Patents

Literature

91 results about "Dialysate flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

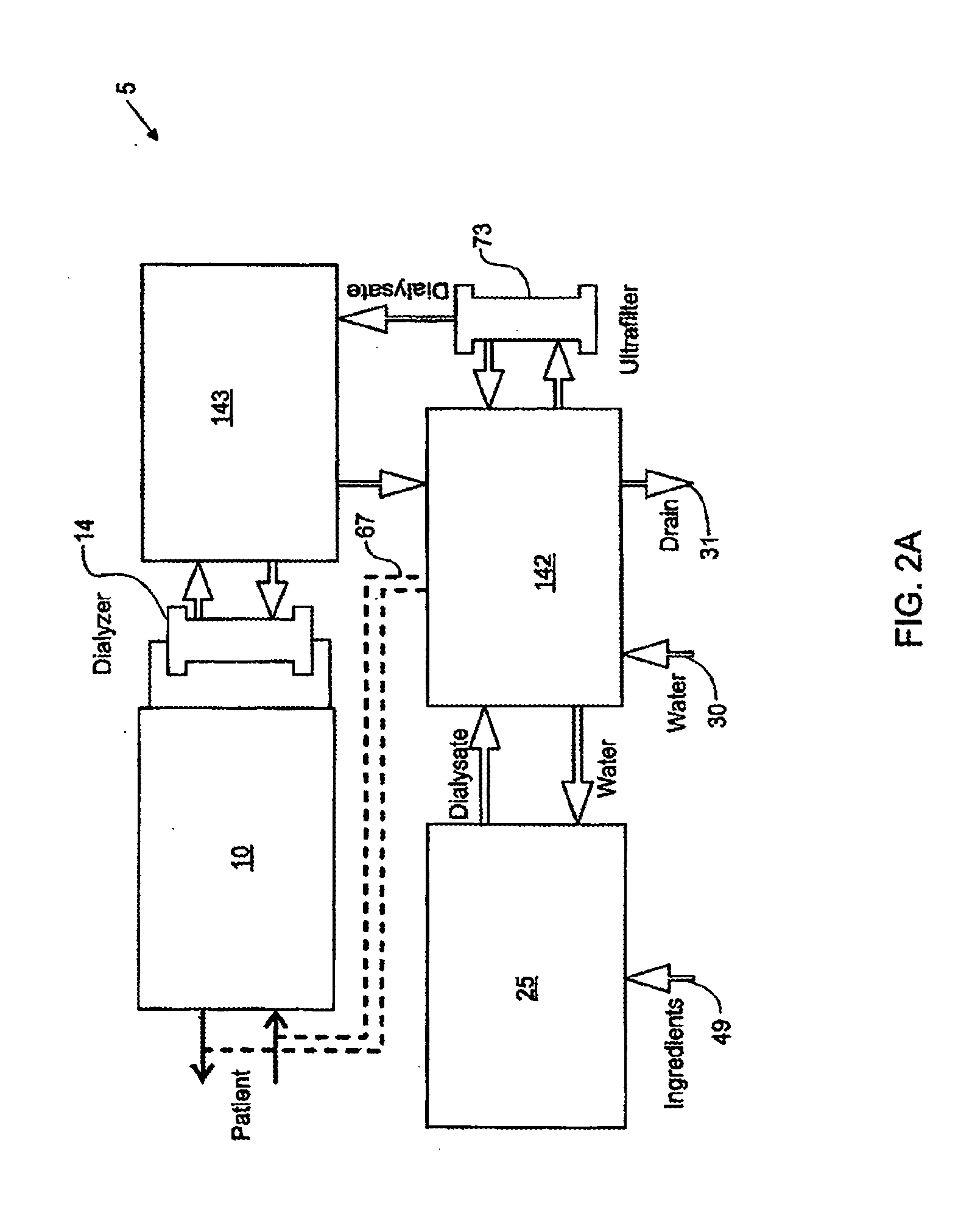

High convection home hemodialysis/hemofiltration and sorbent system

InactiveUS20050131332A1Easily set up sterile blood therapy systemImprove efficiencySemi-permeable membranesHaemofiltrationPositive pressureSorbent

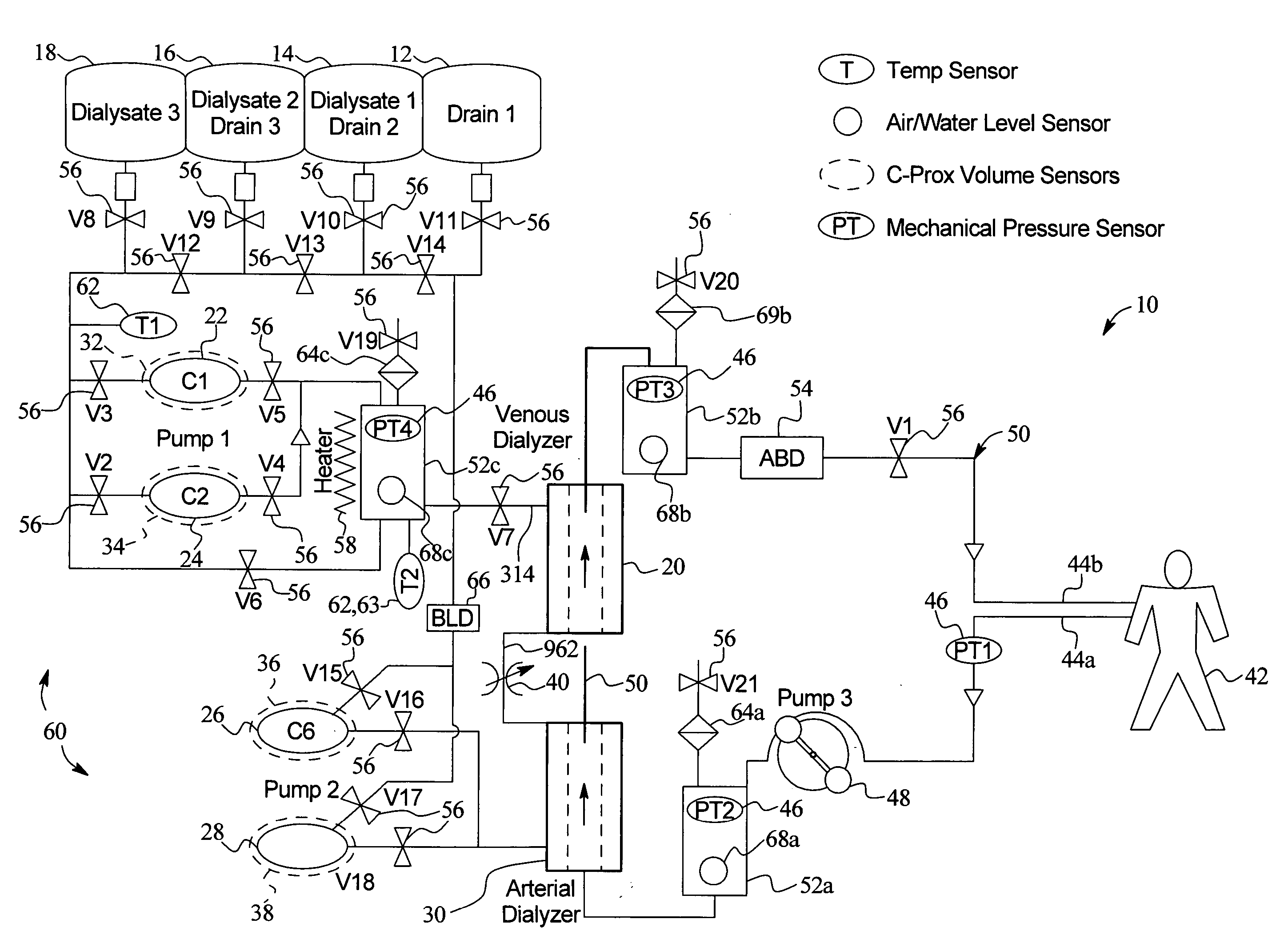

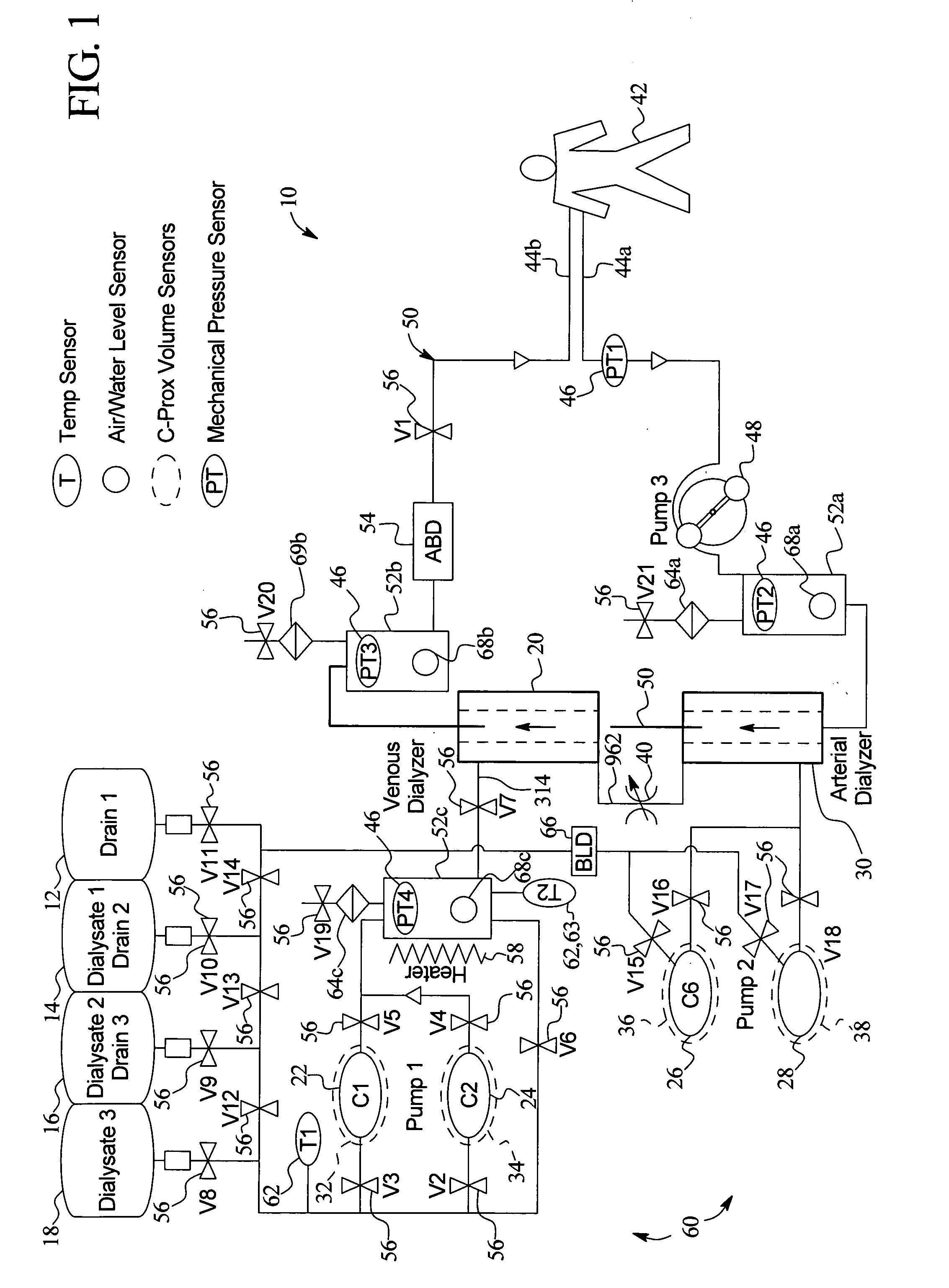

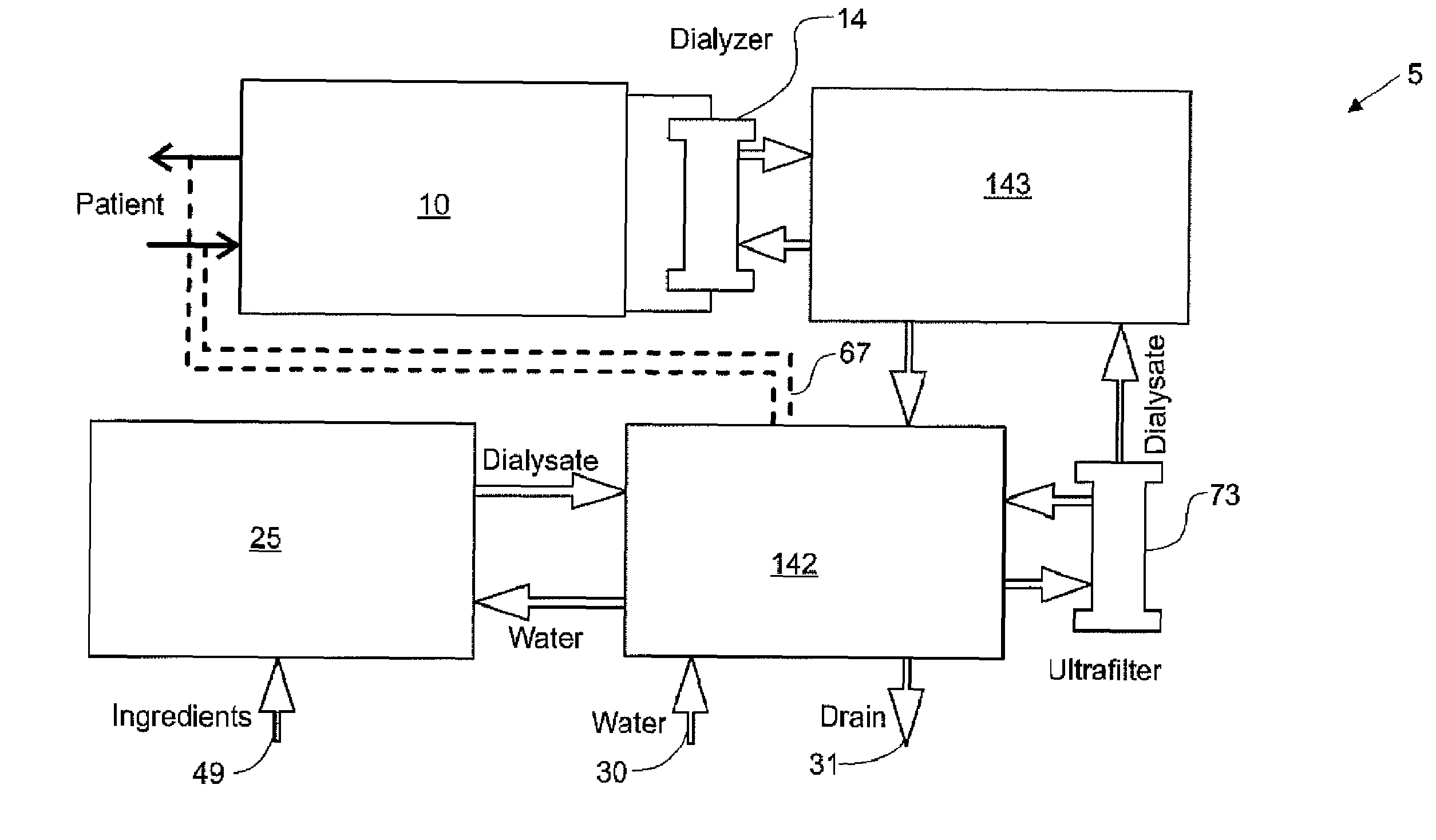

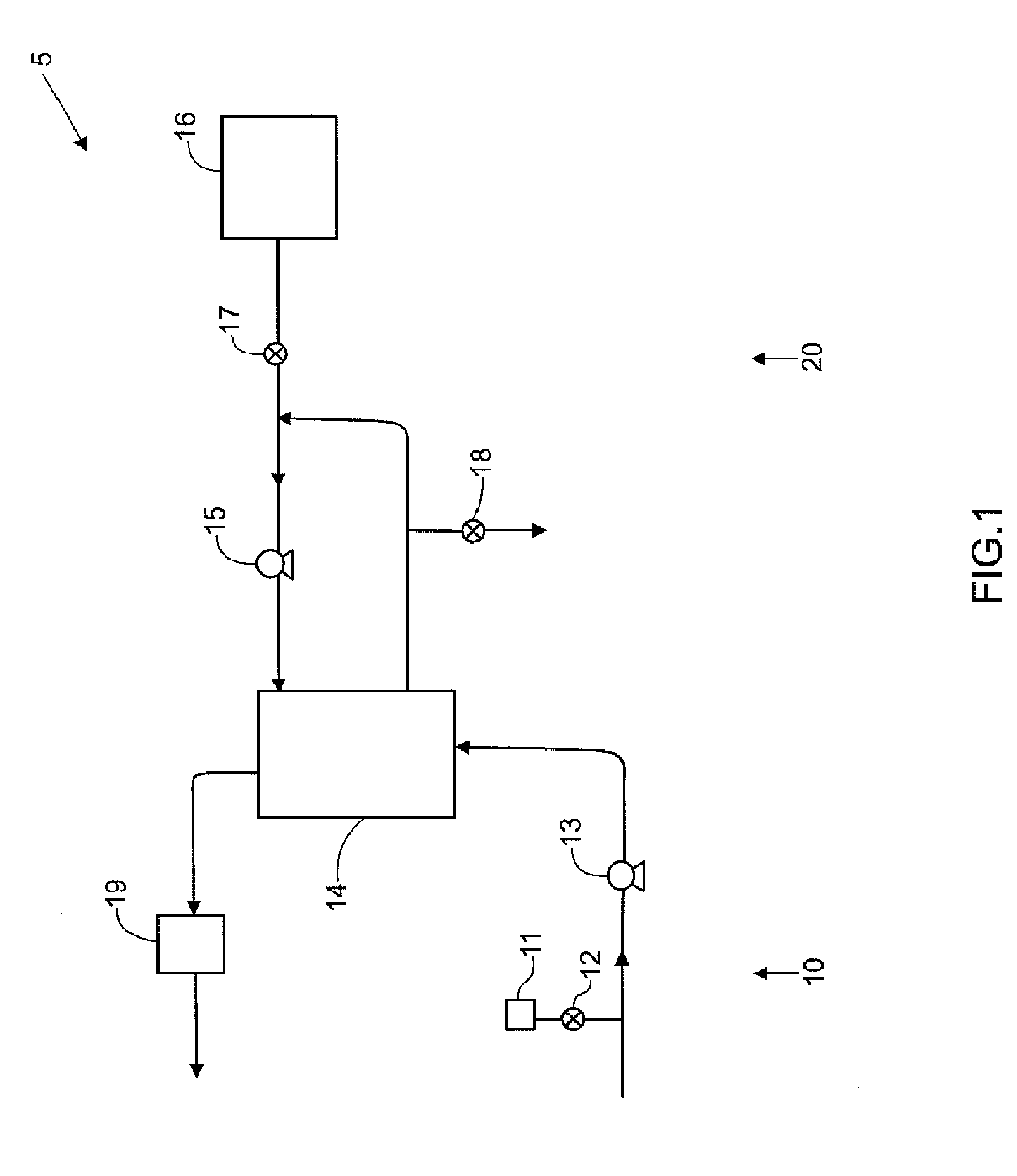

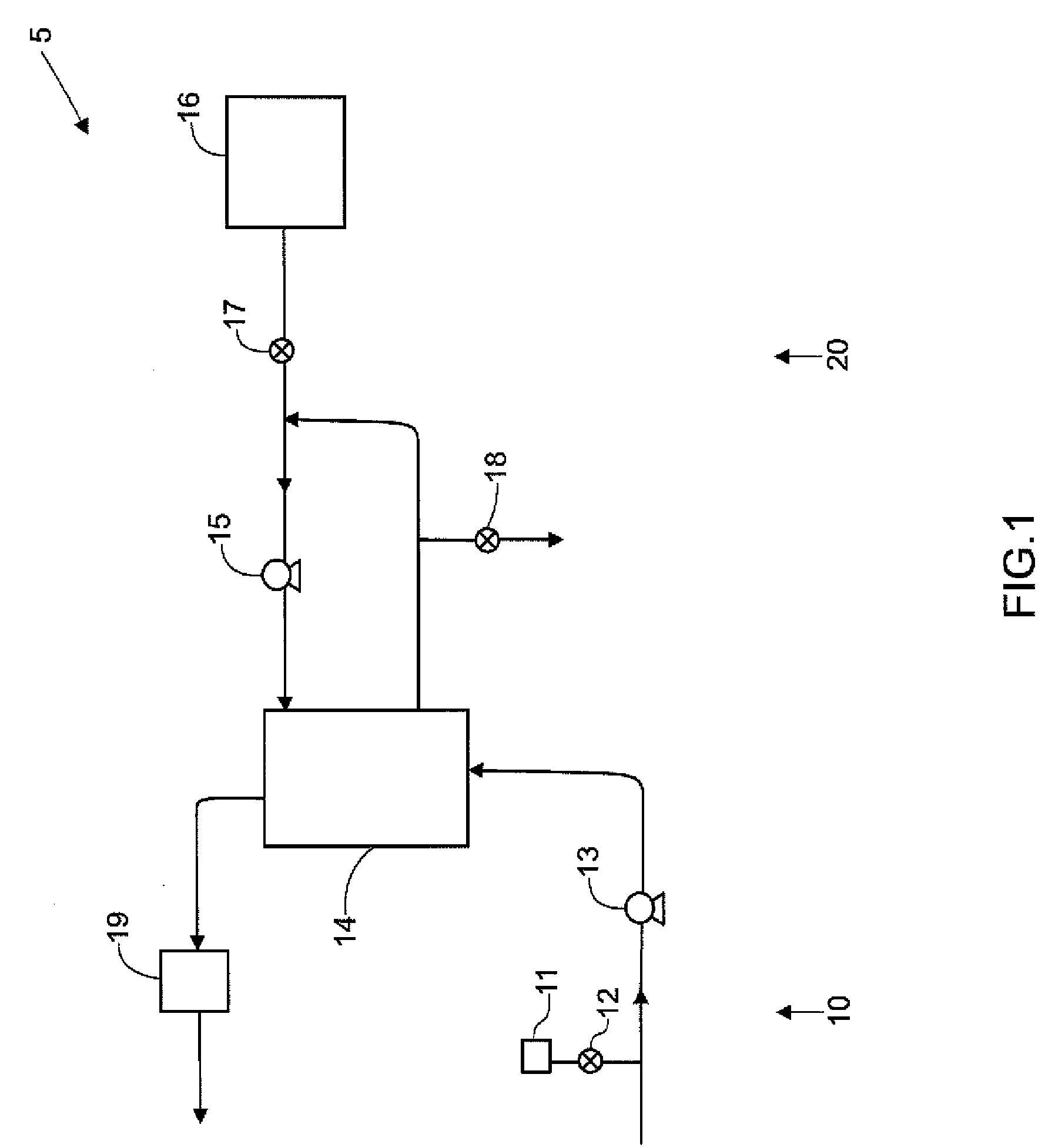

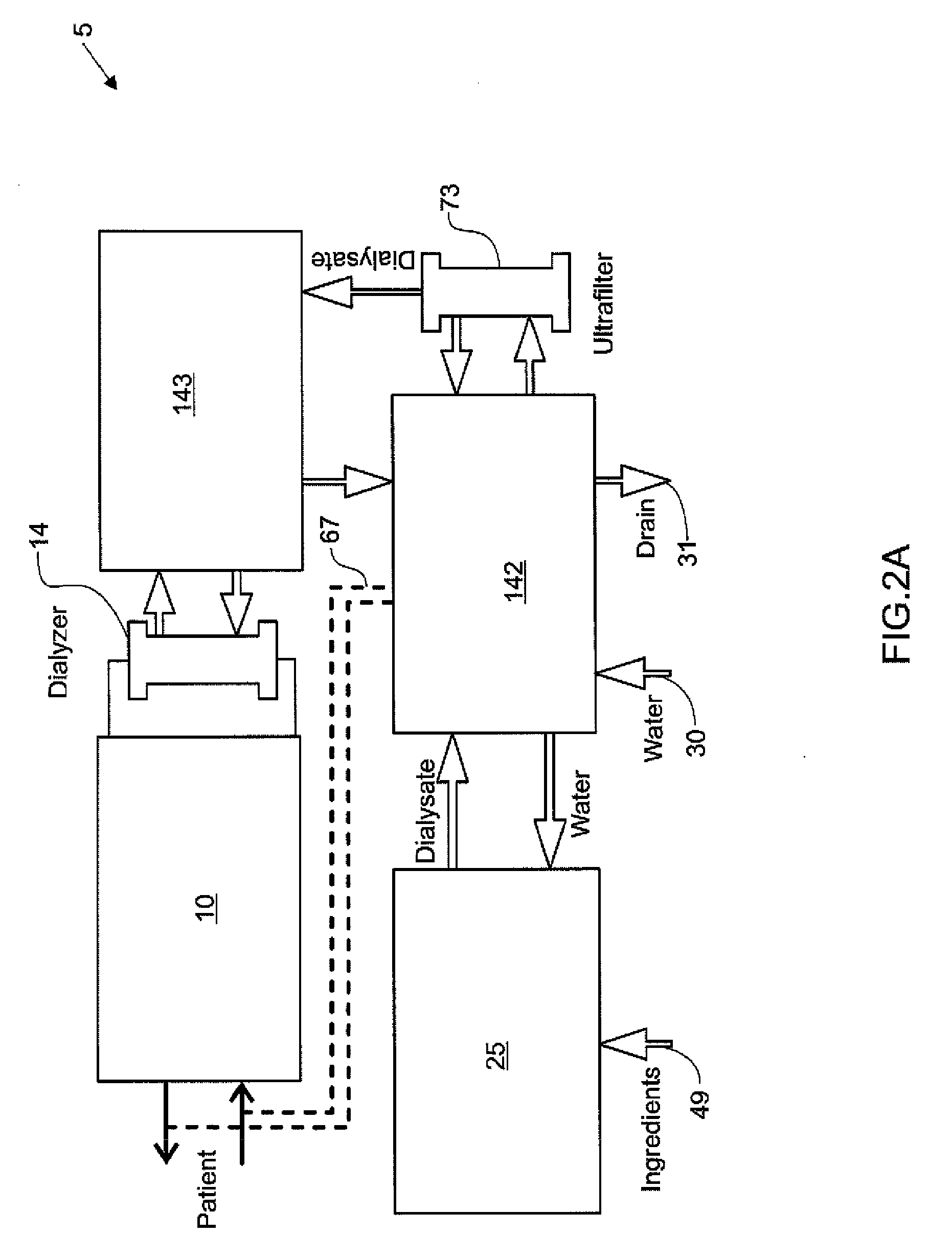

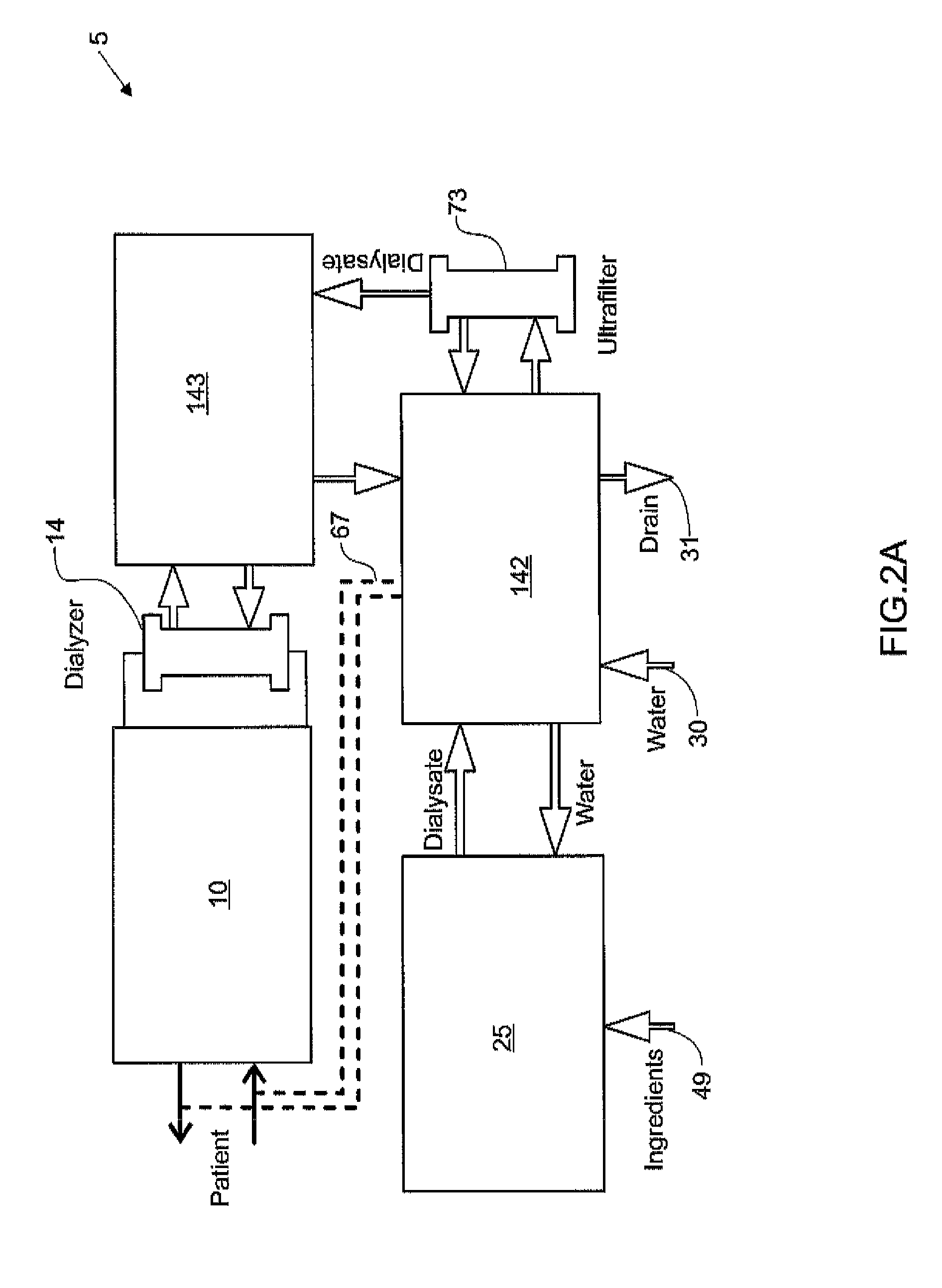

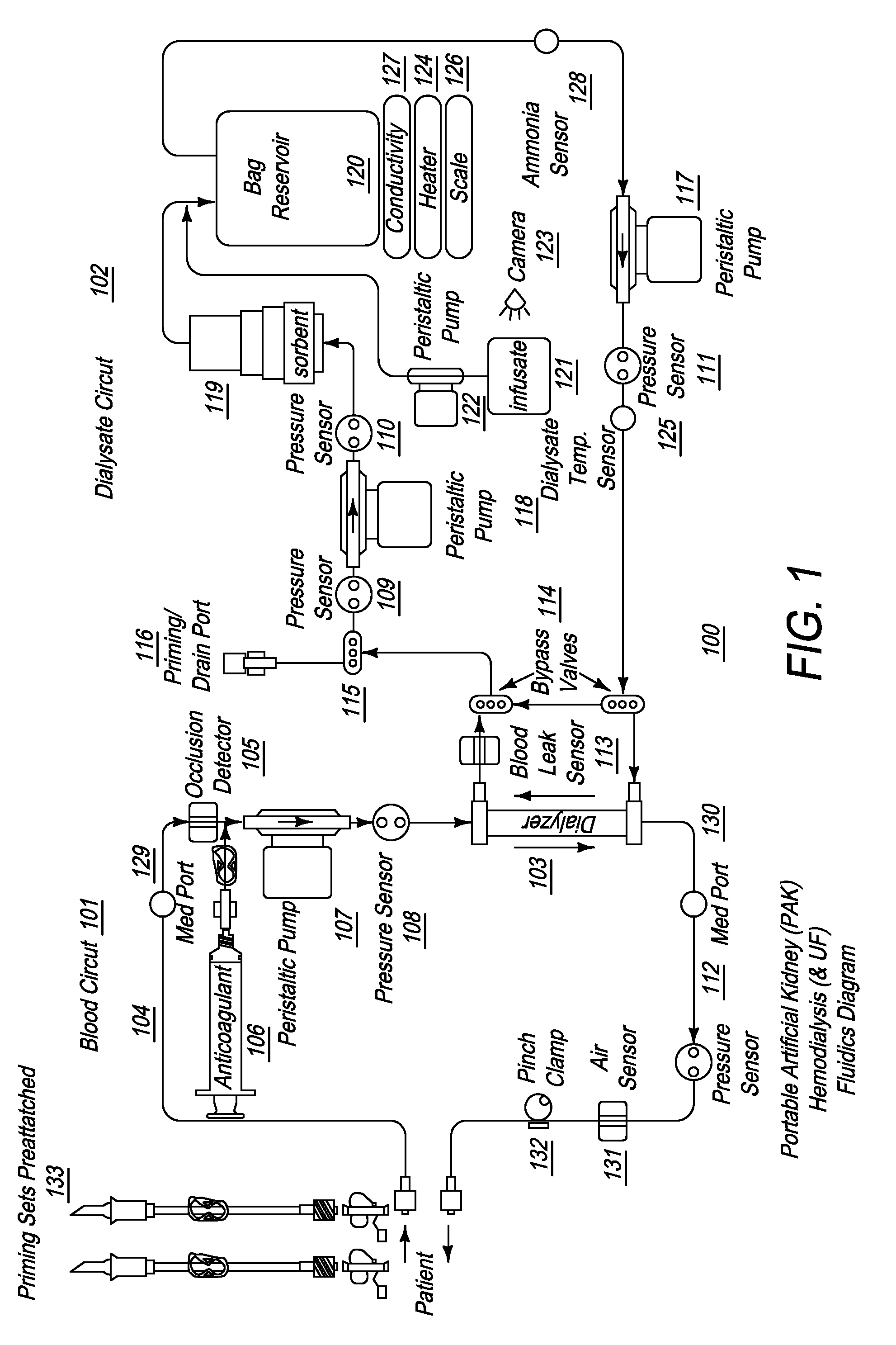

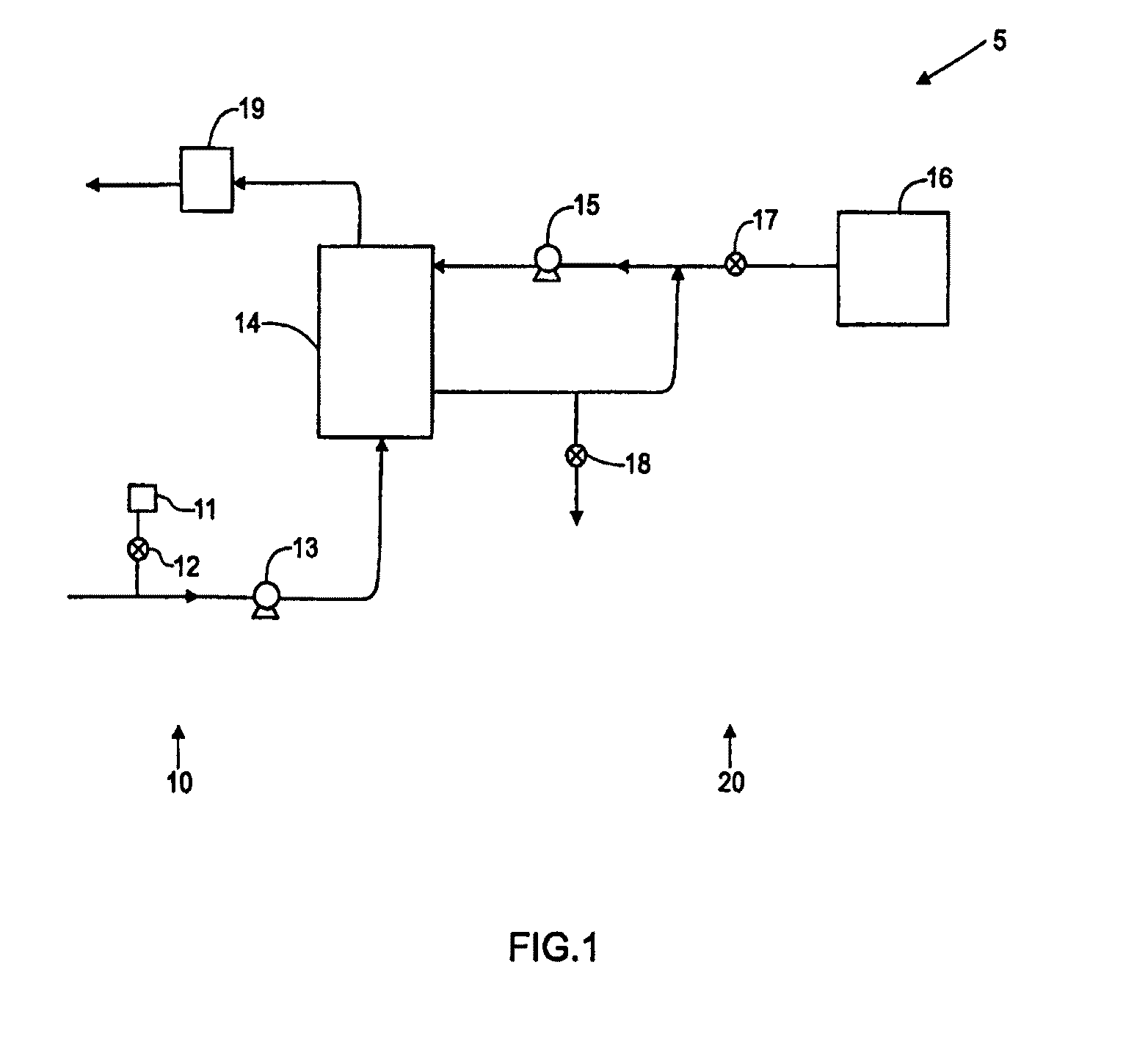

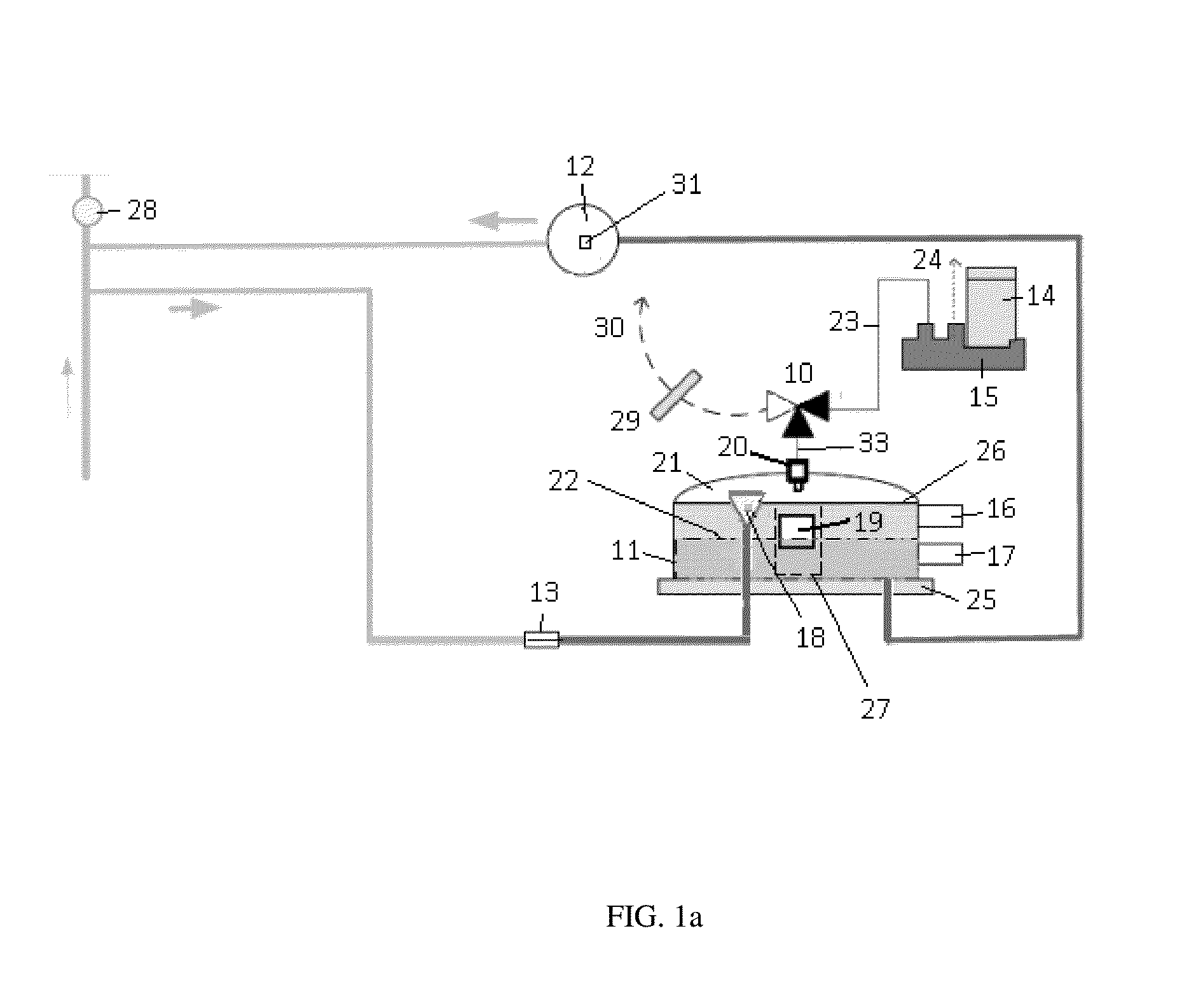

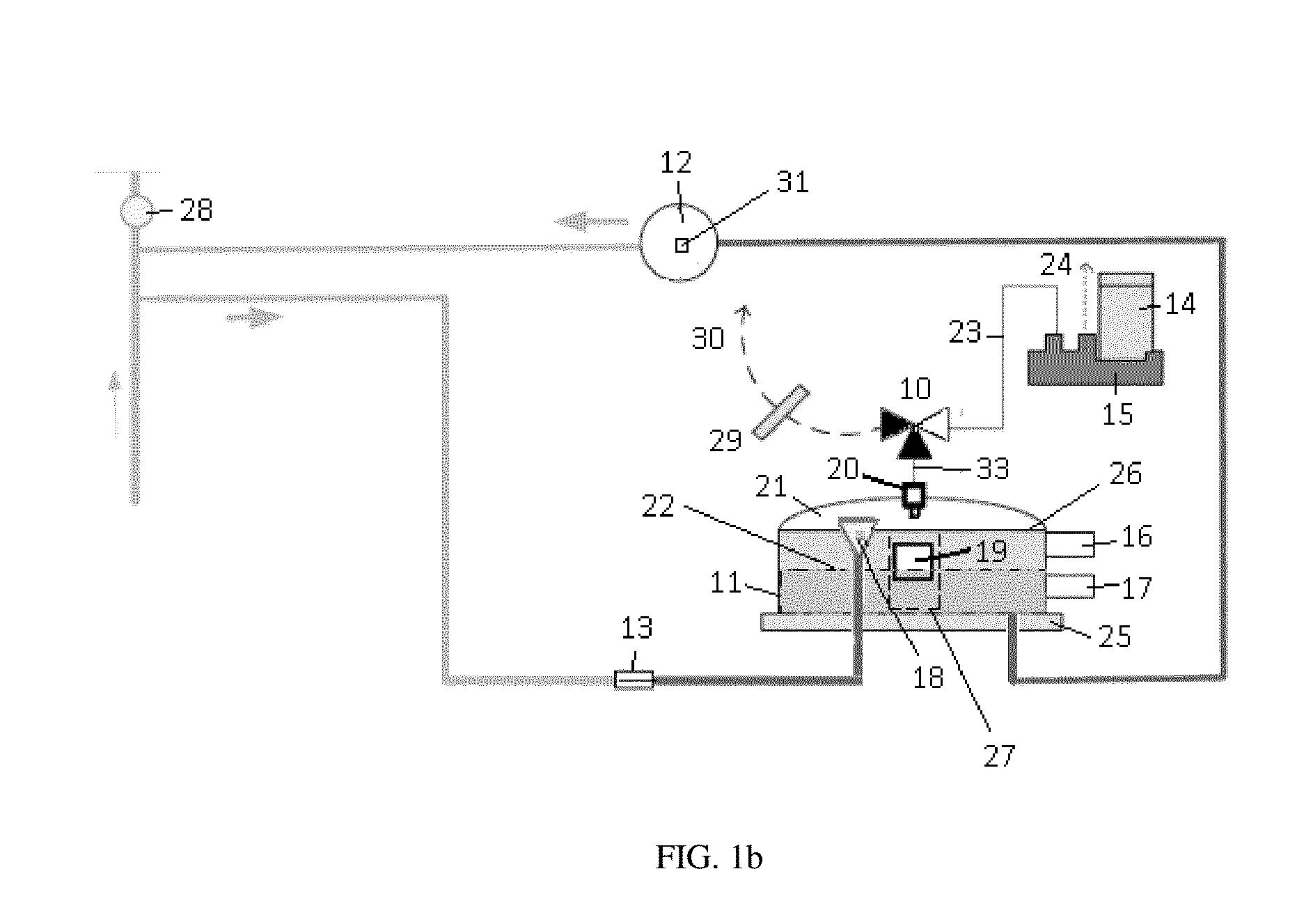

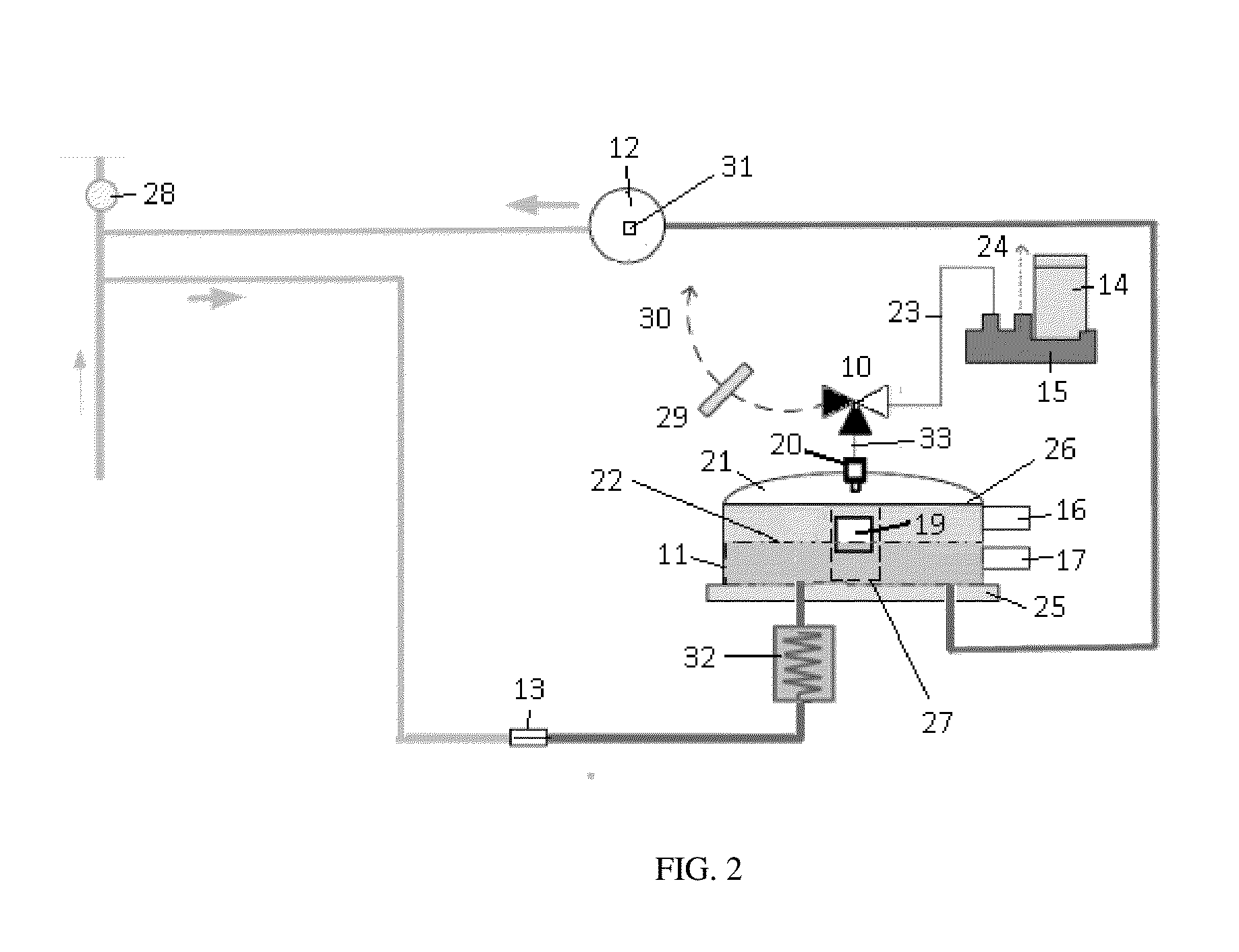

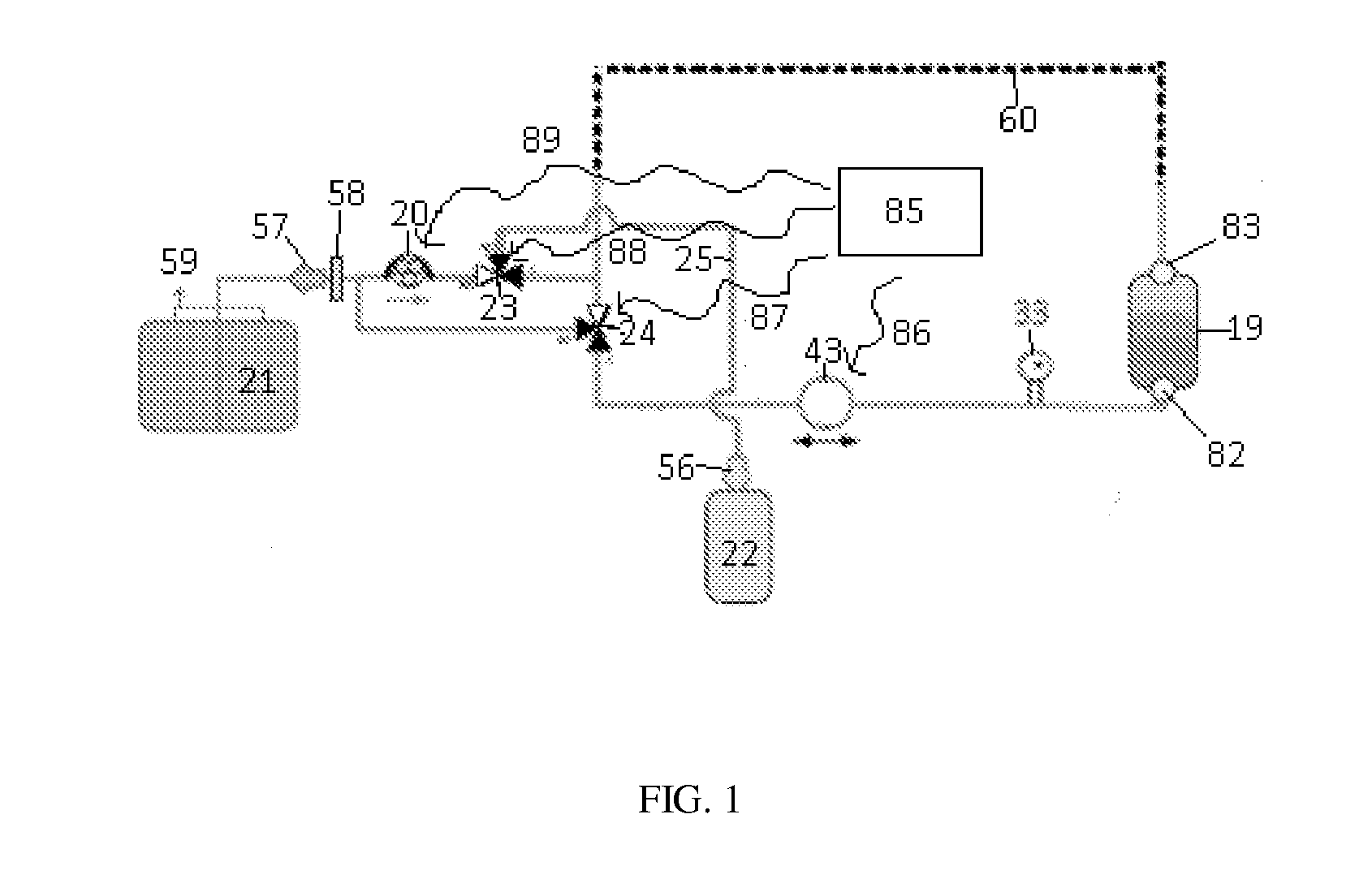

A system, method and apparatus for performing a renal replacement therapy is provided. In one embodiment, two small high flux dialyzers are connected in series. A restriction is placed between the two dialyzers in the dialysate flow path. The restriction is variable and adjustable in one preferred embodiment. The restriction builds a positive pressure in the venous dialyzer, causing a high degree of intentional backfiltration. That backfiltration causes a significant flow of dialysate through the high flux venous membrane directly into the patient's blood. That backfiltered solution is subsequently ultrafiltered from the patient from the arterial dialyzer. The diffusion of dialysate into the venous filter and removal of dialysate from the arterial dialyzer causes a convective transport of toxins from the patient. Additionally, the dialysate that does not diffuse directly into the patient but instead flows across the membranes of both dialyzers provides a diffusive clearance of waste products.

Owner:BAXTER HEALTHCARE SA +1

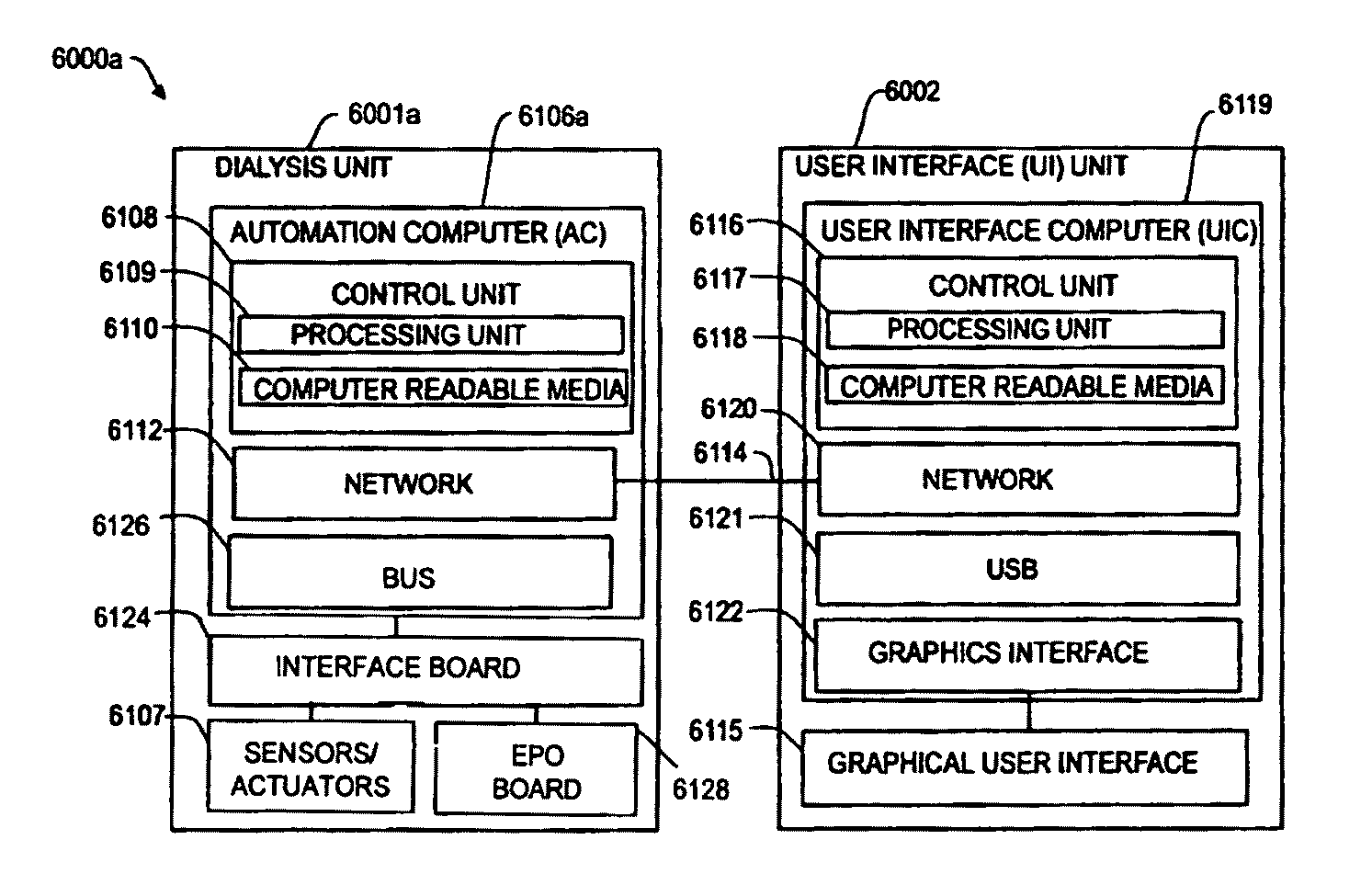

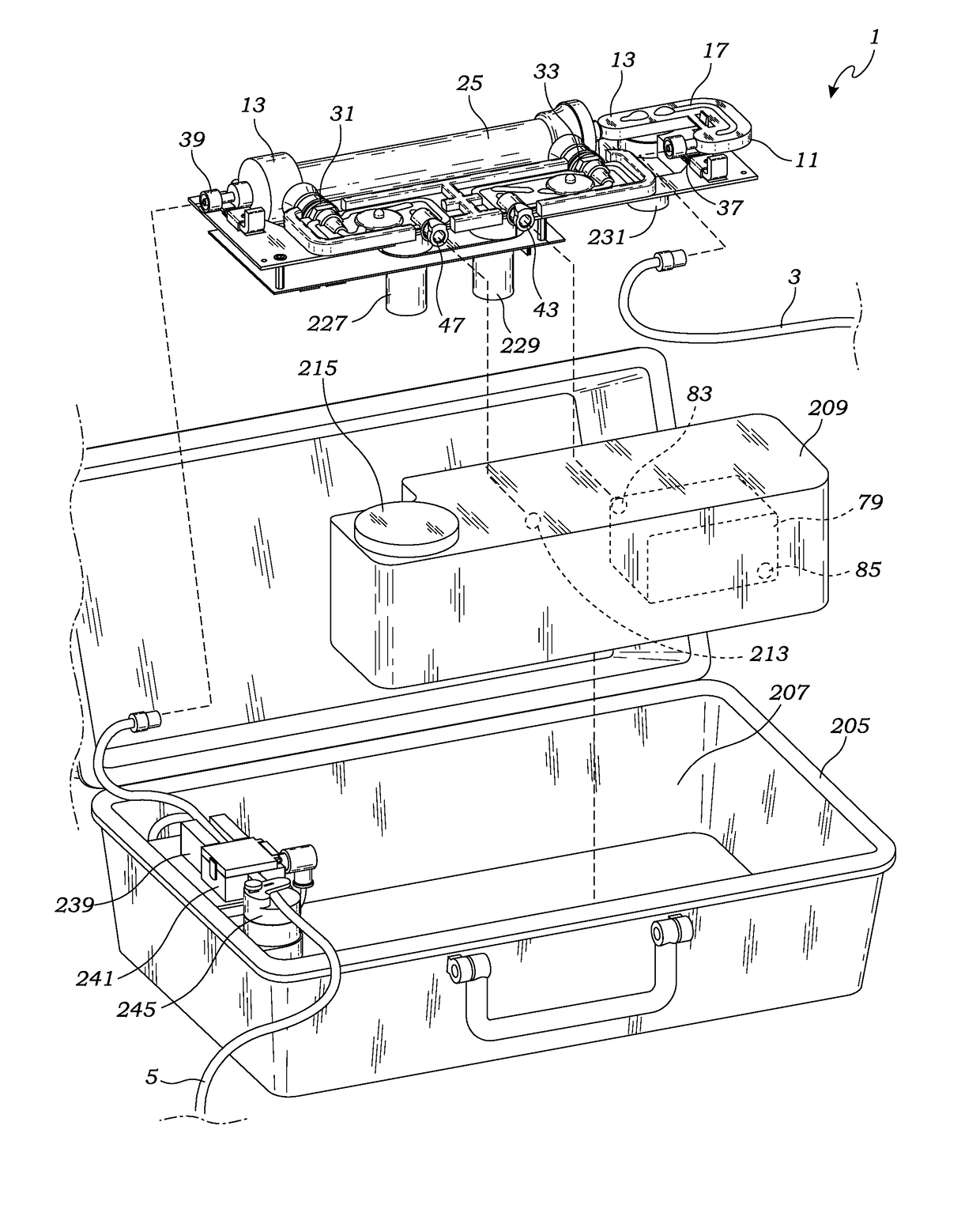

Hemodialysis systems and methods

ActiveUS20090095679A1Mechanical/radiation/invasive therapiesSolvent extractionHaemodialysis machineDialysate flow

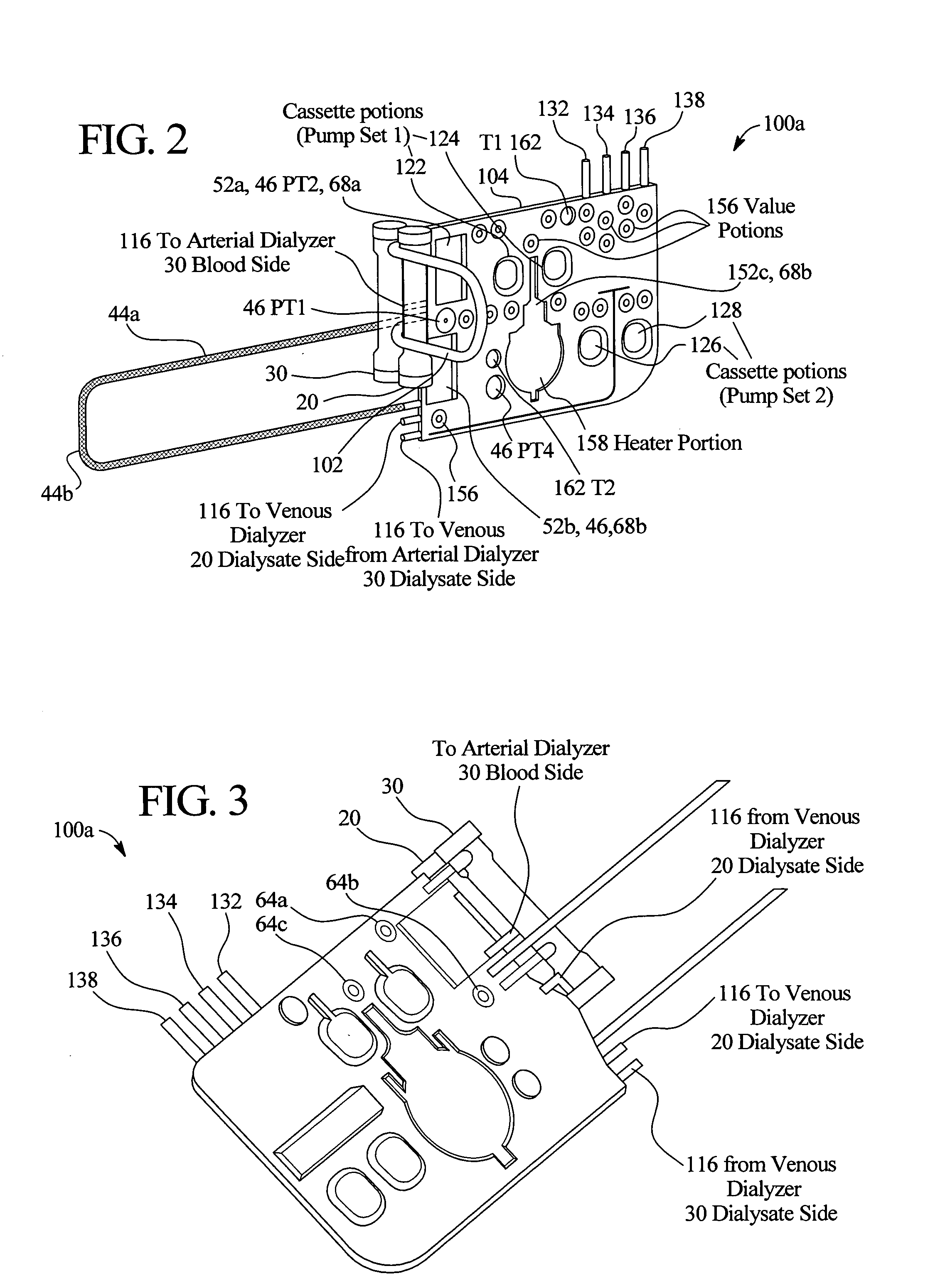

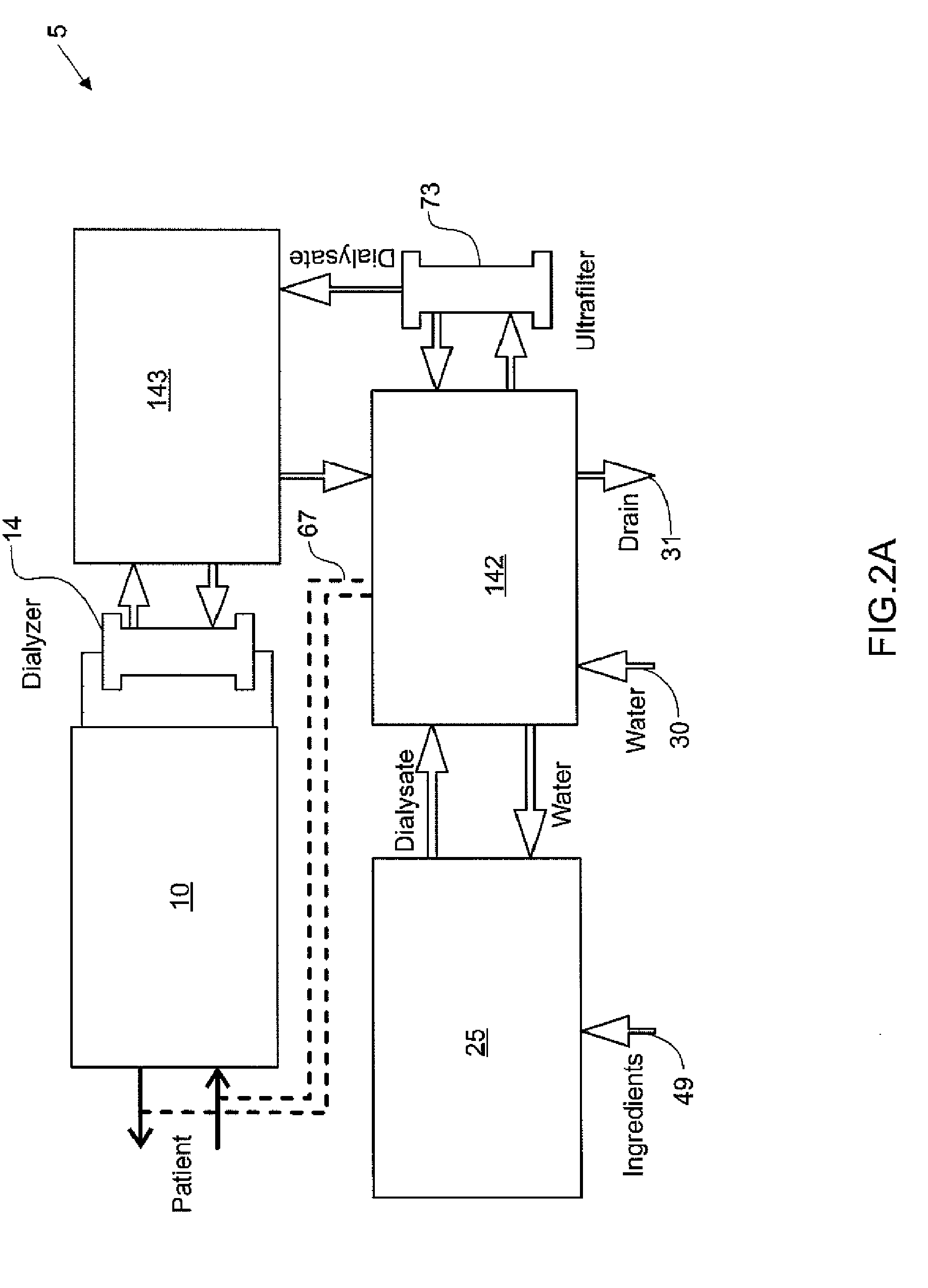

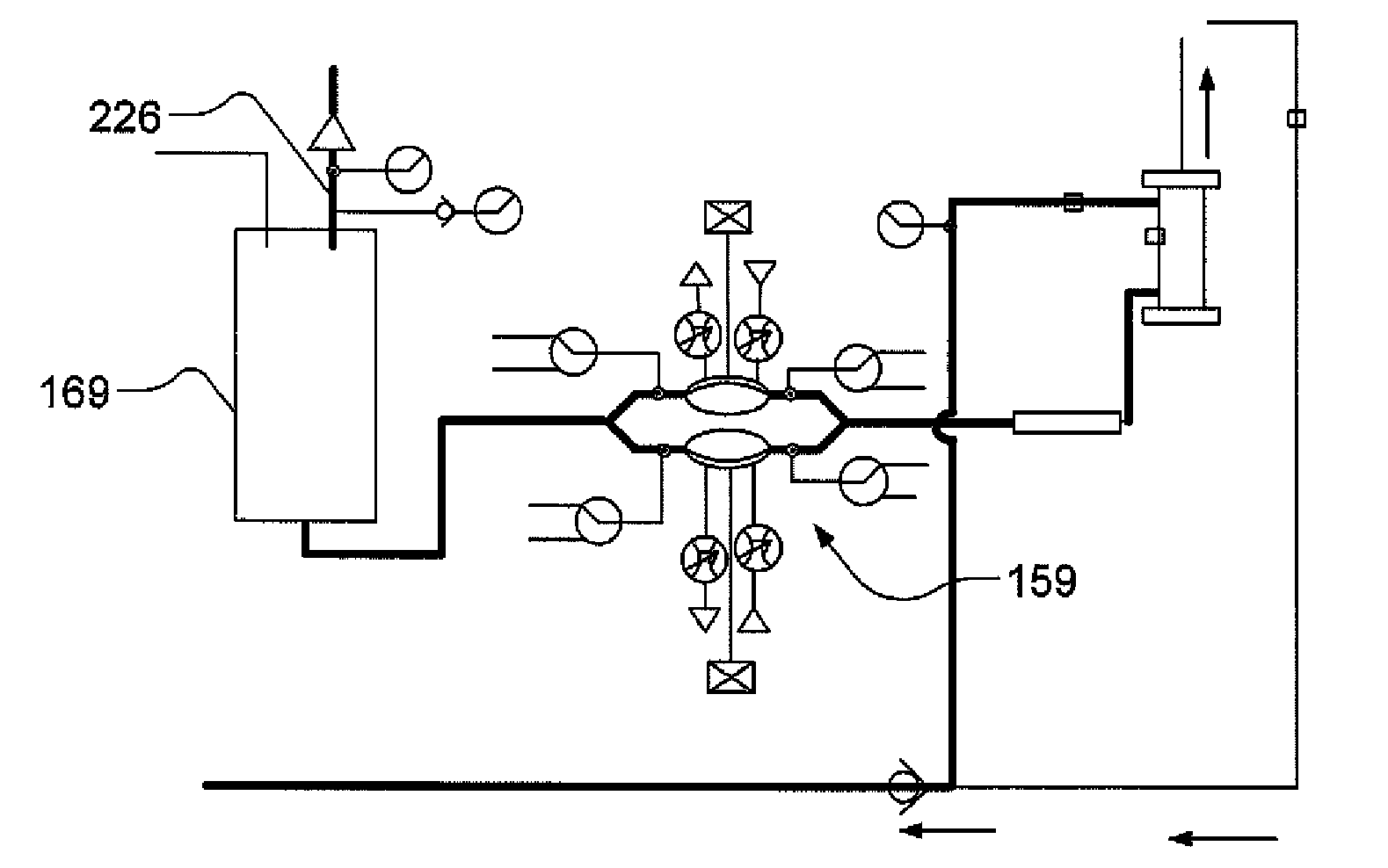

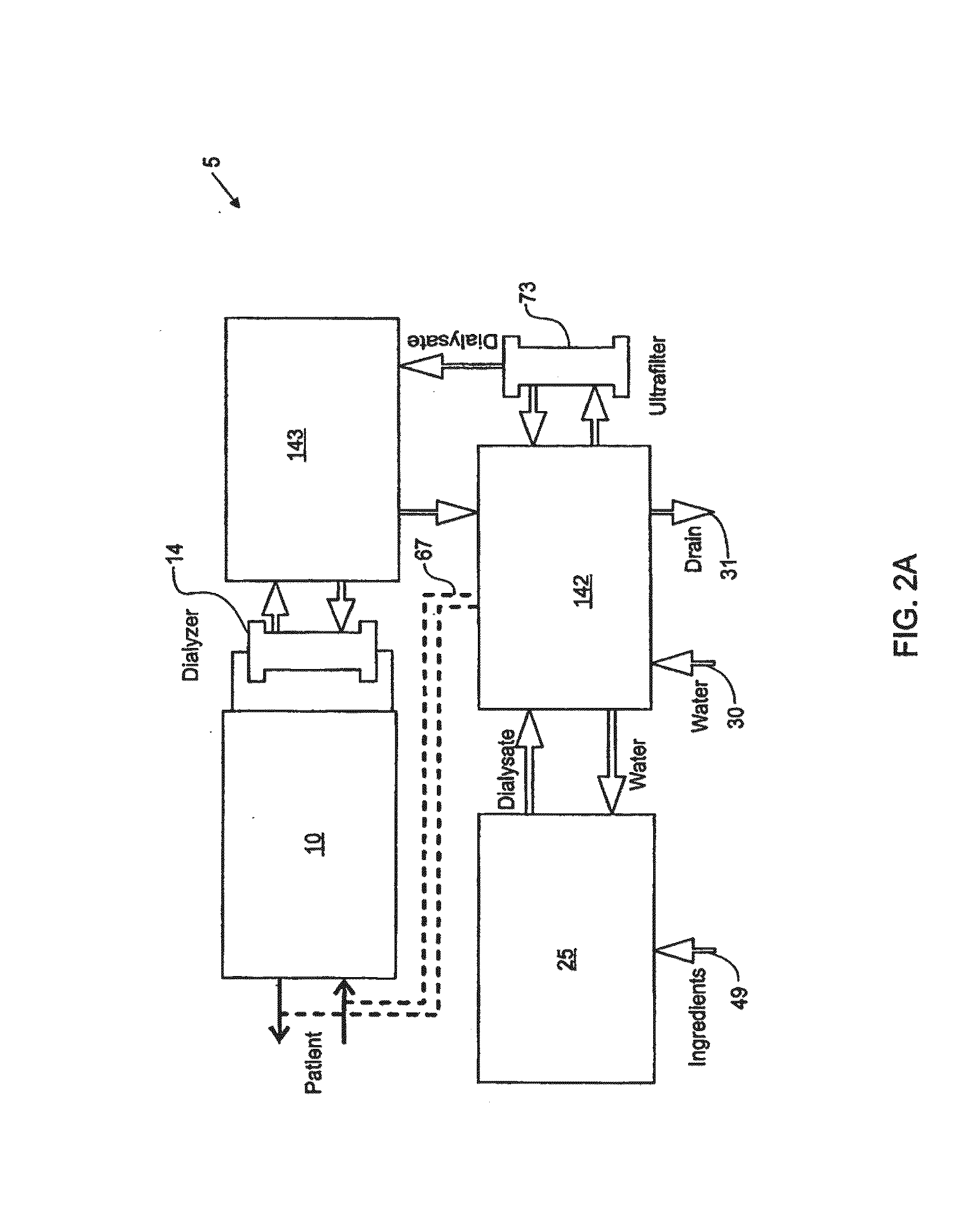

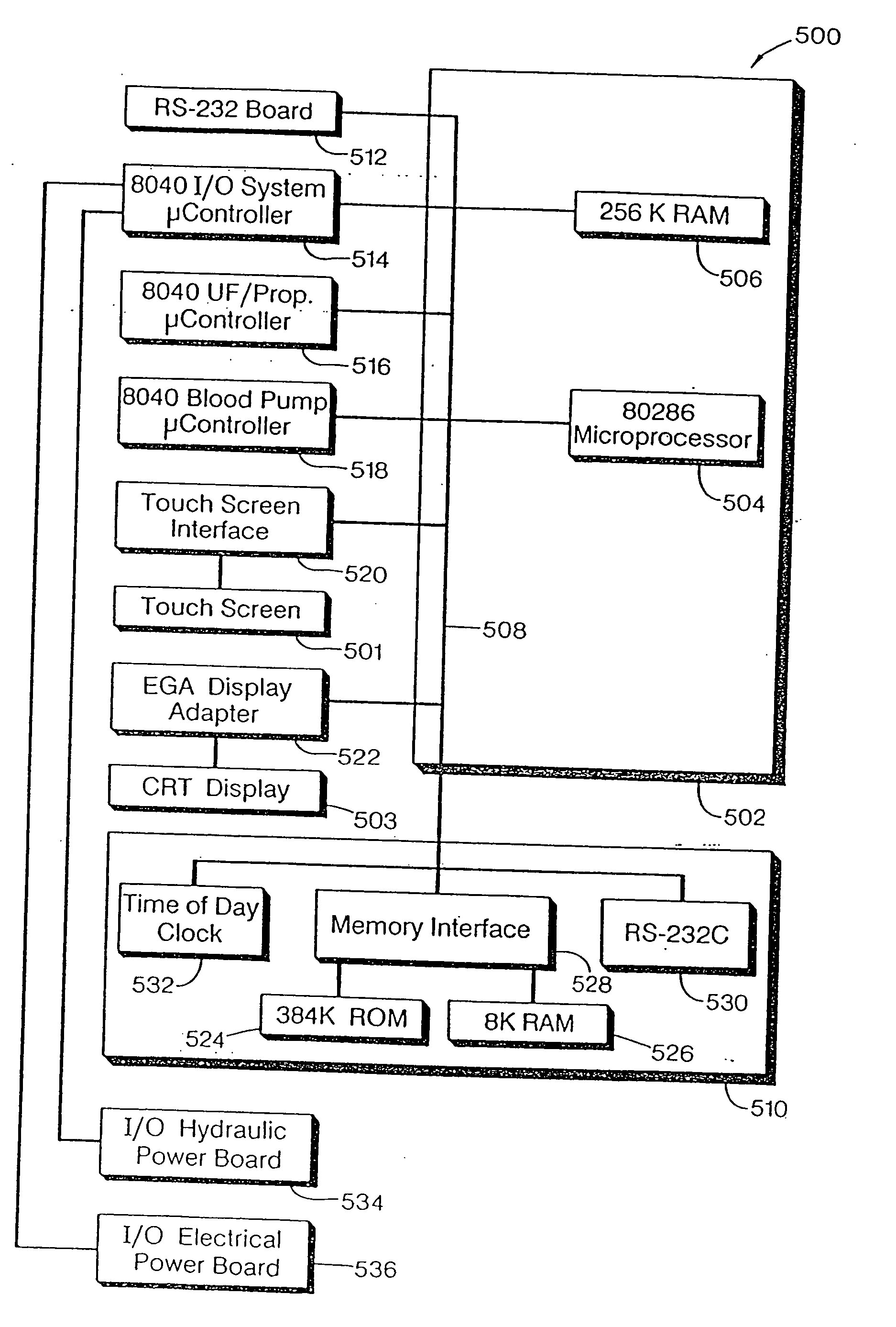

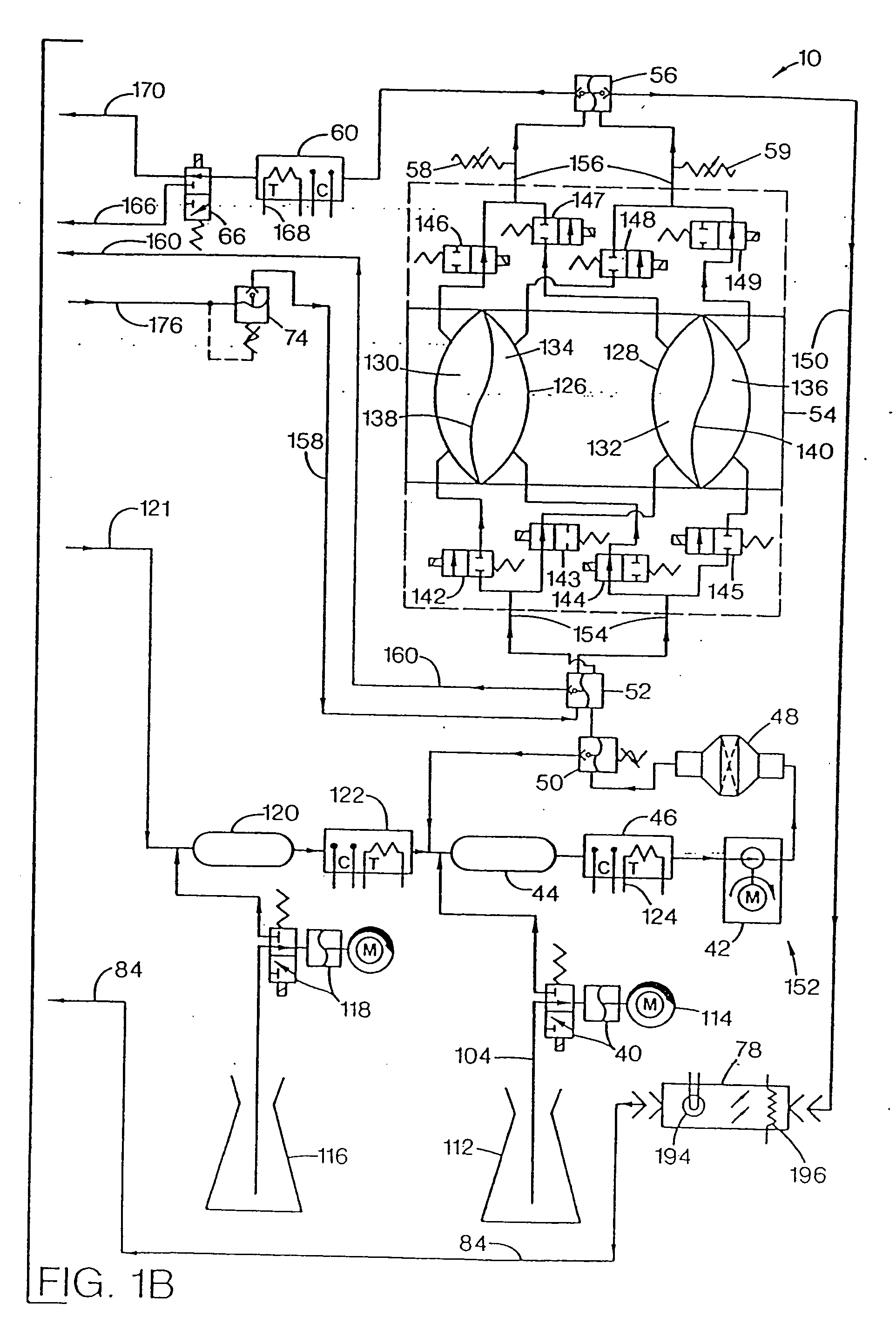

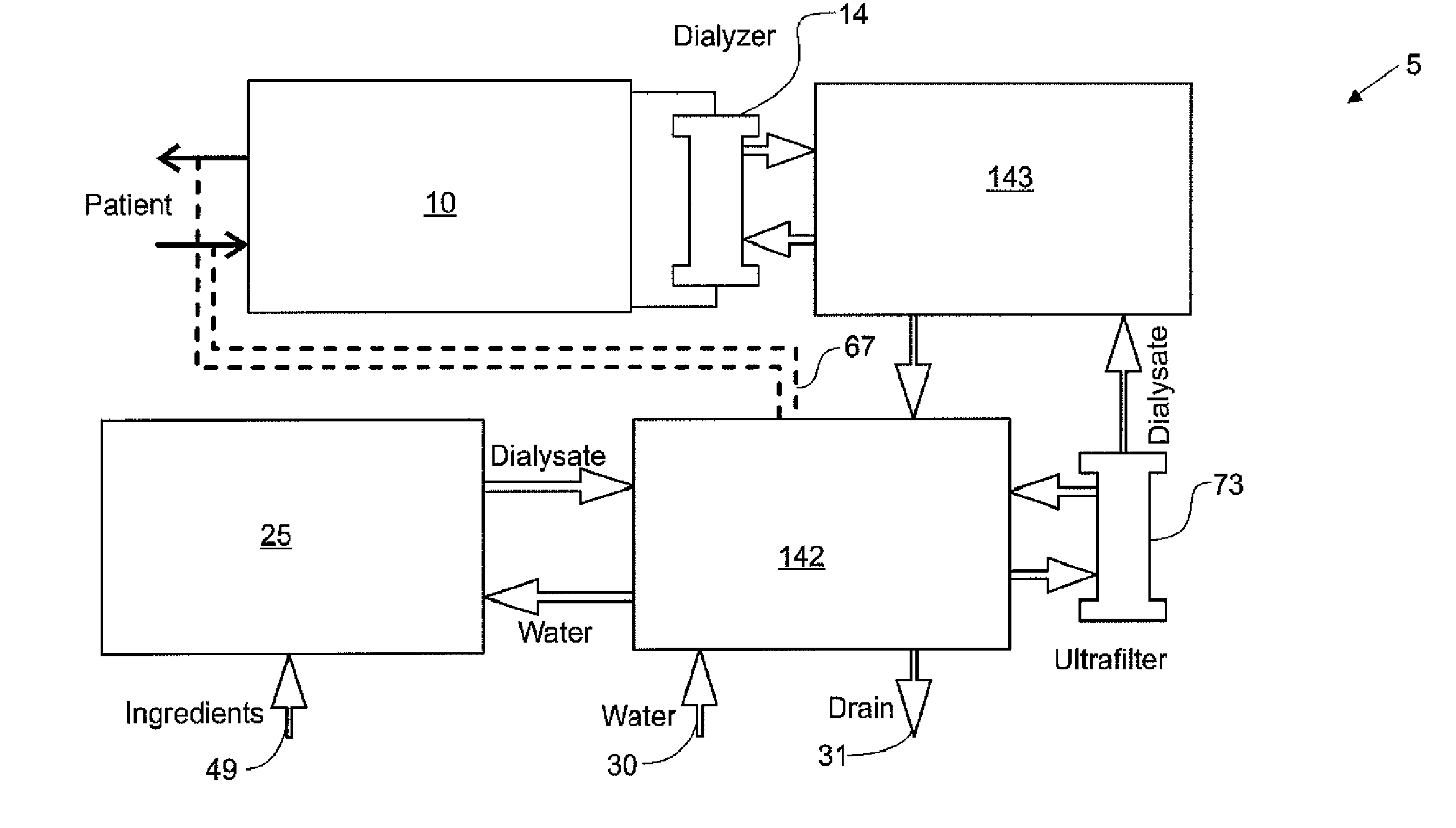

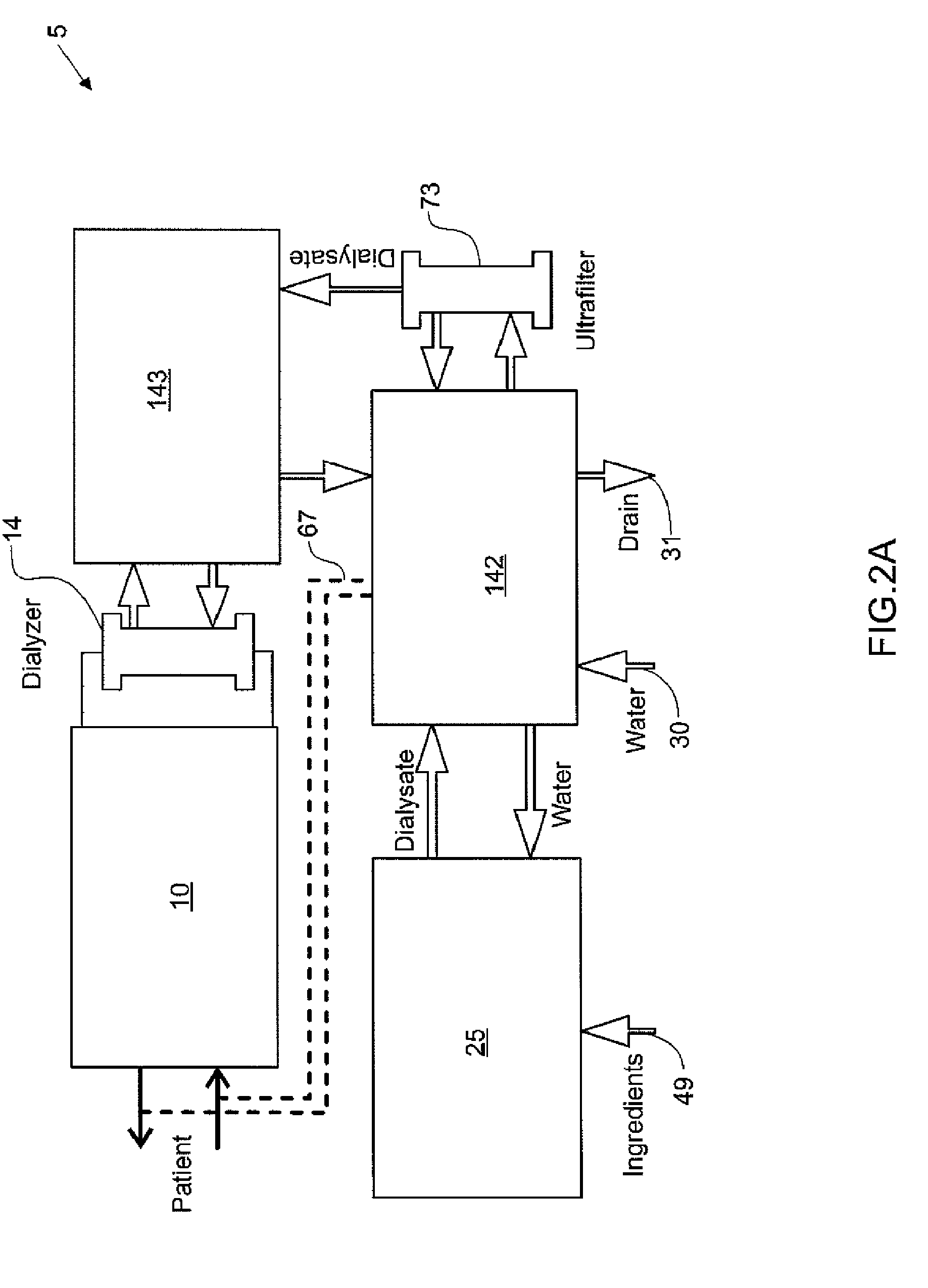

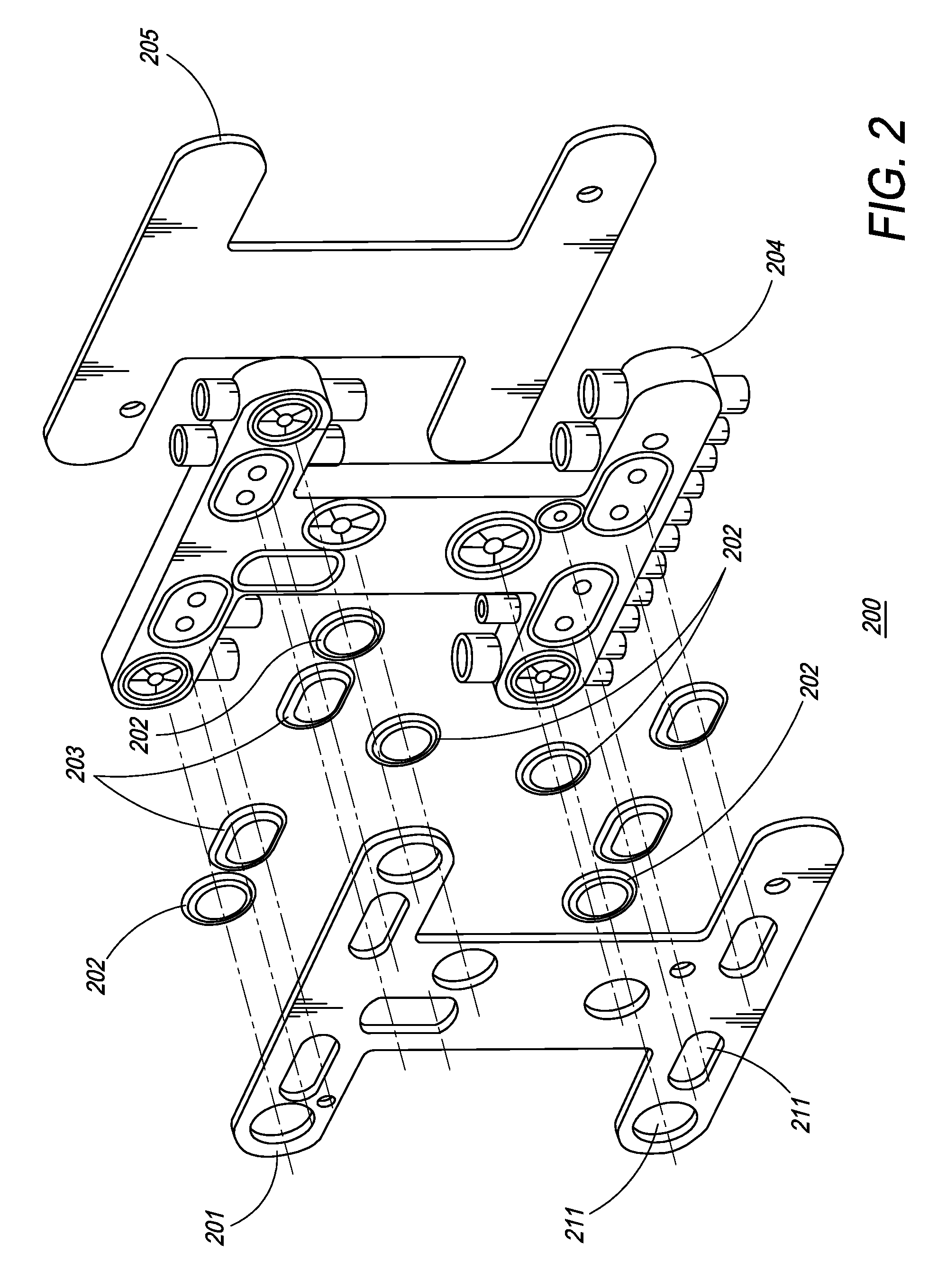

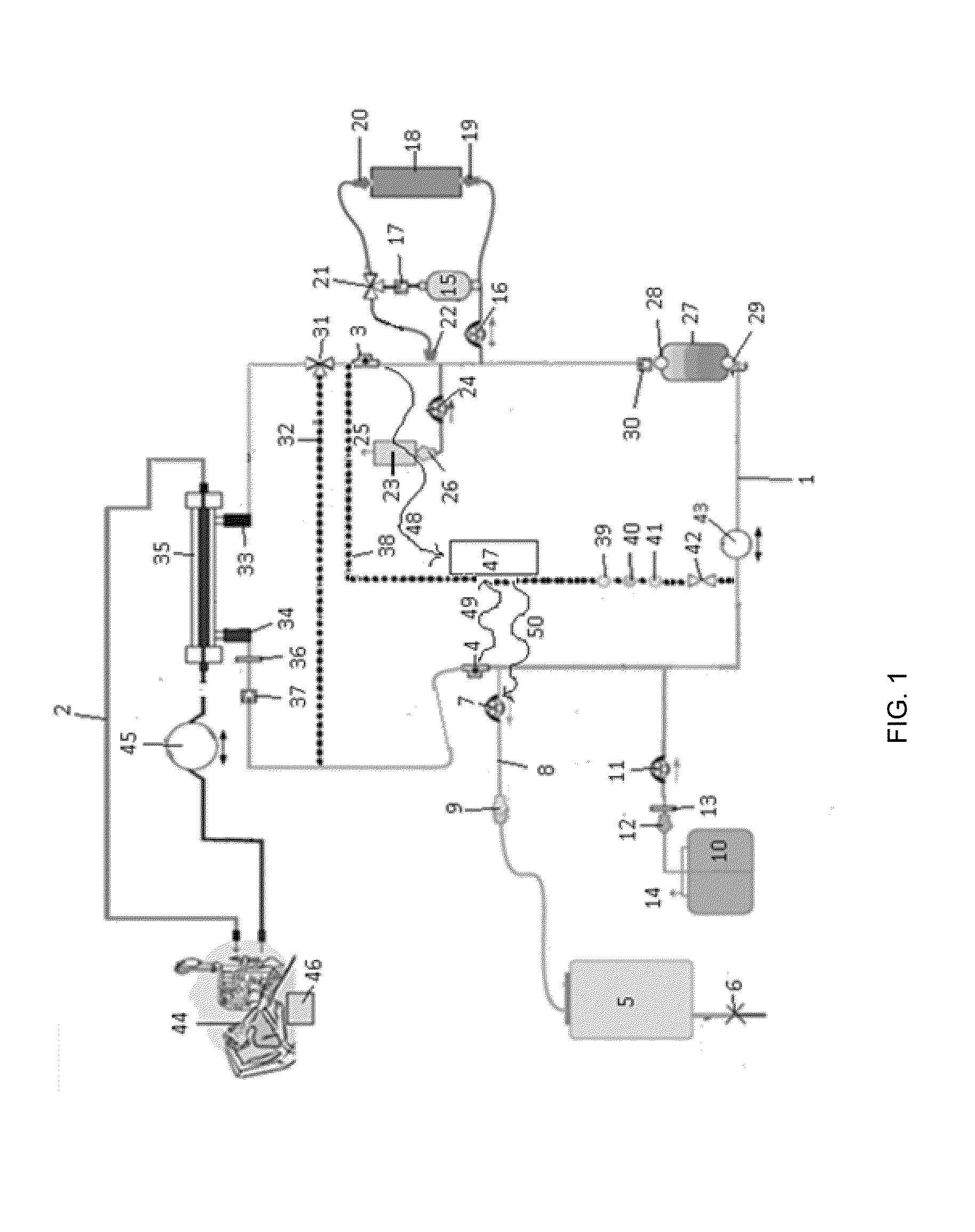

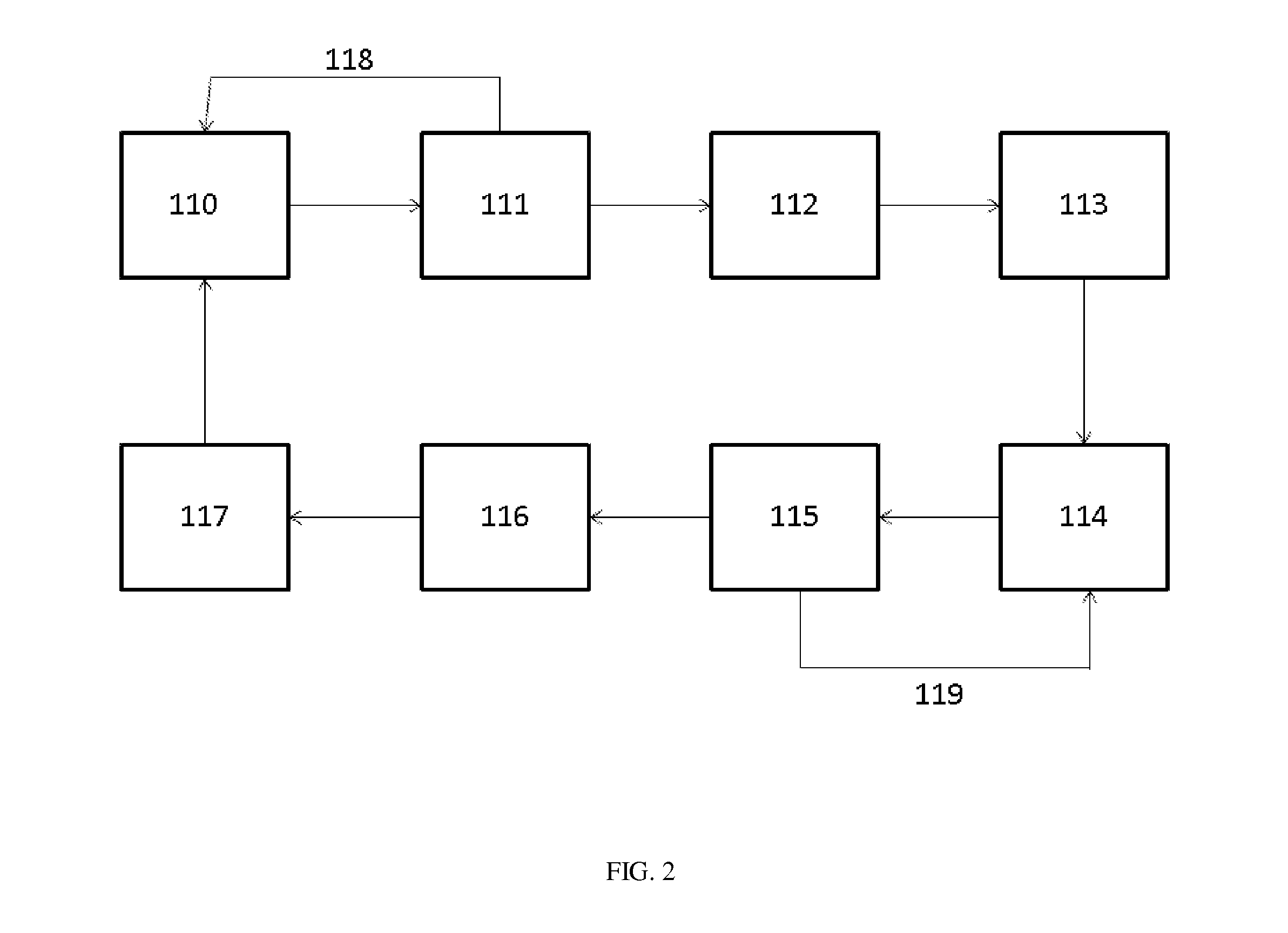

Hemodialysis dialysis systems are disclosed. Hemodialysis systems of the invention may include a dialysate flow path including a balancing circuit, a mixing circuit, and / or a directing circuit. The circuits may be defined within one or more cassettes. The fluid circuits may be at least partially isolated, spatially and / or thermally, from electrical components of the system. A gas supply may be provided in fluid communication with the dialysate flow path and / or the dialyzer to urge dialysate through the dialyzer and blood back to the patient. The hemodialysis systems may include fluid handling devices, actuated using a control fluid, optionally delivered using a detachable pump. Fluid handling devices may be generally rigid and of a spheroid shape, optionally with a diaphragm dividing the device into compartments.

Owner:DEKA PROD LLP

Hemodialysis systems and methods

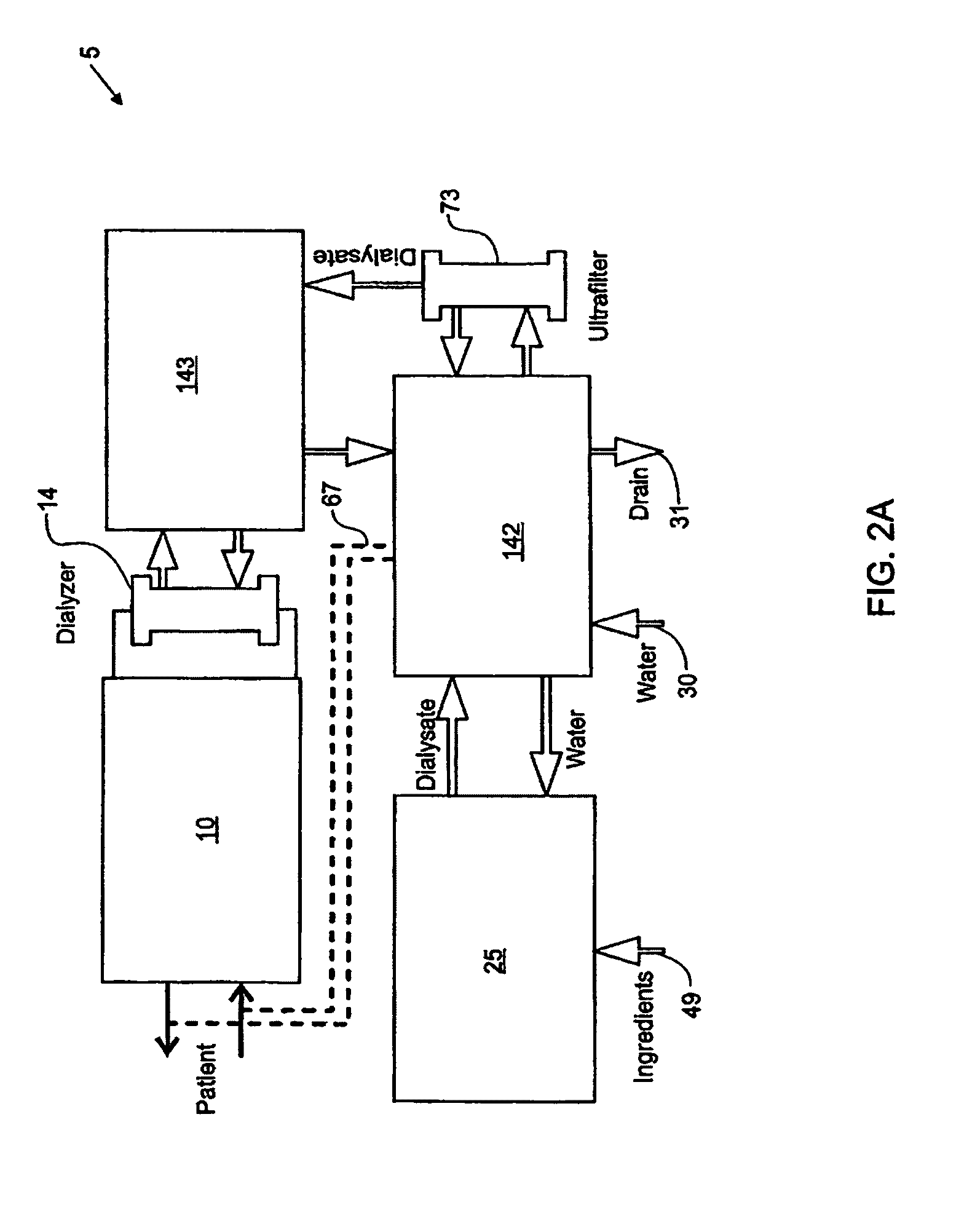

The present invention generally relates to hemodialysis and similar dialysis systems, including a variety of systems and methods that would make hemodialysis more efficient, easier, and / or more affordable. One aspect of the invention is generally directed to new fluid circuits for fluid flow. In one set of embodiments, a hemodialysis system may include a blood flow path and a dialysate flow path, where the dialysate flow path includes one or more of a balancing circuit, a mixing circuit, and / or a directing circuit. Preparation of dialysate by the preparation circuit, in some instances, may be decoupled from patient dialysis. In some cases, the circuits are defined, at least partially, within one or more cassettes, optionally interconnected with conduits, pumps, or the like. In one embodiment, the fluid circuit and / or the various fluid flow paths may be at least partially isolated, spatially and / or thermally, from electrical components of the hemodialysis system. In some cases, a gas supply may be provided in fluid communication with the dialysate flow path and / or the dialyzer that, when activated, is able to urge dialysate to pass through the dialyzer and urge blood in the blood flow path back to the patient. Such a system may be useful, for example, in certain emergency situations (e.g., a power failure) where it is desirable to return as much blood to the patient as possible. The hemodialysis system may also include, in another aspect of the invention, one or more fluid handling devices, such as pumps, valves, mixers, or the like, which can be actuated using a control fluid, such as air. In some cases, the control fluid may be delivered to the fluid handling devices using an external pump or other device, which may be detachable in certain instances. In one embodiment, one or more of the fluid handling devices may be generally rigid (e.g., having a spheroid shape), optionally with a diaphragm contained within the device, dividing it into first and second compartments.

Owner:DEKA PROD LLP

Hemodialysis systems and methods

The present invention generally relates to hemodialysis and similar dialysis systems, including a variety of systems and methods that would make hemodialysis more efficient, easier, and / or more affordable. One aspect of the invention is generally directed to new fluid circuits for fluid flow. In one set of embodiments, a hemodialysis system may include a blood flow path and a dialysate flow path, where the dialysate flow path includes one or more of a balancing circuit, a mixing circuit, and / or a directing circuit. Preparation of dialysate by the preparation circuit, in some instances, may be decoupled from patient dialysis. In some cases, the circuits are defined, at least partially, within one or more cassettes, optionally interconnected with conduits, pumps, or the like. In one embodiment, the fluid circuit and / or the various fluid flow paths may be at least partially isolated, spatially and / or thermally, from electrical components of the hemodialysis system. In some cases, a gas supply may be provided in fluid communication with the dialysate flow path and / or the dialyzer that, when activated, is able to urge dialysate to pass through the dialyzer and urge blood in the blood flow path back to the patient. Such a system may be useful, for example, in certain emergency situations (e.g., a power failure) where it is desirable to return as much blood to the patient as possible. The hemodialysis system may also include, in another aspect of the invention, one or more fluid handling devices, such as pumps, valves, mixers, or the like, which can be actuated using a control fluid, such as air. In some cases, the control fluid may be delivered to the fluid handling devices using an external pump or other device, which may be detachable in certain instances. In one embodiment, one or more of the fluid handling devices may be generally rigid (e.g., having a spheroid shape), optionally with a diaphragm contained within the device, dividing it into first and second compartments.

Owner:DEKA PROD LLP

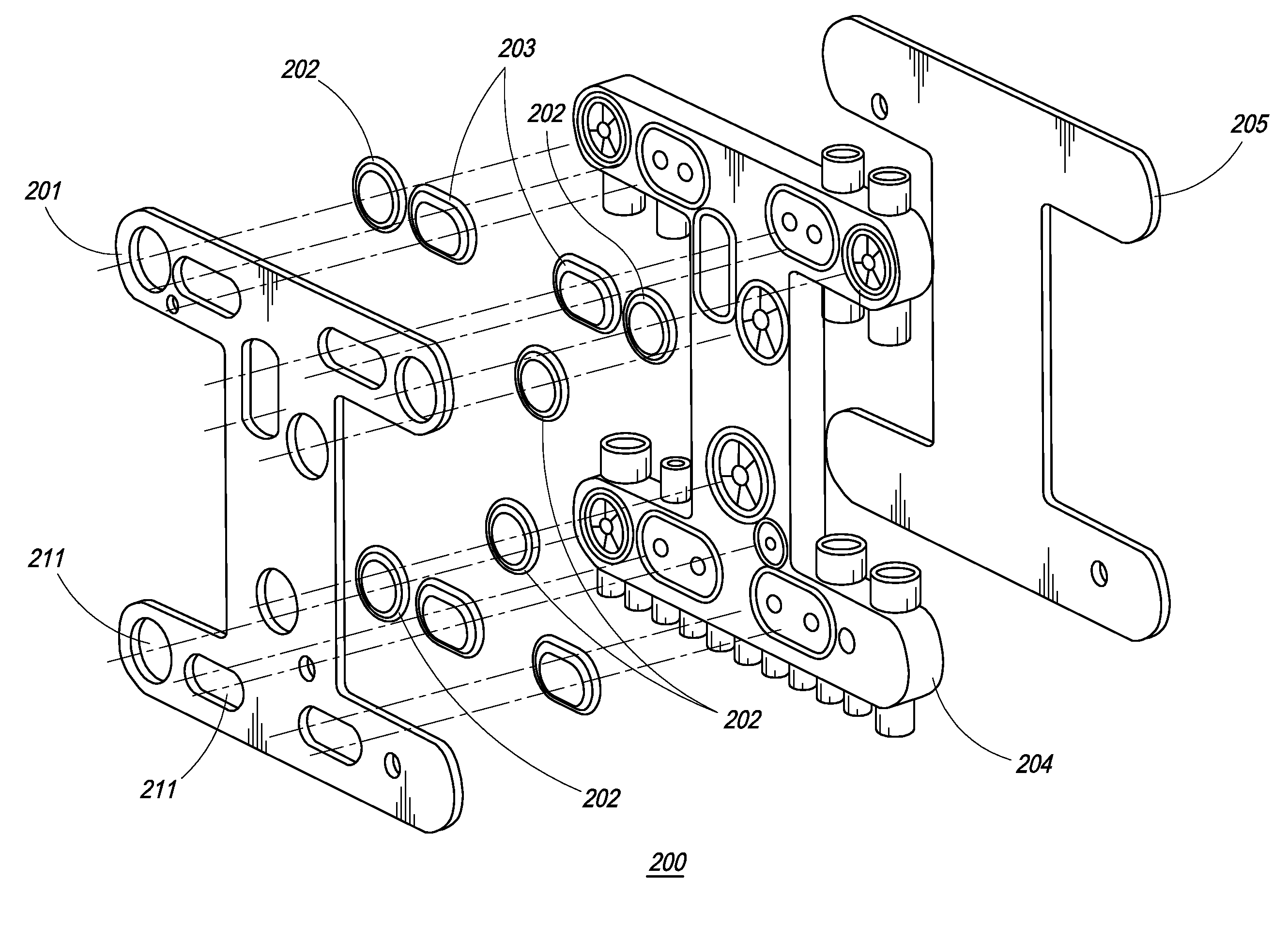

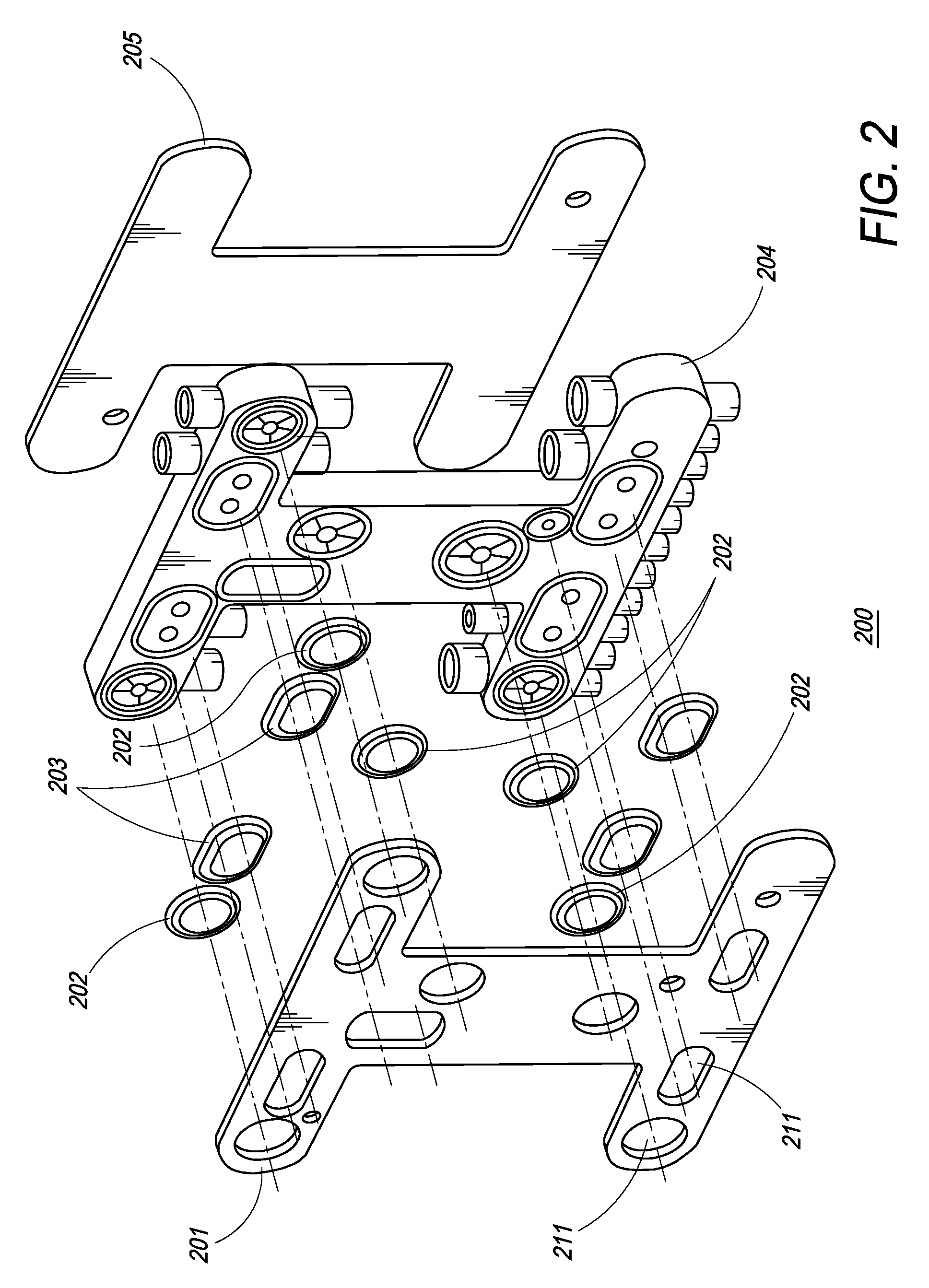

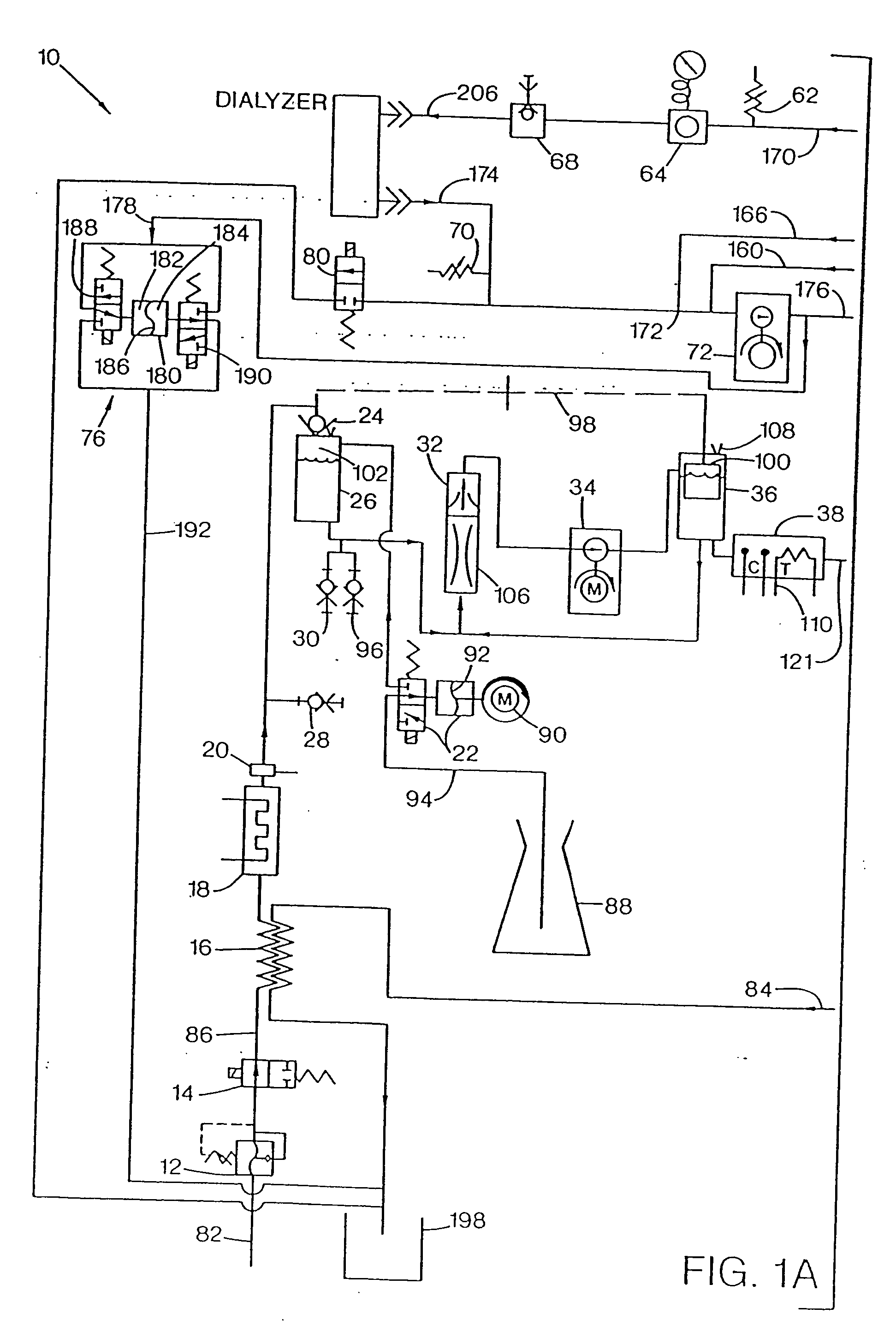

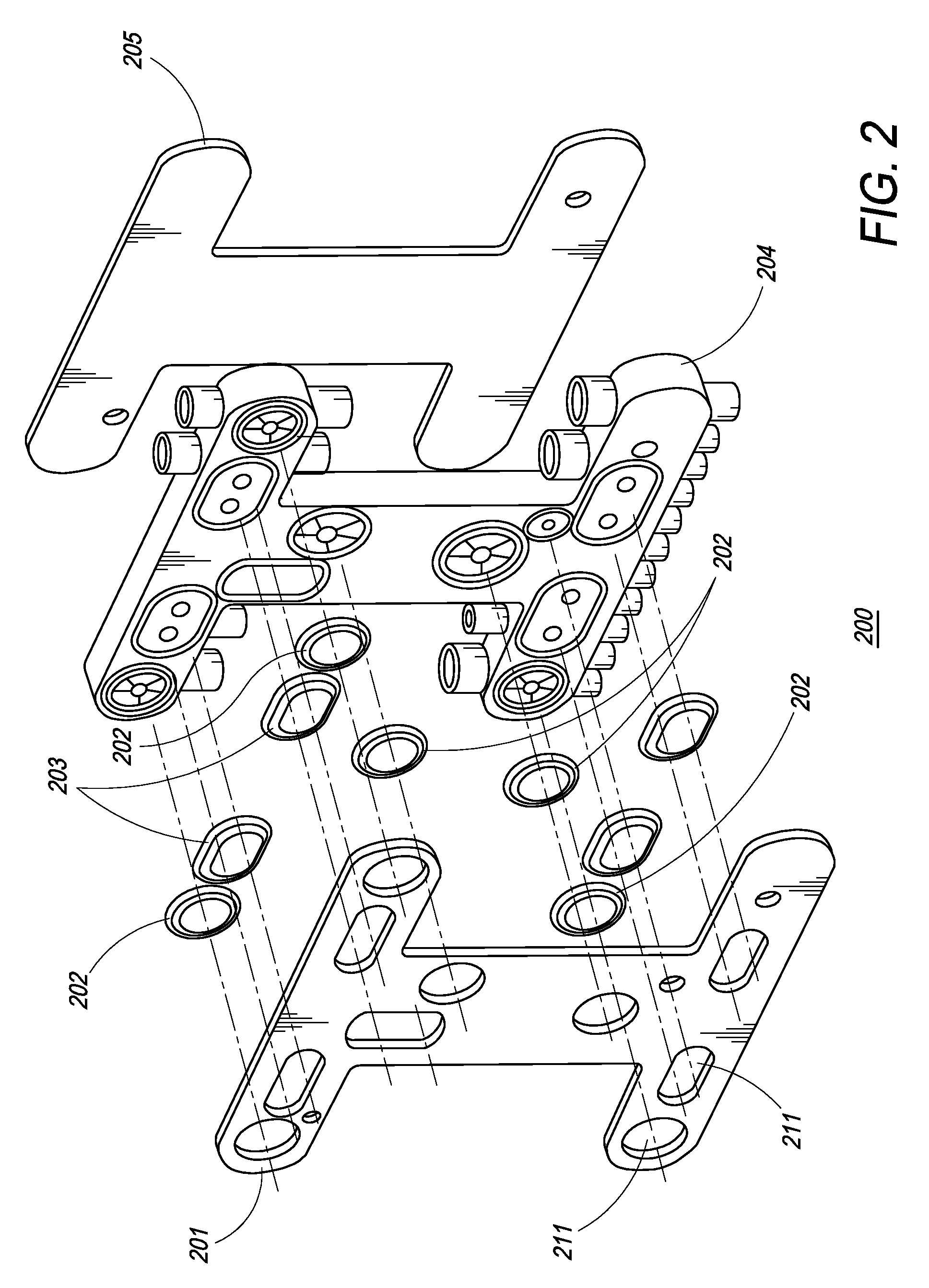

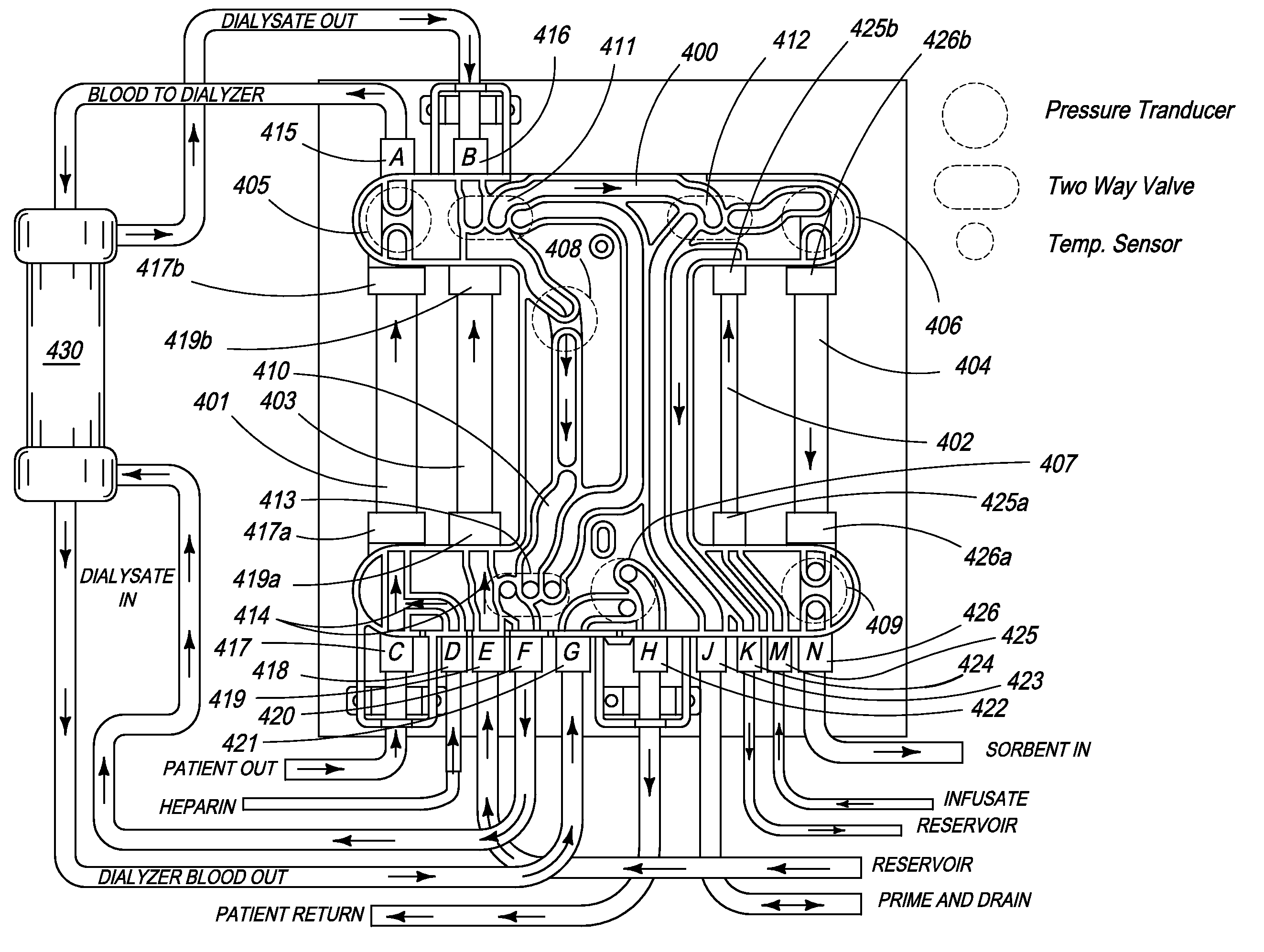

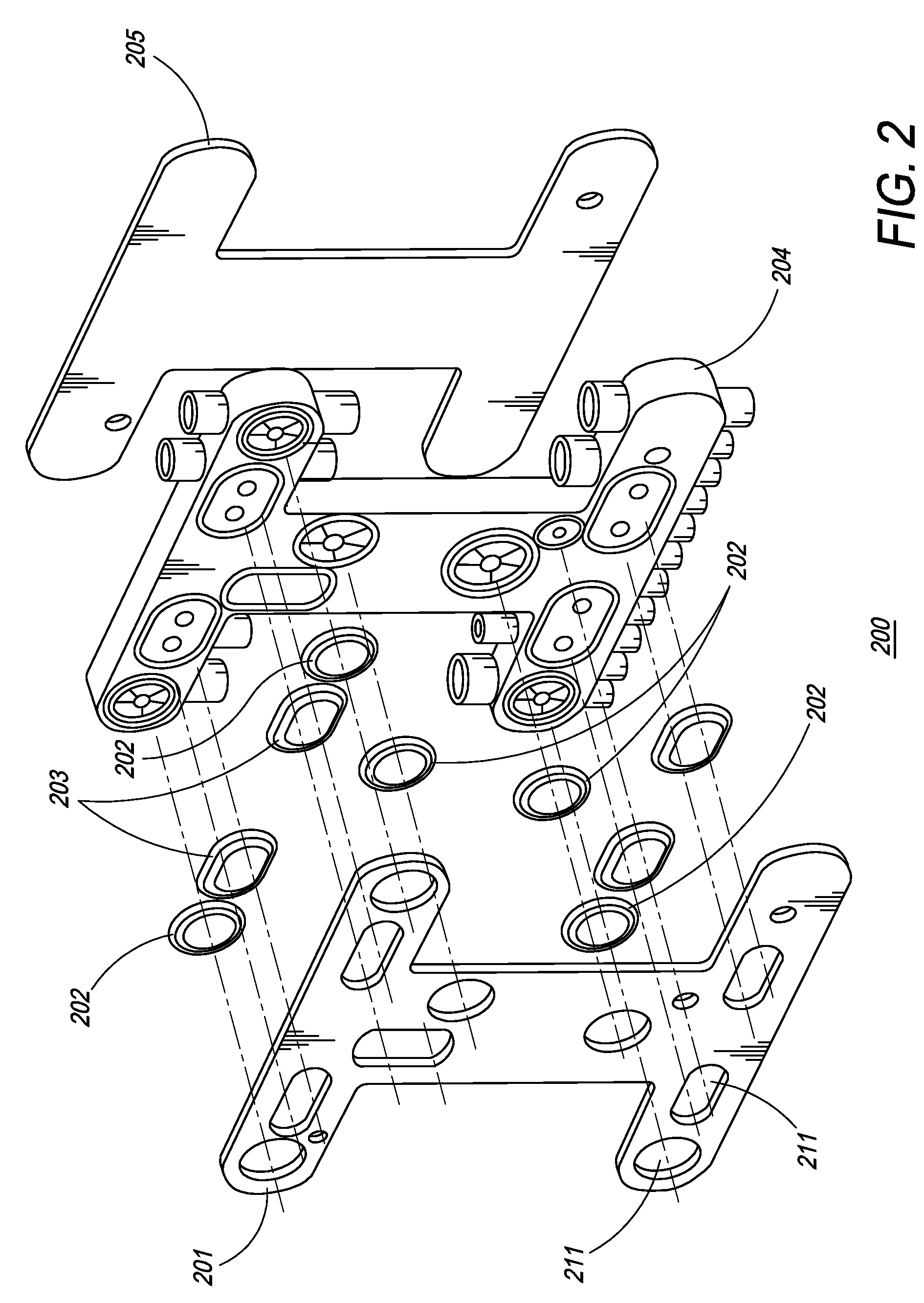

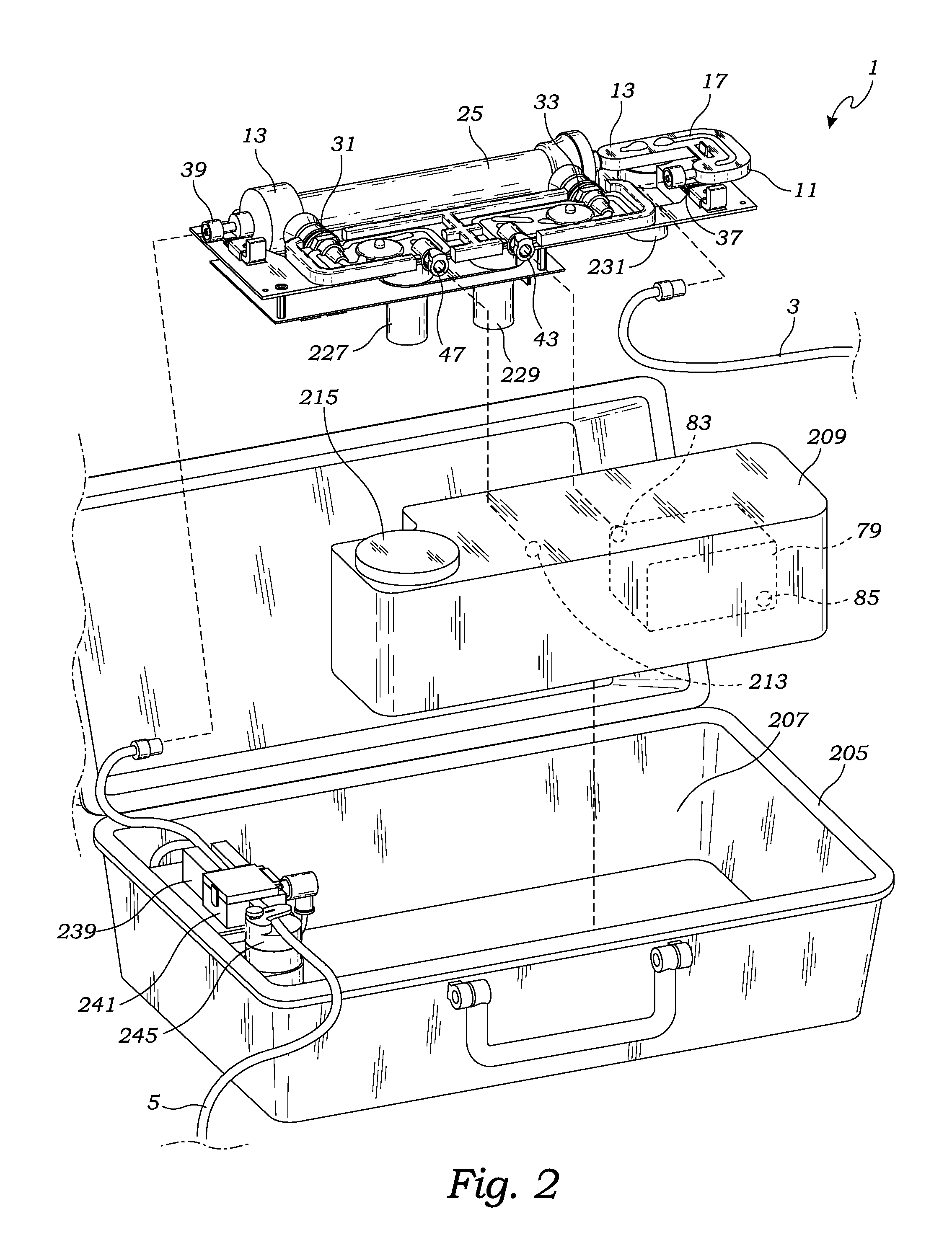

System and Method for Conducting Hemodialysis and Hemofiltration

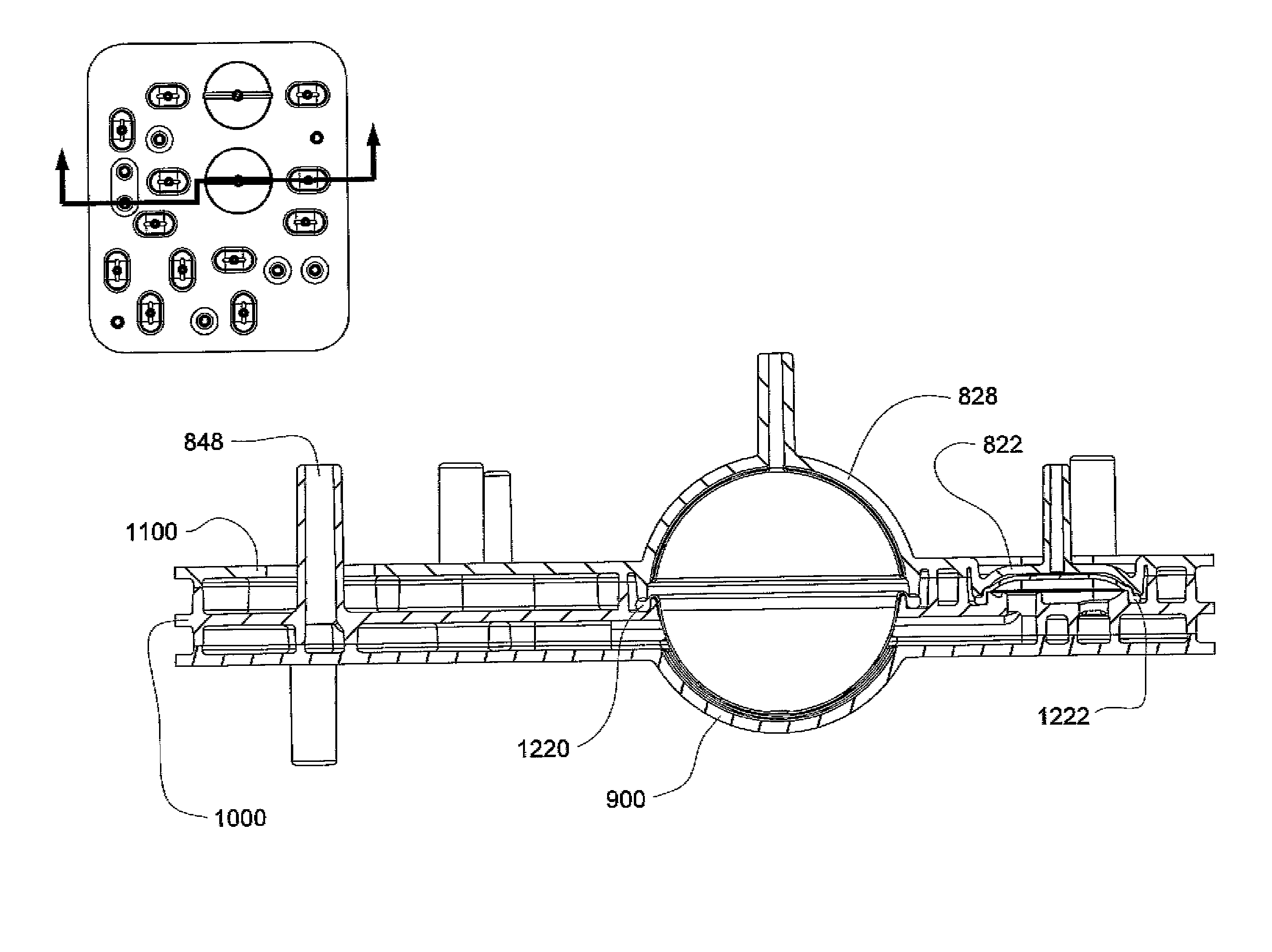

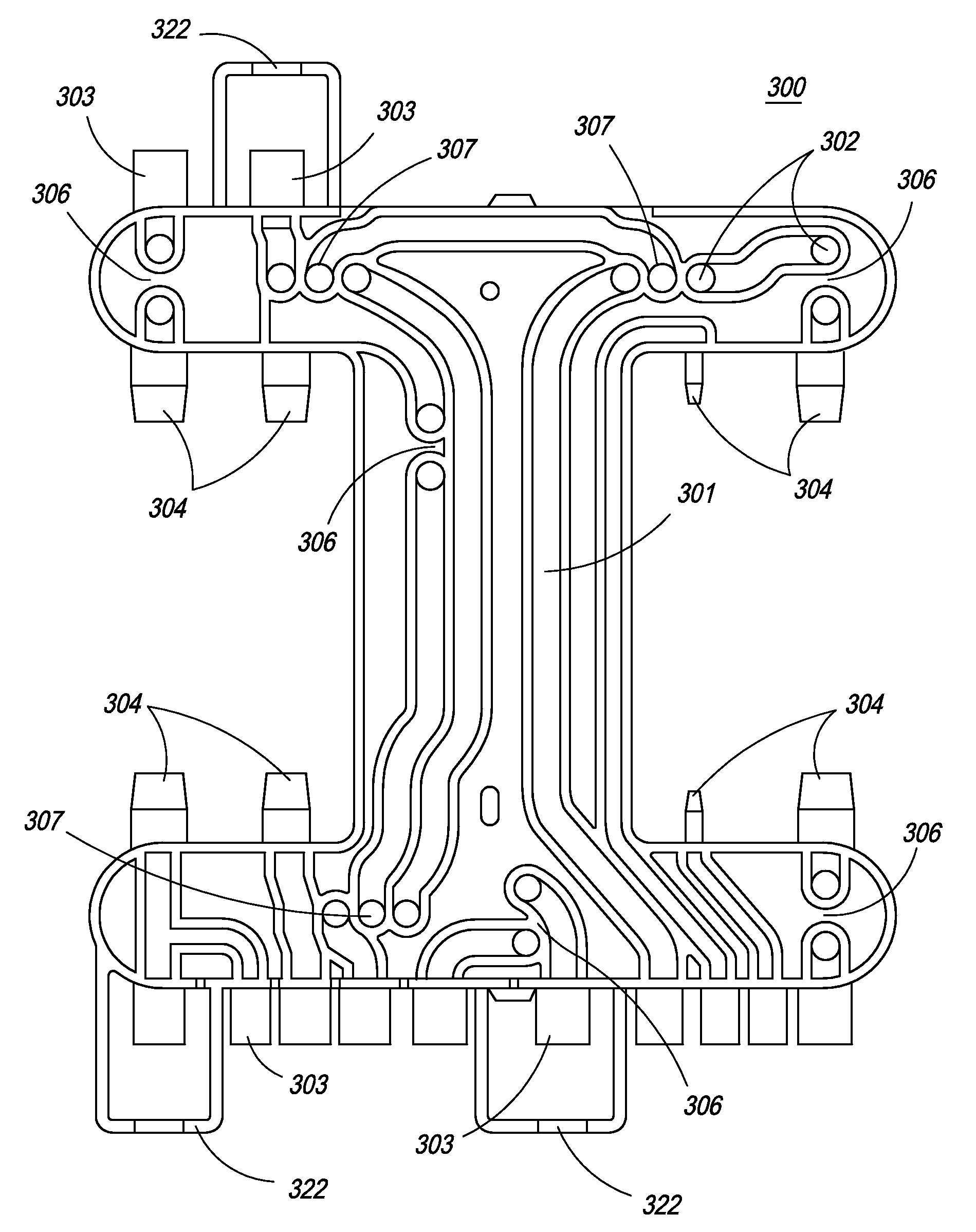

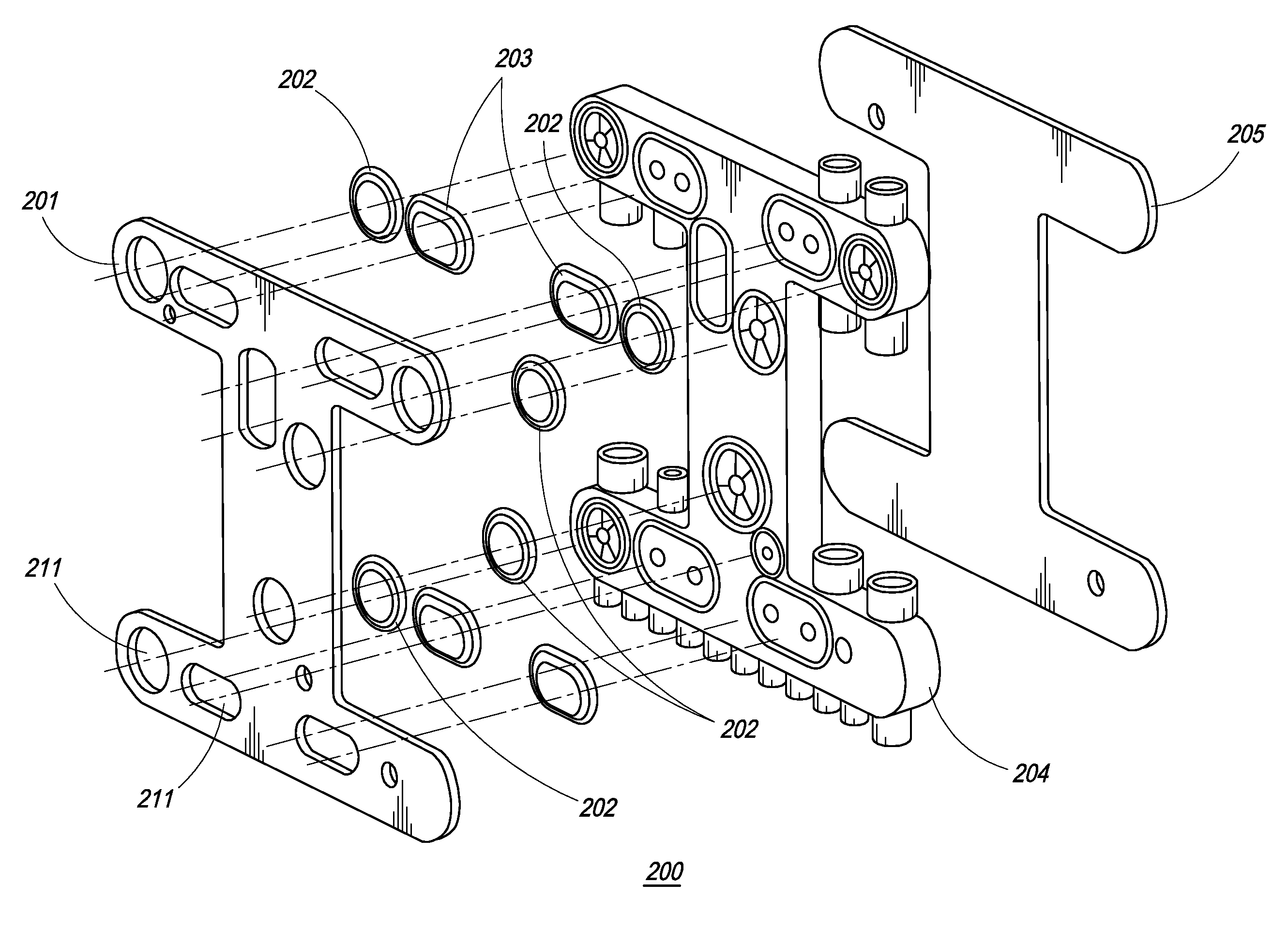

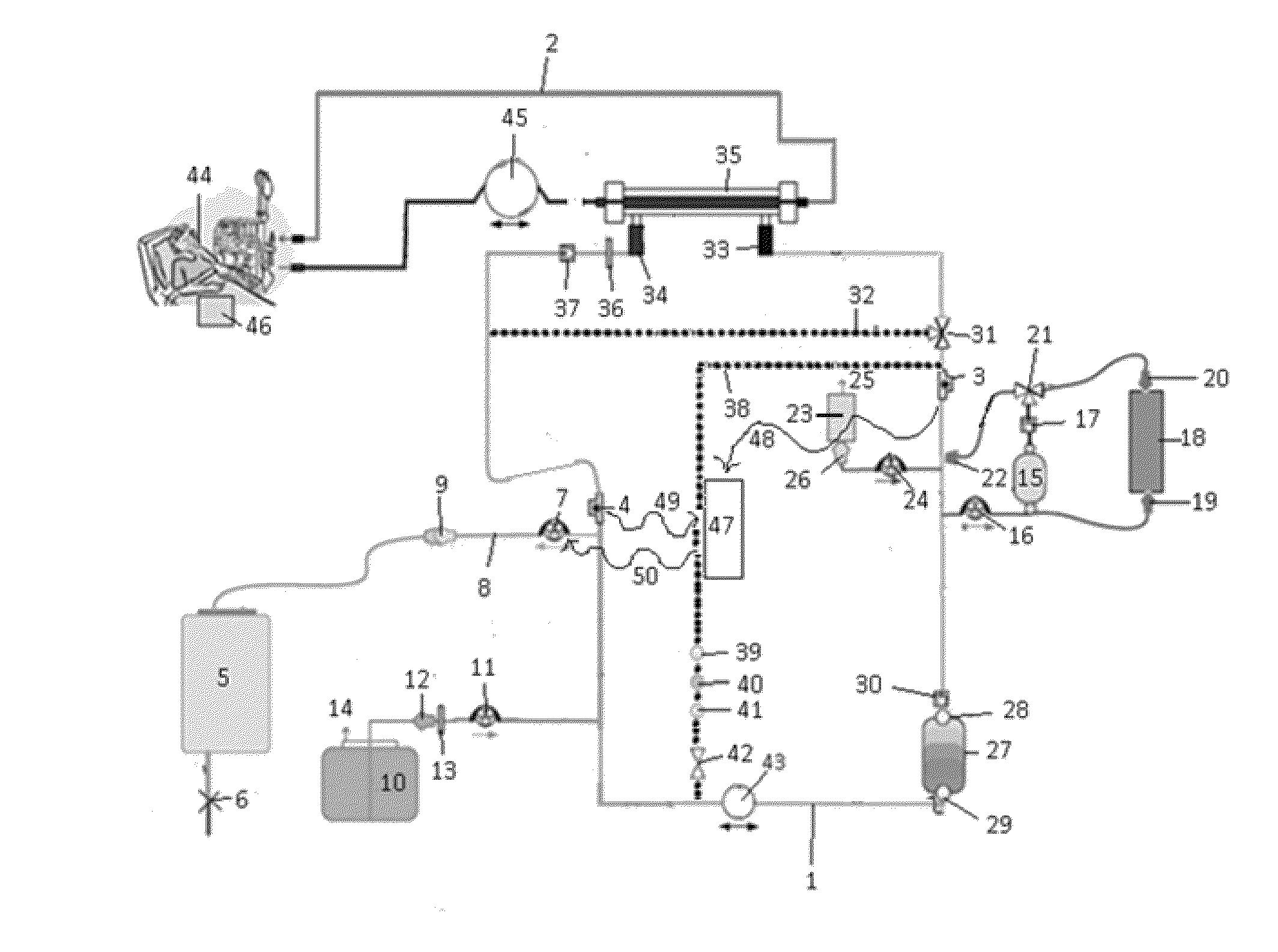

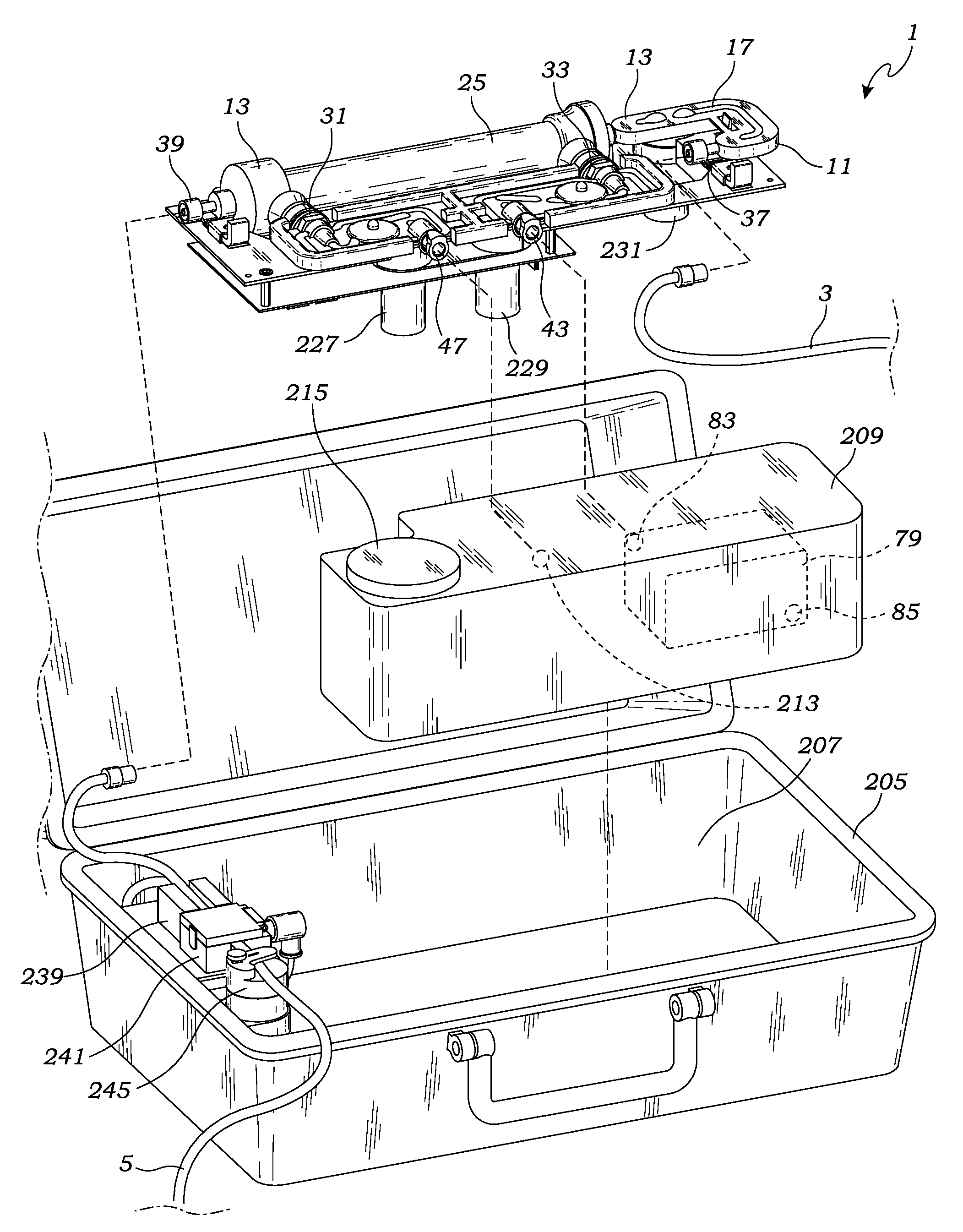

An extracorporeal blood processing system comprises a plastic molded compact manifold that supports a plurality of molded blood and dialysate fluidic pathways along with a plurality of relevant sensors, valves and pumps. A disposable dialyzer is connected to the molded manifold to complete the blood circuit of the system. The compact manifold is also disposable in one embodiment and can be detachably installed in the dialysis machine. Two-way valves in the manifold are used to direct the dialysate flow to the dialyzer in hemodialysis mode of operation and to bypass the dialyzer to direct the flow of infusion grade dialysate directly to the patient in hemofiltration mode of operation.

Owner:FRESENIUS MEDICAL CARE HLDG INC

Blood treatment systems and methods

ActiveUS20130020237A1Increase pressureSemi-permeable membranesMechanical/radiation/invasive therapiesBlood treatmentsDialysate flow

Dialysis systems are disclosed comprising new fluid flow circuits. Systems may include blood and dialysate flow paths, where the dialysate flow path includes balancing, mixing, and / or directing circuits. Dialysate preparation may be decoupled from patient dialysis. Circuits may be defined within one or more cassettes. The fluid circuit fluid flow paths may be isolated from electrical components. A gas supply in fluid communication with the dialysate flow path and / or the dialyzer able to urge dialysate through the dialyzer and urge blood back to the patient may be included for certain emergency situations. Fluid handling devices, such as pumps, valves, and mixers that can be actuated using a control fluid, may be included. Control fluid may be delivered by an external pump or other device, which may be detachable and / or generally rigid, optionally with a diaphragm, dividing the device into first and second compartments.

Owner:DEKA PROD LLP

Method and apparatus for kidney dialysis

InactiveUS20050242034A1Mechanical/radiation/invasive therapiesOther blood circulation devicesUltrafiltrationDischarge measurements

Owner:BAXTER INT INC

Hemodialysis systems and methods

ActiveUS8357298B2Mechanical/radiation/invasive therapiesSolvent extractionHaemodialysis machineDialysate flow

Owner:DEKA PROD LLP

Priming System and Method for Dialysis Systems

The application is directed to an extracorporeal blood processing system capable of using dialysate to prime the system. A plastic molded compact manifold supports molded blood and dialysate fluidic pathways along with relevant sensors, valves and pumps. The compact manifold is also disposable in one embodiment and can be detachably installed in the dialysis machine. A two-way valve in the manifold is used to direct the dialysate flow through the blood circuit to prime the circuit for use in treatment.

Owner:FRESENIUS MEDICAL CARE HLDG INC

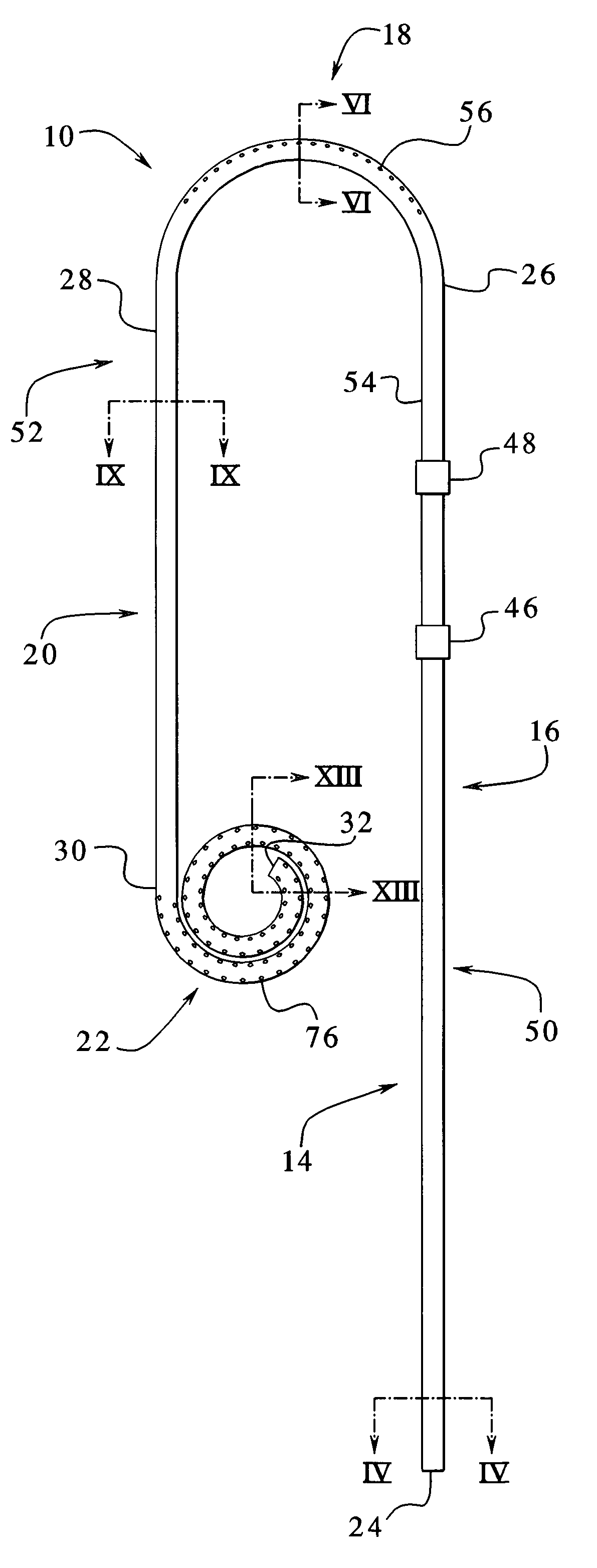

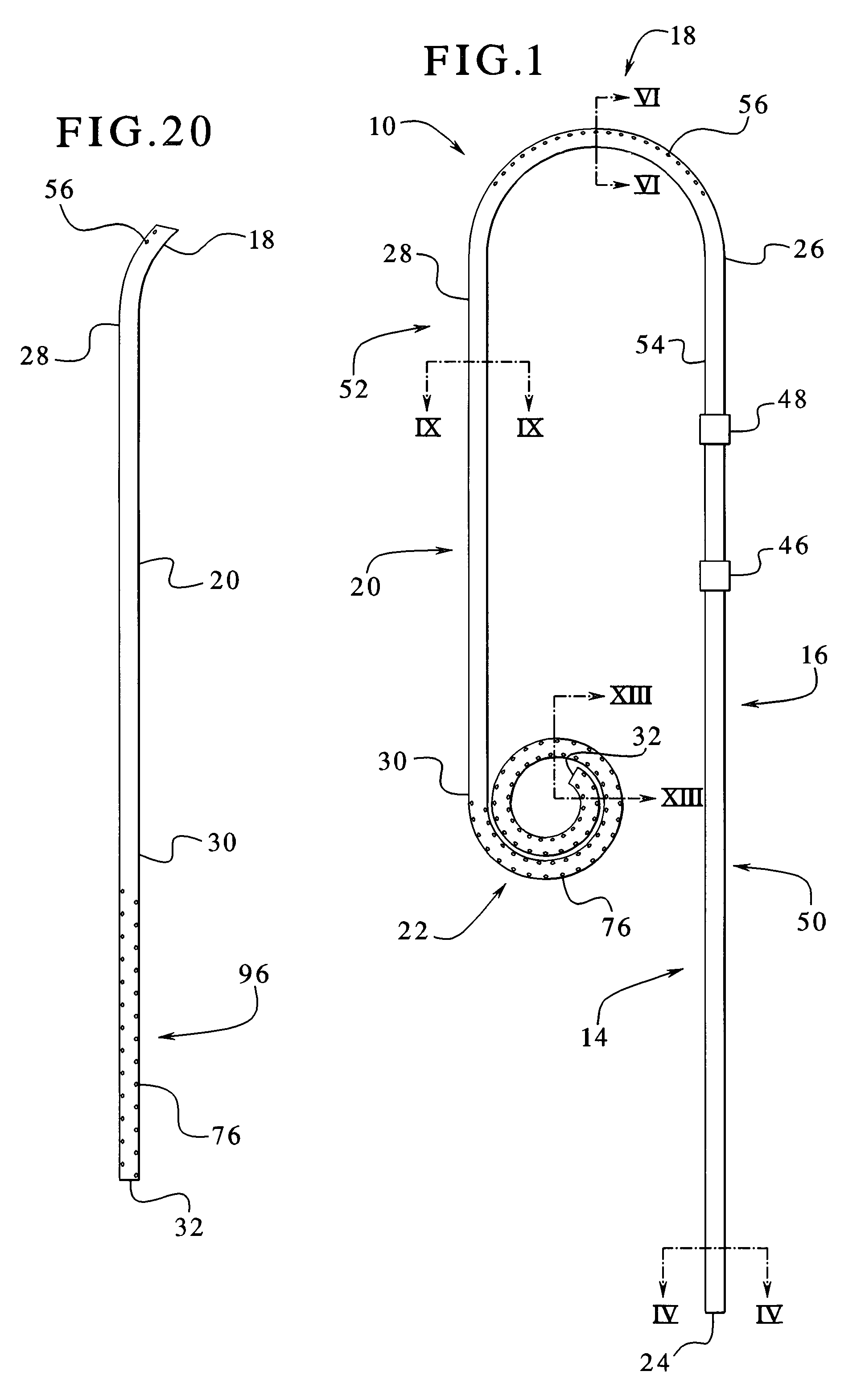

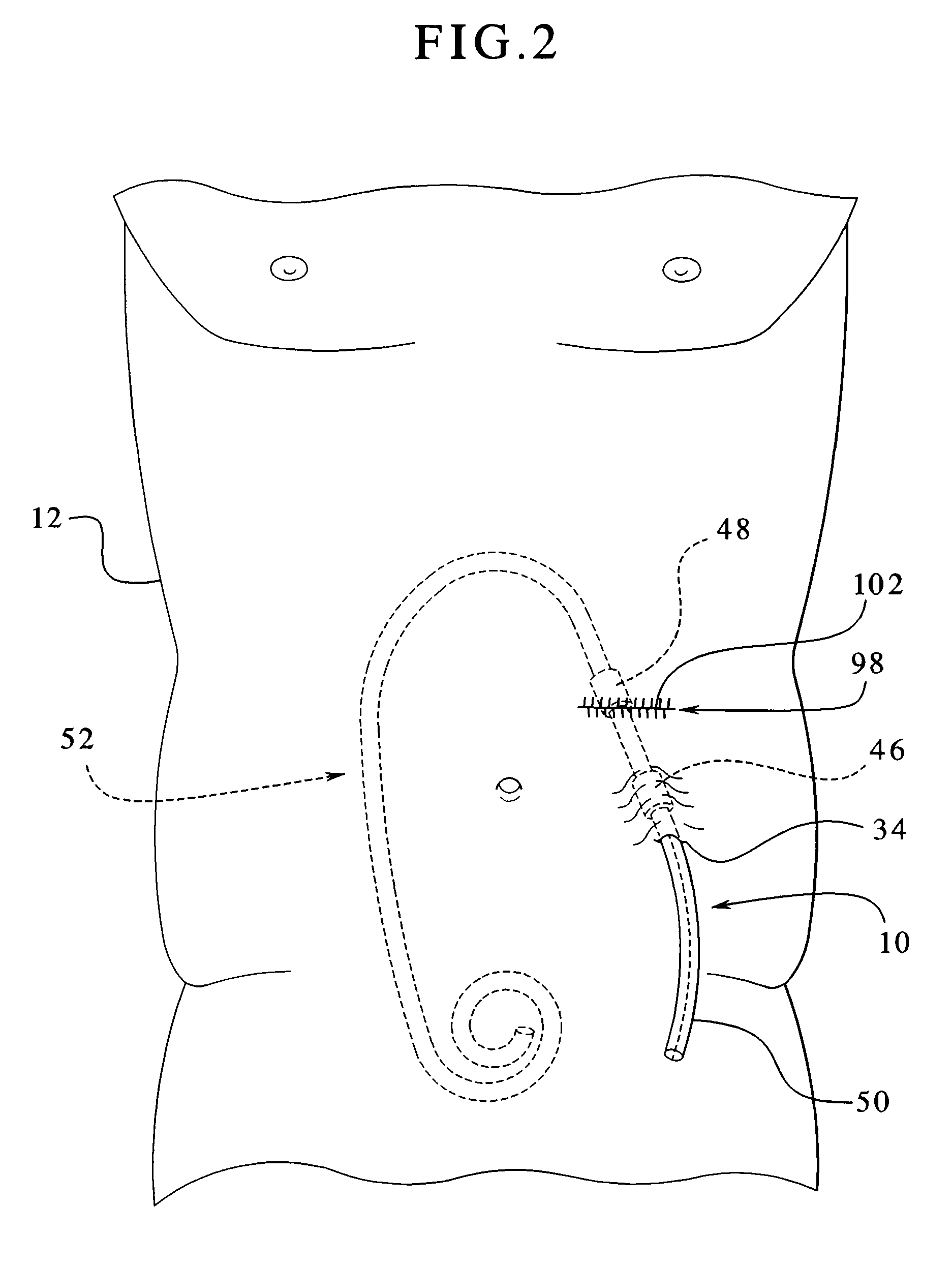

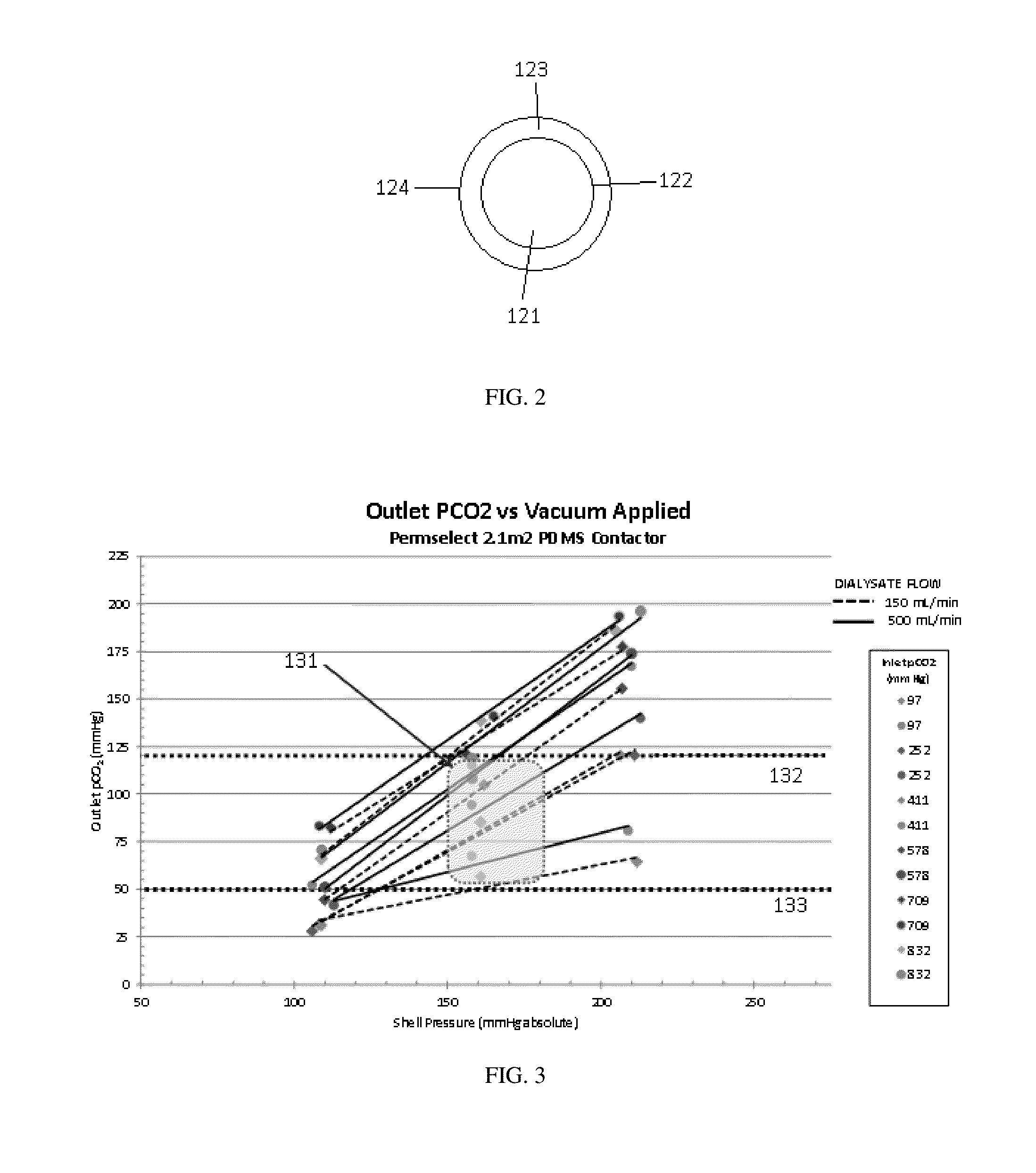

Peritoneal dialysis catheters

InactiveUS6976973B1Well mixedMinimize shuntingMedical devicesCatheterPeritoneal dialysis catheterCatheters dialysis

A catheter suitable for use in performing peritoneal dialysis. The catheter is a dual lumen catheter which allows for continuous flow peritoneal dialysis. Dialysate flows through the catheter into the patient via one lumen and simultaneously flows through the catheter out of the patient via the second lumen. The dual lumen dialysis catheter has a flexible tube which has an implantable portion extending from an external patient portion. Both of the lumens have openings in the external patient portion for connecting to a supply and drain of dialysate, respectively. The implantable portion has a preformed curved segment which has an outlet for the first lumen to flow dialysate into the patient's peritoneal cavity. The implantable portion has an opening for the second lumen at the distal end to flow dialysate out of the peritoneal cavity and removal from the patient. The catheter facilitates mixing of fresh and spent dialysate inside the peritoneal cavity by inflowing fresh dialysate into the cavity at a location substantially separated from the cavity outflow location, and by directing the inflow of dialysate into the cavity opposite the cavity outflow location.

Owner:BAXTER INT INC

Blood treatment systems and methods

ActiveUS20130037485A1Increase pressureMechanical/radiation/invasive therapiesSolvent extractionBlood treatmentsDialysate flow

Owner:DEKA PROD LLP

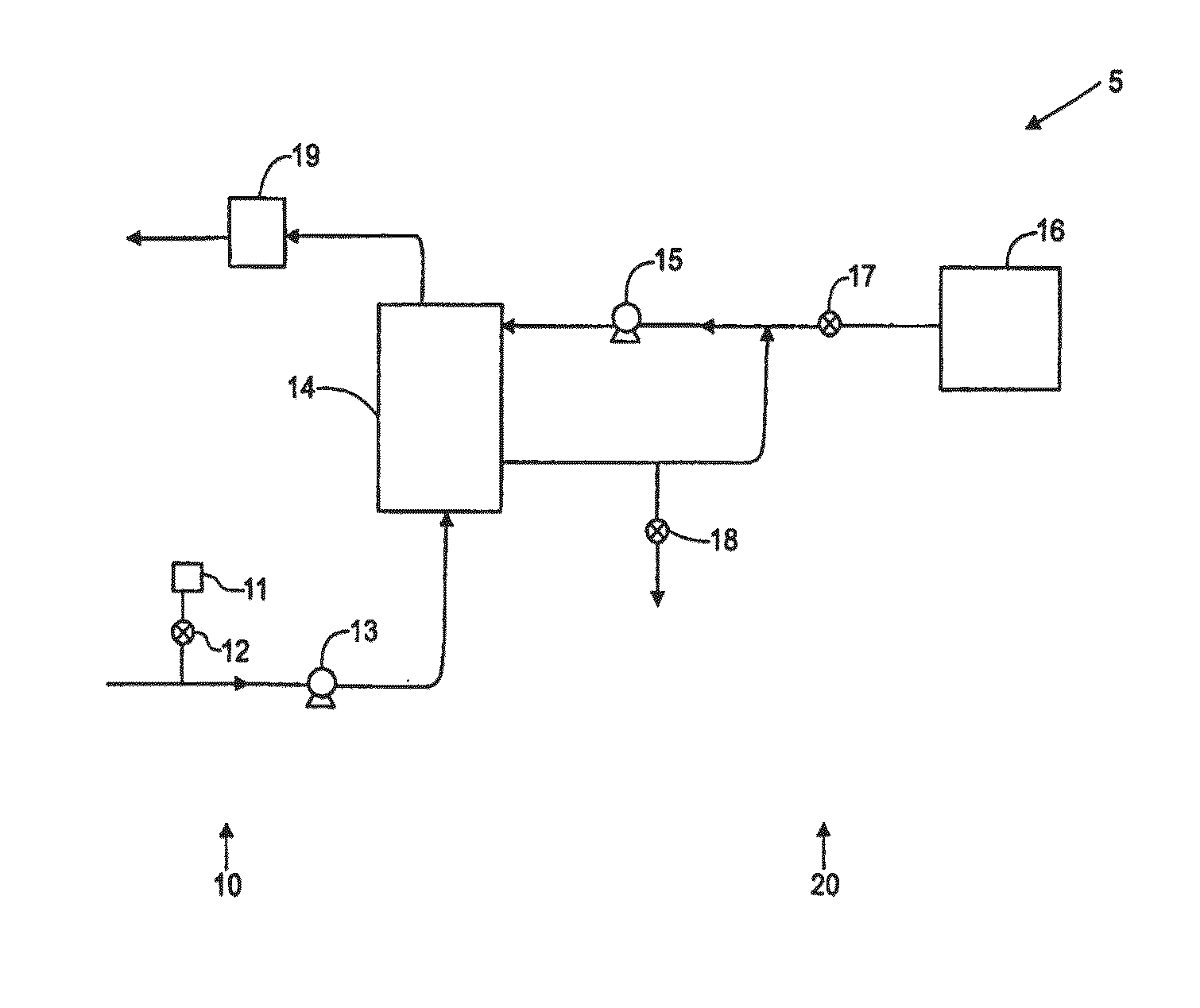

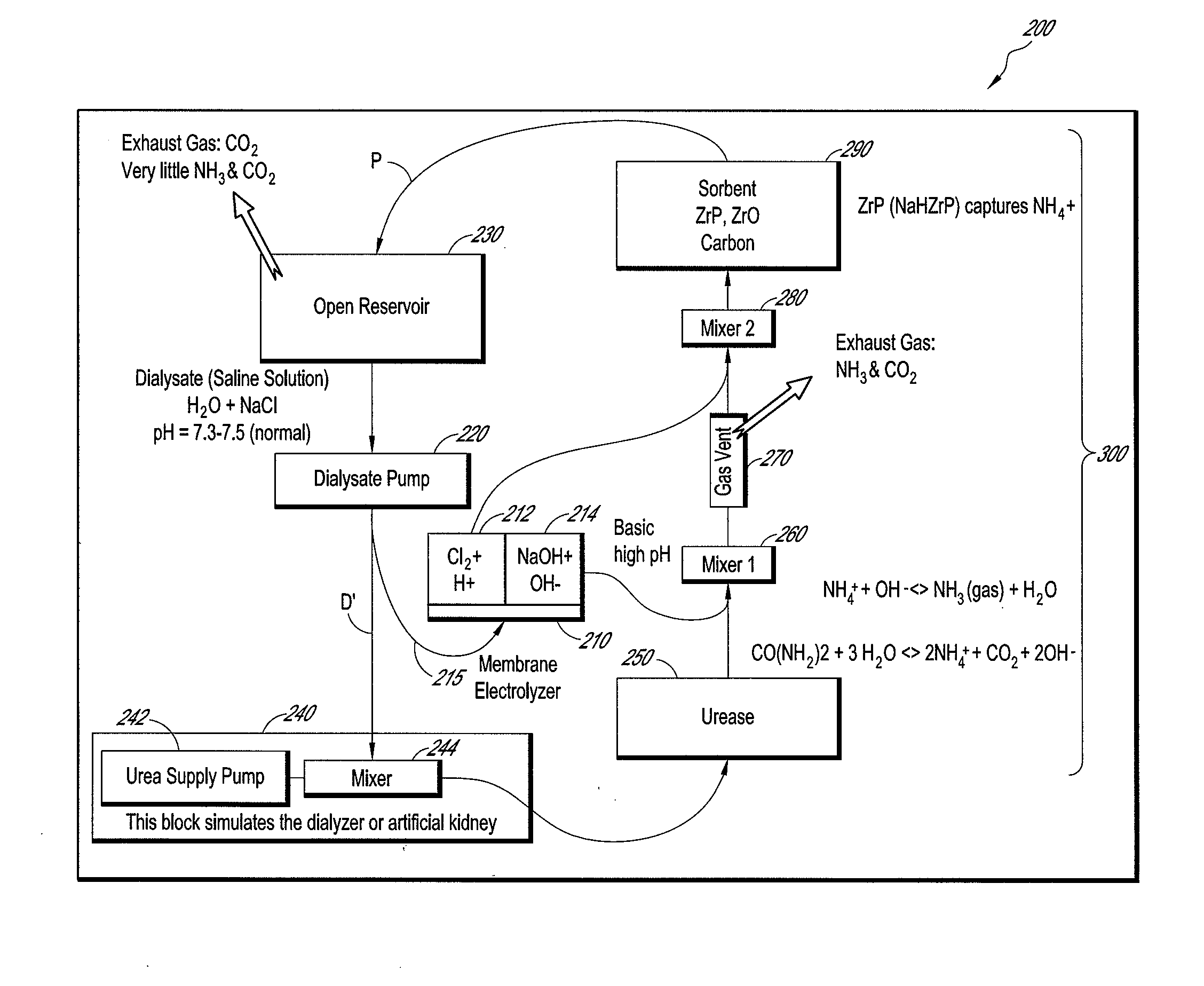

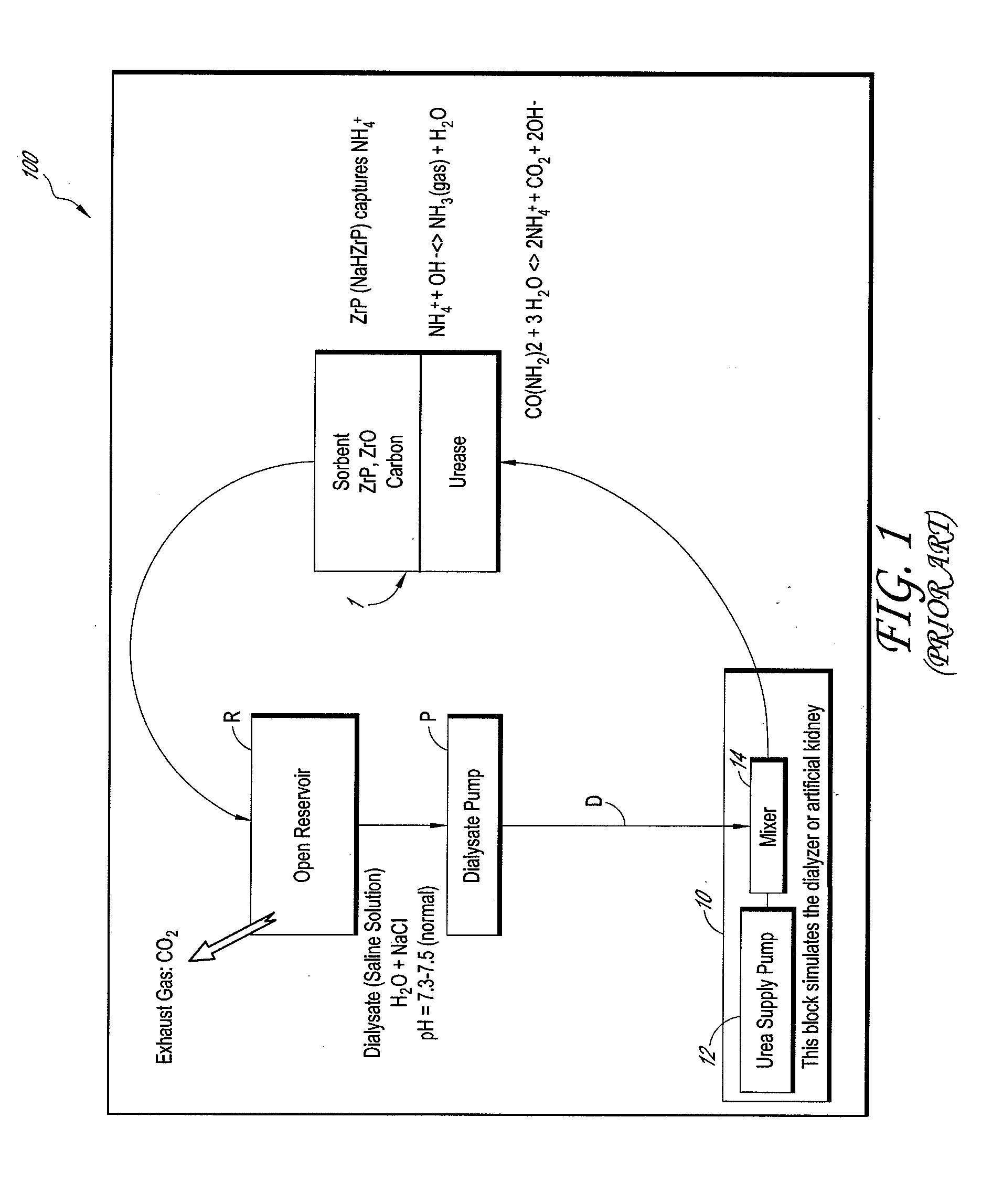

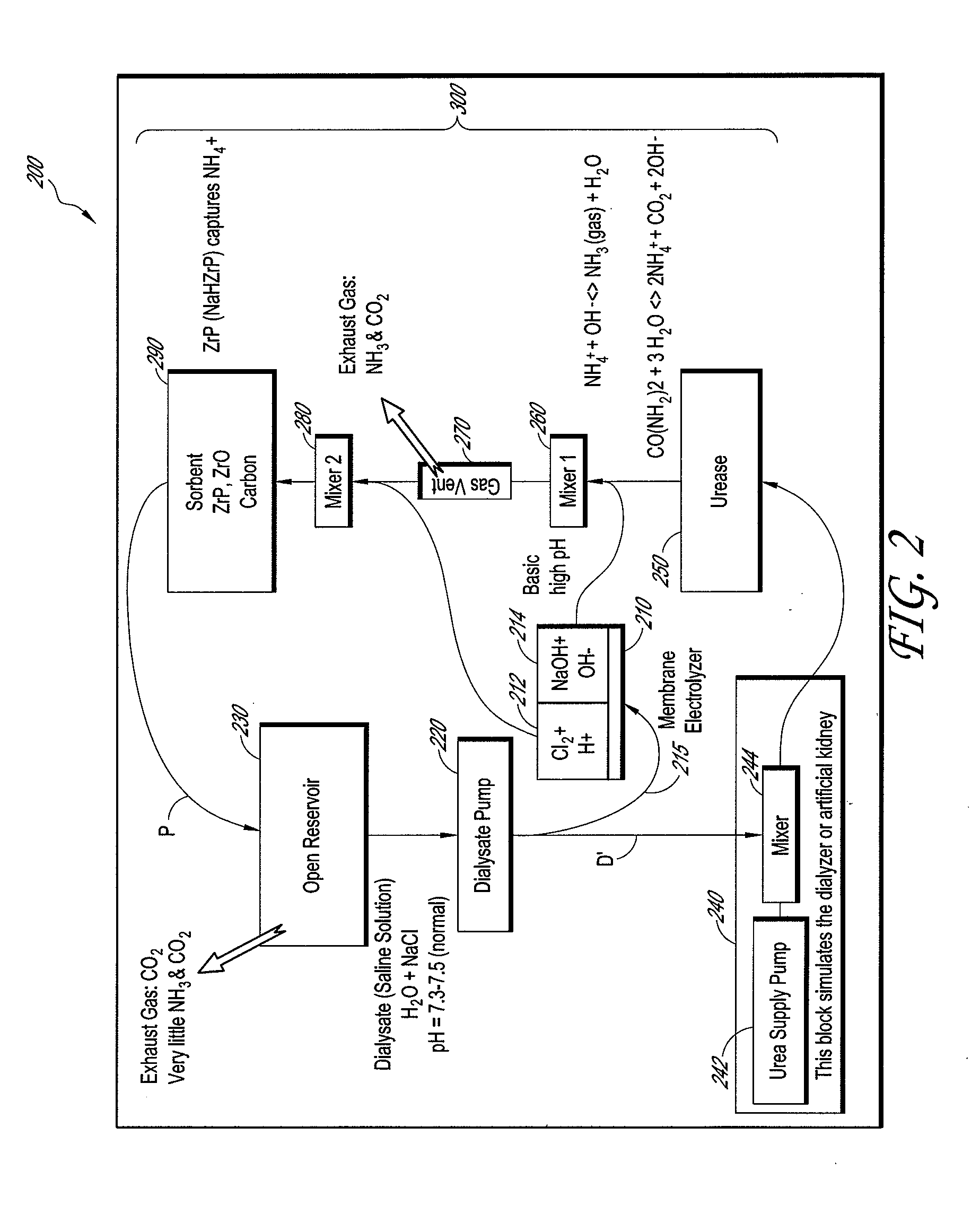

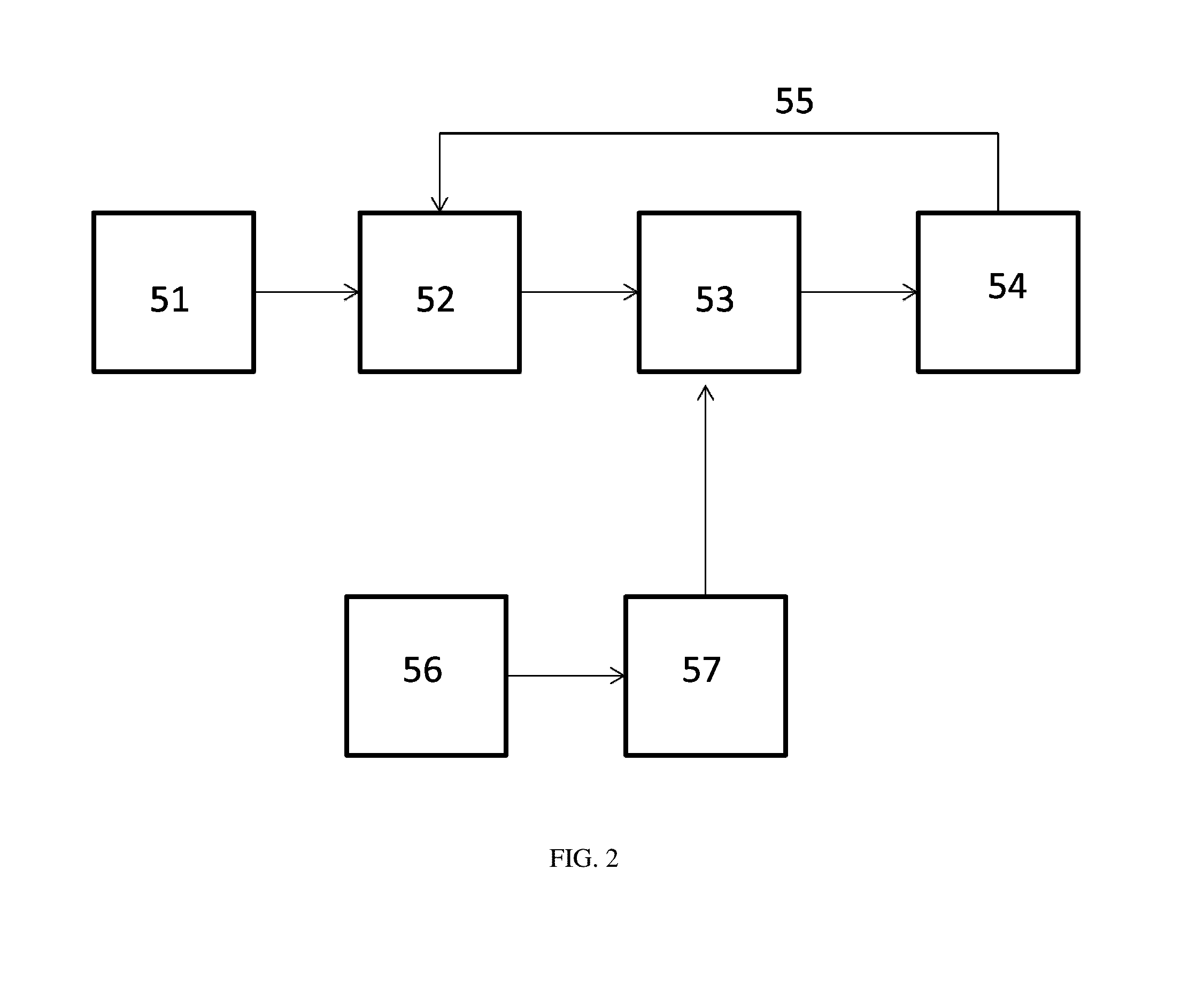

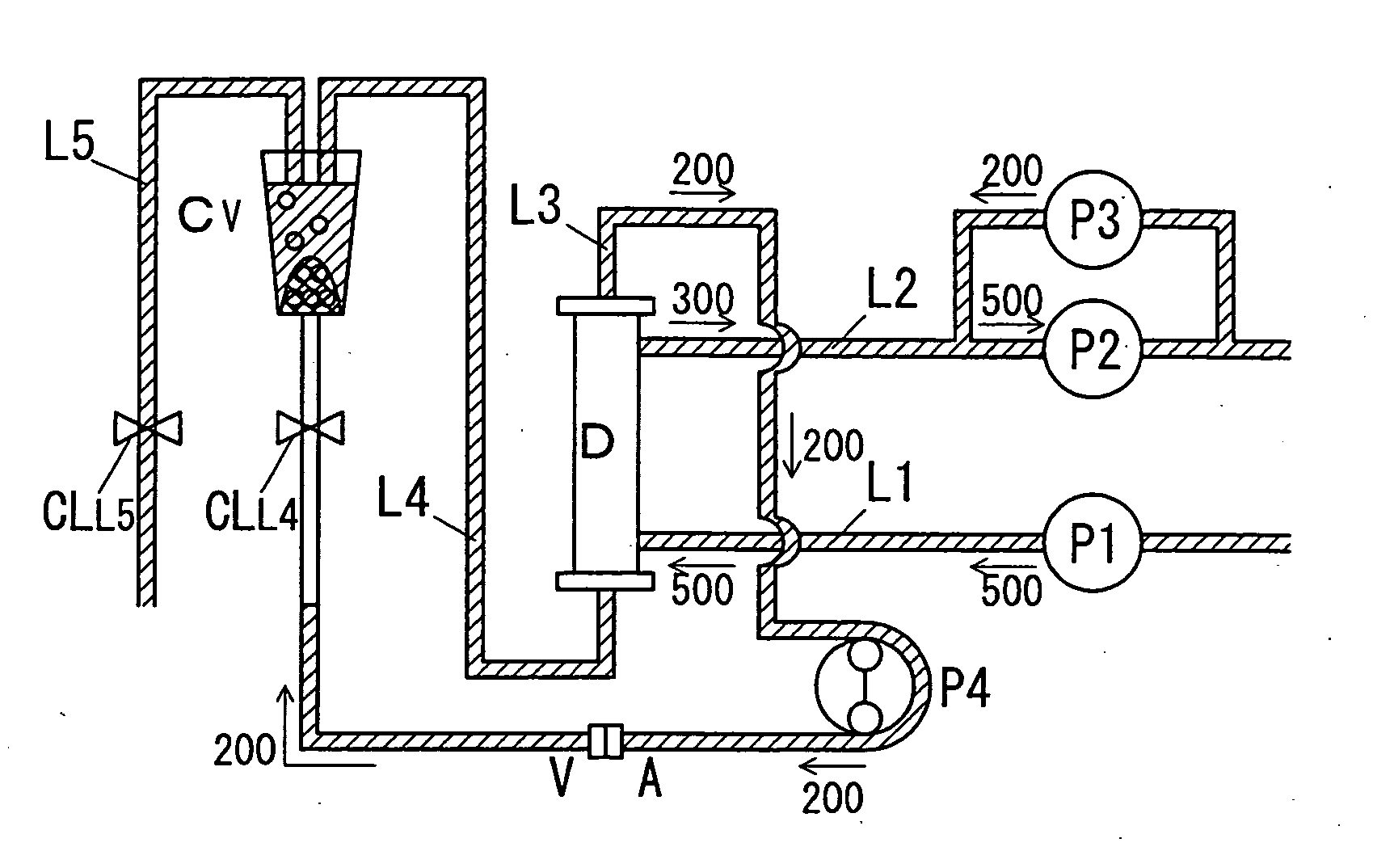

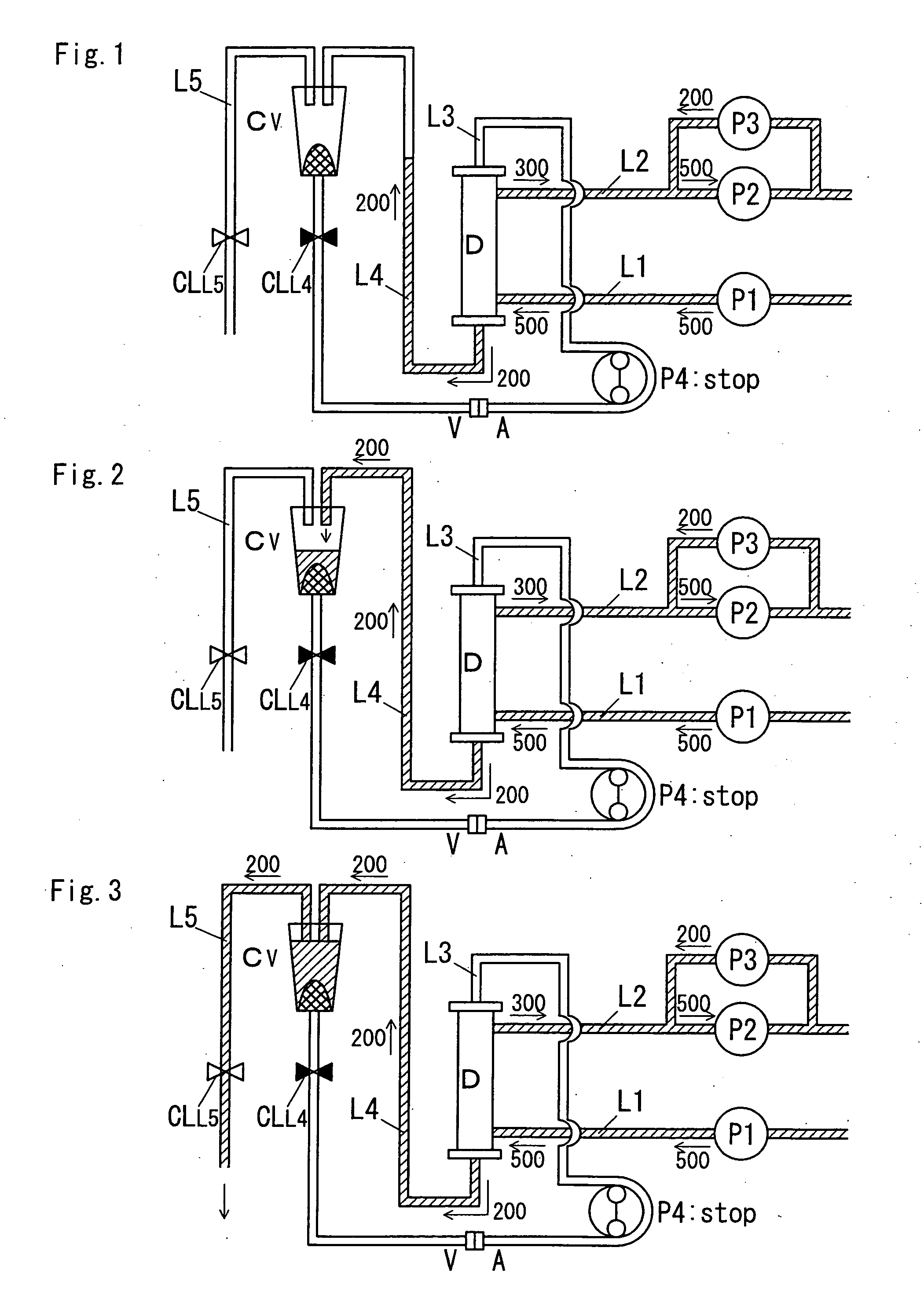

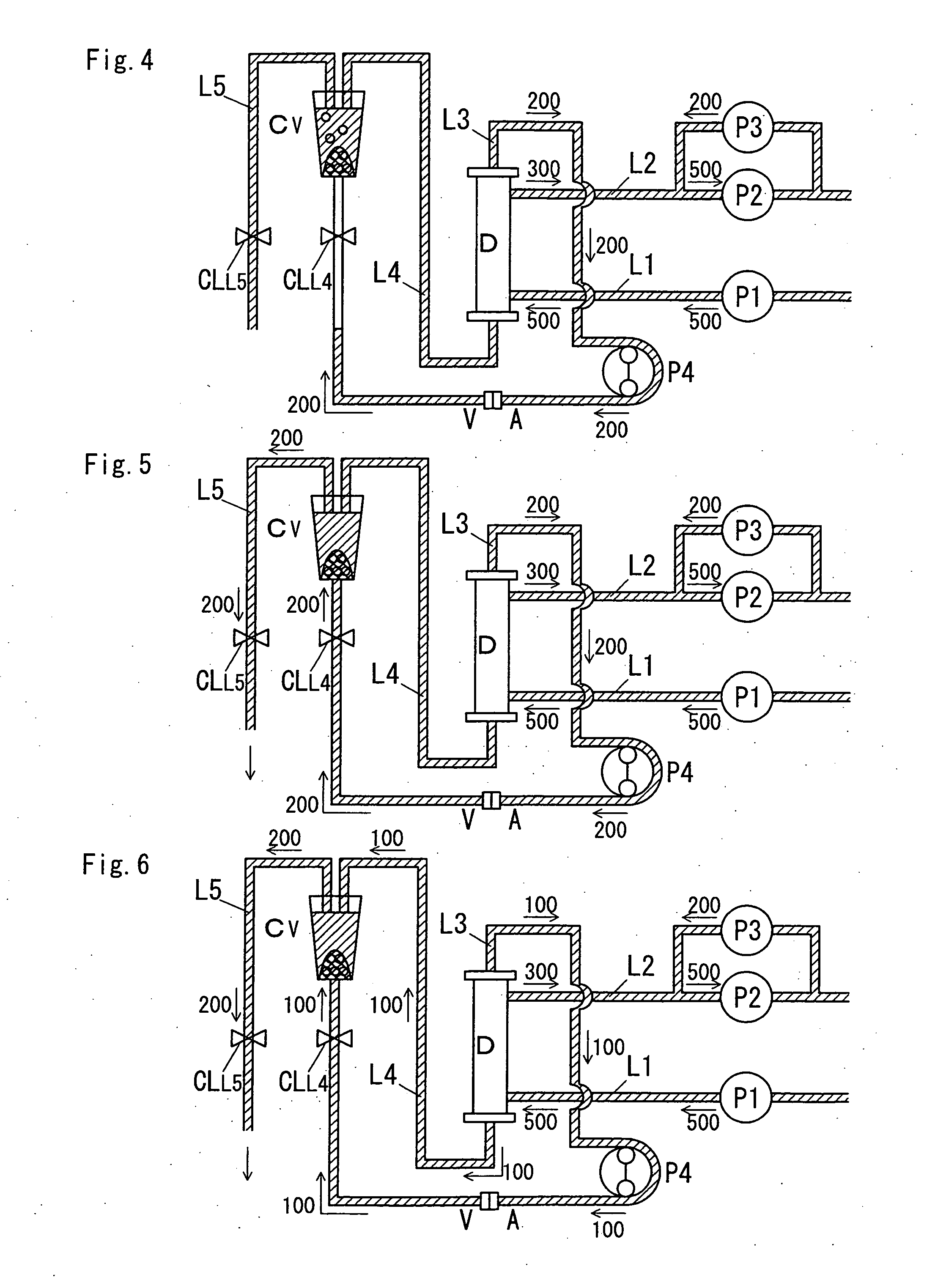

Membrane electrolyzer and hemodialysis system using the same

InactiveUS20110272352A1Raise the pHElectrolysis componentsApparatus sterilizationSorbentHaemodialysis machine

A sorbent hemodialysis system includes a dialyzer configured to receive a flow of clean dialysate from a reservoir and to output an unclean dialysate flow. The system also includes a sorbent component having a urease section and a sorbent section through which the unclean dialysate flow from the dialyzer passes, wherein the sorbent component removes urea from the dialysate. The system further comprises a membrane electrolyzer that receives at least a portion of said clean dialysate flow and separates the dialysate flow into an acidic component flow and a base component flow. A mixing conduit combines the base component flow from the membrane electrolyzer and an output dialysate solution from the urease section of the sorbent component to separate the dialysate solution into an ammonia gas amount and ammonia liquid amount. A gas vent is used to vent the ammonia gas amount, and the sorbent section with a suitable amount of zirconium phosphate (ZrP) removes the ammonia liquid amount from the unclean dialysate flow before flowing the clean dialysate to the reservoir. The system can further include a second mixing conduit upstream of the sorbent section of the sorbent component, the second mixing conduit combining the acidic component flow and the ammonia liquid amount in the dialysate solution to increase the pH of the dialysate solution to about 7.5 prior to returning to the reservoir.

Owner:C TECH BIOMEDICAL

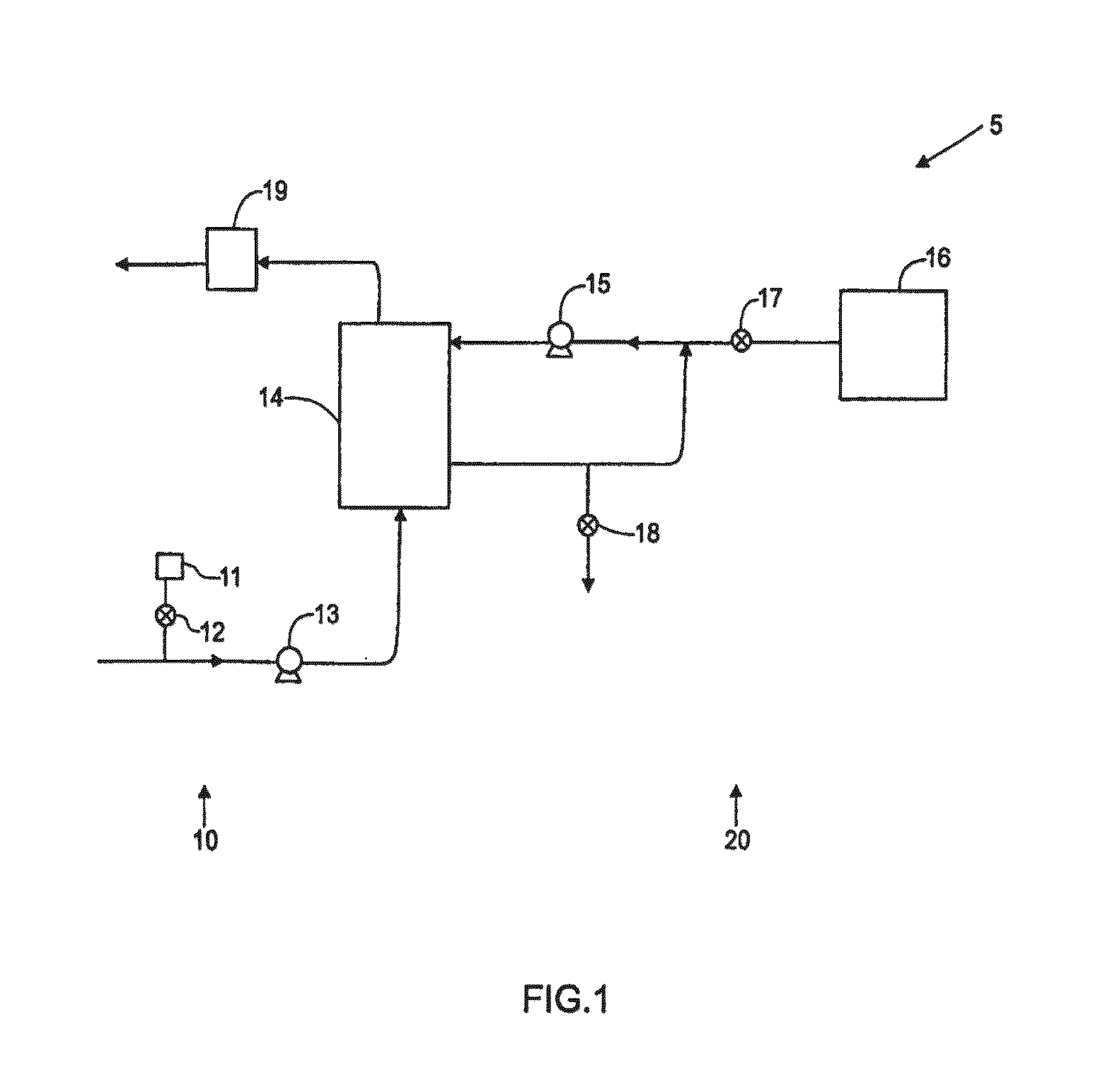

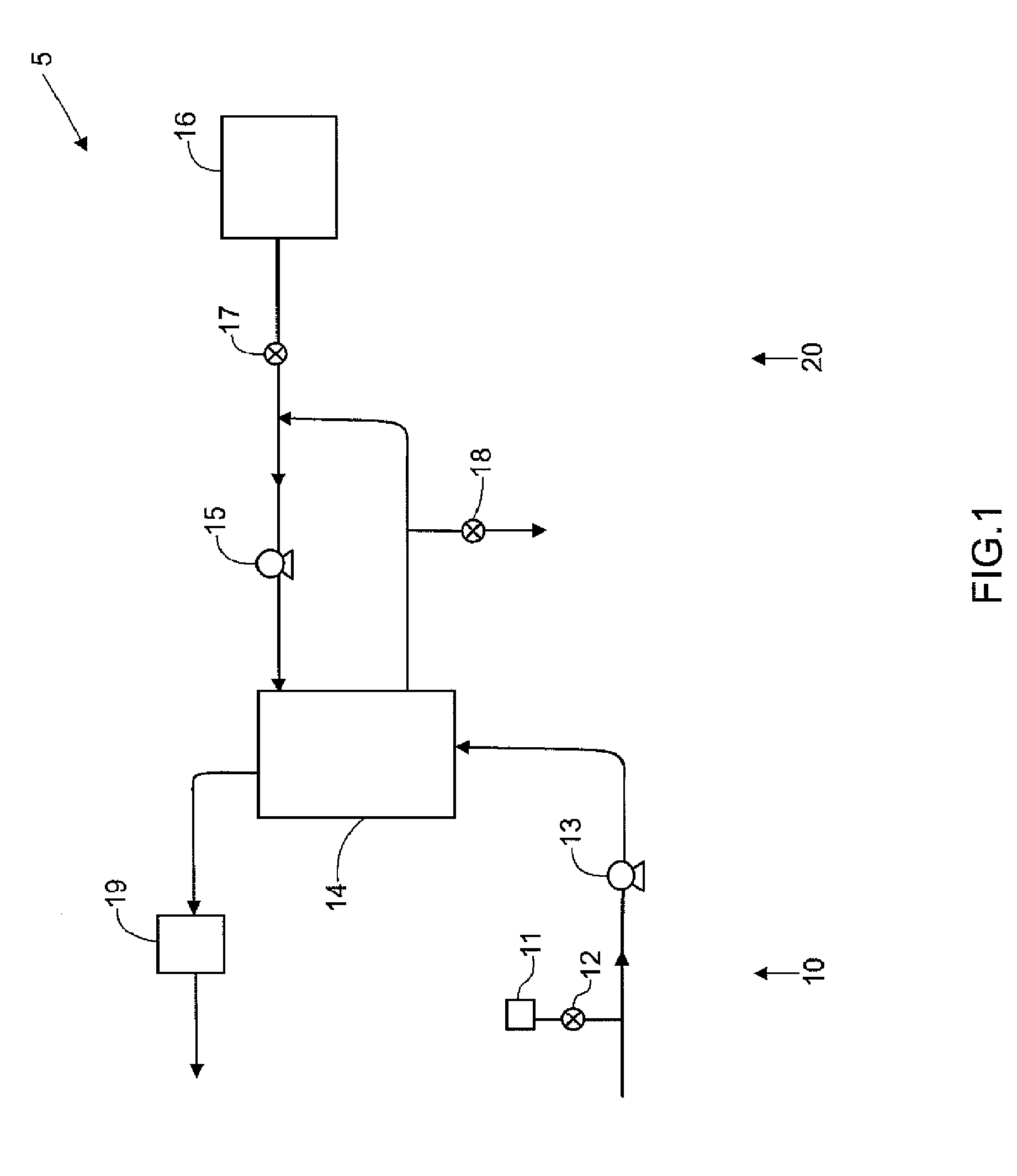

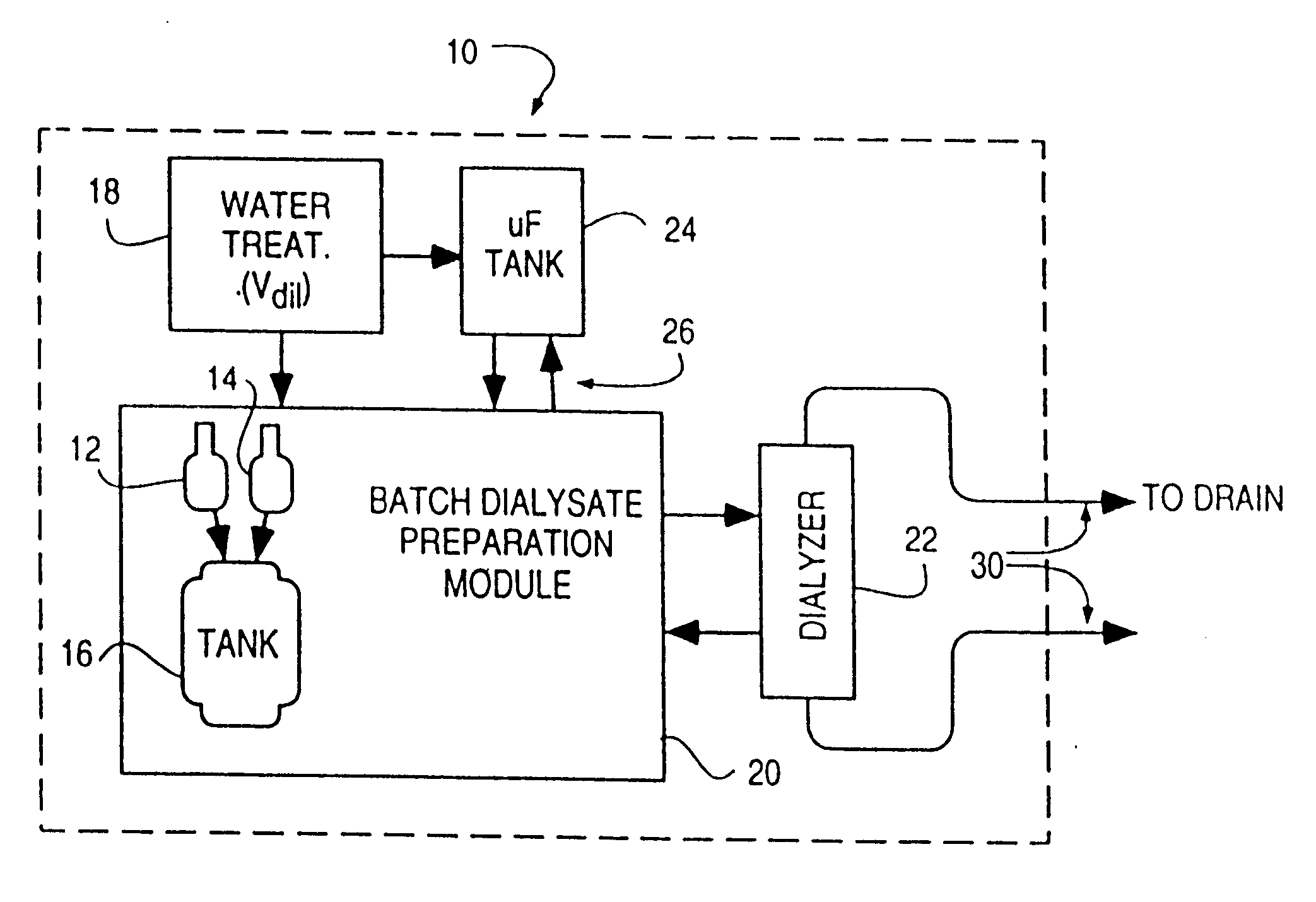

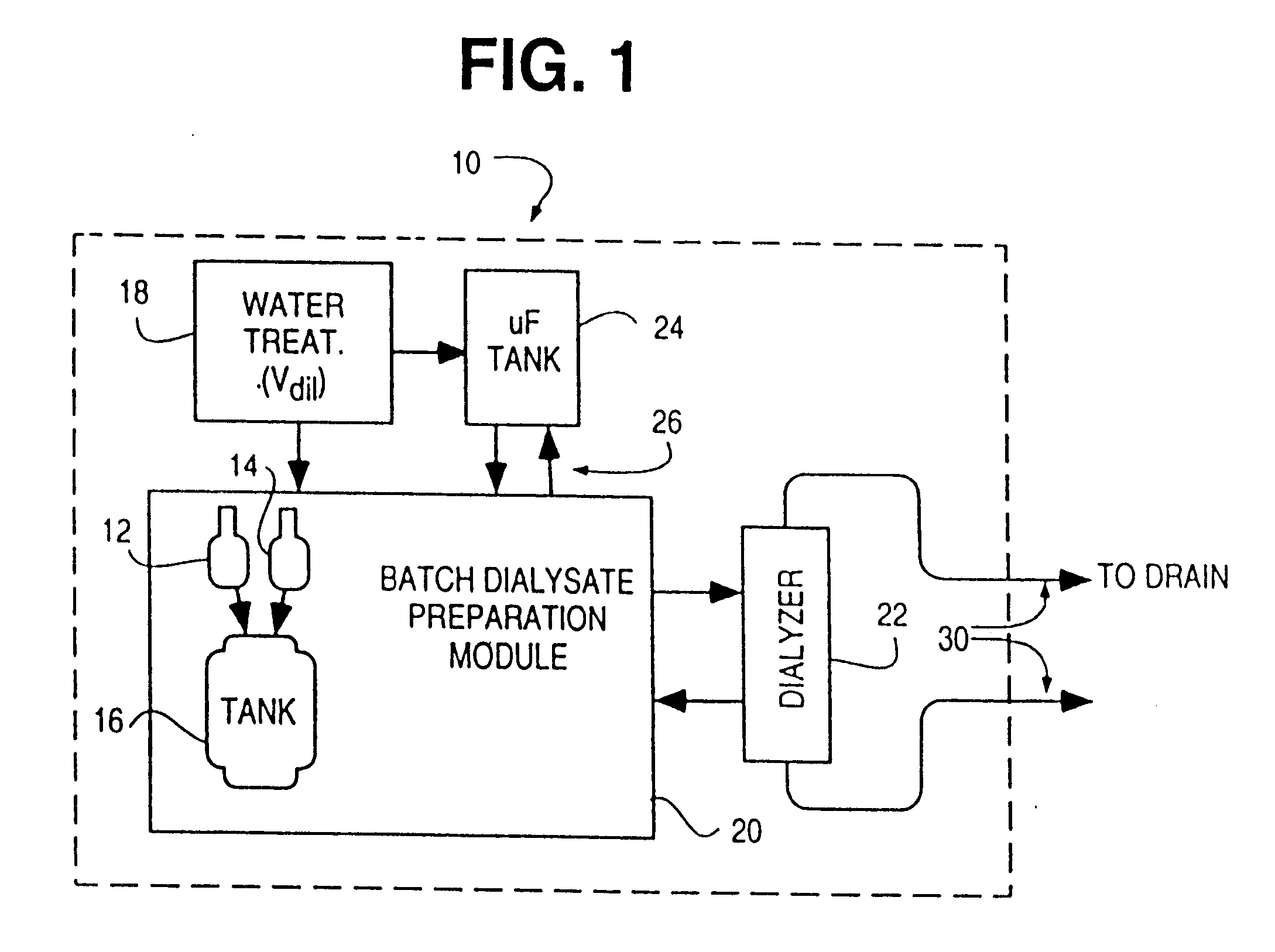

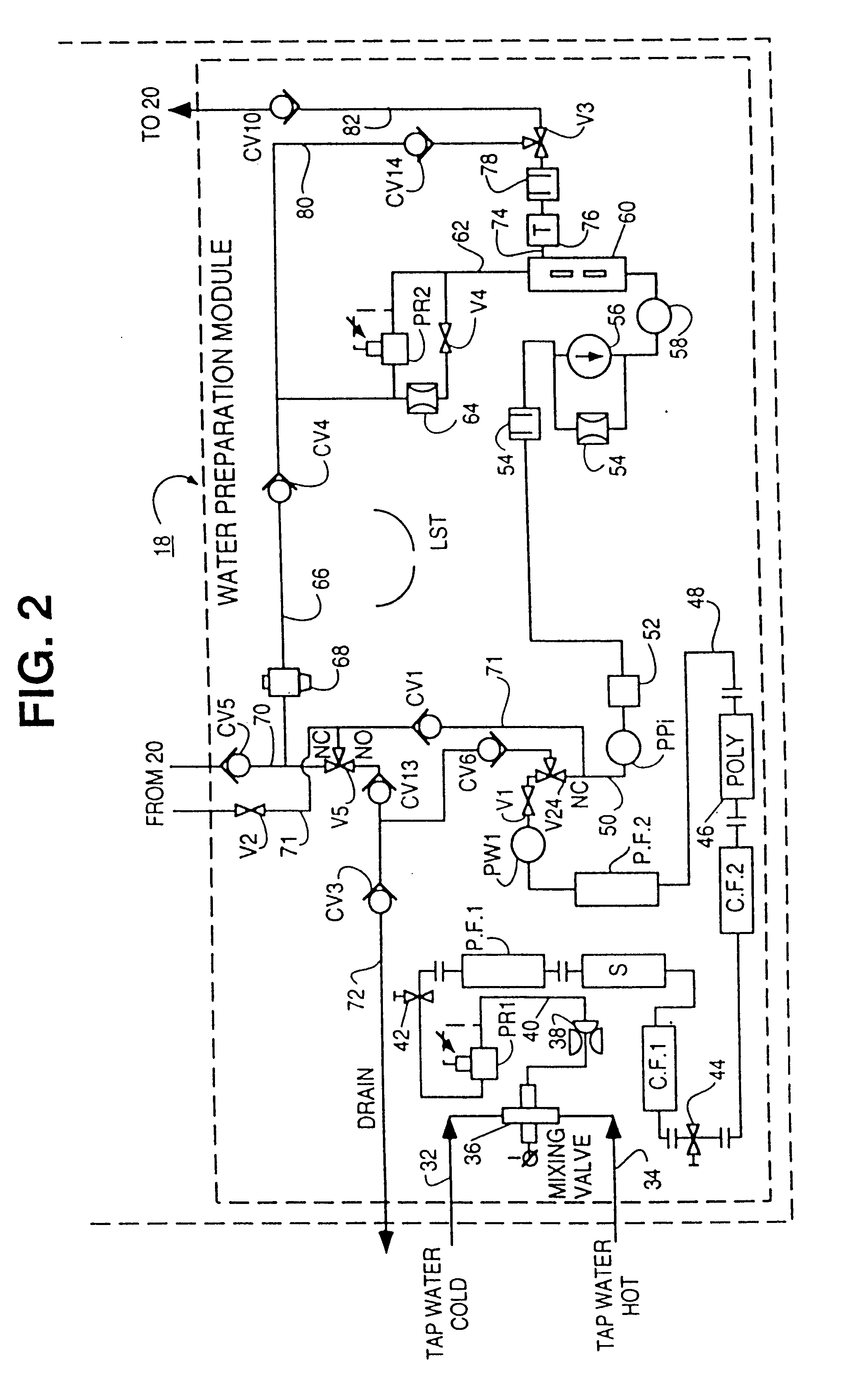

Method of determining system volume of a dialysis machine

A method of calibrating a dialysis machine to determine the volume of a dialysate flow path of the machine including a dialysate preparation tank includes the steps of introducing a known quantity of electrically conductive chemicals into the dialysate preparation tank, filling the dialysate solution flow path with water, mixing the chemicals with water to form a solution, measuring the conductivity of the solution, calculating the system volume (Vsys) according to the relation: Vsys=M / (a1r+b1) where M is the mass in grams of the chemicals, a1 and b1 are a coefficient of linearity and a constant of linearity, respectively, for the chemicals and r is the measured conductivity of the solution.

Owner:HHD LLC A DELAWARE LLC +2

Blood treatment systems and methods

ActiveUS9517295B2Increase pressureMechanical/radiation/invasive therapiesOther blood circulation devicesBlood treatmentsUltrafiltration

Owner:DEKA PROD LLP

System and method for conducting hemodialysis and hemofiltration

An extracorporeal blood processing system comprises a plastic molded compact manifold that supports a plurality of molded blood and dialysate fluidic pathways along with a plurality of relevant sensors, valves and pumps. A disposable dialyzer is connected to the molded manifold to complete the blood circuit of the system. The compact manifold is also disposable in one embodiment and can be detachably installed in the dialysis machine. Two-way valves in the manifold are used to direct the dialysate flow to the dialyzer in hemodialysis mode of operation and to bypass the dialyzer to direct the flow of infusion grade dialysate directly to the patient in hemofiltration mode of operation.

Owner:FRESENIUS MEDICAL CARE HLDG INC

Priming system and method for dialysis systems

The application is directed to an extracorporeal blood processing system capable of using dialysate to prime the system. A plastic molded compact manifold supports molded blood and dialysate fluidic pathways along with relevant sensors, valves and pumps. The compact manifold is also disposable in one embodiment and can be detachably installed in the dialysis machine. A two-way valve in the manifold is used to direct the dialysate flow through the blood circuit to prime the circuit for use in treatment.

Owner:FRESENIUS MEDICAL CARE HLDG INC

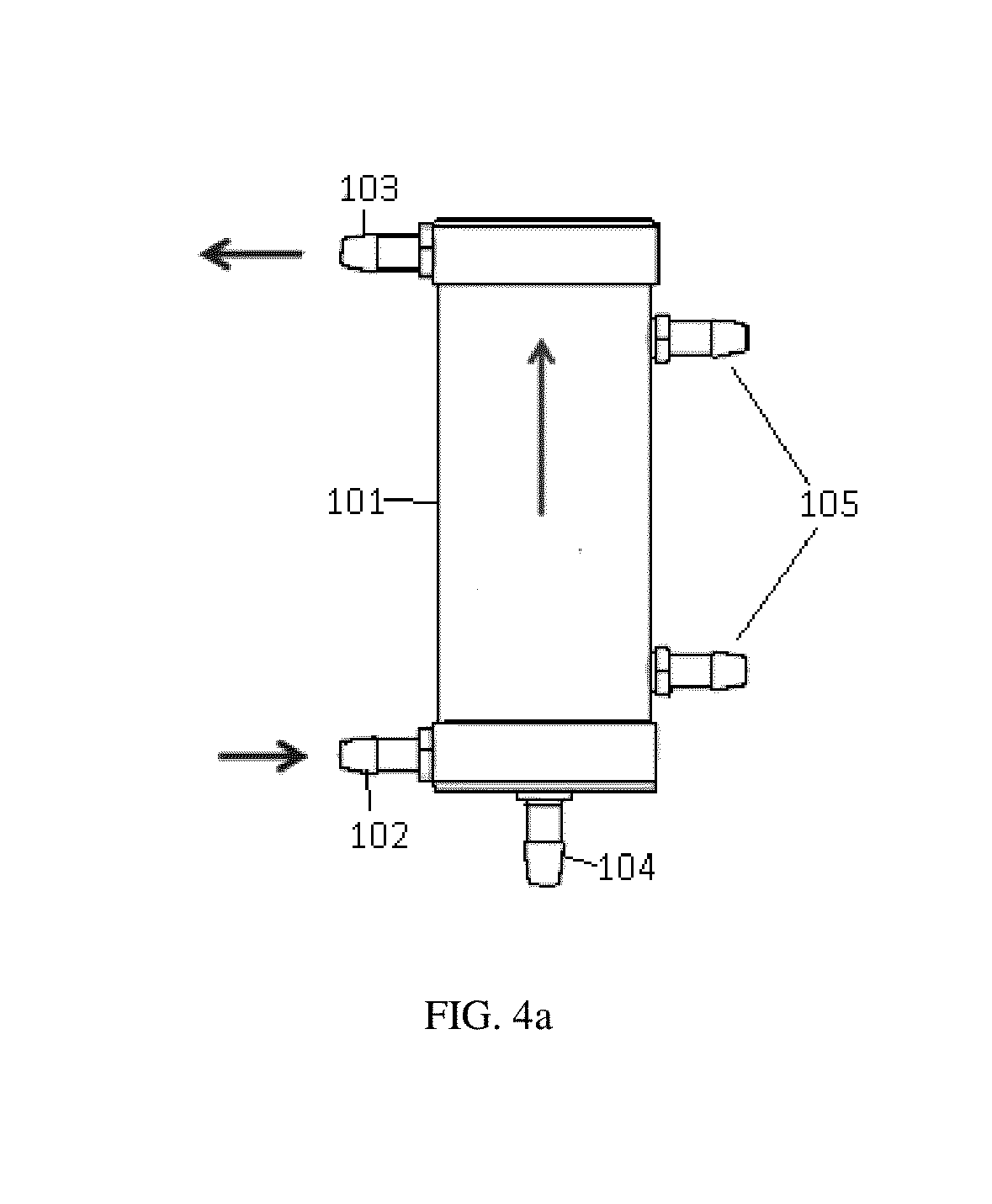

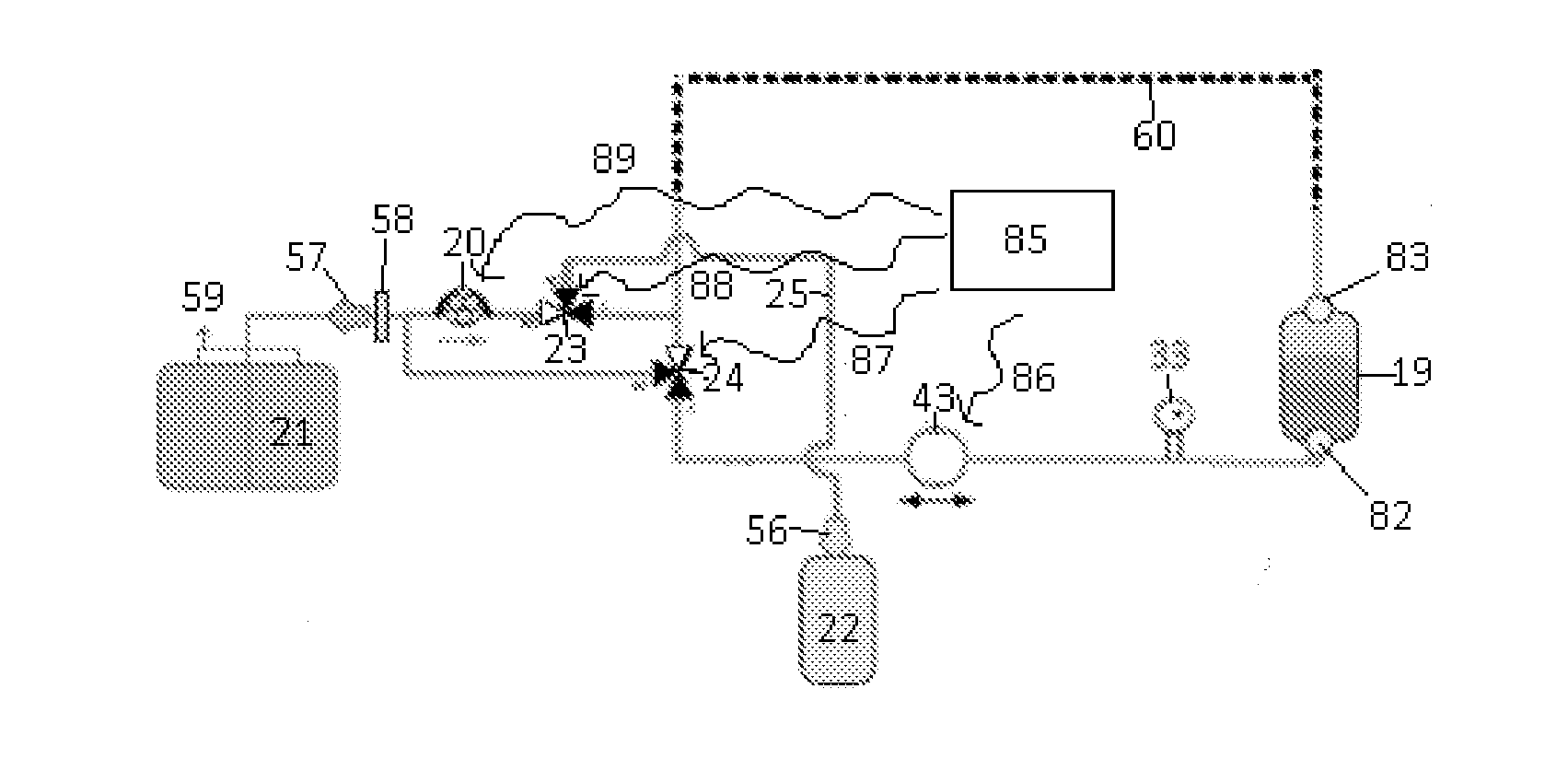

Degassing system for dialysis

The degassing system can include a degassing vessel and can utilize a vacuum pump and a fluid pump located downstream of the degassing vessel to control the pressure within the degassing vessel in order to control the concentration of gases in fluid exiting the degassing system. The degassing system can further comprise sensors in communication with the pumps to control the rate of flow and pressure through the degassing system. The degassing system may be placed in a dialysate flow path to remove dissolved gases including carbon dioxide from the dialysate.

Owner:MOZARC MEDICAL US LLC

Sensing and storage system for fluid balance

A sensing and storage system for fluid balance during dialysis is provided. The sensing and storage system has flow sensors on either side of a dialyzer in a controlled volume dialysate flow path. The sensors are positioned so that no fluid can be added to or removed from the dialysate flow path between the sensors except for that which is added or removed by action of a control pump. The sensing and storage system can have a fluid removal line for the removal of fluid from the dialysate flow loop.

Owner:MOZARC MEDICAL US LLC

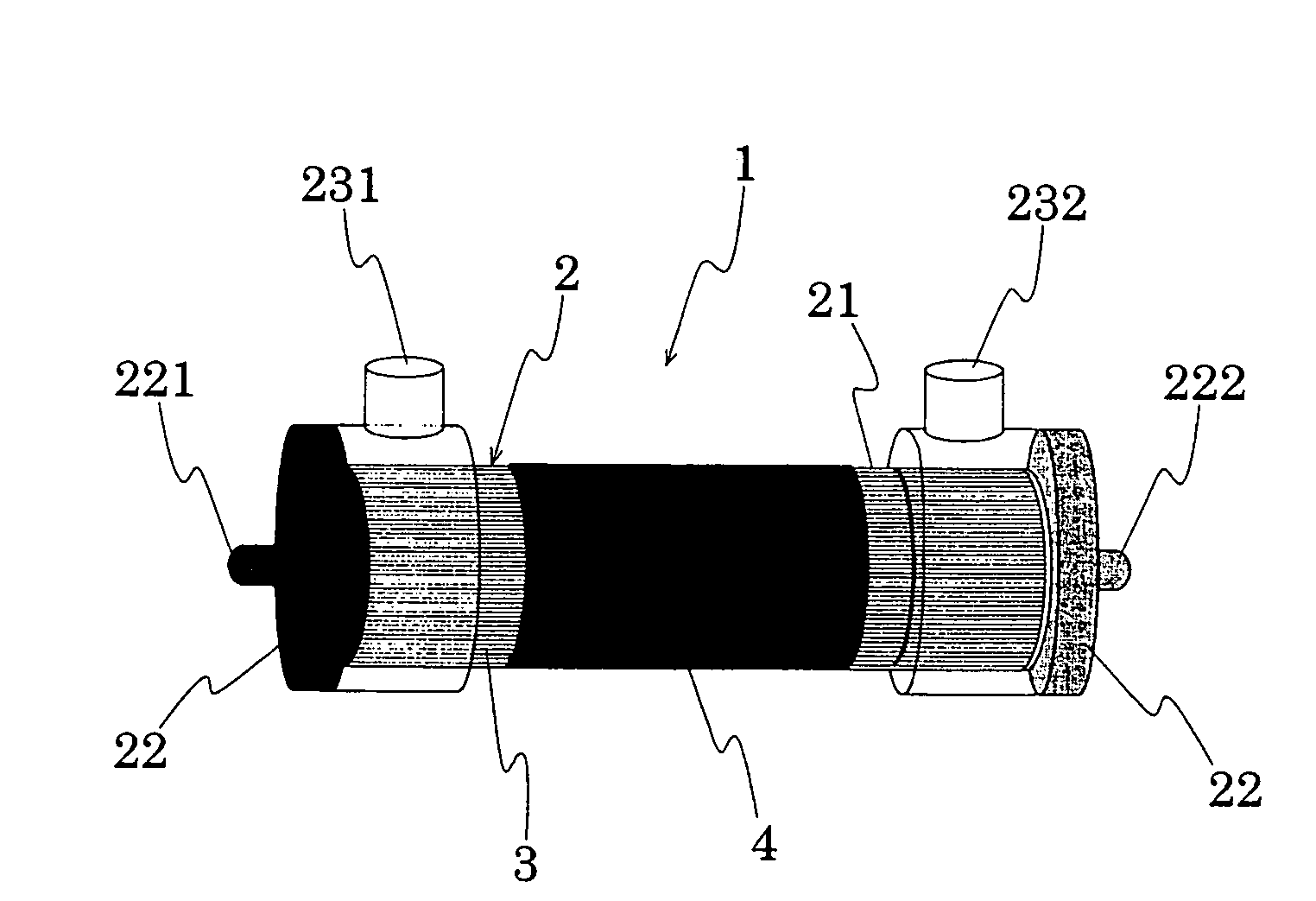

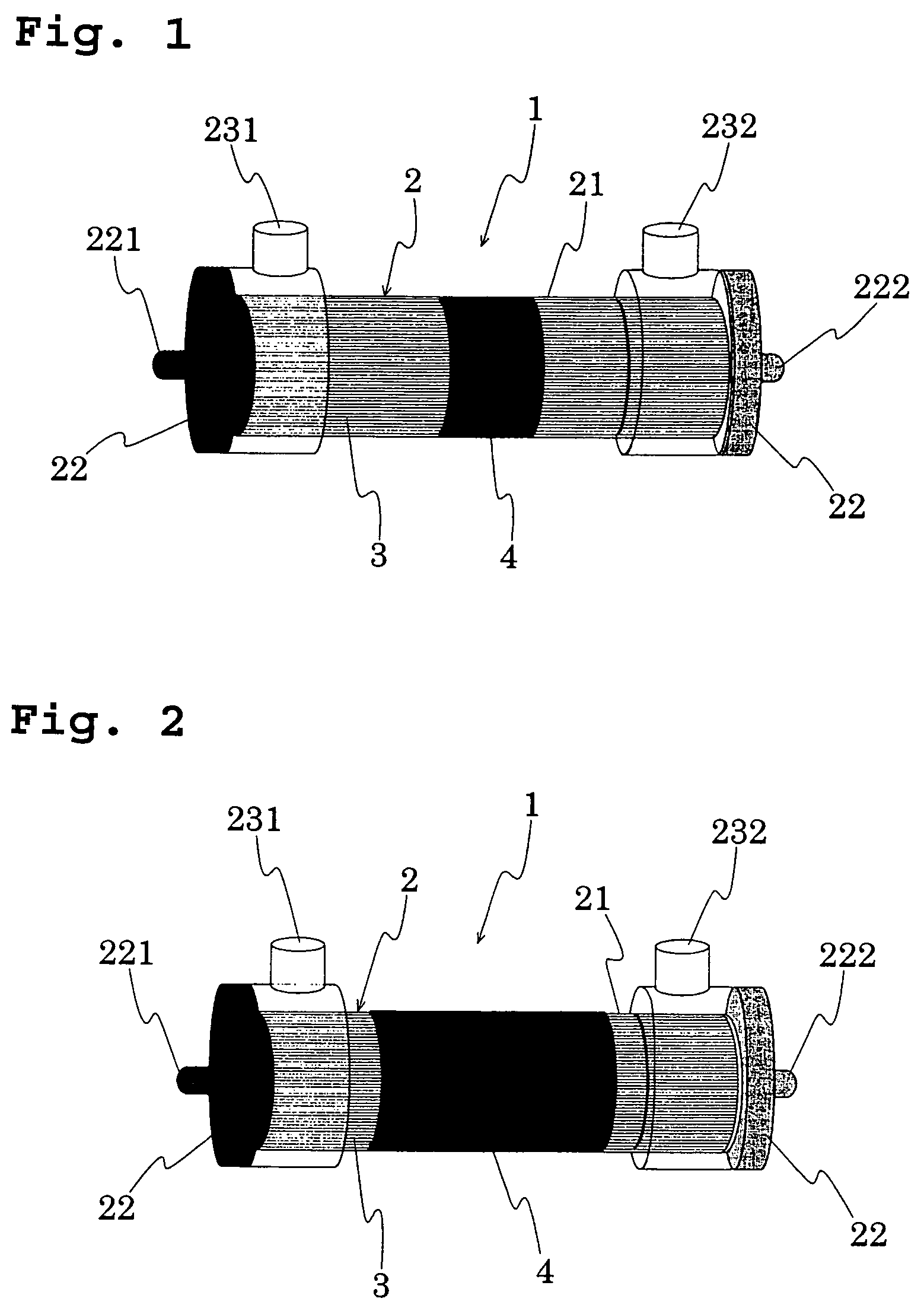

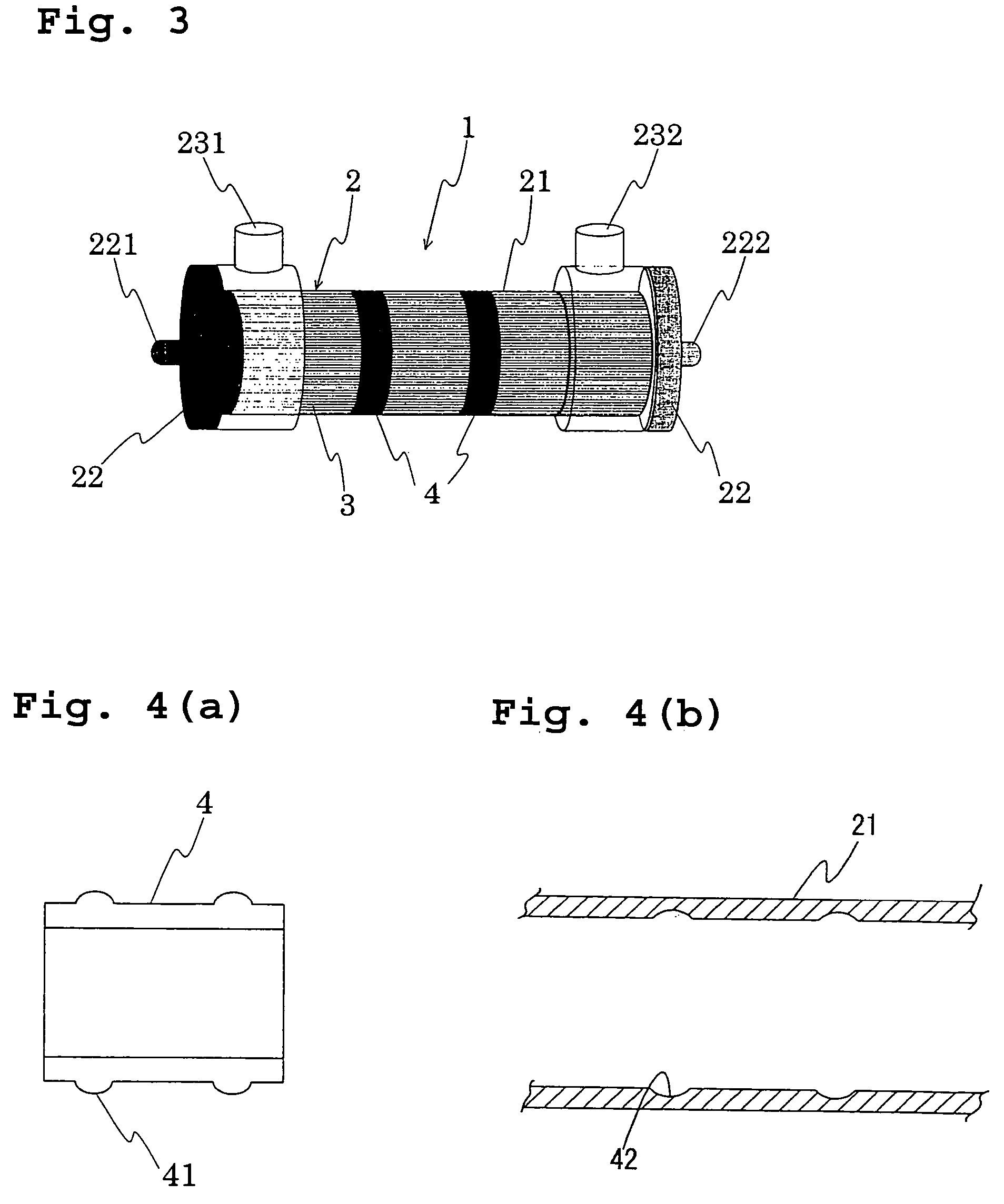

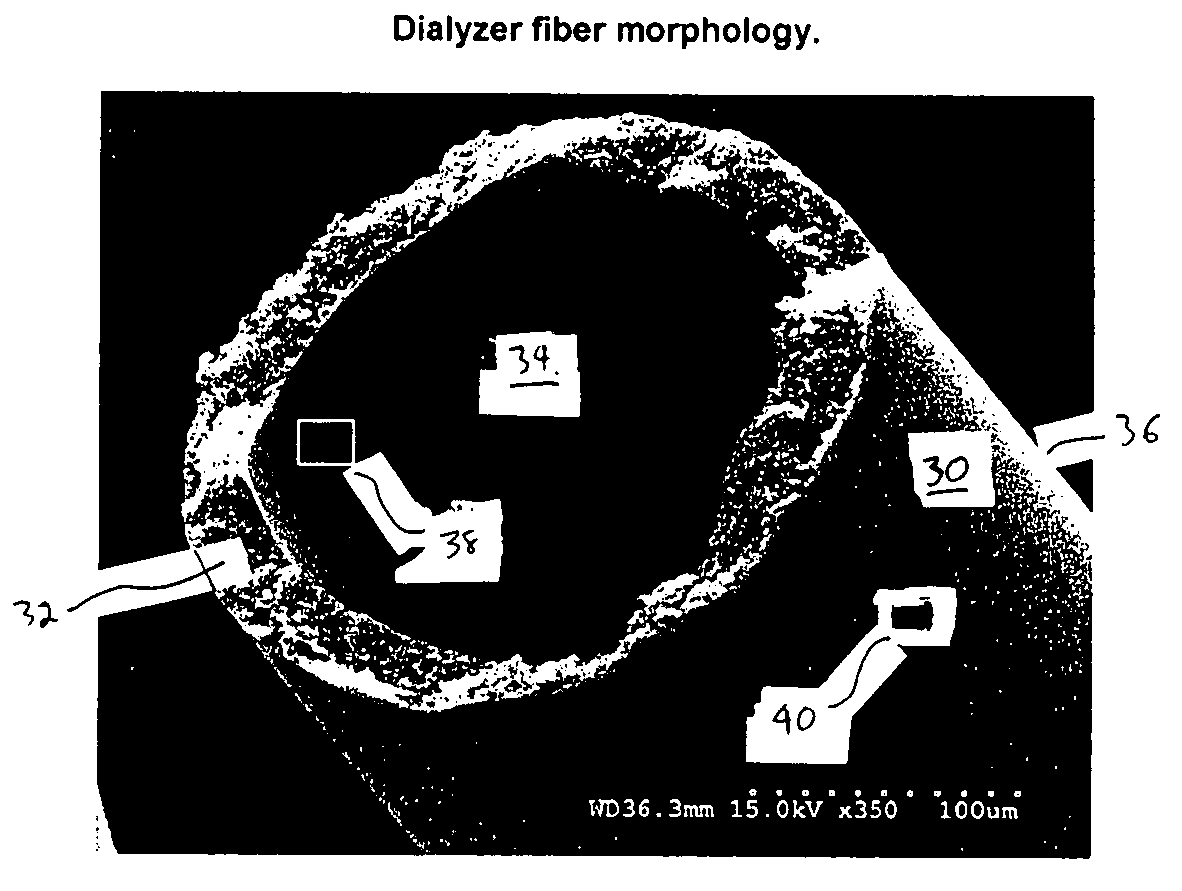

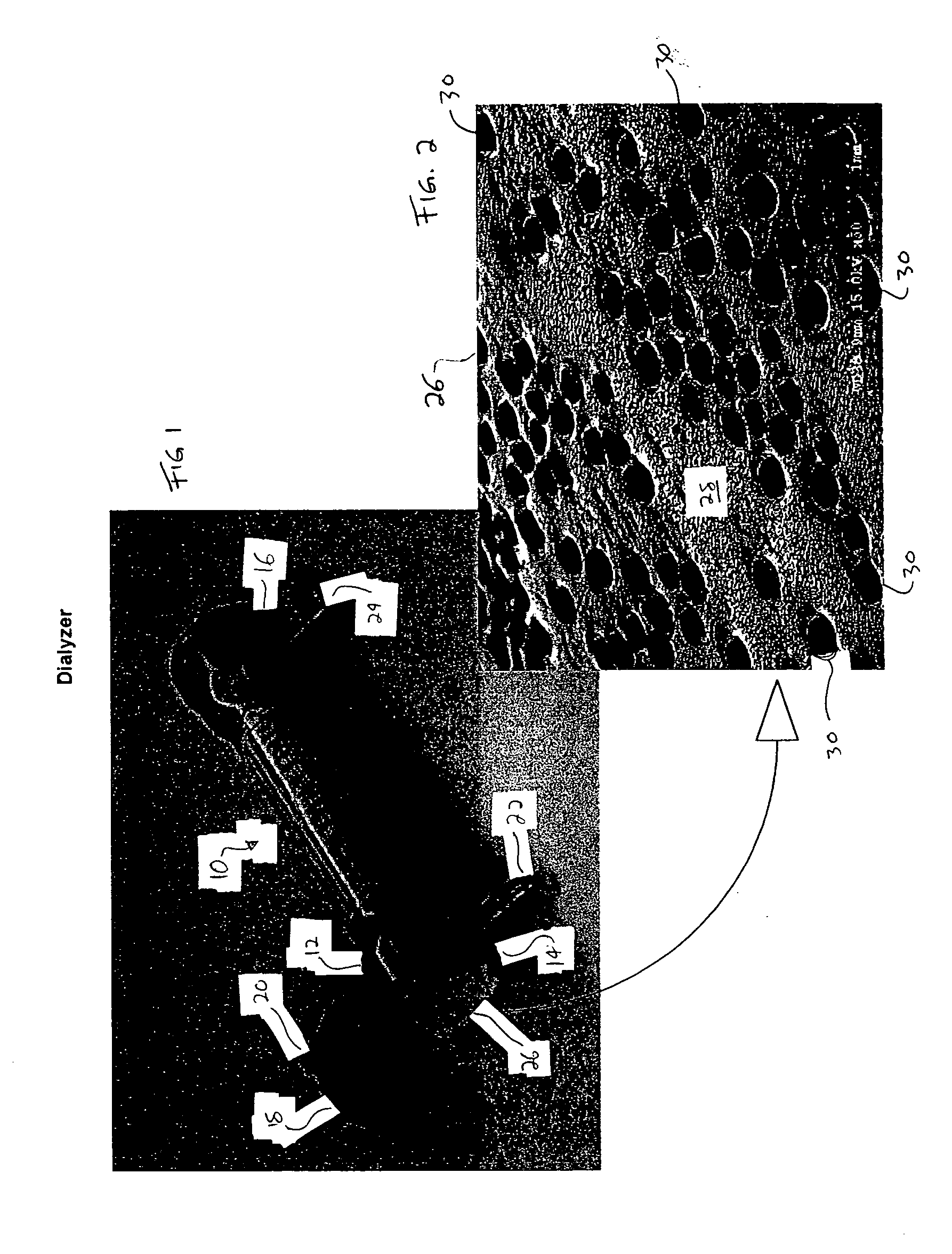

Dialyzer and method for manufacturing the same

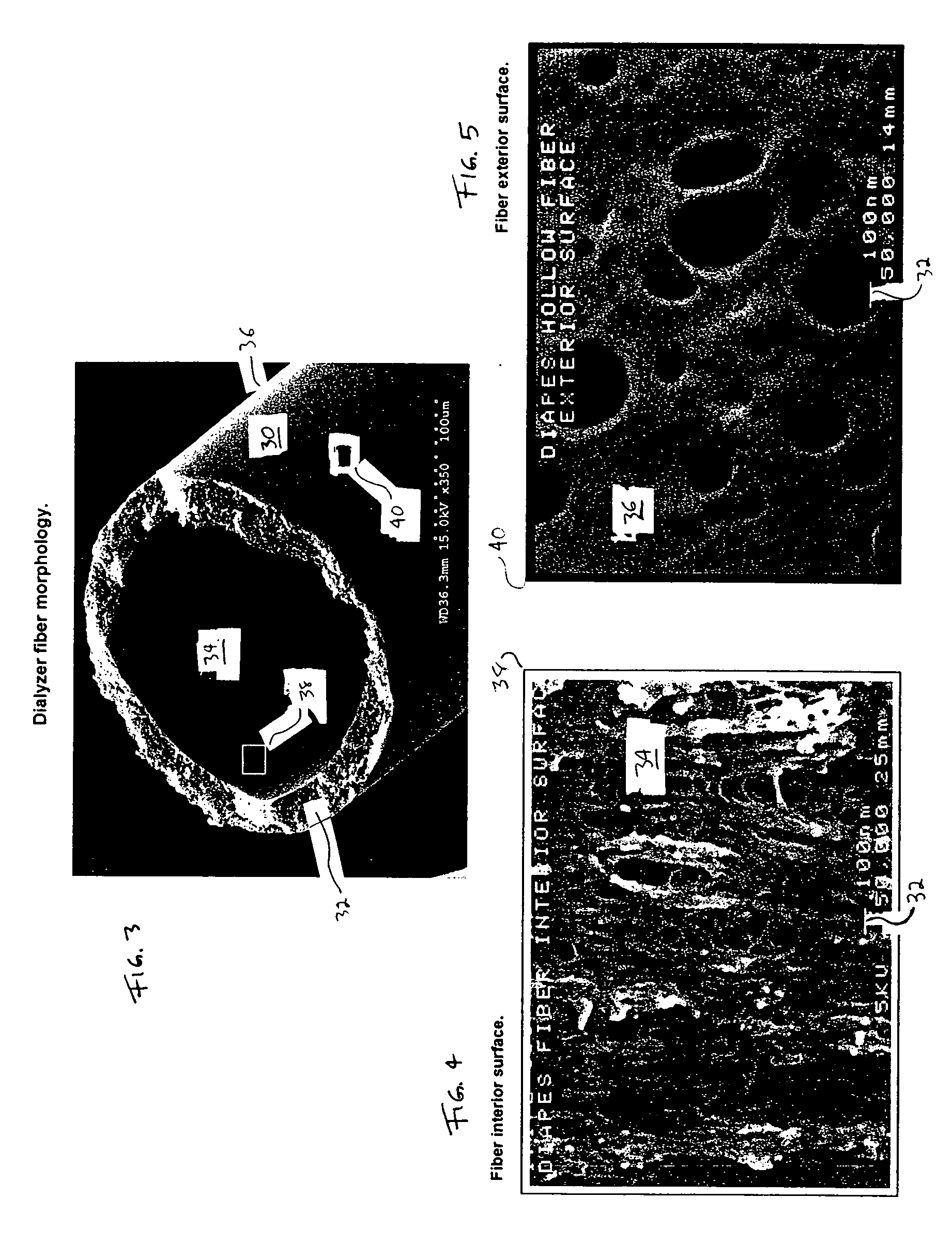

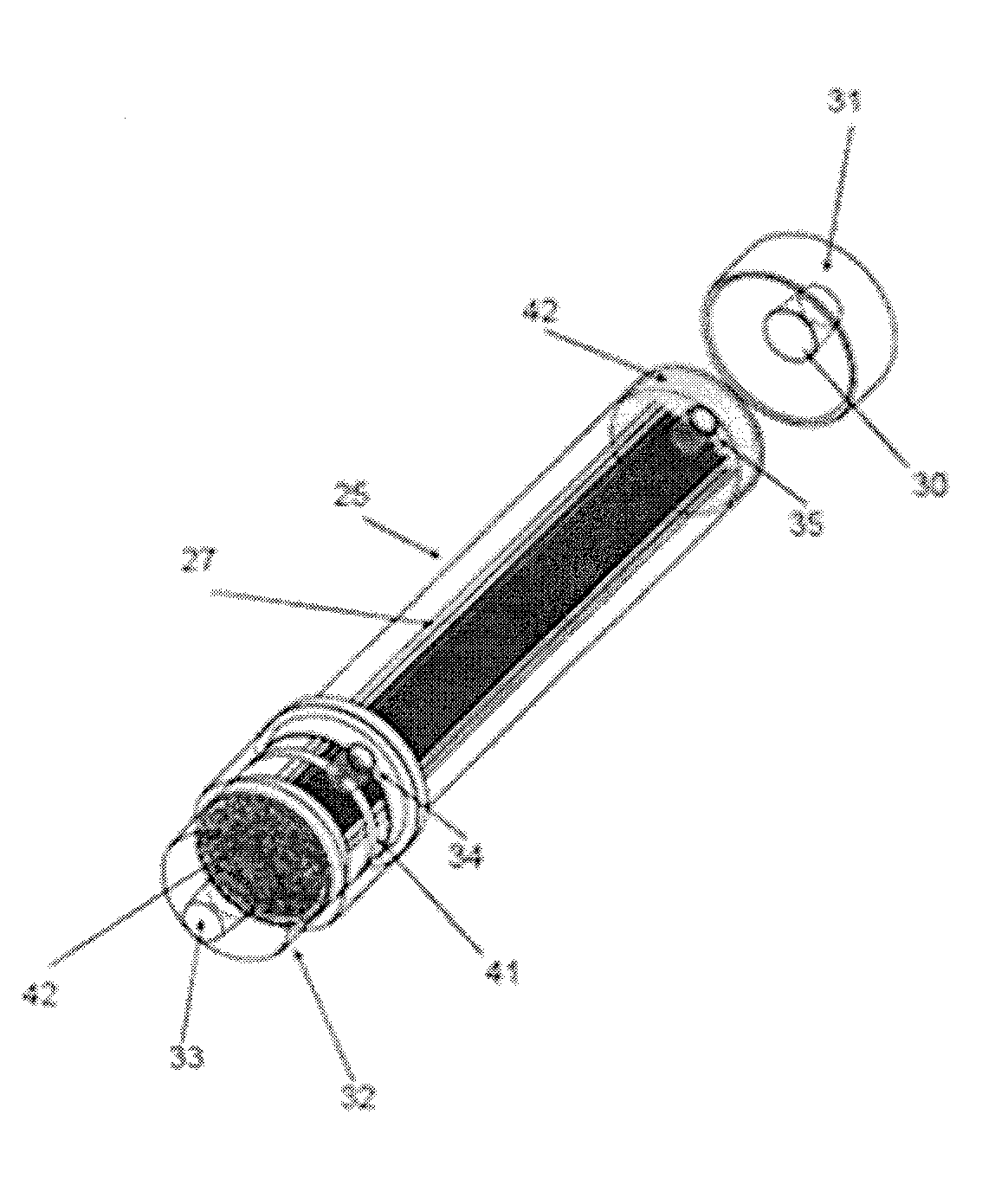

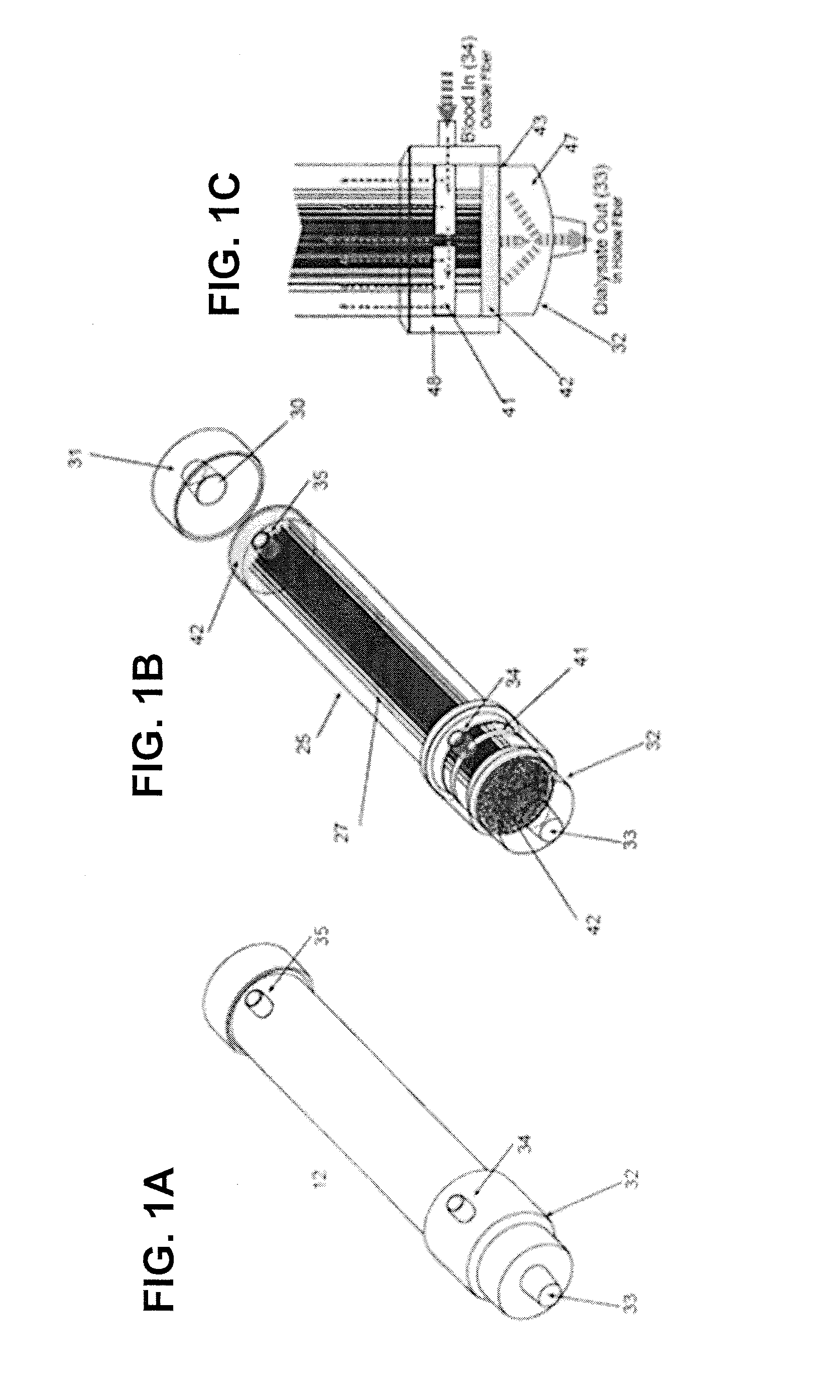

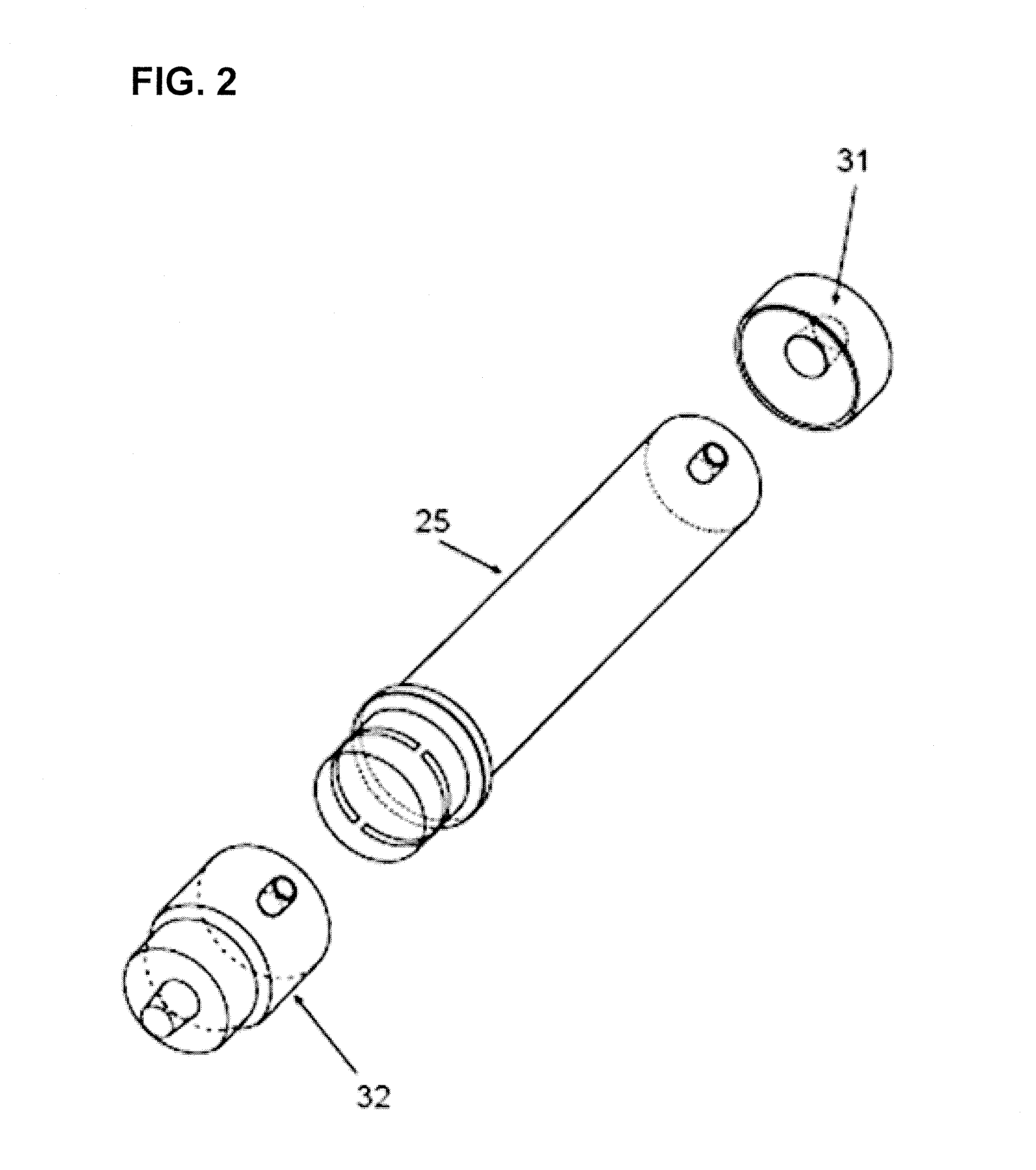

ActiveUS7524417B2Reduce the cross-sectional areaOptimize volumeMembranesHaemofiltrationHollow fibreFiber bundle

A dialyzer including a substantially cylindrical case 2, a hollow fiber bundle 3 made of a plurality of hollow fiber membranes provided in the case 2, a blood flow path formed by lumens of the hollow fiber membranes, a dialysate flow path formed by a gap between the inner wall of the case 2 and the hollow fiber membranes, and a cylindrical elastic tube 4 inserted in the gap between the inner wall of the case 2 and the hollow fiber bundle 3.

Owner:NIPRO CORP

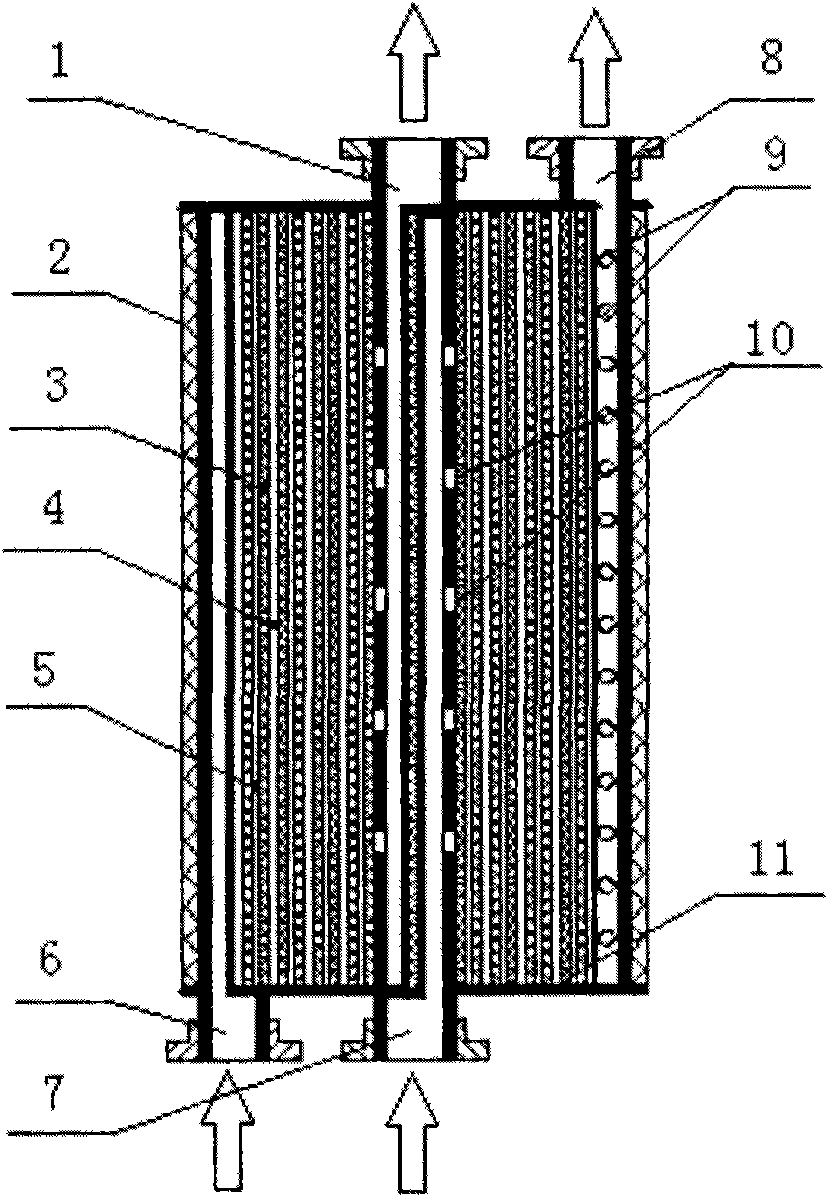

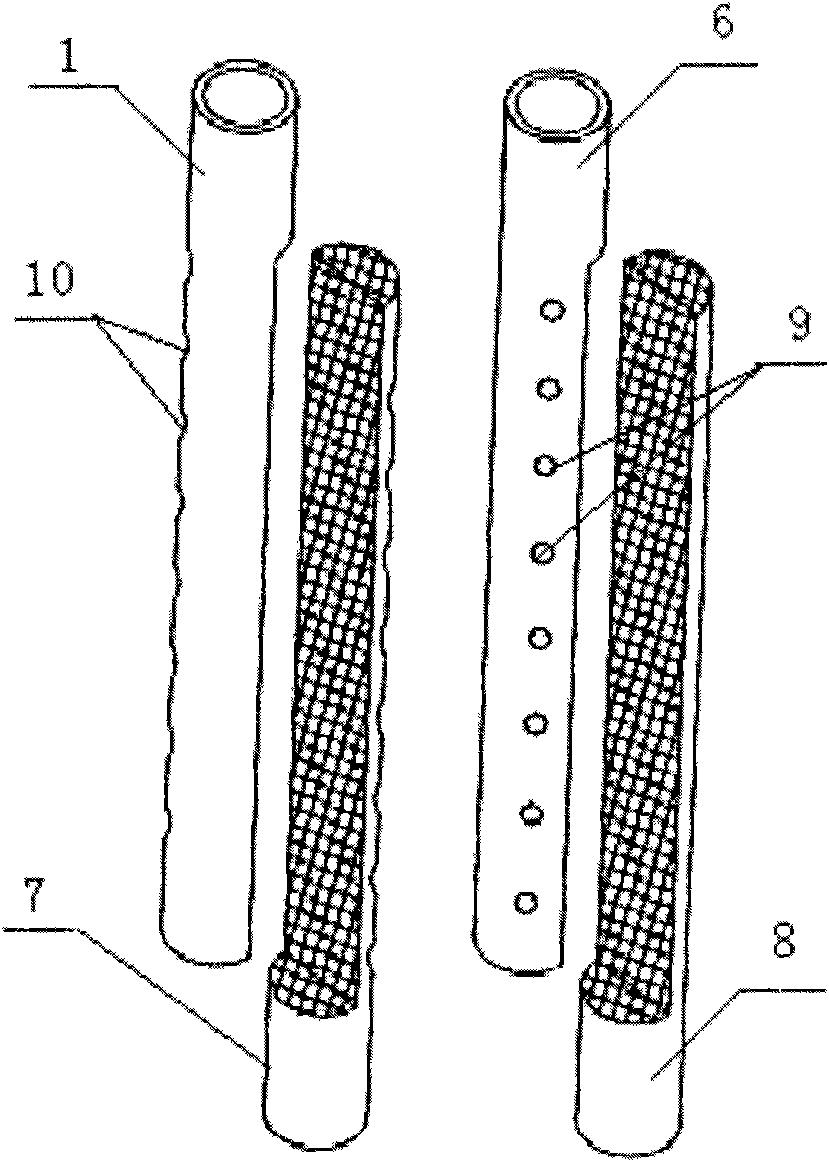

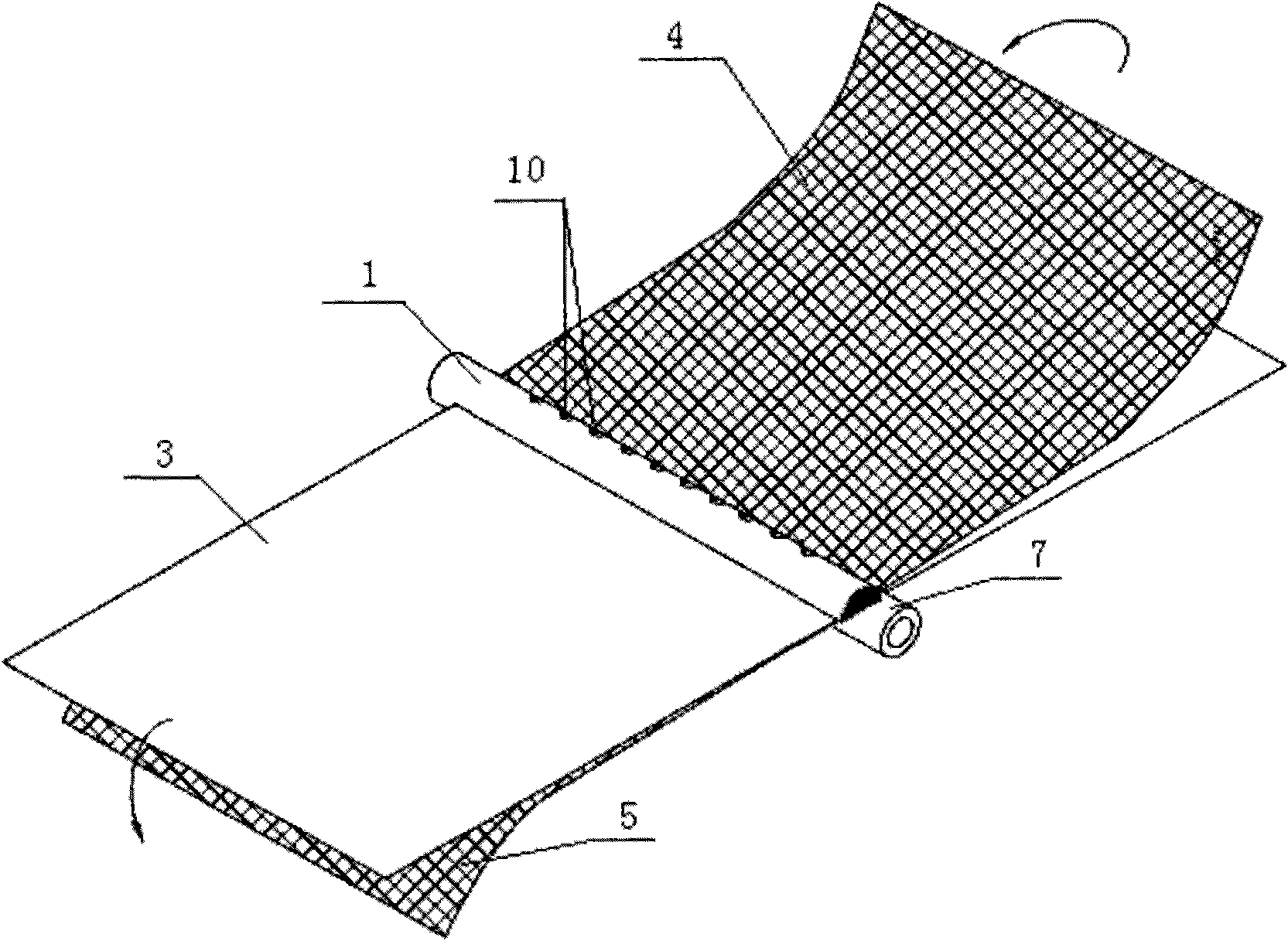

Spiral coil type diffusion dialysis membrane assembly and preparation method thereof

ActiveCN101983756AImprove performanceIncrease the average concentration differenceDialysisDialysis membranesCounter flow

The invention discloses a spiral coil type diffusion dialysis membrane assembly and a preparation method thereof. The spiral coil type diffusion dialysis membrane assembly is characterized in that an ion exchange membrane is clamped between two central tubes, runner screens on two sides mutually and tightly adhere for surrounding the central tubes to coil together according to same direction and are stuck on the axial edge to be sealed into a cylinder; the tail end of the ion exchange membrane forms two tangential runner openings which are radially symmetrical on the outer edge of the cylinder, and a side flow tube is sticked, sealed and fixed respectively by two openings; then the whole cylinder including the side flow tube is tightly wound and fixed by a plastic membrane to form a membrane core, the membrane core is put into a cylindrical shell, and two tips are cast and fixed by adhesive to form the spiral coil type diffusion dialysis membrane assembly with four inlet and outlet adapters. The equipment is compact, has big packing density, can be vertically assembled to occupy small space, can realize the radial spiral counter flow of diffusion liquid and dialysate flow, has big turbulence degree, high mass transfer efficiency and large feed liquid treatment capacity on unit membrane area and is easy to integrate with other reaction or separation equipment.

Owner:HEFEI CHEMJOY POLYMER MATERIALS CO LTD

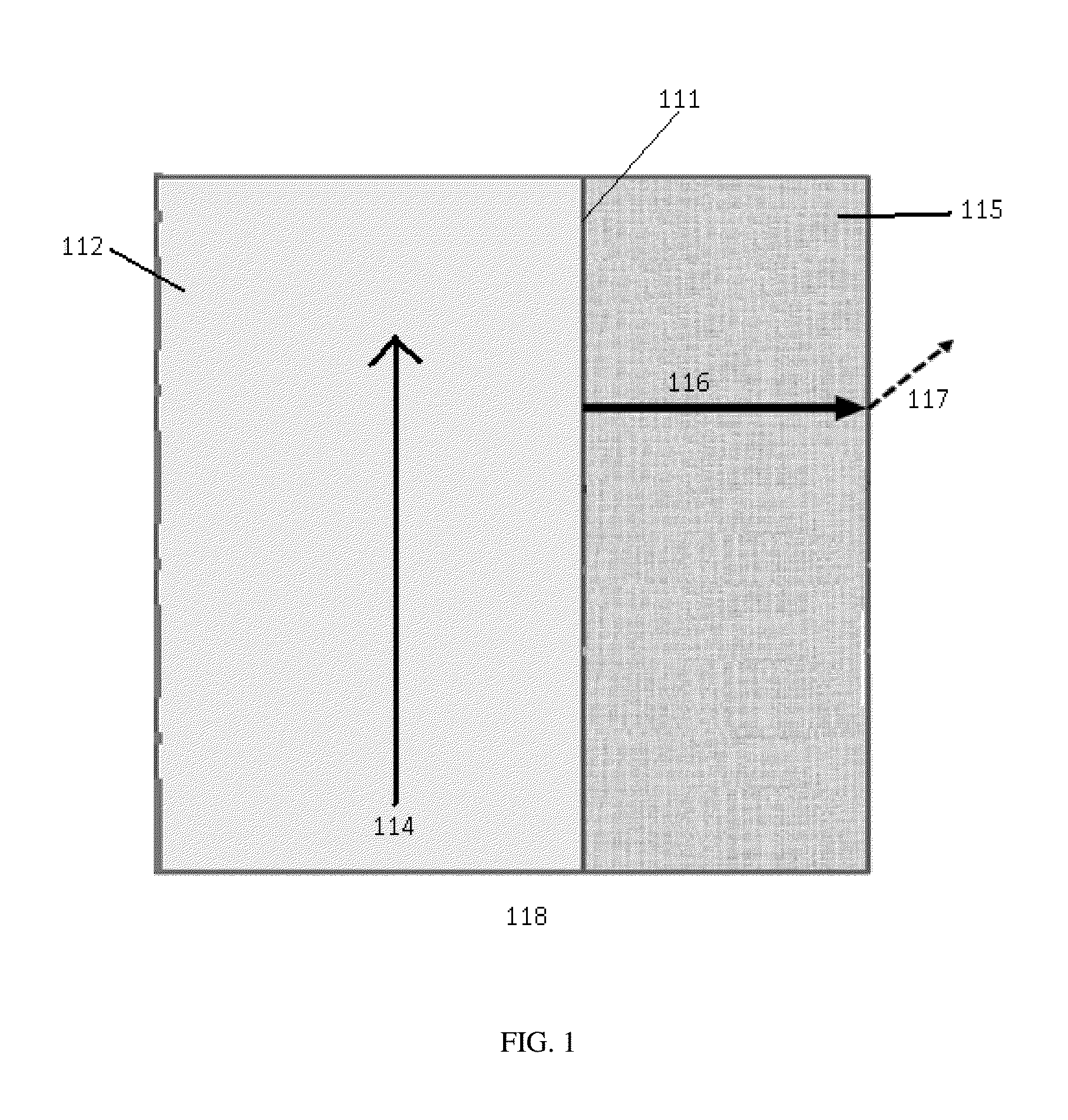

Degassing membrane for dialysis

The degasser can have a degassing membrane that can be constructed from non-porous silica. The degassing membrane can be highly permeable to carbon dioxide but less permeable oxygen or nitrogen gases. Pressure in the dialysate and the degasser can be controlled in order to control the amount of carbon dioxide and other gases in dialysate leaving the degasser. The degassing membrane may be placed in a degassing module in a dialysate flow path to remove dissolved carbon dioxide from the dialysate.

Owner:MOZARC MEDICAL US LLC

Water management system for use in dialysis

A water management system for use in dialysis. The water management system includes apparatuses to generate purified water, and a reservoir for storing the purified water. The reservoir can be connected to a dialysate flow loop and the purified water can be generated, stored, and used for later cleaning and disinfection of the dialysis flow loop and the components thereon.

Owner:MOZARC MEDICAL US LLC

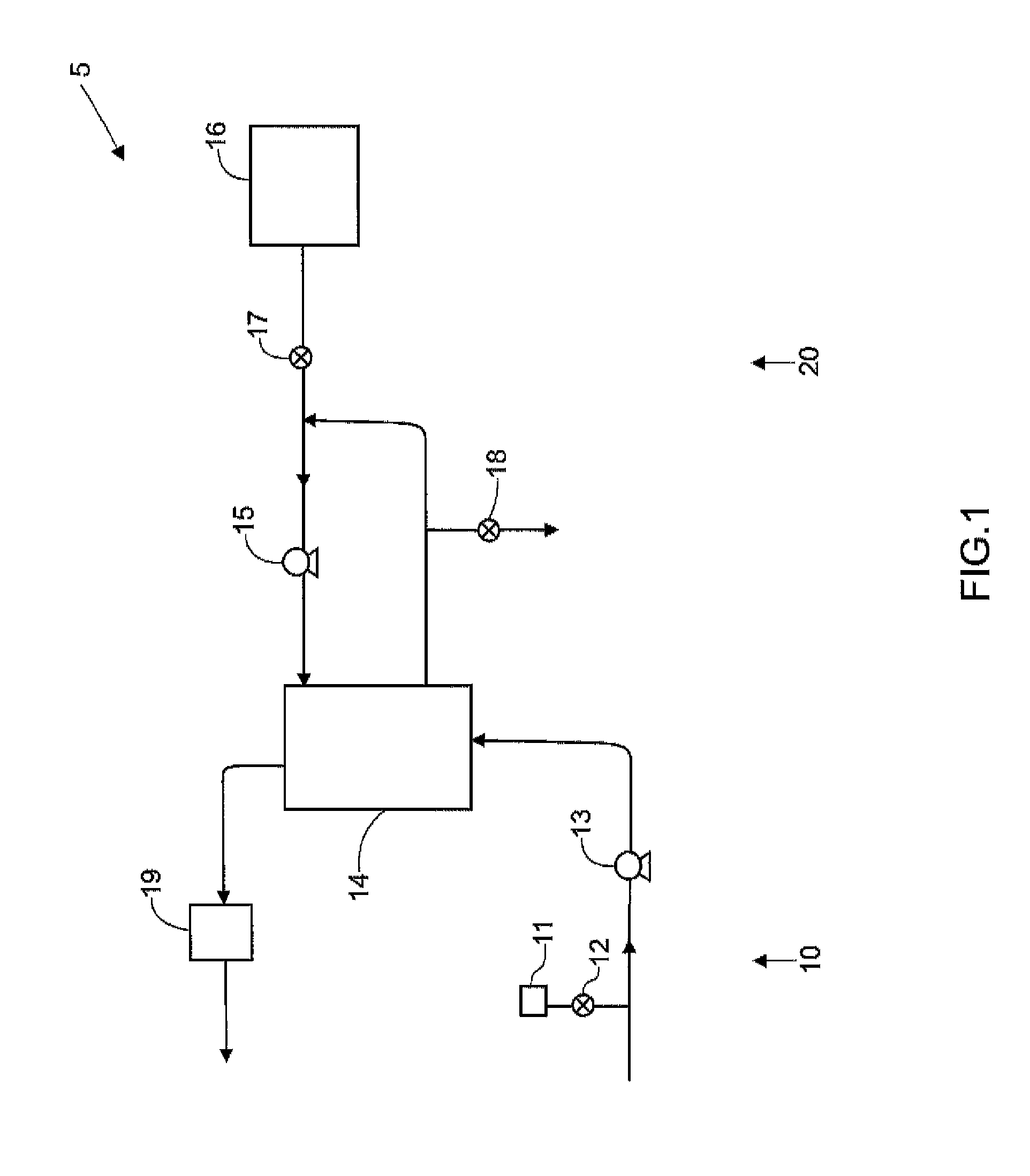

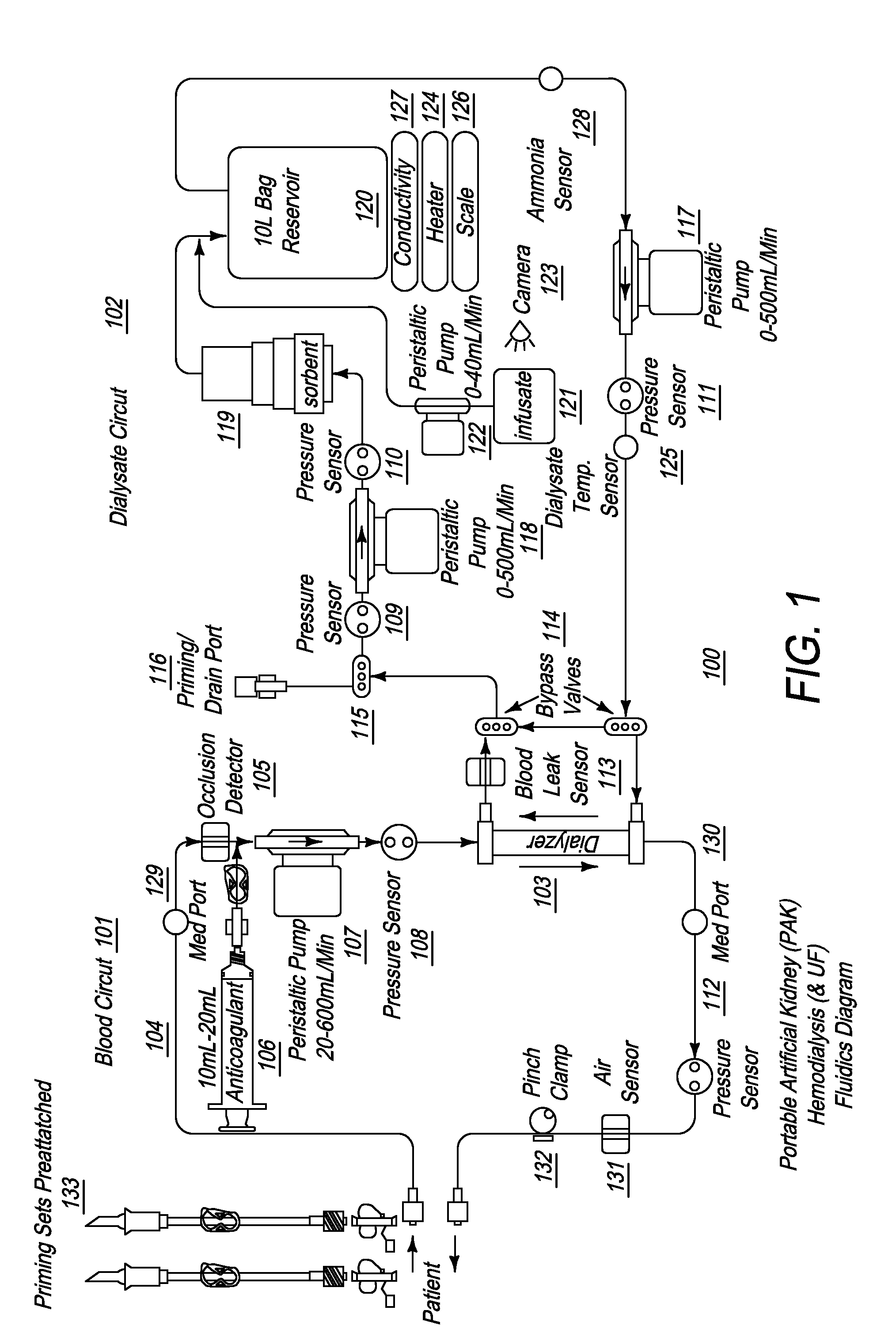

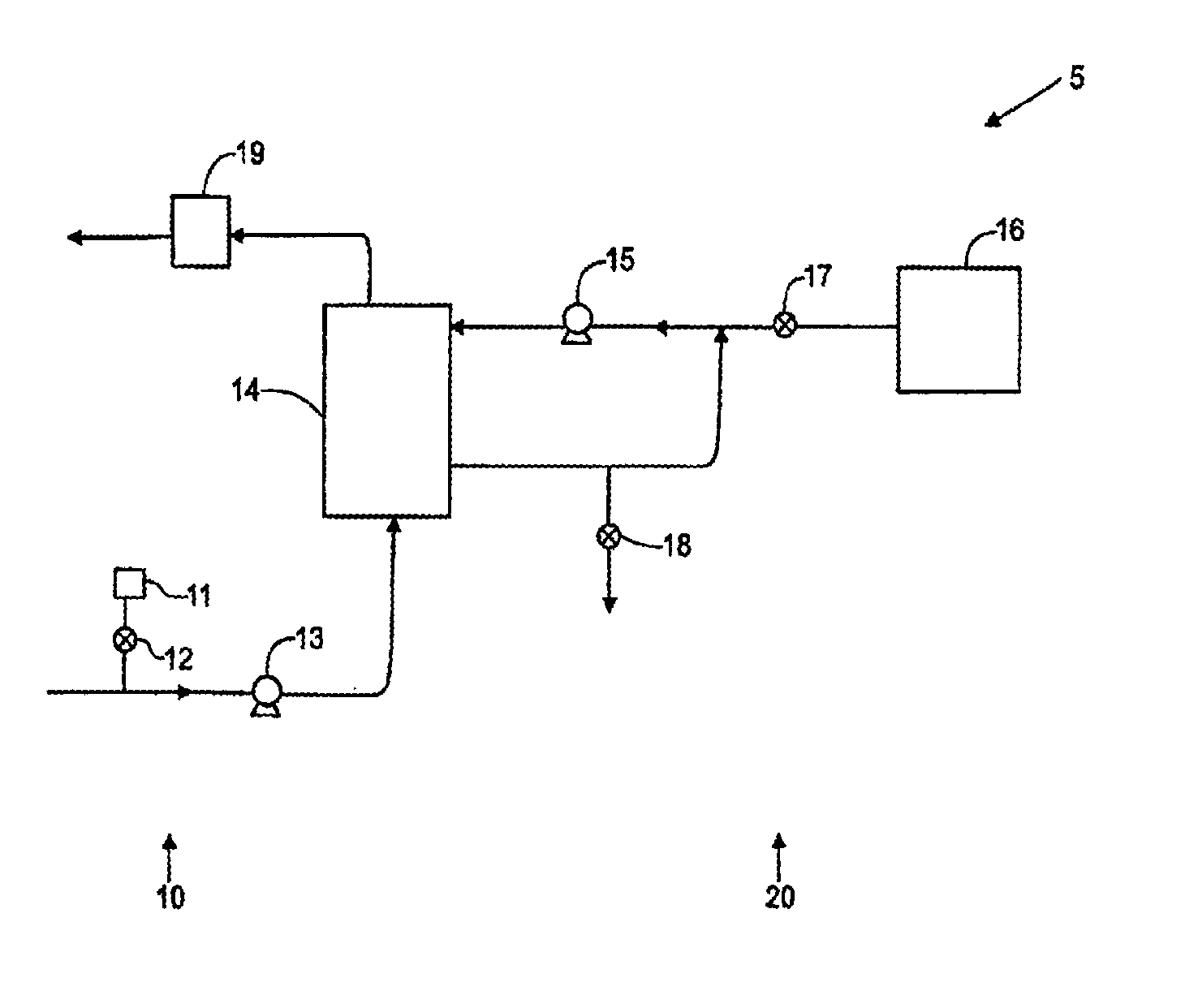

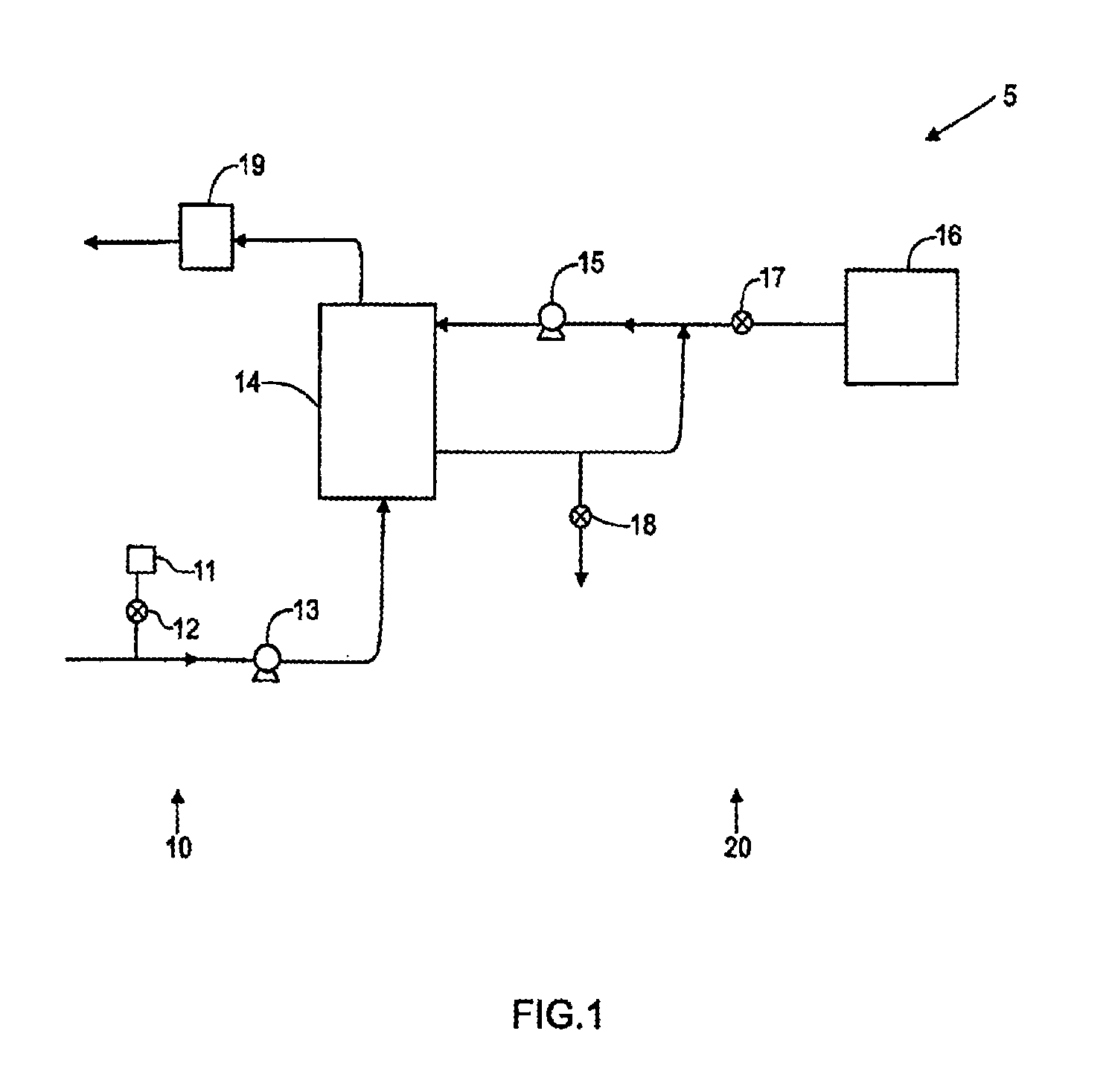

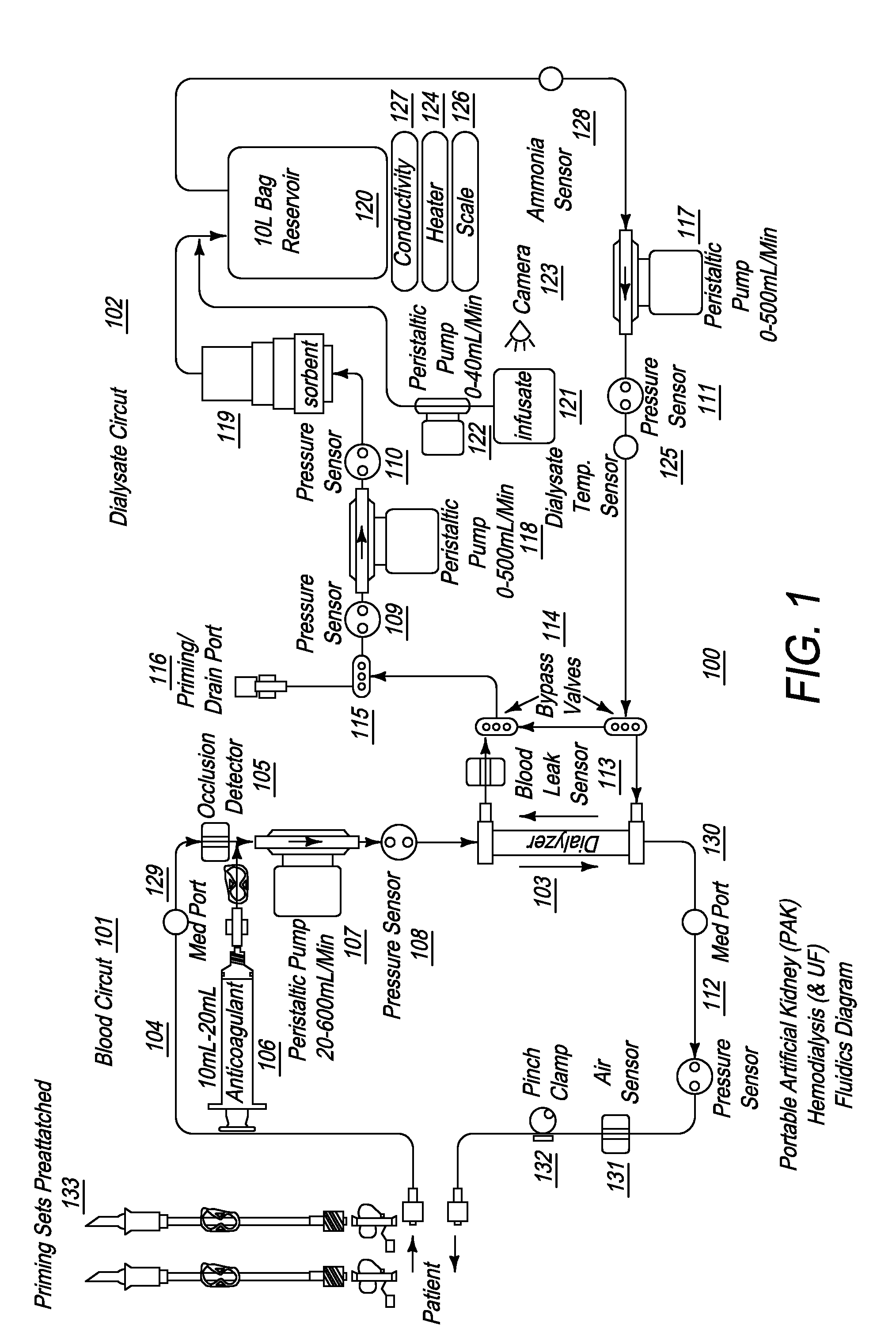

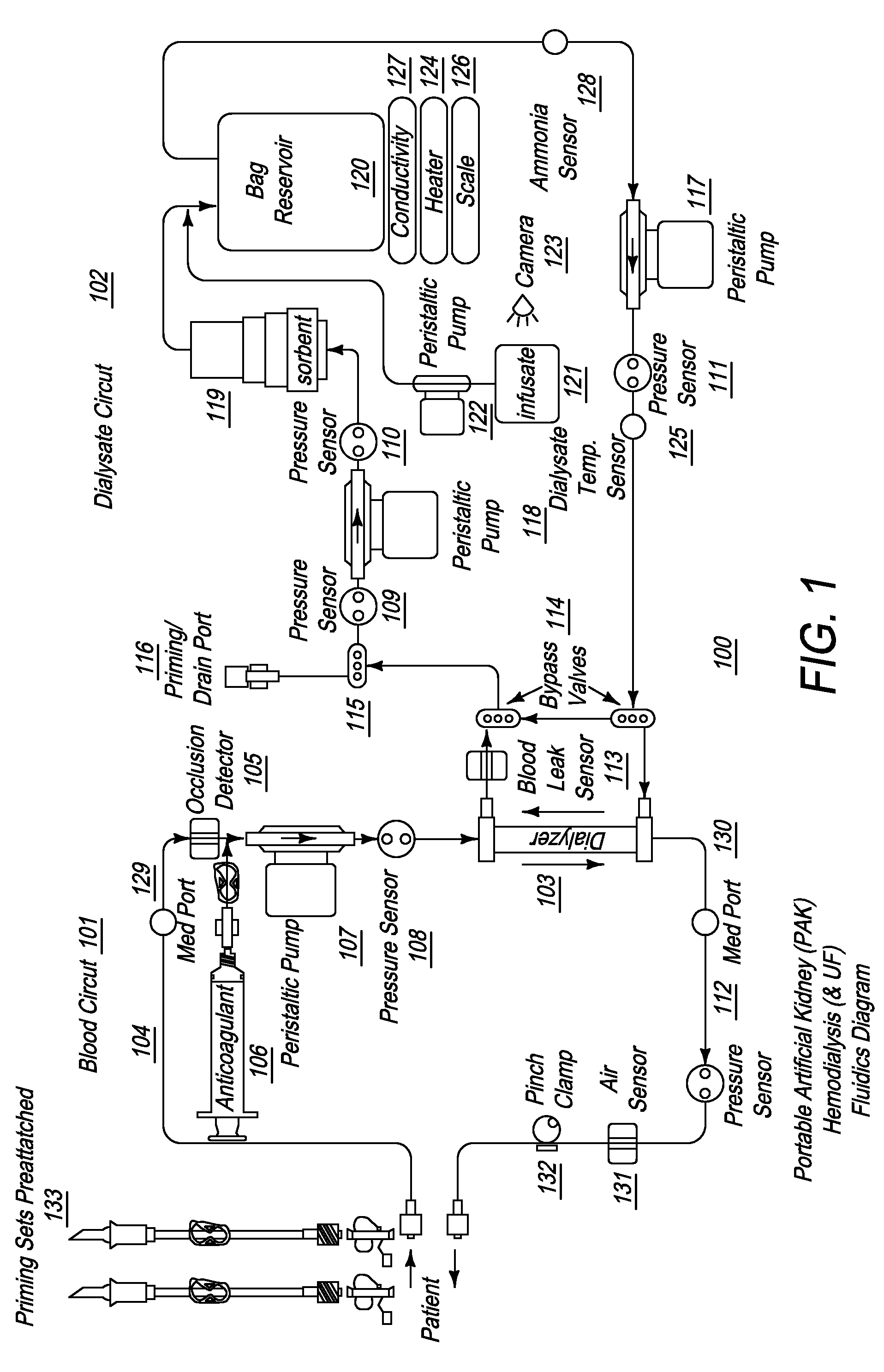

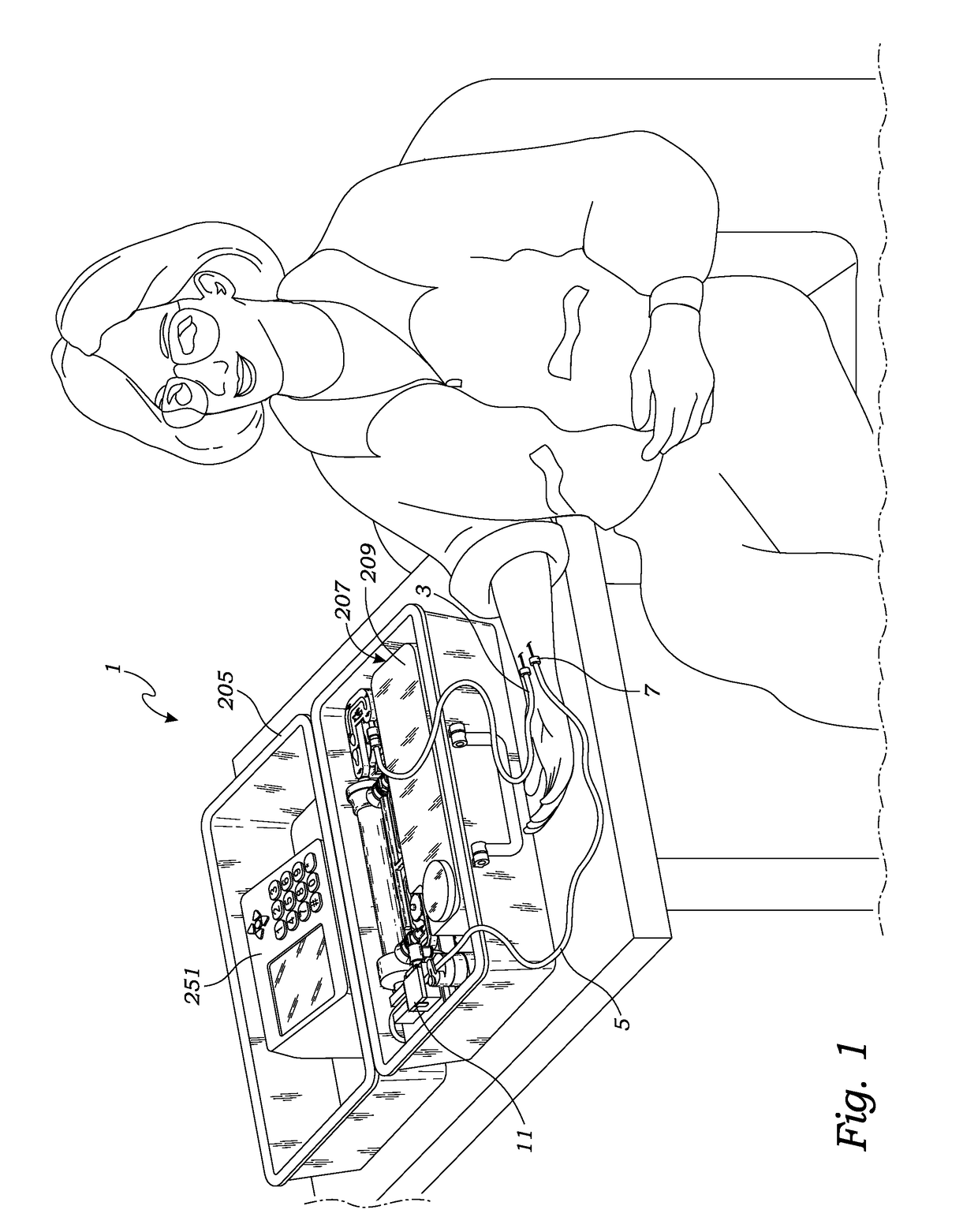

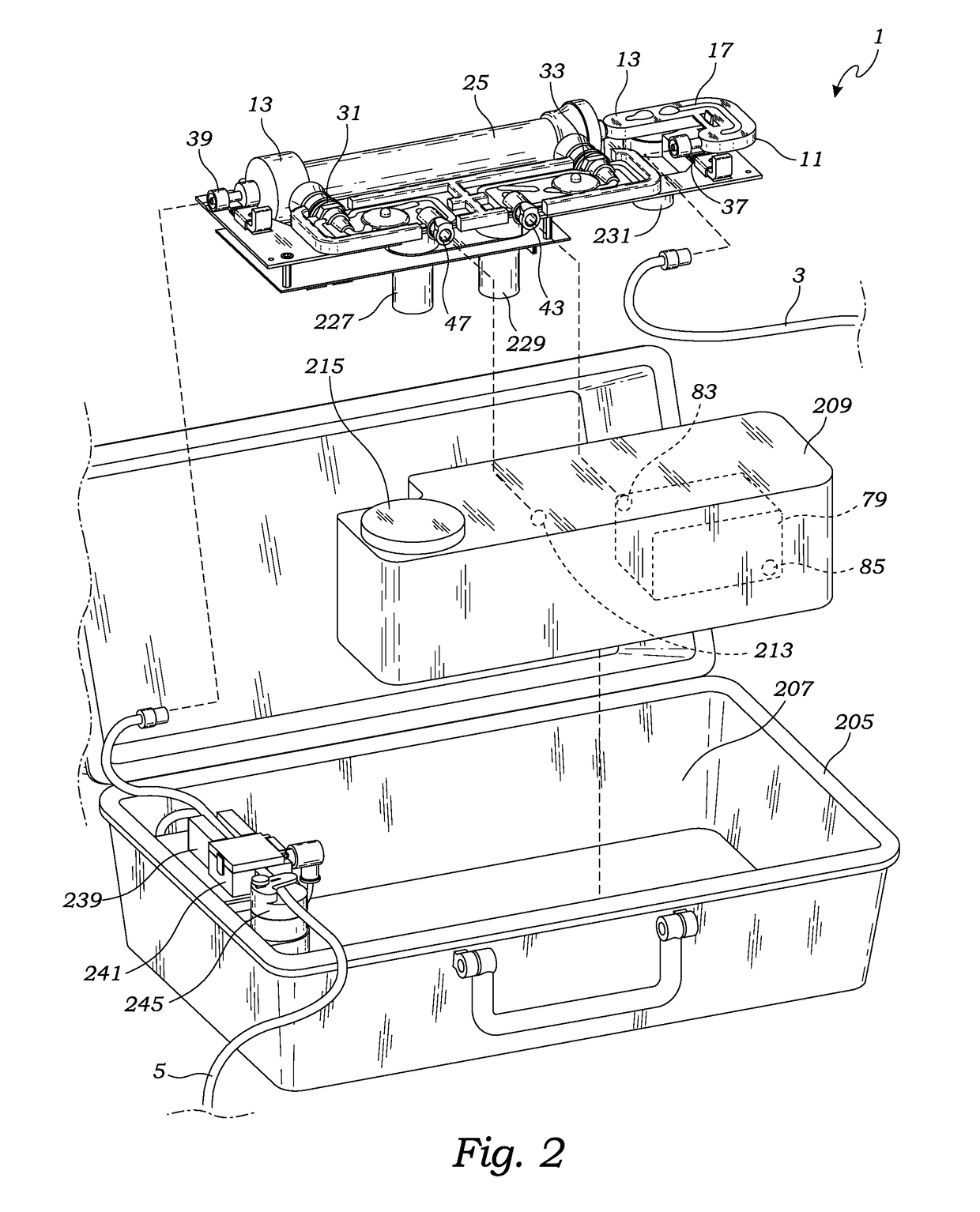

Portable hemodialysis machine and disposable cartridge with flow sensor

ActiveUS20160074565A1Reduce areaImprove patient safetyDialysis systemsMedical devicesHaemodialysis machineMedicine

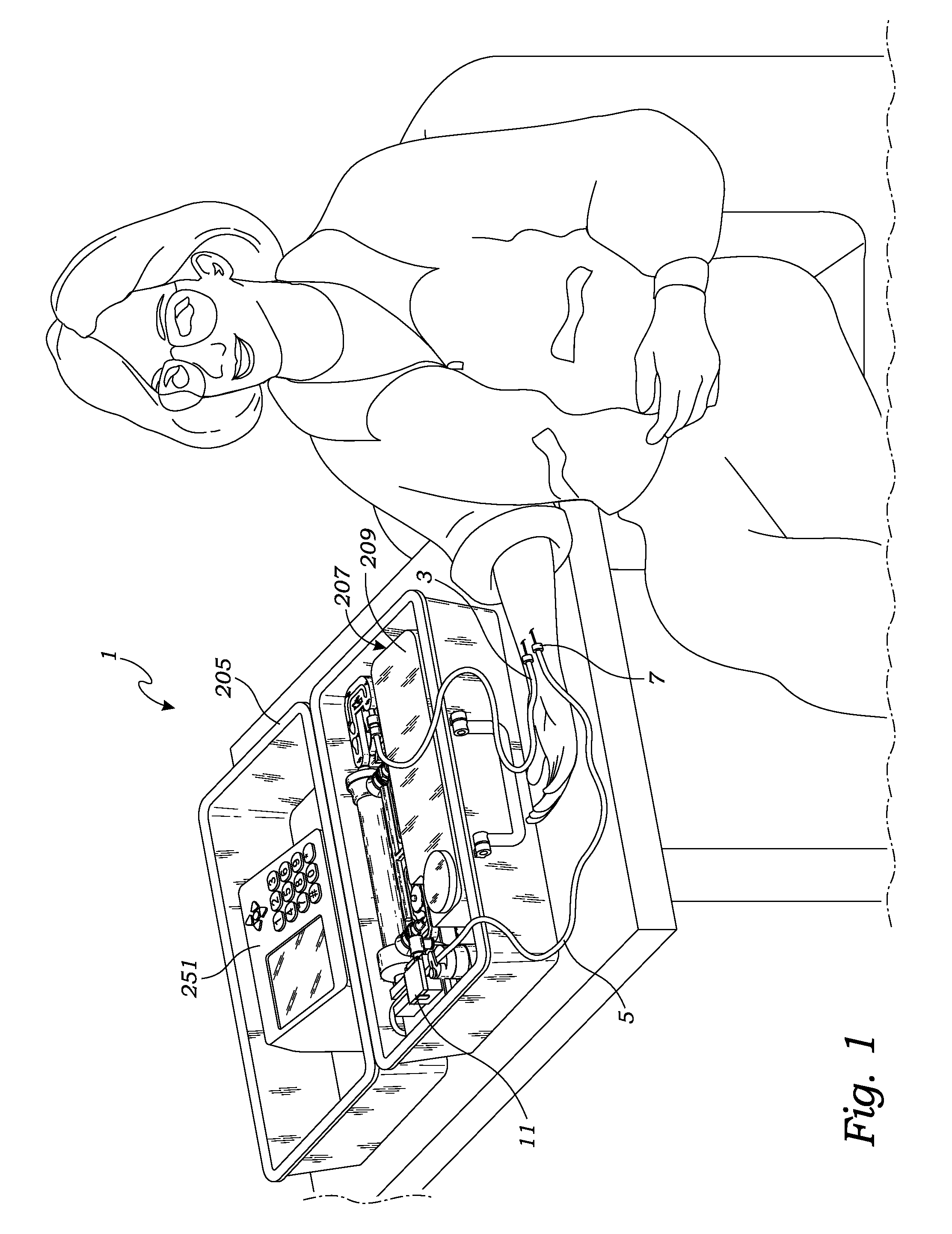

A portable hemodialysis system is provided including a disposable cartridge and a reused dialysis machine. The disposable cartridge includes a dialysate flow path and a blood flow path which flow in opposite directions through a dialyzer. The disposable cartridge further includes a filter for removing waste products from the dialysate as well as one or more flow sensors for measuring the flow of dialysate in the dialysate flow path. The preferred flow sensor includes a rotatable spoked wheel in the dialysate flow path which is rotated by the flow of dialysate. The spoked wheel includes one or more magnets which are rotated with the rotation of the spoked wheel. The flow sensor further includes a magnetic field sensor in the reused dialysis machine which is connected to a processor for monitoring the rotation of the spoked wheel to determine flow of fluid in the dialysate flow path.

Owner:DIALITY INC

Blood dialysis apparatus

Provided is a hemodialysis apparatus which can fundamentally solve a problem in that air is trapped in a mesh disposed in a vein side chamber during priming. A hemodialysis apparatus includes control means that conducts, in the stated order: (A) a process in which a blood pump reversely rotates at the same speed as a reverse filtration speed made by third fluid feeding means, and a dialysate flows in a flow passage extending from a connection portion between a hemodialyzer and an artery side blood line to a vein side chamber through the joint portion in a loop formed by connecting the artery side blood line and the vein side blood line, to thereby prime the flow passage and the hemodialyzer, and (B) a process in which a reverse rotation speed of the blood pump is made lower than the reverse filtration speed made by the third fluid feeding means, and the dialysate of a flow rate corresponding to a speed obtained by subtracting the reverse rotation speed of the blood pump from the reverse filtration speed made by the third fluid feeding means flows in a flow passage extending from a connection portion between the hemodialyzer and the vein side blood line to the vein side chamber, which is a remaining flow passage of the loop, to thereby prime the flow passage and the hemodialyzer.

Owner:JMS CO LTD +1

Apparatus for extracorporeal blood treatment, comprising a measuring device for determining the luminescence of the spent dialysate

InactiveUS20130153474A1Easy and reliable determinationAdequate successSemi-permeable membranesDialysis systemsBlood treatmentsMedicine

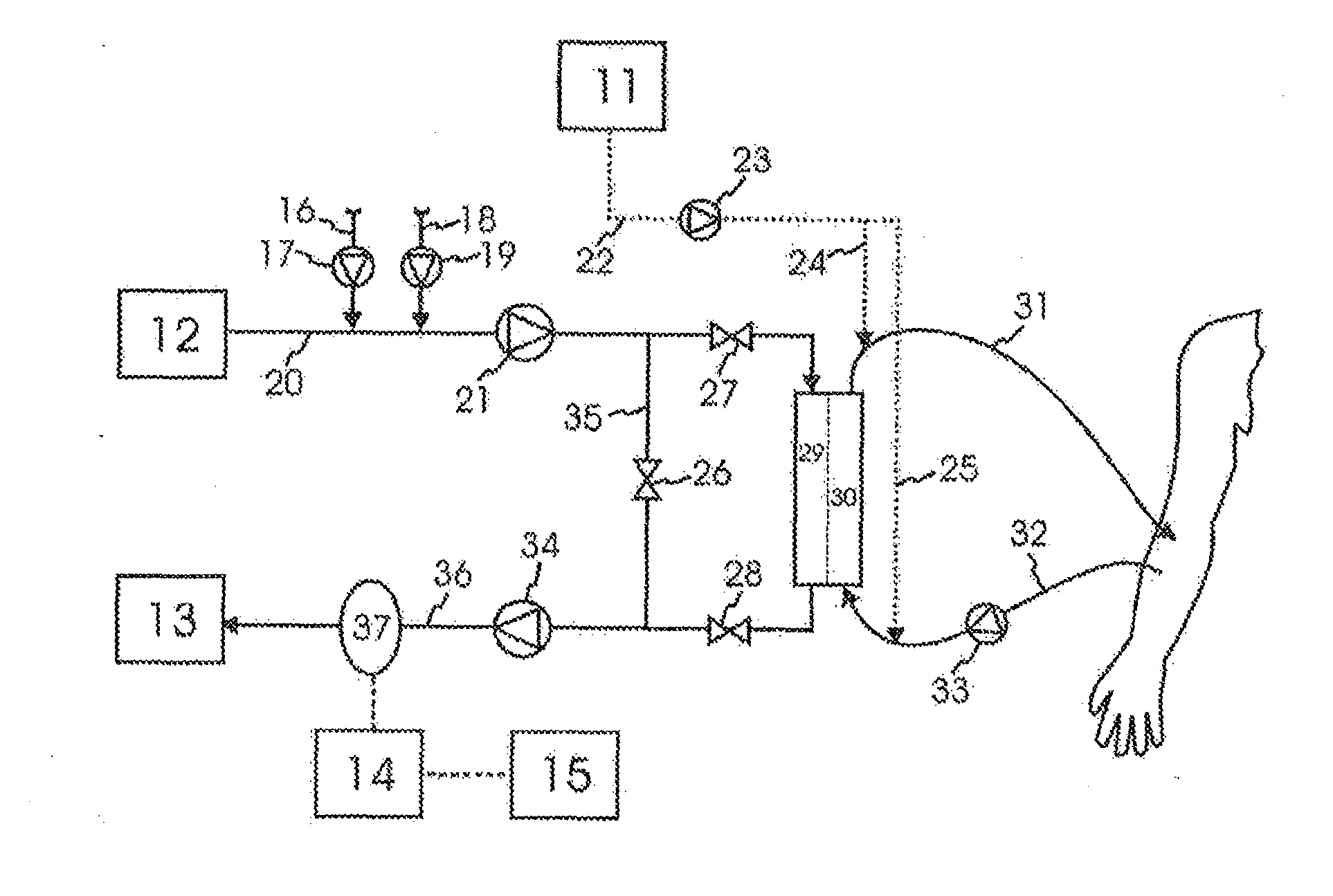

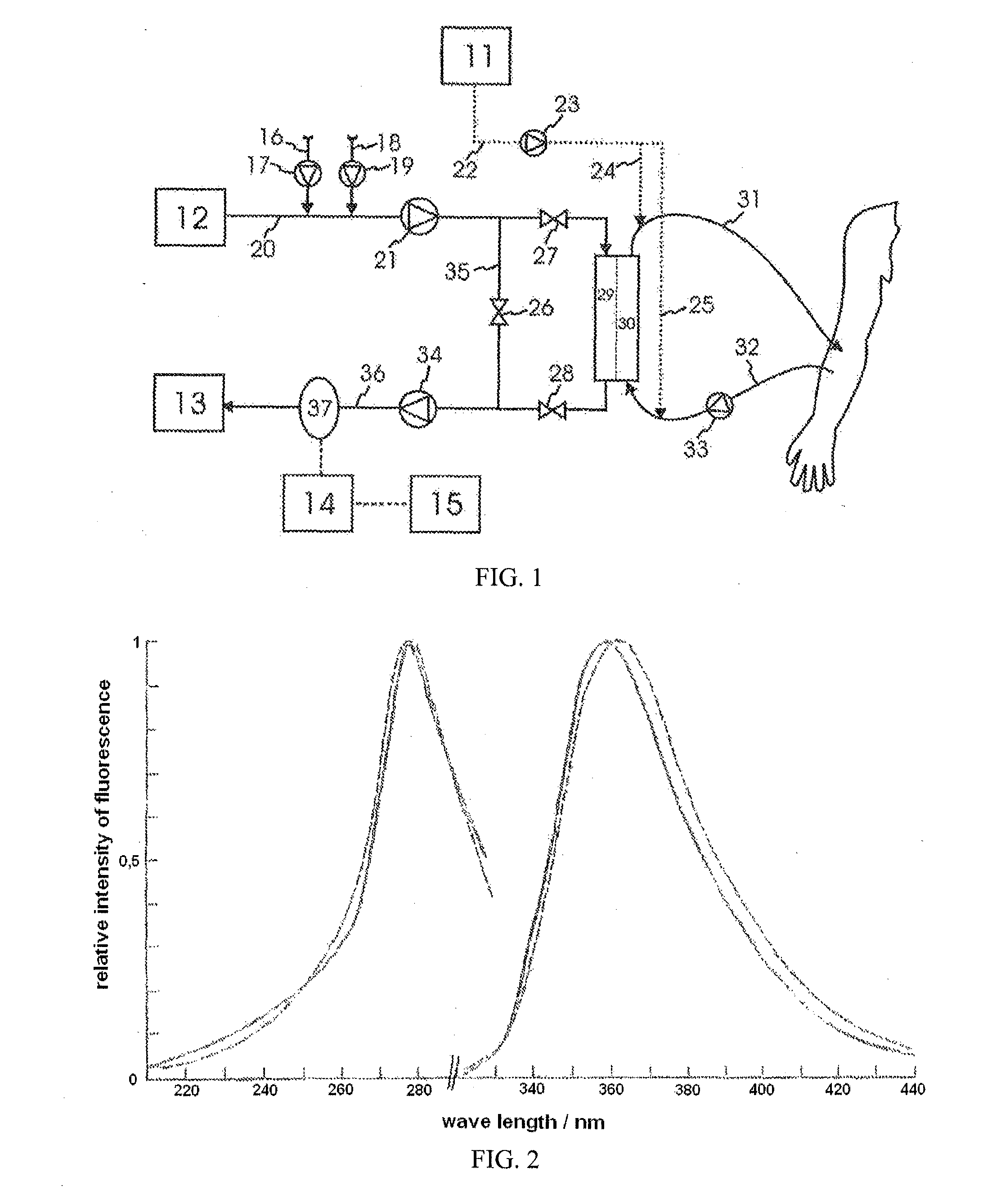

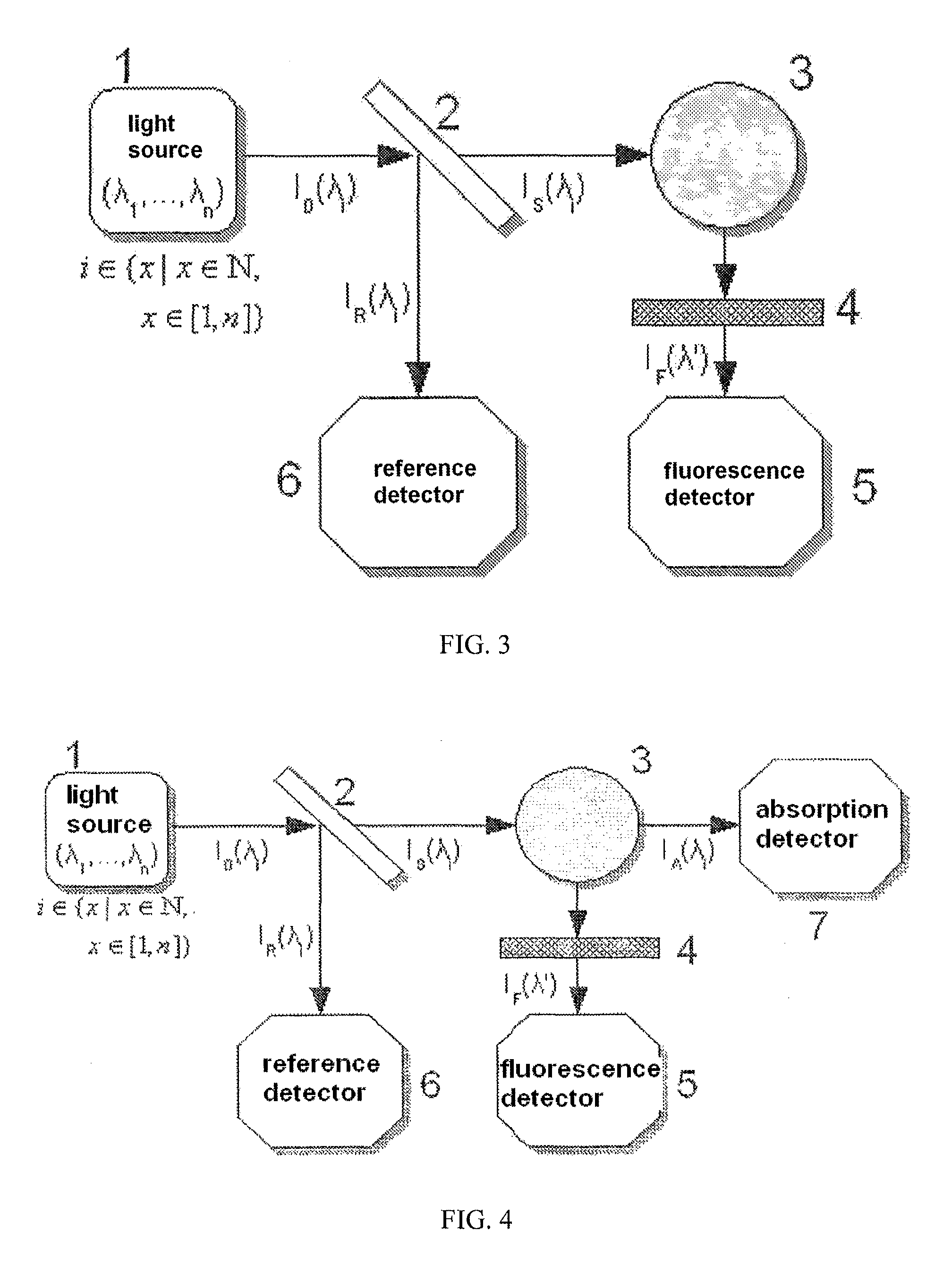

The invention relates to an apparatus for extracorporeal blood treatment having a dialyzer which is divided into a first and a second chamber 29, 30 by means of a semipermeable membrane wherein the first chamber 29 is arranged in a dialysate path and the second chamber 30 can be connected to a patient's blood circulation by means of a blood supply line 32 and a blood discharge line 31, an inlet 20 for fresh dialysate, an outlet 36 for spent dialysate, a measuring device 37, wherein the measuring device 37 has at least one radiation source 1 for substantially monochromatic electromagnetic radiation. Thereby the measuring device 37 for determination of a luminescence of the spent dialysate flowing through the outlet 36 has at least one detector system (5) for detecting the intensity of the electromagnetic radiation generated by luminescence.

Owner:B BRAUN AVITUM

De-airing device for purifying blood

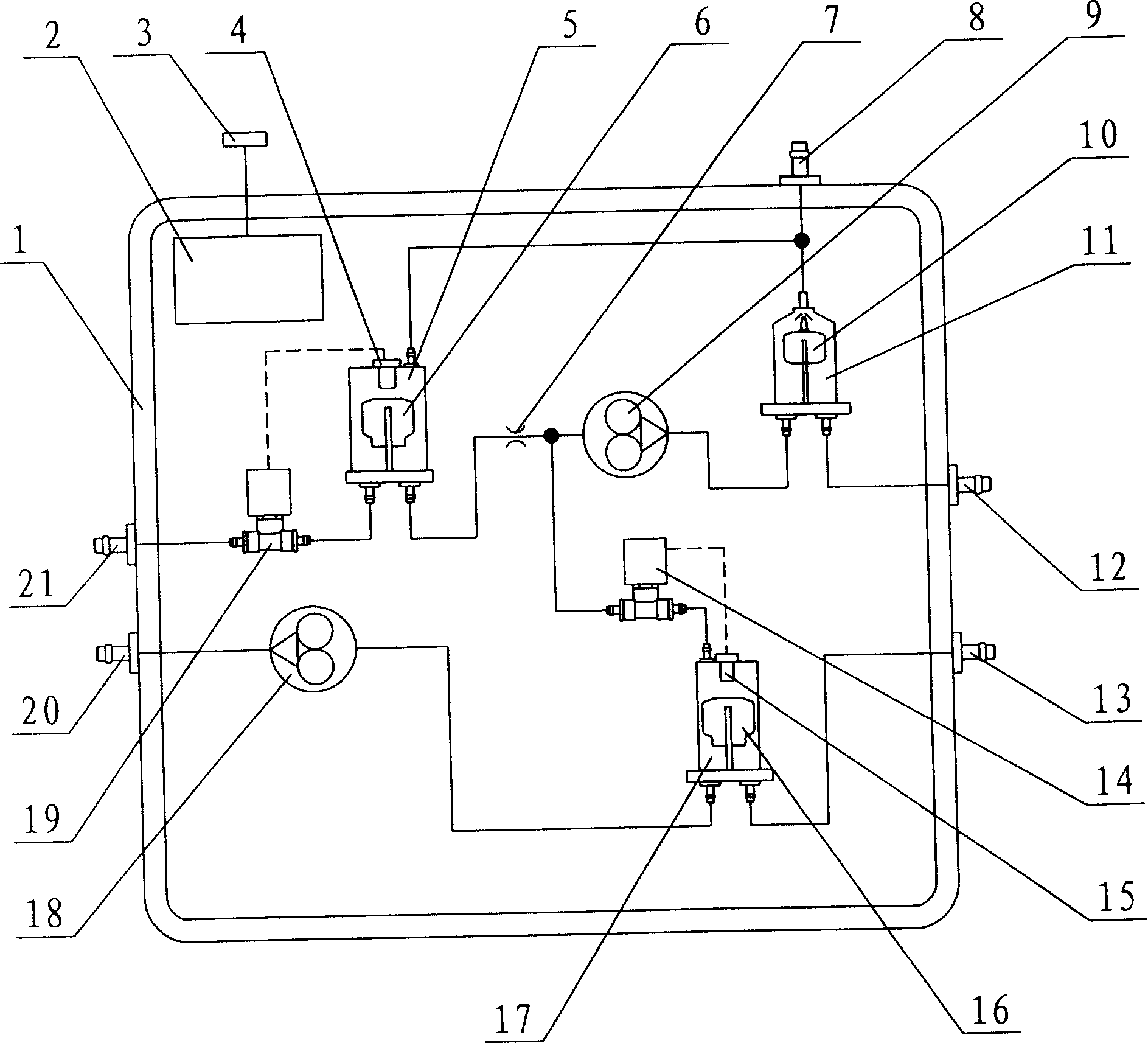

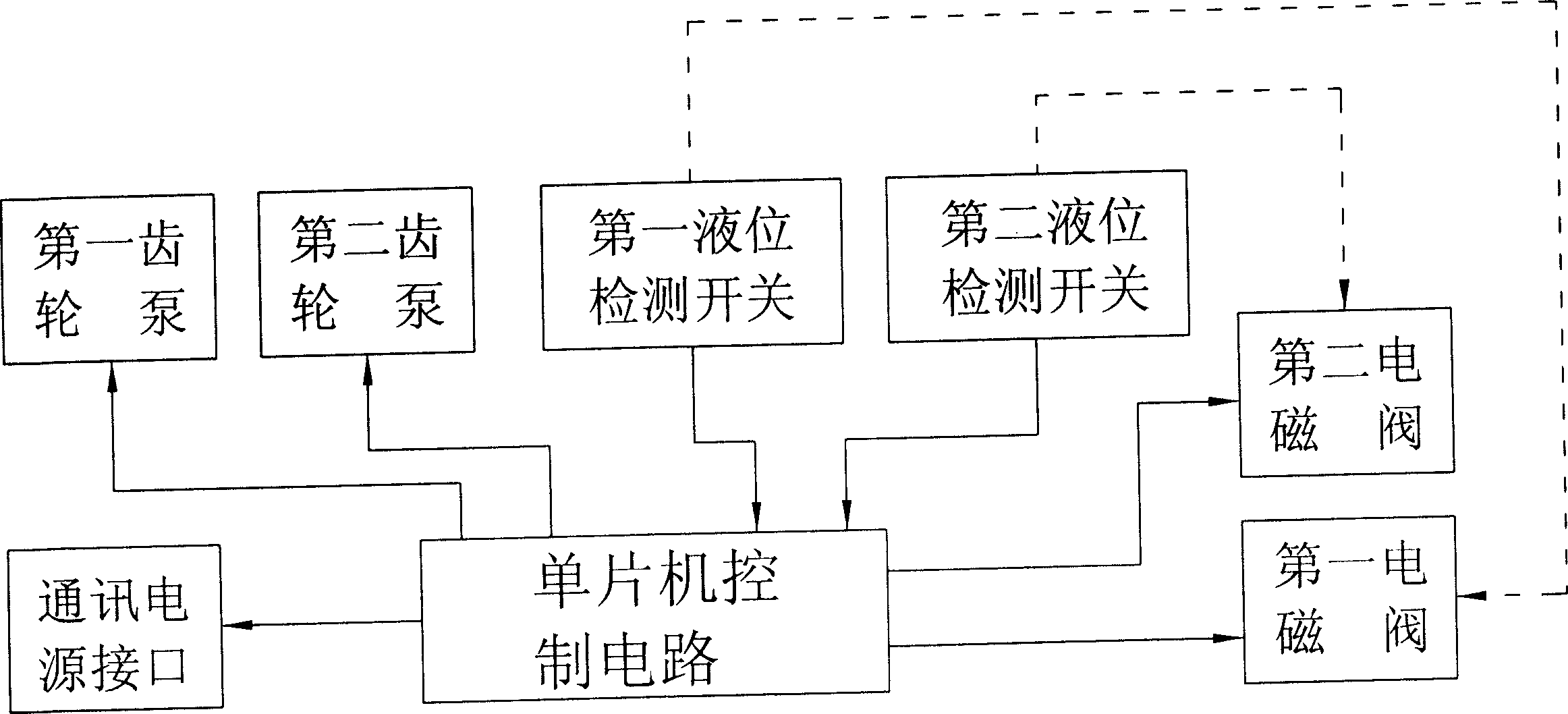

The de-airing device for purifying blood has one box with water inlet, water outlet, air exhaust, dialysate joint and waste liquid joint. The water inlet is connected to the liquid inlet of the flow controlling choke; the liquid outlet of the flow controlling choke is connected to two pipelines, including the first pipeline connected to the liquid inlet of the first de-airing tank via a gear pump and the second pipeline connected to the liquid exhaust of the second de-airing tank via a second solenoid valve; the liquid outlet and the air exhaust of the first de-airing tank are connected separately to the dialysis joint and the air exhaust joint pipeline; and the liquid inlet and the liquid outlet of the second de-airing tank are connected separately to the waste liquid joint pipeline and the water outlet joint via a second gear pump. The present invention can avoid air embolism to blood for normal dialysis treatment.

Owner:SWS HEMODIALYSIS CARE CO LTD

Dry aerosol leak detection for dialyzers

InactiveUS20050050943A1Fast response timeMinimize particle lossDetection of fluid at leakage pointSemi-permeable membranesFiberParticulates

The present invention provides a leak testing method and system therefore for any type of filtering device employing hollow fibers, such as filtration of aqueous or gaseous fluids, ultrafiltration of particulate materials and dialysis of blood. In an embodiment, the leak test is employed in testing a bundle of fibers placed in a dialyzer. The dialyzer includes a blood inlet and a blood outlet, wherein blood flows through the inside of a plurality of hollow fibers. Dialysate flows into the dialyzer through an inlet port, around the outside of the hollow fibers and out of the dialyzer through an outlet port. The test employs a dry aerosol that is injected into the blood inlet, outlet or both, wherein a particle counter counts particles that pass through the fiber walls and exit one or both the dialysate ports. If the counter detects more than an acceptable amount of particles, the dialyzer has a leak.

Owner:BAXTER INT INC

Cartridges and systems for outside-in flow in membrane-based therapies

ActiveUS20160375188A1Increase pressureReduces and even eliminates needMembranesHaemofiltrationDiagnostic Radiology ModalityBlood treatments

Embodiments of the invention pertain to cartridges, systems and methods for performing hemodialysis and related extracorporeal blood treatment modalities and therapies, in which blood flows in the inter fiber space and dialysate flows in the lumens of hollow fibers. Appropriate connectors and fitting orientations may be provided. There may be provided orbital distributors, fanning of fibers, and features to promote uniformity of fiber spacing in the fiber bundle. Orbital distributors may contain contoured surfaces, flow redirectors, non-uniform-conductance flow elements, through-wall distributors, and other features. There may be subdivision of the fiber bundle into two groups of fibers with separate control fluid to each group. Appropriate systems may be provided for various therapies. Flow past the fibers may be parallel, transverse or other configuration. These various features may enable long-term application to all dialysis and ultrafiltration related therapies, and also to other therapies and to applications including implantables, portables and wearables.

Owner:NOVAFLUX INC

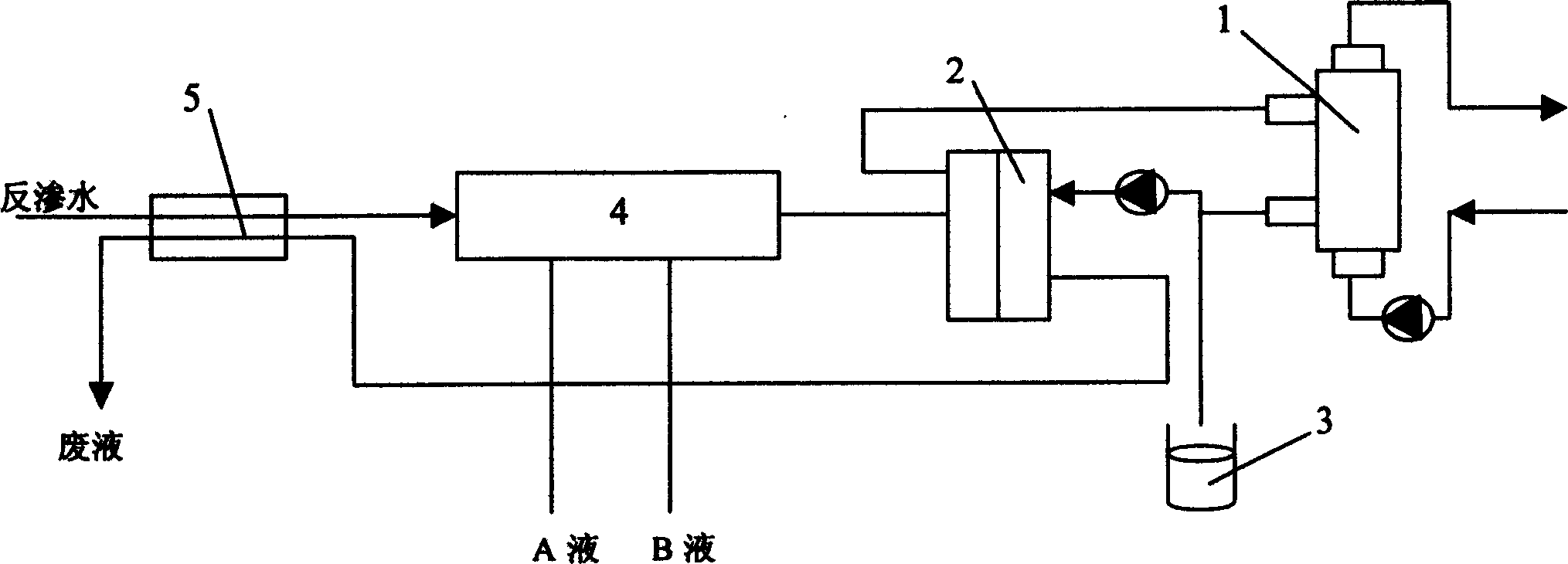

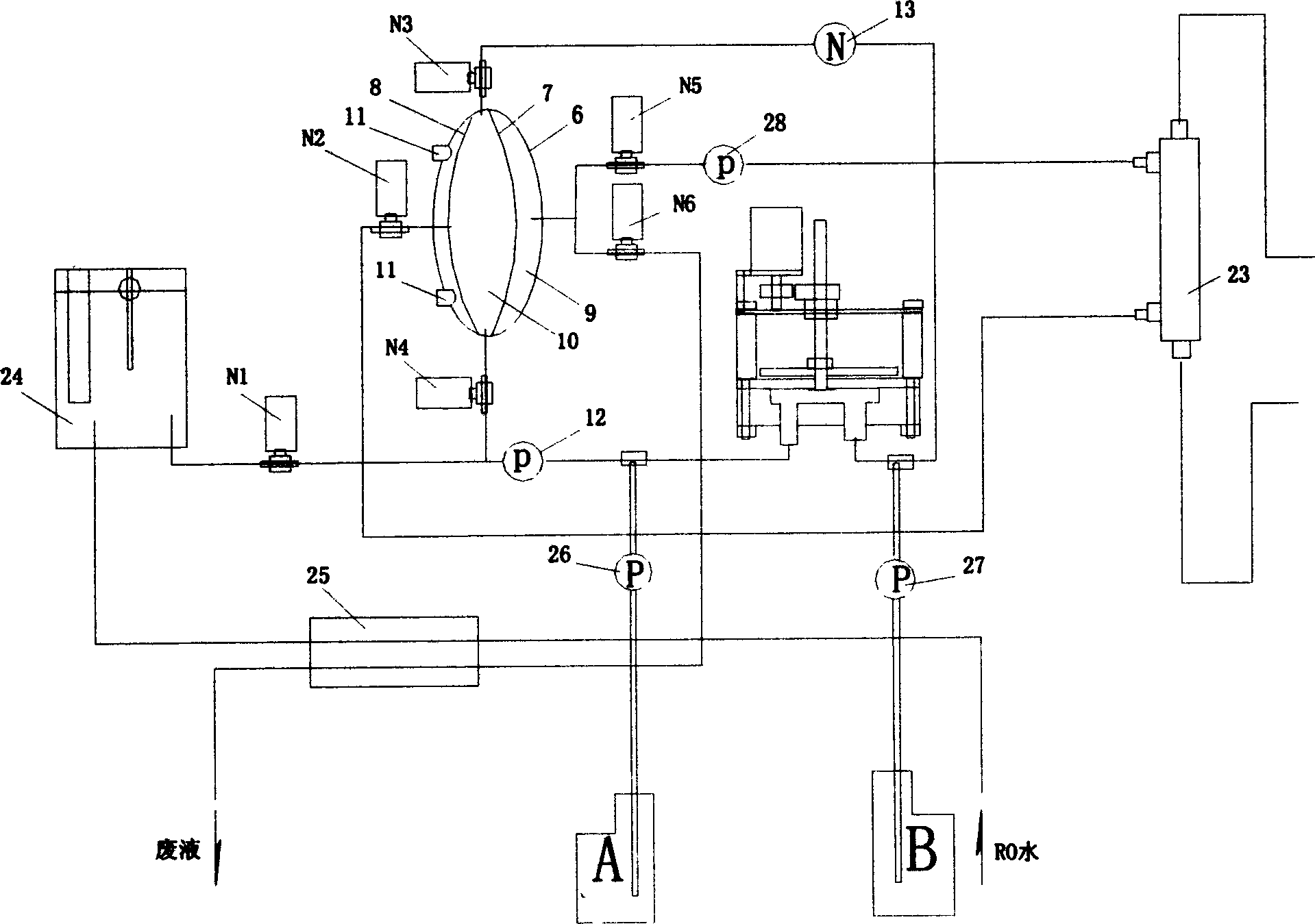

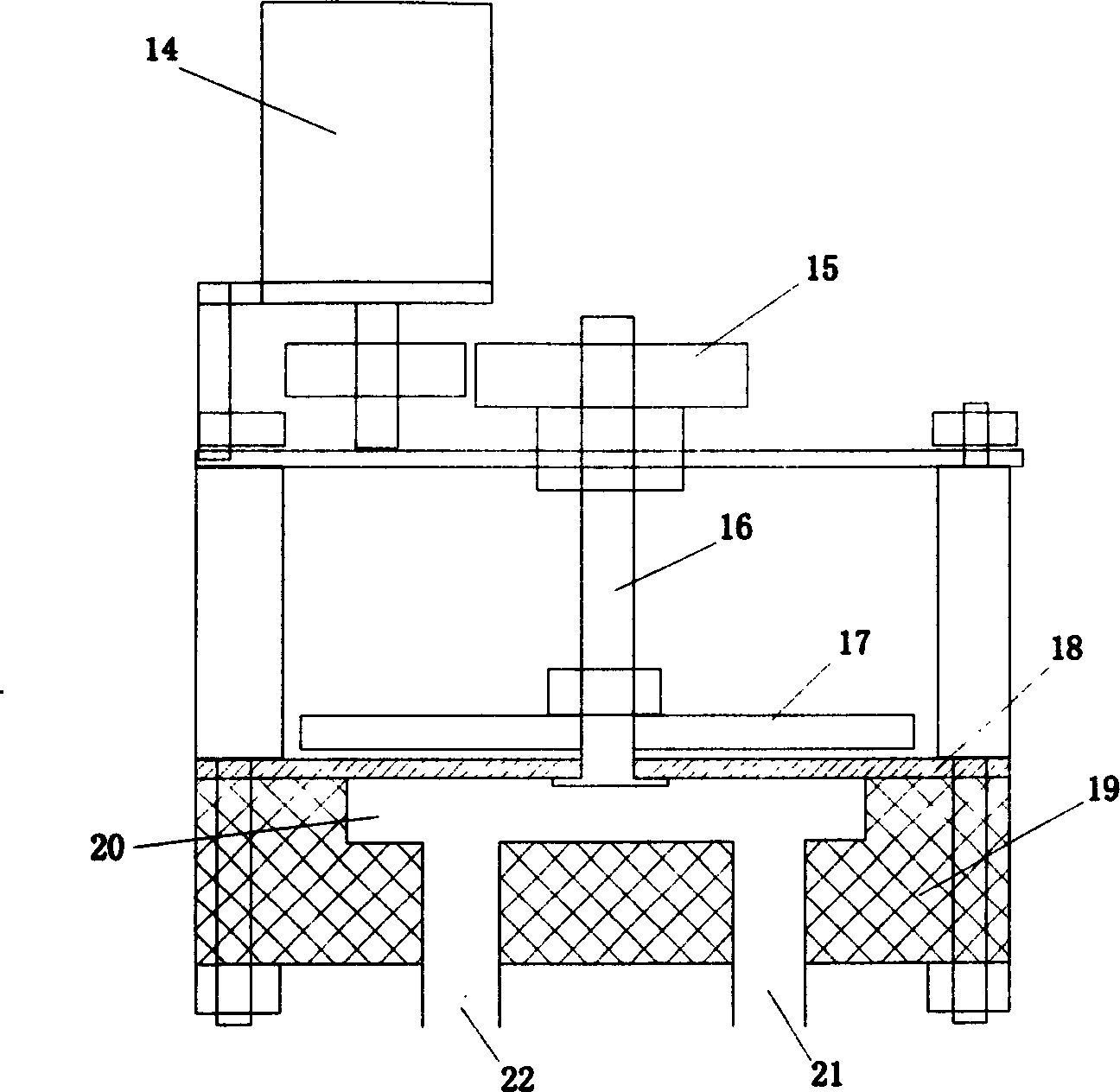

Method and apparatus for dialysate preparation and supply

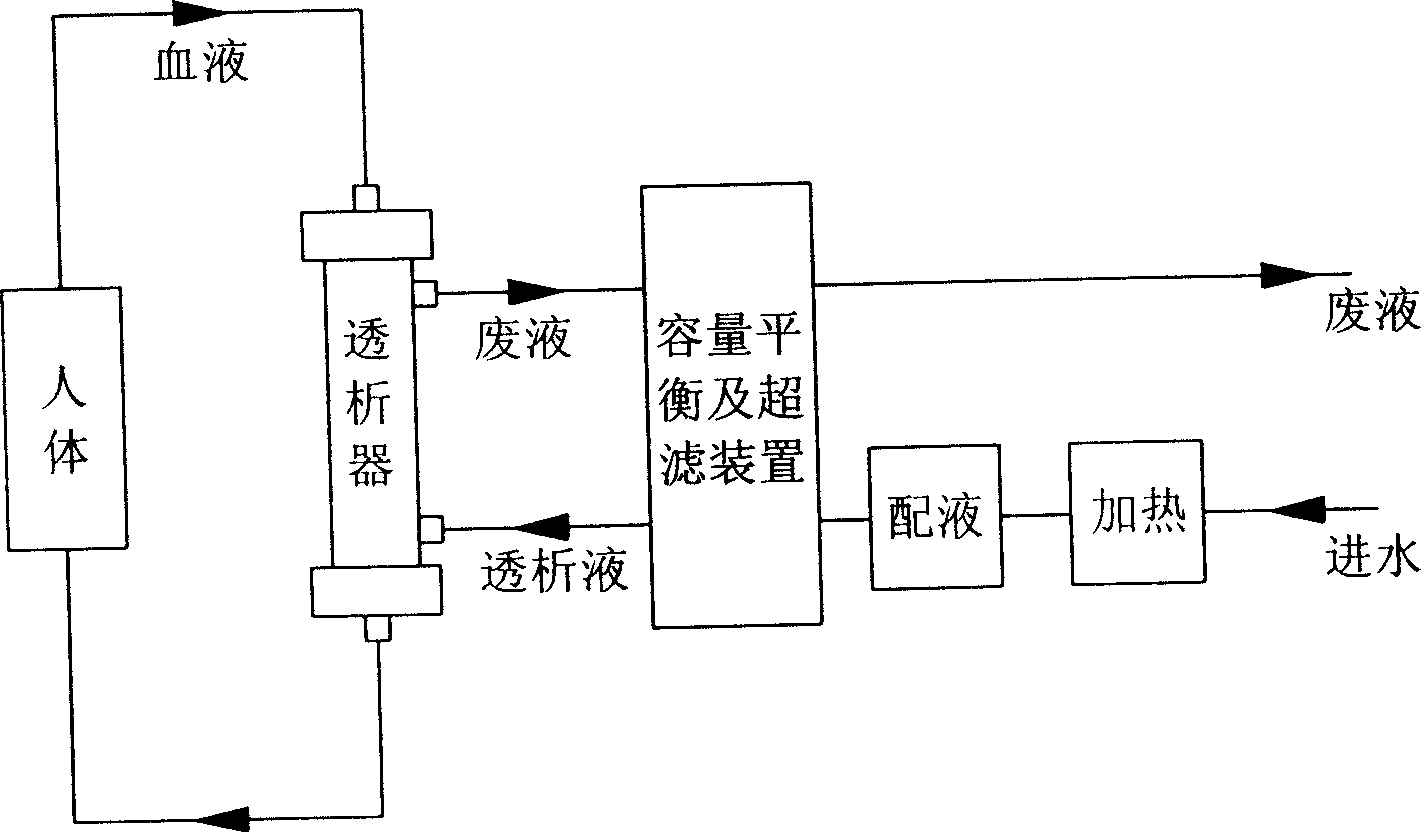

ActiveCN1569265ASimplify the maintenance processOvercoming adjustmentDialysis systemsEngineeringDialysate flow

A liquid dispensing and feeding method is disclosed. It mainly makes use of a chamber to conduct liquor dispensing and balanced liquor feeding. The liquor dispensing and feeding device comprises a isolated chamber and assembly for dispensing. Inside the chamber, a membrane is provided to separate it at least into two spaces, with one of the space communicated with the liquor dispensing assembly to form a liquor dispensing loop. The invention can regulate the dialysate flow as needed without closing down the machine during dialysis treatment. In addition, it has simple structure, lower production cost, favorable stability.

Owner:JINAN UNIVERSITY

Portable hemodialysis machine and disposable cartridge with dialysis reservoir level sensor

ActiveUS9649419B2Avoid flowEasy to useOther blood circulation devicesDialysis systemsDialysis membranesHaemodialysis machine

A portable hemodialysis system is provided including a disposable cartridge and a reused dialysis machine. The disposable cartridge includes a dialysate flow path and a blood flow path which flow in opposite directions through a dialyzer. The disposable cartridge includes a filter for removing waste products from the dialysate. The reused dialysis machine possesses a reservoir for dialysate, various sensors including a reservoir level sensor assembly, and a processor connected to the various sensors for controlling and monitoring hemodialysis treatment. The reservoir level sensor assembly includes a vertically extending electrode array for transmitting electrical signals to the processor detecting whether the reservoir possesses sufficient dialysate for therapy, and for detecting whether there is a fault condition during therapy such as a loss of dialysate in the reservoir or an increase in fluid in the reservoir which may indicate a failure in the dialysis membrane.

Owner:DIALITY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com