Patents

Literature

397results about How to "Cut off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Switch disconnector for galvanic direct current interruption

ActiveCN102349124ACut offHigh-tension/heavy-dress switchesAir-break switchesPhotovoltaic generatorEngineering

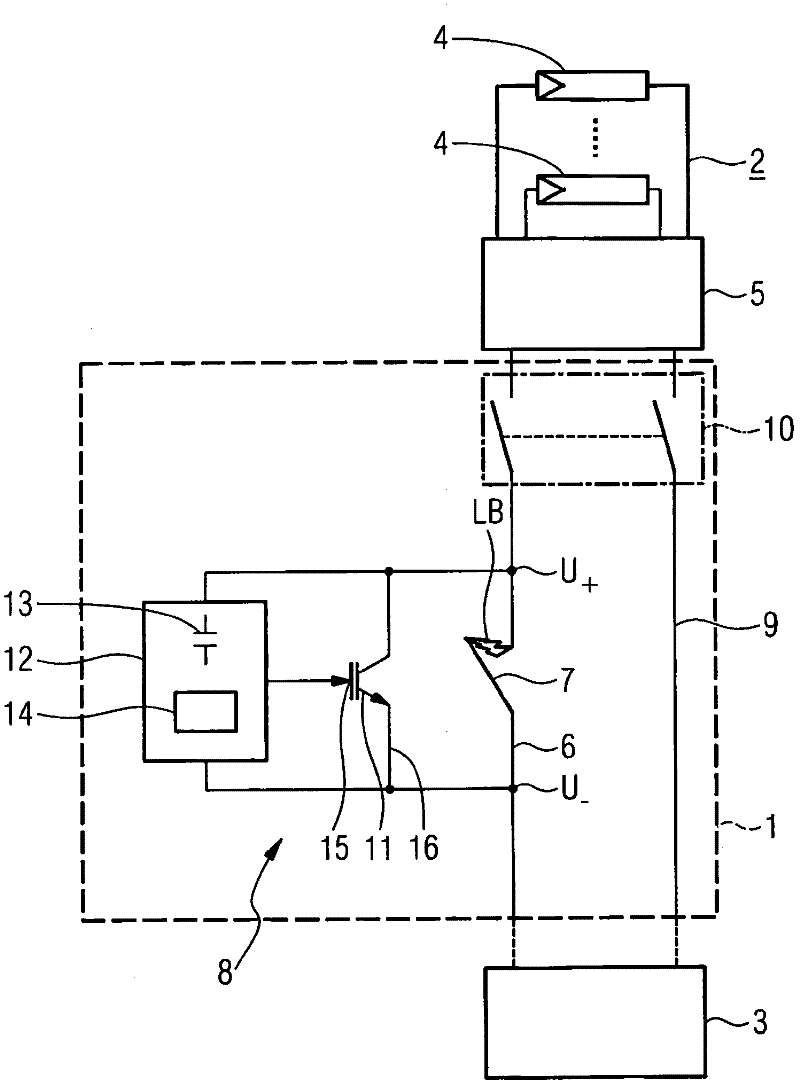

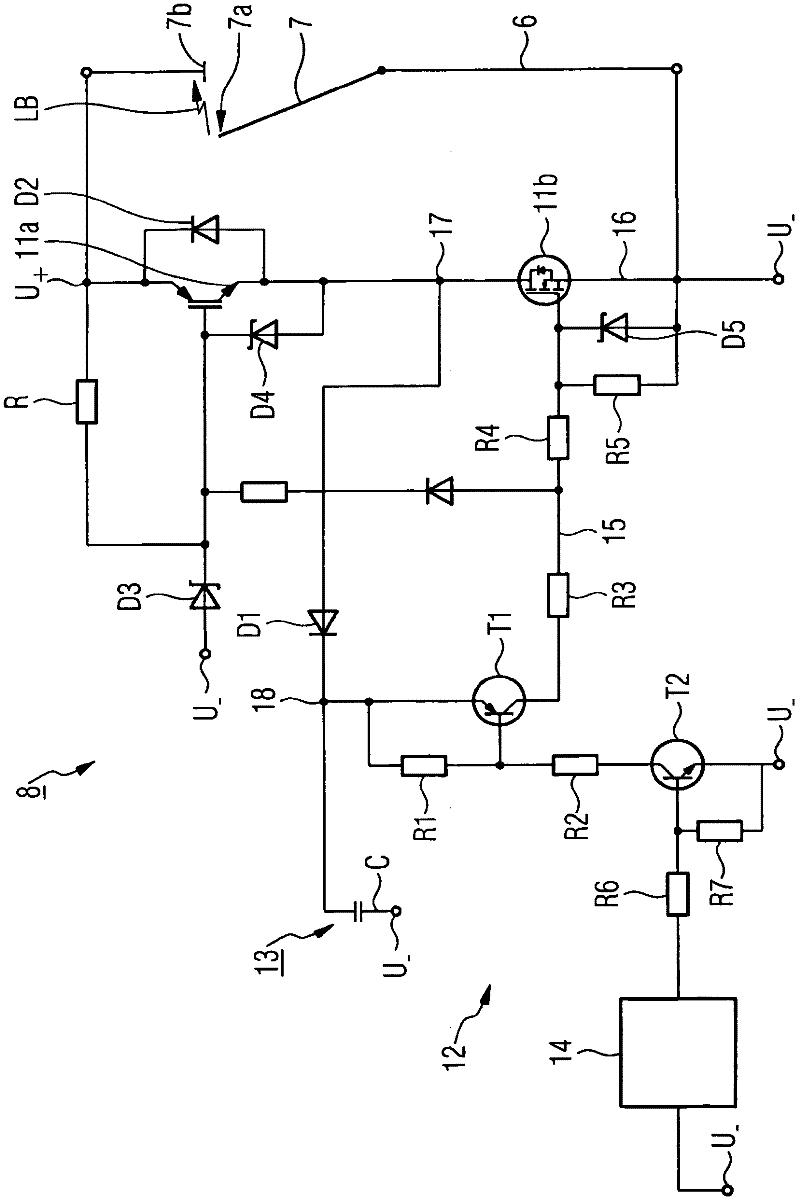

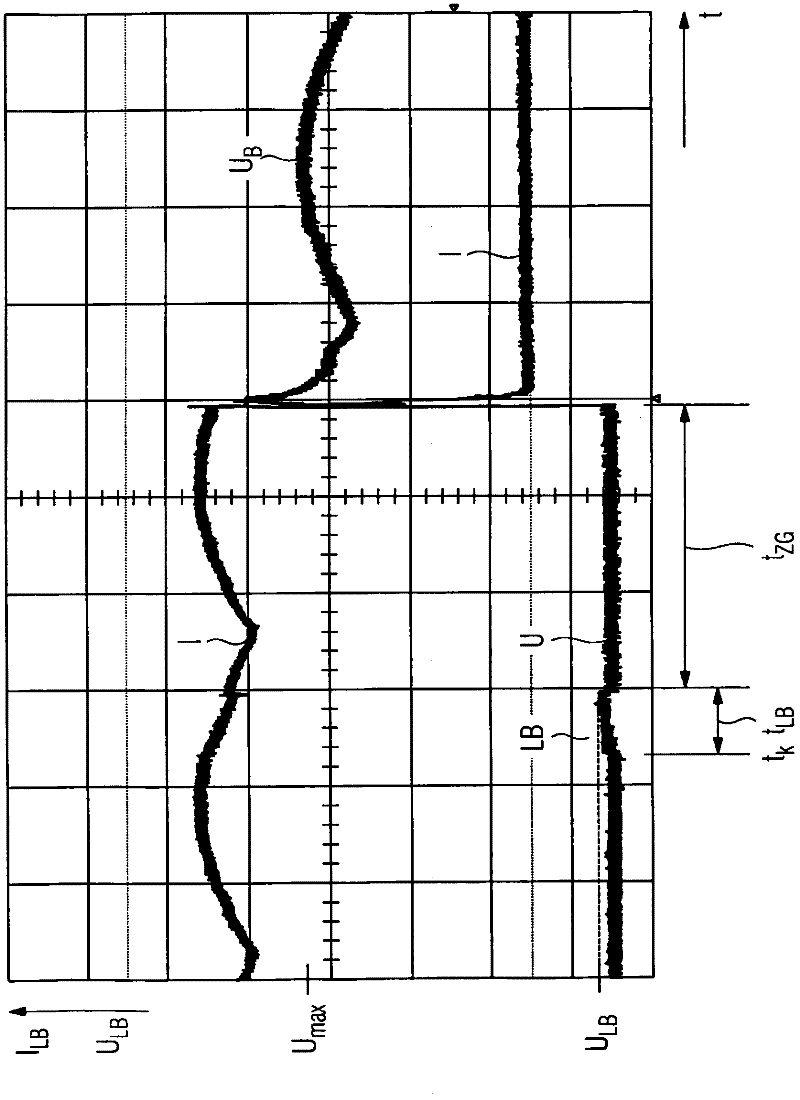

The invention relates to a disconnecting apparatus (1) for direct current interruption between a direct current source (2) and an electrical device (3), in particular between a photovoltaic generator and an inverter, with a current-conducting mechanical switching contact (7a, 7b) and with semiconductor electronics (8) connected in parallel with the switching contact (7a, 7b). The semiconductor electronics (8) are non-conducting when the switching contact (7a, 7b) is closed, wherein a control input (15) of the semiconductor electronics (8) is wired with the switching contact (7a, 7b) in such a way that, when the switching contact (7a, 7b) opens, an arc voltage (ULB)generated as a result of an arc (LB) via the switching contact (7a, 7b) switches the semiconductor electronics (8) to be conducting.

Owner:ELLENBERGER POENSGEN

Coast saline-alkali soil forestation method

ActiveCN101322470ASolve the problem of insufficient fresh water resources for afforestationSmooth infiltrationClimate change adaptationWatering devicesAlkali soilIsolation layer

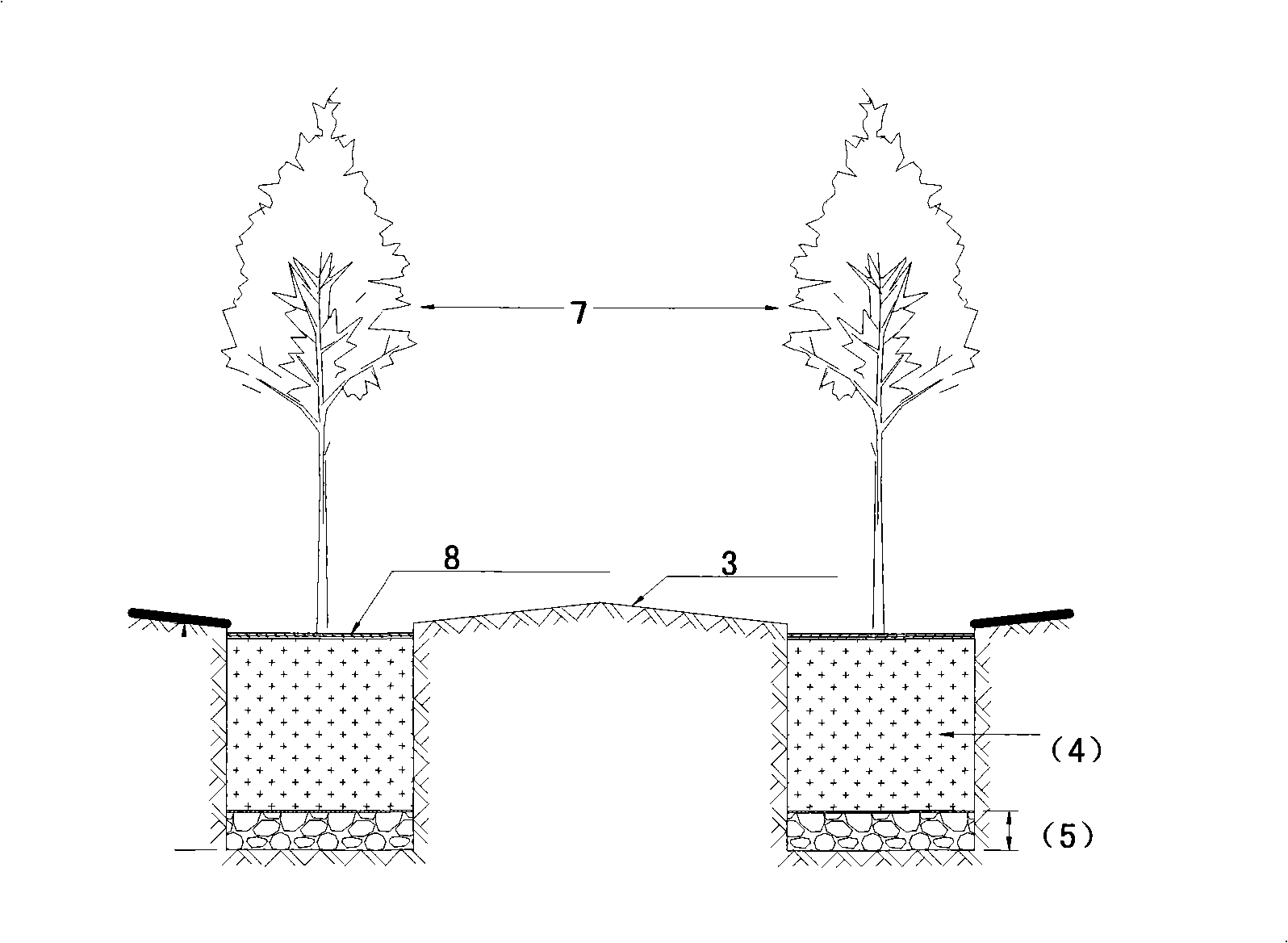

The invention discloses a coastal kaline soil forestation method, comprising the following steps: A. trenching and building ridges, and building rain collection beds; B. setting rain collection surfaces; C. digging plant pits, and setting salt isolation layers; D. collecting tree species and planting; E. setting surface cover layers of plant pits; F. tending, and weeding at proper time; wherein, the step of trenching and building ridges, and building rain collection beds is based on the design of forestation spacing, and flow collection trenches are dug at interval of a row spacing along the direction of rows; the depth of the trench bottom is 20cm to 25cm; the ground surface between the ridge and the trench bottom is trimmed to form a shallow v-shaped groove; the sloping surfaces are leveled and compacted to form the rain collection beds. The coastal moderate kaline soil forestation technology of the invention greatly increases the water content of soil, and the salt is efficiently leached and reduced, thereby efficiently improving the survival rate, save rate and growing speed of forests; the survival rate of forests reaches greater than 85%.

Owner:BEIJING ORIENT LANDSCAPE

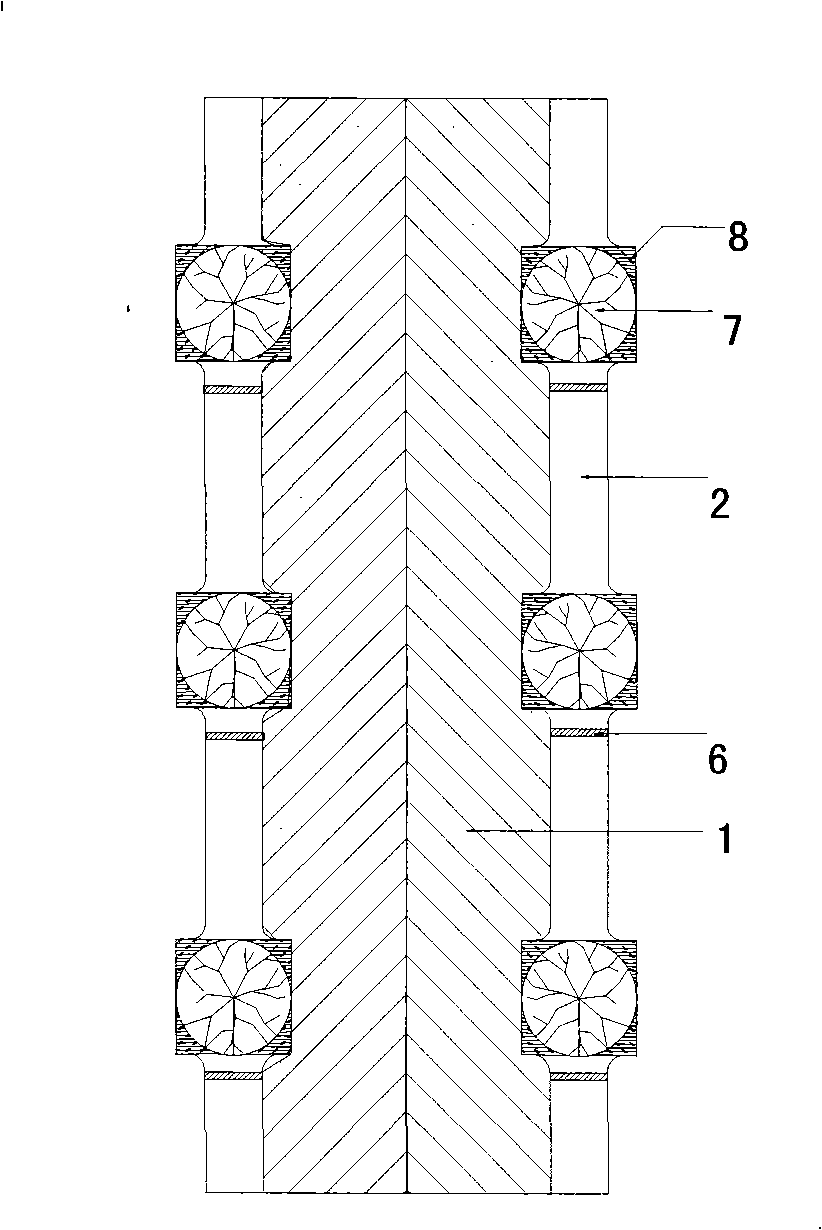

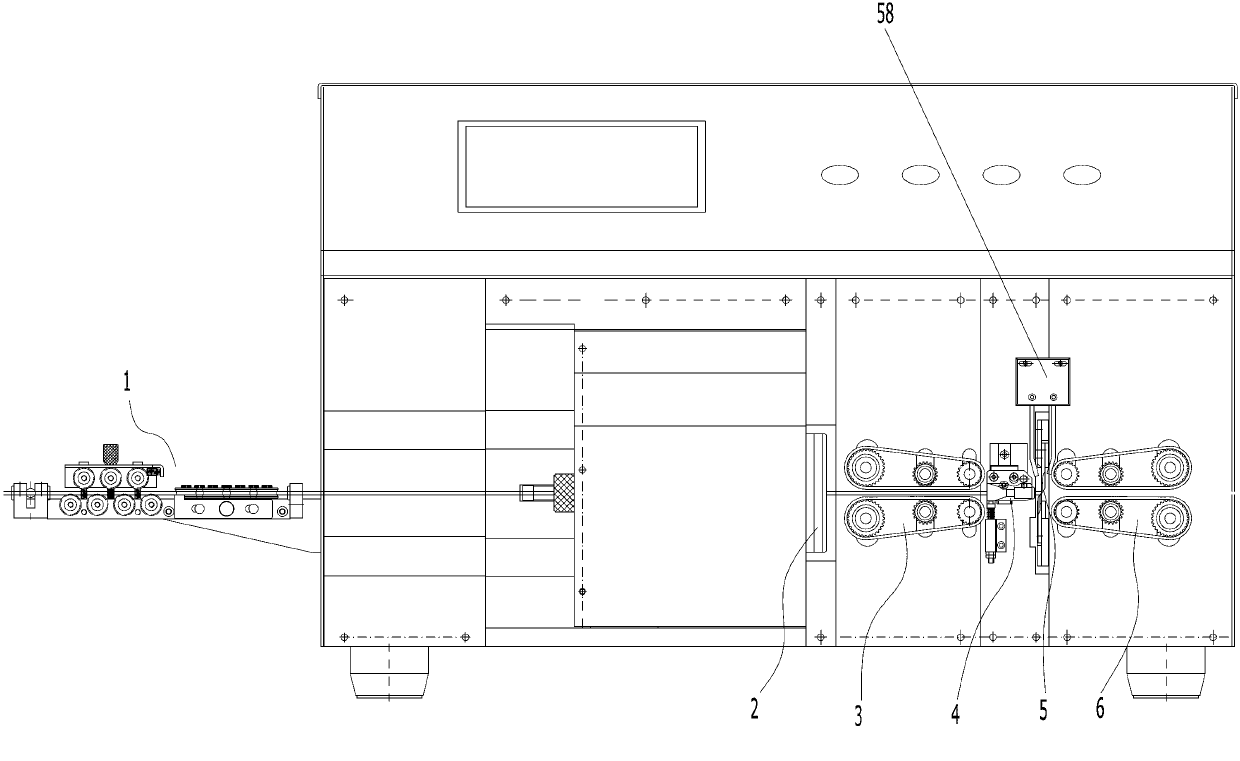

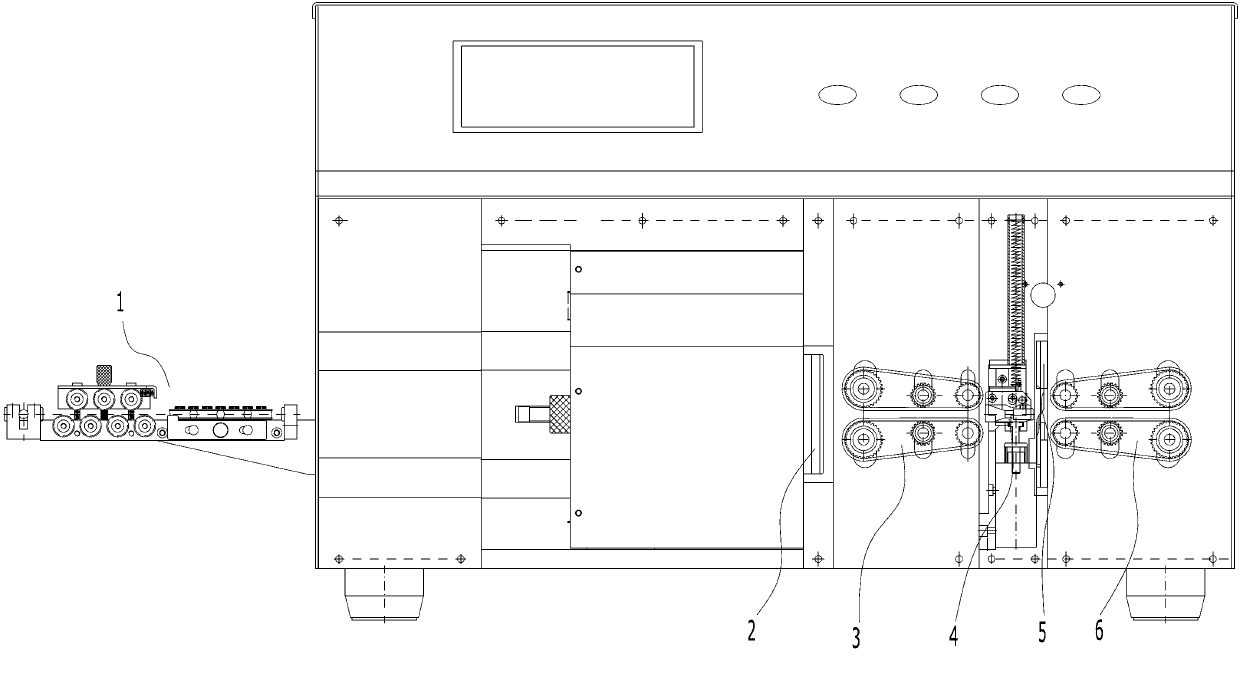

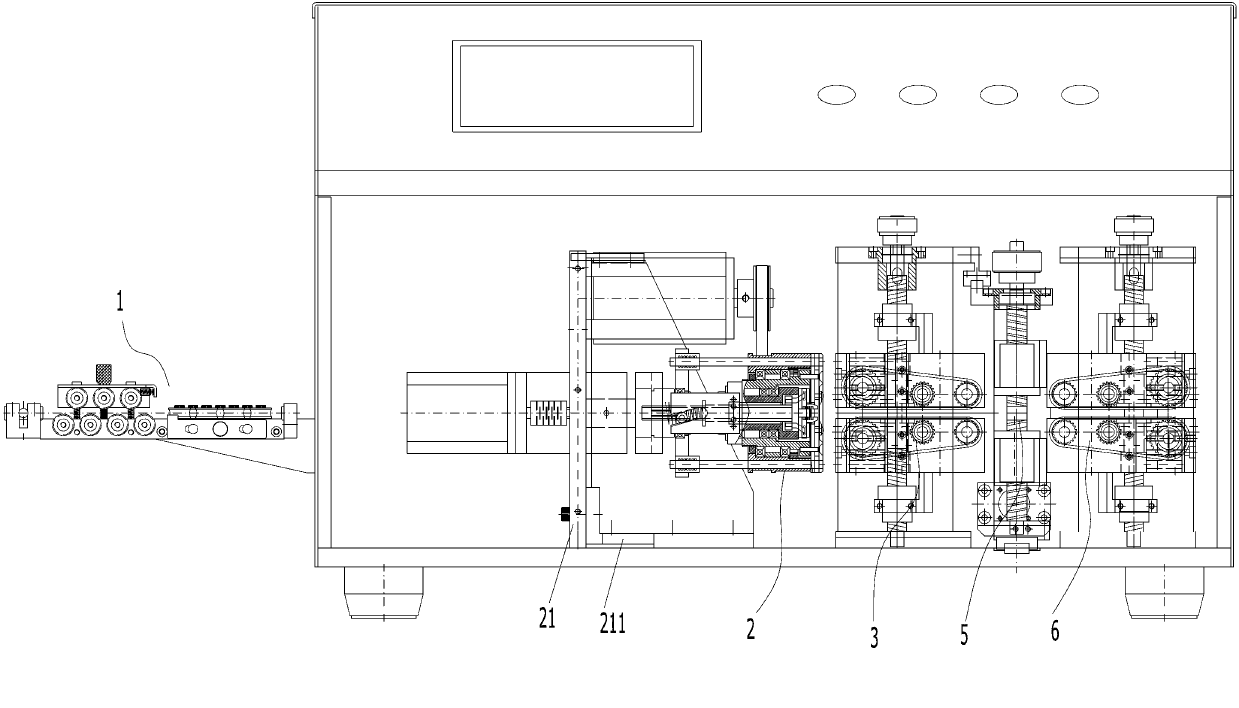

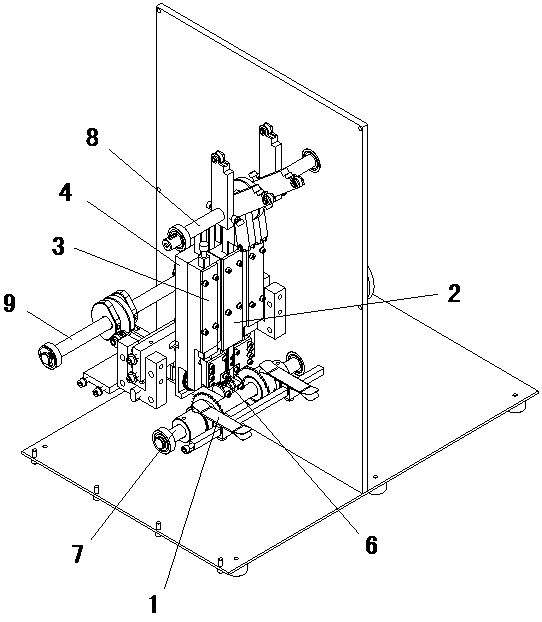

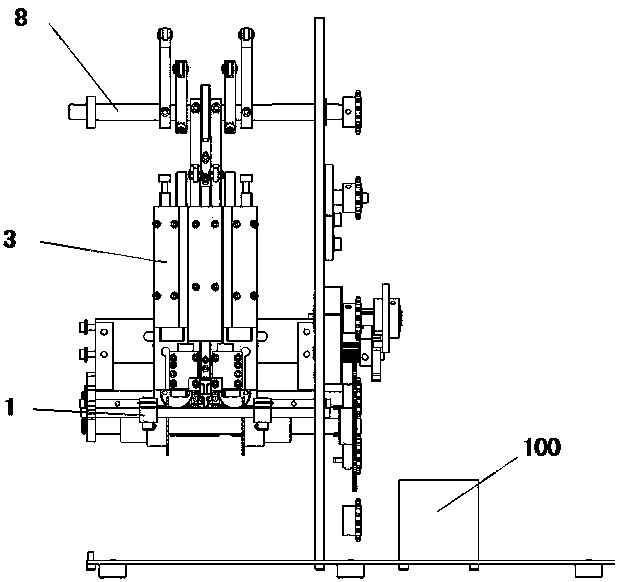

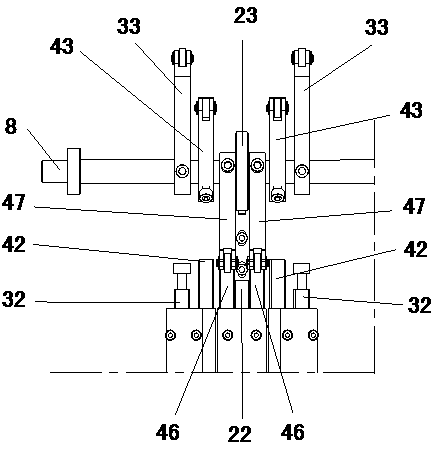

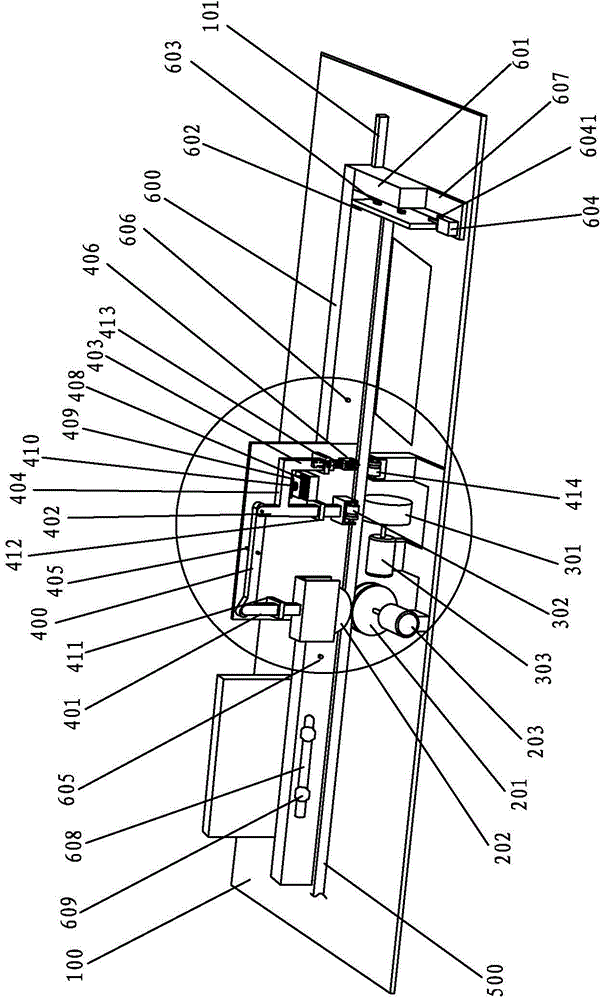

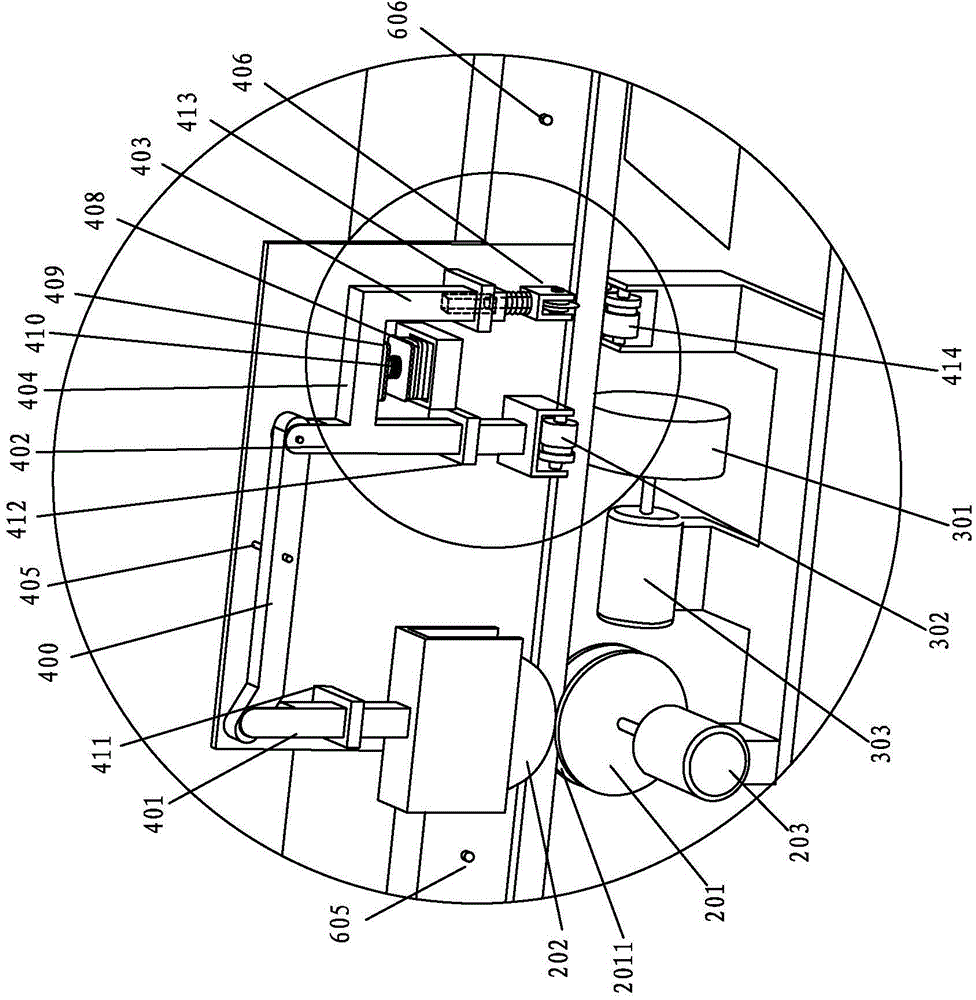

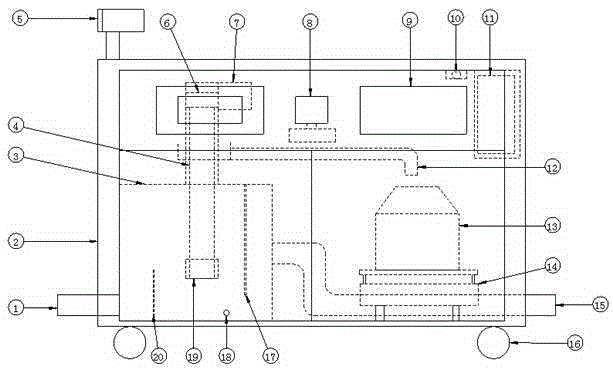

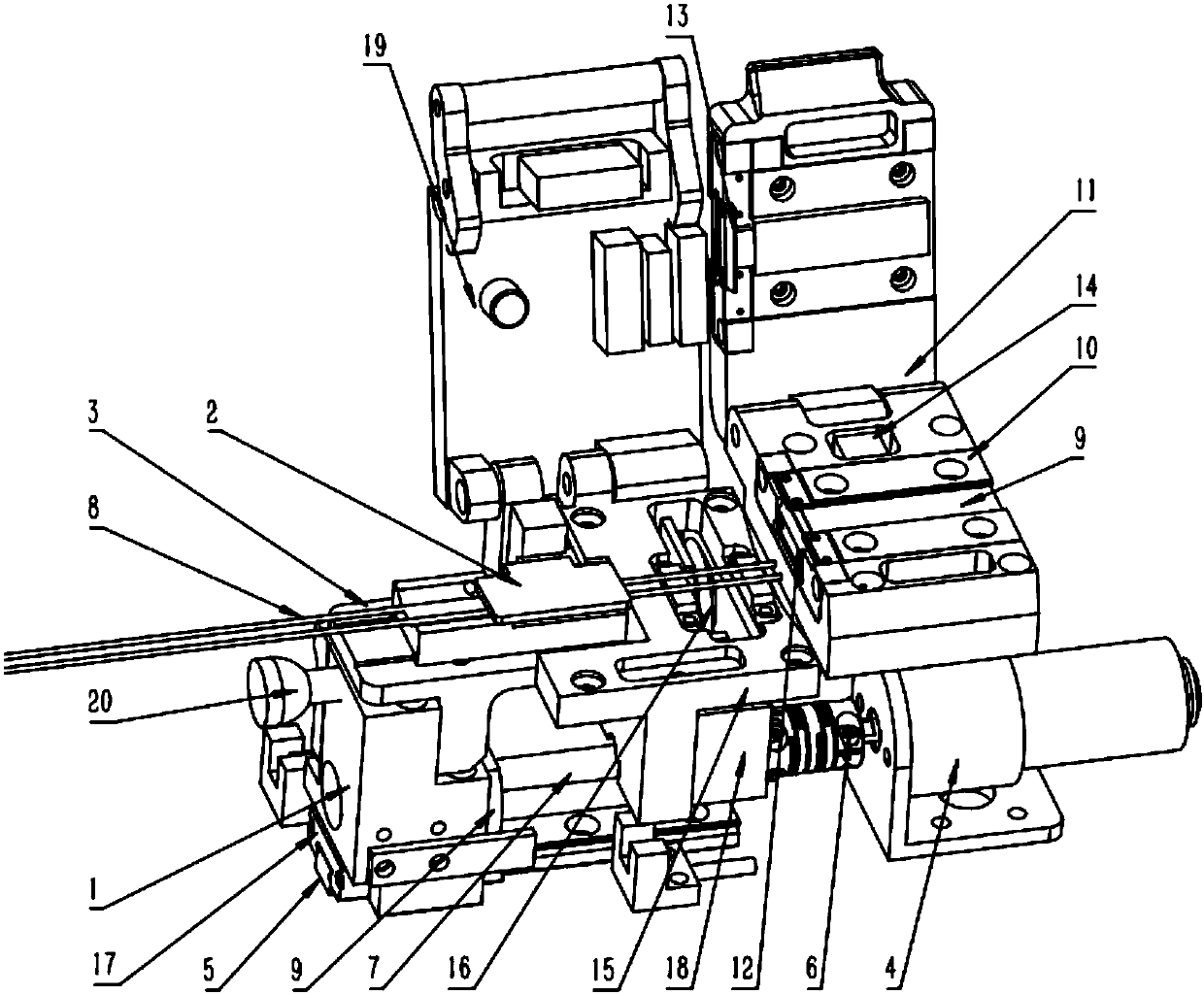

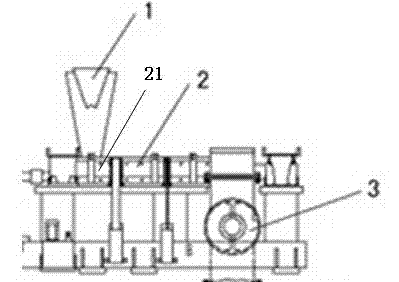

Full-automatic coaxial wire stripping machine

ActiveCN103280743ARealize wire feedingAchieve alignmentApparatus for removing/armouring cablesElectric machineryCoaxial line

The invention relates to the technical field of a wire stripping machine, in particular to a full-automatic coaxial wire stripping machine. The full-automatic coaxial wire stripping machine comprises a case body, wherein a control unit is arranged in the case body; and a feeding alignment unit, a rotary-cut unit, a first wire feeding stripping unit, an automatic demising mechanism, a cutting and stripping unit and a second wire feeding stripping unit are sequentially arranged on the case body in a coaxial wire moving direction. The full-automatic coaxial wire stripping machine has functions of alignment, cutting off wires and both-end peeling. According to parameters including diameters of coaxial wires, thickness of each layer, set lengths of wire sections, stripping length of each layer and the like, the work of wire feeding, alignment, rotary cut, cutting off and both-end peeling can be automatically and quickly realized, and the wire stripping speed can be controlled according to the operation speed of each drive motor, so that the degree of automation of the full-automatic coaxial wire stripping machine can be greatly improved, and production efficiency can be greatly improved.

Owner:DONGGUAN WINGUD MECHANICAL EQUIP CO LTD

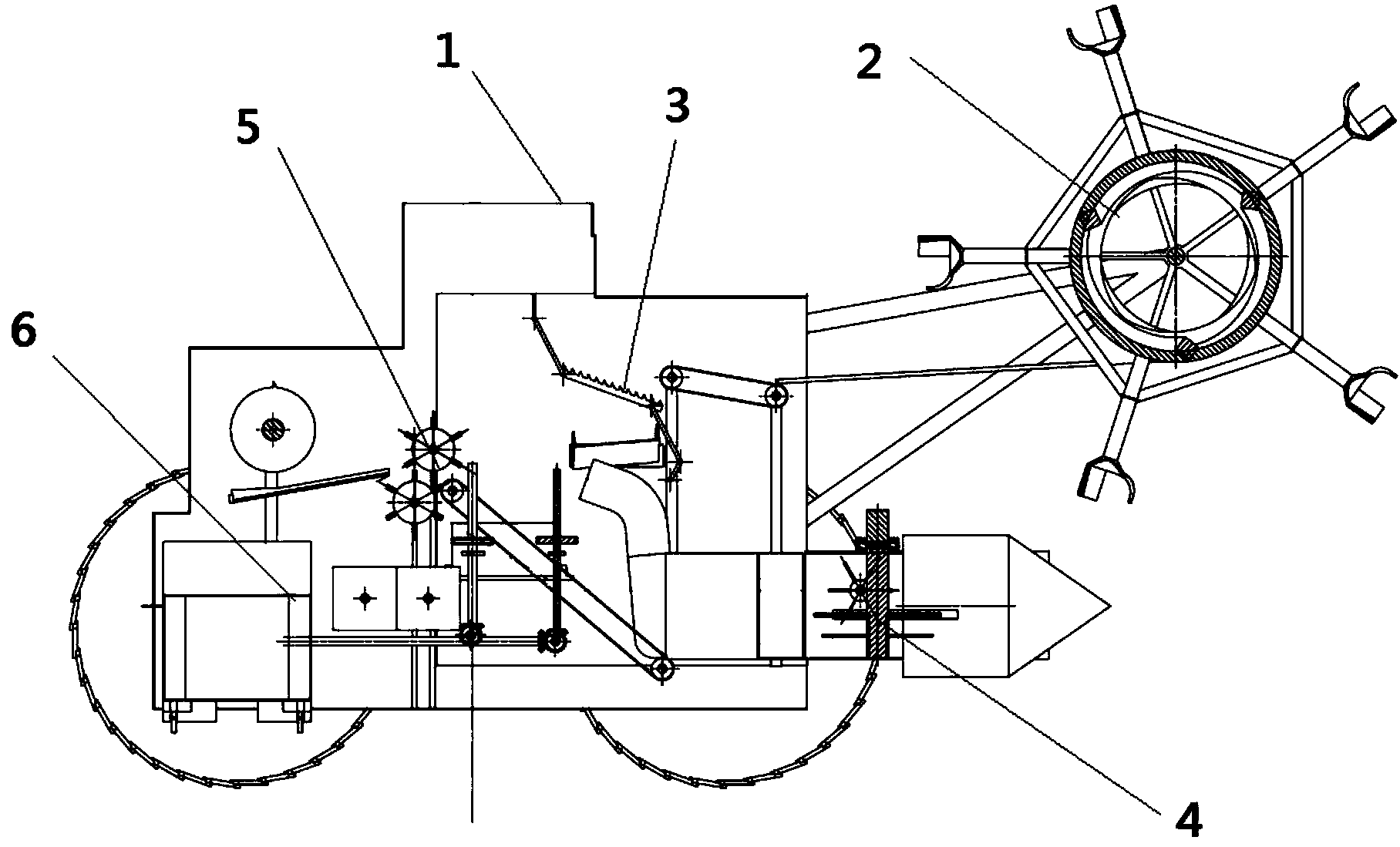

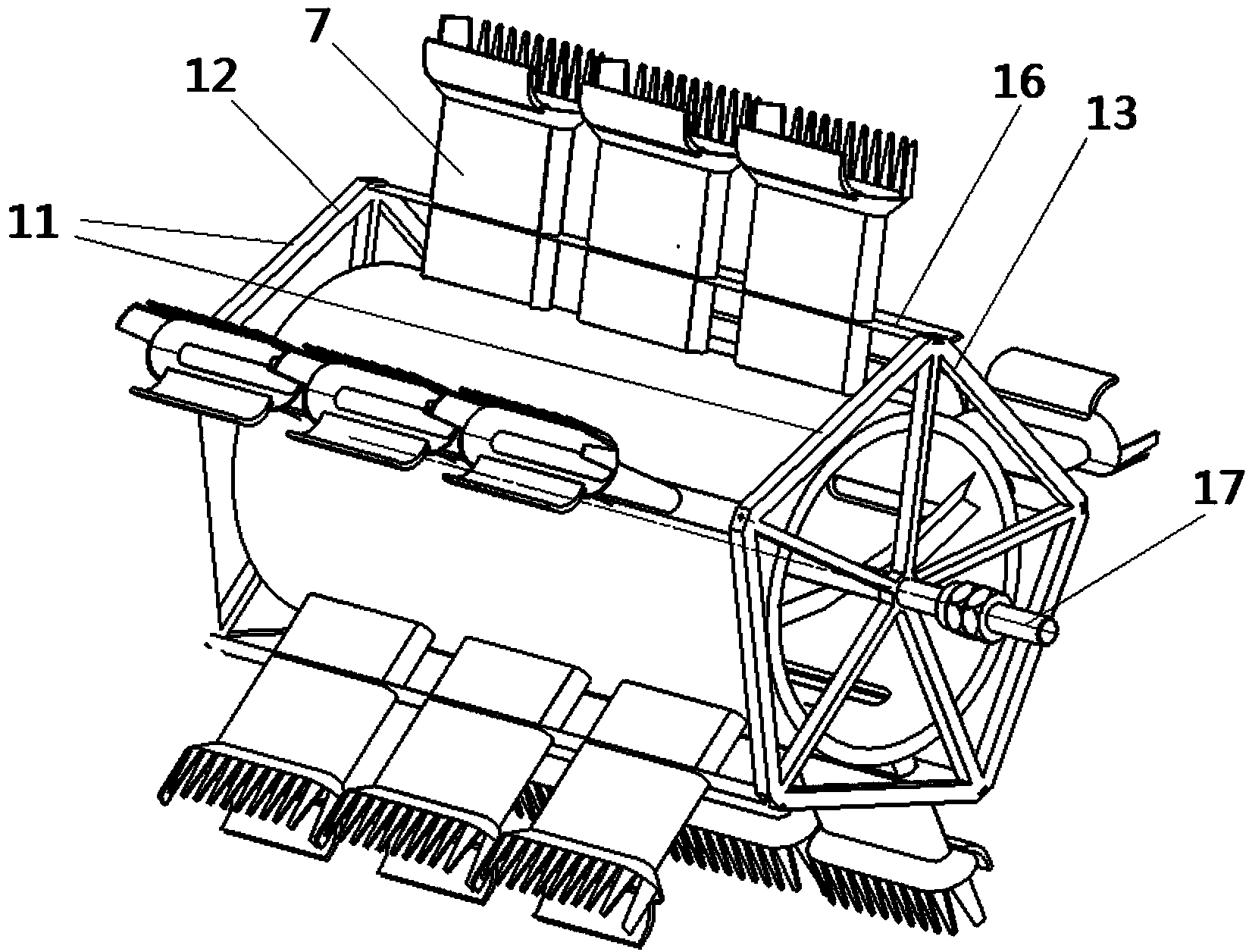

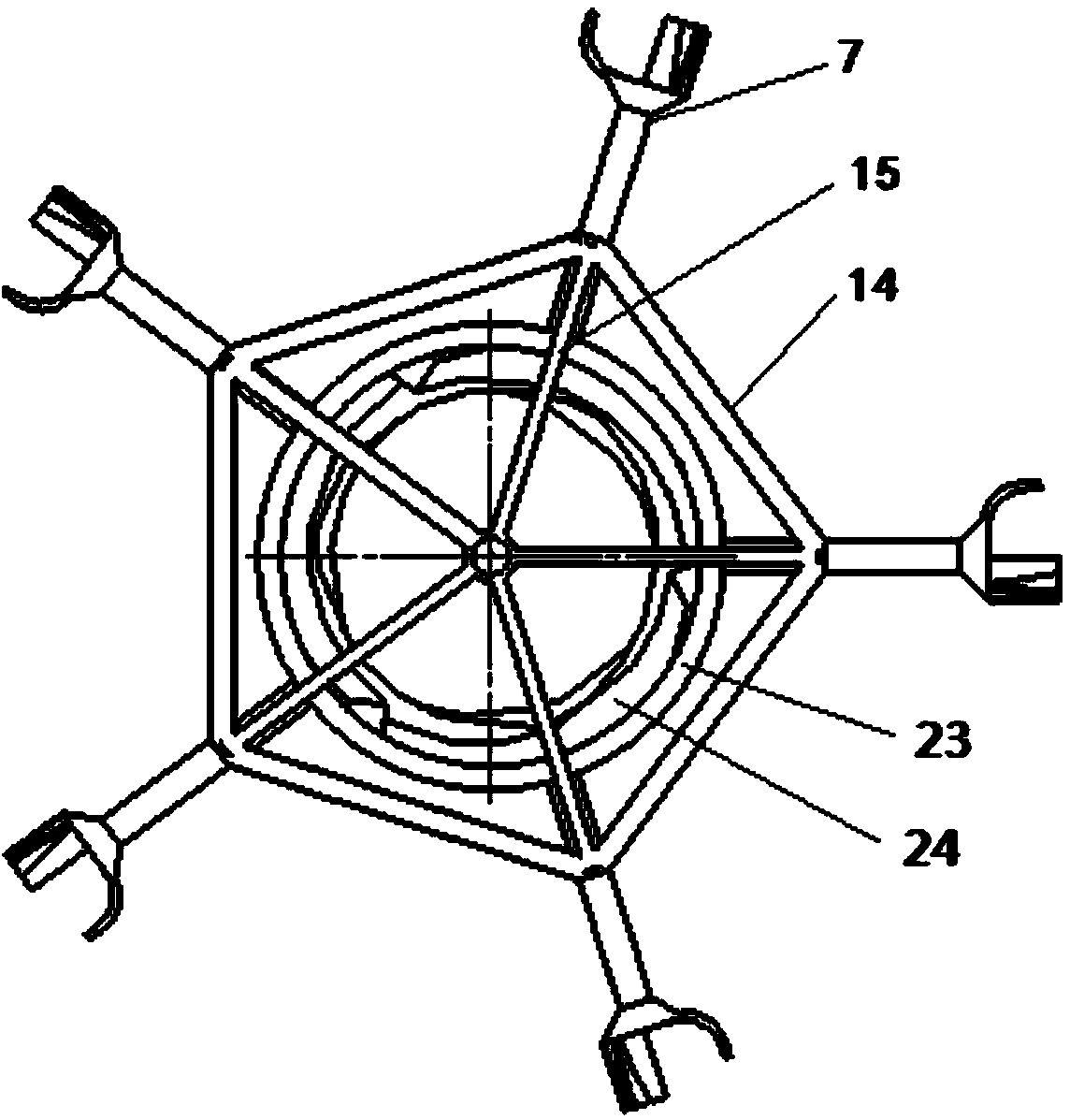

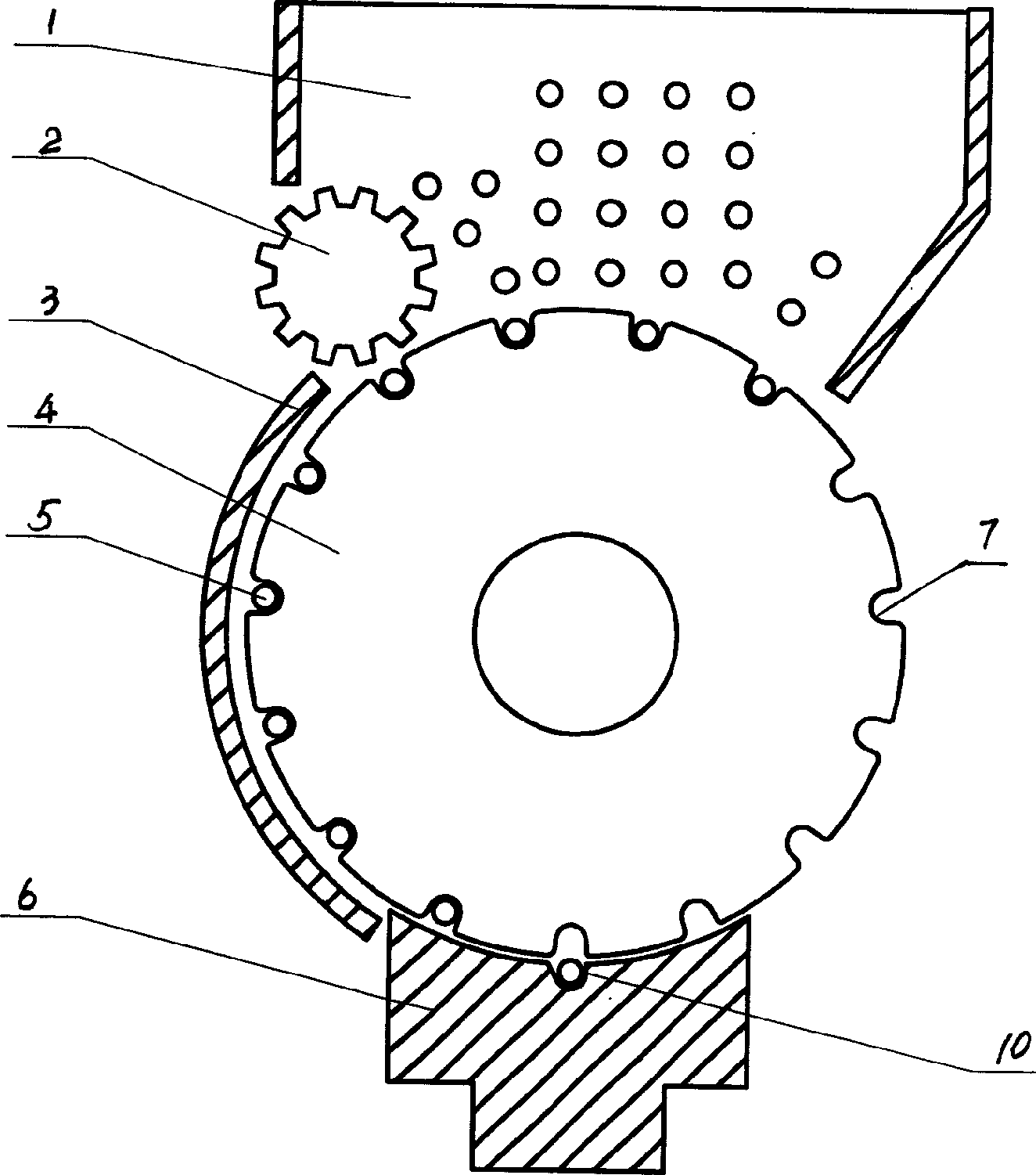

Comb tooth type ricinus communis combine harvester with fruit picking and straw fixed length fixed quantity and bundling functions

The invention relates to a comb tooth type ricinus communis combine harvester with fruit picking and straw fixed length fixed quantity and bundling functions. The combine harvester is reasonable in structure and integrates picking, separating and cleaning of castor seeds with fixed length segmentation, fixed quantity compaction and automatic bundling of straw. A comb tooth picking system and a feed-in disc type header system are located at the front end of a harvester body, a separating and cleaning system and a hob type fixed length segmentation system are located at the middle end of the harvester body, and fixed quantity compaction and bundling systems are located at the rear end of the harvester body; a comb tooth picking device which rotates anticlockwise is adopted for the comb tooth picking system to pick off the castor seeds and send the castor seeds to the separating and cleaning system, the castor seeds after being collected and separated through a grain collection bin are arranged below an outlet of the separating and cleaning system, a divider is arranged in the front of the harvester body, ricinus communis straw is fed into the disc type header system, the cutoff straw is fed into the hob type fixed length segmentation system through a stalk lifting conveyer belt, and an outlet of the hob type fixed length segmentation system is connected with the fixed quantity compaction and bundling systems; all the systems are driven by a power device through corresponding transmission devices.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

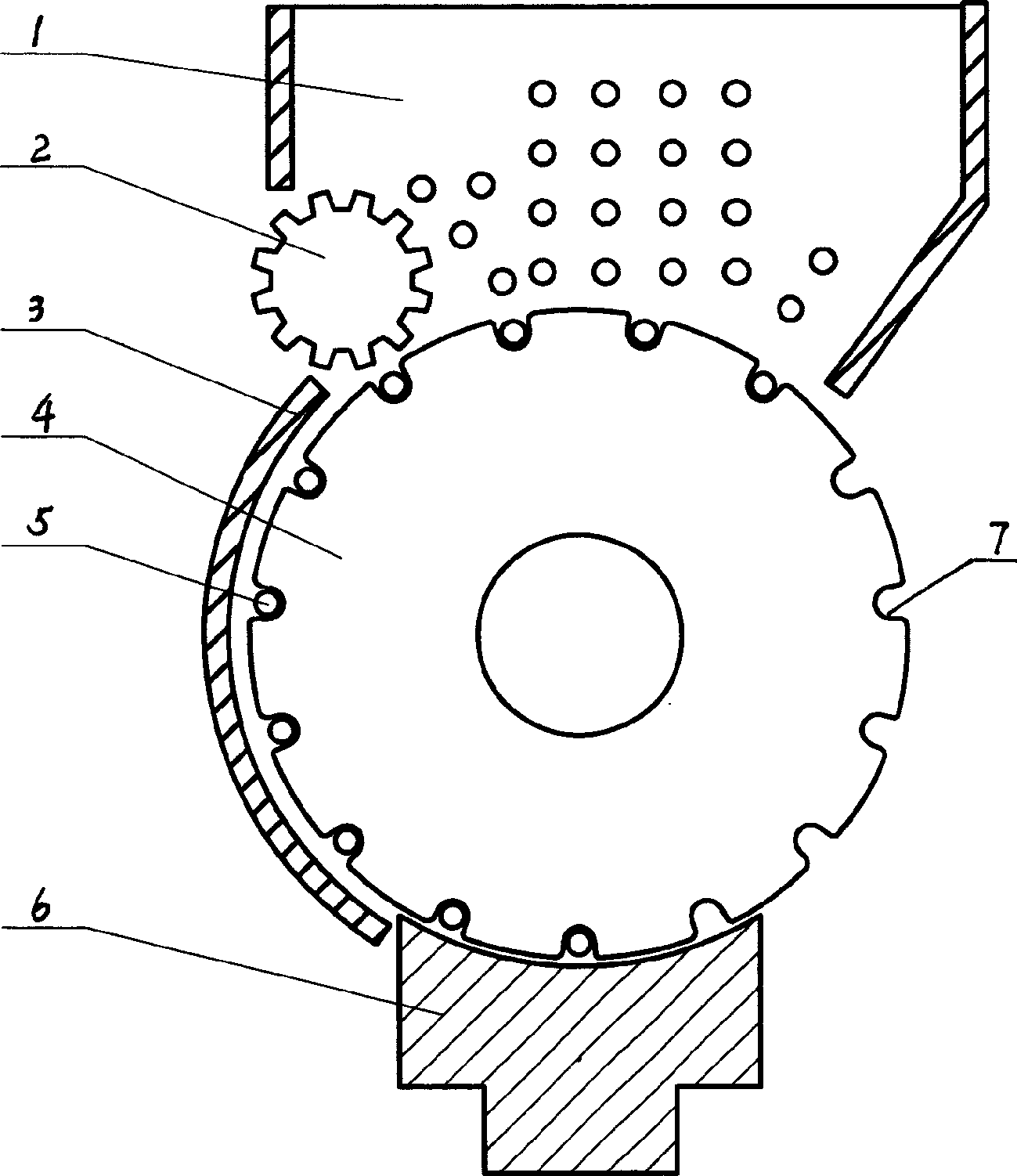

Equipment for conveying rod-shaped object in tobacco product

An apparatus for delivering the rod-shaped tobacco product features that its working mechanism is composed of a vertical dropping-down unit and a horizontal blowing unit. Said vertical dropping-down unit is composed of feeding hopper, drum wheelwith the slots uniformly arranged on its circumferential surface,and a sealing block with a central emitting slot connected to the peumatic delivering pipeline.

Owner:CHANGDE TOBACCO MACHINERY

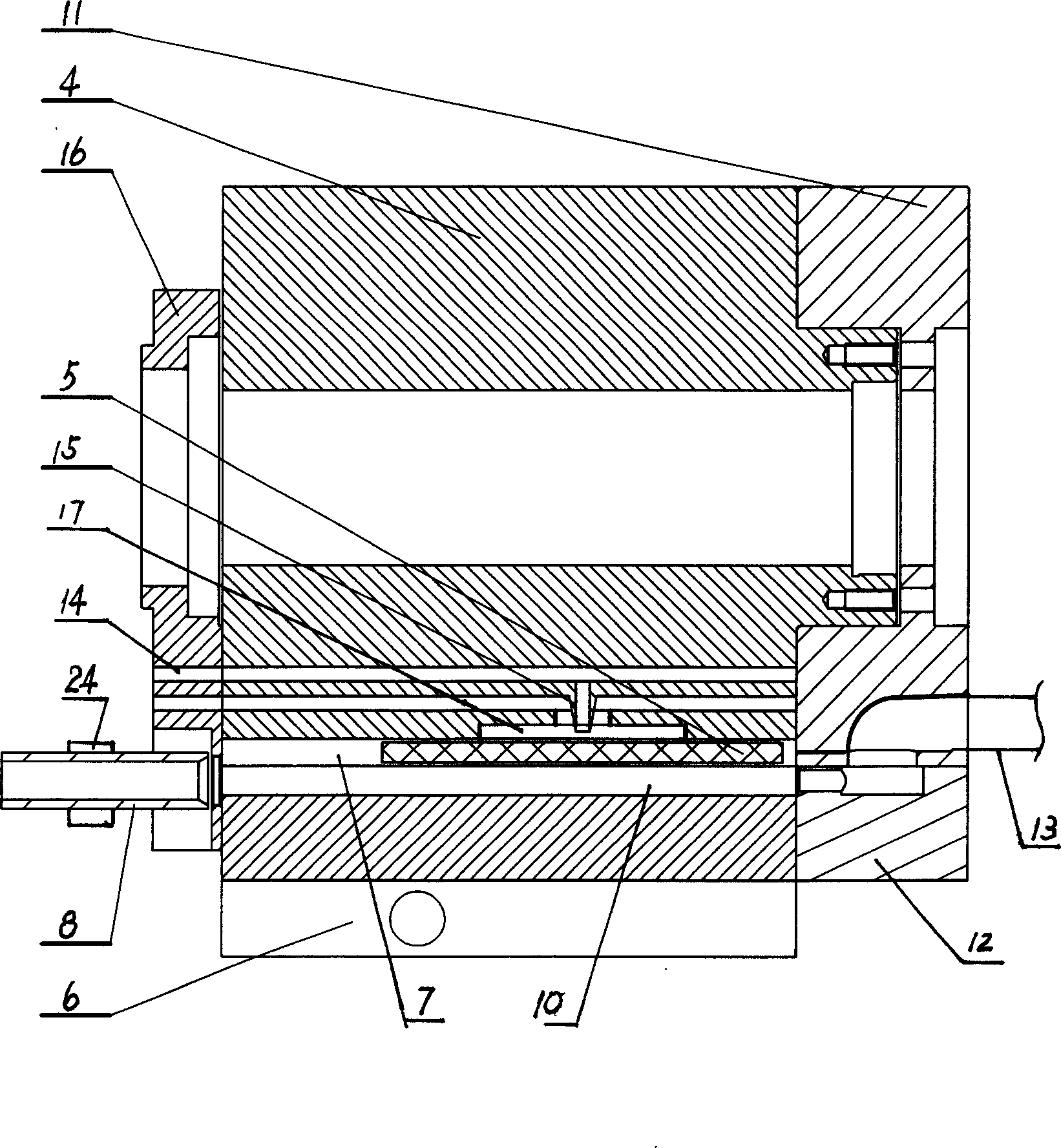

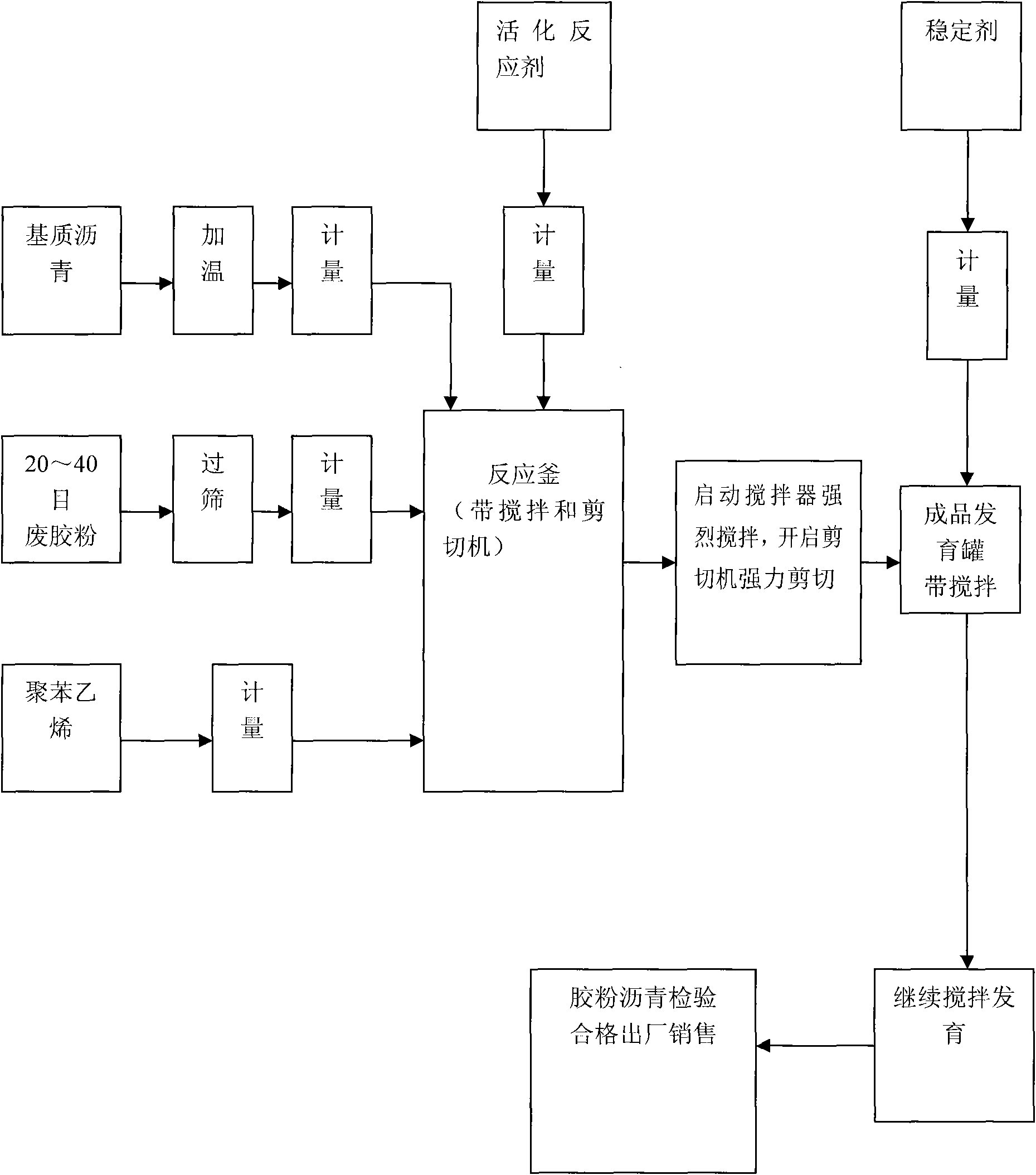

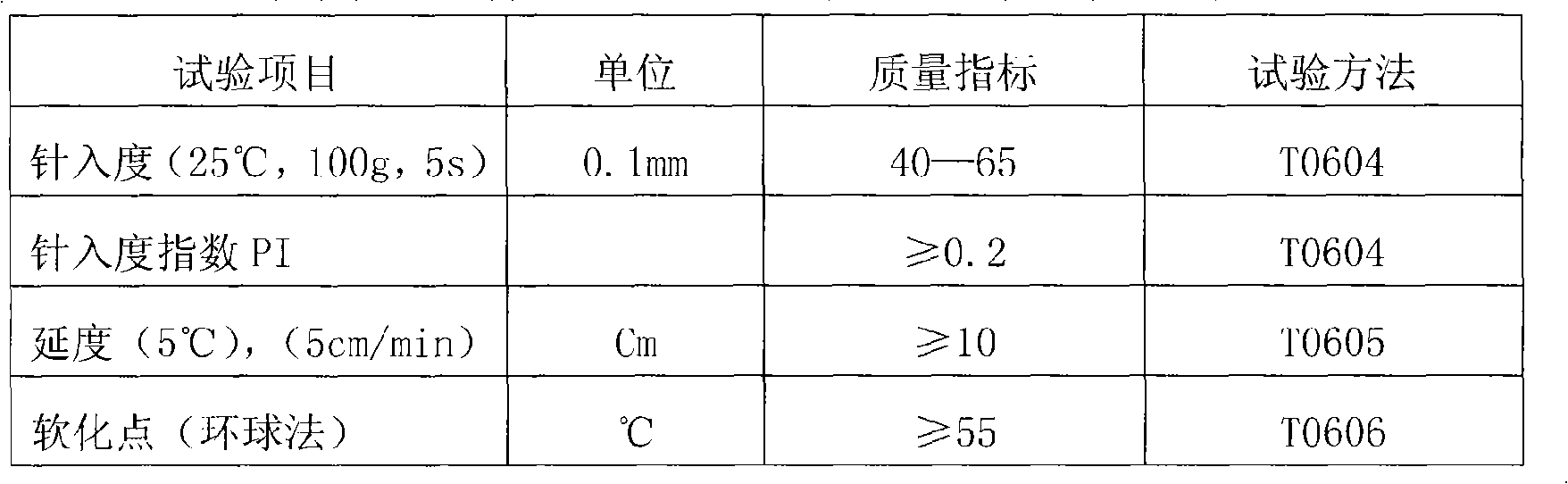

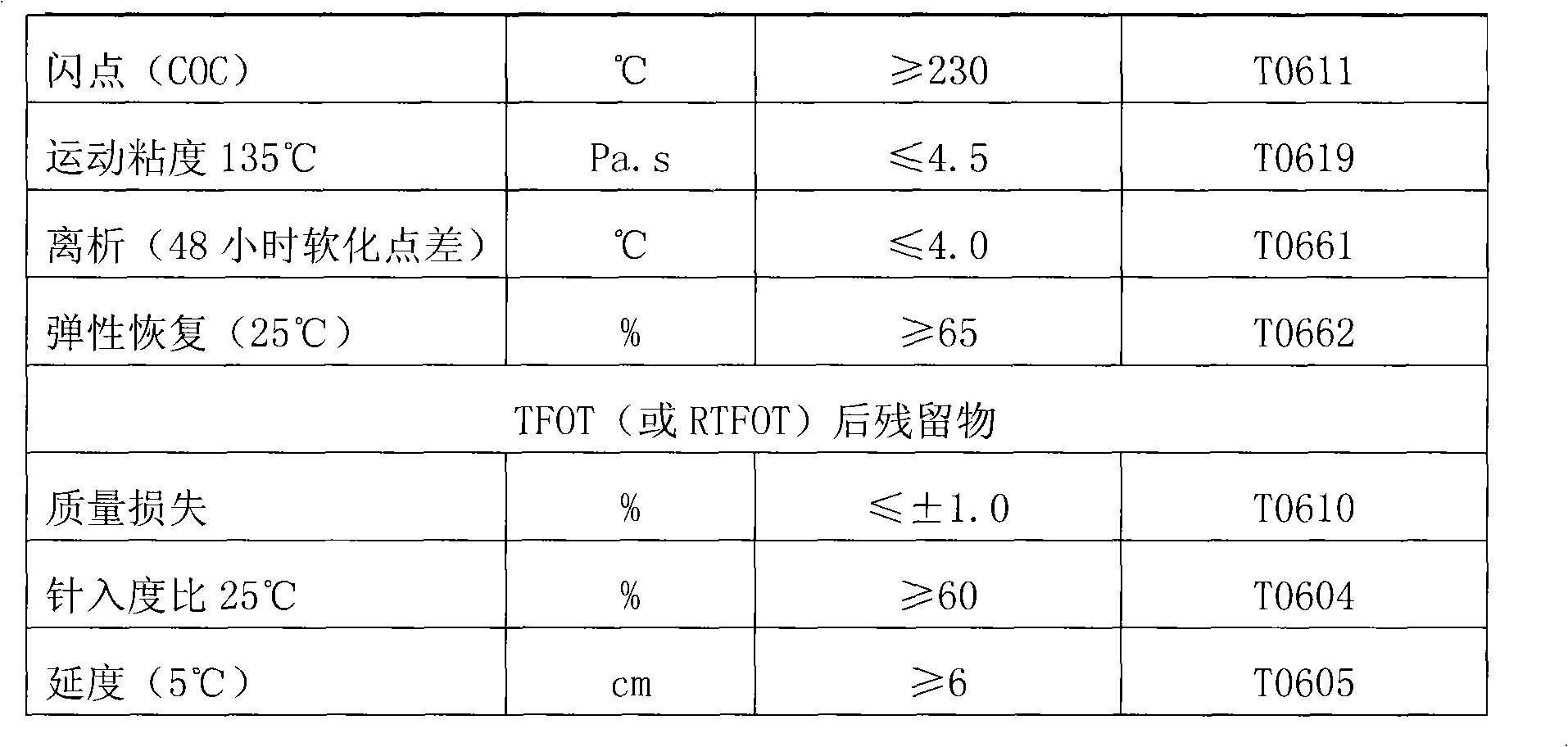

Crumb rubber modified asphalt and prepration method thereof

ActiveCN101550276AHas a linear plastic structureCut offPlastic recyclingBuilding insulationsPolymer scienceWaste rubber

The invention discloses a crumb rubber modified asphalt and a prepration method thereof, which aim at the deficiencies that the crumb rubber powder modified asphalt prepared by the prior art has low stability (appearing stratification phenomenon in storage) and special requirements on the fineness of crumb rubber powder. The proportioning by portions by weight of raw materials is as follows: 20-25 portions of waste rubber powder, 8-12 portions of polystyrene particles, 75-80 portions of based asphalt, 0.2-0.5 portion of high-efficient active reactant and 0.5-0.7 portion of stabilizer. The preparation method is as follows: the crumb rubber powder, the polystyrene particles, the based asphalt, the high-efficient active reactant and the stabilizer with the certain proportioning are added in the based asphalt at 180-190 DEG C and treated by special devices such as stirring, strong shearing and the like, thereby preparing an asphalt product with stable performance, no separation, convenient construction, good high-temperature and low-temperature performances, good anti-stripping performance, no excessive requirements on the fineness of the crumb rubber powder (only 20-40 meshes), good stability and ability of being applicable to large-scale factory production.

Owner:JIANGSU BAOLI INT INVESTMENT CO LTD

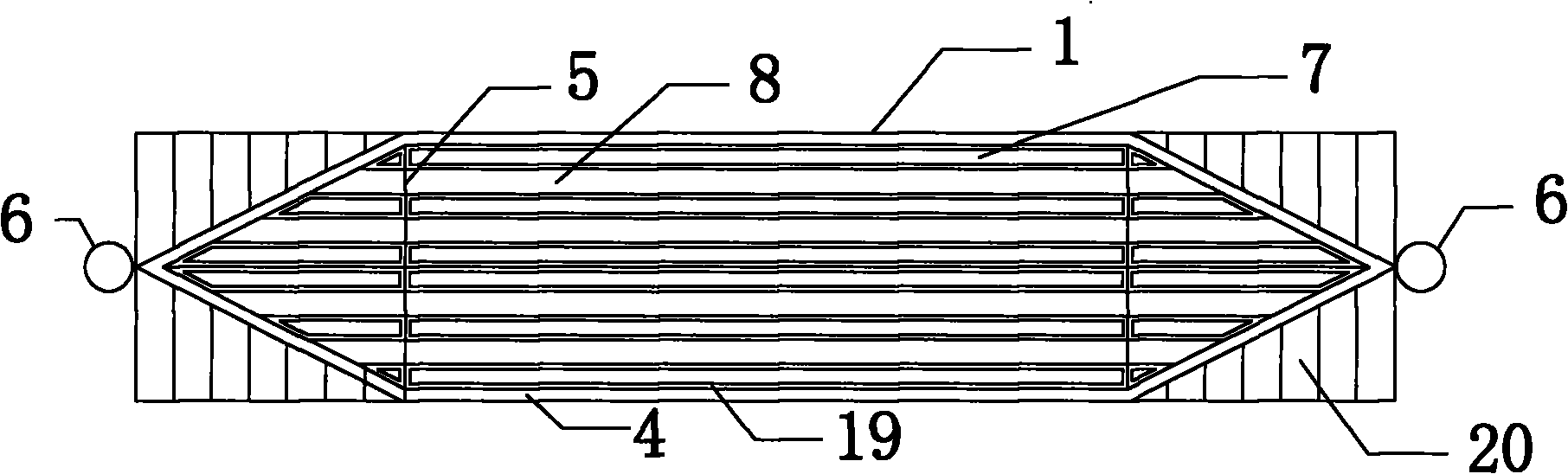

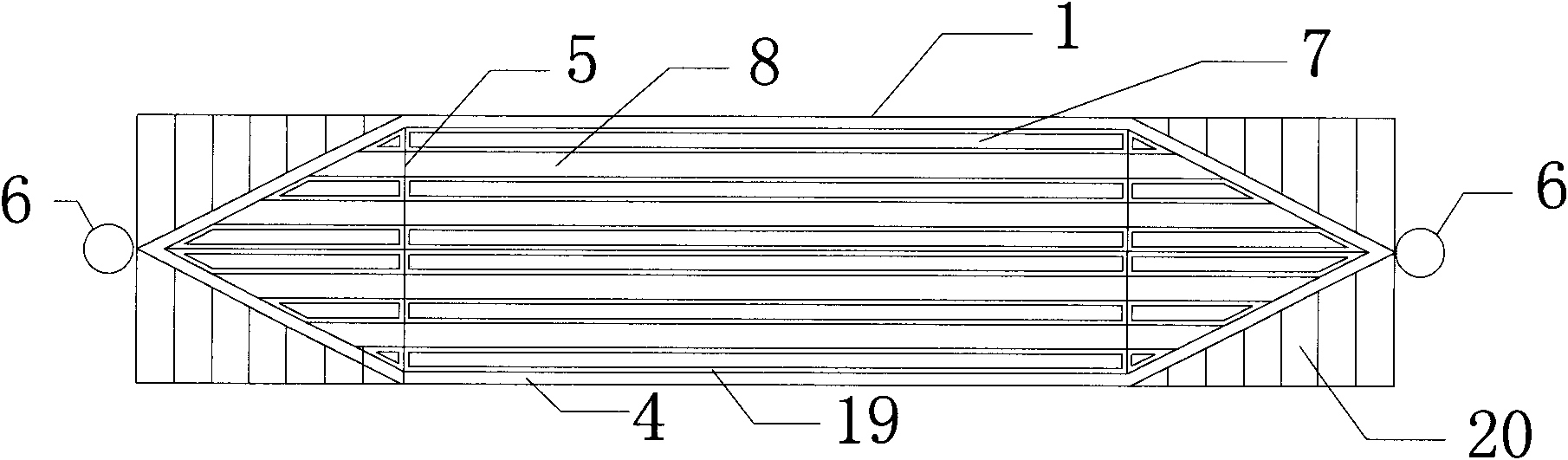

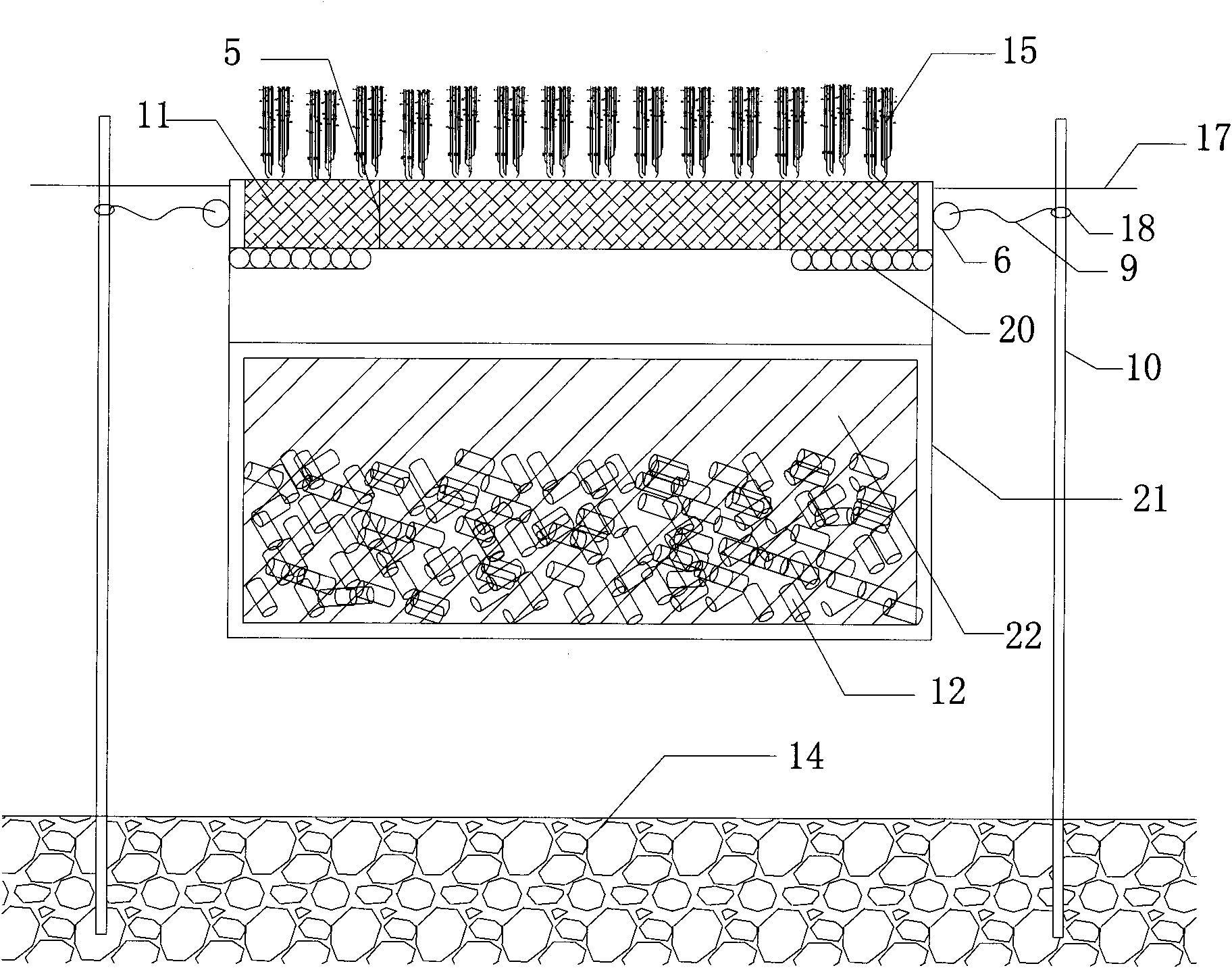

Ecological floating bed suitable for high-sediment large-flow rate water body

InactiveCN101811778AScour stableExtended service lifeBiological water/sewage treatmentPolyvinyl chlorideEconomic benefits

The invention discloses an ecological floating bed suitable for a high-sediment large-flow rate water body. The ecological floating bed is formed by interconnecting two floating bed units, wherein each floating bed unit comprises floating bed fixing rods, hollow PVC tubes, wave eliminating rafts and a gauze; a plurality of hollow PVC tubes are horizontally arranged and fixed by the floating bed fixing rods so as to form a floating raft; the wave eliminating rafts are arranged below the two ends of the floating raft respectively; the gauze in which hollow columnar polyvinyl chloride short corrugated tube packing is packed is hung below the floating raft; and the gauze is positioned below the wave eliminating rafts. The ecological floating bed can treat the water body which contains high sediment and high phosphorus and nitrogen concentration, is suitable for a river with large flow rate, can build a landscape effect without influencing shipping, and can produce part of economic benefits.

Owner:HOHAI UNIV

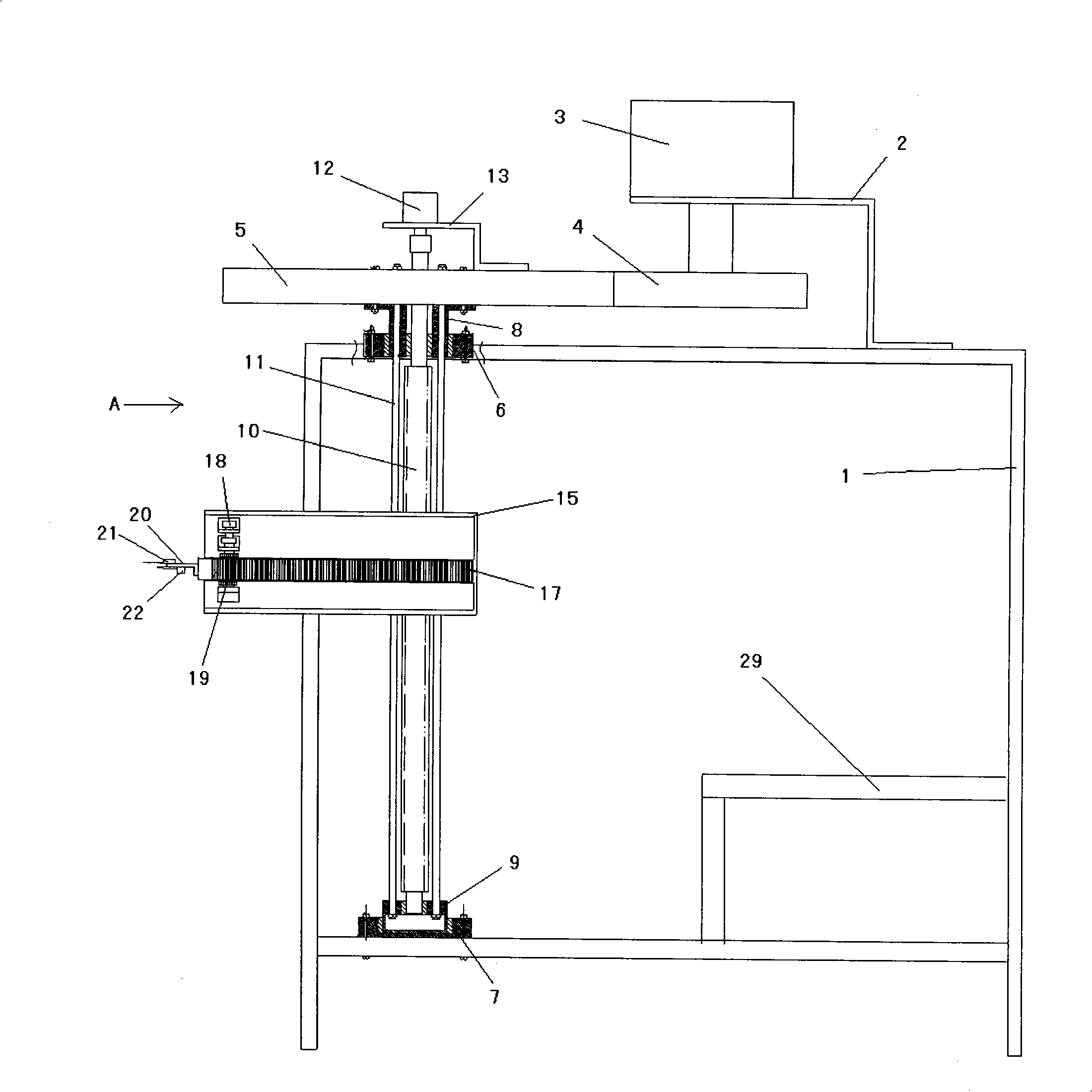

Automatic picking apparatus for middle/low layer of elevated strawberry

The invention relates to a high-frame strawberry middle and lower layer automatic picking device, comprising a workbench; a first disc gear and a second disc gear which are engaged with each other are arranged above the workbench; the first disc gear is driven by a disc gear stepping motor; two bearing seats are respectively fixed at the upper part and the lower part below the second disc gear; two bearing seats are respectively provided with two thread bearing seats by a bearing; the upper thread bearing seat is fixed on the second disc gear. Two leading screws are respectively sheathed on two central holes which push through the two thread bearing seats; two polished holes at the two sides of the leading screw are provided with two polished threads; the input end of the leading screw passes through the upper end of the second disc gear and is connected with a screw motor; the leading screw and the thread are sheathed by a sliding block at the position between the two screw bearing seats; the sliding block is provided with a rack which is arranged horizontally and driven by a gear motor that drives a gear; the extension end of the rack is connected with a claw mechanism. The high-frame strawberry middle and lower layer automatic picking device is driven by three motors and leads the position of the whole mechanism to be adjustable in the three-dimensional space, thus achieving the object of picking.

Owner:CHINA AGRI UNIV

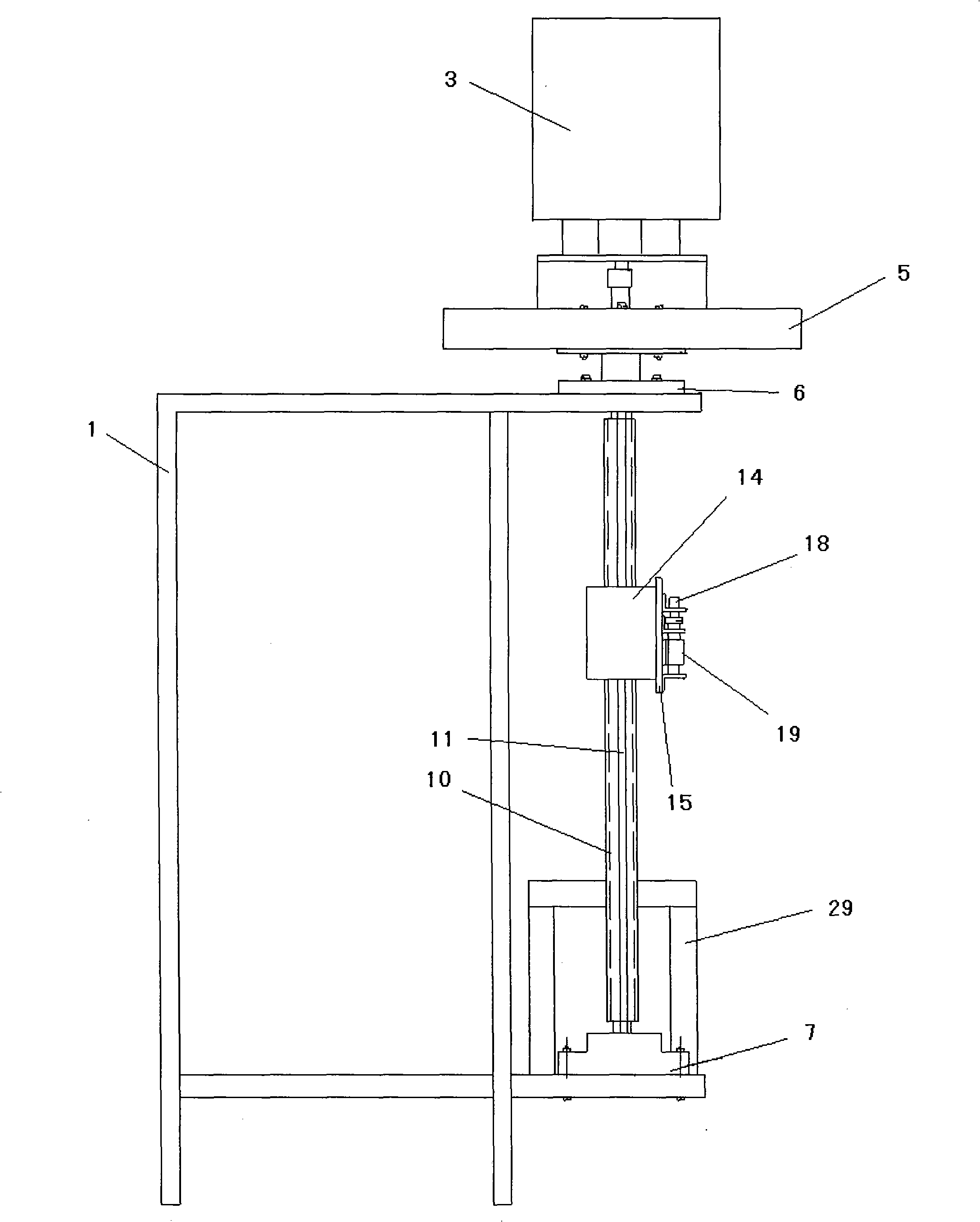

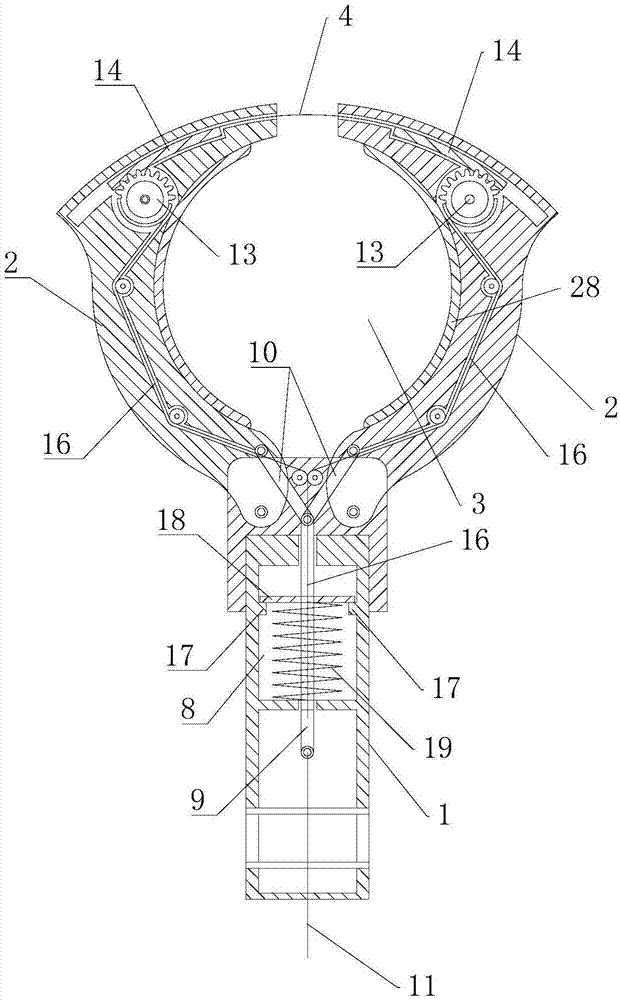

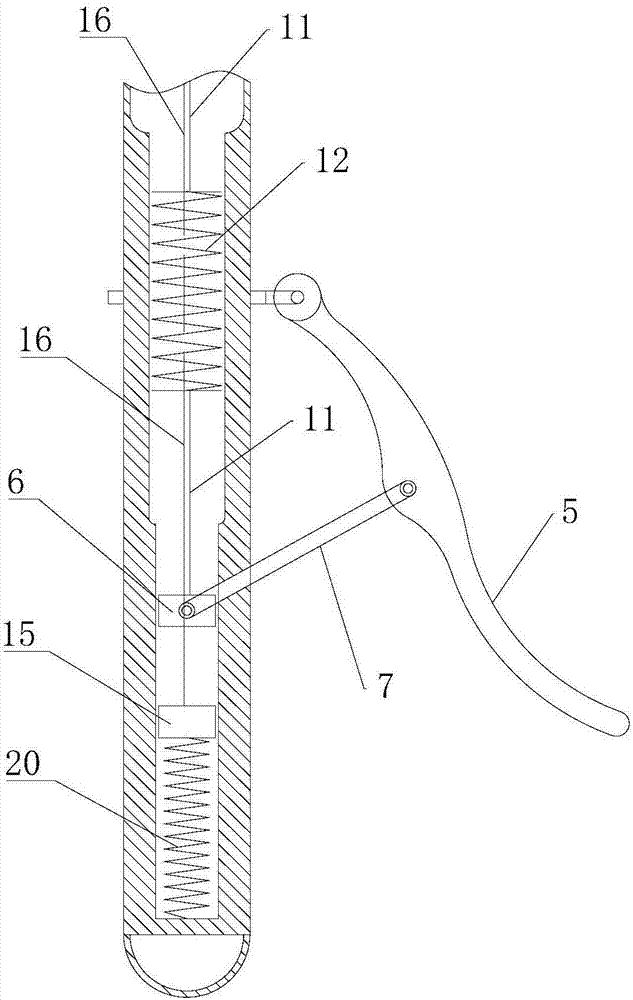

Apple picking manipulator

ActiveCN107455088ASolve rationalitySolve efficiency problemsPicking devicesControl engineeringManipulator

The invention provides an apple picking manipulator, and solves the problems that an apple picking mode is not reasonable and is low in efficiency in the prior art. The manipulator comprises an operation rod, wherein a first sliding block which is positioned in the operation rod is arranged on the lower part of the operation rod; the first sliding block linearly moves along the operation rod in a reciprocating manner; a clamping mechanism is arranged at the upper end of the operation rod and comprises two manipulator bodies; the manipulator bodies are hinged to the operation rod; an accommodating cavity is formed between the two manipulator bodies; a pull rod which is positioned in the operation rod is further arranged at the upper end of the operation rod; the extending direction of the pull rod is the same as that of the operation rod; the upper end of the pull rod is hinged to the two manipulator bodies through two second connecting rods; the first sliding block is connected with the pull rod through a first pull wire; clamping operation of the manipulator bodies is implemented by the first sliding block through the first pull wire, the pull rod and the second connecting rods; a cutting mechanism is further arranged in each manipulator body; and the cutting mechanisms act after action of the clamping mechanism is finished. The apple picking manipulator is simple in structure and convenient to use and has quite good practicality.

Owner:SHANXI AGRI UNIV

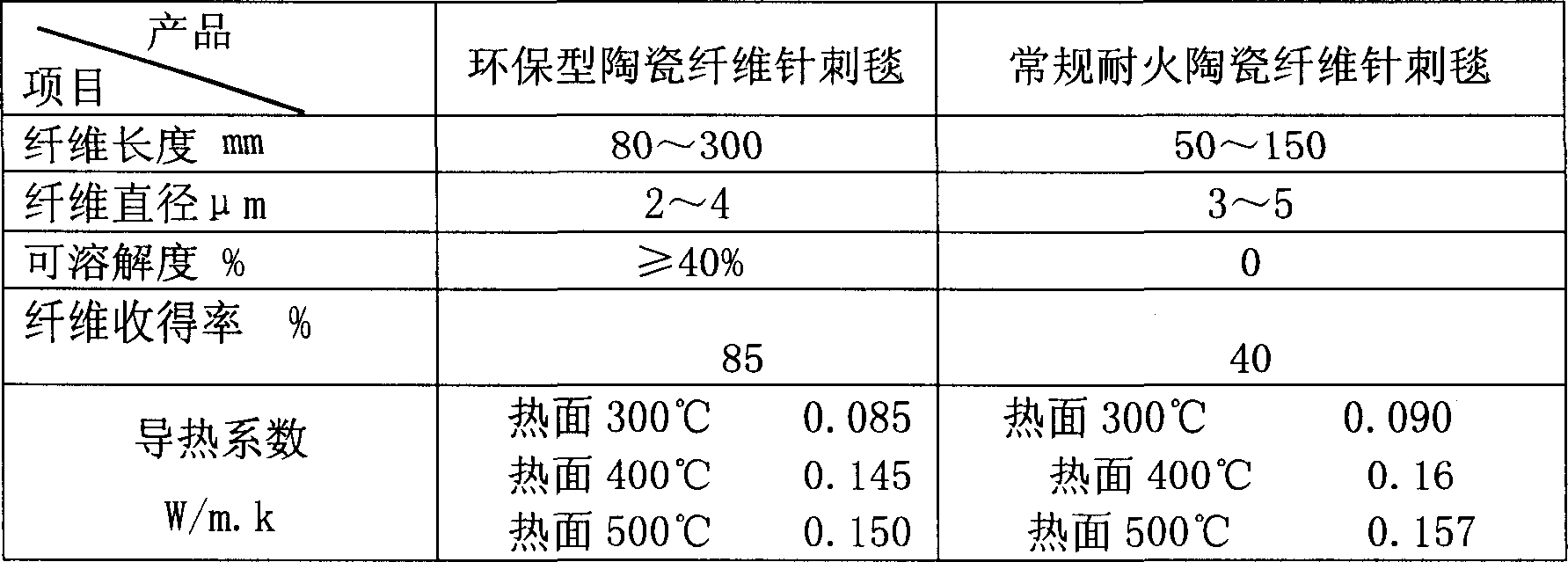

Environment protection type ceramic fibre needling blanket

The present invention belongs to a refractory heat-insulating material, and relates to an environment-protecting ceramic fibre needle-punched carpet and its preparation method. Its raw material silicon dioxide and aluminium oxide are undergone the processes of melting and fibre formation to obtain ceramic fibre, said ceramic fibre is undergone the processes of collecting, needling, heat treatmentand cutting so as to obtain the invented ceramic fibre needle-punched carpet. It is characterized by that its composition also contains 4-6 portions of magnesium oxide and / or calcium oxide, and its fibre-forming process adopts the blowing or centrifugal spinning process. Said fibre is stable in quality and high in yield rate.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

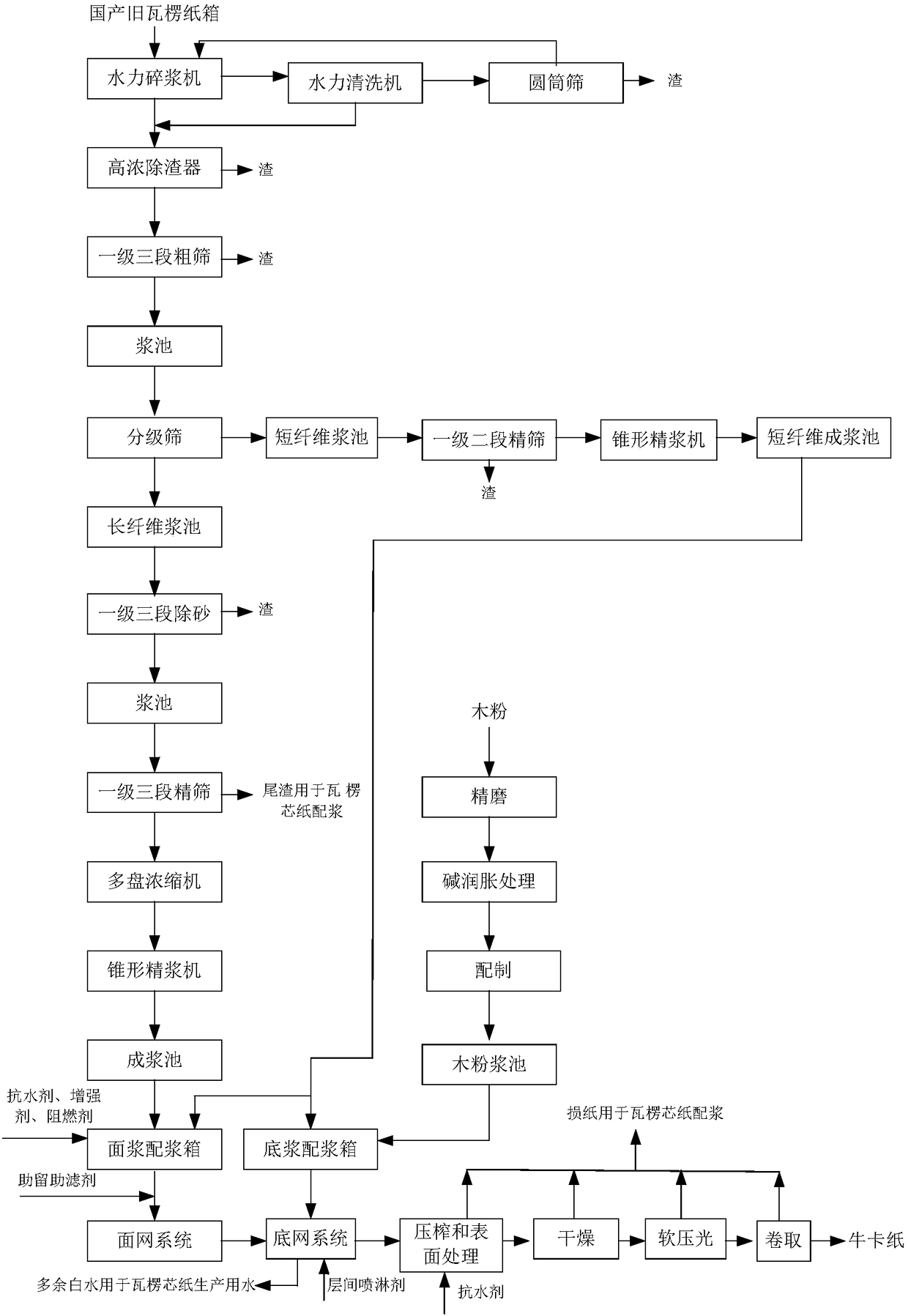

Method for producing e-commerce special craft paper with low gram weight and high strength by using domestic waste paper

ActiveCN108505372ACut offImprove stiffnessWater-repelling agents additionPaper recyclingFiberPapermaking

The invention relates to a method for producing e-commerce special craft paper with low gram weight and high strength by using domestic waste paper, and belongs to the technical field of papermaking.The method comprises a pulping step and a papermaking step. The domestic waste paper is classified by using a classifying screen, and then long fibers are used for surface layers and short fibers areused for bottom layers. According to the invention, a small amount of fine wood powder is added into bottom pulp, so that the stiffness of the craft paper is improved. Starch and a carboxymethylcellulose (CMC) compounding system are sprayed between the two layers, so that the interlayer bonding force of the craft paper is improved. A dual-element reinforcing agent including starch and polyacrylamide is added in pulp, so that the product strength is improved. In addition, the inner-pulp water resistance is combined with the surface water resistance, and simultaneously an inner-pulp flame retardance technology is combined with an interlayer flame retardance technology, so that the water resistance of craft paper products is improved, and simultaneously the flame retardancy of the products isachieved. Therefore, the method provided by the invention saves energy and is environmentally friendly, and the prepared craft paper products are low in weight, high in stiffness, excellent in waterproof performance and good in flame retardance, and are very suitable for e-commerce special paper boxes.

Owner:ZHEJIANG RONGSHENG PAPER IND HLDG

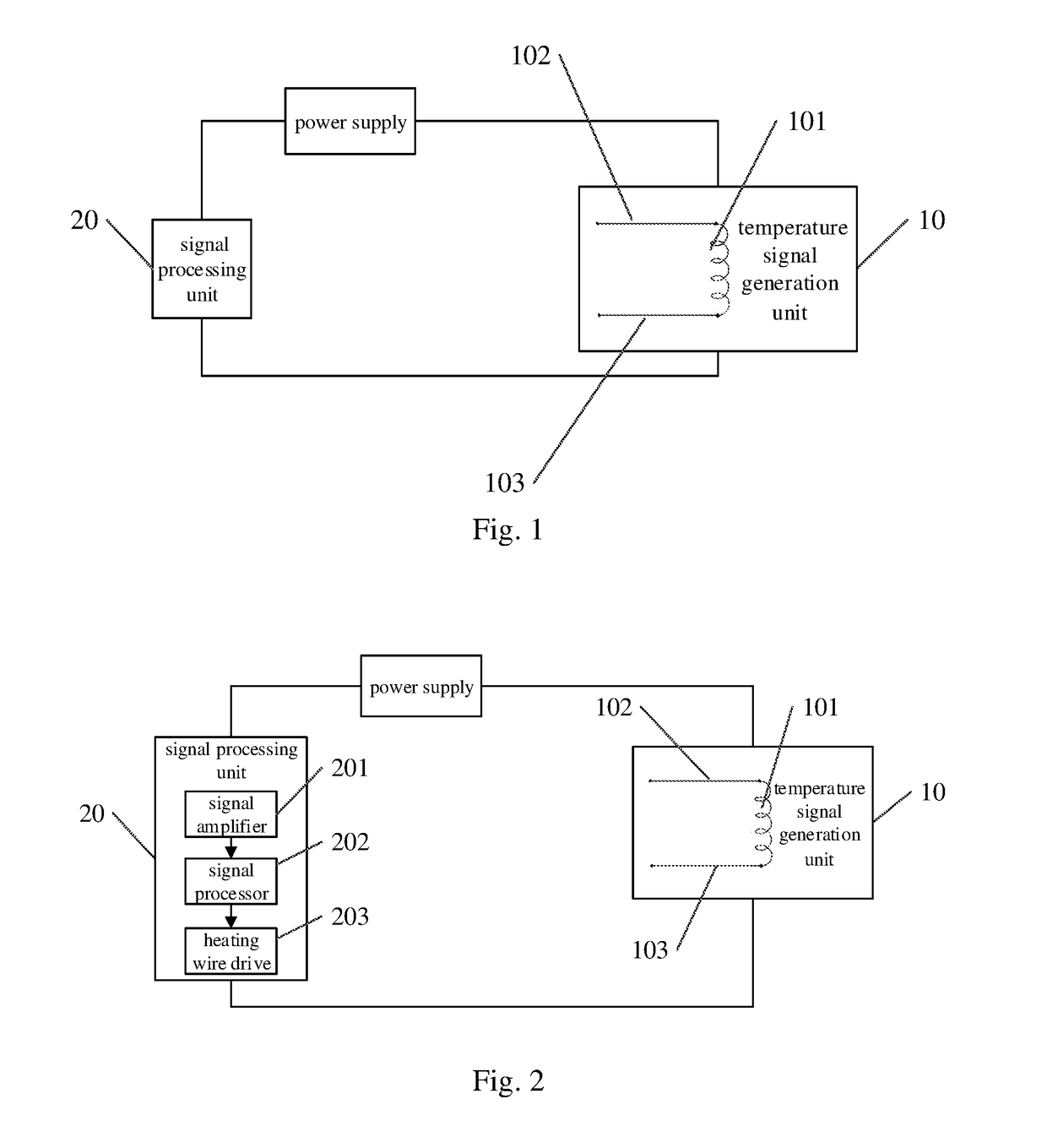

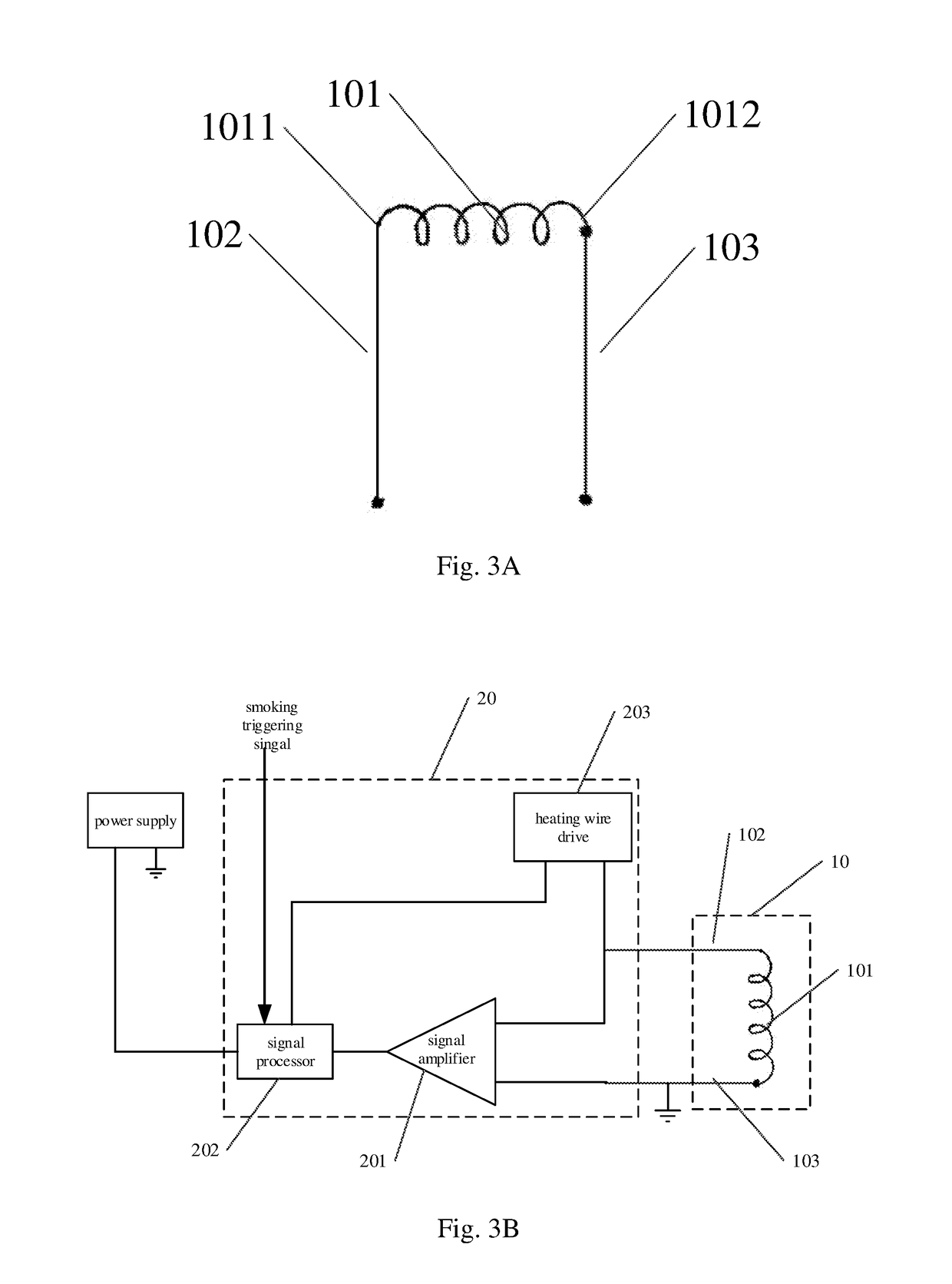

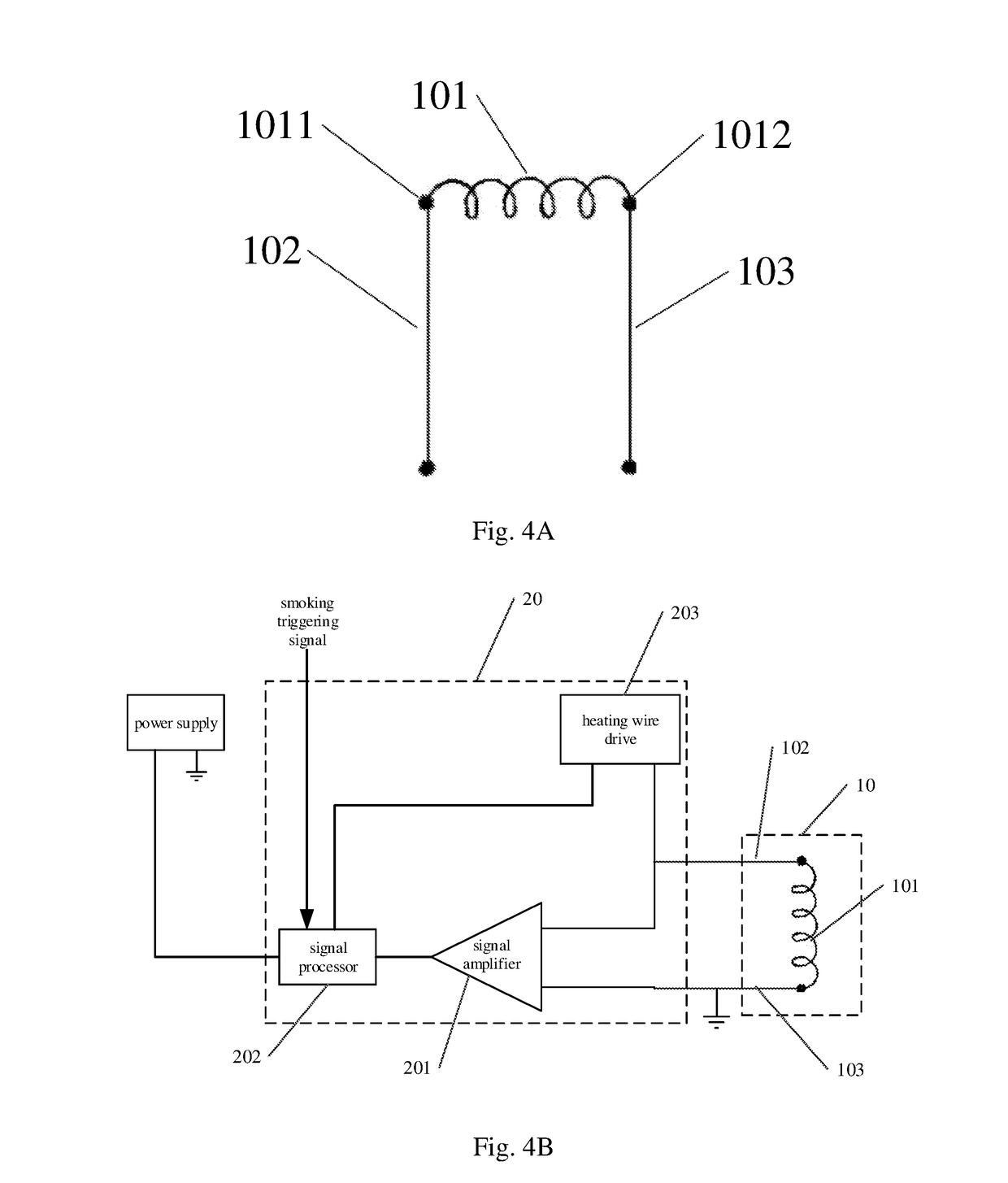

Temperature monitoring and control device and method for atomizer heating wire and electronic cigarette

InactiveUS20170325507A1Suitable rangeEffective dissolutionSteam generation heating methodsElectric heatingElectrical conductorTemperature monitoring

A temperature monitoring and control device and method for an atomizer heating wire, and an electronic cigarette. The temperature monitoring and control device comprises a temperature signal generation unit and a signal processing unit. The temperature signal generation unit comprises a heating wire, a first end wire and a second end wire; the first and second end wires are made of different conductor materials; when the heating wire generates heat, an electromotive force signal is generated. The signal processing unit is configured for controlling to reduce an atomizing power of the heating wire or turn off a power supply circuit of the heating wire when the current temperature value is greater than or equal to a preset value. The technical effect is to keep the temperature of the heating wire in a suitable temperature range.

Owner:HUIZHOU KIMREE TECH

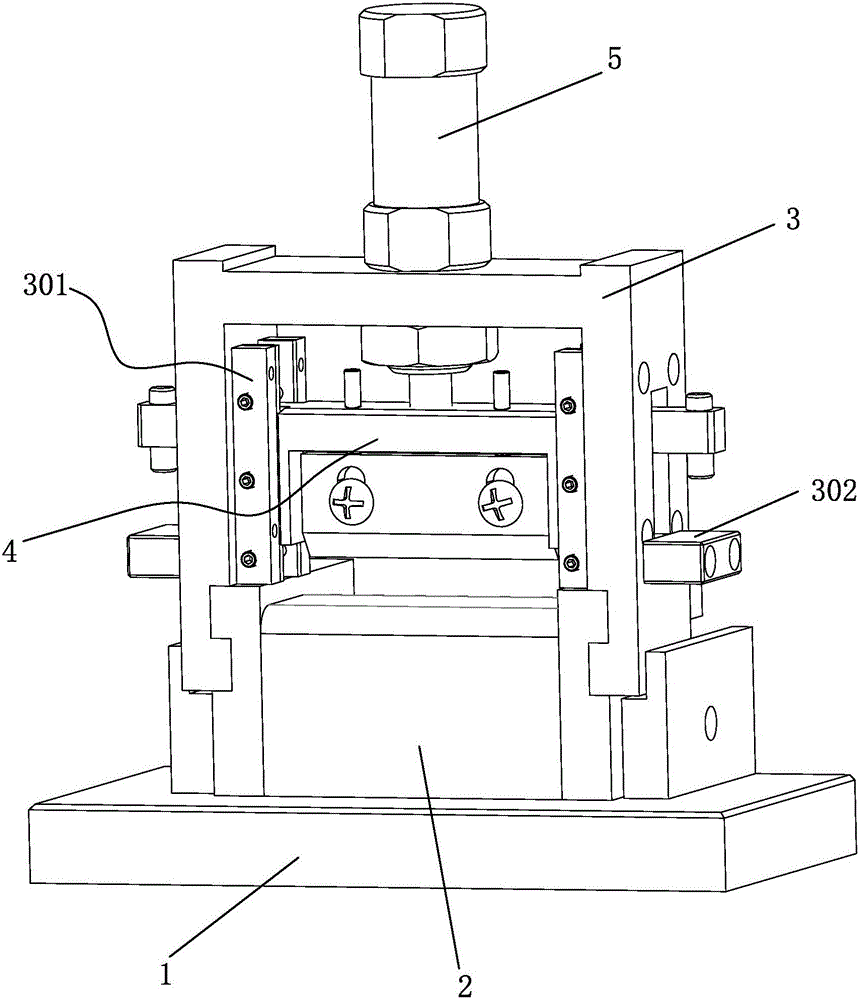

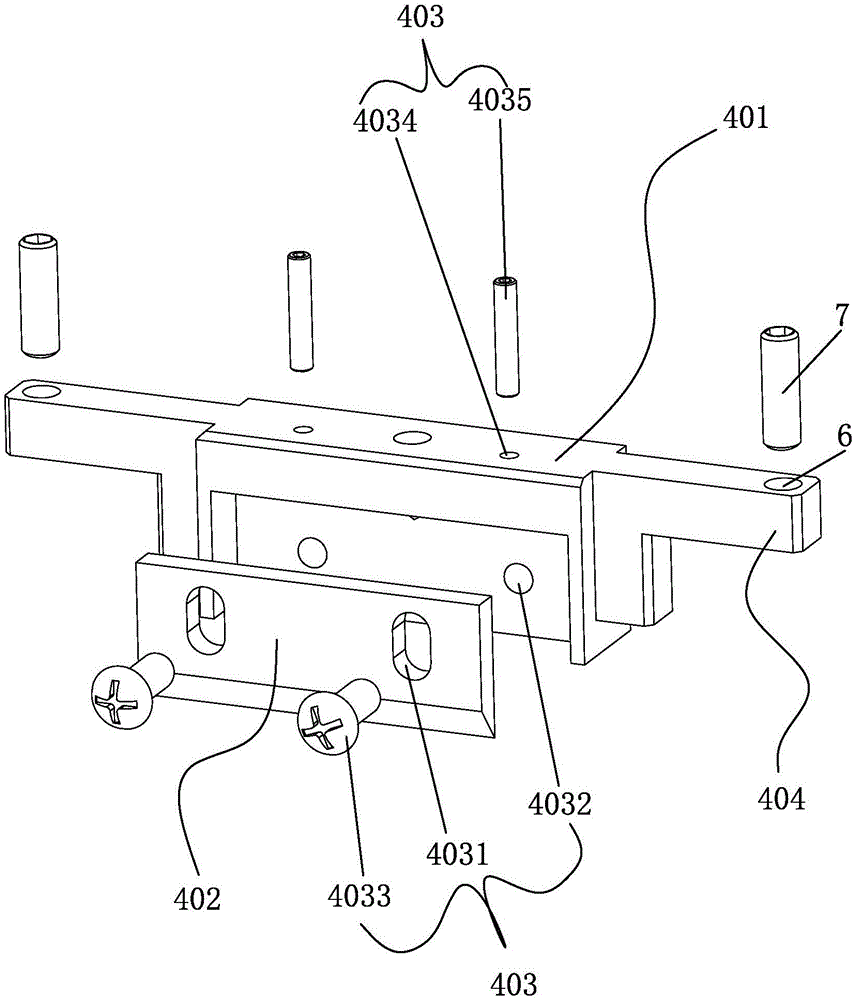

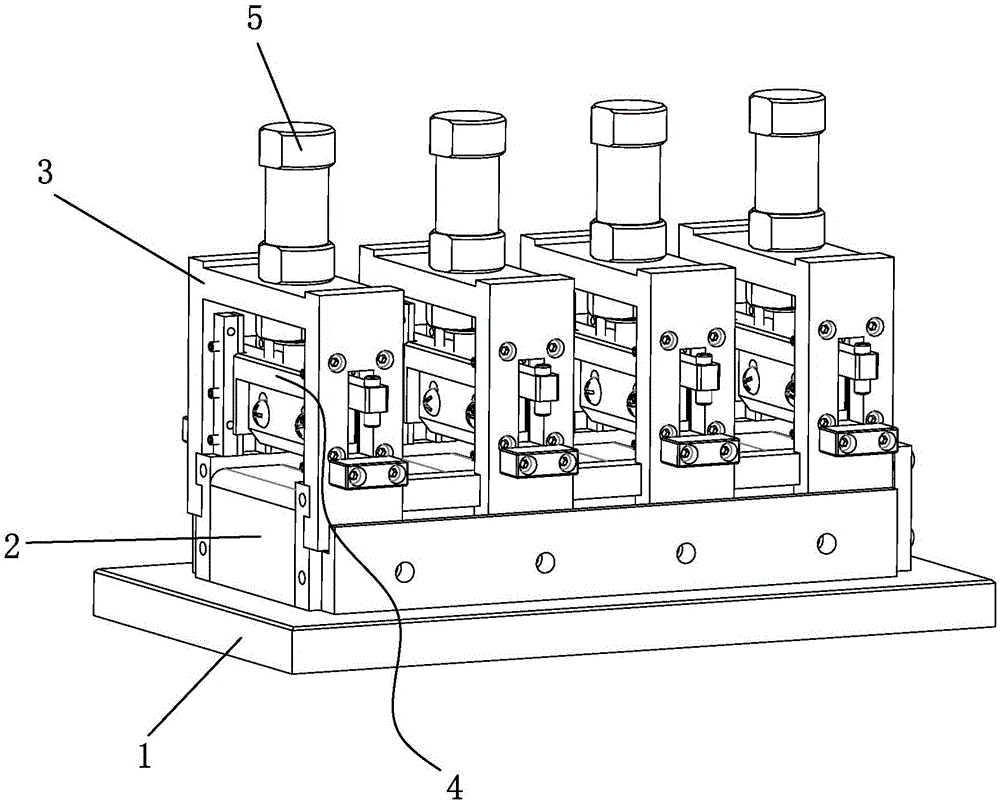

Full-automatic resistor bending machine and resistor bending method

The invention discloses a full-automatic resistor bending machine and a resistor bending method. The full-automatic resistor bending machine comprises a feed mechanism, a pressing mechanism, cutter mechanisms, a bending mechanism and a motor. Resistors are conveyed to a preparation table by the feed mechanism; the pressing mechanism is arranged above the preparation table and compresses the resistors on a workbench from the preparation table; the cutter mechanisms are arranged on two sides of the workbench and cut off redundant pins of the resistors; pins of the resistors are bent by the bending mechanism; the feed mechanism, the pressing mechanism, the cutter mechanisms and the bending mechanism are powered by the motor. The full-automatic resistor bending machine and the resistor bending method have the advantages that the pins of the resistors can be automatically and quickly cut off and bent by the full-automatic resistor bending machine, labor is saved, and the production efficiency is improved; the multiple mechanisms are driven to act by the single motor via chains, so that the cost is saved, actions of the various mechanisms are coordinated during production, the production takt can be changed by means of adjusting the rotation speed of the motor, and the production efficiency is improved; action sequences and action moments of the various mechanisms are controlled by the aid of cams, and accordingly can be controlled precisely.

Owner:QINGDAO JIERUI IND CONTROL TECH CO LTD

Rapid tube cutter

The invention belongs to the field of tube cutting equipment, and particularly relates to a rapid tube cutter. The rapid tube cutter comprises a rack, a tube conveying mechanism, a tube clamping synchronous rotation mechanism, a cutter rest, a control system, a linkage rod, a hinge shaft, a first support arm, a second support arm, a third support arm, an electromagnet, an attraction component, an adjustment arm, a limit plate, a stroke switch, a first elastic component, a second elastic component, a third elastic component, a first infrared probe and a second infrared probe. With the adoption of the technical scheme of the invention, the cutting length of a tube is determined by presetting the distance between the limit plate and a blade assembly, thus reducing the errors due to visual assessment; meanwhile, the matching of a first motor, a second motor, the electromagnet and the stroke switch is realized by the control system, and automatic cutting for the tube can be realized only by placing the tube on a support wheel; compared with manual tube cutting, the rapid tube cutter disclosed by the invention is high in working efficiency; moreover, the tube cutter is compact in structure, relatively small in size, and convenient to move.

Owner:FUJIAN SPIRITFOG ENVIRONMENT SCI & TECH CO LTD

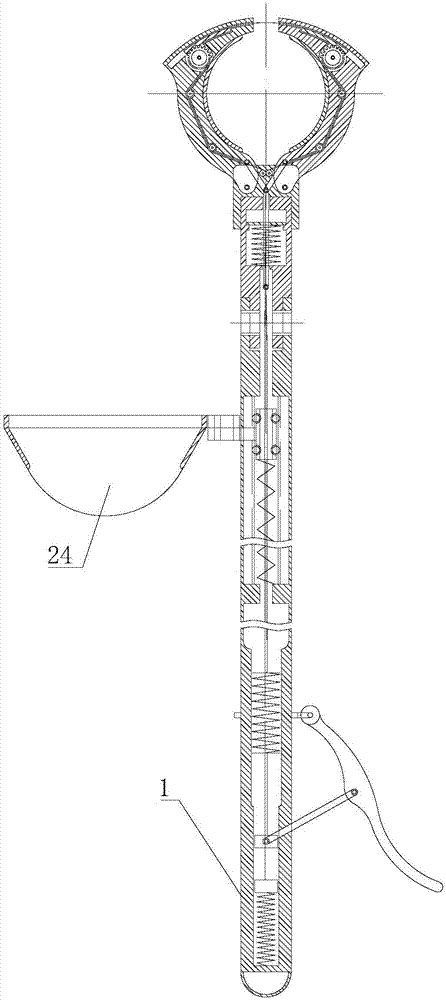

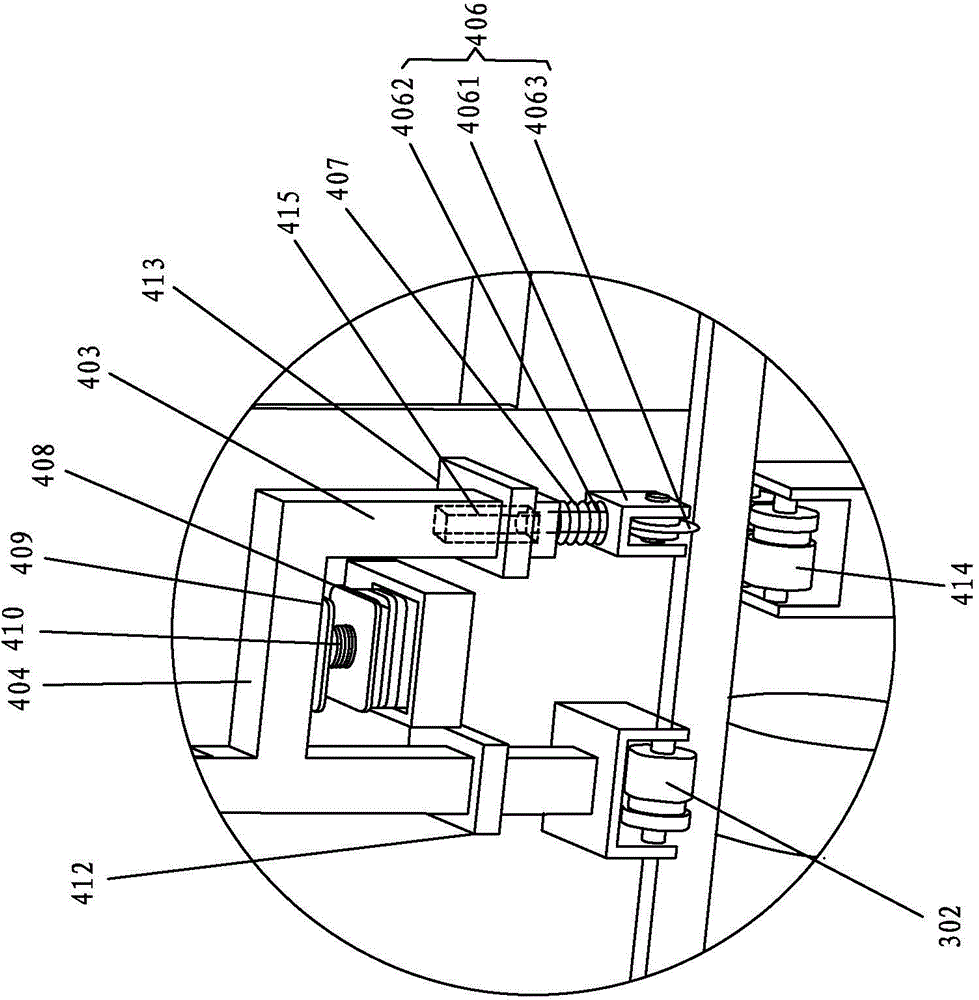

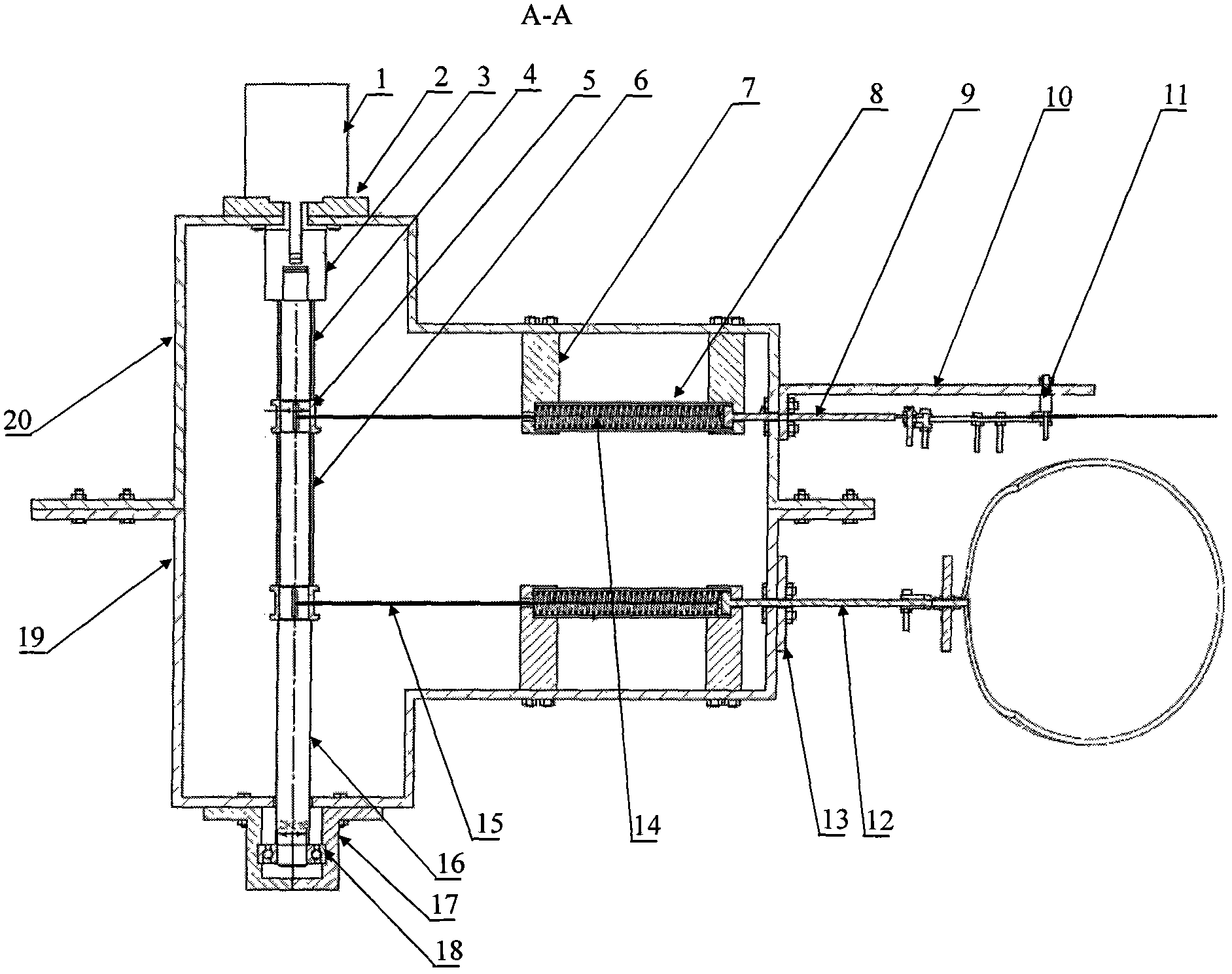

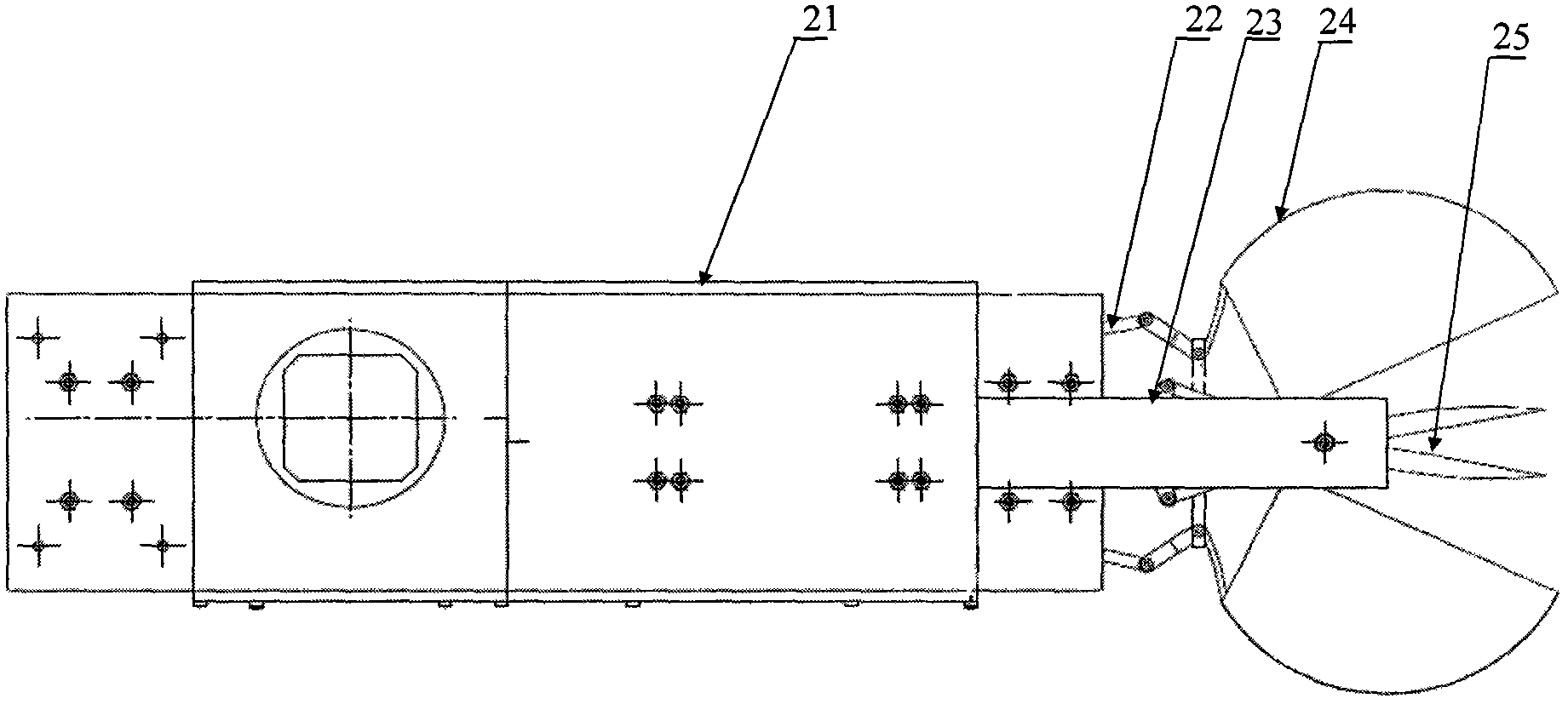

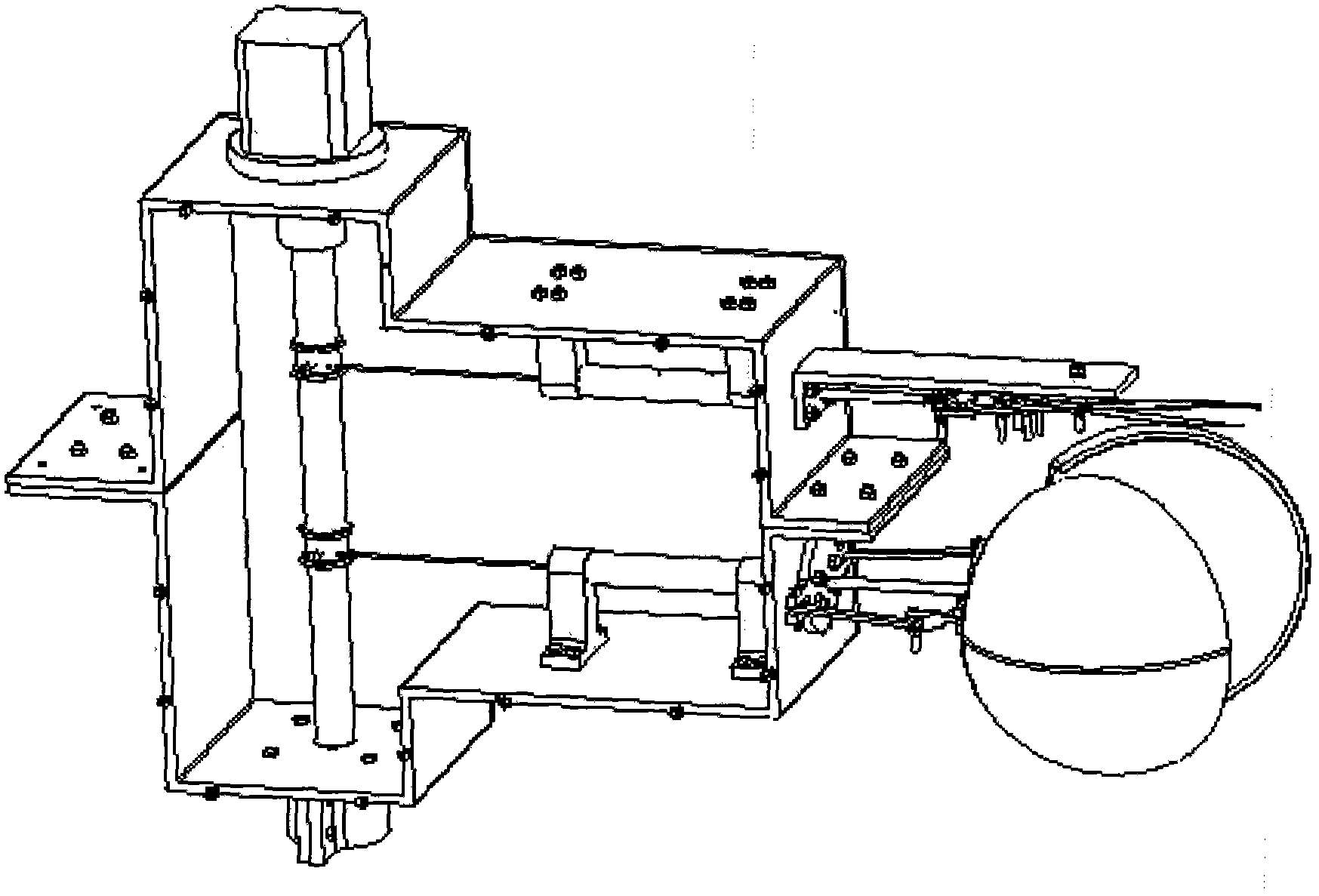

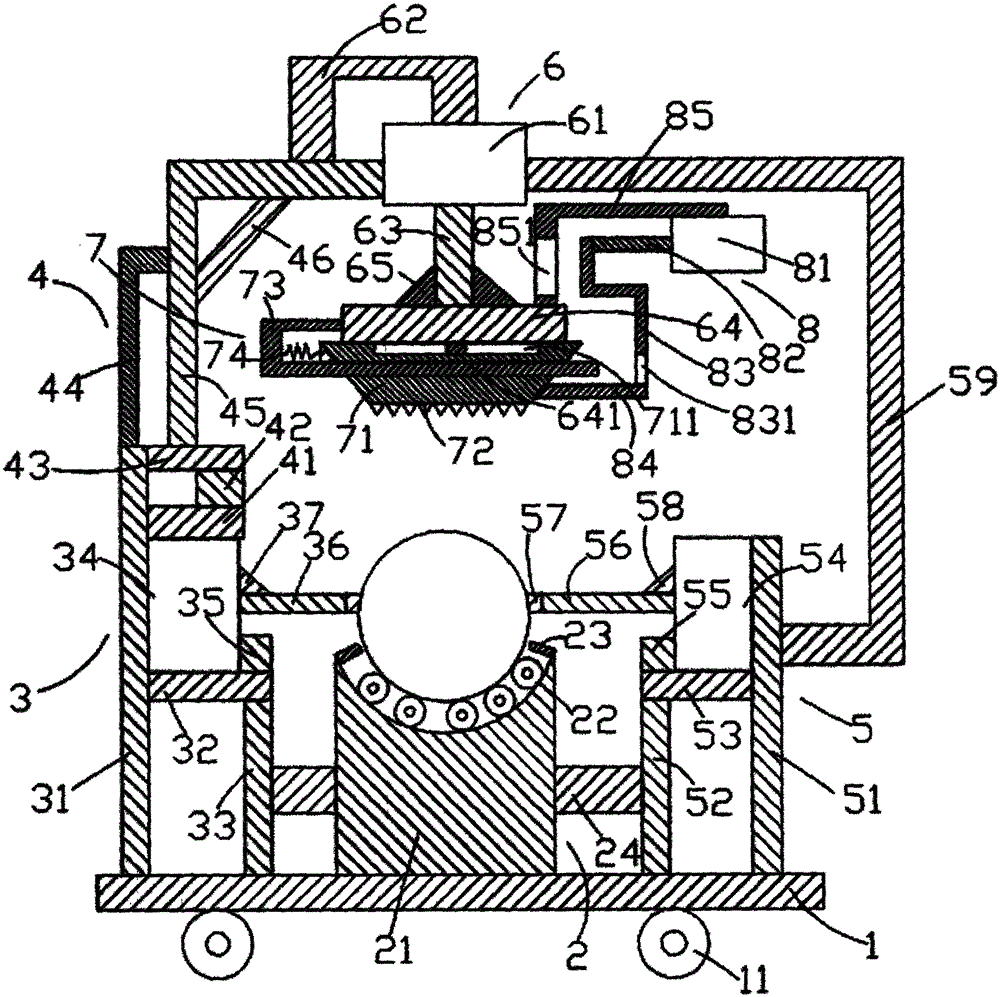

Spherical fruit and vegetable picking end effector

The invention provides a spherical fruit and vegetable picking end effector, and belongs to the technical field of picking robots. The spherical fruit and vegetable picking end effector is composed of a rack, a driving transmission mechanism, a guide sleeve mechanism, a cutoff mechanism and a grabbing mechanism. The rack is composed of an upper machine base, a lower machine base and a machine base lateral plate. The driving transmission mechanism is composed of a motor, a coupler, a transmission shaft, an upper sleeve, a lower sleeve, a winch and a rope, and transmission of the motor is converted into transverse motion of the rope. The guide sleeve mechanism is composed of a guide sleeve and a spring, the spring provides pre-applied force, and the guide sleeve is used for transversely-moving guiding when the spring bears pull force of the rope. The cutoff mechanism is of a similar-scissor structure. The grabbing mechanism is composed of a paw installation plate, a paw pull rod, a paw connecting rod and an arc-shaped finger. According to the spherical fruit and vegetable picking end effector, one motor is adopted, the rope transmission mode is adopted, and the two tasks including fruit and vegetable grabbing and fruit stem cutoff in spherical fruit and vegetable picking operation can be achieved.

Owner:BEIJING FORESTRY UNIVERSITY

Wire shearing mechanism

The invention discloses a wire shearing mechanism. A cutter pad is arranged on a base, and a support is arranged on the cutter pad. A cutter assembly is slidably connected to the support, and the support is further provided with a driving device used for driving the cutter assembly to cut wires. The cutter assembly comprises a tool rest slidably connected with the support, a blade arranged on the tool rest and an adjusting structure for adjusting the wire cutting depth of the blade. According to the wire cutting mechanism, the cutting depth of the blade can be precisely adjusted so that wire rods can be cut off or pre-cut. During wire winding, all sets of wound wires are pre-cut by the wire cutting mechanism, the pre-cutting depth of the wire rods can be adjusted through the adjusting structure, and after wire winding of coils is completed, the ends of windings can be snapped along pre-cut positions with slight force. Accordingly, the wire cutting mechanism improves production efficiency, lowers the labor cost, guarantees uniform quality of all finished coil products, and has the characteristic of high yield.

Owner:宋红光

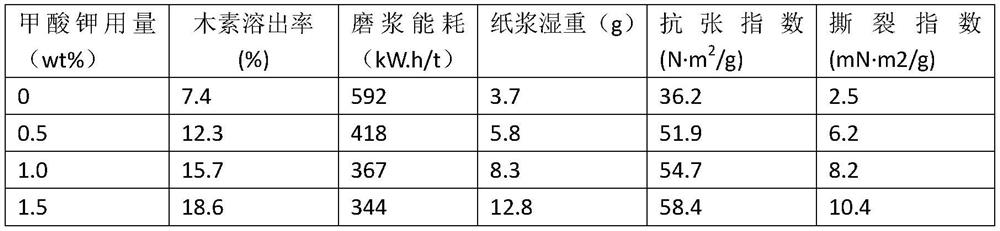

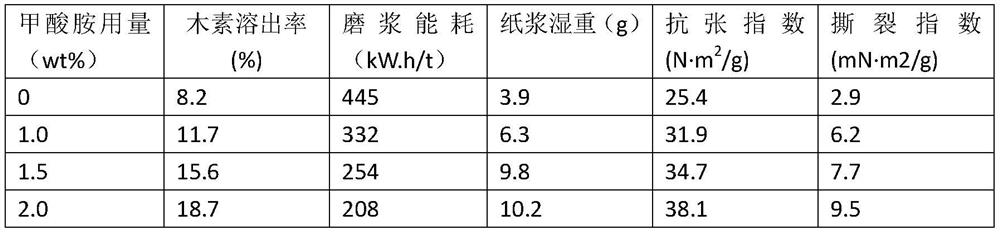

Production method of chemi-mechanical pulp and semi-chemical pulp

ActiveCN112048933AQuality improvementRaise the pHOrganic compound preparationPretreatment with acid reacting compoundsFormateHemicellulose

The invention relates to a method for producing chemi-mechanical pulp or semi-chemical pulp by treating wood or agricultural straw plant raw materials under acidic conditions. The method further comprises the steps of acid recovery and subsequent utilization of hemicellulose and lignin in waste liquid. According to paper pulp production, a formic acid / formate aqueous solution is used for swellingand softening a plant raw material in a mild normal-pressure environment, and lignin and hemicellulose are properly removed. The softened raw materials are hydraulically defiberred and mechanically ground to prepare chemi-mechanical pulp or semi-chemical pulp. In the drying process of the paper pulp and the waste liquid, formic acid recovery and formate co-production are achieved, and the invention further provides a separation method and a subsequent utilization way of lignin and hemicellulose in the waste liquid. Pulping involved in the method is carried out under an acidic condition, and isdifferent from the existing method for producing chemi-mechanical pulp or semi-chemical pulp in an alkaline environment. According to the method, all components of the plant raw materials can be separated and utilized, chemicals are recycled, and good resource utilization benefits and environmental benefits are achieved.

Owner:QILU UNIV OF TECH

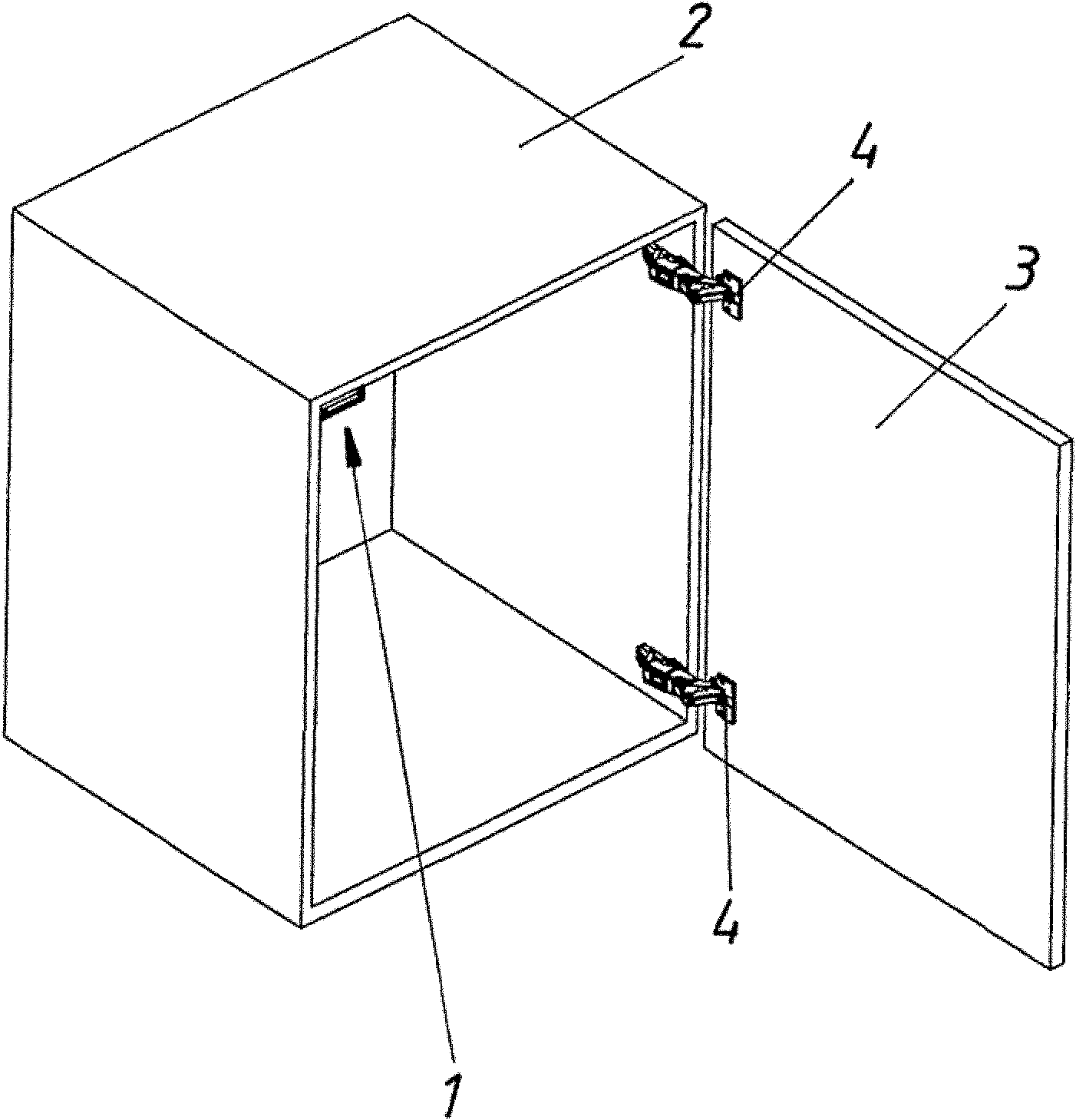

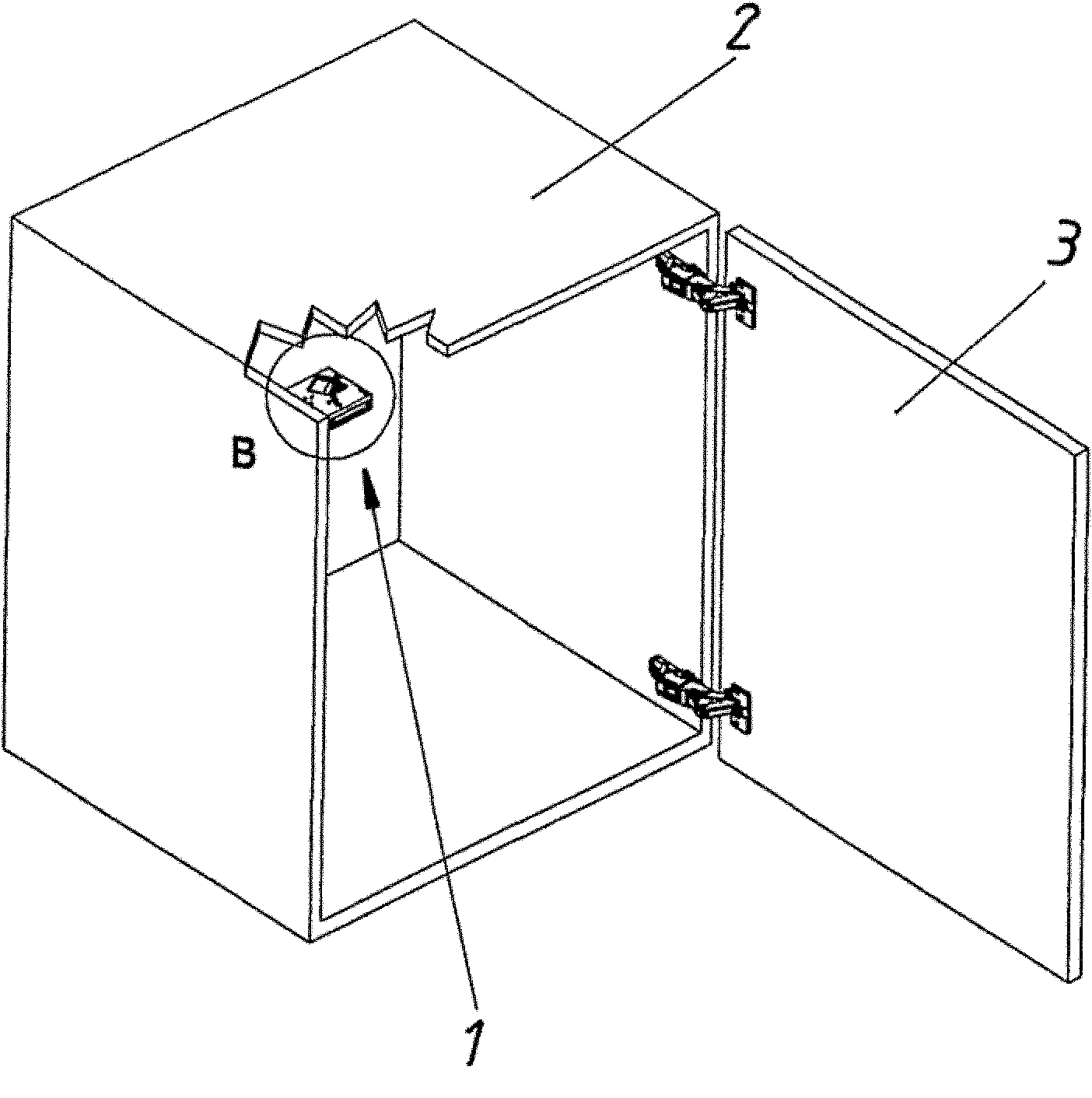

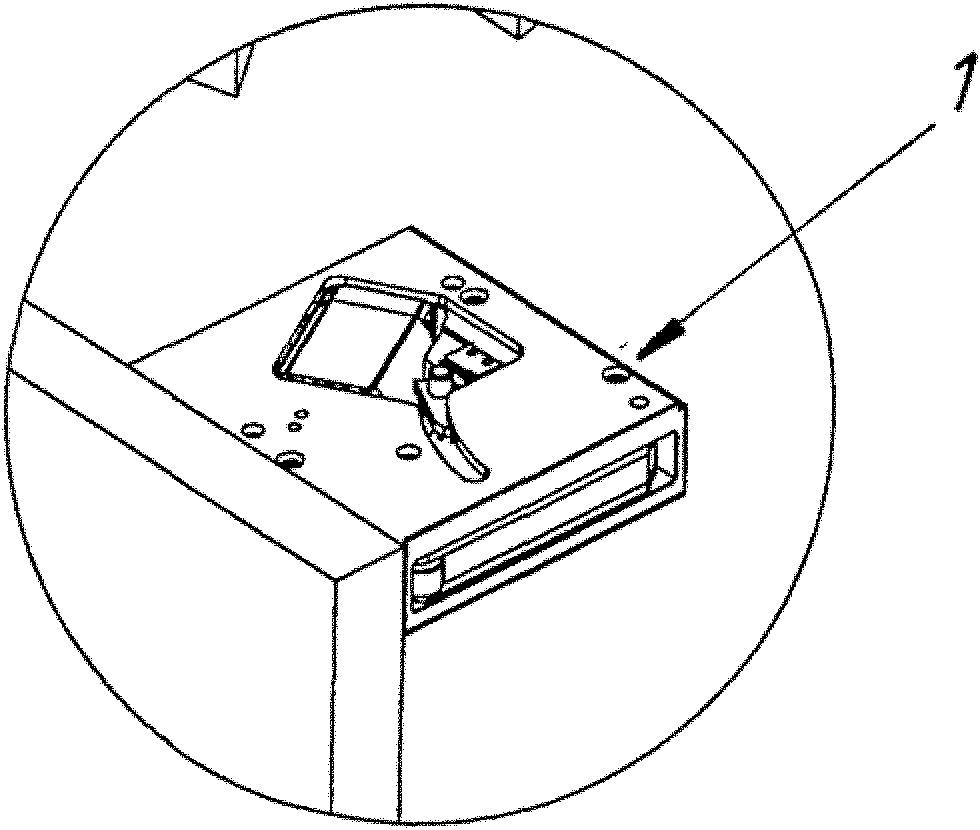

Furniture drive

ActiveCN102066682ASmall structure sizeCut offPower-operated mechanismWing openersEngineeringElectric power

Owner:JULIUS BLUM GMBH

Mechanical cold method for making paper pulp

InactiveCN1827911AQuality improvementCut offDigestersPulping with inorganic basesFiberPulp and paper industry

The invention discloses the method for preparing pulp with mechanical cold process, comprising the following steps: cutting the raw material, then the raw material passing single-helical or double-helical thread rolling machine to form filament wooly mass raw material, softening with vapor, grinding them with pulp grinder, and getting paper pulp. The paper pulp has good quality, and can provide good paper pulp raw material for producing paper. The method has high productivity. The method can directly produce paper pulp, avoiding the water pollution. The invention has the advantages of simple method, low cost and little environmental contamination.

Owner:田永兴

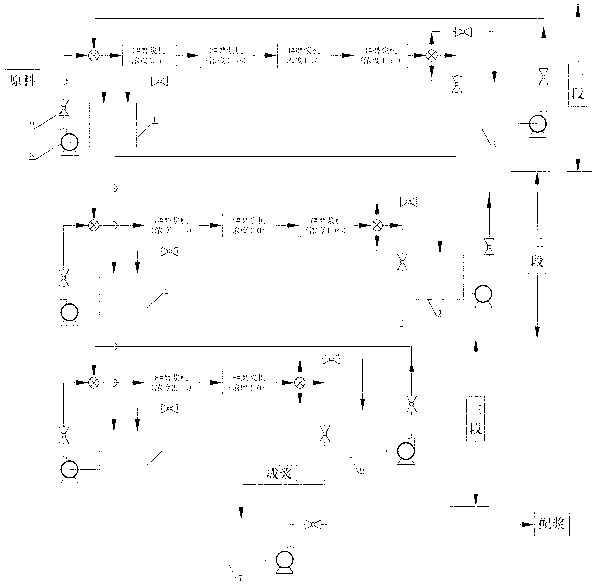

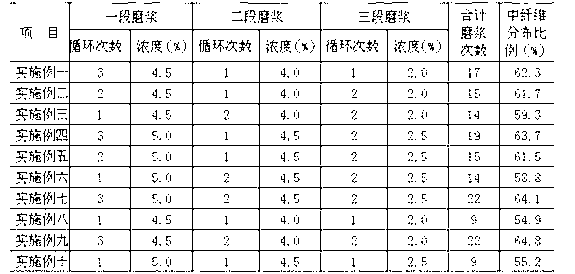

Papermaking tobacco sheet pulp grinding process

The invention discloses a papermaking tobacco sheet pulp grinding process. Specifically speaking, under the light beating condition, three-stage light beating flexible pulp grinding is adopted, each stage needs at least two pulp grinding machines, pulp concentration is decreased gradually, and size circulation process is controlled. In prepared size, fibers with the length of 0.5-1.25mm reach more than 63%, bulk degrees of base tabs reach 2.8-3.0cm <3> / g, spreading rates, filling values, burning velocity of finished sheets are improved greatly, tar contents and carbon oxide contents are reduced greatly, and the bulk degrees of the finished sheets reach 2.3-2.5cm<3> / g. The number of pulp grinding machines arranged in the first stage, the second stage and the third stage in a serial connection mode is respectively 4, 3 and 2. The pulp grinding concentration in the first stage, the second stage and the third stage are respectively set to be 4.5-5.0%, 4.0-4.5% and 2.0-2.5%. Times of self-circulation of the size in the first stage, the second stage and the third stage are respectively 1-3 times, 1-2 times and 1-2 times. The times for which mixed size prepared in different components passes through the pulp grinding machines in the whole process are 9-22 times actually, and all nine pulp grinding machines allow constant power regulation independently.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

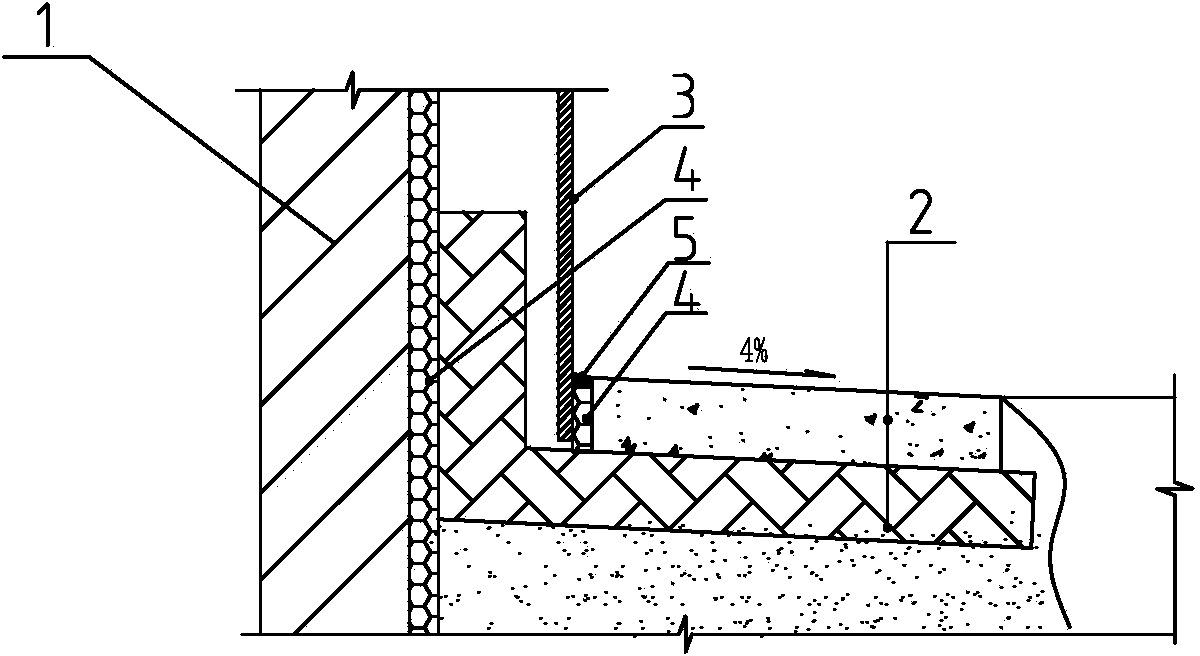

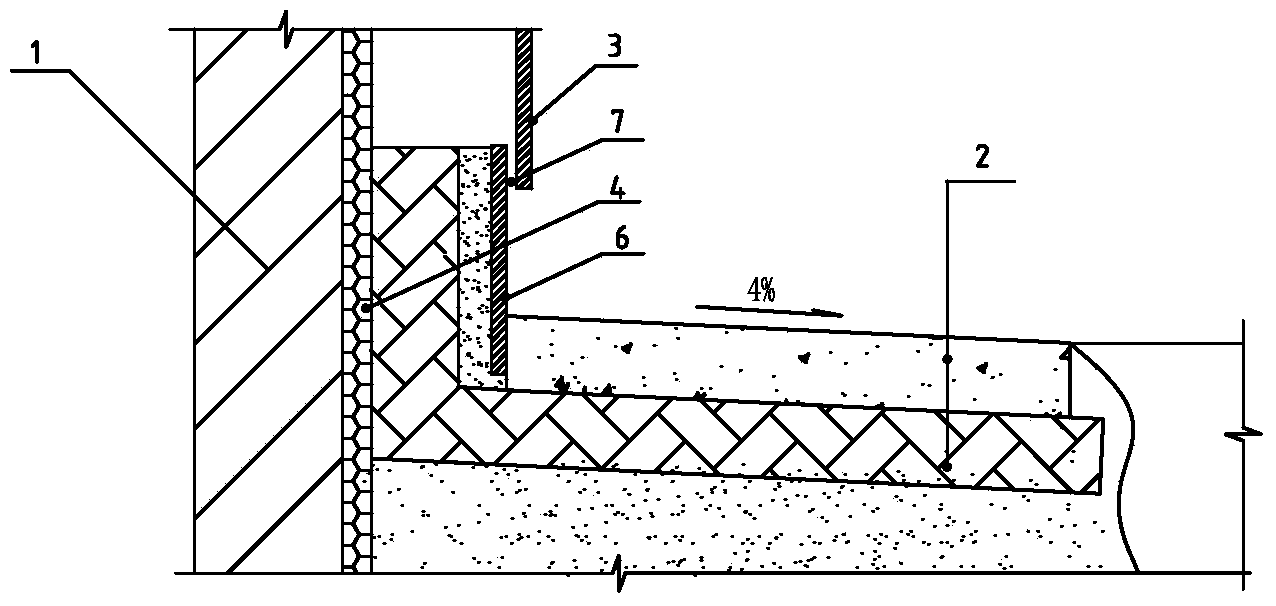

'7'-shaped structure self-waterproof apron design and construction method

InactiveCN103835361ACut offAvoid scour damageSewerage structuresBuilding material handlingPolystyreneCushion

The invention discloses a '7'-shaped structure self-waterproof apron design and construction method. The method includes the steps of a, backfilling and tamping the soil outdoors with a 4% outward slop; b, then paving extruded polystyrene boards along the structural external wall; c, selecting a formwork erecting manner to erect formworks according to a curtain wall board nosing scheme; d, continuously and entirely pouring a '7'-shaped concrete cushion layer according to the sequence of plane first and flange second; e, constructing an external wall decorative layer; f, constructing a apron layer; g, finishing by filling seams.

Owner:ZHONGTIAN CONSTR GROUP

Manufacturing method of high-level colour laser printing paper

PendingCN104790247AImprove stiffnessImprove finenessWater-repelling agents additionPaper coatingPapermakingProcess engineering

The invention discloses a manufacturing method of high-level colour laser printing paper. According to the manufacturing method, softwood pulp and hardwood pulp are used, and the processing steps of beating, blending, auxiliary material adding, papermaking of wet paper sheets, front drying, sizing, after drying, press polishing and finishing are respectively performed, wherein the ratio of the softwood pulp to hardwood pulp is (5-20):(80-95) in percentage by weight; after the pulp is beaten, the freeness of the softwood pulp is 280-320 ml and the freeness of the hardwood pulp is 380-420 ml; during surface sizing, an enzyme prepared on site is converted into starch; the high-level color laser printing paper has the definite quantity of 100g / m<2>, and the main indexes are as follows: moisture accounts for 4.5 to 5.5 percent, the tensile strength is equal to or greater than 5.0 KN / m, the stiffness is 150 mN, the bulk is larger than or equal to 1.15 cm<3> / g, the ash content is less than or equal to 20 percent, the smoothness average value is larger than or equal to 70 S, and the surface absorption weight is smaller than 35 g / m<2>. The manufacturing method provided by the invention has the advantages that the product quality stiffness is high, the dimensional stability is excellent, the passing-machine performance is excellent, the paper cleanliness is high, the smoothness is high, the transfer printing capability is high, the color saturation of a printed product is good, and images are vivid.

Owner:YUEYANG FOREST & PAPER CO LTD

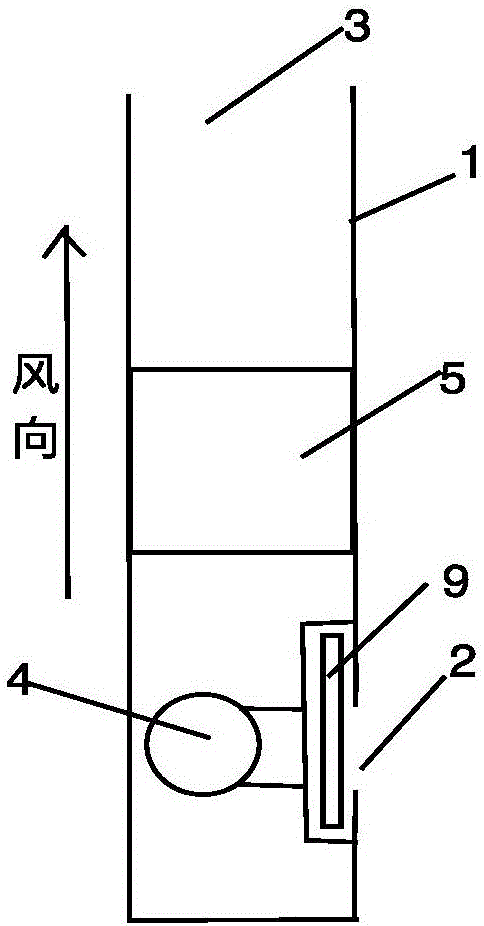

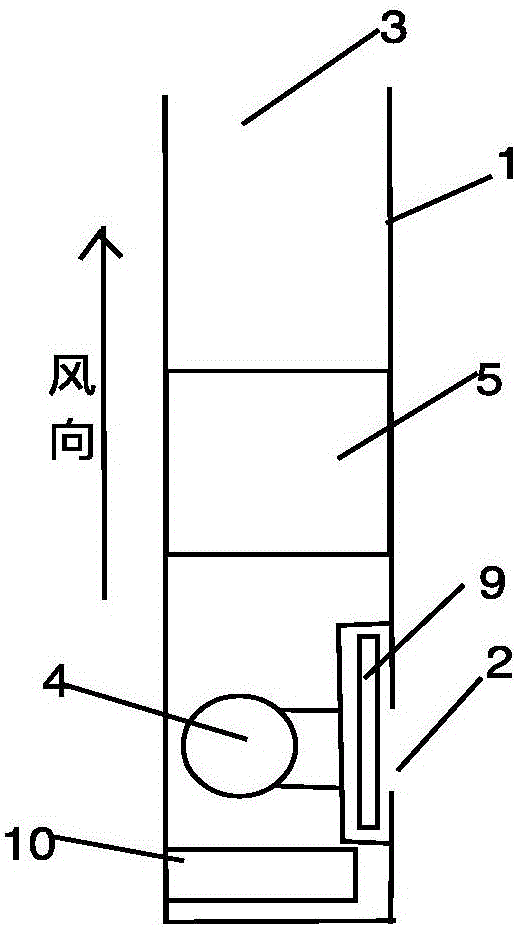

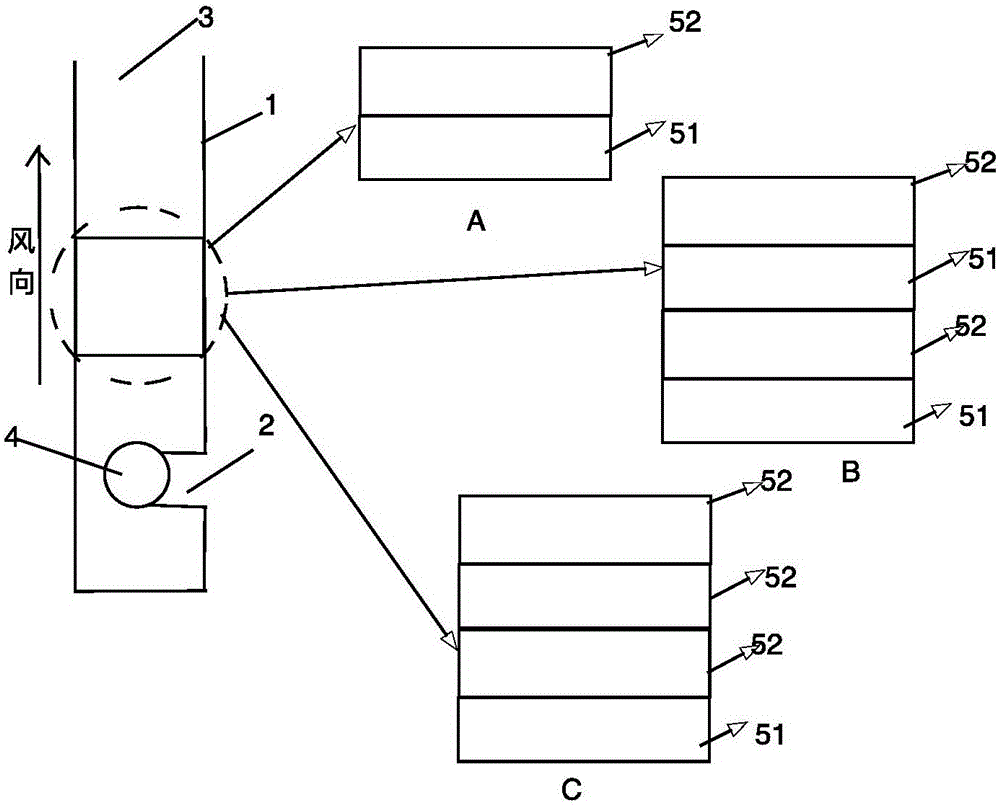

Air purification method and system adopting fresh air

InactiveCN106247522ACut offLower carbon dioxide levelsCombination devicesMechanical apparatusFresh airAir treatment

The invention discloses an air purification method and system adopting fresh air and belongs to the indoor environment purification technology. The air purification system is characterized by comprising a casing, an air quantity regulation part and at least one primary filter screen layer, wherein an air inlet and an air outlet are formed in the casing, and the air inlet is used for introducing outdoor air; a first air treatment assembly and a second air treatment assembly are arranged in the casing, the first air treatment assembly comprises a power fan, the second air treatment assembly comprises a reusable dust collecting device, and the purification performance of the dust collecting device does not get poor after cleaning; the air quantity regulation part is used for controlling the rotating speed of the power fan, so that the speed range of air output from the air outlet ranges from 0.3 m / s to 5 m / s, and the primary purification efficiency of the dust collecting device for PM 2.5 is enabled to be as high as 80%-99.9%.

Owner:格林韦尔(北京)科技发展有限公司

Novel cutting system for reinforcing steel bars

A novel cutting system for reinforcing steel bars comprises a bottom plate, a supporting platform device, a first air cylinder device, a supporting device, a second air cylinder device, a third air cylinder device, a cutting device and a fourth air cylinder device, wherein first rollers are arranged on the bottom plate; the supporting platform device comprises a supporting platform, second rollers, positioning rods and a first transverse rod; the first air cylinder device comprises a first supporting rod, a second transverse rod, a second supporting rod, a first air cylinder, a first fixing block, a first push rod, a first friction block and a first triangular block; the supporting device comprises a third transverse rod, a second fixing block, a fourth transverse rod, a first bracket, a second bracket and a first inclined rod; the second air cylinder device comprises a third supporting rod, a fourth supporting rod, a fifth transverse rod, a second air cylinder, a third fixing block, a second push rod, a second friction block, a second triangular block and a first fixing frame. The system can cut the reinforcing steel bars quickly, is high in working efficiency, quick and high in automation degree and can reduce the labor intensity.

Owner:CHINA JILIANG UNIV

Digital intelligent oil-water separator capable of remotely monitoring and automatically weighing

InactiveCN105413241ACut offMaster whereaboutsFatty/oily/floating substances removal devicesWater contaminantsHuman healthOil separation

The invention discloses a digital intelligent oil-water separator capable of remotely monitoring and automatically weighing. The digital intelligent oil-water separator comprises an automatic oil lifting device, an intelligent weighing device and a collection bucket, which are arranged in a shell, wherein the automatic oil lifting device comprises a water tank and an oil lifting motor; a water inlet pipe and a water outlet pipe, which penetrate through the shell, are connected with the two sides of the water tank respectively; oil separation plates are arranged at the top and bottom in the water tank respectively; a driving wheel on the oil lifting motor is connected with a driven wheel in the water tank through an oil lifting belt; the collection bucket is located under a waste oil collection pipe and a heating pipe is arranged in the water tank on the intelligent weighing device; and the shell is provided with an electronic identity authentication access control device, a video monitor, a geographic position positioning instrument and an electric appliance controller. The digital intelligent oil-water separator has a simple structure and a reasonable design; illegal cooking oil is really eliminated from sources and is prevented from being returned back to dining tables to endanger human health; and the yield of waste grease and oil of each catering unit can be monitored by a government supervision department in a monitoring room, and the discharging direction of the waste grease and oil is grasped.

Owner:徐加强

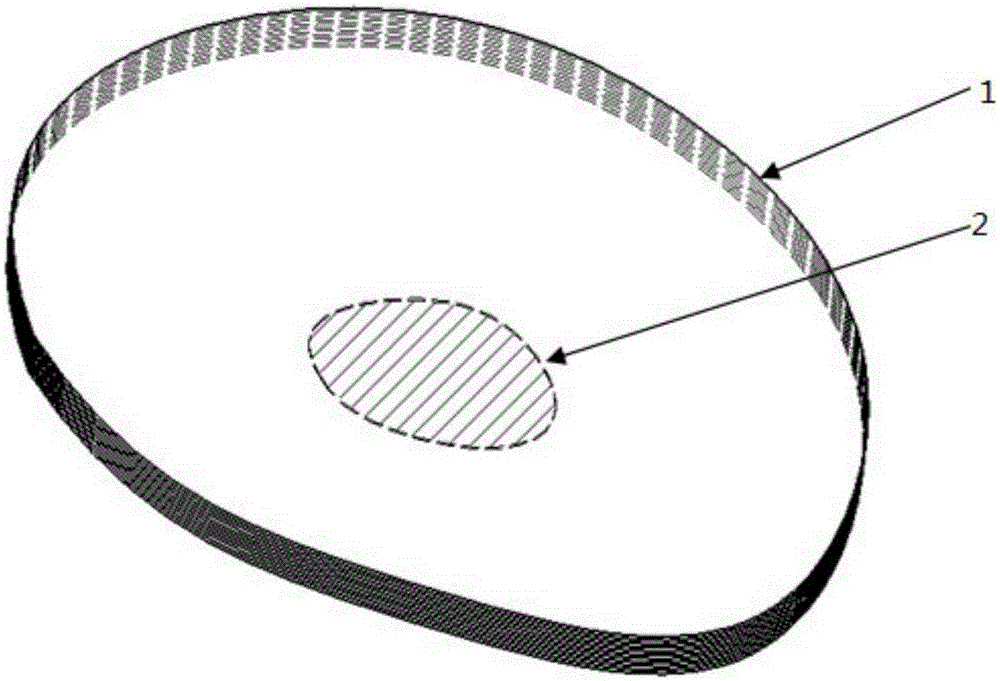

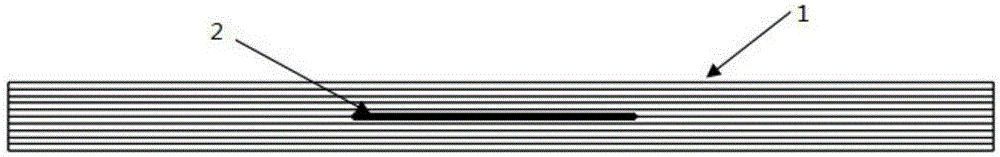

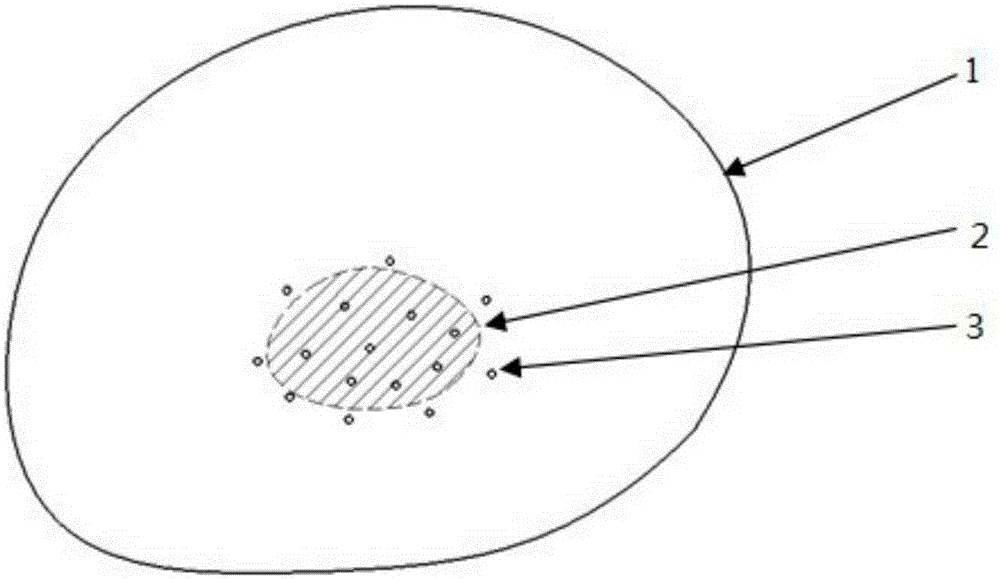

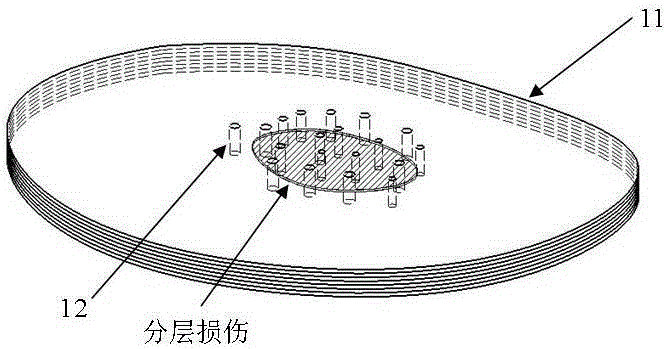

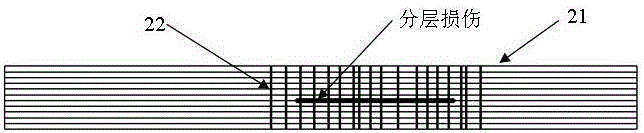

Repair method for delamination damage of composite laminated plate

The invention relates to a repair method for delamination damage of a composite laminated plate, and belongs to the field of laminated plate repair. The repair method includes the steps that firstly, a plurality of small holes are machined in the delamination damage area of the composite laminated plate and the portion around the delamination damage area; secondly, making threads dipped with adhesives sequentially penetrate the small holes to be tightly pulled; and thirdly, the adhesives are solidified so that the threads and composites around the threads can be bonded into a whole. According to the repair method, the diameter of the machined small holes is small, less fiber is cut off, the influences on the performance in the face of the composite laminated plate are low, the lamination prevention capacity of the laminated plate can be greatly improved through the threads and bonding with the surrounding composites, the purpose of enhancing delamination damage of the composite laminated plate is effectively achieved, the repair result of the composite laminated plate can be improved, and wider application of the composites is promoted.

Owner:SHANGHAI JIAO TONG UNIV

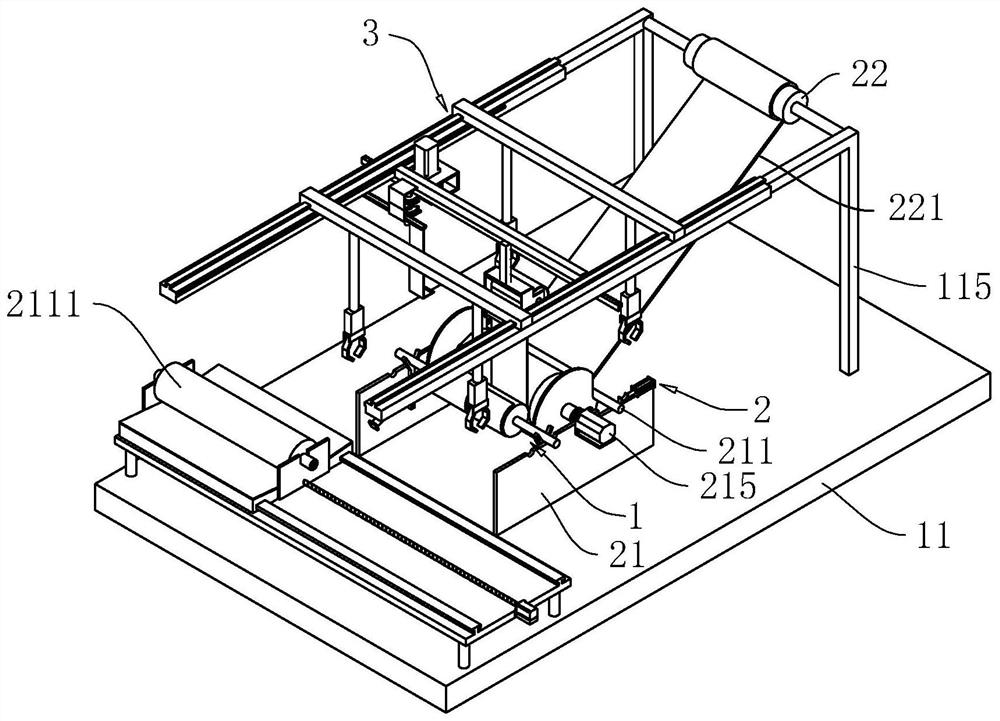

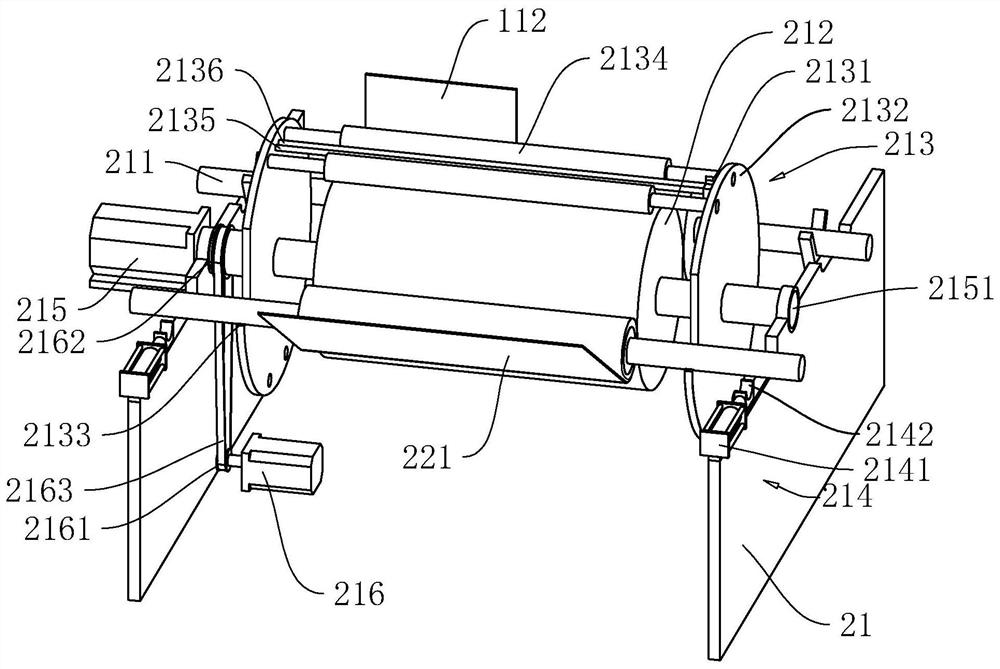

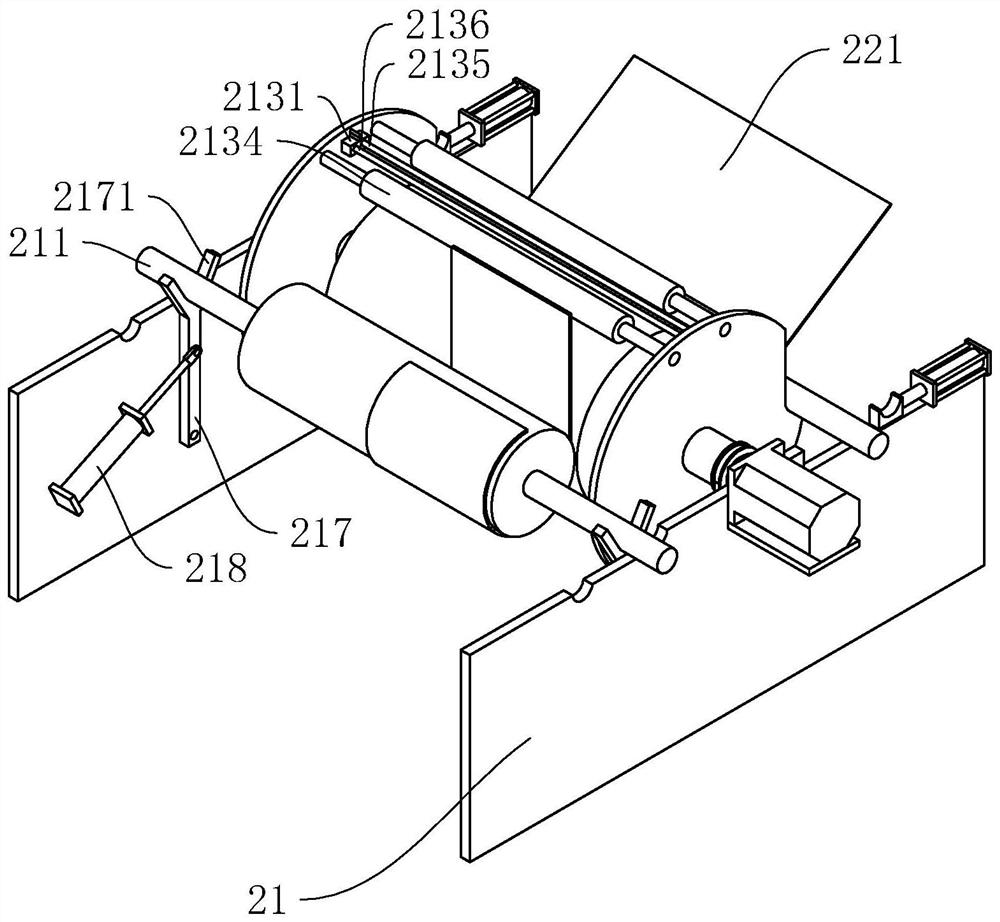

Thin film packaging device and thin film rolling and packaging integrated equipment

The invention relates to a thin film packaging device and thin film rolling and packaging integrated equipment, and relates to the technical field of thin film production equipment. The thin film packaging device comprises a machine body, a fixing frame is arranged on the machine body, a rolling roller is rotationally connected to the fixing frame, a thin film coiled material is wound around the rolling roller, a support is installed on the machine body, the support is provided with a packaging belt body, the end, away from the support, of the packaging belt body is wound around the thin film coiled material, and the machine body is provided with a driving assembly used for driving the support to move in the axis direction of the thin film coiled material. The driving assembly drives the support to move in the axis direction of the thin film coiled material, the thin film coiled material is rotationally connected with the fixing frame, then the packaging belt body is spirally wound on the thin film coiled material, the thin film coiled material can be tightened, the possibility that the thin film coiled material is loosened is reduced, labor is saved, and the packaging efficiency is improved.

Owner:常州新达力塑料机械有限公司

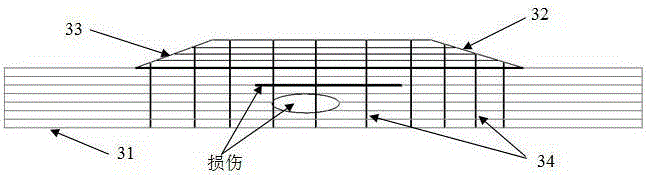

Solidified composite and enhancing method of repairing structure and connecting structure of solidified composite

The invention discloses a solidified composite and an enhancing method of a repairing structure and a connecting structure of the solidified composite, and belongs to the composite enhancing method. The method specifically includes the steps of manufacturing a certain number of small holes in a damaged part of a solidified composite laminated board, a repaired part of a repairing piece and a connecting part of the laminated board and the repairing piece, embedding thin bars soaked with adhesives in the small holes, and solidifying the adhesives to make the thin bars adhere to surrounding materials. By means of the method, the machined small holes are small in diameter, little fiber is cut off, and the performance in the surface of the composite laminated board is little influenced; through the adhesion between the thin bars and the surrounding materials, the interlayer strength and toughness of the composite laminated board can be greatly improved, the problem that in the prior art, the specific part and structure of the solidified composite laminated board can not be enhanced is effectively solved, the mechanical performance of the structure of the composite and the mechanical performance of the repairing structure and the connecting structure of the composite are improved, the bearing efficiency of the structure of the composite is improved, and the composite is promoted to be more widely applied.

Owner:刘龙权

Automatic strip cutting machine of multiple optical fibers

InactiveCN107741614ANo damageEliminate manual factorsCoupling light guidesFiber coatingCeramic coating

The invention provides a multi-channel optical fiber automatic stripping and cutting machine, which comprises a horizontal moving platform, an optical fiber clamp, an optical fiber clamp base, a ceramic heating device, a motor, a cutting platform and a cutting device. Through the present invention, multiple optical fibers can be stripped and cut at the same time. After the ceramic heating device is used to heat the coating layer of the multi-channel optical fiber, the motor moves the mobile platform through transmission to automatically strip the coating layer of the multi-channel optical fiber. It can eliminate the influence of manual factors, has high performance stability, and the thermal stripping method can ensure no damage to the optical fiber; then quickly switch to the cutting state, and use the cutting device to cut the position where the coating layer is removed on the multi-channel optical fiber. Multi-channel optical fiber can realize the stripping of the optical fiber coating layer and the cutting of the end face, which greatly improves the efficiency of the overall stripping and cutting, and is stable and reliable.

Owner:王巍 +2

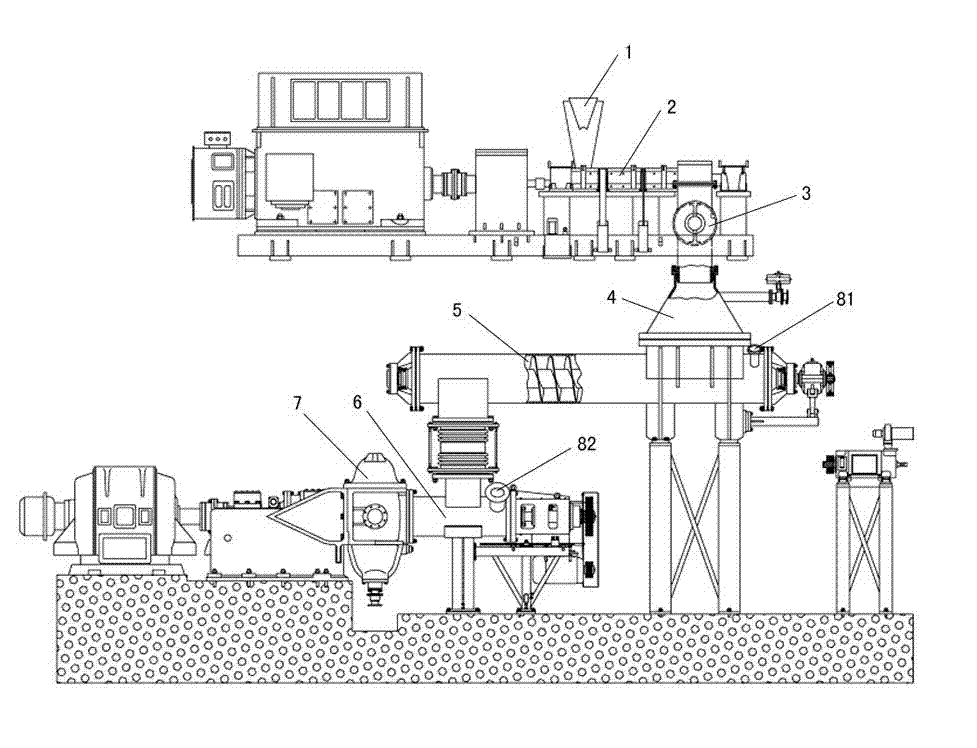

Defibrator system and defibrination method thereof

InactiveCN103088684AIncrease profitIncrease production capacityFibrous raw materialsPulp beating/refining methodsControl systemWood fibre

The invention provides a defibrator system and a defibrination method of the defibrator system, wherein the defibrator system comprises a feed hopper and a defibrator. The feed hopper is longitudinally arranged on the front end of a twin-screw extruder, a back-jet resisting device, a vertical drop hopper, a horizontal preheat tank with screw conveying, a belted screw feeder and the defibrator are sequentially arranged on the rear end of the twin-screw extruder, and steam balance control systems are arranged on inlet and outlet of the horizontal preheat tank. The defibrination method of the defibrator system comprises the following steps: feeding wood chips of a certain specification into the longitudinally arranged feed hopper; conducting primary dissociation and conquassation on the wood chips through dynamic extrusion of the twin-screw extruder; feeding the conquassated wood chips into the vertical drop hopper; conducting precooking on the conquassated wood chips dropping into the horizontal preheat tank by self-weight at temperature from 110 to 130 degrees centigrade in the horizontal preheat tank; feeding the precooked conquassated wood chips into the defibrator by the belted screw feeder through the screw conveying of the horizontal preheat tank; and forming wood fiber with high physical property after defibration of the defibrator. The defibrator system and the defibrination method of the defibrator system are high in using raw materials and capable of improving capacity by at least 50 percents.

Owner:JIEYA TECH KUNSHAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com