Photoelectric combined composite cable and manufacturing process thereof

A comprehensive cable, optoelectronic composite technology, applied in cable/conductor manufacturing, insulated cables, communication cables, etc., can solve the problems of difficult to achieve cable performance indicators, complex performance requirements, and inability to meet market demand, etc., to achieve excellent electrical performance and Optical performance, high absorption coefficient, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

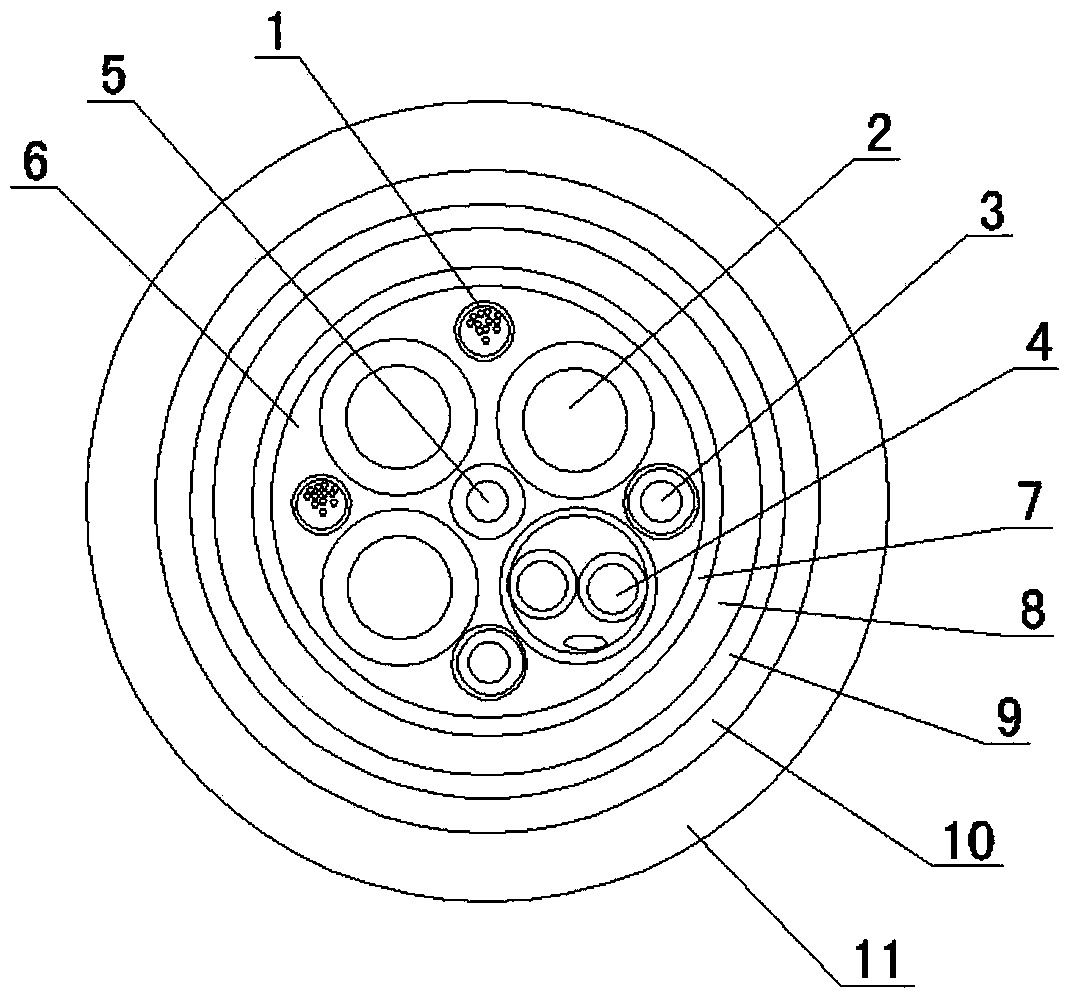

[0048] The structure of the photoelectric composite integrated cable in this embodiment is set as:

[0049] Such as figure 1 As shown, a strengthening core 5 is set, and there are two optical cable units 1, three cable units 2, two coaxial cable units 3 and a twisted unit 4 centered on the strengthening core 5 and twisted around the strengthening core 5 The cable core 6, this form of unit structure arrangement makes the cable structure more compact and stable. On the outside of the cable core 6, a wrapping tape layer 7, a metal overall shielding layer 8, an inner lining layer 9, an armor layer 10 and an outer sheath layer 11 are provided in order from the inside to the outside.

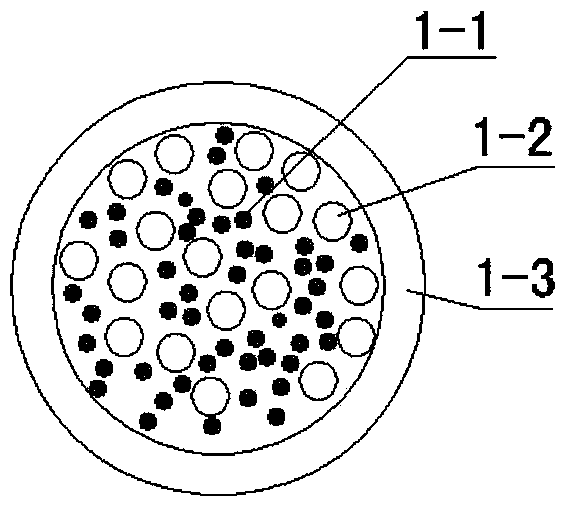

[0050] Such as figure 2 As shown, the optical cable unit 1 in this embodiment is formed by wrapping a plurality of optical fibers 1-1 and filling water-blocking yarn 1-2 with a loose tube 1-3.

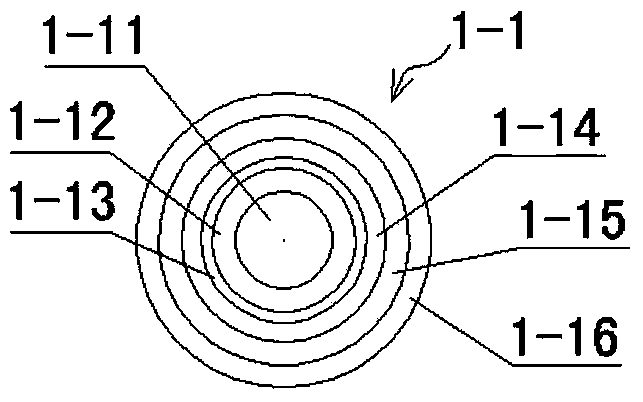

[0051] Such as image 3 As shown, the optical fiber 1-1 in this embodiment is formed with an inner cla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weaving angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com