Patents

Literature

2667results about How to "Large diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

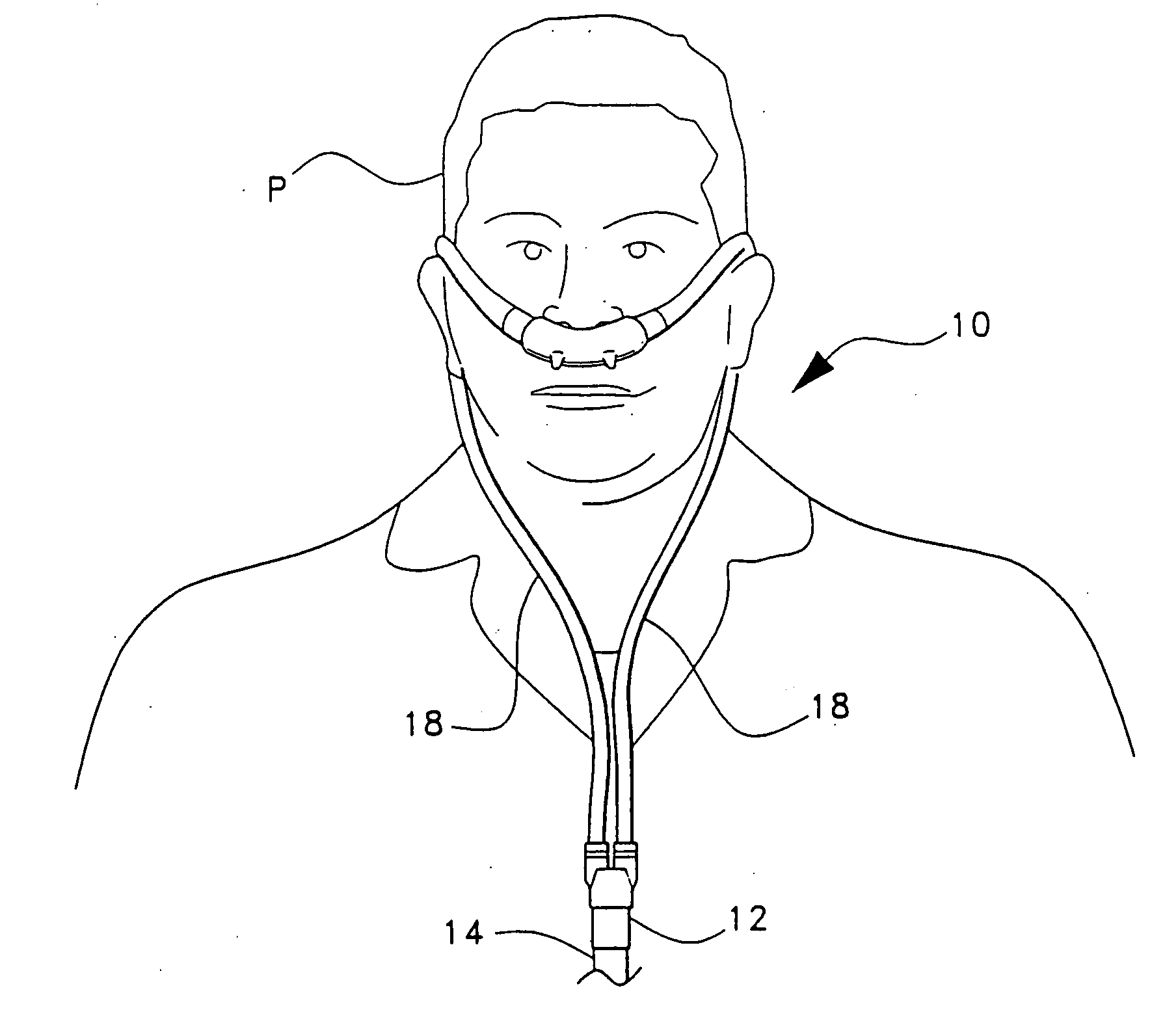

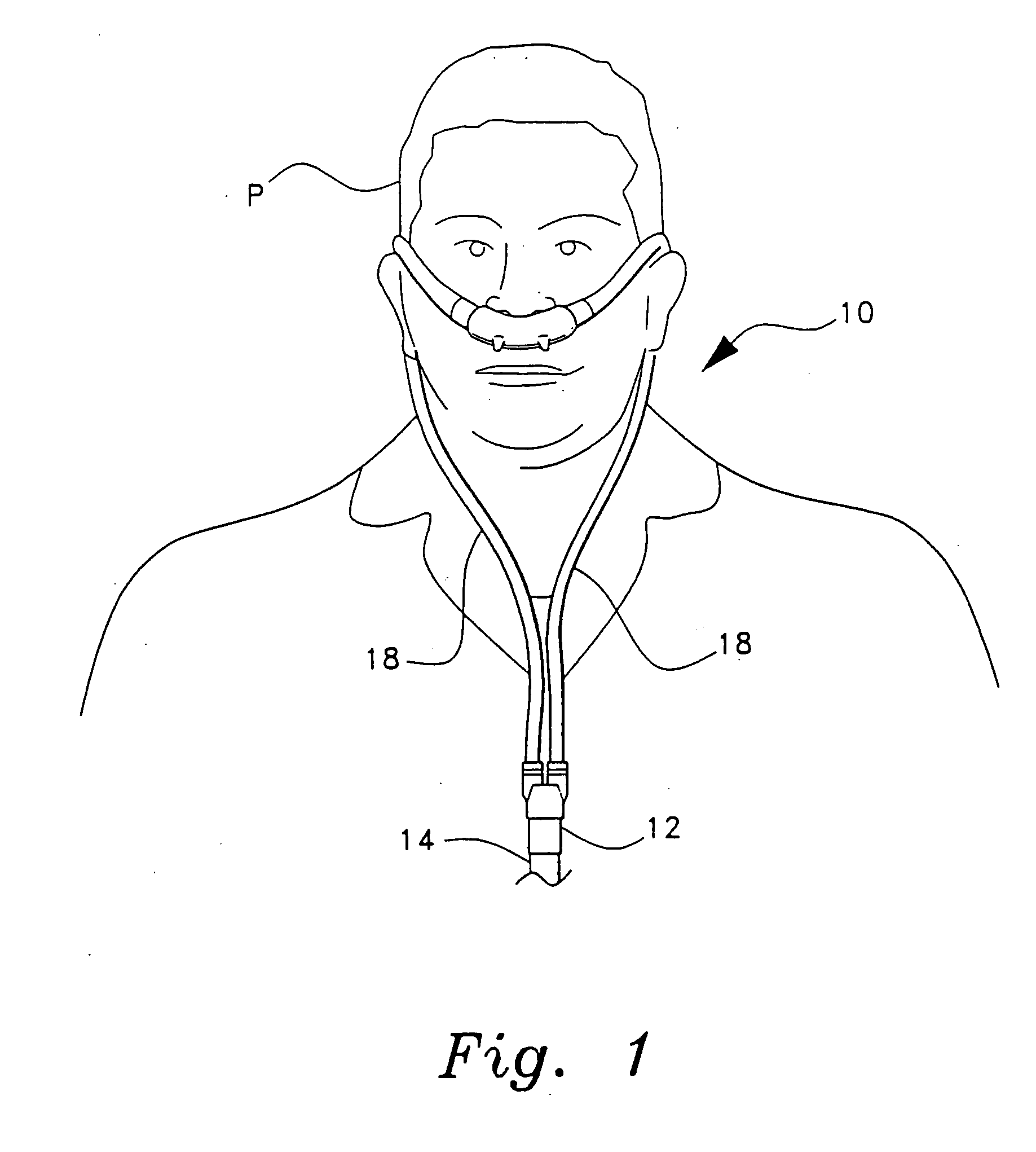

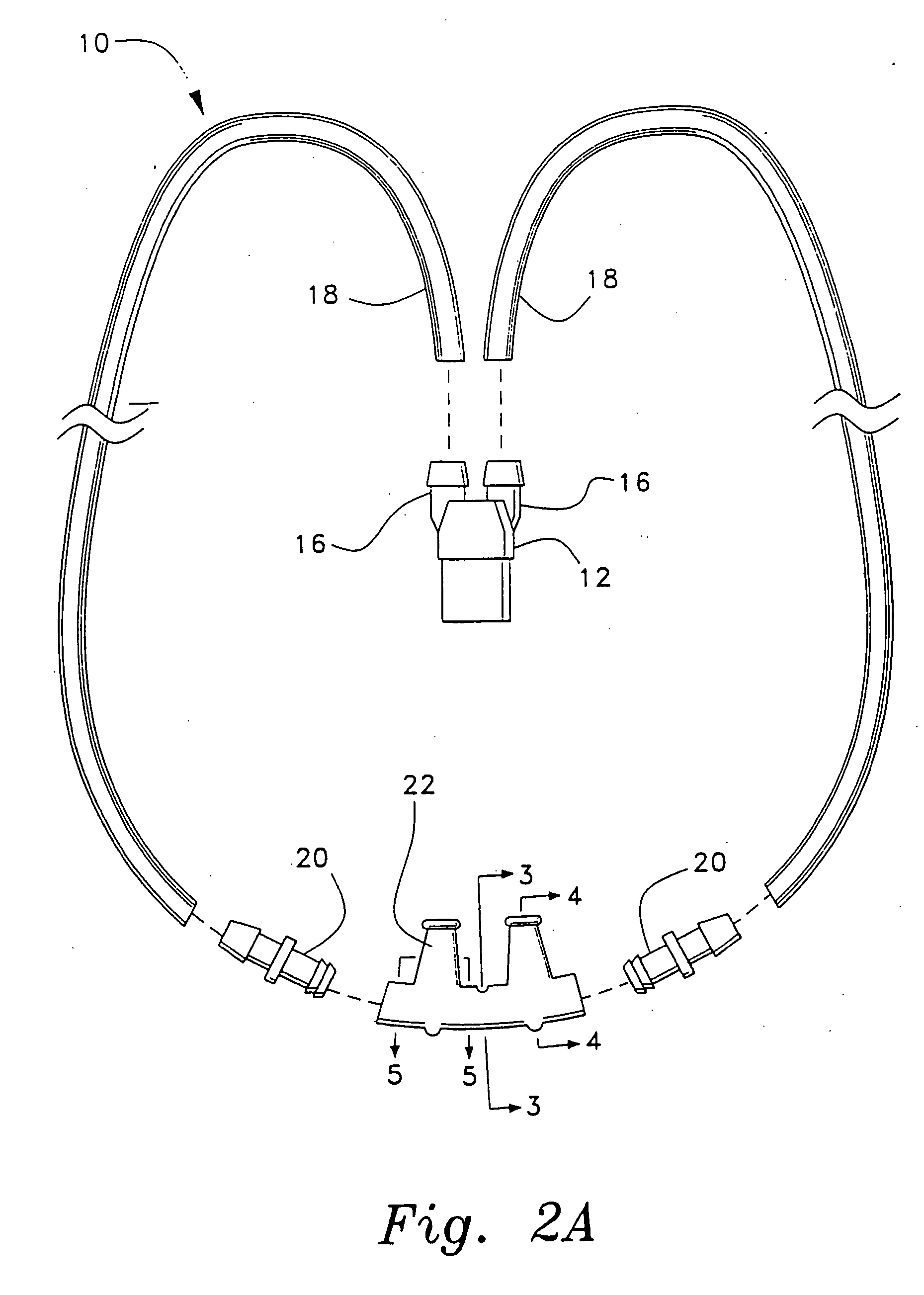

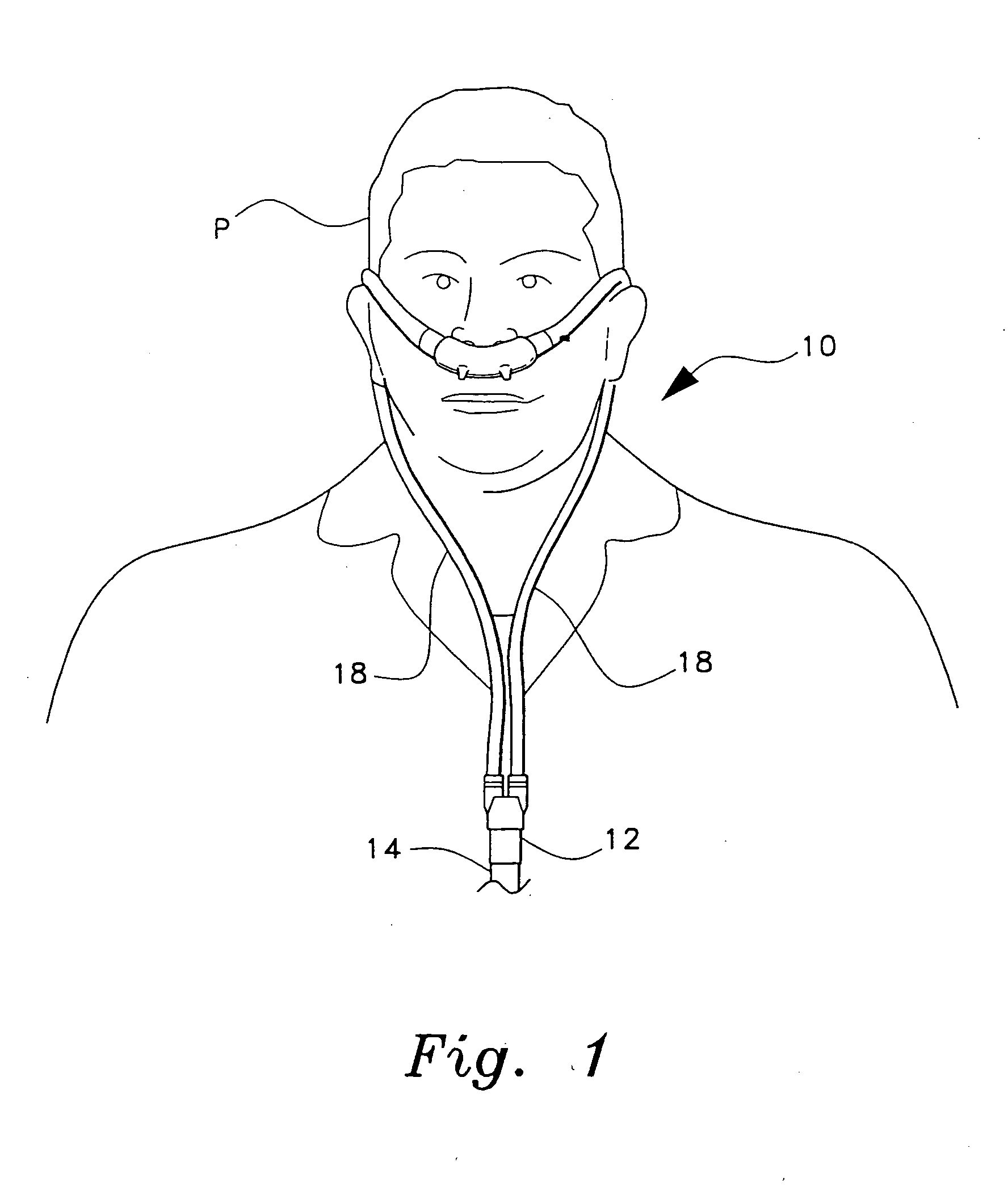

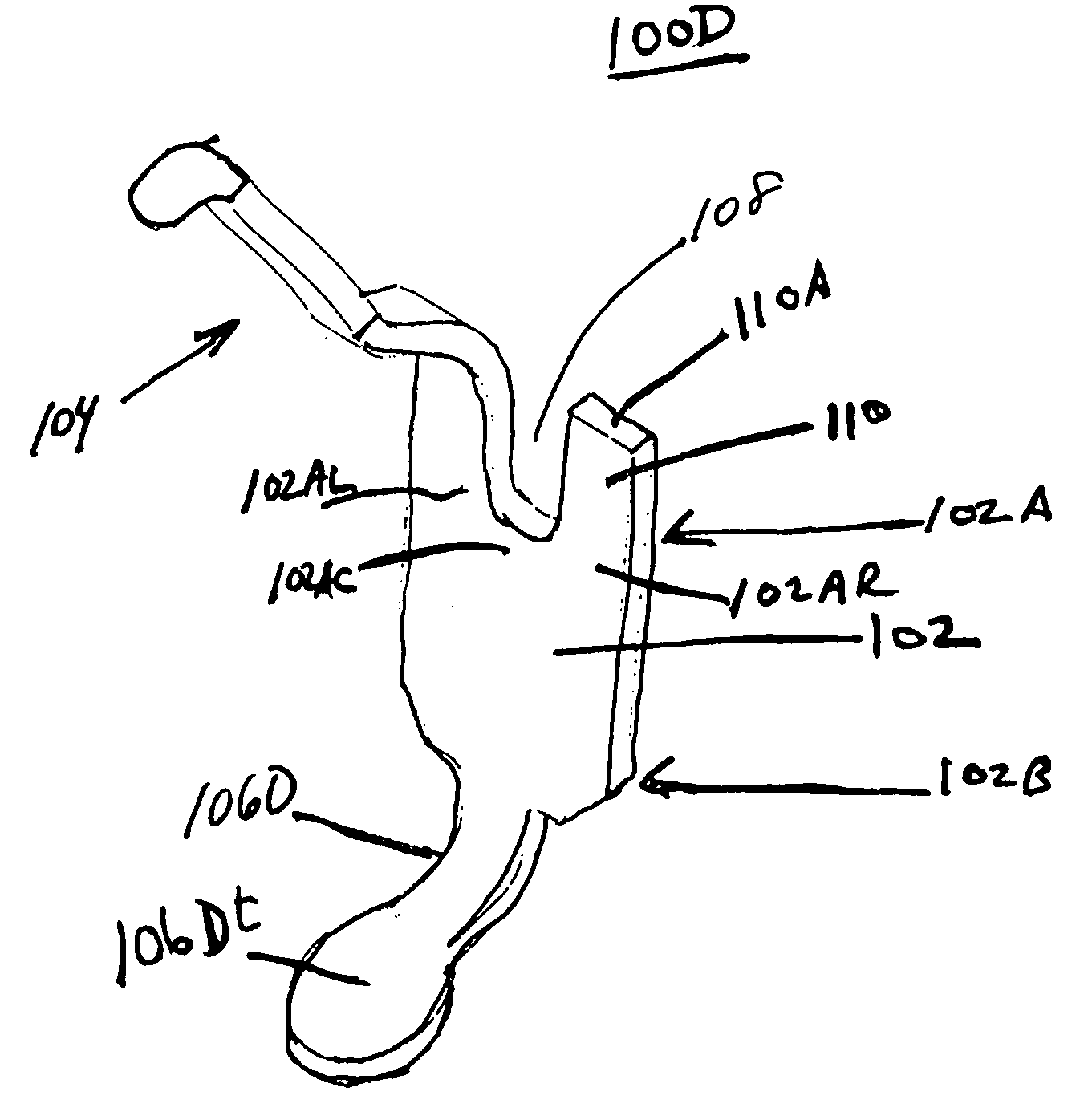

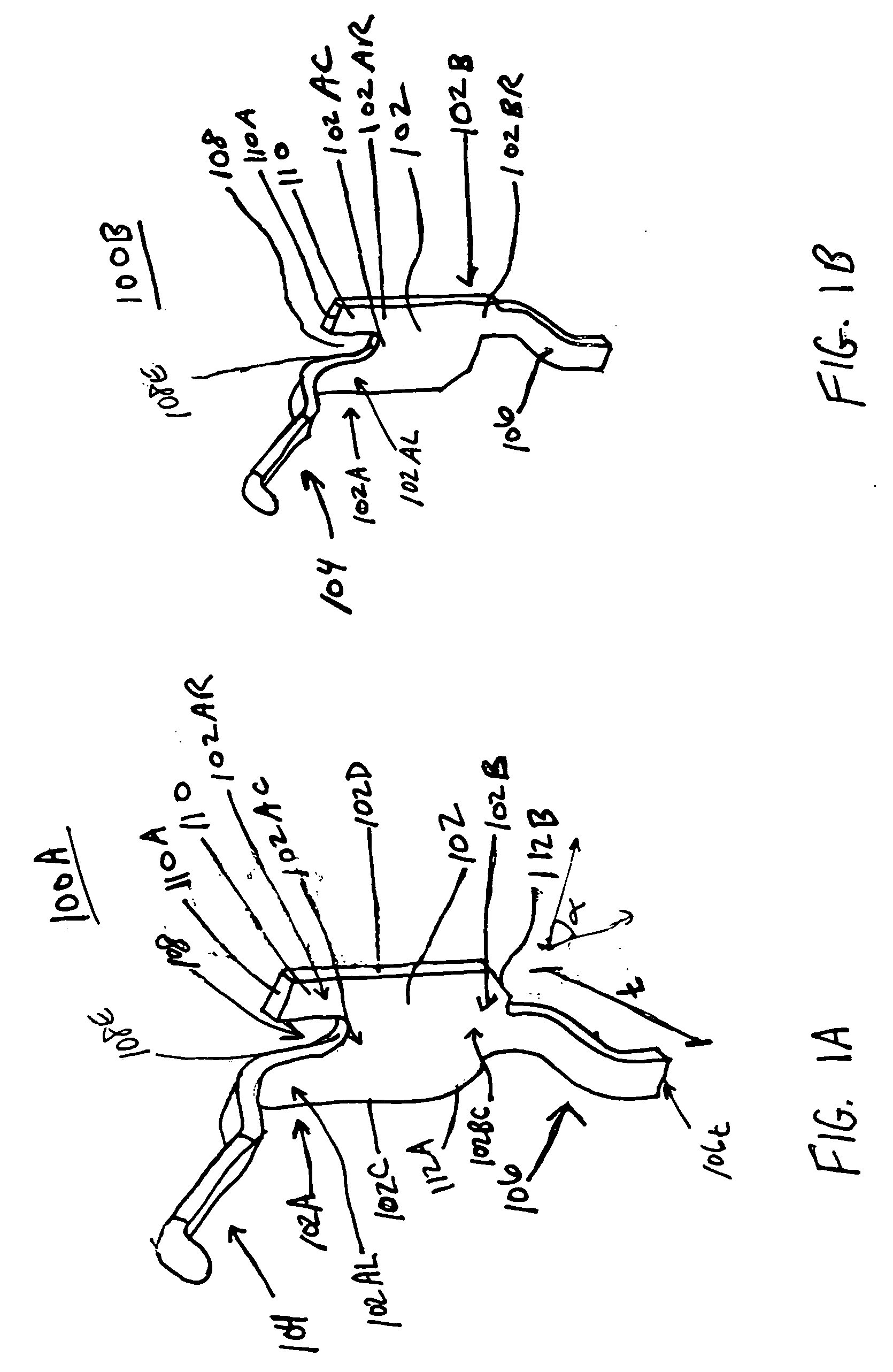

Ventilation interface for sleep apnea therapy

InactiveUS6997177B2Large diameterAvoiding drying and burningRespiratory masksBreathing masksPositive airway pressureNasal cavity

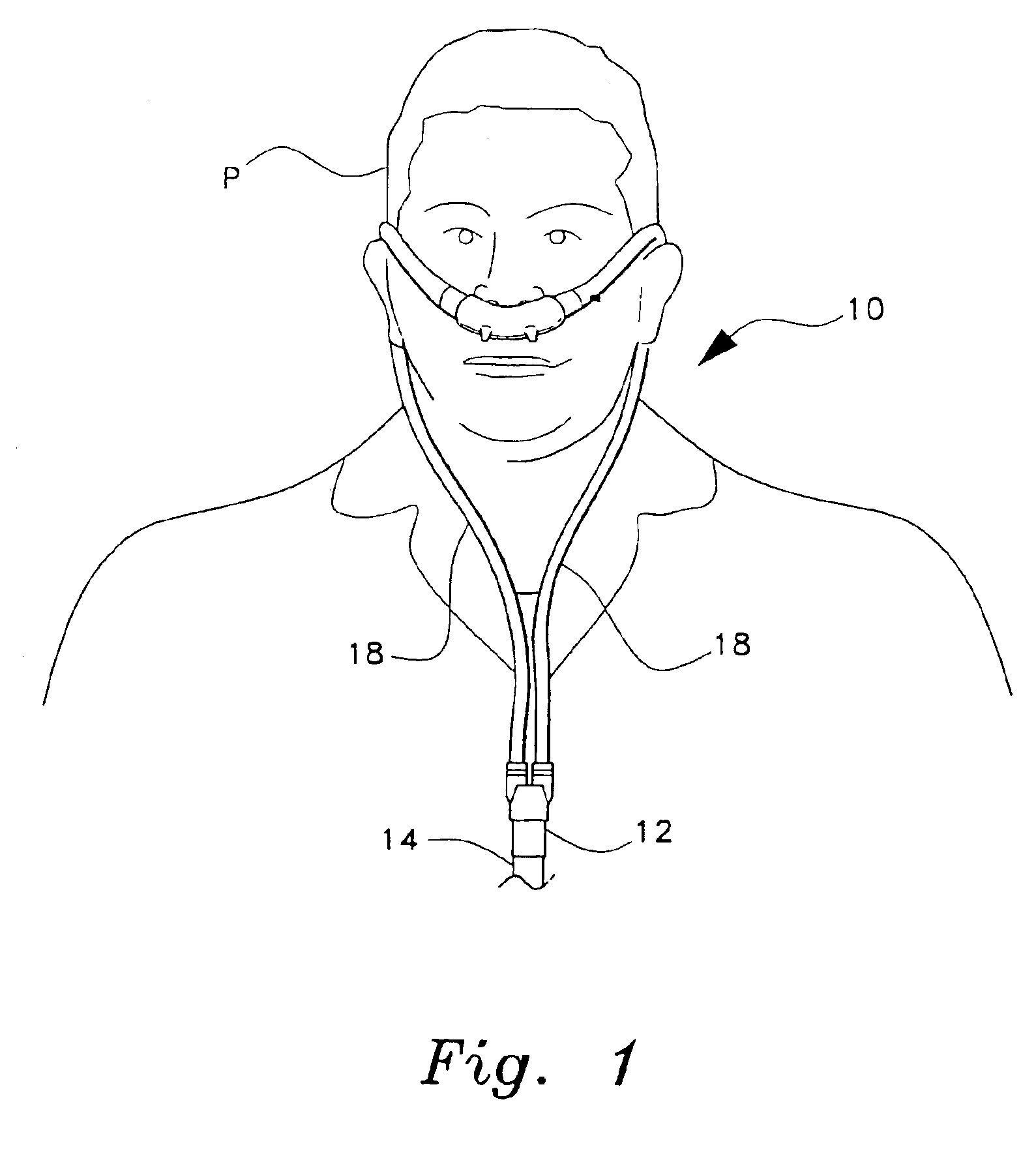

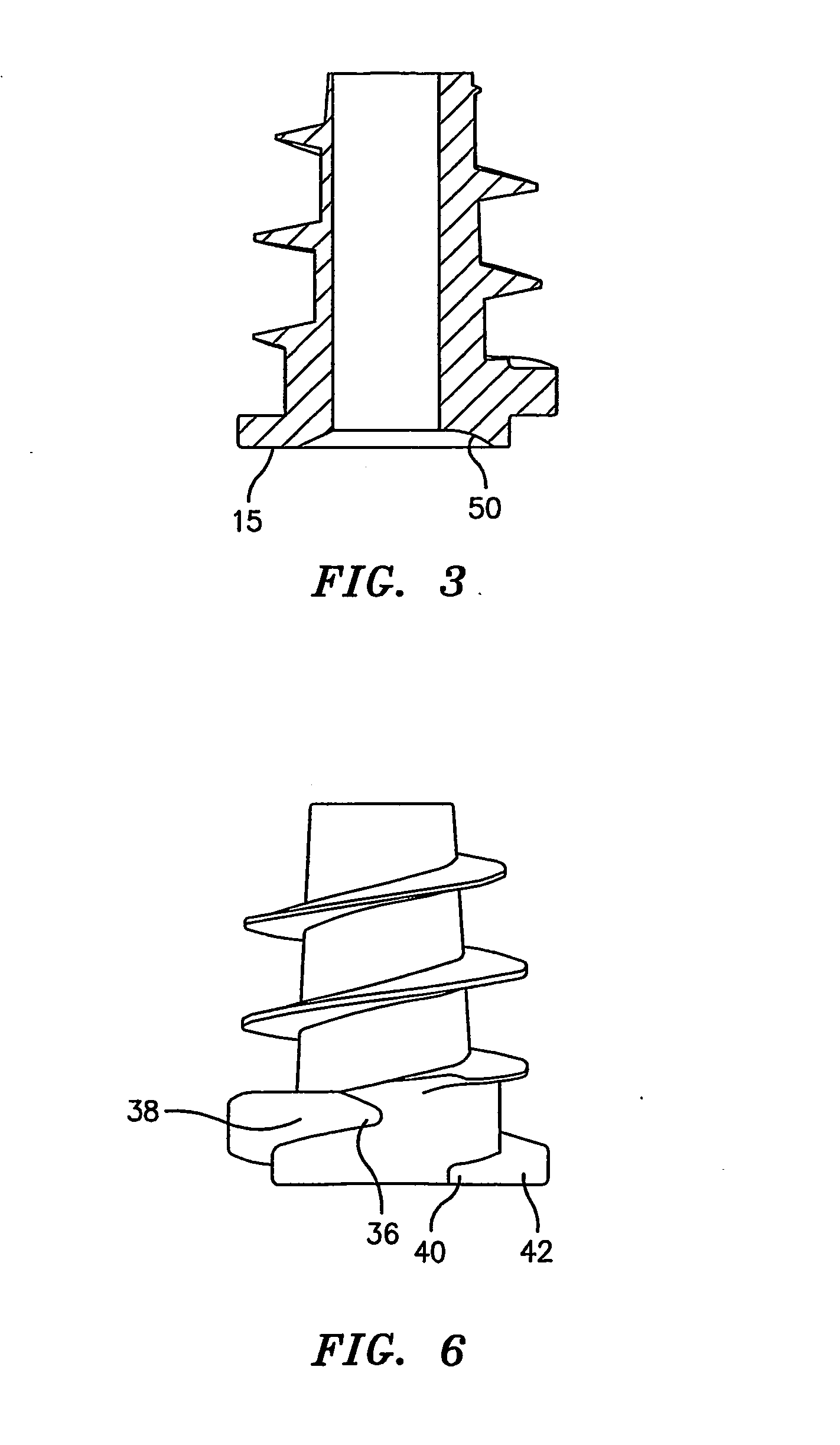

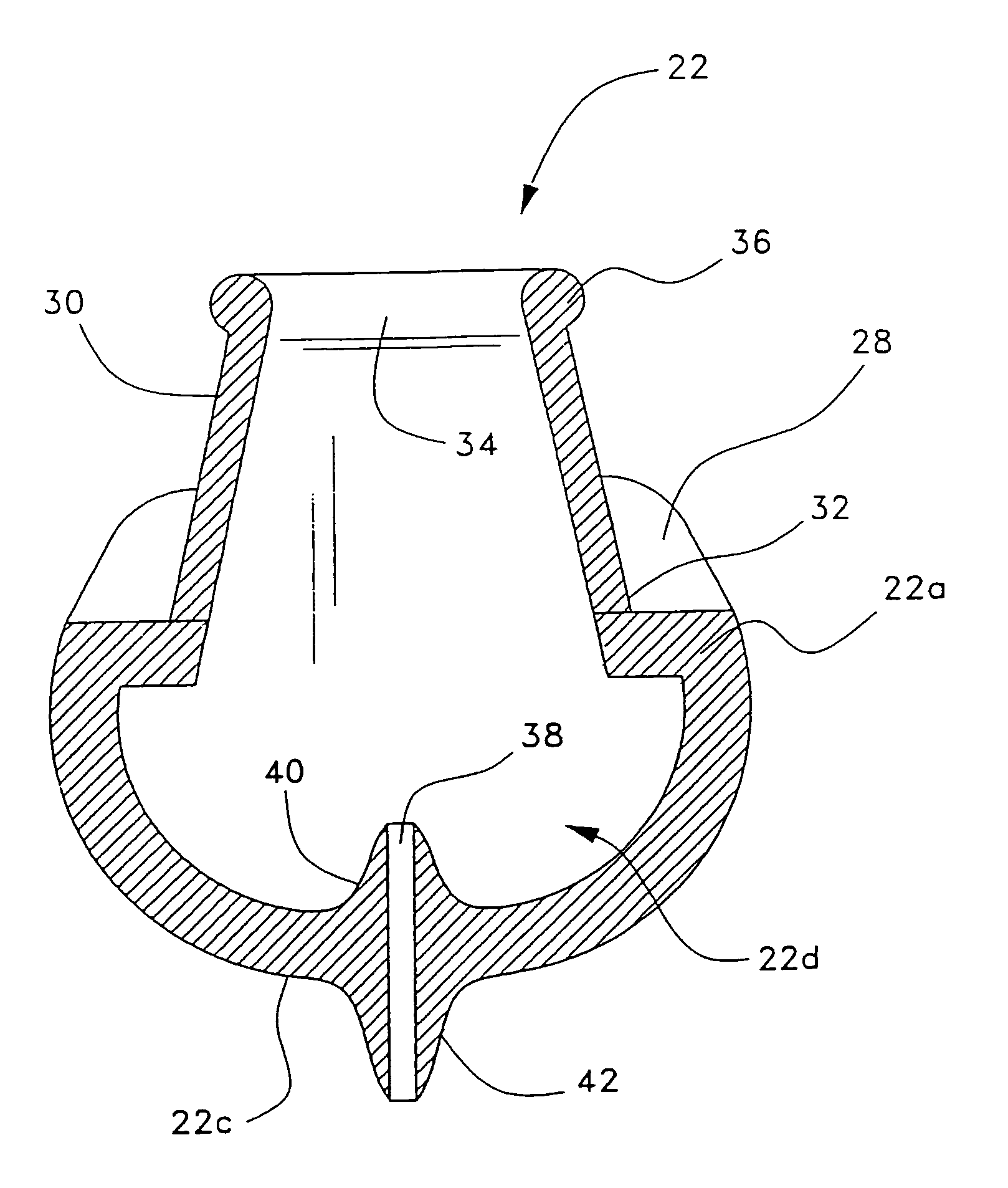

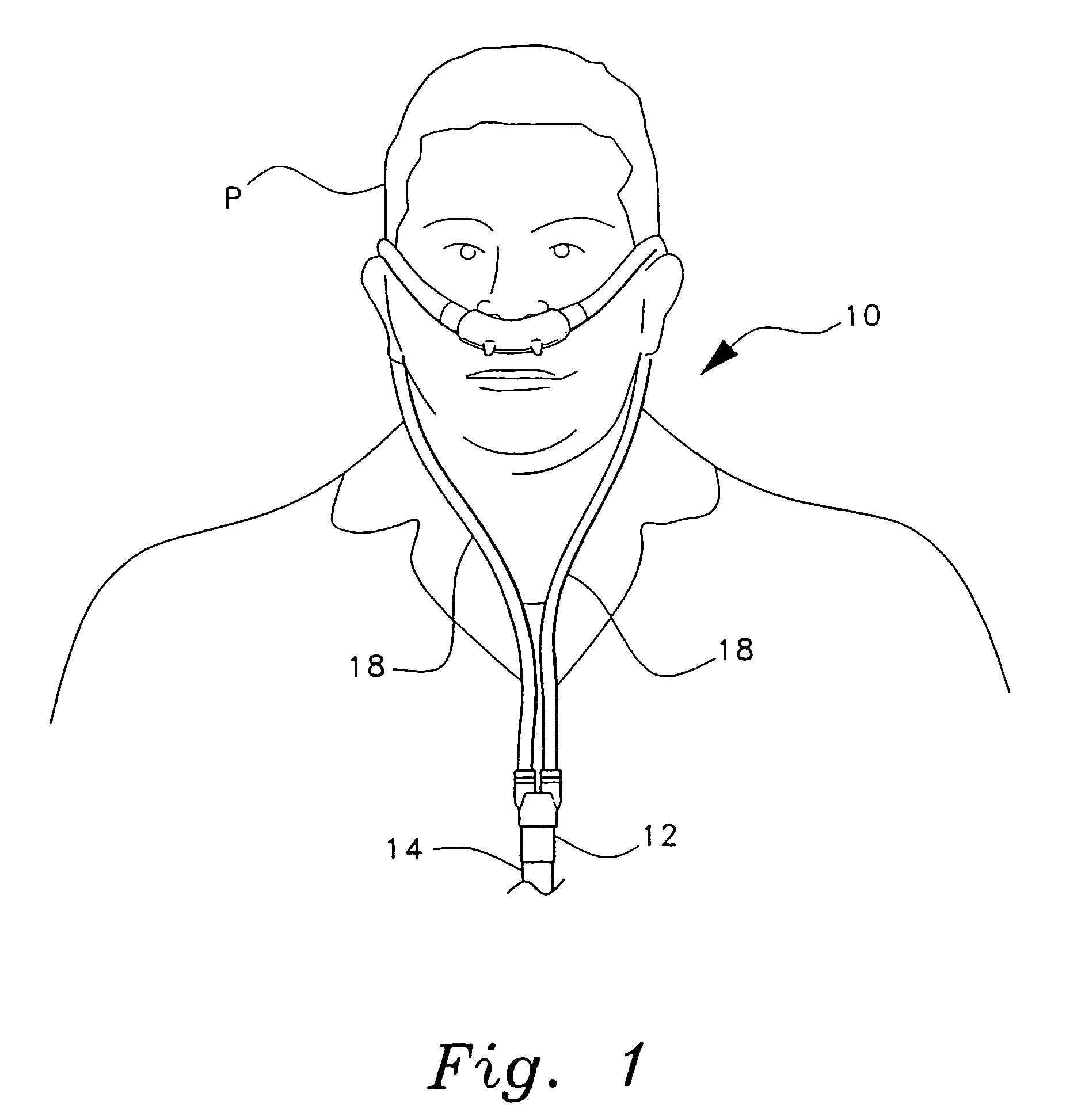

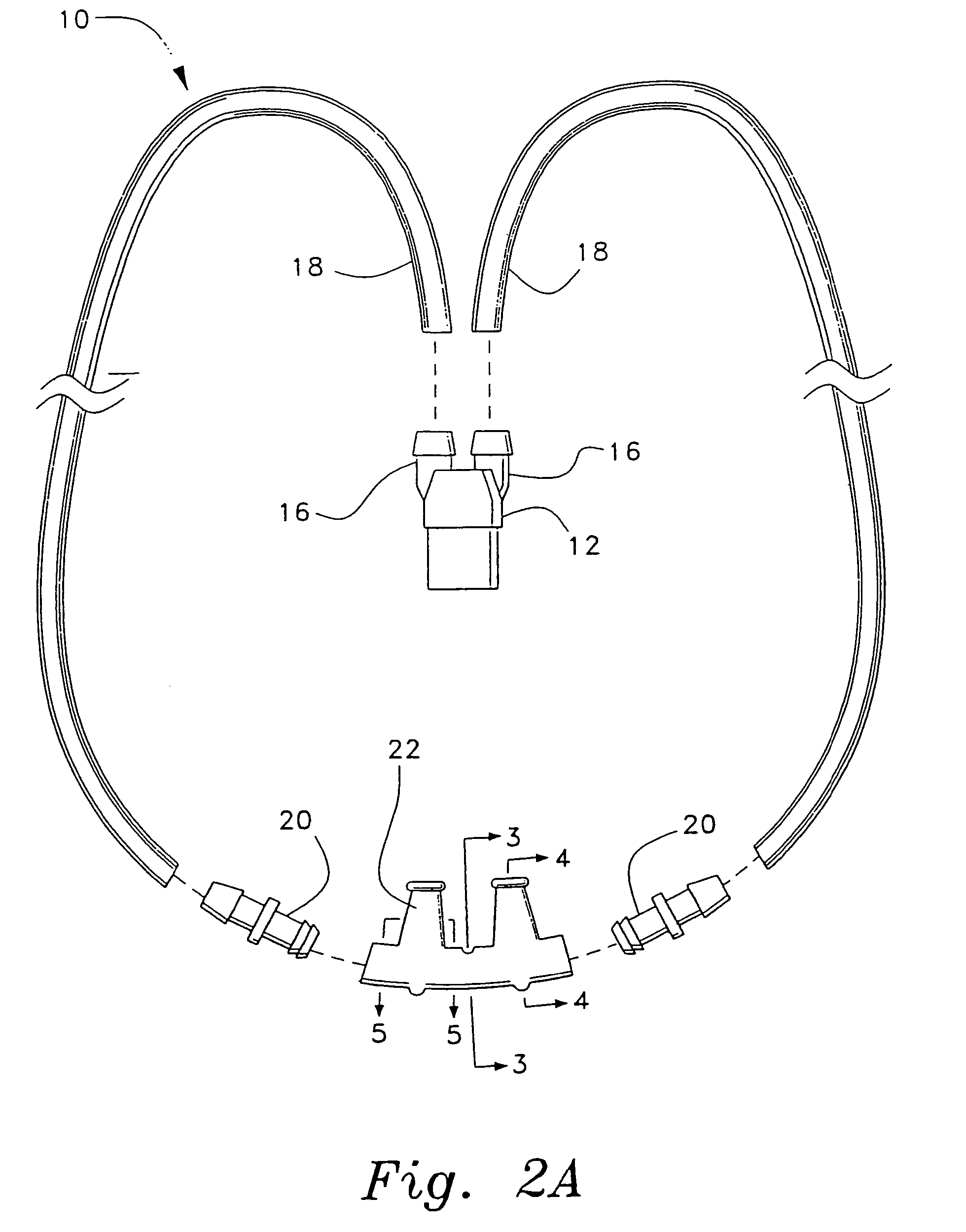

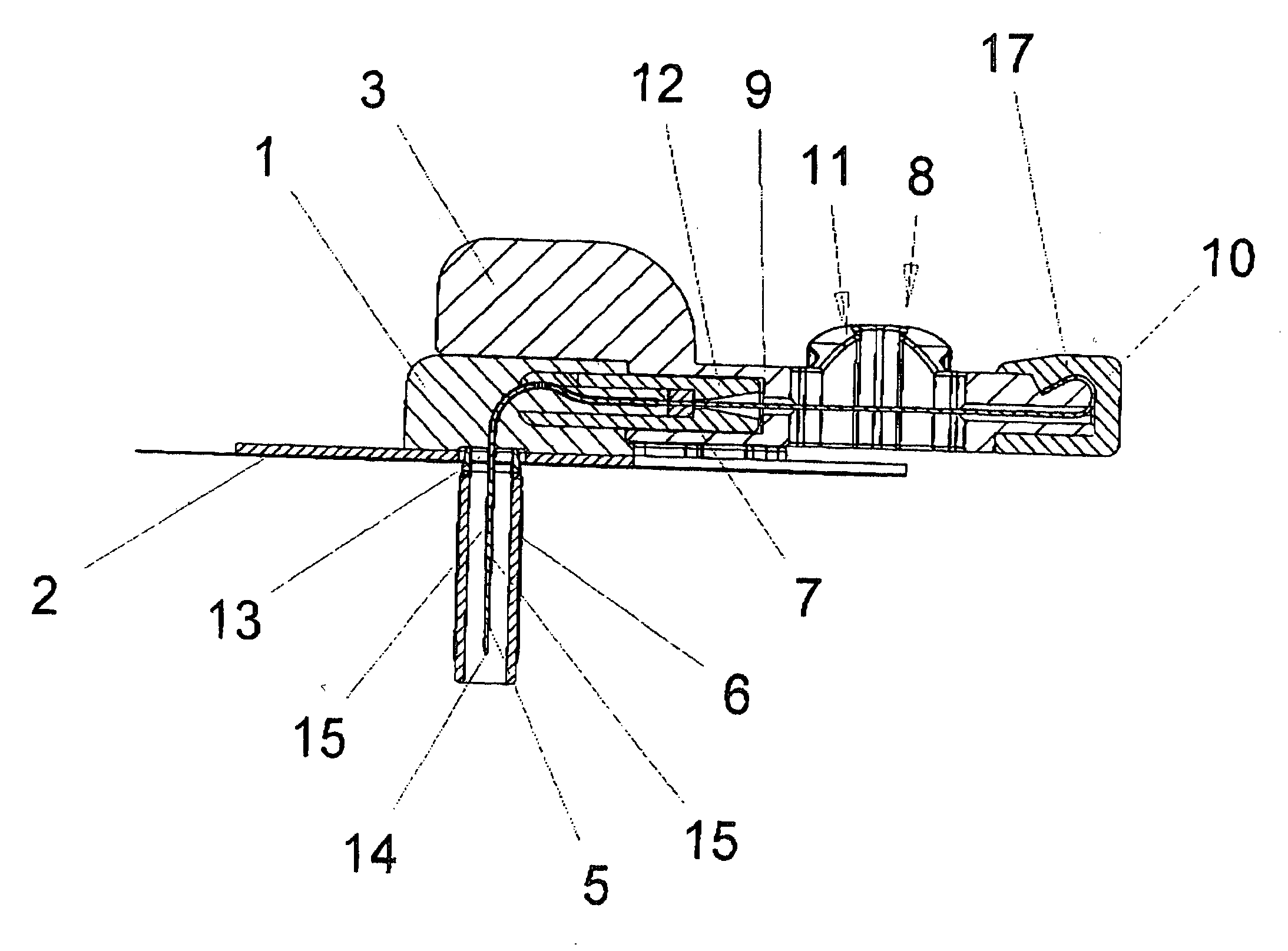

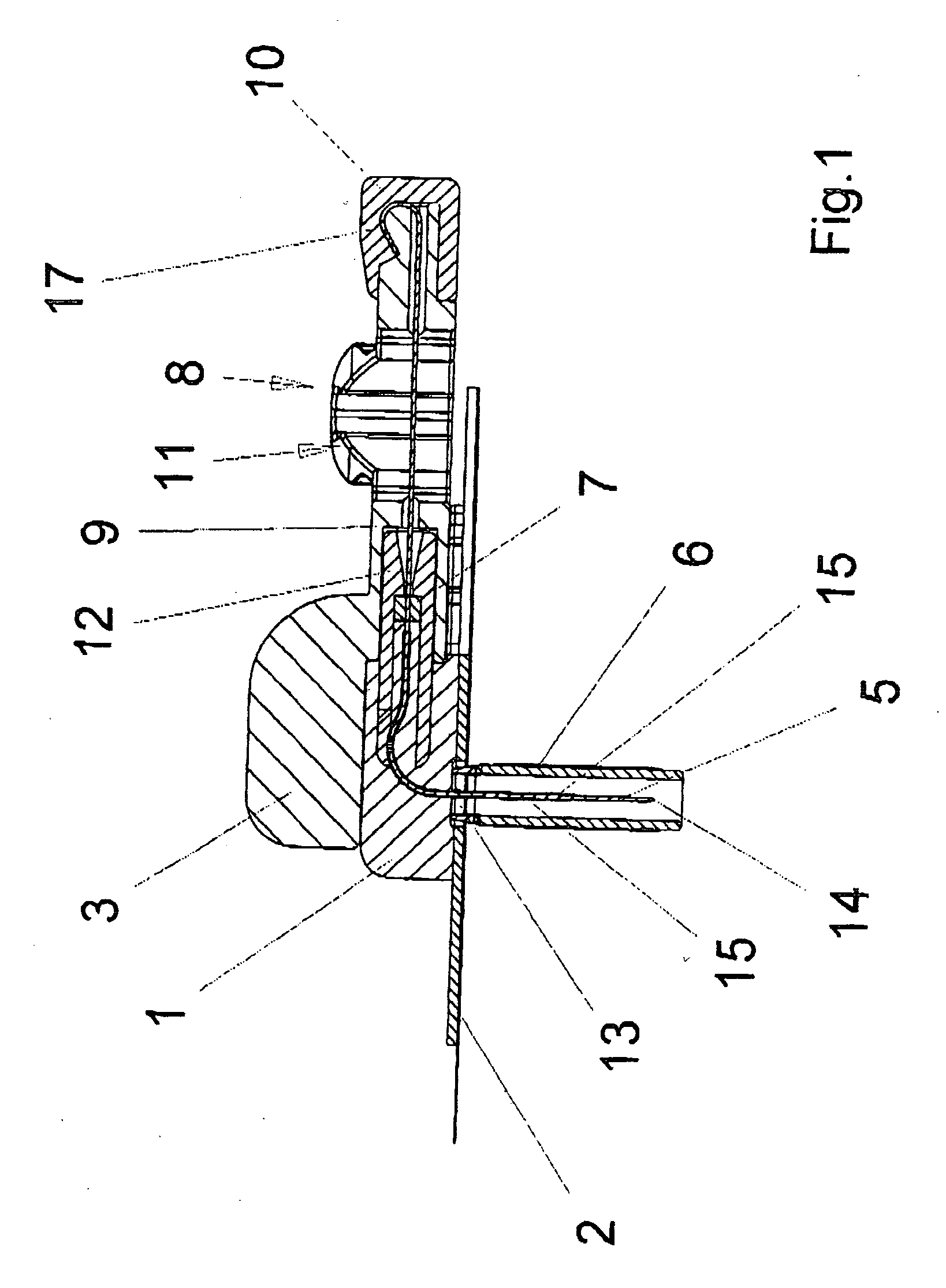

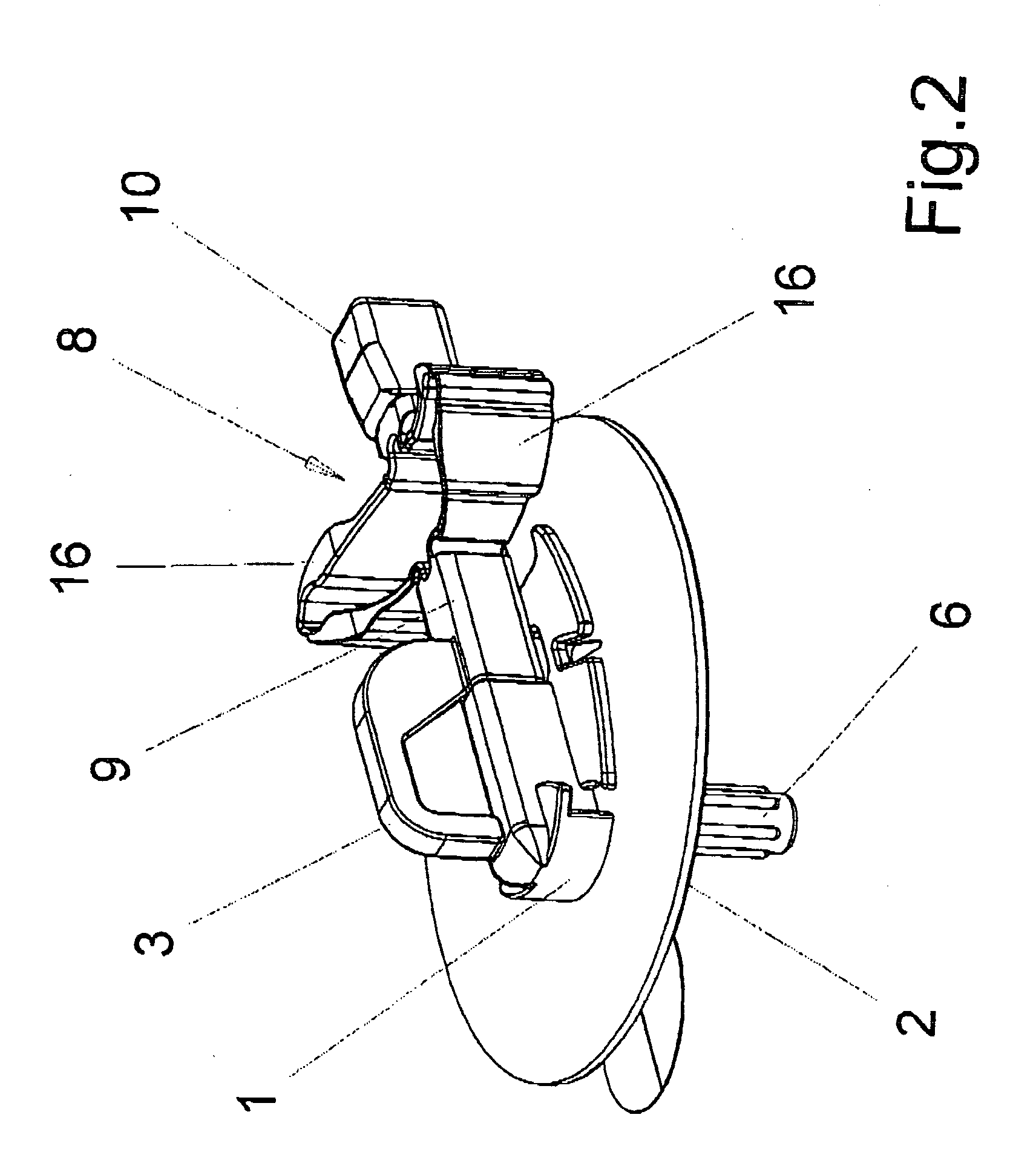

The ventilation interface for sleep apnea therapy interfaces a ventilation device to the patient's airways. The ventilation interface includes a pair of nasal inserts made from flexible, resilient silicone which are oval shaped in cross-section and slightly tapered from a base proximal the ventilation supply to the distal tip end. A bead flange is disposed about the exterior of each insert at the distal end of the insert. In one embodiment, a valve is disposed between the nasal inserts and a source of positive airway pressure, the valve having a rim with a one-way diaphragm pivotally attached to the valve body with an inflatable bladder depending from the rim which seals against an exit port during inspiration and deflates to uncover the exit port on expiration. Another embodiment has nasal inserts without positive airway pressure but with a removable filter in the inserts for filtering inspired air.

Owner:SALTER LABS LLC

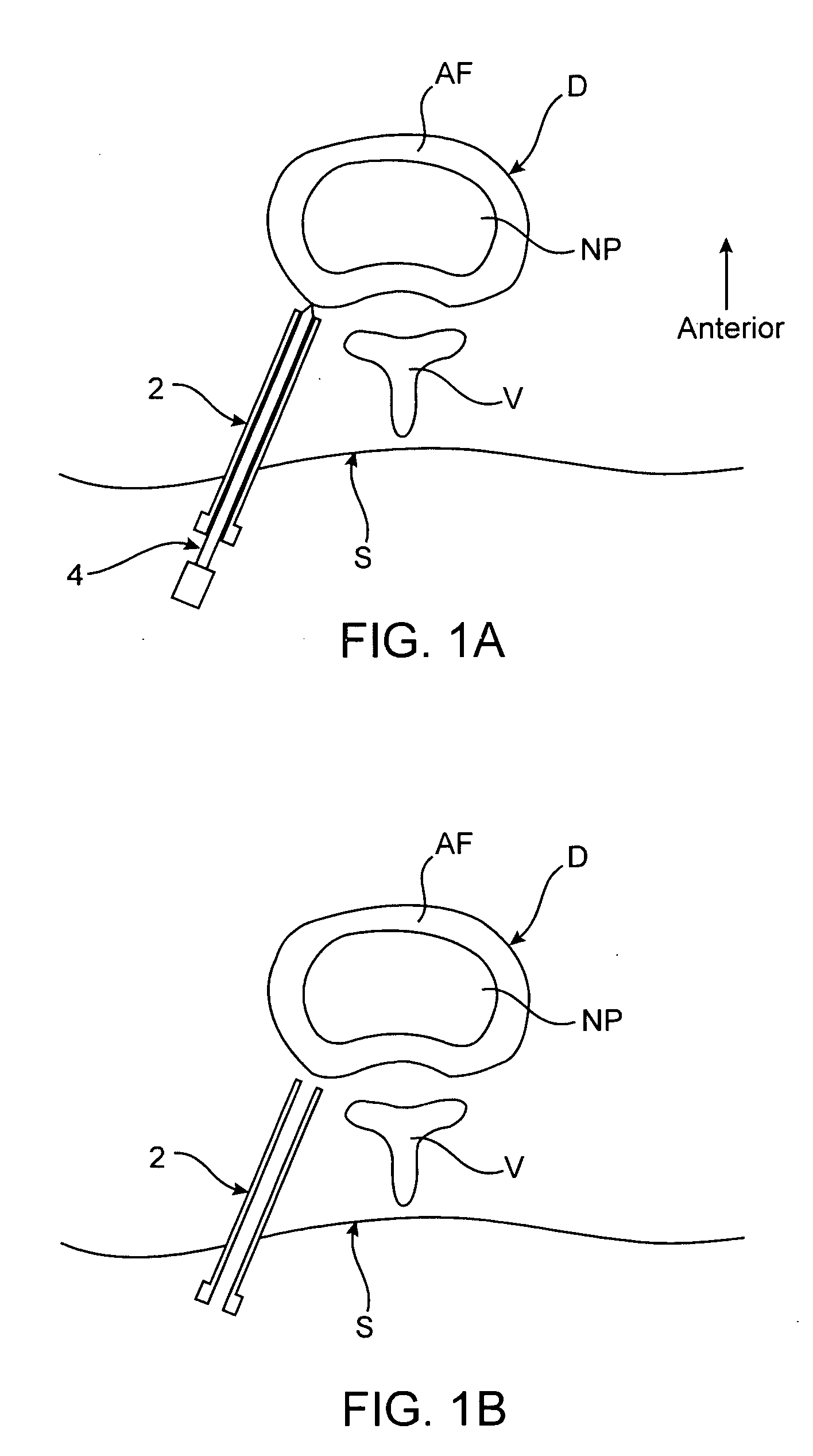

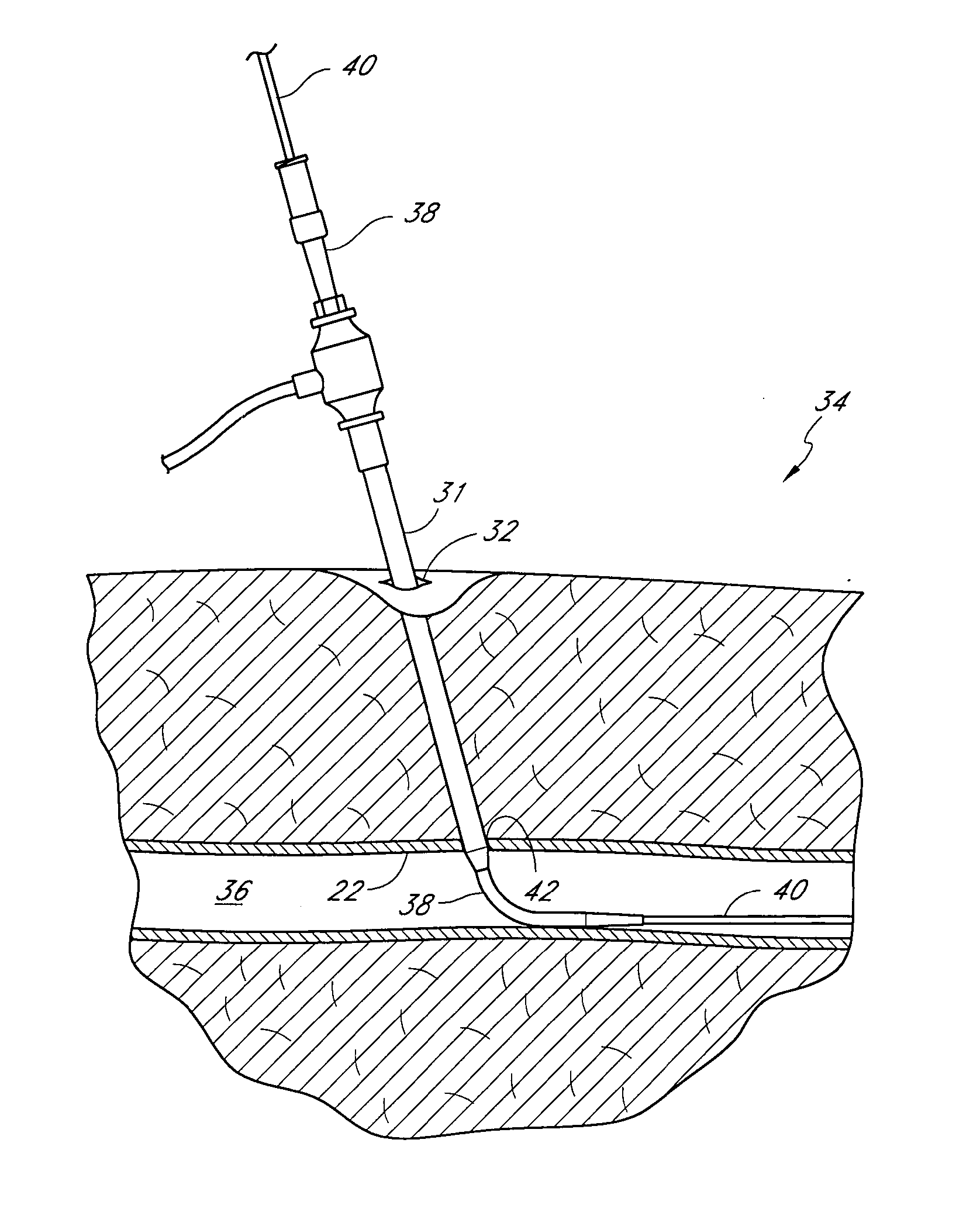

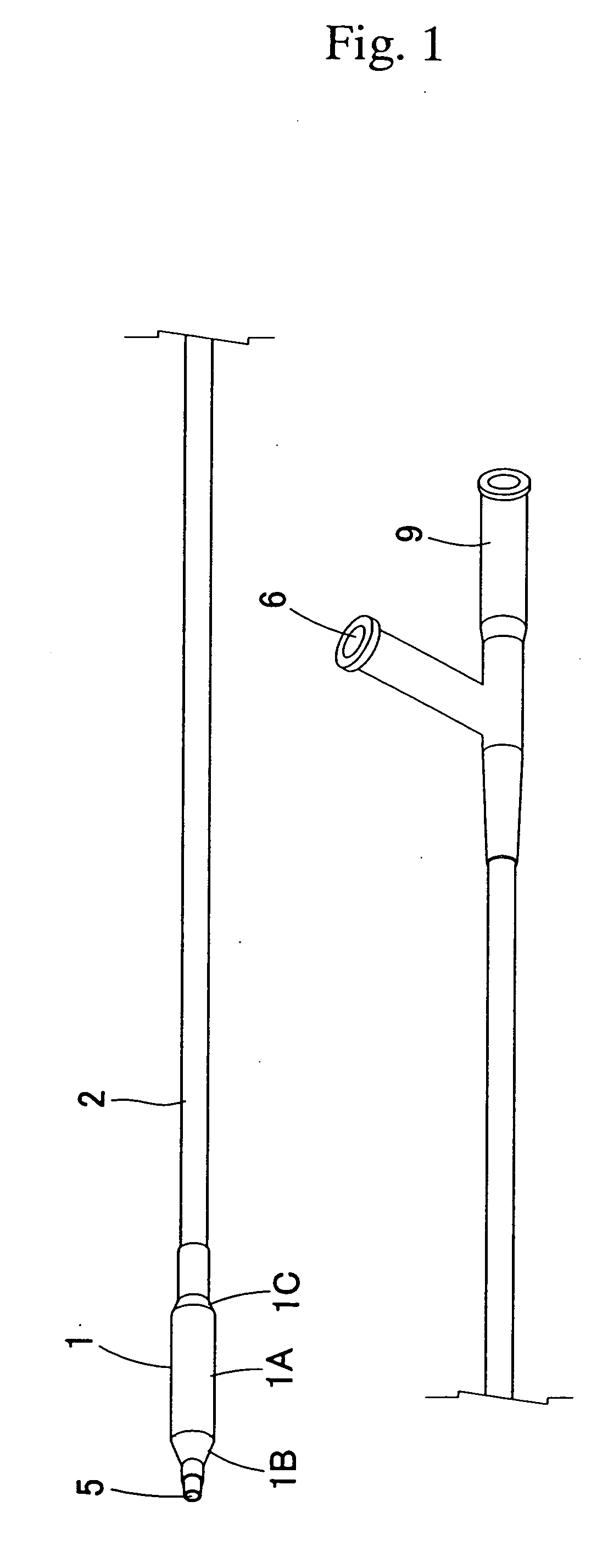

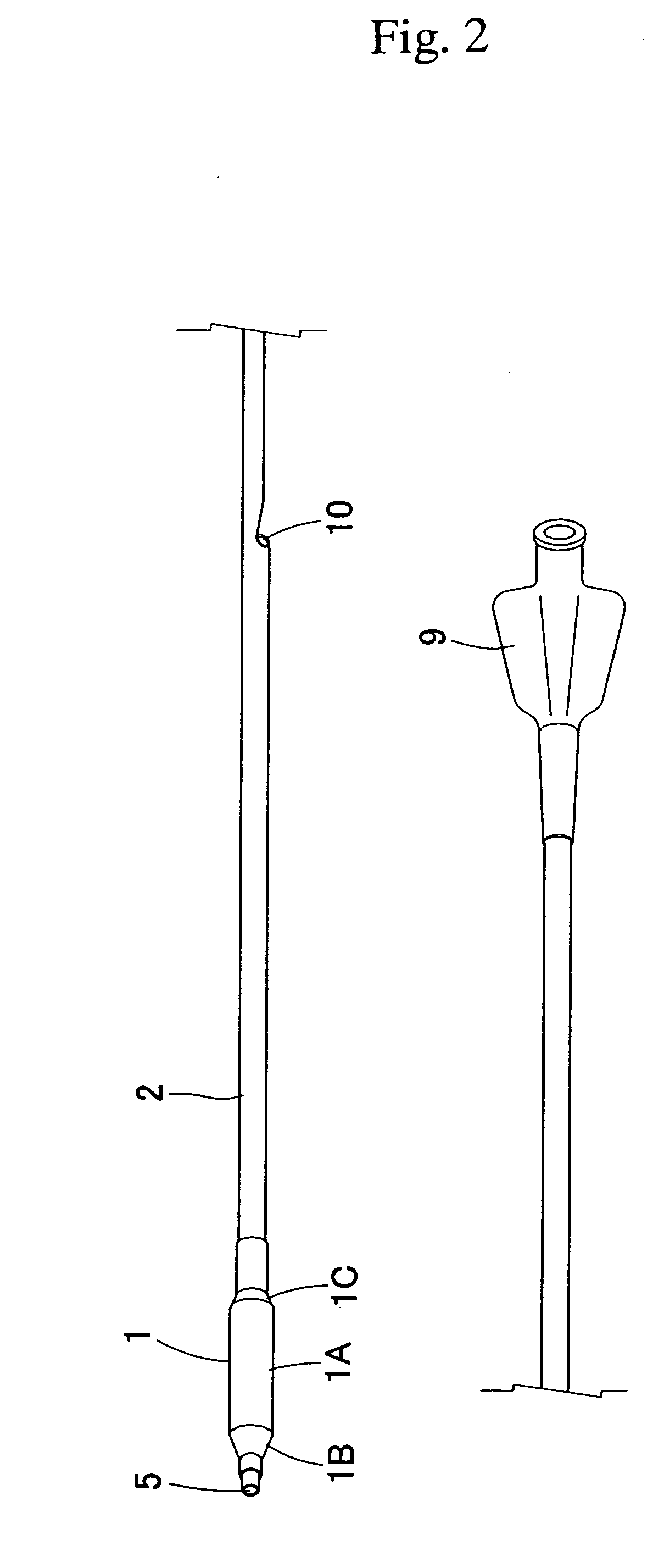

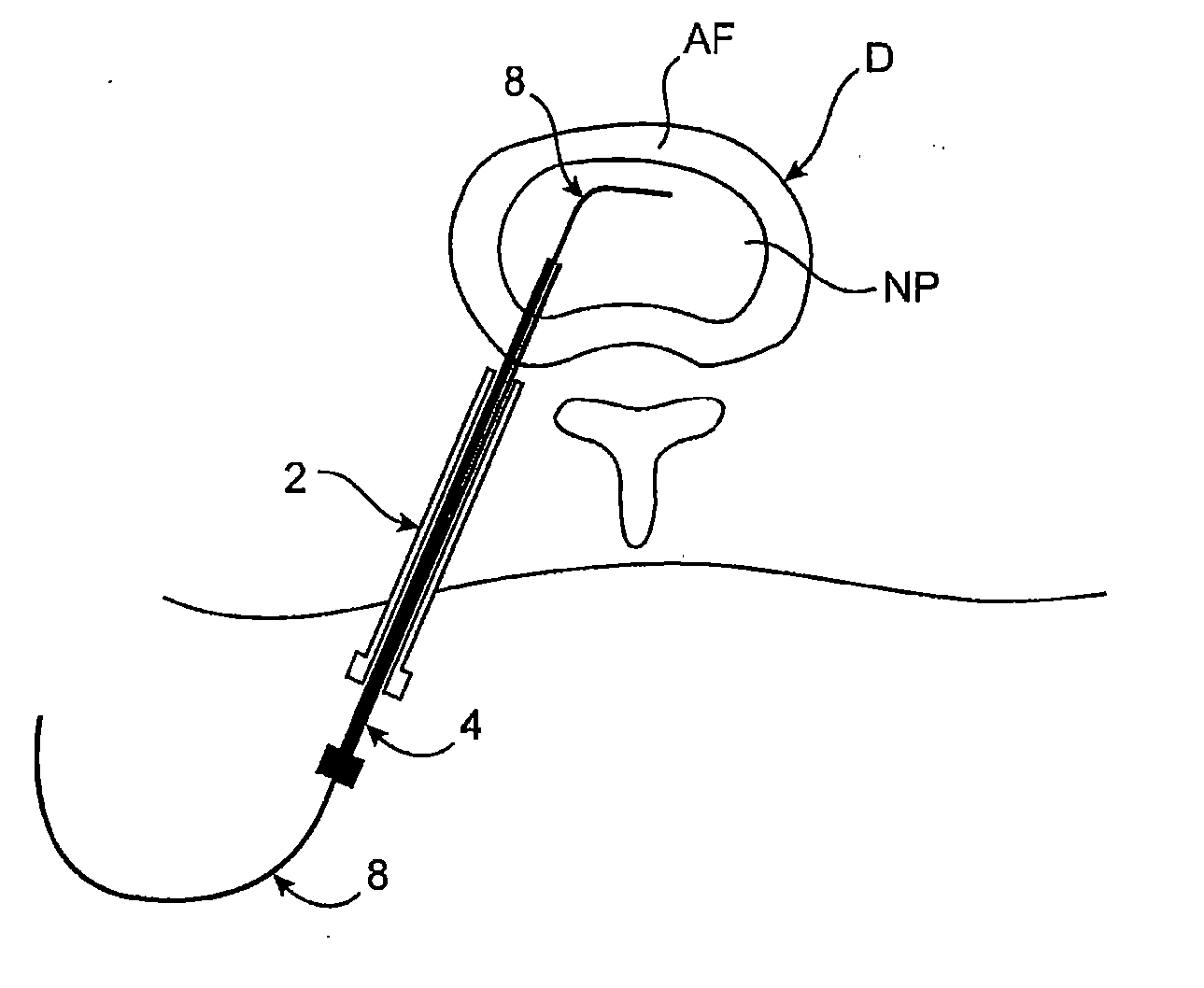

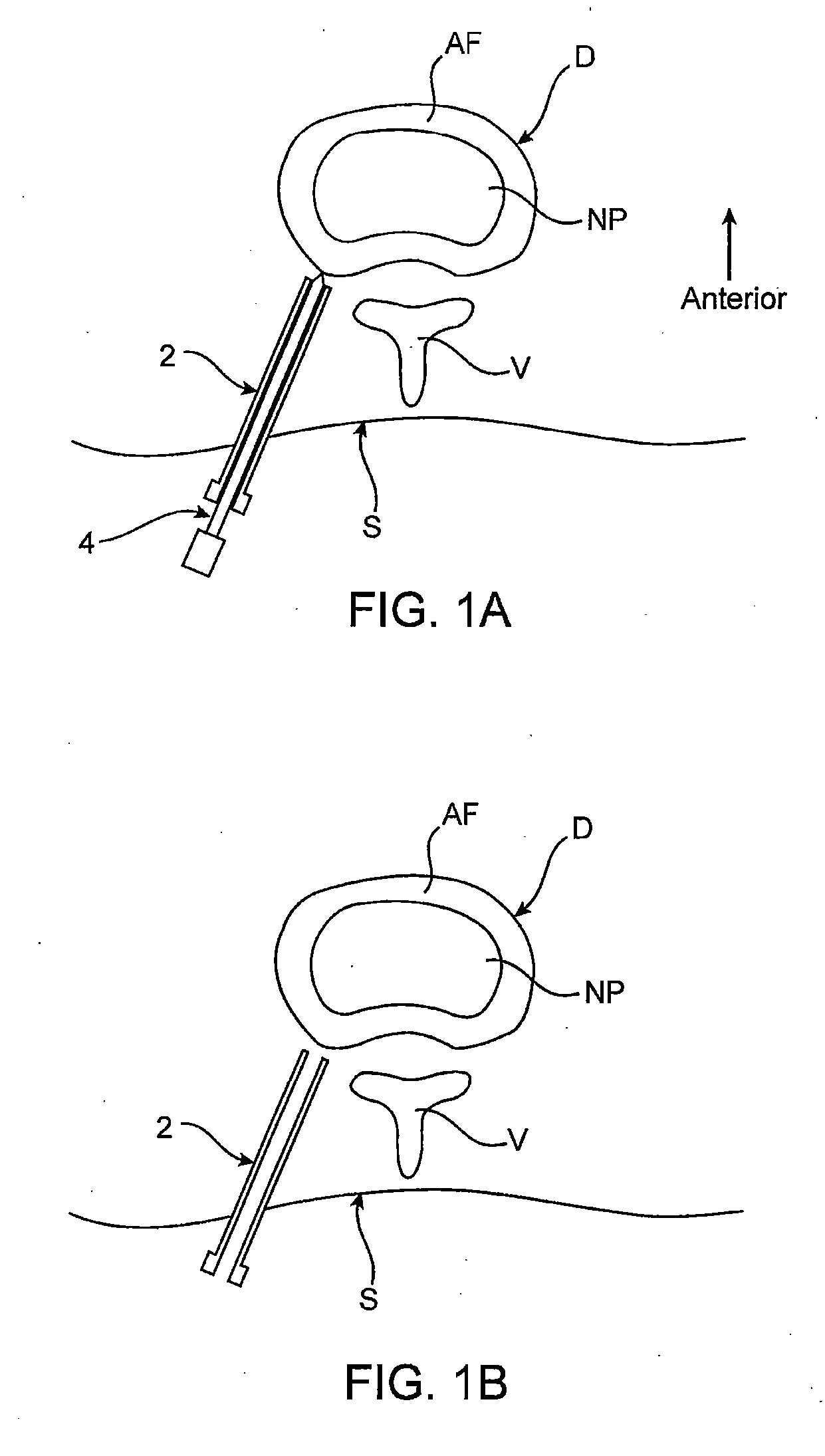

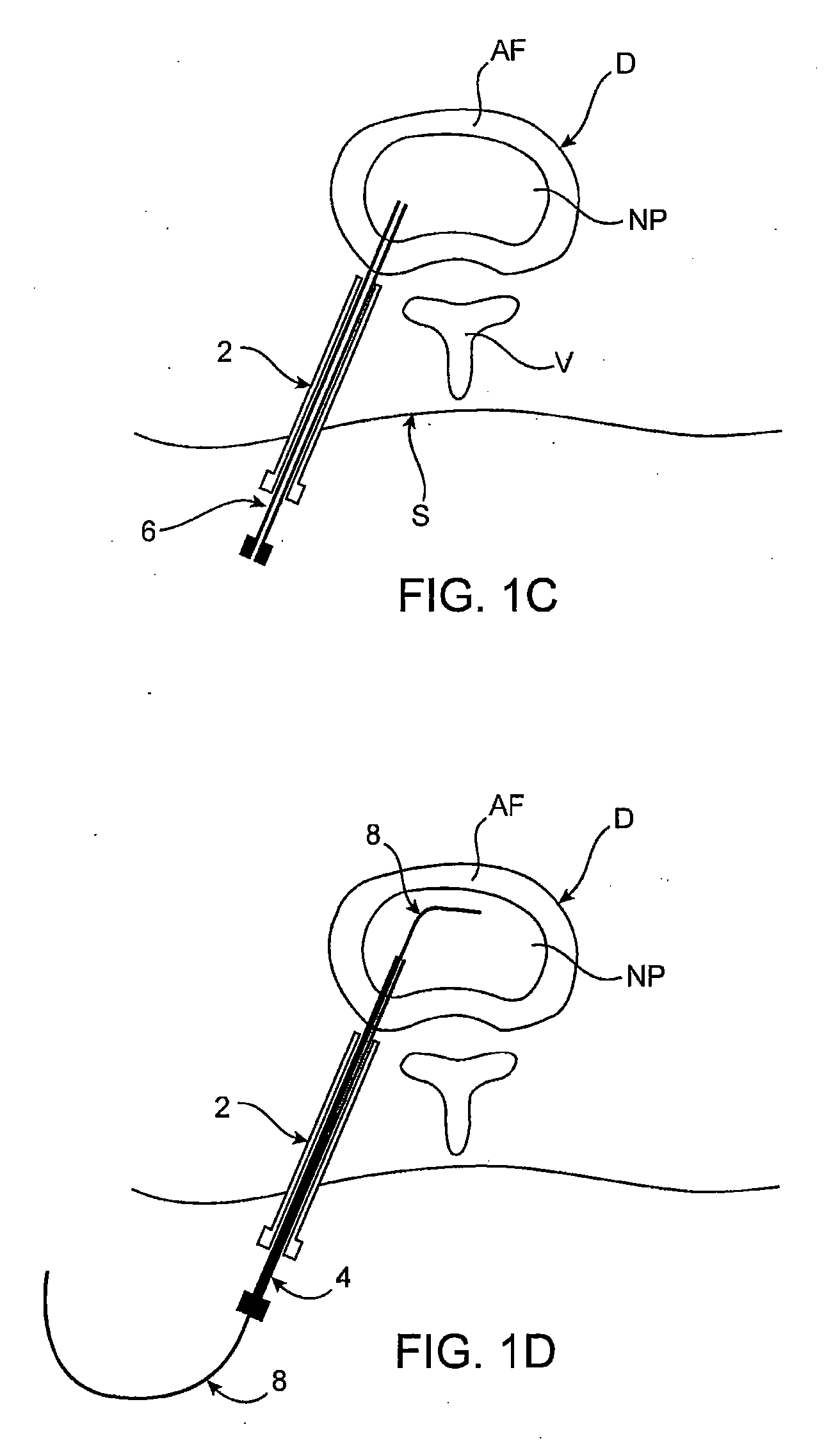

Spinal diagnostic methods and apparatus

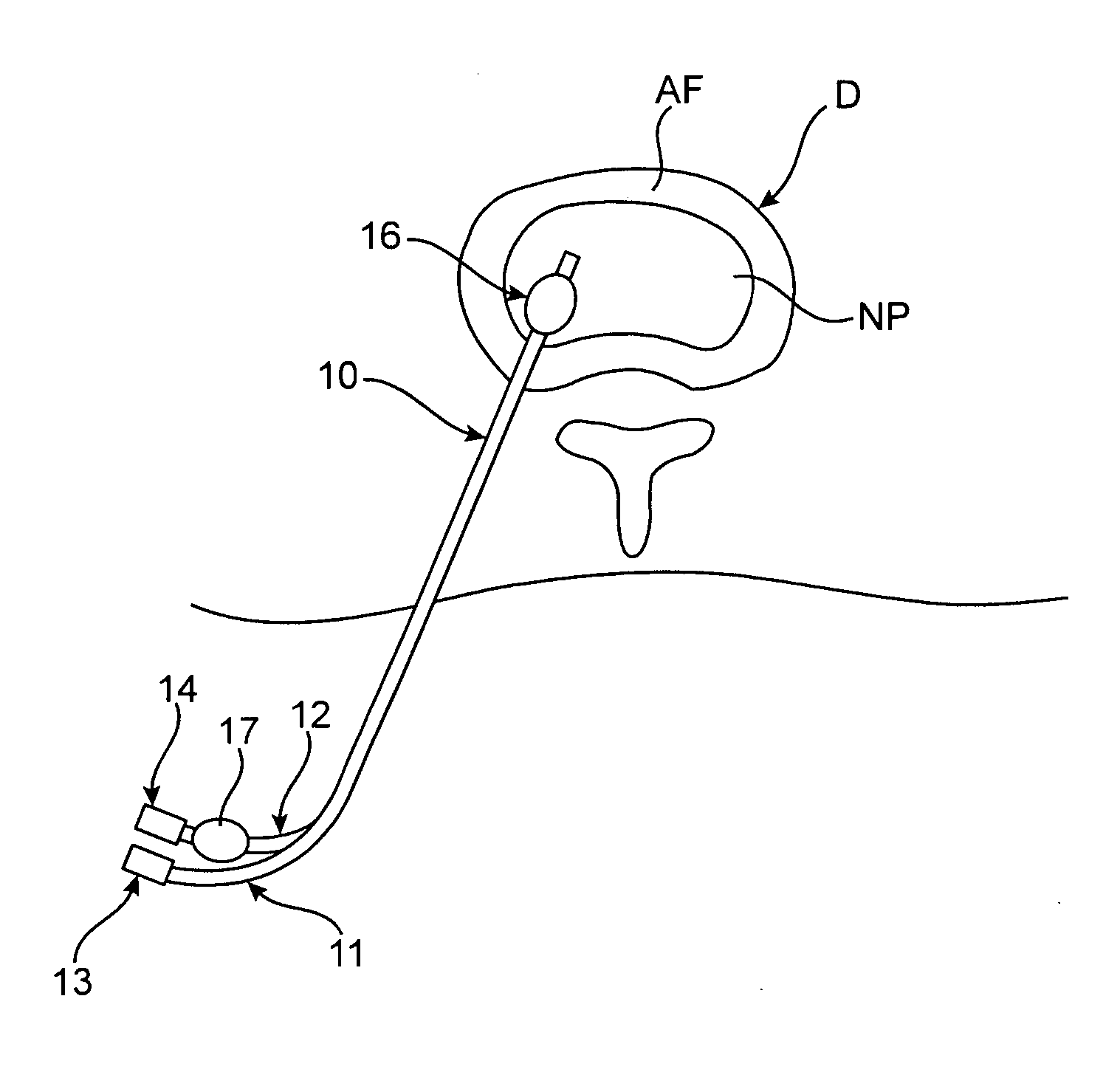

ActiveUS20050234425A1Alleviate painEasy diagnosisCannulasSurgical needlesDistal portionIntervertebral disc

Methods, devices and systems facilitate diagnosis, and in some cases treatment, of back pain originationg in intervertebral discs. Methods generally involve introducing one or more substances into one or more discs using a catheter device. In one embodiments, a patient assumes a position that causes back pain, and a substance such as an anesthetic or analgesic is introduced into the disc to determine whether the substance relieves the pain. Injections into multiple discs may optionally be performed, to help pinpoint a disc as a sources of the patient's pain. In some embodiments, the catheter device is left in place, and possibly coupled with another implantable device, to provide treatment of one or more discs. A catheter device includes at least one anchoring member for maintaining a distal portion of the catheter within a disc.

Owner:GLOBUS MEDICAL INC

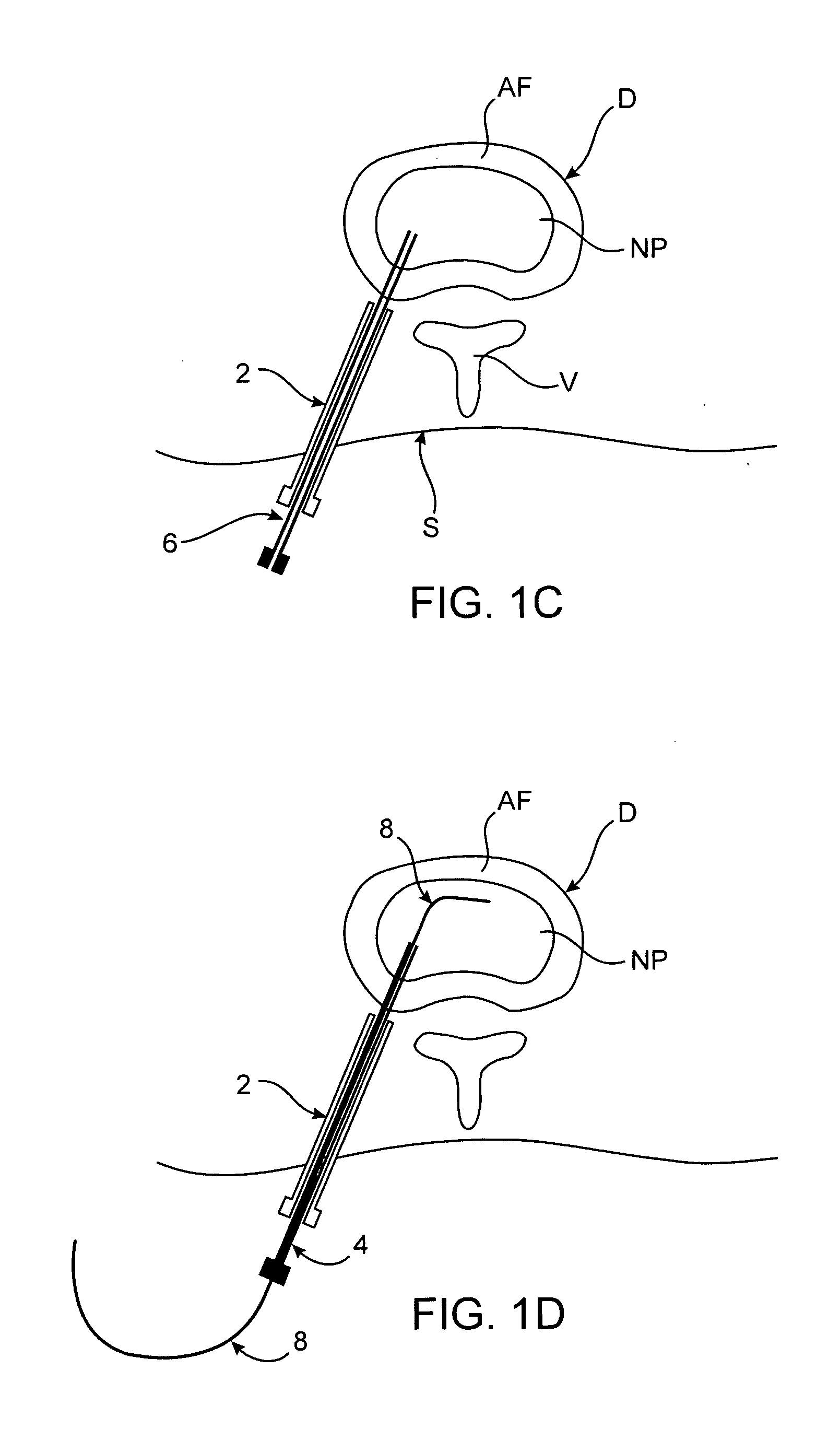

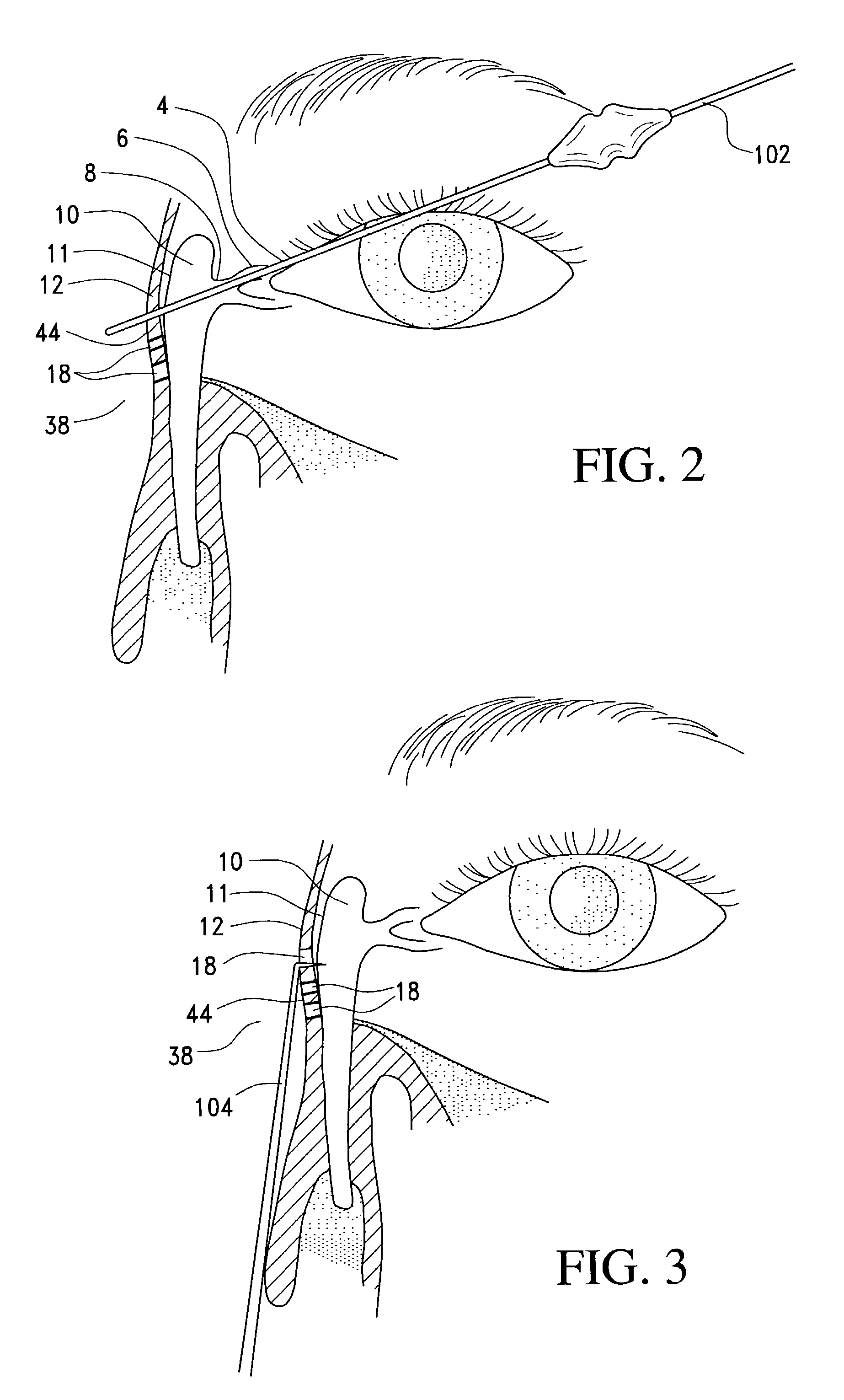

Transnasal method and catheter for lacrimal system

A balloon catheter for treatment of a patient's lacrimal system is applied transnasally without the use of a guide wire or a curve retention member. The catheter uses a stainless steel hypotube of sufficient stiffness and column strength to be pushed from the patent's nasal cavity through an opening-formed through the lateral nasal wall and lacrimal fossa, into the lacrimal sac. The catheter has an inflatable member mounted about a rigid bent distal segment. The opening is first formed by pushing small holes through the medial sac, lacrimal fossa, and lateral nasal wall with an instrument and coalescing the holes. The catheter is then introduced into the nasal cavity and pushed laterally through the opening by manipulating its proximal end. Pressurized fluid is then applied to the catheter to inflate the inflatable member and dilate the opening.

Owner:BECKER BRUCE

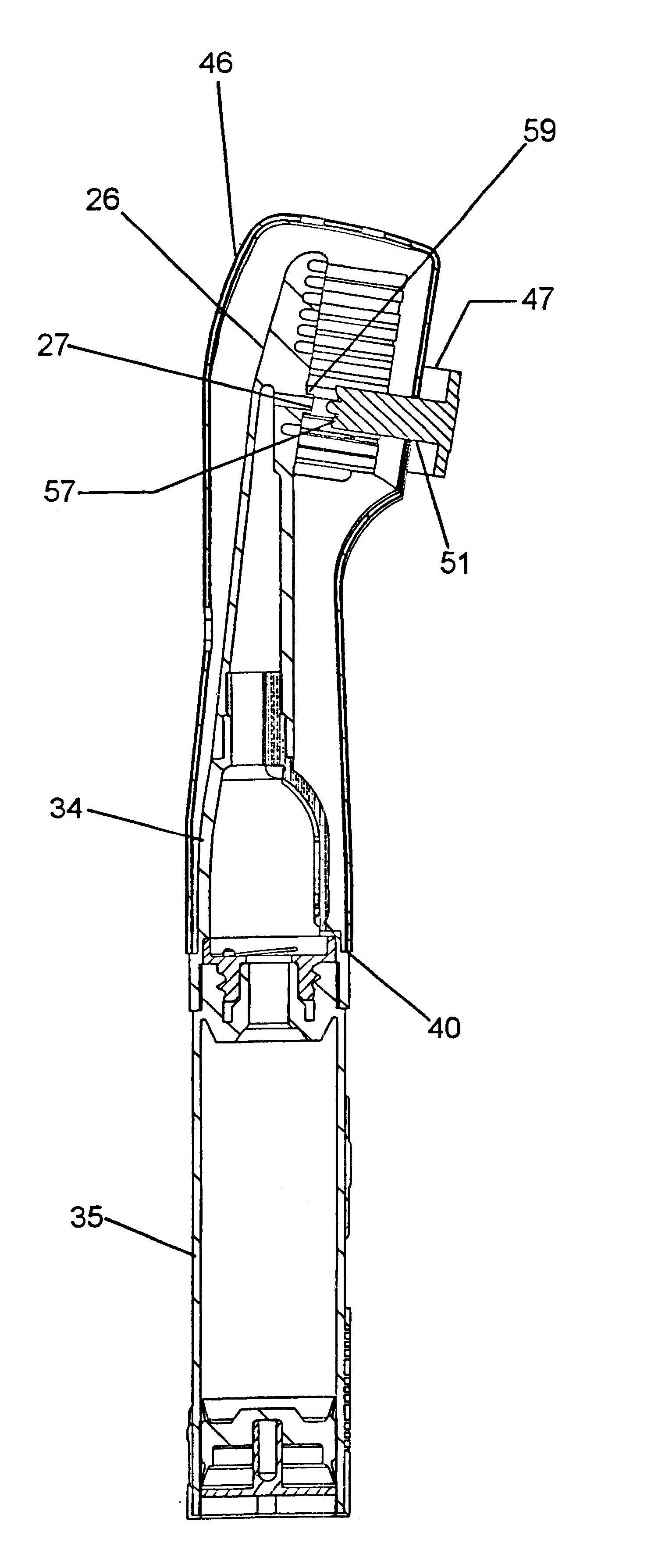

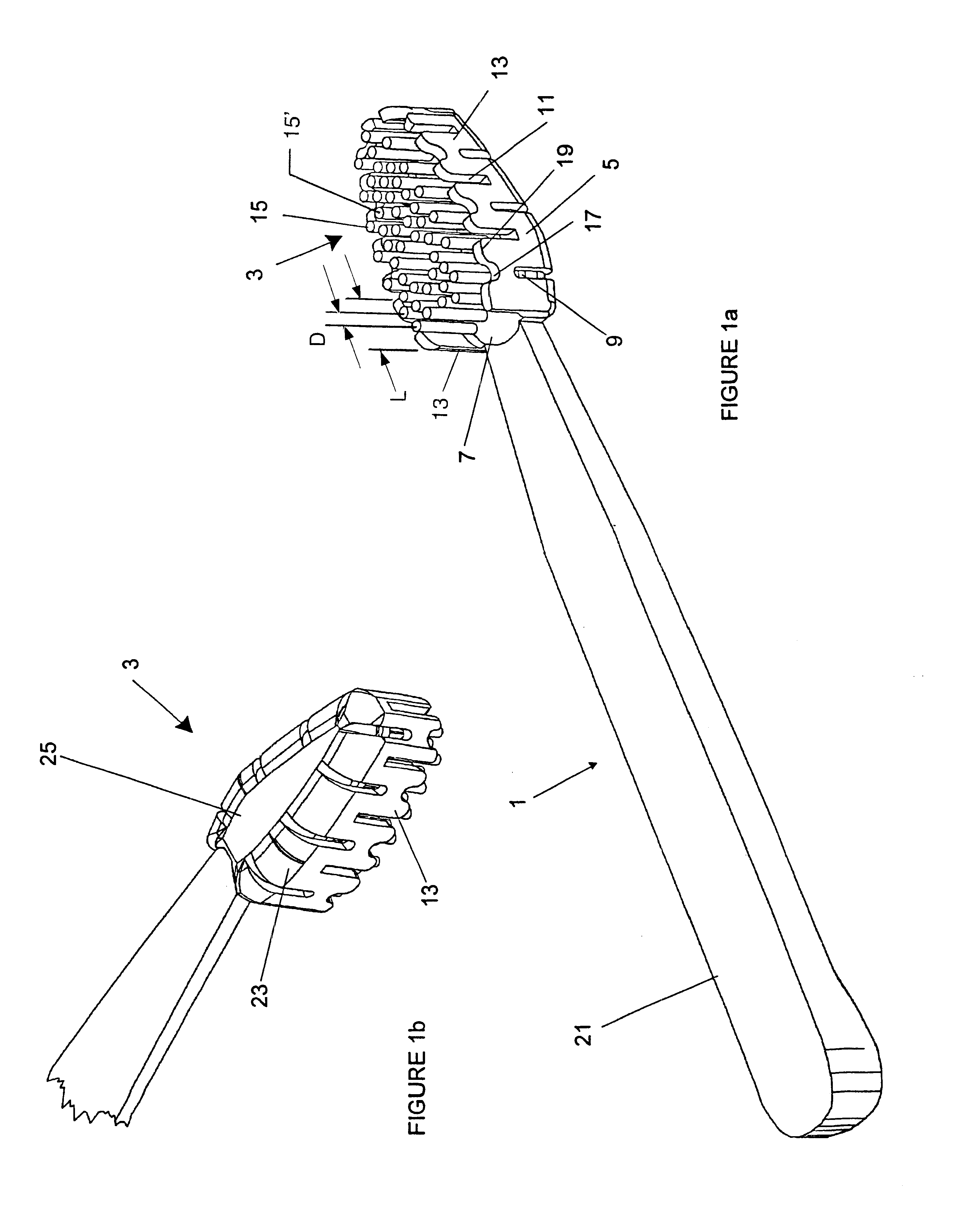

Toothbrush for massaging and protecting gums

InactiveUS6599048B2Control deflectionControl pressureCarpet cleanersFloor cleanersBristleMechanical engineering

A toothbrush that utilizes a replaceable brush head having rubber gum guard on its top surface and a triangular shaped rubber pad on its bottom surface. The rubber gum guard is shorter than the height of the bristles and is positioned on the peripheral edge of a brush head for functioning as a sensor for providing feedback to prevent brushing at excessive pressures and improper angles as well as for massaging the gumlines without the risk of gum damages. The triangular shaped rubber pad is for conforming to and massaging gumlines at the back of teeth. The replaceable brush head having the rubber gum guard and massaging pad features is economically used in conjunction with a permanent handle that dispenses dentifrice material to the top of bristles. The handle has a resilient contractible connector for secure mounting of the replaceable brush head.

Owner:KUO YOUTI

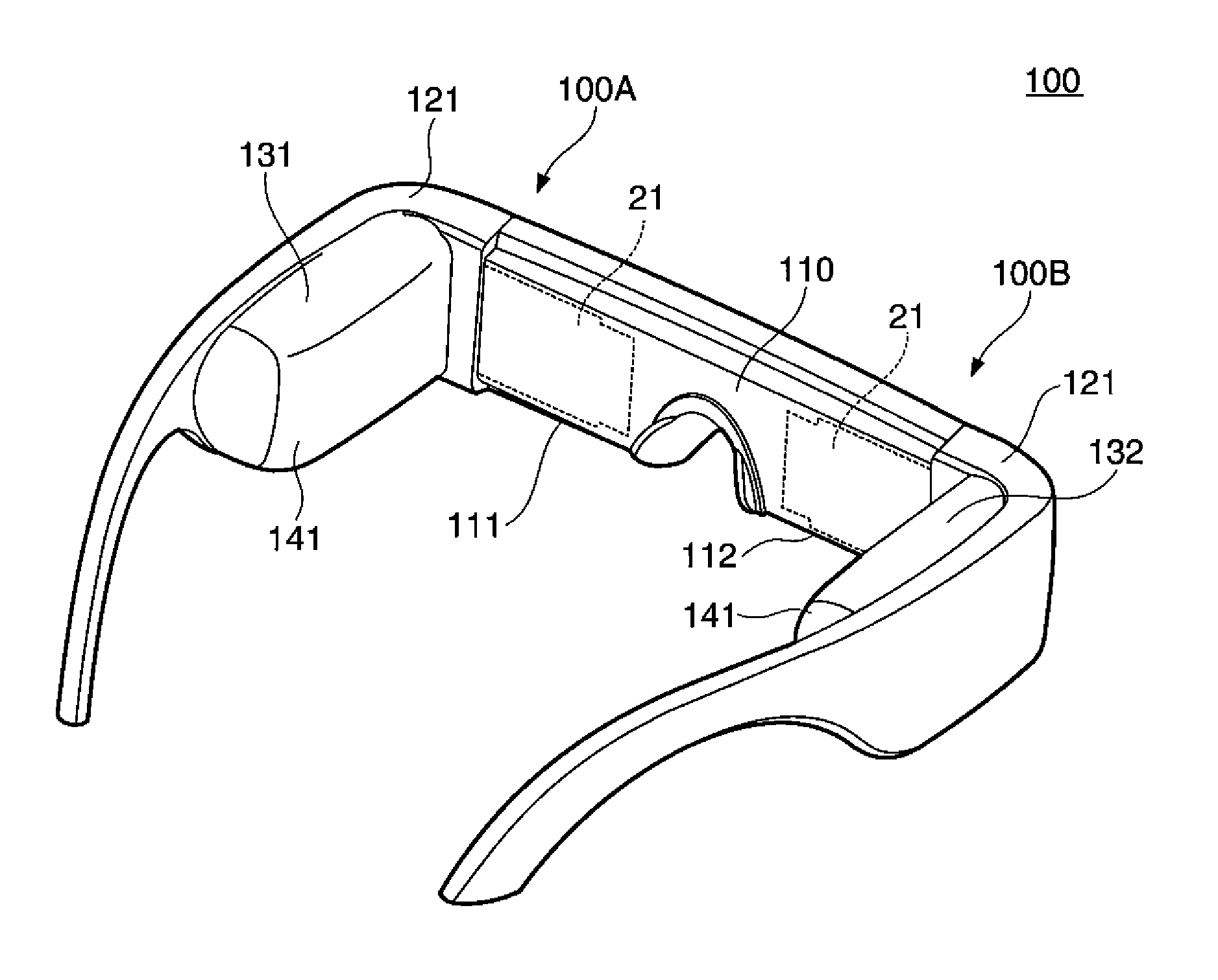

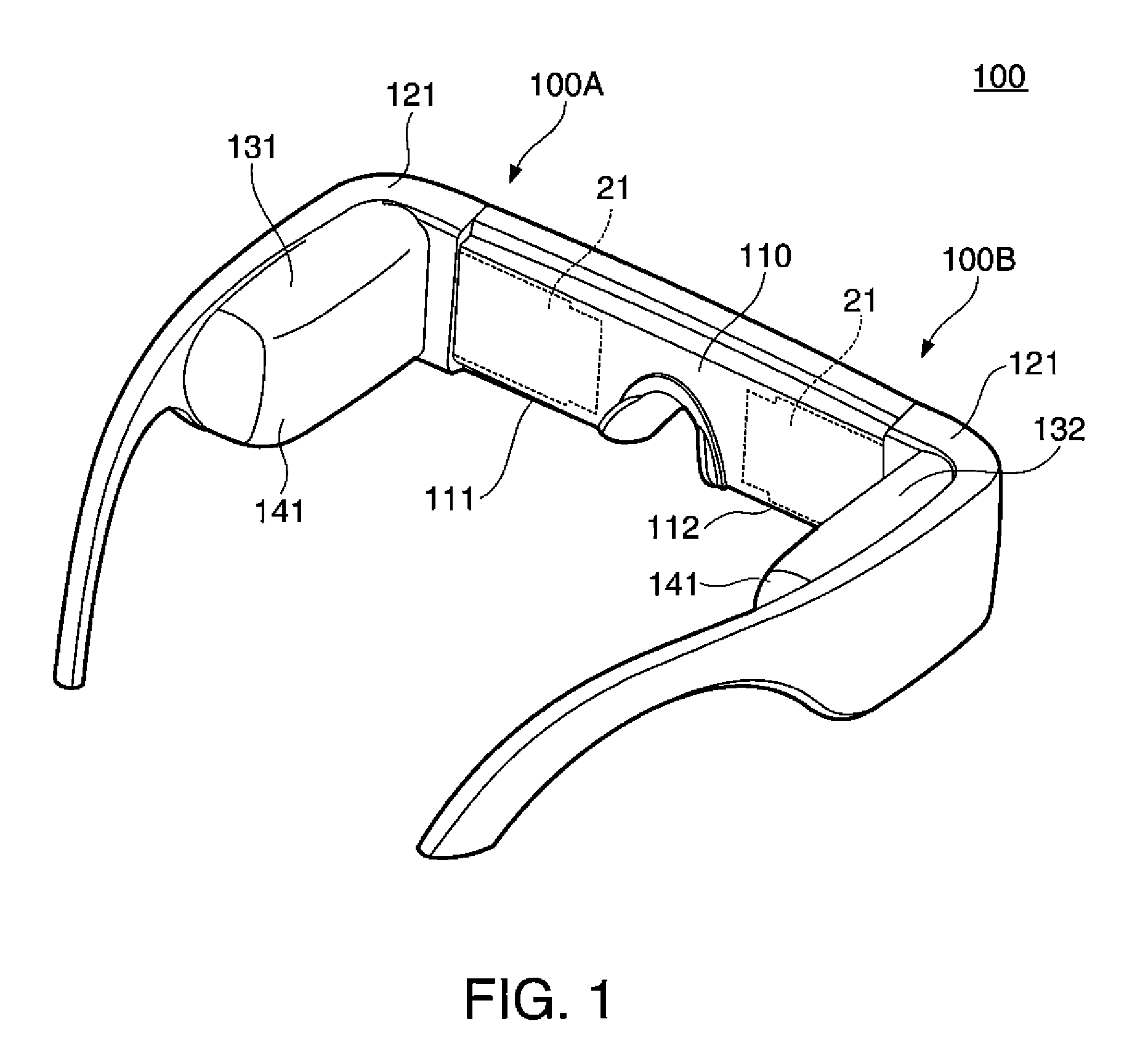

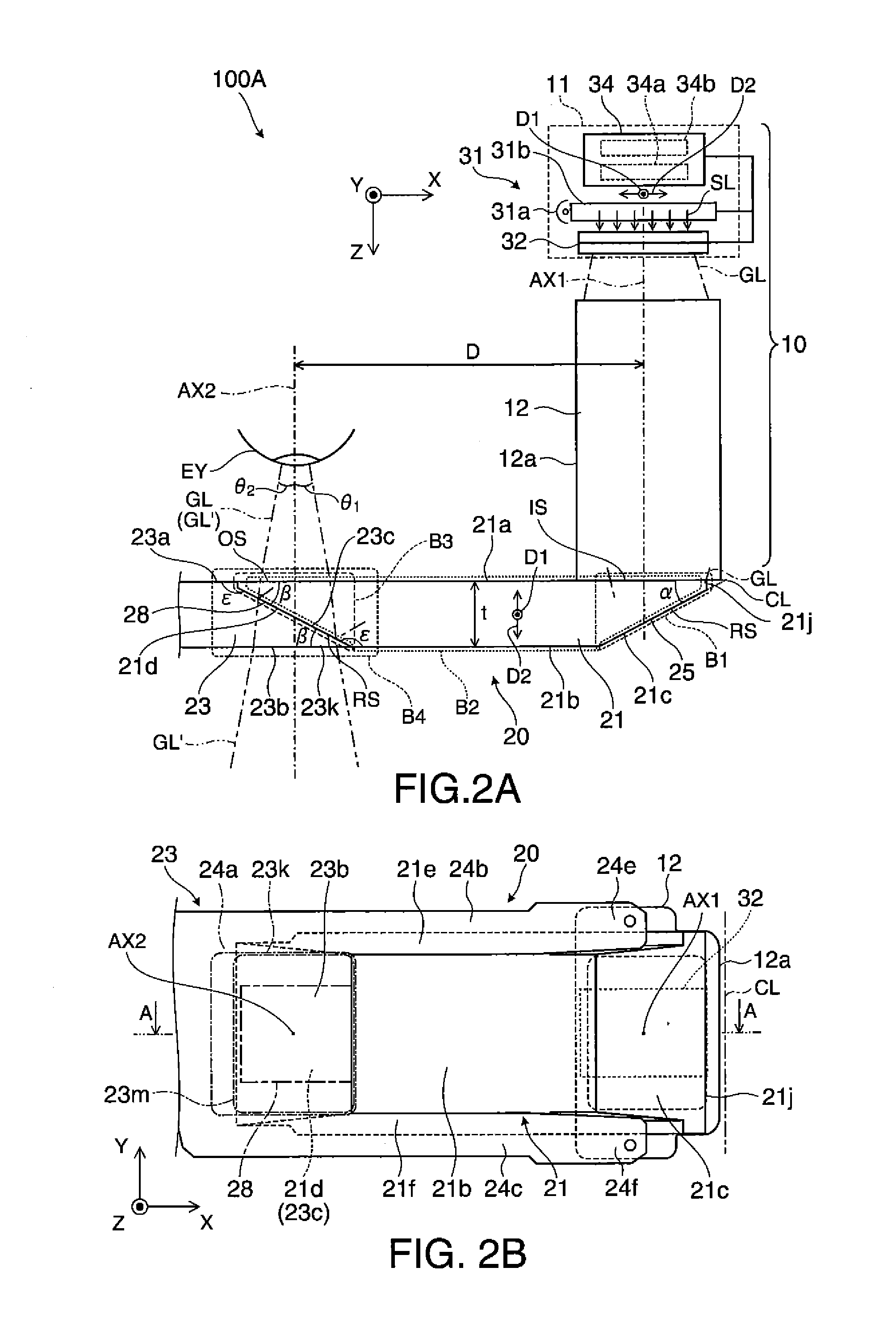

Virtual image display apparatus

ActiveUS20120200935A1Large display sizeSimple configurationOptical light guidesLight guideUltimate tensile strength

A support frame includes a light transmissive portion that is combined with a light guide member to form a see-through portion. The support frame assembled with the light guide member for image light observation therefore allows see-through observation of an outside-world object through the see-through portion. Further, providing the light transmissive portion in the support frame can increase the strength of the support frame while reducing the weight of the light guide member.

Owner:SEIKO EPSON CORP

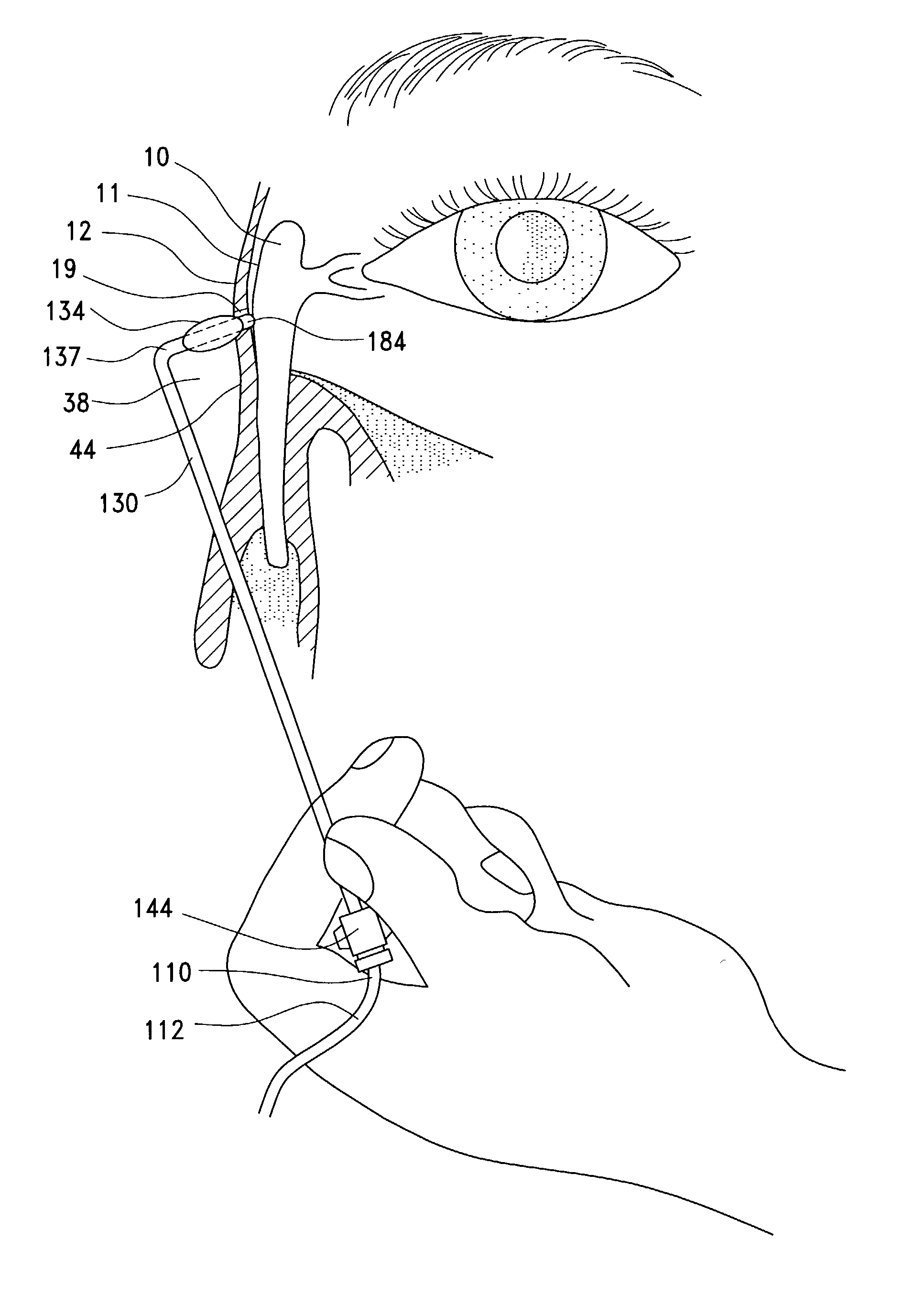

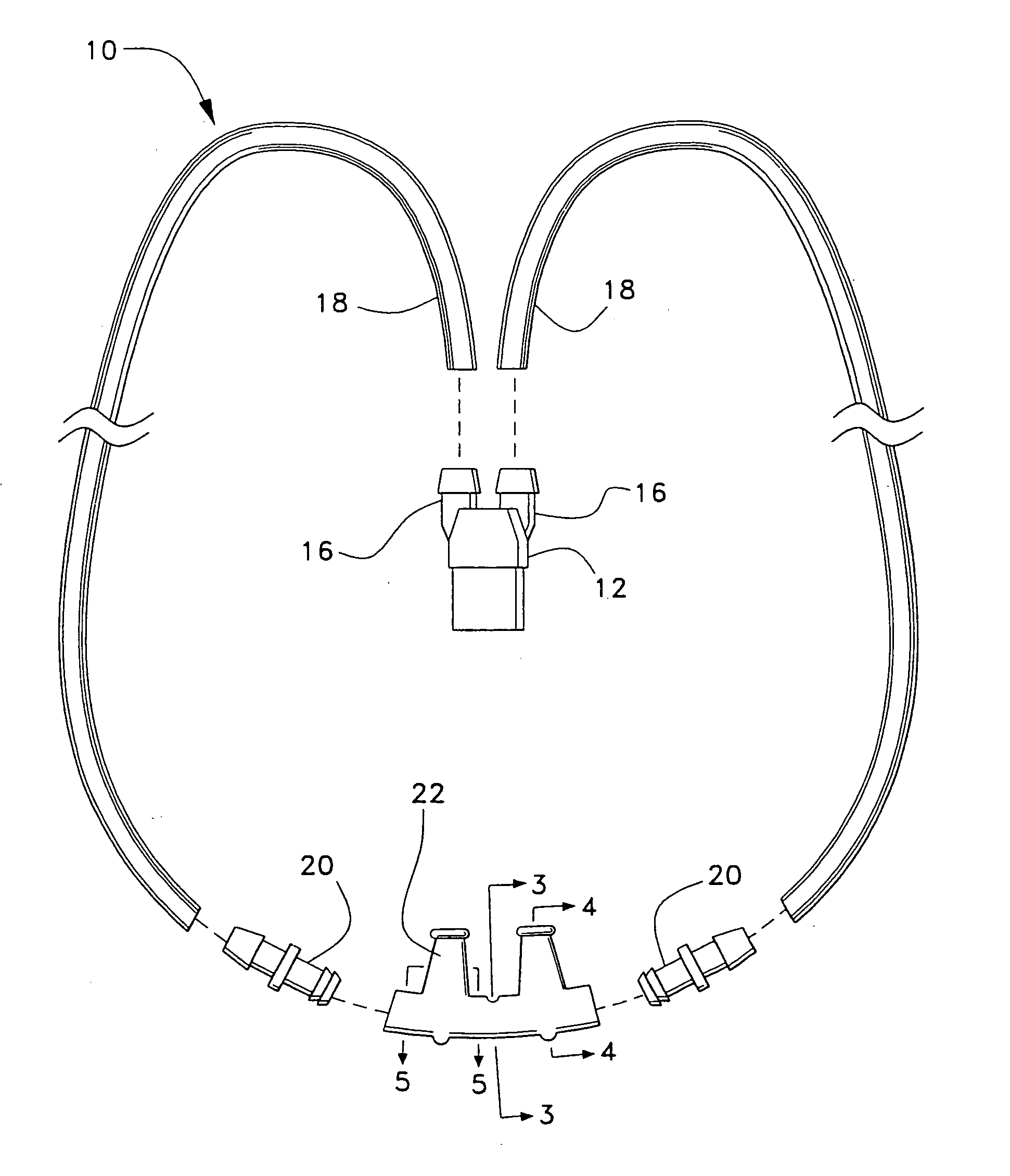

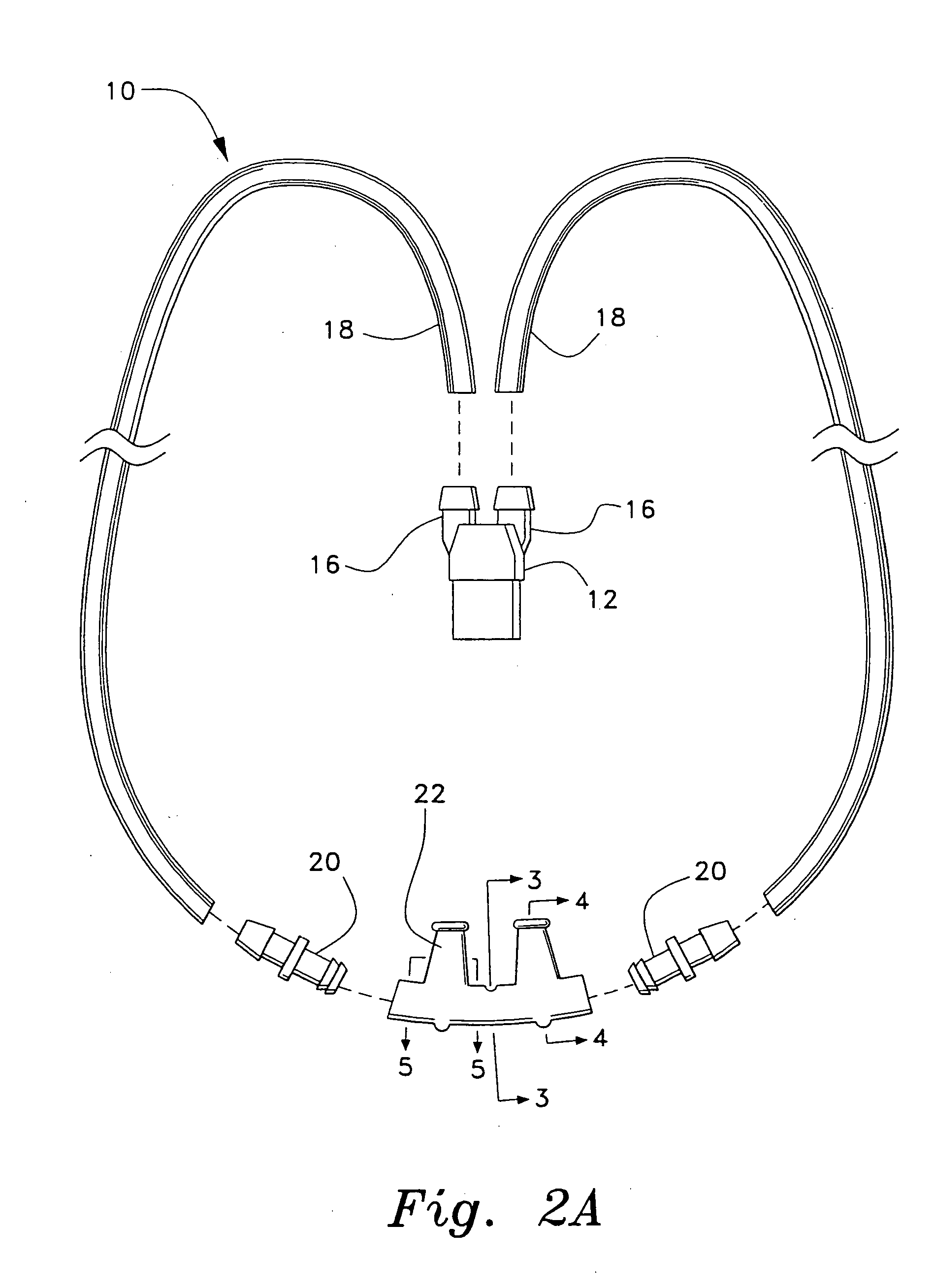

Ventilation interface for sleep apnea therapy

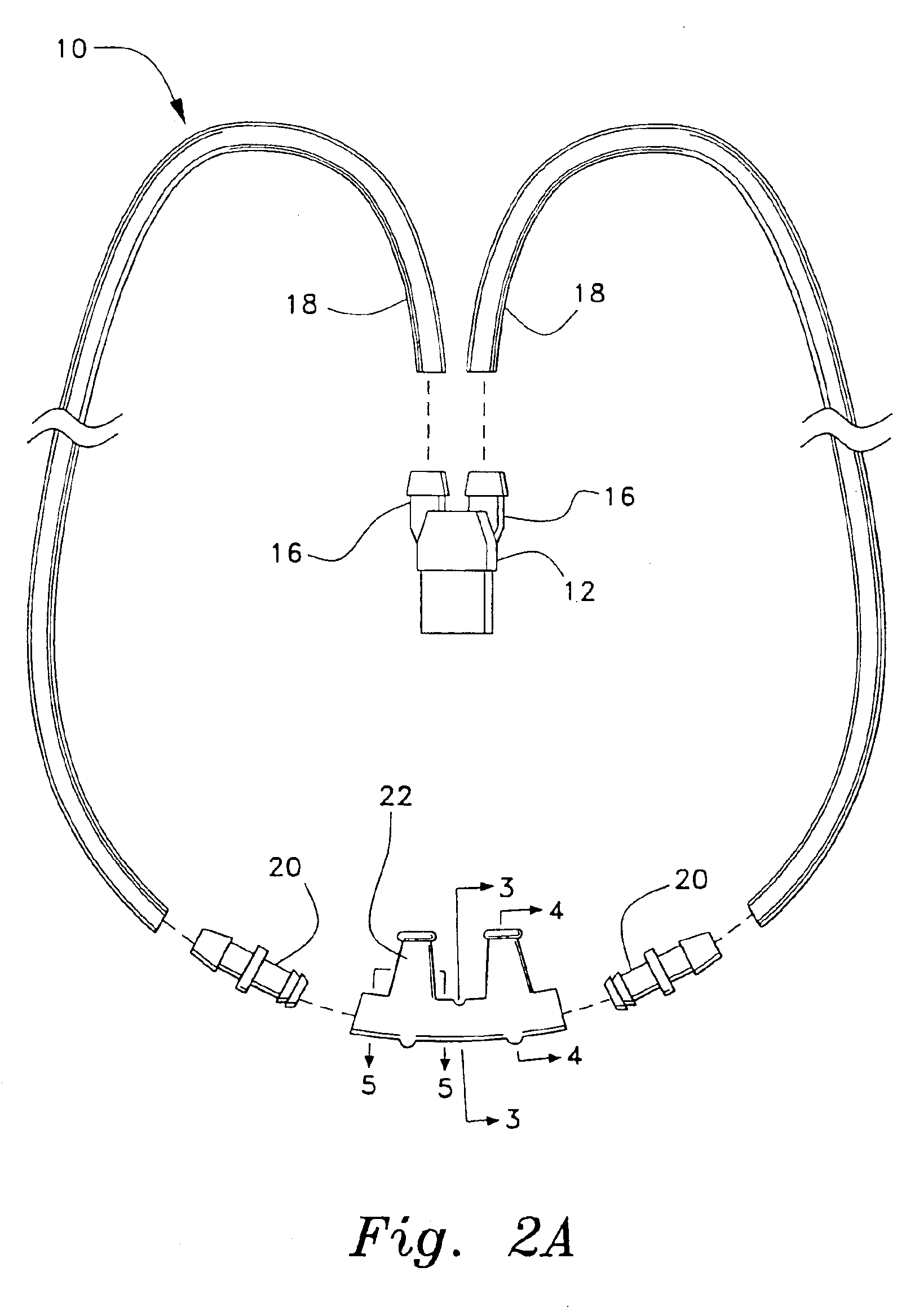

InactiveUS20070137653A1Great volume of airIncrease volumeRespiratory masksMedical devicesThin walledAirflow

The ventilation interface for sleep apnea therapy interfaces a ventilation device to the patient's airways. The ventilation interface includes a pair of nasal inserts made from flexible, resilient silicone which are oval shaped in cross-section and slightly tapered from a base proximal the ventilation supply to the distal tip end. A bead flange is disposed about the exterior of each insert at the distal end of the insert. A bleed port for release of exhaled air is defined through a conical vent projecting normally to the path of the incoming air flow, and continues through a nipple extending to the exterior of the air conduit. In one embodiment, a pair of nasal inserts are integral with a nasal cannula body, with bleed ports axially aligned with each insert. In another embodiment, each insert is independently connected to a separate, thin-walled, flexible supply line.

Owner:WOOD THOMAS J

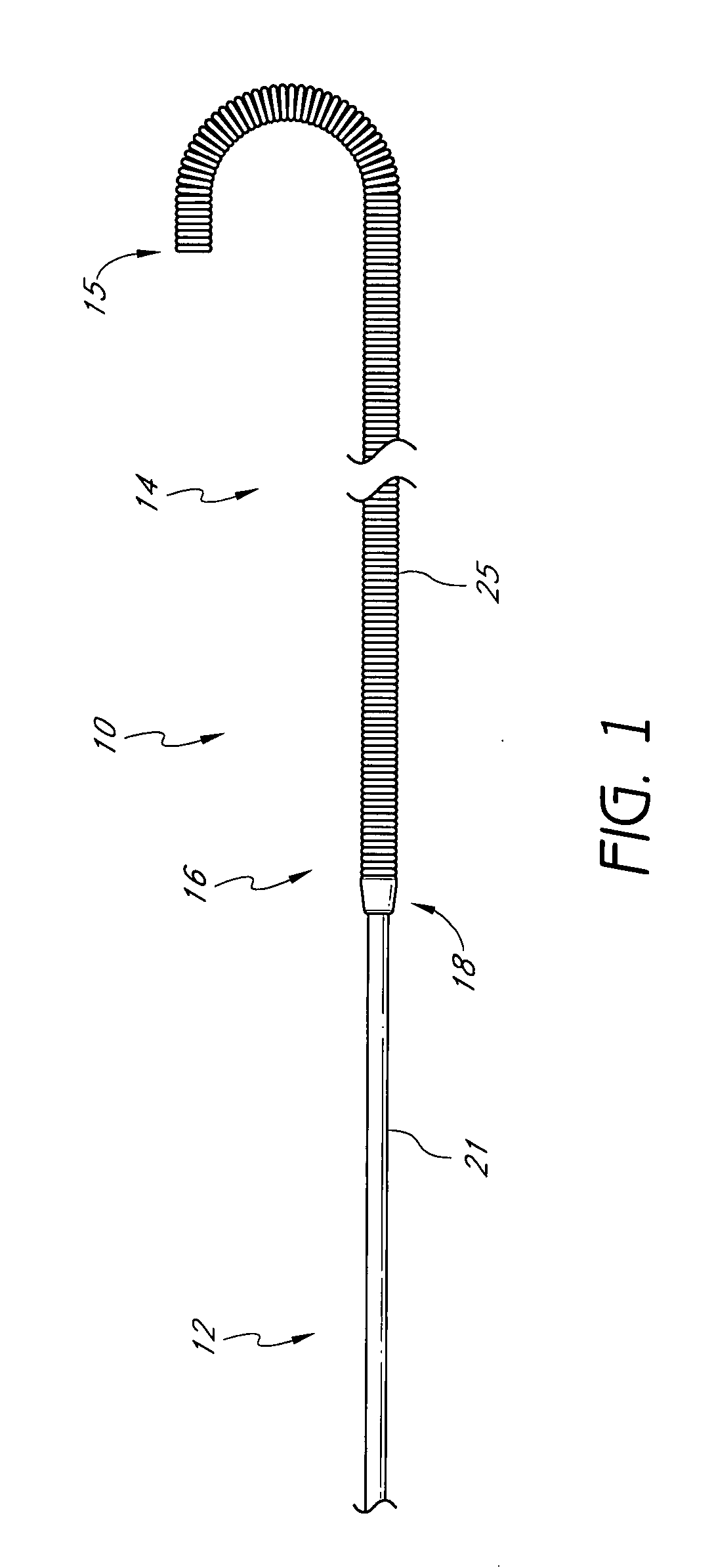

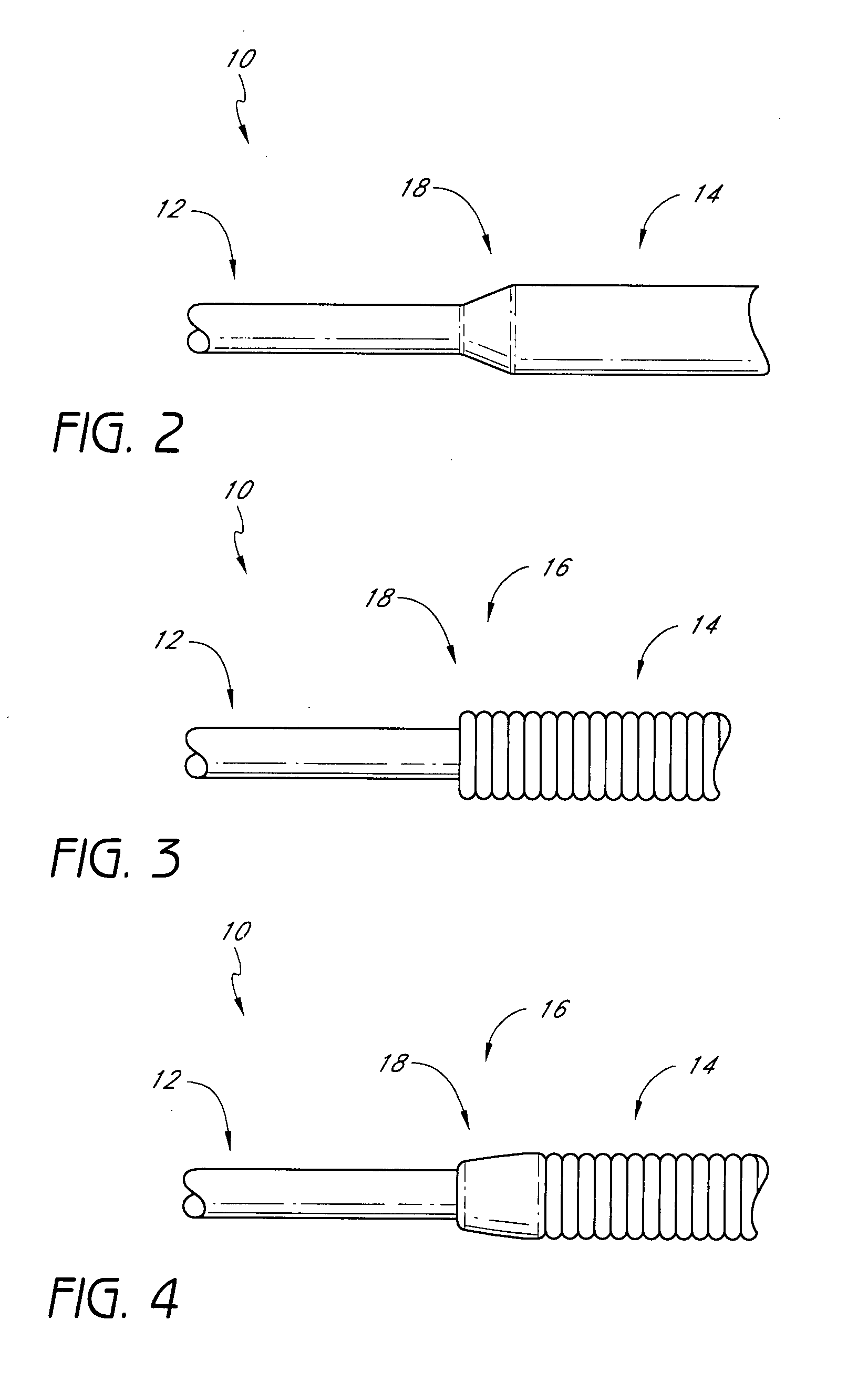

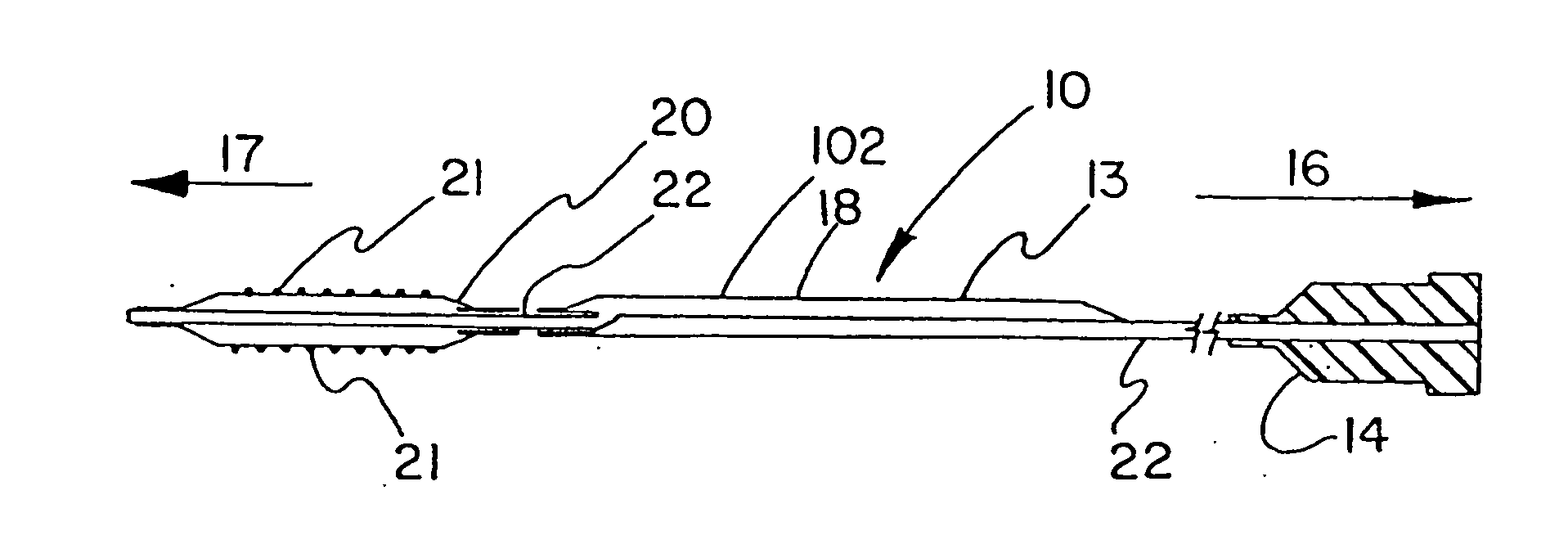

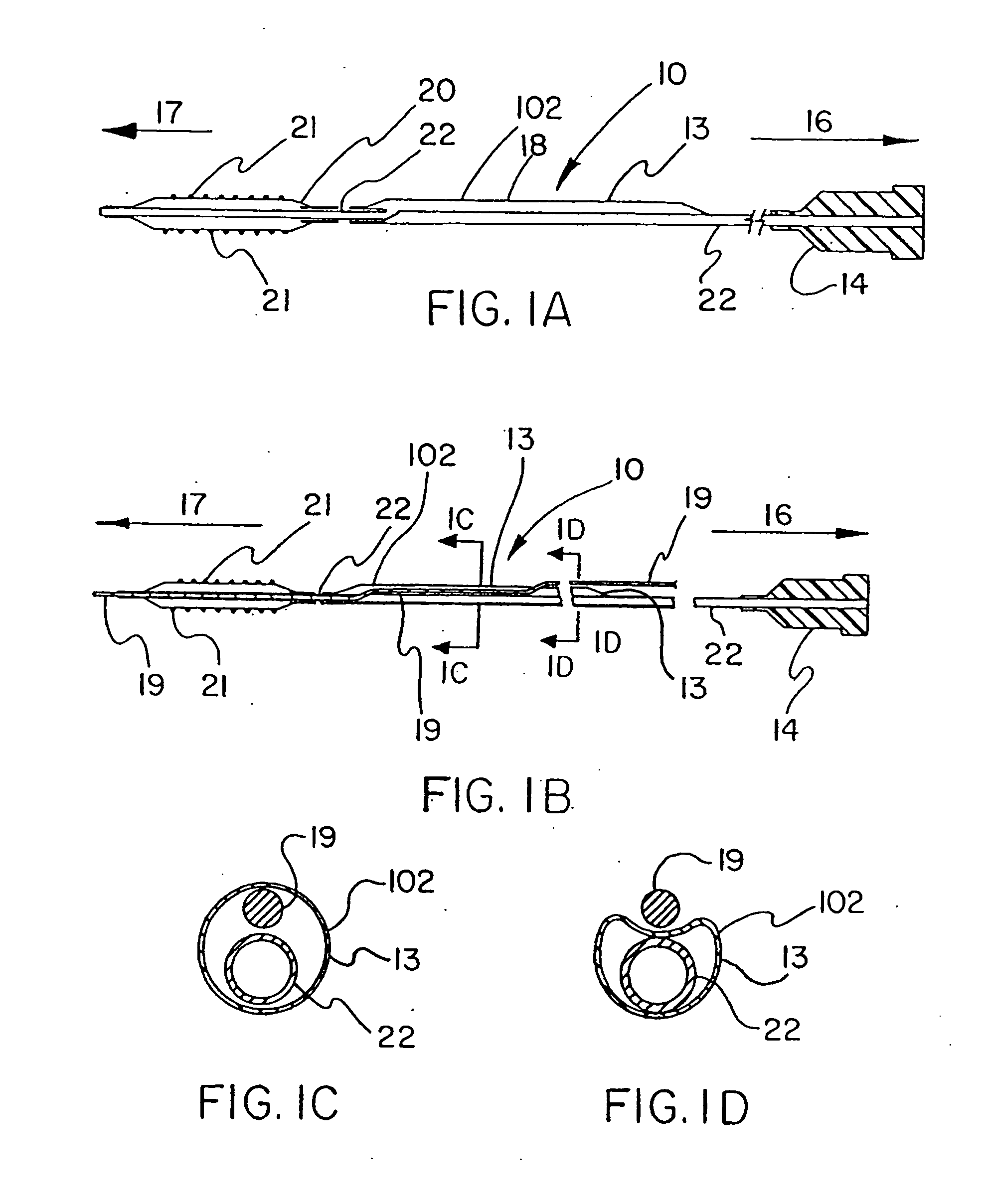

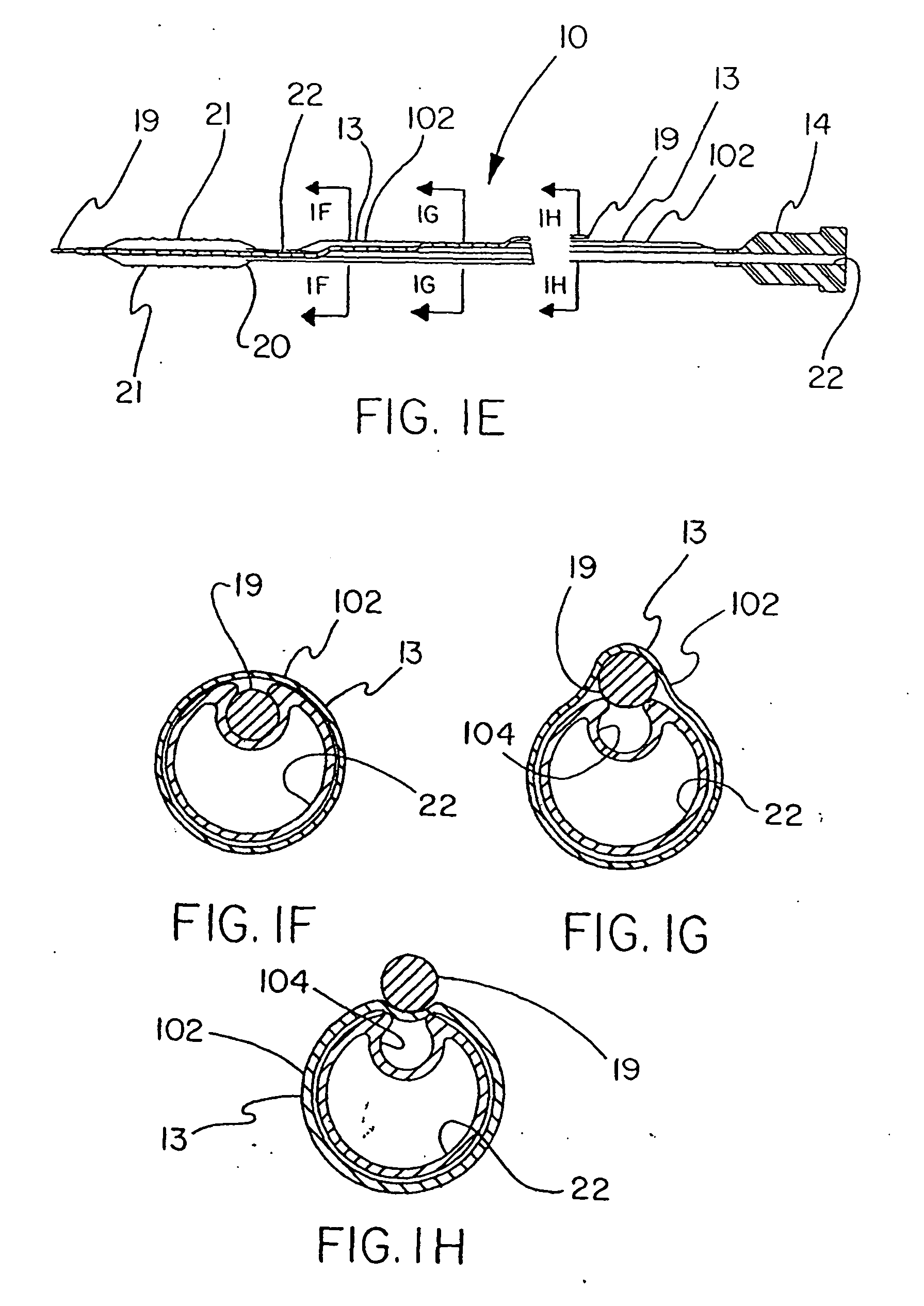

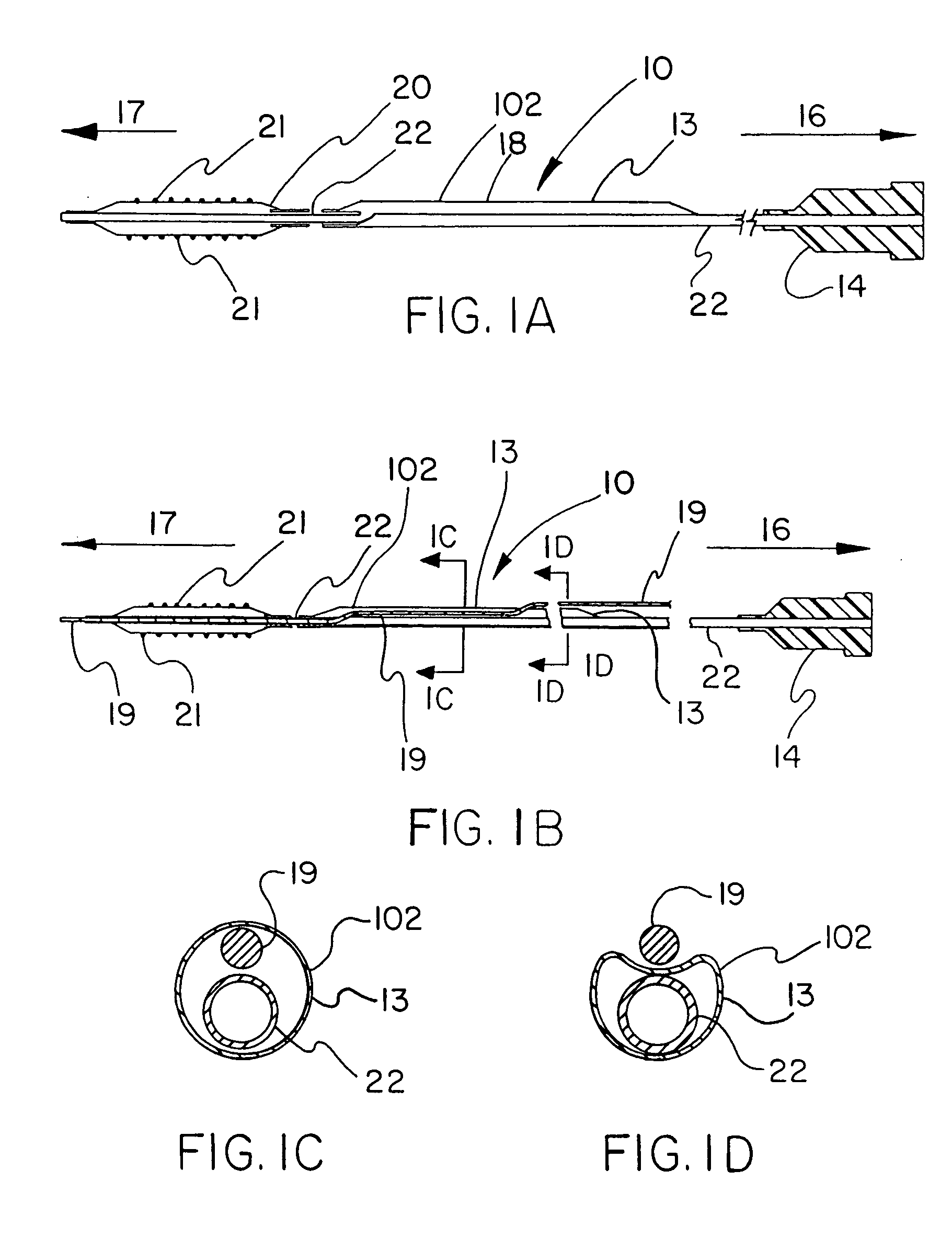

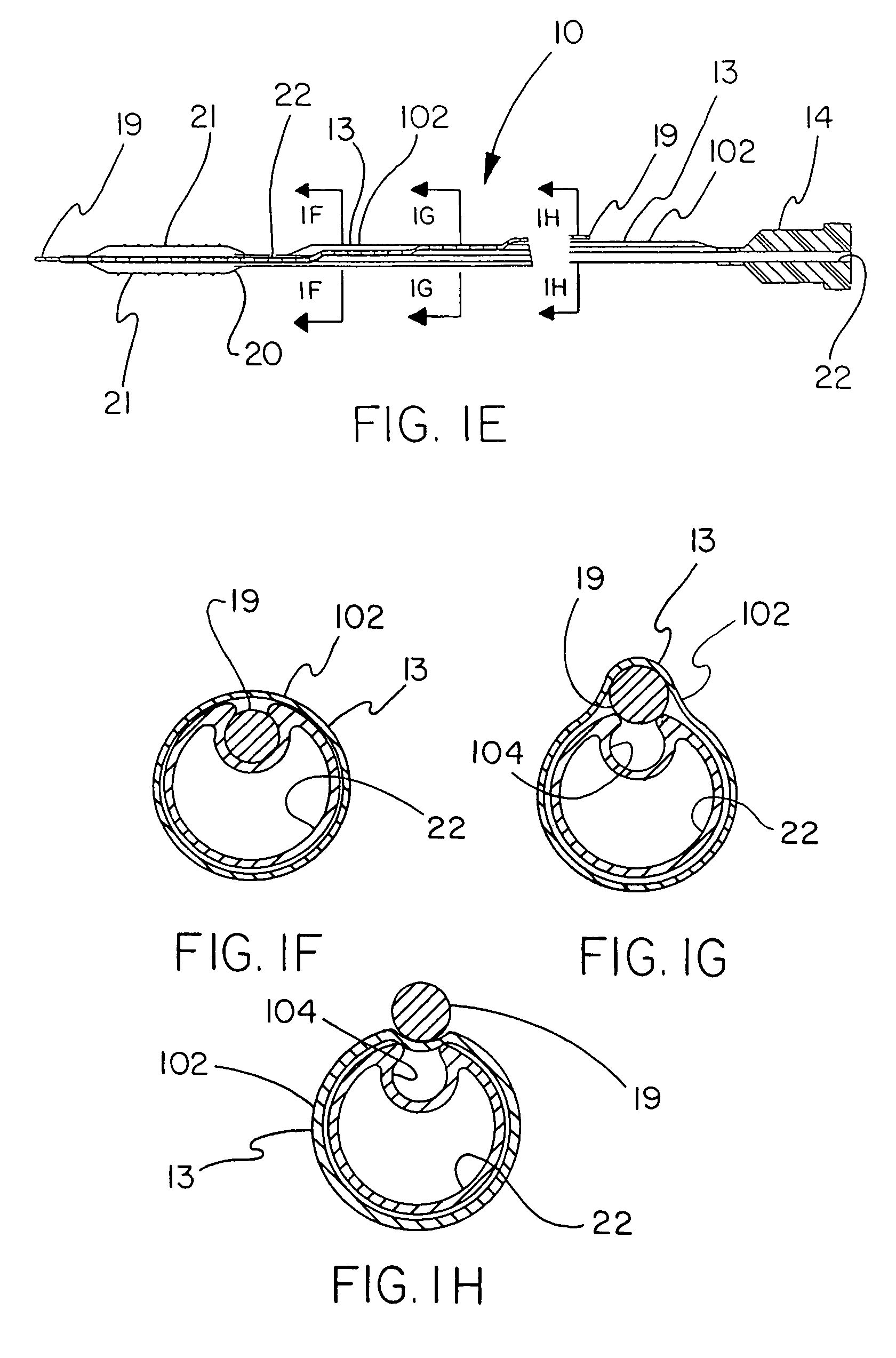

Reverse tapered guidewire and method of use

InactiveUS20080058839A1Sufficient “ pushability ”Sufficient rigiditySuture equipmentsDiagnosticsDistal segmentAccess site

A reverse tapered guidewire may comprise a proximal segment and a distal segment. The proximal segment may have a cross-sectional diameter smaller than a cross-sectional diameter of the distal segment. The guidewire may be inserted through an access site on a patient. A medical device may be advanced over the proximal segment of the guidewire. After the medical device is withdrawn from the patient, the guidewire may be used to re-access the site.

Owner:NOBLES ANTHONY A +1

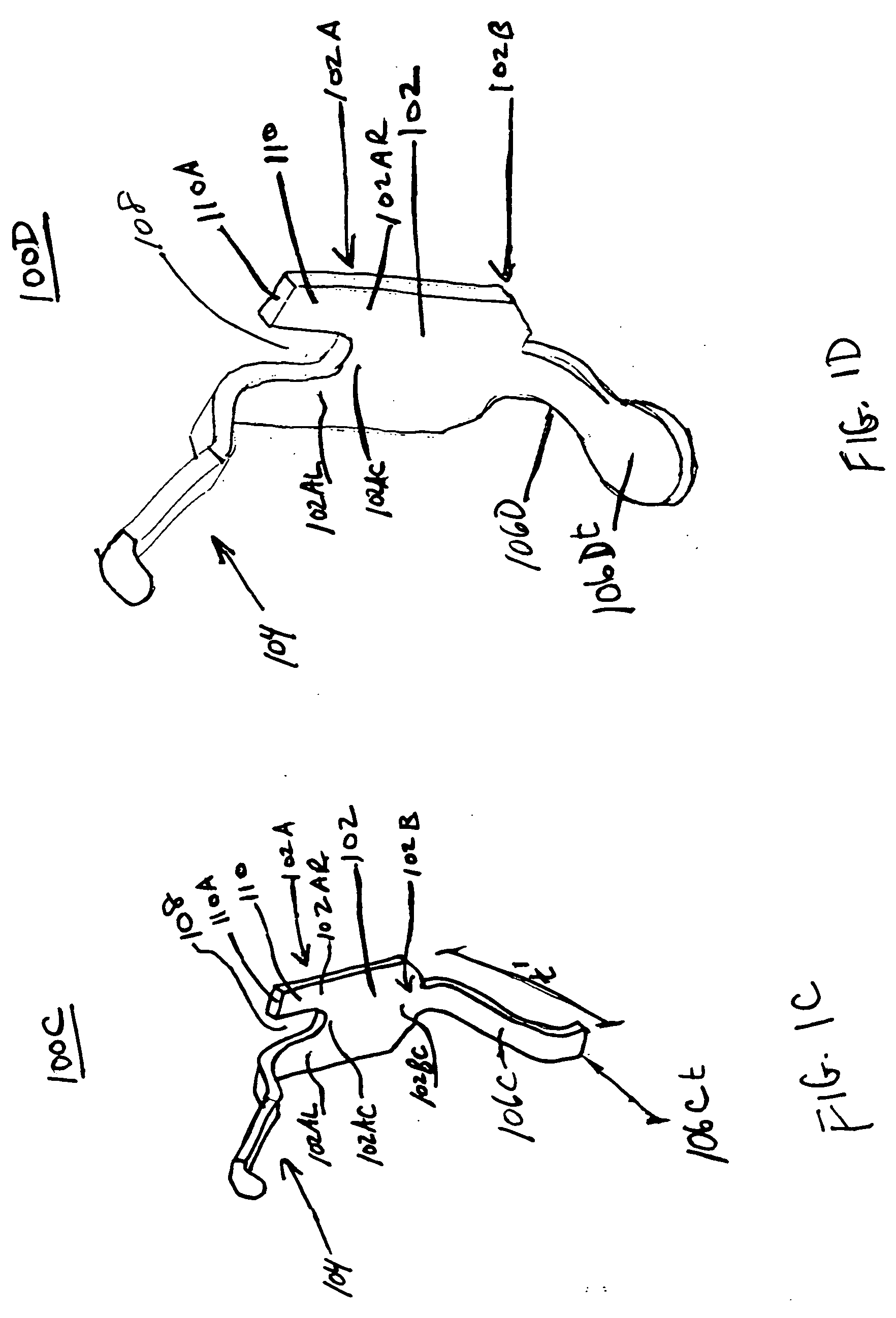

Ventilation interface for sleep apnea therapy

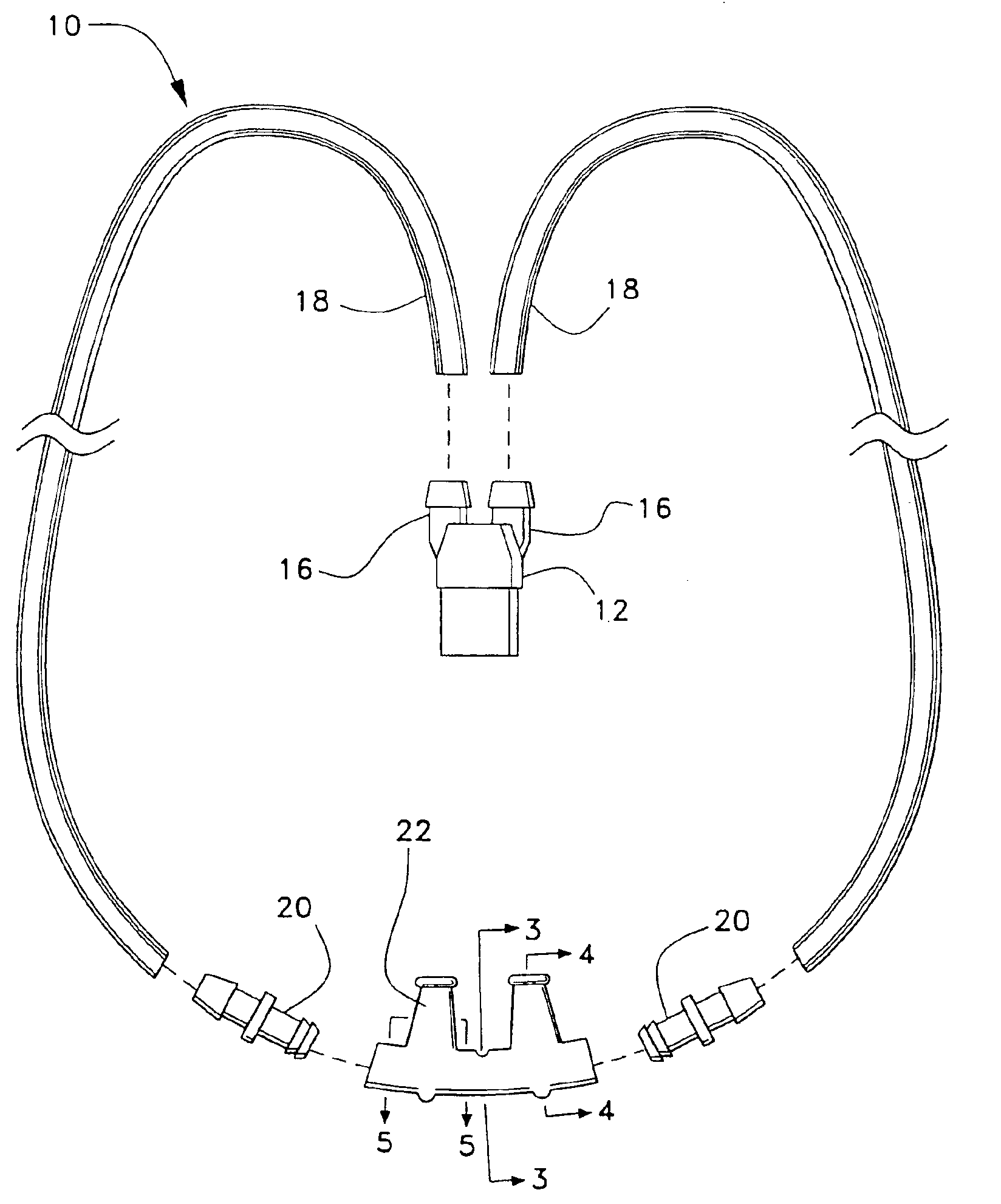

InactiveUS20050039757A1Great internal diameterLarge diameterBreathing masksRespiratory masksPositive airway pressureIntensive care medicine

The ventilation interface for sleep apnea therapy interfaces a ventilation device to the patient's airways. The ventilation interface includes a pair of nasal inserts made from flexible, resilient silicone which are oval shaped in cross-section and slightly tapered from a base proximal the ventilation supply to the distal tip end. A bead flange is disposed about the exterior of each insert at the distal end of the insert. In one embodiment, a valve is disposed between the nasal inserts and a source of positive airway pressure, the valve having a rim with a one-way diaphragm pivotally attached to the valve body with an inflatable bladder depending from the rim which seals against an exit port during inspiration and deflates to uncover the exit port on expiration. Another embodiment has nasal inserts without positive airway pressure but with a removable filter in the inserts for filtering inspired air.

Owner:SALTER LABS LLC

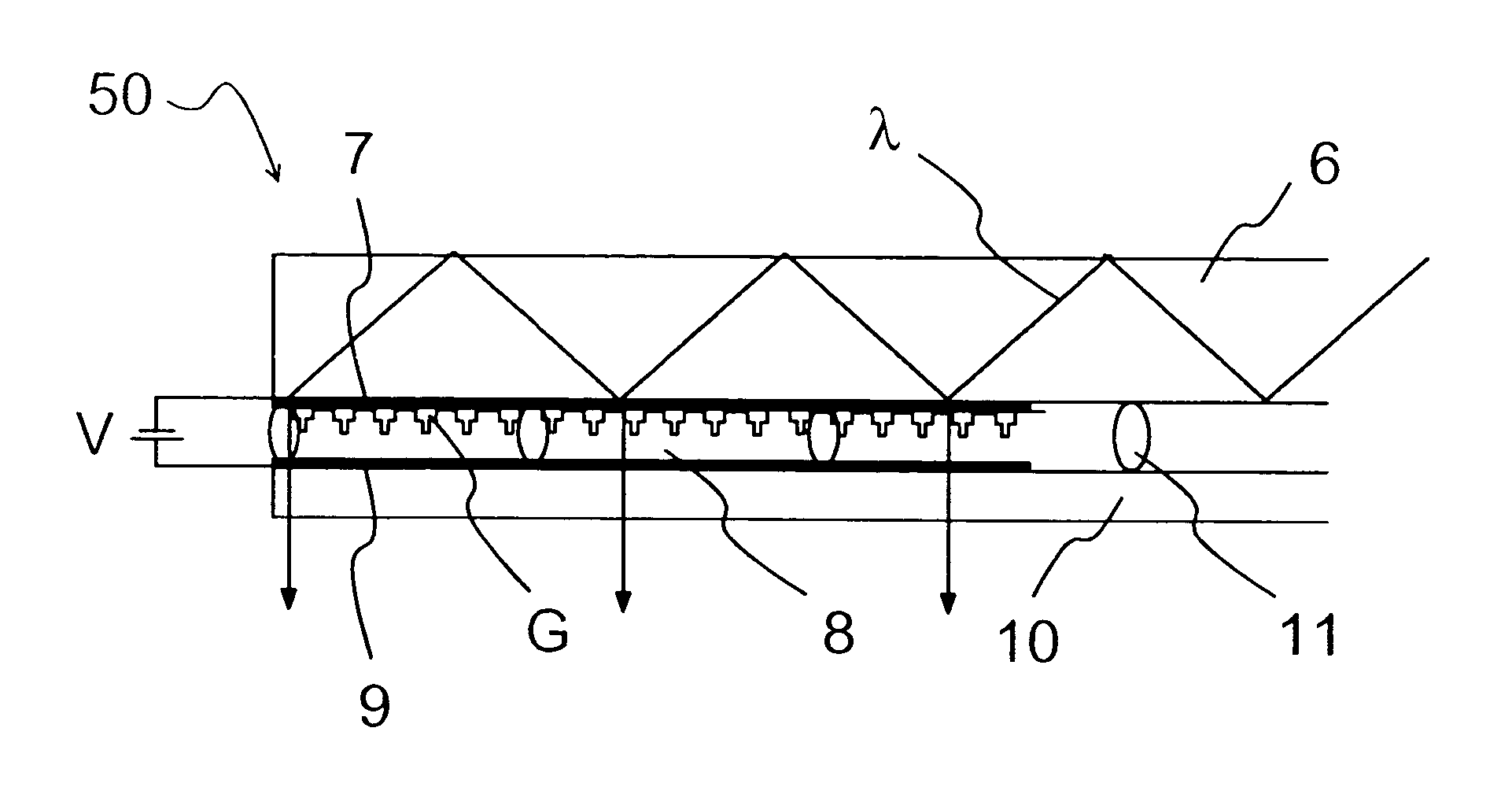

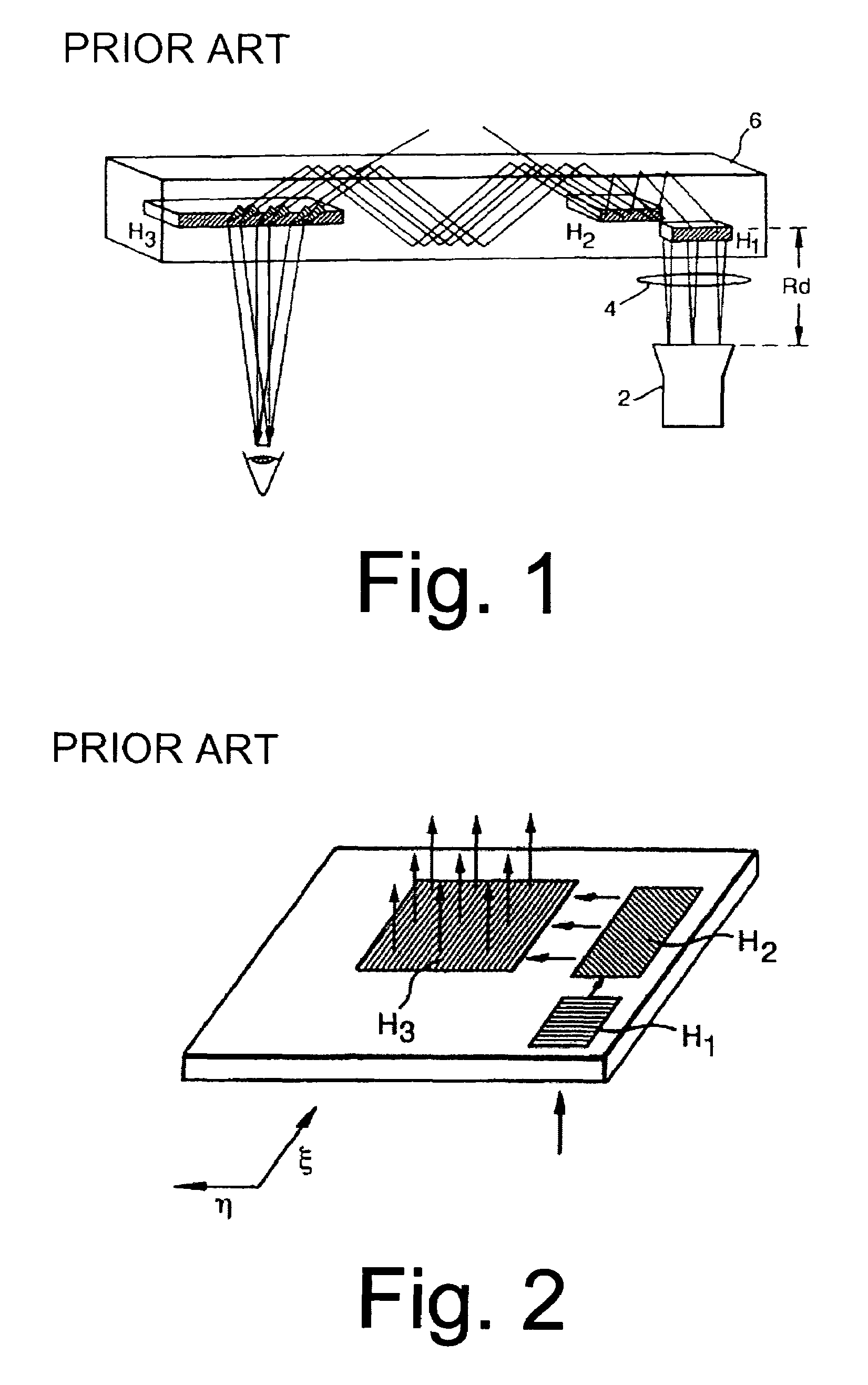

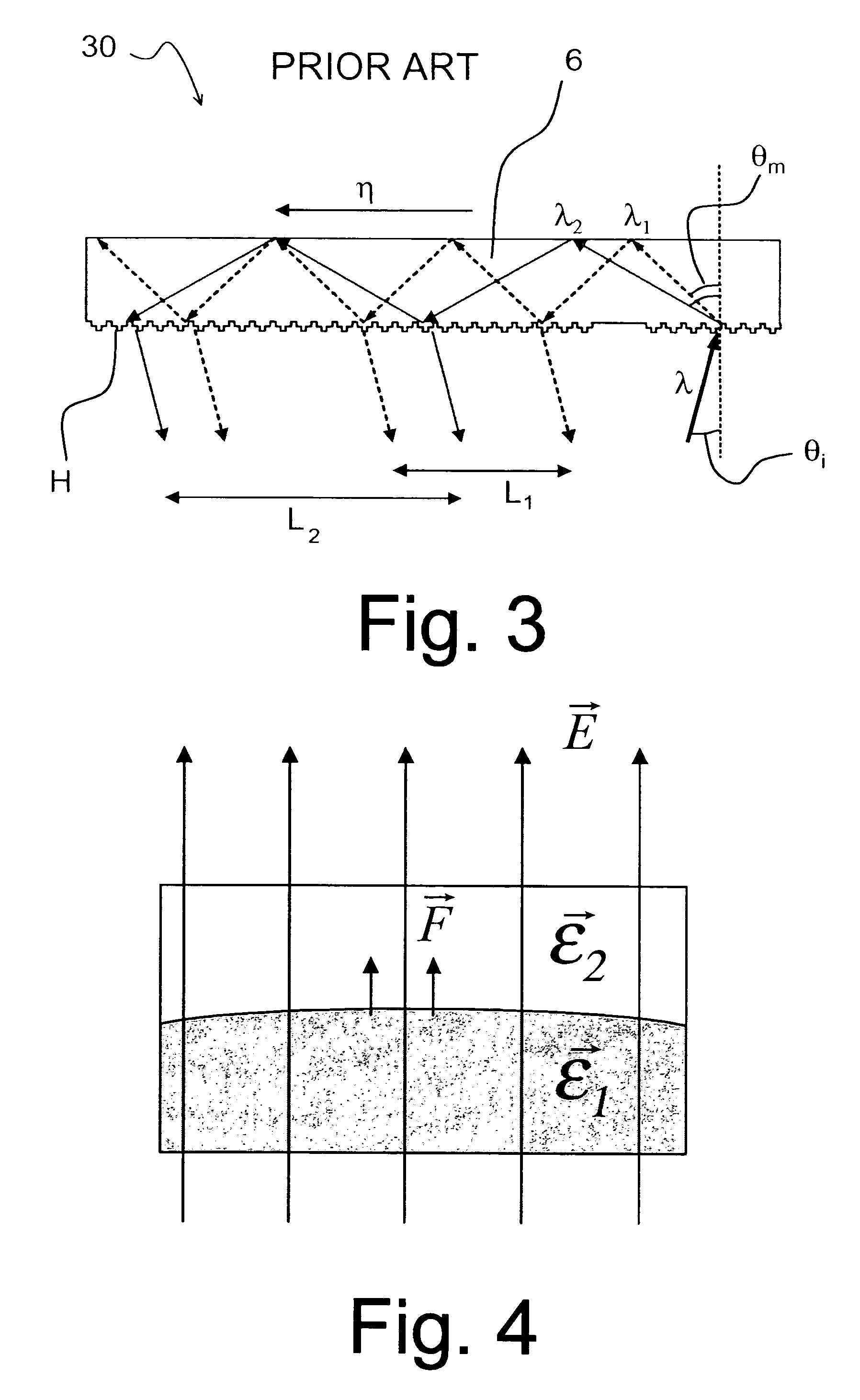

Electrically tunable diffractive grating element

ActiveUS7184615B2Improve color uniformityImprove image qualityDiffraction gratingsCoupling light guidesElectricityExit pupil

The invention relates to an optical device (50) for manipulating a light wave (λ) using a diffractive grating structure (G). According to the basic idea behind the invention a prior art type diffractive grating structure having a permanently shaped surface relief is substituted with an electrically deformable diffractive grating structure (G), where a preformed, basic surface relief of the grating is composed of dielectric and deformable viscoelastic material, which can be electrically and sequentially fine tuned in shape to adjust the diffraction properties of said grating individually for different wavelengths. The invention permits manufacture of virtual display devices with a significantly larger exit pupil diameter than prior art solutions without degrading the color uniformity of the display device.

Owner:MAGIC LEAP

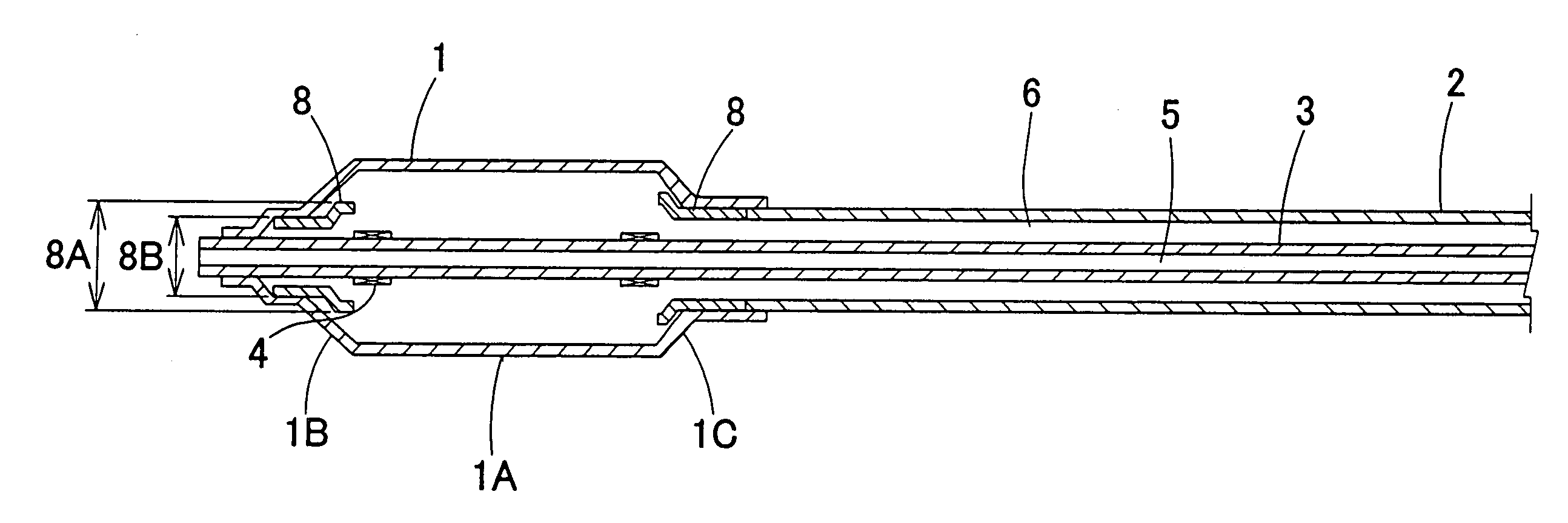

Catheter assembly

InactiveUS20070088323A1Efficient use ofEasily shortened in lengthStentsBalloon catheterPolymer thin filmsGuide wires

Novel catheter constructions comprising thin covering or wrapping materials such as polymer films. A catheter provided with a guidewire catheter lumen having a thin covering that is easily punctured by a guidewire at virtually any desired point along the catheter length. The thin covering may be integral with the catheter shaft, or may be a separate component that covers only the portion of the catheter shaft immediately adjacent the outer portion of the guidewire lumen, or may be a thin tubular construct that surrounds the entire catheter shaft. Moreover, polymer film can be used in combination with one or more elements to produce novel catheter constructions.

Owner:WL GORE & ASSOC INC

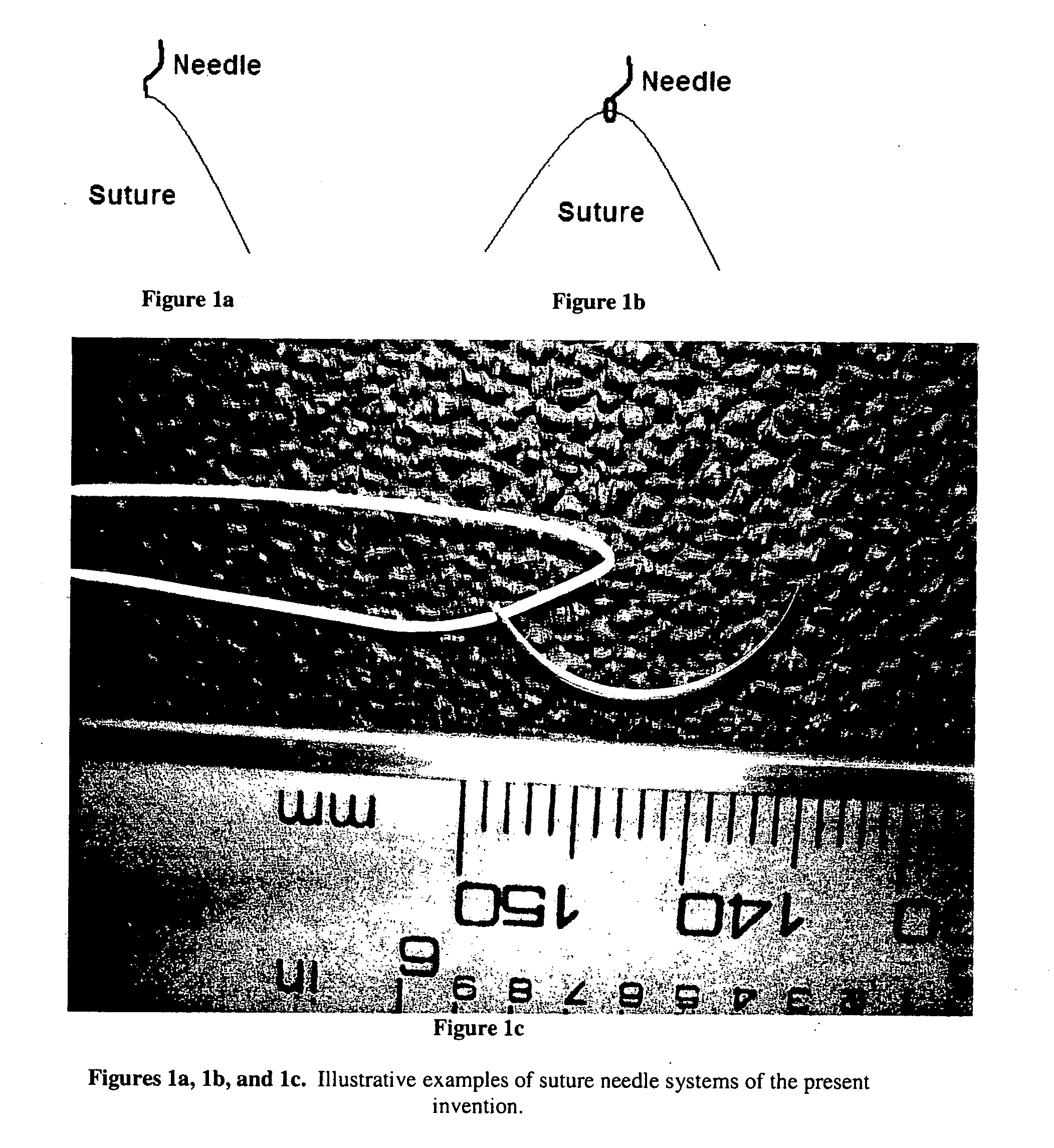

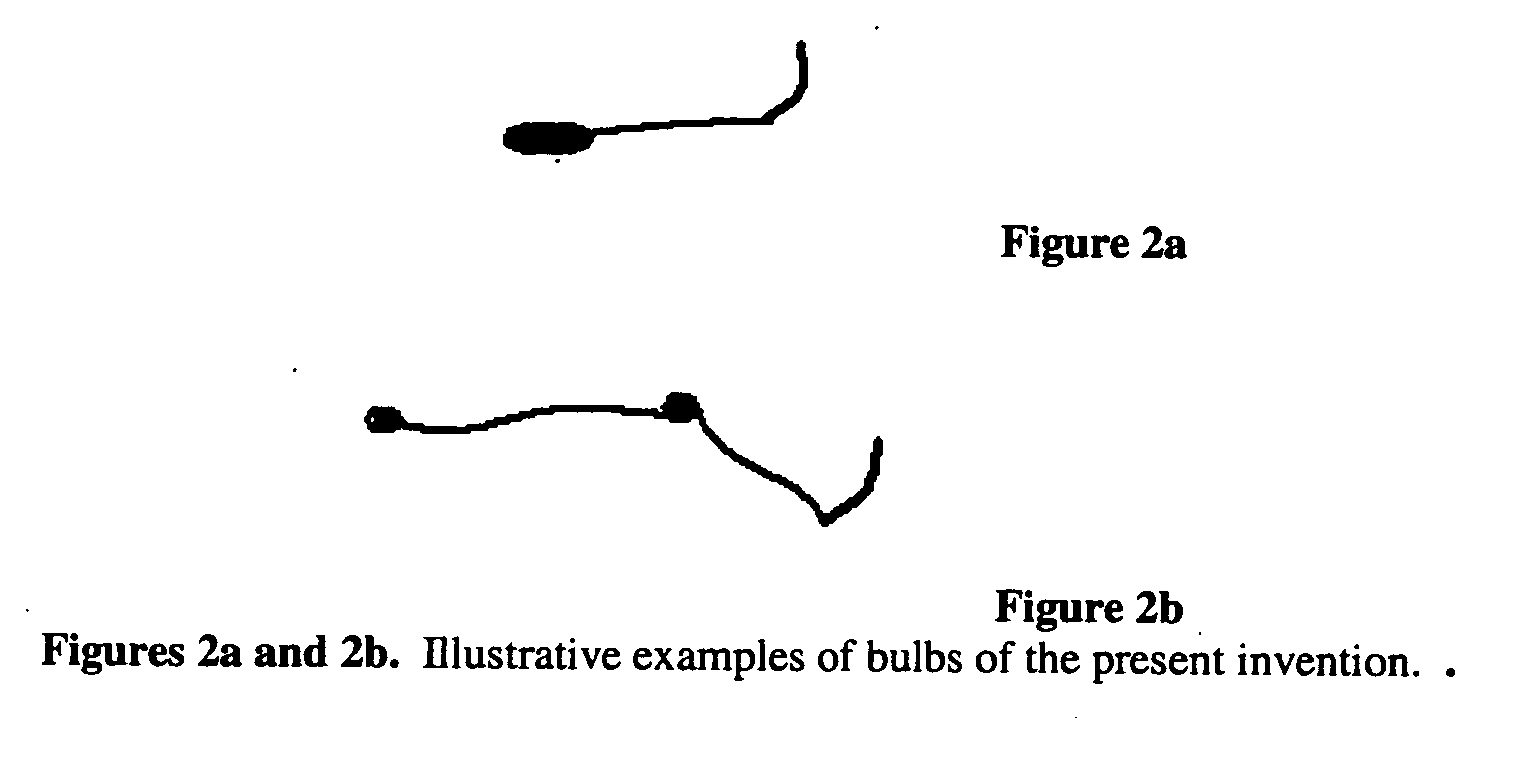

Biodegradable drug-polymer delivery system

ActiveUS20050276841A1Low tensile strengthTensile strengthOrganic active ingredientsBiocideTherapy medicationDisease

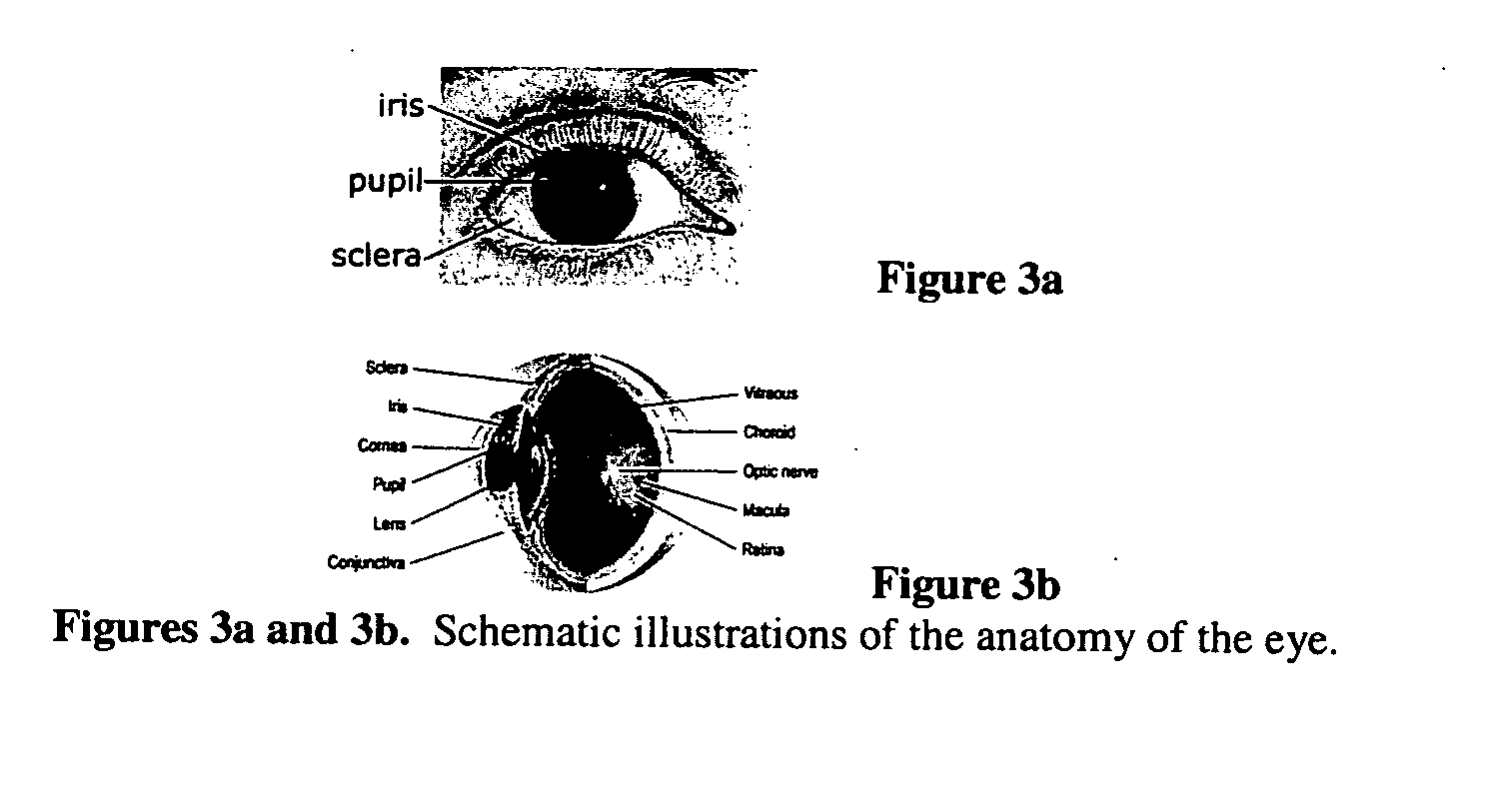

A sustained-release biodegradable polymeric drug-eluting fiber is disclosed. In some embodiments, the therapeutic drug is complexed with cyclodextrin. In certain embodiments, the polymeric component of the fiber comprises cyclodextrin. The fiber may be fabricated to provide a thread and / or suture. The fiber may be used for treatment of ocular diseases or disorders.

Owner:CALIFORNIA INST OF TECH

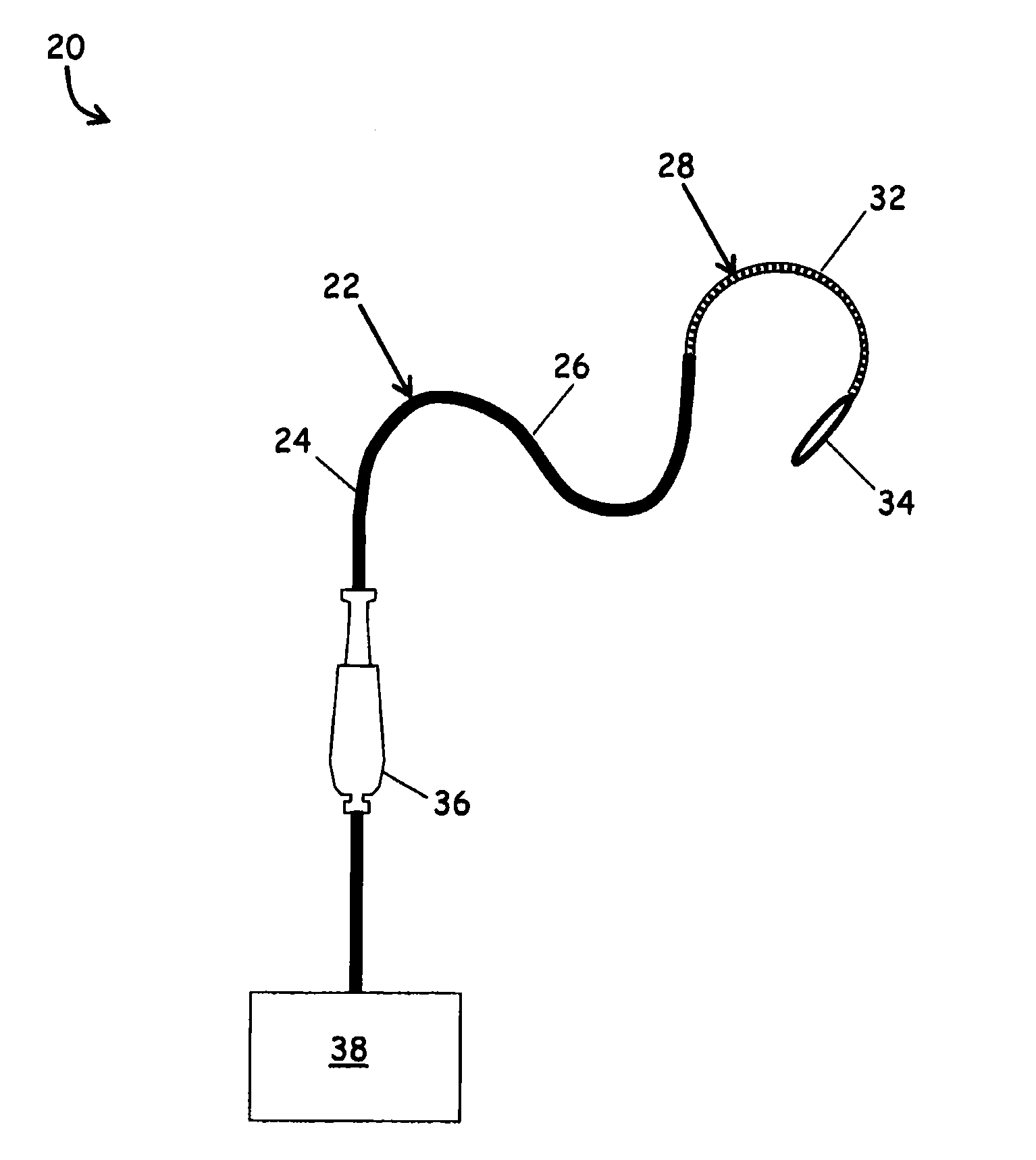

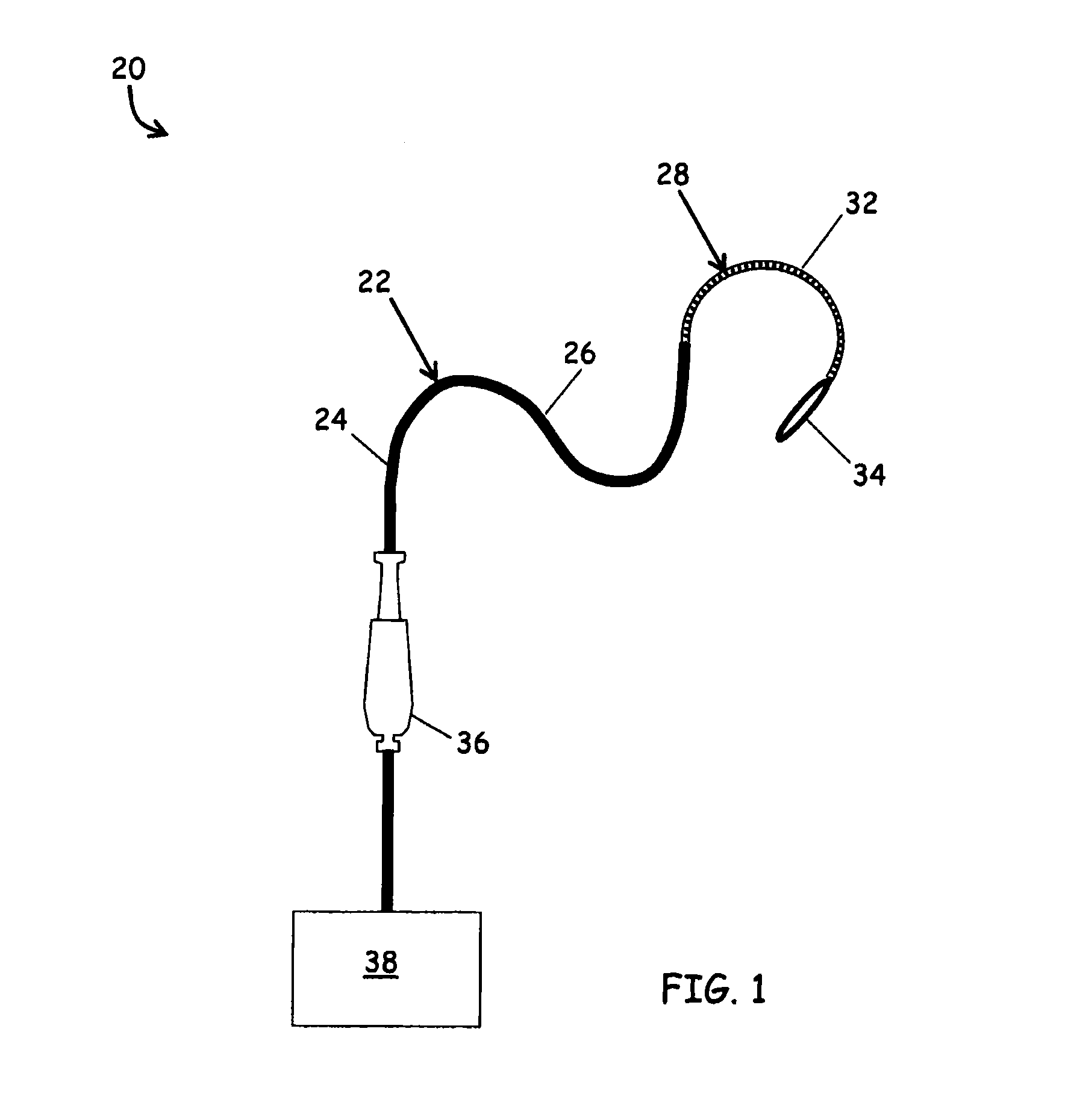

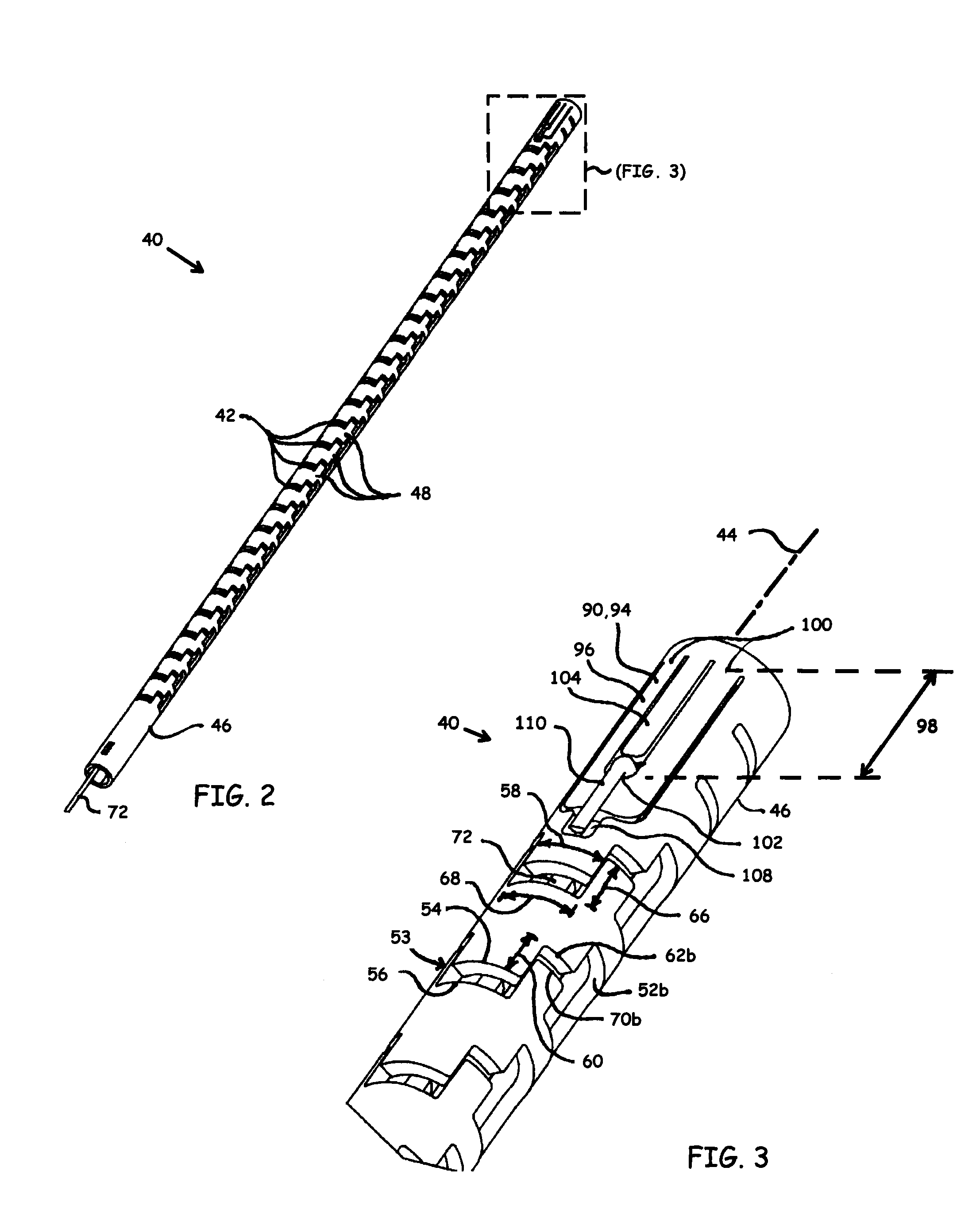

Variable stiffness steering mechanism for catheters

ActiveUS20110251519A1Enabling controlWithout sacrificing torsional strengthGuide wiresEndoscopesTorsional rigidityEngineering

A catheter assembly including a tapered steering spine having a varying stiffness along an axial length. The tapered steering spine is tailored to provide increasing flexibility from proximal to distal in a way that makes the bend radius more uniform along the length of the steering section. In one embodiment, the tapered steering spine includes structures on adjacent rings that engage with each other when the steering section is flexed to limit the minimum bend radius to a predetermined minimum and which enhances the torsional rigidity of the steering section regardless of the degree of flexure of the steering section. The limited bend radius can prevent excessive bending of components such as fiber optics. The enhanced torsional rigidity can negate the need for torque braid in the section of the catheter shaft that surrounds the tapered steering spine.

Owner:ST JUDE MEDICAL INT HLDG SARL

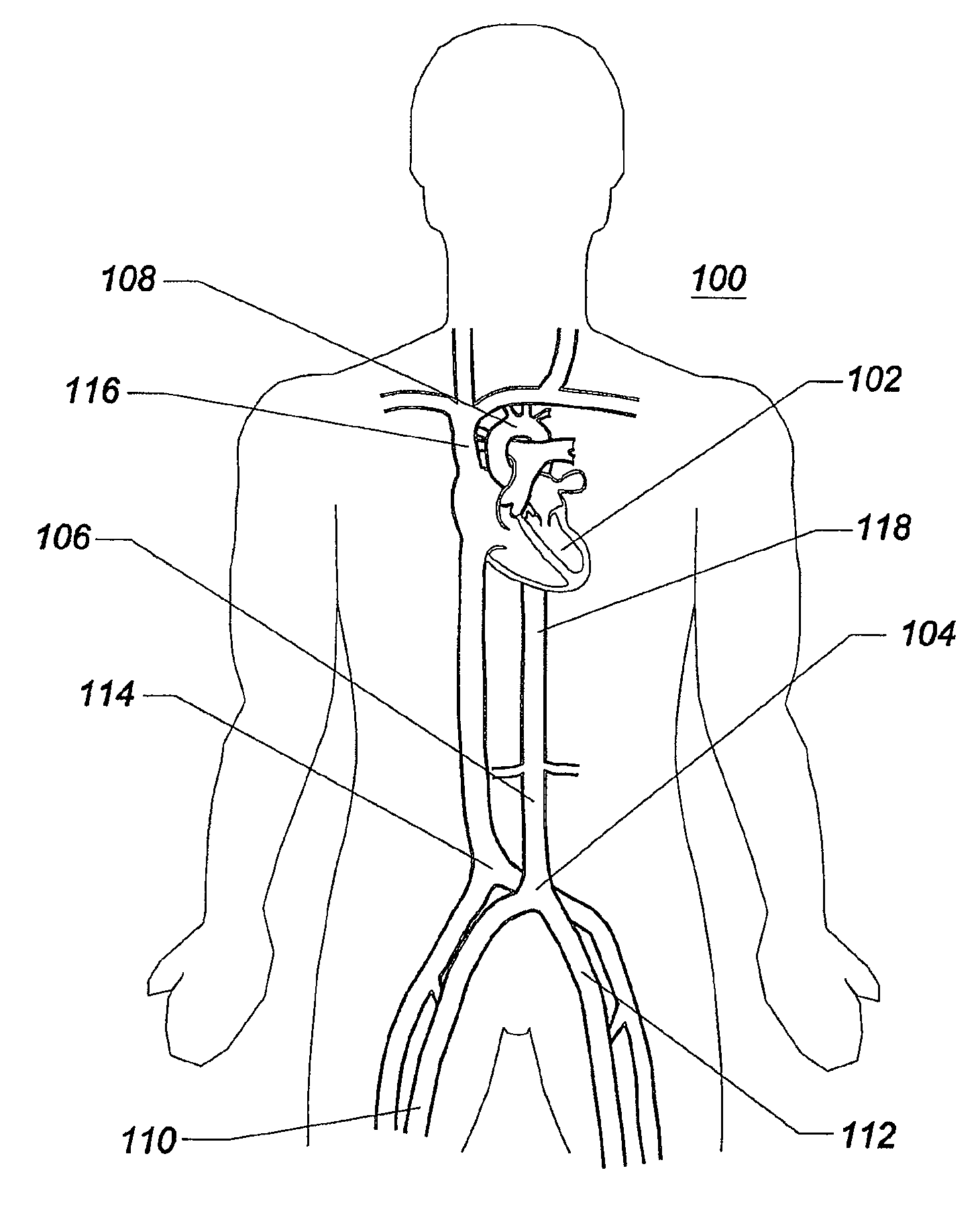

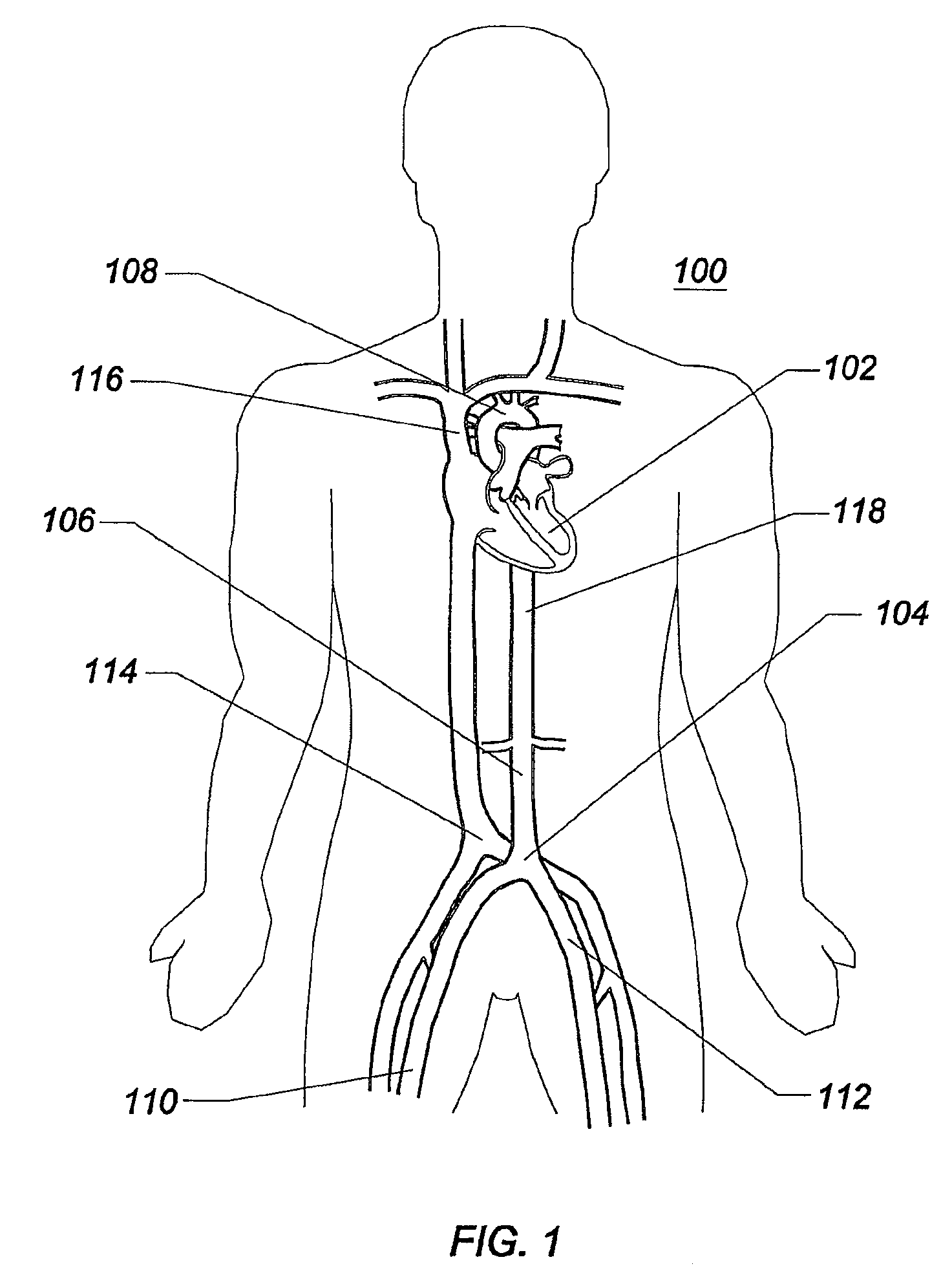

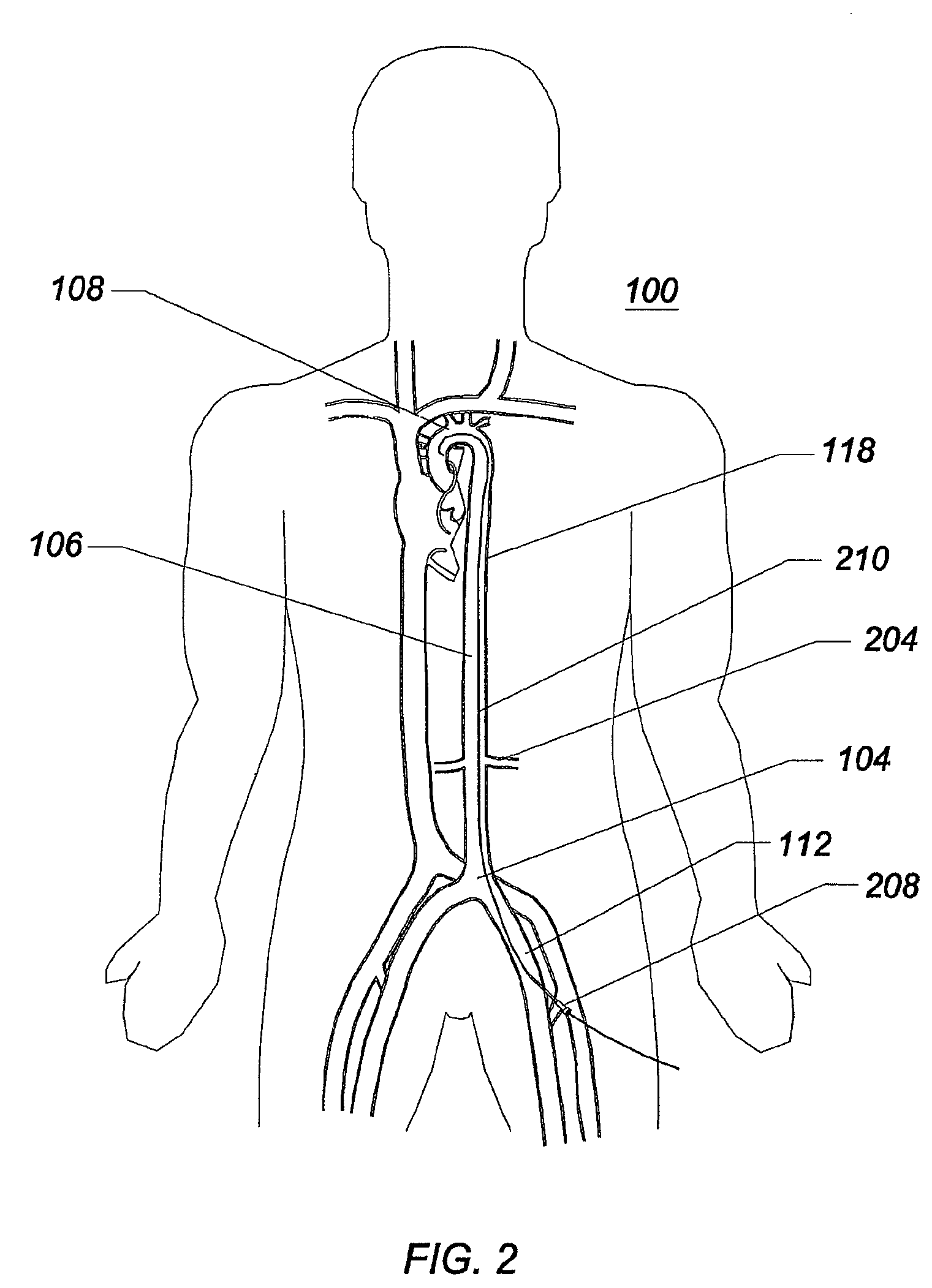

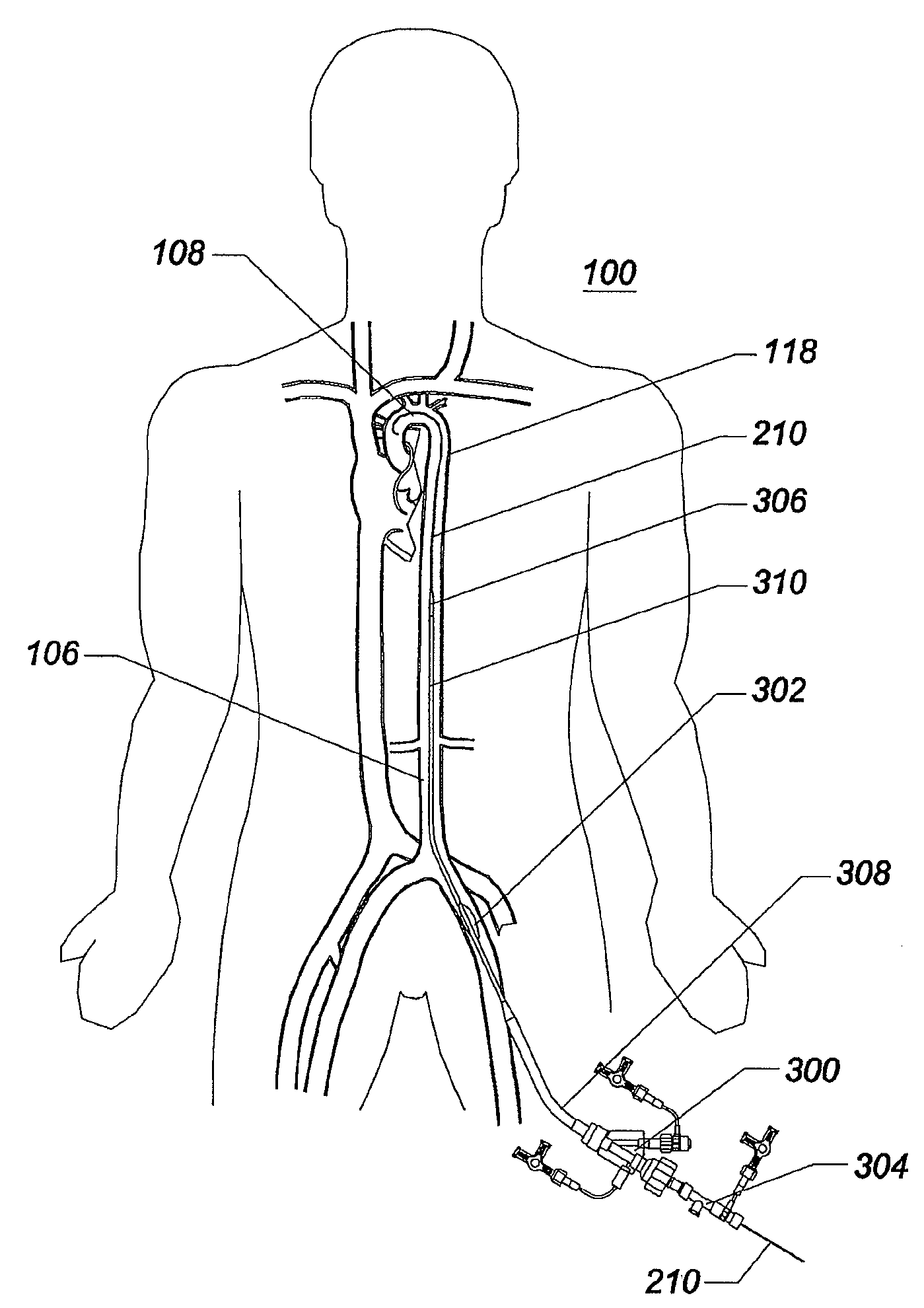

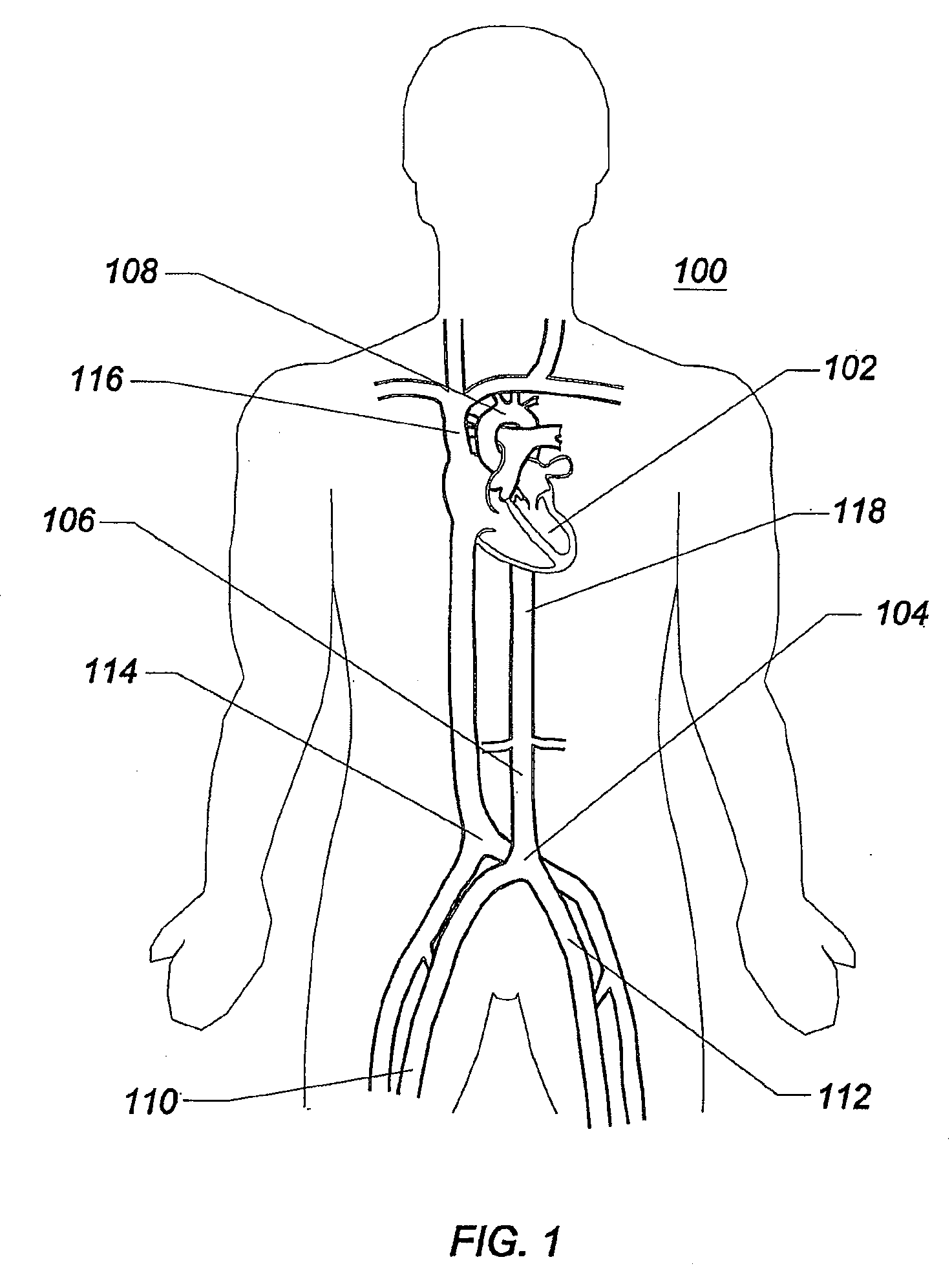

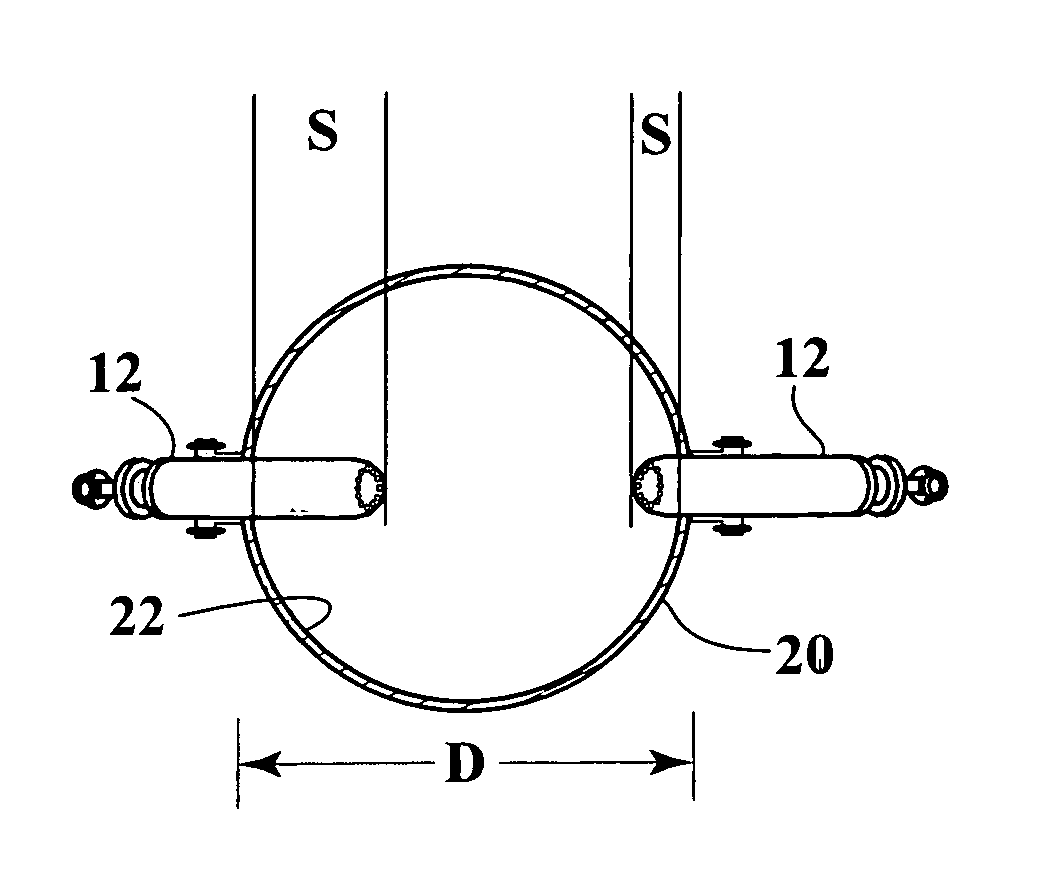

Expandable intra-aortic balloon pump sheath

ActiveUS7722568B2Diameter minimizationMaximally visibleInfusion syringesSurgeryAccess routeAortic balloon pump

Owner:ONSET MEDICAL CORP

Expandable intra-aortic balloon pump sheath

ActiveUS20080183136A1Inhibit bindingAvoid interferenceInfusion syringesCatheterAccess routeIntraaortic balloon pump

Disclosed is an expandable transluminal sheath, for introduction into the body while in a first, low cross-sectional area configuration, and subsequent expansion of at least a part of the distal end of the sheath to a second, enlarged cross-sectional configuration. The sheath is configured for use in the vascular system and has utility in the introduction and removal of balloon counterpulsation catheters. The access route is through the femoral arteries and the iliac arteries into the aorta, where an intra-aortic balloon pump catheter is positioned to provide cardiac support. The distal end of the sheath is maintained in the first, low cross-sectional configuration during advancement to the arteries into the aorta. The distal end of the sheath is subsequently expanded using a radial dilatation device.

Owner:ONSET MEDICAL CORP

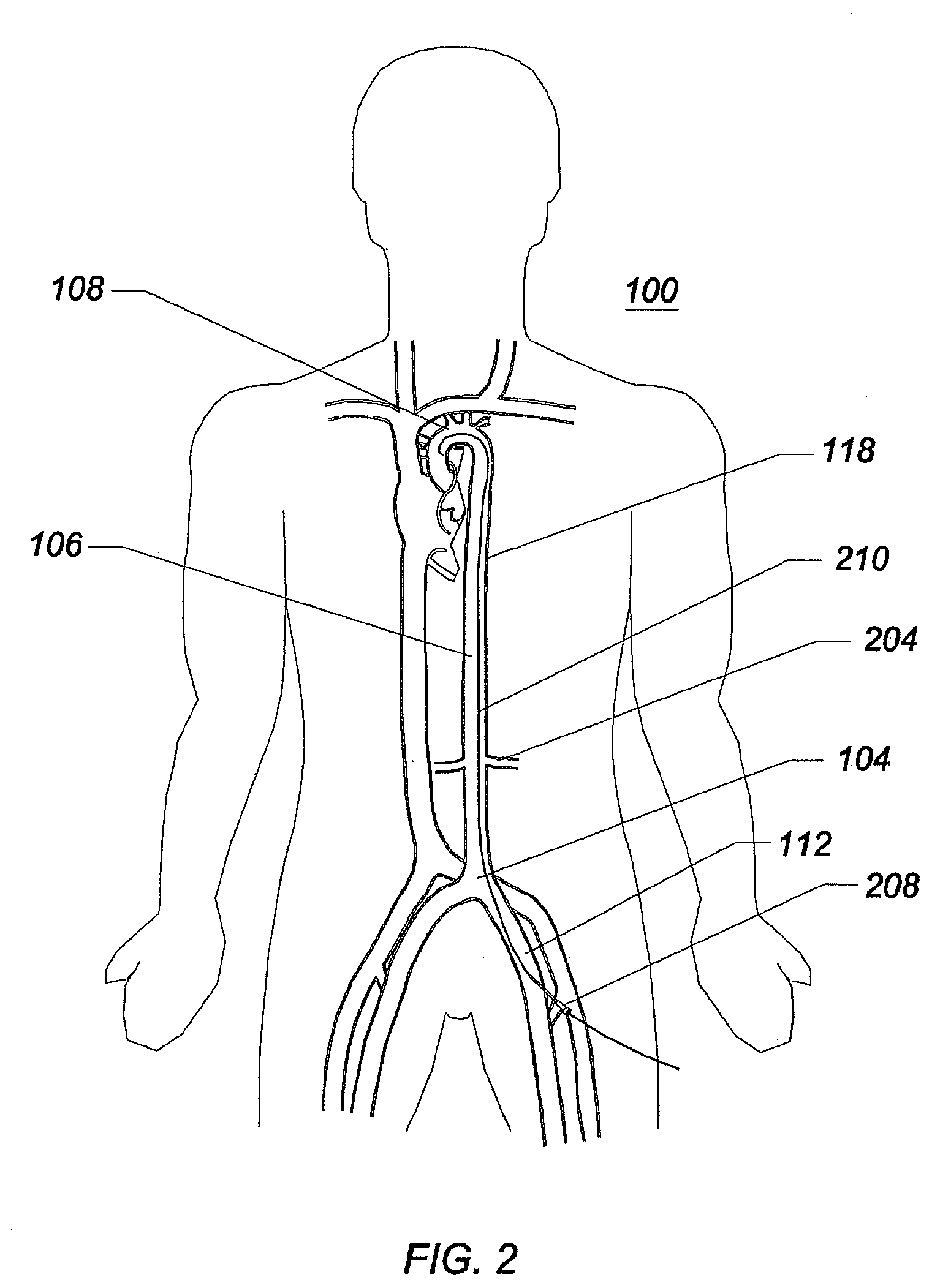

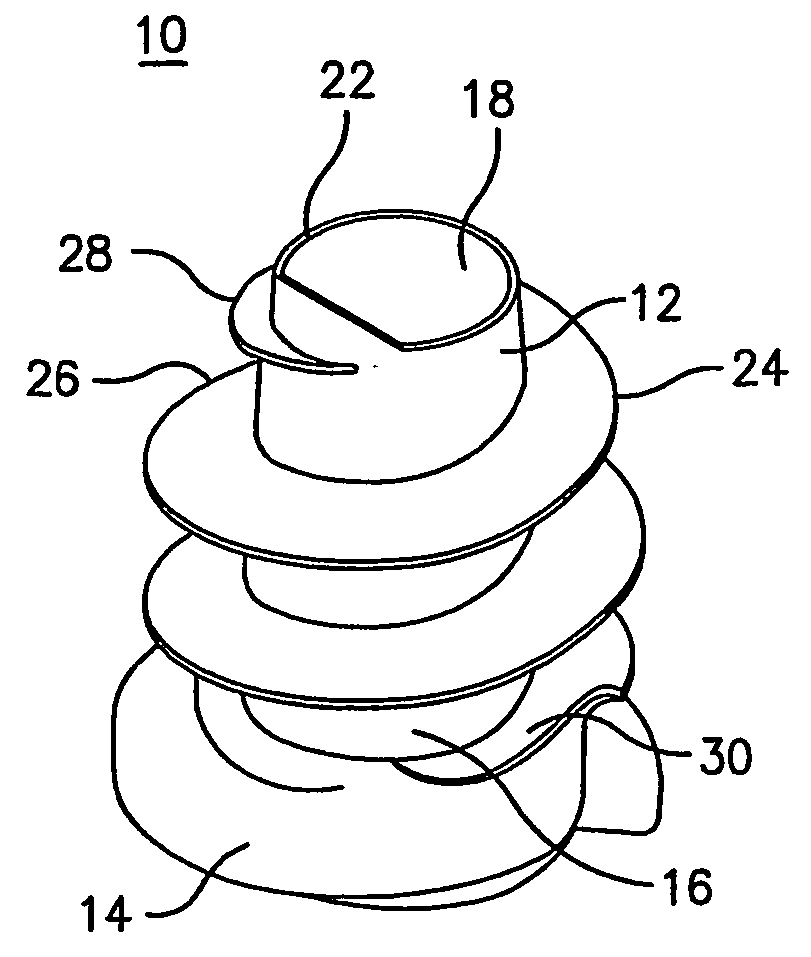

Hernia mesh tacks

InactiveUS20050171562A1Increase drive surface areaEasy to insertSuture equipmentsInternal osteosythesisEngineeringSurgical department

There are disclosed various embodiments of surgical tacks for use in surgical procedures. The tacks generally include a head and a barrel portion extending distally from the head. Preferably the head and the barrel portion define a throughbore for receipt of a drive instrument. A thread on the head is provided to engage threads in the installation tool. A tissue thread is provided on the barrel, portion to engage tissue. Distal and proximal surfaces of the tissue thread may be oriented at various angles relative to the barrel portion. There is also disclosed an insertion instrument to insert one or more tacks as well as a method of use. There is further disclosed a model device for use in explaining the operation of the instrument.

Owner:TYCO HEALTHCARE GRP LP

Ventilation interface for sleep apnea therapy

InactiveUS7059328B2Large diameterAvoiding drying and burningRespiratorsBreathing masksLine tubingNose

The ventilation interface for sleep apnea therapy interfaces a ventilation device to the patient's airways. The ventilation interface includes a pair of nasal inserts made from flexible, resilient silicone which are oval shaped in cross-section and slightly tapered from a base proximal the ventilation supply to the distal tip end. A bead flange is disposed about the exterior of each insert at the distal end of the insert. A bleed port for release of exhaled air is defined through a conical vent projecting normally to the path of the incoming air flow, and continues through a nipple extending to the exterior of the air conduit. In one embodiment, a pair of nasal inserts are integral with a nasal cannula body, with bleed ports axially aligned with each insert. In another embodiment, each insert is independently connected to a separate, thin-walled, flexible supply line.

Owner:INNOMED TECHS

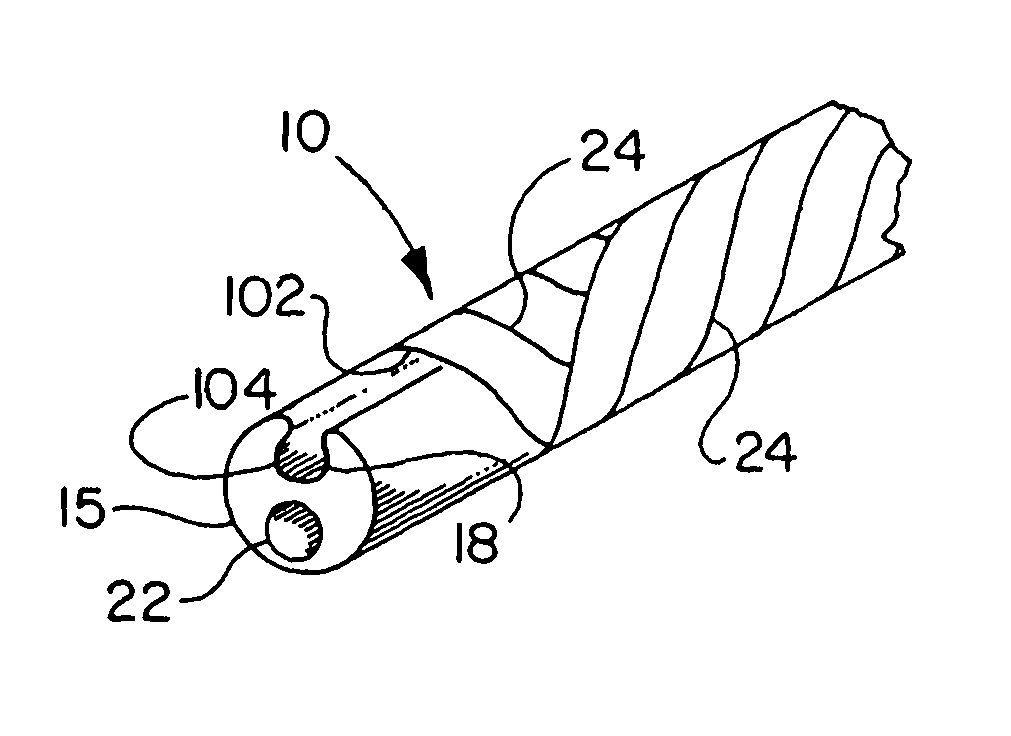

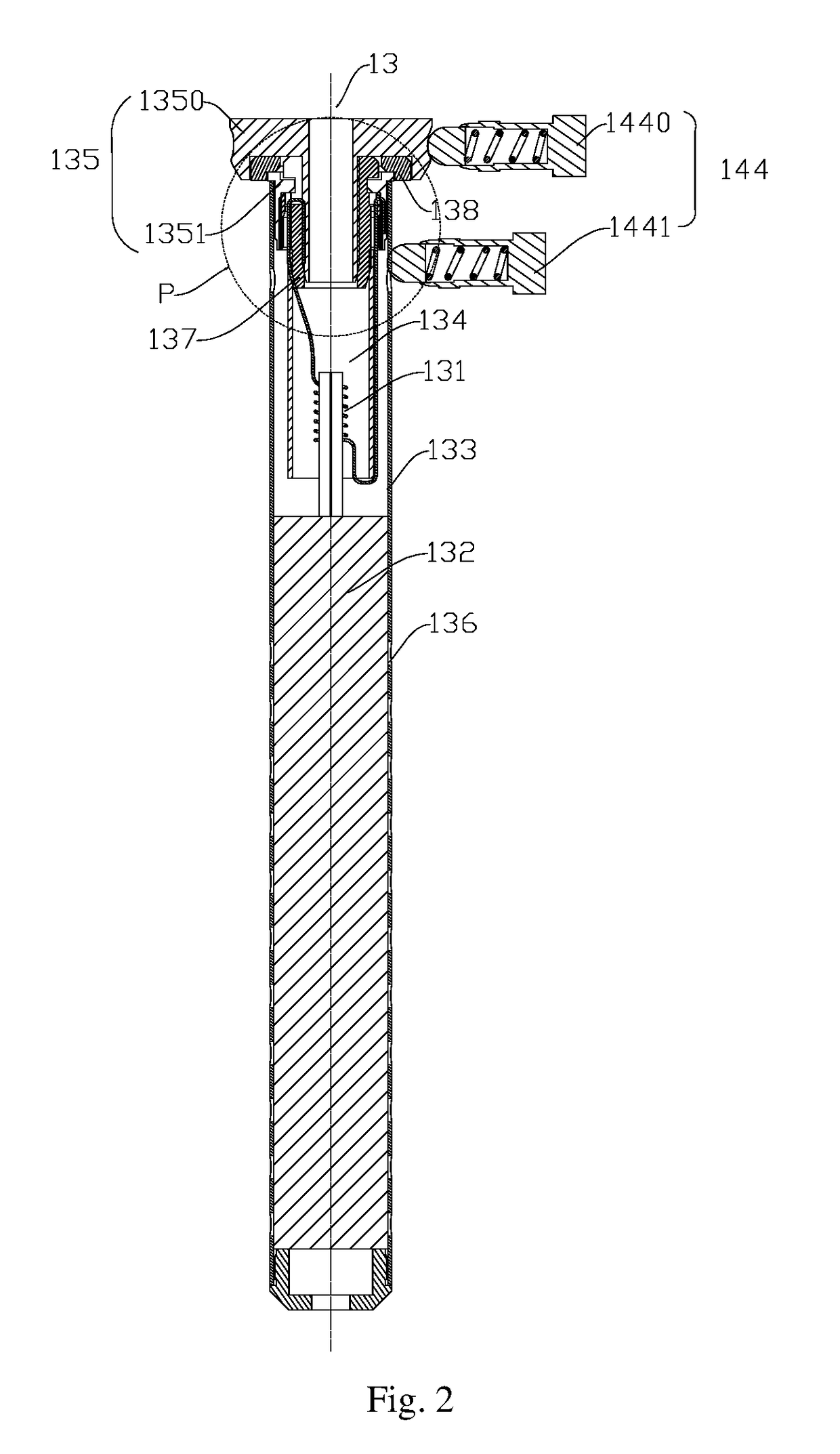

Puncture device with a flexible catheter tube for connecting to a medical infusion line

InactiveUS20060015076A1Easy to handleLarge diameterMedical devicesCatheterCatheter hubMedical treatment

A puncture device with a flexible catheter tube for connecting to a medical infusion line, wherein the device includes a catheter connecting piece or hub attachable at the puncture site on the skin surface of a patient, wherein the catheter hub has a connector for connecting the infusion line and an outlet for the flexible catheter tube; and a needle holder having a puncture needle (stylet), wherein the flexible catheter tube is arranged in the interior of the catheter hub and extends out of the outlet with an output end. The end of the flexible catheter tube opposing the output end is located in the interior of the catheter hub in the area of the connector and is separated from the surrounding area by a septum, wherein the needle holder securely fastens the puncture needle insertable into a passage channel of the catheter tube at the end opposing the pointed or sharp puncture tip. The outlet is located at the bottom side of the catheter hub resting on the surface of the patient in the position of use and the puncture needle is made without a duct.

Owner:CLINICO

Puncturable catheter

Owner:WL GORE & ASSOC INC

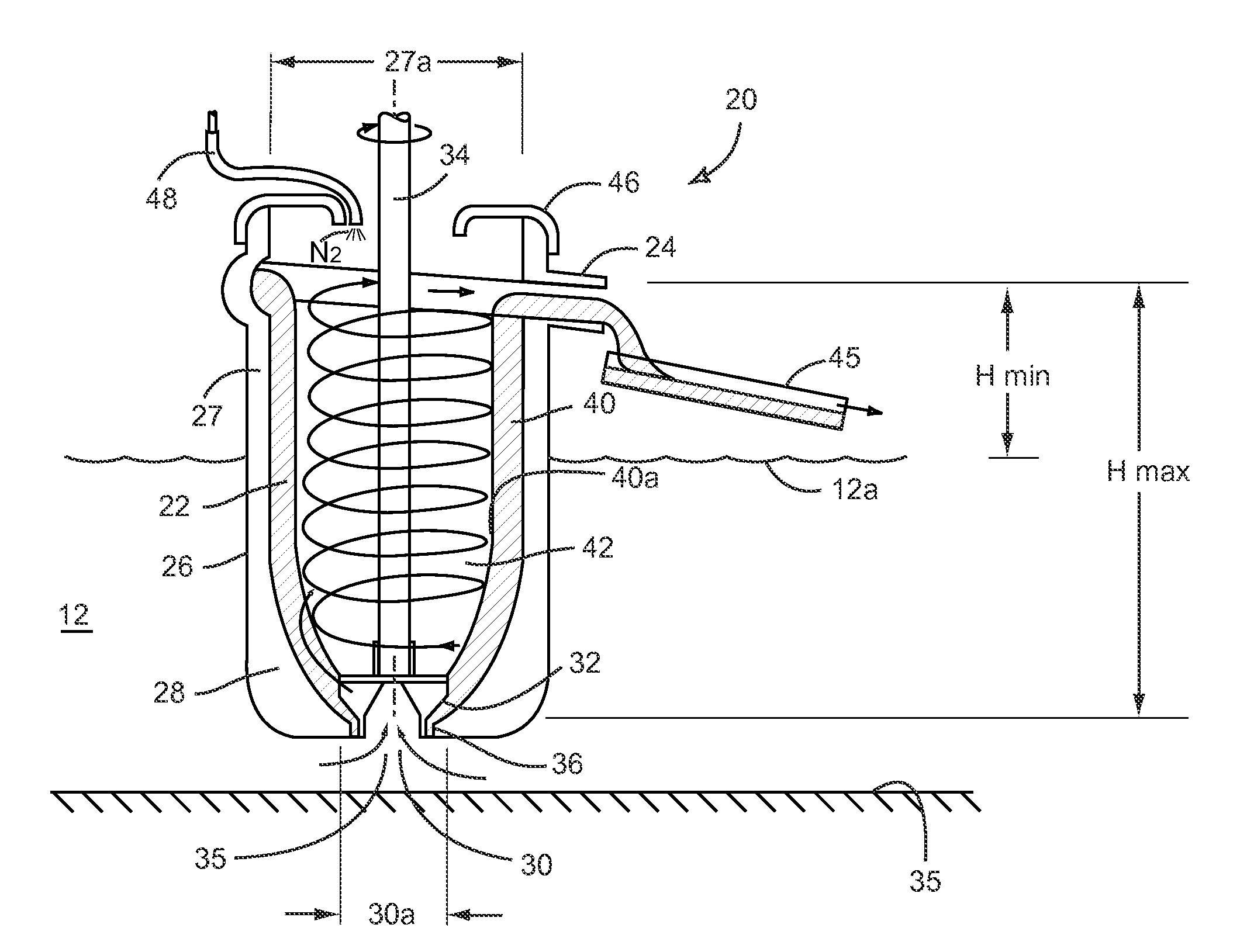

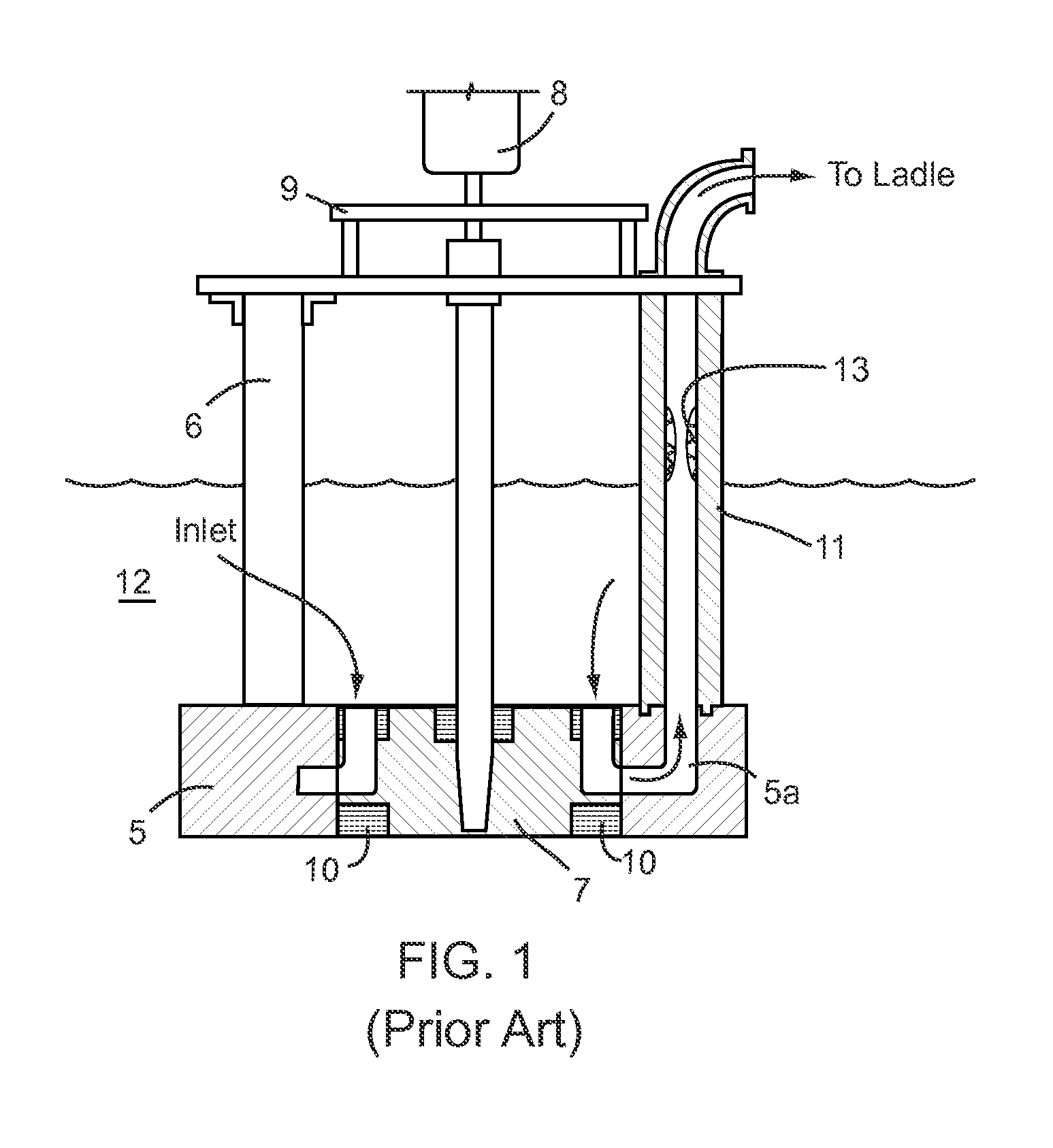

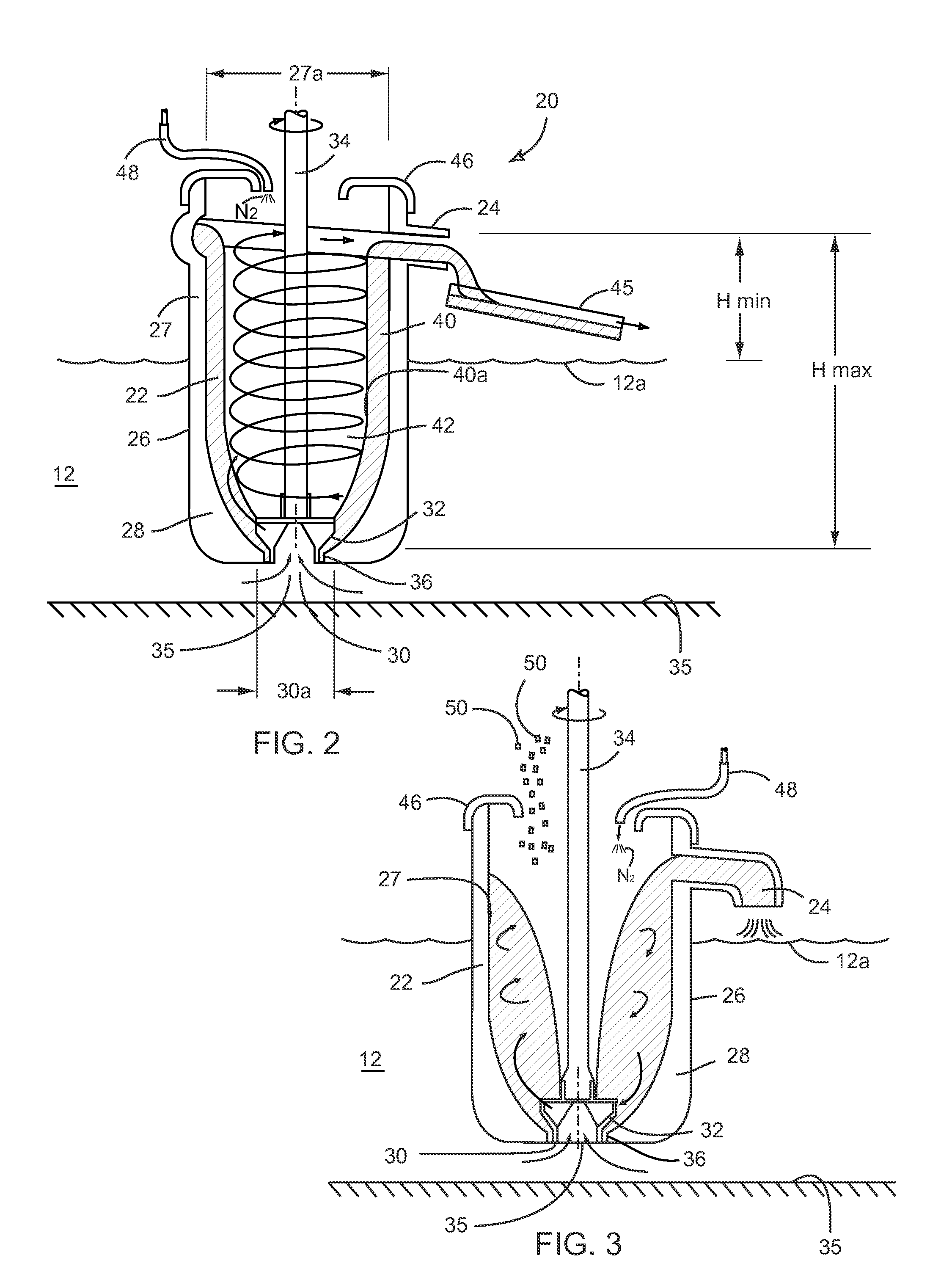

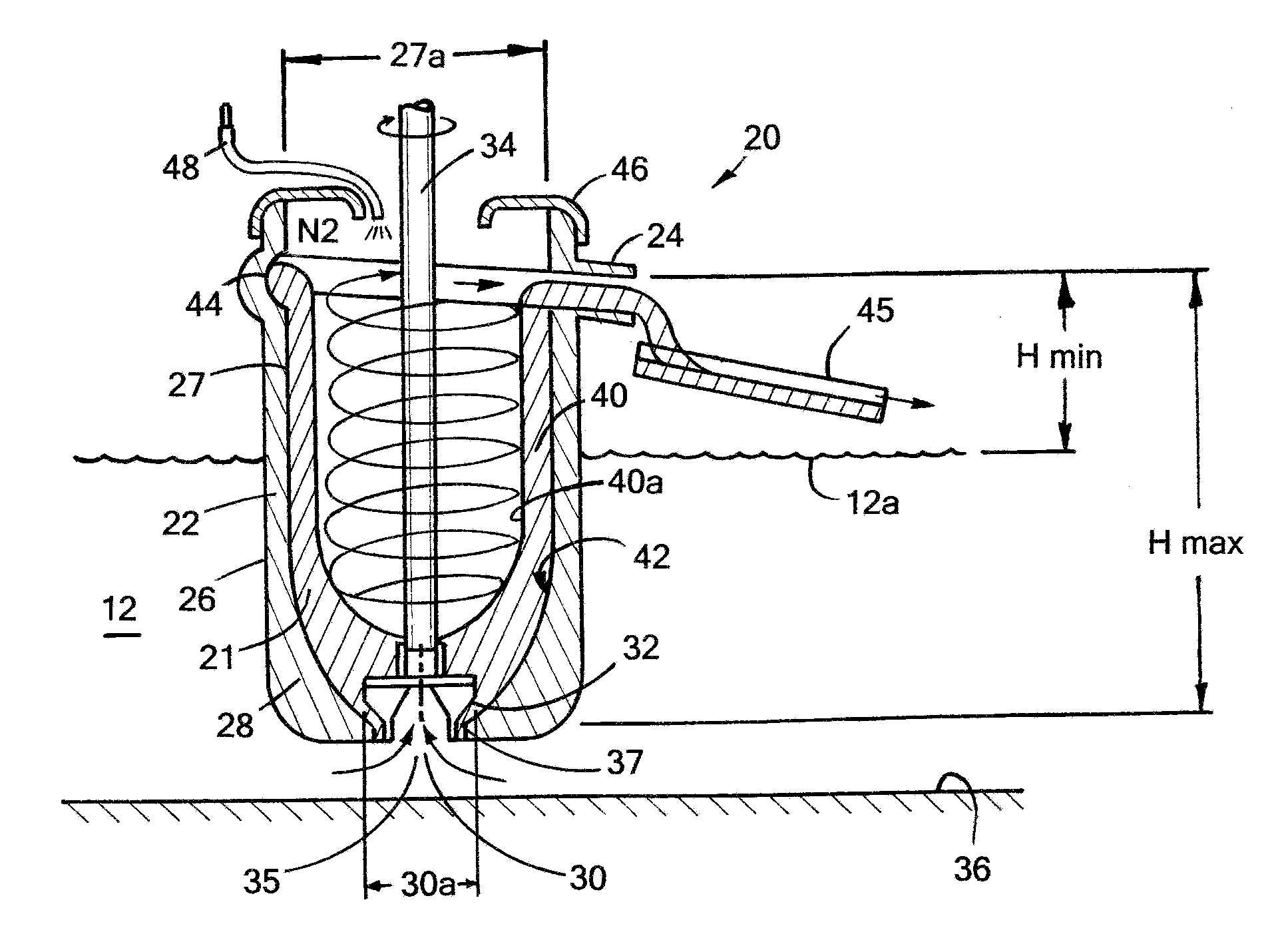

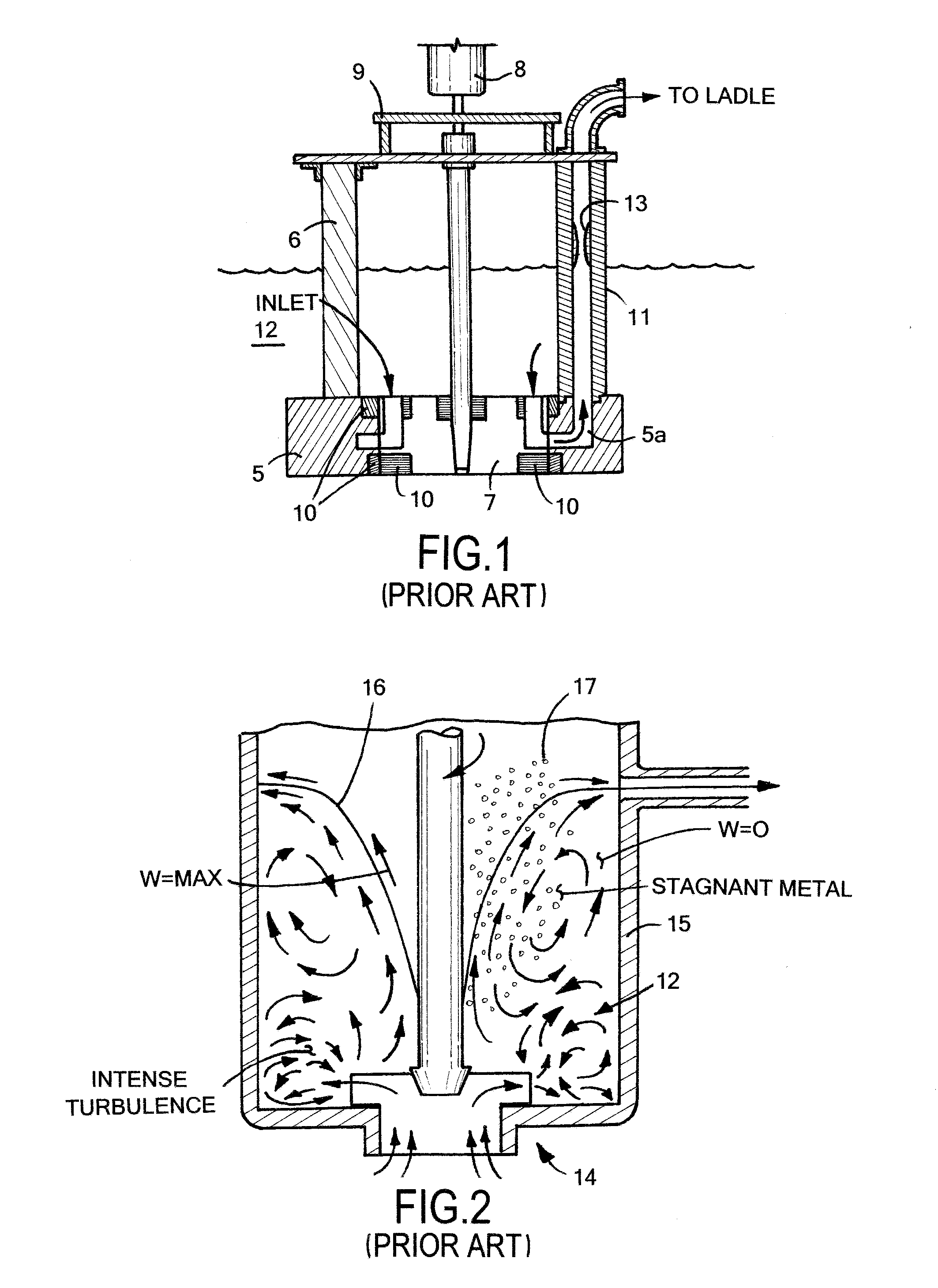

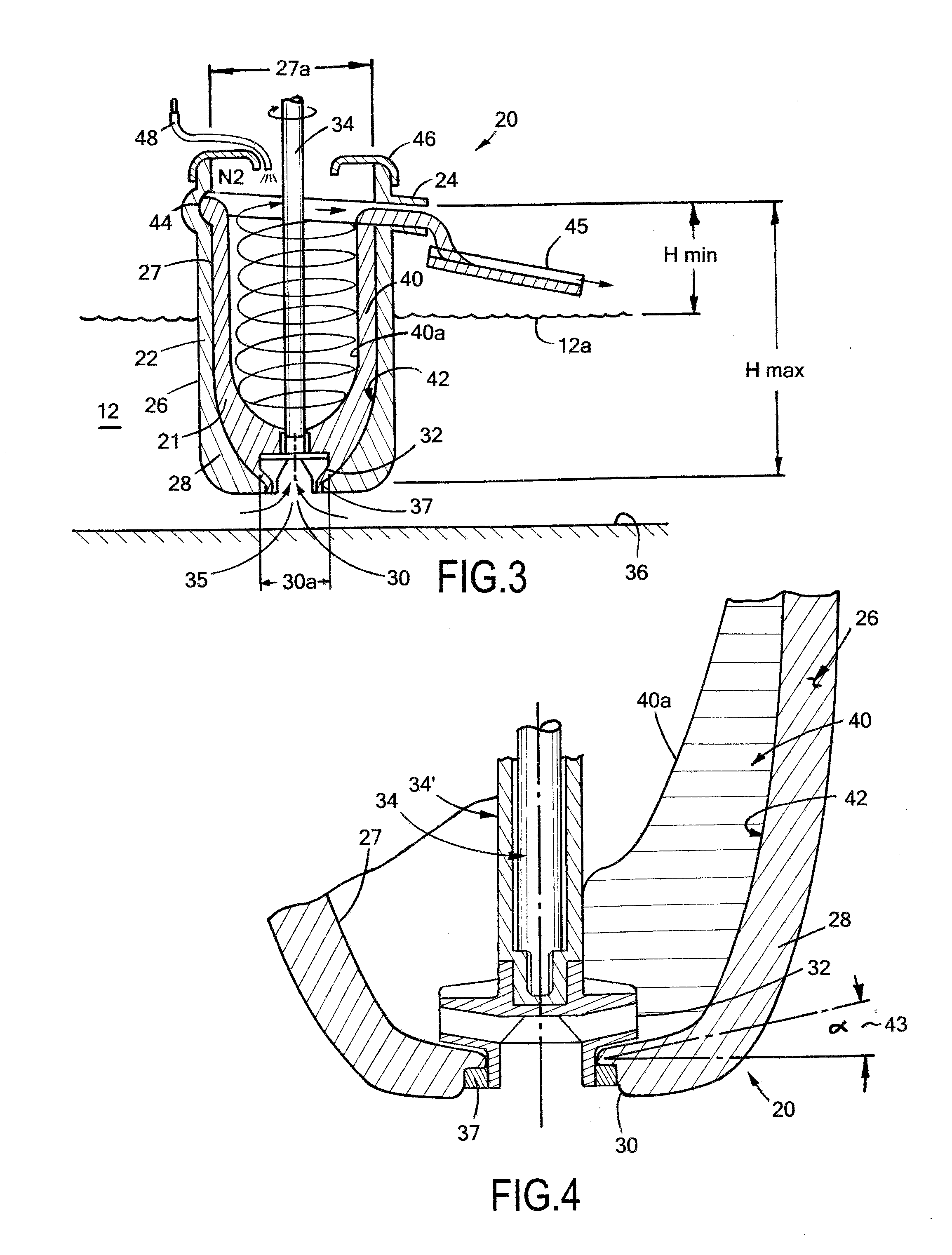

Riserless transfer pump and mixer/pre-melter for molten metal applications

ActiveUS20100104415A1Large internal diameterEasy accessSpecific fluid pumpsPump componentsCentrifugal pumpEngineering

A pump for processing molten metal having an enlarged tubular body which houses a centrifugal pump at its bottom end. The bottom end has a parabolic shape which receives the ejected molten metal from the impeller and forms a vortex within the tubular body. The pump is controlled to cause the vortex to climb up the inner wall of the body up to and out of an outlet formed in the upper end of the body. A radial vane impeller is formed in the back plate of the impeller. When the impeller is rotated, solid particles introduced into the body are accelerated radially by the back plate impeller into the vortex.

Owner:MORANDO JORGE A

Stent delivery catheter

InactiveUS20040267280A1Large outer diameterIncreasing the thicknessStentsBalloon catheterInsertion stentBalloon catheter

The present invention provides a stent delivery catheter that can place a stent in a tortuous narrowed area with good maneuverability while preventing falling or displacement of the stent. The present invention provides a stent delivery catheter for delivering a stent for treating stenosis in a body to a narrowed area. A distal end of the catheter includes a collapsible balloon in a collapsed state and the stent in an undeployed state, the stent being mounted on the outer surface of the collapsed balloon, the balloon having frustoconical tapered segments and a cylindrical straight tubular segment. An inner tube for defining a guidewire lumen extends into the interior of the balloon, and displacement prevention mechanisms for preventing the stent from moving in the longitudinal direction of the stent delivery catheter are affixed to the inner surface of the balloon only. Another aspect of the present invention provides a stent delivery catheter that can prevent the stent from moving in the axis direction of the catheter without requiring additional components or additional steps that complicate the manufacturing process. In this catheter, the thickness T1 of a near-center portion of the distal-end tapered segment and the thickness T2 of a near-center portion of the straight tubular segment satisfy a predetermined relationship, and the thickness T3 of a near-center portion of the proximal-end tapered segment and the thickness T2 of the near-center portion of the straight tubular segment satisfy a predetermined relationship. In this manner, the distal-end and proximal-end tapered segments in the collapsed state prevent the movement of the stent. The present invention also provides a preferable RX balloon catheter, i.e., a stent delivery catheter, having improved maneuverability and enhanced responsiveness for expansion and contraction of the balloon without complicating the manufacturing process or increasing the cost.

Owner:KANEKA CORP

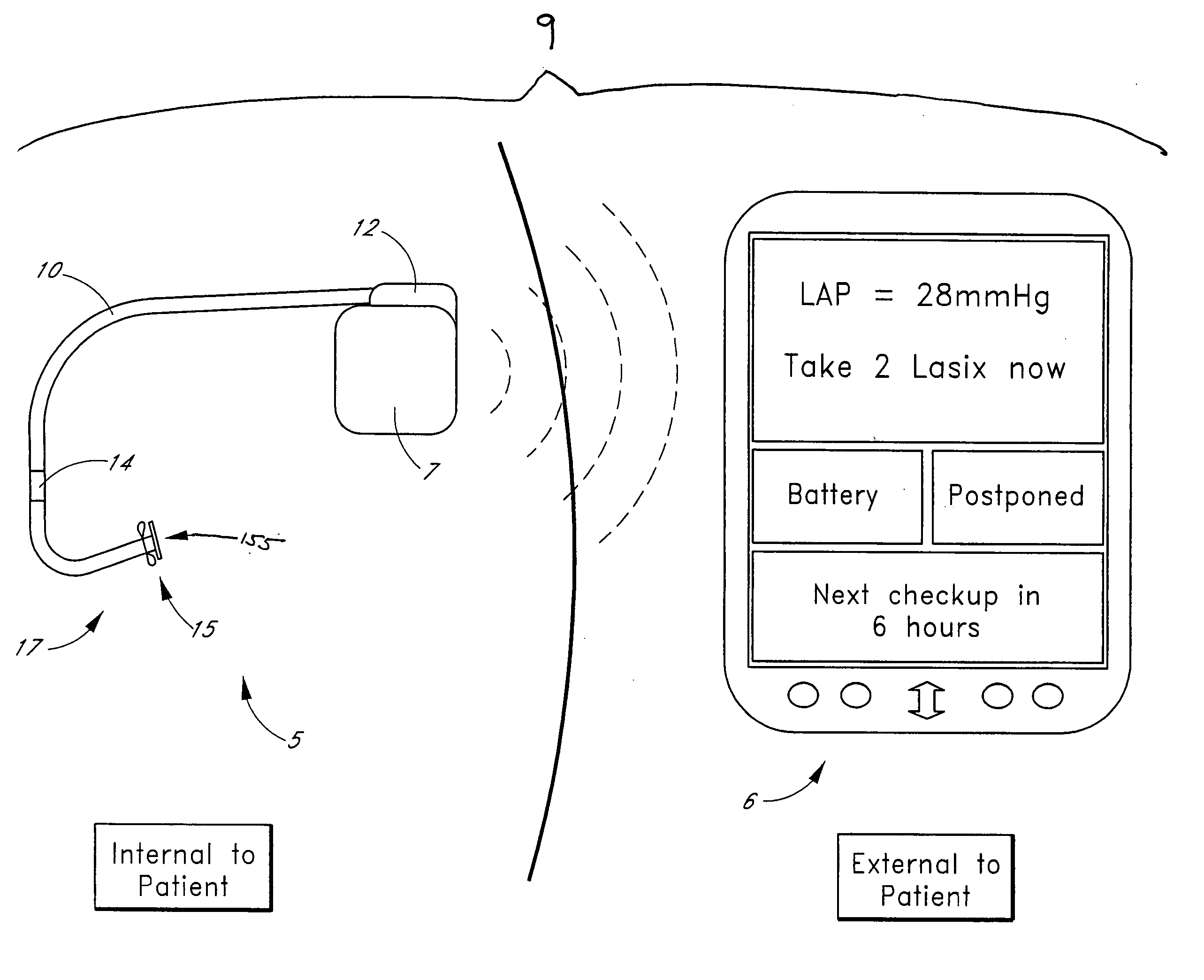

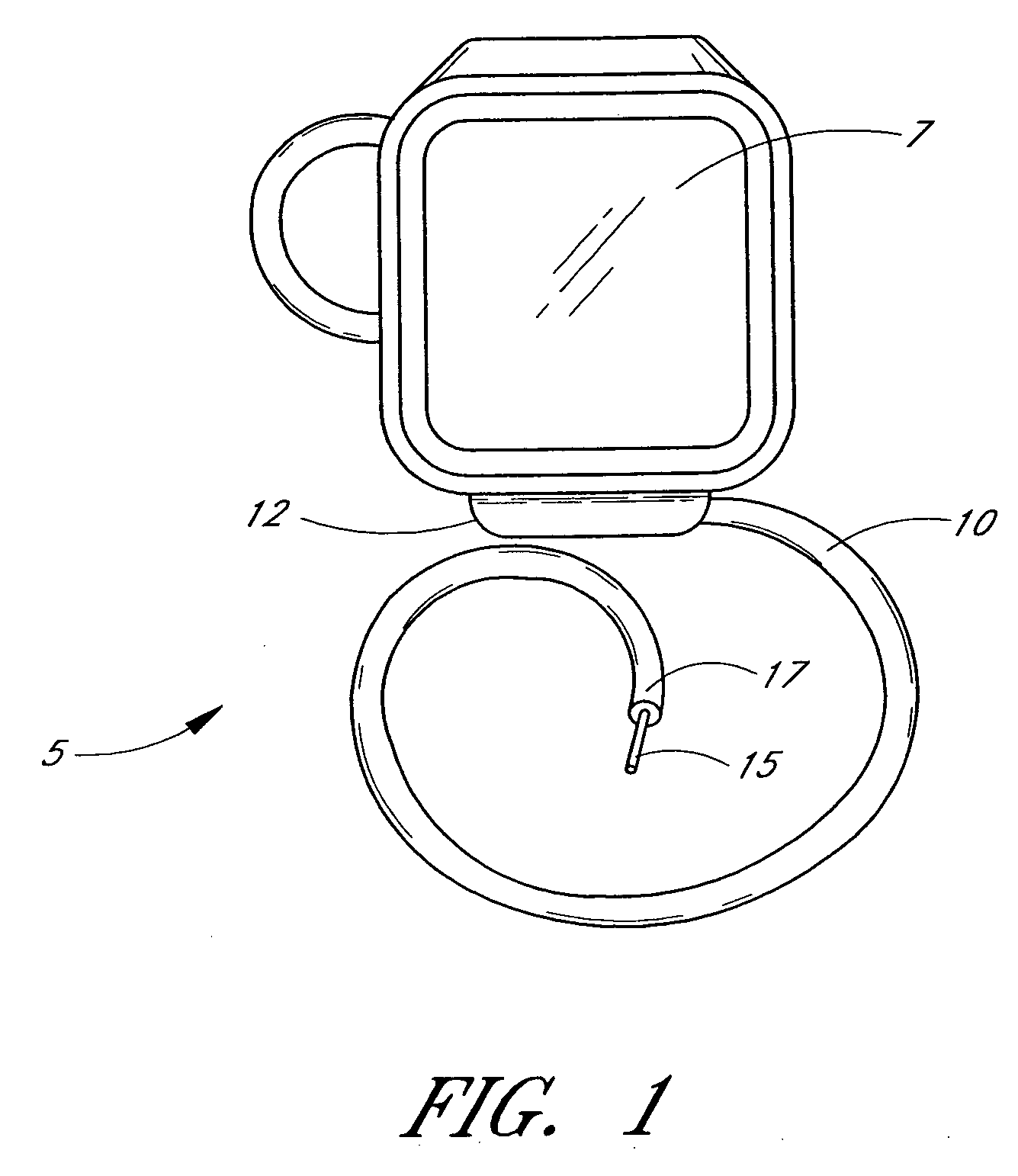

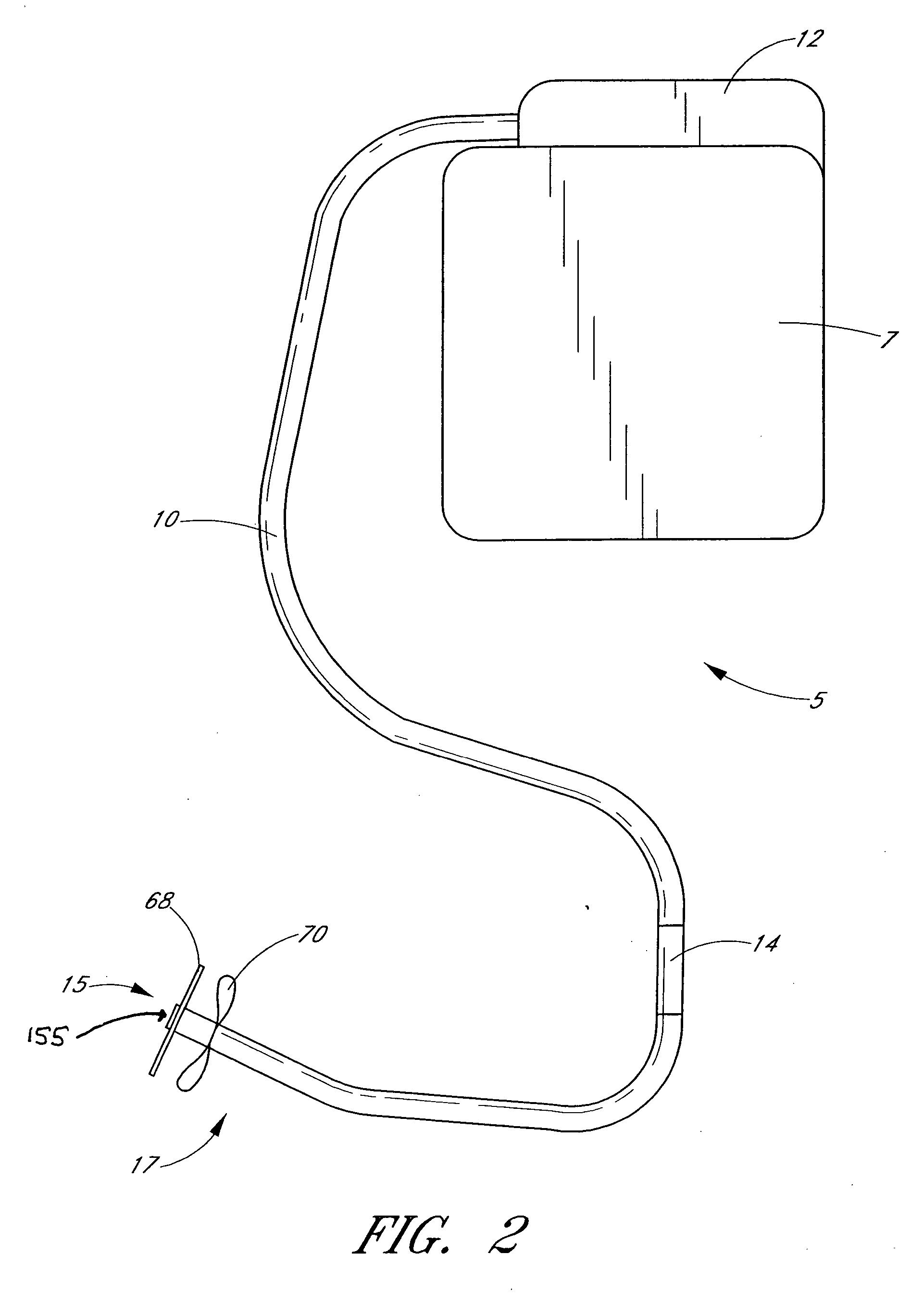

Cardiac rhythm management with interchangeable components

InactiveUS20060149324A1Large diameterLess-flexibleElectrotherapyArtificial respirationElectricityEnergy storage

A cardiac rhythm management apparatus includes a proximal housing, a distal housing and a lead. The proximal housing includes a first energy storage device. The distal module is implantable within a patient's heart, and includes a second energy storage device, at least one electrode, and a control module. The control module controls the delivery of at least one electrical stimulus from the second energy storage device to a location in communication with the patient's heart. The lead connects the proximal housing to the distal module and is configured to communicate one or more digital signals between the proximal housing and the distal module.

Owner:PACESETTER INC

Lignin carbon nanofiber and preparation method thereof

ActiveCN101768799AImprove spinnabilityGuaranteed reliabilityFilament/thread formingFibre chemical featuresFiberCarbon fibers

The invention discloses a lignin carbon nanofiber and a preparation method thereof, belonging to the field of materials. The preparation method comprises 5 steps of lignin pretreatment, preparation of spinning solution, electrostatic spinning, pre-oxidation and carbonization. The preparation method is characterized in that the lignin pretreatment means that lignin with the relative molecular mass within 5,000 to 50,000 is selected, and then the treatment of removing carbohydrate and inorganic salt is respectively carried out on alkali lignin and acetic acid lignin (or formic acid lignin). The diameter of the obtained carbon nanofiber is within 50 to 300nm and the length is within 1 to 10mum. As the obtained lignin has good spinnability, the nanofiber can be spun and further processed into the carbon nanofiber without synthetic macromolecules. In addition, the method adopts simple electrospinning equipment for electrospinning, the diameter of a spinning nozzle is large, the blockage cannot easily occur, and the working reliability of the spinning equipment is ensured.

Owner:SOUTH CHINA UNIV OF TECH

Riserless recirculation/transfer pump and mixer/pre-melter for molten metal applications

ActiveUS20120163959A1Large diameterEasy accessSpecific fluid pumpsPump componentsCurve shapeEngineering

A pump for processing molten metal having an enlarged tubular body which houses a centrifugal lifting pump at its bottom end. The bottom end has a curved shape that aids in the formation and sustainability of: a) a forced vortex; b) a highly forced vortex; and c) a super forced vortex, depending on the application when it which receives the ejected molten metal from the lifting pump's impeller. The lifting pump is controlled to cause the vortex to climb up the inner wall of the body up to and out of an outlet formed in the upper end of the body. A recirculation centrifugal pump is mounted coaxially to and rotates with the lifting impeller.

Owner:MORANDO JORGE A

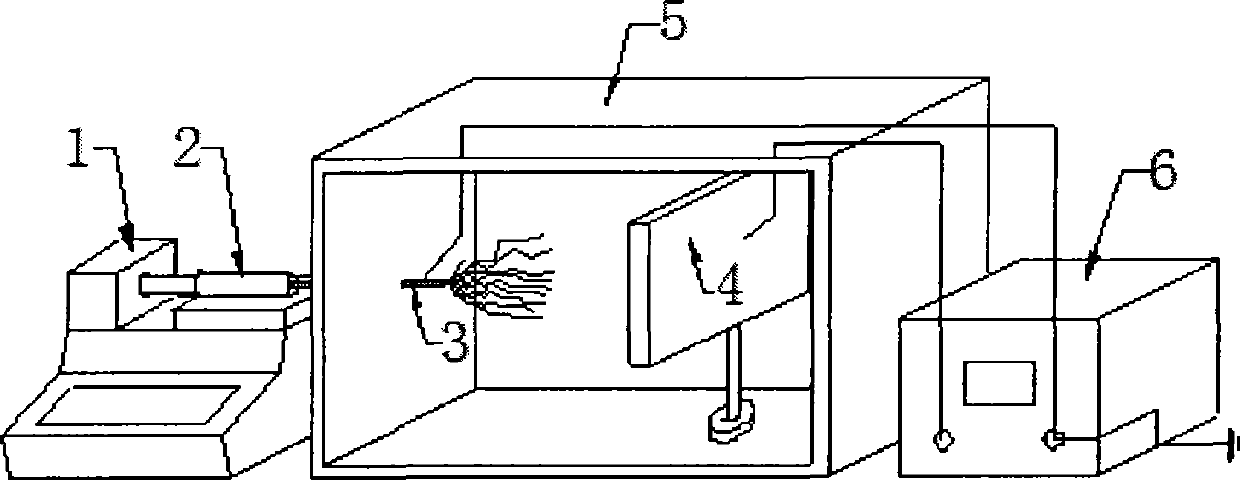

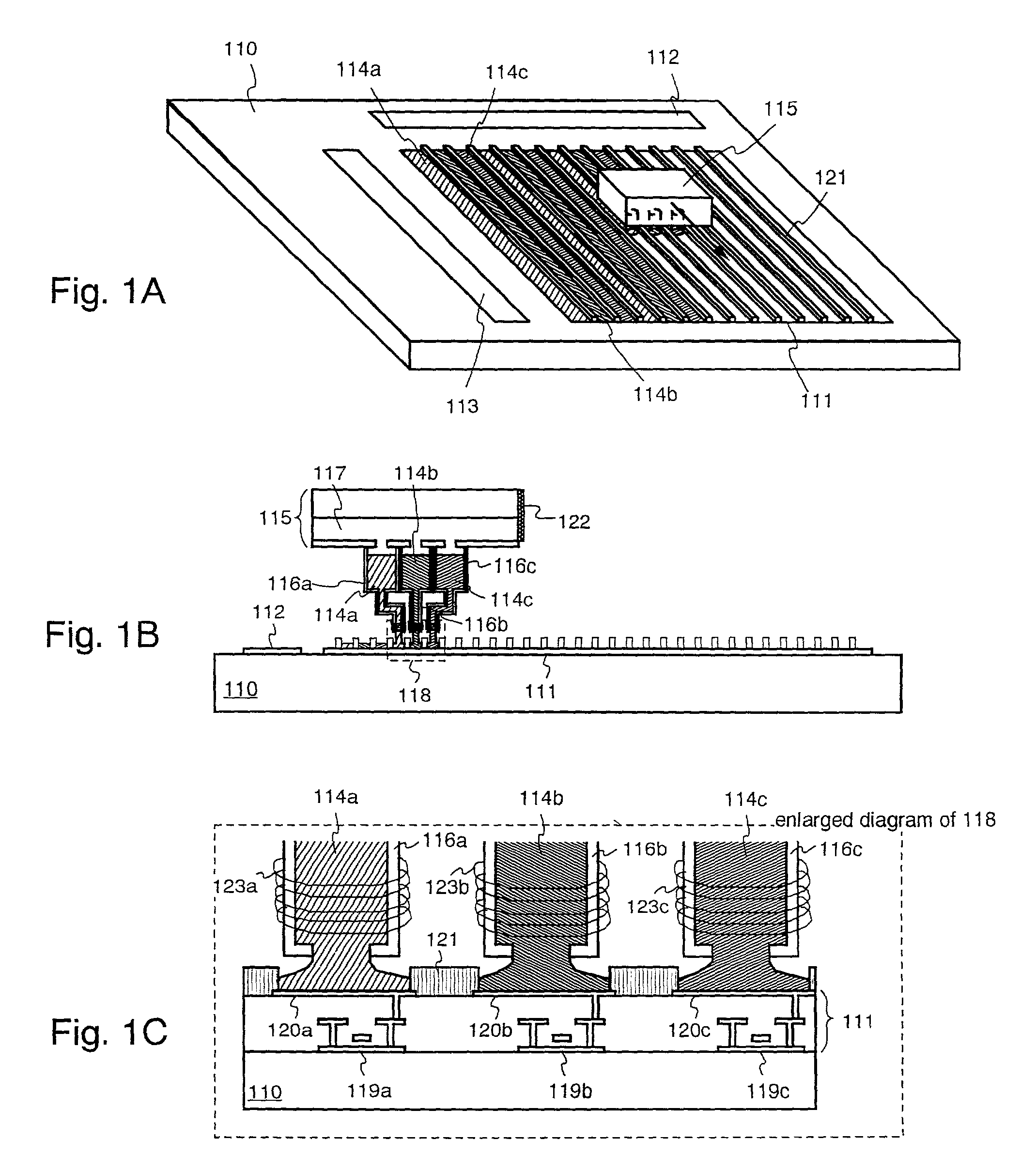

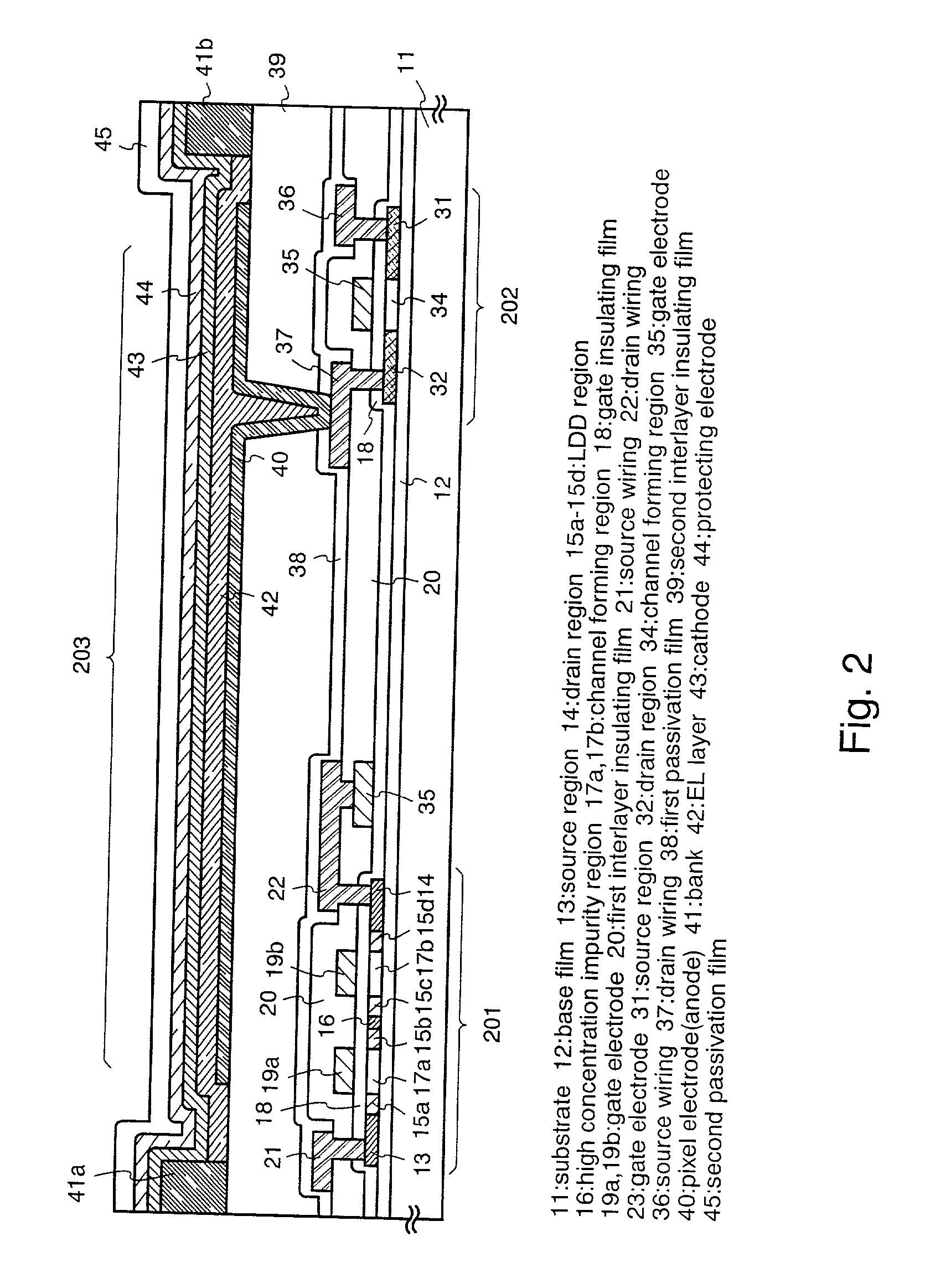

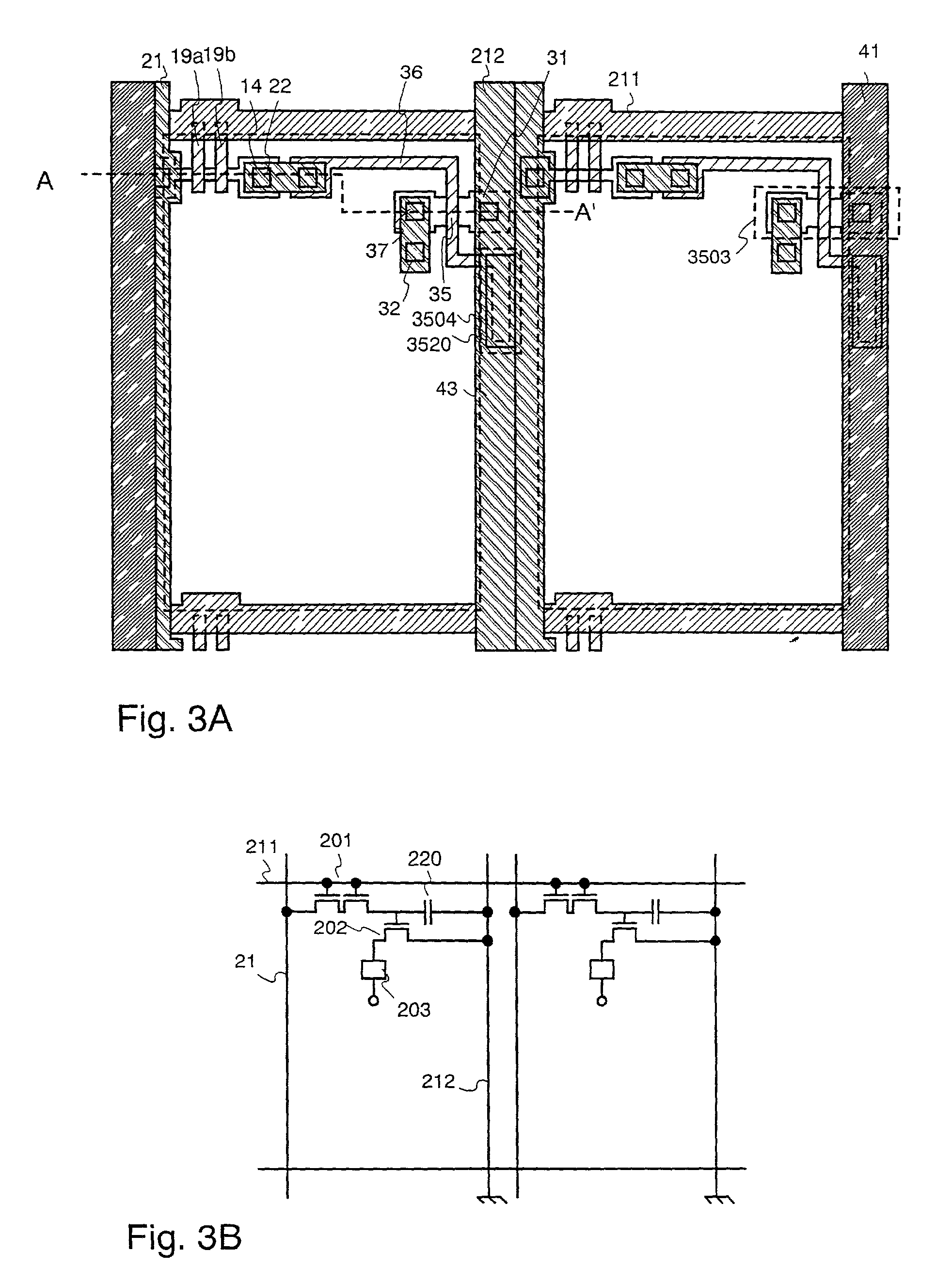

Thin film formation apparatus and method of manufacturing self-light-emitting device using thin film formation apparatus

InactiveUS20010023661A1Solve the real problemLarge diameterFuel elementsSolid-state devicesEngineeringLight emitting device

A means of effectively applying an organic EL material application liquid with good application liquid cut-off is provided. A heater and an ultrasonic oscillator are formed in a thin film formation apparatus when applying the application liquid, and heat and ultrasonic oscillations are imparted to the application liquid. Defective application liquid cut-off and liquid clogging can thus be resolved.

Owner:SEMICON ENERGY LAB CO LTD

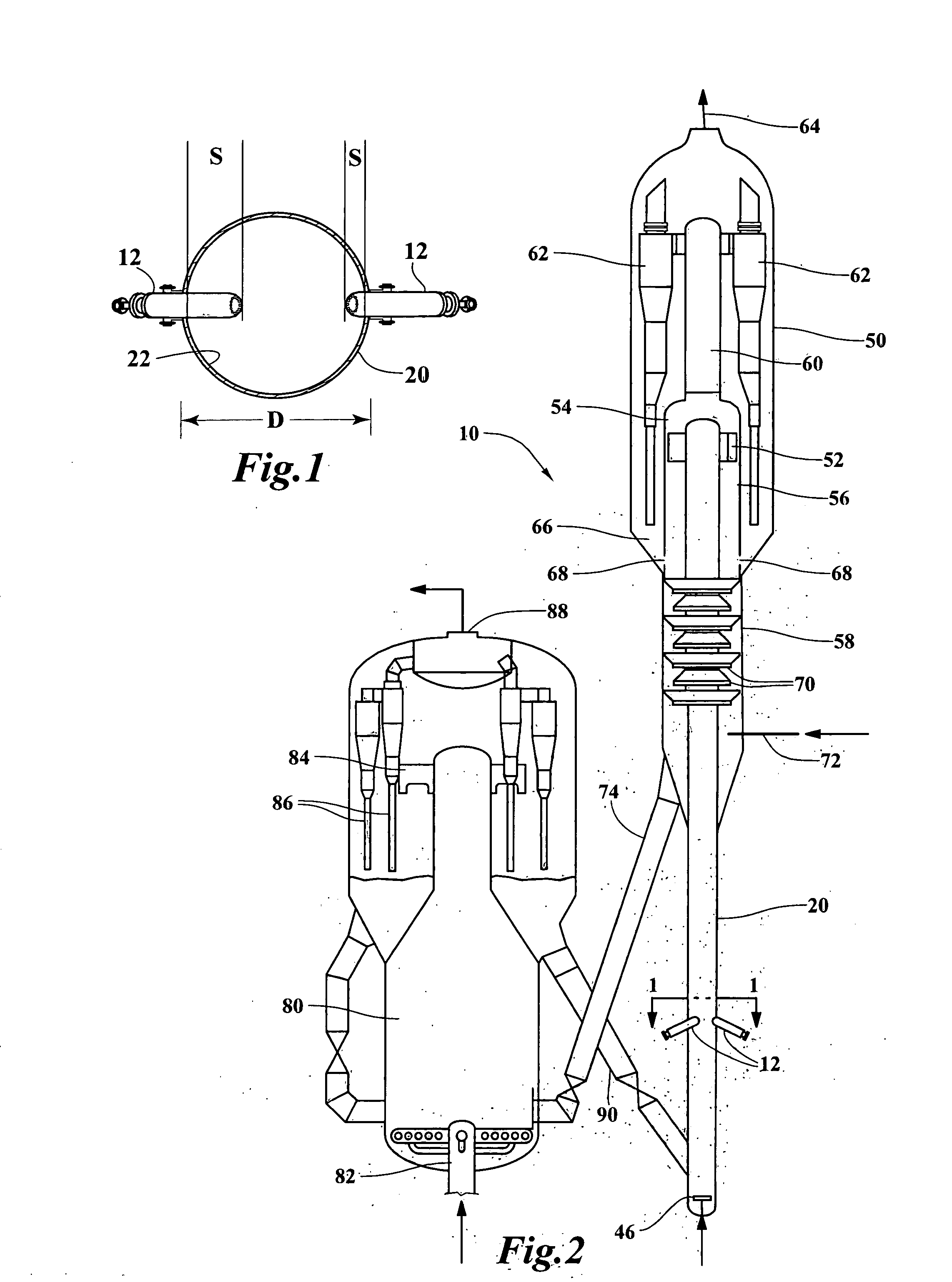

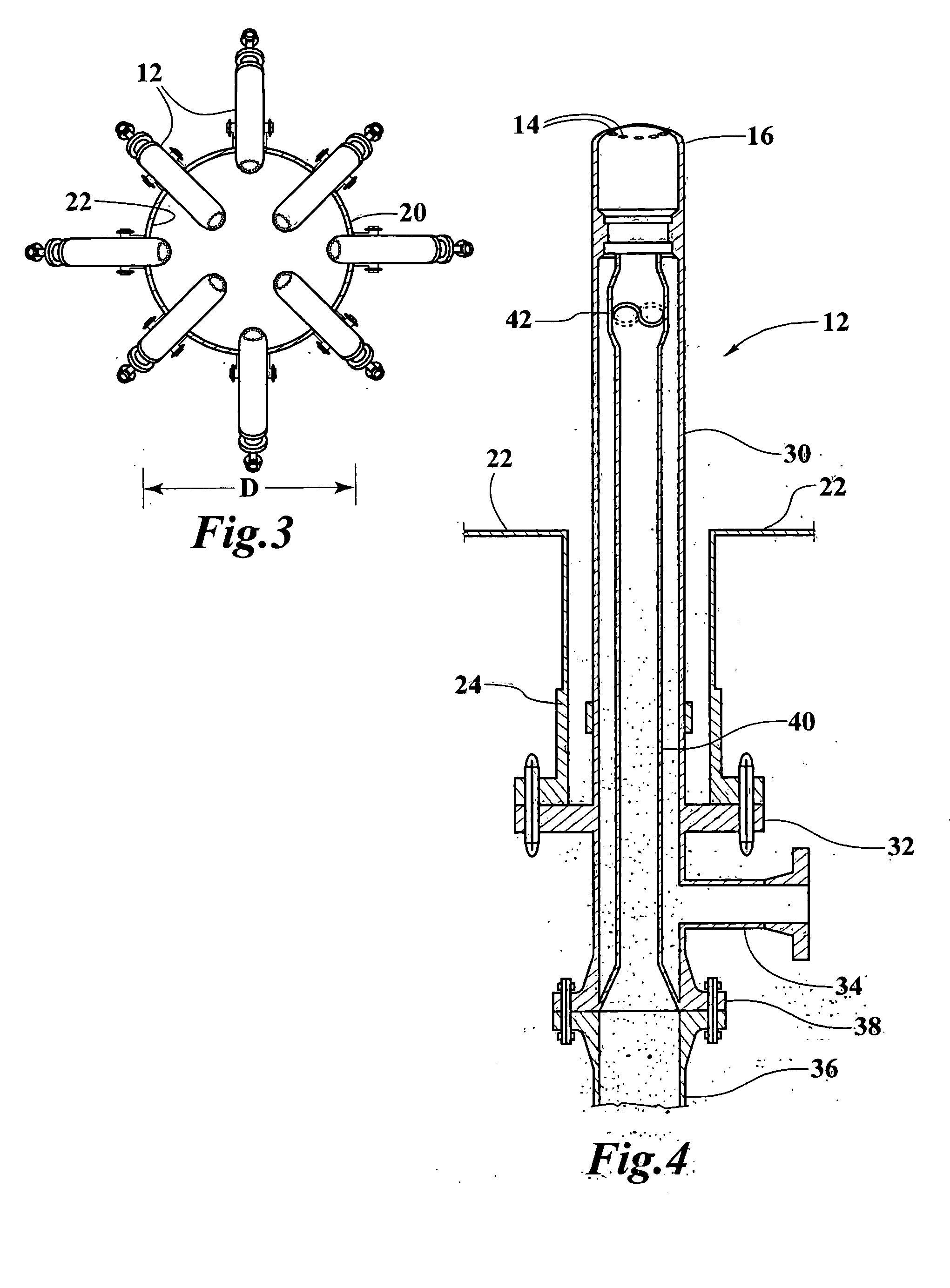

Advanced elevated feed distribution system for very large diameter RCC reactor risers

InactiveUS20080081006A1Good dispersionImprove conversion efficiencyCatalytic crackingChemical/physical/physico-chemical nozzle-type rreactorsRadial positionDistribution system

An FCC process and apparatus may include injecting hydrocarbon feedstock at different radial positions inside a riser. Multiple distributors may be used to position the openings for injecting feedstock at multiple radial positions. In addition, the openings may be away from riser peripheral wall and at different elevations along the riser wall or extending up from the riser bottom. The different opening positions introduce the feedstock across a larger area of the cross-section of the riser, which may improve the feedstock dispersion and mixing with catalyst. Improved mixing may increase conversion of the feedstock. Larger FCC units generally have greater riser diameters that may cause problems for feedstock dispersion and decrease the ability for the feedstock to mix with catalyst. Injecting the feedstock at multiple radial positions may improve feedstock dispersion in larger FCC units and increase mixing.

Owner:UOP LLC

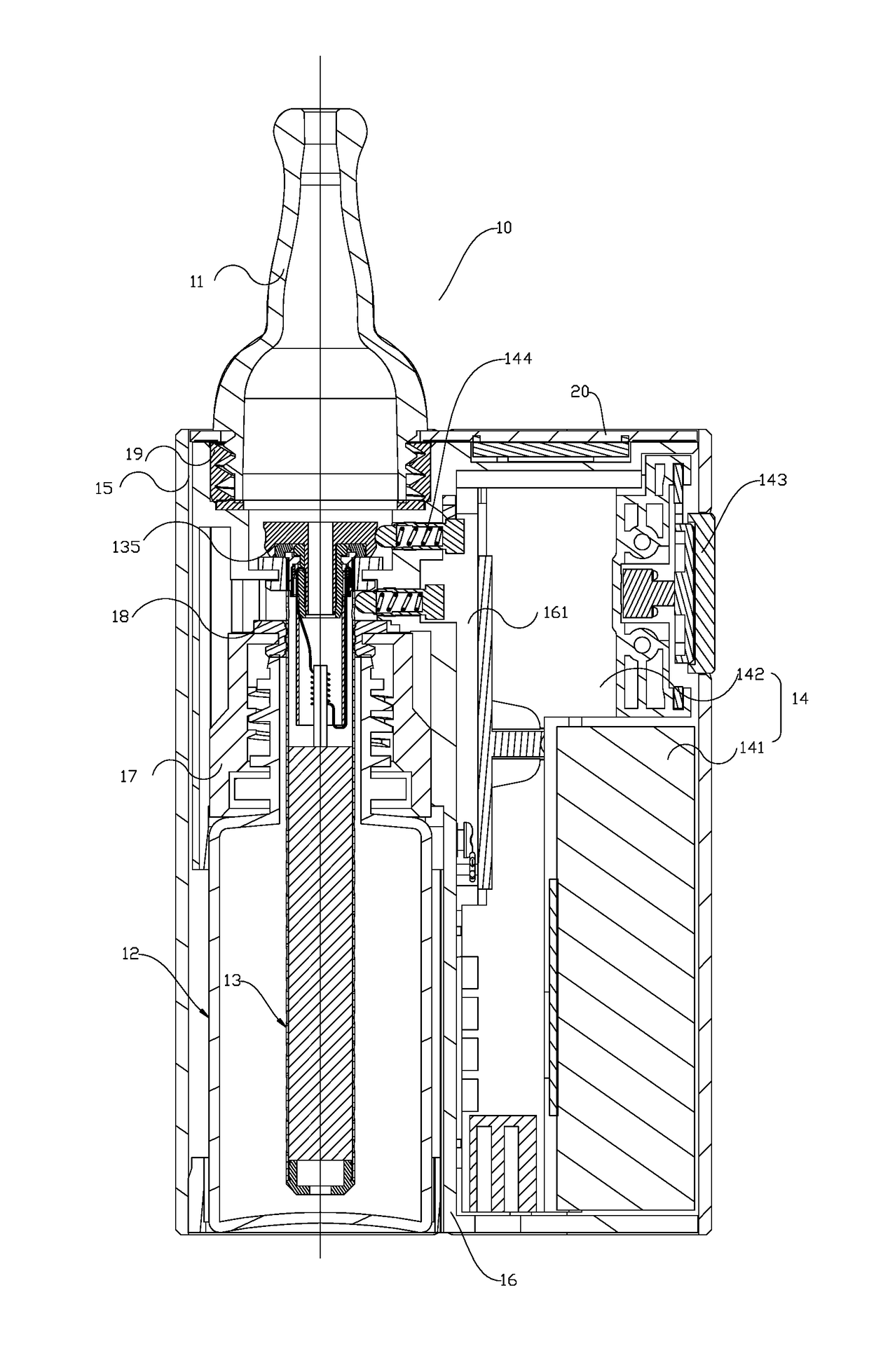

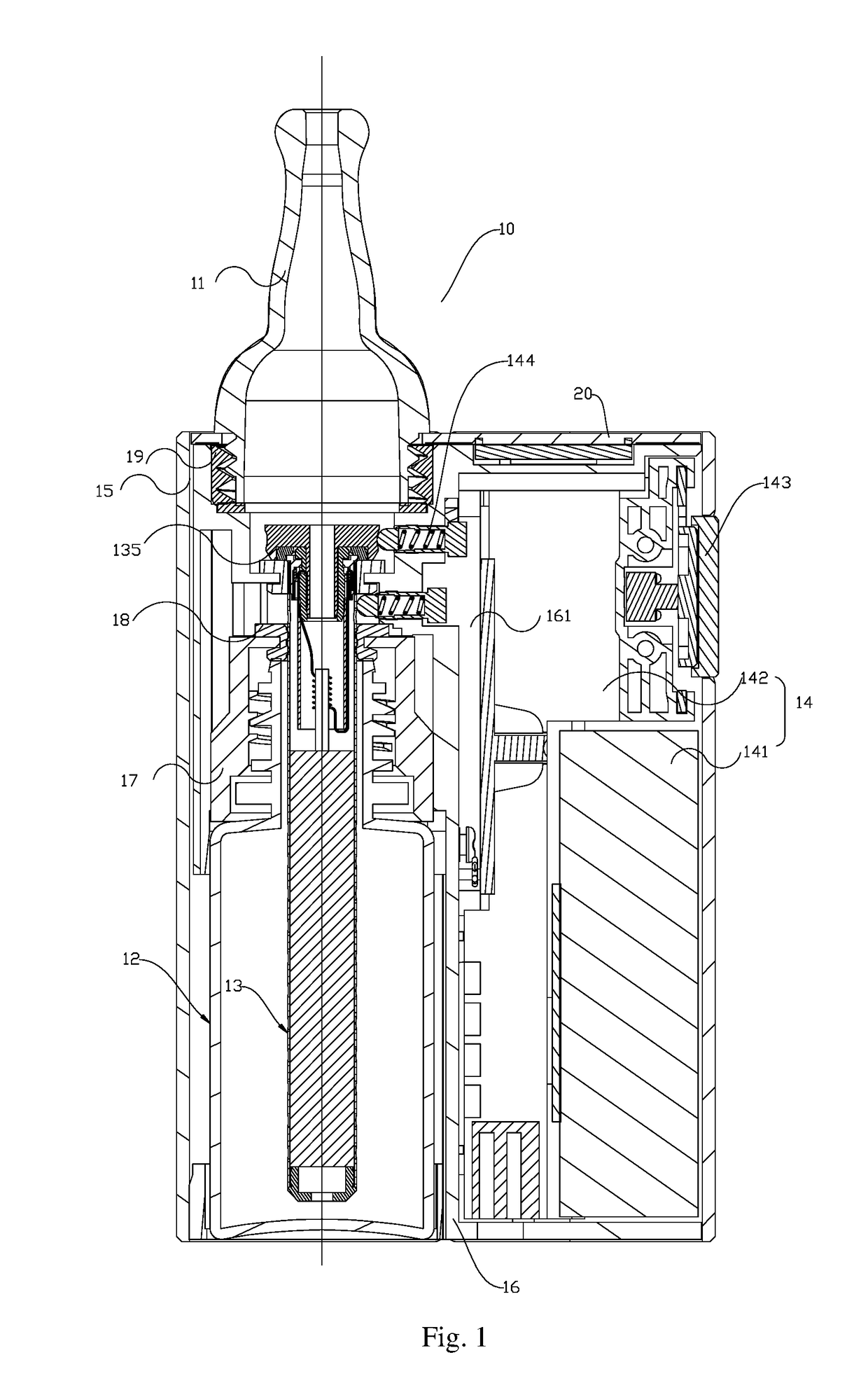

Electronic cigarette

InactiveUS20170196264A1Conveniently disassembledThe electrical connection is firm and reliableTobacco devicesHeating element materialsEngineeringElectronic cigarette

An electronic cigarette comprises a main body. A smoking end, an atomization assembly for atomizing tobacco oil, and a battery assembly for powering the atomization assembly are arranged on the main body. A bottle for storing the tobacco oil is arranged at one end of the main body, away from the smoking end. The atomization assembly is arranged between the smoking end and the bottle. The bottle and the battery assembly are in parallel. An electrical connection component is arranged between the battery assembly and the atomization assembly. One end of the electrical connection component is connected to the battery assembly while the other end of the electrical connection component is resiliently abutted against a side wall of the atomization assembly. Easy assembly, stable and reliable electrical connection, and a great reduction to the possibility that the user sucks the tobacco oil are realized in the electronic cigarette.

Owner:HUIZHOU KIMREE TECH

Spinal diagnostic methods and apparatus

ActiveUS20080009826A1Easy diagnosisRelieve painCannulasSurgical needlesSpinal columnAnesthetic Agent

Methods, devices and systems facilitate diagnosis, and in some cases treatment, of back pain originating in intervertebral discs. Methods generally involve introducing one or more substances into one or more discs using a catheter device. In one embodiment, a patient assumes a position that causes back pain, and a substance such as an anesthetic or analgesic is introduced into the disc to determine whether the substance relieves the pain. Injections into multiple discs may optionally be performed, to help pinpoint a disc as a source of the patient's pain. In some embodiments, the catheter device is left in place, and possibly coupled with another implantable device, to provide treatment of one or more discs. A catheter device includes at least one anchoring member for maintaining a distal portion of the catheter within a disc.

Owner:GLOBUS MEDICAL INC

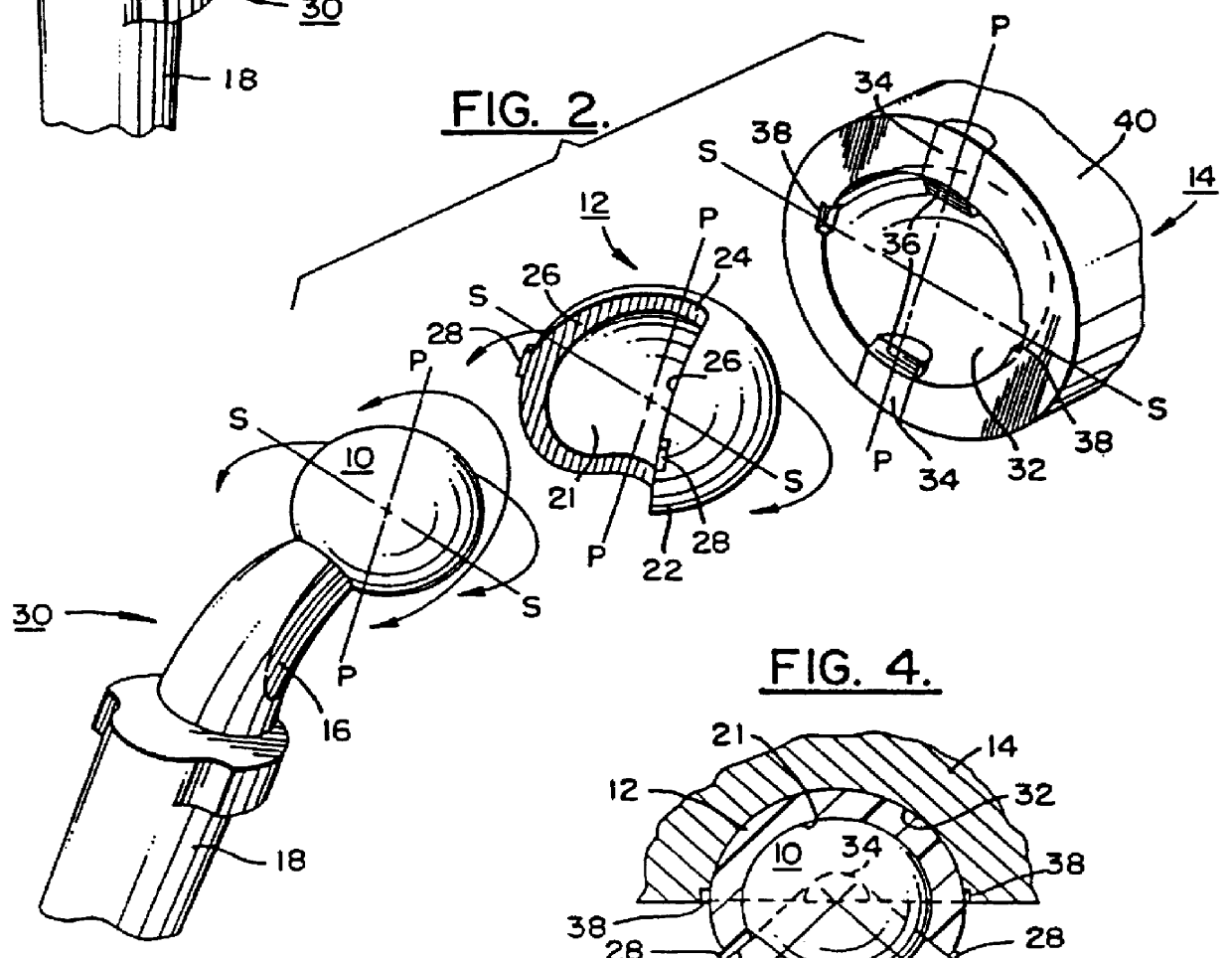

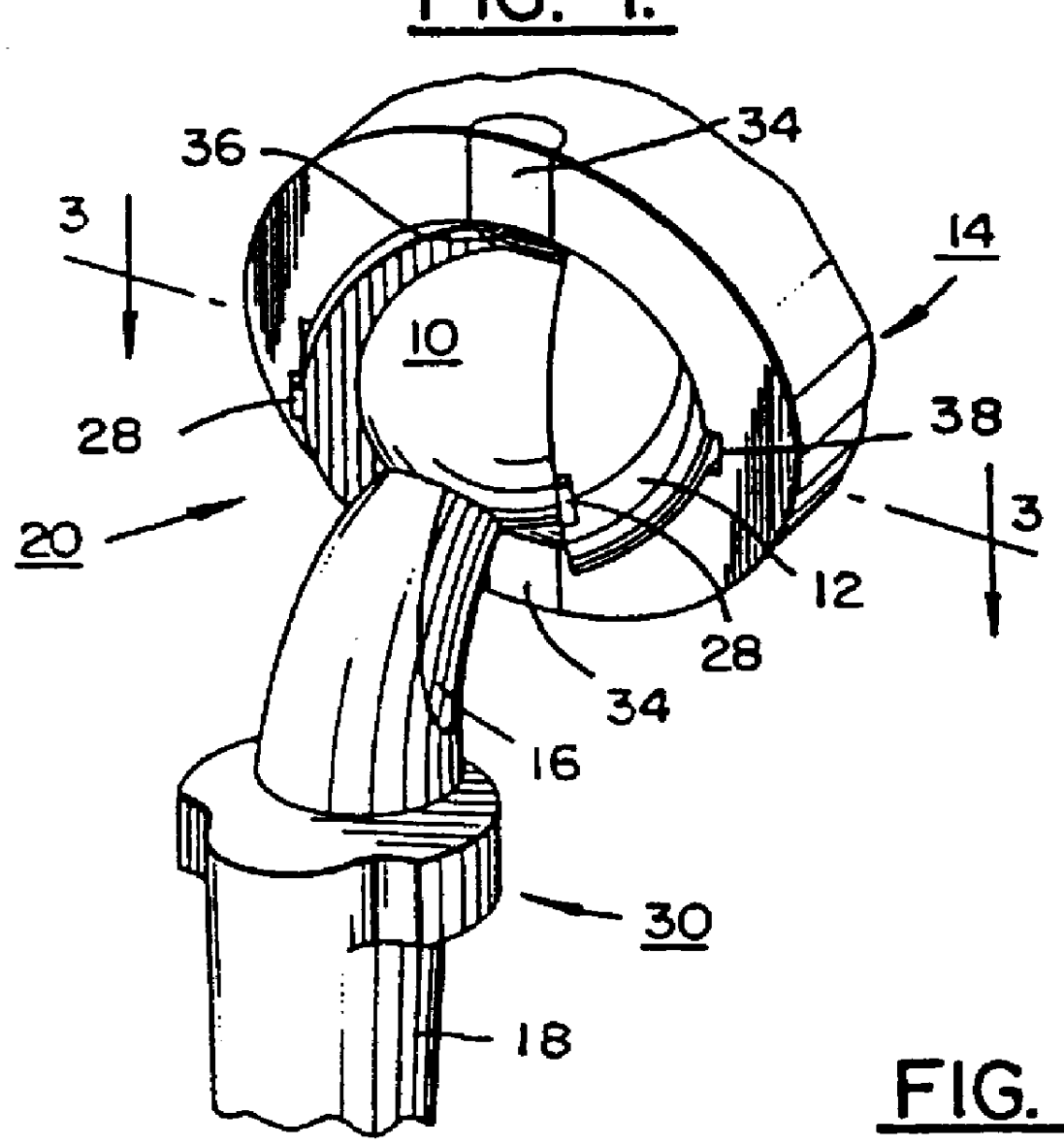

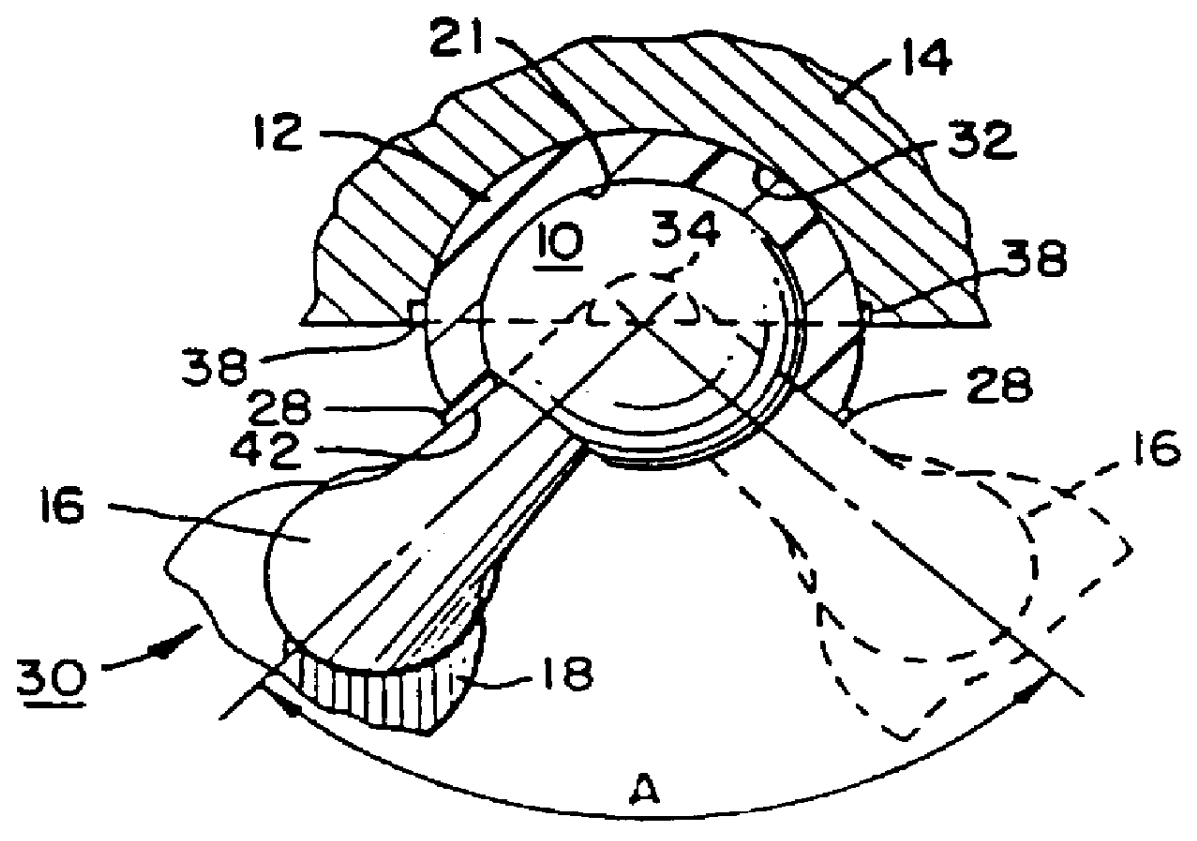

Ball and socket bearing for artificial joint

InactiveUS6042611ALarge range of motionRestrains the ball within the socketJoint implantsFemoral headsArtificial jointsSacroiliac joint

A ball and socket joint for implanting in the body is provided wherein the sooket portion of the joint can have various orientations with respect to the patient's anatomy, and the orientation used for a particular patient can be selected and / or changed in situ, that is, during or after implantation of the joint. In addition, the configuration of the joint, e.g., constrained versus semi-constrained, as well as the materials making up the socket portion of the joint, e.g., plastic versus metal, can be selected and / or changed in situ.

Owner:JOINT MEDICAL PROD

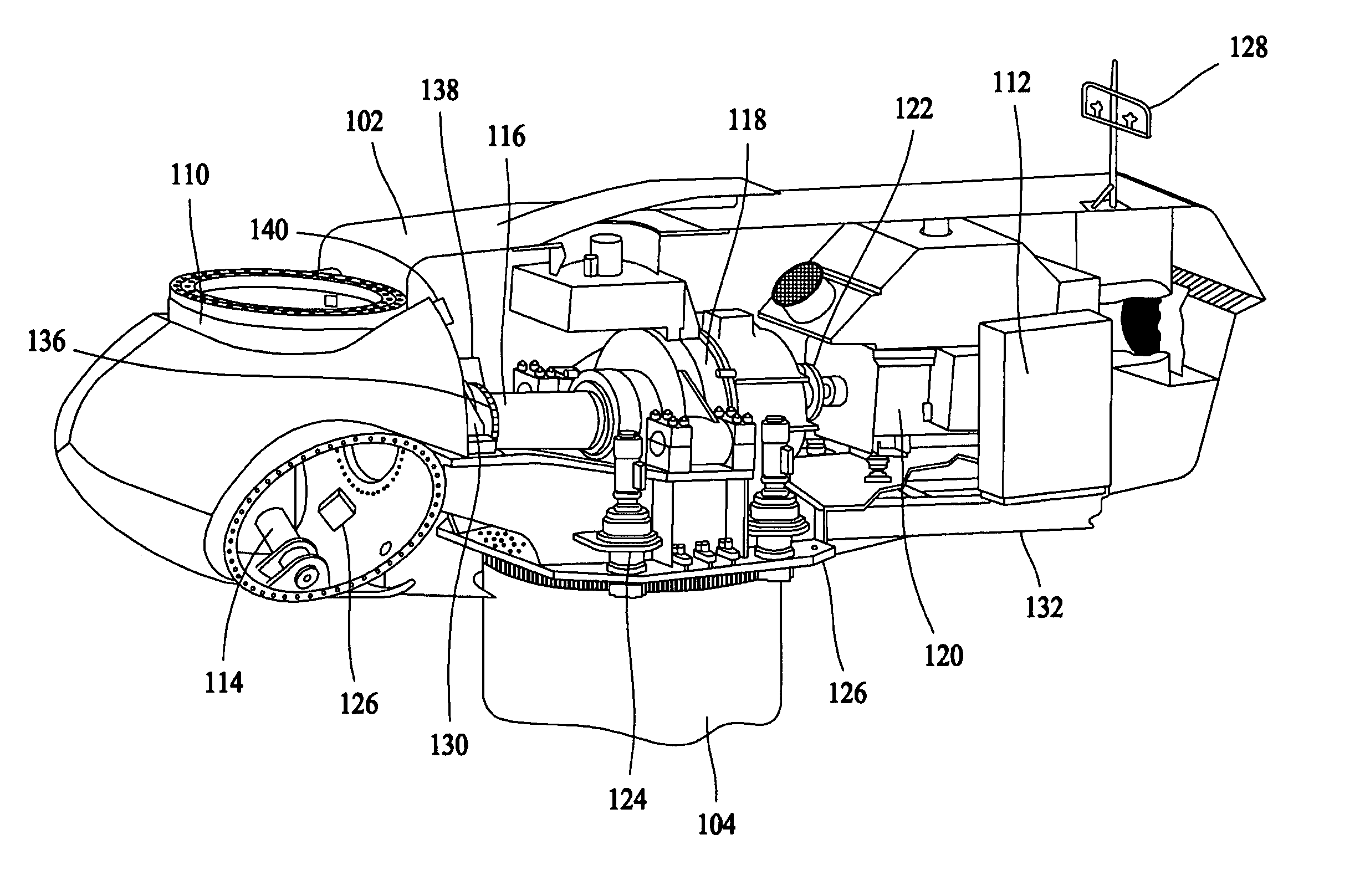

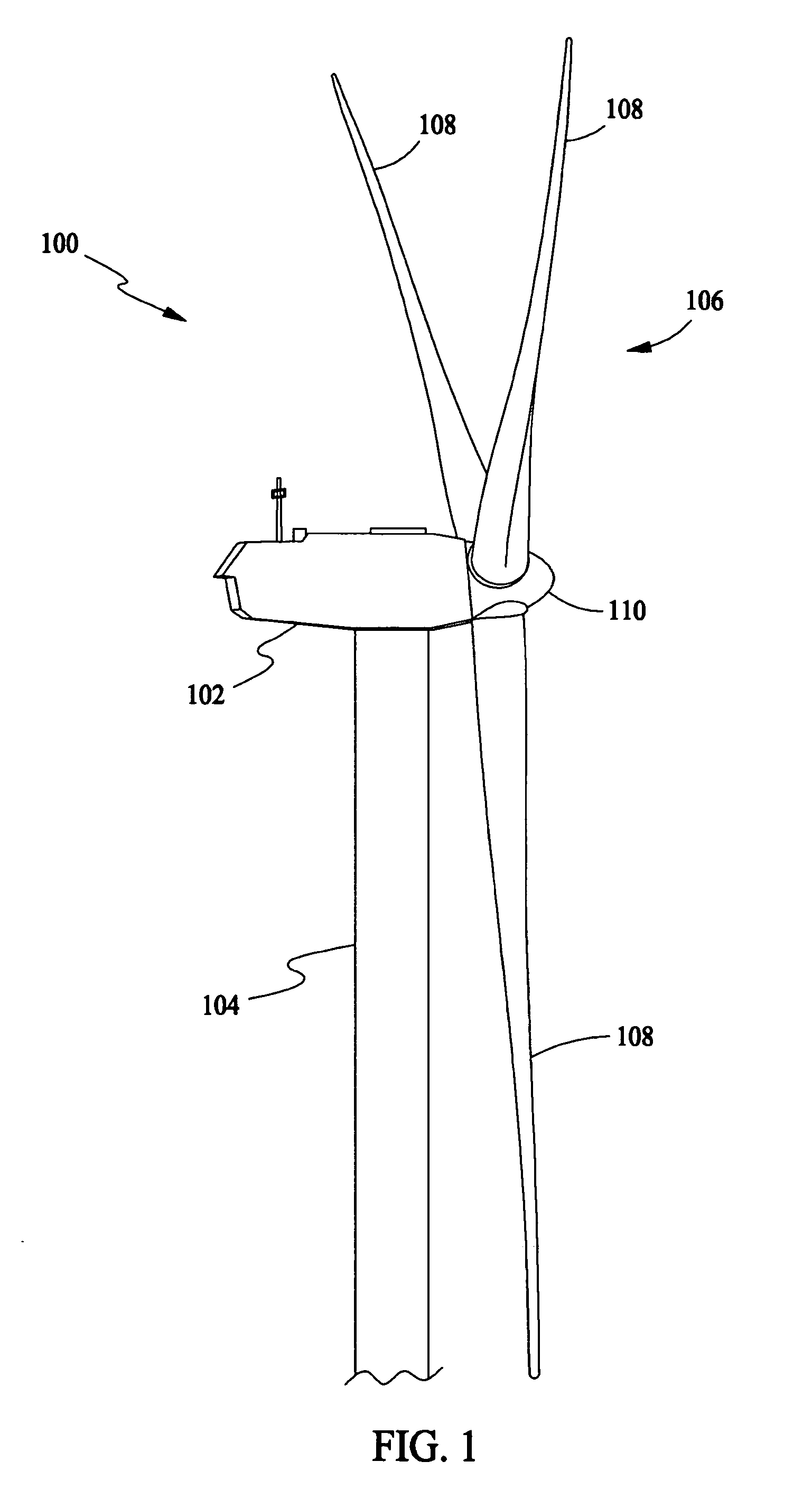

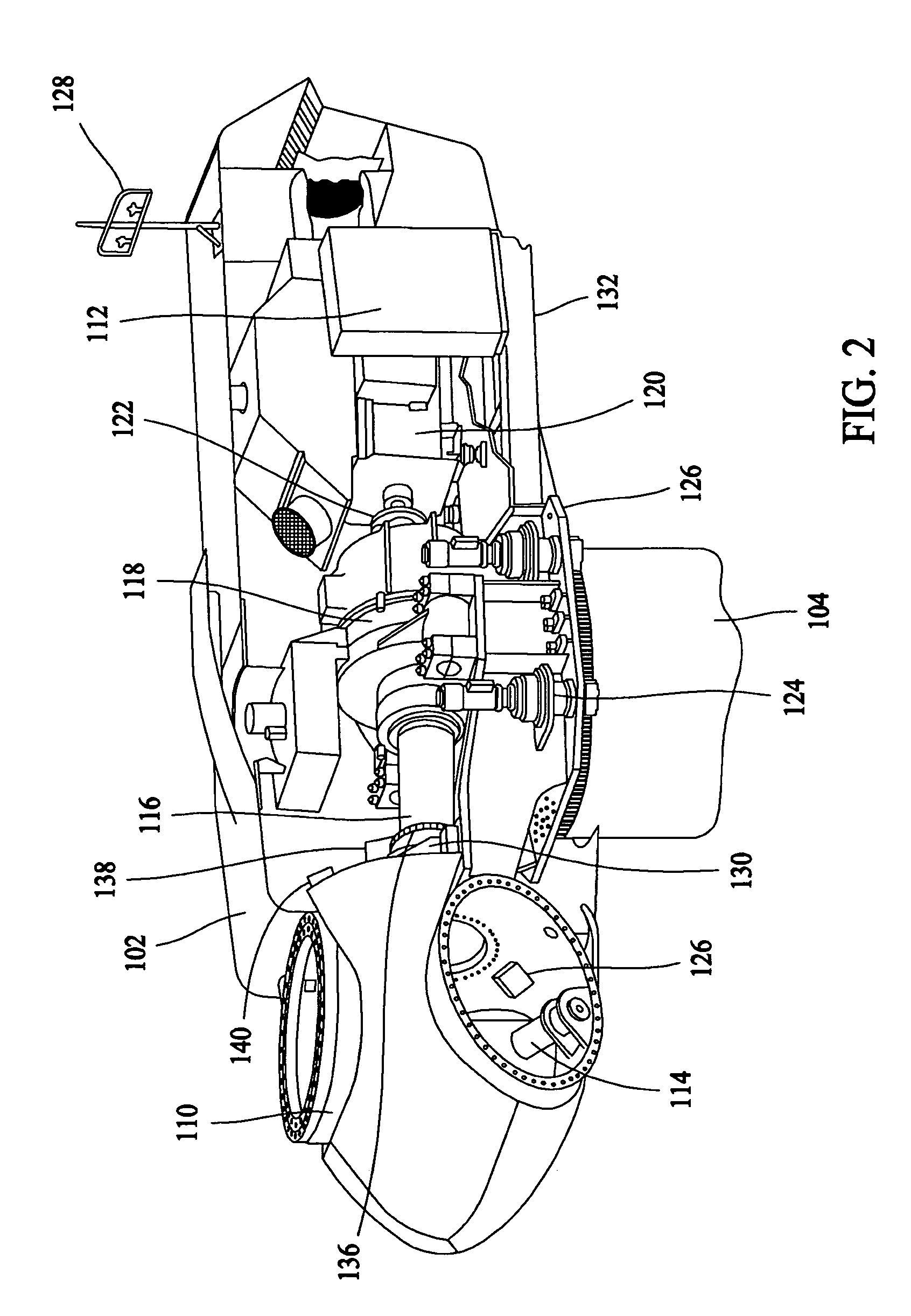

Methods and apparatus for rotor load control in wind turbines

ActiveUS7095129B2Reduce loadReduce wind loadsWind motor controlGeneration protection through controlClassical mechanicsPower grid

A wind turbine having a rotor, at least one rotor blade, and a plurality of generators, of which a first generator is configured to provide power to an electric grid and a second generator is configured to provide power to the wind turbine during times of grid loss. The wind turbine is configured to utilize power provided by the second generator to reduce loads on the wind turbine during times of grid loss.

Owner:GENERAL ELECTRIC CO

LGA-BGA connector housing and contacts

ActiveUS20050124189A1Prevent movementLarge diameterLine/current collector detailsCoupling device detailsEngineeringMechanical engineering

Electrical connectors and contacts are disclosed. An electrical connector may include a housing having a contact receiving well that extends along a contact receiving direction, the contact receiving well having a generally T-shaped cross-section along a direction transverse to the contact receiving direction. An electrical contact may be received in the contact receiving well. The contact may include a generally planar body portion, a first contact portion extending from a first end of the body portion, and a second contact portion extending from a second end of the body portion. The contact is adapted to be received into a generally T-shaped contact receiving well such that the contact receiving well prevents movement of the electrical contact within the contact receiving well.

Owner:FCI AMERICAS TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com