Full-automatic resistor bending machine and resistor bending method

A bending machine, fully automatic technology, applied in the field of resistance manufacturing, can solve the problems of U-shaped structure pin cutting and bending quality not meeting the requirements, and achieve the effects of saving manpower, precise control, and coordinated actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0067] First, a brief description of the orientation involved in this specific embodiment is given: when referring to the front, back, left, and right of each structural member, it is defined by the position relative to the user in the use state. In addition, the terms "first", "second", and "third" are used for descriptive purposes only, and should not be construed as indicating or implying relative importance.

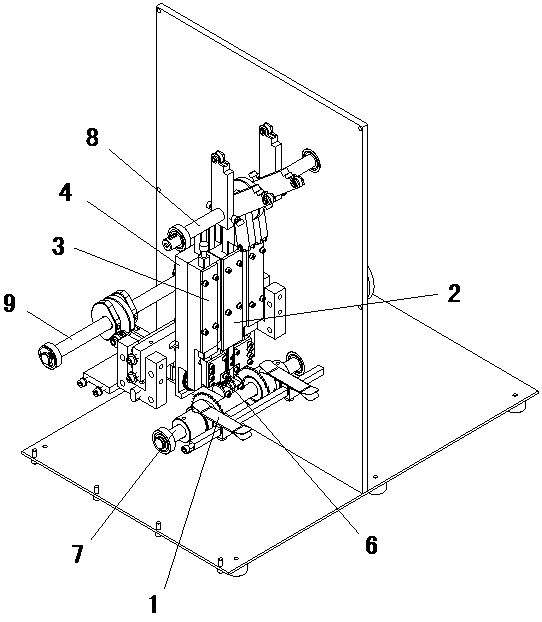

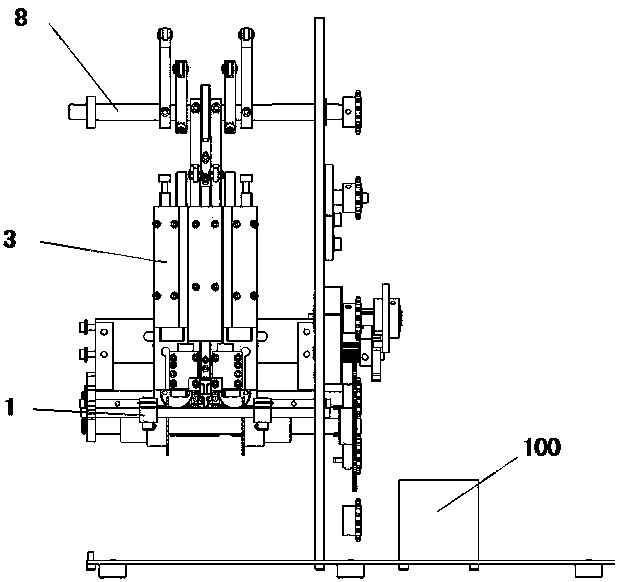

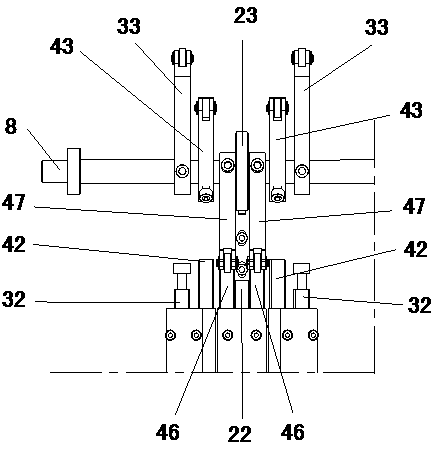

[0068] refer to Figure 1-13 , is an embodiment of the automatic resistance bending machine proposed by the present invention. The automatic resistance bending machine includes a feeding mechanism 1, a tablet pressing mechanism 2, a cutter mechanism 3, a bending mechanism 4, and a motor ( not marked in the figure); the tablet pressing mechanism 2 is arranged above the material preparation table 6, and the cutter mechanism 3 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com