Patents

Literature

431 results about "Degasser" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A degasser is a device used in drilling to remove gasses from drilling fluid which could otherwise form bubbles.

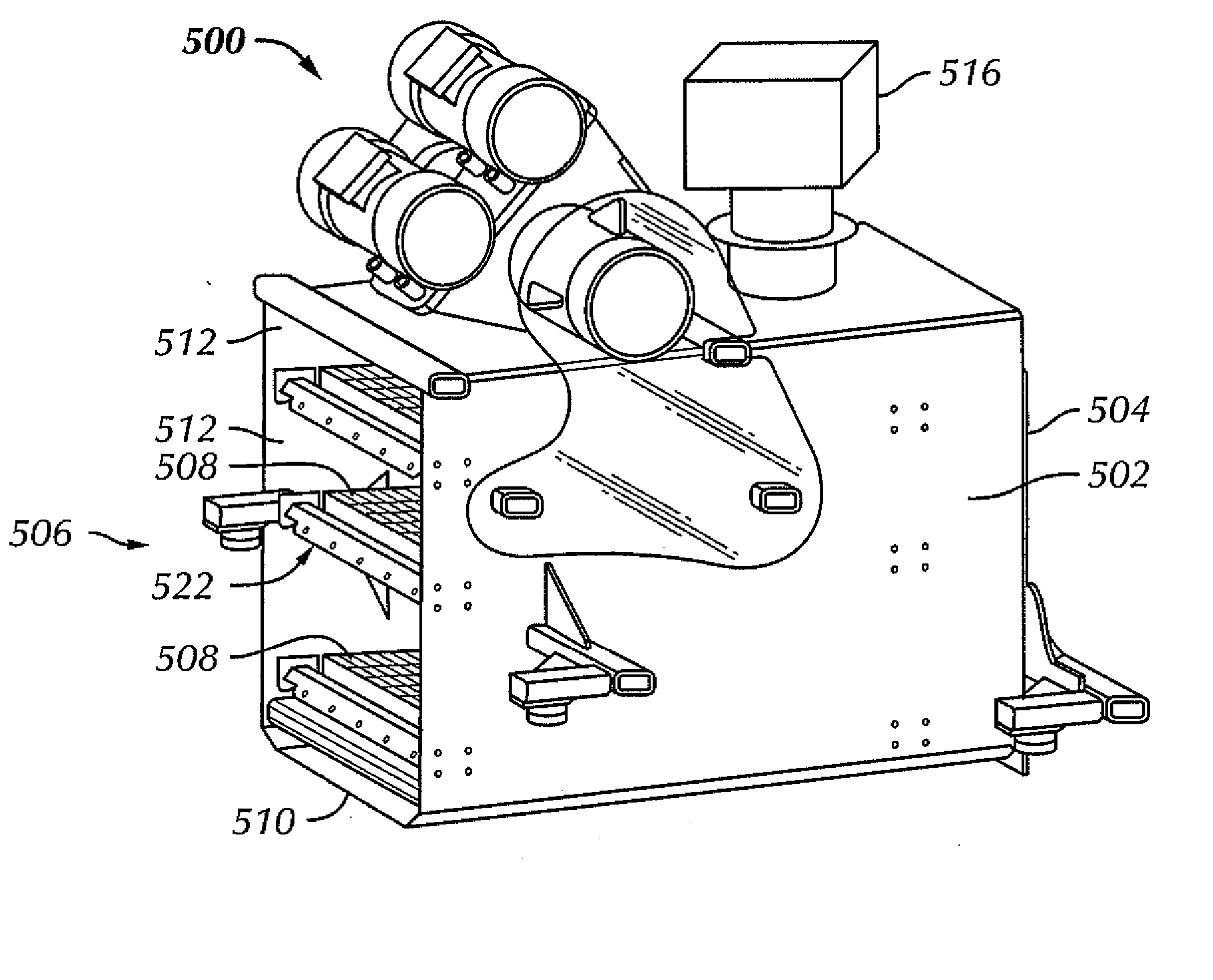

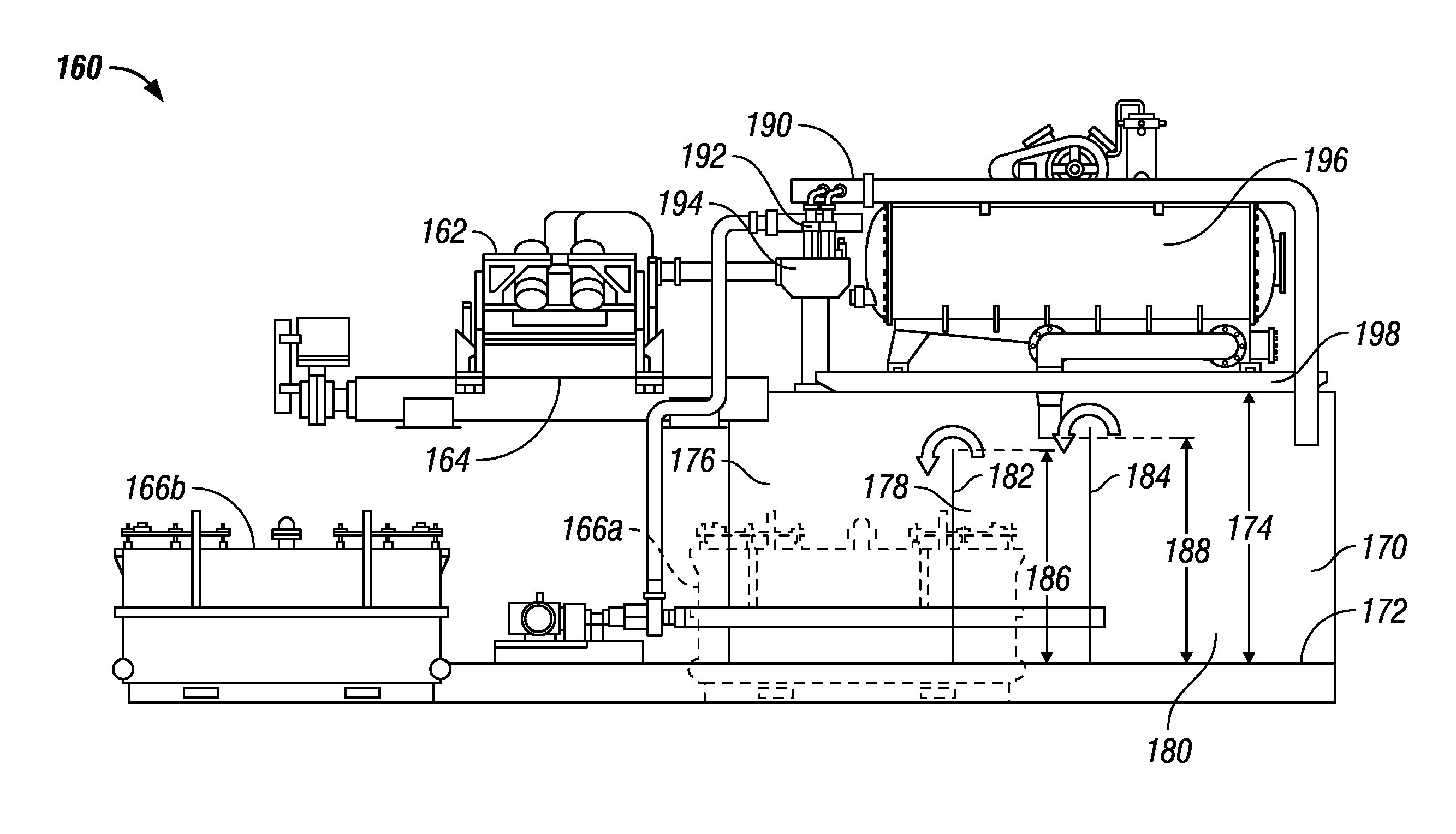

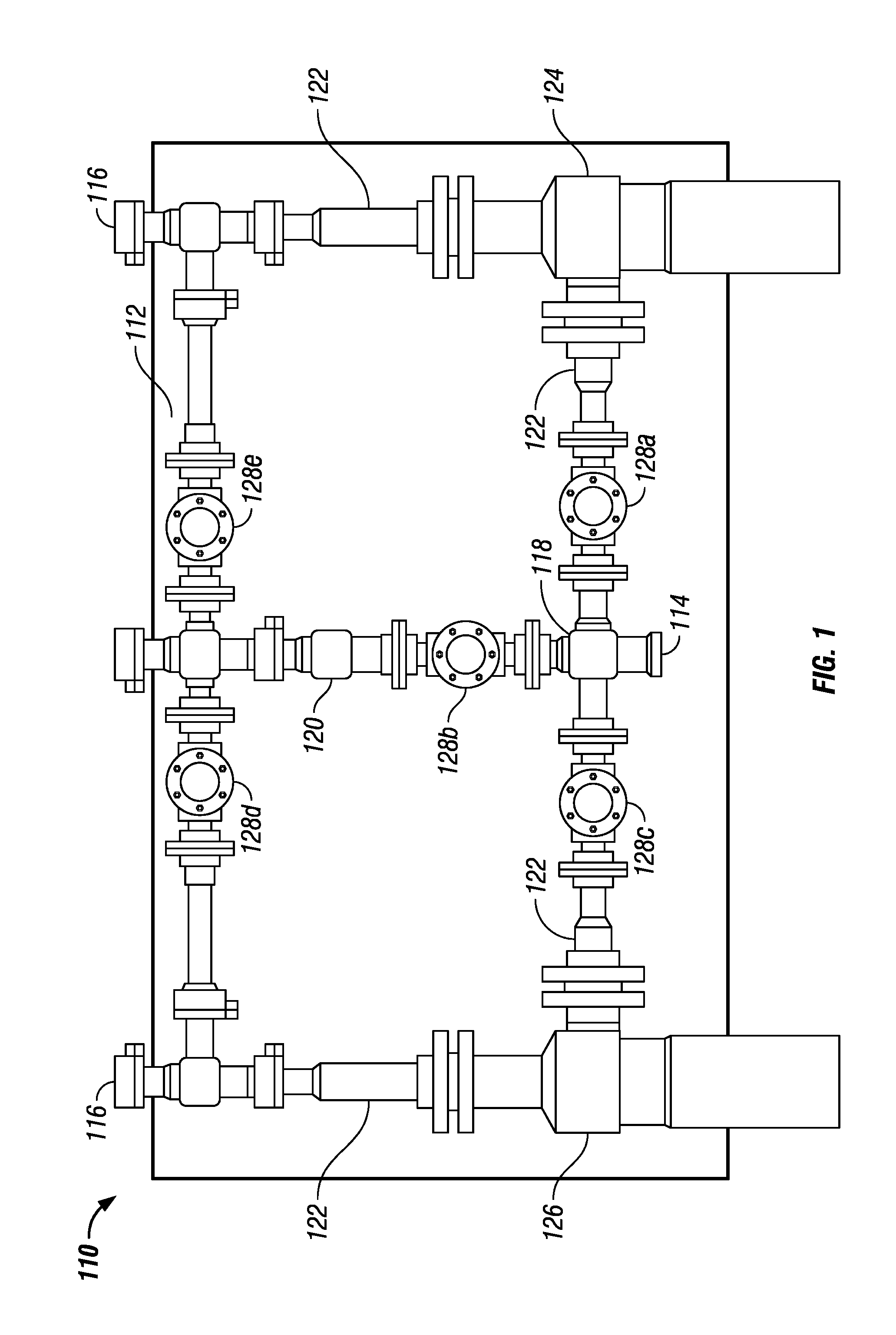

Shaker and degasser combination

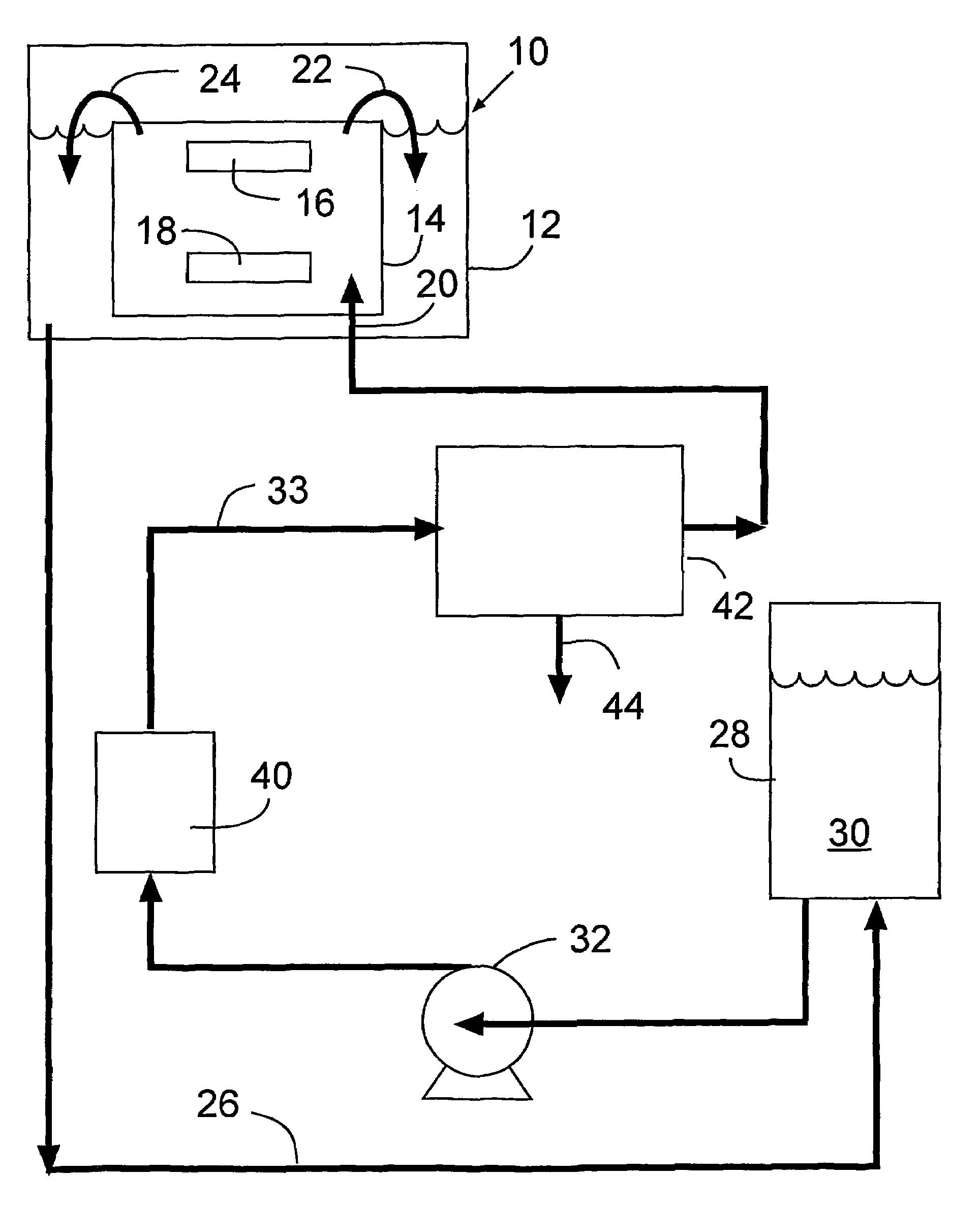

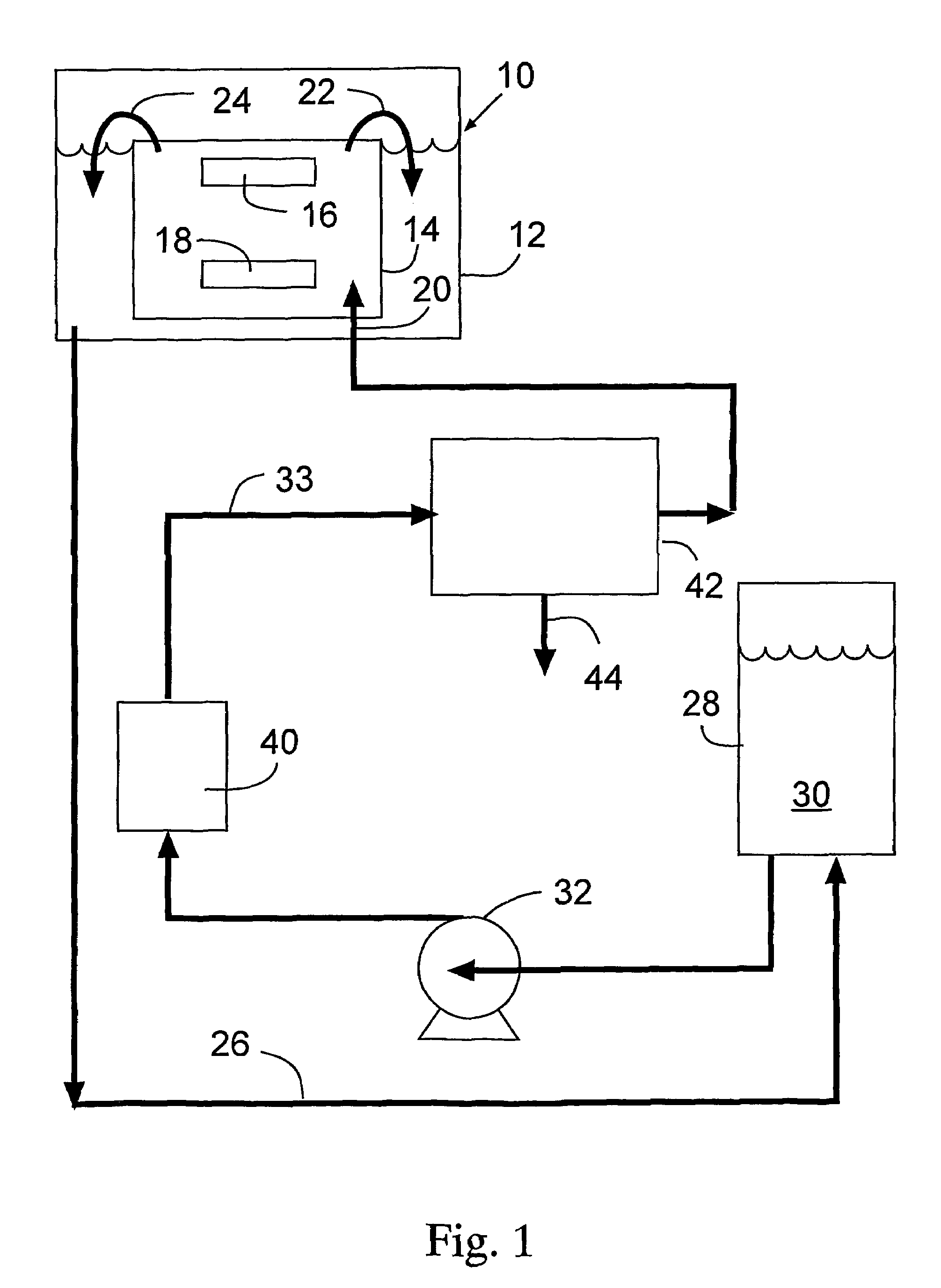

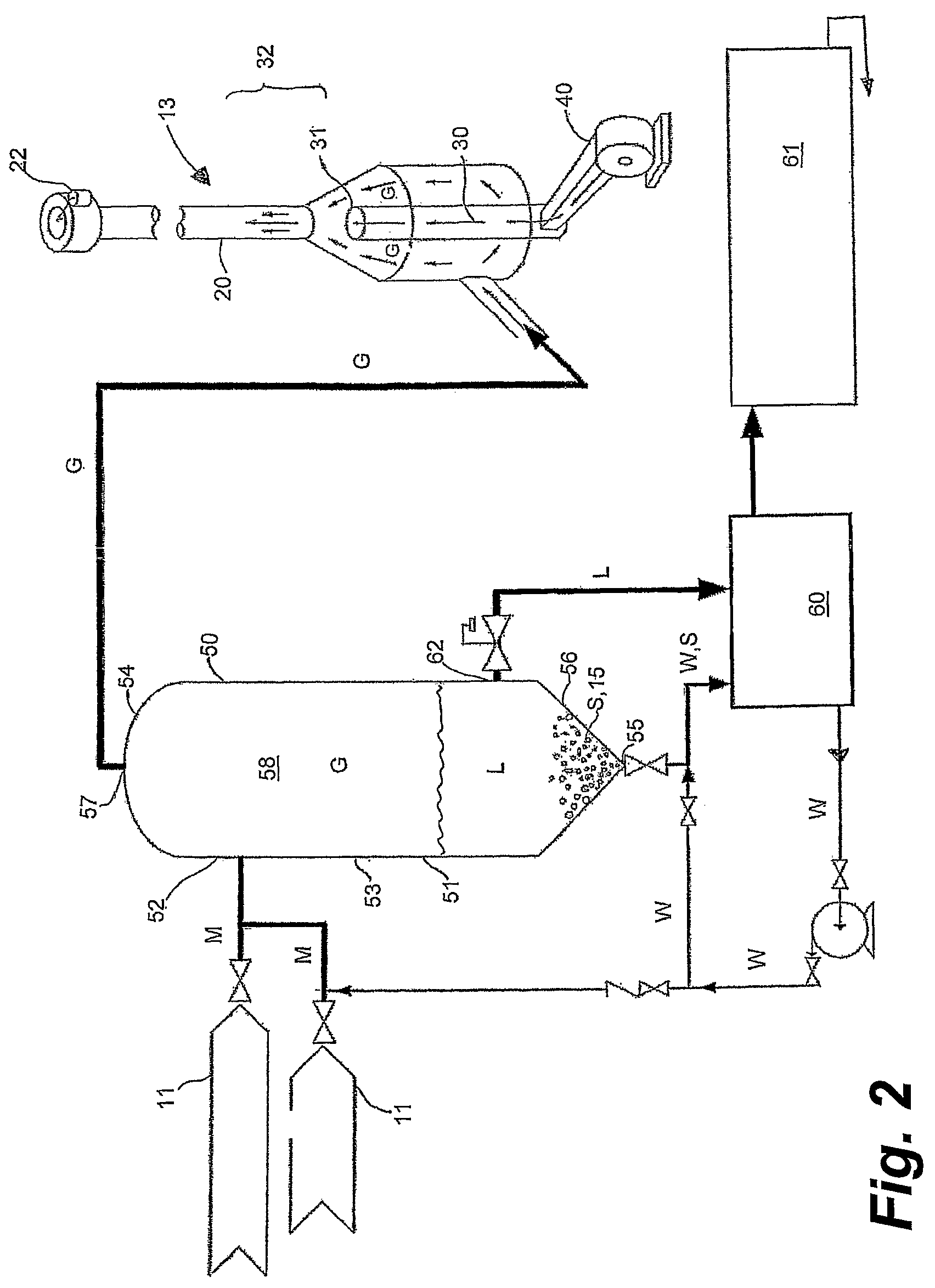

A system for separating components of a slurry is disclosed, the system including a housing; a basket for holding at least one shaker screen, the basket movably mounted in the housing; at least one vibrator coupled to the basket; a sump disposed below the basket to collect at least a portion of the slurry passing through the at least one shaker screen; a pressure differential device fluidly connected to the sump for developing a pressure differential across the at least one shaker screen; and a toggling device for toggling the pressure differential across the screen. A system including a degassing chamber fluidly connected to a sump and a pressure differential device, wherein the degassing chamber is disposed between the sump and the pressure differential device, and a fluid conduit fluidly connected to the degassing chamber for recovering a degassed fluid is also disclosed.

Owner:MI

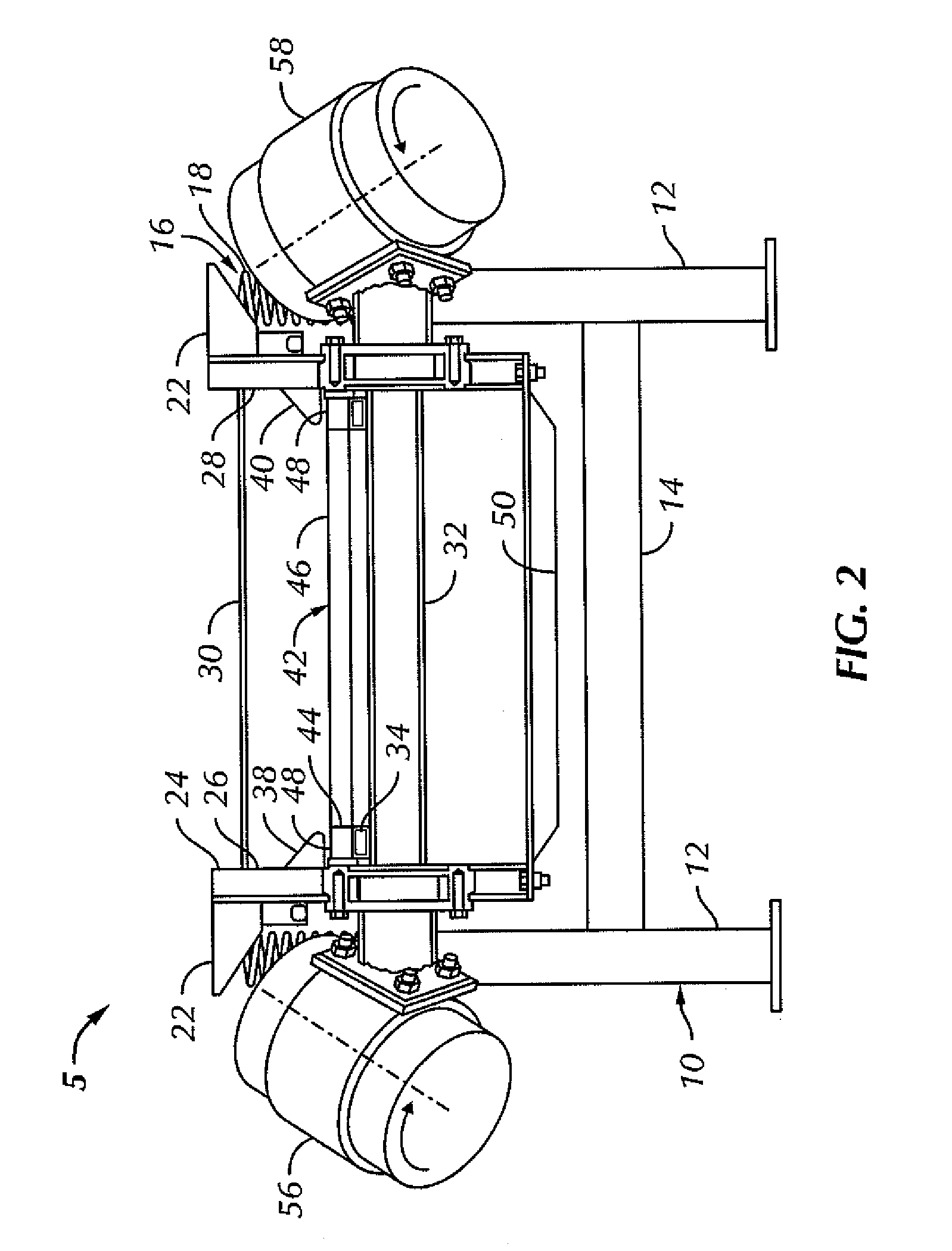

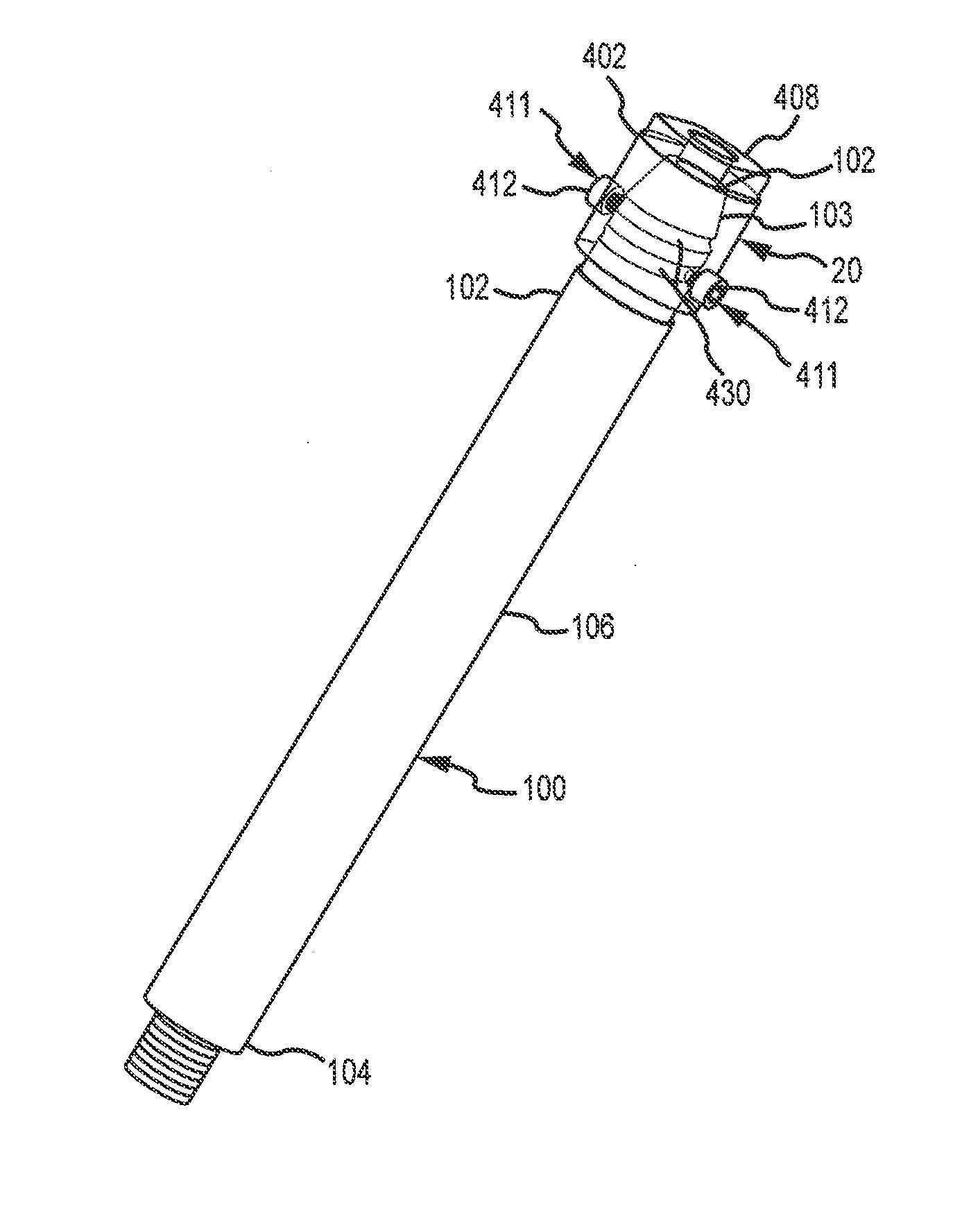

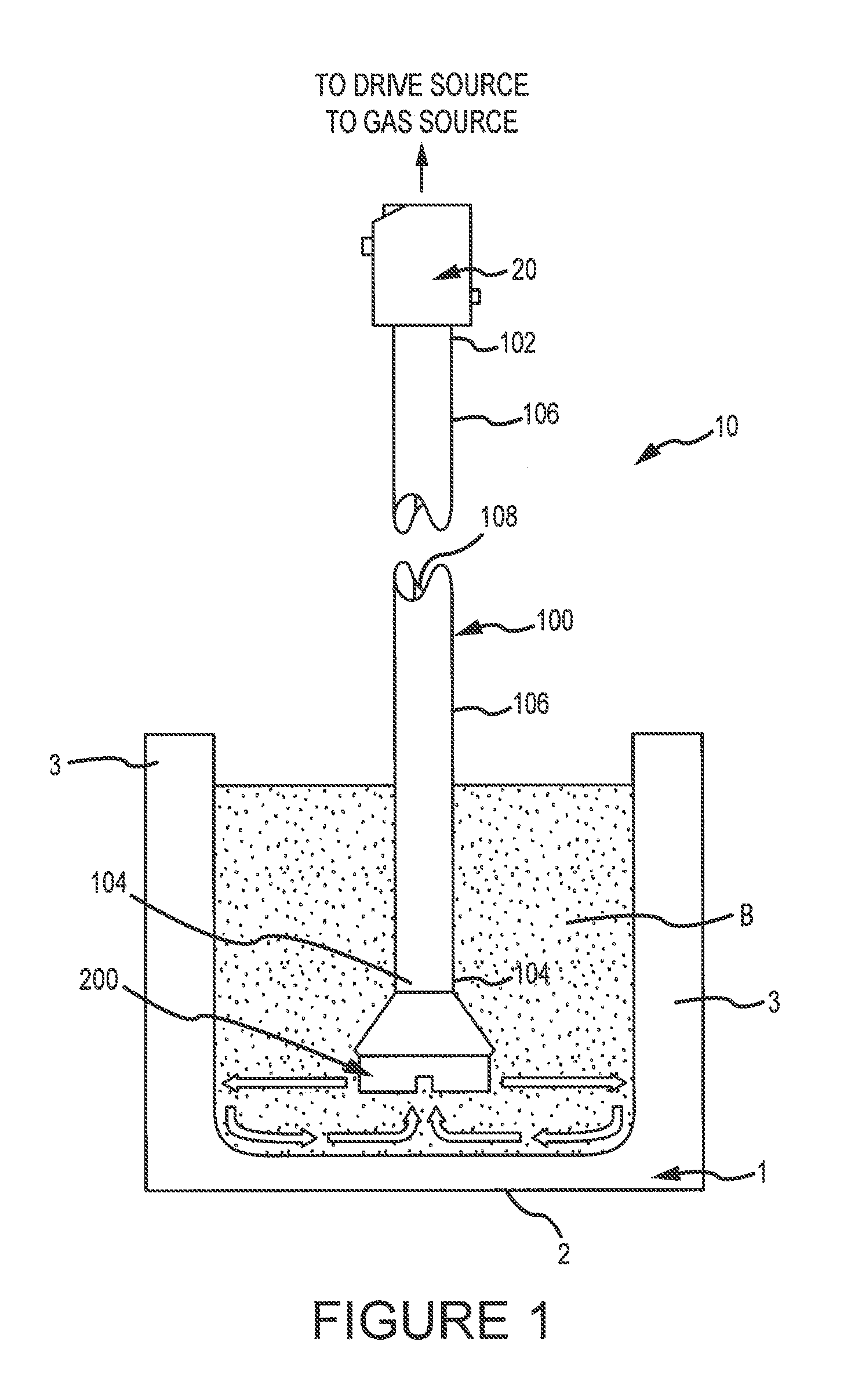

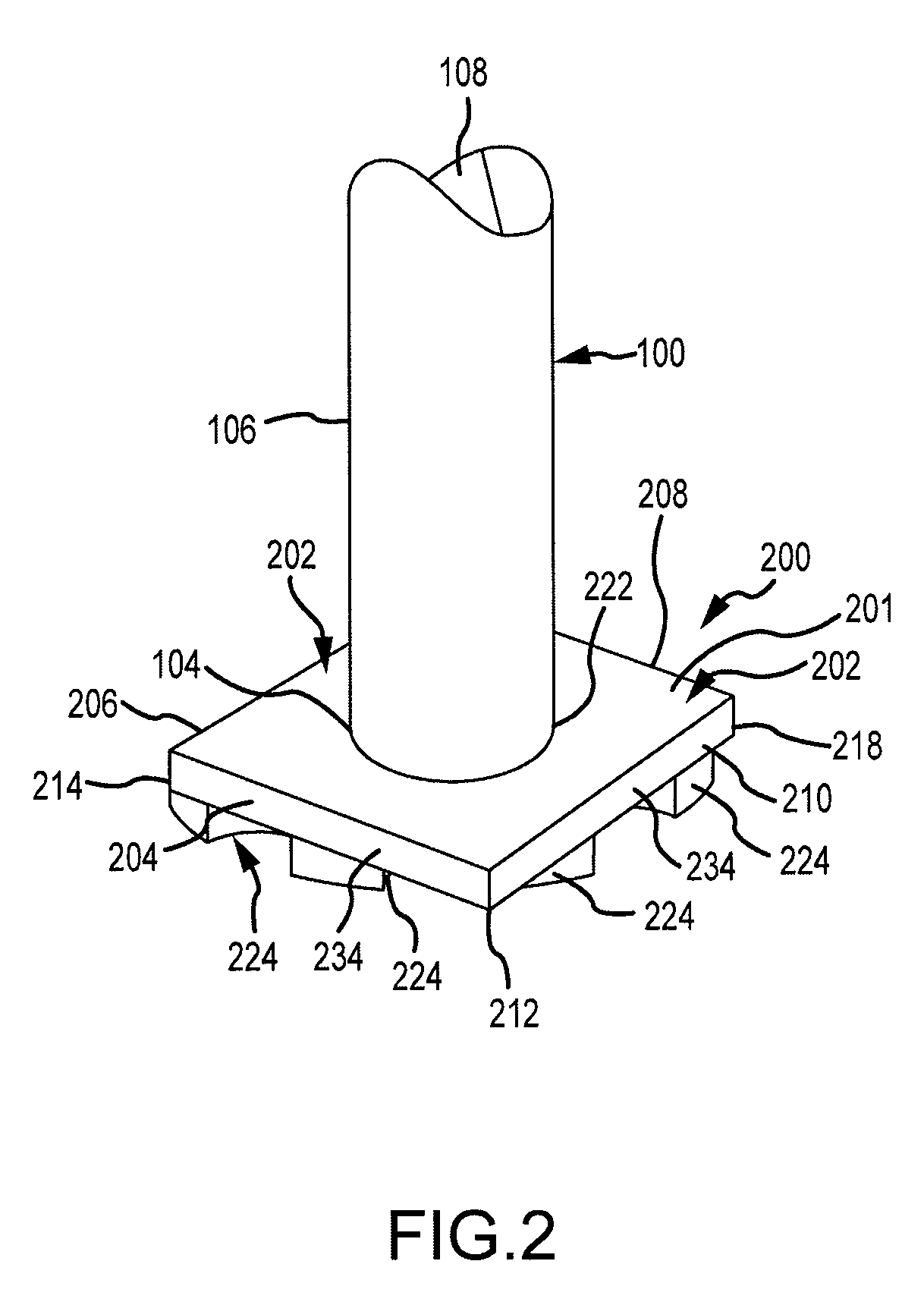

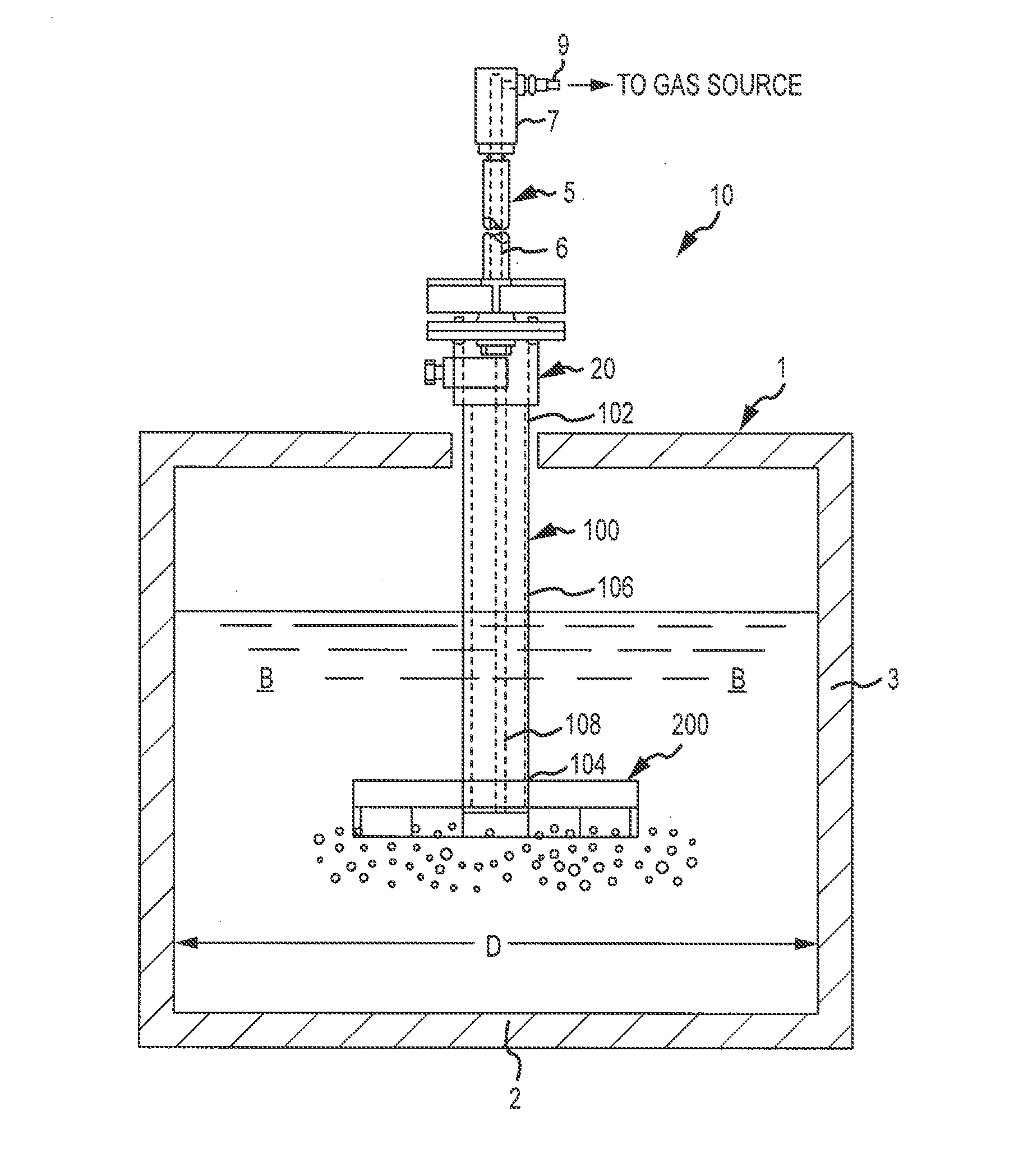

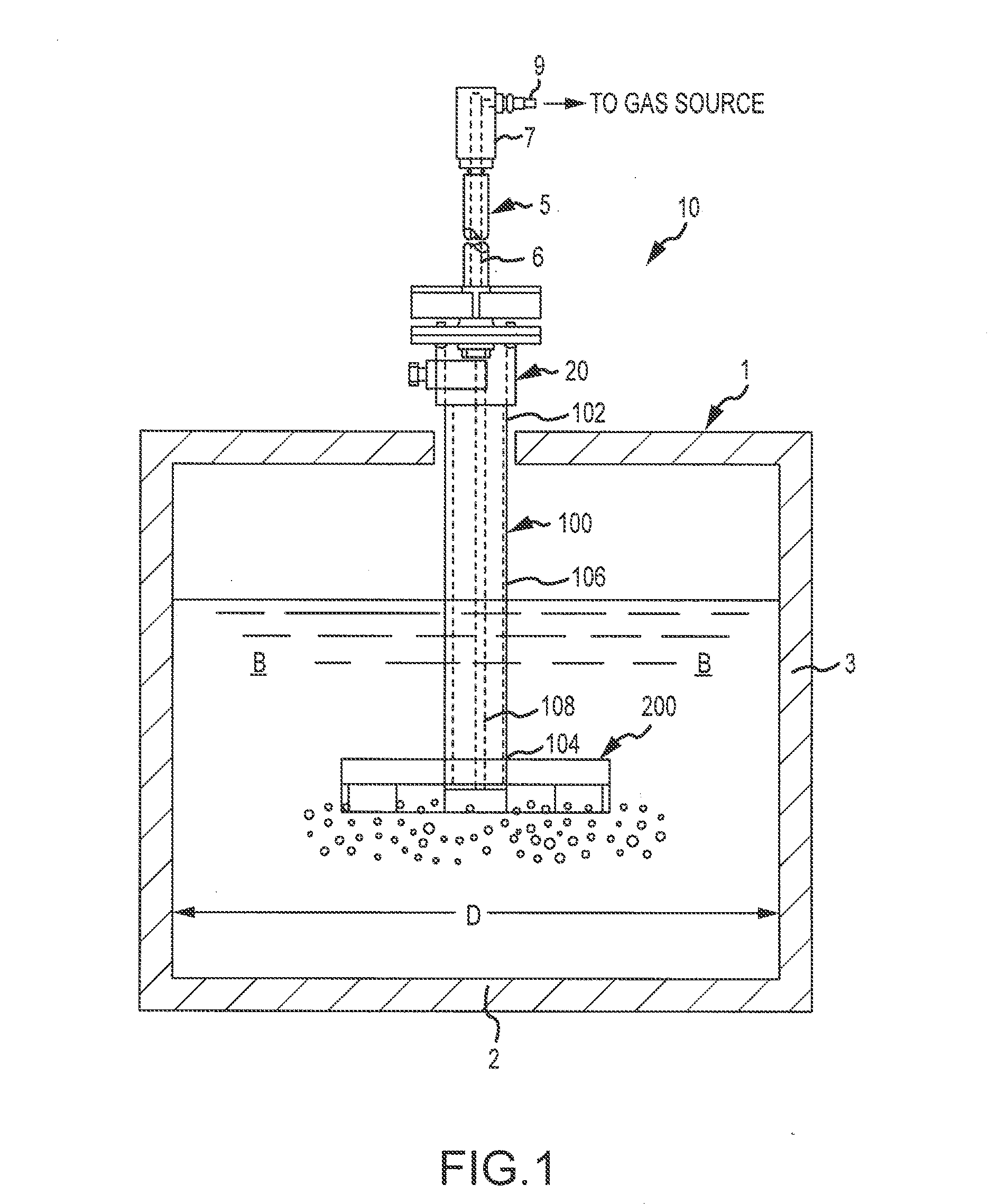

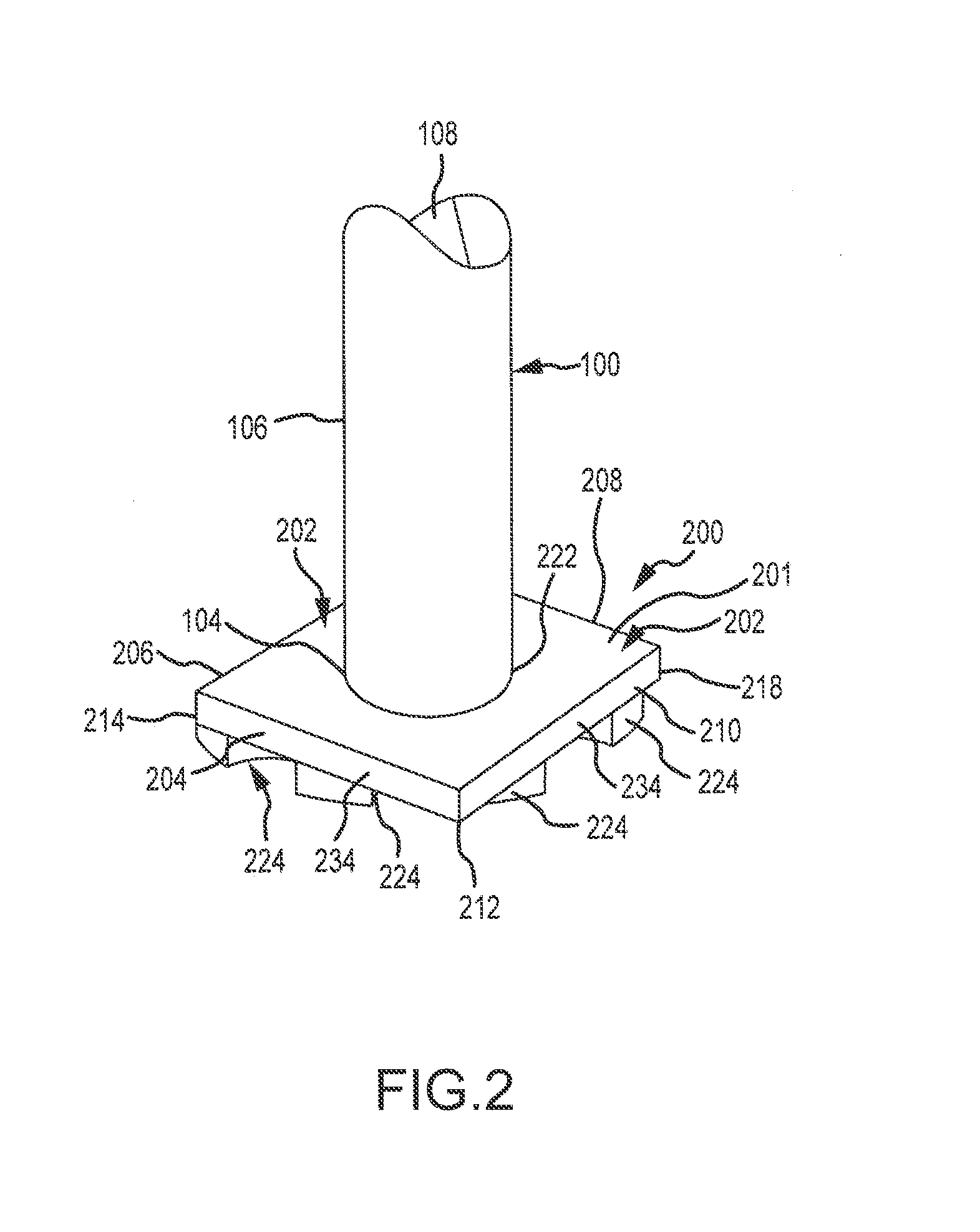

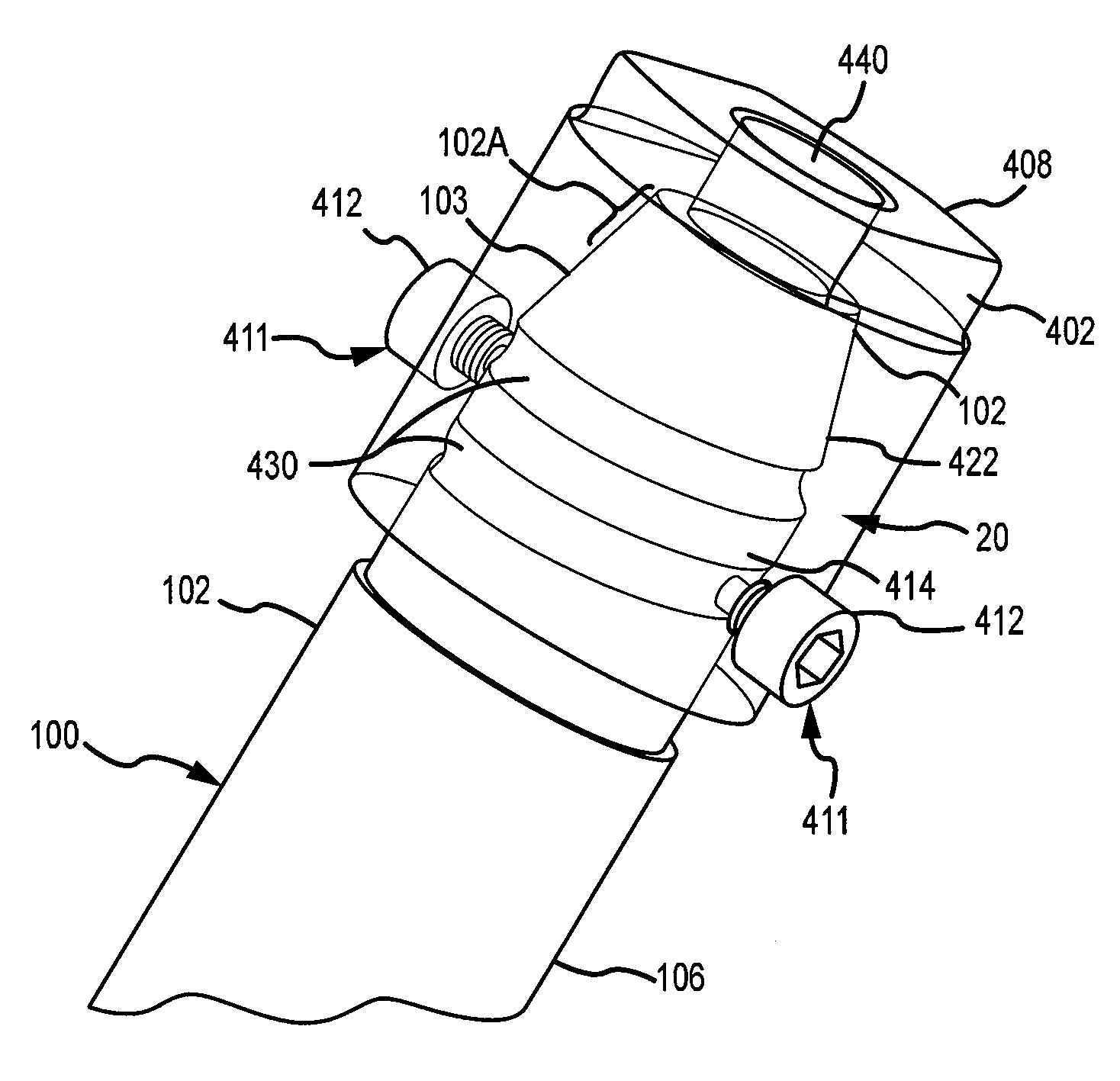

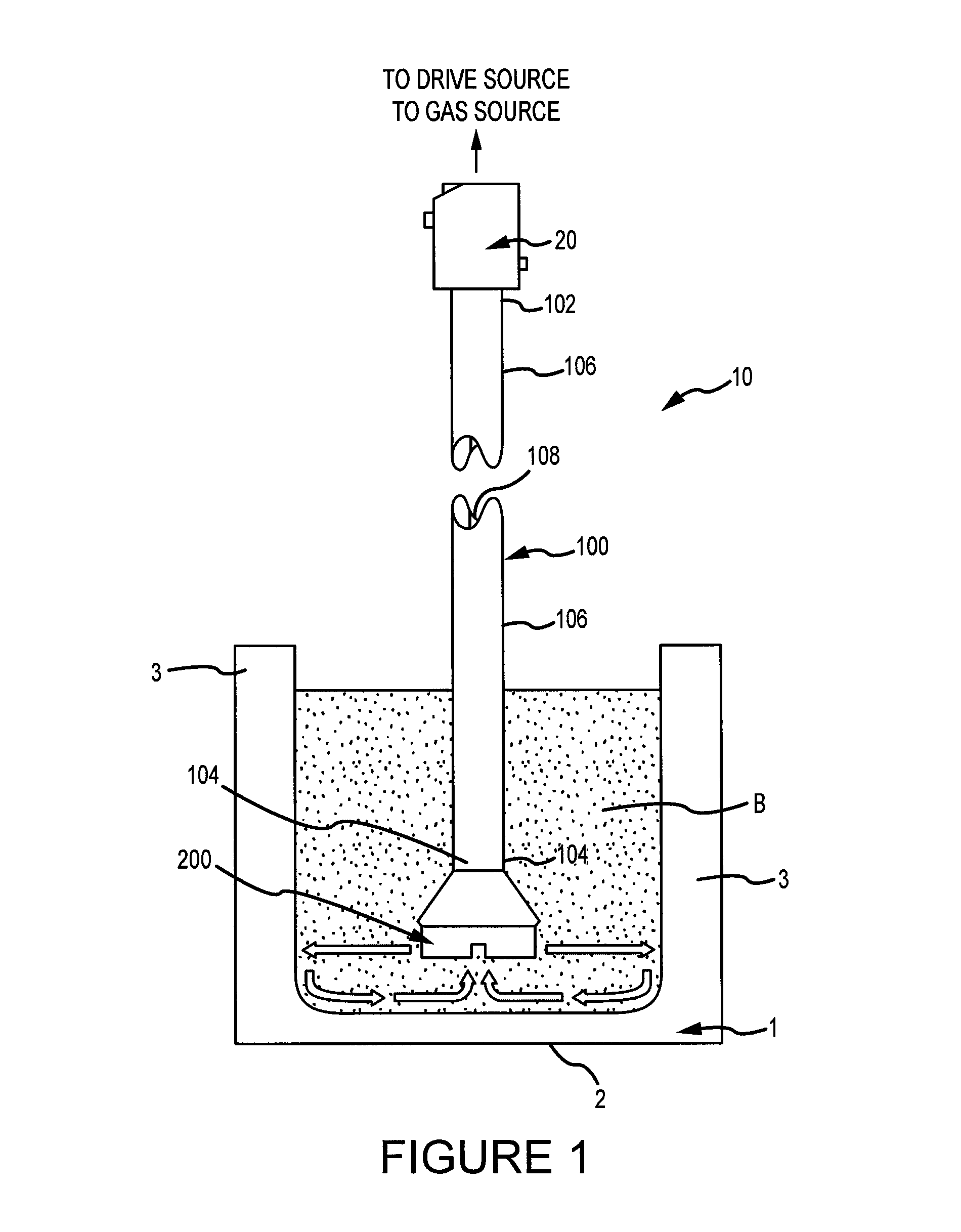

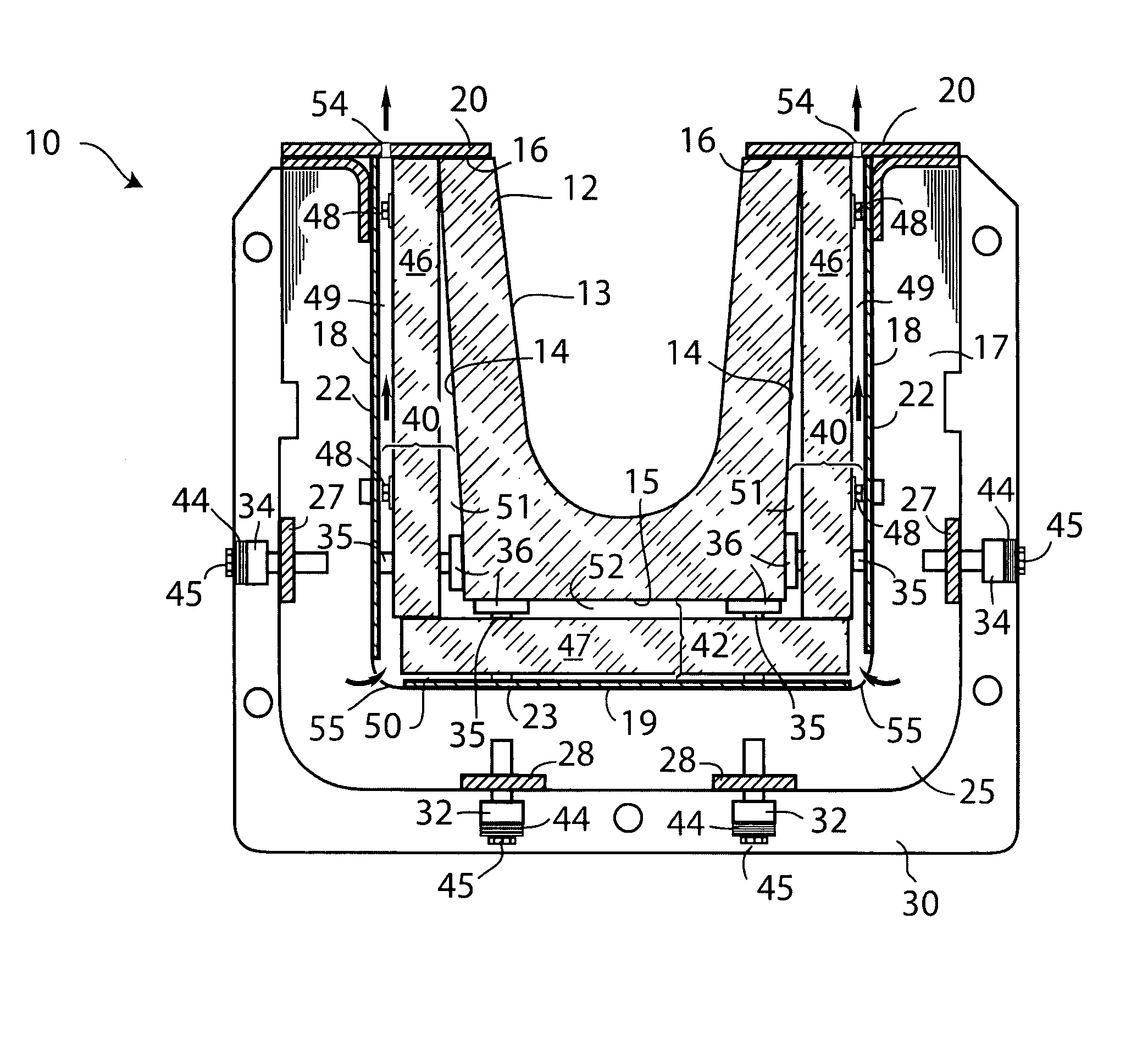

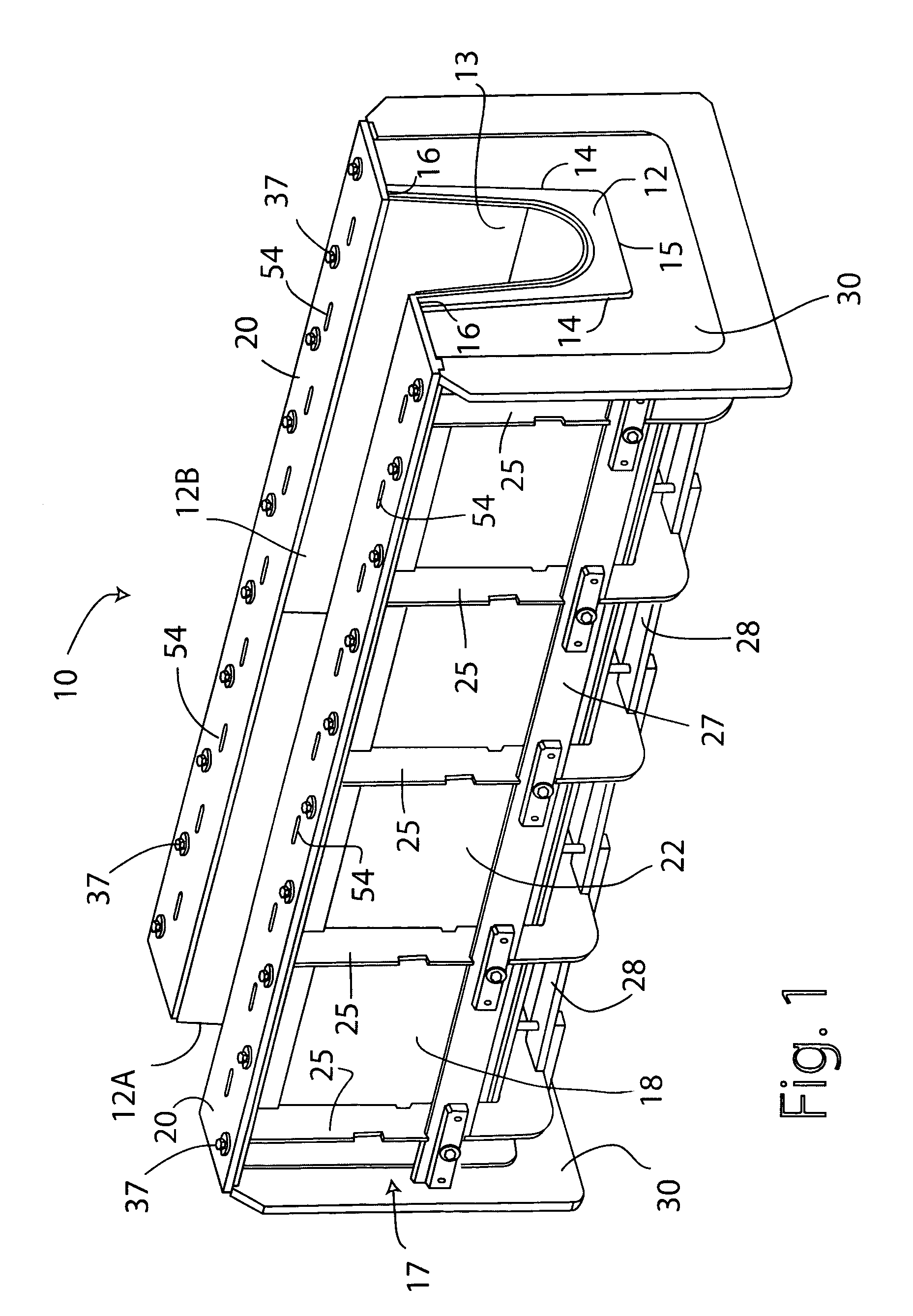

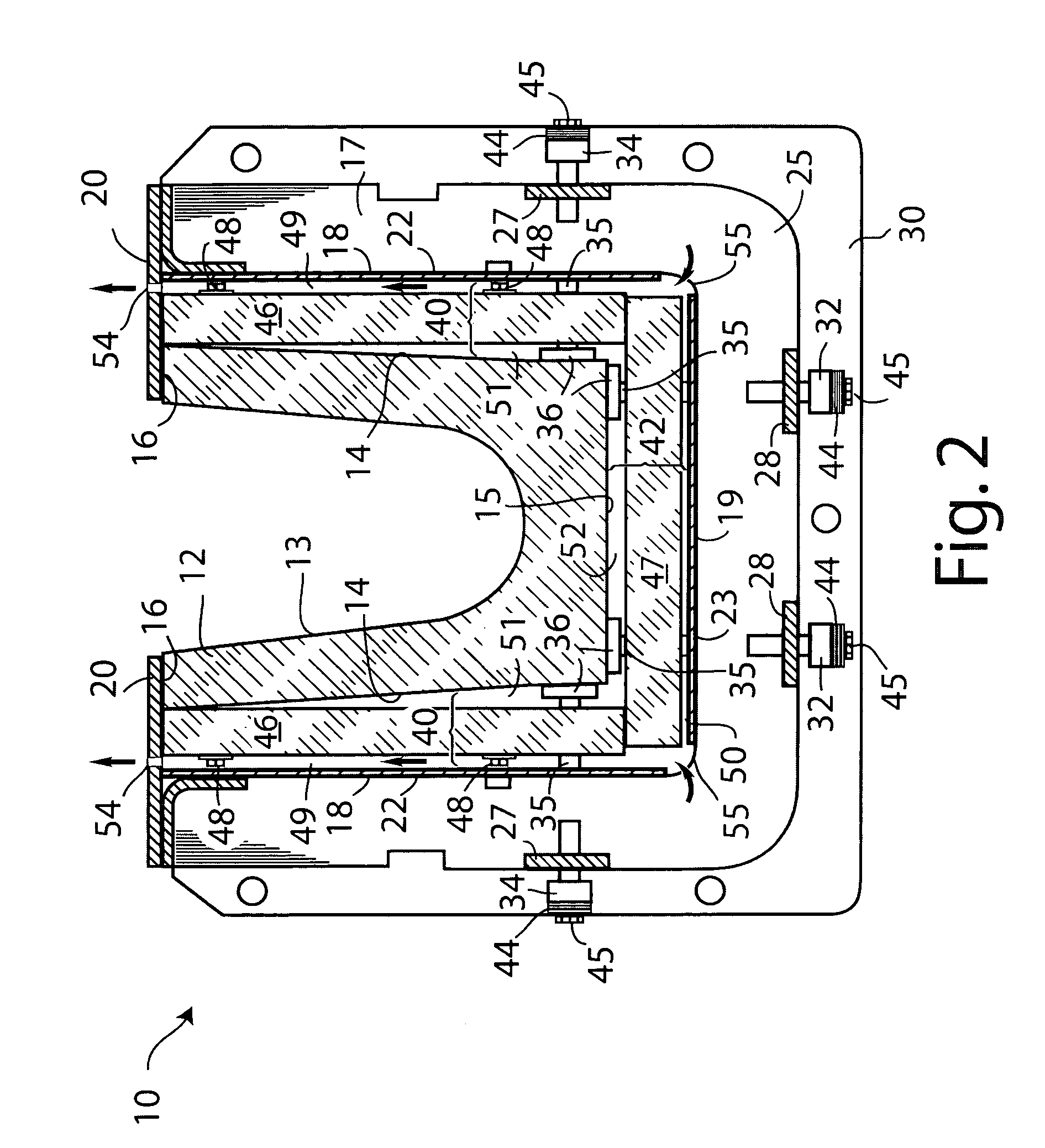

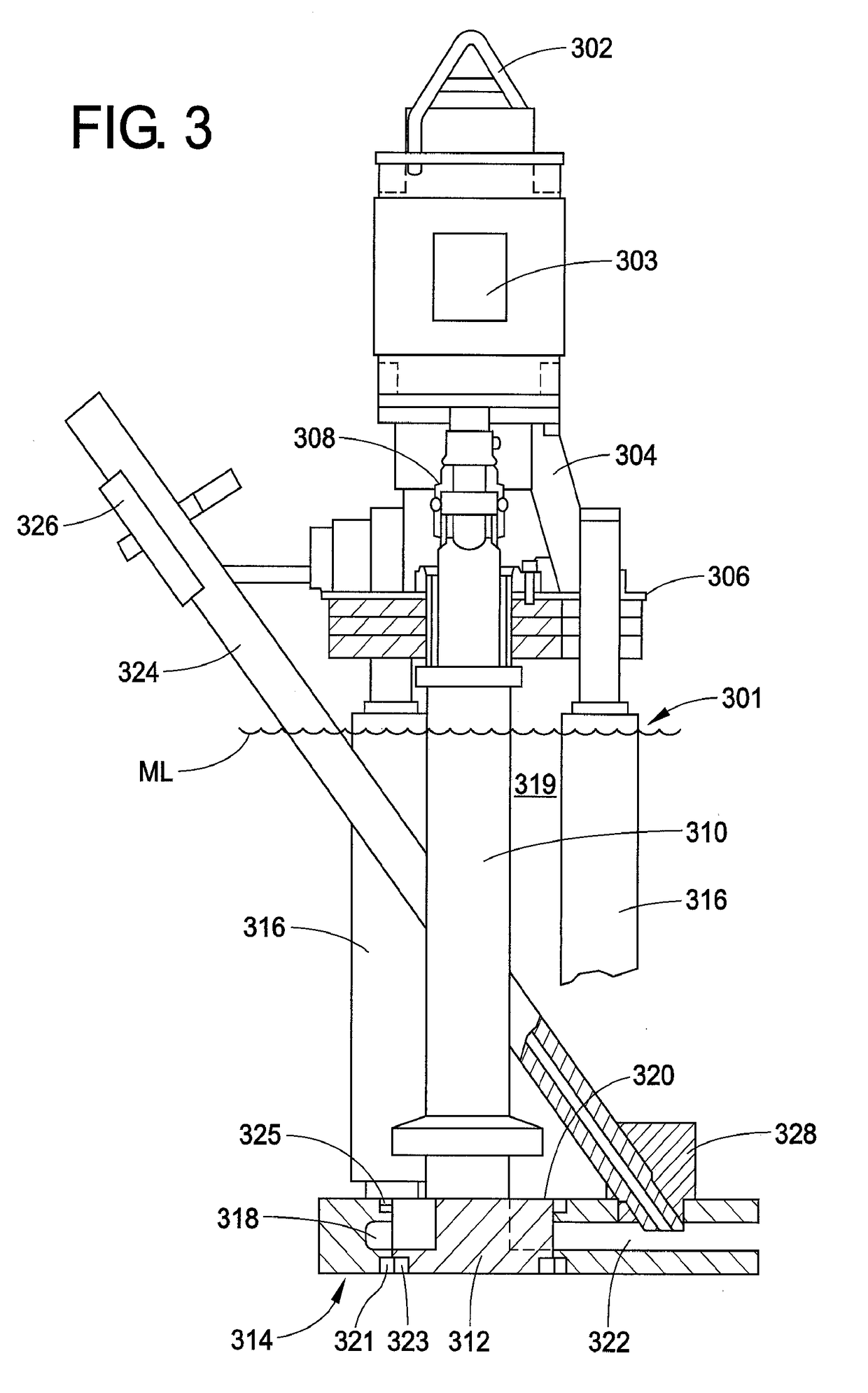

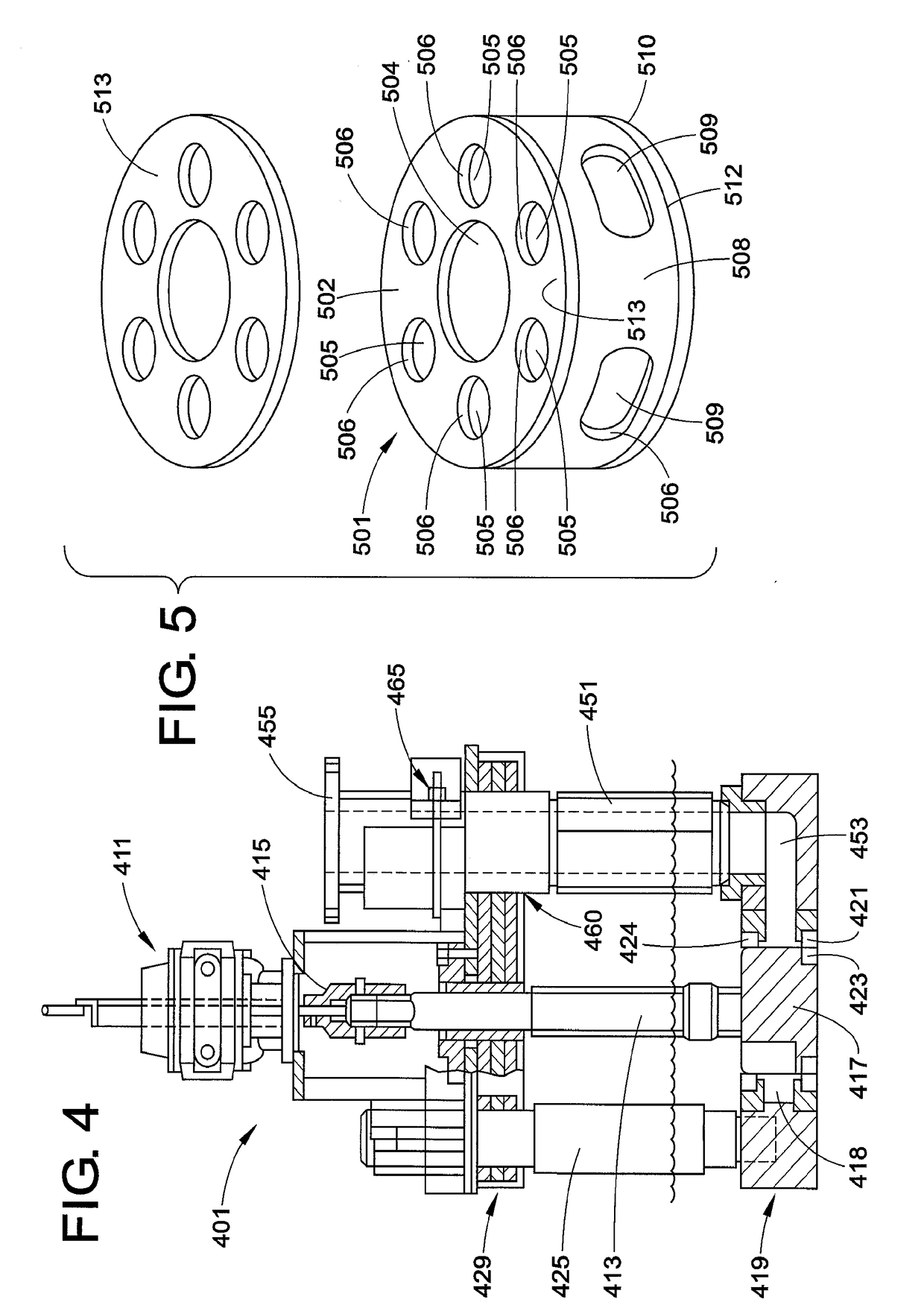

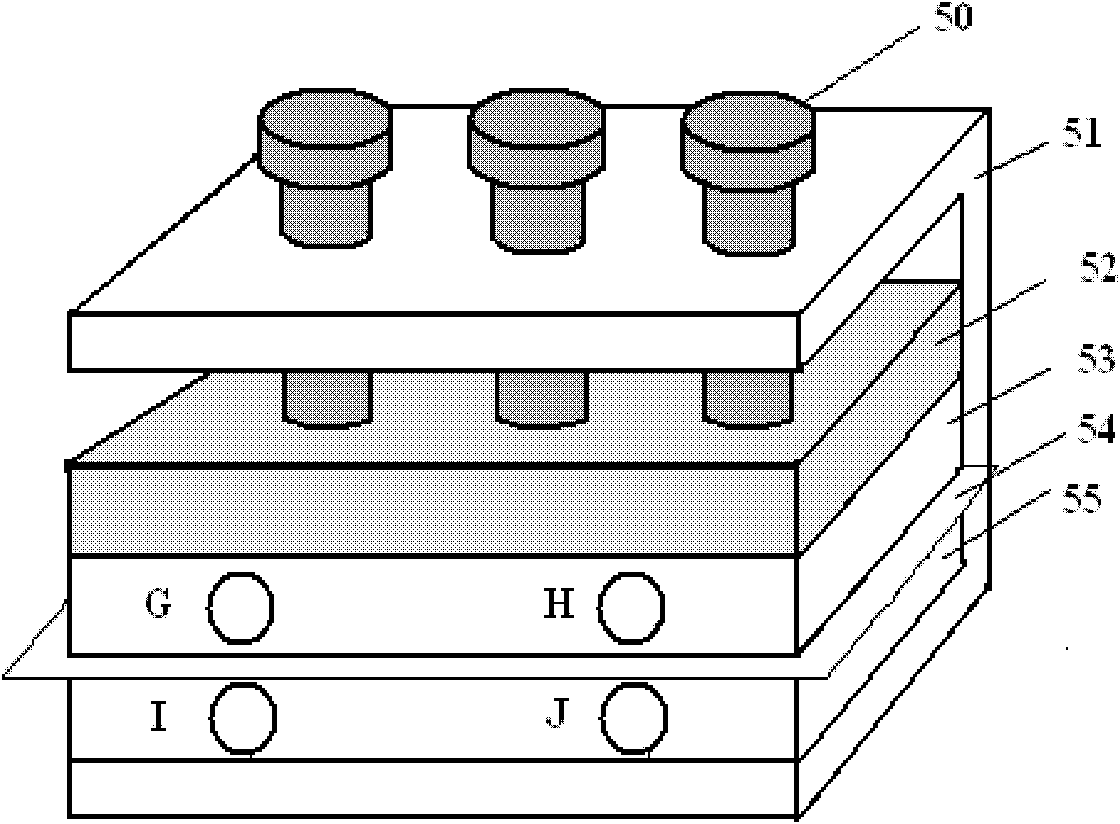

Rotary degassers and components therefor

Disclosed are degassers, couplings, impeller shafts and impellers for use in molten metal. One such coupling transfers gas into an impeller shaft, the coupling having a smooth, tapered internal surface to align with a corresponding surface on the impeller shaft and help prevent gas leakage and to assist in preventing damage to the impeller shaft. Improved impellers for shearing and mixing gas are also disclosed, as is a degasser including one or more of these components.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

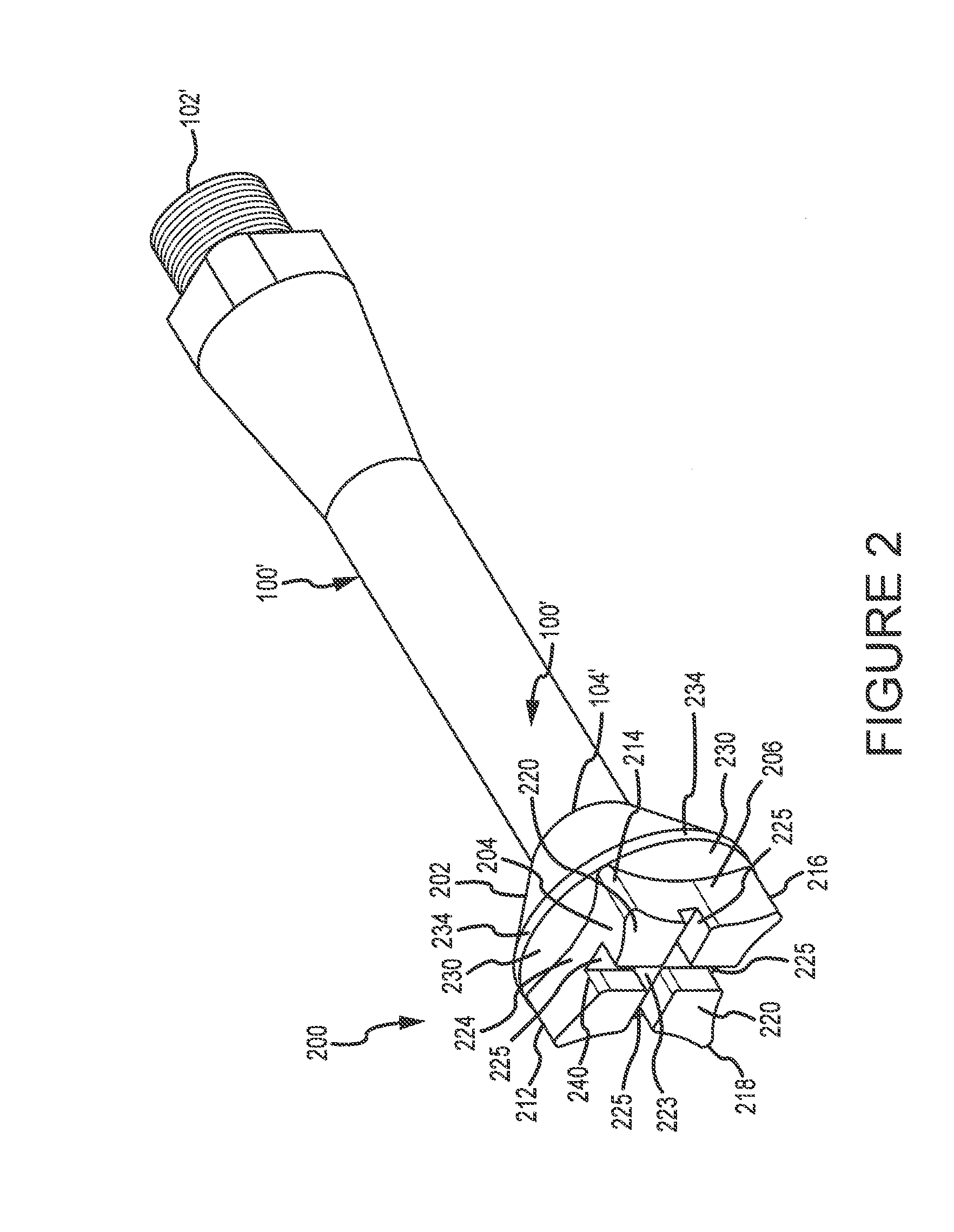

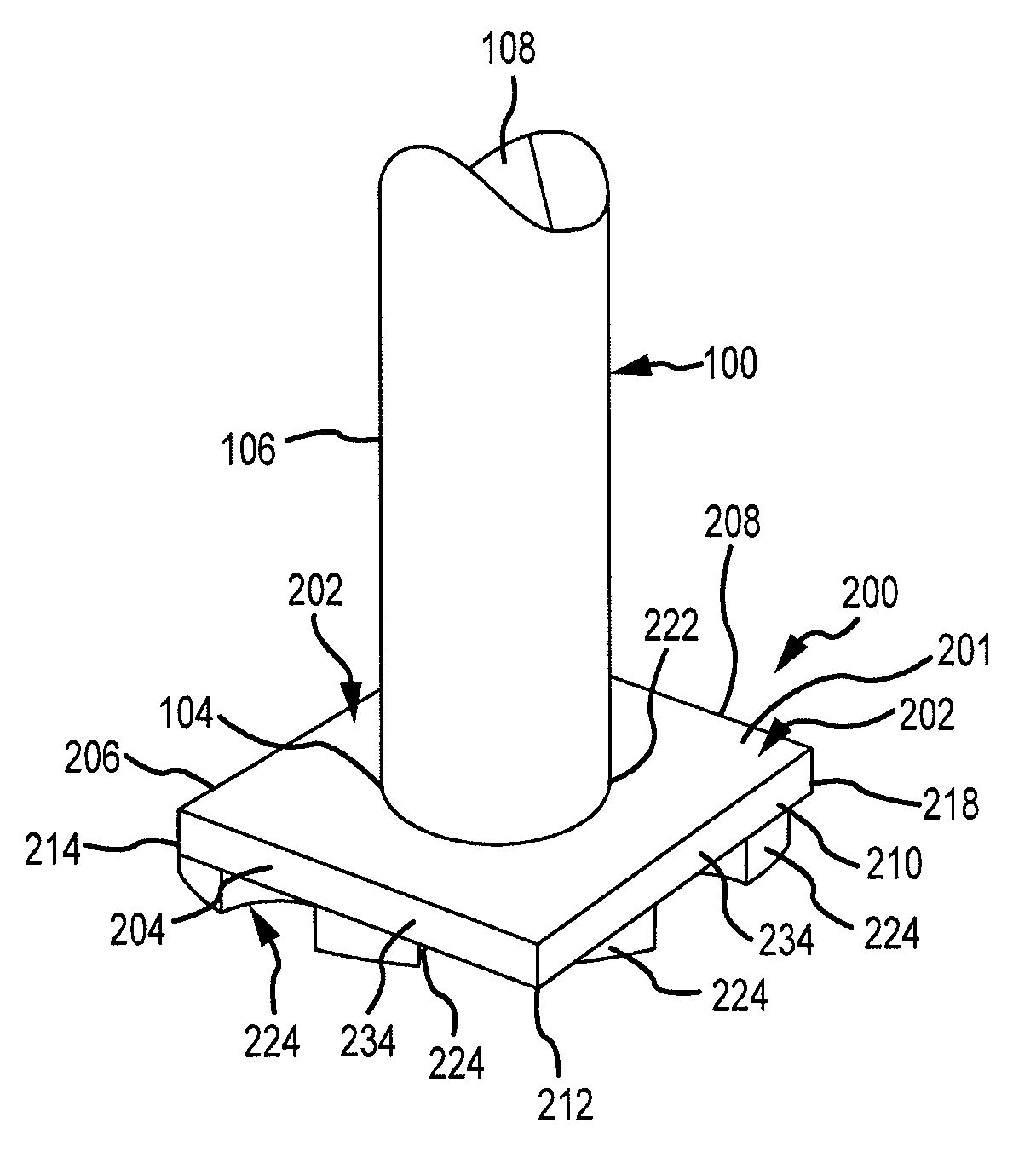

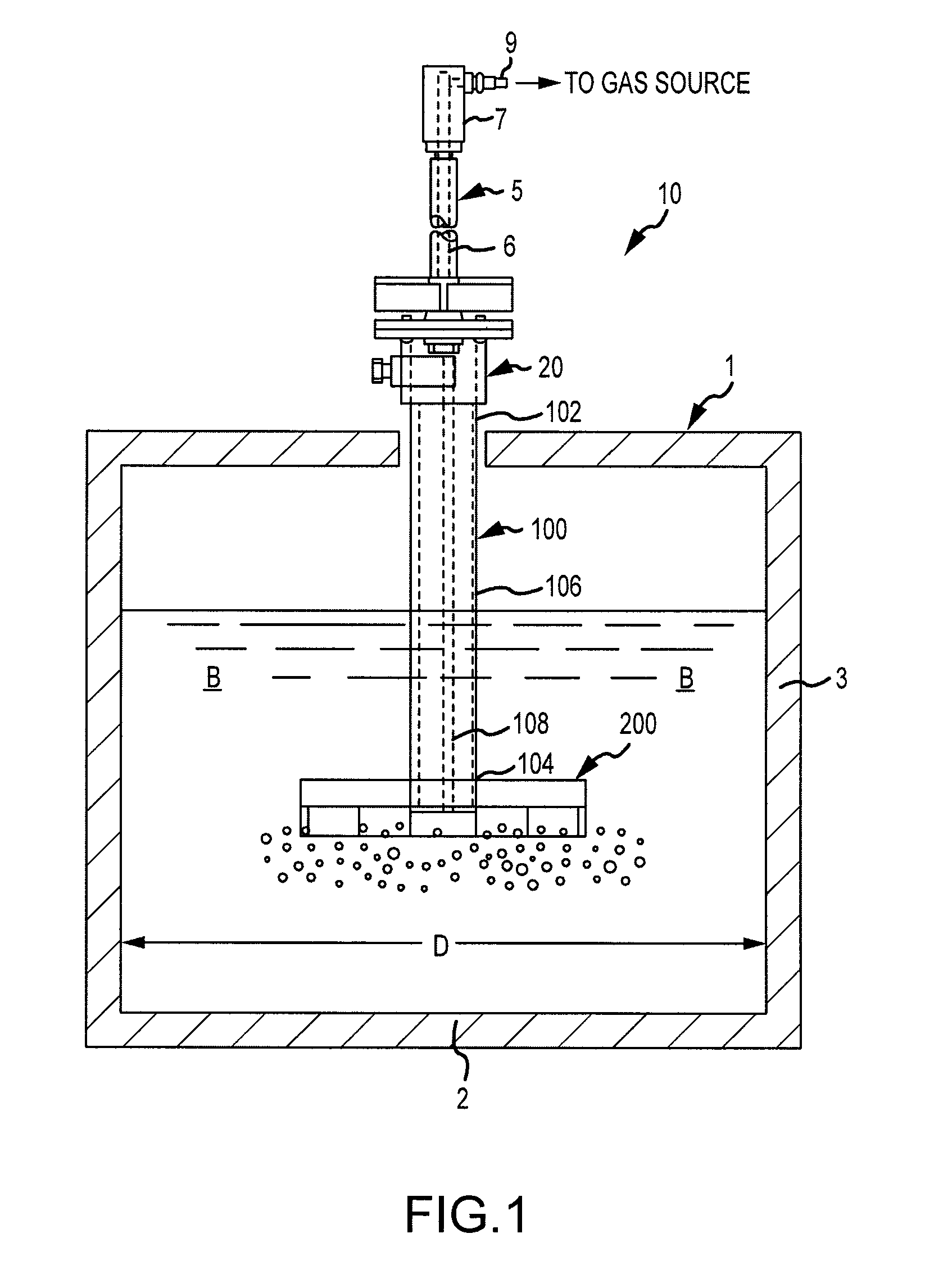

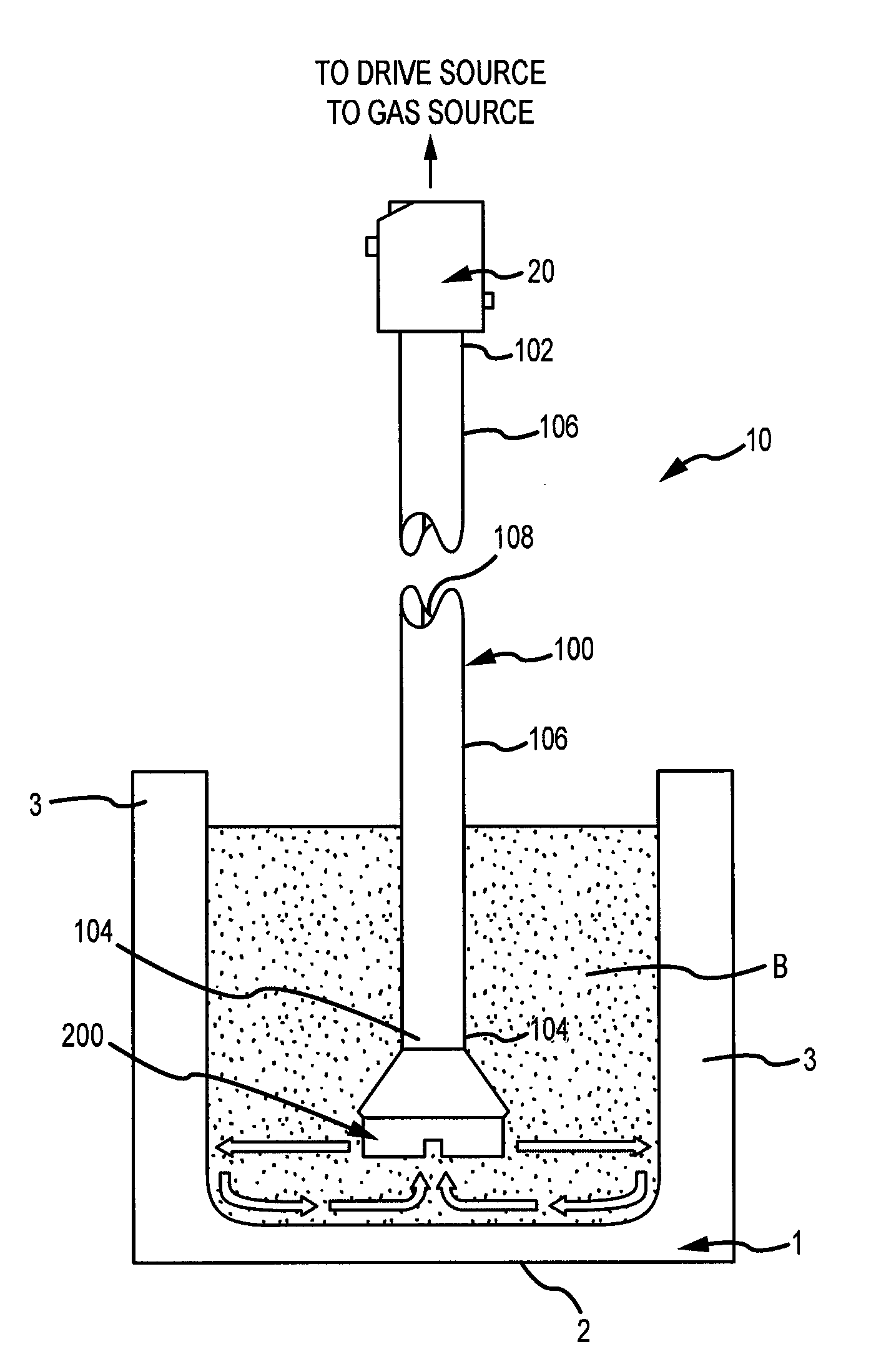

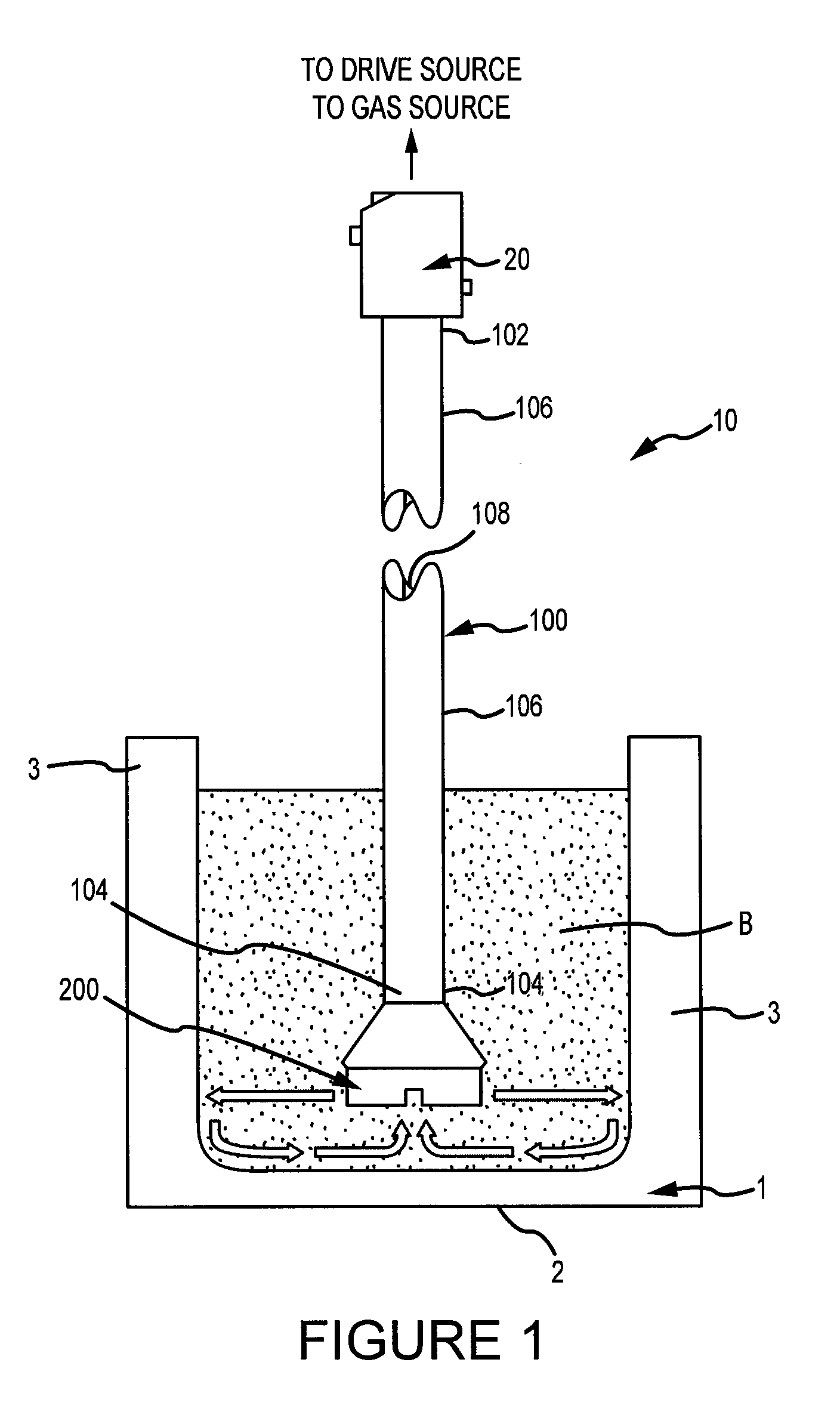

Rotary degasser and rotor therefor

ActiveUS8535603B2Efficiently circulatedWell mixedMelt-holding vesselsStirring devicesImpellerDegasser

A device for dispersing gas into molten metal includes an impeller, a drive shaft having a gas-transfer passage therein, and a first end and a second end, and a drive source. The second end of the drive shaft is connected to the impeller and the first end is connected to the drive source. The impeller includes a first portion and a second portion with a plurality of cavities. The first portion covers the second portion to help prevent gas from escaping to the surface without entering the cavities and being mixed with molten metal as the impeller rotates. When gas is transferred through the gas-transfer passage, it exits through the gas-release opening(s) in the bottom of the impeller. At least some of the gas enters the cavities where it is mixed with the molten metal being displaced by the impeller. Also disclosed are impellers that can be used to practice the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

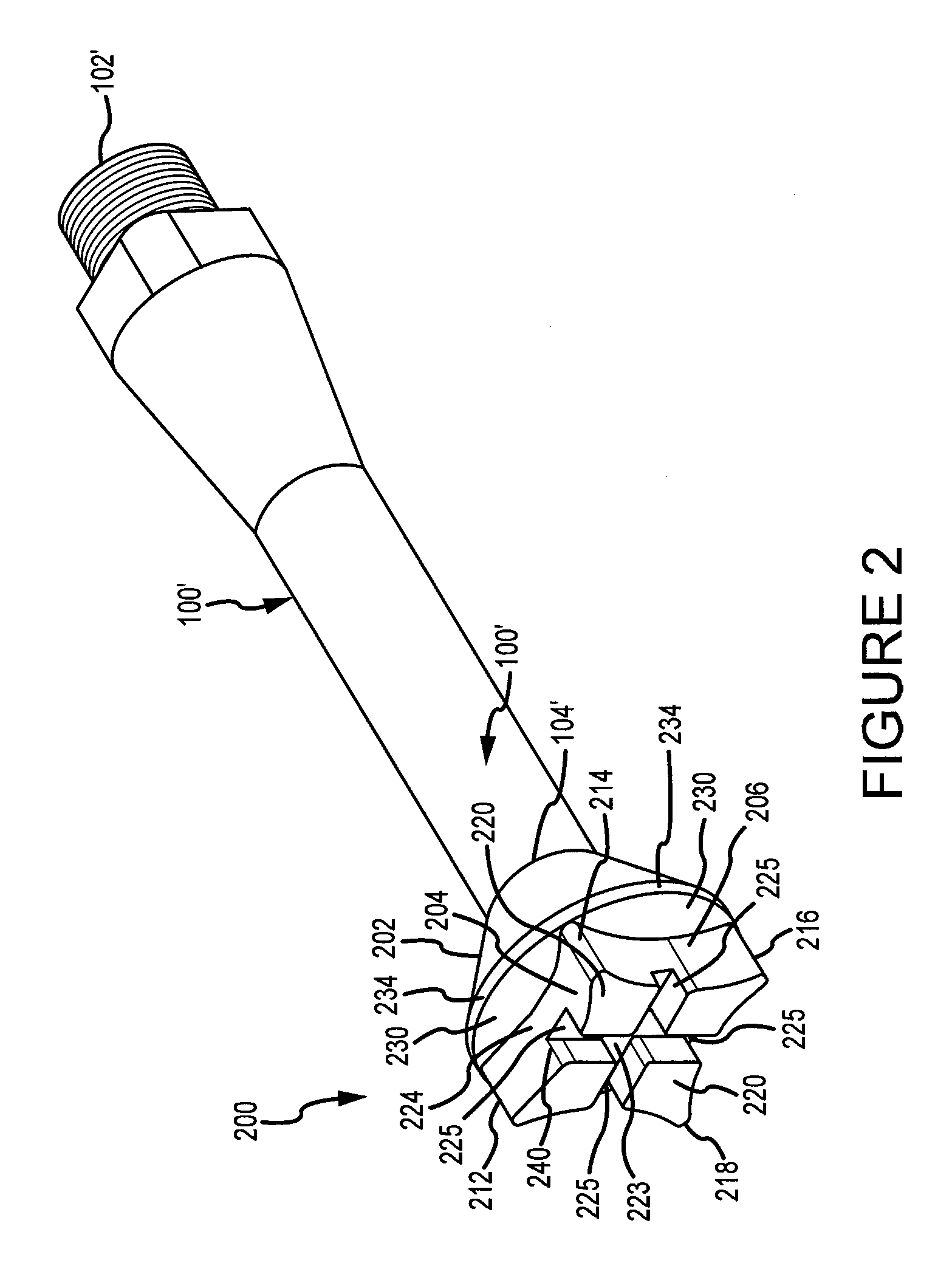

Rotary degassers and components therefor

Disclosed are degassers, couplings, impeller shafts and impellers for use in molten metal. One such coupling transfers gas into an impeller shaft, the coupling having a smooth, tapered internal surface to align with a corresponding surface on the impeller shaft and help prevent gas leakage and to assist in preventing damage to the impeller shaft. Improved impellers for shearing and mixing gas are also disclosed, as is a degasser including one or more of these components.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Rotary degasser and rotor therefor

ActiveUS20140008849A1Efficiently circulatedWell mixedStirring devicesBlade accessoriesImpellerDegasser

A device for dispersing gas into molten metal includes an impeller, a drive shaft having a gas-transfer passage therein, and a first end and a second end, and a drive source. The second end of the drive shaft is connected to the impeller and the first end is connected to the drive source. The impeller includes a first portion and a second portion with a plurality of cavities. The first portion covers the second portion to help prevent gas from escaping to the surface without entering the cavities and being mixed with molten metal as the impeller rotates. When gas is transferred through the gas-transfer passage, it exits through the gas-release opening(s) in the bottom of the impeller. At least some of the gas enters the cavities where it is mixed with the molten metal being displaced by the impeller. Also disclosed are impellers that can be used to practice the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Rotary degassers and components therefor

Disclosed are degassers, couplings, impeller shafts and impellers for use in molten metal. One such coupling transfers gas into an impeller shaft, the coupling having a smooth, tapered internal surface to align with a corresponding surface on the impeller shaft and help prevent gas leakage and to assist in preventing damage to the impeller shaft. Improved impellers for shearing and mixing gas are also disclosed, as is a degasser including one or more of these components.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

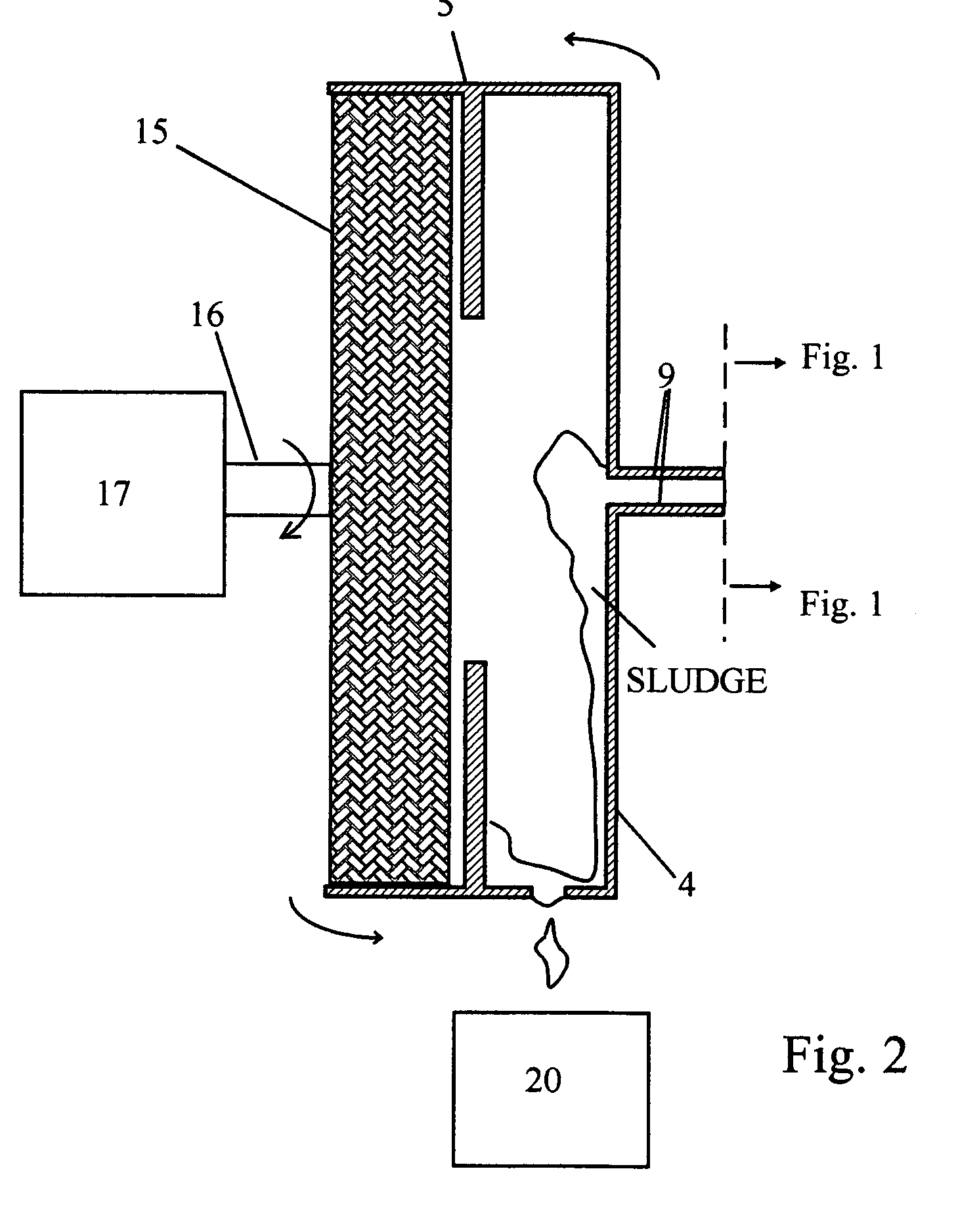

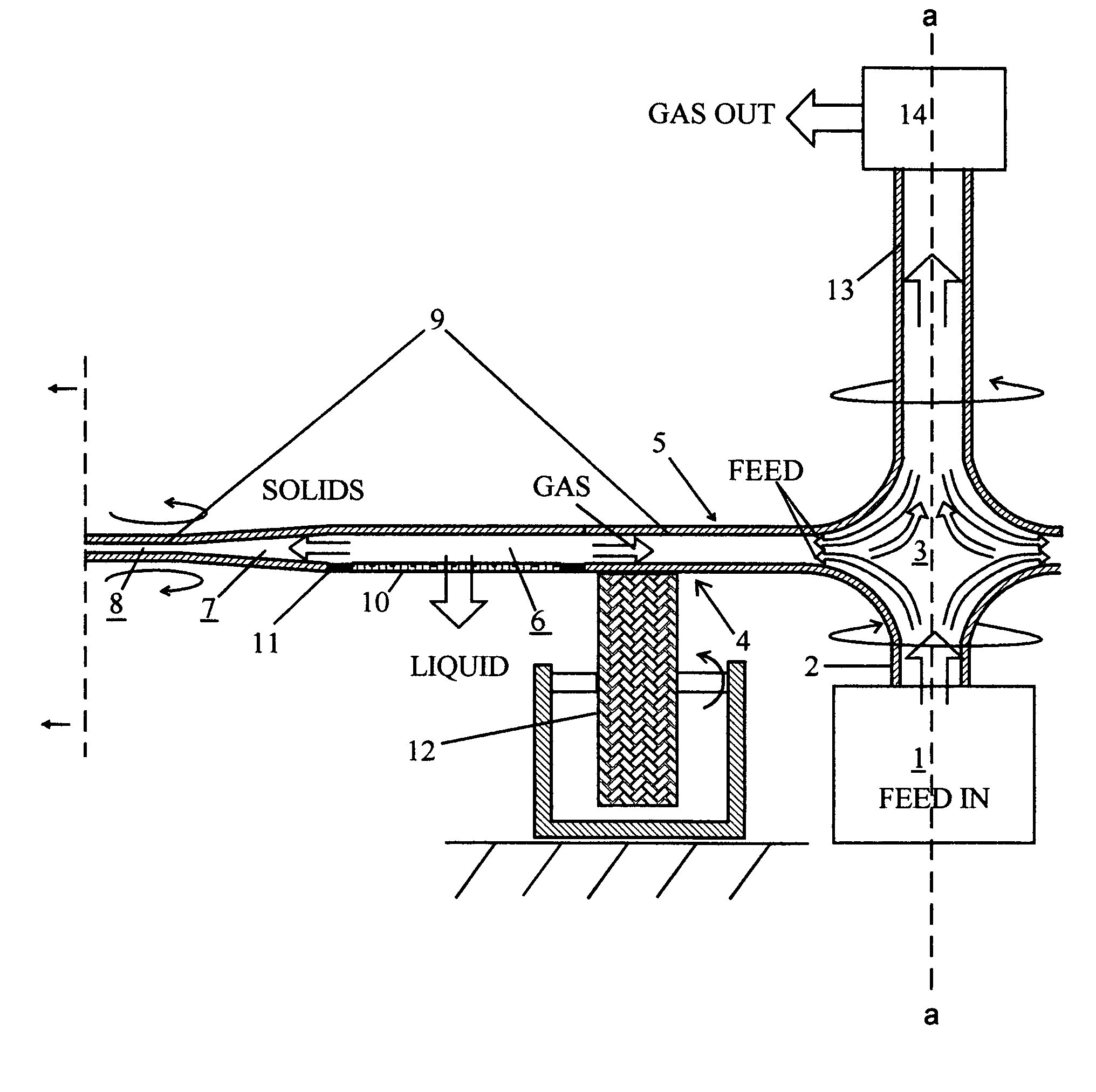

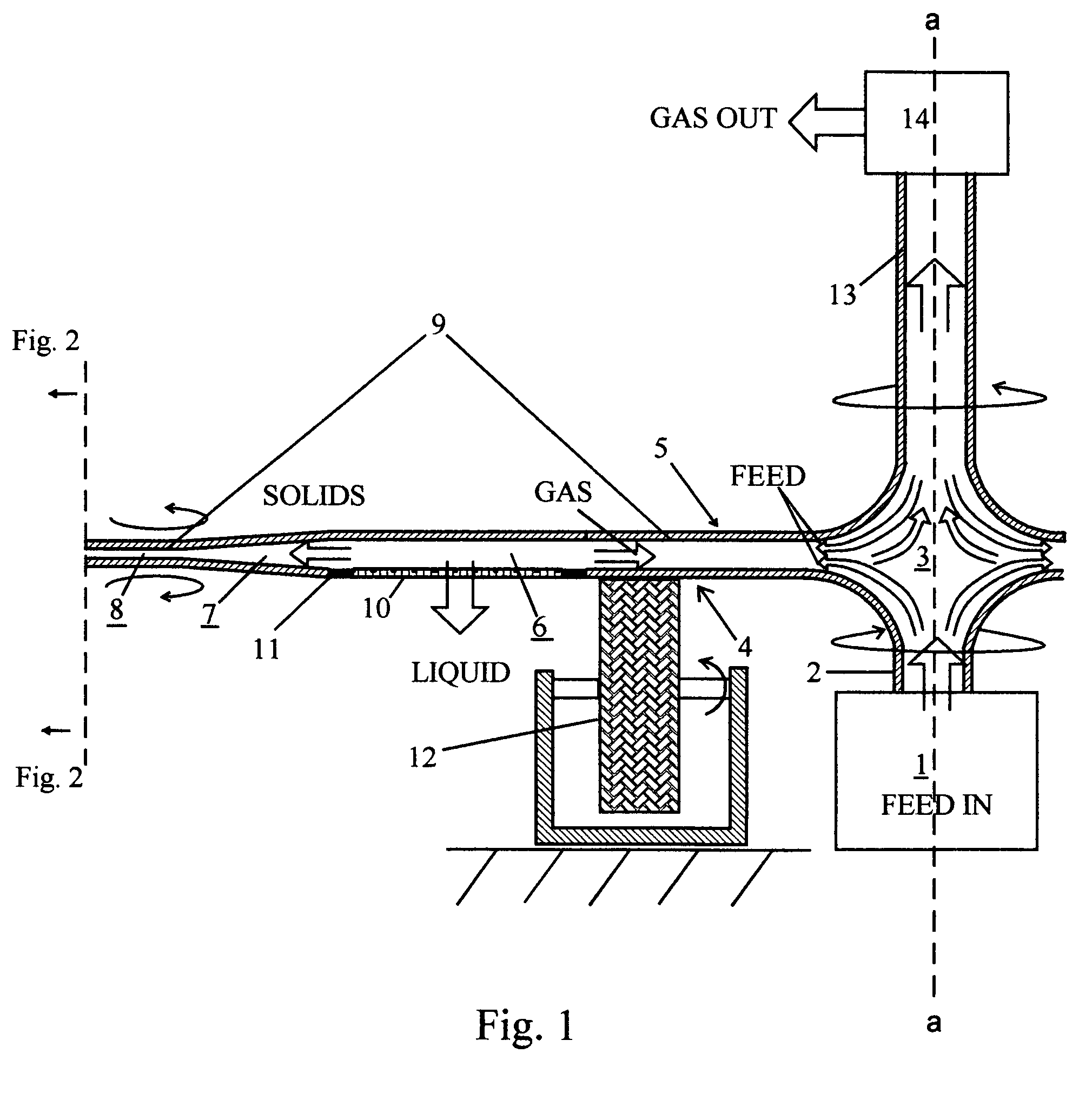

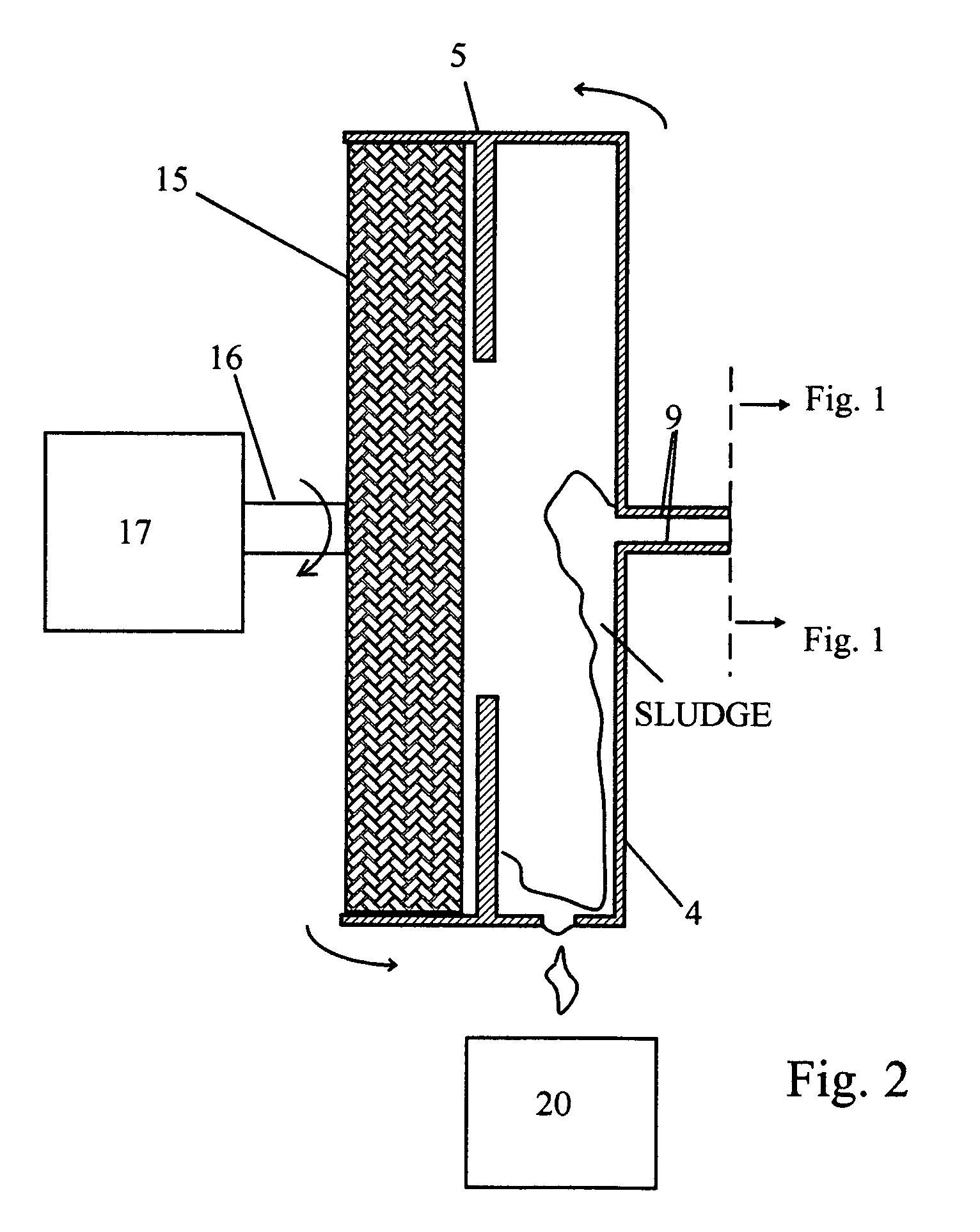

Rotary annular crossflow filter, degasser, and sludge thickener

ActiveUS20090159523A1Accelerate scrubbing reactionAvoid emissionsLiquid degasificationSludge treatmentHigh energySludge

A rotating annular crossflow filter shears radially outward flowing axial feed between counter-rotating coaxial centrifugal impellers. A radial impedance of flow at the impeller periphery slows the radially outward flow and increases residence time of feed between the impellers. Shear lift ejects solids from the boundary layer at the filter surface, and ejected solids collect by centrifugation at the impeller periphery, where they thicken into a sludge and are extruded. Gases, oils, floating solids, and fractions having a specific gravity less than water evolve into radial vortices and are sucked radially inward and out from between the impellers by an axial pump. Three way phase separation proceeds continuously in one pass through a simple mechanical device having a long residence time for feed in the processing zone.Opposing rugose portions of counter-rotating impeller surfaces cause audio frequency pressure pulses. At the impeller periphery, the pressure pulses milk liquid out of sludge. At the portion of the radial passage prior to the filter, pressure pulses evolve gases and degassed cavitation bubbles inactivate microbes. Degassing of the high energy forced periodic cavitation bubbles between the impellers removes the cushion of noncondensibles which would otherwise absorb energy on compression, therefore implosion becomes extremely violent and a barrage of high pressure pulses and ultraviolet light pulses inactivates microbes.Applications include field water purification, municipal and industrial wastewater degassing and sludge thickening, swimming pool filtration, effluent dewatering, wine and beverage degassing and clarification, fruit crushing, olive oil dewatering, produced brine and drilling mud processing, manure slurry dewatering and degassing, and recovery of solvents and fine suspended solids from fluid mixtures such as wastewater from machining operations.

Owner:VORSANA INC

Rotary annular crossflow filter, degasser, and sludge thickener

ActiveUS7757866B2Avoid emissionsImprove responseSludge treatmentLiquid degasificationImpellerDegasser

Owner:VORSANA INC

Modular pressure control and drilling waste management apparatus for subterranean borehole operations

ActiveUS7207399B2Waste water treatment from quariesWater/sewage treatment with mechanical oscillationsDegasserDisposal waste

Owner:MI

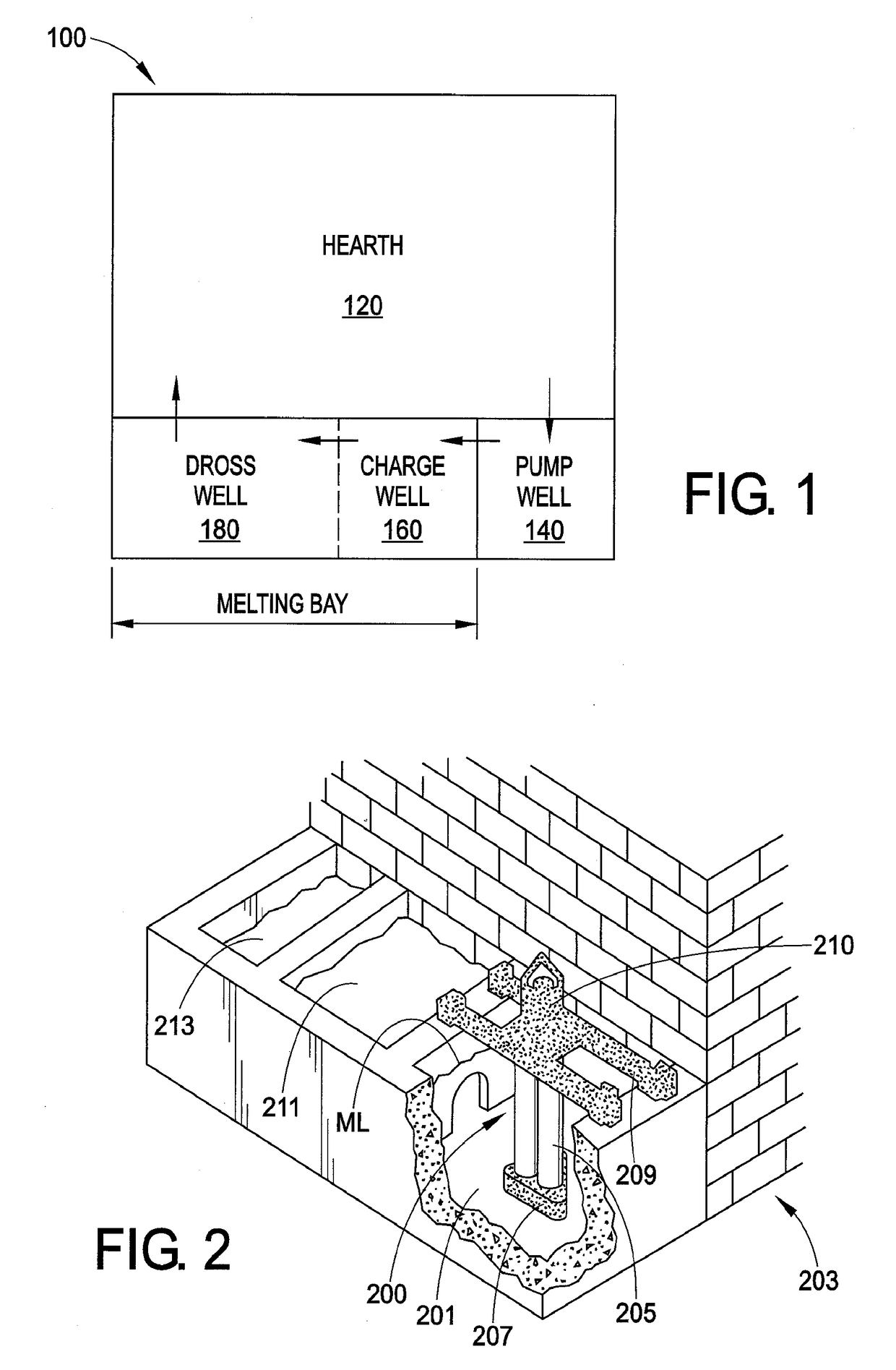

Molten metal containment structure having flow through ventilation

Exemplary embodiments of the invention provide a molten metal containment structure including a refractory molten metal containment vessel having an external surface, and a metal casing for the vessel having an internal surface at least partially surrounding the external surface of the vessel at a distance therefrom forming a spacing between the vessel and the casing. The spacing includes an unobstructed upwardly extending gap that is vented to the exterior of the structure by upper and lower openings in the casing. A layer of insulating material is preferably positioned in the spacing between the internal surface of the casing and the external surface of the vessel, with the layer of insulating material being narrower than the spacing at least at upwardly extending sides of the casing, thereby forming the unobstructed gap. The vessel may be a metal conveying trough, a housing for a metal filter, a container for a metal degasser unit, a crucible, or the like.

Owner:NOVELIS INC

Advanced material for molten metal processing equipment

A molten metal processing apparatus selected from a pump, a degasser, a flux injector, and a scrap submergence device constructed to include at least one element comprised of C / C composite.

Owner:PYROTECK INC

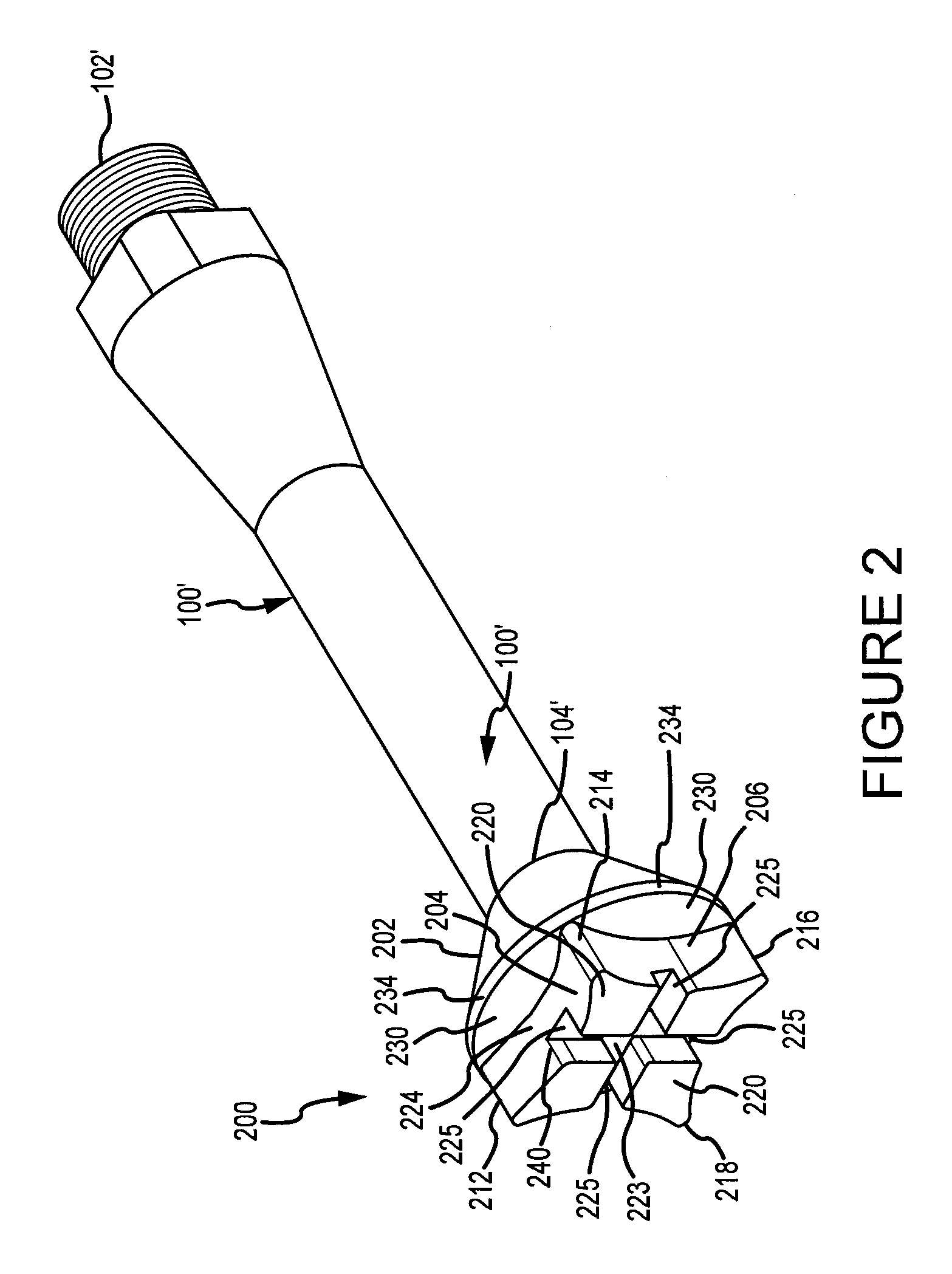

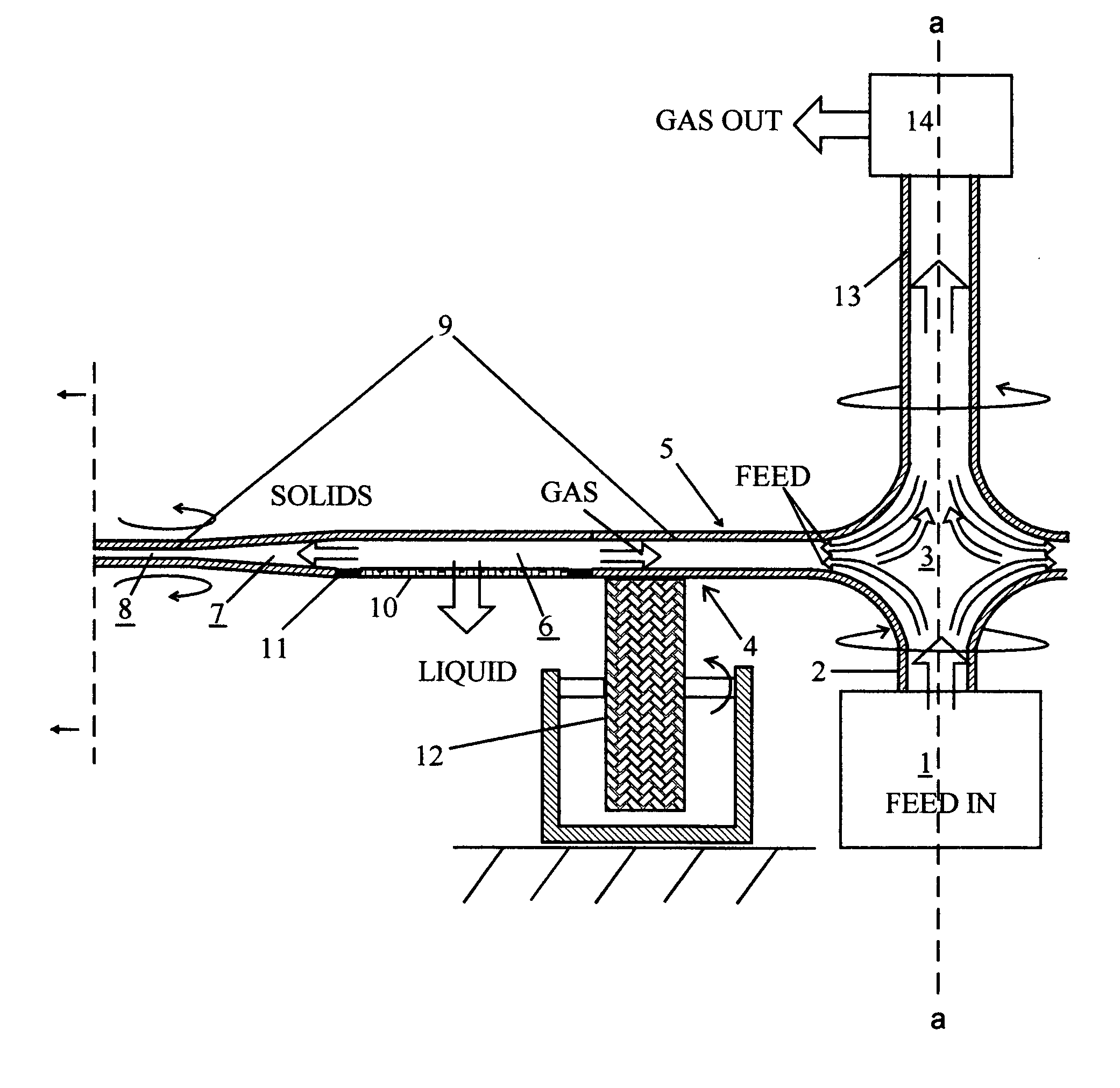

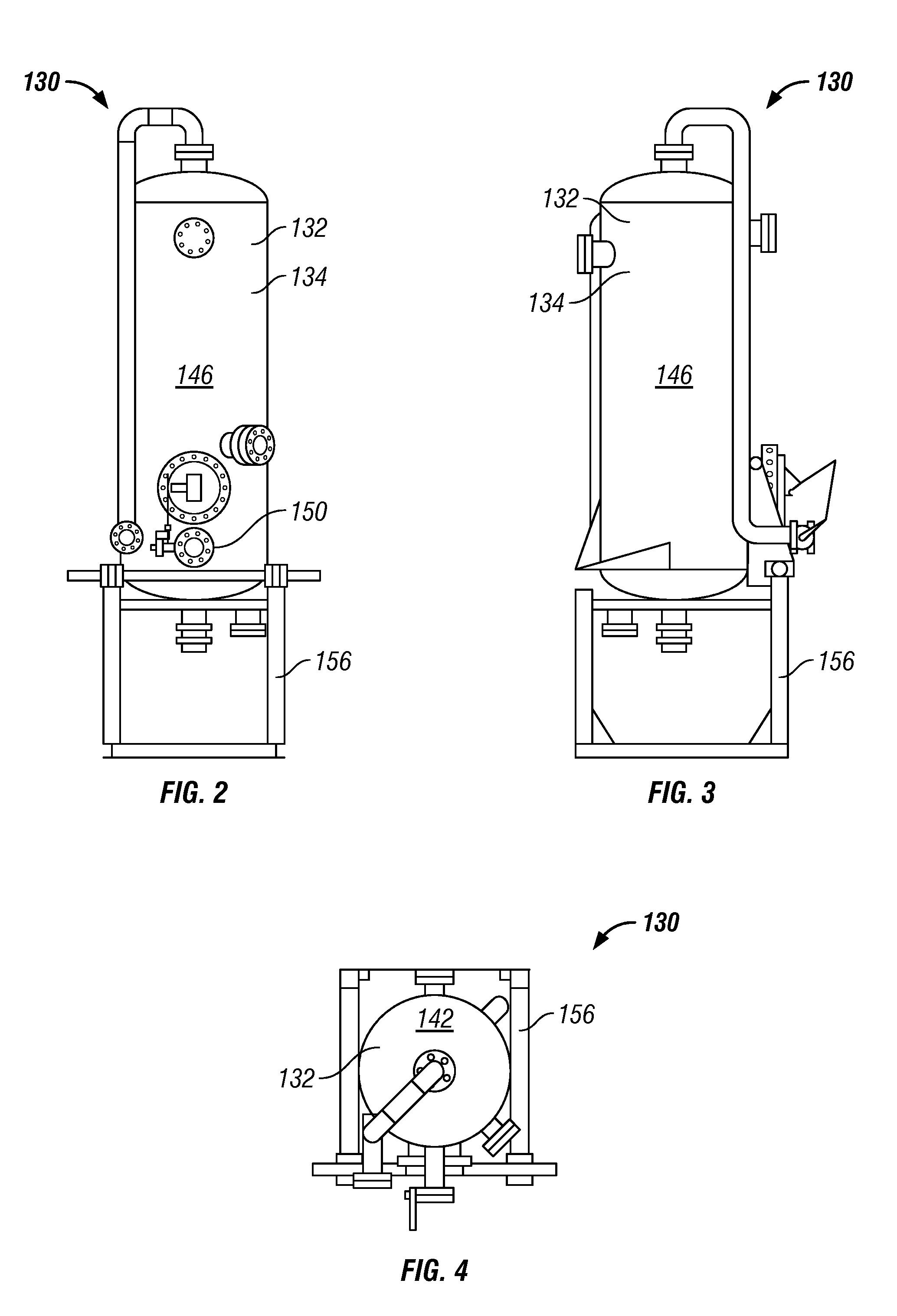

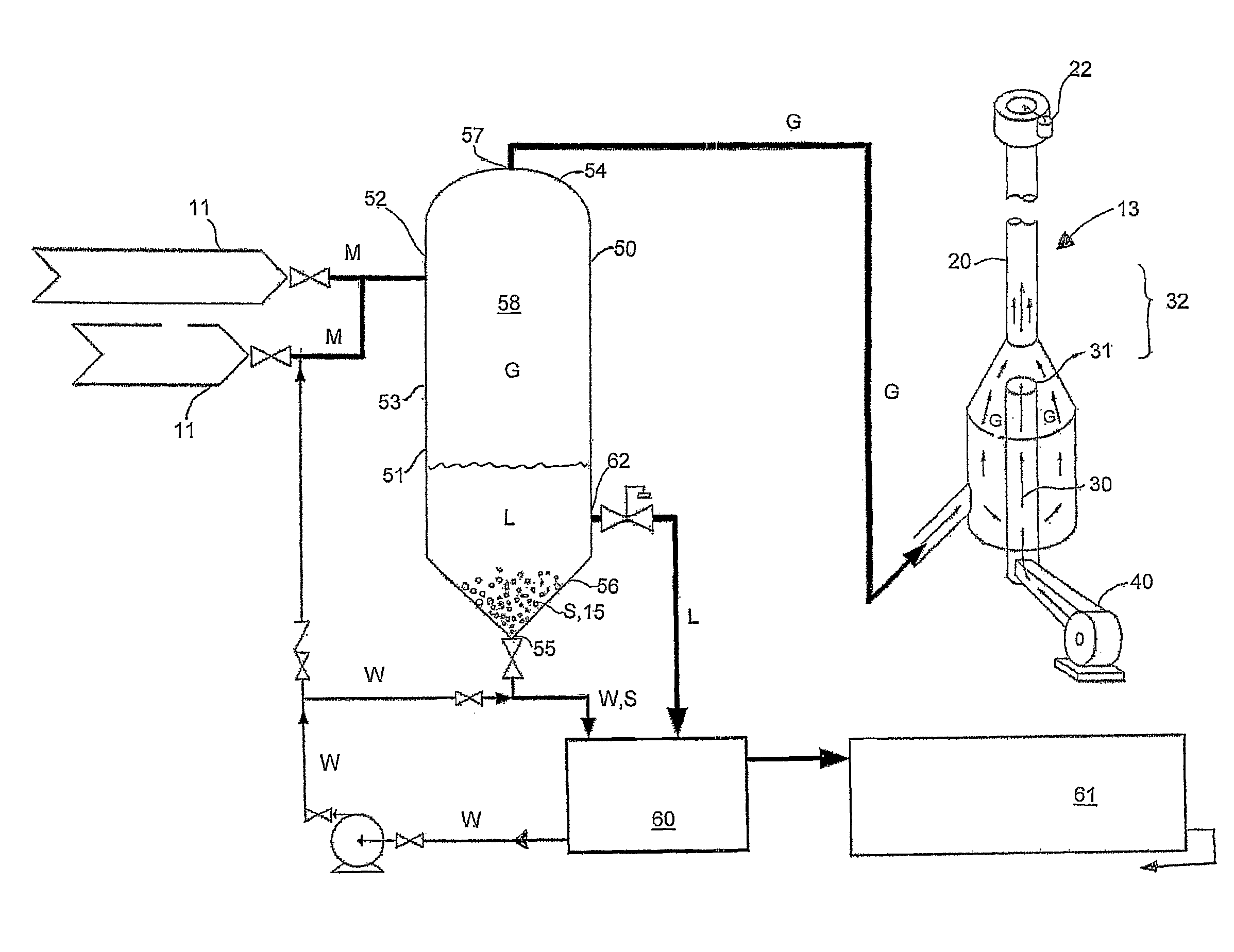

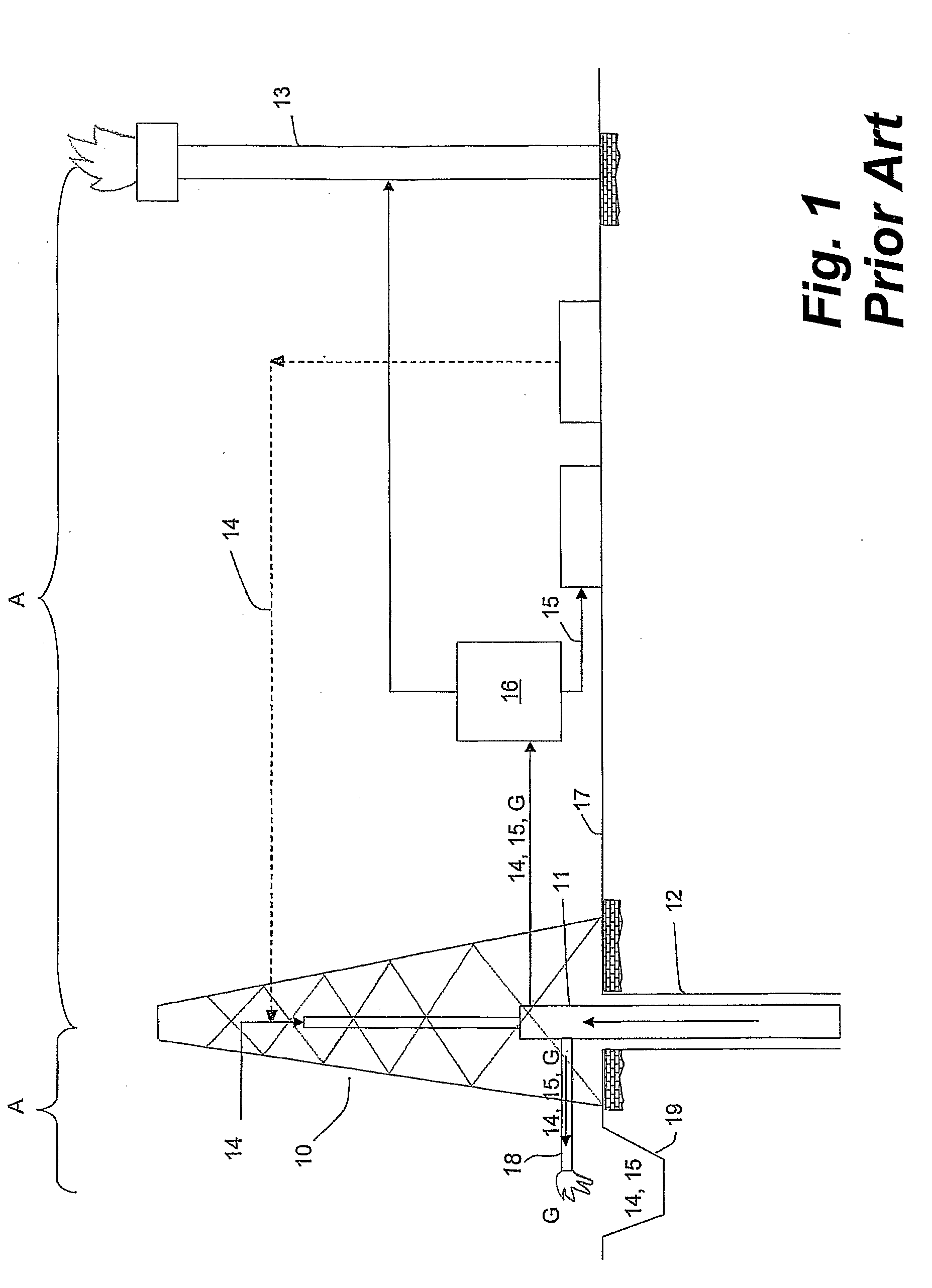

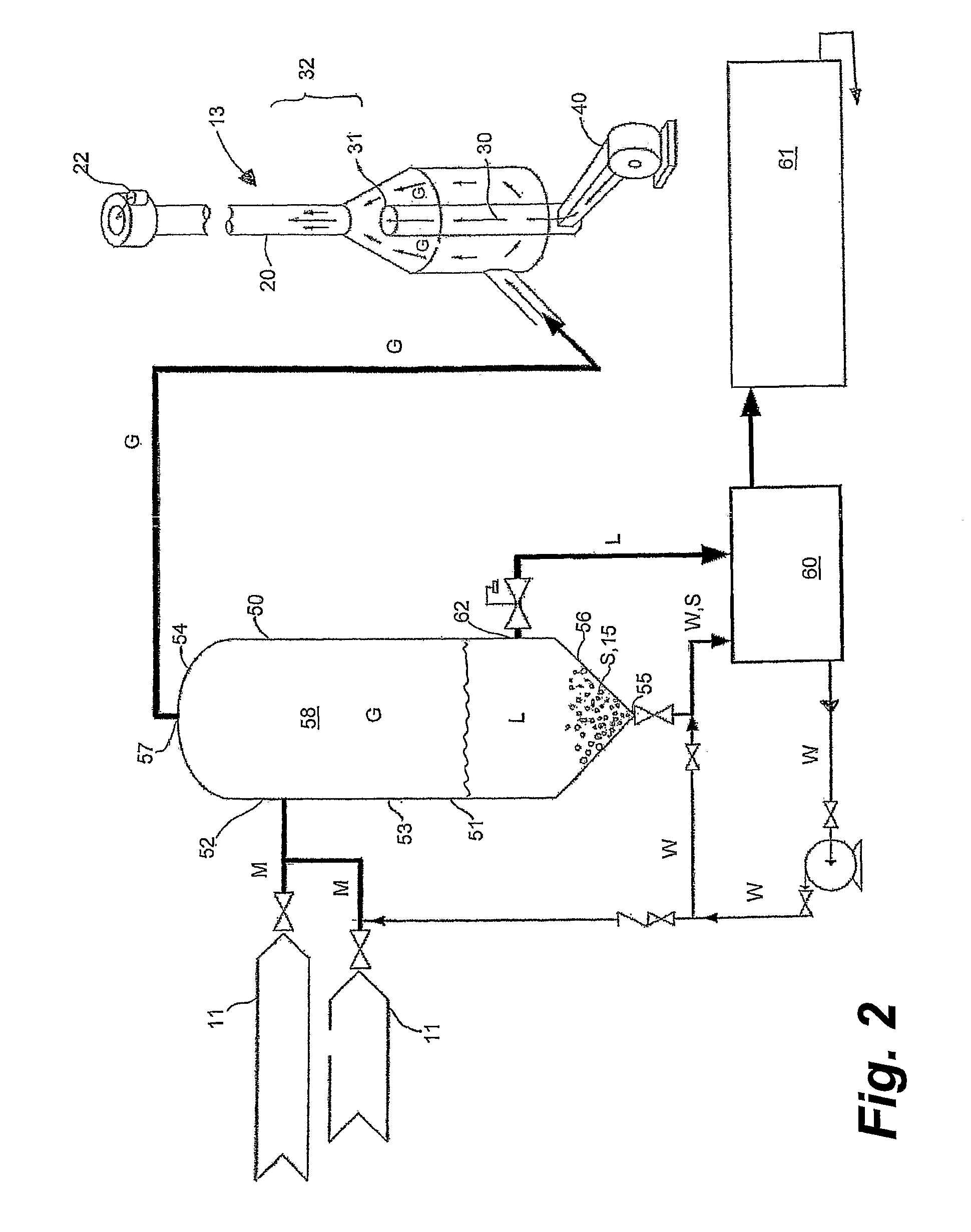

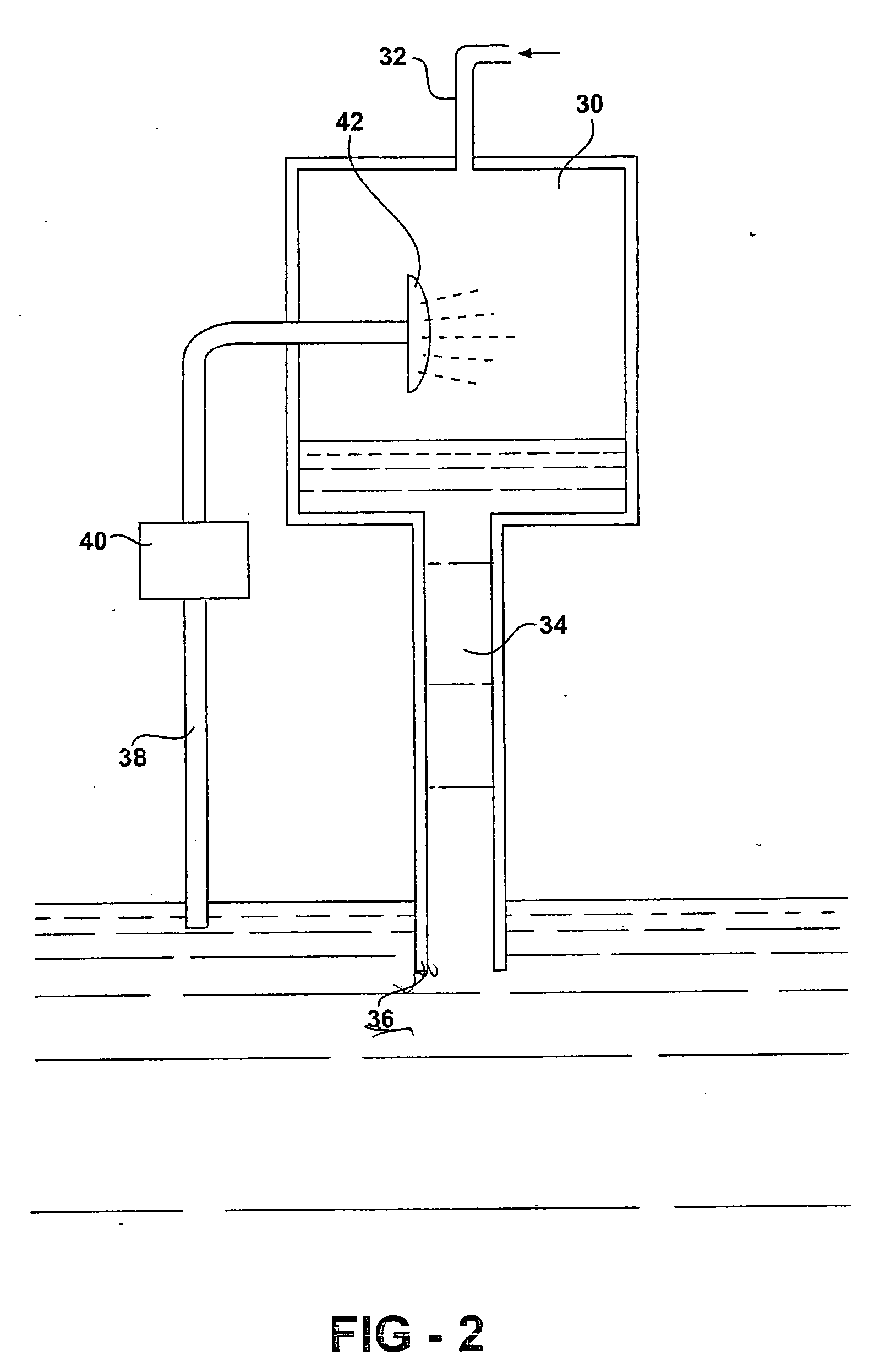

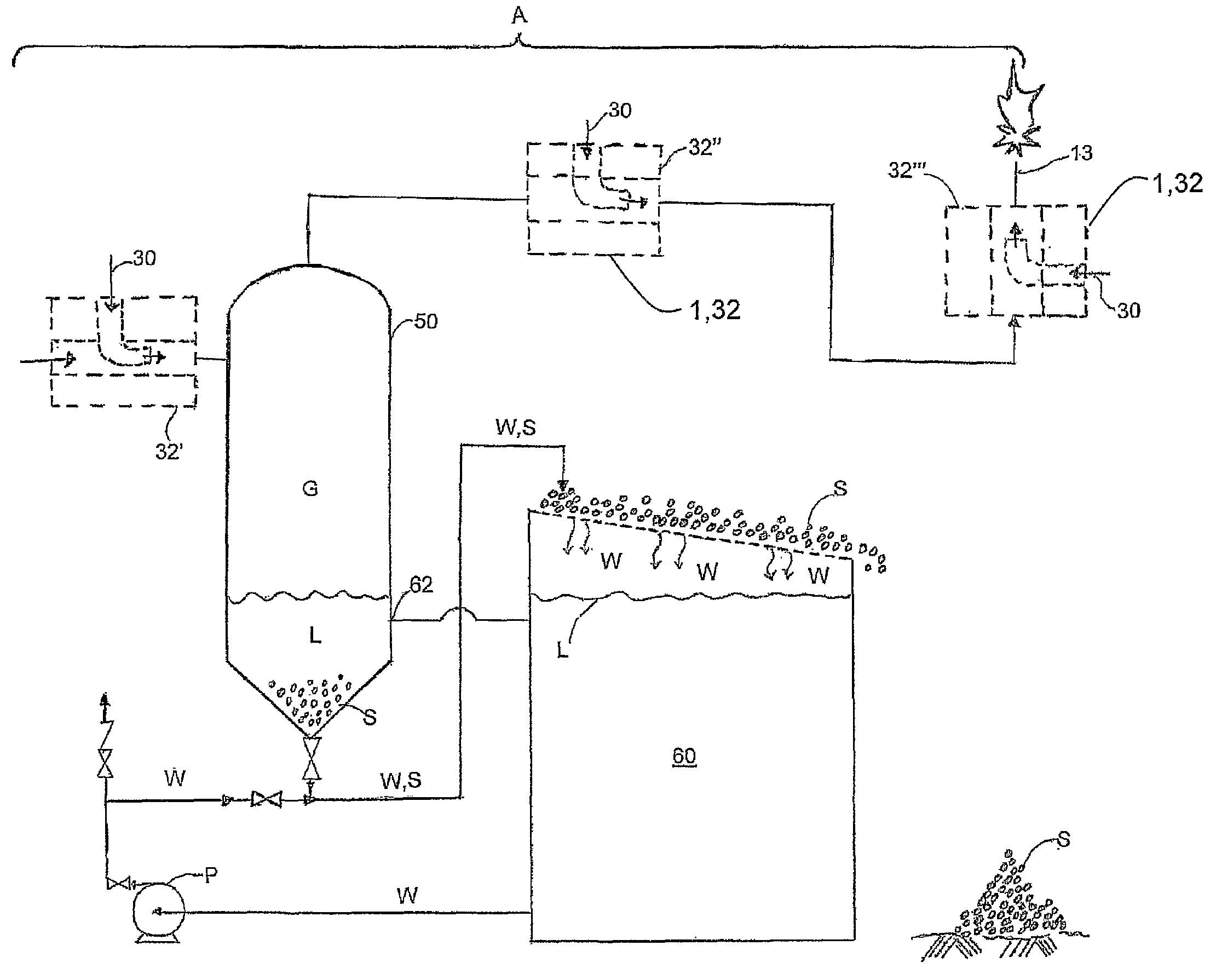

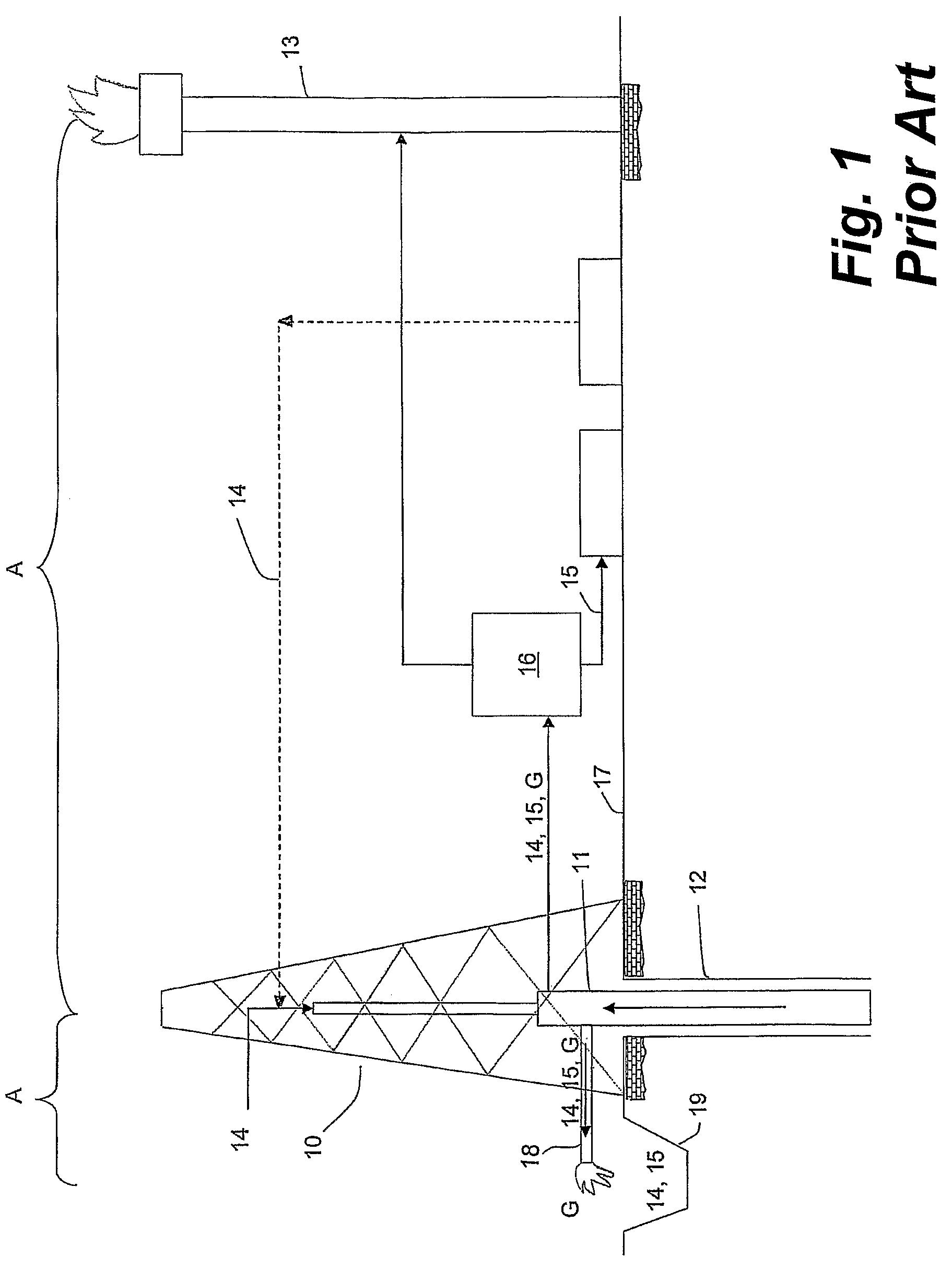

Separation Of Evolved Gases From Drilling Fluids In a Drilling Operation

InactiveUS20080190668A1Minimizes drilling interruptionAvoid evolutionDrilling rodsConstructionsDegasserWell drilling

A fluid handling system for drilling cuttings utilizes a constant and gravity managed liquid level between a substantially atmospheric separator and a shale shaker to maximize fluid residence time within the separator and ensure substantially all of the gas entrained in the cuttings is evolved and passed to a flare thus preventing evolution of the gas at the shale shaker. Solids from the separator are combined with liquid recirculation from and returning to the shale shaker. Optionally, a vacuum degasser is positioned between the separator and the shale shaker and separated gases are passed from the degasser to the flare. This method and system is particularly applicable to balanced, underbalanced and air drilling operations where the flow of gas is intermittent and unpredictable.

Owner:SWARTOUT MATTHEW K

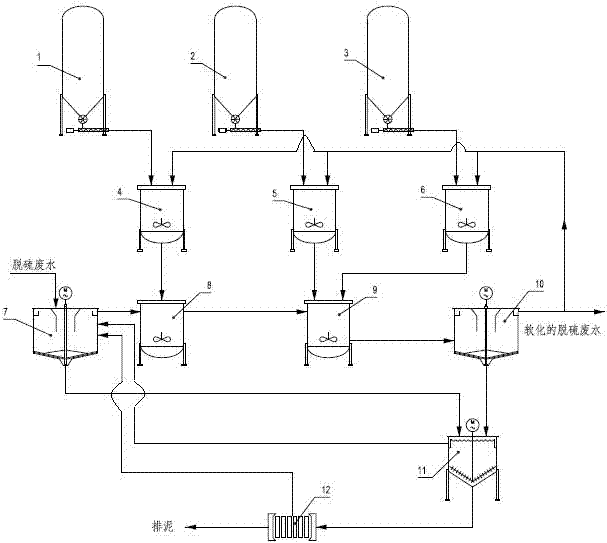

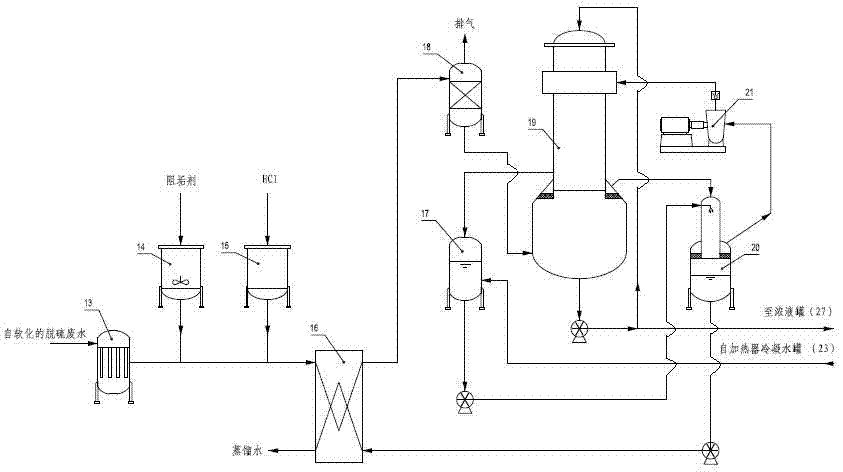

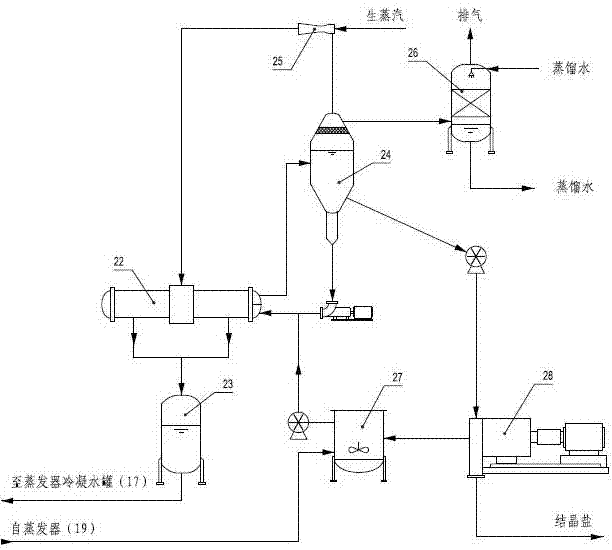

Power plant wastewater zero-discharge treatment technique

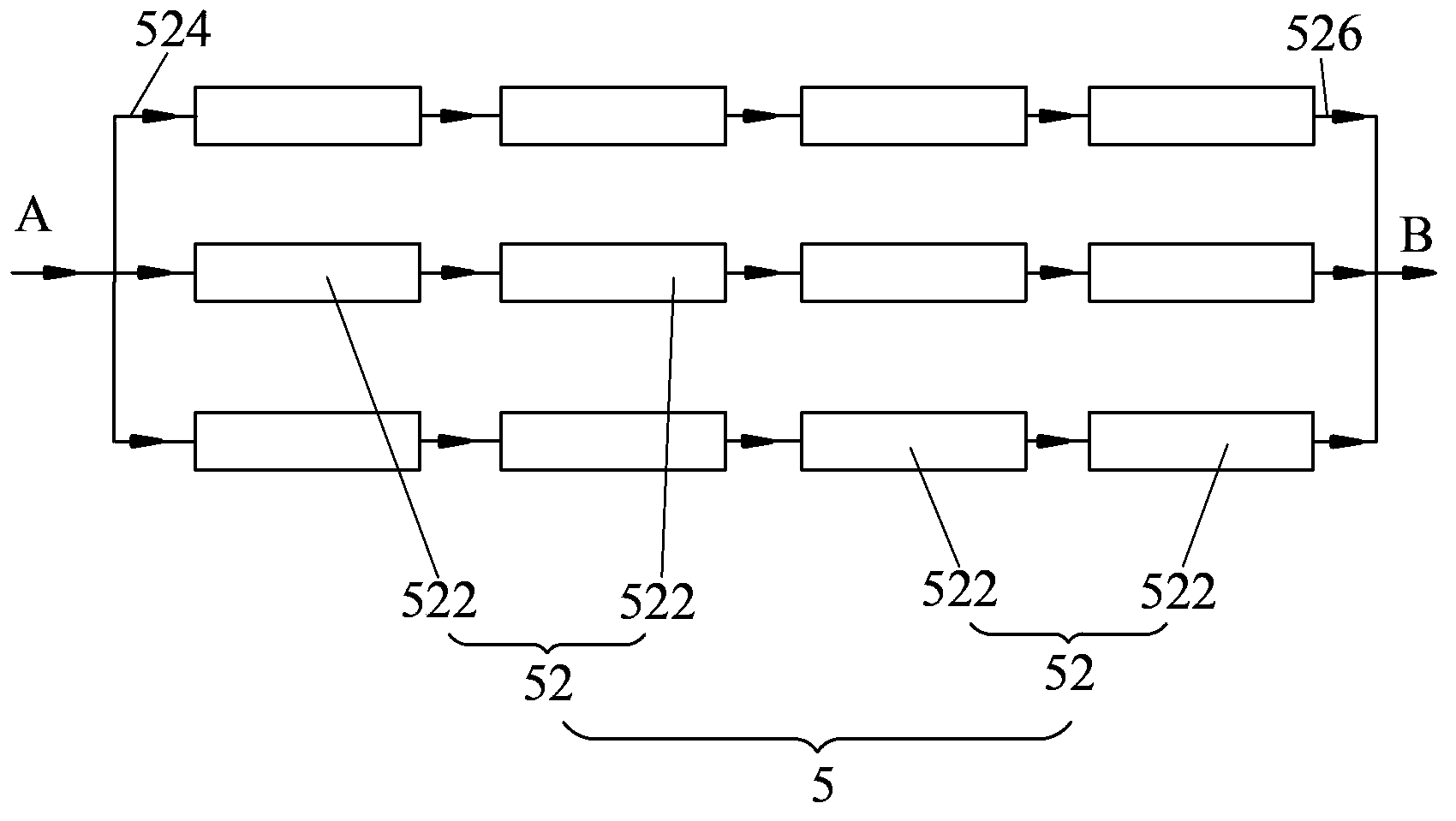

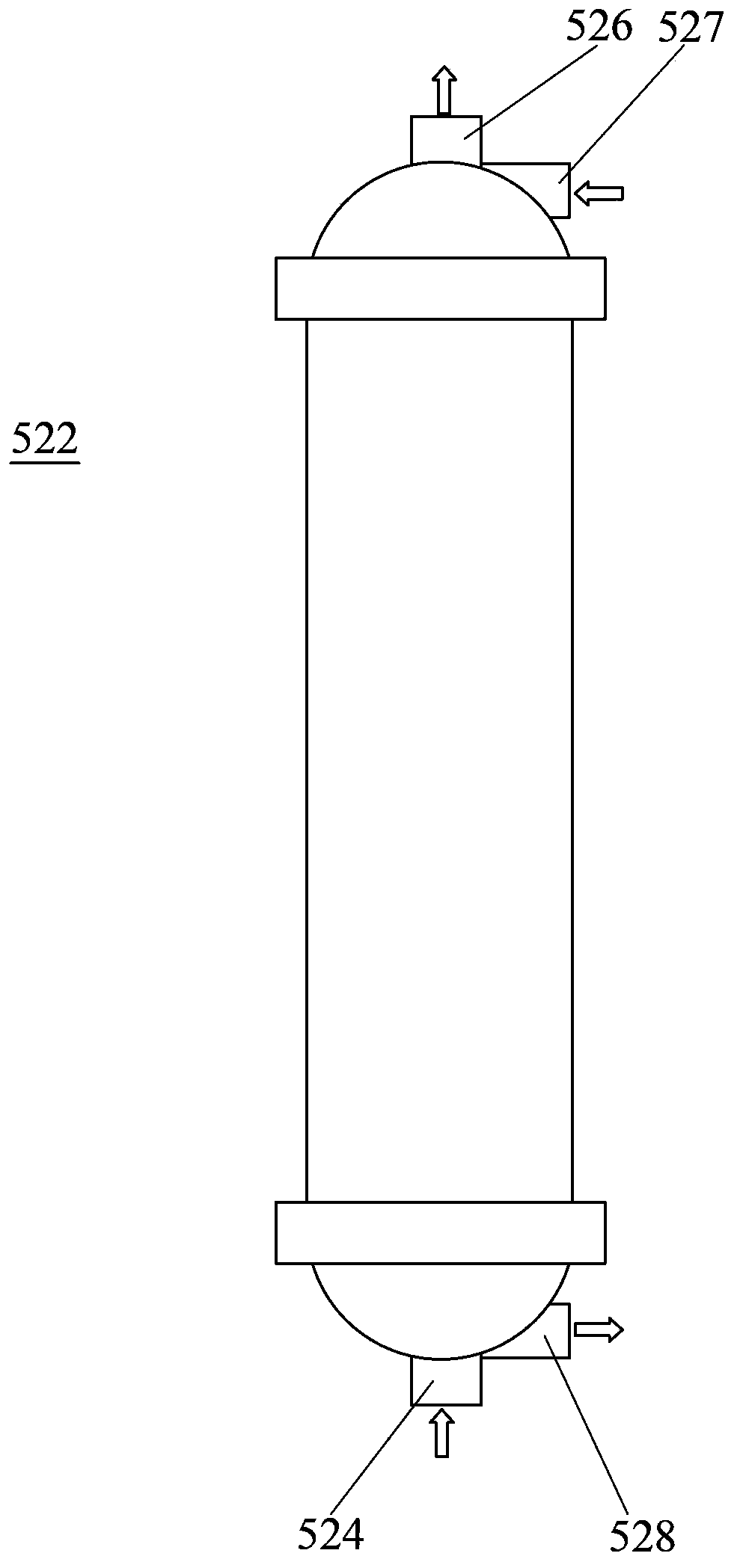

ActiveCN104276708AImprove flushing effectRemove supersaturationMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationProcess equipmentDegasser

The invention discloses a power plant wastewater zero-discharge treatment technique which comprises a pretreatment process, an evaporative concentration process and an evaporative crystallization process, wherein the pretreatment process equipment comprises a precipitation and concentration tank, a sludge dewatering machine, and a raw water precipitation tank, a primary softening reactor, a secondary softening reactor and a softening precipitation tank which are sequentially connected; the evaporative concentration process equipment comprises an automatic back flush filter, a plate-type preheater, a degasser and a falling film evaporator which are sequentially communicated; and the evaporative crystallization process equipment comprises a concentrated solution tank, a crystallizing heater and a crystallizer which are sequentially communicated. The desulfurization water treatment technique is reasonable in step design and performs the pretreatment, evaporative concentration and evaporative crystallization on the desulfurization wastewater, and the end products are only distilled water and crystalline salt, thereby reducing the discharge of the harmful substances, lowering the energy consumption and implementing the goal of zero discharge of desulfurization wastewater.

Owner:JIANGSU JINGYUAN ENVIRONMENTAL PROTECTION

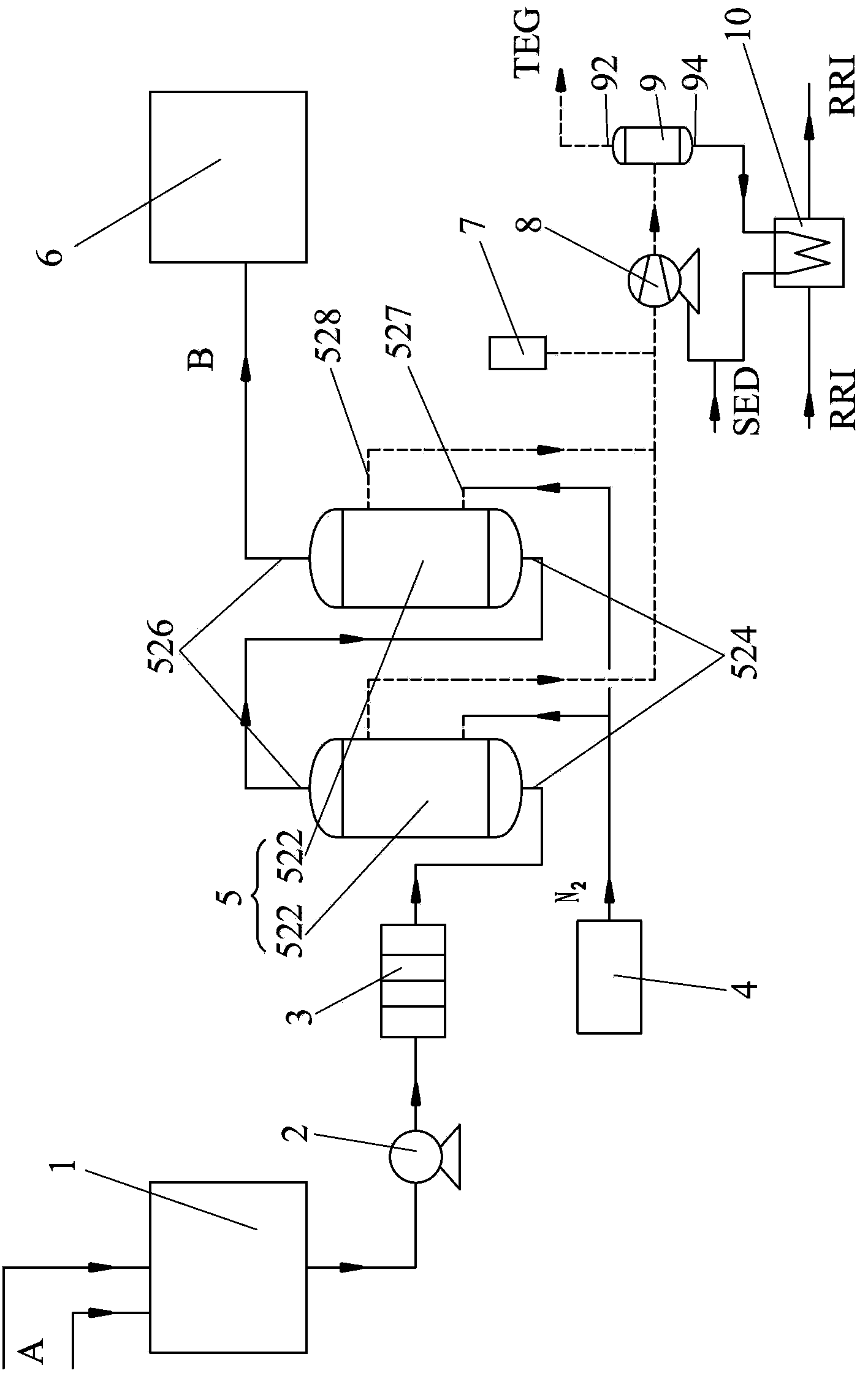

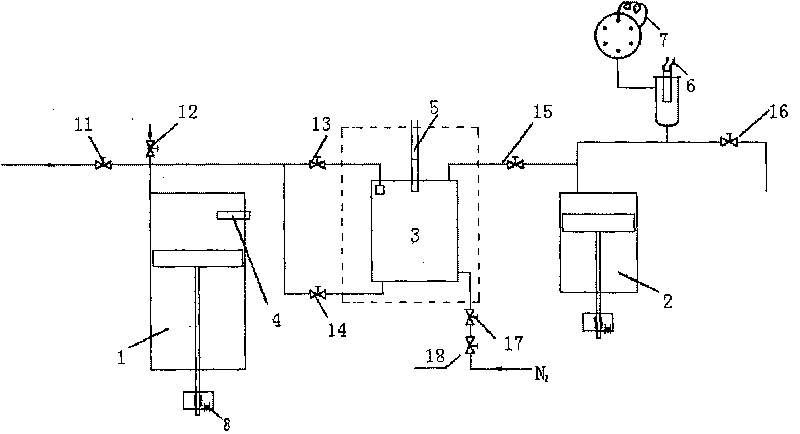

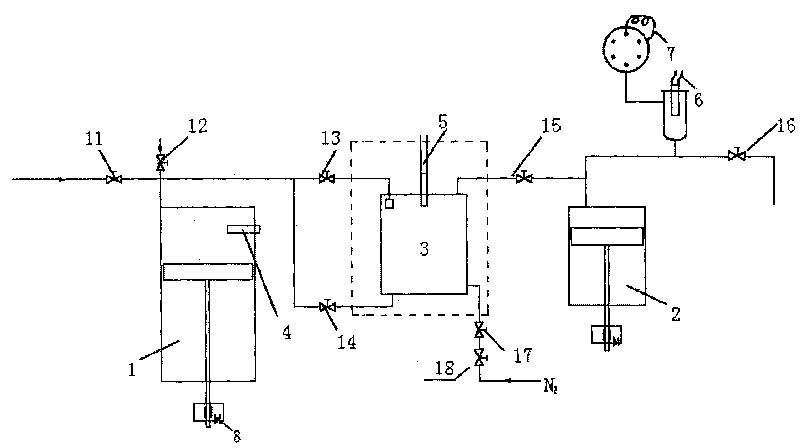

Degasser for removing dissolved gases in reactor coolant of nuclear power station, and method thereof

ActiveCN103405945ALow costLow design process difficultyLiquid degasificationDegasserNuclear engineering

The invention provides a degasser for removing dissolved gases in a reactor coolant of a nuclear power station. The degasser comprises a preposed storage box used for storing the coolant, a degassing membrane unit communicated with the preposed storage box and positioned at the lower reach of the preposed storage box, a vacuum pump and a nitrogen supply device, wherein the vacuum pump and the nitrogen supply device are communicated with the degassing membrane unit; the degassing membrane unit is used for receiving the coolant and removing the dissolved gases in the coolant, and is provided with a gas passage; the vacuum pump is used for vacuumizing the gas passage; the nitrogen supply device is used for inletting nitrogen gases to the gas passage. The degasser is low in energy consumption, low in manufacturing cost, simple in equipment and high in degassing rate. The invention further provides a degassing method for removing the dissolved gases in the reactor coolant of the nuclear power station.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +1

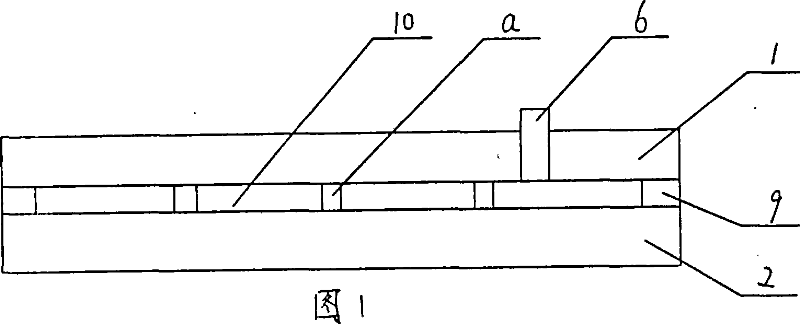

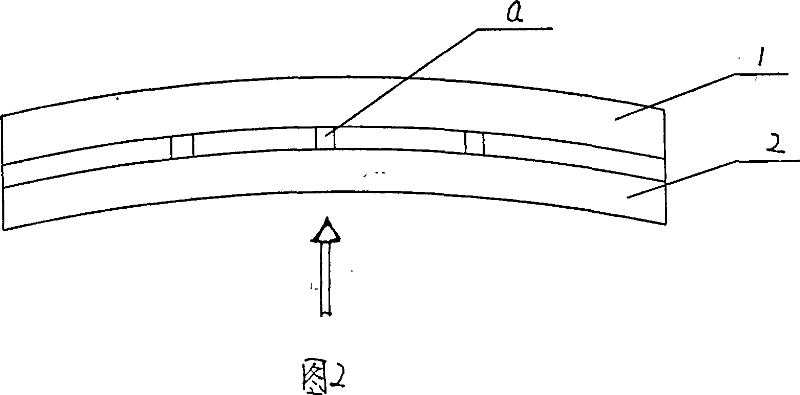

Suspending and balancing pressure type support safety vacuum glass

A suspended and pressure equalized support safe vacuum glass comprises closely connected up and down glass plates with sealed vitreum at four sides, a vacuum cavity in the middle which is formed by up and down glass plates and which has suspended support glass plates that has support at its six sides, corner of the suspended support glass plate having degasser. The vacuum glass has small deformation rate under pressure, high strength, free from after hollow or doubling, with simple structure, low cost, fine energy saving and noise reducing effect and higher social and economical value.

Owner:王汉清

Low energy vacuum distillation method and apparatus

InactiveUS20060157335A1Lower initial costMaintenance freeLiquid degasificationGeneral water supply conservationDegasserWater source

A subatmospheric pressure desalinating still employs a closed top, open bottom pipe filled with source water to be distilled, such as seawater, having a height greater than the height of a column of seawater that can be supported by the pressure at the bottom of the tank so that a subatmospheric pressure volume is formed at the top. Water from the source is also pumped into the subatmospheric volume and passed through an evaporator which enlarges its surface volume. A small percentage of the water is vaporized and the balance is cooled to provide the heat of vaporization and falls into the top of the seawater column, creating a downward flow. The vapor is drawn from the vacuum and condensed, preferably in a second subatmospheric volume above a column of fresh water. A degasser for the water to be distilled prevents the accumulation of gases dissolved in the seawater or the like in the subatmospheric volume.

Owner:LEVINE MICHAEL R +4

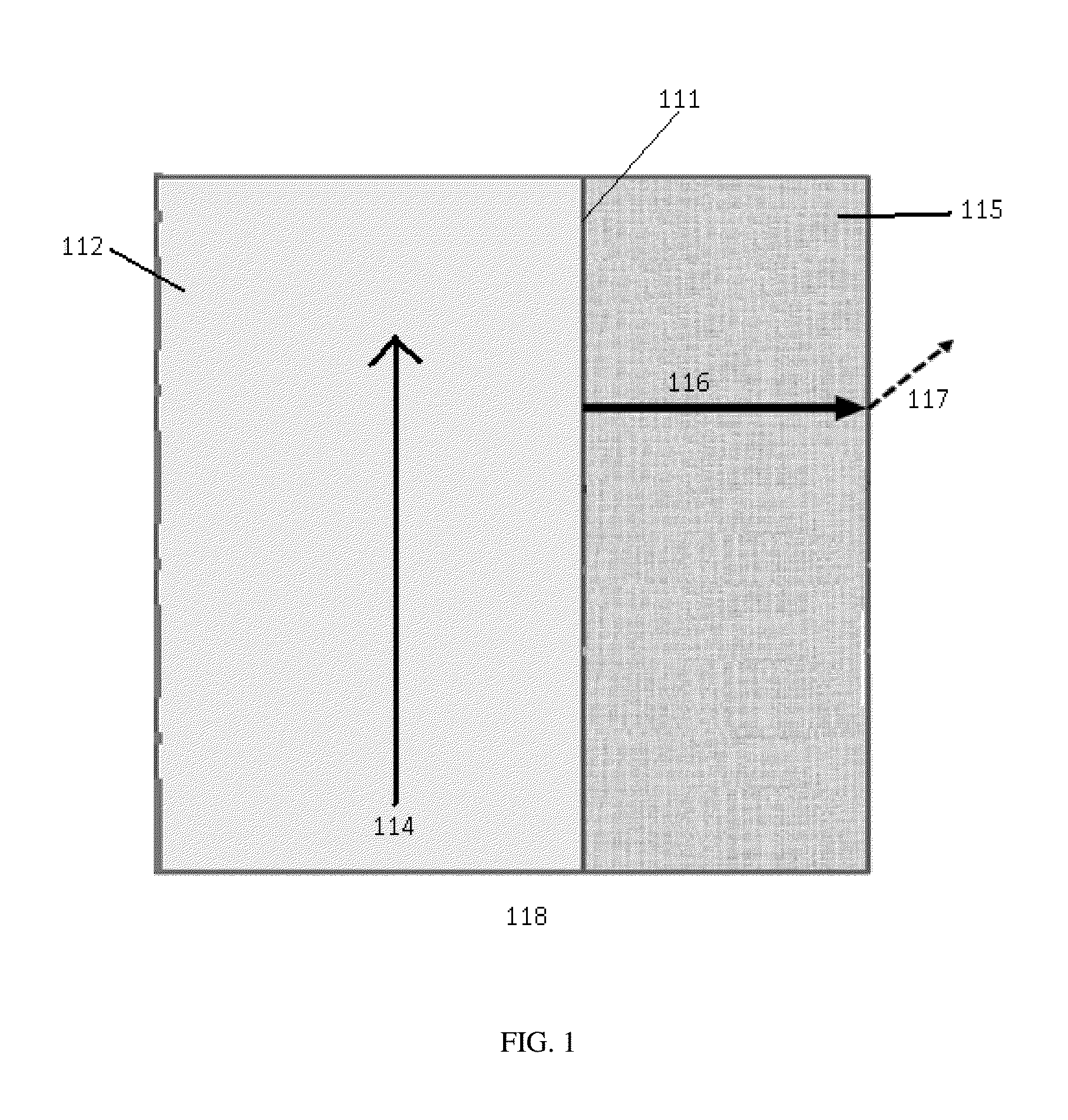

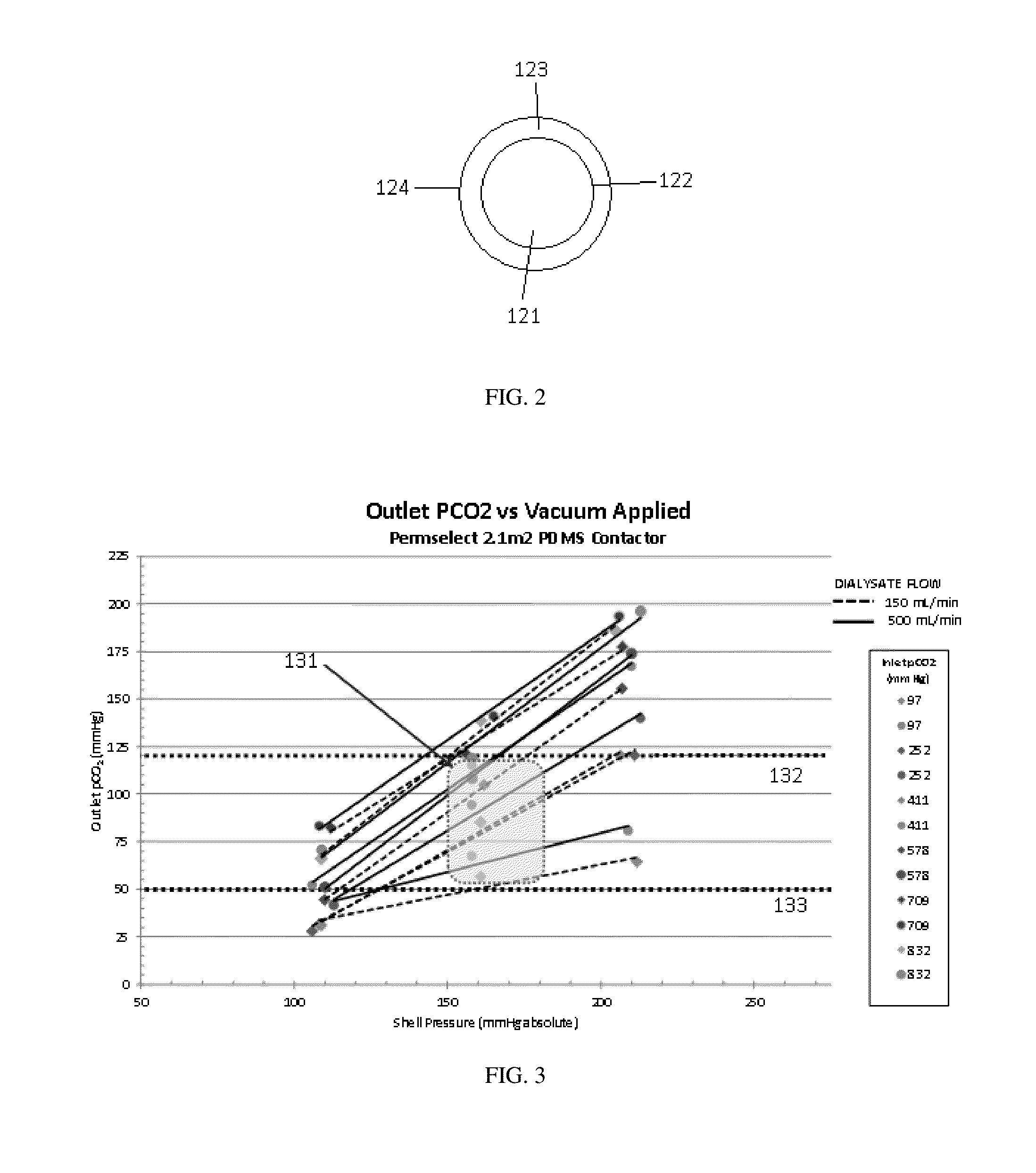

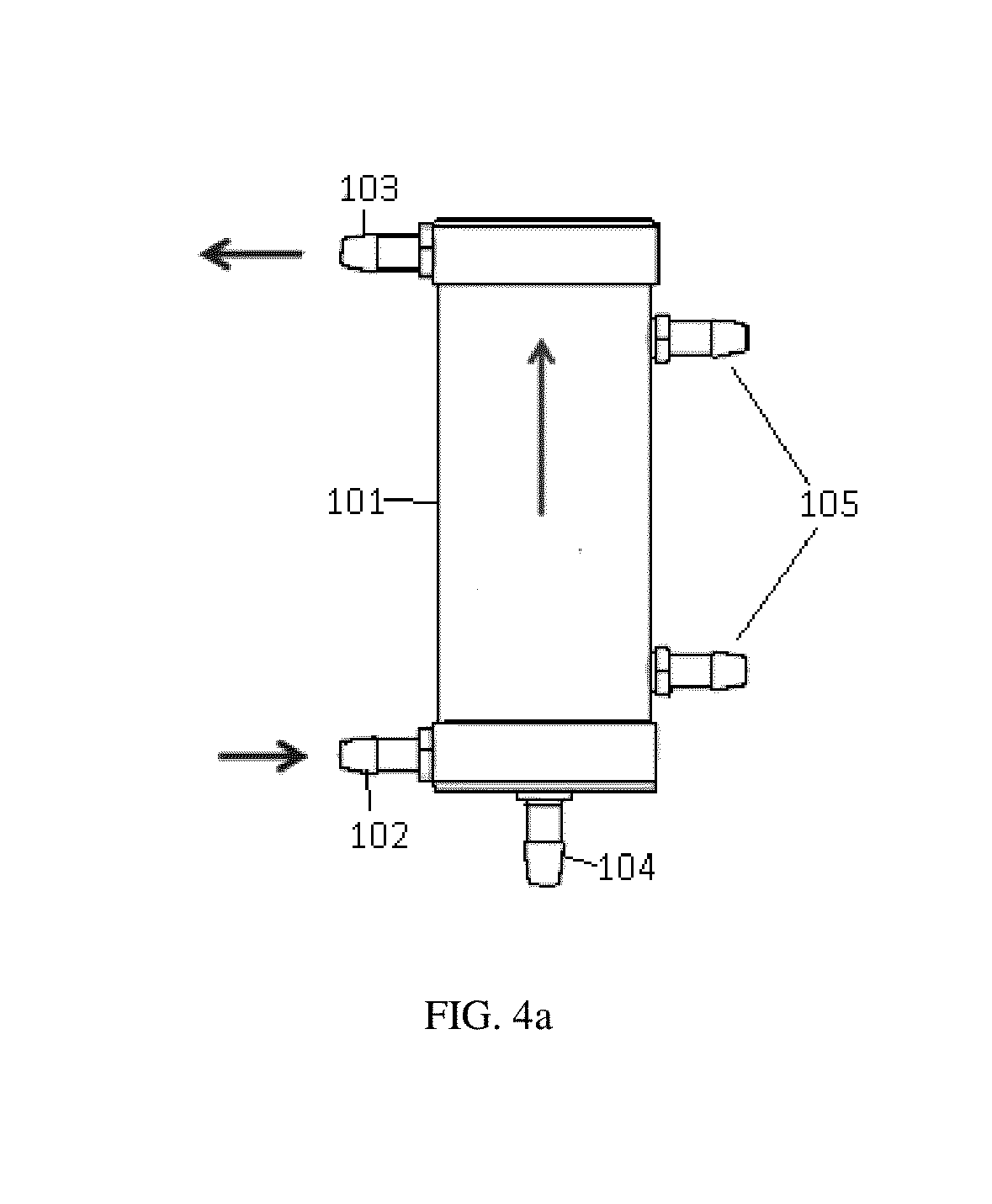

Degassing membrane for dialysis

The degasser can have a degassing membrane that can be constructed from non-porous silica. The degassing membrane can be highly permeable to carbon dioxide but less permeable oxygen or nitrogen gases. Pressure in the dialysate and the degasser can be controlled in order to control the amount of carbon dioxide and other gases in dialysate leaving the degasser. The degassing membrane may be placed in a degassing module in a dialysate flow path to remove dissolved carbon dioxide from the dialysate.

Owner:MOZARC MEDICAL US LLC

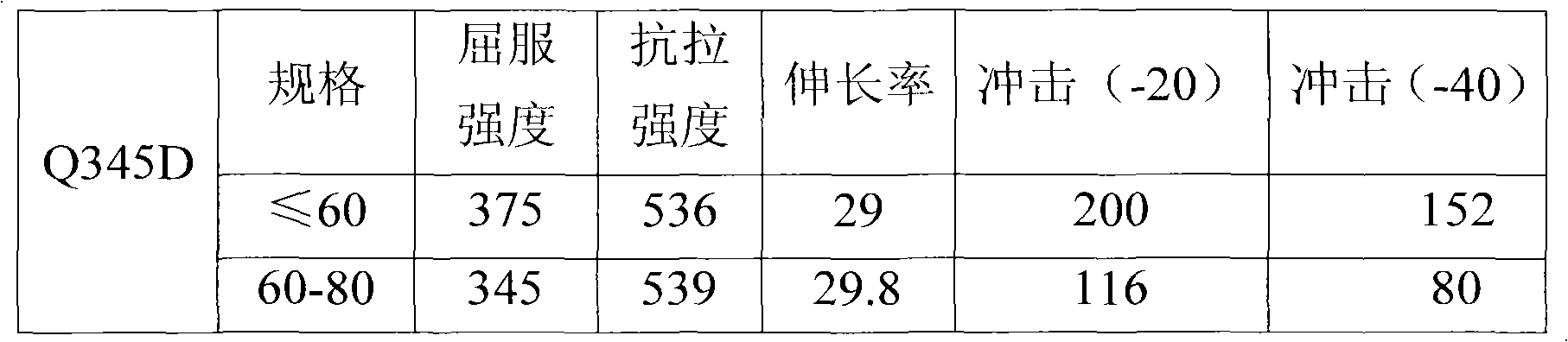

Low-alloy Q345D thick plate produced without adding micro-alloy elements and production method thereof

ActiveCN102080181AGuaranteed purityGuaranteed Performance RequirementsTemperature control deviceThick plateDegasser

The invention discloses a low-alloy Q345D thick plate produced without adding micro-alloy elements and a production method thereof. The method disclosed by the invention is characterized in that on the premise of not adopting vacuum decarburization equipment such as an RH and the like, through using the existing equipment such as a VD (vacuum degasser) and the like of enterprises, the requirements for smelting low-carbon steel plates and extreme low carbon steel plates are met, therefore, under the condition that the profits of the enterprises at the present stage are not high, a heavy investment in large-scale equipment replacement and remodeling is avoided, thereby saving the investment for the enterprises, completely using the existing equipment of the enterprises, greatly reducing the capital investment of the enterprises at the present stage, and providing abundant preparation time for equipment replacement after the market situation takes a favorable turn in the future and the profits of the enterprises are improved.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

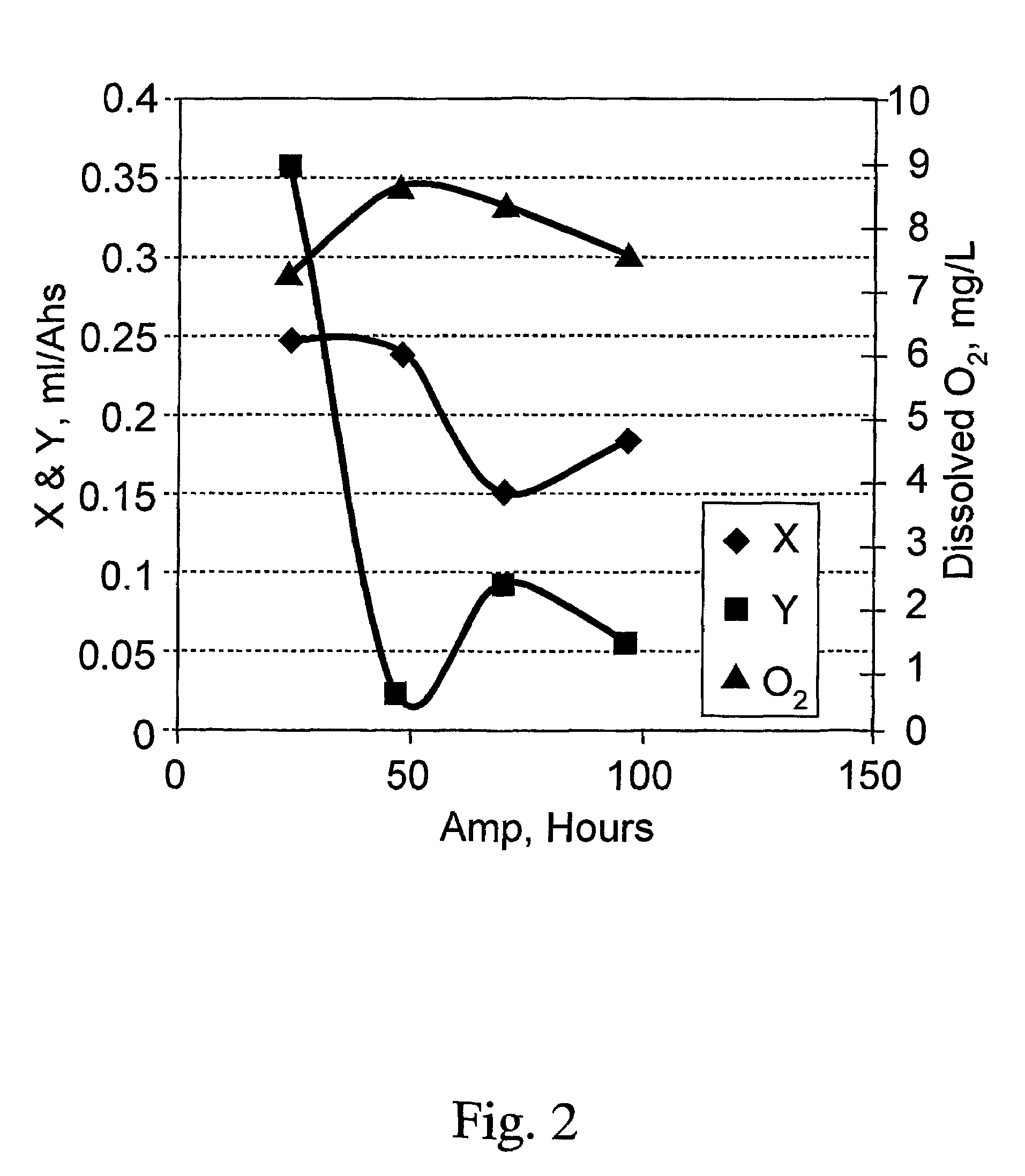

Process for degassing an aqueous plating solution

A process for removing oxygen from a copper plating solution is provided. The solution is passed through a degasser comprising a shell and hollow hydrophobic fiber porous membranes wherein the shell while a vacuum is drawn on the surfaces of the fibers opposite the fiber surfaces contacted by the solution. Gas passed through the fiber walls while liquid is prevented from infiltrating the fiber pores. The composition of the solution is monitored so that the composition can be retained substantially constant by adding components of the solution as needed.

Owner:ENTEGRIS INC

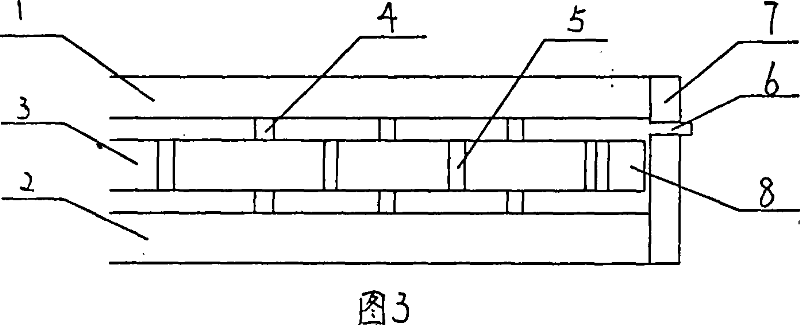

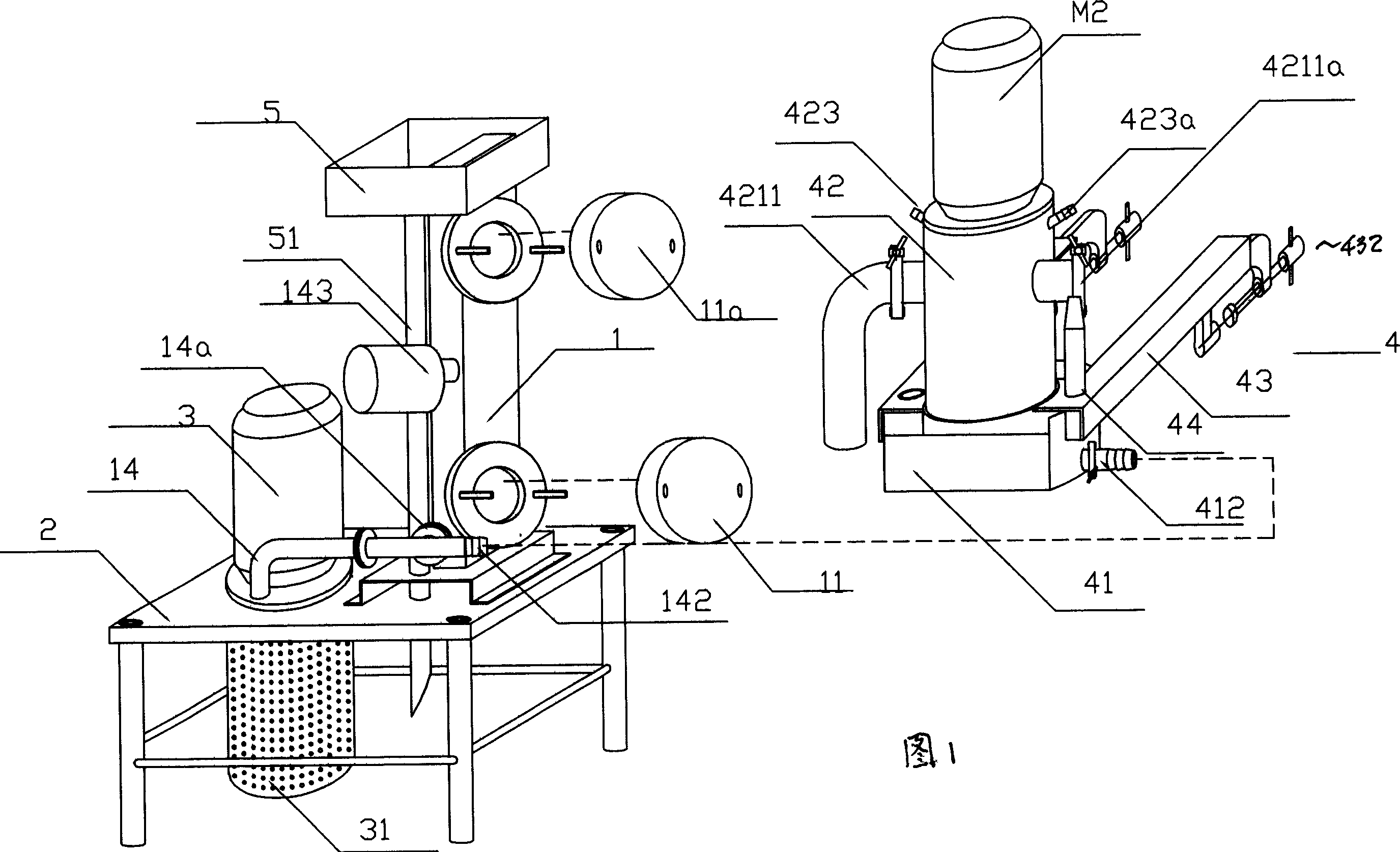

Combined type sensor devices and quantitative degassing apparatus

InactiveCN1687562ASignificant advantagesSignificant beneficial effectSurveySpecific gravity by measuring pressure differencesDegasserEngineering

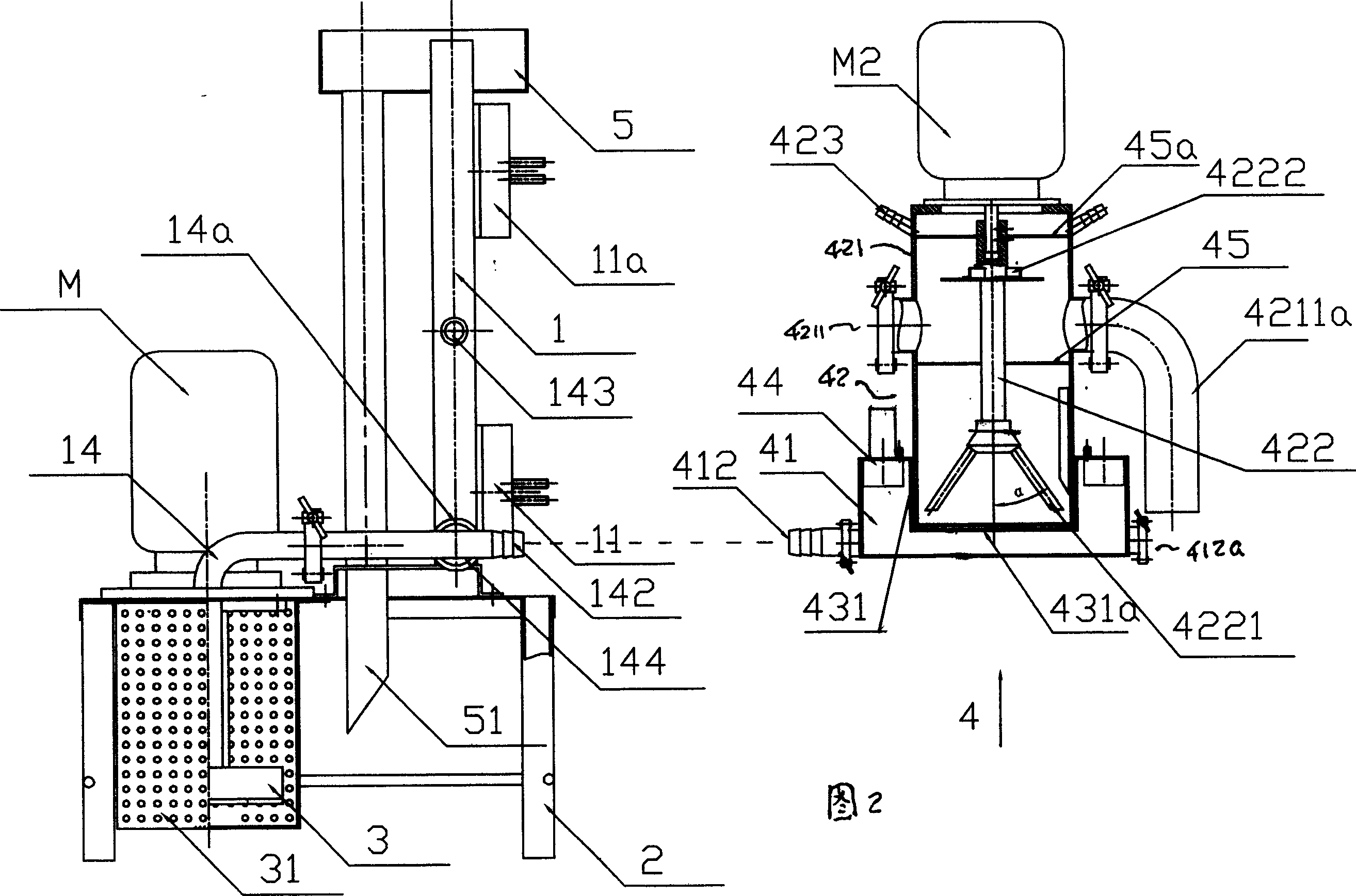

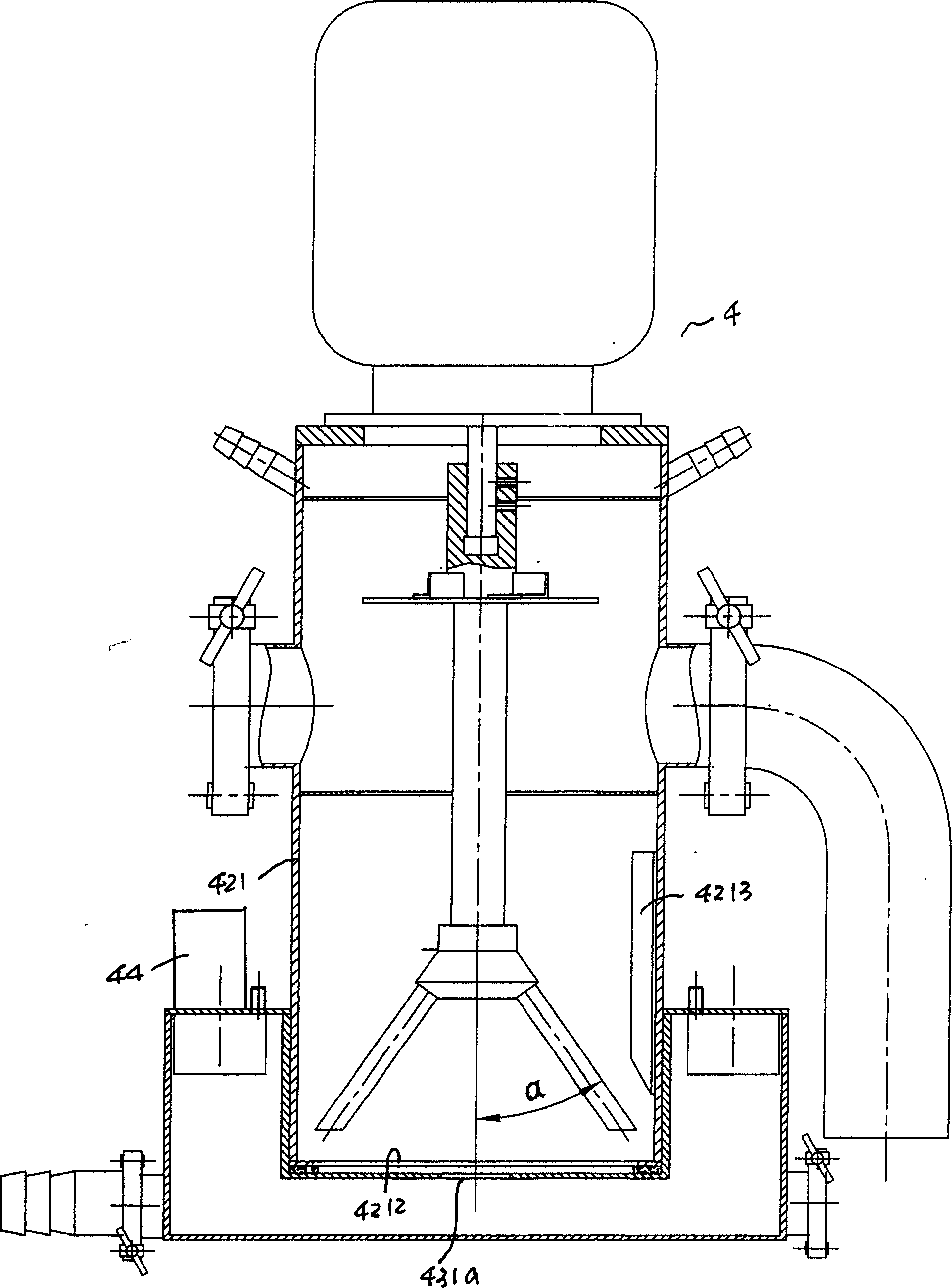

The invention is a composite sensing device and its quantitative degas device. The density sensor and the temperature sensor connect with the detecting container, the slurry pump transmits the waiting detected well liquid by the conveying tube, and the conveying device connects the quantitative degas device. The quantitative box of the degas device is set at the bottom of the degasser, and the bottom of its side wall has the inlet snout and connects the conveying tube, the bracket is on the quantitative box and has the tray of degasser, and the tray has the limiting slurry inlet, the conductive sensing device is equipped on the bracket and can contact the raw liquid position of the quantitative box. The invention can online correctly detects the density of the well liquid, the conductive ratio and the temperature.

Owner:天津港保税区鑫利达石油技术发展有限公司

Automatic analyzer of water soluble sulfide and analysis method

ActiveCN102253231ATest accuratePreparing sample for investigationColor/spectral properties measurementsPeristaltic pumpData connection

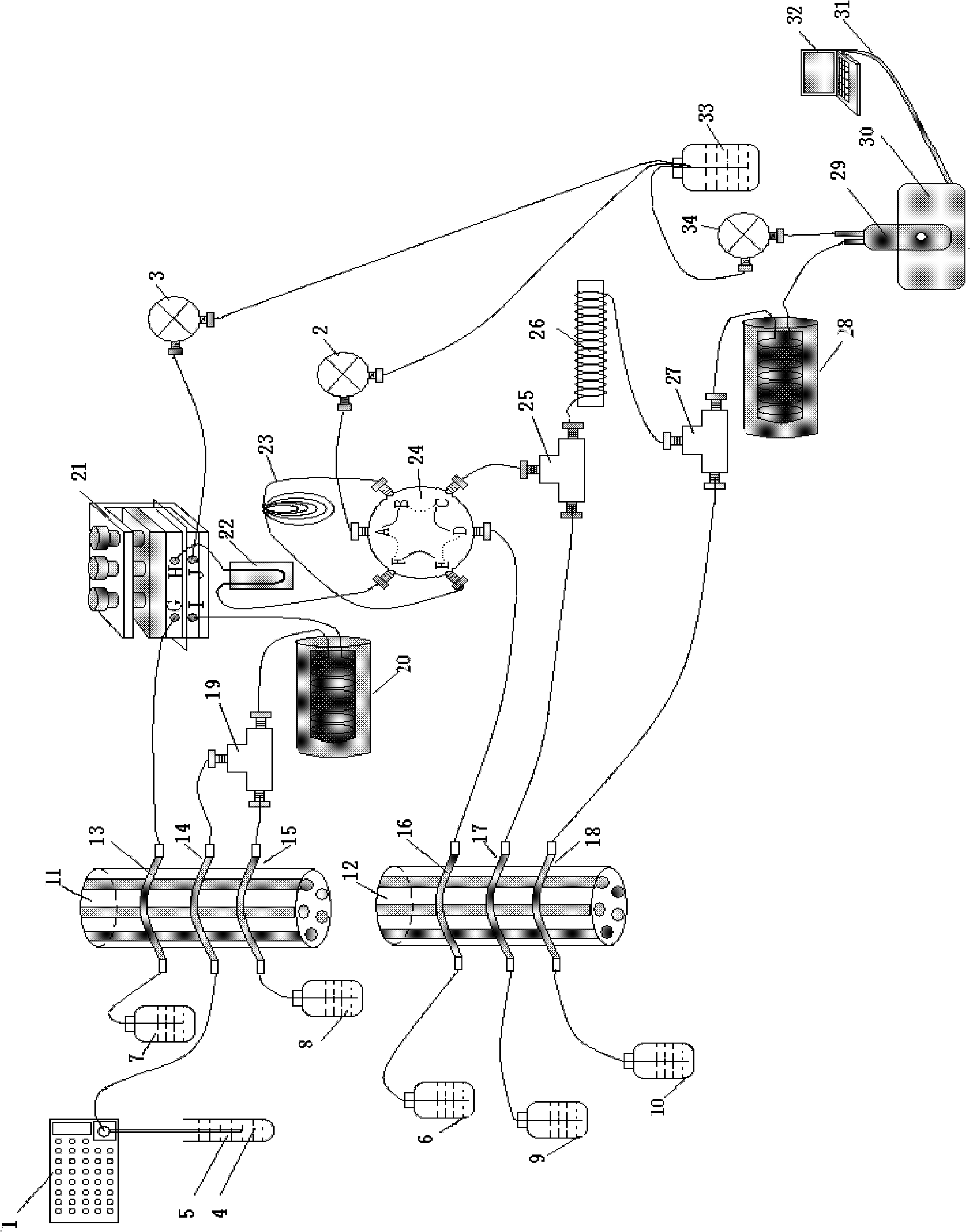

The invention discloses a full-automatic analyzer of a water soluble sulfide compound and an analysis method. The full-automatic analyzer comprises a sample pretreatment device and a chromogenic detection device, wherein the sample pretreatment device comprises an autoinjection device, a first peristaltic pump, a distillation reagent container, a first triple valve, a first line heat module, an on-line distillation module and an on-line degasser; and the chromogenic detection device comprises a second peristaltic pump, a current carrying bottle, a developer bottle, a ferric chloride solution bottle, a sampling ring, a six-way valve, a second backpressure regulator, a second triple valve, a first knotted reactor, a third triple valve, a second line heat module, a flow-through cell, a detector, a waste liquid bottle, a data connection cable, a computer processing system and a first backpressure regulator. The invention also discloses an analysis method of the water soluble sulfide compound. According to the full-automatic analyzer of the water soluble sulfide and the analysis method, samples can be continuously and automatically tested with the detection limit being 1 microgram / L, and the test is accurate and rapid.

Owner:BEIJING JITIAN INSTR CO LTD

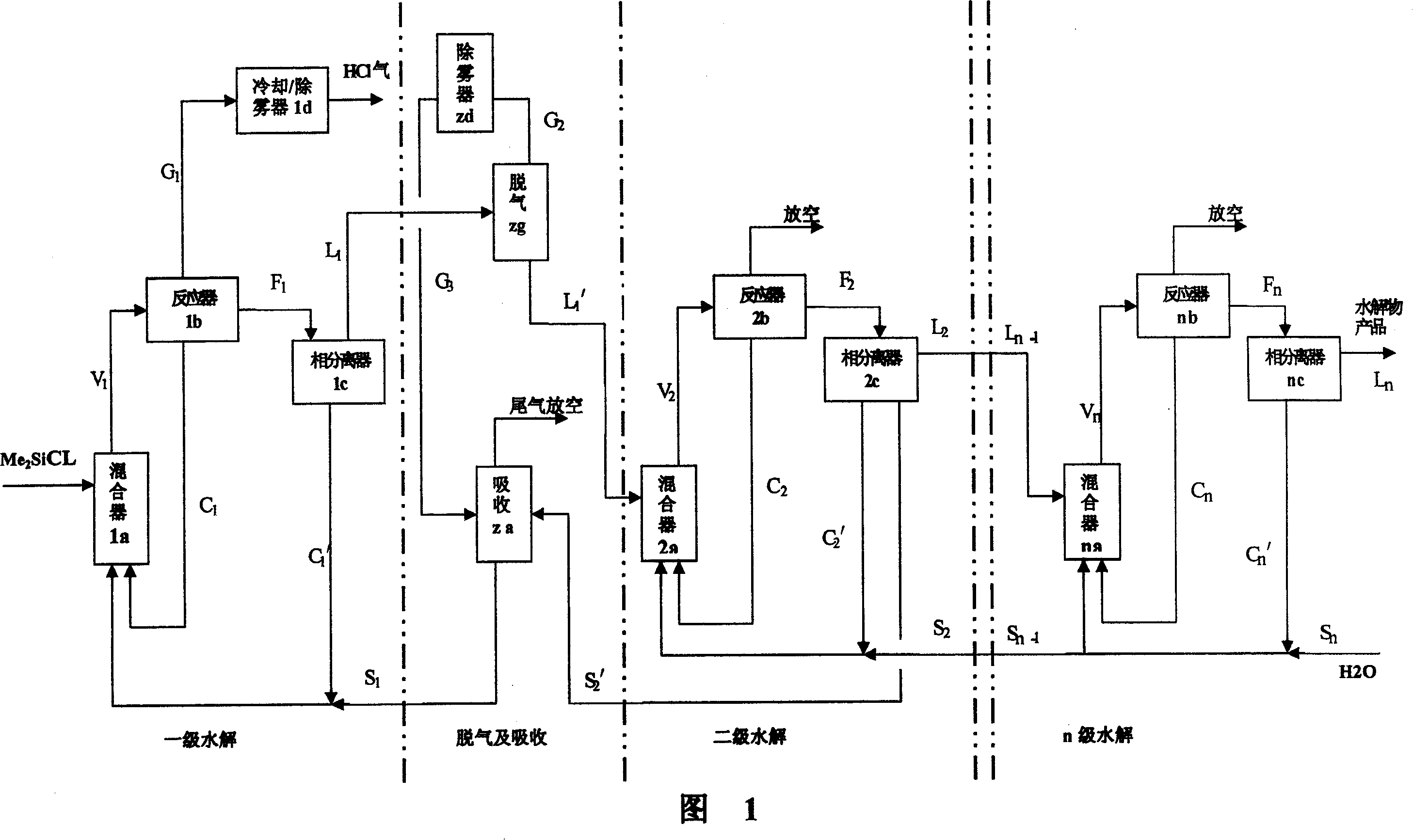

Method for preparing polyorganosiloxane and gas phase hydrogen chloride by multi-stage continuously hydrolyzing dichlorosilane

InactiveCN101148510AReduce pollutionReduce manufacturing costChlorine/hydrogen-chlorideDegasserGas phase

The present invention relates to continuous multistage organic dichlorosilane hydrolyzing process for preparing organic siloxane polymer and gaseous hydrogen chloride. Organic dichlorosilane is hydrolyzed continuously in a circulating hydrolysis reaction system with at least thee stages, each of which includes one inner circulating unit and one outer circulating unit. In the relatively independent hydrolysis reaction stages, the hydrolyzed organic siloxane polymer is fed continuously from the upper stage to the lower stage through one degasser to eliminate great amount of free hydrogen chloride, while hydrolyzed hydrochloric acid is replenished from the lower stage to the upper stage. The present invention has low gaseous hydrogen chloride content in each hydrolysis reaction stage, easy operation, stable product quality, high yield and stable pressure of anhydrous gaseous hydrogen chloride.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

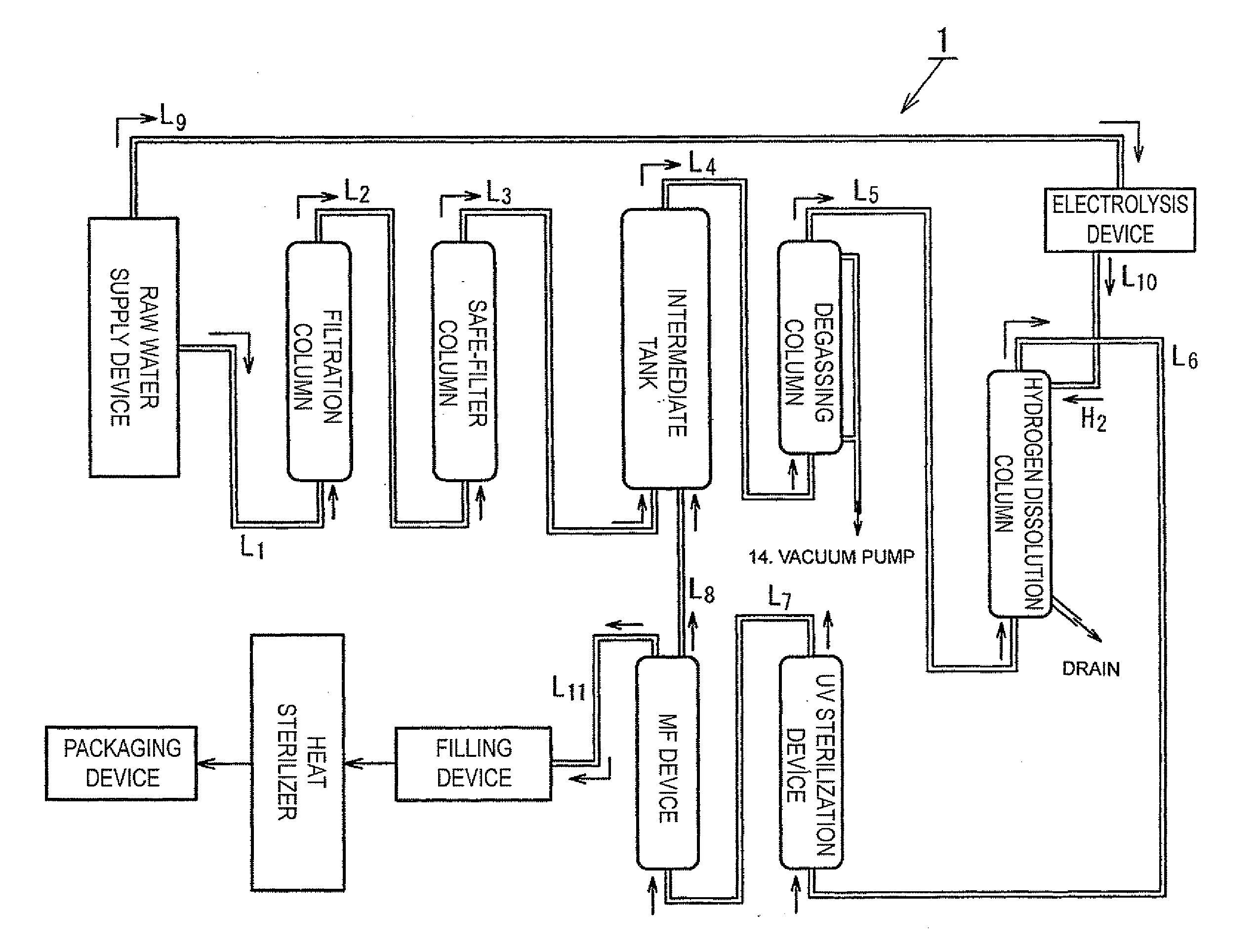

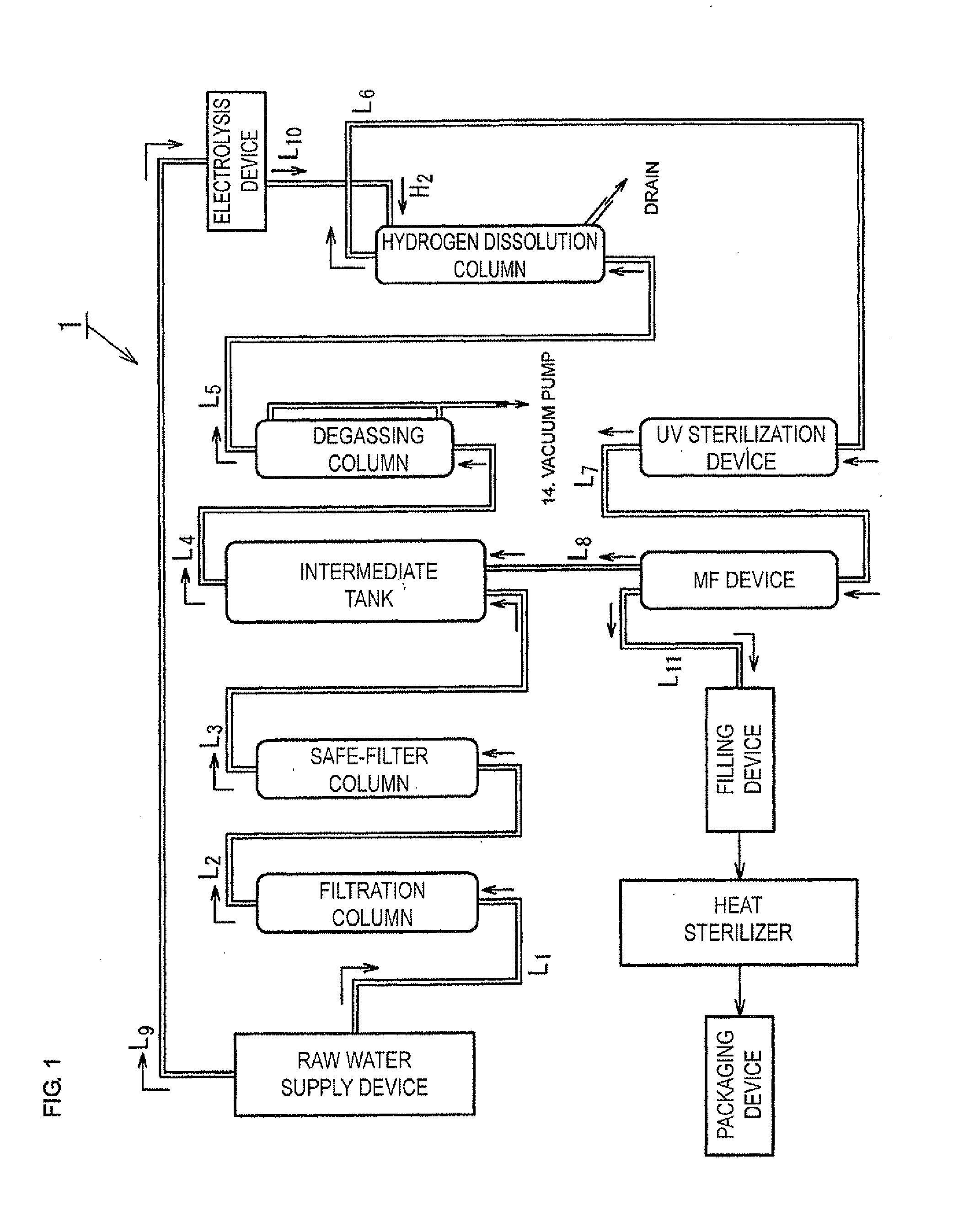

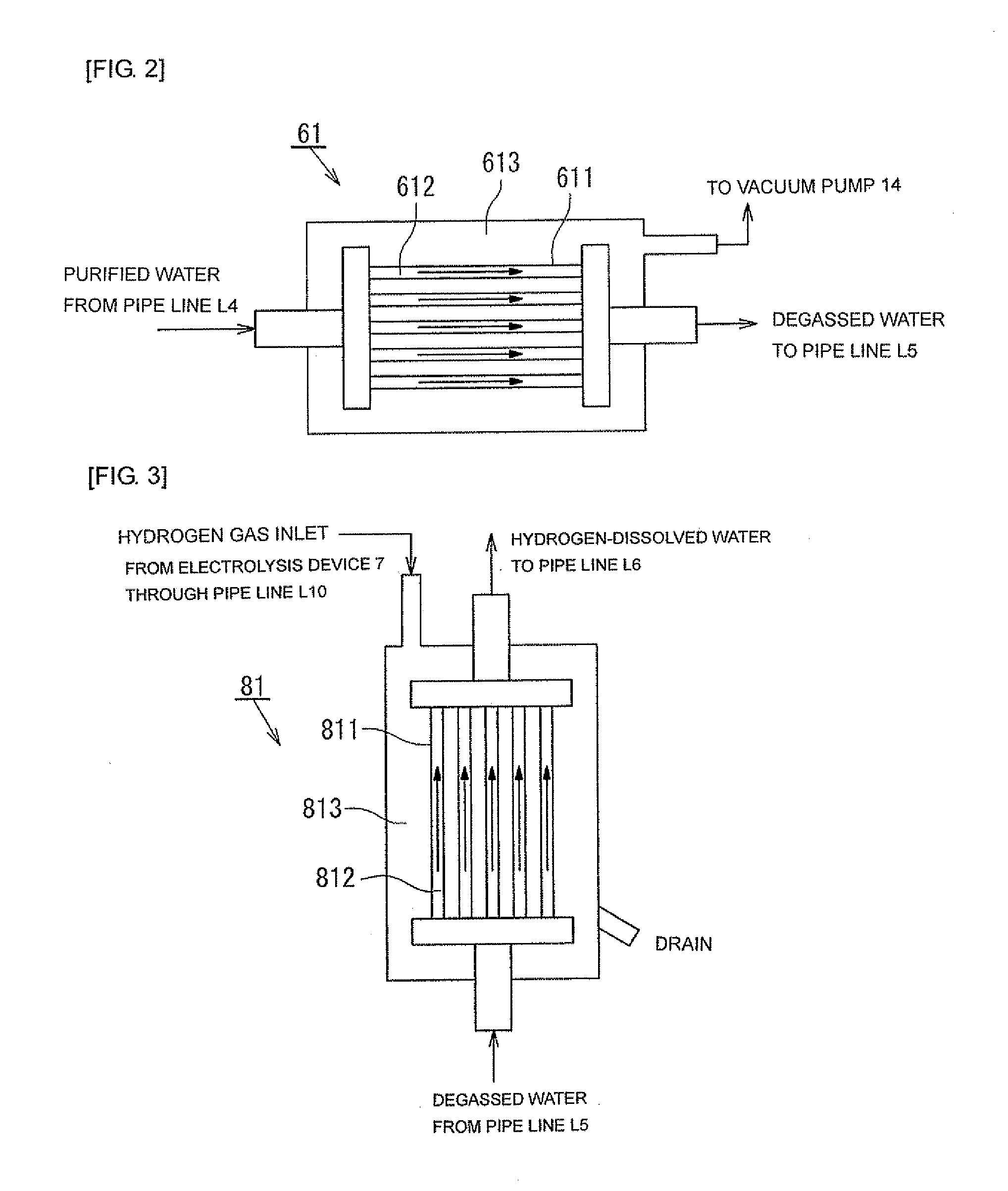

Process for producing hydrogen-containing water for drinking

InactiveUS20120070540A1Efficiently dissolving hydrogenEffective dissolutionFlow mixersLiquid degasification by filtrationDegasserDissolution

There is provided a process for producing hydrogen-containing water for drinking, by which the dissolved hydrogen concentration of the obtained hydrogen water can be more efficiently increased. A process for continuously producing hydrogen-containing water for drinking, comprising (a) a purifying step of filtering and purifying water as a raw material; (b) a degassing step of degassing the purified water supplied to a degasser; (c) a hydrogen-dissolving step of dissolving hydrogen gas in the degassed water supplied to a hydrogen dissolution device; (d) a sterilizing step of sterilizing the hydrogen-dissolved water supplied to a sterilizer; (e) a filling step of filling the hydrogen-containing water supplied to a filling device in a sealed container and transferring the filled water product to a heat sterilizer; and (f) a heat-sterilizing step of heat-sterilizing the water product supplied to the heat sterilizer, wherein part of the hydrogen-containing water obtained in the step (d) is returned to the degasser in the step (b) and the water is circulated through the steps (b) to (d).

Owner:SHEFCO

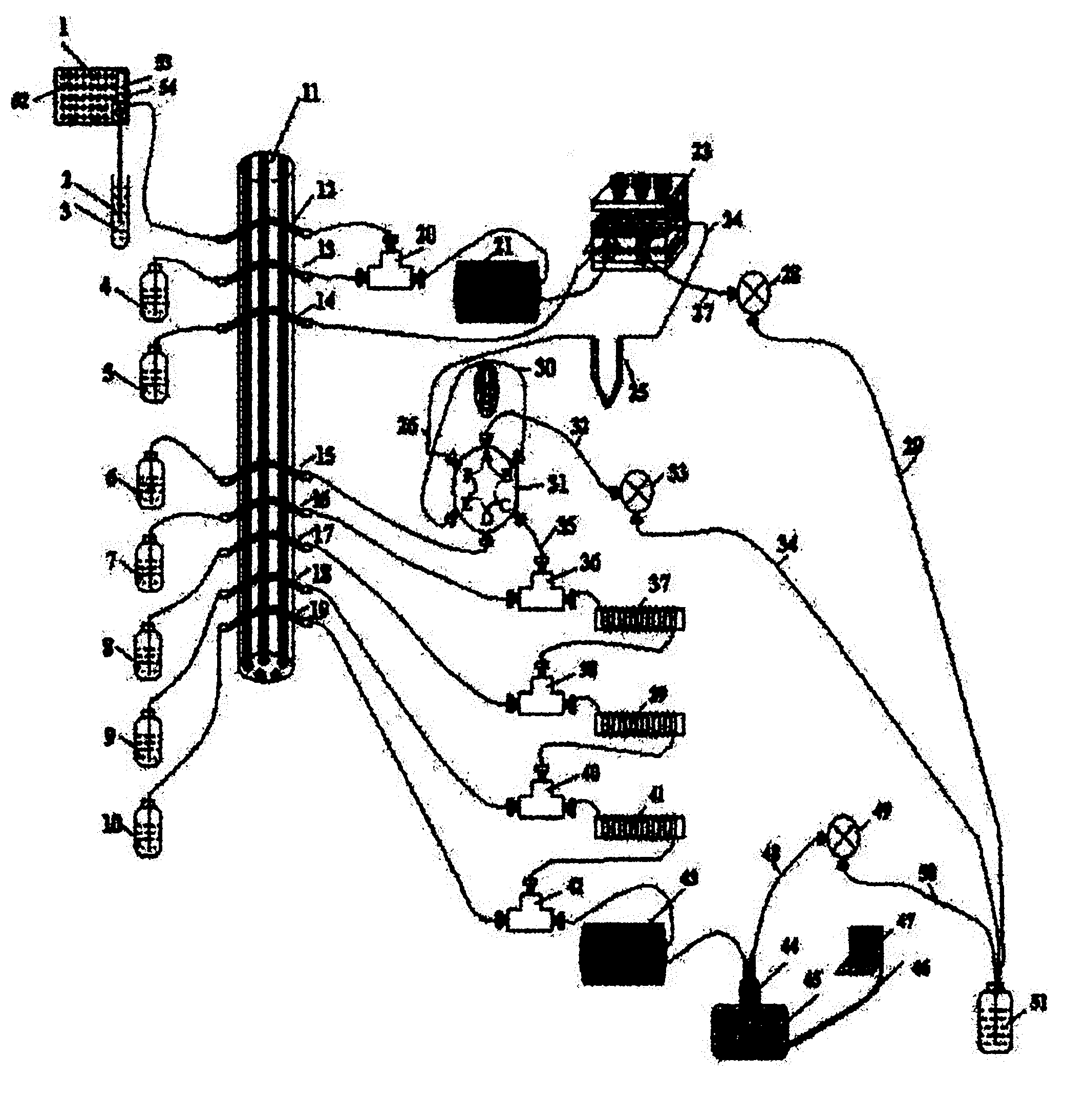

On-line degasser for transformer oil gas

InactiveCN103252113AReduce the dead volume of the spaceReduce hardware costsLiquid degasificationSolenoid valveAir pump

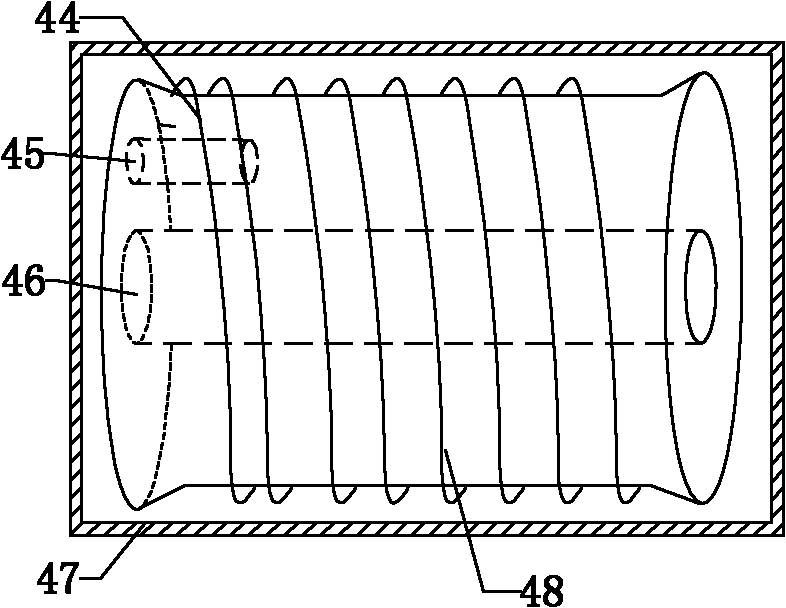

The invention relates to an on-line degasser for transformer oil gas. The on-line degasser is characterized by comprising an oil pump, an air pump, a quantification chamber, a degassing chamber, an oil discharging chamber, an air compressor, a pressure transducer, liquid level sensors, pipelines, solenoid valves and an electric control unit. The oil pump and the air pump use the air compressor as a power source, are controlled in virtue of cylinders and replace a pre-posed oil circulating pump. The quantification chamber, the degassing chamber, the oil discharging chamber and the pipeline are integratedly designed, and integrated installation of the sensors and the solenoid valves is realized. The whole on-line degasser realizes external communication and modularized control based on an independent control system. A discharged oil liquid level sensor is additionally mounted to guarantee safe return discharge of an oil sample. The on-line degasser for transformer oil gas provided by the invention has the advantages of simplified elements, optimized control, integrated design of used parts, reduction in hardware cost and debugging time, capacity of realizing multiple vacuum degassing of transformer oil in a short period of time and accordance with requirements for repeatability and stability of a degassing rate.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST

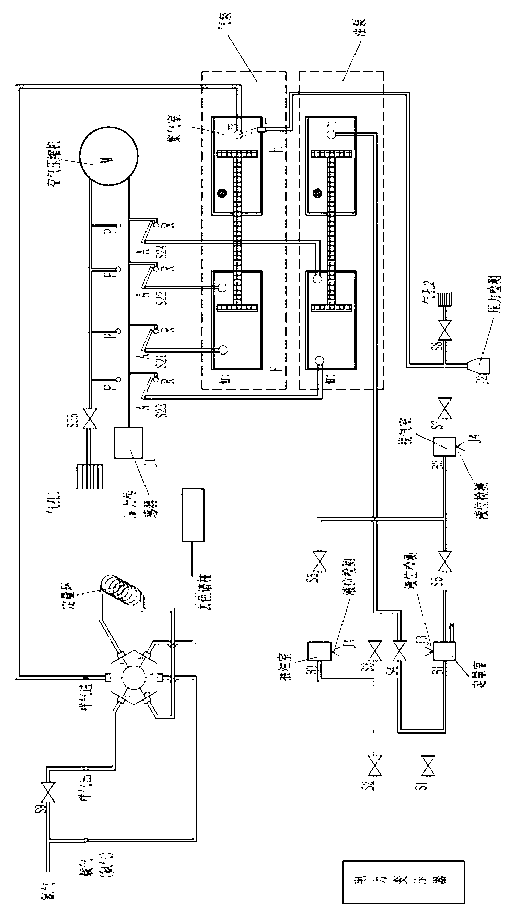

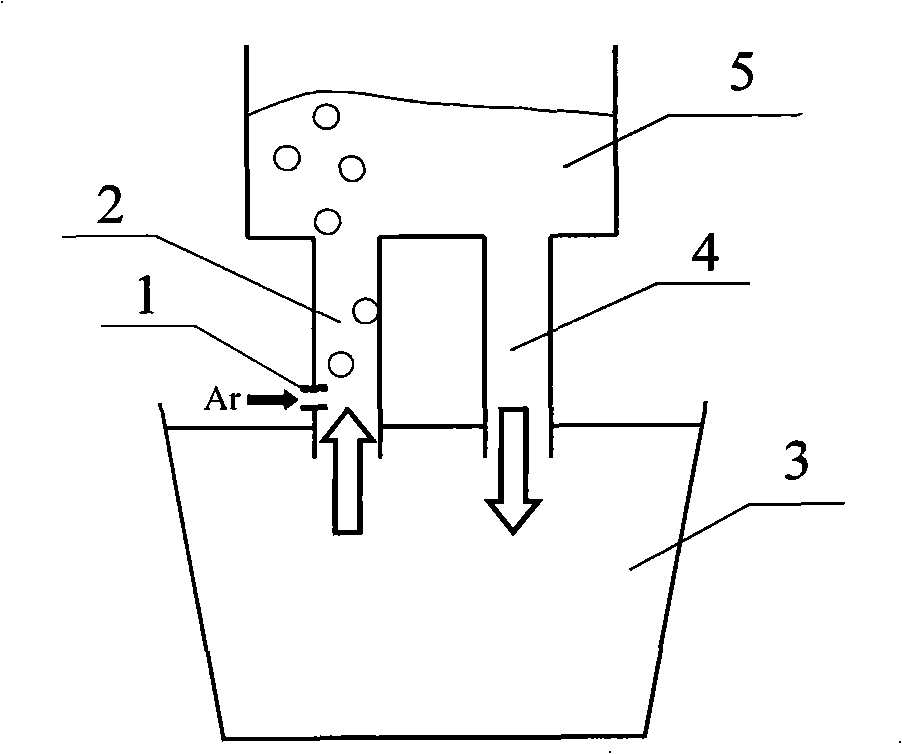

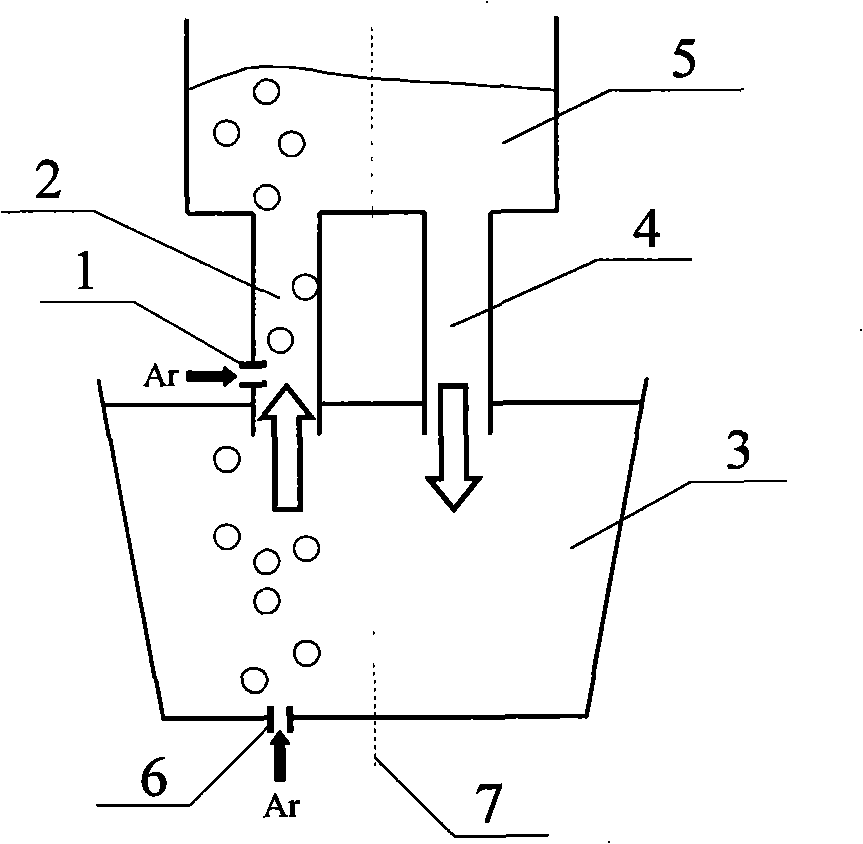

RH bottom blowing argon vacuum circulating degasser

The invention relates to an RH bottom argon blowing vacuum circulating degasser belonging to the technical field of metallurgy and comprising a steel ladle and a vacuum chamber, wherein the bottom wall of the steel ladle is provided with a nozzle or an air brick, and the nozzle or the air brick is connected with an argon blowing device and positioned at one side of the projection of an ascending tube of the vacuum chamber on the bottom wall of the steel ladle. The RH bottom argon blowing vacuum circulating degasser can effectively enhance the circular flow of the RH bottom argon blowing vacuum circulating degasser, increase the internal stirring of the RH vacuum circulating degassing steel ladle, shorten the blending time, accelerate the elimination of deoxidation type inclusions inside the RH vacuum circulating degassing steel ladle and enhance the degassing and the decarburization speed.

Owner:NORTHEASTERN UNIV

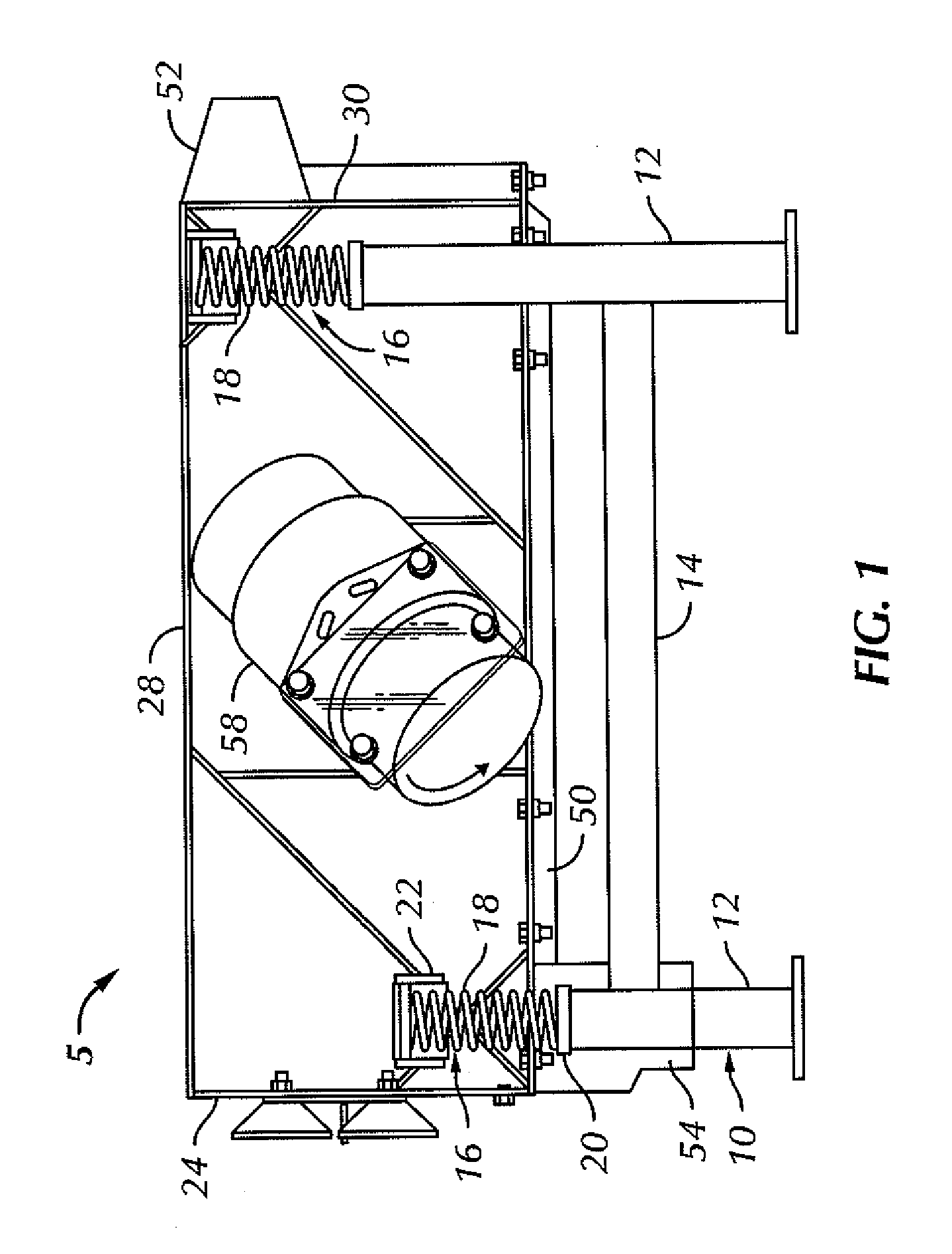

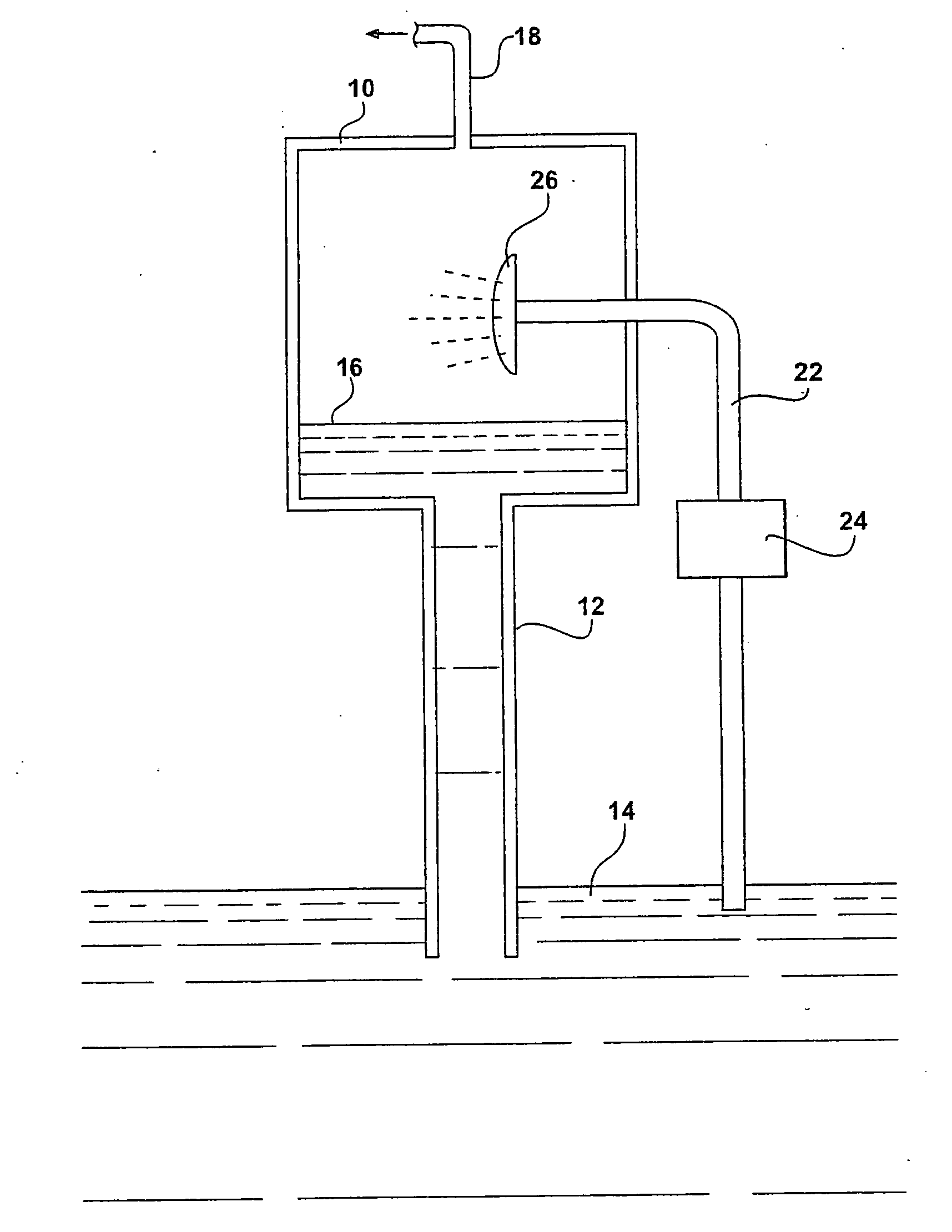

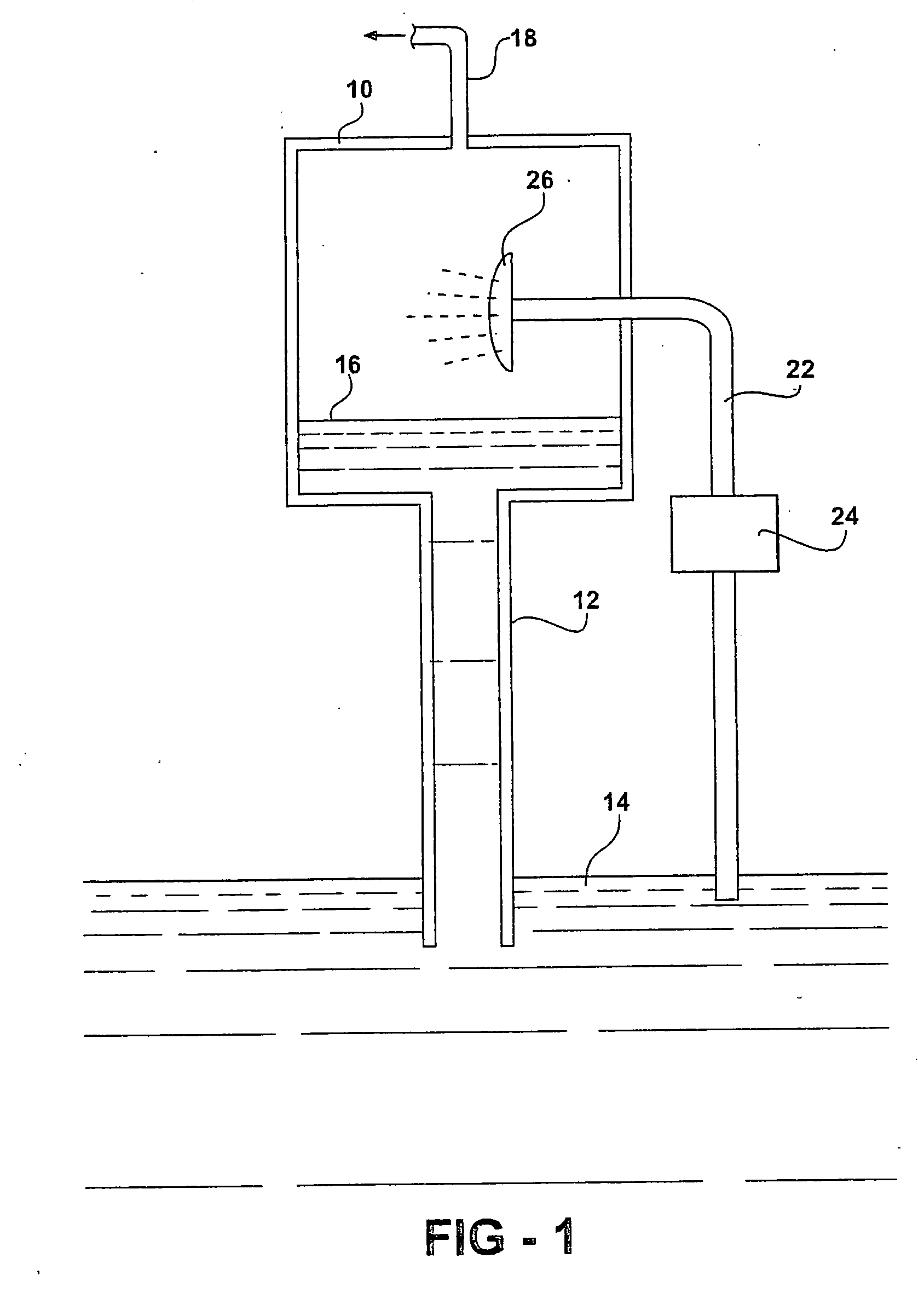

Separation of evolved gases from drilling fluids in a drilling operation

InactiveUS7575073B2Avoid evolutionSafely contained and controlledDrilling rodsConstructionsDegasserWell drilling

A fluid handling system for drilling cuttings utilizes a constant and gravity managed liquid level between a substantially atmospheric separator and a shale shaker to maximize fluid residence time within the separator and ensure substantially all of the gas entrained in the cuttings is evolved and passed to a flare thus preventing evolution of the gas at the shale shaker. Solids from the separator are combined with liquid recirculation from and returning to the shale shaker. Optionally, a vacuum degasser is positioned between the separator and the shale shaker and separated gases are passed from the degasser to the flare. This method and system is particularly applicable to balanced, underbalanced and air drilling operations where the flow of gas is intermittent and unpredictable.

Owner:SWARTOUT MATTHEW K

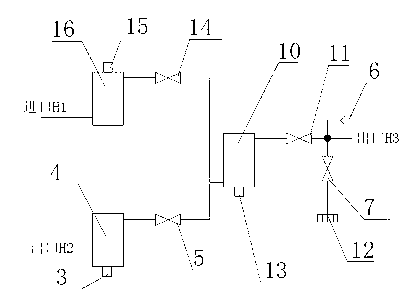

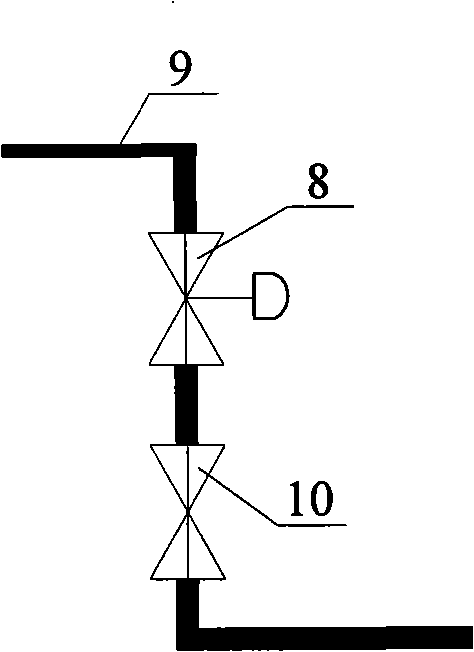

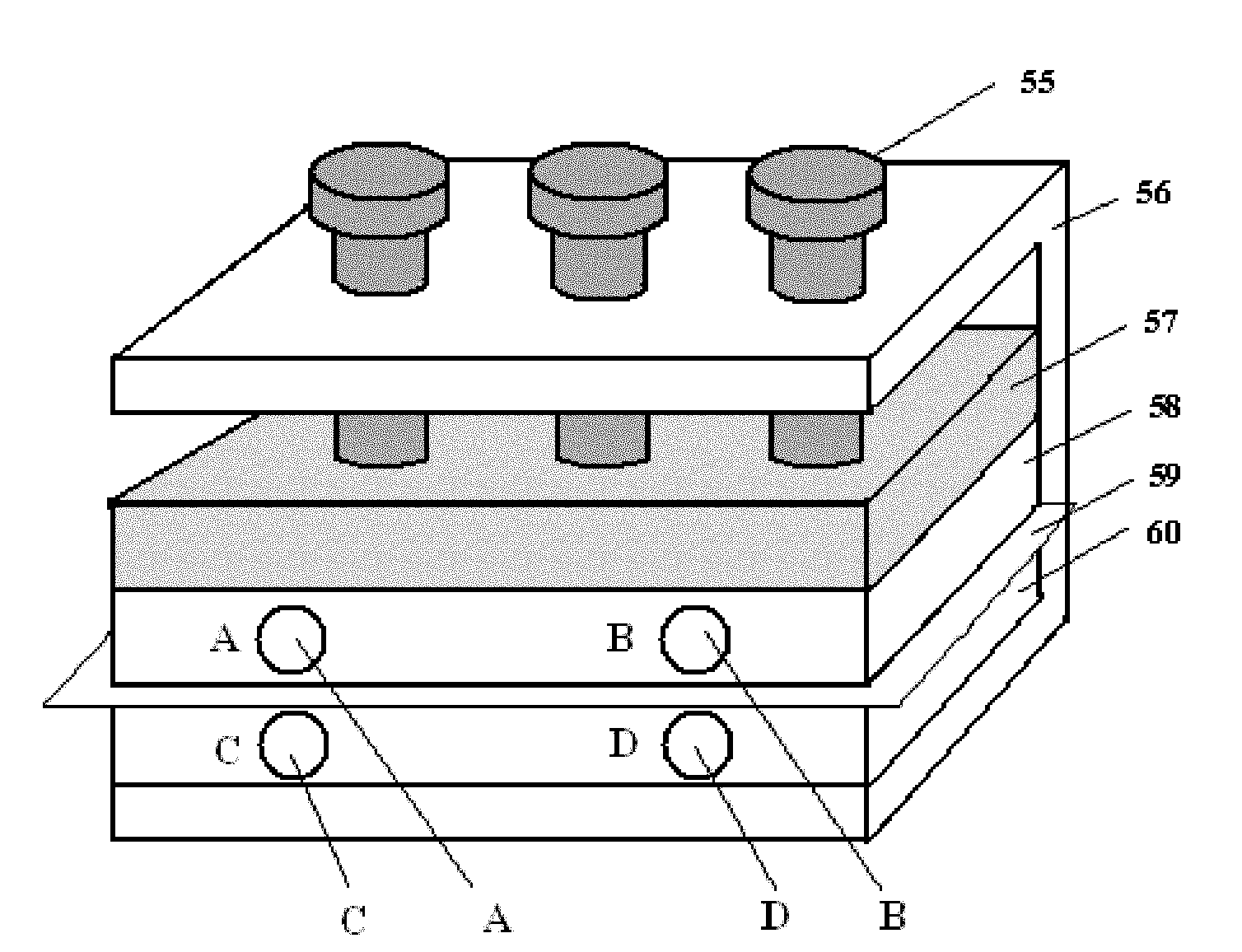

Full-automatic vacuum degasser and degassing method thereof

The invention discloses a full-automatic vacuum degasser and a degassing method thereof. The full-automatic vacuum degasser comprises a first cylinder, a second cylinder and a degassing chamber, and is characterized in that the first cylinder is connected with an oil inlet tube which is provided with a first valve; the first cylinder is connected with an oil outlet tube which is provided with a second valve; the first cylinder is connected with an atomization nozzle of the degassing chamber by a third valve; the oil outlet of the first cylinder is communicated with the oil outlet at the bottom of the degassing chamber by a fourth valve; the degassing chamber is connected with the second cylinder by a fifth valve, the second cylinder is connected with a discharge pipe which is provided with a sixth valve; the piston rods of the first cylinder and the second cylinder are respectively connected with an electric transmission device; the degassing chamber is arranged in a constant temperature space and is internally provided with a vacuum sensor. The full-automatic vacuum degasser of the invention solves difficulty of difficult control of vacuum efficiency, and has the characteristic of stable degassing efficiency, controllability, and convenient and fast usage.

Owner:JIANGSU ELECTRIC POWER RES INST +3

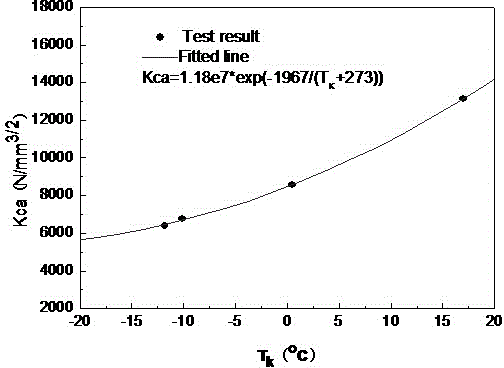

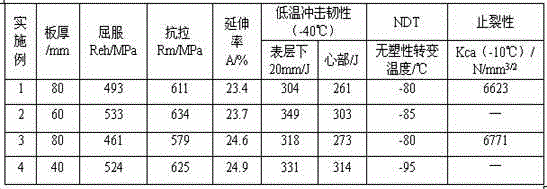

Production method of ultrahigh-strength anti-cracking thick steel plate

The invention relates to a production method of an ultrahigh-strength anti-cracking thick steel plate. The steel comprises the following chemical components in percentage by weight: at most 0.10% of C,0.10%-0.50% of Si, 1.40%-1.80% of Mn, at most 0.015% of P, at most 0.005% of S, 0.02%-0.05% of Nb, 0.008%-0.02% of Ti, 0.015%-0.05% of Al, 0.2%0-0.50% of Ni, at most 0.35% of Cu, at most 0.25% of Gr, at most 0.25% of Mo, and the balance of Fe and inevitable impurities. The production method comprises the following key steps: smelting, continuous casting, heating, rolling and cooling. By adopting the low-carbon high-manganese Nb-Ti-Ni multielement microalloying component design system in combination with LF+VD (ladle furnace+vacuum degasser) compound refining and ultra-fast cooling techniques, the ultra-thick steel plate with the yield strength of 400 MPa above and the maximum thickness of 80mm can be produced. The -40-DEG C impact toughness of the steel plate core can reach 250J above, the nil ductility transition temperature is -80 DEG C below, and the high-strength steel plate has higher toughness, weldability and cracking resistance.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Automatic analyzer for determining ammonia nitrogen in water and automatic analytic method thereof

InactiveCN102374989AFast testHigh sensitivityMaterial analysis by observing effect on chemical indicatorThermometers using electric/magnetic elementsPeristaltic pumpFour-way valve

The invention relates to an automatic analyzer for determining the content of ammonia nitrogen in water and sewage through a flow injection colorimetric process and an automatic analytic method thereof. The automatic analyzer for determining the content of ammonia nitrogen in water and sewage comprises an automatic injection device, a peristaltic pump, a detector, and an online processing assembly, wherein the online processing assembly comprises a sample injection valve, braided reactors, three-way valves, a four-way valve, online heating modules, an online distillation module, an online degasser, and capillary connecting tubes. According to the automatic analyzer of the invention, samples can be continuously and automatically tested, the test speed is fast, fifty samples can be tested each hour, the test sensitivity is high, and the test accuracy is good; and according to the method of the invention, the liner range is 0.02-4.0mg / L, the liner correlation coefficient r is equal to or more than 0.999, the detection limit is 2.49mug / L, the standard addition recovery rate of practical water samples is 90-110%, the precision is high, and the repeatability is good.

Owner:BEIJING JITIAN INSTR CO LTD

Production method of low-titanium bearing steel GCr15

The invention relates to a production method of low-titanium bearing steel GCr15. The method sequentially comprises the following steps: EBT eccentric bottom electric furnace, LF (ladle furnace) refining furnace, VD (vacuum degasser), and continuous casting or die casting. In the electric furnace, oxygen is blown into molten steel by an ultrasonic oxygen lance to remove C and control the tapping C content to be at most 0.40%, the tapping temperature T is greater than or equal to 1640 DEG C and smaller than or equal to 1685 DEG C, and eccentric bottom tapping is subjected to steel-leaving slag-leaving operation to prevent the oxidizing slag. In the tapping process, high carbon ferrochrome, silicomanganese and silicon iron are respectively added according to the Cr content of 1.40 wt%, Mn content of 0.25 wt% and Si content of 0.15 wt%. After tapping, the steel enters the LF refining furnace to perform refining, 0.4kg of aluminum wire is added to every ton of steel in the LF refining furnace to control the Al content to be at most 0.04%, and the refining slag is composed of the following components in percentage by weight: 50-60% of CaO, 25-35% of Al2O3, 5-10% of SiO2 and 6-10% of MgO. The refining temperature is controlled at 1580-1600 DEG C. The smelting process uses common iron alloy to smelt the bearing steel, and can control the titanium content to be not greater than 50 ppm, thereby saving the noble iron alloy and solving the problem of cost increase in low-titanium bearing steel smelting.

Owner:BENGANG STEEL PLATES

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com