Wo-part particle filter and method for producing the same

A particle filter and filter technology, which can be used in fixed filter element filters, chemical instruments and methods, filtration and separation, etc., can solve the problems of difficult filter technology and high realization cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

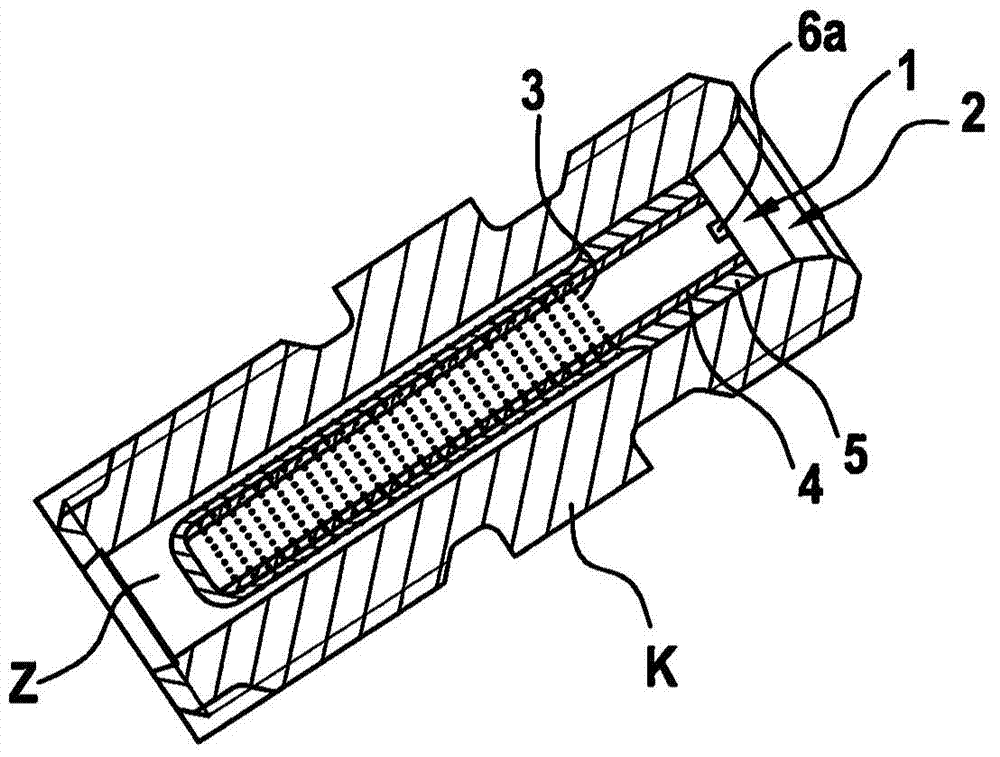

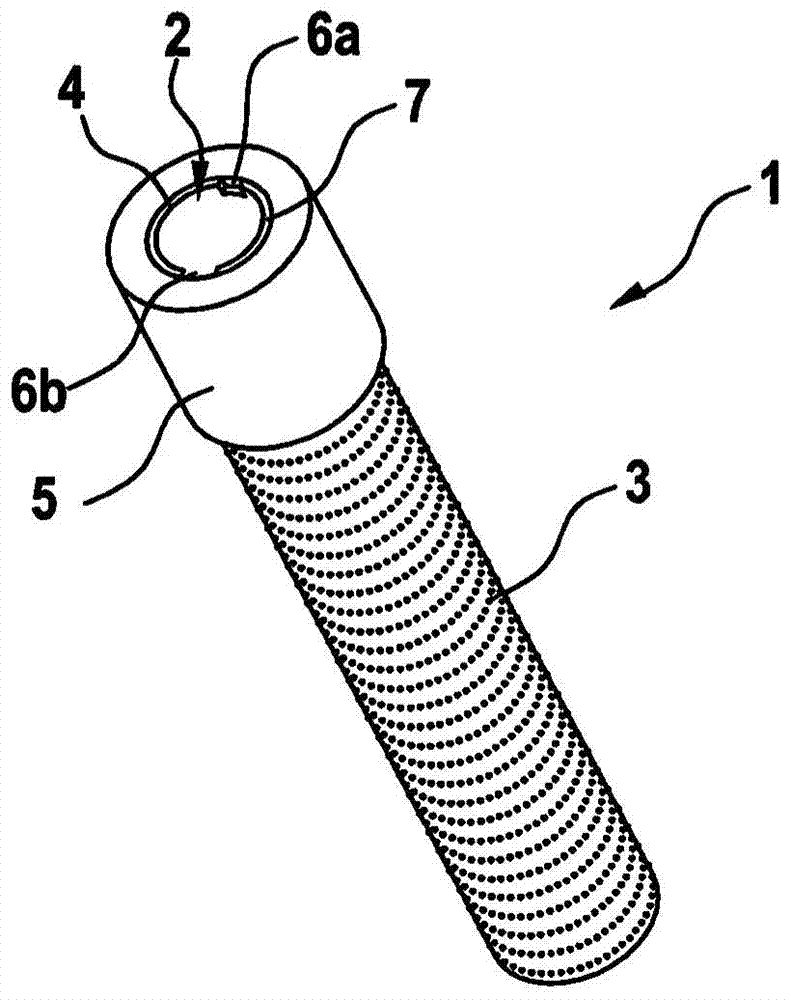

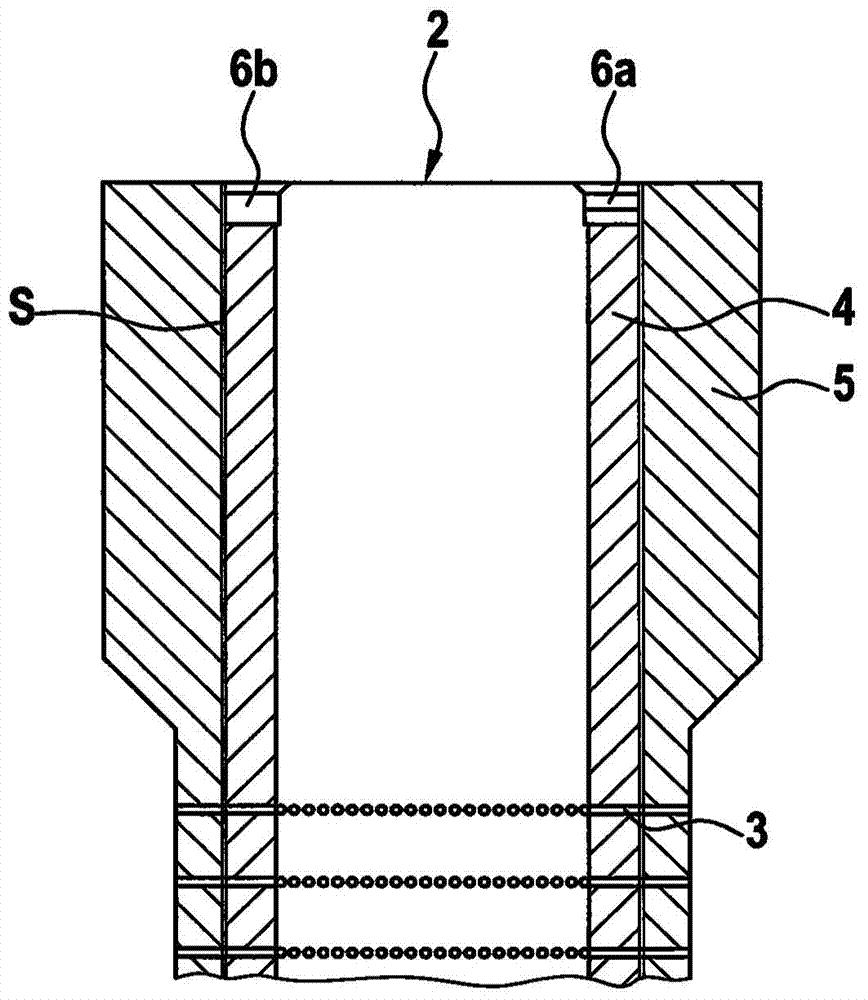

[0029] figure 1 A particle filter is shown which comprises a rod-shaped filter body 1 which is inserted into an inlet channel Z of a fuel injection device K. FIG. The rod filter body 1 consists of a first and a second rod bushing 4 , 5 . Since the rod-shaped filter body is arranged in a high-pressure system, the two rod-shaped filter bodies 4 , 5 are made of metallic material. Here, a first rod-shaped filter bush 4 is inserted into a second rod-shaped filter bush 5 . The rod-shaped filter body 1 also has an inlet 2 on one end face, through which the fluid flows into the particle filter. A plurality of outlets 3 are arranged on the housing surface of the filter body 1 through which the fluid flows out of the filter body 1 again.

[0030] The cross-section of the outlet 3 is dimensioned such that the fluid is filtered and particles whose diameter is larger than the diameter of the outlet 3 cannot escape from the rod-shaped filter body 1 . The cross-section of the outlet 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com