Sheet printing machine and process for sheet printing

A sheet-fed, printing press technology, used in printing presses, rotary presses, offset rotary presses, etc., to solve problems such as use restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

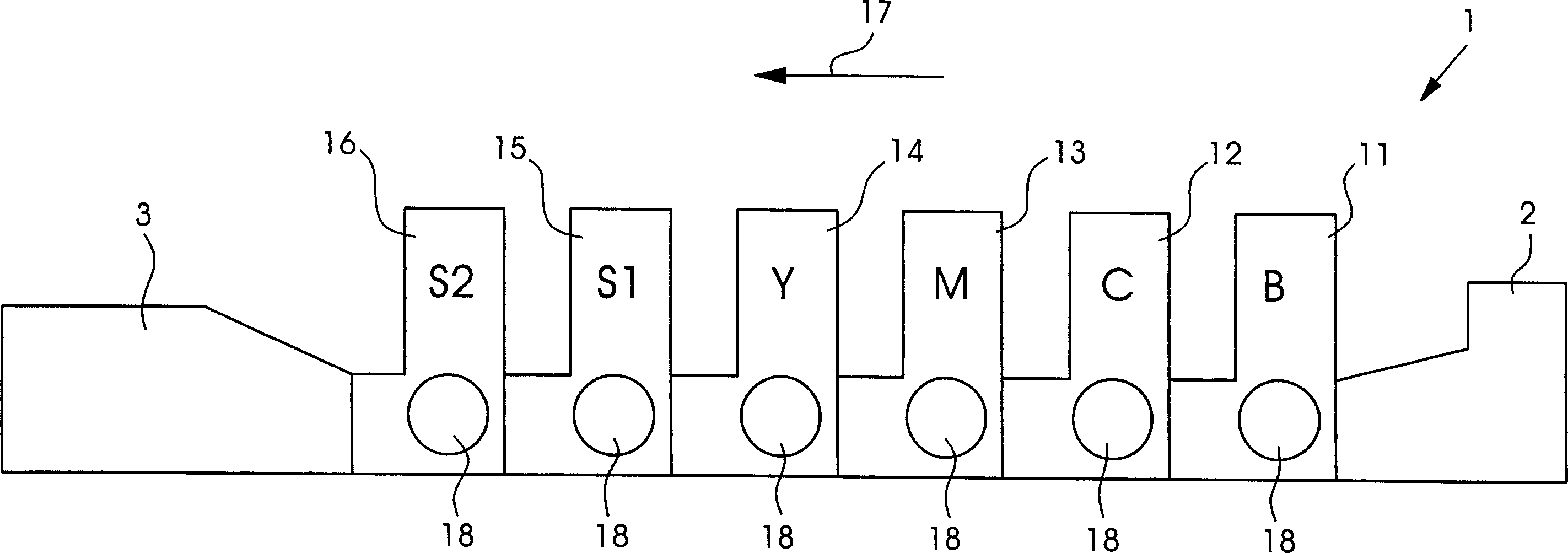

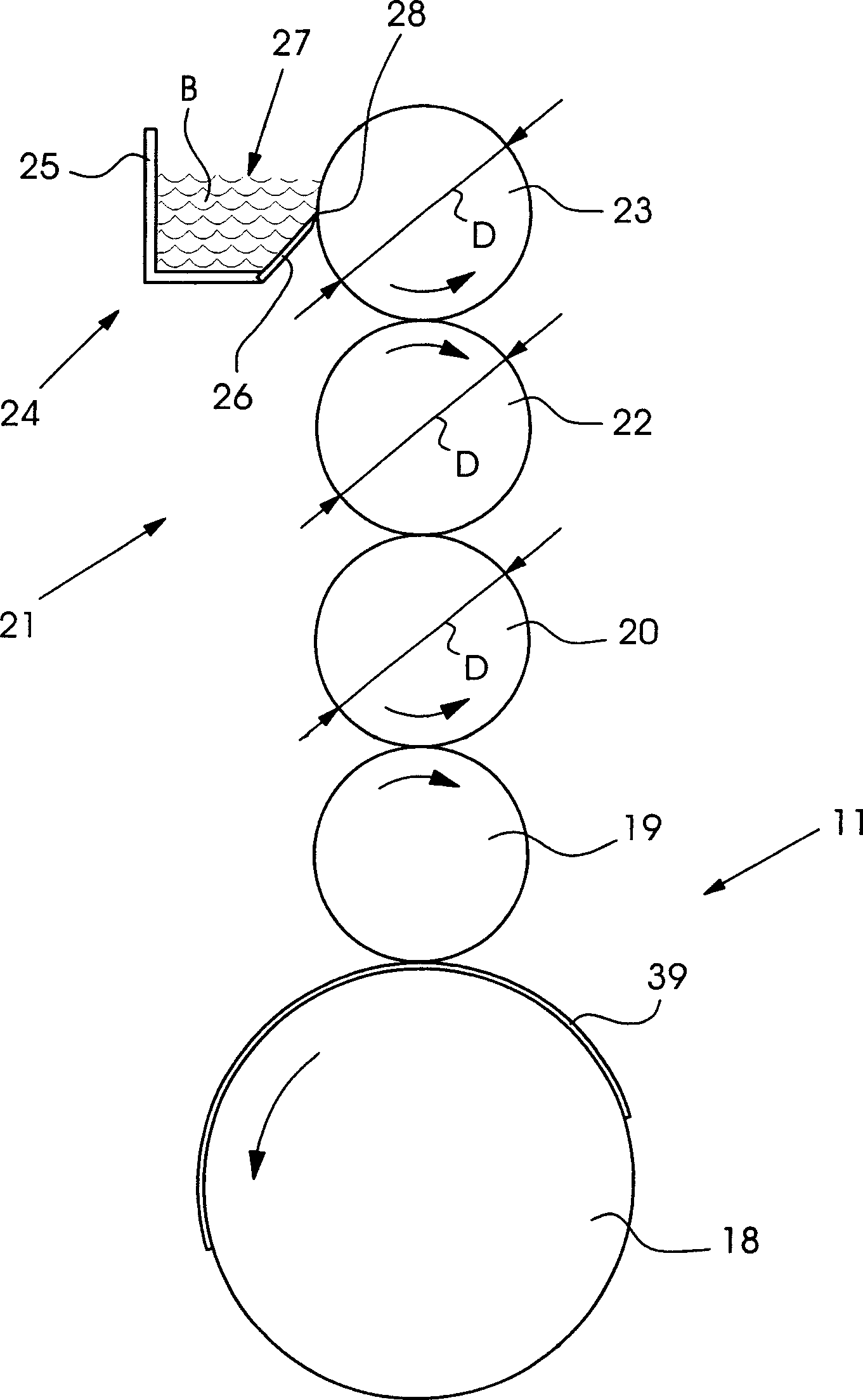

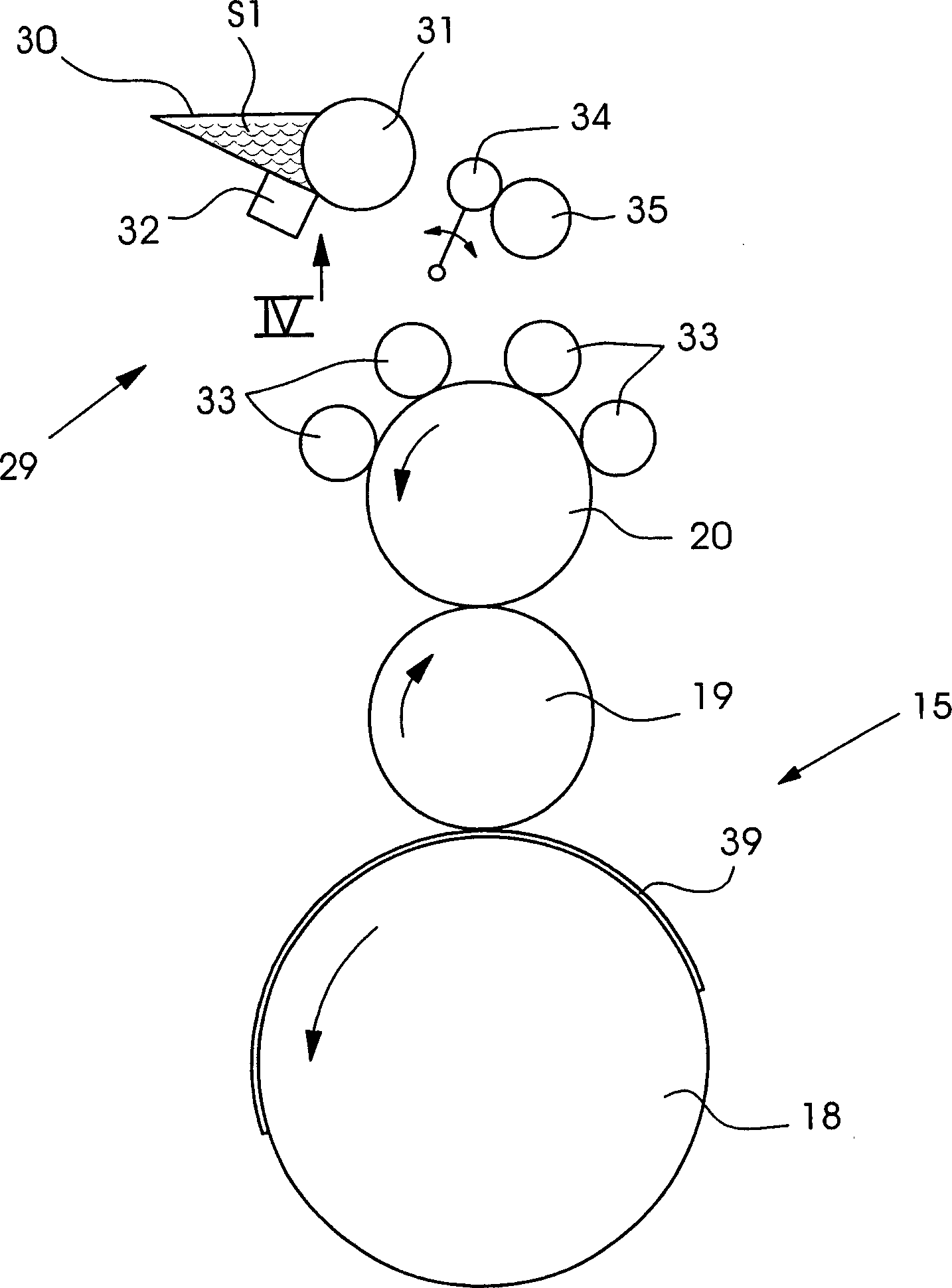

[0018] figure 1 A sheet-fed printing press 1 in a tandem configuration is shown. The sheet-fed printing machine 1 includes a sheet-fed feeder 2 , a sheet-fed reel 3 , and first, second, third, and fourth anilox offset printing devices 11 , 12 , 13 , and 14 . In addition, the sheet-fed printing press comprises additional offset printing units 15 , 16 which are arranged downstream of the four anilox offset printing units 11 to 14 in the direction of sheet travel 17 . Each of the anilox offset printing units 11 to 14 and the additional offset printing units 15 , 16 includes a respective impression cylinder 18 . The black (Black) printing ink B of the four-color printing that is used for printing is stored in the first anilox roller offset printing device 11, the cyan printing ink C of four-color printing is stored in the second anilox roller offset printing device 12, the third Magenta printing ink M for four-color printing is stored in the anilox offset printing device 13 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com