Patents

Literature

112 results about "Shoe industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rapid adhesive stirring device applied to shoe industry

ActiveCN106110989AImprove plasticityGood welding performanceShaking/oscillating/vibrating mixersRotary stirring mixersShoe industryAdhesive

The invention relates to an adhesive stirring device and particularly relates to a rapid adhesive stirring device applied to shoe industry. The invention is to provide a rapid adhesive stirring device to the shoe industry. The rapid adhesive stirring device is novel in structure, simple and convenient to operate and high in operating efficiency. In order to solve the technical problem, the invention provides such a rapid adhesive stirring device applied to the shoe industry. The rapid adhesive stirring device comprises a bottom plate, fixed blocks, a collection framework, a first support rod, a second support rod, a third support rod, a right frame, a first guide sleeve, a first guide rod, a movable framework, a rotating rod, a motor, a second guide sleeve, a second guide rod, a movable rod, a wire tying ring, a drawing wire, a stirring framework and a pipeline; the fixed blocks are symmetrically arranged on the left side of the top of the bottom plate. Through the rapid adhesive stirring device, the effects of being novel in structure, simple and convenient to operate and high in operating efficiency can be achieved; the adhesive can be rapidly and uniformly stirred; the rapid adhesive stirring device can be conveniently applied to production of the shoe industry; through a second spring and a steel ball, the adhesive can be stirred more thoroughly.

Owner:大化瑶族自治县计量检定测试所

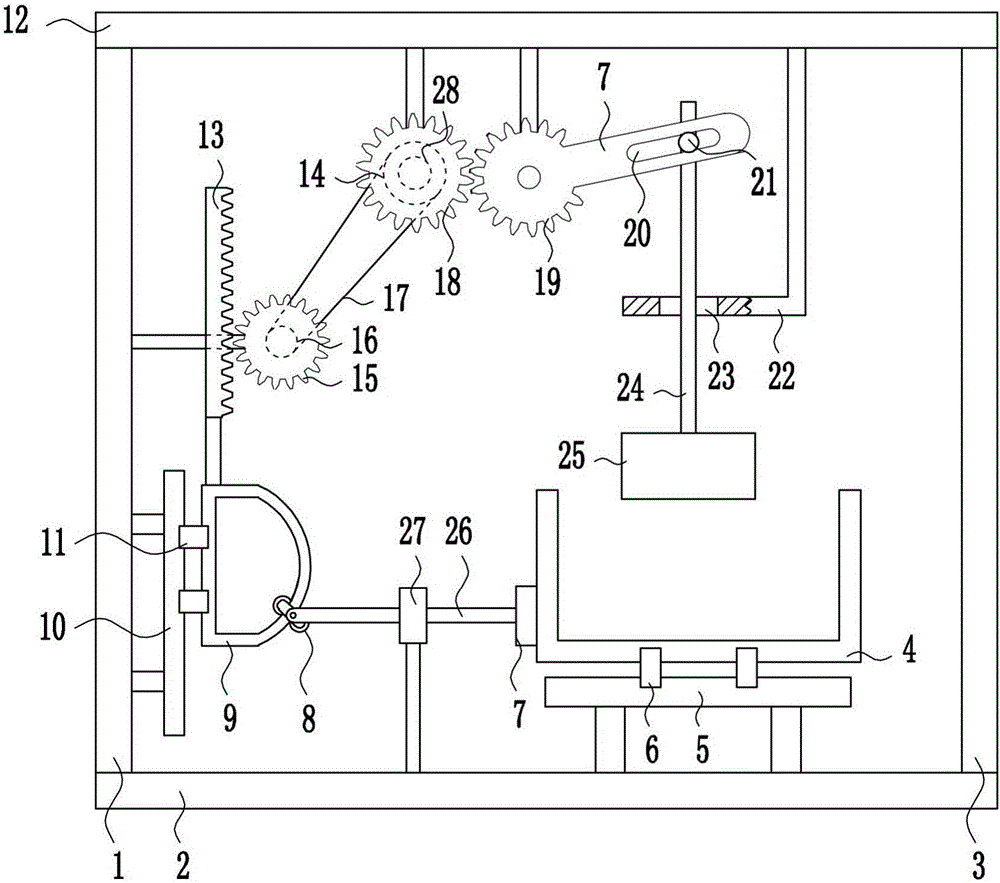

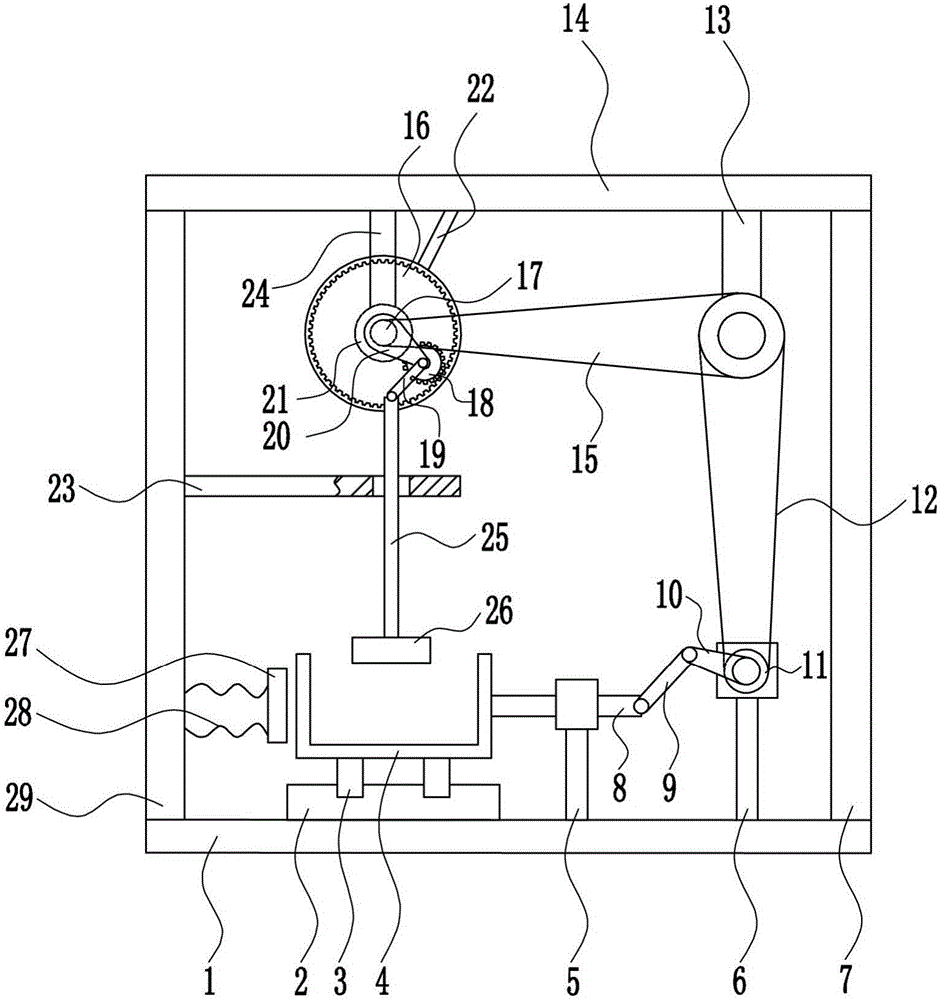

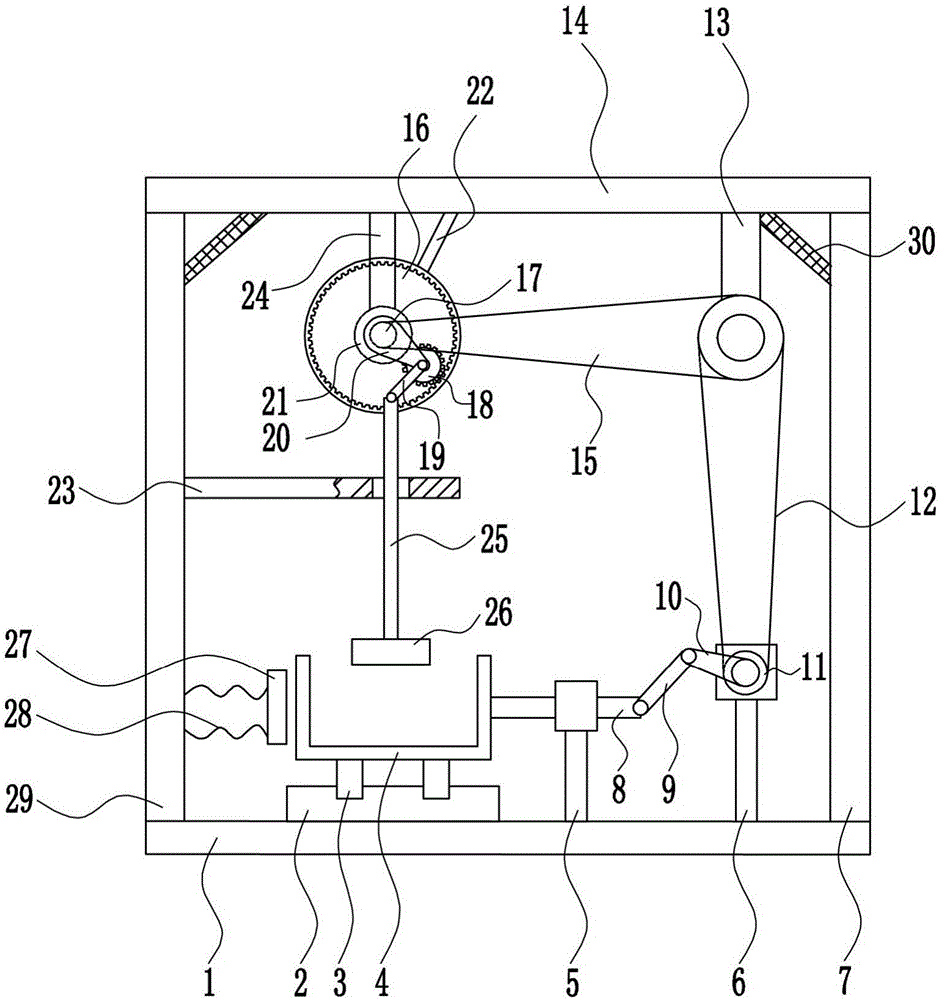

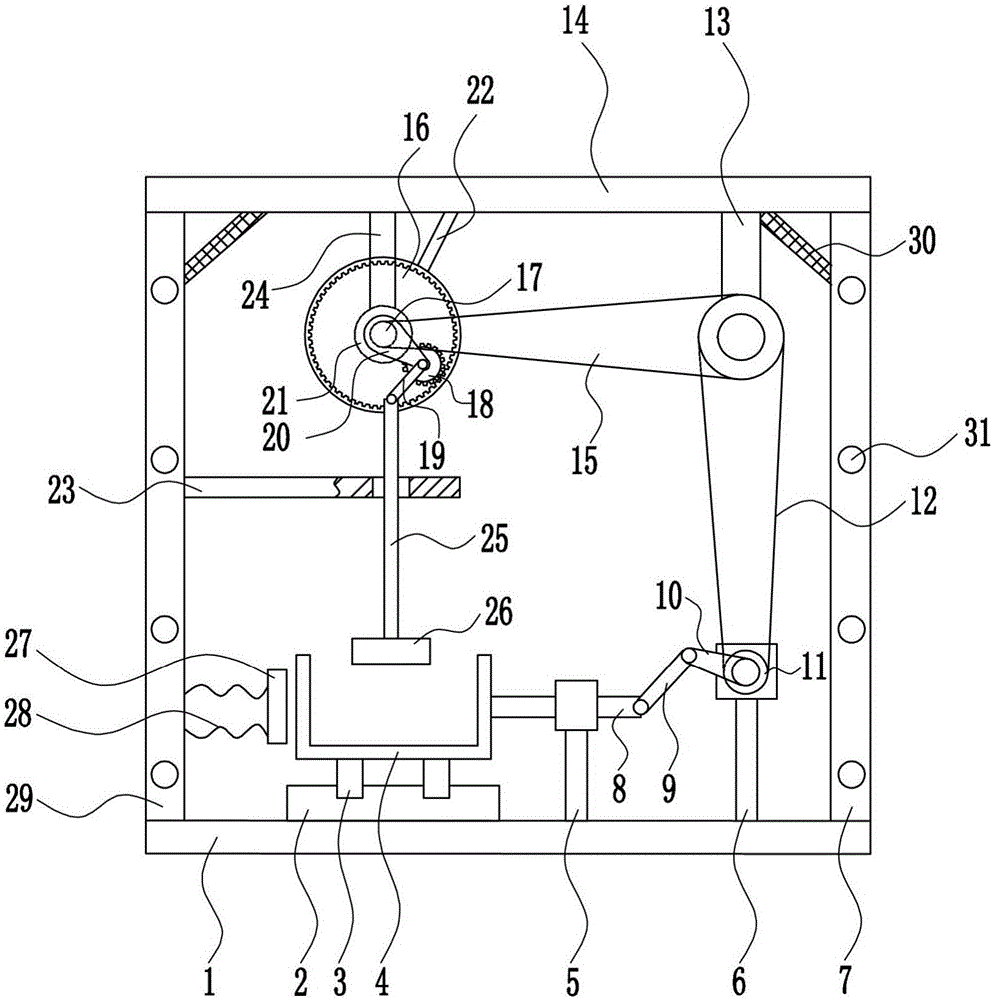

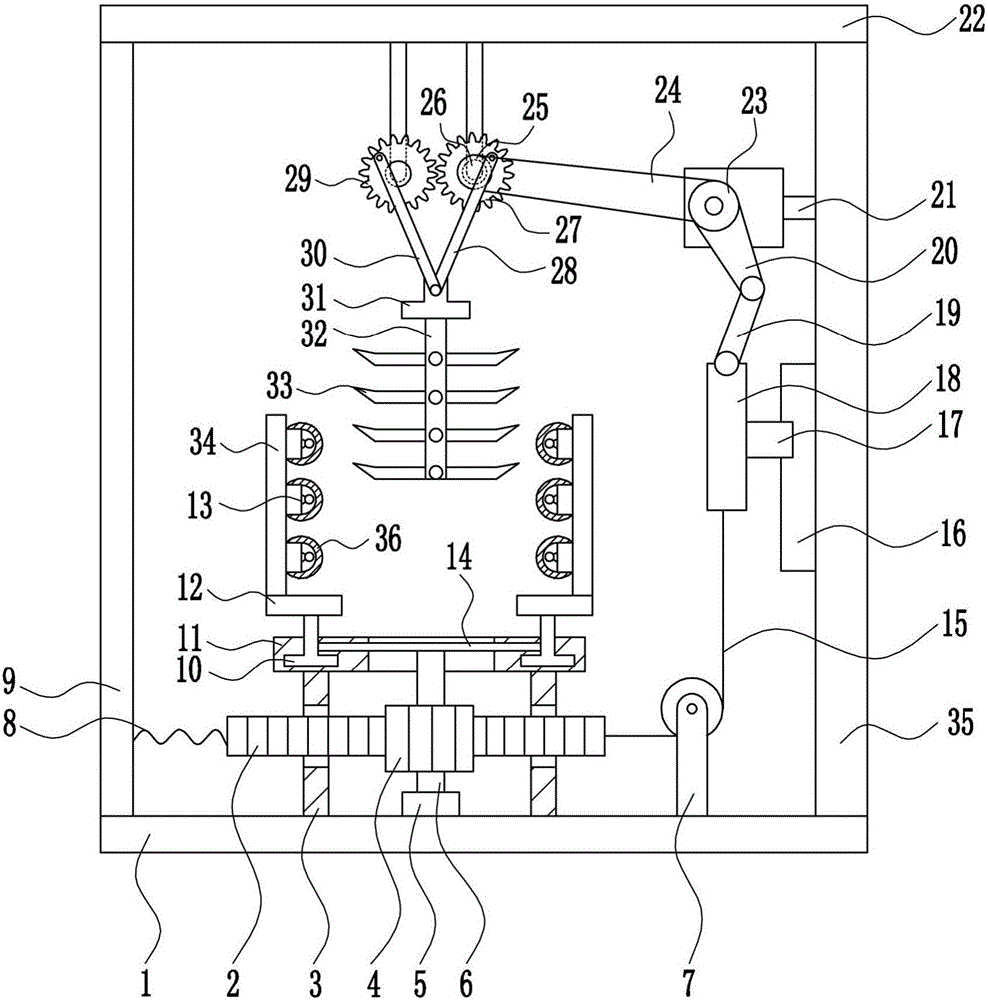

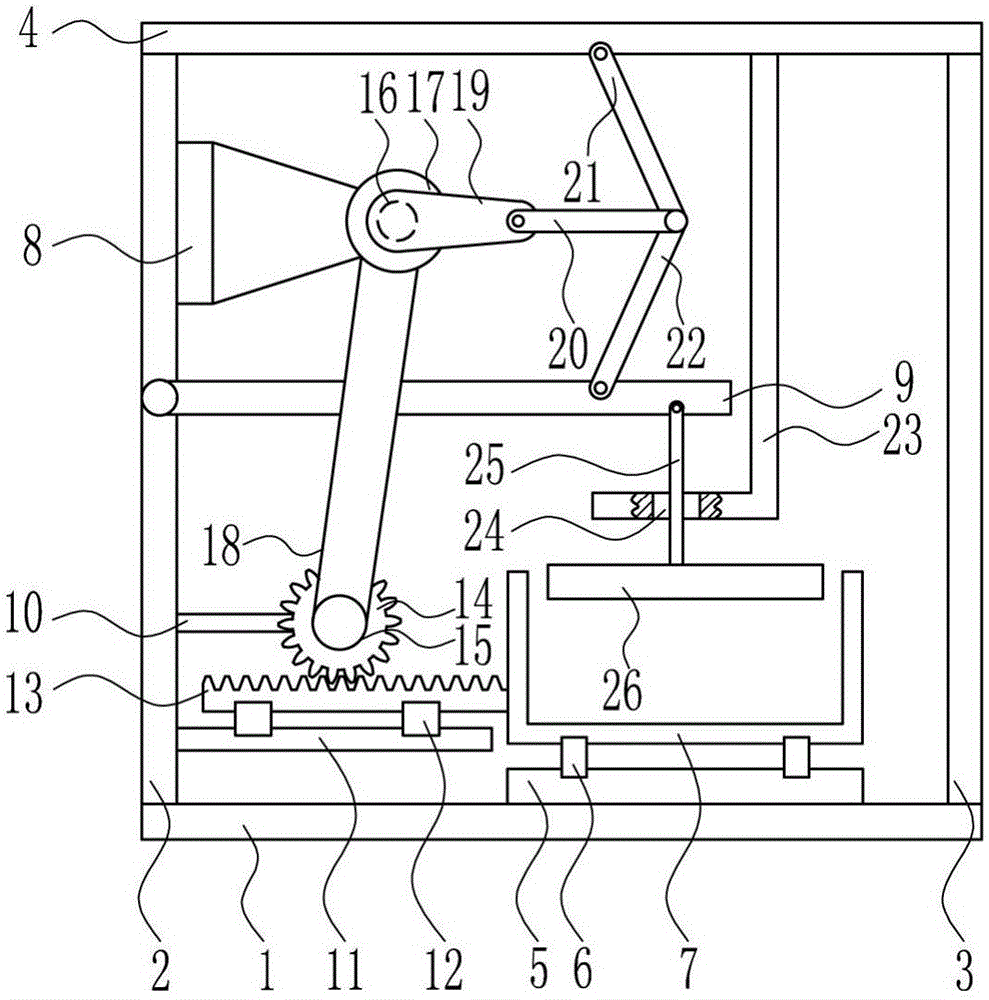

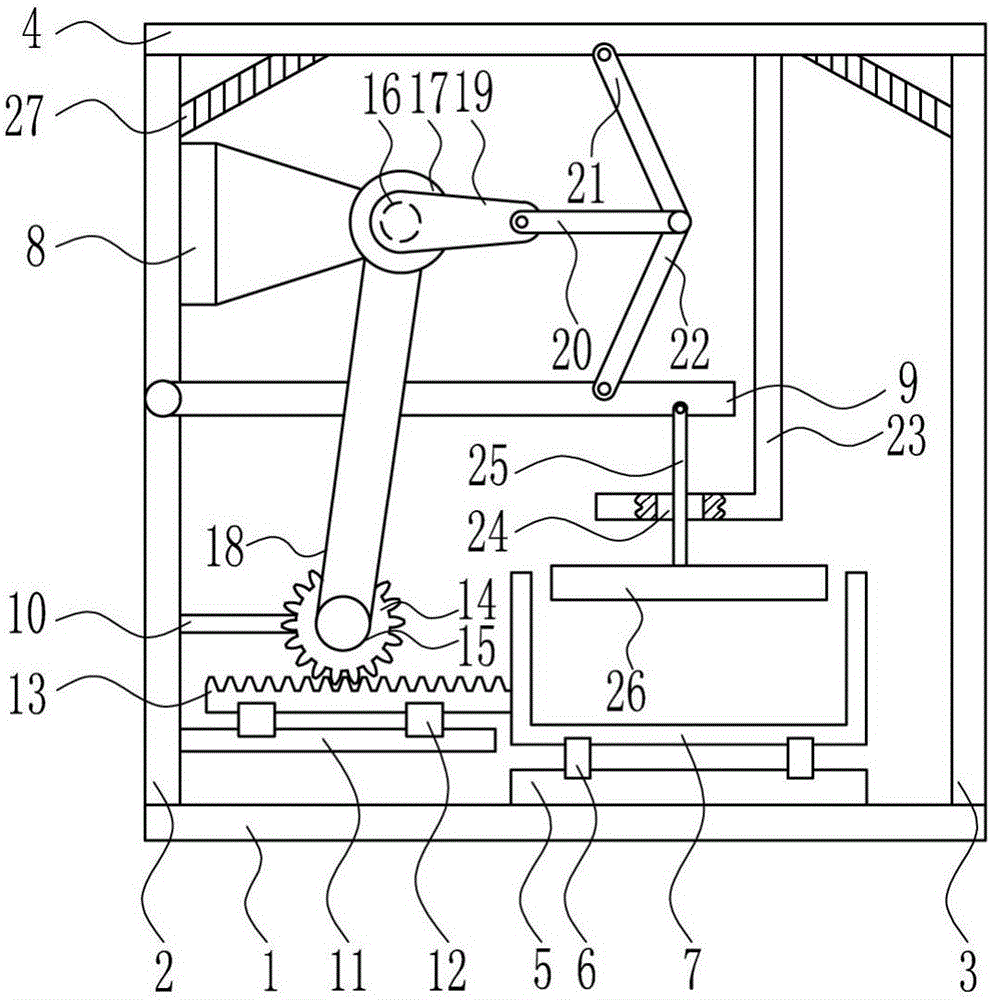

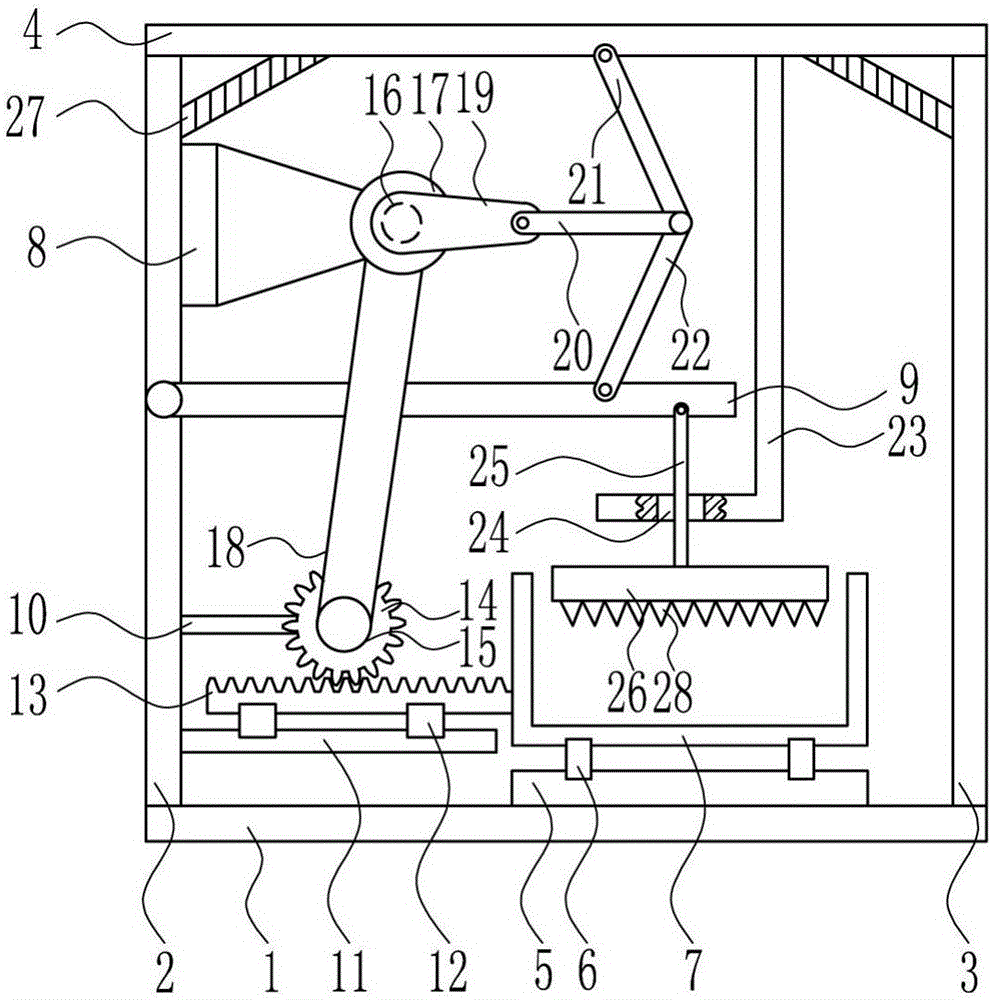

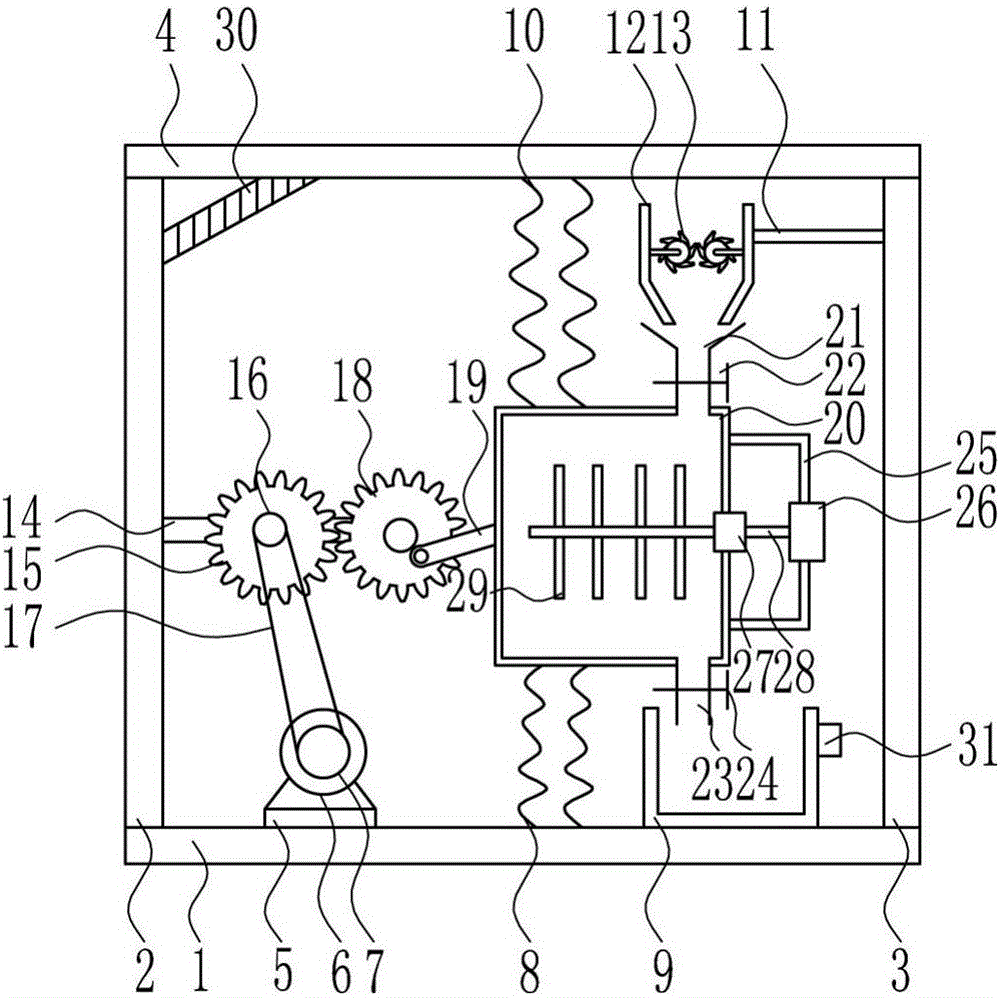

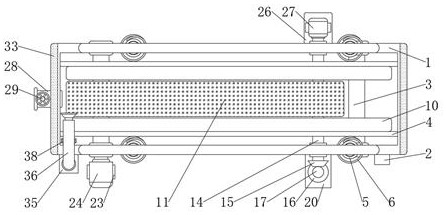

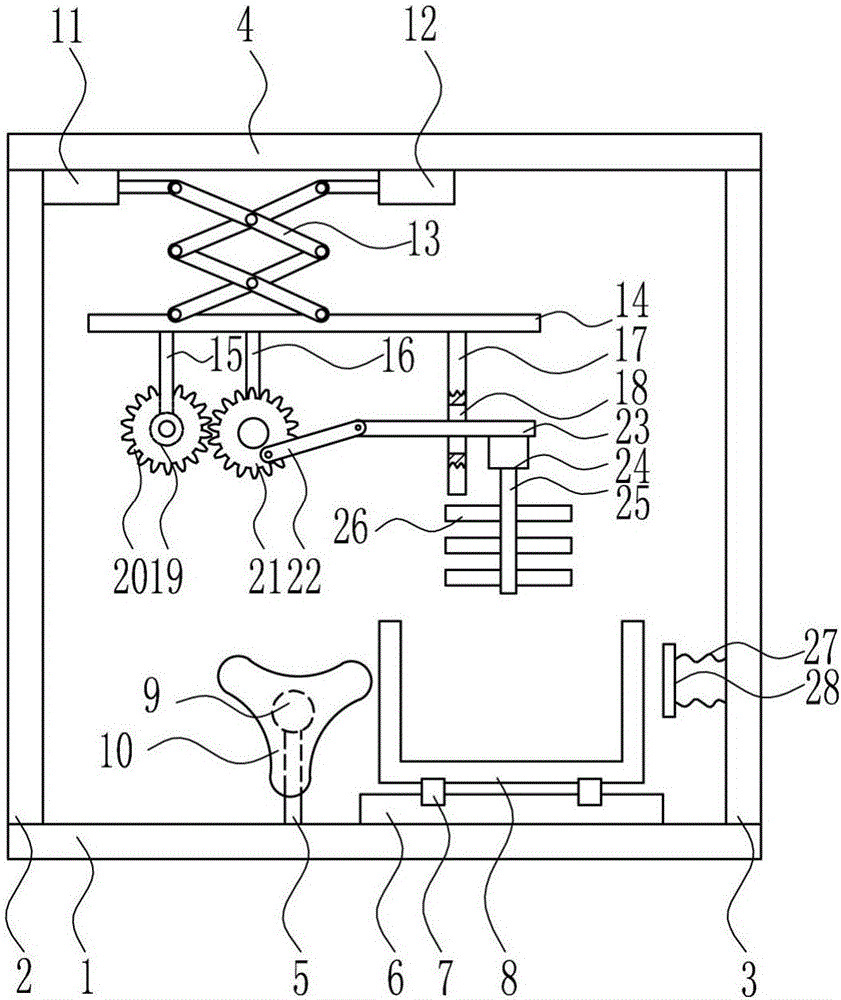

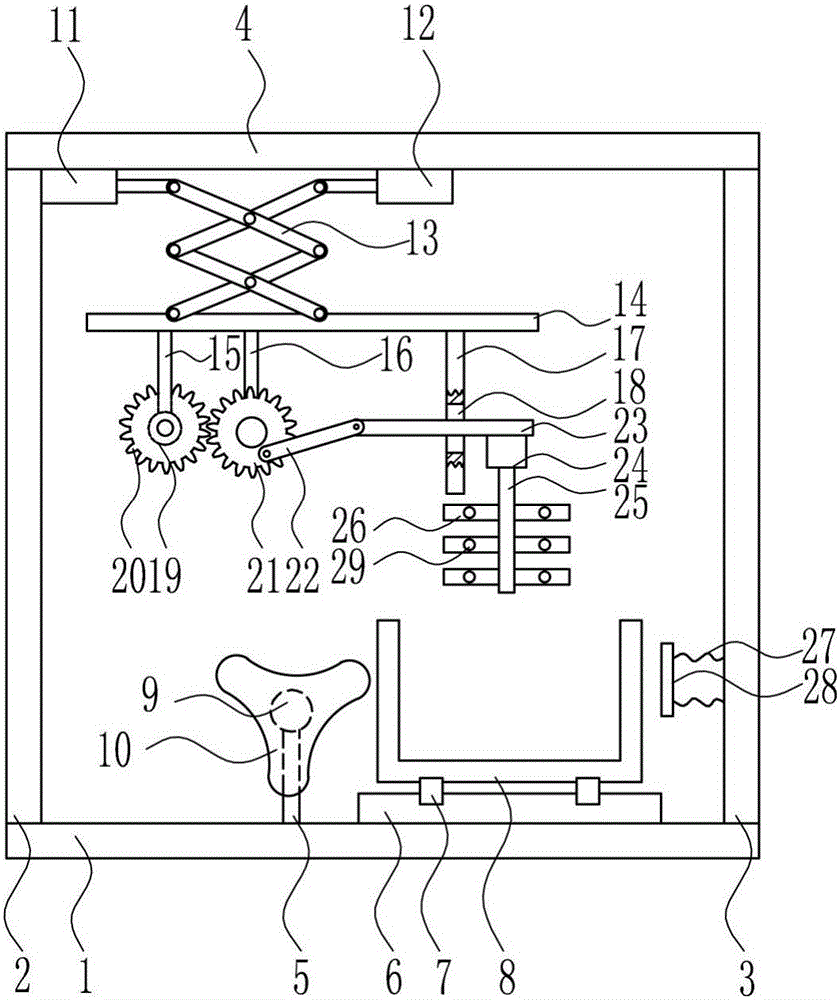

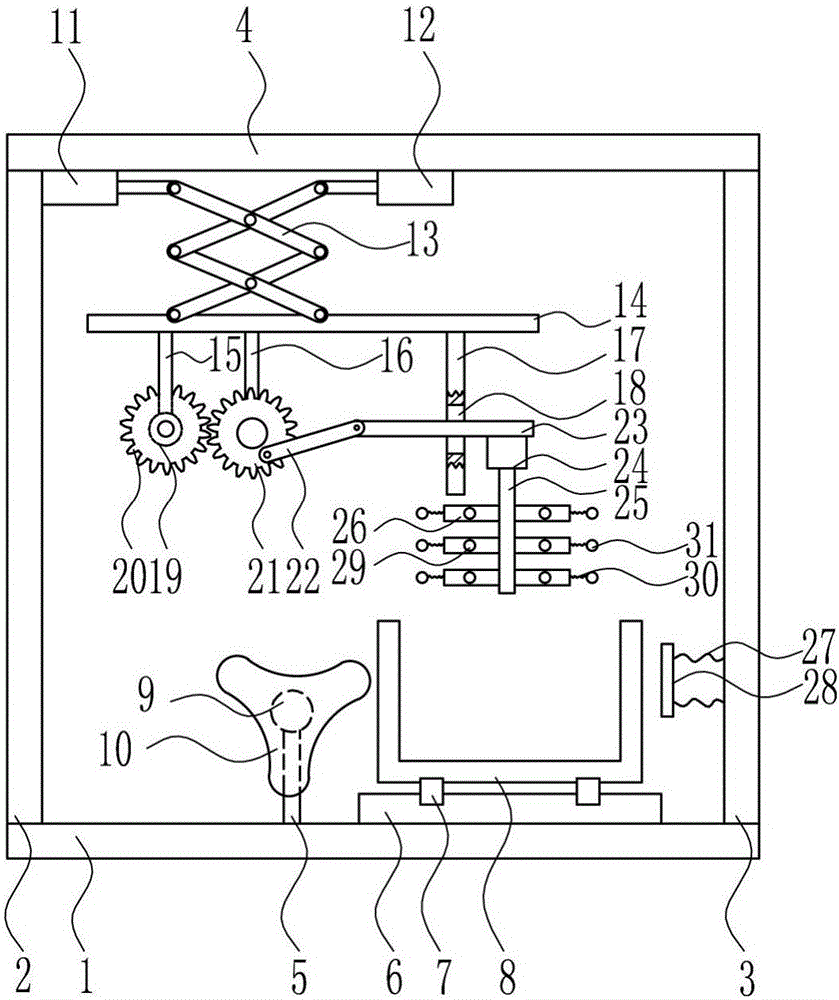

Abandoned mold gear type breaking device for shoe industry

The invention relates to an abandoned mold breaking device for the shoe industry, in particular to an abandoned mold gear type breaking device for the shoe industry. According to the technical purposes to be achieved, the abandoned mold gear type breaking device for the shoe industry is thorough in breaking, convenient to operate and high in breaking efficiency. In order to achieve the above technical purposes, the abandoned mold gear type breaking device for the shoe industry is provided and comprises a left frame, a bottom plate, a right frame, a breaking frame, a first sliding rail, first sliding blocks, a swing rod, a rolling device, a cam, a second sliding rail, second sliding blocks, a top plate, a rack, a large belt wheel, a first gear, a small belt wheel, a flat belt, a second gear, a third gear, a rolling shaft and the like. The top of the bottom plate is sequentially provided with the left frame, a guide sleeve, the first slide rail and the right frame from left to right. The gear type breaking device has the beneficial effects that breaking is thorough, operation is convenient, and the breaking efficiency is high, a broken shoe manufacturing mold is little in occupied space, storage space can be greatly saved, and meanwhile the working efficiency of workers can be improved.

Owner:临沂临港投资管理有限公司

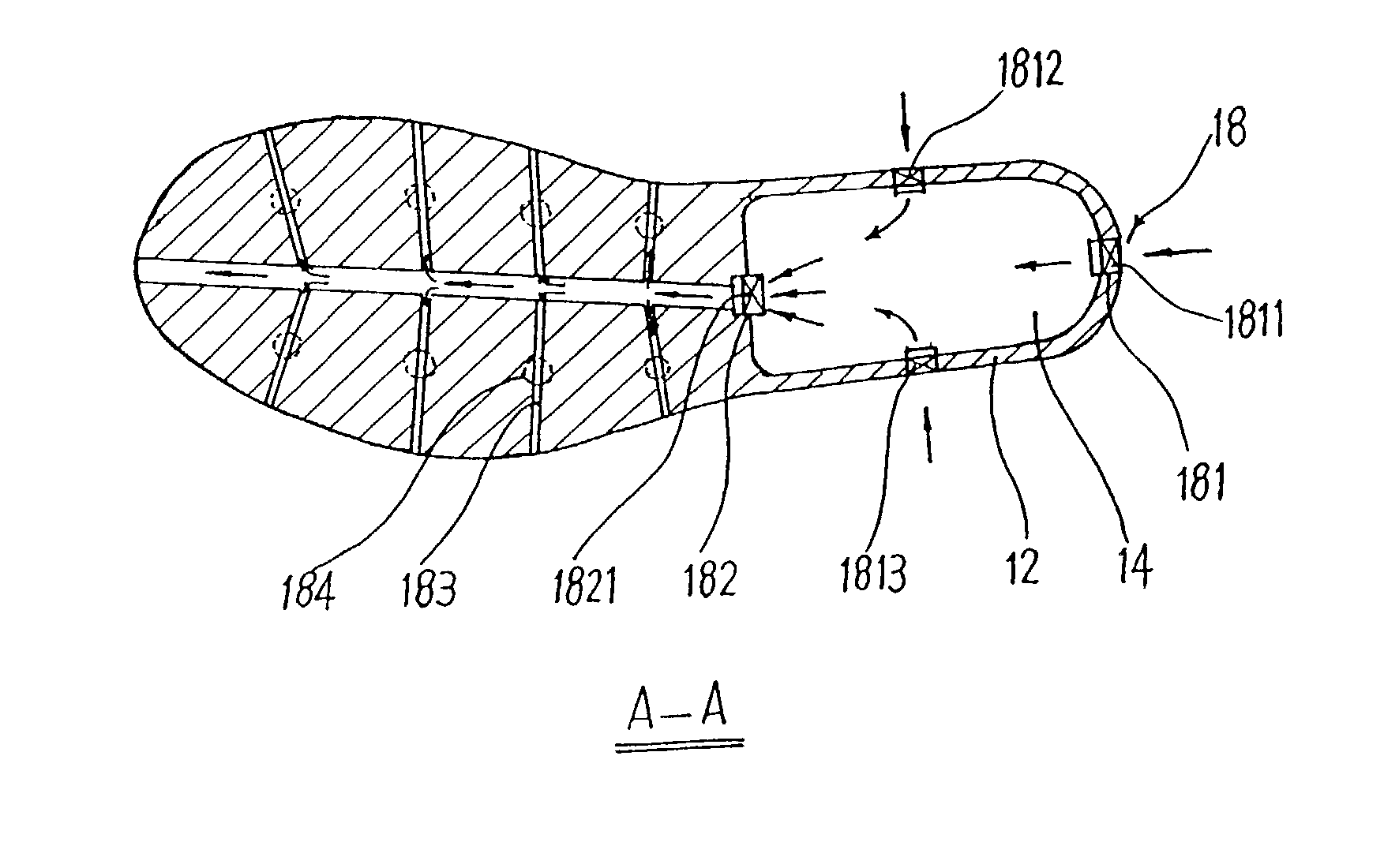

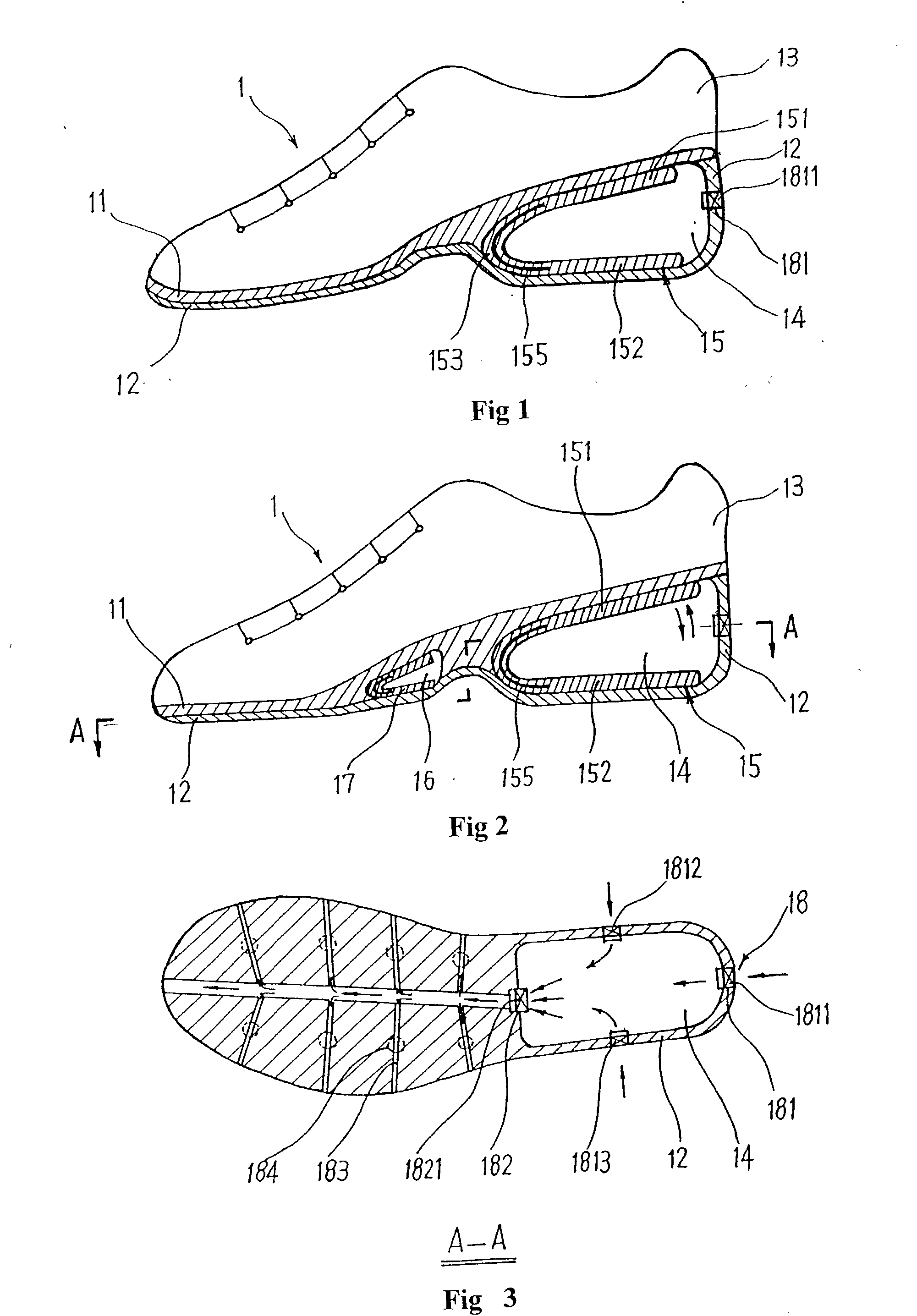

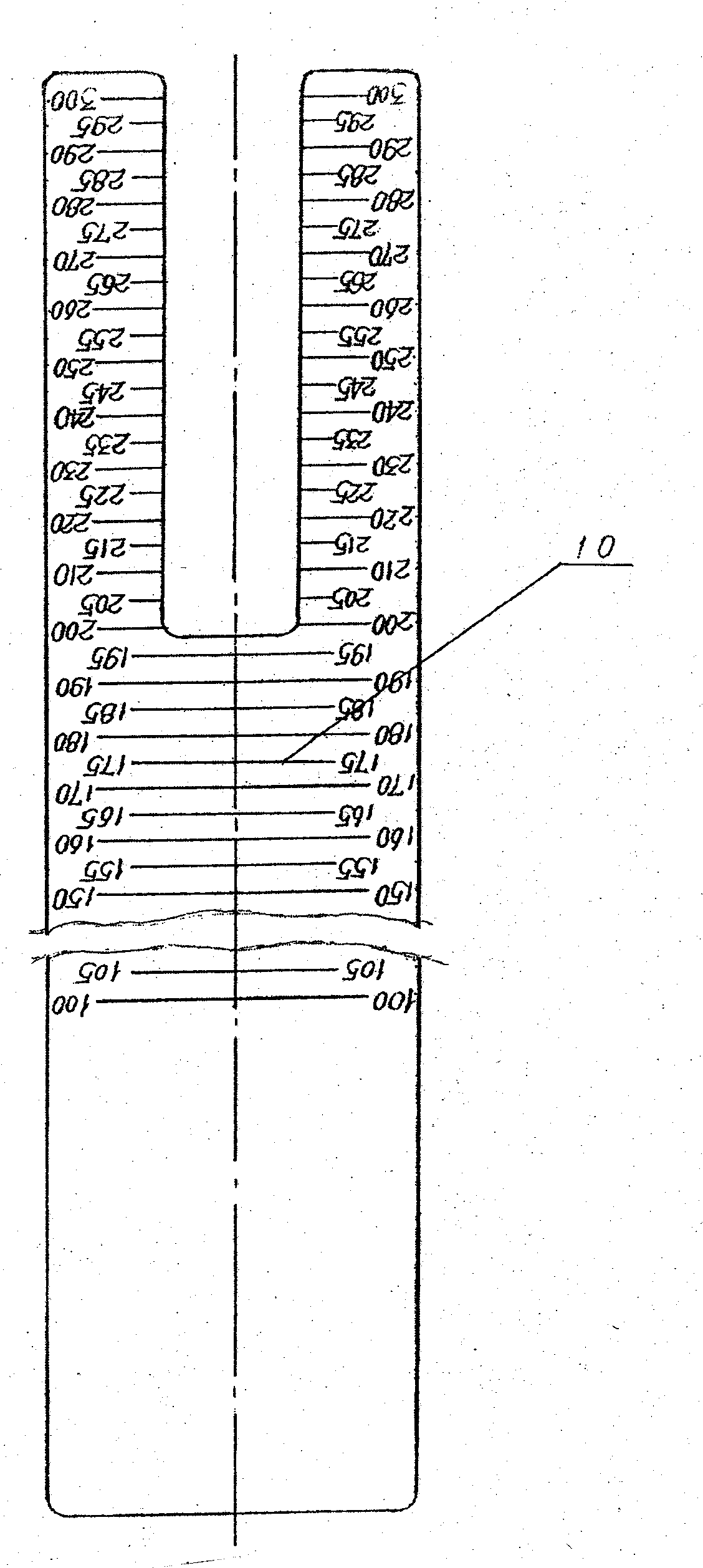

Shoe with elastic sole

A shoe with elastic sole is disclosed. The shoe comprises an inner sole, an outer sole, an upper, and an elastic sole comprising a U-shaped cavity that has openings at the two lateral sides of the sole and a U-shaped spring pad made of carbon fiber plate provided in the cavity and between the inner sole and outer sole forming a highly elastic sole structure. A U-shaped spring tab is added to the core of the U-shaped portion of the U-shaped spring pad. Alternatively, the openings of the cavity at the two lateral sides of the sole can be closed, forming a totally enclosed cavity structure. Additionally, another U-shaped cavity with a U-shaped spring pad can be provided in the anterior portion of the sole, thus forming a sole structure with U-shaped spring pads both in the anterior and heel portion of the sole. A ventilation structure is provided between the inner sole and the outer sole. The vent structure comprises ventilation holes in the lateral and rear sides of the U-shaped cavity with check intake valves provided therein, and a ventilation hole in the front side of the U-shaped cavity with a check exhaust valve provided therein. The shoe has the advantages of large deformation and high elasticity during use that can provide comforts and forced ventilation with its simple structure that is suitable for manufacture by the footwear industry.

Owner:WANG GUOHUA

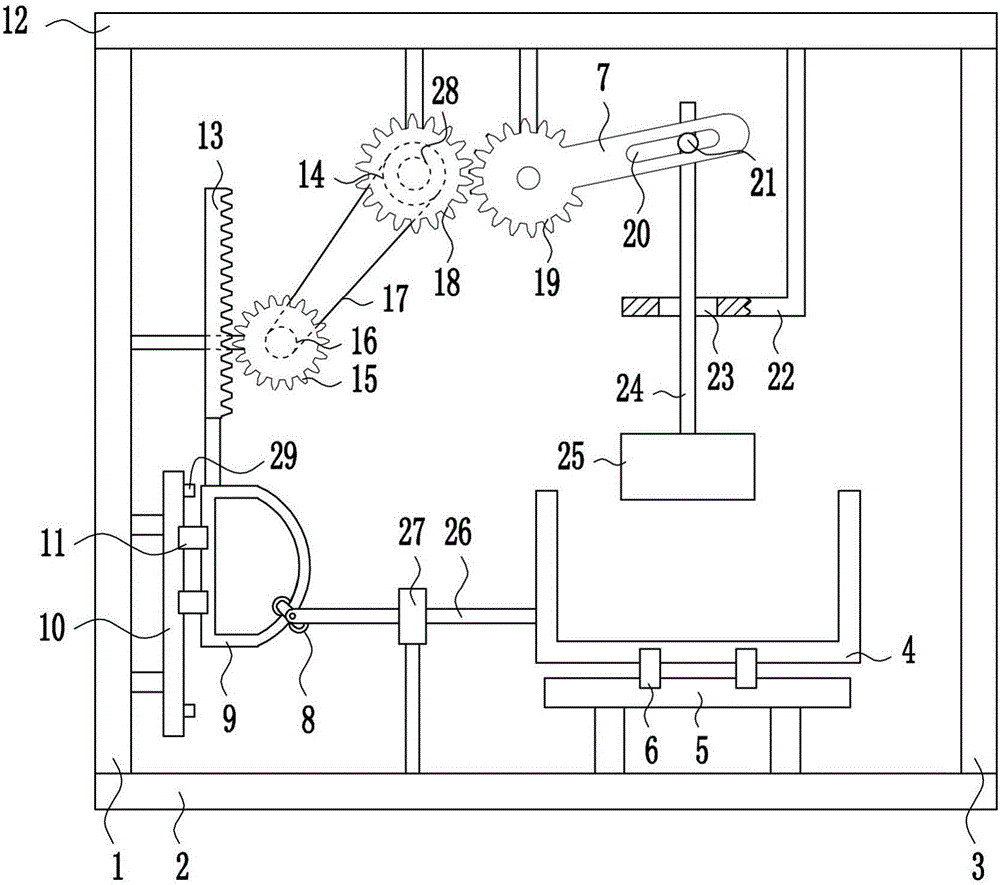

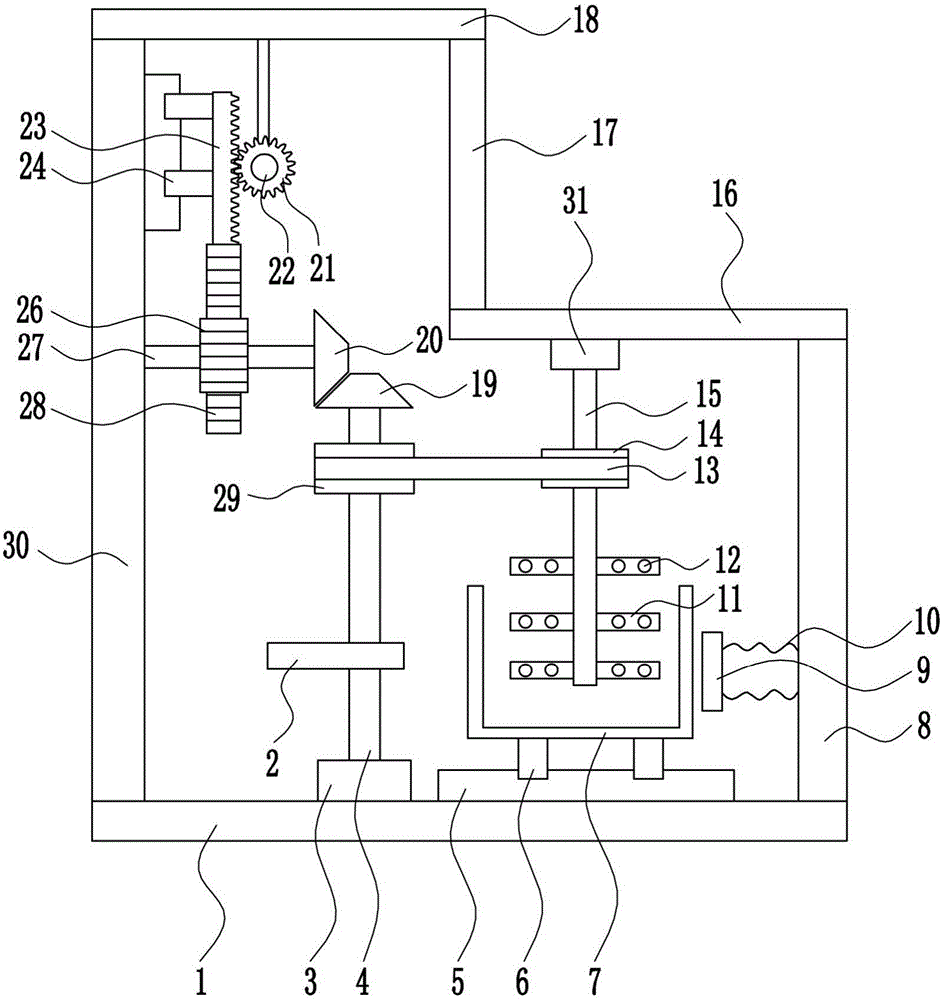

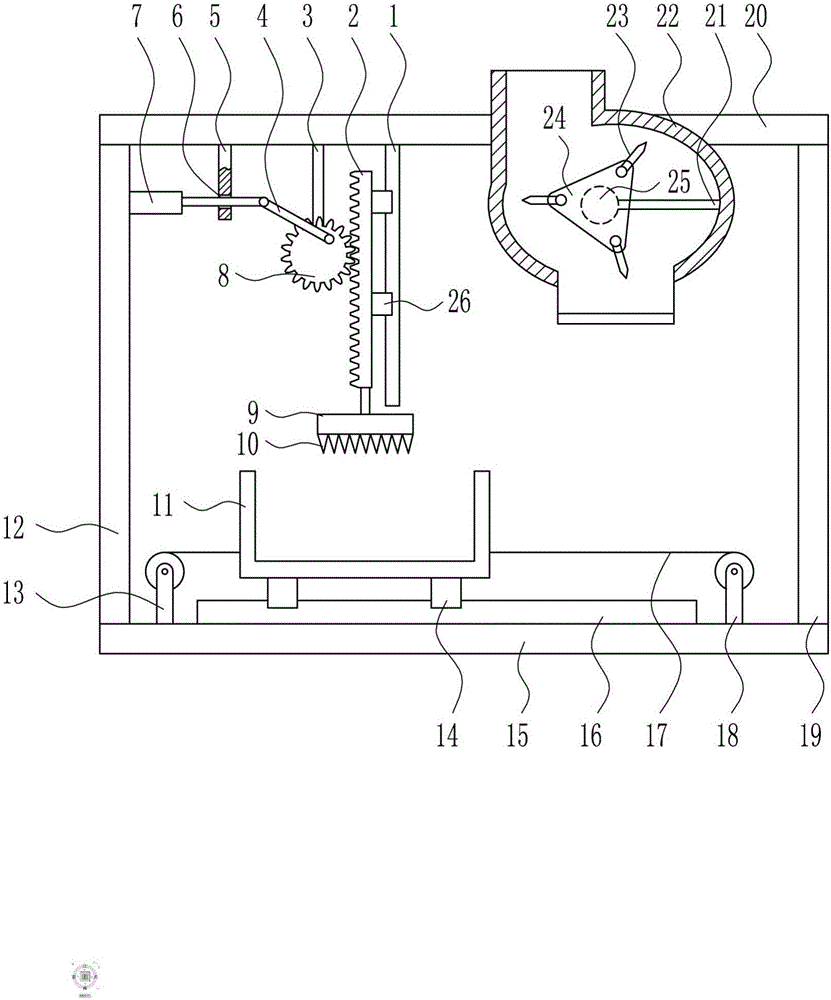

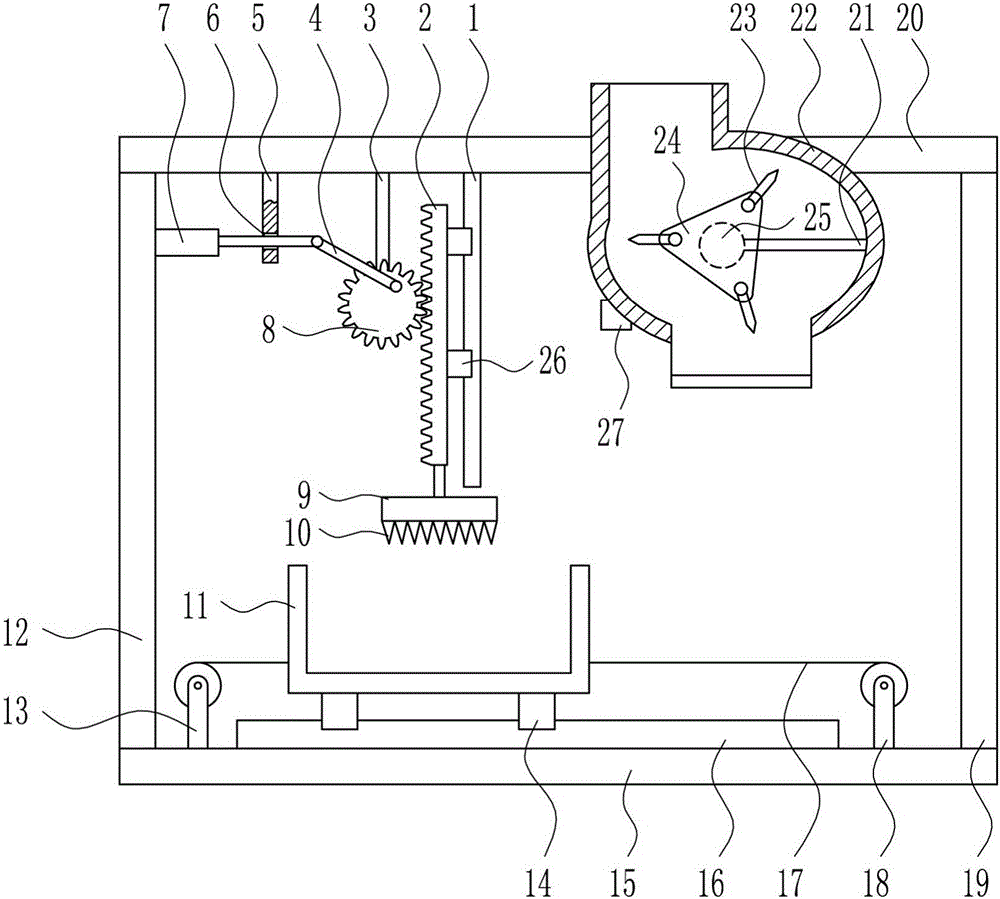

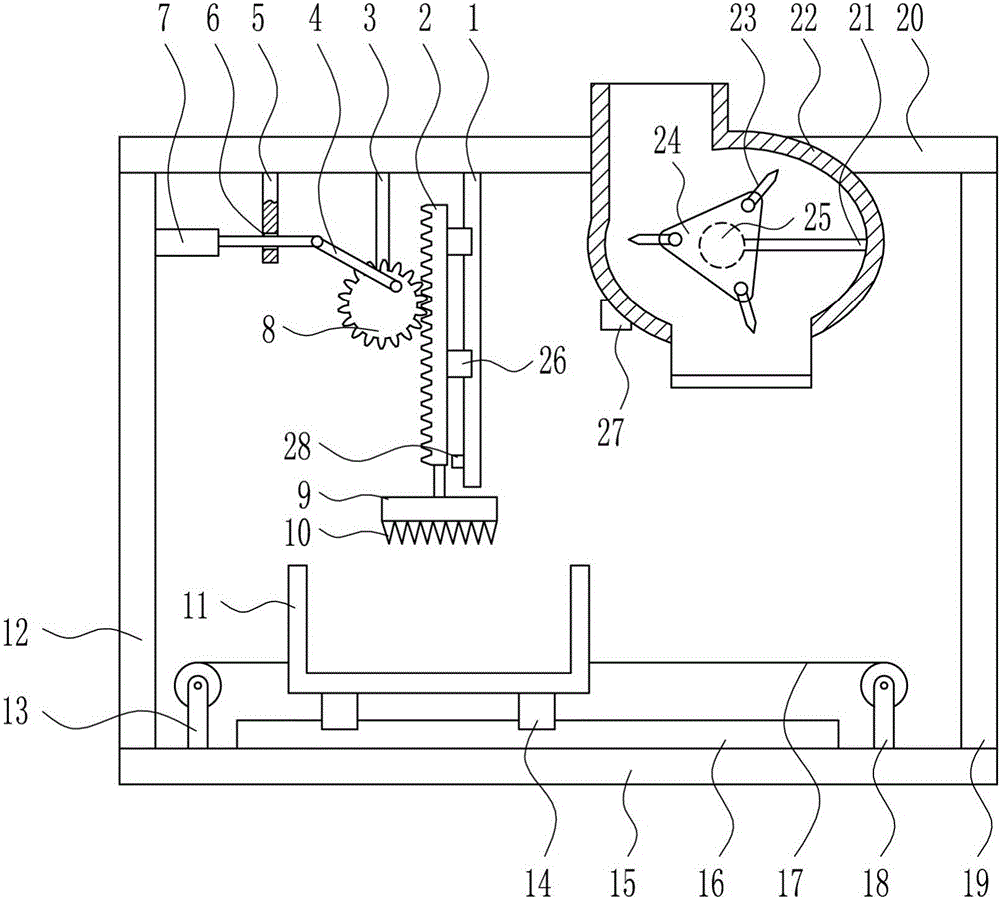

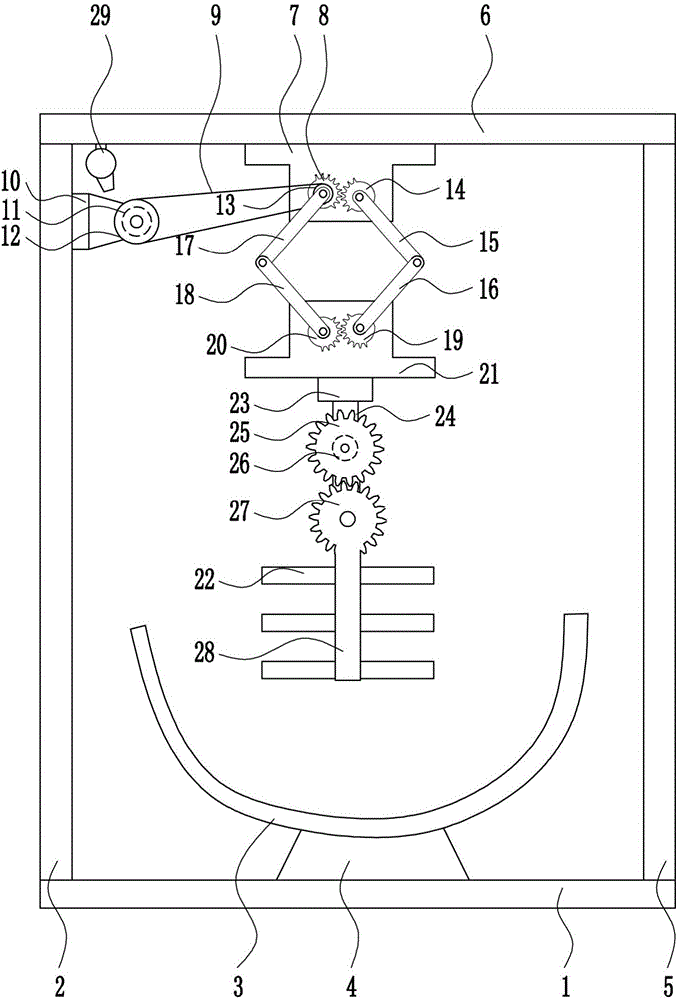

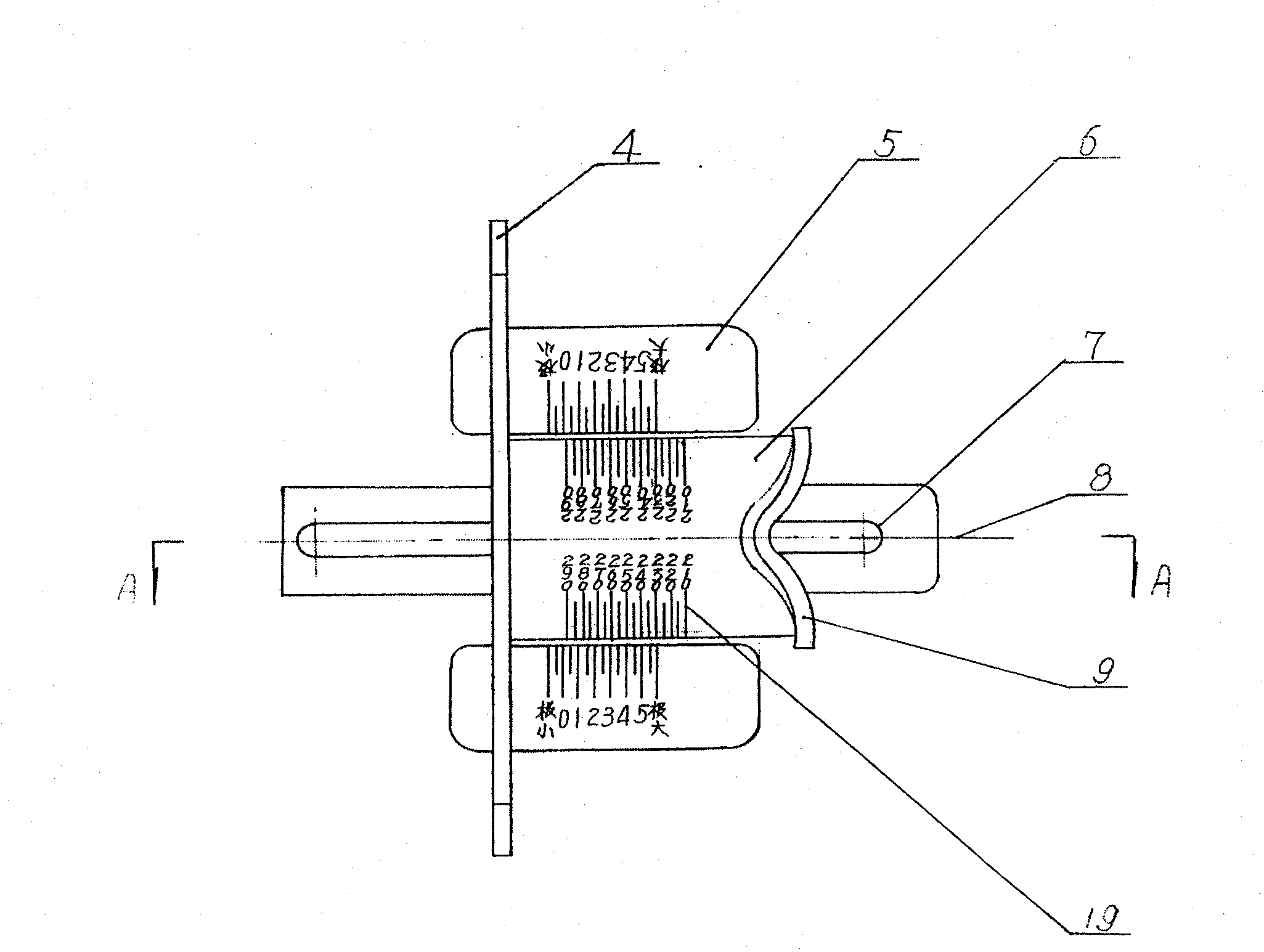

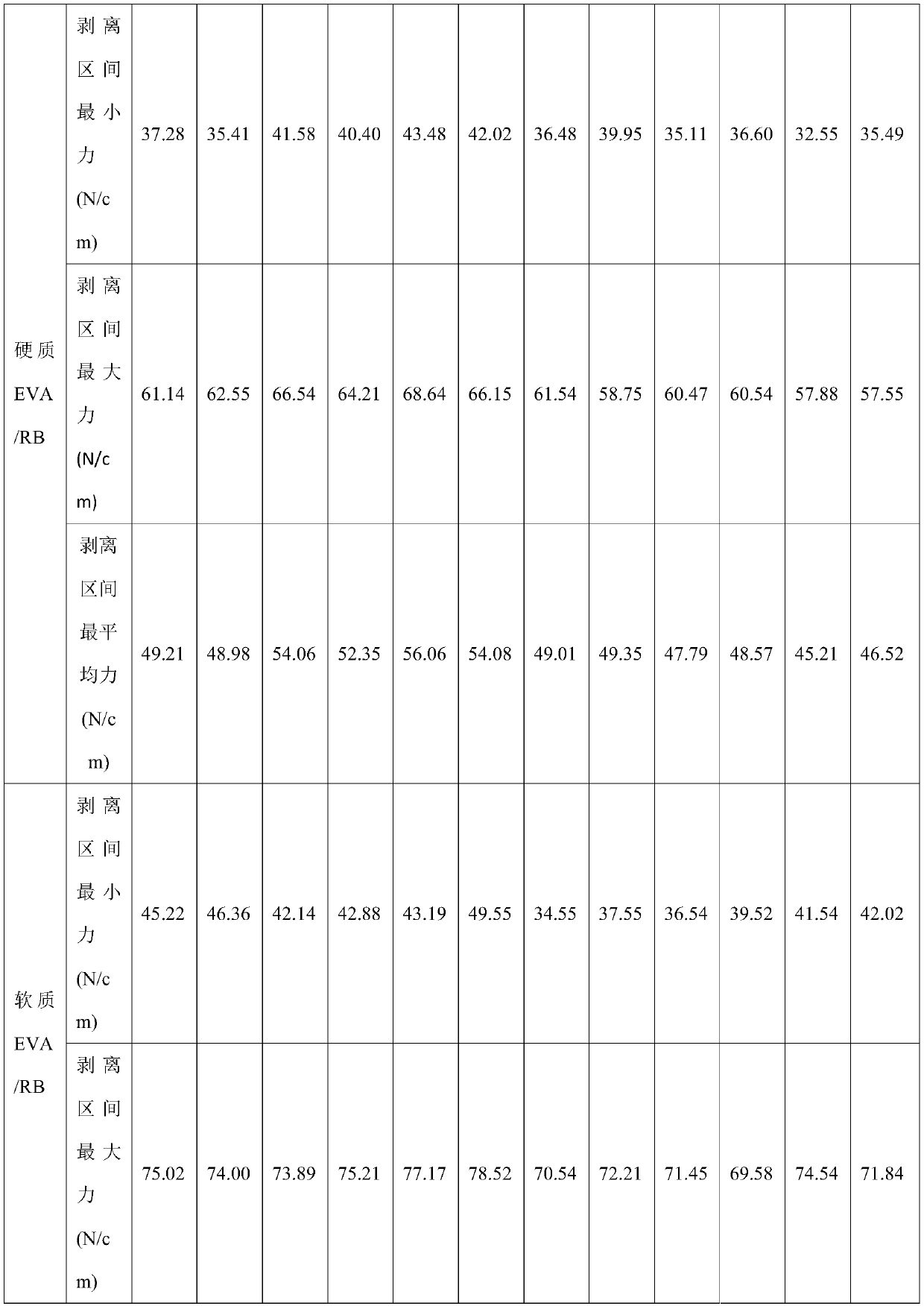

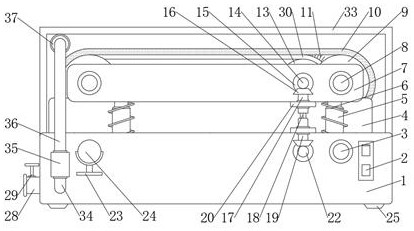

Gear-type raw material stirring device for shoe industry

InactiveCN106139983AHigh hardnessAvoid deformationShaking/oscillating/vibrating mixersTransportation and packagingShoe industryGear wheel

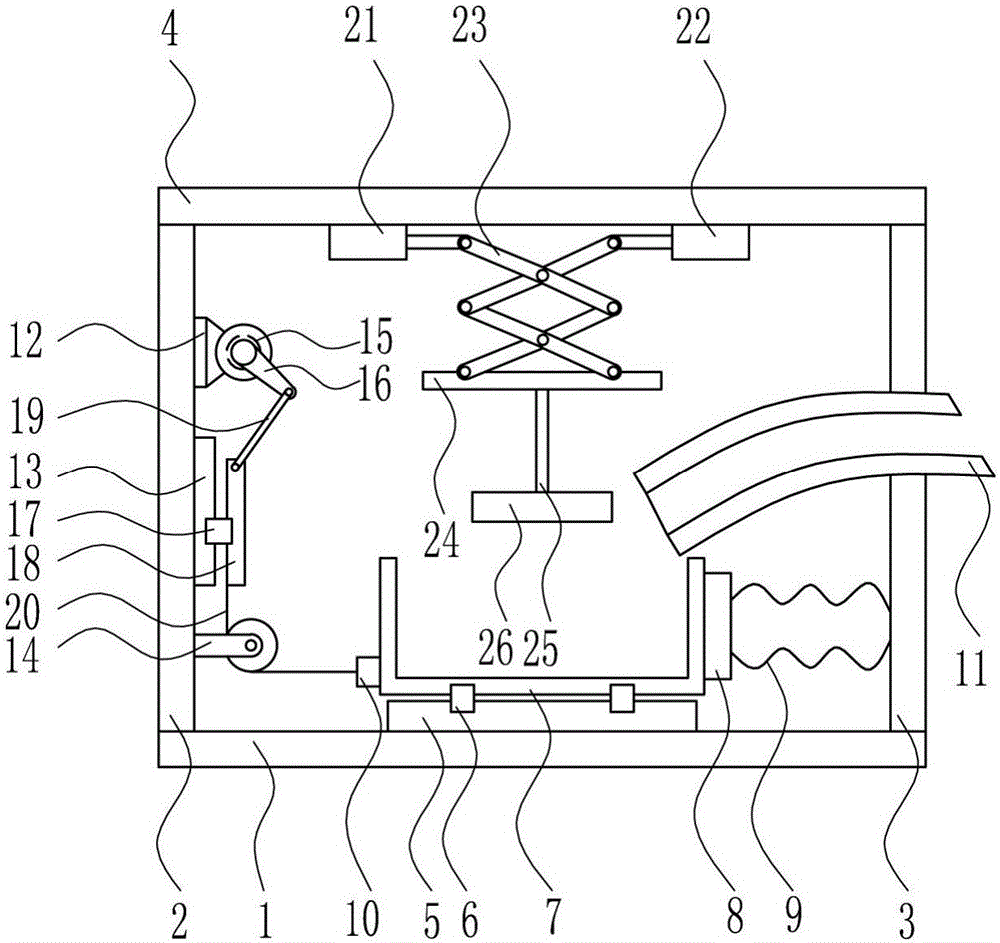

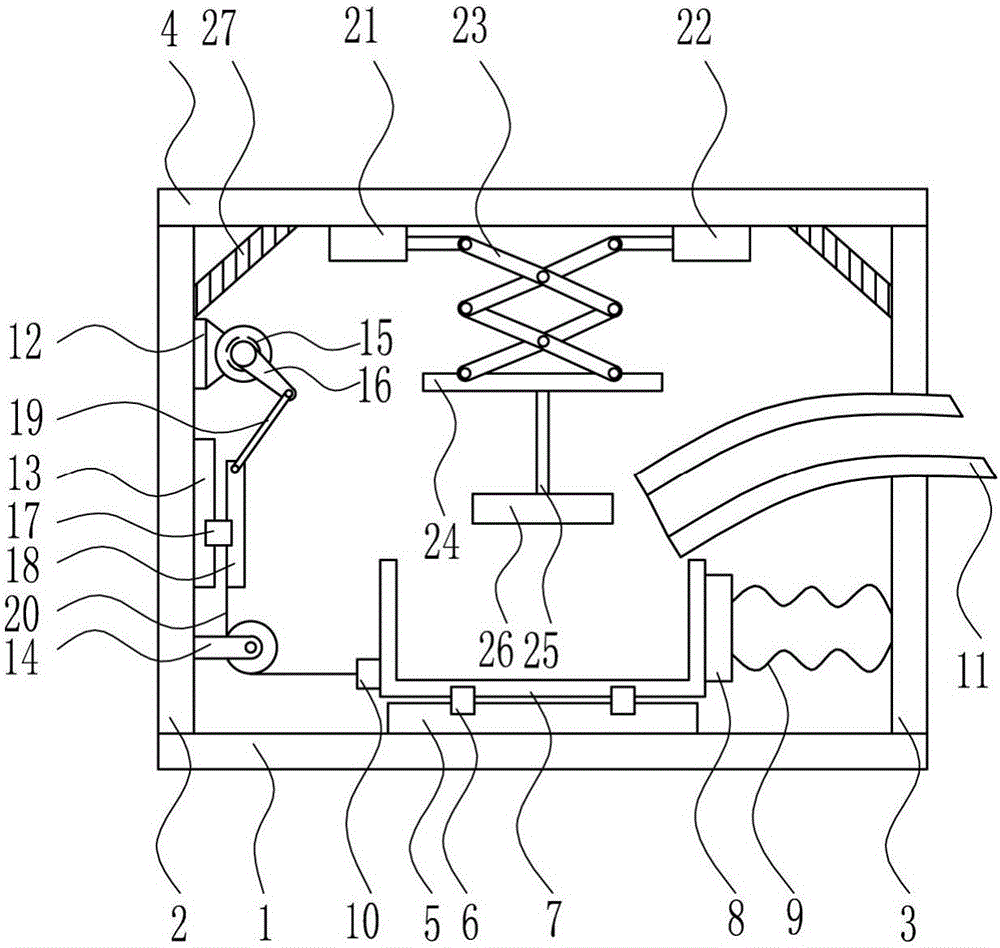

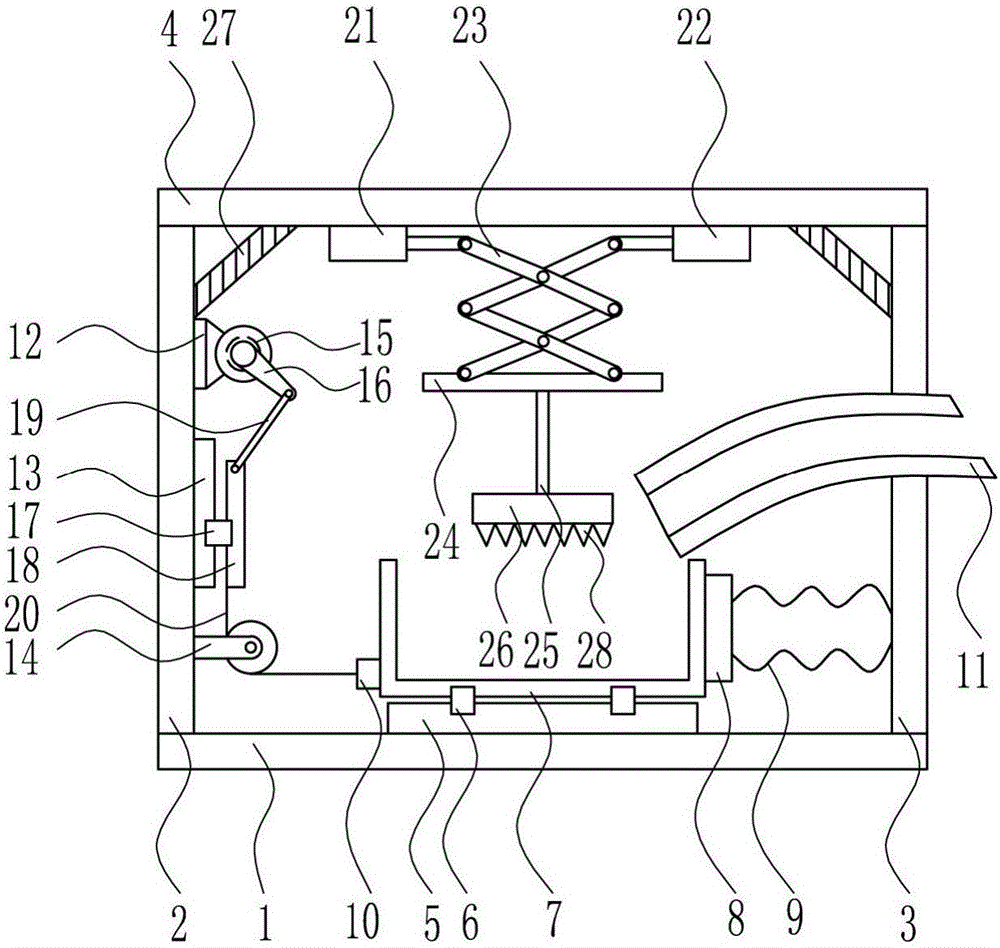

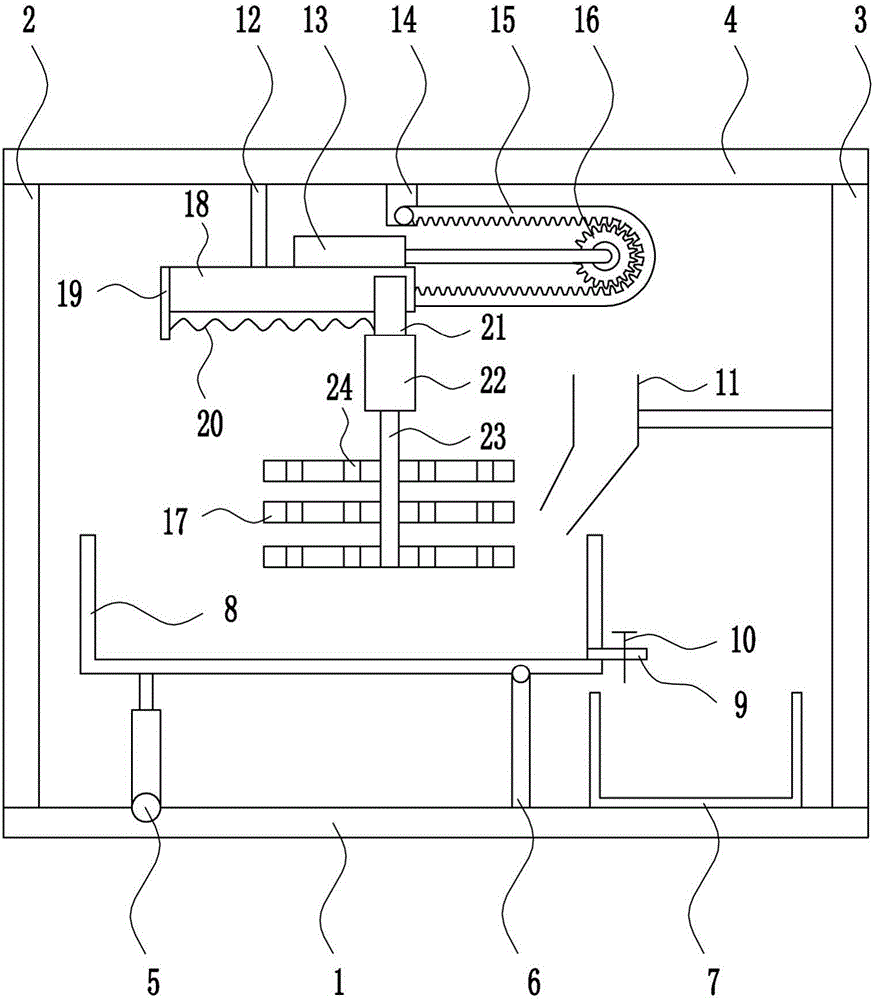

The invention relates to a raw material stirring device for a shoe industry, in particular to a gear-type raw material stirring device for the shoe industry. The gear-type raw material stirring device for the shoe industry achieves the technical purposes of being uniform in stirring, high in stirring speed and convenient to operate. In order to achieve the technical purposes, the gear-type raw material stirring device for the shoe industry comprises a base plate, a cam, a first bearing pedestal, a first rotating shaft, a first sliding rail, a first sliding block, a stirring frame, a right frame, a baffle, a spring, a stirring blade, a flat belt, a small belt pulley, a stirring rod, an installation plate, a support, a top plate, a first bevel gear, a second bevel gear, a first gear, a motor, a first rack and the like. The top of the base plate is sequentially provided with the left frame from left to right. The raw material stirring device has the advantages of being uniform in stirring, high in stirring speed and convenient to operate, the raw material stirring device has the important role, the good stirring effect is achieved, and working efficiency is further improved.

Owner:WENZHOU YIMAIDA SHOES CO LTD

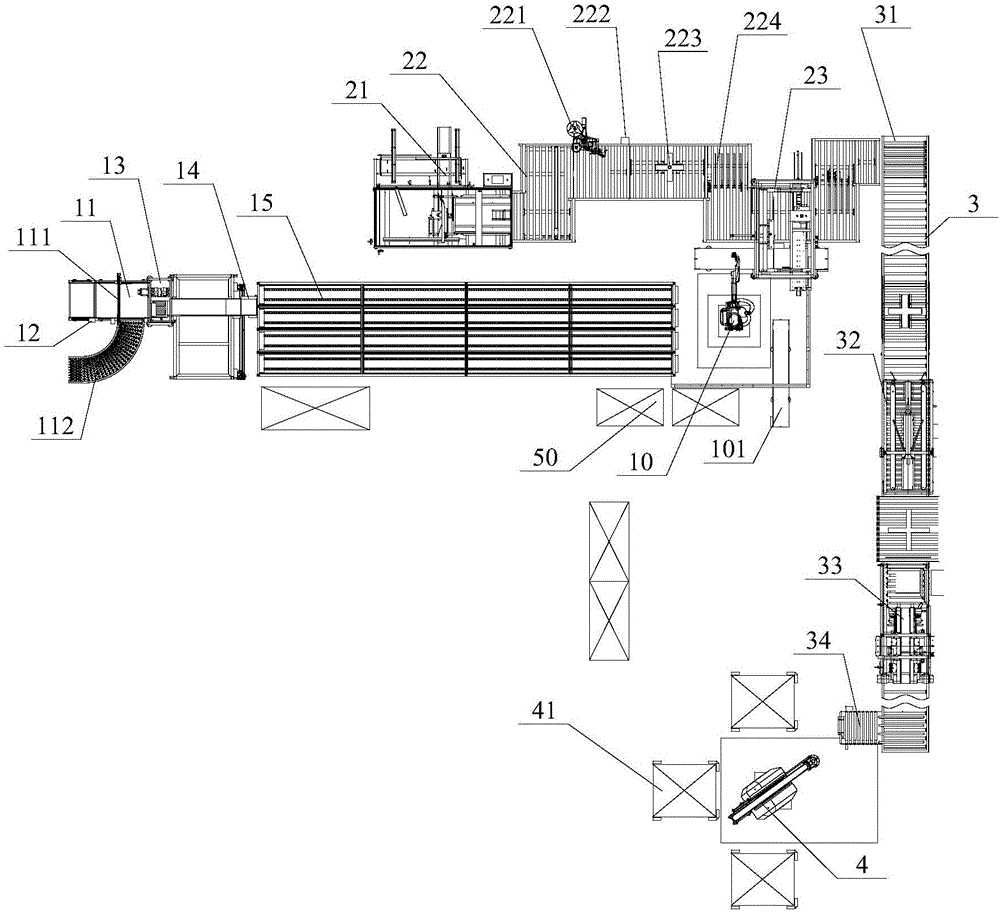

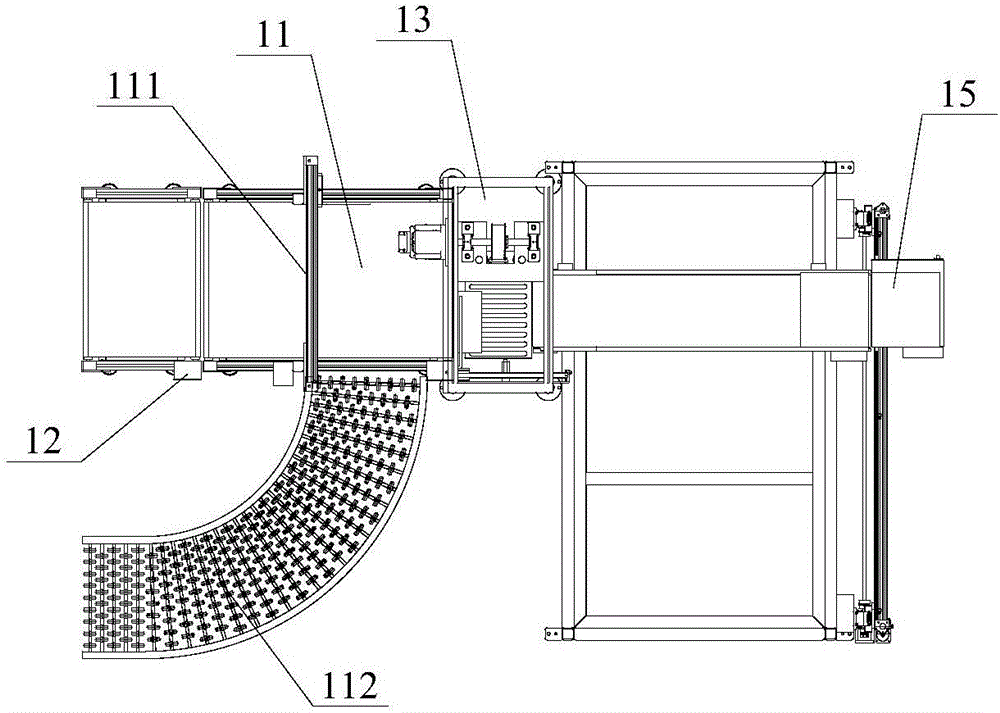

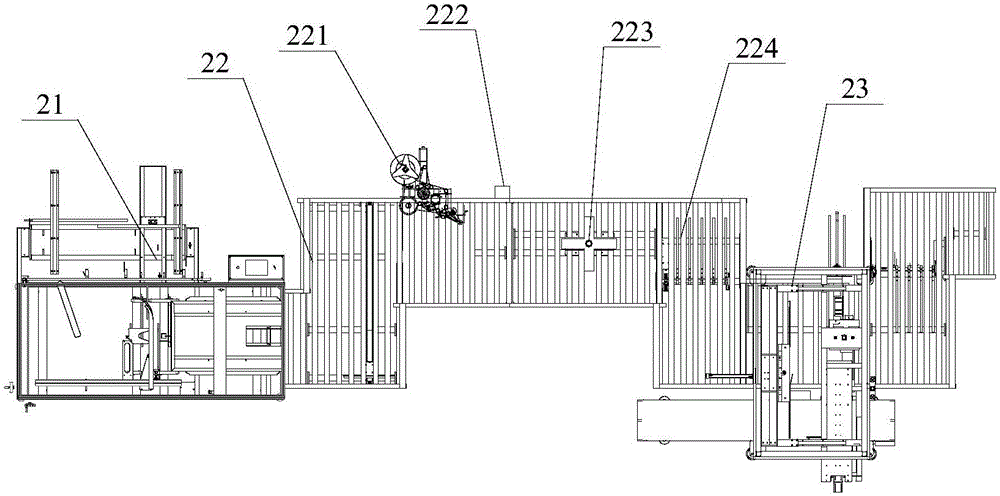

Intelligent back-end packaging system and method for shoe industry

InactiveCN106428821AReduce error rateReduce manual interventionWrapper twisting/gatheringPackaging automatic controlShoe industryEngineering

The invention discloses an intelligent back-end packaging system and method for shoe industry. The intelligent back-end packaging system for the shoe industry comprises a shoe box classifying system, a casing system, a case sealing and conveying rail, a palletizing system and a servo control system; the shoe box classifying system comprises a discriminating system and a classifying and warehousing system which are sequentially connected; the casing system and the shoe box classifying system are arranged in parallel, a robot sorting machine is arranged at one side of a caser, and a stereoscopic warehouse is connected with the caser through the robot sorting machine; the case sealing and conveying rail is provided with a casing device; the palletizing system is connected with the casing system through the case sealing and conveying rail and comprises a palletizing robot and palletizing pallets; the servo control system is connected with the shoe box classifying system, the casing system, the case sealing and conveying rail and the palletizing system separately. According to the intelligent back-end packaging system and method for the shoe industry, only manual charging and discharging assisting is needed in the whole process, manual intervention is greatly reduced, the automation degree is high, the production efficiency is improved, and the system and method are suitable for shoe size-mixed and multi-specification line changing production and high in universality.

Owner:合益(温州)智能装备有限公司

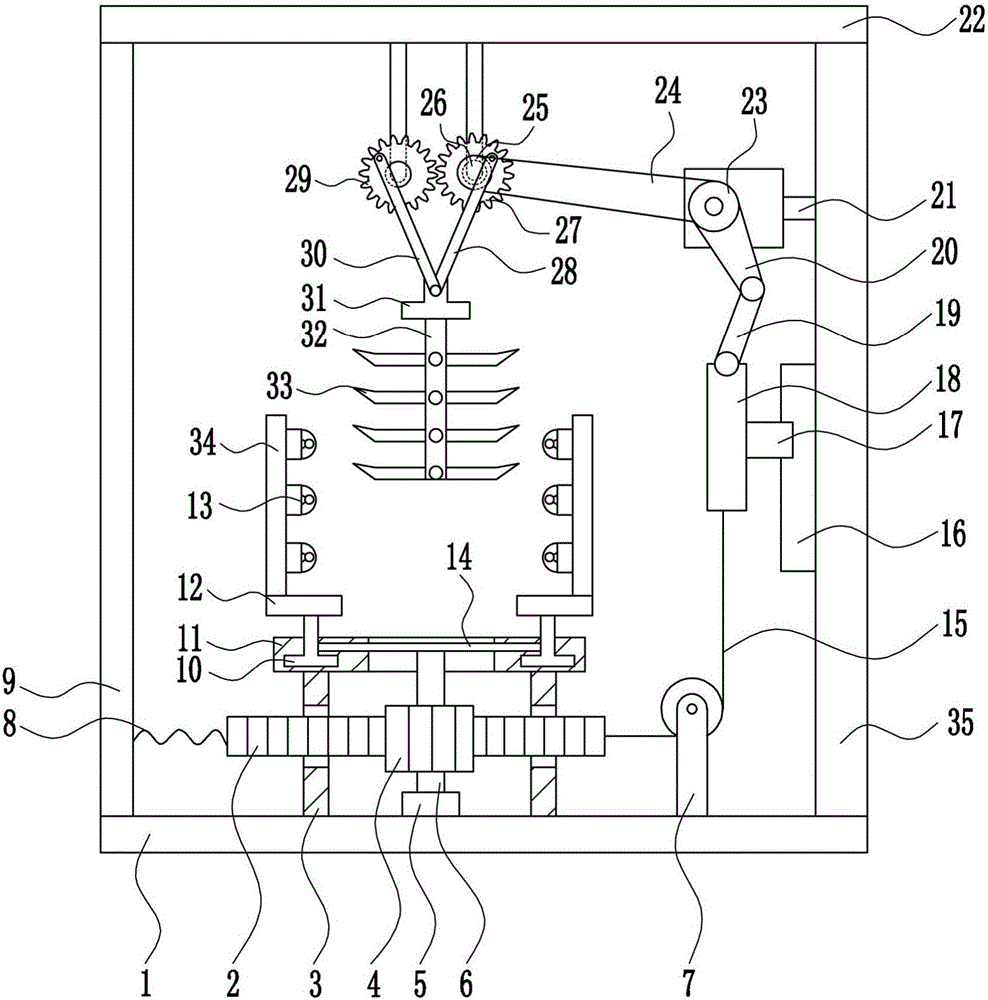

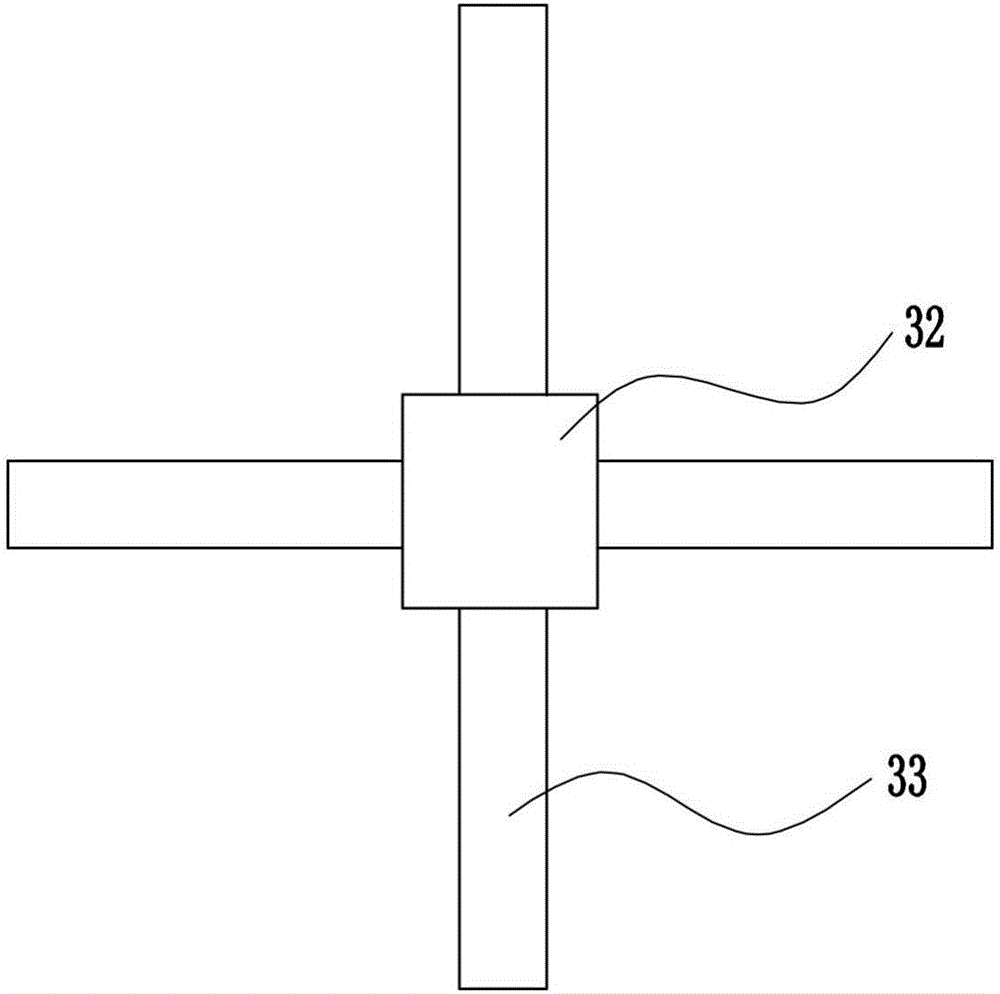

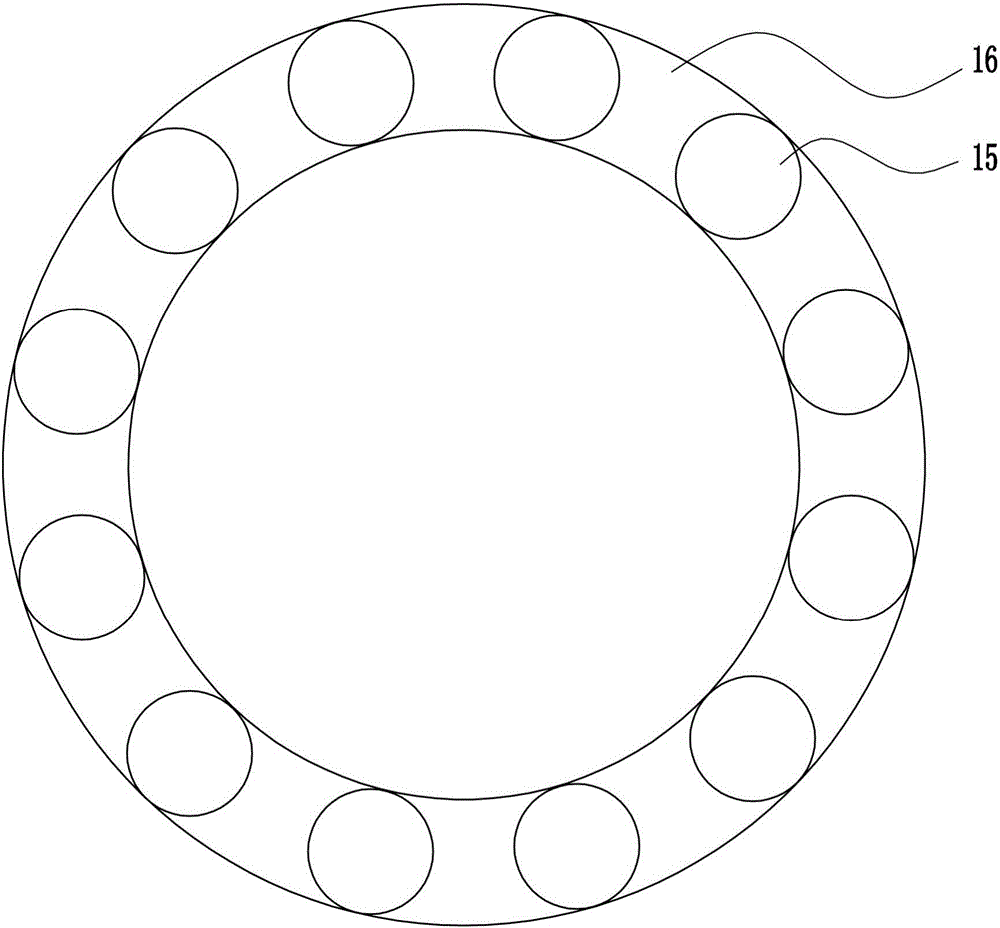

Planet wheel type quick breaking device for waste shoe module for shoe industry

The invention relates to a quick breaking device for a waste shoe module for the shoe industry, in particular to a planet wheel type quick breaking device for the waste shoe module for the shoe industry. The planet wheel type quick breaking device aims at solving the technical problems that breaking is thorough, the breaking speed is high, and operation is convenient. To solve the technical problem, the planet wheel type quick breaking device for the waste shoe module for the shoe industry comprises a bottom plate, a sliding rail, a sliding block, a breaking frame, a guide sleeve, a mounting seat, a right frame, a movable rod, a first connecting rod, a first crank, a first belt wheel, a first flat belt, a second belt wheel, a top plate, a second flat belt, a gear ring and the like. A left frame is sequentially arranged on the top of the bottom plate from left to right. The planet wheel type quick breaking device has the beneficial effects of being thorough in breaking effect, high in breaking speed, convenient to operate and good in breaking effect, plays an important role all the time and improves the working efficiency.

Owner:江苏农航机械设备有限公司

Leather product rapid drying device for shoe industry

The invention relates to a leather product rapid drying device for shoe industry, aiming at solving the technical problem of providing a leather product rapid drying device for shoe industry, which is high in drying efficiency, high in drying speed and convenient to operate. In order to solve the technical problem, the leather product rapid drying device for the shoe industry provided by the invention comprises a base plate, a gear rack, brackets, a first gear, a bearing base, a rotating shaft, a fixed pulley, a spring, a left frame, first sliding blocks, annular sliding rails, first fixed seats, floodlights, a connecting rod, a stay, a first sliding rail, a second sliding block, a moving rod, an oscillating rod, a crank, a fixed block, a top plate, a big belt wheel, a flat belt and the like; and the left frame is arranged on the left side of the top of the base plate. The leather product rapid drying device disclosed by the invention can achieve the purposes of being high in drying efficiency, high in drying speed and convenient to operate; and the device can also play an important role, and the device not only has a good drying effect but also improves working efficiency.

Owner:浙江香香莉鞋业有限公司

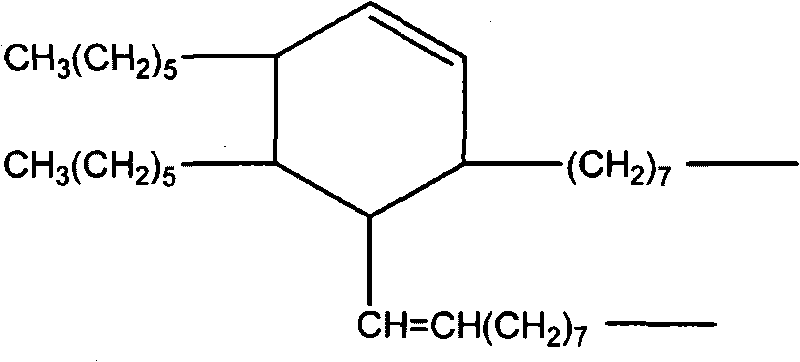

Prepn of polyether-type polyurethane as shoe sole material

InactiveCN1453299AImprove mechanical propertiesSimple processing technologySolesShoe industryPolyurethane elastomer

the present invention is preparation process of polyether-type polyurethane as shoe sole material. Polyether polyol with high activity and low unsaturation degree is synthesized with water as foaming agent and bimetal cyanide as catalyst; and isocyanate capped modified semi-prepolymer is prepared with small molecule modifier containing active hydrogen. The modified semi-prepolymer and the Polyether polyol are further produced into the porous polyurethane elastomer through mixing, casting, foaming and demolding. The material has high tensile strength, tearing strength, elongation and permanent deformation performance, and rather high low temperature embrtittlement and bending performance, and can meet the requirement as shoe material.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Efficient shredding device for discarded shoe soles for shoe industry

The invention relates to a sole shredding device, in particular to an efficient shredding device for discarded shoe soles for the shoe industry. To solve the technical problem, the efficient shredding device for the discarded shoe soles for the shoe industry is provided, wherein the efficient shredding device is high in shredding speed, uniform in shredding and simple in structure. The efficient shredding device for the discarded shoe soles for the shoe industry comprises a first sliding rail, a rack, a first supporting rod, a first connecting rod, a guide plate, an electric push rod, a gear, a pressing block, shredding teeth, a shredding frame, a left frame, a first electric winding wheel, a first sliding block, a bottom plate, a second sliding rail, a pull wire, a second electric winding wheel, a right frame, a top plate, a second connecting rod, a feeding hopper, cutters, a disc-shaped cam, a motor and a second sliding block. By means of the efficient shredding device, the effects that the shredding speed is high, shredding is uniform, and the structure is simple are achieved, the efficient shredding device plays an important role in achieving the good shredding effect, the working efficiency is improved as well, and the safety is high.

Owner:临沂港控能源有限公司

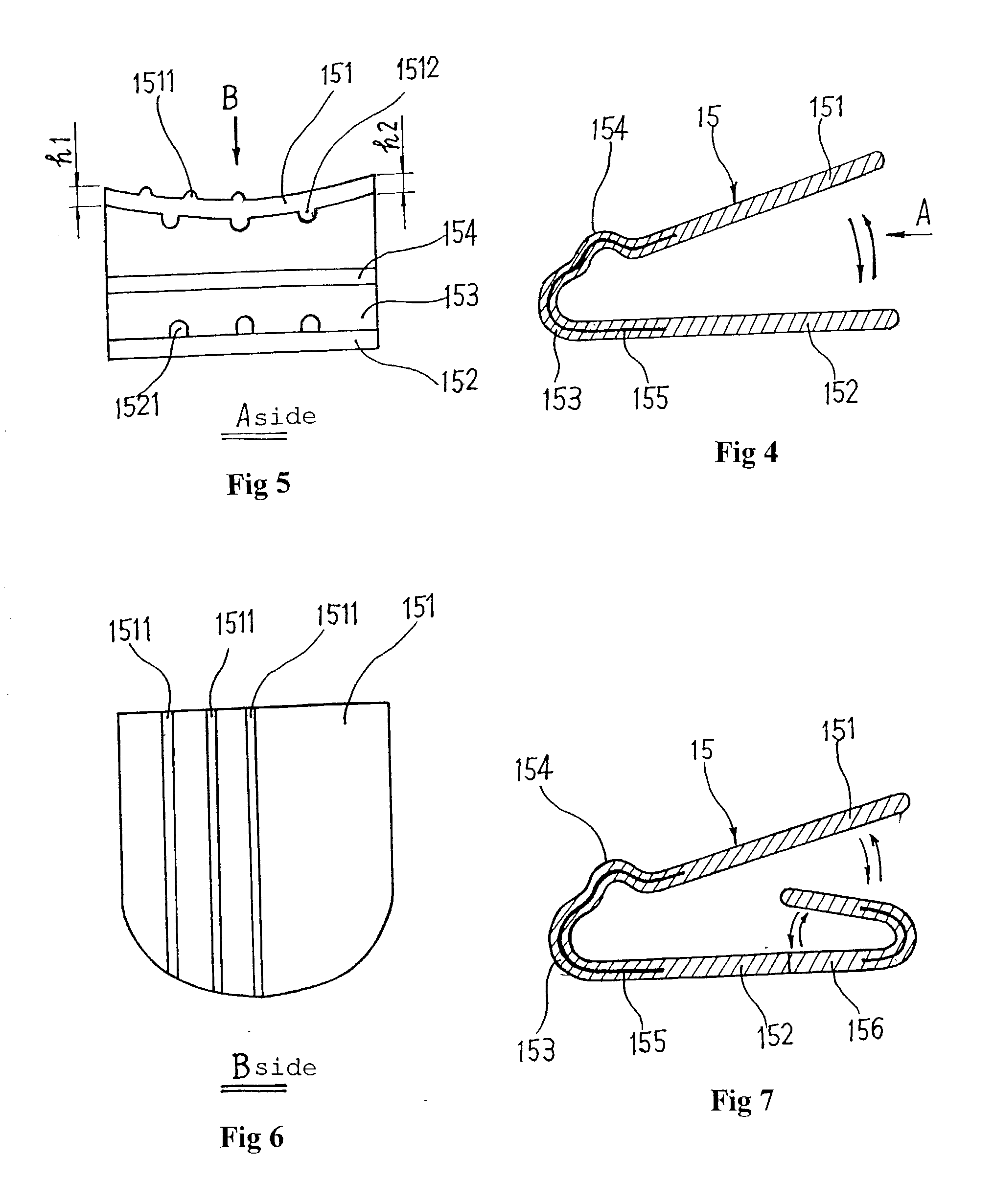

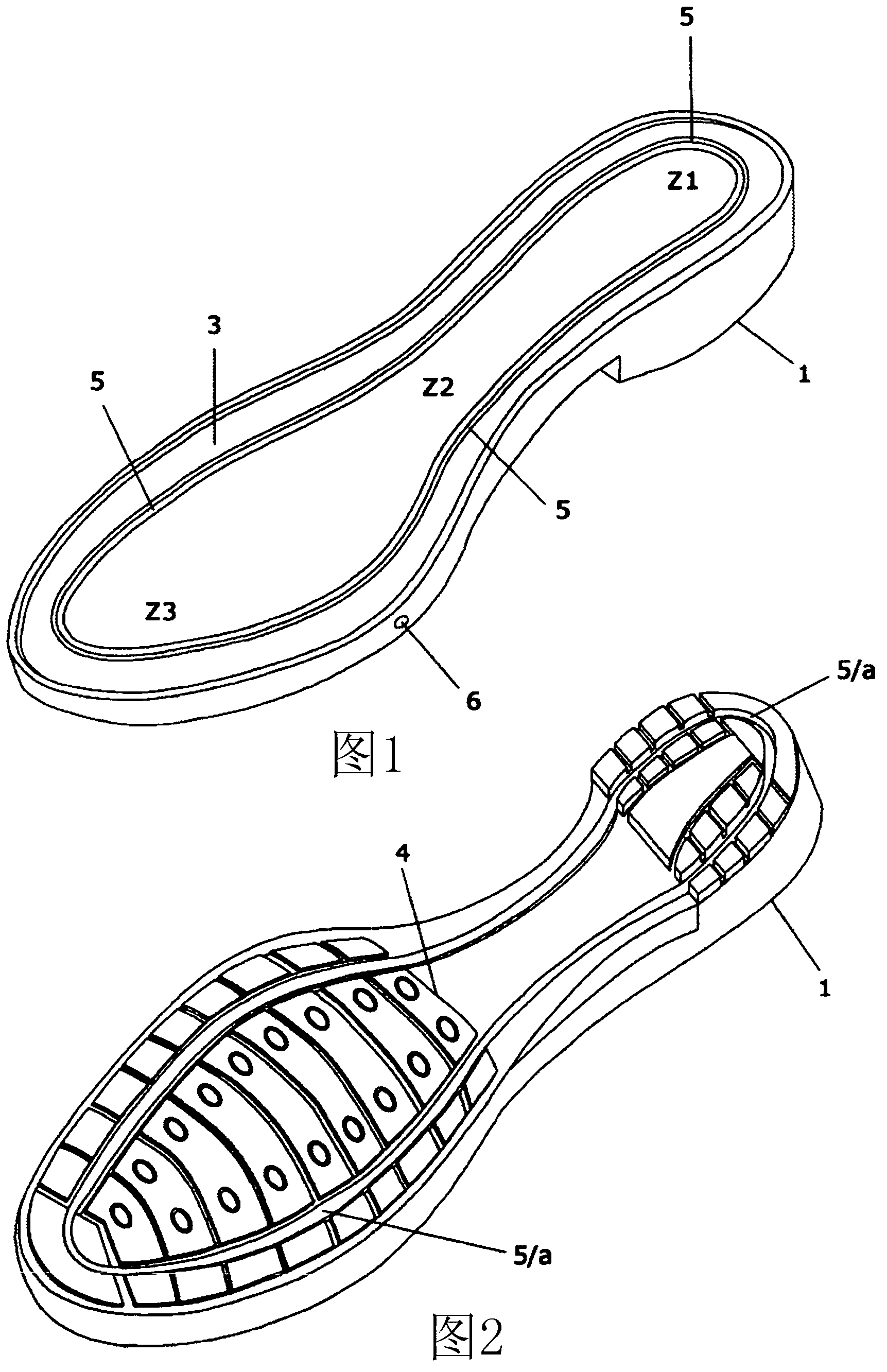

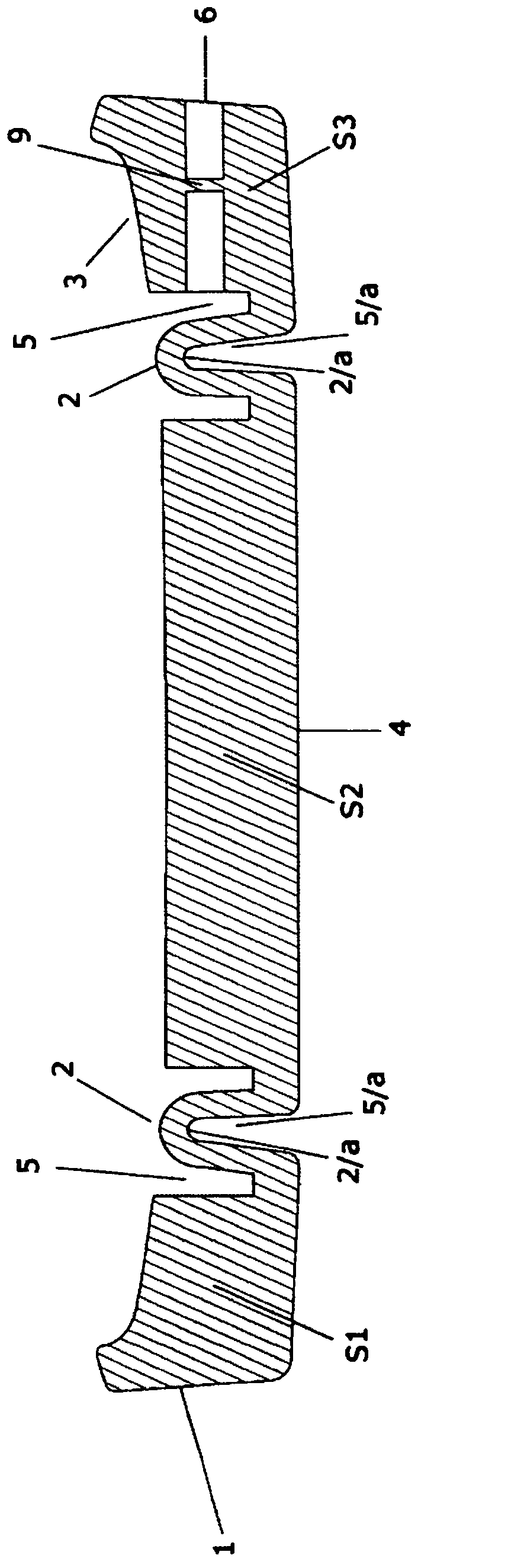

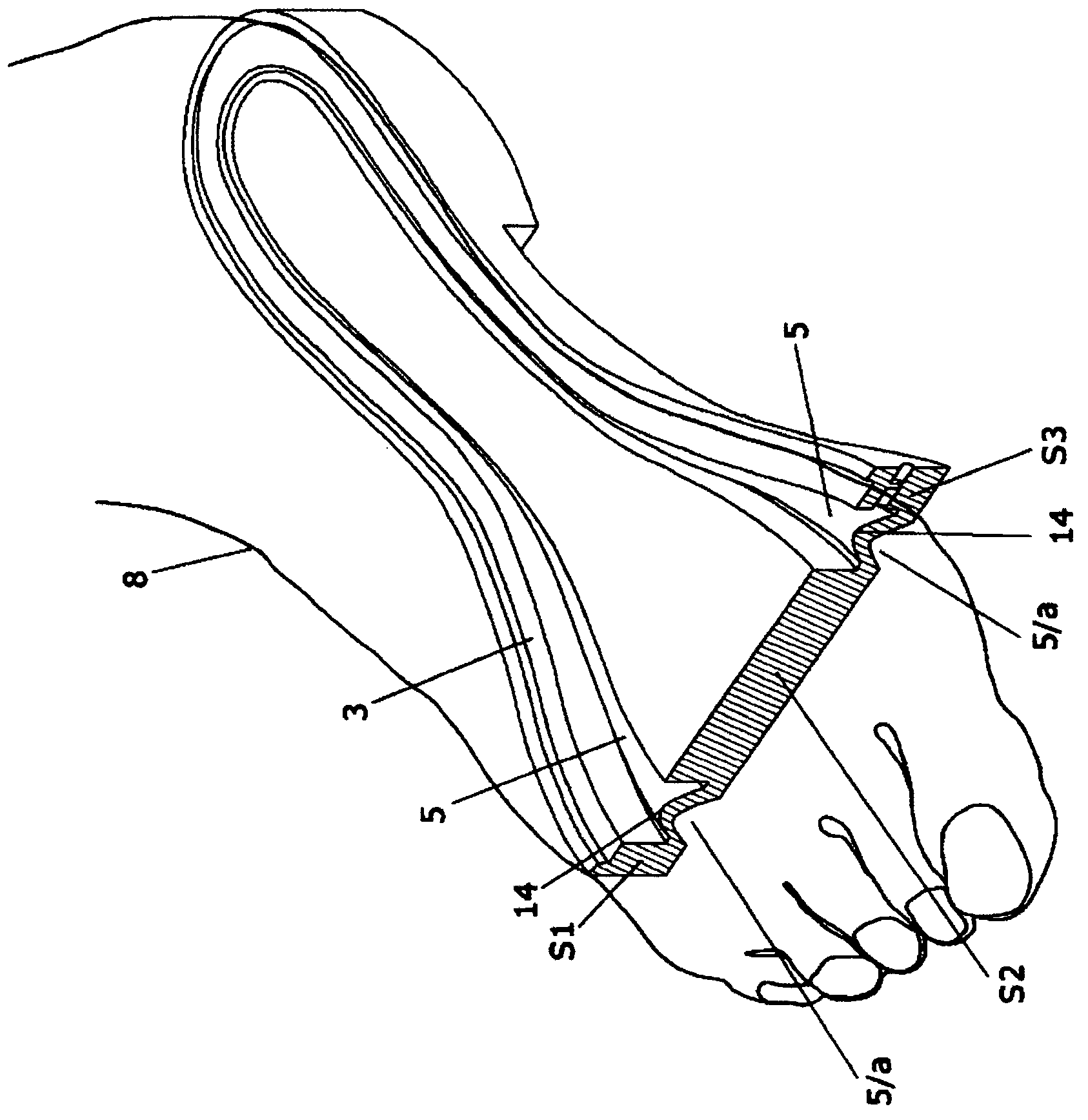

Sole for shoes having one or more vertical elements folded over each other, extensible and adaptable to the different width of the assembly last of the upper and to the variation of the conformation of the foot, even permanently

The present invention regards the shoe industry and more specifically it concerns a sole provided in a single moulding made of non-rigid but elastic material having one or more vertical elements folded over each other in such a manner that the horizontal extension thereof mechanically adapts the width of the sole to the different width of the assembly lasts of the upper of a shoe and also allowing adapting the width of the sole to the variation of the conformation of the feet generated by the daily swellings thereof leaving the normal flexibility and comfort of the shoe unaltered with the possibility for the user to stabilize the width of the sole to the possible deformation of the foot by injecting - from outside into the widened internal cavity - a foamed two-component fluid material which, upon solidification within a few minutes, blocks any widened part of the sole to the conformation or to the deformation of the feet of the user.

Owner:PI

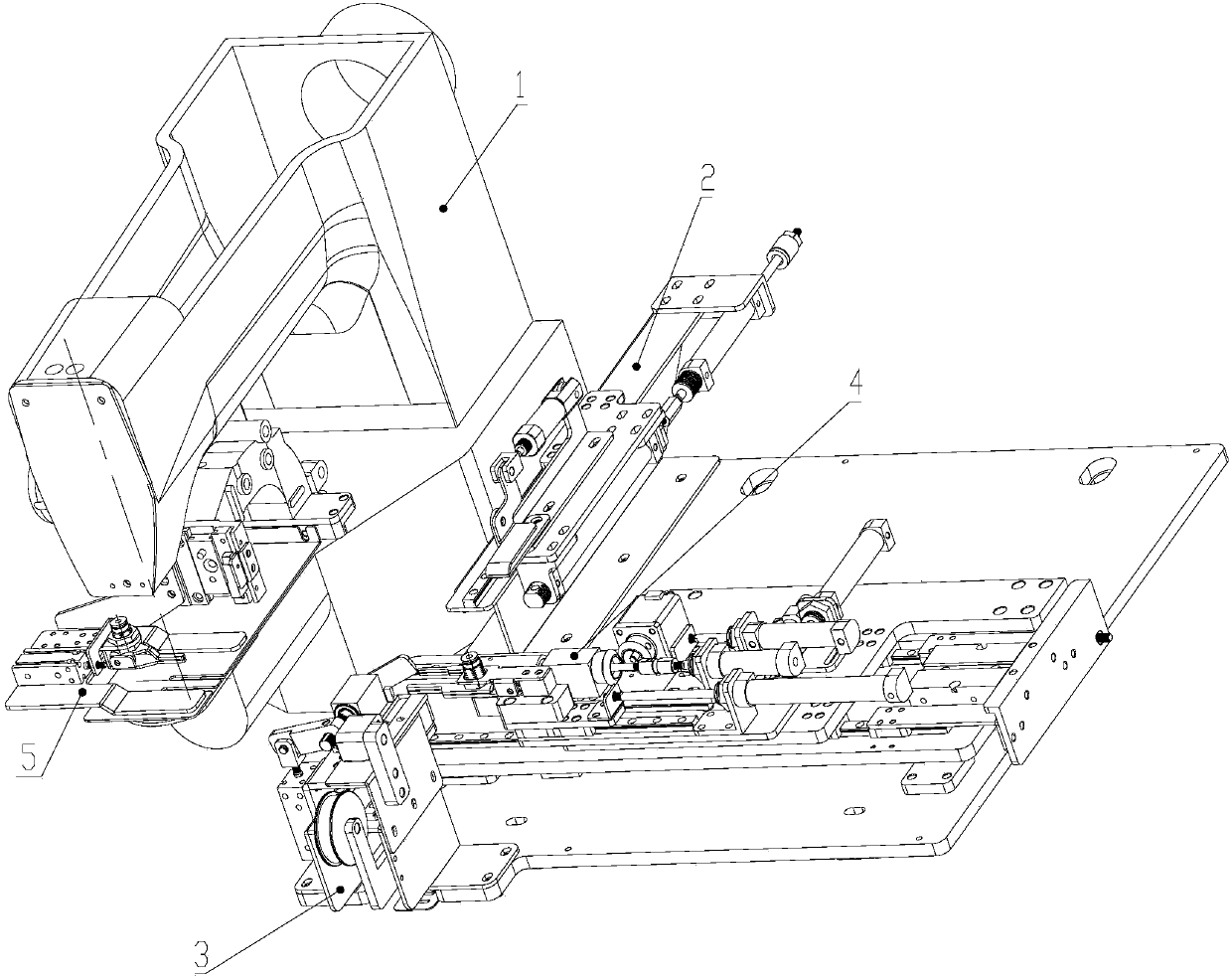

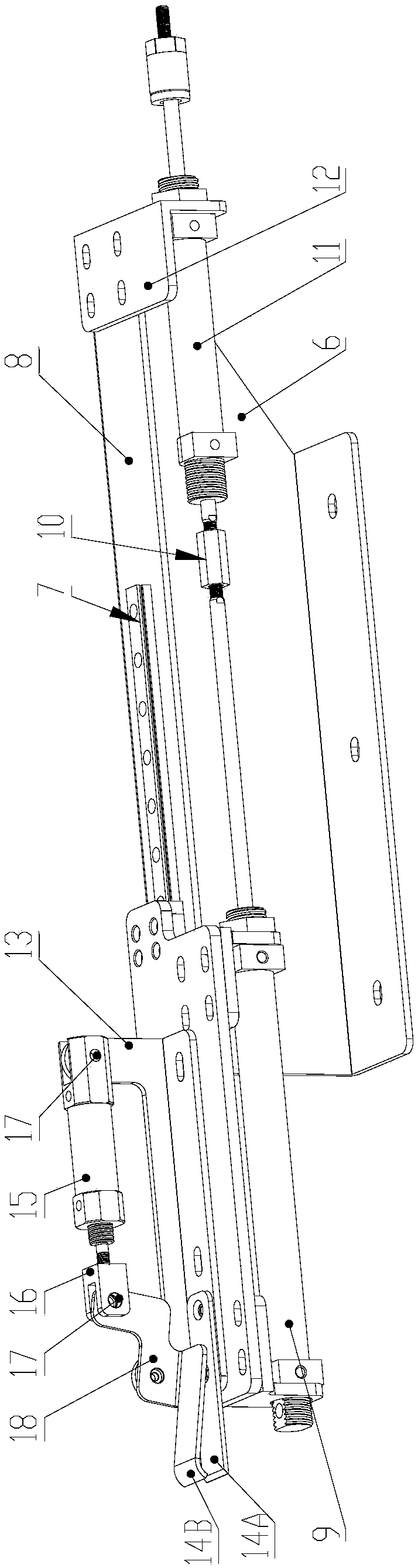

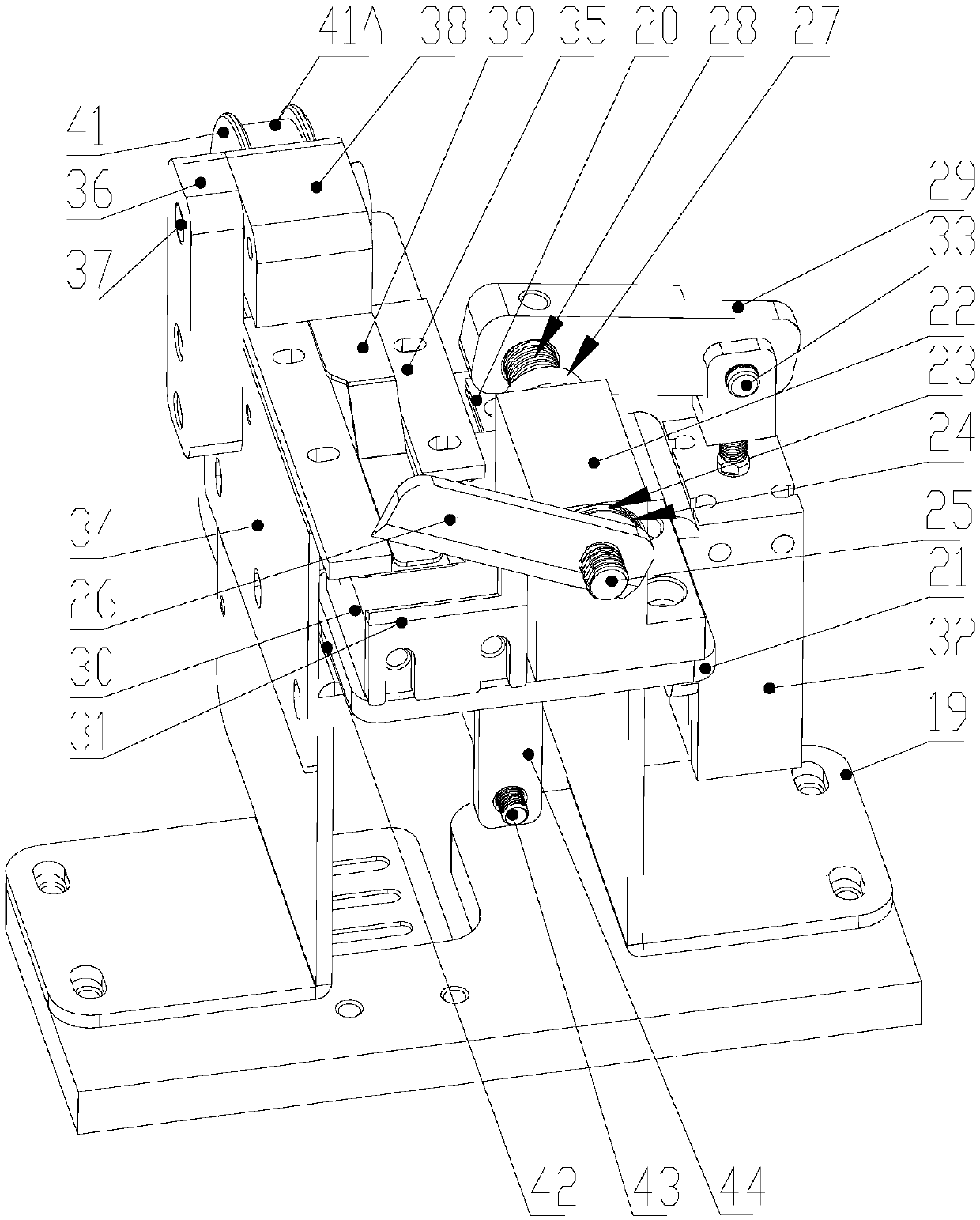

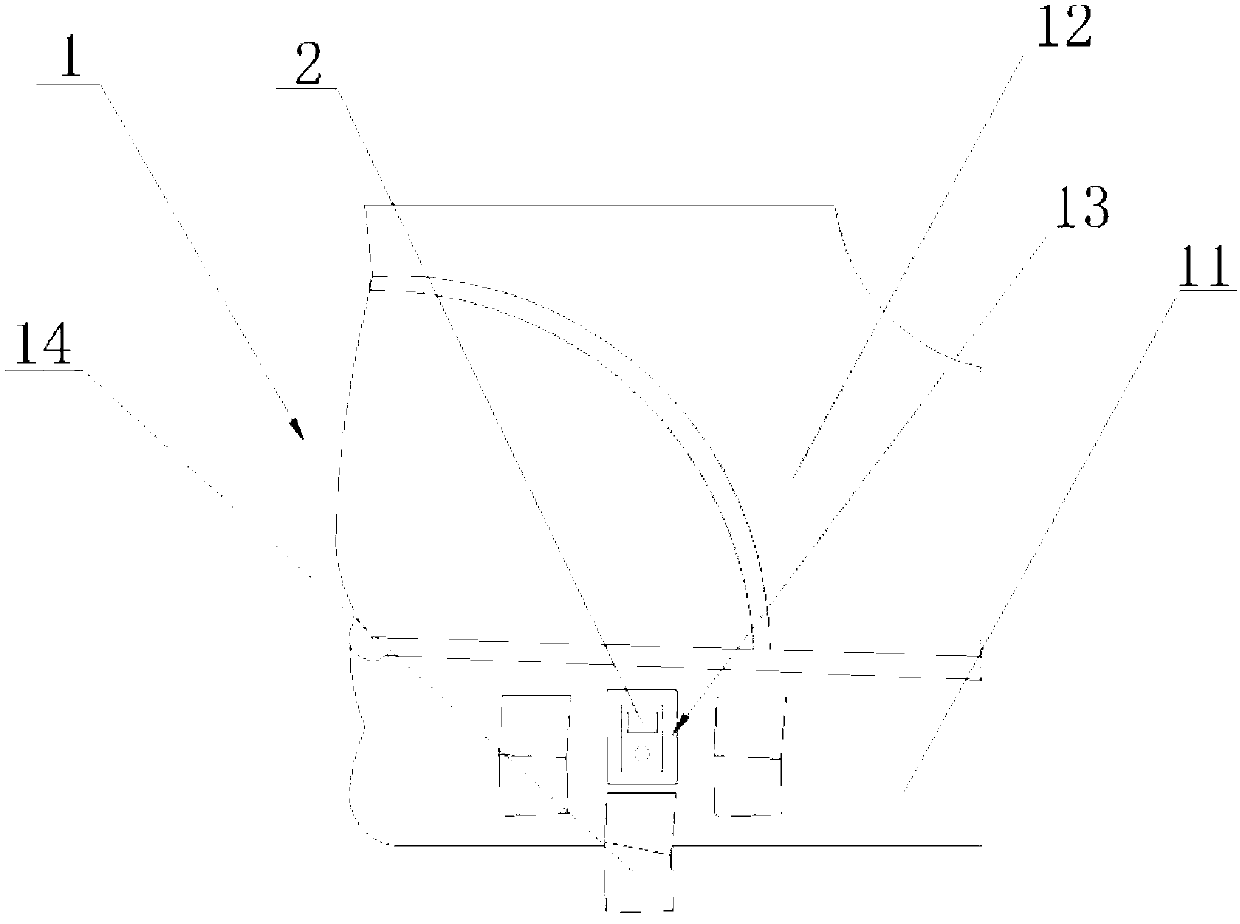

Automatic shoe tongue looping machine

PendingCN107558017AAvoid entanglementGuarantee quality requirementsWorkpiece carriersWork-feeding meansBiomedical engineeringAutomation

The invention belongs to the technical field of sewing equipment, and particularly relates to an automatic shoe tongue looping machine suitable for sewing process in shoemaking industry. The automaticshoe tongue looping machine comprises a machine head (1), a belt drawing mechanism (2) is arranged on the rear portion of the right side of the machine head (1), a belt cutting mechanism (3) is arranged on the front portion of the right side of the machine head (1) and arranged right in front of the belt drawing mechanism (2), a double-clamp belt receiving and feeding mechanism (4) is arranged onthe right side of X-direction axis of a needle bar of the machine head (1), and inner and outer compression sewing mechanisms (5) are arranged in a sewing area of the machine head (1) and arranged onleft-side and right-side sliding rails of a material feeding support (1A) of the machine head (1). Compared with the prior art, the automatic shoe tongue looping machine has the advantages that winding of weaving belts during working can be avoided to enable clamp drawing to be smoother, so that quality requirements on sewing the weaving belts are ensured, integral structure is simplified, and manufacturing cost is lowered substantially; the automatic shoe tongue looping machine is high in automation level, convenient to operate, high in efficiency and excellent in quality.

Owner:上海博岙机电制造有限公司

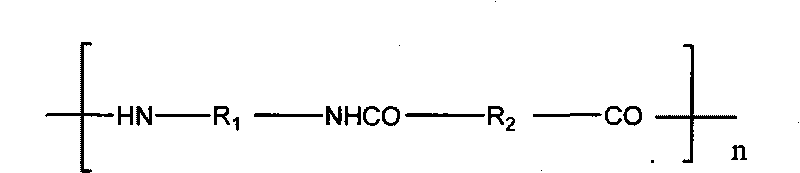

Soybean oil-based dimeric acid type polyamide hot melt adhesive and preparation method thereof

The invention relates to a soybean oil-based dimeric acid type polyamide hot melt adhesive and a preparation method thereof. Soybean oil-based dimeric acid, C6-C11 aliphatic dicarboxylic acid, C6-C11 aliphatic diamine, C13-C14 aromatic diamine, C6-C8 lactam, a molecular weight regulator, water and a catalyst are added into a reaction kettle for melt polycondensation action to generate the polyamide hot melt adhesive, and the prepared hot melt adhesive has the excellent physical and chemical performance of low melting point, solvent resistance, good viscosity and the like and can be used in the fields of clothes, electron, shoe industry and the like.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +1

Efficient drying device for finished shoe for shoe industry

InactiveCN106235533AGuaranteed stabilityImprove plasticityShoemaking devicesShoe industryEngineering

The invention relates to a drying device for a finished shoe, in particular to an efficient drying device for the finished shoe for the shoe industry and aims at achieving the technical purpose of providing the efficient drying device which is used for the finished shoe for the shoe industry and is novel in structure, high in practicality and high in working efficiency. To achieve the technical purpose, the efficient drying device for the finished shoe for the shoe industry is provided and comprises a bottom plate, a left frame, a movable frame, a first fulcrum bar, a second fulcrum bar, a first bearing pedestal, a rotation shaft, a right frame, a blade, a first motor, a guide rod, a guide sleeve, a first rack, a first gear, a baffle, a circular placement plate, a strong light lamp, a fixing plate and the like. The left frame, the first fulcrum bar, the second fulcrum bar, the first bearing pedestal and the right frame are sequentially arranged on the top of the base plate from left to right. The efficient drying device achieves the effect that the structure is novel, the practicality of the device is high, the efficient drying device can be frequently used by people in life and can be used and popularized easily, and the working efficiency of the device is high.

Owner:何昱增

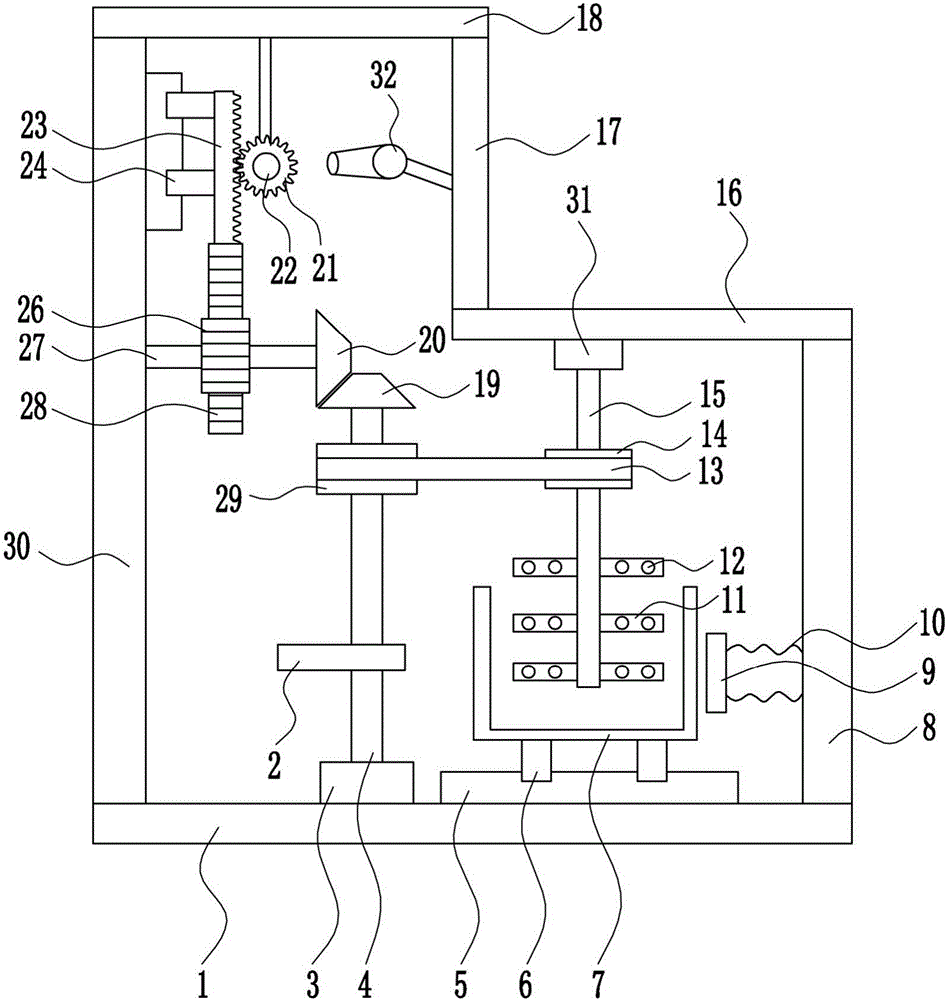

Dye gear lifting type efficient stirring device for shoe industry

ActiveCN106268442AEasy to learnImprove work efficiencyTransportation and packagingRotary stirring mixersShoe industryElectric machinery

The invention relates to a dye stirring device and especially relates to a dye gear lifting type efficient stirring device for shoe industry. The technical problem to be solved by the invention is to supply the dye gear lifting type efficient stirring device for shoe industry with simple structure, high practicability and high working efficiency. For solving the technical problem, the dye gear lifting type efficient stirring device for shoe industry provided by the invention comprises a base plate, a left shelf, a stirring frame, a base, a right shelf, a top plate, a first fixing base, a first half gear, a flat belt, a second fixing base, a first motor, a big belt pulley, a small belt pulley, a second half gear, a first connecting rod and a second connecting rod, wherein the left shelf, the base and the right shelf are successively arranged at the top of the base plate from left to right. The dye gear lifting type efficient stirring device for shoe industry not only can achieve the effect of high practicability but also has a simple structure; the worker can easily learn to use; the device is beneficial to popularization and application; the working efficiency of the device is high.

Owner:玉环市荣康达机械厂

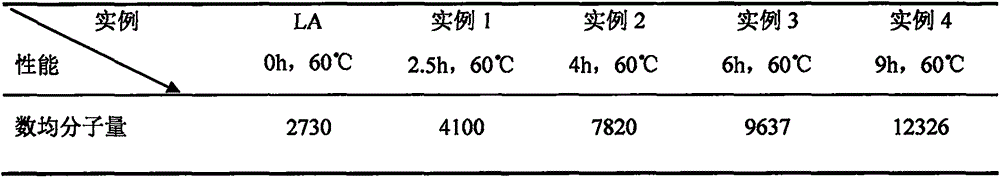

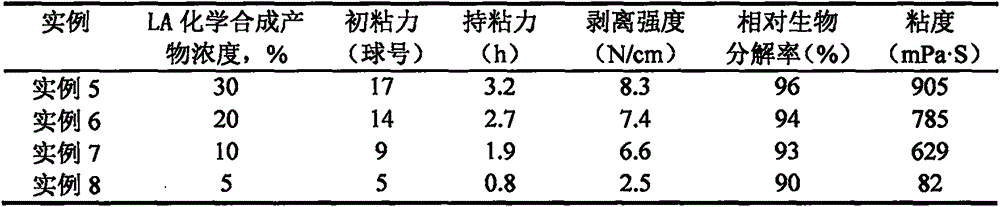

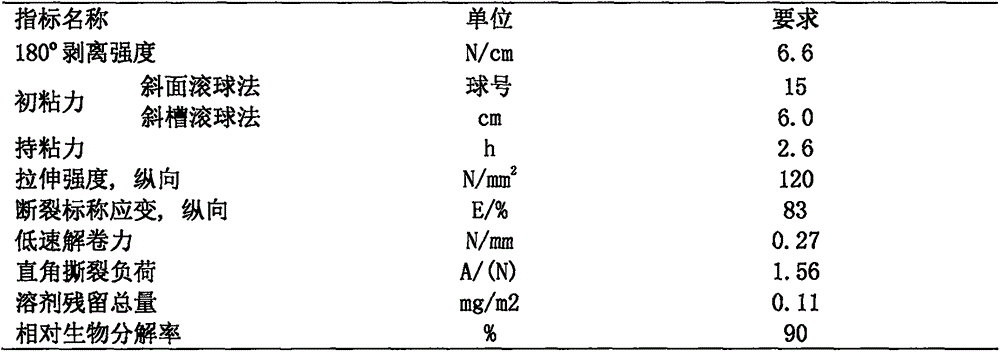

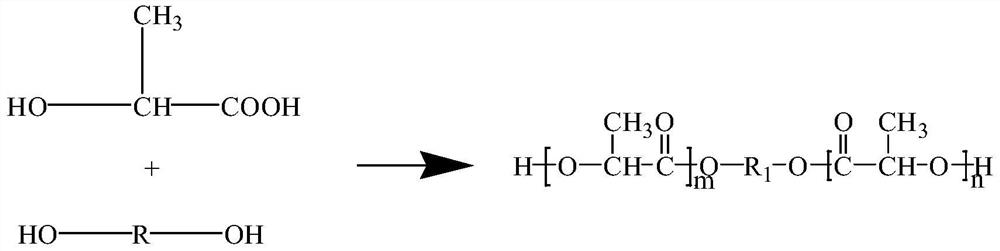

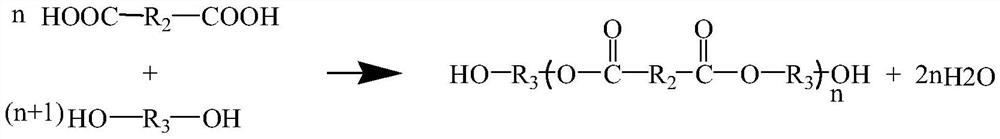

Biodegradable LA (lactide) oligomer bonding agent, and preparation method and purpose thereof

The invention relates to a biodegradable bonding agent material prepared from LA (lactide) chemical synthesis products. The LA materials are poured into a reaction container containing solvents according to the proportion of 5 to 50 percent of the mass of the solvents; a reactor has a stirring and control function; the reactor is controlled under the nitrogen gas protection condition; a certain reaction temperature is controlled; meanwhile, the stirring is performed; after the LA is completely fused, catalysts are added; after reacting for a period of time, stirring is stopped; after the materials are taken out, extraction and centrifugation are performed, so that the LA chemical synthesis products are obtained; then, the LA chemical synthesis products are dissolved by acetic ester, so that the biodegradable bonding agent is obtained. The bonding agent has the characteristics that the preparation is simple; the relative molecular weight and the viscosity are controllable; the biodegradable performance is realized. The biodegradable bonding agent material can be used in the fields of adhesive tapes, leather, sticking paper, stationery, office, electronics, automobile edge trimming fixation, shoe industry, handwork ornament pasting and fixation and the like.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

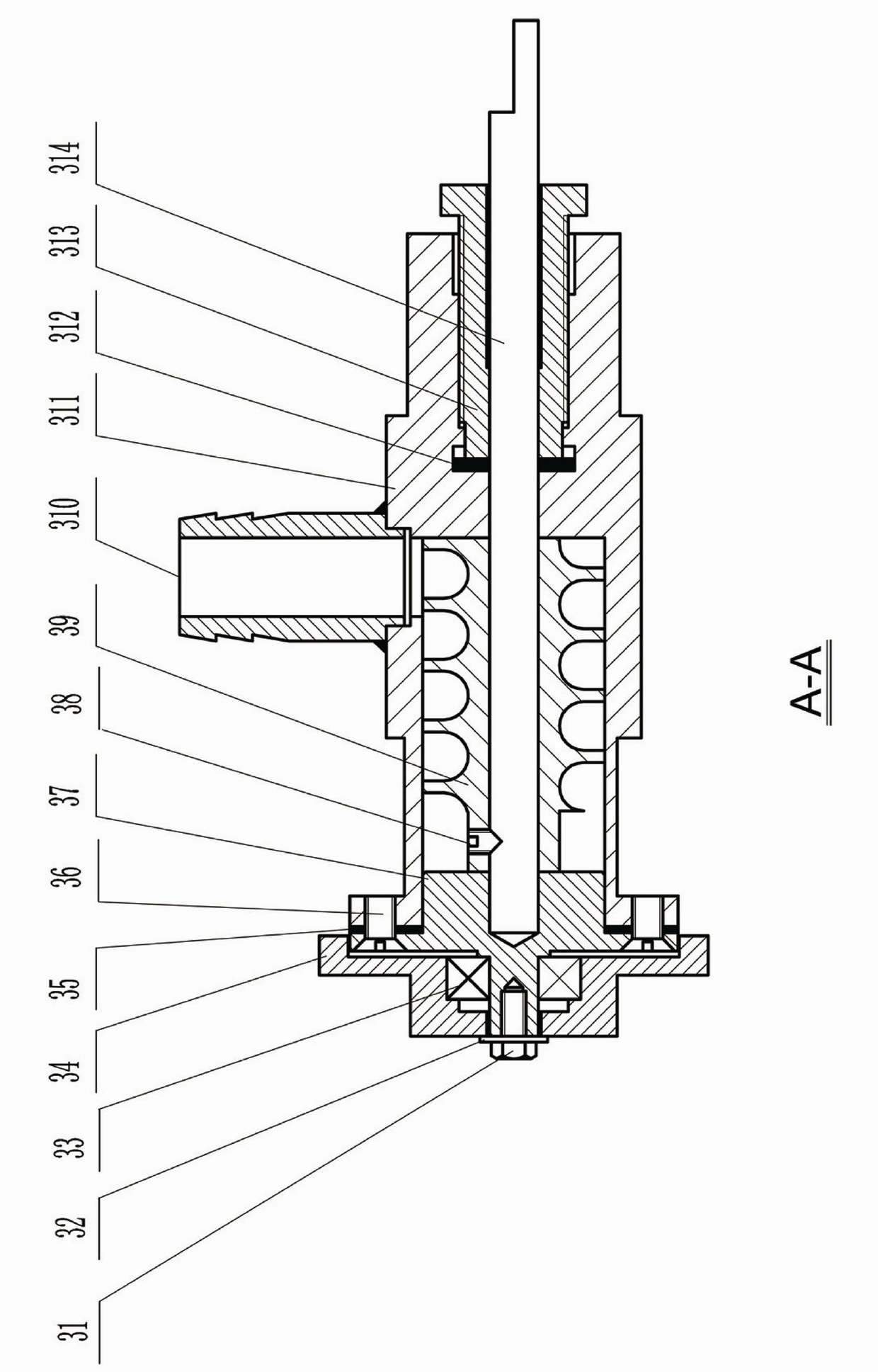

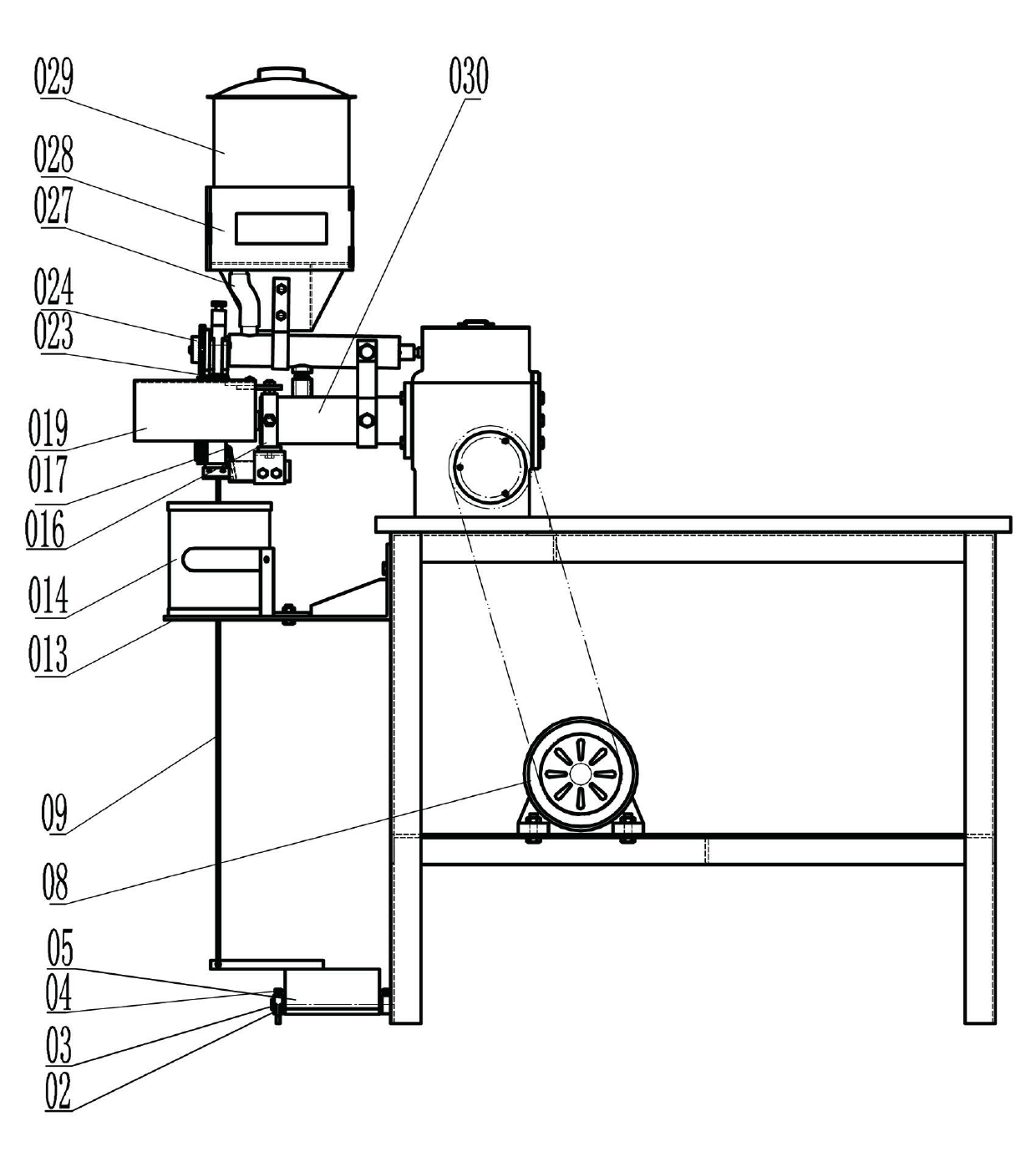

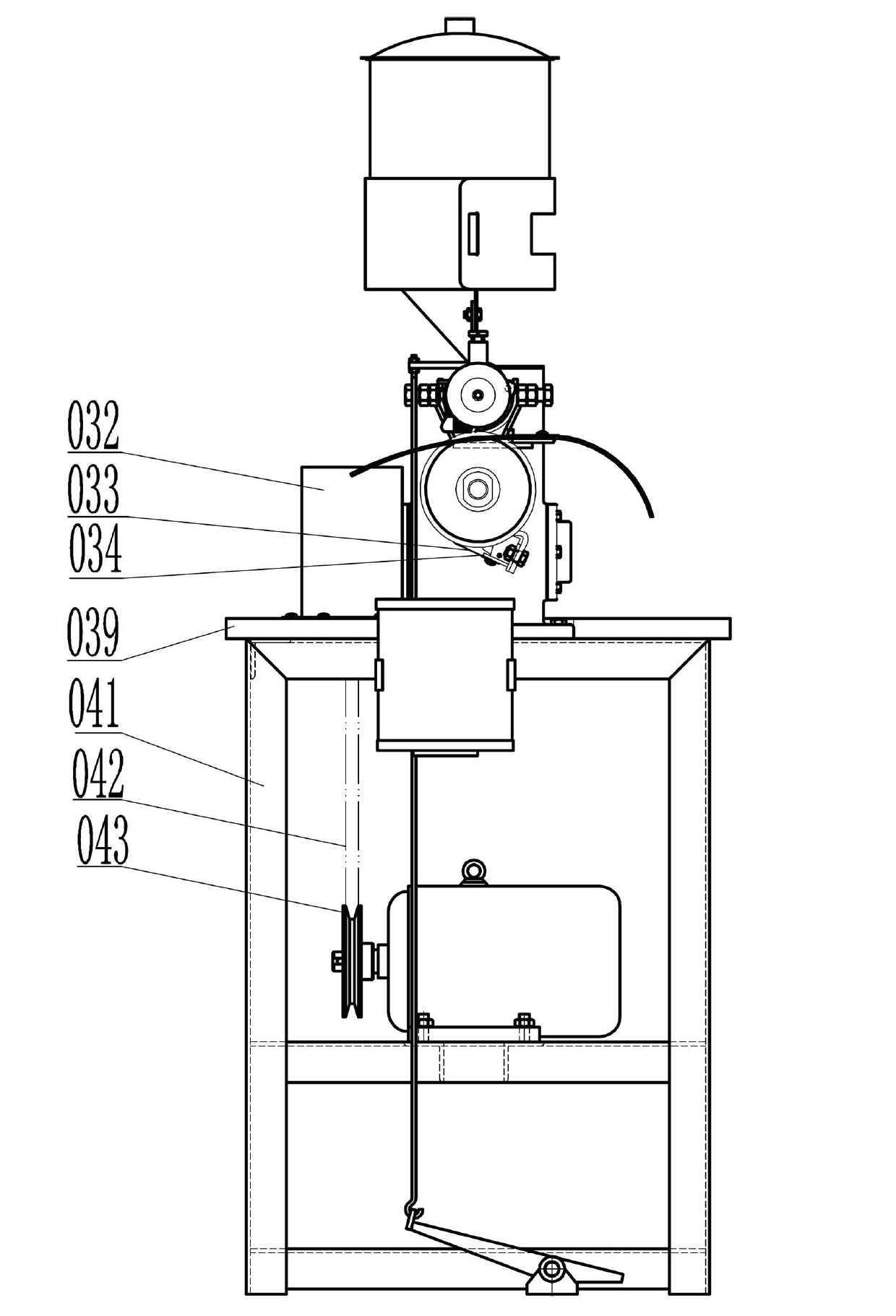

Coating brushing machine

ActiveCN102626264AInnovative designCompact structureShoe gluingShoe industryAgricultural engineering

The invention relates to a coating brushing machine, in particular to a coating brushing machine in shoe industry. The coating brushing machine comprises a stand, a nose device, an electric transmission device, a coating storage device, a manual transmission device and a coating nozzle device, wherein the stand is divided into two layers of support plates, the nose device is arranged on the upper support plate, the electric transmission device is arranged on the lower support plate, the side surface is fixedly provided with a residual coating barrel bracket, the nose device comprises a nose electric transmission mechanism, a nose manual transmission mechanism and an active rolling part; the electric transmission device comprises a motor arranged on the lower support plate of the stand, a belt pulley and a belt; the coating storage device comprises a residual coating barrel arranged on the residual coating barrel bracket, and a coating containing barrel arranged on a coating containing barrel bracket; the manual transmission device comprises a pedal plate arranged on the bottom of the side surface of the stand, and a pull rod connected with the pedal plate and a coating brushing head device; and the coating nozzle device comprises a coating nozzle cylinder mechanism, a coating feeding and pushing mechanism, a coating brushing mechanism, a coating discharging control mechanism and a passive rolling part. The coating brushing machine has the advantages of high efficiency, safety, environmental friendliness, low cost, high quality and the like, and is wide in market application prospect.

Owner:JIHUA 3517 RUBBER PROD

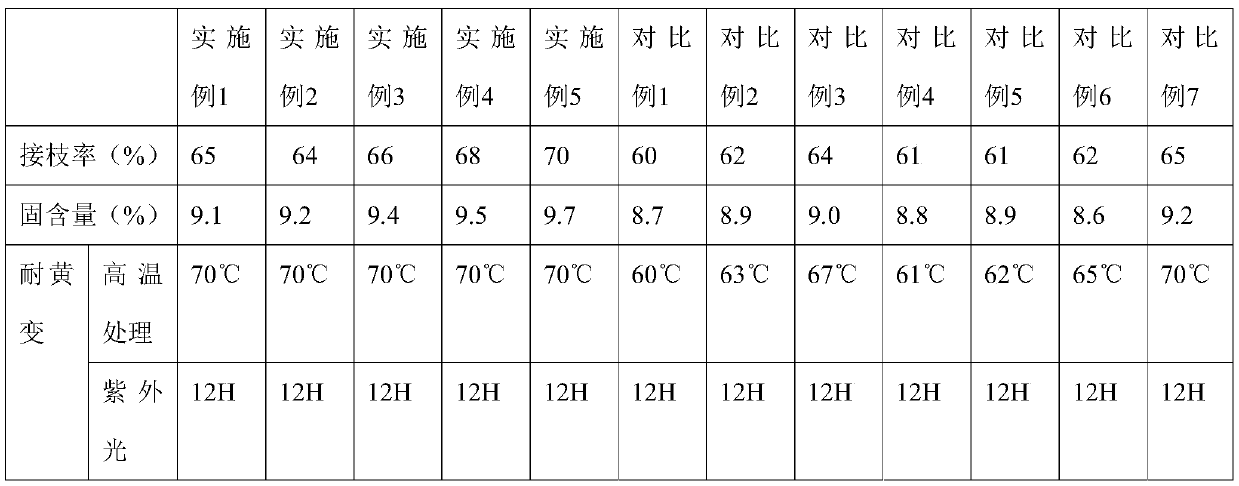

Neoprene adhesive subjected to secondary graft modification and preparation method of neoprene adhesive

InactiveCN103865451AImprove environmental protection requirementsImprove performanceGraft polymer adhesivesShoe industryPolymer science

The invention discloses a neoprene adhesive subjected to secondary graft modification and a preparation method of the neoprene adhesive. The neoprene adhesive comprises the following raw materials (in percentage by weight): 10%-15% of neoprene, 6.3%-13% of grafted monomers, 0.1%-0.5% of initiating agents, 5%-10% of acetone, 15%-30% of butanone, 10%-20% of ethyl acetate, 10%-20% of dimethyl carbonate, 8%-20% of methyl cyclohexane, 5%-10% of thickening agents and 0.3%-1% of terminating agents. The preparation method comprises the following steps of sequentially adding acetone, butanone, ethyl acetate, dimethyl carbonate and methyl cyclohexane, and uniformly mixing and stirring; adding neoprene, and stirring for 2-4 hours; adding a part of the initiating agents, further stirring, then dropping first grafted monomers to react for 0.5-1 hour, and adding second grafted monomers and the rest of initiating agents; adding a terminating agent, and then adding tackifying resin; regulating viscosity, and then discharging. The neoprene adhesive disclosed by the invention is subjected to the secondary graft modification through multiple monomers. The product has the characteristics of high comprehensive property and good environmental friendliness and is suitable for industries, such as furniture making, shoe making and luggage.

Owner:ZHUHAI YUTIAN CHEM PROD

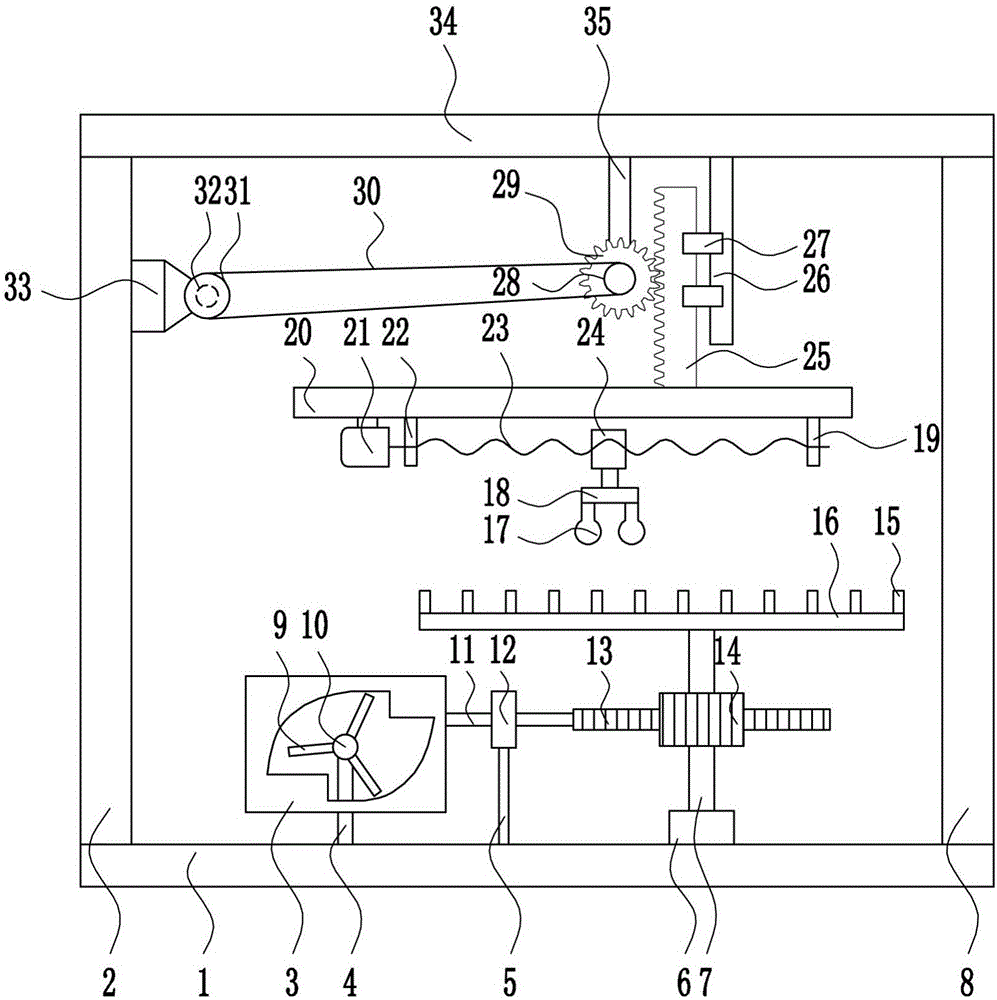

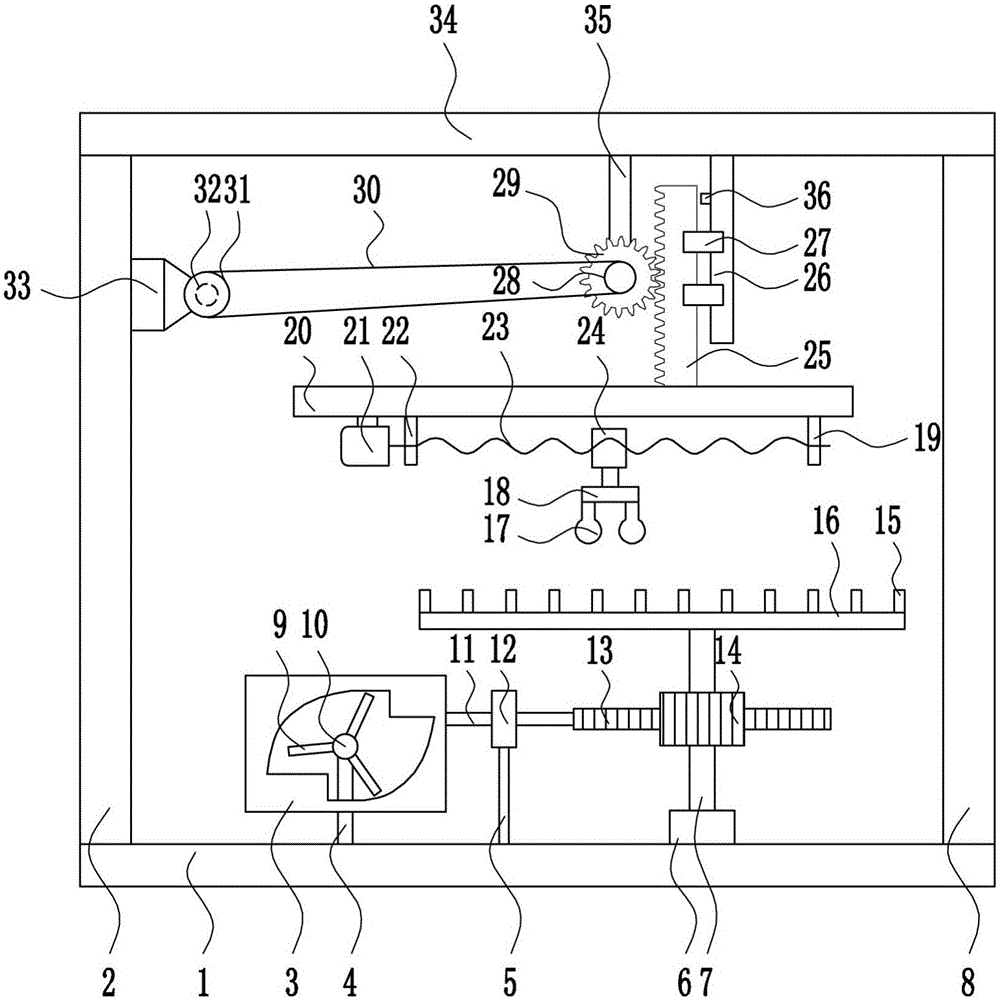

Waste shoe mold quick smashing device for shoe industry

ActiveCN106273075AQuick breakImprove work efficiencyPlastic recyclingGrain treatmentsShoe industryWaste management

The invention relates to a waste shoe mold smashing device for the shoe industry, in particular to a waste shoe mold quick smashing device for the shoe industry. The waste shoe mold quick smashing device for the shoe industry aims at achieving the technical purposes of being good in smashing effect, easy and convenient to operate and high in working efficiency. To achieve the technical purposes, the waste shoe mold quick smashing device for the shoe industry comprises a bottom plate, a left stand, a right stand, a top plate, a first sliding rail, first sliding blocks, a smashing frame, an installation base, a swing rod, a supporting rod, a second siding rail, second sliding blocks, a rack, a gear, a small belt wheel, a motor, a large belt wheel, a flat belt, a crank, a first connecting rod, a second connecting rod, a third connecting rod, a guide plate, a lifting rod and a smashing hammer. The waste shoe mold quick smashing device for the shoe industry has the advantages of being good in smashing effect, easy and convenient to operate and high in working efficiency, and is novel in structure, high in practicability, capable of quickly smashing waste shoe molds, small in size and efficient in running.

Owner:临沂临港投资管理有限公司

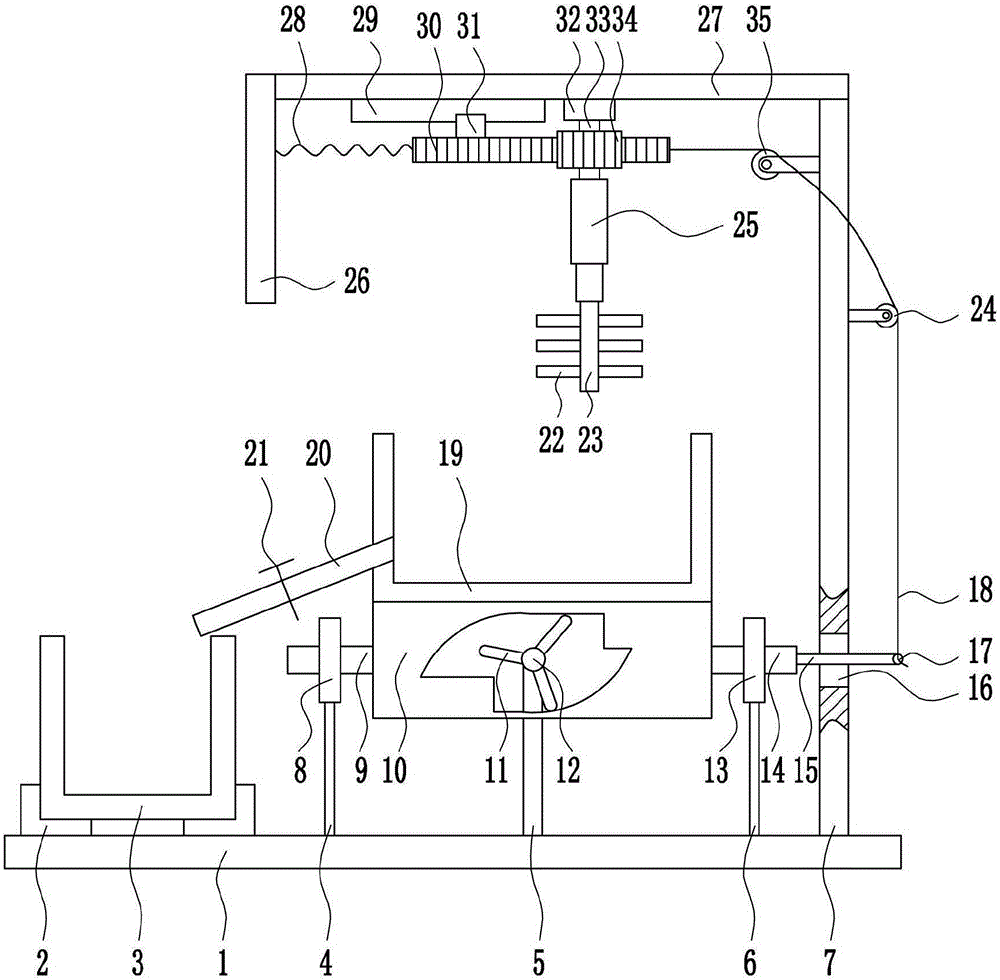

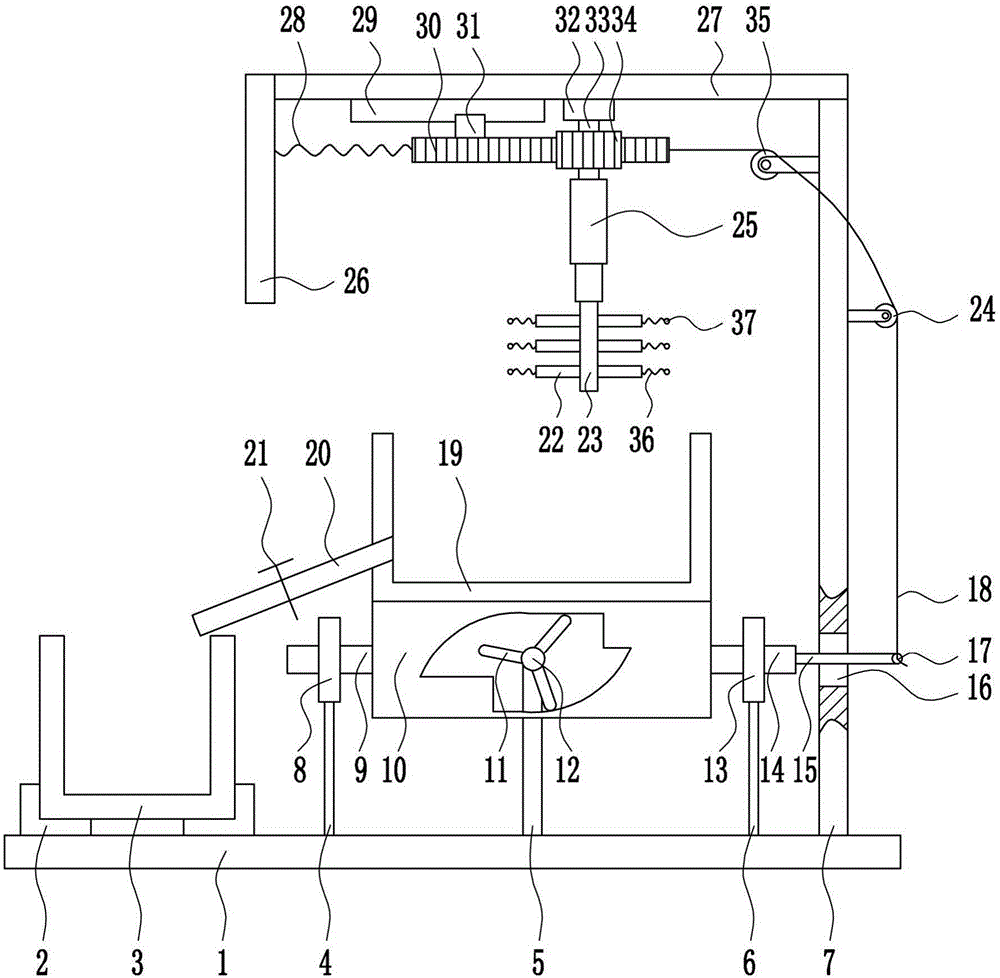

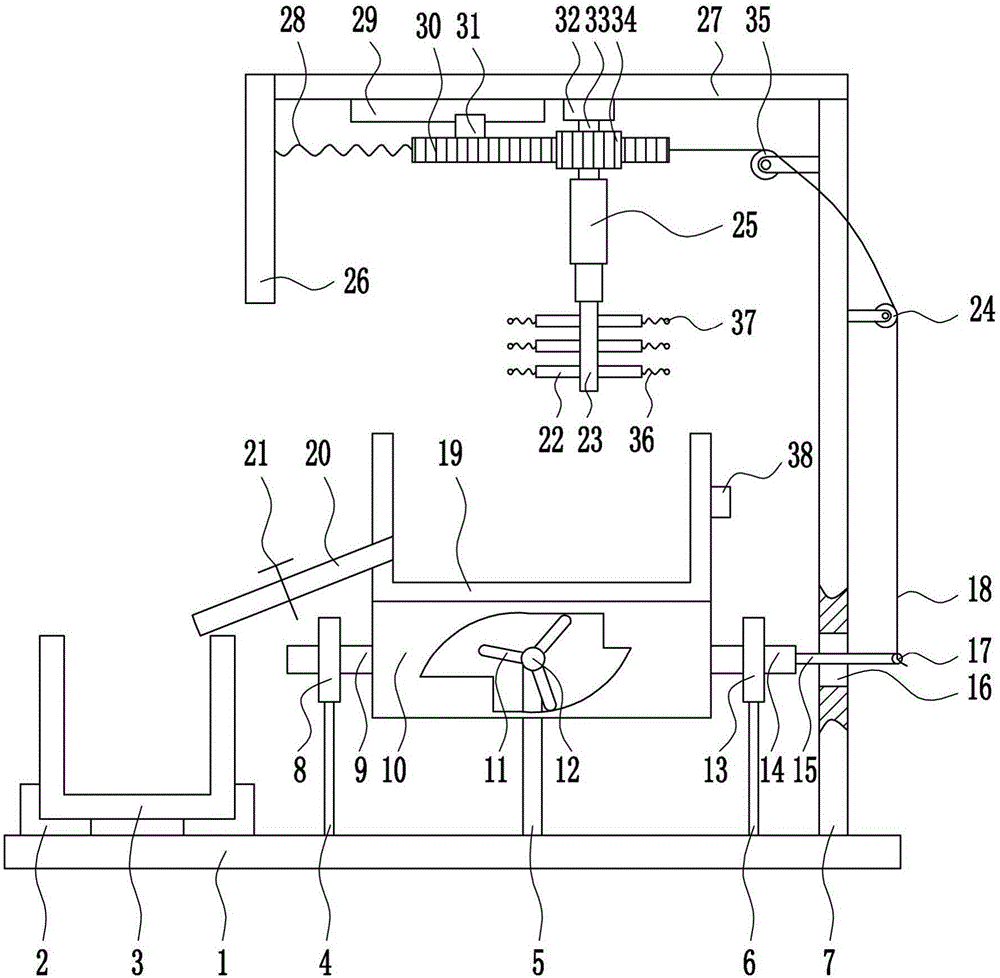

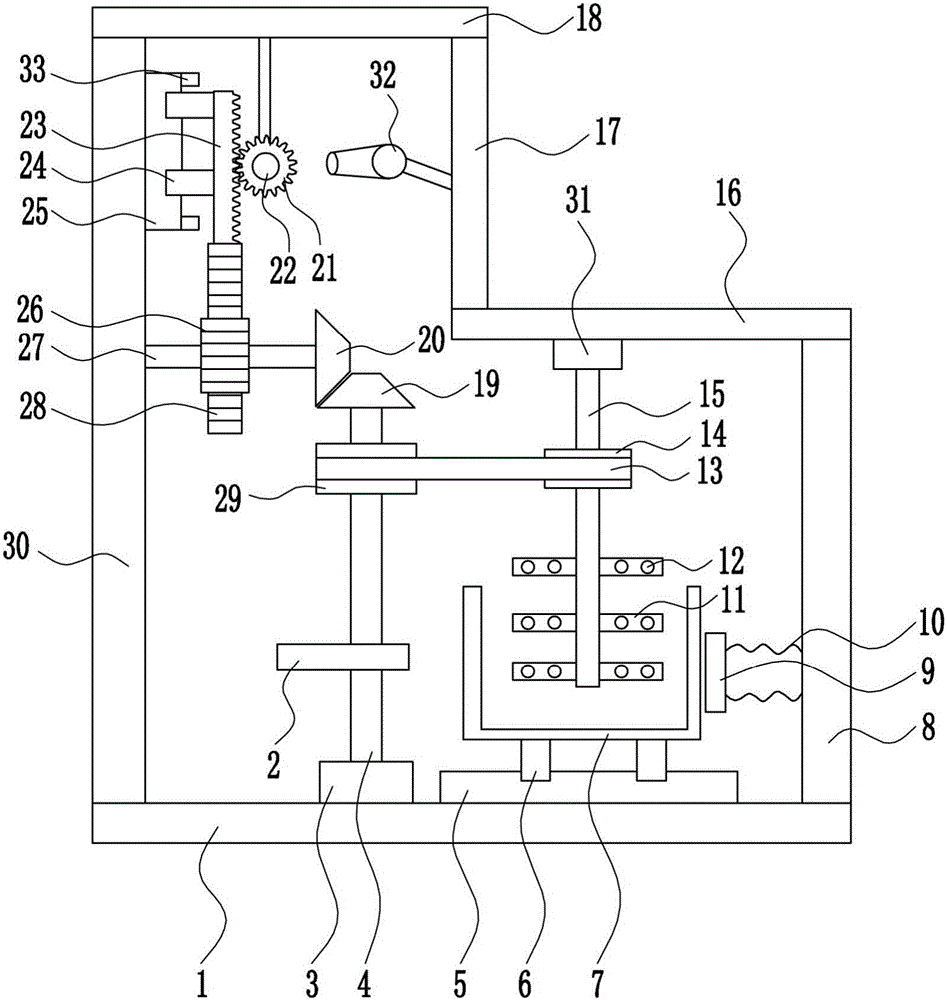

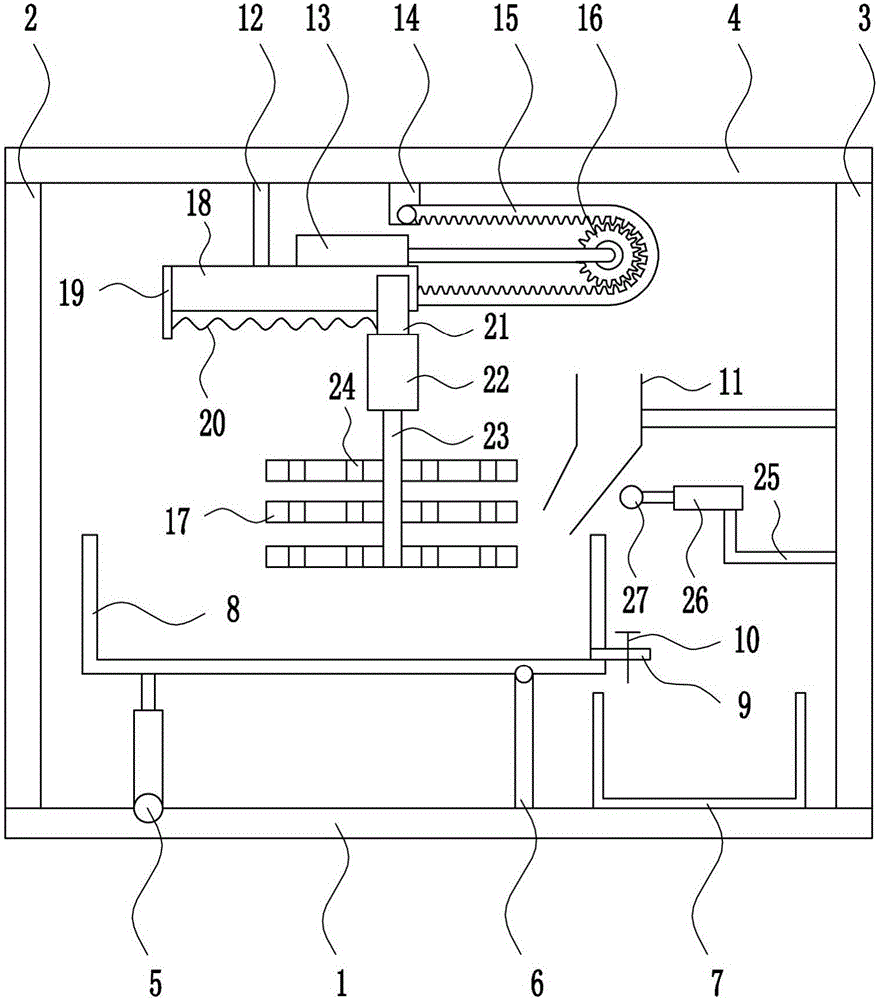

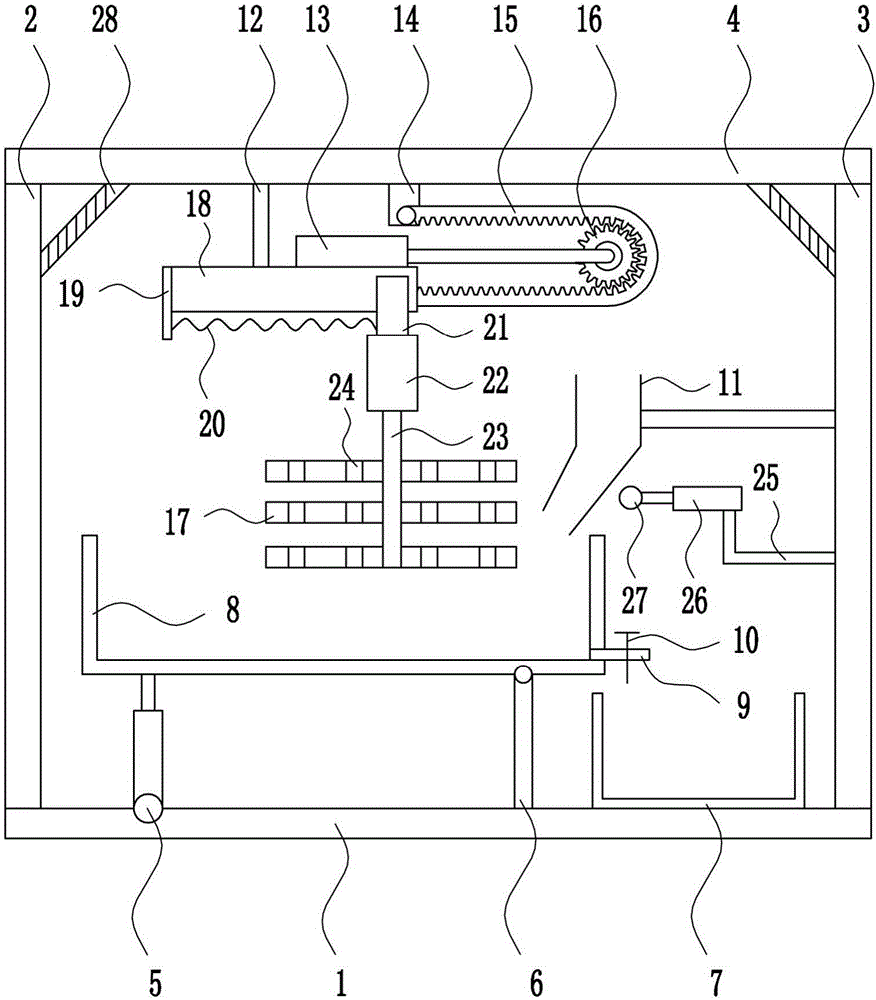

Electric push rod lifting-type waste toepiece crushing device for shoe industry

ActiveCN106179566AExtended service lifeImprove crushing effectGrain treatmentsShoe industryWaste management

The invention relates to a waste toepiece crushing device for shoe industry and particularly relates to an electric push rod lifting-type waste toepiece crushing device for shoe industry. The technical problem to be solved by the invention is to provide the electric push rod lifting-type waste toepiece crushing device for the shoe industry, which is good in crushing effect, simple in operation and high in work efficiency. In order to solve the technical problem, the invention provides the electric push rod lifting-type waste toepiece crushing device for the shoe industry, comprising a bottom plate, a left frame, a right frame, a top plate, a first sliding rail, a first slide block, a crushing frame, a first fixing block, springs, a second fixing block and the like; and the top of the bottom plate is sequentially provided with the left frame, the first sliding rail and the right frame from left to right. By using the waste toepiece crushing device, the effects of good crushing effect, simplicity in operation and high work efficiency are achieved; and the device is novel in structure, high in practicability and capable of rapidly crushing waste toepieces, so that the working benefit of an enterprise is increased.

Owner:安庆市安鑫体育用品有限公司

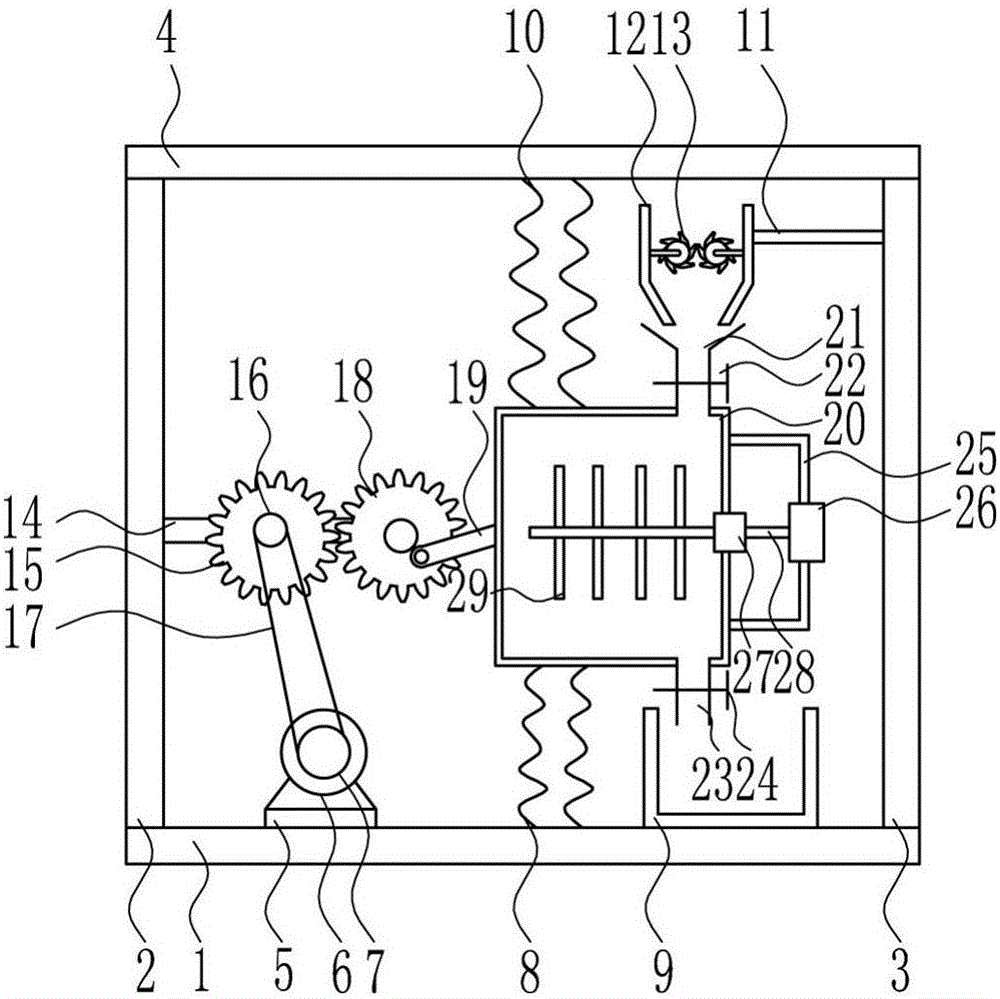

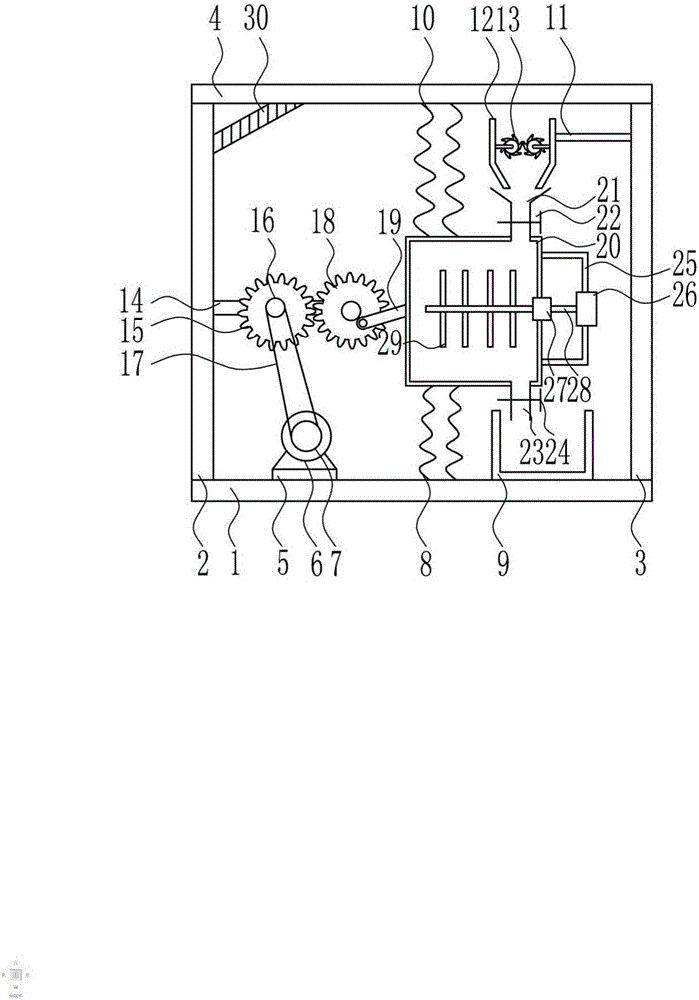

Dye rapid mixing and dispensing device for shoe industry

ActiveCN106237890AFall intoGuaranteed stabilityShaking/oscillating/vibrating mixersRotary stirring mixersShoe industryMaterial resources

The invention relates to a dye dispensing device for a shoe industry, and in particular, relates to a dye rapid mixing and dispensing device for the shoe industry. The technical problem to be solved comprises that provided is the dye rapid mixing and dispensing device for the shoe industry, wherein the device has the advantages of uniform mixing, complete mixing and rapid deployment speed. For solving the technical problem, the invention provides the dye rapid mixing and dispensing device for the shoe industry, wherein the dye rapid mixing and dispensing device comprises a base plate, a left frame, a right frame, a top plate, a cylinder, a first supporting rod, a collecting box, a mixing box, a discharging pipe, an electric control valve, a feed hopper, a connecting rod, a first electric push rod, a fixed block, a chain, a wheel gear, a blade, a slideway, a baffle, a spring, a slide block, a motor and a rotating rod; the left side of the top of the base plate is provided with the left frame. The dye rapid mixing and dispensing device achieves the effects of uniform mixing, thorough mixing and fast dispensing speed, has the advantages of low manufacture cost, reasonable structure, easy maintenance and repairing and convenience in use, reduces investment of manpower and material resources, and reduces costs.

Owner:江苏萨拉曼体育用品有限公司

High-flexibility and high-bonding-strength two-component polyurethane adhesive for shoes and preparation method and application thereof

ActiveCN106147689AGood flexibilityIncrease the lengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesShoe industryPolyurethane adhesive

The invention relates to a high-flexibility and high-bonding-strength two-component polyurethane adhesive for shoes and a preparation method and application thereof. According to the specific technical scheme, the adhesive consists of a component A and a component B, wherein the mass ratio of the component A to the component B is 2-4 to 1. The component A is a hydroxyl terminated polyurethane component obtained through reaction of hyperbranched polyester polyol, polyether polyol and hexamethylene isocyanate. The component B is an isocyanate terminated polyurethane component obtained through reaction of castor oil, hyperbranched isocyanate and toluene diisocynate. At least one of the component A and the component B contains nitrile rubber microspheres and / or soccer. The final product is the polyurethane adhesive having excellent flexibility and bonding strength and is suitable for production in shoe industry.

Owner:GUANGDONG YETOM NEW MATERIALS CO LTD

Shaking outsole raw material mixing and stirring device for shoe industries

ActiveCN106179066AExtended service lifeWell mixedShaking/oscillating/vibrating mixersTransportation and packagingShoe industryEngineering

The invention relates to an outsole raw material mixing and stirring device for shoe industries, in particular to a shaking outsole raw material mixing and stirring device for the shoe industries, and aims to provide a shaking outsole raw material mixing and stirring device which is excellent in mixing effect, good in stirring effect and high in working efficiency for the shoe industries. The shaking outsole raw material mixing and stirring device comprises a bottom plate, a left frame, a right frame, a top plate, a mounting seat, a first motor, a large belt pulley, a first spring, a collection frame, a second spring, a first fixing rod, a feeding hopper, an electric crushing wheel and a second fixing rod, and the left frame is arranged on the leftmost side of the top of the bottom plate. The shaking outsole raw material mixing and stirring device can rapidly mix and stir outsole raw materials, and work efficiency of enterprises is improved.

Owner:JINHOU GRP WEIHAI SHOES

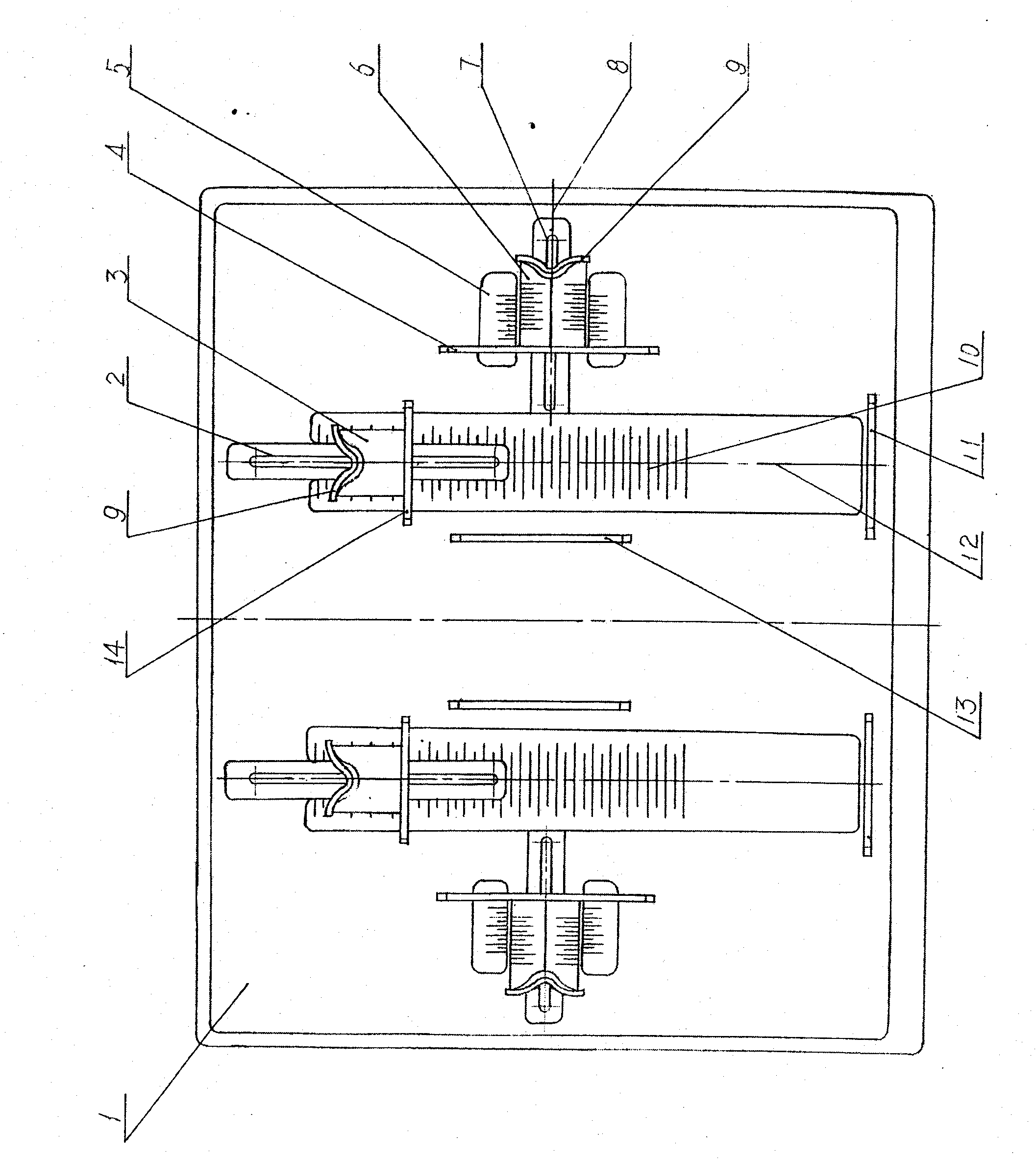

Foot type measurer based on Chinese shoe size and type

The invention relates to a foot type measurer based on the Chinese shoe size and type. Symmetrical left and right measuring devices on a measuring platform thereof comprise a first chute, a shoe size baffle, a shoe size cursor, a first cursor baffle, a second chute, a shoe type baffle, a shoe type cursor and a second cursor baffle respectively. Two sides of the first chute are provided with a shoe size dial respectively, two sides of the second chute are provided with a shoe type dial respectively, and the shoe type cursor is provided with a cursor dial. The foot type measurer based on the Chinese shoe size and type has the advantages and positive effects that: as foot width measurement is arranged at the same time of measuring the foot length, the acquired data comprise not only the foot length or the shoe size but also the foot width or the shoe type, thus obtaining all data of foot type measurement. Besides, both feet can be measured simultaneously, which is more convenient and rapid, is popular with users, brings great convenience for the shoemaking industry and footwear sales departments and promotes the development of Chinese shoe industry.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

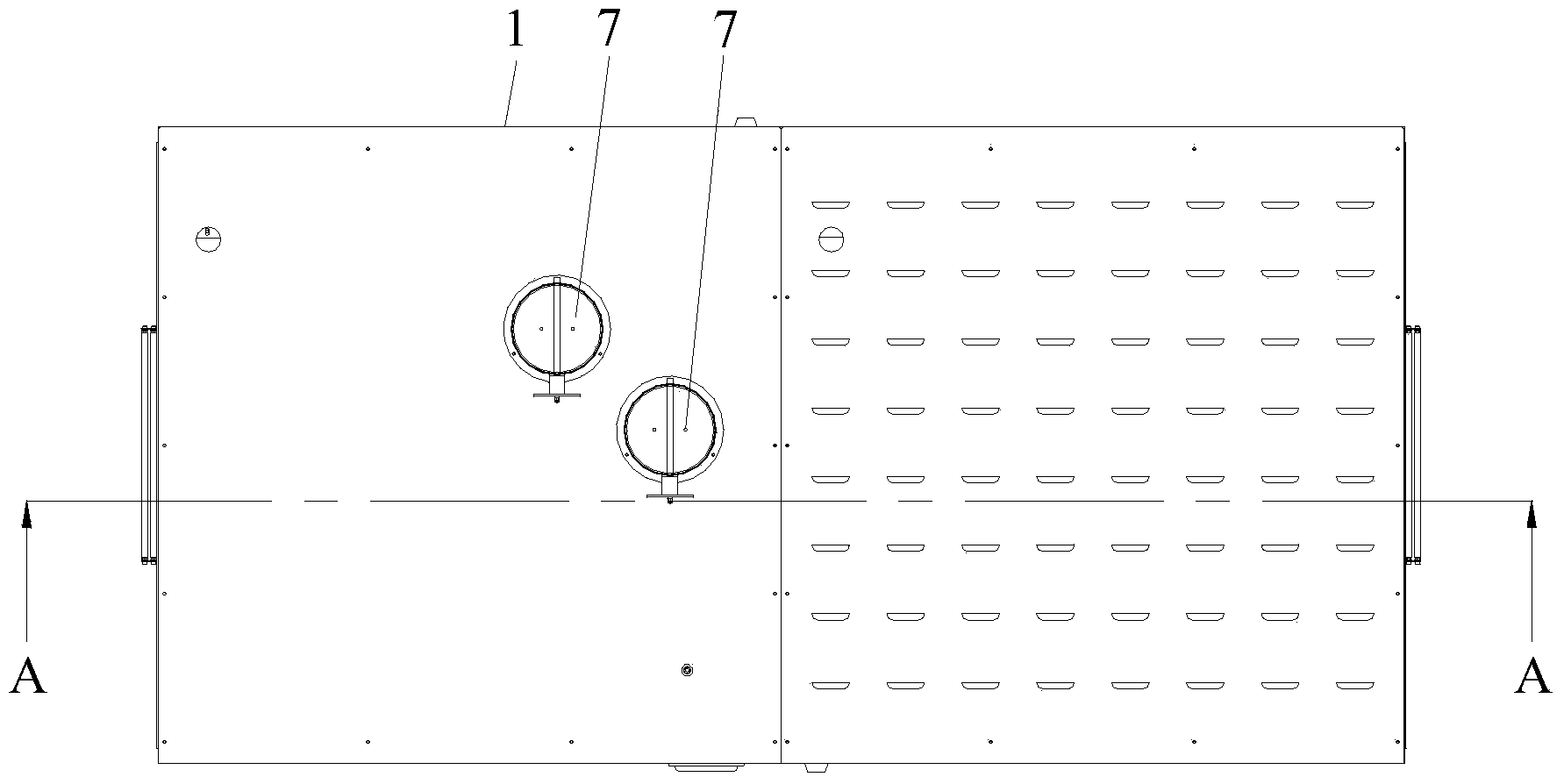

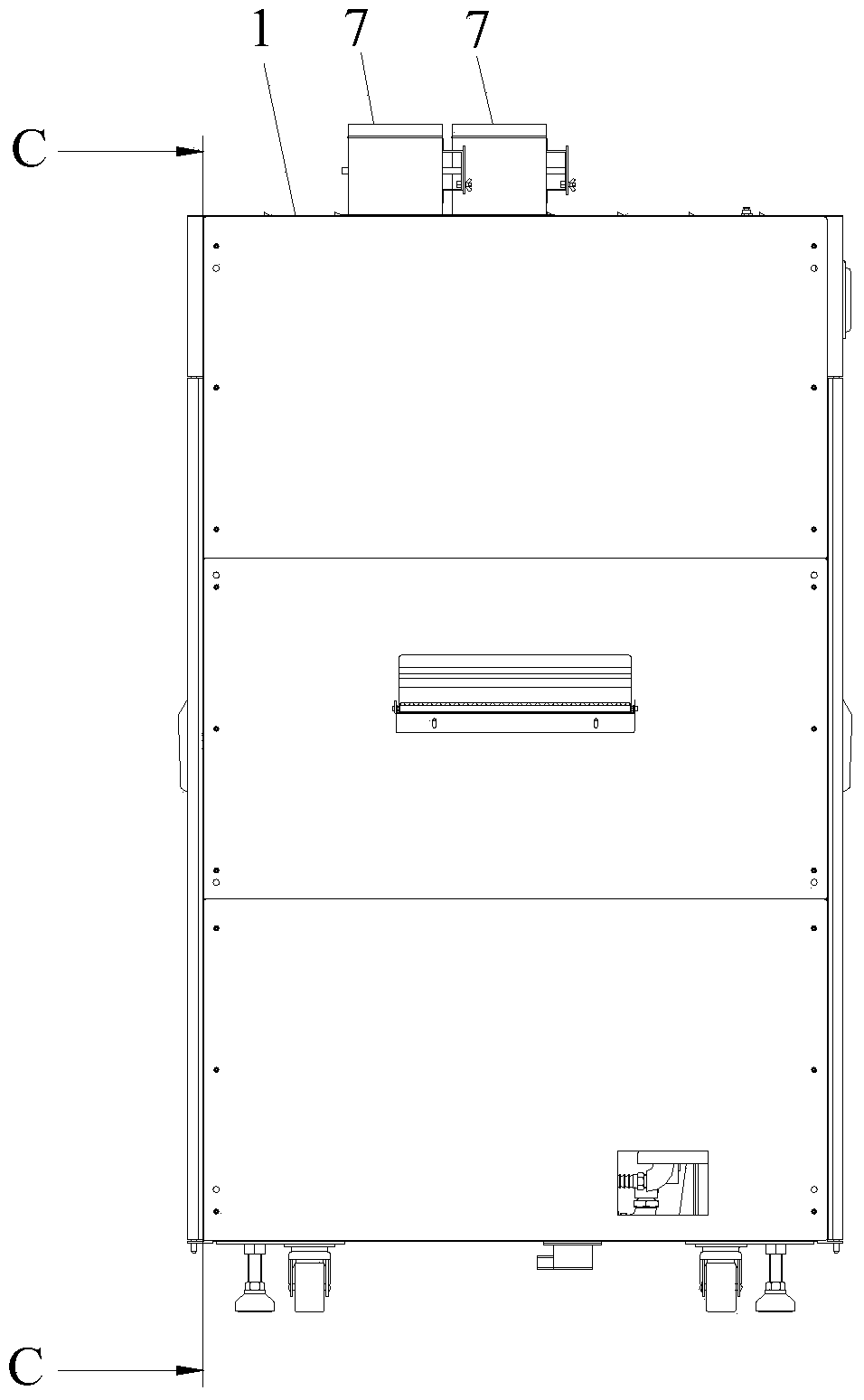

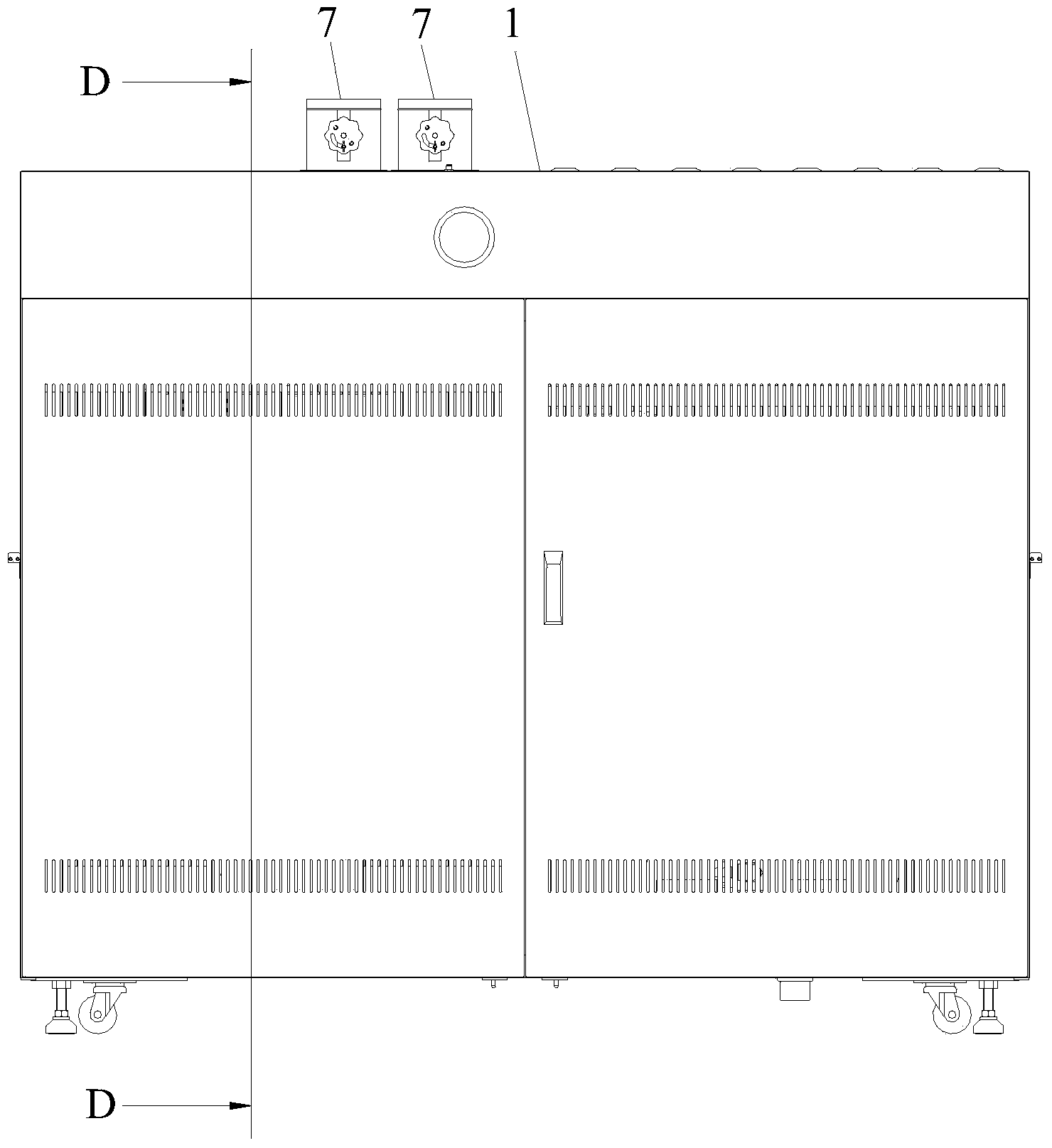

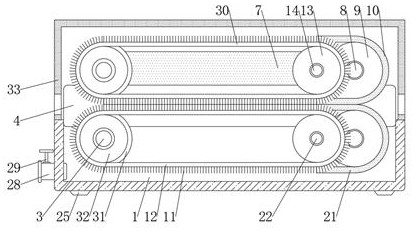

Automatic coating machine for shoe industry and automatic coating production line

ActiveCN103639095AAvoid occupational diseasesAvoid hidden dangersLiquid surface applicatorsShoemaking devicesShoe industryAir knife

The invention discloses an automatic coating machine for shoe industry. The automatic coating machine is characterized in that a shell is internally provided with a horizontal conveying path, an automatic coating part, a conveying part, a flow control part, an air knife part and a net washing part; the flow control part is used for controlling the supplying amount of a treating agent of the automatic coating part; the automatic coating part is positioned at the front part of the horizontal conveying path, is distributed at the upper side and the lower side of the horizontal conveying path and forms a coating area coincident with the horizontal conveying path; the conveying part is positioned at the lower side of the horizontal conveying path and is in butt joint with an access opening of the coating area; the flow control part is positioned at the upper side of the front part of the horizontal conveying path; the air knife part is positioned at the rear part of the horizontal conveying path and is distributed at the upper side and the lower side of the horizontal conveying path; the net washing part is positioned at the rear part of the horizontal conveying path and is distributed at the upper side and the lower side of the horizontal conveying path. The invention also provides an automatic coating production line. The automatic coating machine and the automatic coating production line have the advantages that the production efficiency can be improved and the labor cost can be reduced.

Owner:ZHISHENG SCI & TECH GUANGZHOU

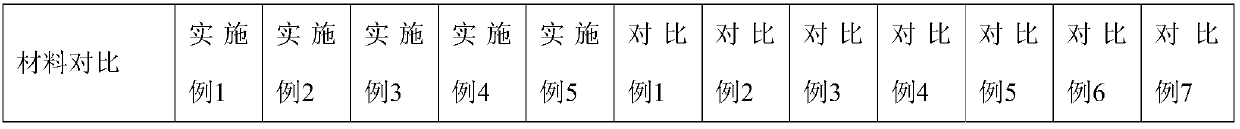

EVA treating agent and preparation method thereof

ActiveCN110938397AHigh bonding strengthStrong surface penetrationNon-macromolecular adhesive additivesEster polymer adhesivesShoe industry(Hydroxyethyl)methacrylate

Owner:ZHUHAI YUTIAN CHEM PROD

Cleaning device for shoe enterprise sole processing and using method thereof

The invention discloses a cleaning device for shoe enterprise sole processing and a using method of the cleaning device, and relates to the technical field of shoe industry production. The cleaning device comprises a water tank, two first bearings are clamped in each of the front side wall and the rear side wall of the water tank, and the same first rotating shaft is connected between the two opposite first bearings in a sleeving mode. According to the cleaning device for shoe enterprise sole processing and the using method thereof, a third conveying belt and a first conveying belt are matchedto drive a sole to move leftwards, so that the sole enters the space between brushes on the upper side and the lower side, a fifth rotating shaft on the right side is driven by a motor to rotate, anda fourth roller on the right side can be driven by the fifth rotating shaft to rotate; the fourth roller on the right side can drive the second conveying belt and a brush on the outer surface of thesecond conveying belt to rotate through cooperation with the fourth roller on the left side and a third bearing, so that cleaning is conducted through the bottom of the brush shoe sole, the working efficiency can be improved, the labor and time of workers are saved, and meanwhile pattern dead corners at the bottom of the shoe sole can be effectively cleaned. And therefore, the problem of impurityomission can be solved.

Owner:湖南嘉泰鞋业有限公司

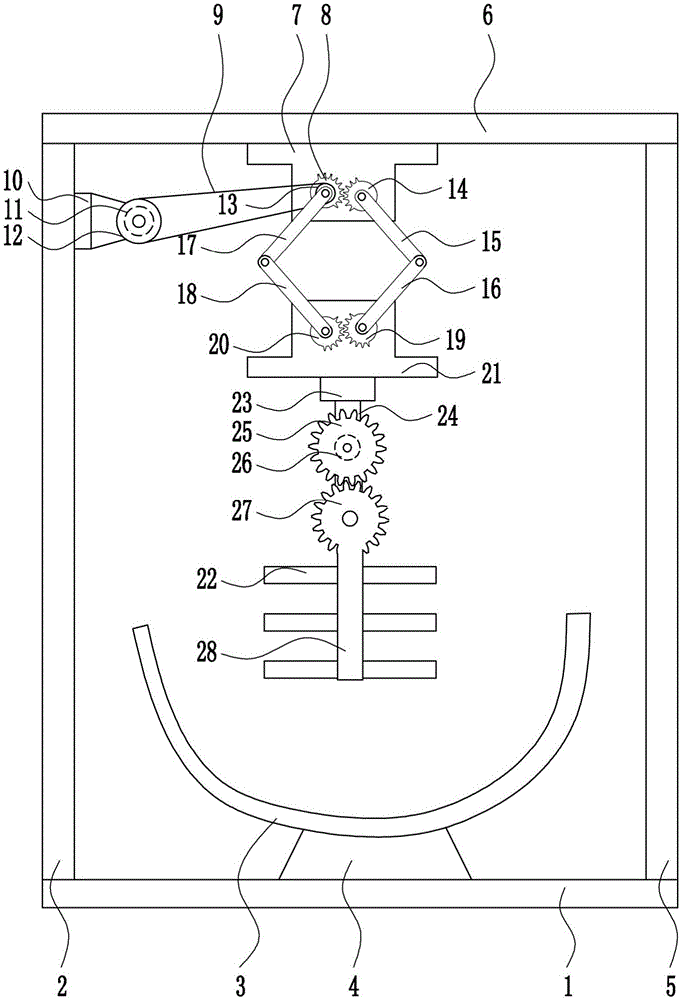

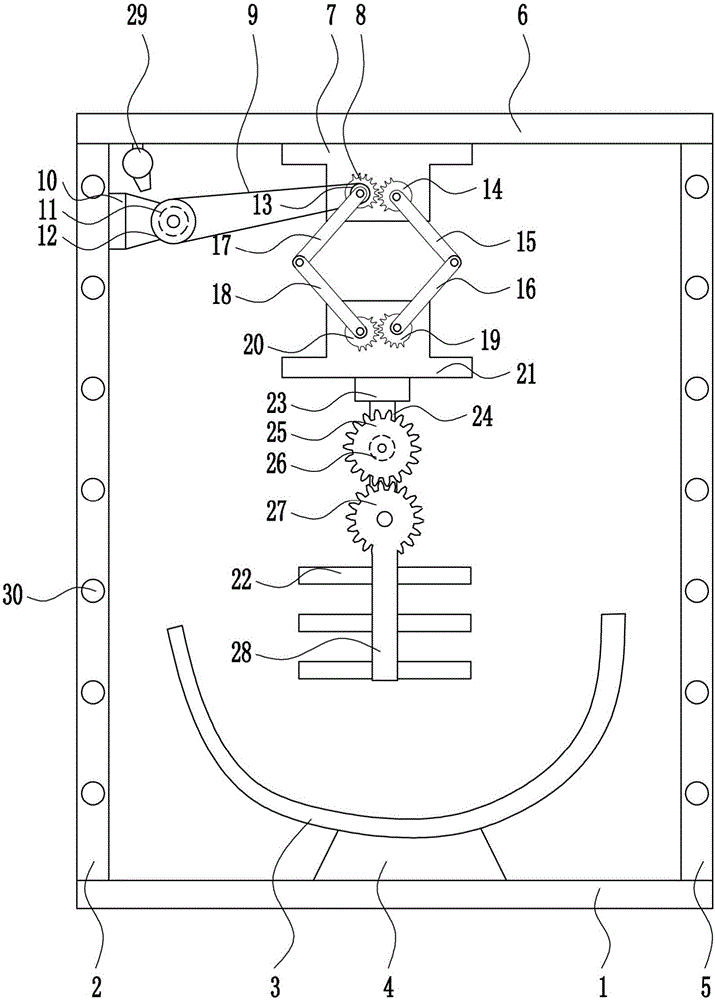

Outsole material gear-type mixing and stirring device for shoe industry

The invention relates to an outsole material mixing and stirring device for the shoe industry, especially to an outsole material gear-type mixing and stirring device for the shoe industry. The invention aims to provide the outsole material gear-type mixing and stirring device for shoe industry with excellent stirring effect, simple structure and high work efficiency. The outsole material gear-type mixing and stirring device for shoe industry comprises a base plate, a left rack, a right rack, a top board, a first pole, a slide rail, a slide block, a stirring tank, a first motor, a disc-shaped cam, a first cylinder, an expansion bracket, a fixed plate, a guide plate, an oscillating rod, a movable lever, a third motor, a stirring bar, stirring vanes, a first spring and a baffle plate, etc. The device of the invention achieves an excellent stirring effect, has a simple structure and has high work efficiency. The device has a novel structure, has strong practicality, can be used for rapidly mixing outsole materials, is simple and convenient to operate, and is small in size.

Owner:江苏中商碳素研究院有限公司

Biodegradable adhesive and preparation method thereof

ActiveCN112226191ASimple manufacturing methodHigh synthesis efficiencyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterShoe industry

The invention discloses a biodegradable adhesive and a preparation method thereof. The biodegradable adhesive comprises the following components in parts by weight: 1-95 parts of polylactic acid copolymer polyol, 5-95 parts of polyester polyol, 0.2-2 parts of a hydrolysis stabilizer, 1-45 parts of an inorganic filler, 0.5-2 parts of a thixotropic agent and 0-8 parts of a curing agent. The biodegradable adhesive prepared by the invention has good biodegradability and controllable relative molecular weight and viscosity, and can be used in the fields of surface adhesion of adhesive tapes, stationery, shoes industry, automotive upholstery, packing materials and other building or decorative materials and the like.

Owner:江苏美境新材料有限公司

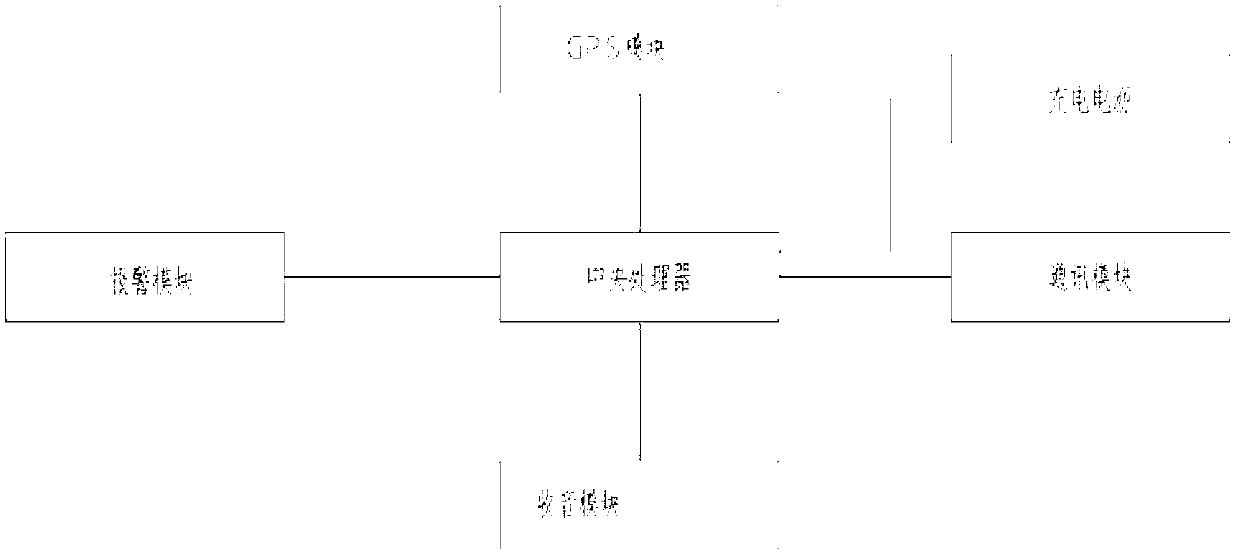

Multi-functional intelligent shoes

The invention relates to shoes, in particular to a pair of multi-functional intelligent shoes. Each multi-functional intelligent shoe comprises a shoe body and a microcomputer module, wherein the microcomputer module is embedded in the shoe body. By embedding the microcomputer module in the shoe body, the shoe possesses the functions of location, sound reception, alarming, calling and the like, the ordinary shoe is enabled to be informational and intelligent, people demands are satisfied perfectly, and social value of a shoe industry is realized.

Owner:WENLING TAIPING SENIOR VOCATIONAL SCHOOL

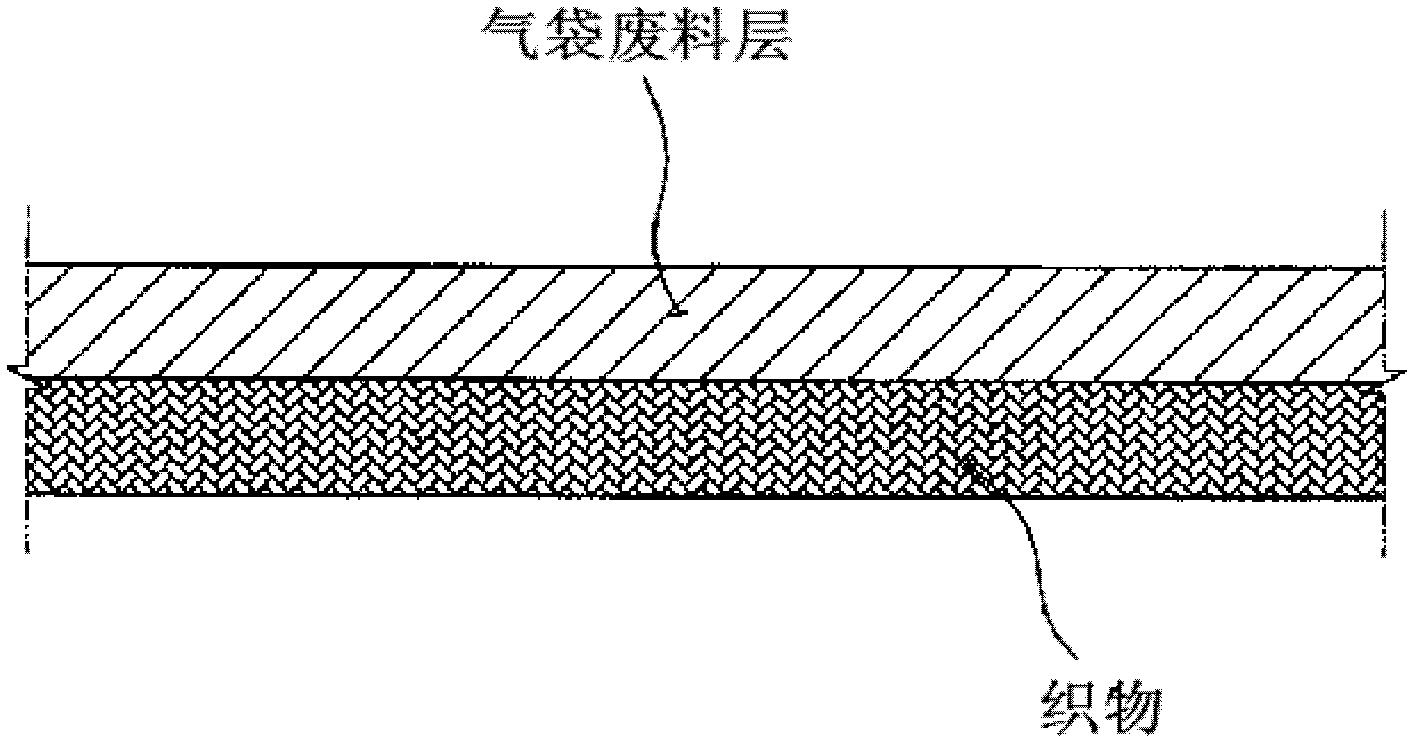

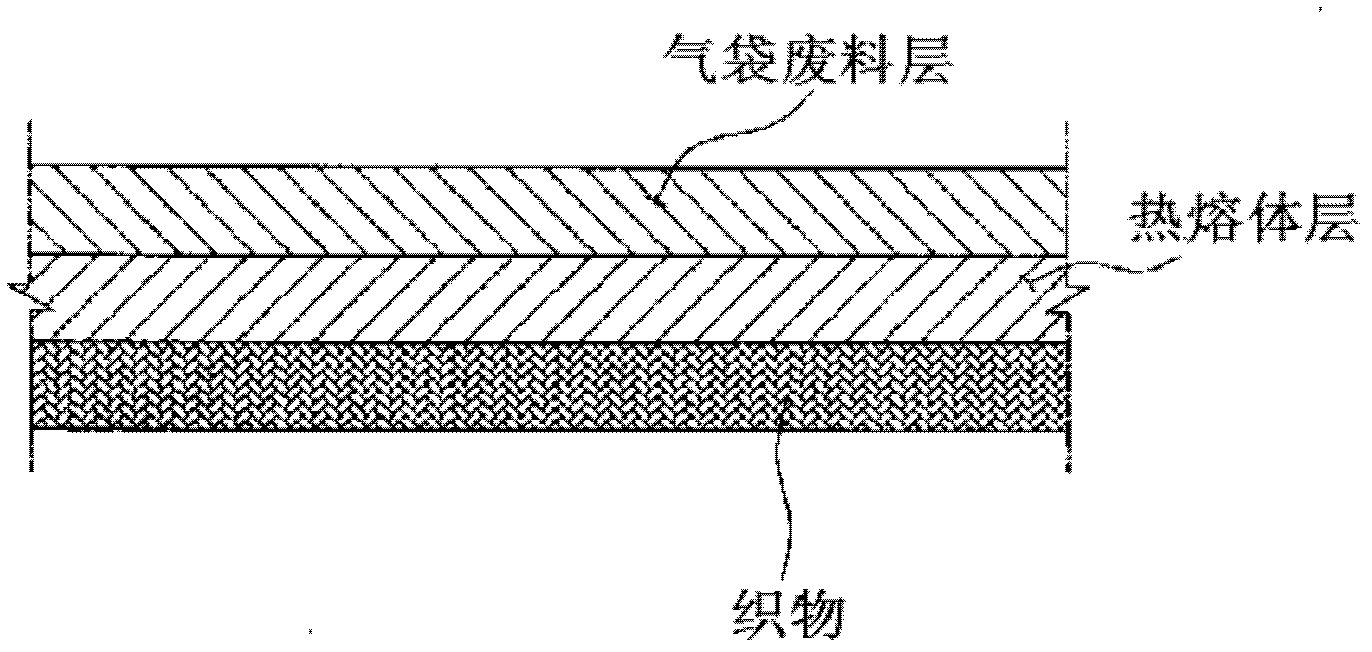

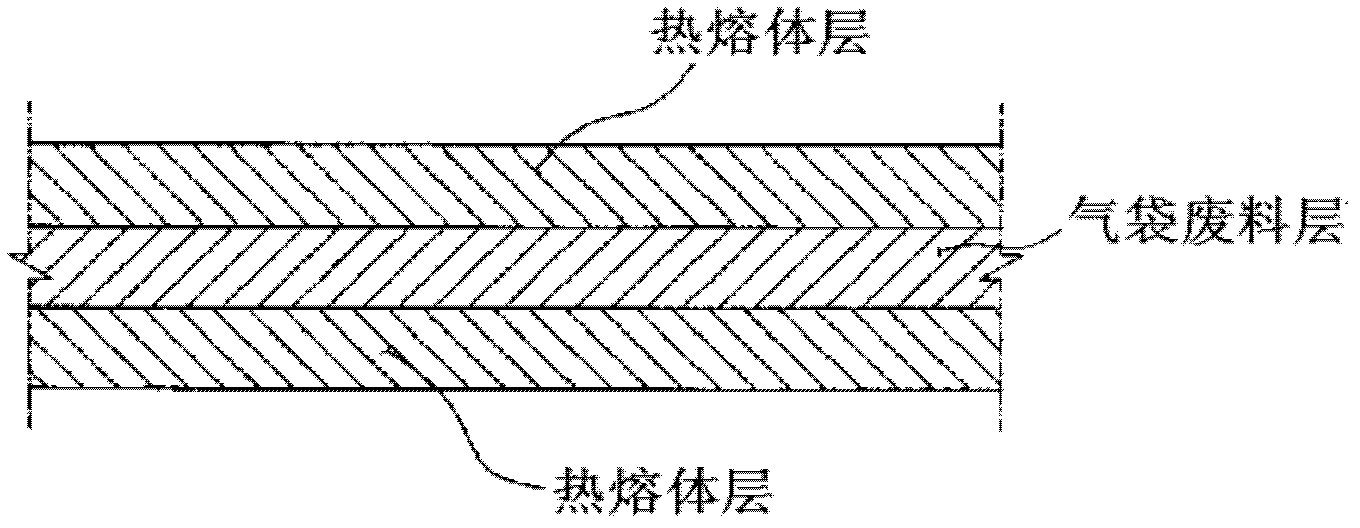

Production method for a hot-melt film recycling air-bag scraps for shoes, and a hot-melt film produced using the method

Provided is a method wherein TPU film scraps, which are generated in large volume in the shoe industry during the production of airbags used as materials for impact cushioning, are collected and are used by being reprocessed to create a hot-melt film by being mixed with other components so as to have the target properties possessed by hot-melt films; particularly with the aim of realising a method for producing a hot-melt film having a multi-layer structure by means of a co-extrusion method.

Owner:朴喜大

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com