Patents

Literature

97results about How to "High spreading rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterborne epoxy floor level coating and preparation method thereof

ActiveCN104087120AIn line with the concept of environmental protectionWill not polluteEpoxy resin coatingsPolymer scienceTap water

The invention discloses a waterborne epoxy floor level coating and a preparation method thereof. The coating comprises a waterborne epoxy seal primer, a waterborne epoxy floor level intermediate coat and waterborne epoxy floor level coating finish, wherein the primer, the intermediate coat and the finish are same in component A which comprises 85-95 parts of liquid epoxy resin and 5-15 parts of an epoxy active diluent; the components B are different according to different characteristics of the primer, the intermediate coat and the finish but the main components consist of a waterborne epoxy curing agent and tap water. The waterborne epoxy floor level coating disclosed by the invention is environment-friendly, low in VOC content, good in wear-resisting property, high in hardness and excellent in chemical corrosion-resisting property.

Owner:西北永新涂料有限公司

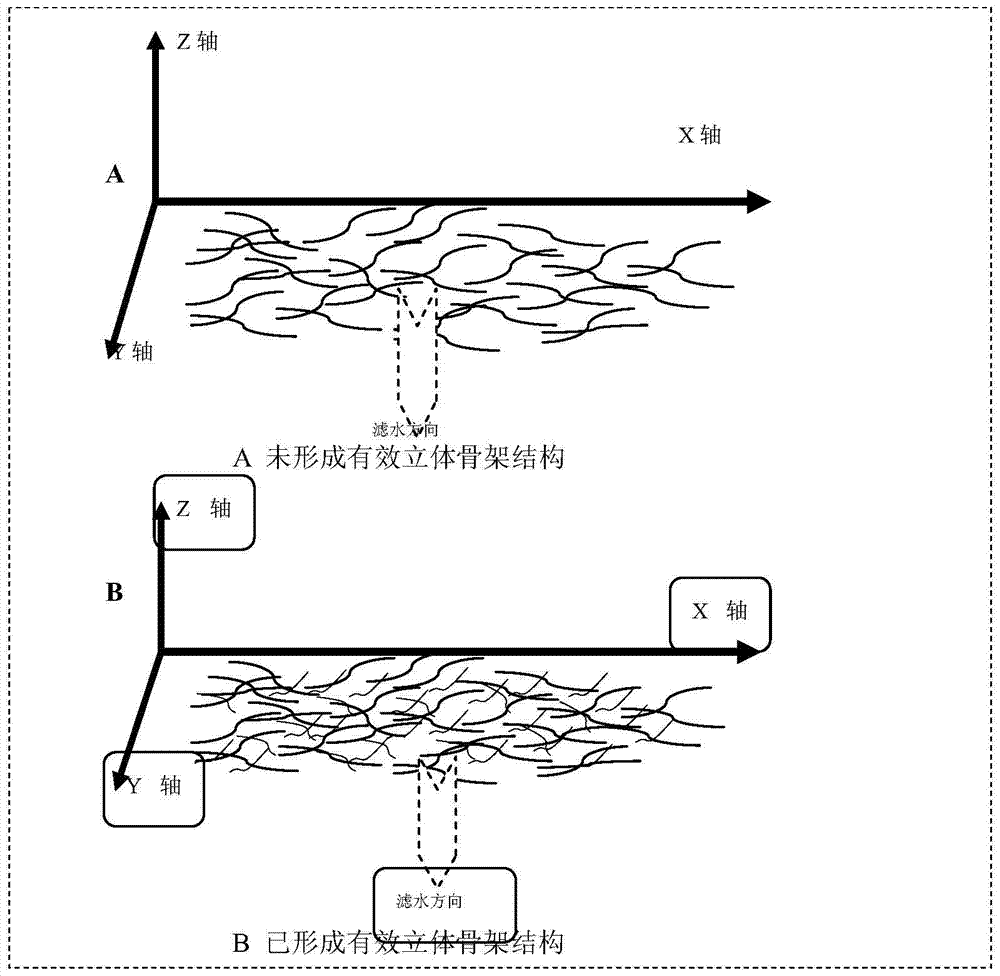

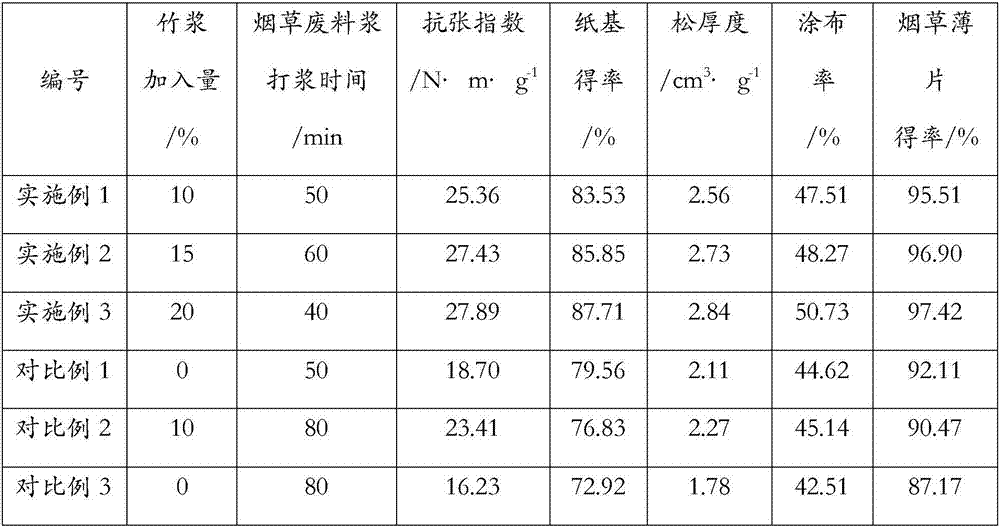

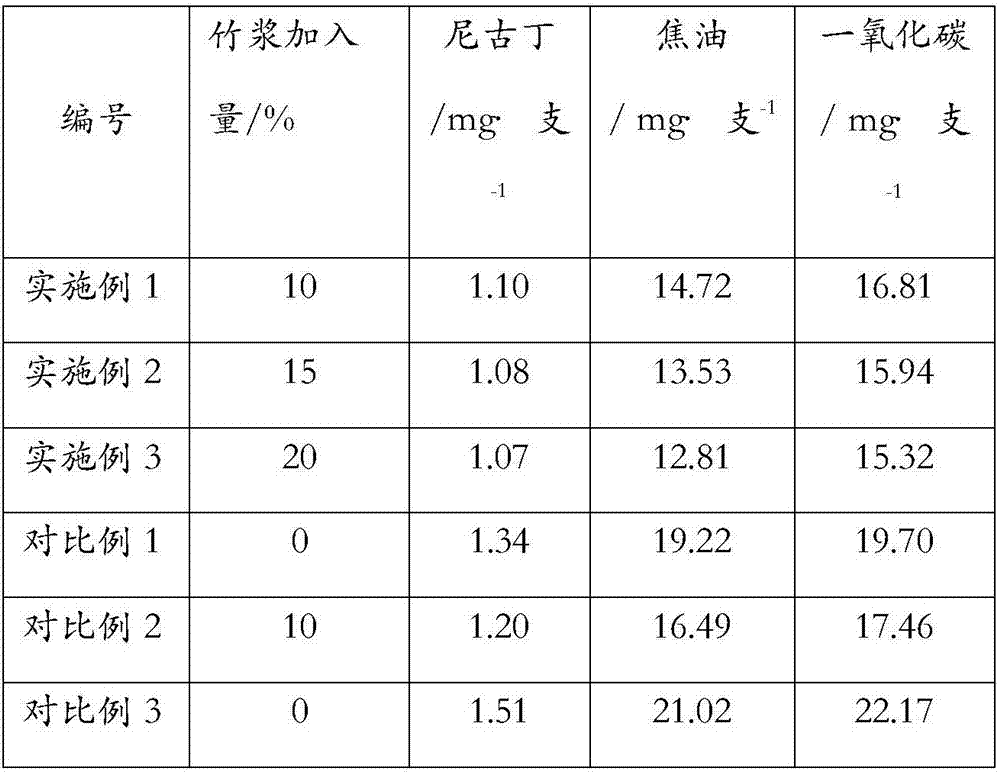

High-bulk papermaking method reconstruction tobacco leaf fiber composition and preparation method and application

ActiveCN106993820AAchieve absorbency and bulkImprove filler retentionTobacco preparationCo releaseTobacco leaf

The invention belongs to the special papermaking production field, and specifically relates to a high-bulk papermaking method reconstruction tobacco leaf fiber composition and a preparation method and application; the reconstruction tobacco leaf comprises a tobacco raw material, wood long fibers and wood short fibers, and is prepared by mixing said compositions; the short fibers are arranged in a Z-type in a water filtering process, thus effectively improving the bulk property and spreading rate while fully ensuring the substrate tensile strength and paper machine operationability, improving filling material retention rate and product yield, reducing production cost, improving product fully combustion level, and reducing CO release amount.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

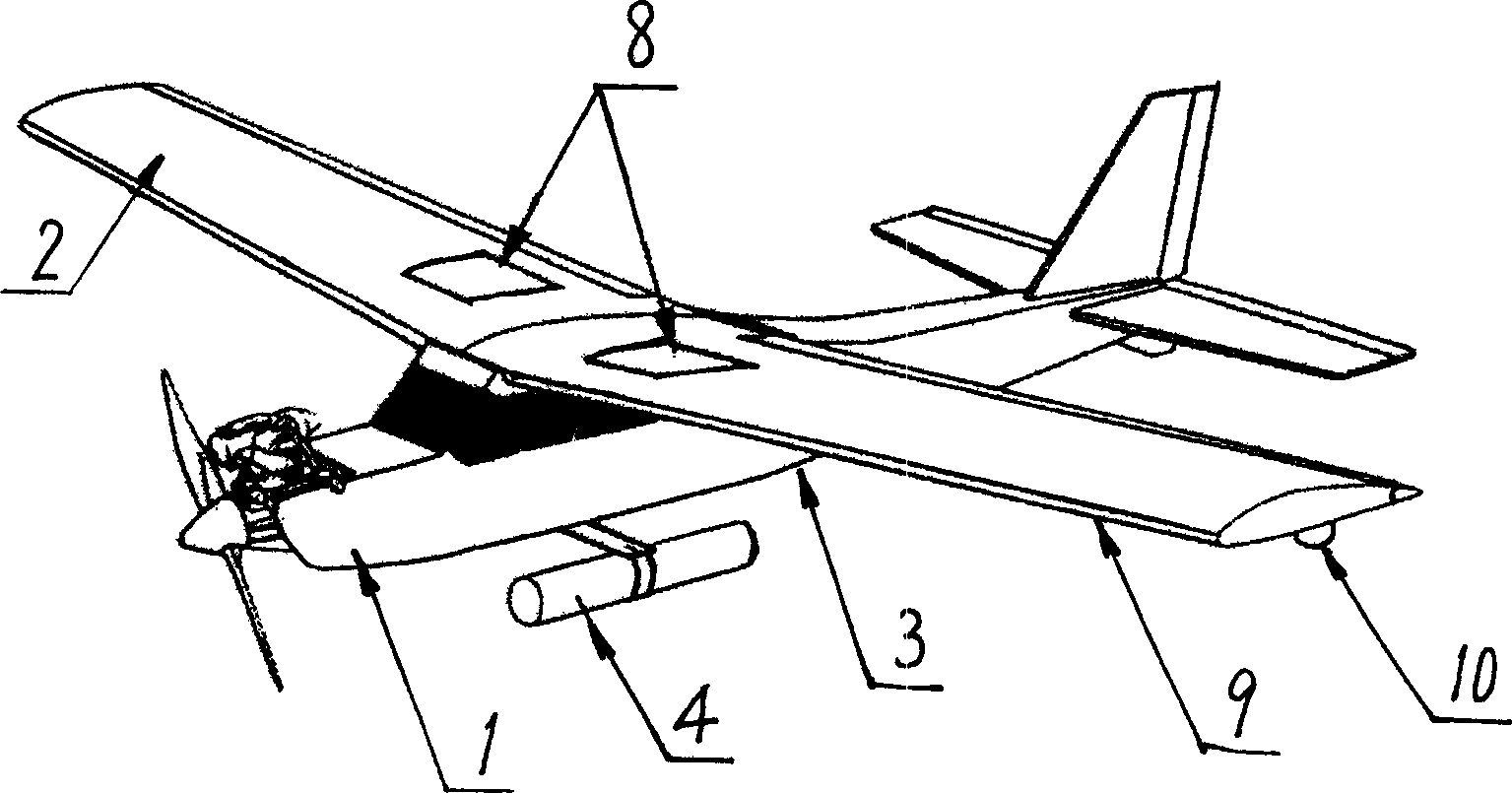

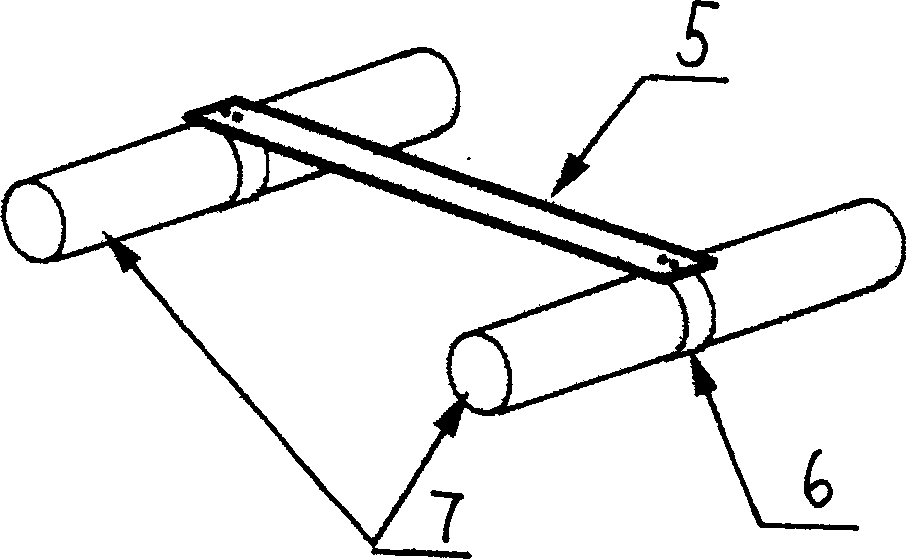

Drone for artificially influenzing weather and its spreading method

InactiveCN1586993AAdaptableImprove mobilityAircraft componentsLaunching weaponsControl systemEngineering

The drone for climate modification includes fuselage, wings, driving and controlling system, parachute cabin in the abdomen, spreading frame comprising transverse aluminum plate and clamping rings to fix the catalyst cylinder on two ends of the aluminum plate and fixed in front of the parachute cabin, transceiver cabin in the root of the wings, airborne sonde inside the outer ends of wings, and night flight lamp. The spreading job process with the drone includes the steps of preparation, taking off, flight regulation, spreading, returning to base and landing. The present invention has the features of strong adaptability to weather, low cost, and both functions of spreading and detecting.

Owner:北京市气象局观象台

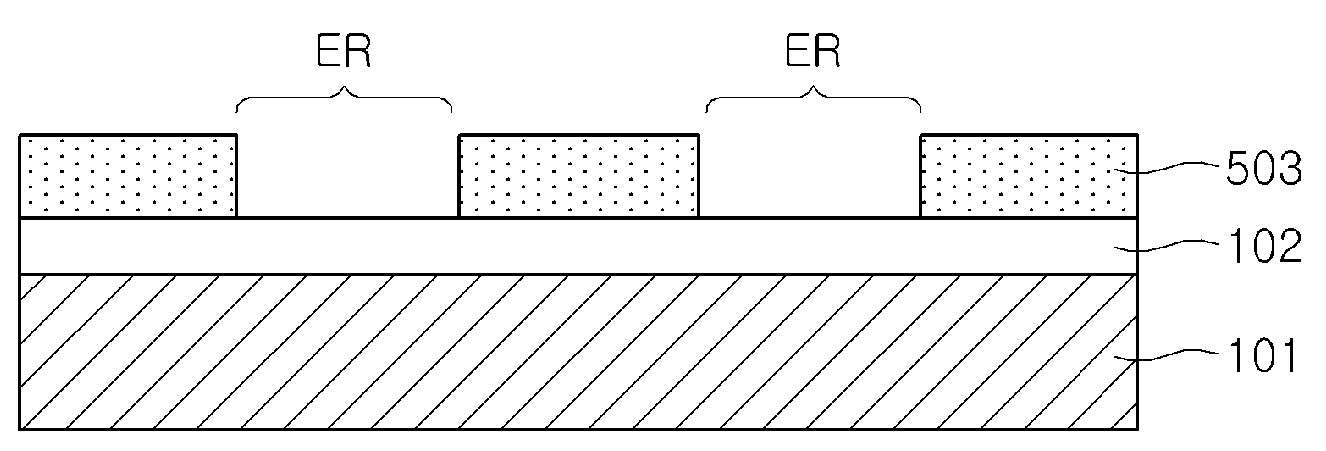

Photoresist composition, coating method thereof, method of forming organic film pattern using the same and display device fabricated thereby

InactiveUS20080213549A1Improve coating uniformityHigh spreading rateDecorative surface effectsSurface layering apparatusResistOrganic film

Disclosed herein is a photoresist composition suitable for coating onto a large substrate and having improved coating uniformity to prevent occurrence of stains, a coating method thereof, a method of forming an organic film pattern using the same, and a display device fabricated thereby. The present invention thus provides a photoresist composition comprising a polymeric resin with an incorporated polysiloxane resin, a photosensitive compound, and an organic solvent. Accordingly, the photoresist composition can be coated onto a large substrate by a spinless coating method, and thereby coating uniformity can be improved, the occurrence of stains such as cumulous stains and resin streaks can be prevented, and the coating rate and quality of a final product prepared using the photoresist composition can also thereby be enhanced.

Owner:SAMSUNG DISPLAY CO LTD

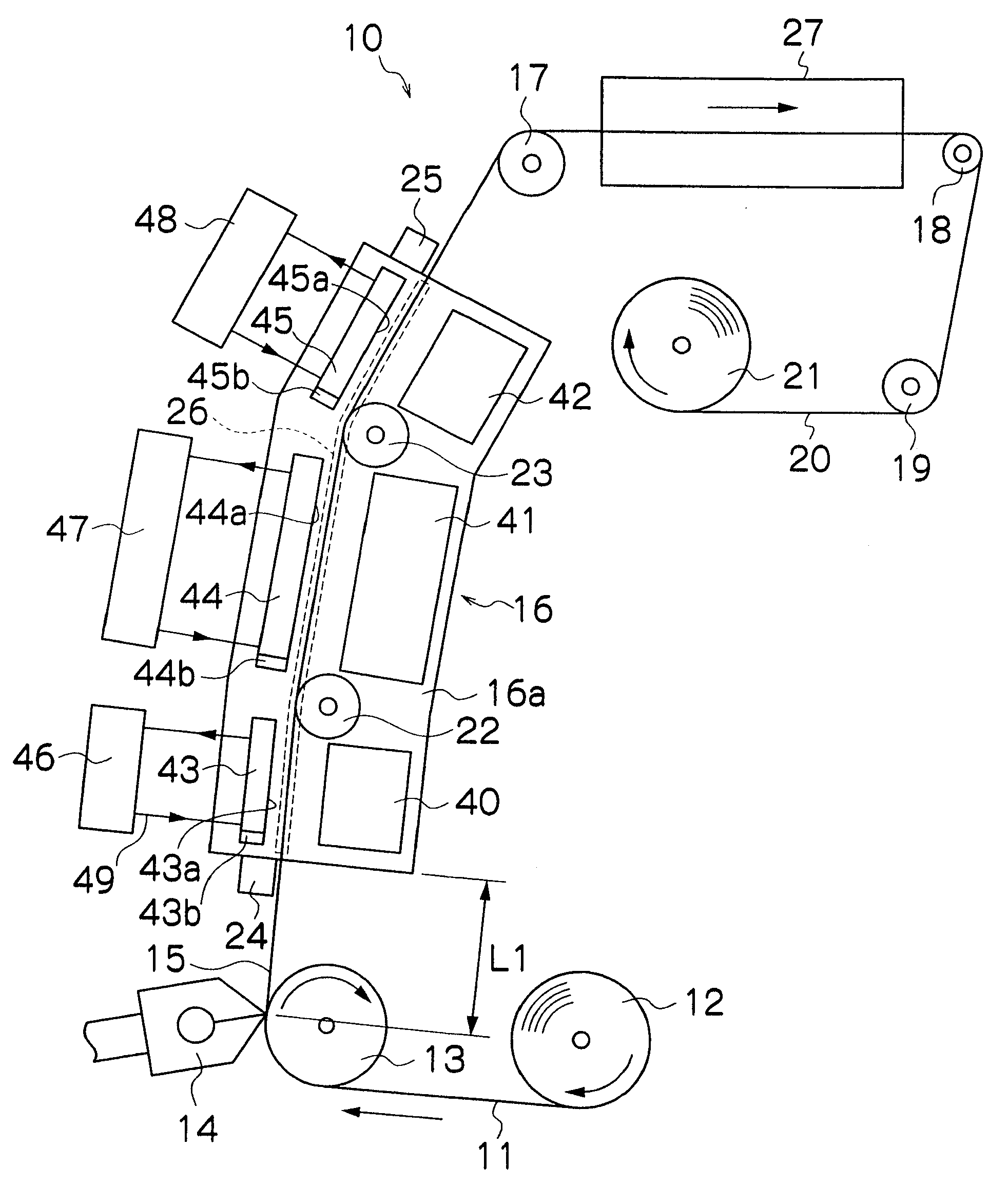

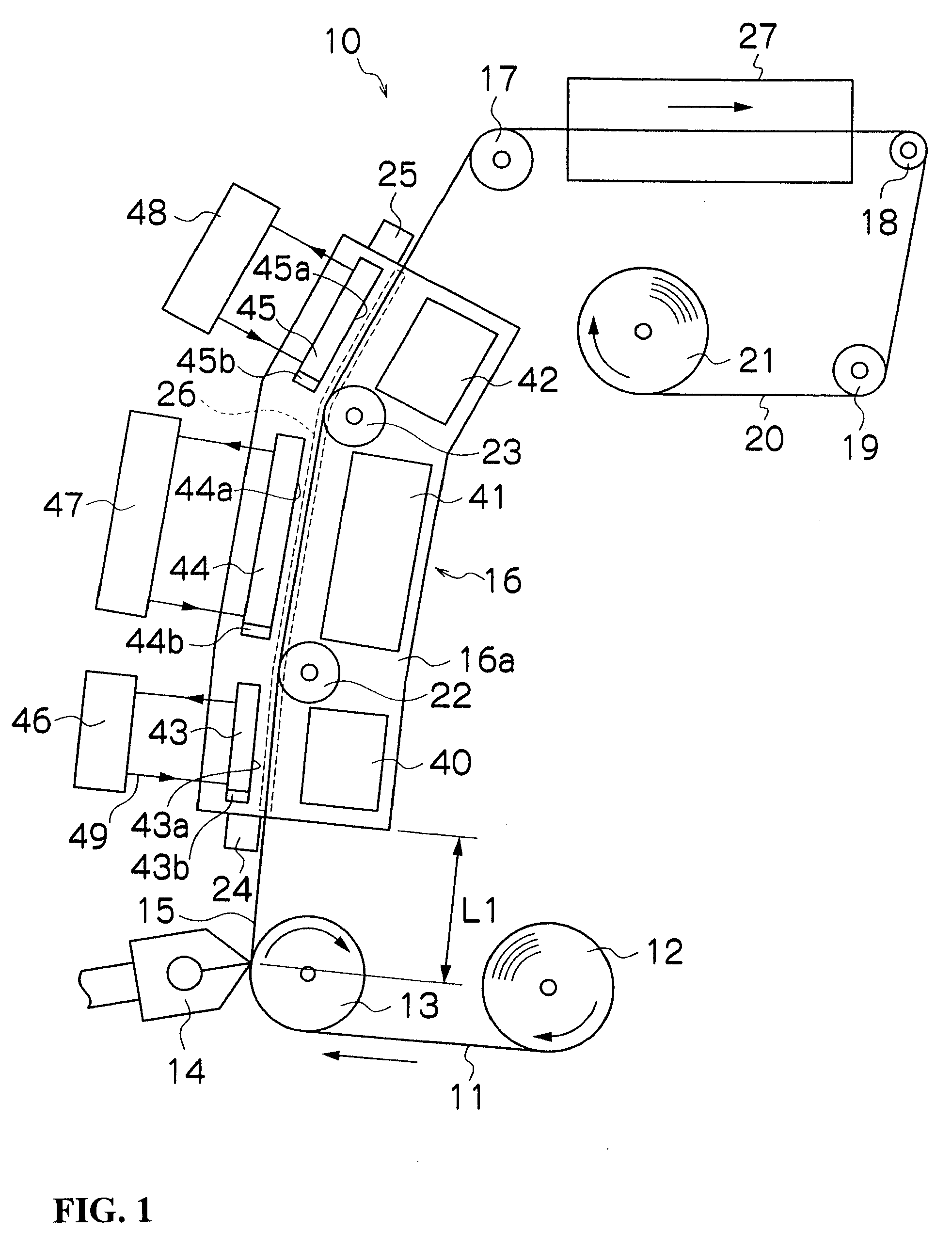

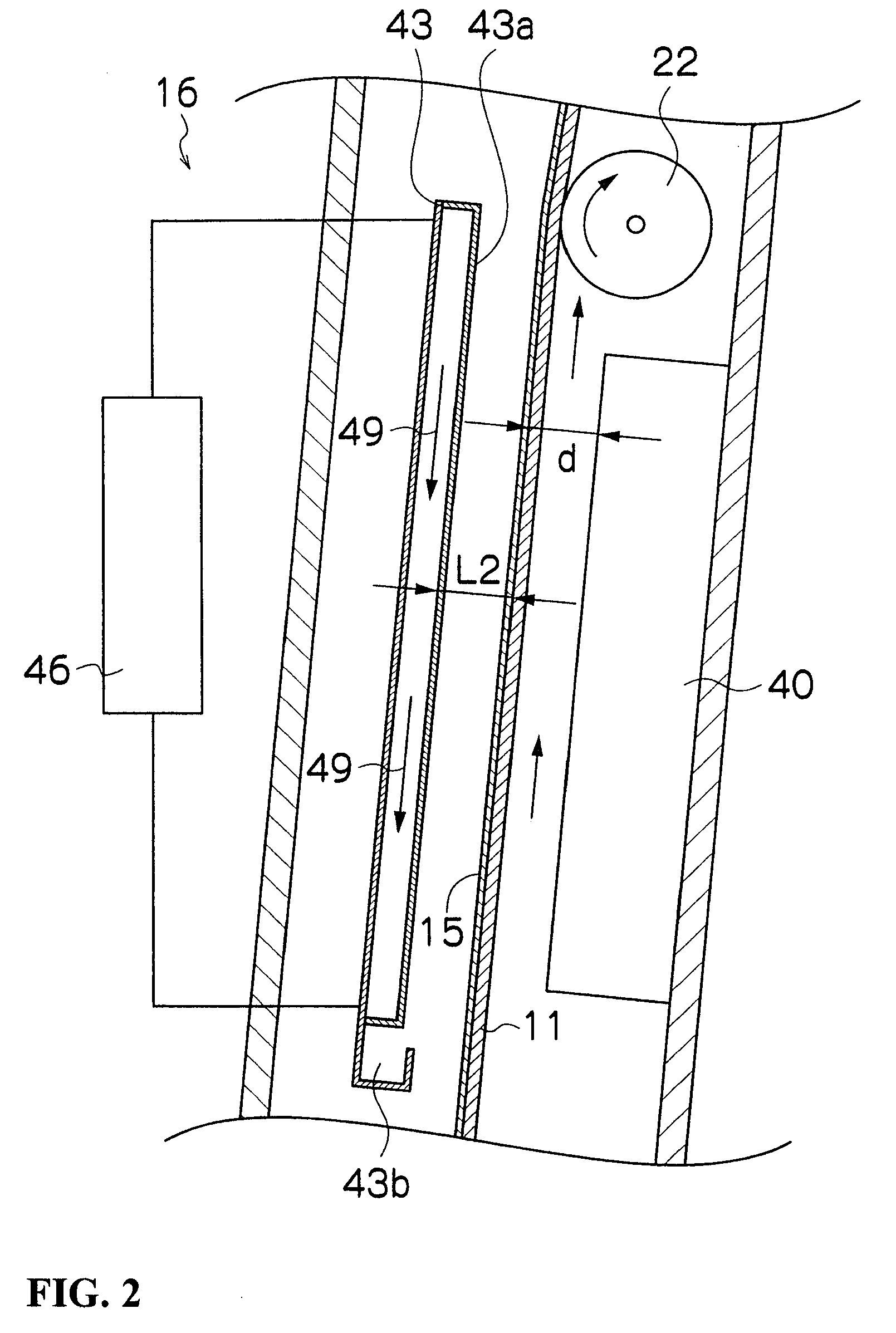

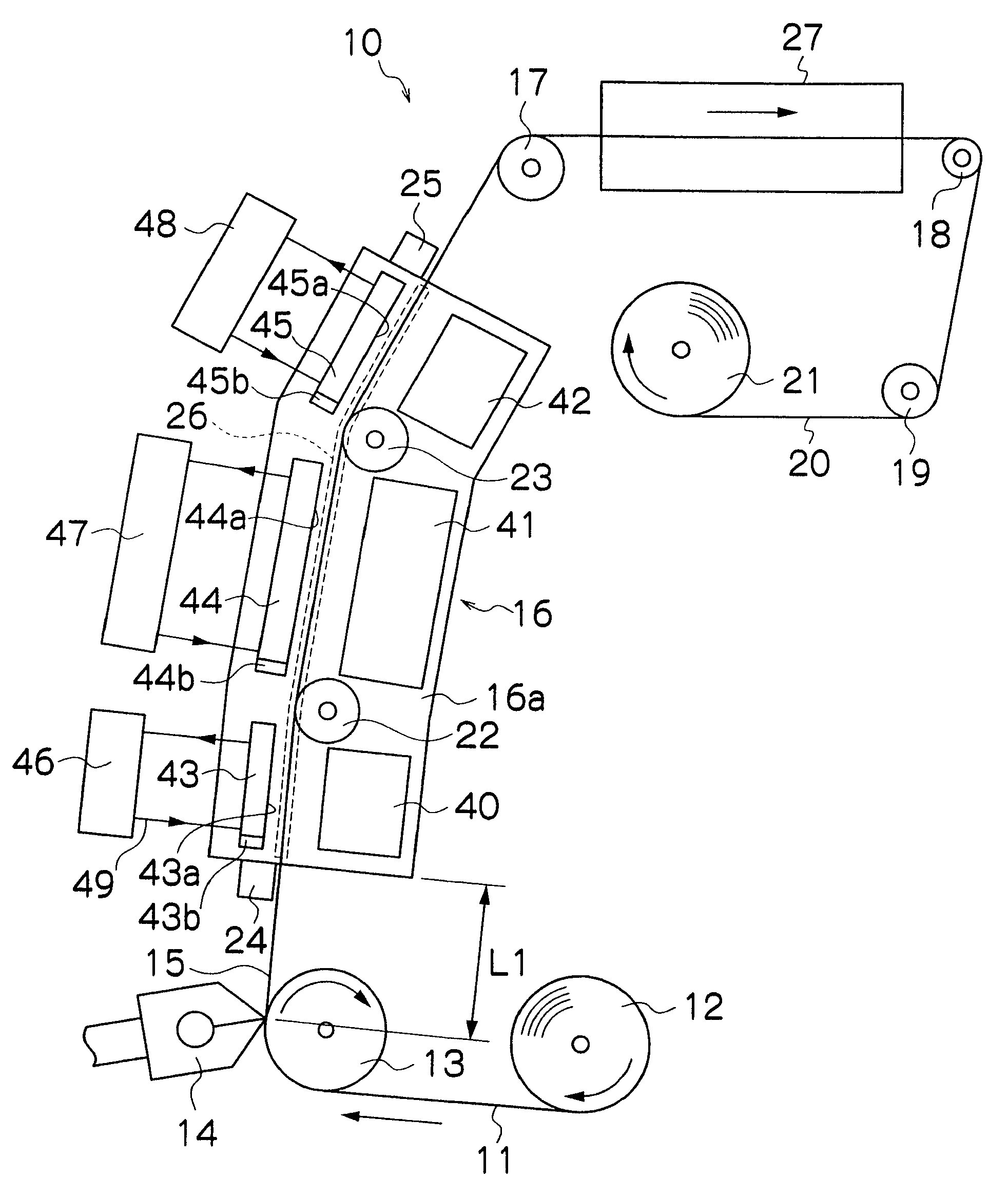

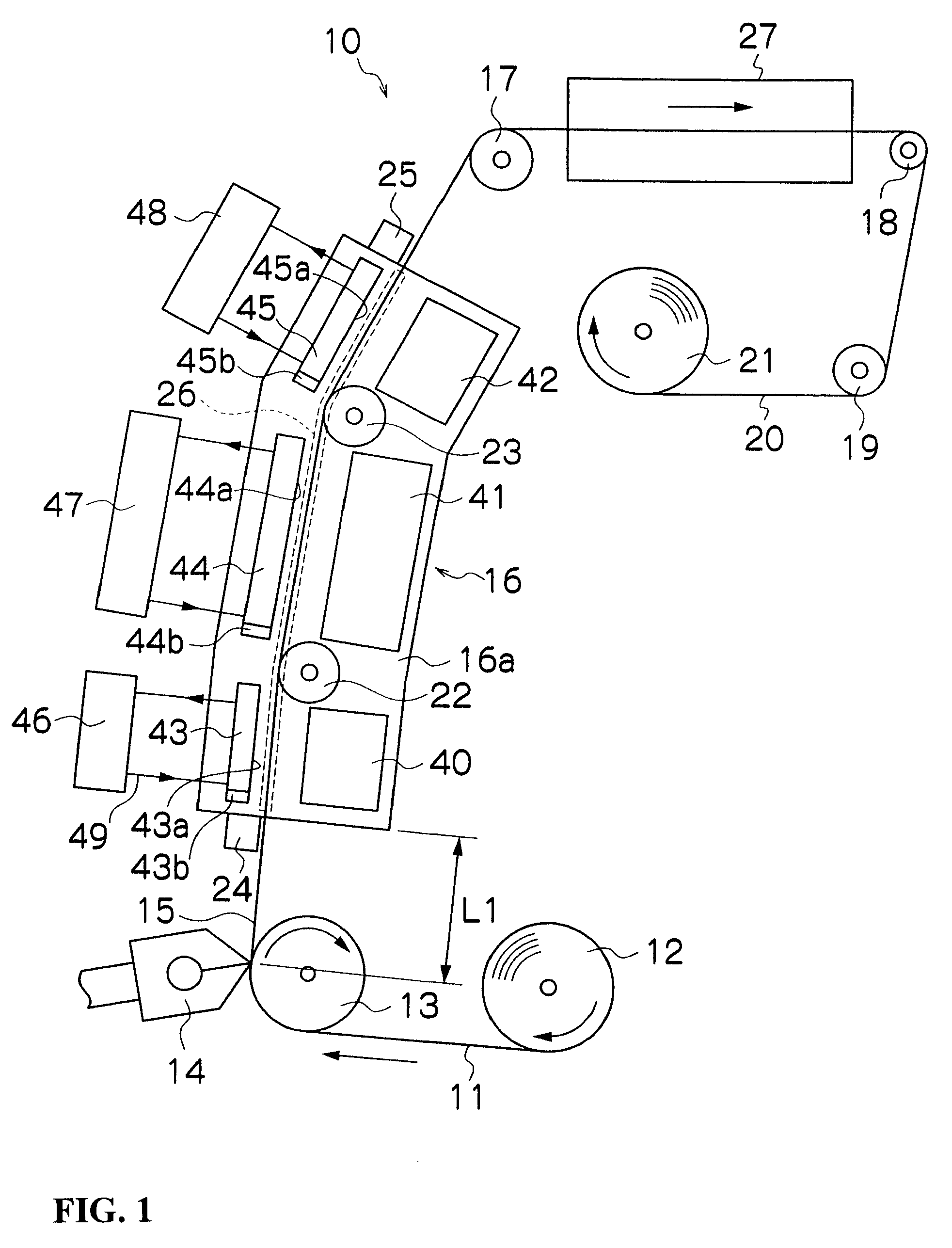

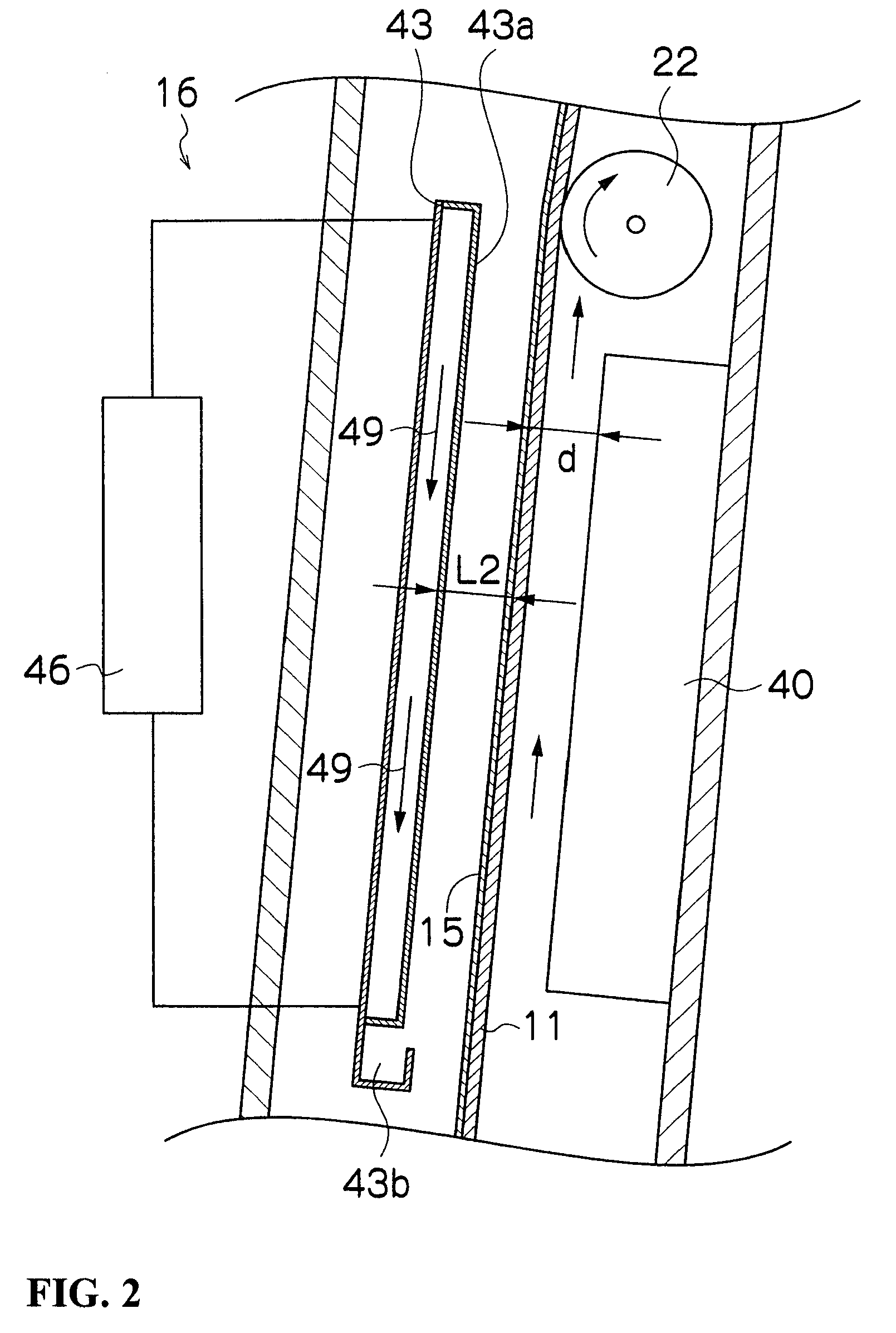

Method and apparatus for drying coating film and method for producing optical film

InactiveUS20080206455A1Efficient heatingHigh spreading rateDrying using combination processesDrying solid materials with heatOrganic solventBand shape

The present invention provides a method for drying a coating film comprising drying a coating film of an organic solvent-containing coating liquid applied to a running band-shaped flexible substrate, the drying method comprising the steps of: providing a heater at a position opposed to the band-shaped flexible substrate at a running position immediately after coating; and heating the band-shaped flexible substrate by the heater; wherein when TW (° C.) denotes the surface temperature of the band-shaped flexible substrate; TH (° C.) denotes the surface temperature of the heater; λ (W / m·K) denotes the heat-transfer coefficient of air; d(m) denotes the distance between the heater and the band-shaped flexible substrate (web); η denotes the efficiency of heat transfer; and σ denotes the Stefan-Boltzmann constant (5.670×10−8 W / m2K4), the ratio of radiant heat transfer represented by QR / (QR+QC) is 0.25 or more and 0.6 or less, wherein QC and QR are represented by the following equations, respectively: QC=λ / d·(TH−TW) where QC denotes heat transfer by air, and QR=η{(TH+273)4−(Tw+273)4} where QR denotes heat transfer by radiant.

Owner:FUJIFILM CORP

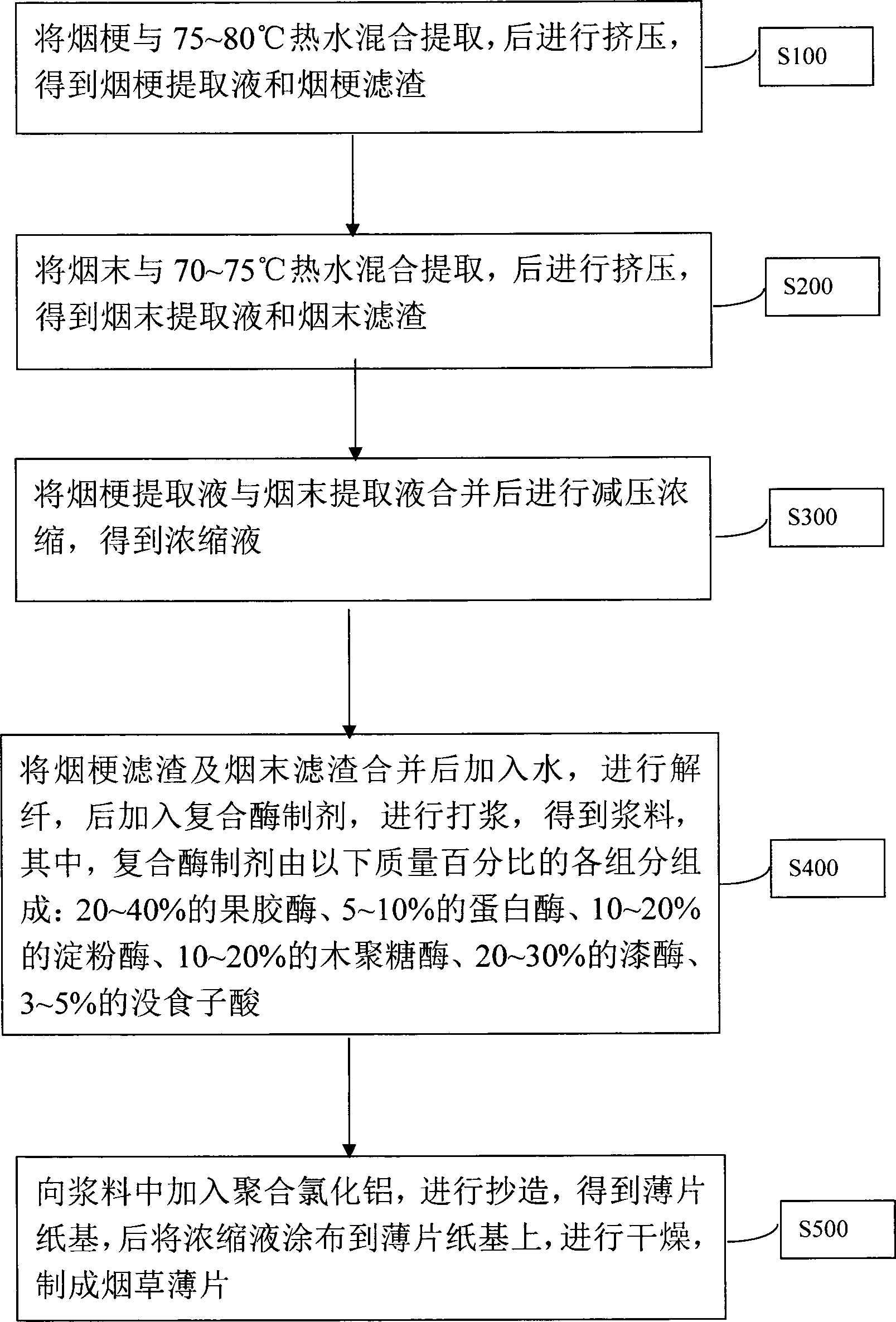

Preparation method of tobacco sheet

The invention provides a preparation method of a tobacco sheet. The preparation method of the tobacco sheet includes the following steps: 1) mixing tobacco stems with hot water of 75-80 DEG C for extraction, and then squeezing to obtain tobacco stem extracting solution and tobacco stem filter residues; 2) mixing tobacco powder with hot water of 70-75 DEG C for extraction, and then squeezing to obtain tobacco powder extracting solution and tobacco powder filter residues; 3) mixing the tobacco stem extracting solution with the tobacco powder extracting solution for decompression concentration so as to obtain concentrated solution; 4) adding water into a mixture of the tobacco stem filter residues and the tobacco powder filter residues for fiber decomposition, and then adding complex enzyme preparations for pulping so as to obtain pulp materials; and 5) adding polymeric aluminum into the pulp materials for manufacturing paper with pulp so as to obtain a sheet paper base, then coating the sheet paper base with the concentrated solution, and drying to obtain the tobacco sheet. According to the preparation method of the tobacco sheet, the complex enzyme preparations are added after fibers of the tobacco stem filter residues and the tobacco powder filter residues are decomposed, and performance of the pulp materials is improved, pulping energy consumption is reduced, and the sheet yield is improved through synergistic effects among a variety of enzymes.

Owner:SUZHOU KUNLAN BIOTECH

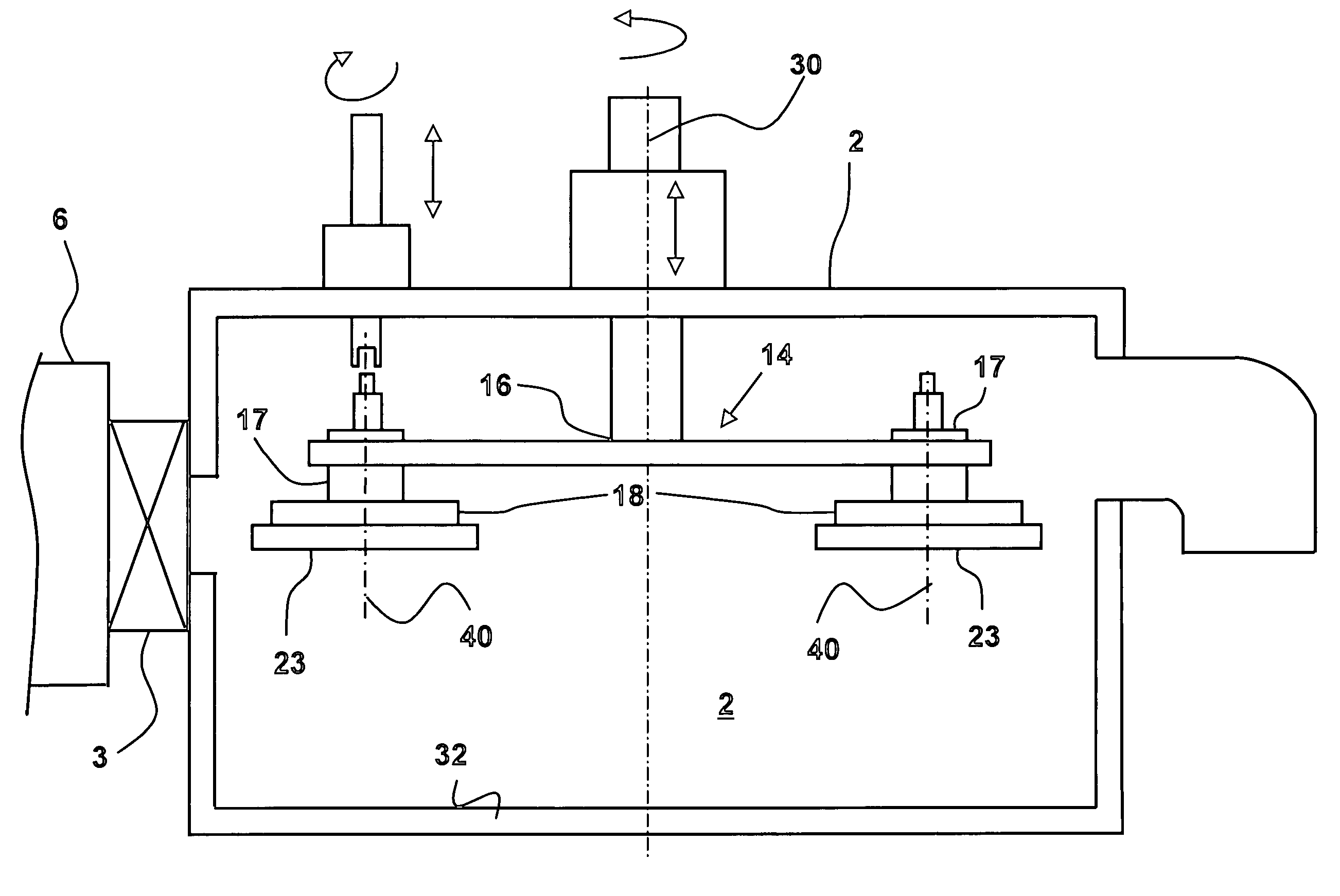

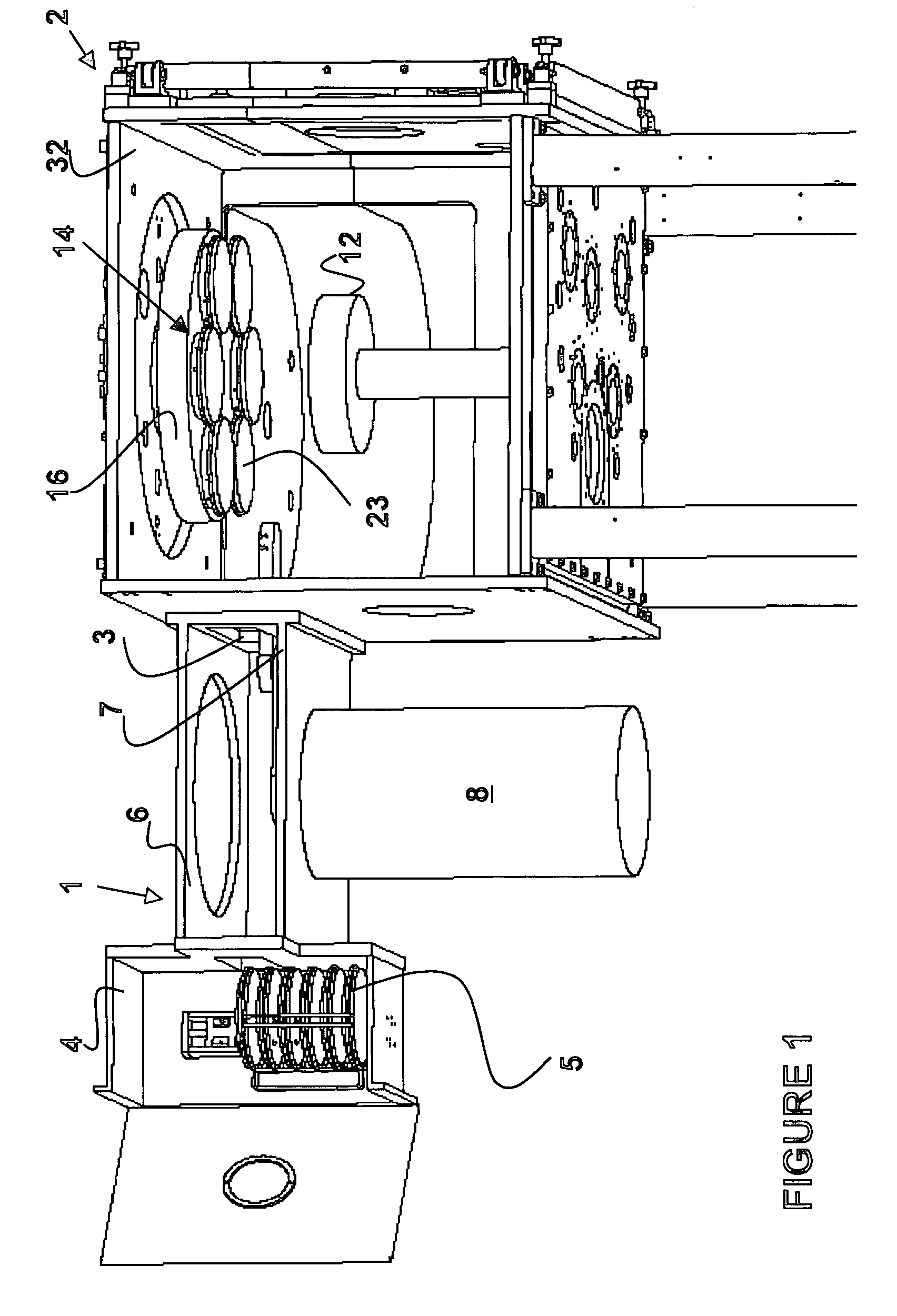

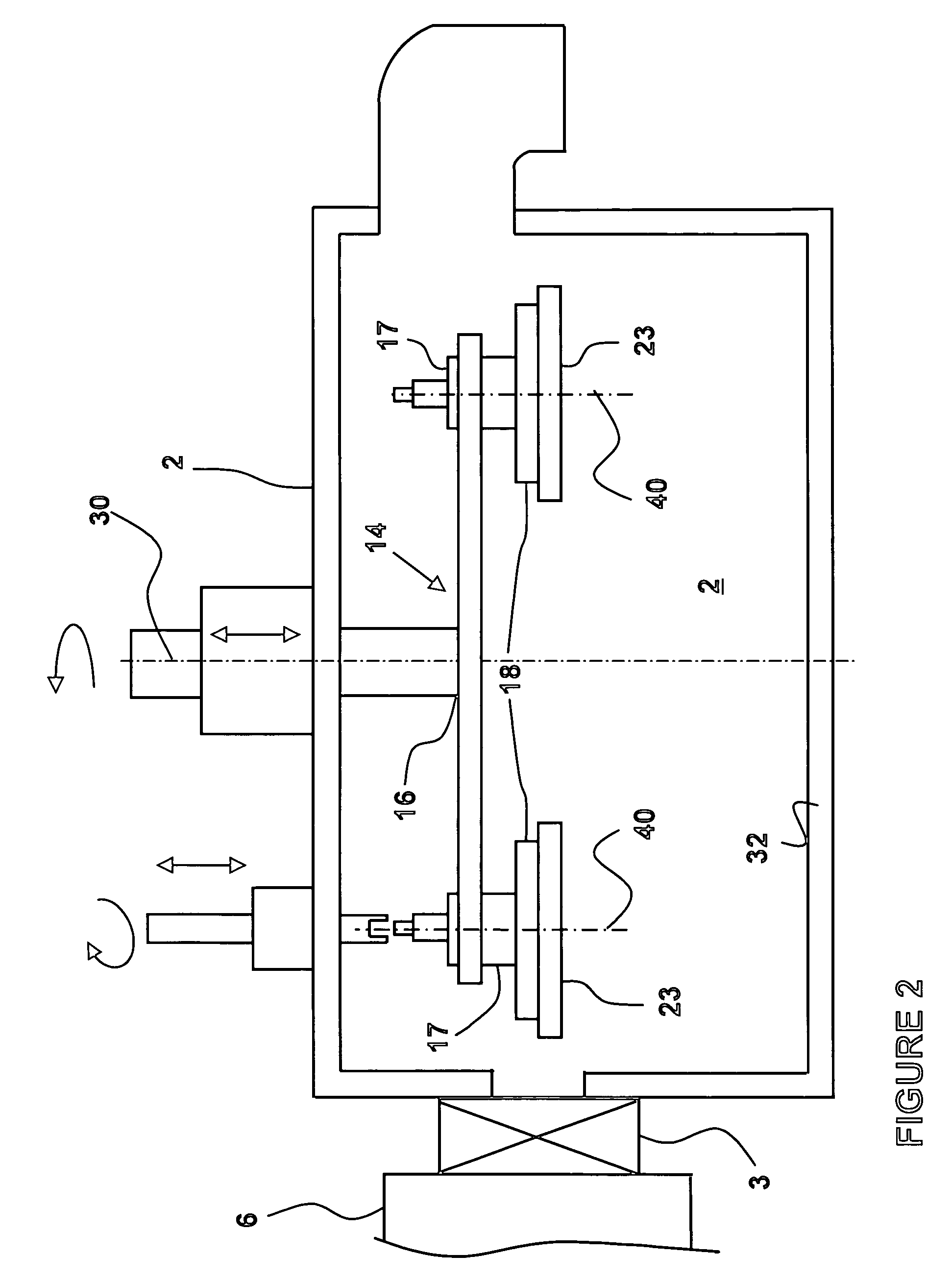

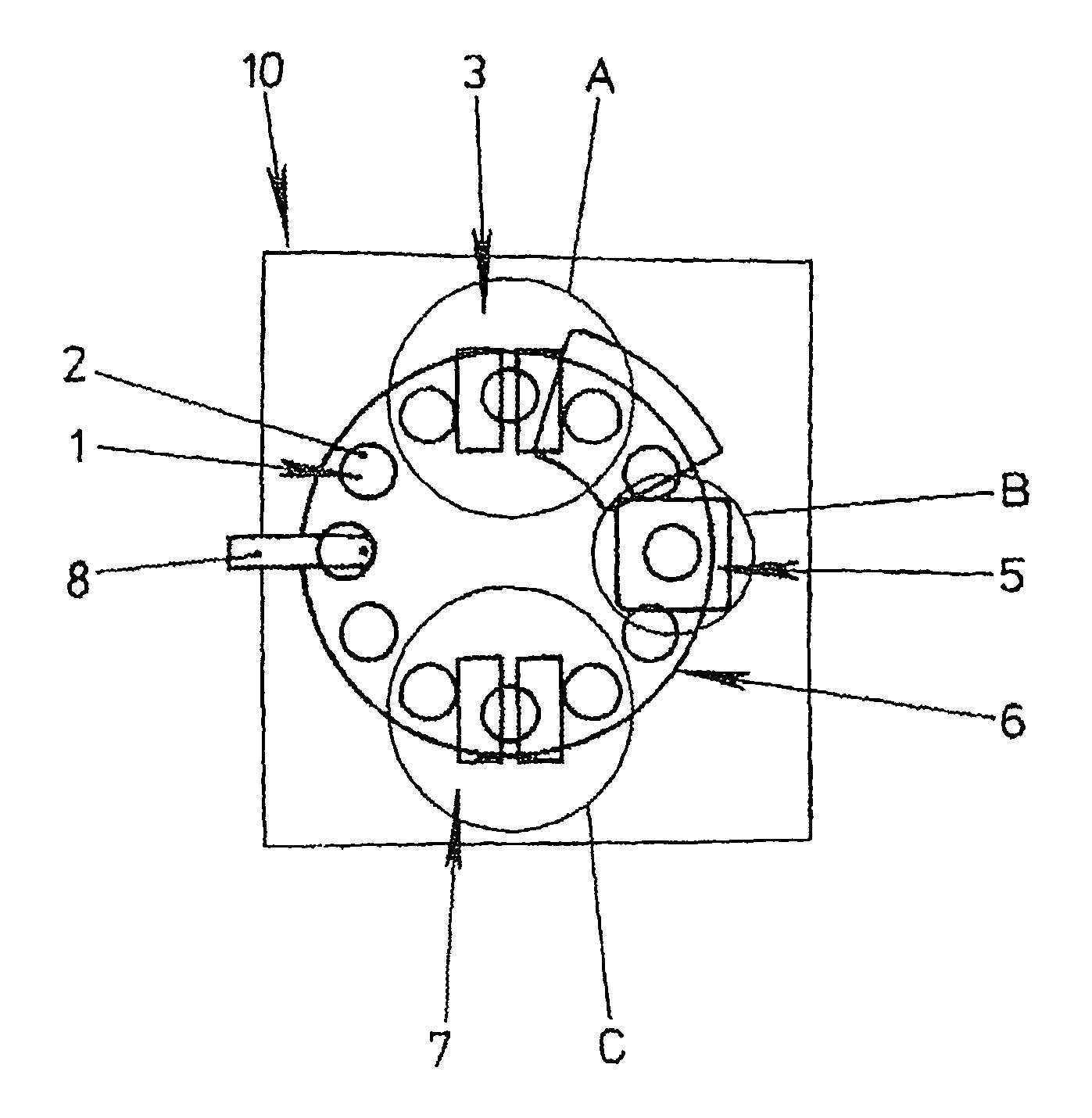

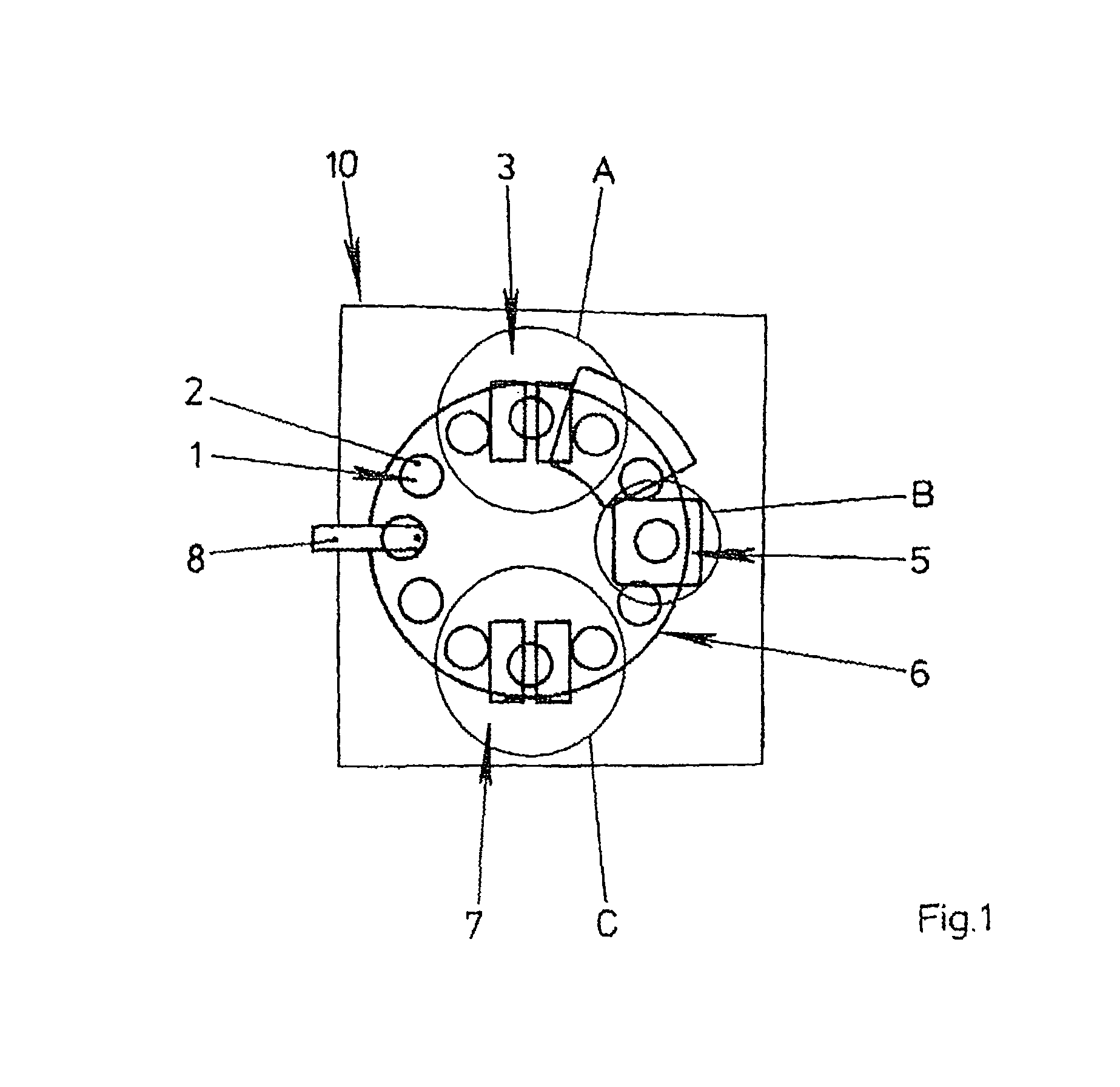

Magnetron sputtering device

ActiveUS20060070877A1Increase productionShorten cycle timeCellsElectric discharge tubesSputteringProduction rate

Owner:VIAVI SOLUTIONS INC

Scaling powder for low-temperature halogen-free low-solid-content lead-free tin soldering

InactiveCN103785973AEnhanced spread rate effectHigh spreading rateWelding/cutting media/materialsSoldering mediaDiethylene glycol diethyl etherSalicylic acid

The invention discloses scaling powder for low-temperature halogen-free low-solid-content lead-free tin soldering. The scaling powder comprises 12 percent to 16 percent of activating agents, 8-10 percent of colophony, 2-3 percent of surface active agents, 0.05-0.1 percent of antioxidants, 5-8 percent of organic amine and the balance organic solvents. The activating agents comprise compound components of 40-57 parts of anhydrous citric acid, 7-14 parts of salicylic acid, 0.6-3.6 parts of lactic acid and 36-43 parts of DL-malic acid, the surface active agents comprise compound component Tween 60 and a Span, the organic amine is one or more of monoethanolamine, diethanol amine and triethanolamine, the antioxidants are tertiary butylhydroquinone, and the organic solvents are mixed solvents of ethylene glycol, diethylene glycol diethyl ether, nitroethane, tetrahydrofurfuryl alcohol and propylene glycol by mass. According to the method, the scaling powder for low-temperature halogen-free low-solid-content lead-free tin soldering has the advantages of improving the coverage rate of the welding materials and reducing the cost.

Owner:SUZHOU LOTTE CHEM TECH

Method and apparatus for drying coating film and method for producing optical film

InactiveUS7526878B2Efficient heatingHigh spreading rateDrying using combination processesDrying solid materials with heatOrganic solventBand shape

The present invention provides a method for drying a coating film comprising drying a coating film of an organic solvent-containing coating liquid applied to a running band-shaped flexible substrate, the drying method comprising the steps of: providing a heater at a position opposed to the band-shaped flexible substrate at a running position immediately after coating; and heating the band-shaped flexible substrate by the heater; wherein when TW( ° C.) denotes the surface temperature of the band-shaped flexible substrate; TH( ° C.) denotes the surface temperature of the heater; λ(W / m·K) denotes the heat-transfer coefficient of air; d(m) denotes the distance between the heater and the band-shaped flexible substrate (web); η denotes the efficiency of heat transfer; and σ denotes the Stefan-Boltzmann constant (5.670×10−8 W / m2K4), the ratio of radiant heat transfer represented by QR / (QR+QC) is 0.25 or more and 0.6 or less, wherein QC and QR are represented by the following equations, respectively: QC=λ / d·(TH−TW) where QC denotes heat transfer by air, and QR=η{(TH+273)4−(TW+273)4} where QR denotes heat transfer by radiant.

Owner:FUJIFILM CORP

Sn0.3Ag0.7Cu lead-free solder paste and preparation method thereof

InactiveCN104785948AGood adhesionNon stickyWelding/cutting media/materialsSoldering mediaActive agentFilm-forming agent

The invention discloses Sn0.3Ag0.7Cu lead-free solder paste. The Sn0.3Ag0.7Cu lead-free solder paste particularly comprises, by mass, 9-11% of scaling powder and 89-91% of soldering tin powder. The scaling powder comprises, by mass, 20-25% of rosin, 15-20% of film-forming agent, 15-20% of active agent, 5-10% of thixotropic agent, 1-3% of acidity regulator and the balance solvent. The invention further discloses a preparation method of the Sn0.3Ag0.7Cu lead-free solder paste. The method comprises the steps that the solvent and the film-forming agent are stirred at 75 DEG C to be transparent, and the mixture is cooled to be at the temperature of 65 DEG C, added with the film-forming agent, cooled to be at the temperature of 55 DEG C and added with the active agent to be stirred to be transparent; the mixture is cooled to be at 55 DEG C and added with the thixotropic agent to be stirred to be transparent; the mixture is cooled to be at normal temperature and added with the acidity regulator to be stirred for 15 min, and then the mixture and solder powder are mixed and stirred to obtain the Sn0.3Ag0.7Cu lead-free solder paste. The solder paste is good in printing technology and welding performance, residues left after welding evenly cover the surface welding spots, and the effects of electrical insulation, welding spot protection and the like are achieved.

Owner:XIAN UNIV OF TECH

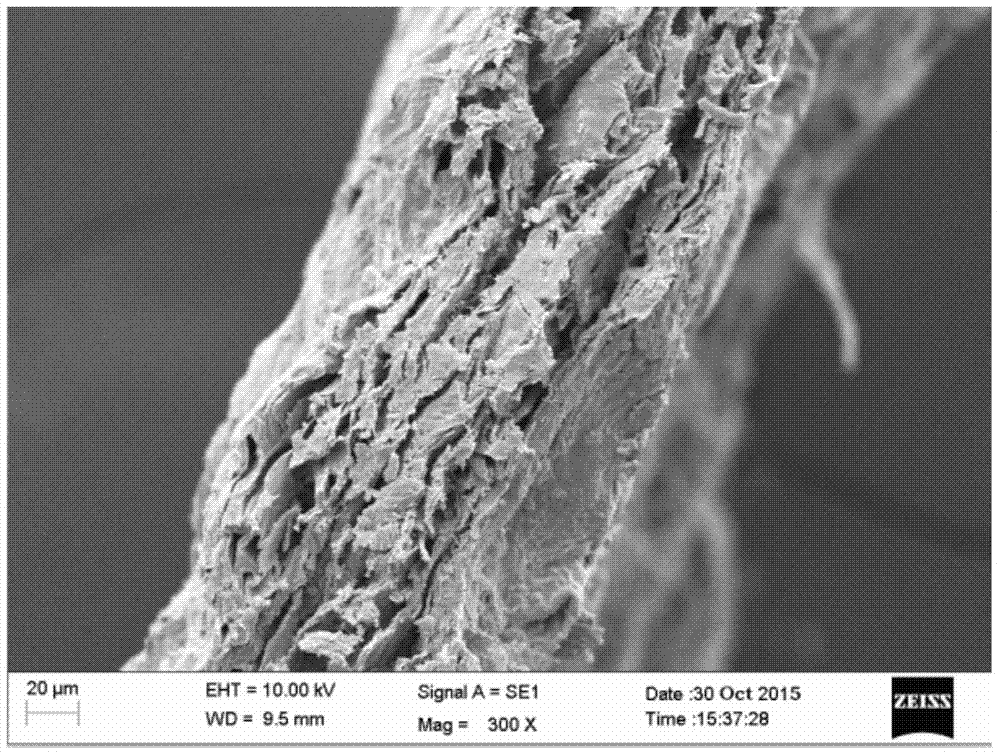

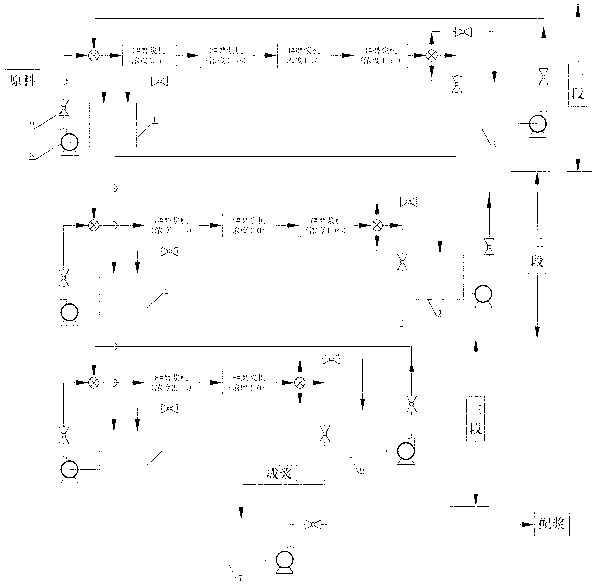

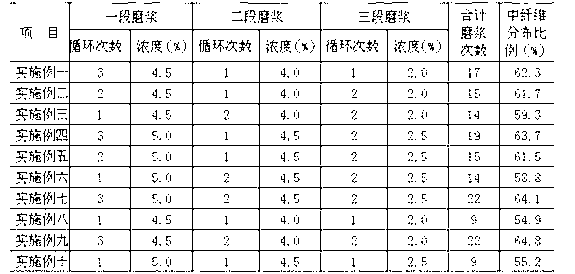

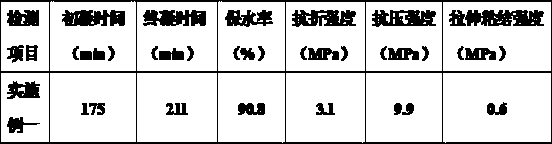

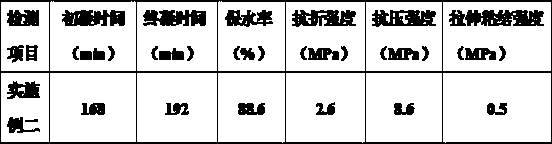

Papermaking tobacco sheet pulp grinding process

The invention discloses a papermaking tobacco sheet pulp grinding process. Specifically speaking, under the light beating condition, three-stage light beating flexible pulp grinding is adopted, each stage needs at least two pulp grinding machines, pulp concentration is decreased gradually, and size circulation process is controlled. In prepared size, fibers with the length of 0.5-1.25mm reach more than 63%, bulk degrees of base tabs reach 2.8-3.0cm <3> / g, spreading rates, filling values, burning velocity of finished sheets are improved greatly, tar contents and carbon oxide contents are reduced greatly, and the bulk degrees of the finished sheets reach 2.3-2.5cm<3> / g. The number of pulp grinding machines arranged in the first stage, the second stage and the third stage in a serial connection mode is respectively 4, 3 and 2. The pulp grinding concentration in the first stage, the second stage and the third stage are respectively set to be 4.5-5.0%, 4.0-4.5% and 2.0-2.5%. Times of self-circulation of the size in the first stage, the second stage and the third stage are respectively 1-3 times, 1-2 times and 1-2 times. The times for which mixed size prepared in different components passes through the pulp grinding machines in the whole process are 9-22 times actually, and all nine pulp grinding machines allow constant power regulation independently.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

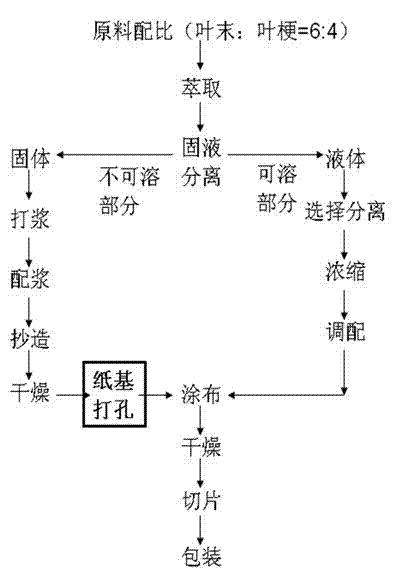

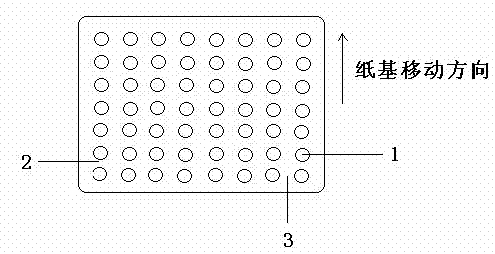

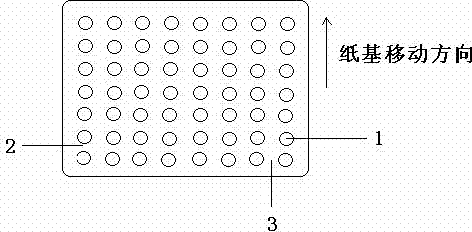

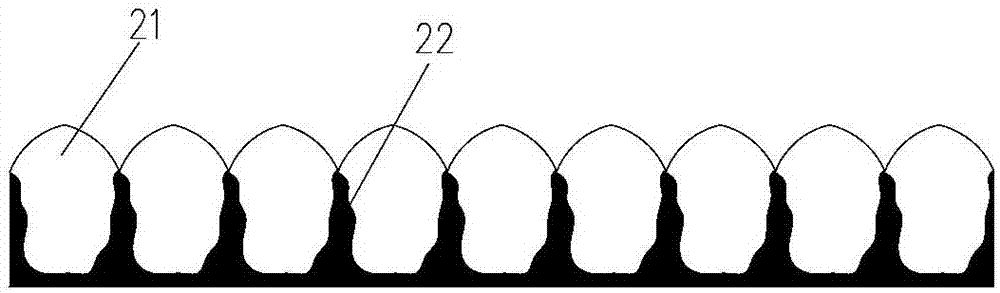

A kind of reconstituted tobacco leaf and its preparation method and application

The invention discloses a reconstituted tobacco leaf and a preparation method and application thereof. The reconstituted tobacco leaf is prepared by a papermaking method; a paper base formed by using pulp is perforated and then coated with a coating solution; and in the paper base, the aperture is 0.4 to 0.8 millimeter, the hole pitch is 1.0 to 3.0 millimeters, and the hole row pitch is 1.5 to 2.0 millimeters. The structure of the paper base is optimized, and perforation design is adopted, so that the contact area of the paper base and the coating solution is increased; and the coating solution is easily penetrated into the paper base, so that the absorption performance of the paper base on the coating solution is remarkably improved, the coating rate is finally remarkably improved, full bearing of soluble components and aroma components of the reconstituted tobacco leaf is ensured, the sensory quality is greatly improved, aroma quality and impurity gas are obviously improved, and the quality of the reconstituted tobacco leaf is integrally improved.

Owner:CHINA TOBACCO GUANGDONG IND

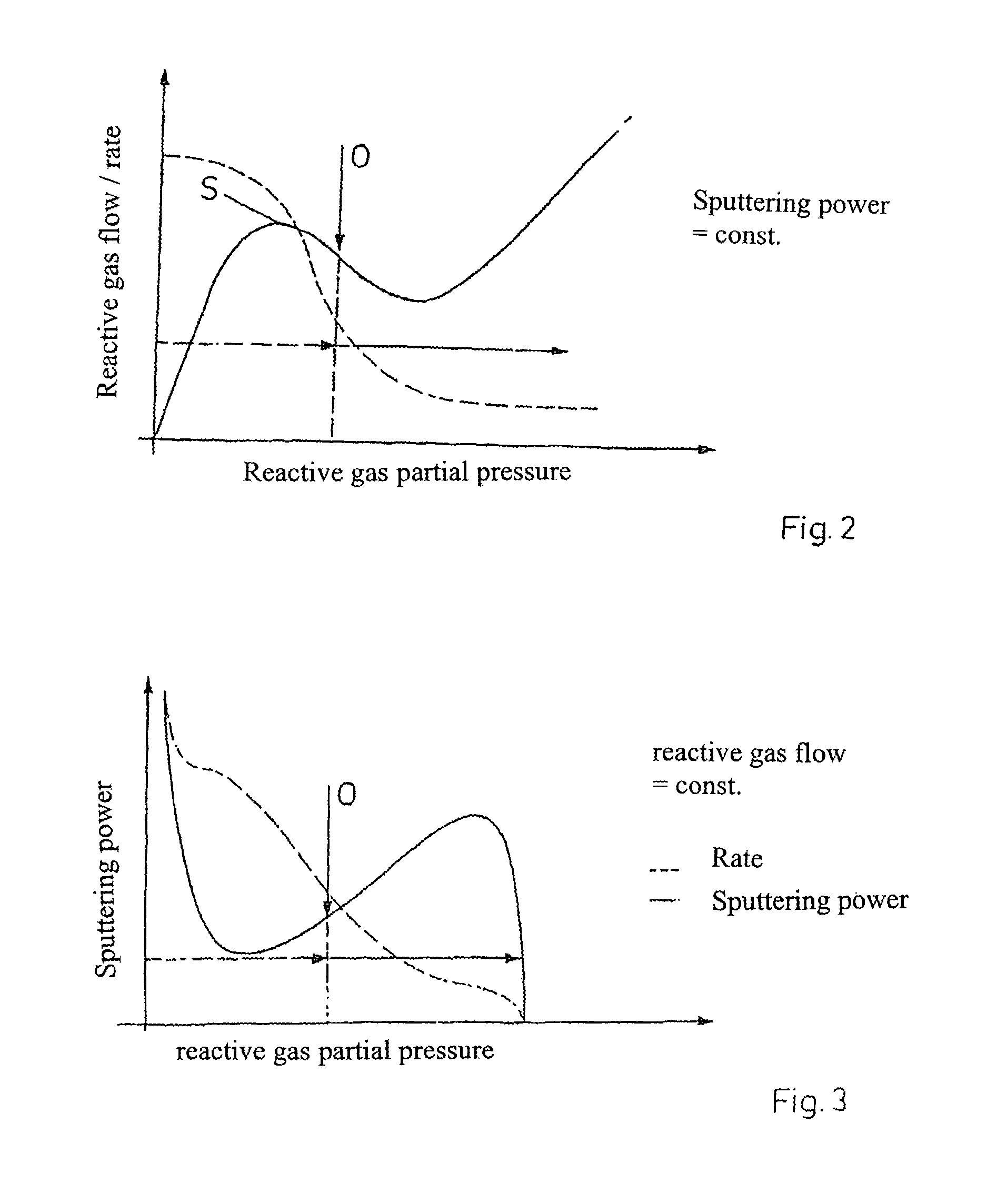

Method for producing a multilayer coating and device for carrying out said method

ActiveUS8956511B2High spreading rateLess timeCellsElectric discharge tubesStoichiometryReactive components

A method for reducing the optical loss of the multilayer coating below a predetermined value in a zone by producing coating on a displaceable substrate in a vacuum chamber with the aid of a residual gas using a sputtering device. Reactive depositing a coating on the substrate by adding a reactive component with a predetermined stoichiometric deficit in a zone of the sputtering device. Displacing the substrate with the deposited coating into the vicinity of a plasma source, which is located in the vacuum chamber at a predetermined distance from the sputtering device. The plasma action of the plasma source modifying the structure and / or stoichiometry of the coating, preferably by adding a predetermined quantity of the reactive component to reduce the optical loss of the coating.

Owner:LEYBOLD OPTICS

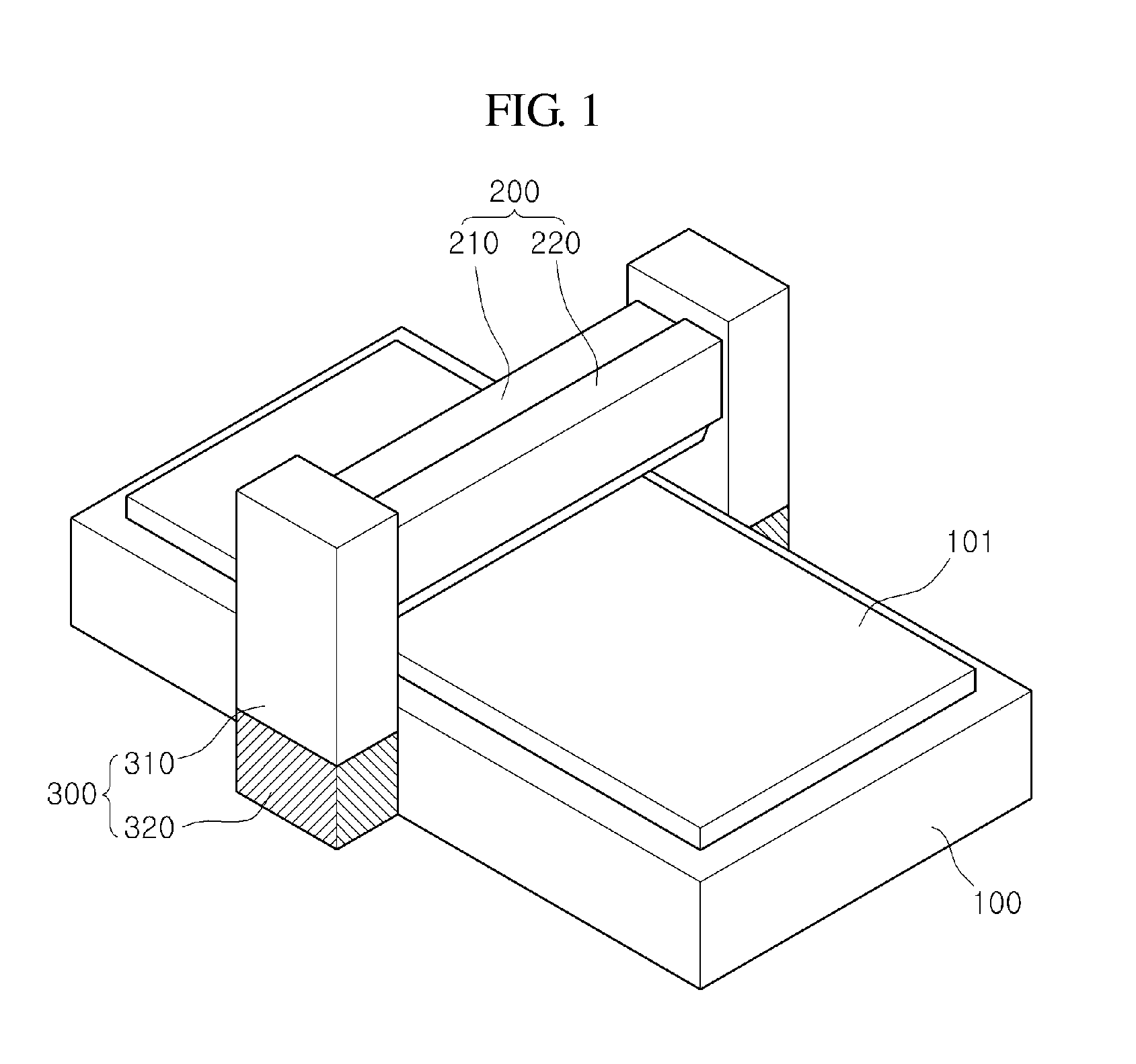

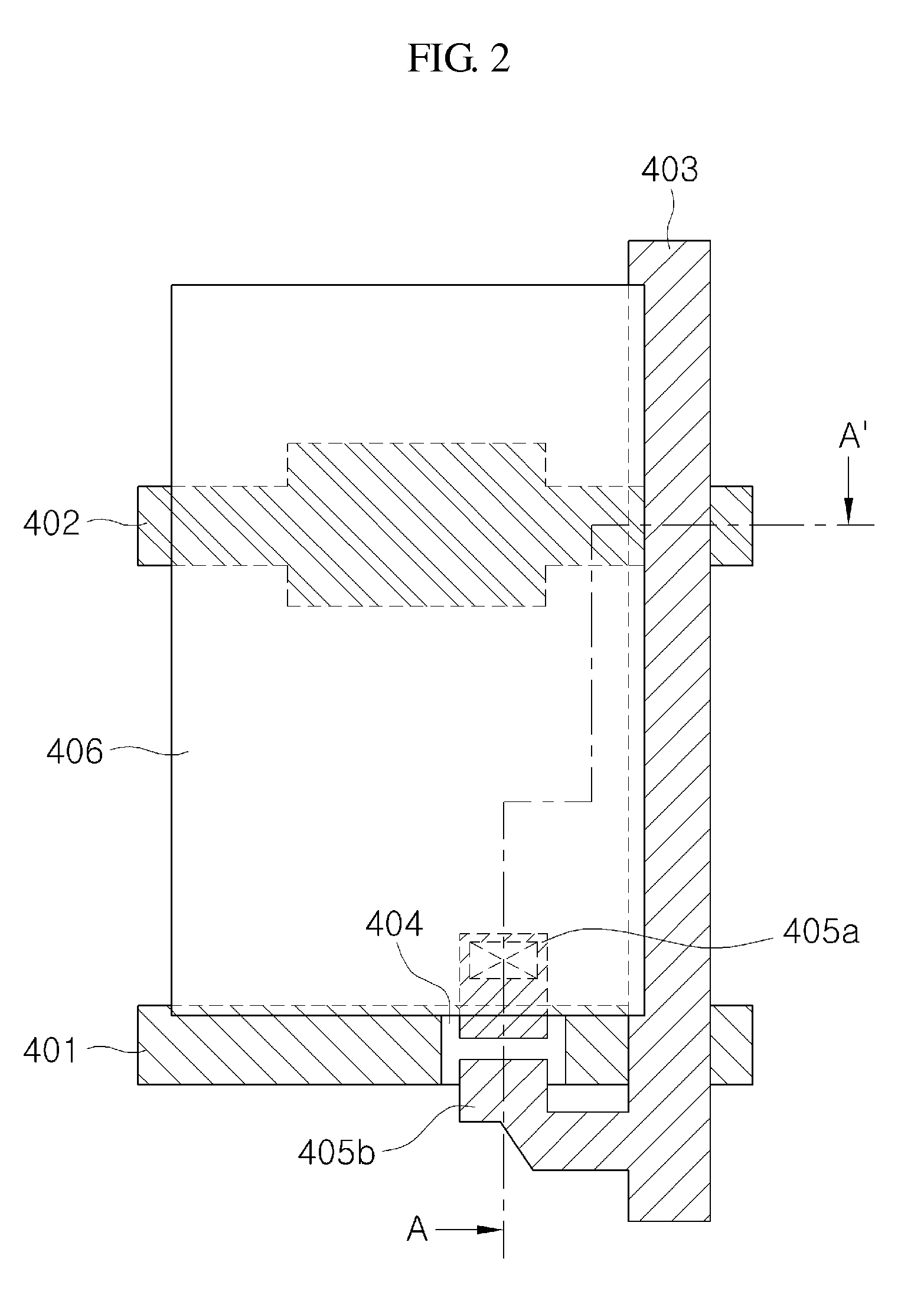

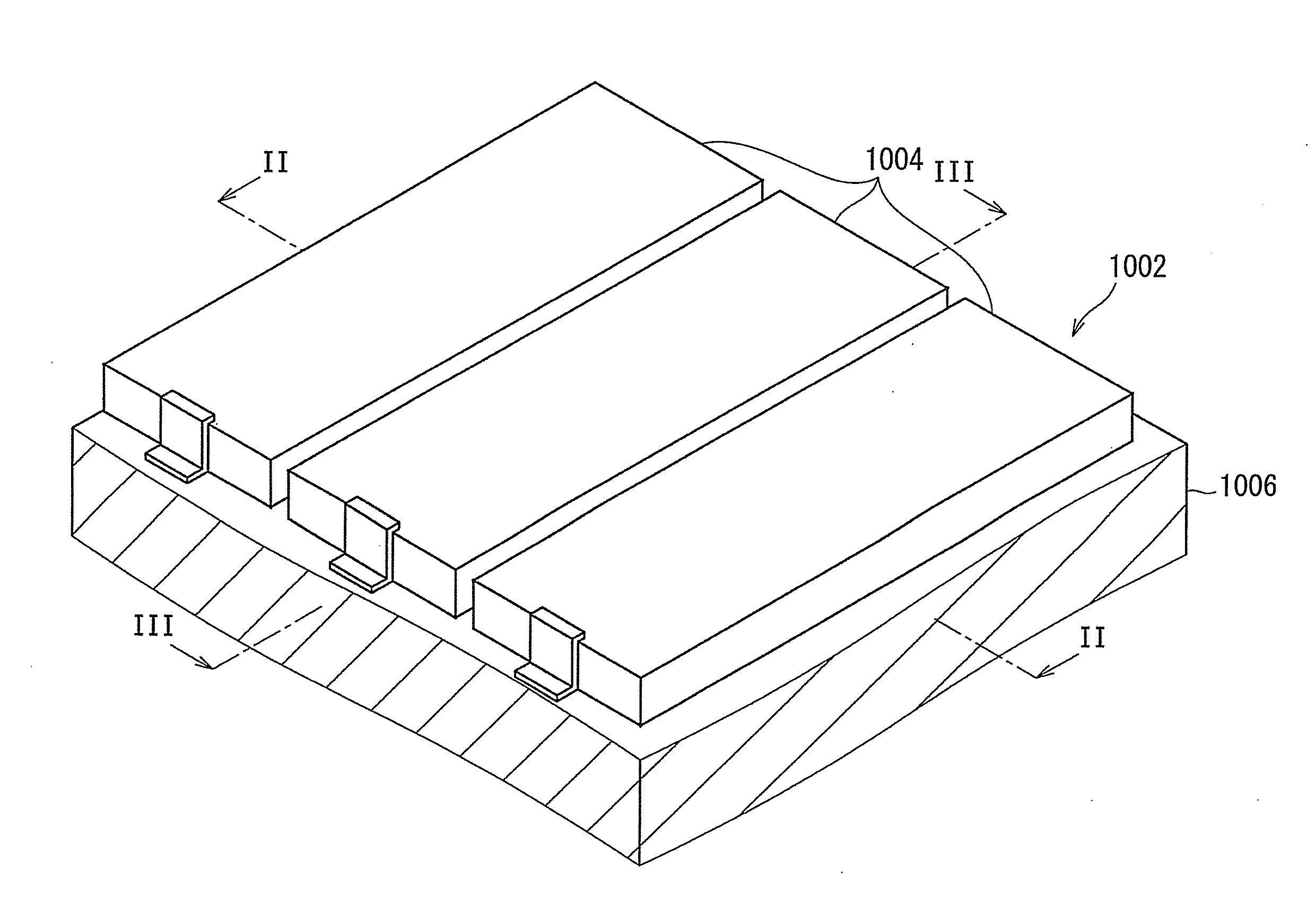

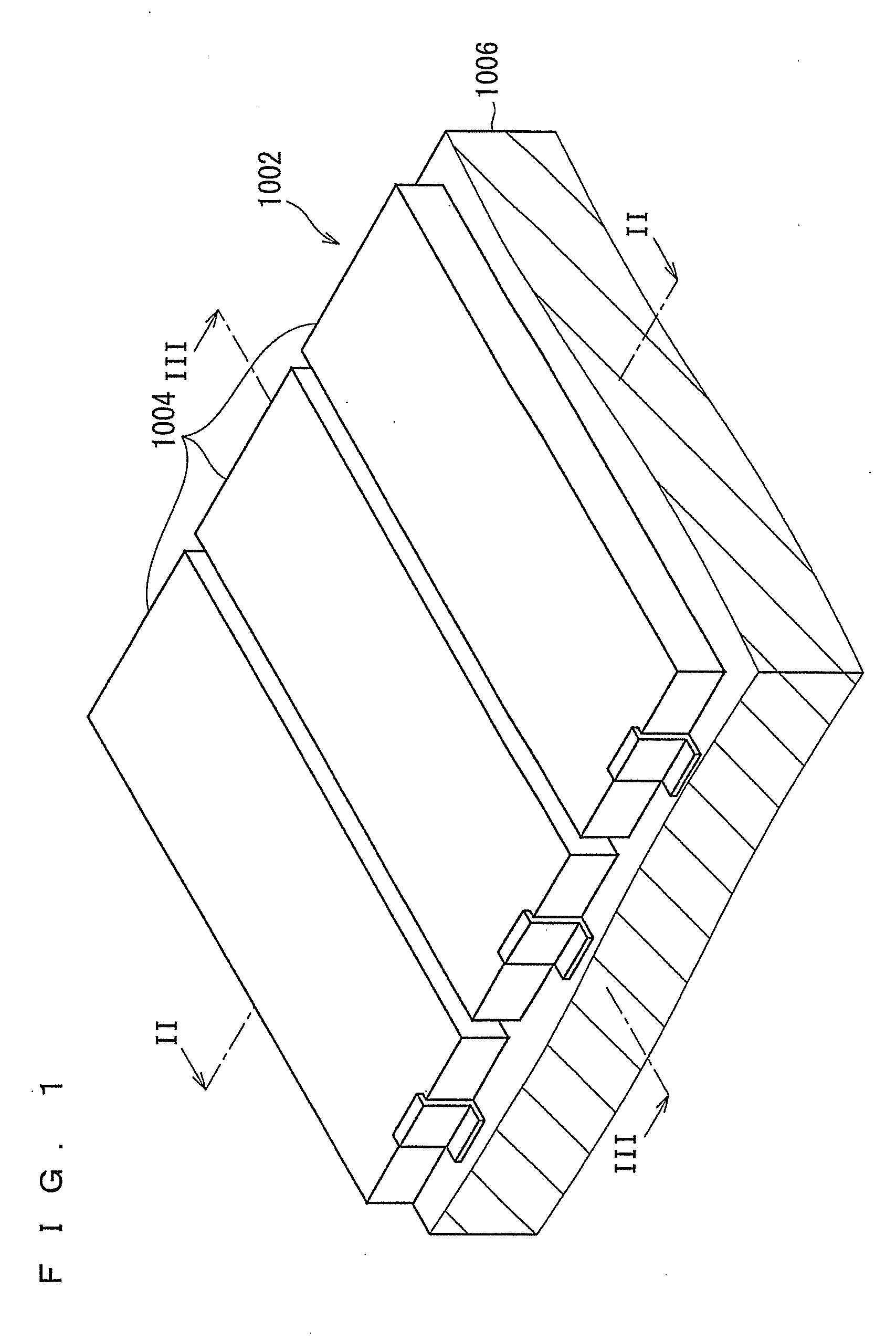

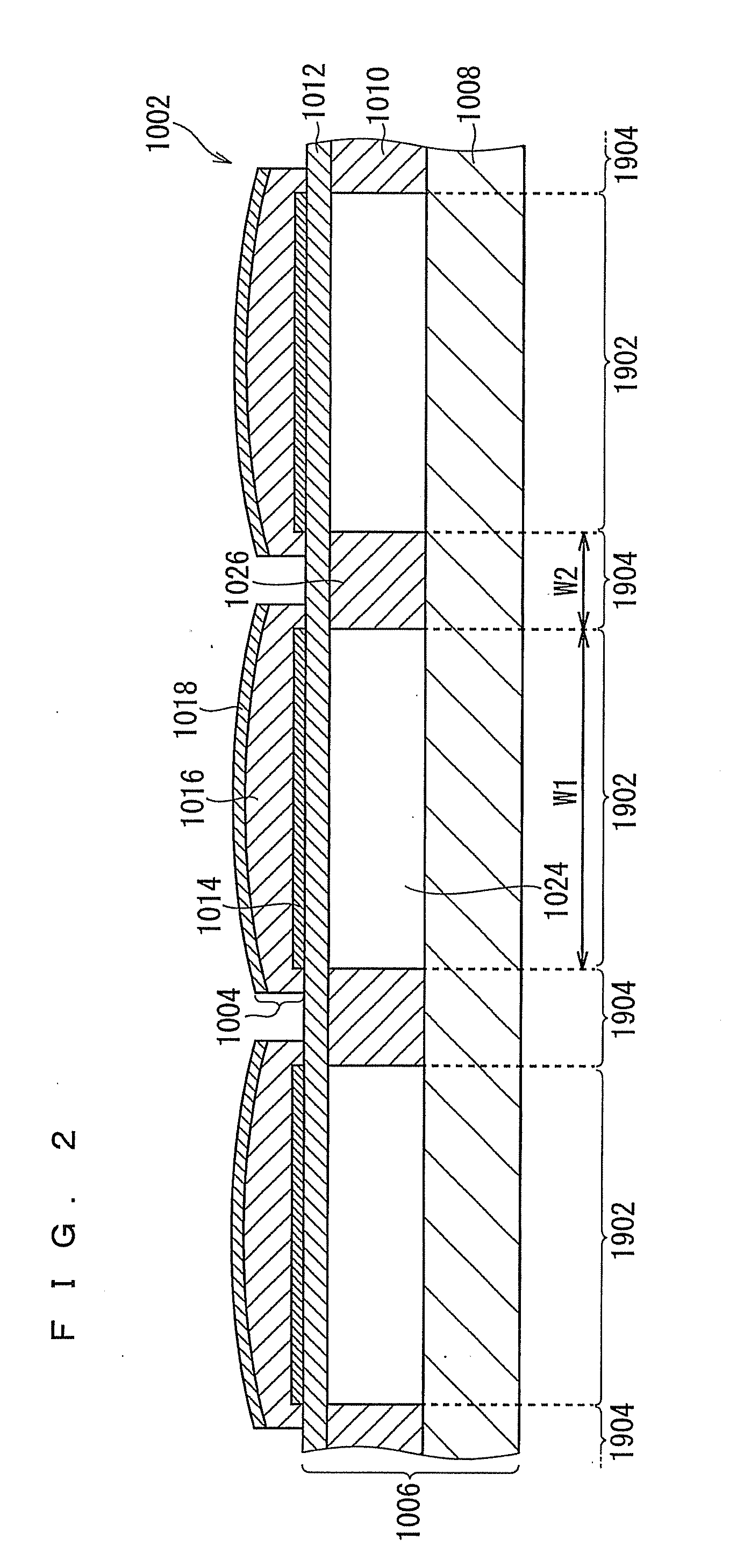

Method of producing piezoelectric/electrostrictive film type device

InactiveUS20110056059A1Improve heat resistanceCoating ratio is increasedPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive transducersPolymer sciencePtru catalyst

Provided is a method of producing a piezoelectric / electrostrictive film type device, the method making it possible to increase the coating ratio of the lowermost electrode film and also, to prevent the deviation of the plane position of the lowermost electrode film from the plane position of the cavity. In the production of a piezoelectric / electrostrictive film provided with a substrate formed with a cavity and an vibrating laminate obtained by laminating a lower electrode film, a piezoelectric / electrostrictive film and an upper electrode film which are aligned with the plane position of the cavity, on the surface of the substrate, the lower electrode film is formed using, as a mask, the substrate in which a light-shielding agent is filled in the cavity by photolithography. The lower electrode film is formed by electroless plating after the catalyst layer is formed.

Owner:NGK INSULATORS LTD

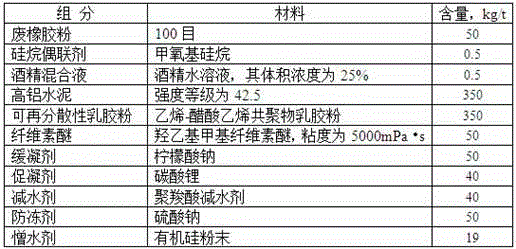

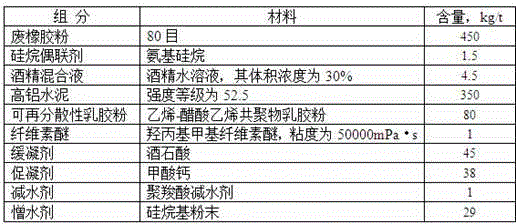

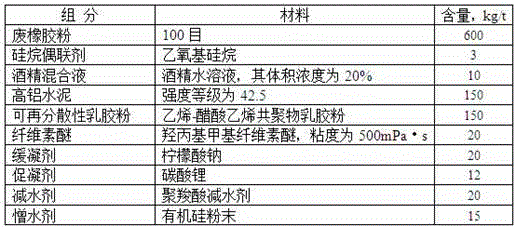

Multifunctional concentrated material used for preparing kitchen and bath cement-based waterproof material

The invention relates to a multifunctional concentrated material used for preparing a kitchen and bath cement-based waterproof material. The multifunctional concentrated material is composed of waste rubber powder, a silane coupling agent, alcohol blend, high-alumina cement, redispersible latex powder, cellulose ether, a delayed coagulant, a coagulation accelerator, a water reducer, an anti-freezing agent (added in winter), and a water repellent, and is a one-component material. The cement-based waterproof material is prepared by mixing the multifunctional concentrated material with cement and quartz powder; is used for kitchen and bath waterproof construction; possesses both excellent characteristics of waterproofing coatings and waterproof mortars, and excellent waterproof performance, so that waterproof effect can be achieved just by a thin coating layer in construction; and also possesses excellent rigidity which is convenient for paving of tiling in following procedures, and is suitable for waterproofing of waterward sides and water lee sides. Addition of waste rubber powder is capable of reducing density of the polymer cement waterproof material, increasing spreading rate of waterproof coatings, changing waste into valuables, and realizing recycling of resources.

Owner:西卡德高(上海)建材有限公司

Manufacturing method for multilayer laminated film

ActiveUS20150132499A1High spreading rateReduce unevennessLiquid surface applicatorsCoatingsShear rateCoating

Provided is a manufacturing method for a multilayer laminated film at a high coating rate, whereby film thickness uniformity is improved and interference unevenness is reduced. The present invention is a manufacturing method for a multilayer laminated film, the method including the step of simultaneous multilayer coating of plural coating liquids onto a substrate at a coating rate of 10 m / min or more, wherein, when A [mPa·s] stands for the viscosity of the coating liquid at a temperature of 45° C. and a shear rate of 10 sec−1, B [mPa·s] stands for the viscosity of the coating liquid at a temperature of 45° C. and a shear rate of 1000 sec−1, and C [mPa·s] stands for the viscosity of the coating liquid at a temperature of 45° C. and a shear rate of 10000 sec−1, at least one coating liquid of the plural coating liquids has A / B in the range of 1.5 to 9 and B / C in the range of 0.6 to 1.4.

Owner:KONICA MINOLTA INC

Natural-color bamboo pulp for reconstituted tobacco additive and preparation method thereof

The invention belongs to the technical field of reconstituted tobacco, and specifically relates to natural-color bamboo pulp for a reconstituted tobacco additive and a preparation method thereof. The method is characterized in that bamboo is used as the raw material and subjected to preparing, stewing, squeezing extrusion, dipping, pulping and papermaking to obtain a high-purity product. The physical performance indexes of the natural-color bamboo pulp are that the tensile index is 35-45N-m / g; the burst index is 2.5-3.5kPa-m<2> / g; the tearing index is 6.5-9.5mN-m<2> / g; the intrinsic viscosity is 800-1000mL / g; the whiteness is 30-40% ISO; the pentosane is less than 8%; the ash content is less than 1.0%; the bulk is 5.0-8.5cm<3> / g. The prepared tobacco slices are added to finished cut tobacco based on ratio; the prepared cigarette is capable of supplying more air intake quantity while smoking, so that the cigarette can be promoted to completely burn, and the quantity of pyrolysis products under oxygen-poor condition can be effectively decreased, and as a result, the releasing quantity of harmful components such as tar and nicotine can be decreased.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Single-walled carbon nanotube reinforced epoxy zinc rich primer and preparation method thereof

InactiveCN108948964AReduce dosageLight weightAnti-corrosive paintsEpoxy resin coatingsEpoxyOrganic solvent

The invention discloses a single-walled carbon nanotube reinforced epoxy zinc rich primer and a preparation method thereof. The single-walled carbon nanotube reinforced epoxy zinc rich primer comprises the following raw materials: epoxy resins, zinc powder, single-walled carbon nanotubes, additives, polyamide and an organic solvent. The preparation method comprises the following steps: preparing adissolving solution from the epoxy resins; uniformly mixing the first part of epoxy resin dissolving solution with a wetting dispersing agent, a second part of organic solvent, a flexibilizer and ananti-settling thixotropic agent, adding the single-walled carbon nanotubes, and shearing and dispersing uniformly at a high speed; adding the zinc powder to be uniformly dispersed at a high speed, andfinally adding a reinforcing agent to be blended into base stock; uniformly mixing the polyamide and the third part of organic solvent, dropwise adding the second part of epoxy resin dissolving solution, and finally adding an accelerant to be uniformly mixed, and blending into a curing agent. The construction method comprises the following steps: mixing the base stock and the curing agent, uniformly stirring, and performing application coating. According to the single-walled carbon nanotube reinforced epoxy zinc rich primer disclosed by the invention, the usage amount of the zinc powder is reduced, the specific gravity of the paint is reduced, the coating rate of the paint is increased, the salt-fog resistance index is greatly enhanced, and the cathode protection function is effectively improved.

Owner:史丹龙涂料(常州)有限公司

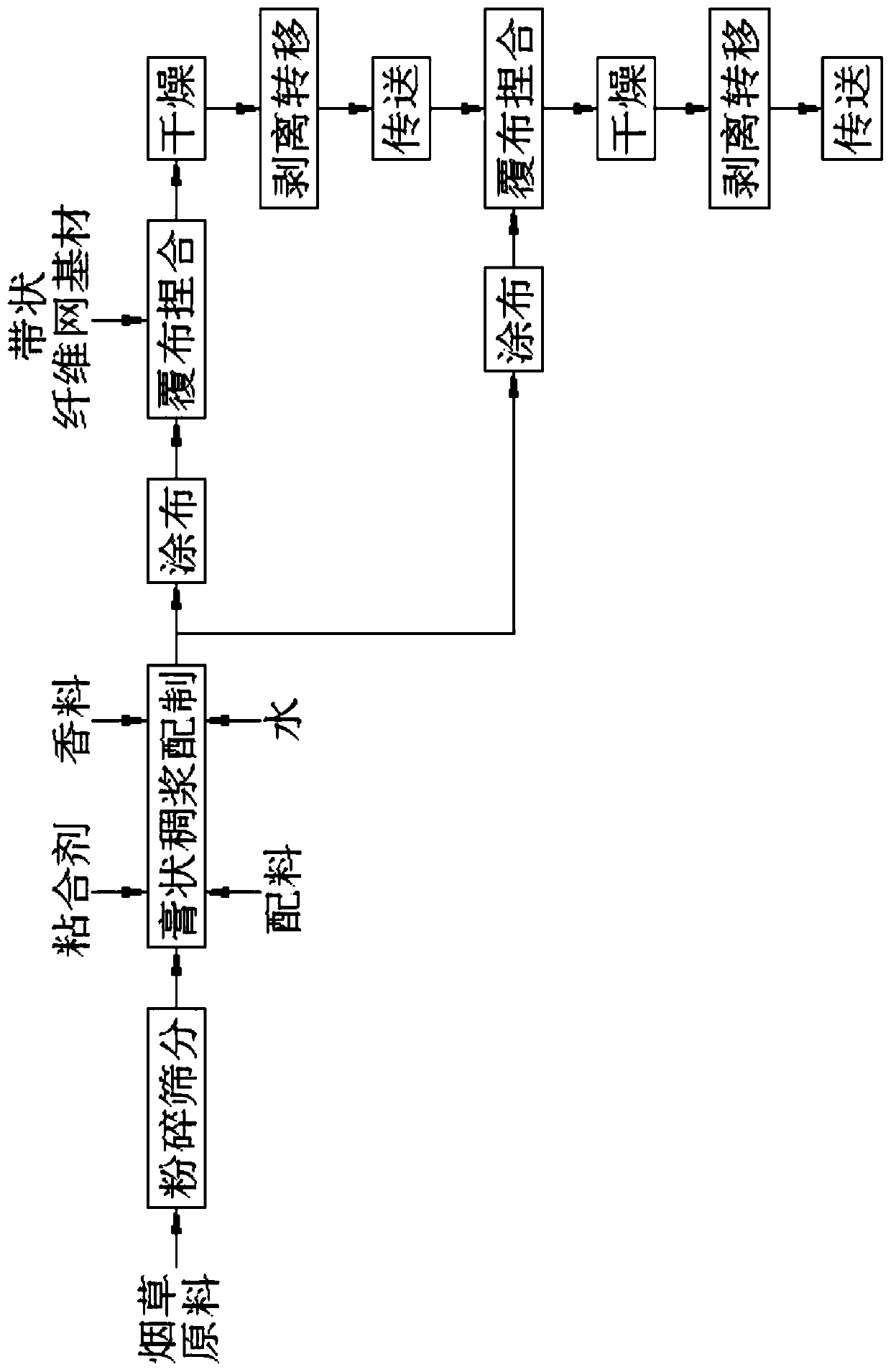

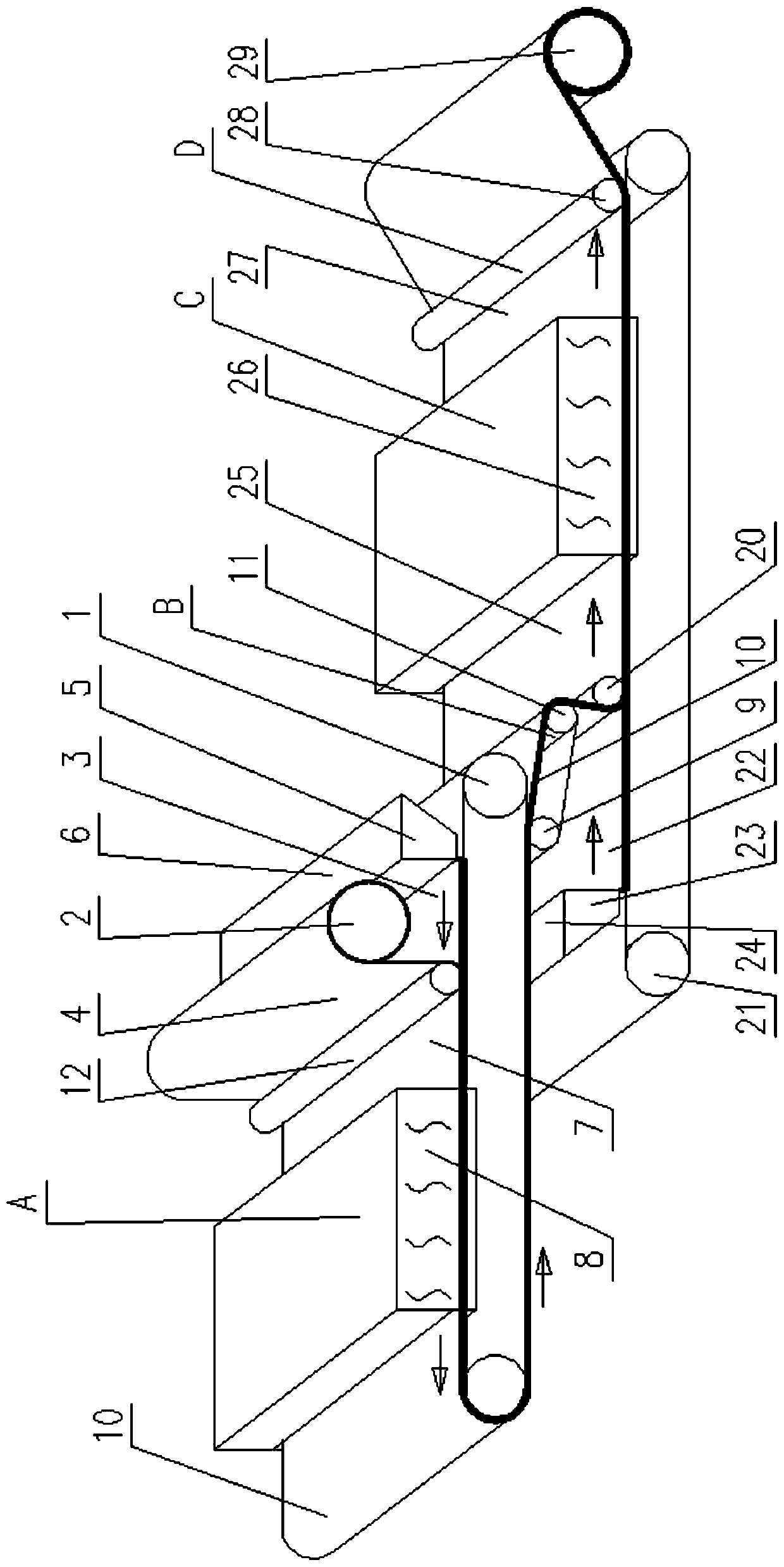

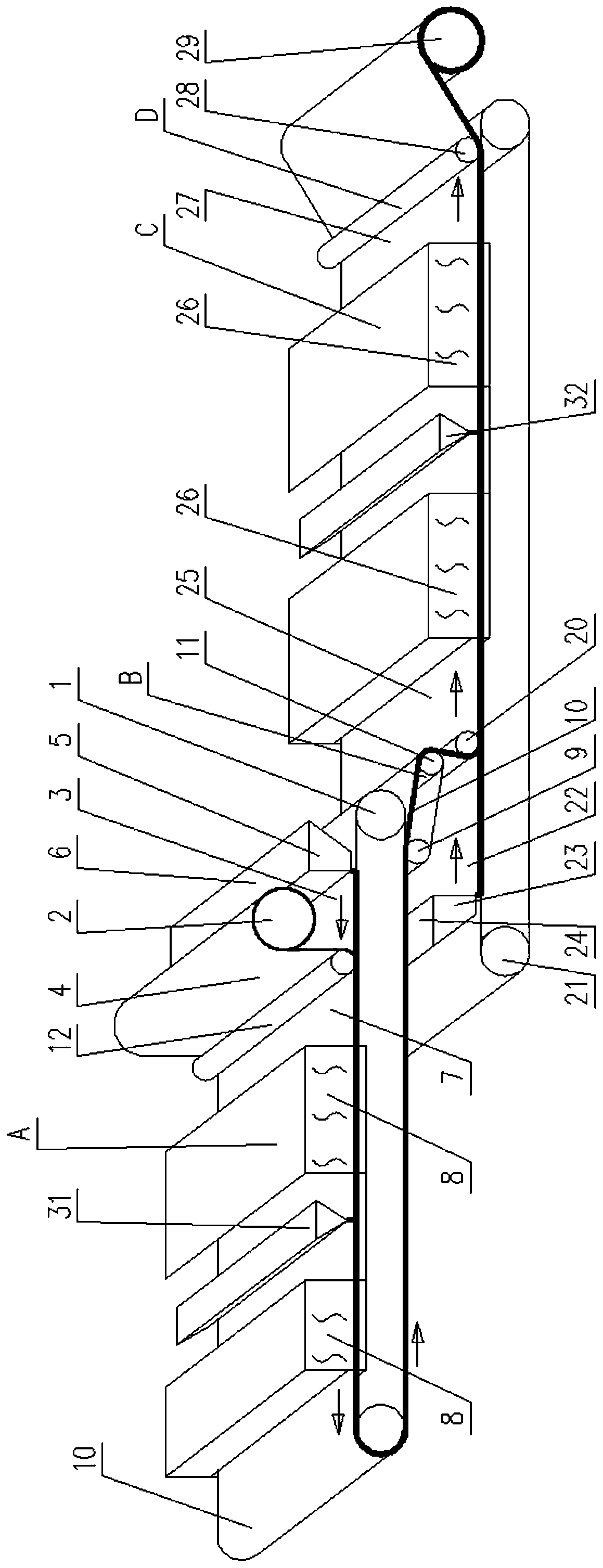

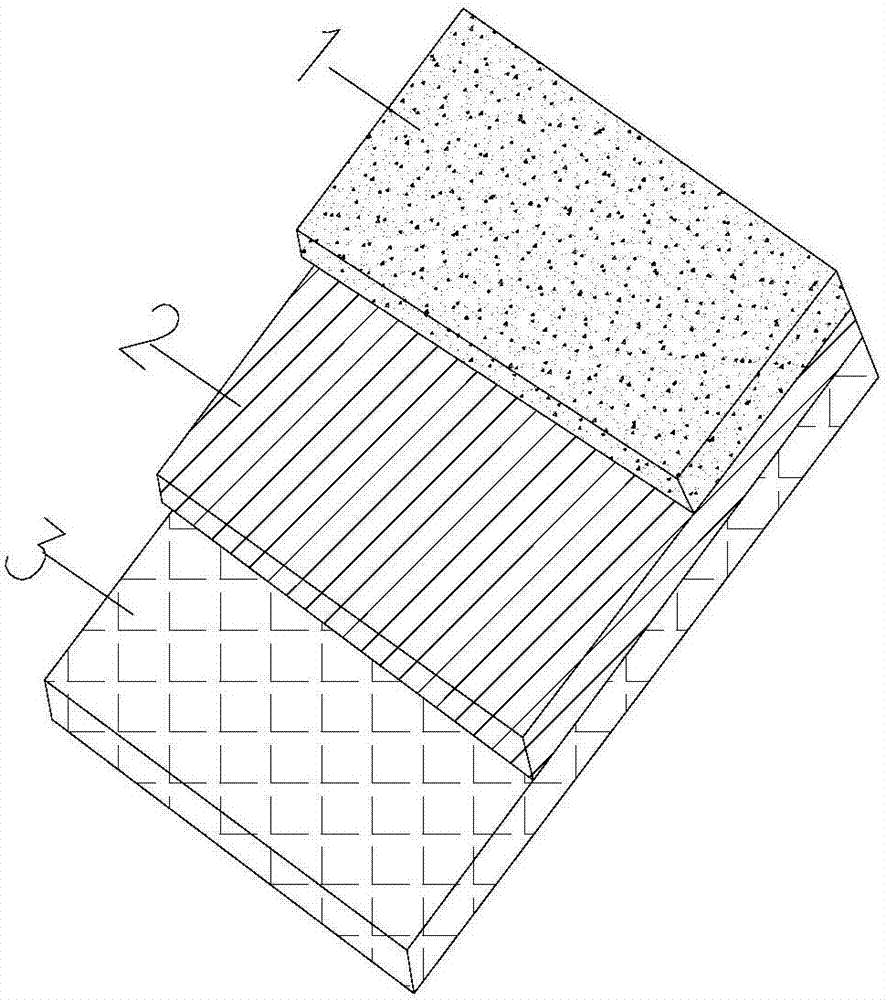

Forming method and forming equipment for ternary composite reconstituted tobacco sheets

PendingCN111134352AReduces the effects of odor inhalationImprove physical strengthTobacco preparationTobacco treatmentFiberPowder mixture

The invention relates to a forming method and forming equipment for ternary composite reconstituted tobacco sheets. The equipment comprises a primary coating composite device, a primary stripping conveying device, a secondary coating composite device and a secondary stripping conveying device. The method comprises the following steps of: coating a tobacco mixture on a first conveying surface in acoating and compounding manner to form a strip-shaped slurry sheet, and coating a fiber net-shaped base material on the surface of the strip-shaped slurry sheet under the condition of smaller tensionto form a strip-shaped binary compound reconstituted tobacco sheet, coating the secondary conveying surface with the tobacco mixture, and coating the surface of the strip-shaped slurry sheet with thestrip-shaped binary composite reconstituted tobacco sheet under the condition of small tension to form the ternary composite reconstituted tobacco sheet. The middle layer of the produced reconstitutedtobacco sheet is a prefabricated strip-shaped fiber net base material, the upper layer and the lower layer are tobacco powder mixtures, the coating rate can be increased, the cigarette smell can be improved, the consistency of finished products can be improved, the tensile strength can be improved, the thickness can be reduced, and the processability can be enhanced.

Owner:YUNNAN KUNCHUAN TOBACCO EQUIP CO LTD

Soldering flux for improving corrosion inhibition

InactiveCN103785975AHigh spreading rateGood corrosion inhibition effectWelding/cutting media/materialsSoldering mediaPolyethylene glycolSuccinic acid

The invention discloses soldering flux for improving corrosion inhibition. The soldering flux comprises, by weight, 2%-4% of activating agent, 3%-5% of cosolvent, 3%-5% of surface active agent, 0.2%-0.3% of film-forming agent, 0.06%-0.10% of corrosion inhibitor, 0.5%-2% of antibacterial agent and the balance water. By mass, the corrosion inhibitor is a mixture formed by compounding benzimidazole (BIA) and benzotriazole (BTA) by the mass ratio of 1:1, the activating agent is a mixture of succinic acid and DL-malic acid by the mass ratio of 1:1, the surface active agent is isomerism tridecane alcohol ethoxylate, the cosolvent is a mixture of compounding ethanediol, isopropanol and butyl cellosolve by the mass ratio of 1:1:1, the film-forming agent is polyethylene glycol-6000, the antibacterial agent is triclosan, and all the chemicals are chemically pure. Through the mode, the soldering flux for improving corrosion inhibition is high in corrosion inhibition and has the advantages of low toxicity, environmental protection and the antibacterial effect.

Owner:SUZHOU LOTTE CHEM TECH

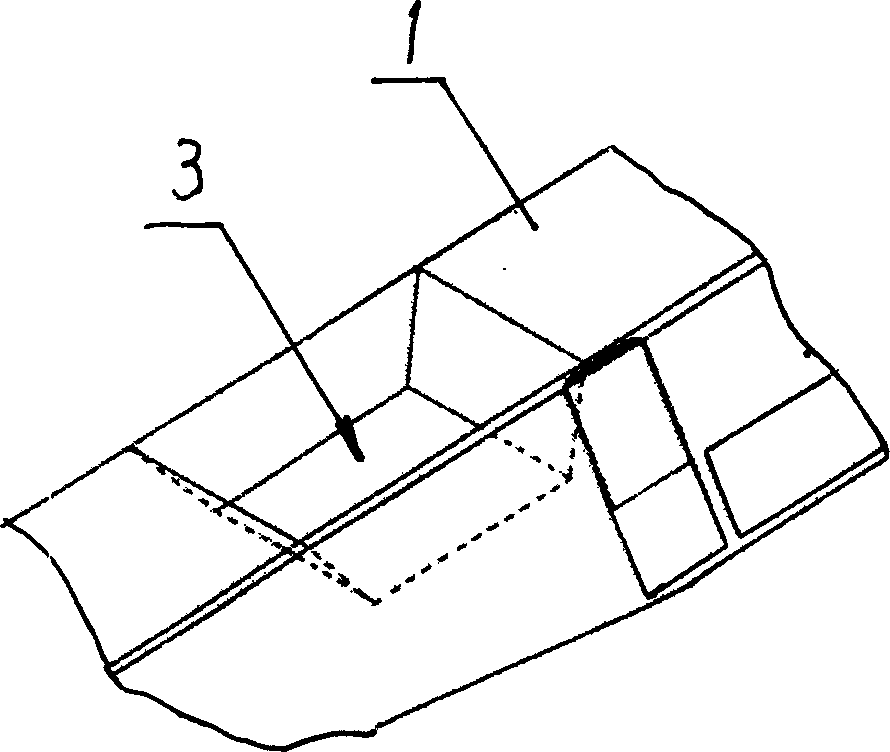

Interlayer structure construction method of asphalt pavement

The invention discloses an interlayer structure construction method of an asphalt pavement. The interlayer structure construction method includes the following steps of cleaning an under bearing layer of the pavement; sprinkling rubber asphalt; sprinkling rubbles; and rolling into the shape. The interlayer structure construction method of the asphalt pavement has the advantages of being high in bonding strength between layers, good in water tightness, excellent in anti-shearing performance, deferring reflection cracks, convenient to construct, low in comprehensive cost and the like. By adoption of the interlayer structure construction method of the asphalt pavement, construction work can be done without closing to traffic or closing to traffic for a short term, therefore, the interlayer structure construction method of the asphalt pavement can not only be suitable for a bonding layer between asphalt surfaces of newly-built roads, but also particularly suitable for repairing and maintaining projects for asphalt surfaces of urban roads.

Owner:北京特希达交通勘察设计院有限公司

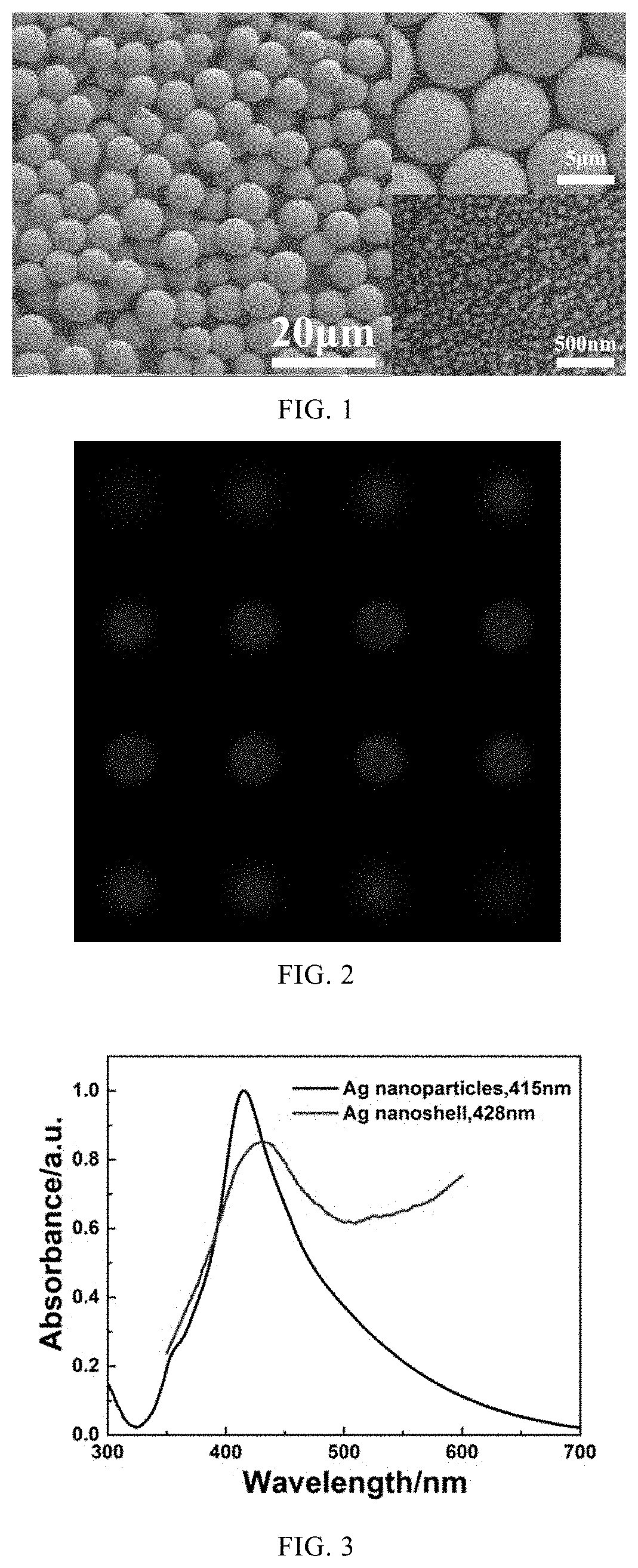

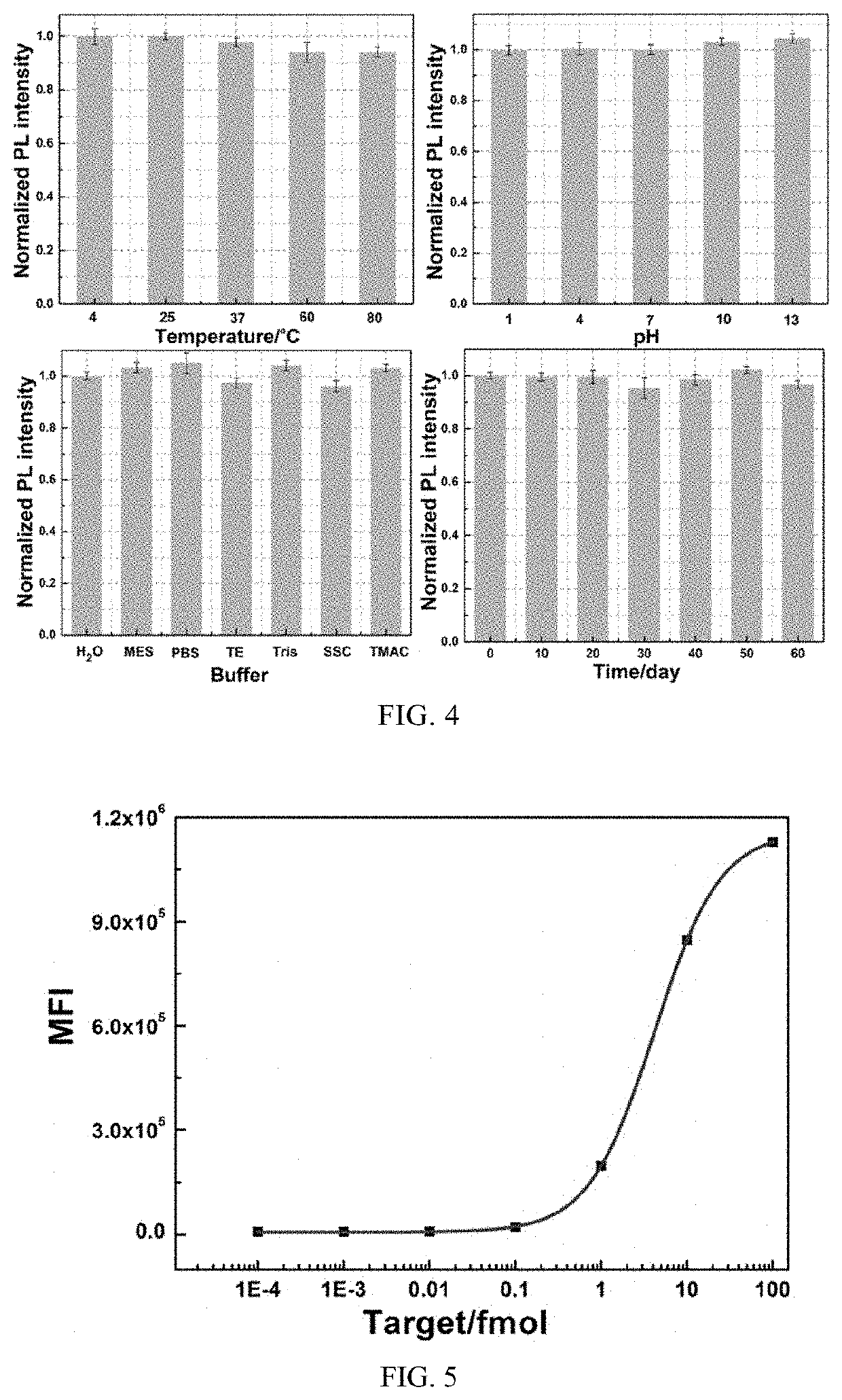

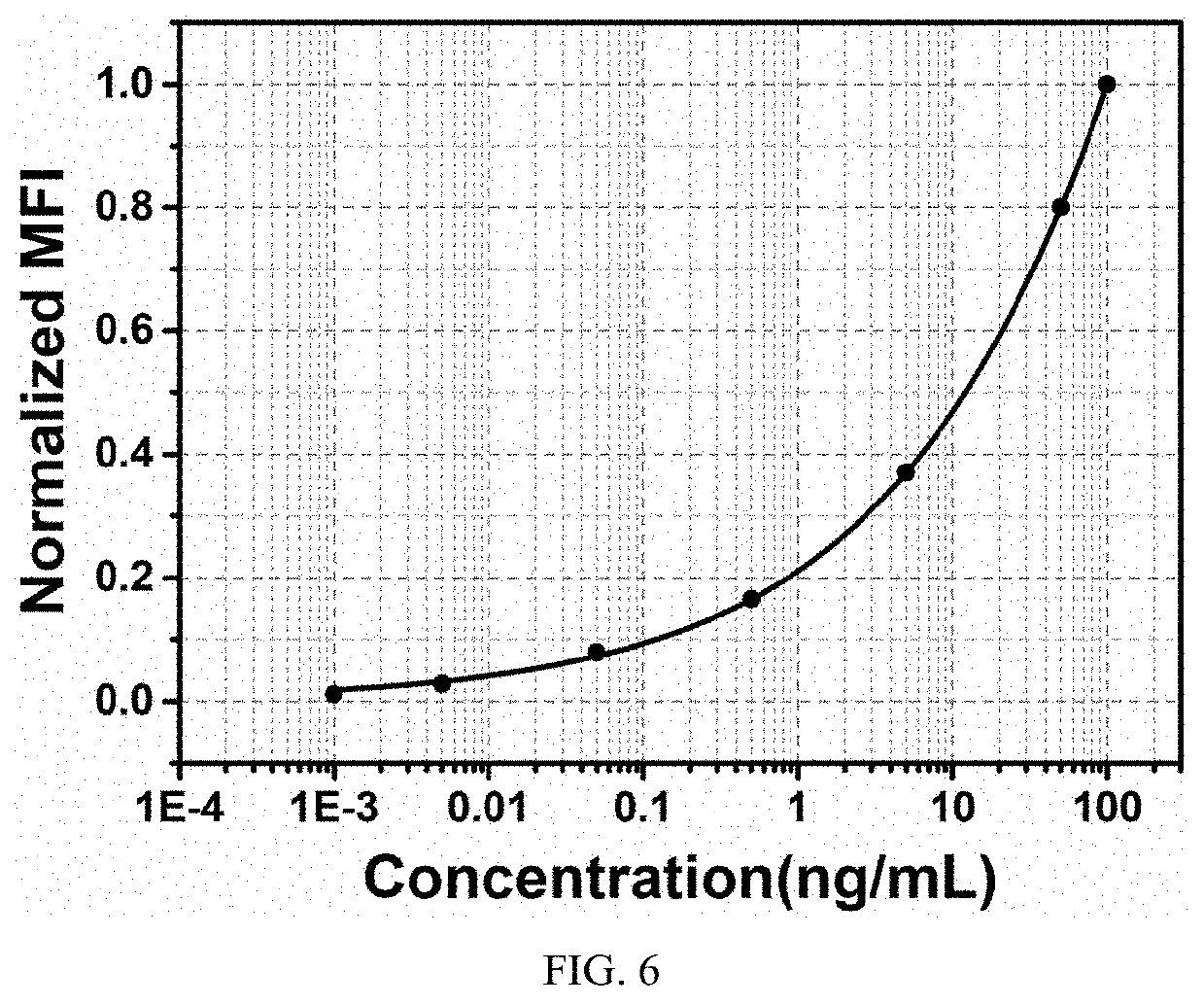

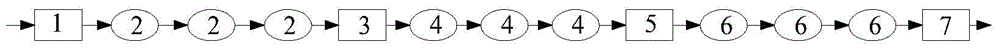

Method for preparing fluorescent-encoded microspheres coated with metal nanoshells

ActiveUS20210269707A1Easy to makeImprove stabilityMaterial nanotechnologyTransportation and packagingNucleic acid detectionMicrosphere

A method for preparing fluorescent-encoded microspheres coated with metal nanoshells is disclosed herein. By using SPG method, metal nano-material modified with a certain ligand is used as a new surfactant in the emulsification process, and different kinds and different amounts of fluorescent materials are doped into polymer microspheres to prepare fluorescent-encoded microspheres with different fluorescent-encoded signals and uniformly coated metal nanoshells in one step. The prepared fluorescent-encoded microsphere comprises a metal nanoshell, a polymer, and a fluorescent-encoded material. The fluorescent-encoded microsphere has a particle size of 1 μm˜20 μm, CV of less than 10%, which can be used for protein / nucleic acid detection. The preparation method has the advantages of simple process, high surface coating rate, good uniformity and controllable LSPR peaks, which can solve the problems of existing commonly used metal nanoshell coating methods such as low surface coating rate, poor uniformity, complex preparation process and uncontrollable local surface plasmon resonance (LSPR) peaks, etc.

Owner:HANGZHOU SHINEDO BIOTECH CO LTD

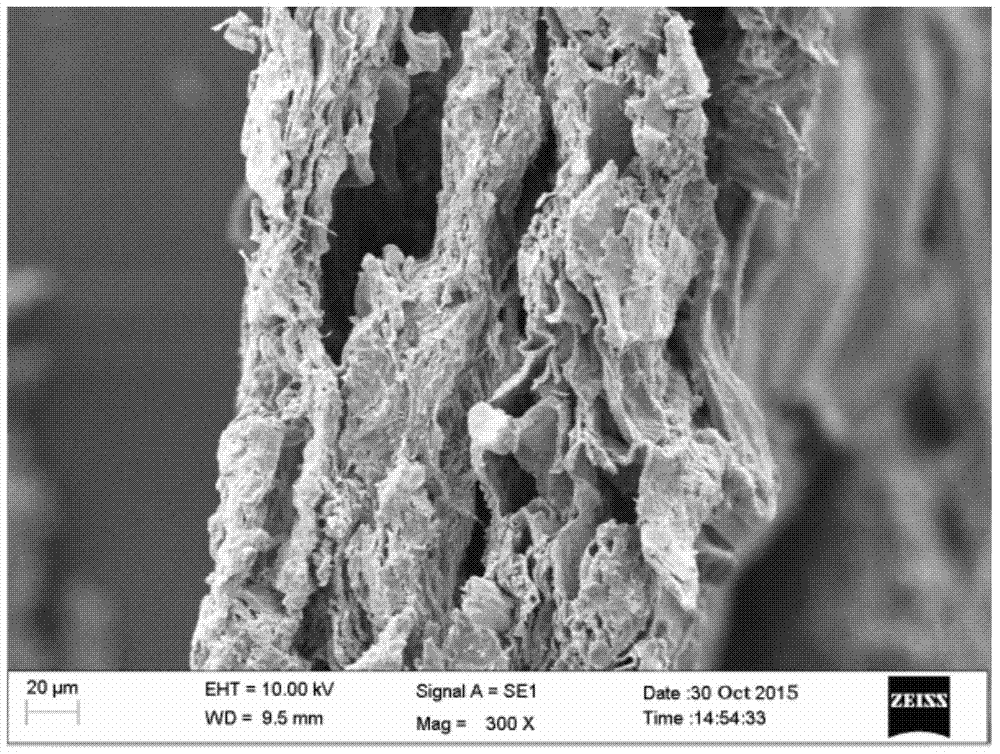

Flexible and controllable tobacco pulp preparation technology

ActiveCN104480761ADissolve evenlyImprove evennessTobacco preparationFibrous raw materialsPulp and paper industryRaw material

The invention discloses a flexible and controllable tobacco pulp preparation technology. Medium consistency pulp grinding and two-stage low consistency pulp grinding are performed according to the tobacco raw material beating degree or low-consistency pulp grinding is directly performed without performing the medium consistency pulp grinding. According to the flexible and controllable tobacco pulp preparation technology, a mode of combining the medium consistency pulp grinding and the low consistency pulp grinding is adopted, advantages of the medium consistency pulp grinding and the low consistency pulp grinding are fully played, or the low consistency pulp grinding is directly performed, a most suitable pulp grinding mode is selected for tobacco raw materials in different states, and the tobacco pulp with stable concentration and beating degree is obtained.

Owner:CHINA TOBACCO ANHUI RECONSTITUTED TOBACCO SCI & TECH CO LTD

Novel efficient spraying heavy ground-floor plastering gypsum mortar

The invention specifically relates to a novel efficient spraying heavy ground-floor plastering gypsum mortar, belonging to the technical field of building materials. The novel efficient spraying heavyground-floor plastering gypsum mortar comprises, by weight, 500-700 parts of flue gas desulfurization gypsum, 50-200 parts of ordinary Portland cement, 50-300 parts of heavy calcium carbonate powder,50-200 parts of talcum powder, 100-300 parts of quartz sand, 0.1-0.5 part of a retarder, 15-25 parts of redispersible latex powder, 3-5 parts of cellulose ether, 1-3 parts of wood fibers, 0.5-2.0 parts of starch ether, 1.0-3.0 parts of a thixotropic lubricant and 1 to 2 parts of polyacrylamide. The novel efficient spraying heavy ground-floor plastering gypsum mortar disclosed by the invention hashigh bonding strength, no phenomena of hollowing and cracking, good heat preservation effect, high coating rate and high construction efficiency.

Owner:BEHOFT NEW BUILDING MATERIALS JIANGSU CO LTD

Cross-linking reaction type sand-in-water colorful granite stone-like coating and preparation method thereof

InactiveCN111484778AGood stabilityHigh spreading ratePolyurea/polyurethane coatingsMulticolor effect coatingsEnvironmental geologyAcrylic acid

The invention discloses a cross-linking reaction type sand-in-water colorful granite stone-like coating which comprises a dispersed phase and a continuous phase in a weight ratio of 1: 1. The dispersed phase comprises the following components in parts by weight: 5-20 parts of deionized water, 2-4 parts of protective glue, 30-40 parts of waterborne polyurethane resin, 30-40 parts of white sand, 1-5parts of inorganic pigment paste, 0.1-0.3 parts of a mildew-proof preservative, 2-5 parts of a coalescing agent, 5-7 parts of an associative rheological agent and 1-2 parts of an internal cross-linking agent. The continuous phase comprises the following components in parts by weight: 5-15 parts of deionized water, 3-5 parts of a separant, 5-8 parts of matte powder, 40-50 parts of water-based acrylic silicon copolymer resin, 3-5 parts of a coalescing agent, 4-5 parts of an anti-settling agent, 0.1-0.2 parts of a mildew-proof preservative, 8-10 parts of an external cross-linking agent and 3-4 parts of an associative rheological agent. The coating disclosed by the invention is an ideal substitute for flamed granite stone.

Owner:嘉兴市威信新材料科技有限公司

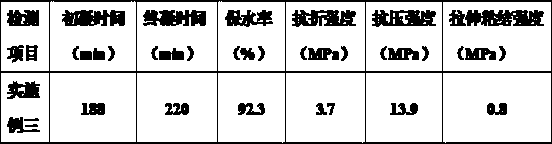

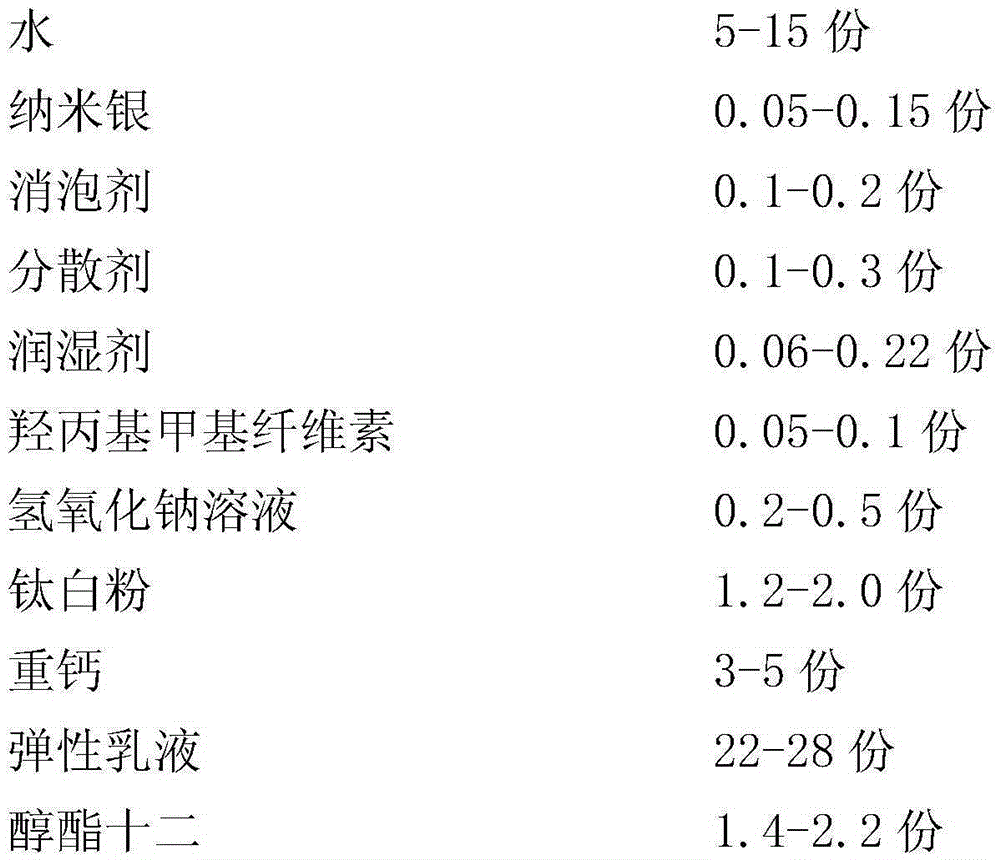

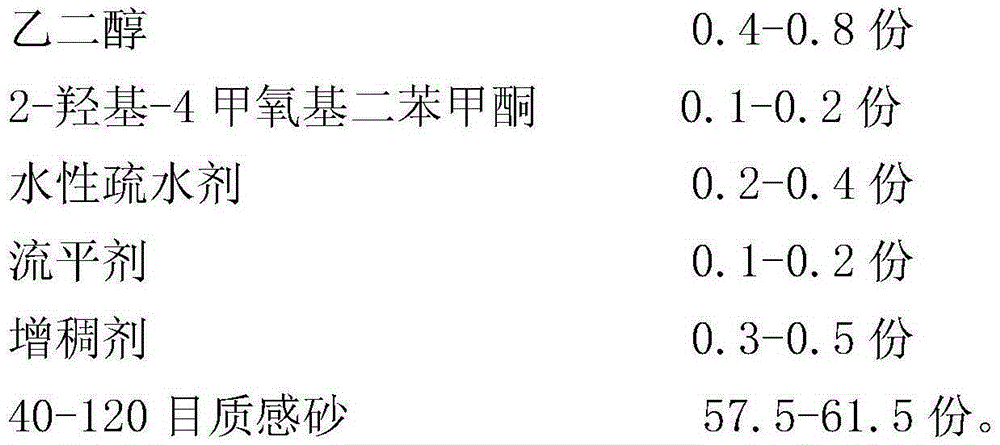

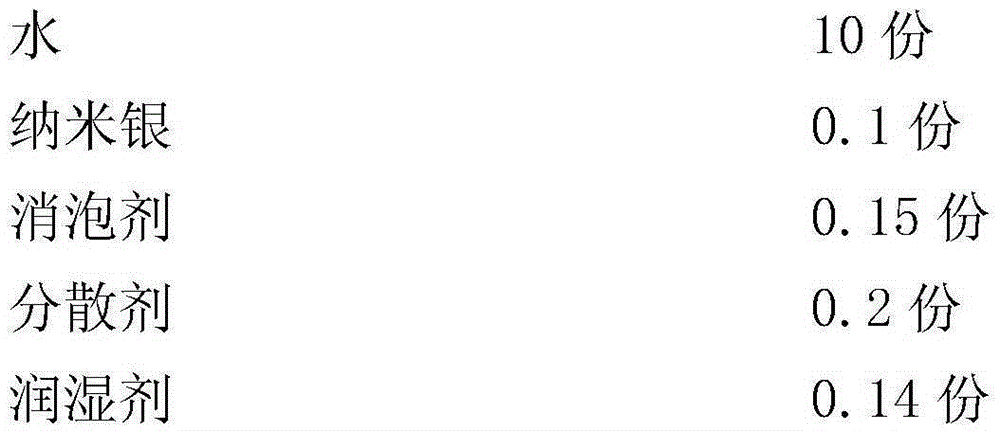

Elastic texture paint and preparation method thereof

The invention relates to elastic texture paint. The elastic texture paint is prepared from water, nano silver, a dofoaming agent, a dispersing agent, a wetting agent, hydroxy propyl methyl cellulose, a sodium hydroxide solution, titanium dioxide, coarse whiting, elastic emulsion, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, ethylene glycol, 2-hydroxy-4-methoxy diphenyl ketone, a water-based hydrophobic agent, a flatting agent, a thickening agent and (40-120)-mesh texture sand. The elastic texture paint has a compact elastic film and is high in coating rate, excellent in dirt resistance, weather resistance and water resistance and remarkable in crazing resistance and tenacity, wall cracks can be effectively warped and connected, and a building is protected better.

Owner:SKSHU PAINT

Rapidly calcined lightweight plastering gypsum and preparation method thereof

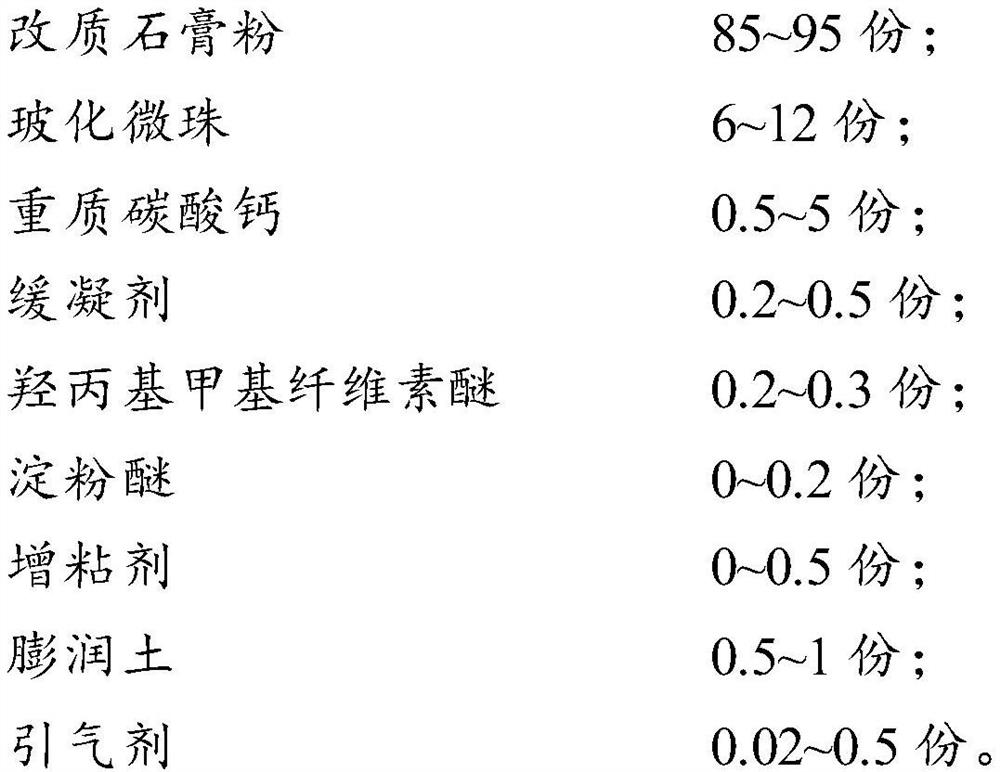

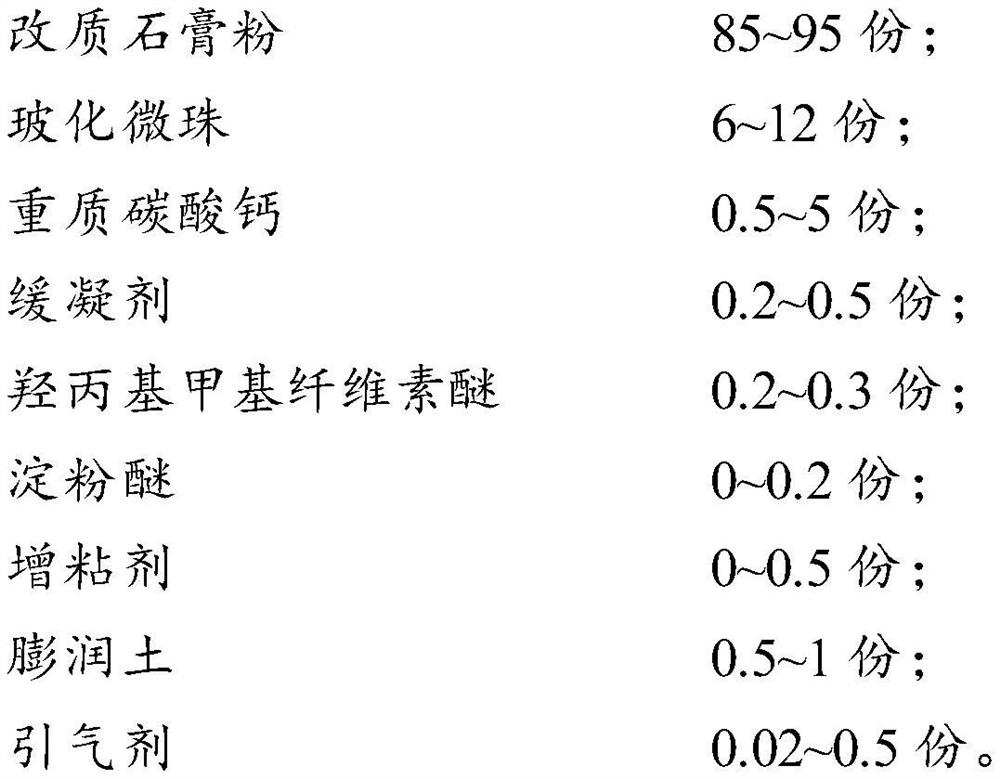

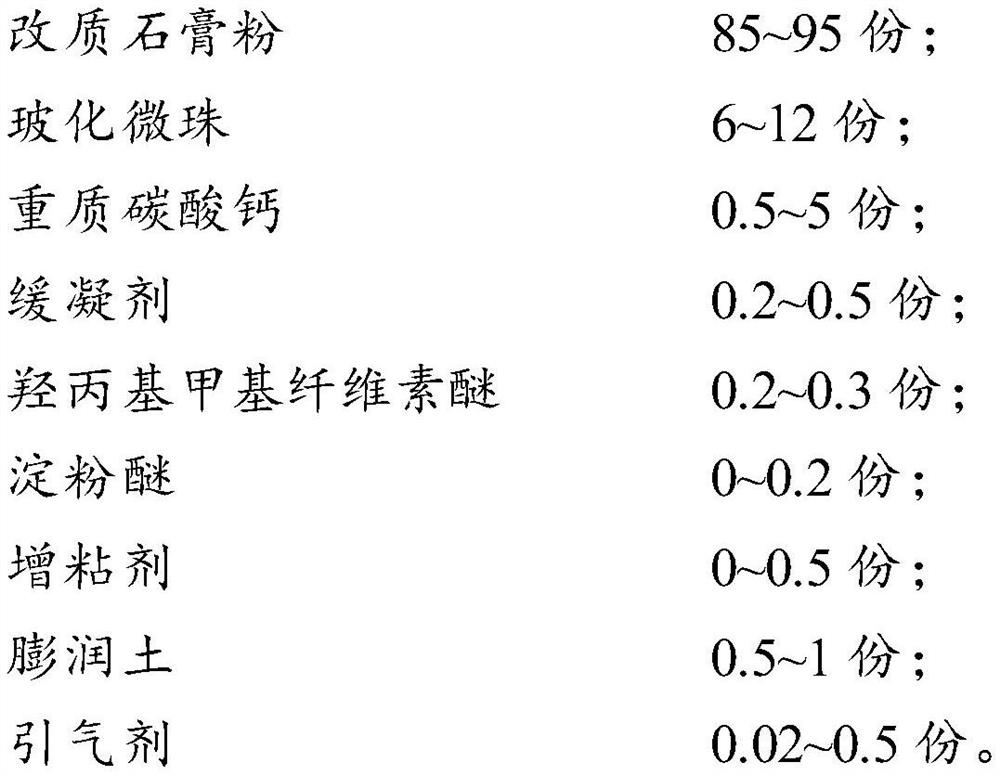

The invention provides rapidly calcined lightweight plastering gypsum and a preparation method thereof. The rapidly calcined lightweight plastering gypsum provided by the invention is prepared from the following raw materials in parts by mass: 85-95 parts of modified gypsum powder; 6 to 12 parts of glass beads; 0.5-5 parts of heavy calcium carbonate; 0.2 to 0.5 part of a retarder; 0.2 to 0.3 part of hydroxypropyl methyl cellulose ether; 0 to 0.2 part of starch ether; 0 to 0.5 part of a tackifier; 0.5 to 1 part of bentonite; and 0.02 to 0.5 part of an air entraining agent. The light plastering gypsum product is prepared by matching certain modified gypsum powder with the specific water-retaining agent, the retarder and other components according to a certain proportion, so that the coating rate can be increased (greater than 130m < 2 > / ton), and the problems of easiness in cracking, low strength and powder falling after construction are solved.

Owner:TAISHAN GYPSUM CO LTD

Formaldehyde-removal health emulsion paint with addition of adsorbing filler and preparation method thereof

InactiveCN105086539AIncrease coverageHigh spreading rateAntifouling/underwater paintsPaints with biocidesPetroleumPolyacrylamide

The invention discloses formaldehyde-removal health emulsion paint with addition of adsorbing filler. The formaldehyde-removal health emulsion paint is characterized by being prepared by the following raw materials in parts by weight: 25 to 28 parts of vinyl acetate-acrylic emulsion, 4 to 6 parts of butyl acrylate, 8 to 10 parts of medical stone powder, 6 to 8 parts of zeolite powder, 6 to 8 parts of bamboo vinegar, 4 to 6 parts of lotus leaf powder, 2 to 4 parts of lithopone, 17 to 20 parts of ground calcium carbonate, 2 to 3 parts of cotton seed oil, 1 to 2 parts of silicon oil, 1 to 2 parts of petroleum sodium sulfonate, 1 to 2 parts of polyacrylamide, 80 to 90 parts of water, and 7 to 9 parts of mixed plant size. The formaldehyde-removal health emulsion paint has the advantages that by adding multiple fillers with adsorbing functions, such as zeolite powder and medical stone powder, the shielding capability is good, and the formaldehyde and free organic volatiles in air can be adsorbed; by adding the mixed plant size, the adhesion force is enhanced, the fragrance is fresh, the safety, environment-friendly, poisonless, corrosion-resistant, antibacterial and antiviral effects are realized, and the freshness index of air is improved; the content of VOC (volatile organic compound) is low, the coating efficiency is high, the shielding capability is good, the bacteria can be effectively inhibited for a long time, and the emulsion paint is suitable for public places, such as hospitals.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

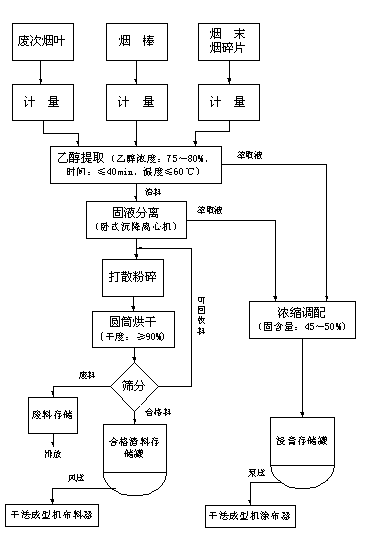

Raw material preparation method of dry method reconstituted tobacco

The invention provides a raw material preparation method of dry method reconstituted tobacco. An ethanol extraction method is adopted, lipid utmost fragrant substances in tobacco residuals such as tobacco powder, broken stalks and fragments are extracted out through a reverse alcohol extraction method and are used for preparing extracta, then, solid-liquid separation is carried out on slag charge, residual ethanol is extracted, remaining moisture is discharged out, and then the slag charge is screened and scattered, and dry method reconstituted tobacco raw materials are manufactured after being dried by a rotary drum dryer. Not only can intrinsic frangrance of natural tobacco be reserved to the maximum degree, but also the pollution of waste water to environment is reduced. The raw material preparation method of the dry method reconstituted tobacco is especially beneficial to accurate measuring of dry method paper-making process reconstituted tobacco equipment to raw materials in the process of manufacturing paper with pulp, and conducive to improving the filling value of the reconstituted tobacco.

Owner:GUANGDONG JINKE REFORGING TOBACCO LEAF CO LTD

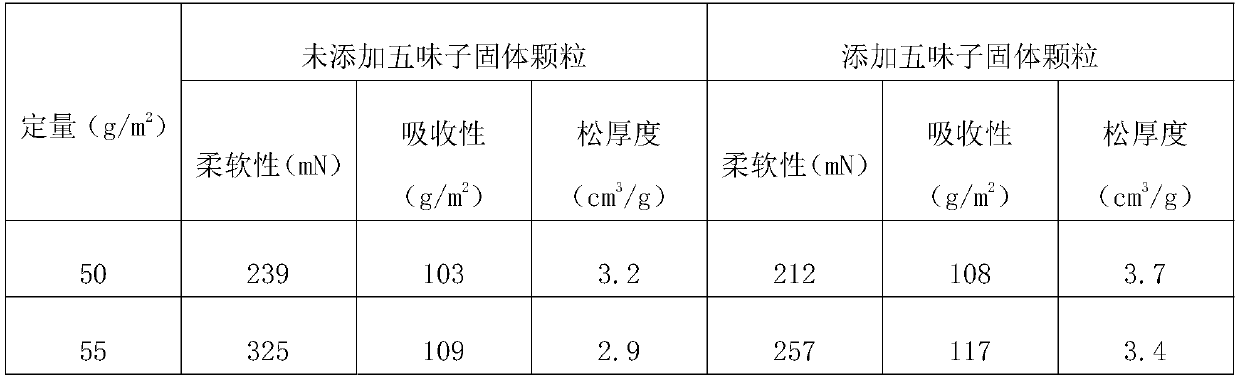

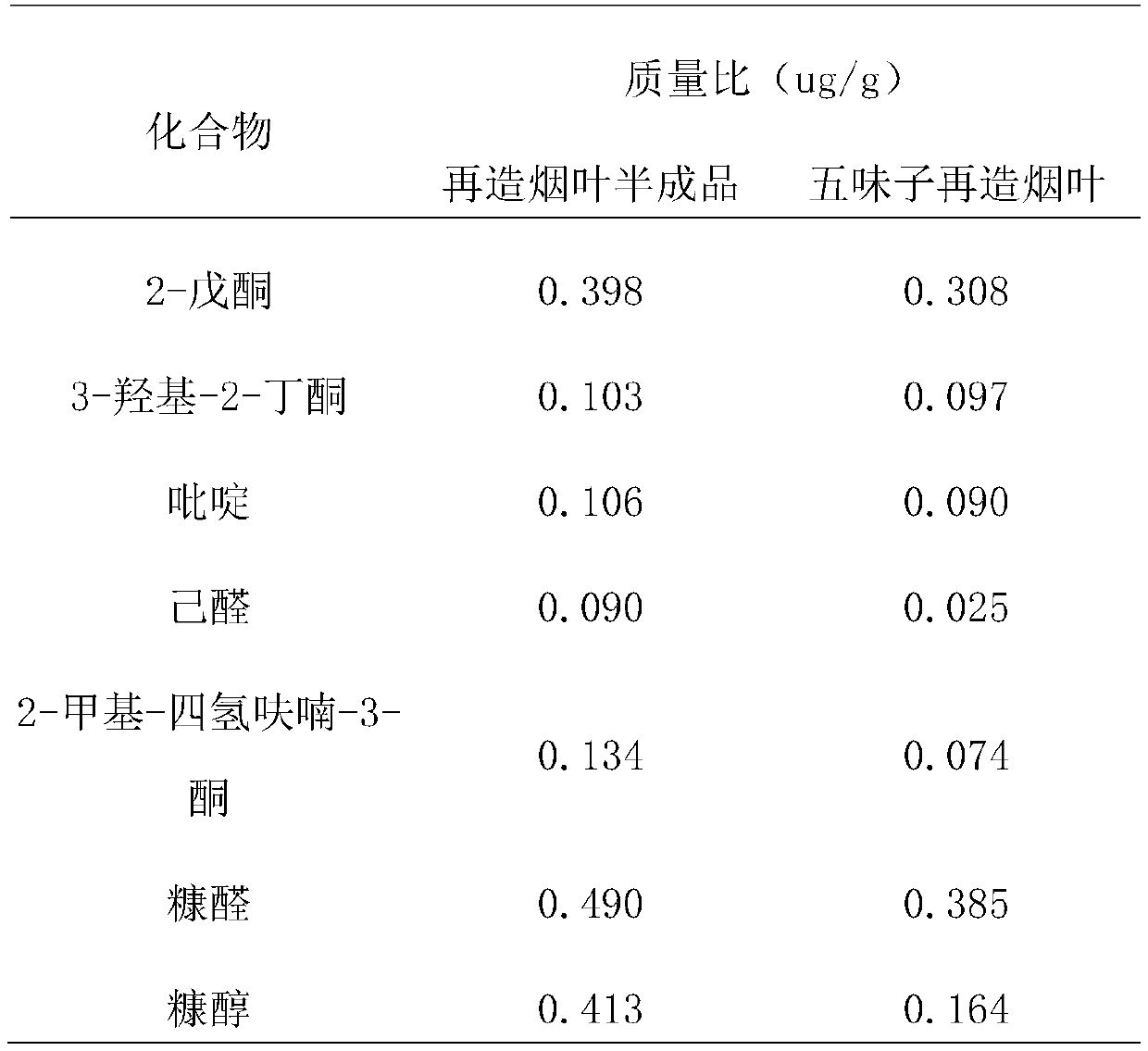

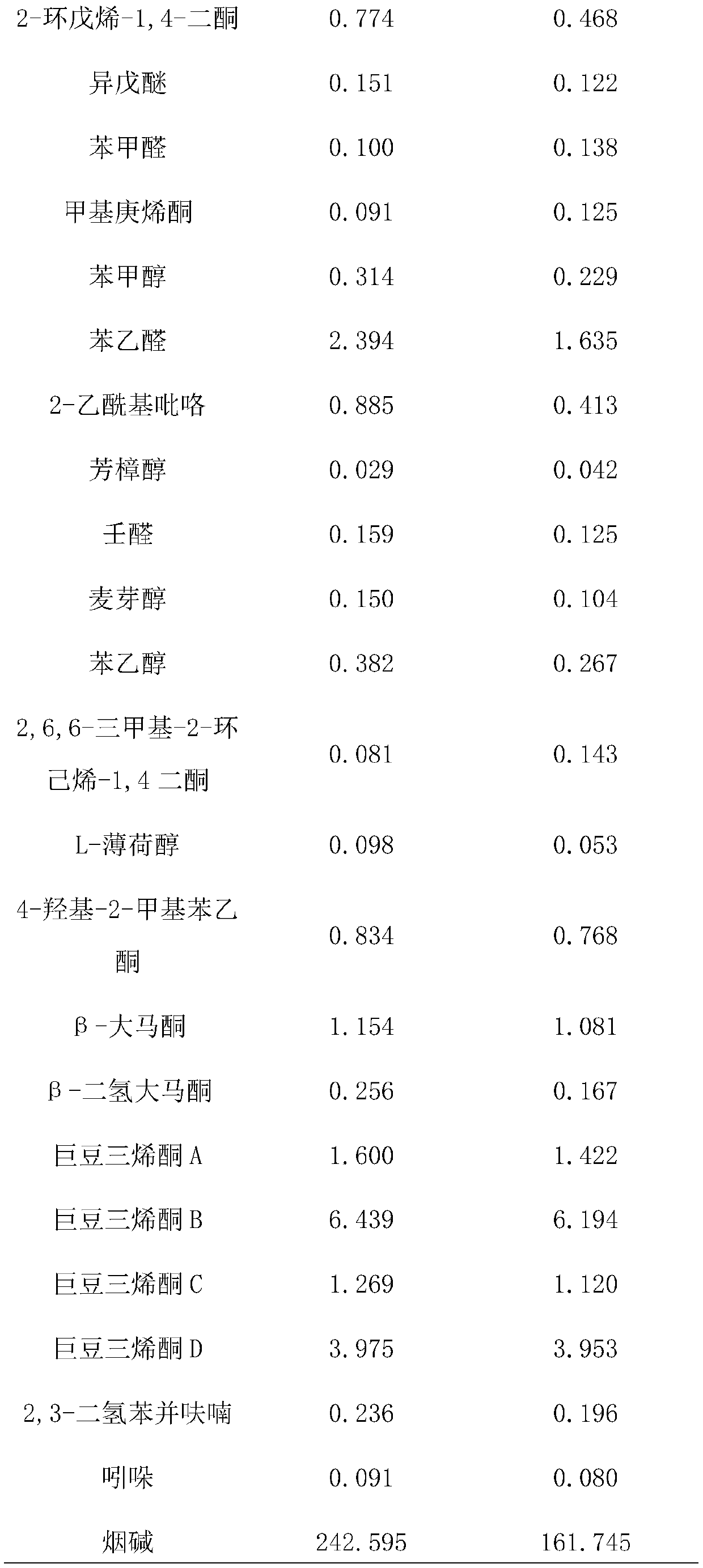

Preparation method and application of high flexible reconstituted tobacco

ActiveCN110731531AHigh spreading rateIncrease bulkTobacco preparationTobacco treatmentBiotechnologyNicotiana tabacum

The invention discloses a preparation method and an application of high flexible reconstituted tobacco. The preparation method comprises the steps of 1, preparation of sheet bases: adding solid matters, formed after extraction, of Schisandra chinensis which is 1-5% of the weight of tobacco materials during a tobacco pulping process, and producing the reconstituted tobacco sheet bases; 2, coating the sheet bases: adding 1-5% of Schisandra chinensis powder into tobacco coating liquid, coating the reconstituted tobacco sheet bases according to a preset coating rate, drying after coating to control moisture of the reconstituted tobacco to be 10-12%; and 3, spraying fragrance to the sheet bases: spraying a Schisandra chinensis extracting solution with the density of Rho that is equal to 1.1-1.20g / cm<3> to the cut sheet bases, controlling the moisture of the reconstituted tobacco to be 10-12% after spraying is completed. A final product can be significantly improved in flexibility, absorbency and bulk of the sheet bases, improves the problems that the reconstituted tobacco is spicy, irritant and relatively high in wood miscellaneous gas, meanwhile, enhances sweet feeling, comfort and compatibility of the reconstituted tobacco, and can relieve cough, eliminate phlegm and improve immunity of a respiratory system.

Owner:CHINA TOBACCO YUNNAN REMFG TOBACCO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com