Coaxial cable for use in shallow sea bed and manufacturing method thereof

A technology of coaxial cable and shallow sea, which is applied in the manufacture of coaxial cable for shallow sea and seabed, and the field of coaxial cable for shallow sea and seabed, can solve the problems of poor adaptability of communication cable, large cable pulling force and influence on signal transmission, etc. Achieve excellent waterproof performance, moisture-proof penetration performance, enhanced longitudinal tensile resistance, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

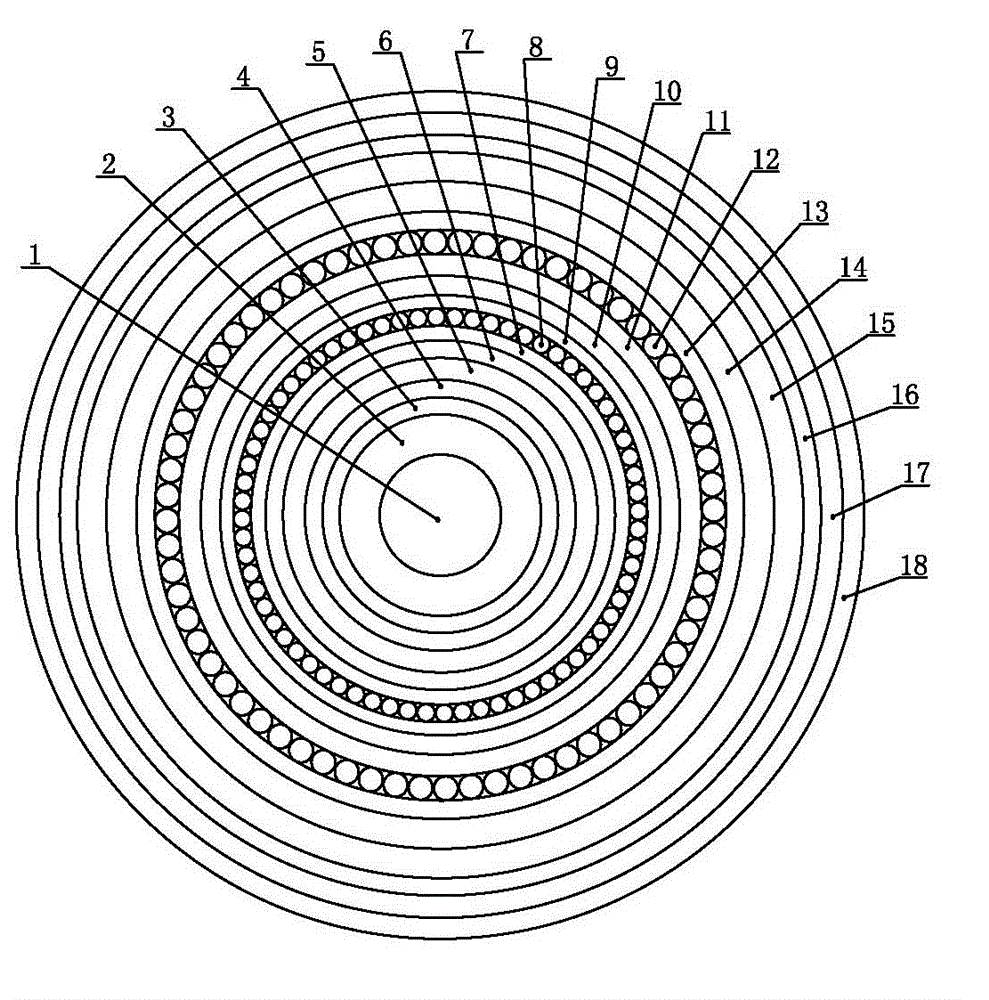

[0019] The coaxial cable used for shallow sea and sea bottom of the present invention is manufactured according to the following steps in turn: (1) extrude a high-voltage polyethylene insulating layer with a nominal thickness of 5.5 mm on a solid annealed copper conductor with a diameter of 4.25 mm, and the minimum thickness of the high-voltage polyethylene insulating layer is The thickness is not less than 90% of the nominal thickness, the maximum thickness is not greater than 110% of the nominal thickness, and the diameter deviation measured by any vertical section is not more than 10%. (2) Nine flexible flat copper wires with a width×thickness of 5.1mm×0.5mm are used to evenly braid the outer conductor on the outer periphery of the high-voltage polyethylene insulating layer. (3) Wrap two layers of polyester film tapes in opposite directions on the outer periphery of the outer conductor, the nominal thickness of the polyester film tape is 0.04mm, and coat the first asphalt co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com