A flexible industrial boiler and its operating method

A technology of industrial boilers and operating methods, which is applied in steam boilers, fluid heaters, steam generation, etc., can solve problems such as not in the system, and achieve the effect of satisfying flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

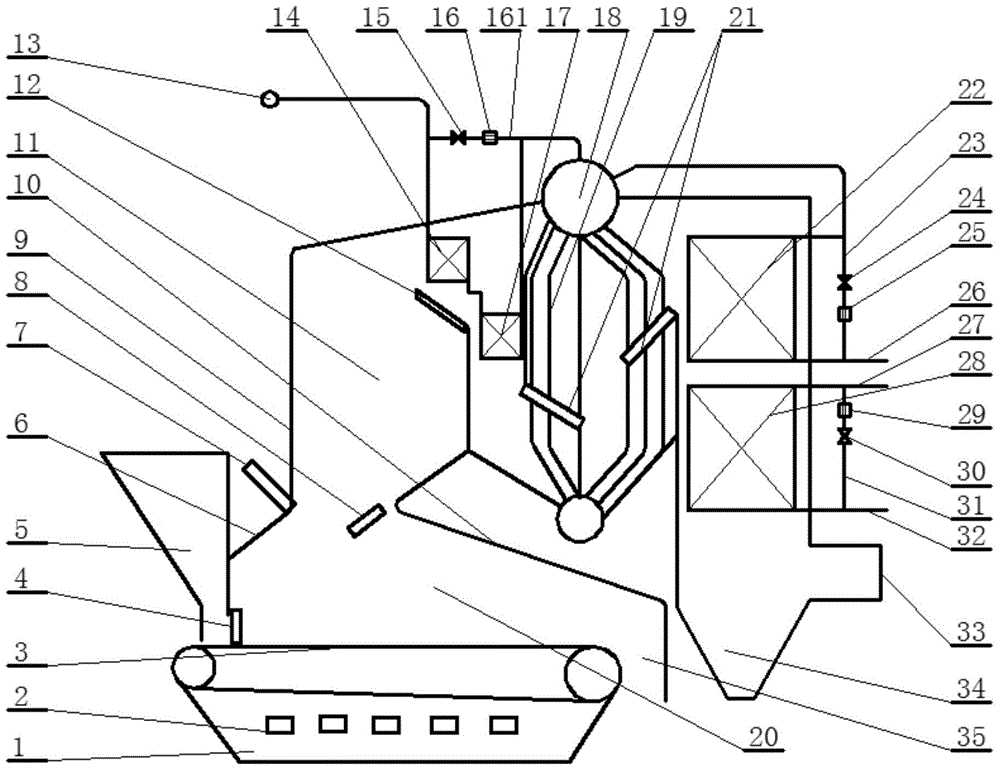

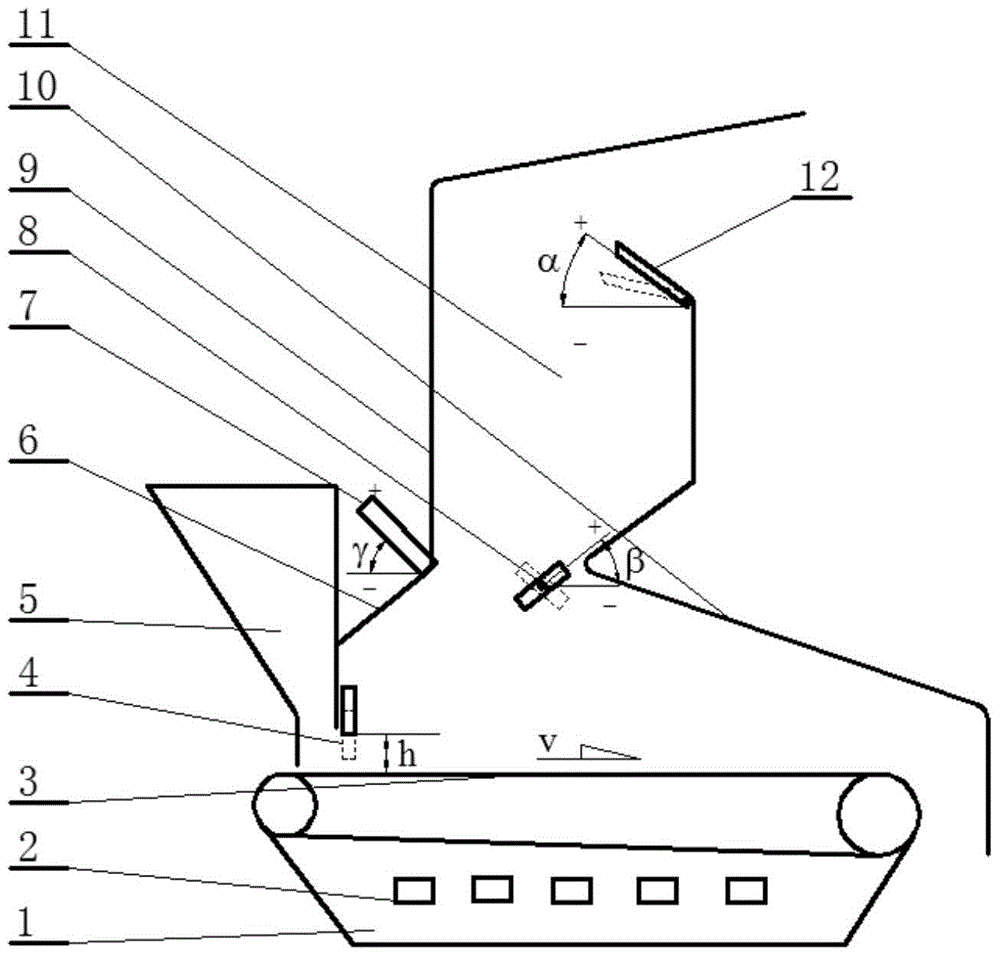

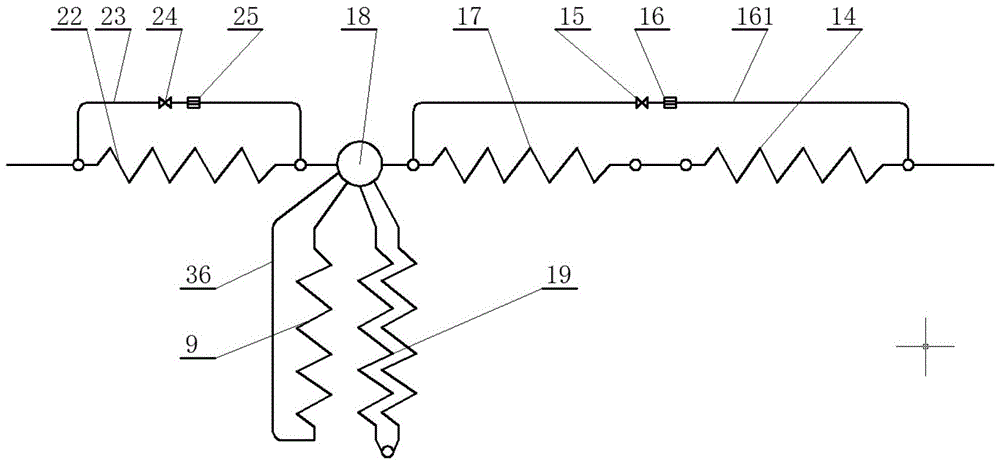

[0023] When the present invention adopts the concept of flexibility to design the industrial boiler, on the one hand, the combustion and flow in the furnace are guaranteed to be flexible on the combustion side, and on the other hand, the heat exchange side of the heating surface is also flexible. That is, a flexible mechanism consisting of an adjustable arch 8, an adjustable flame wall 12, and parallel pipe valves is arranged on the furnace and heating surface of the industrial boiler to adjust the angle of the adjustable arch and the adjustable flame wall. , valve opening of parallel pipelines, etc., thereby changing the distribution ratio of combustion and heat transfer in the furnace, and adapting to changes in boiler load through changes in these flexible factors, while ensuring rigid indicators such as boiler exhaust gas temperature and environmental protection emission indicators remain unchanged.

[0024] When operating a flexible industrial boiler, the position of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com