Thin film packaging device and thin film rolling and packaging integrated equipment

A technology of film packaging and film roll, which is applied in the field of film packaging device and film winding and packaging integrated equipment, which can solve the problems of low packaging efficiency of cast film coils, etc., to improve winding efficiency, save labor, and reduce overlapping area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-6 The application is described in further detail.

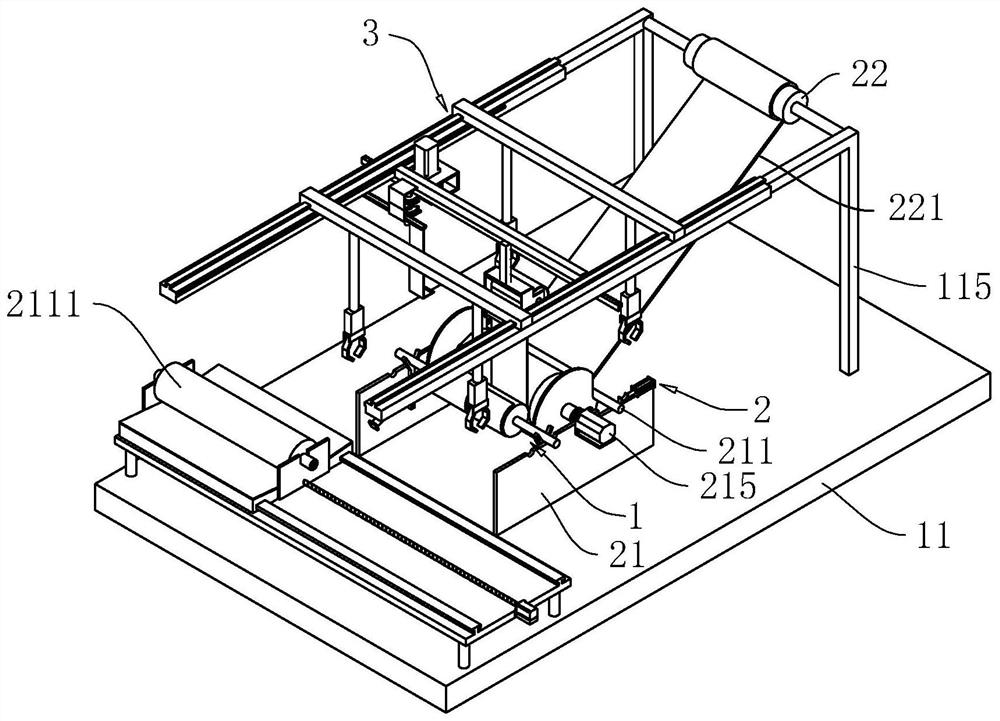

[0040] The embodiment of the present application discloses an integrated equipment for film winding and packaging. refer to figure 1 , an integrated film winding and packaging equipment includes a film winding device 2 for winding a film body 221 and a film packaging device 1 for packaging the film body 221, and the film packaging device 1 and the film winding device 2 pass through The transport device 3 realizes the connection. The film winding device 2 winds the film body 221 to form a film roll 2111 . The conveying device 3 transports the film coil 2111 to the film packaging device 1 for packaging the film coil 2111, which saves labor and improves production efficiency.

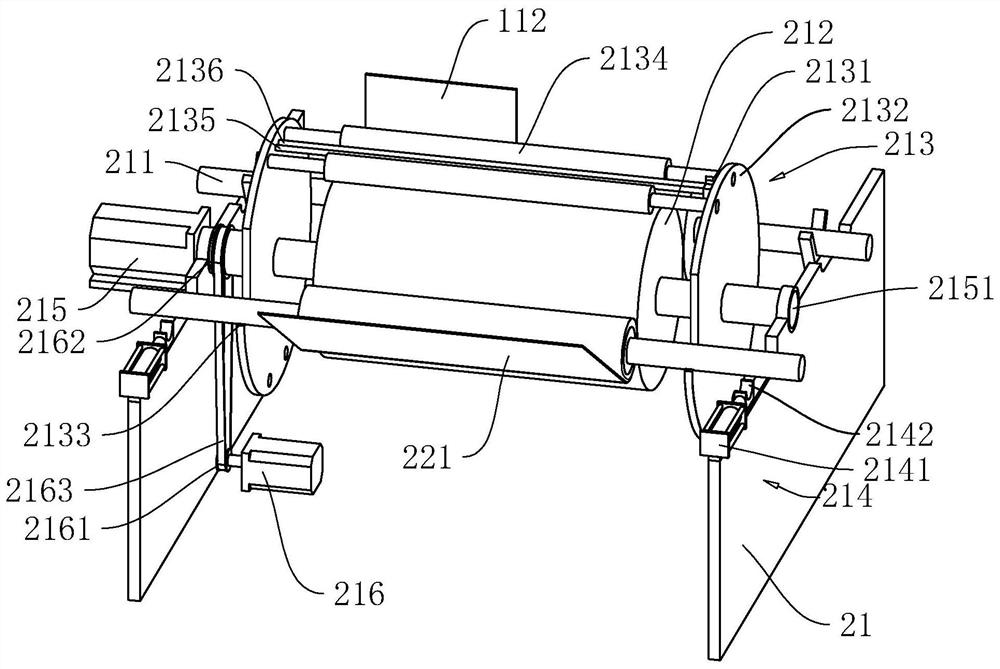

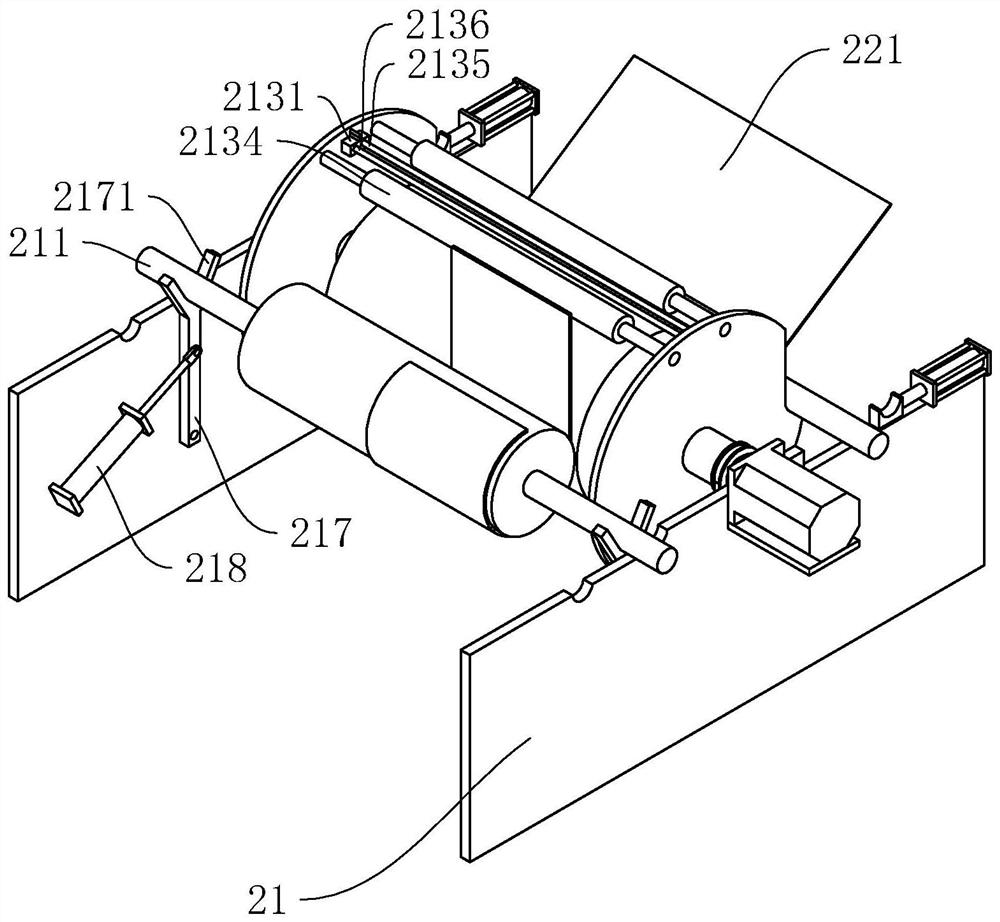

[0041] refer to figure 1 as well as figure 2 The film winding device 2 includes a body 11 and a fixed frame 21, a support frame 115 is welded on the body 11, and an unwinding roller 22 is rotatably connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com