Automatic shoe tongue looping machine

A shoe tongue loop machine, automatic technology, applied in the direction of cloth feeding mechanism, cloth pressing mechanism, sewing machine components, etc., can solve the problems of difficulty in completely ensuring the quality of webbing sewing, high cost, and complicated mechanism, etc., to meet the requirements of transmission The effect of process requirements, manufacturing cost reduction, and structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

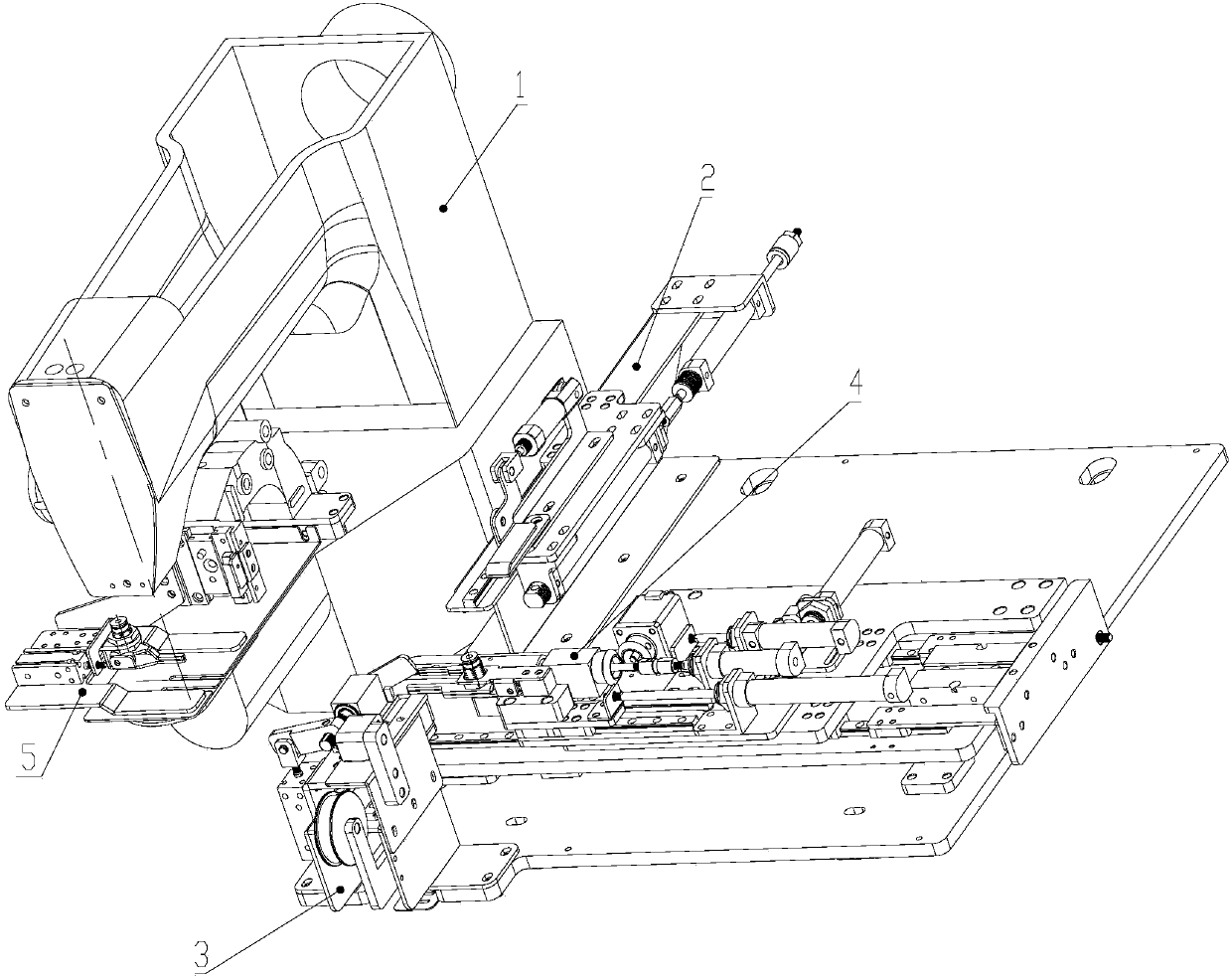

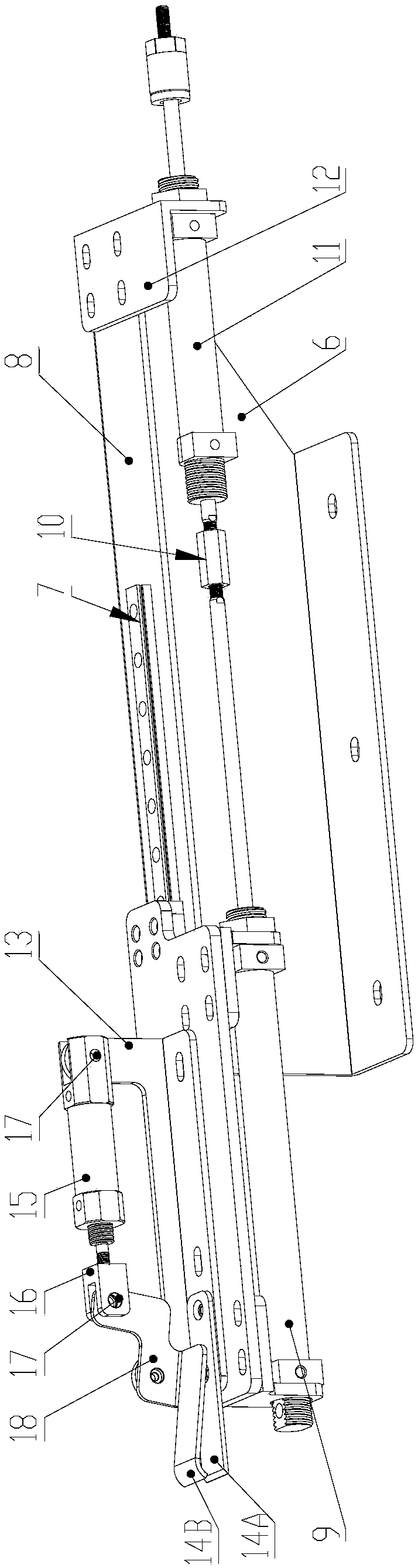

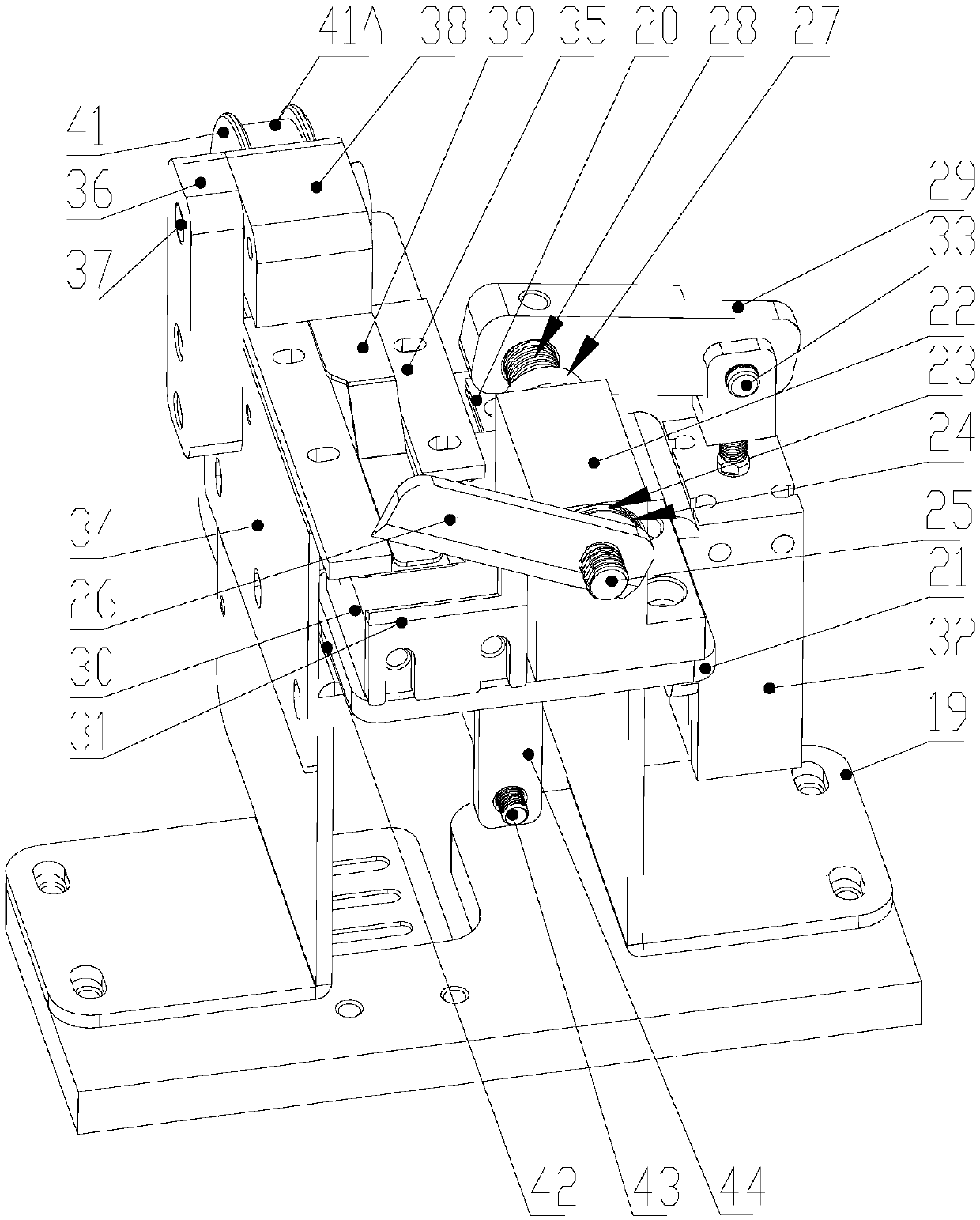

[0023] as attached figure 1 As shown, the present invention includes a tacking machine head 1, a drawstring mechanism 2 is provided at the right rear portion of the head 1, and a tape cutting mechanism is arranged at the right front portion of the head 1, and the tape cutting mechanism is arranged at the bottom of the drawstring mechanism 2. Right in front, on the right side of the X-axis of the needle bar of the machine head 1, there is a double-clip conveyor belt mechanism 4, and the sewing area of the machine head 1 is equipped with an inner and outer pressing sewing mechanism 5, which is set on the machine head 1. The left and right sides of the feeding bracket 1A, where the pull belt mechanism 2 is provided with a linkage structure of the first push cylinder 9 and the second adjustable cylinder 11, the second adjustable cylinder 11 can adjust the cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com