E40 high-strength ship plate steel and method for manufacturing same

A ship plate steel, high-strength technology, applied in the field of E40 high-strength ship plate steel and its preparation, can solve the problems of large deformation resistance of wide and thick rolled pieces, harsh requirements for rolling mill equipment, uneven temperature gradient structure, etc., and achieve good welding performance and microstructure Good uniformity control and uniform tissue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

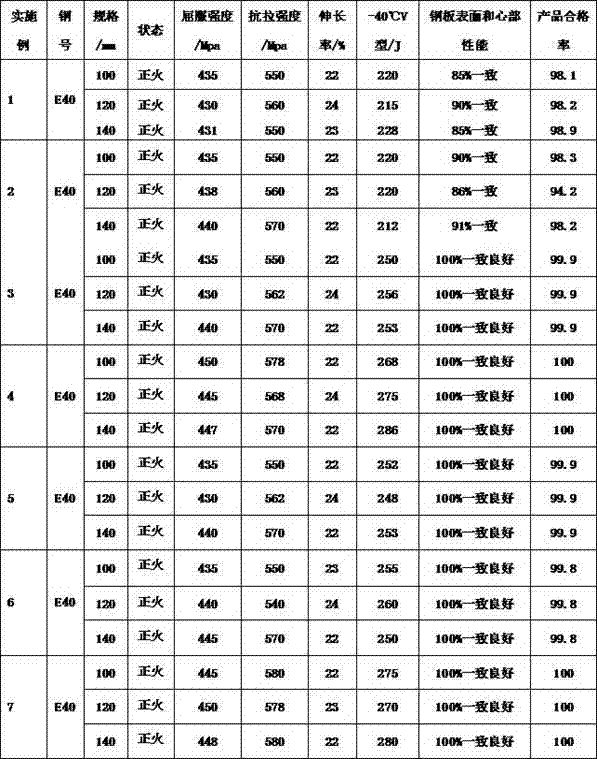

Examples

Embodiment 1

[0029] Embodiment 1, a kind of E40 high-strength ship plate steel, comprises following chemical composition according to quality percentage : C: 0.13%, Si: 0.25%, Mn: 1.56%, P: ≤0.03%, S: ≤0.005%, Ni: 0.25%, V: 0.035%, Nb: 0.030%, Ti: 0.015%, Als: 0.020%, the balance is Fe.

[0030] The preparation method of the above-mentioned E40 high-strength ship plate steel is as follows. In the molten iron pretreatment process, the molten iron at the station must remove the front slag and the rear slag to ensure that the thickness of the slag layer on the liquid surface is ≤20mm. %, to ensure desulfurization cycle ≤ 21min, desulfurization temperature drop ≤ 20 ℃.

[0031] In the converter smelting process, S≤0.005% and P≤0.080% of the molten iron into the furnace, the temperature of the molten iron is ≥1270°C, the loading error of the molten iron is controlled by ±1t, the scrap steel is strictly made of high-quality leftover materials, and the position of the process gun is 1.0~ 1.3m...

Embodiment 2

[0039] Example 2, an E40 high-strength ship plate steel, which contains the following chemical components by mass percentage: C: 0.16%, Si: 0.30%, Mn: 1.6%, P: ≤0.03%, S: ≤0.005%, Ni: 0.35%, V: 0.045%, Nb: 0.040%, Ti: 0.020%, Als: 0.030%, and the balance is Fe.

[0040] The preparation method of the above-mentioned E40 high-strength ship plate steel is as follows. In the molten iron pretreatment process, the molten iron at the station must remove the front slag and the rear slag to ensure that the thickness of the slag layer on the liquid surface is ≤20mm. %, to ensure desulfurization cycle ≤ 21min, desulfurization temperature drop ≤ 20 ℃.

[0041] In the converter smelting process, S≤0.005% and P≤0.080% of the molten iron into the furnace, the temperature of the molten iron is ≥1270°C, the loading error of the molten iron is controlled by ±1t, the scrap steel is strictly made of high-quality leftover materials, and the position of the process gun is 1.0~ 1.3m, mid-term 1.2-1...

Embodiment 3

[0049] Example 3, an E40 high-strength ship plate steel, comprising the following chemical components by mass percentage: C: 0.14%, Si: 0.25%, Mn: 1.5%, P: ≤0.025%, S: ≤0.005%, Ni: 0.006%, V: 0.001%, Nb: 0.006%, Ti: 0.010%, Als: 0.015%, and the balance is Fe.

[0050] The preparation method of the above-mentioned E40 high-strength ship plate steel is as follows. In the molten iron pretreatment process, the molten iron at the station must remove the front slag and the rear slag to ensure that the thickness of the slag layer on the liquid surface is ≤20mm. %, to ensure desulfurization cycle ≤ 21min, desulfurization temperature drop ≤ 20 ℃.

[0051] In the converter smelting process, S≤0.005% and P≤0.080% of the molten iron into the furnace, the temperature of the molten iron is ≥1270°C, the loading error of the molten iron is controlled by ±1t, the scrap steel is strictly made of high-quality leftover materials, and the position of the process gun is 1.0~ 1.3m, mid-term 1.2-1.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com