Method and apparatus for dialysate preparation and supply

A liquid preparation and liquid supply technology, applied in the medical field of hemodialysis, can solve problems such as long time to achieve, unstable conductivity, major medical accidents, etc., and achieve time saving, good stability and high safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

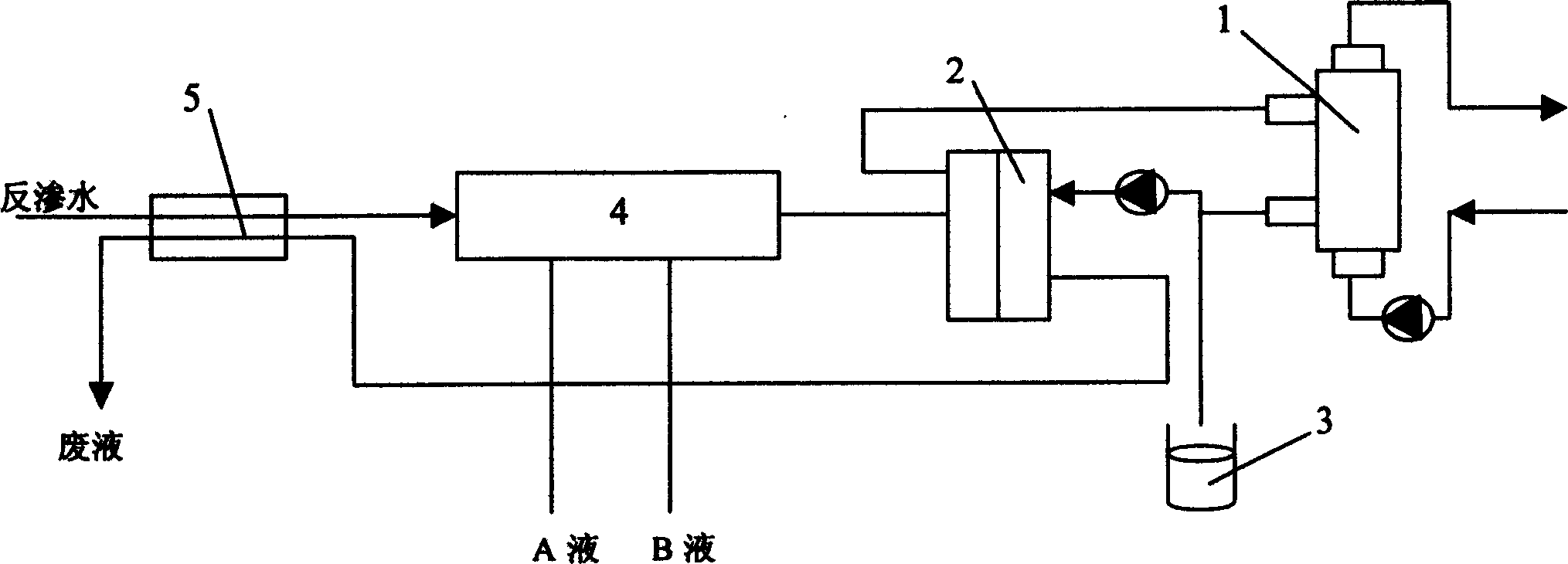

Method used

Image

Examples

Embodiment 1

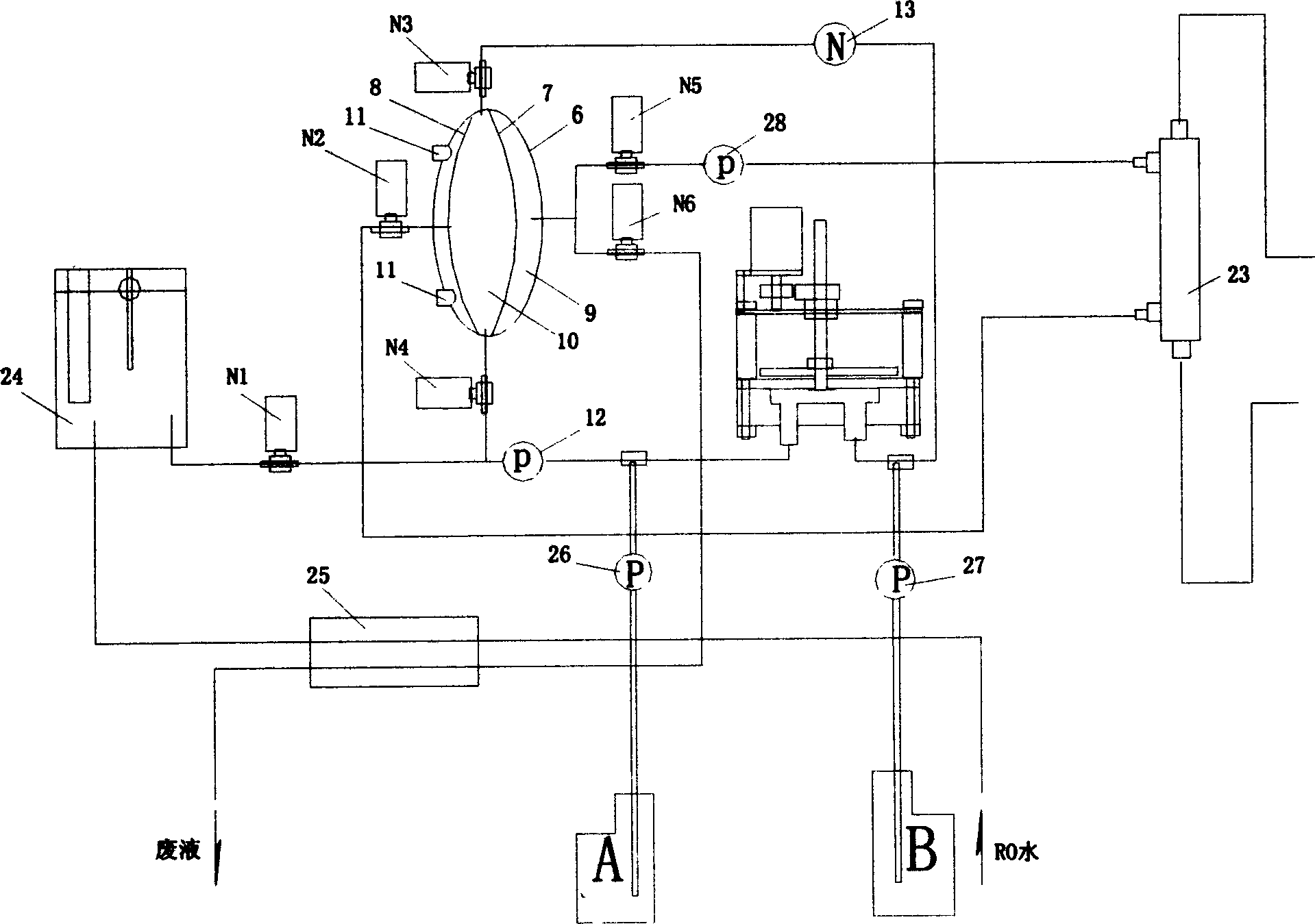

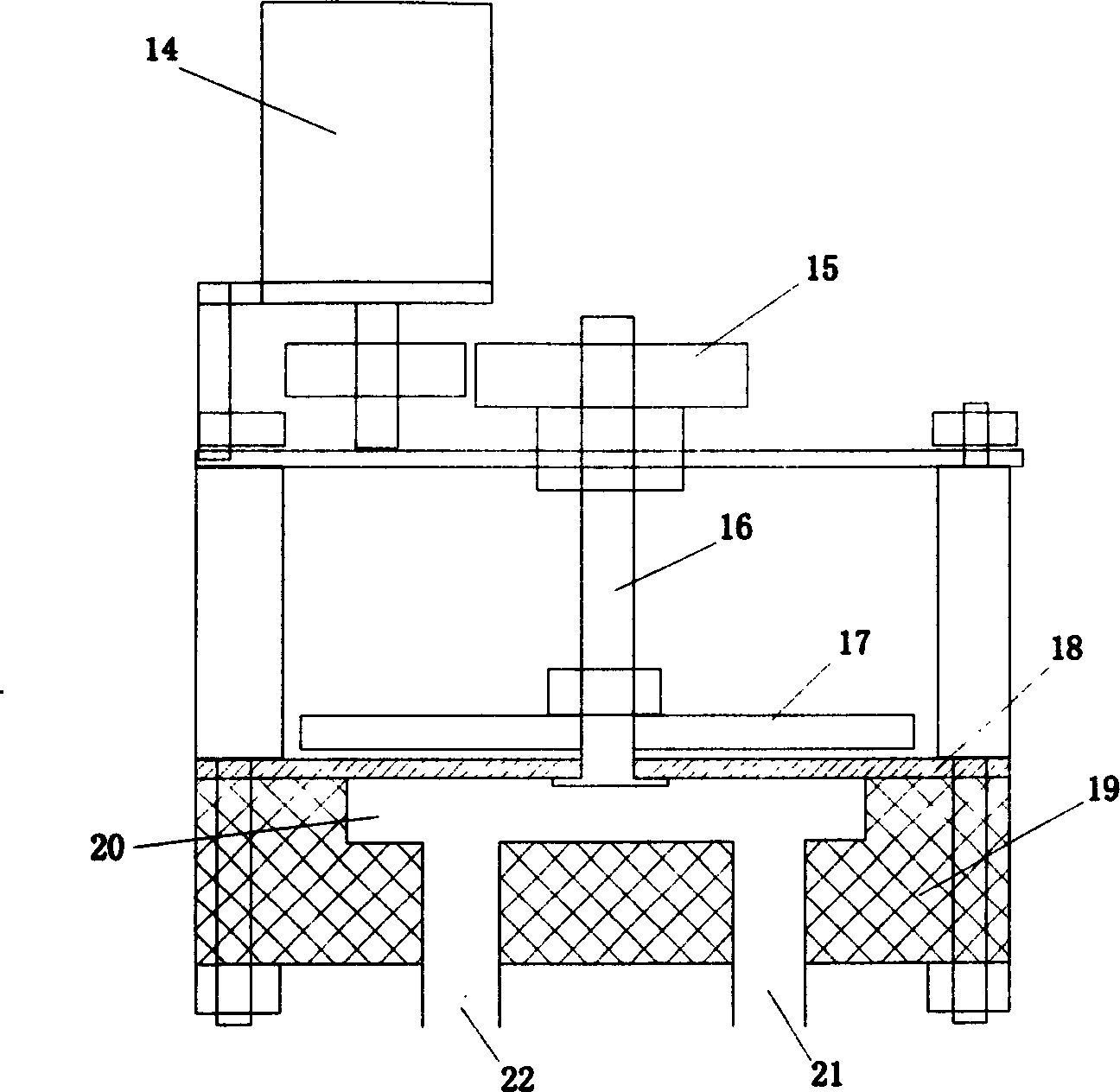

[0027] figure 2 shows the specific structural form of the present invention, by figure 2It can be seen that the liquid dispensing and liquid supply device includes an independent cavity 6, which is divided into two chambers 9, 10 by thin films 7, 8, wherein a thin film 8 is close to the cavity wall of the independent cavity 6, in the cavity The opening on the wall is equipped with a telescopic screw plug 11 that can fine-tune the space volume in the cavity from the outside; a chamber 10 between the two films 7, 8 is provided with a liquid distribution inlet and a liquid distribution outlet; The connecting pipeline is provided with solenoid valves N3 and N4, and the chamber 10 is also provided with an infusion outlet, and the pipeline connected with the infusion outlet is provided with a solenoid valve N2, and the liquid distribution inlet and distribution outlet pass through the pipeline and the liquid delivery pump 12, concentration The fine-tuning device and the conductiv...

Embodiment 2

[0034] This embodiment is the same as Embodiment 1 except for the following features: two identical cavities are used to connect together, see Figure 4 , two identical independent cavities are connected together. In this way, using two cavities with the same structure, when one cavity is dosing liquid, the other cavity will supply liquid in balance. For liquid supply, the two chambers are used alternately to realize uninterrupted balanced liquid supply to the dialyzer 23 . Since the two cavities use the same dosing control, the volumes in the two cavities must be consistent, otherwise the conductivity of the standard dialysate will deviate; for this reason, use the telescopic screw plug 11 on the cavity wall to adjust the volume of the cavity Change to make the volume of the two cavities consistent.

Embodiment 3

[0036] Present embodiment is identical with embodiment 2 except following feature: as Figure 5 As shown, only a piece of film is set in the two cavities; this structure requires that the telescopic screw plug 11 on the cavity wall can adjust the volume in the two cavities, and must withstand the liquid pressure in the cavity without leakage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com