Patents

Literature

39results about How to "Large outer diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

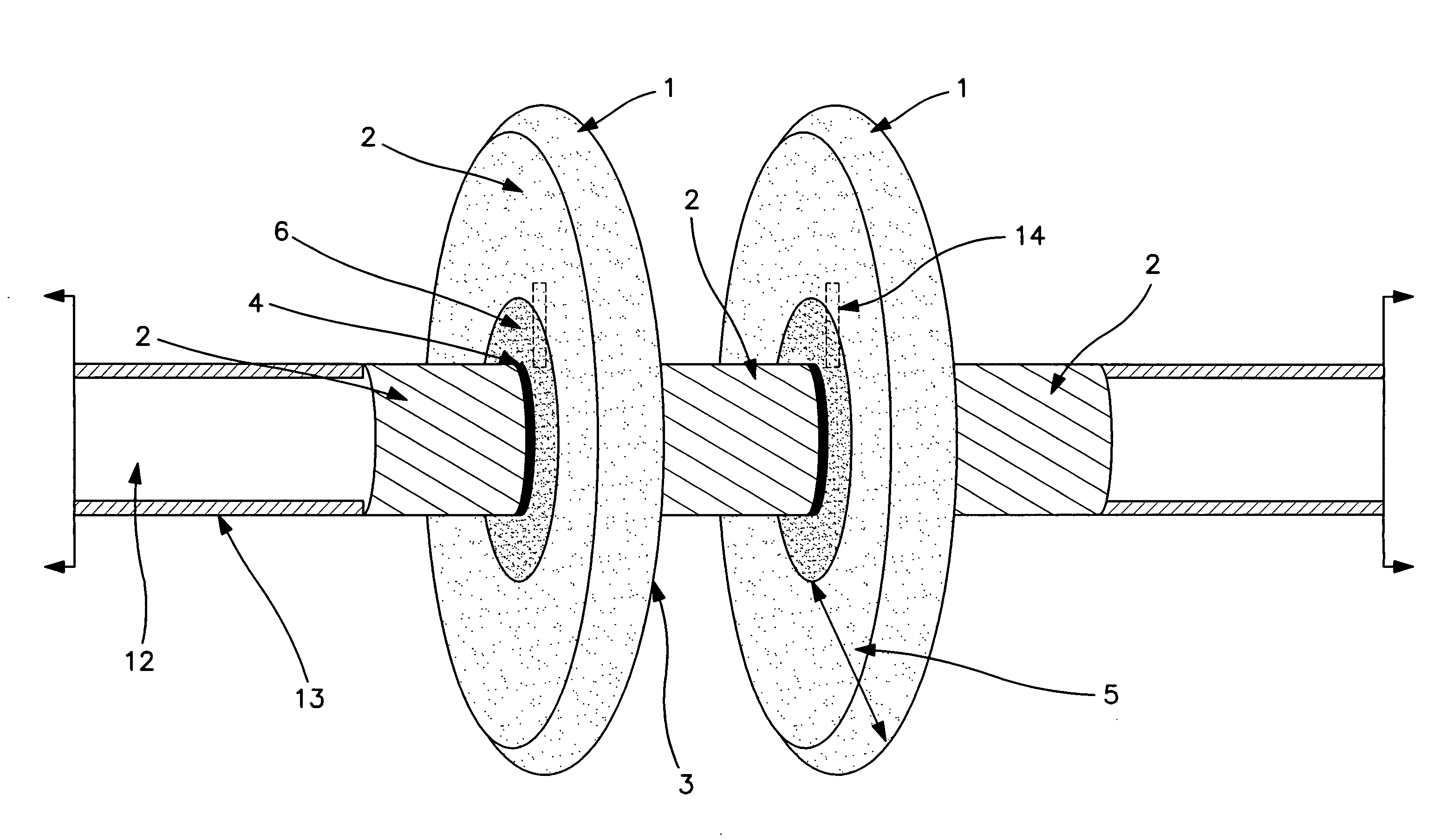

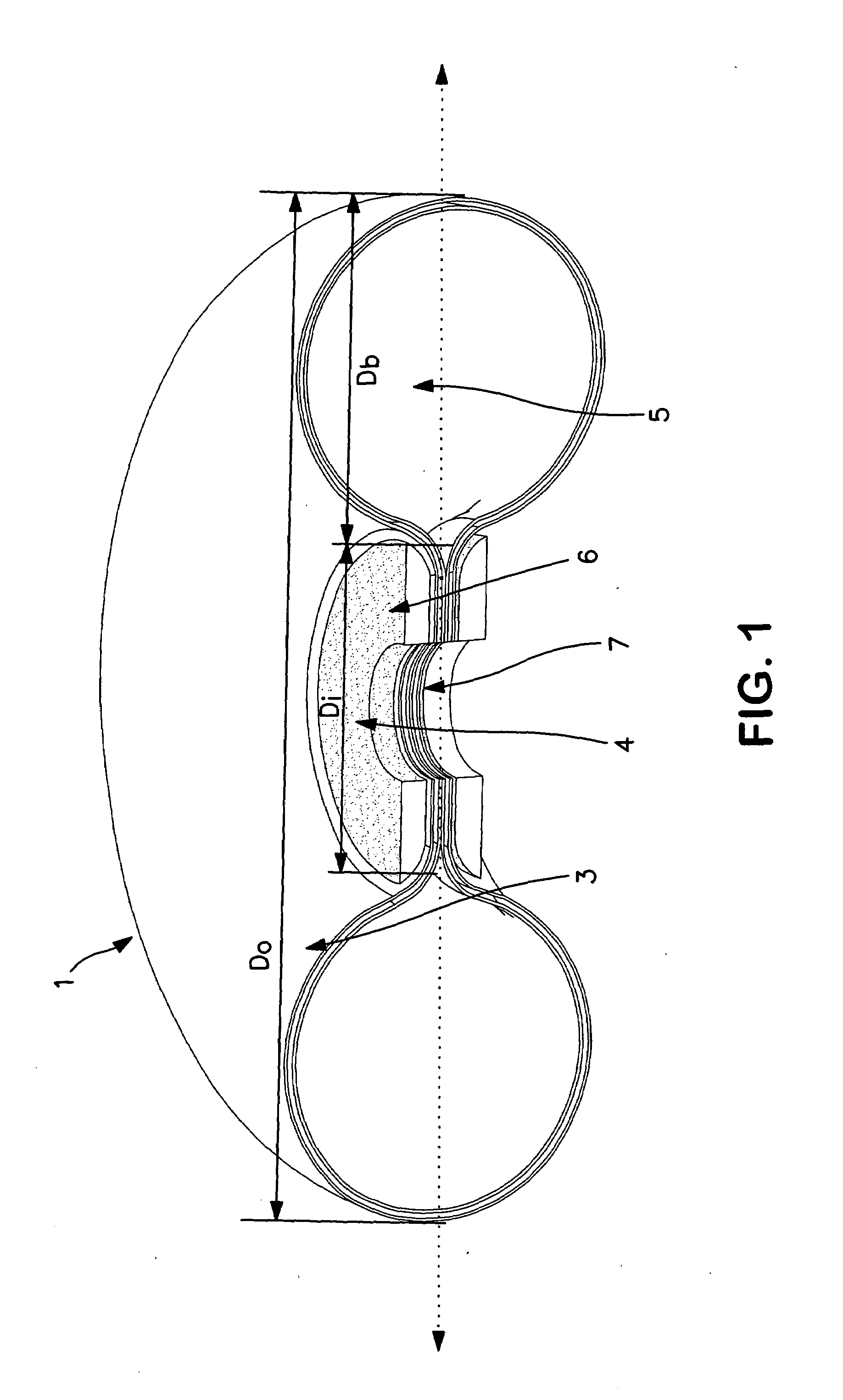

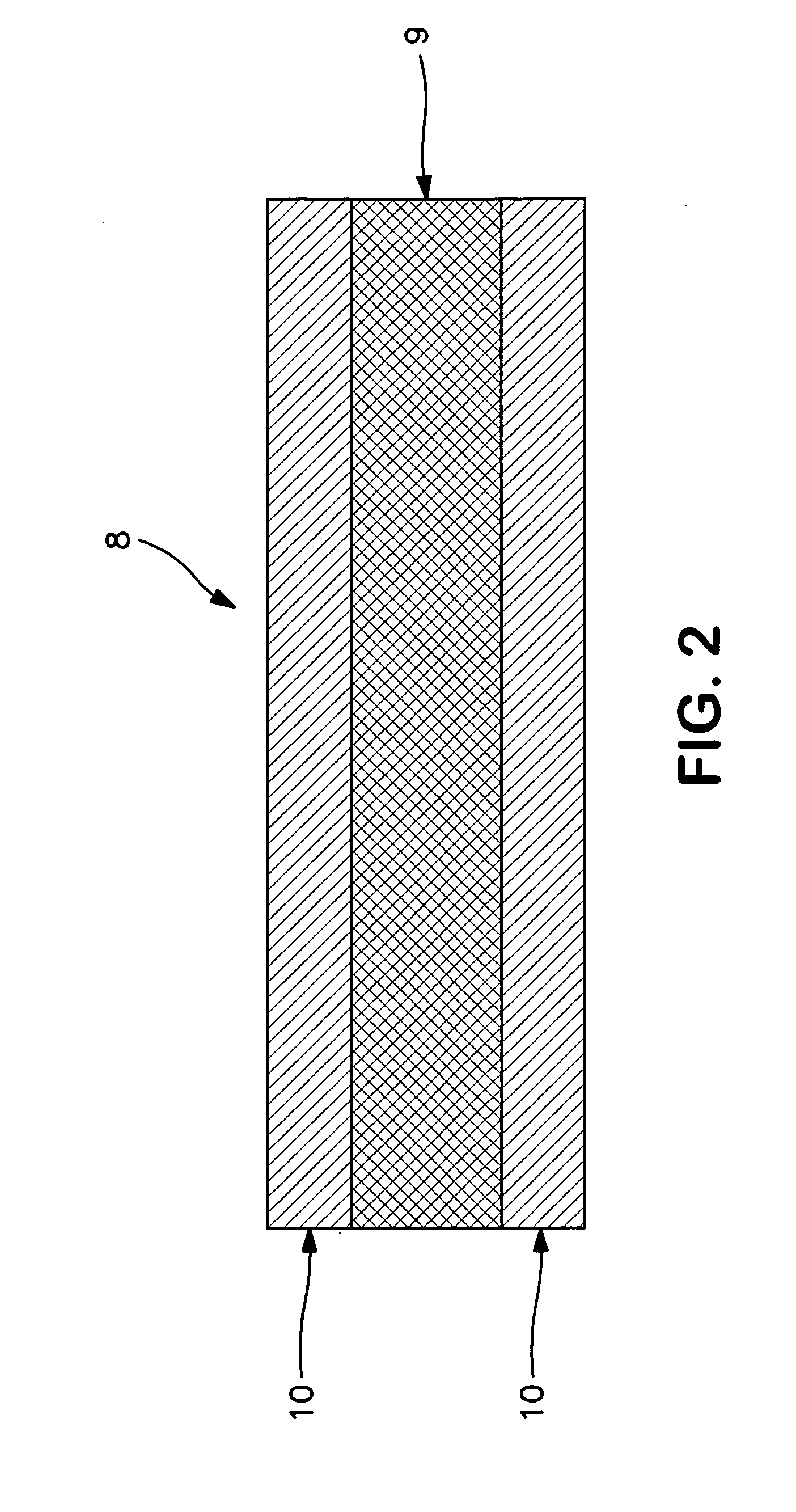

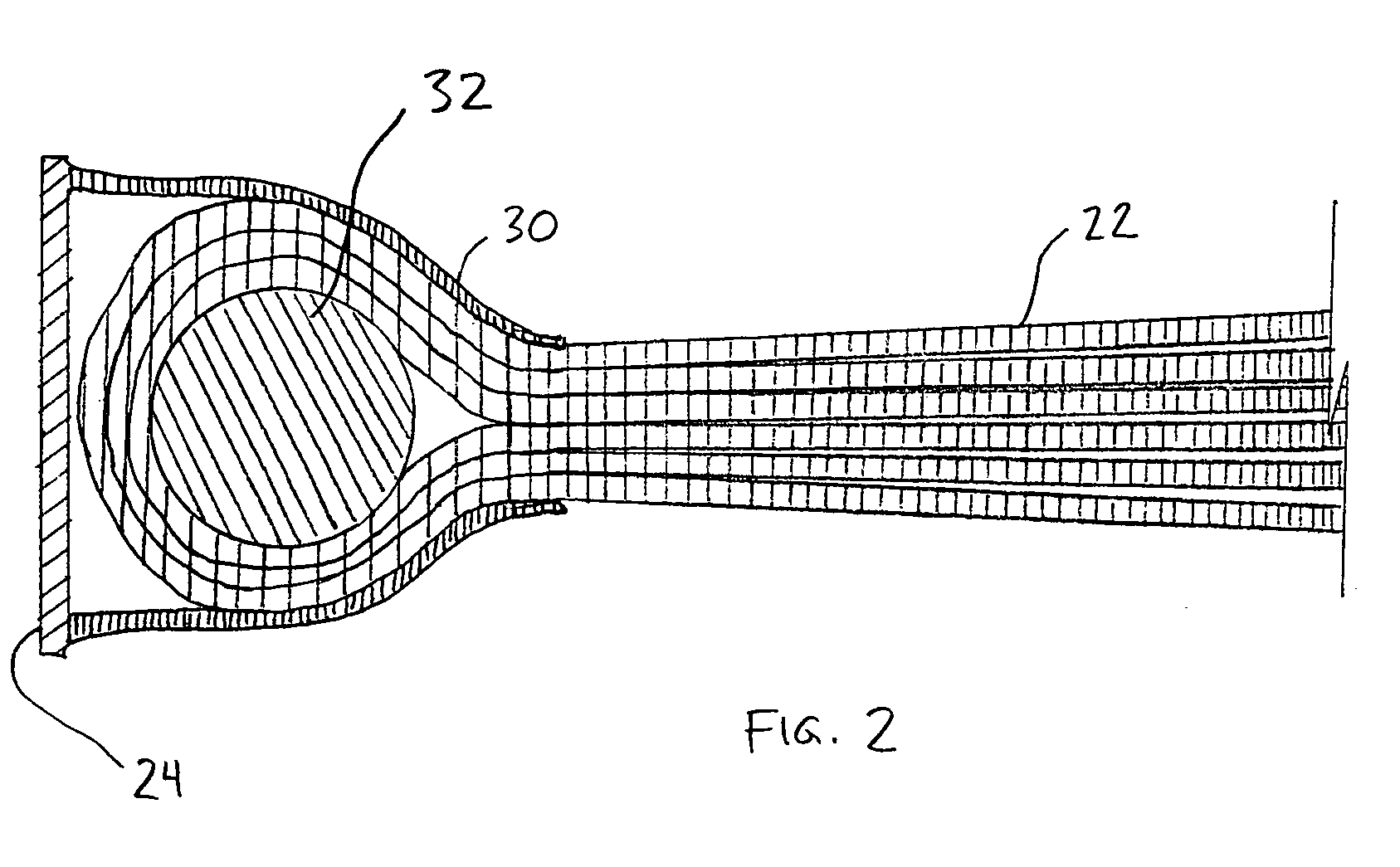

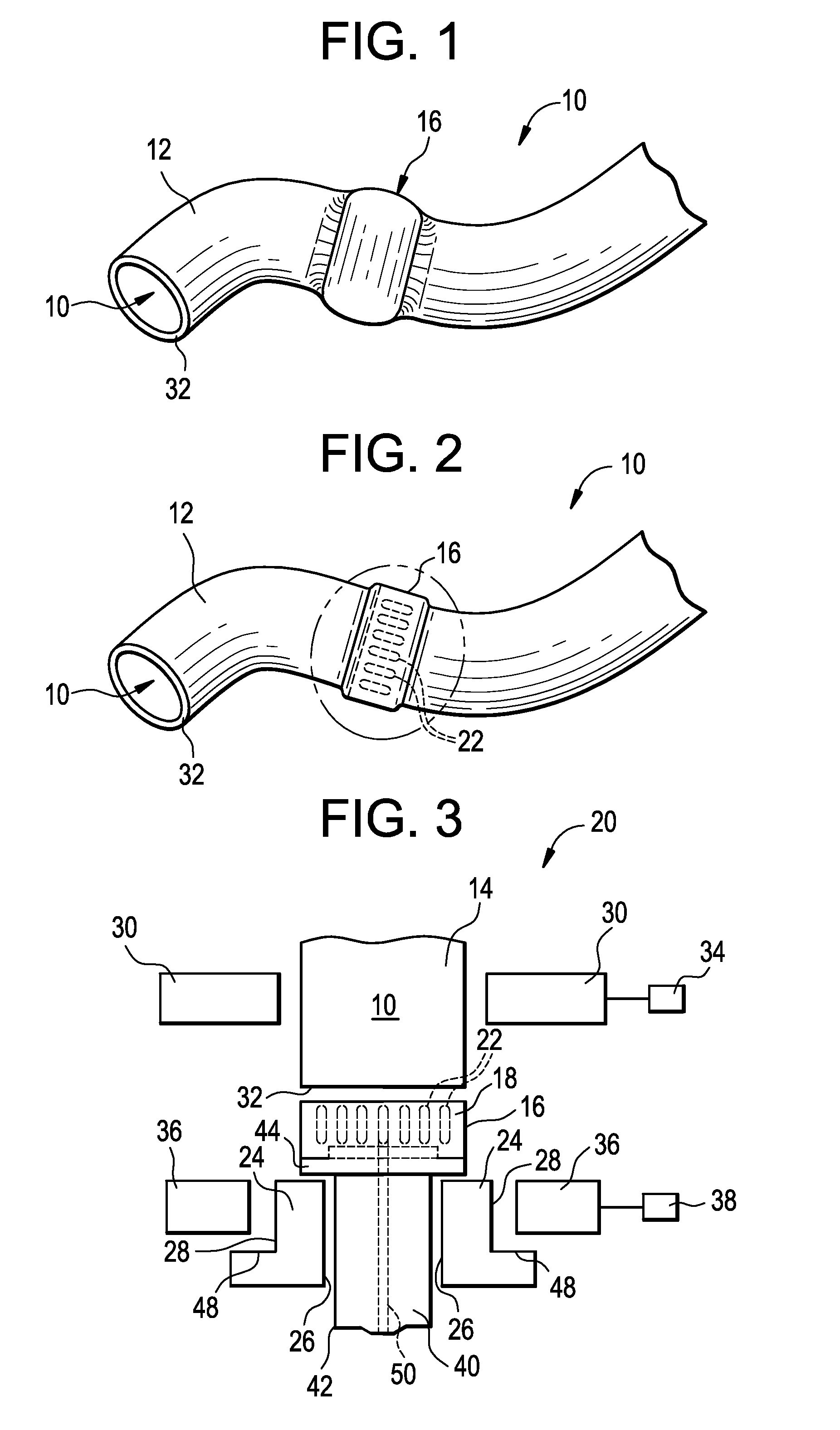

Inflatable toroidal-shaped balloons

ActiveUS20080086083A1High inflation pressureLarge outer diameterStentsBalloon catheterMedical treatmentGeneral surgery

An inflatable toroidal-shaped balloon for medical use is provided with a central opening traversing the balloon in an inflated state. The balloon is useful to achieve larger outer diameters than conventional balloons.

Owner:WL GORE & ASSOC INC

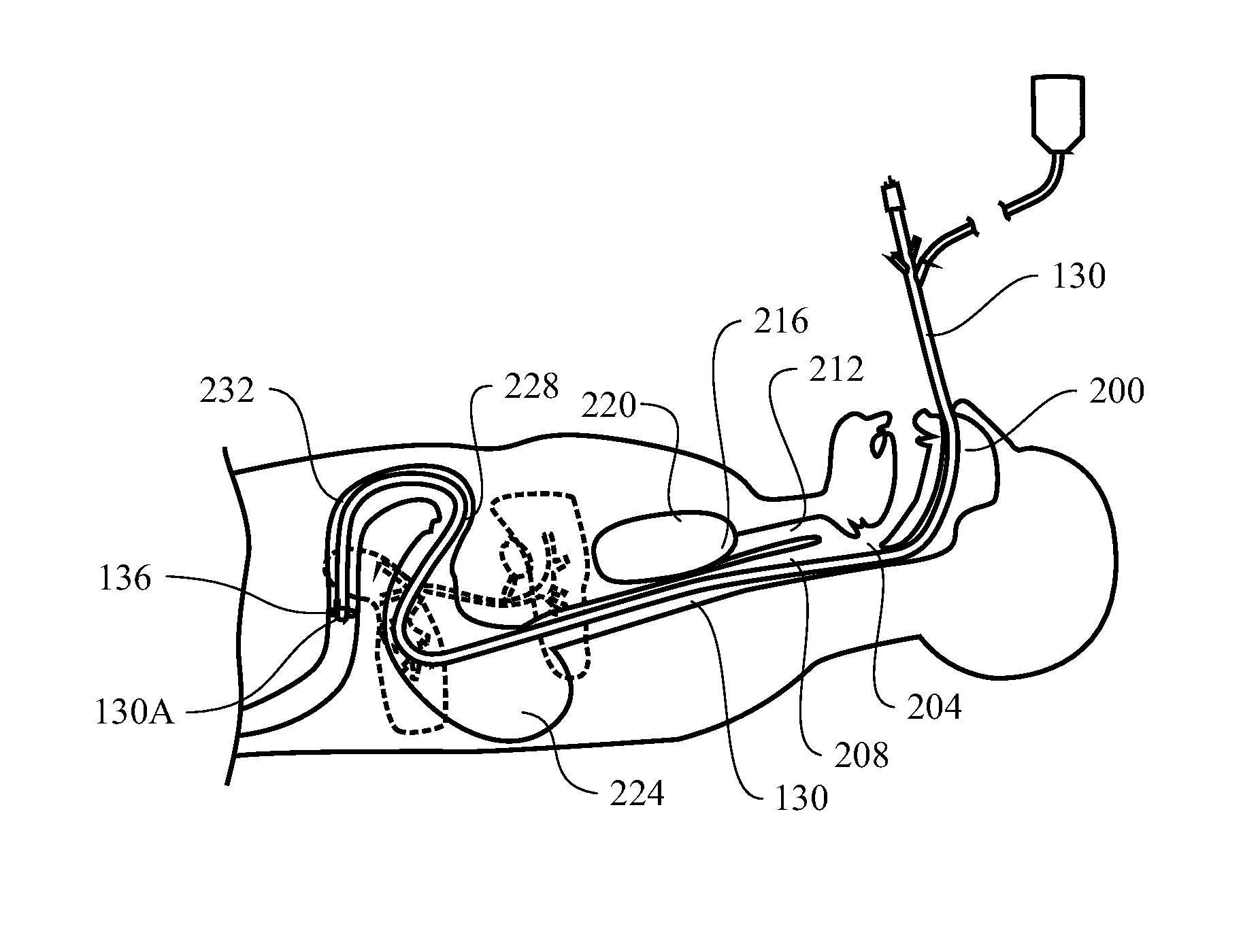

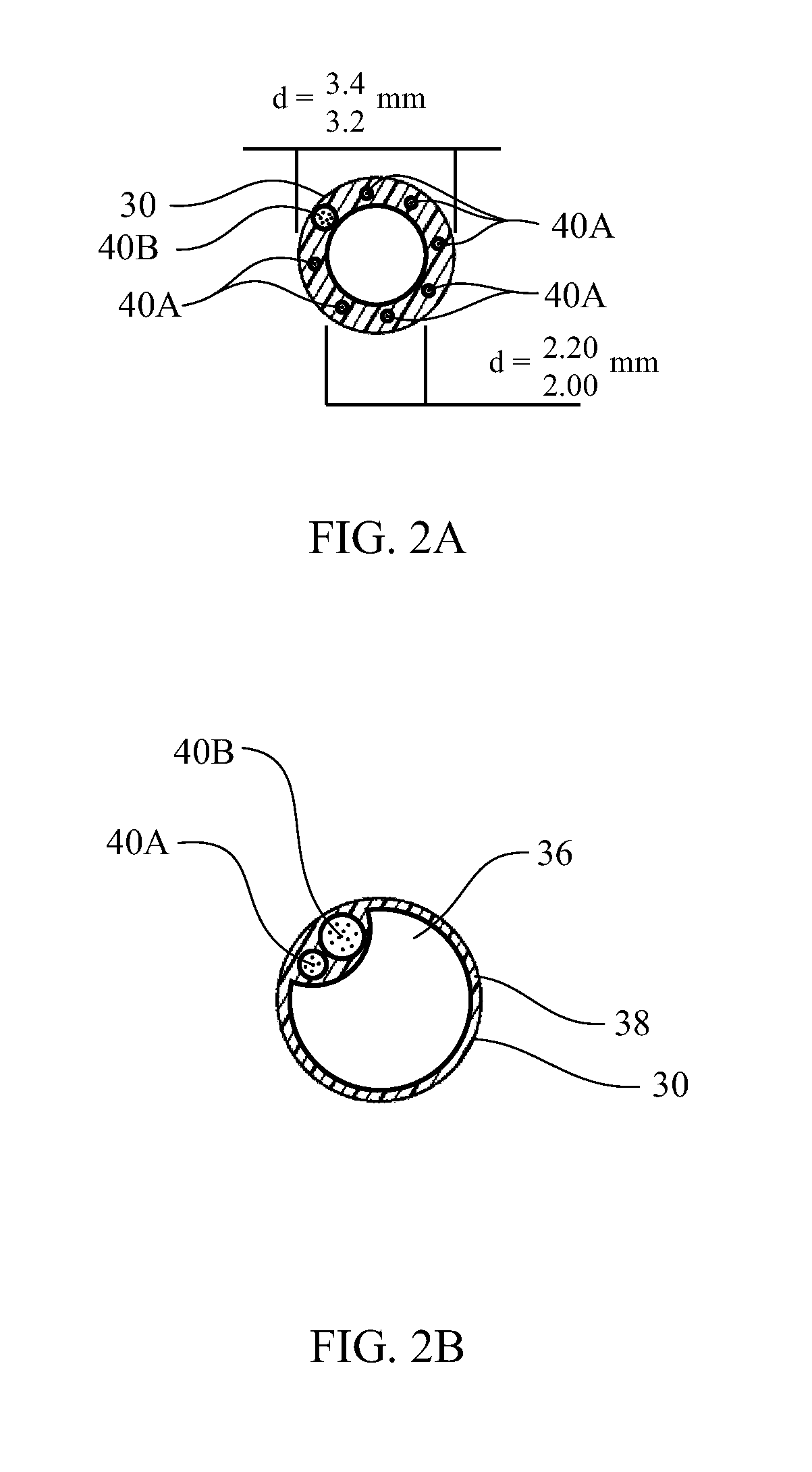

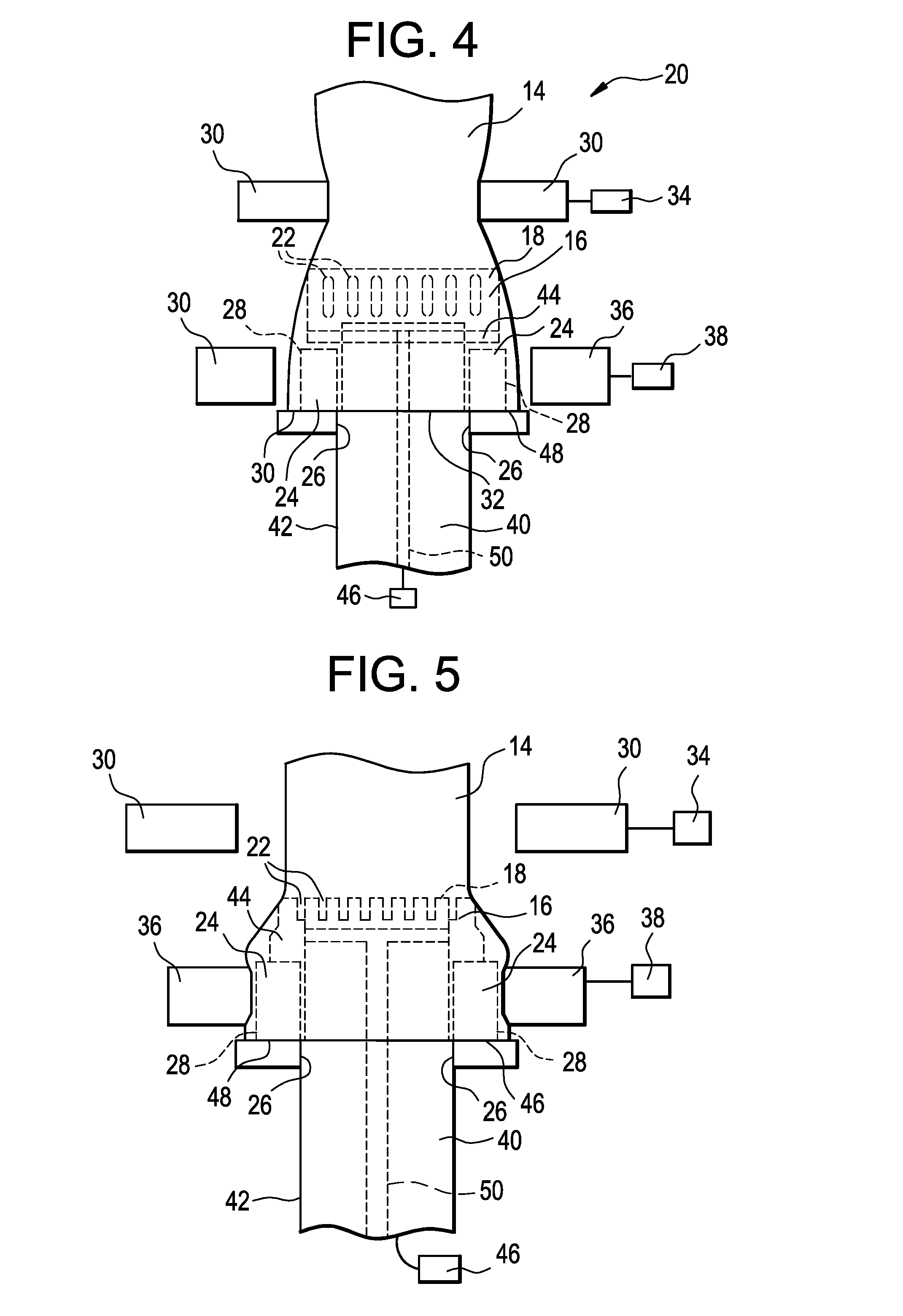

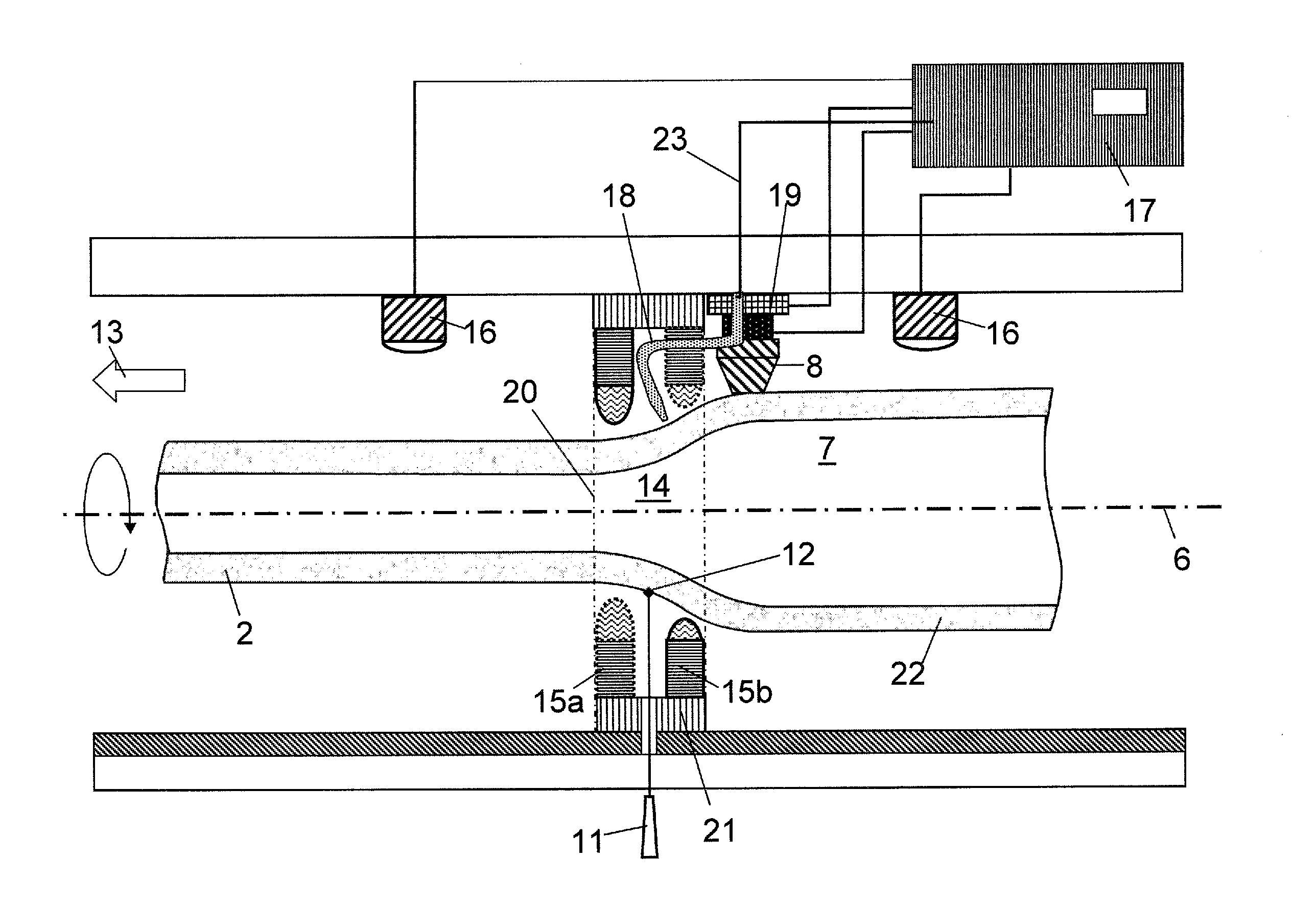

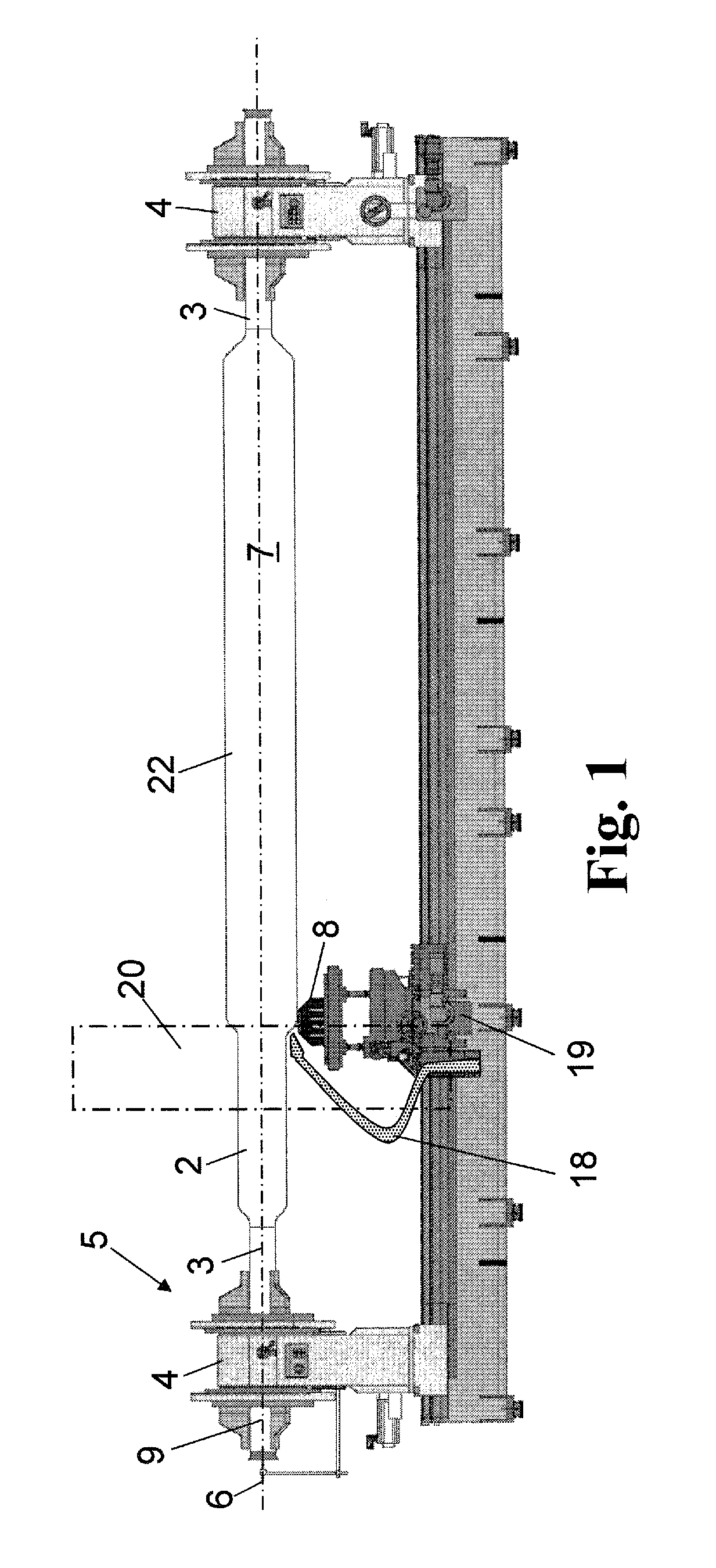

Optically guided medical tube and control unit assembly and methods of use

InactiveUS20120116160A1Solve the lack of spaceLarge outer diameterGastroscopesOesophagoscopesFeeding tubeBiomedical engineering

An optical medical tube and control unit assembly and methods of using the same are provided. The optical medical tube may include a steering mechanism and an imaging device which provides the user a visual aid when placing a tube in the body of a patient. The optical medical tube may be coupled to a coupling adaptor to enable quick and easy connecting of the imaging device and steering mechanism of the tube with a control unit such that a single control unit may be used to place multiple feeding tubes or confirm that a feeding tube remains in its proper position without the need for lengthy sterilization procedures between uses.

Owner:THE UNIV OF UTAH

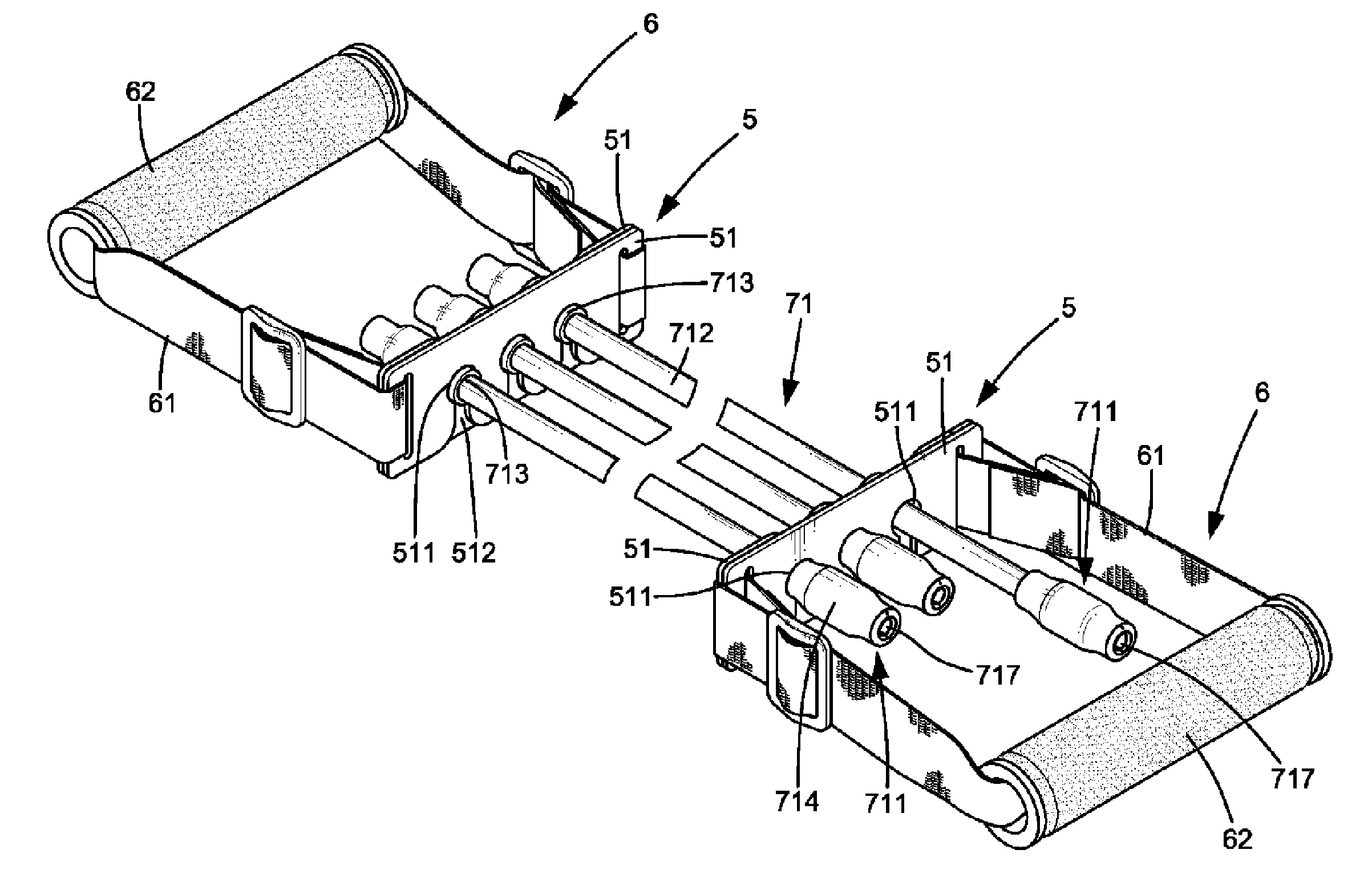

Elastic cord and pull exerciser having the same

A pull exerciser includes at least one attachment device, at least one positioning device coupled to the at least one attachment device, and at least one elastic cord. The positioning device includes at least one positioning hole. At least one of two ends of the elastic cord is hollow and engaged in the positioning hole. The end of the elastic cord includes an inner section and a turnback section surrounding the inner section. The end of the elastic cord and a distal end portion of the turnback section are engaged in the positioning hole. A stop is mounted in the end of the elastic cord and securely held by the inner section and the turnback section. The stop has an outer diameter larger than a diameter of the positioning hole.

Owner:WU YING CHING

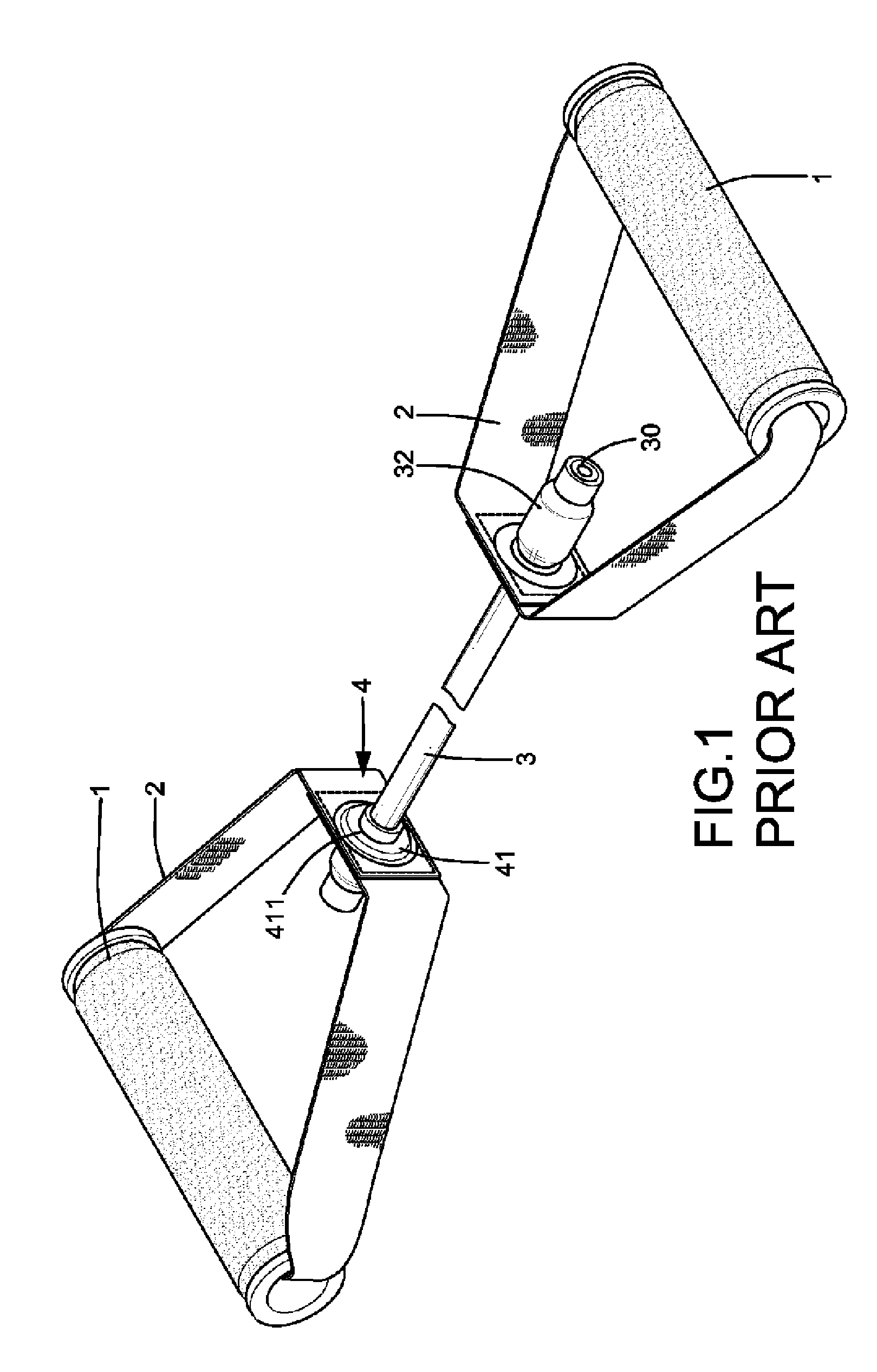

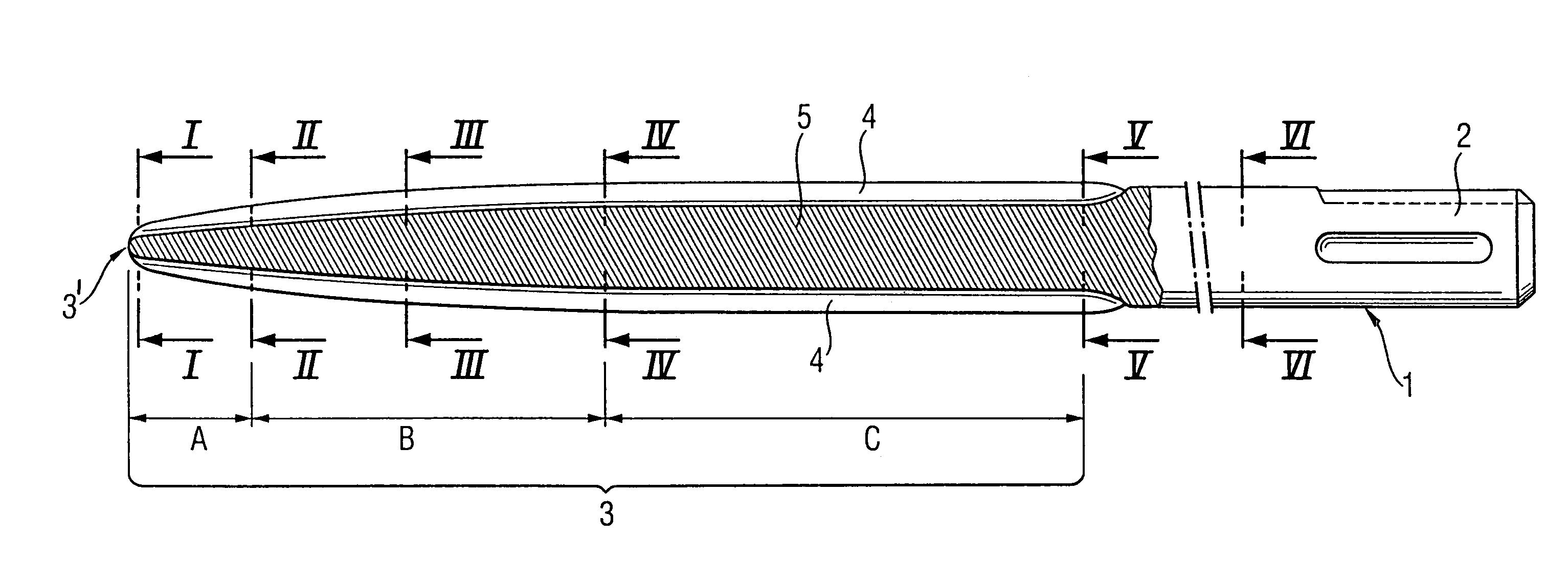

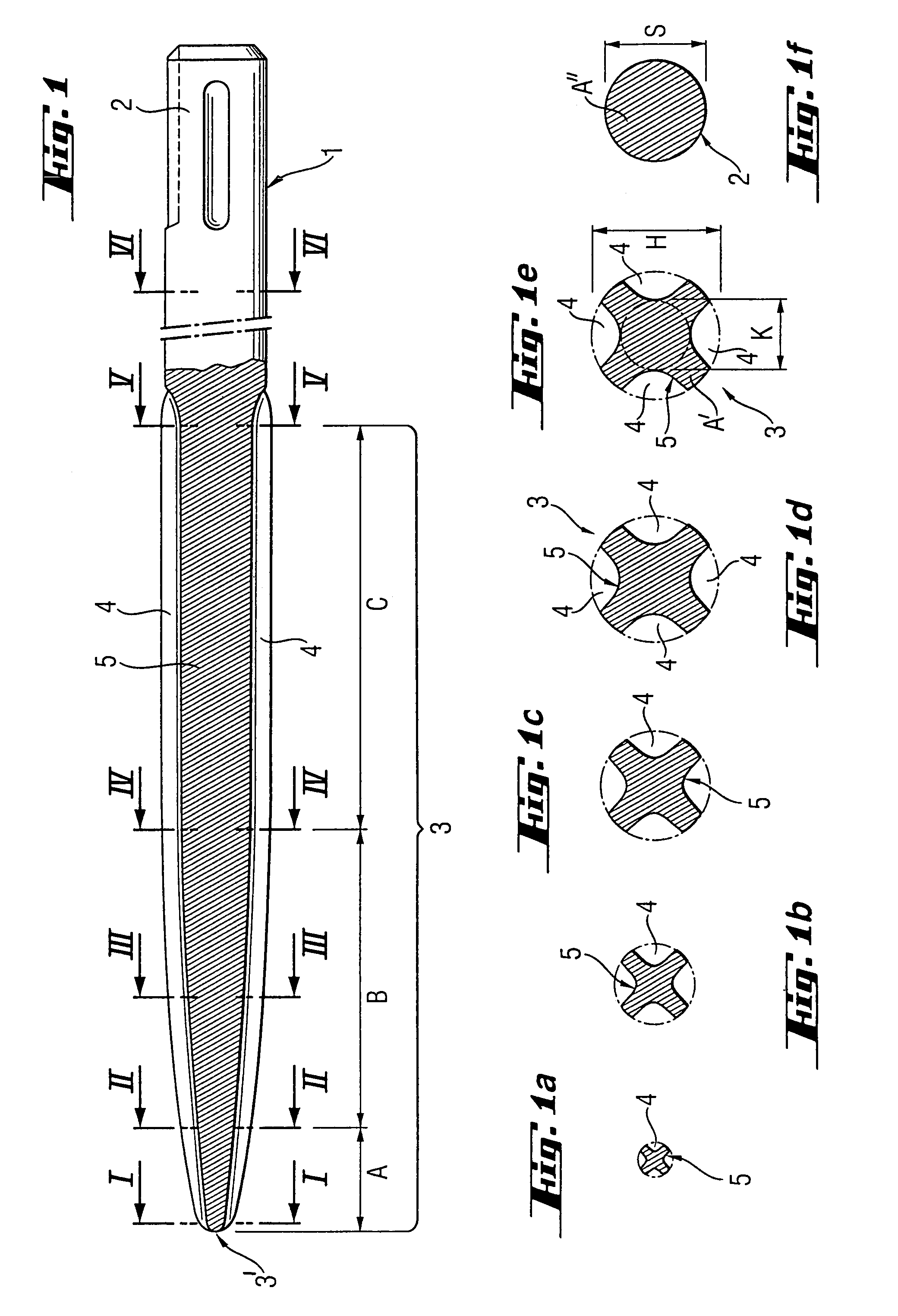

Point chisel

ActiveUS6981496B2Cross-sectional surfaceLarge outer diameterDrill bitsPortable percussive toolsChiselEngineering

A point chisel for use with a power tool includes an elongate stem (1) having, at its power tool side a shank (2) for securing the chisel in the power tool and, at its workpiece side, a useful region (3) having its outer diameter (H) tapering toward its workpiece end and having a cross-section (5) formed as a concave polygon by a plurality of axial grooves (4) extending radially toward a core diameter (K) that likewise tapers toward the workpiece side end of the useful region (3).

Owner:HILTI AG

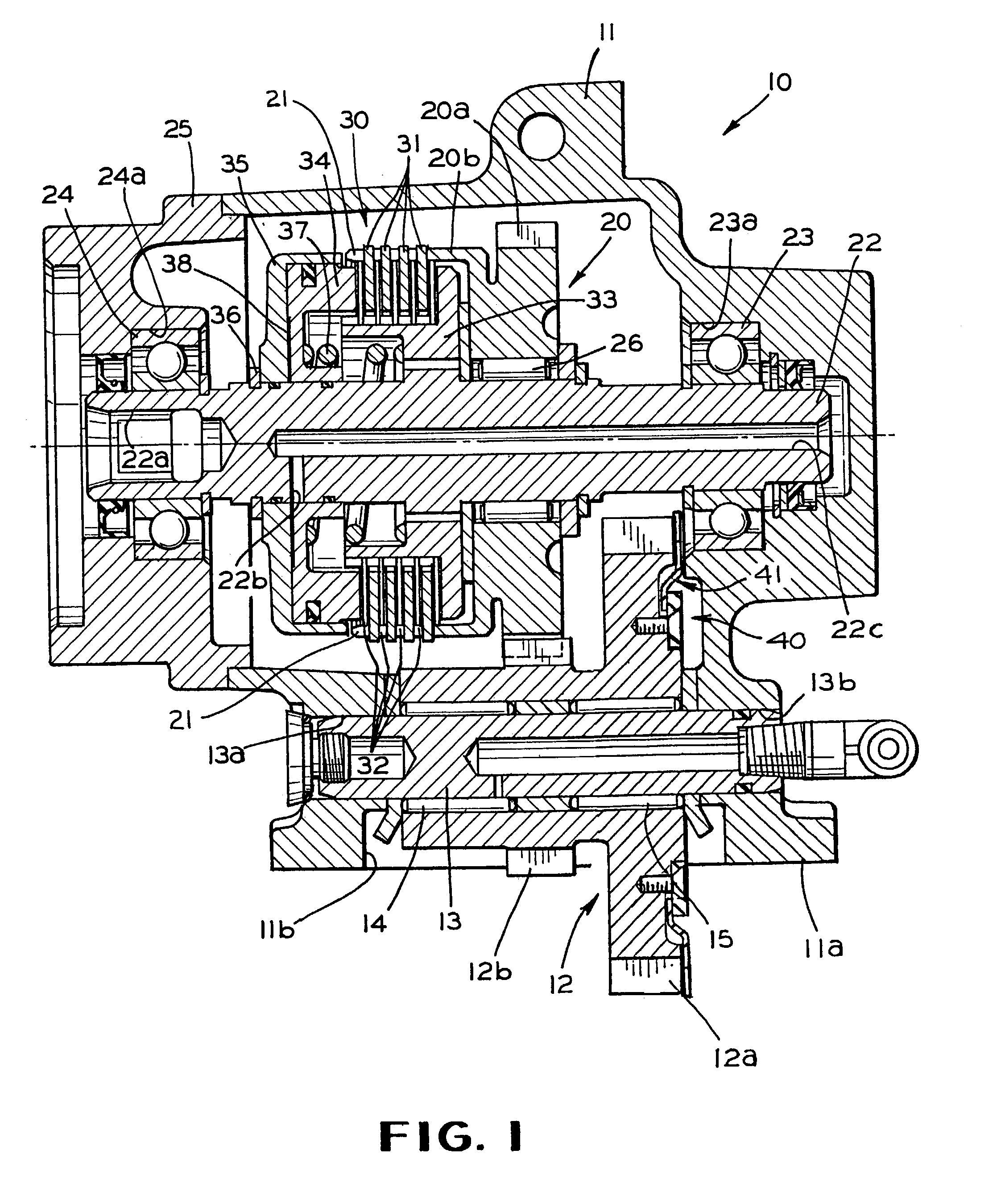

Gear assembly having noise-reduction structure and power take-off unit therewith

InactiveUS7007565B2Improved noise-reduction structureReduce the amount of noiseGear vibration/noise dampingPortable liftingNoise reductionPower take-off

A meshing gear assembly includes a toothed disk that is supported on a first gear so as to be frictionally engaged therewith, but rotationally and radially movable relative thereto. The circumferential width of each tooth formed on the toothed disk is preferably larger than the circumferential width of each tooth formed on the first gear, and the outer diameter of the toothed disk can be larger than the outer diameter of the first gear. The first gear and the toothed disk mesh with a second gear such that as the second gear rotates, the toothed disk and the first gear also rotate. However, the toothed disk and the first gear rotate at different speeds because the difference in the number of teeth formed thereon. Because the teeth formed on the toothed disk have a larger circumferential thickness and a larger outer diameter than the teeth formed on the first gear, a tight meshing engagement with the second gear is provided. This tight meshing engagement, in combination with the frictional engagement of the toothed disk with the first gear, takes up backlash between the first gear and the second gear.

Owner:PARKER INTANGIBLES LLC

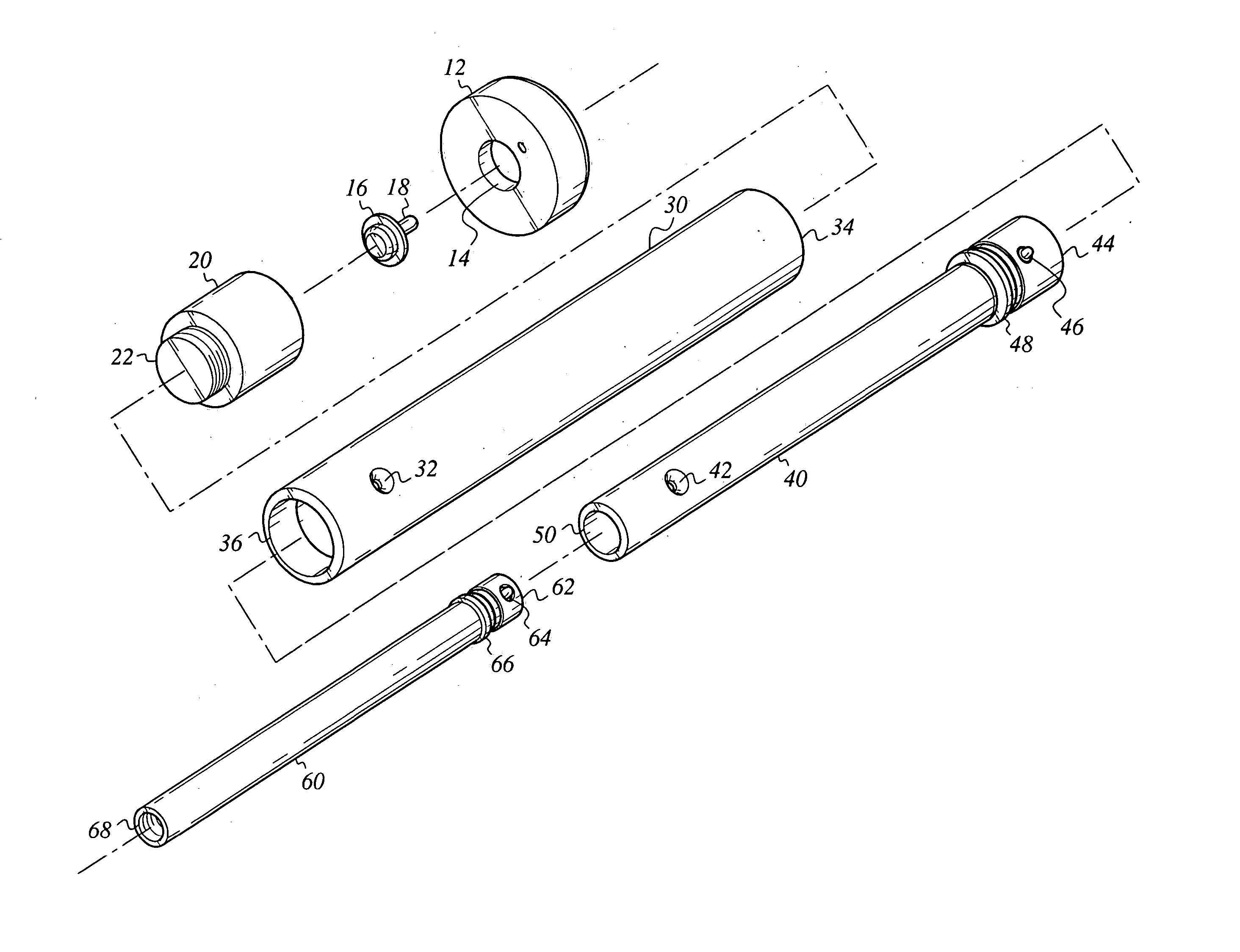

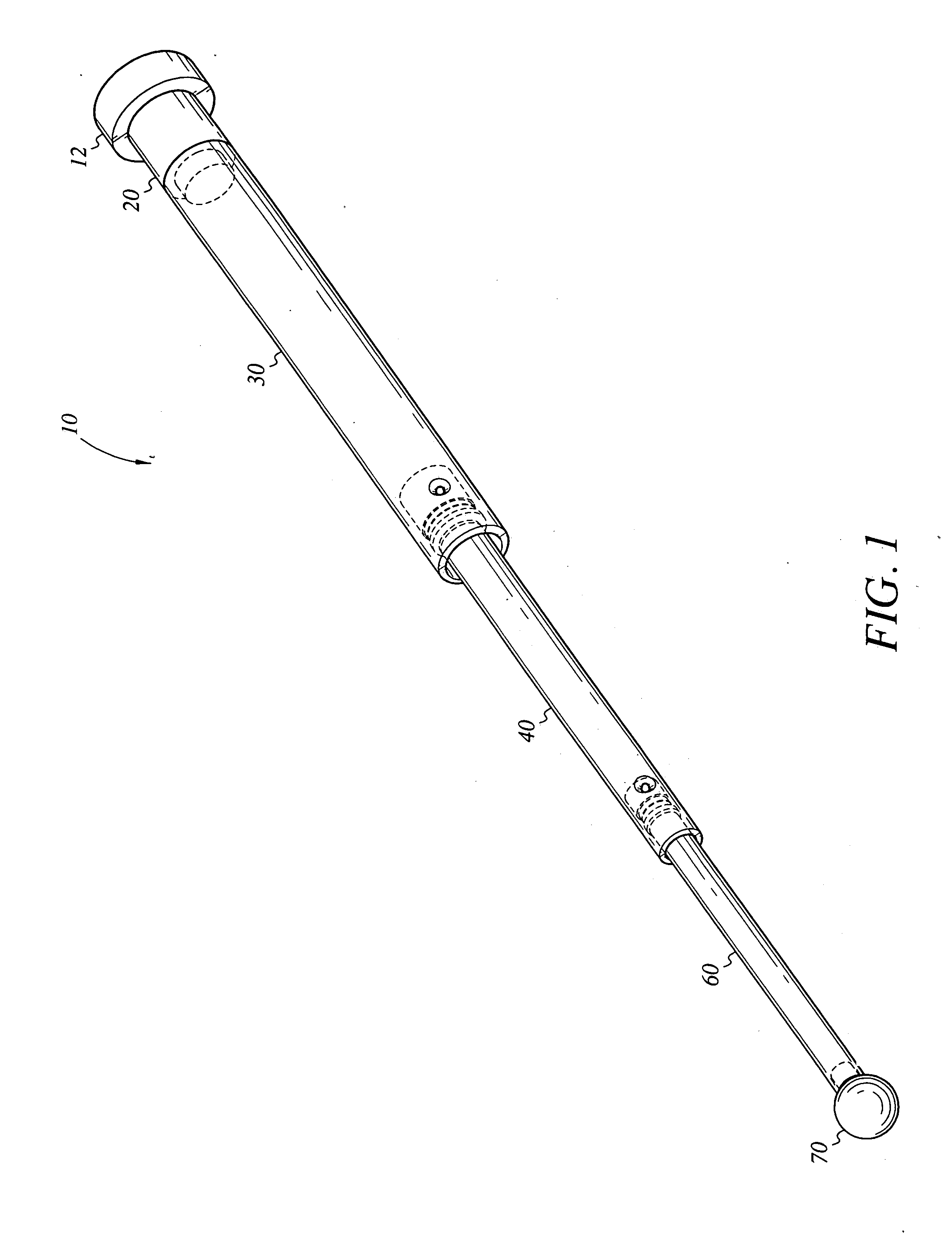

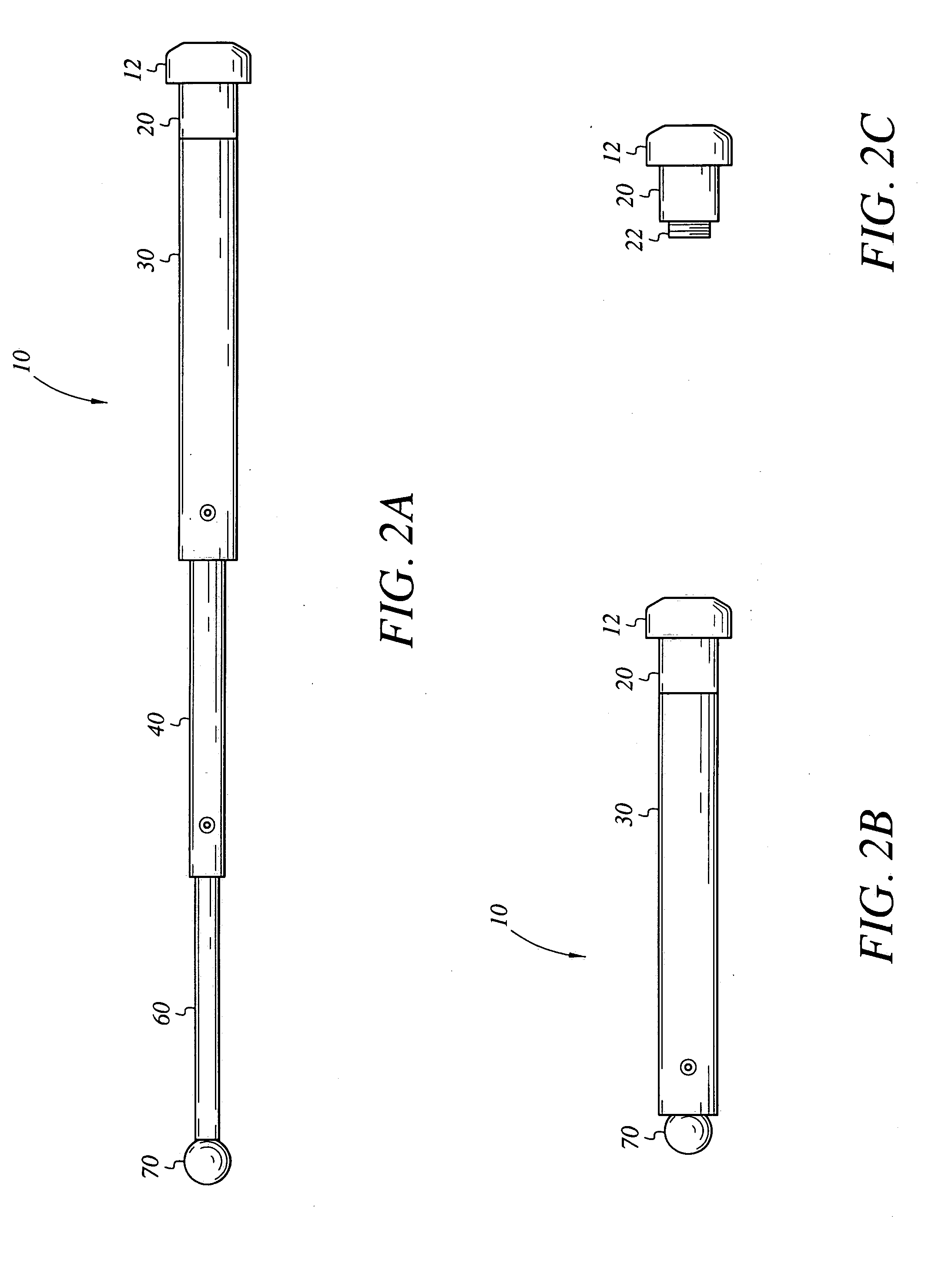

Straight handle baton with mushroom cap

InactiveUS20050083679A1Easy to keepLarge outer diameterWalking sticksClubsEngineeringMechanical engineering

A straight baton includes a bulbous or mushroom shaped cap which releasably receives a light device with a light element, multiple shaft sections including at least first, second, and third shaft sections, and a striking end. The first, second, and third shaft sections are cylindrically shaped, and each shaft section has predetermined inner and outer diameters, a predetermined length, and opposing ends. The inner diameter of the first shaft section is larger than the outer diameter of the second shaft section, and the inner diameter of the second shaft section is larger than the outer diameter of the third shaft section. The first shaft section is configured to enable the second shaft section to releasably retract into or extend out of the first shaft section, and the second shaft section is configured to enable the third shaft section to releasably retract into or extend out of the second shaft section.

Owner:MACIEROWSKI GLENN E +1

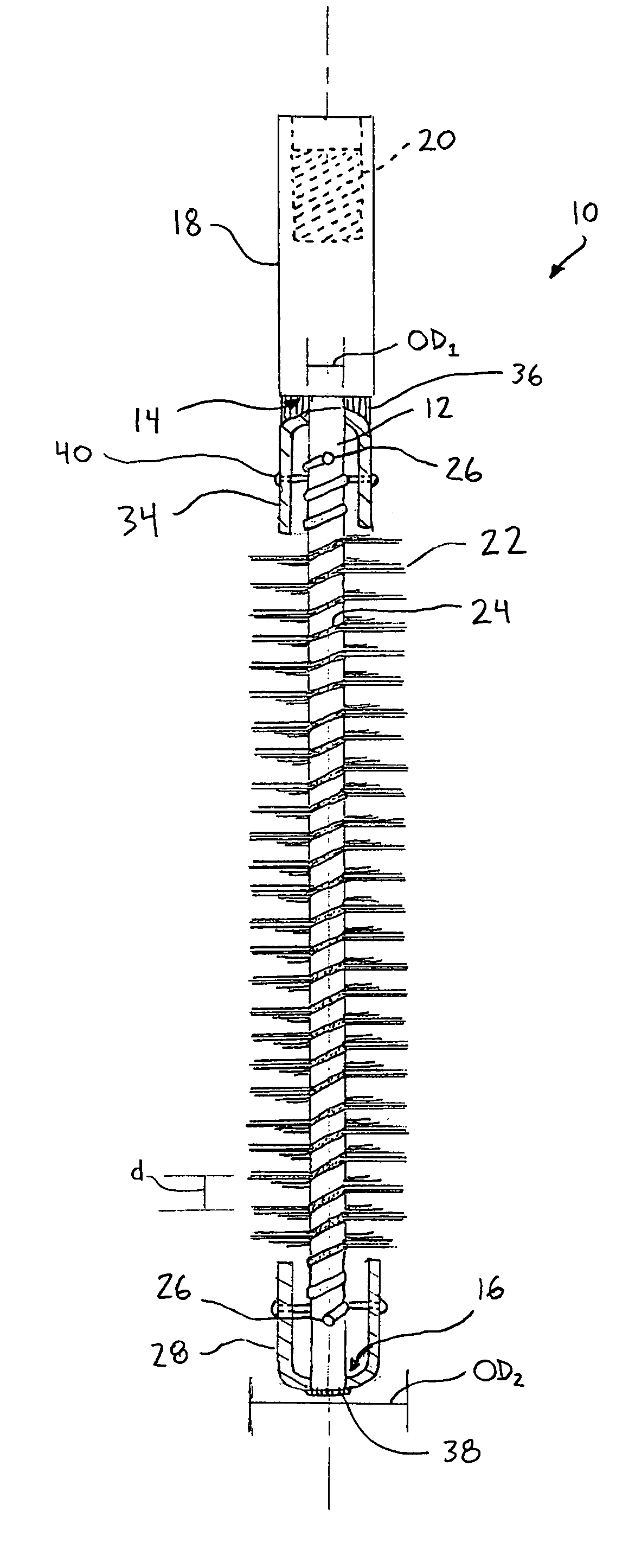

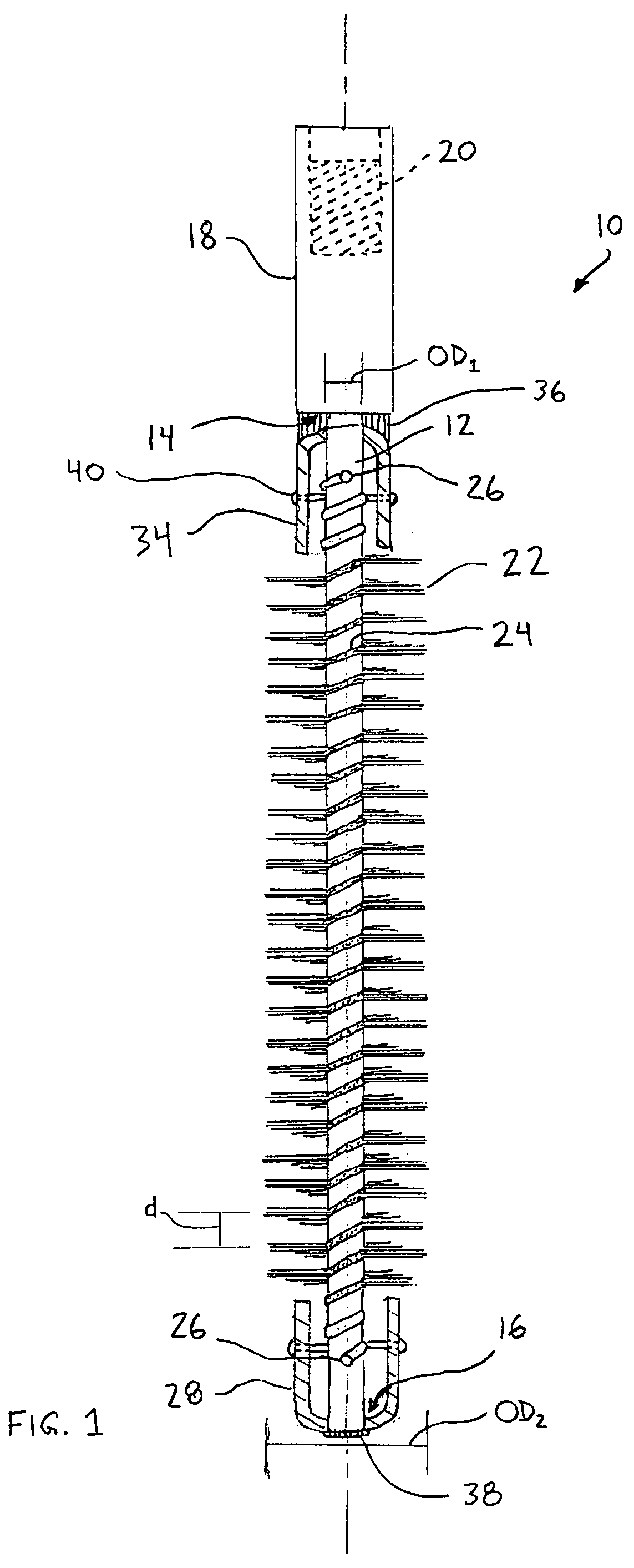

Agitator tool

InactiveUS20060048934A1Efficiently agitatedProduced cost-effectivelyDrilling rodsCleaning apparatusPush and pullScrew pump

A rotatable agitator tool is disclosed for use with a pump mechanism, for agitating production fluid comprising sand or other debris and for breaking out solution gas, comprising an elongate shaft connected to a rotating element such as a rotor, and a plurality of agitation members extending outwardly from the elongate shaft, the agitator tool extending in an upstream direction from the pump mechanism. The agitation members are preferably flexible to allow the agitator tool to be pushed and pulled through a stator (where employed with a progressive cavity pump) without damaging the elastomeric coating on the stator.

Owner:CHARABIN NEIL

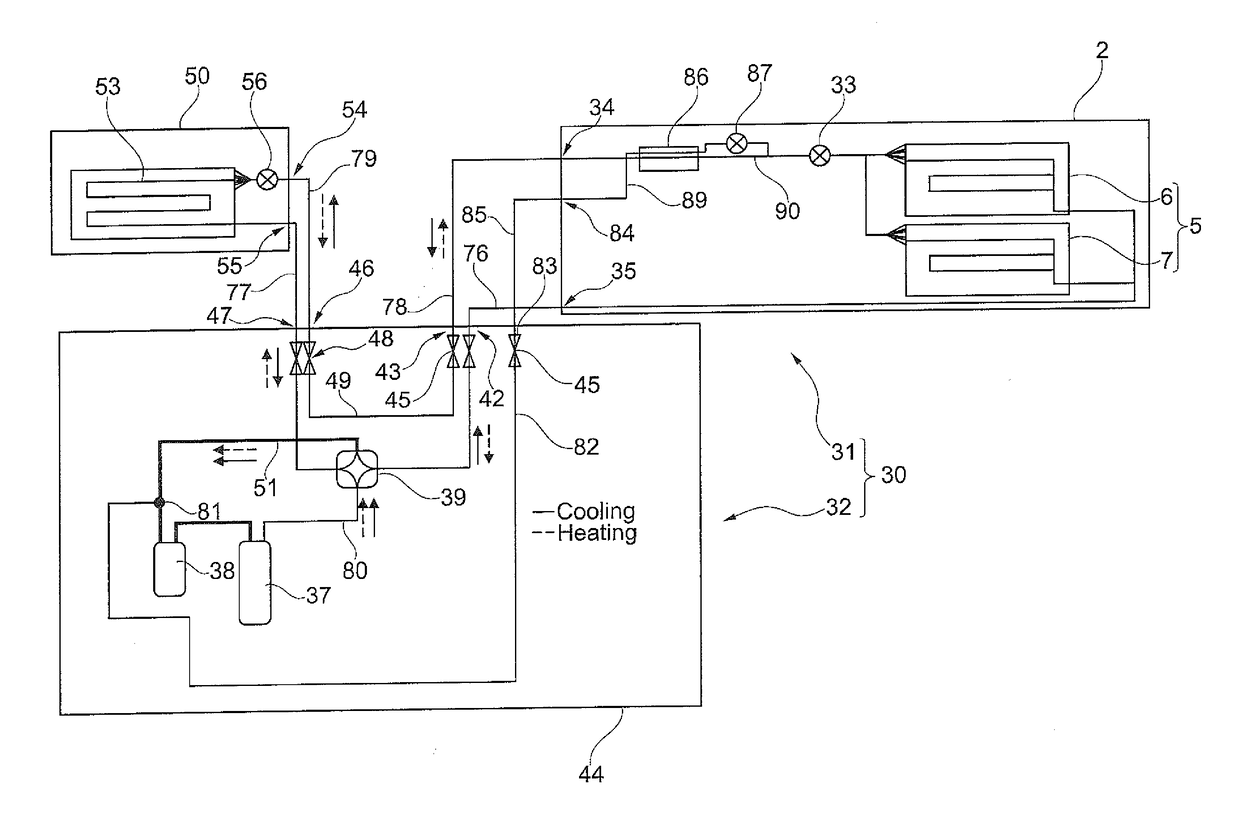

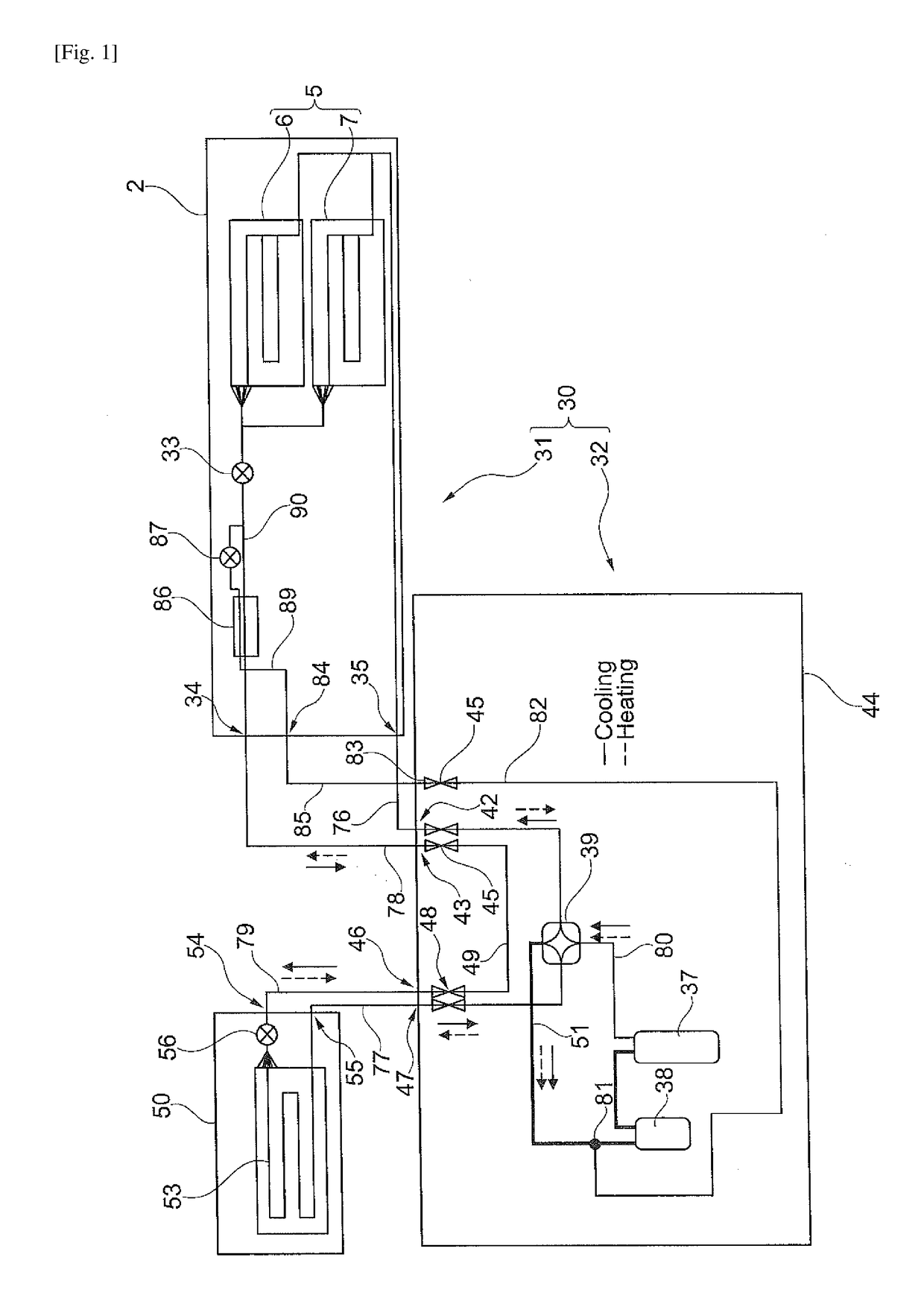

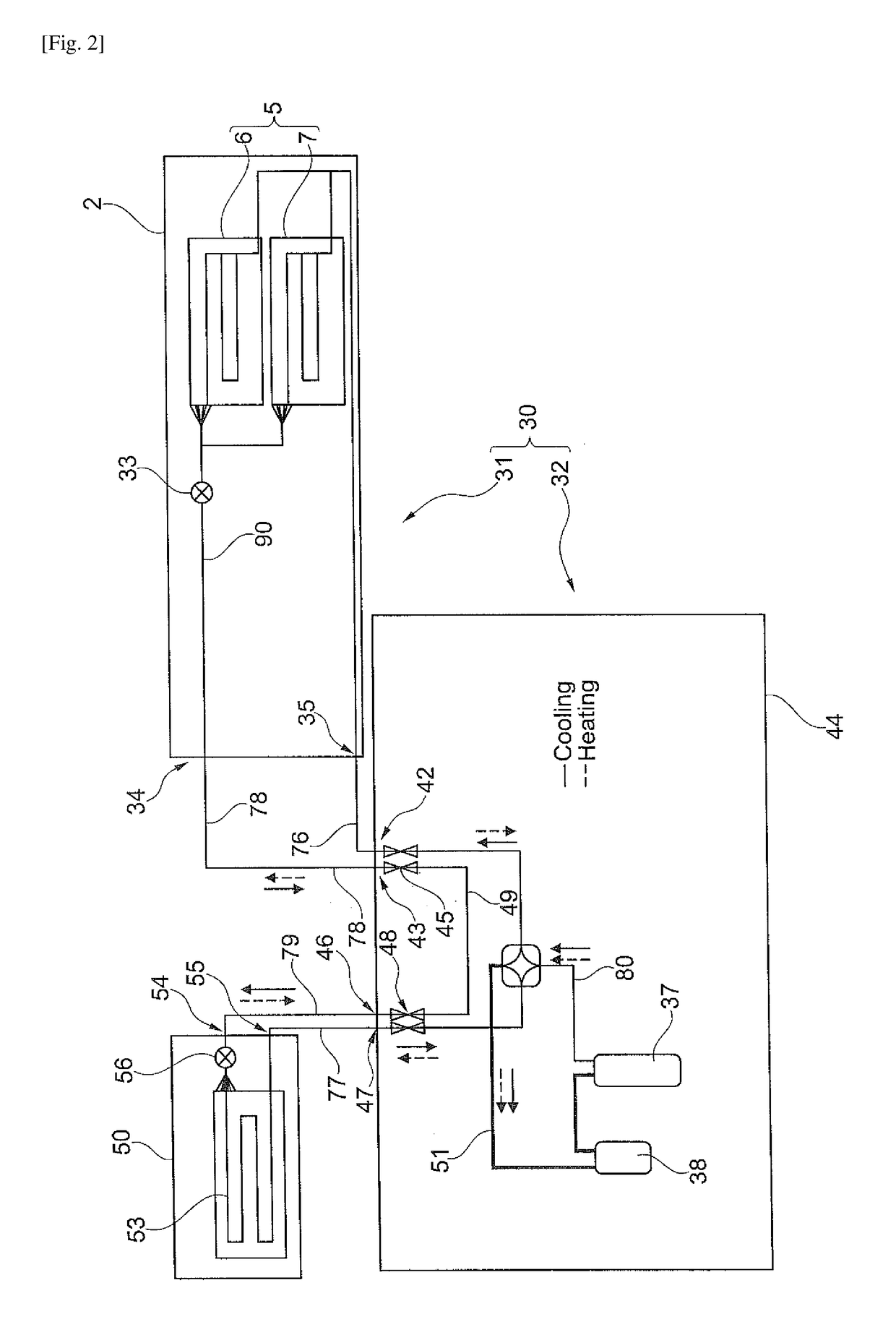

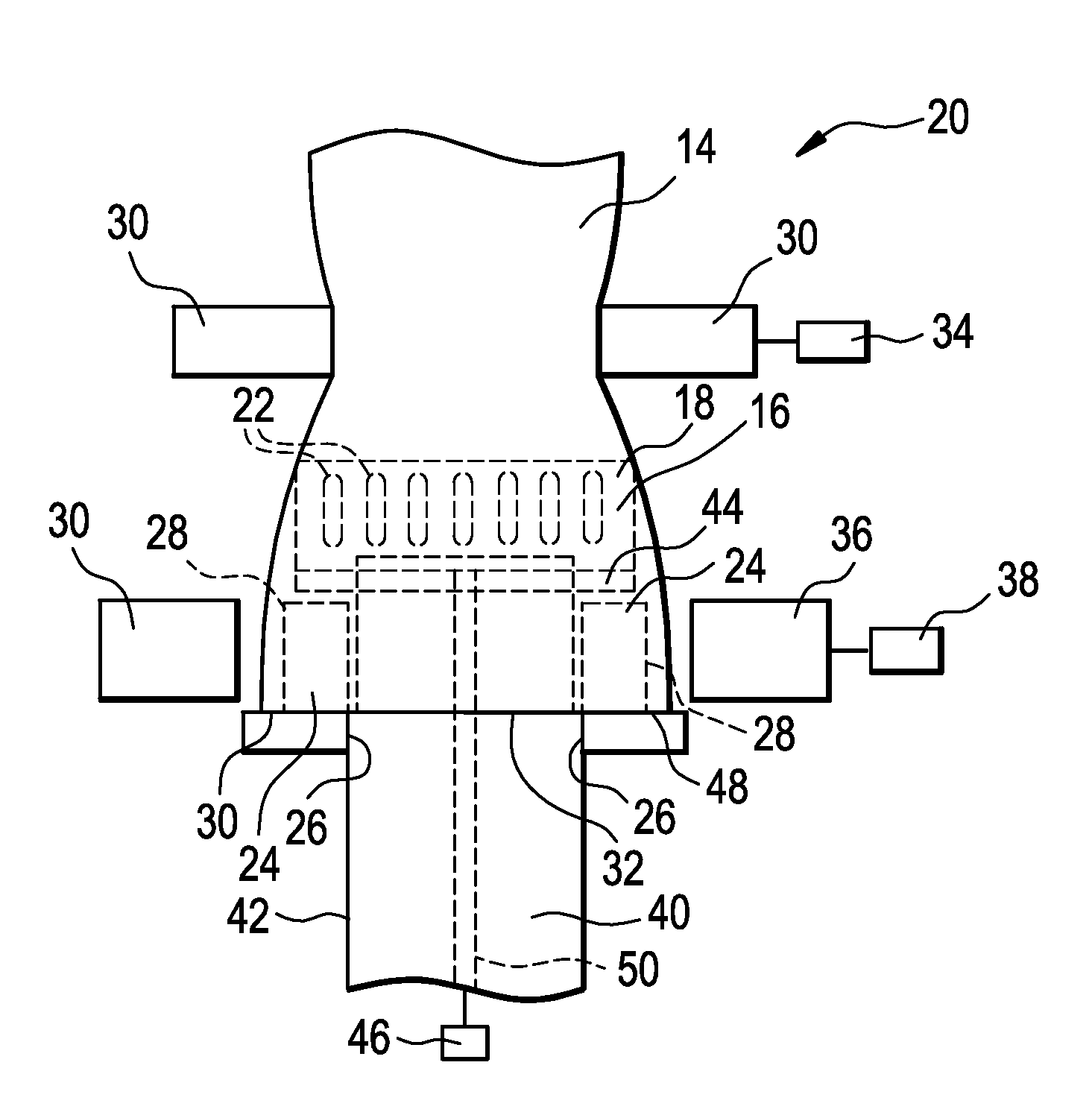

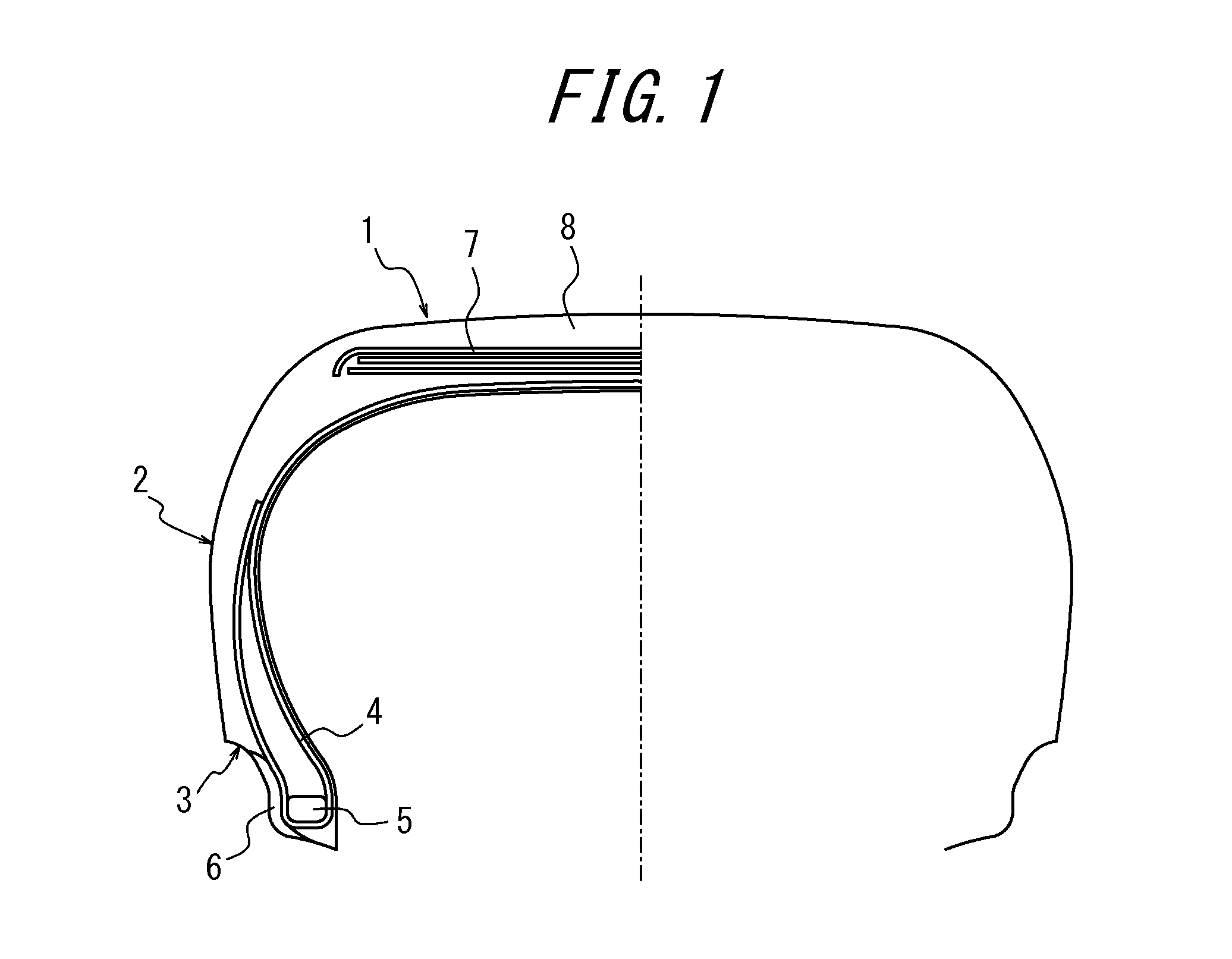

Air conditioner

ActiveUS20180313550A1Improve efficiencyAvoid capacity lossMechanical apparatusFluid circulation arrangementEngineeringRefrigerant

Air conditioner for conditioning a space inside a building includes a heat source unit and at least one indoor unit. The heat source unit has a heat exchanger unit and a compressor unit. The heat exchanger unit includes a first heat exchanger disposed in a first casing and configured to exchange heat with a heat source. The compressor unit includes a compressor disposed in a second casing separate from the first casing, the heat exchanger unit and the compressor unit being fluidly connected via a first liquid refrigerant pipe and a first gaseous refrigerant pipe. At least one indoor unit has a second heat exchanger configured to exchange heat with the space to be conditioned and being fluidly communicated to the heat exchanger unit and / or the compressor unit via a second liquid refrigerant pipe and a second gaseous refrigerant pipe. The outer diameter of the first liquid refrigerant pipe is larger than the outer diameter of the second liquid refrigerant pipe and / or the outer diameter of the first gaseous refrigerant pipe is larger than the outer diameter of the second gaseous refrigerant pipe.

Owner:DAIKIN IND LTD +1

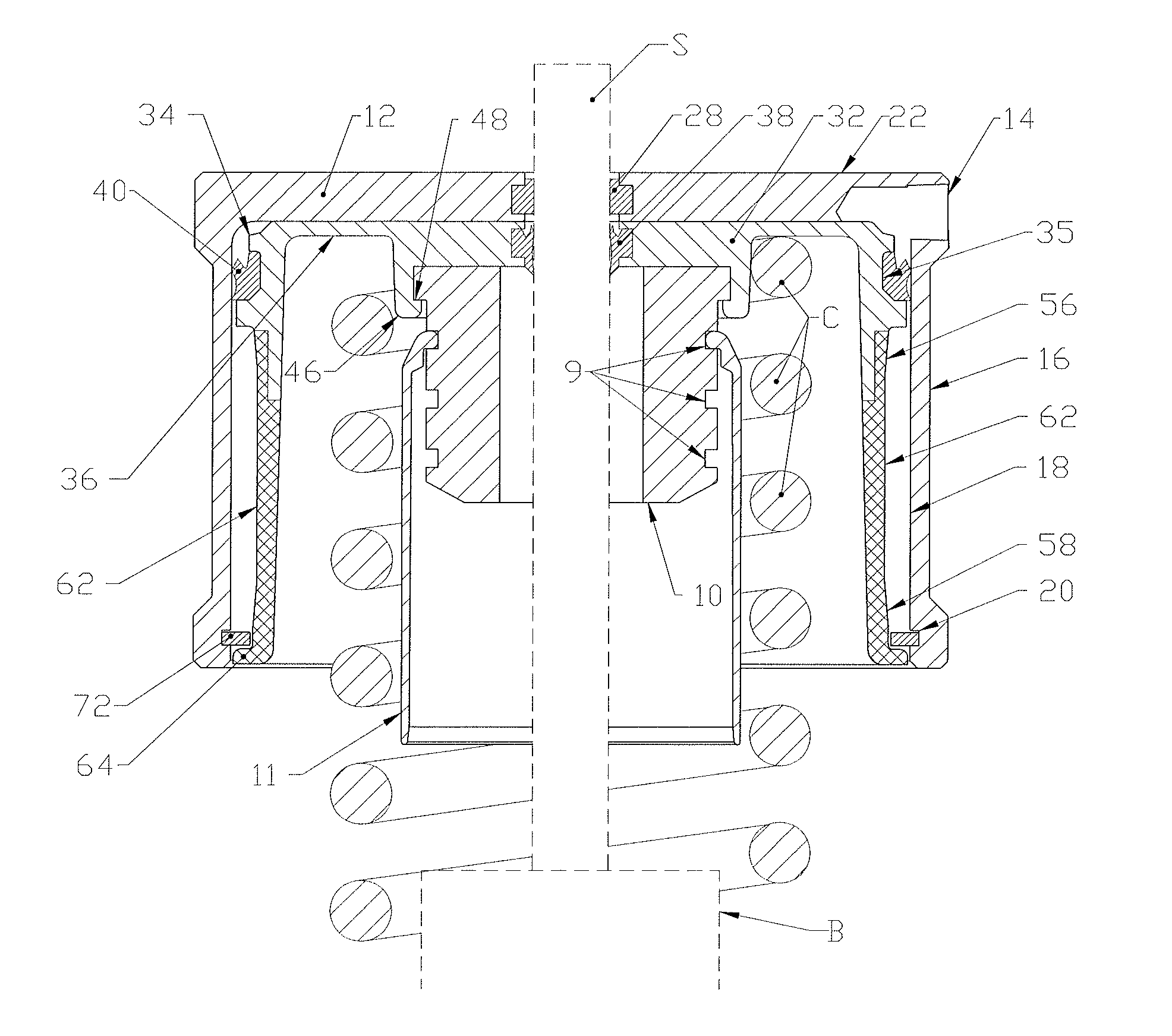

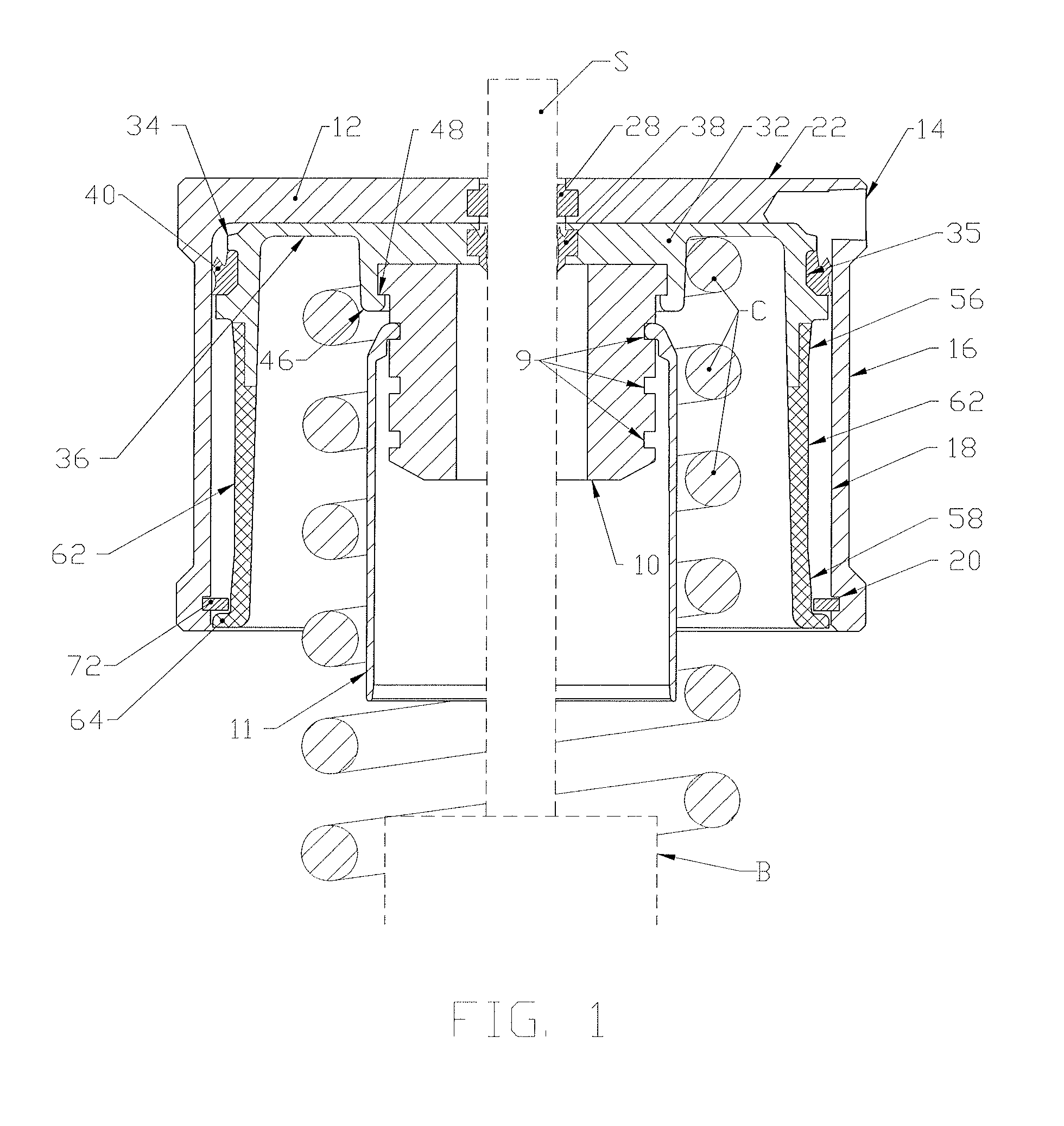

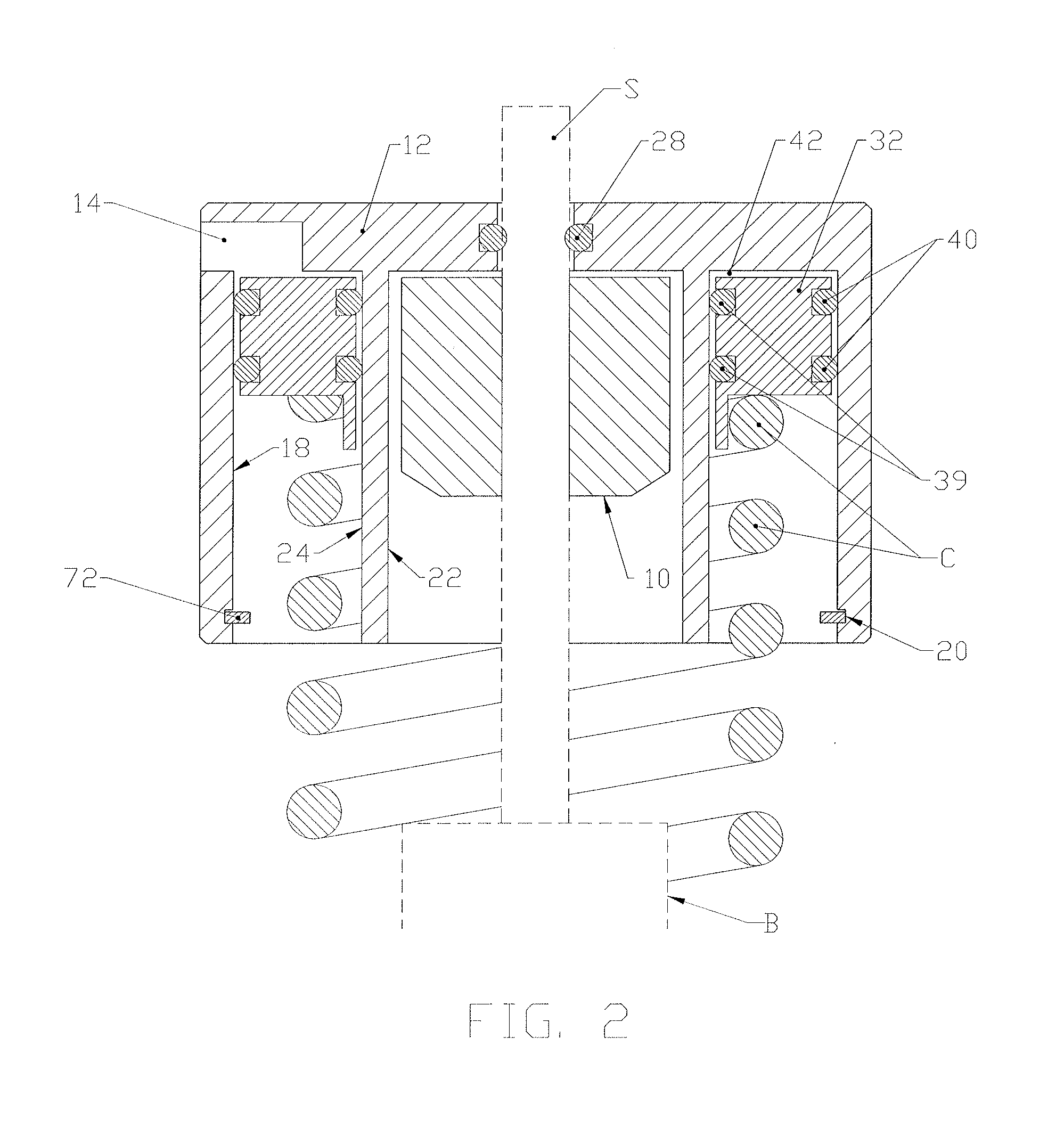

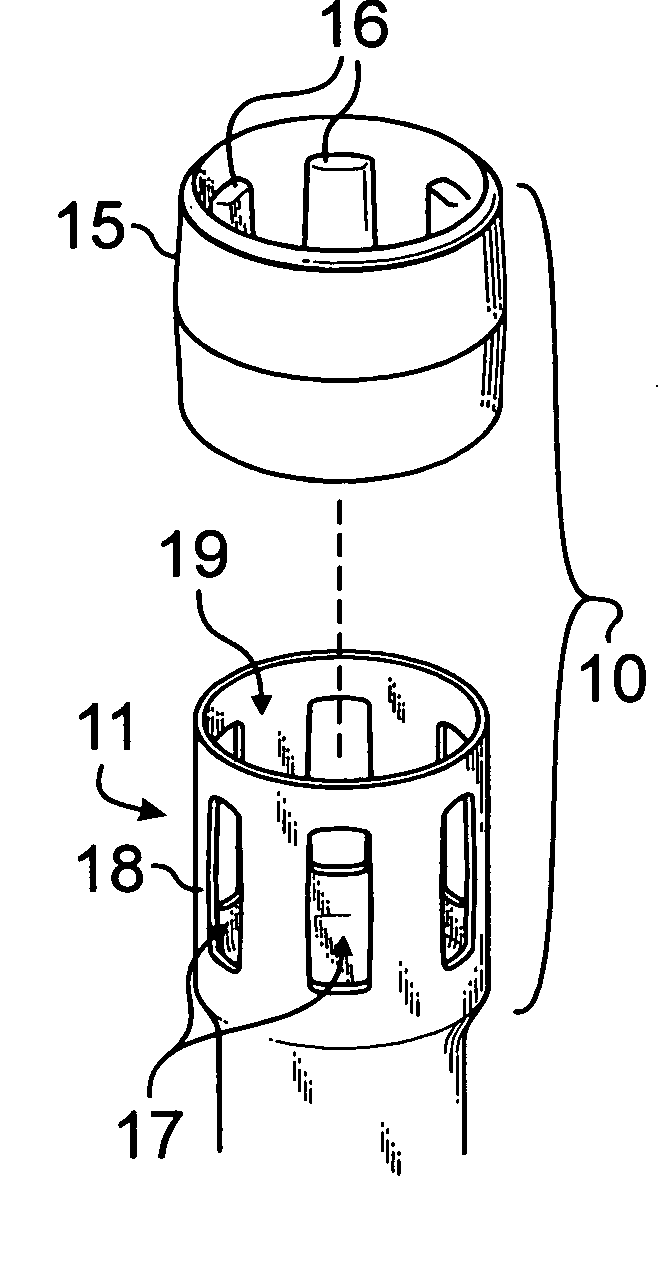

Device for adjusting the height of a vehicle

ActiveUS20130221626A1Large outer diameterSpringsResilient suspensionsElectronic controllerCruise control

The present invention is a system for adjusting the height of vehicles that have coil spring suspensions. The invention may be added to existing vehicle suspensions without the need to remove and replace the existing vehicle suspension components. The invention includes cylinders, pistons, seals, dust shields, pressure pump(s) and storage tank(s). It also may optionally include electronic hardware, such as, an electronic controller and software, to control the functions of the system and sensor(s) which detect ground clearance and speed. The invention may be operated manually by a vehicle driver through push buttons, which may operate through the vehicle's existing cruise control buttons. Alternatively, the system can be automated through an electronic control unit (ECU) to avoid collision with obstacles in the vehicle's path.

Owner:STEALTH INNOVATIVE SYST

Auto-adapting tube fitting

InactiveUS20050167985A1Easy to useReduce manufacturing costSleeve/socket jointsAmmunition loadingEngineeringMechanical engineering

An auto-adapting fitting for releasably connecting in an end-to-end orientation, a first tube end to a second tube end having an outer diameter within a specified range for use between the ammunition feed port of a paintball gun and the outlet port of a paintball magazine. The fitting is formed onto the end portion of the gun inlet tube. The fitting comprises a resilient sleeve-shaped collar having a number of radially, inwardly extending projections that pass through corresponding radially penetrating holes through the side wall of the end portion of the feed port near its upper opening. The projections bear against the outer surface of the magazine outlet tube. Magazine outlet tubes of a larger outer diameter will cause the collar to be resiliently pushed outwardly.

Owner:JT USA

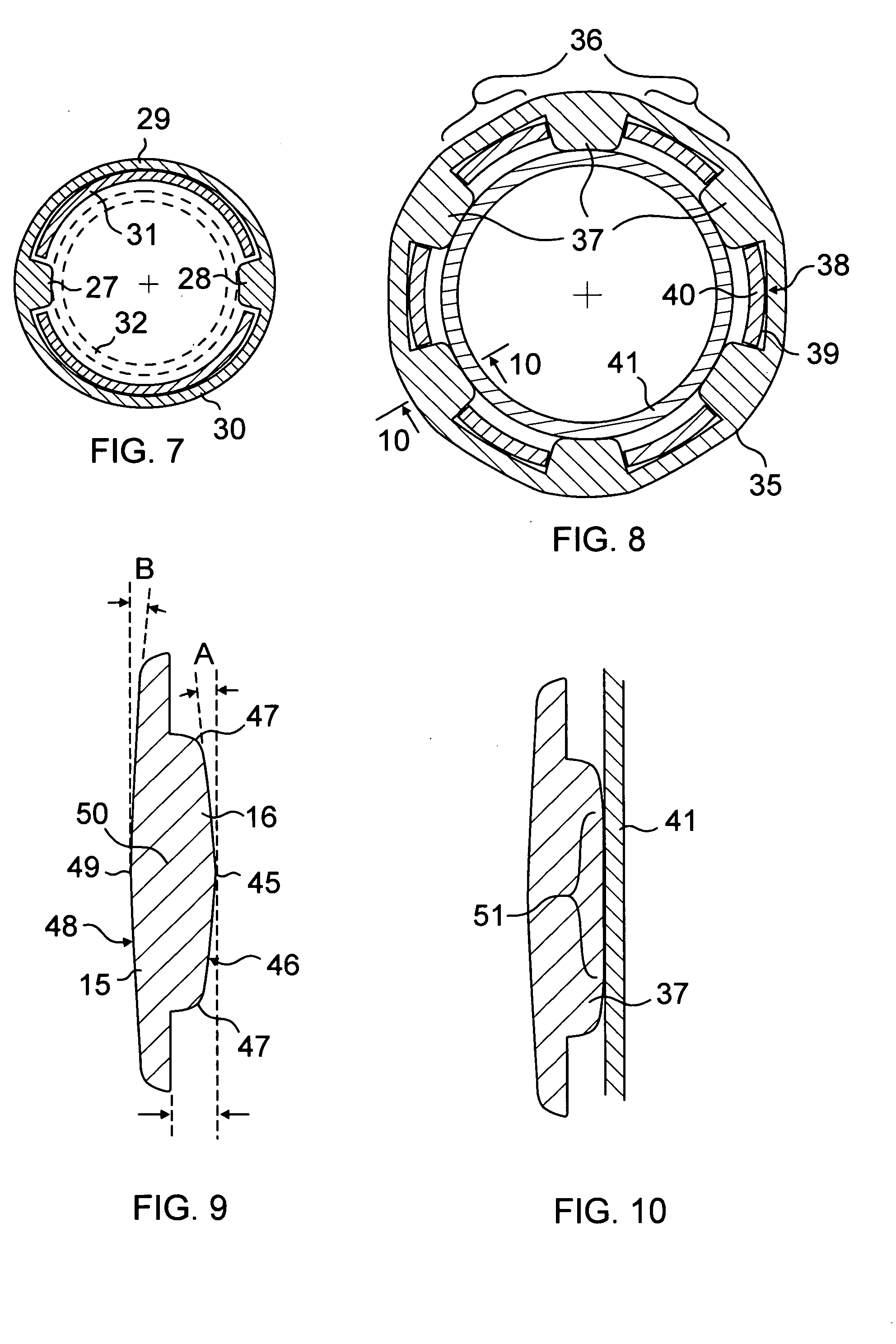

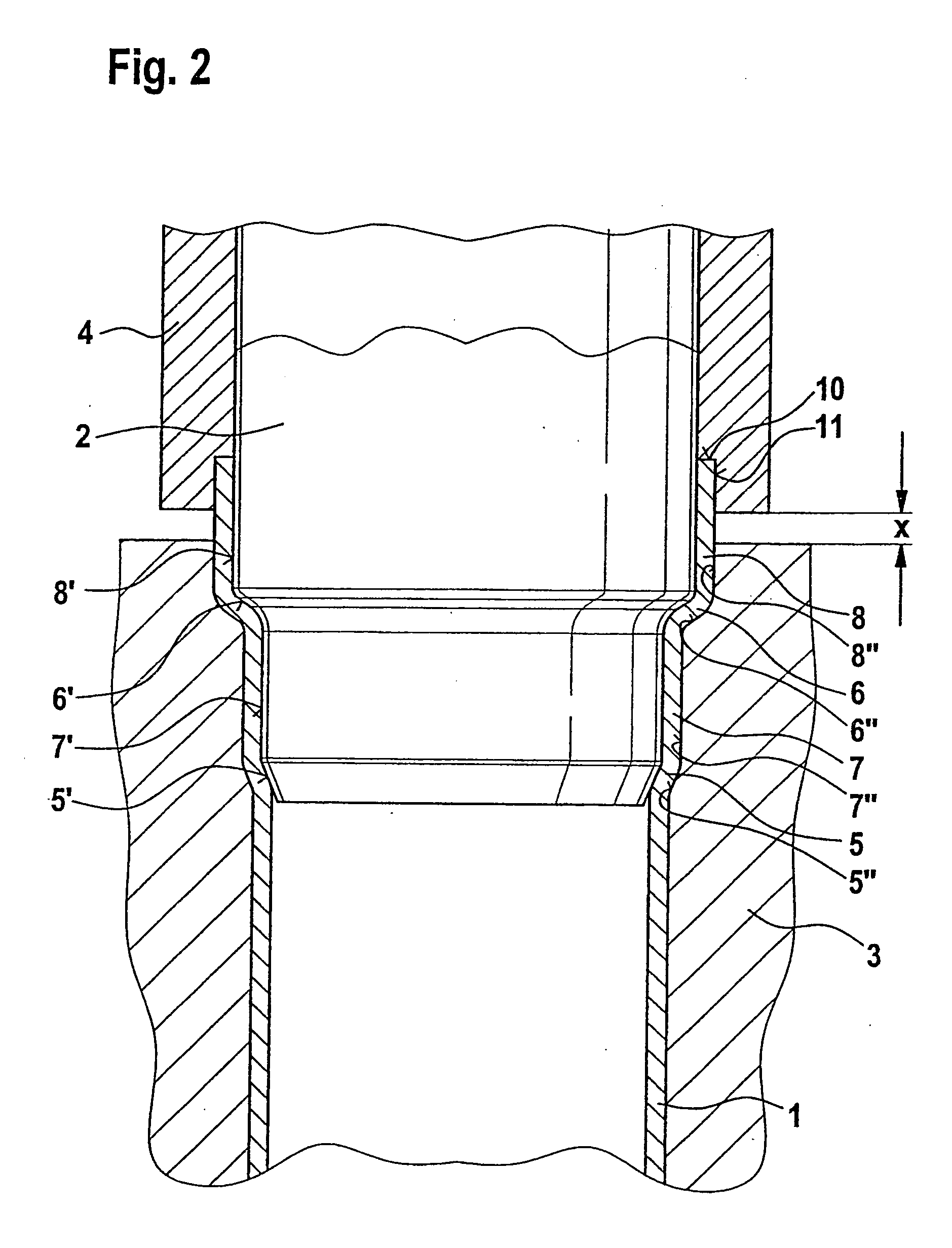

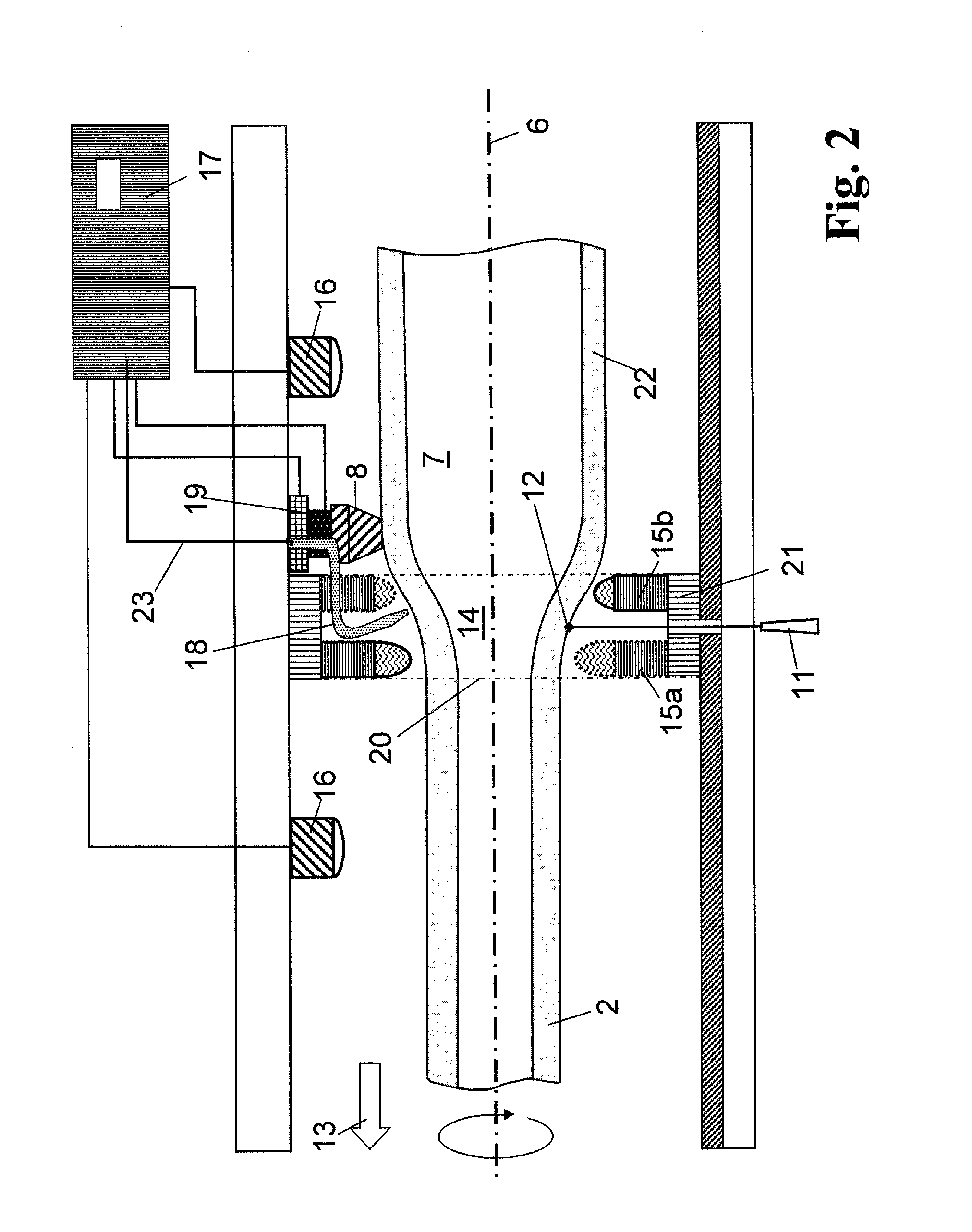

Method for Producing a Coupling on a Pipe and Device for Producing Said Coupling

In a method for producing a coupling on a pipe, preferably consisting of copper or steel or Cu-, Ni-, Fe-alloys, by way of a preferably graduated or one-stage expansion of the pipe end to create a much larger difference in diameter, an expansion tool is introduced axially into the end of the pipe. Once the expansion tool has been introduced into the pipe end, the region of the pipe end that is to be or has been expanded is completely or partially compressed, by a force acting axially on the pipe end, so that the external diameter of the pipe end that is to be processed is delimited by one or more shaping jaws that completely or partially surround the pipe end. The invention also relates to a device for producing a coupling on a pipe end according to the method.

Owner:FFG WERKE +1

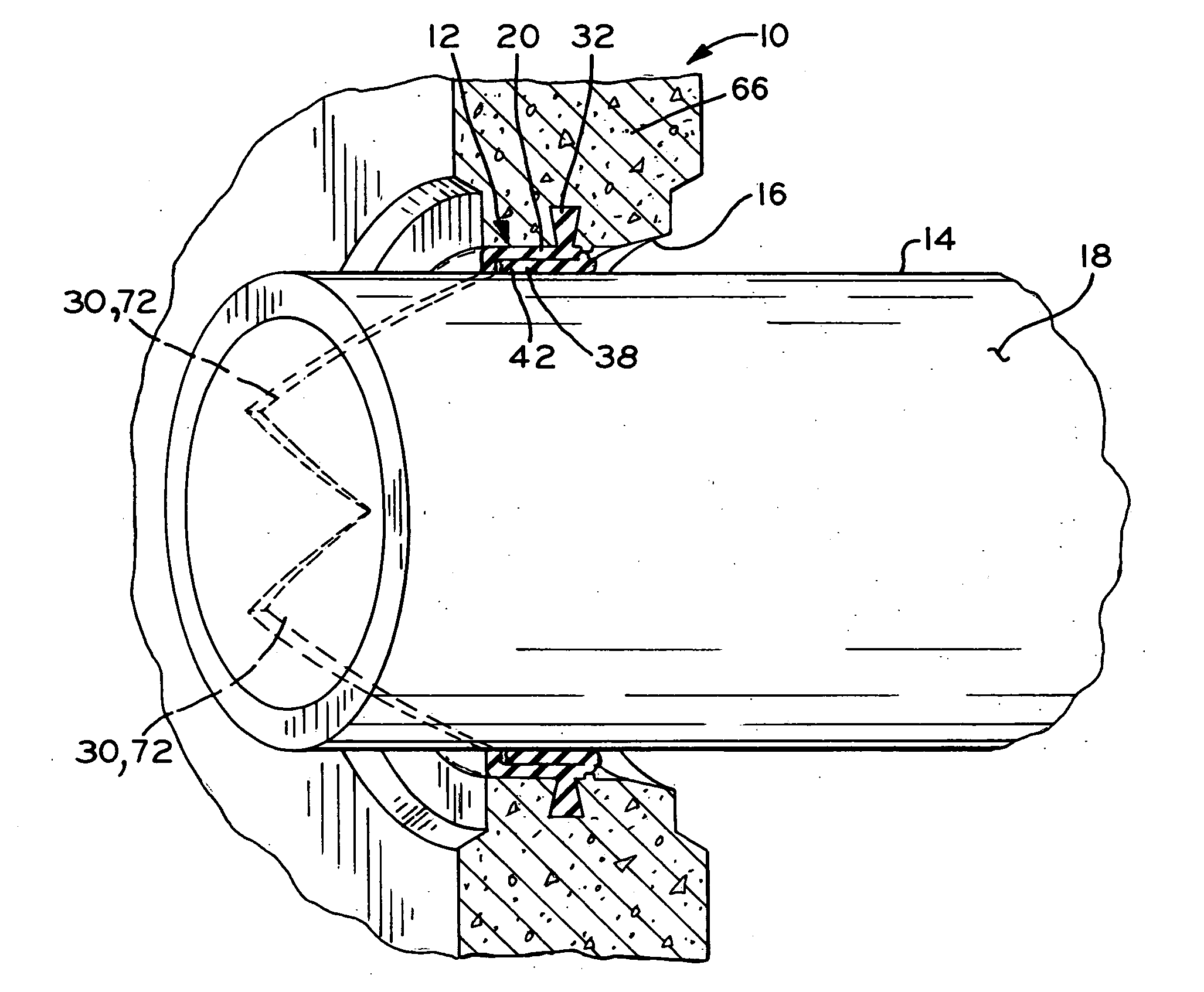

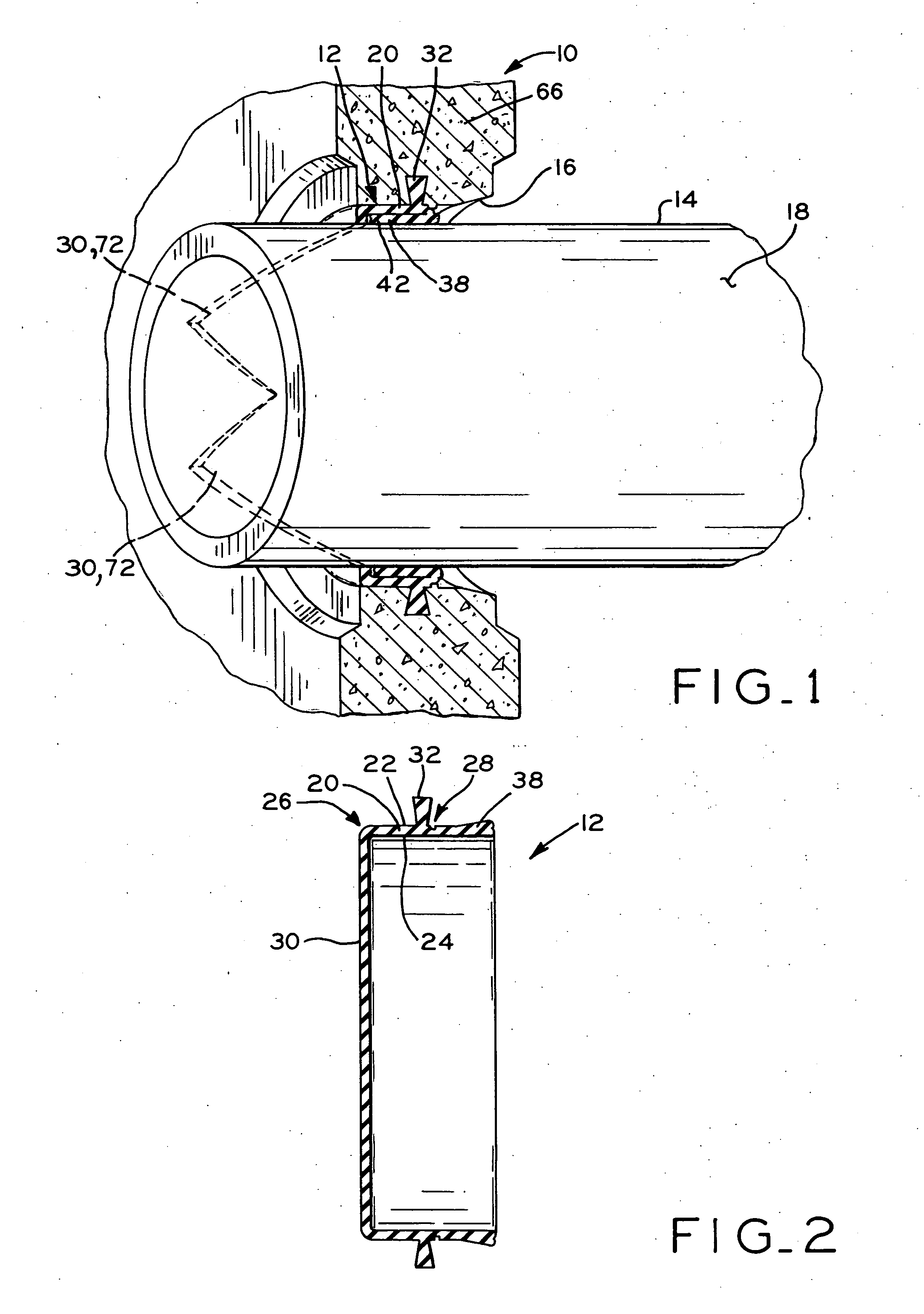

Pipe joint seal with closed end face

InactiveUS20050098961A1Easy to cutEasily slitSleeve/socket jointsFluid pressure sealed jointsInternal pressureEngineering

A pipe joint gasket with a closed end face. An annular anchoring projection extends outwardly from the external surface of the gasket and is embedded within a structure with which the gasket is used. The gasket also includes a sealing projection for engaging a pipe to provide a compressive, fluid tight seal between the pipe and the gasket. In applications in which the gasket is used for a pipe joint, the closed end face of the gasket may be slit or removed to allow a pipe to pass through the gasket. Alternatively, in applications in which the gasket is not used for a pipe joint, the end face remains intact, and has a thickness sufficient to withstand internal pressures within the structure and external pressures from without the structure. In an alternate embodiment, the gasket is configured for use with at least two different sizes of pipe.

Owner:SKINNER JAMES W

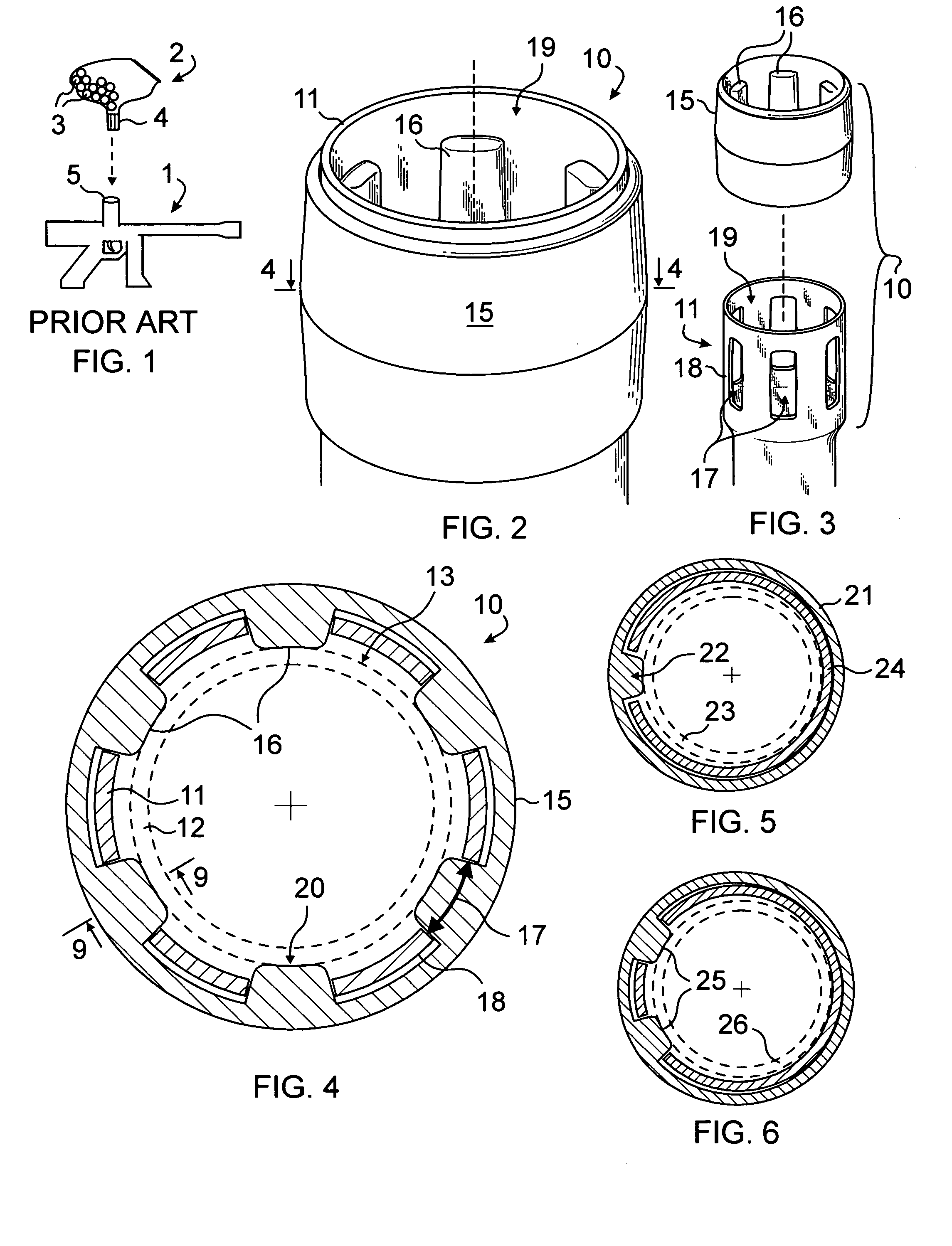

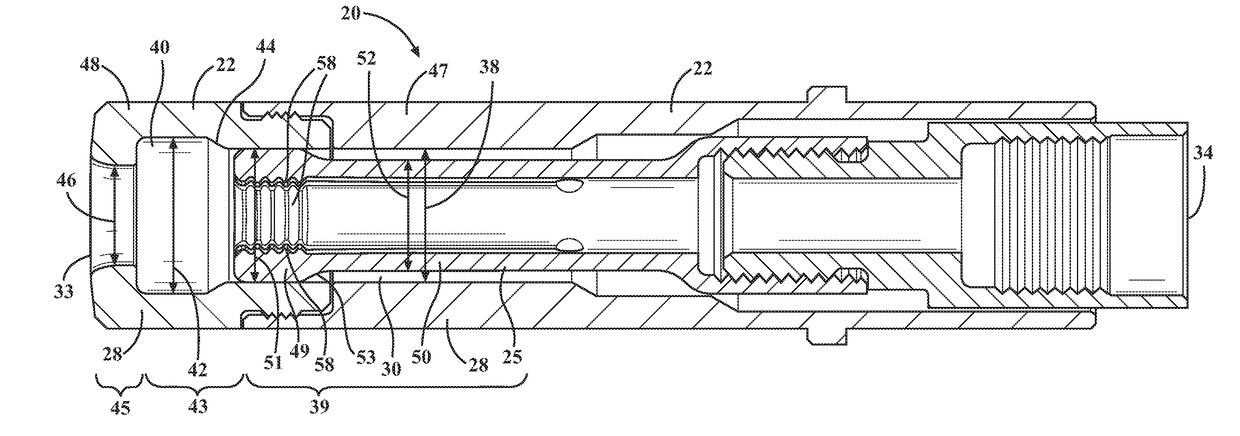

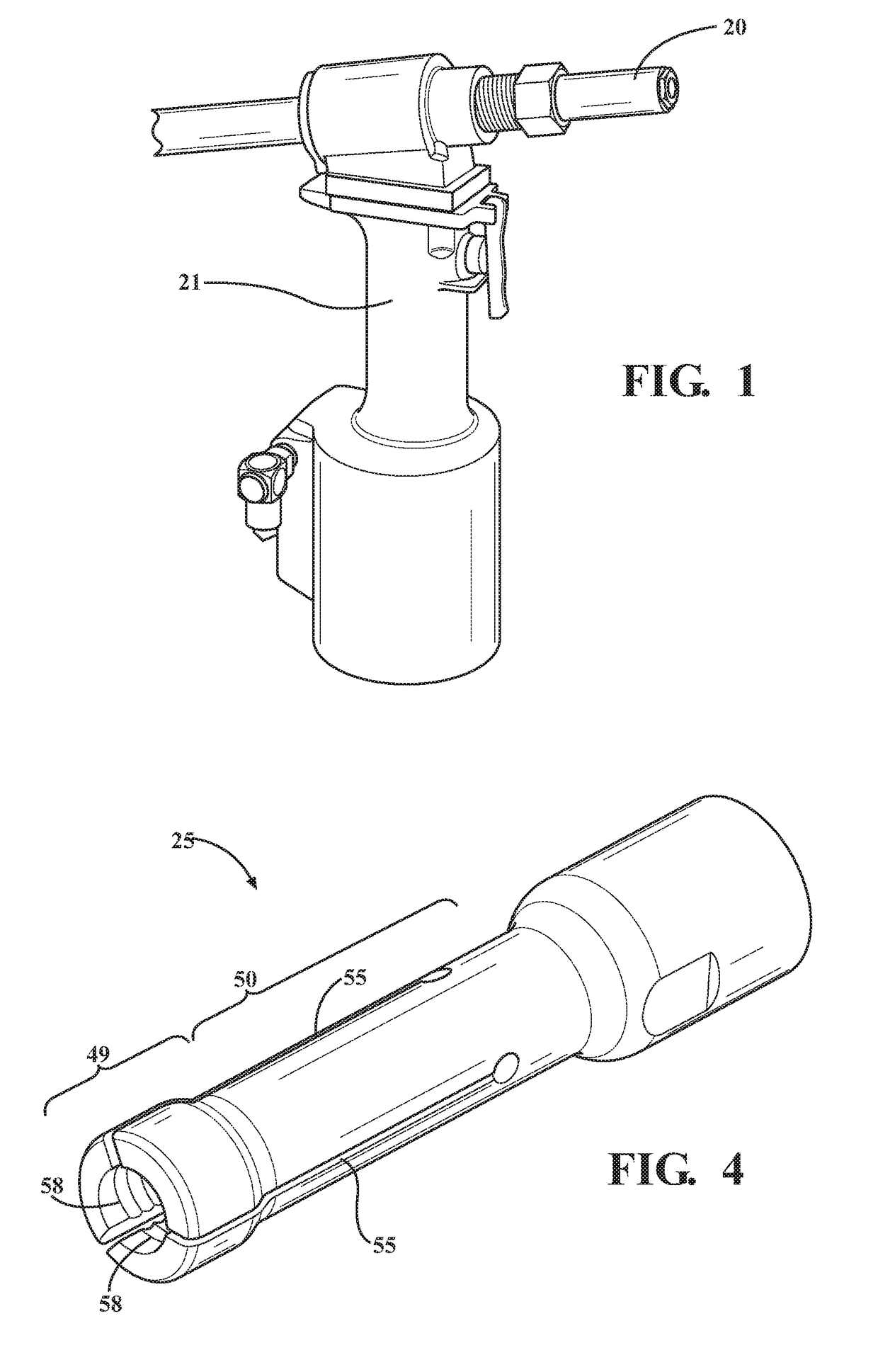

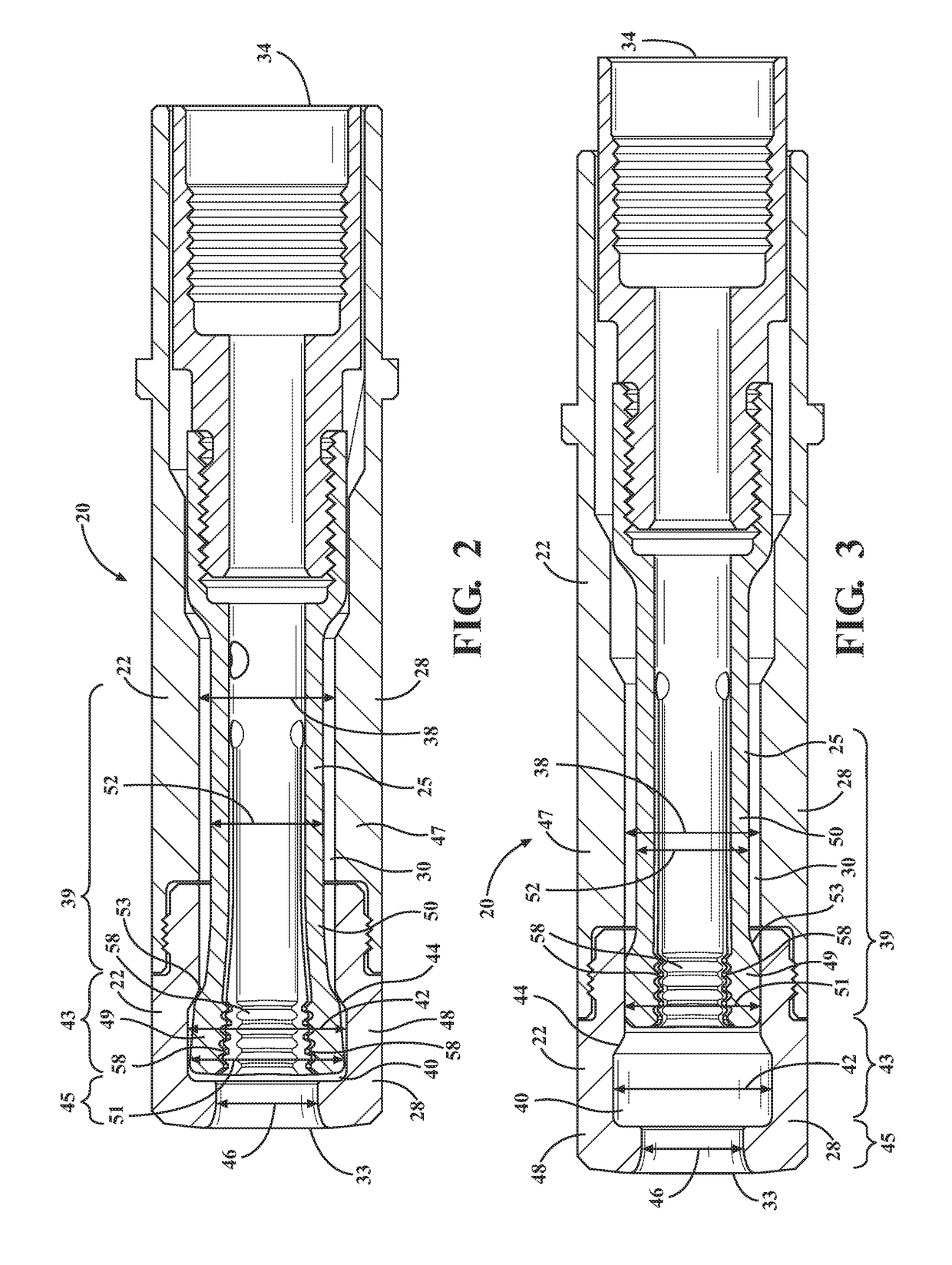

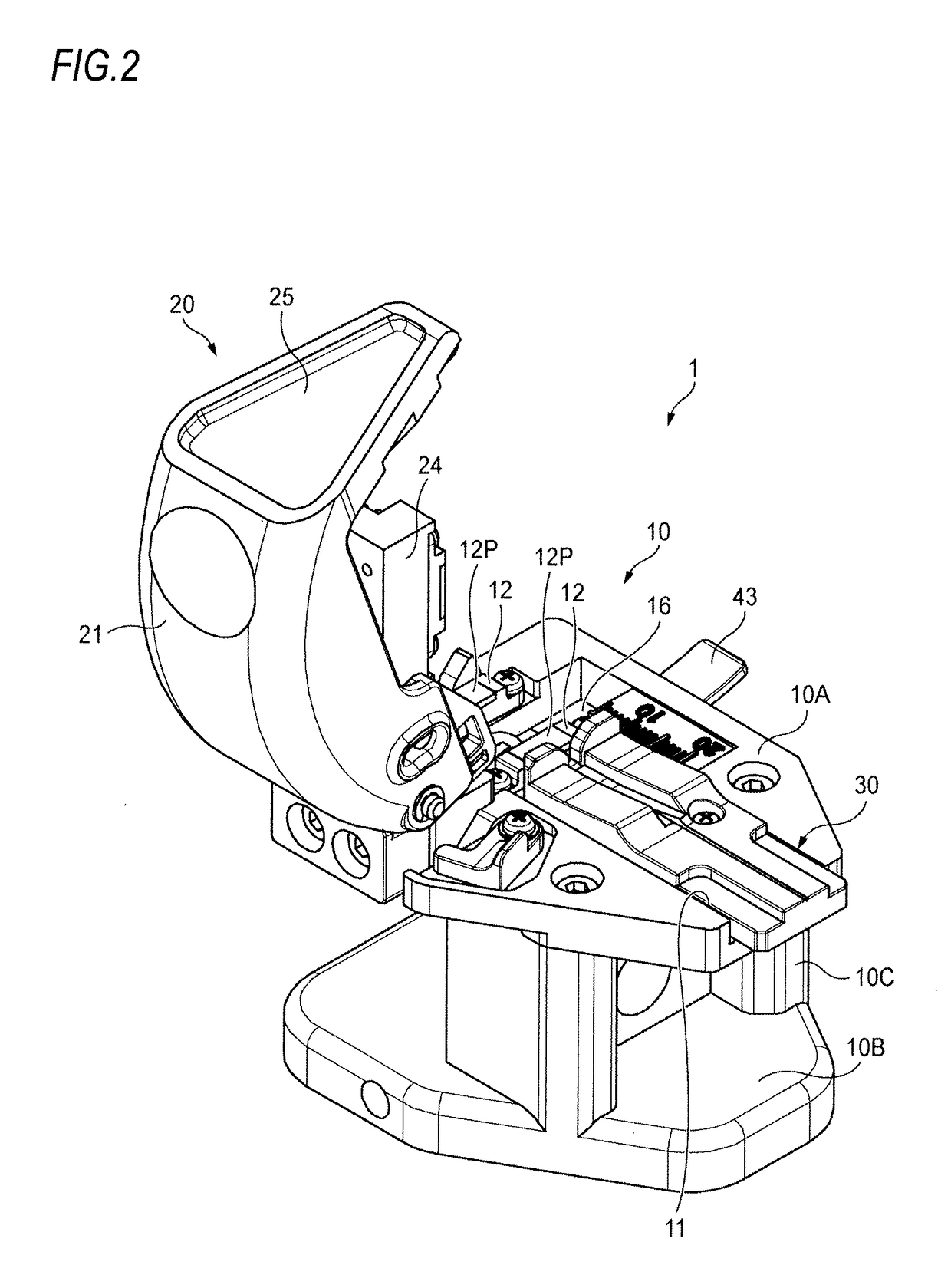

Lockbolt tool nose assembly

The present invention relates to a nose assembly with integrated anvil and puller to assist in swaging a collar to a lockbolt type fastener. The nose assembly has a sidewall defining a hollow axially extending interior and an open terminal end, hollow axially extending interior having a first interior diameter, and an annular recess of a second interior diameter greater than the first interior diameter. A puller is slidably displaceable relative to the holder sidewall. The puller is configured with opposing sets of teeth for gripping a lockbolt pintail and to close grippingly on the lockbolt pintail when the puller is axially displaced relative to the holder sidewall sufficiently to draw a head portion of the puller at least partially out of the recess and into the first interior diameter length.

Owner:GAGE BILT

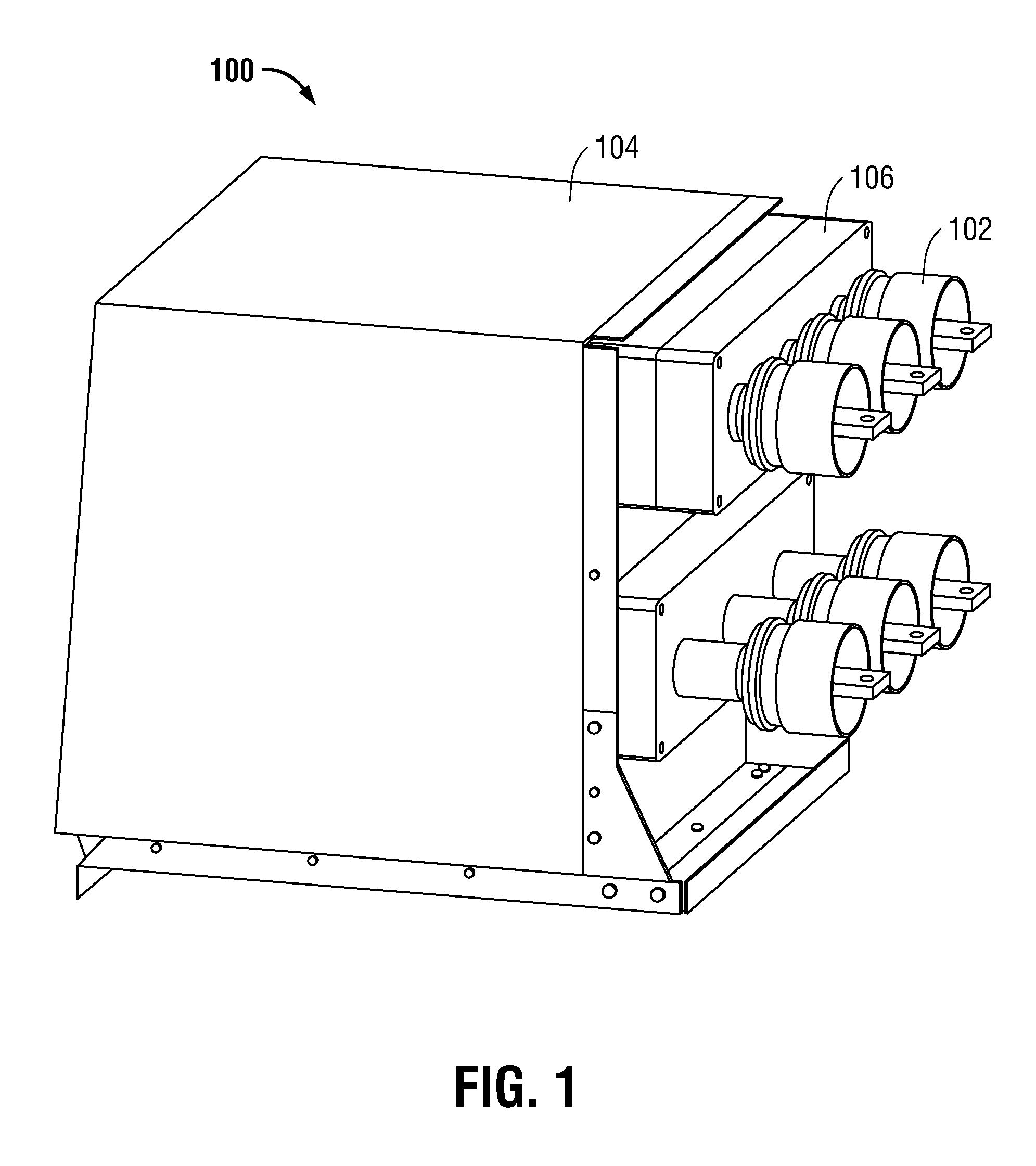

Compact transformer bushing

ActiveUS20150372468A1Increase linear surface distanceGreat linear surface distanceSwitchgear arrangementsTransformersEngineeringSwitchgear

A compact electrical bushing has a separate insulating end cap removably attached to the shaft of the bushing at an end used for mounting a current transformer. The removably attached insulating end cap has a large outer diameter that increases the linear surface distance of the bushing. The outer diameter may be determined in a predefined manner based on the desired length of the shaft, and vice versa, with a larger outer diameter corresponding to a shorter shaft. The increased linear surface distance allows the bushing to meet minimum tracking distance with a shorter shaft relative to existing bushings. The shorter shaft reduces the footprint of switchgear and other electrical isolation equipment to which the bushing may be connected. The insulating end cap may be removed from the bushing as needed to allow the current transformer to be slid onto the bushing without having to pass over the end cap.

Owner:SCHNEIDER ELECTRIC USA INC

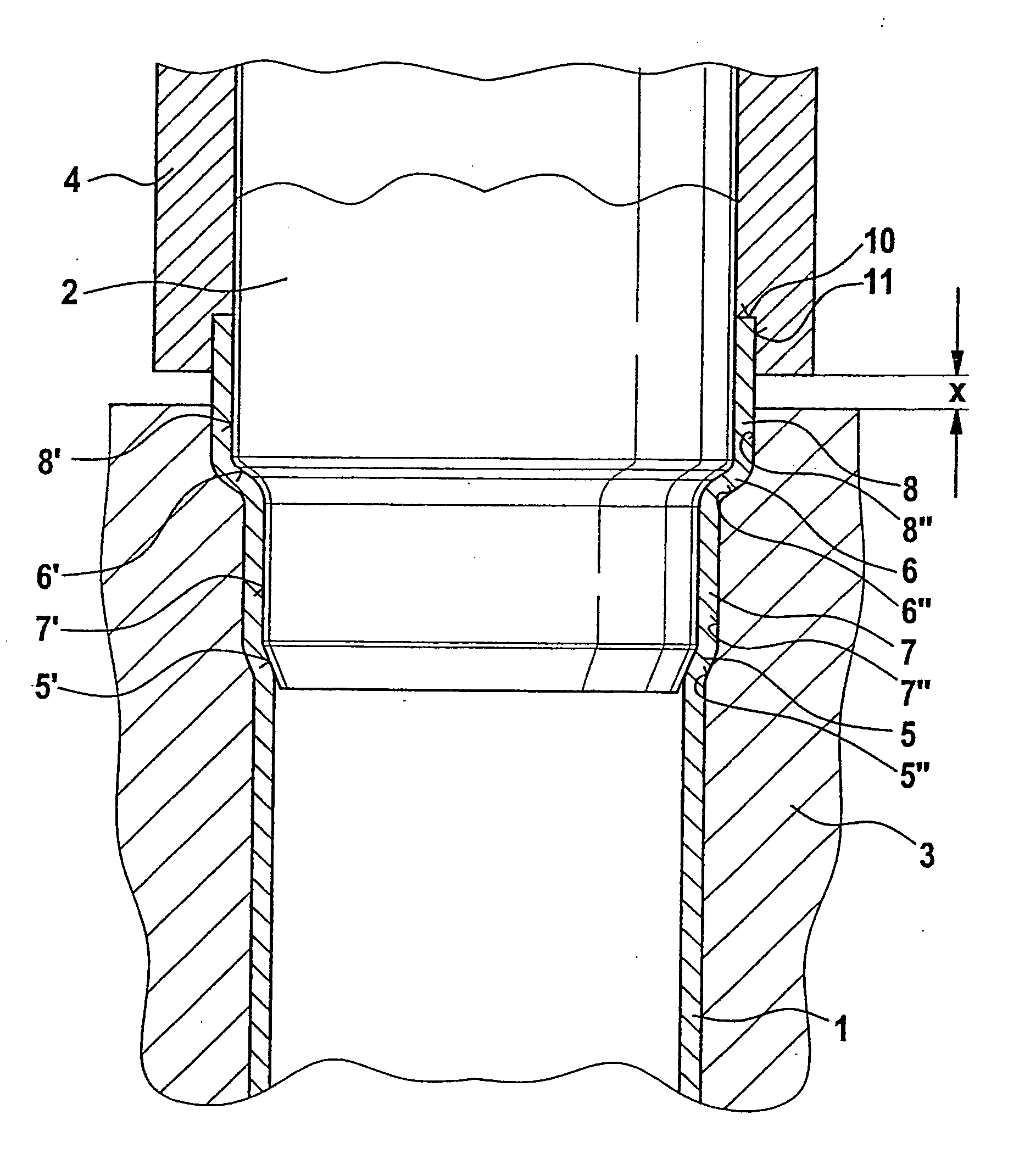

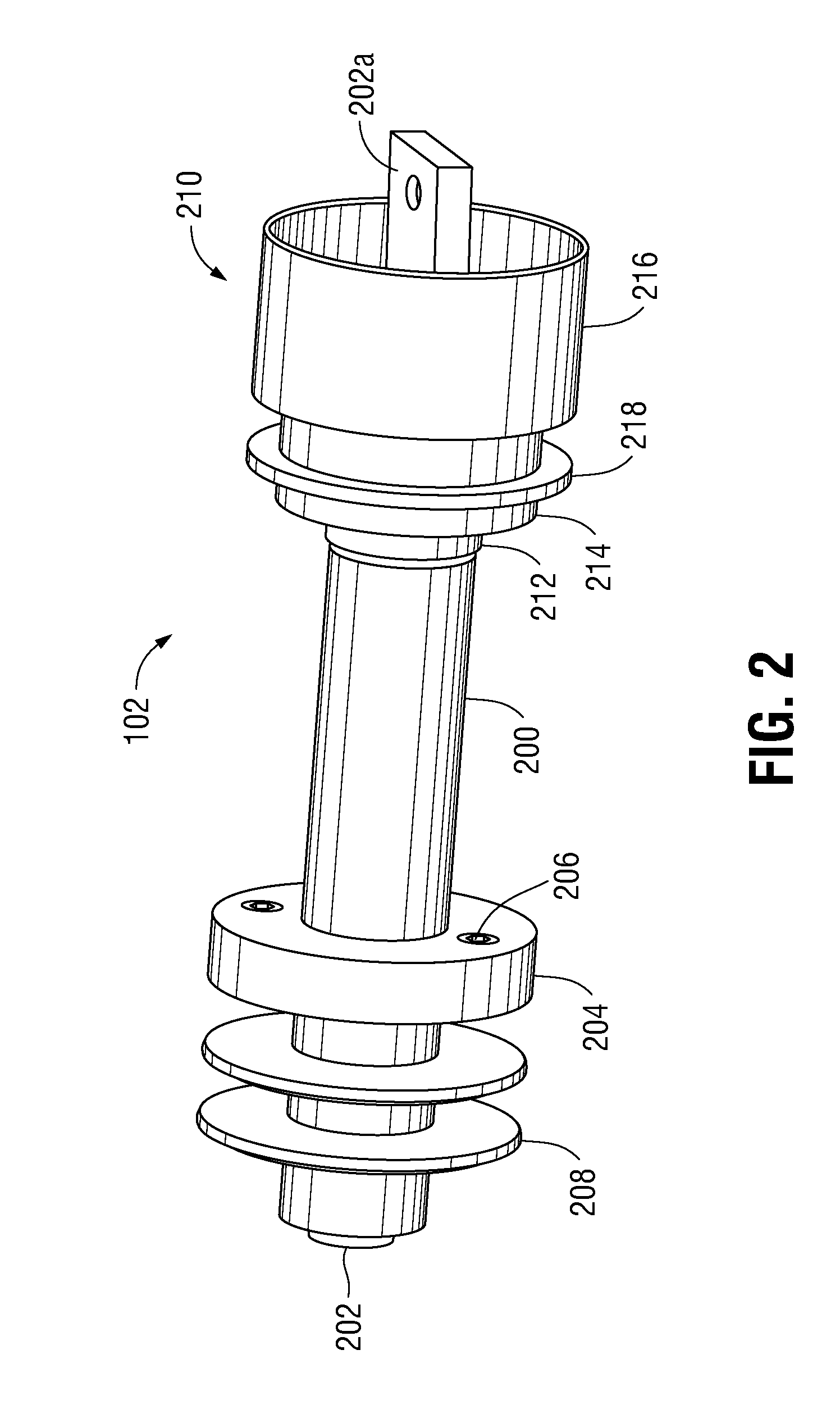

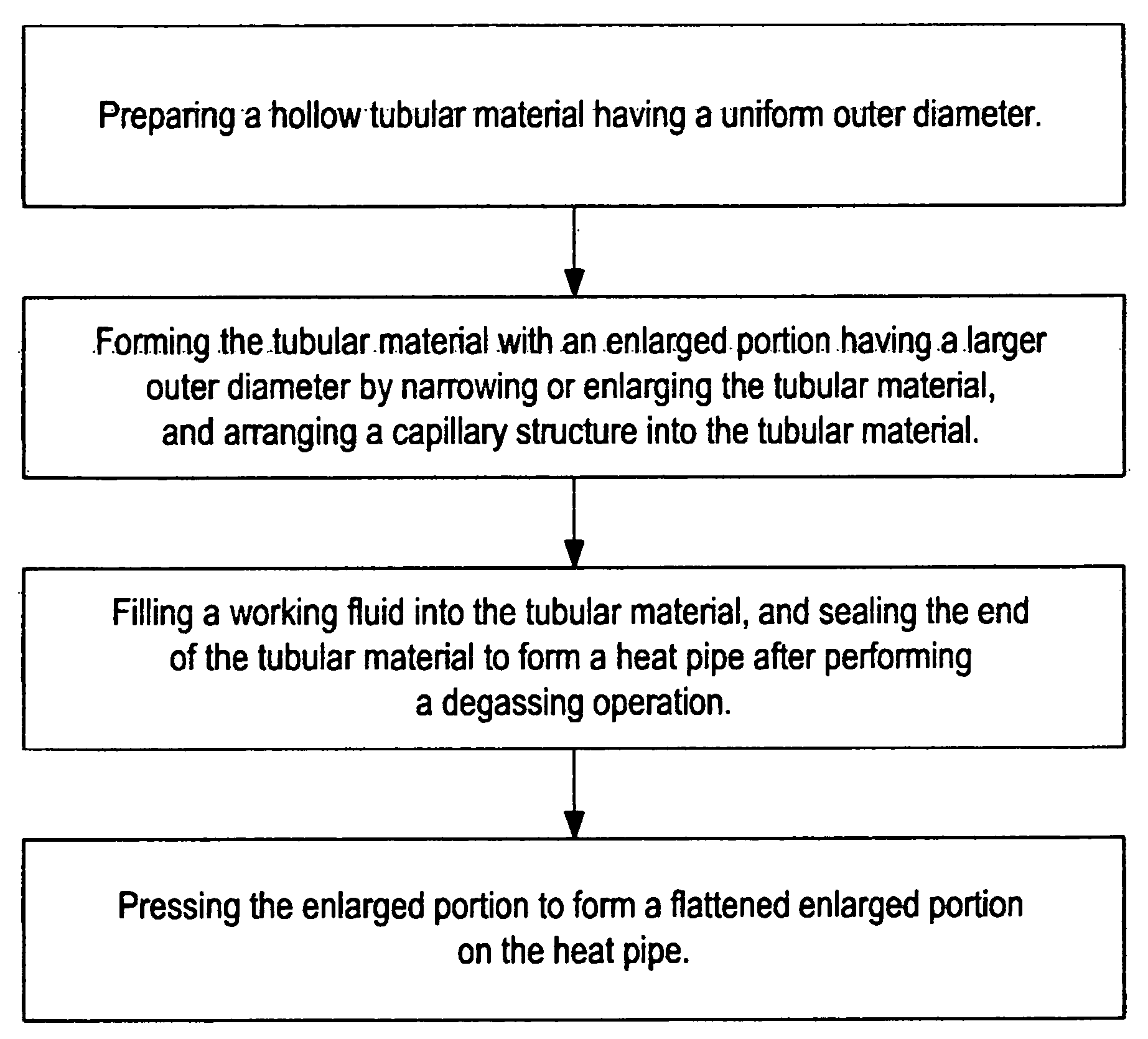

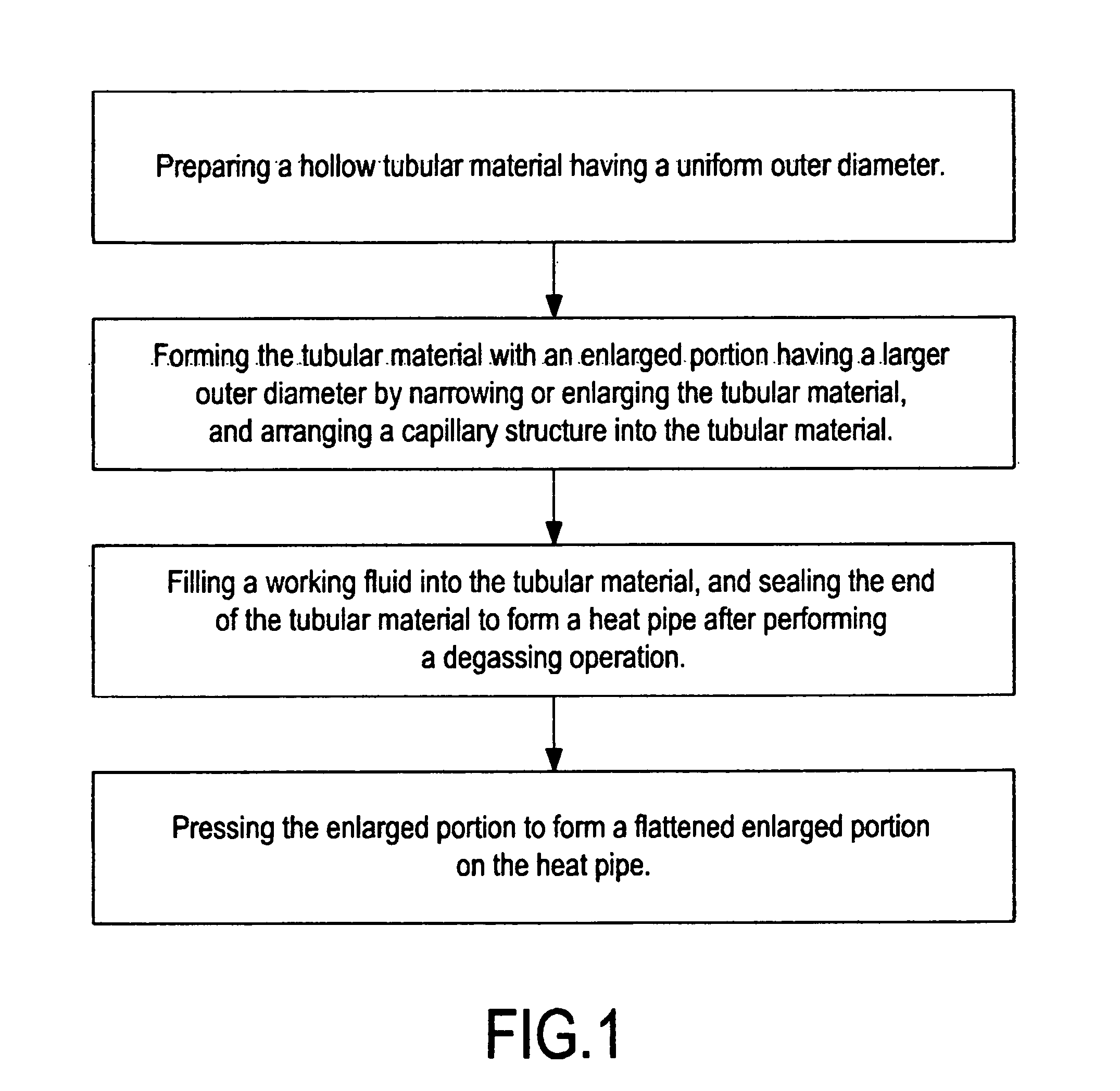

Method for manufacturing a heat pipe having an enlarged portion

InactiveUS7275409B1Large surface areaLarge outer diameterIndirect heat exchangersEngineeringMechanical engineering

A method for manufacturing a heat pipe having an enlarged portion includes the steps of: preparing a hollow tubular material having a uniform outer diameter; forming the tubular material with an enlarged portion having a different or larger outer diameter by narrowing or enlarging the tubular material; arranging a capillary structure into the tubular material; filling a working fluid into the tubular material after sealing one end of the tubular material; sealing the end to form a heat pipe after performing a degassing operation; and pressing the enlarged portion obtained in the previous step to form a flattened enlarged portion on the heat pipe.

Owner:CHAUN CHOUNG TECH

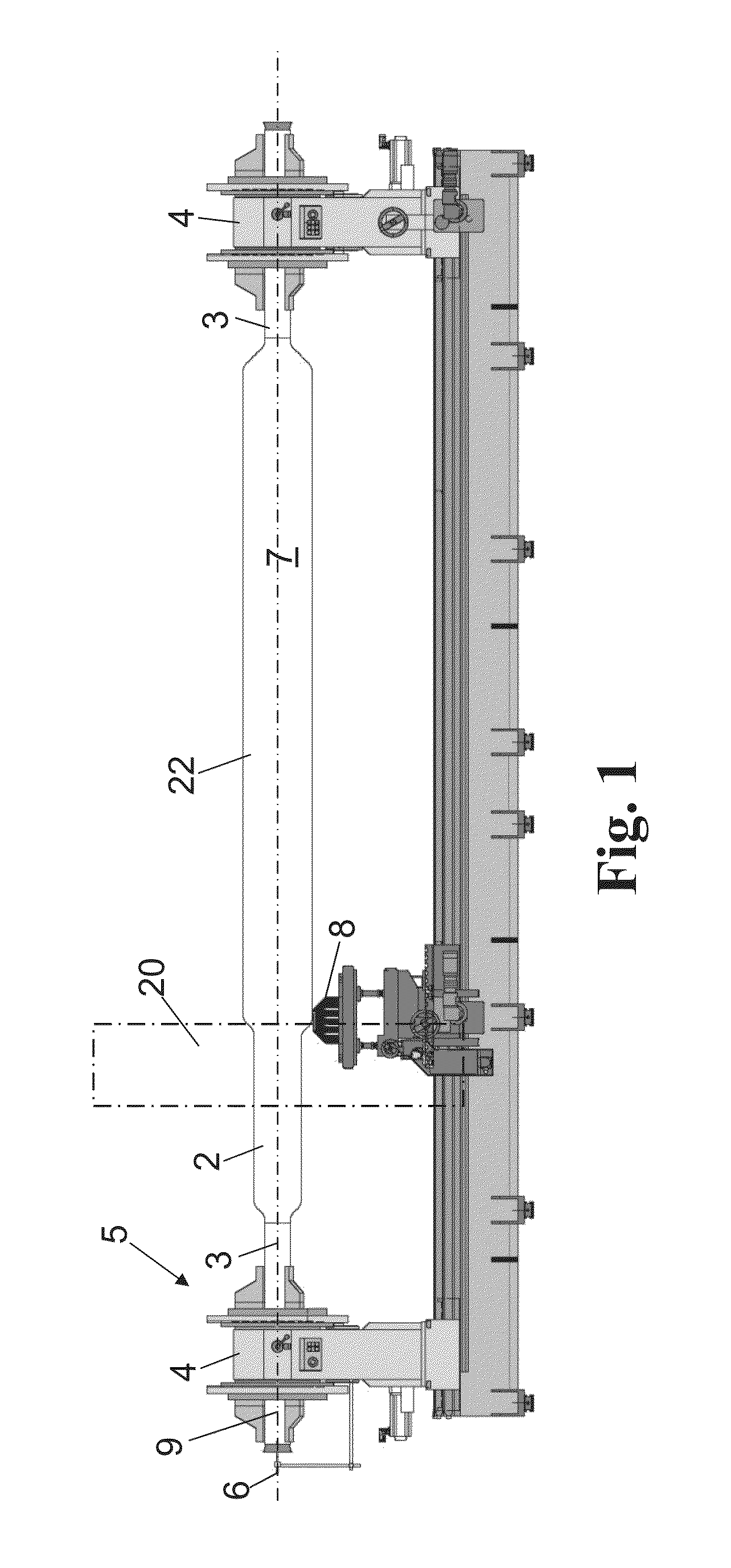

Method for producing a tube of glass

ActiveUS20160176747A1Good dimensional stabilityLarge outer diameterGlass reforming apparatusGlass severing apparatusEngineeringCentrifugal force

A method for forming a hollow cylinder, in a single step or in as small a number of steps as possible, into a quartz glass tube with a large outer diameter and high dimensional stability is provided. The cylinder, while rotating about a rotation axis, is softened in portions in a heating zone which is moved at a relative feed rate Va, and the softened portion is radially expanded by a centrifugal force and / or an internal overpressure applied in the hollow cylinder bore so as to form a deformation zone. The tube is continuously shaped with an outer diameter D2 which is greater than that of the hollow cylinder D1. The radial expansion of the softened portion is carried out at a location-dependent radial expansion rate Vr, the profile of which along the deformation zone has a maximum value Vr,max which is smaller than two times the feed rate Va.

Owner:HERAEUS QUARZGLAS

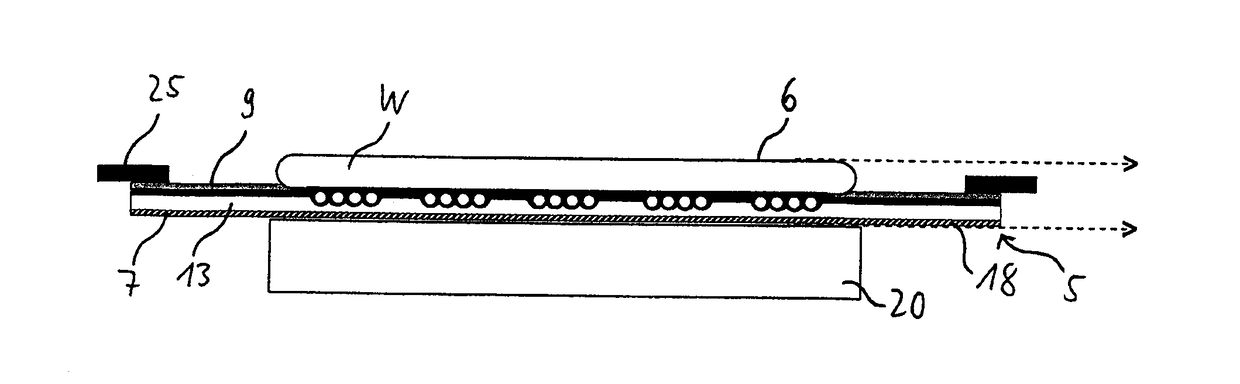

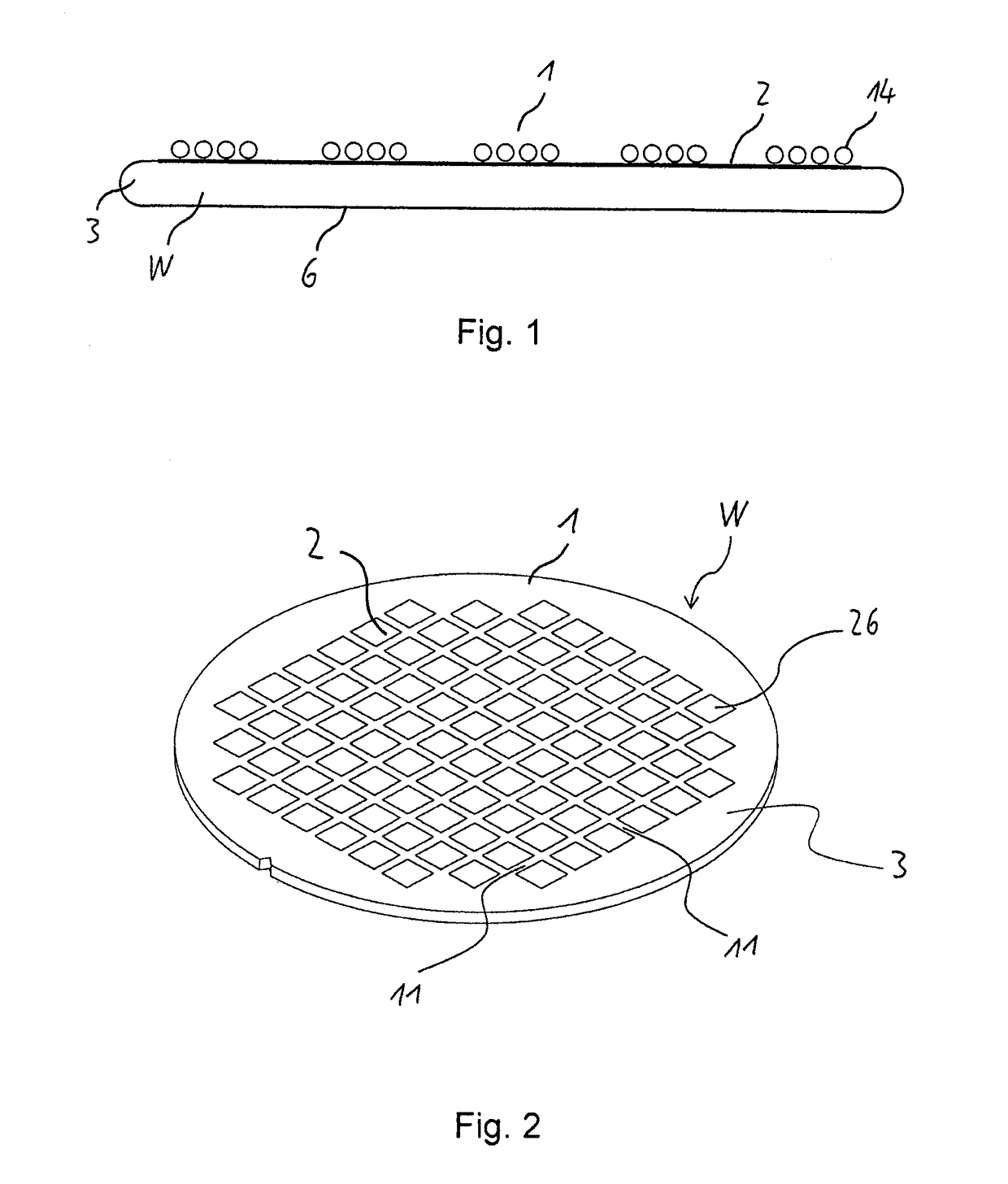

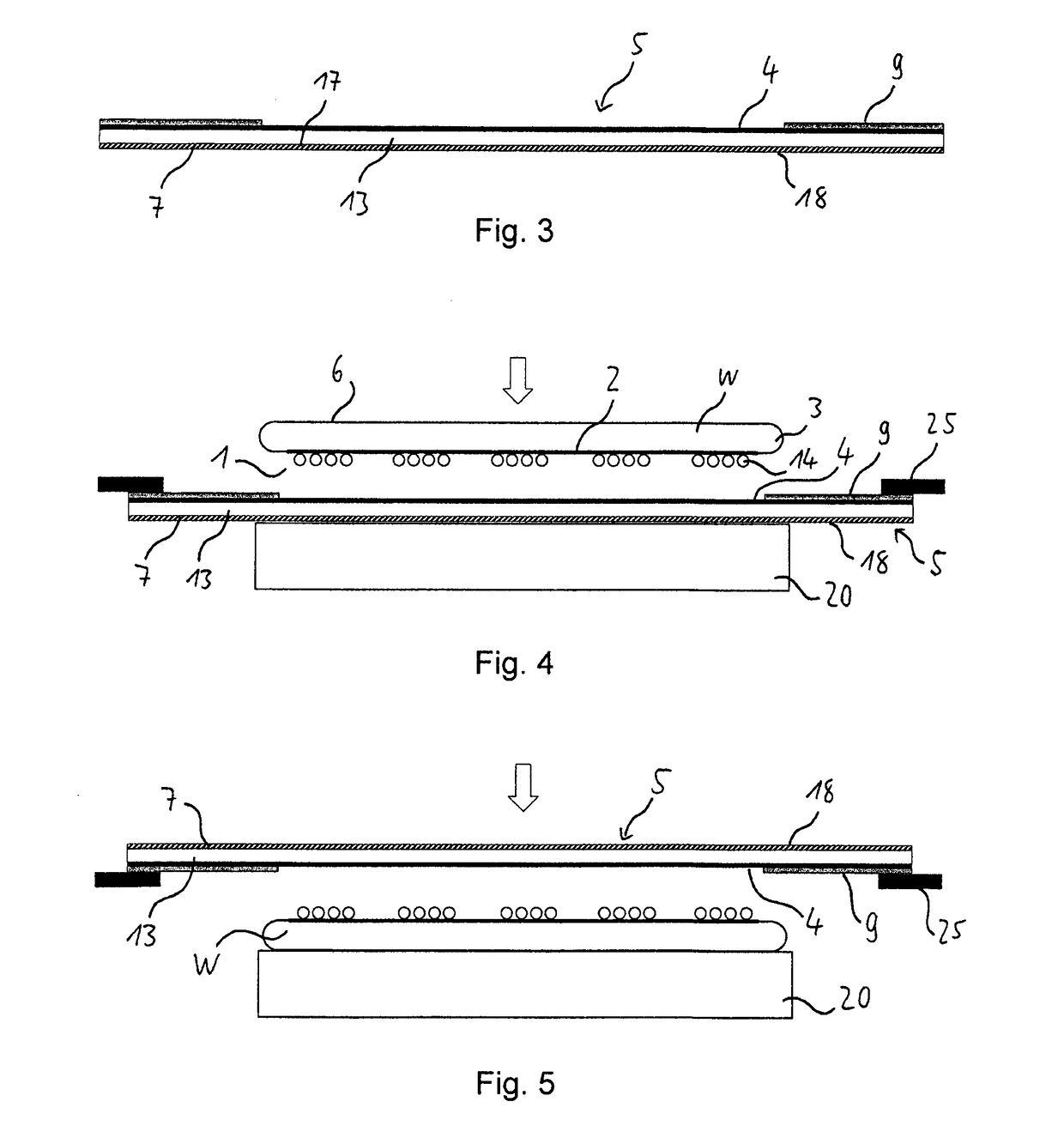

Method of processing wafer and protective sheeting for use in this method

ActiveUS20180247870A1Large outer diameterFirmly attachedSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveCushioning

A wafer has on one side a device area with a plurality of devices, partitioned by a plurality of division lines, and a peripheral marginal area formed around the device area. The device area is formed with a plurality of protrusions protruding from a plane surface of the wafer. The wafer is processed by providing a protective film, having a cushioning layer applied to a front surface thereof, attaching a front surface of the protective film, for covering the devices, wherein the protective film is adhered to at least the peripheral marginal area with an adhesive, and attaching a back surface of the protective film opposite to the front surface thereof to the cushioning layer. The protrusions are embedded in the cushioning. The side of the wafer opposite to the one side is ground for adjusting the wafer thickness.

Owner:DISCO CORP

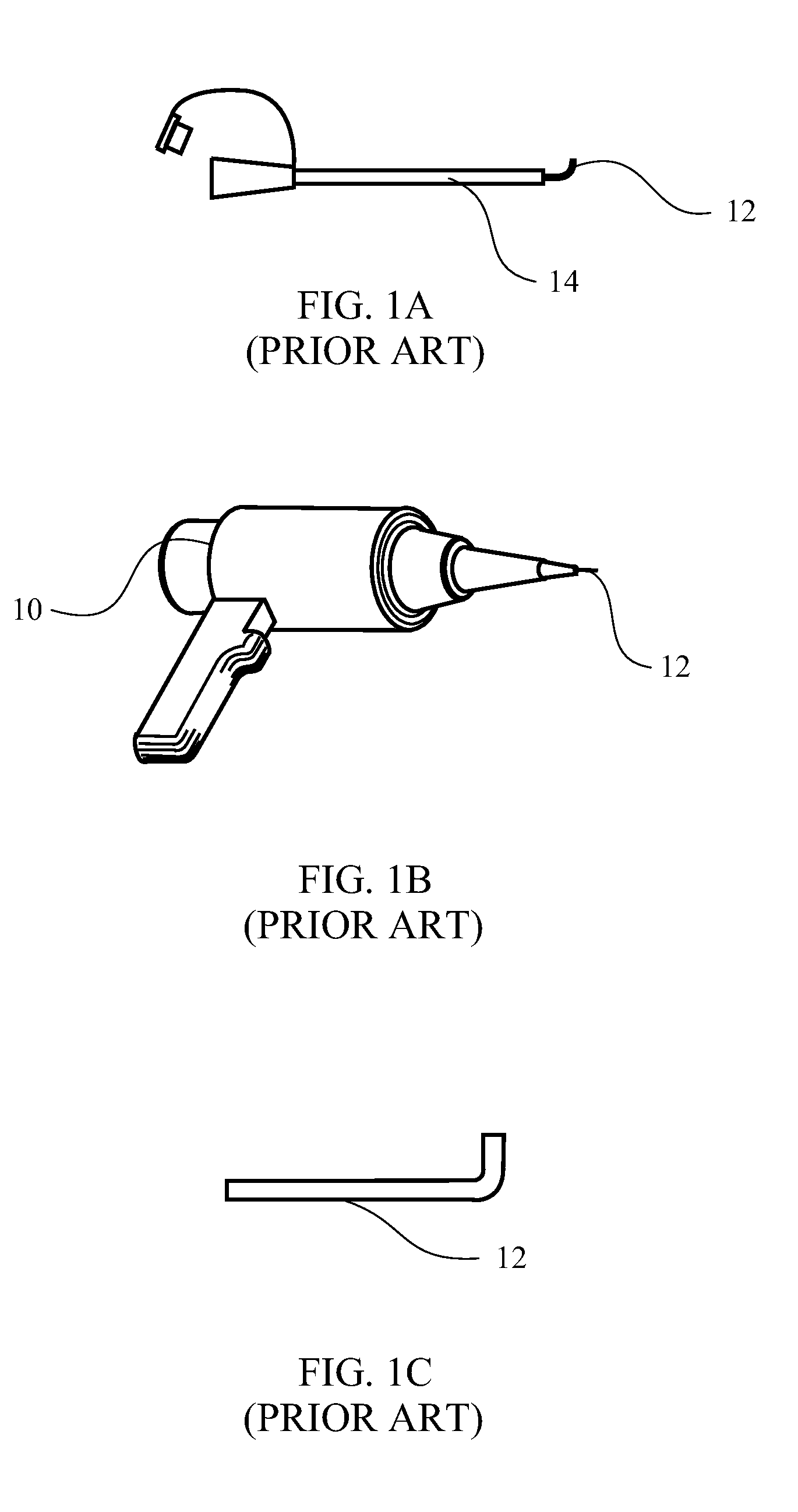

Method and appratus for insertion of an Anti-siphon grid into a hose

InactiveUS20080283124A1Eliminates undesirable shortcomingProvide protectionValve arrangementsPipe elementsSiphonAutomotive fuel

An apparatus for installing an anti-siphon device into an automotive fuel filler comprises; a cylindrical mandrel having an inner surface and an outer surface, the outer surface of the mandrel adapted to receive a proximal end of the hose; a first grasping means configured to grasp the hose at a predetermined distance from a proximal end of the hose, and to insert the proximal end of the hose onto the outer surface of the mandrel; a first actuating means for inducing the first grasping means to grasp the hose at the predetermined distance from the proximal end of the hose, and to insert the proximal end of the hose onto the outer surface of the mandrel; a second grasping means configured to grasp and hold the proximal end of the hose on the mandrel during installation of the anti-siphon device in the hose; a second activating means for inducing the second grasping means to grasp the proximal end of the hose on the mandrel, and hold the hose thereon during installation of the anti-siphon device into the hose; an anti-siphon device insertion means having an outer surface, the anti-siphon device insertion means disposed in the mandrel, wherein the outer surface of the anti-siphon device insertion means is adjacent the inner surface of the mandrel; an anti-siphon device fixture disposed on one end of the anti-siphon device insertion means, wherein the anti-siphon device fixture is adapted to receive the anti-siphon device thereon; and a third activating means for inserting the anti-siphon device inserting means having the anti-siphon device disposed thereon, into the hose and withdrawing the anti-siphon device inserting means to the mandrel upon installing the anti-siphon device in the hose. A method is also described.

Owner:FLUID ROUTING SOLUTIONS

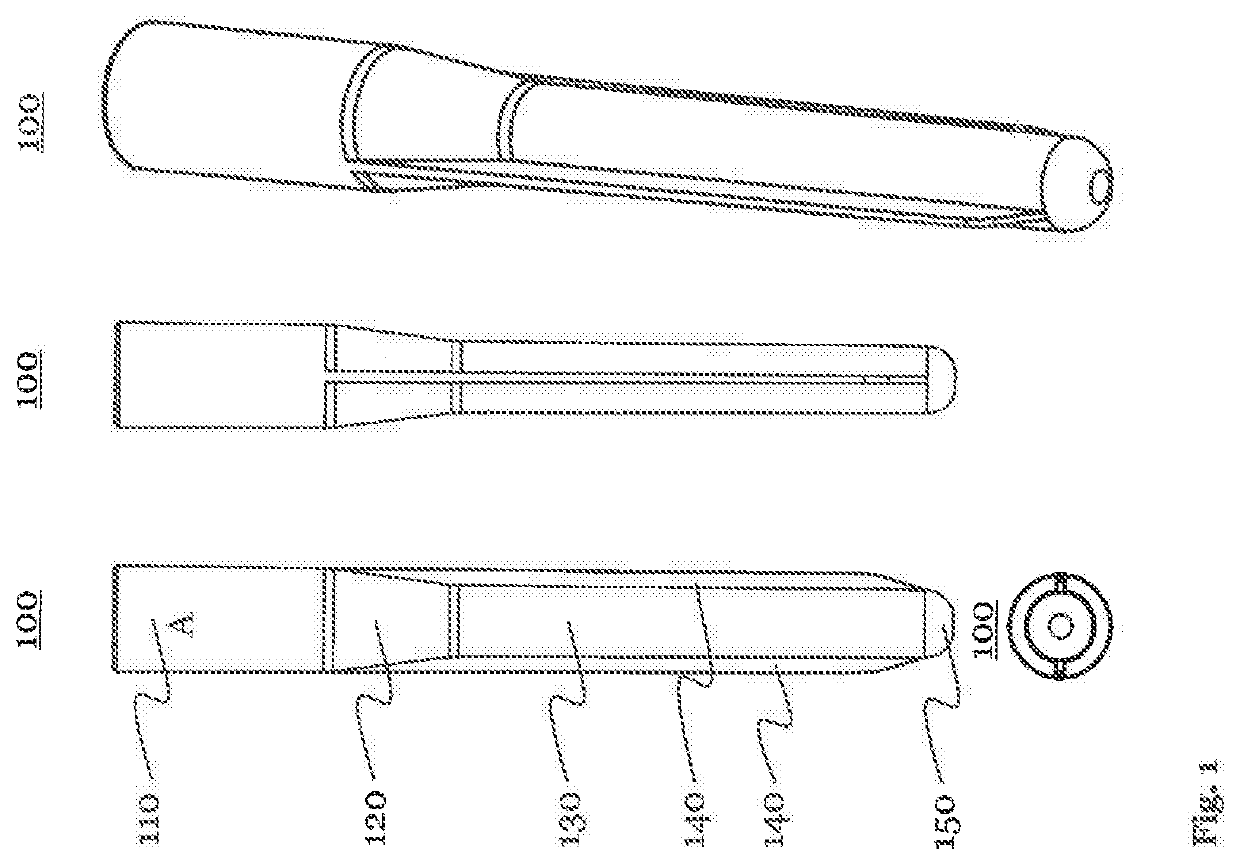

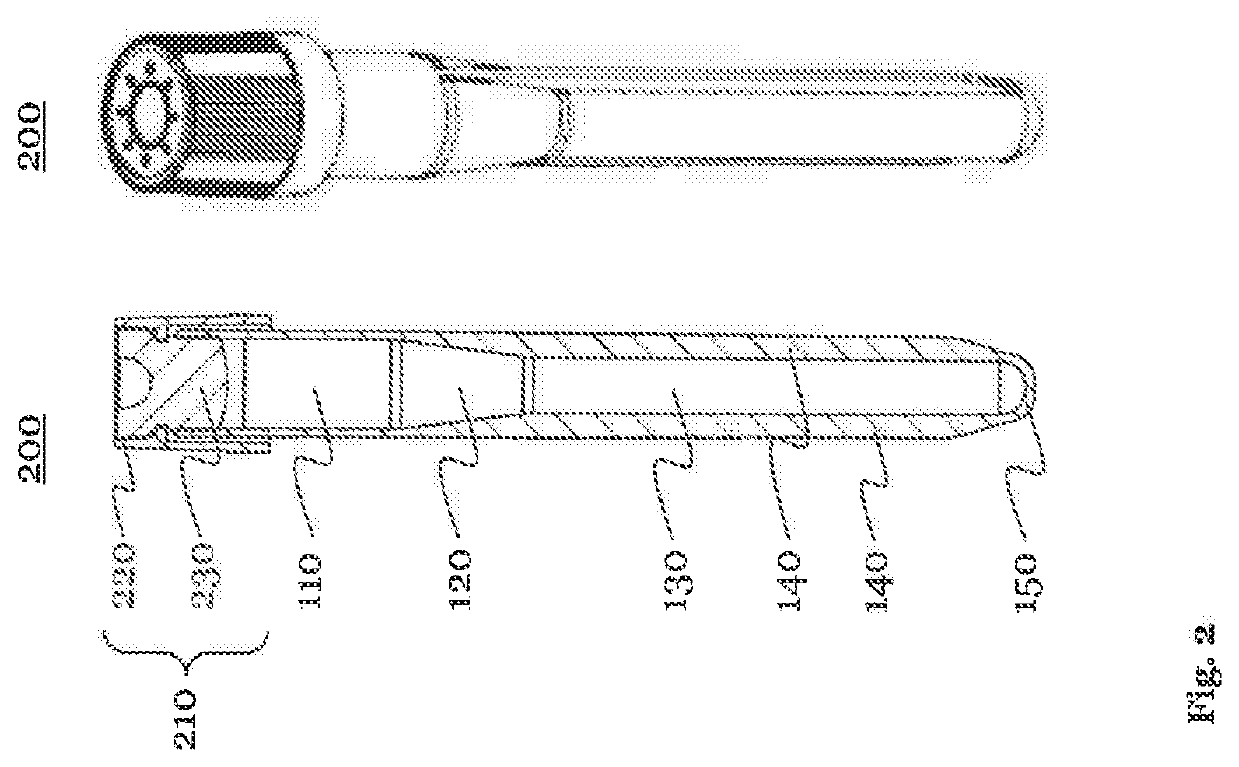

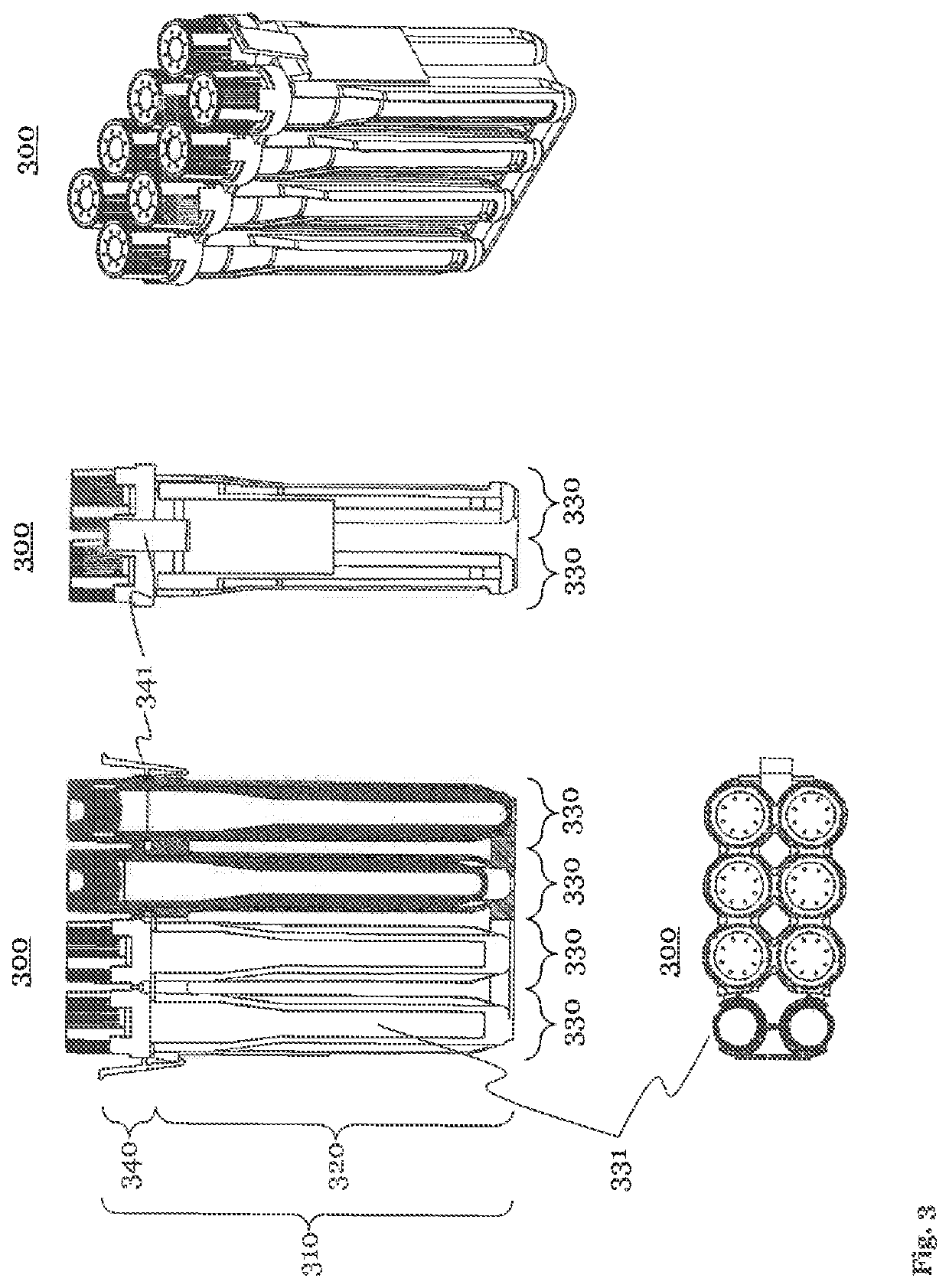

Equipment and methods for automated sample processing for diagnostic purposes

PendingUS20190366328A1Guarantee precision and mechanical stabilityLarge outer diameterLaboratory glasswaresCentrifugesTest tubeSample collection

A tube for sample collection and sample processing in a tube rack includes an upper section, an intermediate section, and a lower section. The intermediate section connects the upper section and the lower section of the tube, and an inner diameter of the intermediate section can decrease from top to bottom. A fastening means can fix the tube in a tube rack. The tube can include a pierceable tube cap sealing the tube, and the tube rack can be configured such that the tube may be pulled off the tube cap by a centrifugation force. The tube can include a volume of density gradient medium covered by a separating gel to enhance sample separation.

Owner:YANTAI AUSBIO LAB

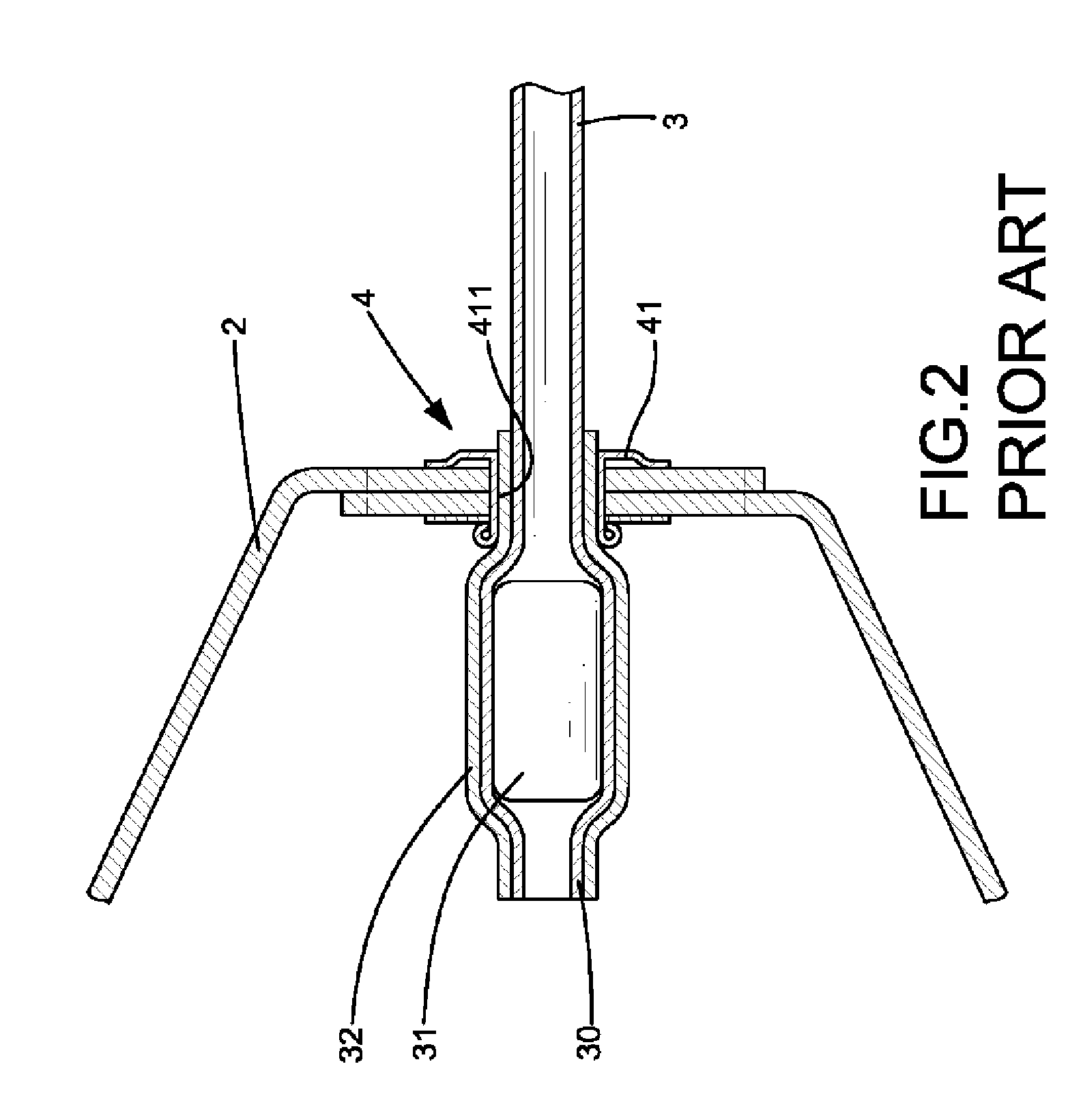

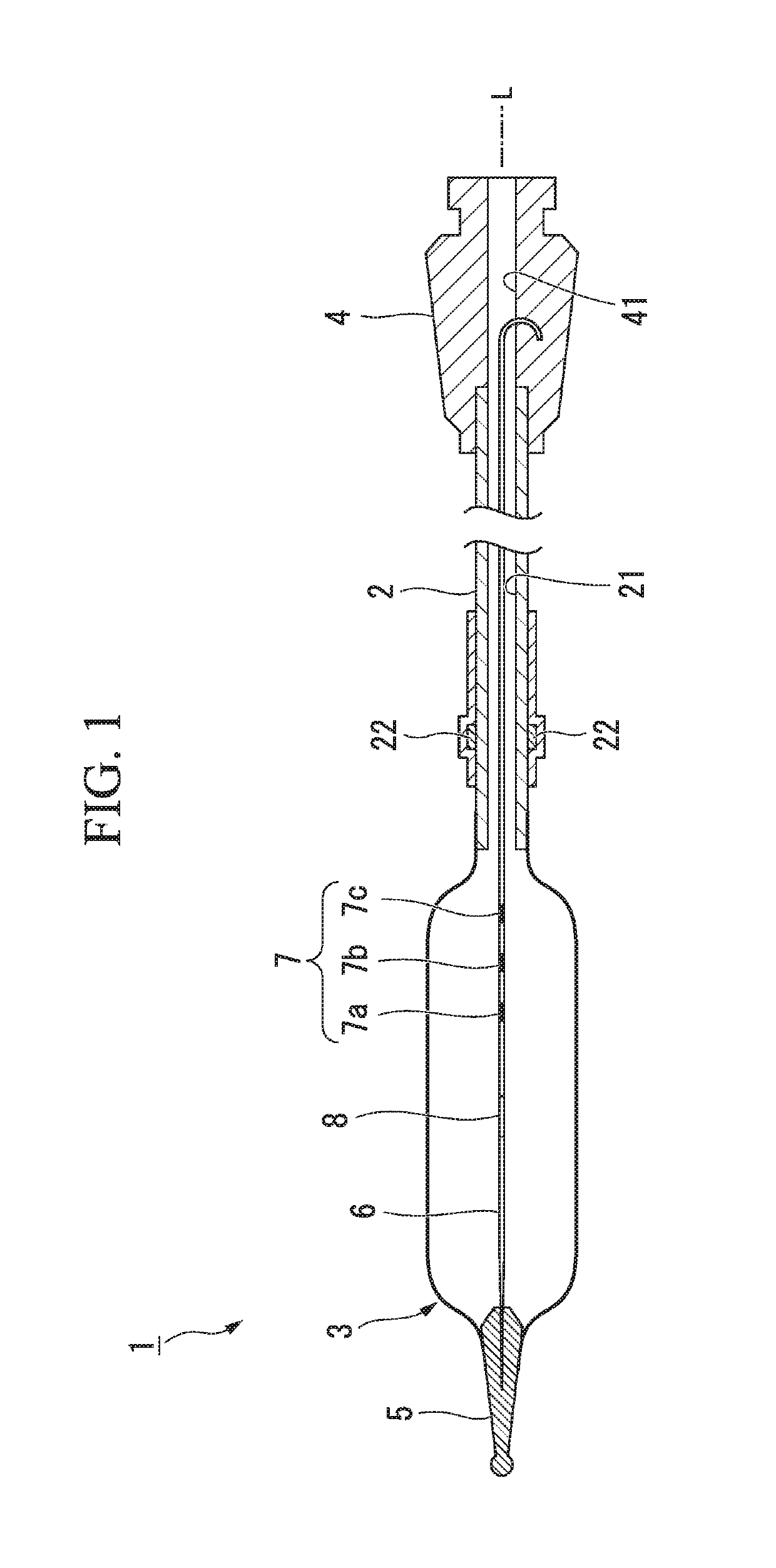

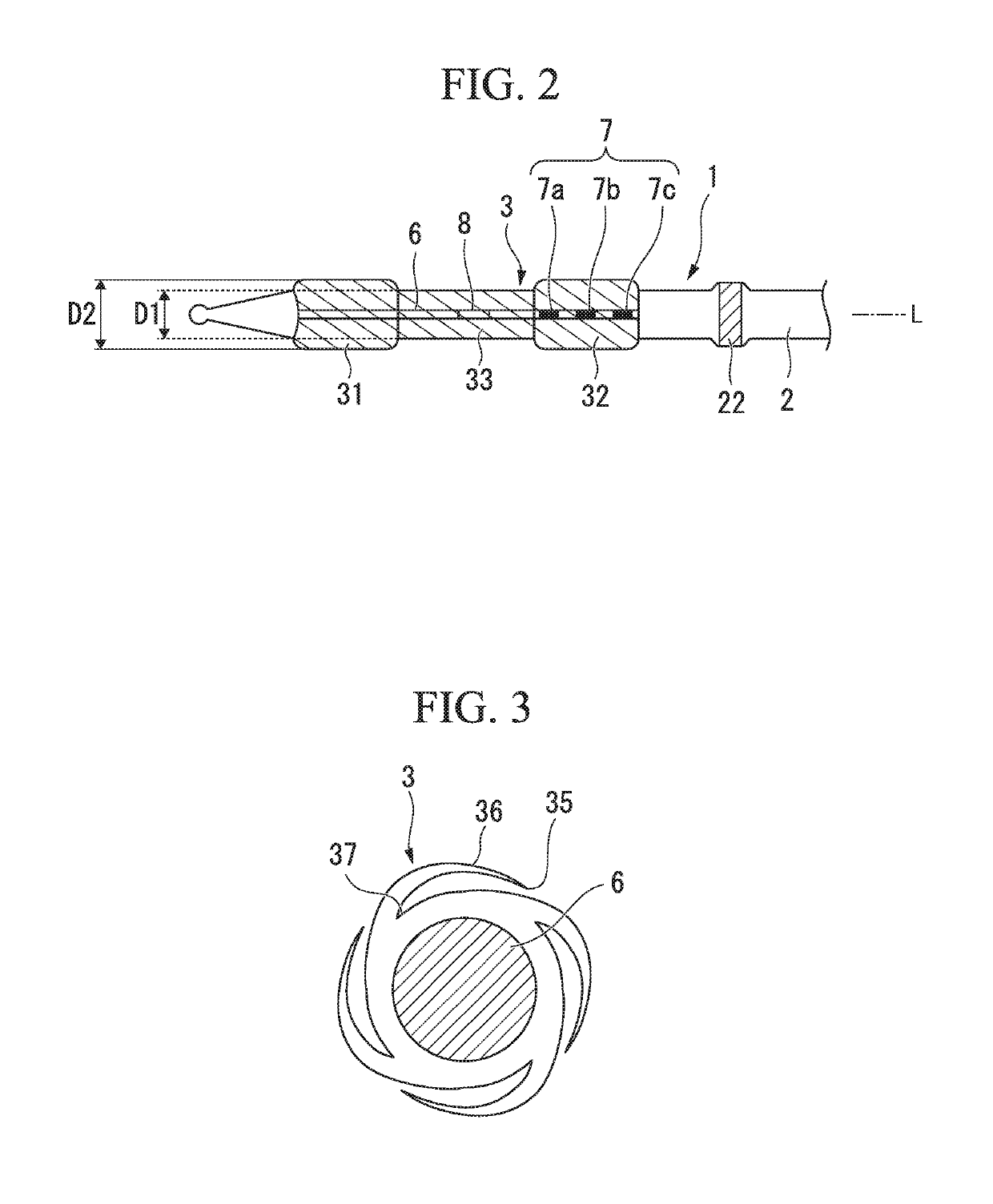

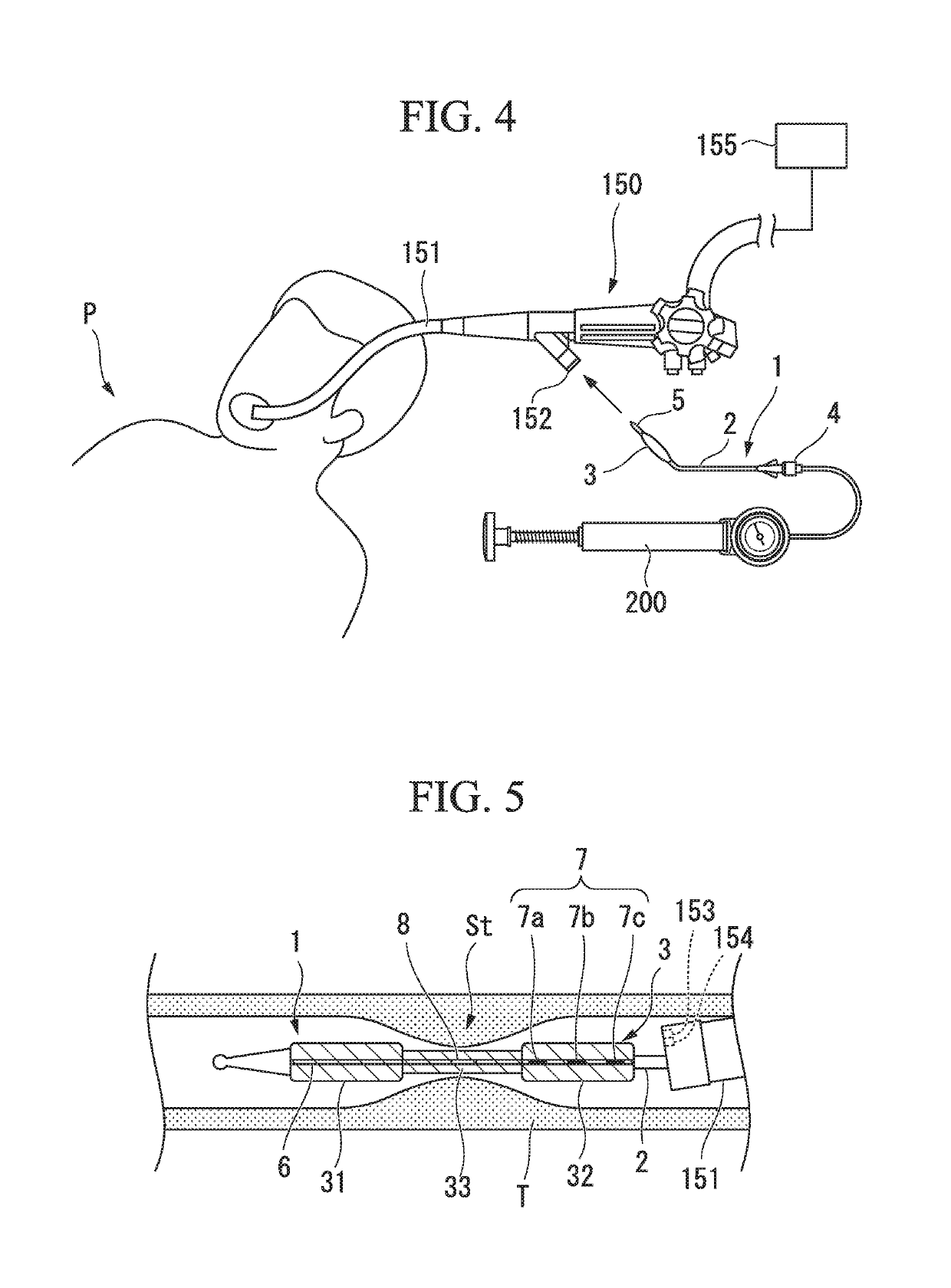

Treatment tool for endoscope

A treatment tool for an endoscope includes: a sheath; a balloon provided at a distal end of the sheath, and configured to be expandable from a folded initial shape to an unfolded inflated shape; an inner shaft configured to protrude from a distal end of the balloon through an inside of the balloon; a middle marker; and at least one or more positioning markers provided on the inner shaft independently of the middle marker. The balloon has a proximal end-side region, a distal end-side region, and a middle part. At least one of the positioning markers is positioned on the inner shaft at same a longitudinal position as the proximal end-side region.

Owner:OLYMPUS CORP

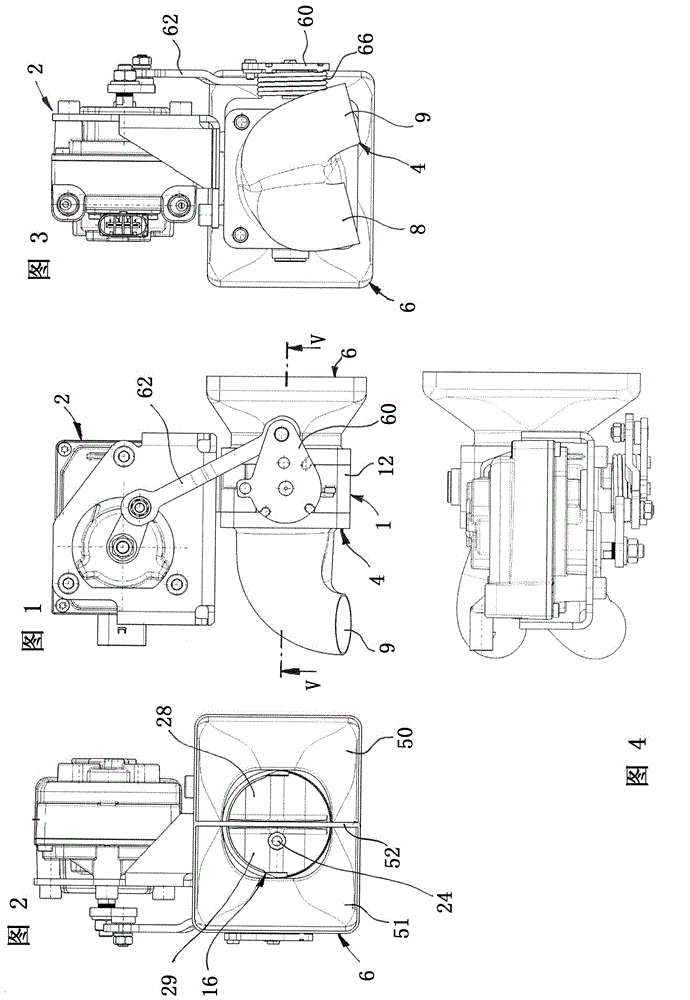

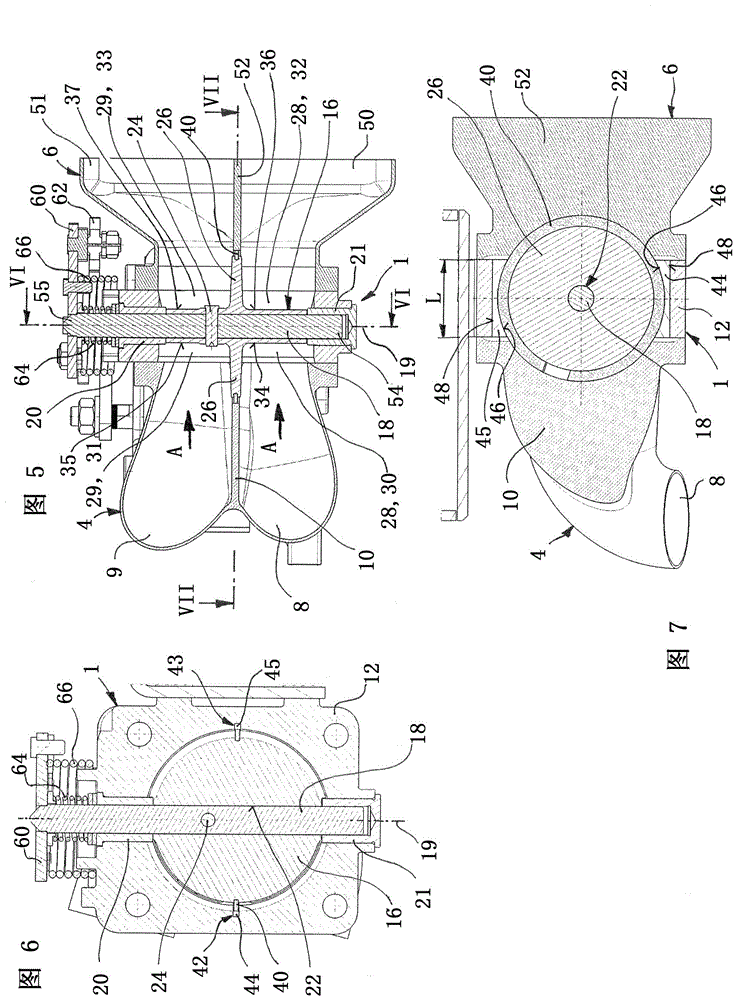

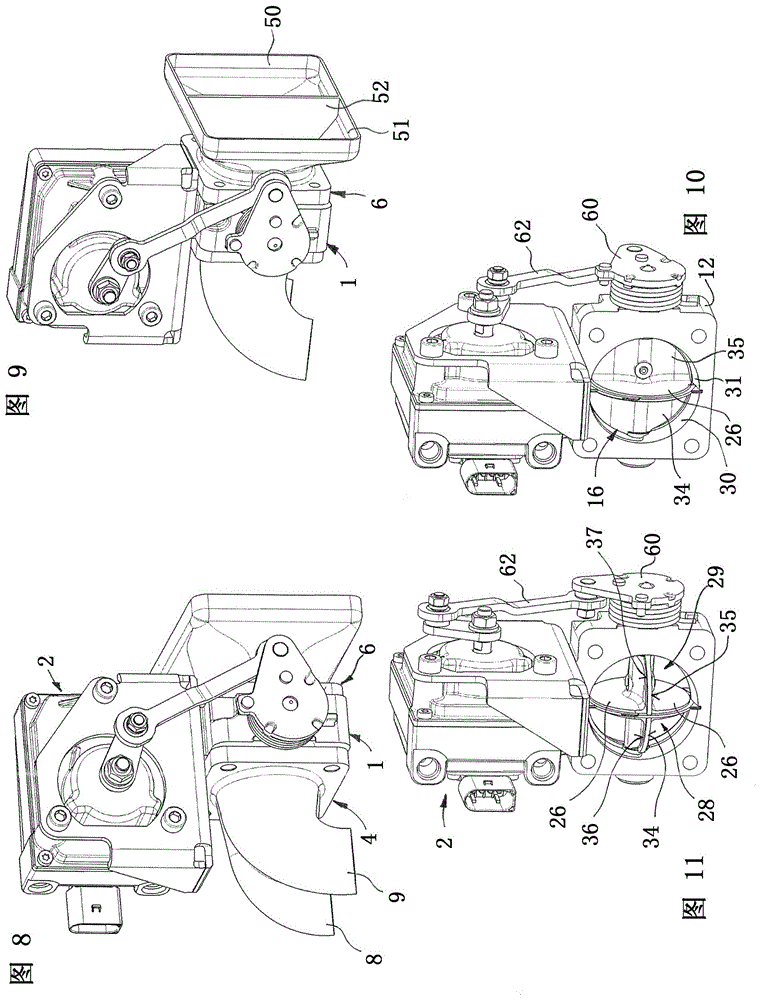

Valve for an exhaust system of an internal combustion engine

InactiveCN106014708ASave installation spaceLow production costOperating means/releasing devices for valvesExhaust gas recirculationInternal combustion engineExhaust gas

The invention relates to a valve (1) for an exhaust system of an internal combustion engine. The valve has the following characteristics: a housing (12) which contains a passage (14) for guiding exhaust gases; a closing body (16) is arranged in the passage (14), with which the passage (14) can be closed; the closing body (16) is fixed in a rotationally fixed manner to a shaft (18) rotatably mounted in the housing and can be pivoted with the shaft (18) around the rotation axis (19) of the shaft (18); the closing body (16) has a partition wall (26) with a circular outer contour which is perpendicular to the rotation axis (19) of the shaft (18) and is separated from the housing (12) and divides the passage (14) into a first channel (28) and a second channel (29) separated from the first channel (28). The closing body (16) has a closed position in which both channels (28, 29) are closed.

Owner:BORGWARNER ESSLINGEN GMBH

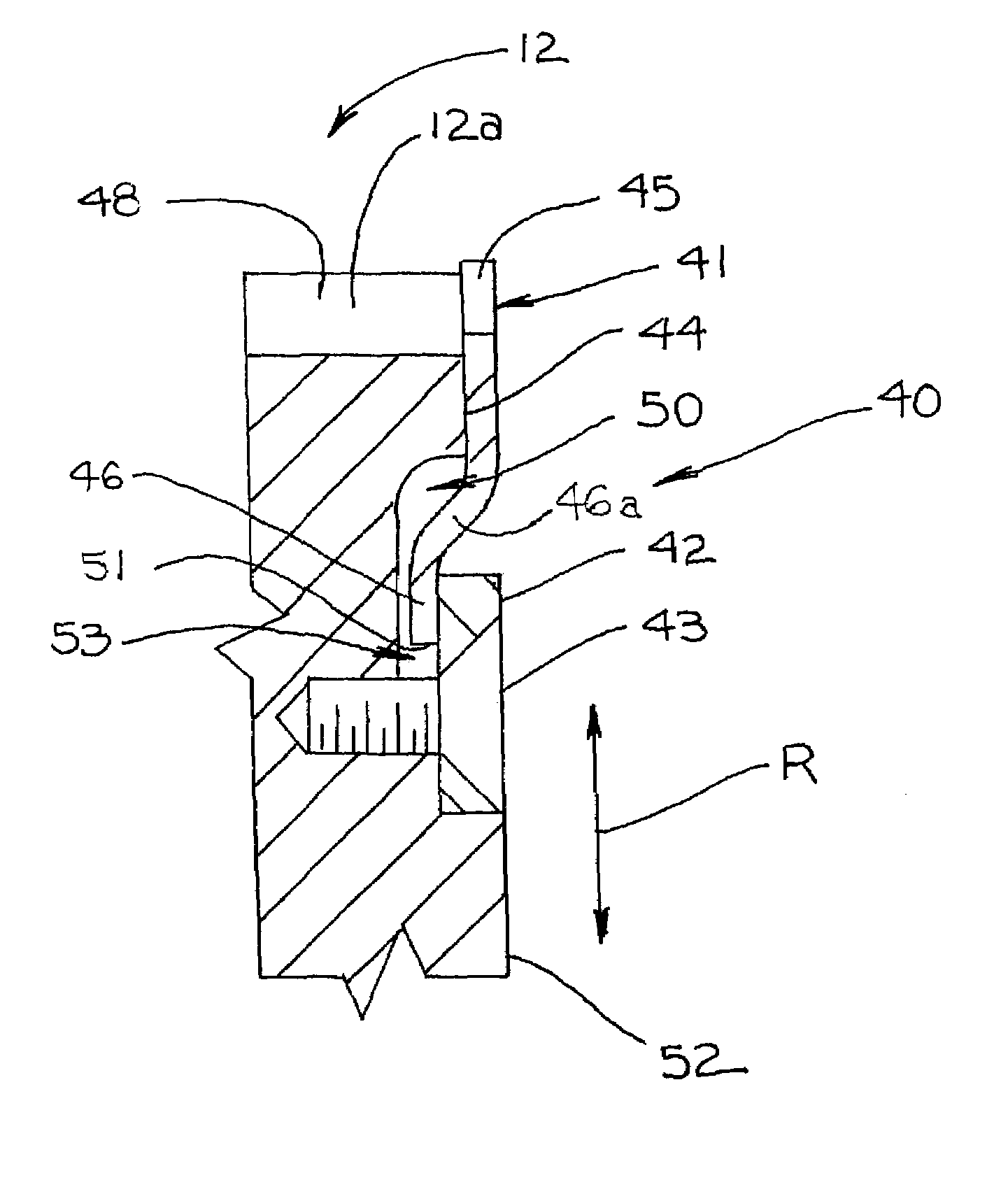

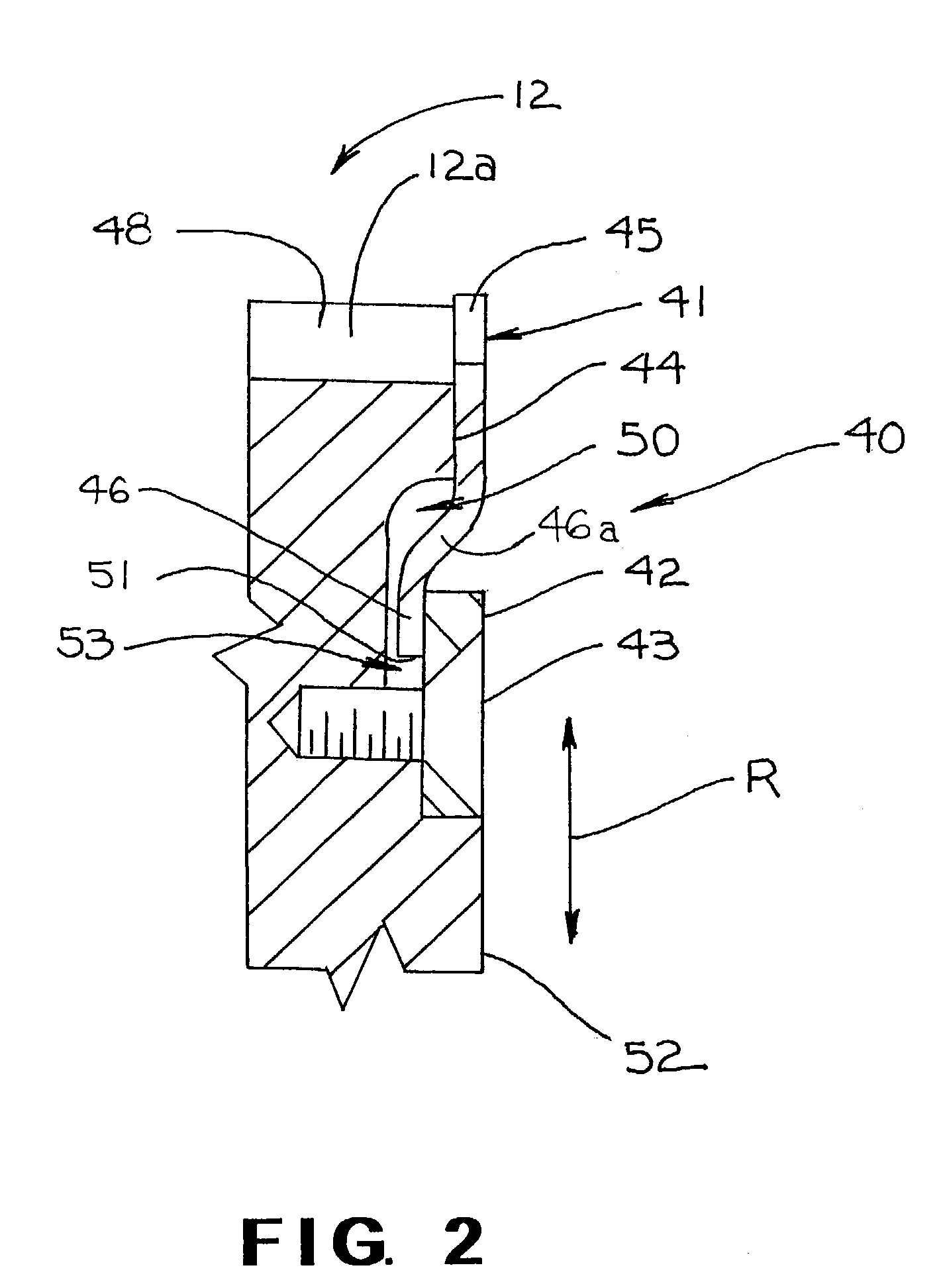

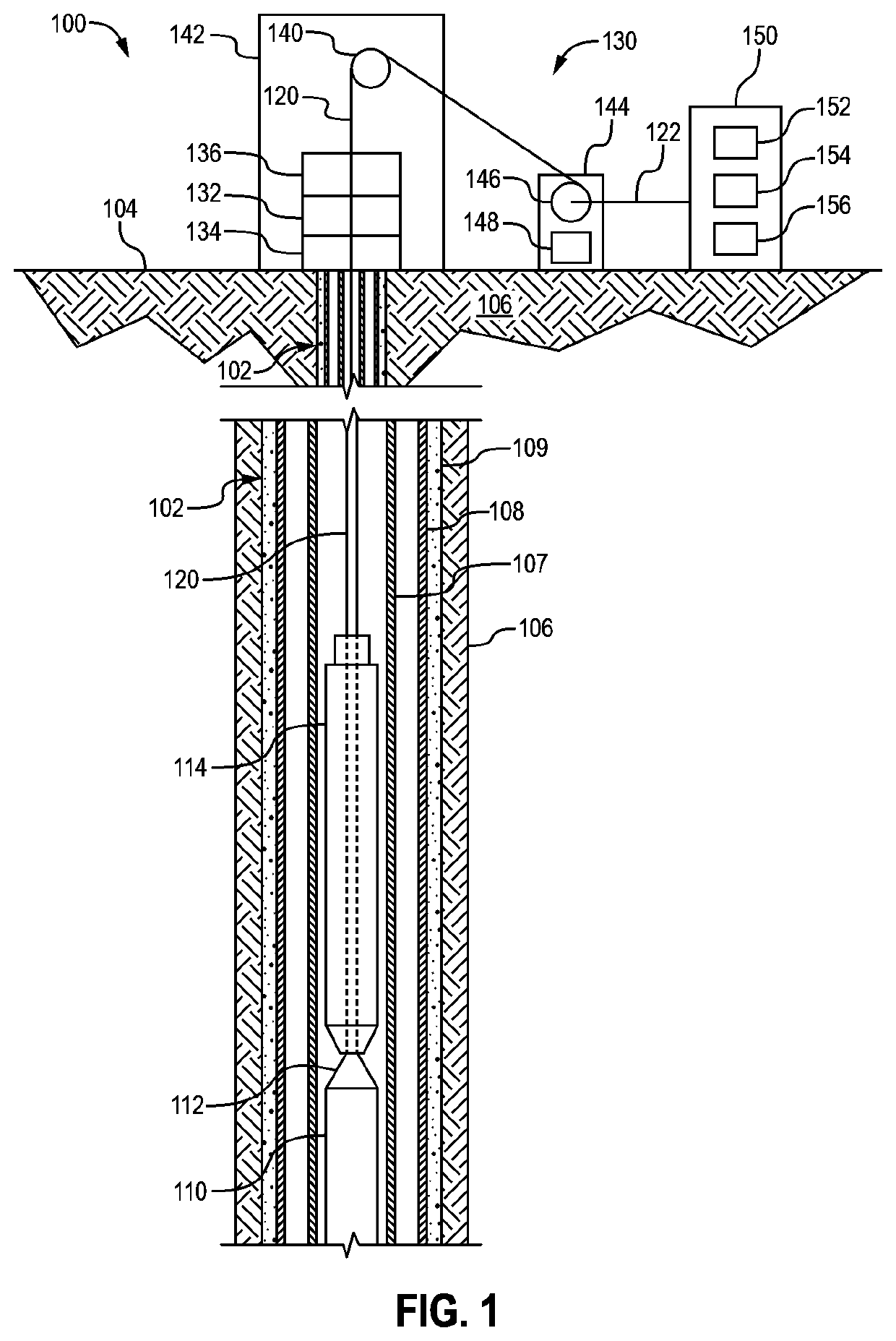

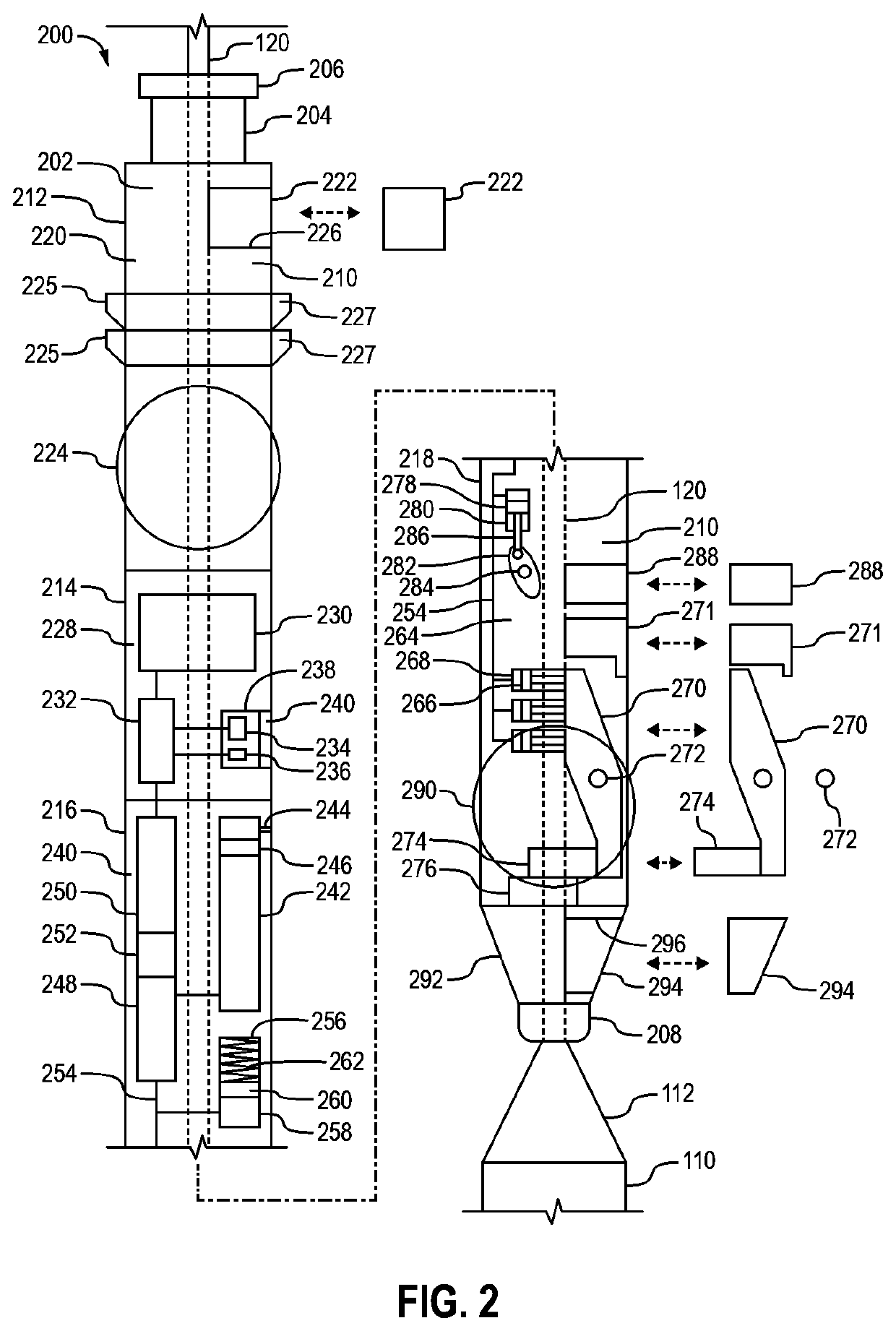

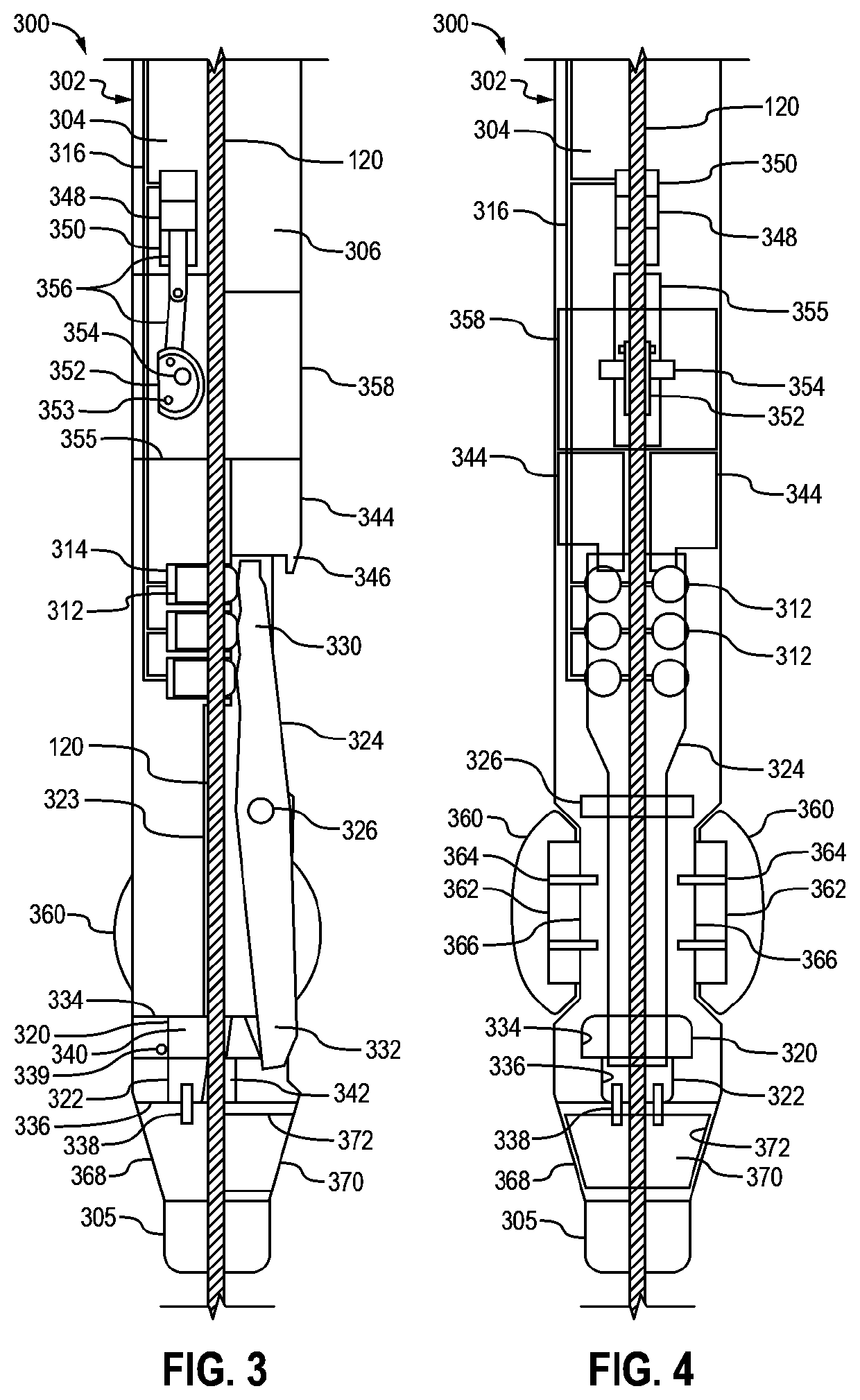

Downhole Conveyance Line Cutter

ActiveUS20210270102A1Large outer diameterDrilling rodsDrilling casingsLine tubingClassical mechanics

A downhole conveyance line cutter operable to be conveyed downhole within a wellbore along a conveyance line that conveys a tool string within the wellbore and then cut the conveyance line. The downhole conveyance line cutter may have a body, a fluid chamber within the body, a piston slidably disposed within the fluid chamber, a knife that is movable with respect to the body, an arm operatively connecting the piston and the knife, and a fluid source operable to pump a fluid into the fluid chamber to cause the piston to move the arm which moves the knife to cut the conveyance line.

Owner:IMPACT SELECTOR INT LLC

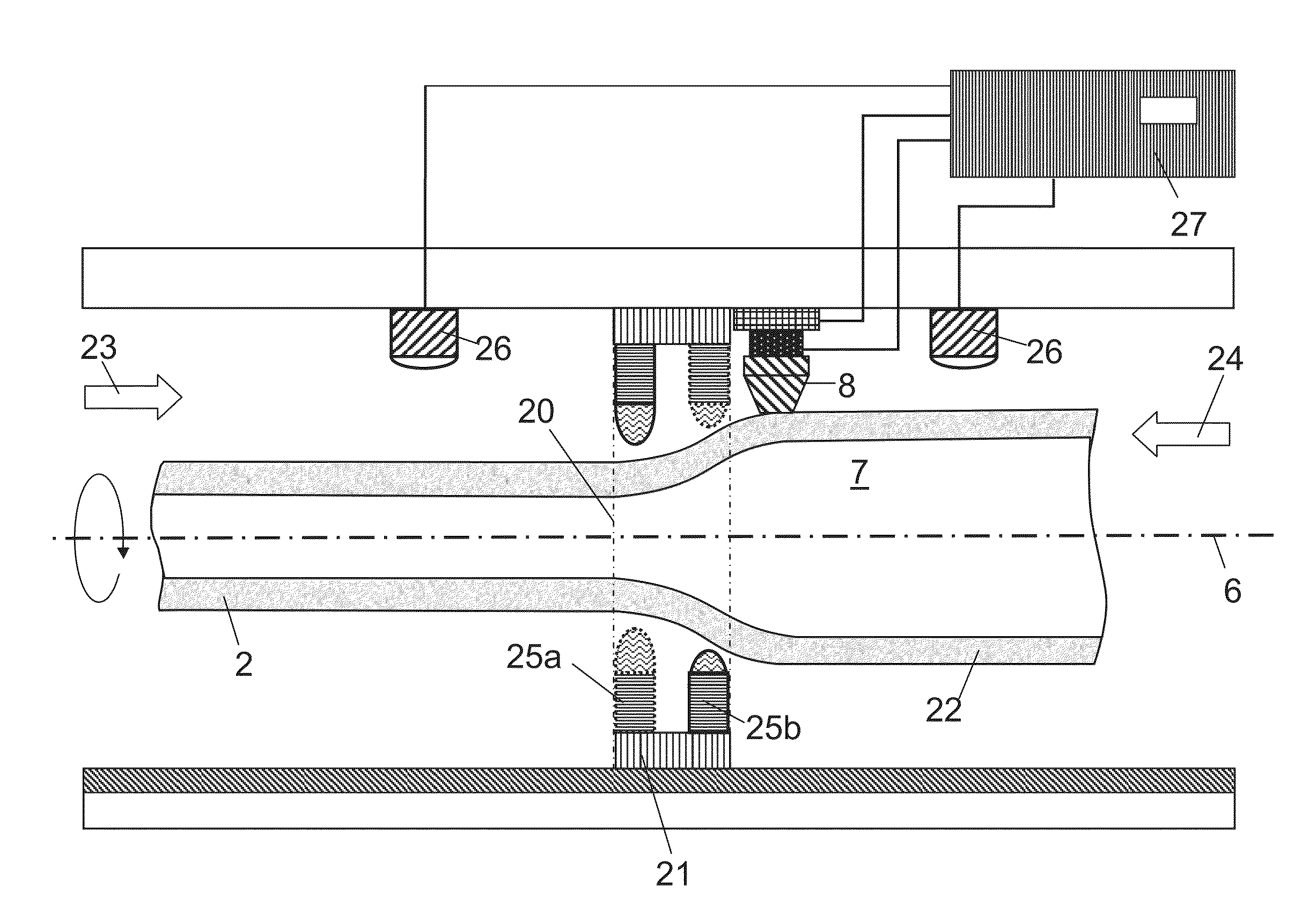

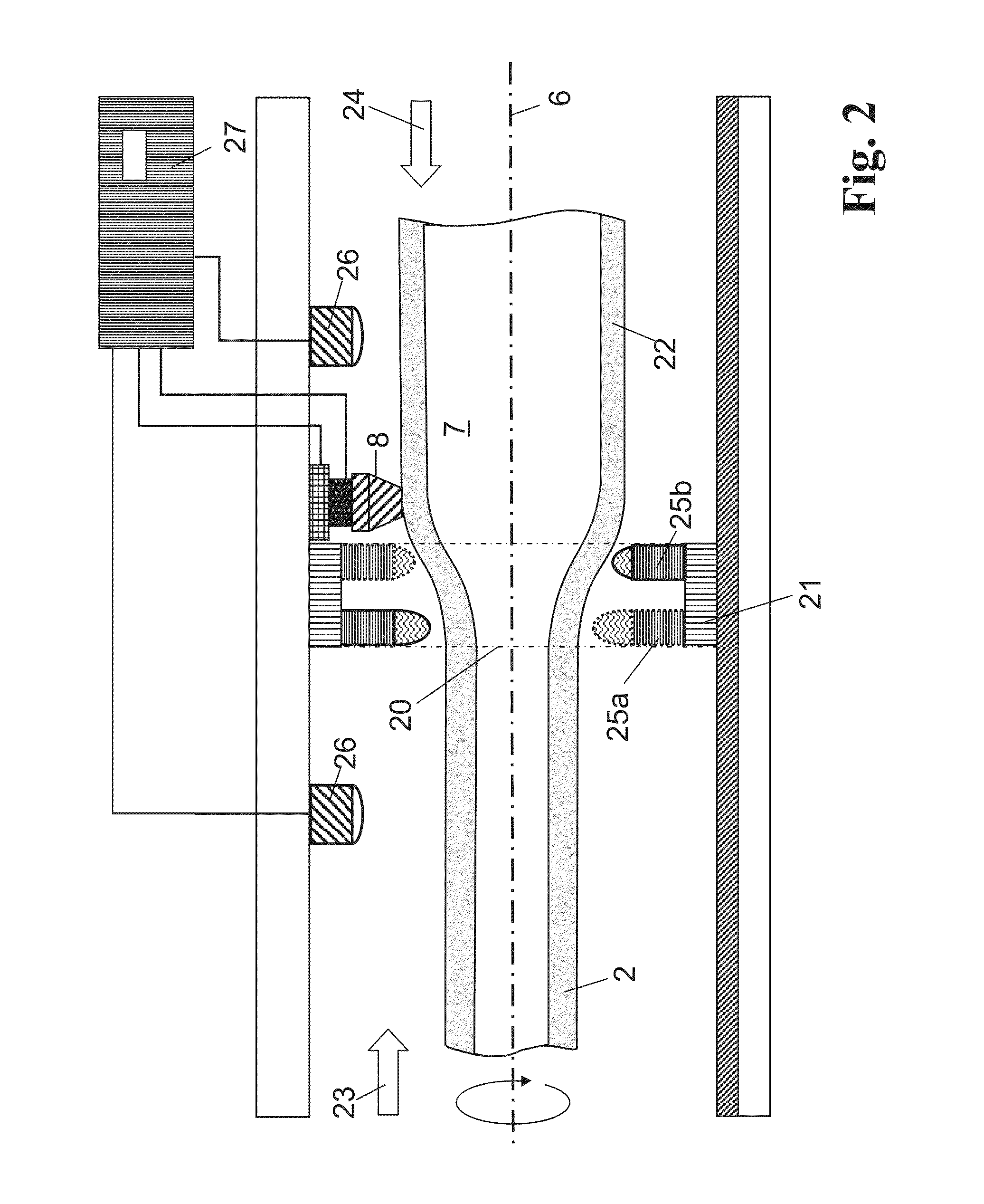

Method and apparatus for producing a tube of glass

ActiveUS20160318789A1High dimensional accuracyLarge outer diameterGlass reforming apparatusGlass tempering apparatusOverpressureHollow cylinder

A method and apparatus are provided for producing a tube of glass by zonewise heating and softening of a hollow cylinder by a movable heating zone while rotating about its rotation axis. The glass tube is continuously formed by radial expansion of the softened region under action of centrifugal force and / or internal overpressure applied in the hollow-cylinder bore. The method and apparatus make it possible to deform the hollow cylinder in a single or a small number of forming steps into a glass tube having a larger outer diameter and high dimensional accuracy by determining a circumferential position at which the wall thickness is comparatively small, and during heating and softening of the rotating hollow cylinder a coolant is dispensed from a coolant source onto the deformation zone only when or predominantly when the circumferential position having the comparatively small wall thickness passes the coolant source.

Owner:HERAEUS QUARZGLAS

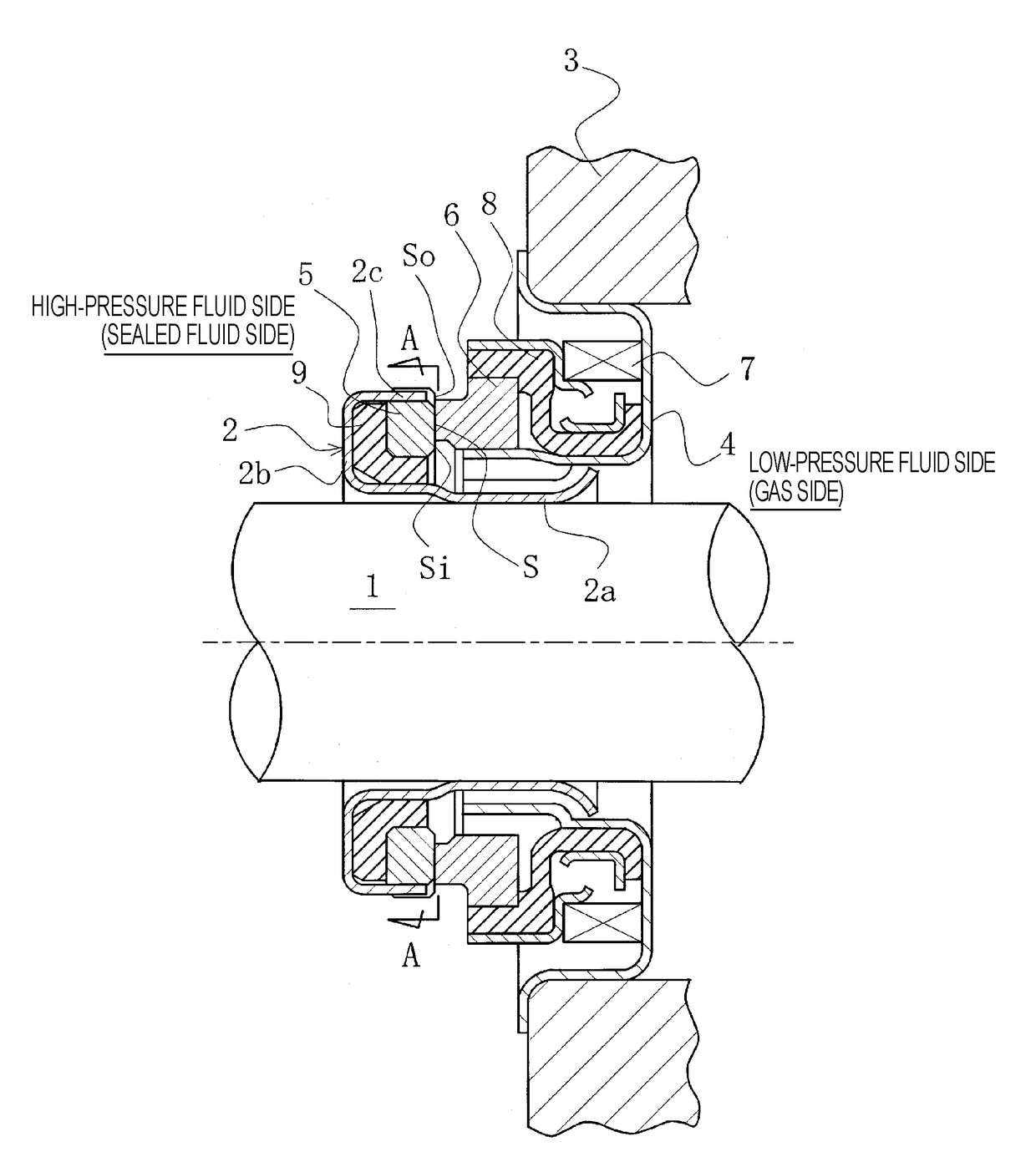

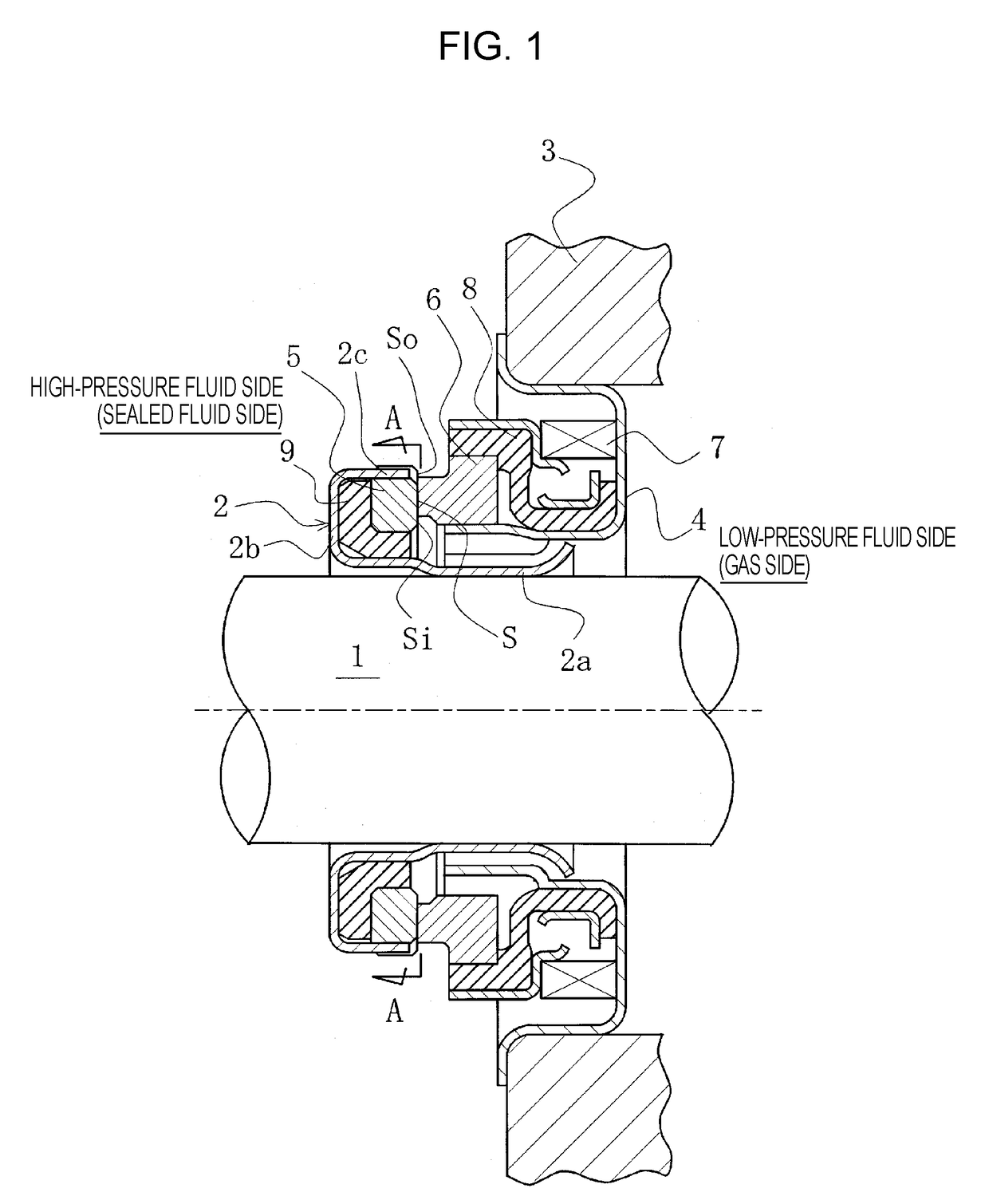

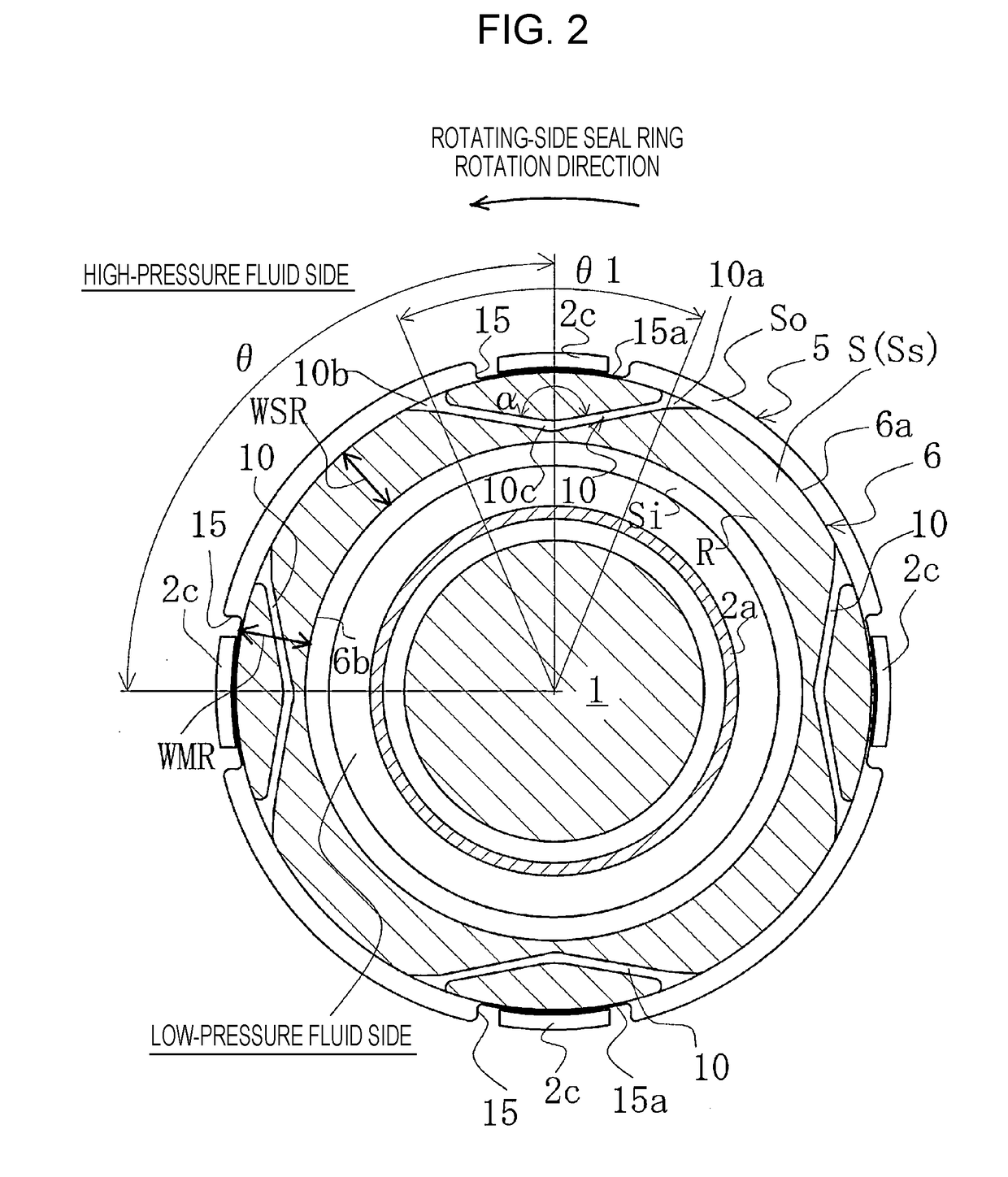

Sliding component

ActiveUS20180187784A1Good effectLarge outer diameterEngine sealsPump componentsEngineeringHigh pressure

In an embodiment, in a sliding component, a sliding face of a stationary-side seal ring 6 has a fluid circulation groove 10 communicating with a high-pressure fluid side via an entrance portion 10a and an exit portion 10b. A rotating-side seal ring 5 has a larger outer diameter and a smaller inner diameter than the seal ring 6. A groove 15 into which a claw is loosely fitted is provided on an outer periphery of the seal ring 5. A width of the groove 15 is smaller than a distance between the portion 10a and the 10b in the circumferential direction. WMR / WSR is set within a range of 0.75<WMR / WSR<1.4 (WMR is a face width between an inner diameter of the groove 15 and an inner diameter 6b of the sliding face; WSR is a face width of the sliding face).

Owner:EAGLE INDS

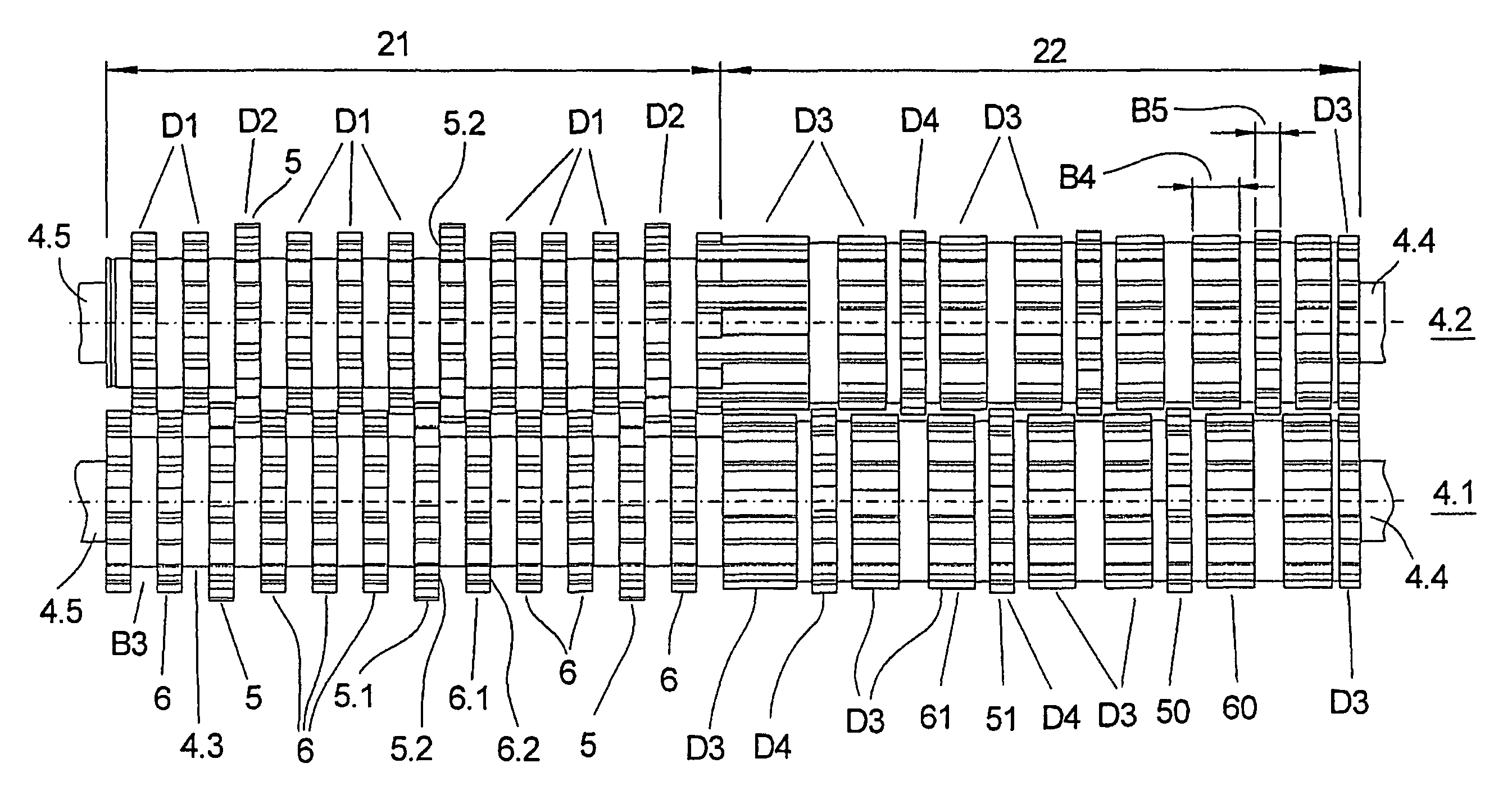

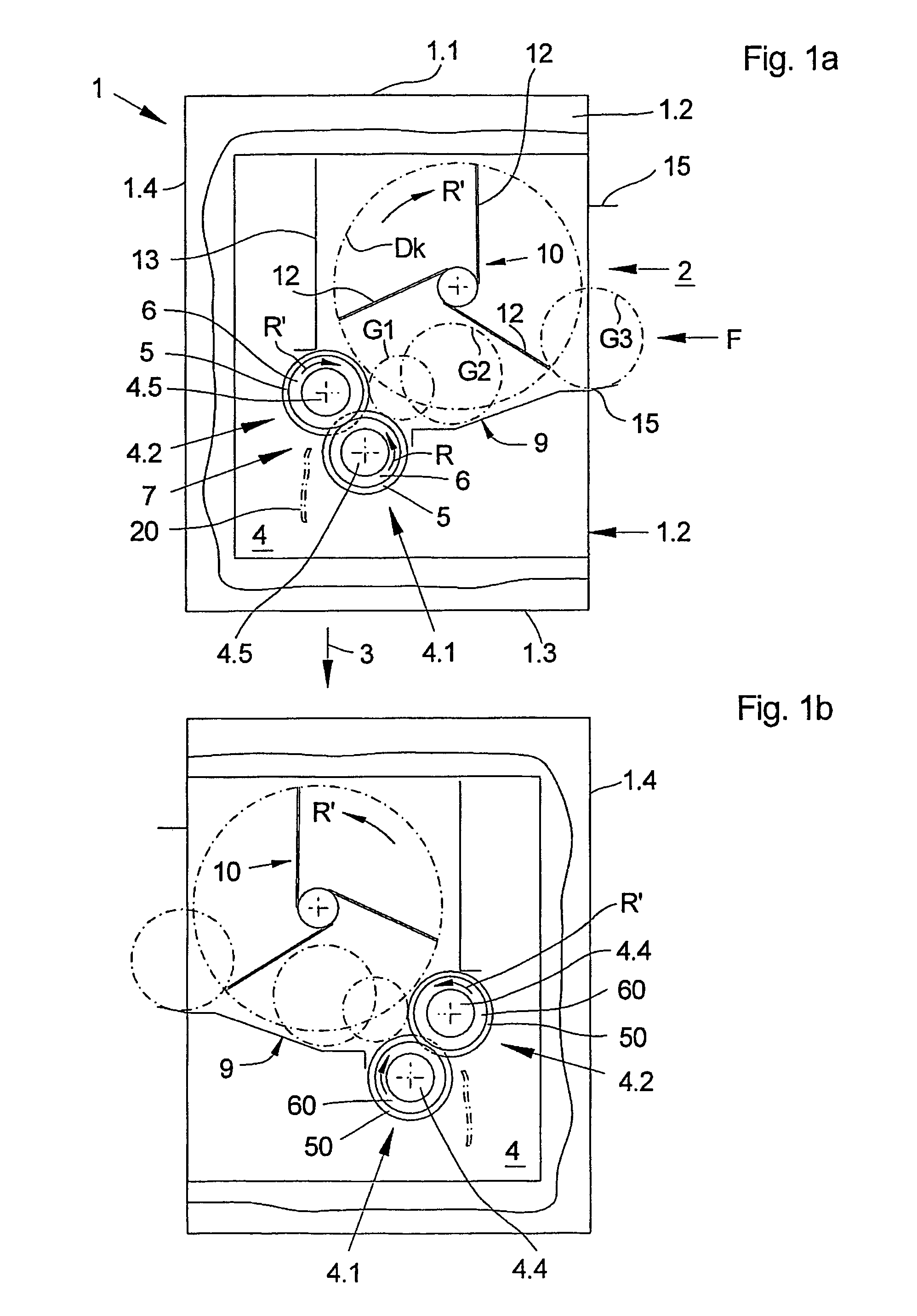

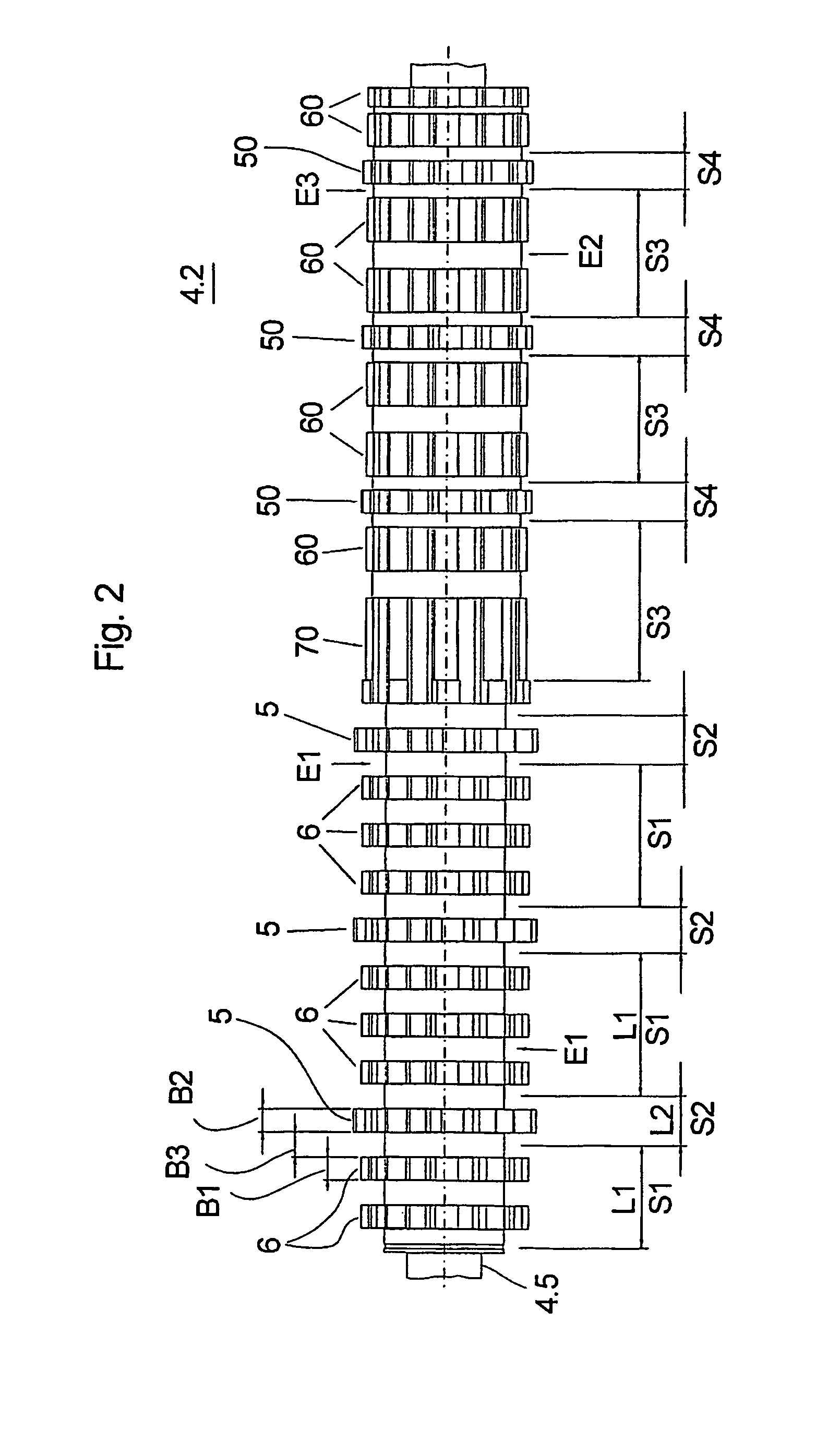

Device for compressing of empty deformable containers

ActiveUS8783173B2Large outer diameterReduce engagementCocoaGrain treatmentsPolyethylene terephtalatePolyethylene terephthalate

An apparatus for compressing empty containers, in particular of beverage bottles or beverage cans made out of plastic, in particular out of polyethylene terephthalate PET, or tin plate. The apparatus has a cutting and pressing unit as well as means for driving and for controlling the cutting and pressing unit, wherein the cutting and pressing unit contains at least two cooperating, oppositely rotating rollers disposed at a distance relative to each other with respect to their rotation axes, wherein each roller has several disks in each case disposed towards each other with an axial distance (free space). According to a special further development it is proposed that at least in the operating region of the two rollers there are disposed axially next to each other a first working region for a compressing of containers made out of plastic and a second working region for a compressing of containers made out of metal.

Owner:SCHWELLING HERMANN

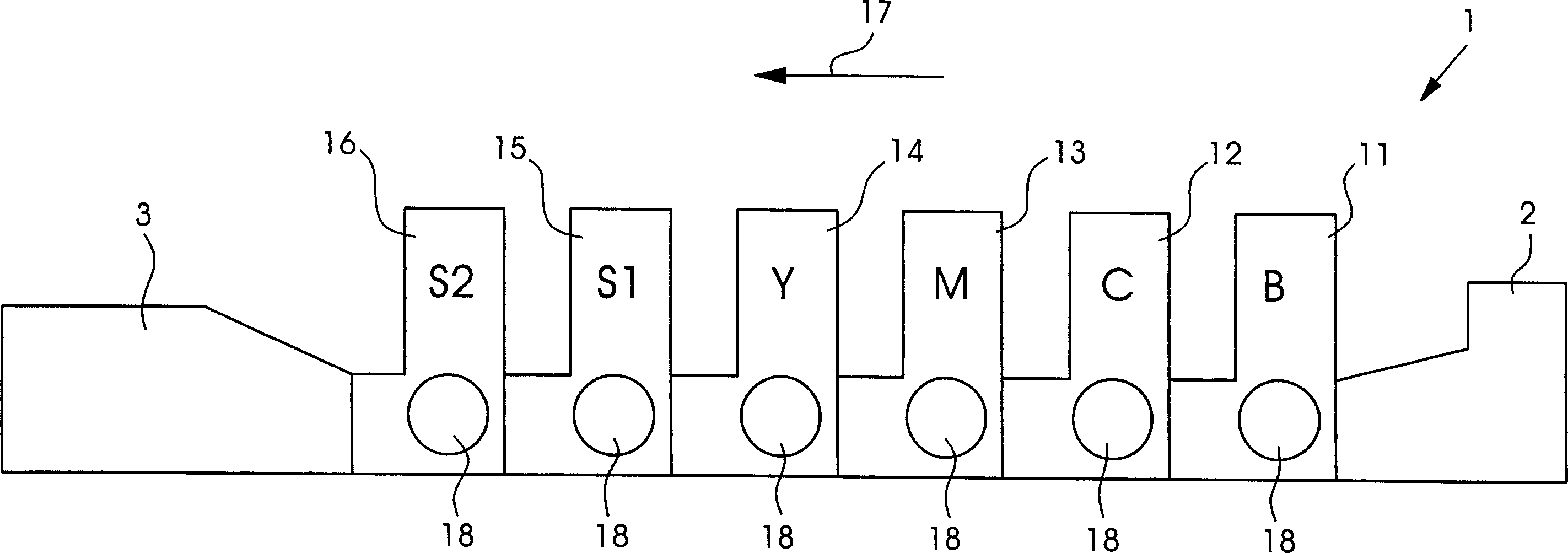

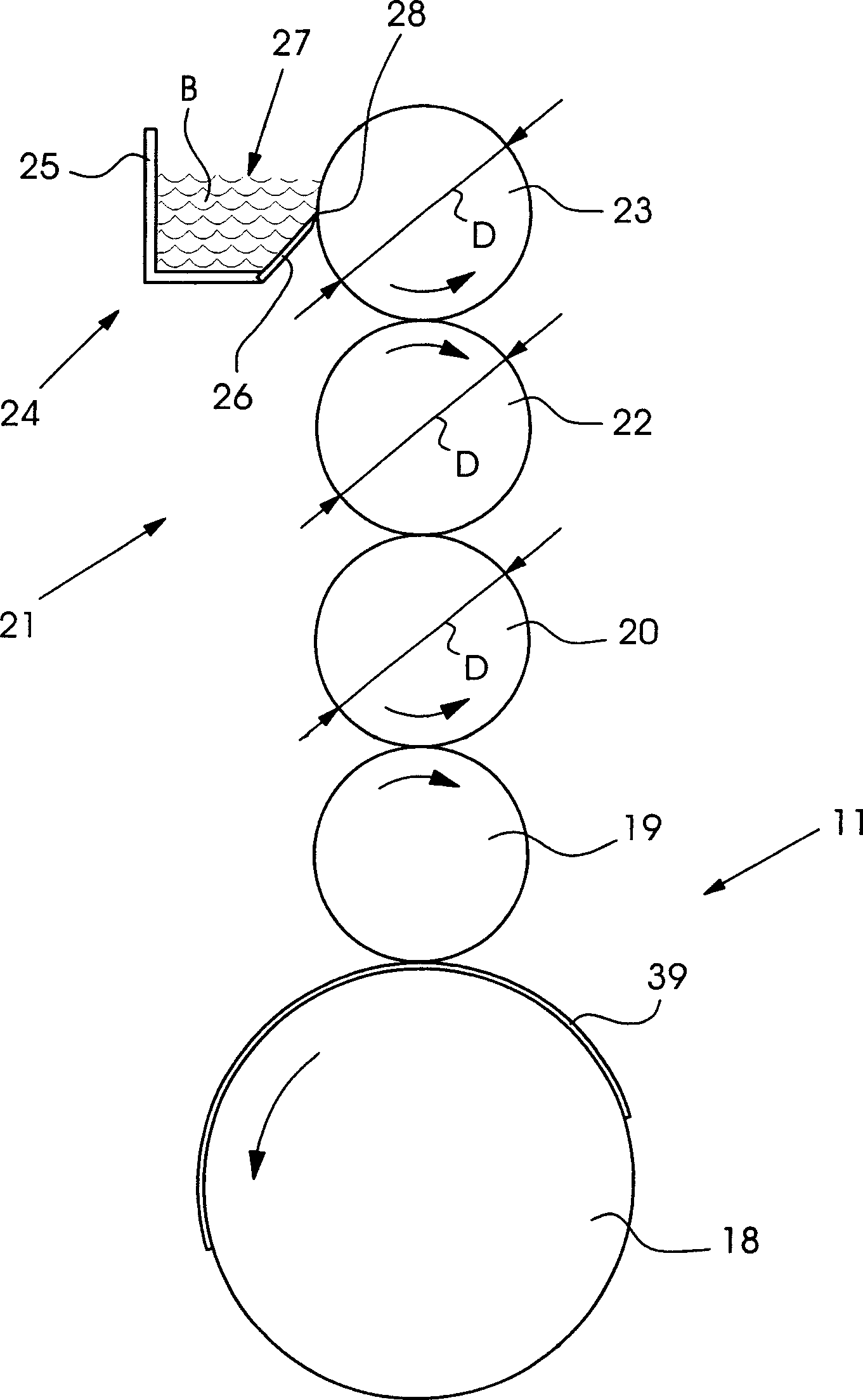

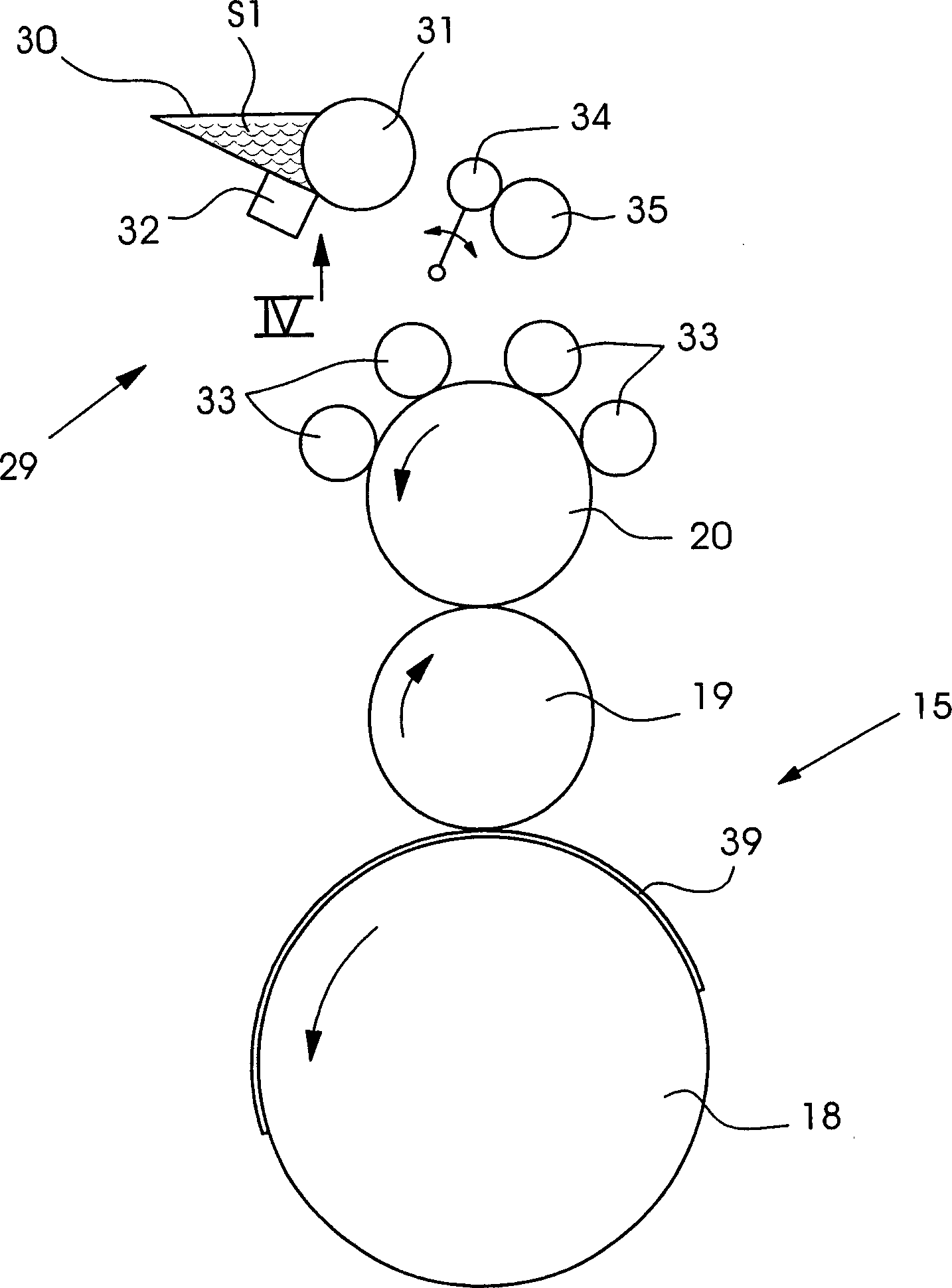

Sheet printing machine and process for sheet printing

InactiveCN1911655ALarge outer diameterOther printing apparatusRotary lithographic machinesPrinting pressPaper sheet

The sheet printing machine (1) has three Anilox offset print units (11, 12, 13), and an offset print unit (15) and provided by a roller-type inking unit (29). A fourth Anilox offset print unit (14) is assigned to the three Anilox offset print units and that the offset print unit (15) provides a special color (S1) with the roller-type inking unit. The Anilox offset print units (11, 12, 13, 14) have four-color printing inks such as Black (B), Cyanogen (C), Magenta (M) and Yellow (Y). The special color is a different printing ink from the four-color printing inks.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

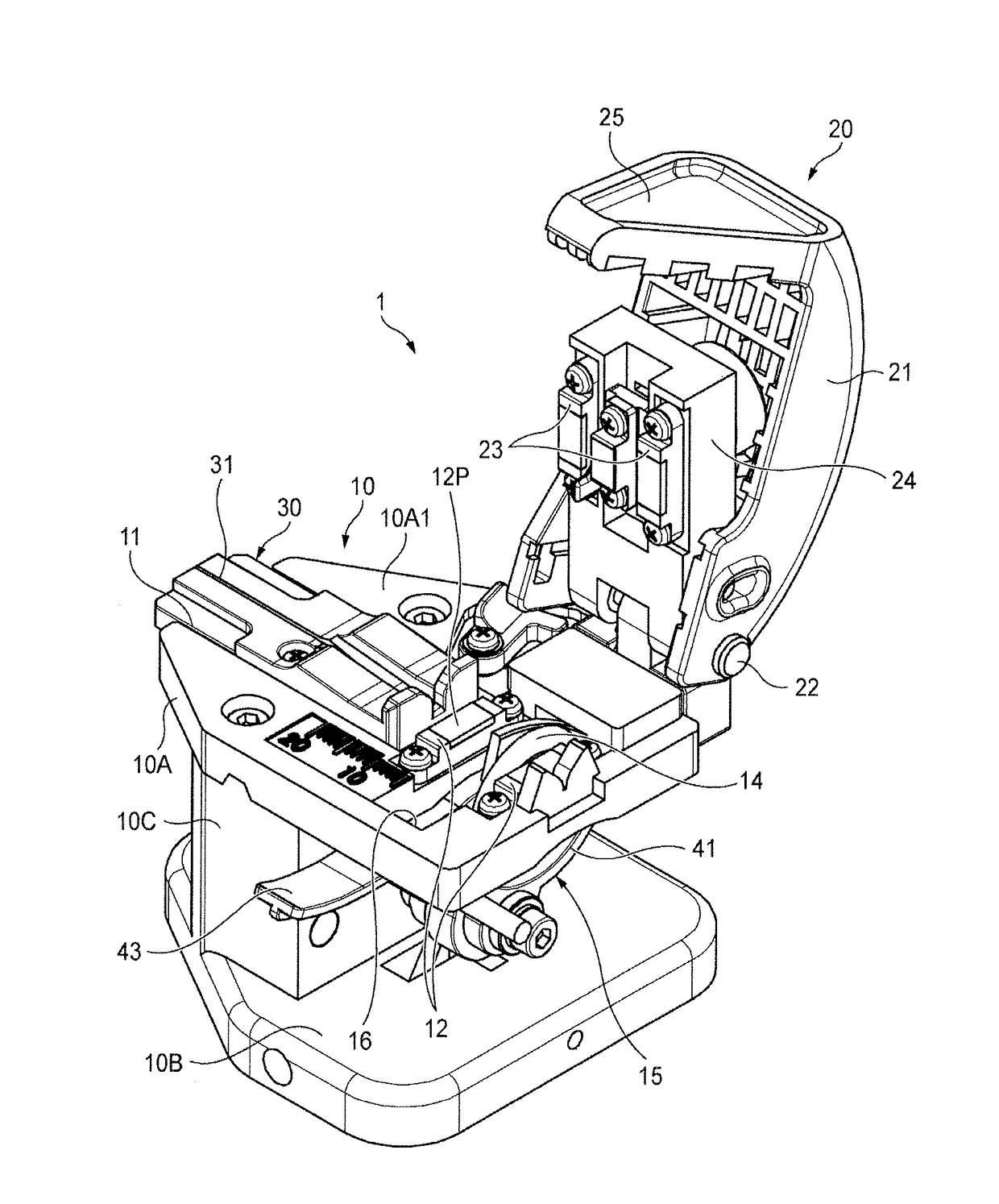

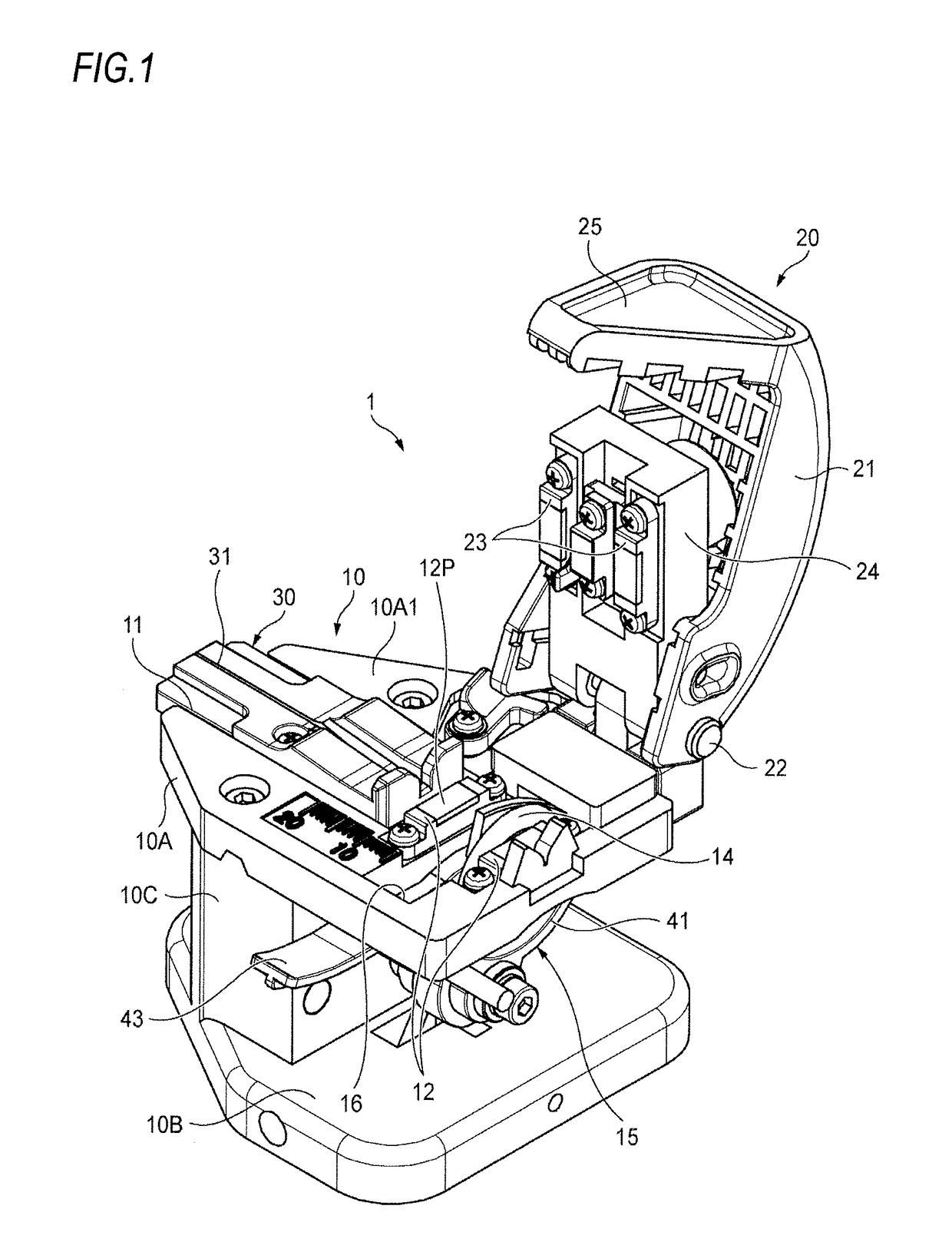

Optical fiber holder and optical fiber cleaving apparatus to which optical fiber holder is attachable

ActiveUS20170235052A1Large outer diameterCoupling light guidesEngineeringElectrical and Electronics engineering

An optical fiber holder includes a holder main body, a V-groove which is formed on an upper surface of the holder main body and accommodates a first optical fiber, a recessed groove which is formed on a same straight line with the V-groove and accommodates a second optical fiber having a coating portion with a larger outer diameter than the first optical fiber, and an abutting portion which is provided on an end portion of the recessed groove on an opposite side to the V-groove and includes an opening portion which has a smaller width than the recessed groove. When the second optical fiber is accommodated in the recessed groove, a fiber core wire of the second optical fiber protrudes to an outside via the opening portion and an end portion of the coating portion of the second optical fiber abuts on the abutting portion.

Owner:SEI OPTIFRONTIER CO LTD

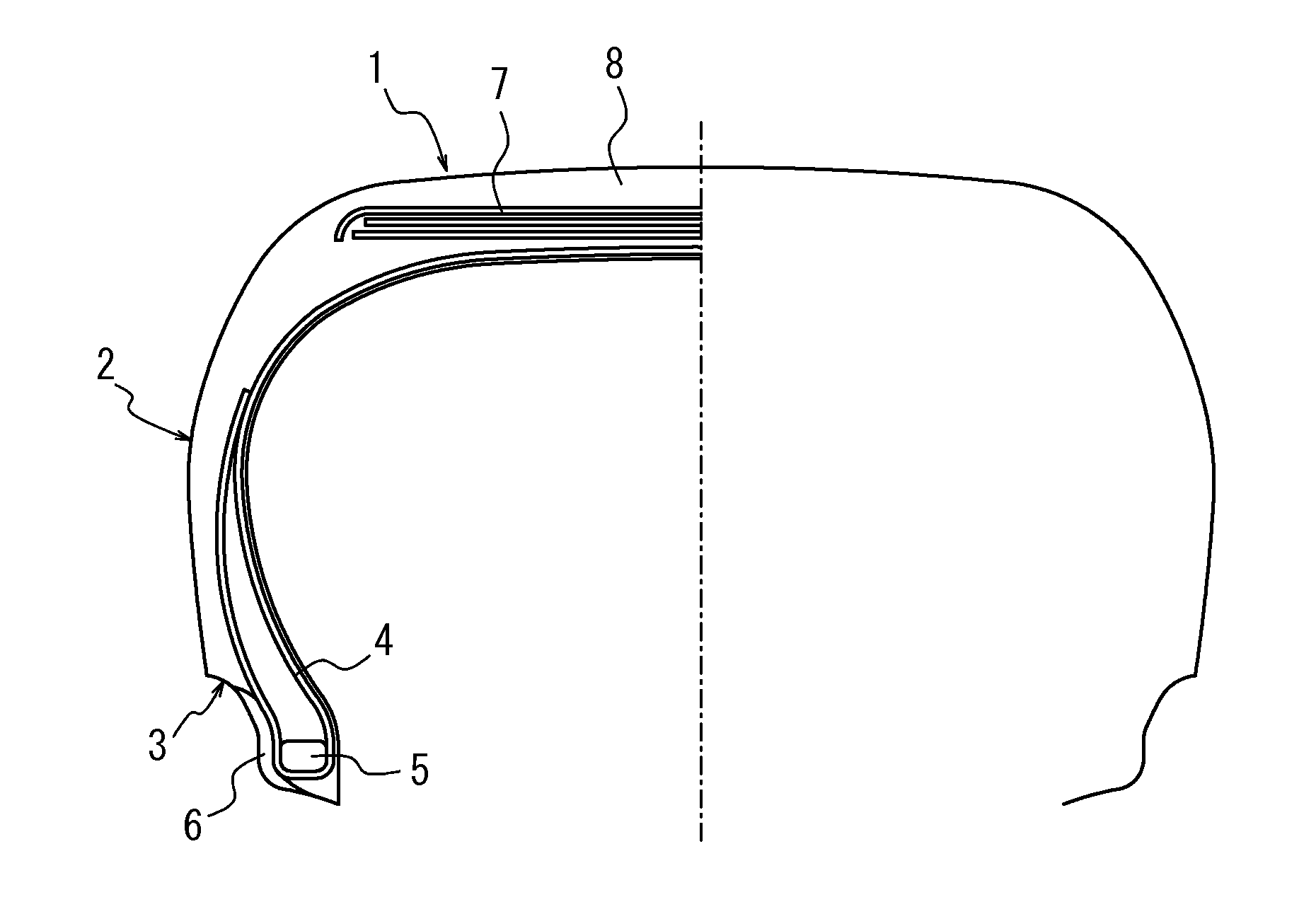

Pneumatic radial tire for passenger vehicle

InactiveUS20160023514A1Improve wettabilityNarrow widthSpecial tyresTyre tread bands/patternsInternal pressureDynamic storage

A pneumatic radial tire for a passenger vehicle, having a carcass constituted of a carcass ply provided to extend in a toroidal shape across a pair of bead portions and a tread rubber provided on the outer side in the tire radial direction of the carcass, wherein:provided that SW and OD represent cross sectional width and outer diameter of the tire, respectively, and that the tire assembled with a rim is inflated at an internal pressure of at least 250 kPa, SW / OD (a ratio of SW with respect to OD of the tire) is 0.26 when SW<165 (mm); SW and OD satisfy a formula OD≧2.135×SW+282.3 when SW≧165 (mm) and; dynamic storage elastic modulus E′ of the tread rubber at 30° C. is in the range of 6.0 MPa to 12.0 MPa.

Owner:BRIDGESTONE CORP

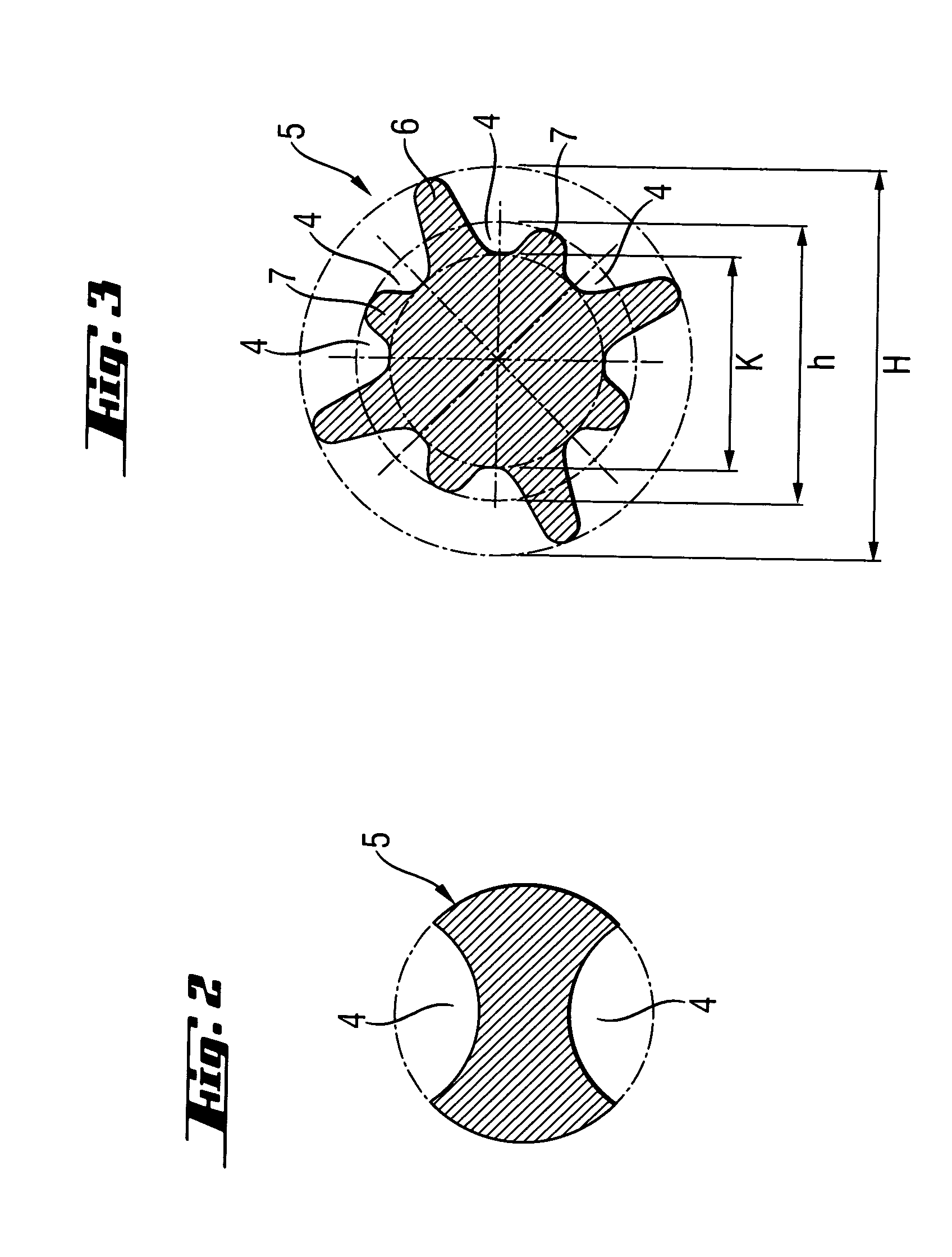

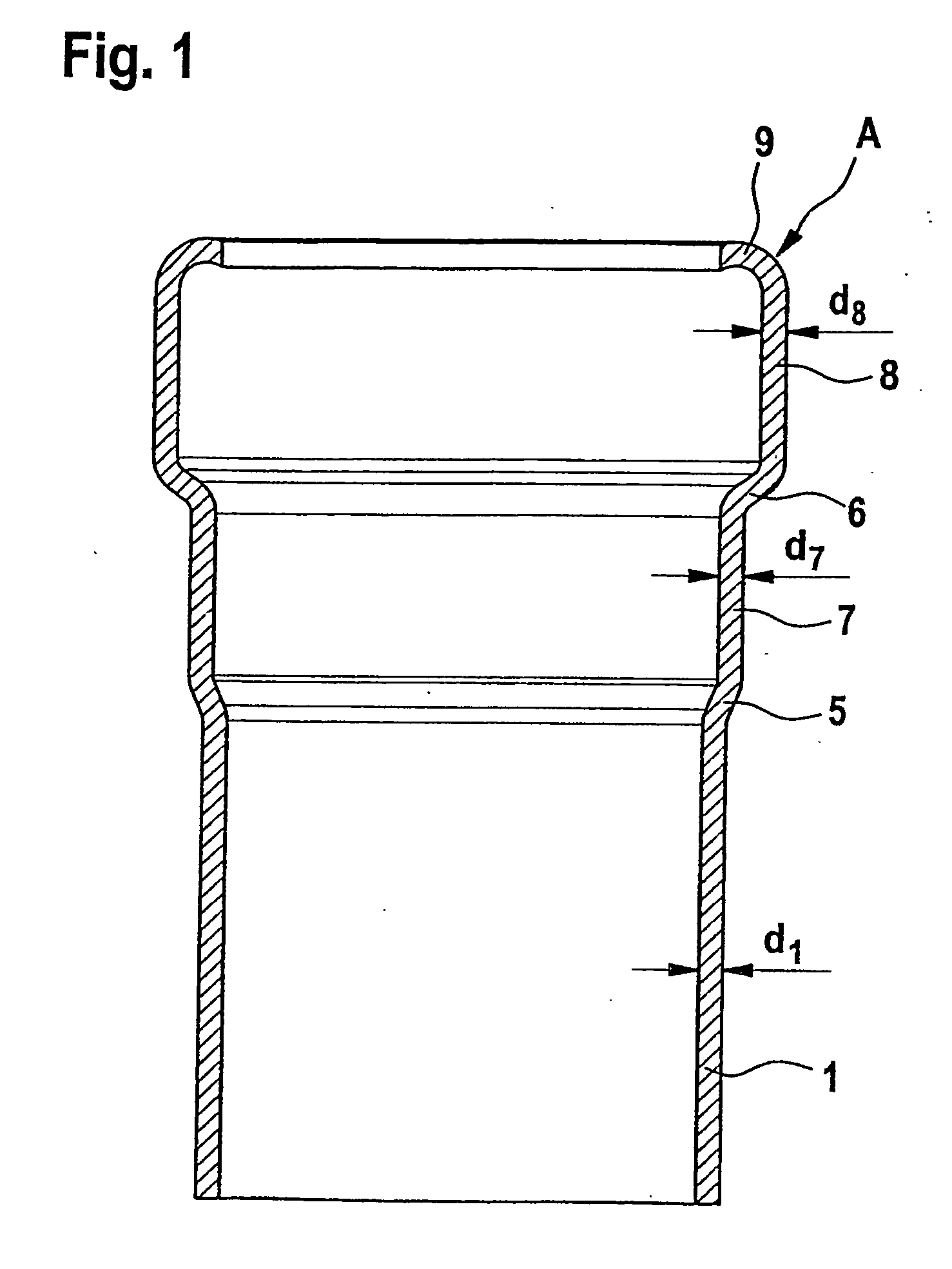

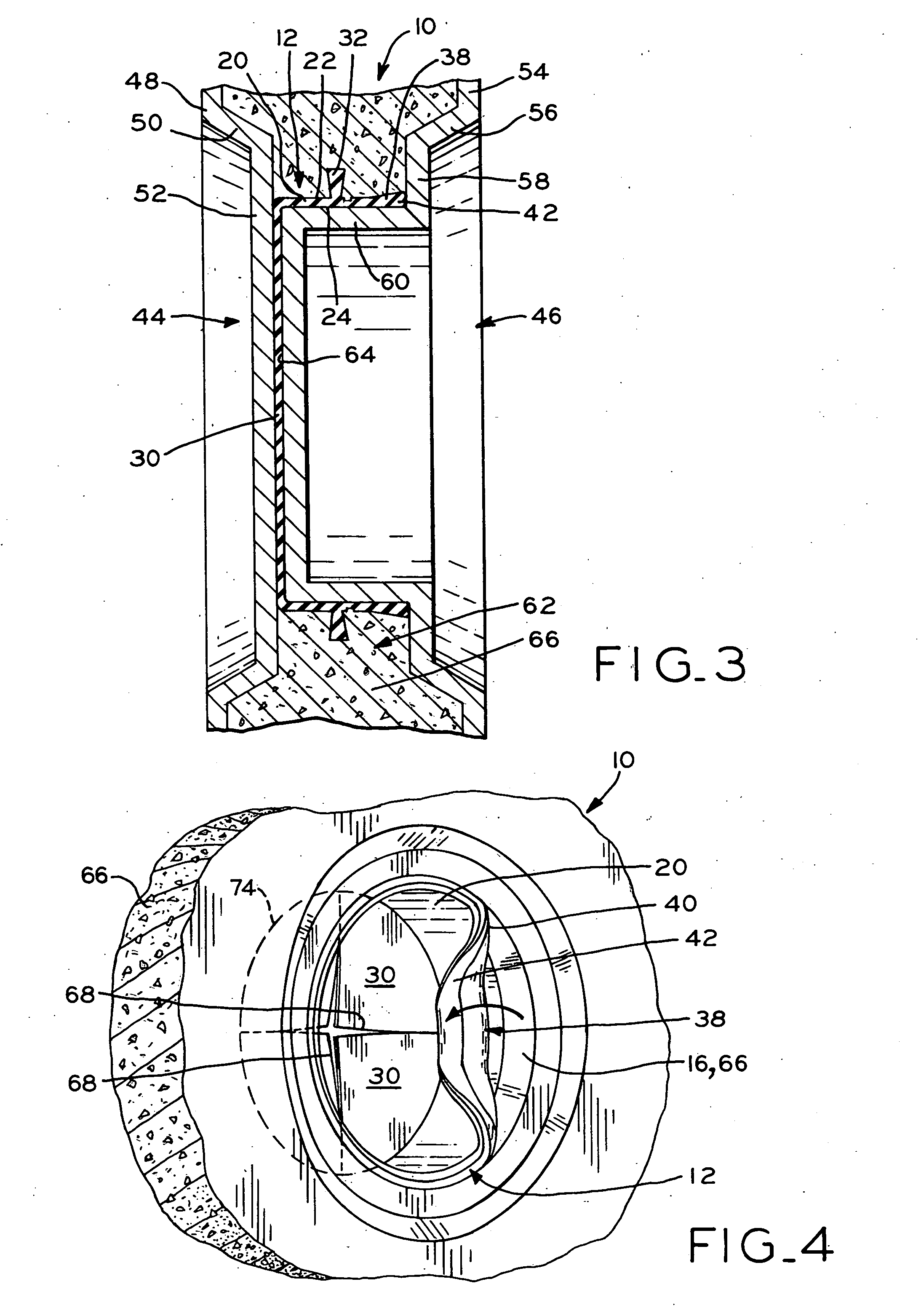

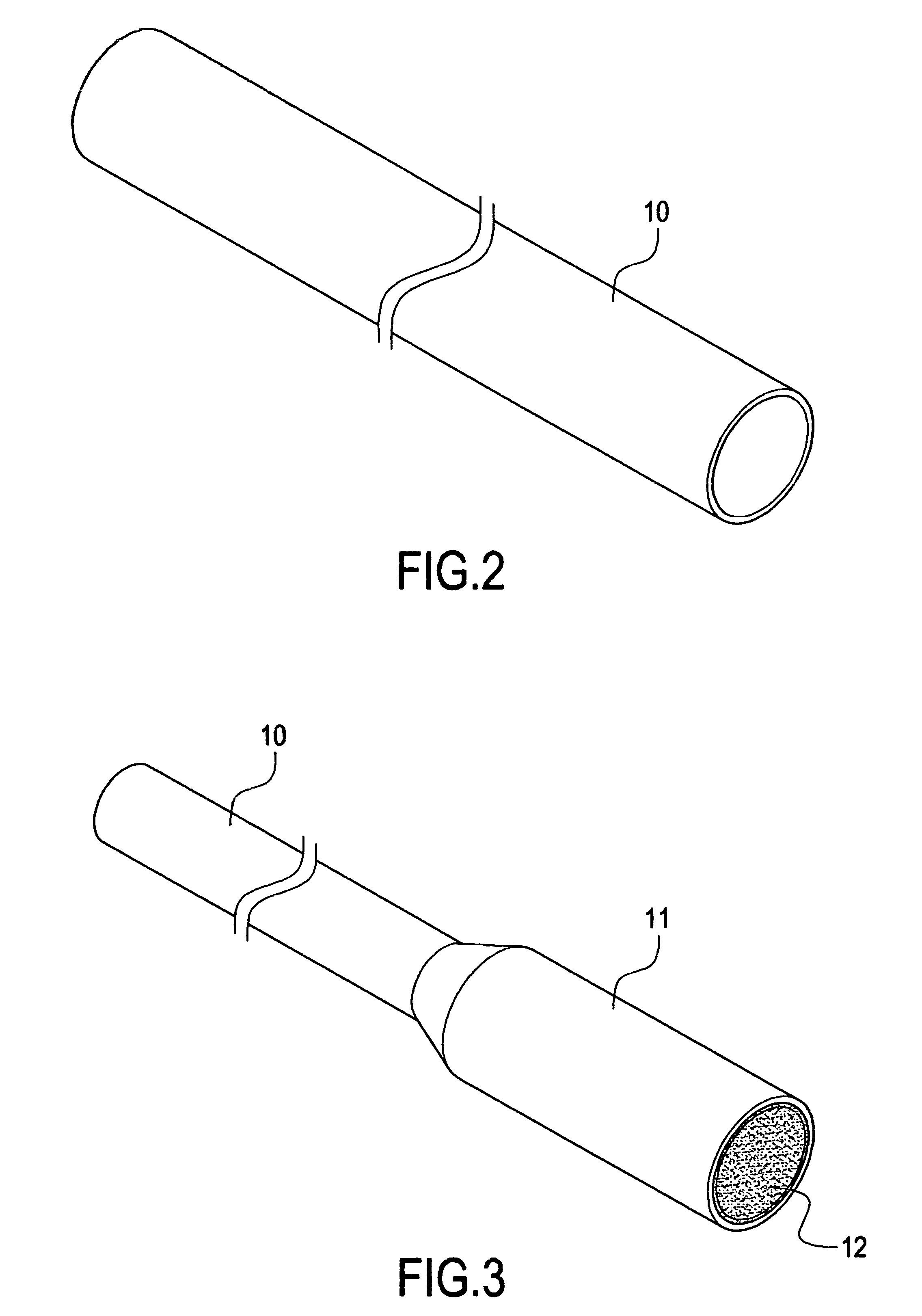

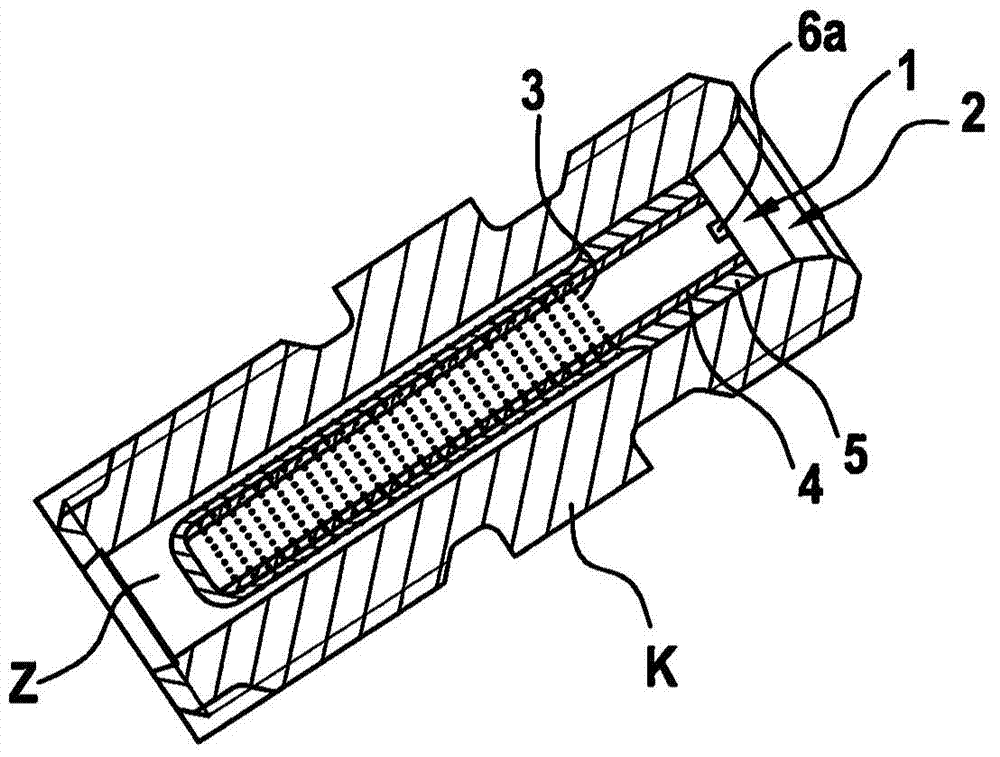

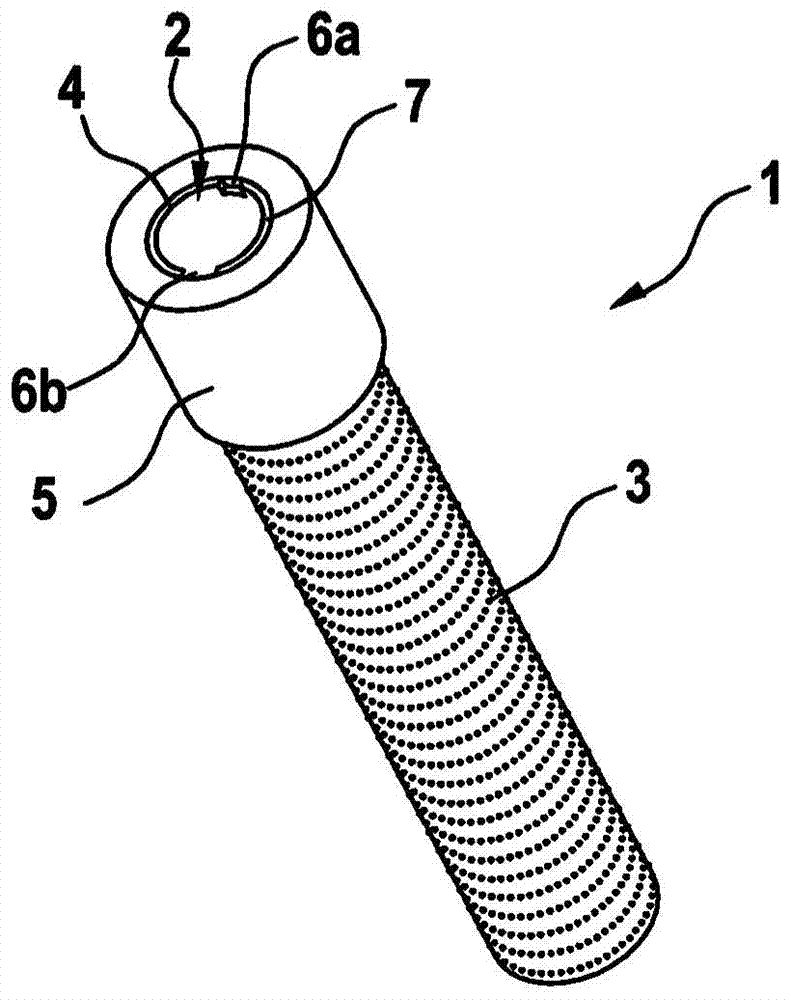

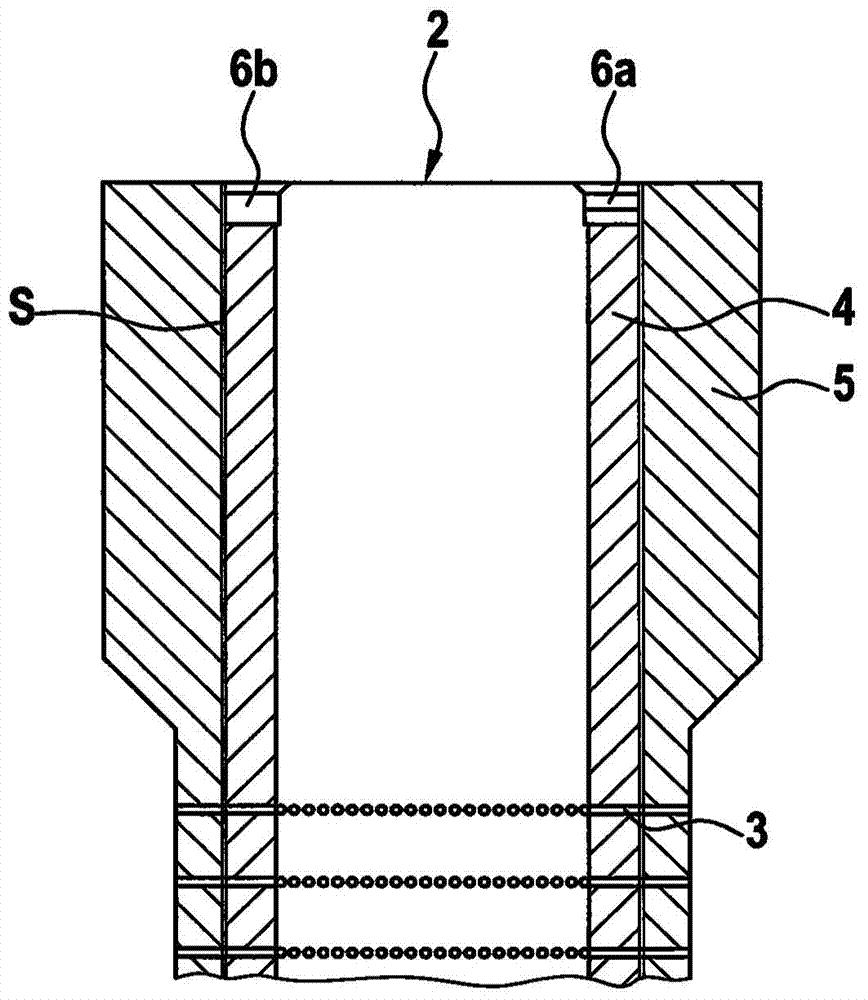

Wo-part particle filter and method for producing the same

InactiveCN103894010AAdjustable flowStop tiltMachines/enginesSpecial fuel injection apparatusEngineeringFuel injection

The particle filter has a rod-shaped filter body (1), which is inserted in a feed channel (Z) of a fuel injector (K). The rod-shaped filter body has an inlet opening (2) and multiple outlet openings (3) arranged on a lateral surface of the rod-shaped filter body. The rod-shaped filter body has a first and a second rod-shaped connectors (4,5), where the first rod-shaped connector is inserted into the second rod-shaped connector.

Owner:ROBERT BOSCH GMBH

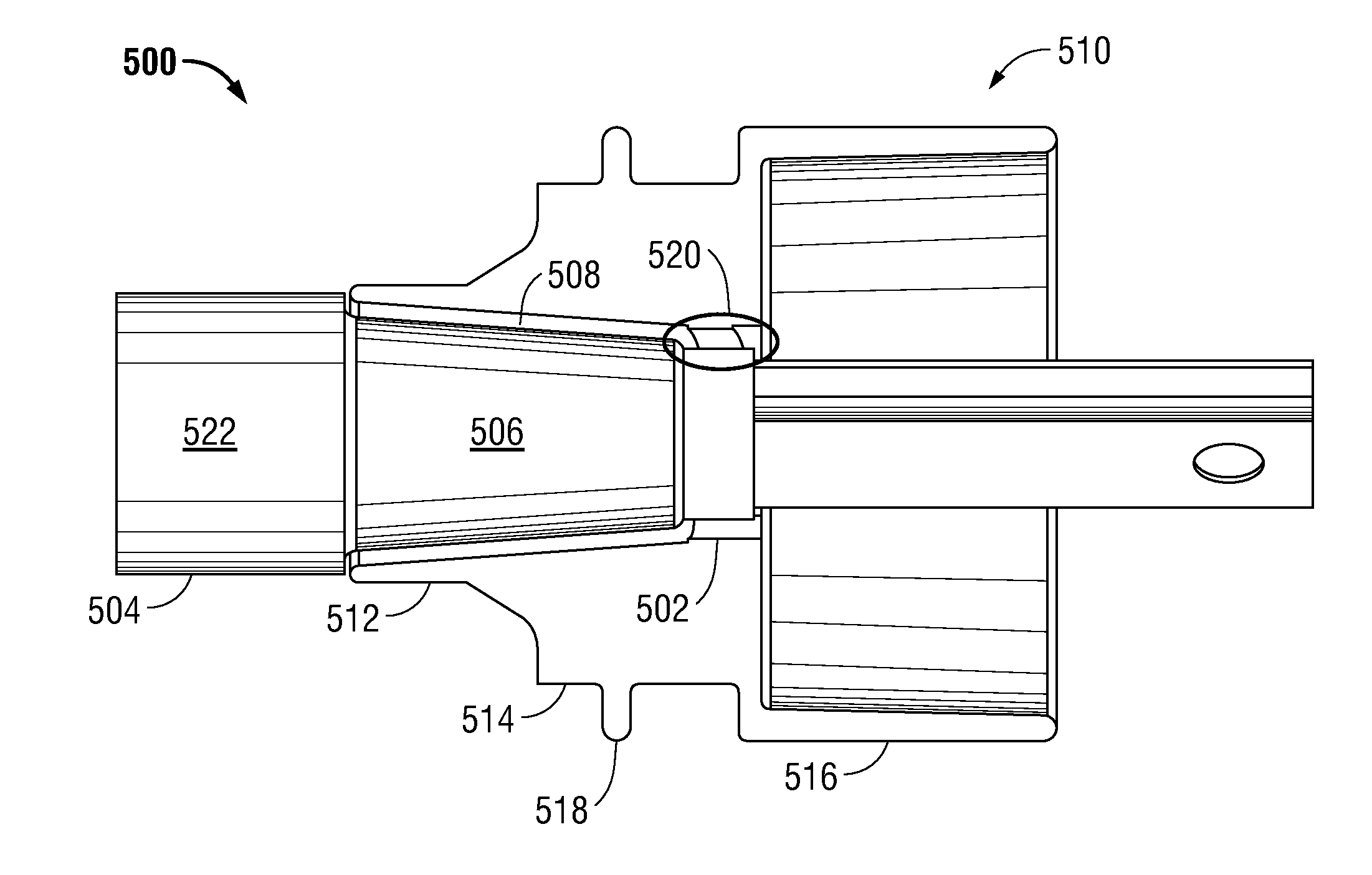

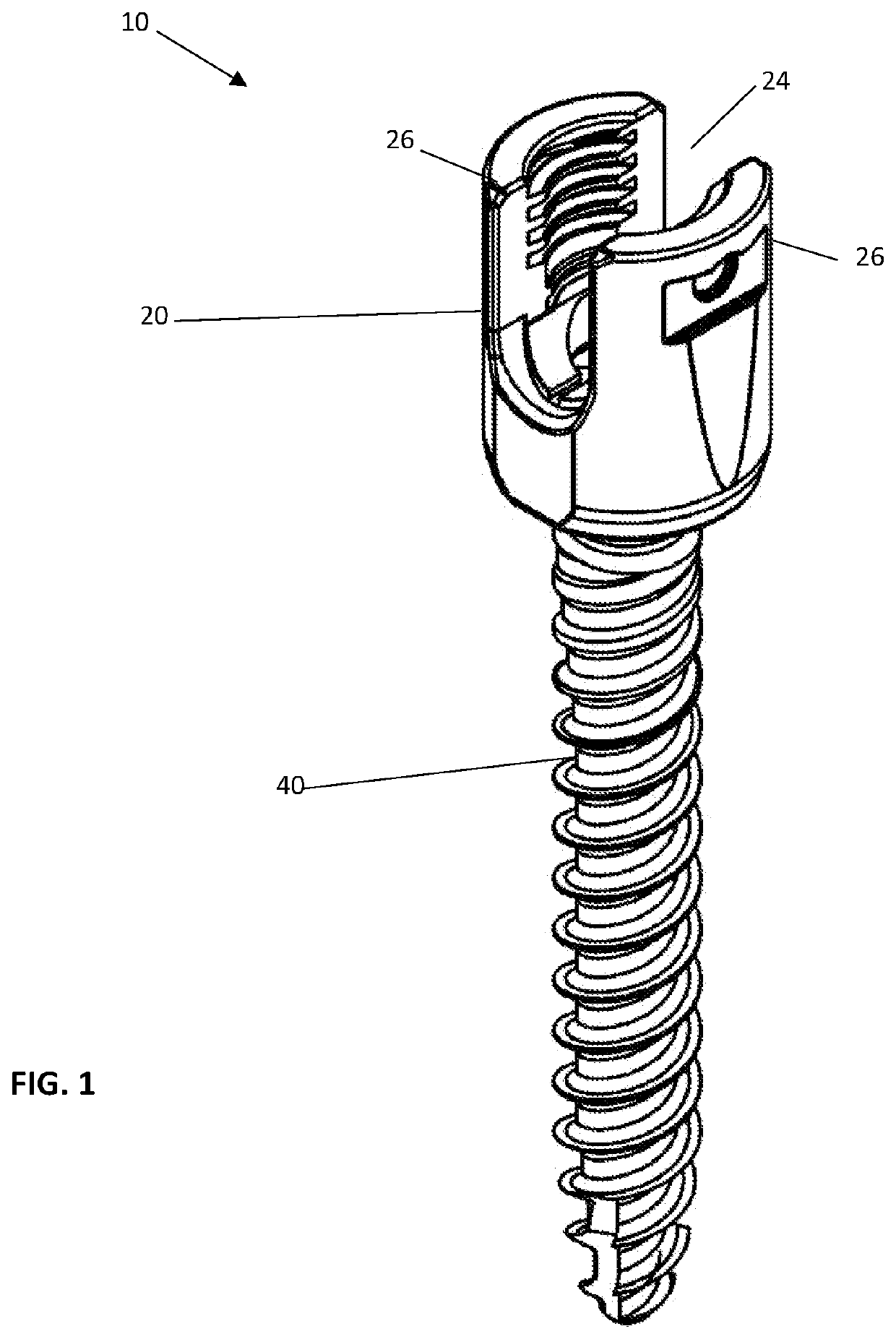

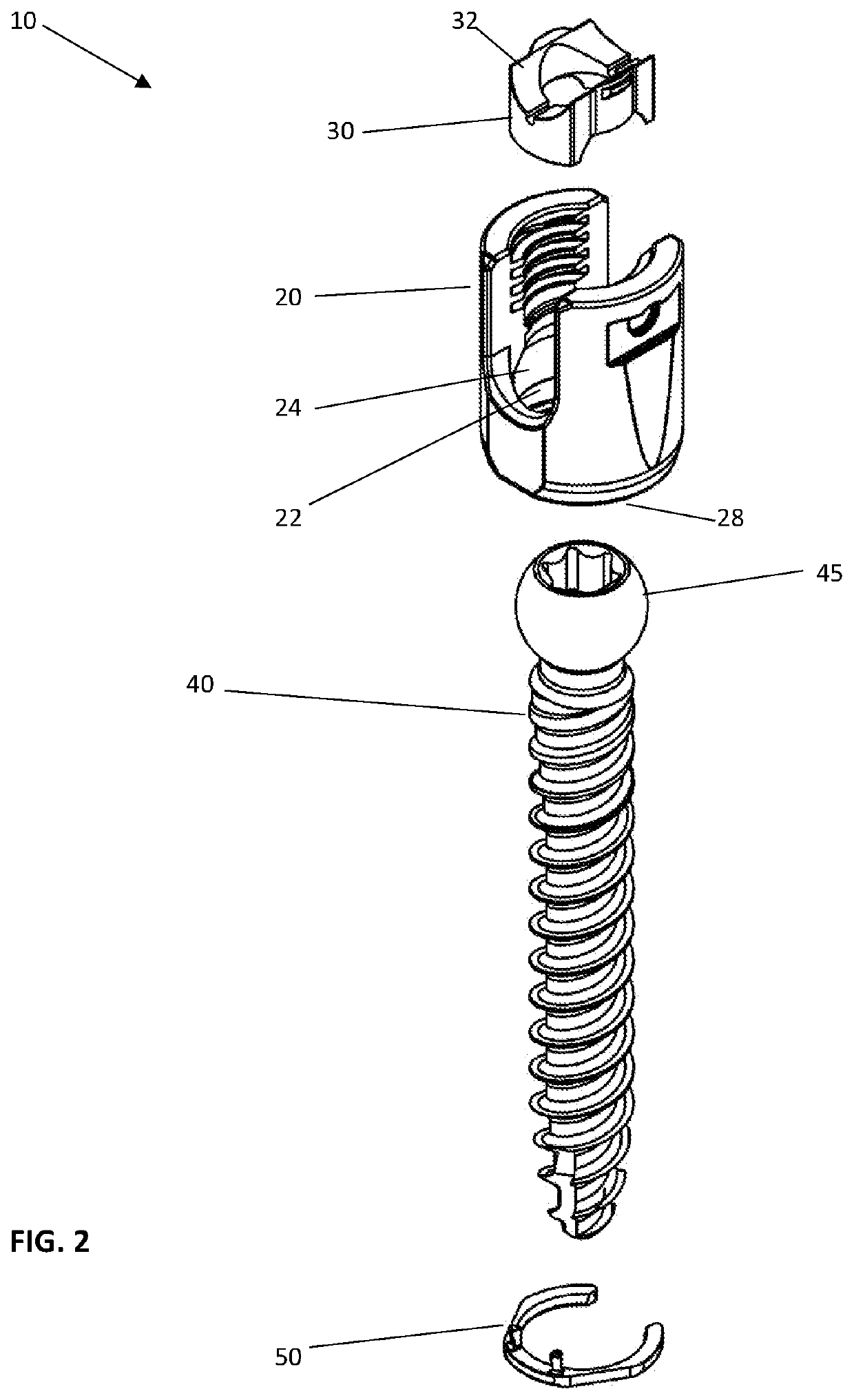

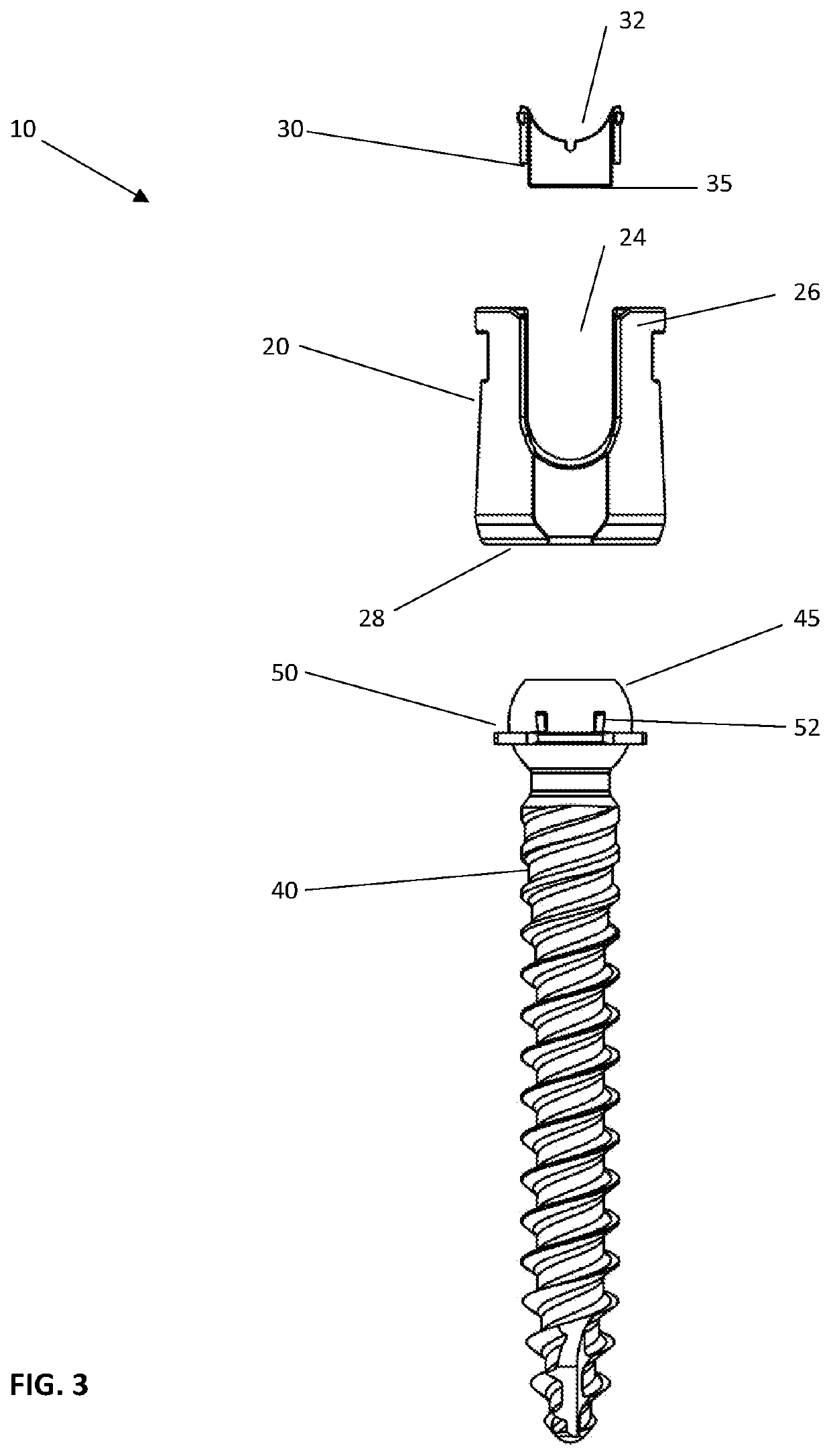

Modular polyaxial pedicle screw assembly with split ring

ActiveUS11369417B1Inhibit sheddingLarge outer diameterInternal osteosythesisPedicle screw fixationSplit ring

A modular head polyaxial pedicle screw assembly has a pedicle bone screw, a tulip, a split locking ring and a saddle. The screw has a head and a threaded shank. The split locking ring has a split ring body with one or more positioning tabs extending from a first surface of the split ring body. The split ring locking ring is configured to be placed internal of the tulip positioned in a recess, groove or undercut of an inner surface of the tulip. Upon assembly of the pedicle screw into the tulip, at least a maximum diameter of the head is positioned above the recess, groove or undercut allowing the split locking ring to be inserted into the recess or groove thereby securing the pedicle screw inside the tulip wherein the head of the pedicle screw abuts the one or more positioning tabs.

Owner:CURITEVA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com