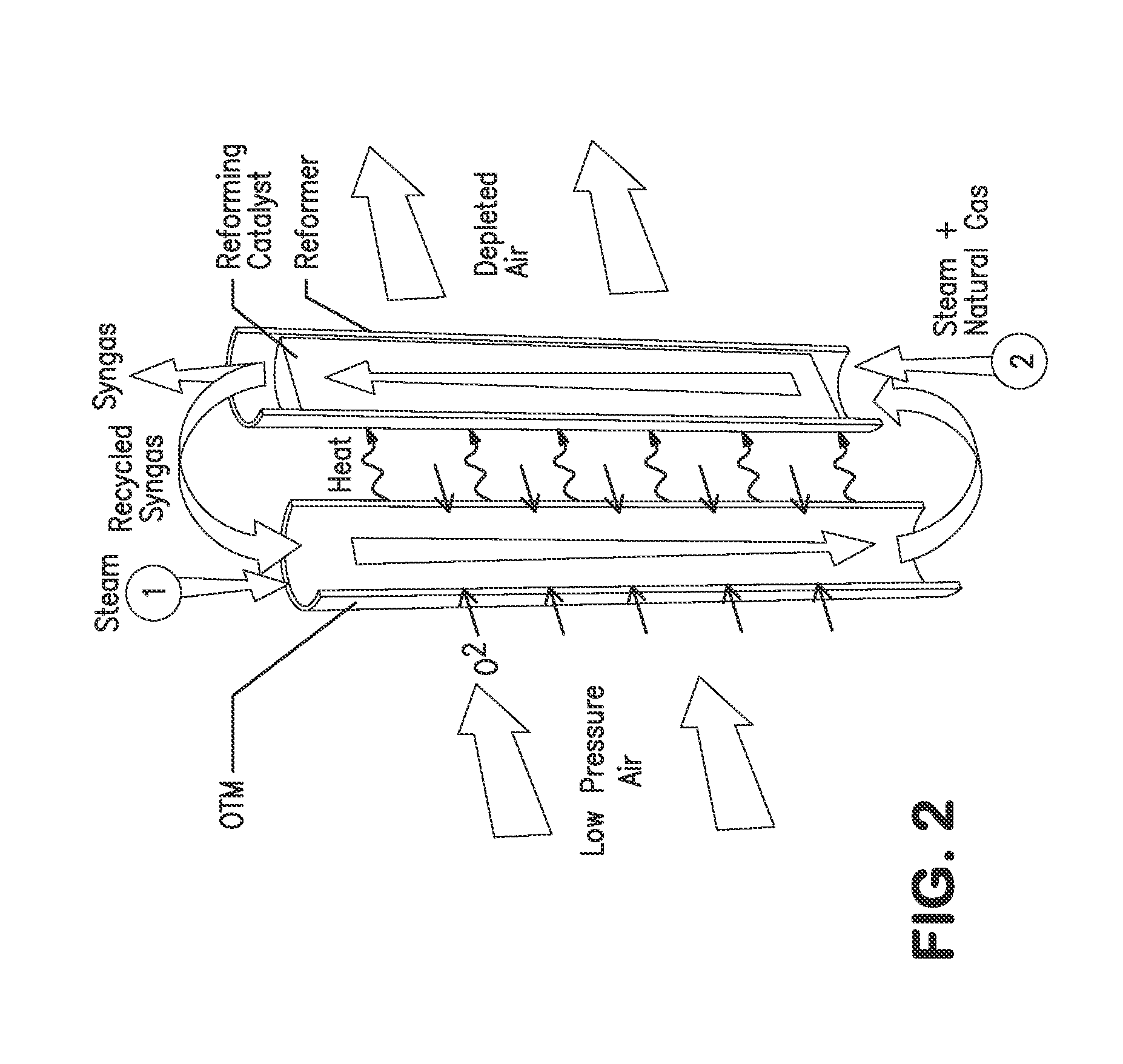

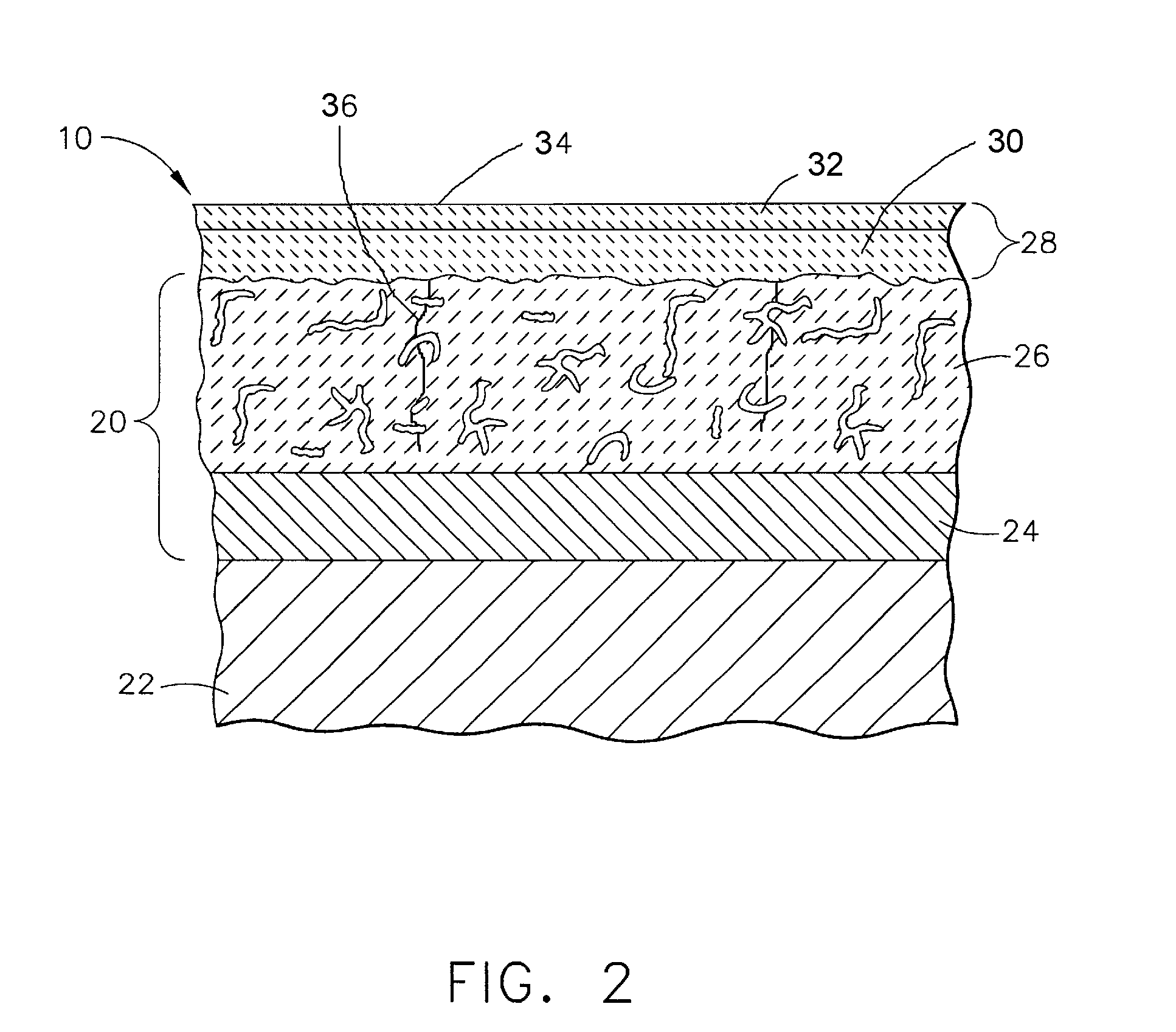

Wafer carrier with varying thermal resistance

InactiveUS20100055318A1Minimize contactImprove temperature uniformityLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringRadiant heat transfer

In chemical vapor deposition apparatus, a water carrier (32) has a top surface (34) holding the wafers and a bottom surface (36) heated by radiant heat transfer from a heating element (28). The bottom surface (36) of the wafer carrier is non-planar due to features such as depressions (54) so that the wafer carrier has different thickness at different locations. The thicker portions of the wafer carrier have higher thermal resistance. Differences in thermal resistance at different locations counteract undesired non-uniformities in heat transfer to the wafer. The wafer carrier may have pockets with projections (553, 853) for engaging spaced-apart locations on the edges of the wafer.

Owner:VEECO INSTR

Food warming apparatus and method

InactiveUS7105779B2Less spaceImprove food qualityDomestic stoves or rangesStoves/ranges shelves or racksEngineeringRadiant heat

In general, one embodiment of the invention is directed to food holding apparatus for holding pre-cooked food at a selected holding temperature. The apparatus comprises a cabinet having at least one holding compartment therein, and pre-cooked food in the holding compartment, the food having been previously cooked in a cooking appliance. At least one radiant heat source is spaced above the food a distance less than 12 inches for delivering radiant heat to the food. A control mechanism varies the amount of radiant heat delivered by the heat source to the food to maintain the food at the selected holding temperature. A related method is also disclosed.

Owner:DUKE MANUFACTURING COMPANY

Heat transfer apparatus

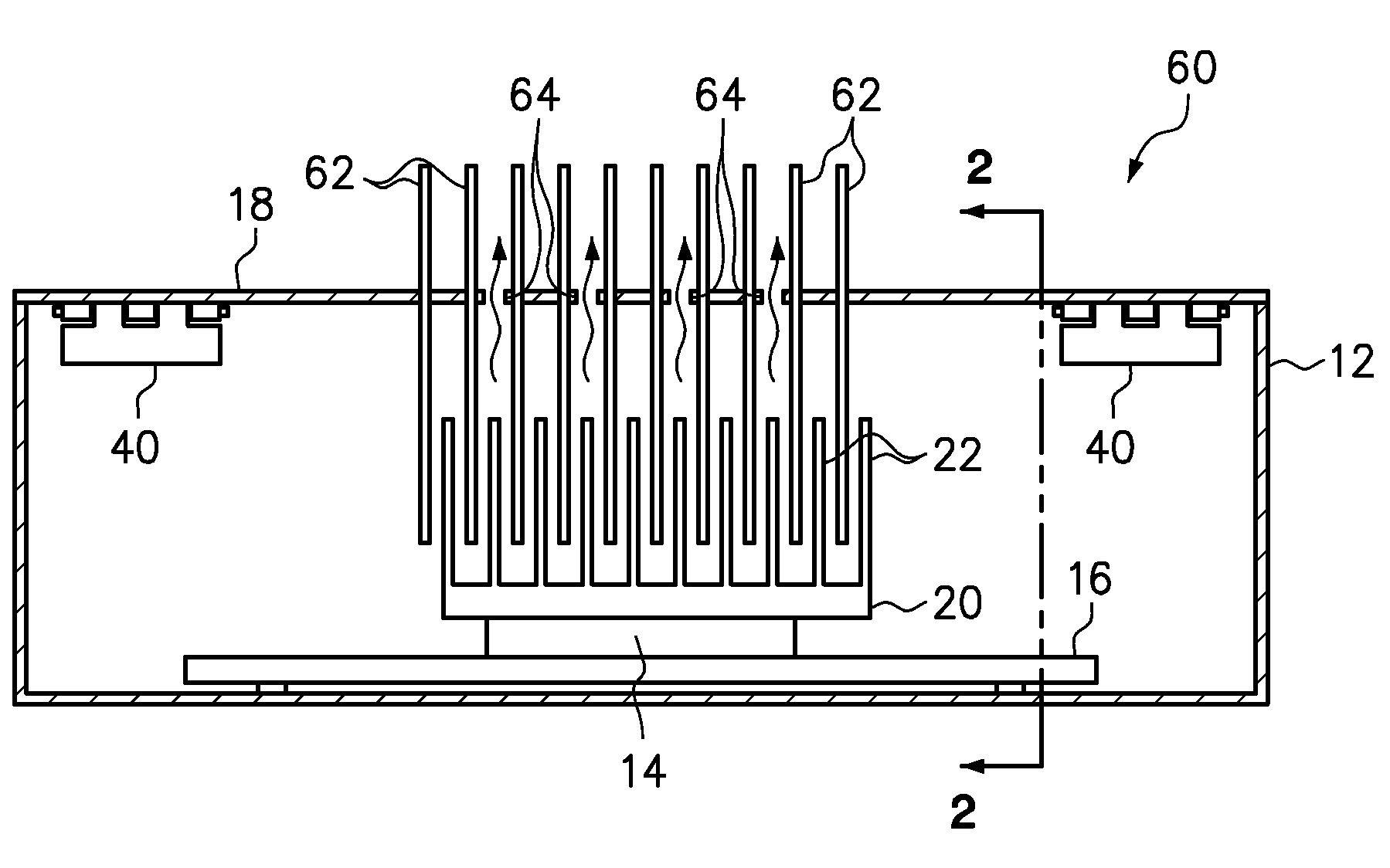

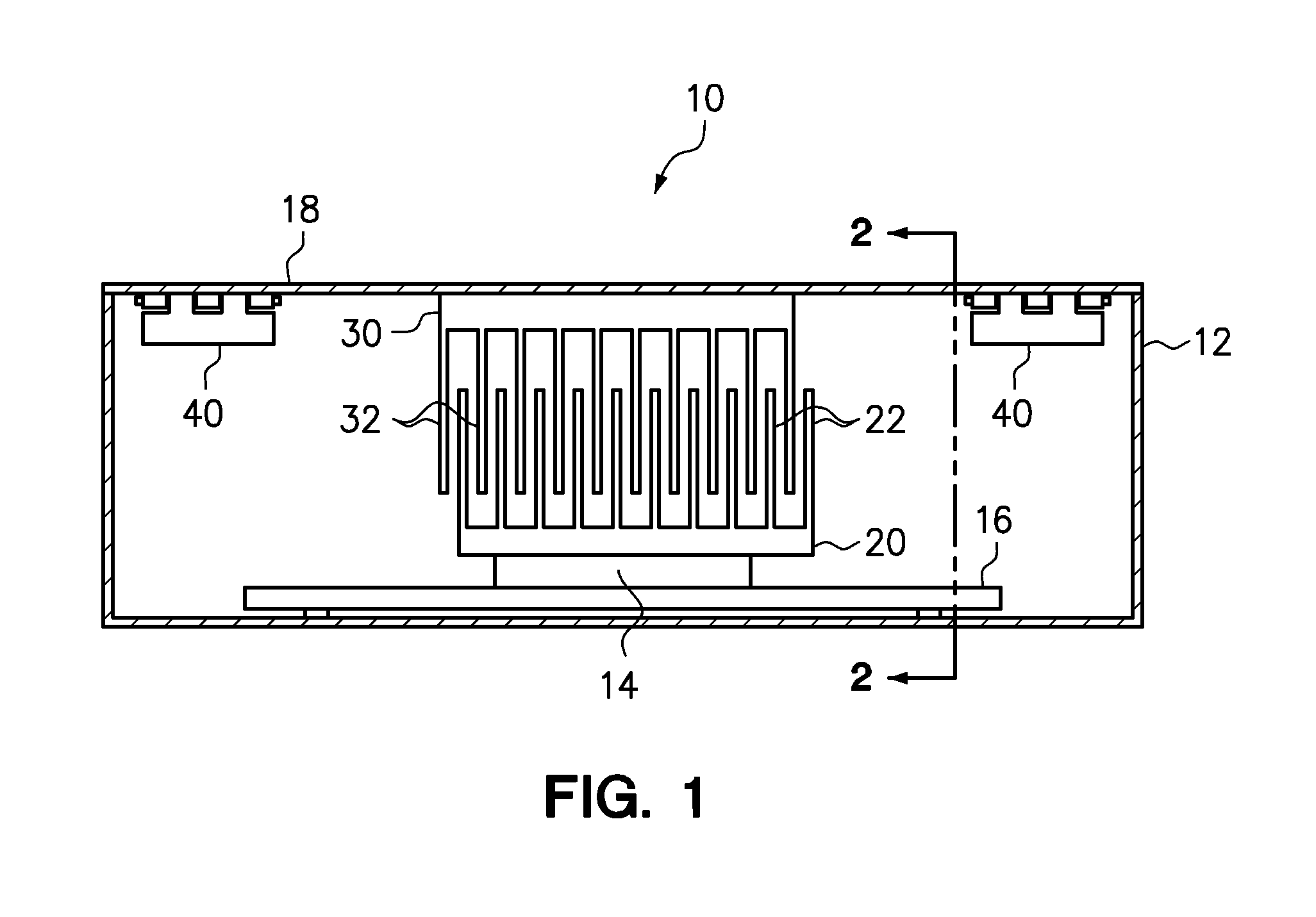

InactiveUS20120293952A1Digital data processing detailsSemiconductor/solid-state device detailsRelative motionEngineering

An apparatus is provided to remove heat from a heat-generating component of a computer, such as a processor. The apparatus comprises a first heat sink having a plurality of leader fins, wherein the first heat sink is thermo-conductively coupled to a heat-generating component that is coupled to a first portion of a chassis; and a second heat sink having a plurality of follower fins, wherein the second heat sink is thermo-conductively coupled to a second portion of the chassis, and wherein the plurality of follower fins are disposed in an interlaced configuration with the plurality of follower fins to promote radiative heat transfer from the leader fins to the follower fins. Optionally, one or more alignment structures may be used to facilitate the relative movement of the first and second chassis portions into an operative position in which the leader and follower fins are in the interlaced configuration. The apparatus may be used to remove heat from a heat-generating component in a closed system with little or no limited air flow.

Owner:IBM CORP

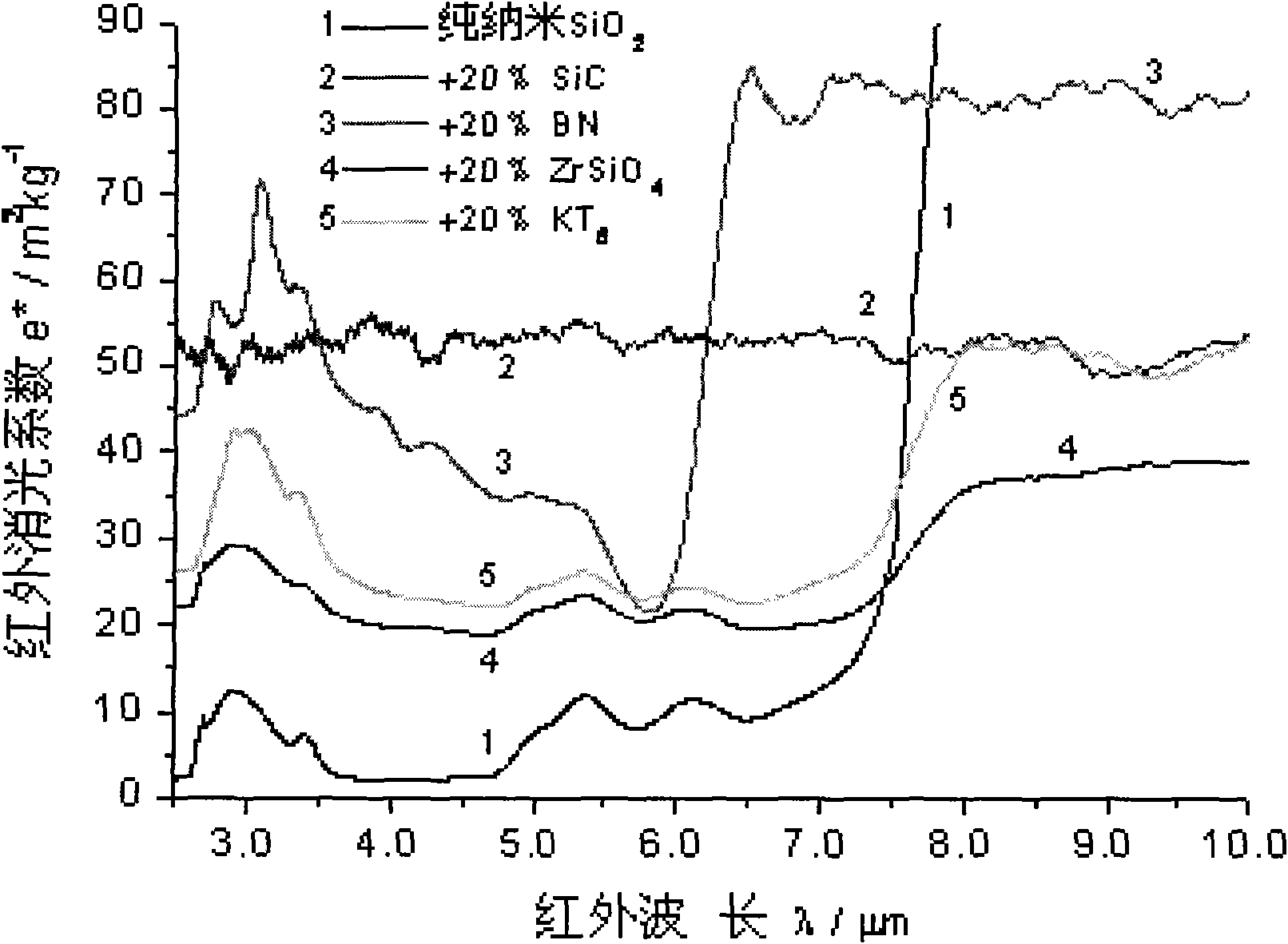

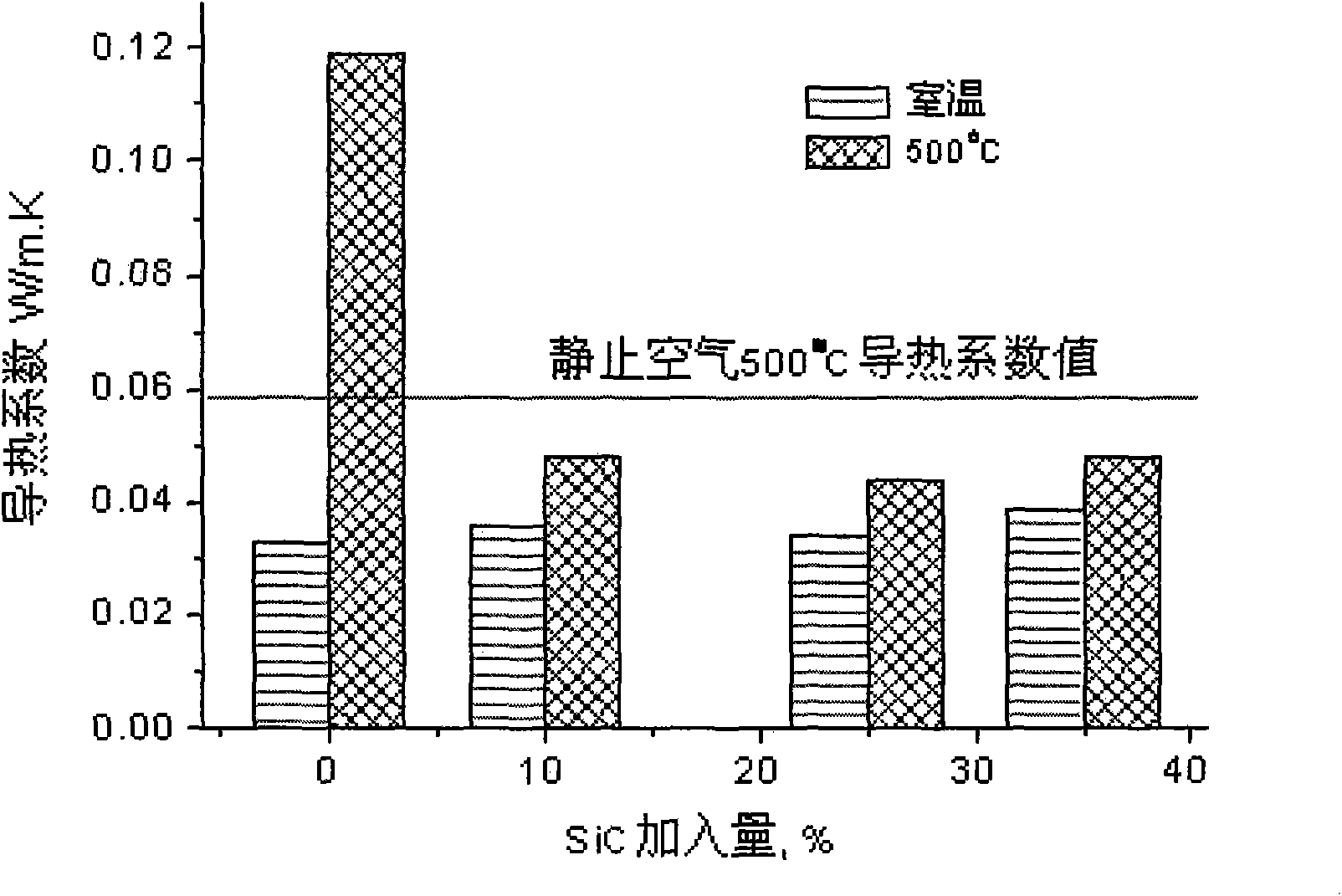

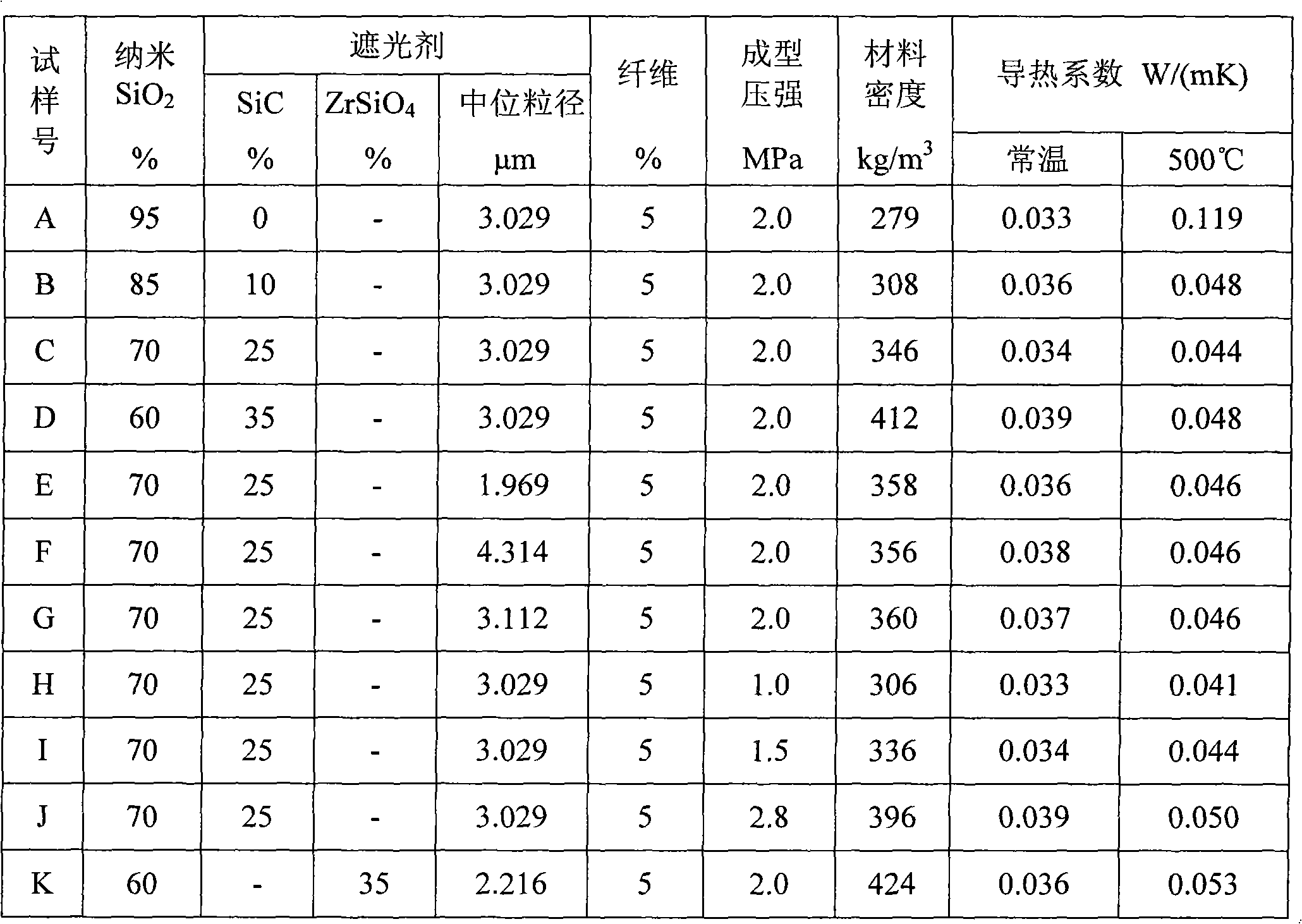

High-efficiency insulating material used for high-temperature pipeline and preparation method thereof

ActiveCN101671157AReduced heat transfer ratioEnhanced inhibitory effectThermal insulationPipe protection by thermal insulationSupercritical dryingFiber

The invention discloses a high-efficiency insulating material capable of being used for a high-temperature pipeline with insulation requirements. The high-efficiency insulating material comprises thefollowing mixed raw materials by weight percentage: 40 to 80 percent of nano SiO2 powder, 5 to 40 percent of infrared opacifier and 0 to 25 percent of reinforcing fiber. The high-efficiency insulatingmaterial is formed by adopting a drying method and overcomes the defect that the sol-gel method for preparing an aerogel-based material needs supercritical drying. The high-efficiency insulating material is designed by a microstructure, carries out full restriction on heat conduction, convection and radiant heat transfer at high temperature simultaneously and leads the heat-conducting coefficientof material under the use temperature to be lower than that of static air.

Owner:NAVAL UNIV OF ENG PLA

Smooth outer coating for combustor components and coating method therefor

InactiveUS7368164B2Suppresses component temperature riseReduce transferMolten spray coatingPropellersZinc titanateSilica matrix

A coating and method for overcoating a TBC on a component used in a high-temperature environment, such as the combustor section of an industrial gas turbine. The coating defines the outermost surface of the component and is formed of at least two layers having different compositions. An inner layer of the coating contains alumina in a first silica-containing matrix material that is free of zinc titanate. An outer layer of the coating contains alumina, a glass material, and zinc titanate in a second silica-containing matrix material. The outer layer of the coating has a surface roughness of not greater than three micrometers Ra and forms the outermost surface of the component. The coating reduces the component temperature by reducing the convective and radiant heat transfer thereto.

Owner:GENERAL ELECTRIC CO

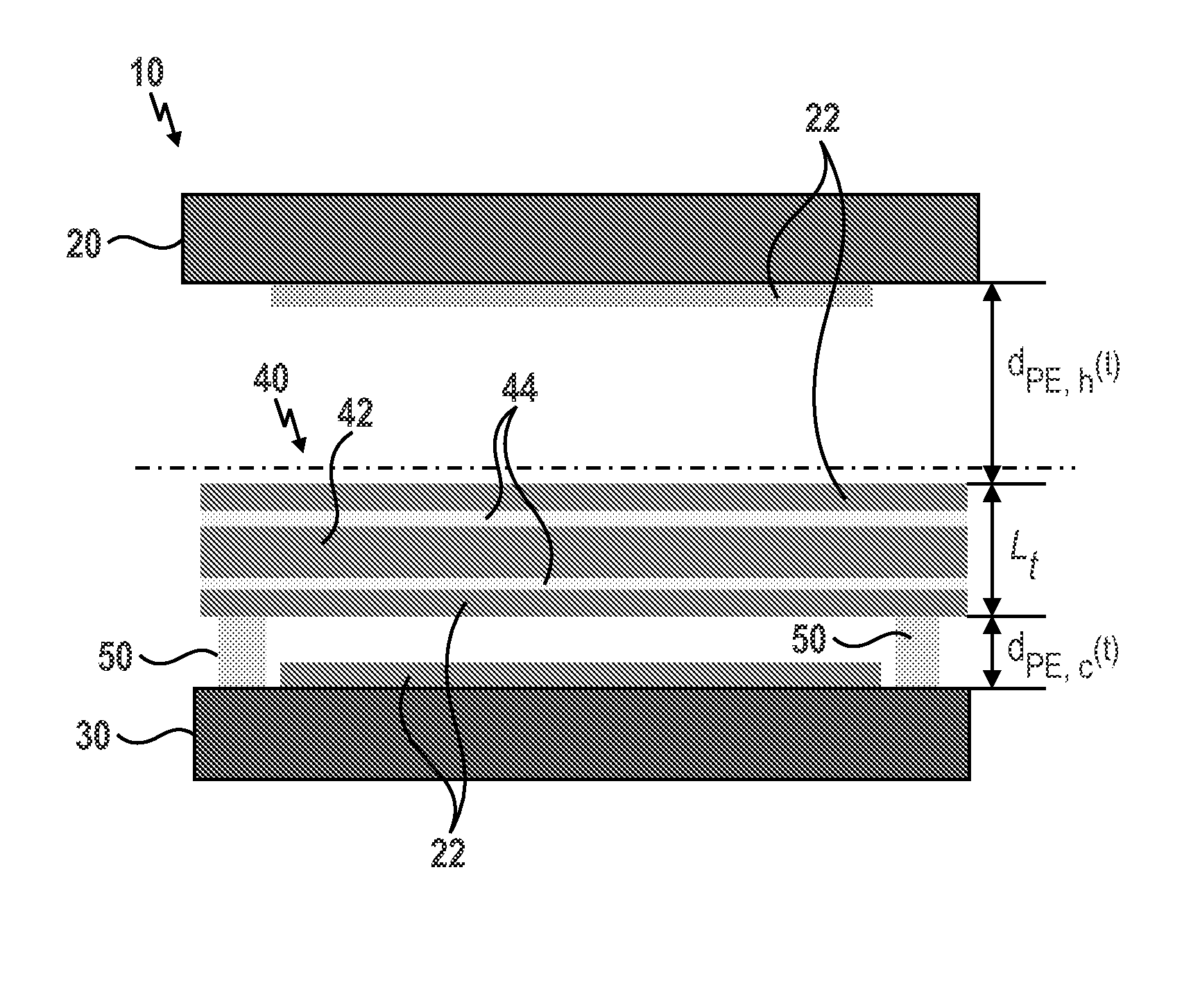

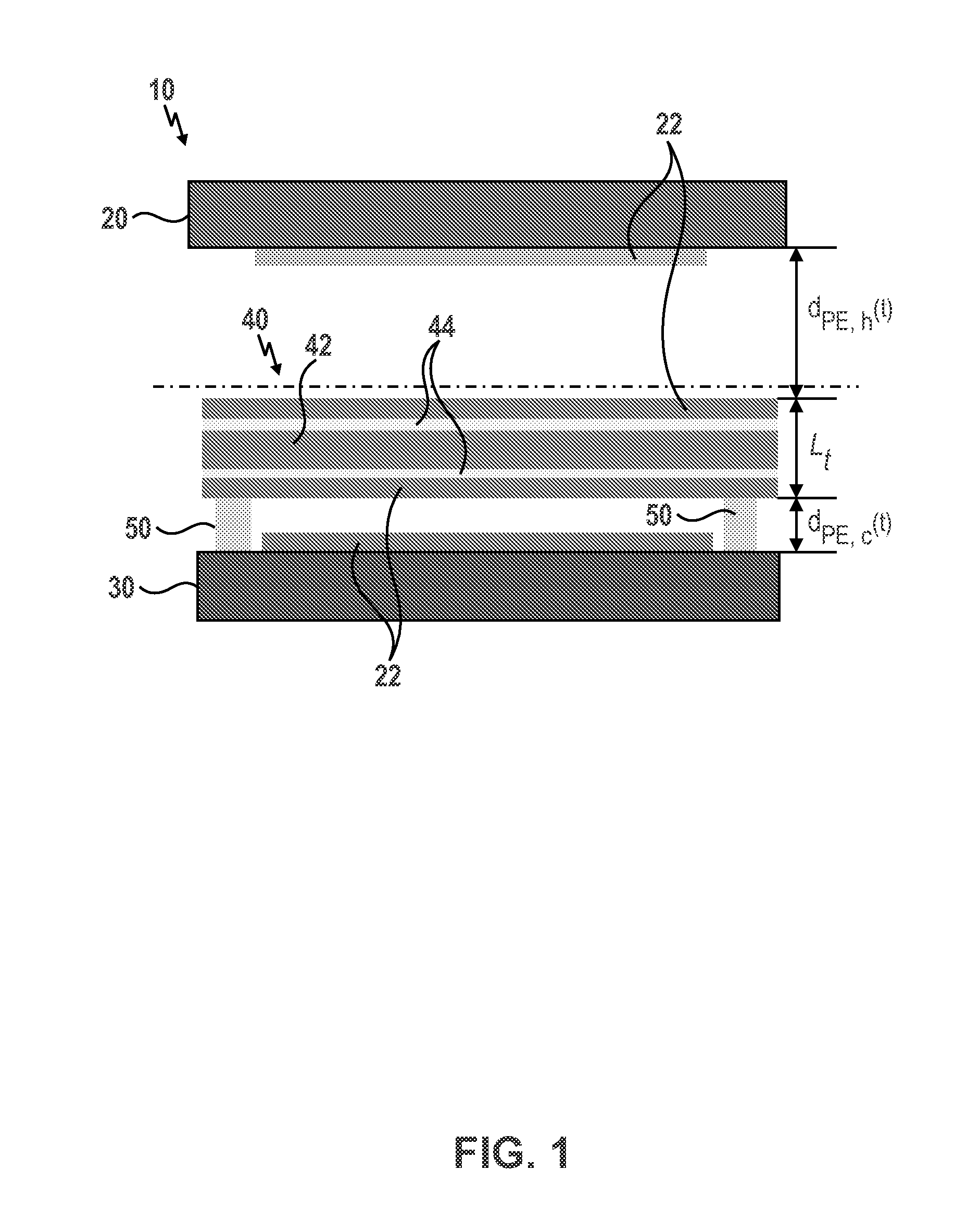

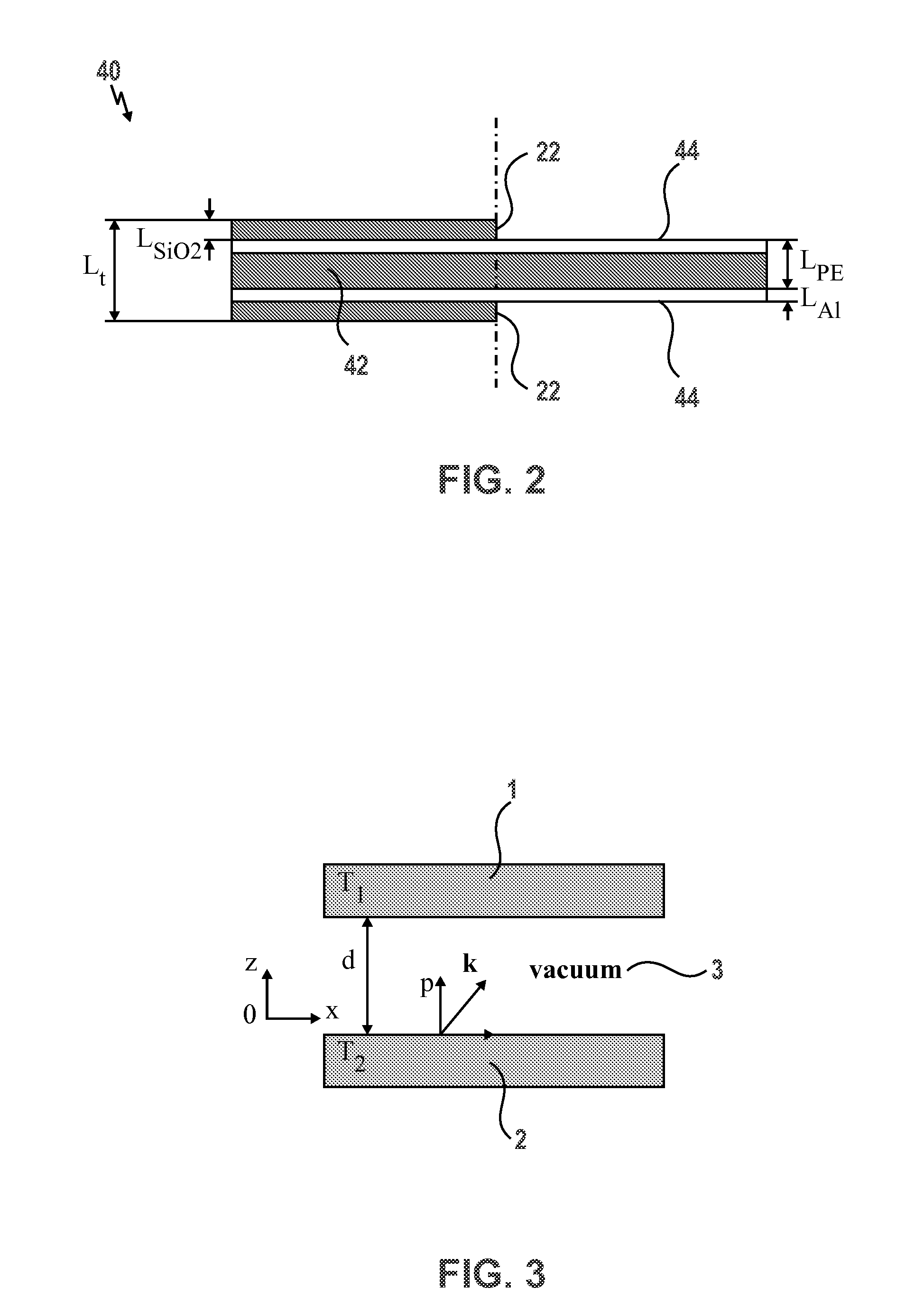

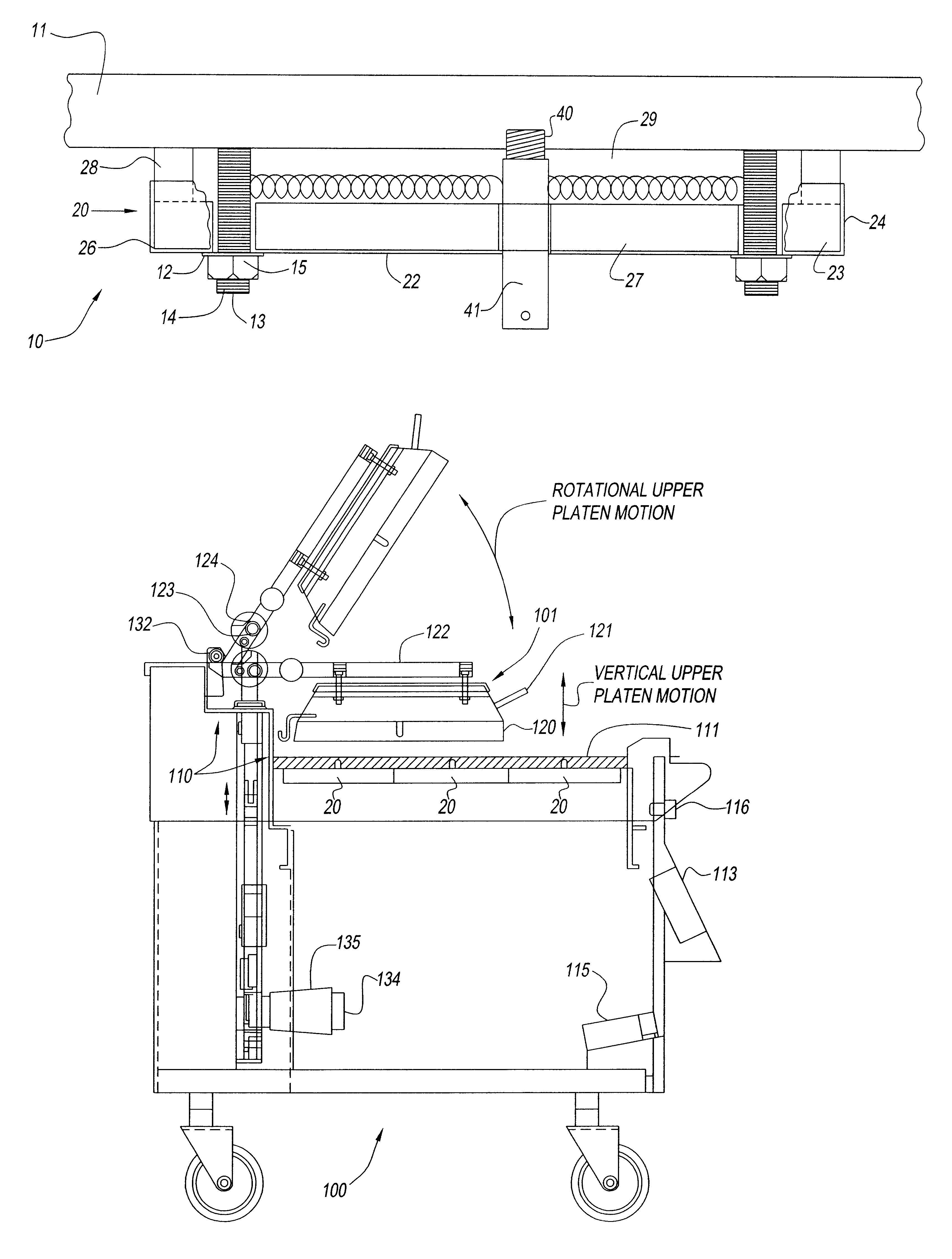

Direct conversion of nanoscale thermal radiation to electrical energy using pyroelectric materials

InactiveUS20110298333A1Minimize thermal contact resistanceEnhance radiative heat fluxThermoelectric device with dielectric constant thermal changeThermal electric motorComposite filmPower cycle

The embodiment provided herein are directed to a pyroelectric (PE) energy converter which is capable of combining nanoscale thermal radiation and pyroelectric energy conversion for harvesting low grade waste heat. The converter advantageously makes use of the enhanced radiative heat transfer across a nanosize gap to achieve high operating frequencies or large temperature oscillations in a composite PE plate. The PE energy converter generally comprises a hot source, a cold source, and a PE plate, wherein the PE plate oscillates between the hot and cold source and the PE plate can be subjected to a power cycle in the displacement-electric field diagram. The hot and cold sources of the converter can be coated with SiO2 absorbing layer to further enhance the radiative heat fluxes. The converter comprising a PE plate made of 60 / 40 P(VDF-TrFE) operated between 273 K and 388 K experiences a maximum efficiency of 0.2% and a power density of 0.84 mW / cm2. The converter comprising a PE plate made of 0.9PMN-PT composite thin films achieve a higher efficiency and a larger power output namely 1.3% and 6.5 mW / cm2, respectively, for a temperature oscillation amplitude of 10 K around 343 K at 5 Hz.

Owner:RGT UNIV OF CALIFORNIA

Griddle plate with infrared heating element

A cooking appliance for grilling food products has a griddle plate and a heating assembly that contains a non-contact infrared heating element to achieve uniform plate temperatures, fast initial warming times and fast recovery times. The heating element is situated in a cavity formed by thermal insulating material in the assembly. When the assembly is secured to the griddle plate, there is a space between the heater element and the griddle plate to allow infrared radiation heat transfer to heat the griddle plate. The insulating material has a relatively high insulating factor so as to minimize heat loss and reduce energy usage.

Owner:THE GARLAND GROUP

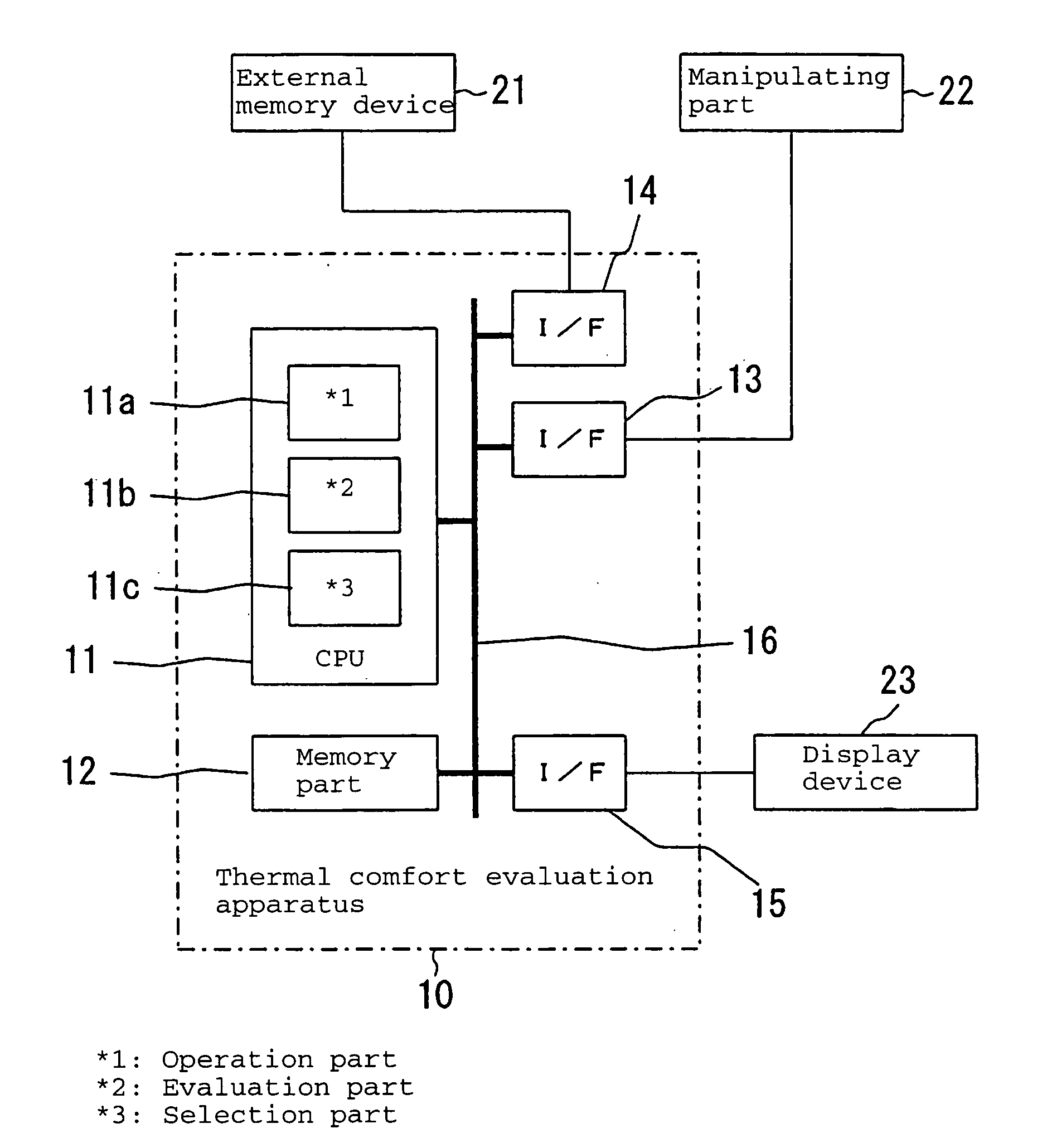

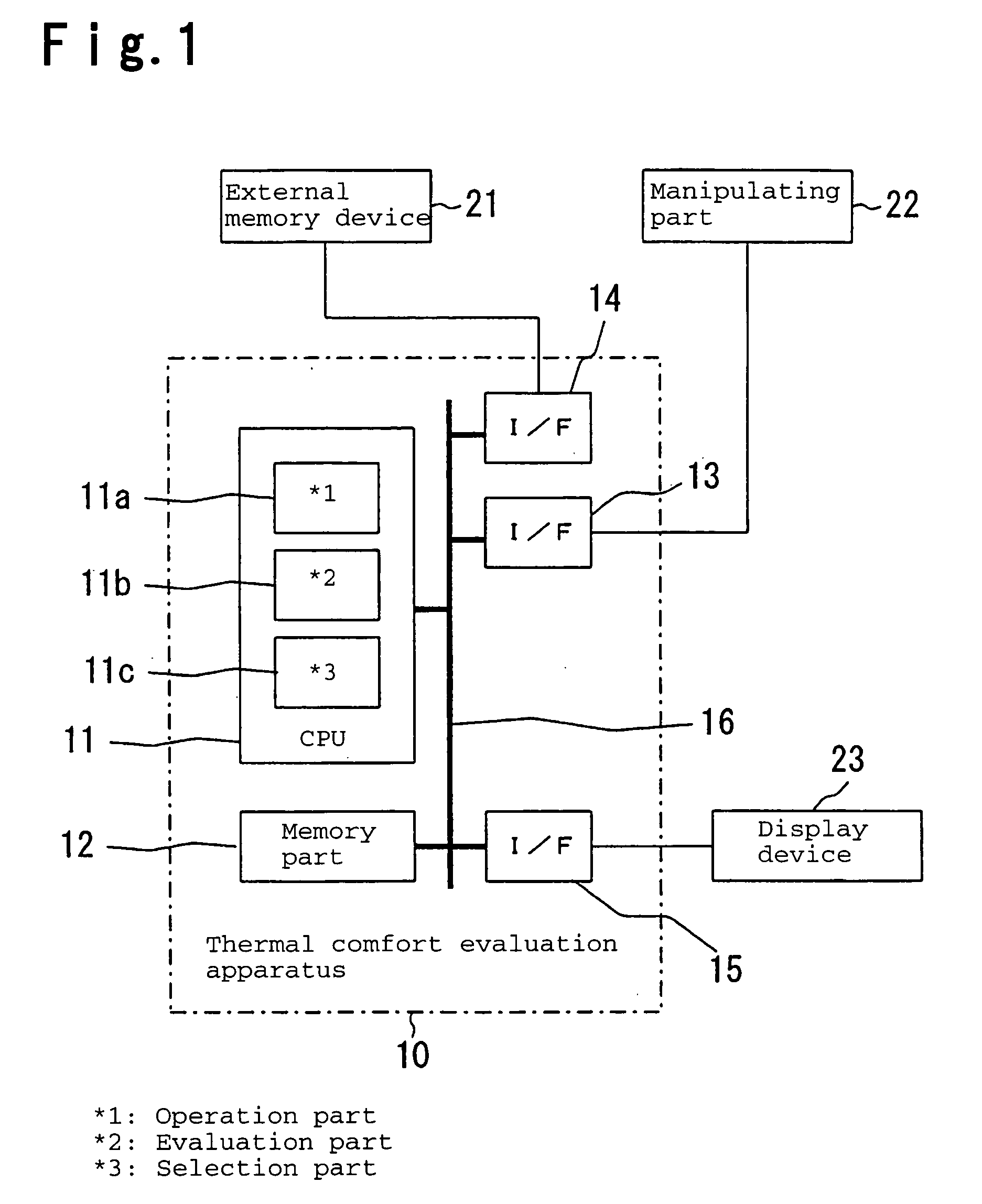

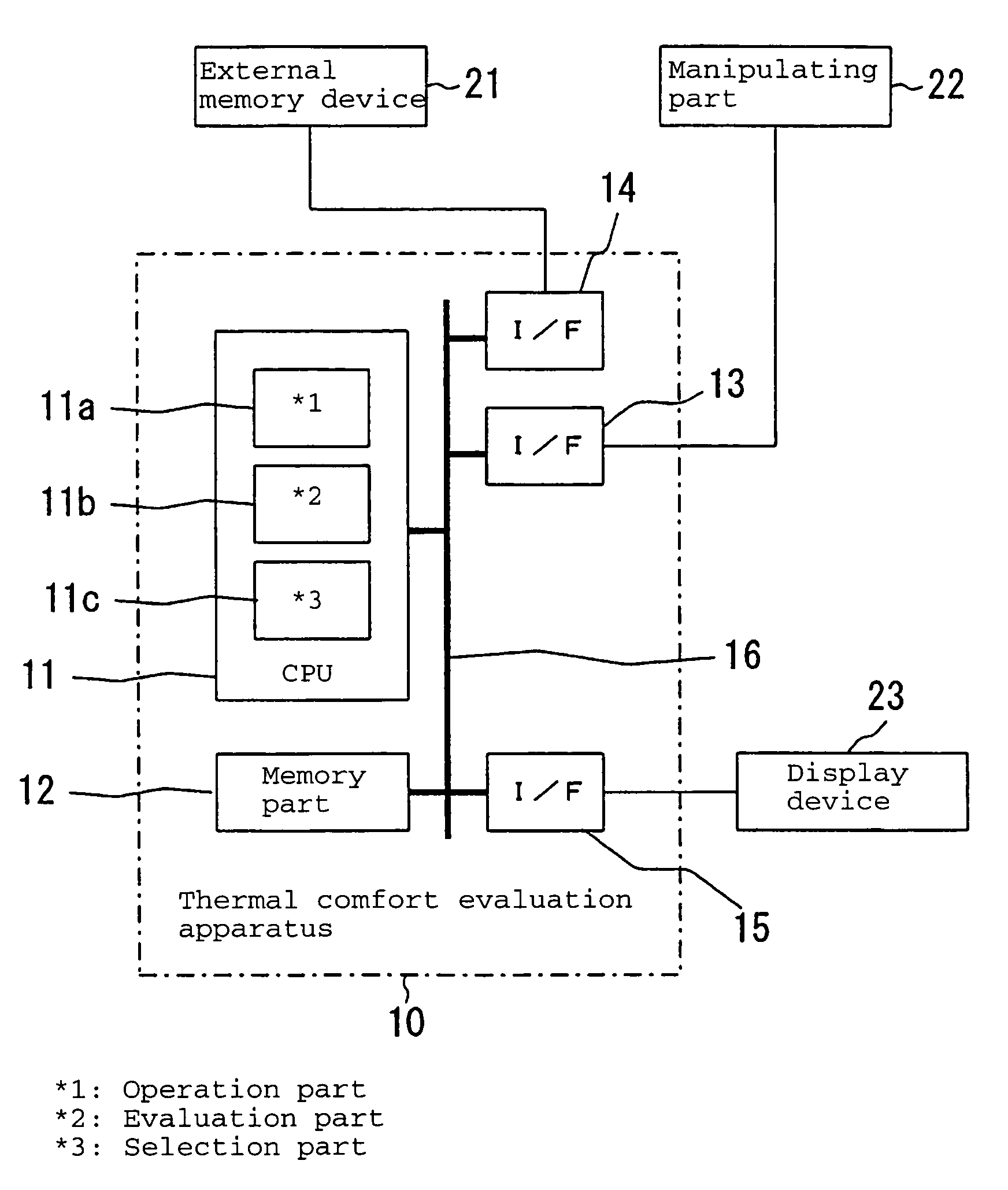

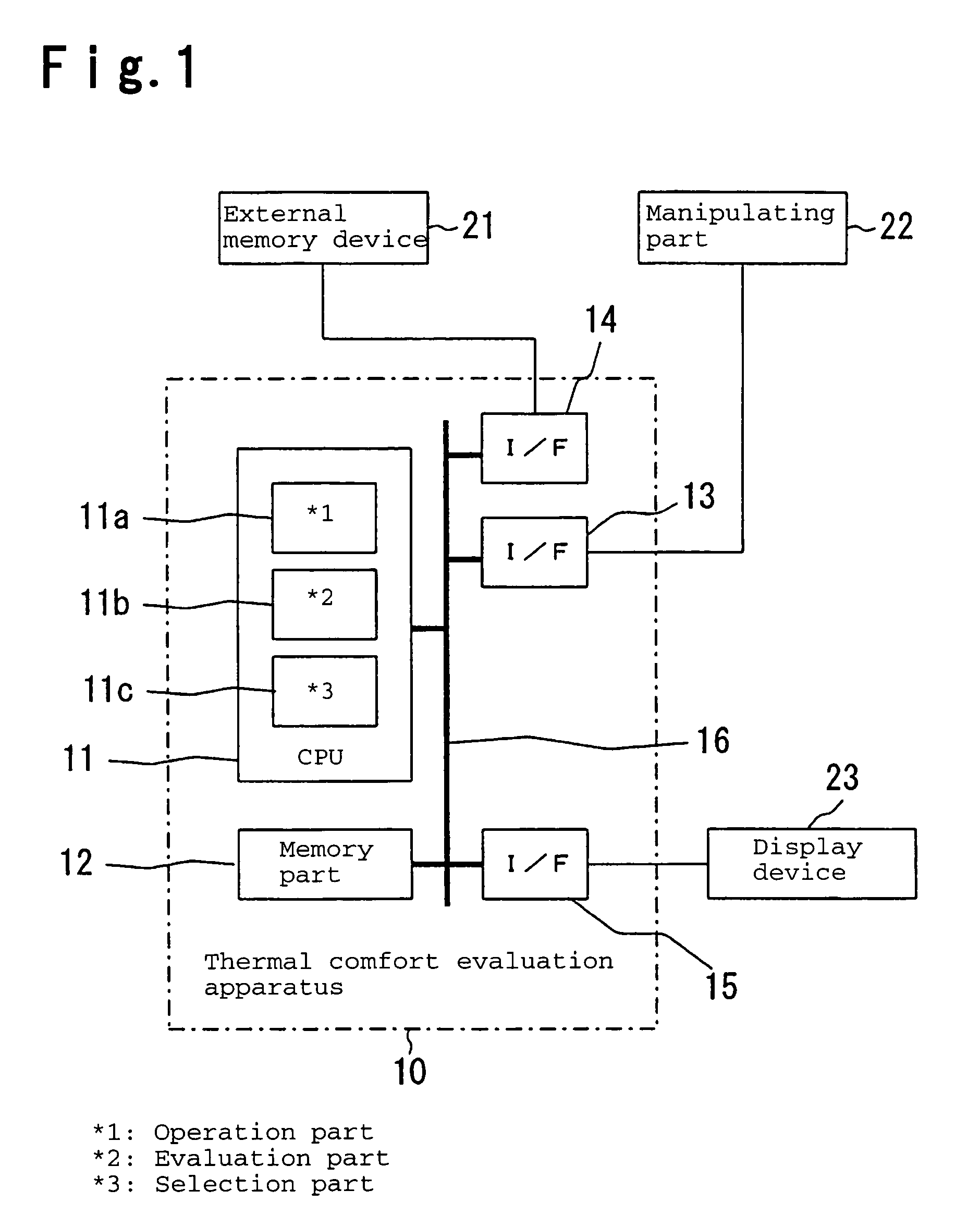

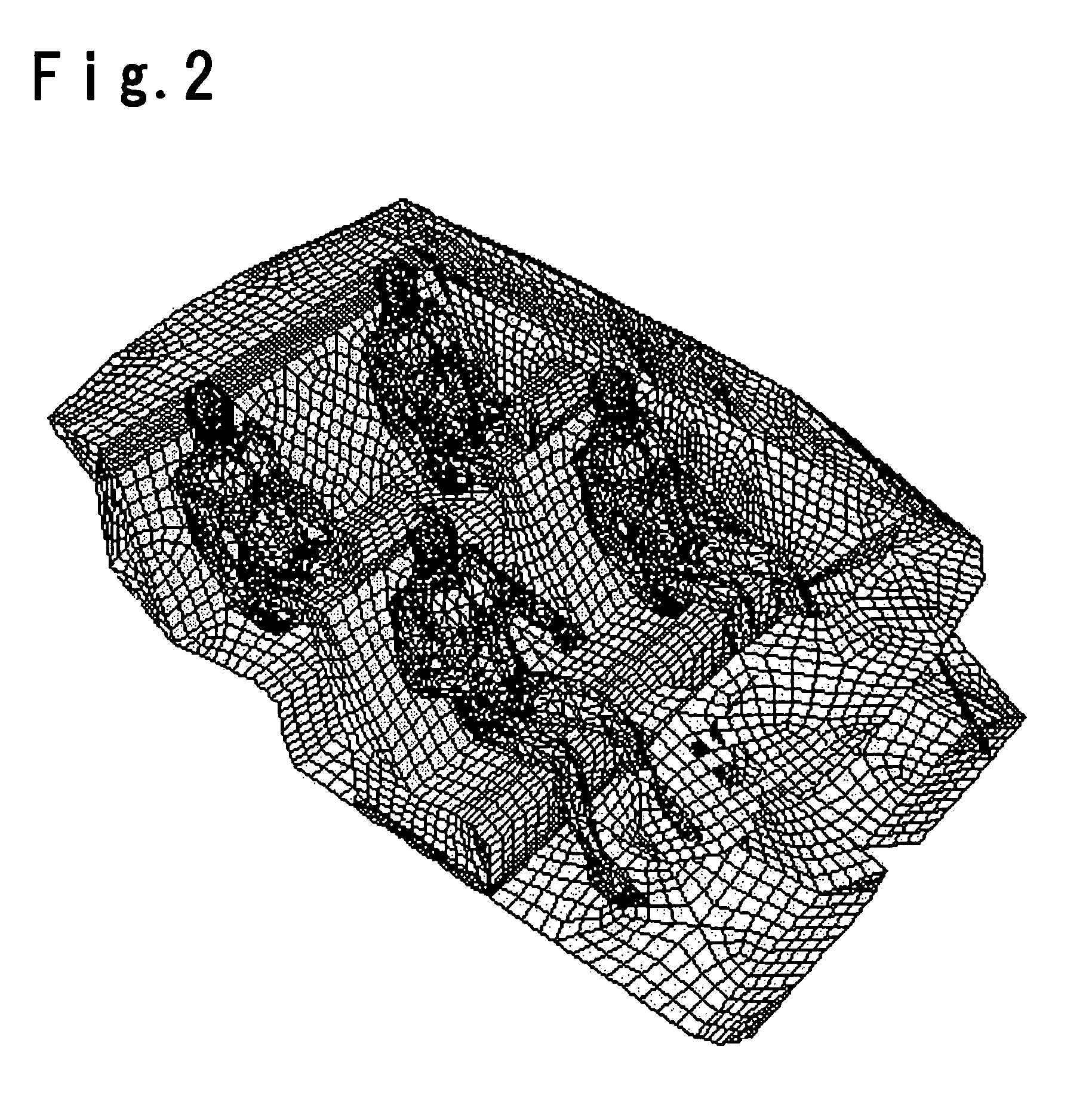

Method for evaluating thermal comfort of a structure and an assisting method, program or system for designing a structure in consideration of thermal comfort

InactiveUS20040133406A1Computation using non-denominational number representationAerodynamics improvementMeasurement deviceLaboratory device

A step of preparing data of (1) material properties of a first part and so on and data of (2) an amount of solar radiation passing through the translucent member to reach a measuring device having a shape imitating a human body part, an amount of solar radiation to the structure, an amount of convection heat transfer in the structure, an amount of radiation heat transfer in the structure, humidity in the structure and / or a thermo-regulating function of the measuring device, and calculating at least one of the amount of heat loss from the surface of the measuring device, the temperature of the measuring device and / or the wettedness at the surface of the measuring device based on at least one in each of data (1) and (2), and a step (b) of calculating a thermal comfort index of the measuring device by using a result of the above calculation, are presented, whereby the thermal comfort of a structure is evaluated without using a laboratory equipment.

Owner:ASAHI GLASS CO LTD

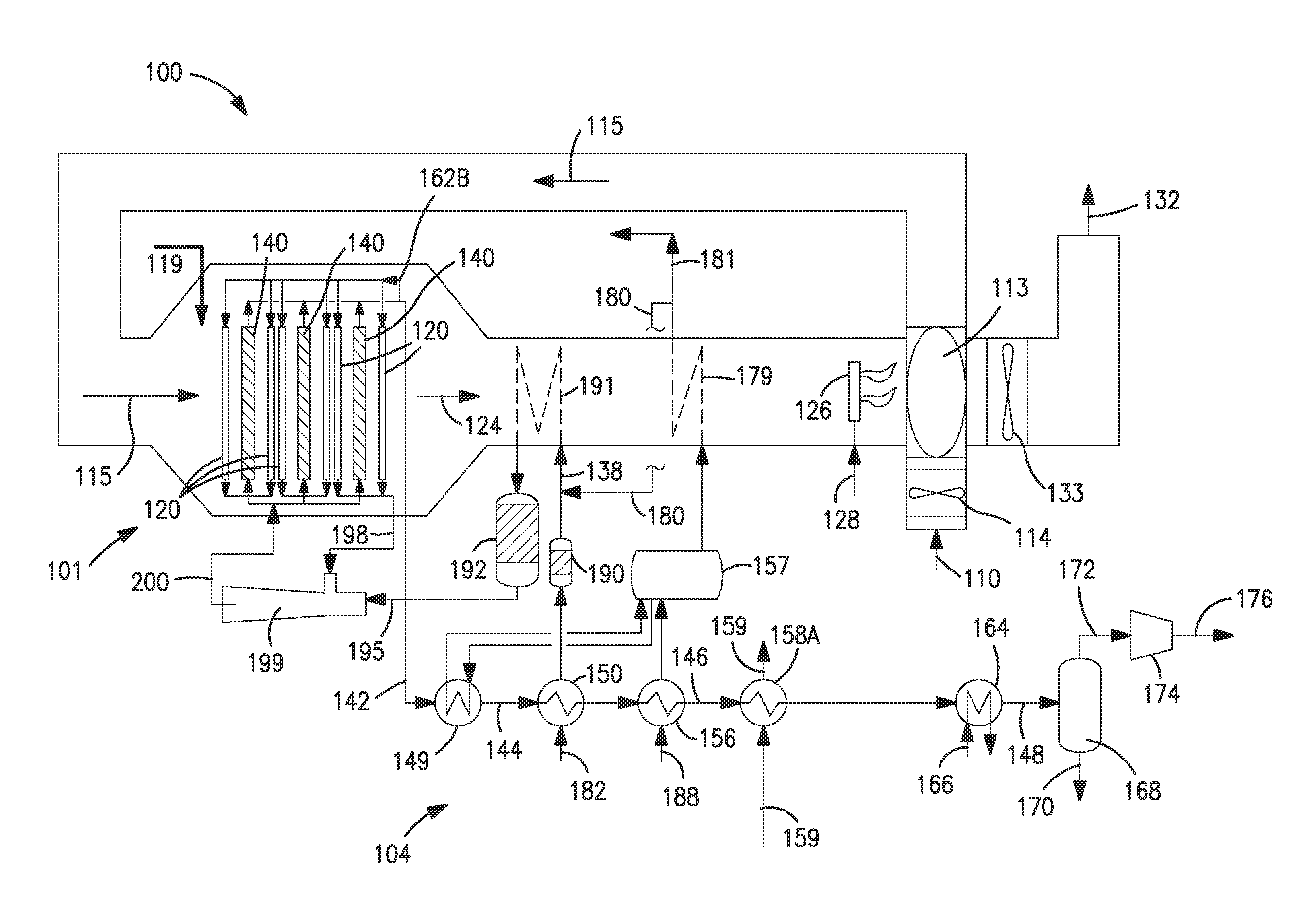

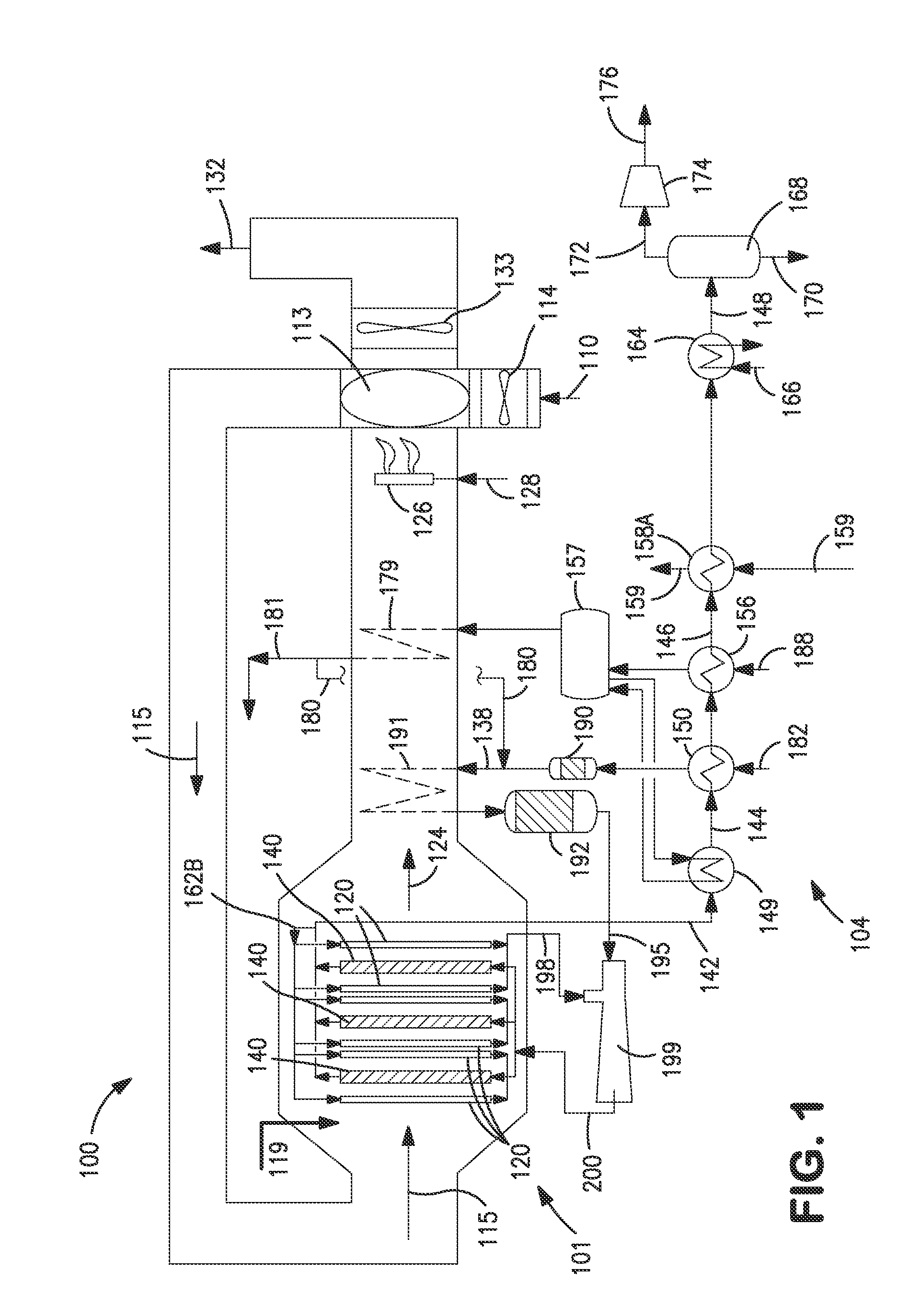

Ceramic oxygen transport membrane array reactor and reforming method

ActiveUS20150096506A1Prevent backflowCatalytic gas-gas reactionHydrogenChemical reactionMembrane array

The invention relates to a commercially viable modular ceramic oxygen transport membrane system for utilizing heat generated in reactively-driven oxygen transport membrane tubes to generate steam, heat process fluid and / or provide energy to carry out endothermic chemical reactions. The system provides for improved thermal coupling of oxygen transport membrane tubes to steam generation tubes or process heater tubes or reactor tubes for efficient and effective radiant heat transfer.

Owner:PRAXAIR TECH INC

Smooth outer coating for combustor components and coating method therefor

ActiveUS20050282020A1Suppresses component temperature riseReducing convective transferLiquid surface applicatorsMolten spray coatingZinc titanateSilica matrix

A coating and method for overcoating a TBC on a component used in a high-temperature environment, such as the combustor section of an industrial gas turbine. The coating defines the outermost surface of the component and is formed of at least two layers having different compositions. An inner layer of the coating contains alumina in a first silica-containing matrix material that is free of zinc titanate. An outer layer of the coating contains alumina, a glass material, and zinc titanate in a second silica-containing matrix material. The outer layer of the coating has a surface roughness of not greater than three micrometers Ra and forms the outermost surface of the component. The coating reduces the component temperature by reducing the convective and radiant heat transfer thereto.

Owner:GENERAL ELECTRIC CO

Nano ceramic high-temperature-resistant thermal-insulation coating, and its preparing method and use

InactiveCN1935912AAchieve insulation effectImprove insulation effectFireproof paintsMicrosphereThermal insulation

The invention discloses new nanometer ceramic high temperature resistant heat preservation paint and the preparing method and use. Its components part by weight are as follows: film forming matter 10-35, filling 50-75, ceramic micro-balloon 8-50, and modified nanometer material 3-12. The produced nanometer ceramic high temperature resistant heat preservation paint can prevent solid heat transfer and radiant heat transfer, thus it can greatly improve heat preservation effect. And its high temperature resistant can reach 1000 degree centigrade.

Owner:王继征

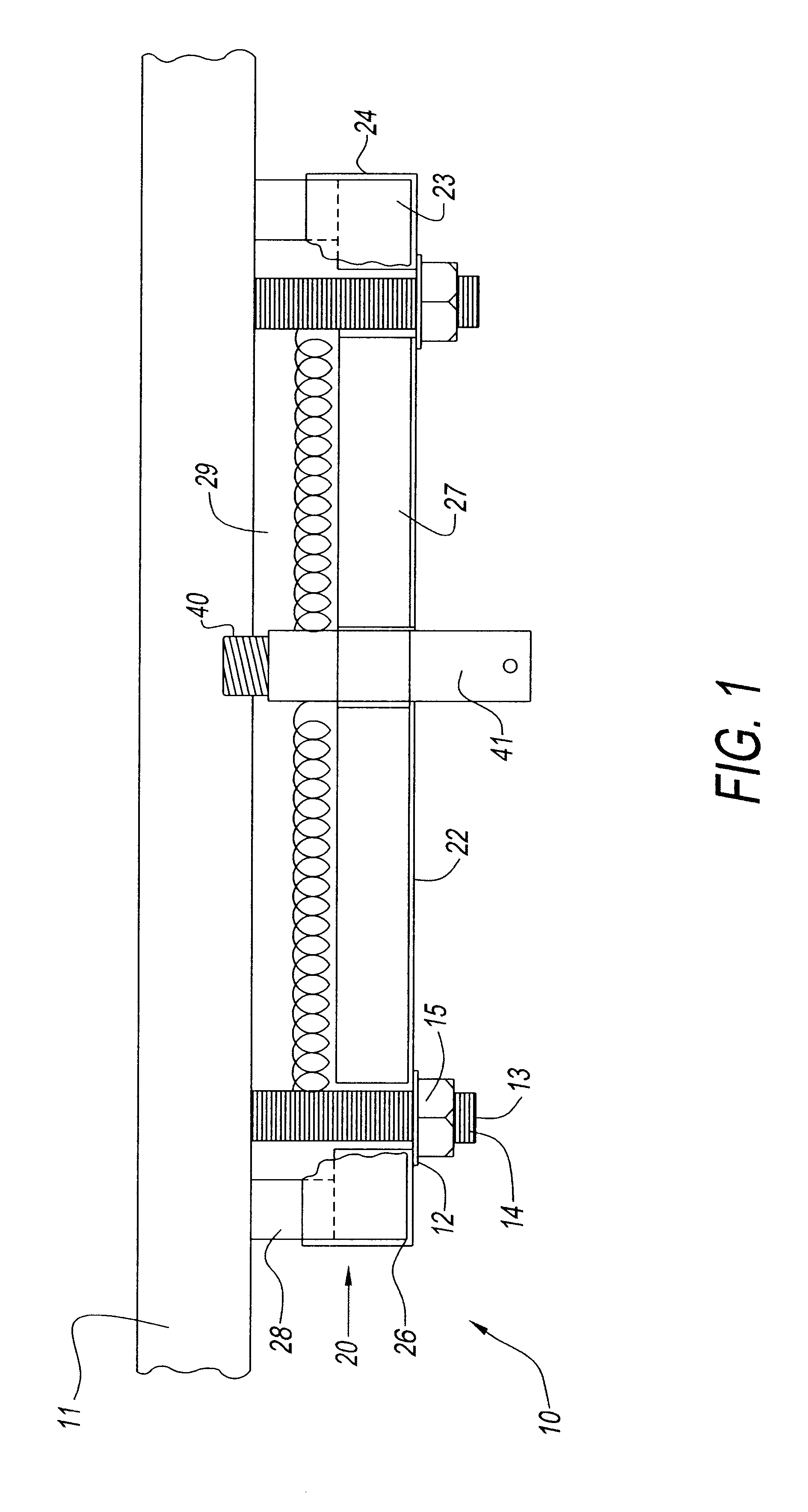

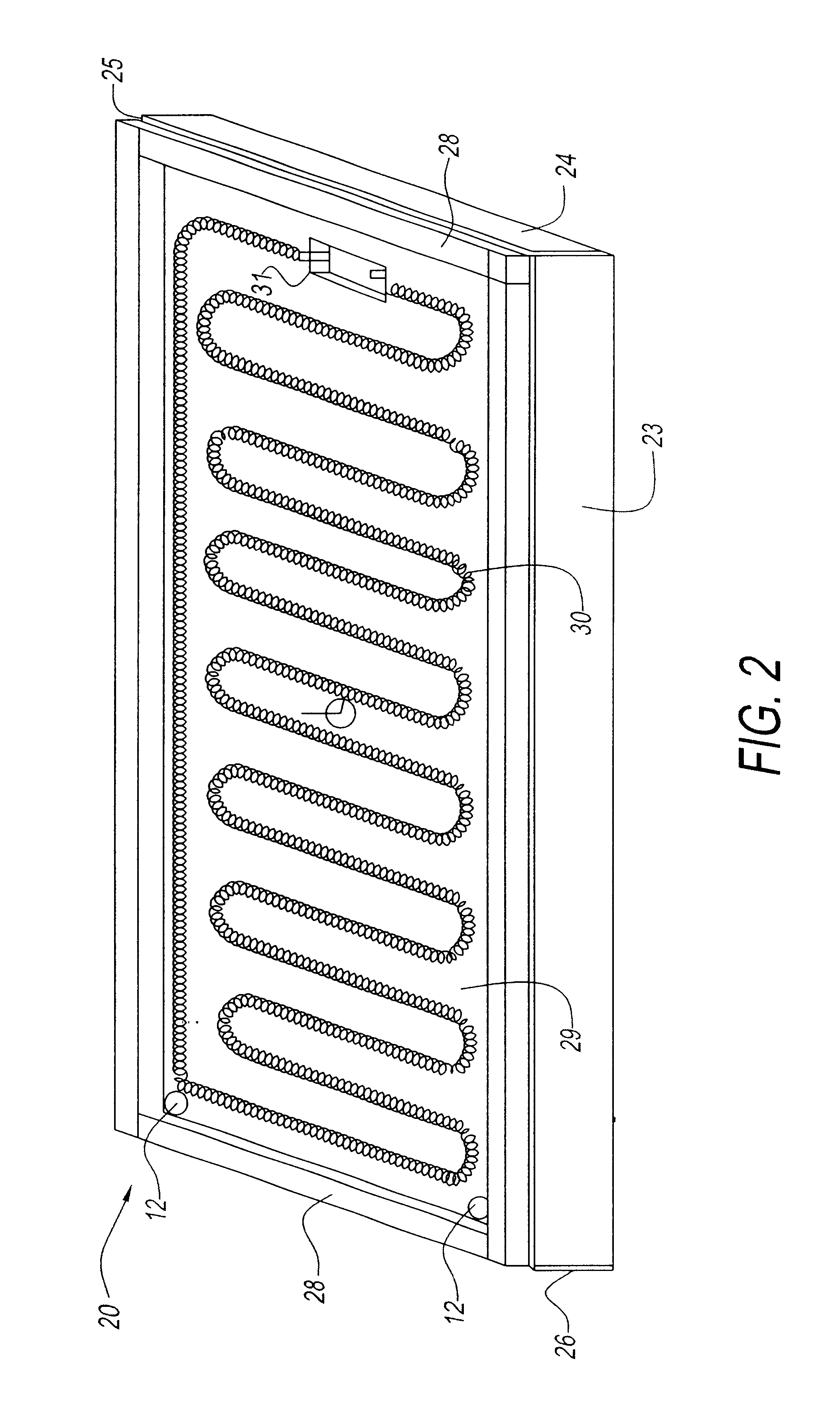

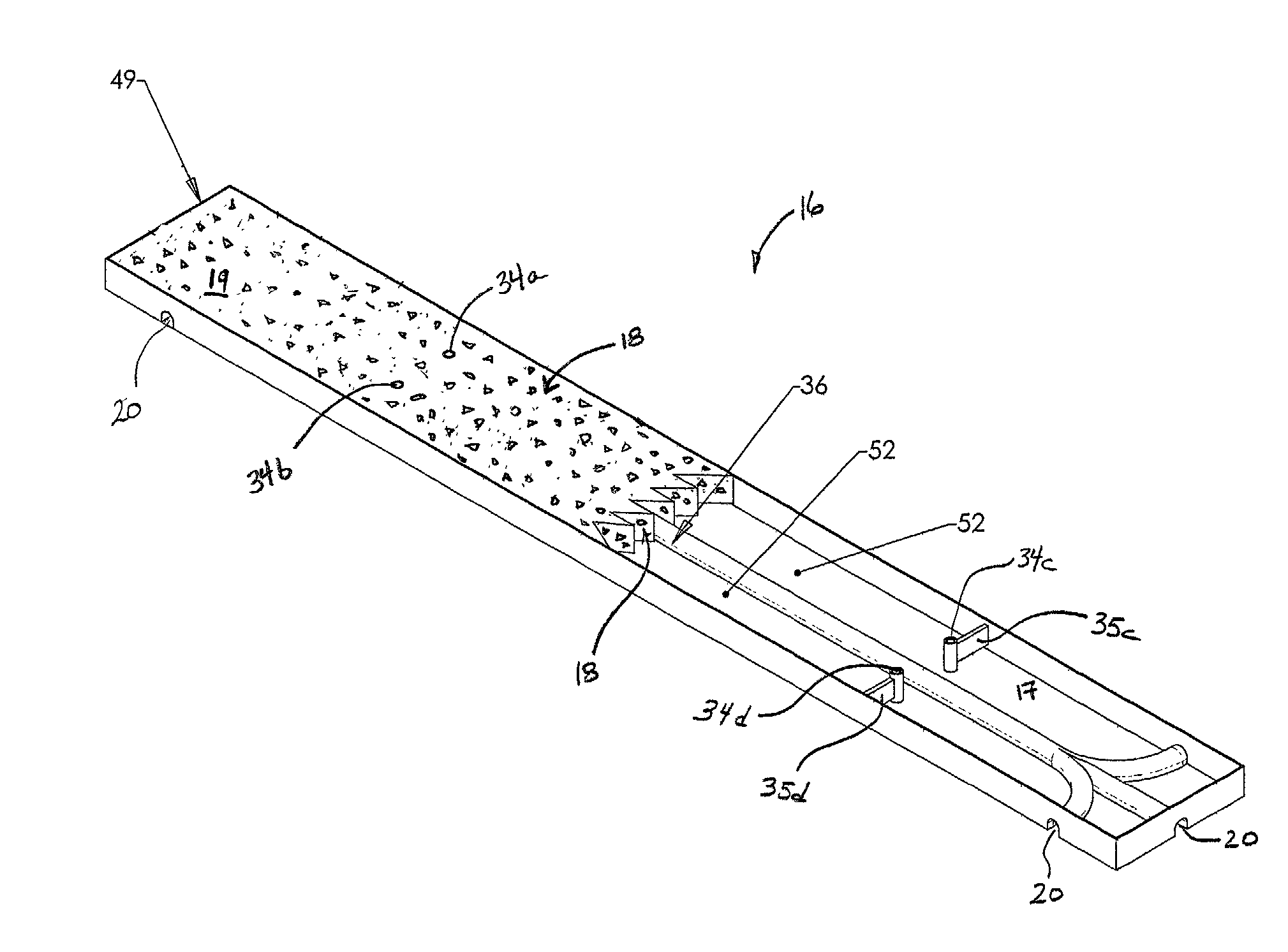

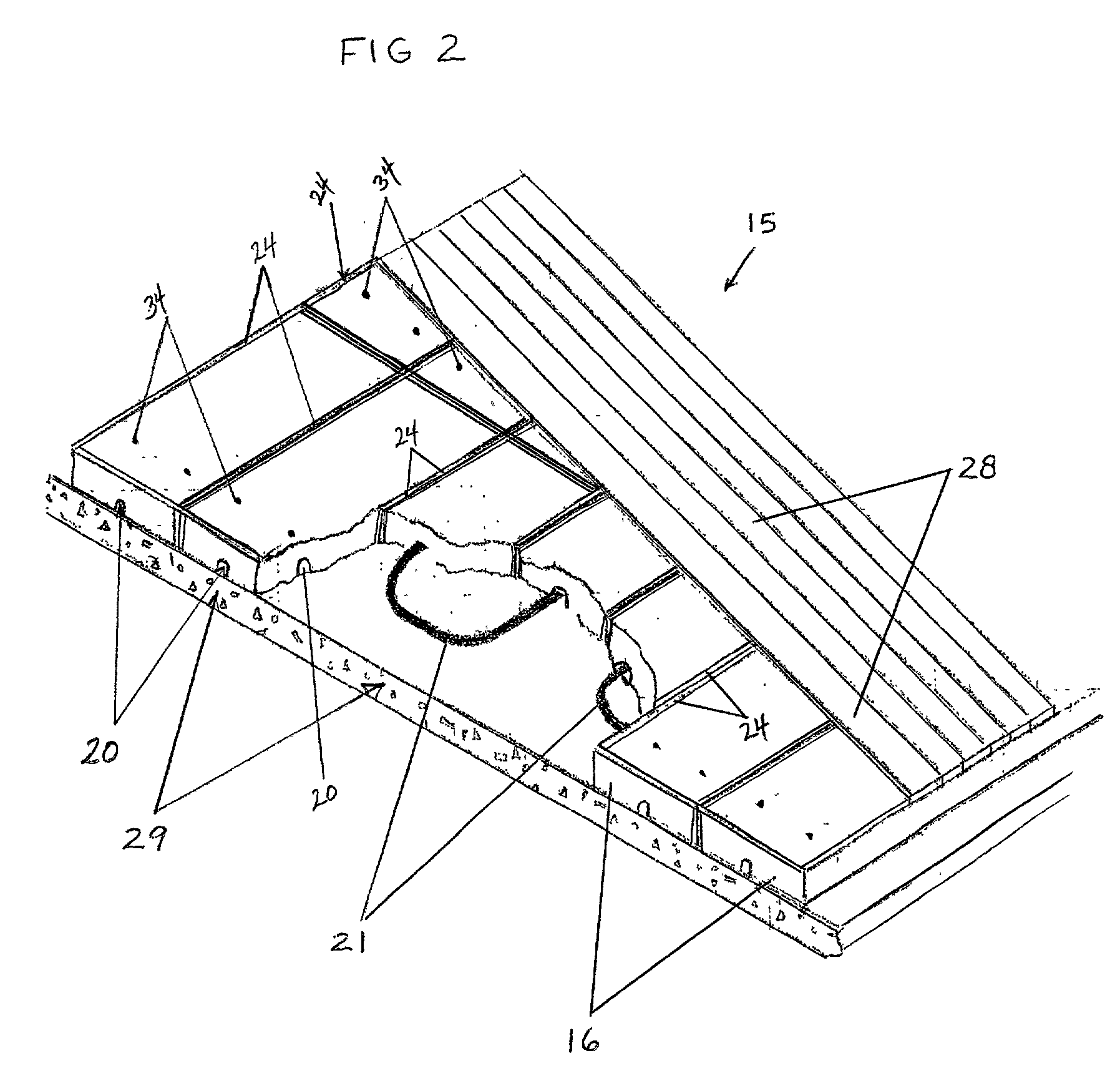

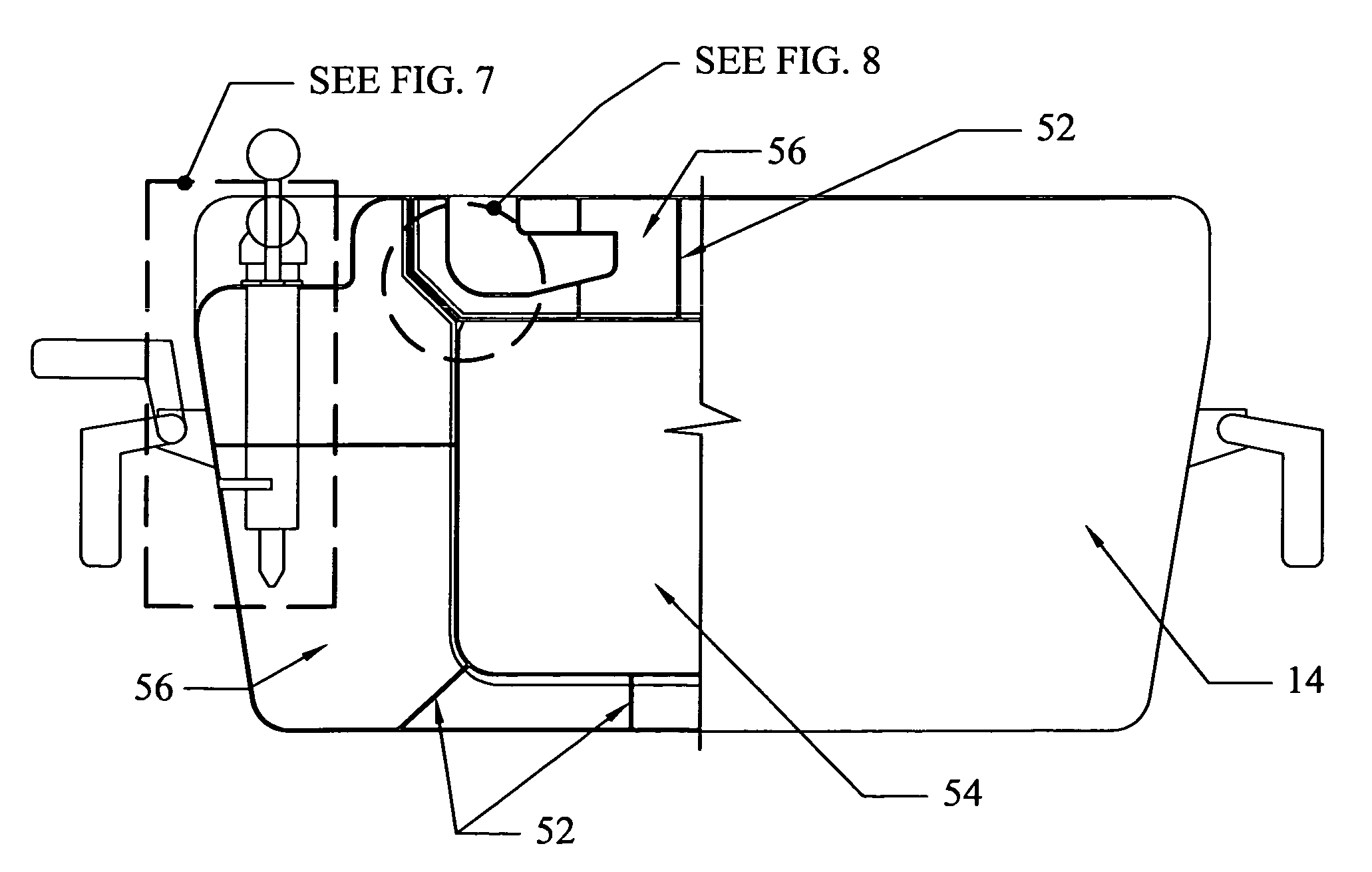

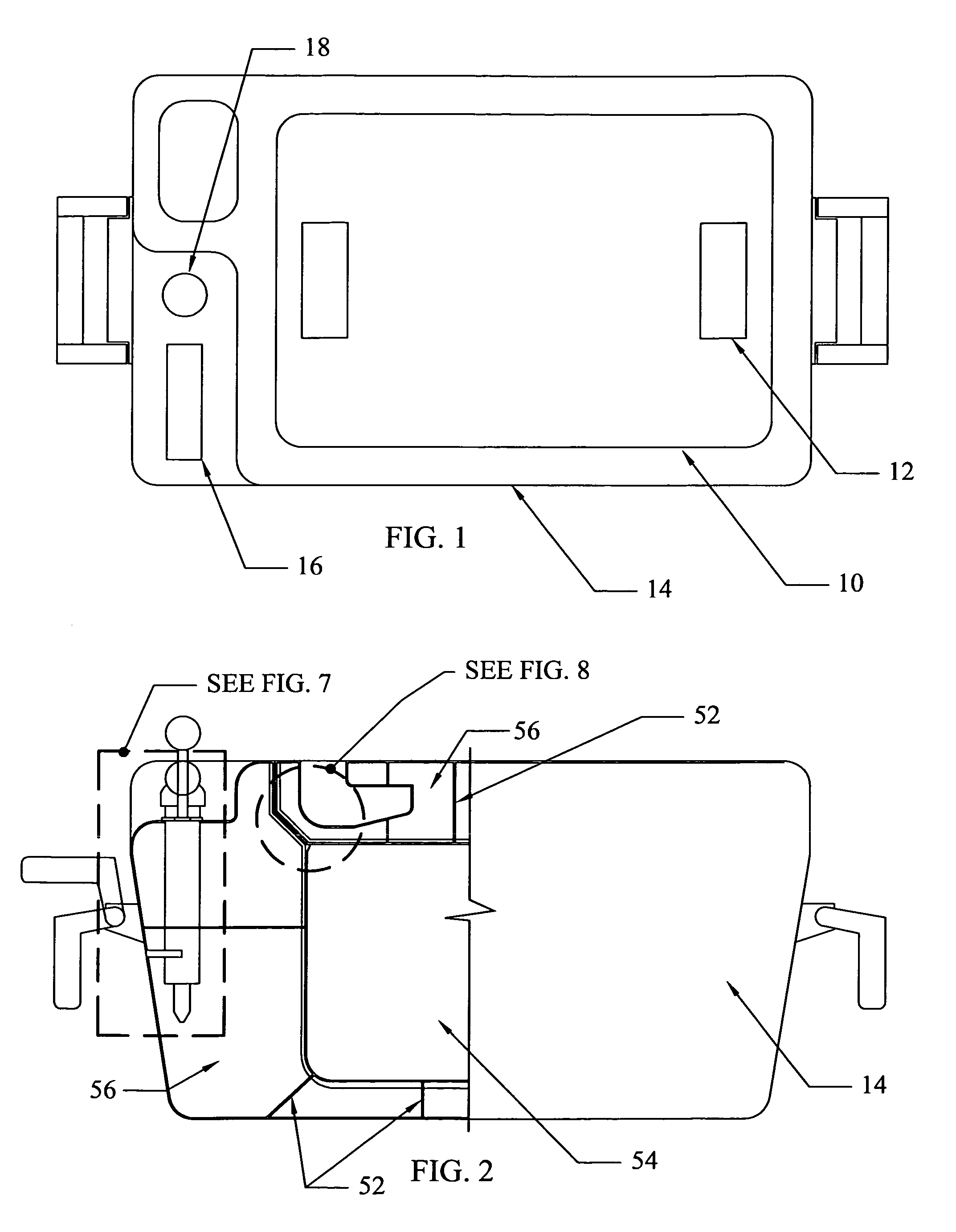

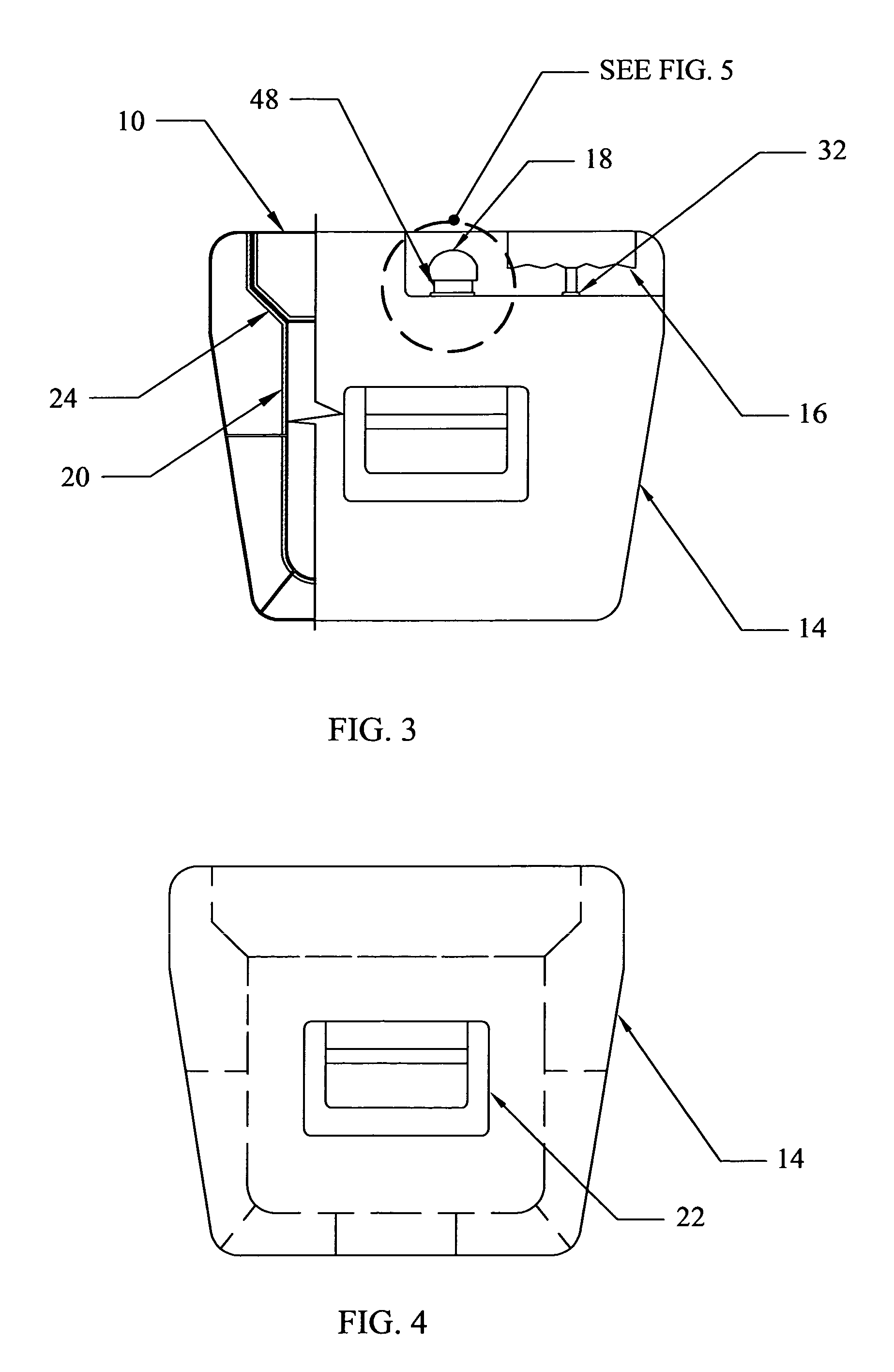

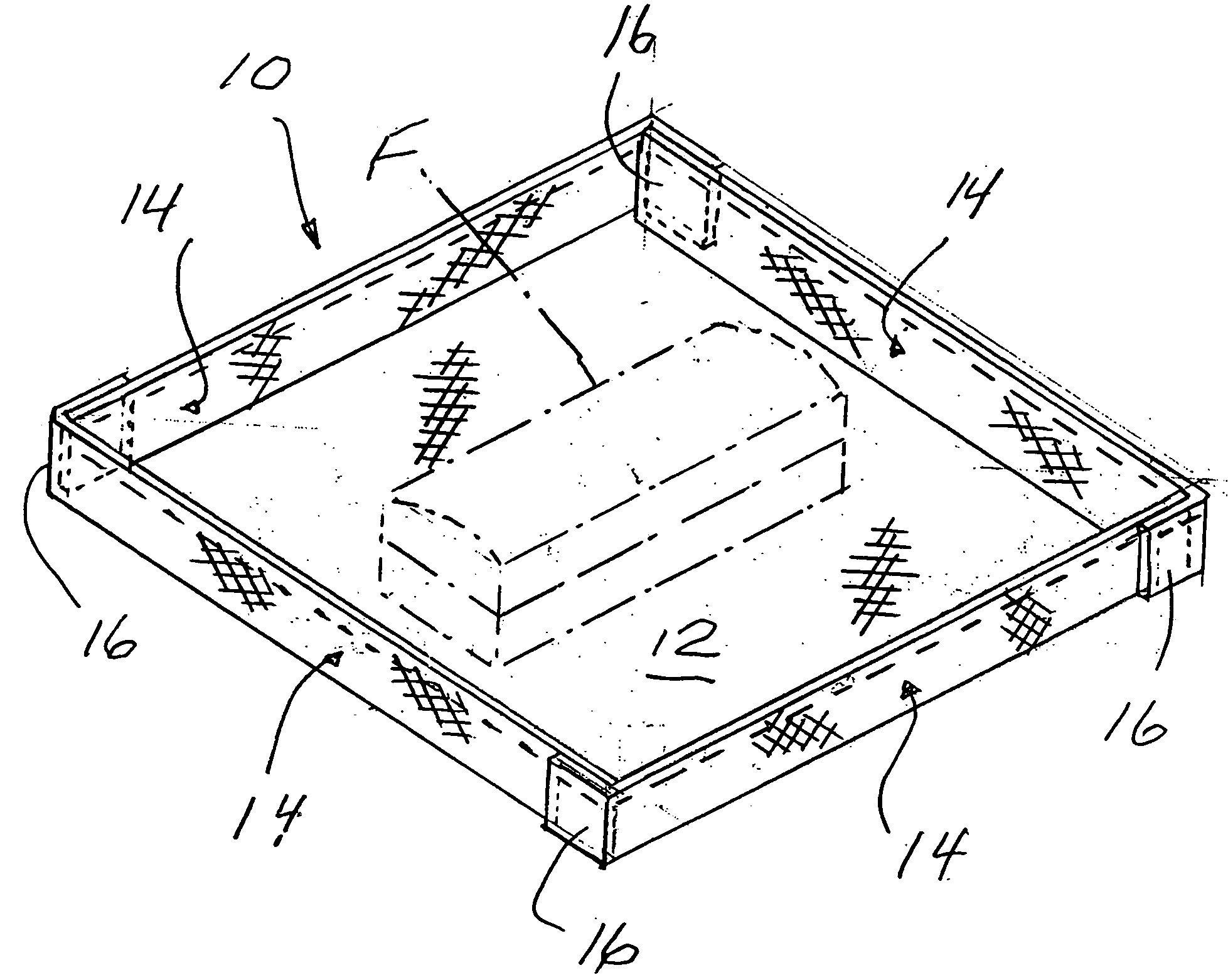

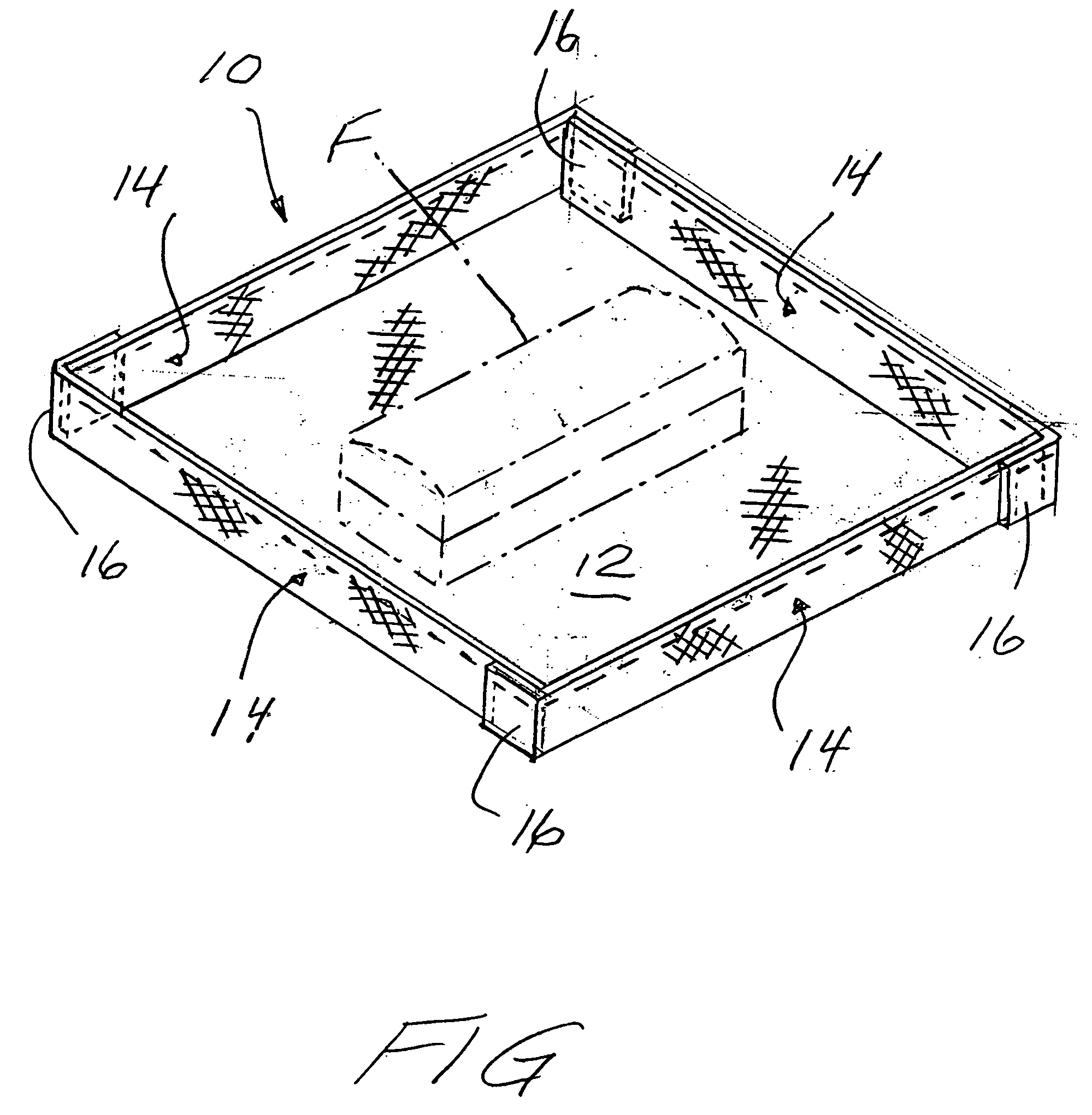

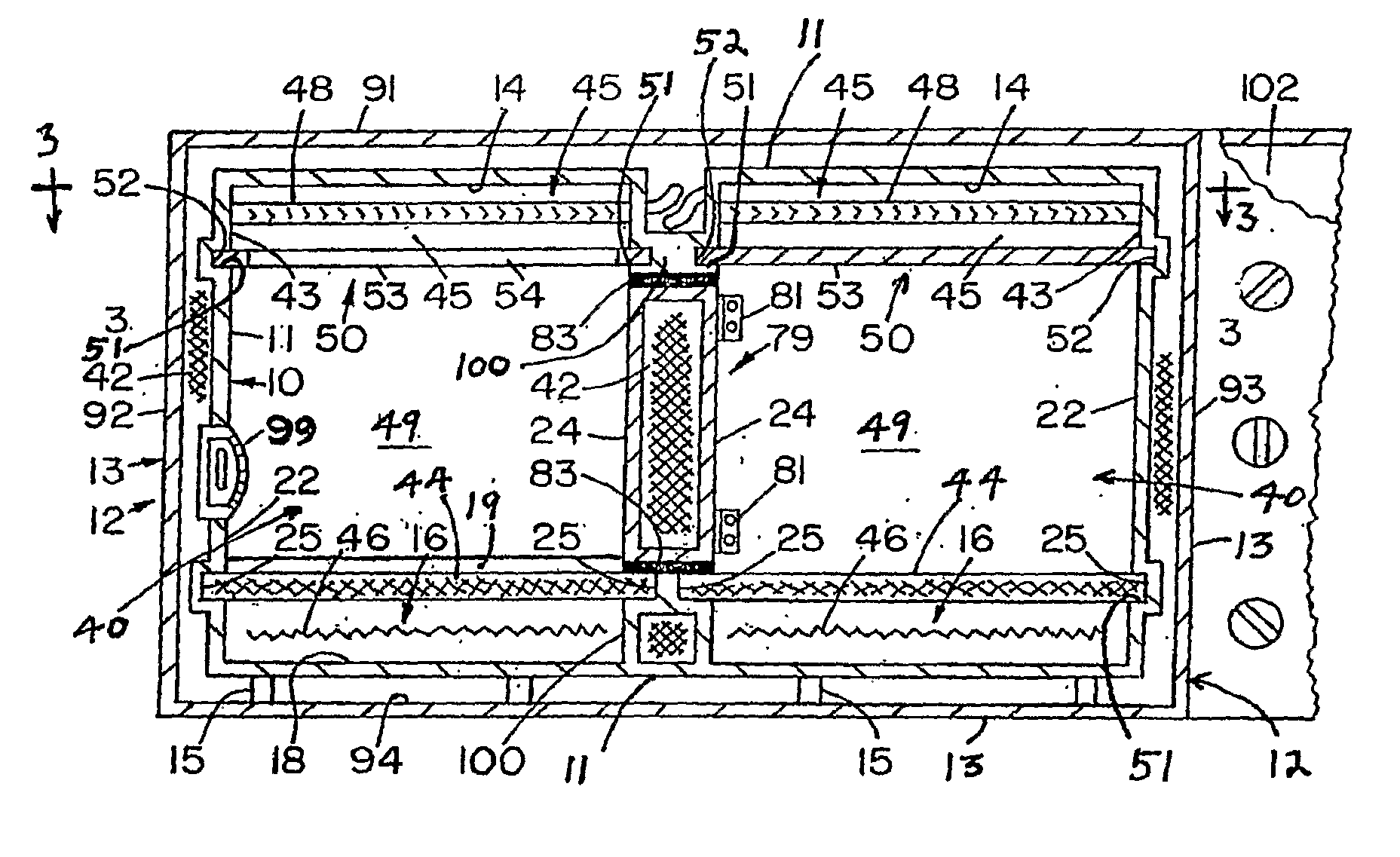

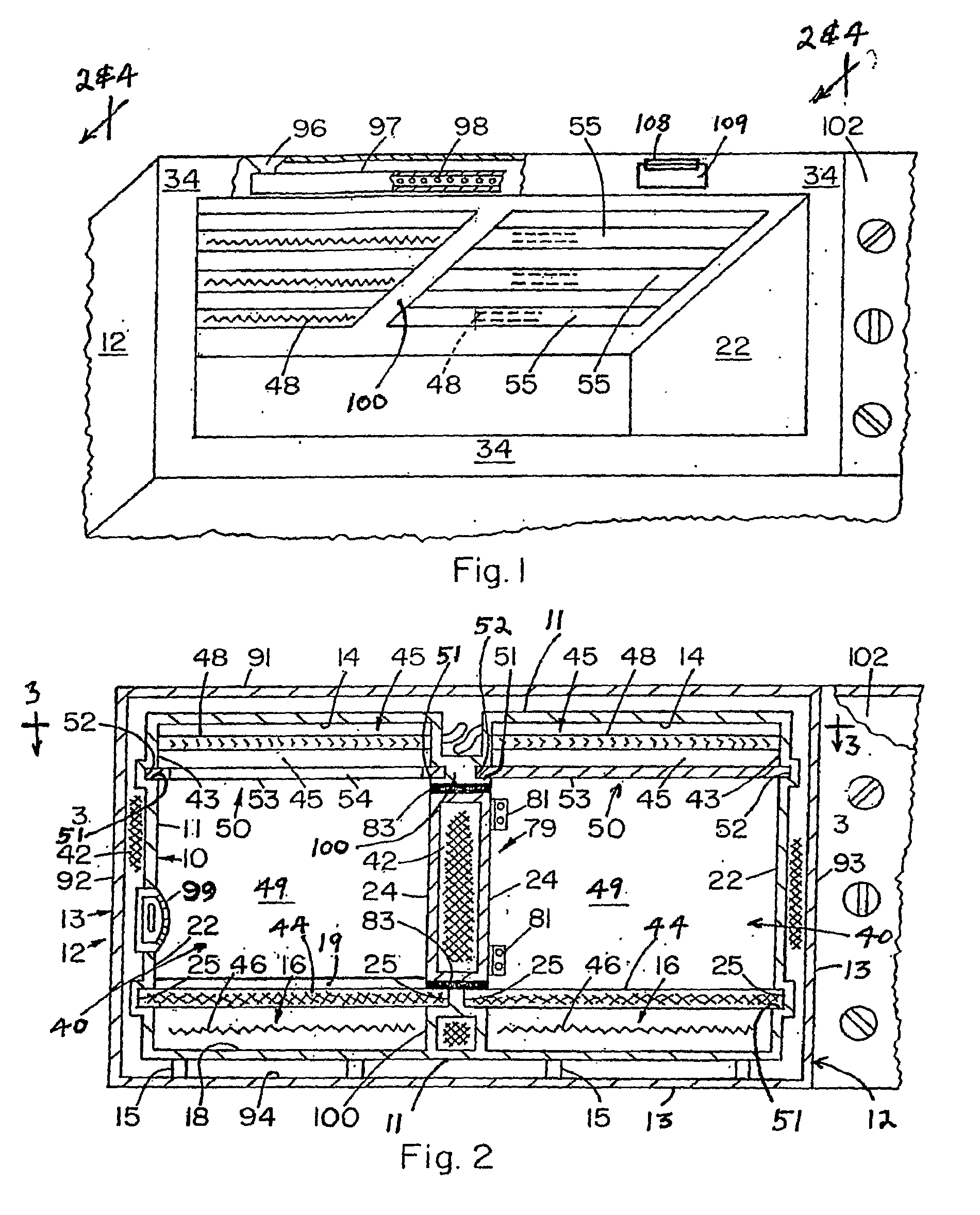

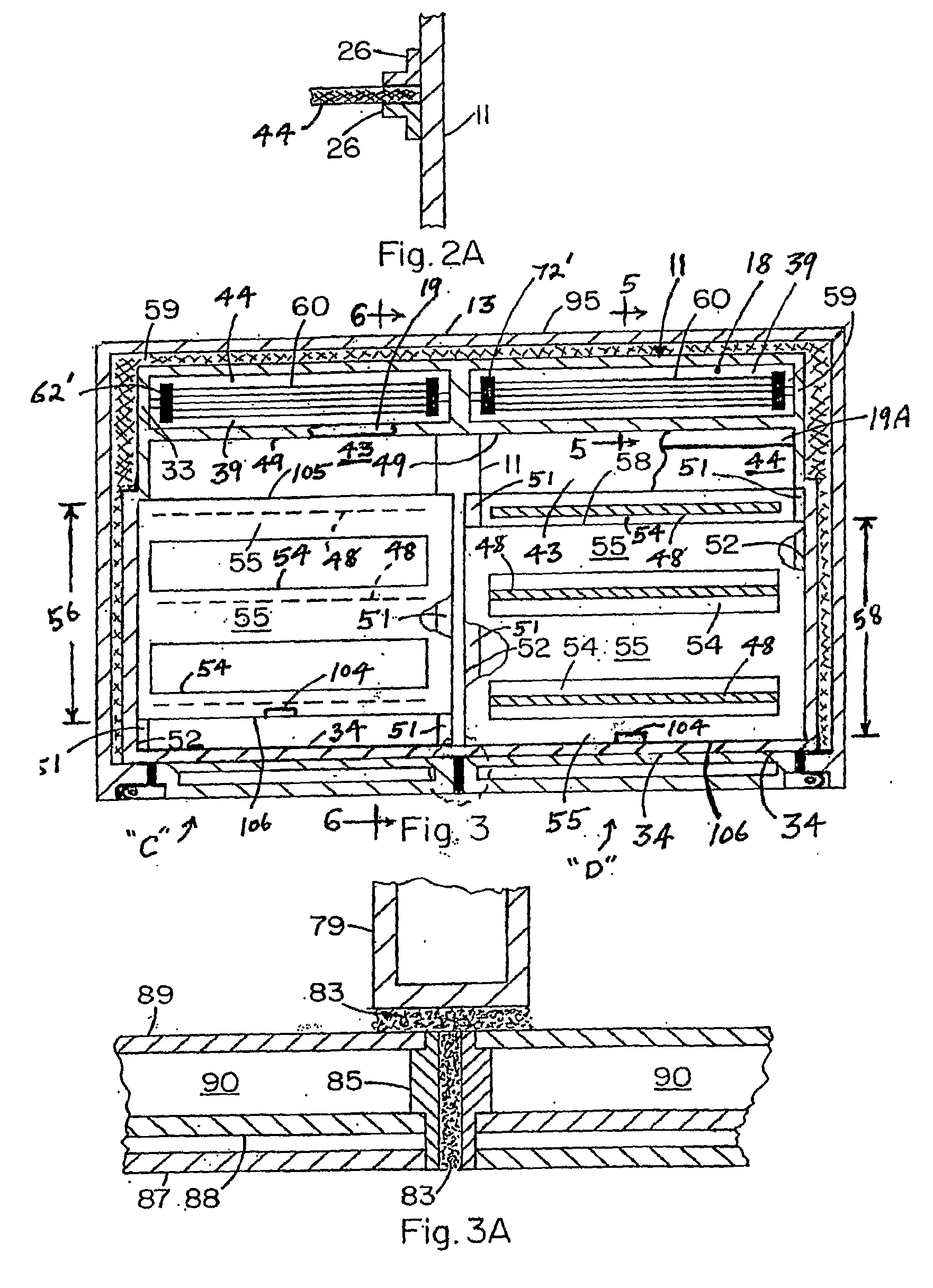

Modular radiant heat panel system

The invention is directed to modular radiant heat panel system. In the preferred embodiment, the system comprises multiple radiant heat transfer panels (16), each of the panels having a thermal mass (18) and a conduit channel (20); a fluid conduit (21), the conduit communicating with an apparatus (23) for heating fluid (22) in the conduit; the multiple panels positioned adjacent each other such that the conduit extends through a series of the conduit channels; the panels, conduit and apparatus so configured and arranged to permit heat transfer from the fluid to the thermal mass of the panel, whereby heat radiates from the panel. The present invention also discloses a radiant heat transfer panel for engagement with a fluid conduit comprising: a formed tray (24); the tray defining a thermal volume (17) and a conduit channel; the volume containing a thermal mass; and the channel, volume and thermal mass configured and arranged to permit heat transfer between the conduit and the thermal mass. The invention also discloses a method for installing a modular radiant heat panel system comprising the steps of: providing an under-layer having a given area (44); providing multiple panels having a thermal mass and a conduit channel; providing conduit; position the conduit over or under the under-layer in a predetermined pattern; and positioning the panels on or under the under-layer such that the conduit extends through at least a portion of the conduit channel of the panels.

Owner:HYDOCK GARY J

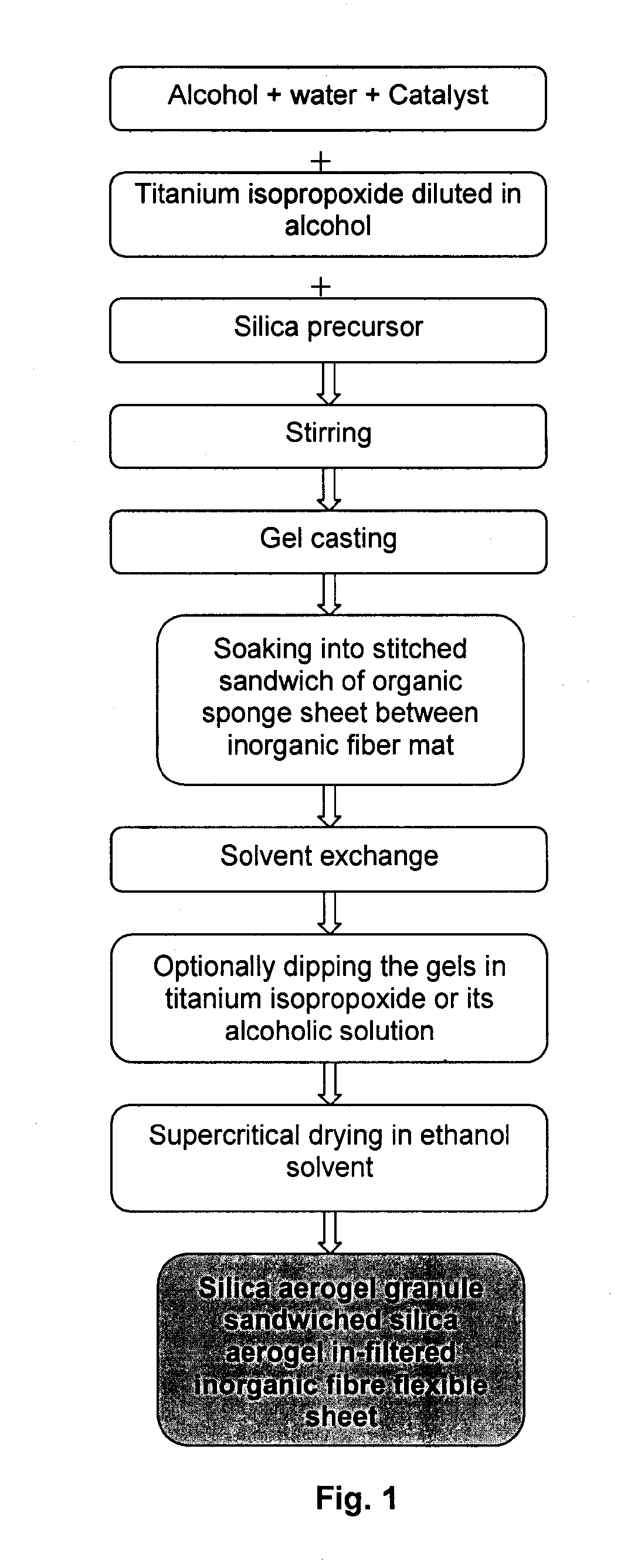

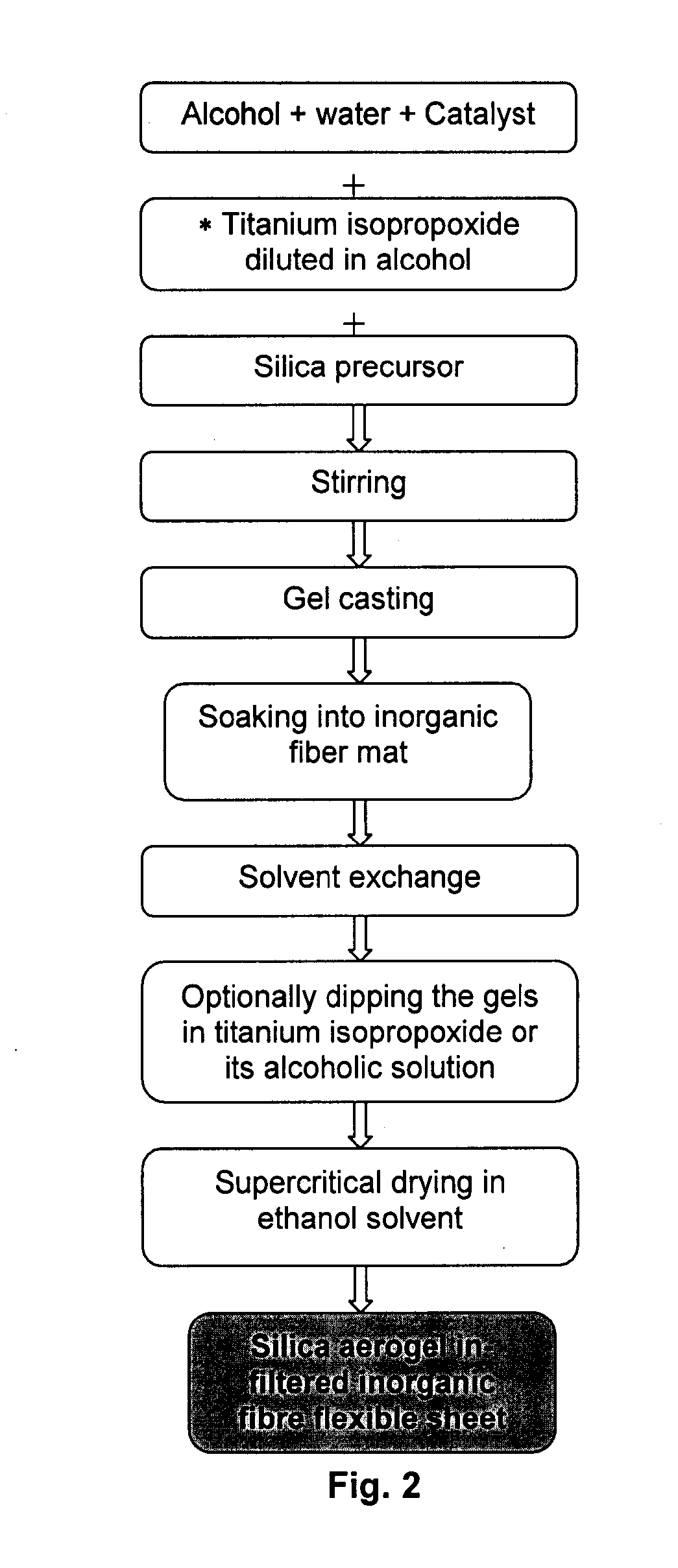

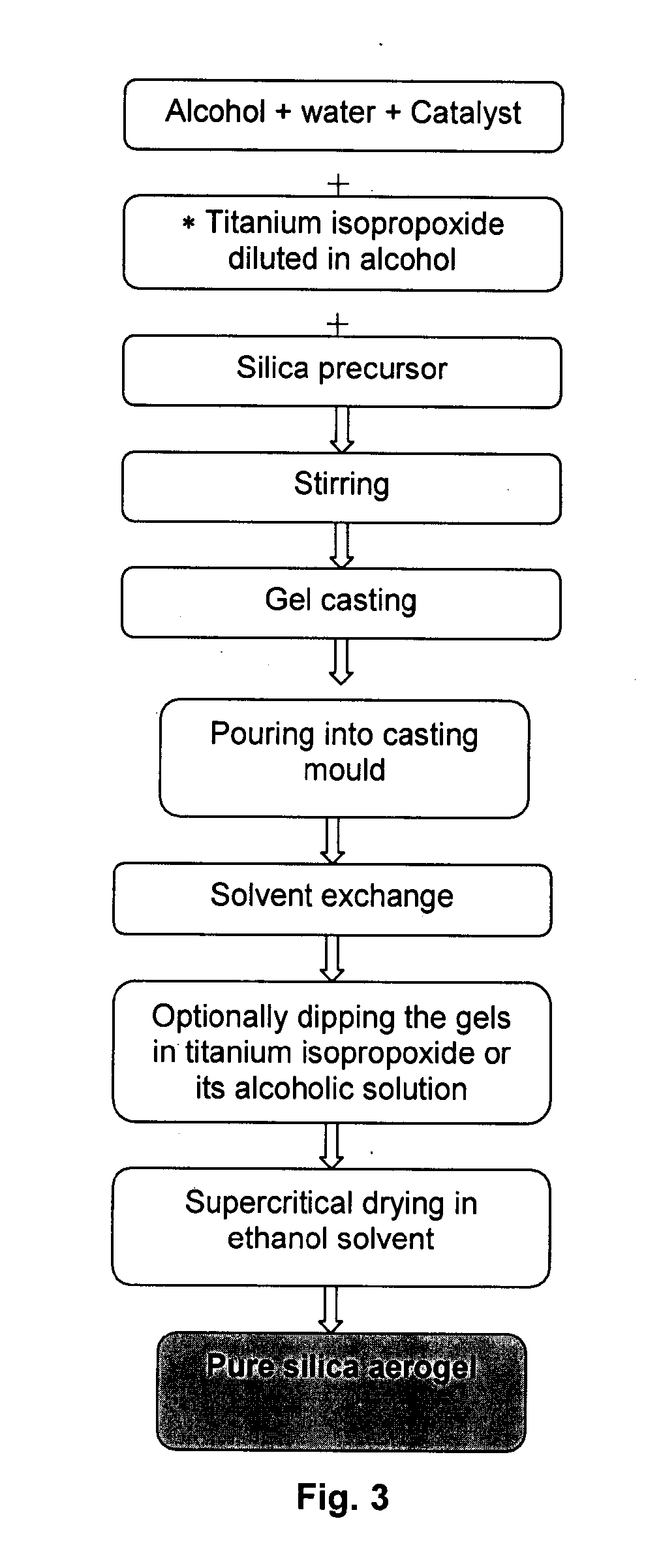

Improved process for producing silica aerogel thermal insulation product with increased efficiency

InactiveUS20190002356A1Easy to solveImprove insulation effectThermal insulationLayered productsFiberThermal insulation

The invention relates to an improved method for producing silica aerogel in pure and flexible sheet form having effective suppression of radiative heat transport at high temperatures and increased thermal insulation property. The suppression of radiative heat transport was achieved by in-situ production of titanium dioxide nanoparticles in very minor concentrations during gelation of silica precursor, with nanoporous surface area more than 300 m2 / g and acts as an infra red reflecting agent. When aerogel is subjected to heat during hot object insulation, it automatically turn into infra red reflecting material. Said silica aerogel can be incorporated into the inorganic fibre mat matrix individually or into two or more layers with organic sponge sheet placed in between and stitched together to form a sandwich sheet to form highly insulating flexible sheet.

Owner:M S INT ADVANCED RES CENT FOR POWDER METALLURGY & NEW METERIALS ARCI

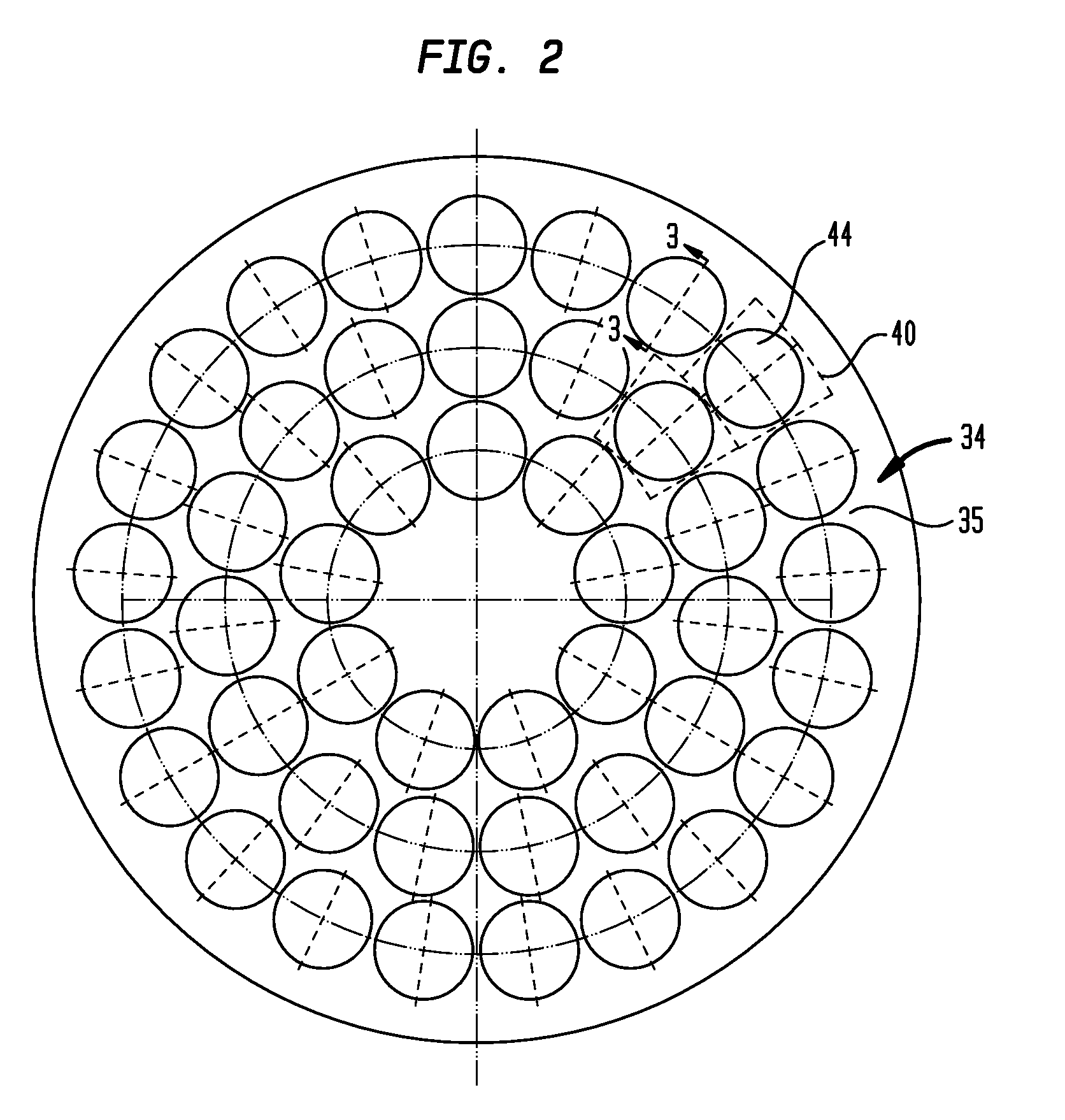

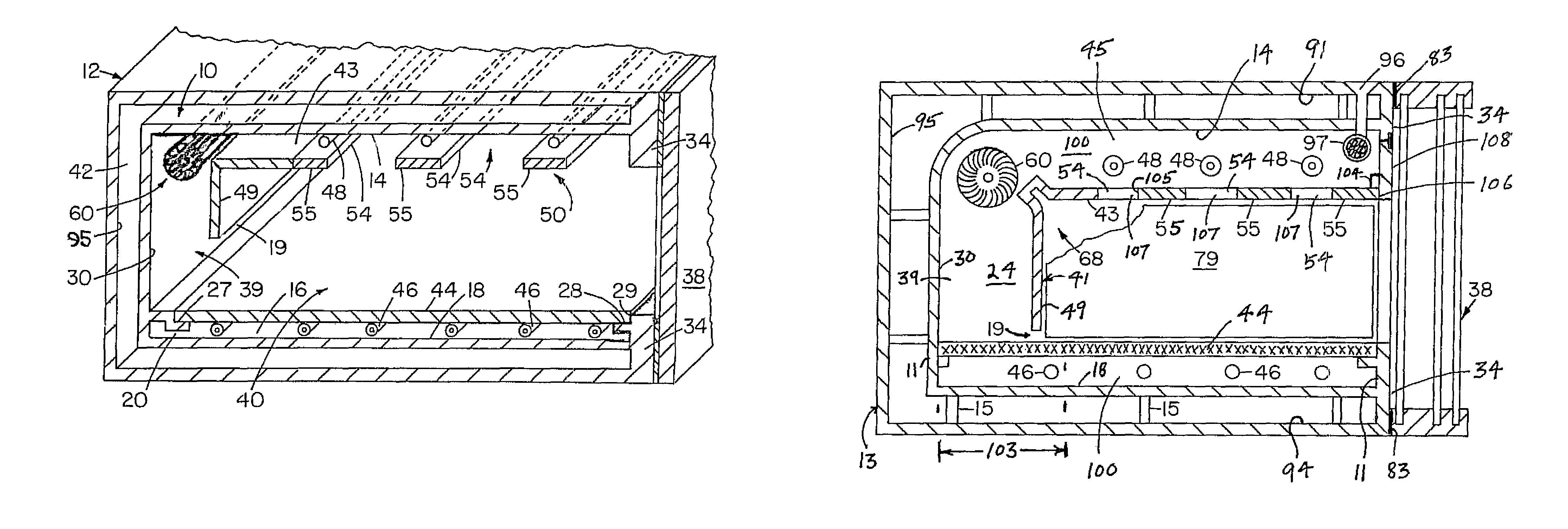

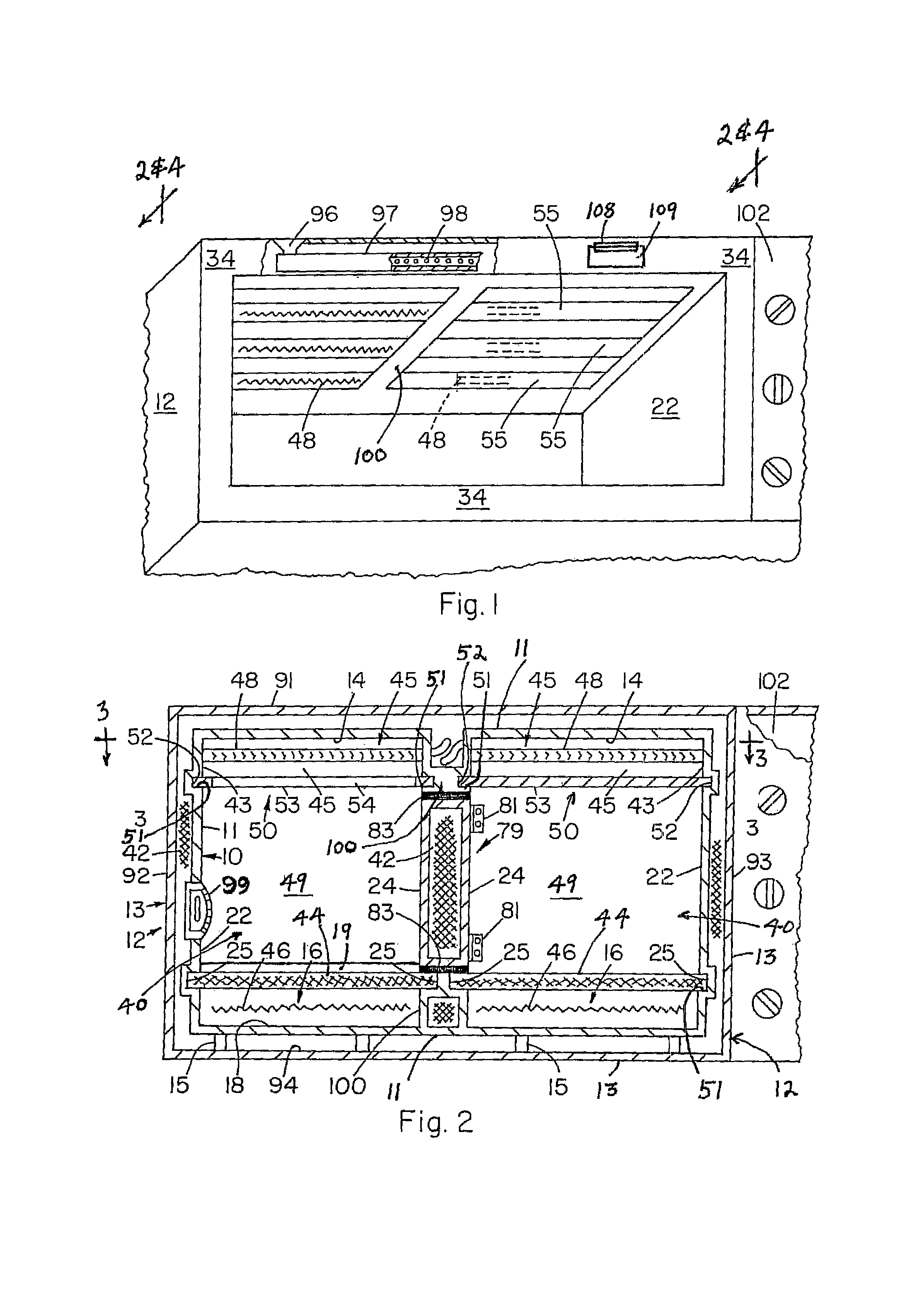

Cooking oven

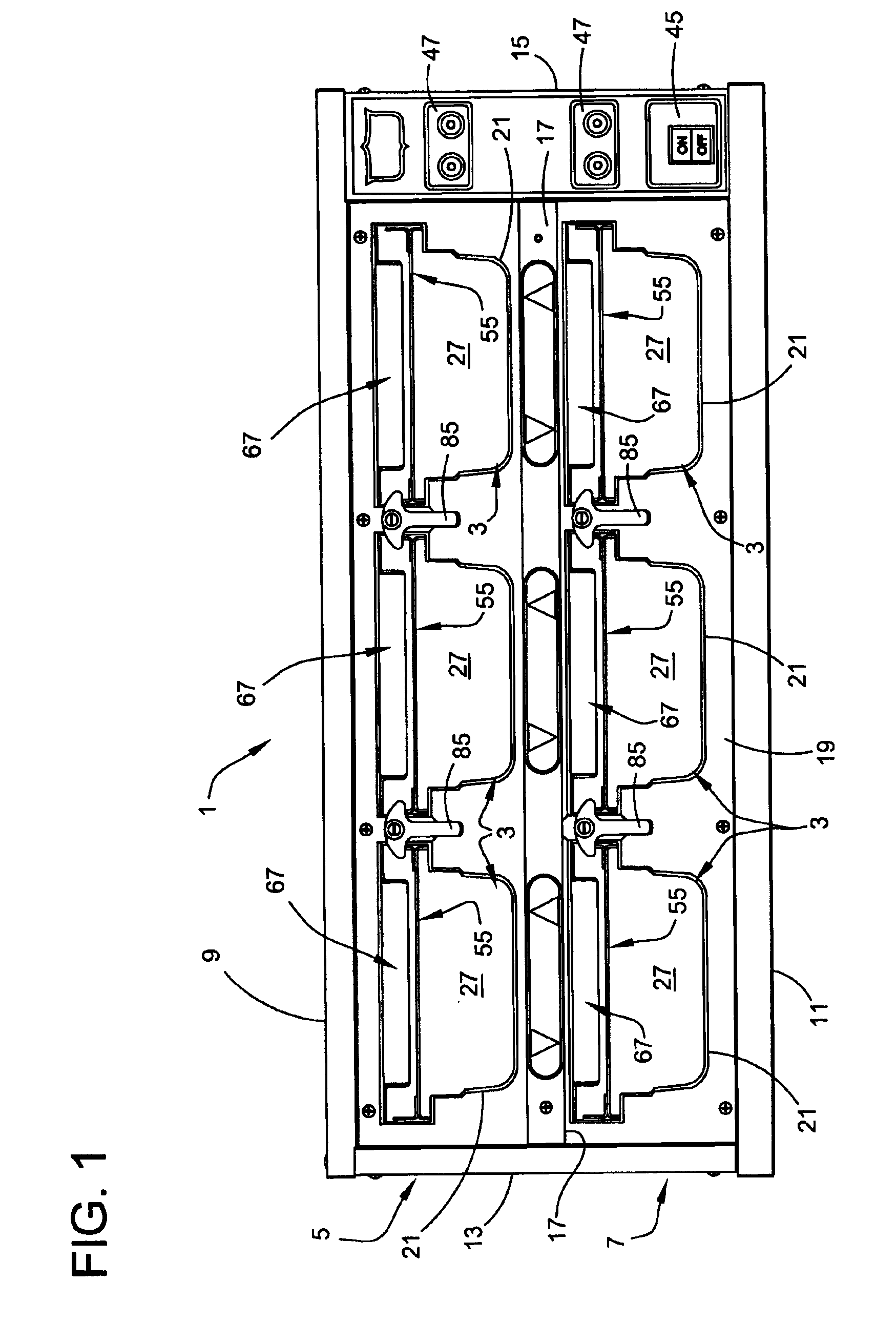

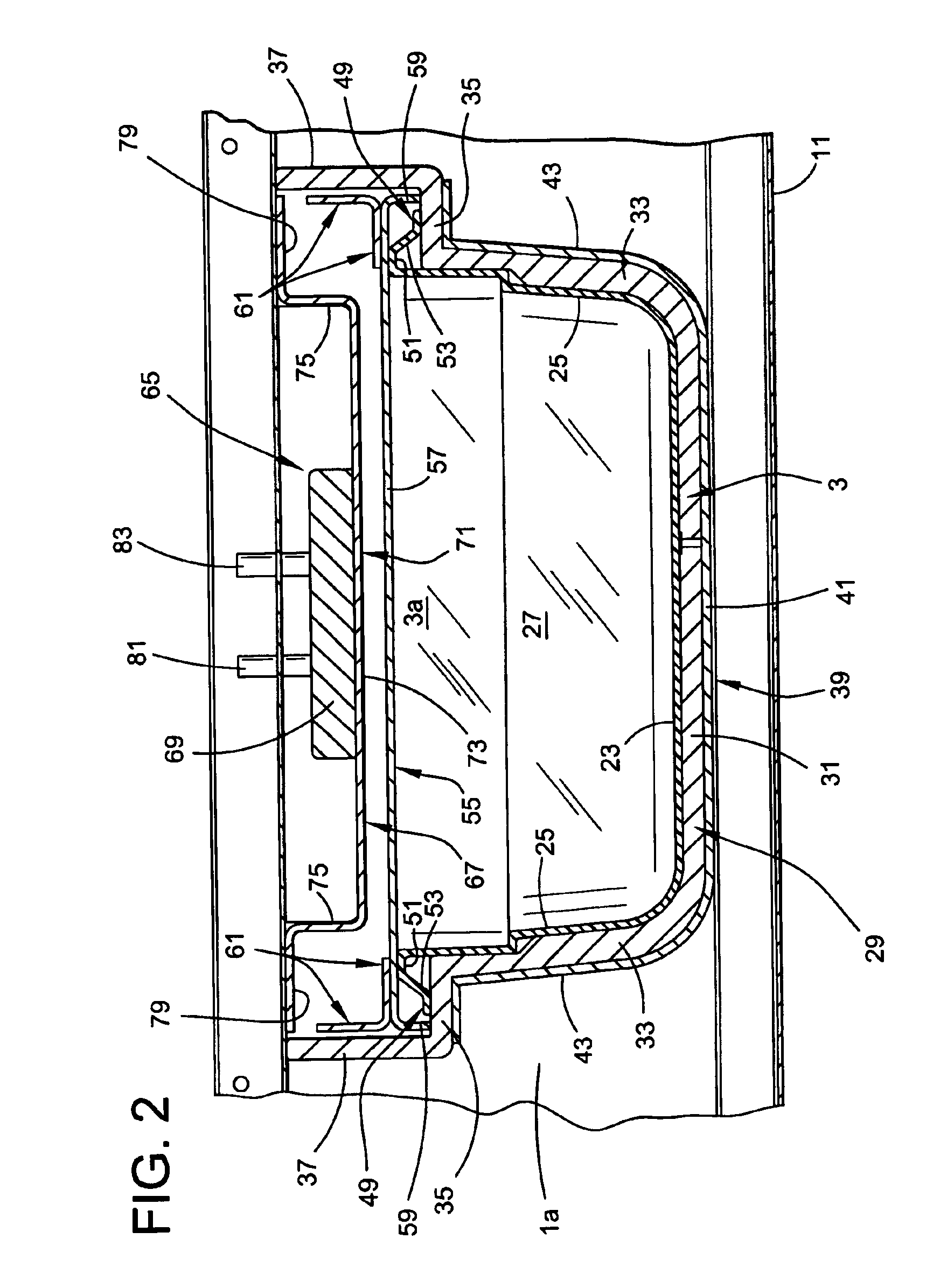

InactiveUS20070108179A1Avoid burnsPoor heat conductorDomestic stoves or rangesElectrical heating fuelEngineeringRadiant heat transfer

A cooking structure which provide for two or more side-by-side ovens separated by vertical, movable, hinged partition(s) whereby the oven structure may function as one large oven or as two or more smaller independent ovens, wherein for each oven a tangential fan blows air substantially evenly over upper electrical heating elements strung generally from side-to-side of the oven, wherein a flow director functions as a radiant heat shield which is operator movable to either expose to or occlude from the oven cooking chamber to direct radiation from its heating elements depending on the need to roast, bake, or broil the food product. Also provided are lower electrical heating elements positioned below a ceramic cooking surface for ensuring evenness of radiant heat transfer therefrom. Also provided for is operator controlled top vs. bottom heating using a slide control that reciprocally affects the duty cycle of the top and bottom electrical heating elements, further allowing precision baking control.

Owner:HINES ROBERT STICKLEY JR

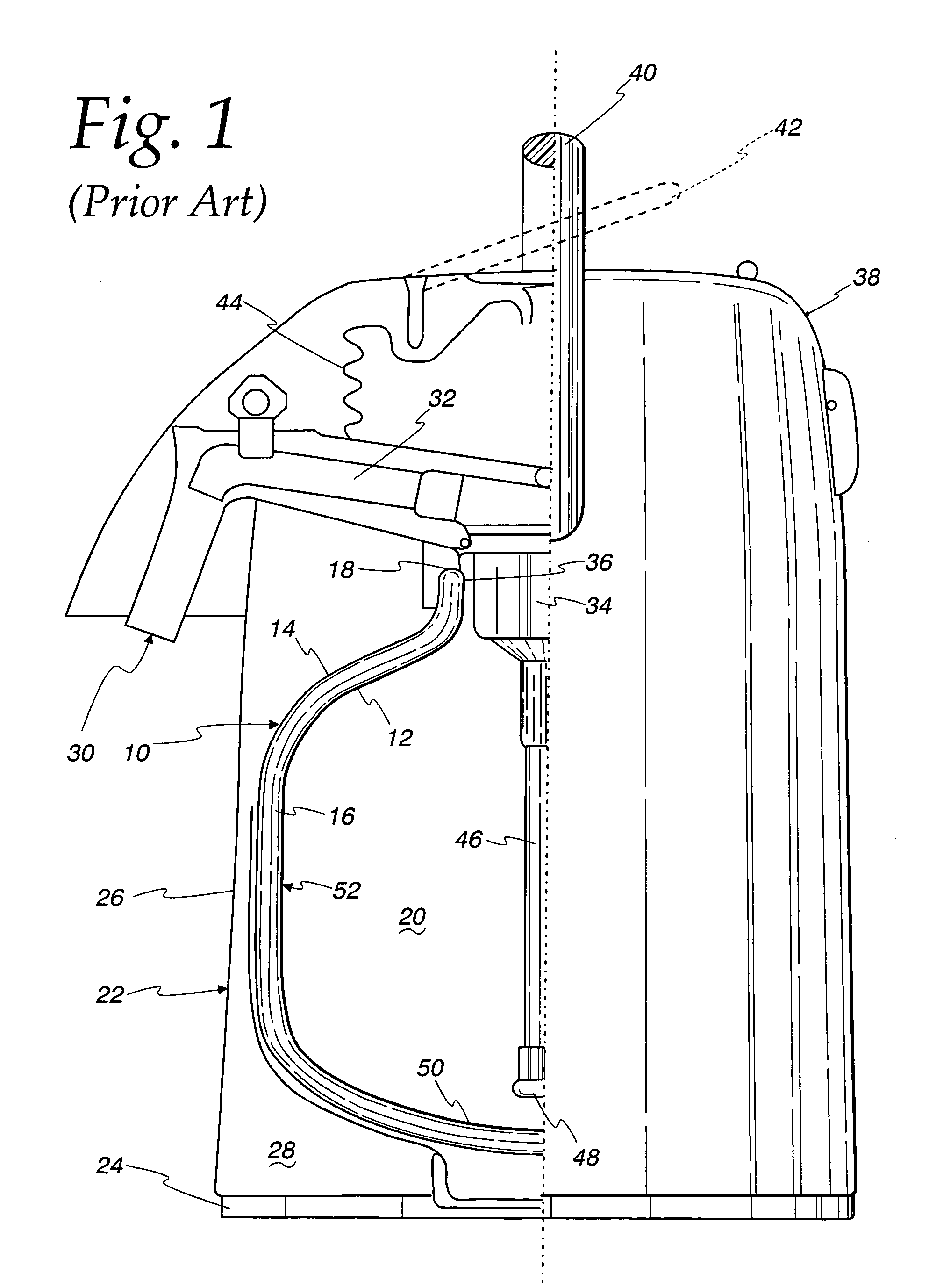

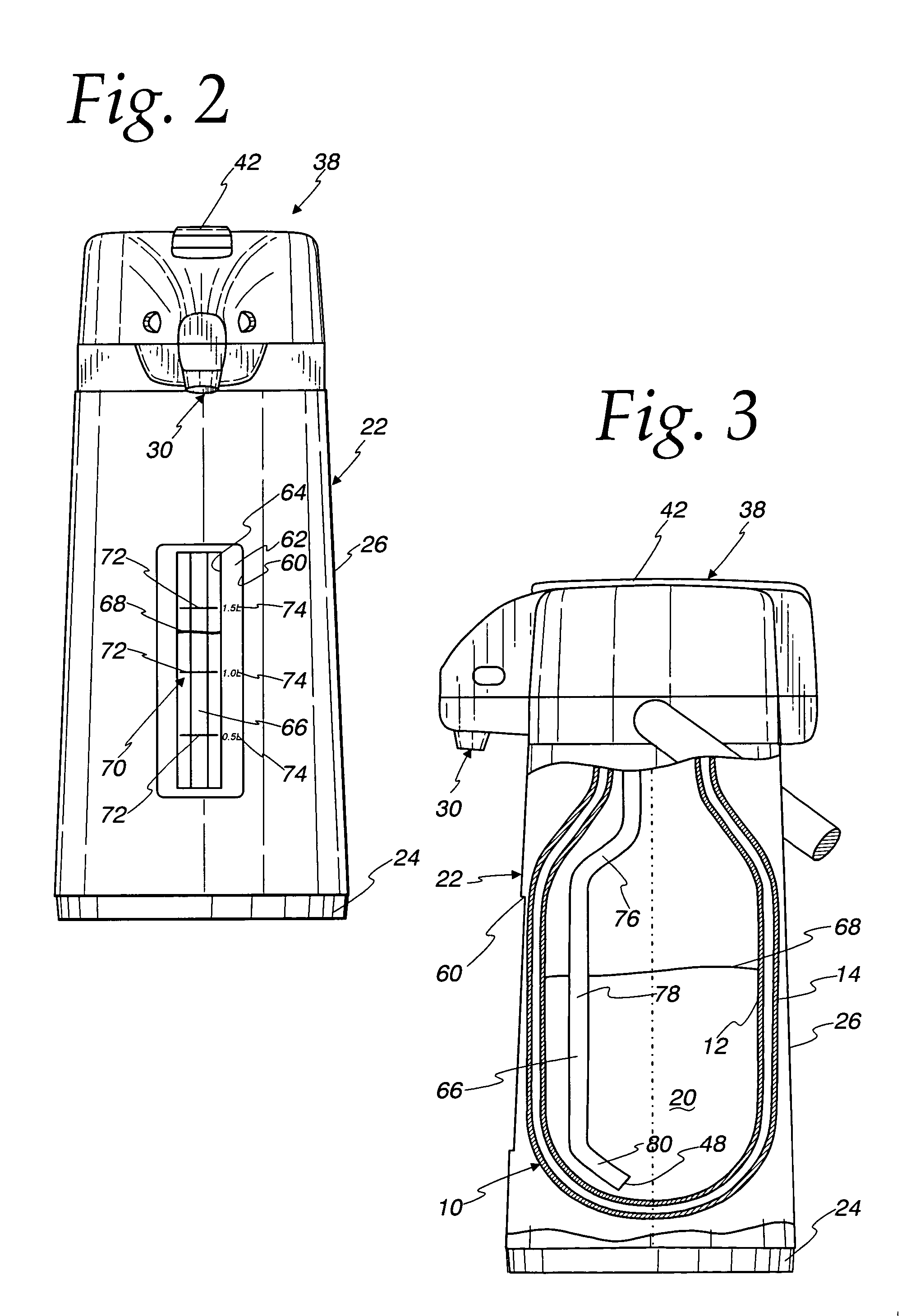

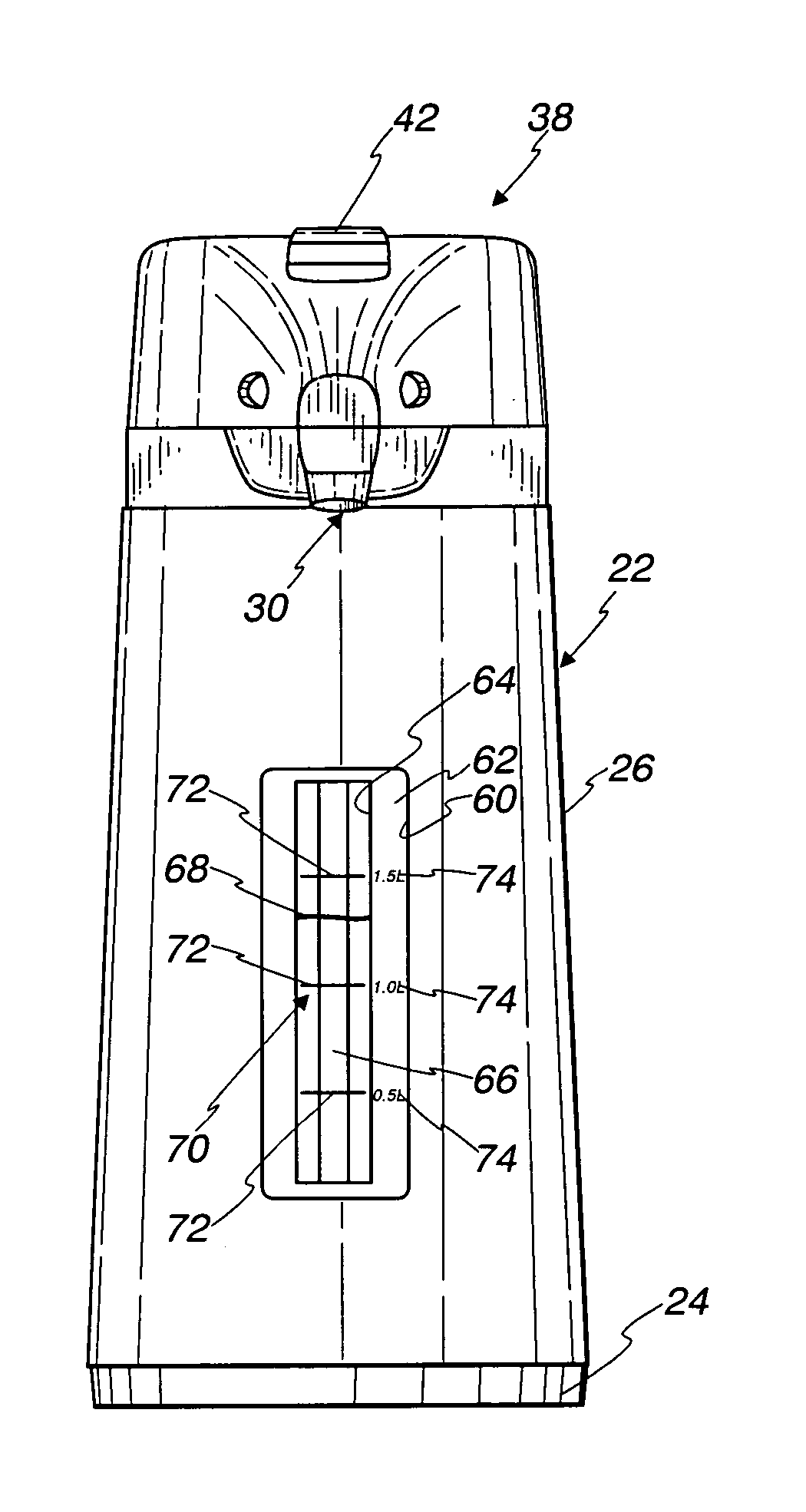

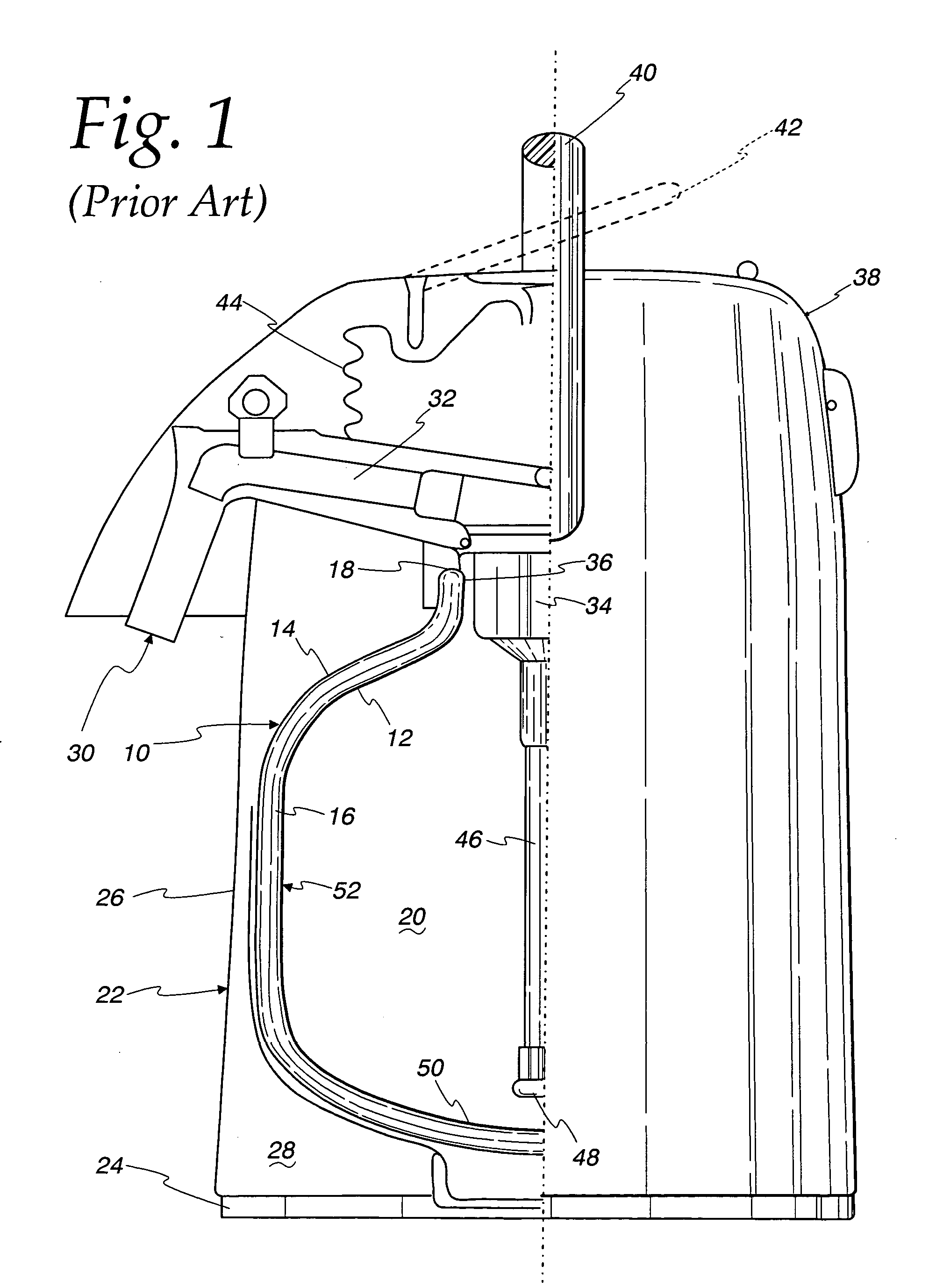

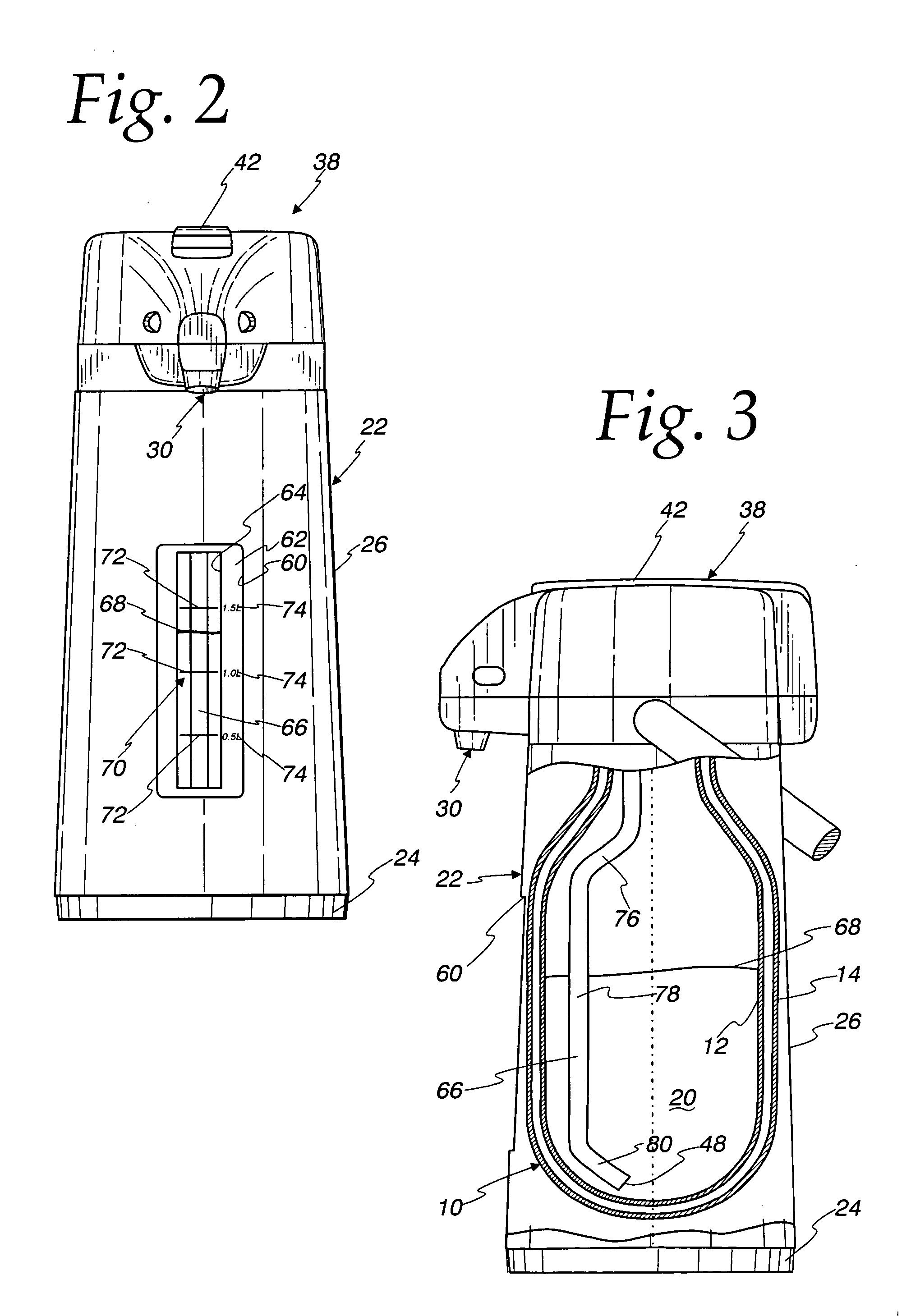

Carafe with contents volume indicator

ActiveUS7163125B2Accurately determineMaximize efficiencyCapsClosure lidsEngineeringRadiant heat transfer

An inexpensive, readily visible indicator for liquid levels in a vacuum bottle that includes a coating of reflective material to minimize radiation heat transfer from the interior of the vacuum bottle to the exterior of the assembly. The vacuum bottle assembly includes a container receiving the vacuum bottle and a transparent or translucent window is located in the side wall of the container and in alignment with an interruption in the reflective coating. An indicator is located within the vacuum bottle and is aligned with both the windows and the interruption so as to be visible therethrough to provide an indication of the level of the liquid contained within the inner liner of the vacuum bottle.

Owner:THERMOS LLC

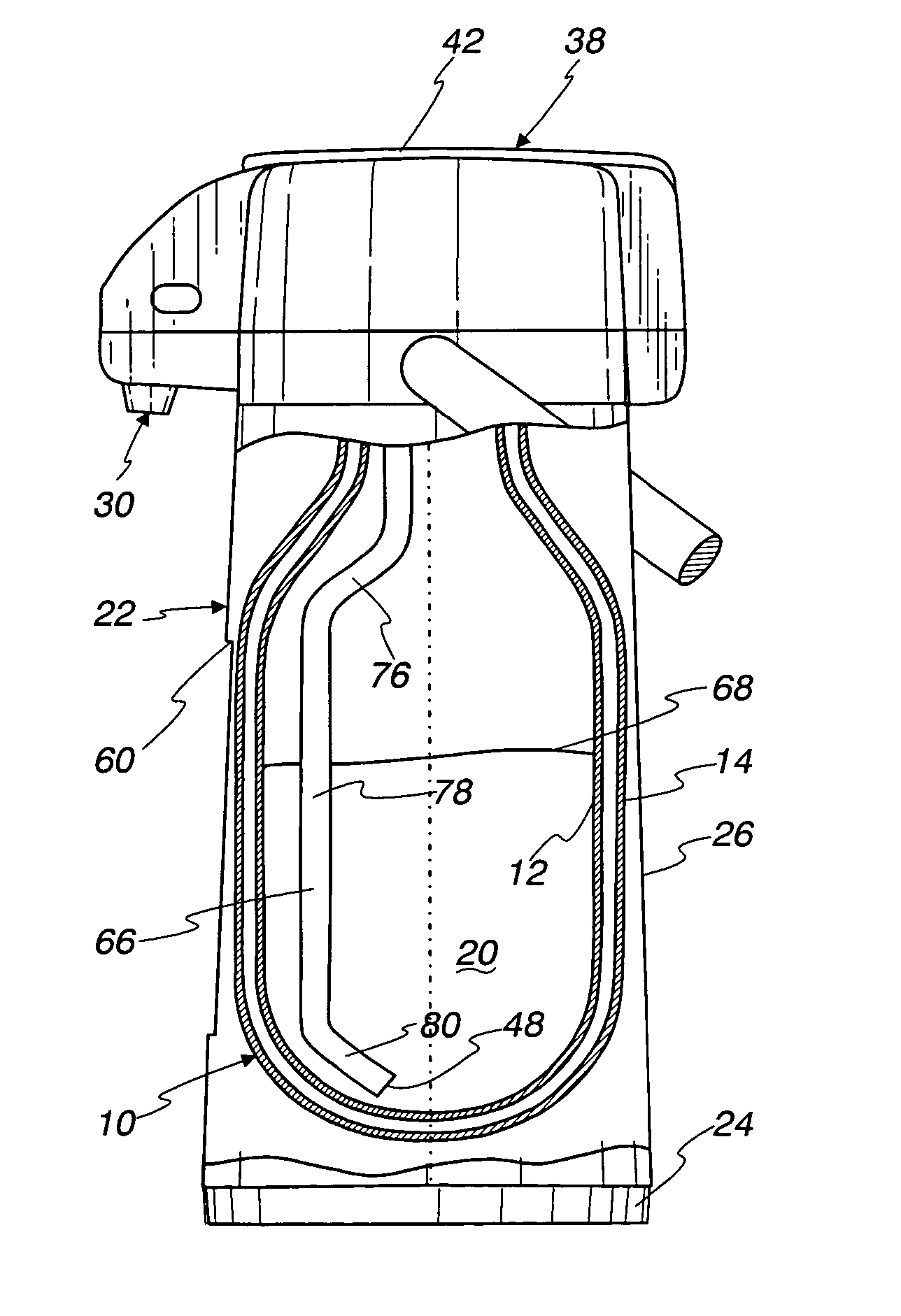

Vacuum cooler

ActiveUS9296543B2Domestic cooling apparatusLighting and heating apparatusSystems designDecomposition

A portable, durable, lightweight cooler system designed to maintain beverages, food, medical supplies, drugs, and other heat sensitive products at existing temperatures with substantially reduced heat gain or loss from the surrounding environment for extended periods of time, when no power source is available. This container is designed to greatly reduce radiant heat transfer along with conductive and convective heat transfer while diminishing decomposition effects of stored items and thus maintaining freshness. This system includes a cooler housing, a reinforced lid, a radiation reflective material application, and a system to remove air from the containment area, thus creating a vacuum within the cooler itself and sealing the lid to the cooler housing. Upon actuation of a vacuum release device, air is reintroduced into the containment area thus allowing the lid to be removed and the stored products be accessed.

Owner:H E B LP

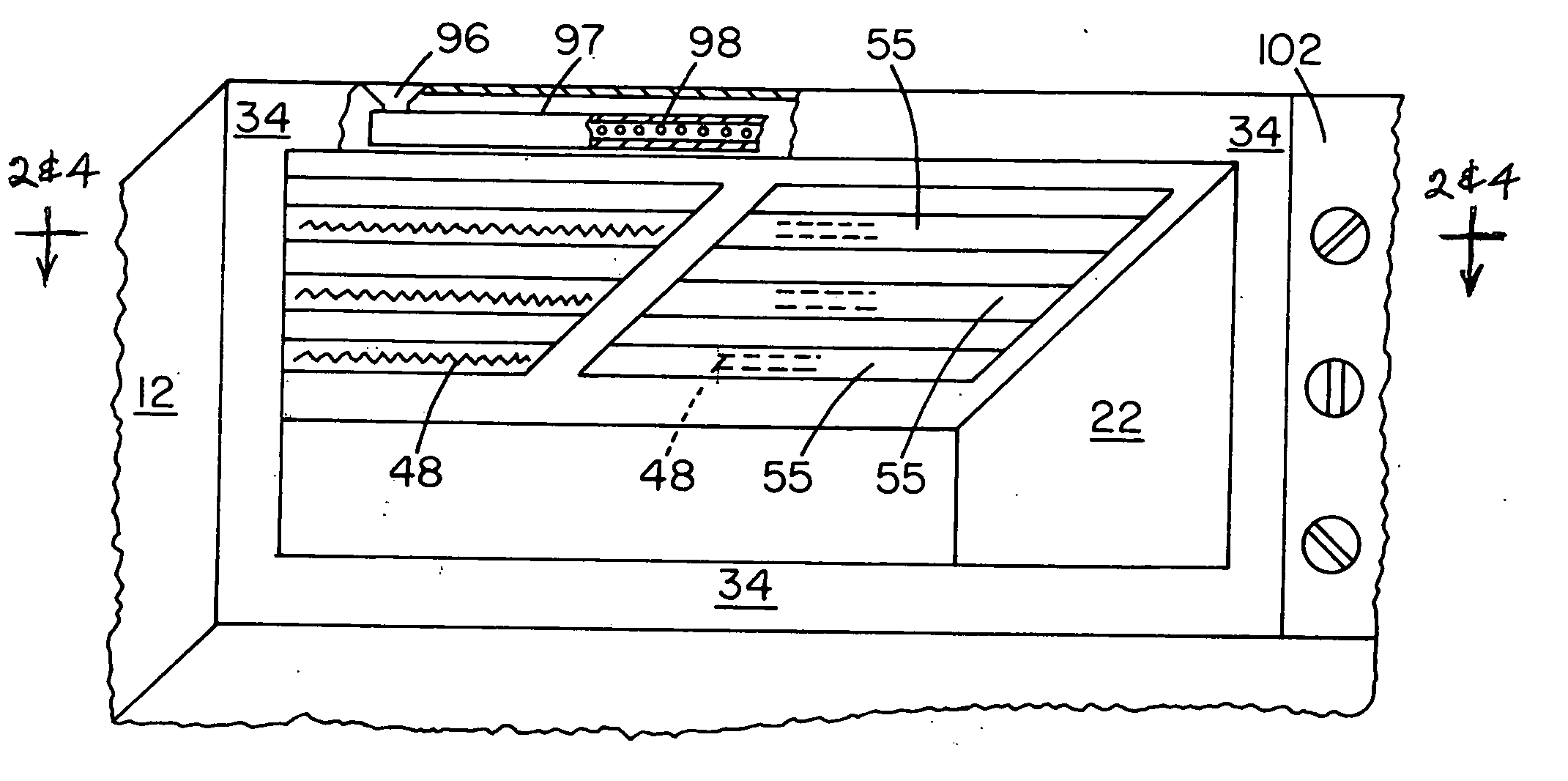

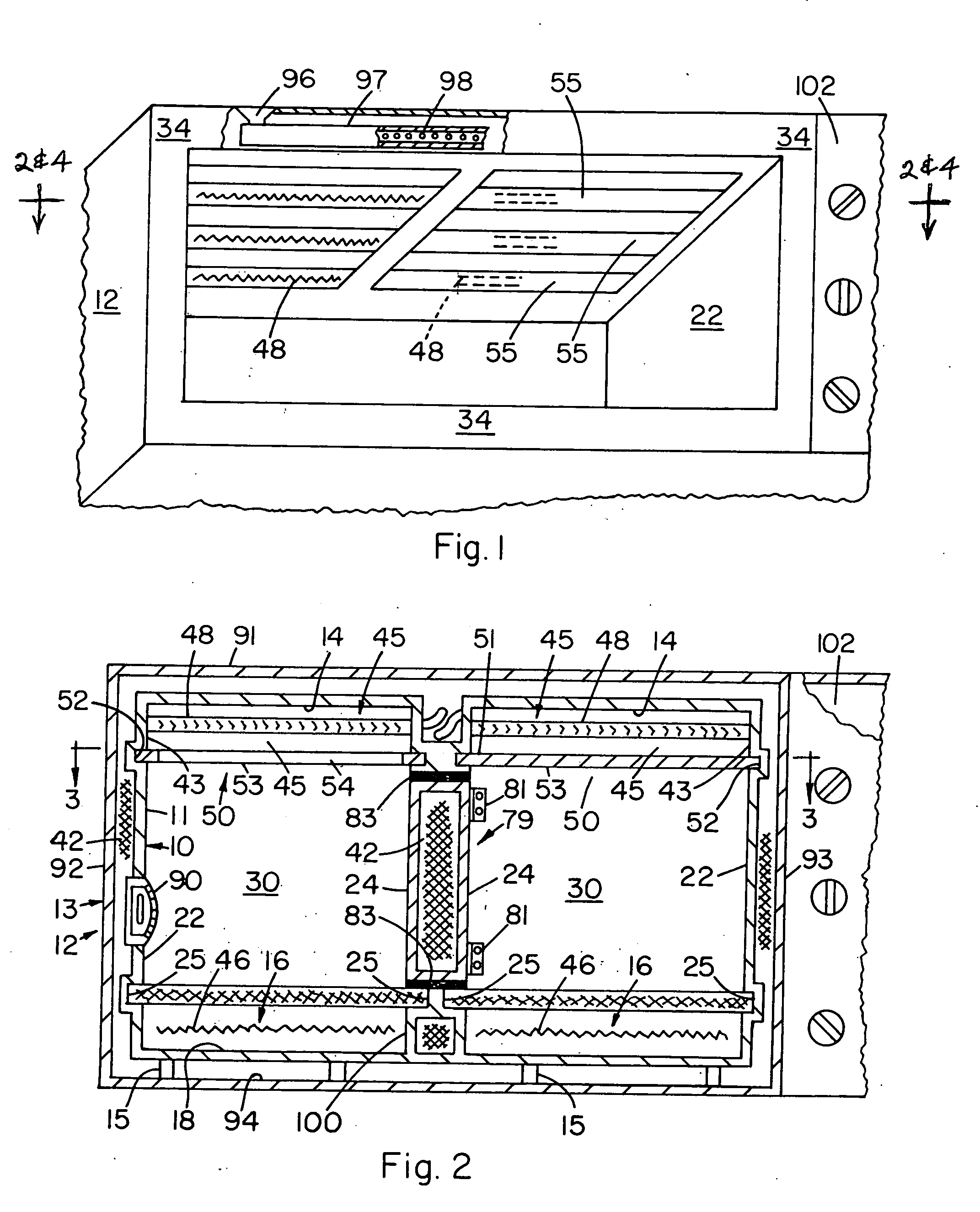

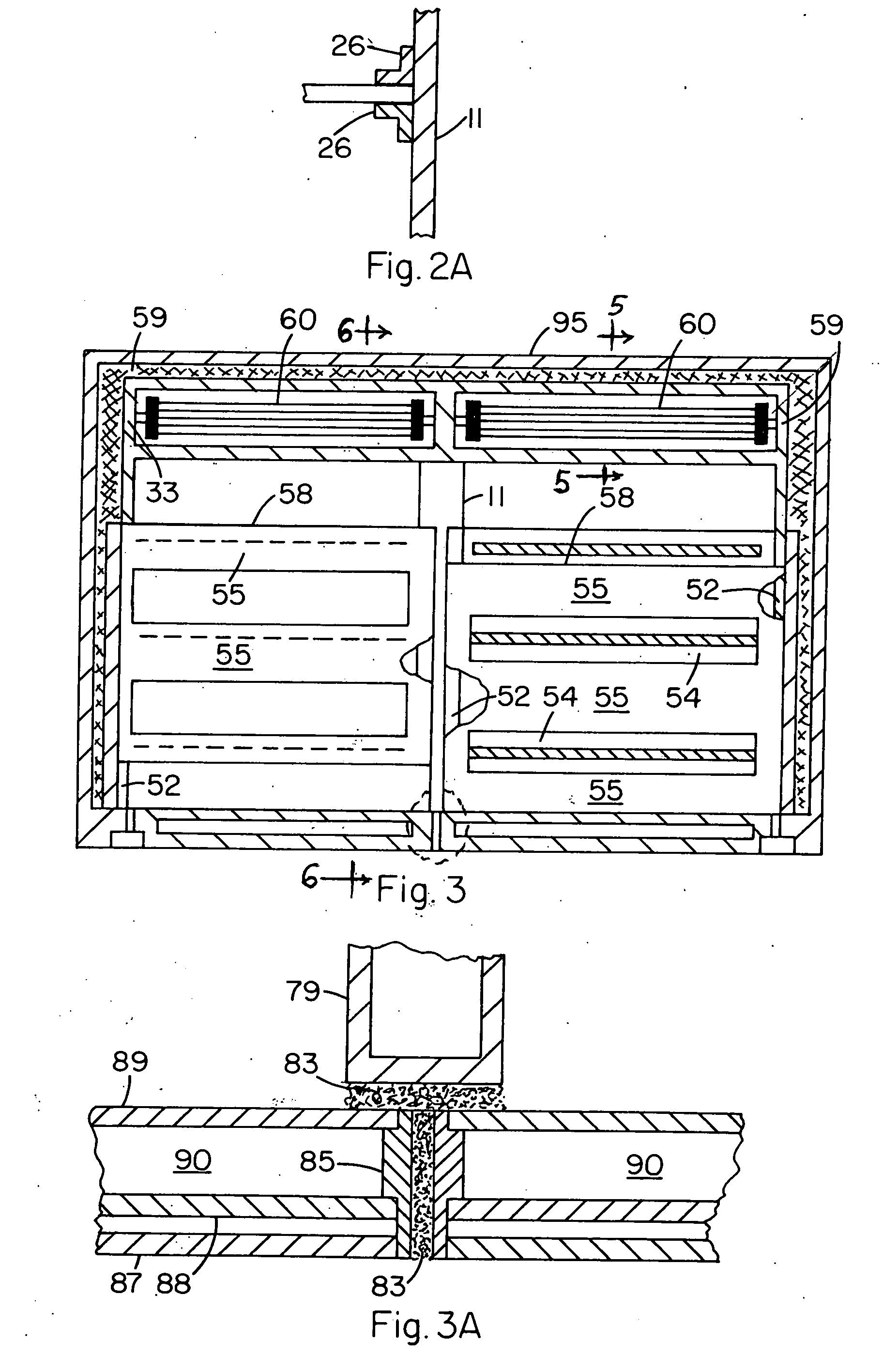

Cooking oven

InactiveUS8063342B2Highly controlled heatingReduce the overall heightDomestic stoves or rangesElectrical heating fuelCooking & bakingStructure function

A cooking structure which provide for two or more side-by-side ovens separated by vertical, movable, hinged partition(s) whereby the oven structure may function as one large oven or as two or more smaller independent ovens, wherein for each oven a tangential fan blows air substantially evenly over upper electrical heating elements strung generally from side-to-side of the oven, wherein a flow director (baffle) structure functions as a radiant heat shield which is operator movable to either expose to or occlude from the oven cooking chamber the direct radiation from its heating elements, depending on the need to roast, bake, or broil the food product. Also provided are lower electrical heating elements positioned below a ceramic cooking surface for ensuring evenness of radiant heat transfer therefrom. Also provided is operator controlled top vs. bottom heating using a slide control that reciprocally affects the duty cycle of the top and bottom electrical heating elements, further allowing precision baking control.

Owner:HINES JR ROBERT STICKLEY

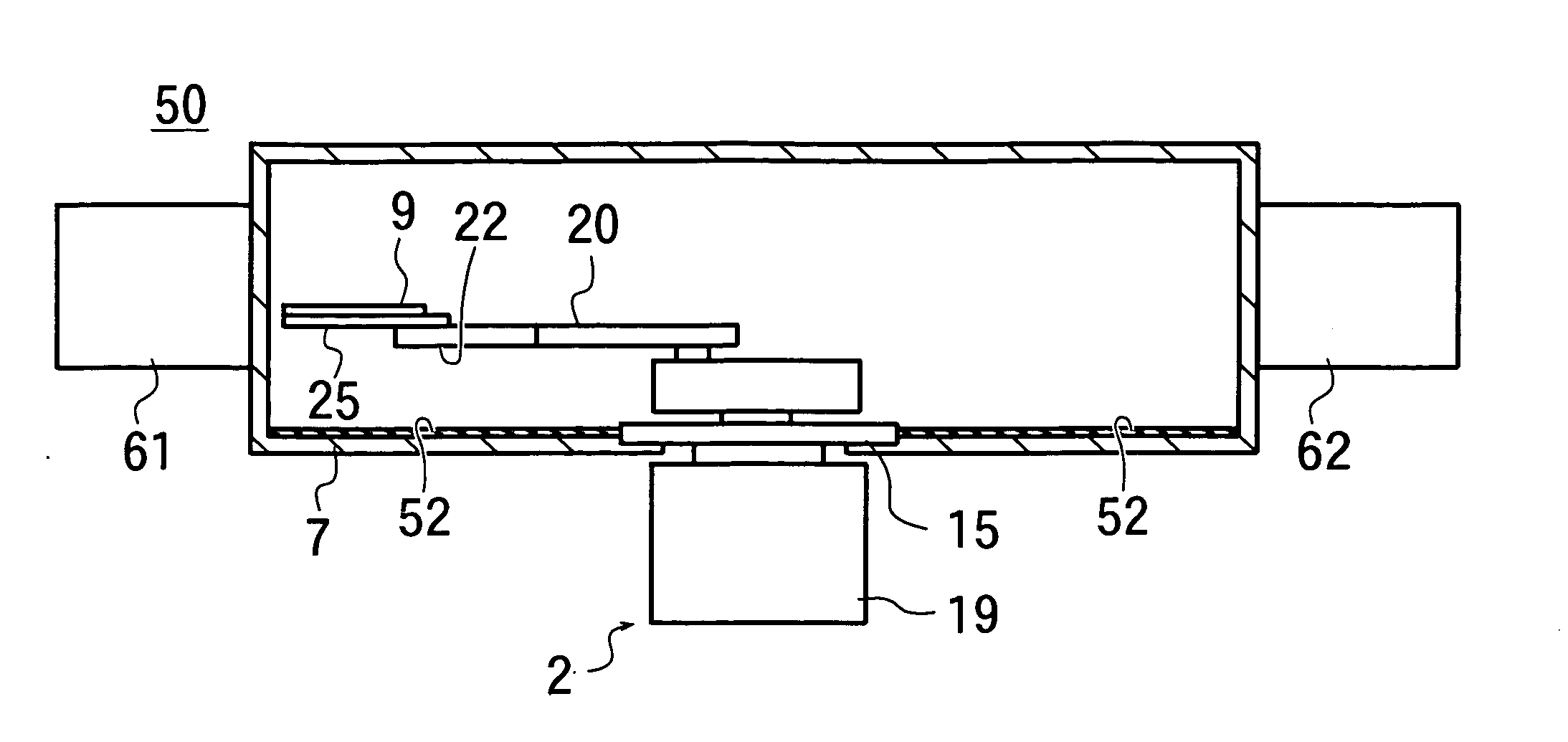

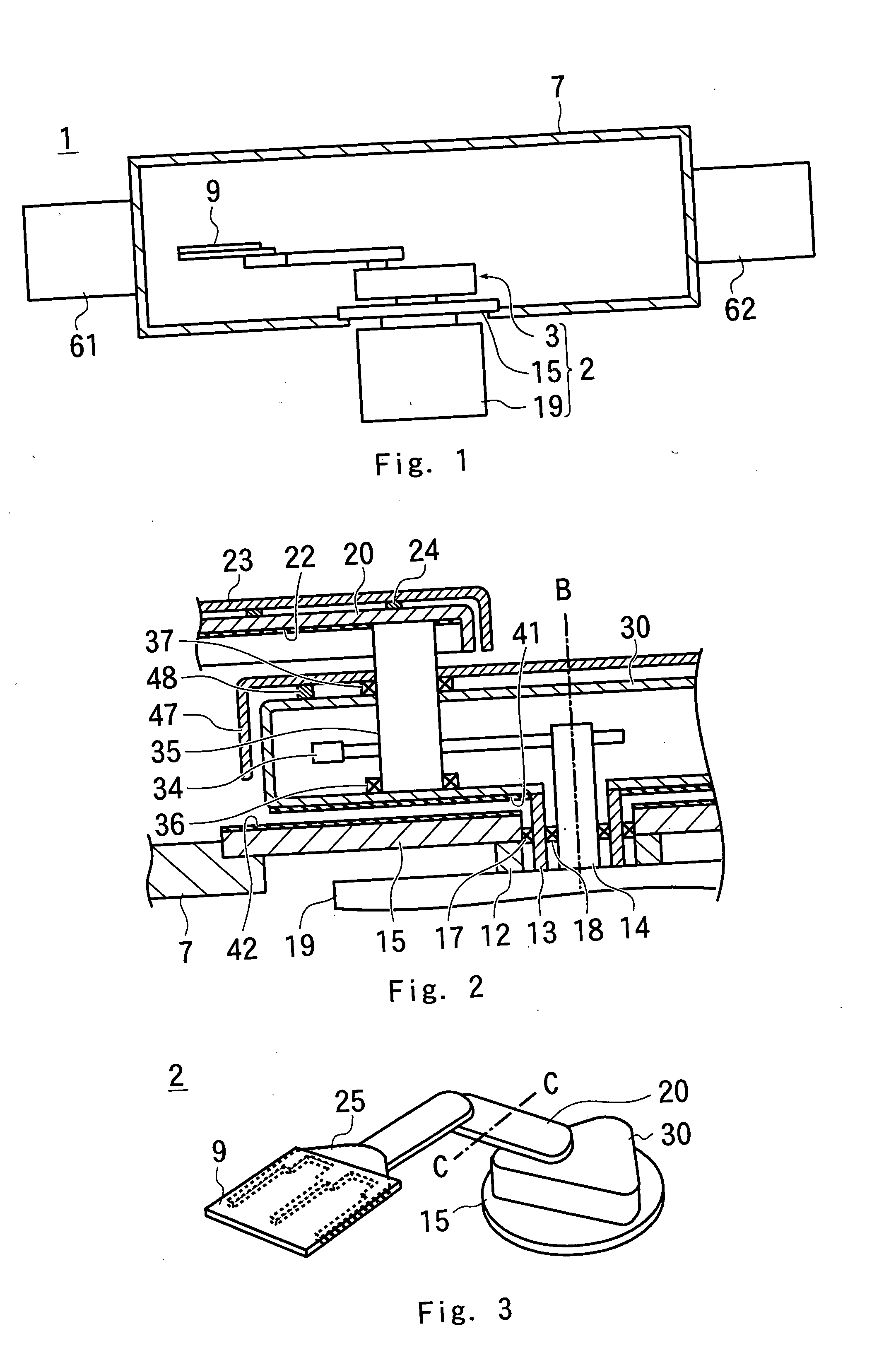

Transport robot and transport apparatus

ActiveUS20070166135A1Avoid temperature riseSuppress evaporationData processing applicationsCharge supportsTransport systemOptoelectronics

A transport robot including a release-side high radiation ratio portion and a receive-side high radiation ratio portion that face each other. Heat in a substrate conducted to a base portion due to thermal conduction is released as radiant heat from the release-side high radiation ratio portion, and the radiant heat is absorbed by the receive-side high radiation ratio portion. The receive-side high radiation ratio portion is formed on a heat-receiving plate that is thermally connected to a vacuum chamber so that radiant heat absorbed by the receive-side high radiation ratio portion is transferred to the vacuum chamber. As a result, even in the case where the high-temperature substrate is transported in a vacuum atmosphere, heat from the substrate is not accumulated in a transport system, and the transport system hardly reaches a high temperature.

Owner:ULVAC INC

Method for evaluating thermal comfort of a structure and an assisting method, program or system for designing a structure in consideration of thermal comfort

InactiveUS7206728B2Computation using non-denominational number representationAerodynamics improvementHuman bodyMeasurement device

A step of preparing data of (1) material properties of a first part and so on and data of (2) an amount of solar radiation passing through the translucent member to reach a measuring device having a shape imitating a human body part, an amount of solar radiation to the structure, an amount of convection heat transfer in the structure, an amount of radiation heat transfer in the structure, humidity in the structure and / or a thermo-regulating function of the measuring device, and calculating at least one of the amount of heat loss from the surface of the measuring device, the temperature of the measuring device and / or the wettedness at the surface of the measuring device based on at least one in each of data (1) and (2), and a step (b) of calculating a thermal comfort index of the measuring device by using a result of the above calculation, are presented, whereby the thermal comfort of a structure is evaluated without using a laboratory equipment.

Owner:AGC INC

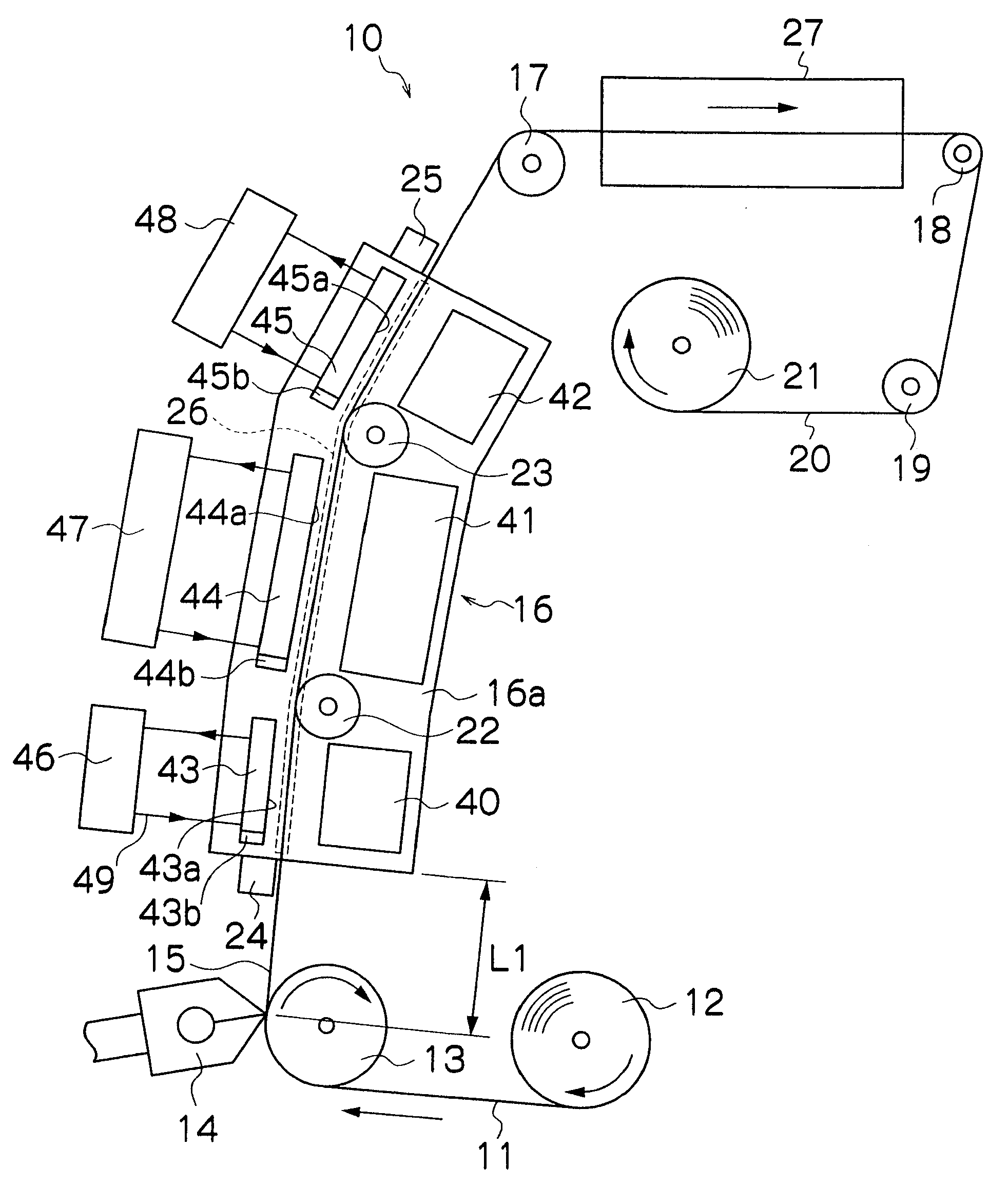

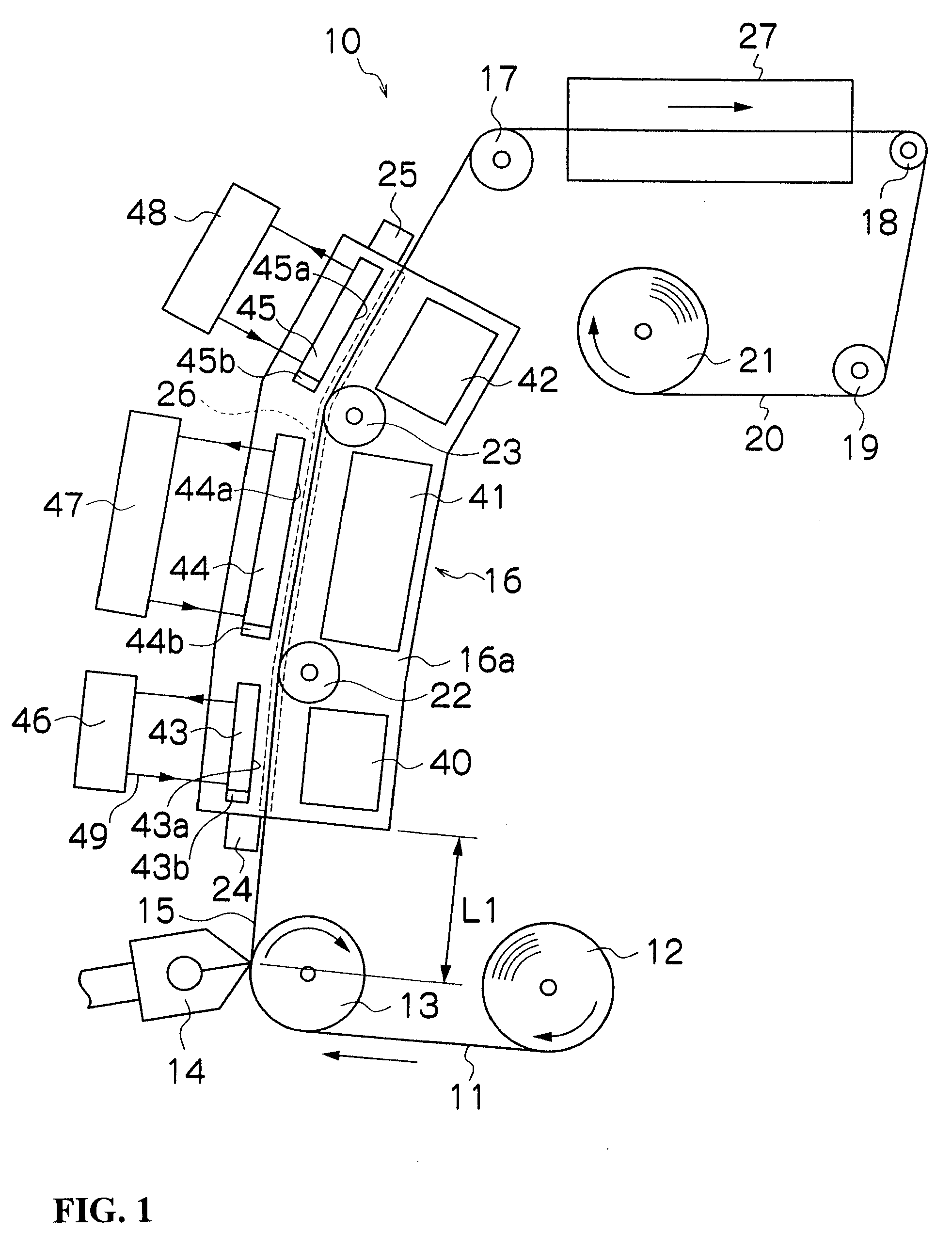

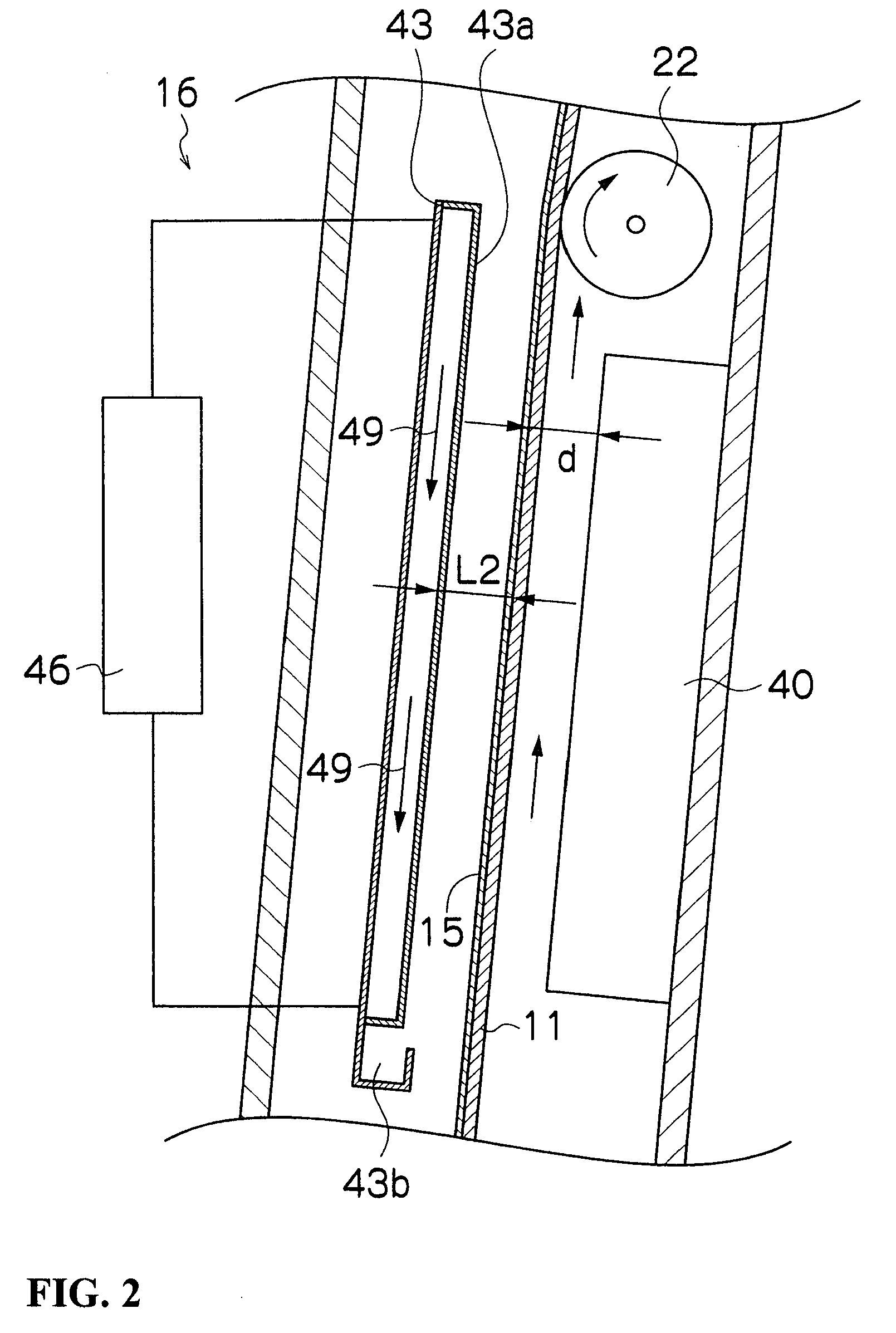

Method and apparatus for drying coating film and method for producing optical film

InactiveUS20080206455A1Efficient heatingHigh spreading rateDrying using combination processesDrying solid materials with heatOrganic solventBand shape

The present invention provides a method for drying a coating film comprising drying a coating film of an organic solvent-containing coating liquid applied to a running band-shaped flexible substrate, the drying method comprising the steps of: providing a heater at a position opposed to the band-shaped flexible substrate at a running position immediately after coating; and heating the band-shaped flexible substrate by the heater; wherein when TW (° C.) denotes the surface temperature of the band-shaped flexible substrate; TH (° C.) denotes the surface temperature of the heater; λ (W / m·K) denotes the heat-transfer coefficient of air; d(m) denotes the distance between the heater and the band-shaped flexible substrate (web); η denotes the efficiency of heat transfer; and σ denotes the Stefan-Boltzmann constant (5.670×10−8 W / m2K4), the ratio of radiant heat transfer represented by QR / (QR+QC) is 0.25 or more and 0.6 or less, wherein QC and QR are represented by the following equations, respectively: QC=λ / d·(TH−TW) where QC denotes heat transfer by air, and QR=η{(TH+273)4−(Tw+273)4} where QR denotes heat transfer by radiant.

Owner:FUJIFILM CORP

Cooking tray for rapid cook oven

A cooking tray (optionally interstices-defining, microwave-transparent and providing an appropriate view factor) has a one-piece, integral, unitary construction formed of a food-grade, non-stick material suitable for use in a rapid cook oven which cooks by a combination of at least two heat transfer mechanisms selected from the group consisting of radiant heat transfer, convection heat transfer and microwave energy transfer. The construction defines a base and an upstanding peripheral sidewall about the base for the collection of solid debris created during cooking. Preferably the material is food-grade fiberglass with a non-stick coating.

Owner:TURBOCHEF TECH INC

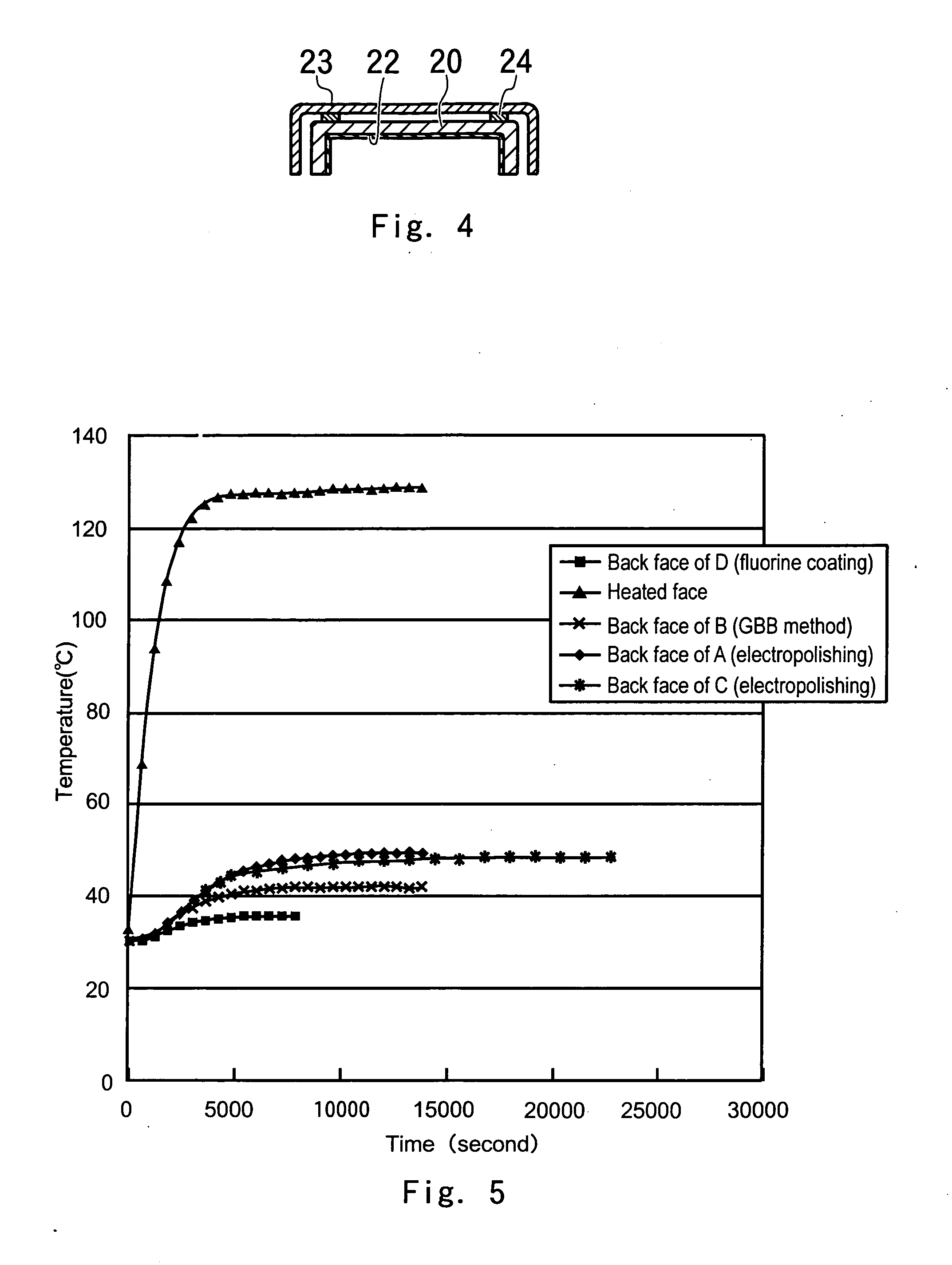

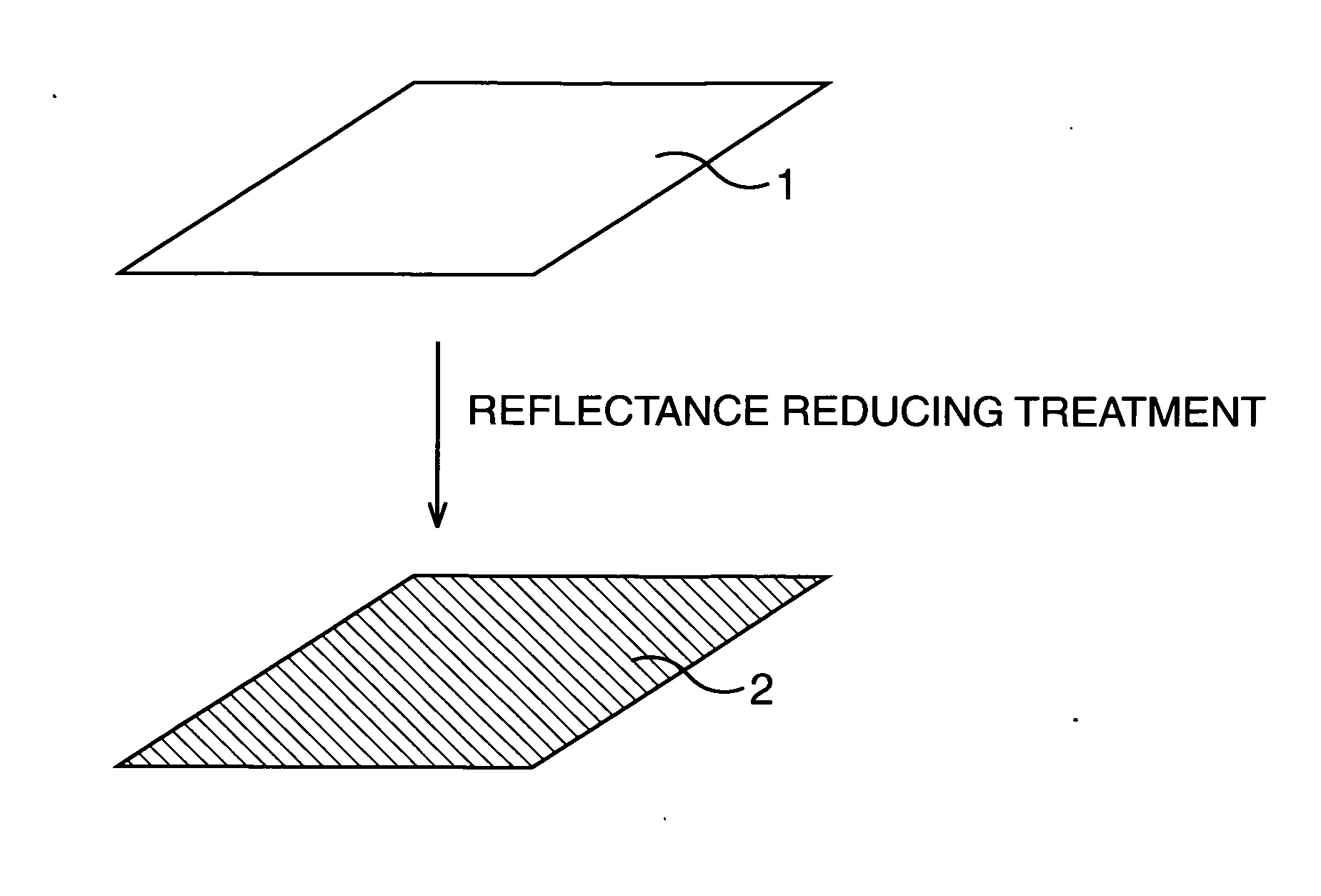

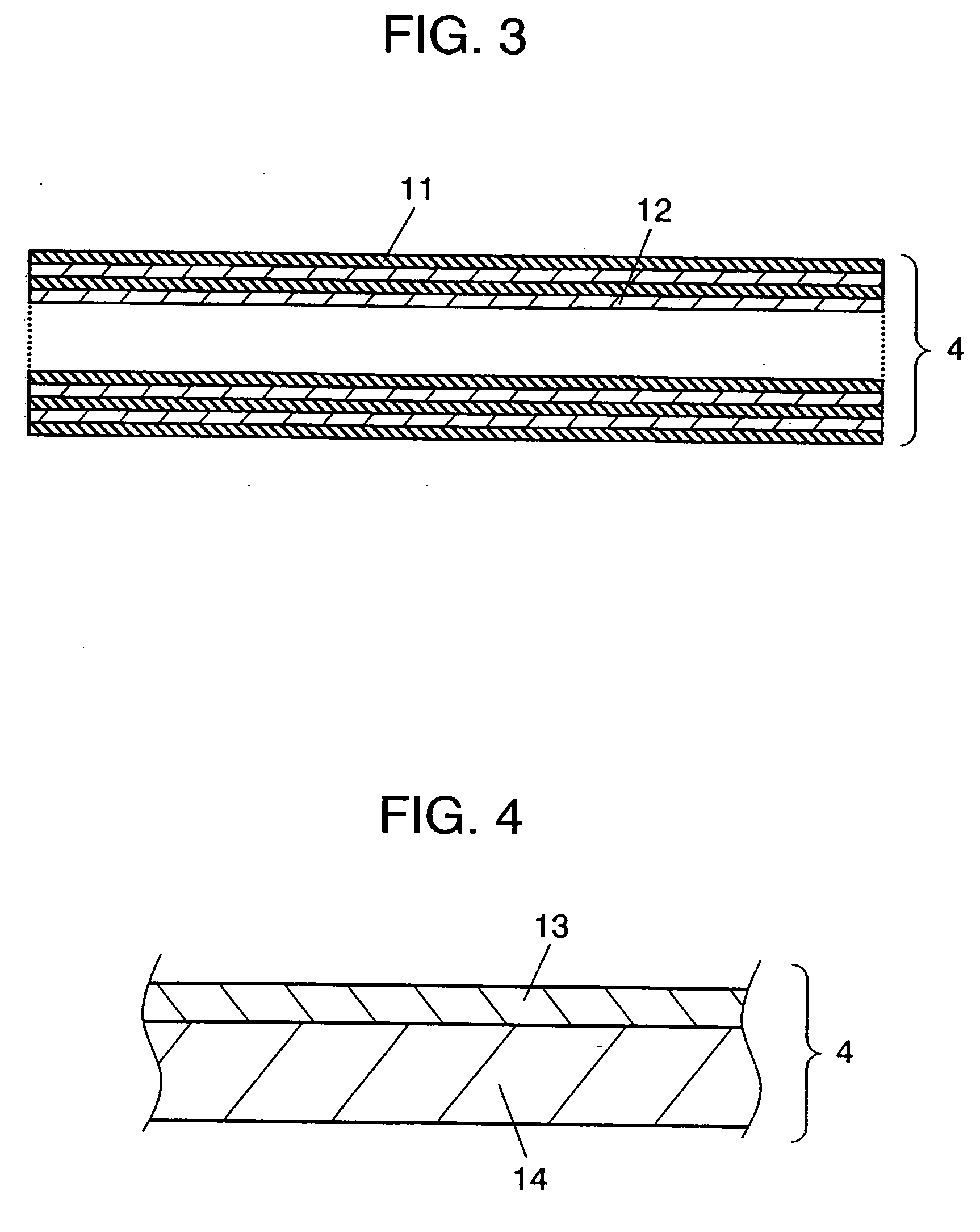

Metal plate to be heated by radiant heat transfer and method of manufacturing the same, and metal processed product having portion with different strength and method of manufacturing the same

ActiveUS20120135263A1Improve heating efficiencySpecific heatMolten spray coatingDomestic stoves or rangesHot stampingThermal spraying

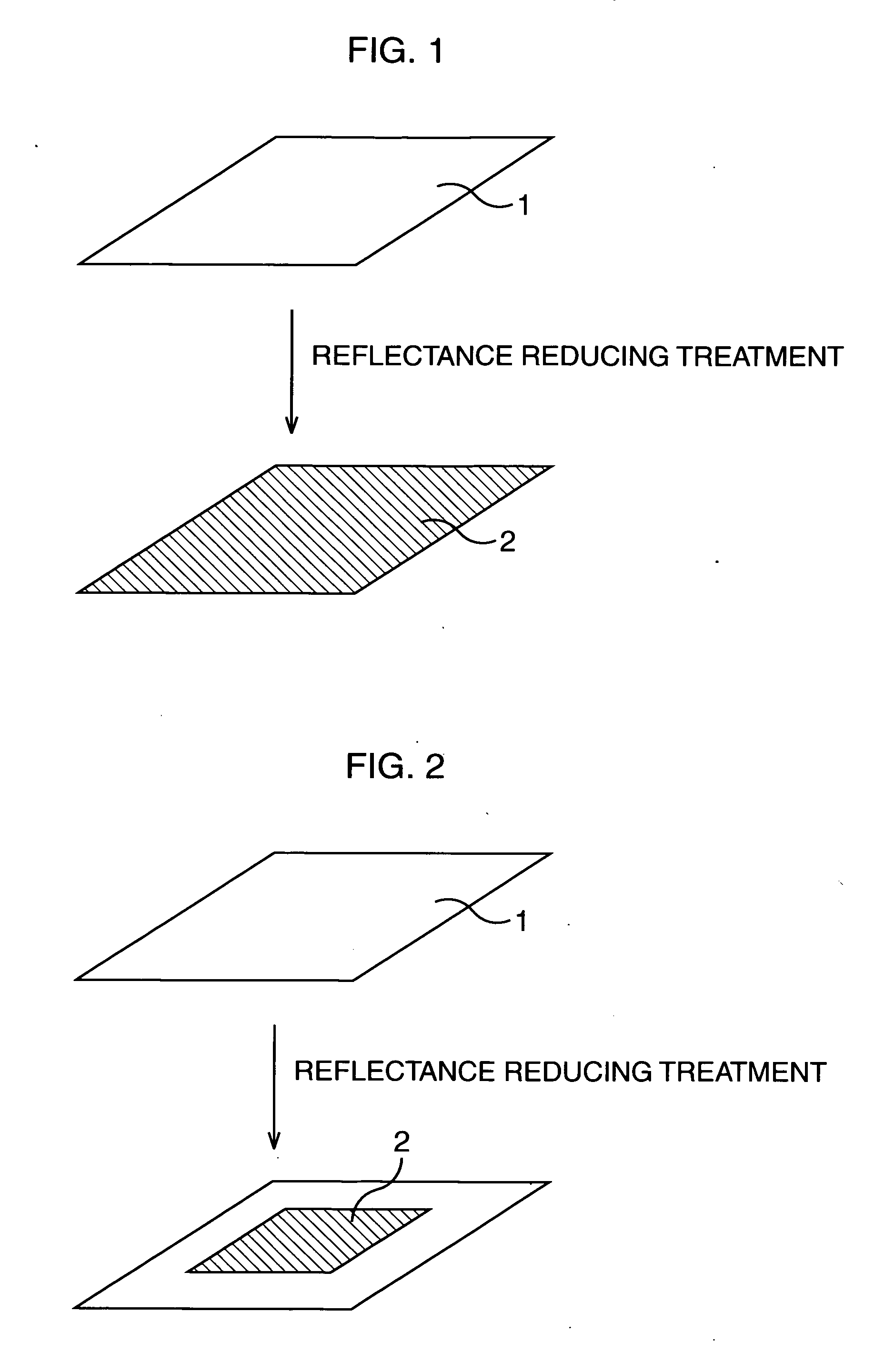

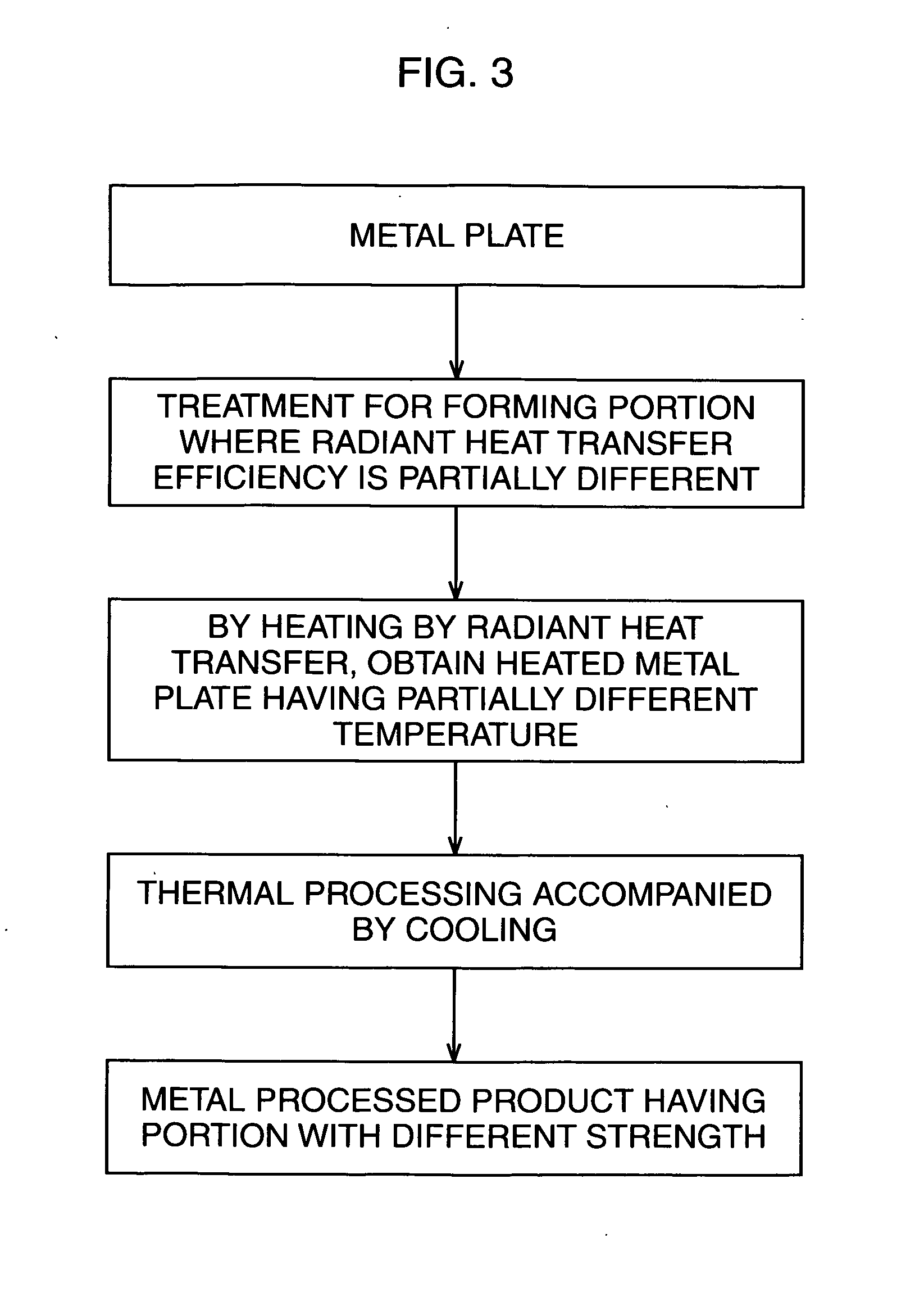

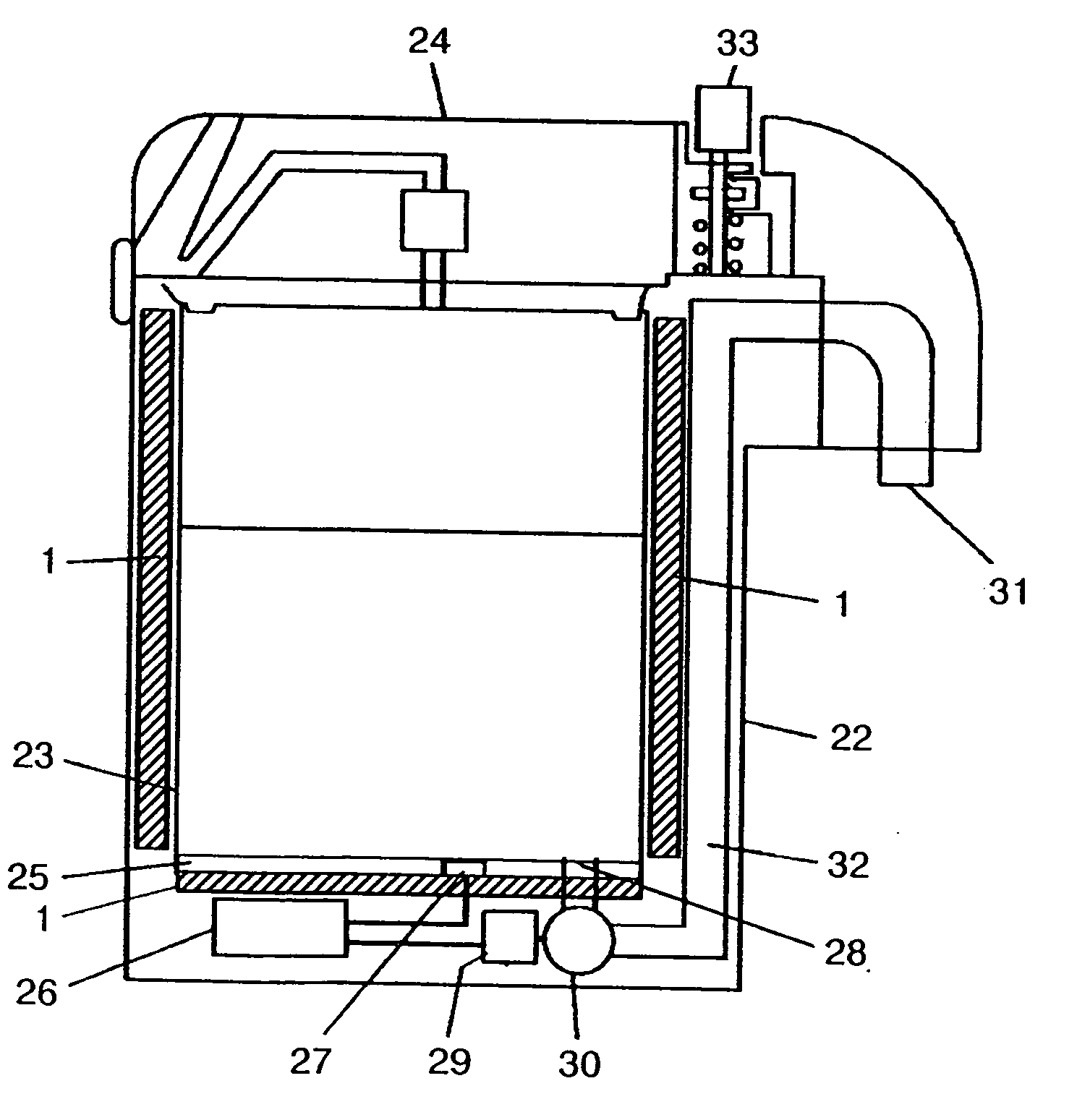

On part of a surface of a metal plate that is to be heated by radiant heat transfer with a near-infrared ray, a region where reflectance for a radiant ray is made lower than that of the original surface of the metal plate is formed. As reflectance reducing treatment, painting or thermal spraying in a blackish color, plating in a blackish color, treatment for increasing roughness of the surface of the metal plate, blasting, etching, blackening, surface layer quality changing treatment of the metal plate, or the like can be adopted. The metal plate is turned into a heated metal plate partially having a different temperature by being heated by radiant heat transfer, and thereafter, the heated metal plate is subjected to thermal processing accompanied by cooling, for example, by hot stamping.

Owner:NIPPON STEEL CORP

High-manganese medium-carbon peritectic steel continuous casting crystallizer casting powder and preparation method thereof

ActiveCN103121090AReduced infrared transmission performanceReduced radiative heat transfer performanceLiquid slagManganese

The invention discloses high-manganese medium-carbon peritectic steel continuous casting crystallizer casting powder and a preparation method thereof. 2%-8% of MnO is added into the casting powder, infrared transmitting performance of the casting powder is obviously reduced, infrared light transmittance of the casting powder is reduced, radiant heat transfer performance of the casting powder is reduced, the cracking rate can be reduced and can be effectively controlled under 0.8%, and therefore production cost is greatly reduced. Through effective control on crystallization performance of the casting powder, the condition that crystallization occurs in liquid flux films can be effectively avoided, and therefore the production accidents such as bonding and even bleed-out can be effectively avoided.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

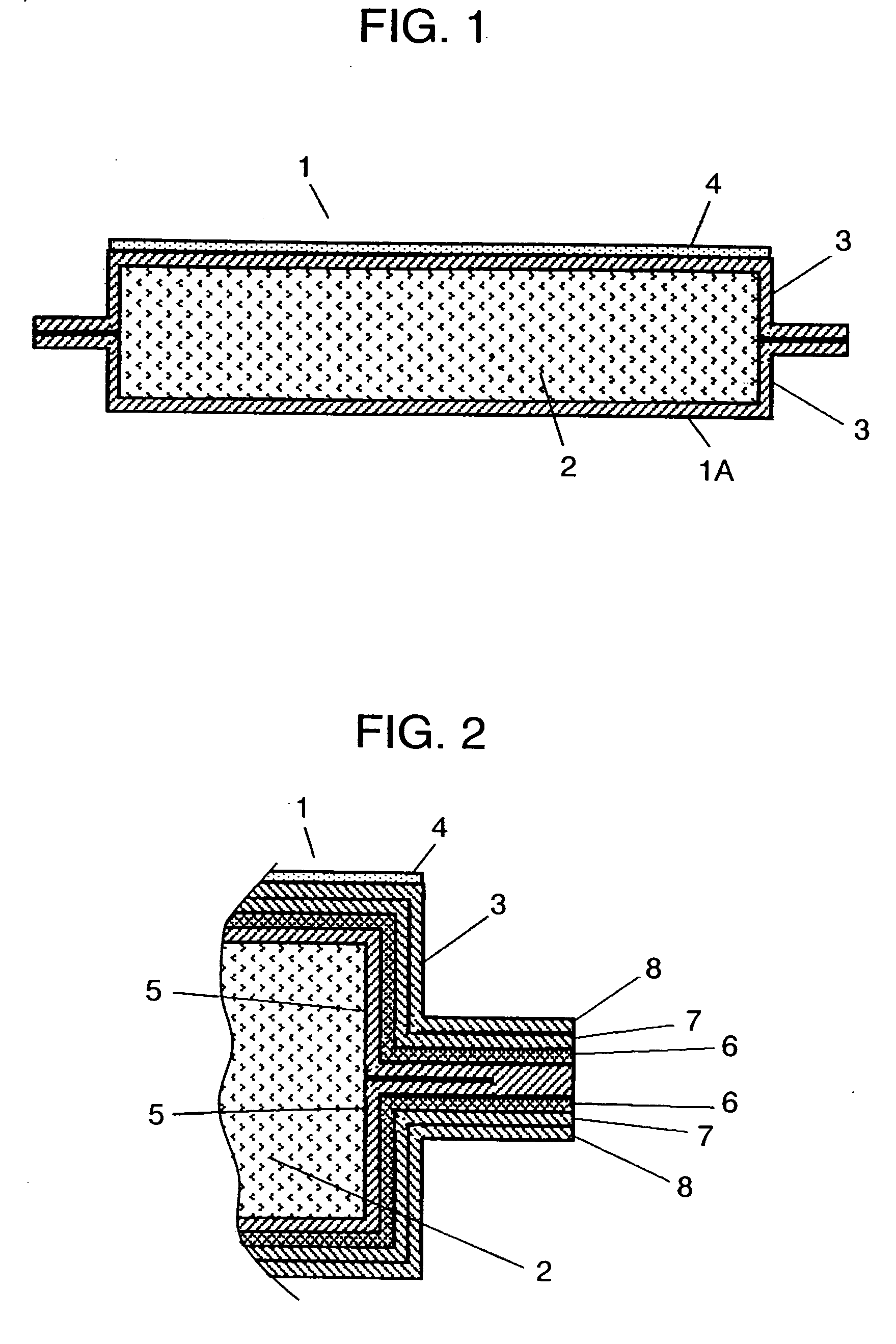

Vacuum thermal insulation material and equipment using the same

InactiveUS20060159436A1Improve performanceAvoid absorptionEnvelopes/bags making machineryThermal insulationInfraredThermal insulation

A radiation heat transfer suppressor for inhibiting heat transfer by infrared rays is provided on the external surface of the enveloping member of a vacuum heat insulator. In heat-blocking or keep warm using a vacuum heat insulator, a surface having a radiation heat transfer suppressor is faced to a high-temperature side. Thus, the vacuum heat insulator exhibits excellent heat-insulating performance in a temperature range of 150° C. or higher.

Owner:PANASONIC CORP

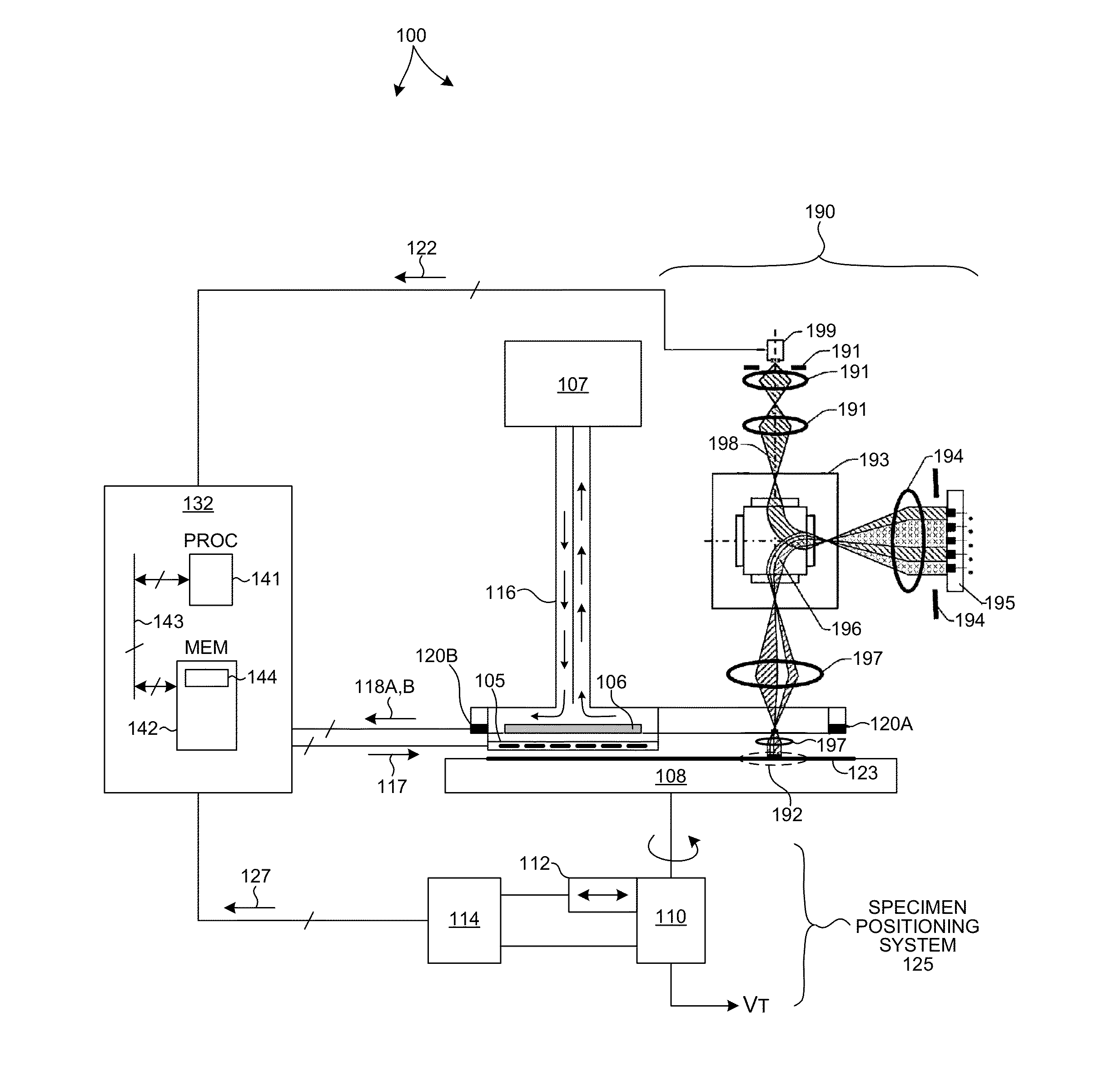

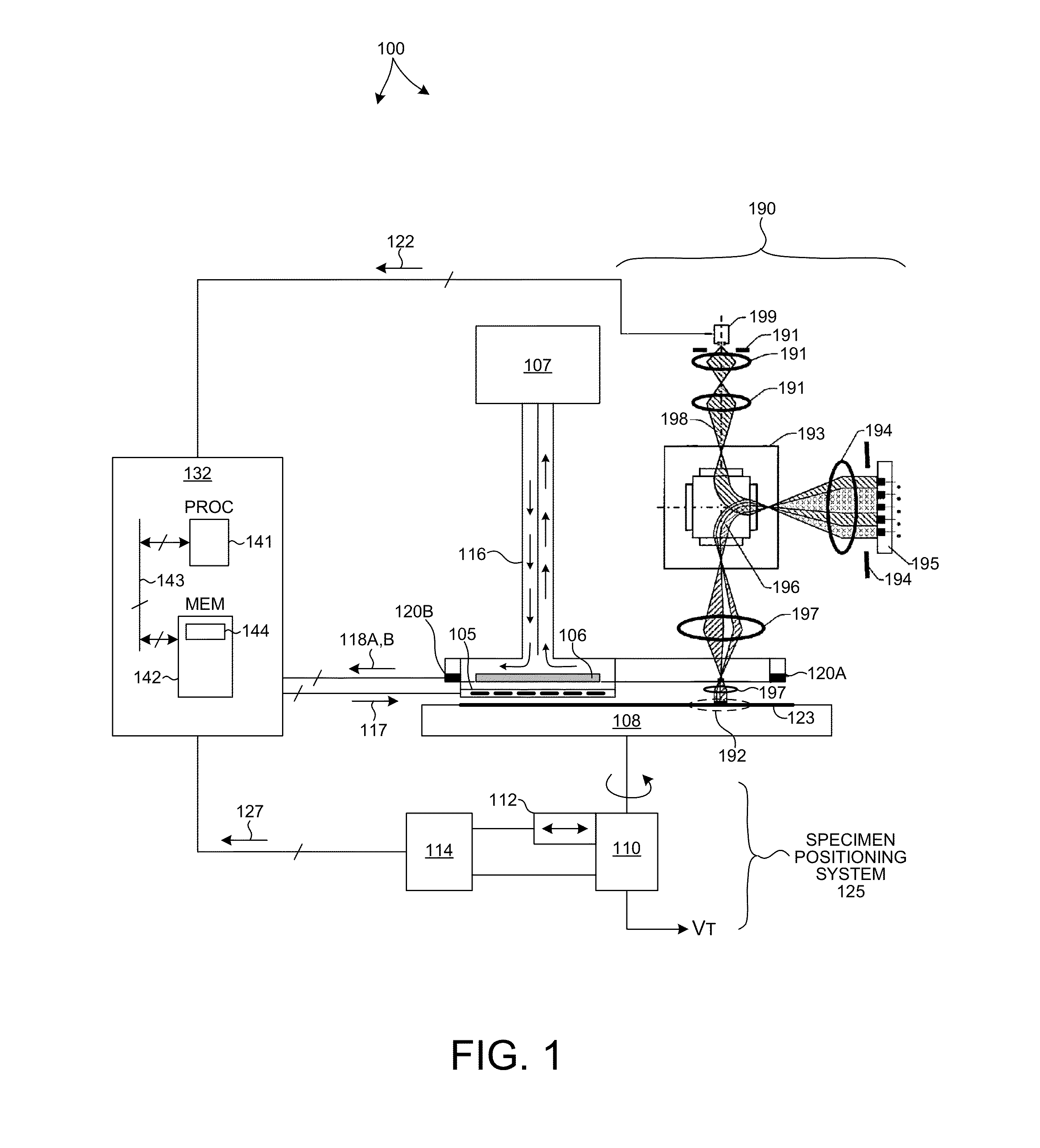

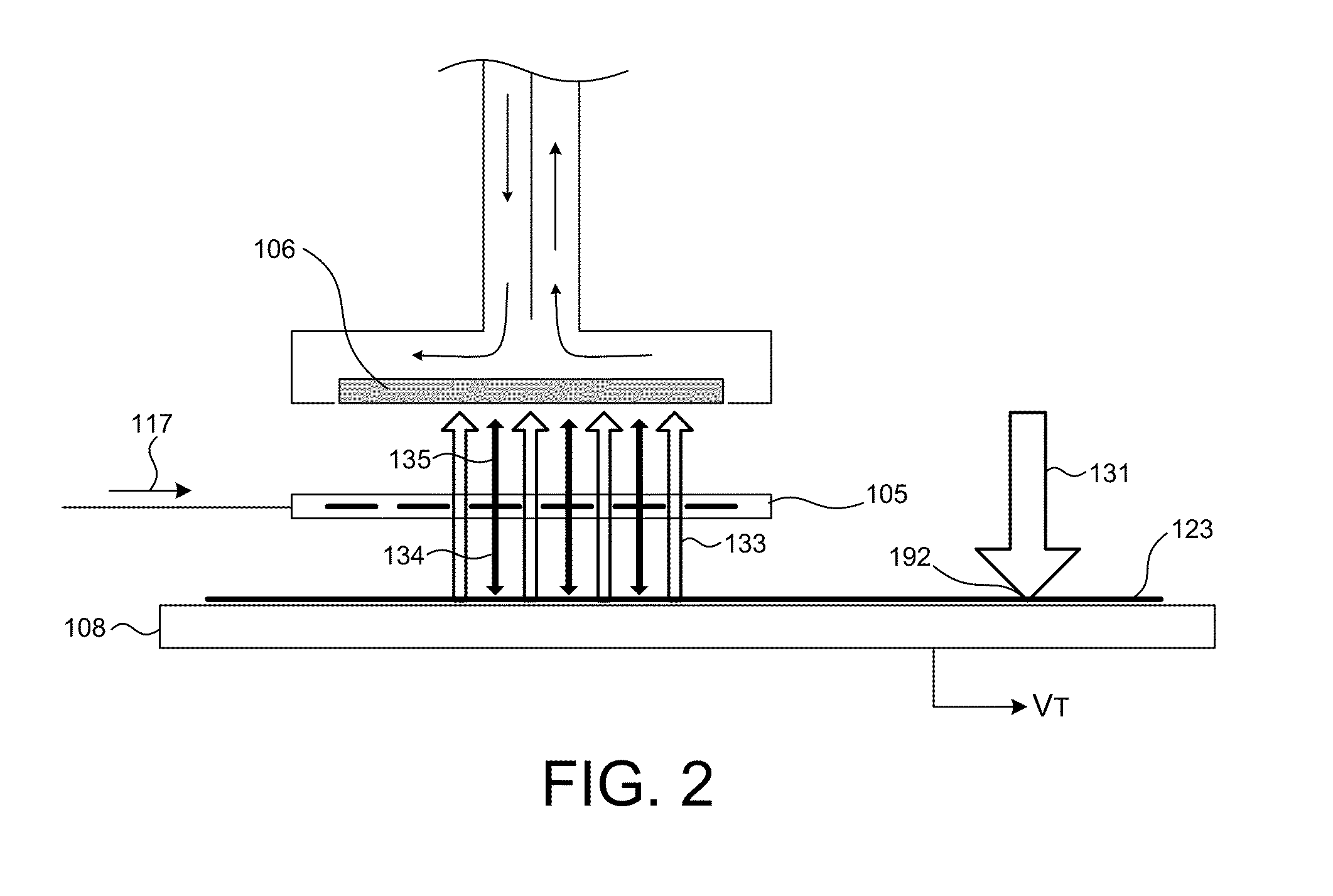

Heat Removal From Substrates In Vacuum

InactiveUS20130105108A1Increase and decrease areaAir-treating devicesElectric discharge tubesTemperature controlControl signal

Systems and methods to precisely balance the amount of heat removed from a specimen with the amount of heat generated during processing are presented. In some embodiments, the heat introduced into the specimen is rapidly removed by a temperature controlled cooling element via radiative heat transfer. In some embodiments, a heating element is disposed between the specimen and the cooling element. The heating element is controlled to precisely balance the amount of heat removed from the specimen with the amount of heat generated. A control signal is generated based on the amount of process energy known apriori. The control signal may also be based on an indication of a temperature of the specimen. In some embodiments, an adjustable aperture is employed to change the surface area of the cooling element exposed to the specimen, and thus control the amount of heat absorbed from the specimen by the cooling element.

Owner:KLA CORP

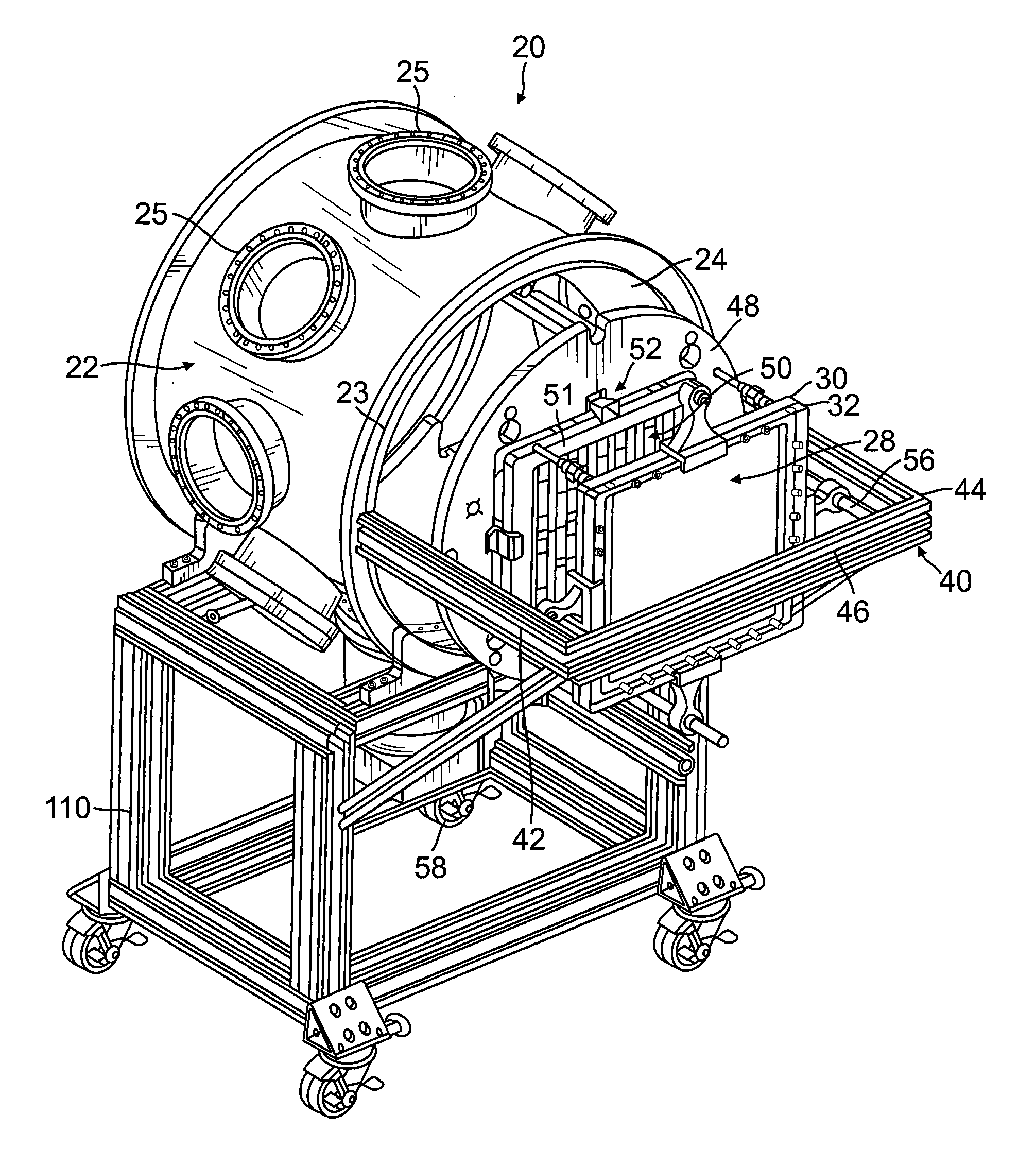

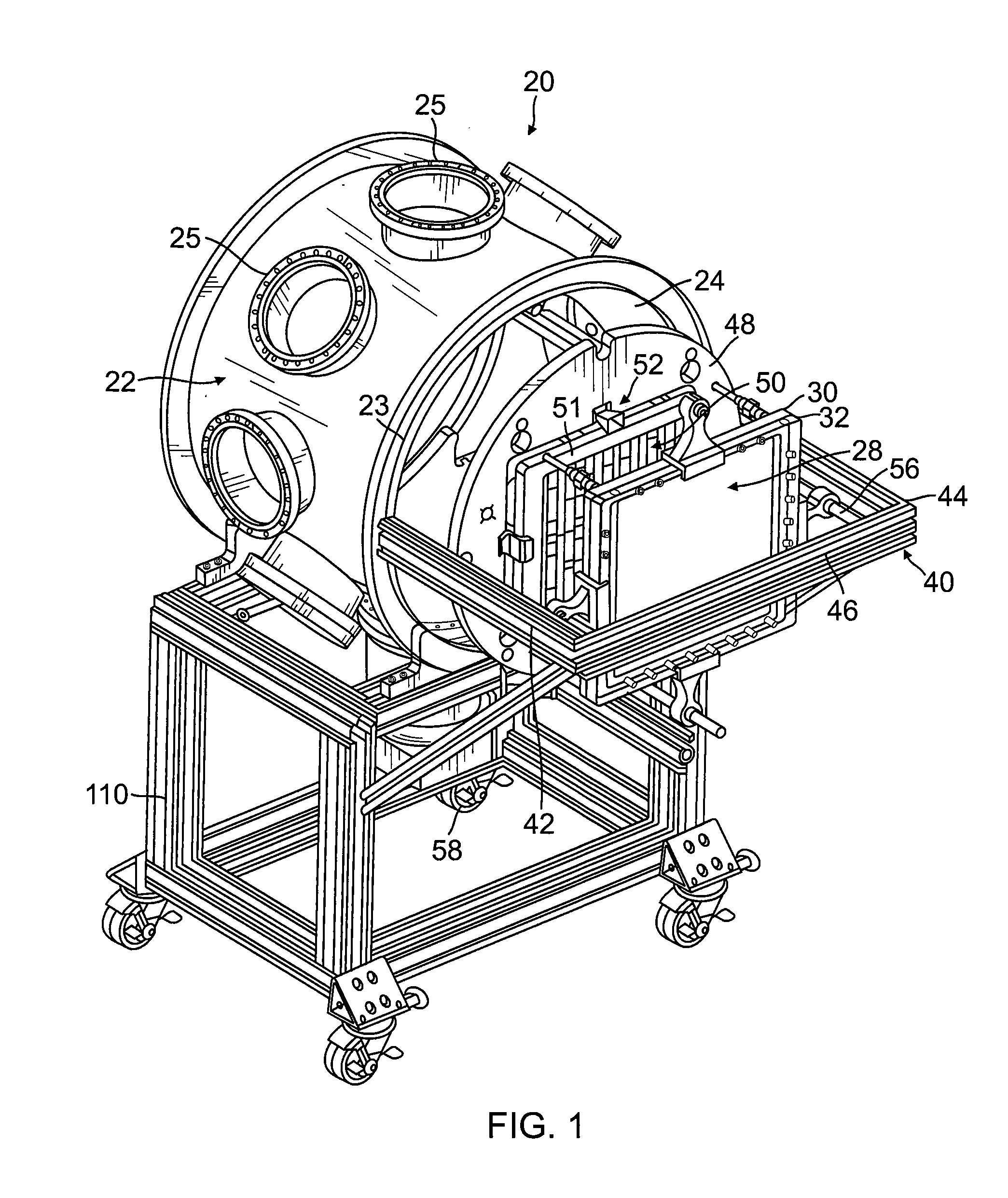

Radio frequency transparent thermal window

ActiveUS20130125676A1Cosmonautic condition simulationsWeather/light/corrosion resistanceHeat transmissionRadio frequency signal

A radio-frequency transparent window having internal conduits for the passage of cooling fluid is configured for simulating a highly uniform thermal environment for testing a device intended for use in space. The device to be tested is placed within a chamber in which a vacuum condition is maintained by a radio-frequency transparent pressure window under a pressure seal. Within the chamber, the thermal window is positioned adjacent, but not in contact with, the pressure window. A radio frequency signal is capable of passing directly through both the thermal window and the pressure window to permit communication with the device being tested within the housing. The thermal window is not in contact with the device so there in no conduction of heat from the device. Radiant heat transfer may occur from the device to the thermal window.

Owner:THE AEROSPACE CORPORATION

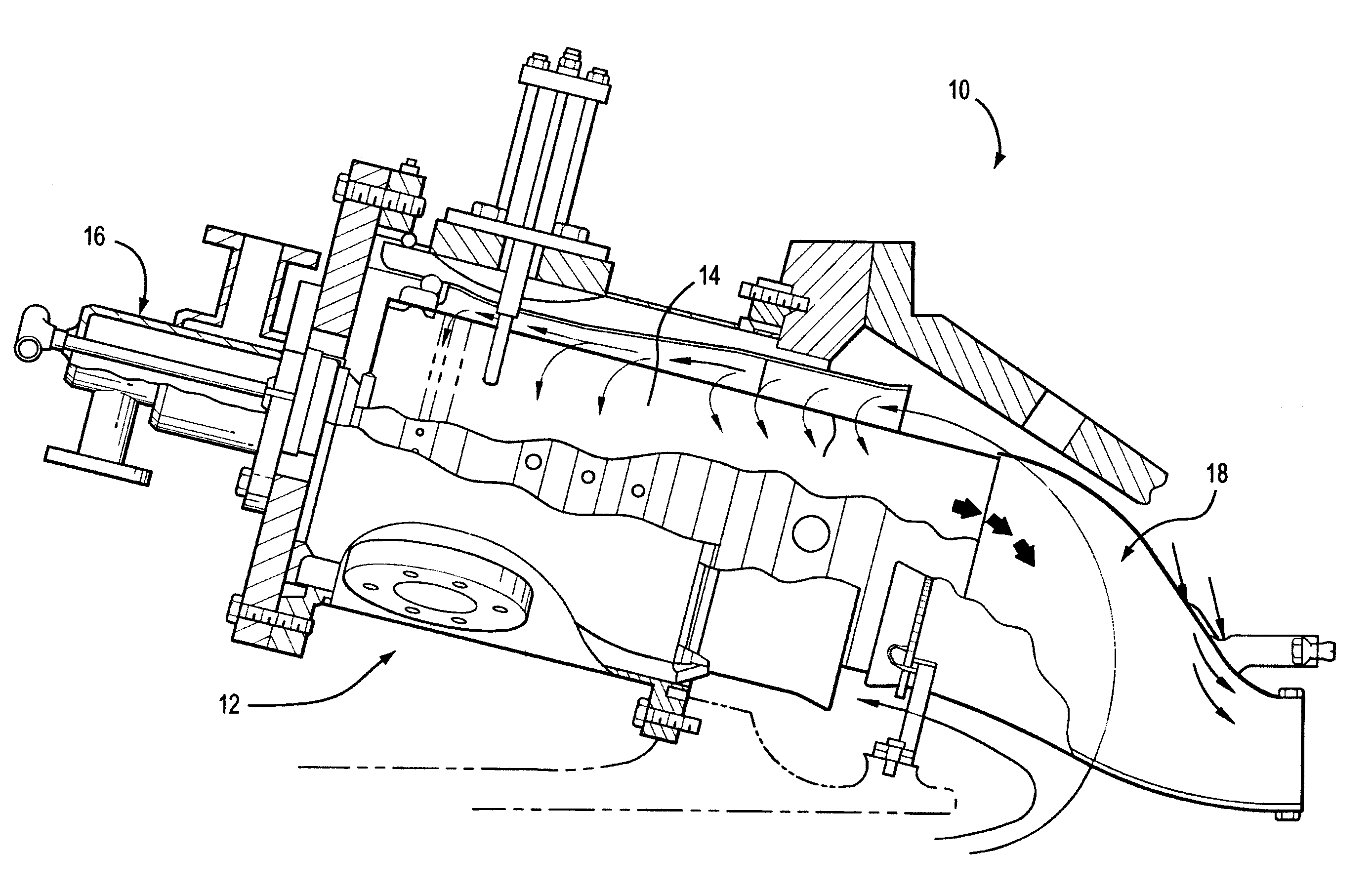

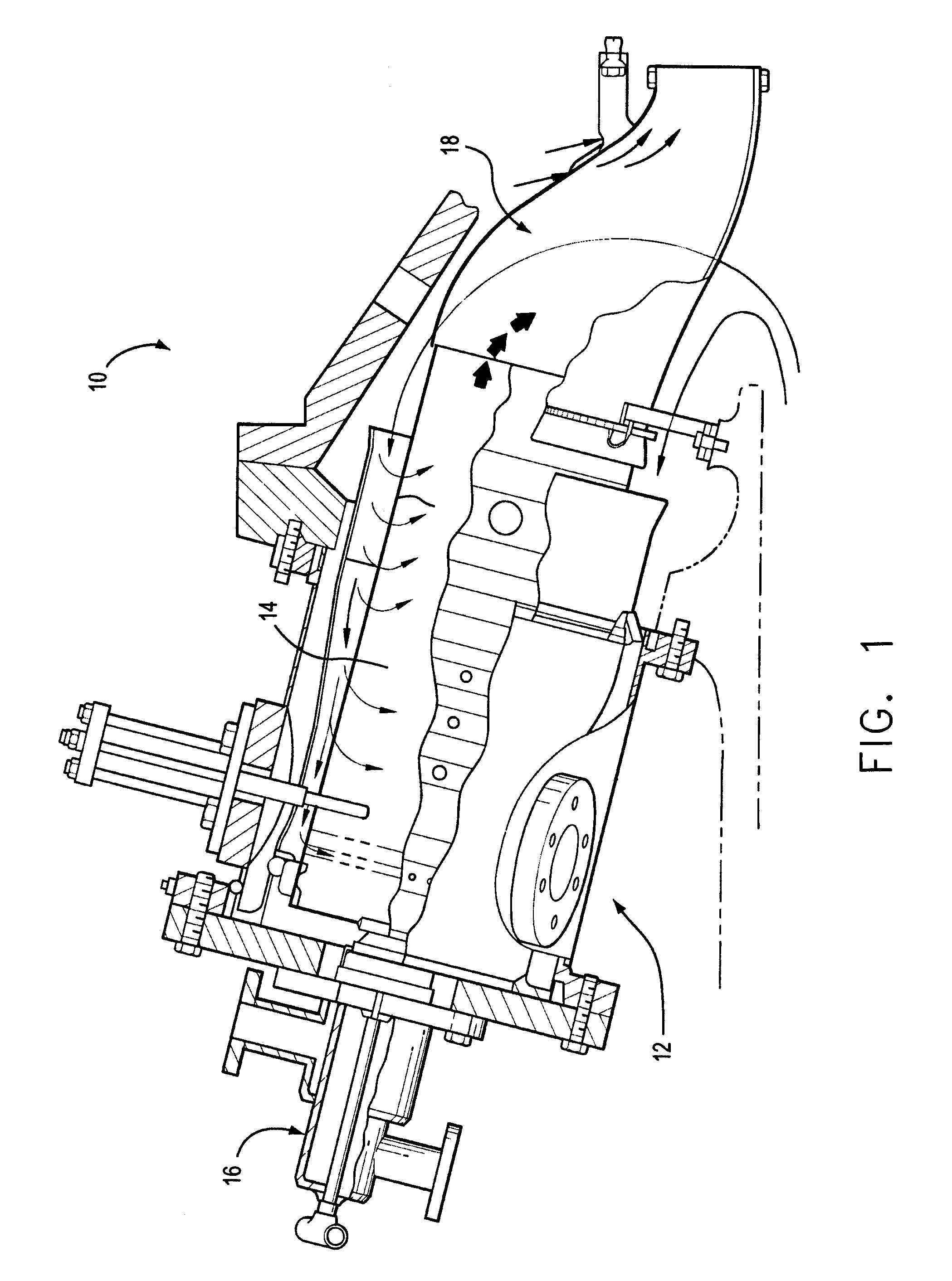

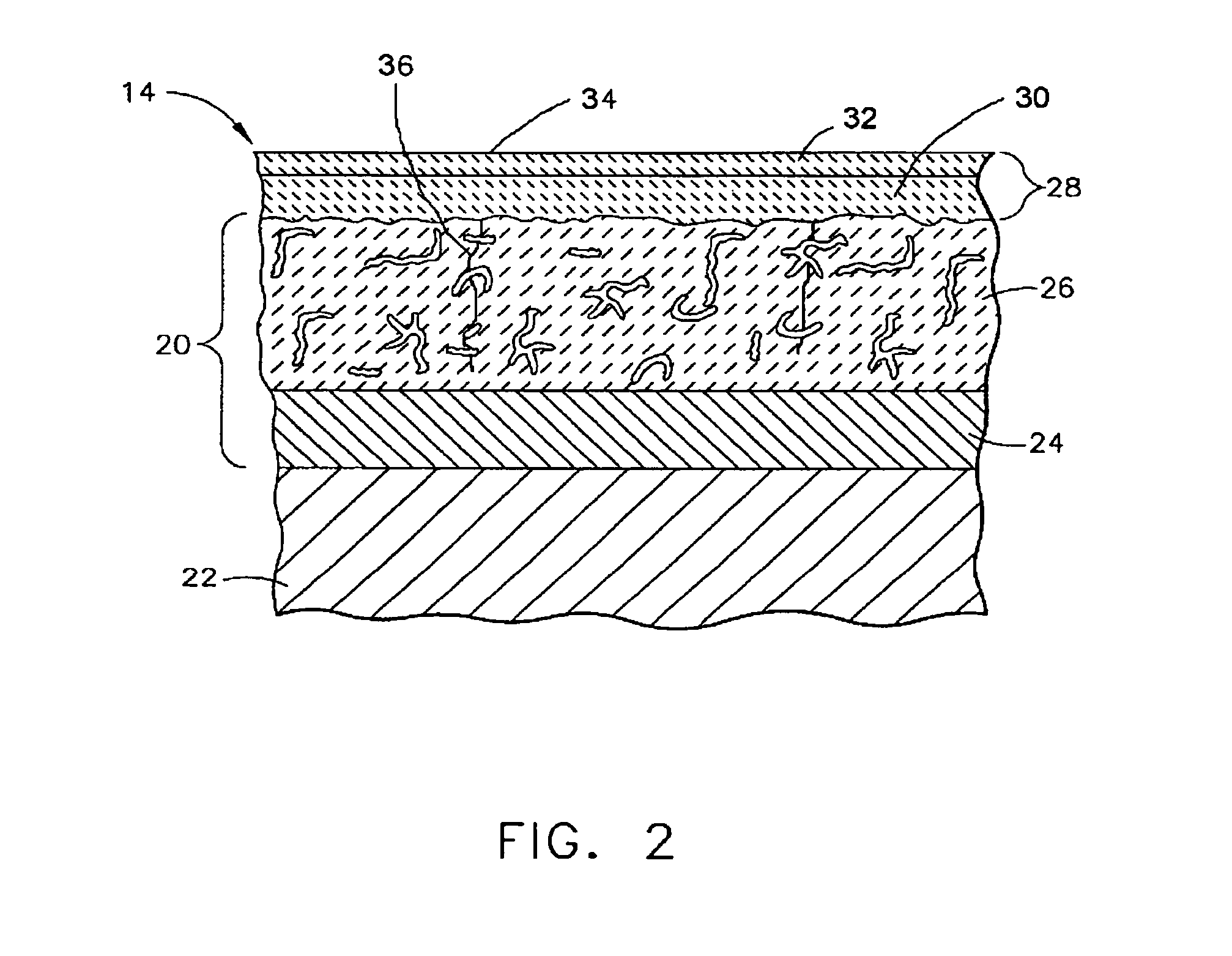

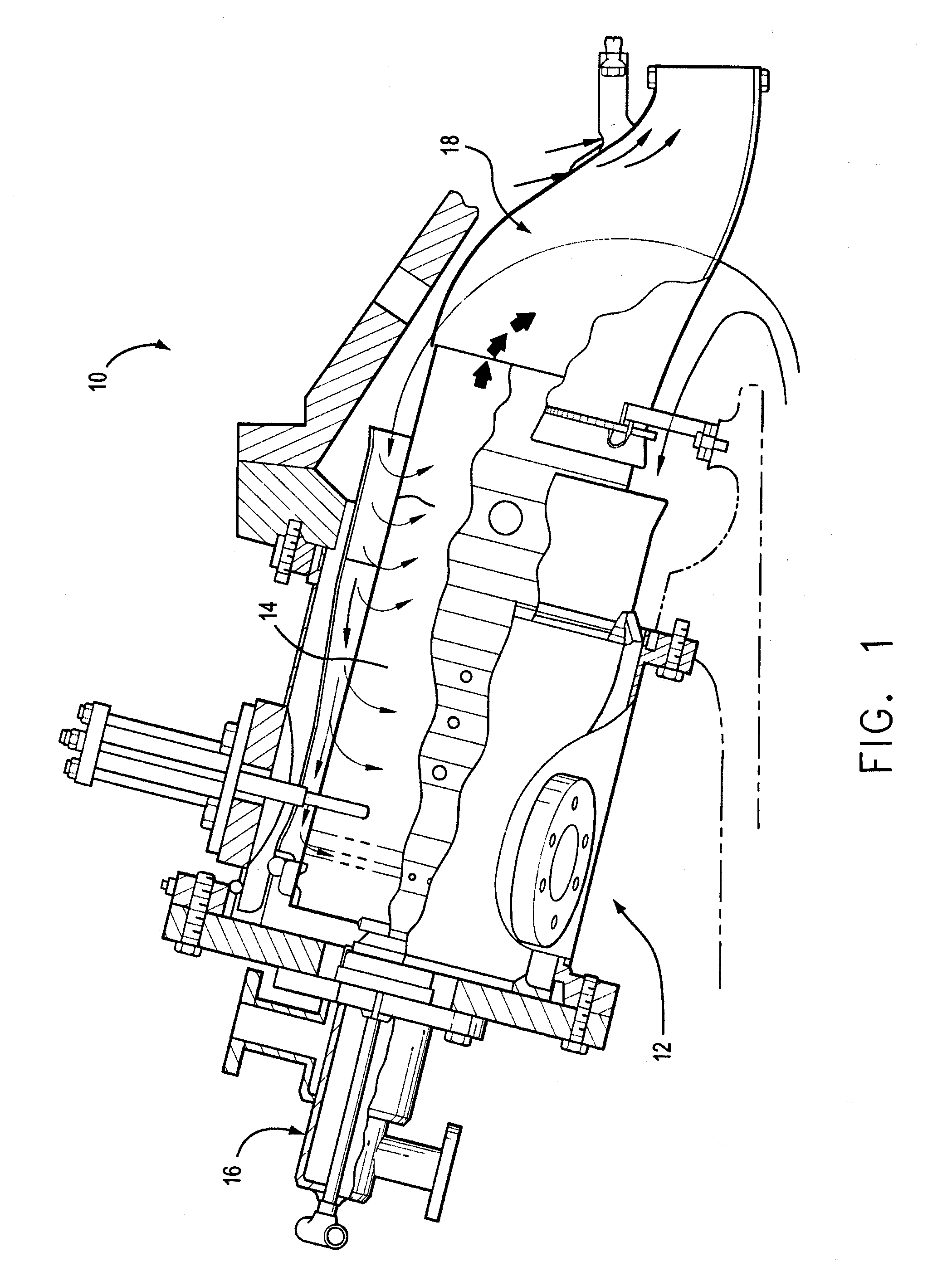

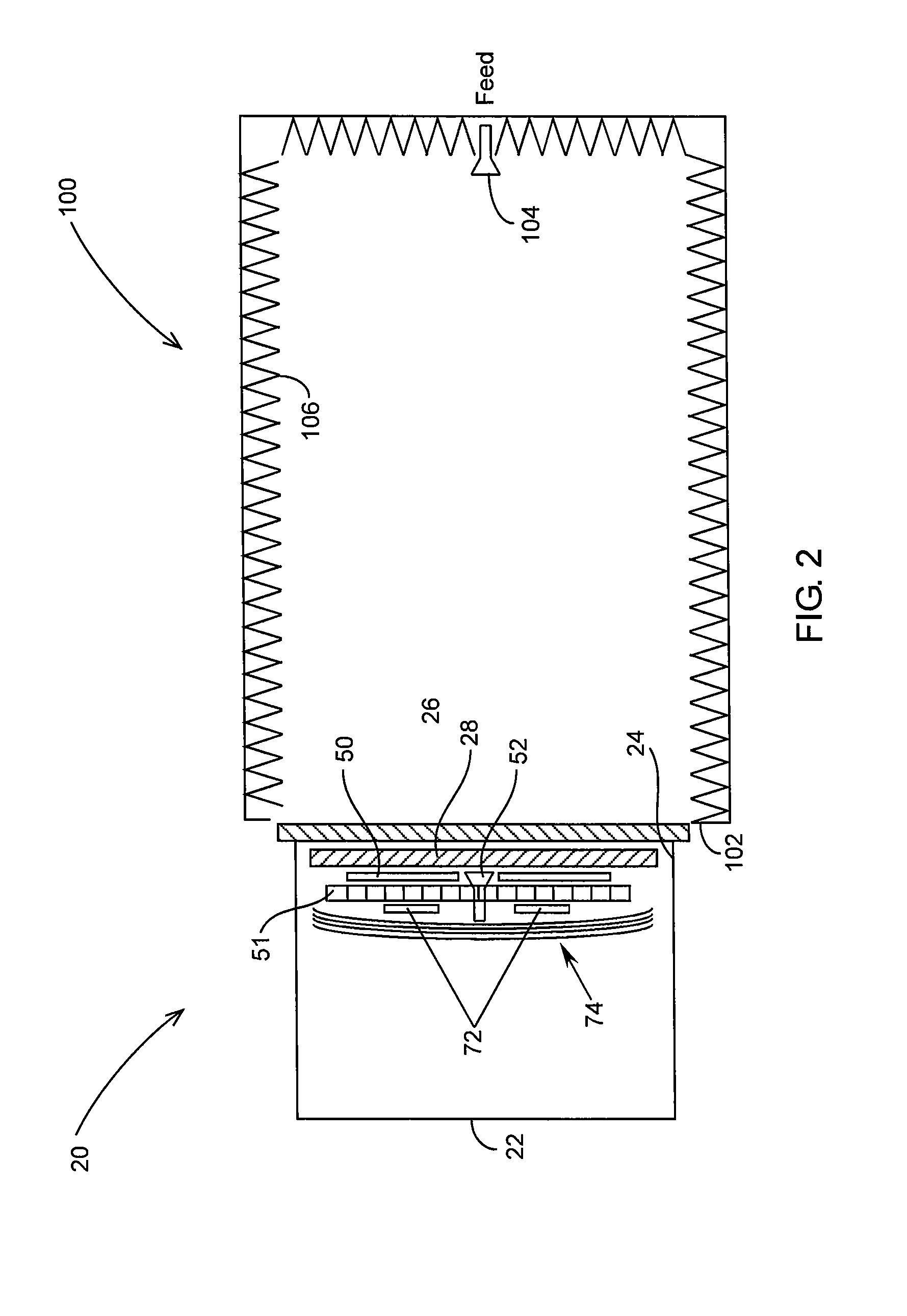

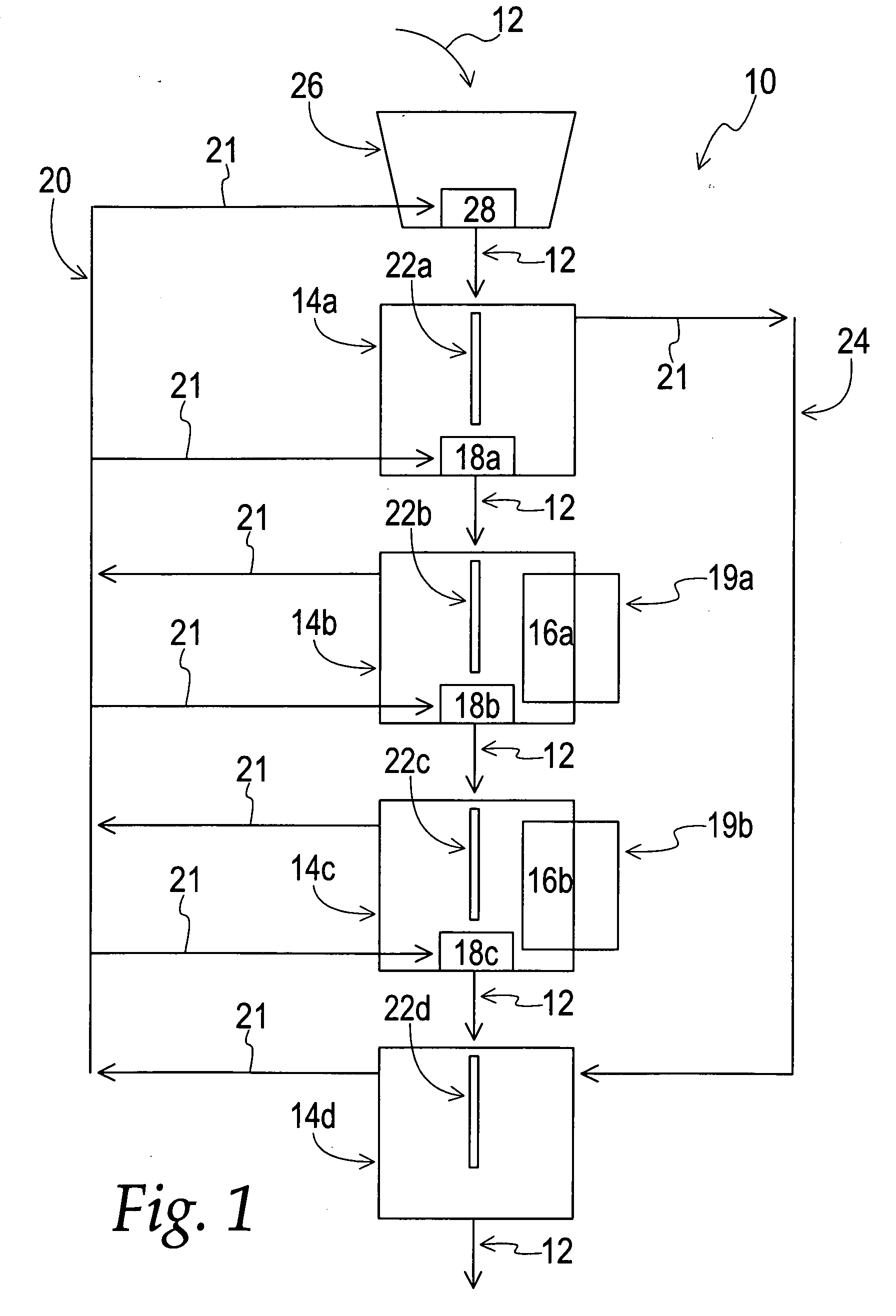

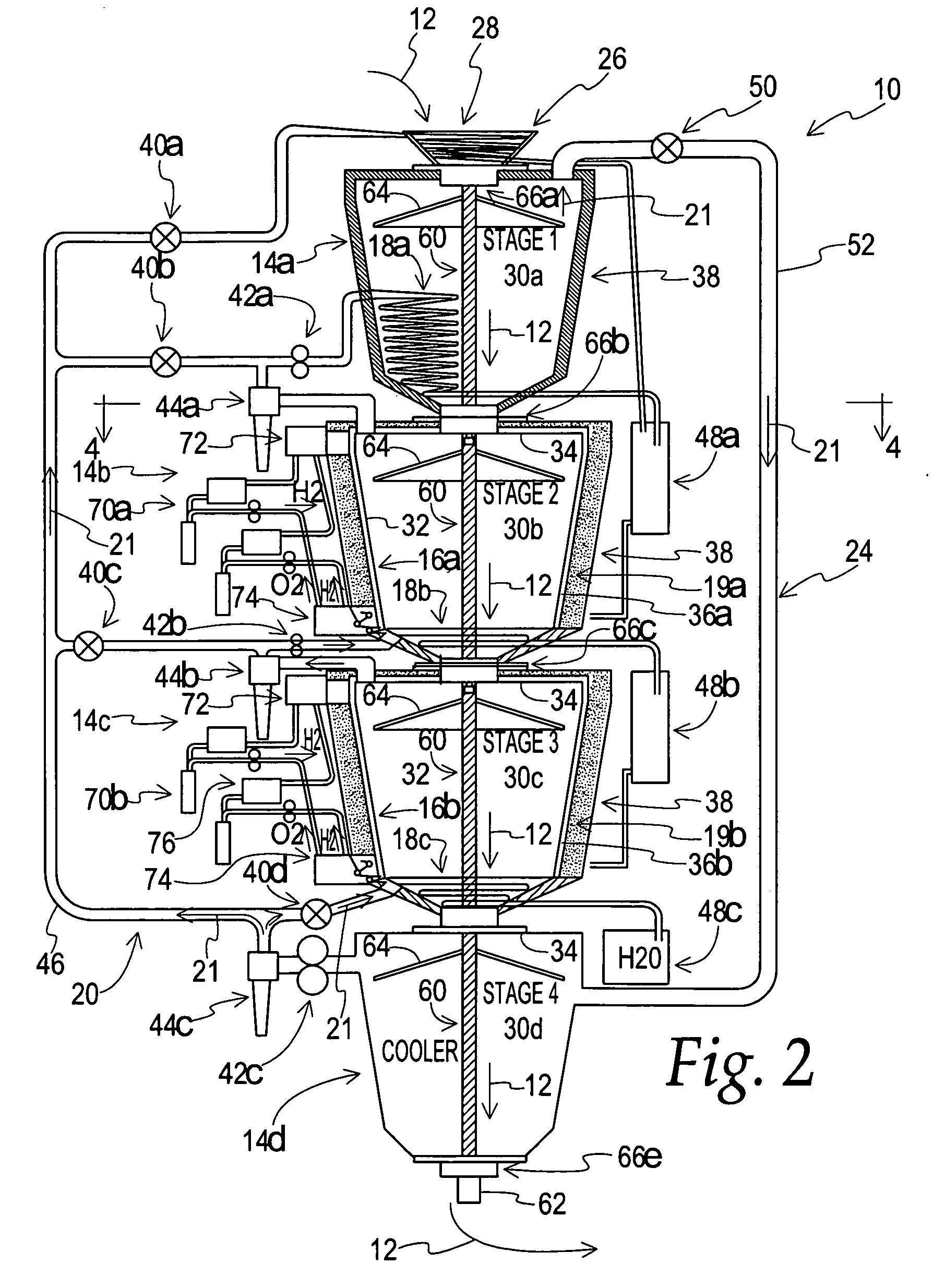

Harvest drying method and apparatus

InactiveUS20100088920A1Drying solid materials with heatHeat recovery systemsProcess engineeringRadiant heat transfer

A multi-stage harvest dryer (10) is provided for drying an agricultural harvest product (12), such as, for example, corn, sunflowers, beans, seeds, etc. The dryer (10) includes multiple drying stages (14a-14d) connected in sequence to dry a volume of harvest product (12) passed from one drying stage (14) to the next. Heat exchangers (16a, 16b, 18a, 18b, 18c) are located in the stages (14a-14c) to transfer heat to the harvest product (12) in each of the corresponding stages (14a-14d). The heat exchangers (16a and 16b) are radiant heat exchangers that efficiently heat the harvest product (12) via radiant heat transfer, with heaters (19a, 19b) being provided to maintain the heat exchangers (16a, 16b) within a desired temperature range. The heat exchangers (18a-18c) are condensers that efficiently recycle the heat within the dryer (10) by transferring heat back to the harvest product (12) by condensing water that has been evaporated from the harvest product (12) elsewhere in the dryer (10).

Owner:LAROU ALBERT M & LAROU MILDRED R FAMILY TRUST

Cooking oven

ActiveUS20090065493A1Highly controlled heatingReduce the overall heightDomestic stoves or rangesElectrical heating fuelStructure functionEngineering

A cooking structure which provide for two or more side-by-side ovens separated by vertical, movable, hinged partition(s) whereby the oven structure may function as one large oven or as two or more smaller independent ovens, wherein for each oven a tangential fan blows air substantially evenly over upper electrical heating elements strung generally from side-to-side of the oven, wherein a flow director (baffle) structure functions as a radiant heat shield which is operator movable to either expose to or occlude from the oven cooking chamber the direct radiation from its heating elements, depending on the need to roast, bake, or broil the food product. Also provided are lower electrical heating elements positioned below a ceramic cooking surface for ensuring evenness of radiant heat transfer therefrom. Also provided is operator controlled top vs. bottom heating using a slide control that reciprocally affects the duty cycle of the top and bottom electrical heating elements, further allowing precision baking control.

Owner:HINES JR ROBERT STICKLEY

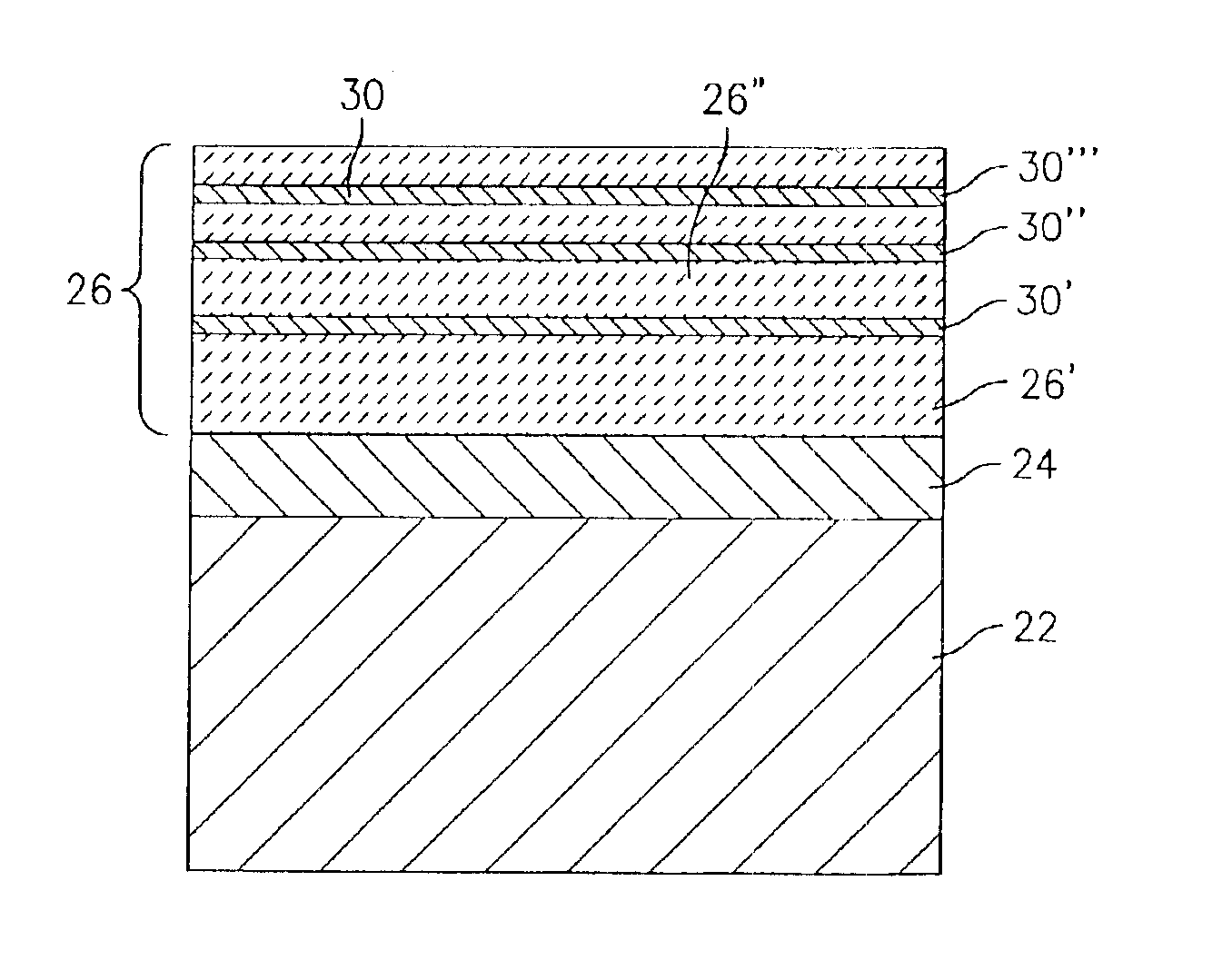

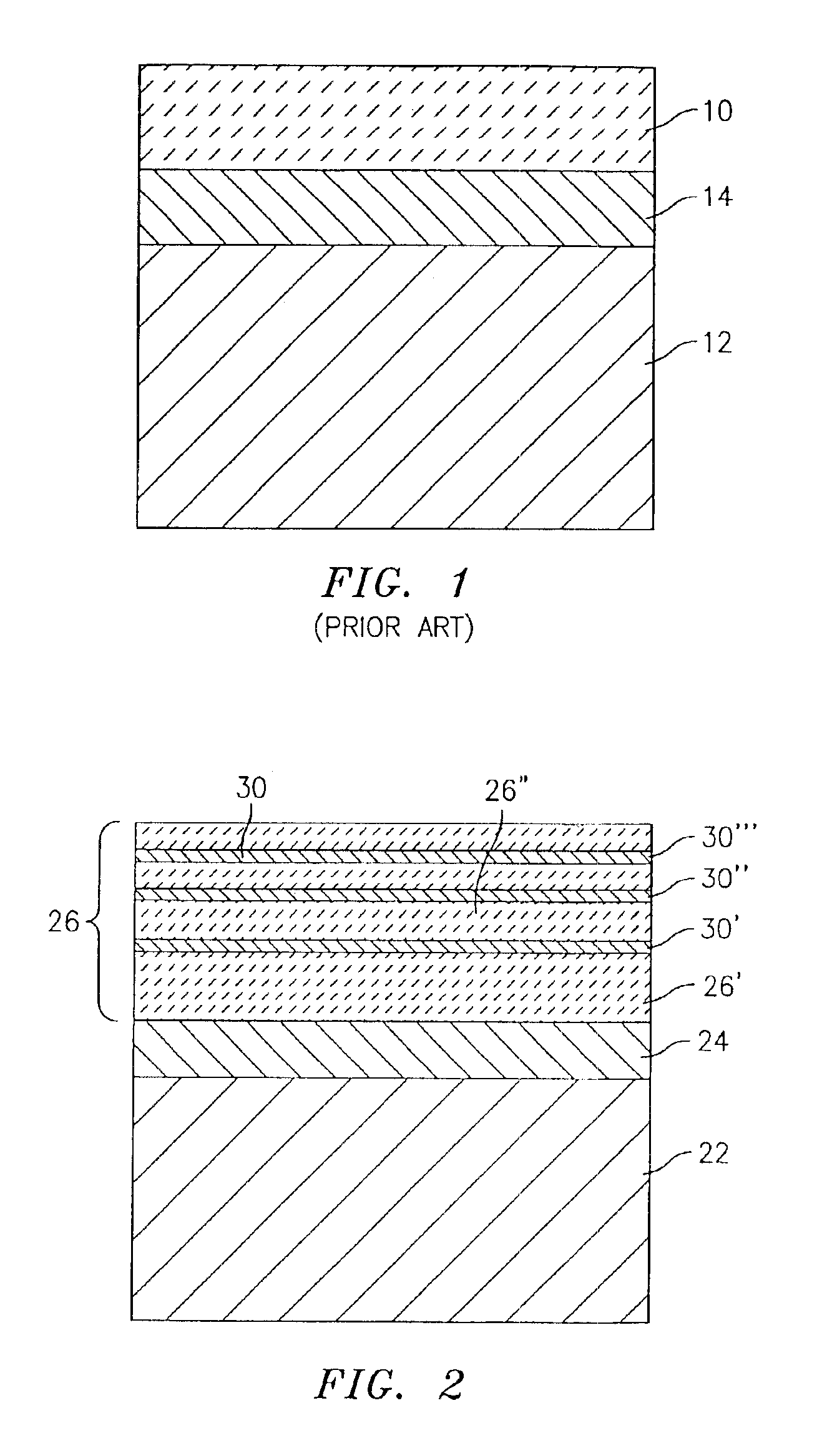

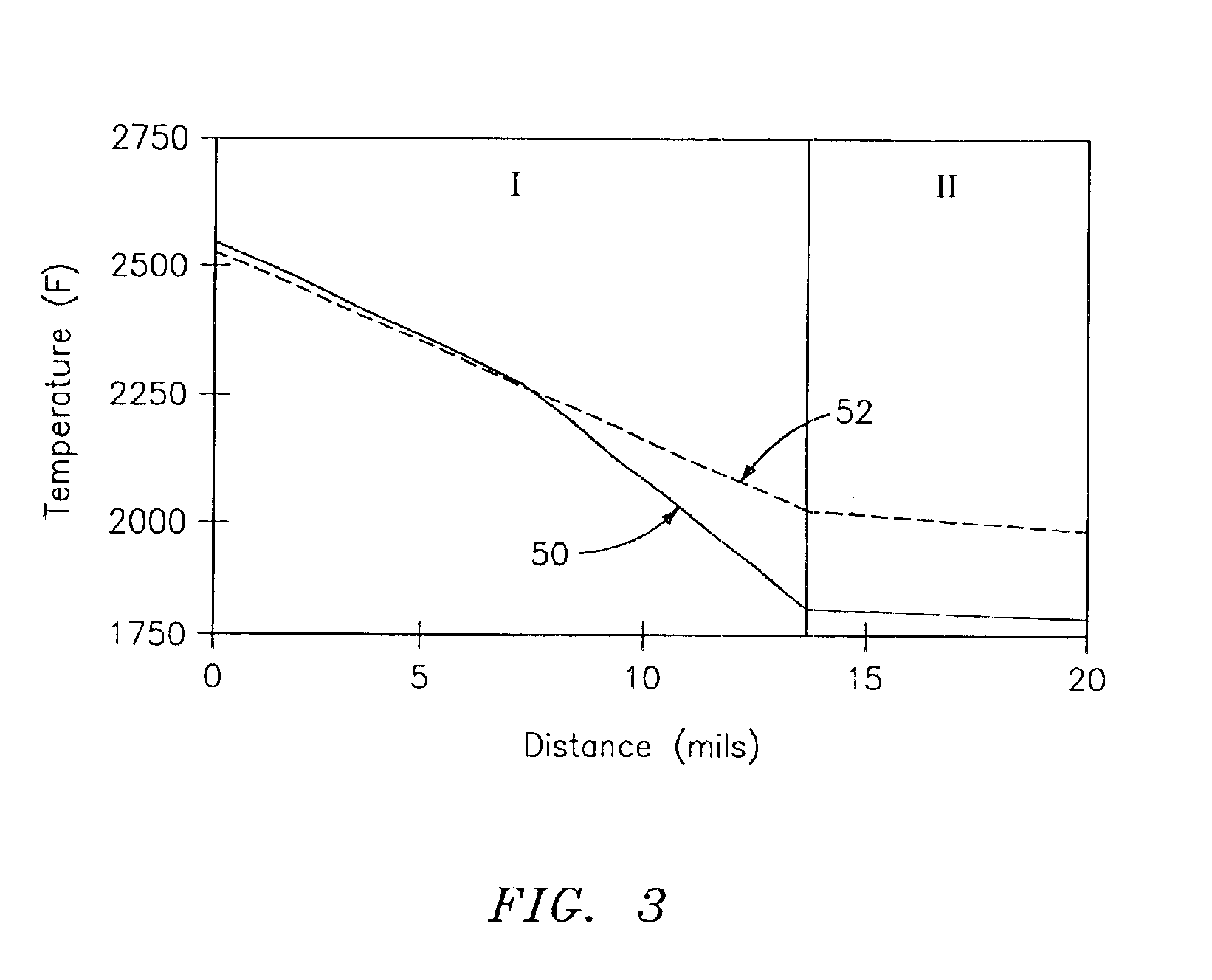

Reflective coatings to reduce radiation heat transfer

InactiveUS6887587B2Reduces radiation heat transportReduce transportationPropellersVacuum evaporation coatingMetallurgyCeramic coating

The present invention relates to a method for forming an article having a protective ceramic coating which reduces radiation heat transport through the ceramic coating. The protective ceramic coating includes one or more embedded reflective metallic layers for reducing the radiation heat transport. The method for forming the protective coating broadly comprises the steps of forming a ceramic coating on a substrate and embedding at least one reflective metallic layer within the ceramic coating.

Owner:RAYTHEON TECH CORP

Carafe with contents volume indicator

ActiveUS20050109794A1Accurately determineMaximize efficiencyCapsClosure lidsEngineeringRadiant heat transfer

An inexpensive, readily visible indicator for liquid levels in a vacuum bottle that includes a coating of reflective material to minimize radiation heat transfer from the interior of the vacuum bottle to the exterior of the assembly. The vacuum bottle assembly includes a container receiving the vacuum bottle and a transparent or translucent window is located in the side wall of the container and in alignment with an interruption in the reflective coating. An indicator is located within the vacuum bottle and is aligned with both the windows and the interruption so as to be visible therethrough to provide an indication of the level of the liquid contained within the inner liner of the vacuum bottle.

Owner:THERMOS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com