Patents

Literature

725results about "Coaxial cables/analogue cables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

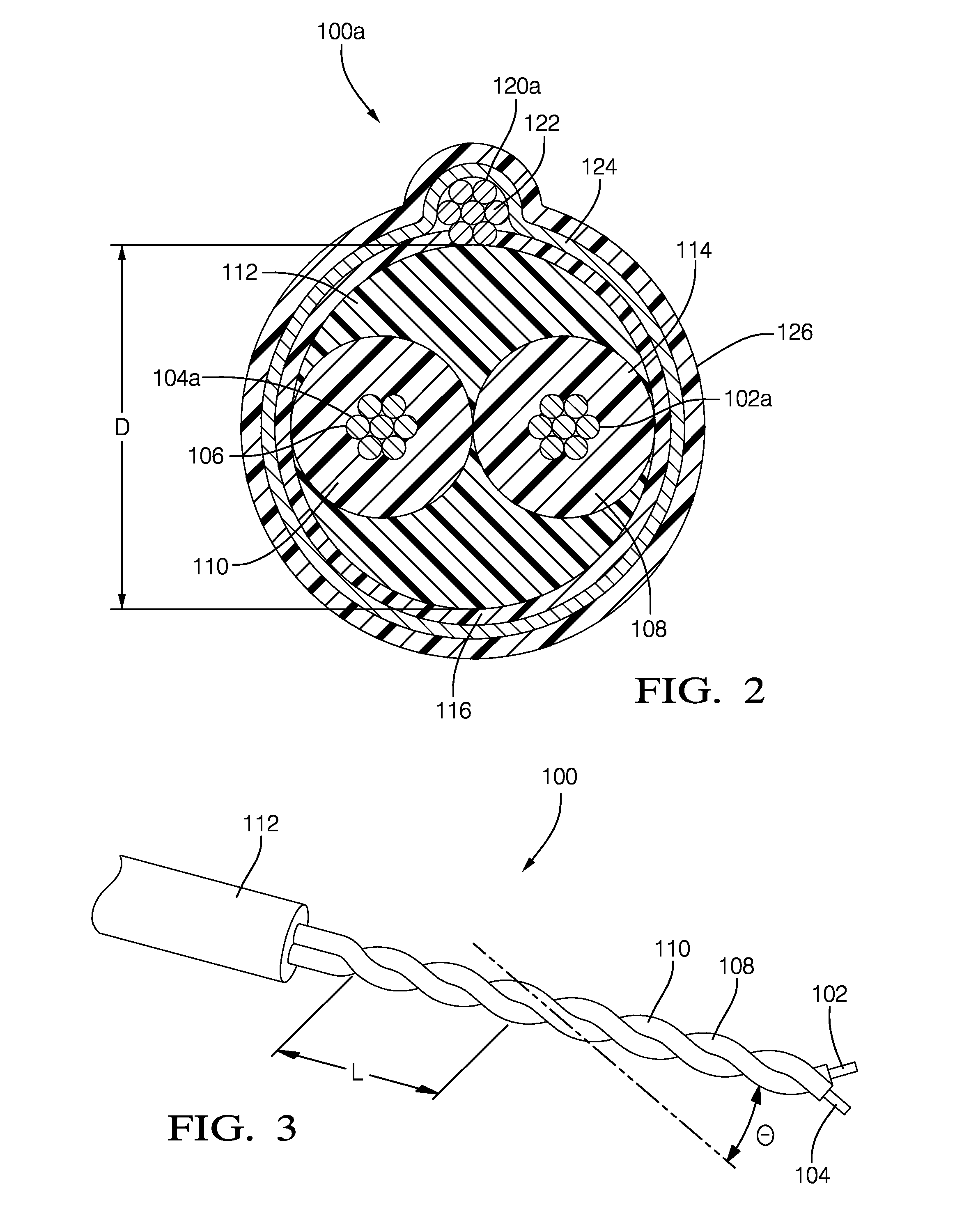

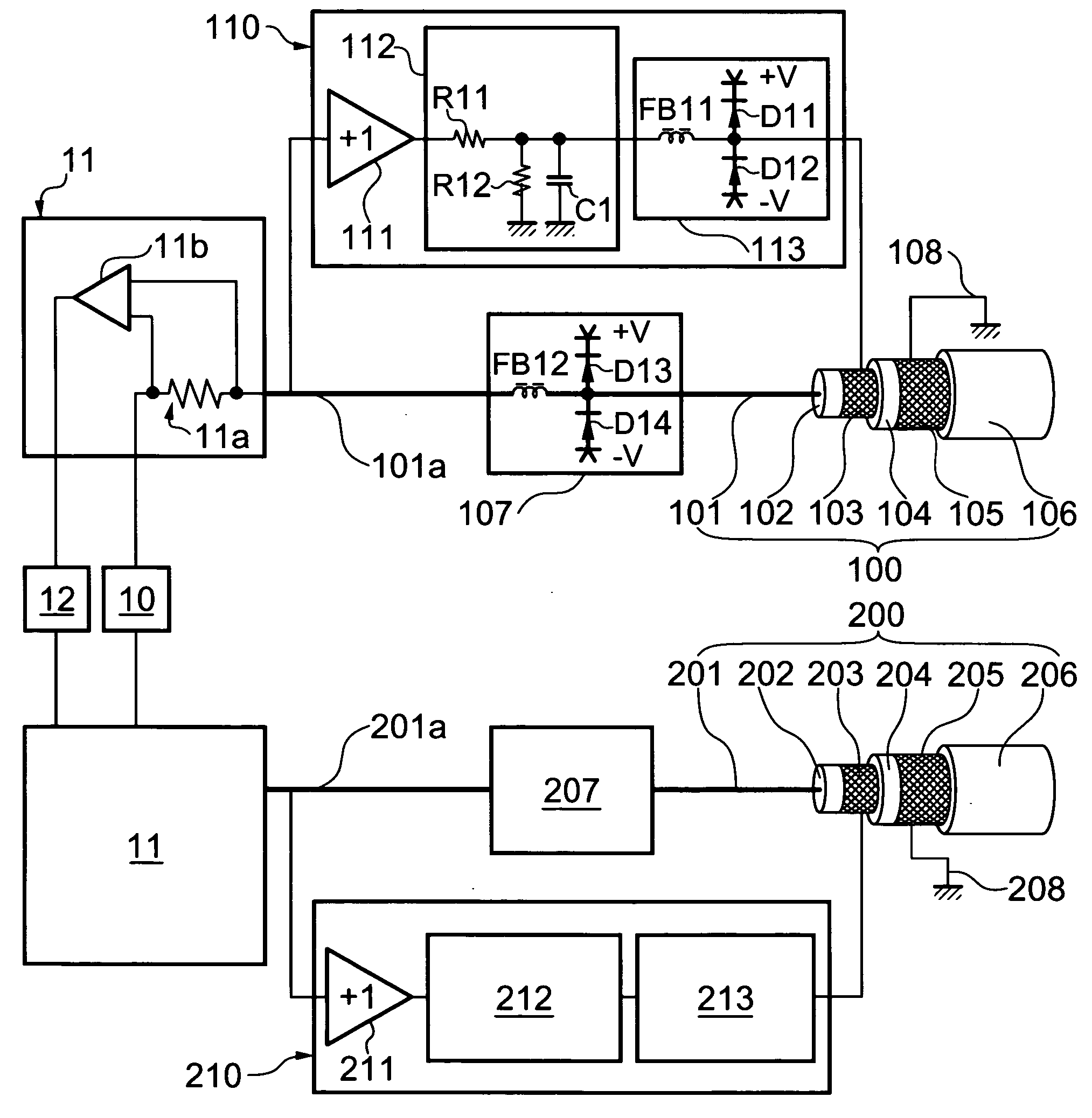

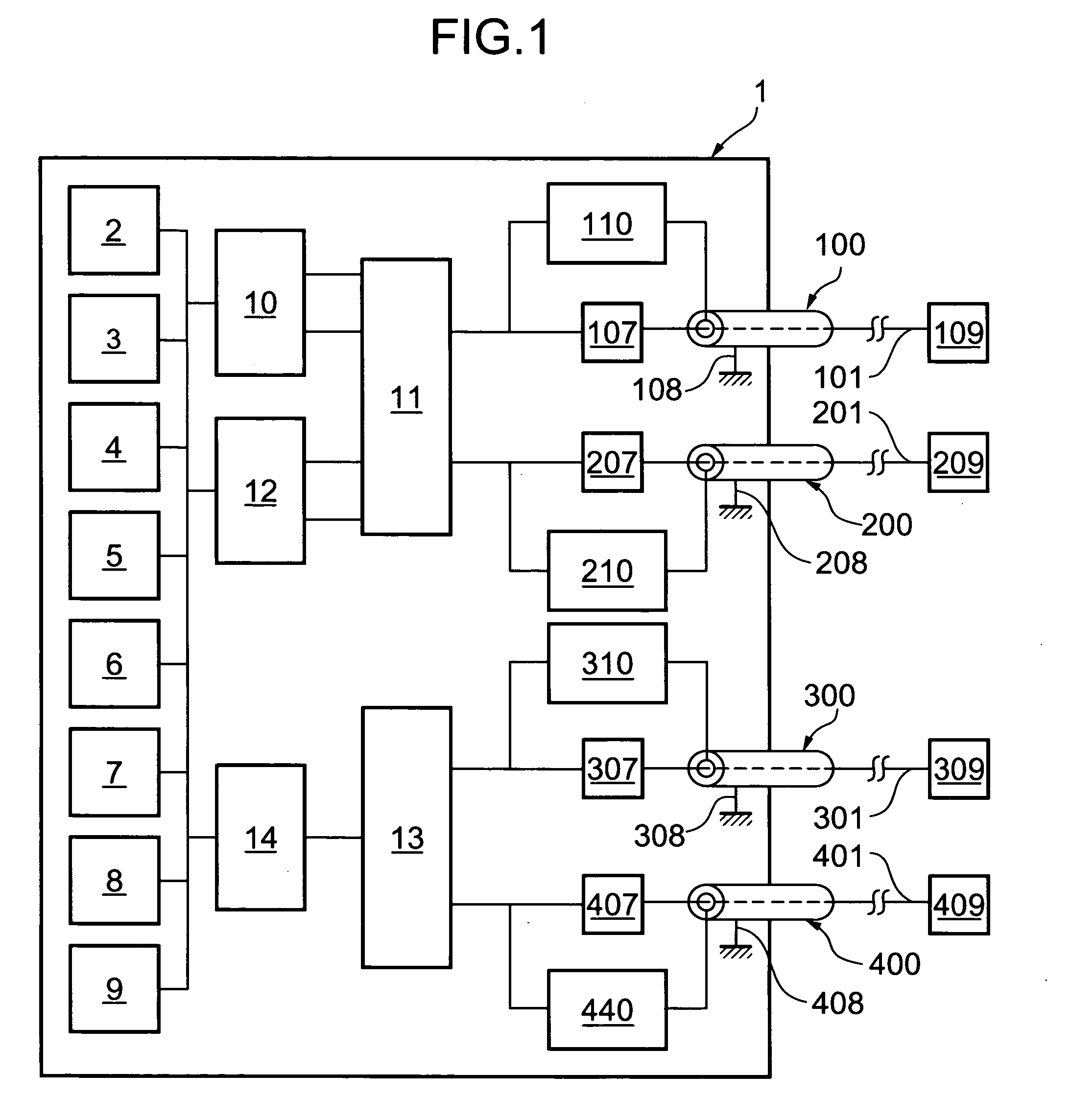

Electrically optimized hybird "last mile" telecommunications cable system

InactiveUS6091025AEqual performanceEquivalent signal performanceCoaxial cables/analogue cablesQuad constructionsElectrical conductorTelecommunications cable

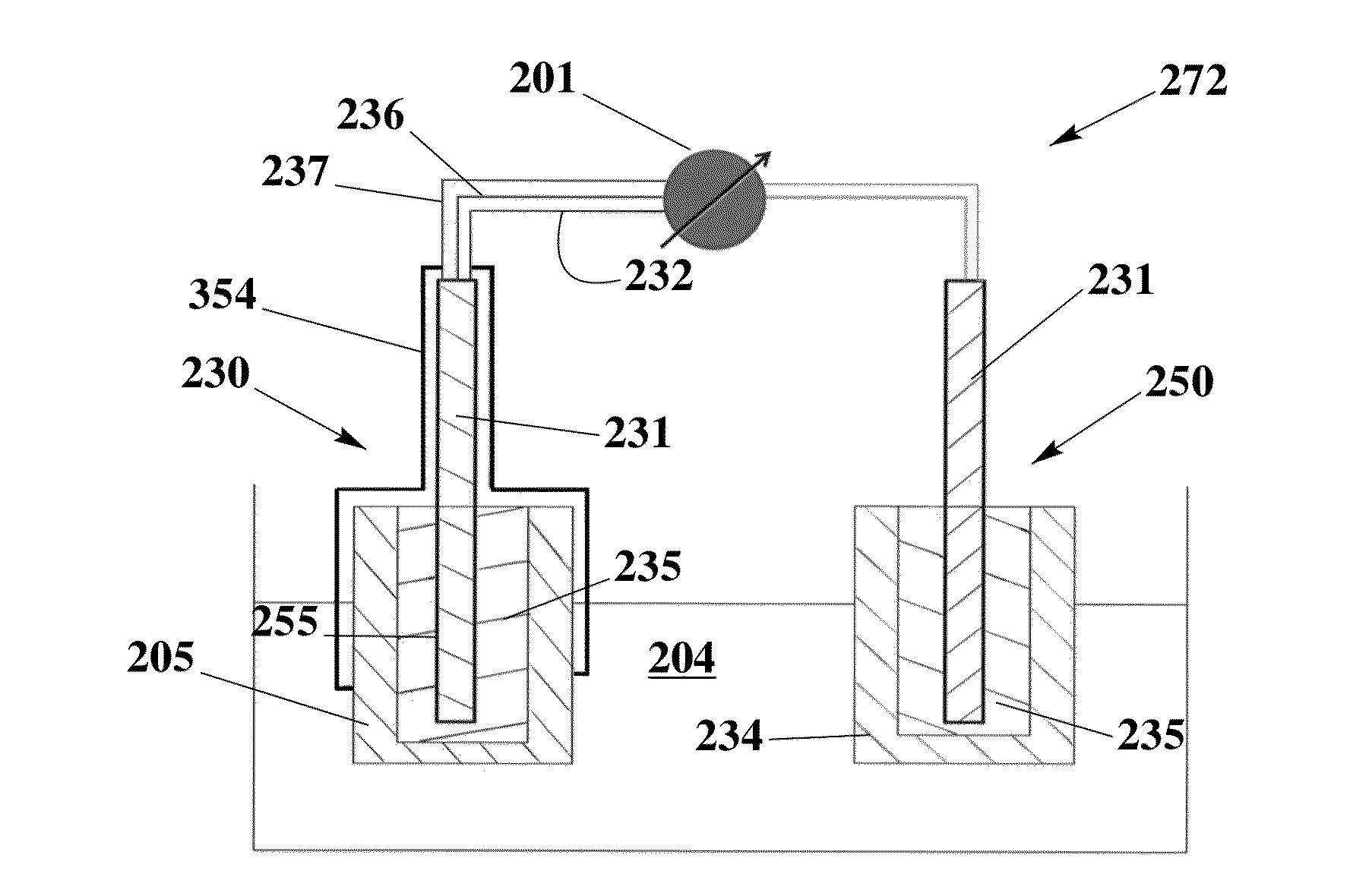

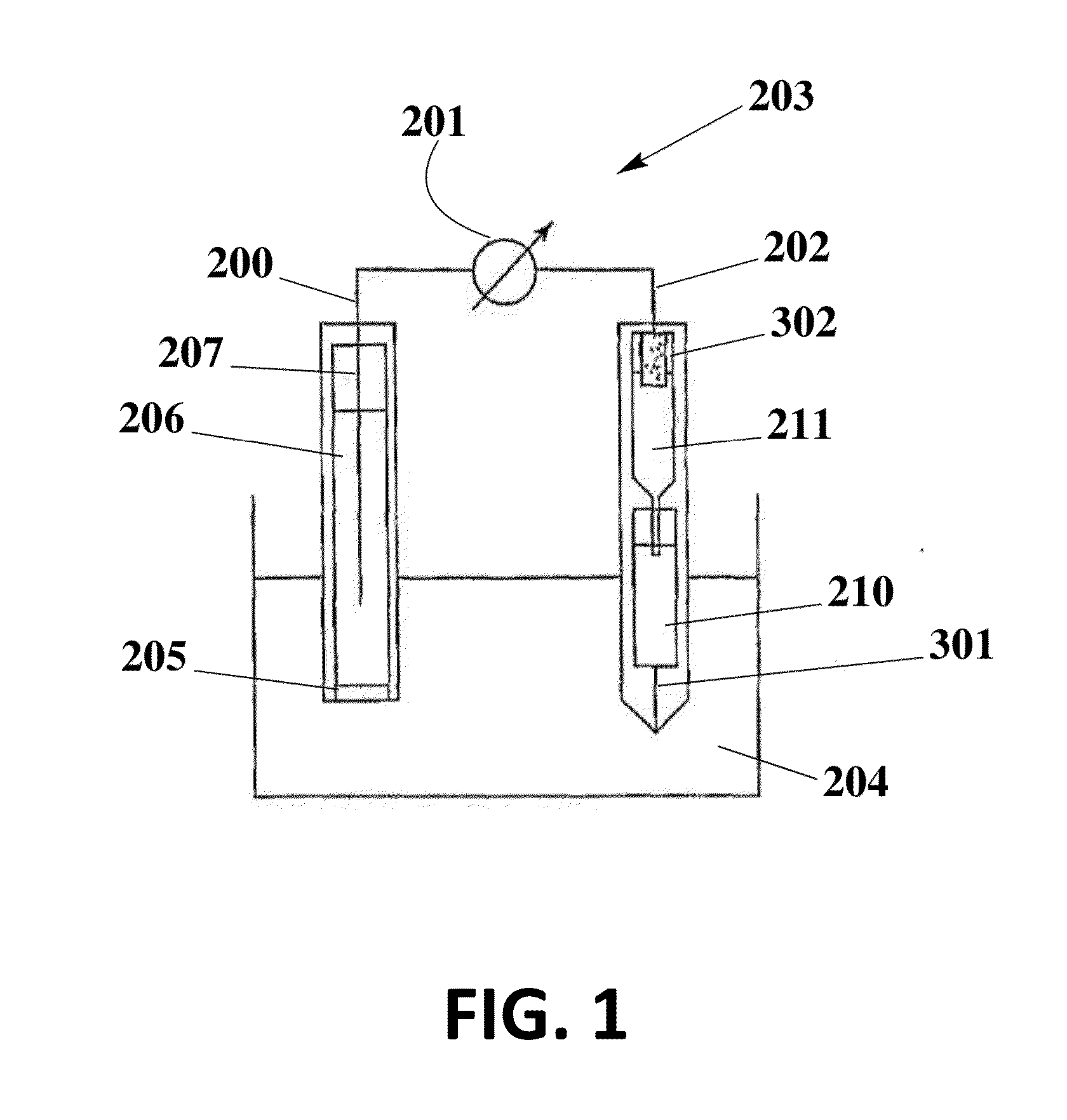

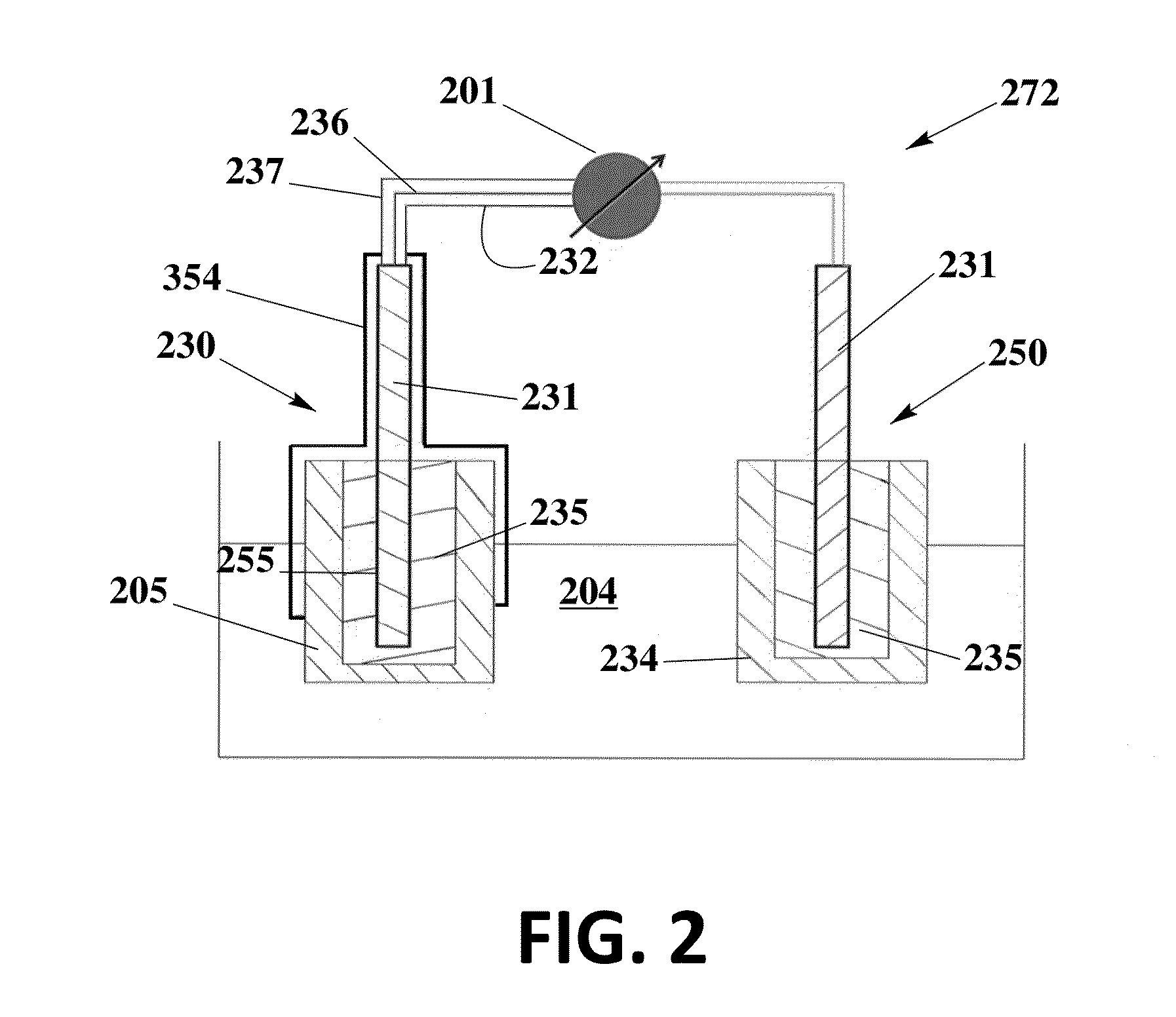

A cable system is provided which can accomodate electrical and optical cabling. The conductors of the system employ a layer which is impedance-matched to space, decreasing their cross-section to electromagnetic interference. The conductors of the system also employ a layer which symmetrizes electromagnetic interference signals, reducing the effect of interference and crosstalk on the signals carried by the conductors. The system also includes a node interface device for connection to a global electrical and fiber network. The node interface device connects to a user interface device through the cable.

Owner:KHAMSIN TECH LLC

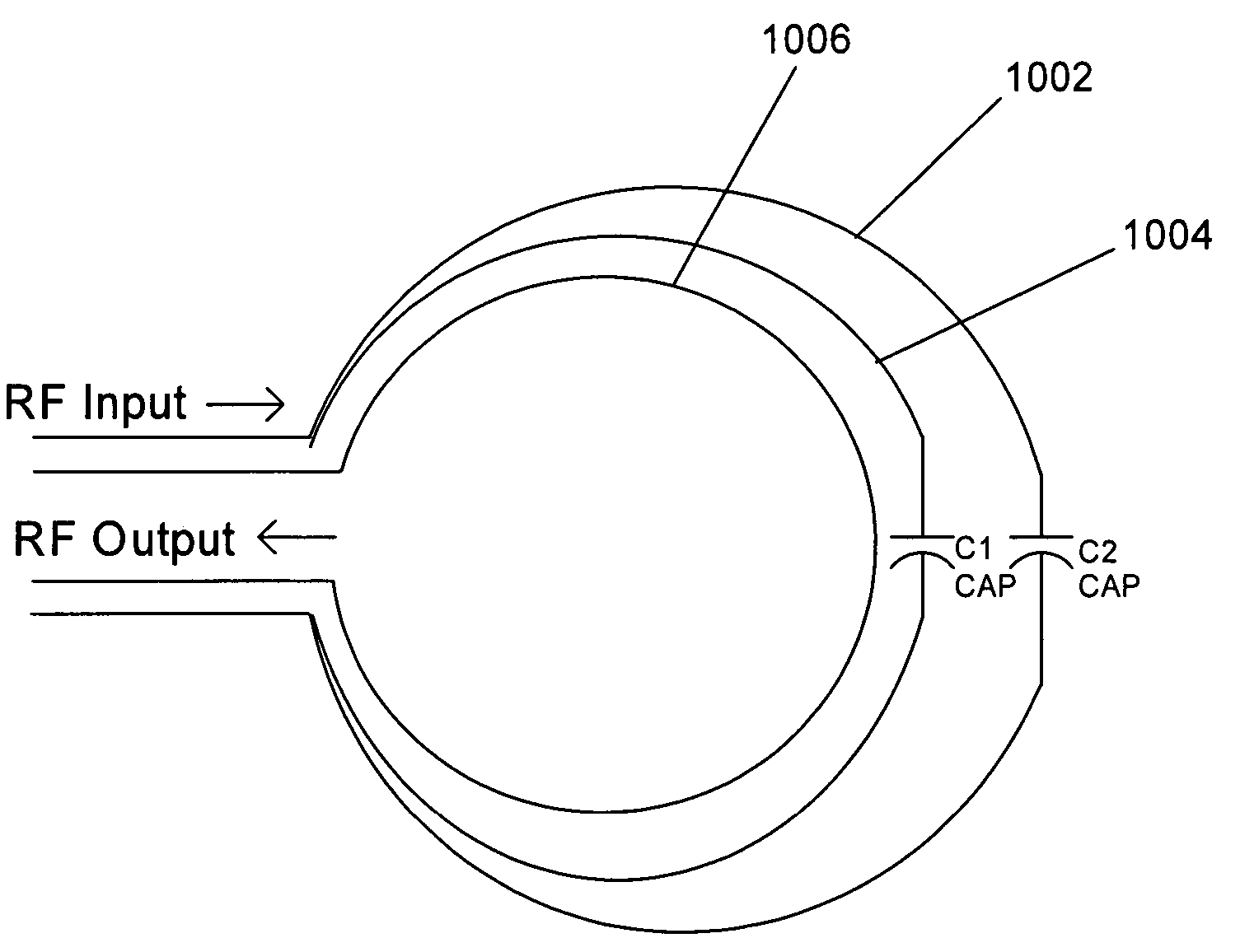

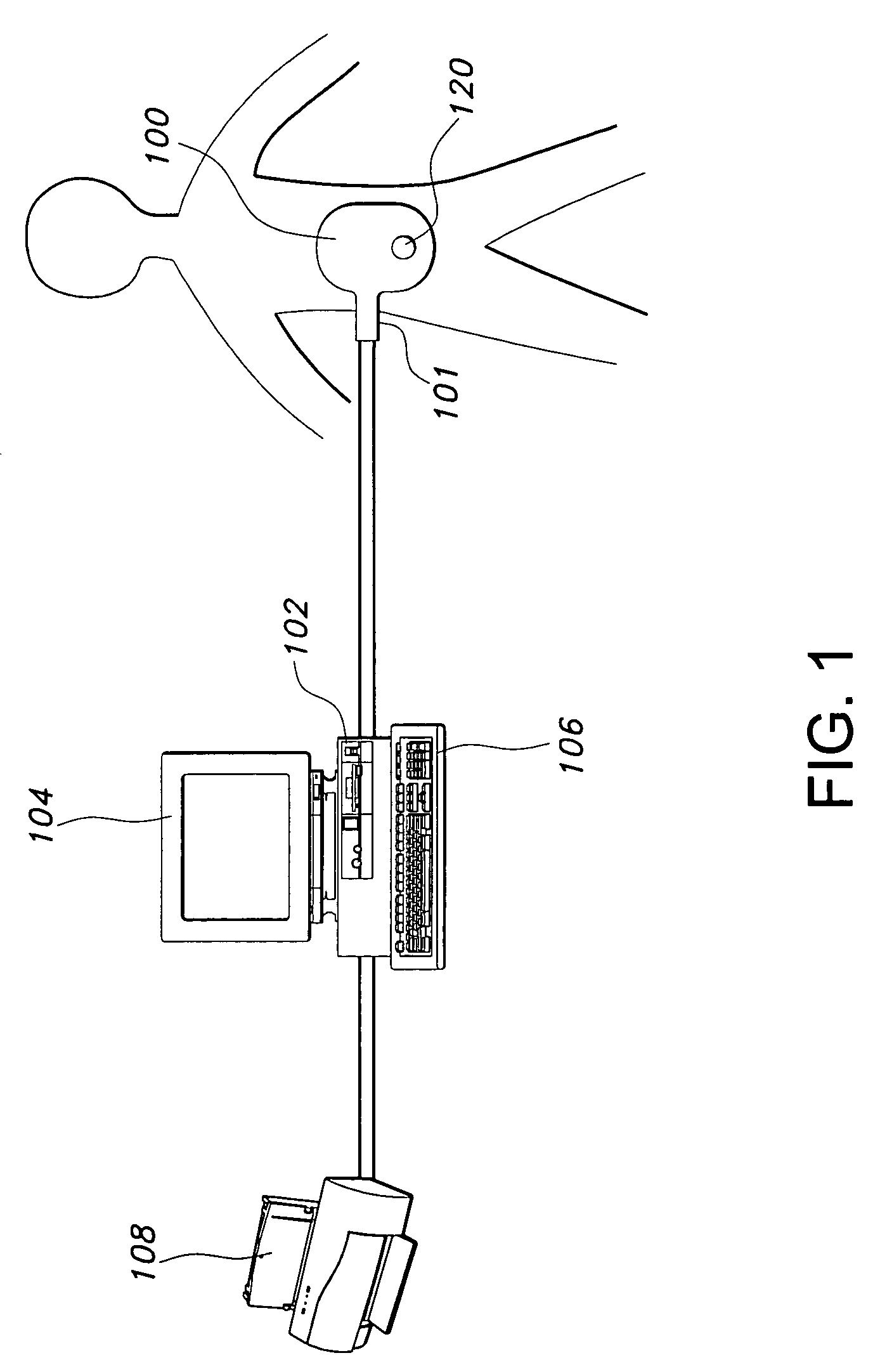

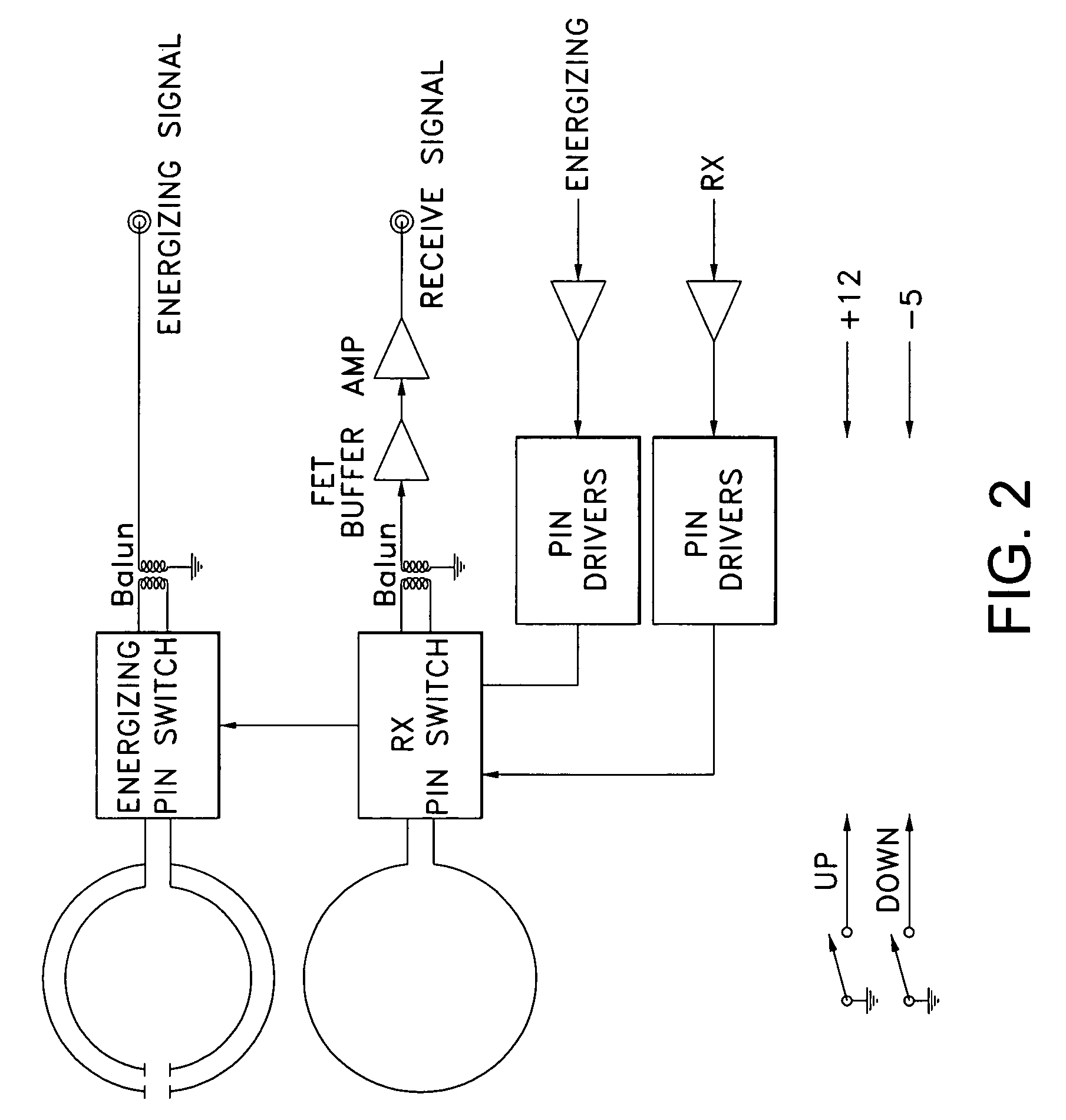

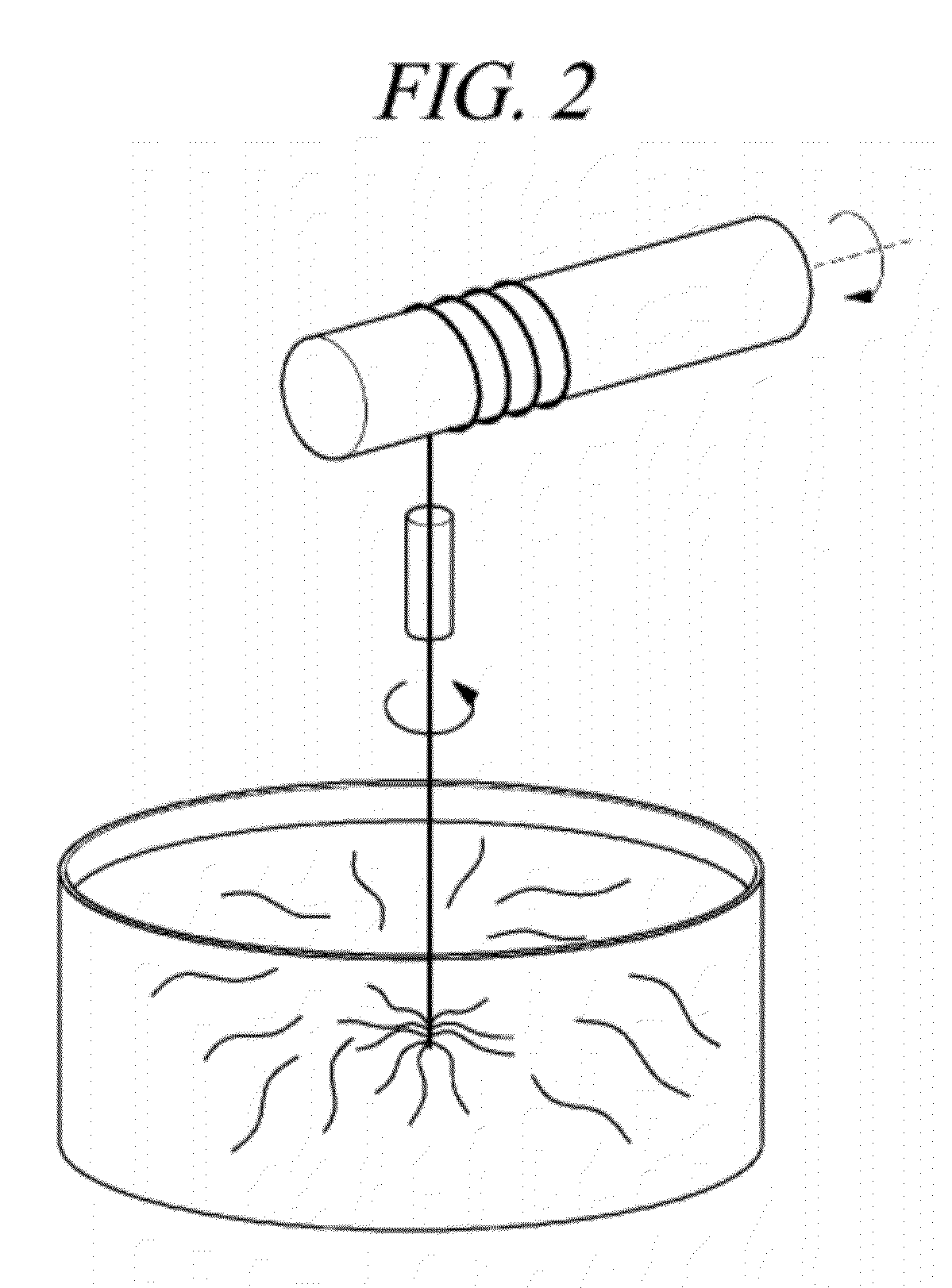

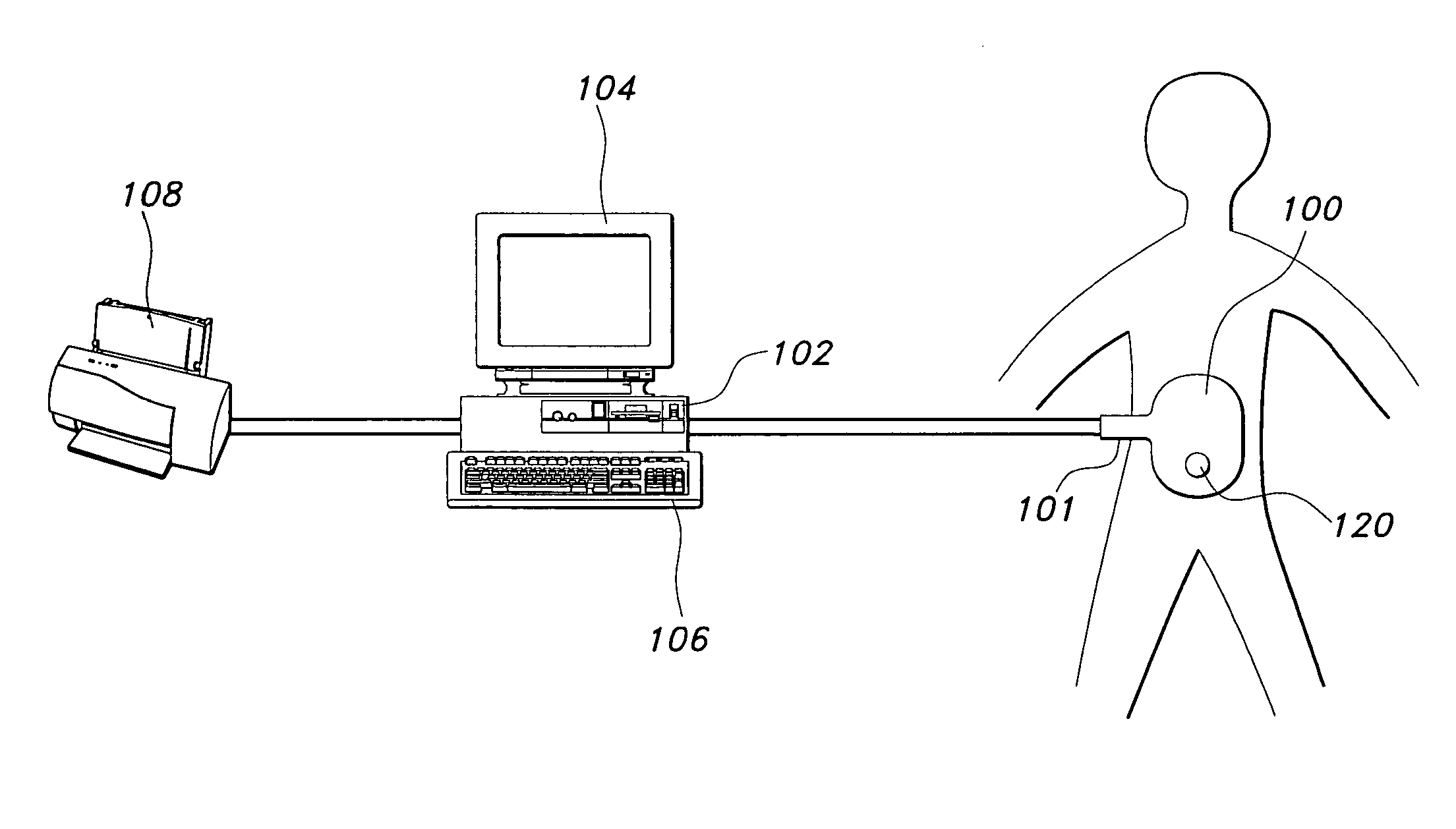

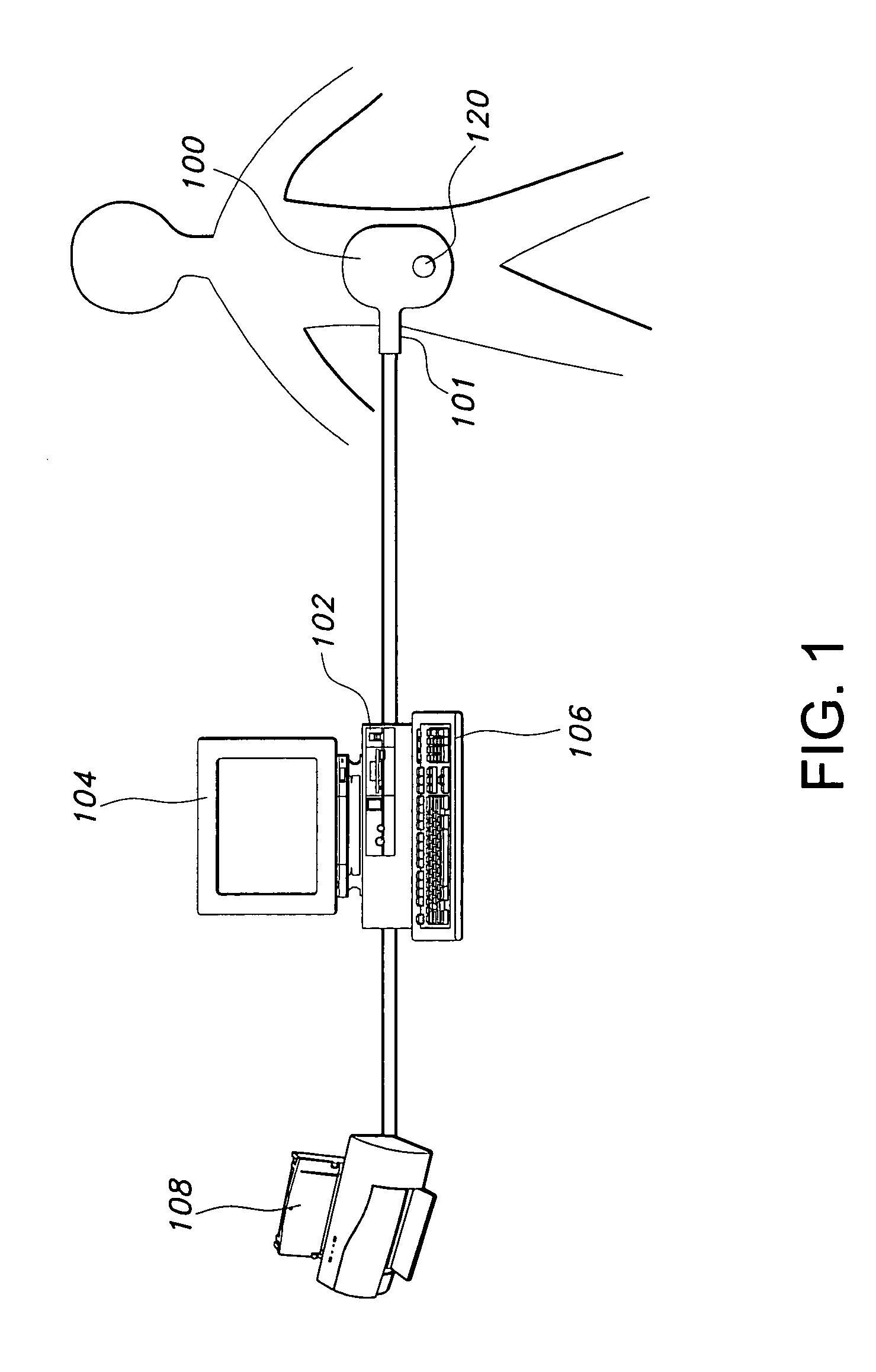

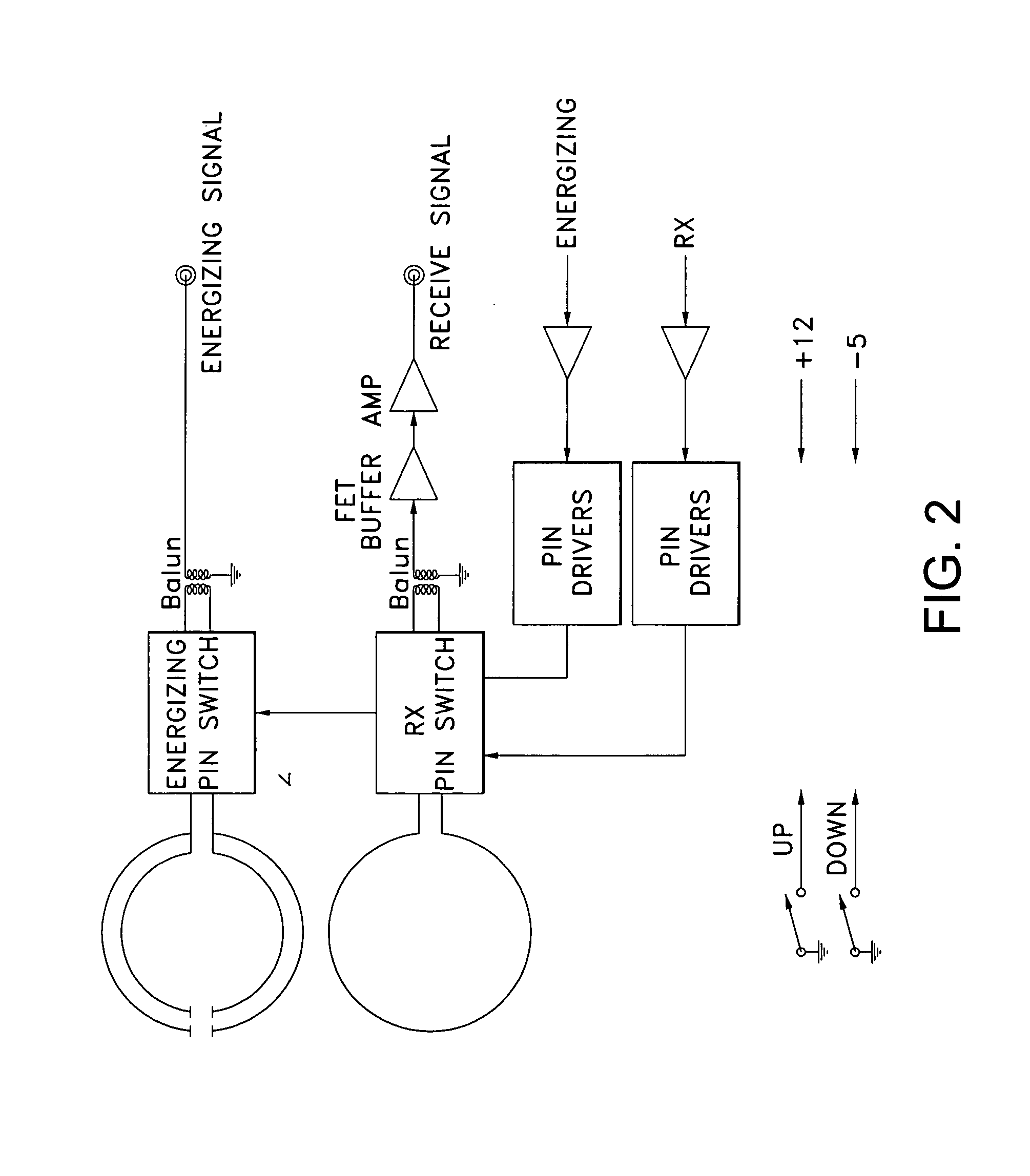

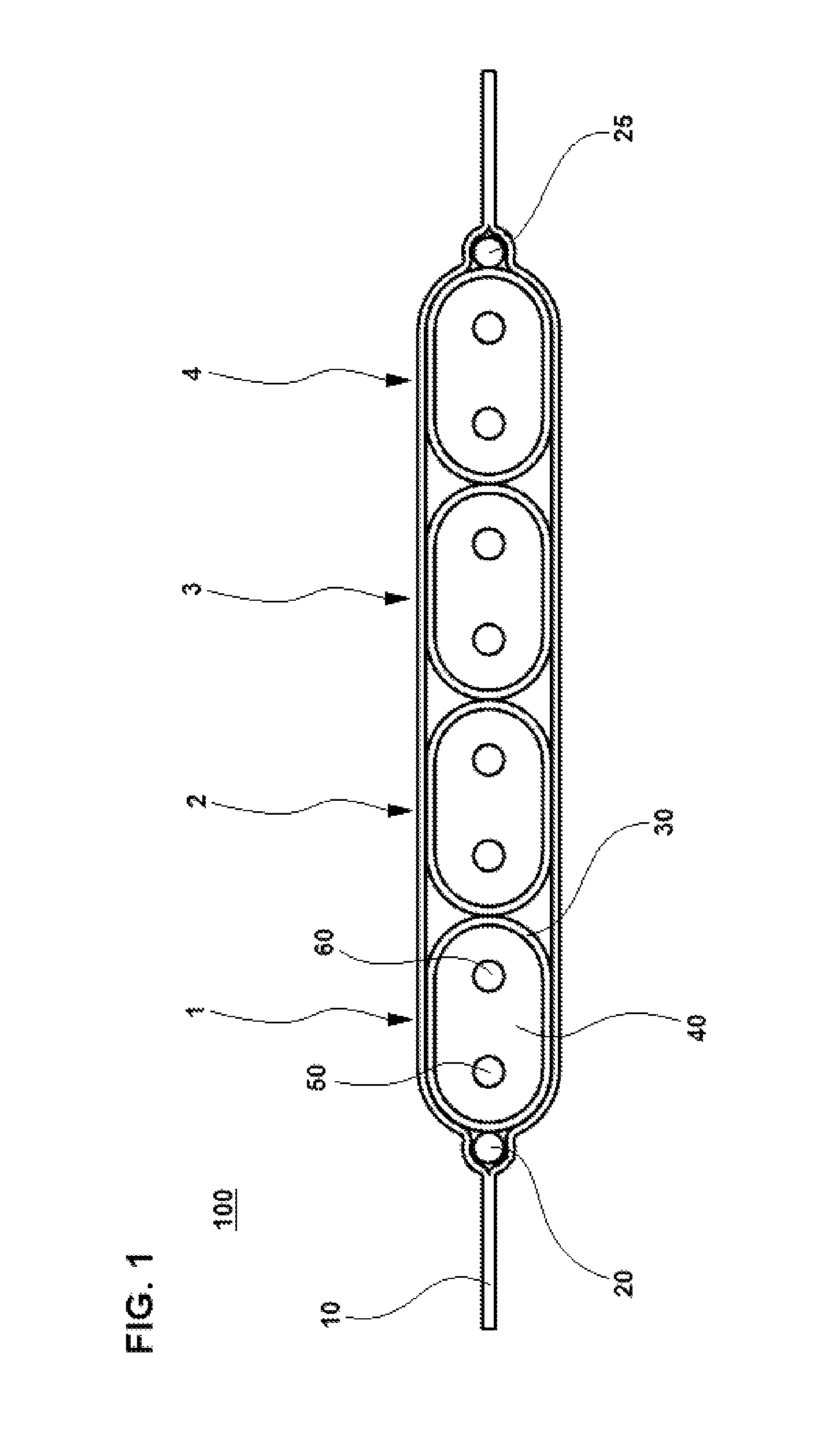

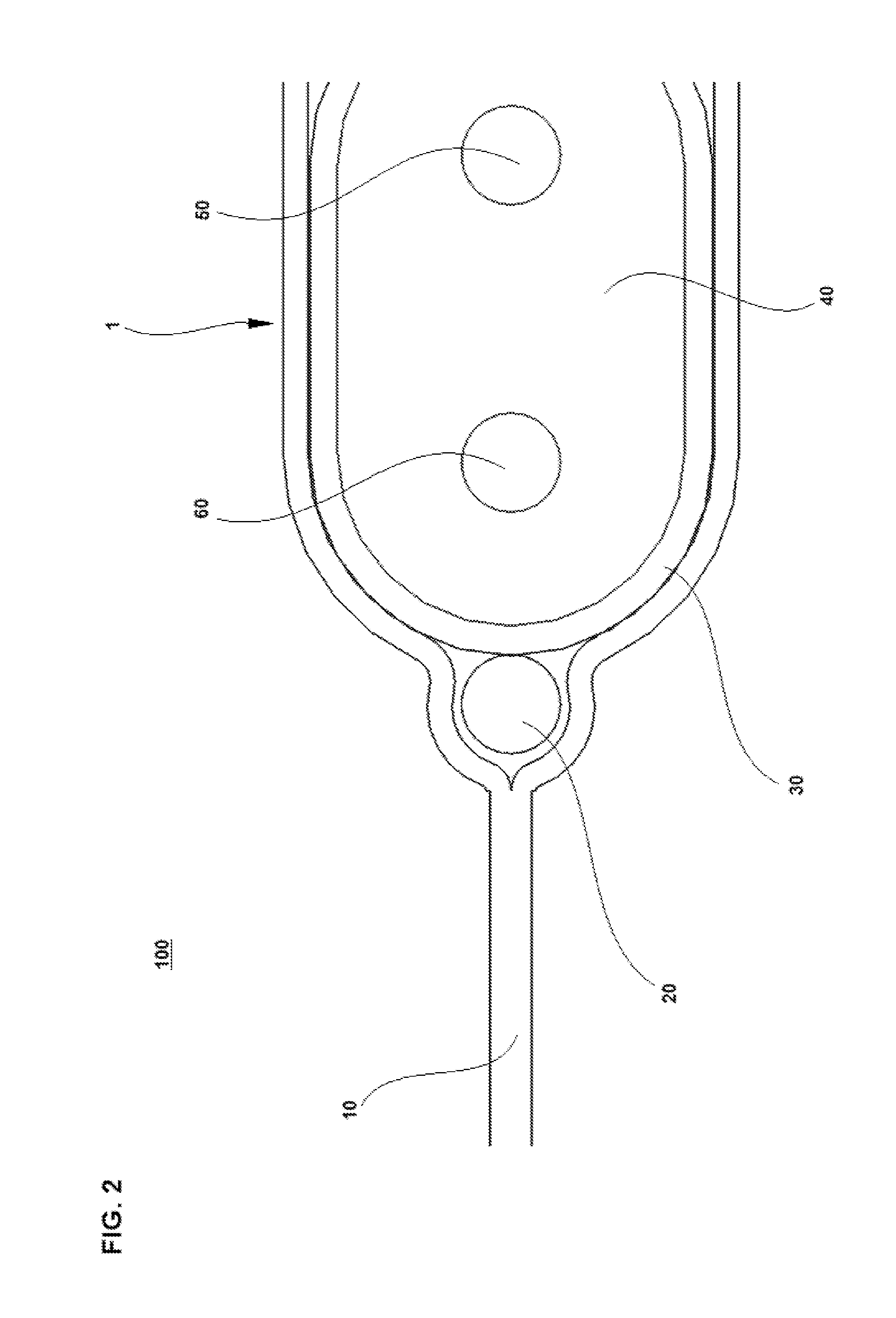

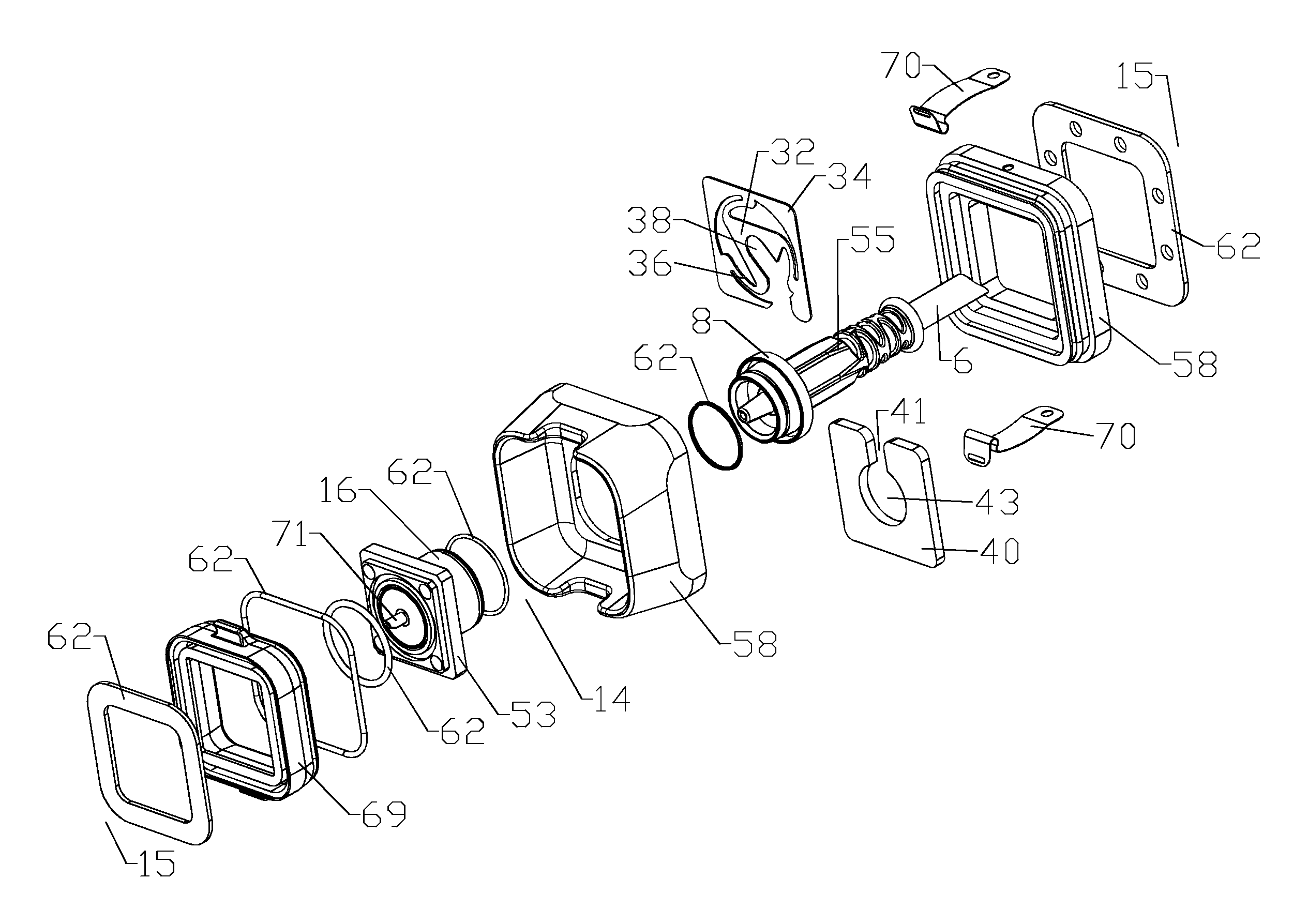

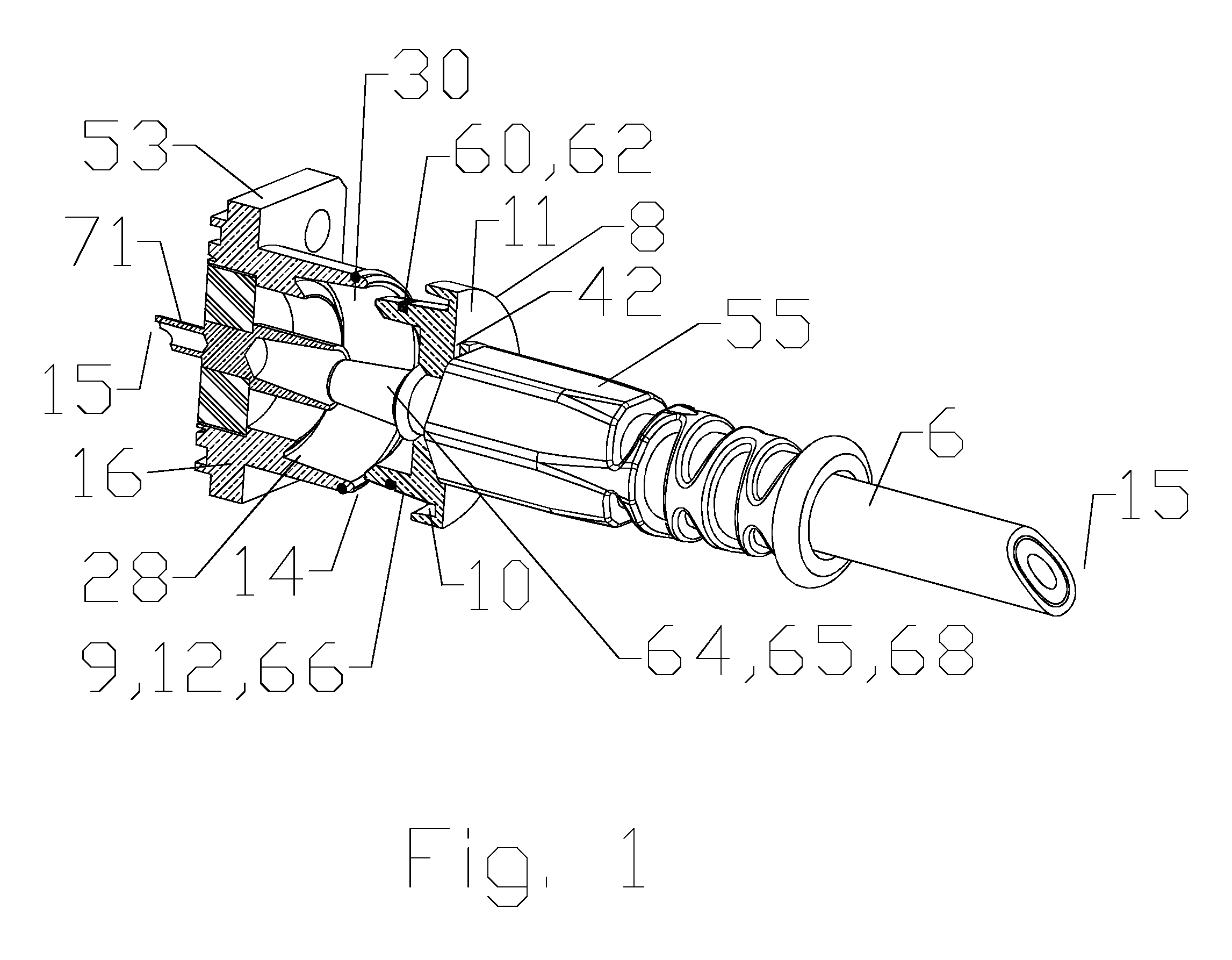

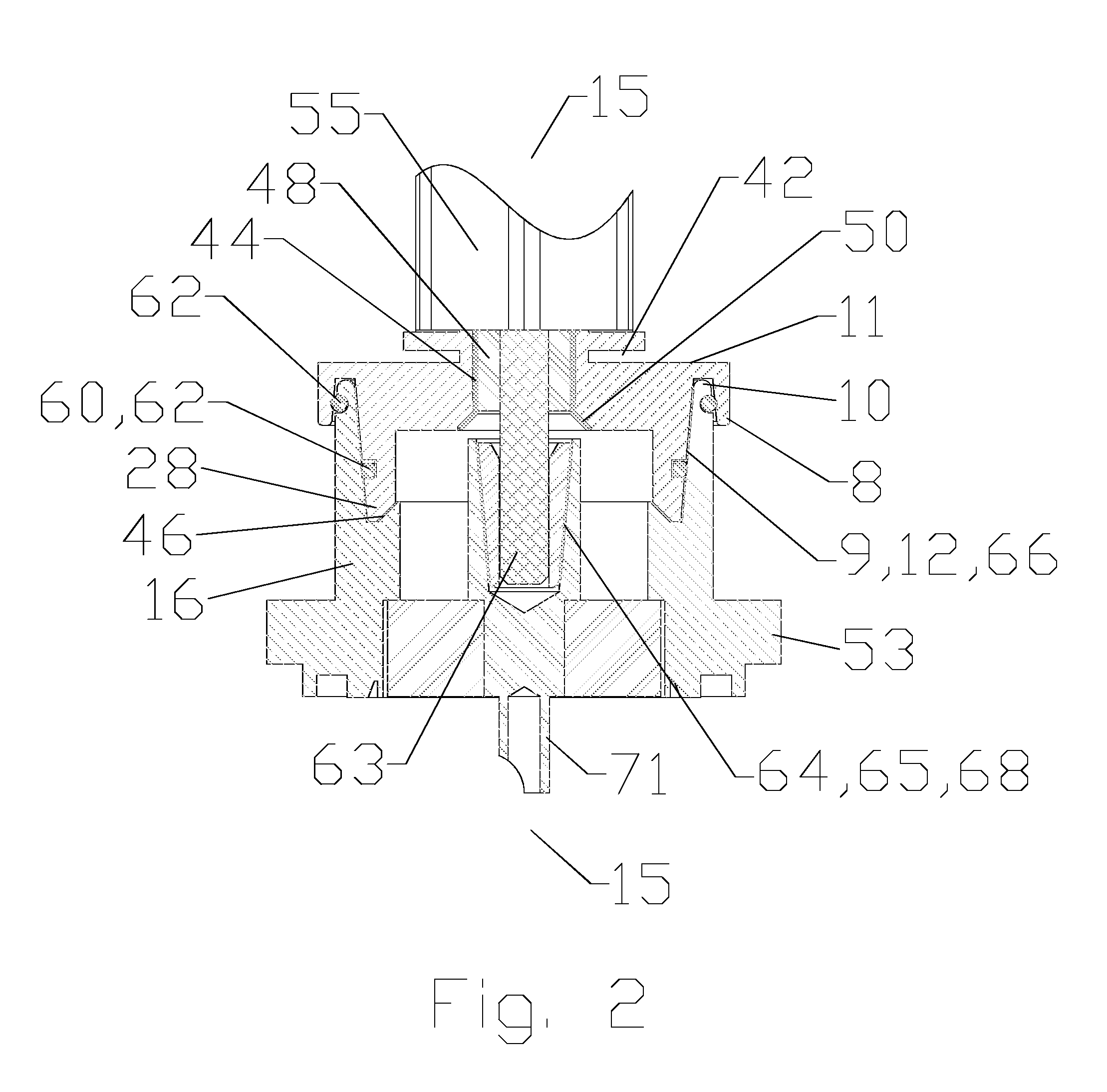

Coupling loop

ActiveUS7432723B2Increase opportunitiesAvoid breakingCoaxial cables/analogue cablesNear-field transmissionCouplingFrequency matching

A coupling loop or antenna is provided that can be used with a system that determines the resonant frequency of a sensor by adjusting the phase and frequency of an energizing signal until the frequency of the energizing signal matches the resonant frequency of the sensor. The coupling loop includes multiple loops. Preferably two tuned loops are used for transmitting the energizing signal to the sensor and an un-tuned loop is used for receiving the sensor signal from the sensor. Orientation features on the housing for the coupling loop and the sensor are provided to assist in positioning the coupling loop relative to the sensor to maximize the coupling between the sensor signal and the coupling loop.

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG II S A R L SJM LUX II

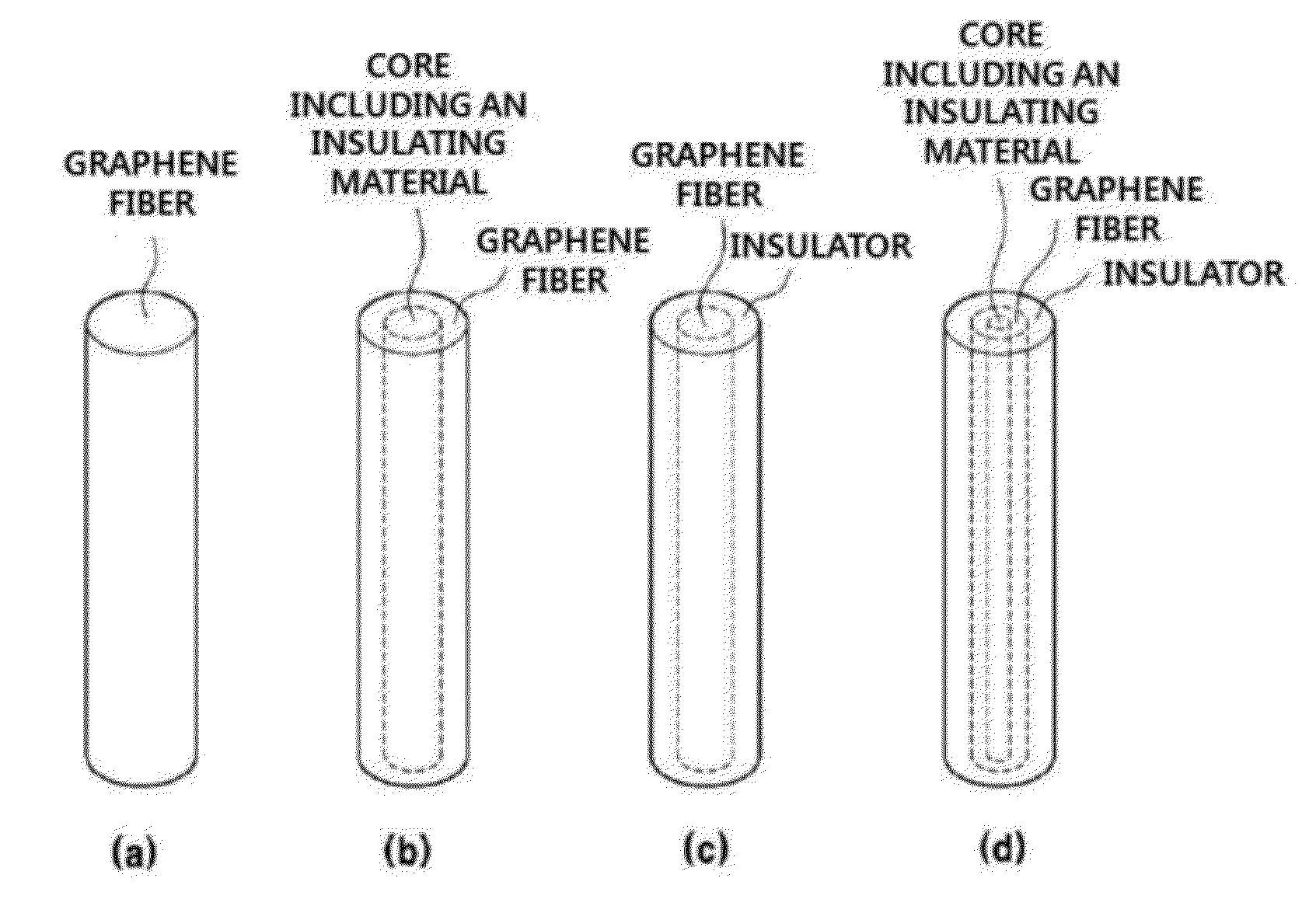

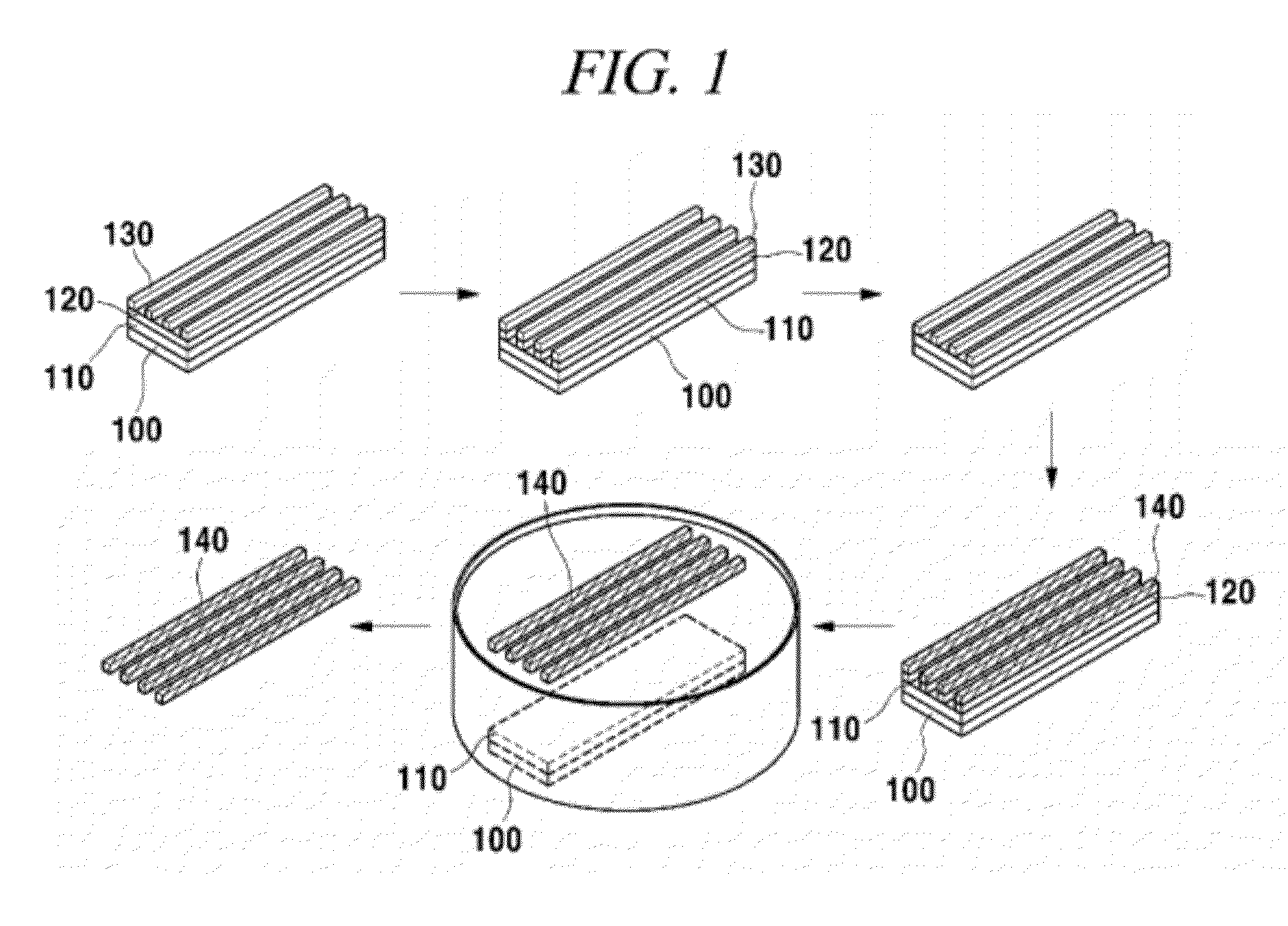

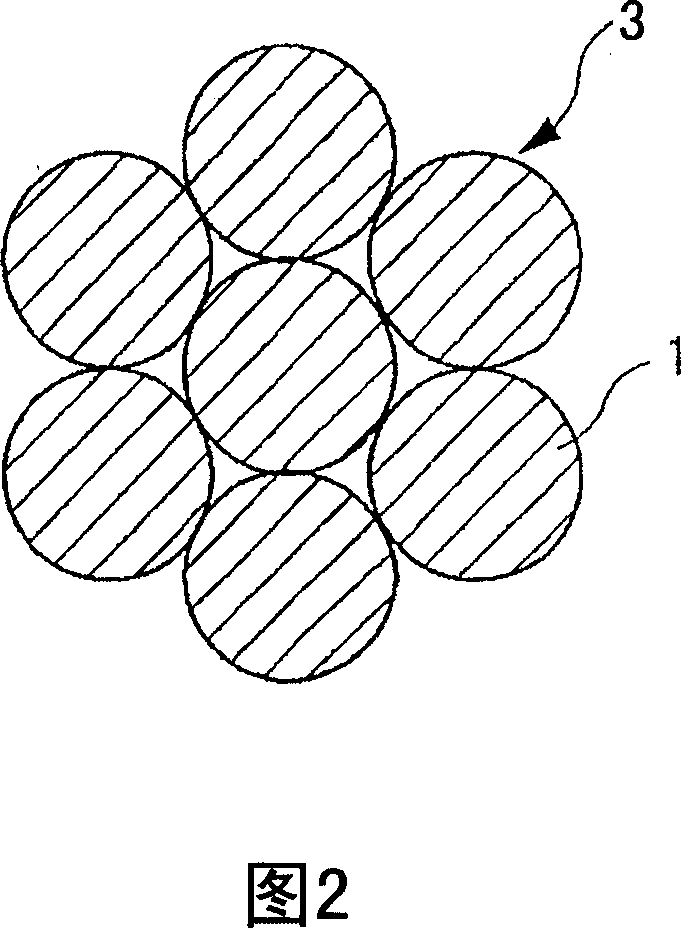

Graphene fiber, method for manufacturing same and use thereof

ActiveUS20120298396A1Quality improvementLow costCoaxial cables/analogue cablesMaterial nanotechnologyFiberCoaxial cable

The present disclosure relates to a manufacturing method of a graphene fiber, a graphene fiber manufactured by the same method, and use thereof. The graphene fiber formed by using graphenes of linear pattern can be applied to various fields such as an electric wire and coaxial cable.

Owner:GRAPHENE SQUARE

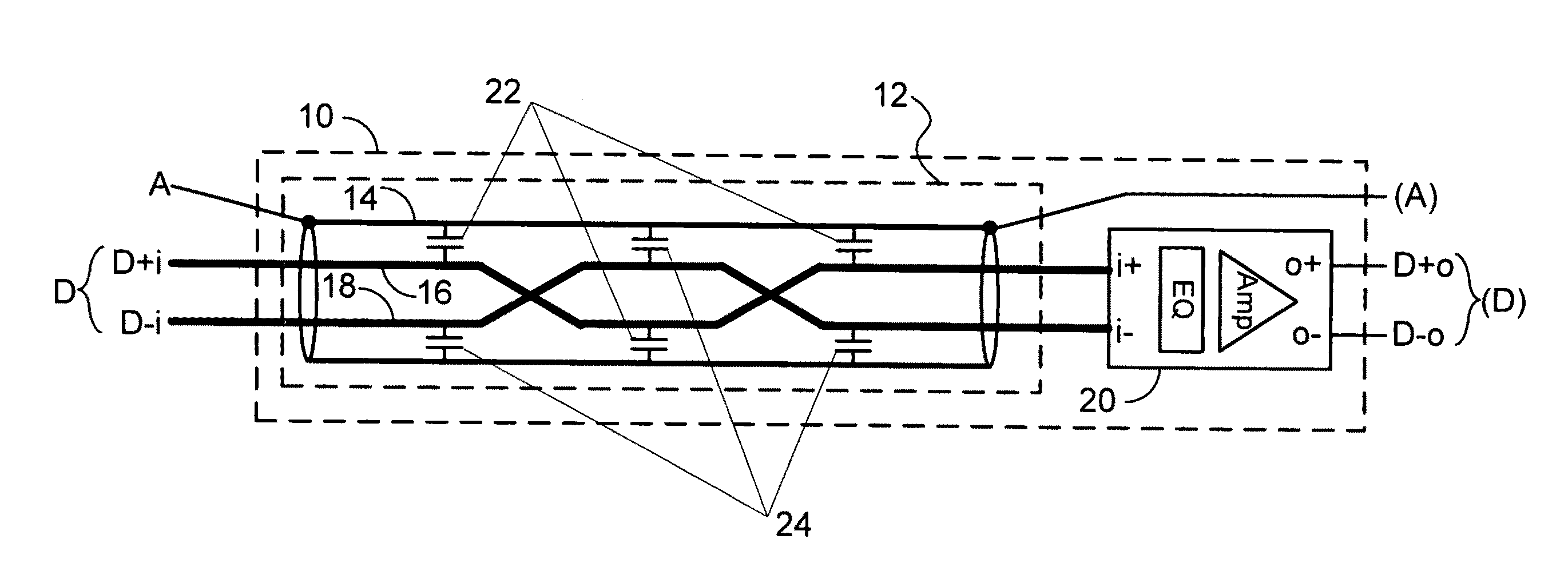

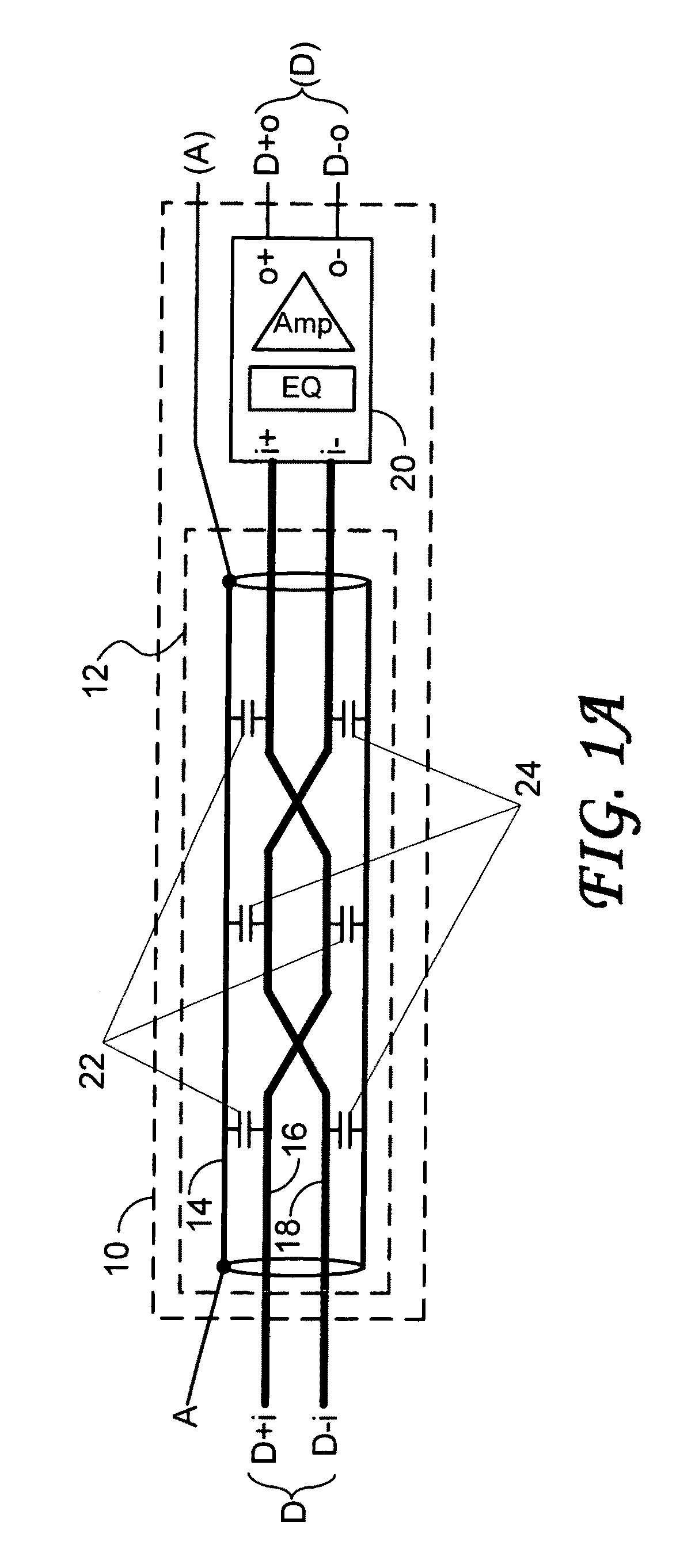

High speed data cable with impedance correction

ActiveUS20120012358A1Maintain good propertiesExact impedanceCoaxial cables/analogue cablesLine-transmission detailsCoaxial lineHigh speed video

A high speed video cable carries signals according to the High-Definition Multimedia Interface (HDMI) or DisplayPort standards, and includes a raw cable and may include a boost device. The raw cable includes coaxial lines of a characteristic cable impedance higher than the impedance implied in the standards. The correct impedance is observed at the sending end by shunt resistors mounted in the first cable connector. The resultant loss of signal may be made up with the boost device mounted in the connector at the other end of the cable in the case of a long cable. Increasing the cable impedance reduces the inherent loss of the raw cable thus permitting the use of low cost material such as tinned wires. Similar advantages are obtained regardless whether Shielded Twisted Pairs (STP) or coaxial lines are used.

Owner:REDMERE TECH

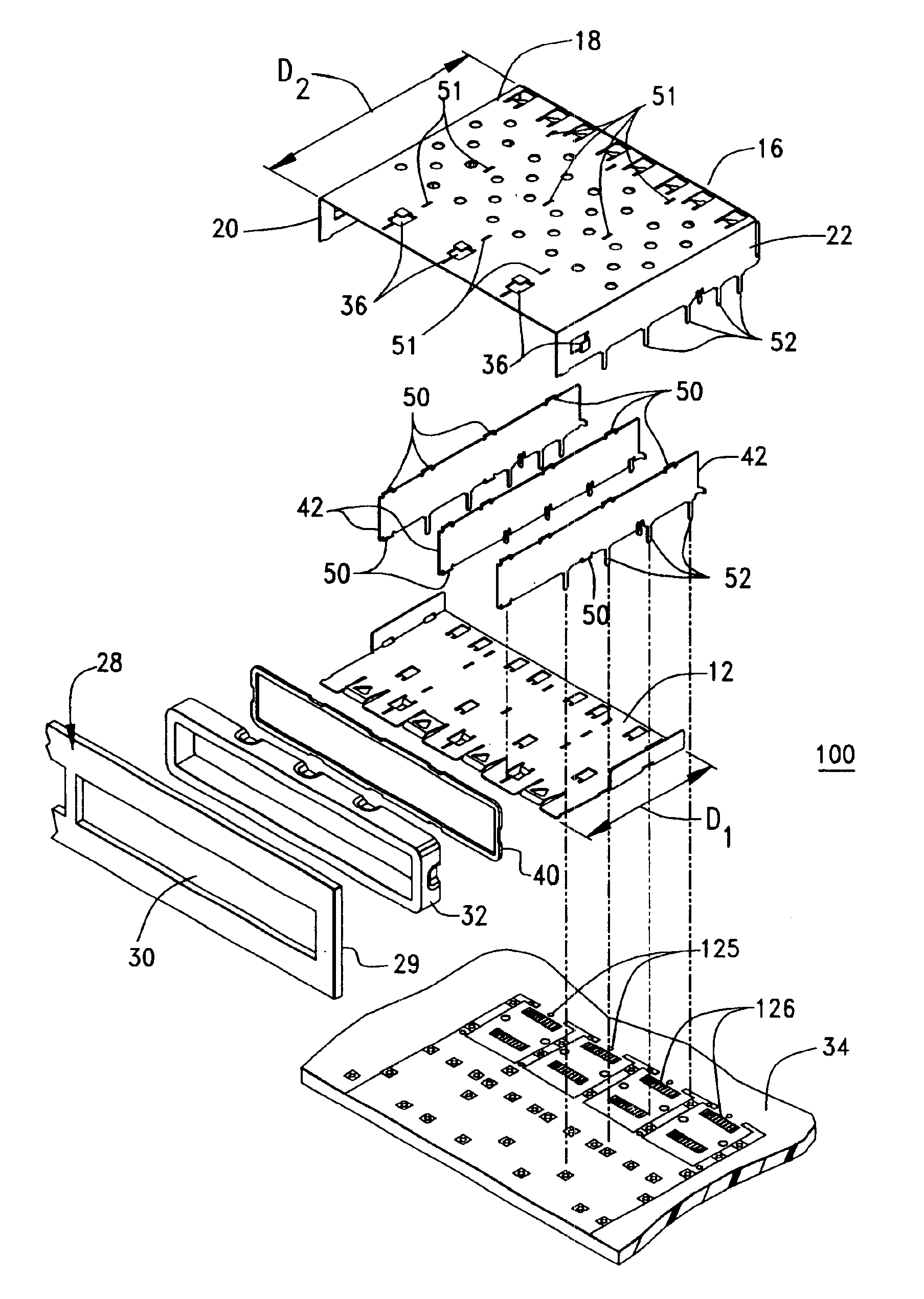

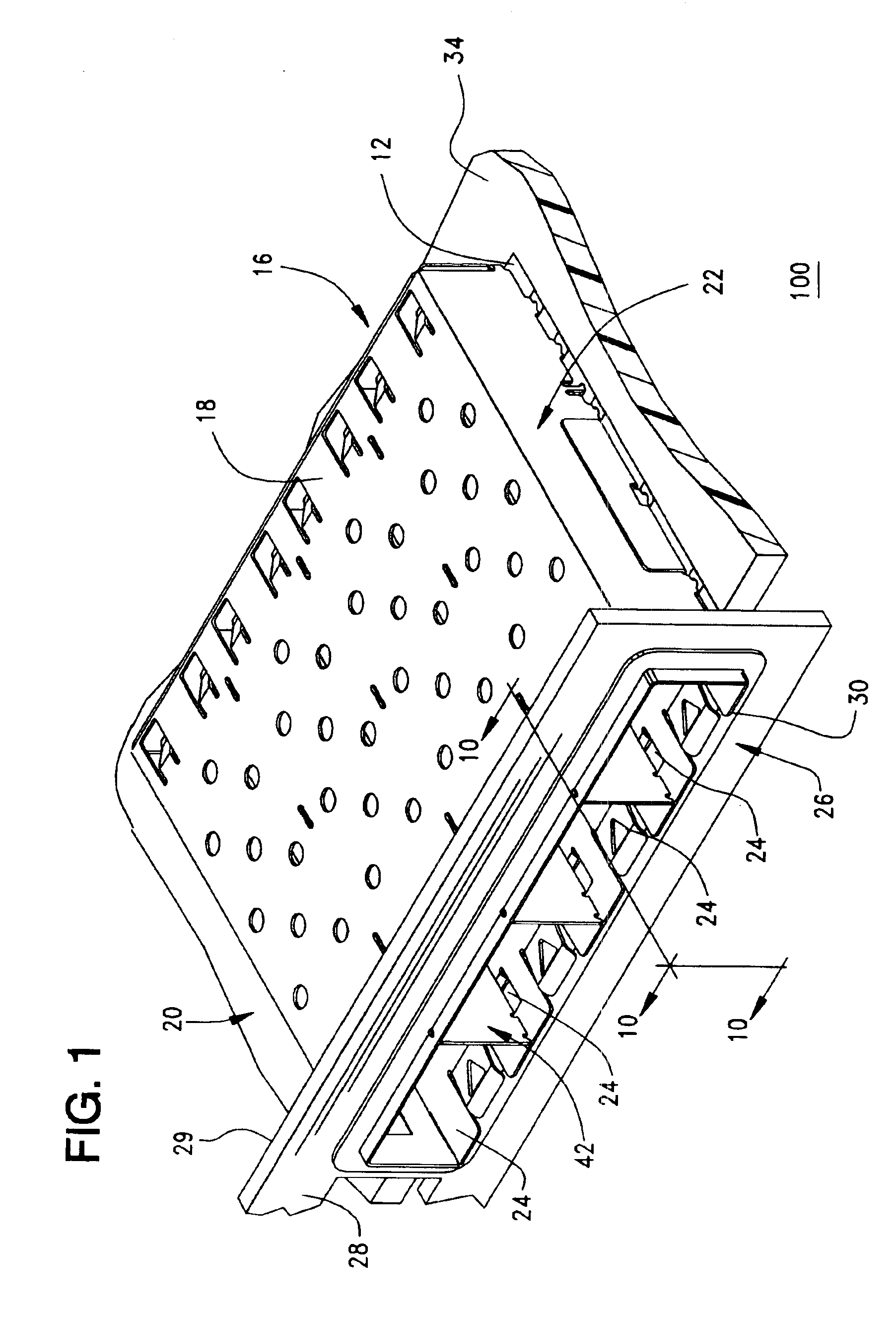

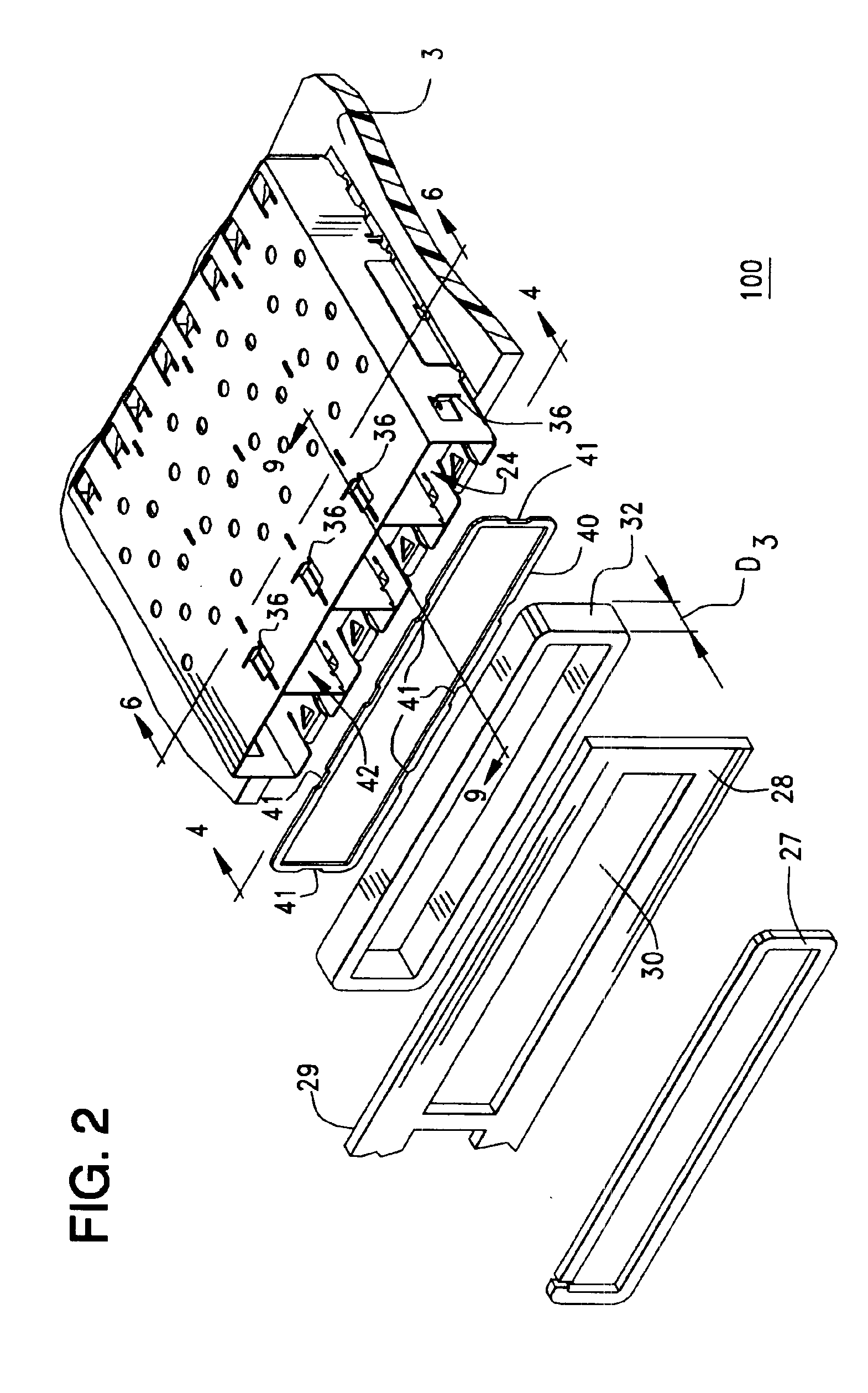

Shielding cage with improved EMI shielding gasket construction

ActiveUS6943287B2Provide supportCoaxial cables/analogue cablesElectrically conductive connectionsElectromagnetic interferenceElectrical connection

An electromagnetic interference (EMI) shielding cage for an electronic module is comprised an electrically-conductive bottom, an electrically-conductive rear panel electrically coupled to said bottom, an electrically-conductive, elongated cover electrically coupled to said bottom and first and second side walls that are electrically and mechanically coupled to said bottom, said rear panel and said elongated cover. Numerous ground lugs, electrically coupled to at least one of: said bottom; rear panel; and first and second side walls provide an electrical pathway for EMI signals to a reference potential. An electrically-conductive, compressible gasket encircling the bottom, top and side walls provides an electrical connection to a front panel, providing additional EMI suppression. Gasket engagement tabs in the top and bottom provide electrical connection between the gasket and panels.

Owner:MOLEX INC

Coupling loop and method for positioning coupling loop

ActiveUS20060244465A1Avoid breakingIncrease opportunitiesCoaxial cables/analogue cablesNear-field transmissionCouplingFrequency matching

A coupling loop or antenna is provided that can be used with a system that determines the resonant frequency of a sensor by adjusting the phase and frequency of an energizing signal until the frequency of the energizing signal matches the resonant frequency of the sensor. The coupling loop includes multiple loops. Preferably two tuned loops are used for transmitting the energizing signal to the sensor and an un-tuned loop is used for receiving the sensor signal from the sensor. Orientation features on the housing for the coupling loop and the sensor are provided to assist in positioning the coupling loop relative to the sensor to maximize the coupling between the sensor signal and the coupling loop.

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG II S A R L SJM LUX II

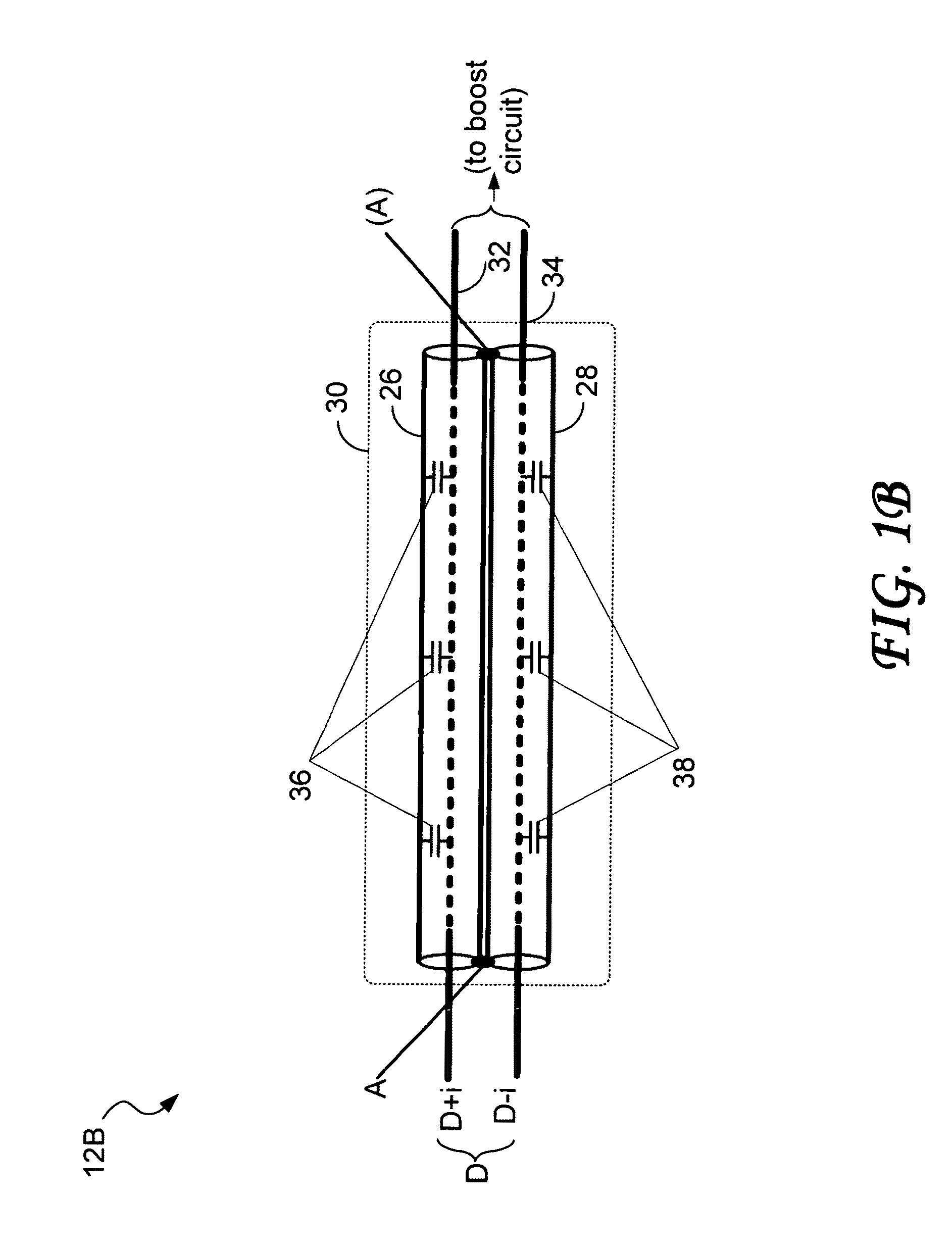

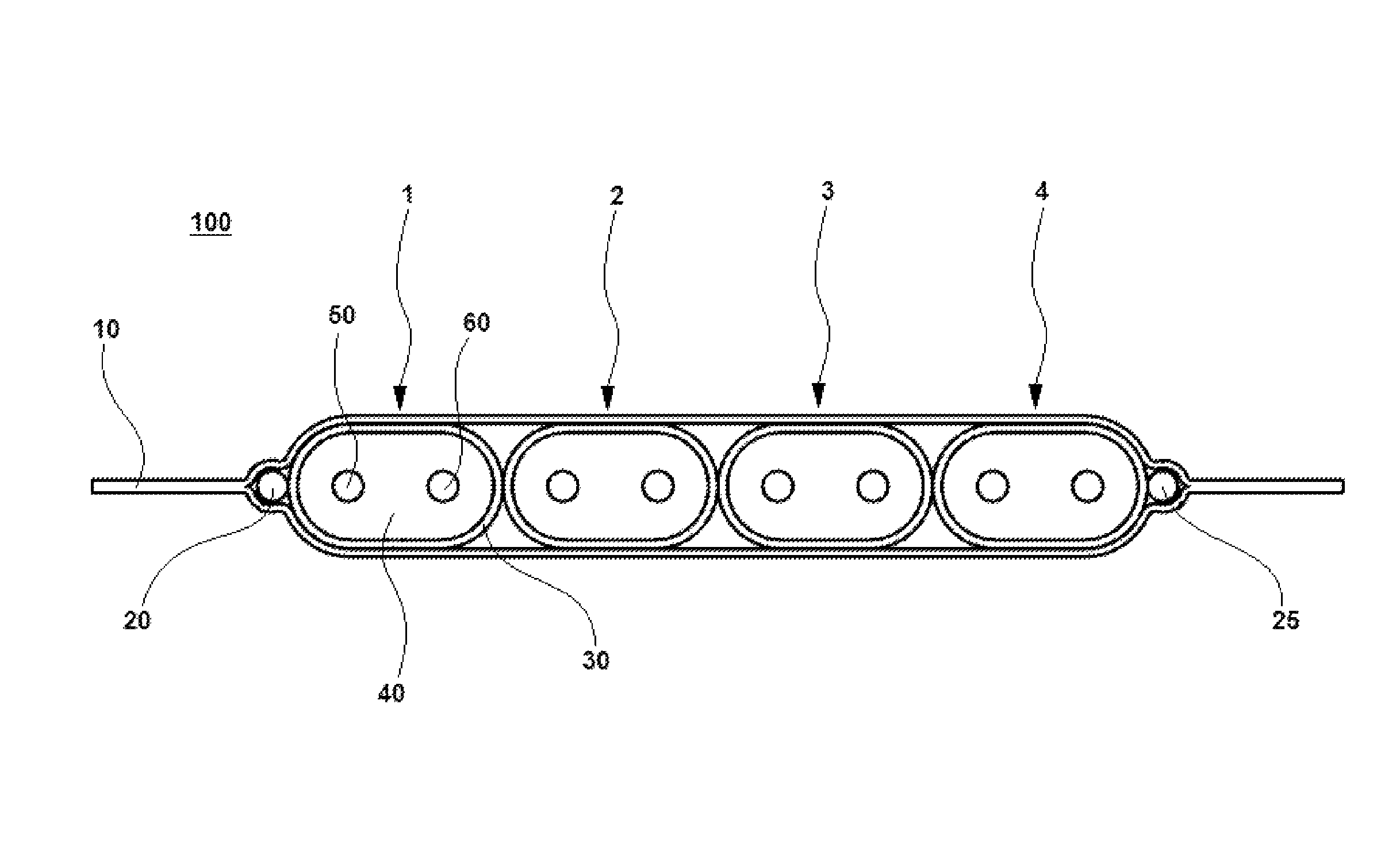

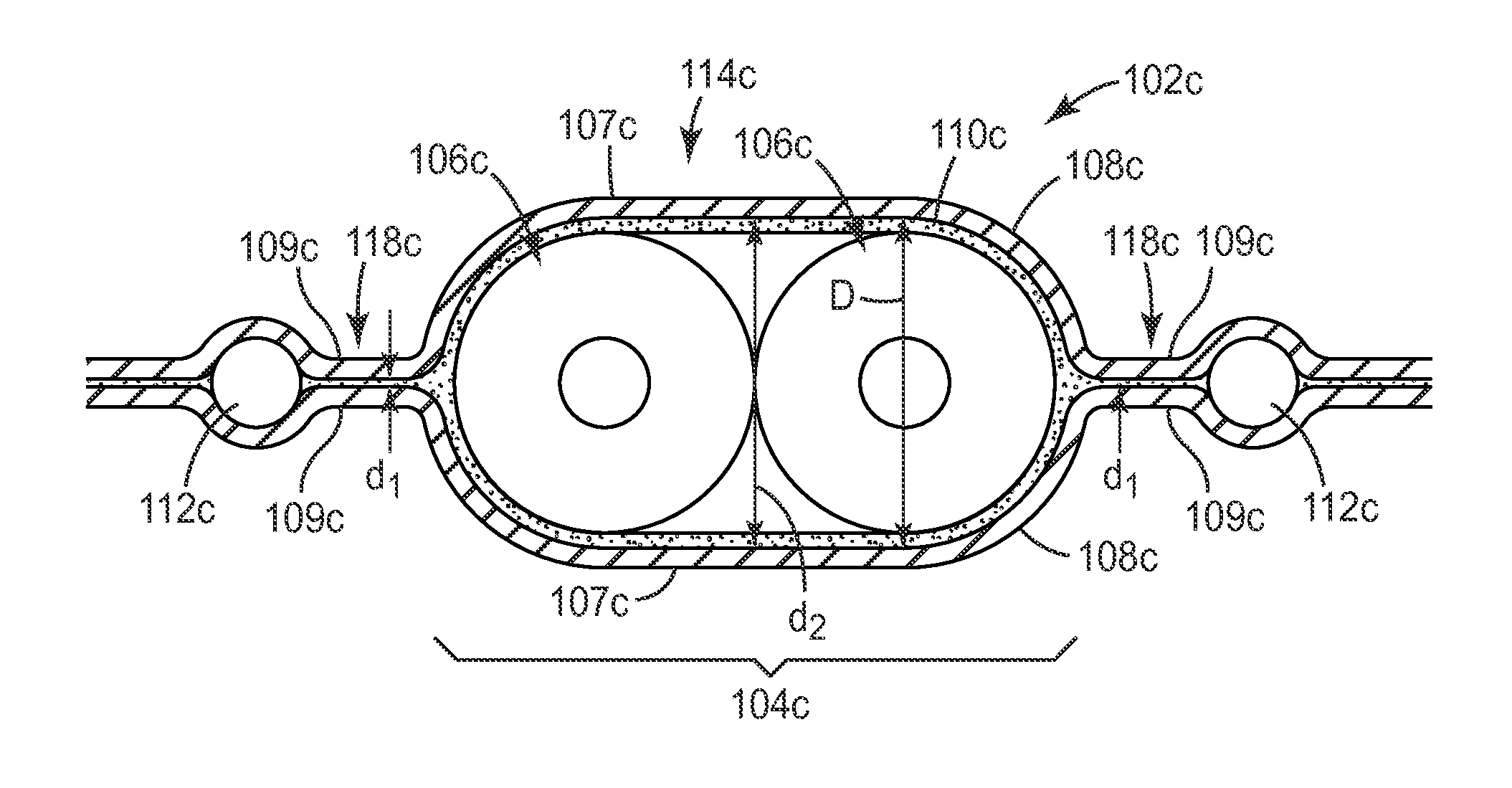

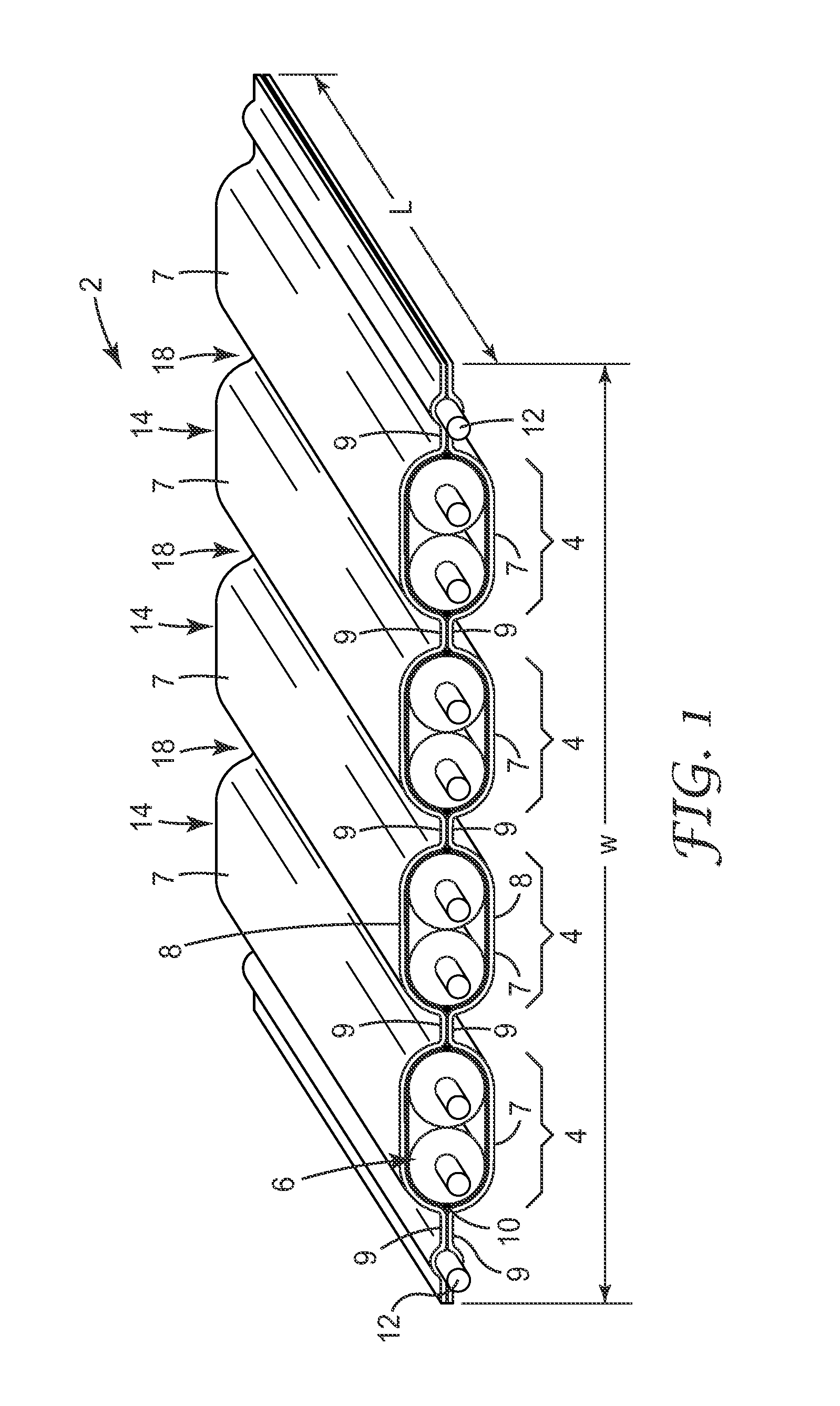

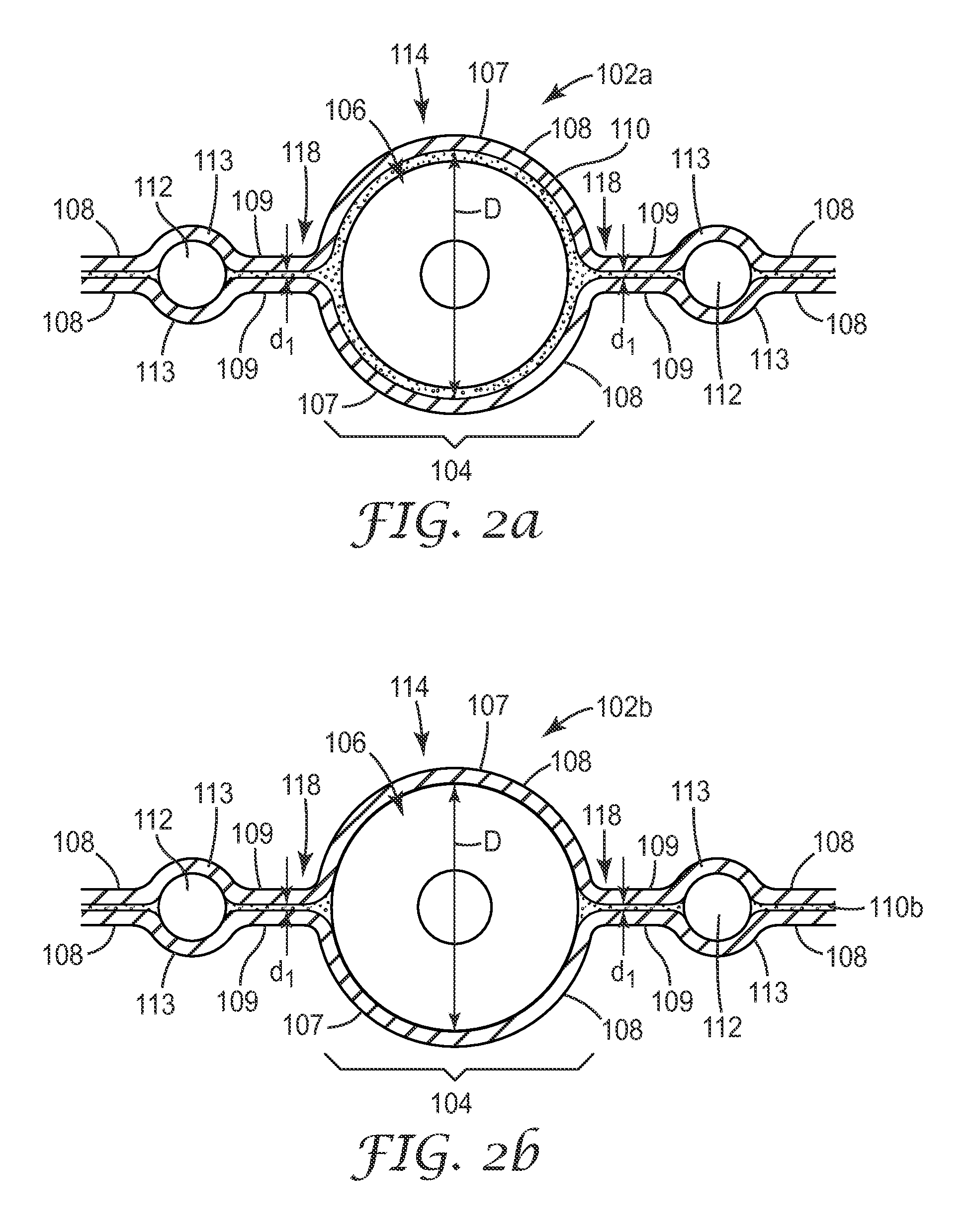

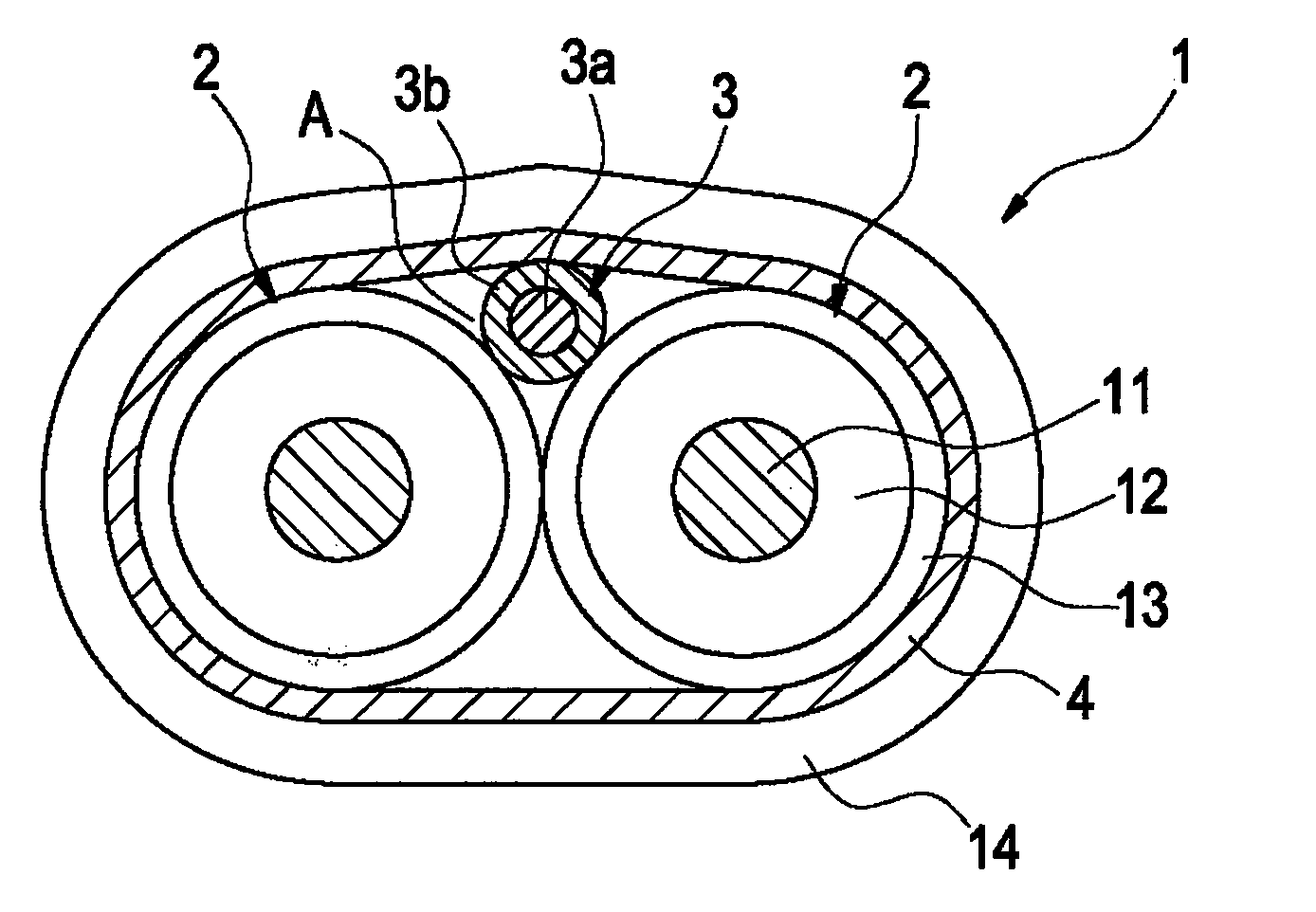

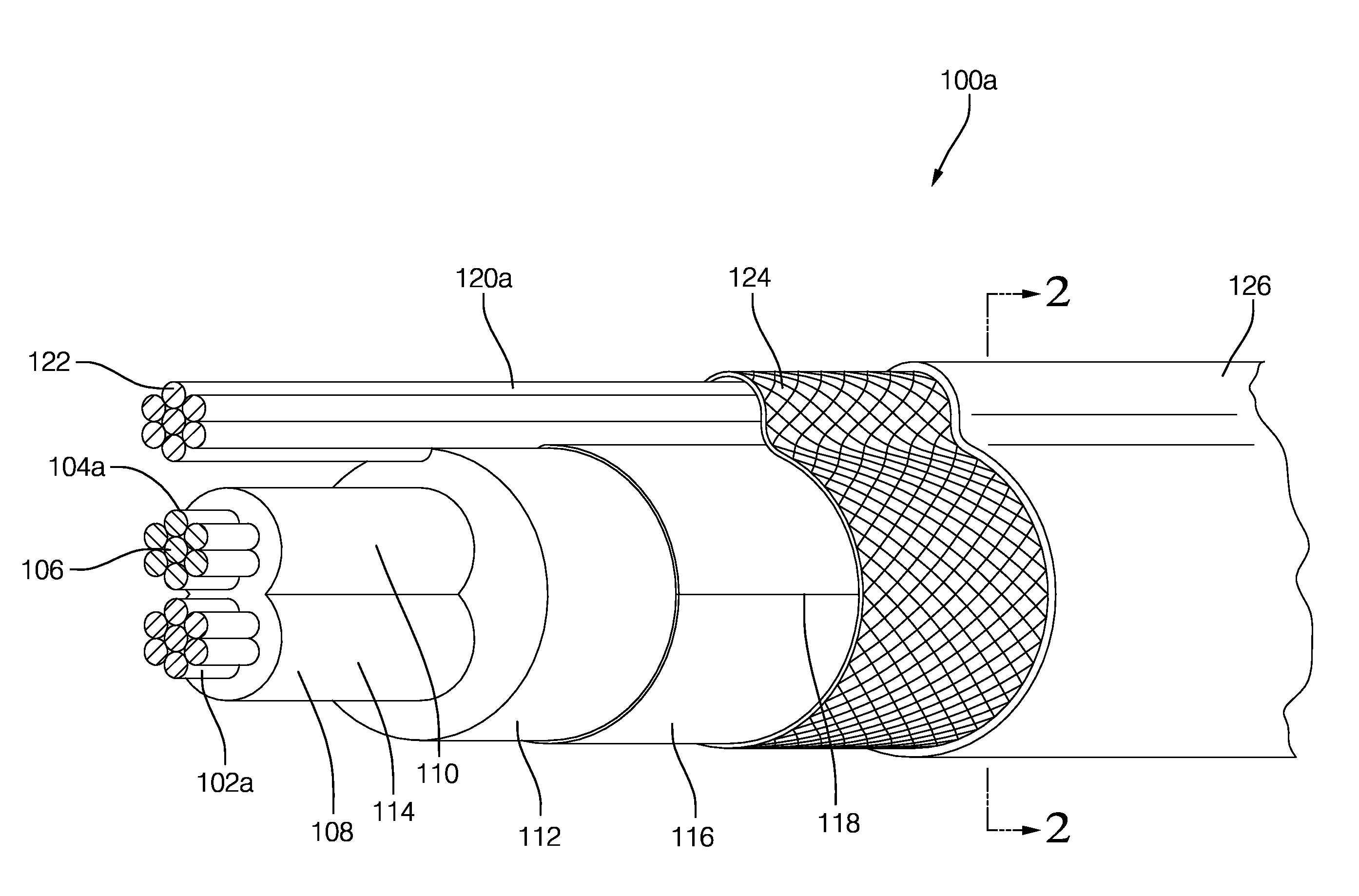

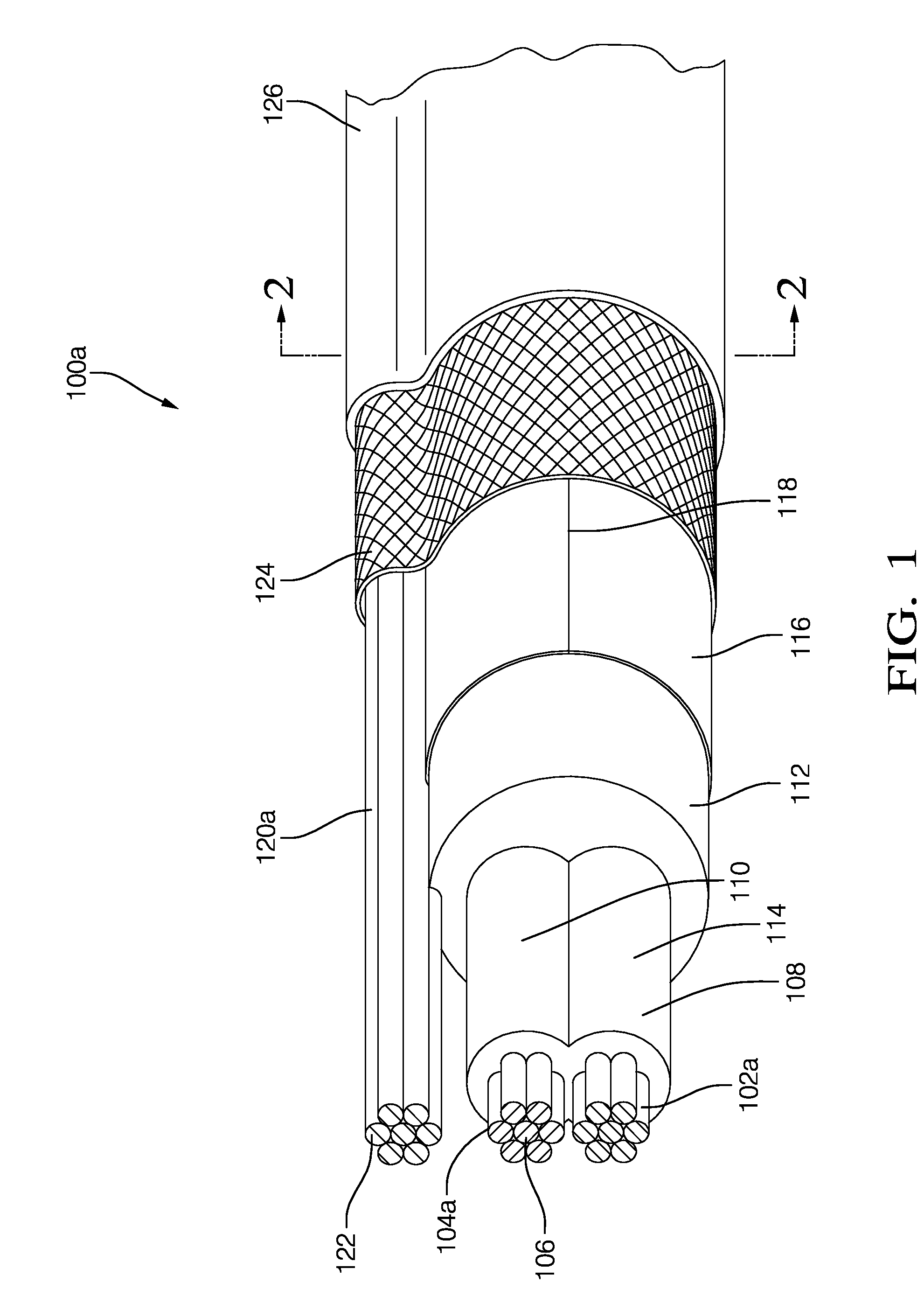

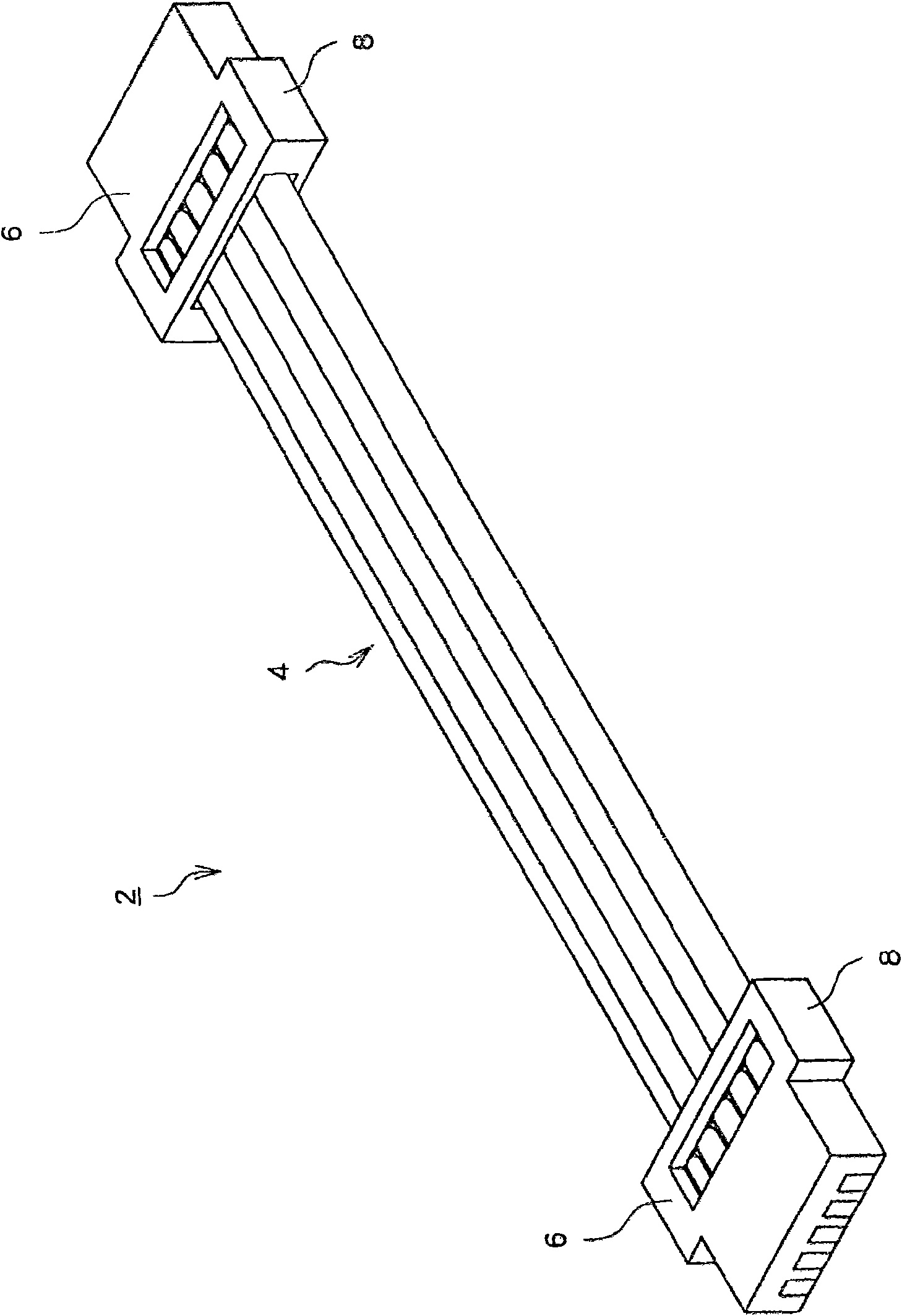

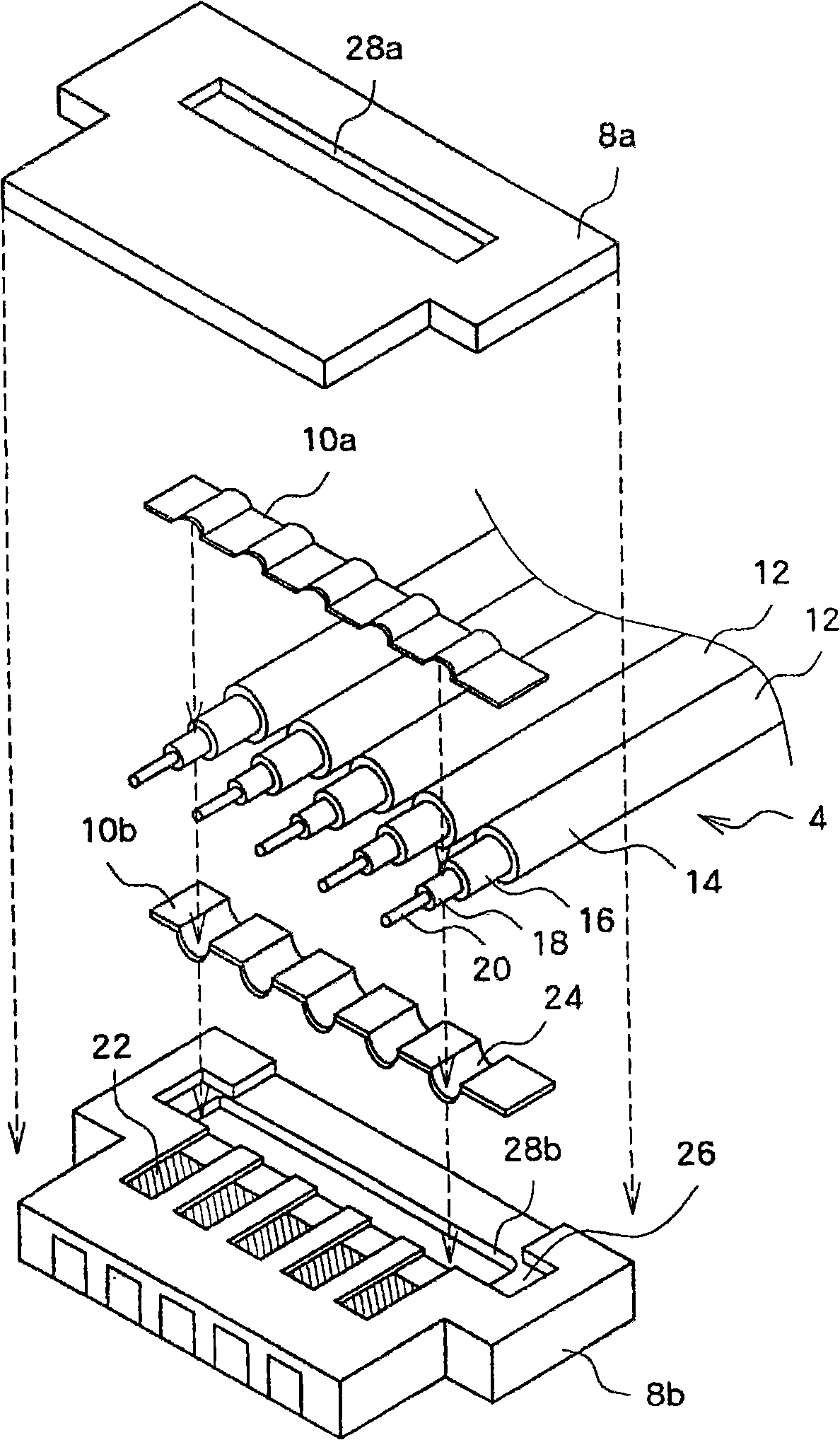

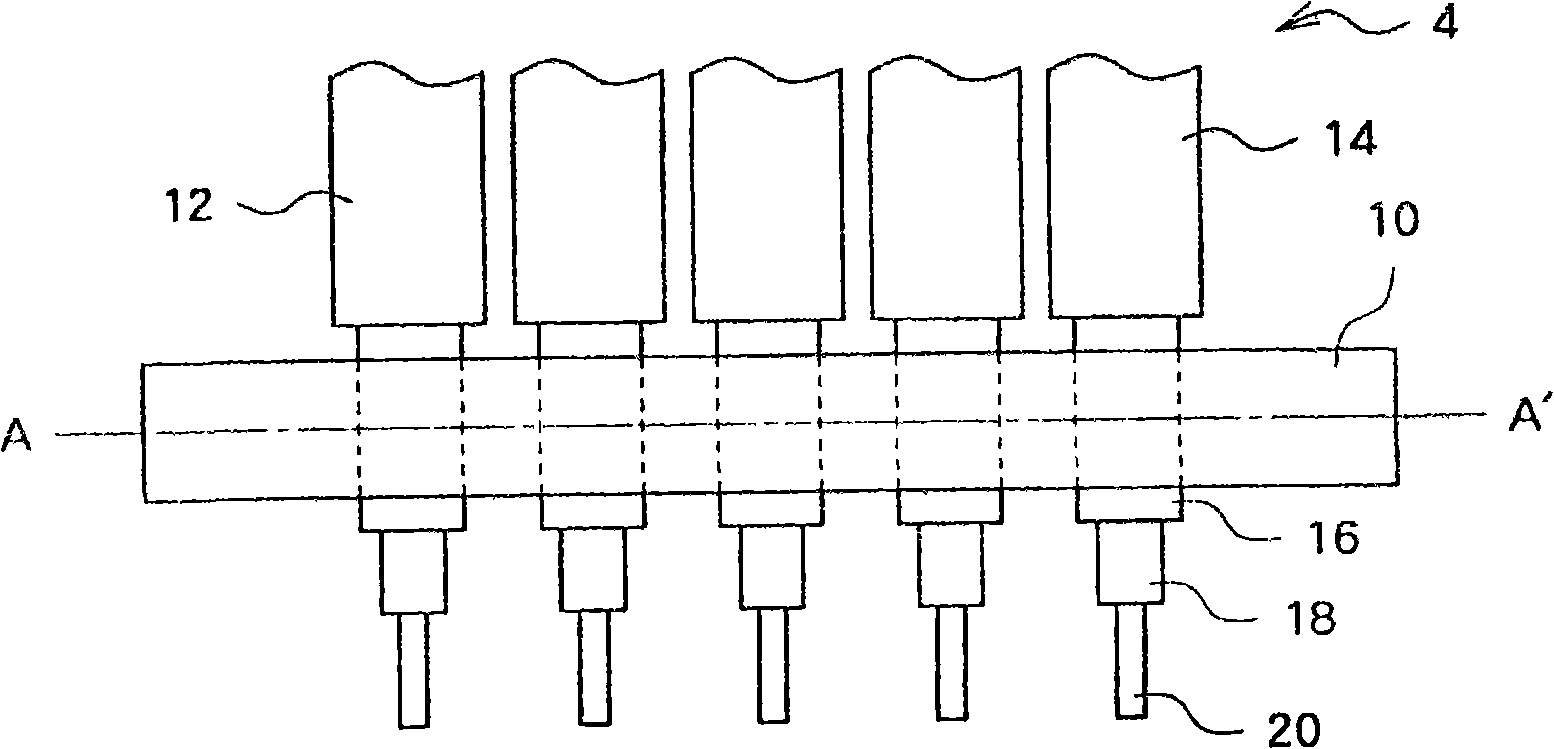

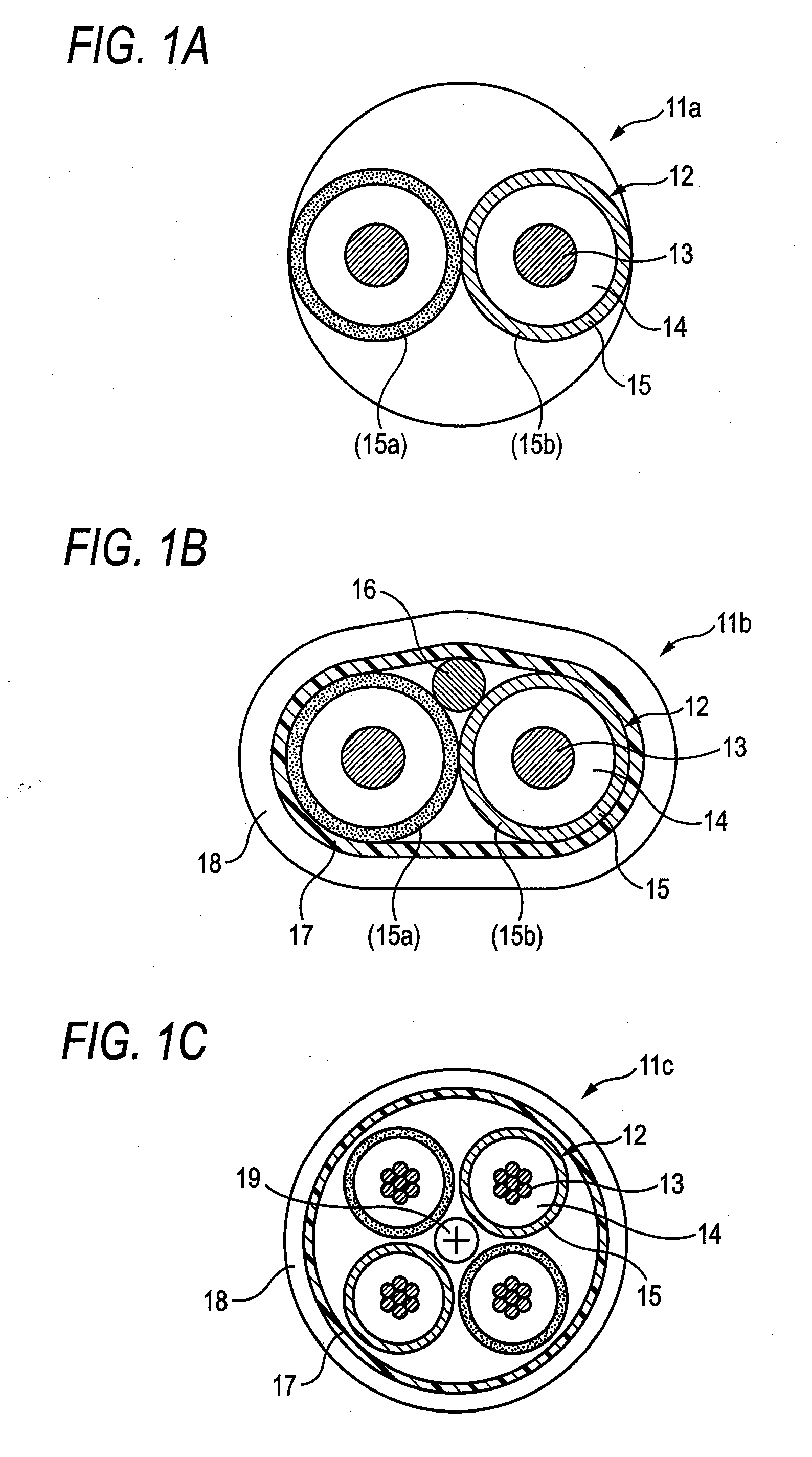

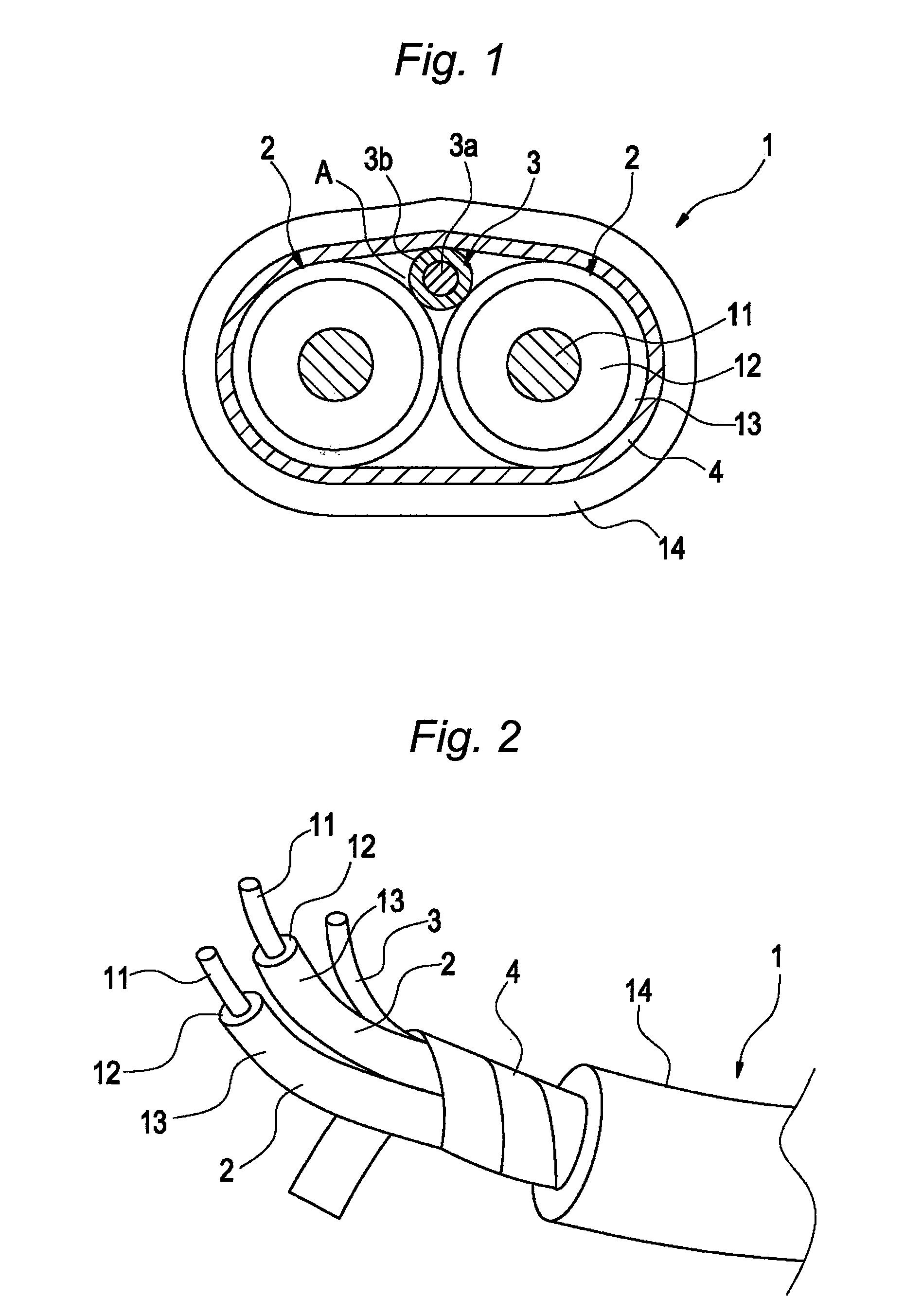

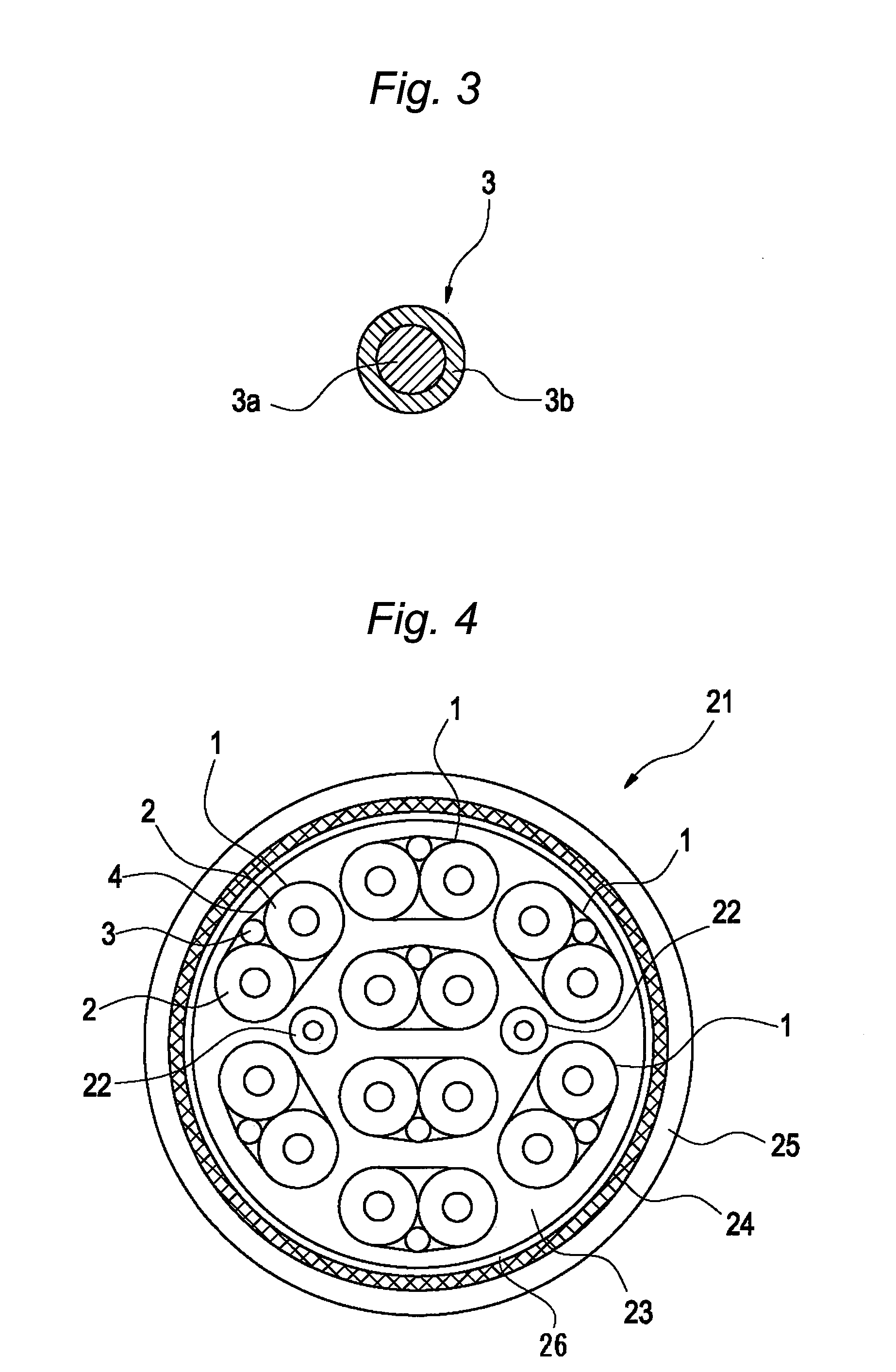

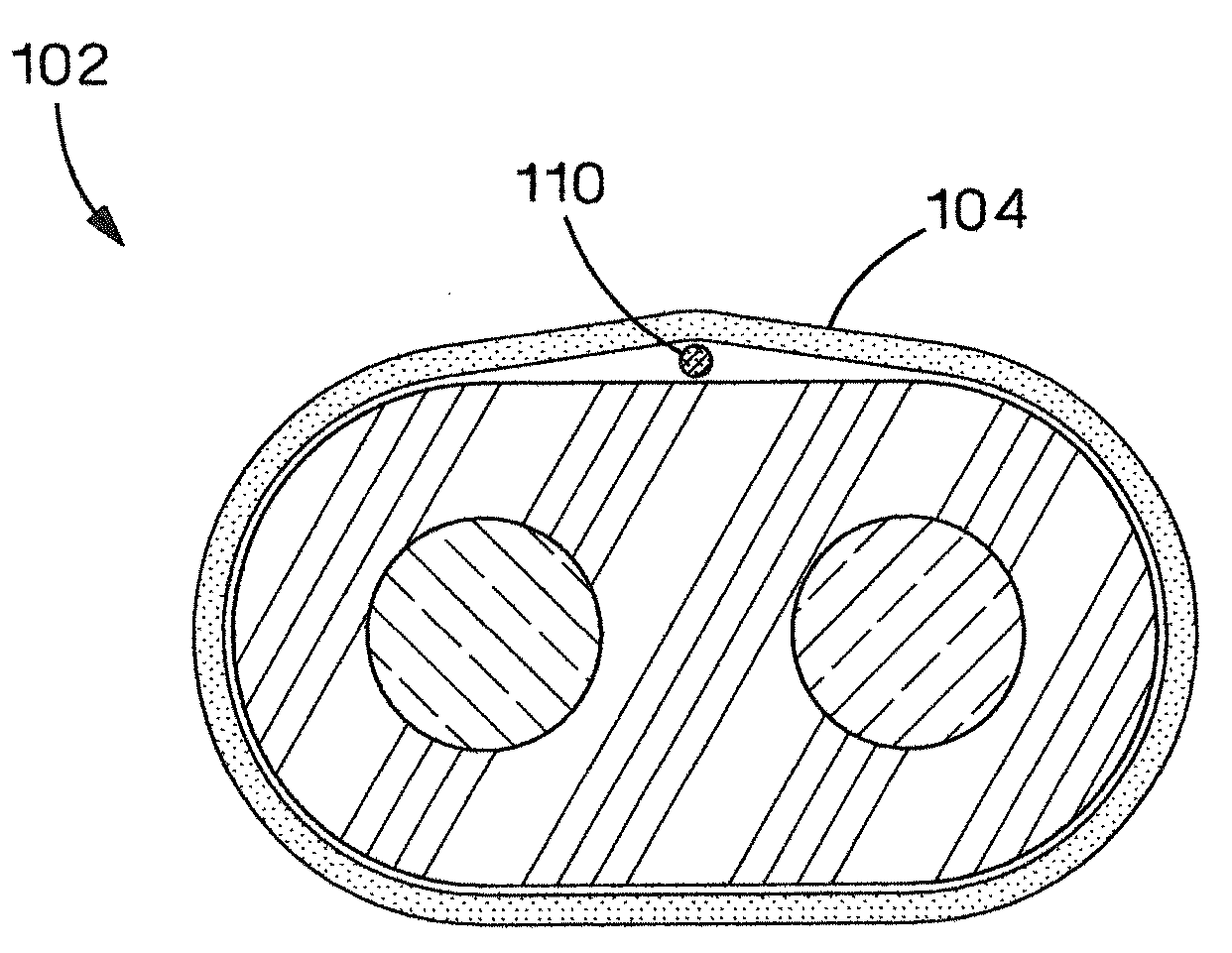

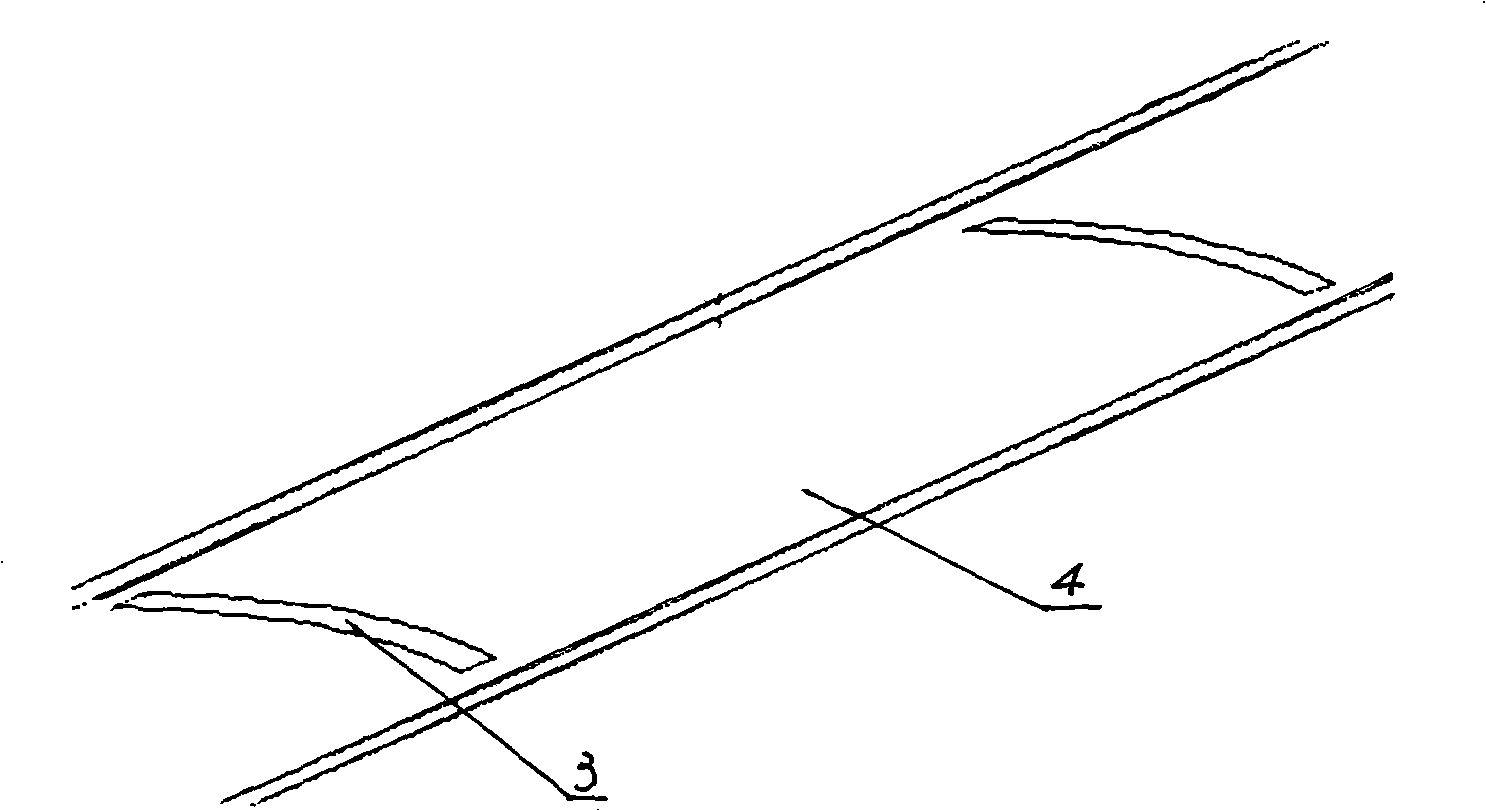

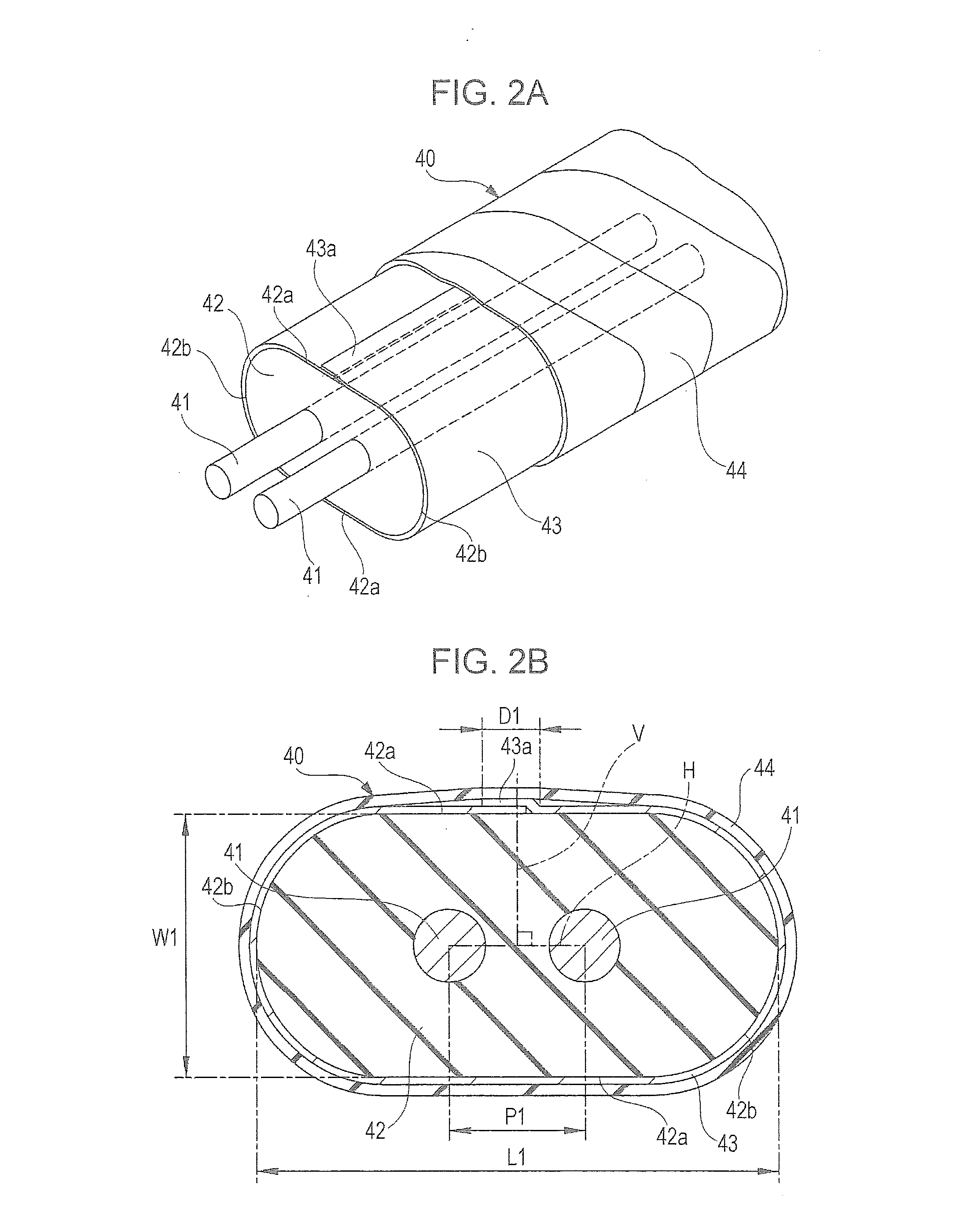

Twinaxial cable and twinaxial cable ribbon

ActiveUS9040824B2Low costIncrease speedCoaxial cables/analogue cablesPrinted circuit assemblingElectric wireElectrical wiring

Owner:SAMTEC

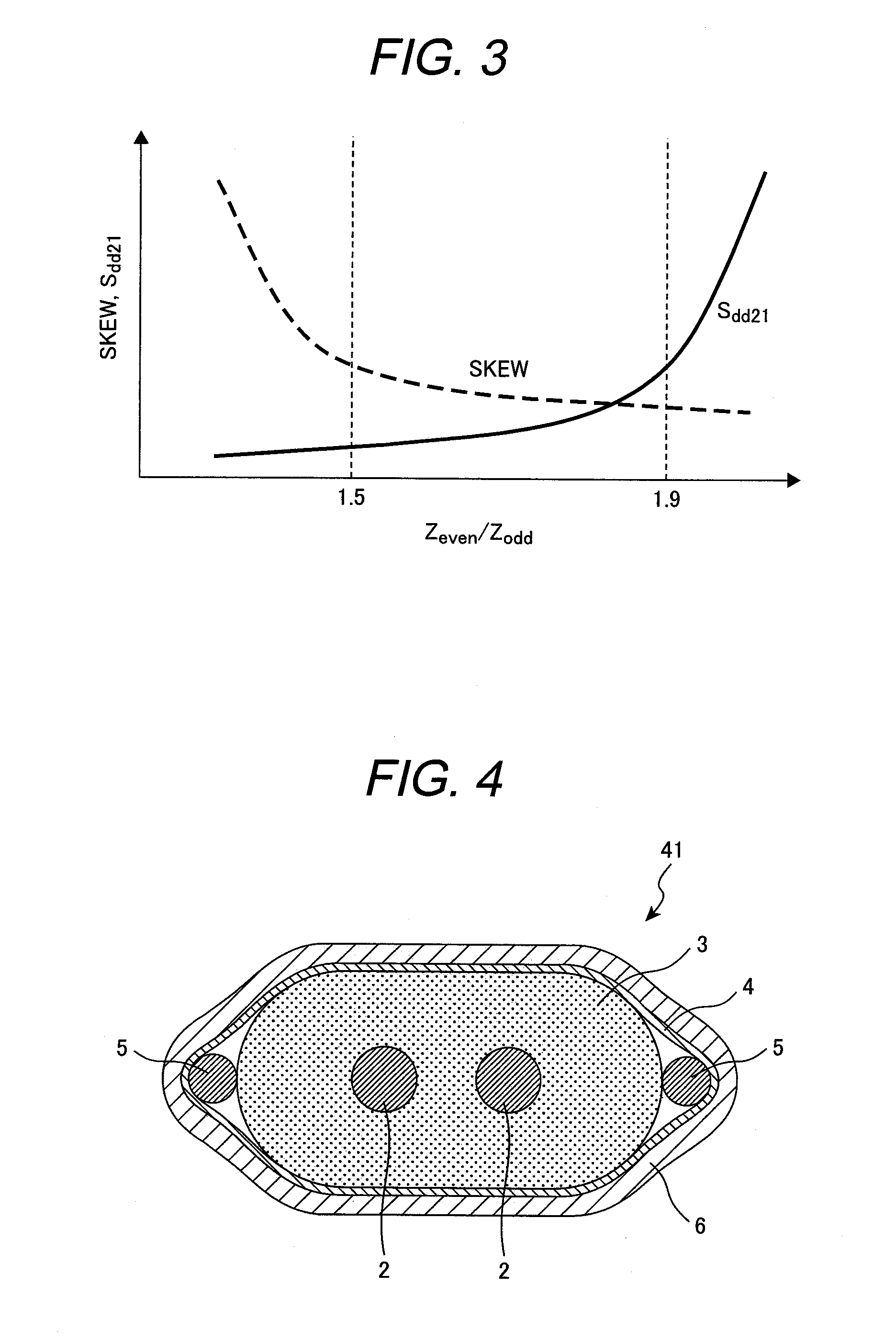

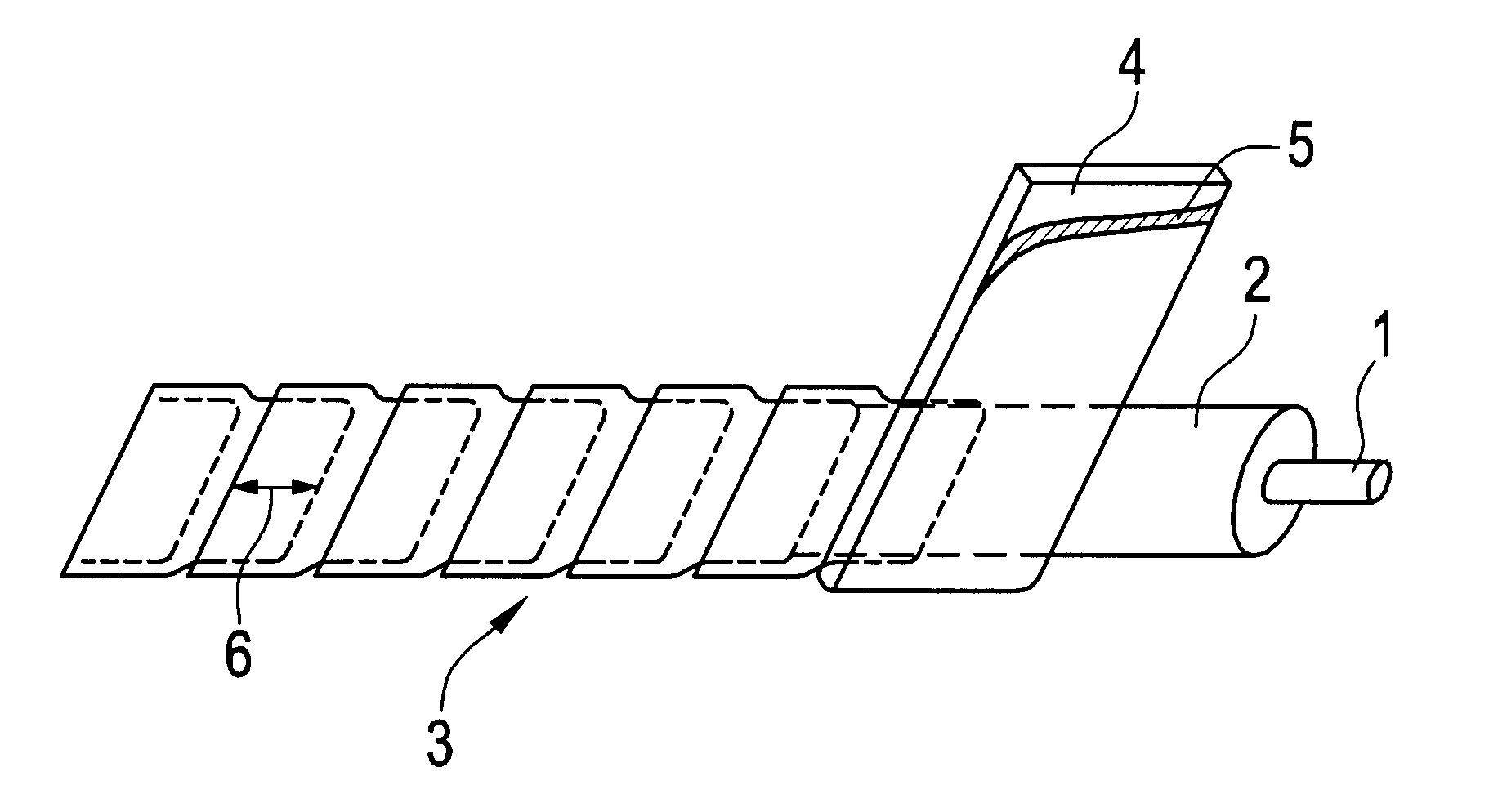

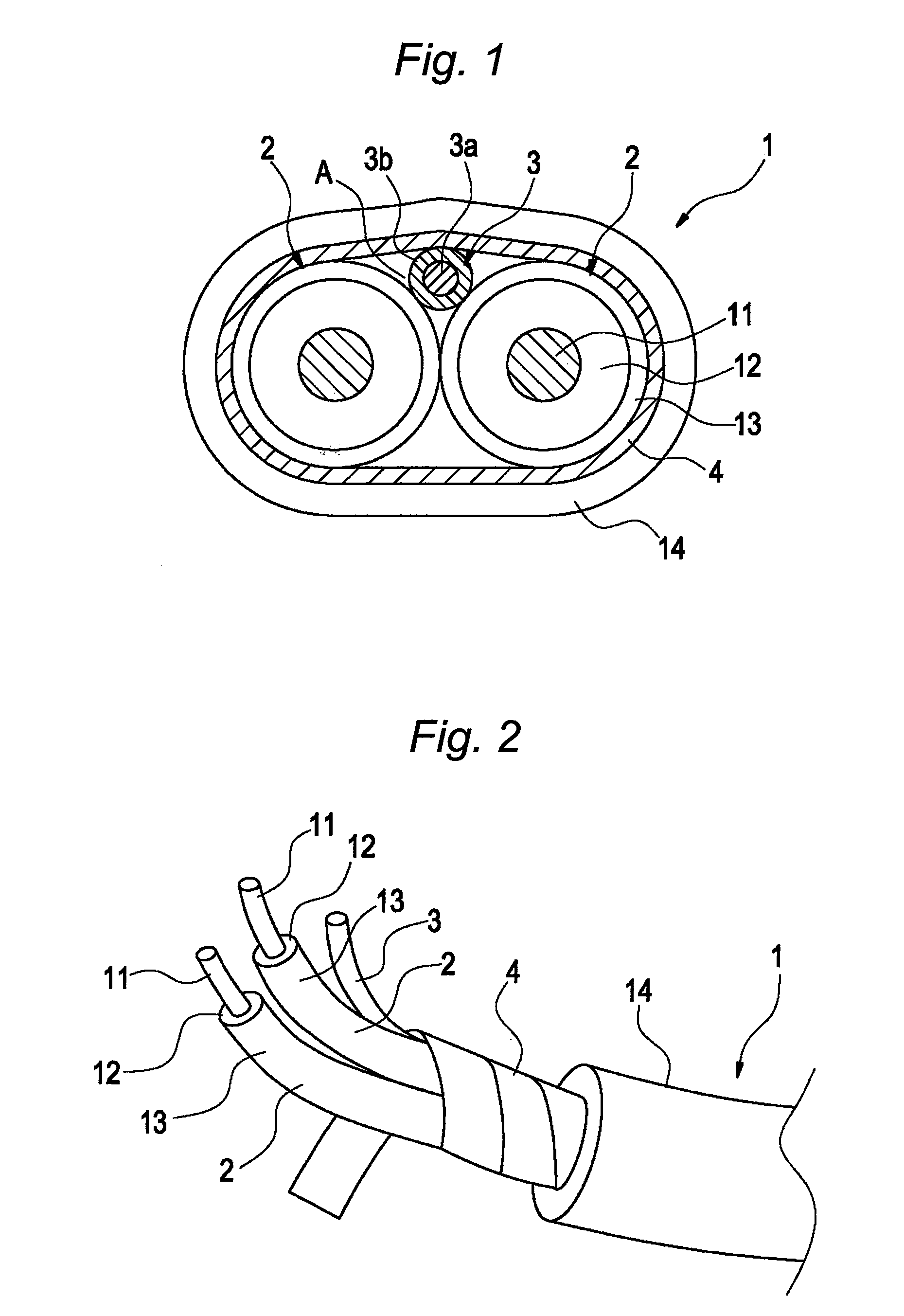

Differential signaling cable, transmission cable assembly using same, and production method for differential signaling cable

ActiveUS20110083877A1Stable productionElectric characteristicCoaxial cables/analogue cablesInsulated cablesDifferential signalingElectric cables

A differential signaling cable according to the present invention comprises: a pair of signal conductors provided in parallel; an insulator which covers the periphery of the pair of signal conductors in a batch; and a shield conductor provided on the outer periphery of the insulator, in which an interval between the pair of signal conductors is specified so that even-mode impedance becomes 1.5 to 1.9 times odd-mode impedance.

Owner:HITACHI METALS LTD

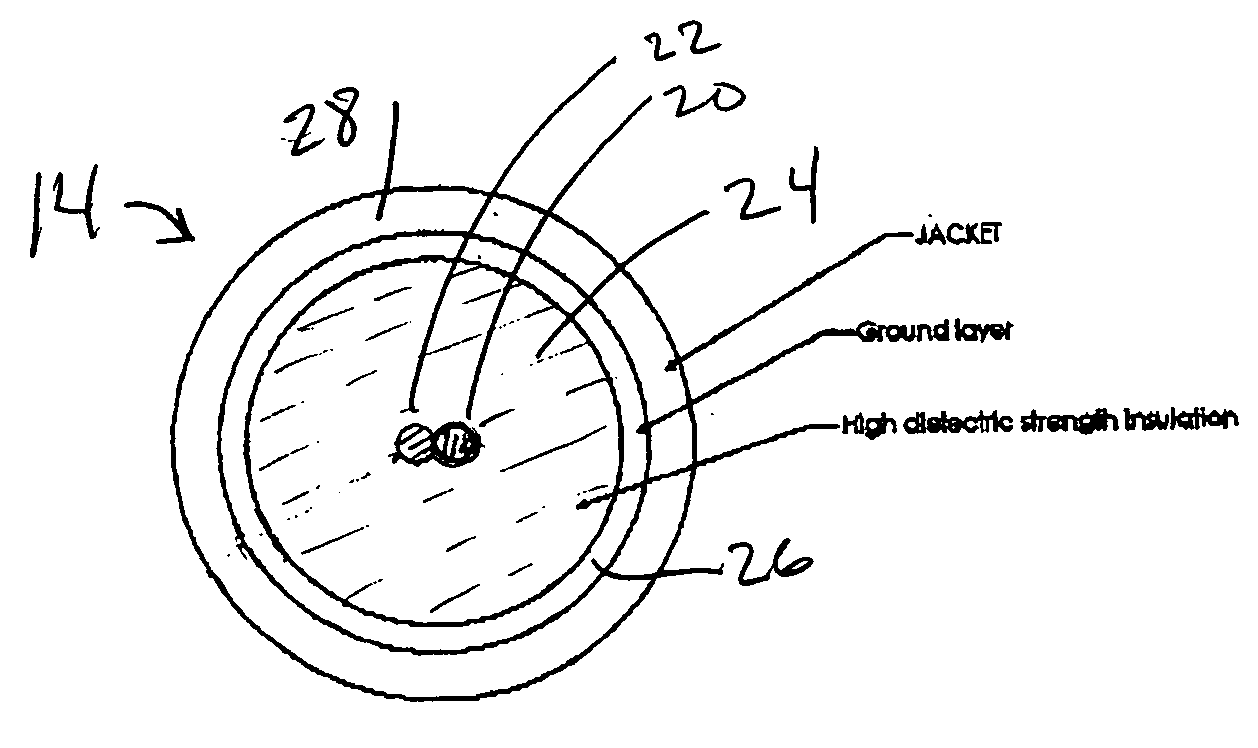

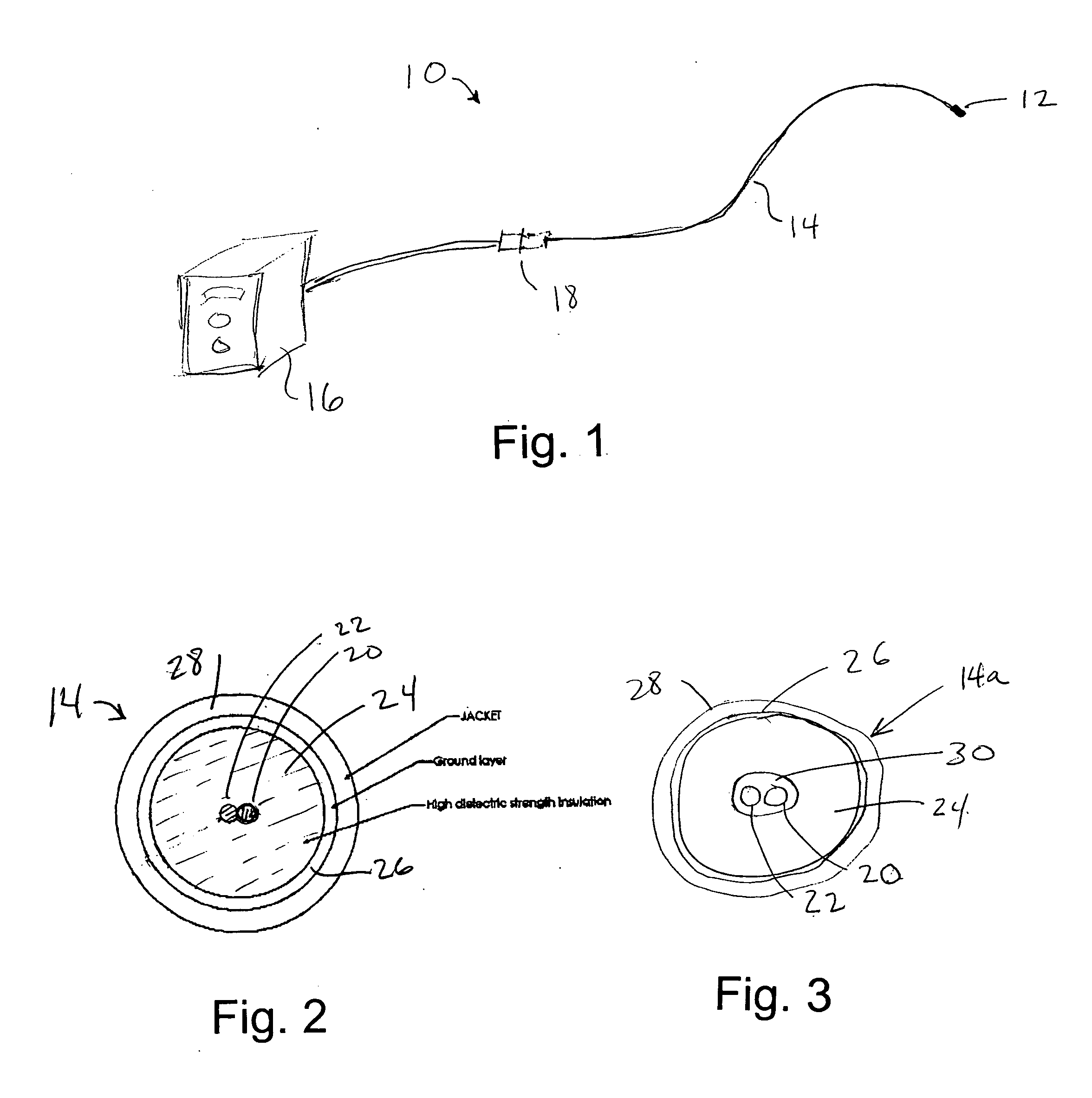

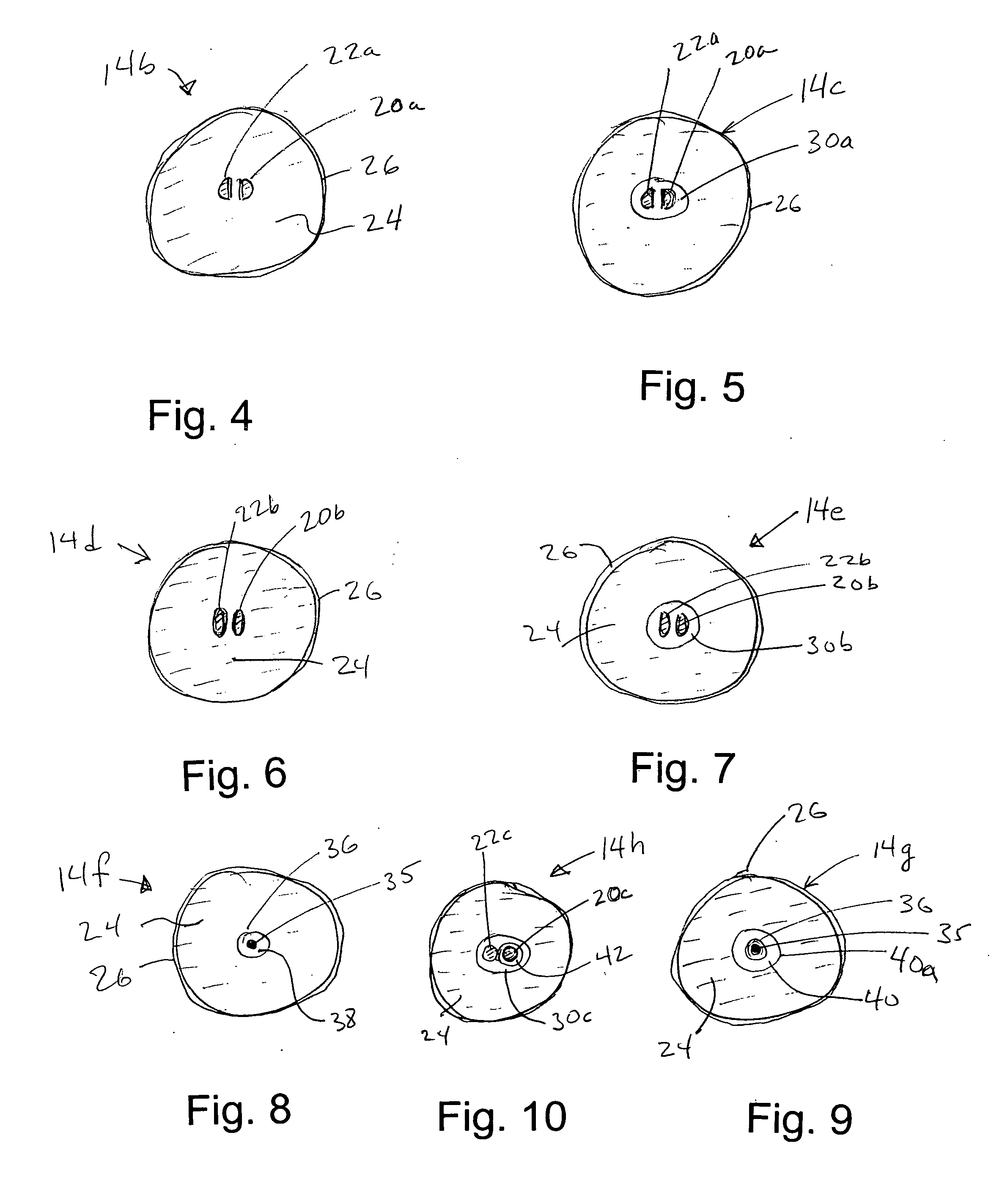

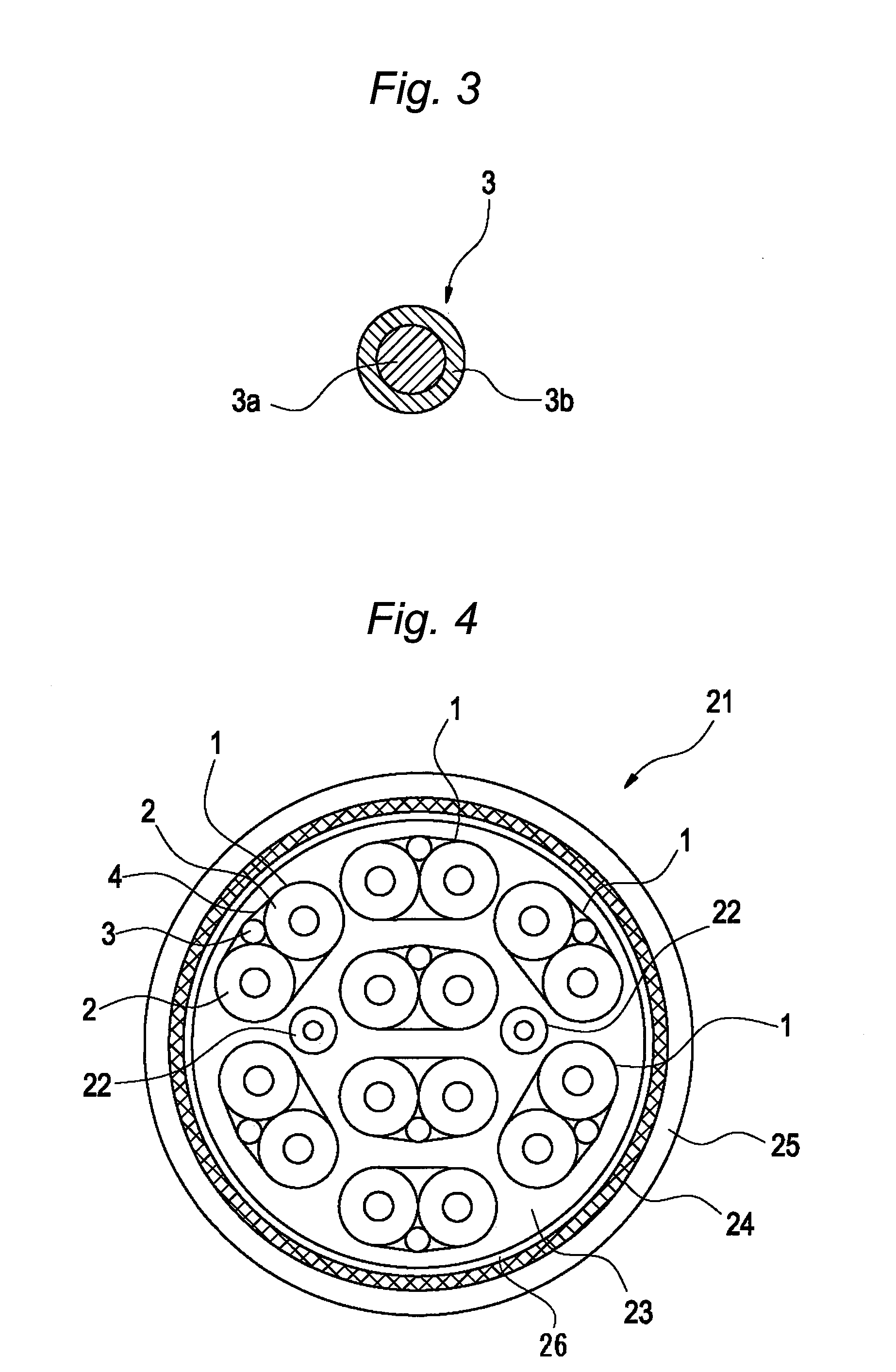

High voltage cable for a miniature x-ray tube

InactiveUS20050061533A1High strengthIncrease pressureCoaxial cables/analogue cablesX-ray tube electrodesDielectricElectricity

In a miniature x-ray tube, which may be on the order of approximately 1 mm in diameter or even less, a high voltage cable is provided in various embodiments for conducting current to the cathode of the x-ray tube and for conducting high voltage to the cathode and anode of the tube. In various embodiments of the cable, two conductors occupy a center region of the cable, packed as closely together as possible, in various shapes that are compact and present as smooth as possible an external shape for maximizing dielectric properties against the exterior high voltage ground, surrounding and generally concentric with the inner conductors. The inner conductors, which carry high voltage in opposition to the outer ground, can be in opposed D shapes, coaxial, two flattened conductors side by side, or simply a pair of cylindrical wires positioned as closely as possible. The space between the inner conductors and the outer ground can be occupied by a glass insulator, polymer, successive layers of polymers and adhesive, air, gas, vacuum or other dielectrics. A partially conductive region can surround the inner conductors.

Owner:XOFT INC

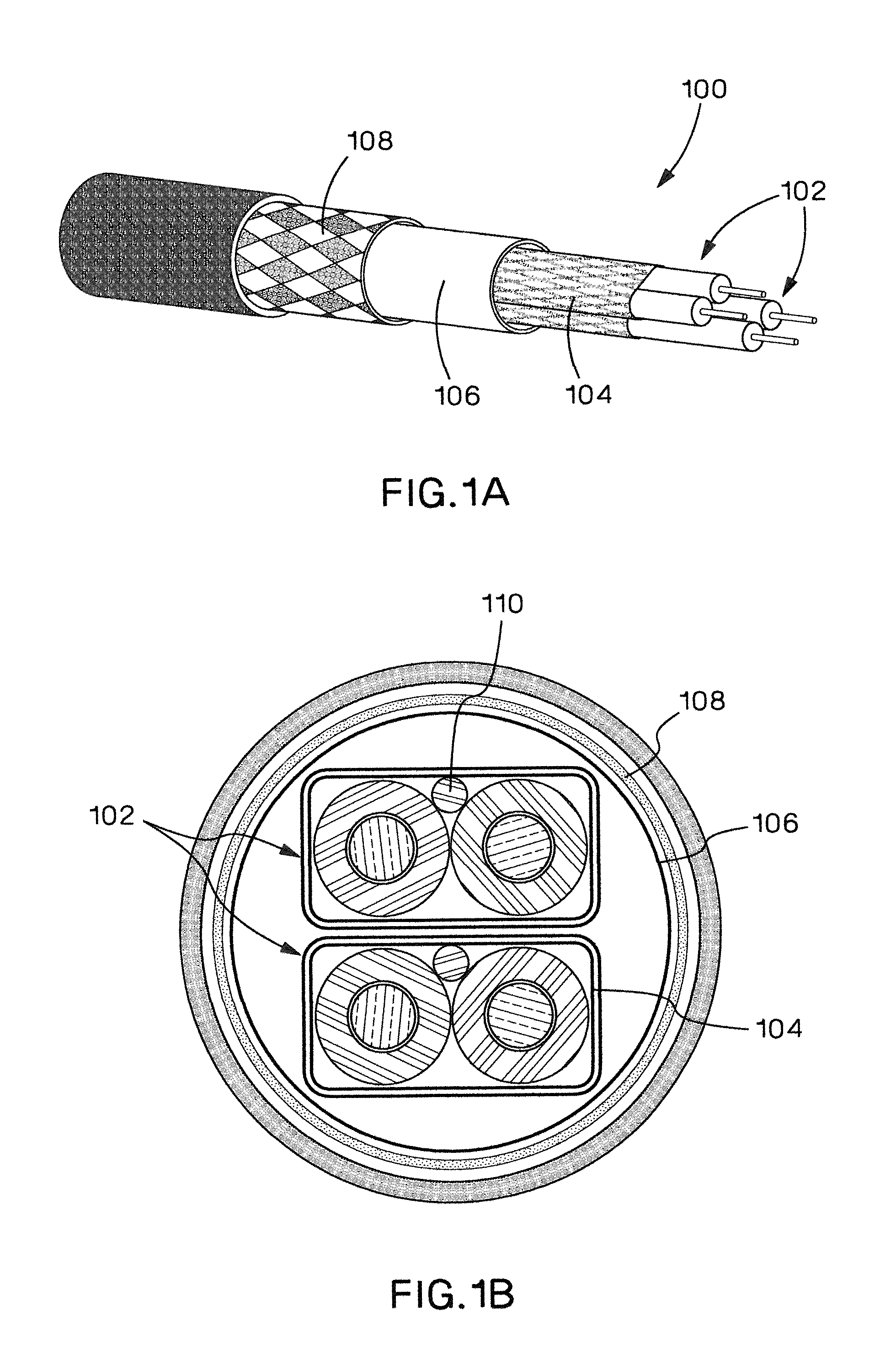

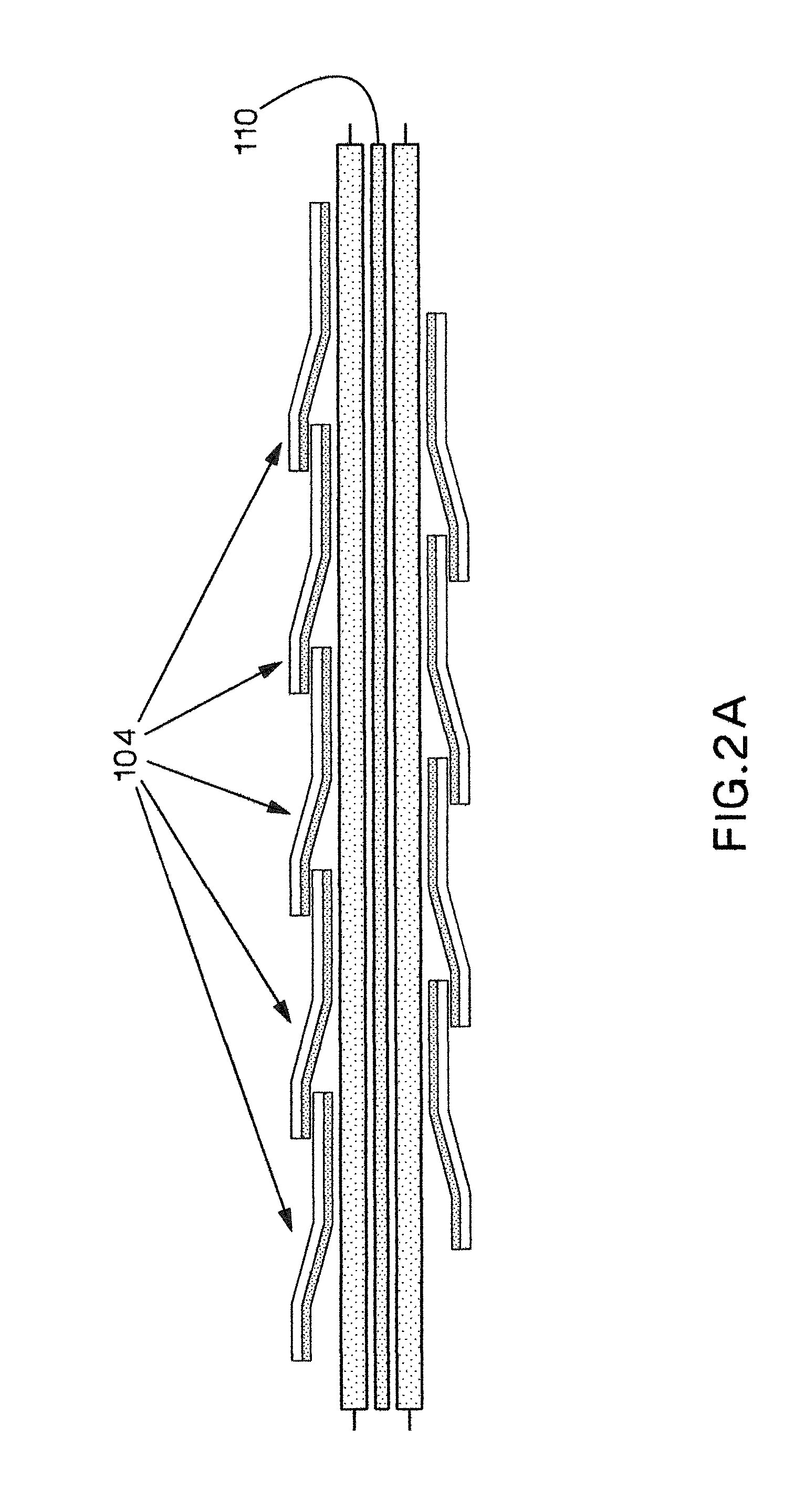

High density shielded electrical cable and other shielded cables, systems, and methods

ActiveUS8841554B2Improve manufacturing speedReduce complexityCoaxial cables/analogue cablesQuad constructionsShielded cableElectricity

Owner:3M INNOVATIVE PROPERTIES CO

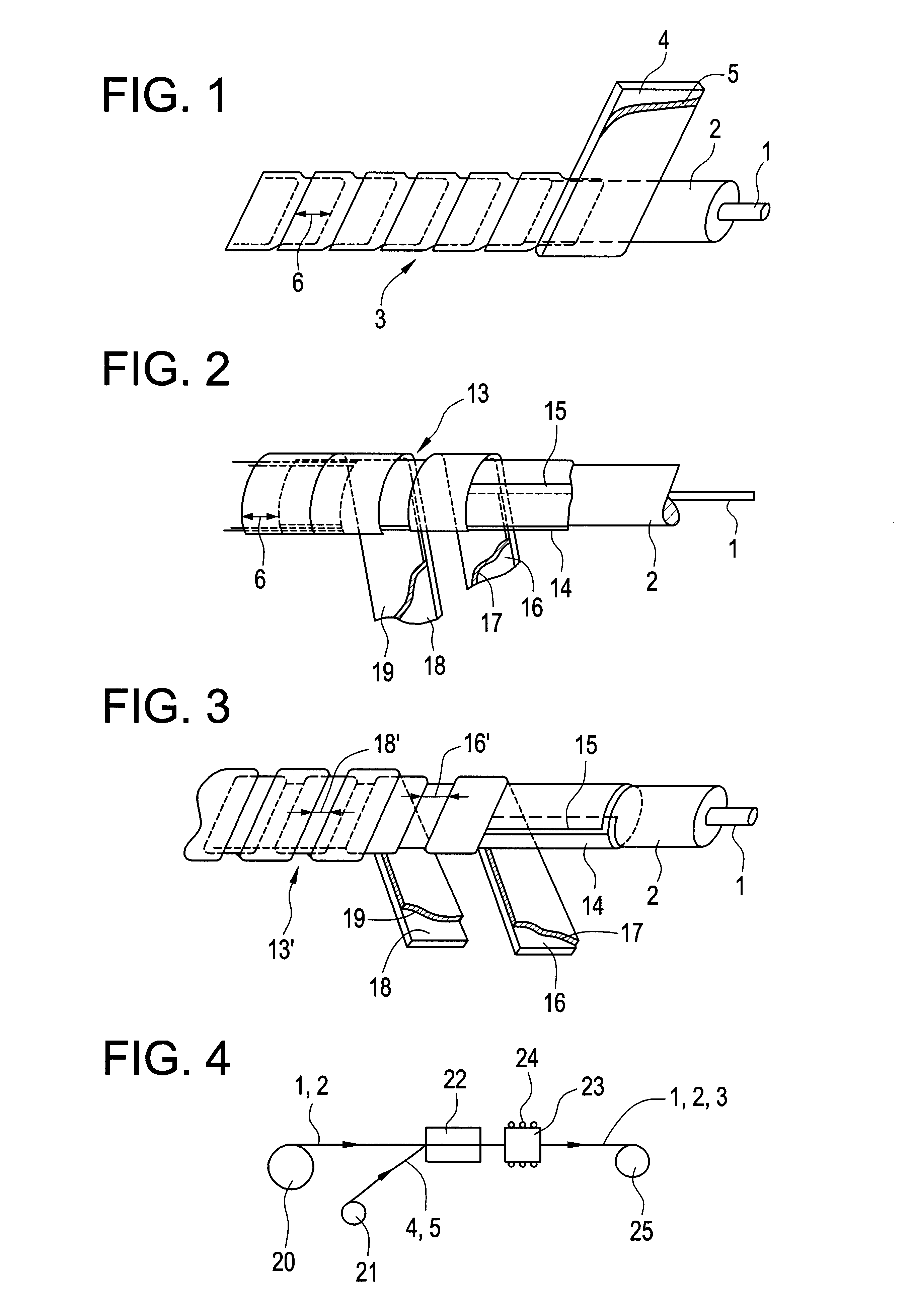

Flexible coaxial cable and a method of manufacturing it

InactiveUS6583361B2The process is simple and fastStable structureCoaxial cables/analogue cablesPower cables with screens/conductive layersMetal coatingCoaxial cable

A flexible coaxial cable includes a shield formed by at least one metal tape provided with a metal coating and wound helically around the insulated core of the cable. The shield is sealed to itself in leakproof manner by the coating which is melted so as to bond directly together the overlapping turns of a single tape or the overlapping turns of two superposed tapes by subjecting the cable provided with the shield to peripheral induction heating.

Owner:NEXANS

Differential transmission signal cable and composite cable containing the same

ActiveUS20100025072A1Improve reliabilityNot to damageCoaxial cables/analogue cablesNon-insulated conductorsSemiconductor materialsDifferential transmission

Owner:SUMITOMO ELECTRIC IND LTD +1

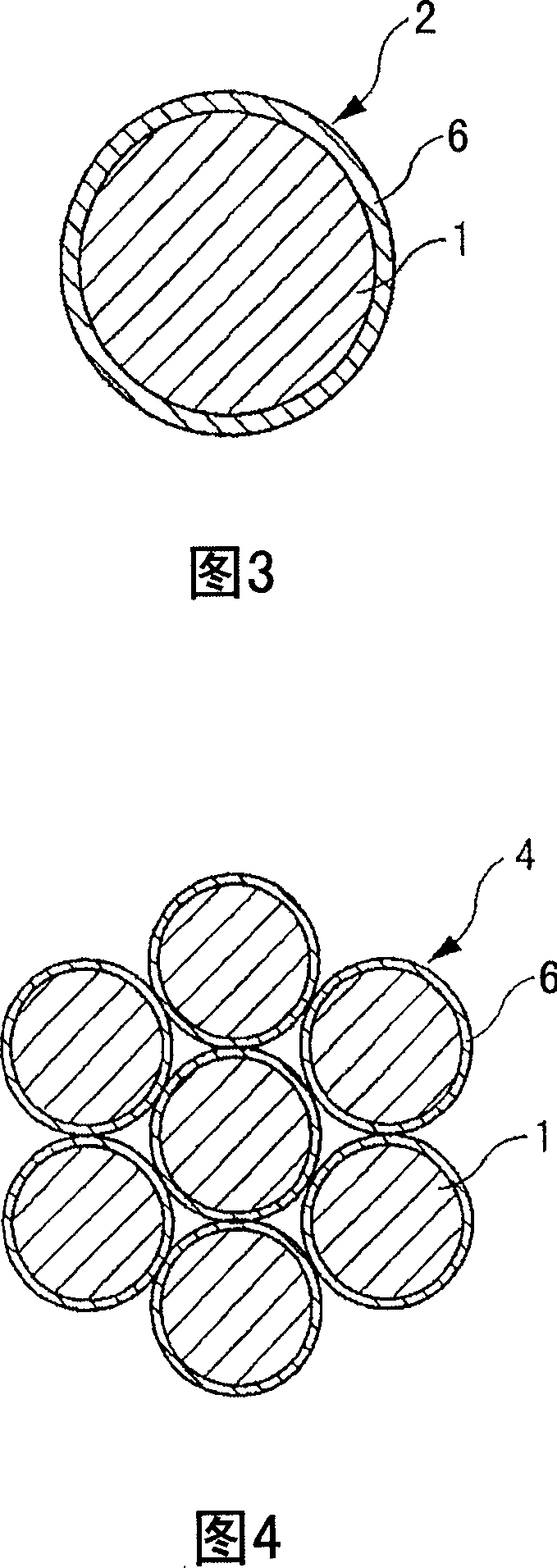

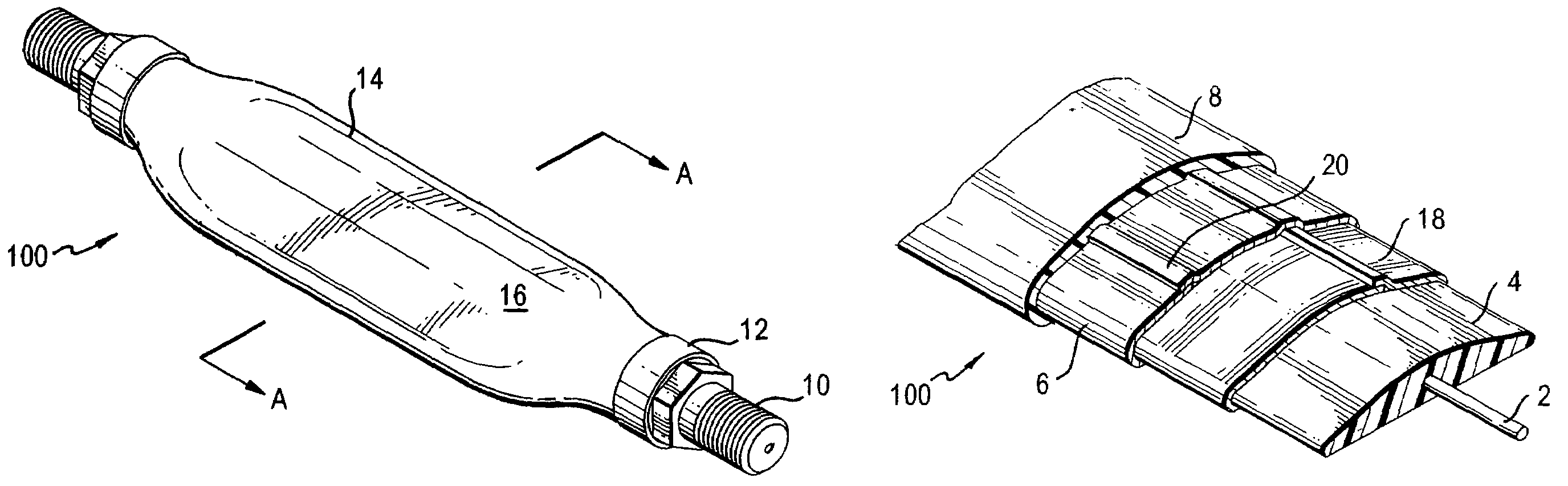

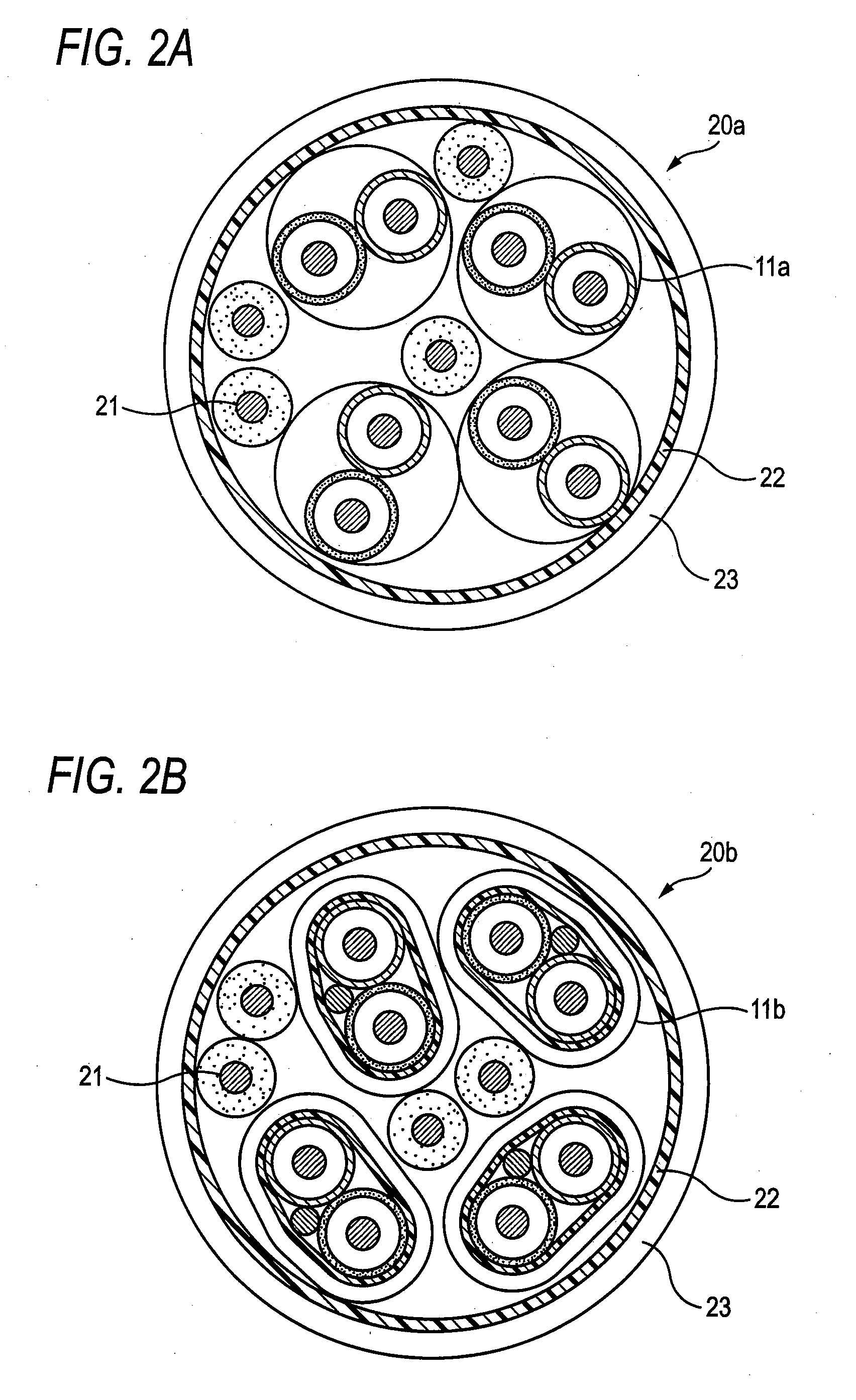

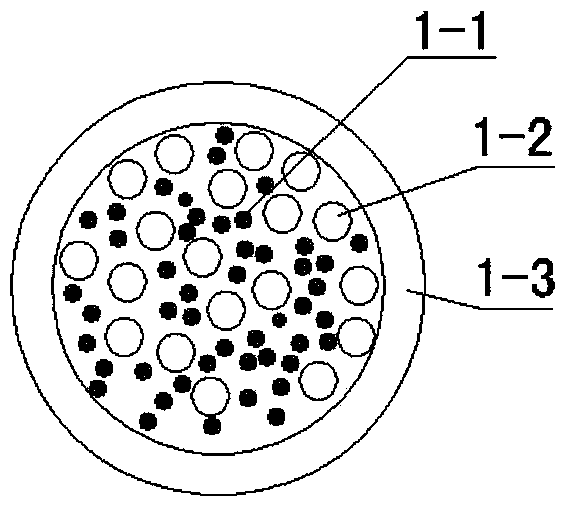

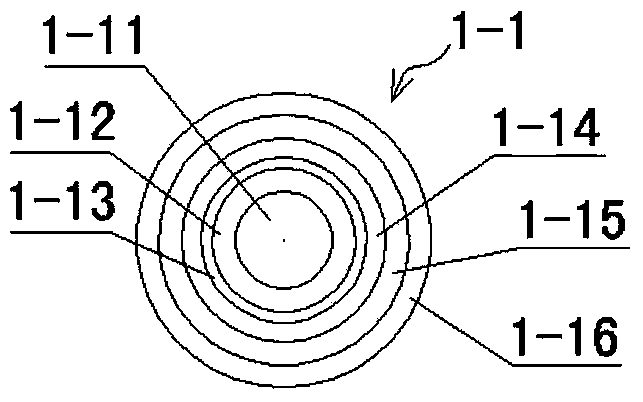

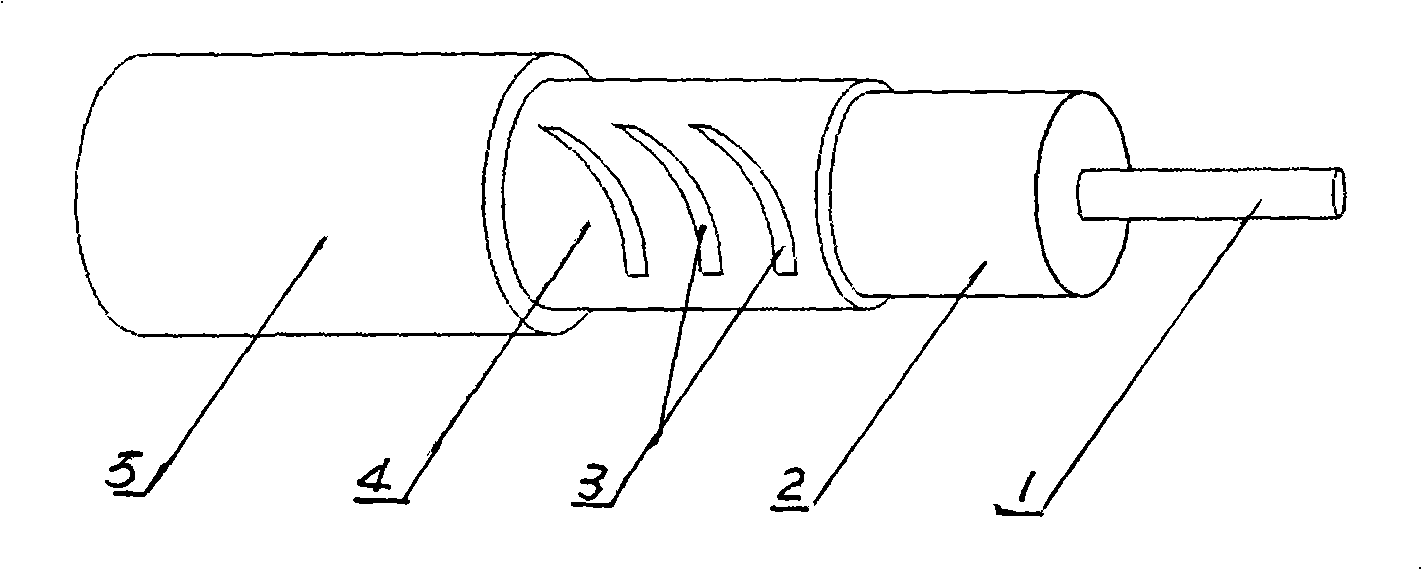

Extra-fine copper alloy wire, extra-fine copper alloy twisted wire, coaxial cable, multi-core cable and manufacturing method thereof

ActiveCN1988055AImprove heat resistanceHigh strength propertiesCoaxial cables/analogue cablesSingle bars/rods/wires/strips conductorsMulticore cableElectrical conductor

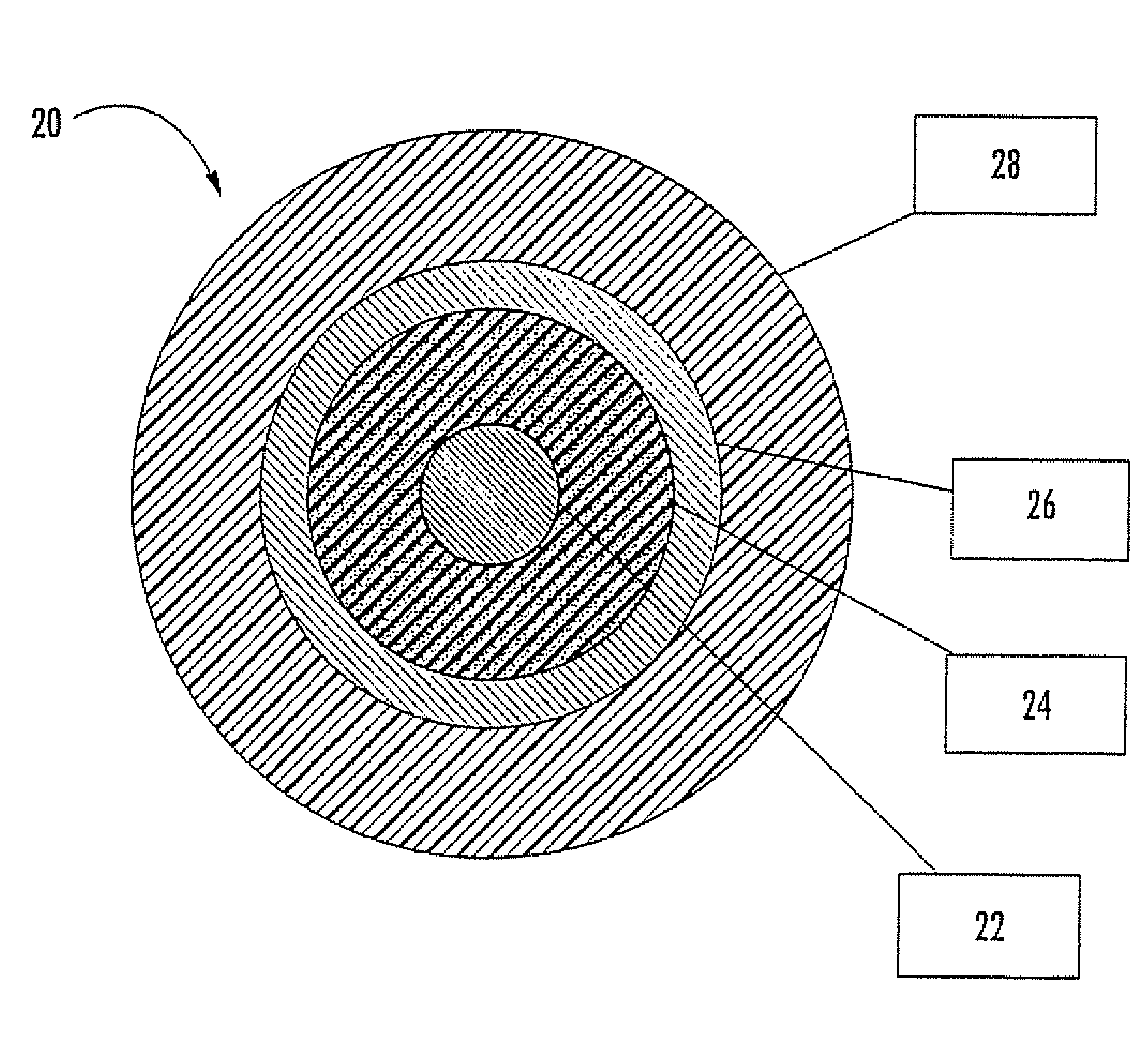

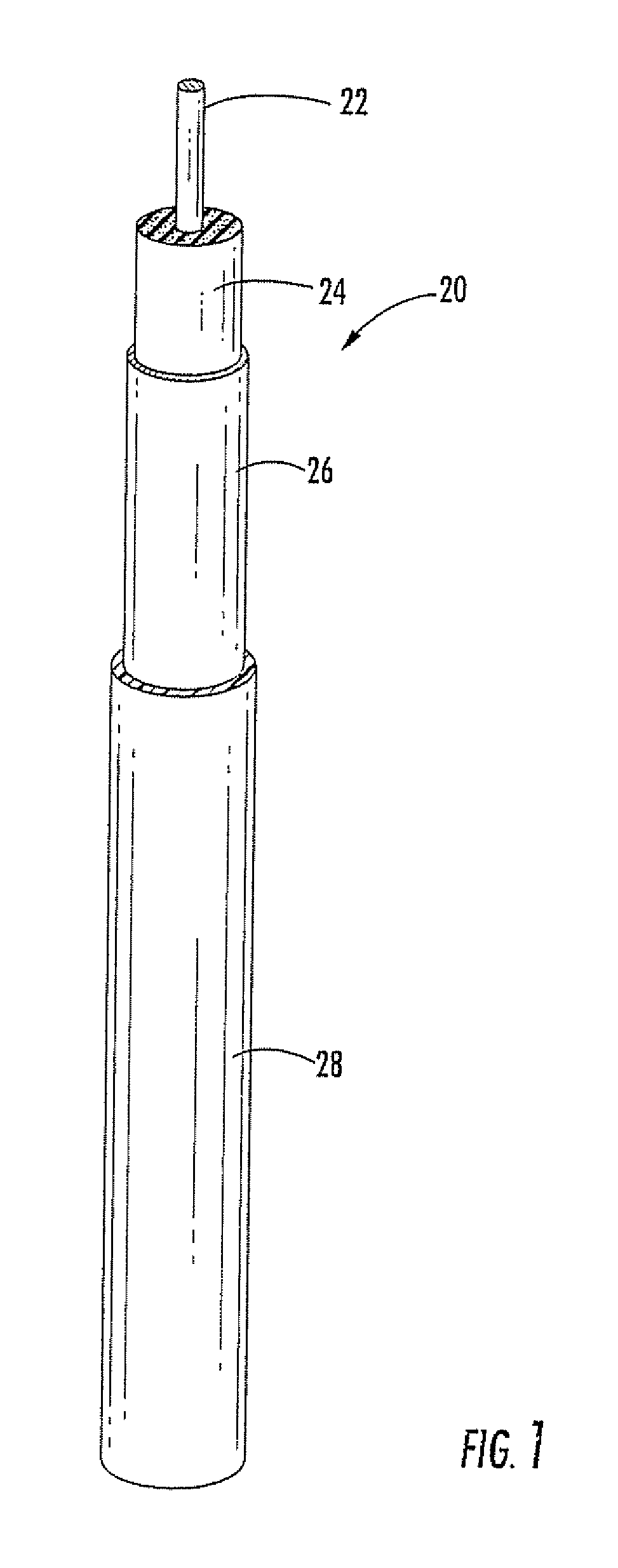

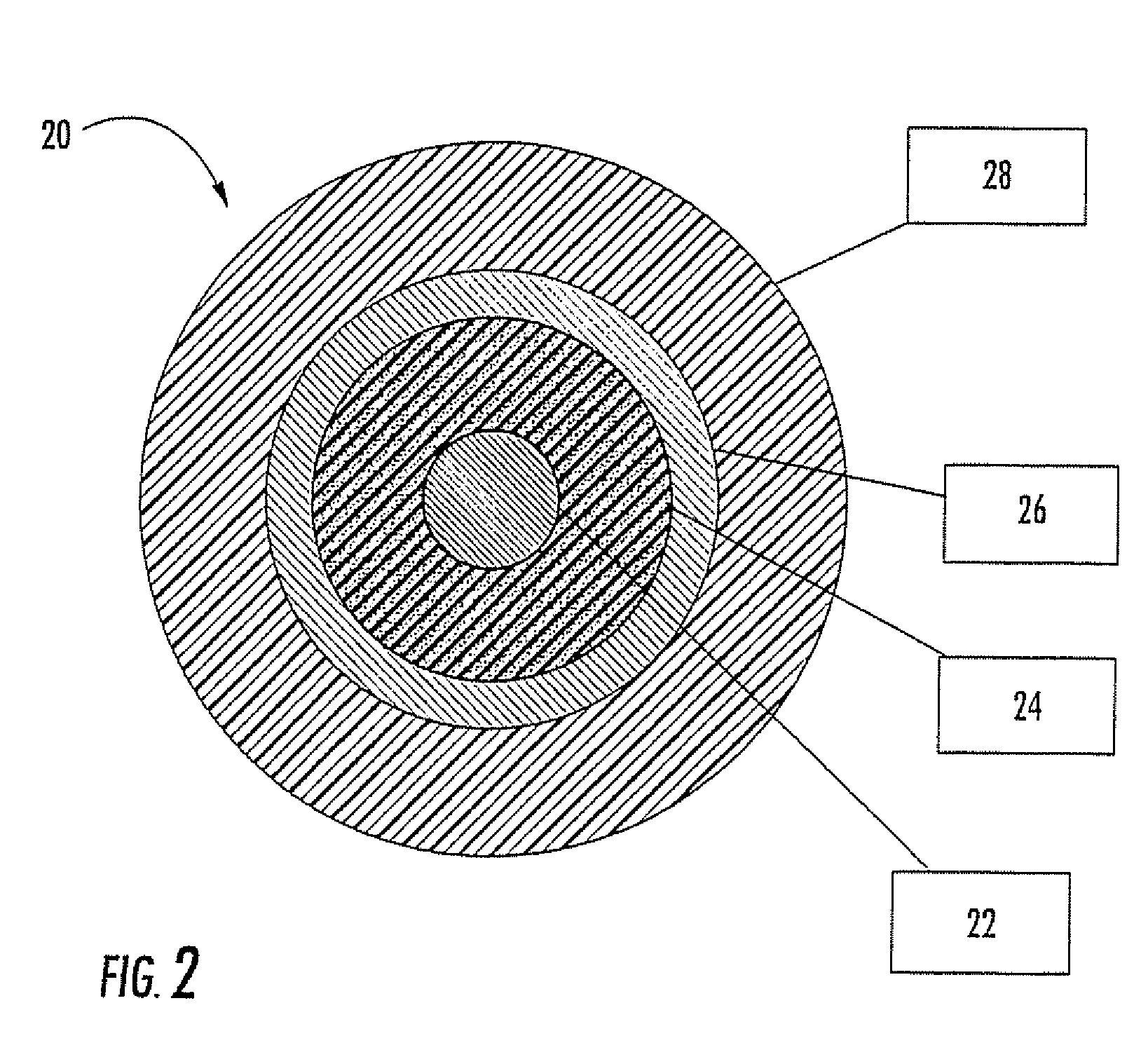

The object of the invention is to provide an extra-fine copper alloy wire, an extra-fine copper alloy twisted wire, an extra-fine insulated wire, a coaxial cable having high intensity, low resistance and high heat tolerance, their manufacturing method and a multicore cable thereof. The extra-fine copper alloy wire has 1 to 3 weight % of silver in the copper, a wire diameter less than 0.025 mm, and a tensile strength of more than 850 MPa, an electrical conductivity of more than 85% IACS after heat treatment; the coaxial cable (20A) is configured that, an inner conductor is formed by an extra-fine copper alloy twisted wire (3) twisted from seven extra-fine copper alloy wires (1), the inner conductor is then peripherally envelopped with a solid insulator (5a) to form an extra-fine insulated wire (10), a plurality of conductor wires (13) are winding in a screw shape on the periphery of the extra-fine insulated wire along a length direction of the extra-fine insulated wire to form an outer conductor (15), thereafter, the outer conductor is envenlopped with a protection layer (17).

Owner:HITACHI CABLE

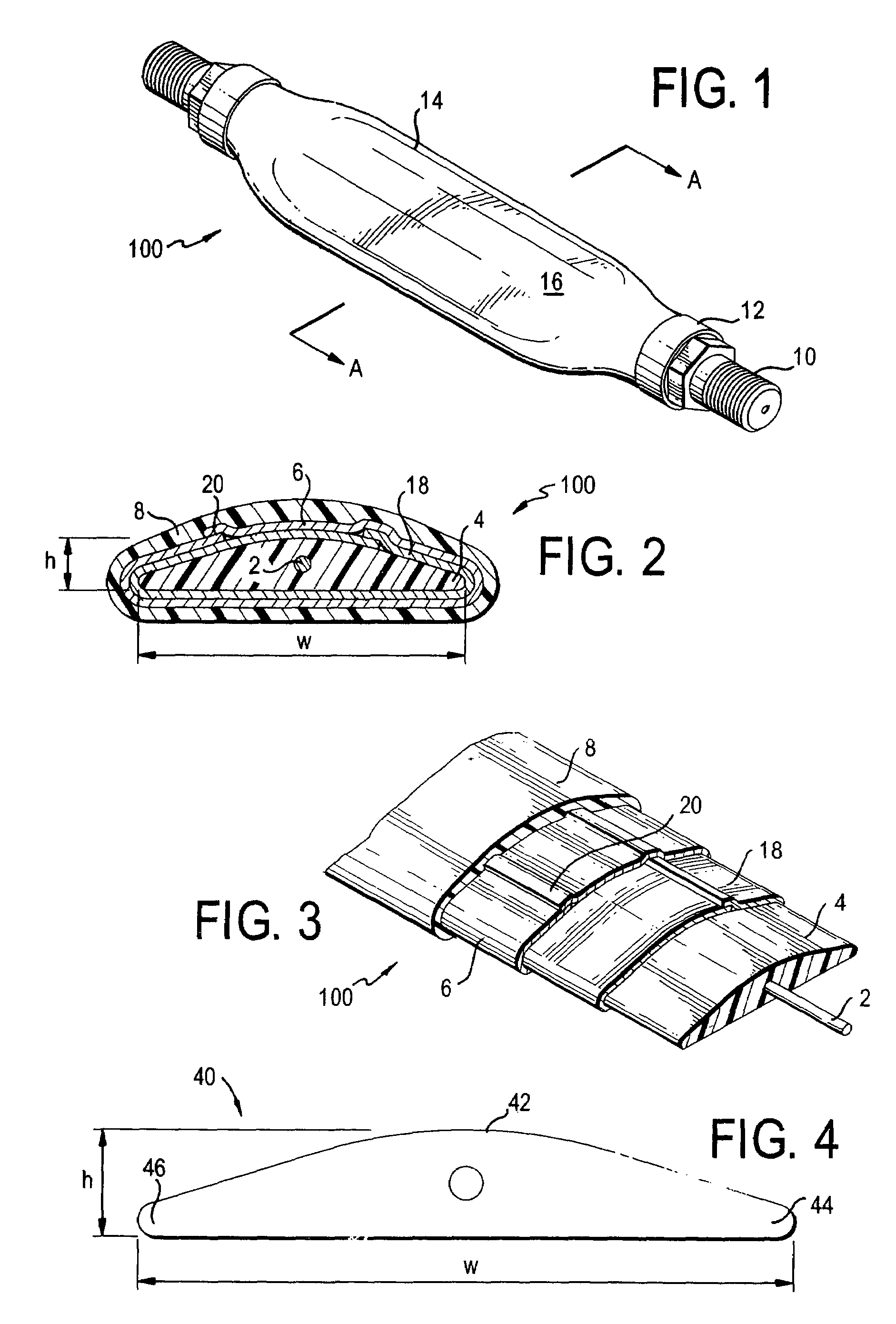

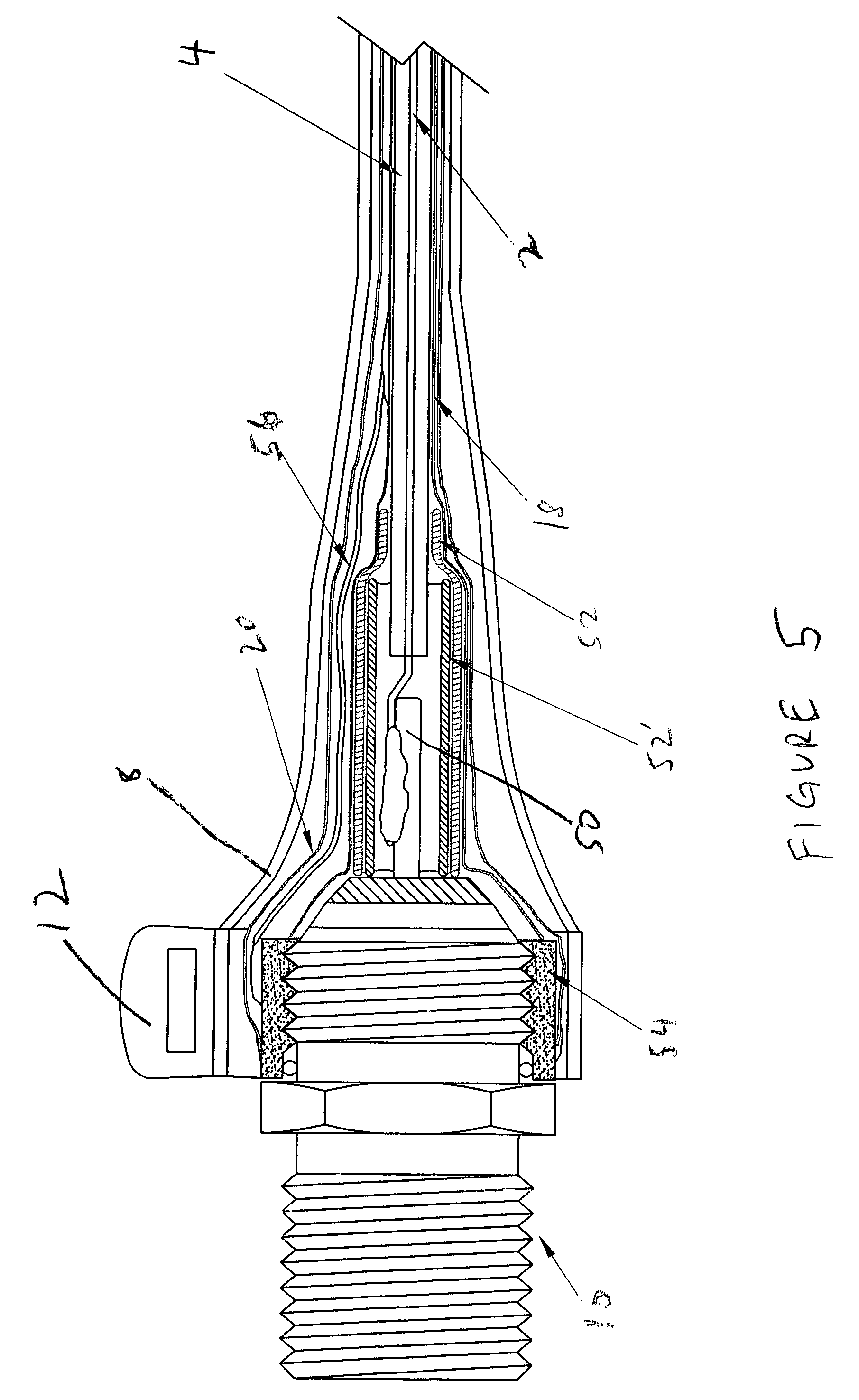

Coaxial cable jumper device

ActiveUS7314998B2Easily through spaceProvide stabilityCoaxial cables/analogue cablesElectrically conductive connectionsElectrical conductorCoaxial cable

The present invention relates to a coaxial cable having a flat portion, so that the cable can be used, for example, as a jumper cable that passes through a window sill or a door. Because the cable is flat, it can easily pass through a crack in the door or window without requiring holes to be dilled into the building structure. The flat portion of the cable contains a central conductor that is sequentially surrounded by a substantially flat dielectric, an outer conductor, and a jacket.

Owner:TIMES FIBER COMMUNICATIONS INC

Shielded cable assembly

InactiveUS20140273594A1Coaxial cables/analogue cablesCoupling contact membersShielded cableElectrical conductor

A wire cable assembly capable of transmitting signals at speeds of 5 Gigabits per second over a single pair or conductors. The cable has a characteristic impedance of 95 Ohms and can support transmission data according to either USB 3.0 or HDMI 1.3 performance specifications. The wire cable includes a pair of conductors, a shield surrounding the conductors, and a dielectric structure configured to maintain a first predetermined spacing between the conductors and a second predetermined spacing between said the conductors said shield. The shield includes an inner shield conductor enclosing the dielectric structure, a ground conductor external to the inner shield conductor, extending generally parallel to the pair of conductors, an outer shield conductor enclosing the inner shield conductor and the ground conductor.

Owner:DELPHI TECH INC

Wire harness

InactiveCN101542640ASuppression of localized heatingIncrease contact areaCoaxial cables/analogue cablesLine/current collector detailsLaser bondingCoaxial cable

A wire harness using a coaxial cable, in which a ground bar and the shield of the coaxial cable are connected at a connection section in an environmentally friendly process and in a manner providing the harness with good electric characteristics. The ground bar (10) is made of a material having a lower melting point than the shield (16). For example, the ground bar (10) is made of brass or aluminum having a lower melting point than copper that forms the shield (16). The ground bar (10) and the shield (16) are connected together by applying a laser beam to the ground bar (10) and laser bonding them together by spots (30). Since the shield (16) has a higher melting point than the ground bar (10), melting of the shield (16) is suppressed because of the use of the laser bonding and, further, thermal damage to an inner dielectric layer under the shield (16) is suppressed. The environment is less affected because solder is not used.

Owner:PHOETON CORP

Sensor Apparatus

InactiveUS20140158536A1Coaxial cables/analogue cablesMaterial analysis by electric/magnetic meansPolyvinyl chlorideEngineering

In the present invention, the solid contacted ISE and the solid contacted reference are based on a conductive porous network with a solid contact and membrane disposed thereon. The porous networks are not only mechanically stable, but also provide pore structure for the solid contact and membrane to intercalate, which enhances the life time and stability of the sensors. The invention further incorporates a unique fluidic fitting sensor and sealing mechanism so that measurements can be taken at high pressures. The fitting design has many benefits, such as low cost and disposability, which allows them to be mass manufactured. These sensors can be produced for detection of many different kinds of ions by applying different types of ion selective membranes, including polyvinylchloride (PVC) based ion-selective membranes and fluorous matrixes based ion-selective membranes.

Owner:UNITED SCI LLC

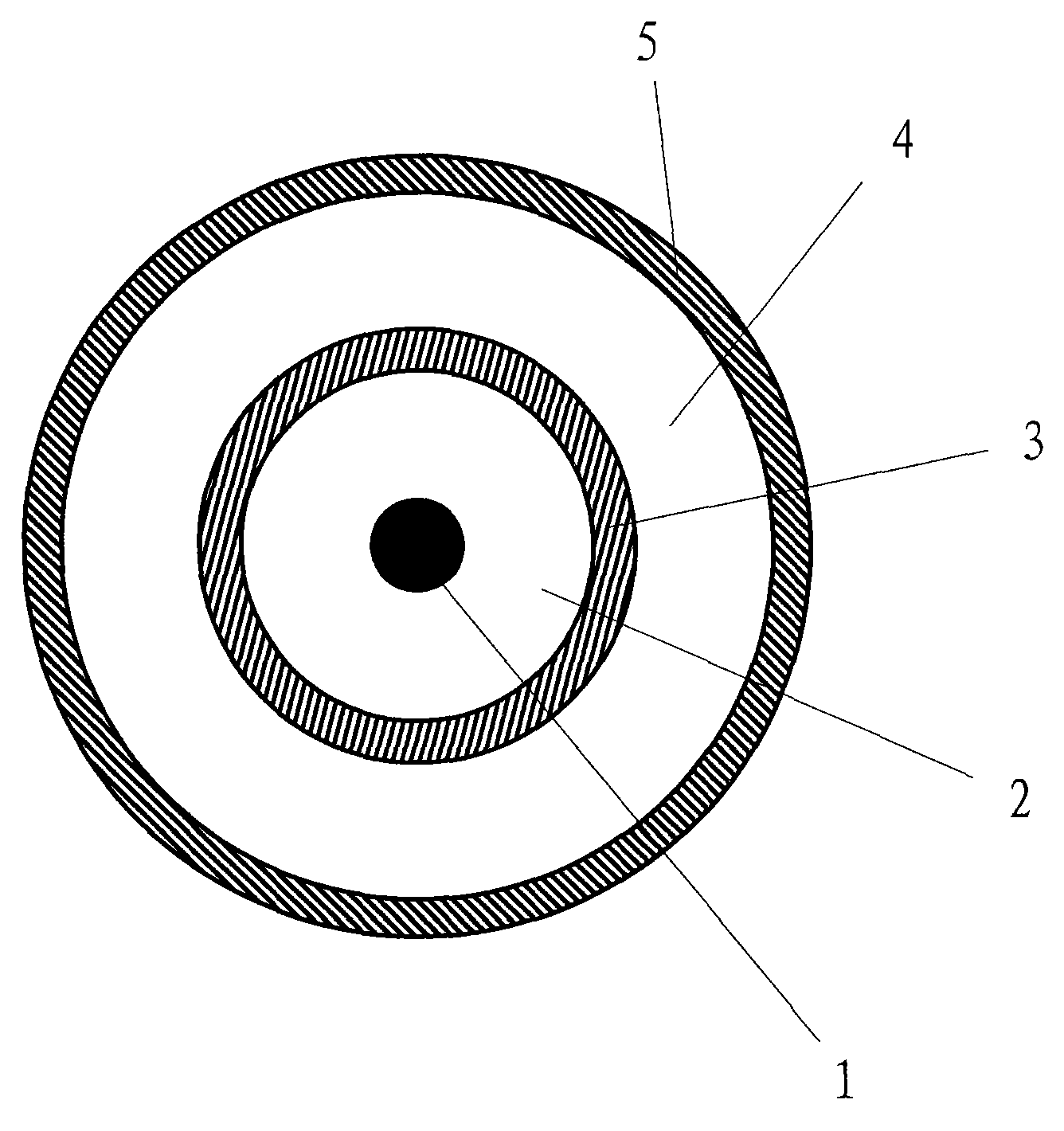

Coaxial cable having wide continuous usable bandwidth

InactiveUS7692098B2Coaxial cables/analogue cablesOptical transmission adaptationsElectrical conductorCoaxial cable

A coaxial cable includes: a metallic inner conductor formed of a first material and having a first thickness; a dielectric layer circumferentially surrounding the inner conductor formed of a second material and having a second thickness; a metallic outer conductor circumferentially surrounding the dielectric layer formed of a third material and having a third thickness; and a polymeric jacket circumferentially surrounding the outer conductor formed of a fourth material and having a fourth thickness.

Owner:COMMSCOPE INC +2

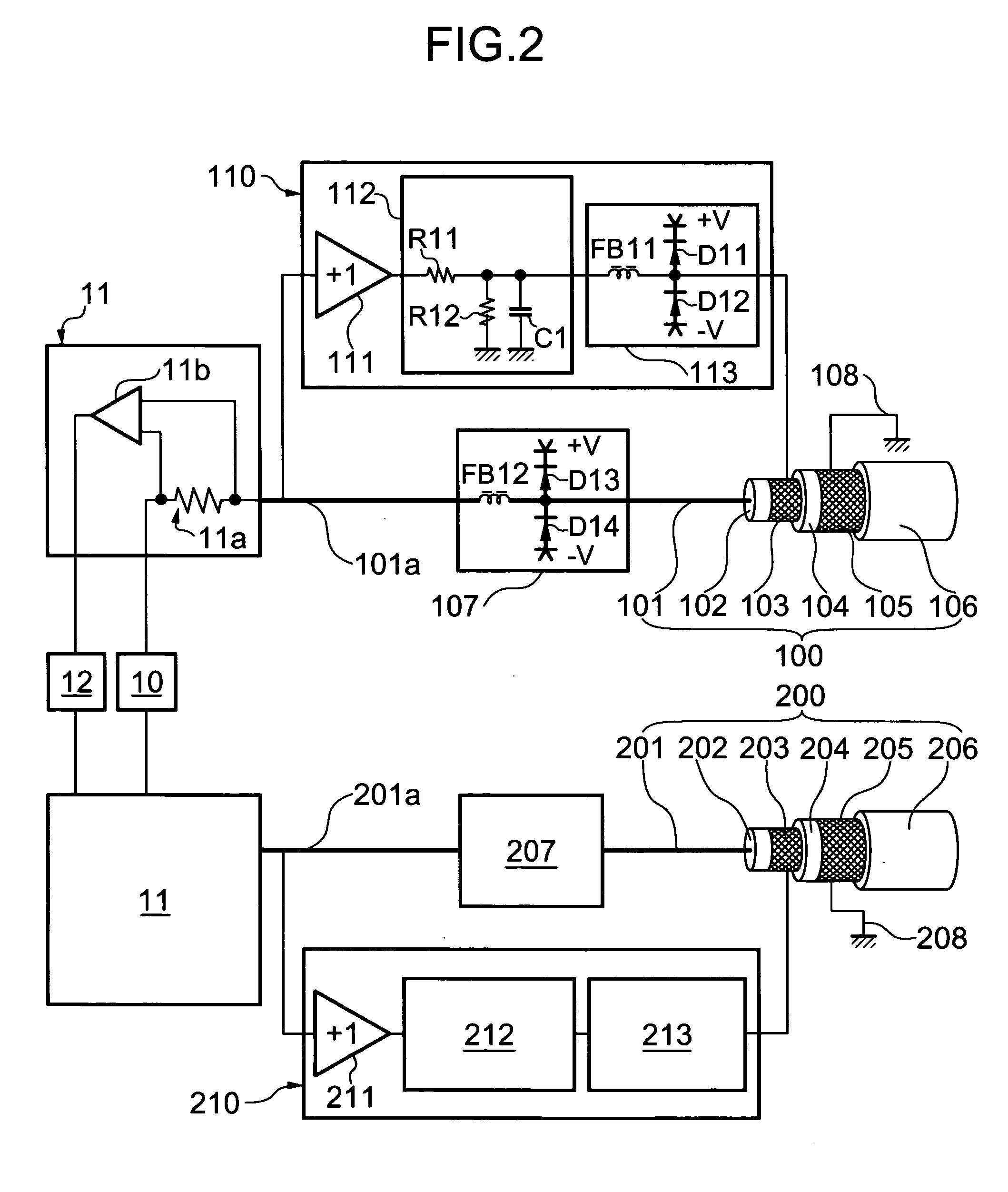

Shielded cable, and bioelectrical impedance value or biological composition data acquiring apparatus using the same

ActiveUS20050098343A1Reducing electromagnetic wave noiseReduce output voltageCoaxial cables/analogue cablesPower cables with screens/conductive layersShielded cableElectrical resistance and conductance

There are provided a shielded cable comprising a core wire for carrying an electrical signal, and a shield provided around the circumference of the core wire and connected to the core wire via a drive circuit, wherein the drive circuit has a band limiting circuit which decreases an output voltage in a predetermined frequency band; and an apparatus which acquires a bioelectrical impedance value or biological composition data by using the shield cable.

Owner:TANITA CORP

Fluoropolymer Wire Insulation

ActiveUS20080283271A1Return lossGood dissipation factorCoaxial cables/analogue cablesPlastic/resin/waxes insulatorsPolymer scienceElectrical conductor

FEP compositions are provided that provide foam insulation in coaxial cable that surpasses the return loss obtained when PFA is used to make the foamed insulation, one composition comprising a blend of tetrafluoroethylene / hexafluoropropylene copolymers, one of said copolymers exhibiting a strip force of at least about 3 lbf (13.3 N) and another of said copolymers exhibiting a strip force no greater than about 2.5 lbf (11.1 N), said blend exhibiting a strip force of at least about 3 lbf (13.3 N), each said strip force being the force necessary to break adhesion between conductor and said one of said copolymers, said another of said copolymers, and said blend, respectively, and another composition comprising tetrafluoroethylene / hexafluoropropylene copolymer having an MFR of no greater than about 16 g / 10 min and containing —CF3 end groups and an effective amount of wire affinity end groups to exhibit a strip force of at least about 3 lbf (13.3 N), said strip force being the force necessary to break adhesion between conductor and said copolymer, the coaxial cable exhibiting an average return loss of no greater than about −26 dB at 800 MHz to 3 GHz and having a void content of about 20 to 65% and (b) forming an outer conductor over said foamed insulation.

Owner:THE CHEMOURS CO FC LLC

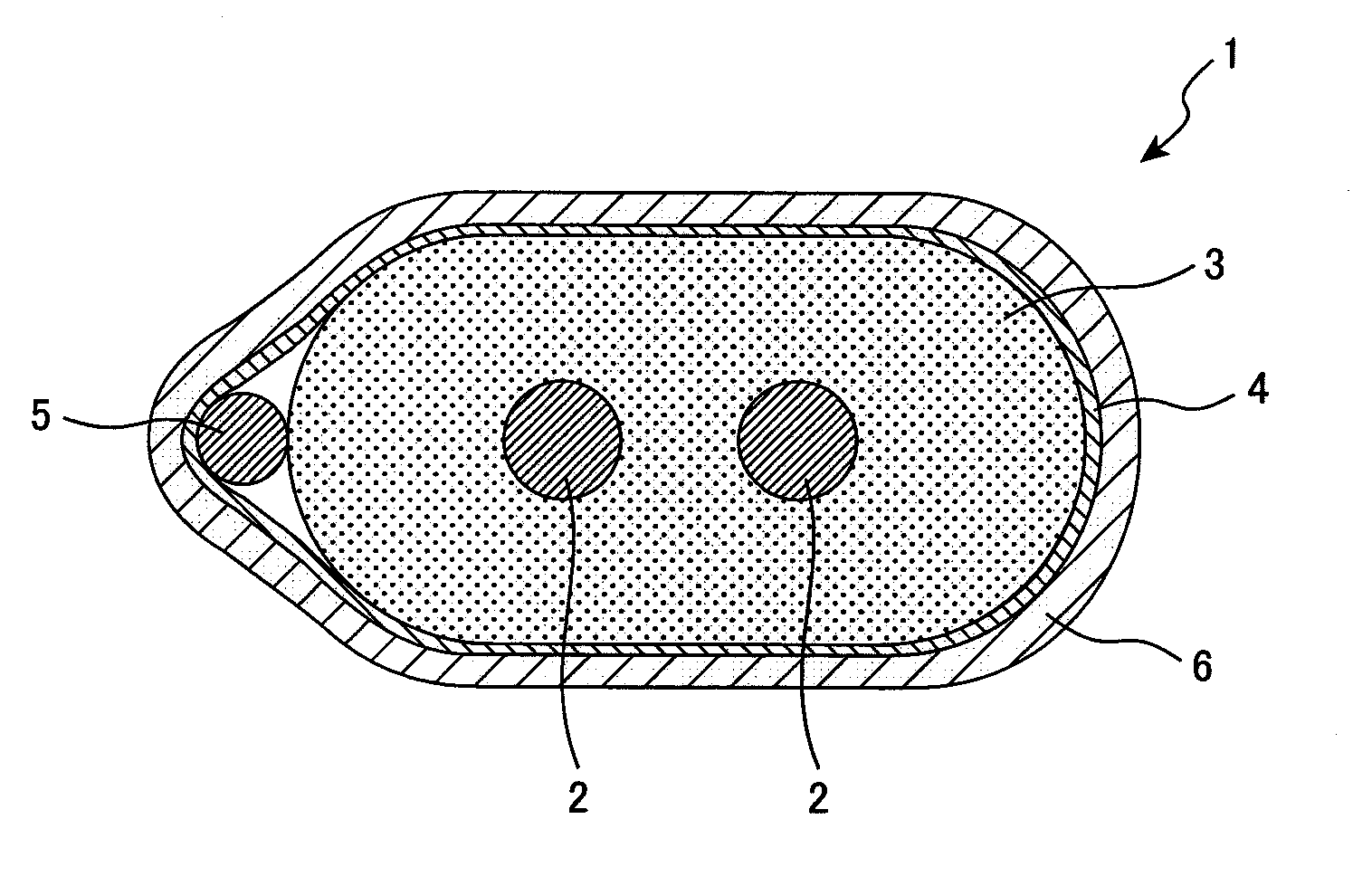

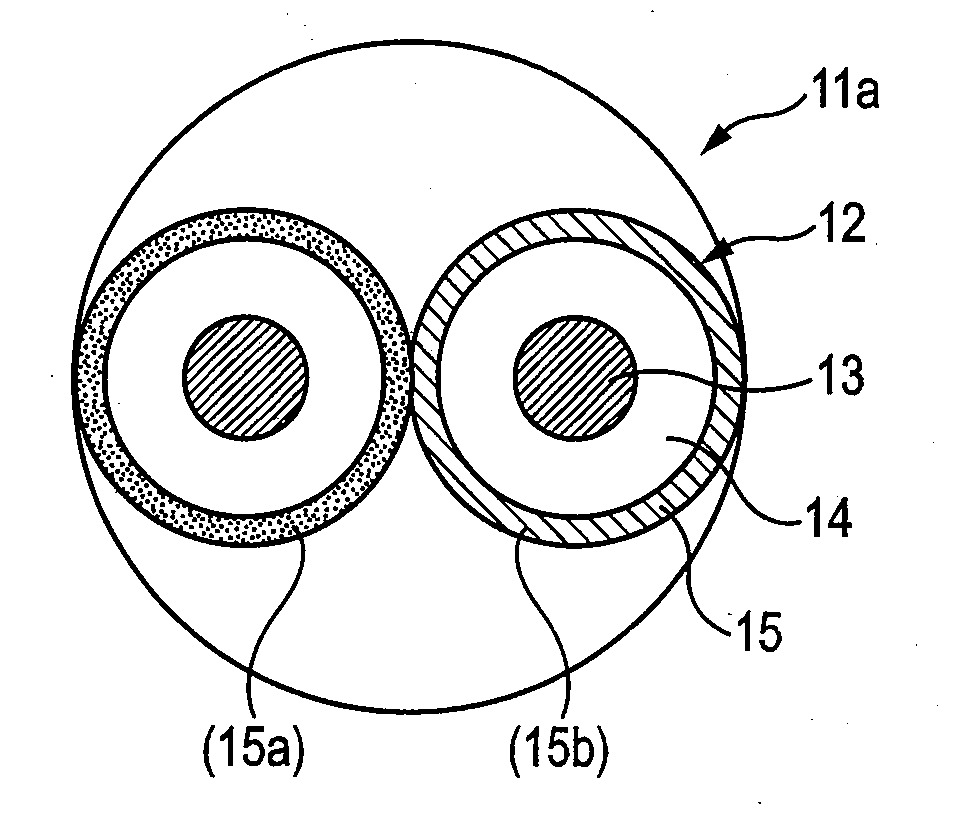

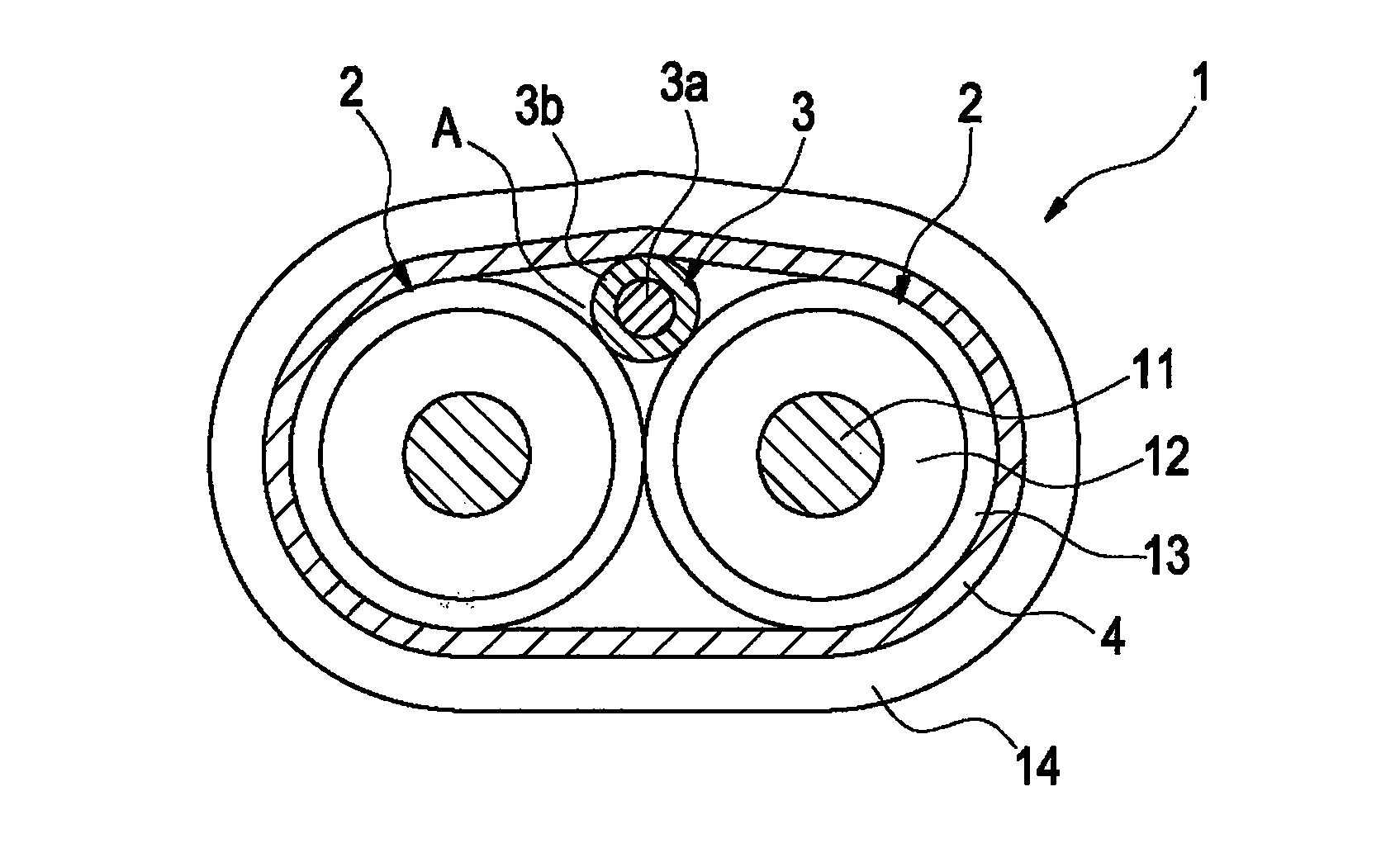

Twinax cable

InactiveUS20100307790A1High dielectric constantHigh mechanical strengthCoaxial cables/analogue cablesInsulated cablesEngineeringElectrical conductor

A twinax cable includes at least a pair of core wires, each of which includes a conductor and an insulator covering an outer periphery of the conductor. The insulator includes an inner insulator covering the outer periphery of the conductor and an outer insulator covering an outer periphery of the inner insulator. The inner insulator is formed by a non-colored compressed insulator. The outer insulator is formed by a colored compressed insulator. A thickness of the outer insulator is formed thinner than a thickness of the inner insulator. The outer insulators of the pair of core wires are formed to have hues that are set respectively differently.

Owner:SUMITOMO ELECTRIC IND LTD

Blind mate capacitively coupled connector

ActiveUS8622762B2Increase surface areaCoaxial cables/analogue cablesElectrically conductive connectionsCapacitanceDielectric

A connector with a capacitively coupled connector interface for interconnection with a female portion is provided with an annular groove, with a sidewall, open to an interface end of the female portion. A male portion is provided with a male outer conductor coupling surface at an interface end, covered by an outer conductor dielectric spacer. The male portion is retained with a range of radial movement, with respect to a longitudinal axis of the male portion, by a bias web of a float plate. The male outer conductor coupling surface is dimensioned to seat, spaced apart from the sidewall by the outer conductor dielectric spacer, within the annular groove, when the male portion and the female portion are in an interlocked position.

Owner:COMMSCOPE TECH LLC

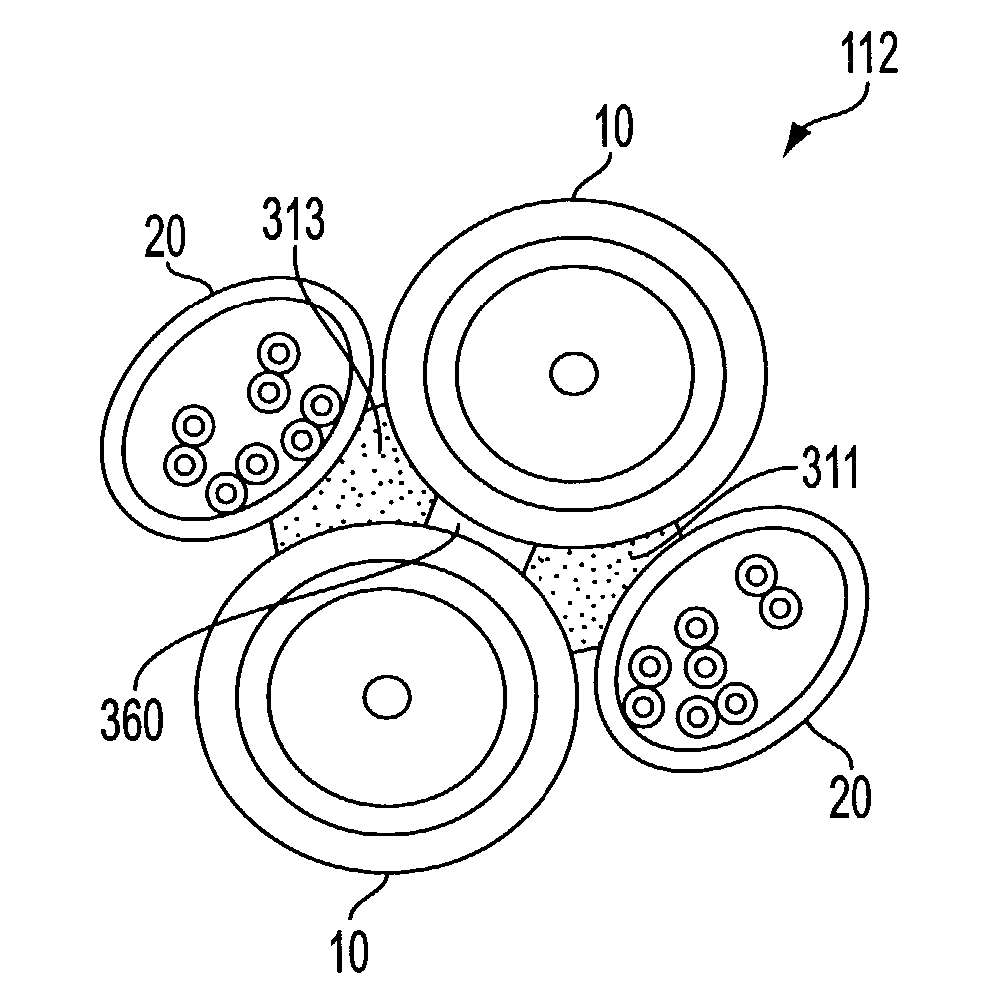

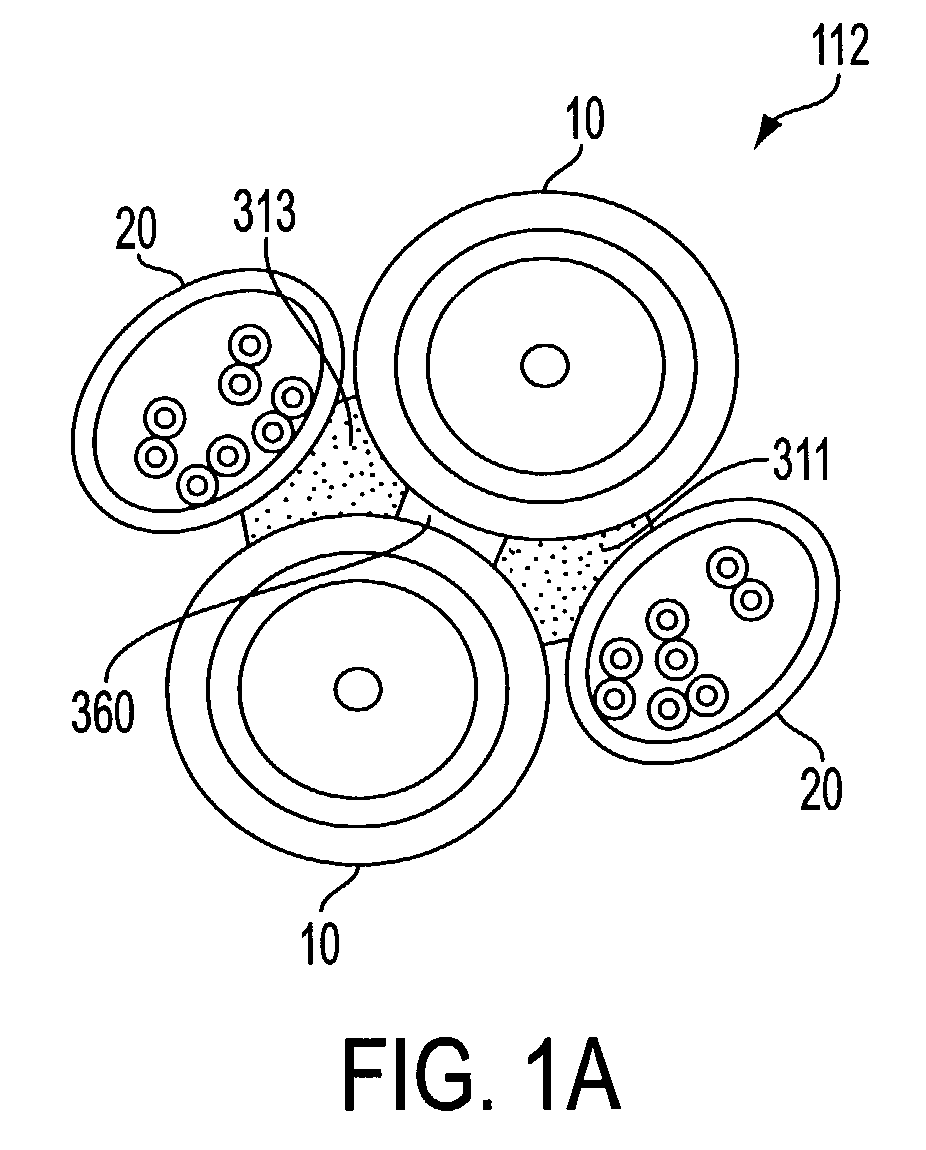

Differential transmission signal cable and composite cable containing the same

ActiveUS8039749B2Improve reliabilityNot to damageCoaxial cables/analogue cablesNon-insulated conductorsSemiconductor materialsDifferential transmission

A differential transmission signal cable is provided. The differential transmission signal cable includes one pair of signal wires including a central conductor covered by an insulating layer, a drain wire arrayed along the signal wires, and an outer conductor for covering the signal wires and the drain wire. The drain wire is covered by a covering film made of a semi-conductive material having flexibility and containing an electrically conductive filler.

Owner:SUMITOMO ELECTRIC IND LTD +1

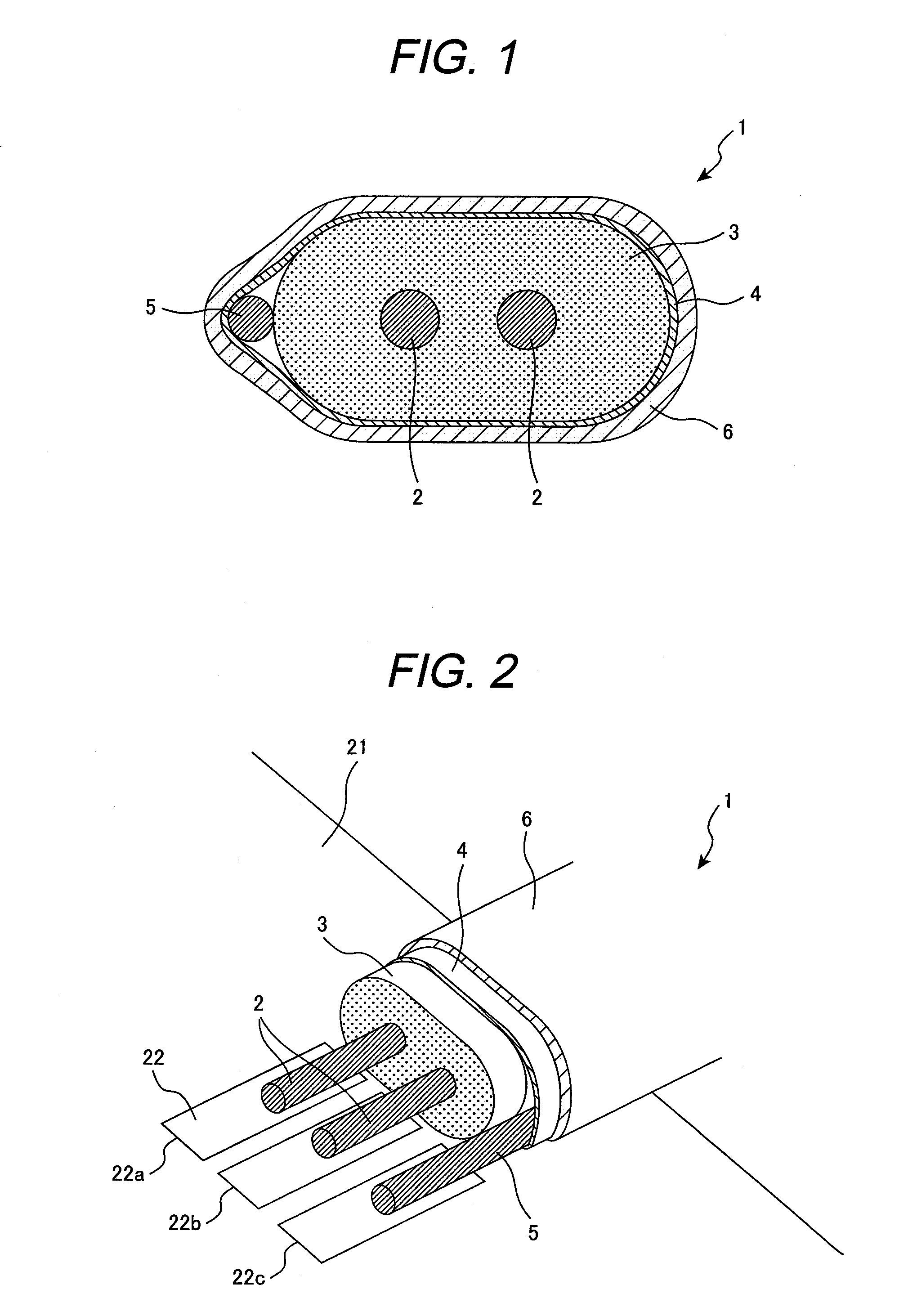

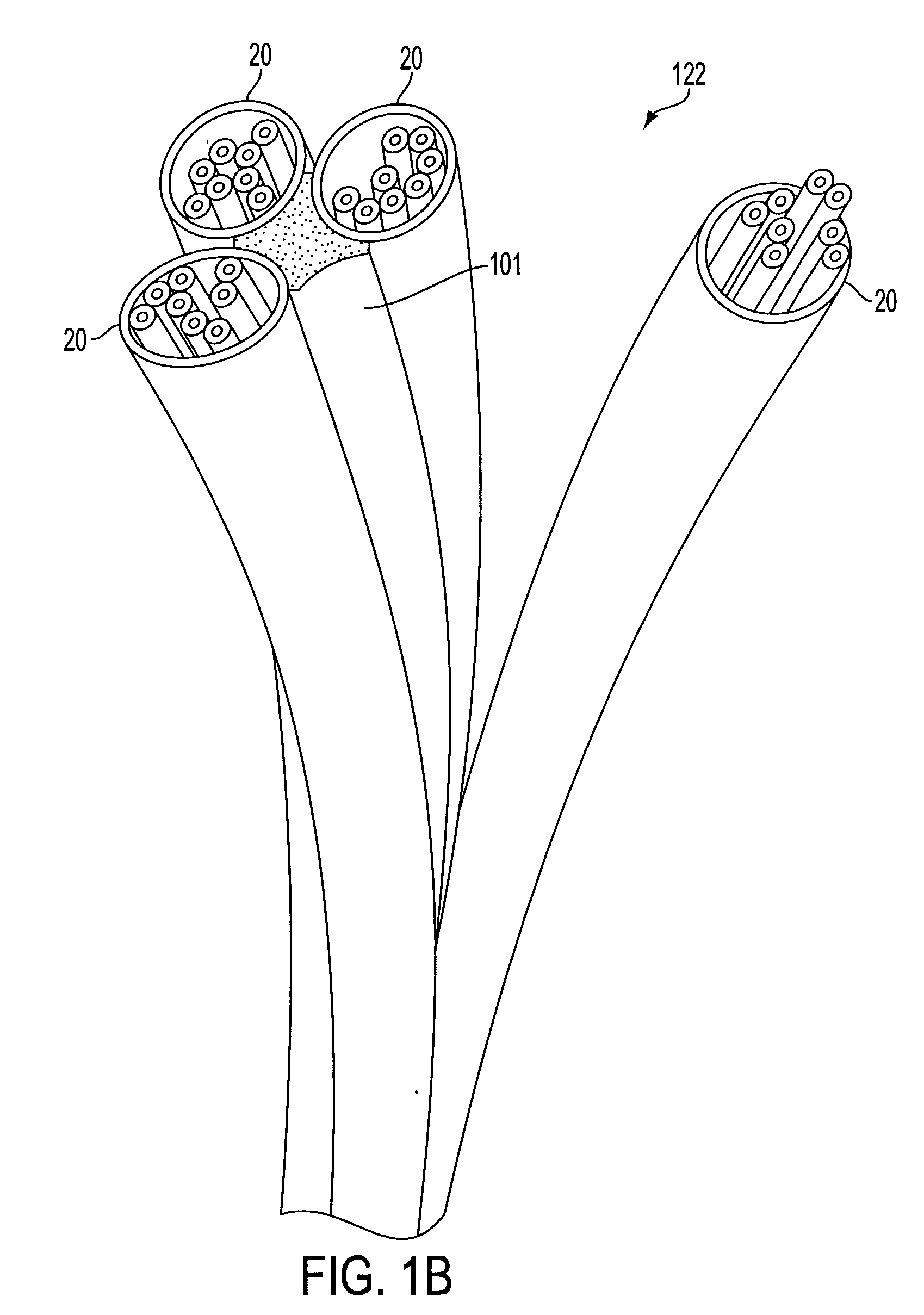

Separable multi-member composite cable

InactiveUS20040062496A1Coaxial cables/analogue cablesInsulated cablesElectrical and Electronics engineering

Discussed herein are multi-member cables which are comprised of two or more components (including component cables and non-cable components) held together by at least one adhesive element placed between the components, and methods for manufacturing such cables. Multi-member cables which are compromised of jacketed cables whose jackets are adhered together without the use of an adhesive element, such as by co-forming the jackets, and methods for manufacturing such cables are also discussed. Generally, the components will be separated from the multi-member cable by an installer, although other methods may also be used.

Owner:BELDEN TECHNOLOGY INC

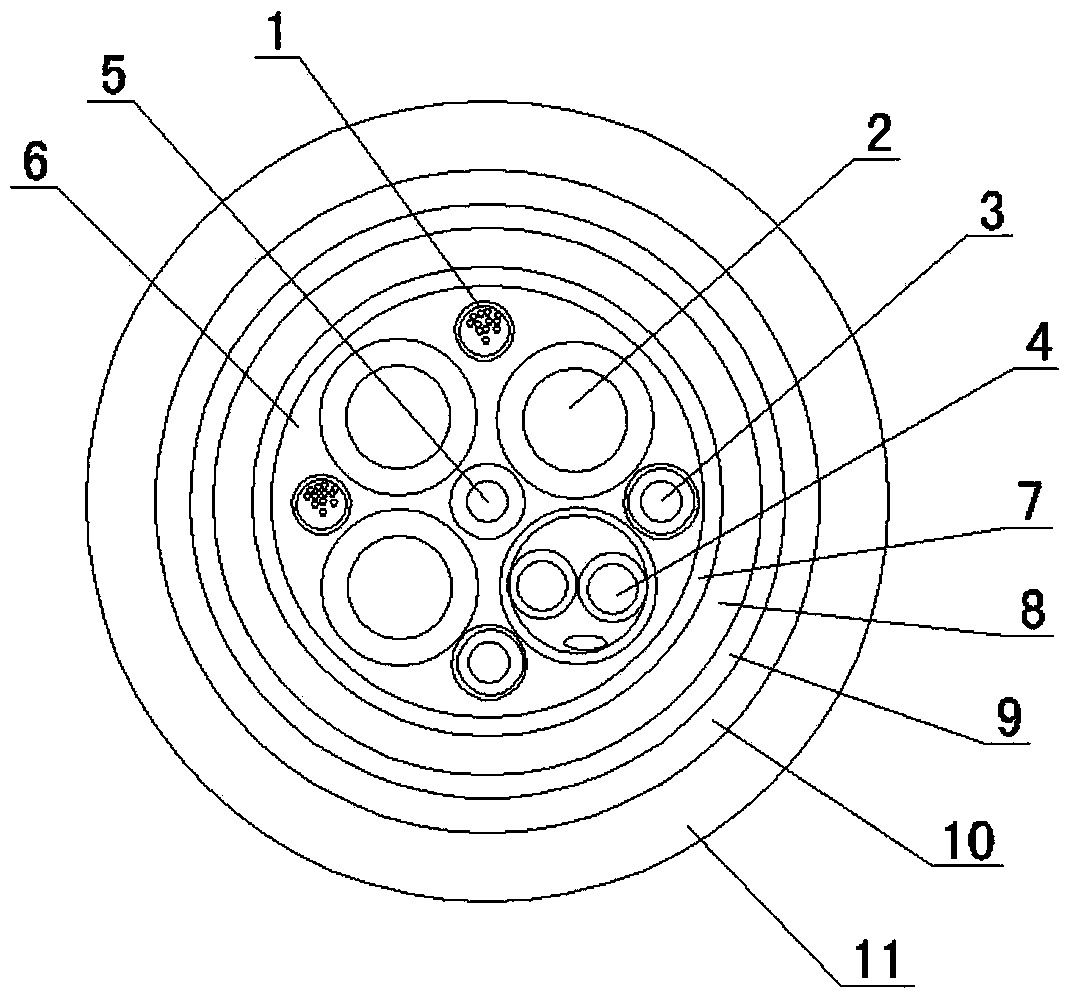

Photoelectric combined composite cable and manufacturing process thereof

ActiveCN104269209AConducive to electrical equipment needsSmall outer diameterCoaxial cables/analogue cablesFibre mechanical structuresElectric power transmissionCoaxial cable

The invention relates to a photoelectric combined composite cable and a manufacturing process of the photoelectric combined composite cable. The manufacturing process is characterized in that a reinforcement core is arranged, two optical cable units, three cable units, two coaxial cable units and a pair twist unit are twisted into a cable core around the reinforcement core with the reinforcement core as the center, and a wrapping tape layer, a main metal shielding layer, a lining layer, an armor layer and an outer sheath layer are sequentially arranged outside the cable core from inside to outside. The advantages of optical fiber communication and the unique function of electric signal transmission are reasonably and organically combined, the related units are independent and do not interfere with one another in the working process, and the function of integrating power transmission, signal transmission and equipment control is realized. The photoelectric combined composite cable is small in outer diameter, light in weight, good in bending performance, electric performance and optical performance, favorable for transportation and installation and suitable for electric communication and control connecting lines in many fields and on many occasions.

Owner:安徽龙联智能光电有限公司

Fluoropolymer wire insulation

ActiveUS7638709B2Lower return lossAccelerated dissipationCoaxial cables/analogue cablesPlastic/resin/waxes insulatorsCoaxial cableElectrical conductor

FEP compositions are provided that provide foam insulation in coaxial cable that surpasses the return loss obtained when PFA is used to make the foamed insulation, one composition comprising a blend of tetrafluoroethylene / hexafluoropropylene copolymers, one of said copolymers exhibiting a strip force of at least about 3 lbf (13.3 N) and another of said copolymers exhibiting a strip force no greater than about 2.5 lbf (11.1 N), said blend exhibiting a strip force of at least about 3 lbf (13.3 N), each said strip force being the force necessary to break adhesion between conductor and said one of said copolymers, said another of said copolymers, and said blend, respectively, and another composition comprising tetrafluoroethylene / hexafluoropropylene copolymer having an MFR of no greater than about 16 g / 10 min and containing —CF3 end groups and an effective amount of wire affinity end groups to exhibit a strip force of at least about 3 lbf (13.3 N), said strip force being the force necessary to break adhesion between conductor and said copolymer, the coaxial cable exhibiting an average return loss of no greater than about −26 dB at 800 MHz to 3 GHz and having a void content of about 20 to 65% and (b) forming an outer conductor over said foamed insulation.

Owner:THE CHEMOURS CO FC LLC

Twinax Cable Design for Improved Electrical Performance

ActiveUS20120145429A1Coaxial cables/analogue cablesMagnetic/electric field screeningElectrical performanceTwinaxial cabling

Owner:PANDUIT

Broad band radiation type leak coaxial cable for subway and its production method

ActiveCN101404350AUniformly foamed poresUniform field strengthCoaxial cables/analogue cablesPlastic/resin/waxes insulatorsInsulation layerElectrical conductor

The invention relates to a broadband radial pattern leaky coaxial cable used for subway and a manufacturing method thereof, and the leaky coaxial cable has the double functions of transmission line of information and duplexer. The structure of the leaky coaxial cable consists of an inner conductor, an insulation layer, an outer conductor and a jacket, wherein, the inner conductor is externally covered with the insulation layer which is externally covered with the outer conductor that is externally sheathed with the jacket, and the insulation layer that covers on the surface of the inner conductor adopts nitrogen or carbon dioxide physical foam to form a foamed polyethylene insulation layer; cambered slotted holes are opened on a clutch gold belt of the outer conductor covered outside the insulation layer. The manufacturing method comprises the steps: (1) a spiral wrinkle inner conductor is manufactured by longitudinal covering welding and embossing by using a copper strip; (2) the nitrogen or the carbon dioxide are adopted to be injected into the smelted polyvinyl plastics, and then the physical foamed polyethylene insulation layer is formed on the surface of the inner conductor by extrusion and cladding; (3) the slotted holes broken out by the clutch gold belt of the outer conductor are the cambered slotted holes; (4) the clutch gold belt of the outer conductor is covered on the insulation layer longitudinally, and the surface of the clutch gold belt of the outer conductor is crowded and covered with the jacket.

Owner:ZHONGTIAN RADIO FREQUENCY CABLE CO LTD

Double-shielded mineral-insulated cable and manufacturing method thereof

ActiveCN101673598AHigh temperature resistantOxidation resistantCoaxial cables/analogue cablesInsulated cablesAviationSilicon dioxide

The invention relates to a double-shielded mineral-insulated cable which is mainly applied to the fields of high-frequency signal transmission in occasions with high ambient temperature and high radiation, such as the communication fields of metallurgy, medical treatment, aerospace, military and the like. The double-shielded mineral-insulated cable comprises an inner conductor, an insulating medium, an outer conductor, an insulating medium and a protective sleeve in sequence from inside to outside, and is characterized in that the insulating medium is magnesium oxide, aluminum oxide or silicondioxide. Compared with the existing double-shielded cable, the double-shielded mineral-insulated cable has the advantages of longer service life and wider use range; in addition, the double-shieldedmineral-insulated cable has excellent performance, has little interference to transmitted signals and can be used for the communication fields of metallurgy, medical treatment, aerospace, military andthe like.

Owner:久盛电气股份有限公司

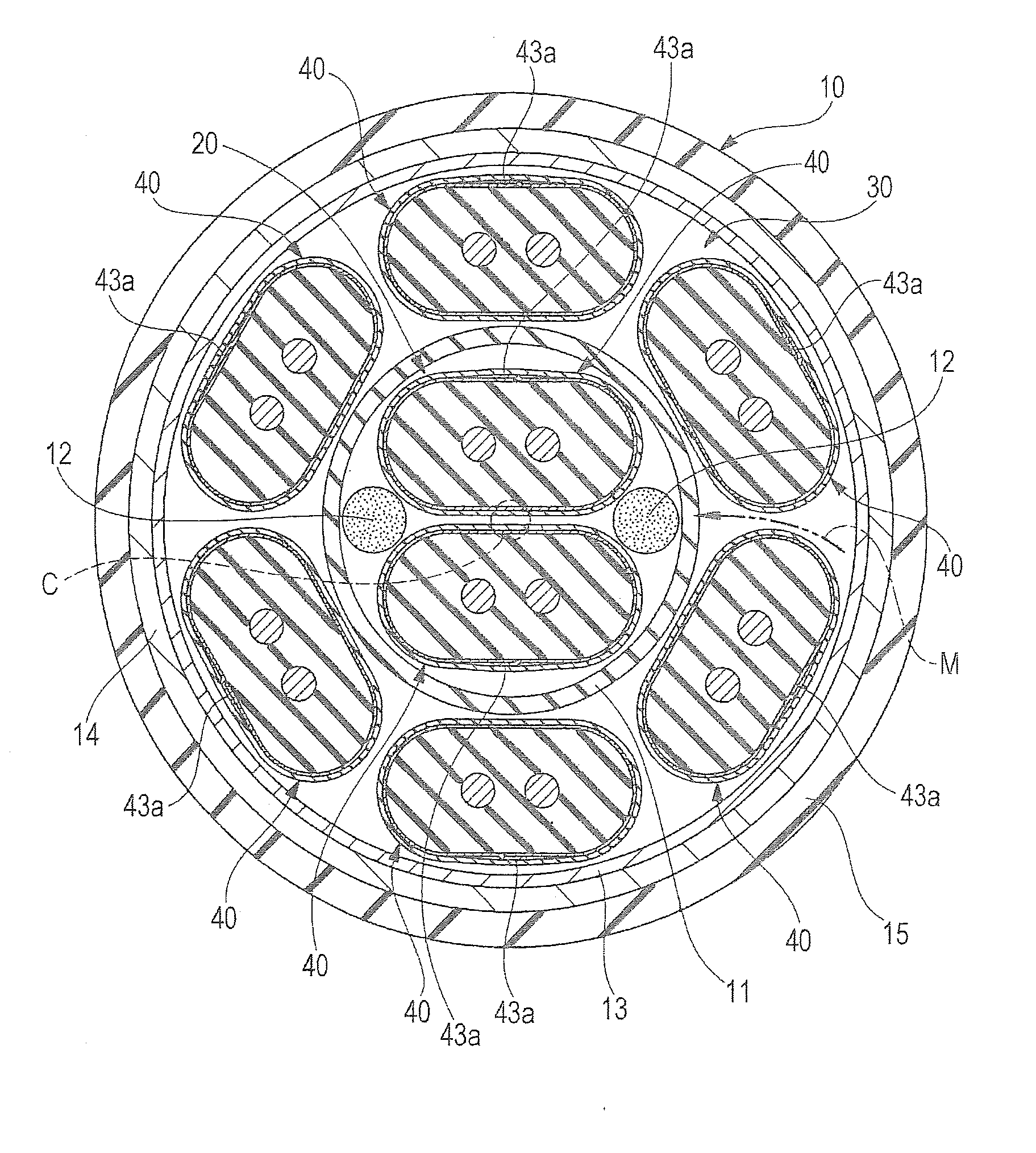

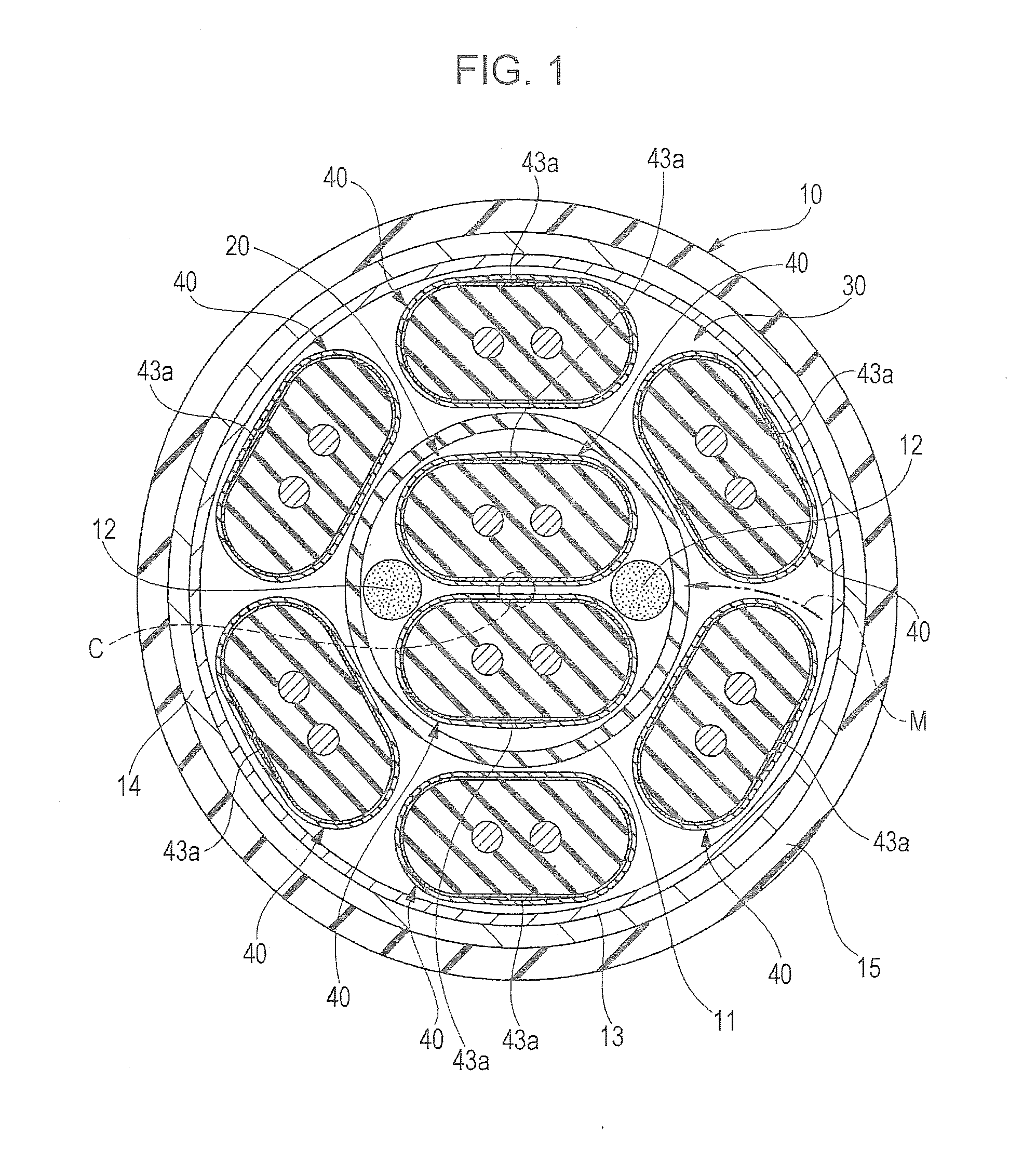

Multi-pair differential signal transmission cable

ActiveUS20150000954A1Slow changeContainment leakCoaxial cables/analogue cablesPower cables with screens/conductive layersDifferential signalingEngineering

A pair of second intervening members configured to hold a transverse cross-section of a first intervening member in a circular shape is disposed inside the first intervening member together with a first cable assembly. An overlap portion of each of differential signal transmission cables that form the first cable assembly and a second cable assembly is oriented toward a second shielding tape conductor.

Owner:HITACHI METALS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com