Patents

Literature

409results about How to "Guarantee quality requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

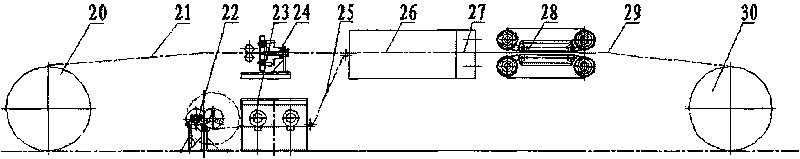

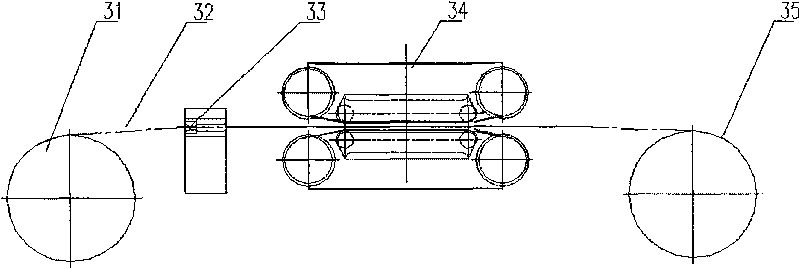

Technology for mechanical and clean processing of black tea in different shapes

InactiveCN1792200ARich shapeIncrease color varietiesPre-extraction tea treatmentBlack teaEngineering

A technology for mechanically preparing to black tea with different shapes including needle shape, spiral shape, flat shape and particles is disclosed.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

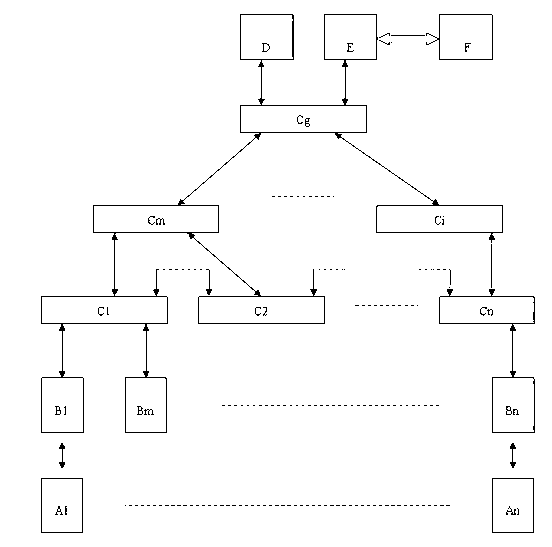

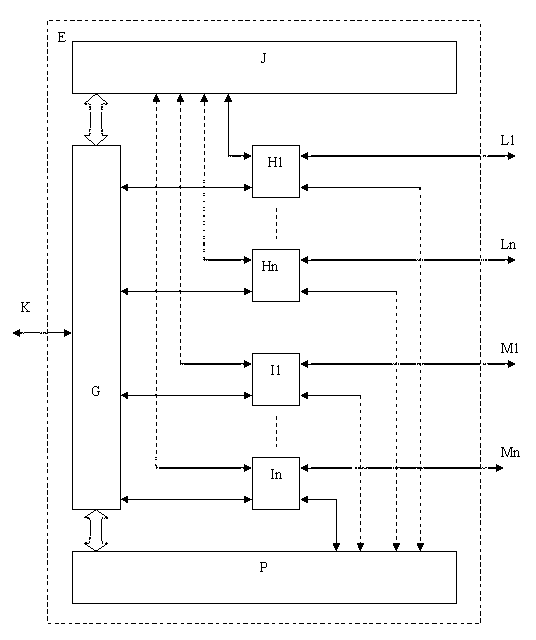

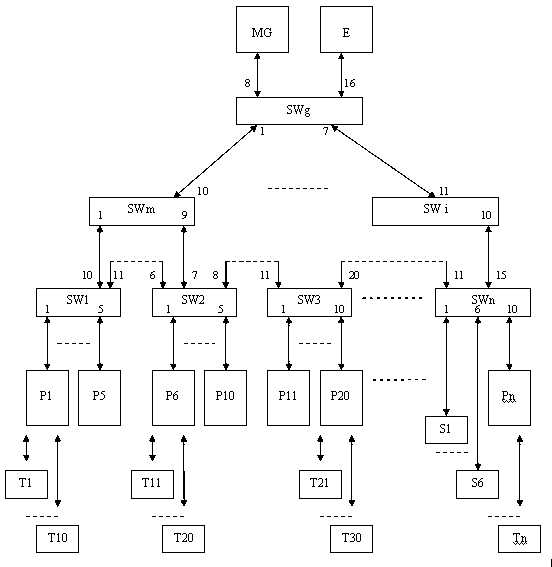

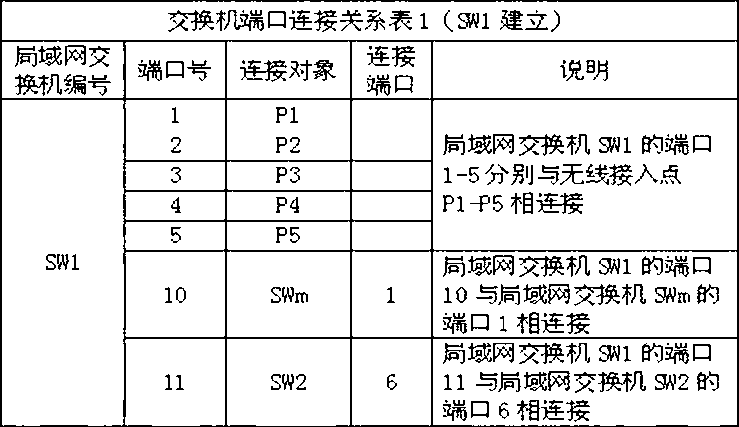

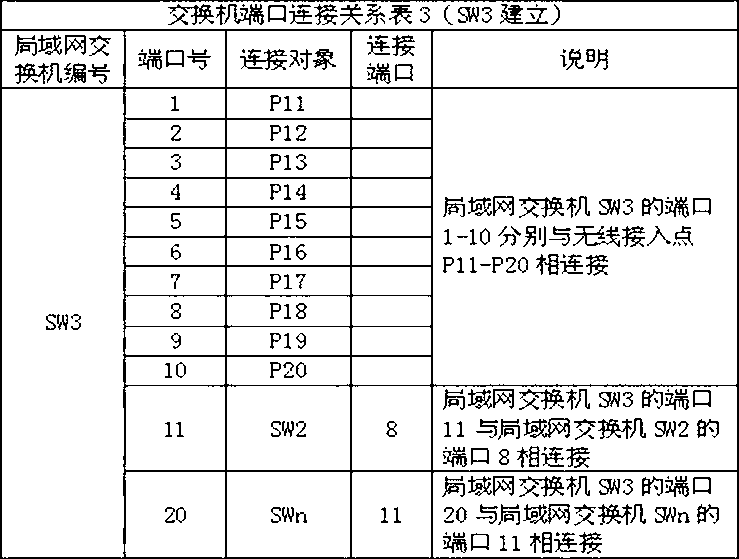

Talkback and video data transmitting method based on wireless local area network, and talkback commutator

ActiveCN102710995AEnsure real-time requirementsGuarantee quality requirementsPulse modulation television signal transmissionNetwork topologiesData transmissionLocal area network

The invention discloses a talkback and video data transmitting method based on a wireless local area network, and a talkback commutator, which are realized by adopting a plurality of wireless local area network user terminals, a plurality of wireless local area network wireless access stations, a wireless local area network switch and a talkback and video management server, can provide the characteristics of high connection speed, strong instantaneity, high voice quality, and absolute forced prior communication in priority level for talkback and video data transmission of the wireless local area network user terminals under the condition of keeping the prior functions of data access and transmission of the wireless local area network on the basis of an equipment network and external line transmission system provided by the existing wireless local area network equipment, and have functions of general calling, group calling and notification. Meanwhile, during needing, the communication connection between the wireless local area network user terminals and public telephone communication network users can be realized, so that demands on talkback and video data transmission of the wireless local area network user terminals are met.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER COMPANY DONGYANG POWER SUPPLY

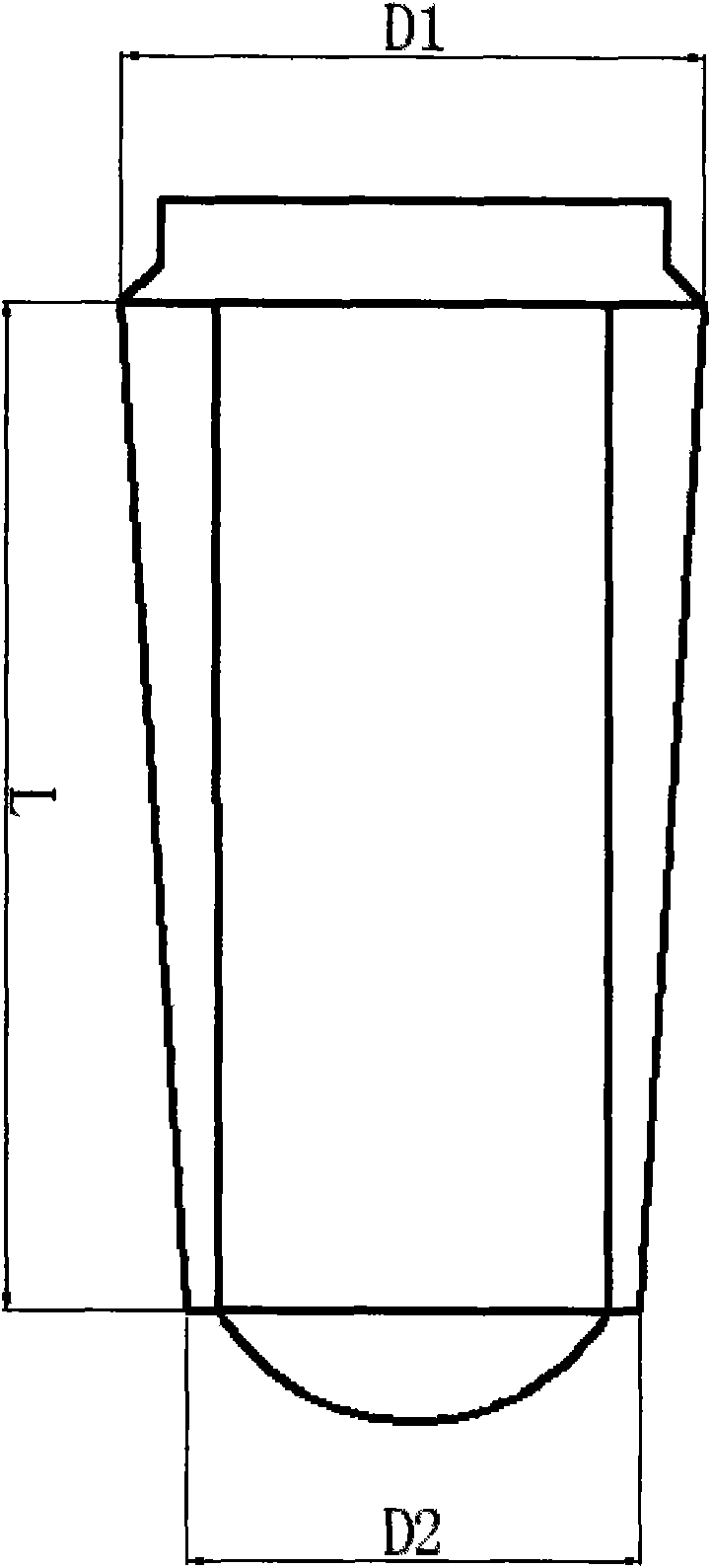

Forging method of AP1000 nuclear-power main pipeline forging piece

InactiveCN101954439AGuaranteed size requirementsGuarantee quality requirementsMetal-working apparatusEngine componentsNuclear powerMaterials science

The invention relates to a forging method of an AP1000 nuclear-power main pipeline forging piece, belonging to the technical field of forging. The forging method comprises the following steps of: firstly, forging an irregularly-shaped part of the forging piece; and then, integrally forging. The invention not only ensures the dimensional requirement of the irregularly-shaped part of the forging piece, but also ensures the quality requirement of the integral forging piece, can lower forging heating frequency, increases the utilization rate of raw materials and the qualified rate of the forging piece at the same time, achieves the expectation effect before forging and successfully solves the problem on forging the AP1000 nuclear-power main pipeline.

Owner:吉林昊宇电气股份有限公司

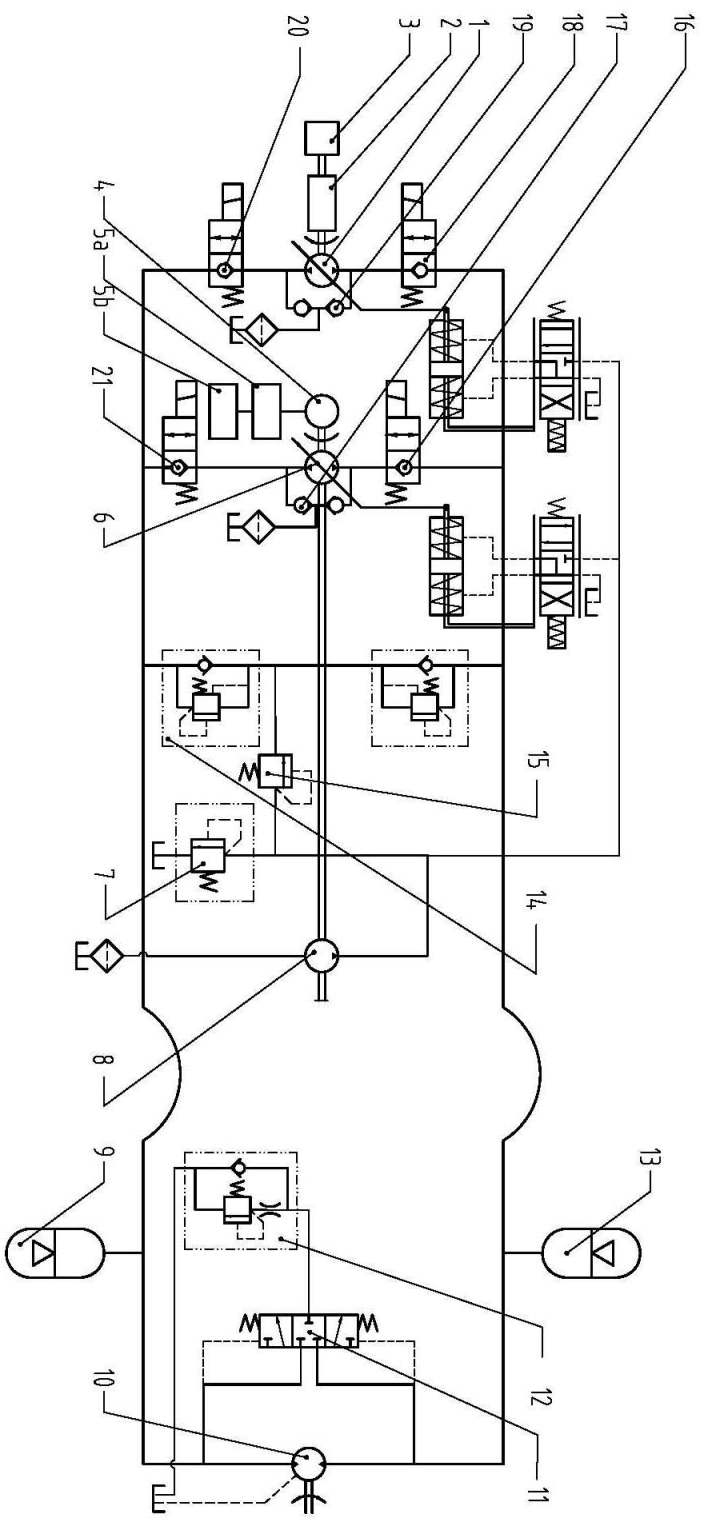

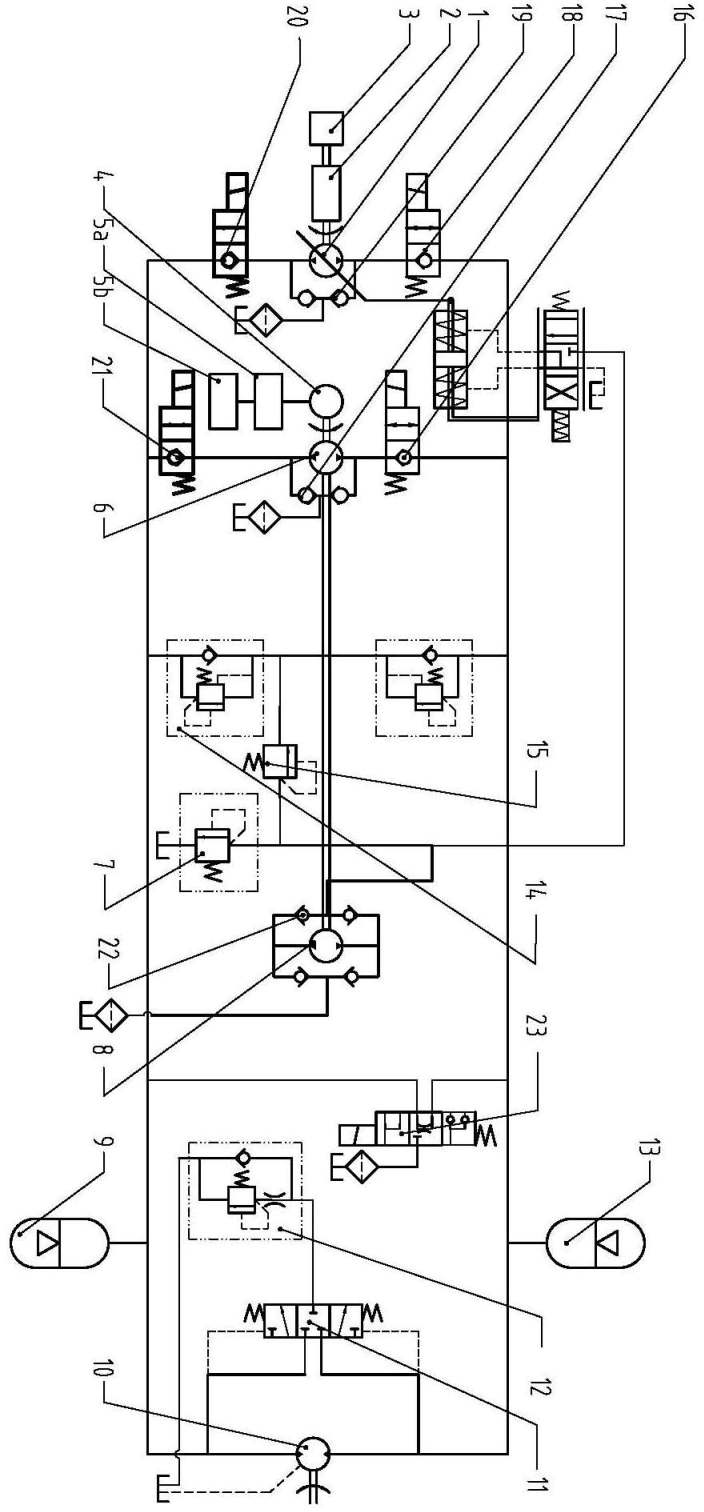

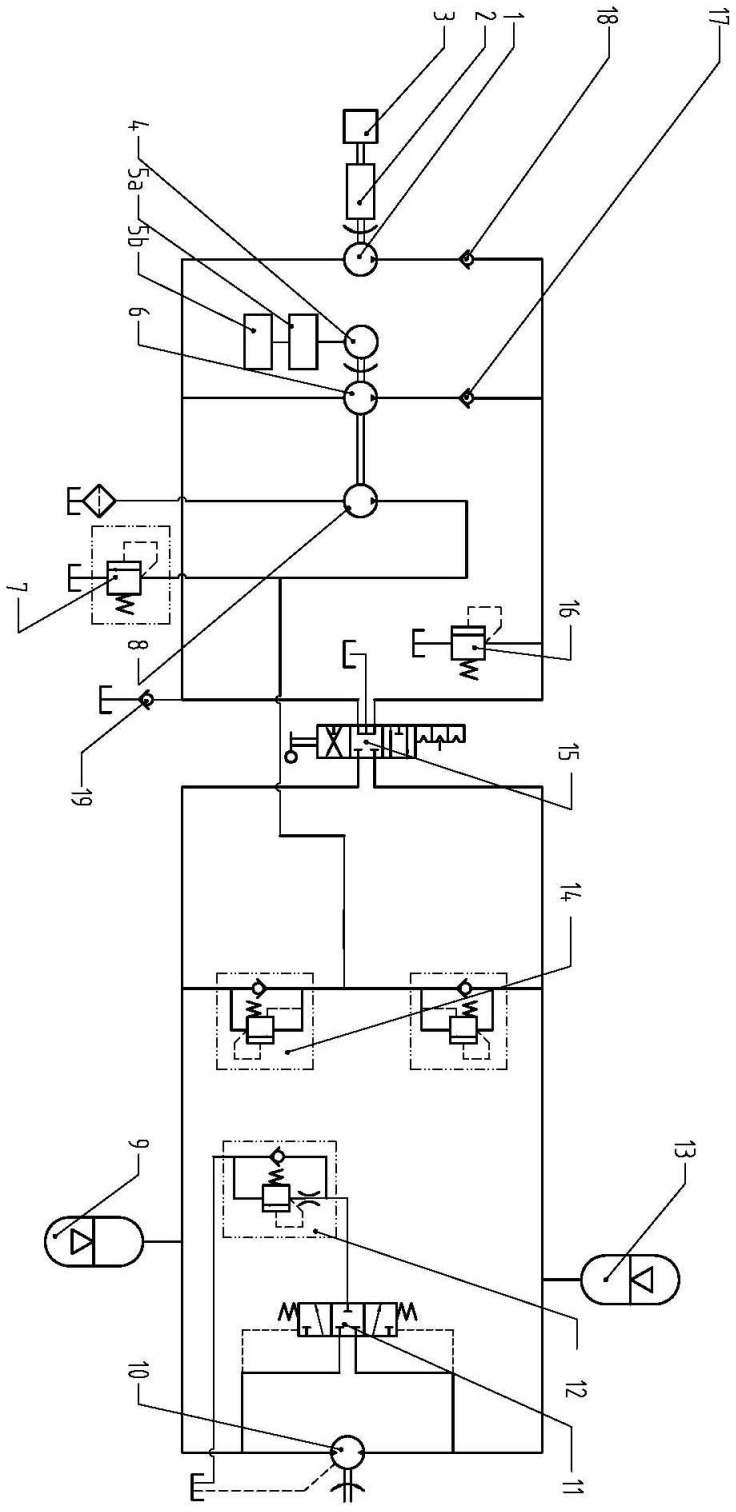

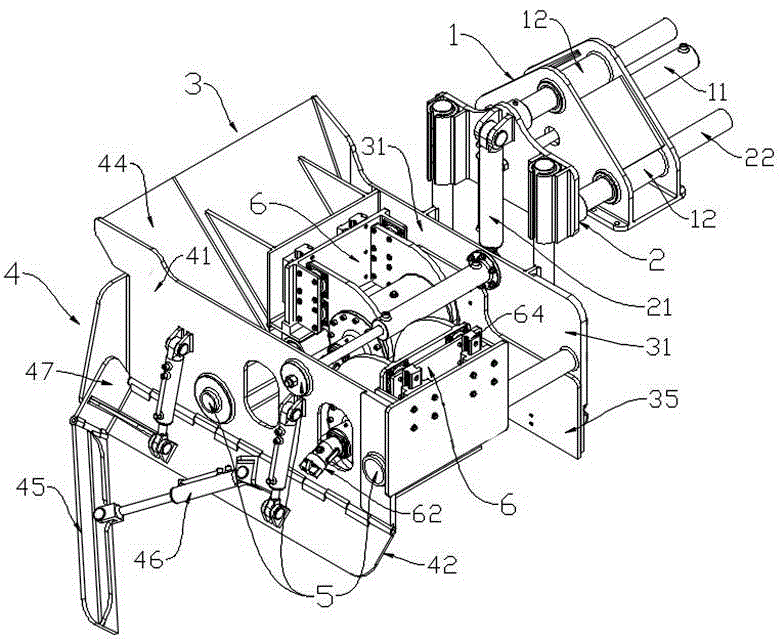

A new type of rotating drive system for mixing drum of concrete mixer truck

InactiveCN102275223AReduced power ratingImprove work efficiencyCement mixing apparatusPrime moverHydraulic motor

The invention relates to a novel rotation driving system for a mixing drum of a concrete mixing transport vehicle. In the system, two prime movers, two hydraulic main pumps, an oil supply pump and a hydraulic motor form a hydraulic closed loop together with a hydraulic valve block with the functions of relatively completing oil supply, cooling and safe buffering; the delivery volumes of the two hydraulic main pumps are different; and the low-delivery volume hydraulic main pump is used for separately realizing slow and constant mixing action of the mixing drum, and the high-delivery volume hydraulic main pump is used for rotating the mixing drum along positive and negative directions at a high speed during feeding and discharging when separately operated or combined with the low-delivery volume hydraulic main pump. The system aims to solve the problems of the influence on the concrete uniformity and the influence on the driving dynamic performance and driving safety performance which are caused by driving a roller to rotate by separately using a chassis engine under different working conditions and different road conditions in the mixing drum, fuel waste caused by the long-term operation of the high-power chassis engine at low-efficiency points and the hydraulic shock generated during the switching of the mixing drum under different working conditions.

Owner:SICHUAN UNIV

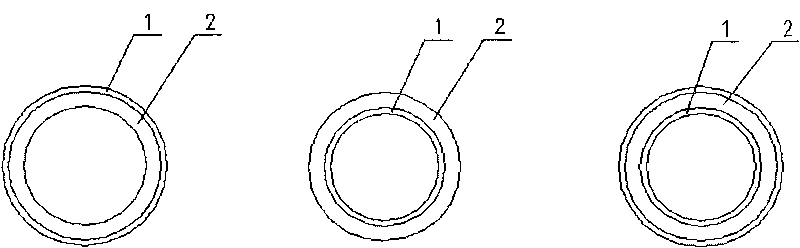

Method for manufacturing copper-aluminum composite tube

InactiveCN101737565AEffective combinationCombined with effective maintenanceRigid pipesSurface cleaningAluminum composites

The invention relates to a method for manufacturing a copper-aluminum composite tube, and belongs to the technical field of manufacturing a metal composite tube. The method is characterized by comprising the following steps: A, preparing an inner tube and a covering belt, B. performing surface cleaning on the inner tube and the covering belt, C. covering the covering belt after surface cleaning on the surface of the inner tube after surface cleaning, performing vertical covering welding to manufacture a copper-aluminum composite tube blank, D. performing linear drawing on the copper-aluminum composite tube blank without strain furling, E. final annealing, and F. winding and furling to manufacture a finished product and other processing steps. The method can be used for manufacturing a copper-clad aluminum tube, an aluminum-clad copper tube and the copper-aluminum composite tube of which an inner layer and an outer layer are copper and the middle part is aluminum; and firm metallurgical bonding can be achieved between the copper and the aluminum.

Owner:JIANGSU XINGRONG HI TECH

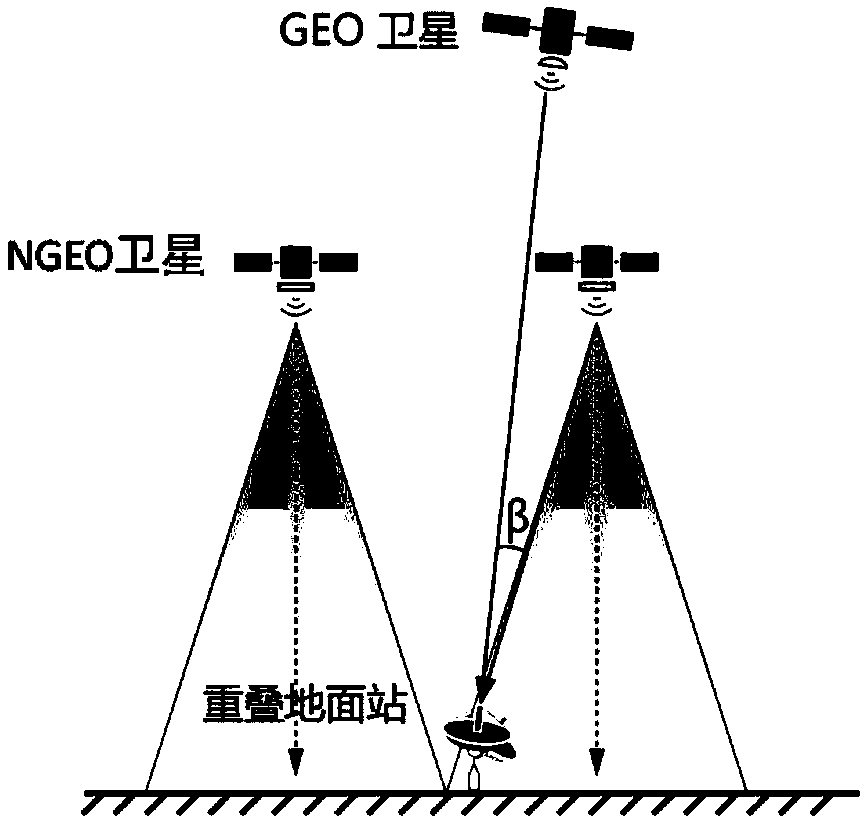

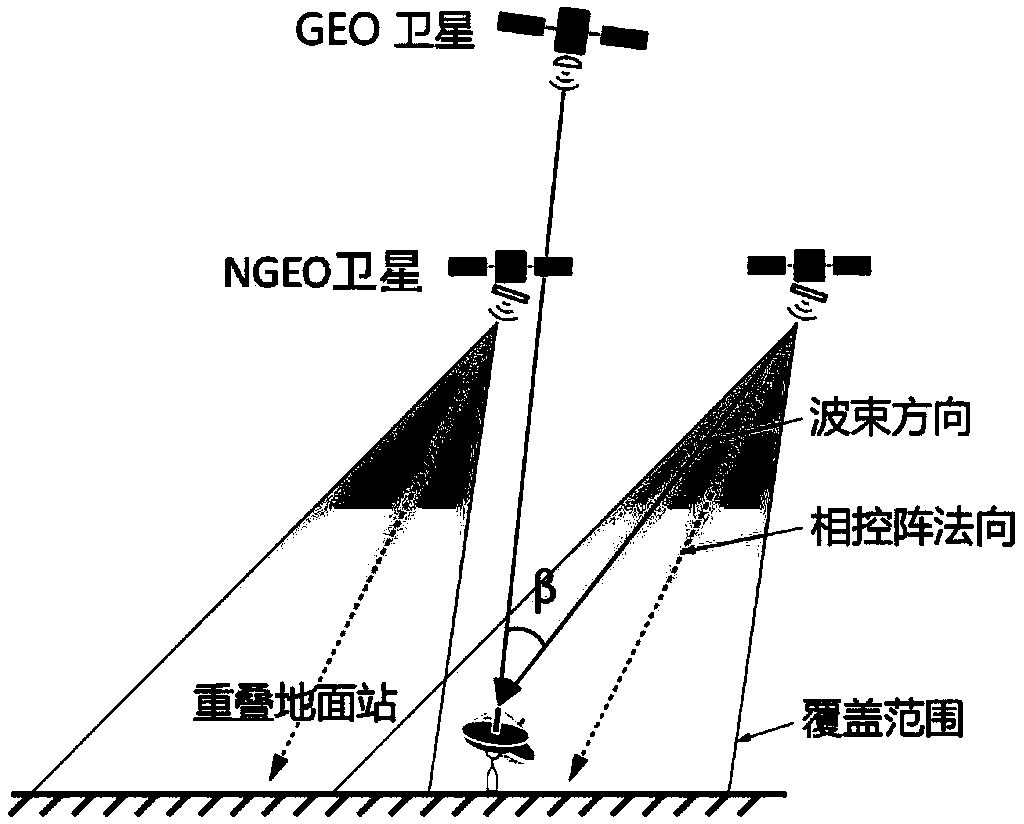

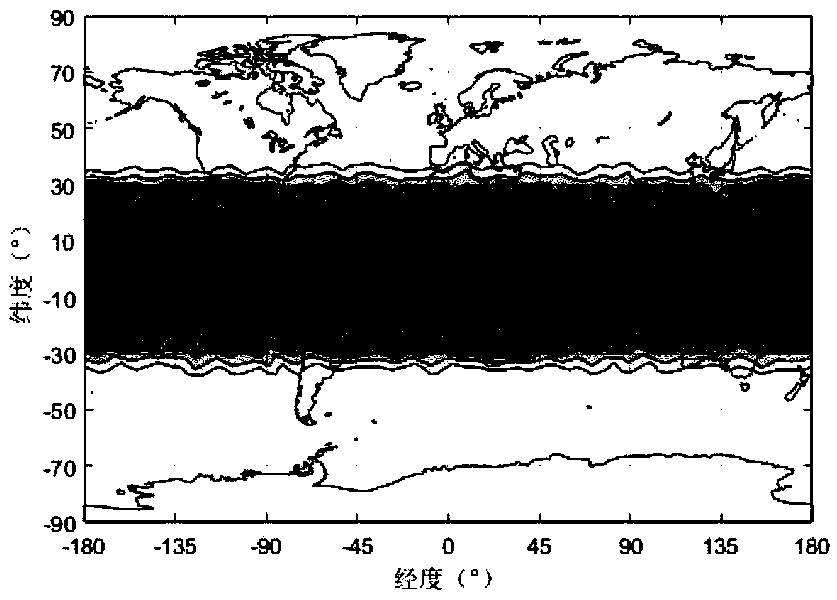

Method for evading co-channel interference through deflection antenna pointing and satellite communication system

ActiveCN108712202AIncreased average coverageAvoid co-channel interferenceRadio transmissionTelecommunications linkCommunications system

The invention relates to a method for evading co-channel interference through deflection antenna pointing and a satellite communication system. The method comprises the following steps: arranging morethan one space-borne antenna on an NGEO communication satellite; determining a constellation configuration of the NGEO satellite communication system, and ground user type and distribution, and selecting variables to describe the normal orientation of the space-borne antenna of the NGEO satellite communication system; according to an interference protection regulation for the GEO satellite systemof ITU, selecting a group of indexes alpha for balancing the interference degree of the satellite communication system to the GEO satellite system; determining a group of indexes beta for balancing link quality of the satellite communication system; establishing a nonlinear optimization model of the normal orientation of the phased array antenna according to the indexes alpha and the indexes beta; and solving optimal variables through iterations and outputting a set of optimal phased array antenna deflection pointing setting scheme. The method for evading co-channel interference through deflection antenna pointing and the satellite communication system in the present invention ensure own communication link quality and reliability requirements, so that the satellite system can coexist effectively with the GEO satellite system at the same frequency.

Owner:TSINGHUA UNIV

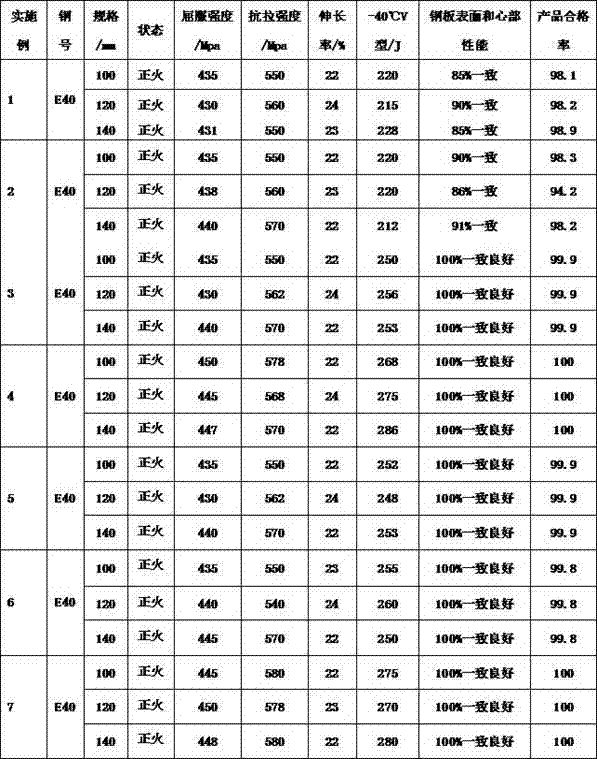

E40 high-strength ship plate steel and method for manufacturing same

The invention discloses E40 high-strength ship plate steel. The E40 high-strength ship plate steel comprises, by mass, from 0.13% to 0.16% of C, from 0.2% to 0.4% of Si, from 1.5% to 1.6% of Mn, lower than or equal to 0.03% of P, lower than or equal to 0.005% of S, from 0.30% to 0.35% of Ni, from 0.055% to 0.065% of V, from 0.035% to 0.045% of Nb, from 0.010% to 0.020% of Ti, from 0.015% to 0.035% of Als and the balance Fe. A method for manufacturing the E40 high-strength ship plate steel includes a pretreatment process for melted iron, a smelting process implemented by the aid of a converter, an argon blowing treatment process, an LF (ladle furnace) refining process, a VD (vacuum degasser) refining process, a continuous casting process, a heating process, a controlled rolling and controlled cooling process, a stack cooling process and a heat treatment process. The E40 high-strength ship plate steel and the method have the advantages that the E40 high-strength steel is successfully developed, the yield strength of the E40 high-strength ship plate steel ranges from 430MPa to 450MPa, the tensile strength of the E40 high-strength ship plate steel ranges from 550MPa to 580MPa, the elongation of the E40 high-strength ship plate steel ranges from 22% to 24%, V-type impact power of the E40 high-strength ship plate steel ranges from 210J to 280J at the temperature of minus 40 DEG C, and performance indexes of a steel plate made of the E40 high-strength ship plate steel completely meet standards and requirements of clients.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Technique for dyeing and finishing flax and Lyocell fiber mixed fabrics

ActiveCN101298740AAvoid damageDamage Strength DecreasedBiochemical fibre treatmentBleaching apparatusTextile technologyCarboxylic acid

The invention relates to a dyeing and finishing process used for a fabric blended by flax and Lyocell fiber, belonging to the textile technique field and aiming at providing an improved blended fabric dyeing and finishing process. The technical proposal of the process is that: after singeing and before desizing-boiling-off, bio-enzymes agent is adopted for cold-dome treatment; low-alkali boiling-off and a hydrogen peroxide bleaching one-step method are adopted; before dyeing, a polybasic carboxylic acid cross-linker EH is adopted to carry out an anti-fibrillation treatment to the Lyocell fiber; after dyeing, a cellulose is adopted to carry out flexibility treatment to the flax fiber; nano-finishing agent is adopted to carry out a four-proofing finishing. The dyeing process not only can preserve the original characteristics of flax fabric but also has better four-proofing capability, low-loss of strength, high dyefastness and functions of ventilation and proper process. After detection, various chemical indexes of the product can meet the requirement of Oeko-Tex100 and the process has the advantages that the operation is easy and process can be easily controlled, etc.

Owner:安徽中天新材料科技股份有限公司

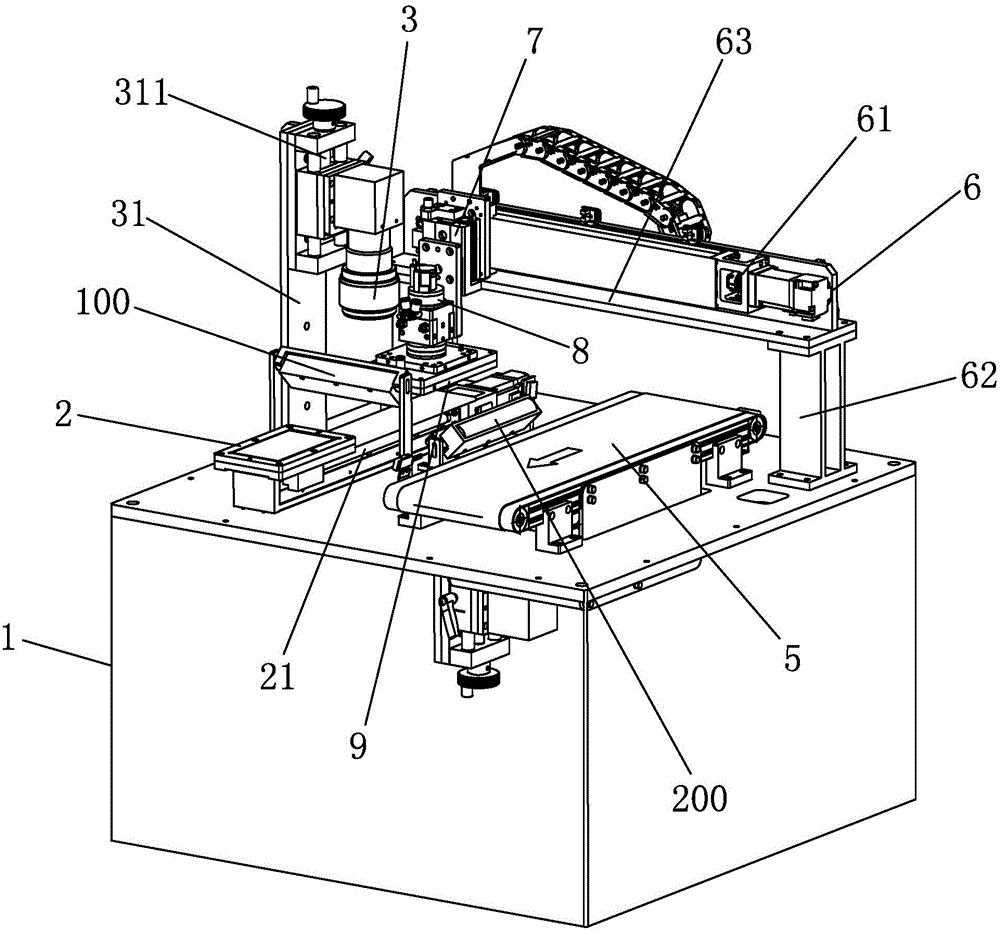

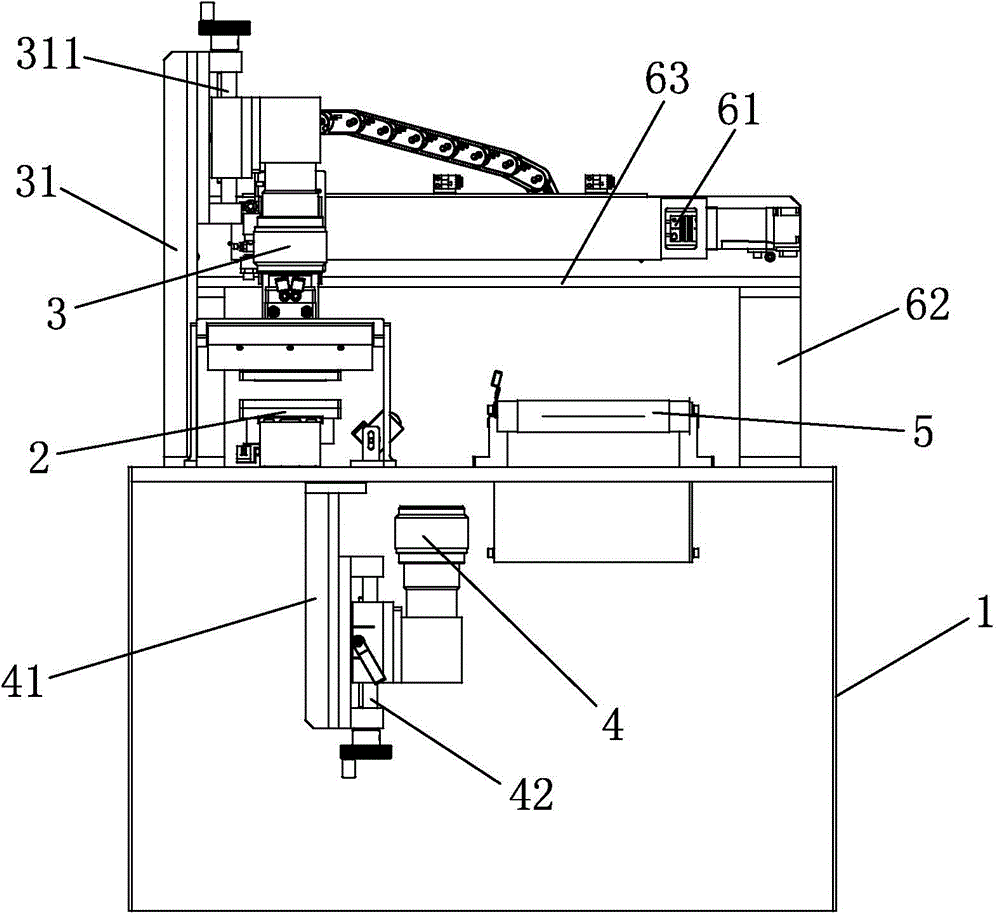

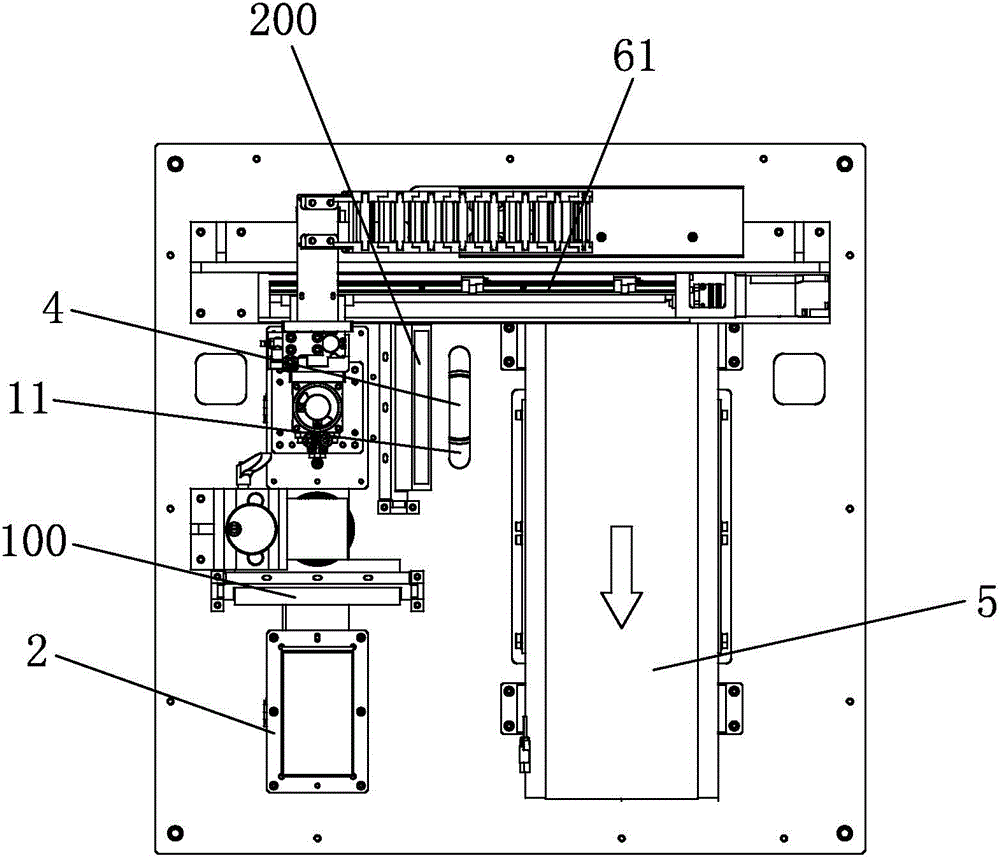

Detection device for detecting front and back surfaces of liquid crystal panel

ActiveCN104101606ADetection will notEfficient detectionOptically investigating flaws/contaminationLiquid-crystal displayEngineering

The invention discloses a detection device for detecting the front and back surfaces of a liquid crystal panel. The detection device comprises an operating platform body, a bearing pallet, a first line array camera, a loading and moving device and a second line array camera, and further comprises a first lighting unit and a second lighting unit, wherein the loading and moving device comprises a bracket unit and a vacuum adsorption board used for loading the liquid crystal panel to be detected; the vacuum adsorption board is movably arranged on the bracket unit. The detection device has the advantages that appearance detection of the front and back surfaces of the liquid crystal panel can be realized automatically in one step; suitability for liquid crystal panels of various dimensions is realized; manual appearance detection working stations are completely eliminated during liquid crystal panel detection; various appearance defects such as notches, breakup, burrs, fracture and metal corrosion on the appearance of the liquid crystal panel can be detected effectively and fast.

Owner:SUZHOU HUAXING YUANCHUANG TECH CO LTD

Sampling method for testing quality of tube plate forged piece of reactor vapor generator

ActiveCN103389225AComply with process evaluation requirementsGuarantee quality requirementsWithdrawing sample devicesChemical compositionManufacturing technology

The invention provides a sampling method for testing the quality of a tube plate forged piece of a reactor vapor generator. The sampling method comprises the following steps of: firstly, equally dissecting the tube plate forged piece, taking one or multiple dissection pieces as test pieces, carrying out sulphur print inspection, hardness measurement and chemical component analysis on the dissection surfaces of the test pieces before carrying out layering cutting on the test pieces, and then intercepting the test pieces in a layering manner along cross sections perpendicular to the thickness directions of the test pieces for sampling. The sampling method provided by the invention has the advantages that the overall quality of the tube plate forged piece of the reactor vapor generator can be completely inspected, and the complete evaluation on a manufacturing technology of the tube plate forged piece can be carried out, so that the procedure qualification requirements of nuclear power standards RCC-M are satisfied; during mass production, the quality is ensured, the progress requirements are satisfied, and further, the sampling cost is reduced.

Owner:SUZHOU NUCLEAR POWER RES INST +1

Biochemical feed and preparation method thereof

InactiveCN101983578AGuarantee quality requirementsFood processingAnimal feeding stuffGenus LoliumWater Hyacinths

The invention relates to a biochemical feed and a preparation method thereof. The raw materials of the biochemical feed adopts the residues of crops such as straws, cornstalks, wheat straws and various soybean stalks and soybean pods, and the seeds, fruits, roots, stalks, leaves, flowers and husks of the following raw material crops: one or more of cassava, ryegrass, Rumex, comfrey and grassiness which are wild grass capable of being processed and chopped and forage grass capable of being planted; vine plants, namely the vines and leaves of potato, the vines and leaves of sweet potato and the leaves and stalks of Canna Edulis Ker; all kinds of green grass; aquatic plants, namely water hyacinth, mizuna and duckweed; all kinds of melons and fruits; and the processing wastes of agricultural and sideline products such as distiller grain, soybean residues, oil cake, rice brans and wheat brans. The preparation method of the biochemical feed comprises the following steps: performing physical machining to the raw materials, mixing and fermenting to obtain the biochemical feed. Animals fed by the biochemical feed of the invention hardly get ill and suffer from parasitic diseases, and the quality requirements of pollution-free products can be ensured.

Owner:杨绍林

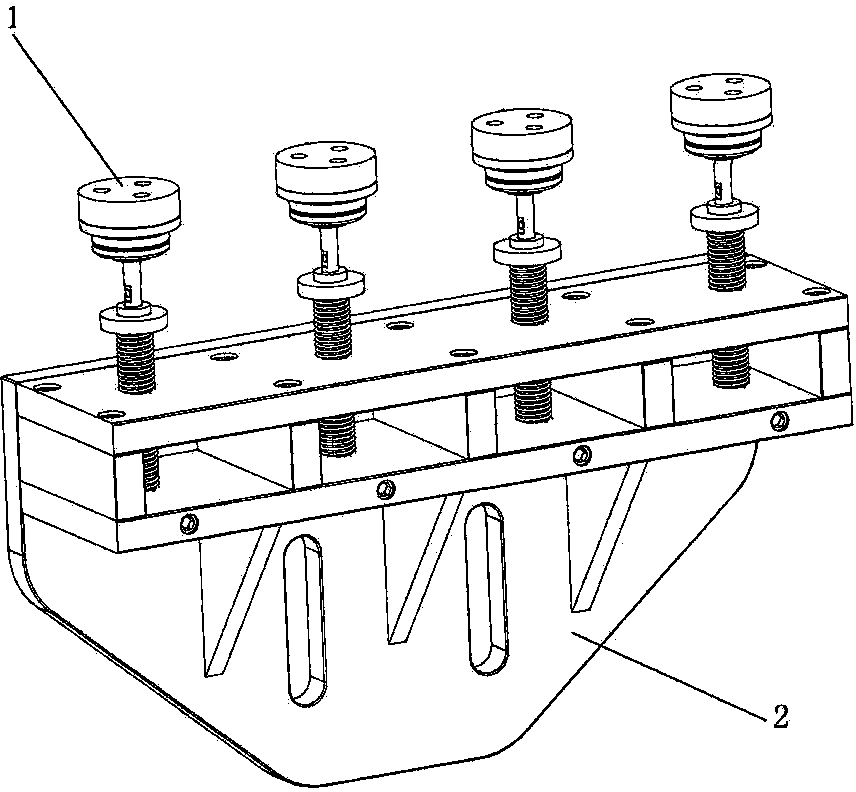

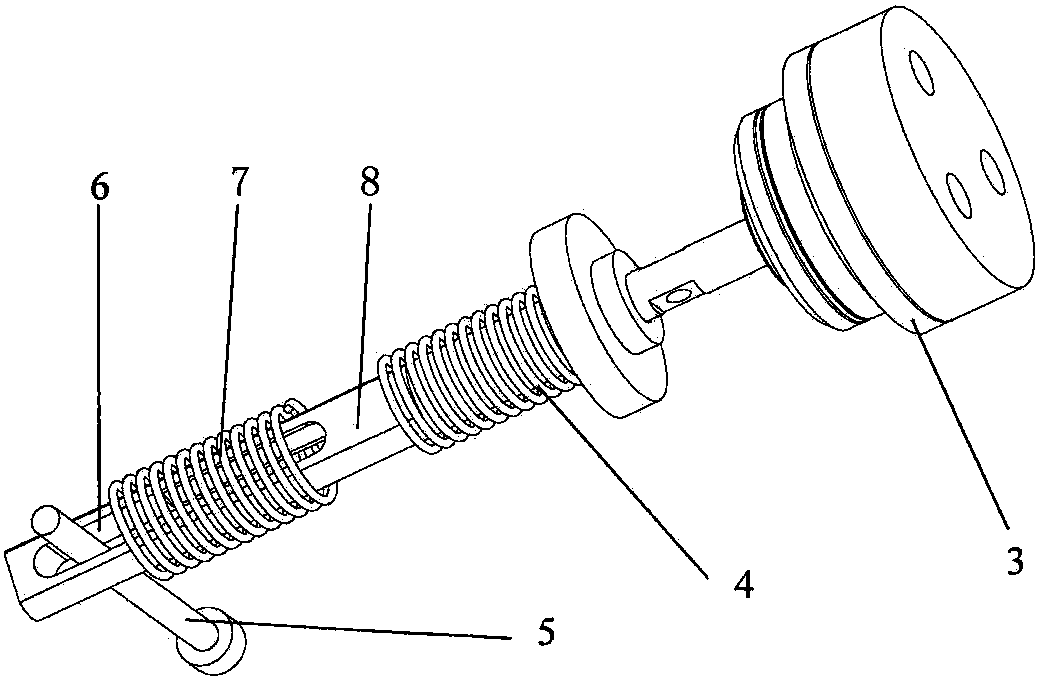

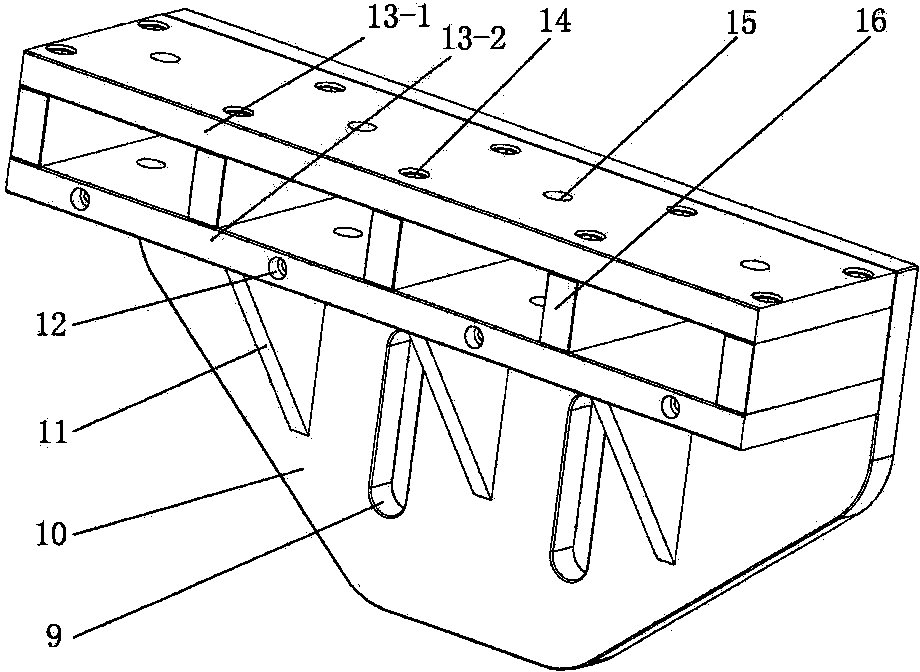

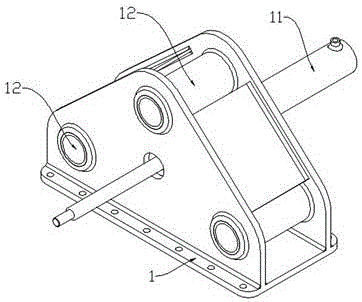

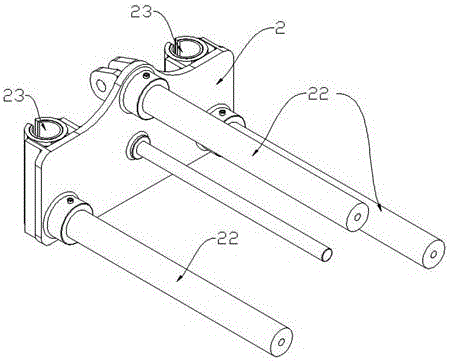

Self-adaptive flexible supporting and positioning mechanism

ActiveCN103447988ASupport positioning realizationMeet the needs of multi-state supporting positioningWork holdersAircraft assemblyEngineeringSelf adaptive

The invention discloses a self-adaptive flexible supporting and positioning mechanism which comprises self-adaptive flexible positioning units and a supporting frame component. The self-adaptive flexible positioning units are connected with the supporting frame component. Through supporting and positioning of the supporting frame component and adjusting of the self-adaptive flexible positioning units, a supporting and positioning function for riveting and assembling of drilling machines of various airplane models by using one supporting and positioning mechanism can be realized, universality and convenience of a supporting positioner are realized, airplane manufacturing cost is saved, the problem that space is occupied by tools is solved to a large extent, riveting, assembling and manufacturing efficiency of an airplane drilling machine is improved, and the self-adaptive flexible supporting and positioning mechanism is simple and reliable in structure.

Owner:SHENYANG AIRCRAFT CORP

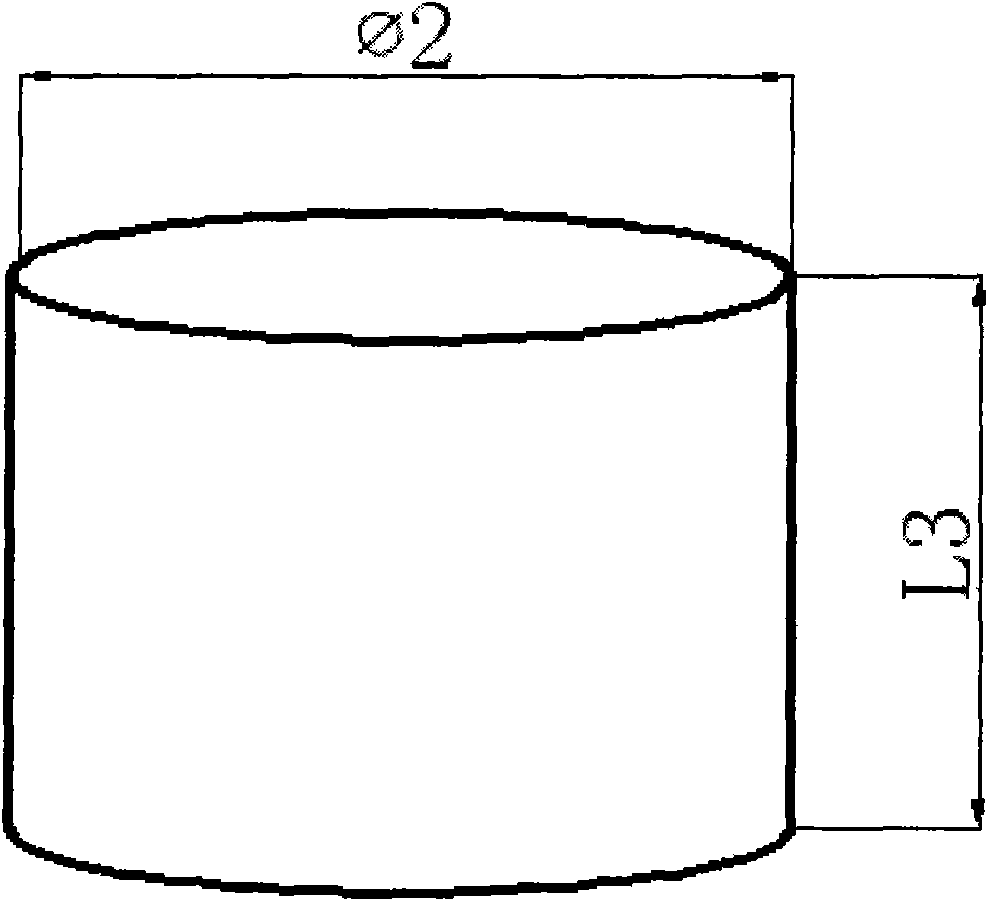

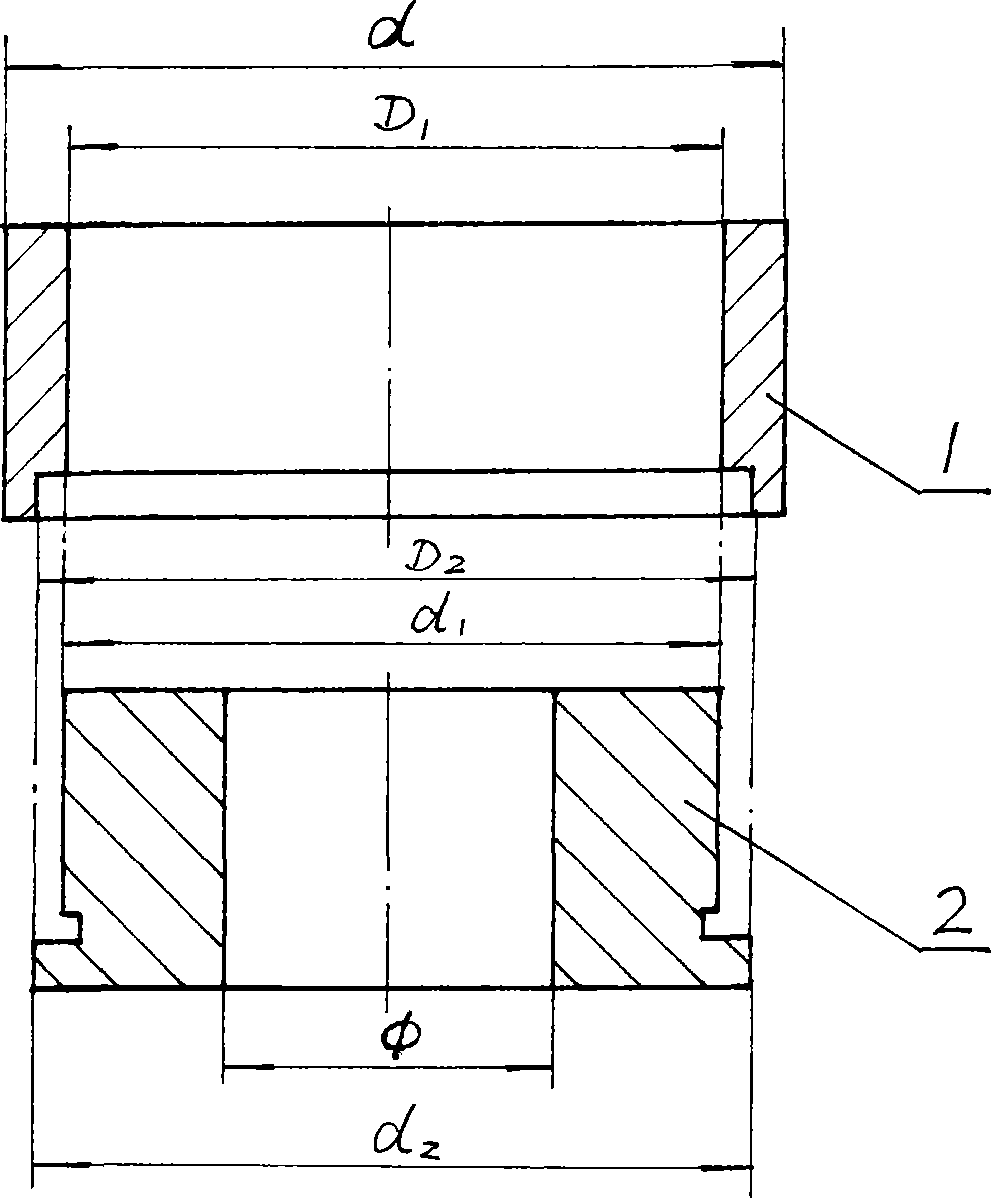

Carburization quenching method for round hole thin wall work-piece

InactiveCN101168795AEasy to operateProcess specificationFurnace typesHeat treatment furnacesQuenchingThin walled

The invention discloses a round hole thin wall type work piece cementing and quenching method. After a work piece processed mechanically is cemented routinely, the work piece is taken from a furnace, and a round column shaped pre-expanding mold is installed into an inner hole immediately, the outer diameter of the pre-expanding mold is processed to be 0.1 to 0.25 mm larger than the drawing size of the hole diameter of the work piece, then the work piece and the pre-expanding mold are immersed into the quenching oil quickly and vertically according to the quenching technology, and then are tempered after the work piece and the pre-expanding mold are taken out of oil, the pre-expanding mold is pressed out steadily through a hydraulic machine after being cooled, and rotoblasting, examination and warehousing are performed finally. If the attrition of the pre-expanding mold is out of tolerance, the pre-expanding mold can be reused after being renovated. The method is suitable for the round hole thin wall type work piece cementing and quenching method such as a vehicle gear ring, and a bearing sleeve ring, the distortion of the work piece can be avoided or reduced, the product quality is guaranteed, the operation is simple, the technology is normative, the investment is less, the cost is low, and the production efficiency is high.

Owner:TAIZHOU SANJING MECHINE MFG

Cutting machining technology for semi-hole plate provided with copper plating holes at plate edges

ActiveCN102387668AEliminate copper deficiencyReduce scrapPrinted circuit manufactureCopper platingMolding machine

The invention relates to a cutting machining technology for a semi-hole plate provided with copper plating holes at plate edges. The cutting machining technology is characterized by comprising the following technology steps: inserting a drill bit used for drilling pin holes on a cutter holder, starting a forming machine, and drilling deep holes in an electric wood plate of the forming machine; placing a pulp plate on the electric wood plate, fixing four edges of the pulp plate with the electric wood plate, inserting the drill bit used for drilling large holes on the cutter holder, and drilling the large holes in the pulp plate; carrying out cutting machining on the pulp plate to fish out a groove body; selecting pins, inserting the pins on four corners of the pulp plate, sheathing a printed circuit plate, and hitting the pins well; taking out a shaft printed circuit plate to be sheathed on the pins, fixing four edges of the printed circuit plate by masking tape; and carrying out cutting machining on the plate edges of the printed circuit plate. With the cutting machining technology implemented, the requirements on the quality of a semi-hole plate provided with PTHs (plated though hole) at the plate edges can be guaranteed, waste of unqualified products and the complaints of clients are reduced, and the creditworthiness on client terminals is promoted.

Owner:GULTECH WUXI ELECTRONICS CO LTD

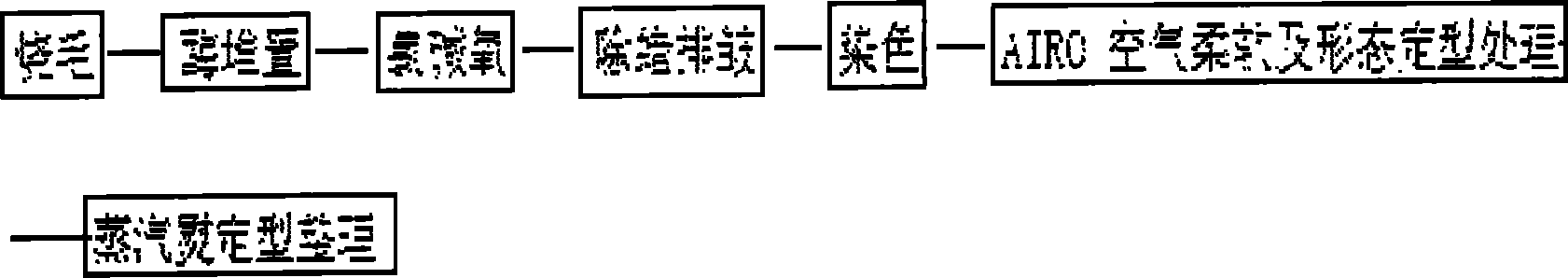

Dyeing and finishing process of pure-flax Huashu textile fabric

ActiveCN102021840AWith shape memory functionMaintain the shape of micro-creasesBiochemical fibre treatmentBleaching apparatusWaxWater resources

The invention relates to a dyeing and finishing process of a pure-flax Huashu textile fabric, comprising the following steps of: singeing fabrics, stacking enzymes, oxidizing chlor-alkali, removing wax and crimples, dyeing, softening by AIRO air, shaping and ironing and finishing by steam. The pure-flax Huashu textile fabric not only maintains the original excellent characteristics of pure-flax fabrics, but also has good drapability, skin intimacy, low strength loss and high dye fastness, has the functions of shaping details and remembering small folds, eliminates itchy feeling and expands the use field of fabrics. The invention has reasonable process design, is environment-friendly and greatly reduces the use of energy and water resources.

Owner:安徽中天新材料科技股份有限公司

Phase-changing temperature-adjusting energy storage floor

InactiveCN1864957AHigh quality raw materialFormulation ScienceWood working apparatusFlat articlesFiberSolvent

The invention relates to a phase-change temperature-adjust energy-storage floor and relative production. Wherein, the inventive floor extracts wood from broken wood, wood wool, and chip, to be added with fiber extracted from waste paper; the wood cell wall is formed by the cellulose and hemicellulose of amylase and the wood with aromaticity. It uses the polymerization process and special extruder to make the temperature-adjust energy-storage floor at 180-280Deg. C, which will not be corrupted by general solvent, acid and alkali. The inventive production will not discharge waste and harmful gas, and it only uses wood powder, macromolecule synthetic material and agent, to save the energy and resource.

Owner:王方怡雪

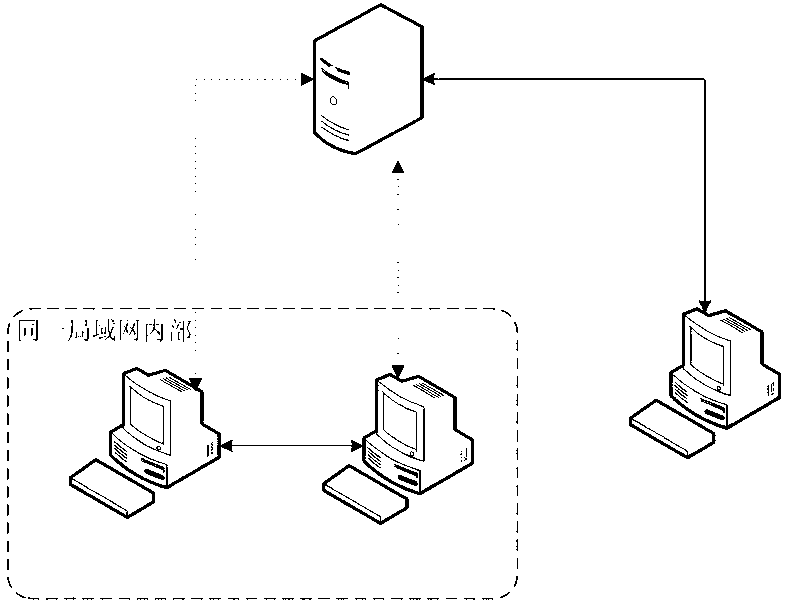

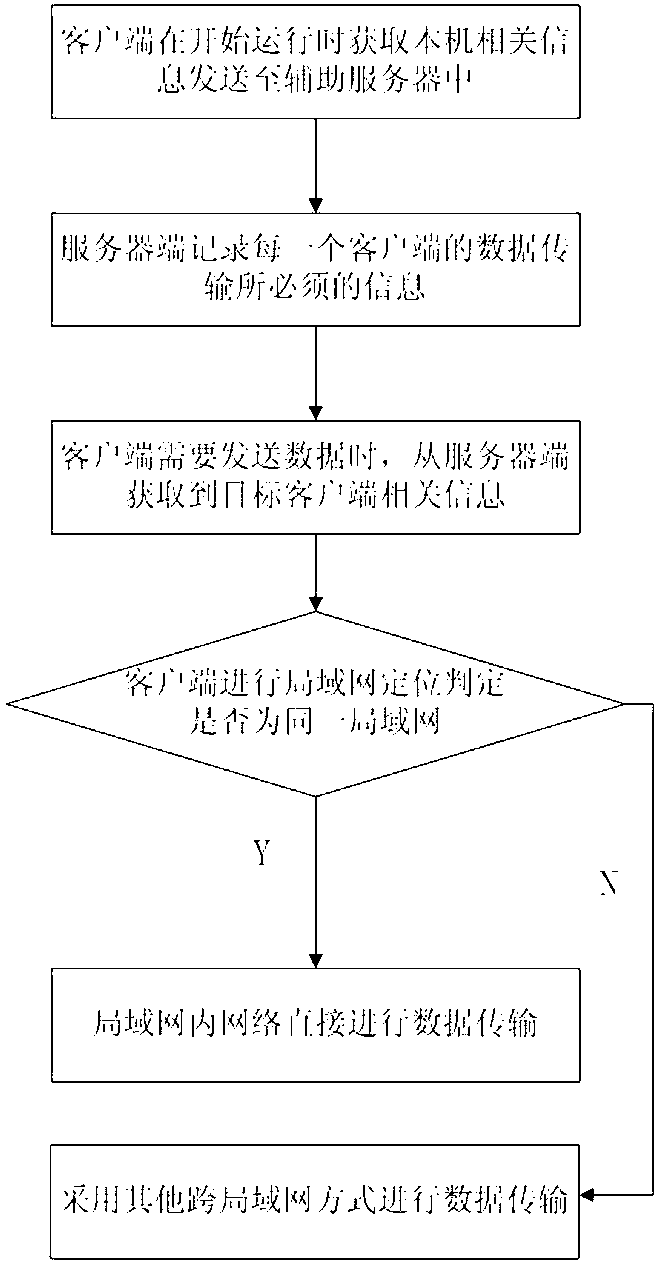

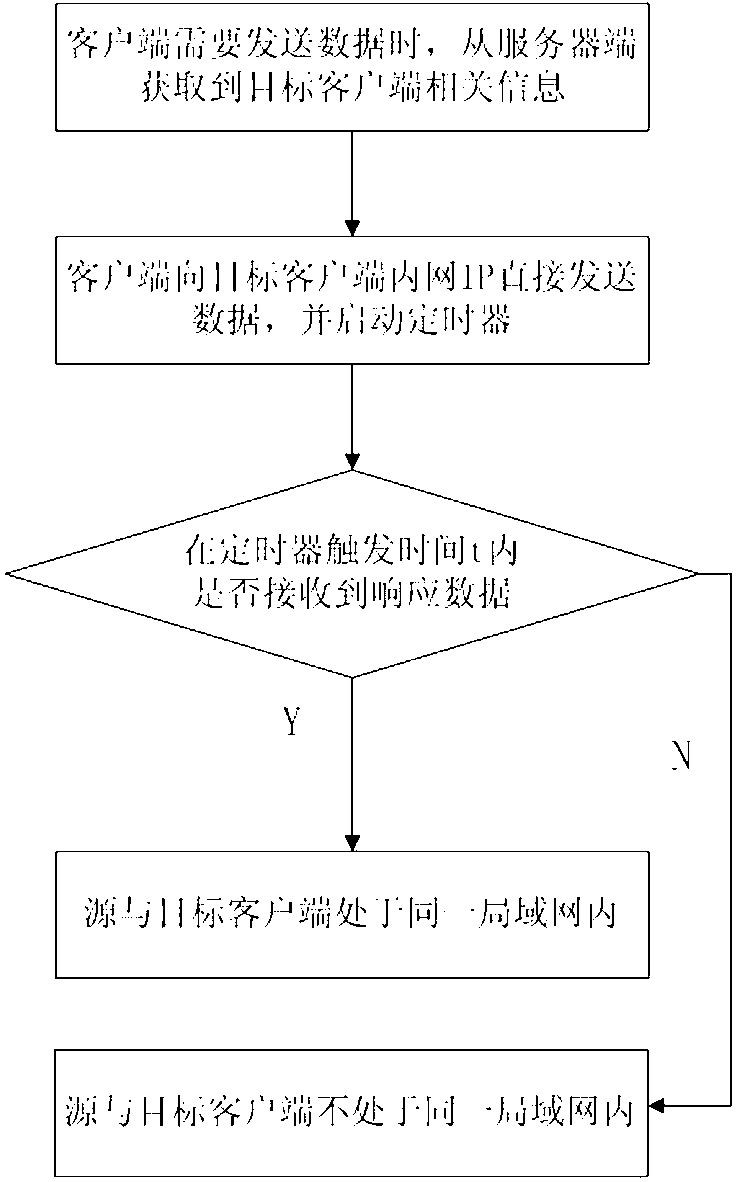

Method for local area network positioning in instantaneous network data transmission

InactiveCN103297324AGuaranteed immediacyGuarantee quality requirementsData switching networksRelevant informationBody area network

The invention relates to a method for local area network positioning in instantaneous network data transmission. The method includes the steps: a), connecting clients; b), recording client information, client IDs (identities), client intranet IPs (internet protocols) and ports and client public network IPs and ports by a server; c), acquiring related information of a target client; d) positioning and judging local area networks; e), if a source client and the target client are in the same local area network, performing direct data transmission; and f), if the source client and the target client are not in the same local area network, adopting an existing data transmission method. According to the method, a sender and a receiver in data transmission are judged whether in the same local area network or not, and then different transmission schemes are adopted according to judgment; if the sender and the receiver are in the same local area network, data is transmitted through the local area network without occupying bandwidth of a public network, so that network resources are saved; meanwhile, by the aid of bandwidth advantages inside the local area network, instantaneity of data transmission is guaranteed, and quality requirements of data transmission are met.

Owner:SHANDONG COMP SCI CENTNAT SUPERCOMP CENT IN JINAN

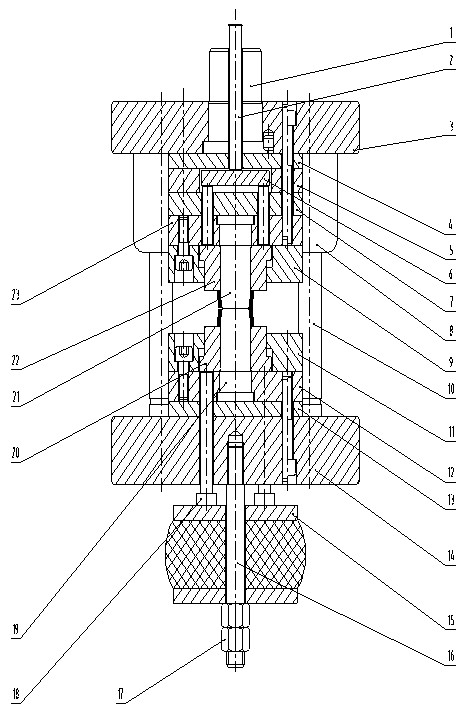

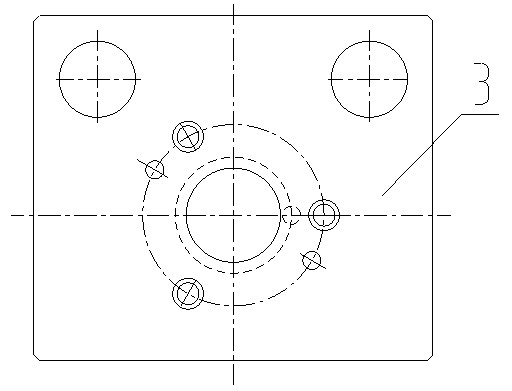

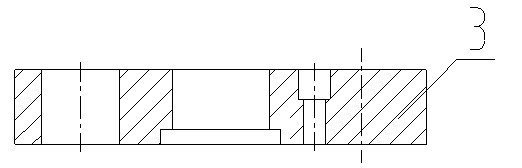

Mould for tubing material forming

The invention discloses a mould for tubing material forming, comprising an upper mould part, a lower mould part and a guide part, wherein the upper mould part comprises a mould handle, a knocking rod, an upper mould seat, an upper cushion plate, an upper cover plate, an upper convex mould, an upper top block and an upper fixed plate; the upper top block is sleeved in the upper cover plate; the upper convex mould passes through the upper top block; the top of the upper convex mould is in contact with the upper cushion plate; the upper convex mould is in sliding fit with the upper top block; the lower mould part comprises a lower cover plate, a lower fixed plate, a lower cushion plate, a lower mould seat, a lower convex mould and a lower top block; the lower top block is sleeved in the lower cover plate; the lower convex mould passes through the lower top block; the bottom of the lower convex mould is in contact with the lower cushion plate; the lower convex mould is in sliding fit with the lower top block; the guide part comprises a guide sleeve and a guide column; the guide sleeve penetrates in the upper mould seat; and the guide column penetrates in the lower mould seat. The mould uses the upper and lower convex moulds to press parts, so that the tubing materials are deformed to necessary shapes; the lengths of products are controlled by the upper and lower top blocks, the sizes of the two ends of each product are ensured to be consistent, the quality requirements of products are ensured, and the material pushing operation is convenient.

Owner:隆昌山川机械有限责任公司

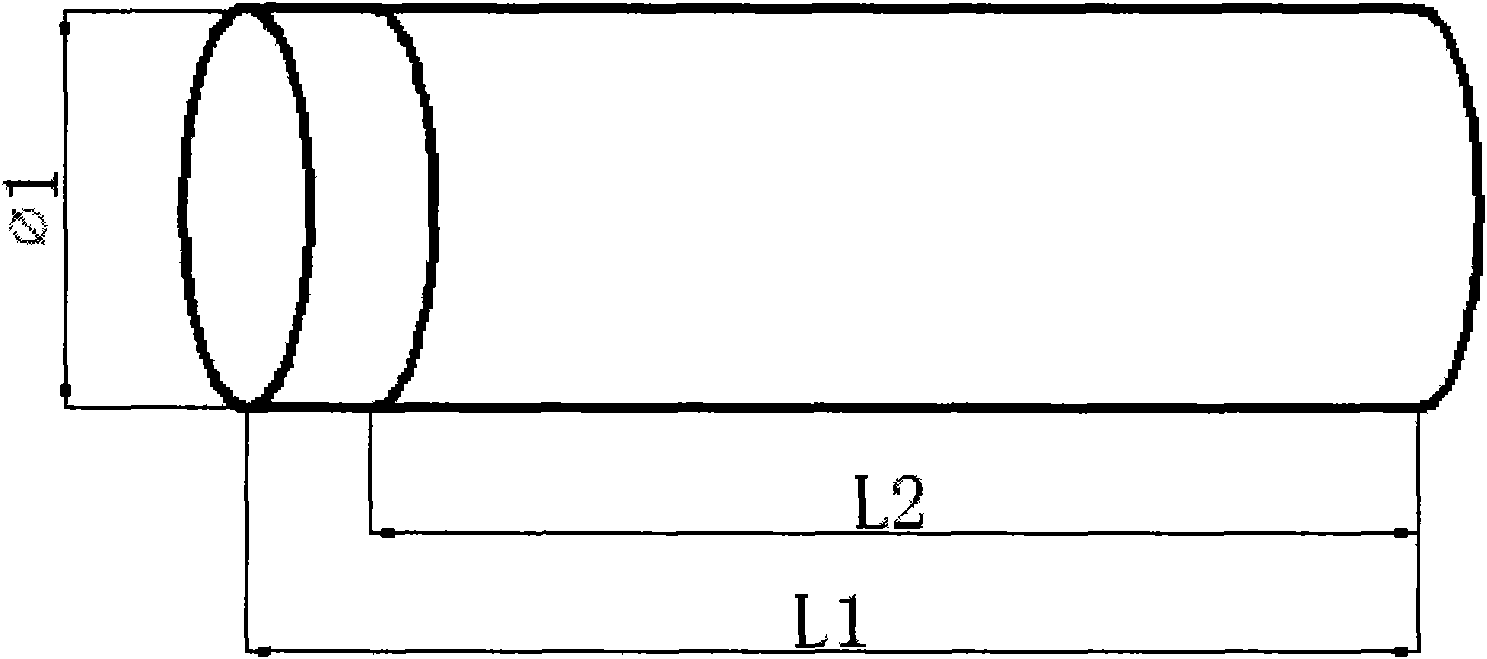

Steel bar for high-ductility and superhigh-strength pre-stressed concrete and machining method thereof

ActiveCN103484789AReduce intensityImproved resistance to hysteresis fractureUltra high pressurePre stress

The invention discloses a steel bar for high-ductility and superhigh-strength pre-stressed concrete and a machining method of the steel bar. The steel bar comprises, by weight, 0.3-0.5% of C, 0.3-1.8% of Si, 0.6-1.5% of Mn, 0.02-0.2% of Nb, 0.01-0.1% of V, 0.01-0.2% of Ni, 0.1-0.5% of Cr, 0.01-0.1% of Mo, 0.001-0.005% of B and the balance Fe, wherein the Ceq is smaller than 0.8%. Because an online continuous superhigh-pressure quenching control technology is adopted, the strength of the steel bar can be larger than 1860MPa or even larger than 2000MPa; because an online continuous quenching heat insulation and control technology is adopted, the ductility of the steel bar can be larger than 7%, the structural state of few ultra fine ferrites and tempered troostite is kept, and the steel bar has the advantages of being good in ductility and resistant to delayed fractures.

Owner:江苏森林建筑新材料股份有限公司

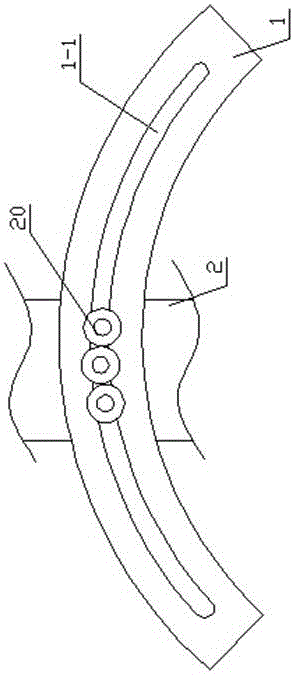

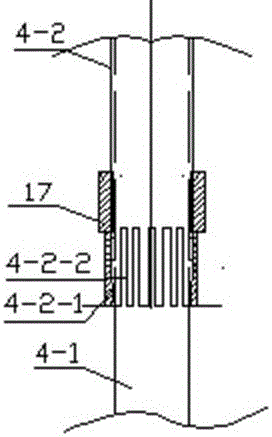

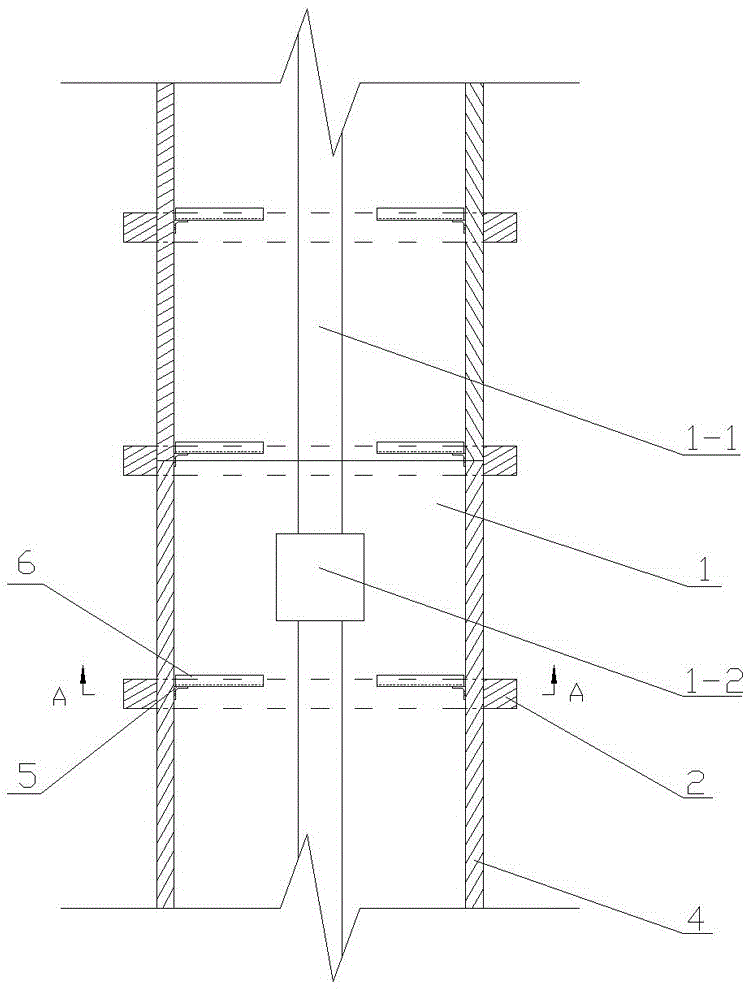

Slip form mould for road shoulder forming

Owner:云南穿山机甲能源装备科技有限公司

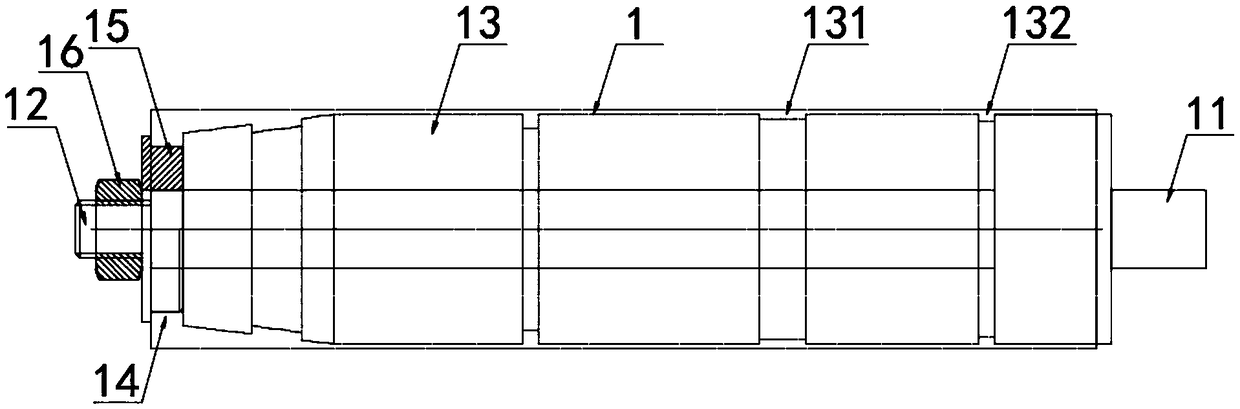

Ball mill main bearing bush repair process

Bearing bushes of main bearings of ball mills can be abraded easily after years of usage, and bush backs might expose from parts of bush bottoms, so that bearing bushes must be cast again; babbitt metal is required to be cast in original manufacturers in prior bearing bush repair, and accordingly, the cost is high, the period is long, and the production is affected seriously. The repair process comprises five steps of cleaning, tinning, casing, quality inspection and scraping to complete repair of the damaged bearing bushes. Performances of the bearing bushes repaired through the repair process can all reach requirements, and more than 30 thousand yuan of repair costs can be saved for enterprises.

Owner:LUOYANG JIAWEI BEARING MFG

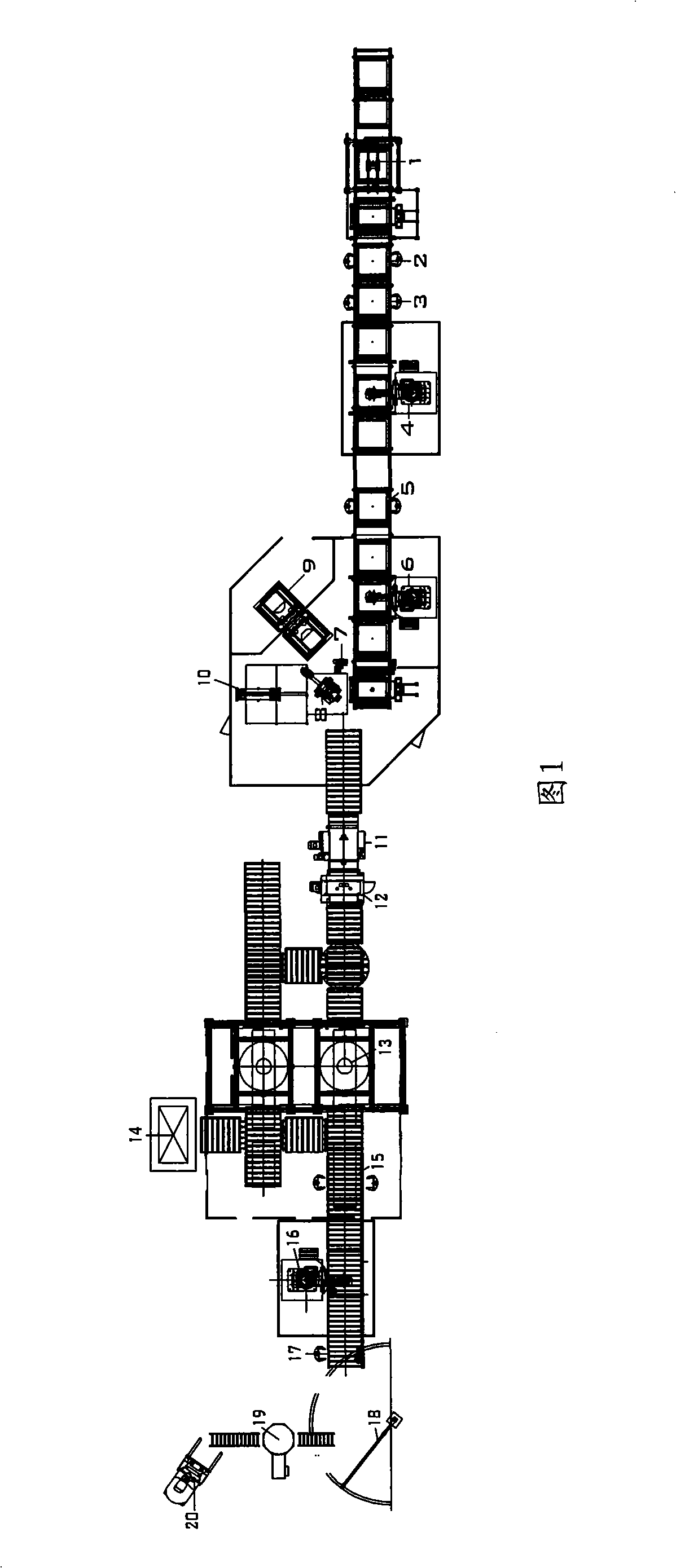

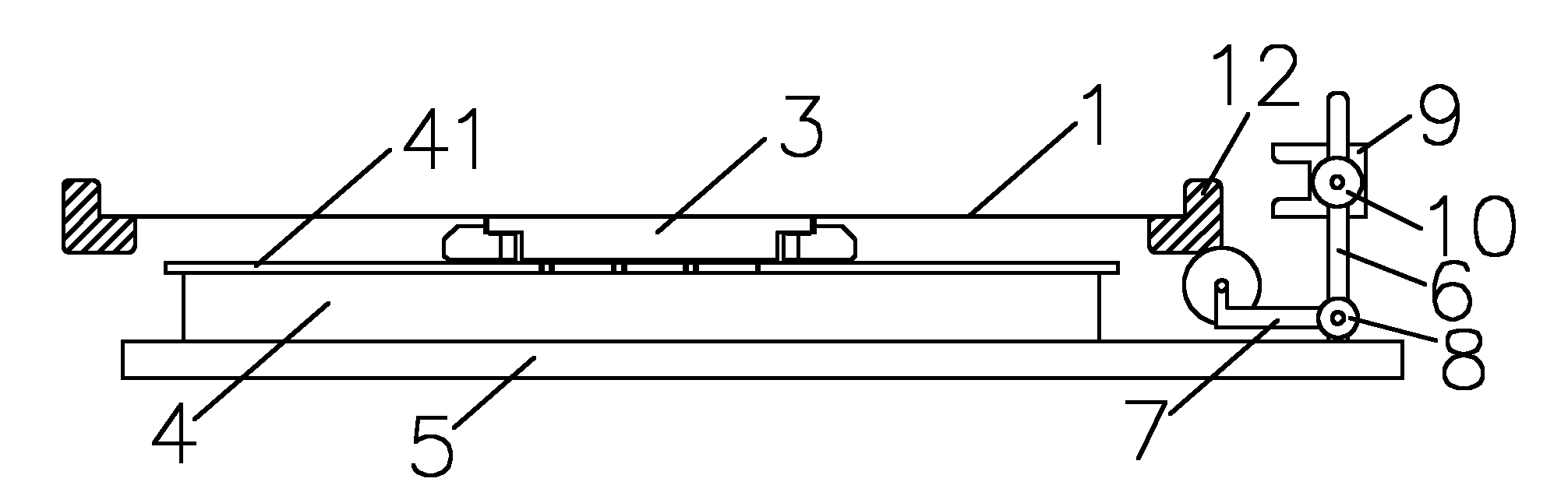

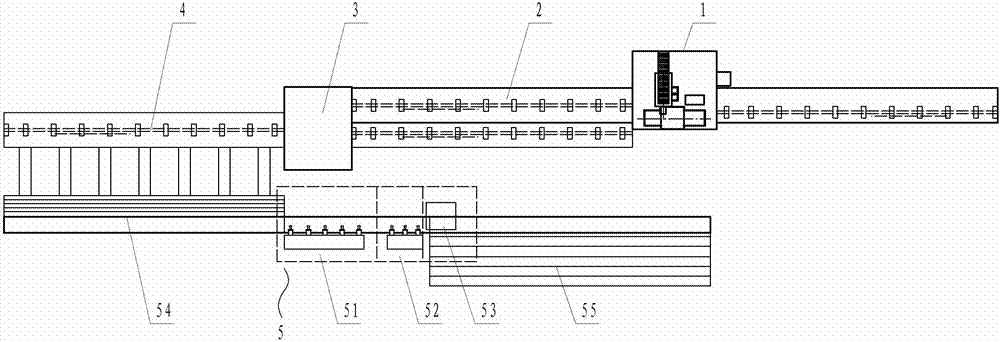

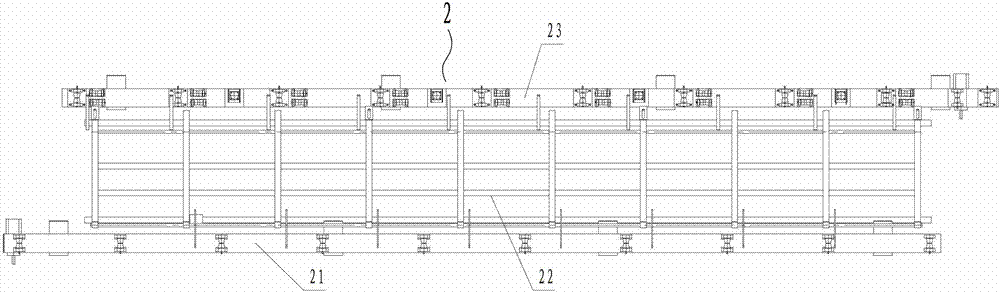

Production method and assembly line of insulation box for liquid natural gas carrier

ActiveCN101319753AAvoid backlogIncrease productivityThermal insulationContainer filling methodsProduction lineVolumetric Mass Density

The invention relates to a method and production line to manufacturing an insulating tank for a liquefied natural gas carrier. The method includes the working procedures of ''mould piggybacking'', ''clapboard assembling'', ''temporary clapboard fixing'', ''clapboard fixing by nailing'', ''roof plate assembling and temporary fixing'', ''roof plate fixing by nailing'', ''bar code affixing'', ''tank body overtuning'', ''double-layer roof plate assembling and temporary fixing'', ''double-layer roof plate fixing by nailing'', ''tank body leveling up'', ''insulating material filling'', ''filling density checking'', ''bottom plate assembling and temporary fixing'', ''bottom plate fixing by nailing'', ''tank body finishing'', ''tank body conveying and cleaning'', ''tank body packaging'' and ''tank body transporting''. By implementing such technical process for producing insulating tanks applied to LNG ships, the labor is largely saved, the production efficiency is improved, and the requirement of high precision of insulation tanks is satisfied.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

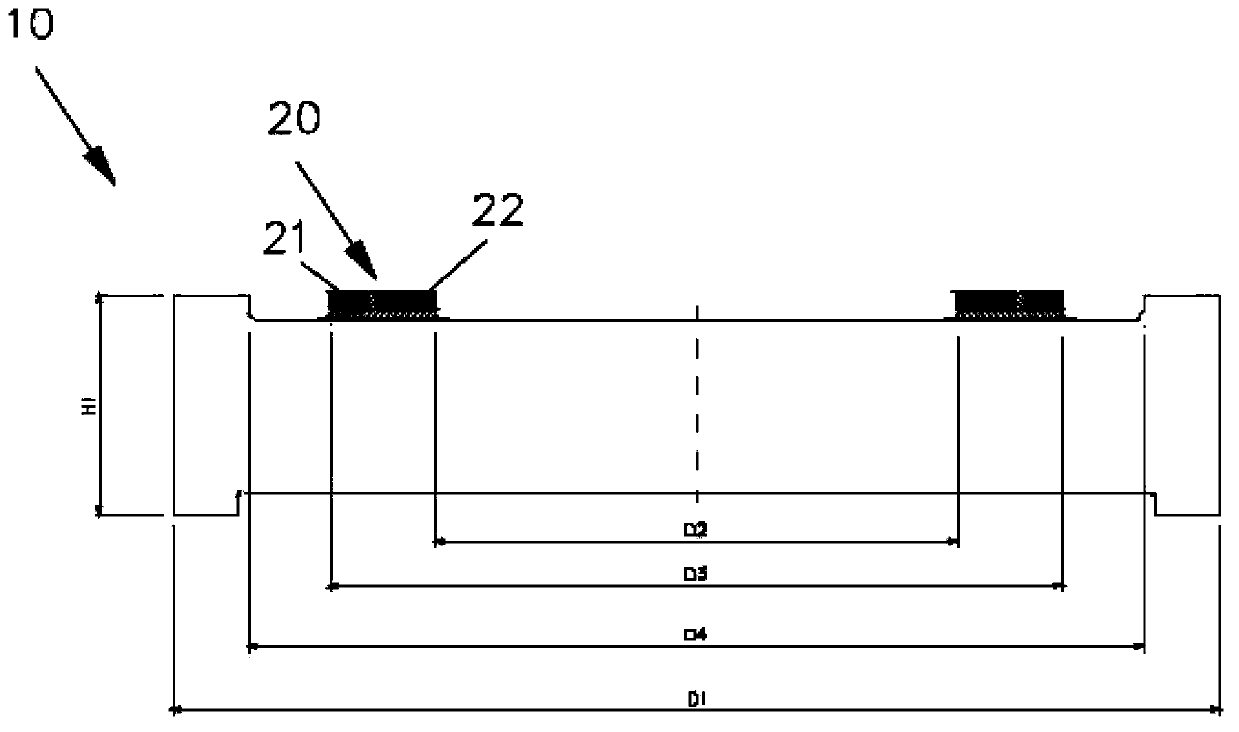

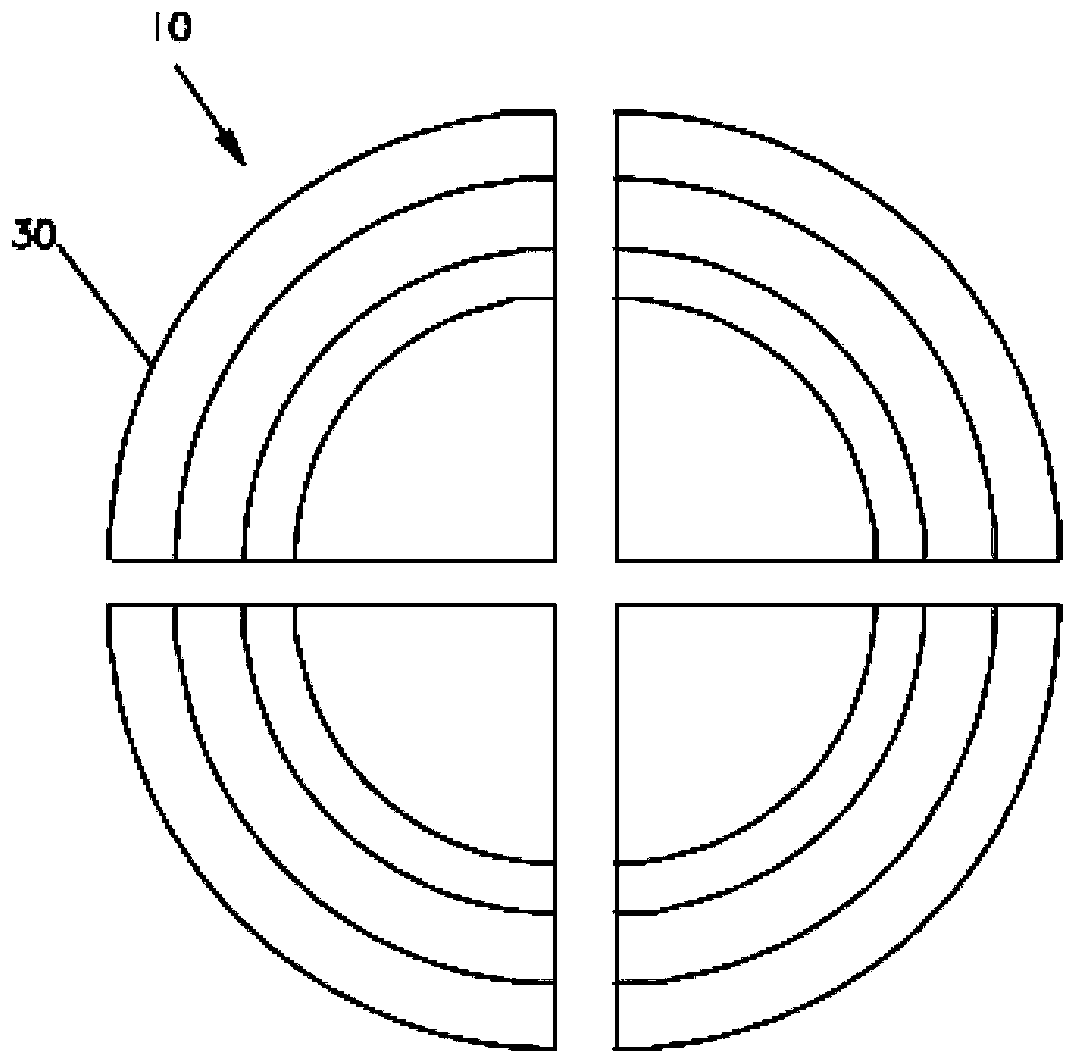

Thin-wall shell processing method

ActiveCN109396766ARestricted degrees of freedomGuarantee quality requirementsWork clamping meansPositioning apparatusEngineeringThermal treatment

The invention discloses a thin-wall shell processing method which comprises a tool clamp, wherein the tool clamp comprises a mandrel; one end of the mandrel is equipped with a mounting column; the outer part of the mandrel is fixedly equipped with an outer ring body in a sleeving mode; a wide ring-shaped slot and a narrow ring-shaped slot are formed in the outer ring body; a step is arranged between one end of the outer ring-shaped body and the mandrel; an auxiliary pressure plate is arranged on the outer part of the step in the sleeving mode; one side of the auxiliary pressure plate is equipped with a nut; and the nut is in threaded connection with the mounting column. The thin-wall shell processing method comprises the following specific steps: step I, outer wall rough turning; step II,high-temperature tempering; step III, left end surface turning; step IV, right end surface turning; step V, clamp mounting; step VI, outer wall fine turning; and step VII, appearance processing. The thin-wall shell processing method performs processing through a high-efficiency machine tool, and a thermal-treatment tempering distressing process is added to release part processing inner stress; andthe necessity of designing a special clamp is combined, so that processing deformation is prevented, and part processing quality requirements are guaranteed.

Owner:河南红宇精密机械有限公司

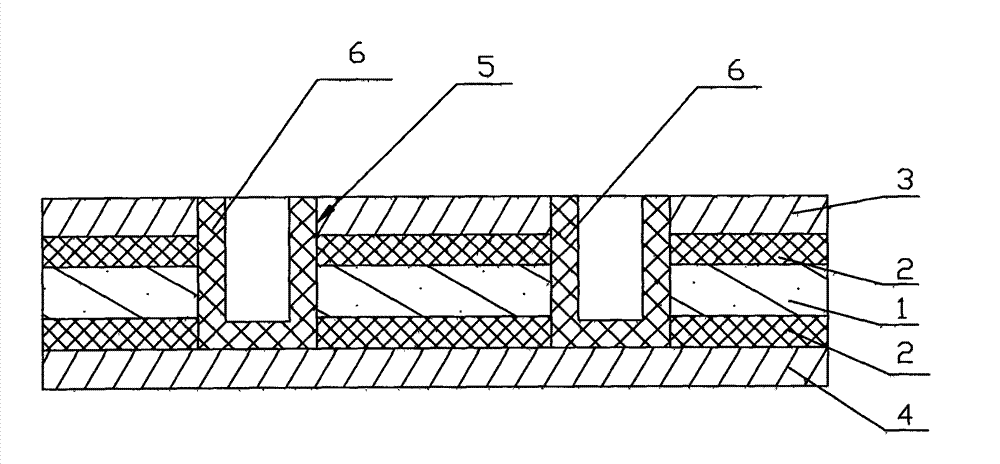

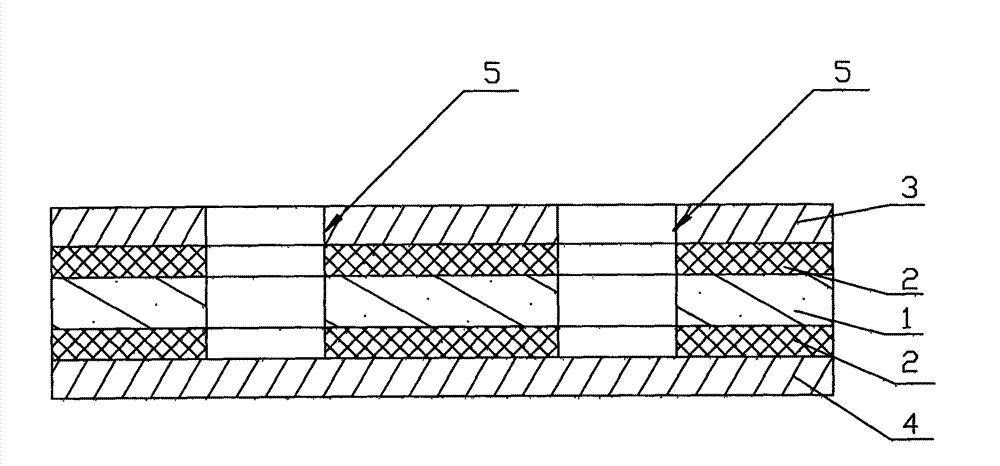

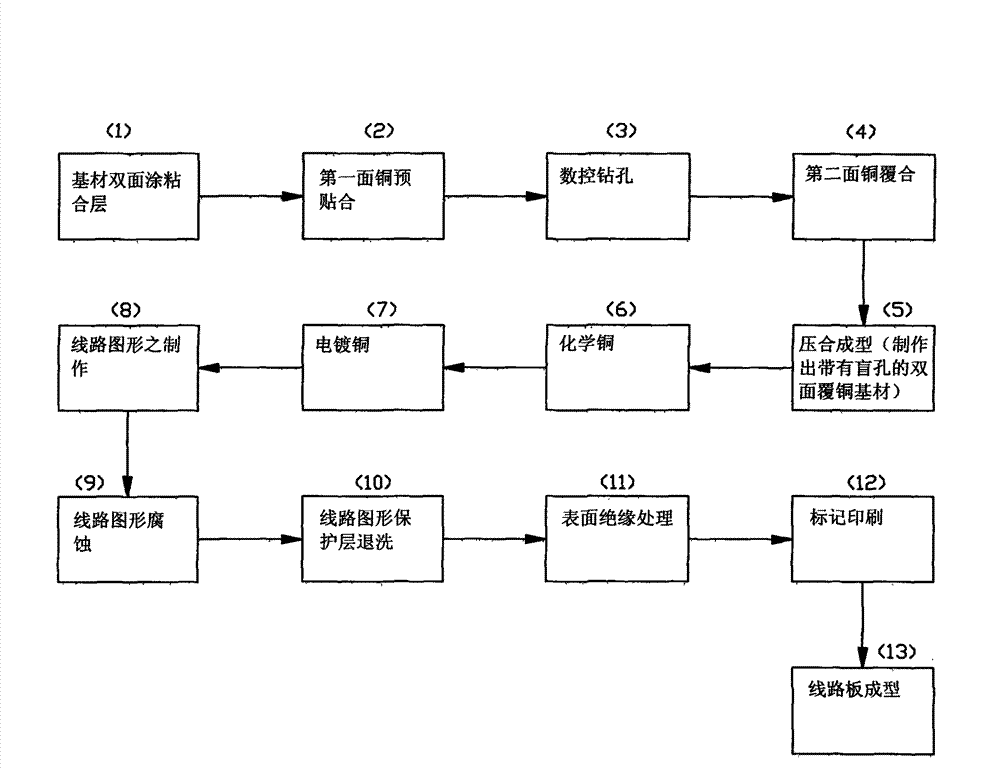

Blind-hole-conduction double-sided circuit board and processing method thereof

InactiveCN102858087ASmall apertureHigh precisionElectrical connection printed elementsPrinted element electric connection formationCopperPrinted circuit board

The invention discloses a blind-hole conduction double-sided circuit board and a processing method thereof. The blind-hole conduction double-sided circuit board comprises a substrate layer, an upper circuit layer and a lower circuit layer, wherein the upper circuit layer and the lower circuit layer are integrally adhered on the upper side and the lower side of the substrate layer via adhesive layers, conduction blind holes are arranged on the substrate layer and the upper circuit layer above the lower circuit layer, and an electroplating conduction wall conducting the upper circuit layer and the lower circuit layer are electroplated along the wall surface of the conduction blind holes. The blind-hole-conduction double-sided circuit board realizing blind hole conduction by copper electroplating via electroplating has the advantages of simple structure, fine conduction performance, environment friendliness and the like. The invention further provides a processing method of the blind-hole conduction double-sided circuit board, and by the processing method, production efficiency is improved, energy source consumption is reduced, conductive performance is improved, cost is reduced, and besides, the processing method is fine in quality guarantee coefficient, convenience in operation and the like.

Owner:吴祖

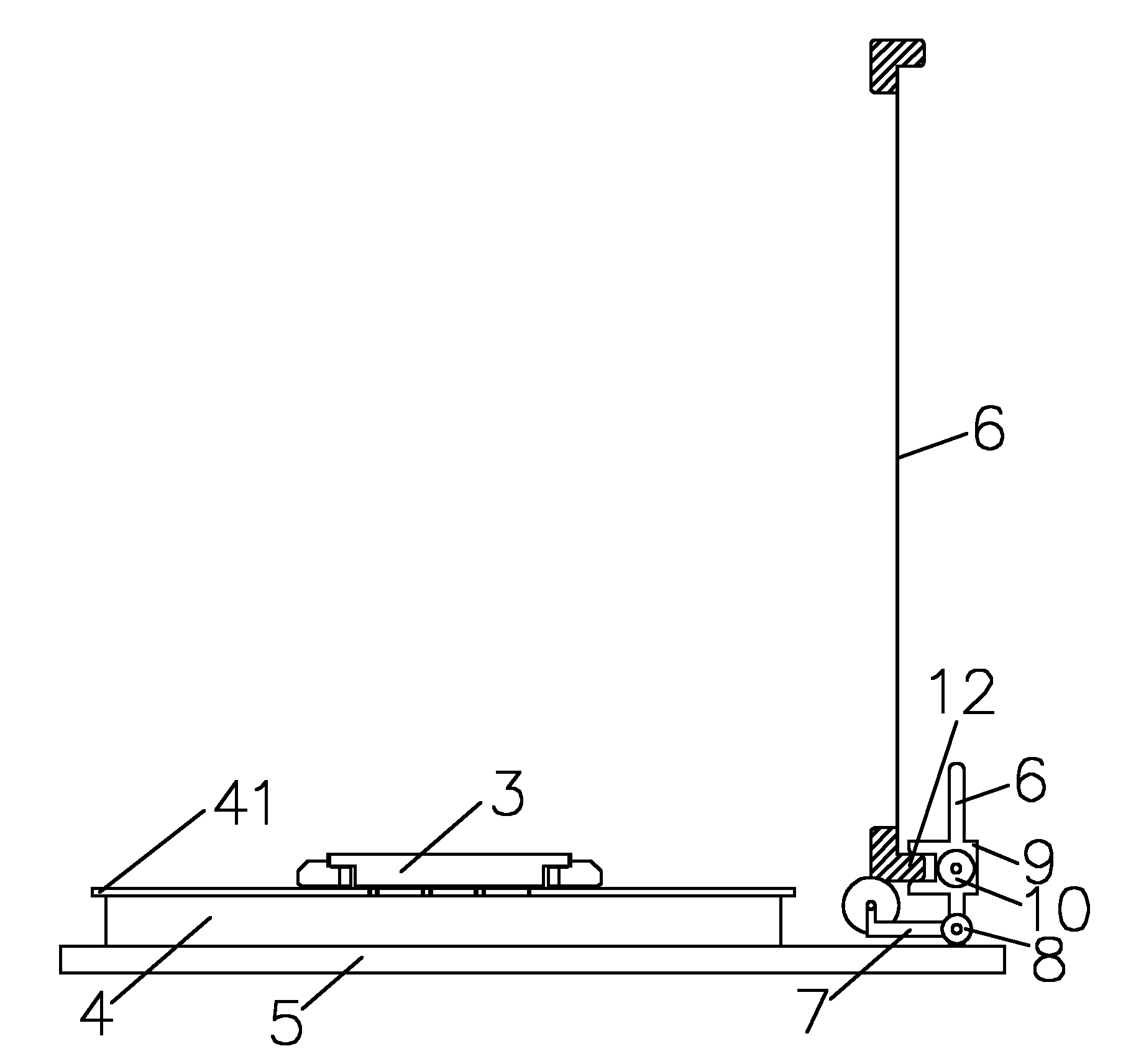

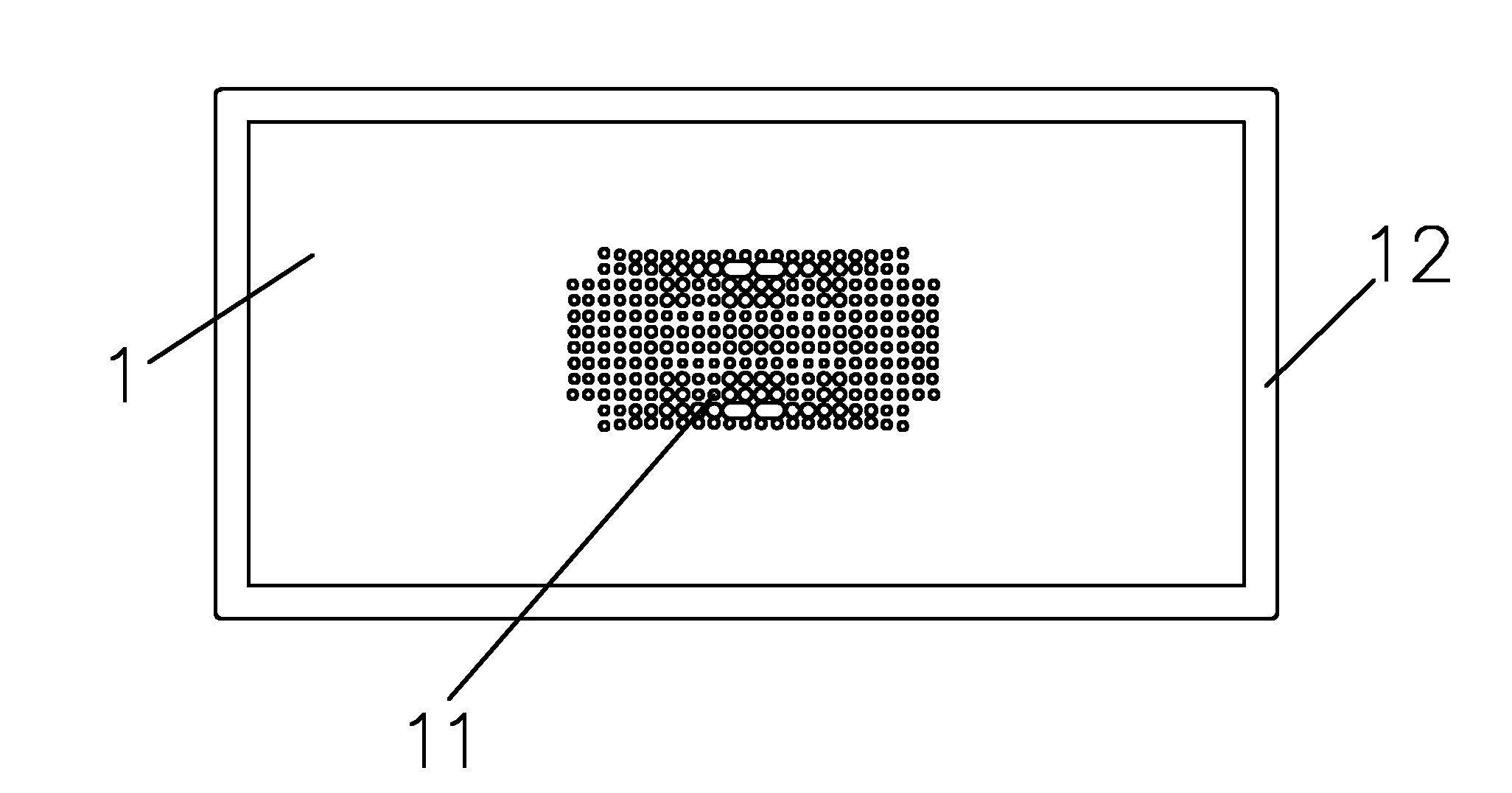

Device for coating heat-conducting silicone grease on radiation surface of insulated gate bipolar translator (IGBT) module and related coating method

InactiveCN102120207AIngenious designSimple structureLiquid surface applicatorsCoatingsBiomedical engineeringRadiation

The invention relates to a device for coating heat-conducting silicone grease on the radiation surface of an IGBT module, which comprises a mesh plate and a mesh leveling tool, wherein the mesh plate is provided with a mesh area which is used to be tightly jointed on the radiation surface of the IGBT module; the mesh leveling tool is used in combination with the mesh area so that the meshes in the mesh area can be leveled by the heat-conducting silicone grease when the heat-conducting silicone grease is coated; and preferably, the meshes are in completely different sizes. The device also comprises an upright post and a connecting block, wherein the connecting block is arranged on the upright post in a manner of being capable of moving up and down; and the mesh plate is rotationally arranged on the connecting block. The invention also provides a method for coating heat-conducting silicone grease on the radiation surface of the IGBT module. The device for coating heat-conducting silicone grease on the radiation surface of the IGBT module is smartly designed and has a simple structure. When the device is used, the coating quality of the heat-conducting silicone grease can be assured, the service life of the IGBT module can be prolonged, the operation is convenient, the working efficiency can be improved, and the waste of the heat-conducting silicone grease is reduced. The device is suitable to be widely promoted and used.

Owner:SHANGHAI ZHONGKE SHENJIANG ELECTRIC VEHICLE

Semiautomatic streamline type production system and method for high-strength threaded steel bar

The invention discloses a semiautomatic streamline type production system and method for a high-strength threaded steel bar and relates to a production system and method for the high-strength threaded steel bar. The production system comprises a centerless lathe, a screw rolling machine and a heat treatment system, wherein the centerless lathe is connected together with the screw rolling machine through an automatic joining device; and the screw rolling machine is connected together with the heat treatment system through an automatic discharging mechanism of the screw rolling machine. The method comprises the steps of feeding S1 blanking, S2 turning, S3 roll threading, S4 heat treatment and S5checking. According to the semiautomatic streamline type production system and method disclosed by the invention, the production efficiency can be increased, the cost of products is reduced and the quality of the products is ensured; and the semiautomatic streamline type production system and method are suitable for producing the high-strength threaded steel bars with the diameter being 50-80mm and the length being 12m.

Owner:LIUZHOU OVM MASCH CO LTD

Real-time data transmission method based on local area network

ActiveCN102801591AEnsure real-time requirementsGuarantee quality requirementsNetwork topologiesNetworks interconnectionReal-time dataLAN switching

The invention provides a real-time data transmission method based on a local area network, comprising a real-time data user terminal, a wireless accessing point, a local area network switchboard and a real-time data transmission managing center. The real-time data transmission method can provide real-time data transmission which has fast connection speed, strong instantaneity and priority grade and has absolute enforced preferential communication for a real-time data user terminal on the basis of a network system of the existing local area network and under the condition of keeping the existing data accessing and transmission functions of the local area network; and the real-time data transmission method has general calling, group calling, announcing and urgent inserting functions and can meet the requirements of the real-time data user terminal on the transmission of voice data, video data and real-time control data.

Owner:STATE GRID CORP OF CHINA +1

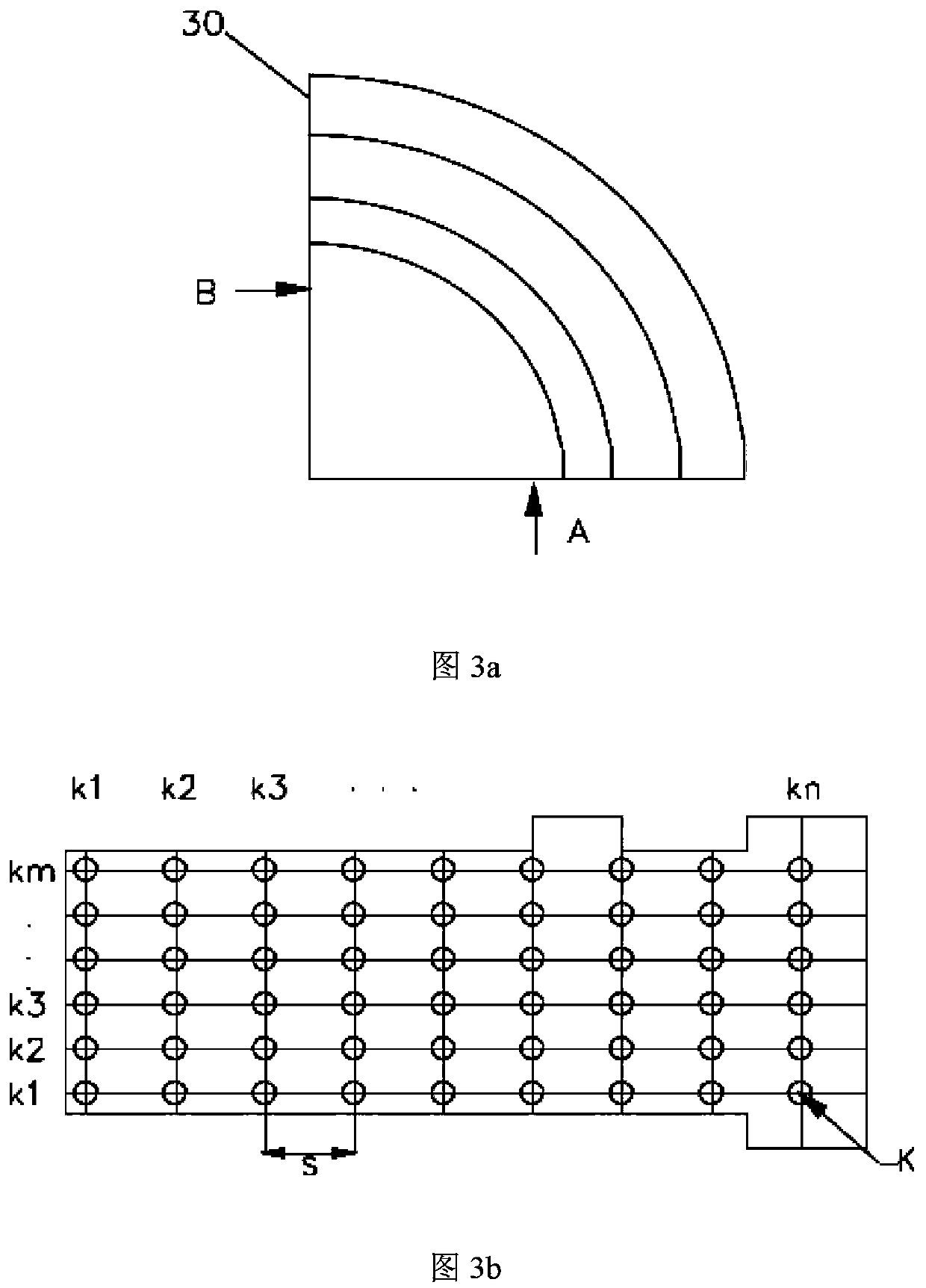

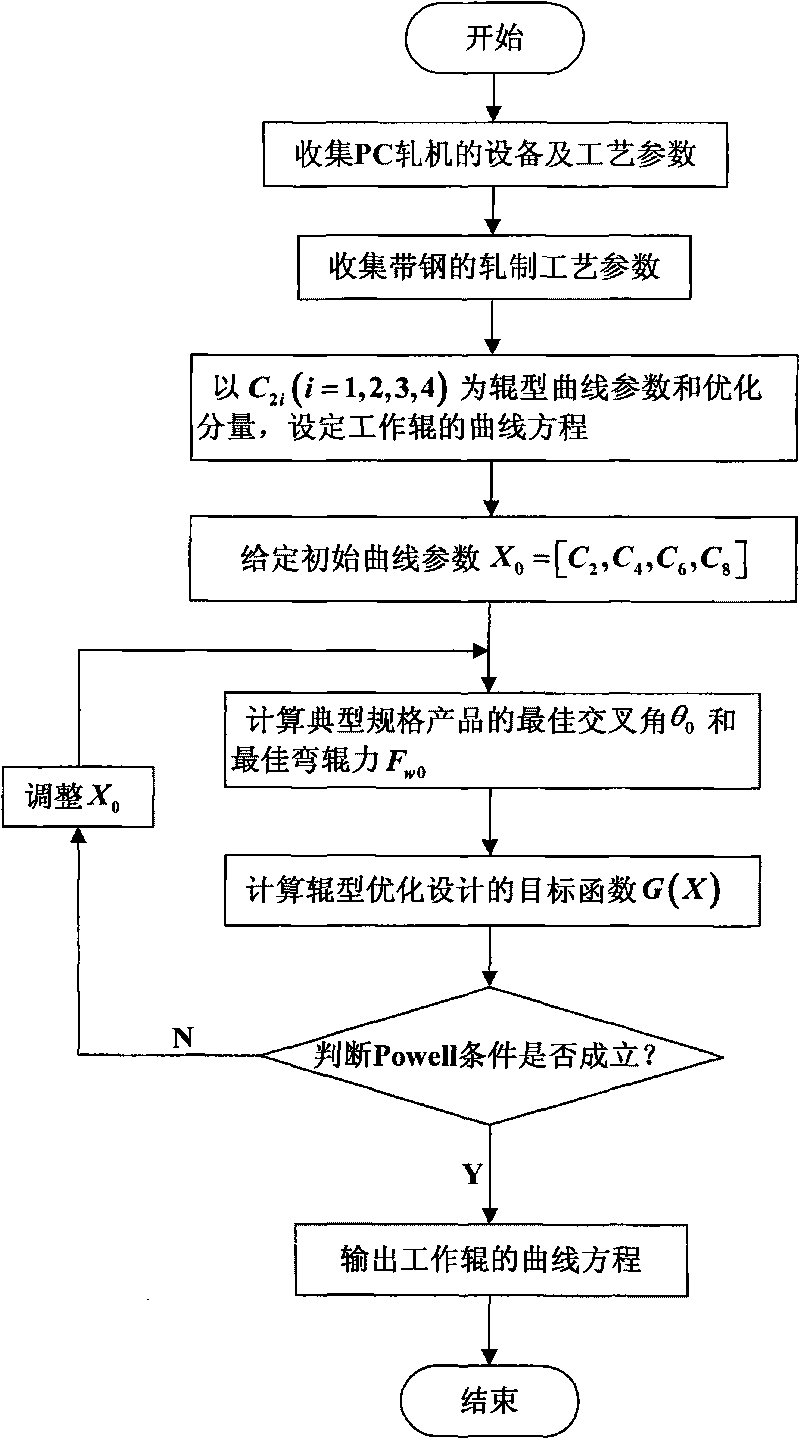

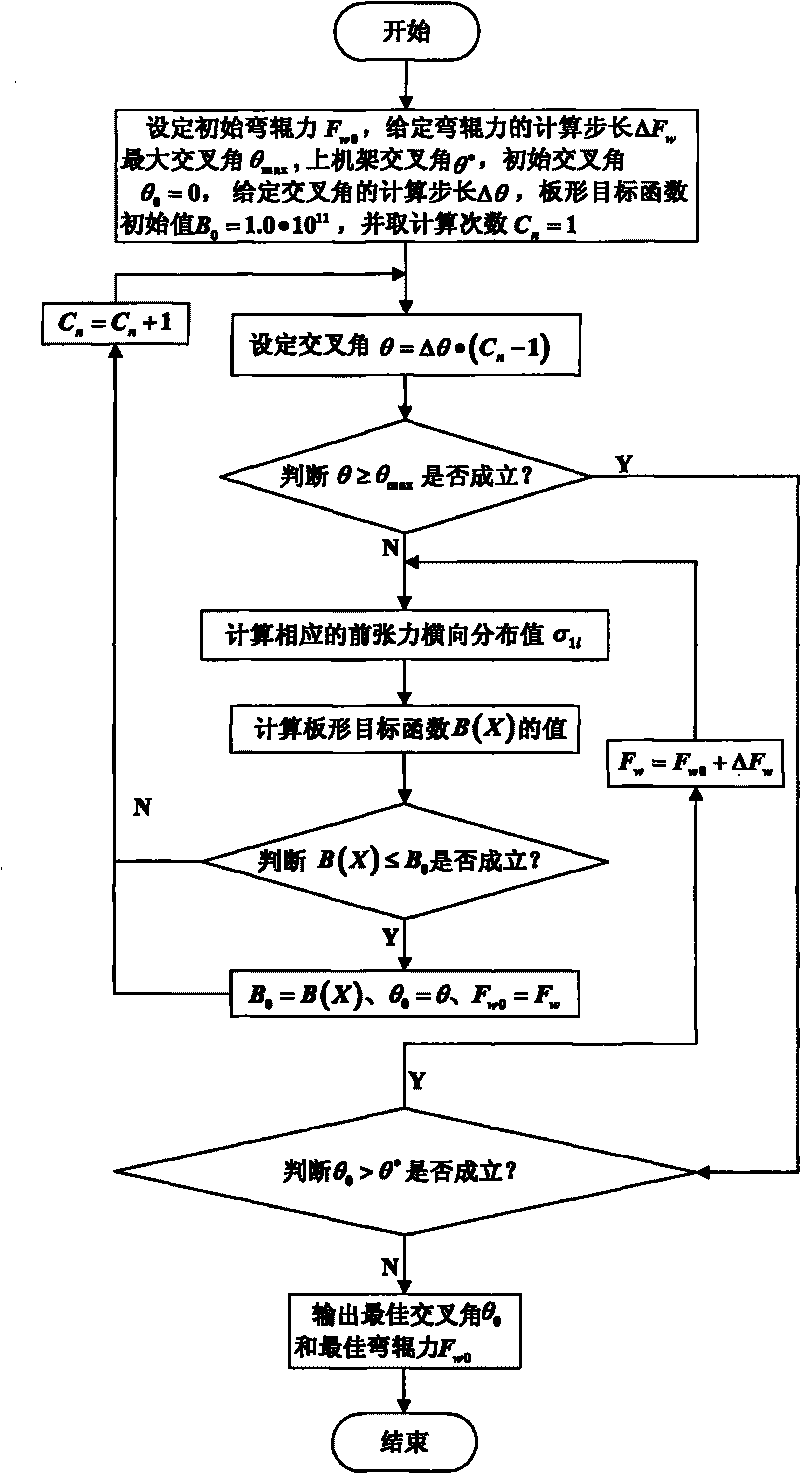

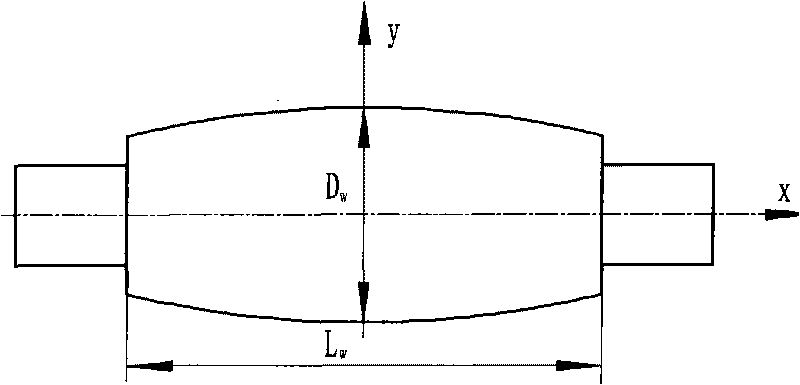

Crossing angle and roll bending force reduction based roll shape design method of work roll of PC rolling mill

InactiveCN101714177AImprove plate crown control abilityImprove stabilityRollsSpecial data processing applicationsWork rollStrip mill

The invention provides a crossing angle and roll bending force reduction based roll shape design method of a work roll of a PC rolling mill, aiming at the rolling characteristics of the PC rolling mill. The roll shape design method comprises the following steps of: (a) collecting equipment parameters and process parameters of the PC rolling mill; (b) collecting rolling process parameters of typical band steel; (c) setting a curve equation of the work roll; (d) optimally computing curve parameters of a roll shape; and (e) substituting the curve parameters of the roll shape into the roll shape curve equation of the work roll so as to obtain an optimized roll shape curve equation of the work roll. The invention enhances the stability of the PC rolling mill because a roll shape curve of the work roll reduces the crossing angle and the roll bending force, prolongs the service life of the work roll, enhances the convexity control capacity of the PC rolling mill, not only ensures the qualityrequirement of a profile shape, but also meets the requirement for industrial application precision, and can also be used for the roll shape curve design of the work roll of any rack according to actual field situation.

Owner:YANSHAN UNIV

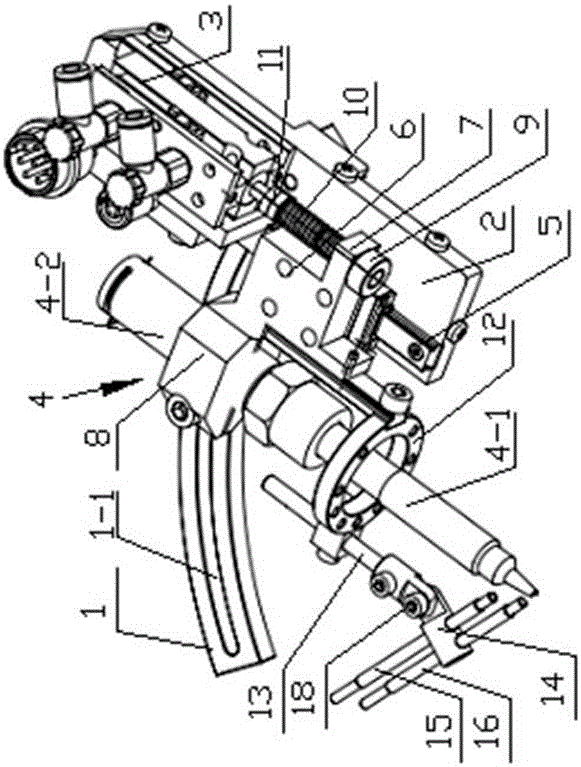

Welding gun device of soldering equipment

PendingCN106695051AFull transmissionEasy to send tin actionWelding/cutting auxillary devicesAuxillary welding devicesHeat transmissionEngineering

The invention provides a welding gun device of soldering equipment, and relates to the field of welding equipment. The welding gun device comprises an arc-shaped fixed support, a welding gun base, a lifting cylinder and a welding gun assembly. An arc-shaped groove is formed in the arc-shaped fixed support. A bolt is arranged in the arc-shaped groove. The back side of the welding gun base is connected with the bolt in the arc-shaped groove in a threaded mode so that the welding gun base can slide relative to the arc-shaped groove, and the welding gun base and the arc-shaped fixed support can be fixed into a whole by screwing the bolt. The welding gun assembly is mounted on the welding gun base in a vertical sliding mode. The lifting cylinder is mounted on the welding gun base and used for driving the welding gun assembly to slide along the welding gun base. According to the welding gun device of the soldering equipment, the welding gun base can slide relative to the arc-shaped sliding groove in the arc-shaped fixed support, and a welding gun is made to incline relative to a welded product so that tin can be fed conveniently, a welding head can be closely attached to the welded product effectively, a sufficient heat transmission is achieved, the quality and qualification rate of products are greatly increased accordingly, and pseudo soldering and soldering omission are completely eradicated.

Owner:江苏洛柳精密科技有限公司

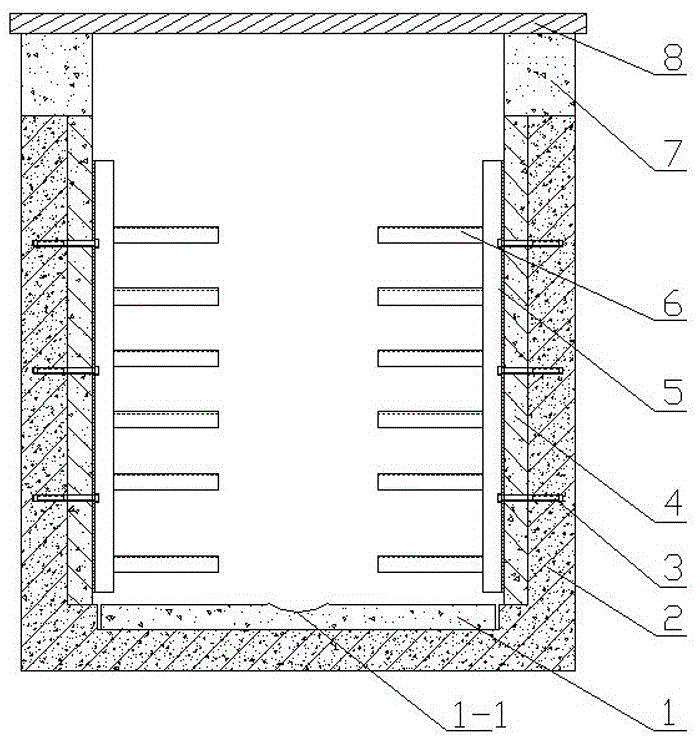

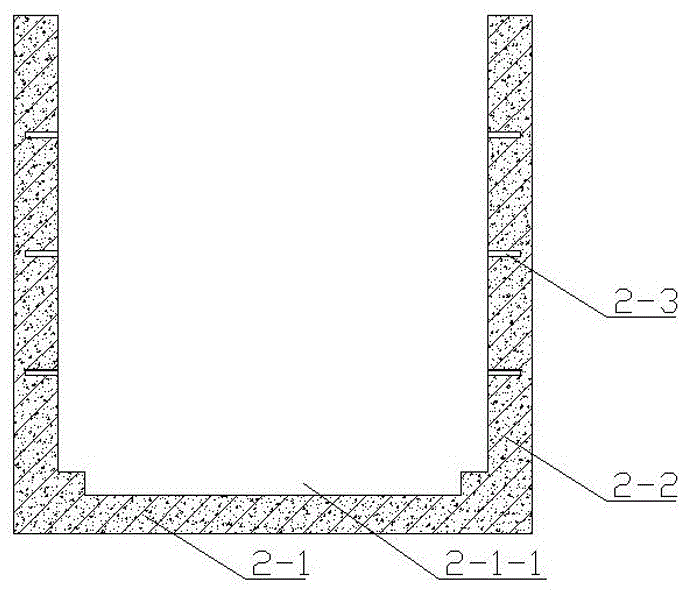

Assembly type electric cable trench and construction method therefor

InactiveCN106253188AReduce volumeAct as a frameCable installations on groundApparatus for laying cablesUltimate tensile strengthElectric cables

The invention discloses an assembly type electric cable trench and a manufacture method therefor. The assembly type electric cable trench comprises a U-shaped groove and a matching cover plate; the U-shaped groove comprises at least two U-shaped support racks having assembly holes, side vertical plates, electric cable support racks and base plates tiled on bottom parts of the U-shaped support racks; the side vertical plates and the electric cable support racks are respectively and orderly connected with stand columns at two sides of the U-shaped support racks in an assembled manner via use of connecting pieces; the U-shaped groove is formed between the at least two U-shaped support racks by the side vertical plates and the base plates via use of sealing gum. According to the assembly type electric cable trench, components are prefabricated or processed based on marked design; split type transport and on-site ground pit excavation are conducted; manufacture of a cushion ply layer is completed; after steel angles are welded on the cable support racks, the electric cable trench can be assembled via the connecting pieces such as screw bolts and the like. According to the assembly type electric cable trench disclosed in a technical solution of the invention, the U-shaped groove is broken up into the U-shaped support racks functioning as frames, the base plates having plate type structures and the side vertical plates; convenience of transportation can be realized, and strength of the electric cable trench is improved via the U-shaped support racks functioning as the frames.

Owner:河北超能投资管理有限公司 +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com